Patents

Literature

1194results about "Ammonia compounds" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

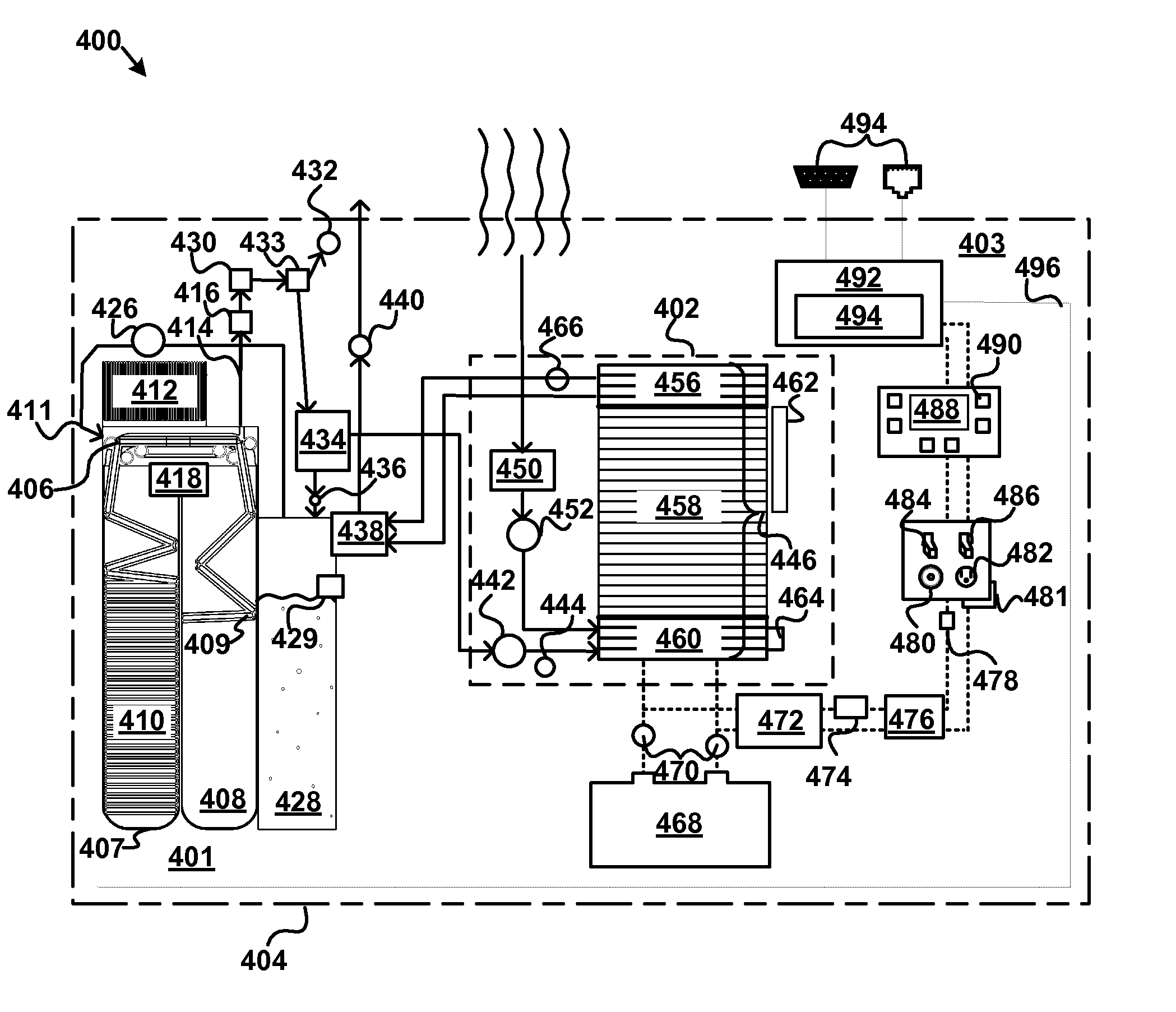

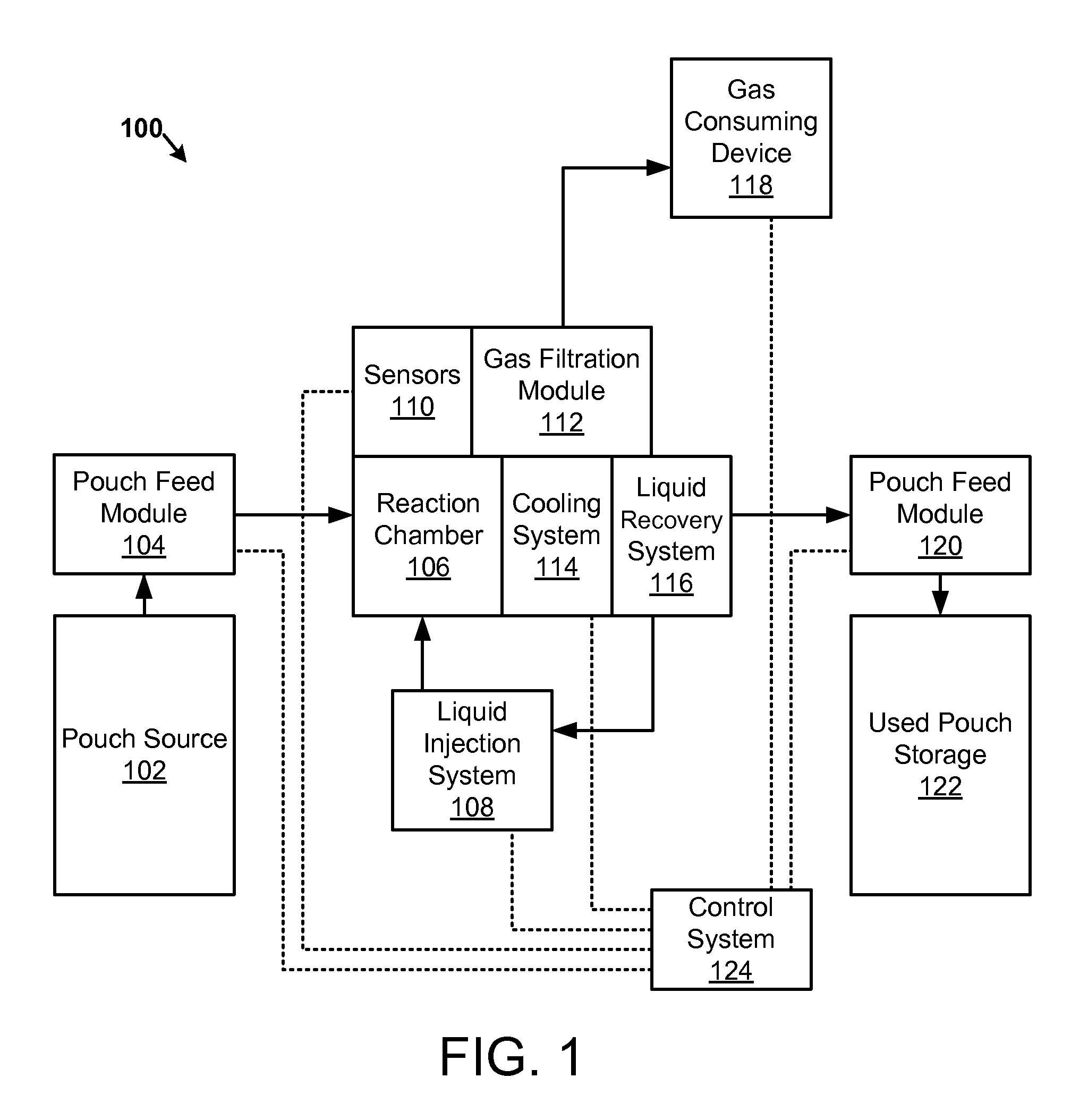

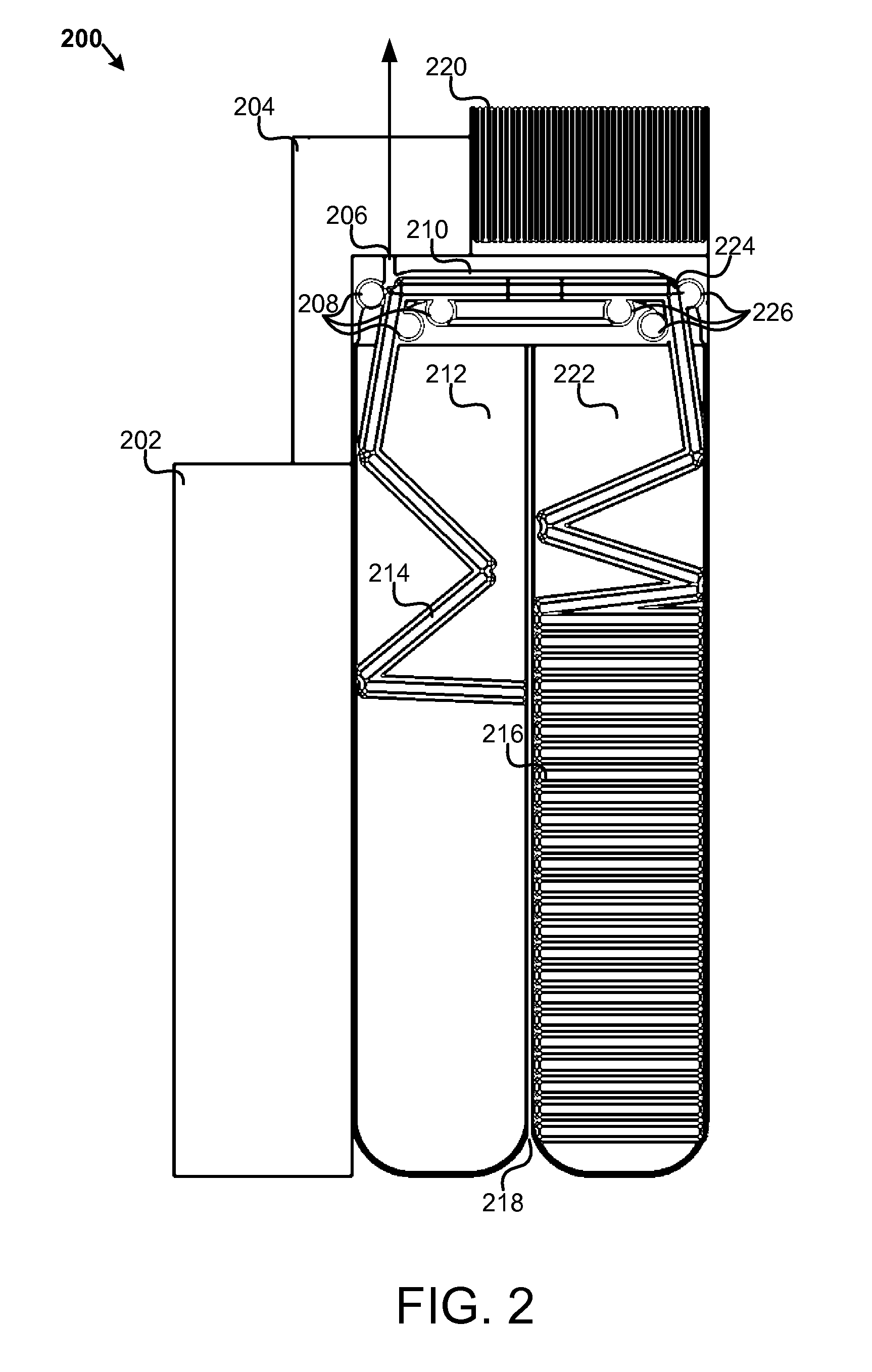

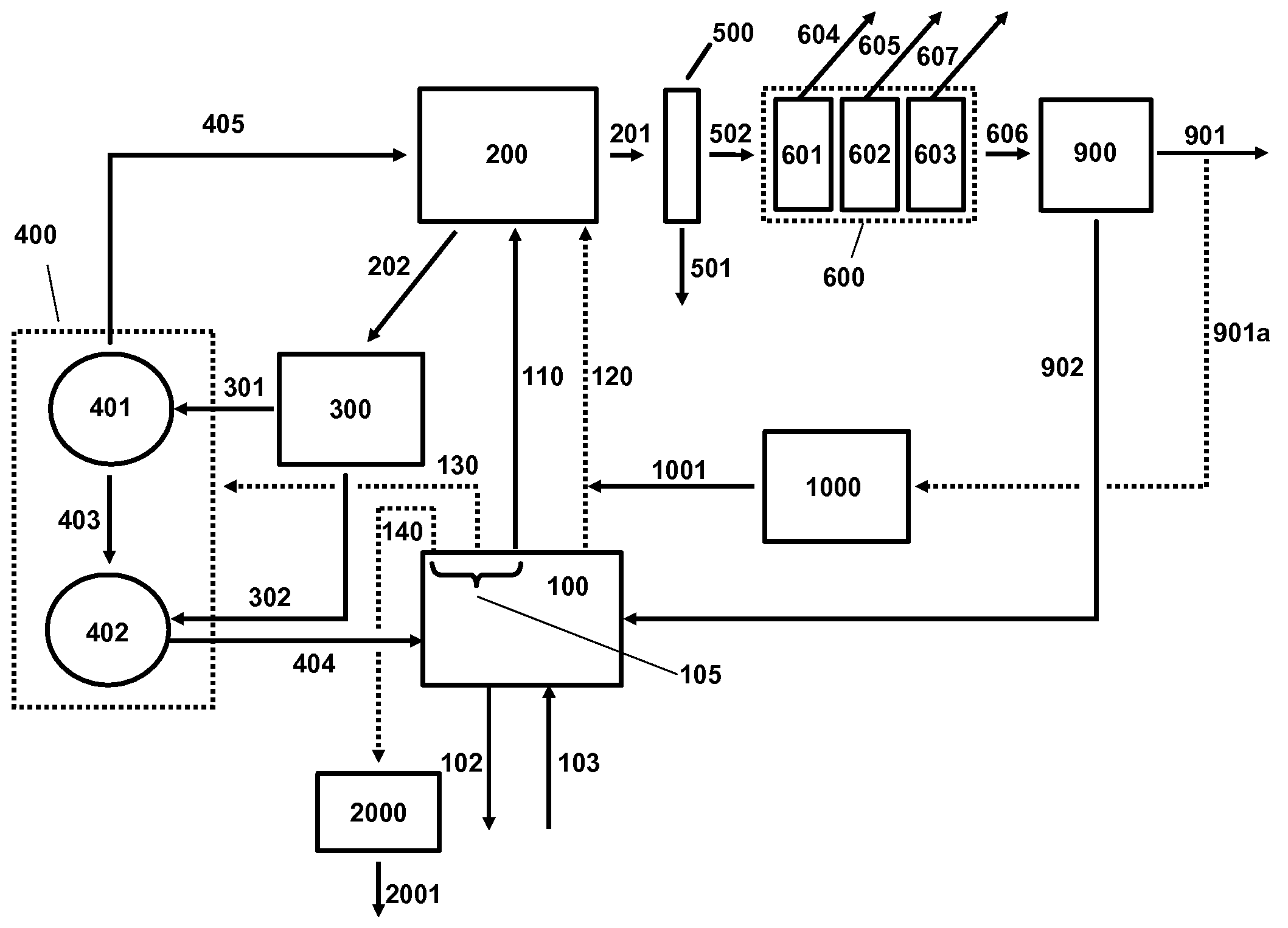

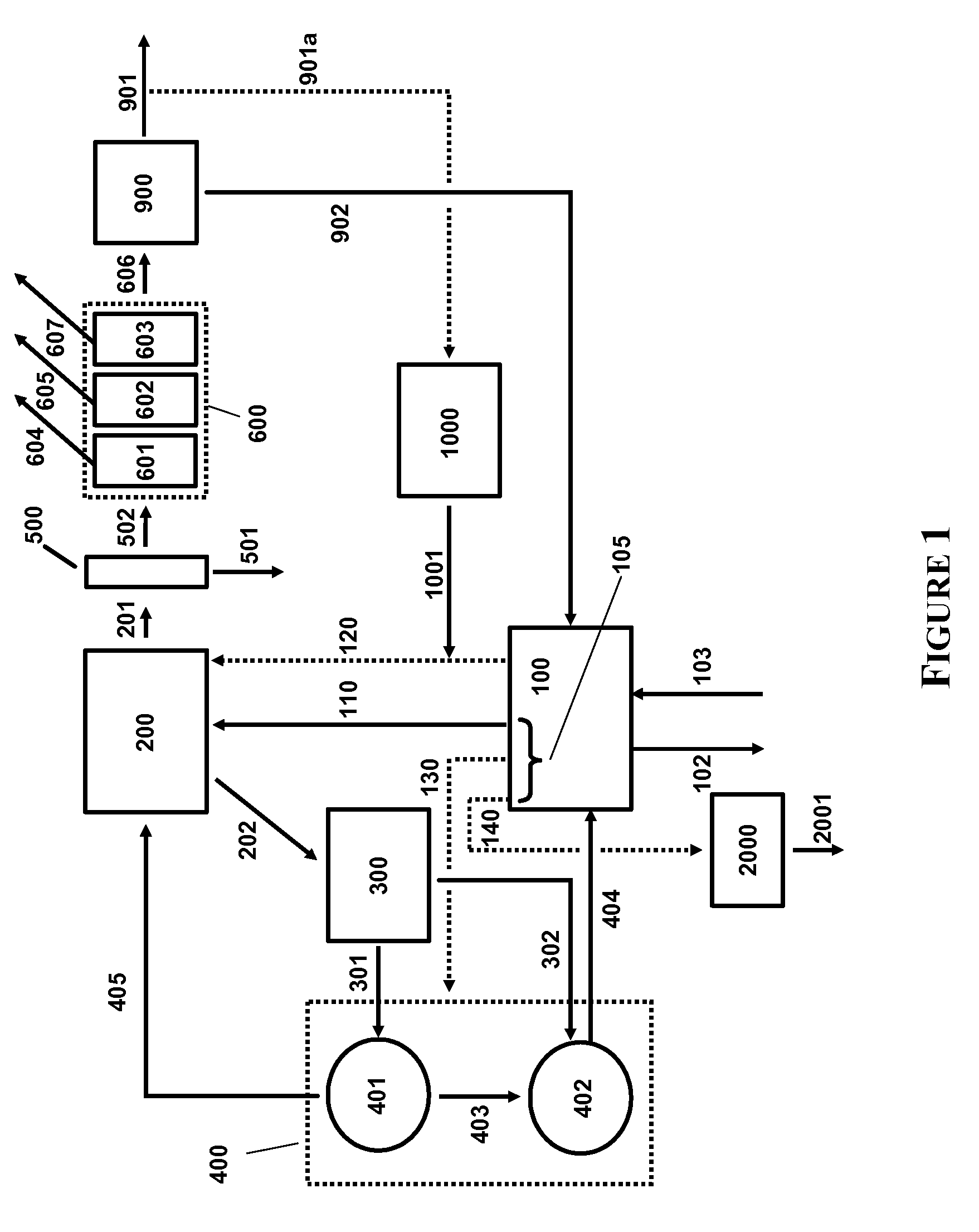

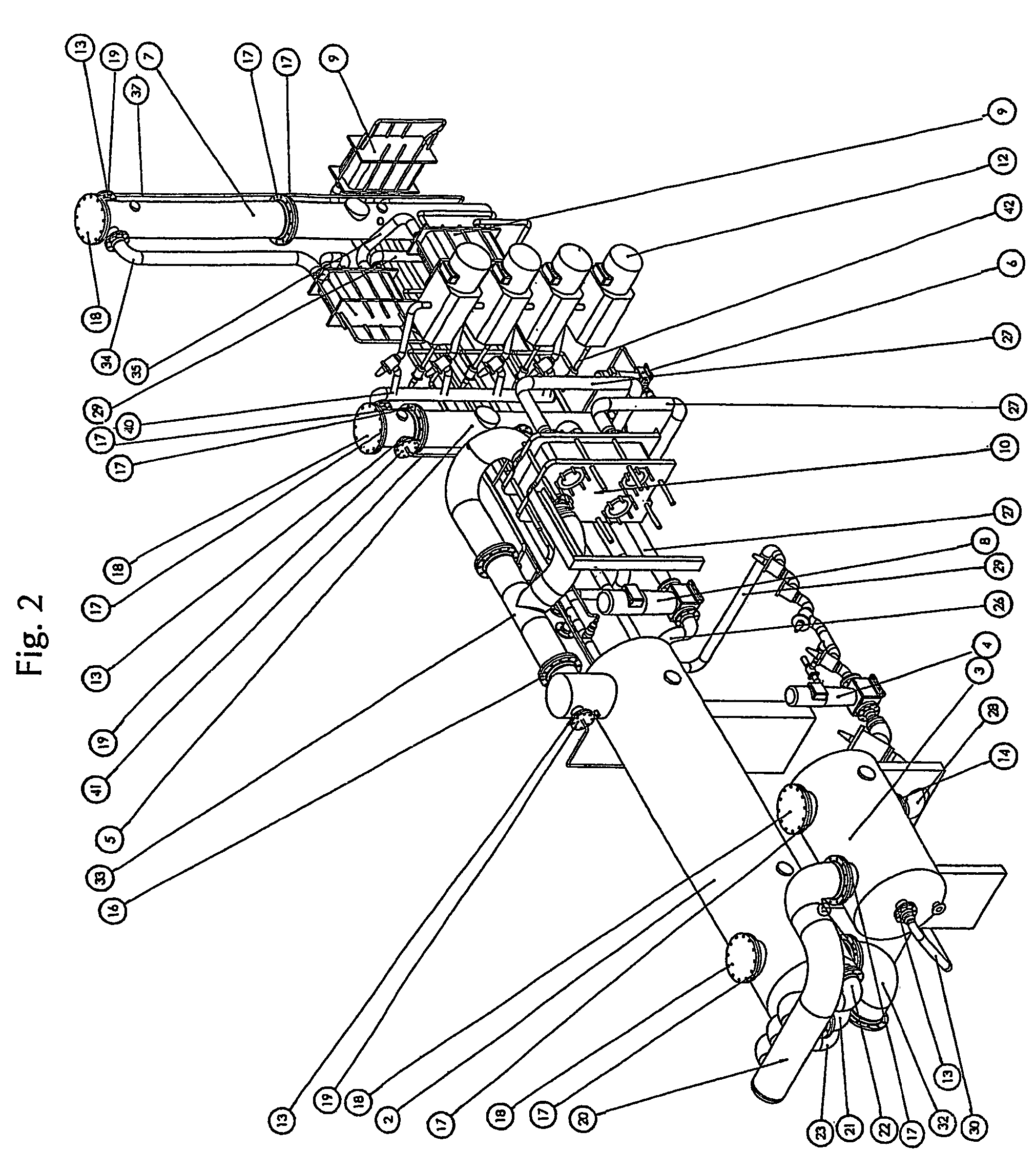

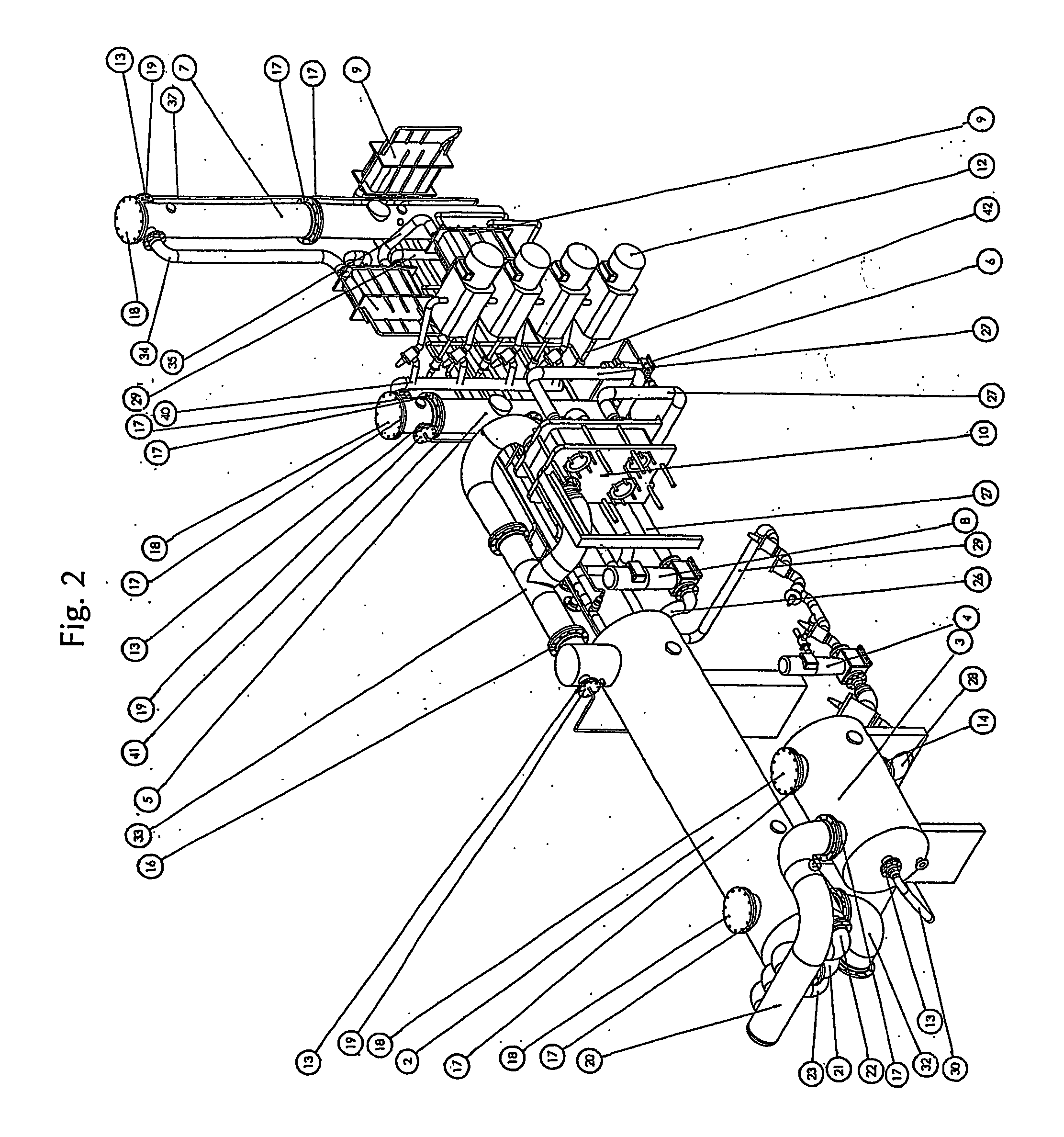

Apparatus, system, and method for generating a gas from solid reactant pouches

An apparatus, system, and method are disclosed for generating a gas. One or more liquid permeable pouches each define a cavity that contains a solid anhydrous reactant, such as a chemical hydride. A reaction chamber made of a heat, chemical and / or pressure resistant material receives the one or more pouches from a pouch feeder that transfers the one or more pouches into the reaction chamber successively at a feed rate. One or more liquid sources inject a liquid reactant into the reaction chamber so that the liquid reactant contacts a portion of the one or more pouches. The one or more liquid sources inject the liquid reactant at an injection rate that corresponds to the feed rate. A gas outlet releases a gas, such as hydrogen, oxygen, ammonia, borazine, nitrogen, or a hydrocarbon, that is produced by a reaction between the solid reactant and the liquid reactant.

Owner:TRULITE INC

Catalytic Gasification Particulate Compositions

ActiveUS20090229182A1Efficient use ofBiofuelsGas modification by gas mixingPtru catalystPetroleum coke

Particulate compositions are described comprising a carbonaceous material, such as petroleum coke and / or coal, treated or otherwise associated with a gasification catalyst, where the catalyst is at least in part derived from a leachate from a biomass char, for gasification in the presence of steam to yield a plurality of gases including methane and at least one or more of hydrogen, carbon monoxide, and other higher hydrocarbons are formed. Processes are also provided for the preparation of the particulate compositions and converting the particulate composition into a plurality of gaseous products.

Owner:SURE CHAMPION INVESTMENT LTD

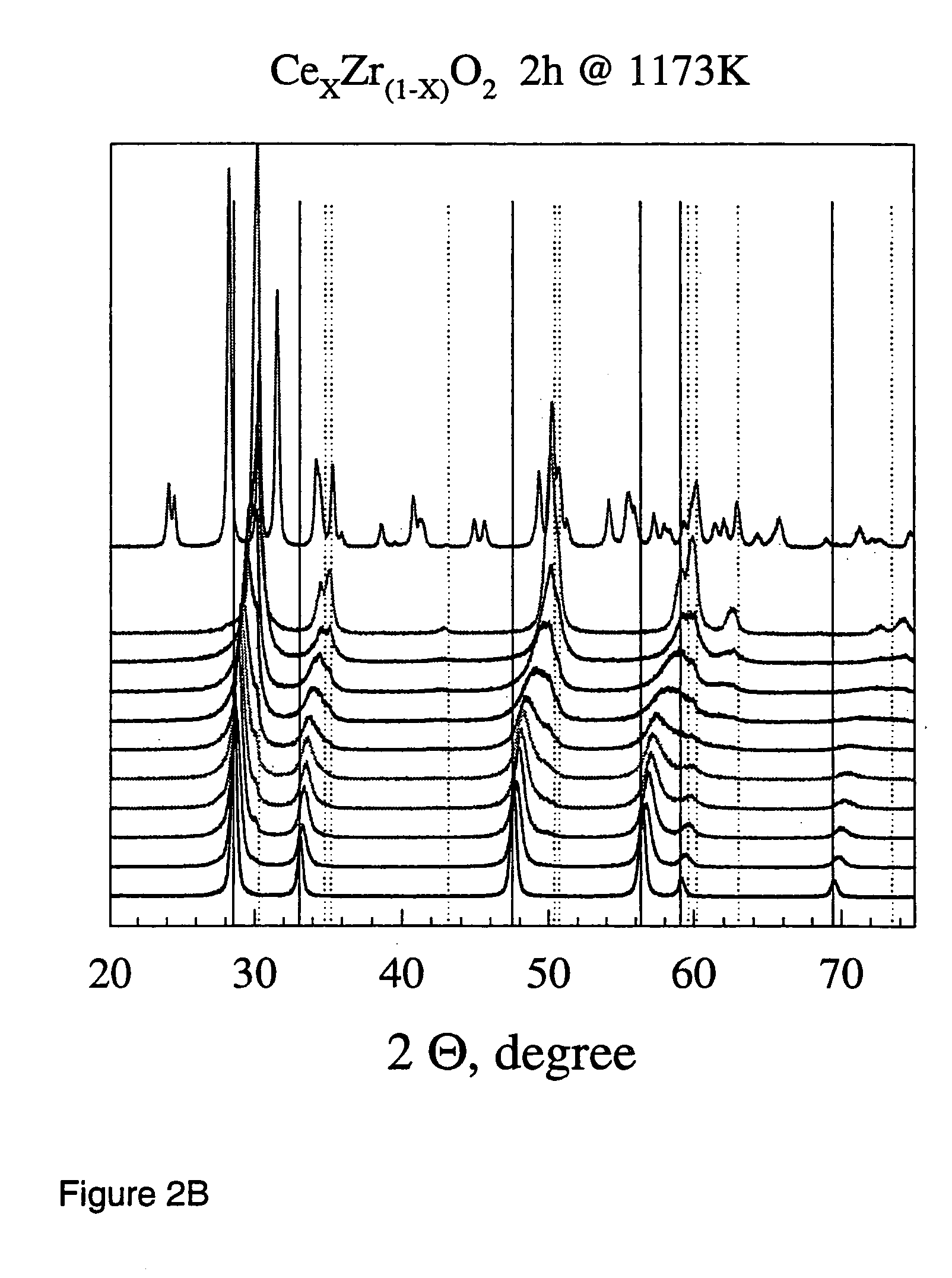

Ternary oxide nanostructures and methods of making same

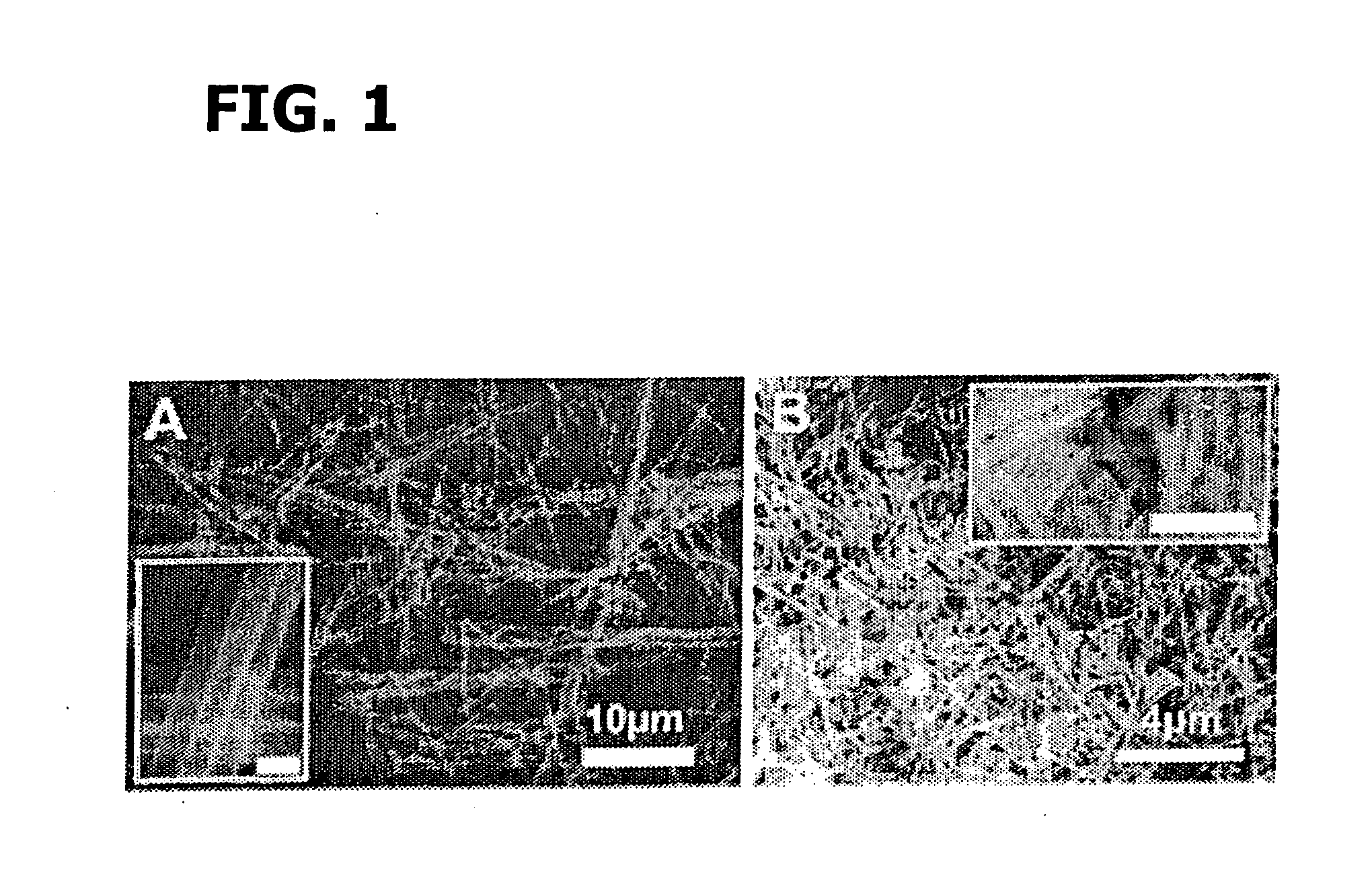

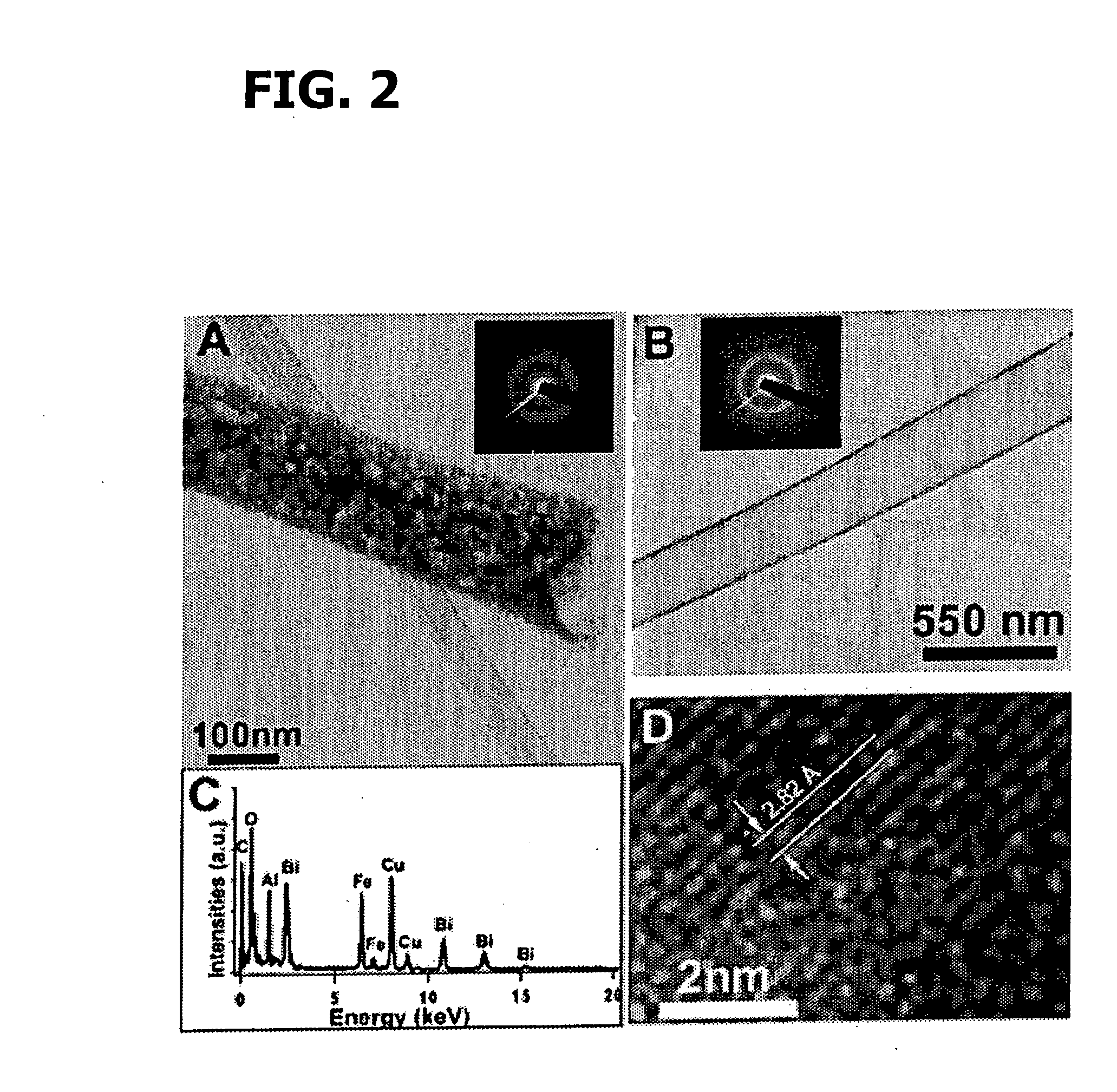

InactiveUS20070138459A1Suitable for preparationFrom gel stateAlkaline earth titanatesNanostructureDislocation

A single crystalline ternary nanostructure having the formula AxByOz, wherein x ranges from 0.25 to 24, and y ranges from 1.5 to 40, and wherein A and B are independently selected from the group consisting of Ag, Al, As, Au, B, Ba, Br, Ca, Cd, Ce, Cl, Cm, Co, Cr, Cs, Cu, Dy, Er, Eu, F, Fe, Ga, Gd, Ge, Hf, Ho, I, In, Ir, K, La, Li, Lu, Mg, Mn, Mo, Na, Nb, Nd, Ni, Os, P, Pb, Pd, Pr, Pt, Rb, Re, Rh, Ru, S, Sb, Sc, Se, Si, Sm, Sn, Sr, Ta, Tb, Tc, Te, Ti, Ti, Tm, U, V, W, Y, Yb, and Zn, wherein the nanostructure is at least 95% free of defects and / or dislocations.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

Flame made metal oxides

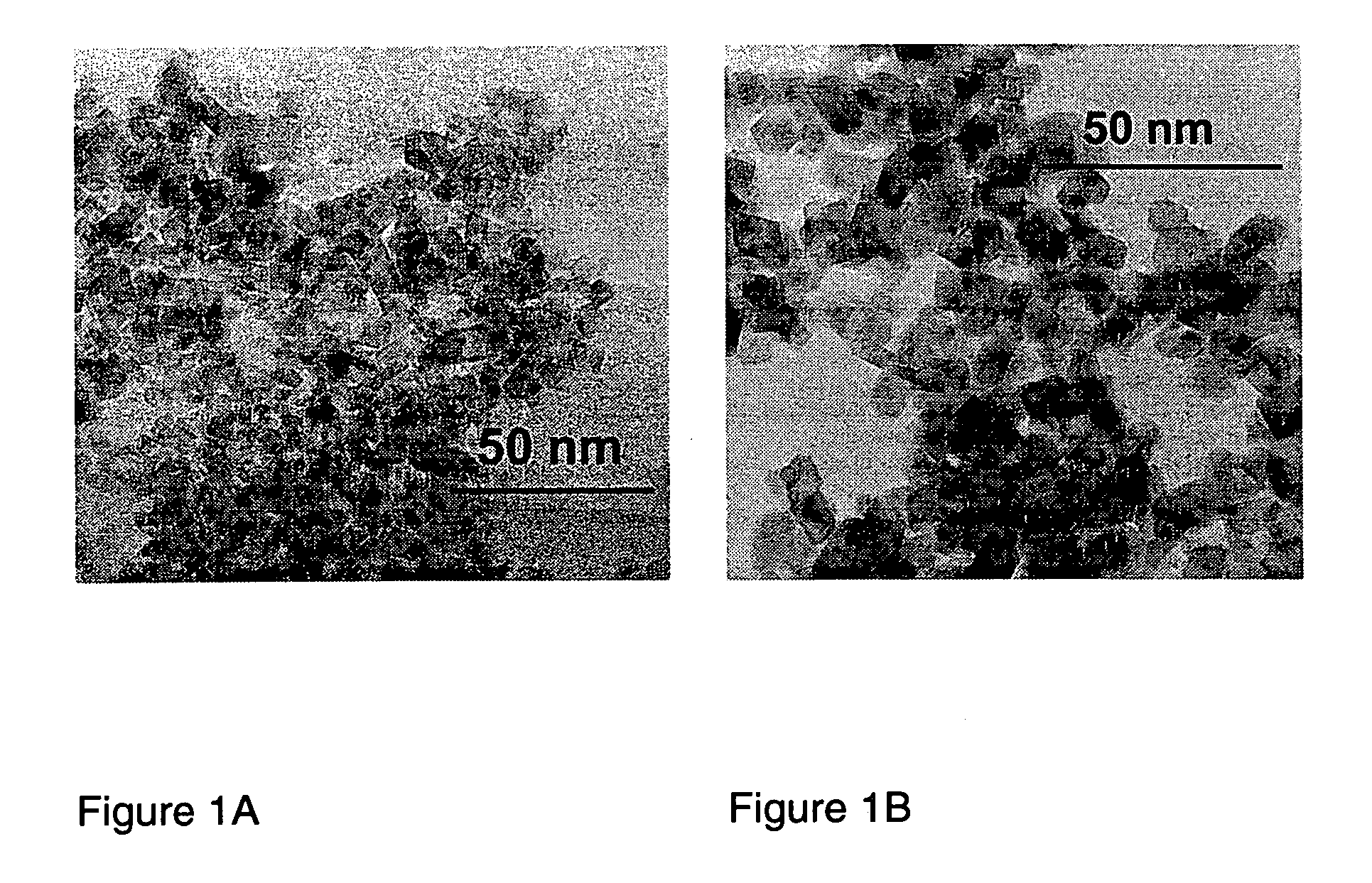

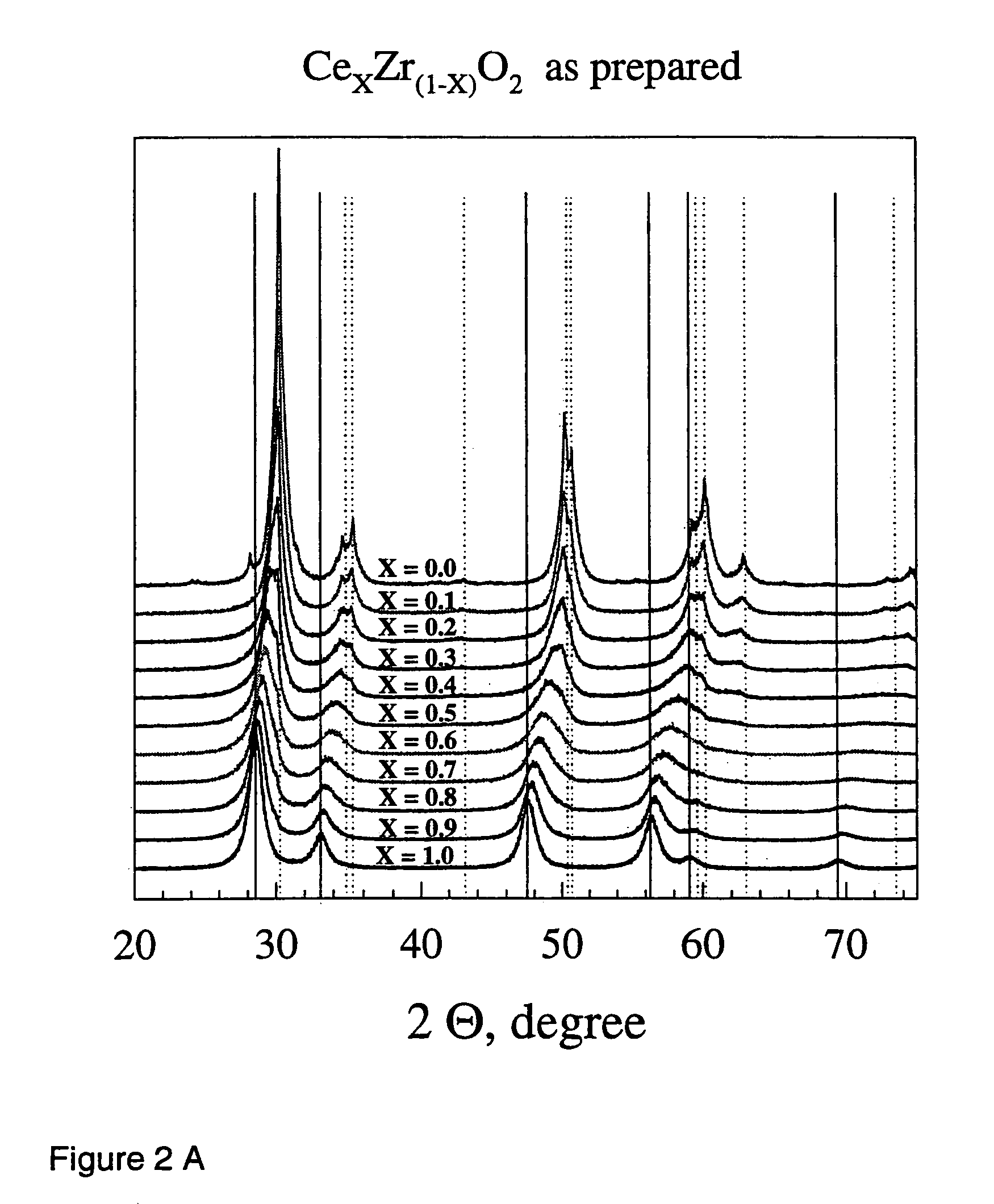

ActiveUS7211236B2Add featureWell mixedMaterial nanotechnologyZirconium oxidesSpray pyrolysisCarboxylic acid

Described is a method for the production of metal oxides by flame spray pyrolysis, in particular mixed metal oxides such as ceria / zirconia, and metal oxides obtainable by said method. Due to high enthalpy solvents with a high carboxylic acid content said metal oxides have improved properties. For example ceria / zirconia has excellent oxygen storage capacity at high zirconium levels up to more than 80% of whole metal content.

Owner:EIDGENOSSISCHE TECHN HOCHSCULE ZURICH

Carbonaceous Fines Recycle

ActiveUS20090217589A1Sufficient amountHydrogen productionCarbon monoxideParticulatesParticle composition

Owner:SURE CHAMPION INVESTMENT LTD

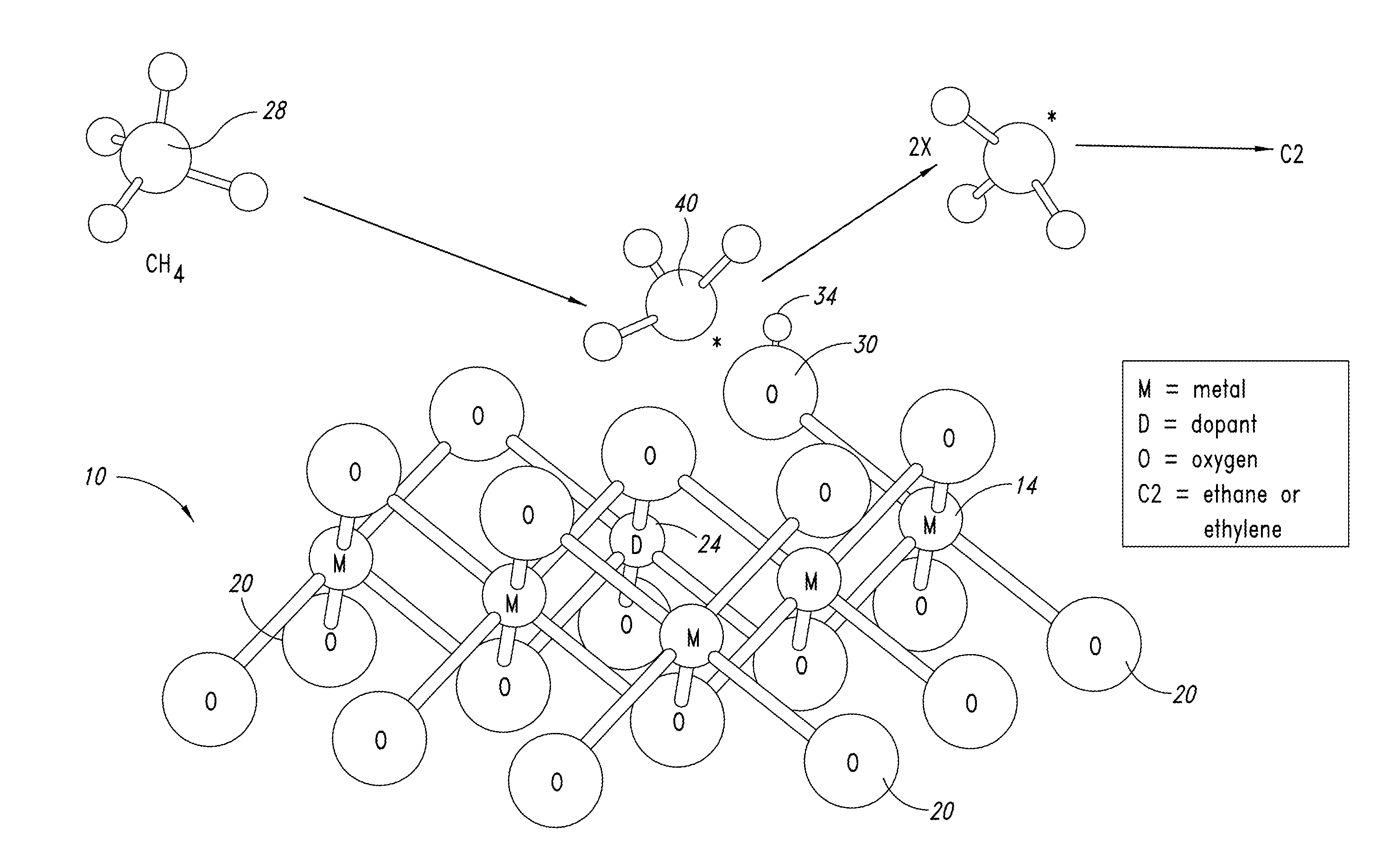

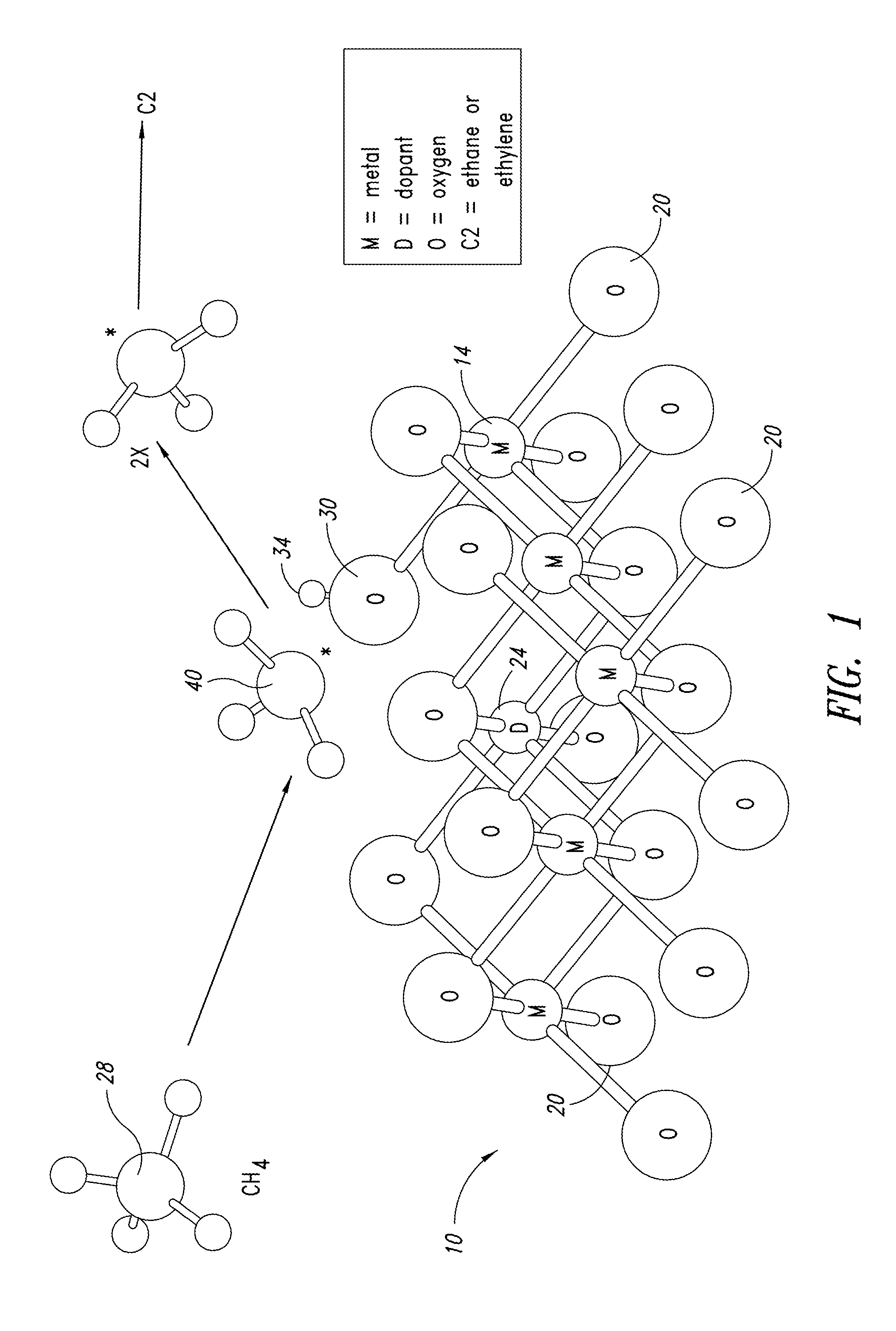

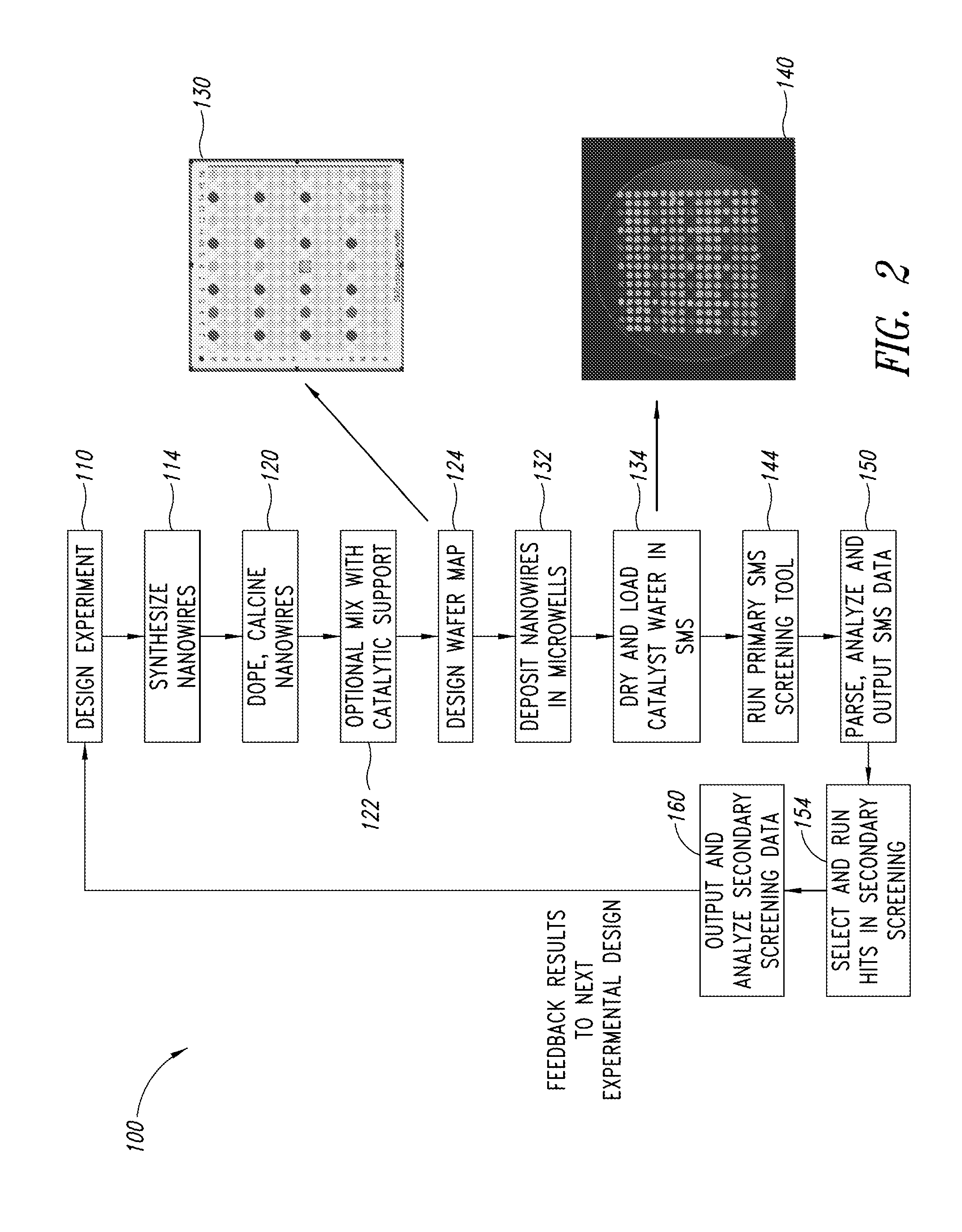

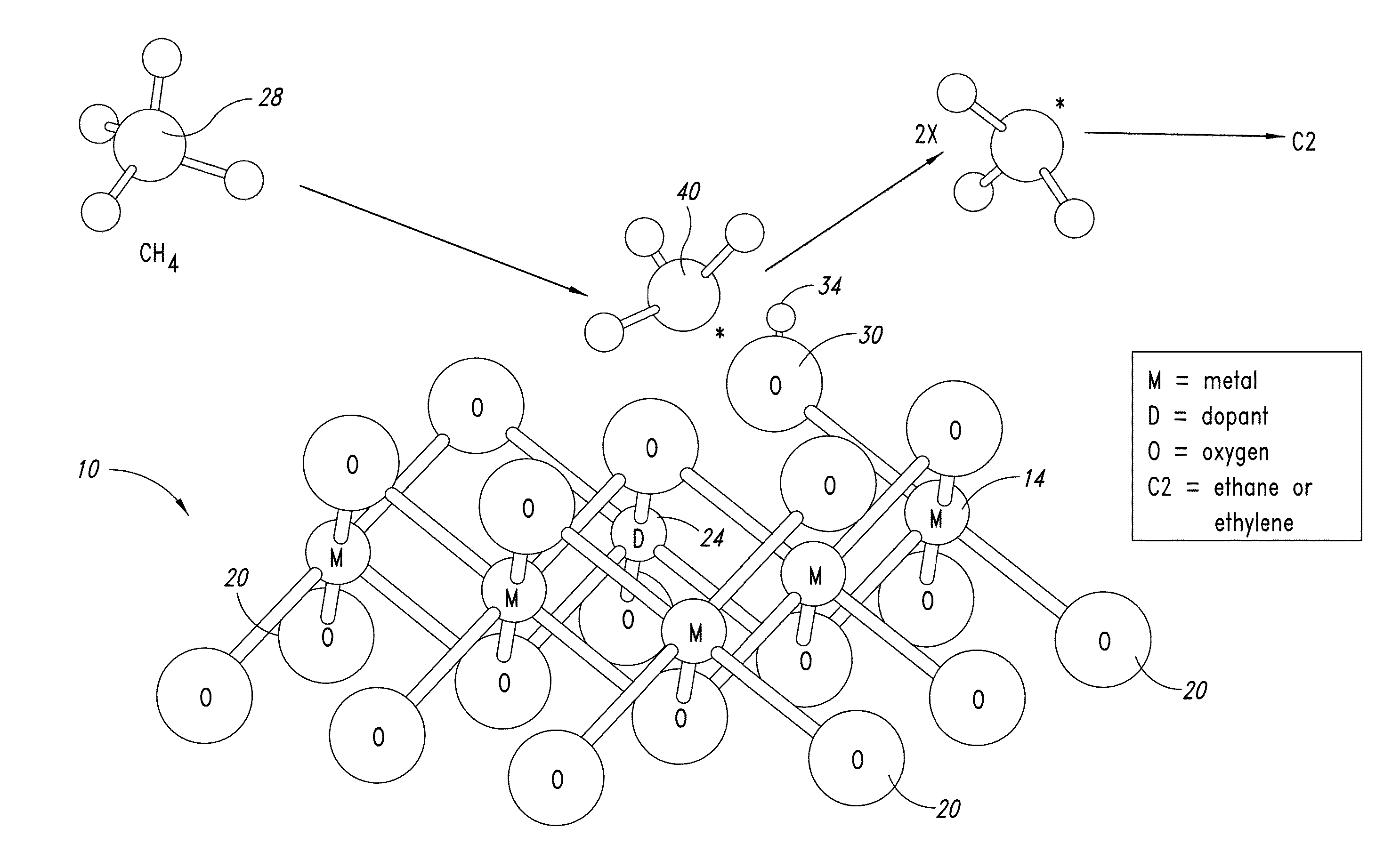

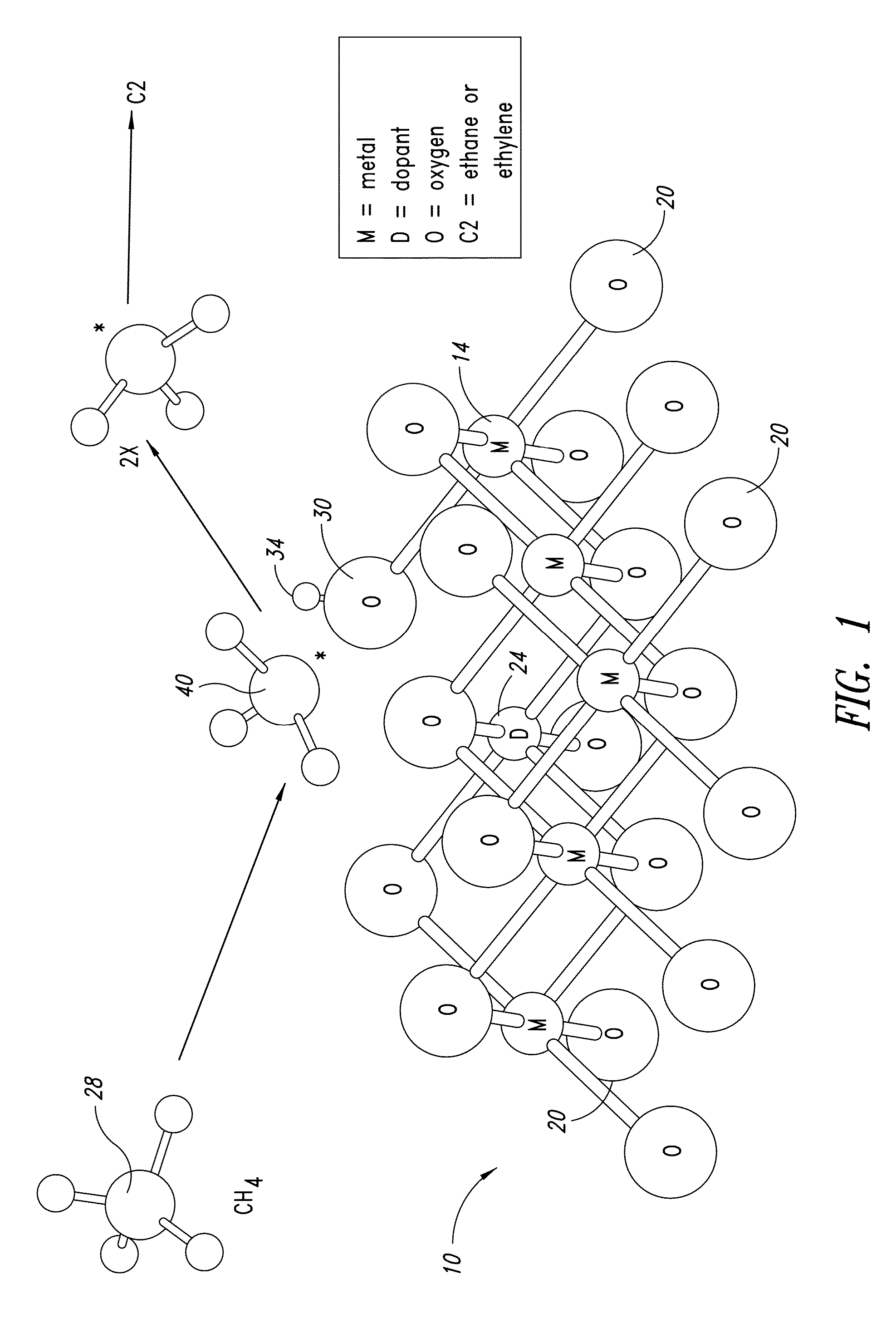

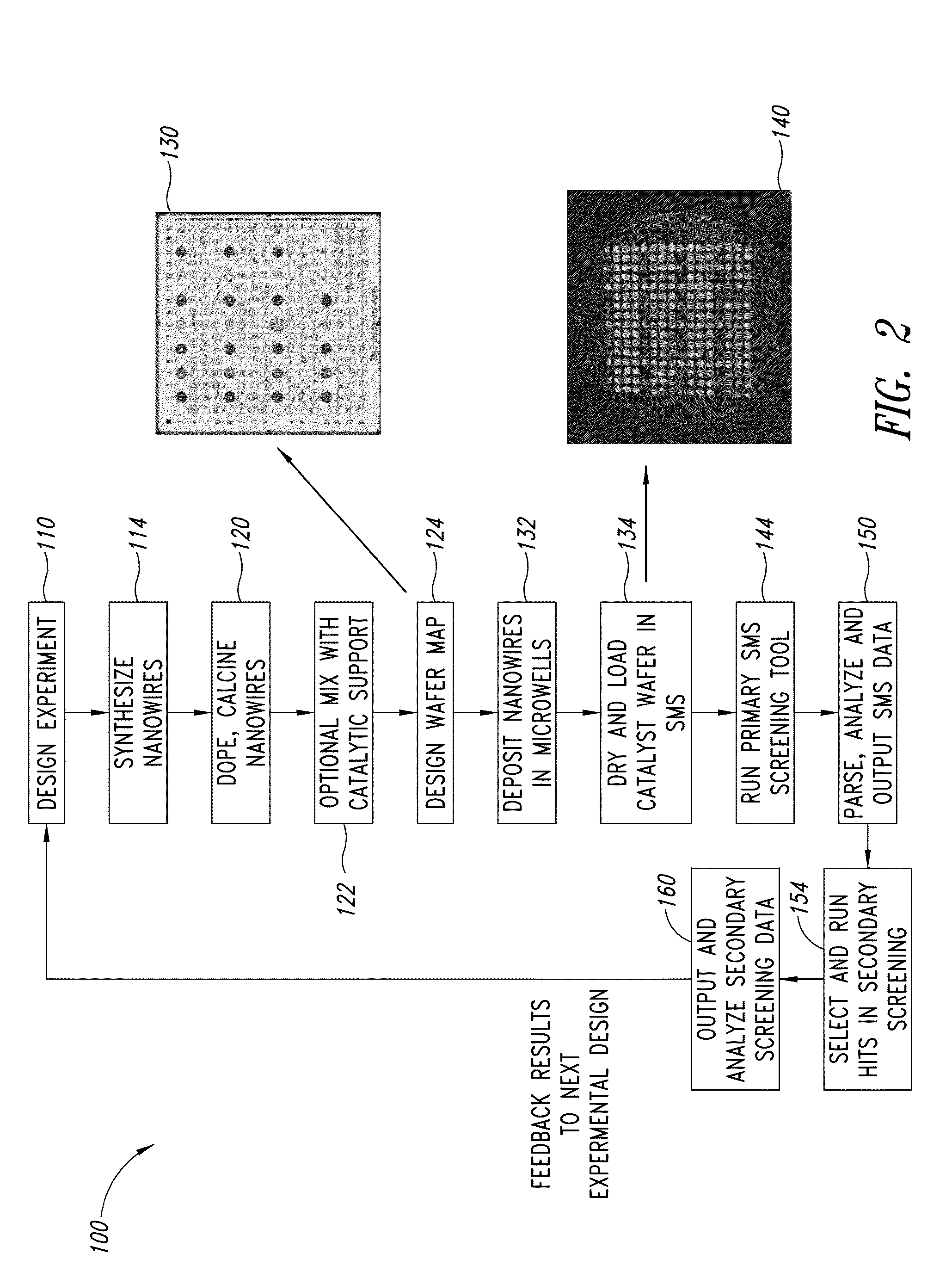

Nanowire catalysts and methods for their use and preparation

ActiveUS20130165728A1Material nanotechnologyManganese oxides/hydroxidesNanowireOxidative coupling of methane

Nanowires useful as heterogeneous catalysts are provided. The nanowire catalysts are useful in a variety of catalytic reactions, for example, the oxidative coupling of methane to C2 hydrocarbons. Related methods for use and manufacture of the same are also disclosed.

Owner:LUMMUS TECH LLC

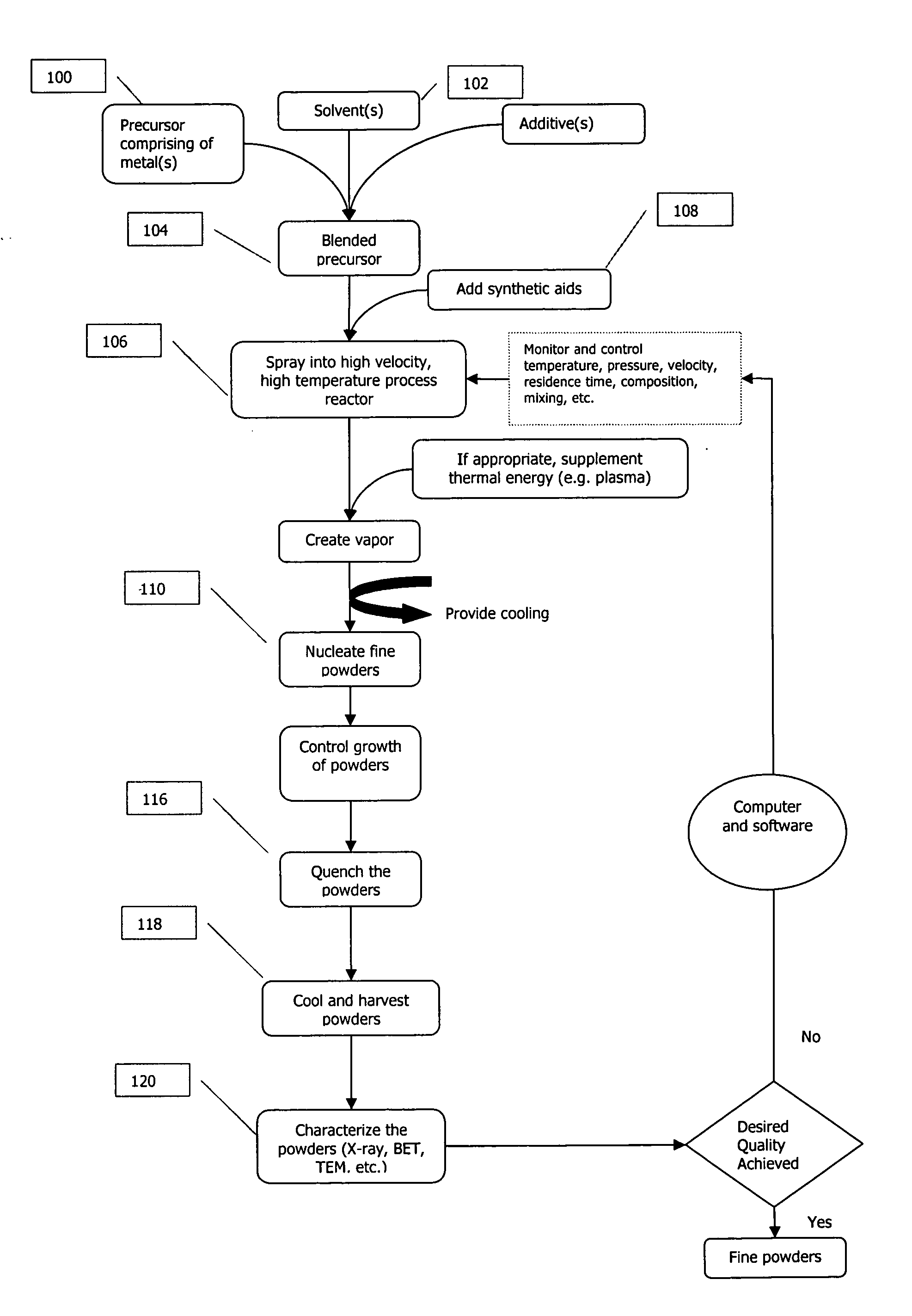

Mixed-metal oxide particles by liquid feed flame spray pyrolysis of oxide precursors in oxygenated solvents

Liquid feed flame spray pyrolysis of solutions of a metal oxide precursor which is an alkoxide or C1-6 carboxylate and at least one second metal oxide precursor and / or second metal compound dissolved in oxygenated solvent by combustion with oxygen lead to the formation of sub-micron mixed-metal oxide powders not accessible by other processes or by the pyrolysis of metal chlorides or nitrates. The powders have numerous uses in advanced materials applications including particulate solid state lasers, advanced ceramic materials, and as catalysts in organic synthesis and automobile exhaust systems.

Owner:TAL MATERIALS +1

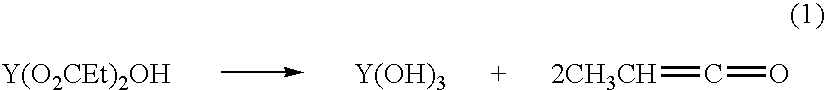

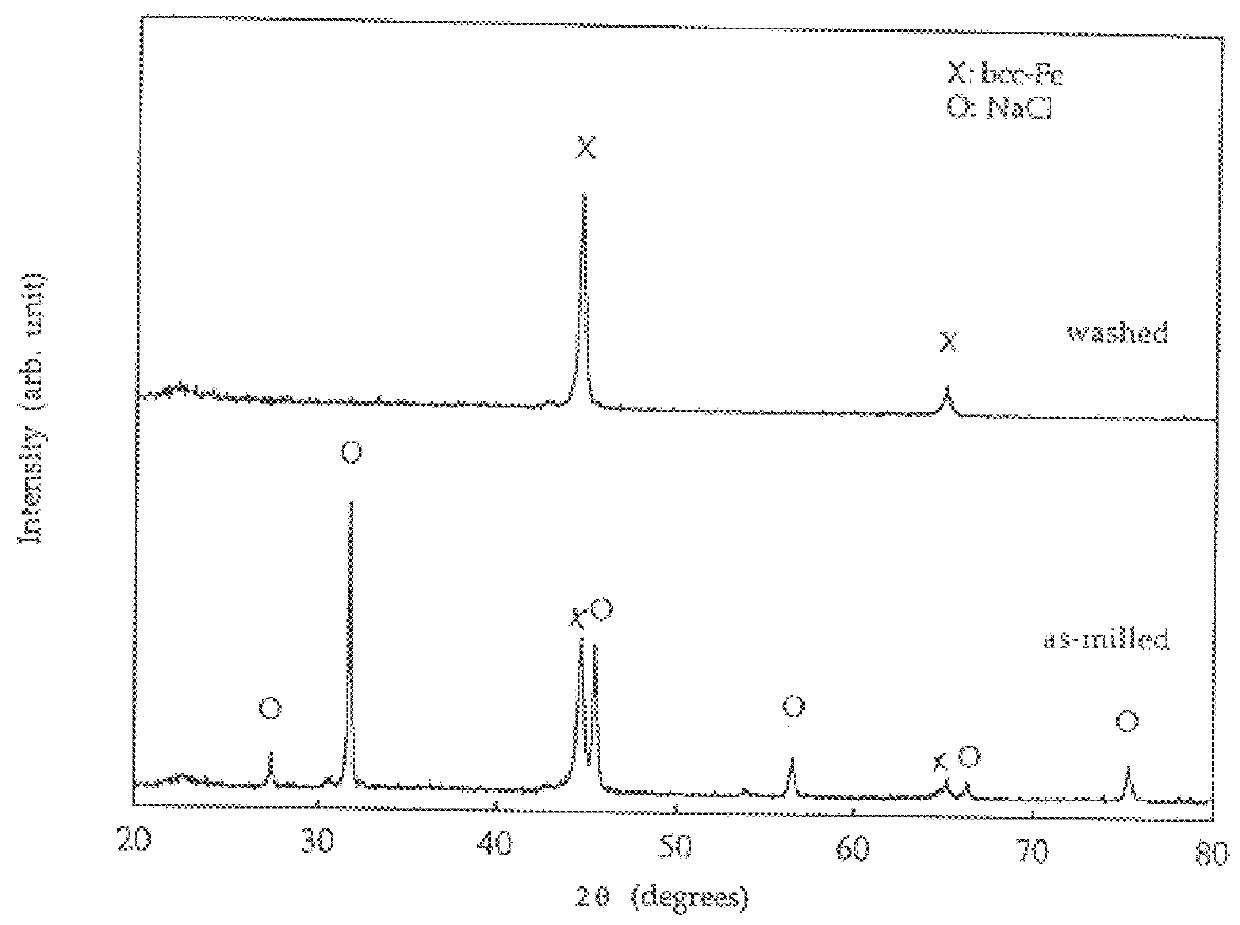

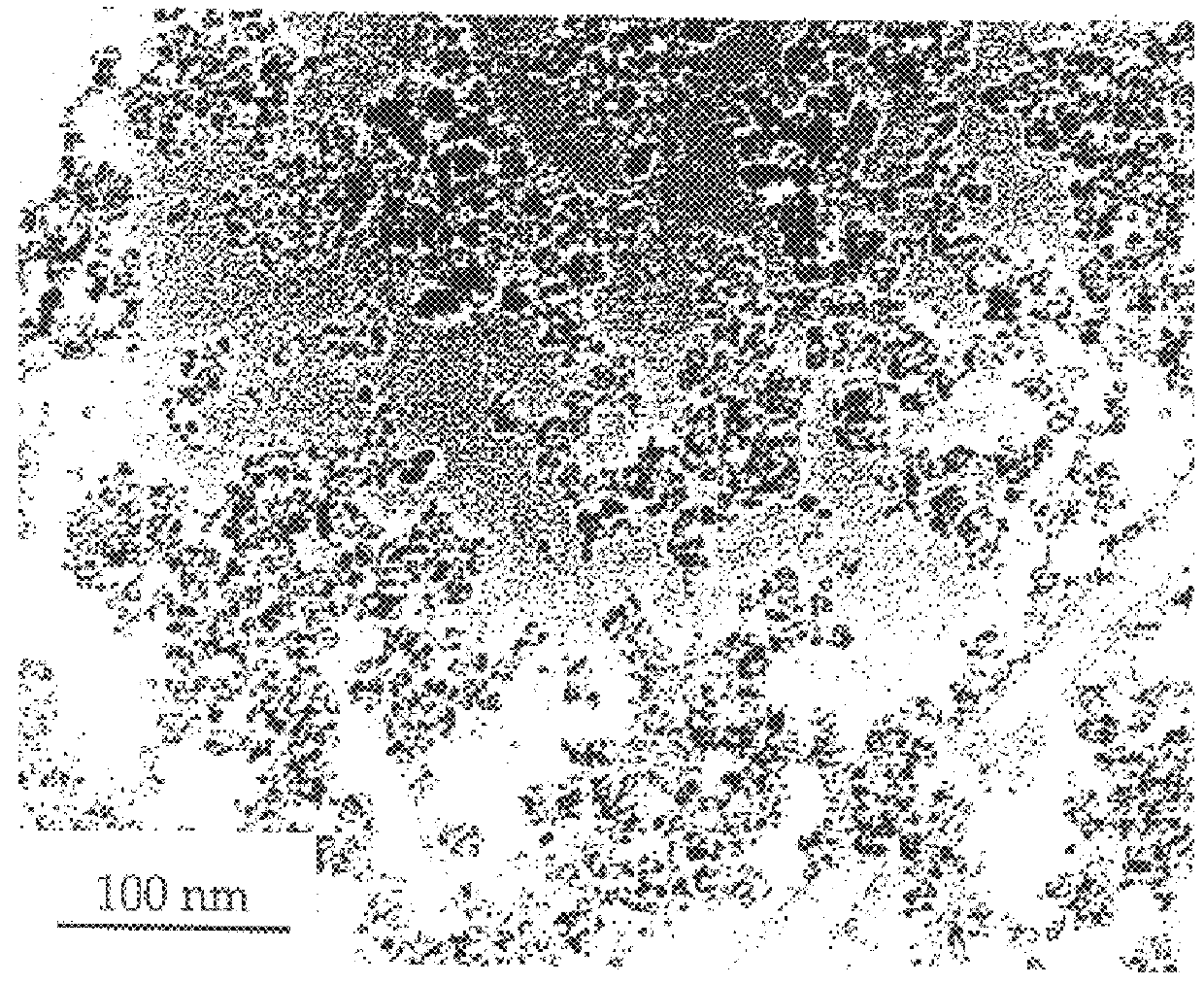

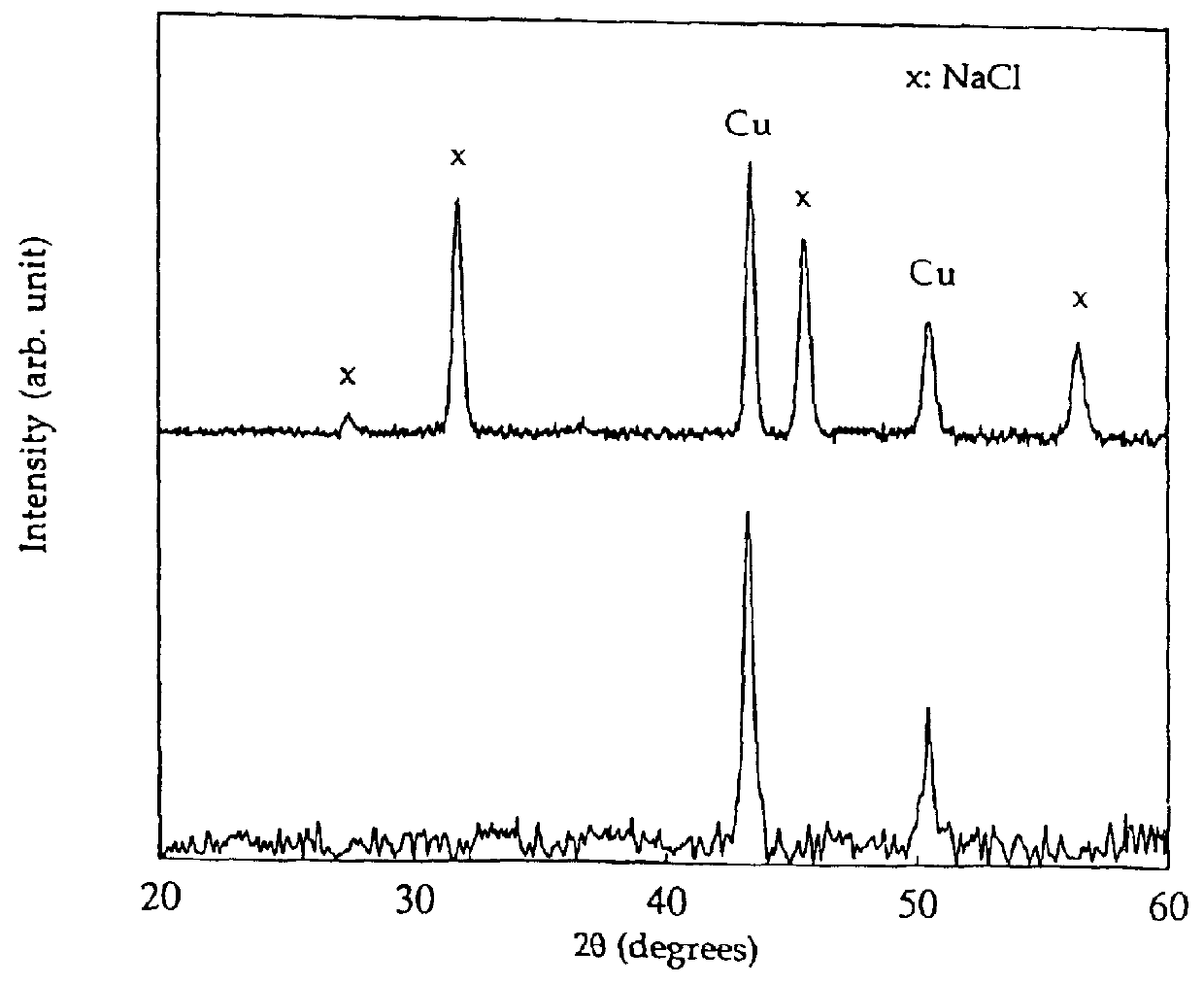

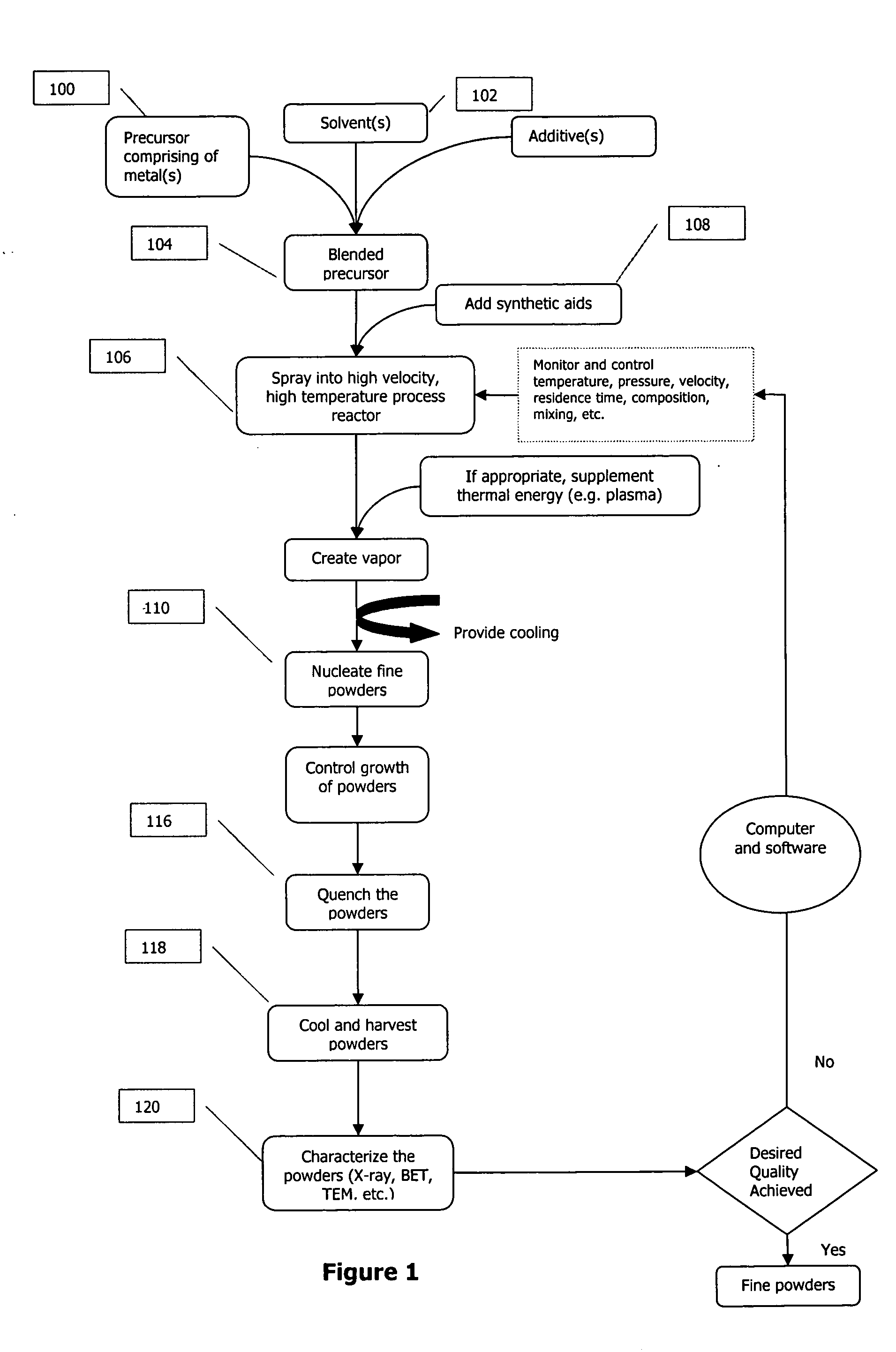

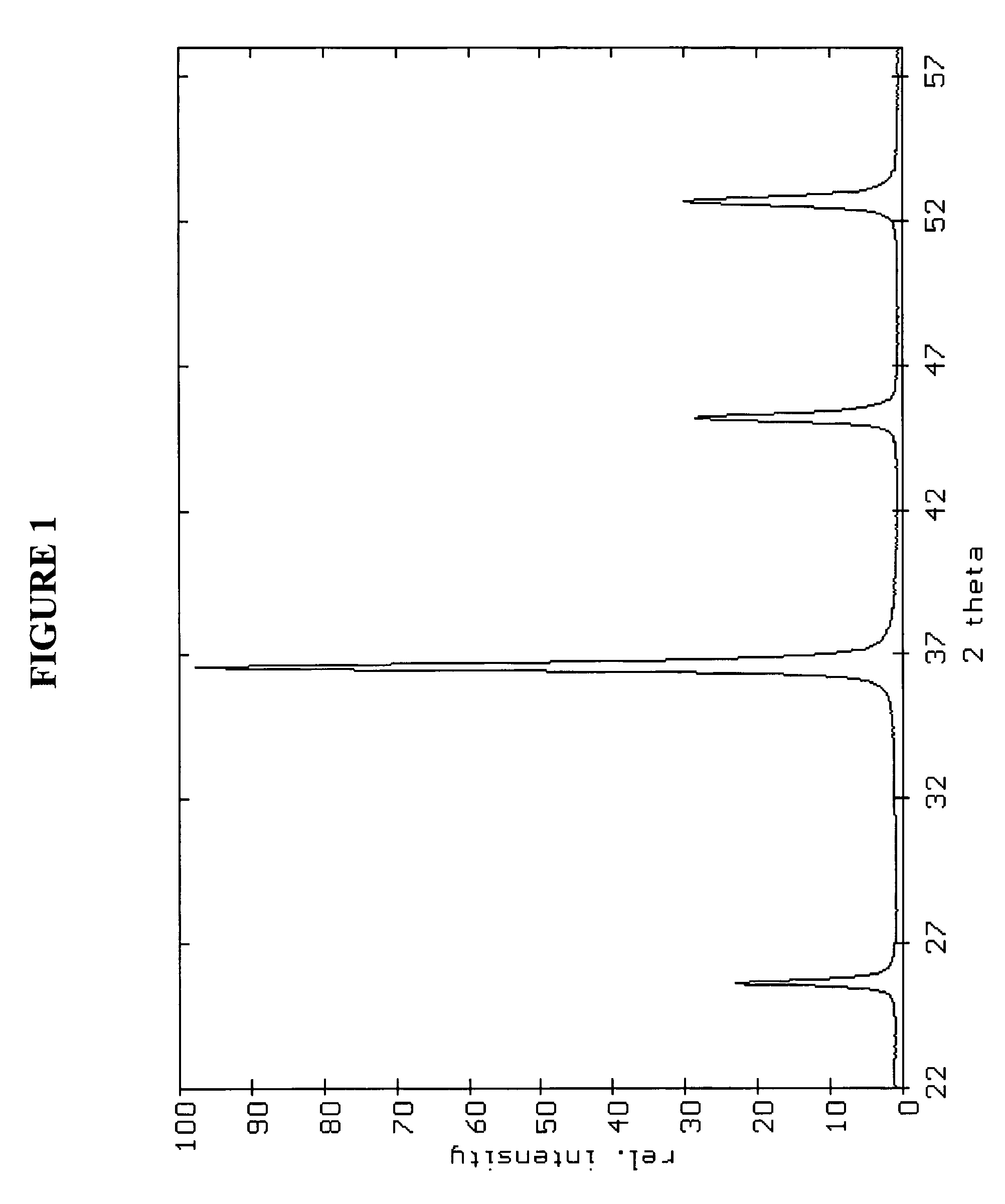

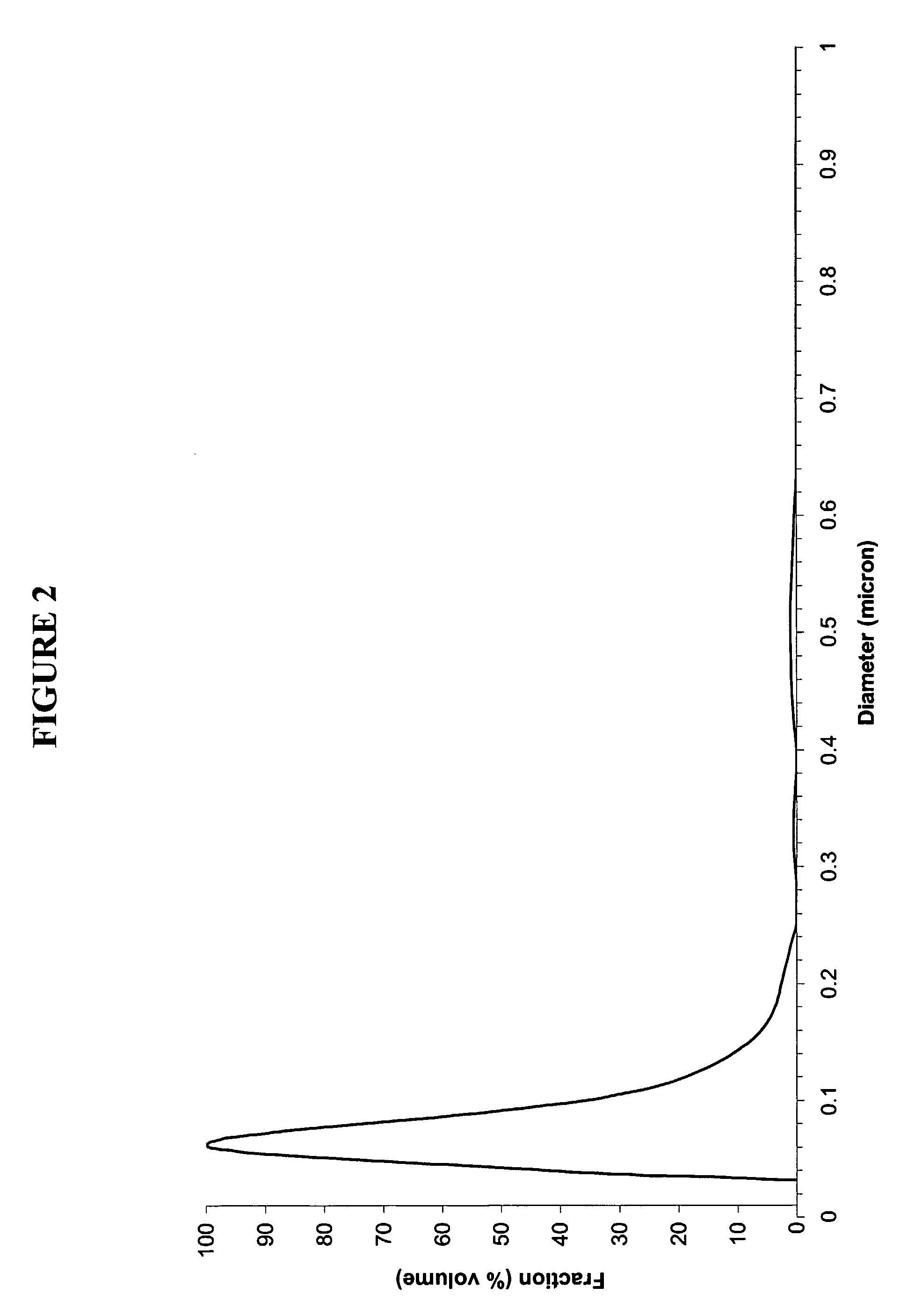

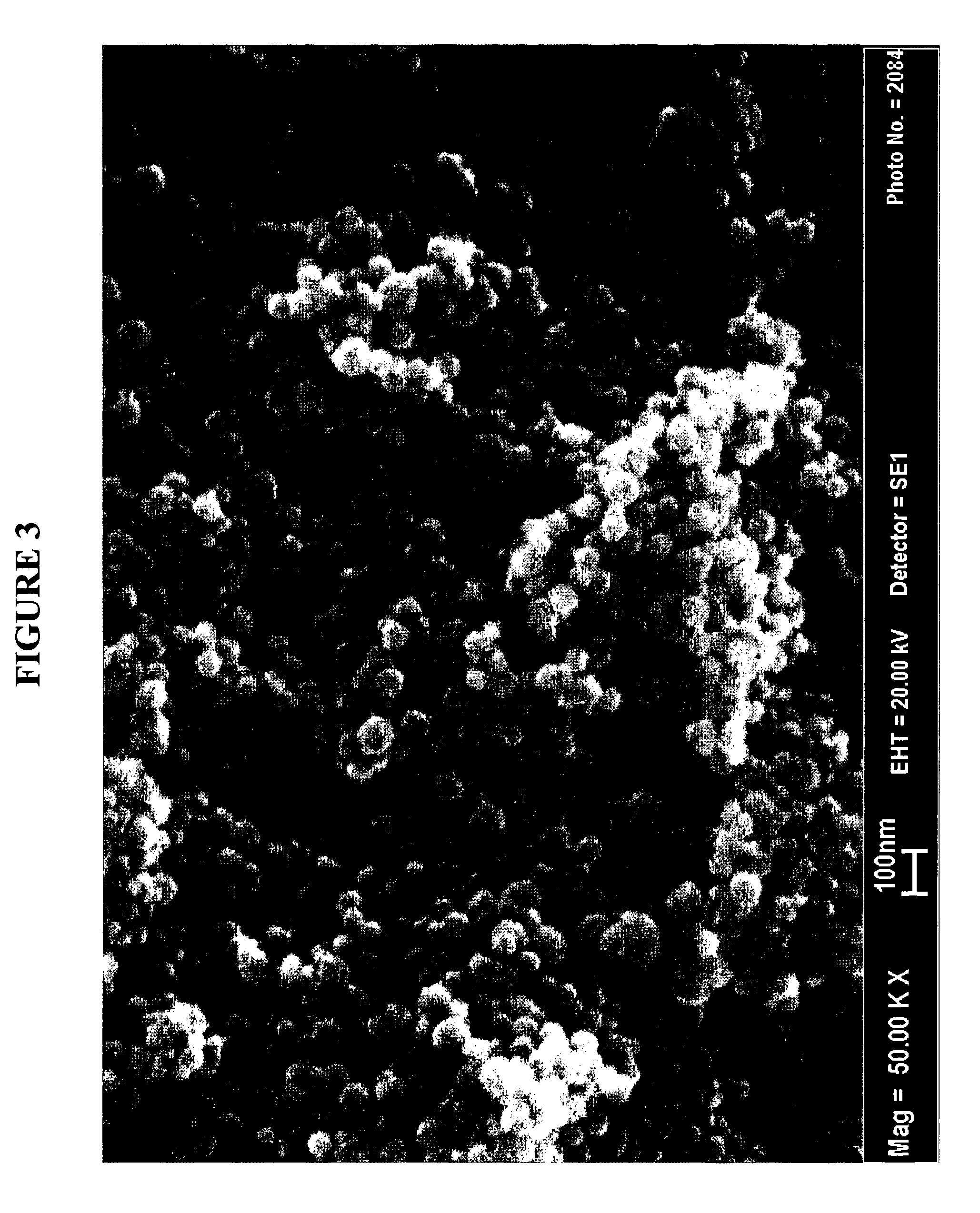

Process for the production of ultrafine particles

A new, cost effective process for the production of ultrafine particles which is based on mechanically activated chemical reaction of a metal compound with a suitable reagent. The process involves subjecting a mixture of a metal compound and a suitable reagent to mechanical activation to increase the chemical reactivity of the reactants and / or reaction kinetics such that a chemical reaction can occur which produces a solid nano-phase substance. Concomitantly, a by-product phase is also formed. This by-product phase is removed so that the solid nano-phase substance is left behind in the form of ultrafine particles. During mechanical activation a composite structure is formed which consists of an intimate mixture of nano-sized grains of the nano-phase substance and the reaction by-product phase. The step of removing the by-product phase, following mechanical activation, may involve subjecting the composite structure to a suitable solvent which dissolves the by-product phase, while not reacting with the solid nano-phase substance. The process according to the invention may be used to form ultrafine metal powders as well as ultrafine ceramic powders. Advantages of the process include a significant degree of control over the size and size distribution of the ultrafine particles, and over the nature of interfaces created between the solid nano-phase substance and the reaction by-product phase.

Owner:WESTERN AUSTRALIA UNIV OF THE

Reduced Carbon Footprint Steam Generation Processes

Processes for the generation of steam are provided for use in an integrated catalytic gasification process for converting carbonaceous materials to combustible gases, such as methane. Generally, the exhaust gas from a steam generating reactor is provided along with steam, a carbonaceous feedstock, and a gasification catalyst, to a catalytic gasifier, wherein under appropriate temperature and pressure conditions, the carbonaceous feedstock is converted into a plurality of product gases, including, but not limited to, methane, carbon monoxide, hydrogen, and carbon dioxide. As substantially all the carbon dioxide produced from the steam generation process and the gasification process are subsequently directed though gas purification and separation processes, substantially all the carbon dioxide may be recovered, yielding a process having a near zero carbon footprint.

Owner:SURE CHAMPION INVESTMENT LTD

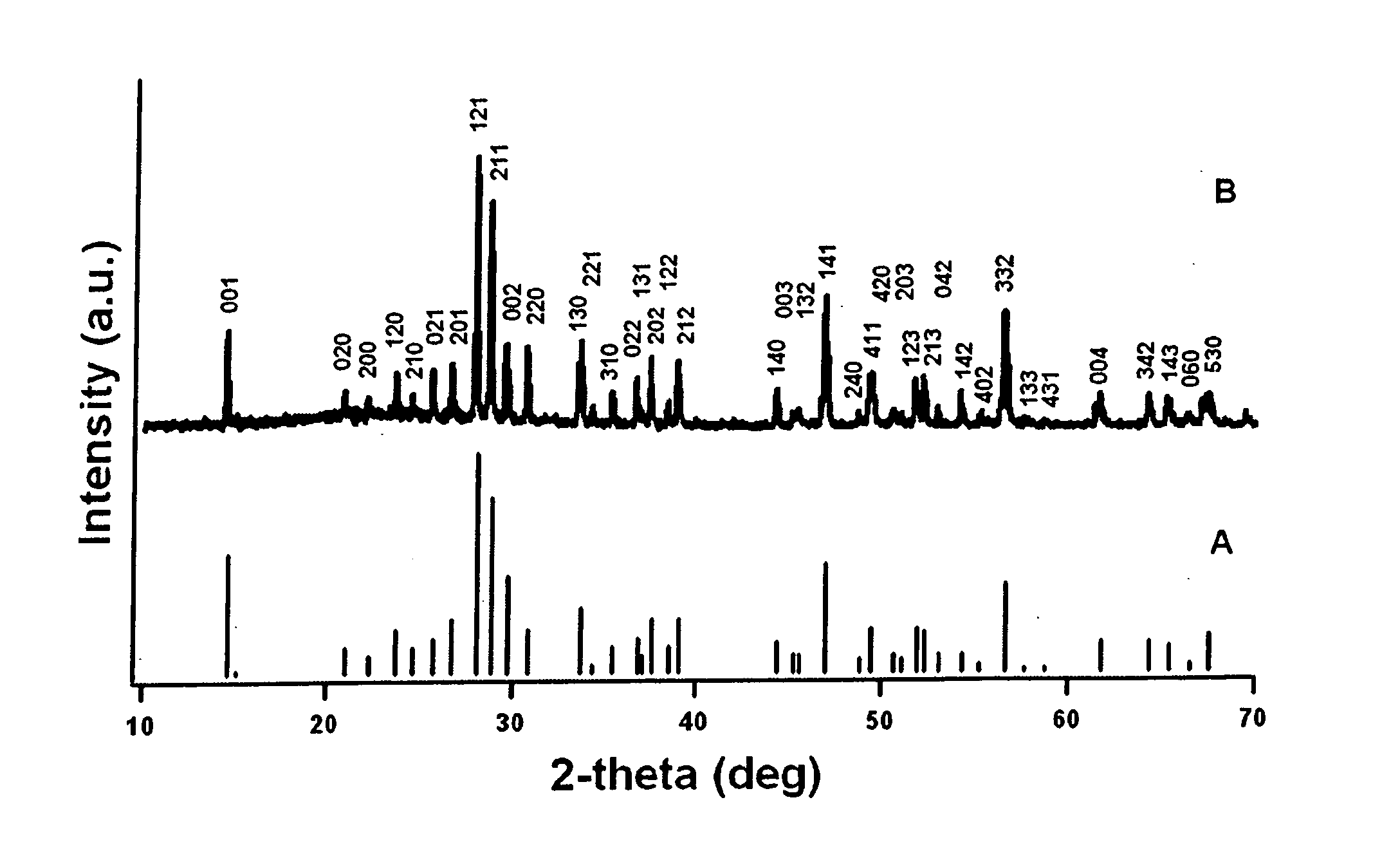

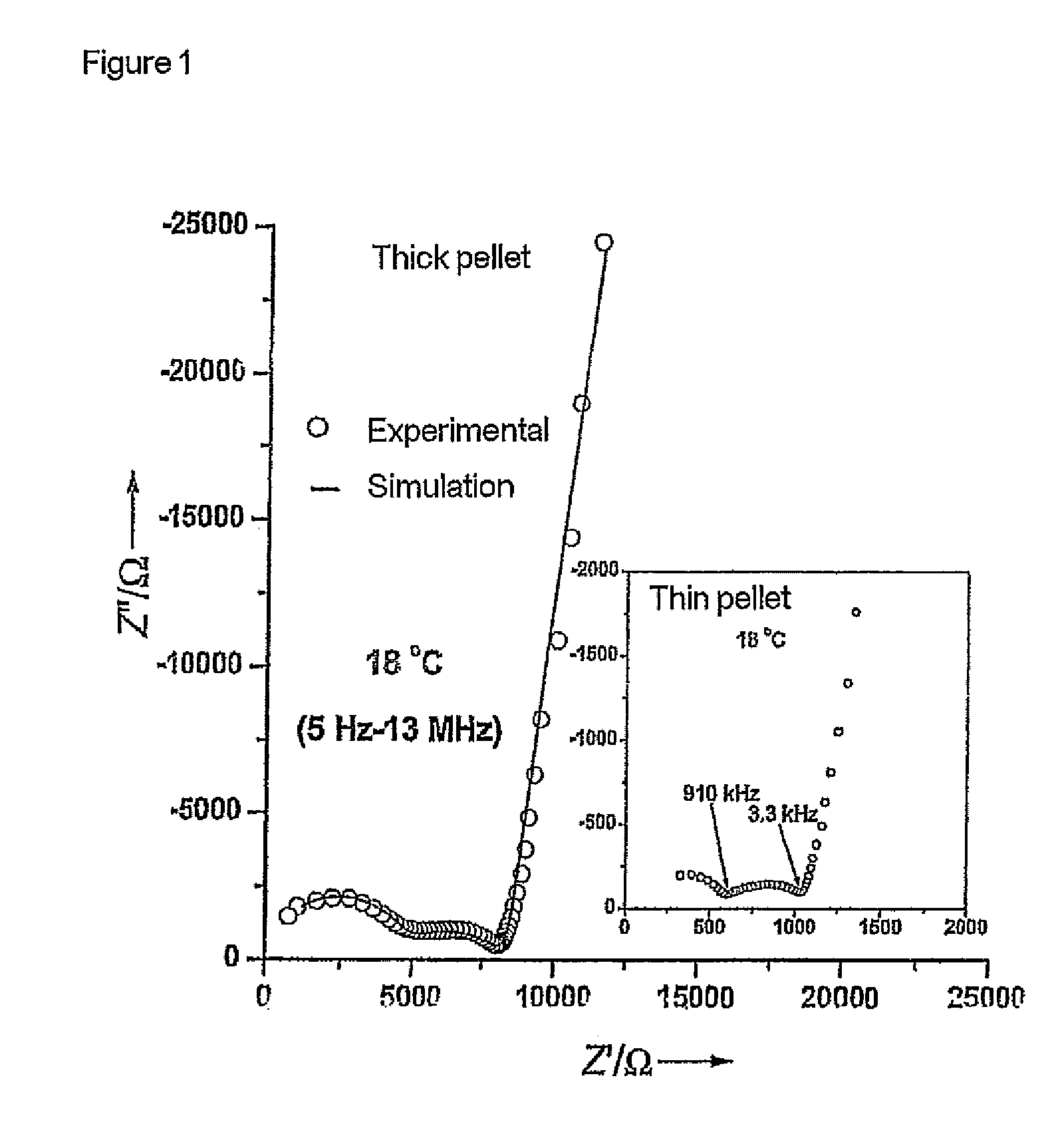

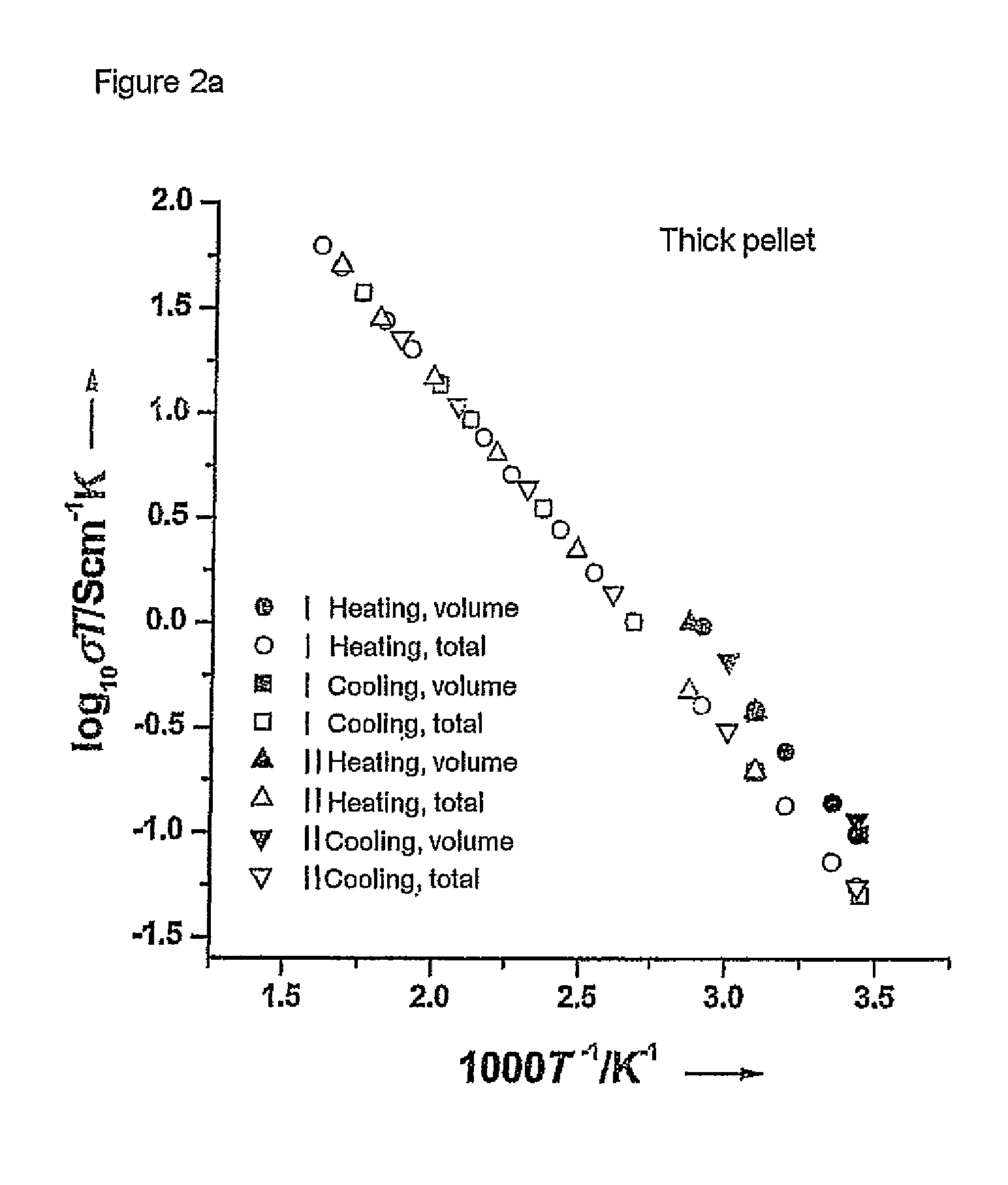

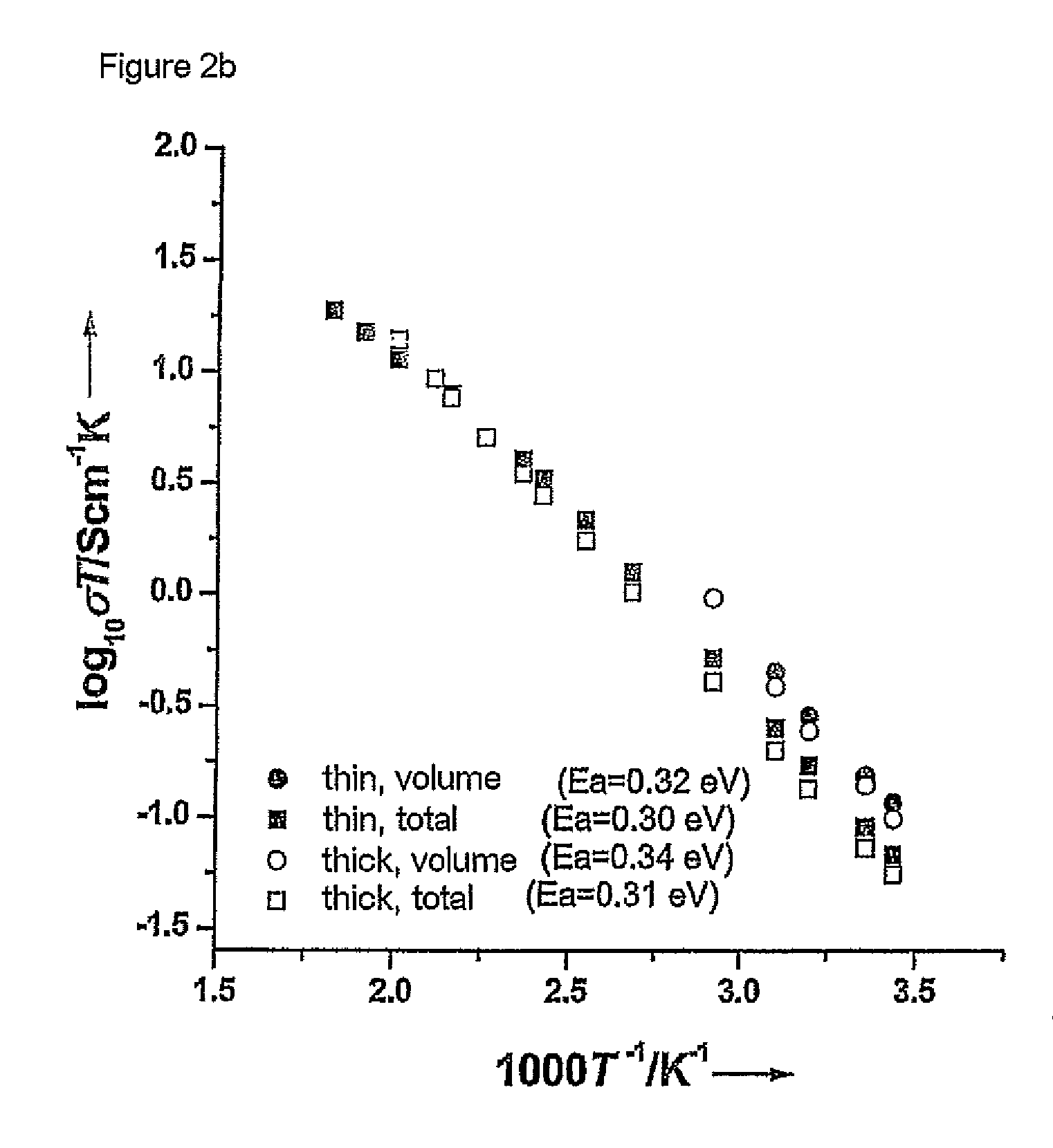

Solid ion conductor which has a garnet-like crystal structure and has the stoichiometric composition L7+XAXG3-XZr2O12

ActiveUS8658317B2Easily employedImprove ionic conductivityFinal product manufactureCell electrodesElectrical conductorCrystal structure

The invention is directed to a solid ion conductor which has a garnet-like crystal structure and has the stoichiometric composition L7+xAxG3−xZr2O12, whereinL is in each case independently a monovalent cation,A is in each case independently a divalent cation,G is in each case independently a trivalent cation,0≦x≦3 andO can be partly or completely replaced by divalent or trivalent anion.

Owner:BASF AG

Polymer templated nanowire catalysts

InactiveUS20130158322A1Improve drawing legibilityMaterial nanotechnologyManganese oxides/hydroxidesNanowirePolymer science

Nanowires useful as heterogeneous catalysts are provided. The nanowire catalysts are prepared by polymer templated methods and are useful in a variety of catalytic reactions, for example, the oxidative coupling of methane to ethane and / or ethylene. Related methods for use and manufacture of the same are also disclosed.

Owner:SILURIA TECH INC

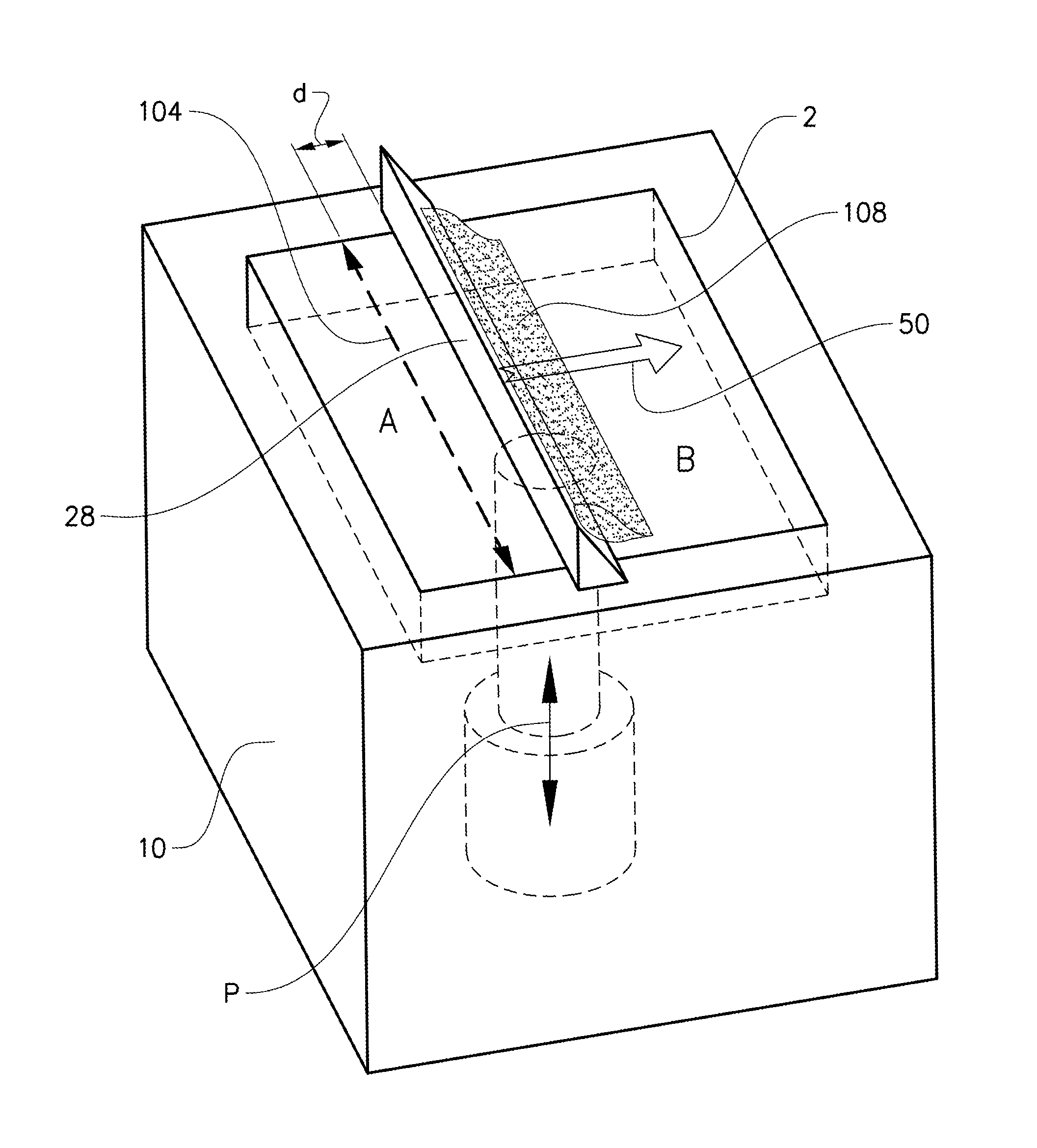

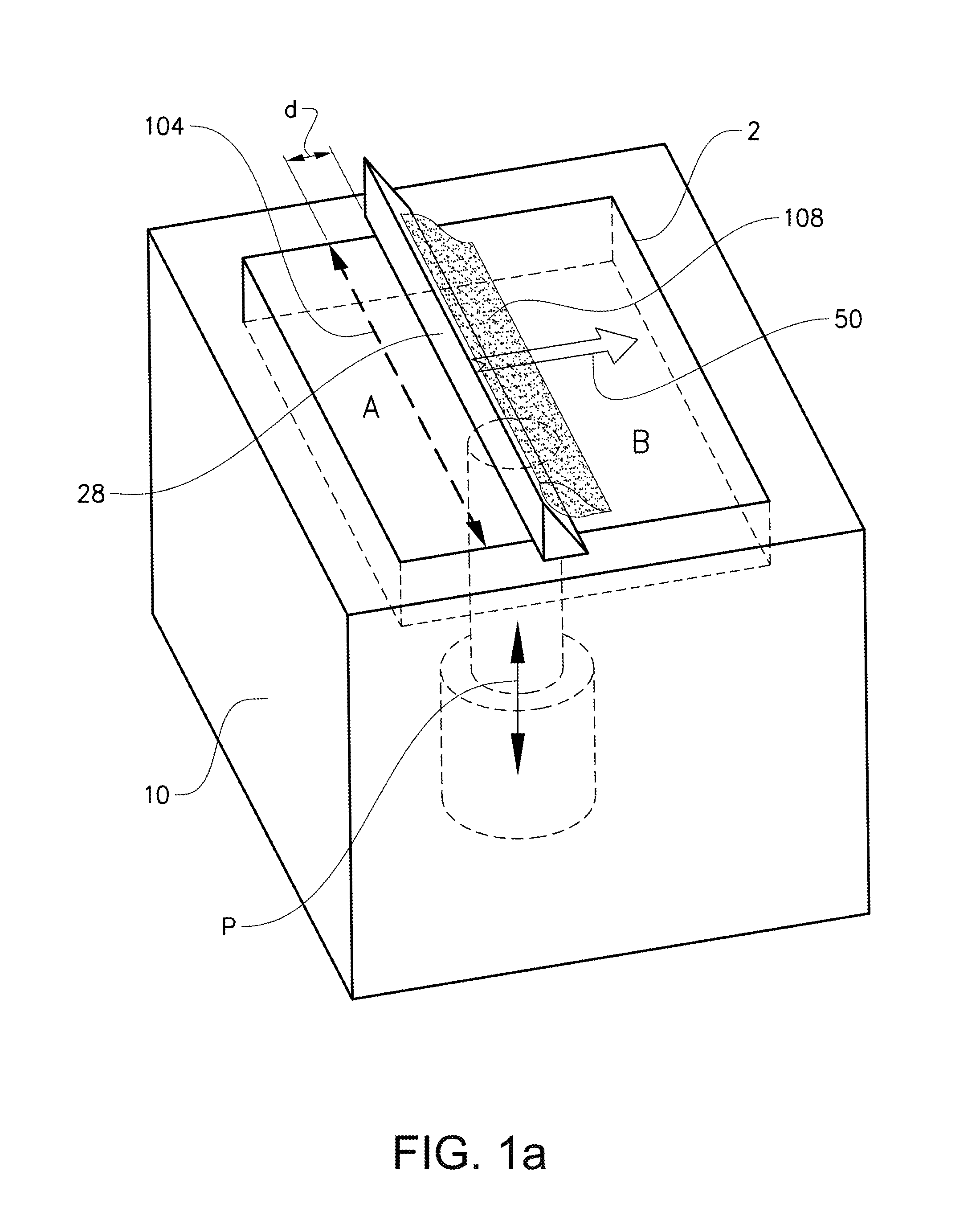

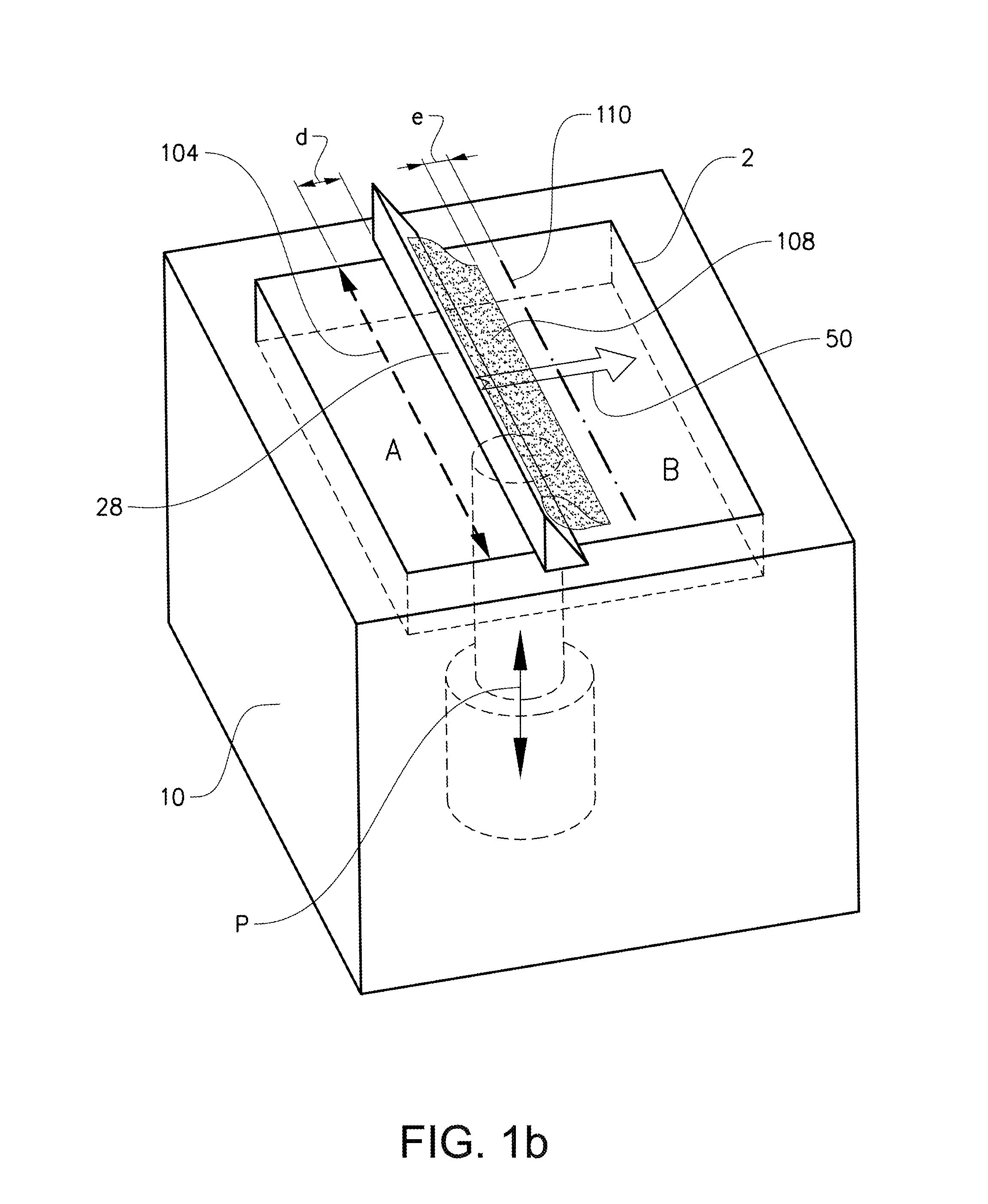

Additive manufacturing of three-dimensional articles

ActiveUS20150165524A1Short manufacturing timeQuality improvementHydrogenAdditive manufacturing apparatusLaser additive manufacturingSupport surface

The present invention relates to a method for forming a three-dimensional article through successively depositing individual layers of powder material that are fused together so as to form the article, the method comprising the step of heating a first portion of a support surface while depositing a layer of powder material on a second portion of the support surface.

Owner:ARCAM AB

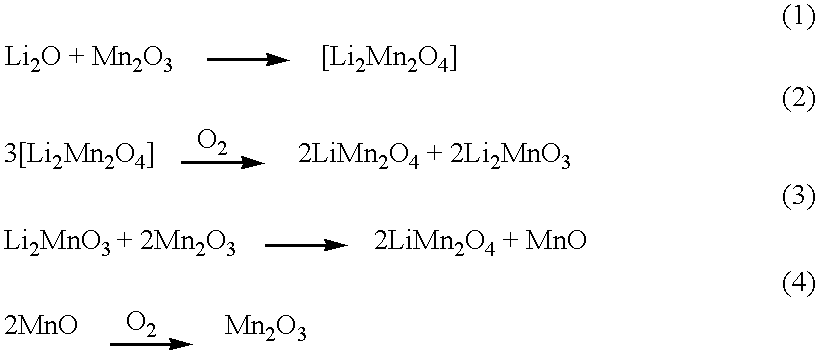

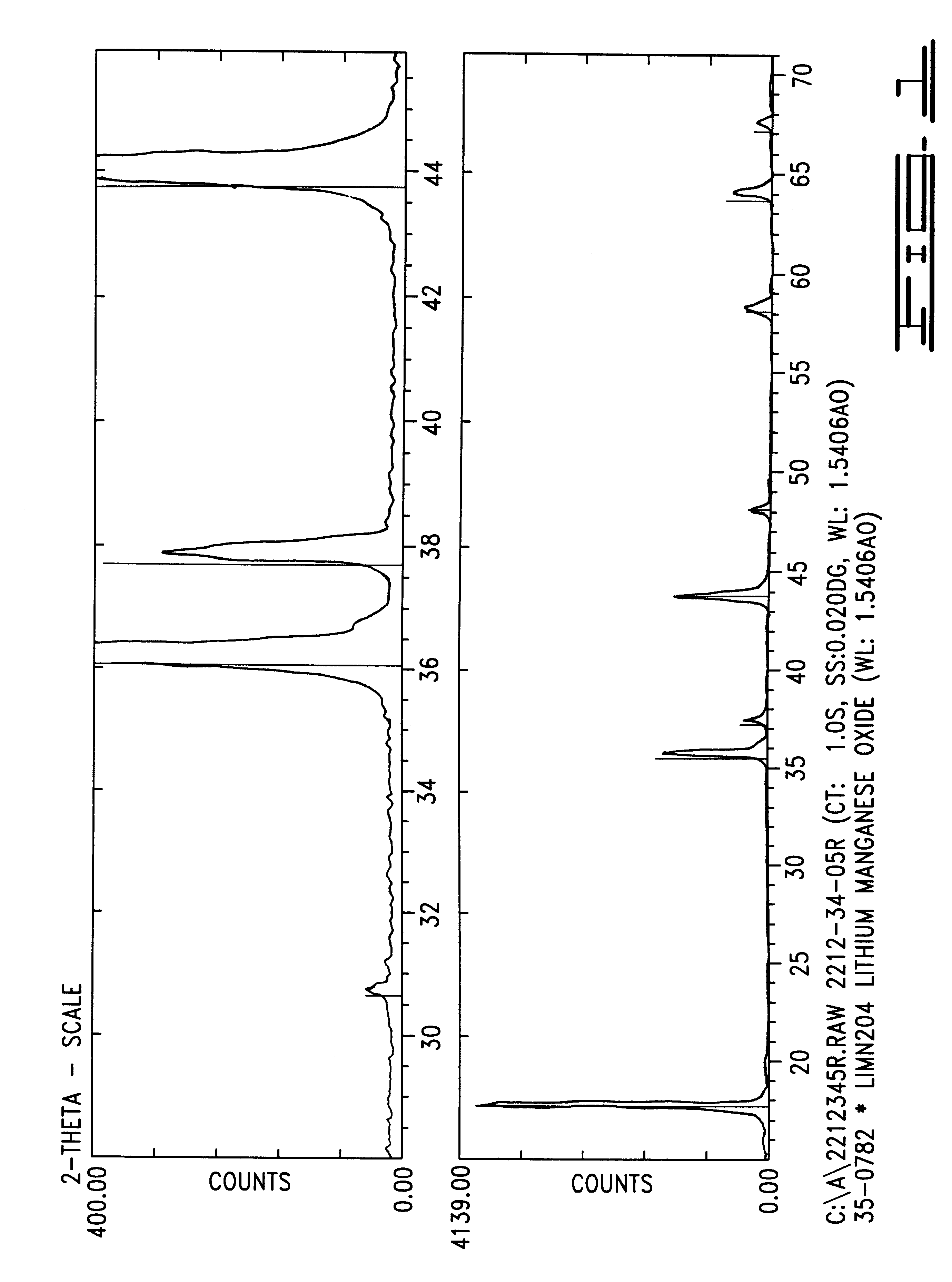

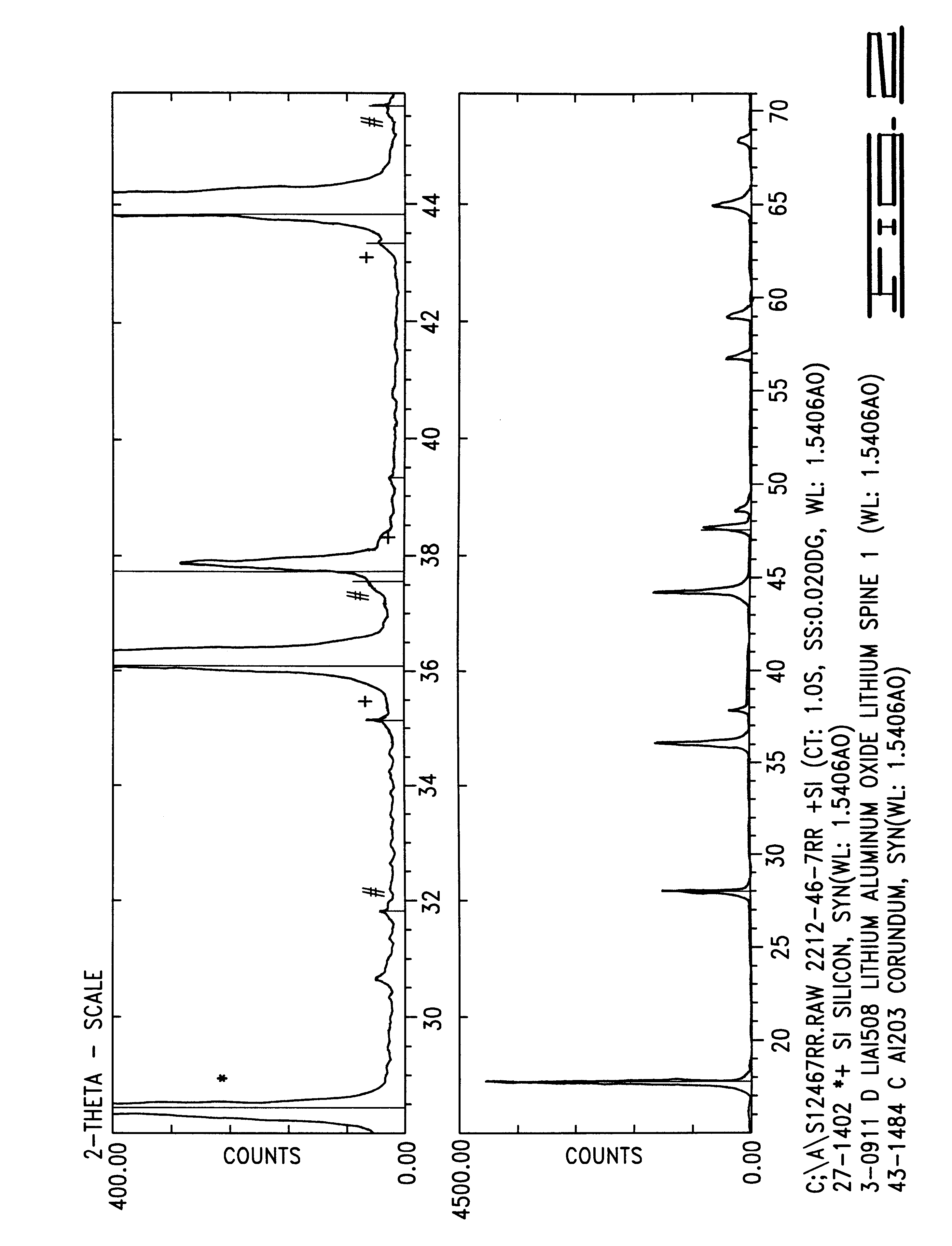

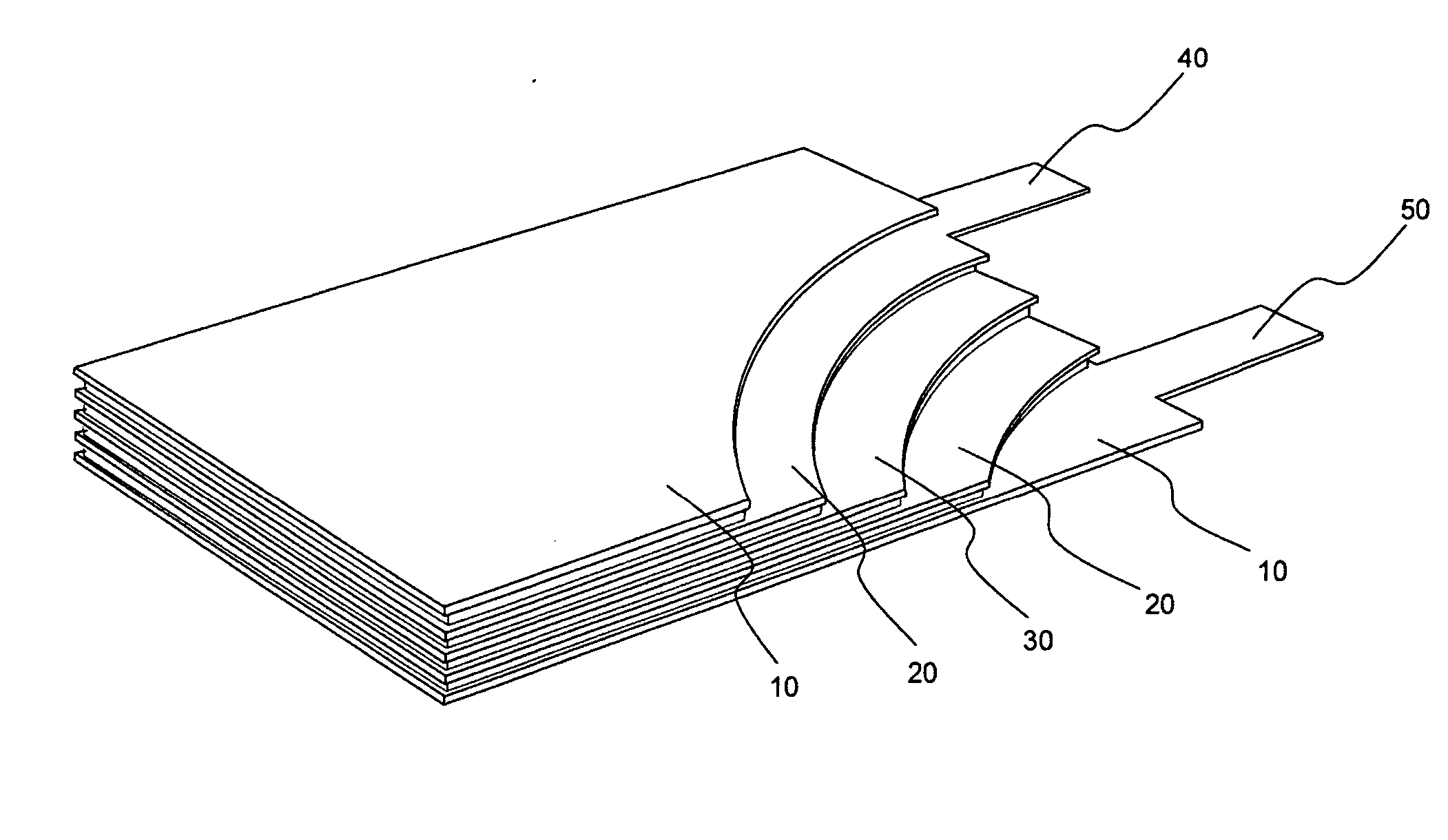

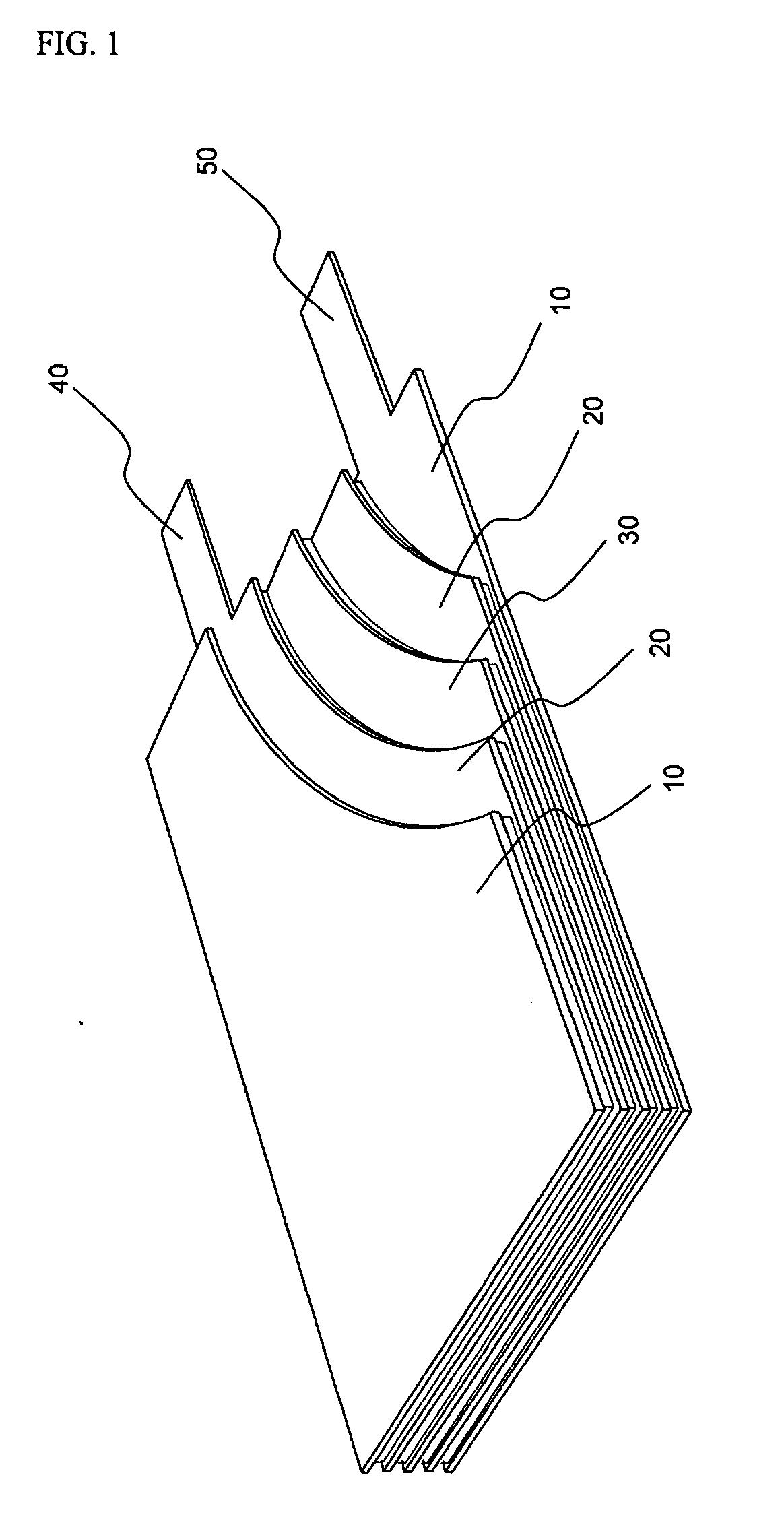

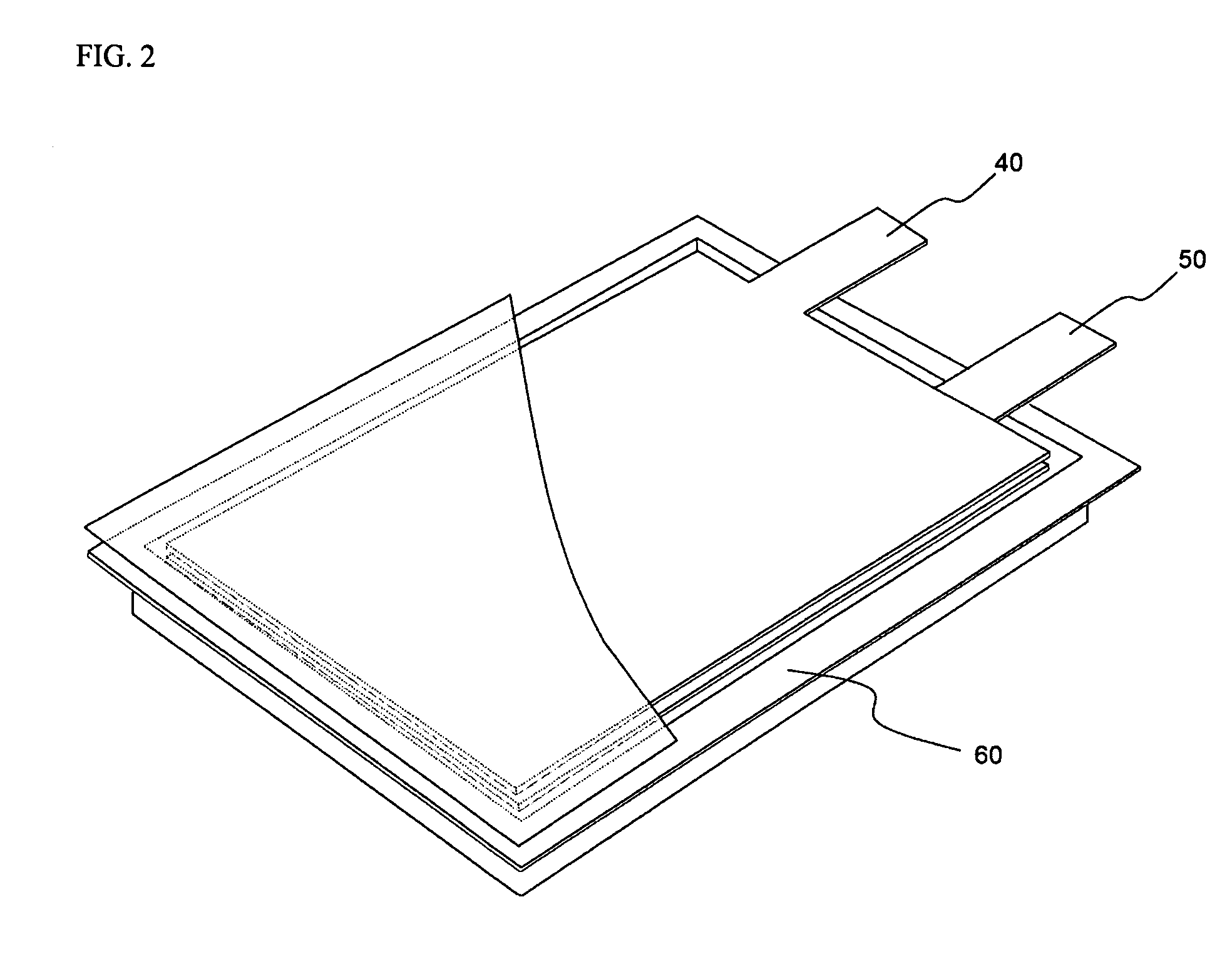

Cathode intercalation compositions, production methods and rechargeable lithium batteries containing the same

InactiveUS6248477B1Easy to adaptOxygen/ozone/oxide/hydroxideElectrode thermal treatmentMetalSpinel group

Intercalation compositions having spinel structures with crystallites of metal oxides (M2O3) dispersed throughout the structure are provided having the general formula Li1+xMyMn2-x-yO4. Methods of producing the intercalation compositions and rechargeable lithium batteries containing the compositions are also provided.

Owner:EMD ACQUISITION LLC

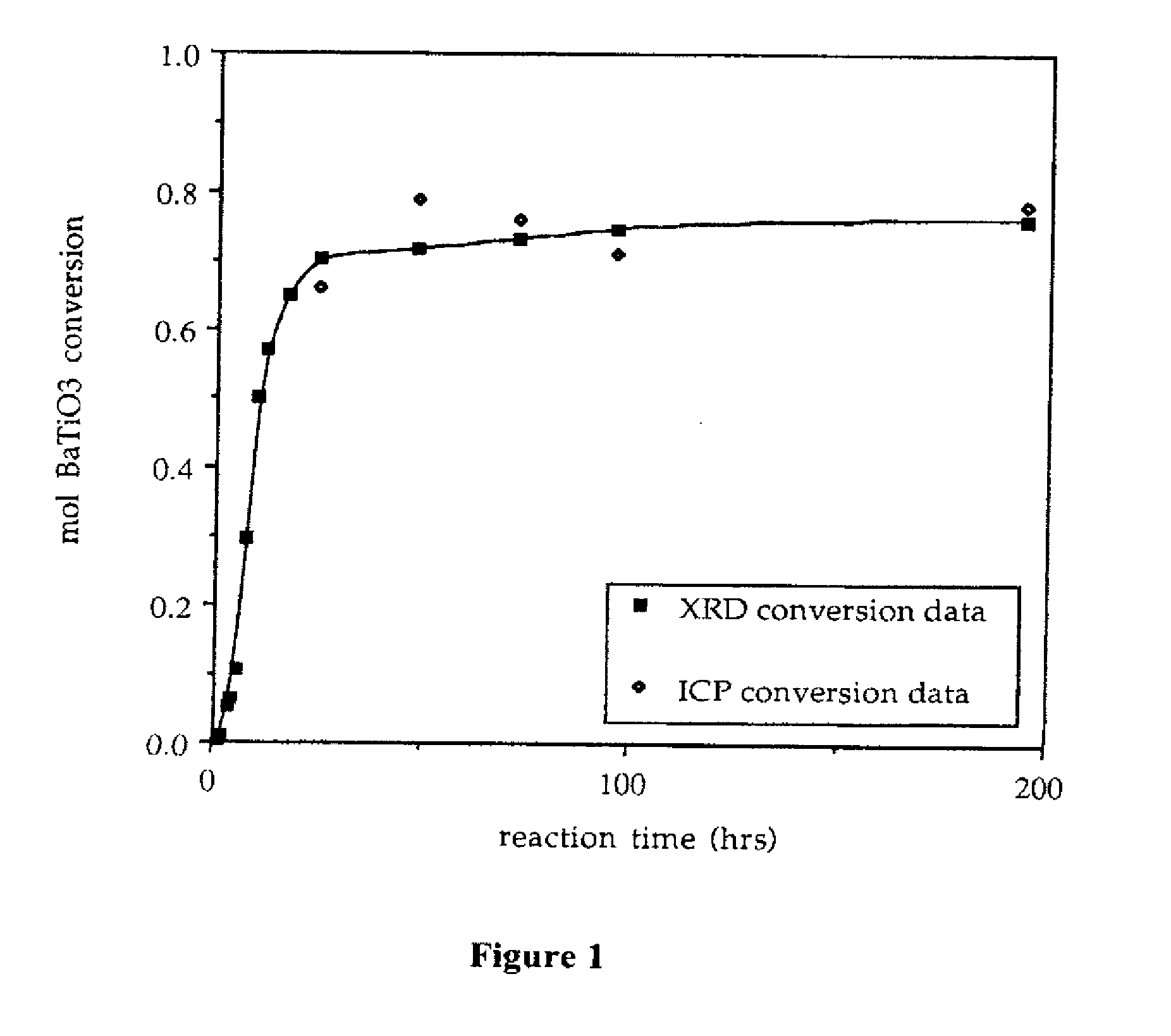

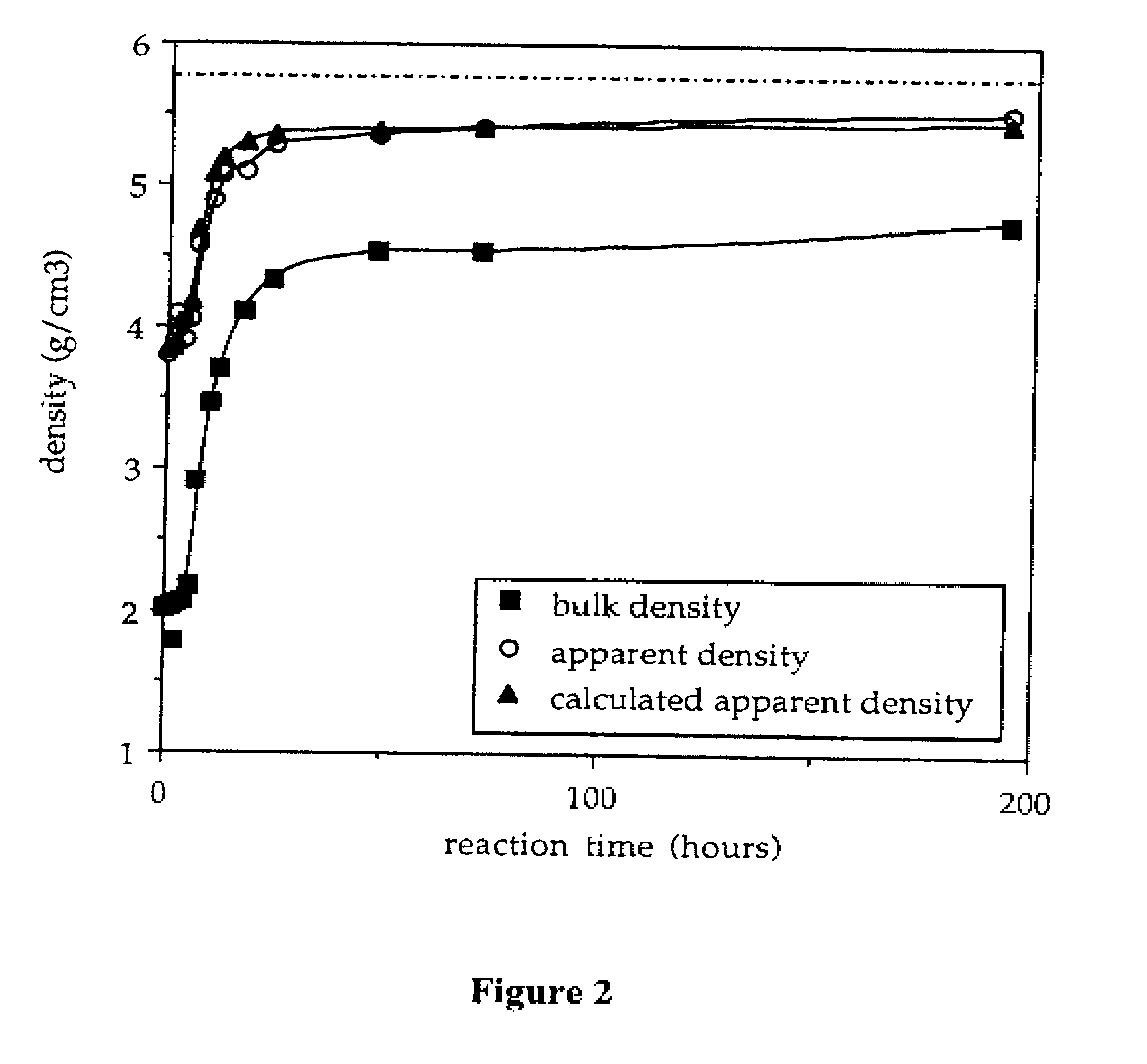

Method of hydrothermal liquid phase sintering of ceramic materials and products derived therefrom

Provided here is a method of producing a monolithic body from a porous matrix, comprising: (i) providing a porous matrix having interstitial spaces and comprising at least a first reactant; (ii) contacting the porous matrix with an infiltrating medium that carries at least a second reactant; (iii) allowing the infiltrating medium to infiltrate at least a portion of the interstitial spaces of the porous matrix under conditions that promote a reaction between the at least first reactant and the at least second reactant to provide at least a first product; and (iv) allowing the at least first product to form and fill at least a portion of the interstitial spaces of the porous matrix, thereby producing a monolithic body, wherein the monolithic body does not comprise barium titanate.

Owner:RUTGERS THE STATE UNIV

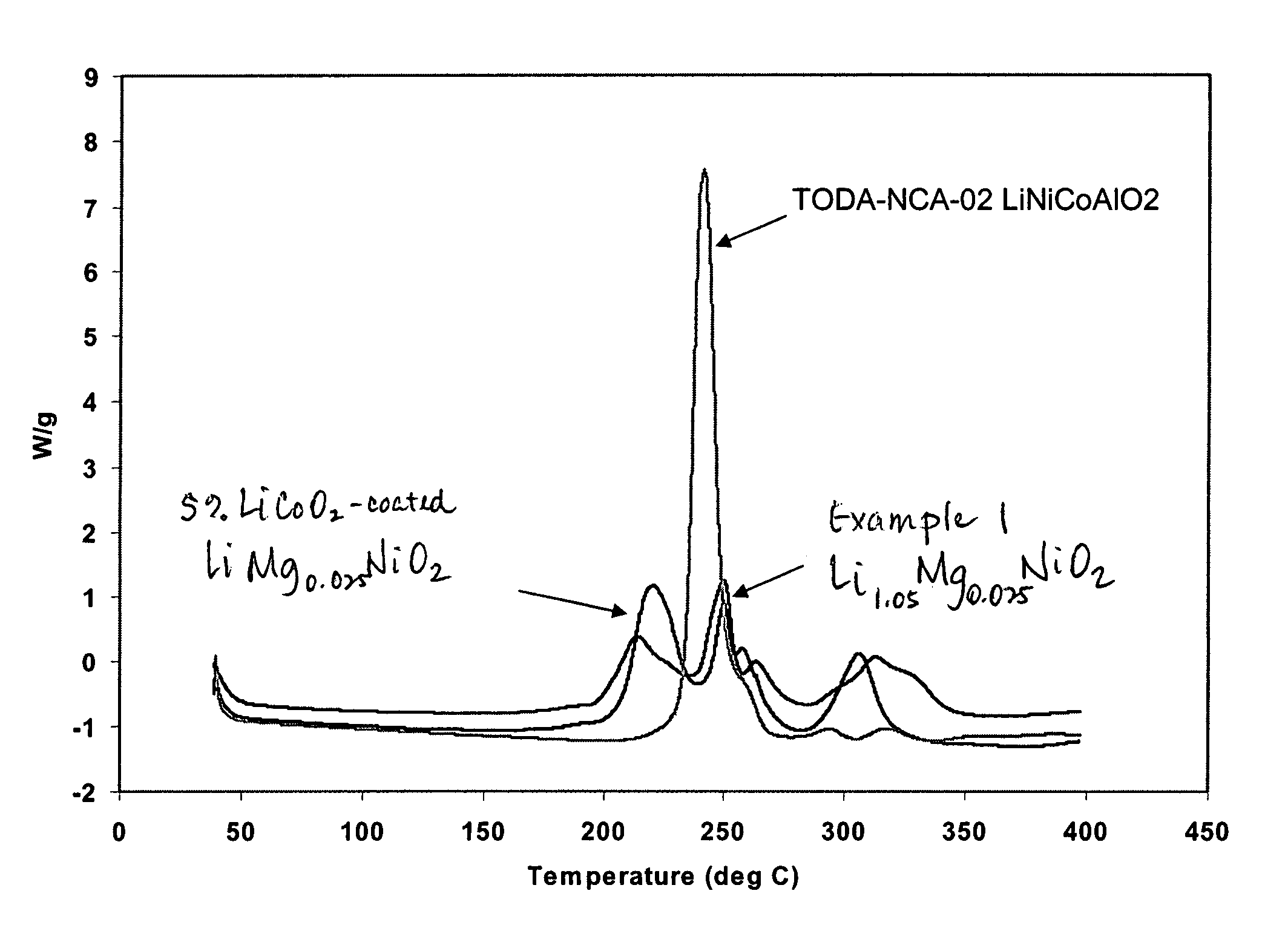

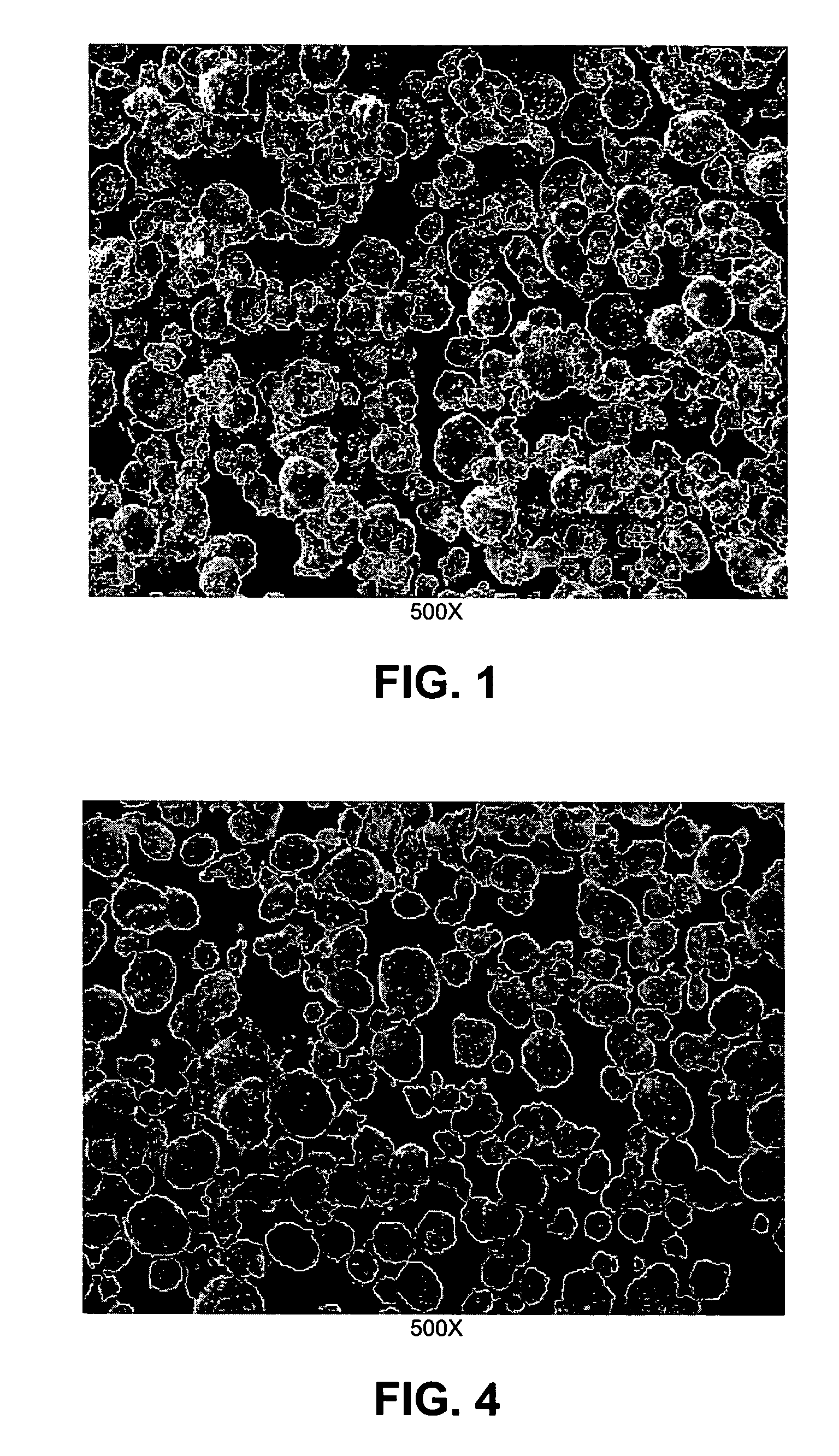

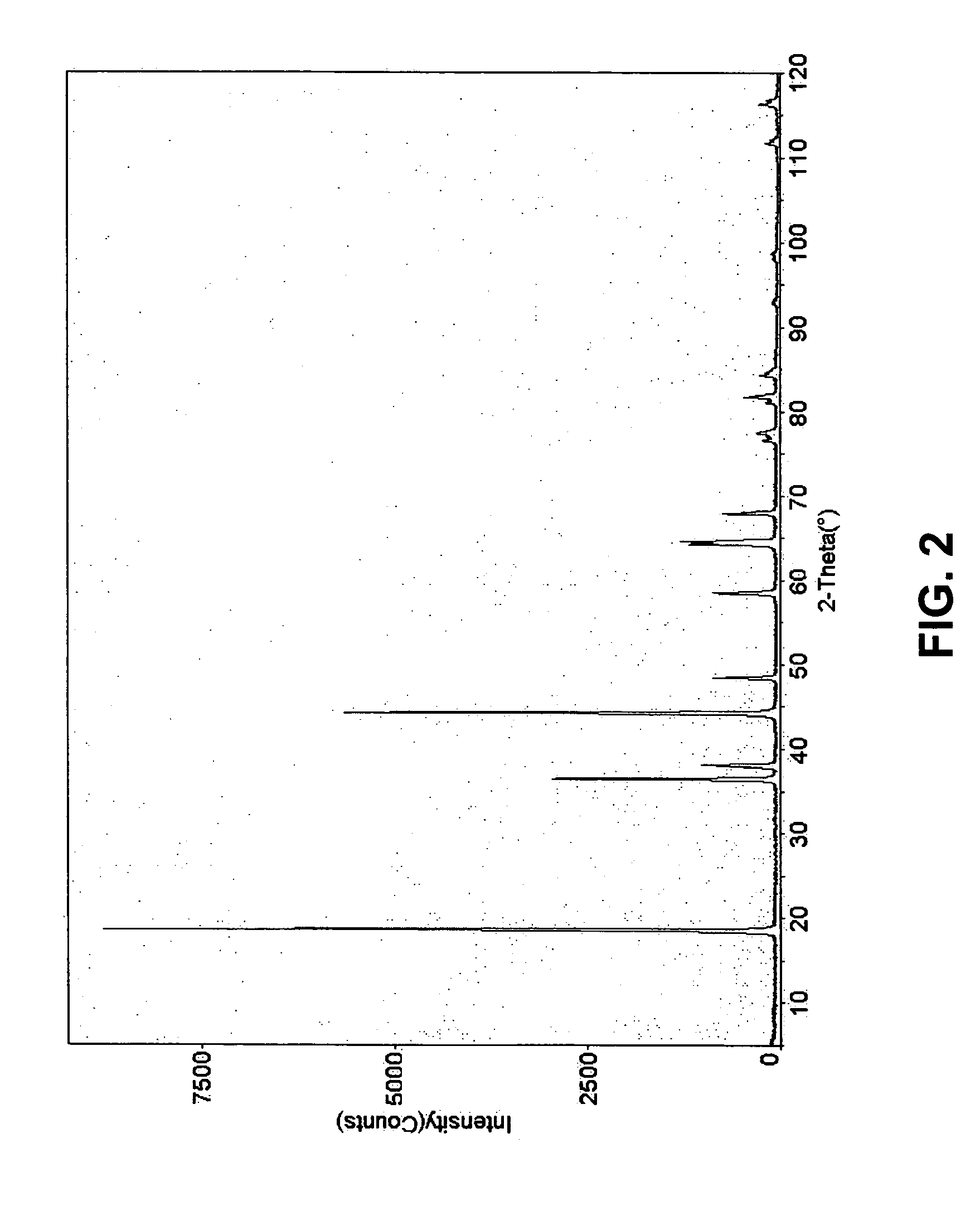

Lithium metal oxide materials and methods of synthesis and use

ActiveUS7381496B2Large capacityImprove cycle lifeOxide/hydroxide preparationNickel compounds preparationLithium metalElectrochemical cell

A composition having a formula LixMgyNiO2 wherein 0.9<x<1.3, 0.01<y<0.1, and 0.91<x+y<1.3 can be utilized as cathode materials in electrochemical cells. A composition having a core, having a formula LixMgyNiO2 wherein 0.9<x<1.3, 0.01<y<0.1, and 0.9<x+y<1.3, and a coating on the core, having a formula LiaCobO2 wherein 0.7<a<1.3, and 0.9<b<1.2, can also be utilized as cathode materials in electrochemical cells.

Owner:TIAX LLC

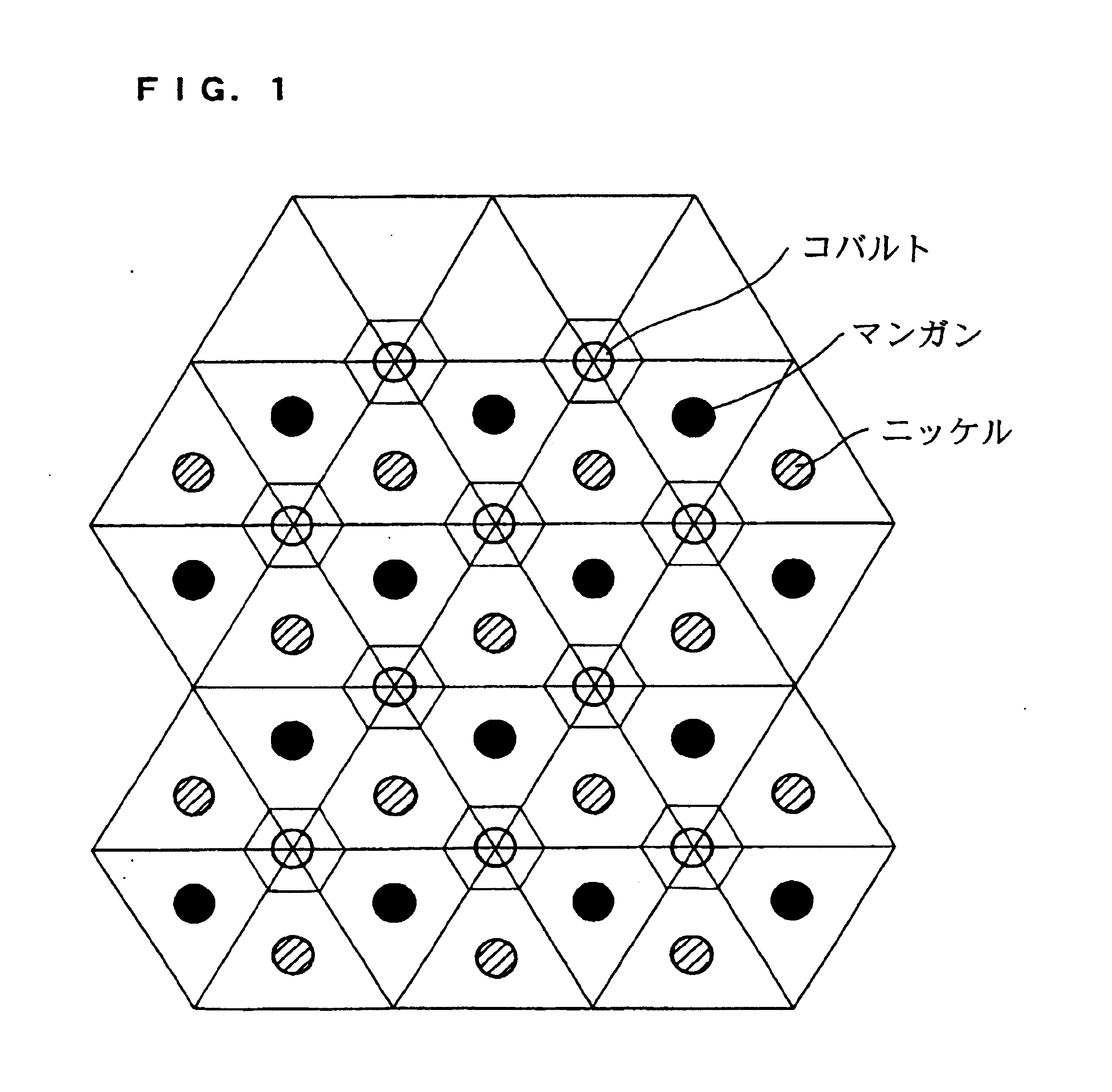

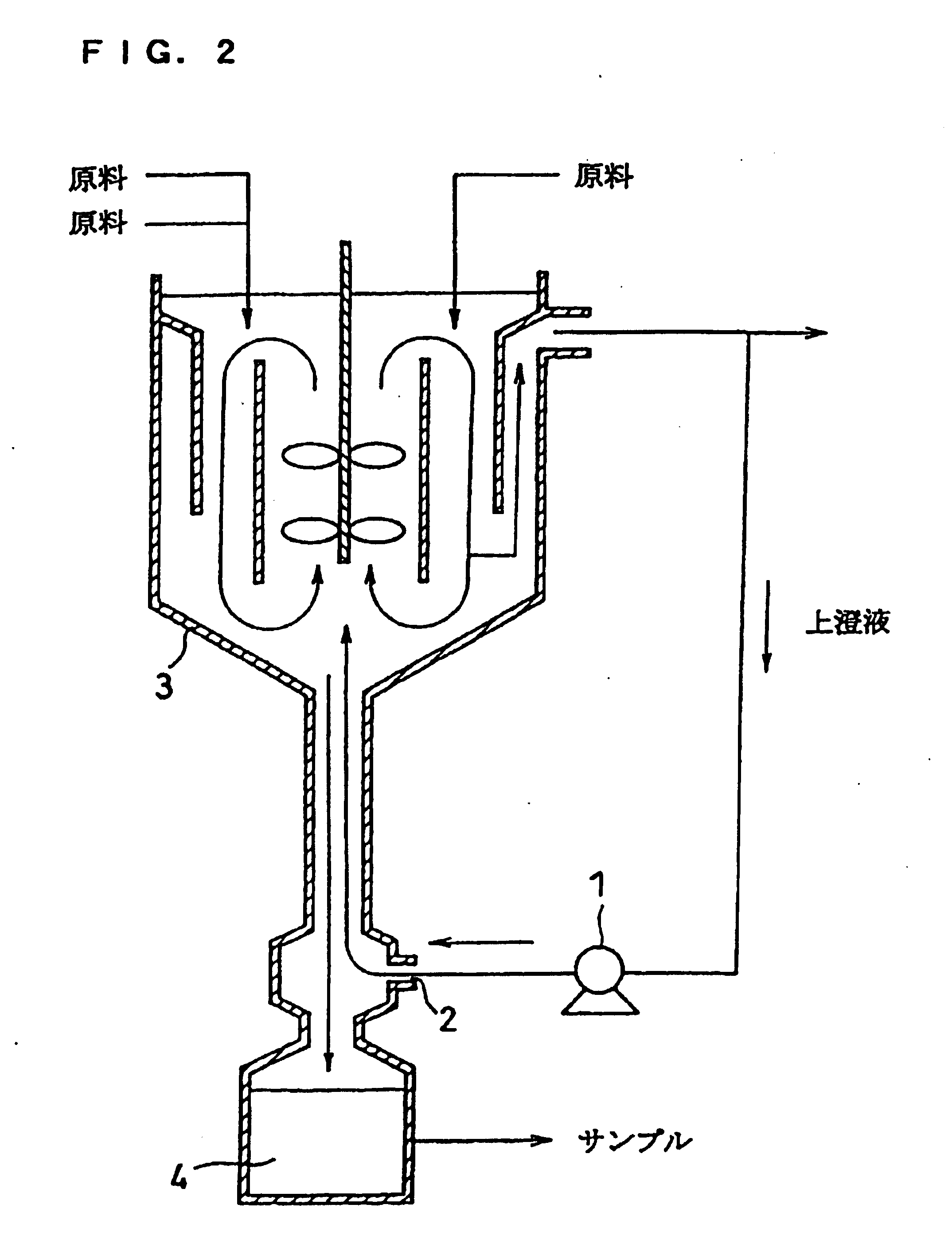

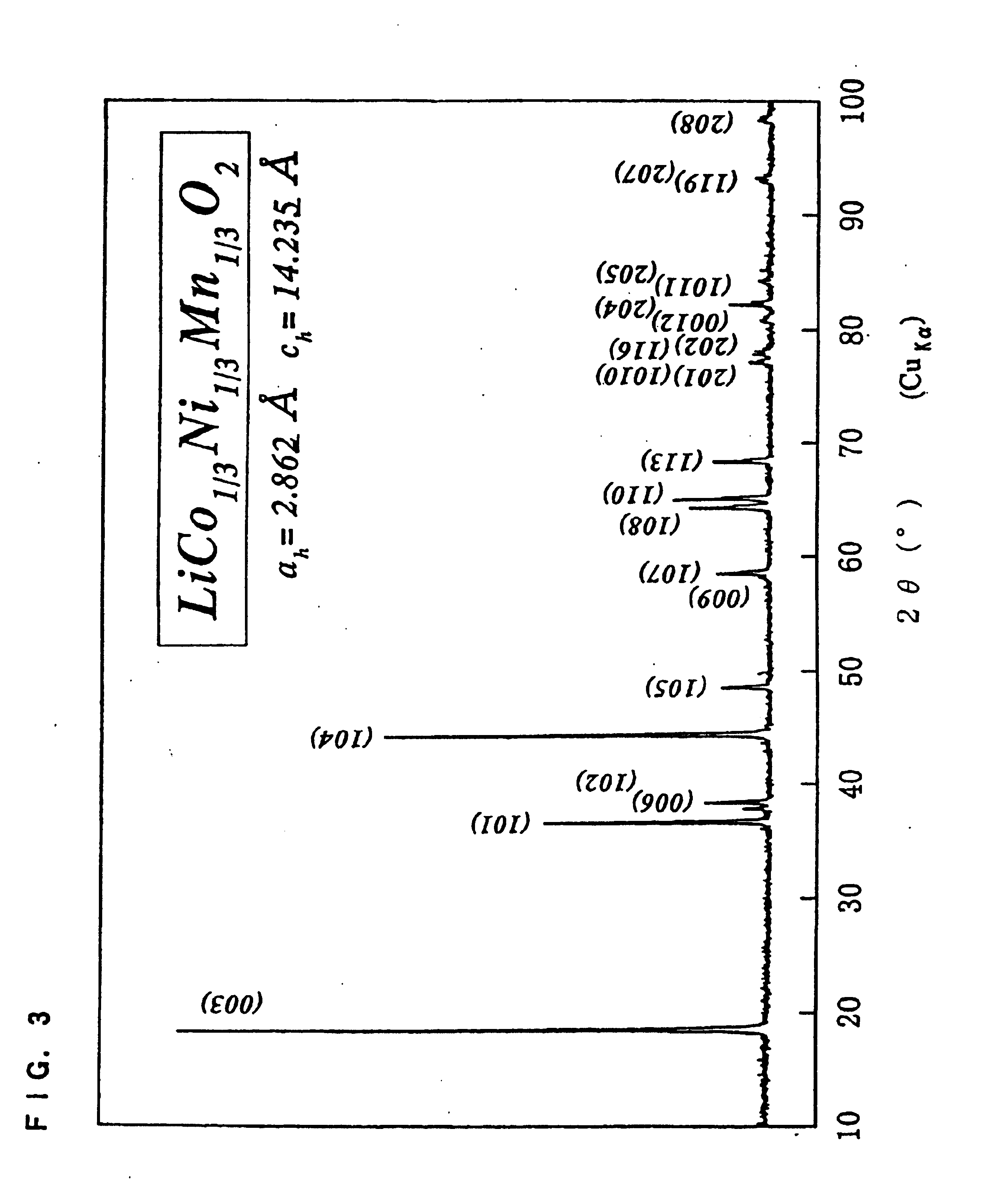

Positive electrode active material and nonaqueous electrolyte secondary cell including the same

InactiveUS20050079416A1Large capacityImprove charge and discharge efficiencyOxygen/ozone/oxide/hydroxideIron oxides/hydroxidesMetallic lithiumManganese

A nonaqueous electrolytic secondary cell produced at low cost and having a large capacity comprises a negative electrode having an active material mainly composed of a material that at least absorbs and releases lithium ions or metallic lithium, a positive electrode, and an electrolyte. The active material of the positive electrode is an oxide containing nickel, manganese, and cobalt, and the contents of the elements are substantial the same.

Owner:PANASONIC CORP +1

Tungsten comprising nanomaterials and related nanotechnology

InactiveUS20050271566A1High volumeIncrease volumeNanostructure manufactureCell electrodesManufactured nanoparticlesTungsten

Nanoparticles comprising tungsten, methods of manufacturing nanoparticles comprising tungsten, and applications of nanoparticles comprising tungsten, such as electronics, optical devices, photonics, reagents for fine chemical synthesis, pigments, and catalysts are provided.

Owner:PPG IND OHIO INC

Production Of Barium Titanate Compounds

InactiveUS20070202036A1High purityLow costMaterial nanotechnologyAlkaline earth titanatesBarium titanateSpherical shaped

An ultrafine powder of barium titanate including solid solutions and doped compounds that meets up to specific characteristics is produced by method comprising two main steps. The first step is a reaction, typically in a Segmented Flow Tubular Reactor, between reactants to produce cubic-structure barium titanate composed of non-agglomerated ultrafine particles having a shape of given aspect ratio, usually a generally spherical shape, of low density corresponding at most to 90% of the intrinsic density, all particles being smaller than 1 micron and having a narrow particle size distribution and wherein the ratio of Ba:Ti including substitutents and dopants is very close to the ideal stoichiometry. This is followed by subjecting the powder produced in the first step to a second stage solvothermal post treatment typically in an autoclave at temperature less than 400° C. to convert the cubic-structure particles of low density to ultrafine tetragonal particles of increased density corresponding to at least 90% of the intrinsic density while maintaining the same aspect ratio, and maintaining the size of all particles below 1 micron, the narrow particle size distribution span, and the given ideal stoichiometry. The produced particles can have a non-spherical facetted shape such as cube-like.

Owner:JONGEN NATHALIE +1

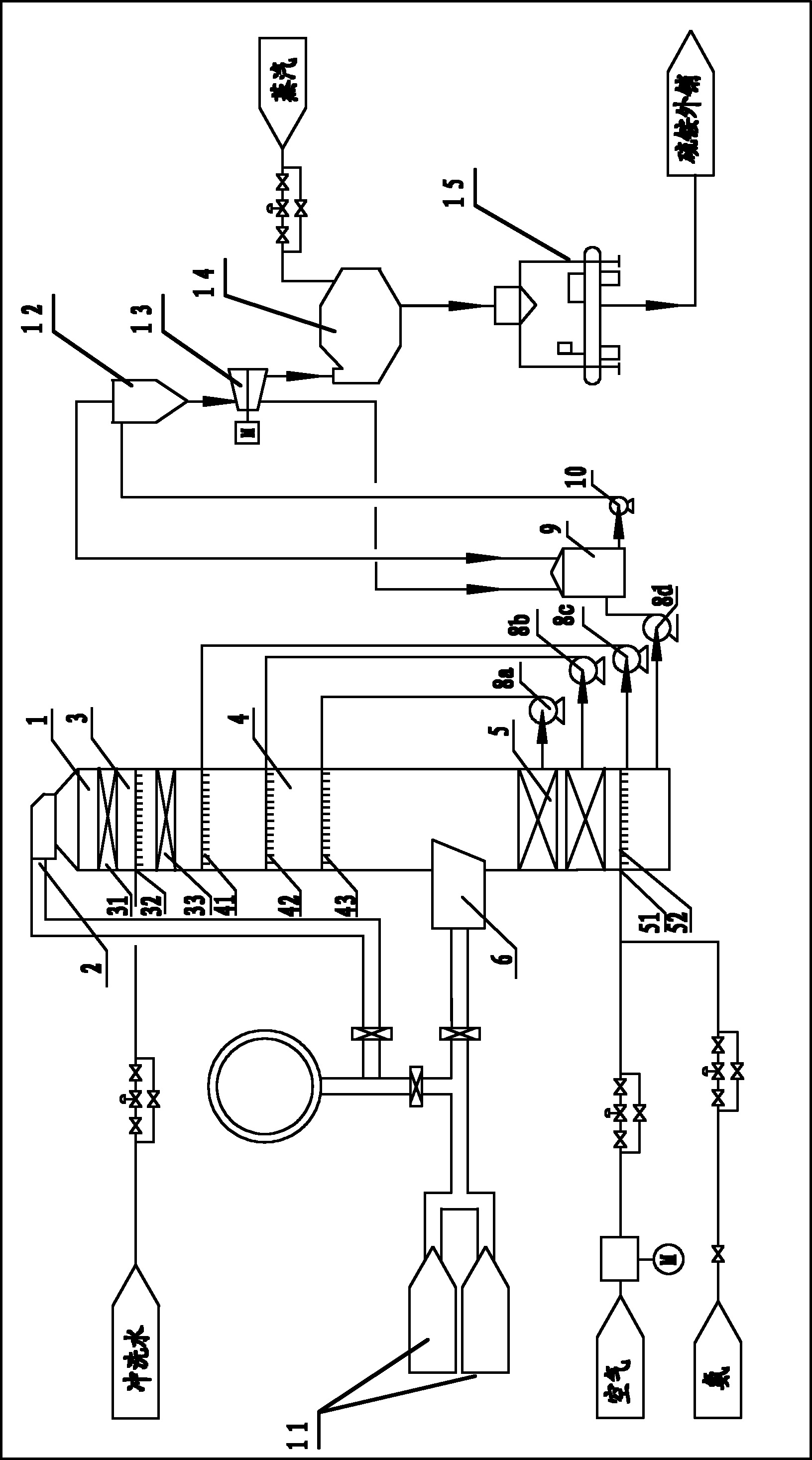

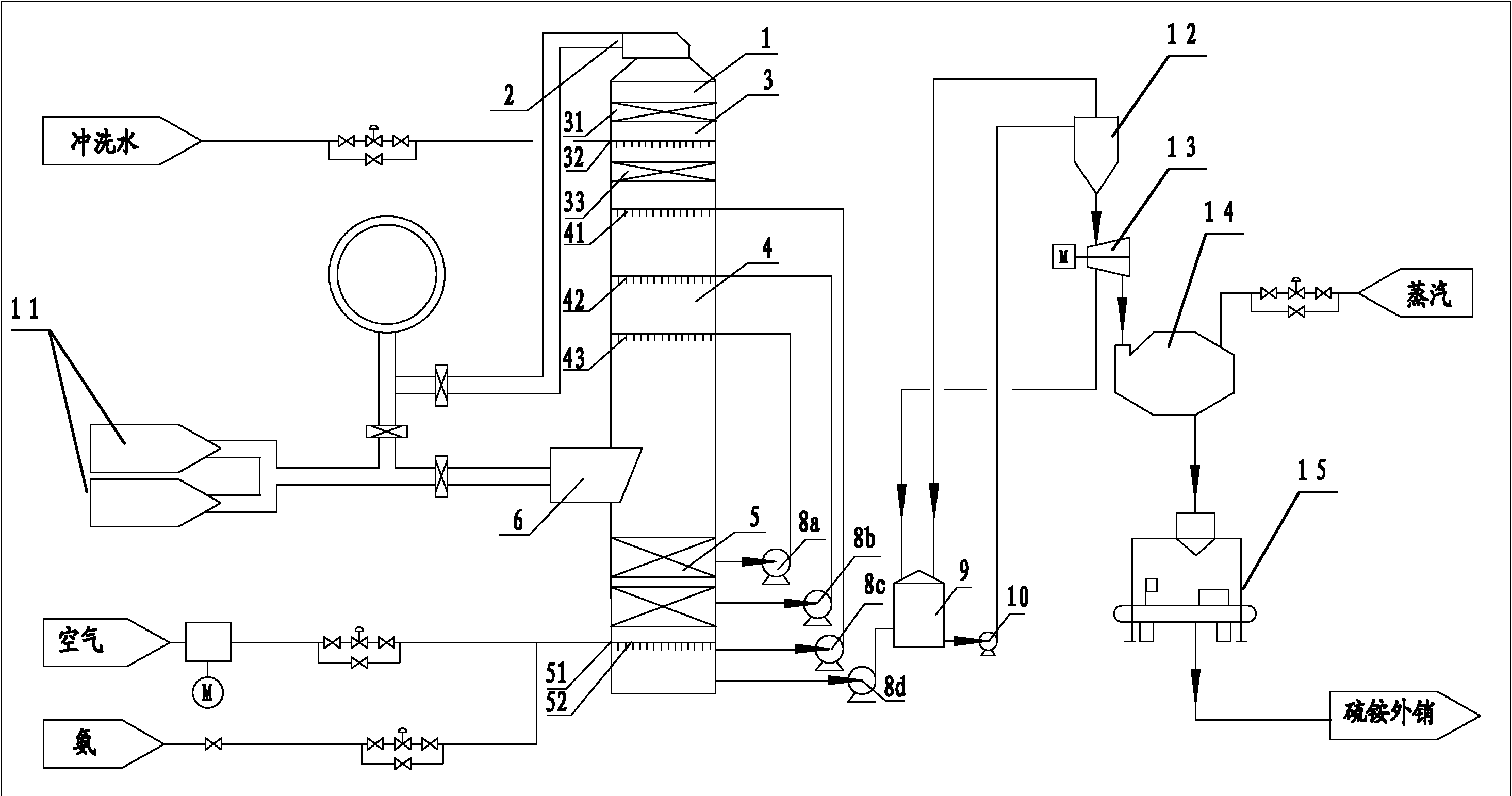

Method for desulfurizing and denitrating smoke simultaneously through ammonia method

ActiveCN101934191AIncrease profitReduce ammonia consumptionDispersed particle separationAmmonia compoundsAmmoniaAmmonium sulfate

The invention relates to a method for desulfurizing and denitrating smoke simultaneously through an ammonia method, which is carried out in a desulfurizing and denitrating system. The desulfurizing and denitrating system comprises a desulfurizing and denitrating tower, the desulfurizing and denitrating tower is provided with a washing demisting segment, an absorption segment and an oxidation segment, wherein the absorption segment is provided with a first desulfurizing spray layer, a second desulfurizing spray layer and a denitrating spray layer from top to bottom; the oxidation segment is provided with a denitrating circulation layer, a desulfurizing circulation layer and an oxidation layer from top to bottom, wherein the denitrating circulation layer, the desulfurizing circulation layerand the oxidation layer are respectively communicated with the denitrating spray layer, the second desulfurizing spray layer and the first desulfurizing spray layer through circulating pipelines positioned outside the desulfurizing and denitrating tower; smoke enters from a smoke inlet, sequentially contacts with the absorption liquid of the denitrating spray layer, the second desulfurizing spraylayer and the first desulfurizing spray layer for denitration and desulfurization, then enters the washing demisting segment and then is exhausted; the absorption liquid of the spray layers descends to the oxidation segment and reacts on the oxidation layer to generate ammonium sulfate; and the absorption liquid of the denitrating circulation layer, the desulfurizing circulation layer and the oxidation layer is respectively delivered to the denitrating spray layer, the second desulfurizing spray layer and the first desulfurizing spray layer through the circulating pipelines positioned outsidethe desulfurizing and denitrating tower.

Owner:NANJING NEW CENTURY JIANGNAN ENVIRONMENTAL PROTECTION CO LTD

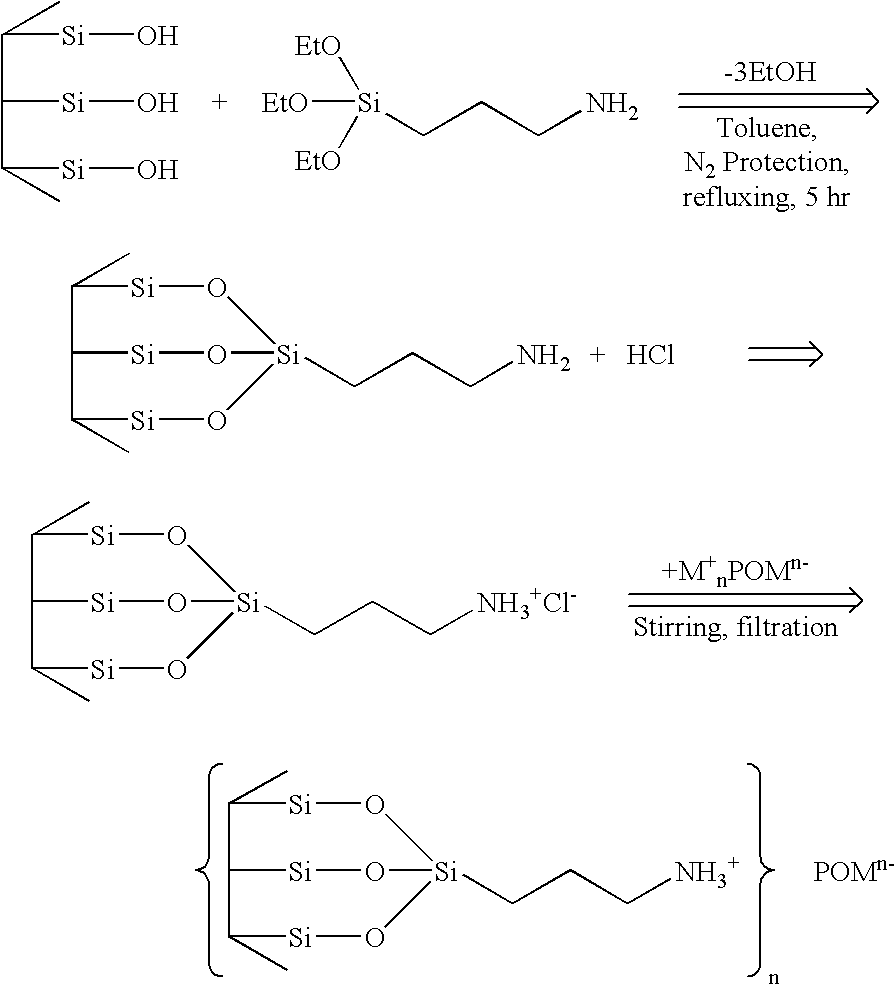

Supported polyoxometalates and process for their preparation

InactiveUS7417008B2Group 4/14 element organic compoundsOxygen/ozone/oxide/hydroxideCatalytic oxidationMesoporous silica

Owner:EXXONMOBIL CHEM PAT INC

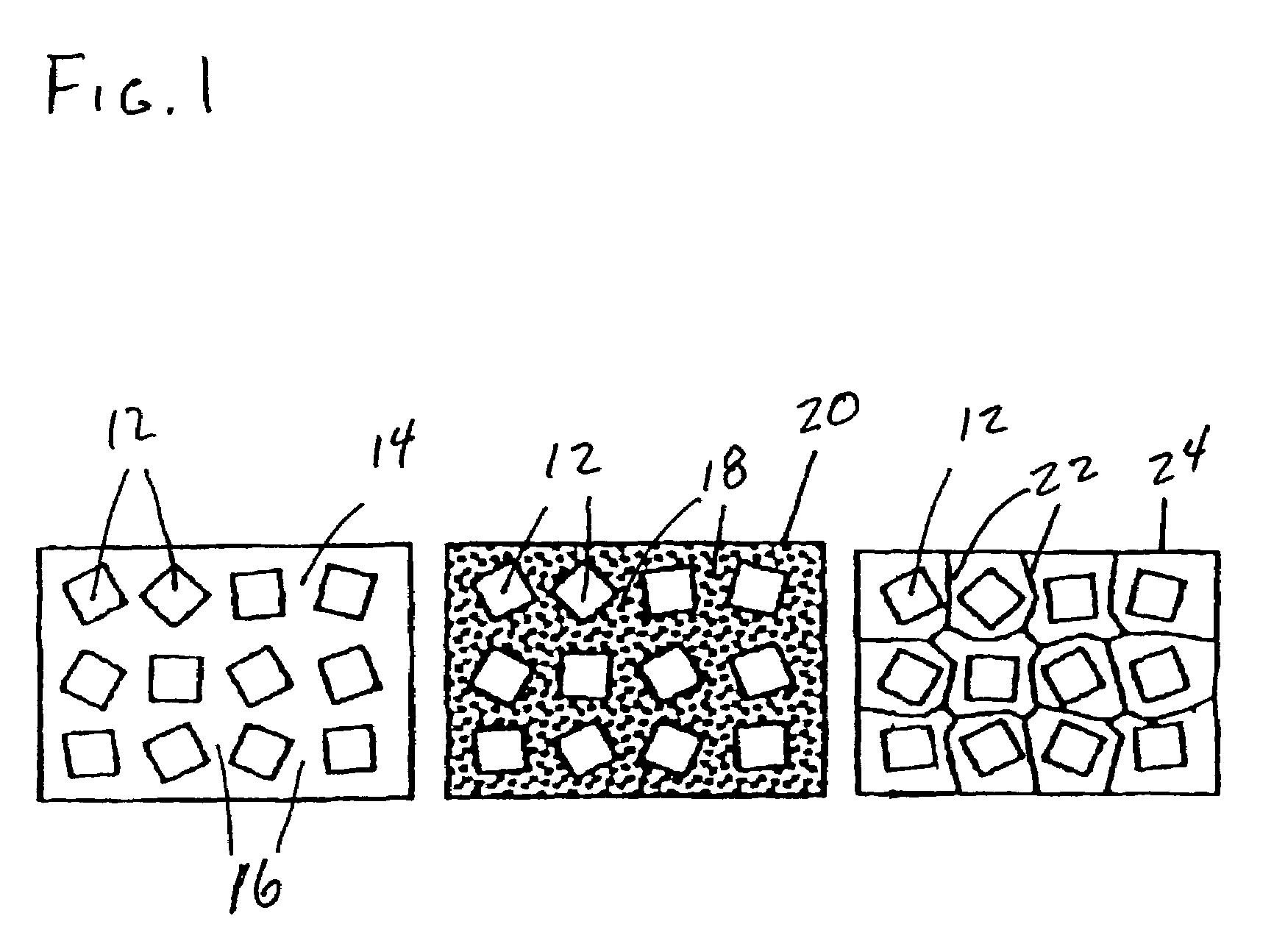

Single-crystal-like materials

InactiveUS7022303B2Improve fracture toughnessReadily apparentMagnesium fluoridesCalcium/strontium/barium fluoridesMetallurgySingle crystal

Polycrystalline materials of macroscopic size exhibiting Single-Crystal-Like properties are formed from a plurality of Single-Crystal Particles, having Self-Aligning morphologies and optionally ling morphology, bonded together and aligned along at least one, and up to three, crystallographic directions.

Owner:RUTGERS THE STATE UNIV

Non-volatile resistance-switching oxide thin film devices

Owner:THE TRUSTEES OF THE UNIV OF PENNSYLVANIA

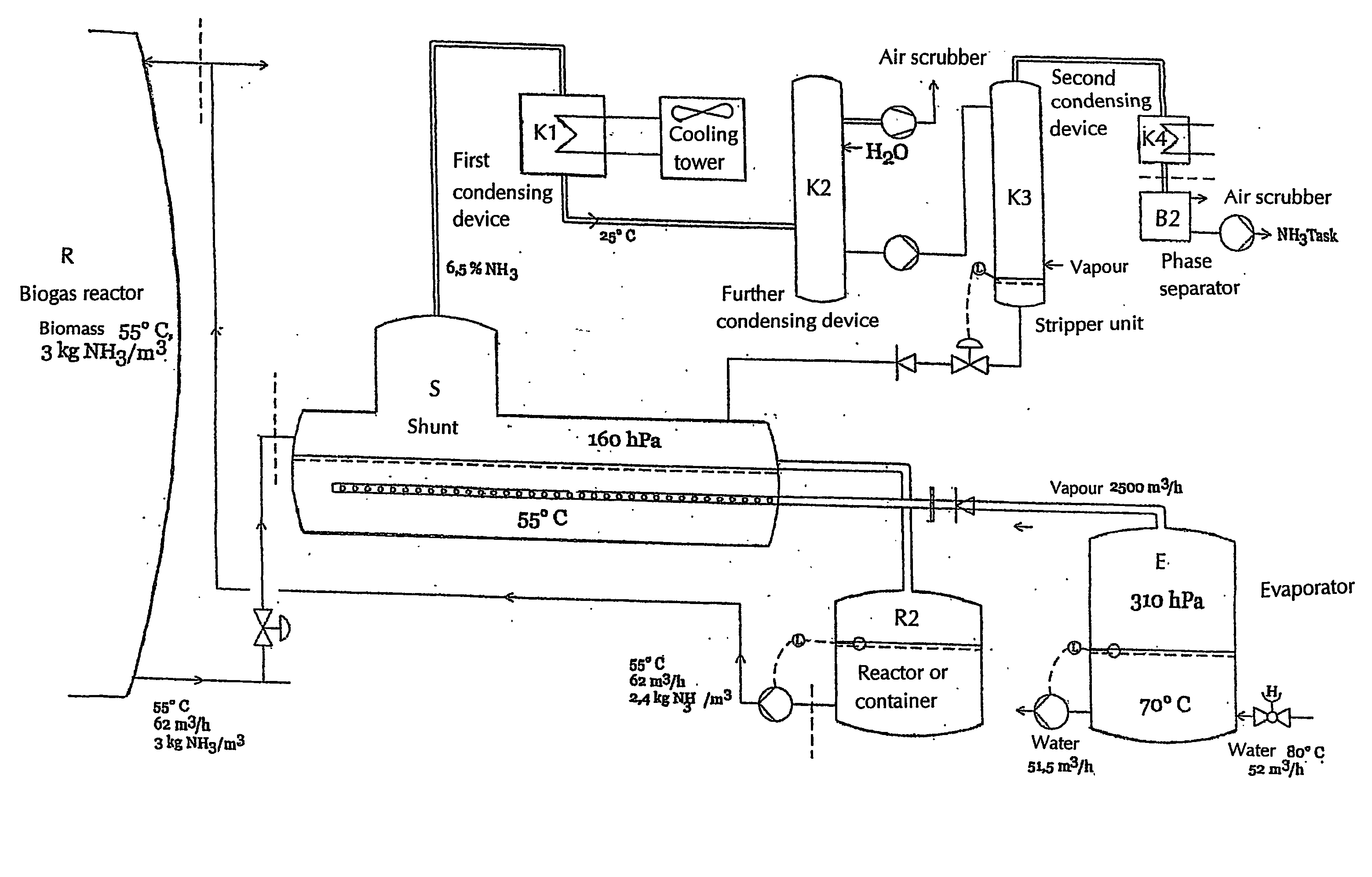

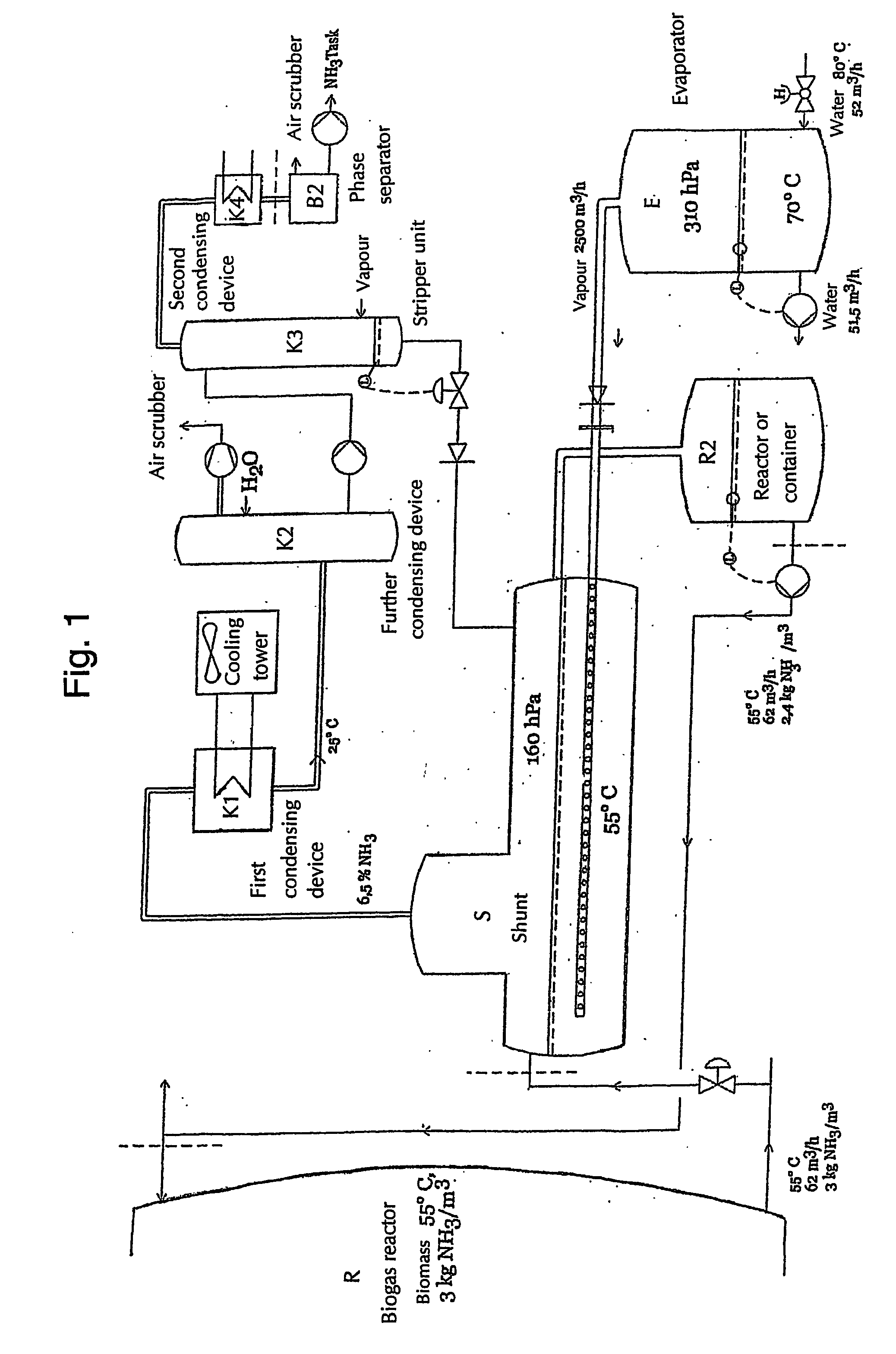

Method and device for stripping ammonia from liquids

InactiveUS7416644B2Simple and economic in operationLow-valuedBioreactor/fermenter combinationsBiological substance pretreatmentsLiquid mediumHigh pressure

Owner:GFE PATENT AS

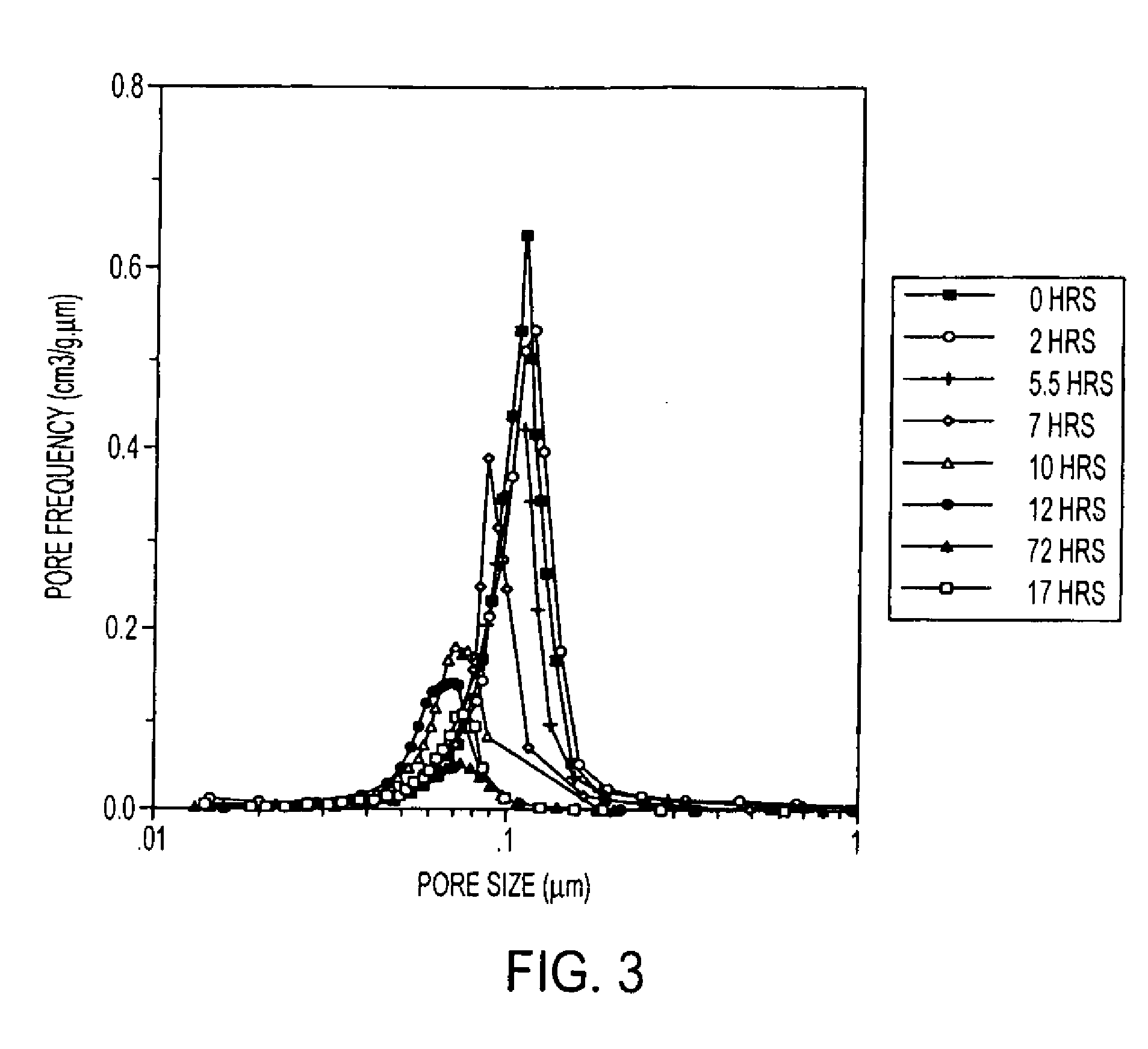

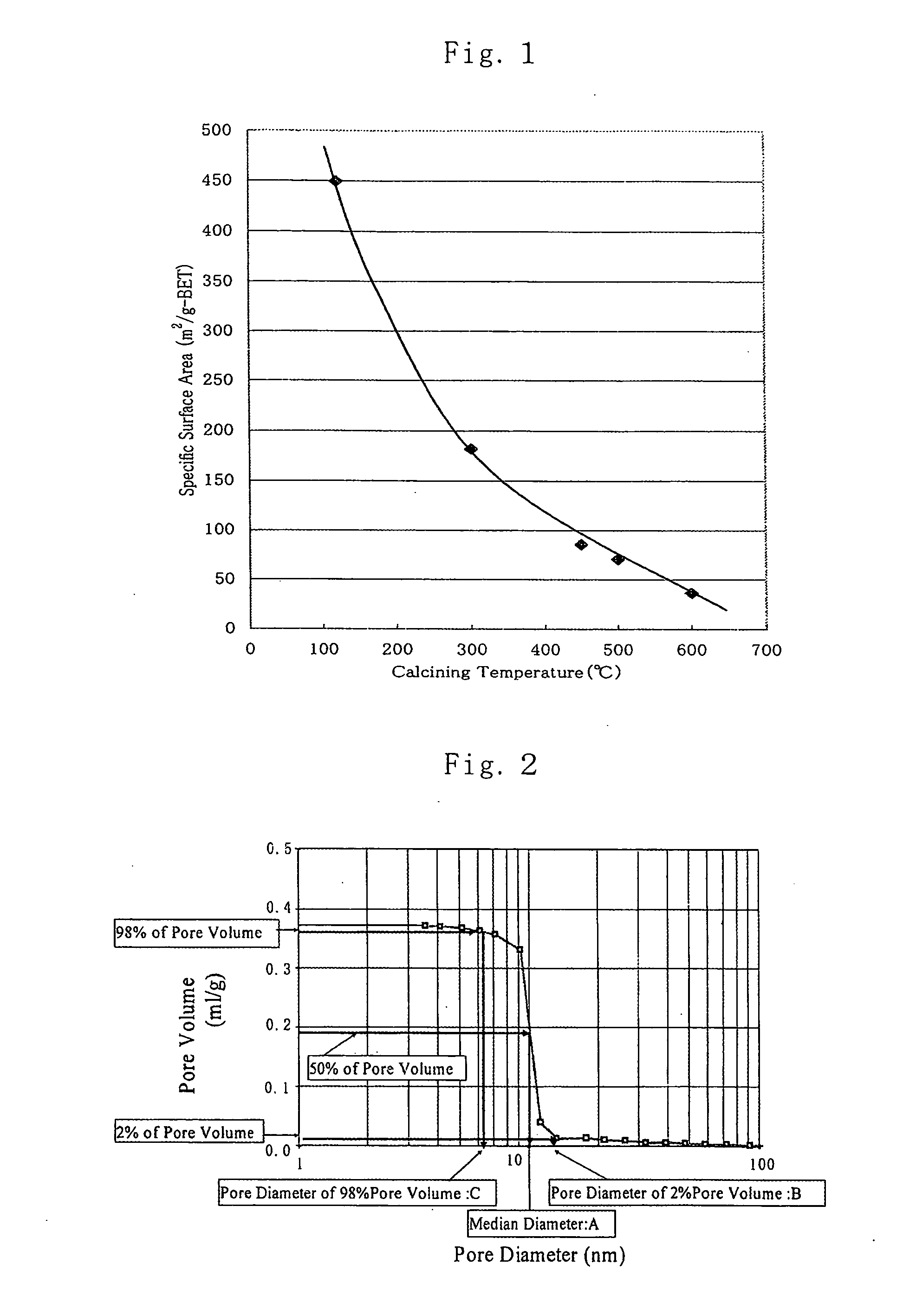

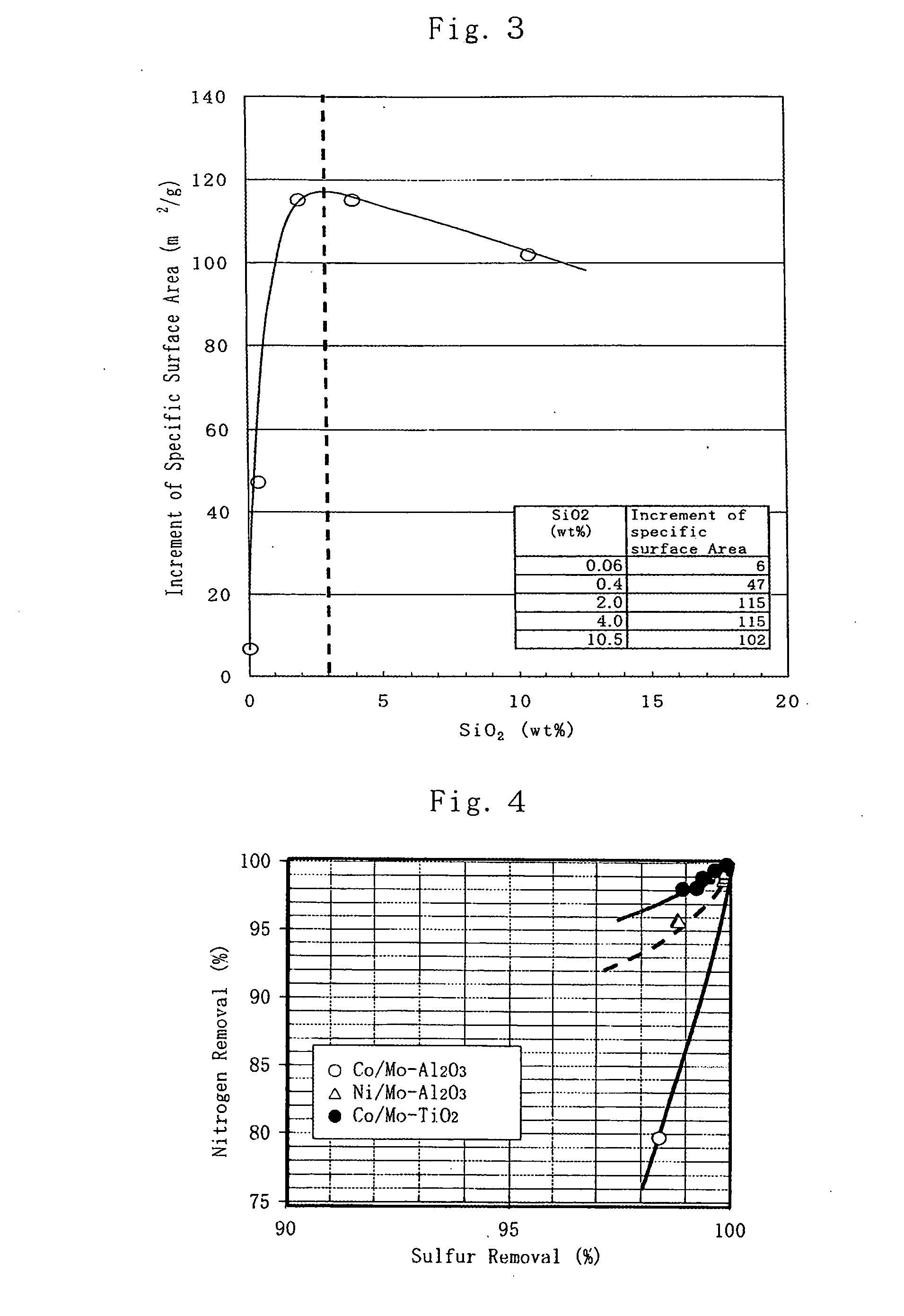

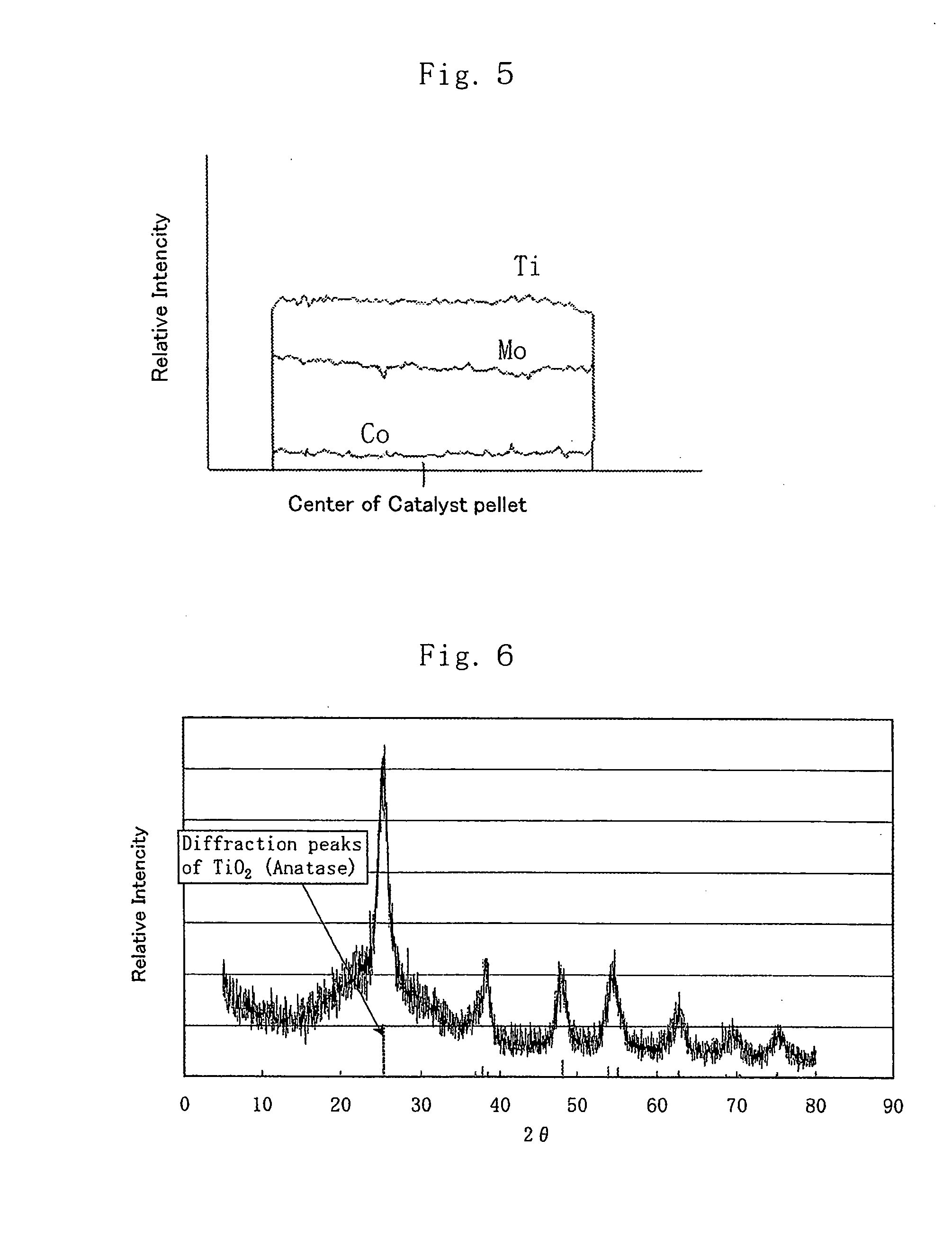

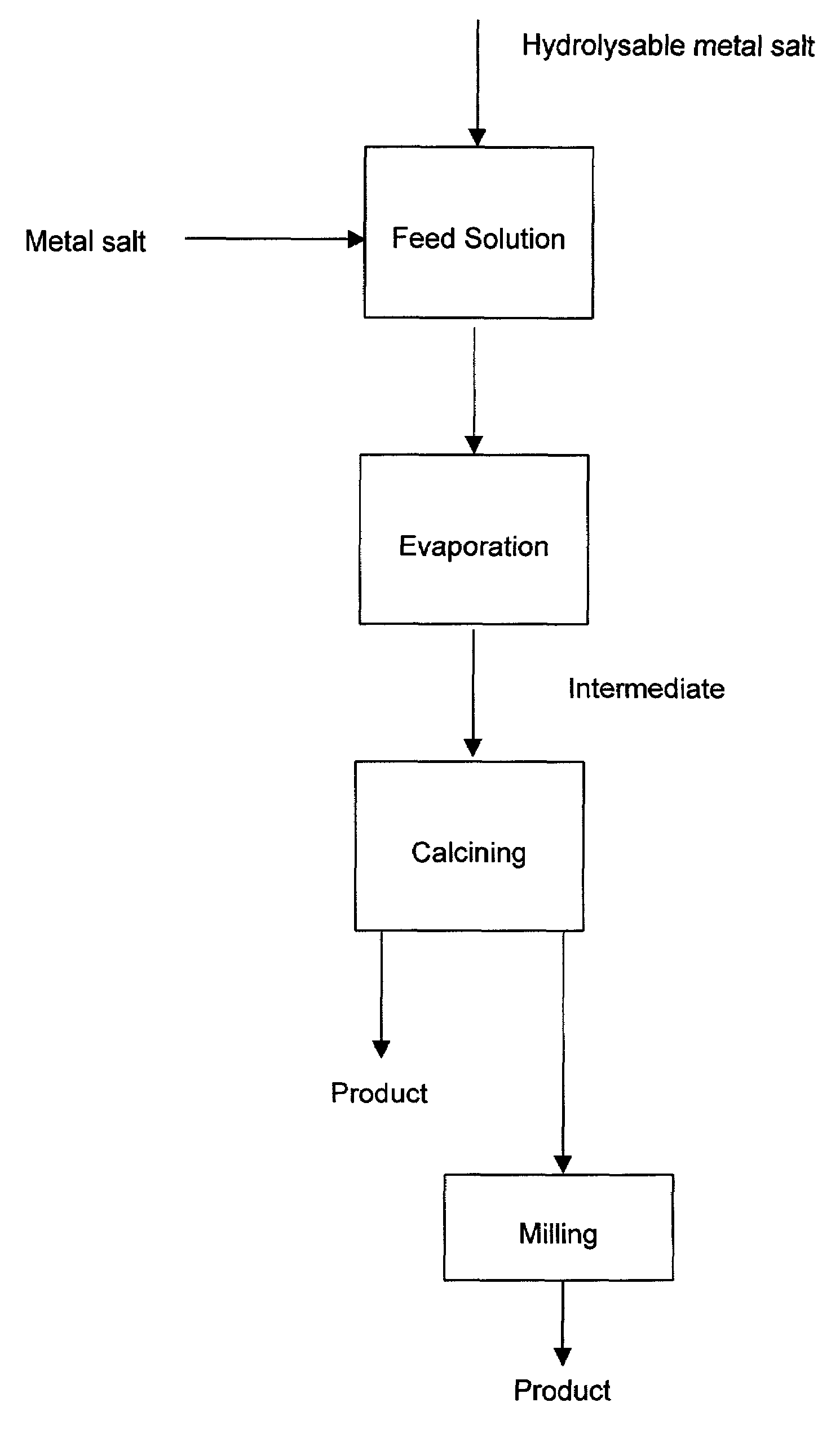

Porous 4 group metal oxide and method for preparation thereof

This invention relates to a 4 group metal oxide and to a method for preparation thereof and the 4 group metal oxide prepared by adding a particle growth inhibiter to a hydrosol a hydrogel or a dried product of a hydrous 4 group metal oxide represented by MO(2-x)(OH)2x (wherein M denotes a 4 group metal and x is a number greater than 0.1 or x>0.1) followed by drying and calcining has a specific surface area of 80 m<2> / g or more, a pore volume of 0.2 ml / g or more and a pore sharpness degree of 50% or more and excellent heat stability and is useful for a catalyst or a catalyst carrier in which a catalyst metal is dispersed to a high degree. This invention further relates to a porous 4 group metal oxide and to a method for preparation thereof and the 4 group metal oxide prepared by application of a pH swing operation is characterized by a large specific surface area, excellent heat stability, high dispersion of a catalyst metal and a controlled and sharp pore distribution and is useful for a catalyst or a catalyst carrier of excellent reaction selectivity.

Owner:CHIYODA CORP

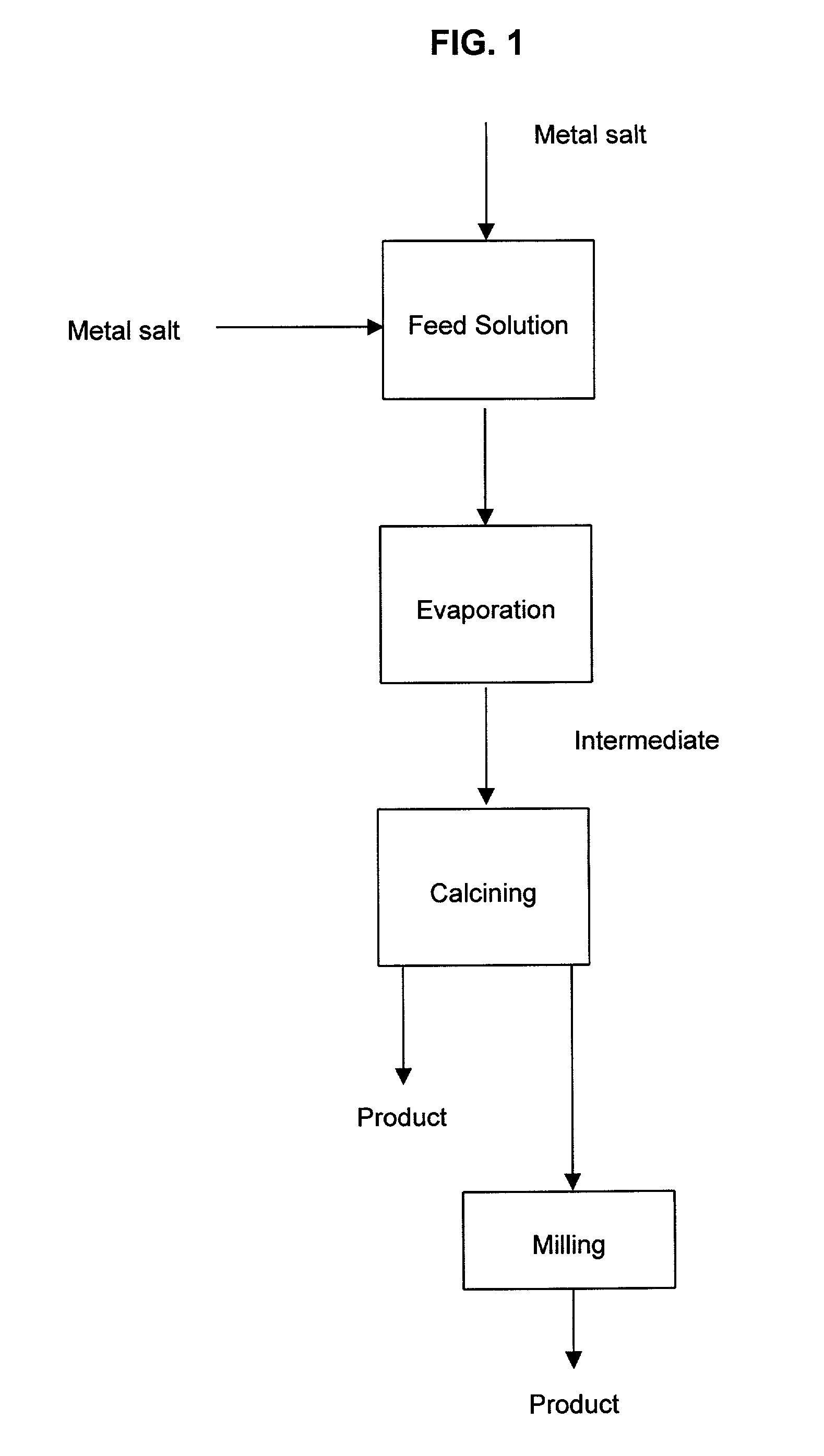

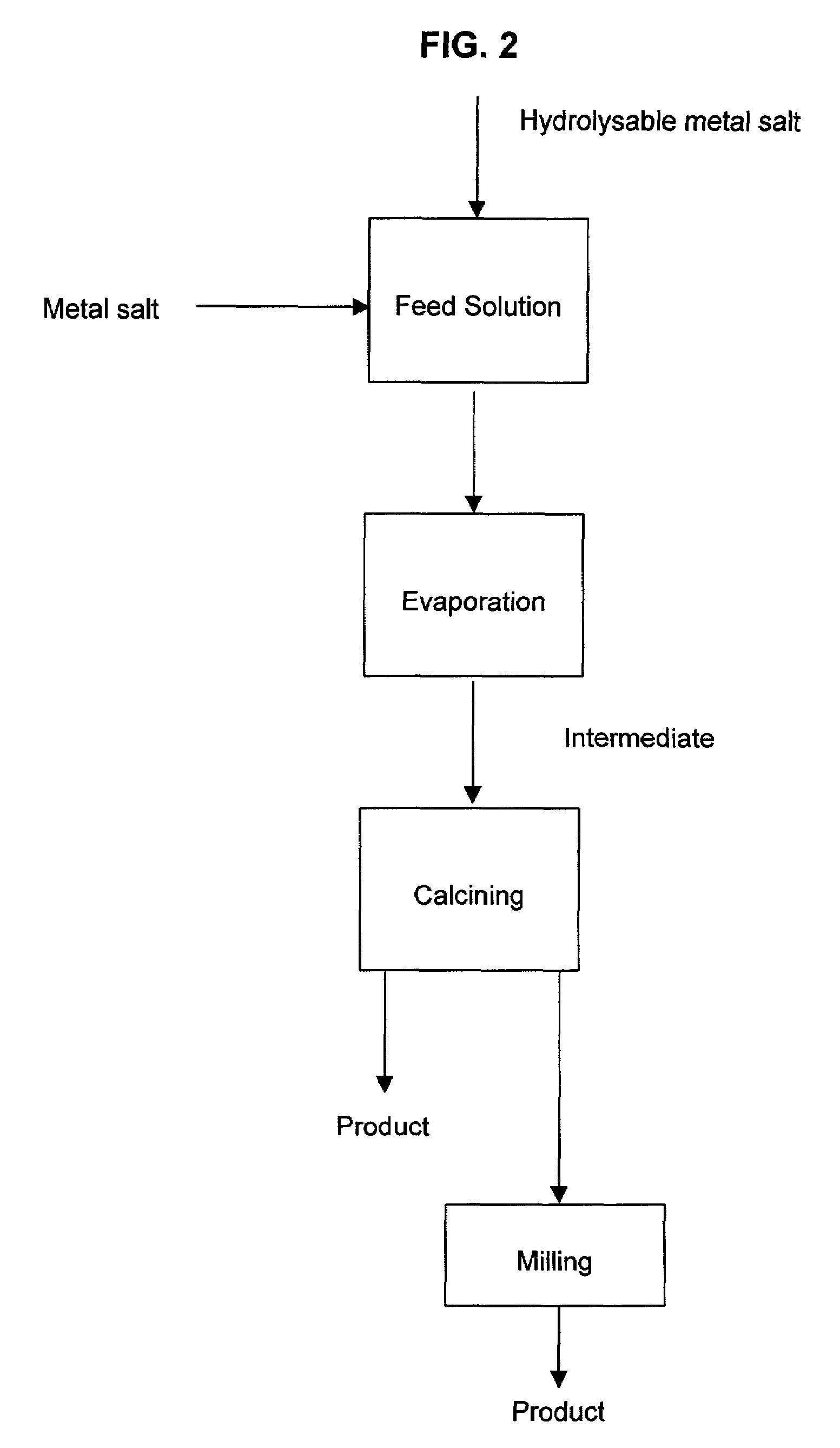

Method for producing mixed metal oxides and metal oxide compounds

A process to produce mixed metal oxides and metal oxide compounds. The process includes evaporating a feed solution that contains at least two metal salts to form an intermediate. The evaporation is conducted at a temperature above the boiling point of the feed solution but below the temperature where there is significant crystal growth or below the calcination temperature of the intermediate. The intermediate is calcined, optionally in the presence of an oxidizing agent, to form the desired oxides. The calcined material can be milled and dispersed to yield individual particles of controllable size and narrow size distribution.

Owner:ALTAIR NANOMATERIALS INC

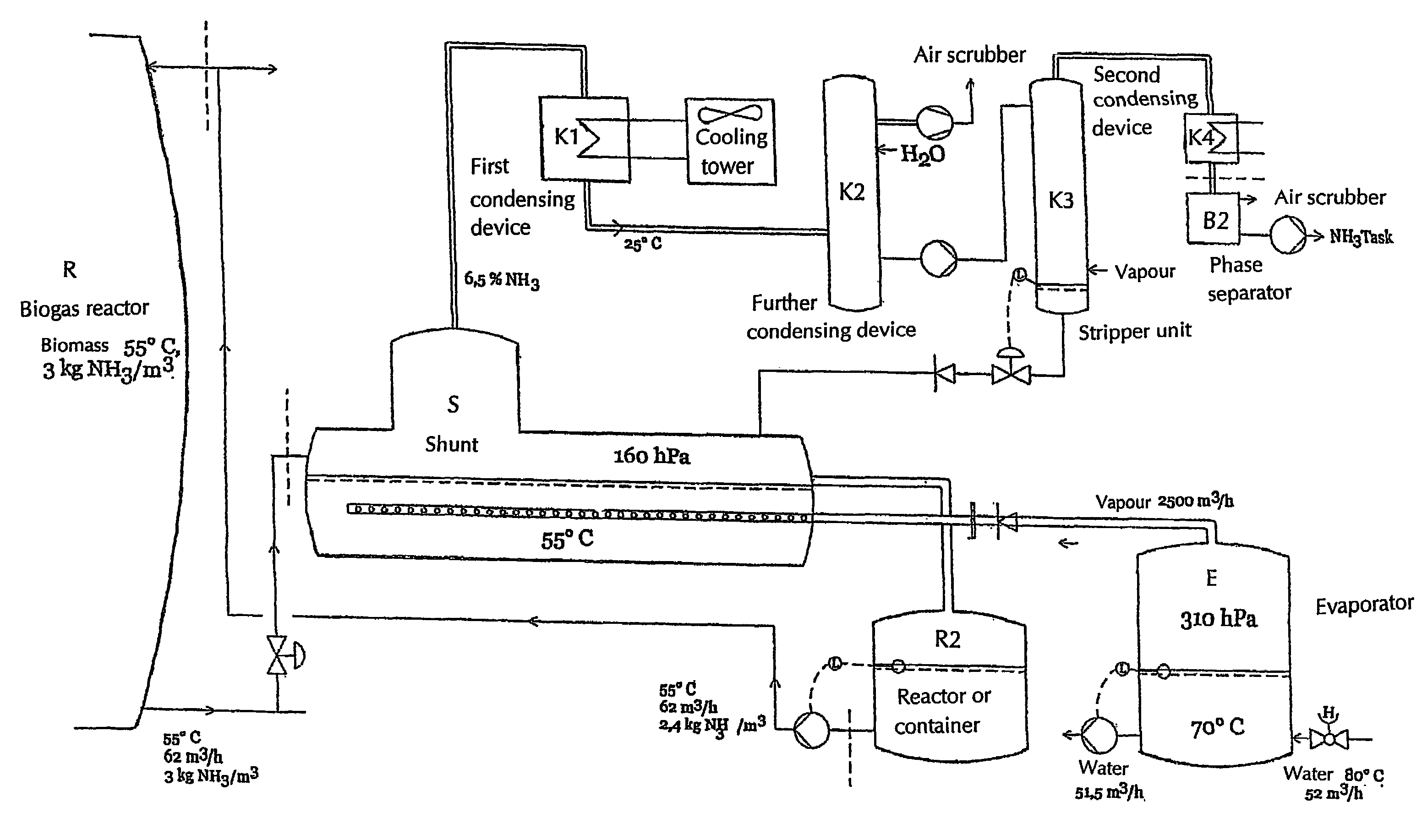

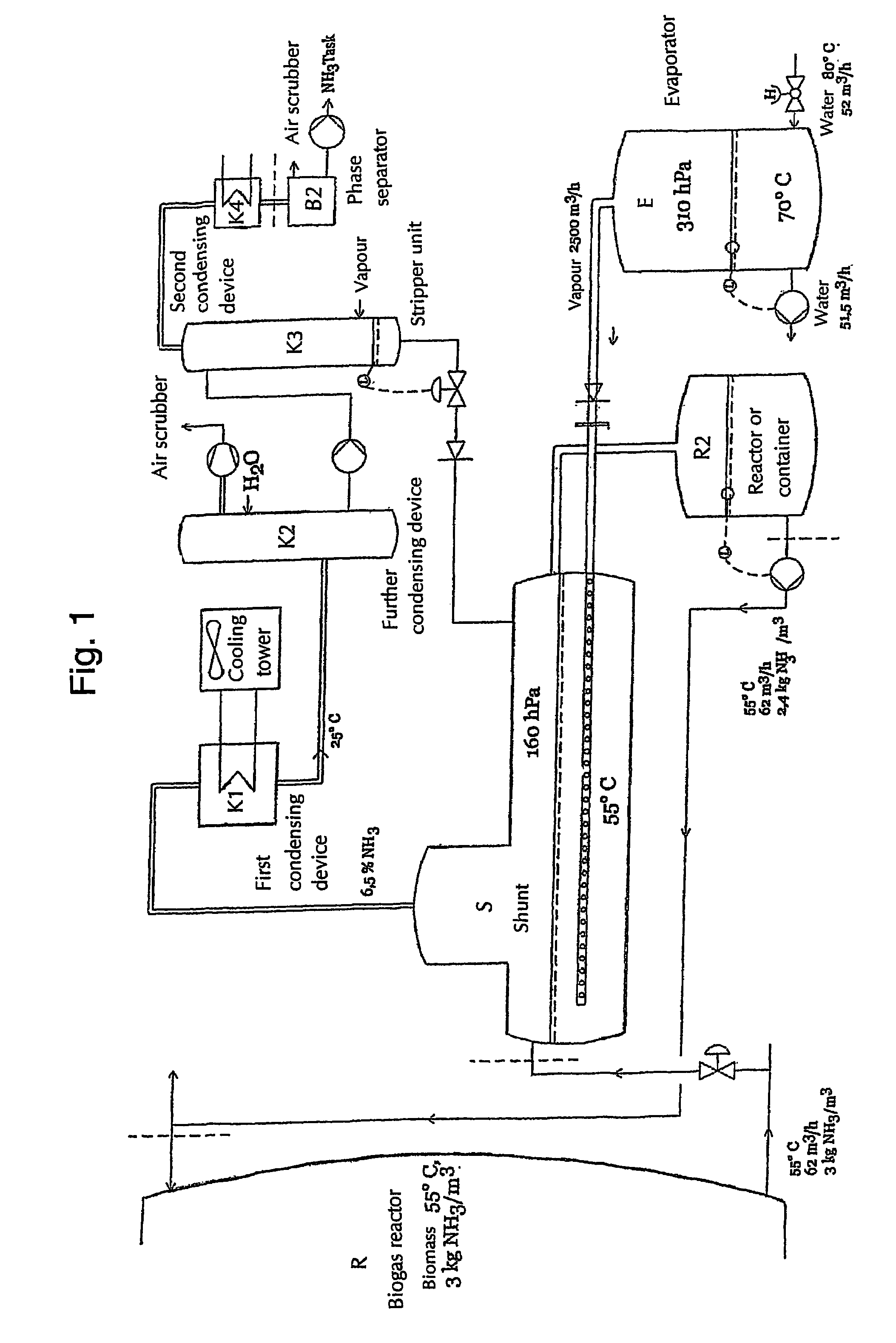

Method and device for stripping ammonia from liquids

InactiveUS20060006055A1Simple and economic in operationLow-valuedBioreactor/fermenter combinationsBiological substance pretreatmentsLiquid mediumHigh pressure

The present invention in a first aspect provides a method and a system for stripping volatile compounds such as ammonia from e.g. fermentation liquids. Part of the ammonia is stripped from the liquid in a stripper system comprising a shunt through which liquid such as e.g. fermentation medium comprising a biomass can be diverted in the form of a side stream in liquid contact with a main fermentor(s). The stripper system is connected to an evaporator. In the evaporator aqueous liquid is heated at a pressure below atmospheric pressure whereby vapour is developed at a temperature below 100° C. The vapour from the evaporator is directed to the liquid medium comprising ammonia and this results in ammonia being stripped from the liquid and transferred to the vapour phase. The vapour phase is condensed in a first condenser at a low pressure, e.g. a pressure well below 1 bar, and the liquid thus obtained is further treated in a stripper unit at a higher pressure, such as e.g. a pressure at or above 1 bar, to obtain a more concentrated solution of ammonia. When stripped for at least part of the ammonia the liquid initially obtained from the biogas reactor and diverted to the shunt can be returned to the reactor.

Owner:GFE PATENT AS

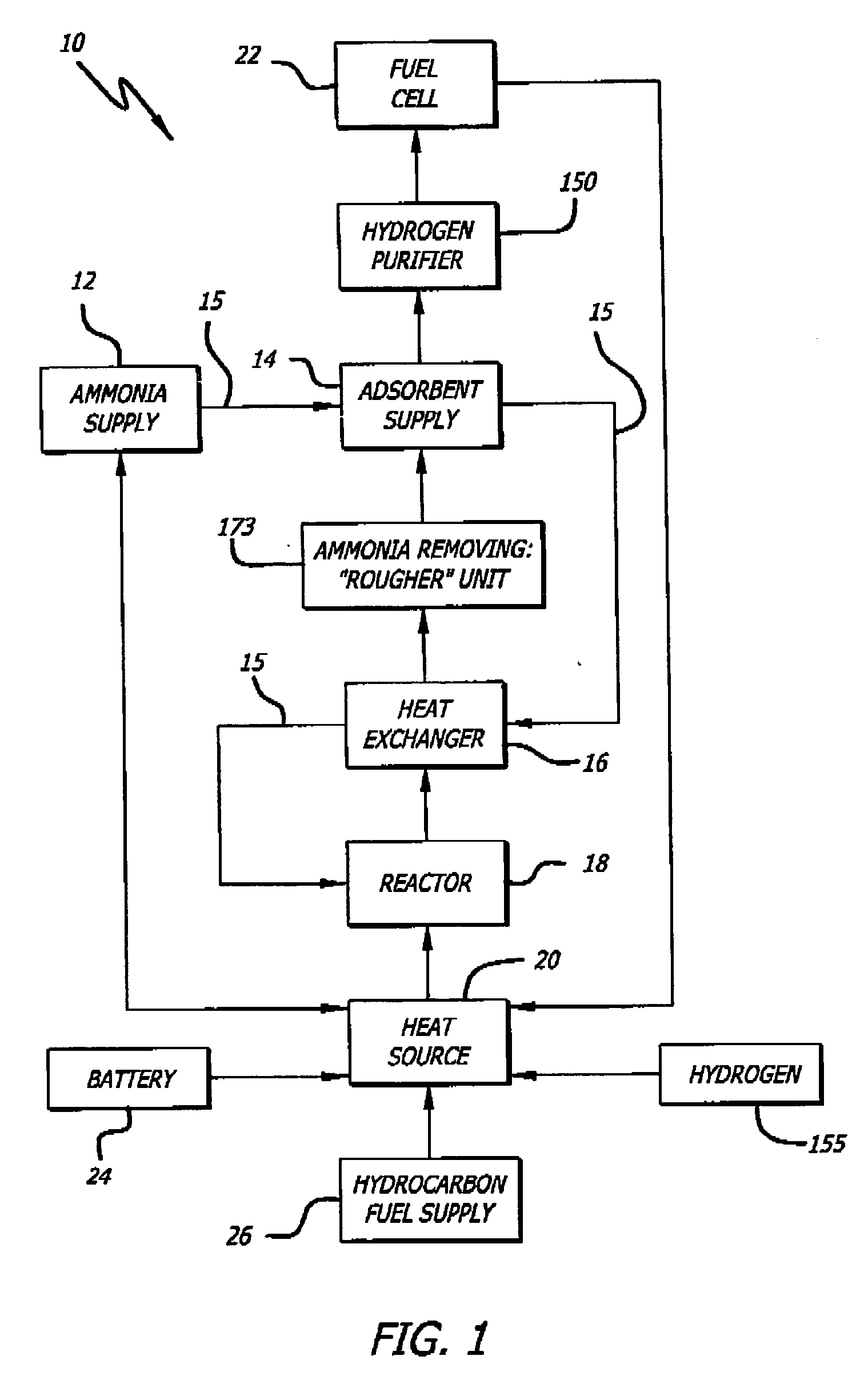

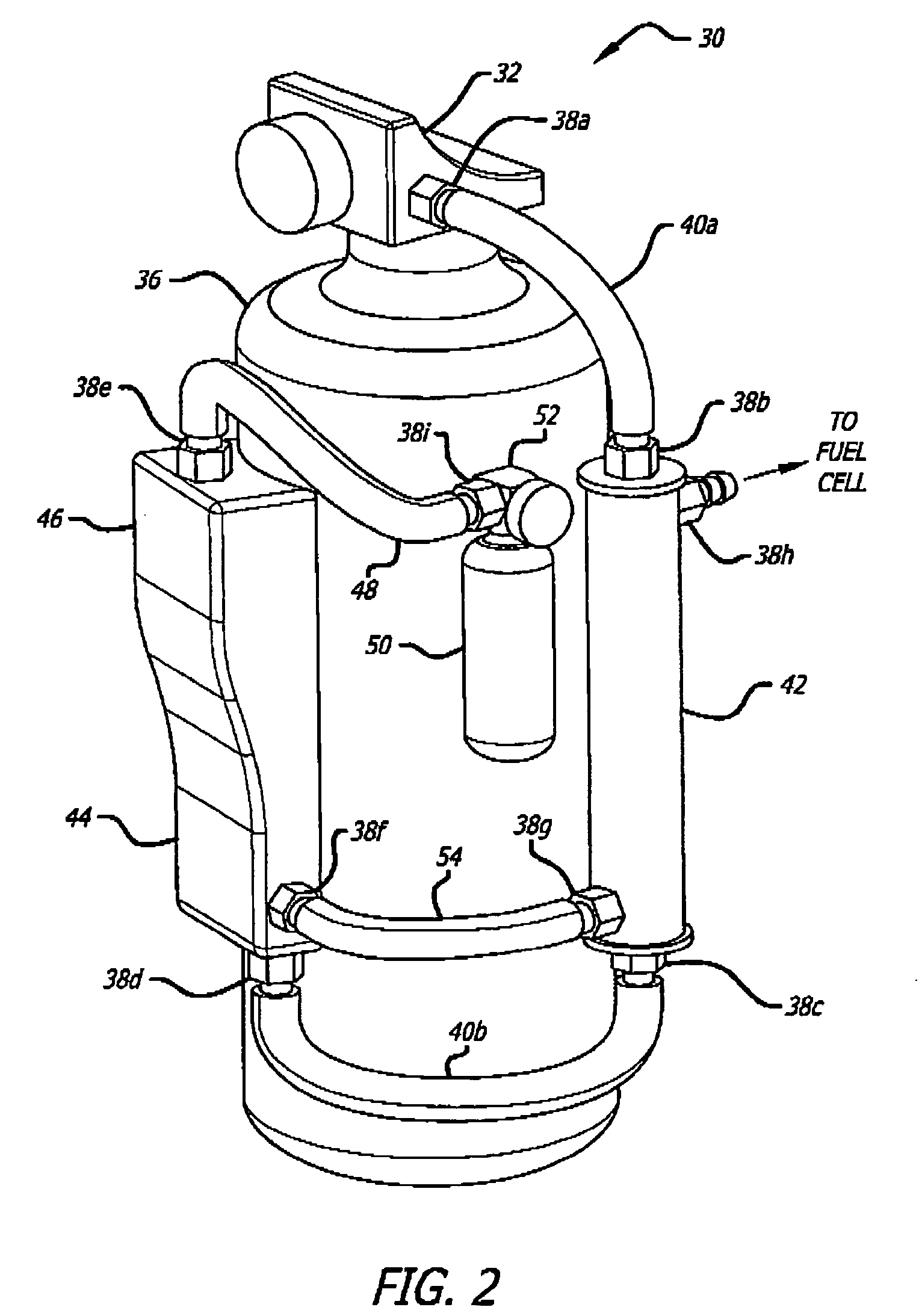

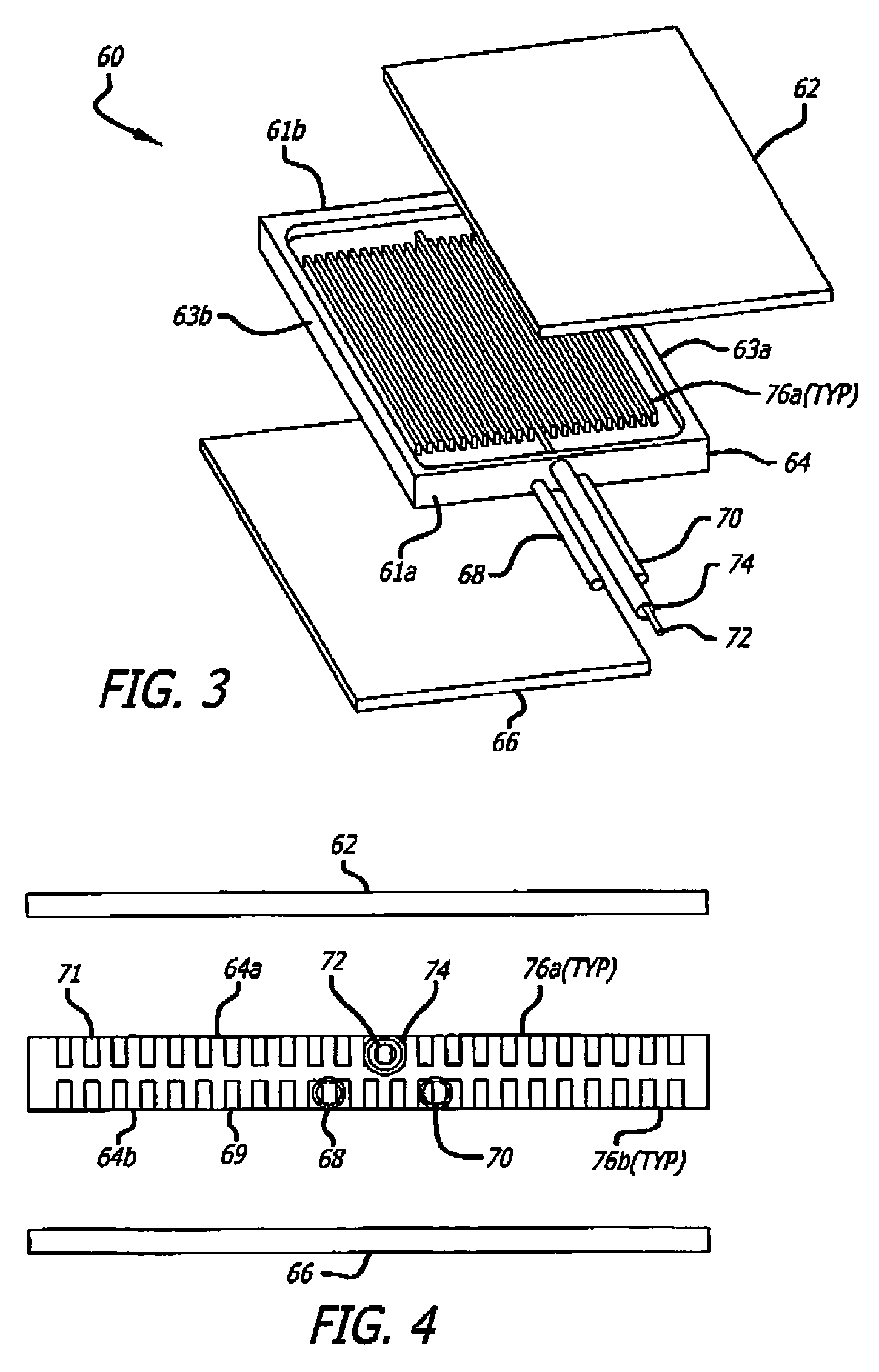

Ammonia-based hydrogen generation apparatus and method for using same

InactiveUS20060112636A1Reduce manufacturing costImprove heat transfer effectCyanogen compoundsNitrogen compoundsHydrogenCombustion chamber

The present disclosure provides teachings relating to ammonia-based hydrogen generation apparatus and associated methods of use. Exemplary methods and apparatus comprise a thermocatalytic hydrogen generation reactor which includes a reaction chamber containing a catalyst-coated substrate, and a combustion chamber containing a catalyst-coated substrate. Exemplary catalyst-coated substrates include, but are not limited to, metal foam, monolith, mesh, ceramic foam or ceramic monolith.

Owner:INTELLIGENT ENERGY INC

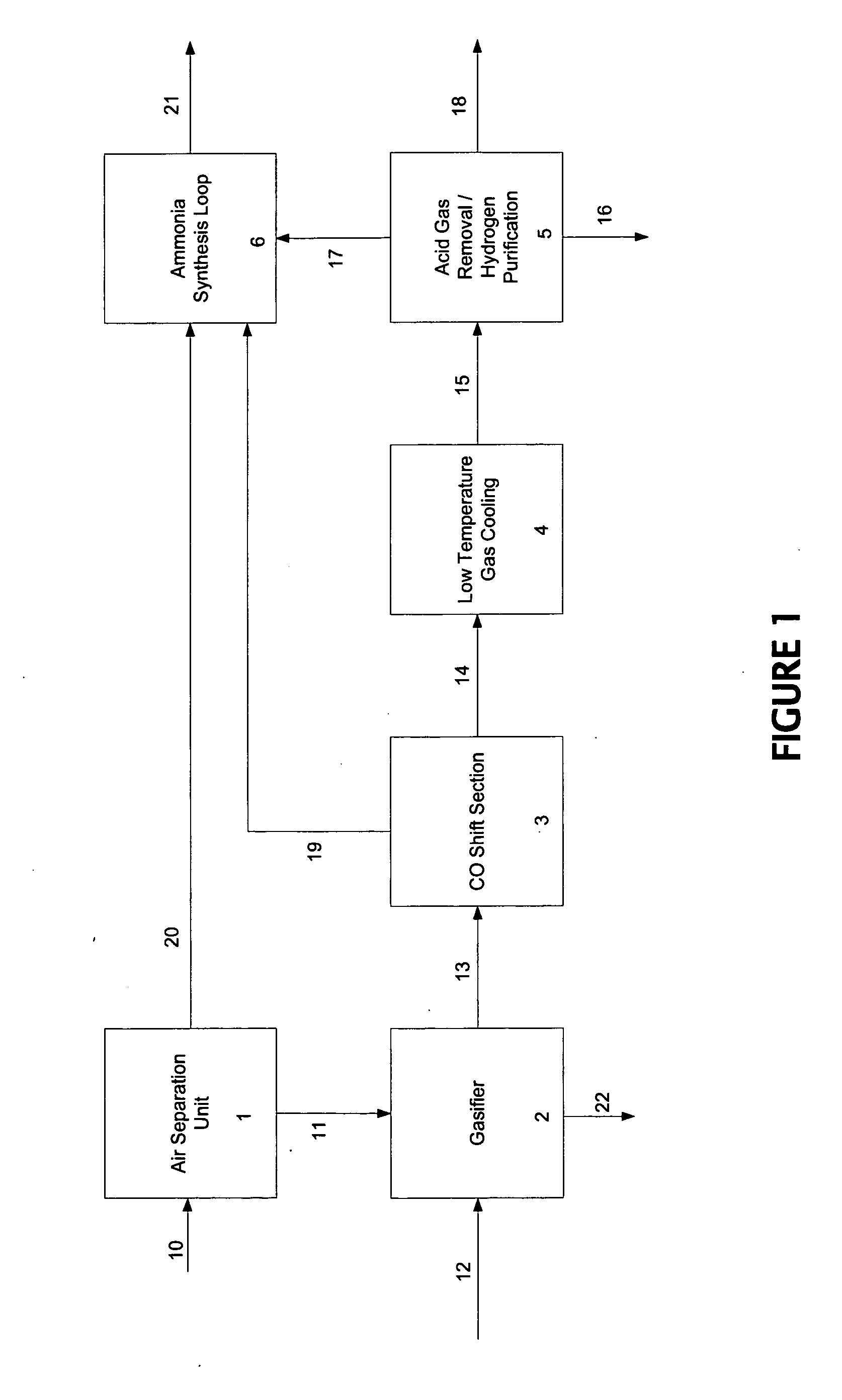

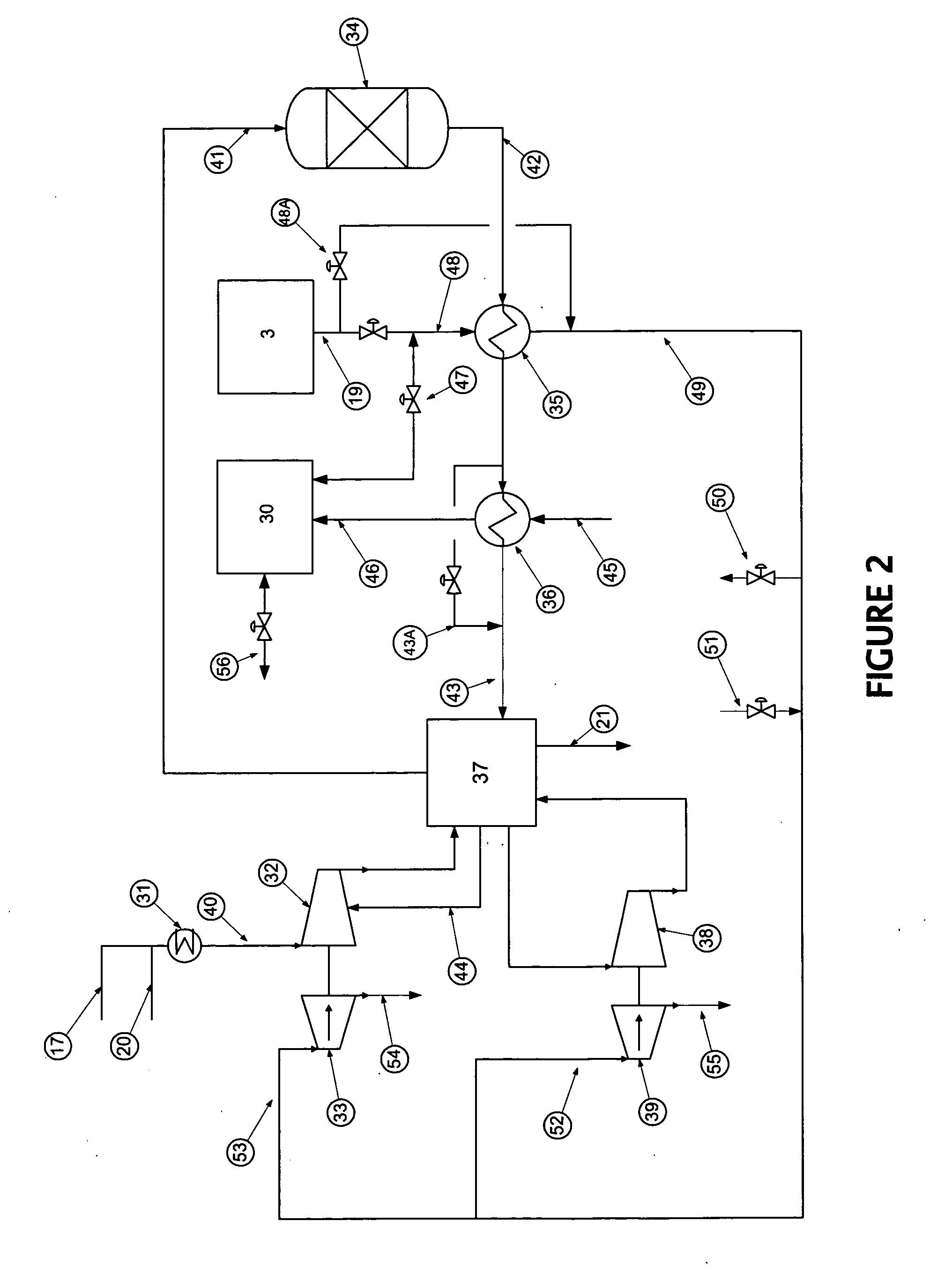

Integration of gasification and ammonia production

A method and system are described for making ammonia using hydrogen from a gasification process and for integrating the steam systems of the two processes. The gasification process provides high-pressure, purified hydrogen and high-pressure, saturated steam. The high pressure hydrogen lowers the overall compression requirement for the ammonia process. In addition, the high-pressure, saturated steam can be converted into superheated steam by recovering heat from ammonia synthesis and used to power steam turbines for compression and refrigeration needs.

Owner:EASTMAN CHEM CO

Lithium secondary battery with high power

ActiveUS20050271943A1Improves high-temperature cycle characteristicReduce concentrationAlkali metal oxidesIron compoundsElectrical batteryManganese

The present invention provides a non-aqueous electrolyte-based high power lithium secondary battery having a long-term service life and superior safety at both room temperature and high temperature, even after repeated high-current charging and discharging, wherein the battery comprises a mixture of a particular lithium manganese-metal composite oxide (A) having a spinel structure and a particular lithium nickel-manganese-cobalt composite oxide (B) having a layered structure, as a cathode active material.

Owner:LG ENERGY SOLUTION LTD

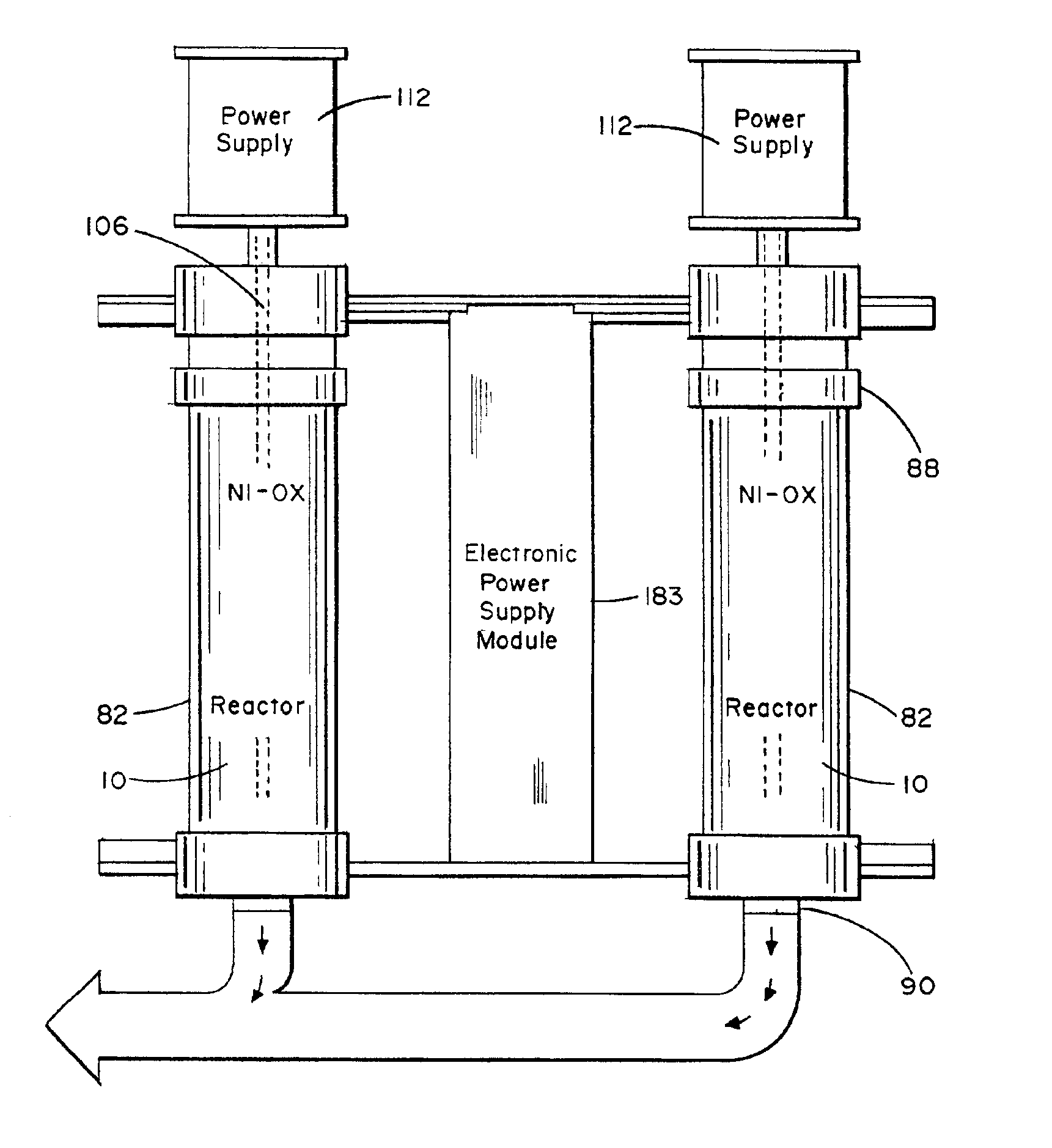

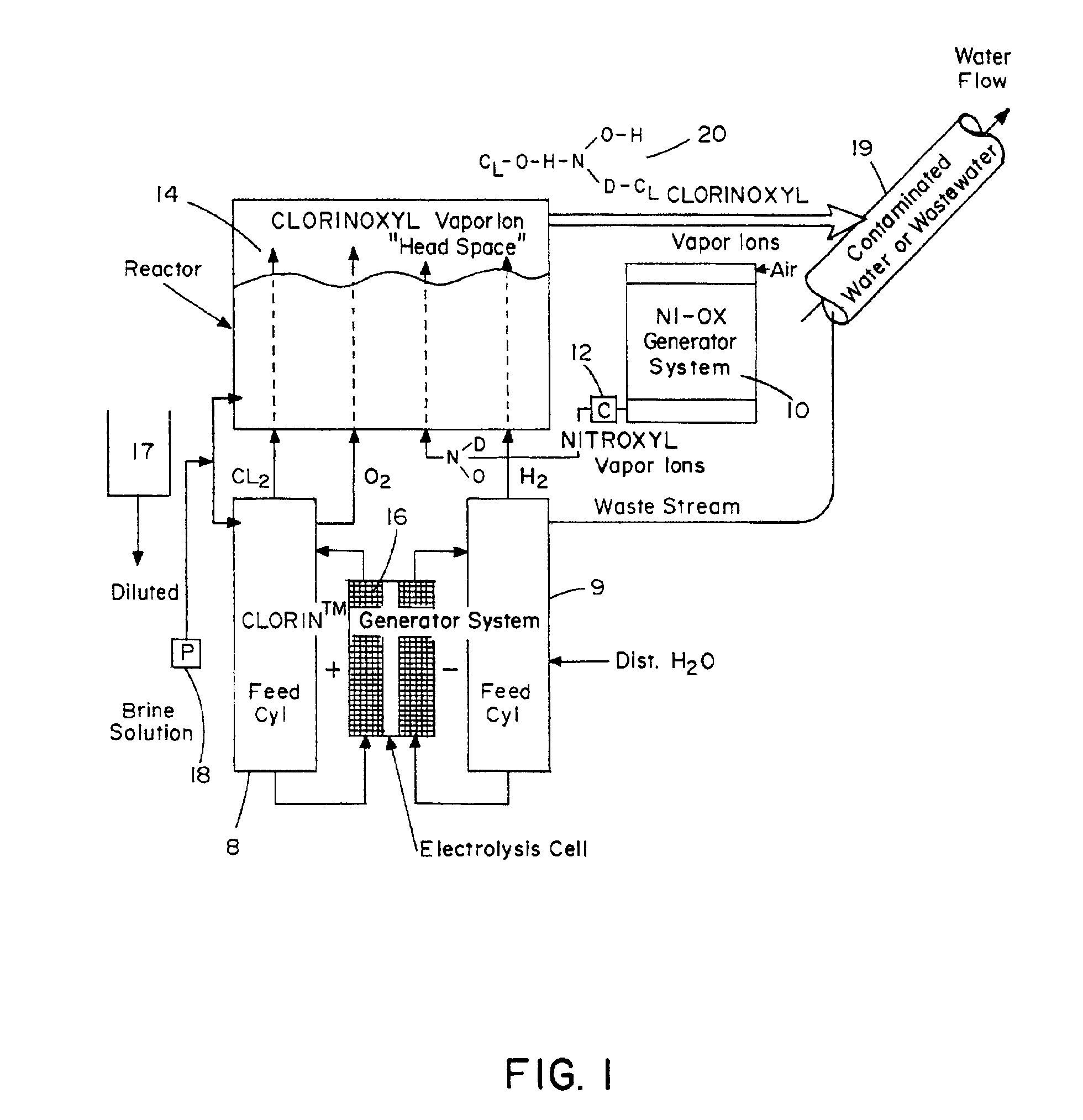

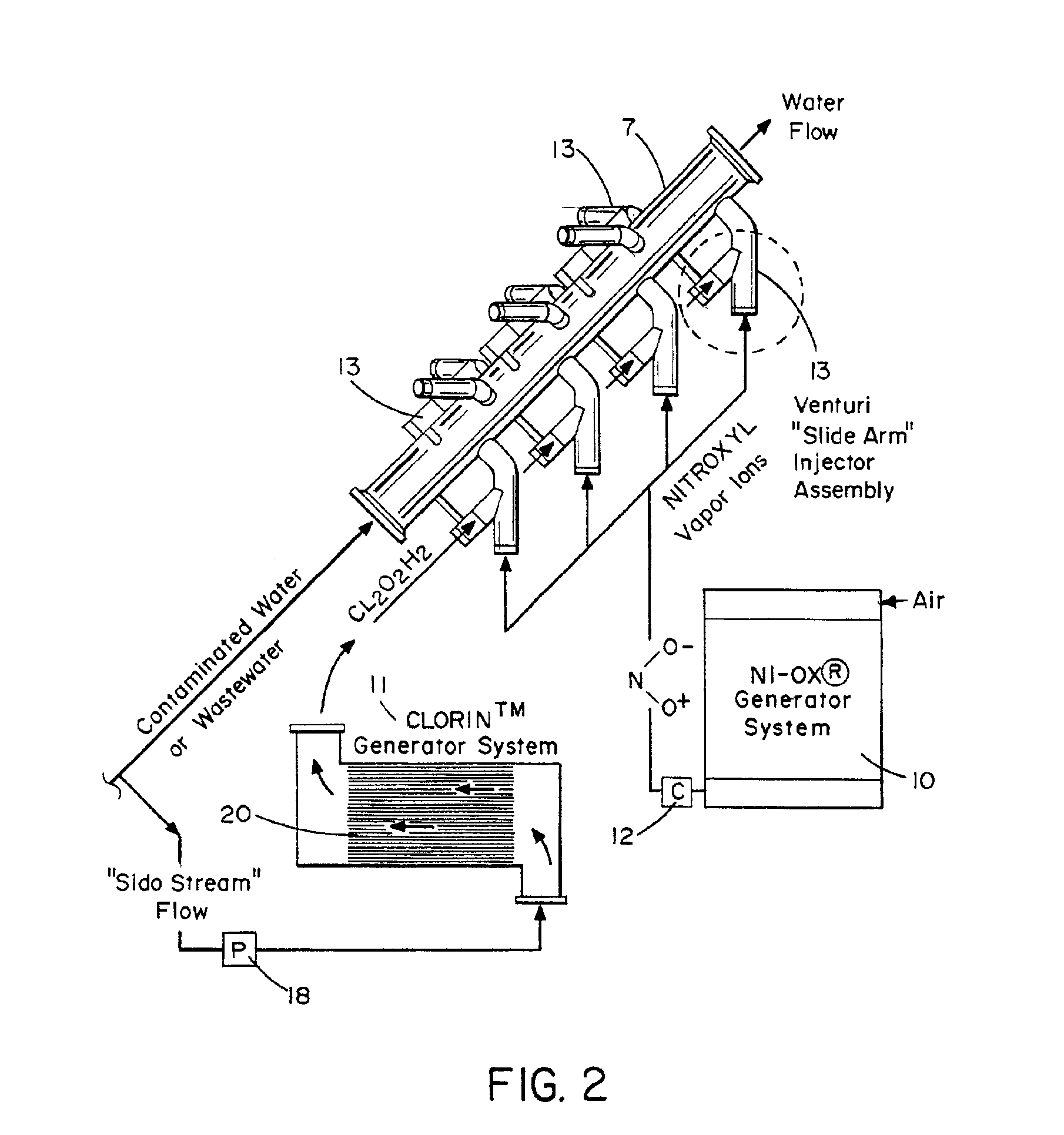

Non-chemical water treatment method and apparatus employing ionized air purification technologies for marine application

InactiveUS6923901B2Reduce maintenanceReduce energy costsCyanogen compoundsNitrogen compoundsElectrolysisDihydrogen oxide

Contaminated water, particularly, ballast water, blackwater, galley water, accommodation water, laundry water, fresh water and seawater, is disinfected by admixture of a highly reactive gas stream containing ions of oxygen and nitrogen, formed by exposure of air to short-wavelength ultraviolet radiation, and of chlorine, formed in situ by electrolysis of salt in the water. Solids removal can be accomplished by electrophoresis in the same unit employed for electrolysis to release chlorine, or in a separate unit. Heavy metals maybe removed by plating or sacrificing electrodes.

Owner:IONZ BLUEWATER SOLUTIONS +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com