Method for desulfurizing and denitrating smoke simultaneously through ammonia method

A technology for desulfurization, denitrification and flue gas is applied in the field of environmental protection, which can solve the problems of difficult operation and operation, complex structure and high cost, and achieve the effects of simple process and system, simplified process flow and small investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

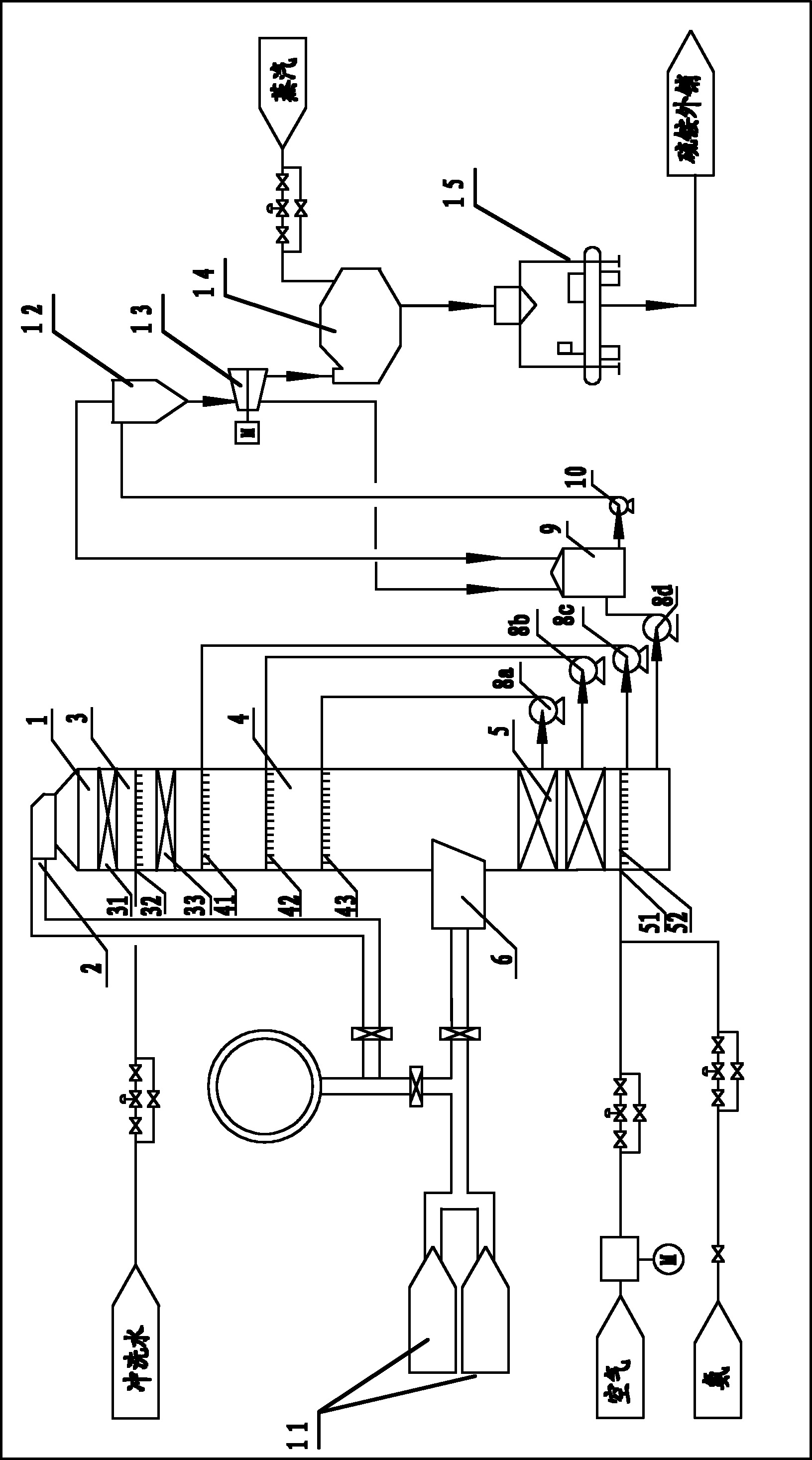

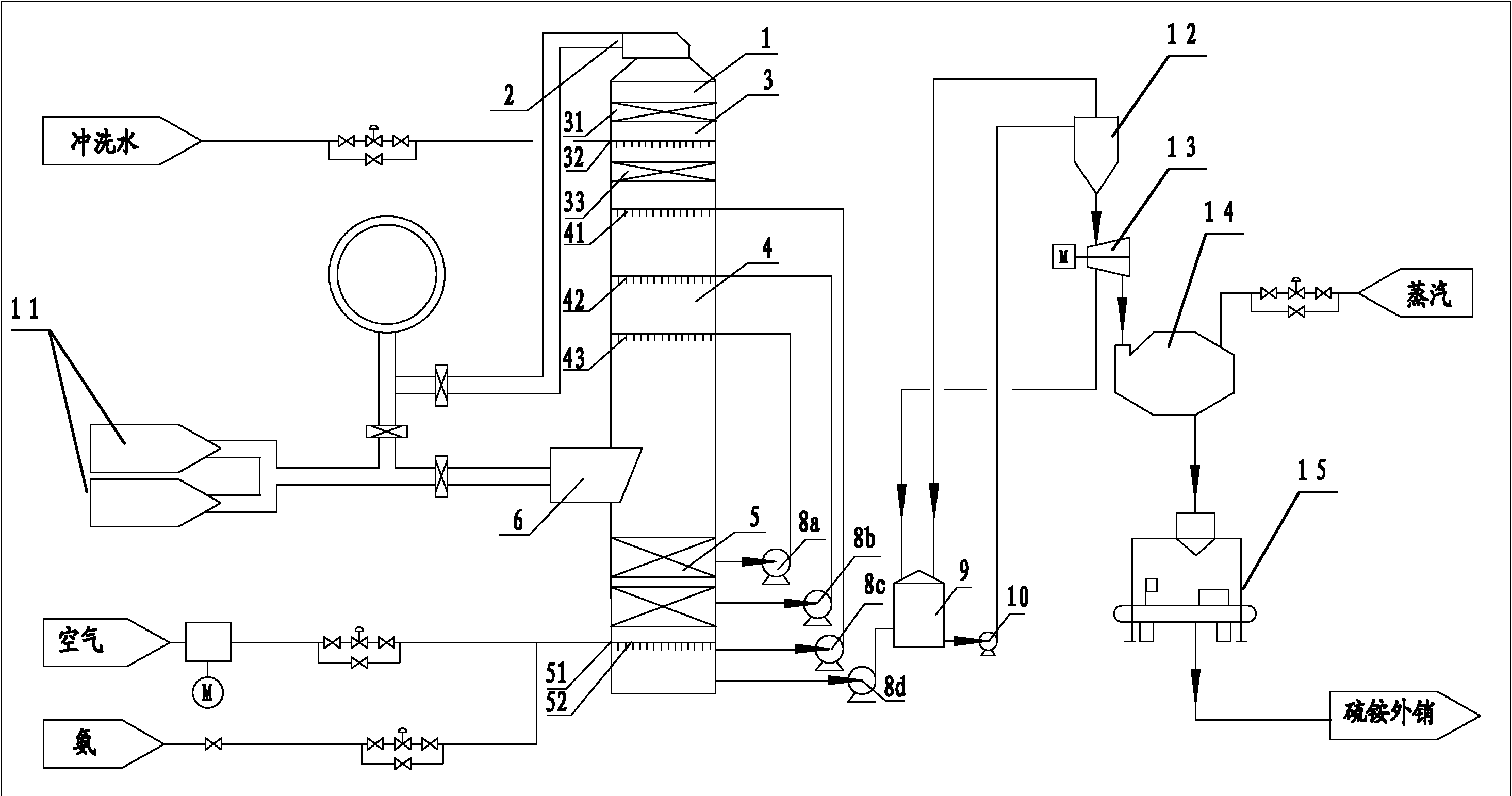

[0048] like figure 1 As shown, the flue gas transported by the induced draft fan 11 enters the absorption section 4 from the flue gas inlet 6 in the middle of the desulfurization and denitrification tower 1, and contacts with the absorption liquid from the denitrification spray layer 43, desulfurization spray layer 41, 42, denitrification and denitrification. Desulfurization, at the same time, the flue gas is cooled to below 70°C, and enters the upper water washing and demisting section 3 upwards, passes through the water washing layer 33 and the water spraying layer 32, absorbs and removes unreacted ammonia in the flue gas, and then passes through the demisting layer 31 , and discharge the net flue gas from outlet 2 after demisting. The upper part of the oxidation section 5 at the lower part of the tower is a denitrification circulation layer, the middle part is a desulfurization circulation layer, and the bottom is an oxidation layer. The oxidation layer is provided with an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com