Patents

Literature

325 results about "Coalescer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

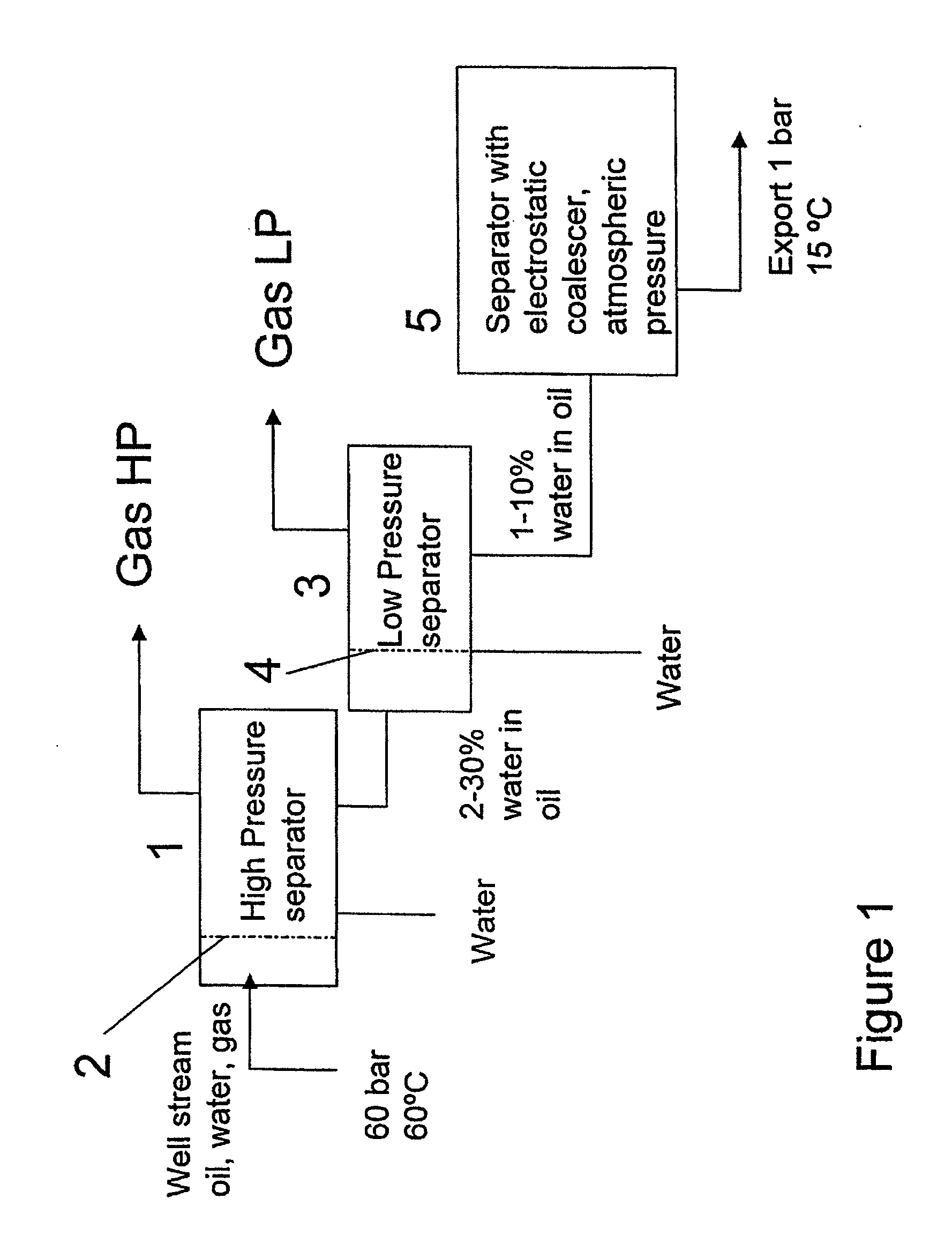

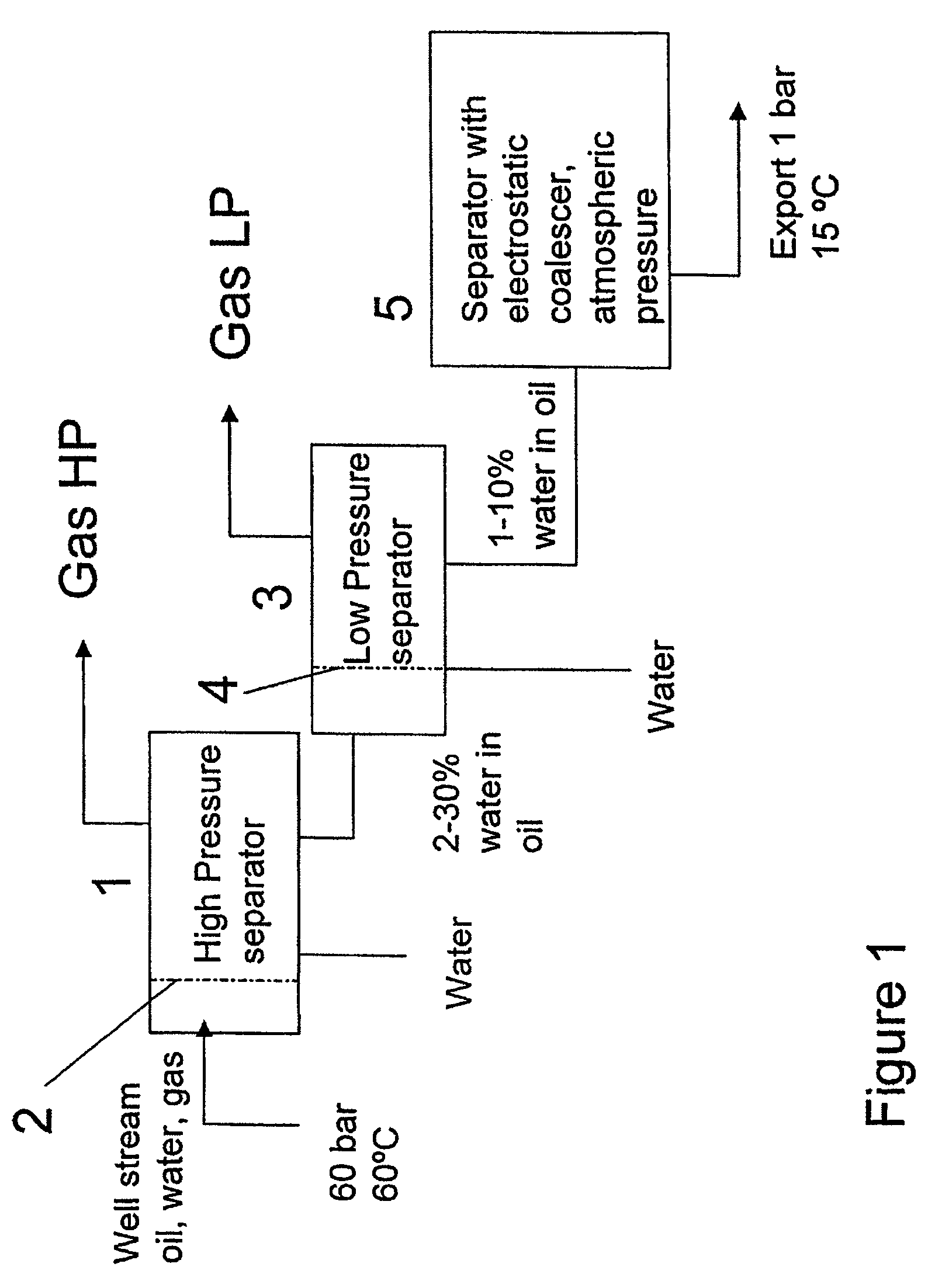

A coalescer is a technological device performing coalescence. They are primarily used to separate emulsions into their components via various processes; operating in reverse to an emulsifier. There are two types of coalescers. Mechanical coalescers use filters or baffles to make droplets coalesce while electrostatic coalescers use DC or AC electric fields (or combinations).

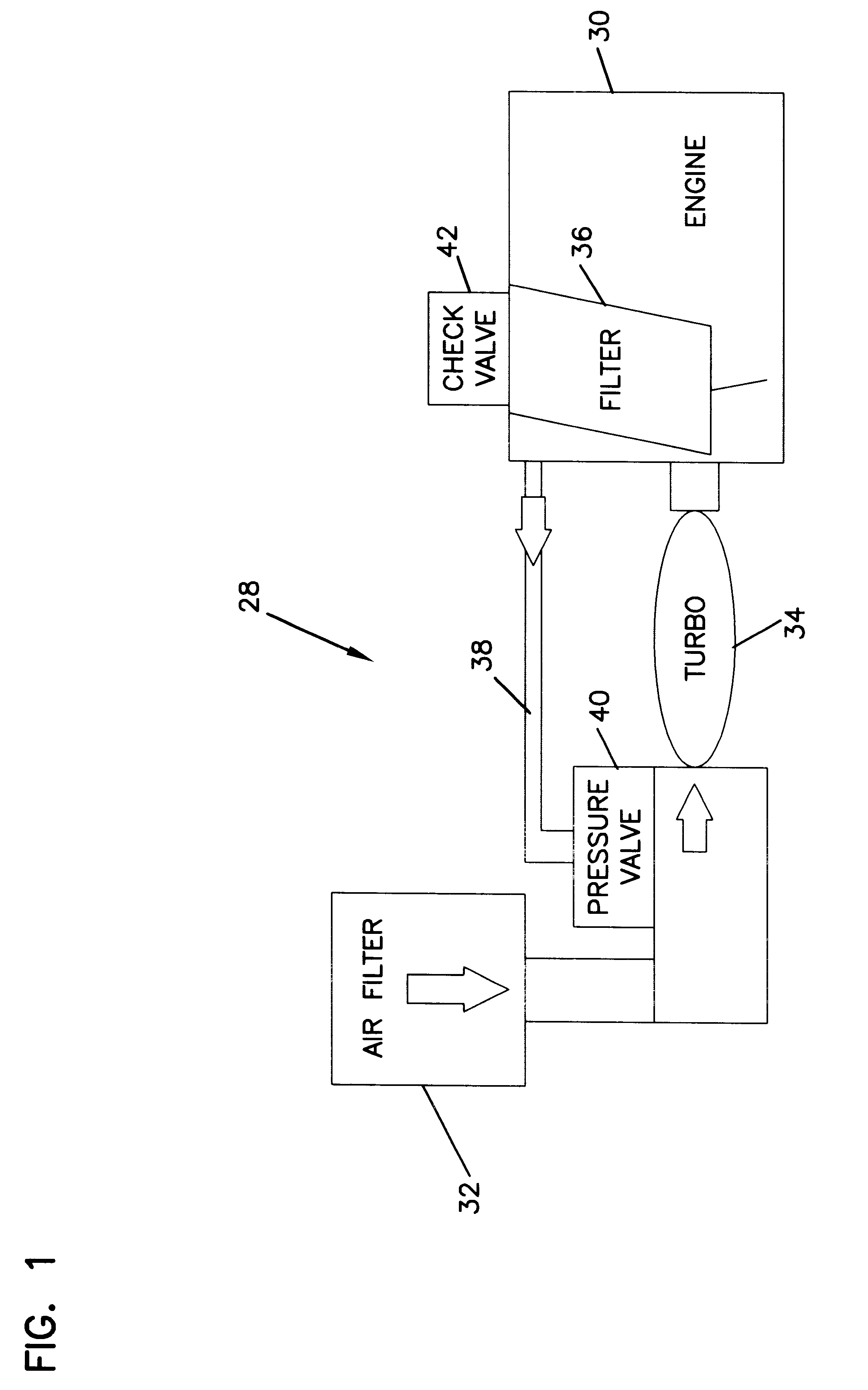

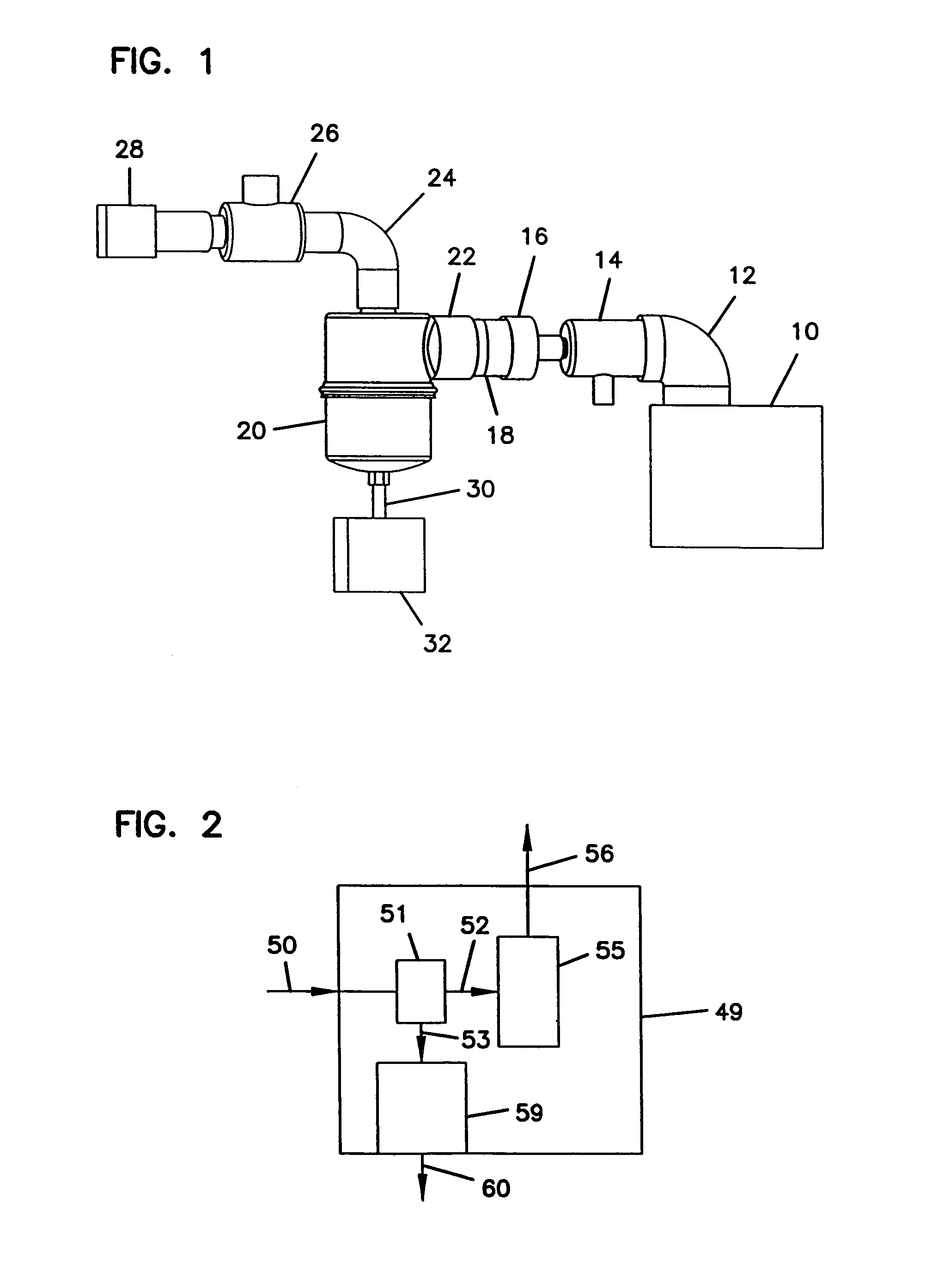

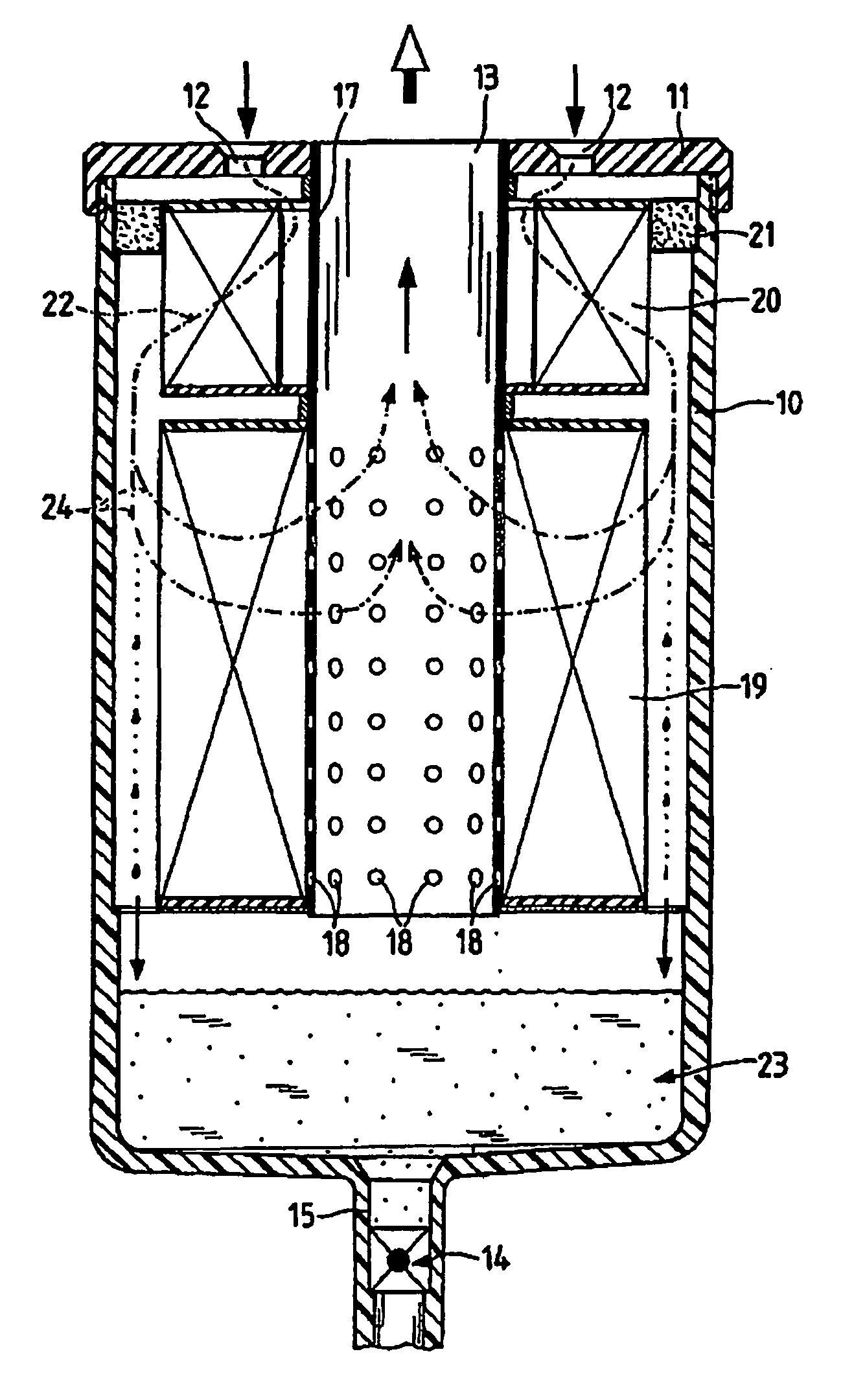

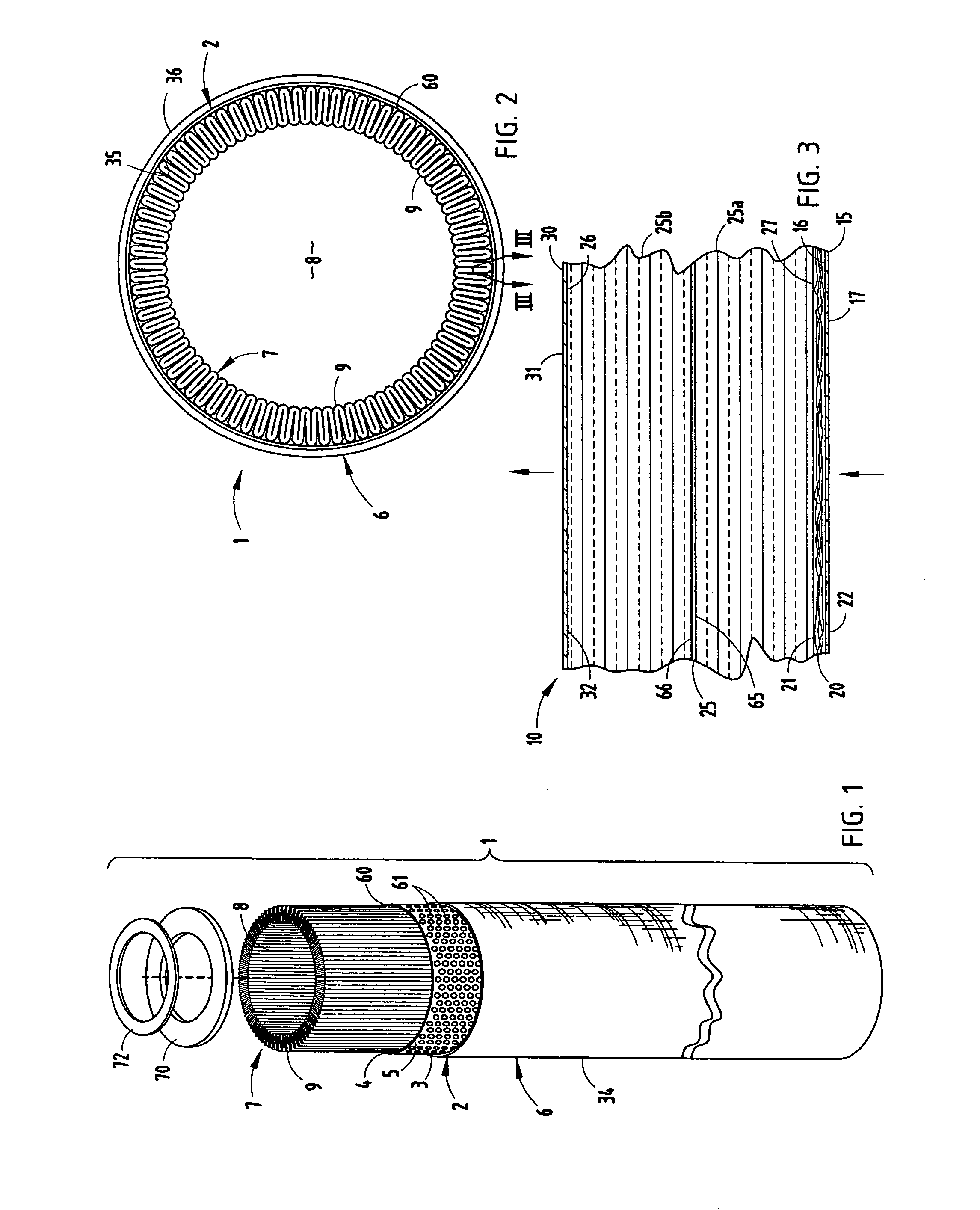

Air cleaner; aerosol separator; and method

InactiveUS6187073B1Easy collection and removalAvoid flowCombination devicesNon-fuel substance addition to fuelCoalescerFilter element

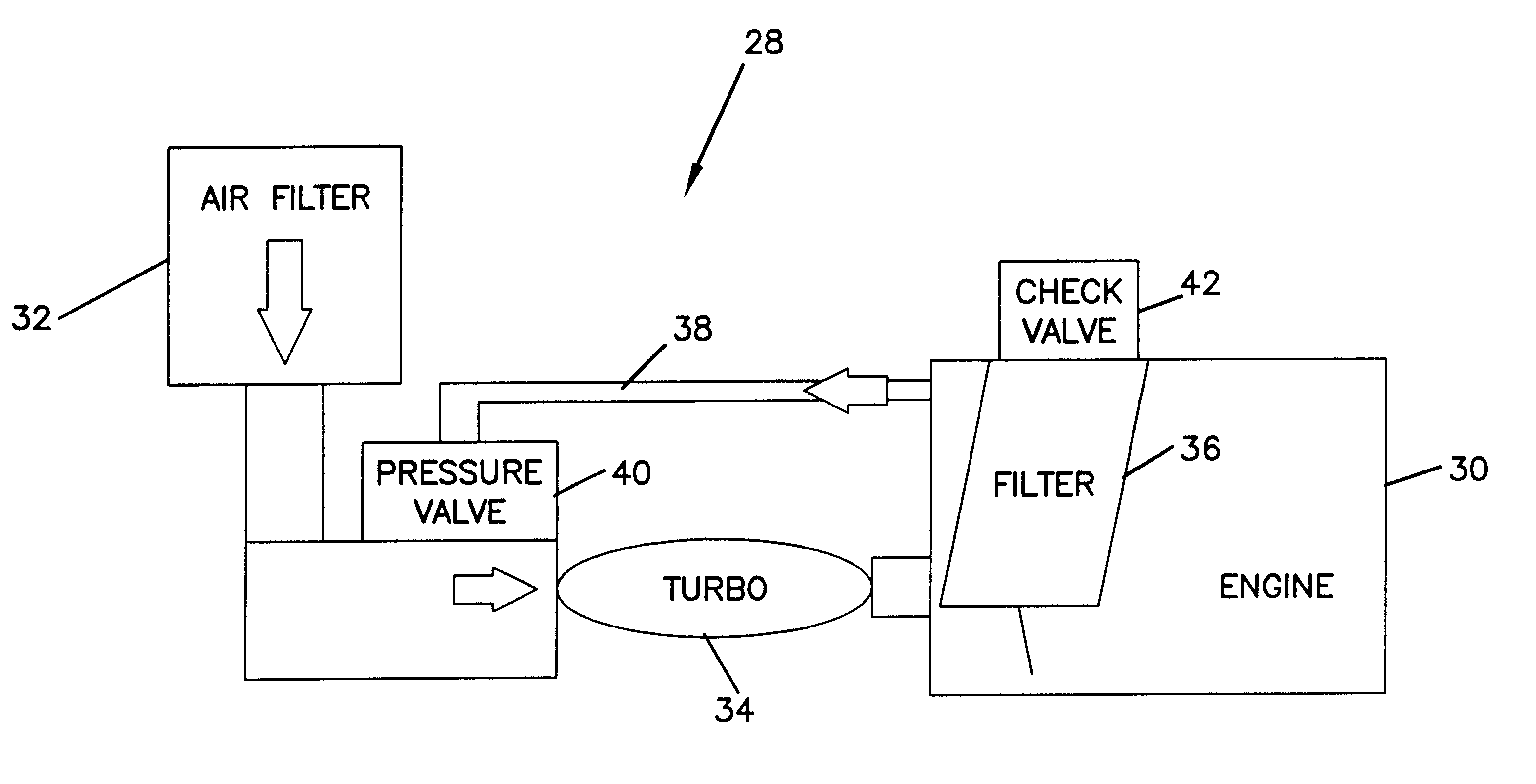

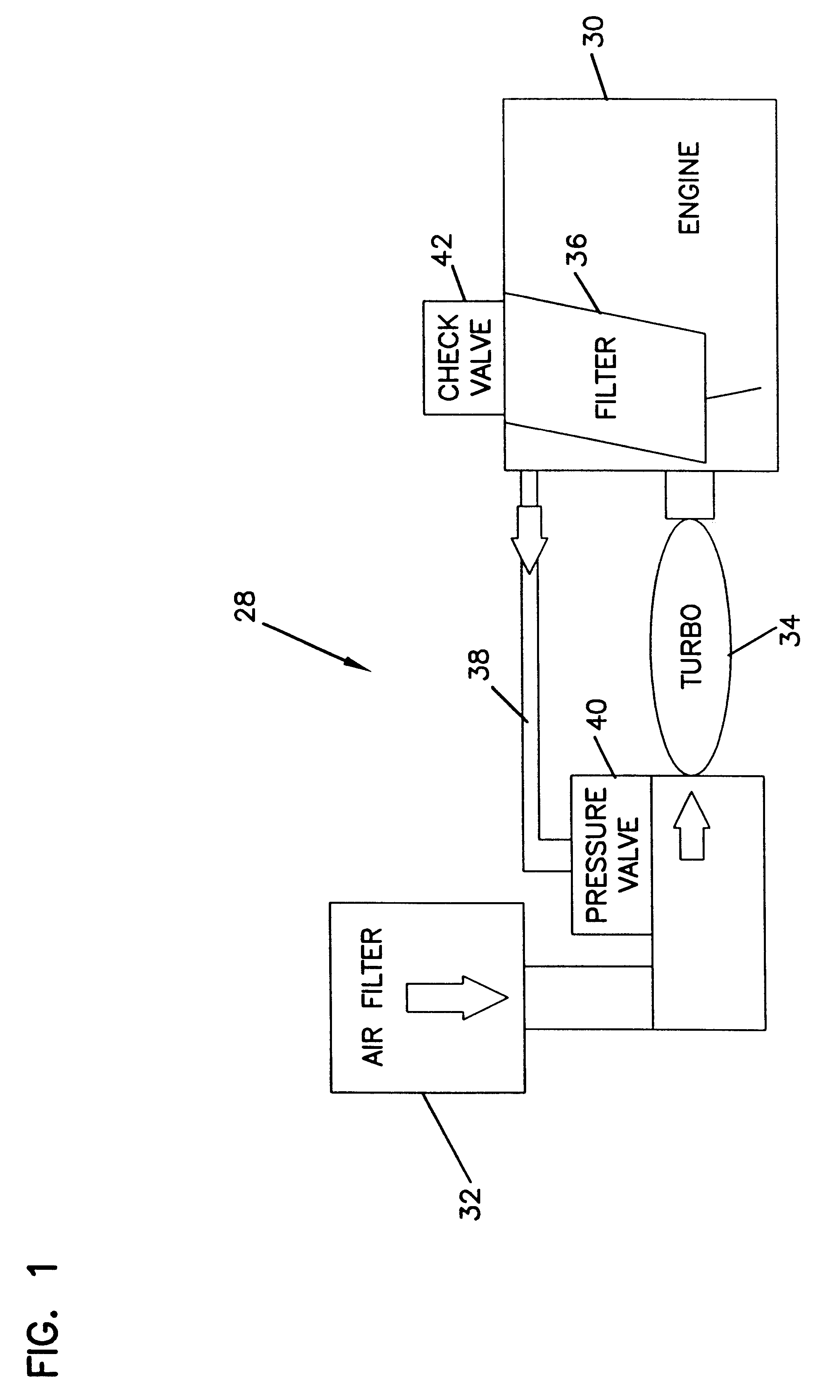

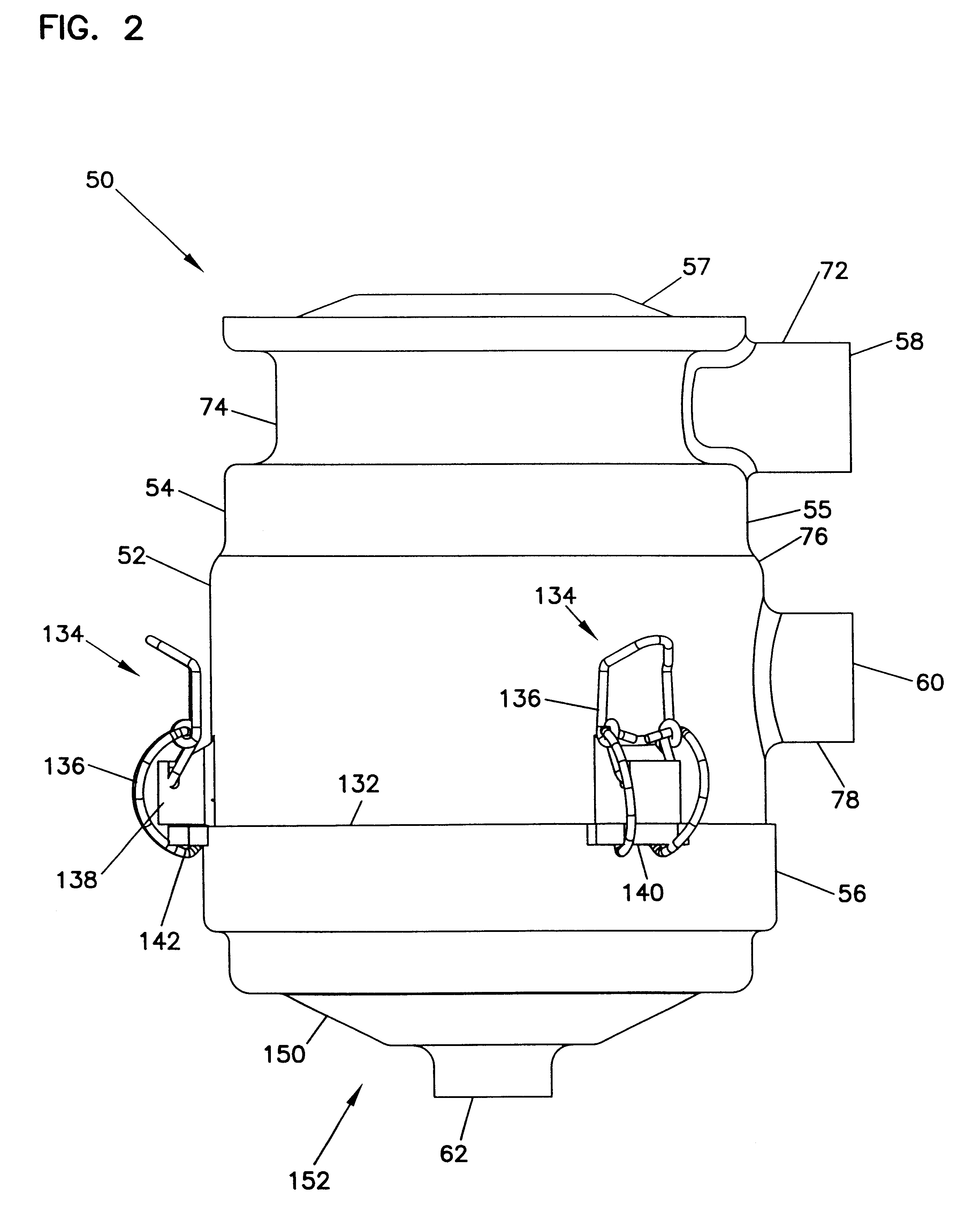

A filter arrangement includes a tubular first filter element having a first media pack defining a first open filter interior and an air flow outlet. The air flow outlet is in gas flow communication with the first open filter interior. A housing construction has a gas flow inlet and a gas flow outlet. The air flow outlet of the first filter element is in gas flow communication with the gas flow outlet. A coalescer filter element is oriented in the housing construction in fluid communication with the gas flow inlet. A tubular second filter element is oriented in the housing construction and has a second media pack defining a second open filter interior. The second open filter interior is in gas flow communication with the gas flow outlet.

Owner:DONALDSON CO INC

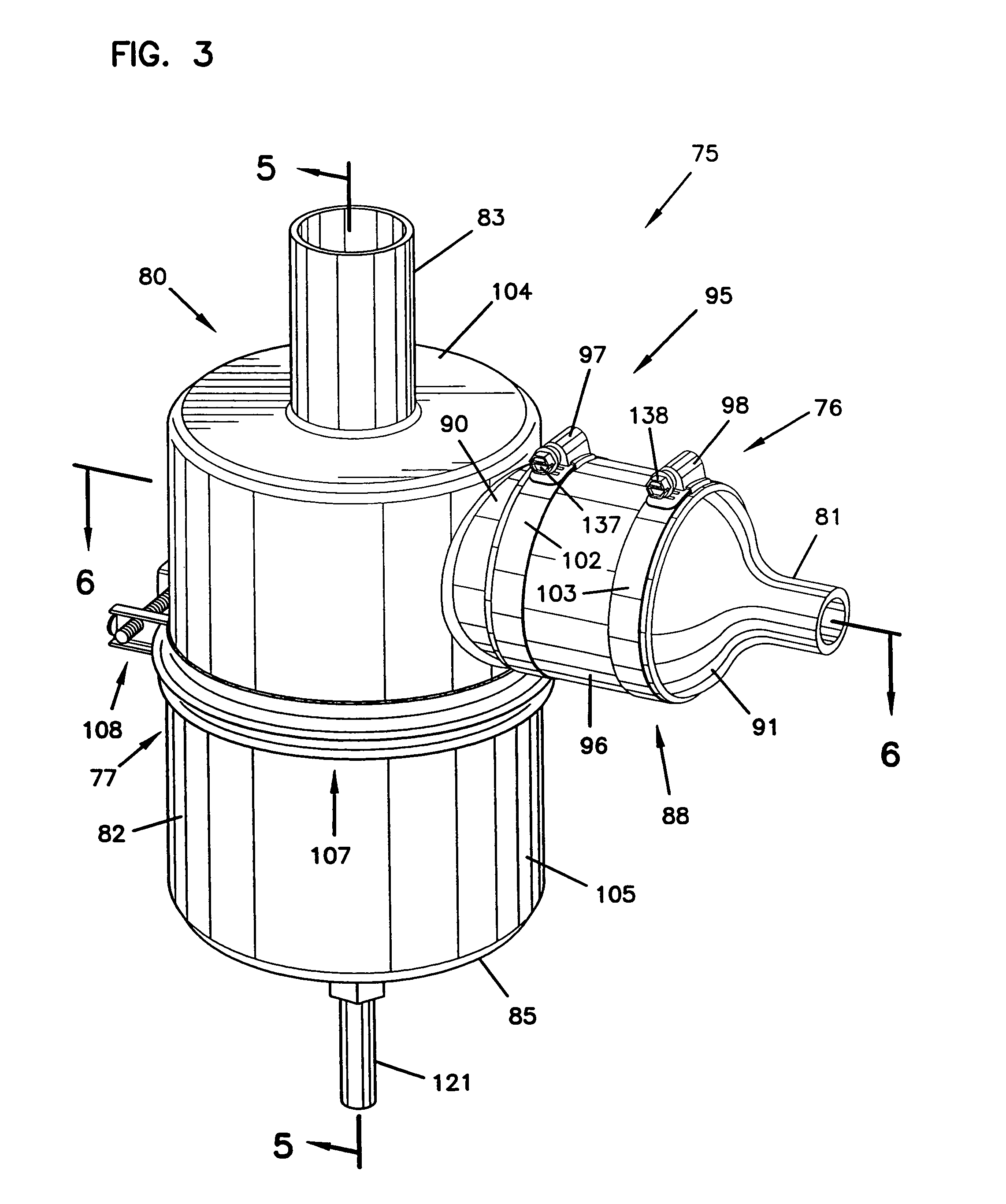

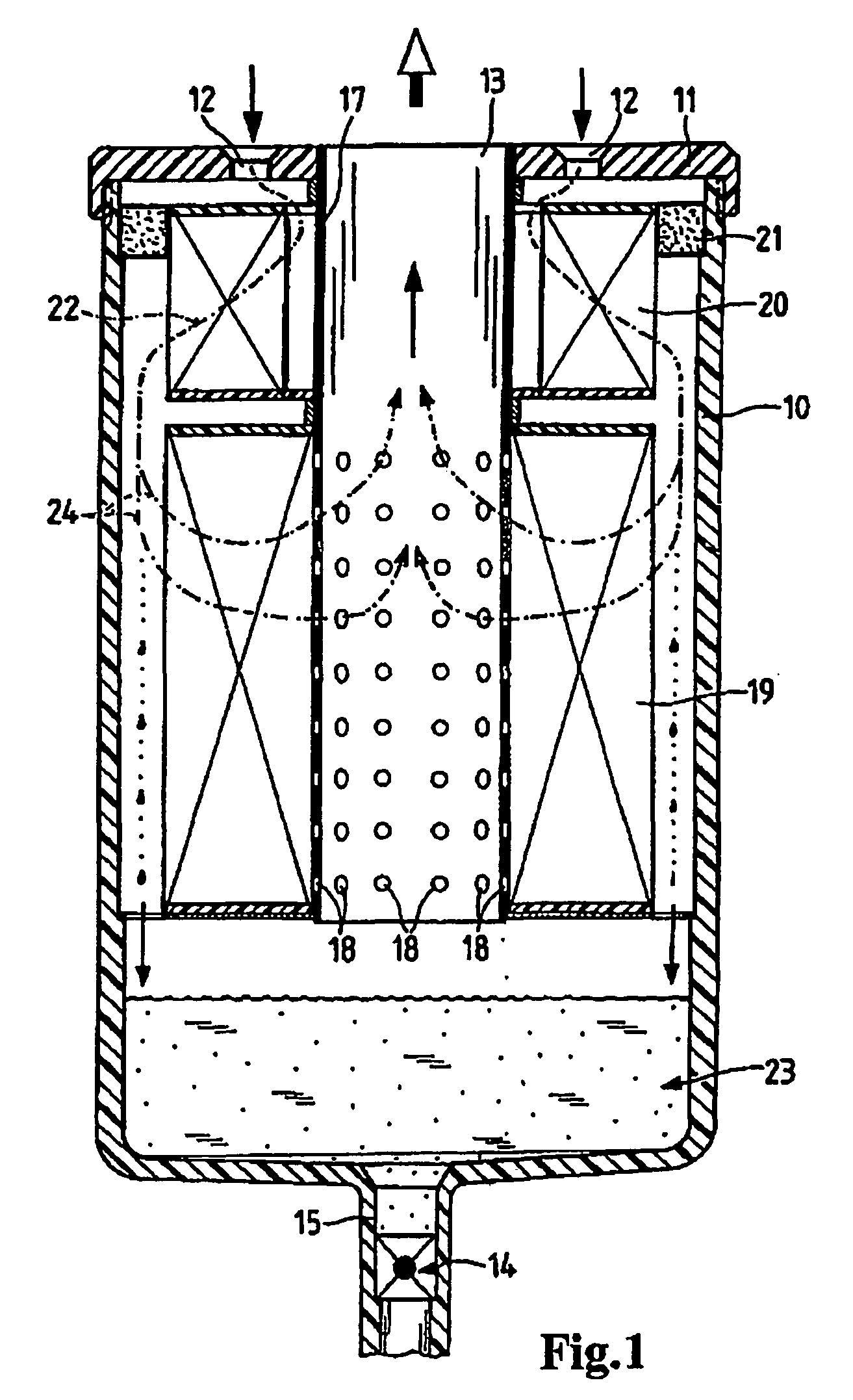

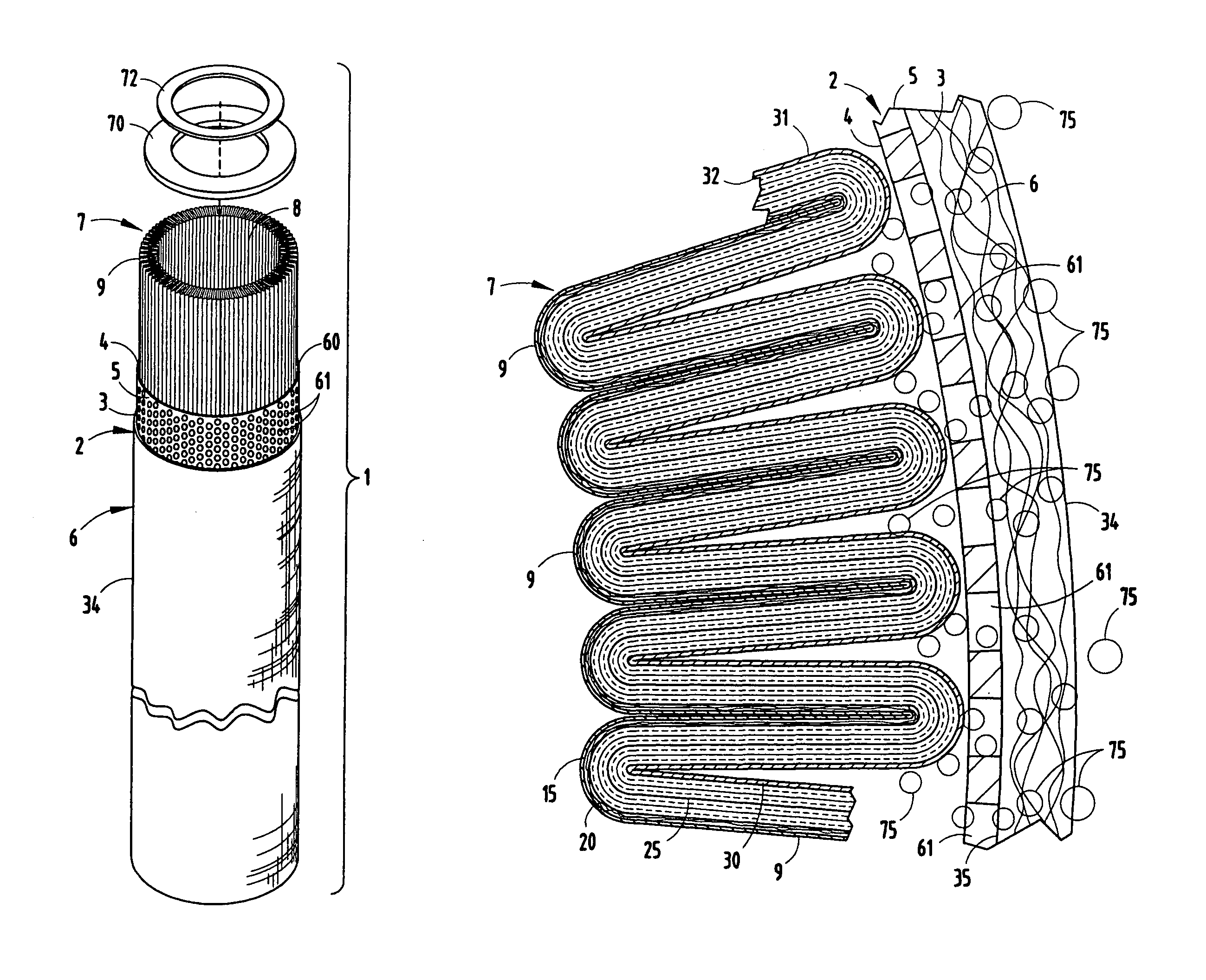

Aerosol separator; and method

InactiveUS6290739B1Reduce the overall diameterReduce pressureCombination devicesNon-fuel substance addition to fuelFiberCoalescer

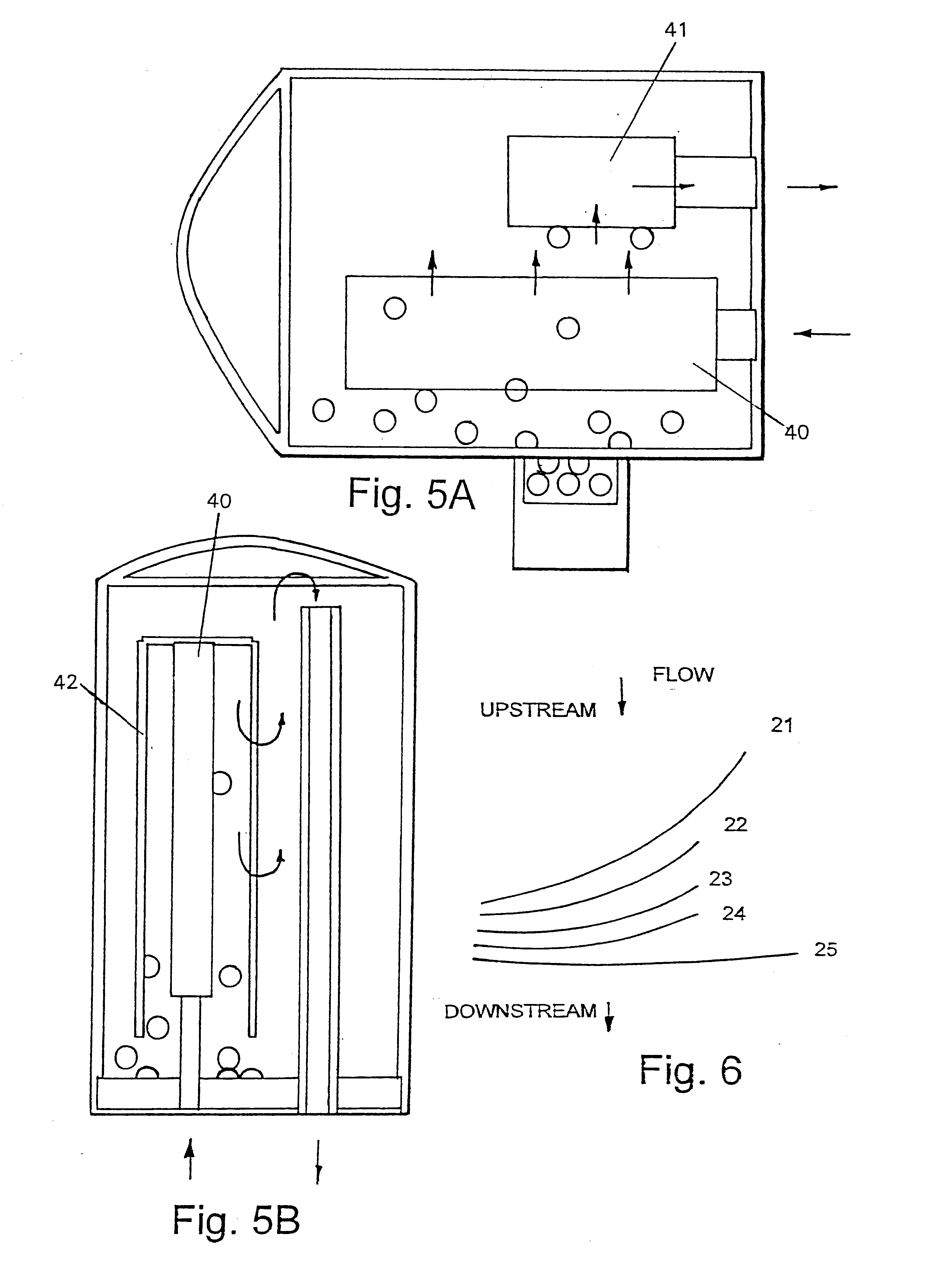

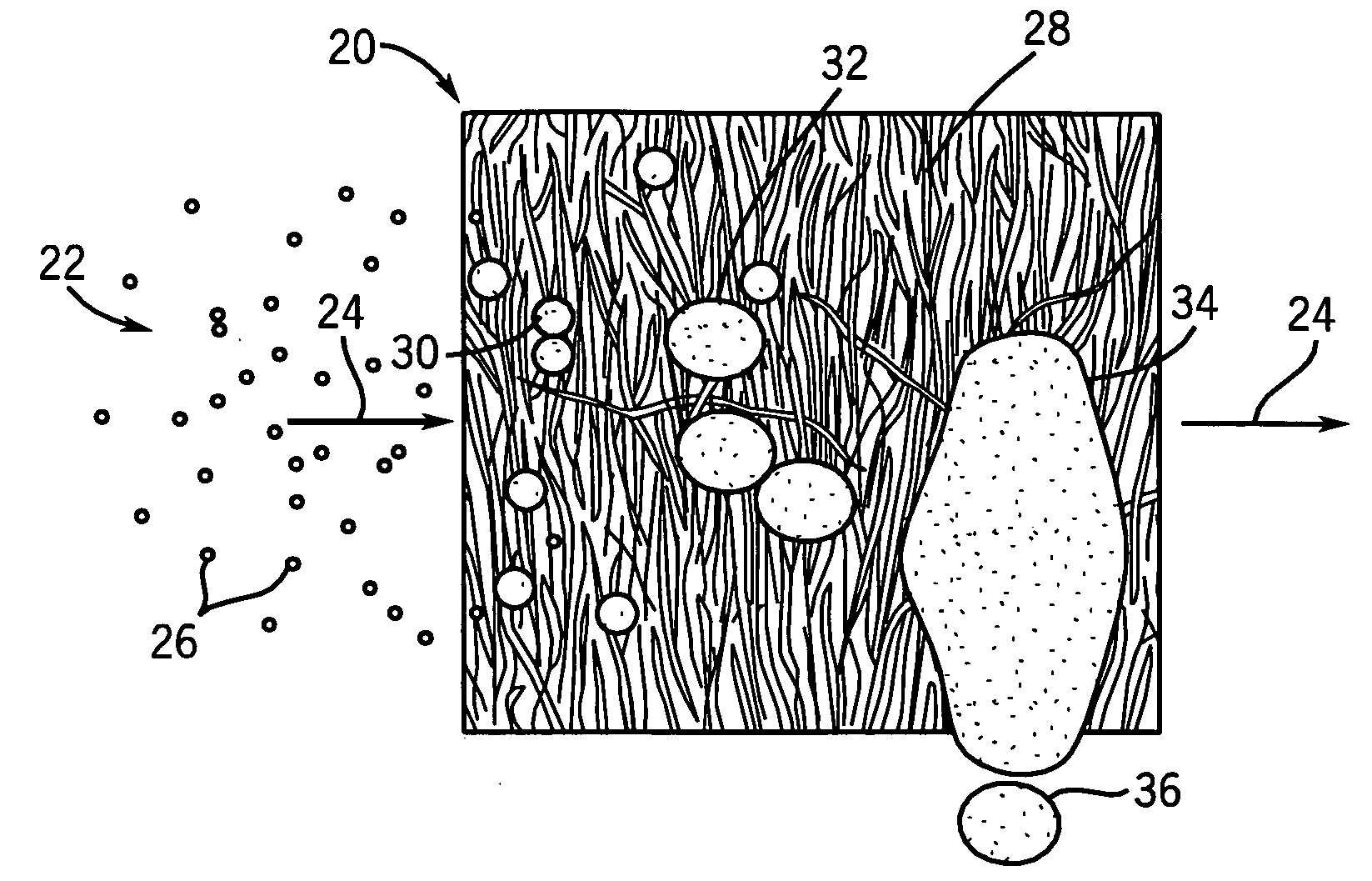

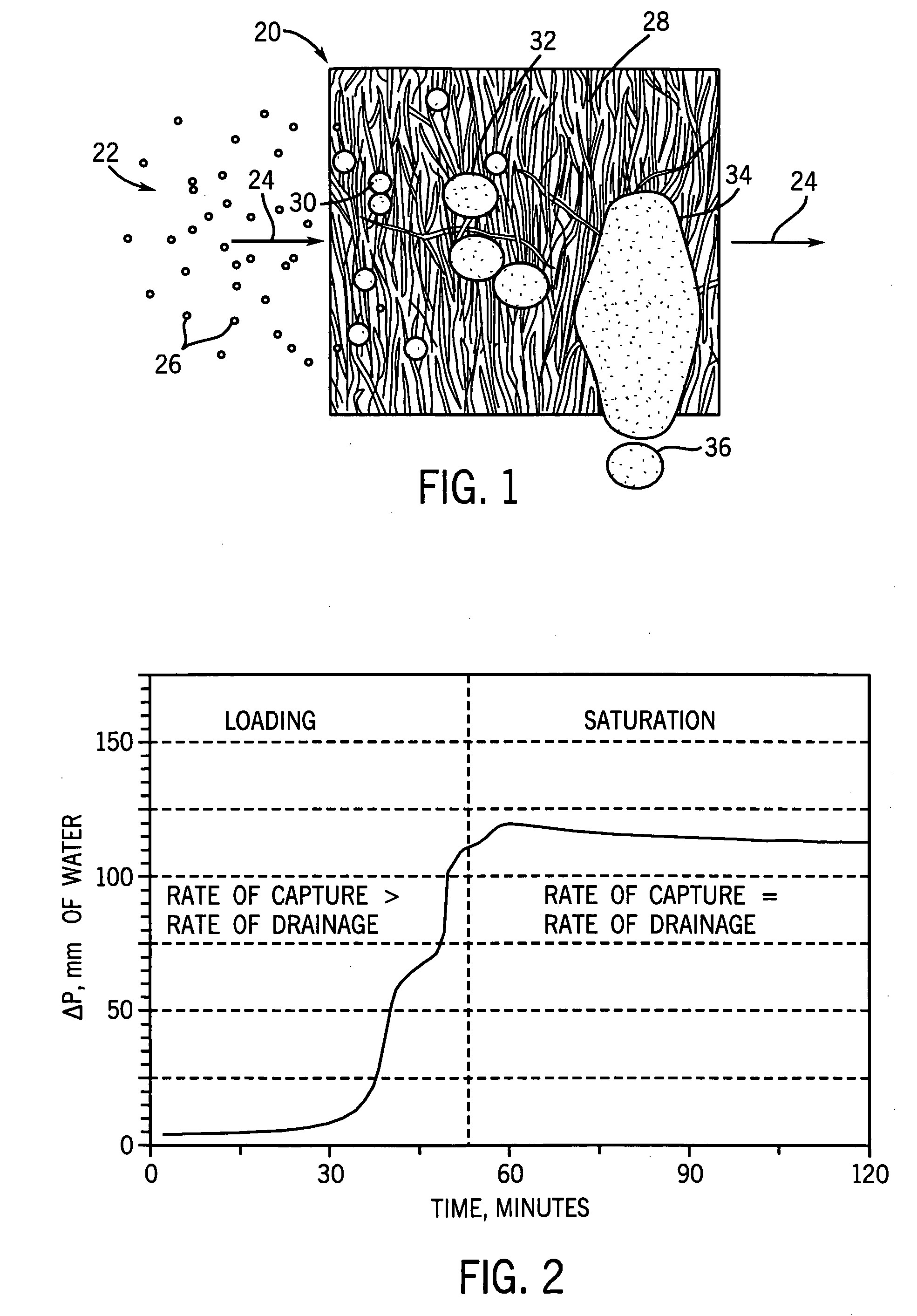

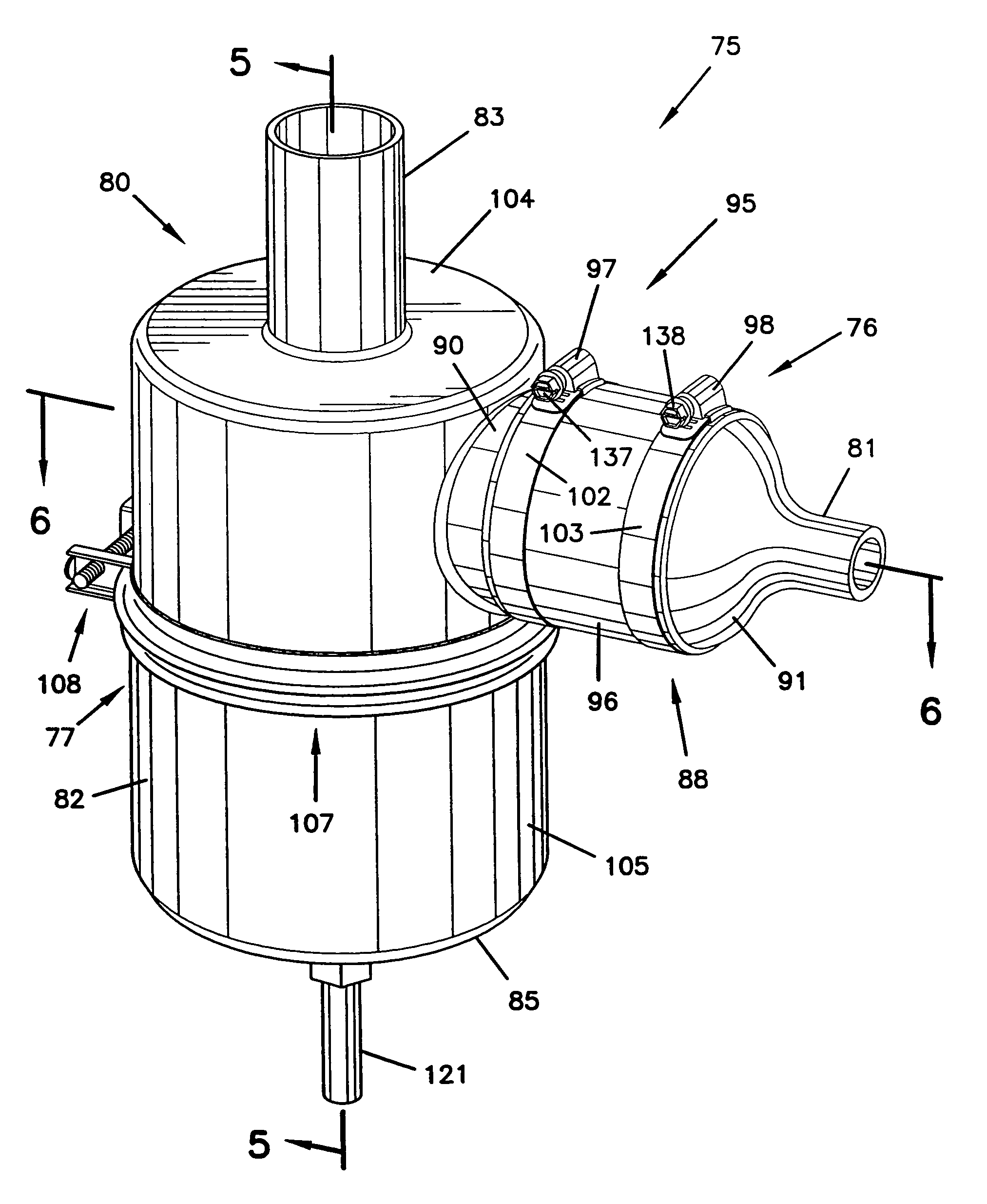

An arrangement for separating a hydrophobic liquid phase from a gaseous stream includes a coalescer filter, a housing, a gas flow direction arrangement, and a liquid collection arrangement. The coalescer filter includes a non-woven media of fibers. The housing includes an interior having a gas flow inlet and a gas flow outlet. The liquid collection arrangement is positioned within the housing construction and is oriented for receiving liquid collected from the coalescer filter and drained therefrom.

Owner:DONALDSON CO INC

Coalescer for hydrocarbons containing surfactant

A coalescer filter element for the separation of water from hydrocarbon fluids, such as kerosene, jet fuel, diesel fuel, and gasoline under surfactant conditions such as thermal stability additive and dispersant. Coalescer fibrous material has hydrophobic properties which resist surfactant coating of the fibers thereby allowing breakdown of water emulsion in the hydrocarbon fluids. The coalescer has a negative media density gradient in the liquid flow direction.

Owner:KAYDON CUSTOM FILTRATION CORP

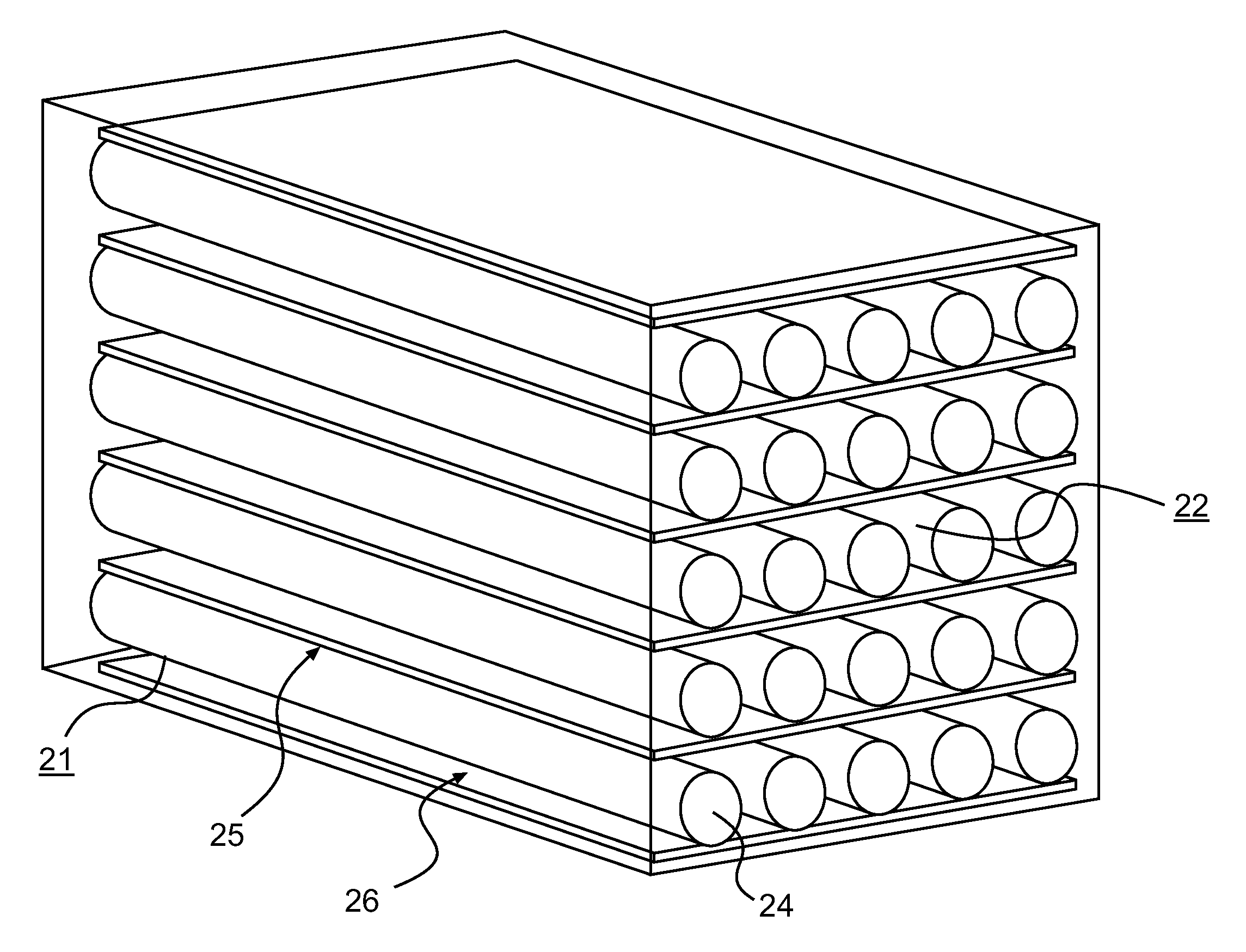

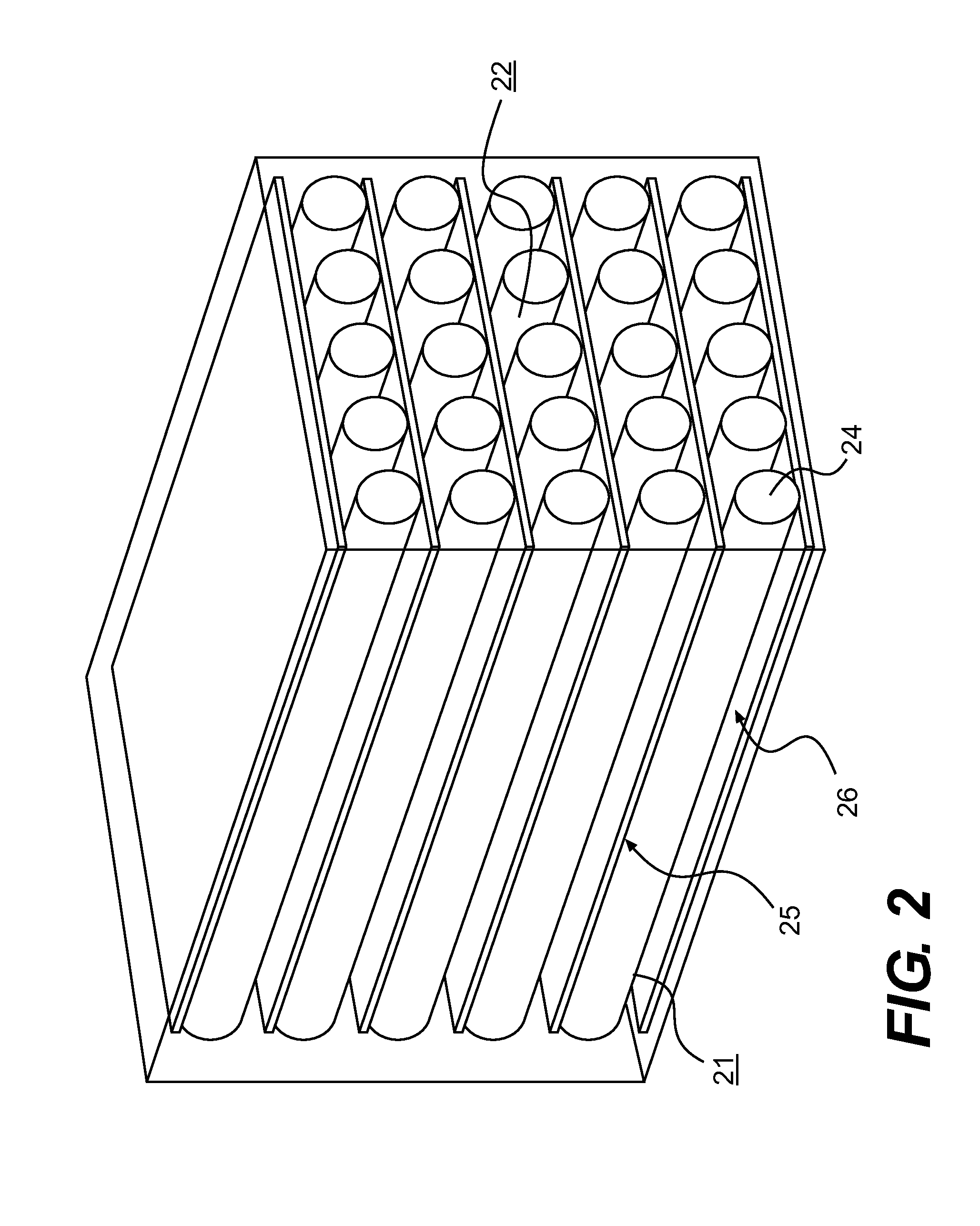

Space optimized coalescer

ActiveUS20070062887A1Improve removal efficiencyLower overall pressure dropDispersed particle filtrationLiquid suspension thickening by filtrationEngineeringTrade offs

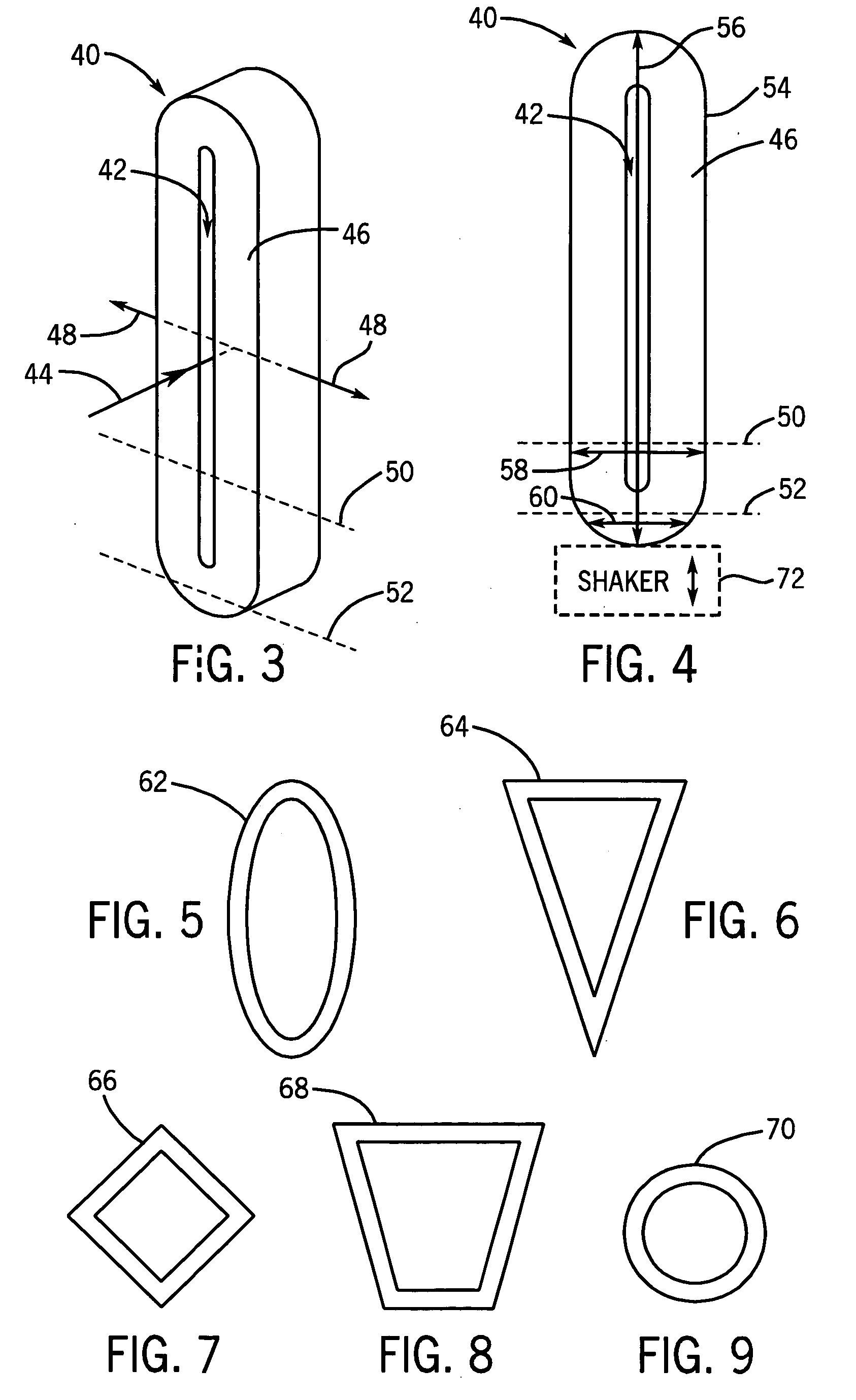

A coalescer is provided minimizing trade-offs among high removal efficiency, low pressure drop, long service life, and small size.

Owner:CUMMINS FILTRATION IP INC

Aerosol separator; and method

InactiveUS6530969B2Reduce pressureIncrease pressureCombination devicesNon-fuel substance addition to fuelFiberCoalescer

Owner:DONALDSON CO INC

Aerosol separator; and method

An arrangement for separating a hydrophobic liquid phase from a gaseous stream includes a coalescer filter, a housing, a gas flow direction arrangement, and a liquid collection arrangement. The coalescer filter includes a non-woven media of fibers. The housing includes an interior having a gas flow inlet and a gas flow outlet. The liquid collection arrangement is positioned within the housing construction and is oriented for receiving liquid collected from the coalescer filter and drained therefrom. Methods for conducting the separations are also provided.

Owner:DONALDSON CO INC

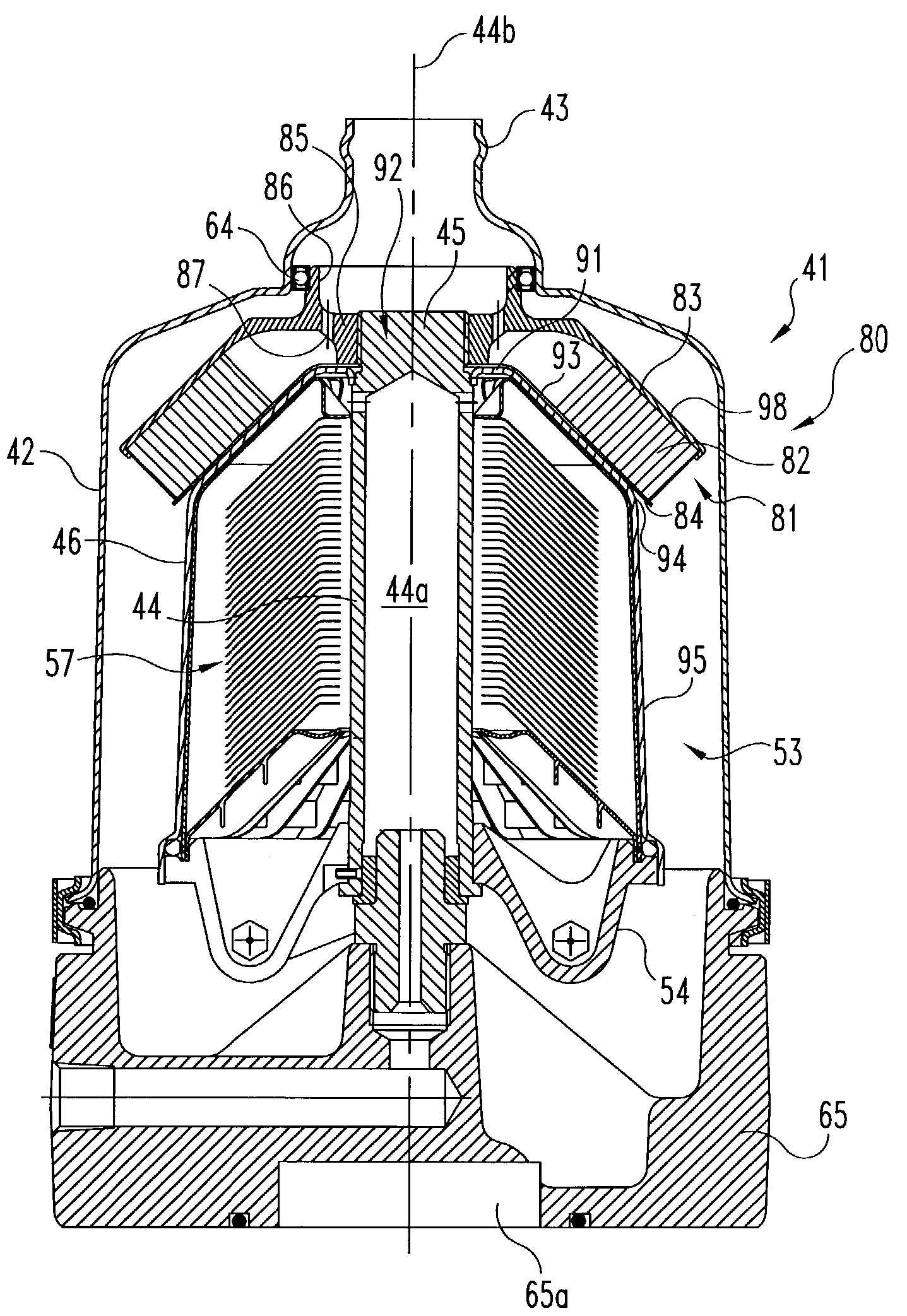

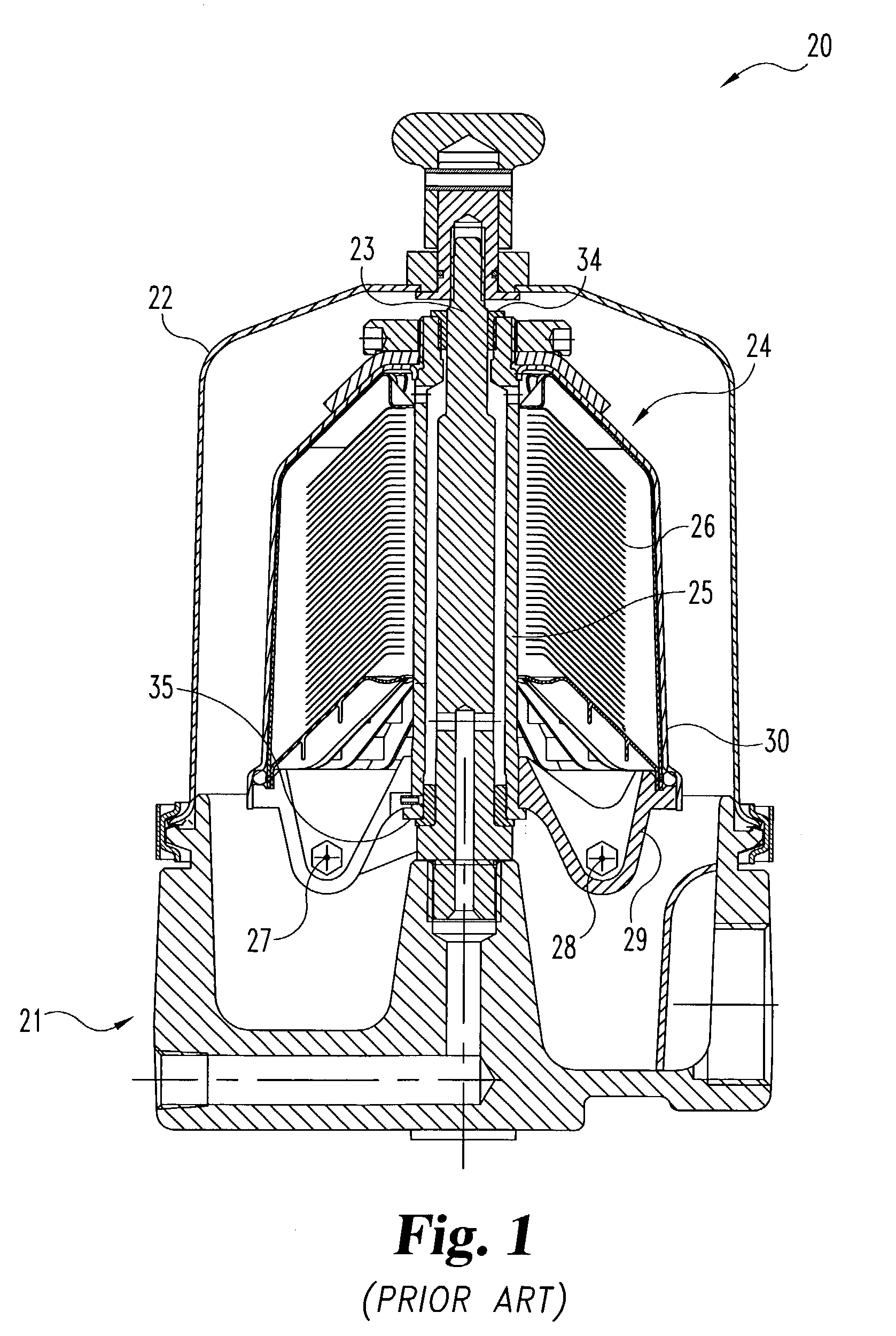

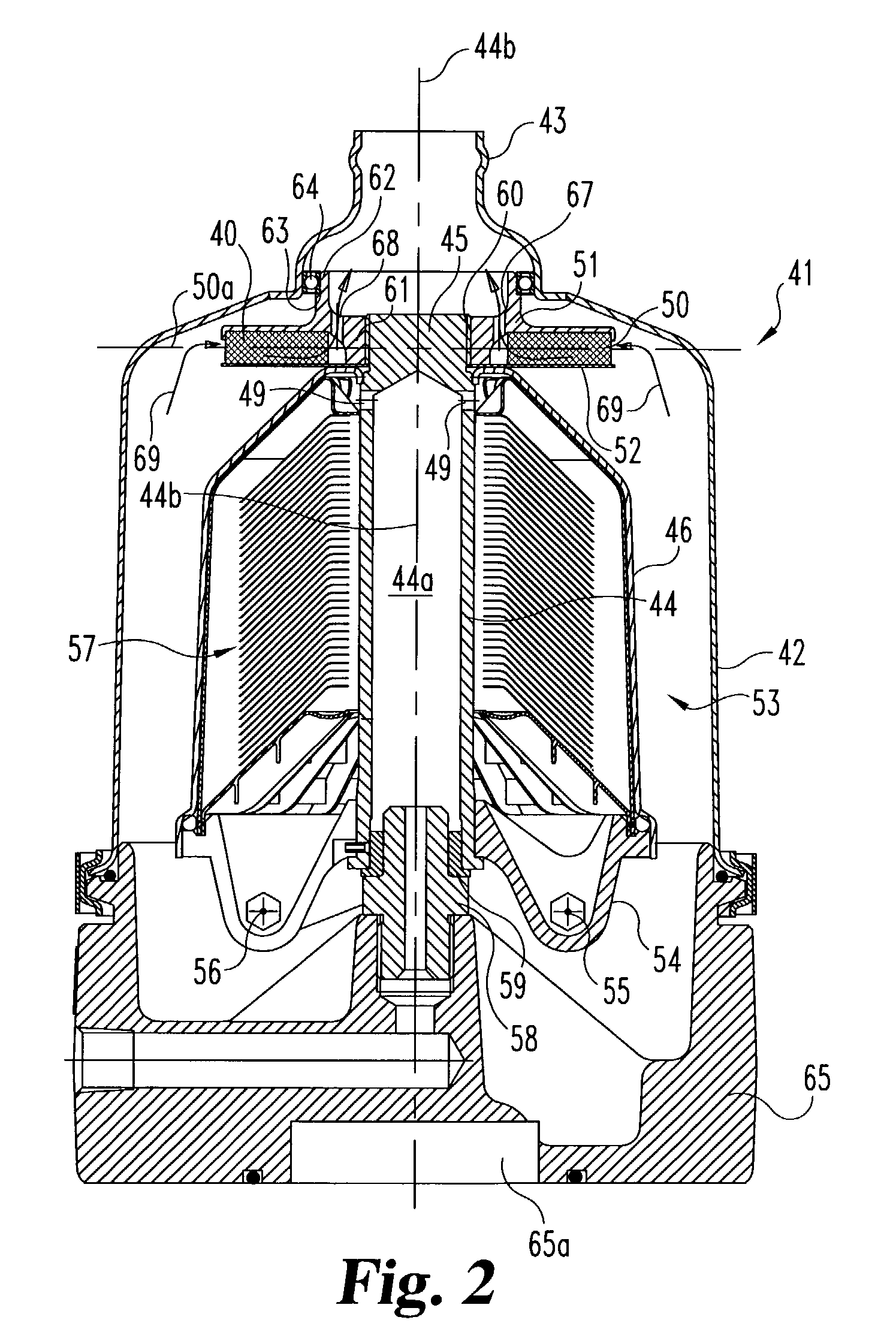

Integral air/oil coalescer for a centrifuge

InactiveUS7235177B2Combination devicesDispersed particle filtrationParticulatesMechanical engineering

A centrifuge for separating particulate matter from circulating fluid includes a centrifuge enclosure including a housing and a base joined together so as to define a hollow interior. A rotor is positioned in the hollow interior and is supported by the base in a manner to permit rotary motion of the rotor relative to the centrifuge enclosure. A coalescing filter assembly is secured to the rotor and is constructed and arranged for removing oil aerosol from a blowby gas which is introduced into the centrifuge. A roller bearing, press fit into the centrifuge housing, receives a portion of the coalescing filter assembly.

Owner:FLEETGUARD INC

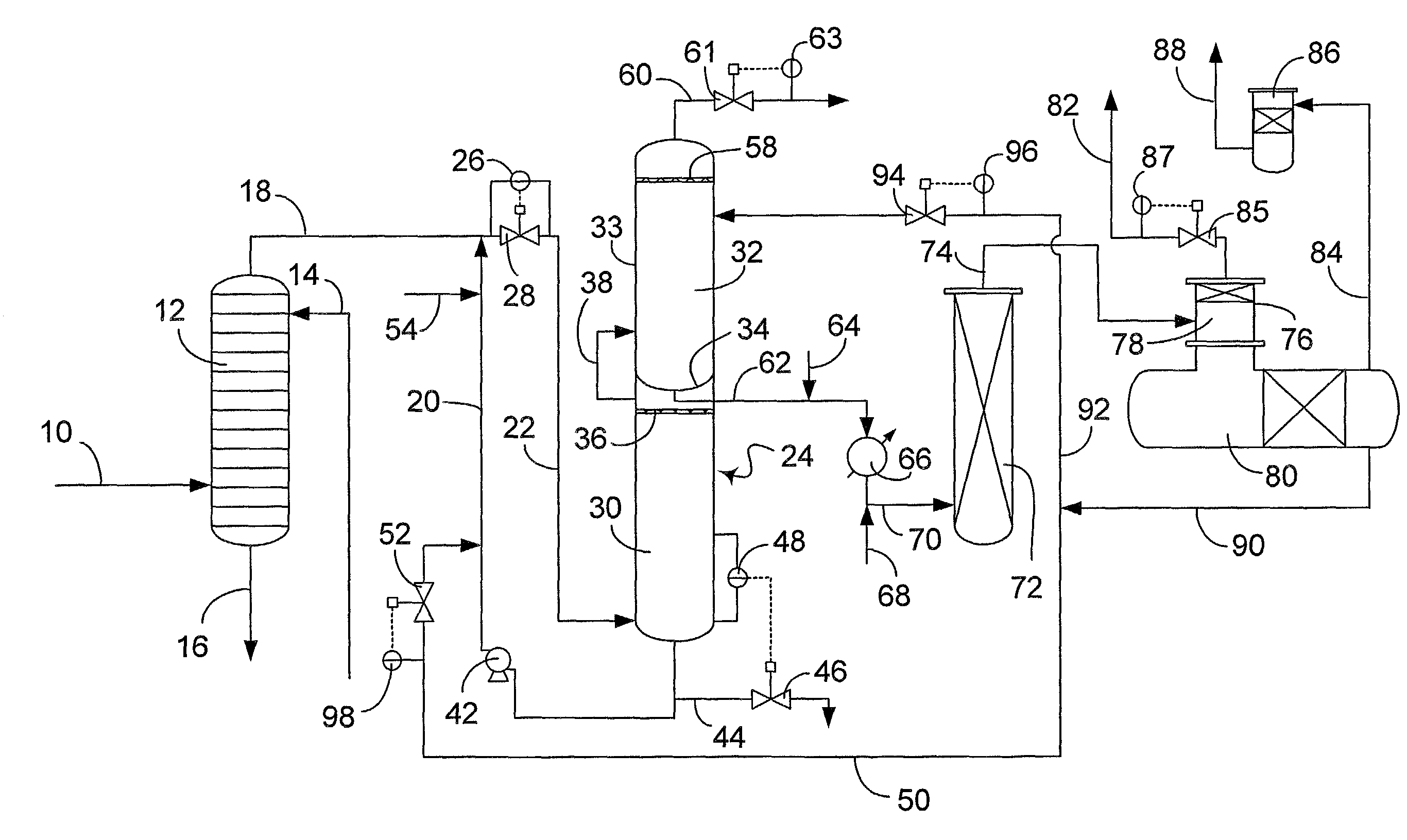

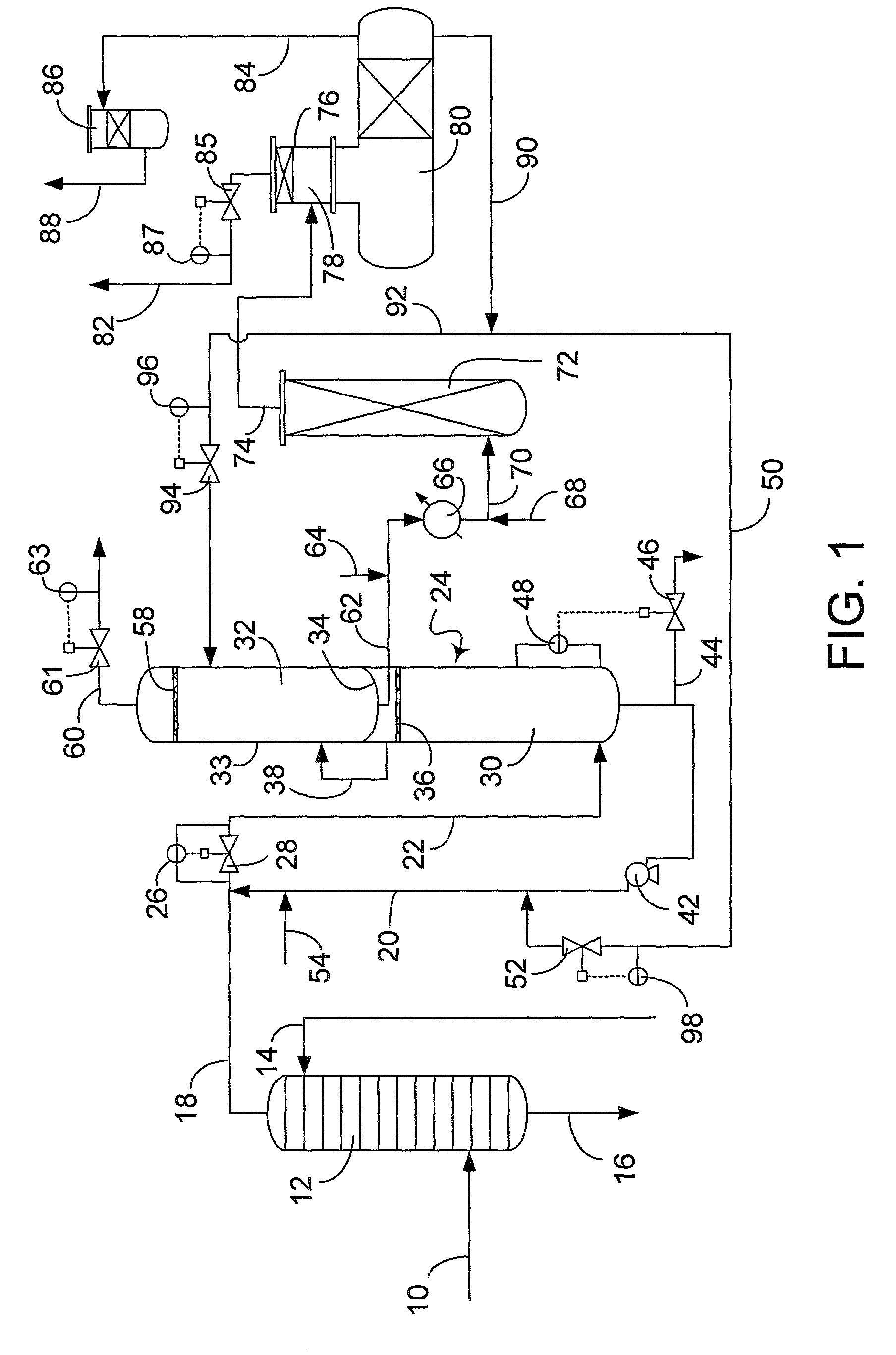

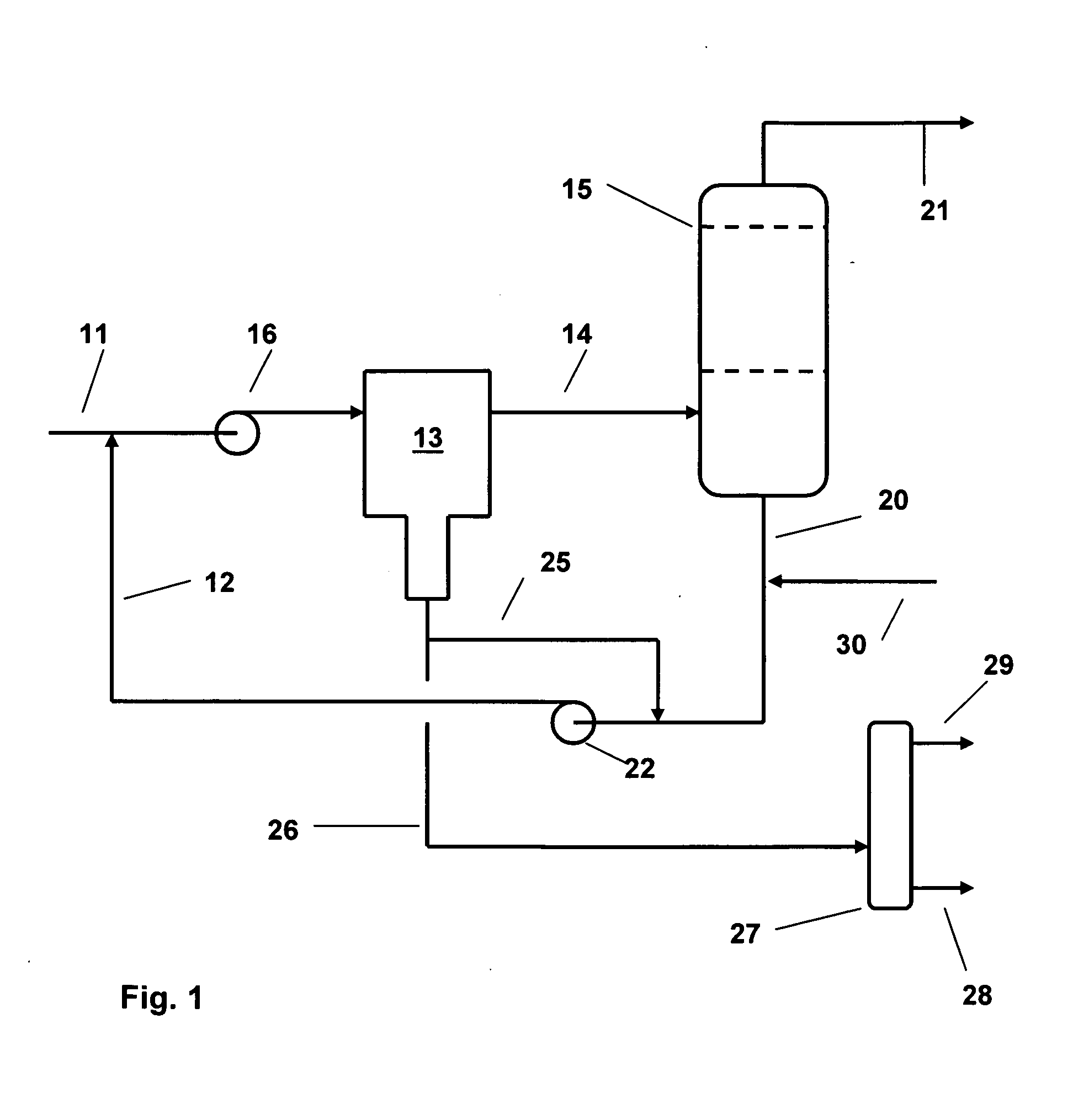

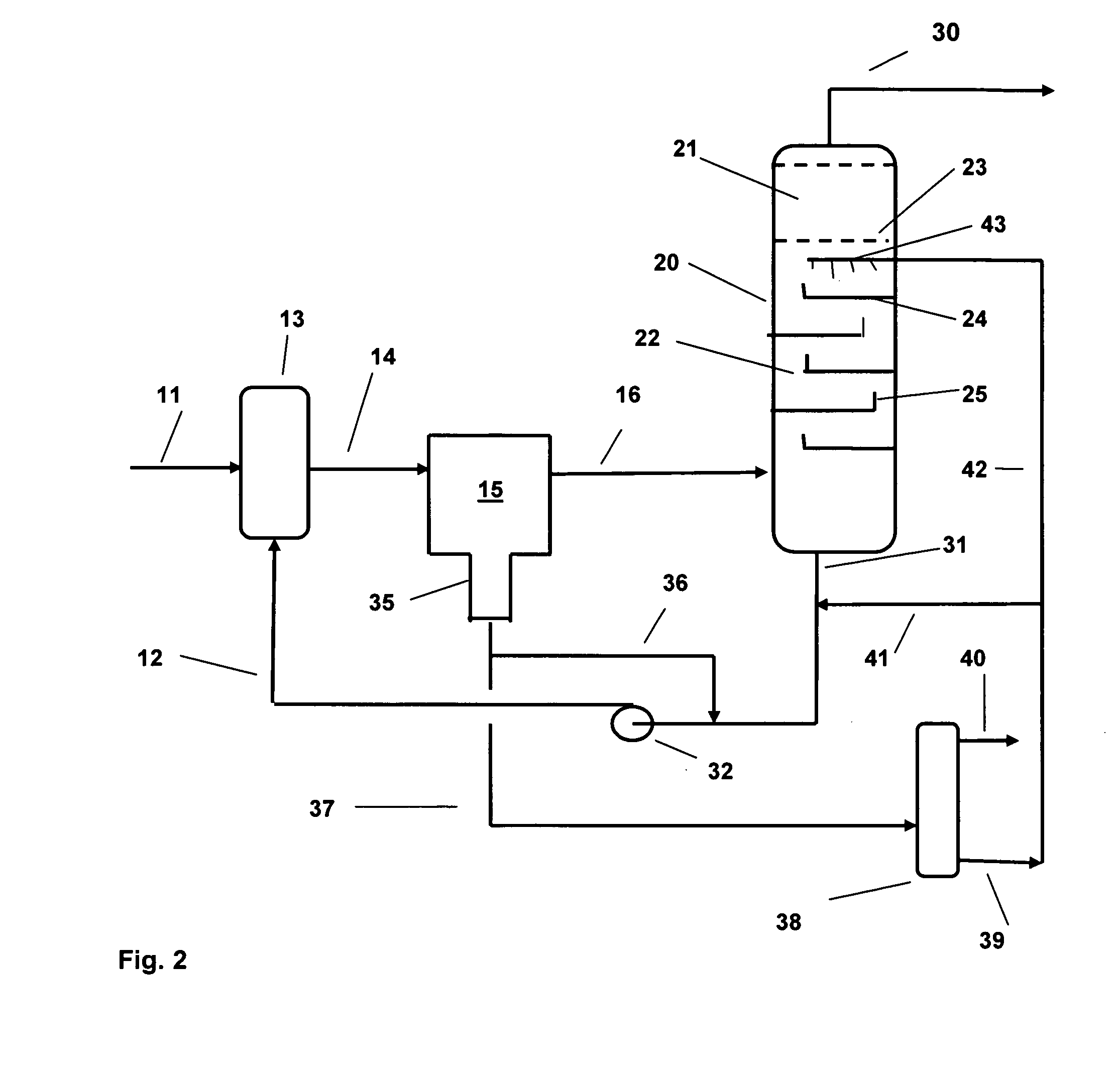

Apparatus and process for extracting sulfur compounds from a hydrocarbon stream

Described is an apparatus and process for extracting sulfur compounds from a hydrocarbon stream. A prewash section for converting hydrogen sulfide to sodium sulfide by reaction with an alkali such as caustic communicates with an extractor section disposed directly above the prewash section for converting mercaptans to mercaptides by reaction with alkali. Hydrocarbon product exits the extractor section through a coalescer that prevents alkali from exiting with the hydrocarbon product stream.

Owner:UOP LLC

Fuel filter system

ActiveUS7938963B2Efficient separationAvoid disadvantagesSeparation devicesSedimentation separationFilter systemFuel filter

A fuel filter system, particularly a diesel filter, including a housing, a particle filter arranged in the housing, and a coalescer element mounted on the particle filter. Fuel passes successively through the serially connected coalescer and particle filter. The coalescer element improves the separation of any water contained in the fuel to be filtered, while exhibiting no or no significant fuel-filtering properties.

Owner:MANN HUMMEL GMBH

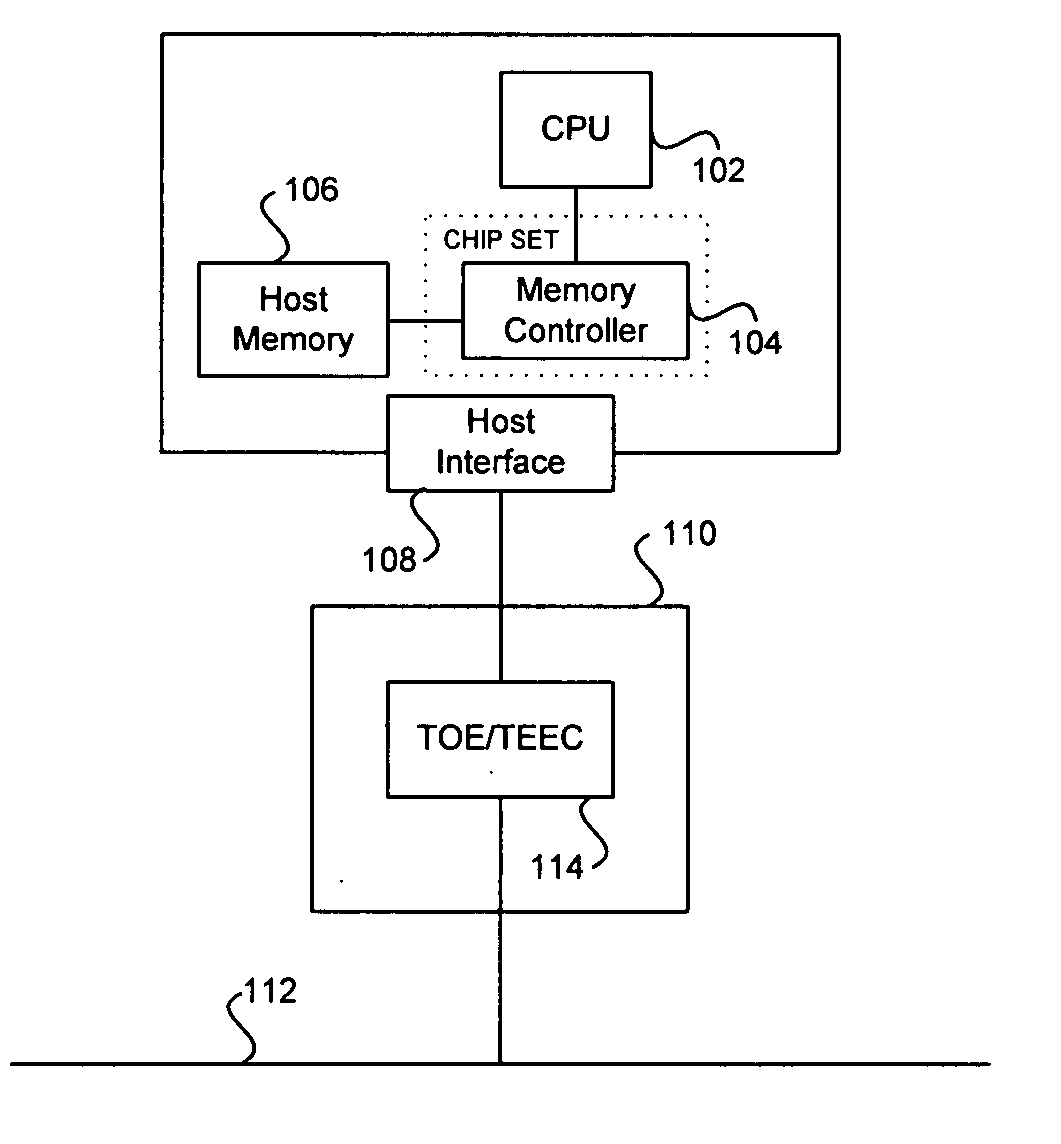

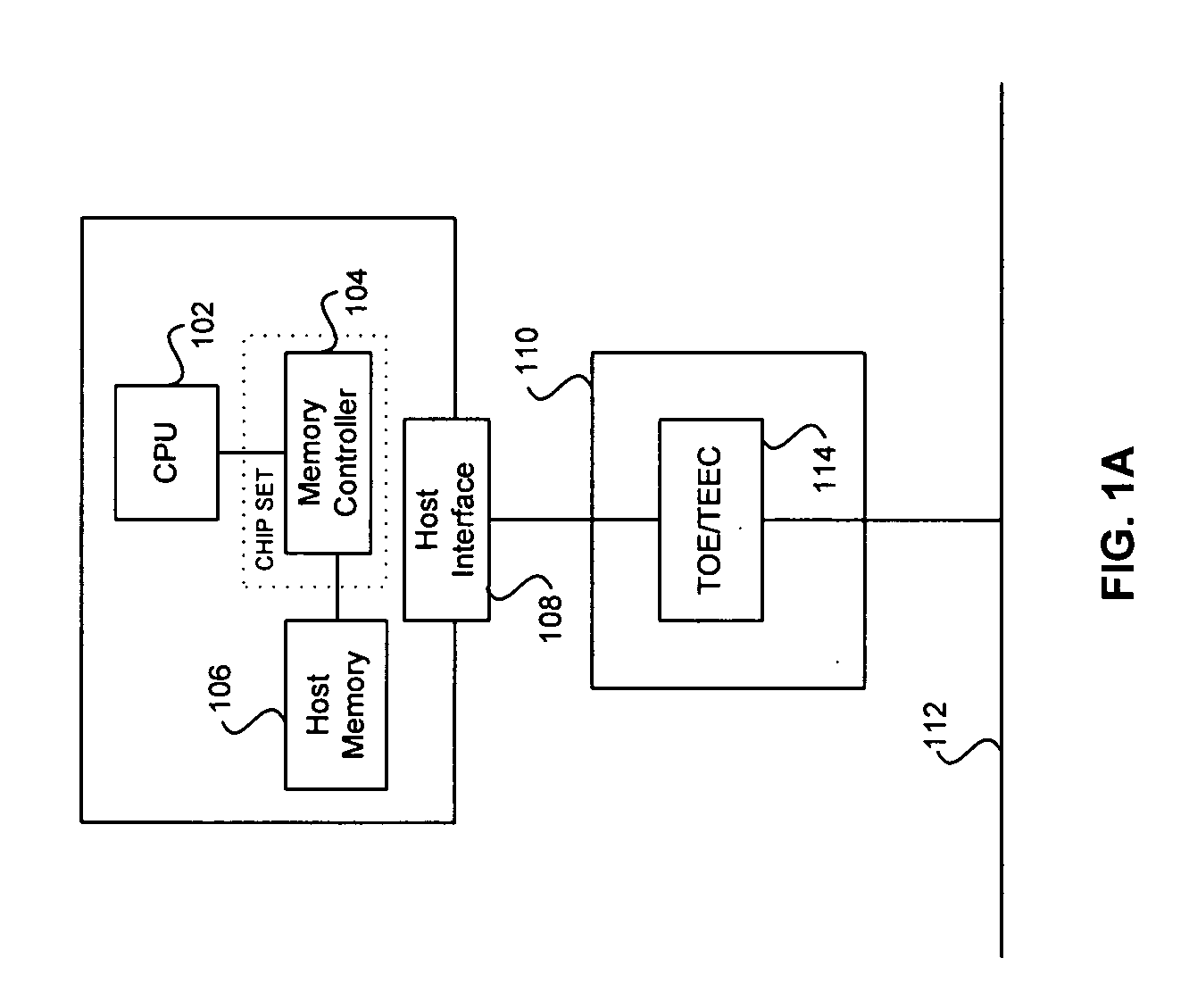

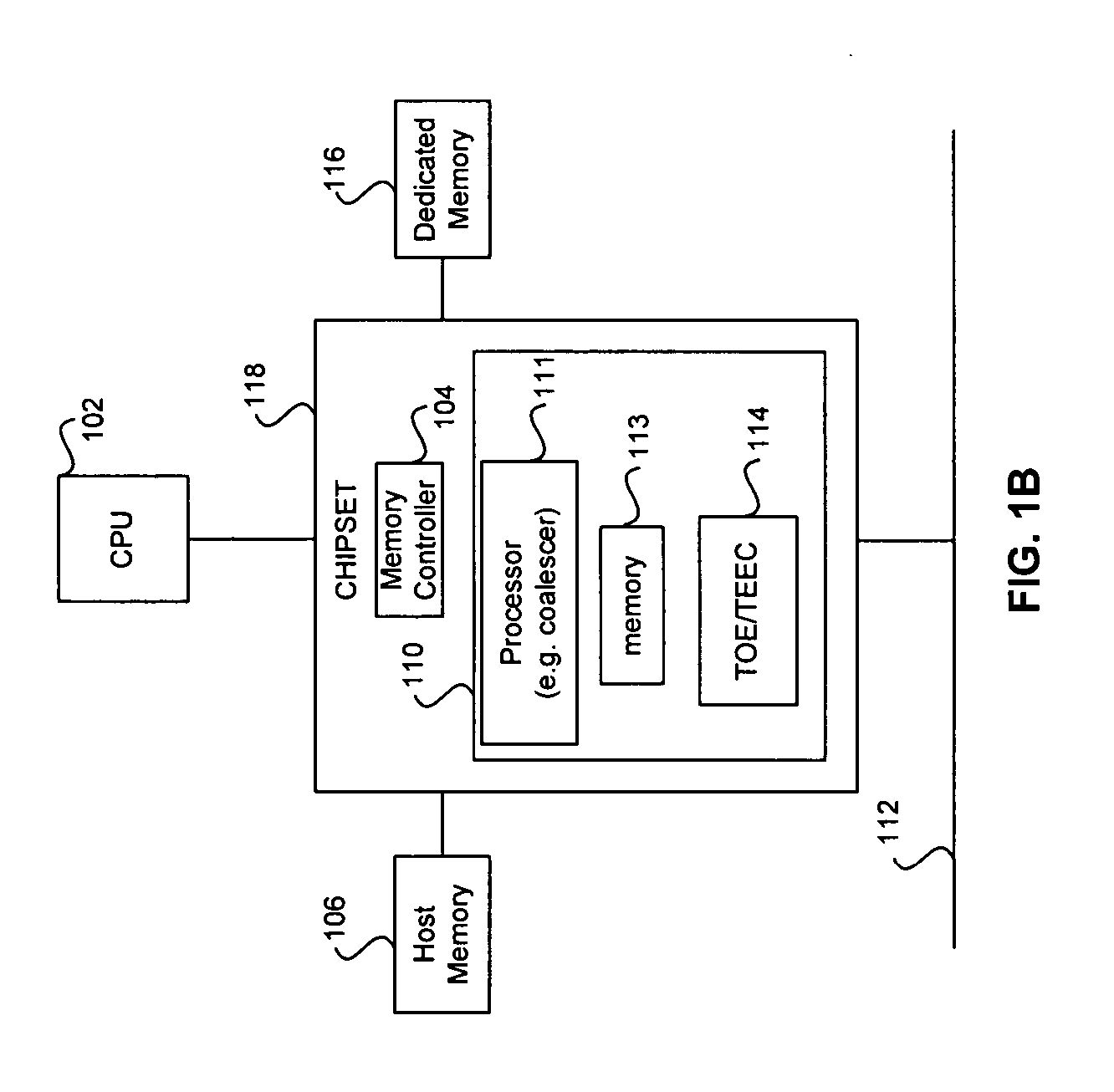

Method and system for TCP large receive offload

Certain embodiments of the invention may be found in a method and system for transmission control protocol (TCP) large receive offload. A coalescer may be utilized to collect TCP segments in a network interface card (NIC) without transferring state information to a host system. The collected TCP segments may be buffered in the coalescer. The coalescer may verify that the network connection associated with the collected TCP segments has an entry in a connection lookup table (CLT). When the CLT is full, the coalescer may close a current entry and assign the network connection to the available entry. The coalescer may also update information in the CLT. When an event occurs that terminates the collection of TCP segments, the coalescer may generate a single coalesced TCP segment based on the collected TCP segments. The coalesced TCP segment and state information may be communicated to the host system for processing.

Owner:AVAGO TECH WIRELESS IP SINGAPORE PTE

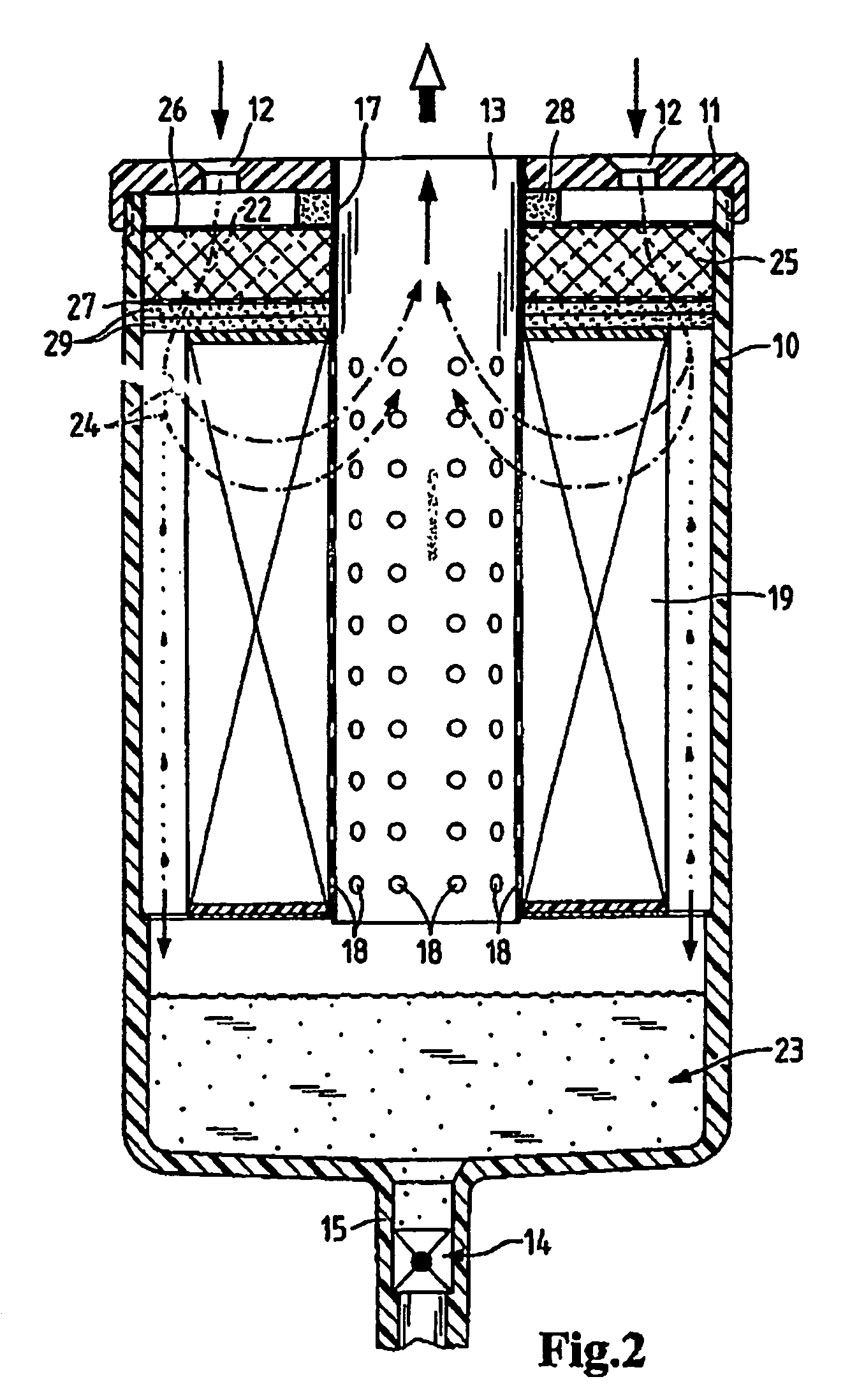

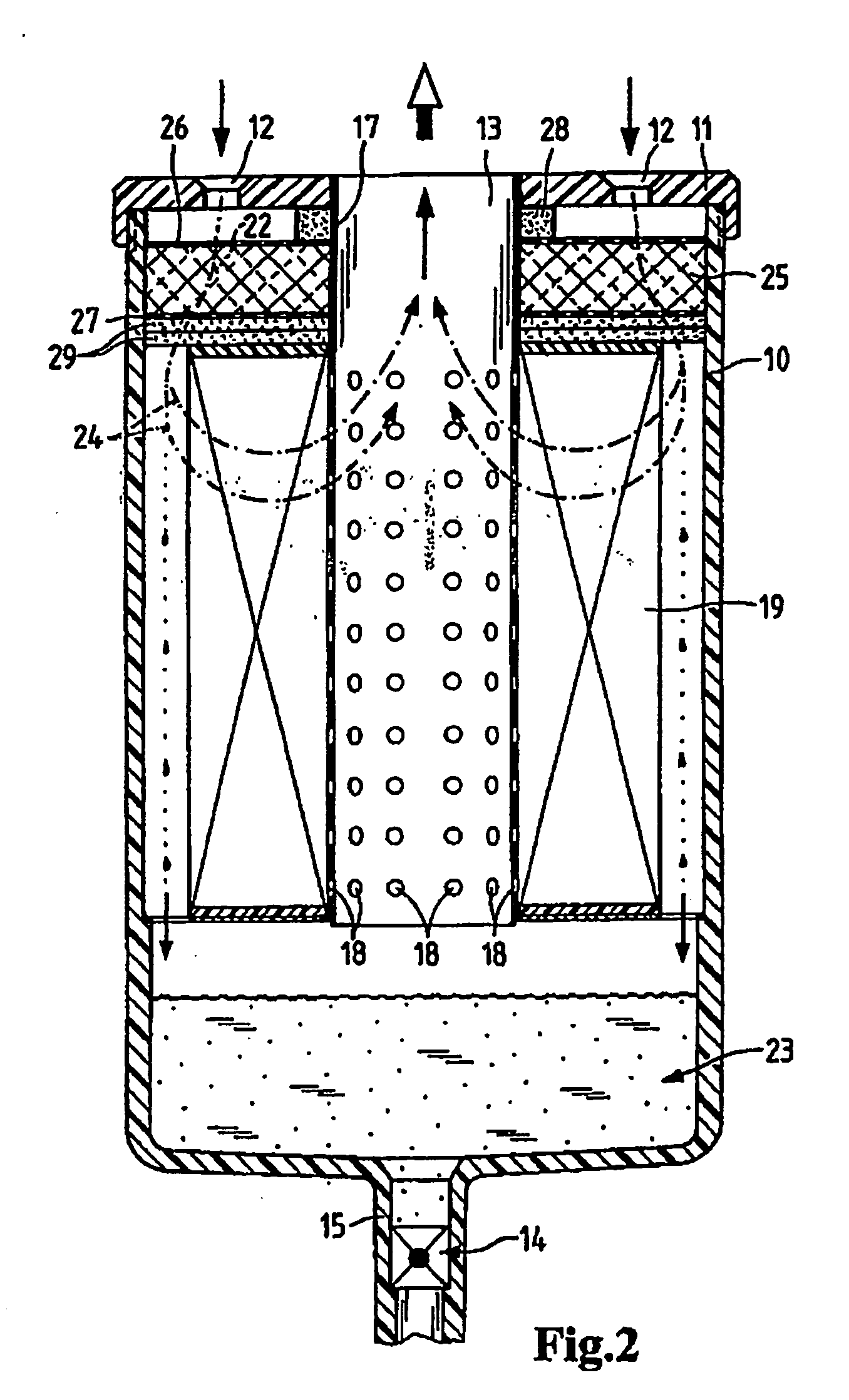

Fuel filter system

ActiveUS20060006109A1Improves separation of waterEfficient separationSeparation devicesSedimentation separationEngineeringFuel filter

A fuel filter system, particularly a diesel filter, including a housing, a particle filter arranged in the housing, and a coalescer element mounted on the particle filter. Fuel passes successively through the serially connected coalescer and particle filter. The coalescer element improves the separation of any water contained in the fuel to be filtered, while exhibiting no or no significant fuel-filtering properties.

Owner:MANN HUMMEL GMBH

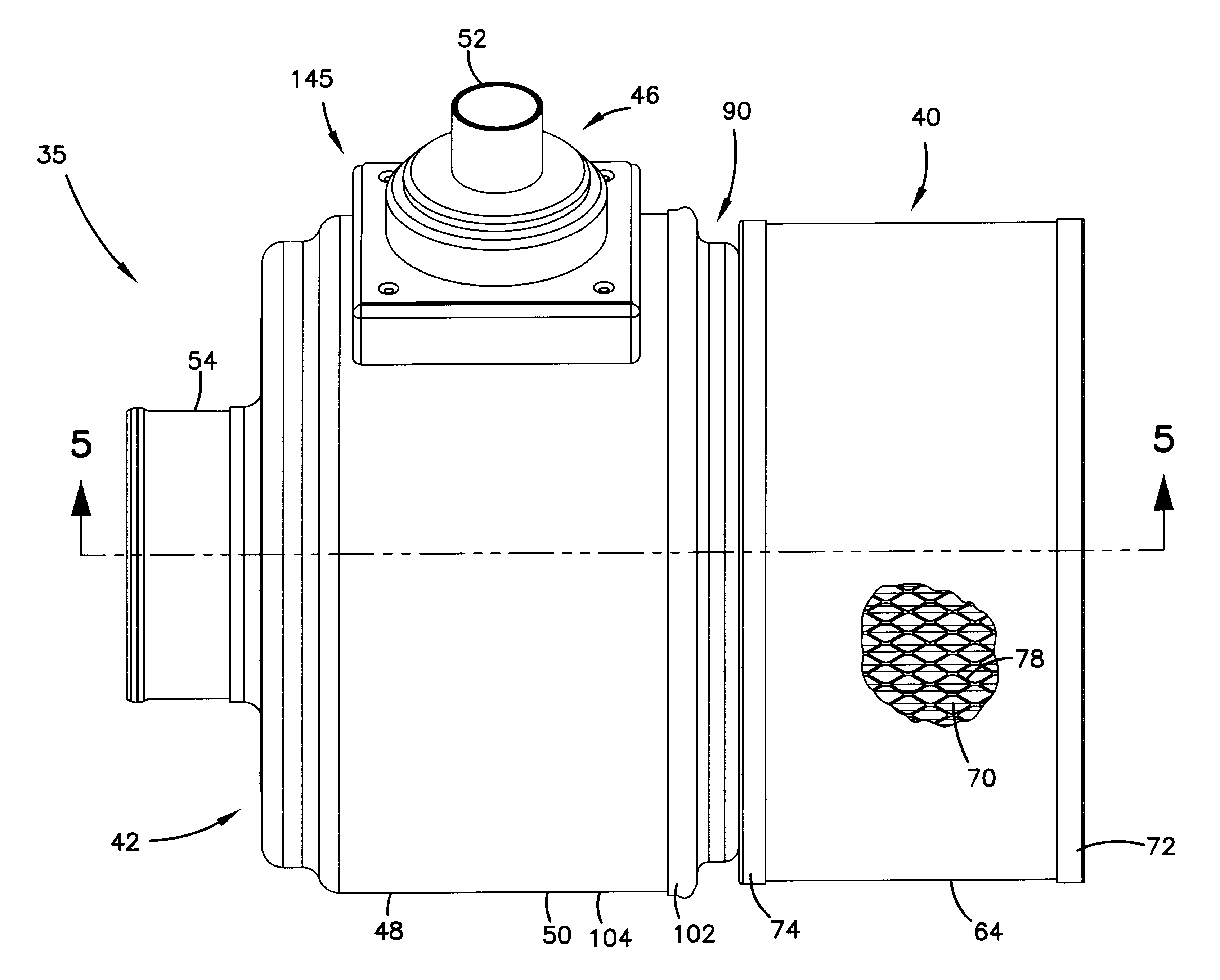

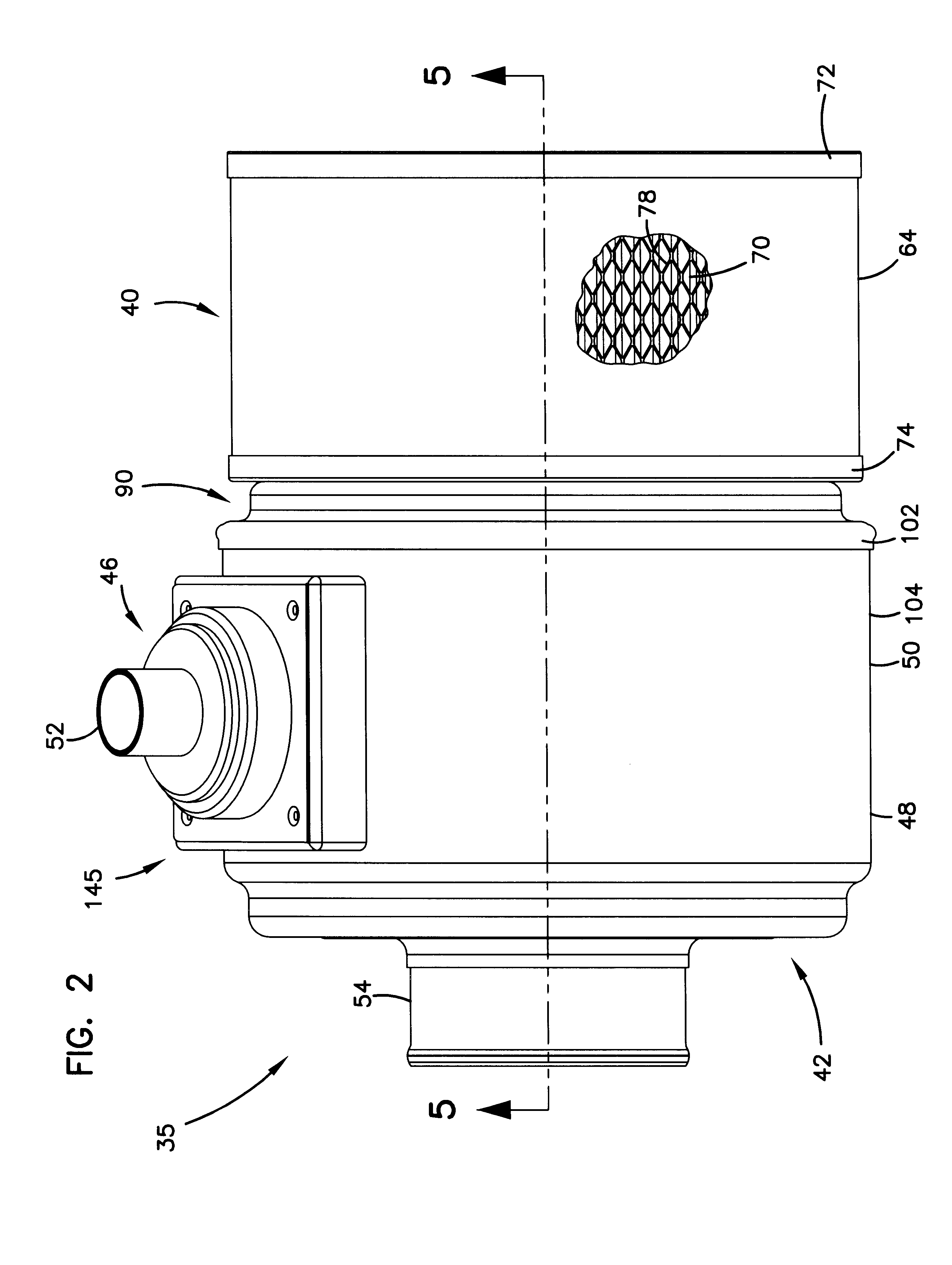

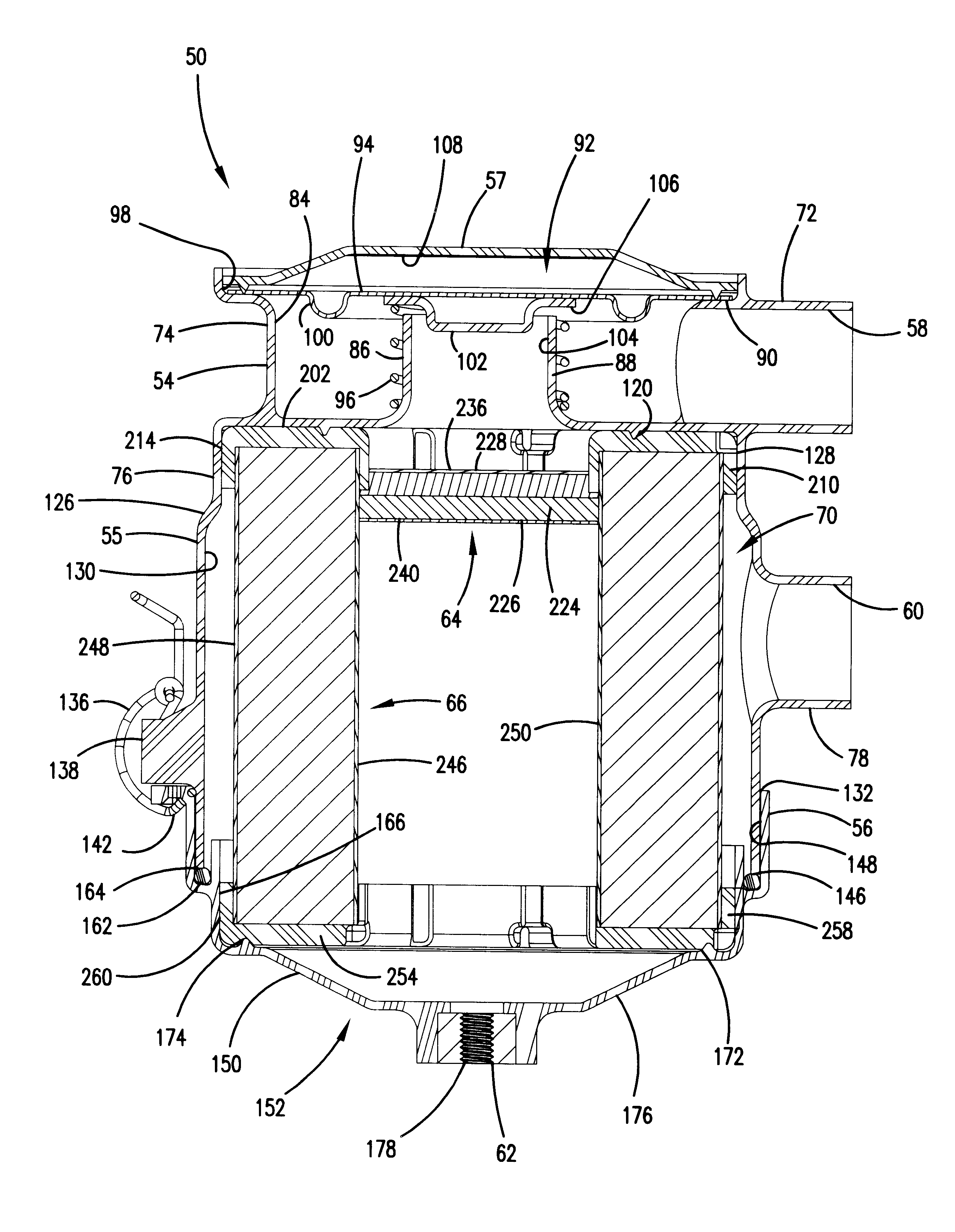

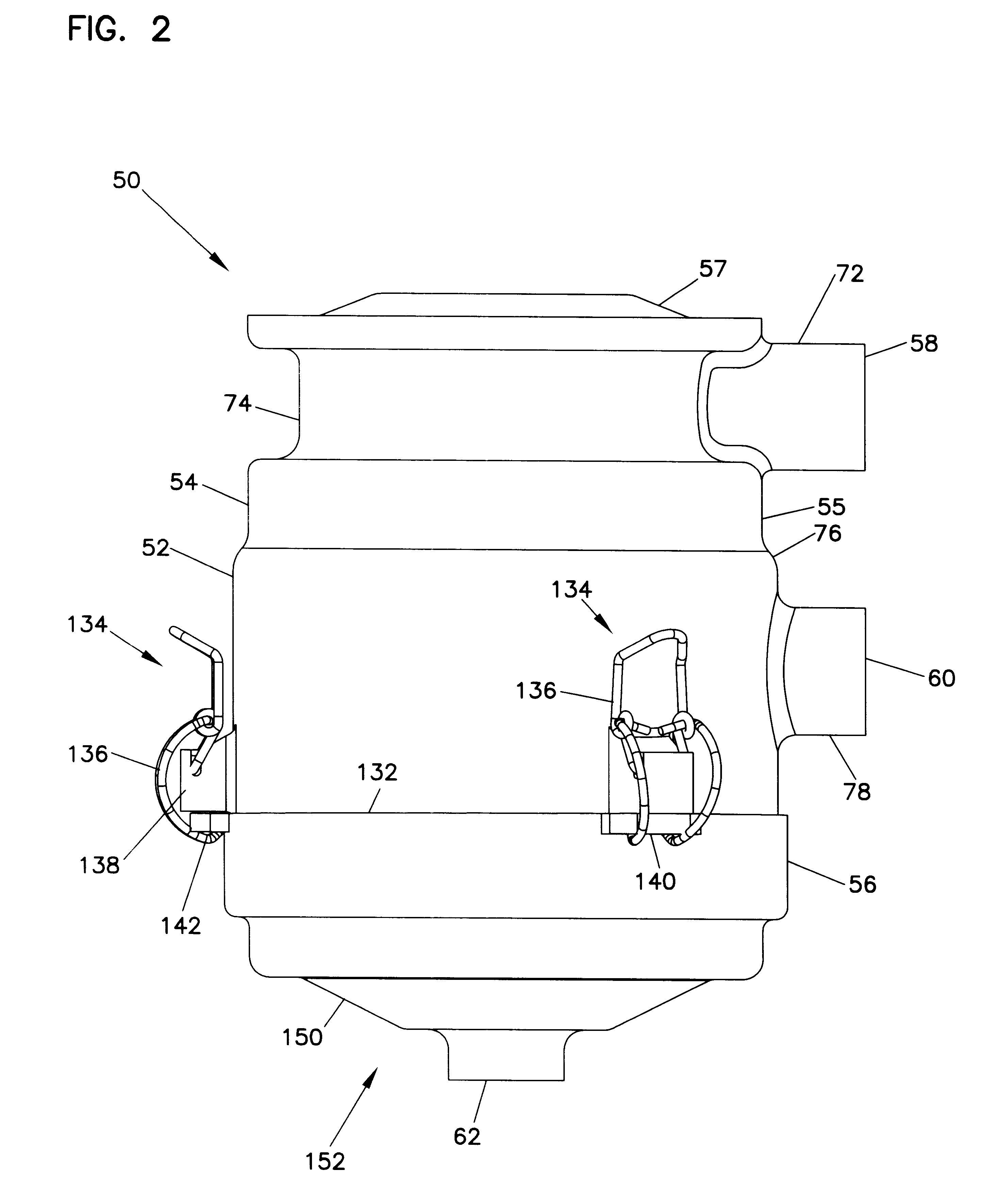

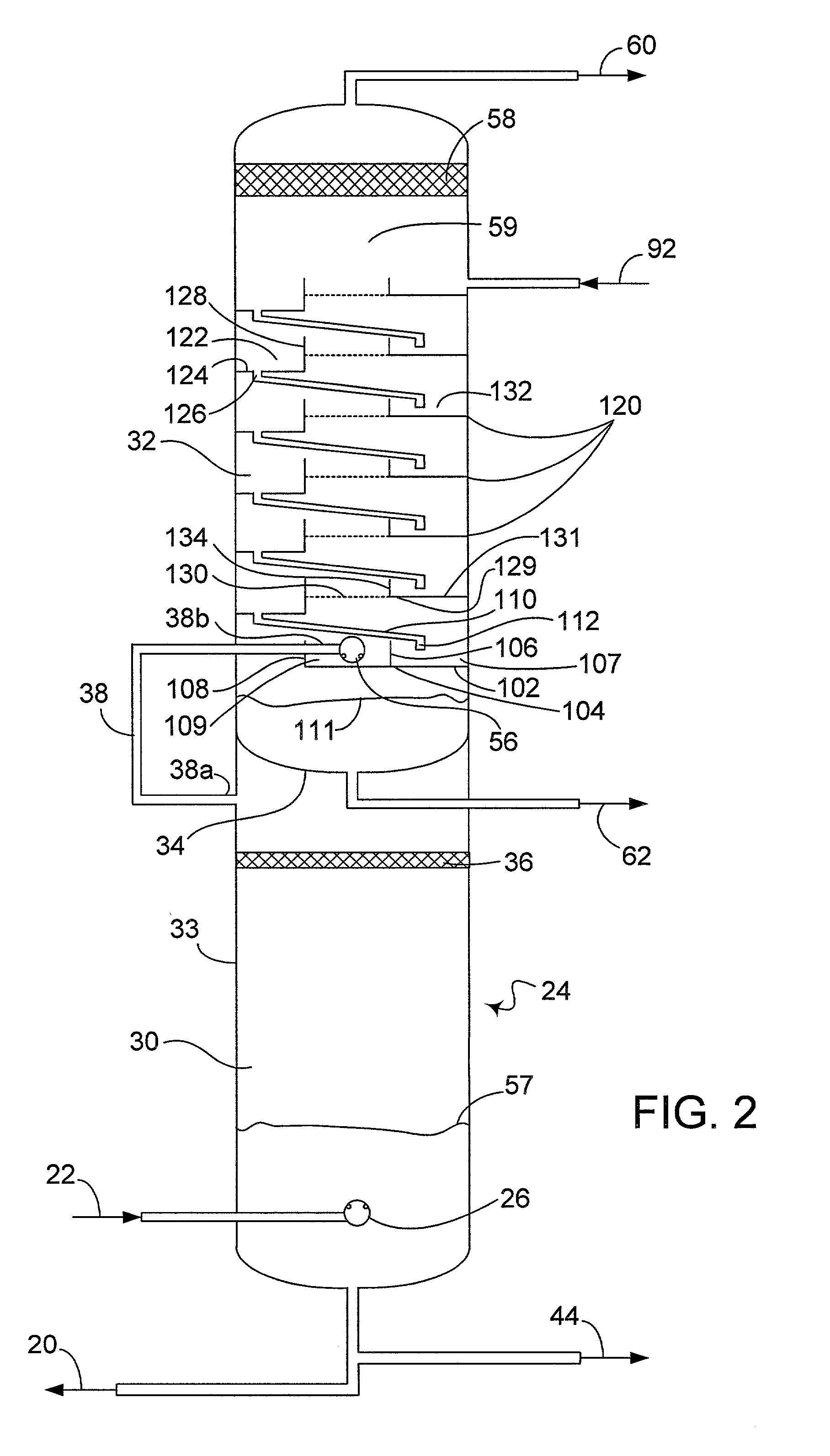

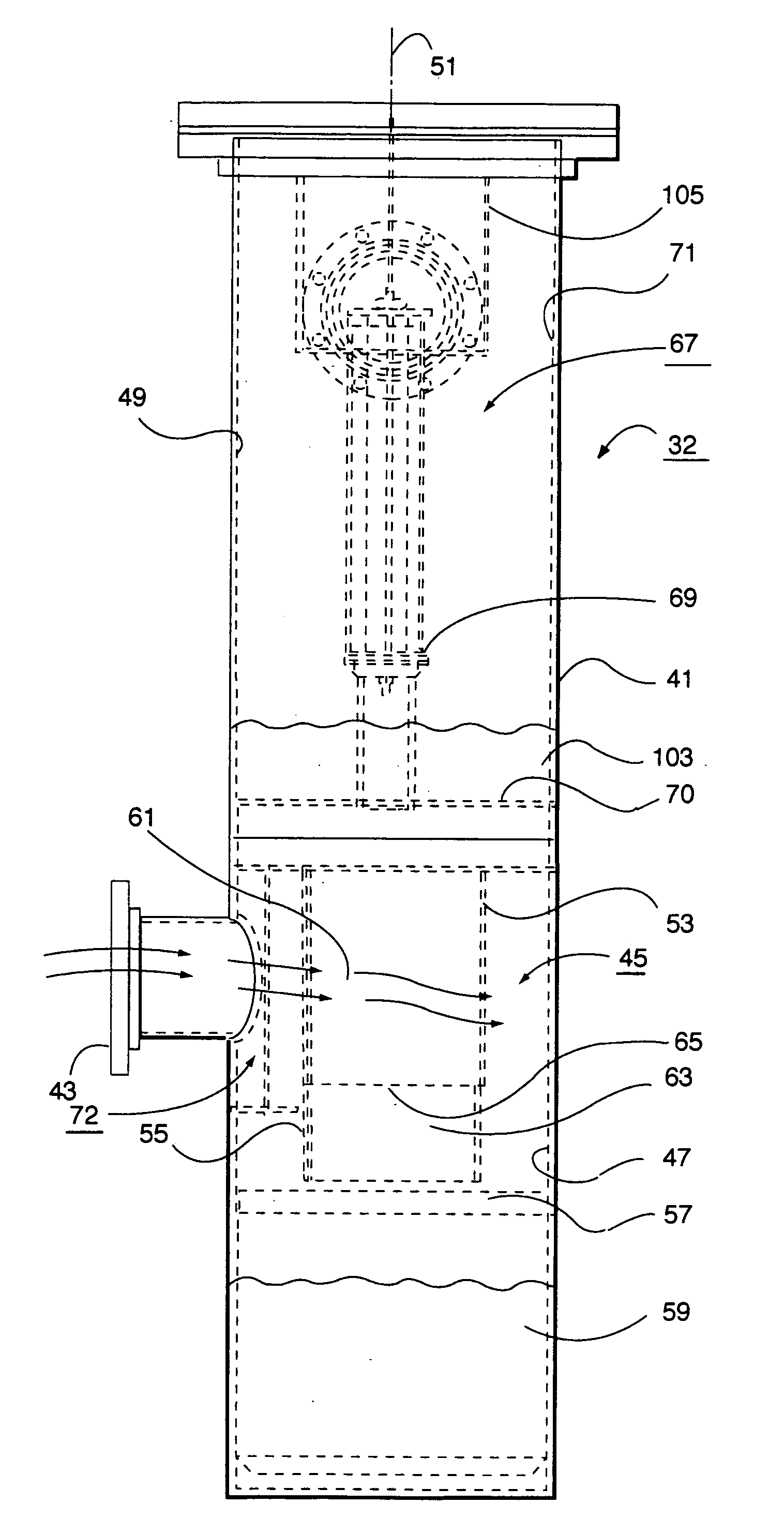

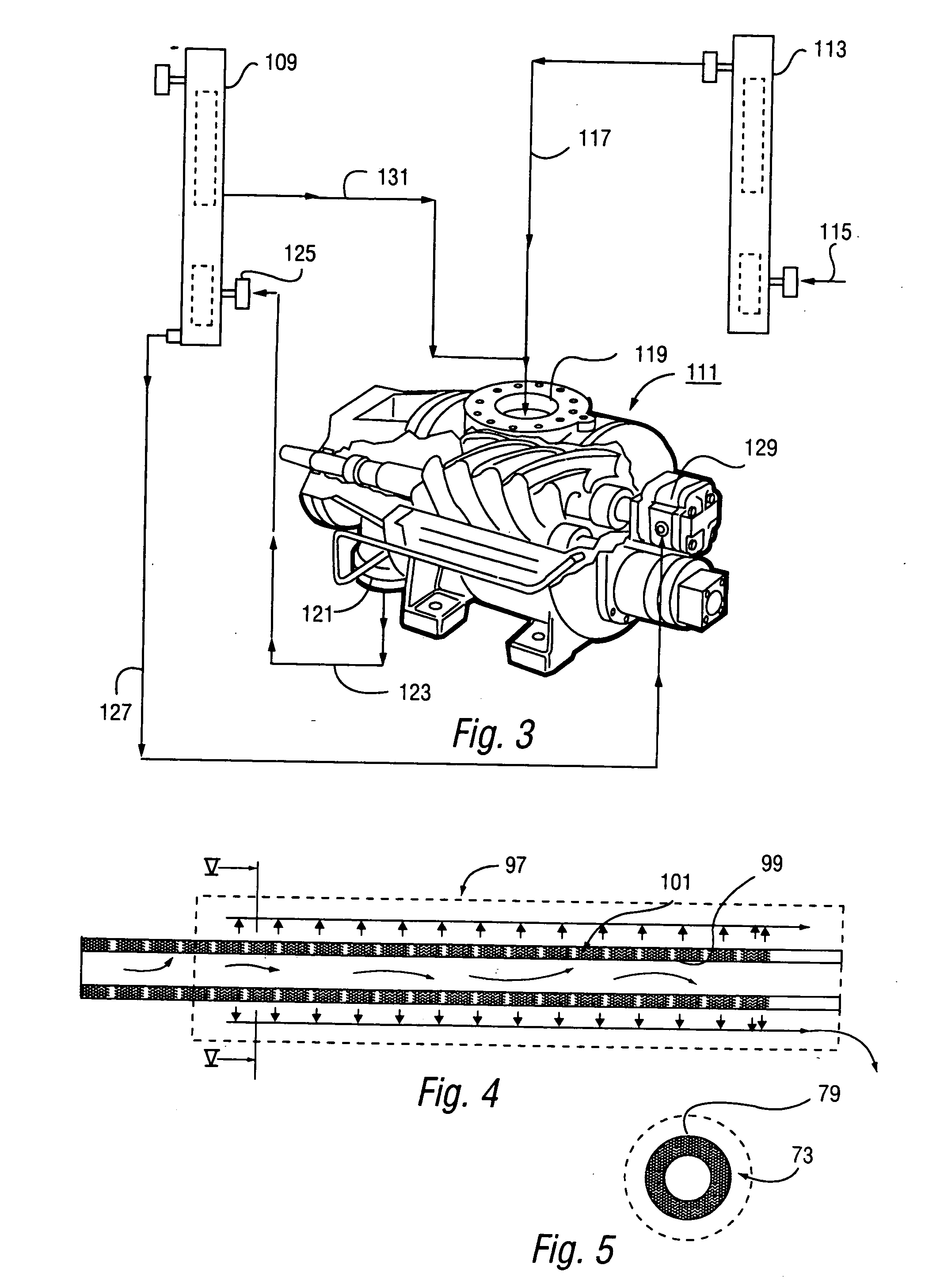

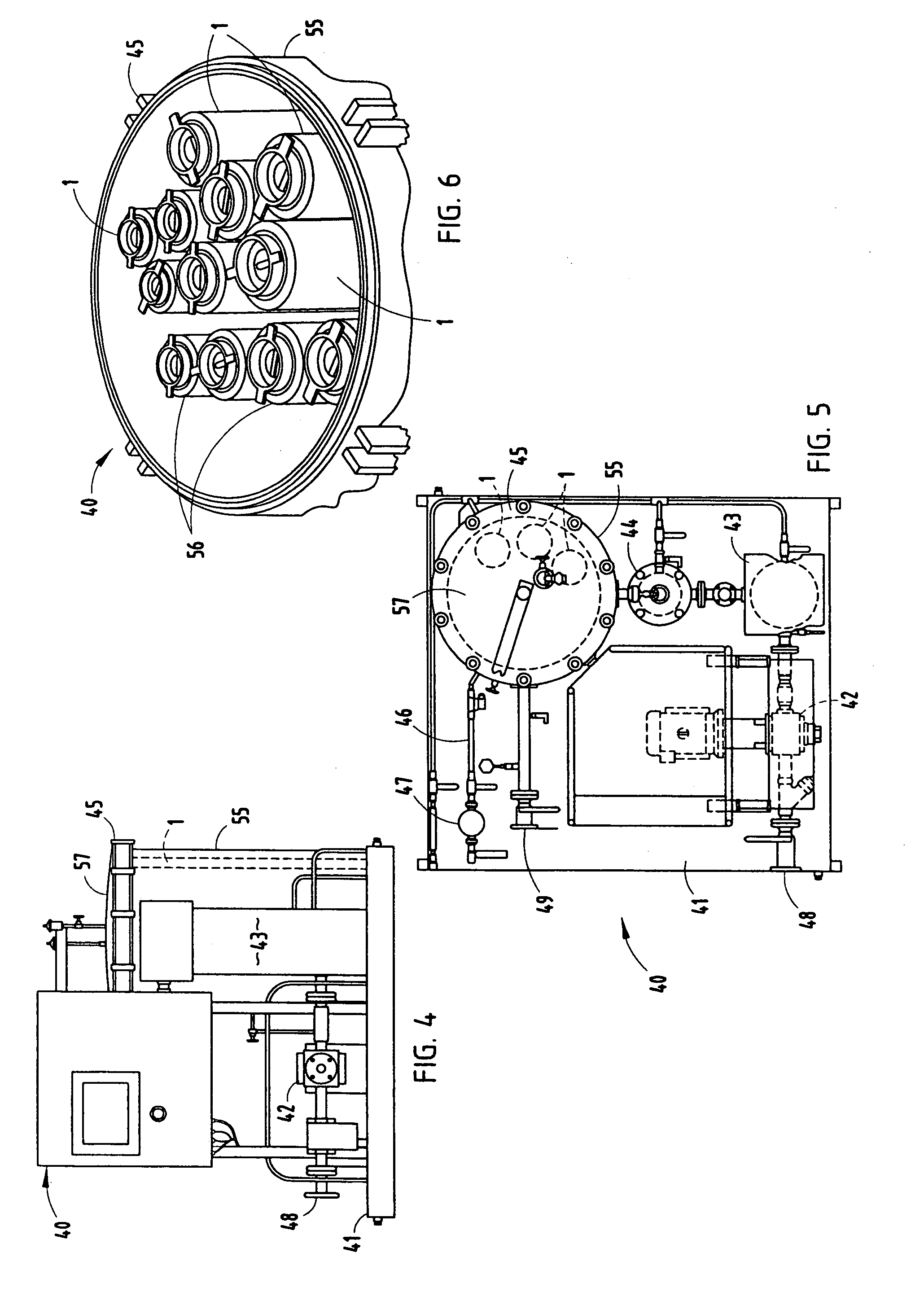

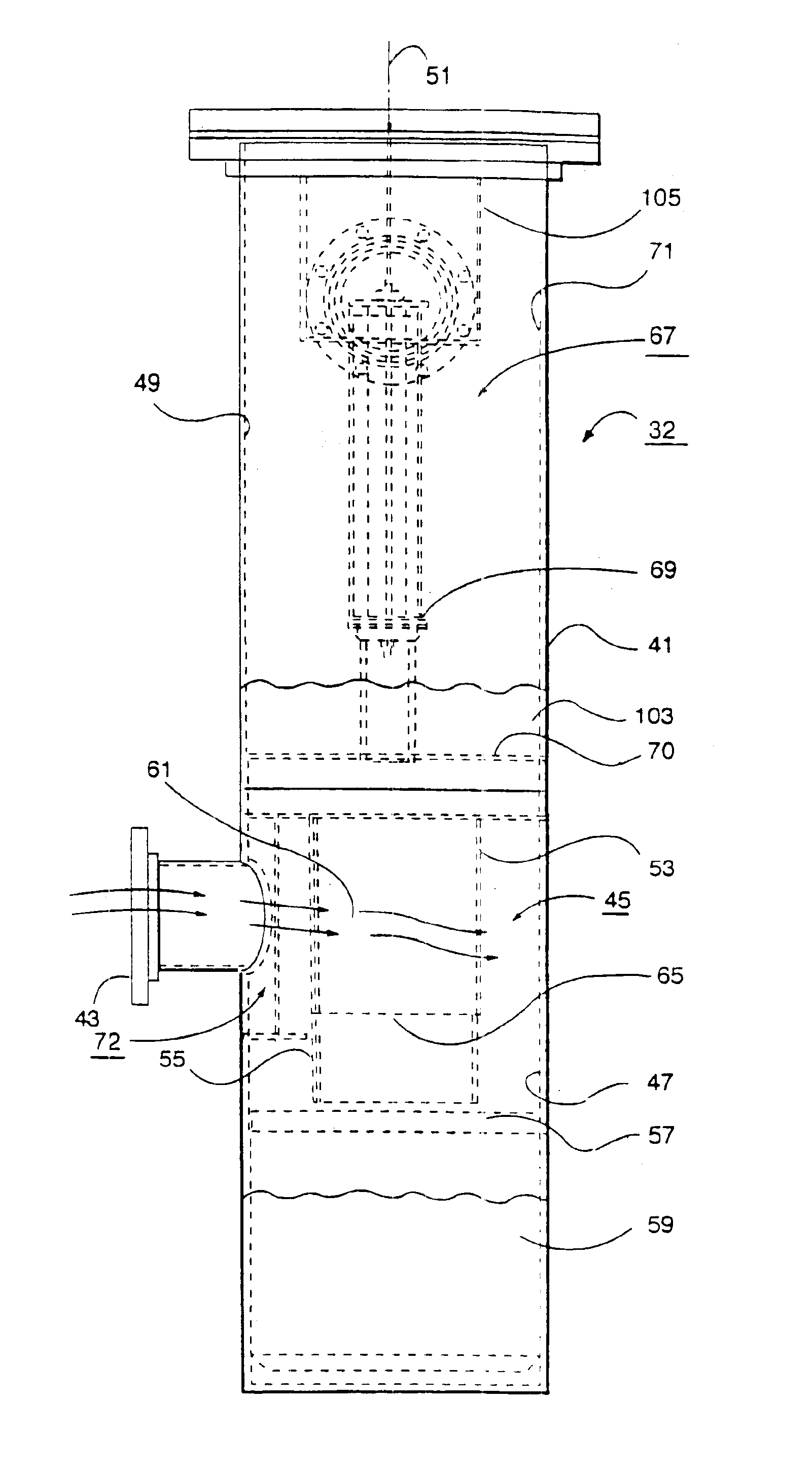

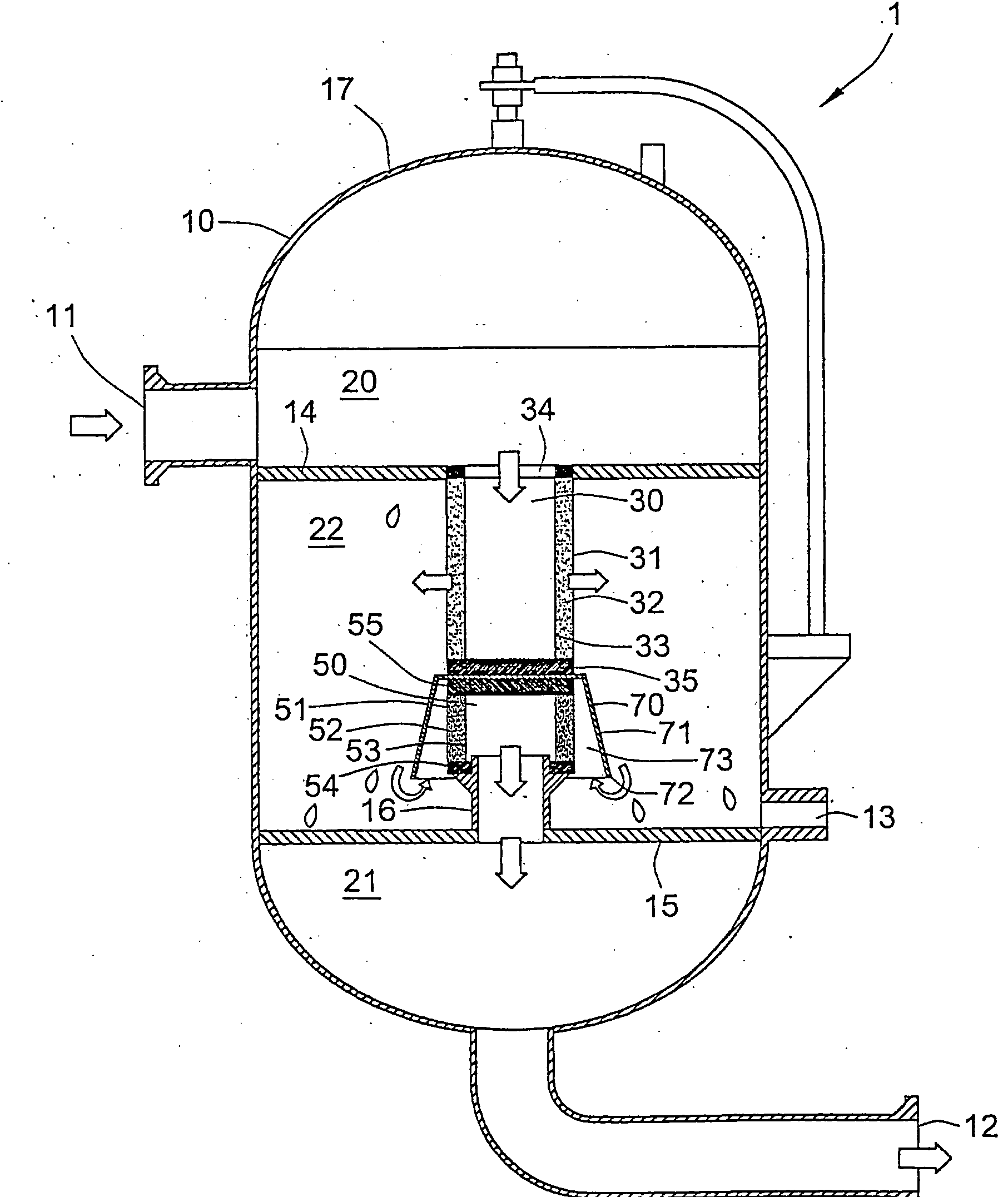

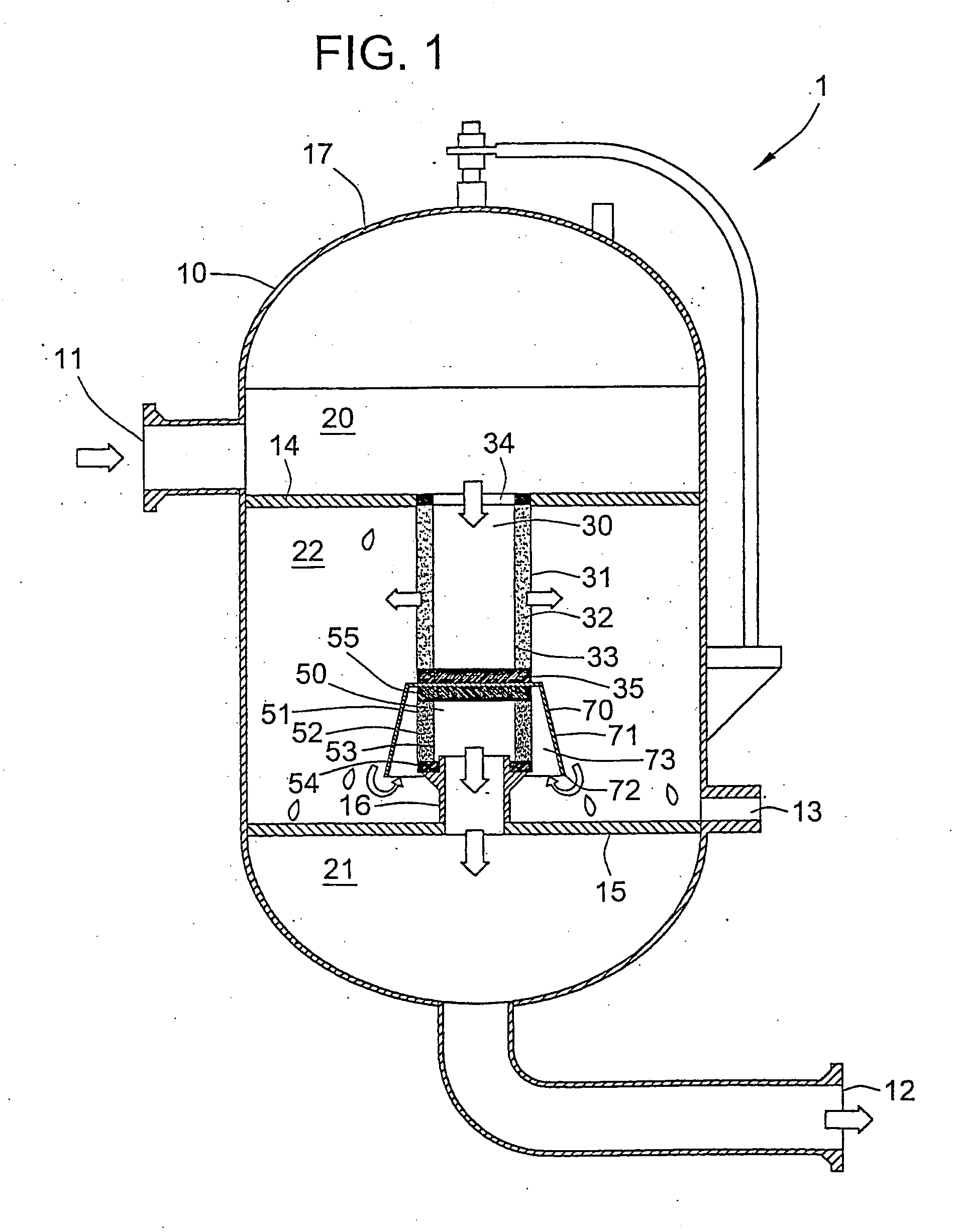

Filtration vessel and method for rotary gas compressor system

A filtration vessel is shown for use with a rotary screw compressor which receives a compressed liquid / gas mixture from the compressor. The vessel utilizes a first stage vortex knockout region to remove bulk liquids through a circular motion which imposes centrifugal forces on the gas and liquid mixture. A coalescer region located above the vortex knockout region receives the relatively lighter fluids and separates any remaining entrained liquids from the fluids. The discharge from the filtration unit is an essentially liquid free compressed gas. The liquid discharge, in the case of lube oil can be recirculated to the compressor for another cycle.

Owner:PARKER INTANGIBLES LLC

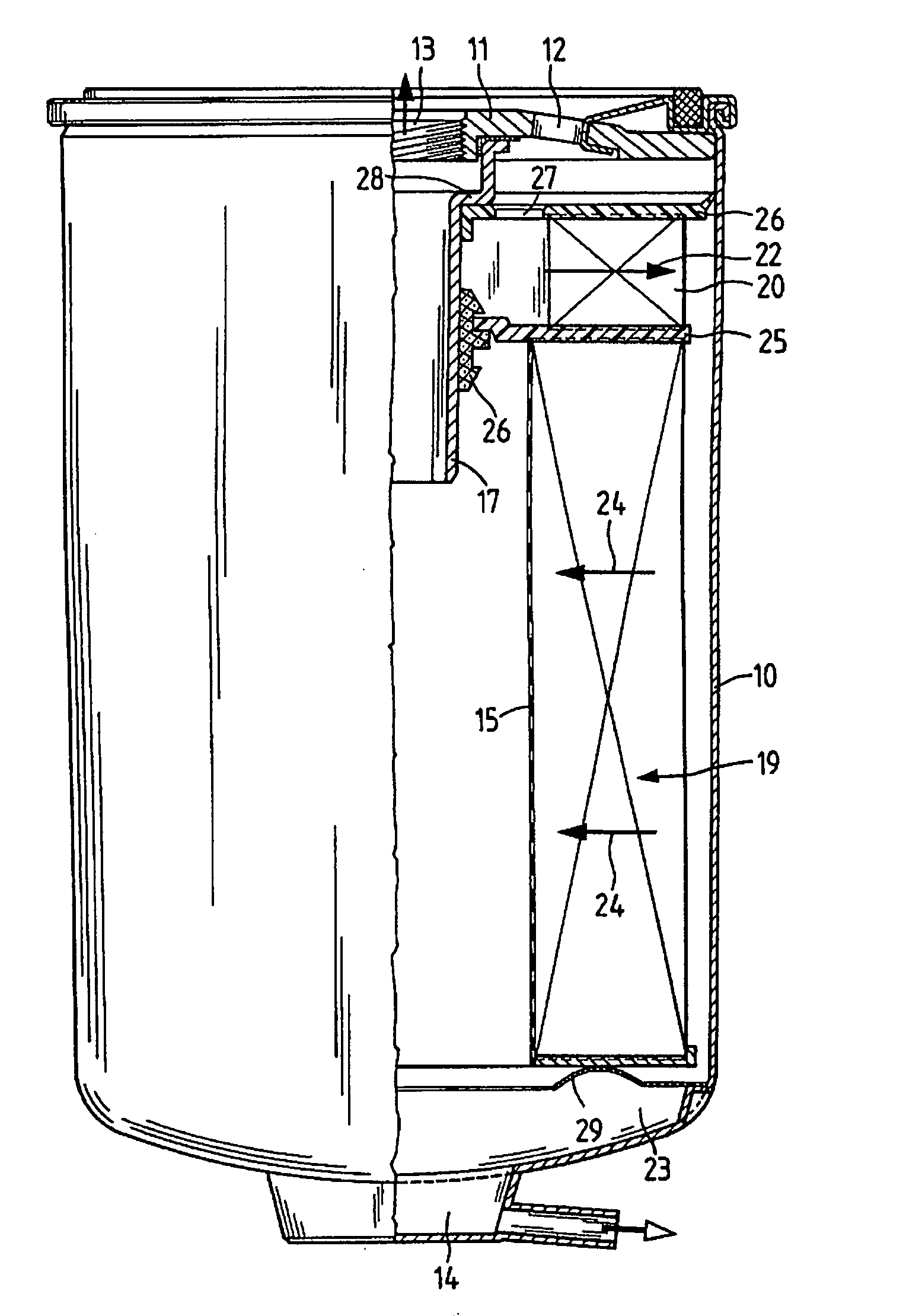

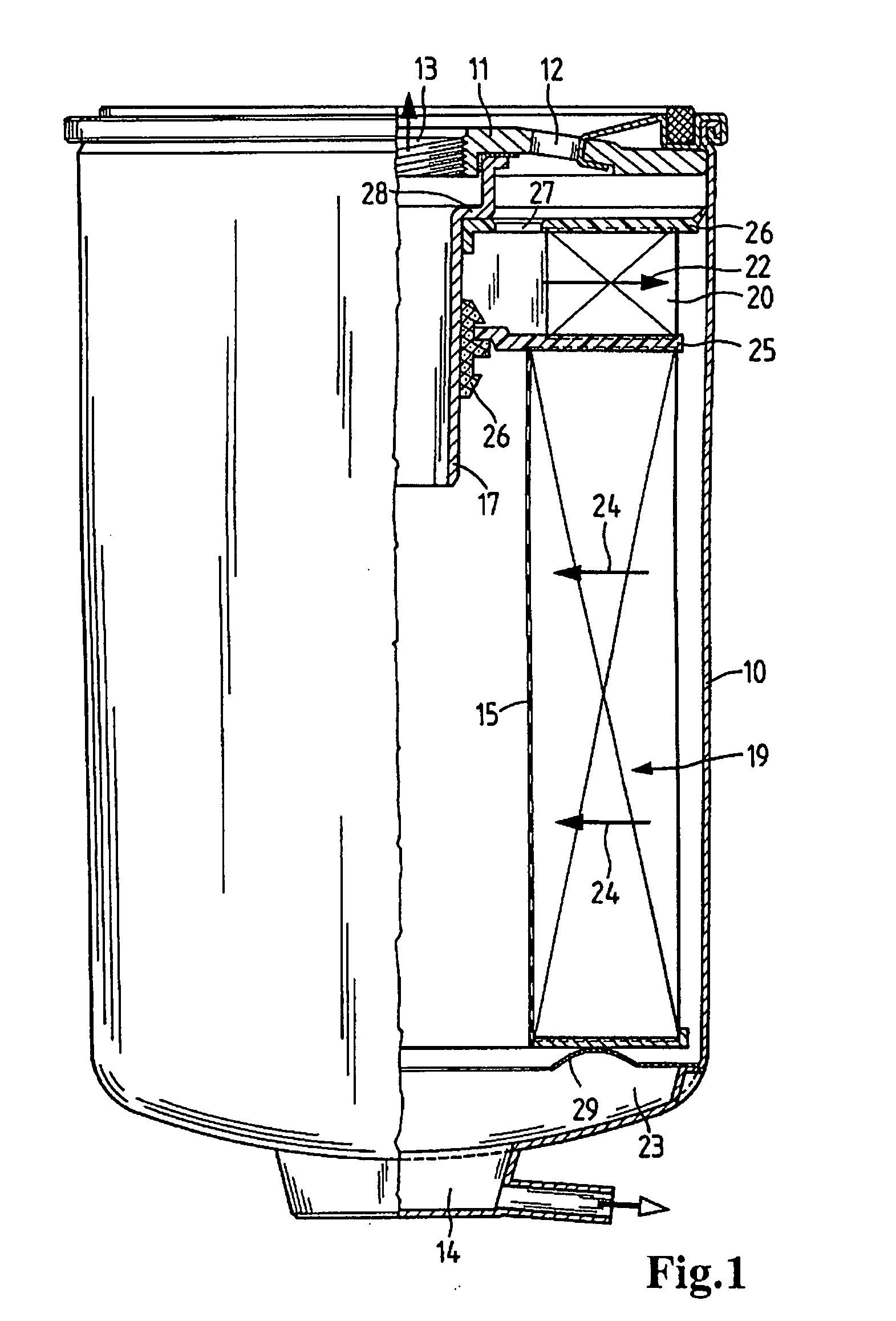

Fuel filter system

InactiveUS20080035537A1Simple structureEliminate needMultistage water/sewage treatmentMachines/enginesFuel filterInjection moulding

A fuel filter system characterized by a simple design provided with a coalescer element (20) disposed in the immediate fuel inlet region for improving the elimination of water droplets. The coalescer element includes an upper end plate (26) that extends to the inner wall of the housing (10), thereby sealing the coalescer element as well as the inlet region and the outer unfiltered fluid region. The coalescer element (20) and the particle filter (19) are arranged on a common separating element (25), which rests against the discharge tube (17) located in the center of the fuel filter via a profiled seal. The end plate of the coalescer element can be produced with the profiled elastomeric seal molded thereon by two-component injection molding or by overmolding.

Owner:MANN HUMMEL GMBH

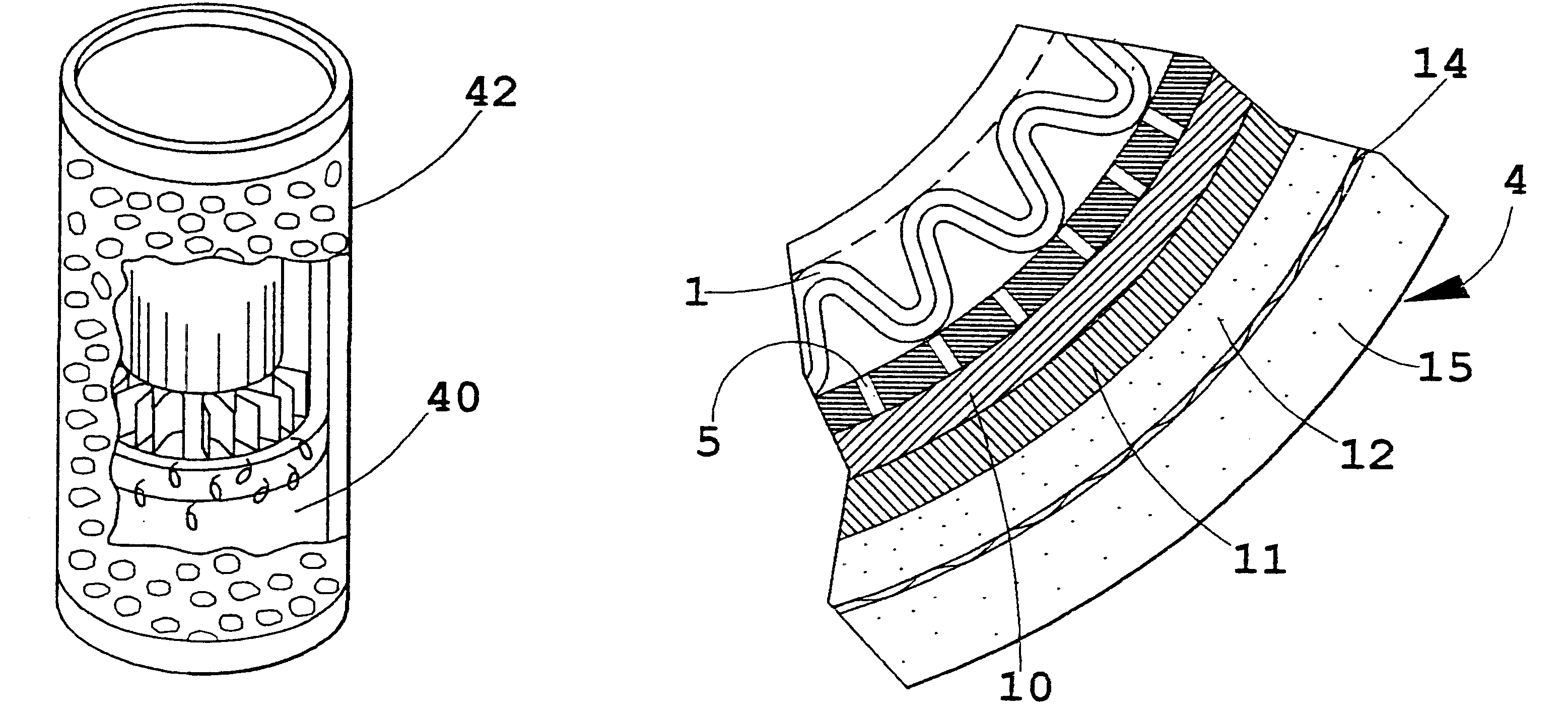

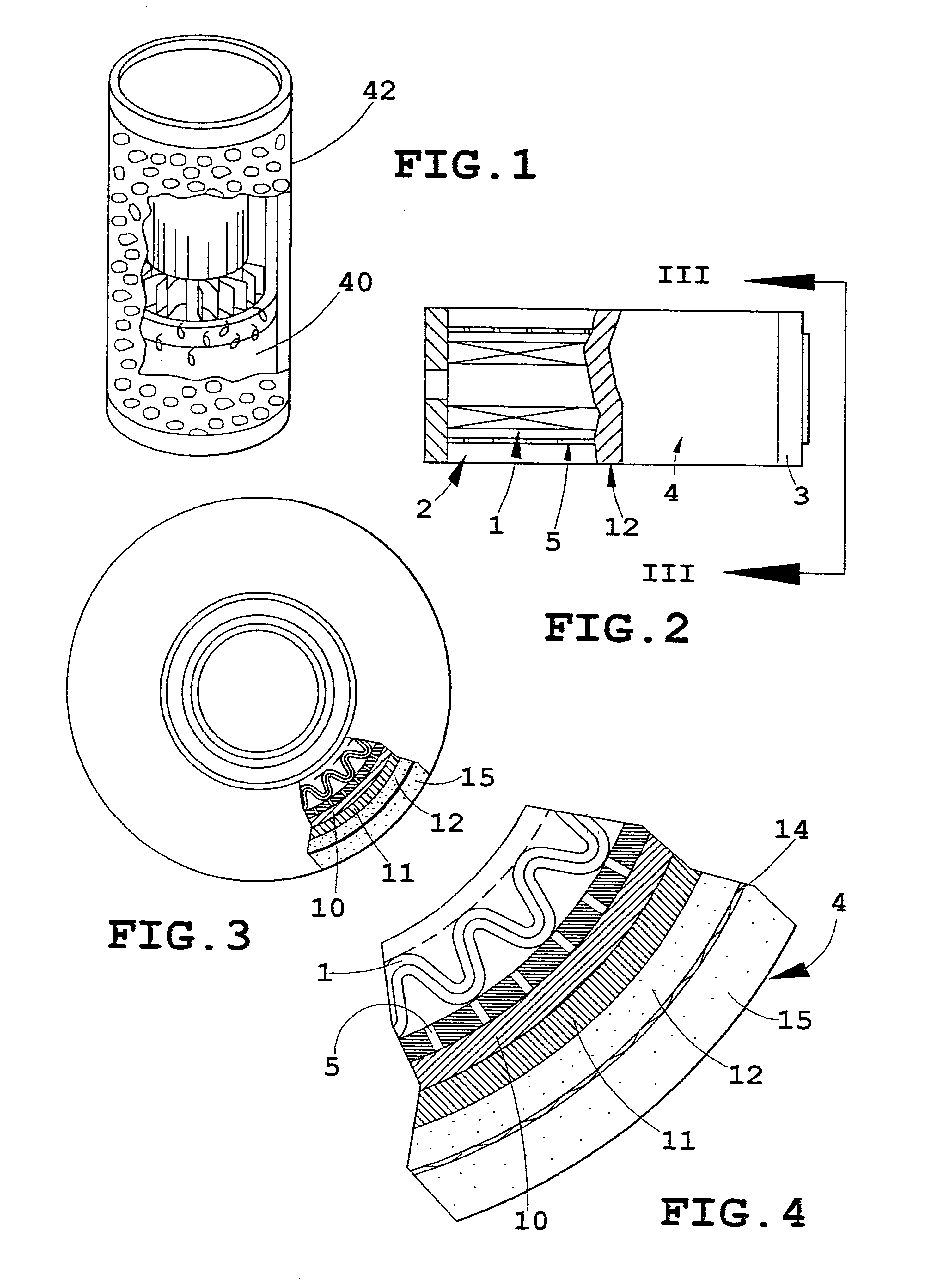

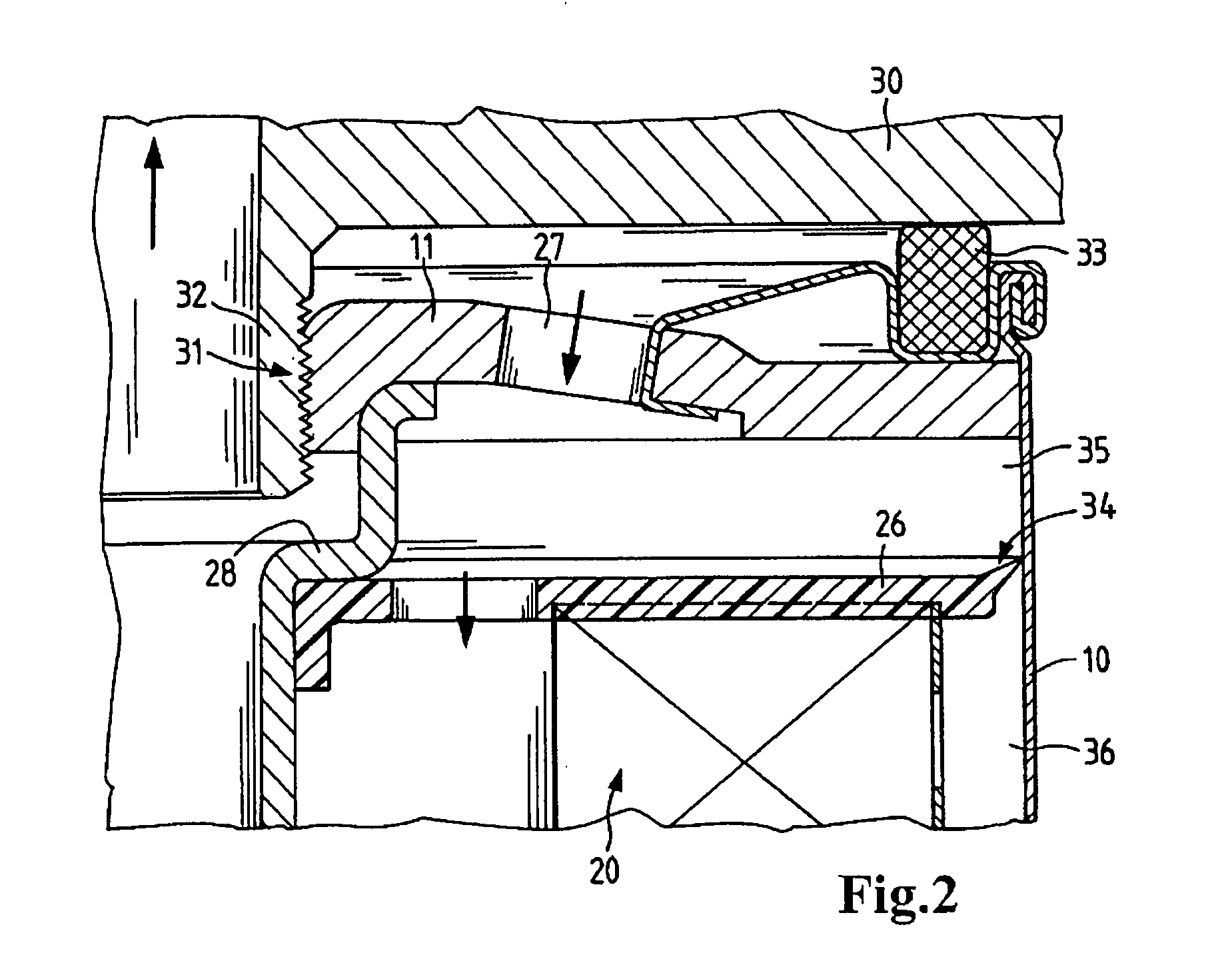

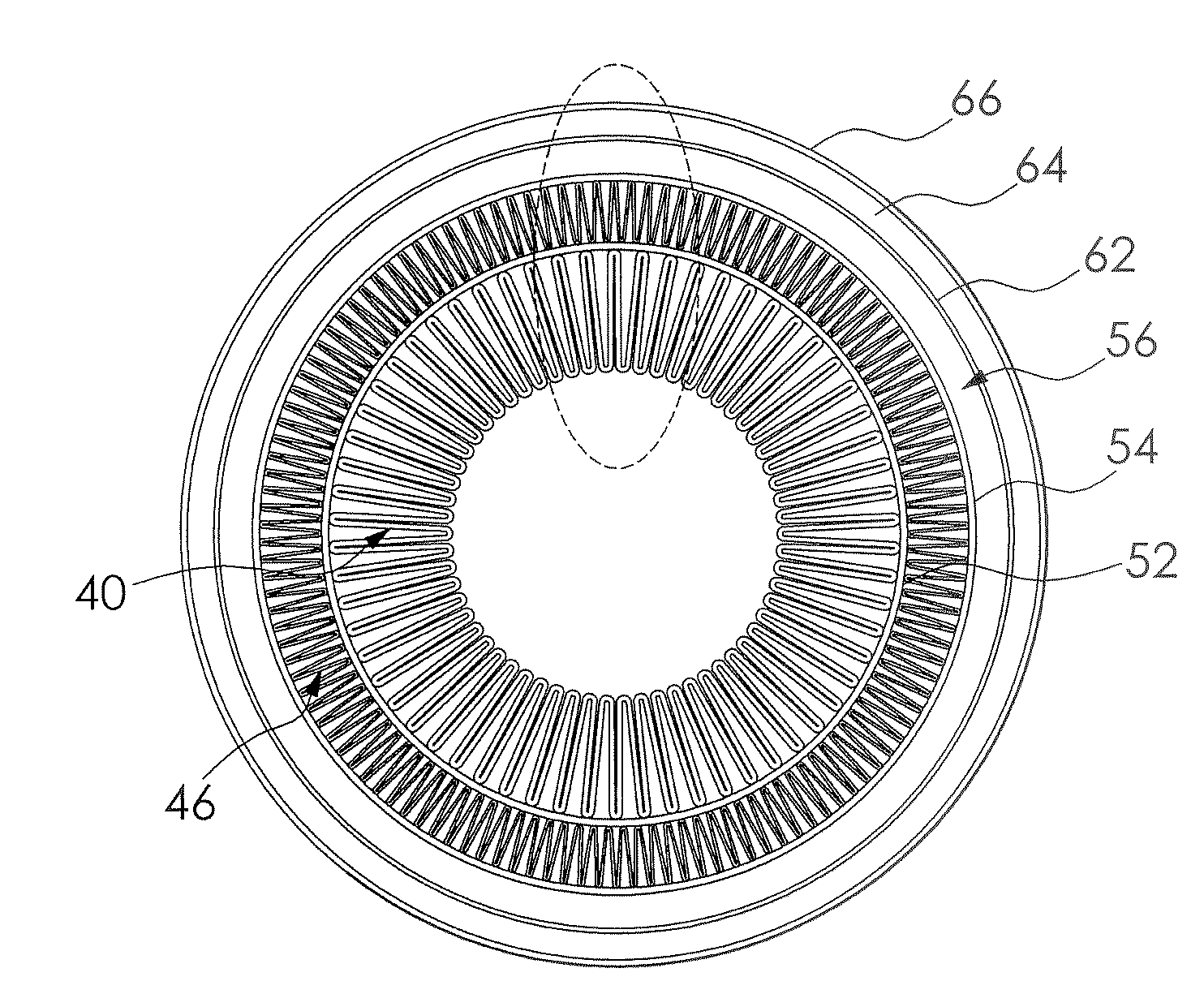

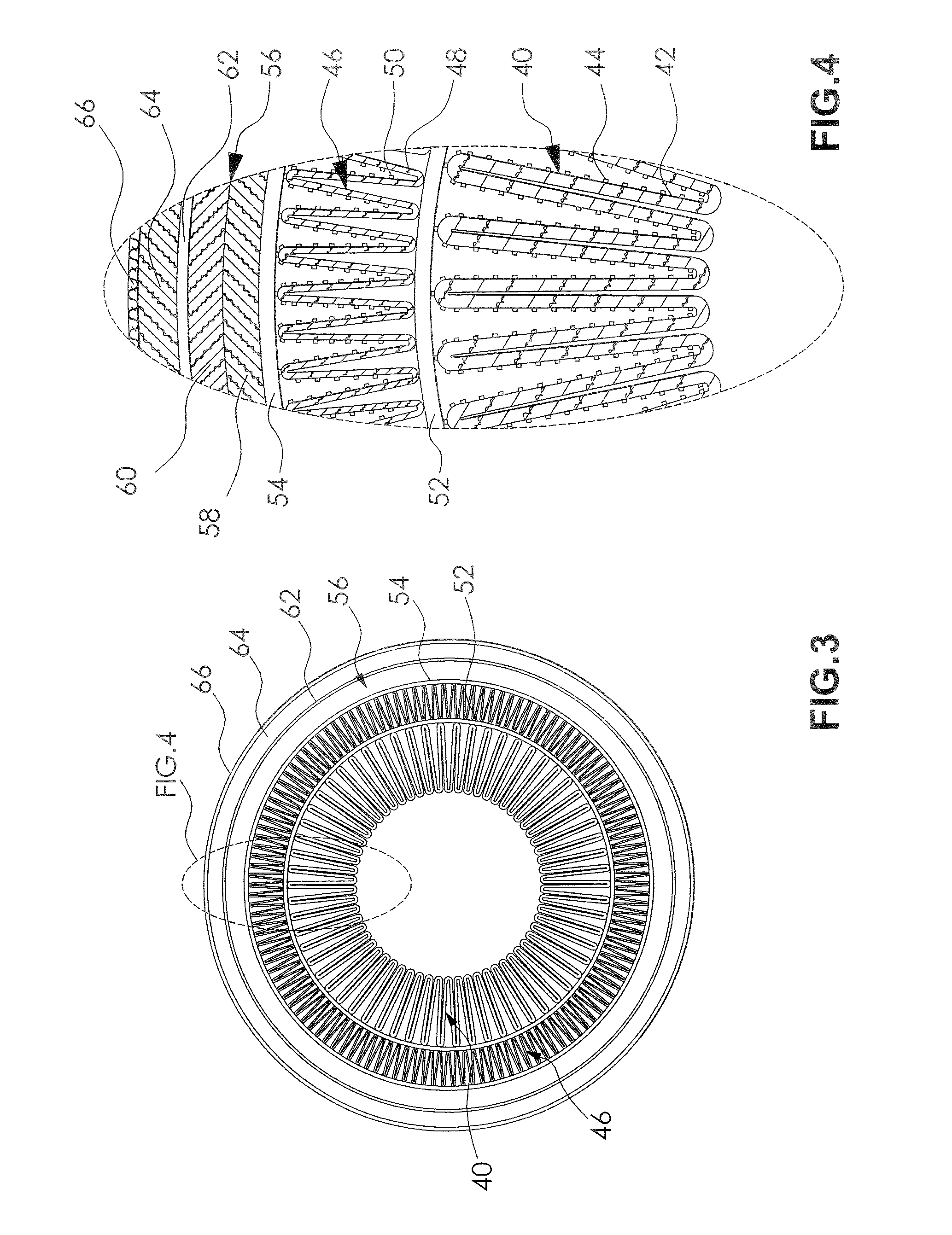

Pleated single phase filter coalescer element and method

ActiveUS8017011B2Improve efficiencyLow flow resistanceMechanical working/deformationSeparation devicesEngineeringSolid particle

A filter coalescer element for oil based industrial fuels includes a rigid, porous support tube, and a hydrophobic drainage layer covering the outer surface of the same. A single phase, dual function combination water coalescer and particle filter pleat block is positioned in the support tube, and is formed from a multilayer material having a first porous support layer, a synthetic microfiber layer, a synthetic fiber media layer and a second porous support layer. As the fluid passes through the pleat block, solid particles are physically filtered therefrom, and water is coalesced into droplets which pass from the pleats directly through the support tube and directly into the drainage layer, where the droplets grow into a size sufficient that they fall under gravity to the bottom of the element for collection.

Owner:KAYDON CUSTOM FILTRATION CORP

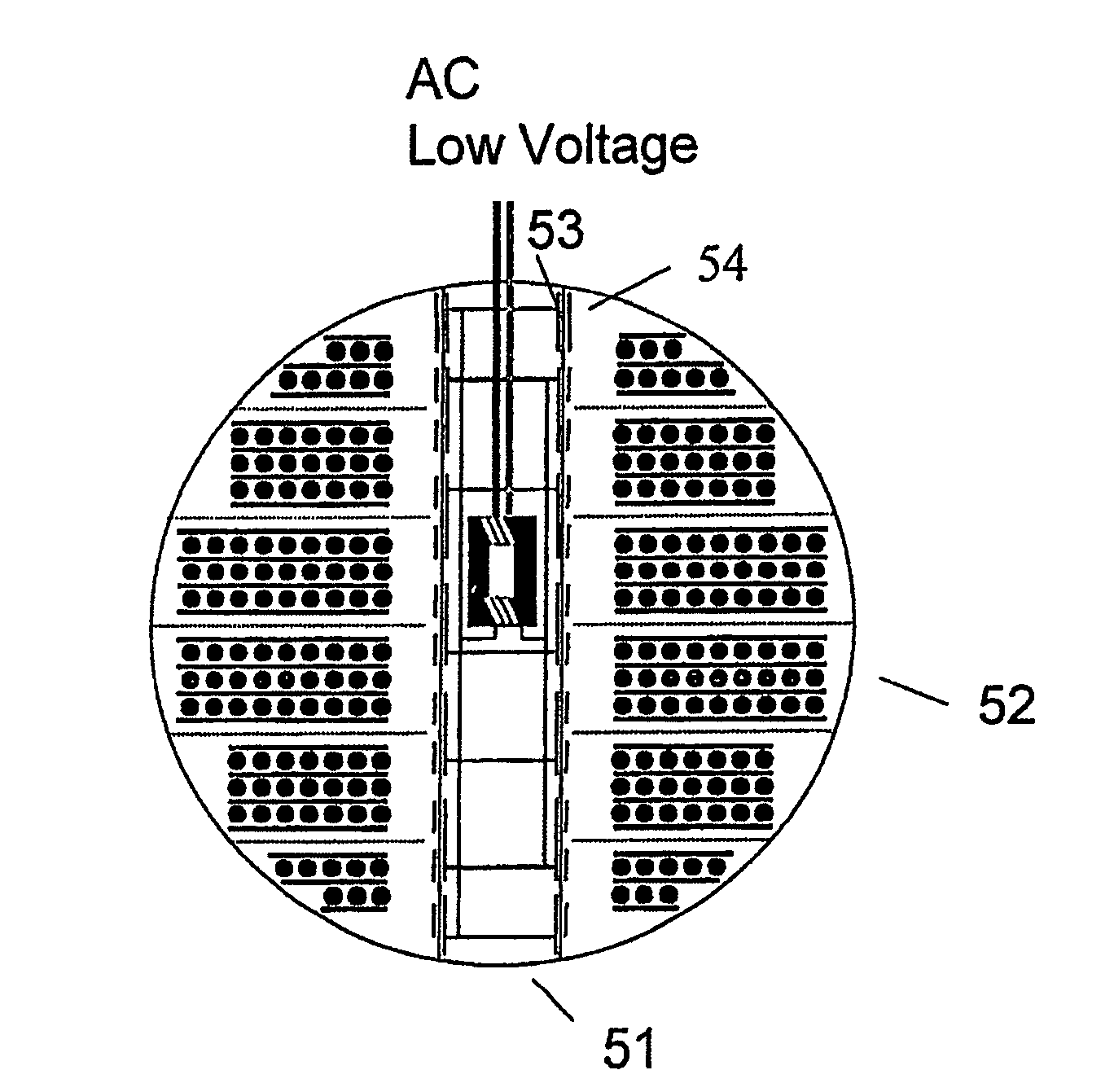

Electrostatic coalescer device and use of the device

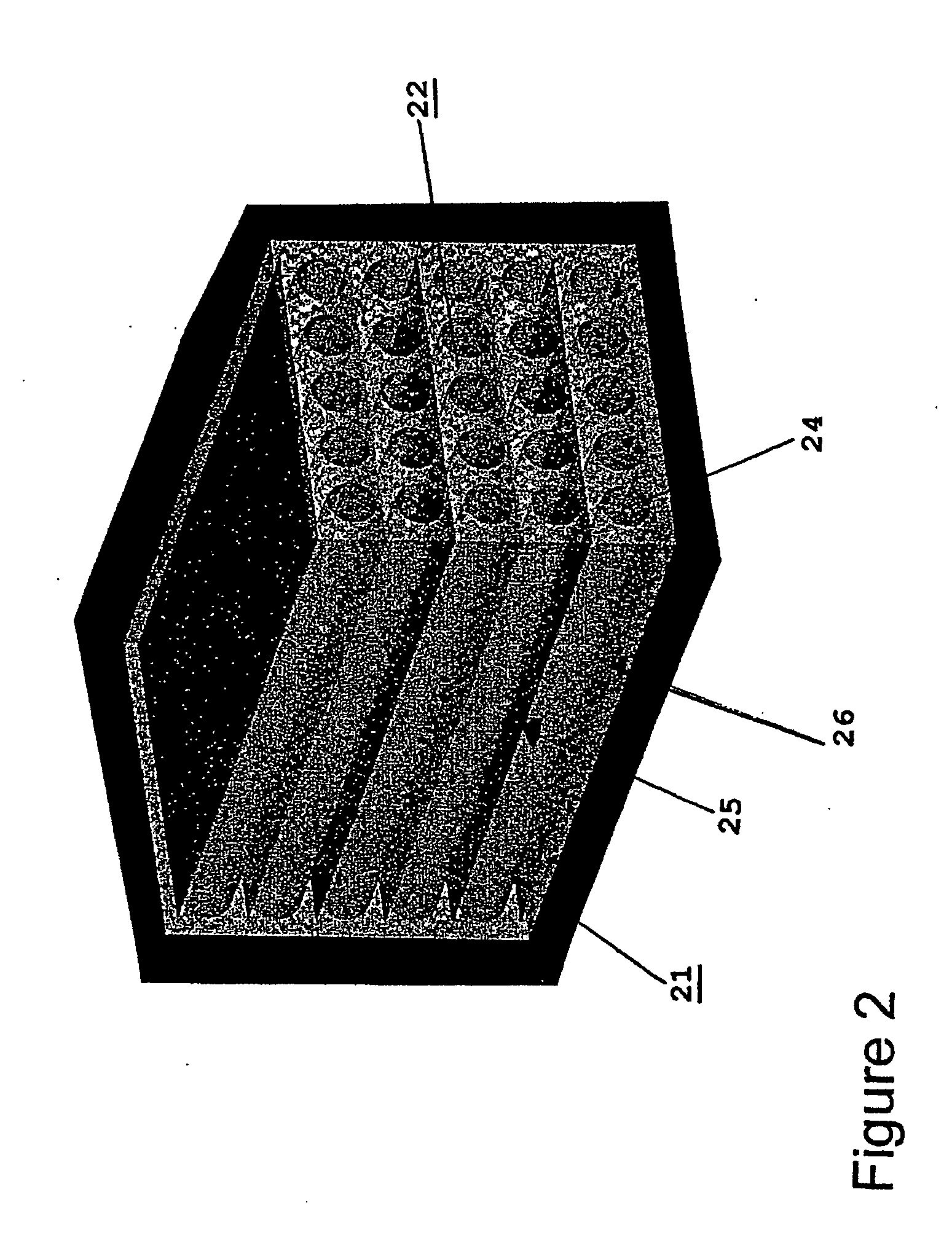

InactiveUS20050040045A1Small sizeReduce in quantitySludge treatmentElectrostatic separatorsBiomedical engineeringElectric field

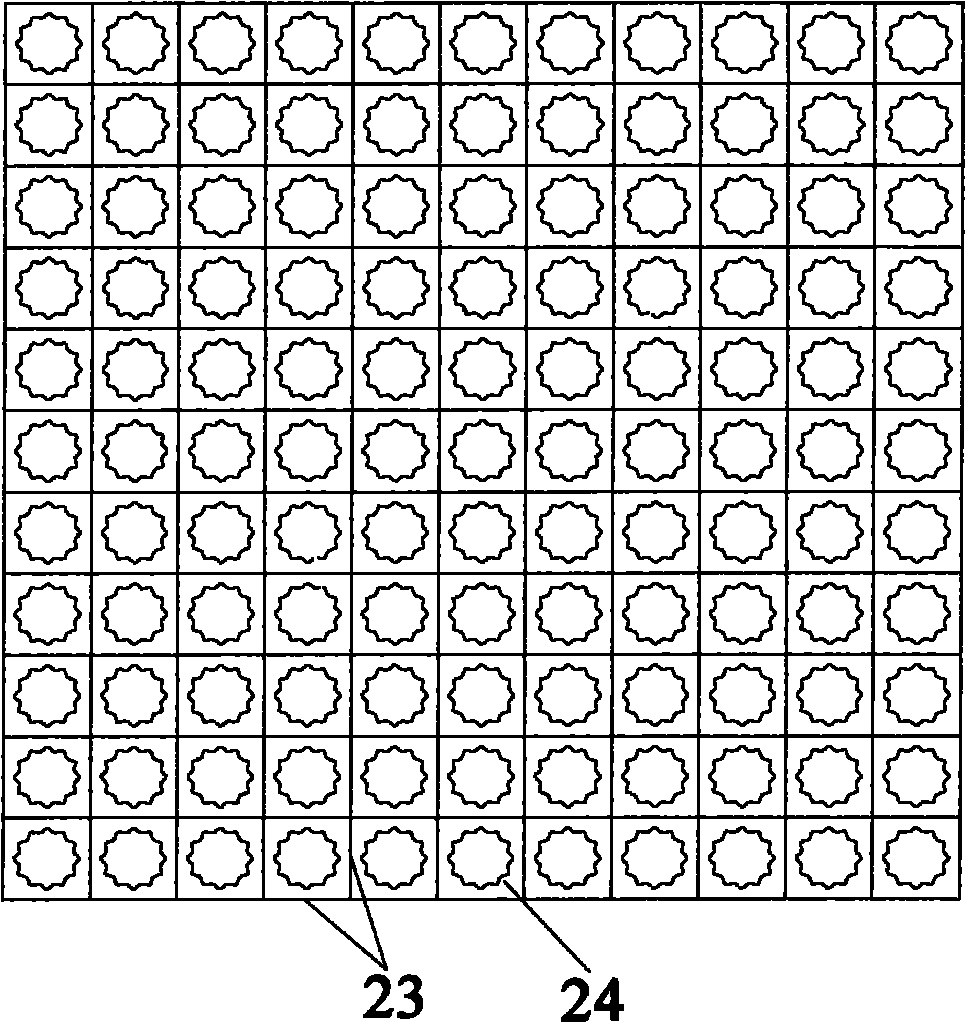

A device, located in a separator vessel having an inlet and a number of outlets, through which a mixture of fluids flows, for promoting electrostatic coalescence of a first conductive fluid emulsified in a second fluid, said device comprises a number of tubular electrostatic coalescer elements extending in the flow direction which are arranged in a matrix substantially covering the entire cross sectional area of said vessel, and means to apply an electrical field to the fluids flowing through said coalescer elements.

Owner:SULZER MANAGEMENT AG

Filtration vessel and method for rotary gas compressor system

InactiveUS6858067B2Easy to separateCombination devicesDispersed particle filtrationLighter fuelFiltration

A filtration vessel is shown for use with a rotary screw compressor which receives a compressed liquid / gas mixture from the compressor. The vessel utilizes a first stage vortex knockout region to remove bulk liquids through a circular motion which imposes centrifugal forces on the gas and liquid mixture. A coalescer region located above the vortex knockout region receives the relatively lighter fluids and separates any remaining entrained liquids from the fluids. The discharge from the filtration unit is an essentially liquid free compressed gas. The liquid discharge, in the case of lube oil can be recirculated to the compressor for another cycle.

Owner:PARKER INTANGIBLES LLC

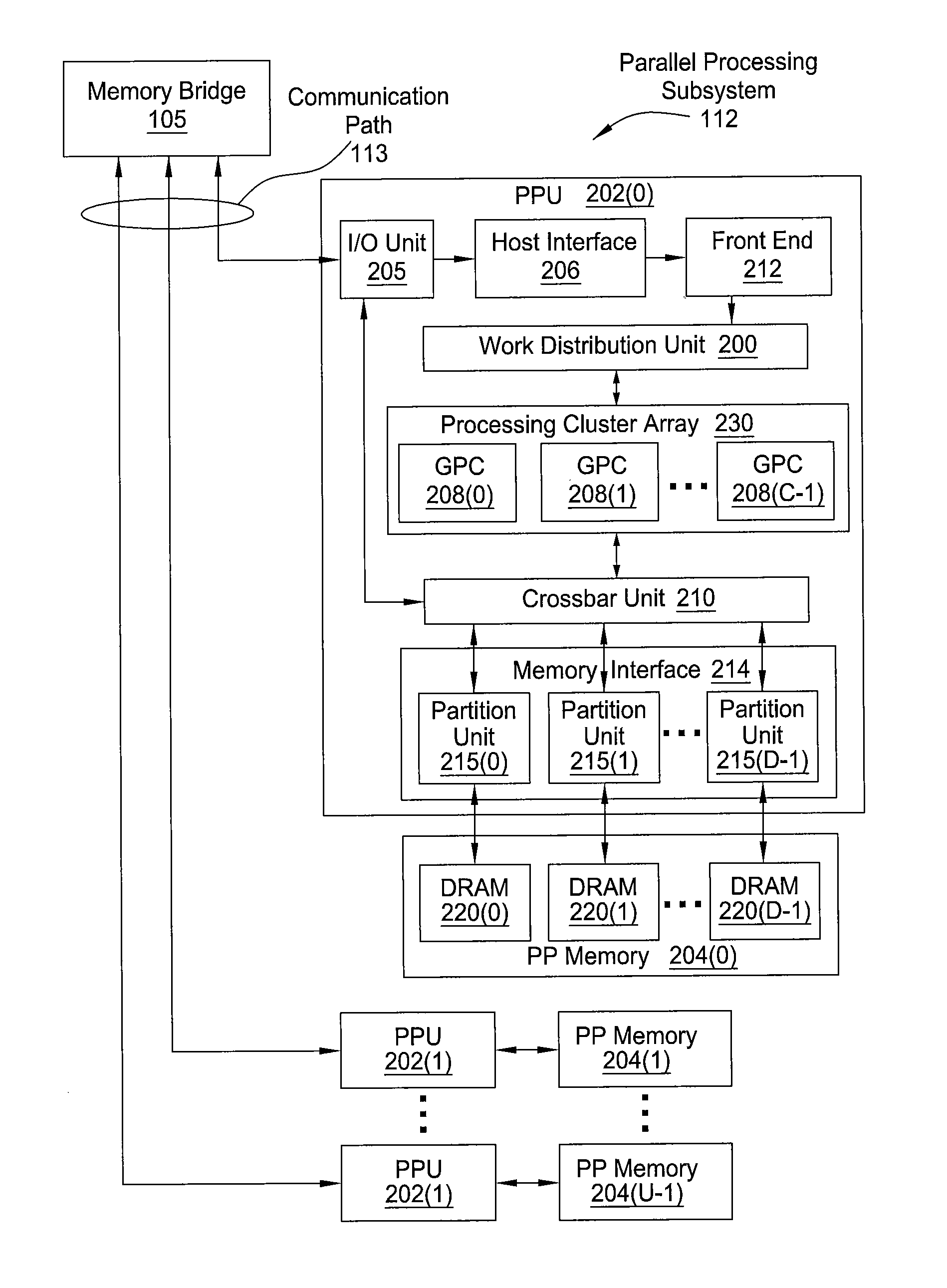

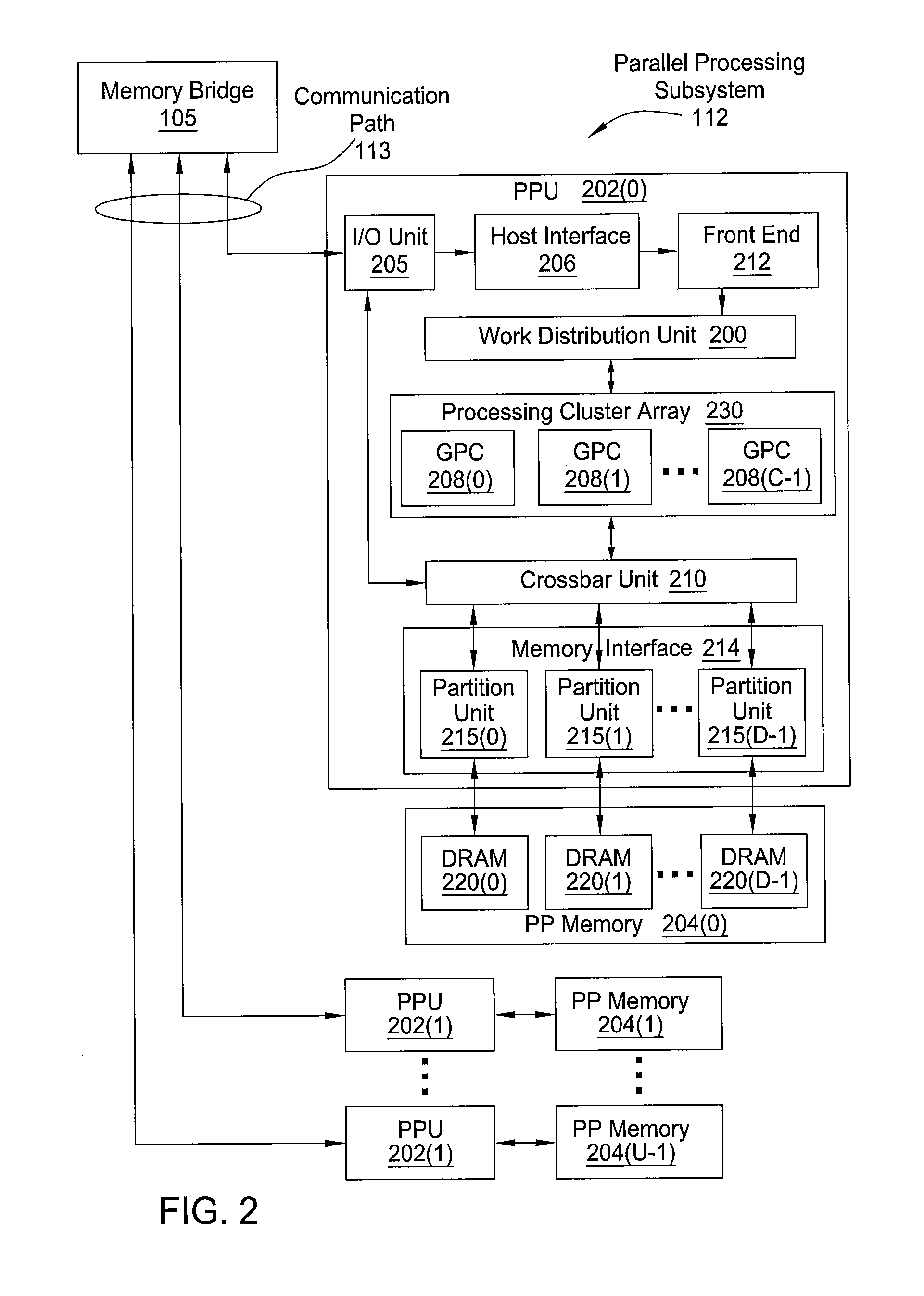

Rasterization tile coalescer and reorder buffer

ActiveUS8605102B1Lower memory access latencyImage memory managementCathode-ray tube indicatorsGraphicsGrating

A raster unit generates graphic data for specific regions of a display device by processing each graphics primitive in a sequence of graphics primitives. A tile coalescer within the raster unit receives graphic data based on the sequence of graphics primitives processed by the raster unit. The tile coalescer collects graphic data for each region of the display device into a different bin before shading and then outputs each bin separately.

Owner:NVIDIA CORP

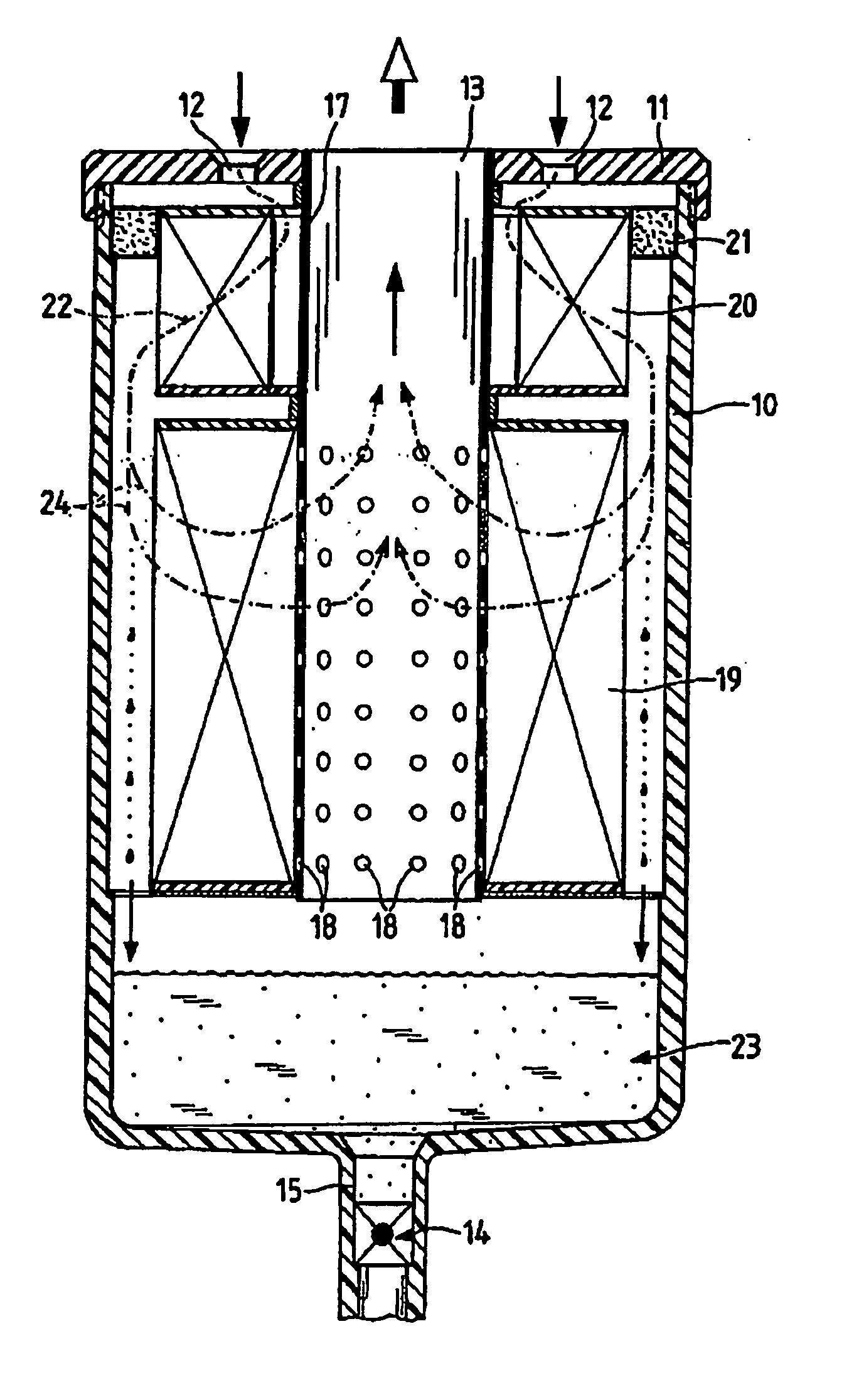

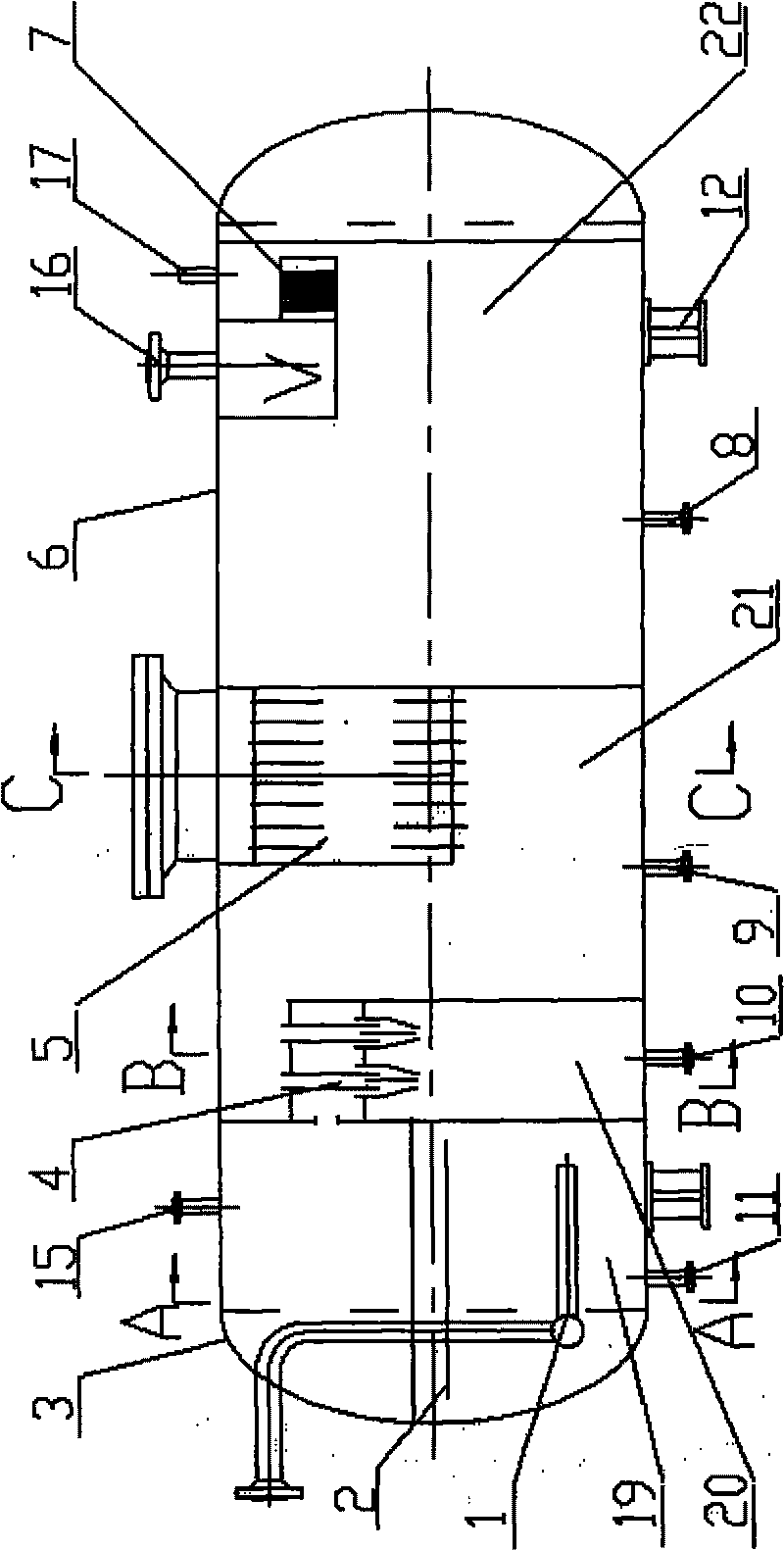

Novel high-efficiency crude oil electric dehydration and desalination method and equipment

InactiveCN102021019AEnough time to stayThoroughly dehydratedLiquid separation by electricityDewatering/demulsification with electric/magnetic meansDielectrophoresisHigh pressure

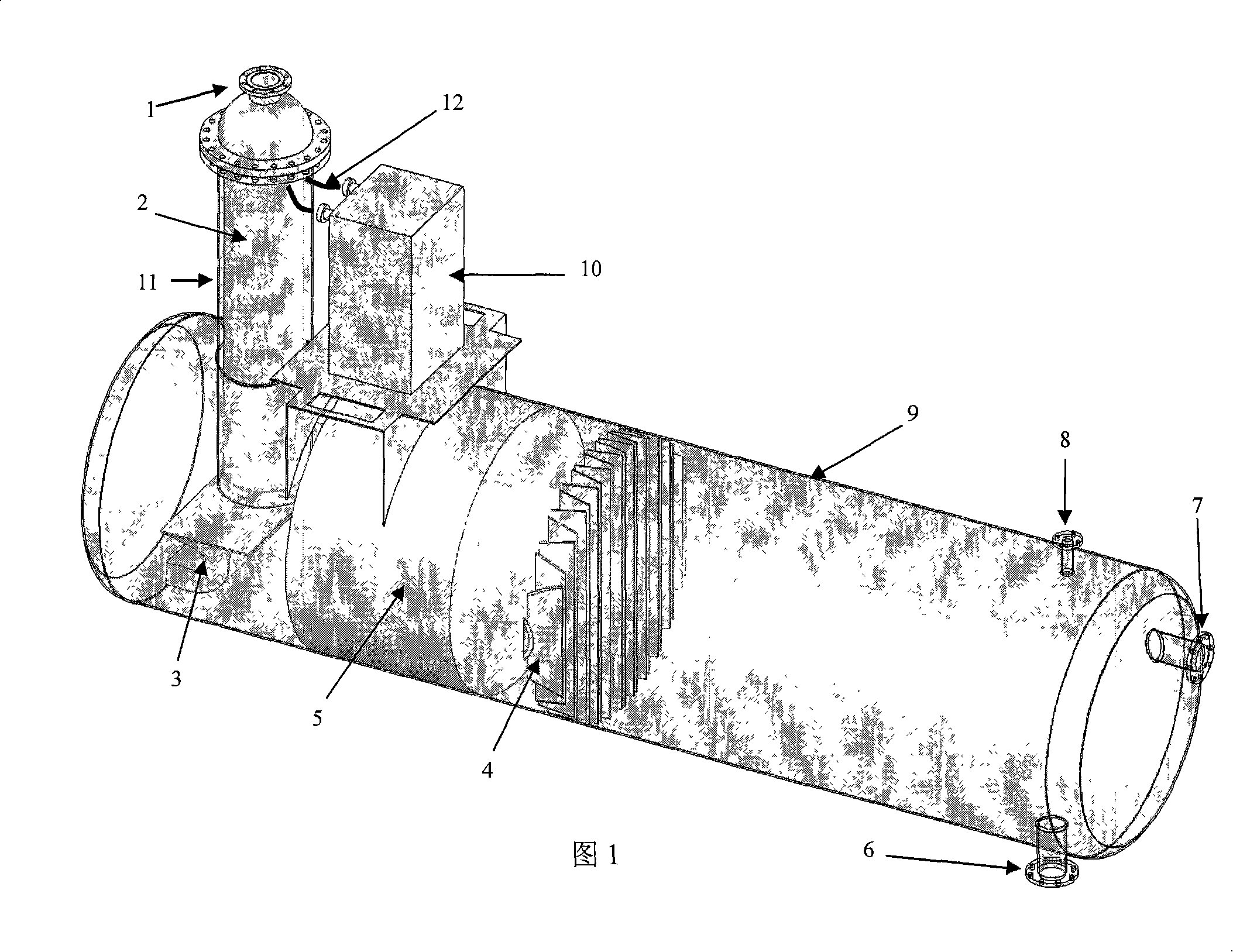

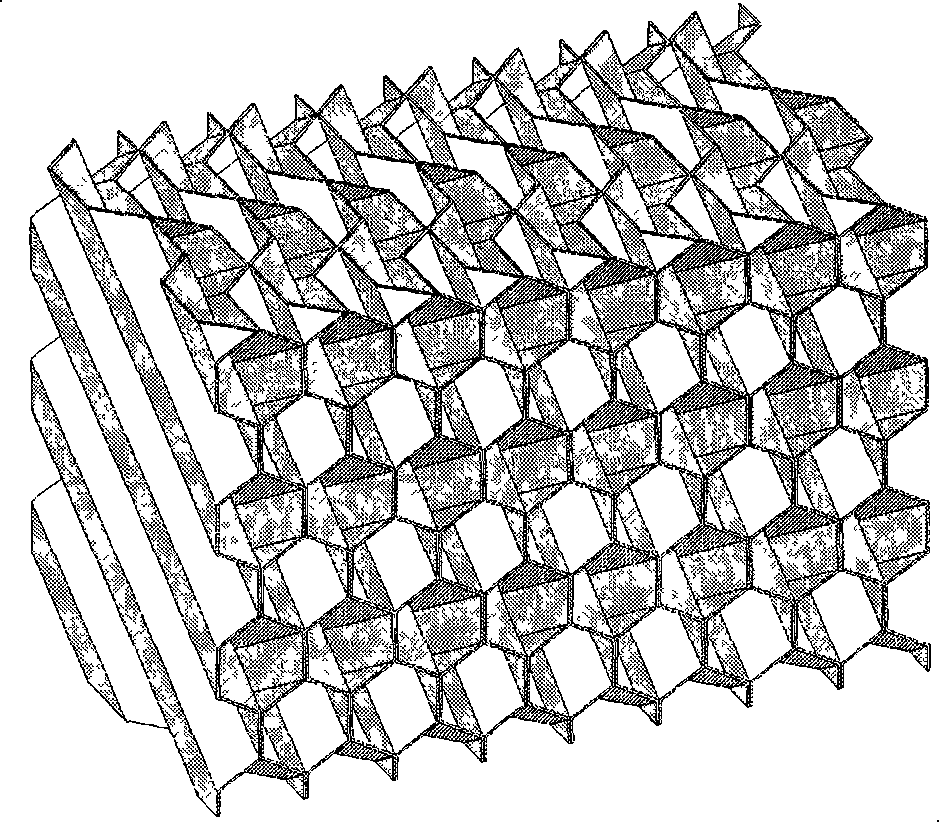

The invention discloses a novel high-efficiency crude oil electric dehydration and desalination method and novel high-efficiency crude oil electric dehydration and desalination equipment, which can be used for dehydrating and desalinating crude oil emulsion in oil refineries. The processing equipment mainly comprises an inlet component, a tank and an electrostatic precoalescer; when a high-voltage explosion-proof transformer outside the device applies high-voltage alternating current to the crude oil emulsion in a corrugated hollow tube through metal electrode plates by a high-voltage insulating wire, a non-uniform alternating current field is produced between the electrode plates to cause dielectrophoresis coalescence of dispersed phase water particles; the flow state of the crude oil emulsion in the hollow tube is turbulent flow, and the turbulent flow increases the collision probability of the dispersed phase water particles in the crude oil emulsion and obviously shortens hydraulic retention time; and a flowing passage in the electrostatic precoalescer can be designed to be corrugated circular or wavelike quasi-rectangular. By using the method and the equipment, the dispersed phase water particles subjected to electrostatic precoalescence can obviously reduce subsequent gravity settling time and improve the processing efficiency; and after the crude oil emulsion enters the tank from the inlet component at the left end, the crude oil emulsion flows along the horizontal direction and can reduce the power consumption of an inlet.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

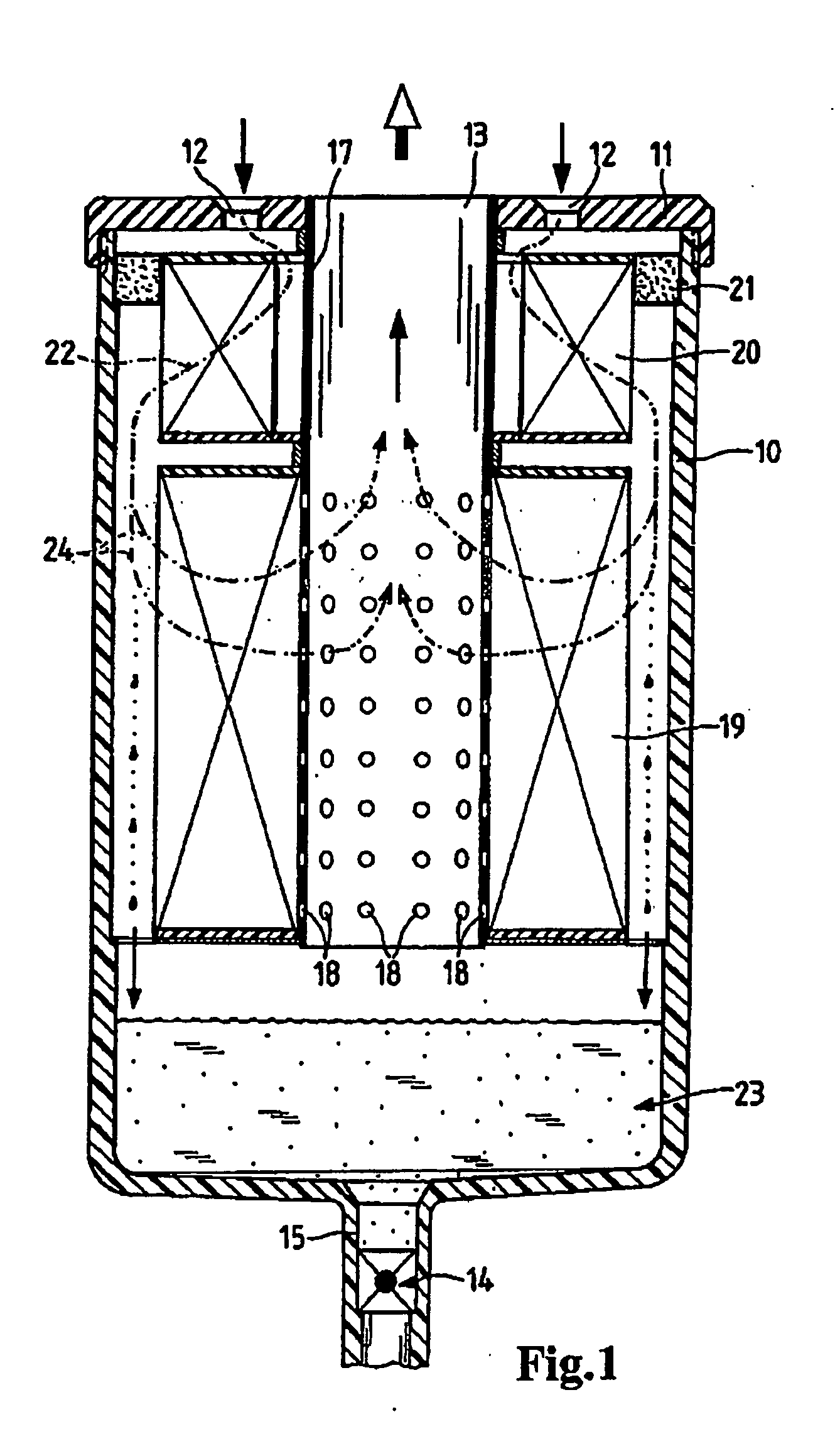

Novel crude oil emulsion electrostatic dehydrator

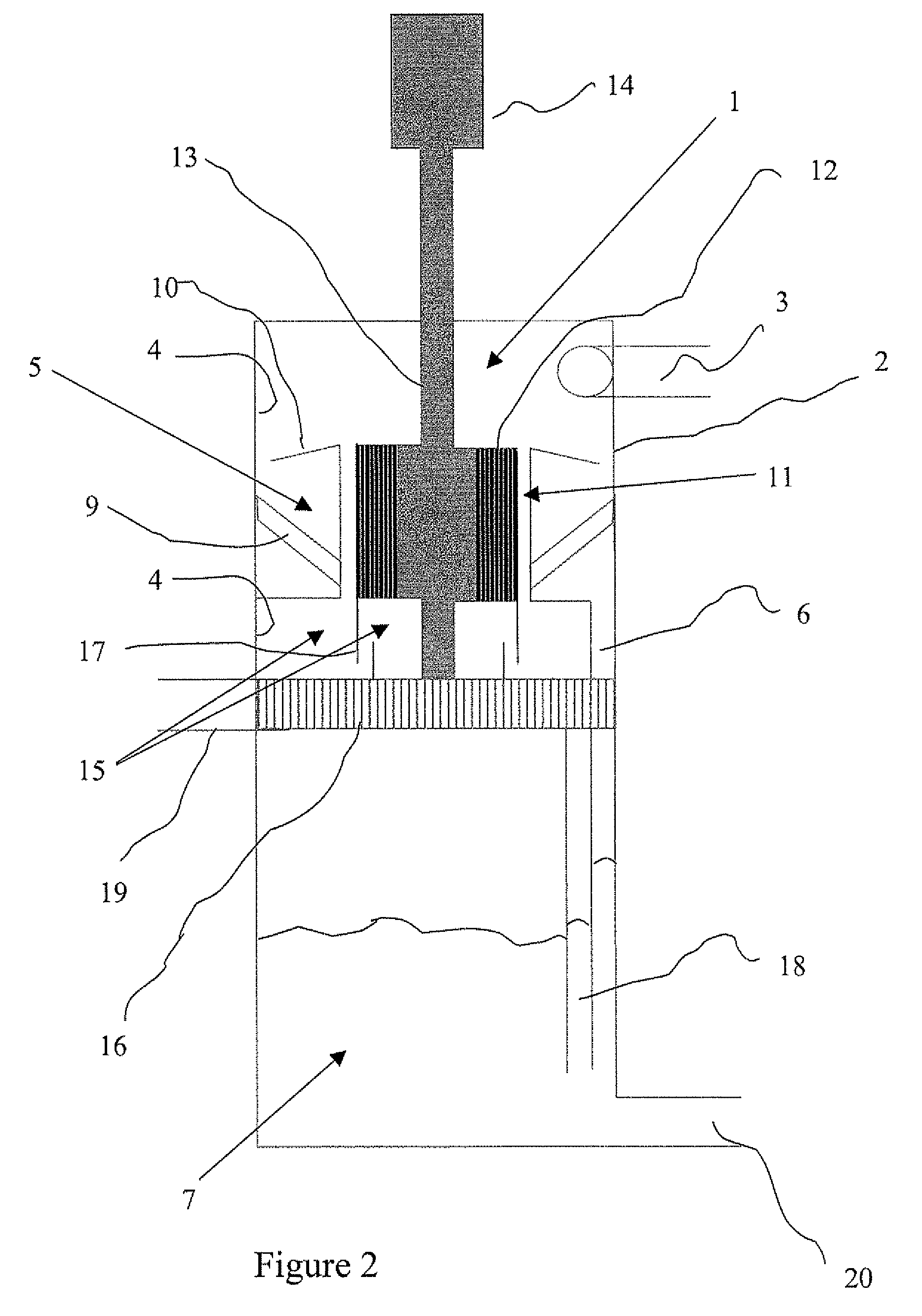

InactiveCN101173182ACompact structureSmall footprintDewatering/demulsification with electric/magnetic meansInsulation layerEngineering

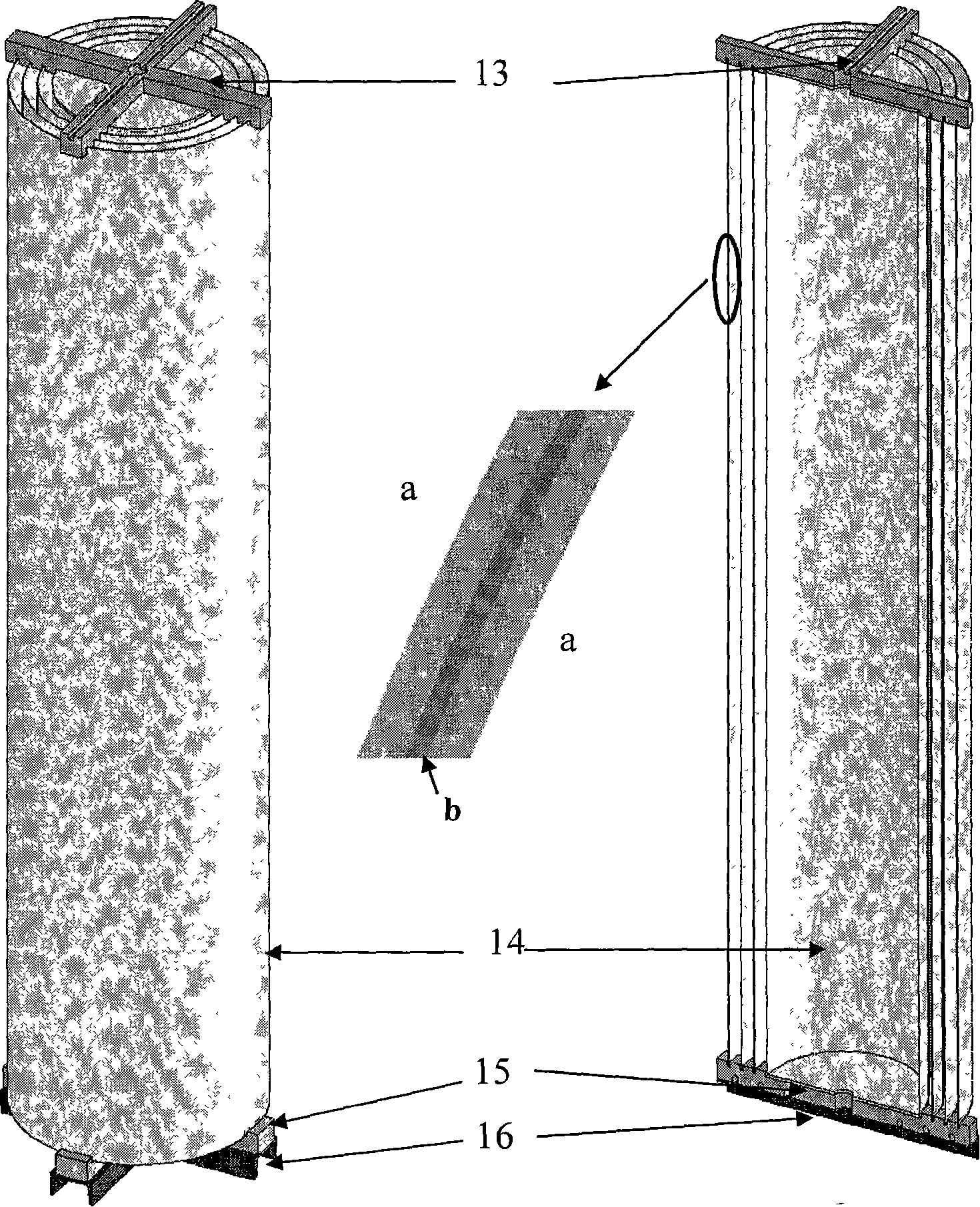

The invention relates to an electrostatic coalescer with high efficiency, which is a piece of compact equipment for the electrostatic dehydration of crude oil emulsion with high efficiency, and is applied for the crude oil dehydration in the production process of oil fields. The invention is characterized in that: the invention comprises a housing, which comprises a coalescence part arranged vertically and a sedimentation and separation part arranged horizontally; the coalescence part is a vertical cylinder shaped structure with a cylinder shaped electrode assembly arranged inside; the sedimentation and separation part is a horizontal tank structure arranged below a dehydrator, with an emulsion distribution device, a spoiler and a staggered corrugated coalescing plate arranged inside. A high voltage transformer is arranged on the sedimentation and separation part and is connected with the cylinder shaped electrodes by a high voltage insulated cable. The cylinder shaped electrodes are covered by a compact insulation layer which can reduce leakage current and prevent the short circuit among the electrodes. The distance among the cylinder shaped electrodes is small, so a narrow runner is formed, and high strength electric field is formed in the narrow runner. The invention has the advantages that: the crude oil emulsion successively experiences the effects of electrostatic coalescence, staggered corrugated coalescing plate coalescence and the eddy current coalescence of the spoiler; the contained water drops grow bigger; the settling velocity is accelerated, and the rapid separation between crude oil and water is realized.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Coalescer For Co-Current Contactors

ActiveUS20160263516A1Increase droplet sizeIncrease in sizeGas treatmentDispersed particle separationSolventDroplet size

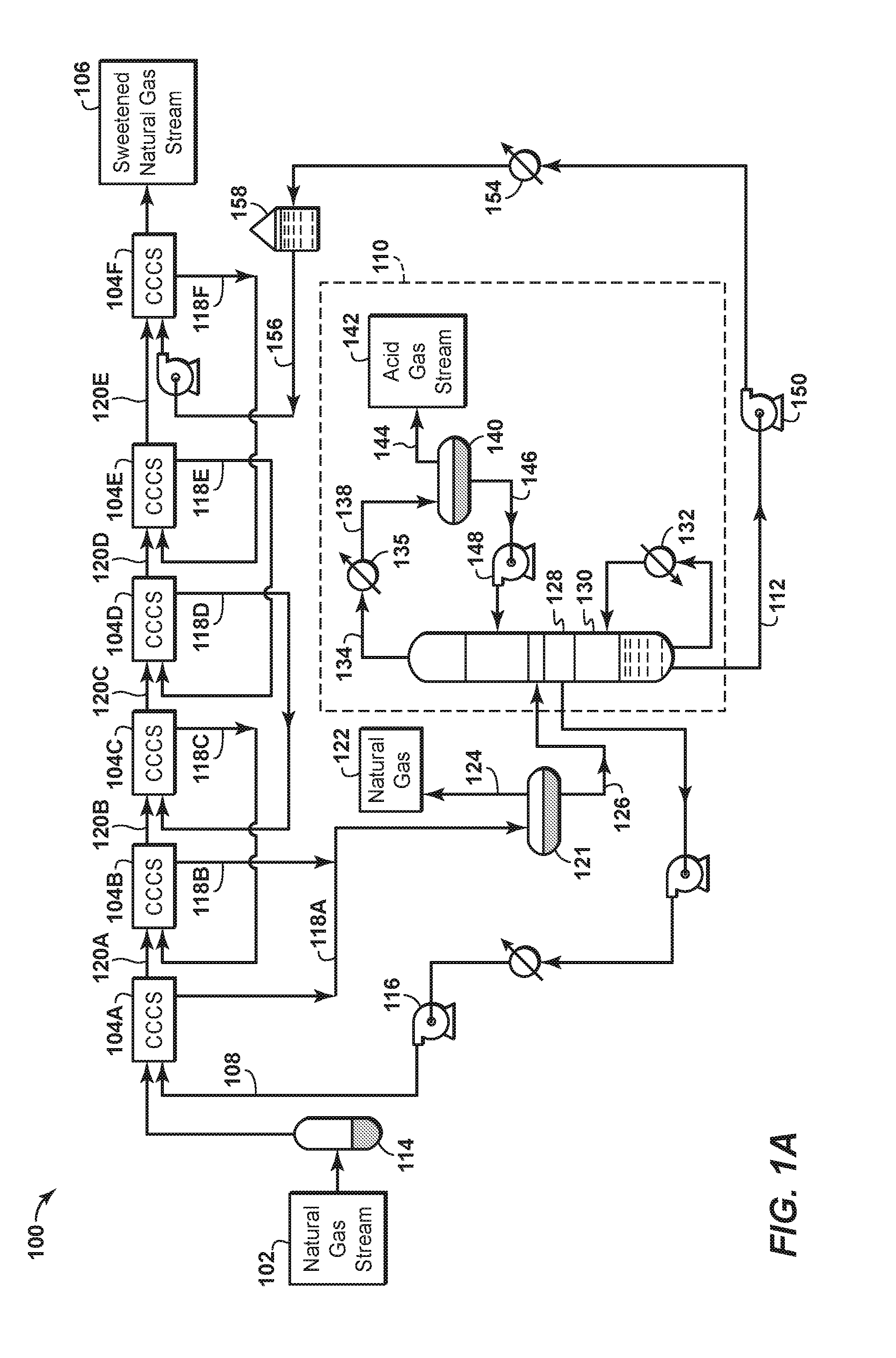

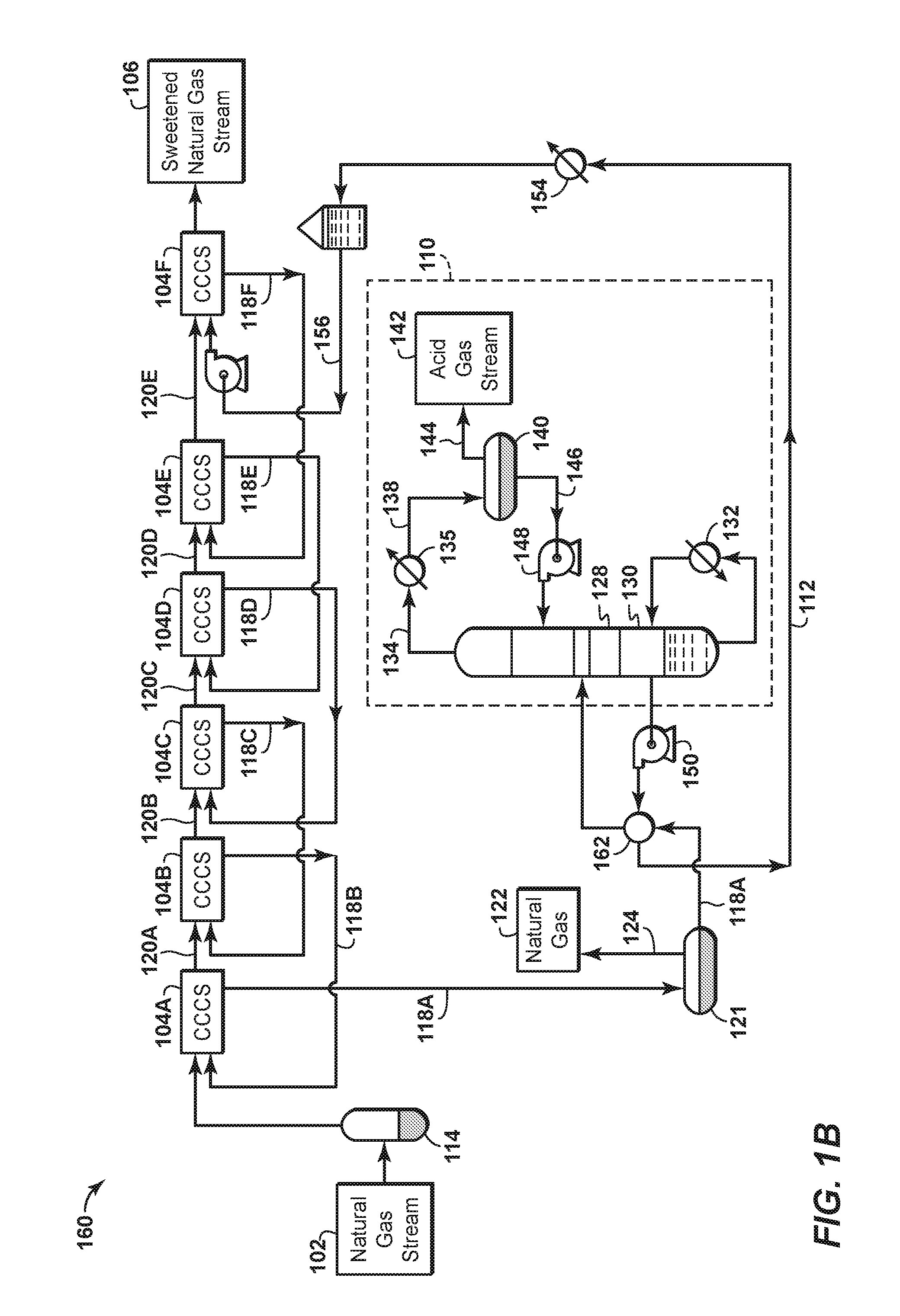

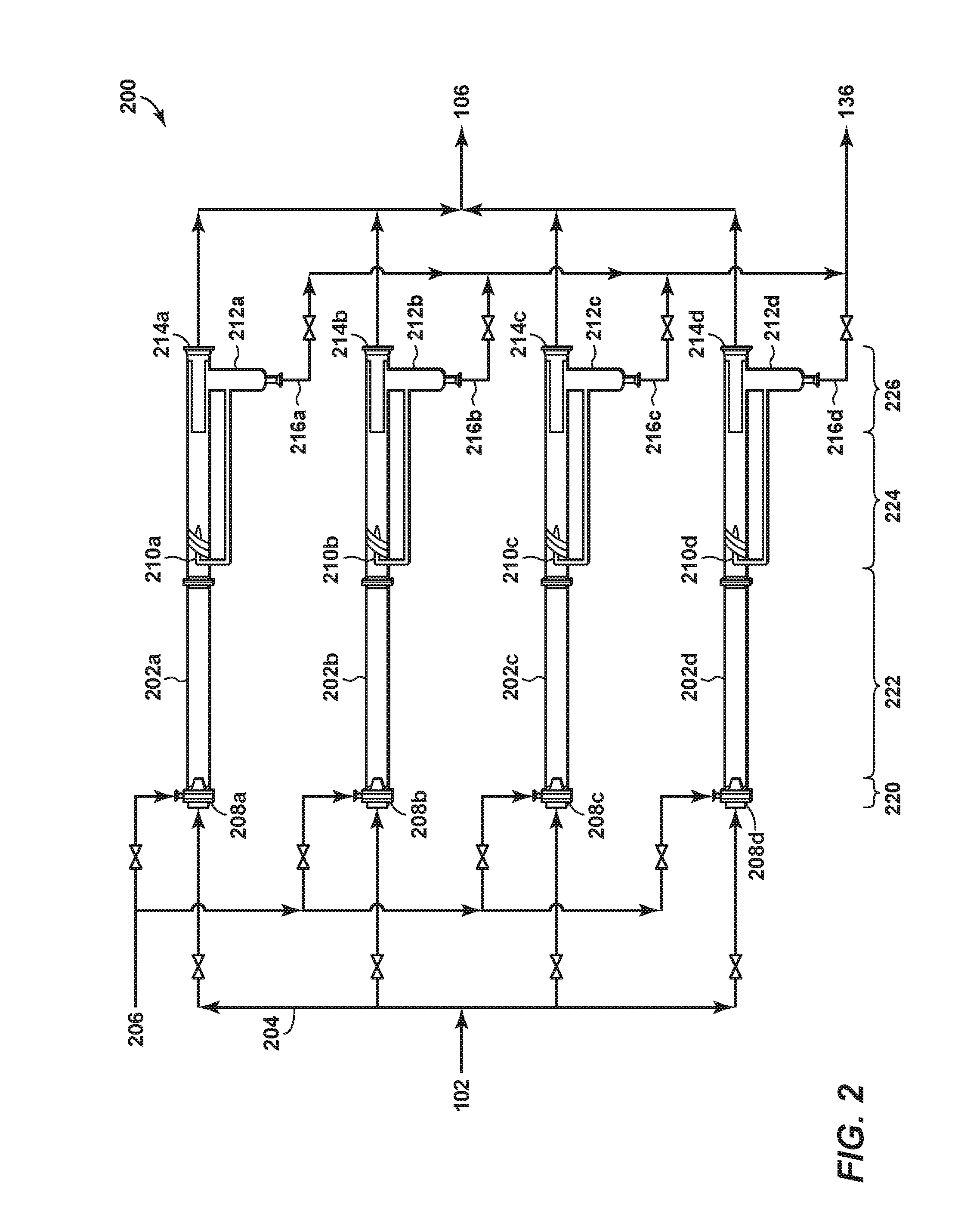

The disclosure includes a method, comprising passing a fluid into a co-current contactor, passing a solvent into the co-current contactor, dividing the solvent into solvent droplets having a first average droplet size, placing the fluid in contact with the solvent droplets to create a combined stream, coalescing at least a portion of the solvent droplets to create solvent droplets having a second average droplet size, wherein the second average droplet size is greater than the first average droplet size, and separating the fluid and the solvent.

Owner:EXXONMOBIL UPSTREAM RES CO

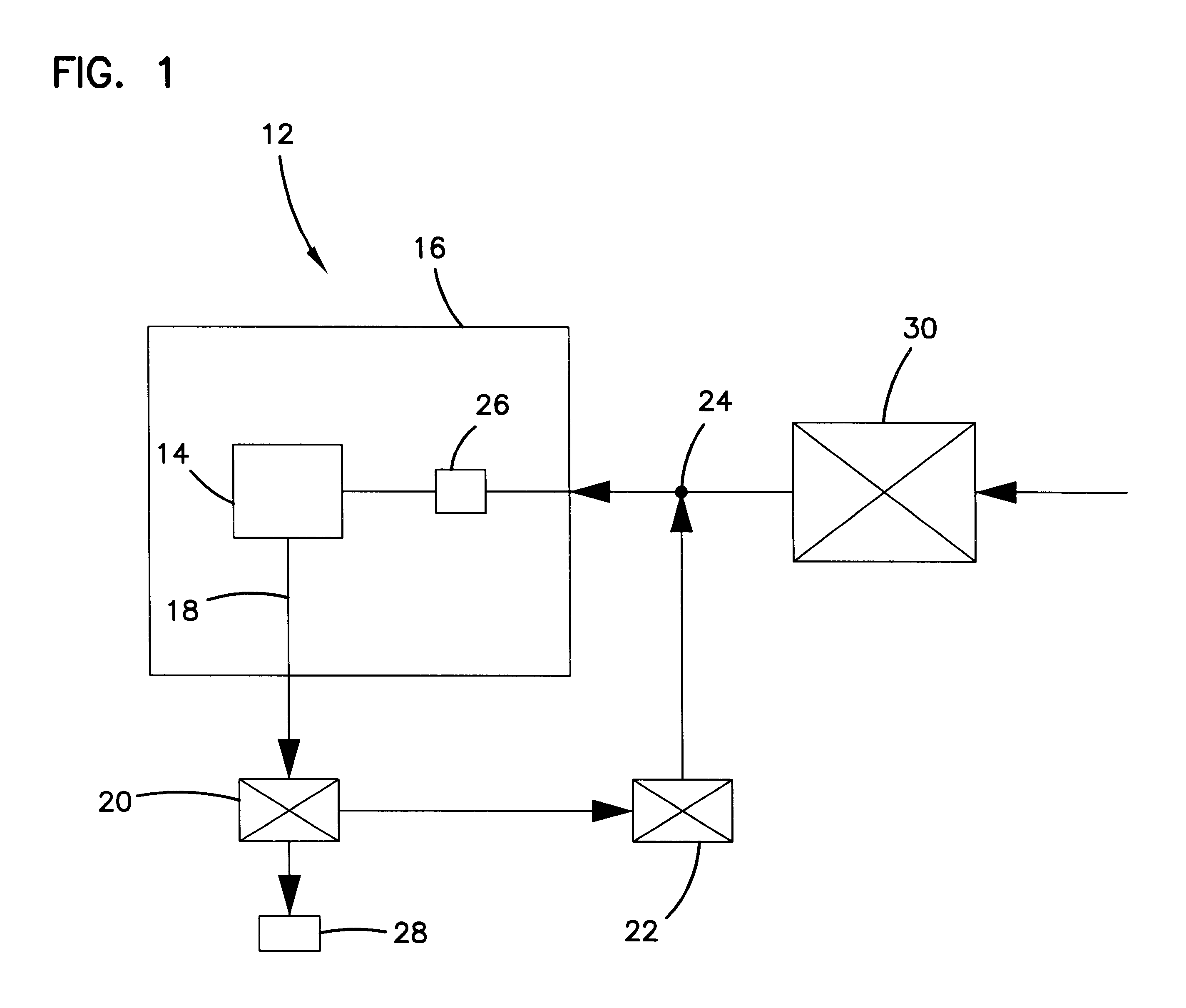

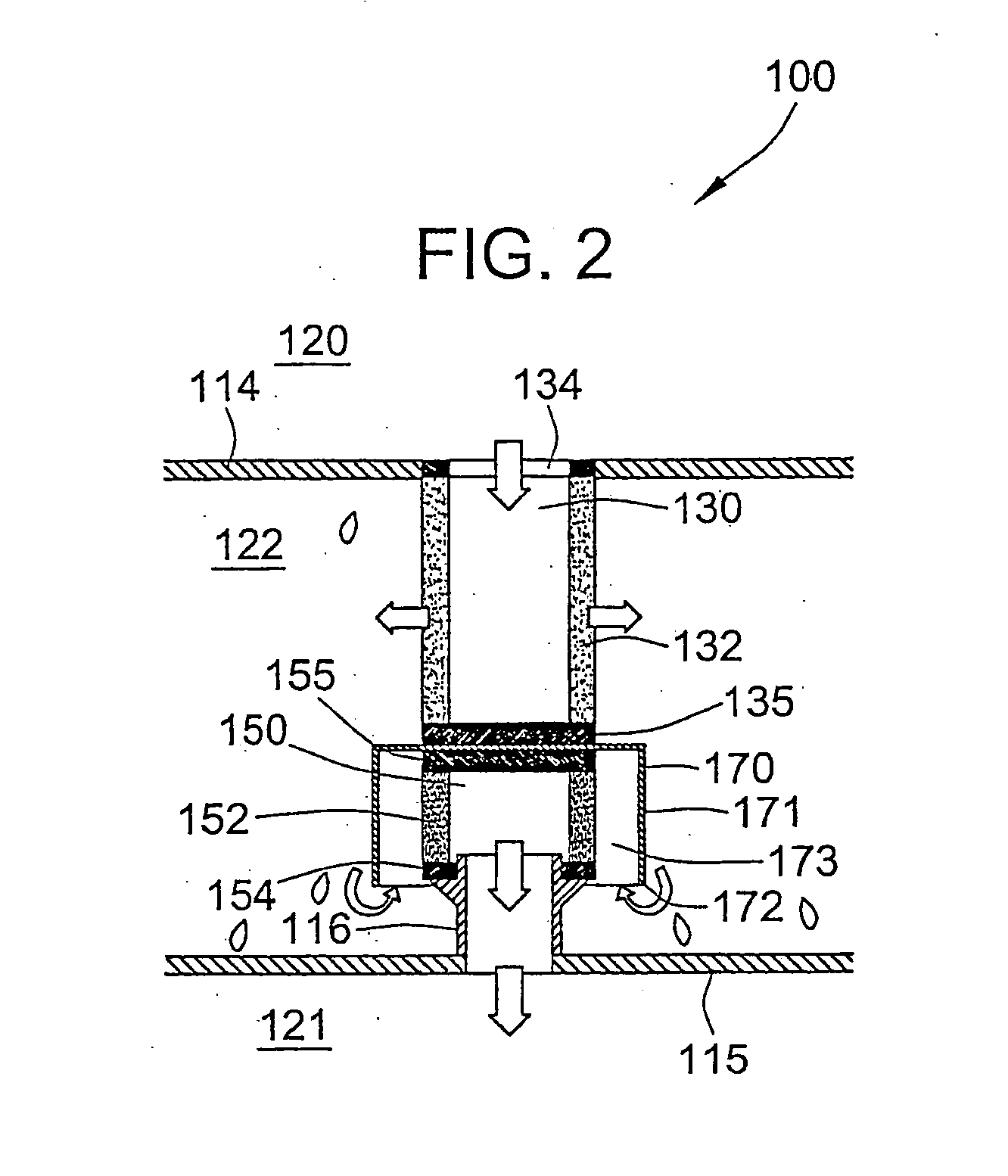

Coalescing and separation arrangements systems and methods for liquid mixtures

InactiveUS20050178718A1Separation efficiency can be improvedReduce the amount requiredLiquid suspension thickening by filtrationSettling tanks feed/dischargeChromatographyCoalescer

Coalescing and / or separating arrangements for separating a discontinuous phase liquid from a continuous phase liquid may comprise two or more of a coalescer (30), a separator (50) and a flow director (70).

Owner:PALL CORP

Salt drying process

ActiveUS20090133577A1Improve efficiencyReduce consumptionDewatering/demulsification with chemical meansGas treatmentDesiccantAqueous solution

A method of drying liquid and gaseous hydrocarbons by contacting a feed stream of the hydrocarbon with an aqueous solution of a salt drying agent prior to passing the stream through a salt dryer to remove part of the water in the stream. The aqueous solution of the salt drying agent is generated in the salt dryer when the partly dried stream comes into contact with the drying salt and forms the solution. The solution is circulated in a loop from the salt dryer to the incoming feed and then through a liquid / liquid coalescer which removes a portion of the water together with dissolved salt from the mixture before the mixture is passed on to the salt dryer where further removal of water occurs. The salt dryer is off-loaded by a substantial factor by the initial partial dehydration and does not require to remove such a large amount of water; the salt consumption is therefore reduced in proportion to the amount of water removed in the treatment steps which precede the dryer.

Owner:EXXON RES & ENG CO

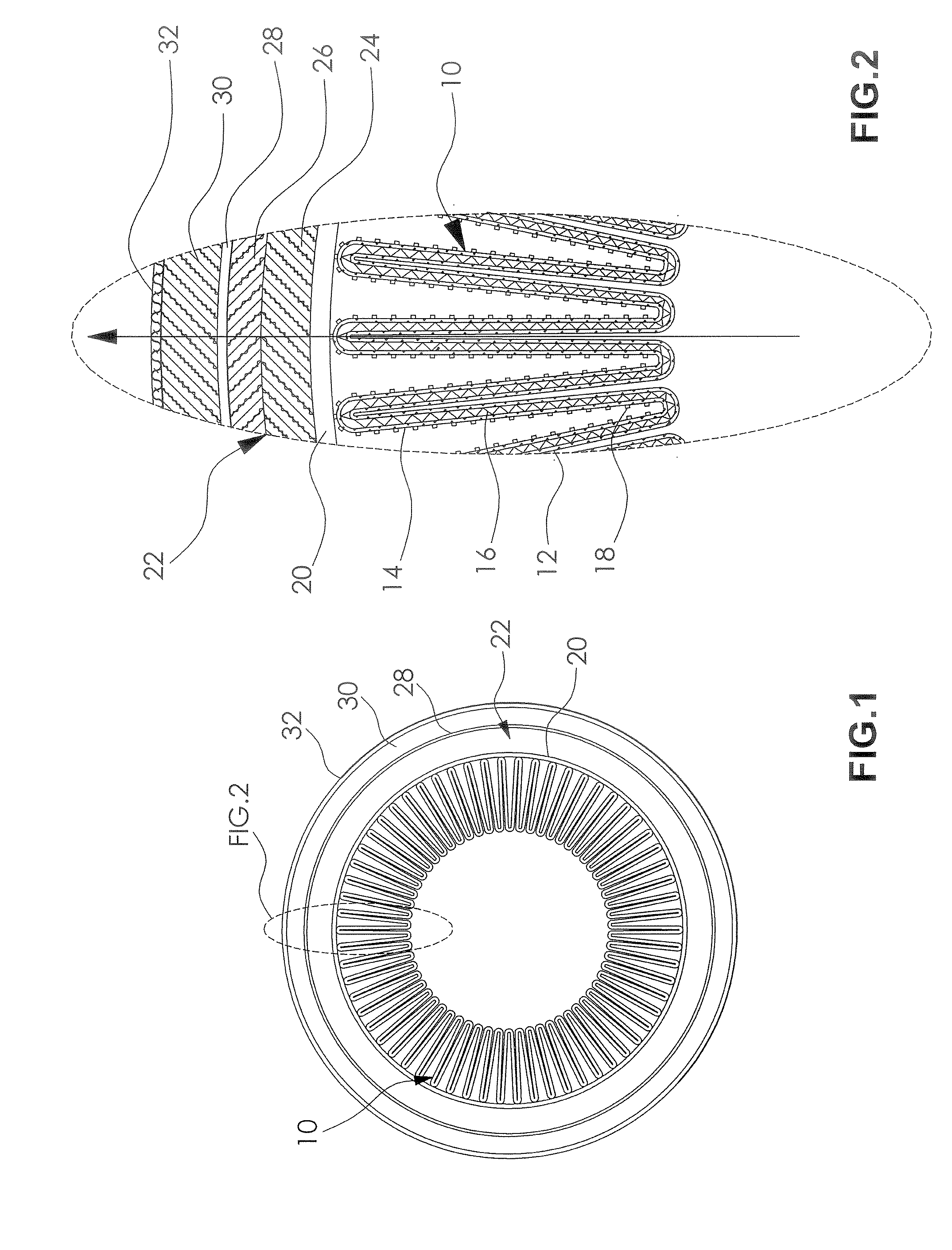

Bio-resistant filter coalescer cartridge

A filter coalescer cartridge for treating jet fuels is disclosed. The filter coalescer cartridge has spaced apart filter / coalescer layers to effectively remove particulate contaminates and water from the transient fuel being treated. The outer most layer is a knitted sock material formed from cotton threads including a metallic silver disposed thereon to provide an anti-microbial property to the sock material.

Owner:VELCON FILTERS

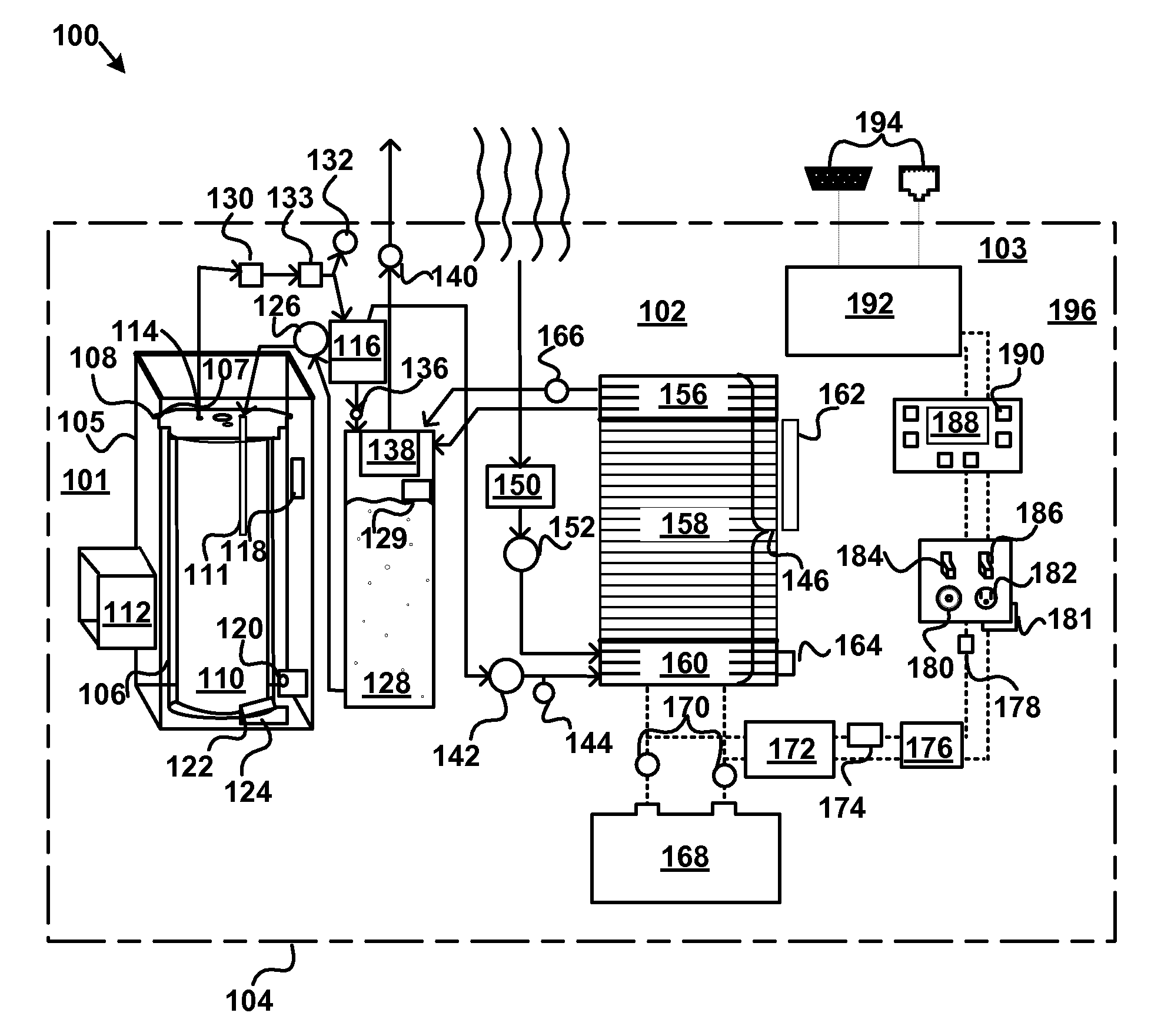

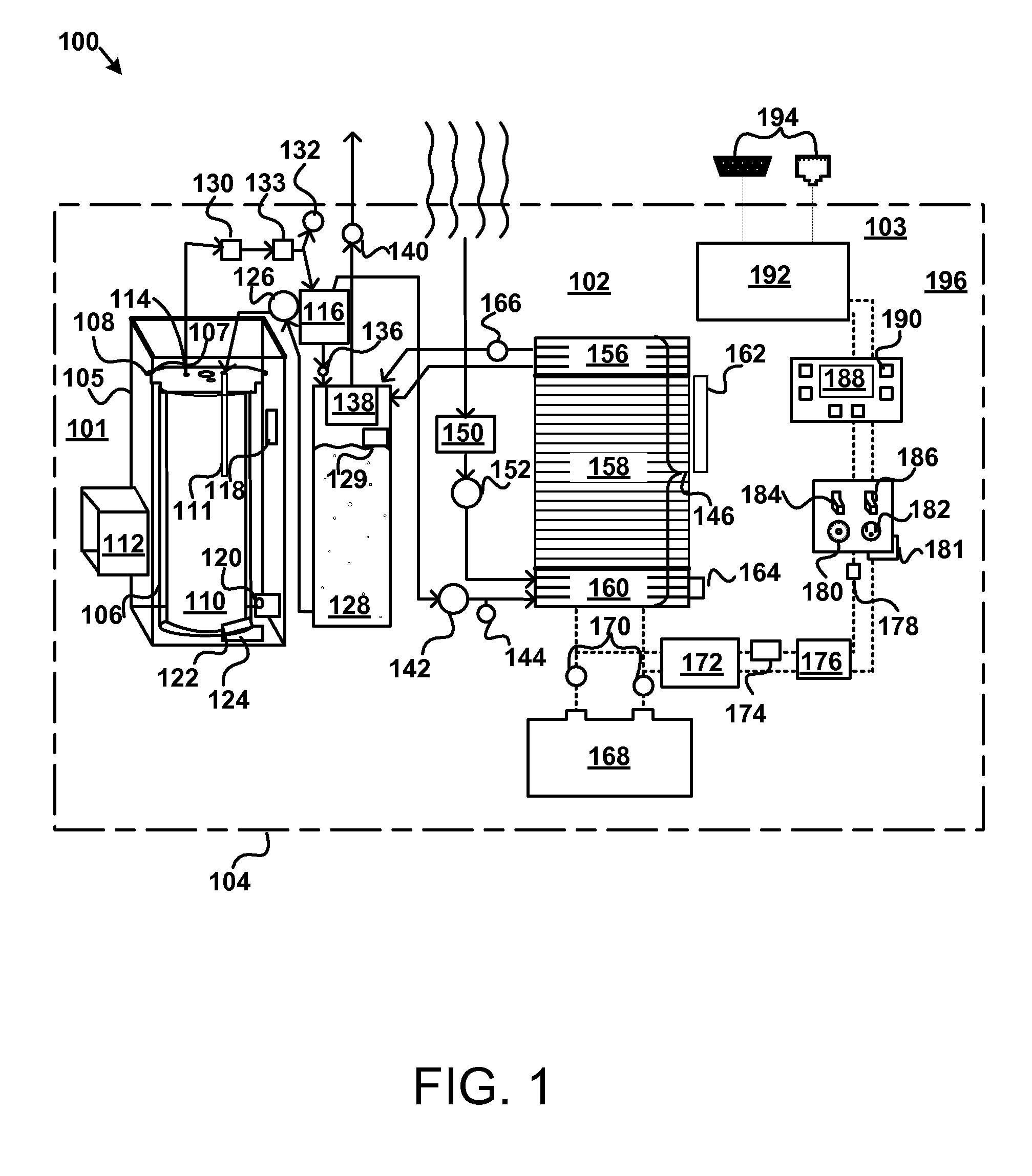

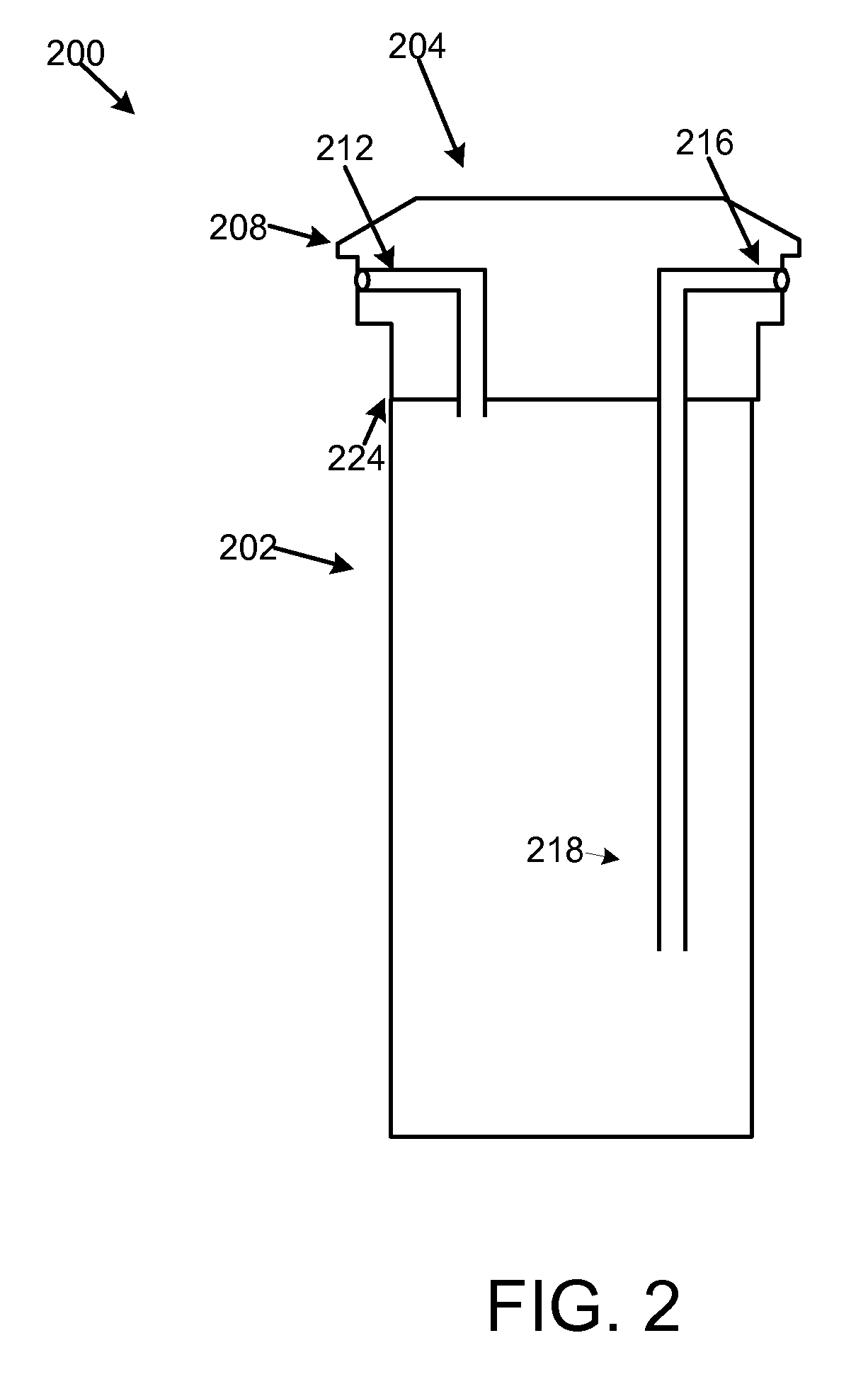

Apparatus, system, and method for processing hydrogen gas

InactiveUS20090025293A1Fuel cell heat exchangeHydrogen separation using solid contactHydrogenFiltration

An apparatus, system, and method are disclosed for processing a hydrogen gas stream comprising a housing, a condensing media, a mechanical filtration element, a coalescer element, and an outlet port. The housing comprises a heat- and pressure-resistant material and has an internal chamber configured to receive a hydrogen gas stream. A condenser may cool the hydrogen gas stream to promote water condensation. The condensing media removes entrained liquid water from the hydrogen gas stream. The mechanical filtration element receives the hydrogen gas stream as the hydrogen gas stream exits the condensing media. The mechanical filtration element collects particulate matter from the hydrogen gas stream. The coalescer element receives the hydrogen gas stream as the hydrogen gas stream exits the mechanical filtration element. The coalescer element removes substantially all of the liquid water formed in the hydrogen gas stream. The outlet port delivers the hydrogen gas stream outside the housing.

Owner:TRULITE INC

Electrostatic coalescer device and use of the device

InactiveUS7749459B2Easy to separateReduce in quantityElectrostatic separatorsSludge treatmentBiomedical engineeringElectric field

A device, located in a vessel having an inlet and at least one outlet, through which a mixture of fluids flows, for promoting electrostatic coalescence of a first conductive fluid emulsified in a second fluid. The device includes a number of tubular electrostatic coalescer elements extending in the flow direction which are arranged in a matrix arranged over the cross sectional area of the vessel, and an applicator operative to apply an electrical field to the fluids flowing through the coalescer elements.

Owner:SULZER MANAGEMENT AG

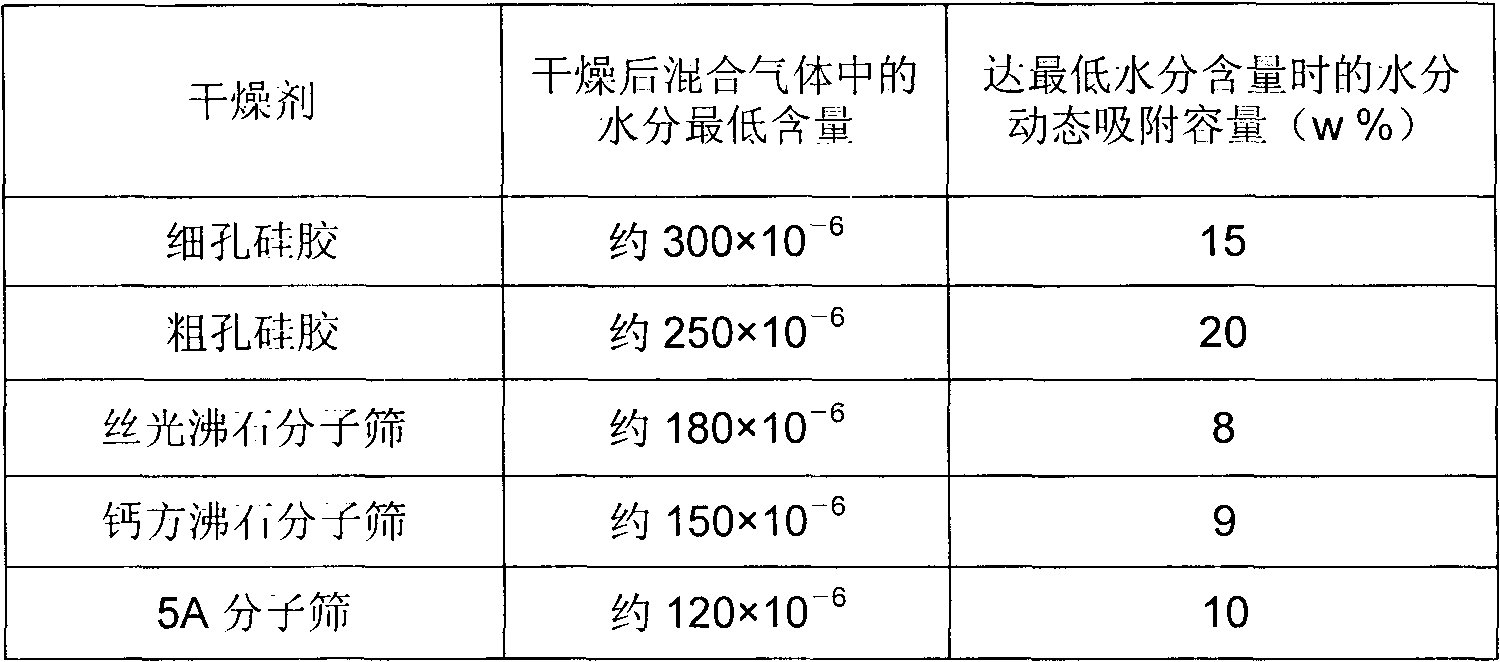

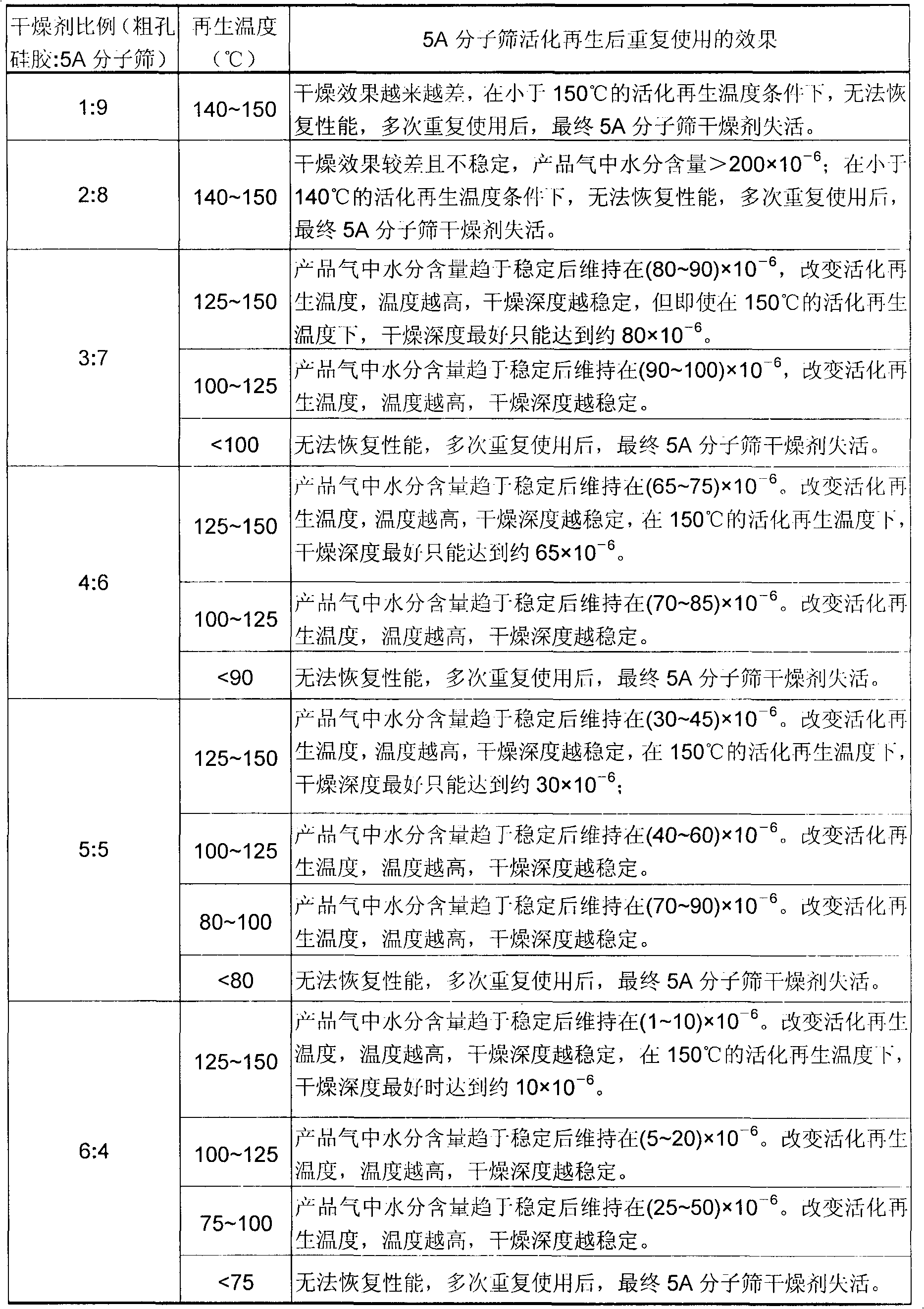

Method for removing moisture from chloroethylene or gas mixture with chloroethylene

ActiveCN101898068AReduce moisture contentReduce the content of other impuritiesDispersed particle separationHalogenated hydrocarbon preparationDesorptionSilica gel

The invention relates to a method for removing moisture from chloroethylene or gas mixture with chloroethylene. The method comprises the following steps: sending moisture-contained chloroethylene or gas mixture with chloroethylene from the entrance end into a dryer which is at least filled with macropore silica gel and 5A molecular sieve desiccant; performing adsorption drying under the gauge pressure of 0.30-0.70MPa; obtaining dry chloroethylene or gas mixture product with chloroethylene from the exit end of the dryer, at least heating desiccant in the dryer for desorption and cooling the desiccant to regenerate the desiccant, and performing the next adsorption drying operation repeatedly, wherein the average pore diameter of the silica-gel desiccant is 8.0-10.0nm, the specific surface area is 300-400m<2> / g, the pore volume is 0.8-1.0ml / g and the heat regeneration temperature of the desiccant is 70-150 DEG C. The total moisture content of the gas product dried by the method of the invention is up to (10-100)*10<-6>; and compared with the common drying methods and technologies such as solid caustic soda method, before and subsequent gravity dewatering method and coalescer dewatering and drying method, the method has the advantages of high dewatering accuracy, low operating cost, high recovery rate, more environmental friend and the like.

Owner:四川开元科技有限责任公司

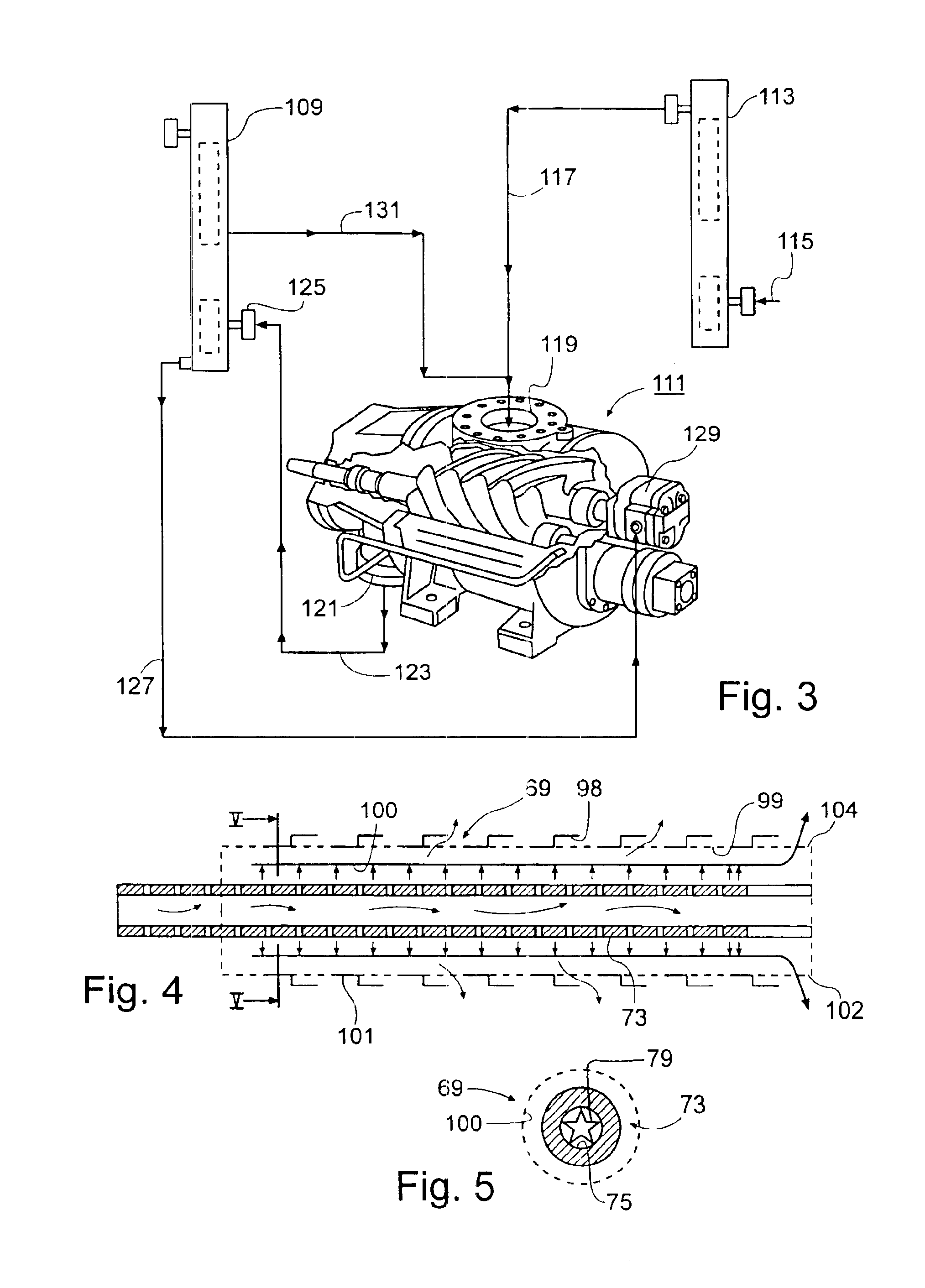

Separation device for removing liquid from a mixture comprising a gas and liquid

InactiveUS8790447B2Separation efficiency can be improvedCombination devicesLiquid degasificationEngineeringCOMPONENT II

A separation device for removing at least part of a liquid from a mixture which comprises a gas and the liquid in the form of droplets, comprises:a) a housing comprising first, second and third separation sections for separating liquid from the mixture, wherein the second section is arranged below the first section and above the third section, the respective sections are in communication with each other, and the second section comprises a rotating coalescer element;b) tangentially arranged means to introduce the mixture into the first section;c) means to remove liquid from the first section;d) means to remove liquid from the third section; ande) means to remove a gaseous stream, lean in liquid, from the third section.A separation process for removing at least part of a liquid from a mixture comprising the liquid in the form of droplets using the separation device.

Owner:SHELL OIL CO

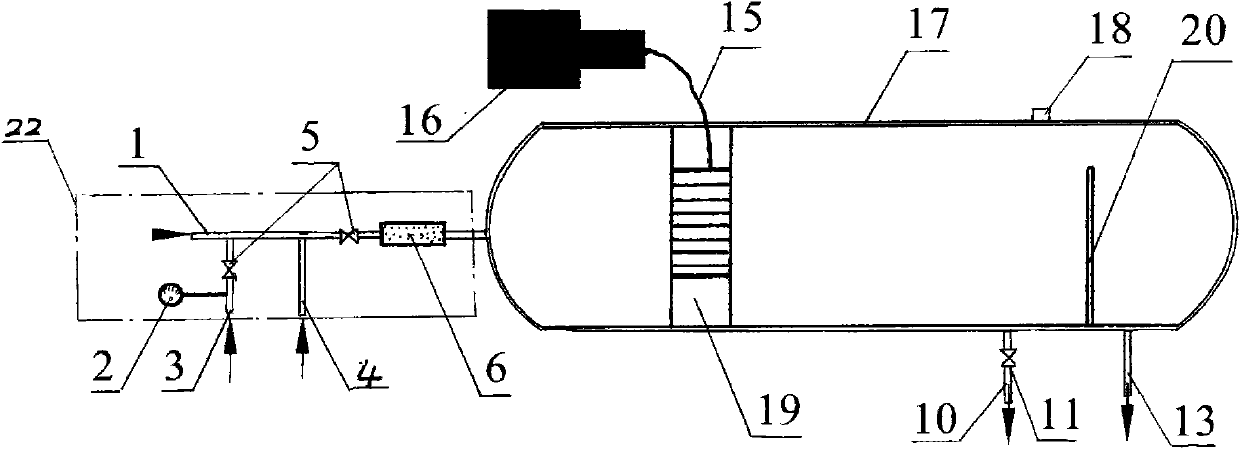

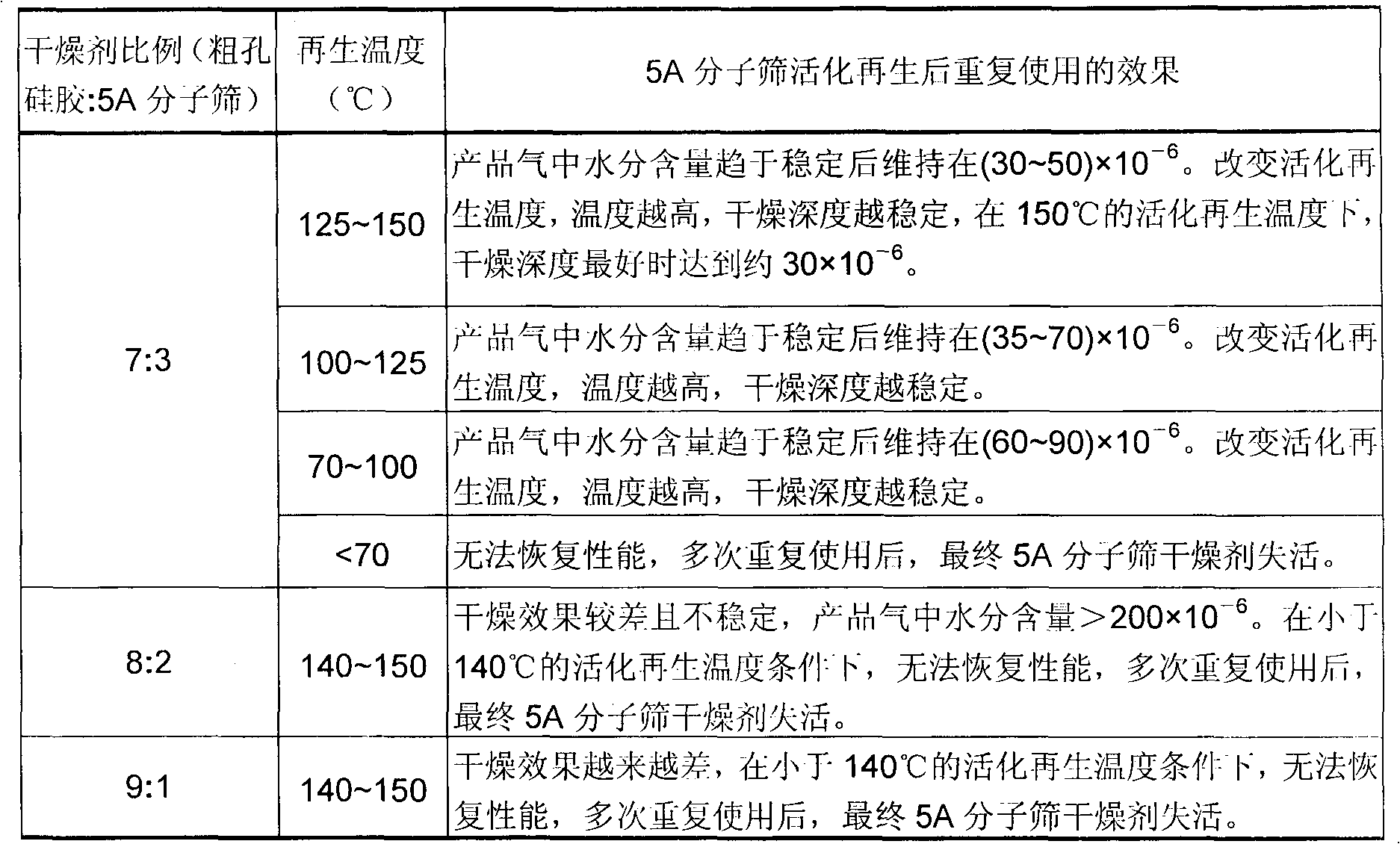

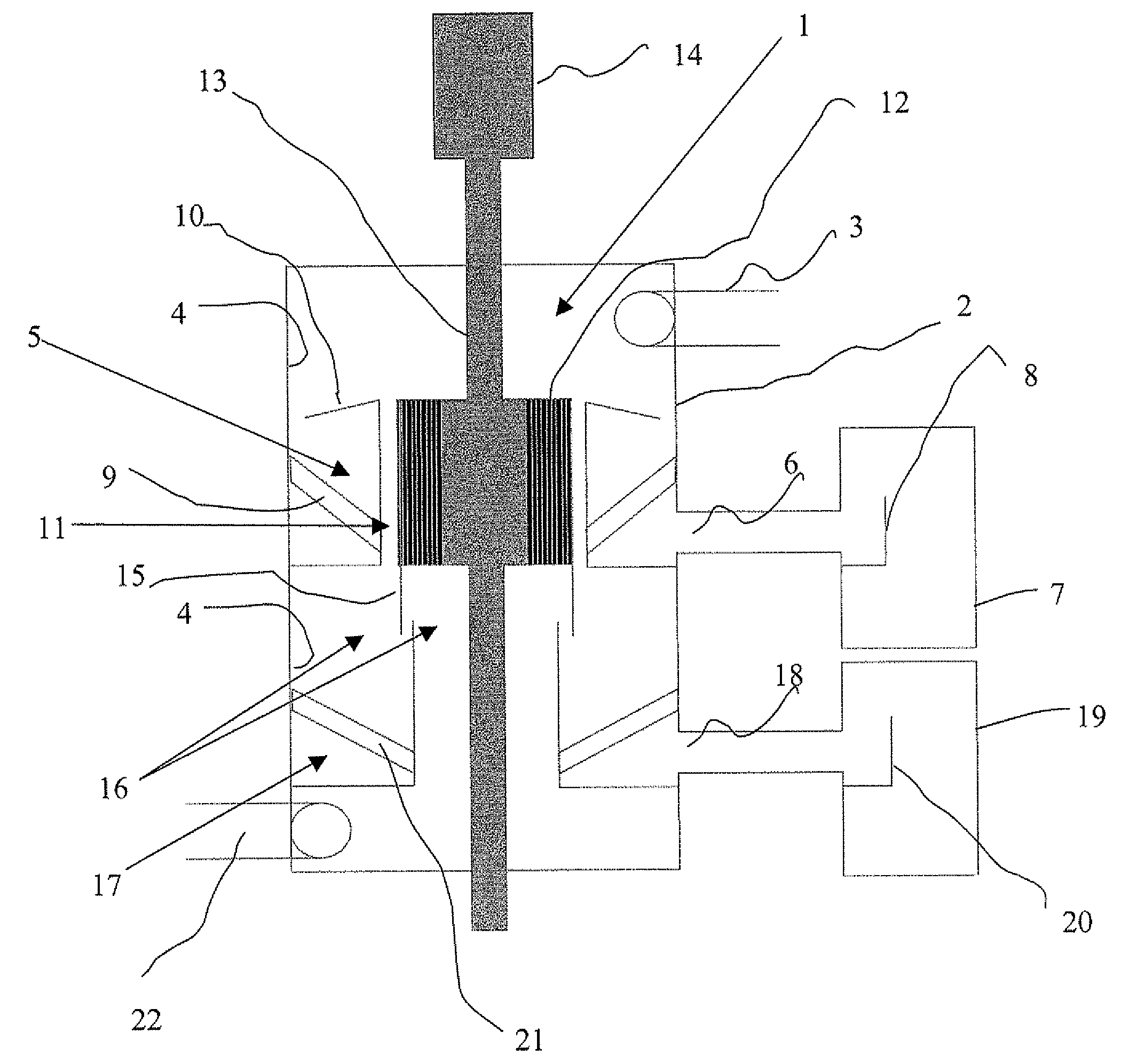

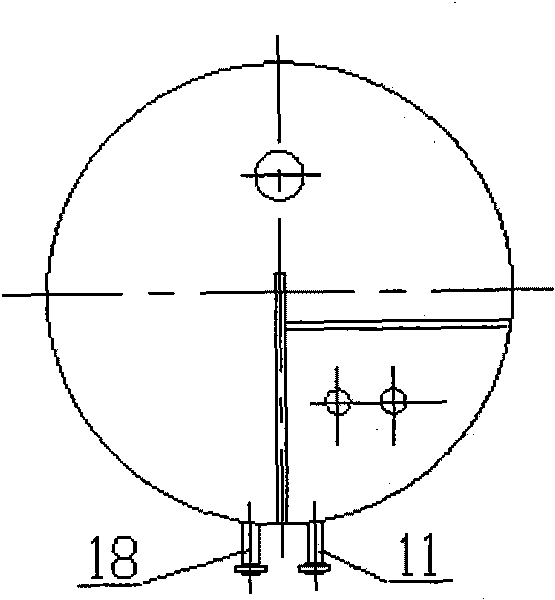

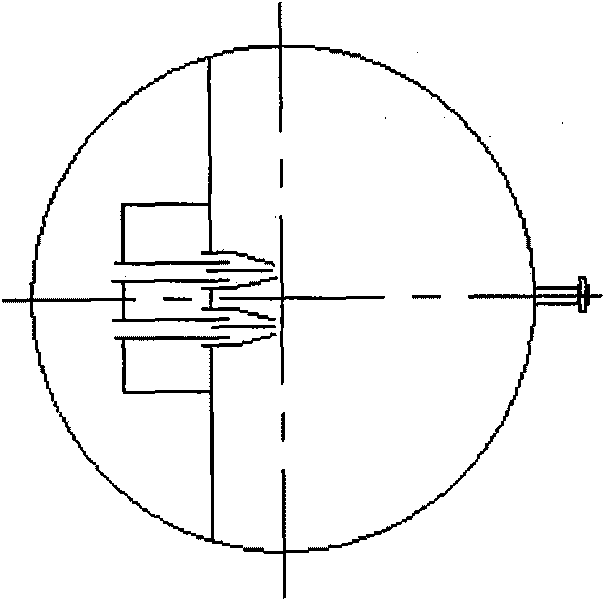

Oil, water and solid multi-phase separation method for natural gas

InactiveCN101721875ASimplify traditional craftSolution to short lifeCombination devicesGaseous fuelsCycloneEngineering

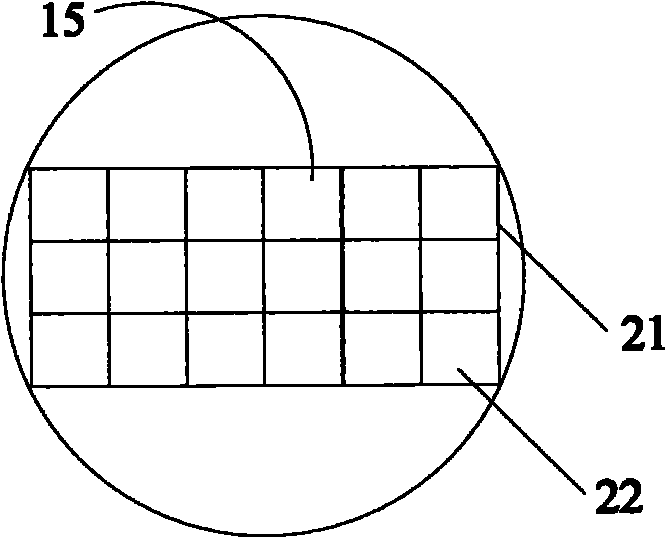

The invention discloses an oil, water and solid multi-phase separation method for natural gas. The method is characterized in that: a shell is a horizontal tank structure; the horizontal tank is partitioned into four sections, namely a gas inlet water-washing region (19), a cyclone separation region (20), a coalescing separation region (21) and a tail end mist catching region (22); fluid produced by a gas well in the gas inlet water-washing region (19) enters the gas inlet water-washing region (19) through a gas inlet distributing pipe (1) of a multi-phase separator, and a solid phase and an oil phase in the gas can be separated rapidly; a large amount of saturated water is separated in the cyclone separation region (20) via a cyclone (4); saturated water mist and oil mist remaining in the gas are conglomerated once again by a coalescer (5) in an oil-water coalescing section of the coalescing separation region (21); and condensate oil and the water mist in the gas are fully removed by catching in the tail end mist catching region (22), and is finally discharged from a gas outlet (16) on the top of the tail end mist catching region (22). The method has small floor area, low investment and convenient maintenance, can not only simplify the process, but also achieve the aim of deep dehydration.

Owner:XIAN TIANXIANG ENERGY TECH

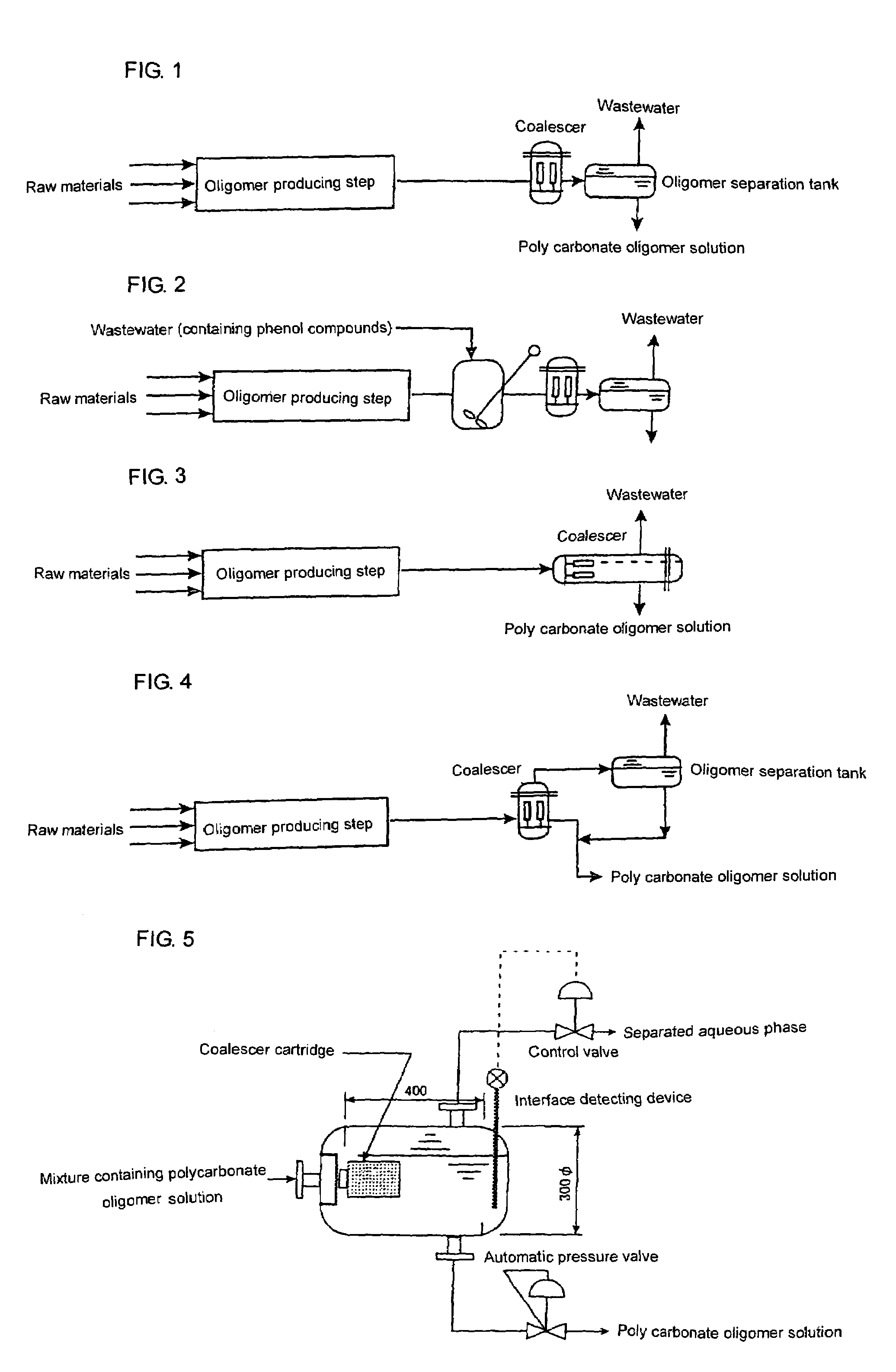

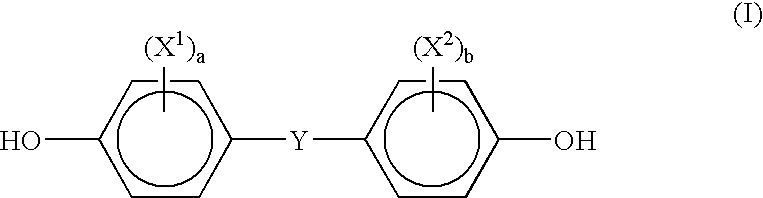

Process for producing polycarbonate

InactiveUS7517944B2Reduce contentQuality improvementCombination devicesAuxillary pretreatmentOligomerEmulsion

Provided a process for producing a polycarbonate which comprises reacting an aqueous alkali solution of a dihydric phenol with phosgene in the presence of an organic solvent to produce a polycarbonate oligomer and subsequently polycondensing the oligomer, wherein an emulsion solution of a polycarbonate oligomer-containing organic solvent obtained in the polycarbonate oligomer production step is introduced into a coalescer to separate the emulsion solution into a polycarbonate oligomer-containing organic solvent phase and an aqueous phase, and the polycarbonate oligomer-containing organic solvent phase is subjected to polycondensation. Thus the emulsion solution of a polycarbonate oligomer-containing organic solvent obtained in the polycarbonate oligomer production step is efficiently separated to reduce the content of impurity-containing water in the oligomer for producing a polycarbonate having excellent quality and to a obtain wastewater having a low content of organic materials.

Owner:IDEMITSU KOSAN CO LTD

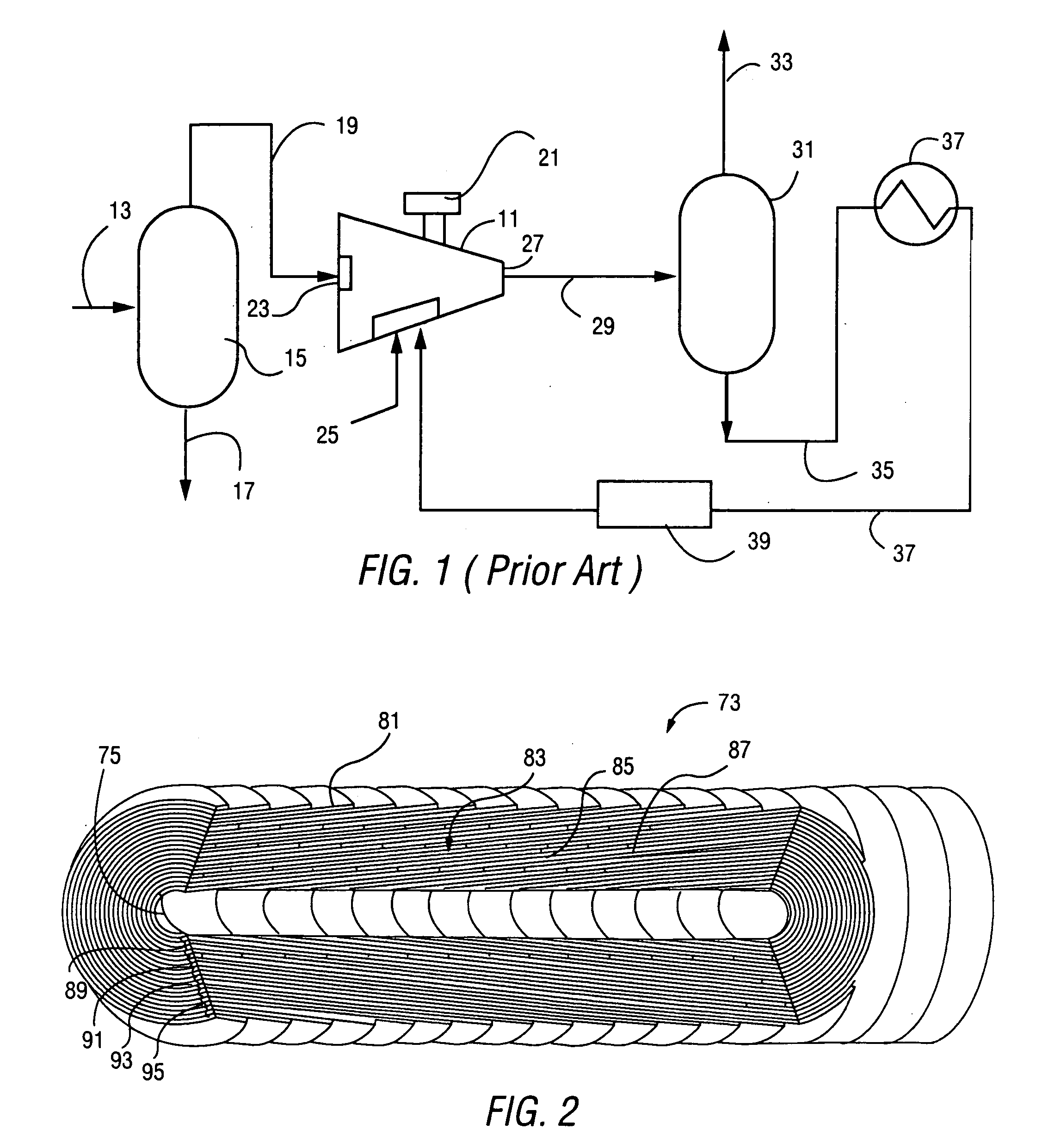

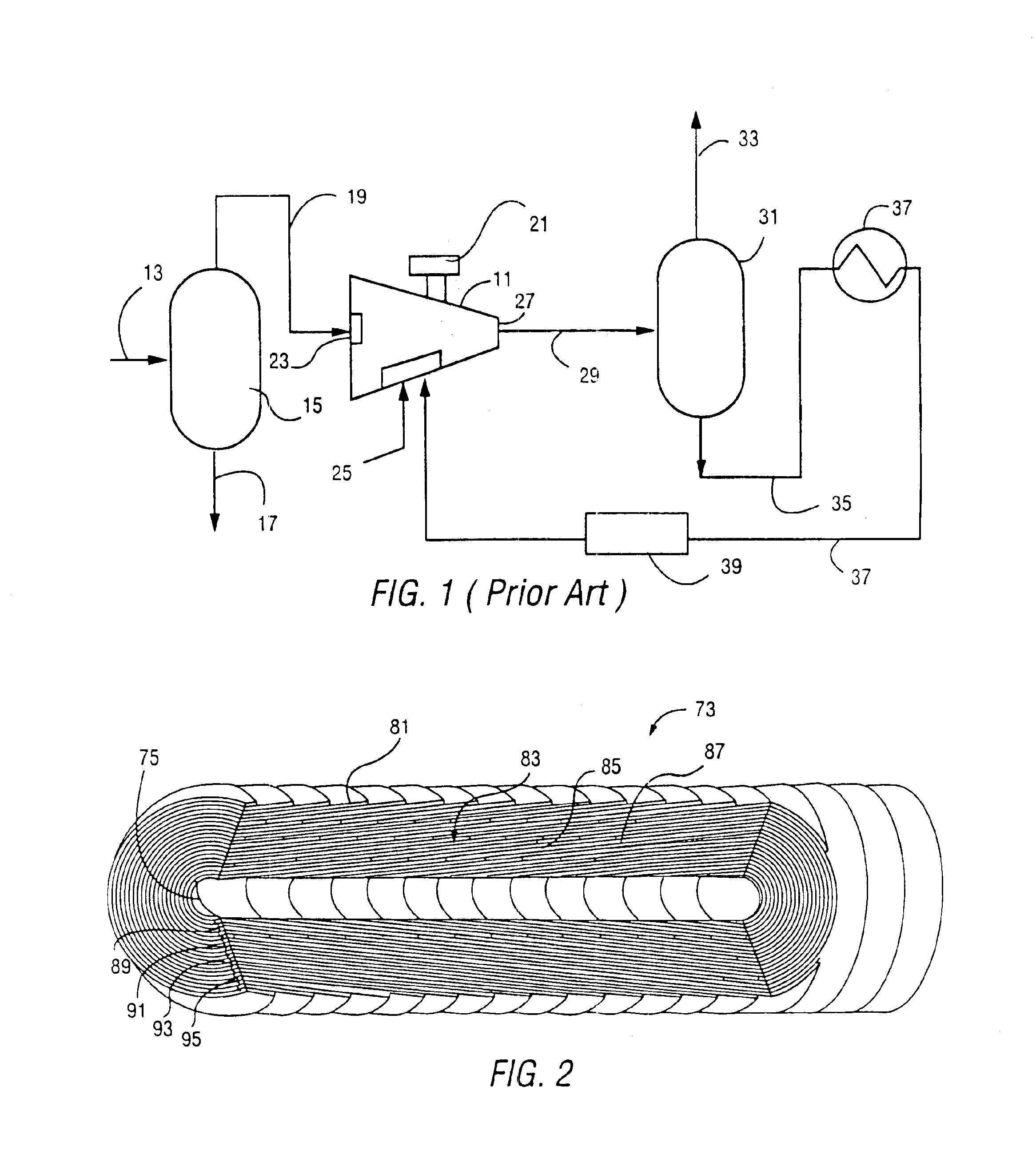

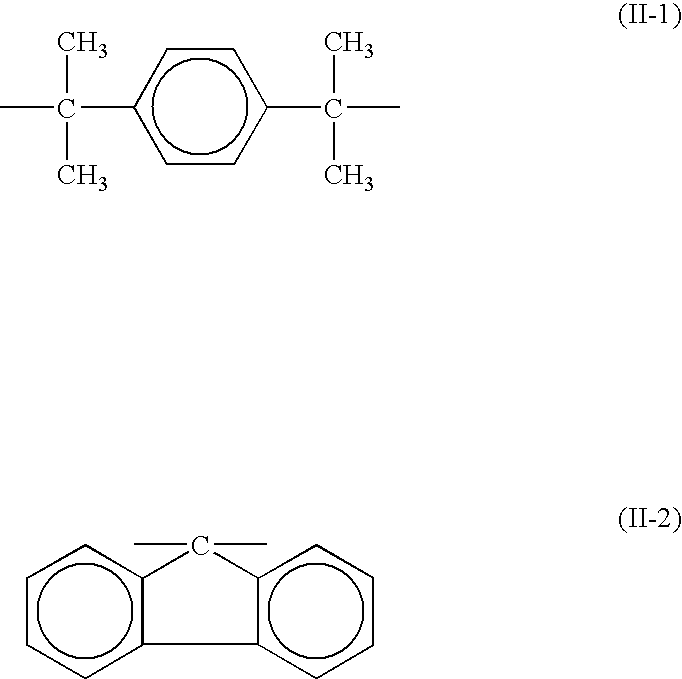

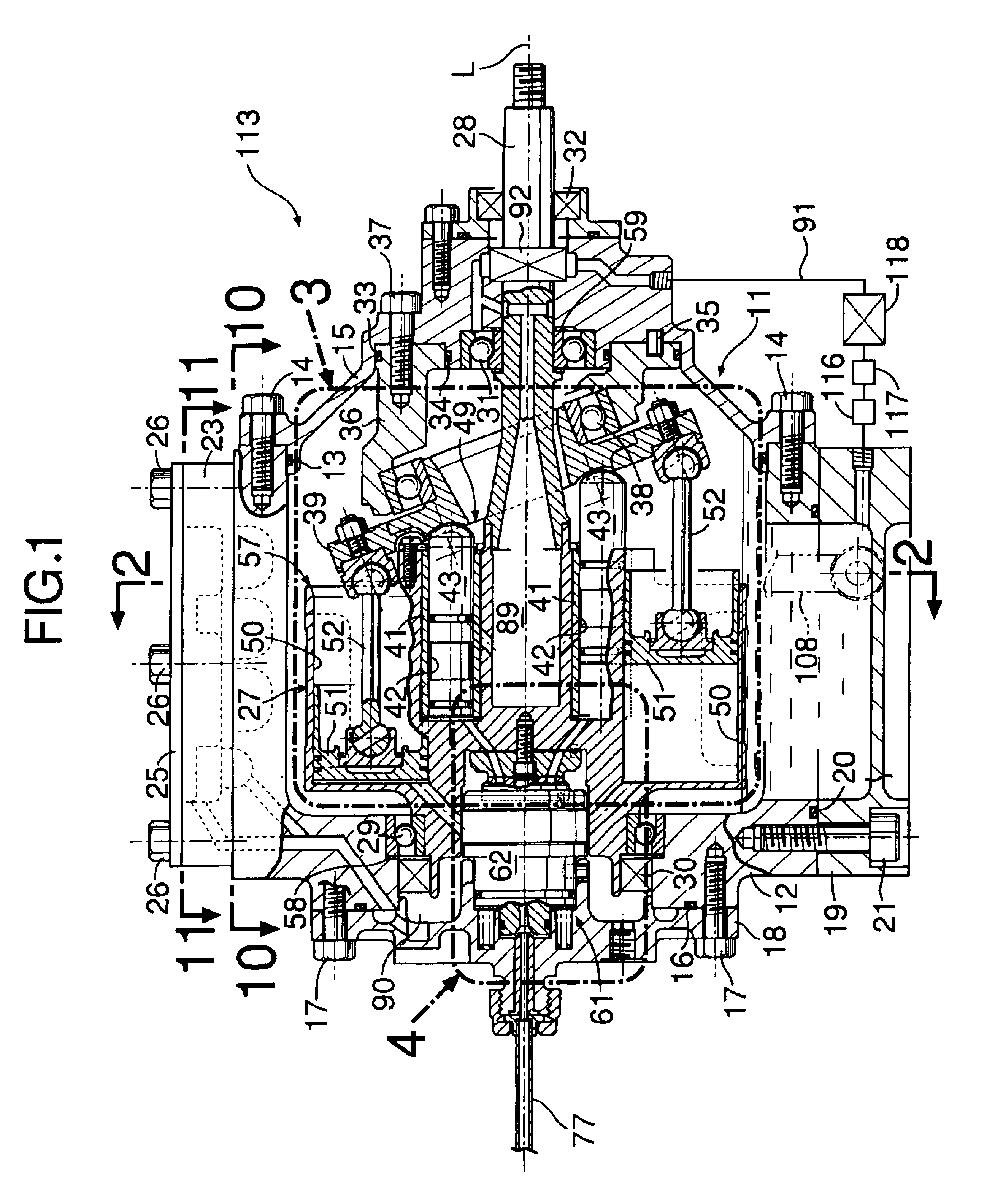

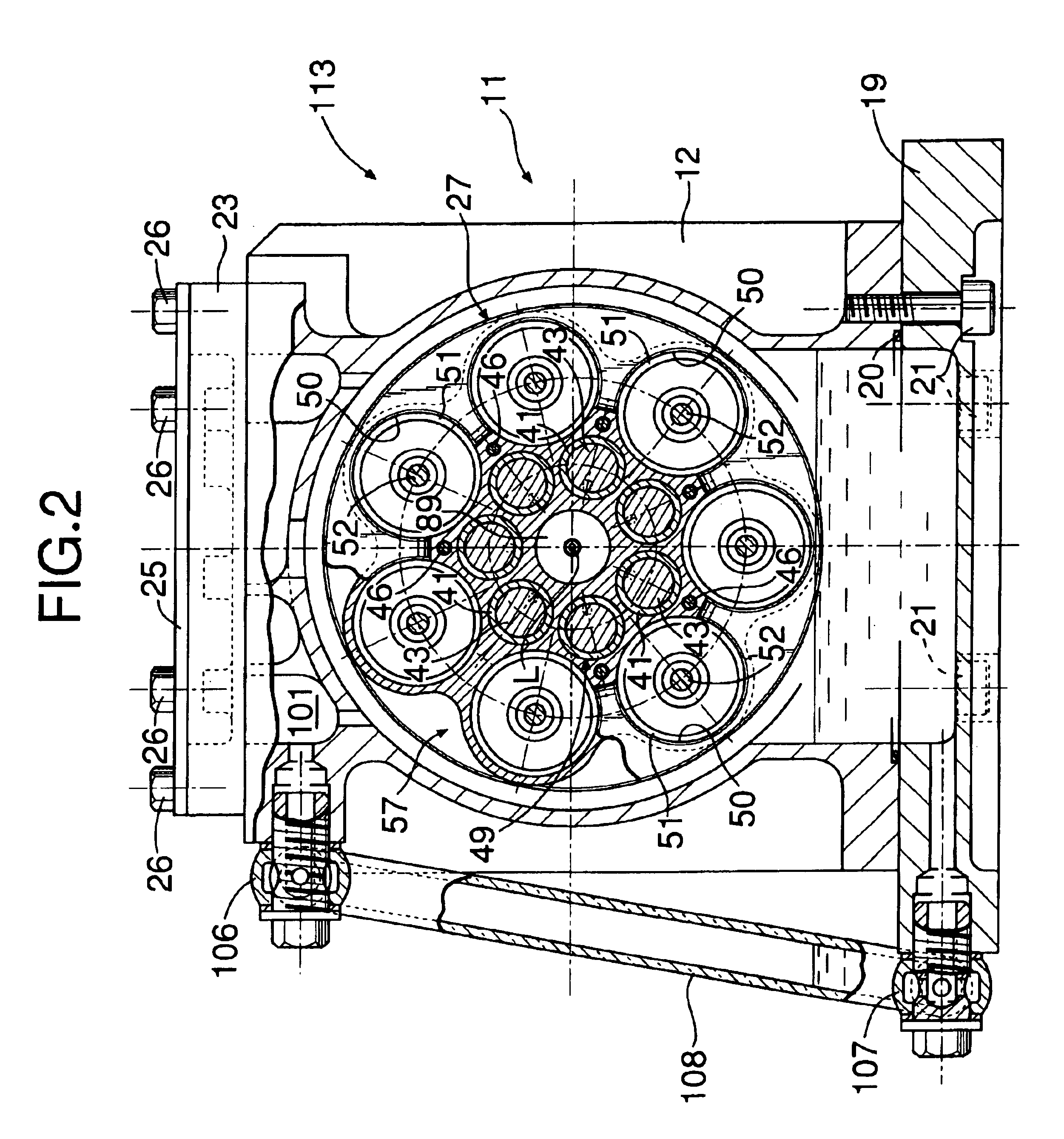

Rankine cycle system

InactiveUS6948316B2Avoid performance degradationEasy to separateReciprocating combination enginesCombination enginesEnvironmental engineeringEngineering

A Rankine cycle system having a working medium circulation circuit (110) that includes an evaporator (112), an expander (113), a condenser (114), and a feed pump (115) is provided in which a mixture of oil for lubricating the expander (113) and water, which is a working medium and has become mixed with the oil, is supplied to coalescer type water separating means (118), thus separating the water from the oil. The oil from which water has been separated in water separating means (118) is returned to the expander (113), and the water separated from the oil is returned to the working medium circulation circuit (110). It is thus unnecessary to replenish the working medium circulation circuit (110) with water or replenish the expander (113) with oil.

Owner:HONDA MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com