Solid waste incineration system with exhaust gas secondary combustion drying ignition device and treatment method thereof

A secondary combustion and ignition device technology, applied in the direction of combustion methods, combustion types, incinerators, etc., can solve the problems of high investment cost, difficult operation, and increased operating costs of solid waste treatment and hazardous waste treatment in the secondary combustion chamber, and achieve Reduce energy consumption, good heat storage effect, reduce construction investment and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The structure and working method of the present invention will be further described below in conjunction with the accompanying drawings.

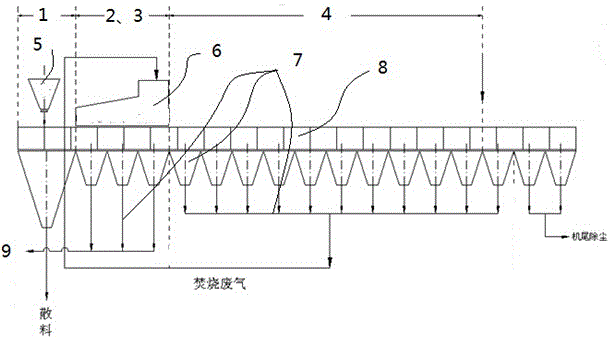

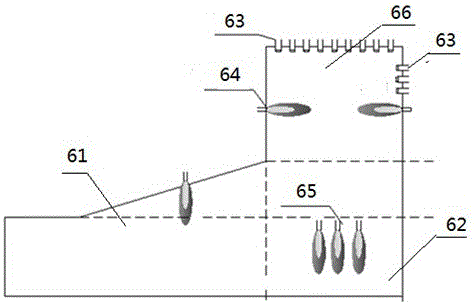

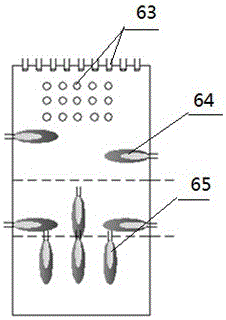

[0024] The present invention utilizes the now mature metallurgical sintering production equipment, and transforms it on the basis to form such figure 1 The solid waste incineration system shown has a high-temperature waste gas secondary combustion dry point device, and the system includes an incineration device and an exhaust system. The incineration device includes a cloth section 1 at the front, a drying section 2, an ignition section 3, and an incineration section 4 at the rear. The drying section 2 and the ignition section 3 are realized by a waste gas secondary combustion dry ignition device 6 . The waste gas secondary combustion dry ignition device 6 is obtained by reforming the igniter of the current sintering machine. It is in the form of a hood that is placed over the incinerated material, see figure 2 and image 3 , th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com