Patents

Literature

100results about How to "Enough time to stay" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

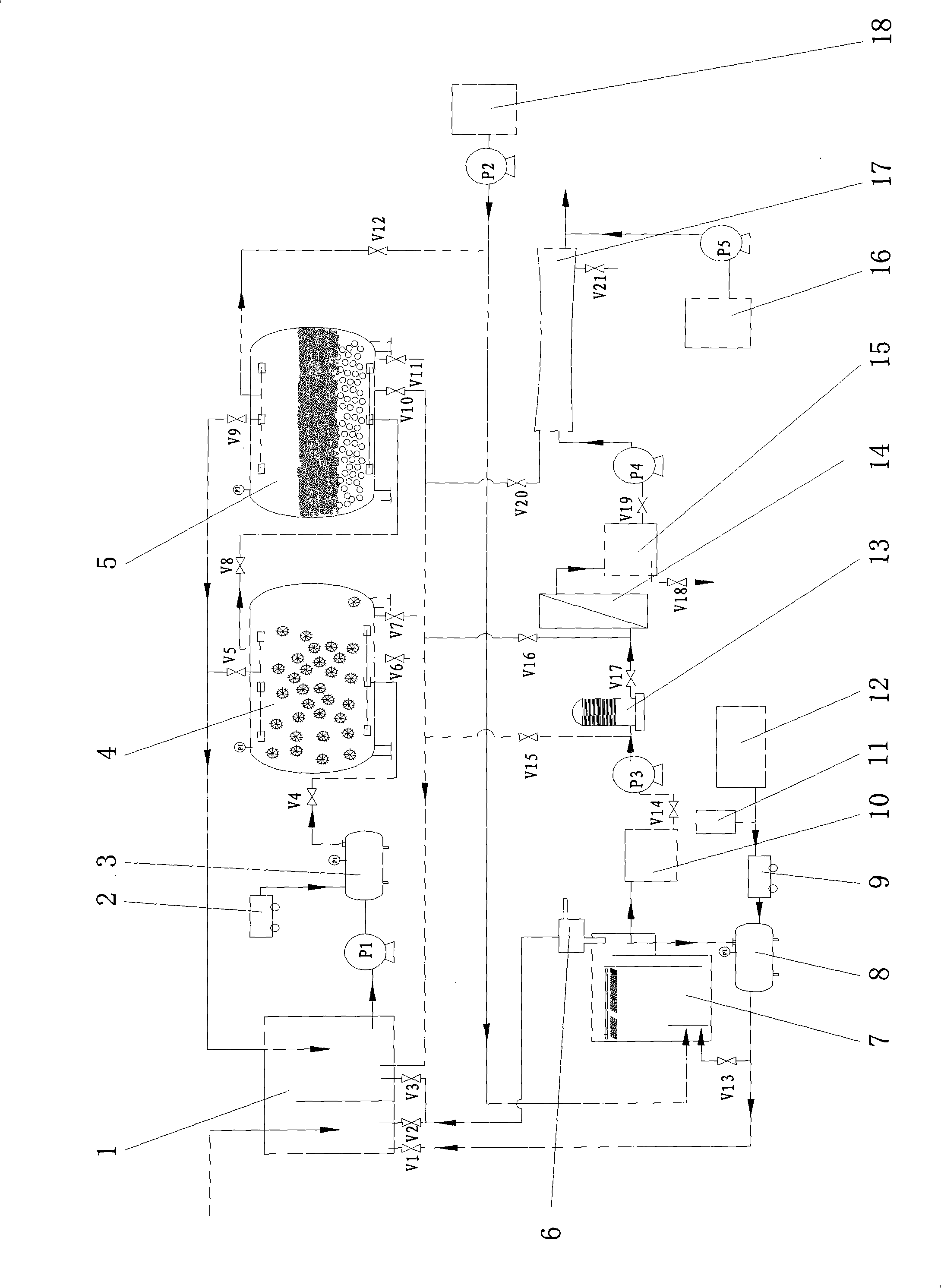

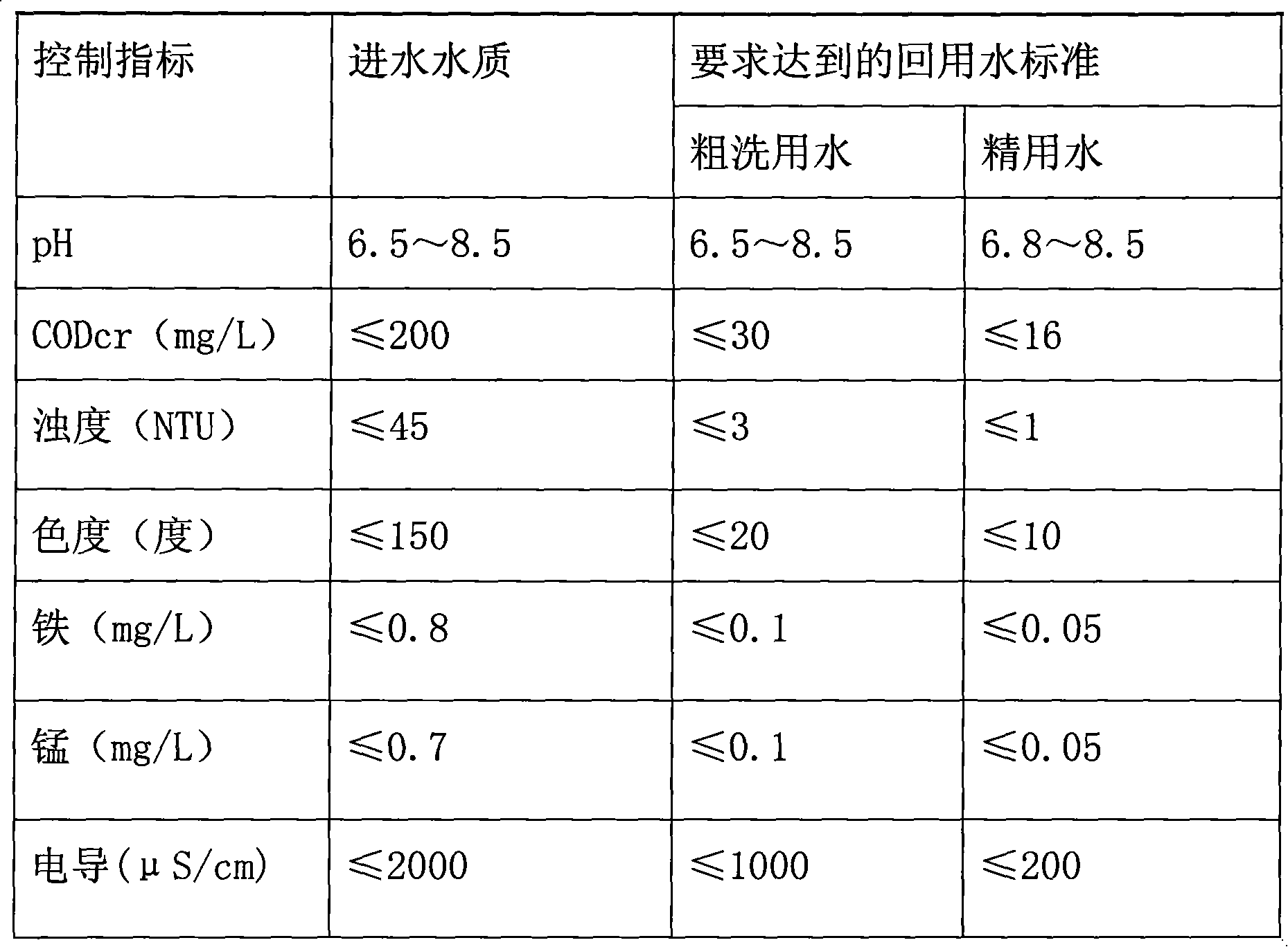

Integrated technology for deep purification treatment for printing and dyeing waste water

InactiveCN101633541AReduce ozoneEnough time to stayTreatment using aerobic processesWater/sewage treatment bu osmosis/dialysisFiltrationBiological filter

The invention discloses integrated technology for reclaiming lightly-polluted printing and dyeing waste water or printing and dyeing waste water achieving a certain discharge standard through deep purification treatment for production. A related process of the technology mainly comprises an adjusting tank, a pressure moving bed bio-film reactor, a ceramsite and activated carbon biological filter, an air floating system, a laminated filter and an ultra-filtration and reverse osmosis system. The technology is characterized in that the technology improves the prior biochemical technology, and carries out process integration by combining technology such as ozone oxidation, air flotation, membrane separation and the like. The regeneration of the printing and dyeing waste water can be realized by adopting the treatment technology, and the regenerated water quantity can reach 70 to 80 percent; and the technology not only can effectively solve the pollution problem of the printing and dyeing industry and protect the environment, but also can provide theoretical and technical support for realizing closed-loop circulation of the printing and dyeing waste water and popularizing clean production in the printing and dyeing industry.

Owner:ZHEJIANG STONE ENVIRONMENTAL ENG CO LTD +2

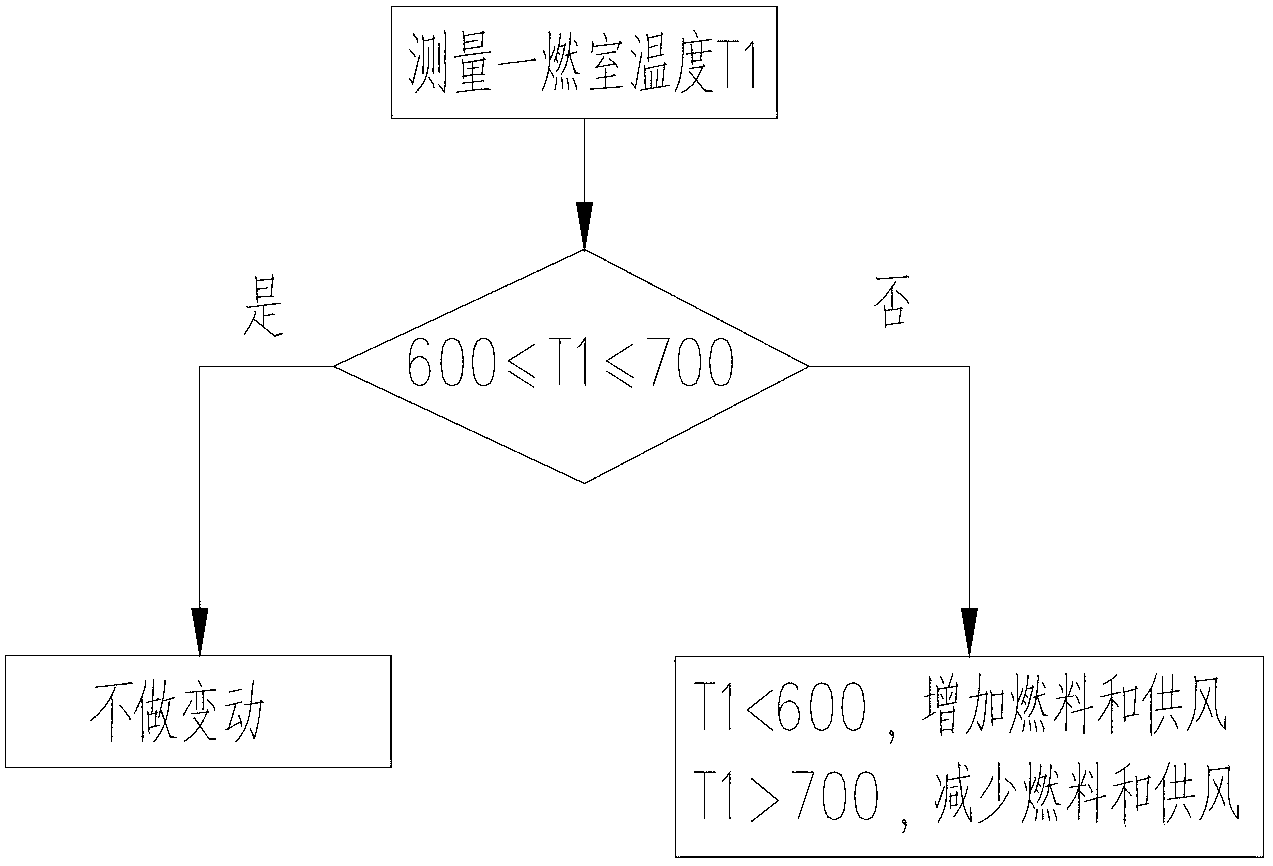

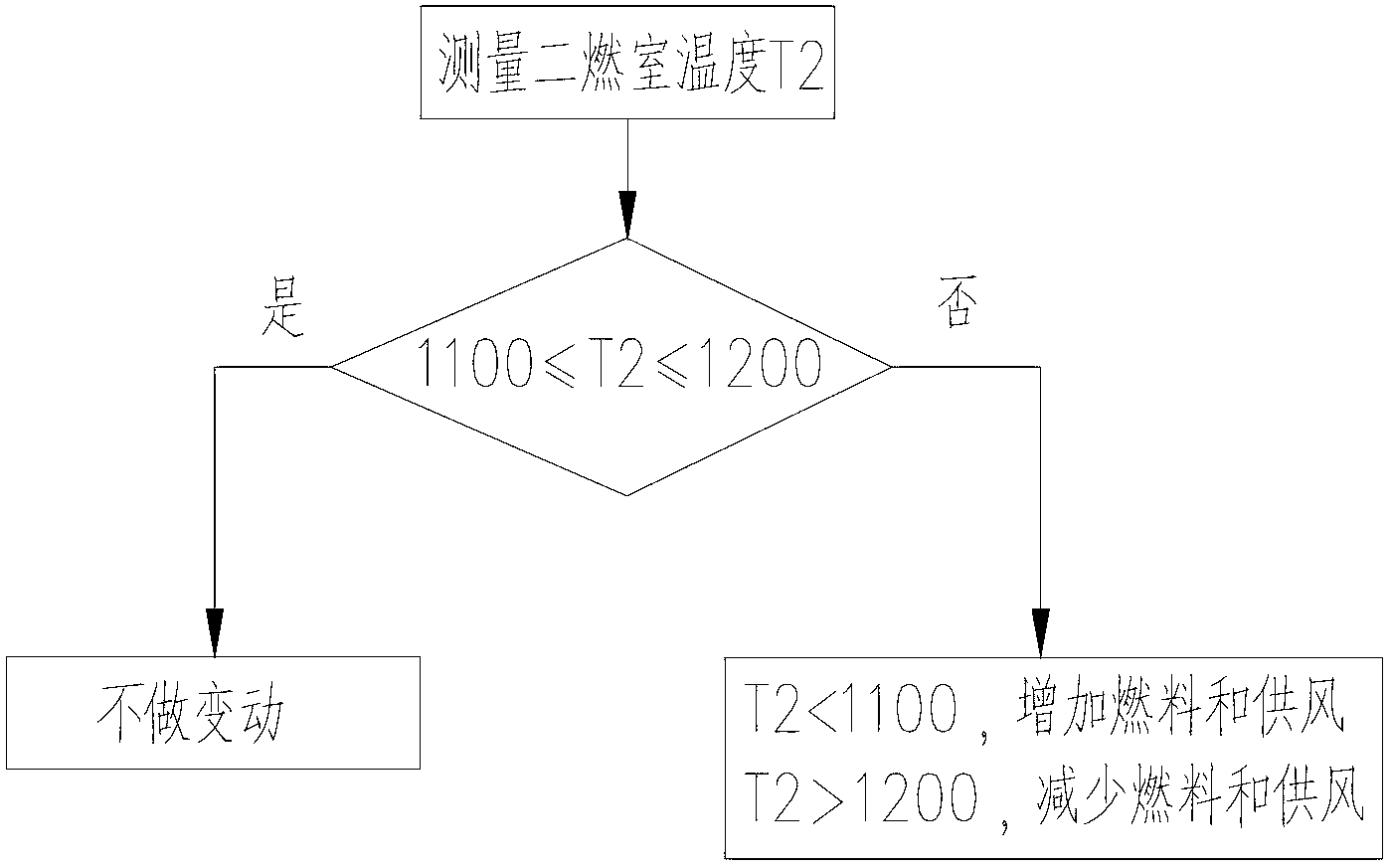

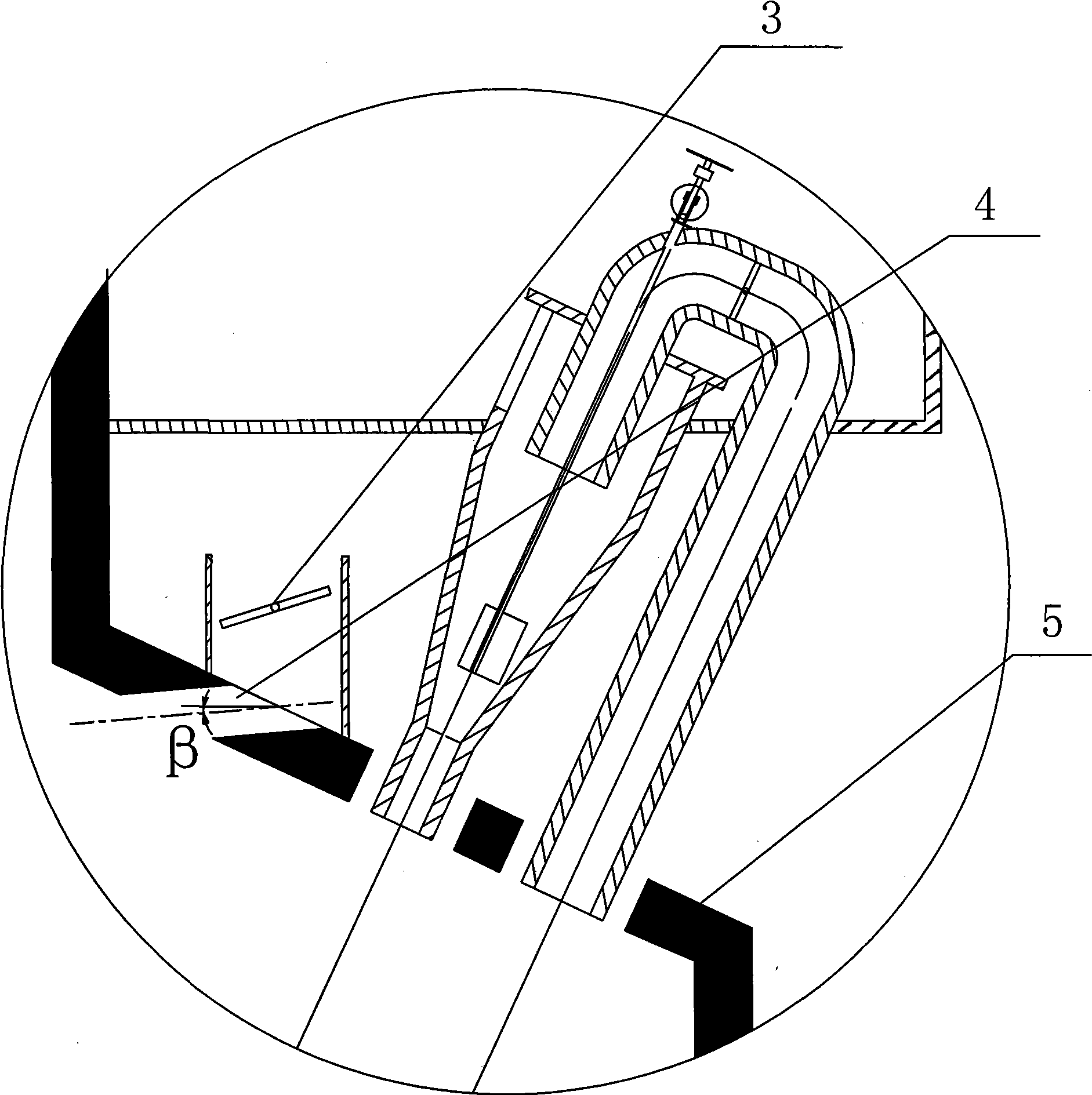

Incineration disposal method for high-salinity wastewater

InactiveCN103017177AAvoid redissolutionReduce salt contentIncinerator apparatusSteam generation using hot heat carriersComing outFurnace temperature

The invention discloses an incineration disposal method for high-salinity wastewater. The high-salinity wastewater is sprayed into a combustion chamber I after being atomized by utilizing a waste liquid spray gun through compressed air. In the combustion chamber I, the consumption of auxiliary fuel and air supply volume are controlled through temperature feedback to keep furnace temperature at 600-700 DEG C. Smoke generated in the combustion chamber I enters a combustion chamber II under the action of an induced draft fan; in the combustion chamber II, the consumption of the auxiliary fuel and the air supply volume are controlled through the temperature feedback to keep the furnace temperature at 1100-1200 DEG C, and moreover, the standing time of the smoke is longer than 2 seconds. Smoke coming out from the combustion chamber II enters a waste heat boiler, and the heat of the smoke is recycled through heat exchange. Smoke coming out from the waste heat boiler is respectively dedusted and deacidified through a bag type dust collector and a smoke deacidification unit, and then, is discharged on the standard. According to the incineration disposal method for the high-salinity wastewater, not only can saline matter in the high-salinity wastewater be separated out through the evaporation of water without coking but also hazardous organic matters in the smoke can be fully destroyed by fire.

Owner:BMEI

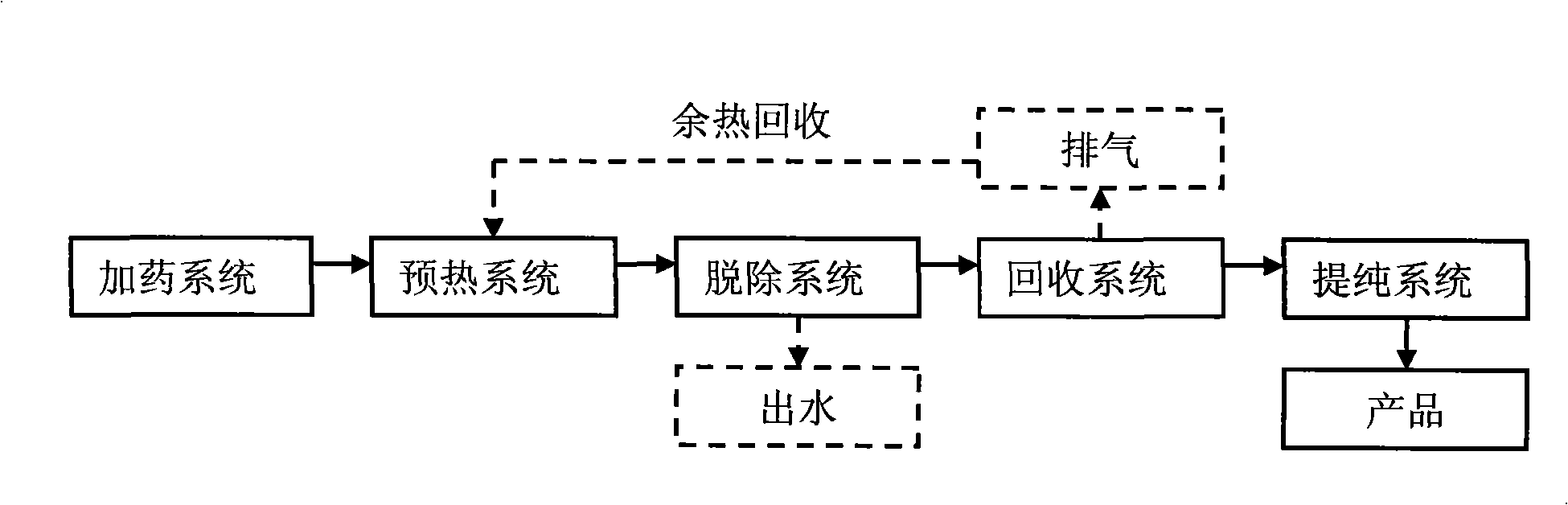

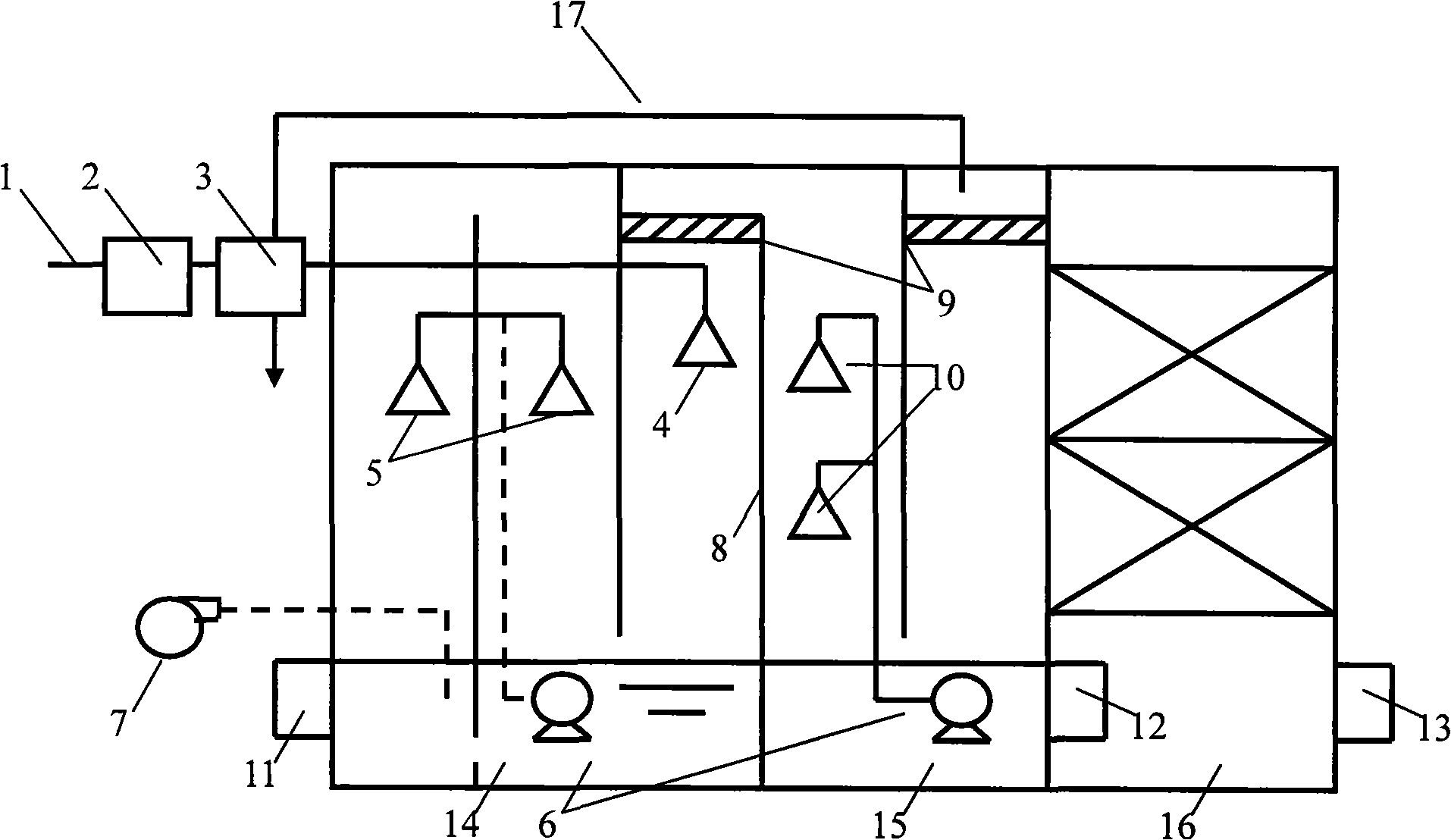

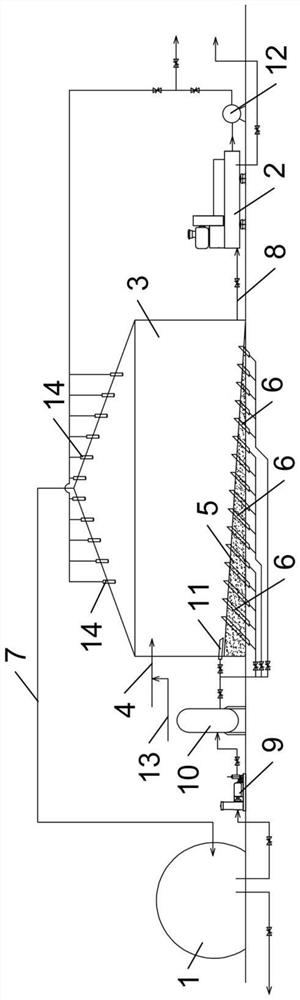

Treatment method and apparatus for recycling ammonia nitrogen wastewater

InactiveCN101318752AReduce dosageGuaranteed preprocessing effectMultistage water/sewage treatmentWater/sewage treatment by heatingResource utilizationSewage

The invention relates to a method and a device for recycling treatment of ammonia nitrogen wastewater. The use method combining the device comprises the following steps that: a PH value of ammonia nitrogen wastewater is adjusted in an automatic medicine addition device; the ammonia nitrogen wastewater is preheated in a preheater, evenly distributed by a spraying device in a removal working section and collected in a bottom liquid storage zone; after ammonia is blown off by adopting forced-air blast, the ammonia in the wastewater is repeatedly removed by a circulating spraying system, purified and discharged from an effluent weir; ammonia-containing waste gas is filtered by a demisting device and subject to multilevel spraying and absorption so as to reclaim an ammonia crude product; and the purified gas is exhausted from the top part. The method and the device for recycling treatment of the ammonia nitrogen wastewater are suitable for ammonia nitrogen wastewater produced in the process of various industrial and agricultural productions, the treatment of domestic sewage and the resource utilization of materials, reclaim useful substances as possible while treating wastewater, reduce the cost for pollutant treatment and the emission of the pollutants and improve economical benefit while protecting environment.

Owner:ZHEJIANG UNIV

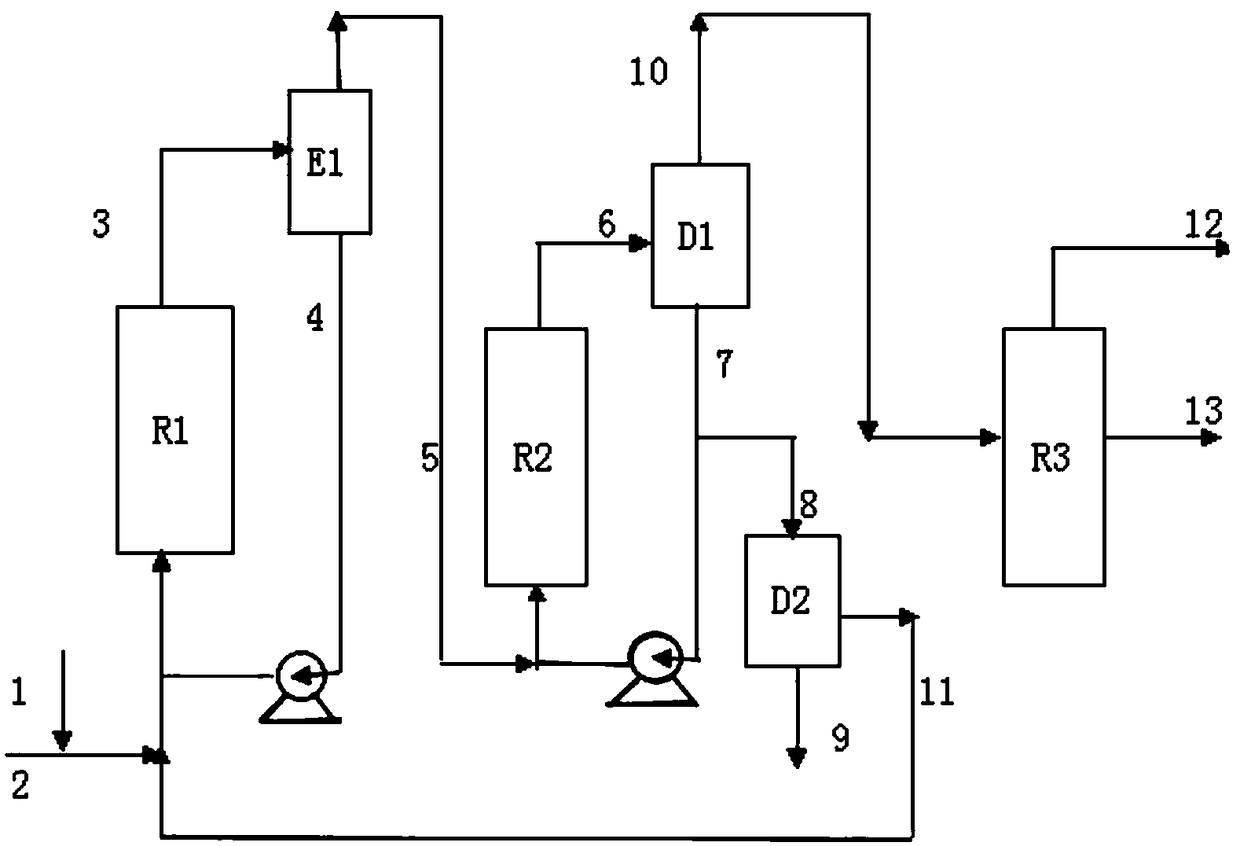

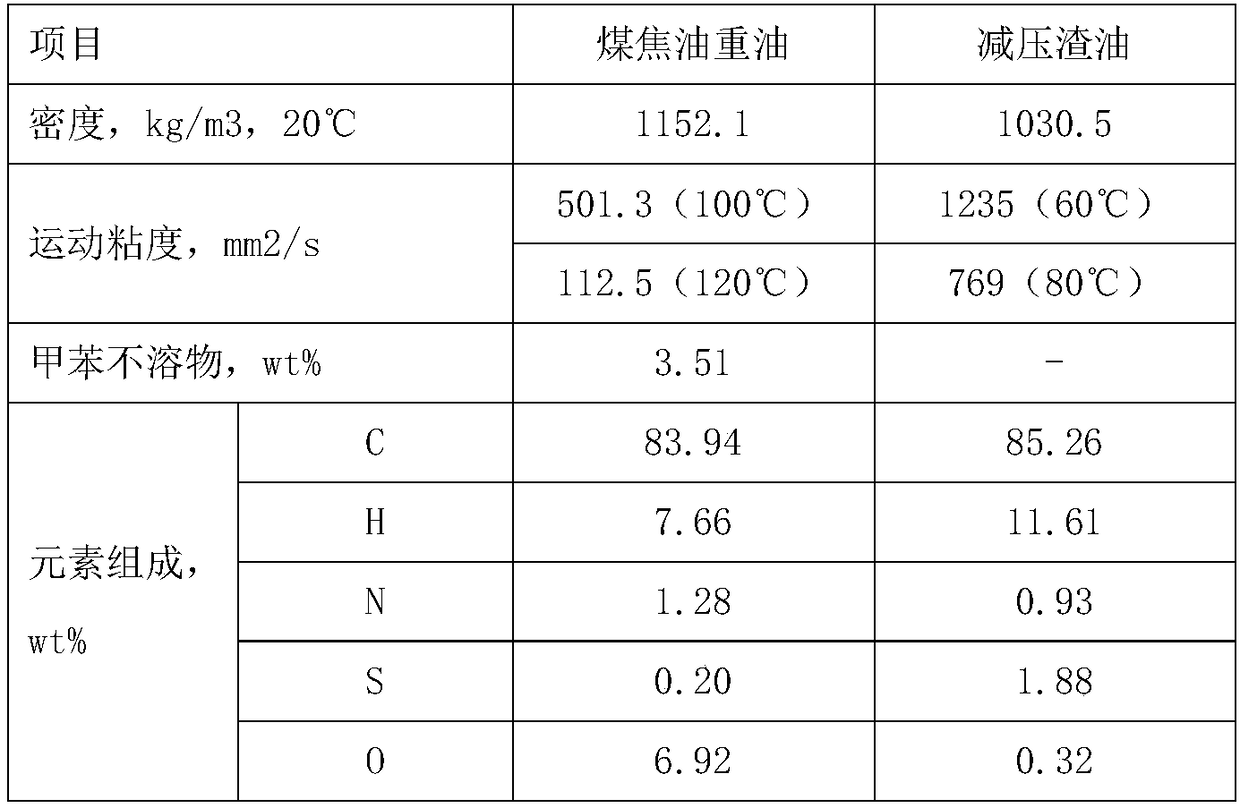

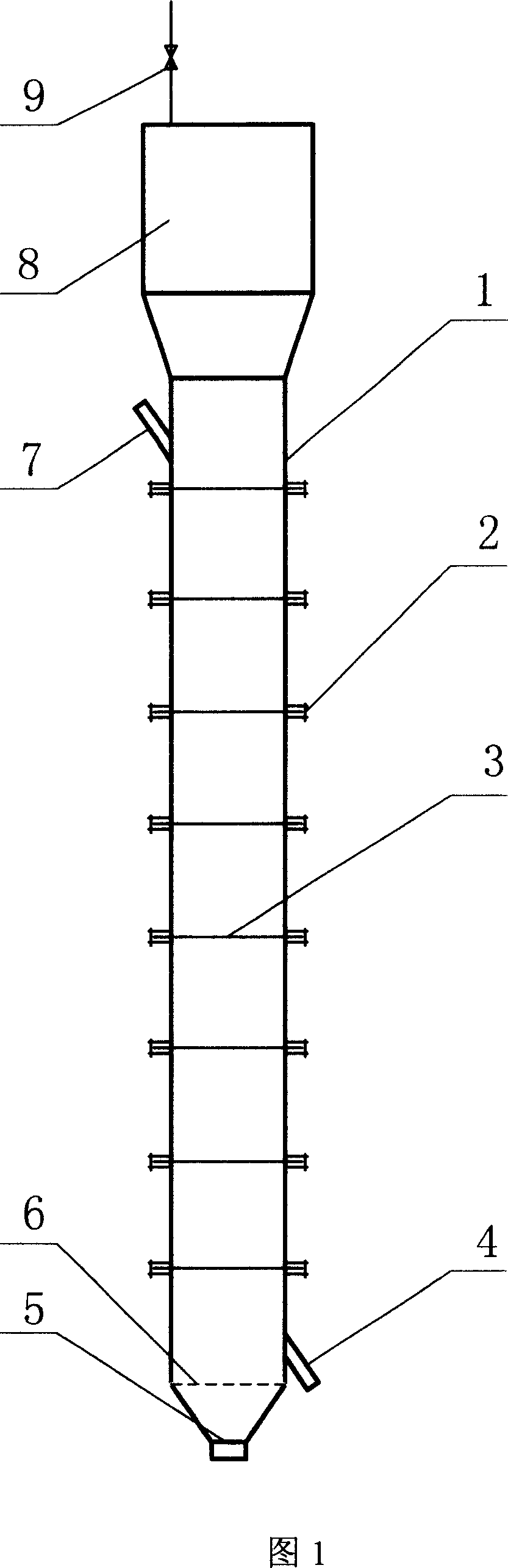

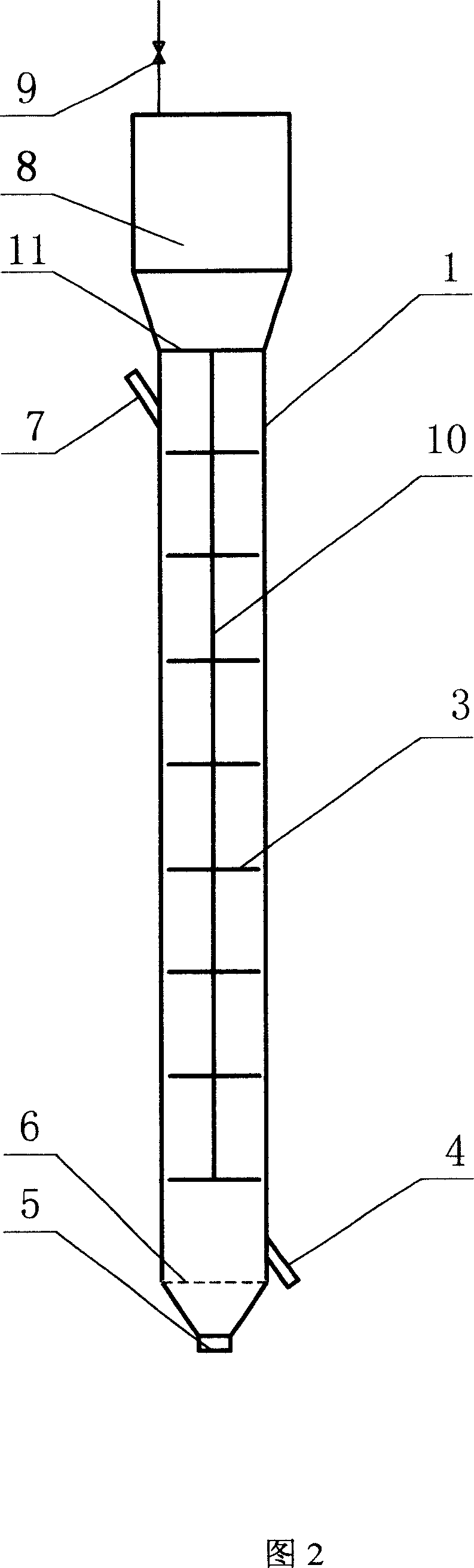

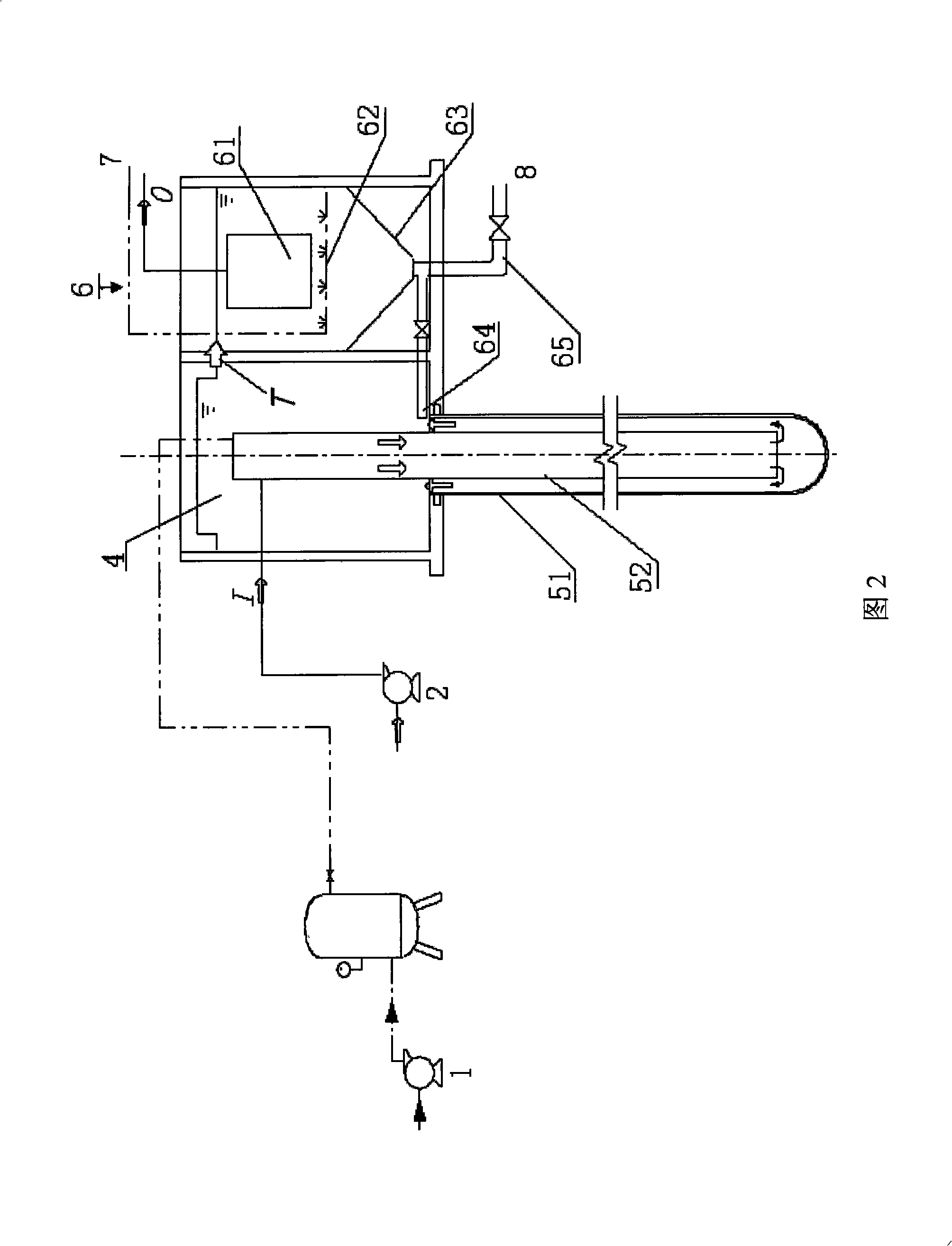

Heavy oil hydrogenation method and hydrogenation system

ActiveCN108659882AEnough time to stayGuaranteed conversion rateTreatment with hydrotreatment processesHydrogenRetention time

The invention relates to a heavy oil hydrogenation method and a hydrogenation system. The heavy oil hydrogenation method comprises the steps of mixing heavy oil, circulation oil, a valcanizer and a catalyst, performing hydrocracking on the heavy oil, the circulation oil, the valcanizer, the catalyst and hydrogen in a first reactor to form a first reaction product, allowing part of first reaction product to return to the first reactor, performing hydrocracking on the rest of the first reaction product in a second reactor to form a second reaction product, dividing the second reaction product into a light component and a heavy component, returning part of the heavy component to the second reactor, separating the rest of the heavy component to form distillate oil as the circulation oil, and hydrofining the light component in a third reactor to form a light oil product. The method improves heat transfer and mass transfer efficiency, ensures retention time of the material in the reactors, and increases a heavy oil conversion rate and a light oil yield. According to the hydrogenation system for the method, internal members of the reactors are simplified, and equipment investment and operation energy consumption are reduced.

Owner:CCTEG CHINA COAL RES INST

Fluidized-bed reactor for oxidizing carbon black through ozone

InactiveCN1958145AEliminate channelingElimination of Broken AgglomeratesPigmenting treatmentChemical/physical processesFluidized bedProduct gas

A fluidized-bed reactor for oxidizing carbon black by ozone with stable fluidizing and no coagulation of carbon black particles has a main body with lower carbon black discharging outlet, gas inlet on its bottom, upper carbon black inlet, gas outlet on its top, internal barrier plate with slits, and gas distributing plate under the carbon black discharging outlet.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

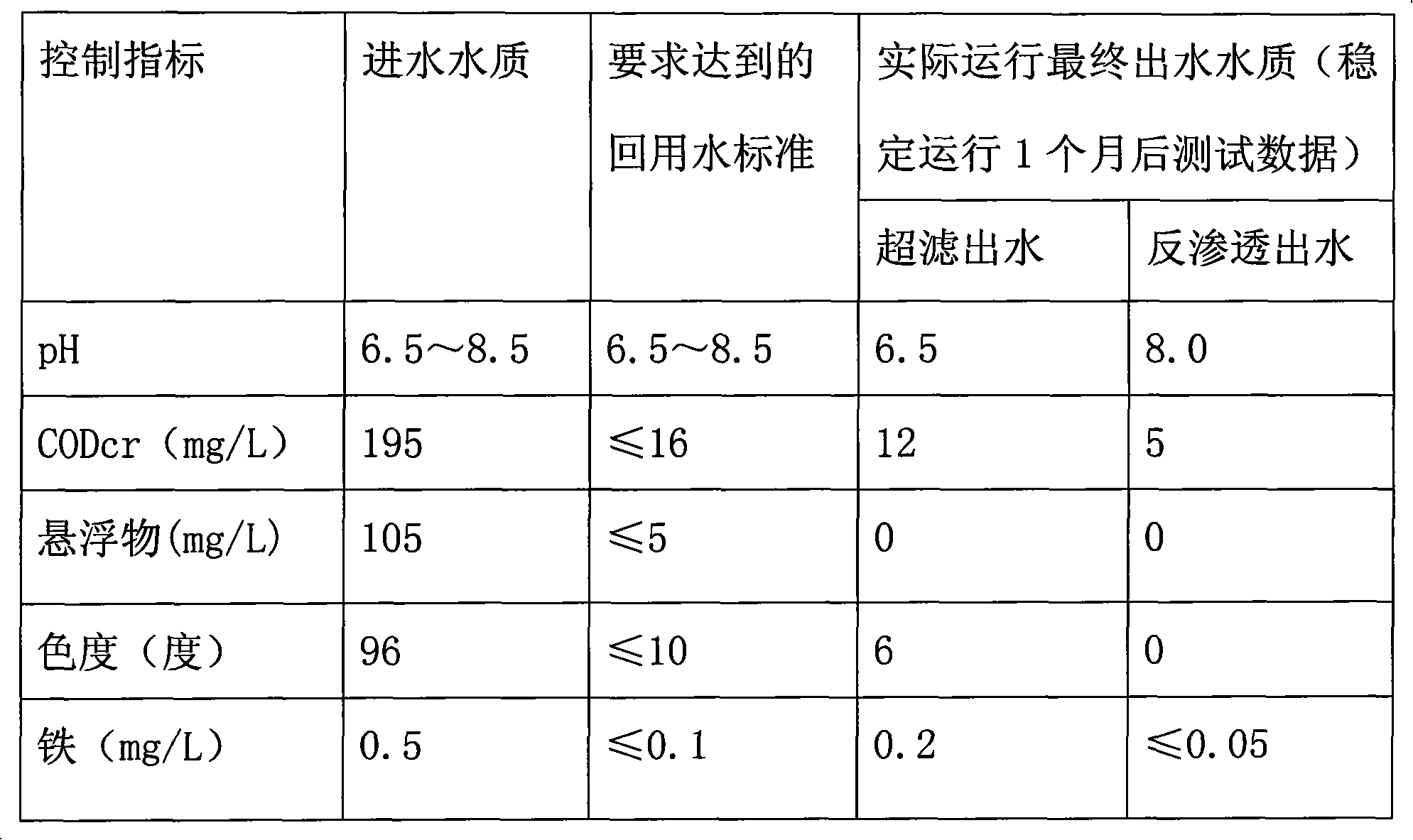

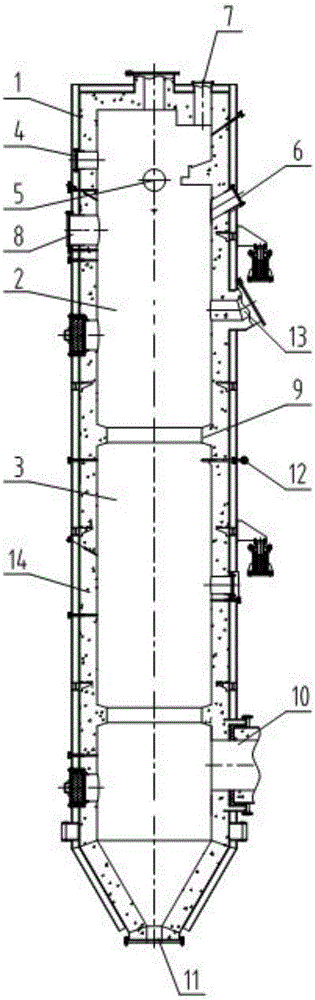

Organically-polluted soil remediation method

ActiveCN103495598AAchieve the purpose of repairPrevent leakageContaminated soil reclamationDesorptionEngineering

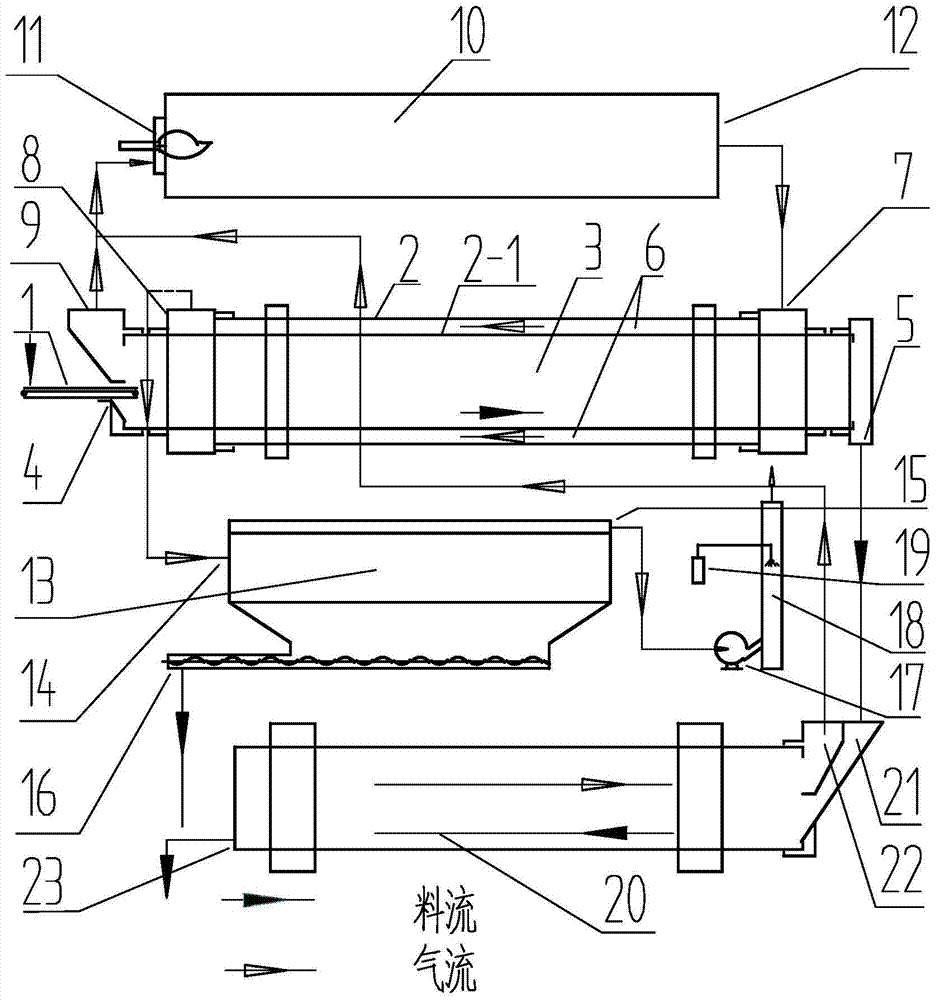

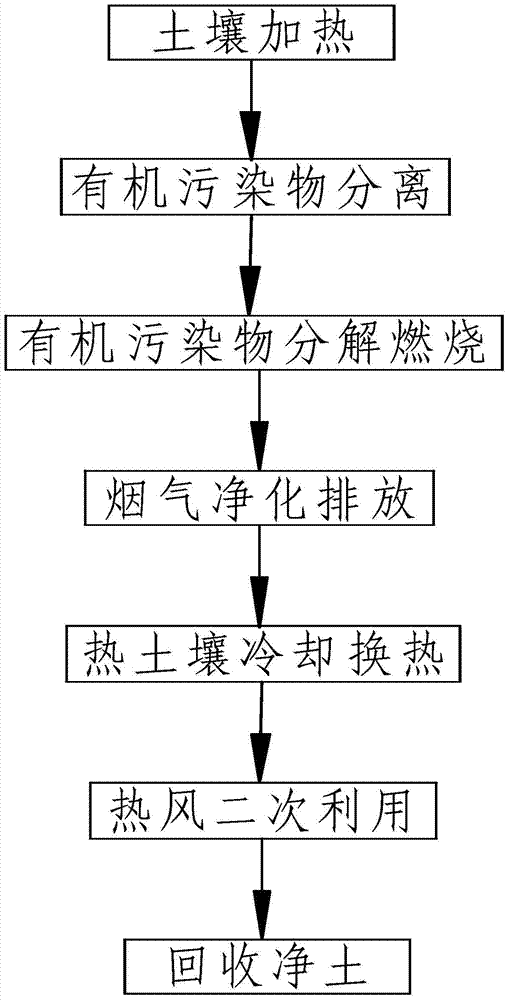

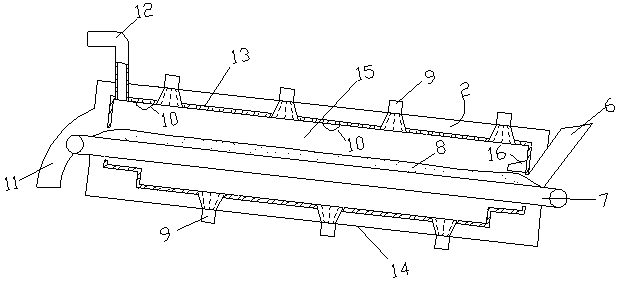

The invention discloses an organically-polluted soil remediation method which refers to a conveyer, a rotary kiln, a roasting furnace wall, a roasting chamber, a material inlet, a material outlet, a heating channel, a heating channel heat inlet, a heating channel heat outlet, a polluting gas outlet, a combustion furnace, a combustion furnace gas inlet, a combustion furnace heat outlet, a bag deduster, a bag deduster air inlet, a bag deduster smoke outlet, a soil particle outlet, an exhaust fan, a chimney, a deacidification device, a cooler, a cooler feed port, a cooler hot air outlet and a cooler discharge port. Since indirect heating desorption is adopted, hot air and soil are not in direct contact, energy consumption is low, desorption efficiency is high, and the soil can be thoroughly remedied; separated organic pollutants enter the combustion furnace to be completely combusted and decomposed by enriched oxygen, as a result, exhausted air quantity is small, secondary pollution is not caused, energy is saved, efficiency is improved, and investment is low.

Owner:LUOYANG CEMENT ENG DESIGN & RES INST

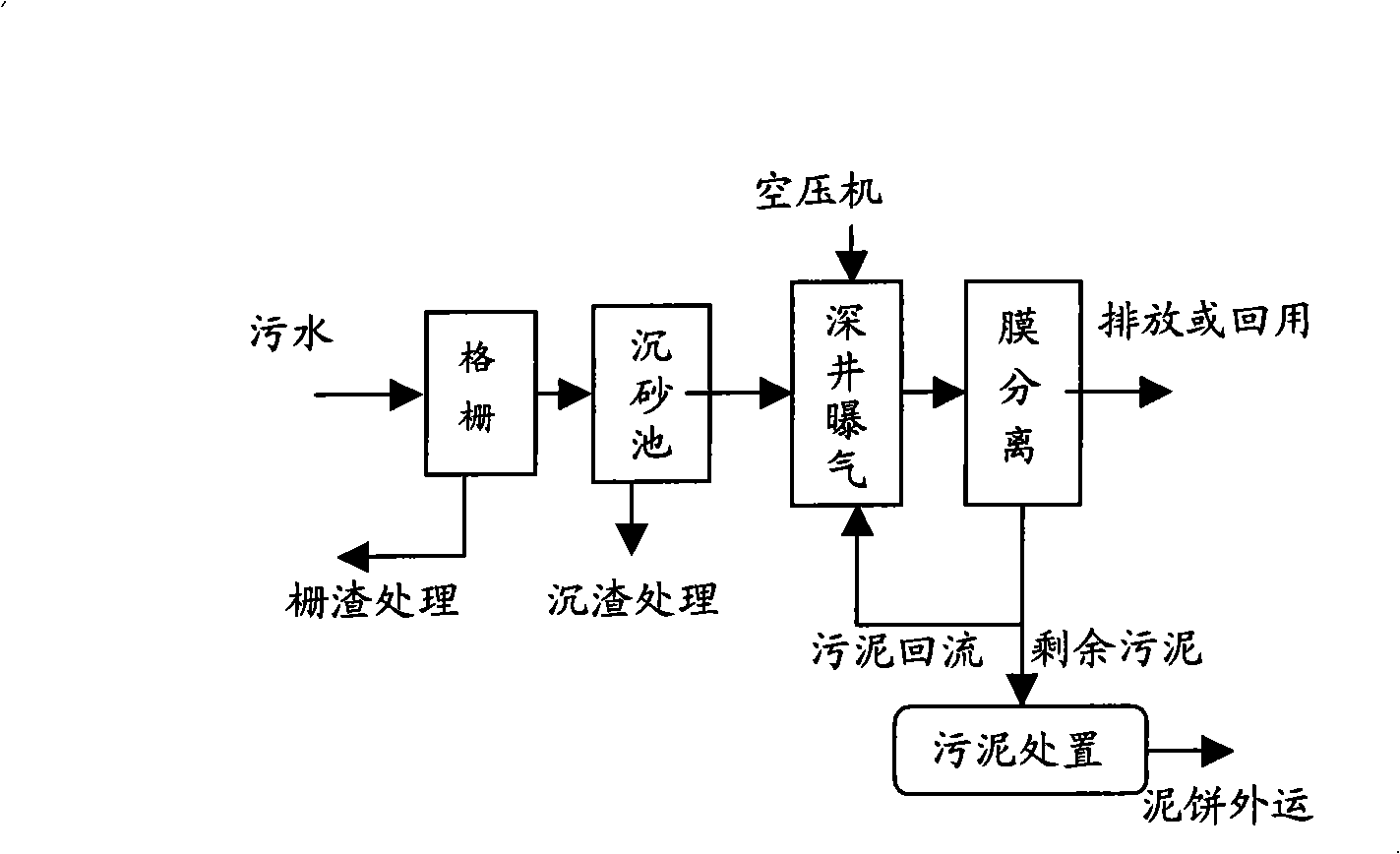

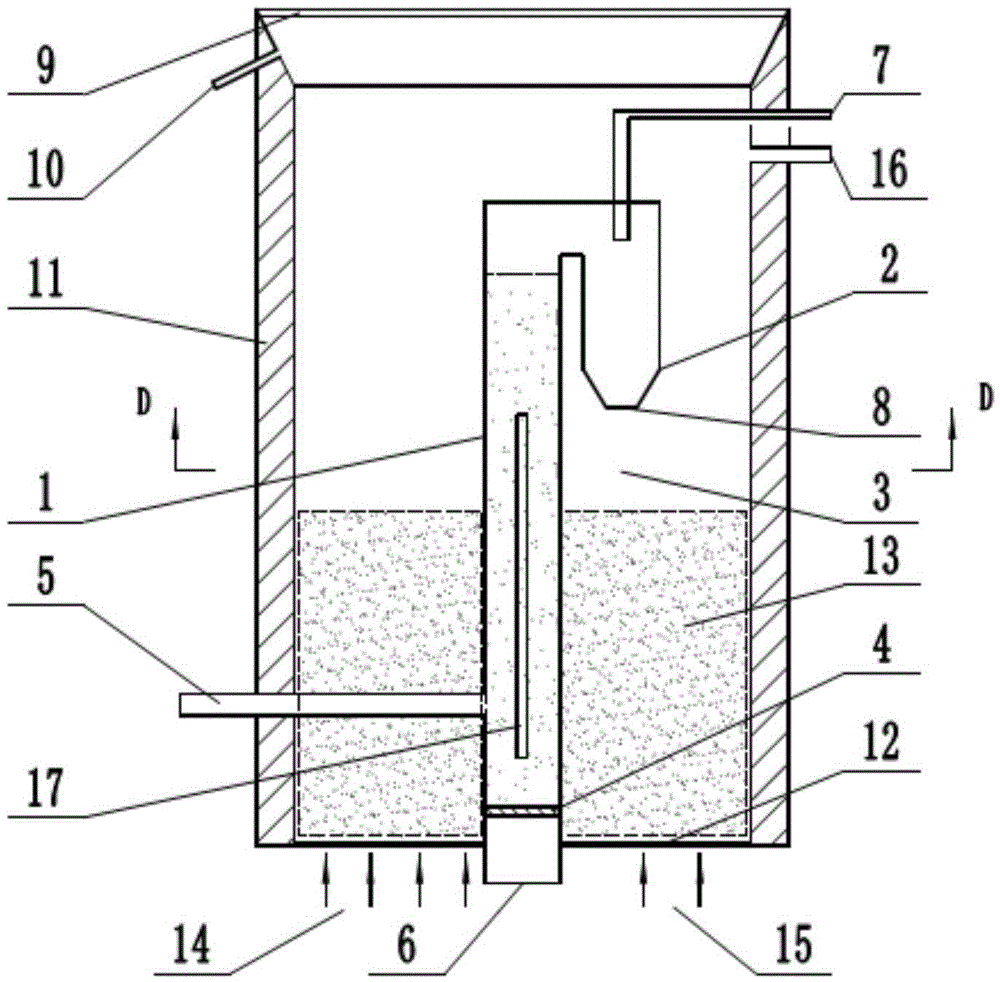

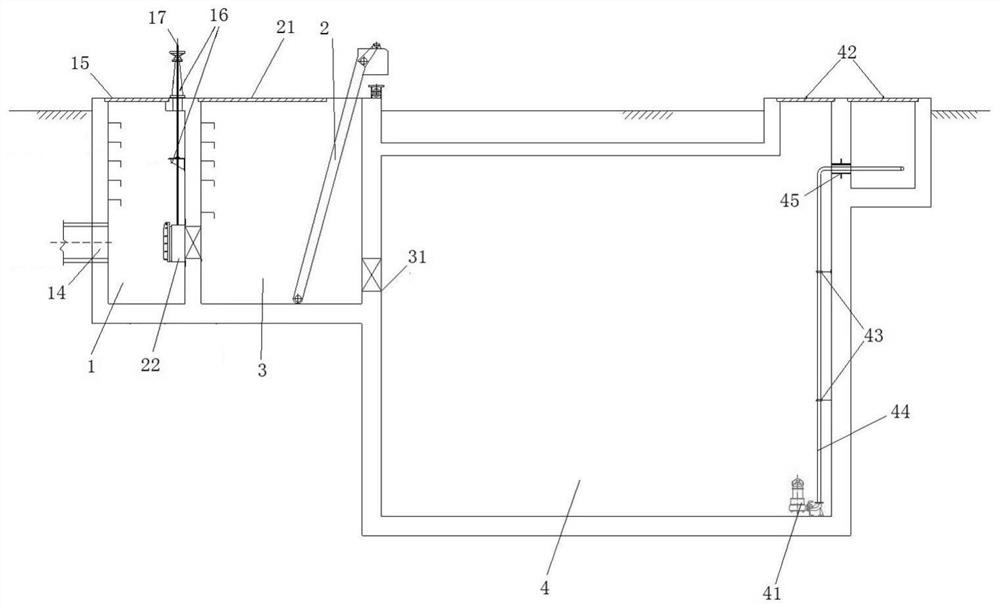

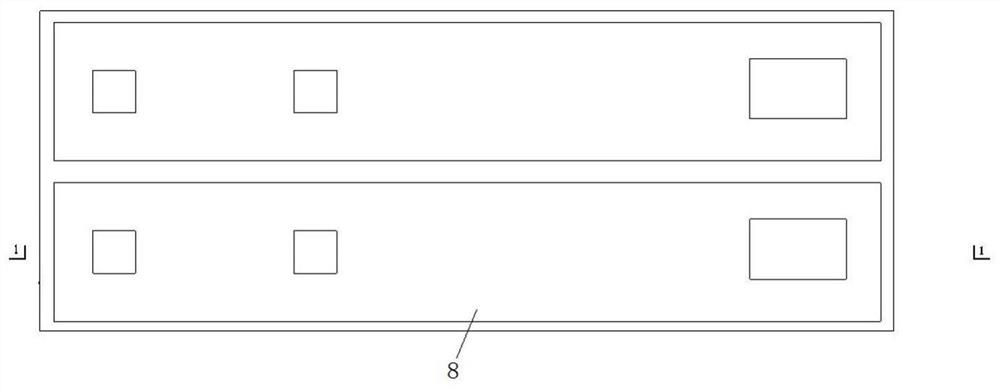

Deep well aeration film bioreactor waste water treatment process and apparatus

ActiveCN101323482AImprove mass transfer efficiencyIncrease concentrationWater/sewage treatment bu osmosis/dialysisSustainable biological treatmentActivated sludgeHigh density

A deep-well aeration membrane biological reactor waste-water disposal process and a corresponding apparatus relate to the waste-water disposal technique field, aiming at solving the technical problems of further reducing occupied area and energy cost by the deep-well aeration waste-water disposal. The waste-water disposal apparatus comprises a deep well and a top trough; the top of the deep well is connected with the bottom of the top trough, and a liquid raising circulation system is arranged in the deep well. The apparatus is characterized in that the apparatus also comprises a membrane biological reactor connected with the top trough; a membrane element which is connected with a water outlet tube and is arranged on the upper-internal part of the membrane biological reactor; an aeration device which is connected with a fan and is arranged on the lower part of the membrane element; a sludge hopper is arranged on the lower (bottom) part of the membrane biological reactor; a sludge backflow pipe connected with the bottom of the top trough and a sludge-draining pipe connected with a sludge-removing device which are respectively arranged at the bottom of the sludge hopper and are controlled by valves respectively. The invention makes use of the suction of the circulation flow to the sludge backflow pipe to absorb the sludge to the deep well to be mixed with sewage. The invention is characterized in that the occupied area is small; the activated sludge has high density; the rest sludge is less and the energy cost is low.

Owner:SHANGHAI GUANGLIAN ENVIRONMENTAL & GEOTECHNICAL ENG CO LTD

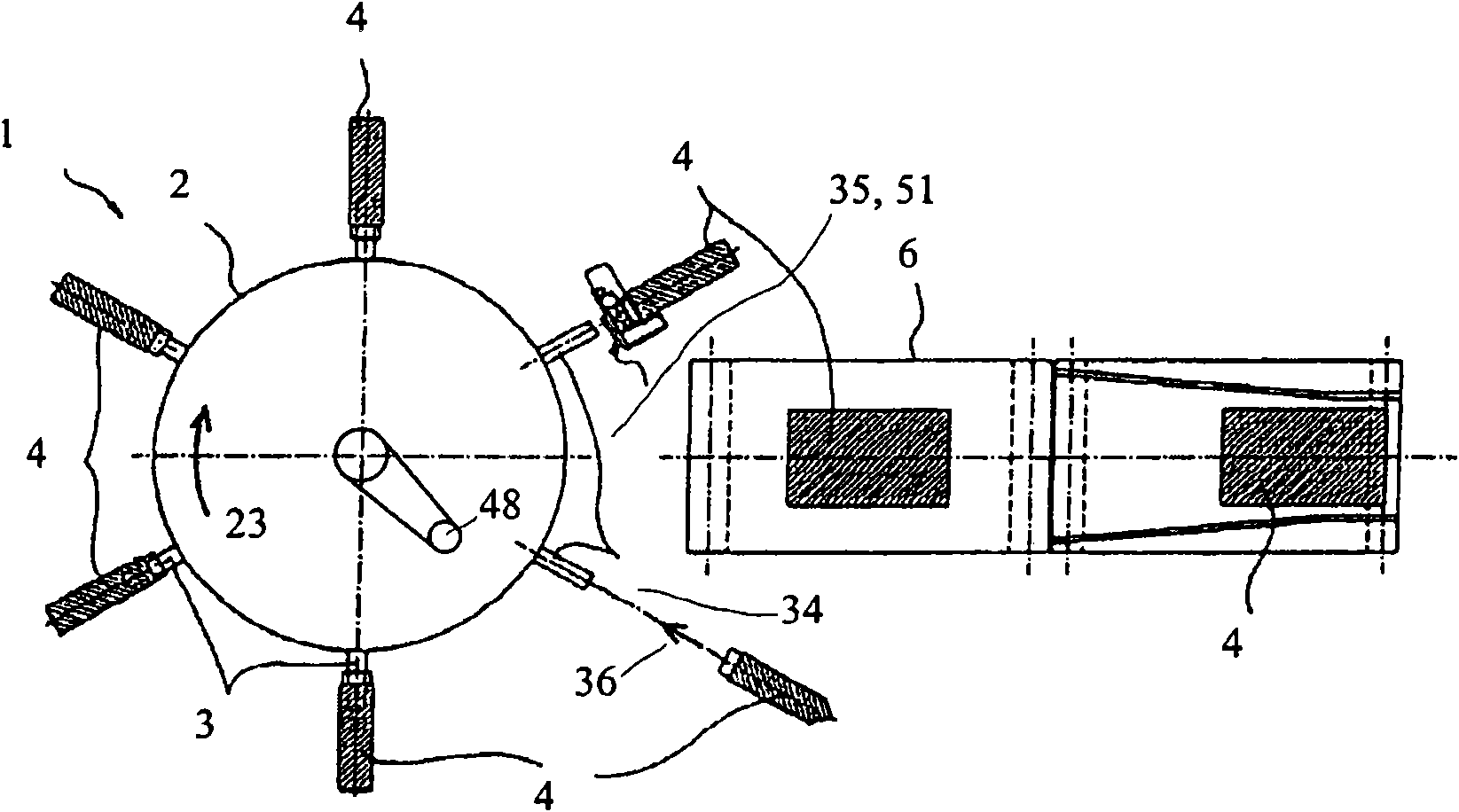

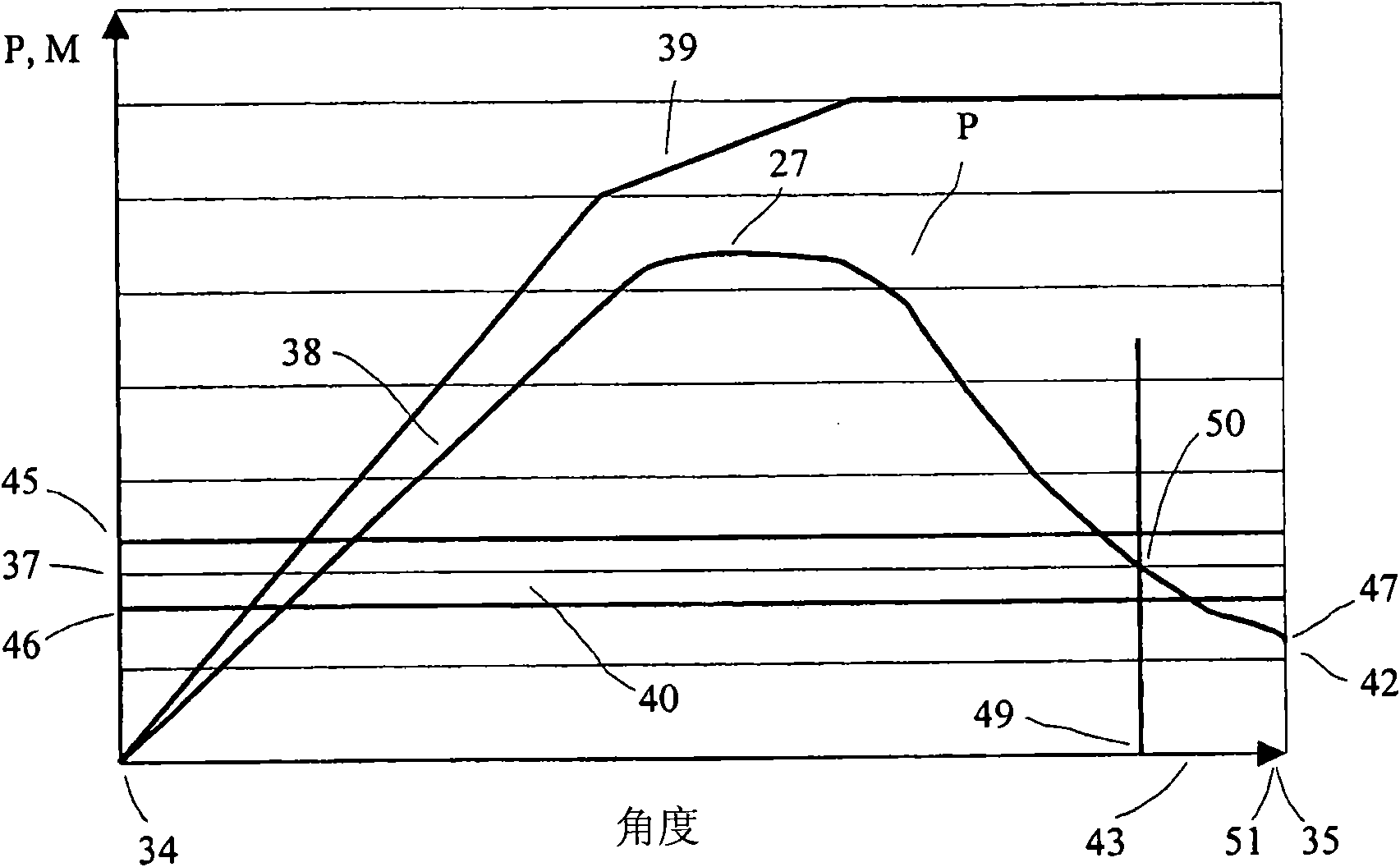

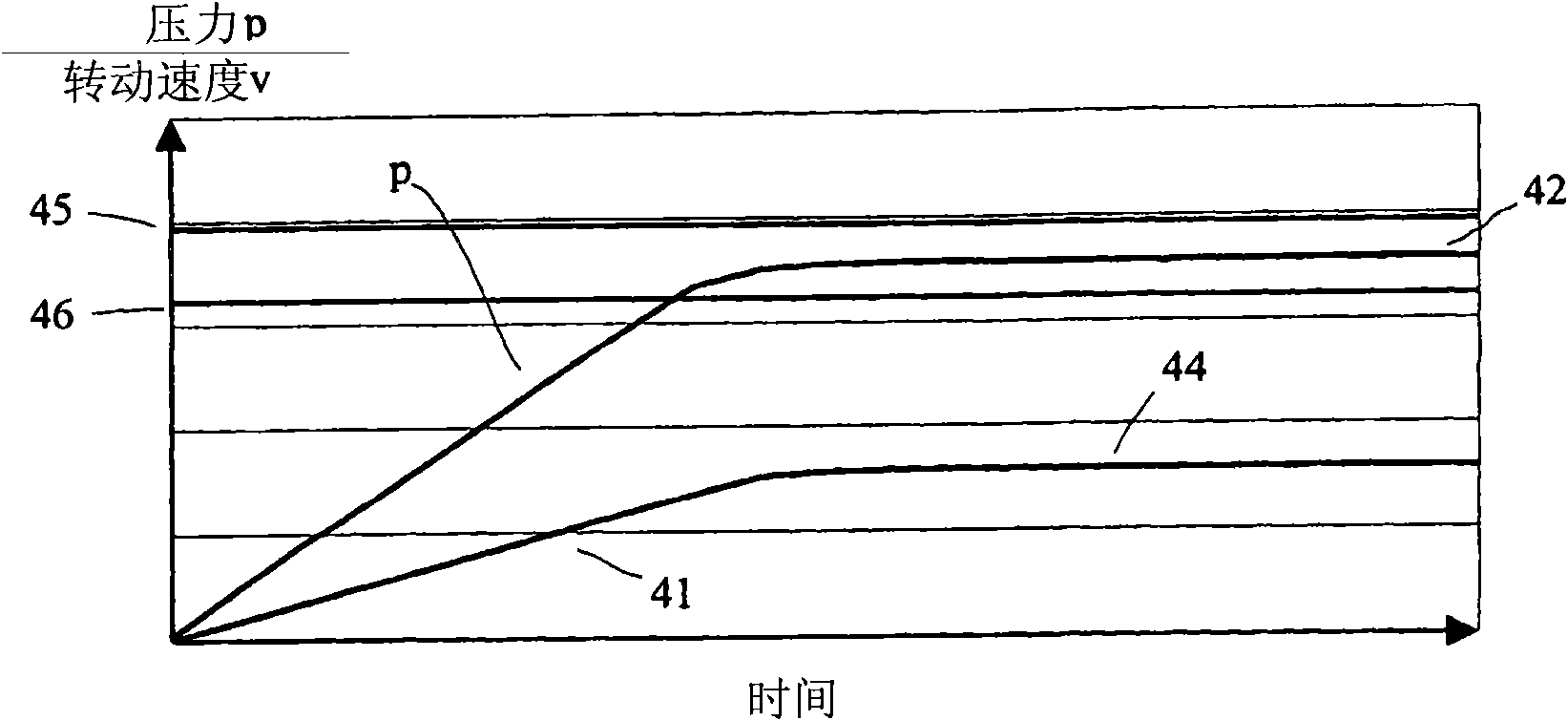

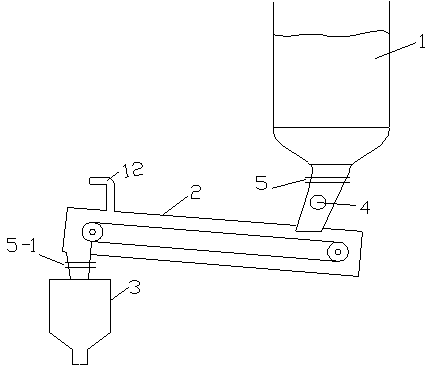

Method and filling system for filling bags

ActiveCN102046471AWaiting Time OptimizationReduce waiting timeSolid materialEngineeringPressure sensor

The invention relates to a filling system for filling valve bags, and to a method for operating a filling system, which comprises at least one rotating packing machine having a drive for rotating the packing machine, and a plurality of filling nozzles, which are distributed across the periphery of the rotating packing machine. The filling nozzles are provided for receiving the valve bags and can be fixed to the filling nozzles at an opening, and they may be filled with a pourable material through the filling nozzles. The valve bags are placed onto the filling nozzles at a defined insertion position and are automatically released at a defined release position. The invention provides a controller in order to control the filling process. A pressure sensor (10) is associated with at least one filling nozzle in order to determine a degree of the filling pressure of the valve bag disposed at the filling nozzle. The controller determines a representative characteristic pressure value for the filling pressure present at a predetermined position (51) in front of the release position by means of a pressure sensor, and adjusts a rotational speed of the packing machine to the speed of the drive by way of a control unit.

Owner:HAVER & BOECKER

Solar energy-driven coal pyrolysis coupling coalite gasification reactor and method

InactiveCN105623744AAchieve matchingSimple structureEnergy inputGasification processes detailsInsulation layerFluidized bed

The invention discloses a solar energy-driven coal pyrolysis coupling coalite gasification reactor and a method. The reactor mainly comprises a lifting pipe, a cyclone separator and an annulus inner circulation fluidized bed, wherein an outlet of the lifting pipe is connected to the cyclone separator, and the lifting pipe and the cyclone separator are arranged inside the annulus inner circulation fluidized bed; the lifting pipe is located at the center of the annulus inner circulation fluidized bed, a pipe wall of the lifting pipe is parallel to the wall surface of the annulus inner circulation fluidized bed, and an inlet of the lifting pipe extends out of the bottom of the annulus inner circulation fluidized bed for a distance; an air distributor is arranged at the bottom of the lifting pipe, and a coal feeding pipe is connected to the side wall of the lifting pipe; the top of the annulus inner circulation fluidized bed is provided with a light inlet window, the outer wall of the annulus inner circulation fluidized bed is coated with a heat insulation layer, and the bottom of the annulus inner circulation fluidized bed is provided with an annular air distributor.

Owner:NORTHWEST UNIV(CN) +1

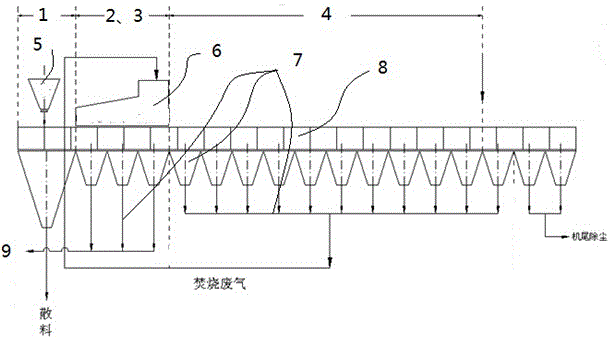

Solid waste incineration system with exhaust gas secondary combustion drying ignition device and treatment method thereof

ActiveCN105910111ALow investment costReduce operating expensesIncinerator apparatusCombustion chamberFlue gas

The invention discloses a solid waste incineration system with an exhaust gas secondary combustion drying ignition device and a treatment method thereof. The solid waste incineration system comprises an incineration device and an air extraction system, wherein the incineration device comprises a cloth section, a drying section, an ignition section and an incineration section; operation at the drying section and the ignition section is achieved through the exhaust gas secondary combustion drying ignition device; the exhaust gas secondary combustion drying ignition device is in a cover body form, covers sintering materials, and is divided into an exhaust gas secondary combustion drying part at the front section and an ignition part arranged at the tail end; the incineration exhaust gas returns to the ignition device and burns in the situation that gas fuel is externally added, and a secondary combustion chamber is formed; and combustible matters in the flue gas are completely combusted, and harmful substances such as CO, NOx and dioxin in the flue gas are decomposed and are effectively treated. According to the solid waste incineration system, a high temperature gas generated during combustion ignites the materials, and waste heat of the exhaust gas dries and preheats the materials before ignition.

Owner:CHONGQING ANGRUIYUE SCI & TECH

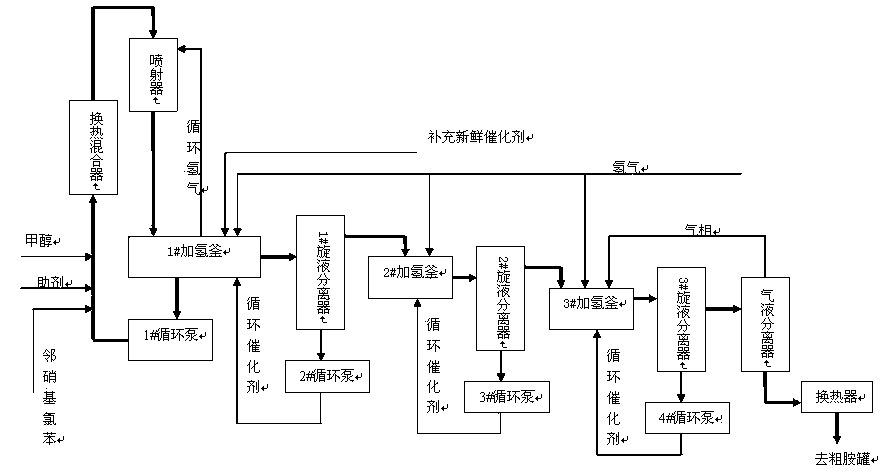

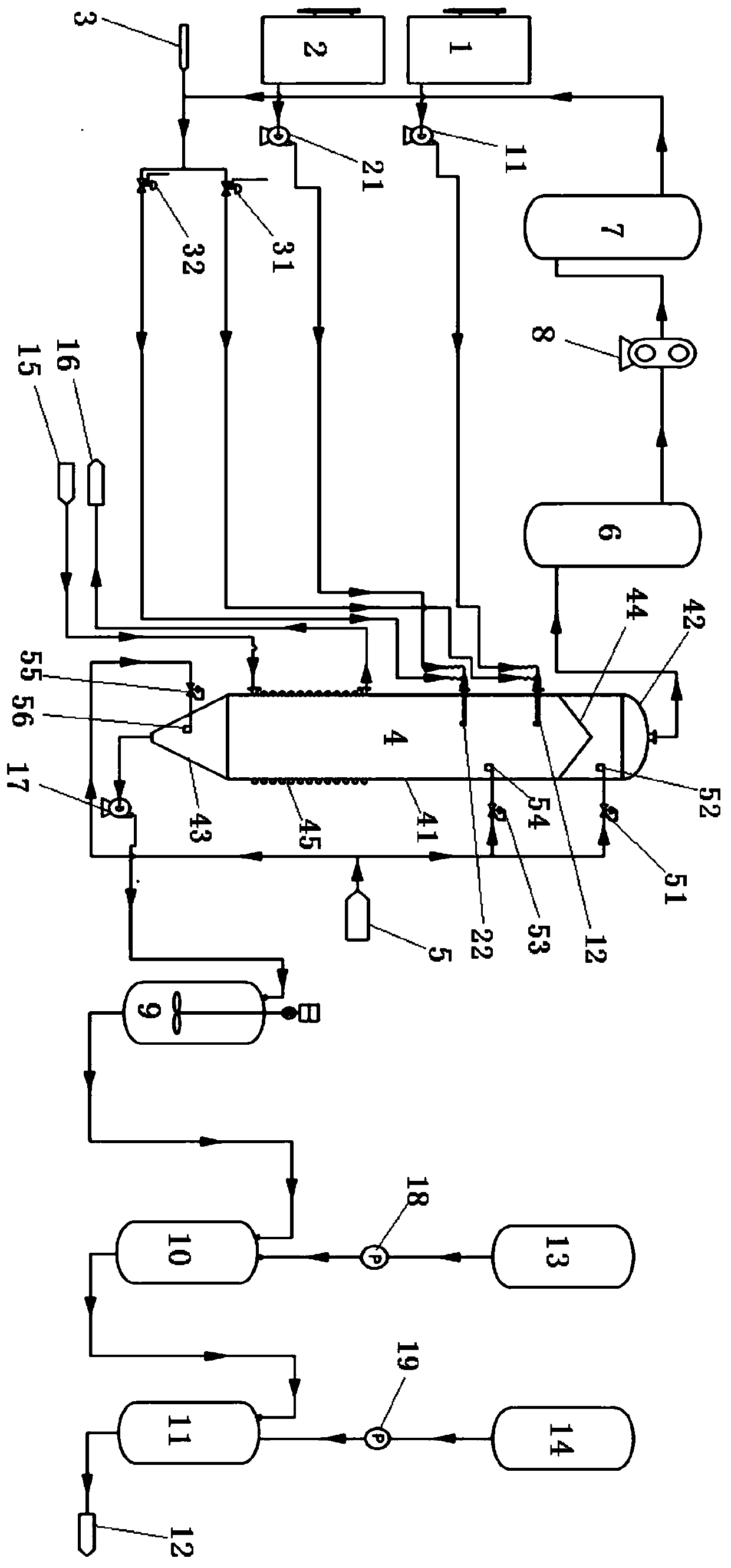

Continuous liquid-phase catalytic hydrogenation reduction method for production of o-chloroaniline

InactiveCN103360267AEnough time to stayShort processOrganic compound preparationChemical recyclingO-nitrochlorobenzeneHydrogenation reaction

The invention discloses a continuous liquid-phase catalytic hydrogenation reduction method for production of o-chloroaniline. The method is characterized in that (1) multi-kettle cascade reaction is adopted during the hydrogenation reaction process, a No.1 hydrogenation kettle is provided with a heat exchange mixer and an injector, part of reaction materials circulate among the heat exchange mixer, the injector and the No.1 hydrogenation kettle through a circulating pump so as to fully convert o-nitrochlorobenzene to o-chloroaniline; and (2) a cyclone hydraulic separator is installed at the back of each hydrogenation reaction vessel to separate a catalyst in a hydrogenation liquid, and the separated catalyst returns to a corresponding hydrogenation kettle through the circulating pump for recycling. The process flow of the method is short; equipment used is simple; and defects of large investment of batch production, low utilization rate of equipment, large labor intensity, short service life of the catalyst, large loss of hydrogen and solvents, large fatigue strength of hydrogenation equipment and short service life are solved.

Owner:淮安嘉诚高新化工股份有限公司

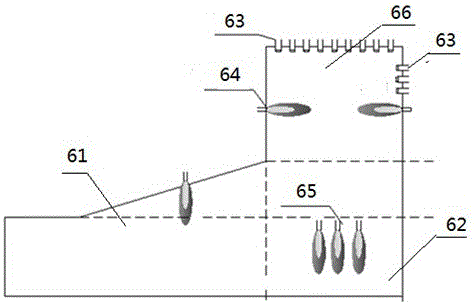

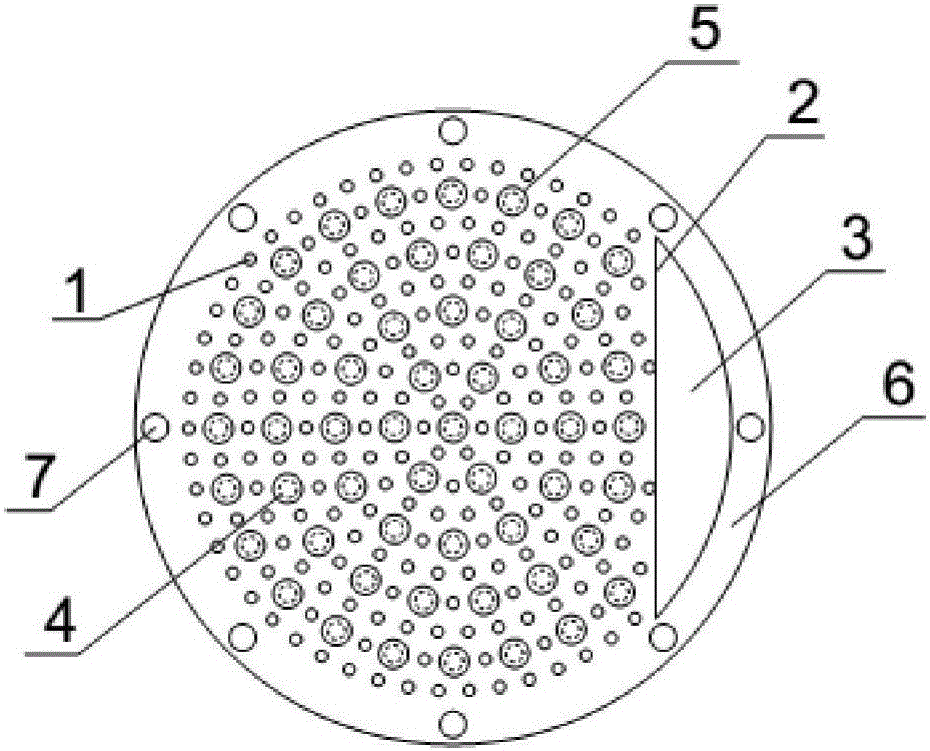

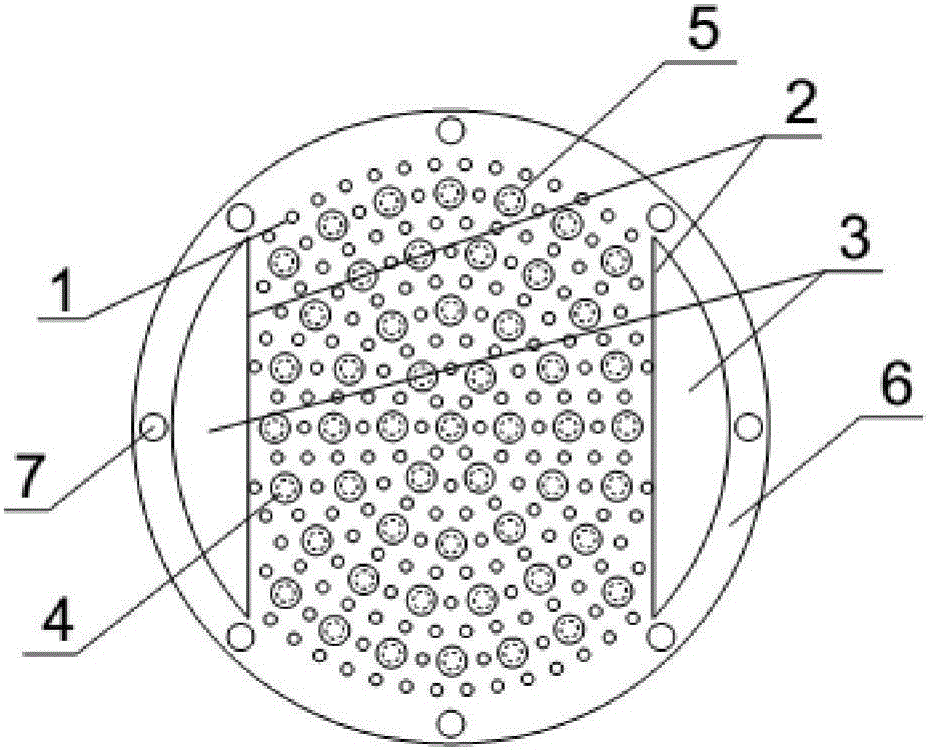

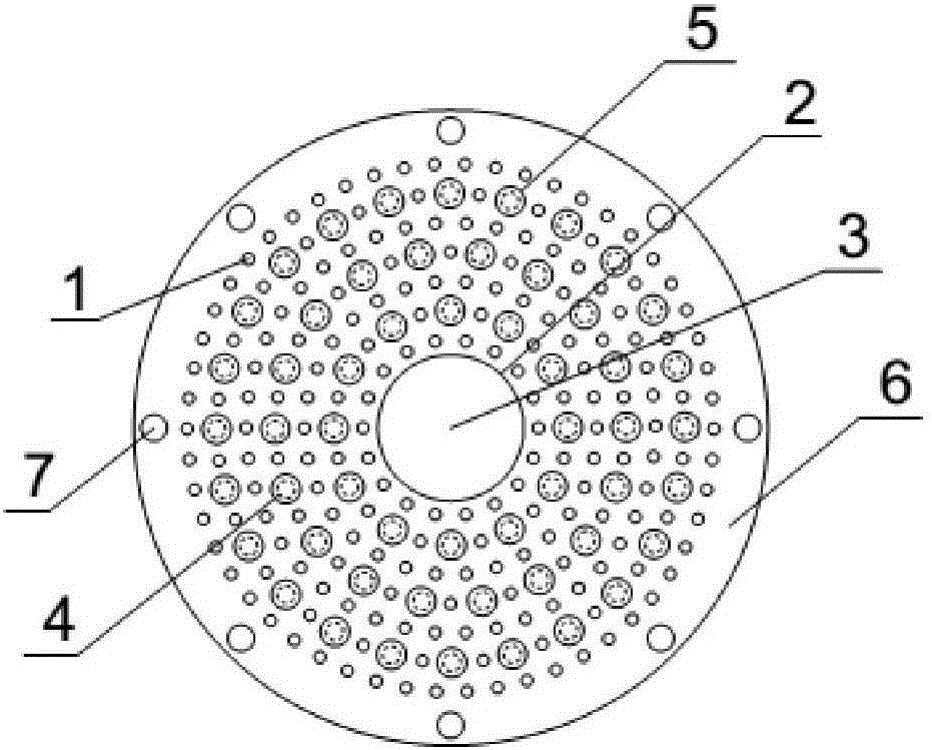

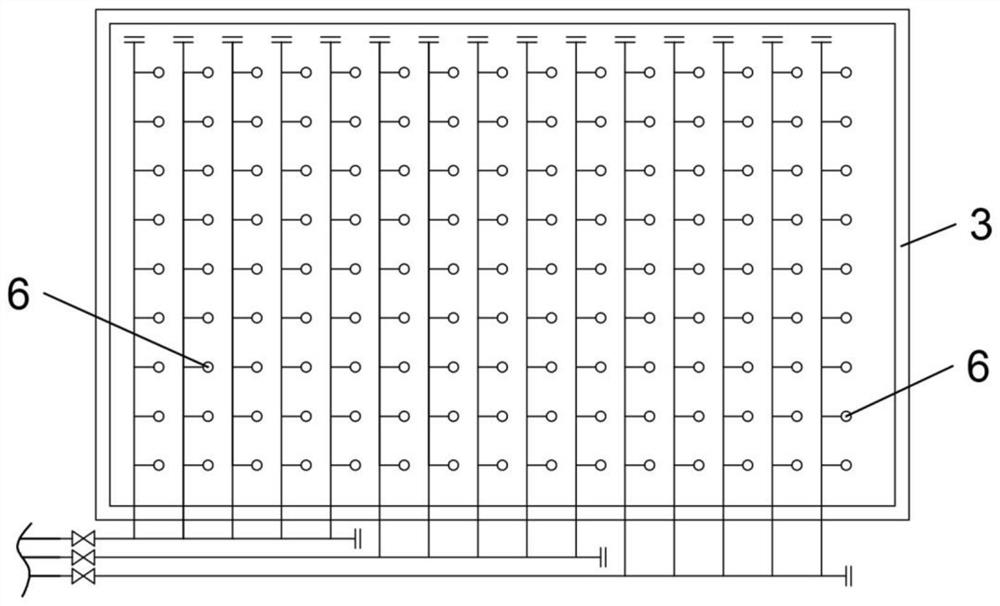

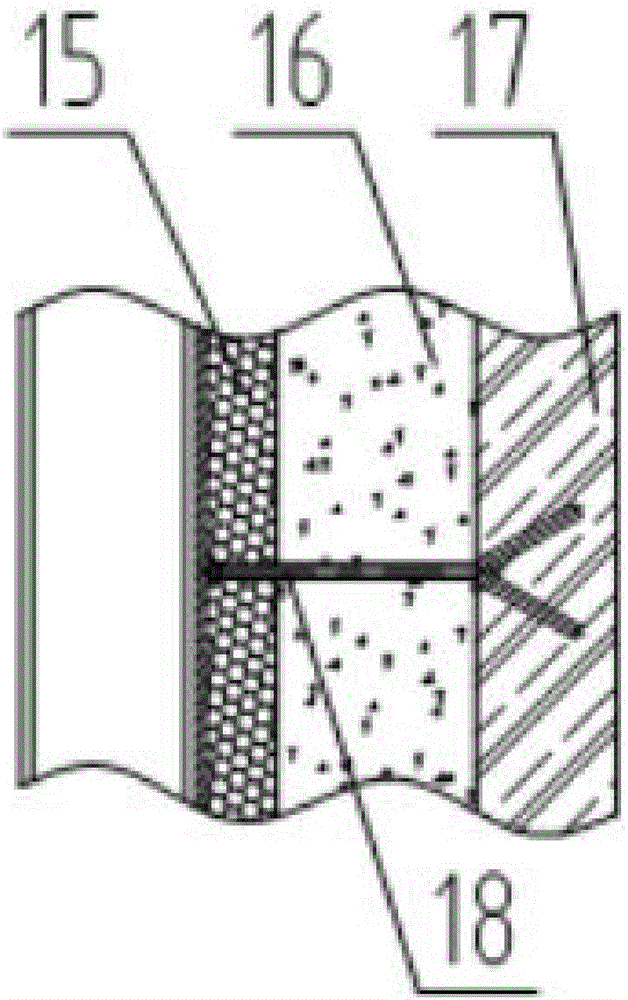

Novel lower-pressure-drop distribution plate applicable to multilayered bed

PendingCN105749819ASmall pressure dropMixed flowGas treatmentDispersed particle separationFlue gasEngineering

The invention discloses a novel lower-pressure-drop distribution plate applicable to a multilayered bed. The novel lower-pressure-drop distribution plate comprises sieve holes (1), an overflowing weir (2), a material dropping hole (3), large-hole nozzles (4) and matched air caps (5) thereof, a flange edge (6) and flange holes (7), wherein the distribution plate is an incomplete round plate and a notch is the material dropping hole (3); the overflowing weir (2) vertical to the distribution plate is arranged at the edge of the notch; the large-hole nozzles (4) are uniformly distributed on the plate and are matched with the air caps (5); air cap small holes (18) are uniformly distributed in the air caps (5); the sieve holes (1) are formed among the large-hole nozzles at intervals; and the edge of the distribution plate is the flange edge (6) and is provided with the flange holes (7). With the adoption of the novel lower-pressure-drop distribution plate, the pressure drop of the multilayered bed can be effectively reduced, and gas-liquid flowing is disordered; the contact area between flue gas and a solid purifying agent is large, and a gas flowing path is long, so that enough gas retention time is guaranteed; and the flue gas is in sufficient reaction with the solid purifying agent, and the novel lower-pressure-drop distribution plate has operational flexibility.

Owner:BEIJING SPC ENVIRONMENT PROTECTION TECH

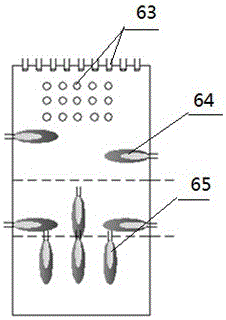

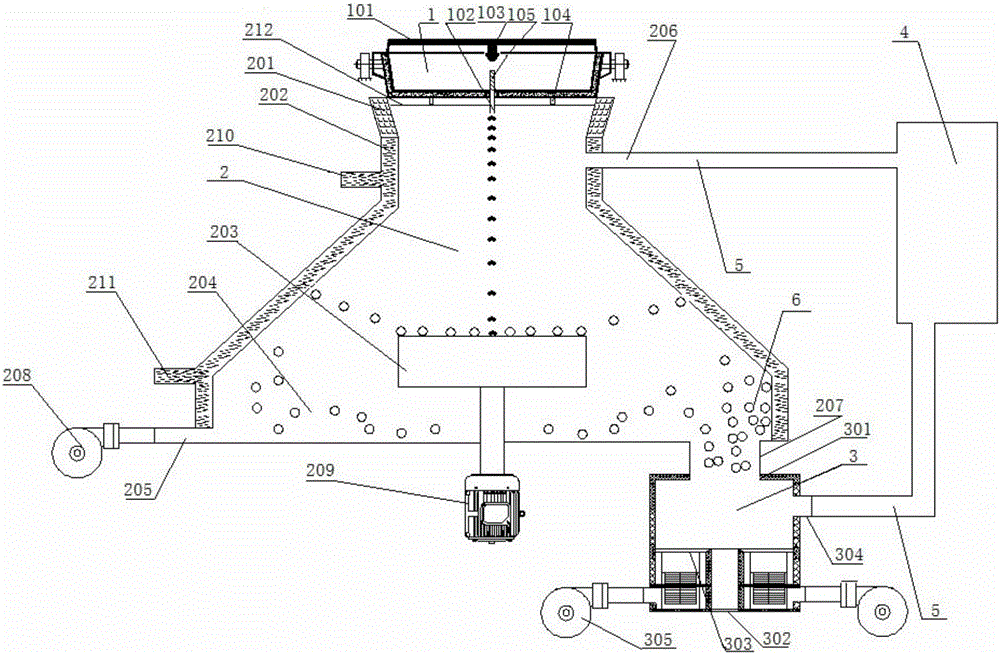

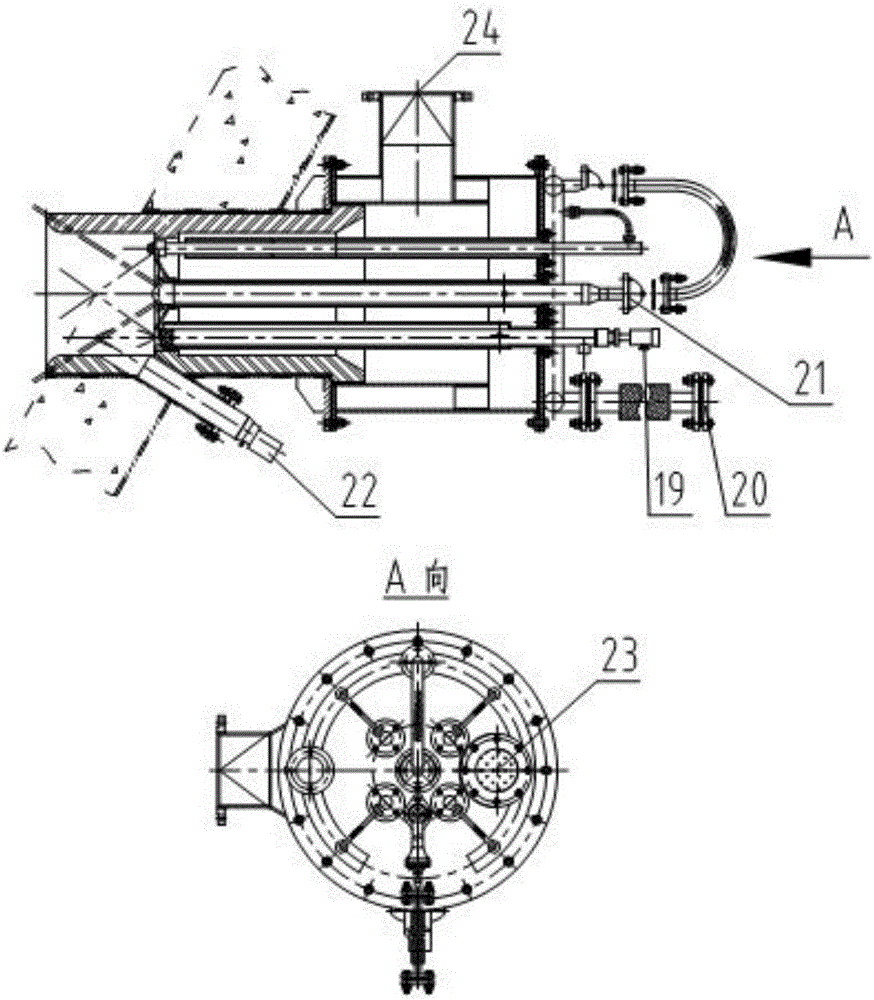

Blast furnace slag thermal fracture centrifugal drying method granulation device and method

InactiveCN105779673AEmission reductionSave drying energyRecycling and recovery technologiesProcess efficiency improvementSlagWater content

The invention aims at the problem existing in the prior art for blast furnace slag treatment, provides a blast furnace slag thermal fracture centrifugal drying method granulation device and method and belongs to the technical field of treating devices for blast furnace metal smelting waste. The device comprises an intermediate tank, a granulation chamber, a filling type countercurrent heat exchanger and a high-temperature air collecting purifier. The intermediate tank is located on the upper portion of the granulation chamber. The granulation chamber is located on the upper portion of the filling type countercurrent heat exchanger. The intermediate tank, the granulation chamber and the filling type countercurrent heat exchanger are sequentially connected. The high-temperature air collecting purifier is located outside and is connected with the granulation chamber and the filling type countercurrent heat exchanger through pipelines. According to the device and the method, a drying method is adopted for treating blast furnace slag, high-temperature sensible heat of the blast furnace slag can be utilized for generating power, precious water resources can be saved, emission of harmful gas is reduced, and energy consumption is reduced. Moreover, for the treated blast furnace slag, due to the extremely low water content of the dried slag, the vitrification rate can be kept 95% or above.

Owner:于良富 +2

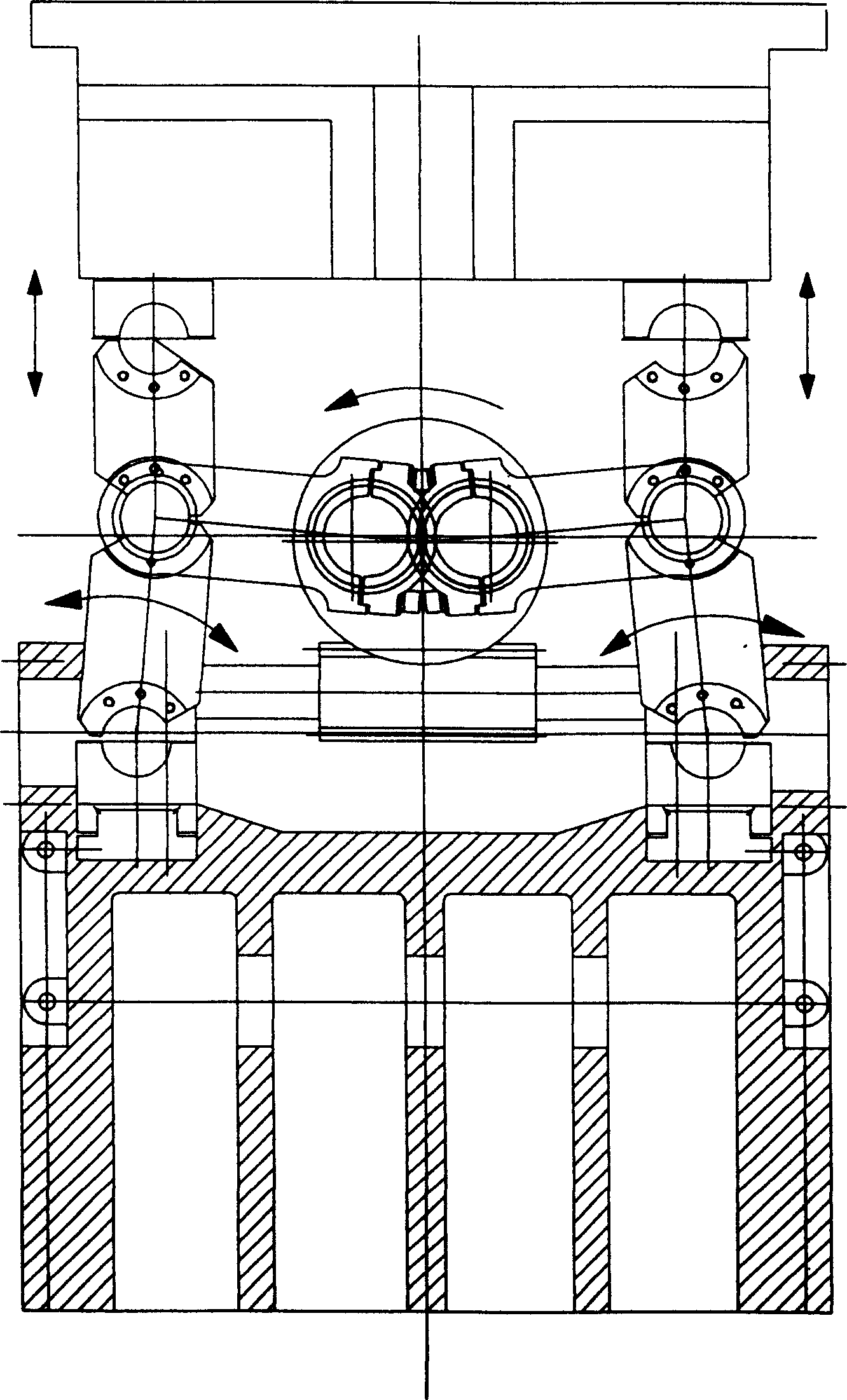

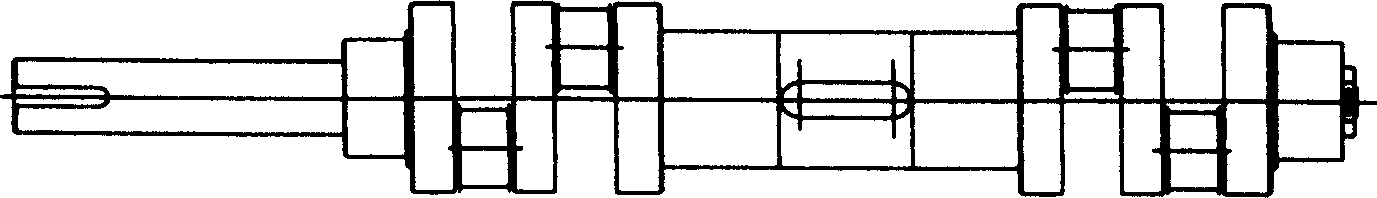

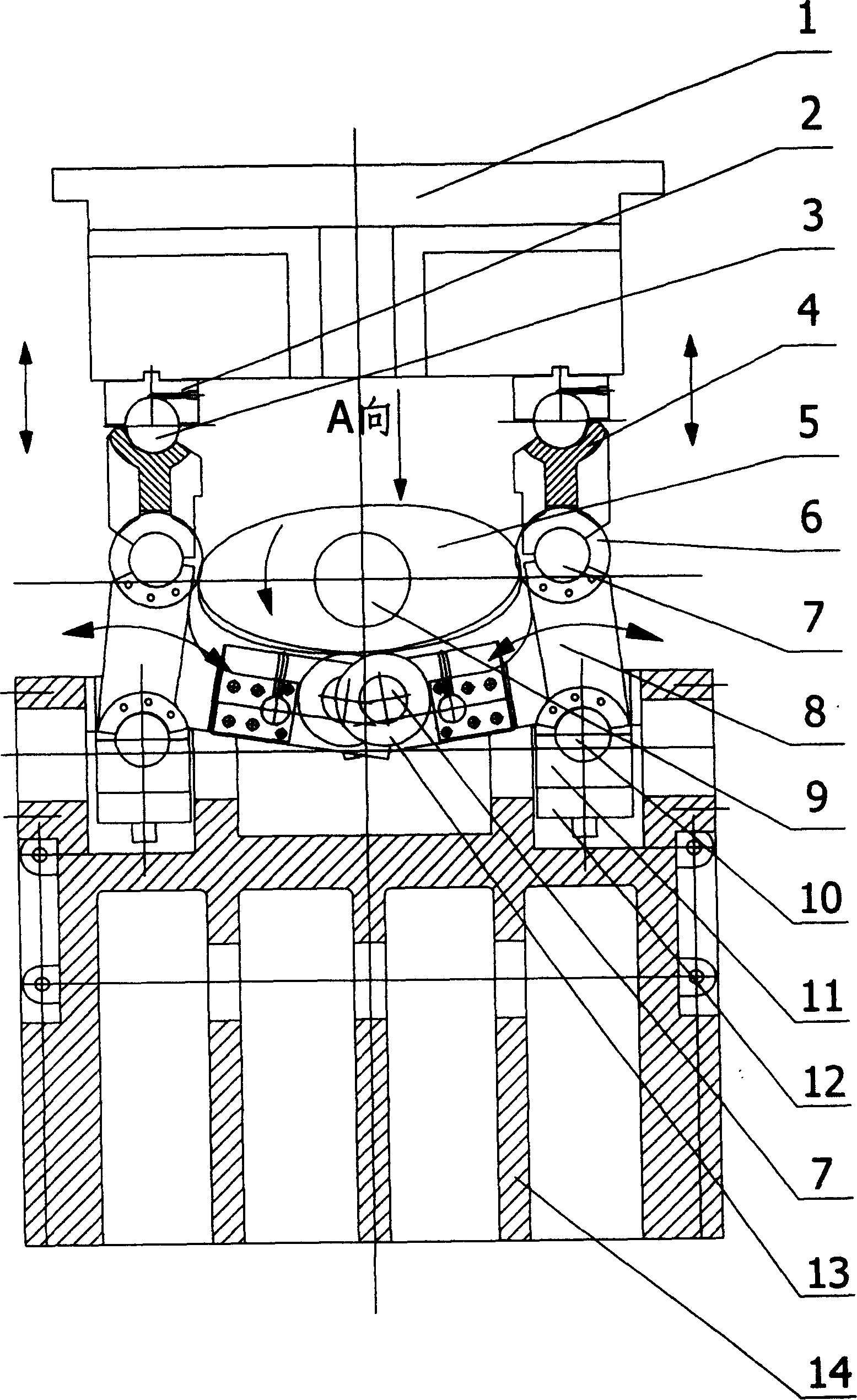

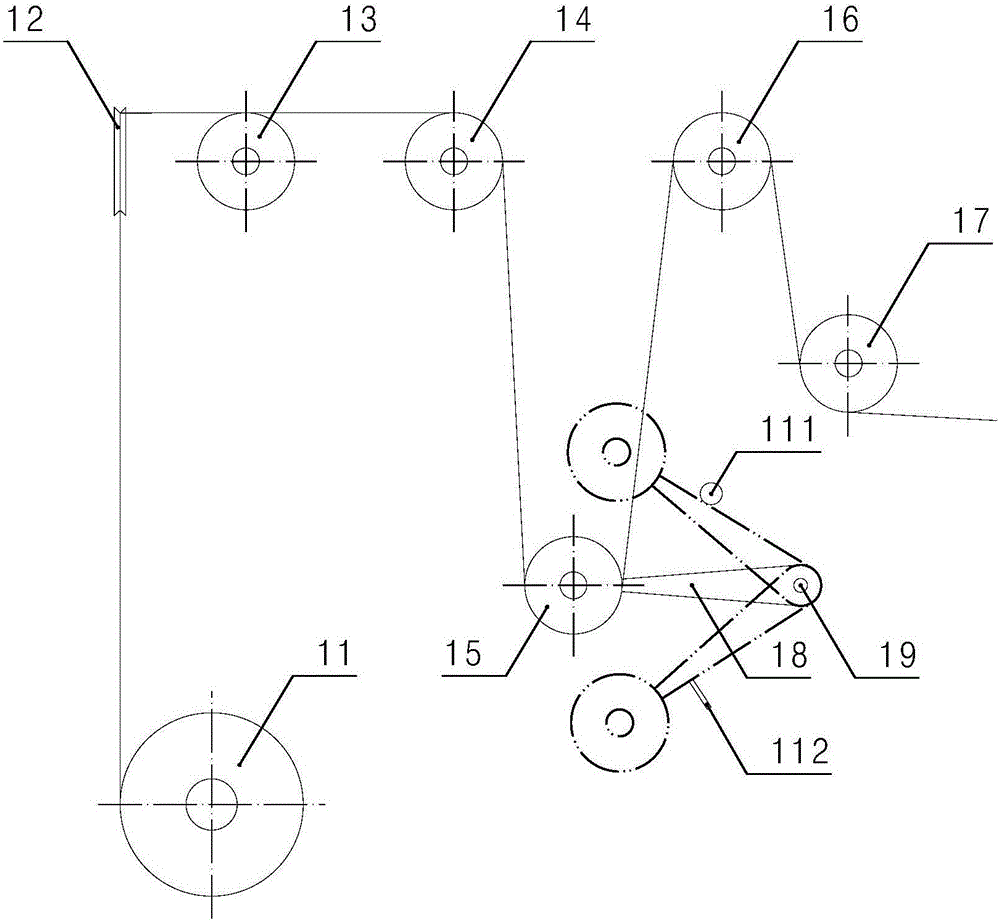

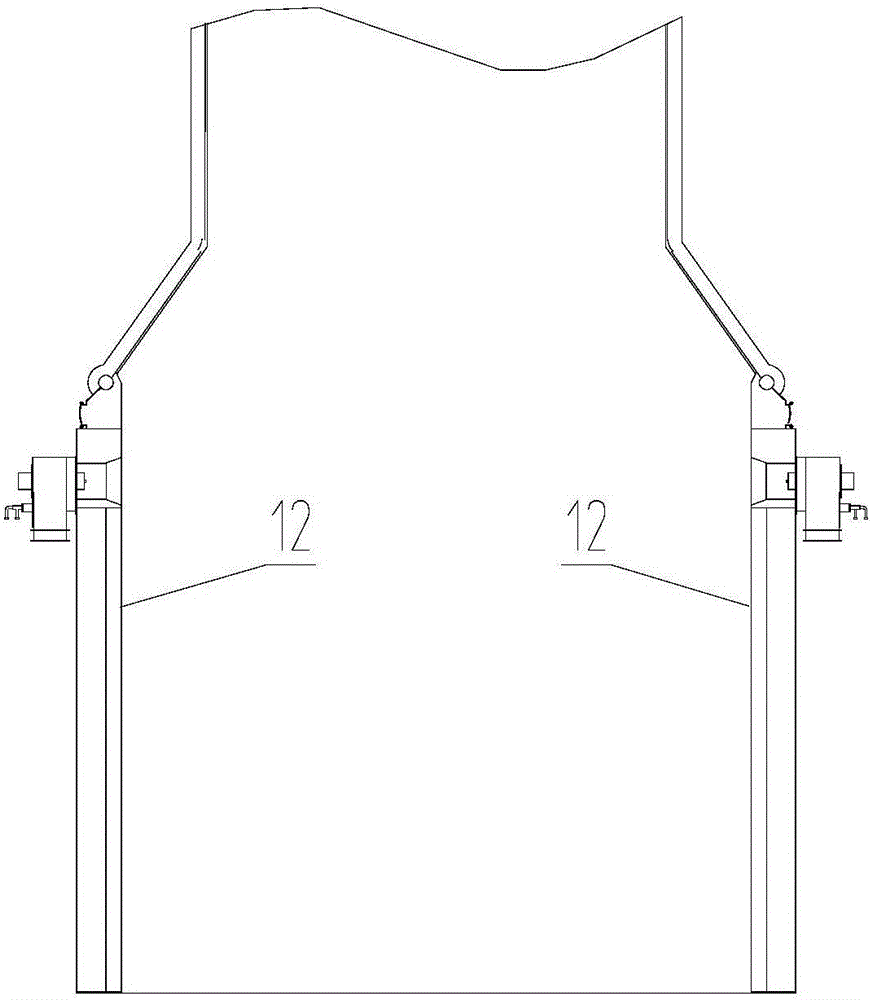

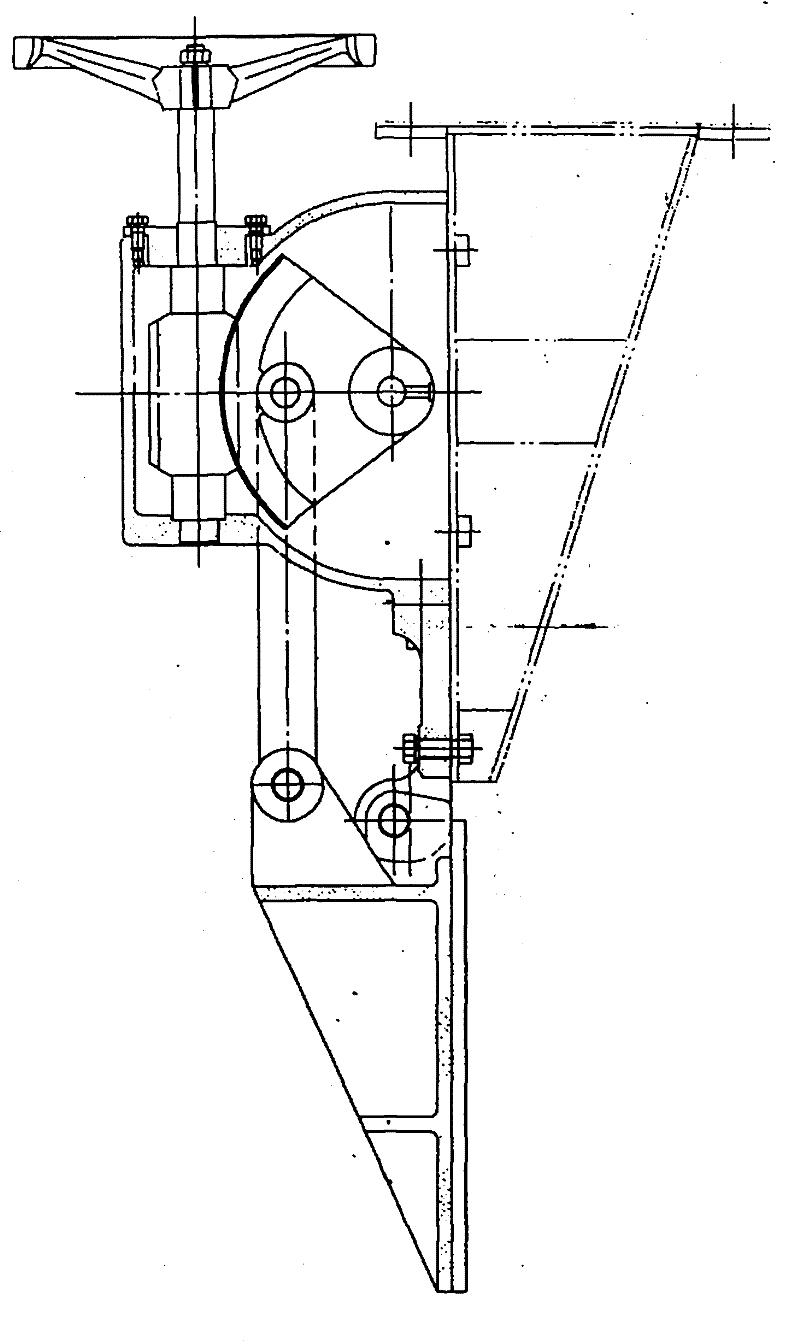

Main transmission changeover mechanism in flat crushing flat auto dir cutting hot stamping machine

The main transmission and conversion mechanism for automatic die cutting and thermoprinting machine includes pedestal, movable platform, four upper shaft seats connected to the movable platform and four toggle rod upper shafts, and features that between the four toggle rod upper shafts and the pedestal one combination of four conjugated cams and one lower toggle rod transmission mechanism are installed. The present invention has smart design of converting the rotation of conjugated cams into vertical straight line motion to make the platform obtain sufficient staying time in the highest point and the lowest point and fast ascent and descent speed and to meet the special technological requirement for pressing and gold stamping. The present invention has simple and compact structure, high processing quality, high production efficiency and wide application foreground.

Owner:MASTERWORK GROUP CO LTD

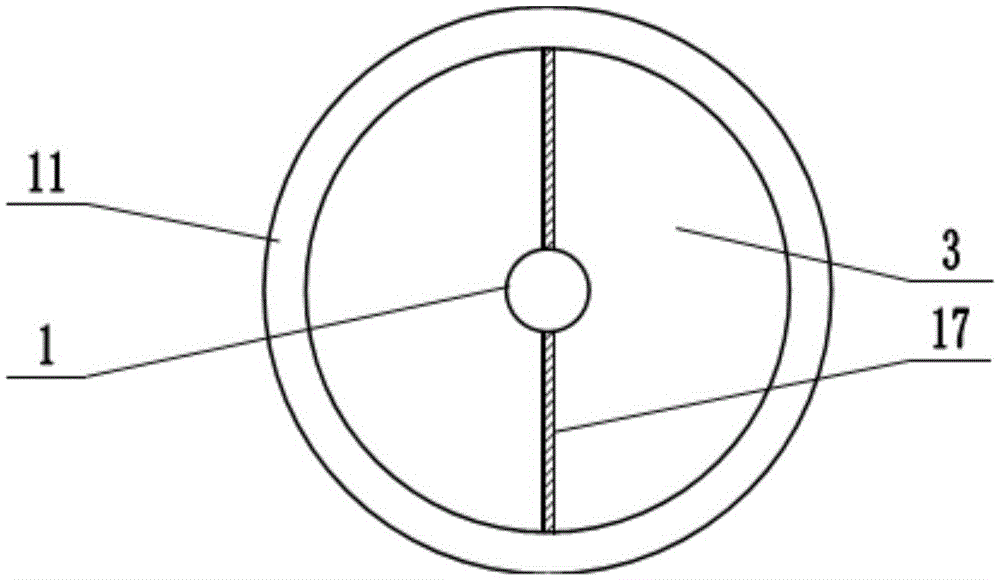

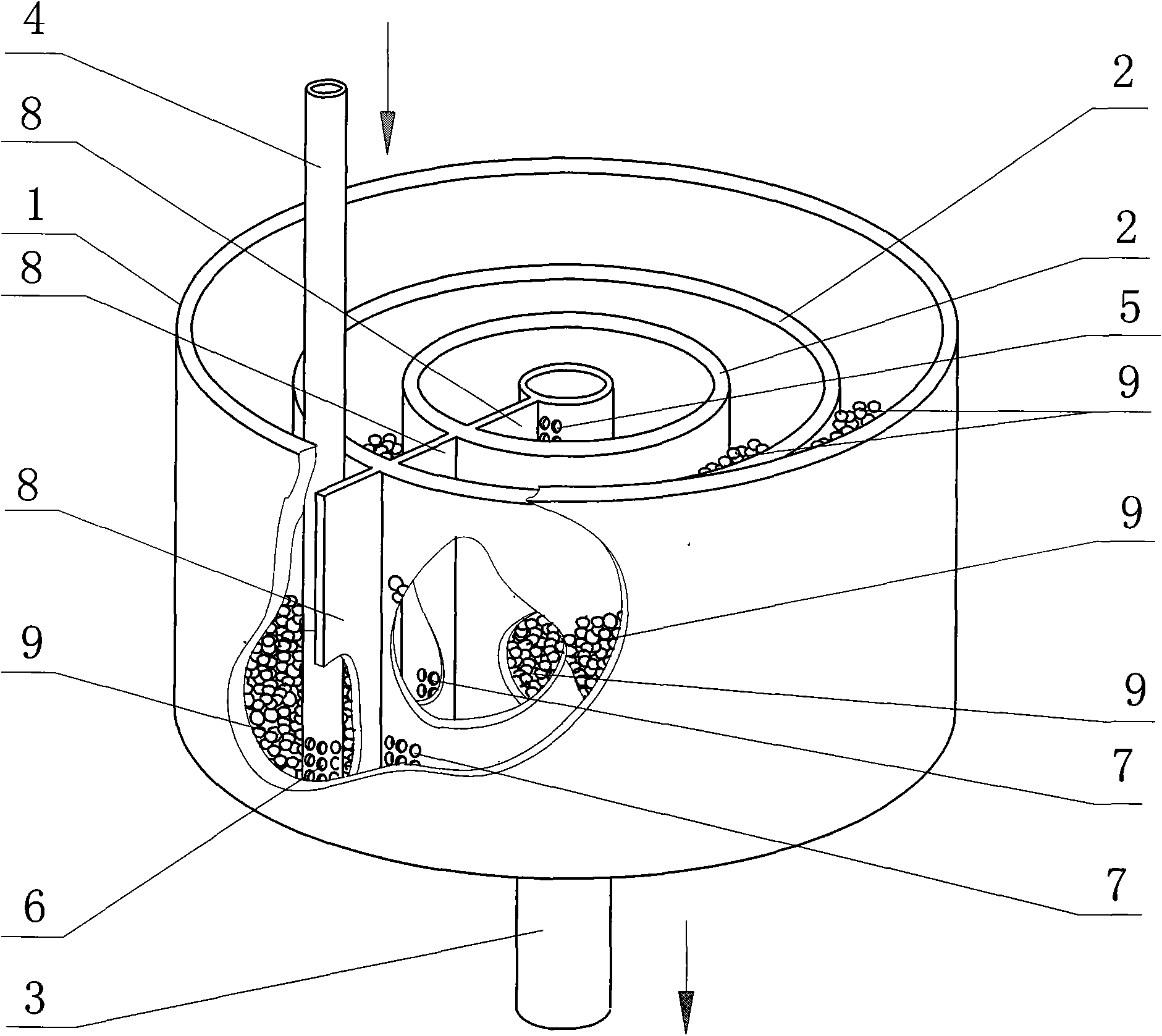

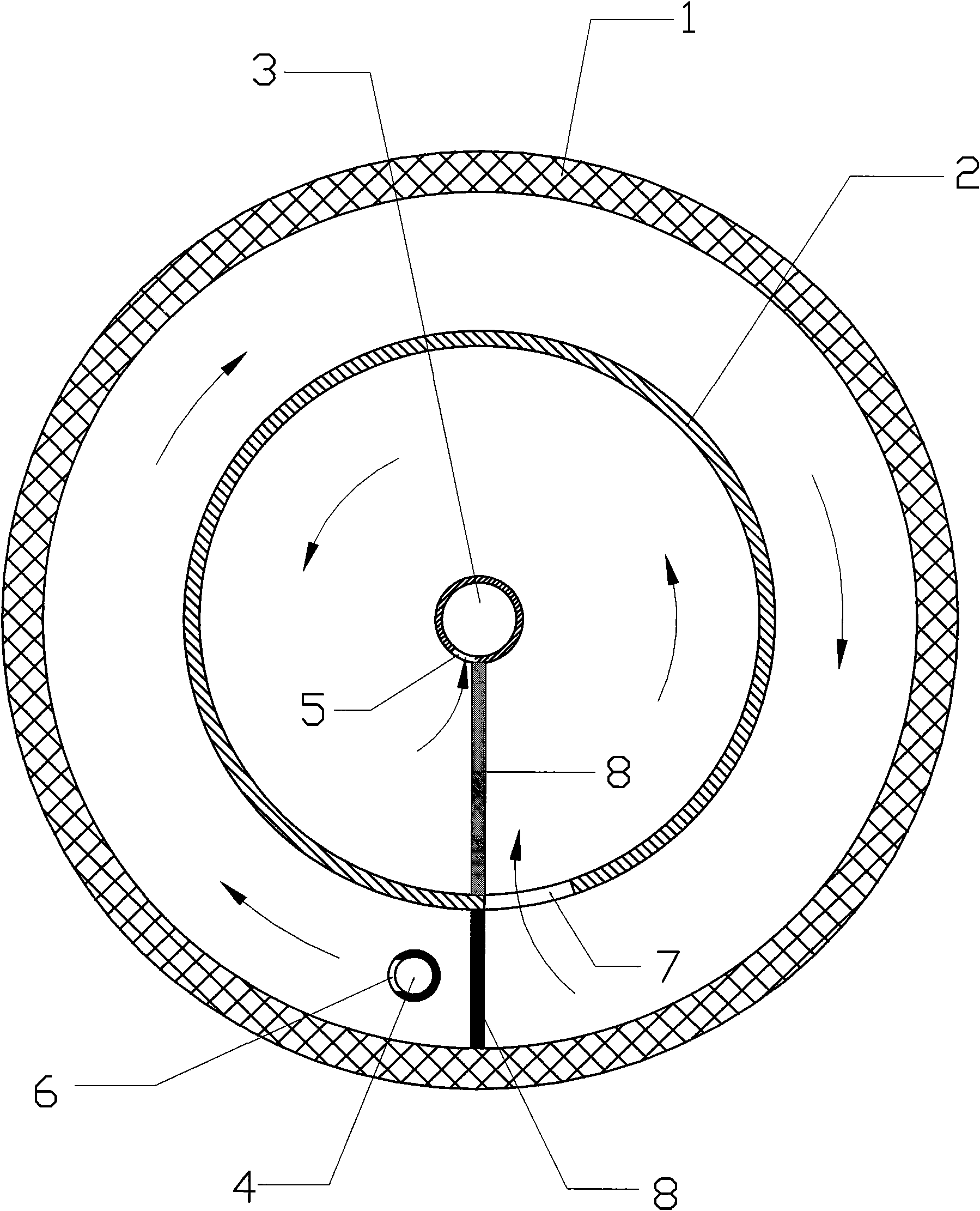

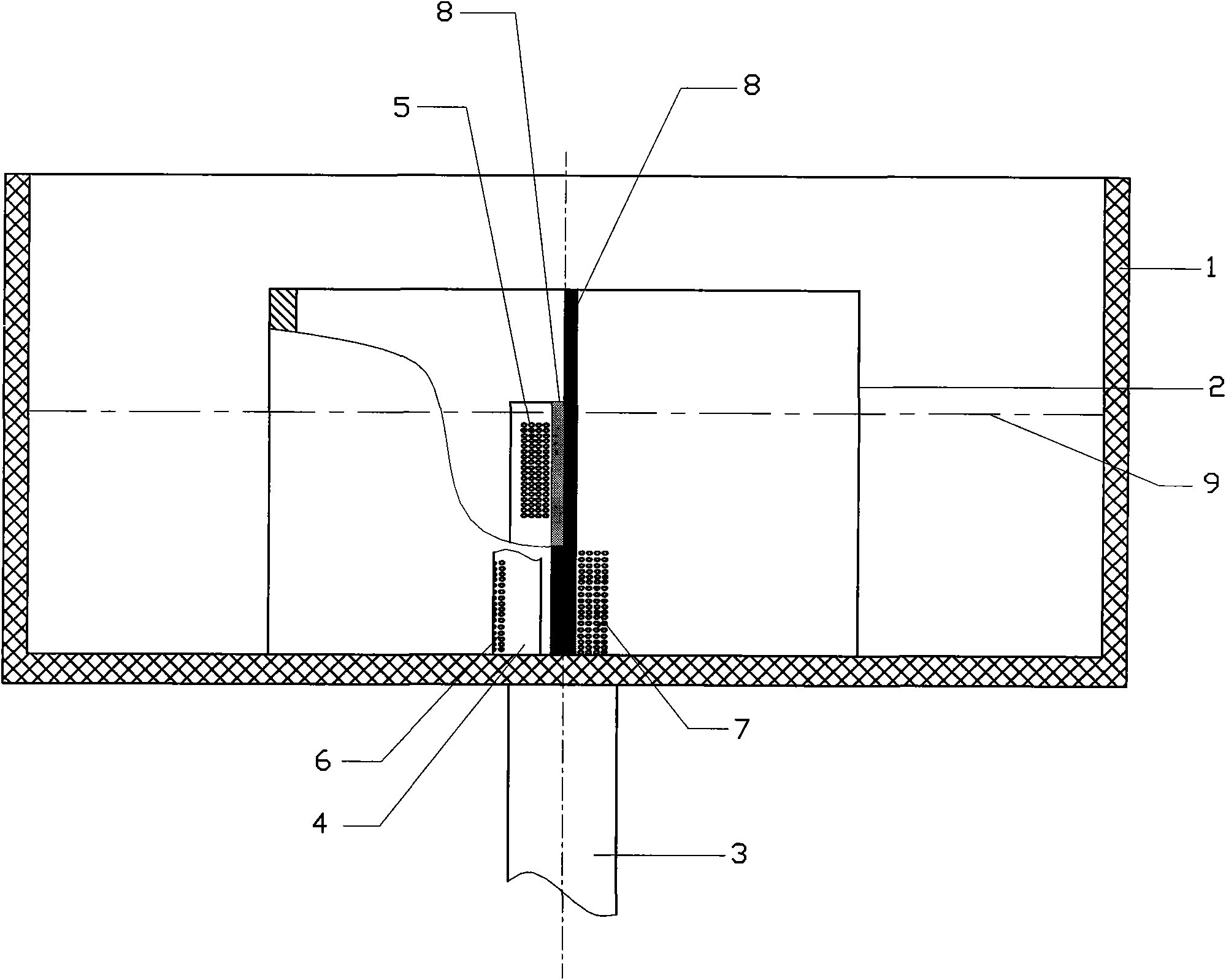

Rotary type culture water purifying device

InactiveCN101658156AFully contactedSufficient hydraulic retention timePisciculture and aquariaWater dischargeWater quality

The invention relates to a rotary type culture water purifying device which comprises an outer barrel and inner barrels which are arranged in the outer barrel, wherein a vertical clapboard is arrangedbetween the outer barrel and the inner barrel of the outermost layer, a water inlet pipe is arranged between the outer barrel at one side of the clapboard and the adjacent inner barrel, water inlet holes are formed at the lower part of the water inlet pipe, and water passing holes are formed on the side wall of the inner barrel of the outermost layer at the other side of the clapboard; a verticalclapboard is also arranged between two layers of adjacent inner barrels from bottom to top, and water passing holes are alternately arranged on the side wall of the inner barrel of the outer layer atone side of the clapboard and the side wall of the inner barrel of the inner layer at the other side of the clapboard; a water discharge pipe is arranged in the centremost inner barrel, a vertical clapboard is arranged between the water discharge pipe and the centremost inner barrel, and water discharge holes on the water discharge pipe and water passing holes on the centremost inner barrel are respectively positioned on the two sides of the clapboard; and the inner barrels and the outer barrel are filled with filtering material dielectric layers, and the water inlet holes, the water passingholes and the water discharge holes are lower than the top surfaces of the filtering material dielectric layers. The rotary type culture water purifying device has the characteristics of convenient movement and installation, good purifying effect, low manufacturing cost and the like, and is favorable for regulating and controlling the culture water quality, improving the culture effect and savingthe water for culture.

Owner:FISHERY MACHINERY & INSTR RES INST CHINESE ACADEMY OF FISHERY SCI

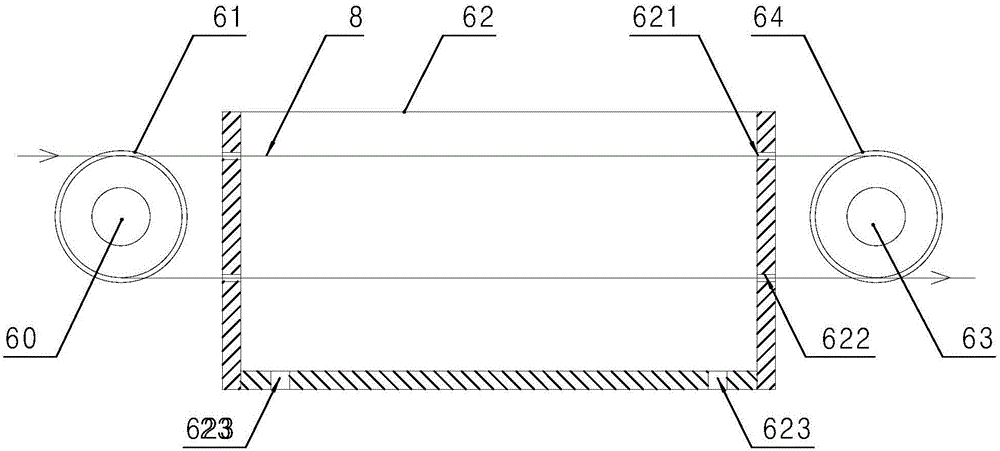

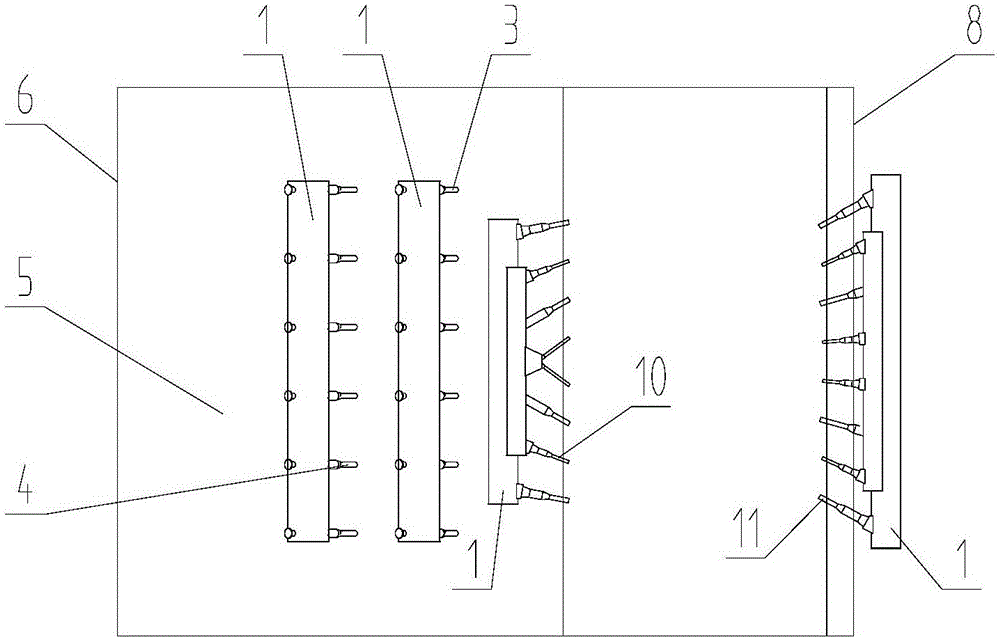

Diamond wire saw production line

ActiveCN106011981AEnough time to stayIncrease travel speedElectrolysis componentsElectrolytic coatingsProduction lineWire speed

The invention discloses a diamond wire saw production line capable of ensuring enough sanding time for a metal wire and improving the moving speed of the metal wire. The production line comprises a wire placing device, an alkali washing device, a before-acid water washing device, a acid washing device, a before-sanding water washing device, a sanding device, an after-sanding washing device, a sand consolidating device, an after-sand-consolidation water washing device, a drying device and a wire taking device which are disposed successively along the moving direction of the metal wire used for electro-plating diamond micro powder. The sanding device comprises a sanding tank; at least one liquid inlet is disposed on the bottom or the lower part of the sanding tank; both sides of the sanding tank are respectively provided with a tumbling barrel; the pair of tumbling barrels are disposed parallelly and horizontally; a plurality of wire grooves are formed on the tumbling barrels; and an upper and a lower wire passing hole are formed on the sanding tank at the sides near the corresponding tumbling barrels. Compared with the traditional diamond wire saw production lines, the wire speed of the production line disclosed by the invention is improved by more than 5 times.

Owner:ZHANGJIAGANG SHUNCHEN MACHINERY CO LTD

Microwave pretreatment desulfurization coking method and device

InactiveCN103059889AReduce heat consumptionReduce processingCharging devicesMicrowave frequency rangeProcess engineering

The invention discloses a microwave pretreatment desulfurization coking device, and particularly provides a device for coking coal. The device comprises a coal blending process, a coal charging process and a coking process; and the method further comprises a microwave pretreatment process between the coal blending process and the coal charging process. The microwave pretreatment process adopts a microwave pretreatment device with the microwave frequency ranged from 300MHz to 300GHz for irradiating, dewatering and desulfurizing the blended coal; and the temperature of the pretreated coal sample is controlled between 150 and 250 DEG C; and then coal is prepared to be charged into a stove and coked. The microwave pretreatment device comprises a microwave reaction chamber body, a connecting device, a conveyor, an exhaust duct and a detection control system, wherein the connecting device, the conveyor, the exhaust duct and the detection control system are arranged among the microwave reaction chamber body, a coke stove coal tower and a coal charging trolley or a material bin. The device is simple; after being quickly preheated, dewatered and desulfurized, the blended coal can be coked so as to improve the bulk density, shorten the coking time and promote the yield of a single furnace as well as the coal quality; and clean and effective utilization of energy can be realized.

Owner:CHINA UNIV OF MINING & TECH

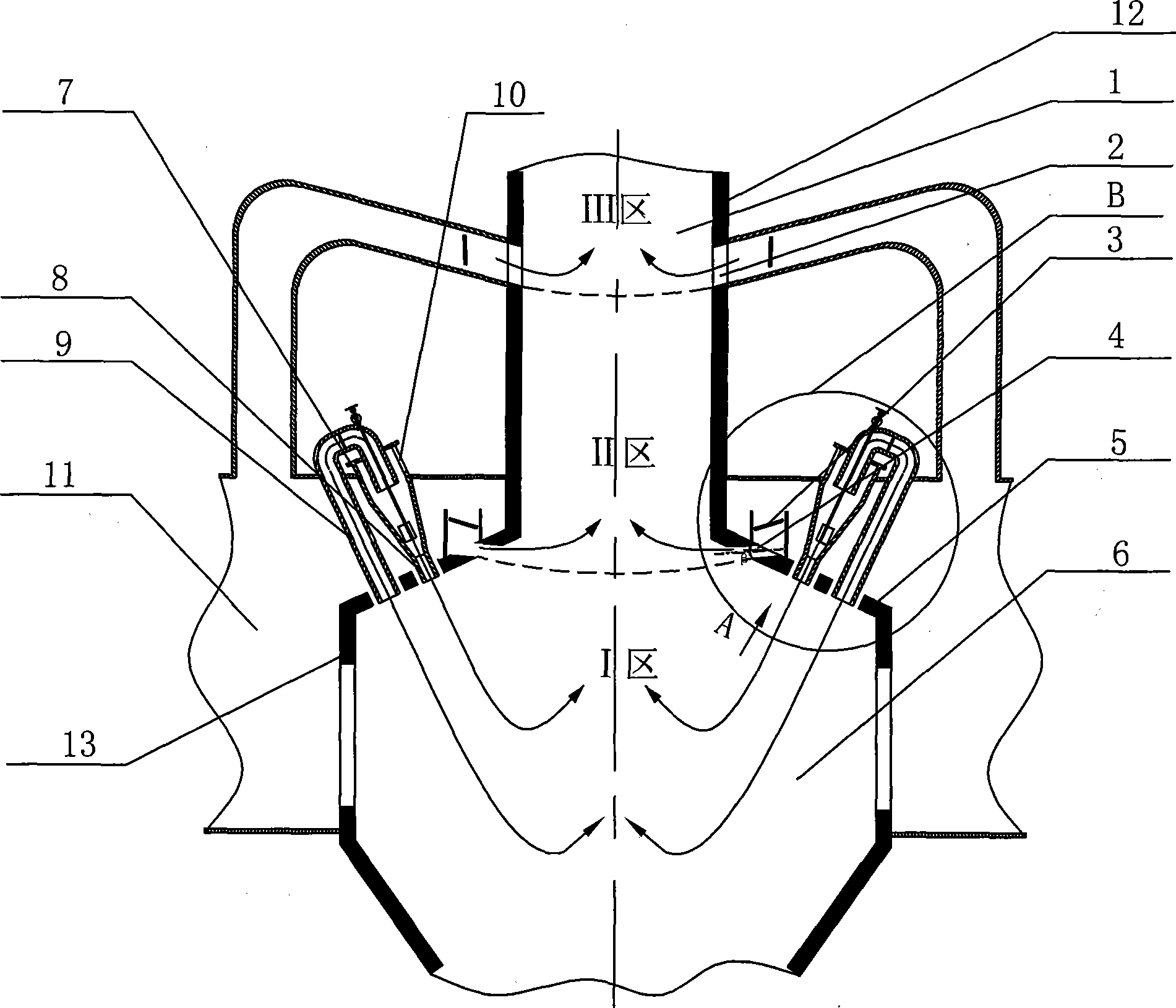

W-shaped flame boiler with two-stage over-fire wind

InactiveCN101476739AGuaranteed burnout rateGood for burnoutNon-combustible gases/liquids supplyCombustorSingle stage

The invention discloses a W-shaped flame boiler with two stages of burn-out wind, which relates to the W-shaped flame boiler and aims at the problems that the W-shaped flame boiler of the prior single-stage burn-out wind device has high content of fly ash inflammable matters and low burn-off rate of coal dust. The W-shaped flame boiler comprises a superior OFA nozzle (2) and an inferior OFA nozzle (4) which is arranged on a furnace arch (5) close to an hearth throat inlet, is communicated with a lower hearth (6), is arranged on the outer side of a burner (8), and is communicated with a secondary wind box (11). The W-shaped flame boiler not only can replenish air for the unburned coal dust in time to benefit the burnout of the coal dust and greatly reduce the content of the fly ash inflammable matters, but also can better achieve the fractional combustion of the coal dust and greatly reduce the emission of NOx.

Owner:HARBIN INST OF TECH

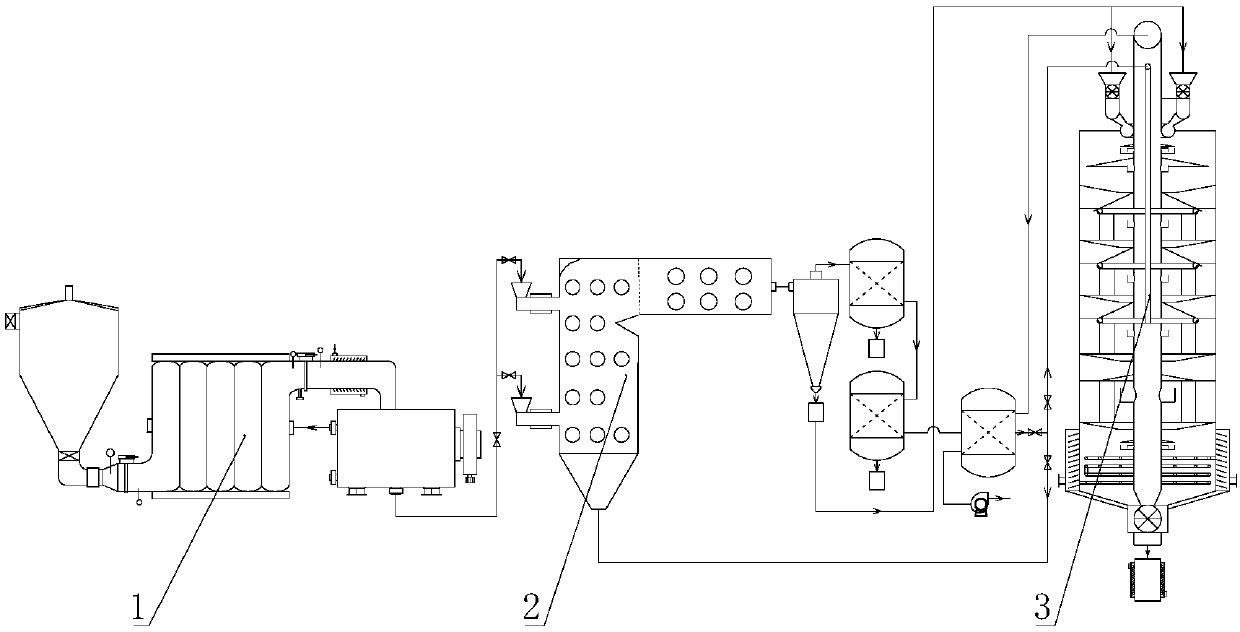

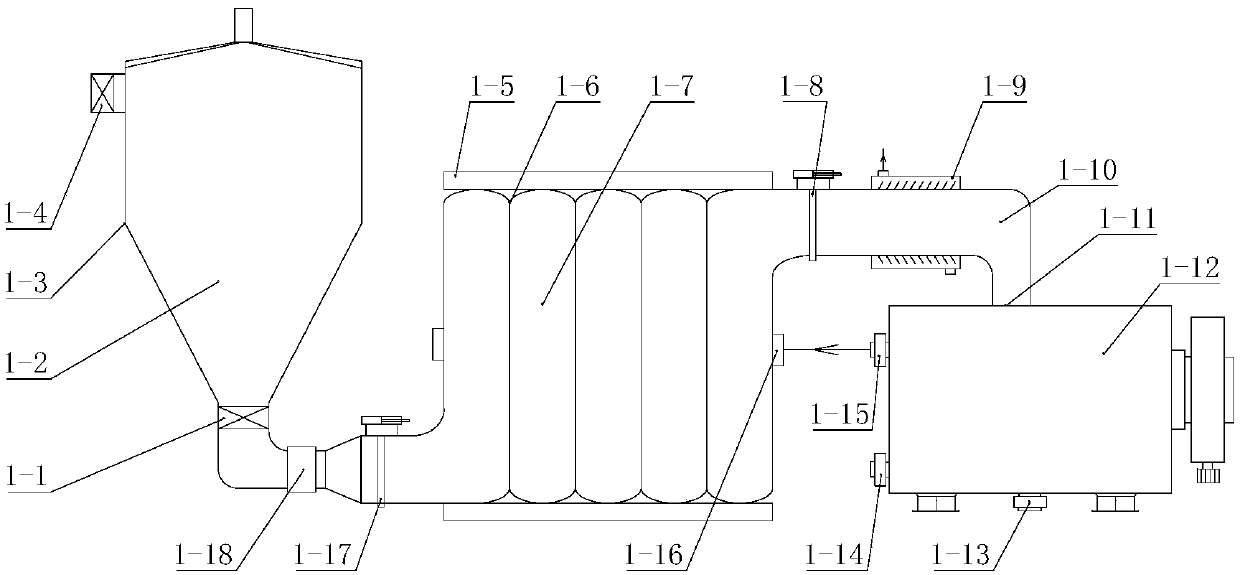

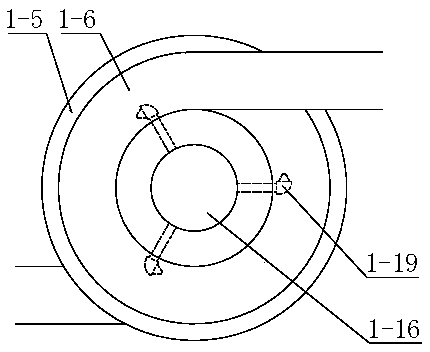

System and method for graded co-production of energy chemical and silicon carbon material through rice husks

ActiveCN109628121ATo achieve hierarchical utilizationAchieve enrichmentBiofuelsLiquid hydrocarbon mixture productionHuskCarbonization

The invention discloses a system for graded co-production of an energy chemical and silicon carbon material through rice husks. The system comprises a hydrothermal baking subsystem (1), a medium temperature pyrolysis subsystem (2) and a high temperature carbonization subsystem (3) which are connected in sequence, wherein the hydrothermal baking subsystem (1) is used for preparing a liquid productrich in furfural and hydrothermal charcoal; the medium temperature pyrolysis subsystem (2) is used for obtaining bio-oil rich in sugar and medium-temperature pyrolysis carbon; the high temperature carbonization subsystem (3) comprises a rotary feeding valve (3-1), a multi-stage high temperature electric furnace (3-2), a gas channel distribution pipeline (3-3), a product cooling device (3-8), a coke cooling tank (3-12) and a volatile condensing device (3-20), and is used for multi-stage high temperature carbonization and activation of the pyrolysis carbon to obtain the silicon carbon material with a energy storage characteristic. The invention also provides a method for the graded co-production of the energy chemical and silicon carbon material through the rice husks. The system and methodhave the advantages that the high-quality energy chemical and silicon carbon material can be simultaneously obtained, the treatment efficiency is high, the heat utilization rate is high, and the operation is convenient.

Owner:HUAZHONG UNIV OF SCI & TECH

Horizontal plug flow anaerobic reactor and treatment method for kitchen waste materials

InactiveCN111808727AAchieving stirringReduce construction costsBioreactor/fermenter combinationsBiological substance pretreatmentsProcess engineeringEnvironmental engineering

The invention discloses a horizontal plug flow anaerobic reactor for kitchen waste materials. The reactor comprises a biogas tank, a biogas booster fan, a dehydrator and at least one anaerobic reaction tank. A feed pipe is arranged on a tank body of the anaerobic reaction tank; a slope structure is formed at the bottom of the tank body, a plurality of first gas nozzles are installed on the slope structure, and are used for spraying into the tank body to achieve stirring of materials, and the materials flow to the front of the tank body along the slope structure under stirring; the biogas tankis arranged on one side of the tank body, and communicates with the inside of the tank body through a first biogas pipe; the biogas booster fan is also arranged between the tank body and the biogas tank; and the dehydrator is also arranged in the front of the tank body, and the materials enter the dehydrator to achieve solid-liquid separation by the dehydrator. The horizontal anaerobic reactor with functions of gas stirring and plug flow is innovatively developed, and can reduce the construction cost of the tank body and the whole operation cost; and meanwhile, the problem of layering of bottom accumulation materials, top scum and the like can also be effectively solved.

Owner:SUZHOU CLEAR IND CO LTD

Efficient purifying method for exhausted tail gases from firing of gangue baked bricks in portable tunnel kiln

InactiveCN104776727ASolve the problem of desulfurization and purificationSave energyWaste heat treatmentTunnel kilnChemical reaction

The invention discloses an efficient purifying method for exhausted tail gases from firing of gangue baked bricks in a portable tunnel kiln. The efficient purifying method comprises the following process steps of stacking raw materials: stacking green gangue bricks and limestone in an annular kiln bottom between annular tracks of the portable tunnel kiln; roasting the green gangue bricks and the limestone in the kiln to desulfurize: roasting the green gangue bricks and the limestone in an arc kiln body according to a certain temperature raising procedure, and performing primary desulfurization by high-temperature roasting; performing wet flue gas desulfurization: feeding the calcined limestone into a desulfurizing liquid adjusting pool, and adjusting the basic strength in the adjusting pool; introducing tail gases in the kiln body into a desulfurizing tower, sprinkling the desulfurizing liquid in the desulfurizing liquid adjusting pool into the desulfurizing tower, and performing secondary desulfurization by a chemical reaction generated in the desulfurizing tower. According to the efficient purifying method disclosed the invention, by the adoption of a combined desulfurization method of desulfurization by roasting in the kiln and the wet flue gas desulfurization, the problems of desulfurization and purification of the tail gases in the portable tunnel kiln are successfully solved; meanwhile, energy sources can be saved, and the purification cost is reduced.

Owner:HEBEI DINGLEI BUILDING MATERIAL CO LTD

Gas-liquid-solid combined waste incinerator

InactiveCN106765121AImprove incineration efficiencyIncrease incineration functionEmission preventionIncinerator apparatusLiquid wasteCombustor

The invention discloses a gas-liquid-solid combined waste incinerator. The gas-liquid-solid combined waste incinerator comprises a shell, a holding furnace wall and a combustion chamber which is used for fuel combustion and defined by the shell and the holding furnace wall which are fixedly connected. Elutriating rings are arranged on the holding furnace wall. The combustion chamber is divided into a first incineration chamber, a second incineration chamber and a heat recovery chamber by the elutriating rings. A waste inlet and a combustor joint are arranged on the side wall in the first incineration chamber. The waste inlet comprises a waste gas inlet, a waste liquid inlet and a waste solid inlet. The combustor joint is connected with the combustor. An ammonia gas inlet is formed in the side wall in the secondary incineration chamber and is connected with an ammonia adding mechanism. According to the gas-liquid-solid combined waste incinerator, waste in different states is added to the waste incinerator and brunt, the multiple kinds of waste can be incinerated at the same time through the waste incinerator, the incineration function of the waste incinerator is added, and the waste incineration efficiency is improved; and by the adoption of the elutriating ring structure, it is guaranteed that the waste fuel has the enough dwell time in the incinerator, and it is guaranteed that the waste can be completely burnt in the incinerator.

Owner:TIANHUA INST OF CHEM MACHINERY & AUTOMATION

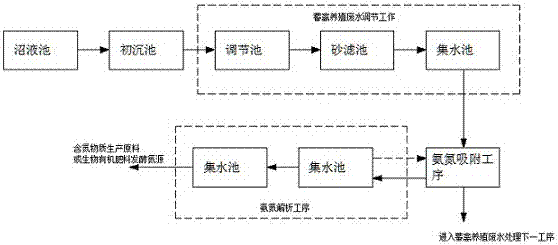

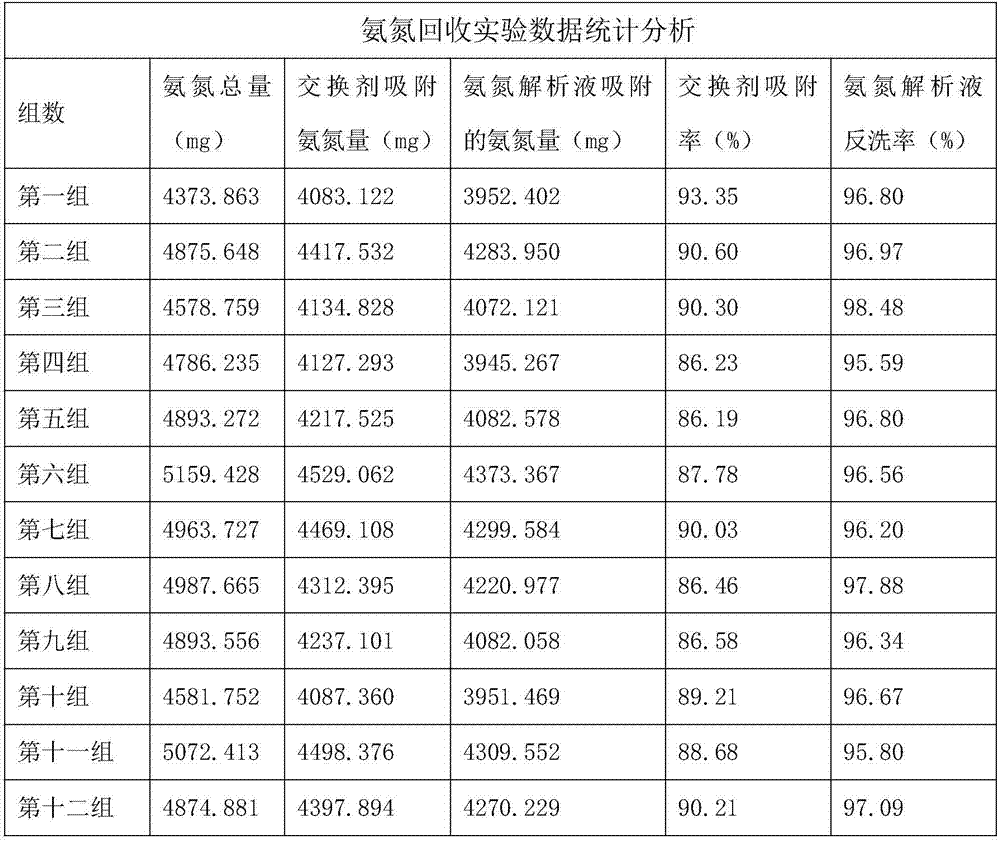

Method for recovering ammonia nitrogen in livestock and poultry breeding wastewater

InactiveCN107487903AFacilitate solid-liquid separationPromote decompositionWater contaminantsWaste water treatment from animal husbandryNitrogen sourceAmmonia nitrogen

The invention relates to the field of wastewater treatment, and particularly discloses a method for recovering ammonia nitrogen in livestock and poultry breeding wastewater. An exchanger and an ammonia nitrogen analysis solution in step c), step d) and step e) in the method can sufficiently recover most of ammonia nitrogen in the livestock and poultry breeding wastewater, and the ammonia nitrogen recovered in the exchanger and the ammonia nitrogen analysis solution can be produced into products as needed, such as ammonium chloride, ammonium sulfate and the like, and can also be used as a nitrogen source for fermentation of agricultural straws. Moreover, after most of the ammonia nitrogen in the livestock and poultry breeding wastewater is recovered, a ratio of C / N in the livestock and poultry breeding wastewater is increased, so as to facilitate biochemical treatment of the livestock and poultry breeding wastewater in a later period, so that the treatment cost of the livestock and poultry breeding wastewater can be effectively reduced. The scheme can reduce the recovery cost of the ammonia nitrogen in the livestock and poultry breeding wastewater.

Owner:重庆融极环保工程有限公司

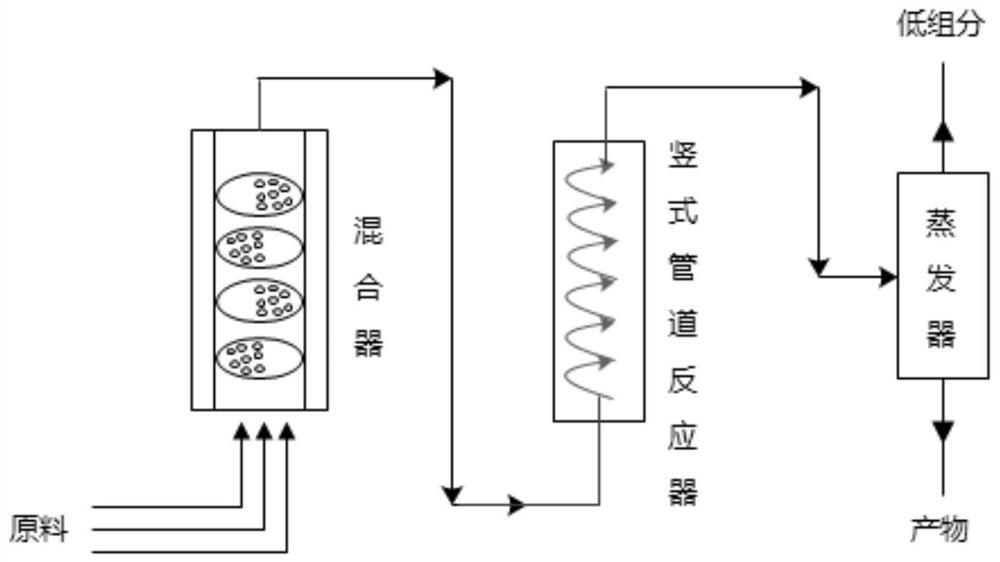

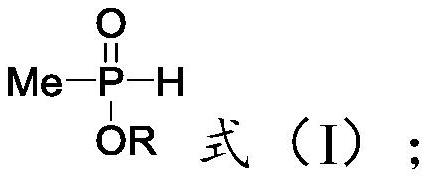

Method for tubular continuous synthesis of (3-acetoxy-3-cyanopropyl)-methyl phosphinic acid alkyl ester

ActiveCN113004325AQuick mixImprove mixing efficiencyGroup 5/15 element organic compoundsAcetic acidDistillation

The invention provides a method for tubular continuous synthesis of (3-acetoxy-3-cyanopropyl)-methyl phosphinic acid alkyl ester, which comprises the following steps: a) continuously feeding acetic acid-1-cyano-2-propenyl ester, methyl phosphinic acid alkyl ester and an initiator into a mixer, and mixing to obtain a mixed material; b) feeding the mixed material obtained in the step a) from the bottom of a vertical pipeline reactor, and reacting to obtain a reaction mixture; and c) feeding the reaction mixture obtained in the step b) into an evaporator, and purifying to obtain the (3-acetoxy-3-cyanopropyl)-methyl phosphinic acid alkyl ester. The method comprises the following steps: fully mixing reaction raw materials through a mixer, directly introducing the mixture into a vertical pipeline reactor, discharging the material from the upper part of the reactor, introducing the material into an evaporator, and carrying out low-temperature removal and distillation purification to obtain the (3-acetoxy-3-cyanopropyl)-methyl phosphinic acid alkyl ester, the method is simple in process steps, industrial control and continuous production are easy to realize, and the synthesized product is high in purity and good in yield.

Owner:ZHEJIANG XINAN CHEM INDAL GROUP

A buccal pellicle for treating gingivitis and oral mucosa canker as well as its preparation method

InactiveCN101156846AFast absorptionQuick effectOrganic active ingredientsDigestive systemOral mucosaCalcium EDTA

The invention relates to slow release liposome mouth dissolving film agent for remedying gingivitis and oral mucosa helcosis and the preparation technology thereof. The invention belongs to the biologic medicine field, in particular relates to slow release liposome mouth film agent taking high-fat catechin as a main component. The preparation of the slow releasing liposome applies the package technology of sodium alginate and calcium salt conversion liposome. The product of the technology is used for remedying the gingivitis and the oral mucosa helcosis, the invention is simple, the curative effect is reliable, the price is cheap, and the invention is adaptive to the national situation.

Owner:BEIJING UNION GENIUS PHARMA TECH +1

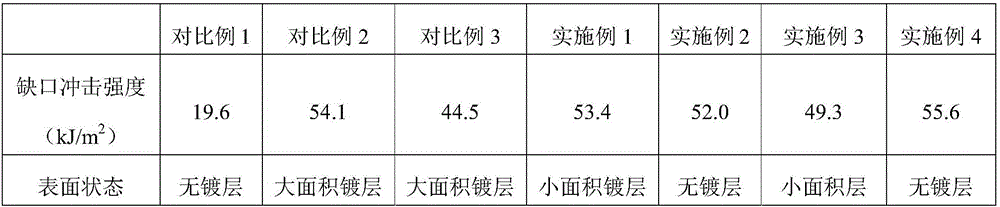

Non-electroplated PC/ABS (Polycarbonate/Acrylonitrile Butadiene Styrene) alloy material suitable for two-color injection molding and preparation method thereof

The invention relates to a non-electroplated PC / ABS (Polycarbonate / Acrylonitrile Butadiene Styrene) alloy material suitable for two-color injection molding and a preparation method thereof. The non-electroplated PC / ABS alloy material is prepared from the following components in parts by weight: 40 to 65 parts of PC resin, 25 to 45 parts of high rubber powder masterbatch, 10 to 25 parts of SAN (Styrene-acrylonitrile) resin, 0.1 to 1 part of antioxidant and 0.1 to 1 part of lubricant, wherein the high rubber powder masterbatch is prepared from the following components in parts by weight: 30 to 50 parts of PC resin, 30 to 50 parts of ABS high rubber powder, 10 to 30 parts of compatibilizer, 0.1 to 0.5 part of initiator, 0.1 to 1 part of the antioxidant and 0.1 to 1 part of the lubricant. Compared with the prior art, the non-electroplated PC / ABS alloy material provided by the invention adopts a reactive extrusion method to obtain strong shear by an extruder and screw combination with a large aspect ratio, and prepare high rubber powder masterbatch coated with PC on the rubber surface; by utilizing acid resistance and hydrophobicity of PC, the situation that the rubber phase is prevented from being etched by a roughing solution is ensured during electroplating, and the application prospects are very good.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

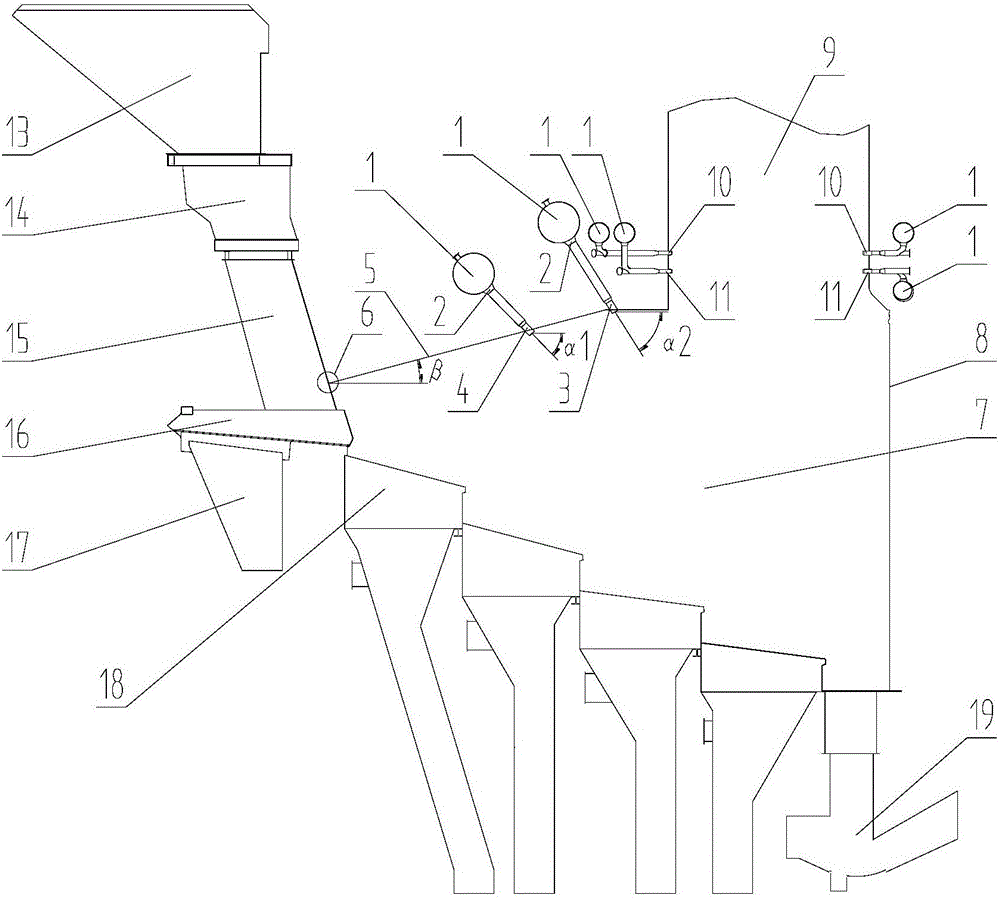

Rear-arch-free flow smoothening device for garbage incinerator

PendingCN106838922AGood effect of incineration treatment of garbageExtend exercise timeIncinerator apparatusNon-combustible gases/liquids supplyEnvironmental engineeringHearth

The invention relates to a rear-arch-free flow smoothening device for a garbage incinerator, and belongs to devices special for environment-friendly enterprises. The device comprises a flue (9), a hearth (7) is arranged below the flue (9), a rear wall (8) is arranged on one side of the hearth (7), a front arch (5) and a front arch lower collection box (6) are arranged in the hearth (7), water-cooling wall fins on the upper portion of the front arch (9) are provided with at least one upper layer secondary air nozzle (3), throat upper layer secondary air nozzles, at least one lower layer secondary air nozzles (4) and throat lower layer secondary air nozzles 11, an air inlet of each secondary air nozzle on each layer is communicated with one secondary air pipe (1), and a secondary air door (2) is arranged on the joint of each secondary air nozzle on each layer and the corresponding secondary air pipe (1). The device achieves the aims of treatment of low-heat-value high-water-content high-ash content garbage in China and power generation.

Owner:GRANTOP GRP CO LTD

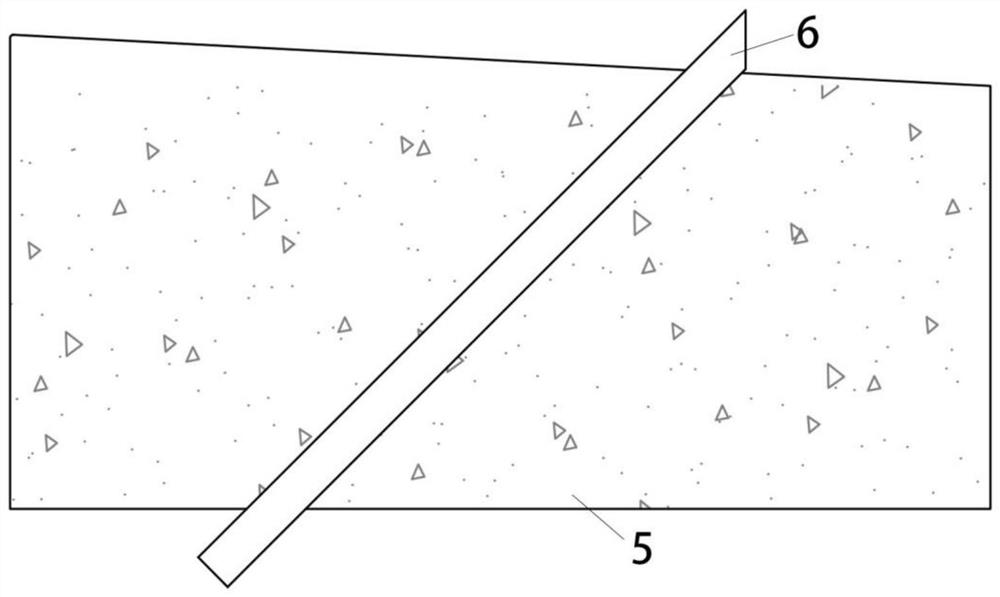

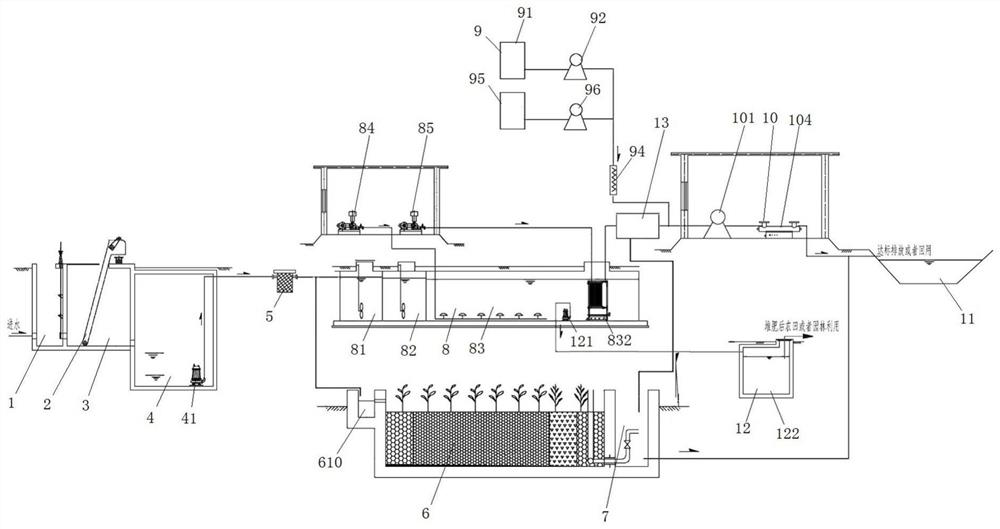

Rural domestic sewage composite ecological purification system

PendingCN111792798ASolve the problem of non-compliance with emissionsTake advantage ofWater/sewage treatment by irradiationSpecific water treatment objectivesConstructed wetlandWater treatment system

The invention discloses a rural domestic sewage composite ecological purification system, which comprises a water inlet well, a primary sedimentation tank and an aeration regulating tank, wherein a grid is obliquely arranged in the primary sedimentation tank, the water outlet of the aeration regulating tank is respectively connected with an artificial subsurface flow wetland and buried integratedsewage treatment equipment in parallel, the sludge outlets of the artificial subsurface flow wetland and the buried integrated sewage treatment equipment are connected with a sludge tank, the water outlet of the buried integrated sewage treatment equipment is communicated with an integrated equipment produced water treatment system, and the water outlet of the integrated equipment produced water treatment system and the water outlet of the artificial subsurface flow wetland are respectively communicated with big pits. According to the invention, a stable purification effect can be exerted throughout the year, the problem that existing rural constructed wetlands do not reach the standard in winter treatment or are difficult to operate and manage is solved, the system can be communicated with a matched sewage collection pipe network in a village, the problem that rural domestic sewage discharge does not reach the standard is solved, treated water reaches the standard and is discharged into nearby drainage ditches or used for farmland irrigation, water resources are fully utilized, and meanwhile ecological and ecological benefits are remarkable.

Owner:河北冀水规划设计有限公司

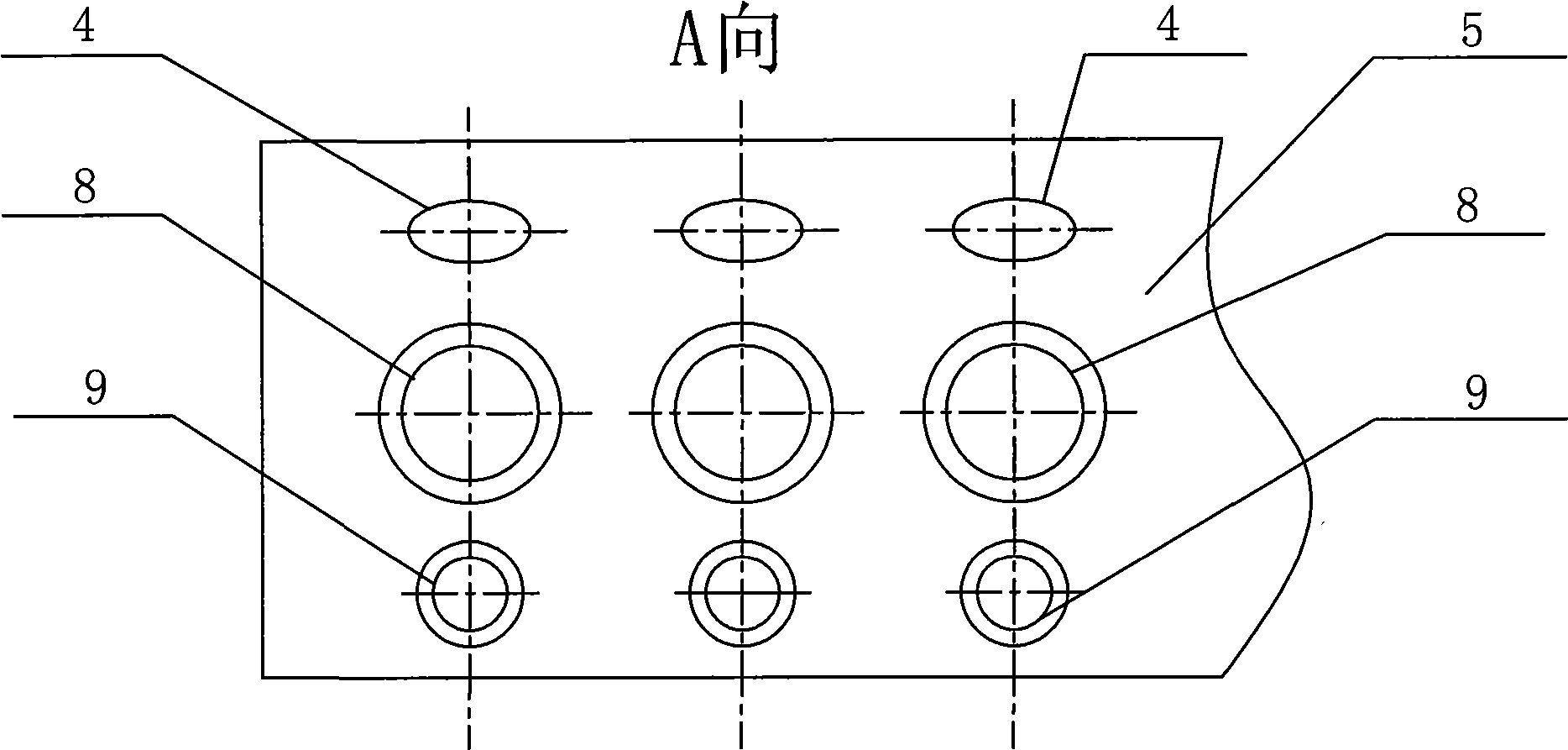

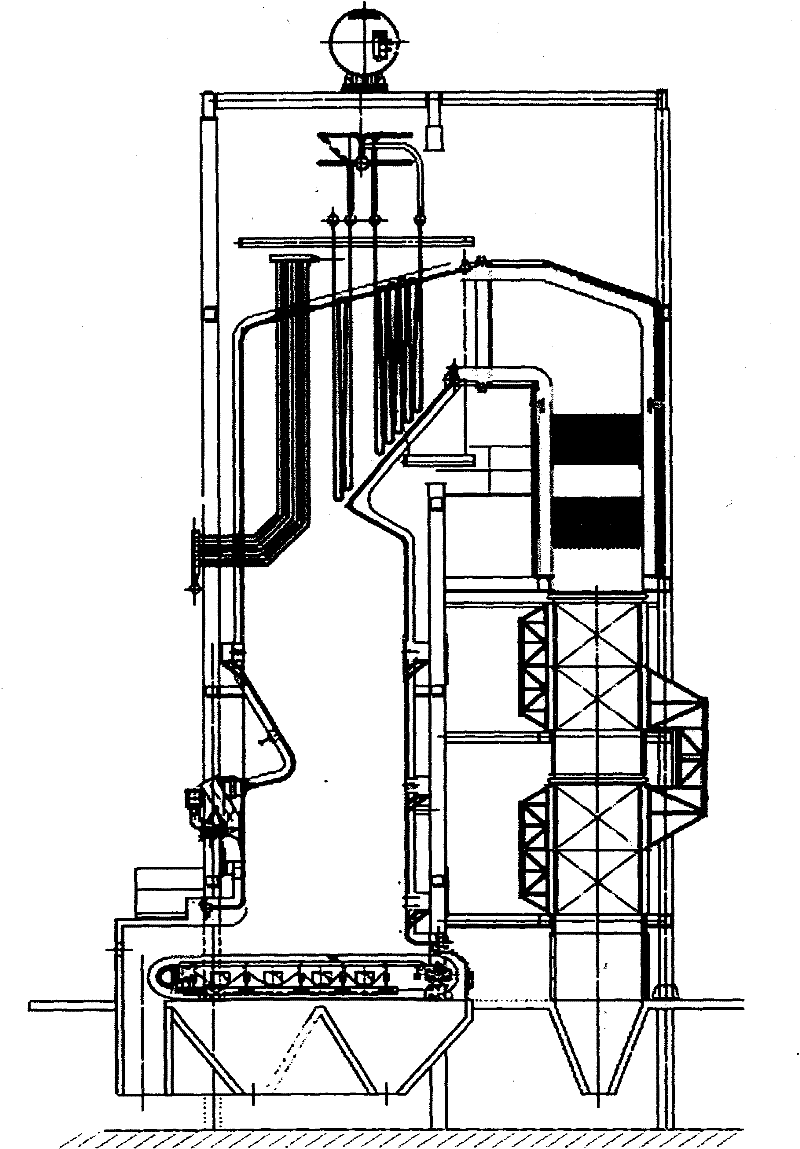

High-moisture-content biomass fuel boiler

InactiveCN102345875AEnough time to stayReduce accidentsLump/pulverulent fuel feeder/distributionFiberPalm fruit

The invention relates to a boiler, which is characterized in that high-moisture-content biomass fuels such as palm fruit shells, fibers, bran coats, bagasse and the like generate steam through a specific combustion method for electricity generation and steam supply. The boiler adopts a wind dispersal mode, and a layer combustion mode by using the suspension combustion in a furnace as a main means and using a rotating fire grate or a water cooling fixing fire grate as an auxiliary means is adopted. The boiler comprises main components such as a feeding machine, a spraying device, the fire grate, a multi-stage wind supply device, a diaphragm type water cooling wall hearth, a water cooling screen, an overheater, a water spraying temperature reducer, a coal economizer with fins and the like and is shown as Figure 1. In the boiler, the high-moisture-content biomass is pretreated and processed and is then directly dispersed by wind to the hearth by the variable-frequency speed-regulation feeding machine through high-pressure head wind, and medium and short fibers are rapid dried, fired and completely combusted in a high-temperature smoke gas environment in the furnace. Long fibers fall in the middle or back position of the fire grate, the fire grate rotates from the back end to the grate front, the detention time of the biomass fuels on the fire grate is effectively prolonged, the complete combustion is favorably realized, the probability of the coking on the fire grate is greatly reduced, and the operation reliability is improved.

Owner:SHANGHAI PUHAO PULP MAKING PAPER MAKING ENG

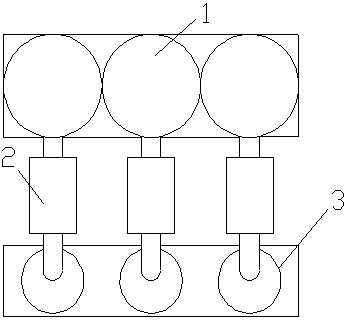

4-aminoantipyrine continuous production system

The invention discloses a 4-aminoantipyrine continuous production system. The 4-aminoantipyrine continuous production system includes an antipyrine sulfuric acid solution storage tank, a sodium nitrite solution storage tank, an impinging stream reactor, a reducing agent storage tank, a reduction reaction kettle, a hydrolysis tank, a neutralization tank and a product storage tank, wherein a first spray gun is installed in an antipyrine sulfuric acid solution inlet of the impinging stream reactor, a second spray gun is installed in a sodium nitrite solution inlet, and an injector is installed ina reducing agent inlet; the antipyrine sulfuric acid solution storage tank is connected with the first spray gun, the sodium nitrite solution storage tank is connected with the second spray gun, andthe reducing agent storage tank is connected with the injector; and a material outlet in the impinging stream reactor is connected with the reduction reactor kettle, the hydrolysis tank, the neutralization tank and the product storage tank sequentially. The continuous production process of 4-aminoantipyrine has simple operation and easy monitor, extra manpower and material resources consumed by starting and stopping of intermittent production, and energy consumption is reduced.

Owner:QINGDAO UNIV OF SCI & TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com