Patents

Literature

59results about How to "Reduce ammonia consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

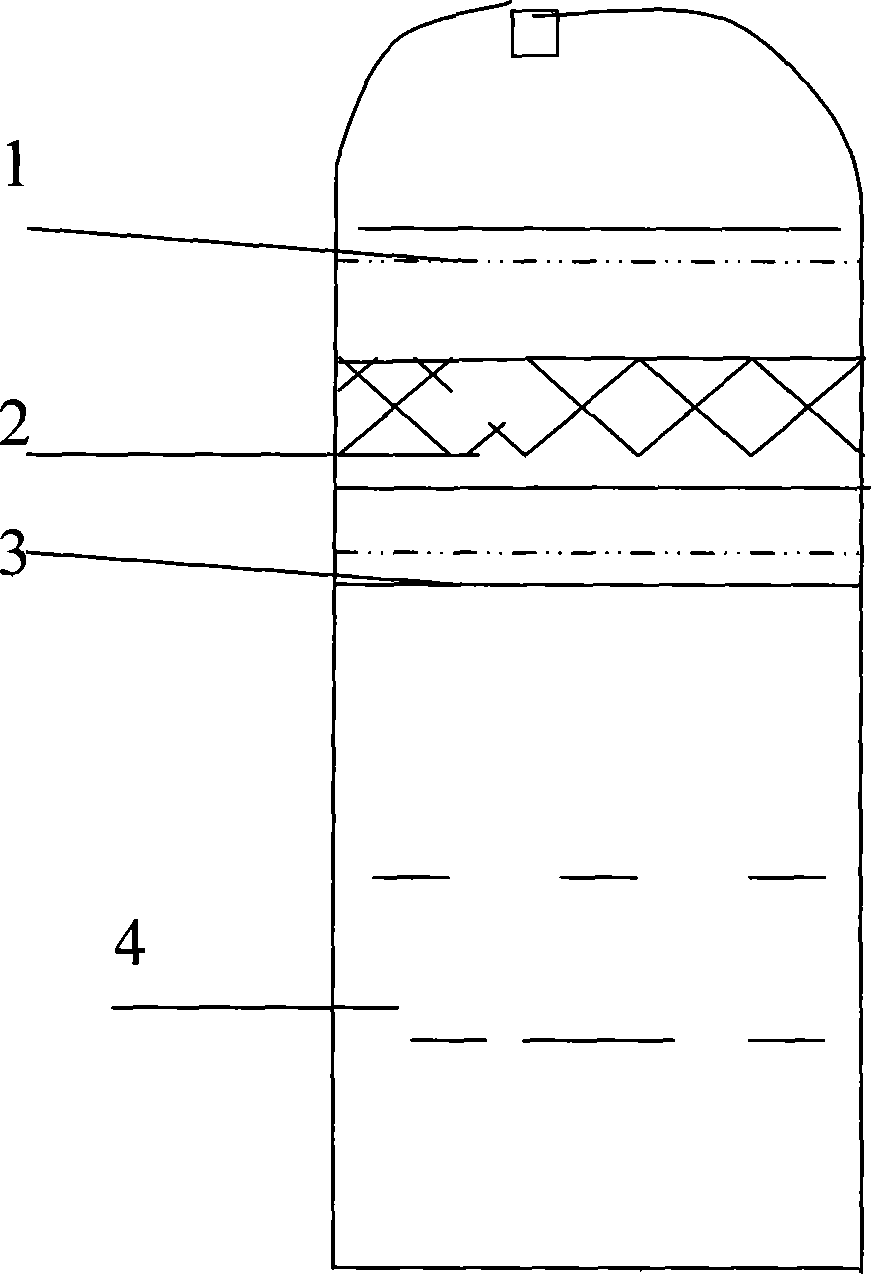

Method for desulfurizing and denitrating smoke simultaneously through ammonia method

ActiveCN101934191AIncrease profitReduce ammonia consumptionDispersed particle separationAmmonia compoundsAmmoniaAmmonium sulfate

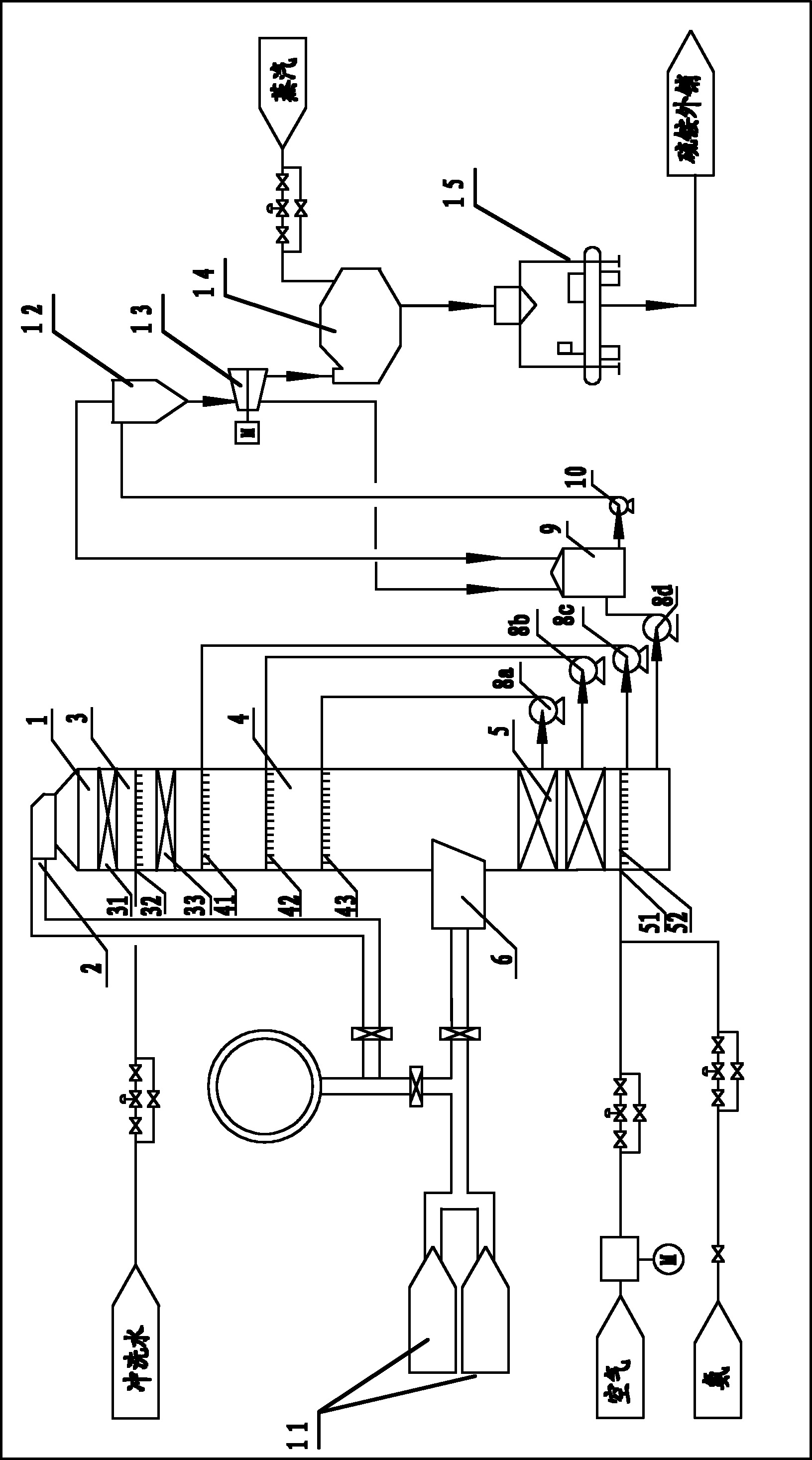

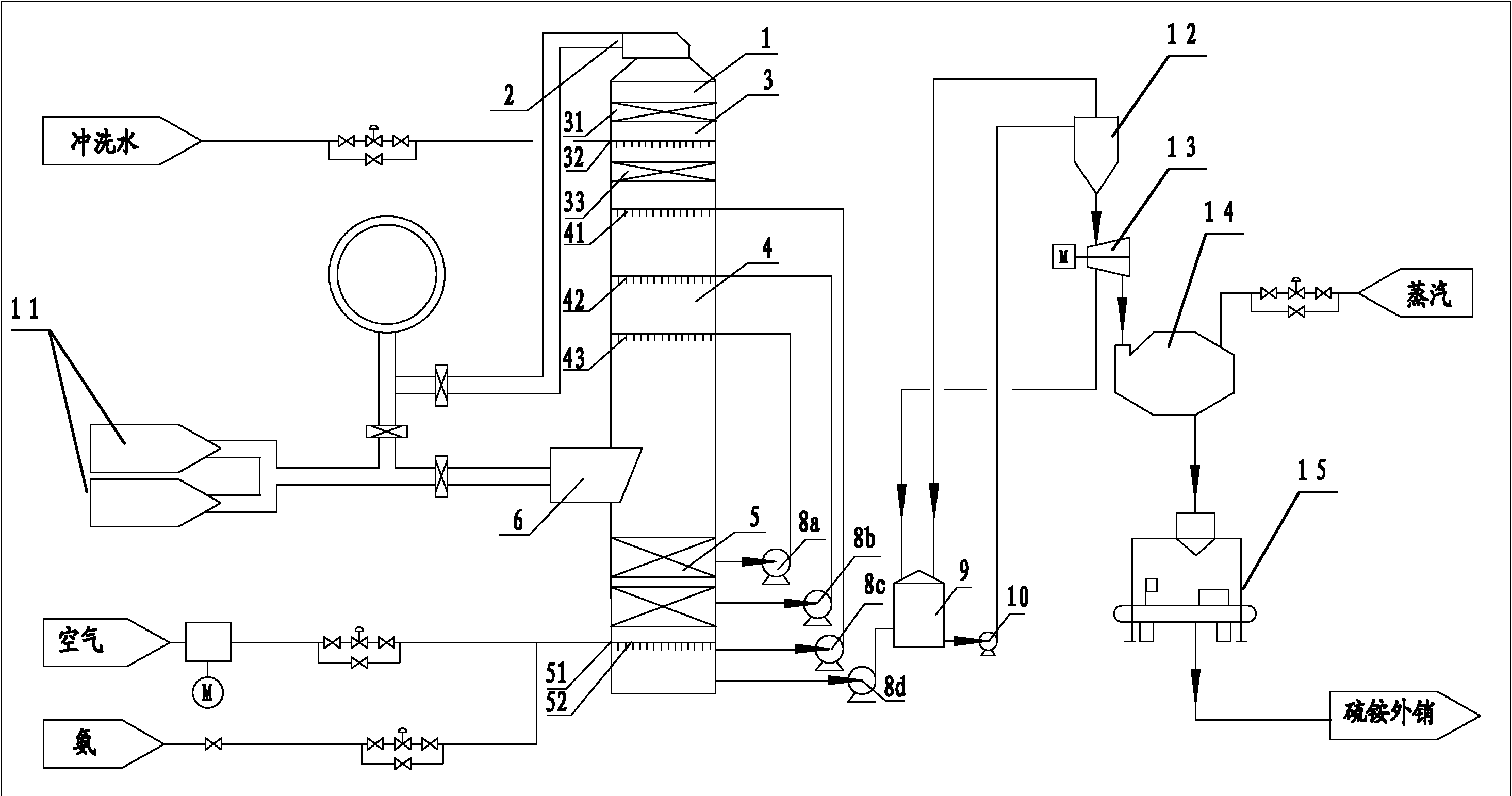

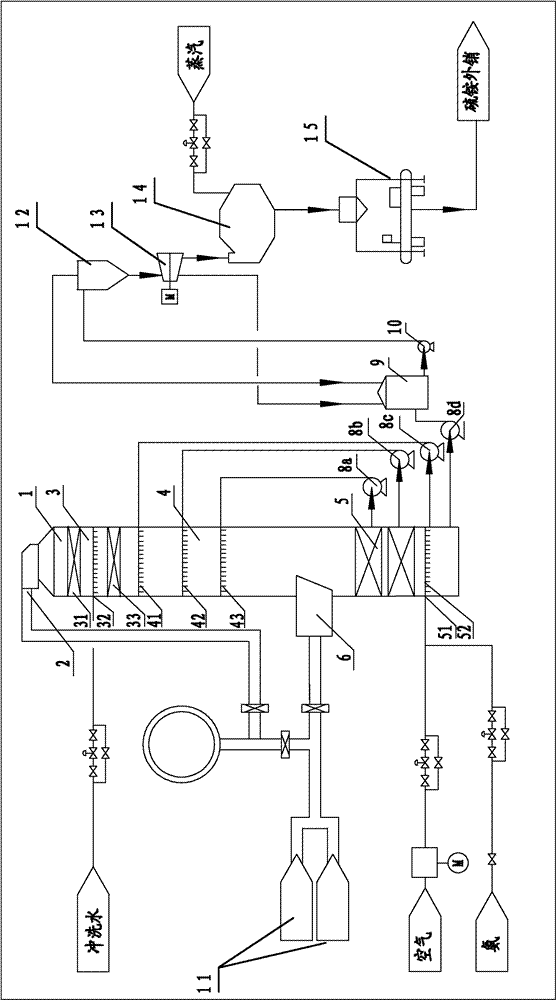

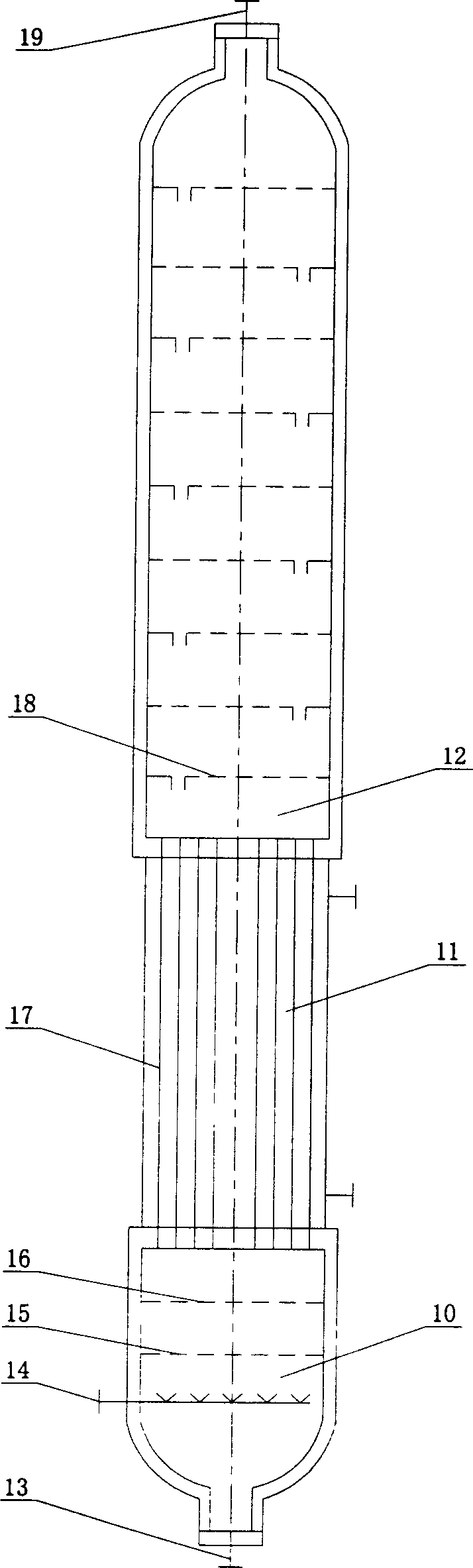

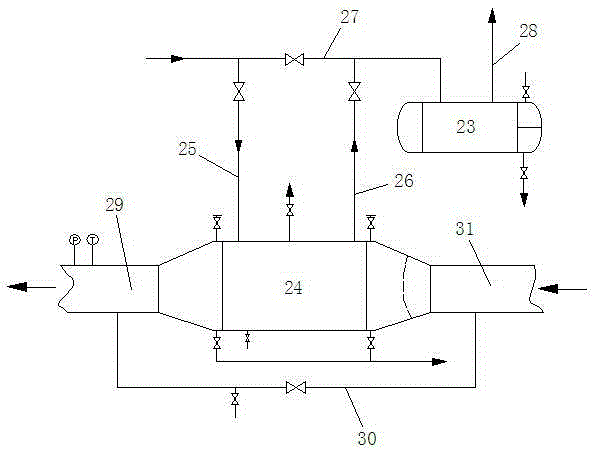

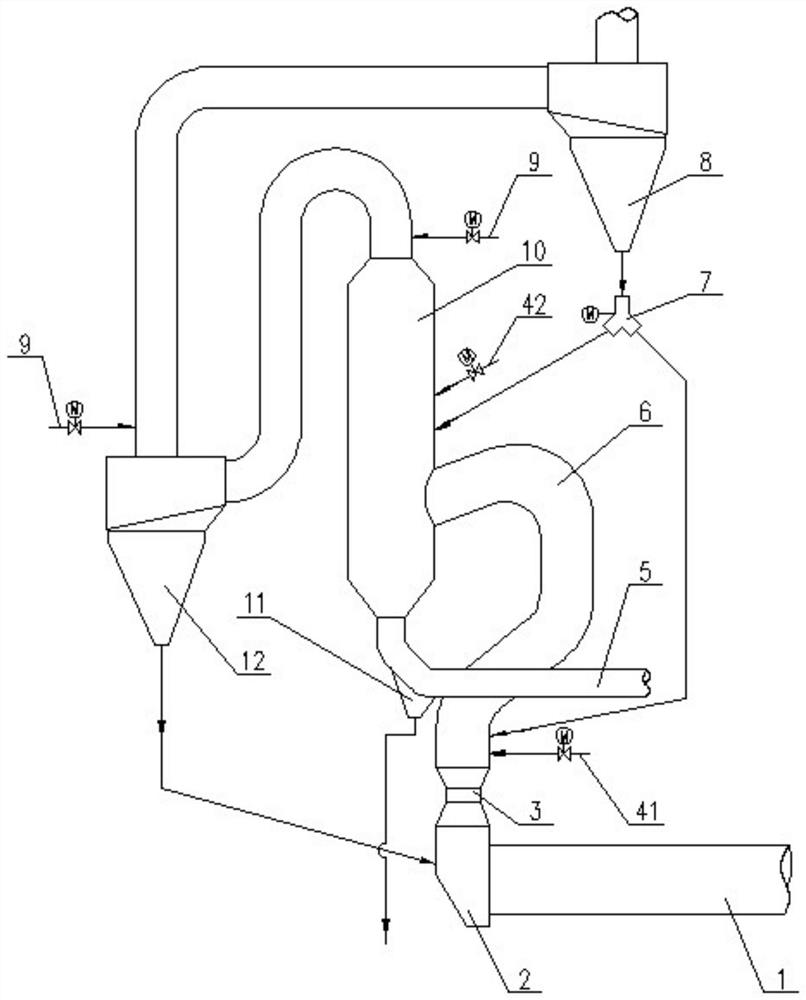

The invention relates to a method for desulfurizing and denitrating smoke simultaneously through an ammonia method, which is carried out in a desulfurizing and denitrating system. The desulfurizing and denitrating system comprises a desulfurizing and denitrating tower, the desulfurizing and denitrating tower is provided with a washing demisting segment, an absorption segment and an oxidation segment, wherein the absorption segment is provided with a first desulfurizing spray layer, a second desulfurizing spray layer and a denitrating spray layer from top to bottom; the oxidation segment is provided with a denitrating circulation layer, a desulfurizing circulation layer and an oxidation layer from top to bottom, wherein the denitrating circulation layer, the desulfurizing circulation layerand the oxidation layer are respectively communicated with the denitrating spray layer, the second desulfurizing spray layer and the first desulfurizing spray layer through circulating pipelines positioned outside the desulfurizing and denitrating tower; smoke enters from a smoke inlet, sequentially contacts with the absorption liquid of the denitrating spray layer, the second desulfurizing spraylayer and the first desulfurizing spray layer for denitration and desulfurization, then enters the washing demisting segment and then is exhausted; the absorption liquid of the spray layers descends to the oxidation segment and reacts on the oxidation layer to generate ammonium sulfate; and the absorption liquid of the denitrating circulation layer, the desulfurizing circulation layer and the oxidation layer is respectively delivered to the denitrating spray layer, the second desulfurizing spray layer and the first desulfurizing spray layer through the circulating pipelines positioned outsidethe desulfurizing and denitrating tower.

Owner:NANJING NEW CENTURY JIANGNAN ENVIRONMENTAL PROTECTION CO LTD

Flotation method of low ore grade manganous carbonate ore

The invention relates to a process that raw mine is ground into powder which is added with water to be prepared into pulp. Under certain pH value, inhibitor of carboxymethylcellulose nano solution, industrial water glass and tannin solution are added proportionally for absorbing calcium, magnesium and silicate. Then, sodium oleate is added as a collector for closed circuit circulation floating. Foam products after the floatation are flushed by water and then enter a sedimentation tank for the sedimentation or the pressure filtration. Thus, manganese concentrate fines above 20 percent are obtained. In the process, floatation is implemented on low grade poor manganese mine containing 10-14 percent of manganese, carbonaceous rock with the manganese content of 4-9 percent and electrolytic manganese leached slags with the manganese content of 1-3 percent to obtain manganese ore fines, the manganese content of which reaches above 20 percent. The recovery of manganese is more than 85 percent. And non-manganese emission for tailings can be realized. The manganese resources are lead to have extremely high utilization rate. Produced products can also lower acid consumption and ammonia consumption for electrolytic manganese production of downstream industry of manganese mines.

Owner:HUAYUAN QIANGHUA MINING

Method for desulfurizing and denitrating smoke simultaneously through ammonia method

ActiveCN101934191BImplement resourcesSimple processDispersed particle separationAmmonia compoundsTowerAmmonia

The invention relates to a method for desulfurizing and denitrating smoke simultaneously through an ammonia method, which is carried out in a desulfurizing and denitrating system. The desulfurizing and denitrating system comprises a desulfurizing and denitrating tower, the desulfurizing and denitrating tower is provided with a washing demisting segment, an absorption segment and an oxidation segment, wherein the absorption segment is provided with a first desulfurizing spray layer, a second desulfurizing spray layer and a denitrating spray layer from top to bottom; the oxidation segment is provided with a denitrating circulation layer, a desulfurizing circulation layer and an oxidation layer from top to bottom, wherein the denitrating circulation layer, the desulfurizing circulation layerand the oxidation layer are respectively communicated with the denitrating spray layer, the second desulfurizing spray layer and the first desulfurizing spray layer through circulating pipelines positioned outside the desulfurizing and denitrating tower; smoke enters from a smoke inlet, sequentially contacts with the absorption liquid of the denitrating spray layer, the second desulfurizing spraylayer and the first desulfurizing spray layer for denitration and desulfurization, then enters the washing demisting segment and then is exhausted; the absorption liquid of the spray layers descends to the oxidation segment and reacts on the oxidation layer to generate ammonium sulfate; and the absorption liquid of the denitrating circulation layer, the desulfurizing circulation layer and the oxidation layer is respectively delivered to the denitrating spray layer, the second desulfurizing spray layer and the first desulfurizing spray layer through the circulating pipelines positioned outsidethe desulfurizing and denitrating tower.

Owner:NANJING NEW CENTURY JIANGNAN ENVIRONMENTAL PROTECTION CO LTD

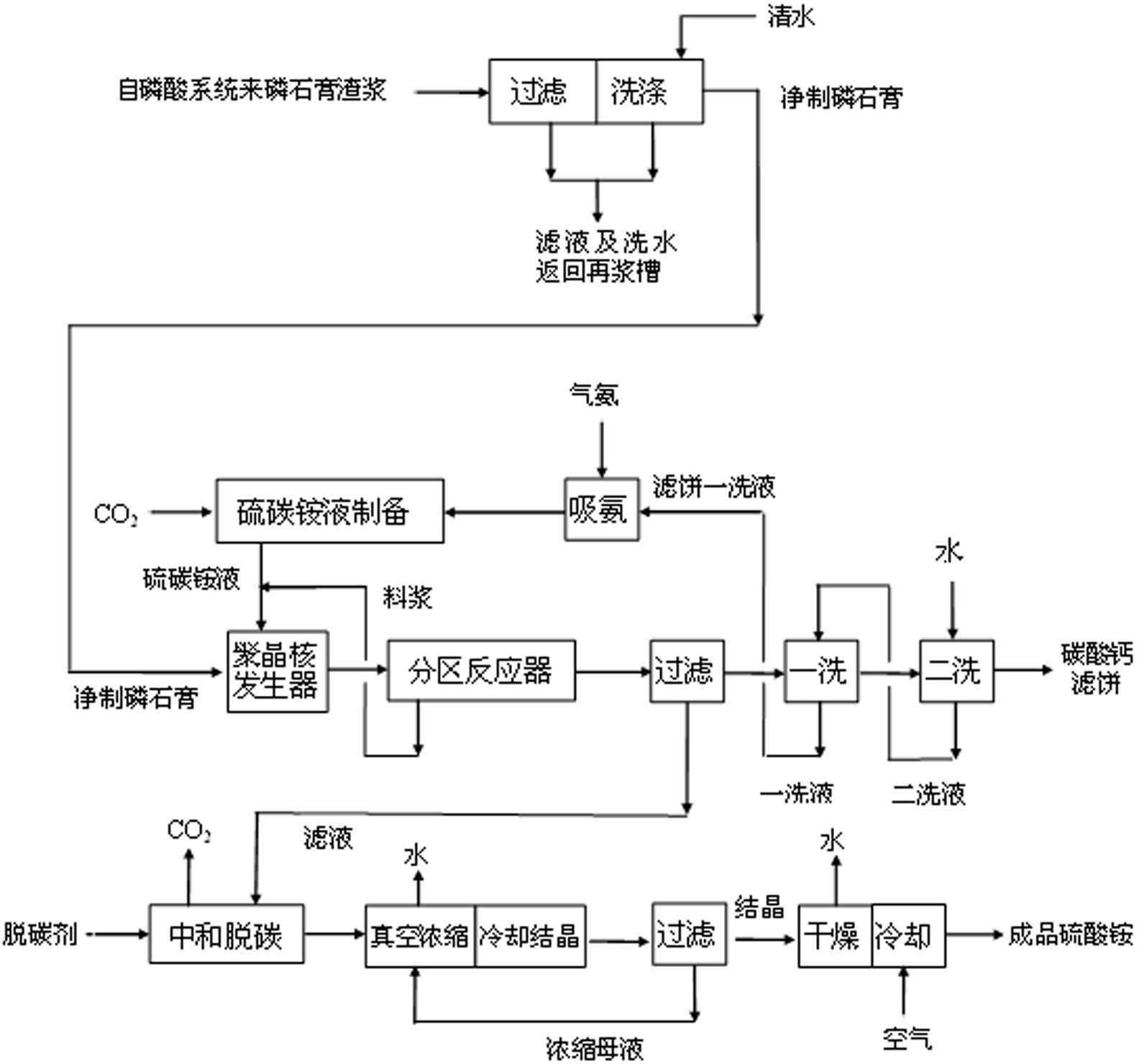

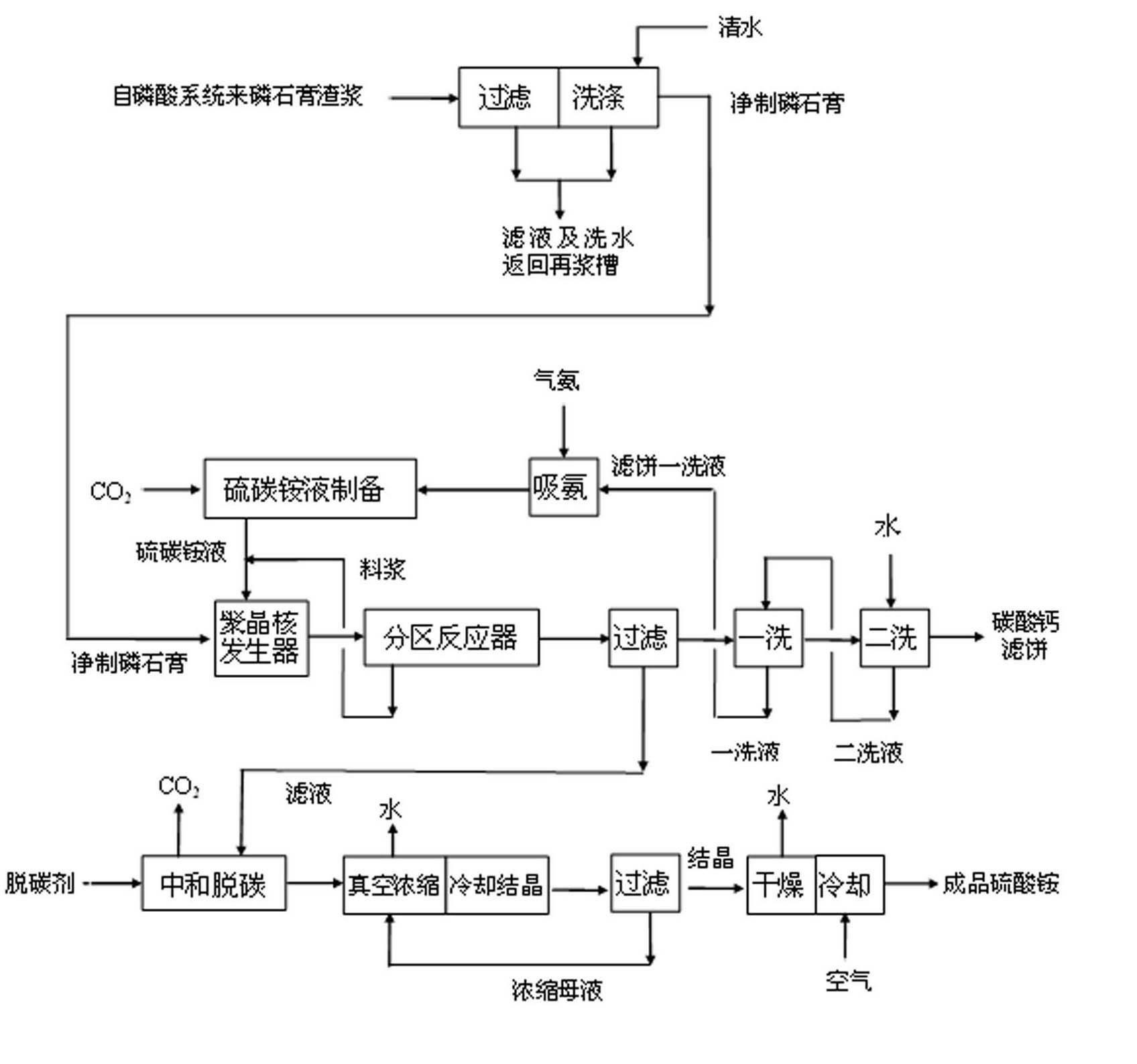

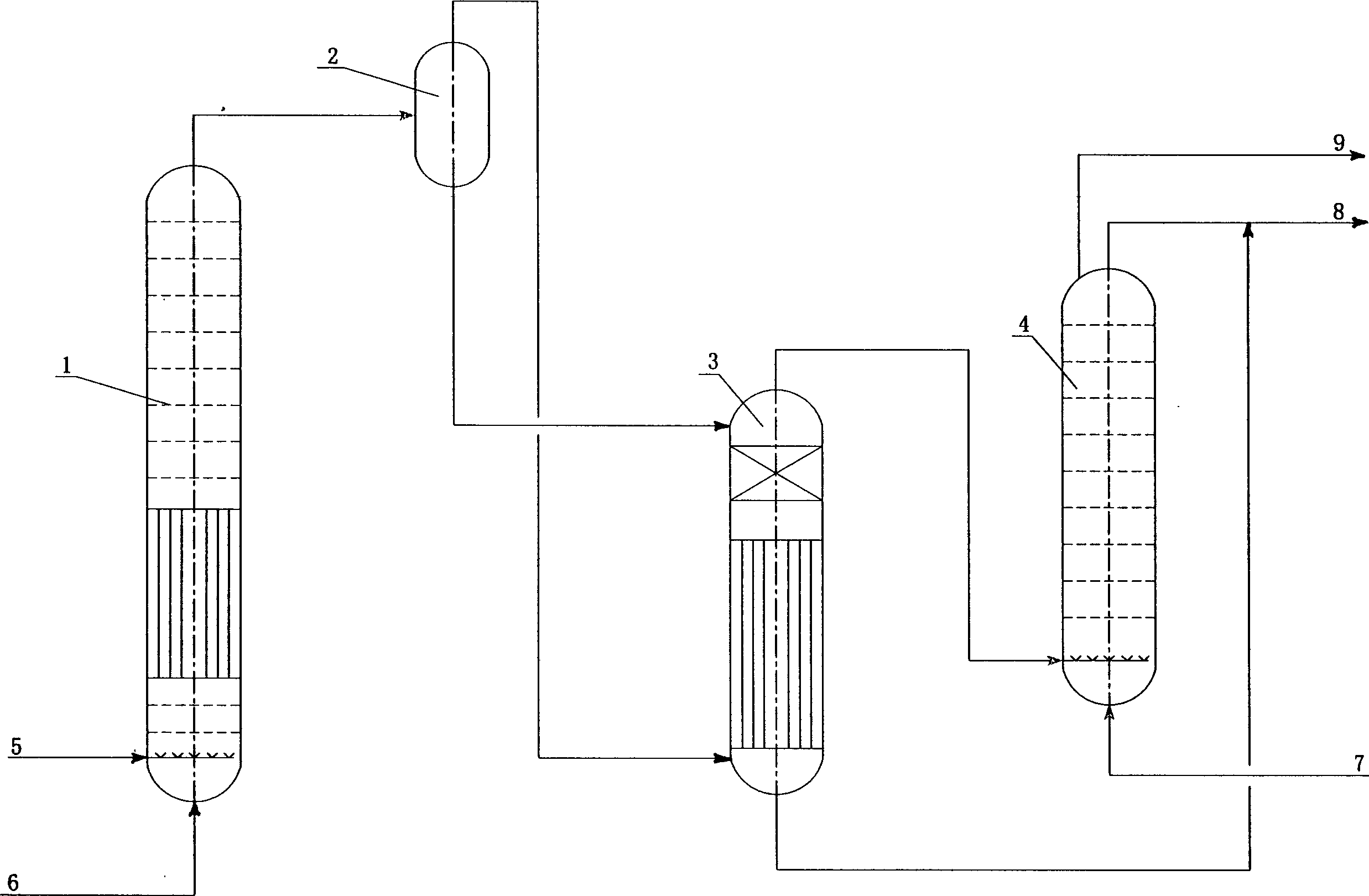

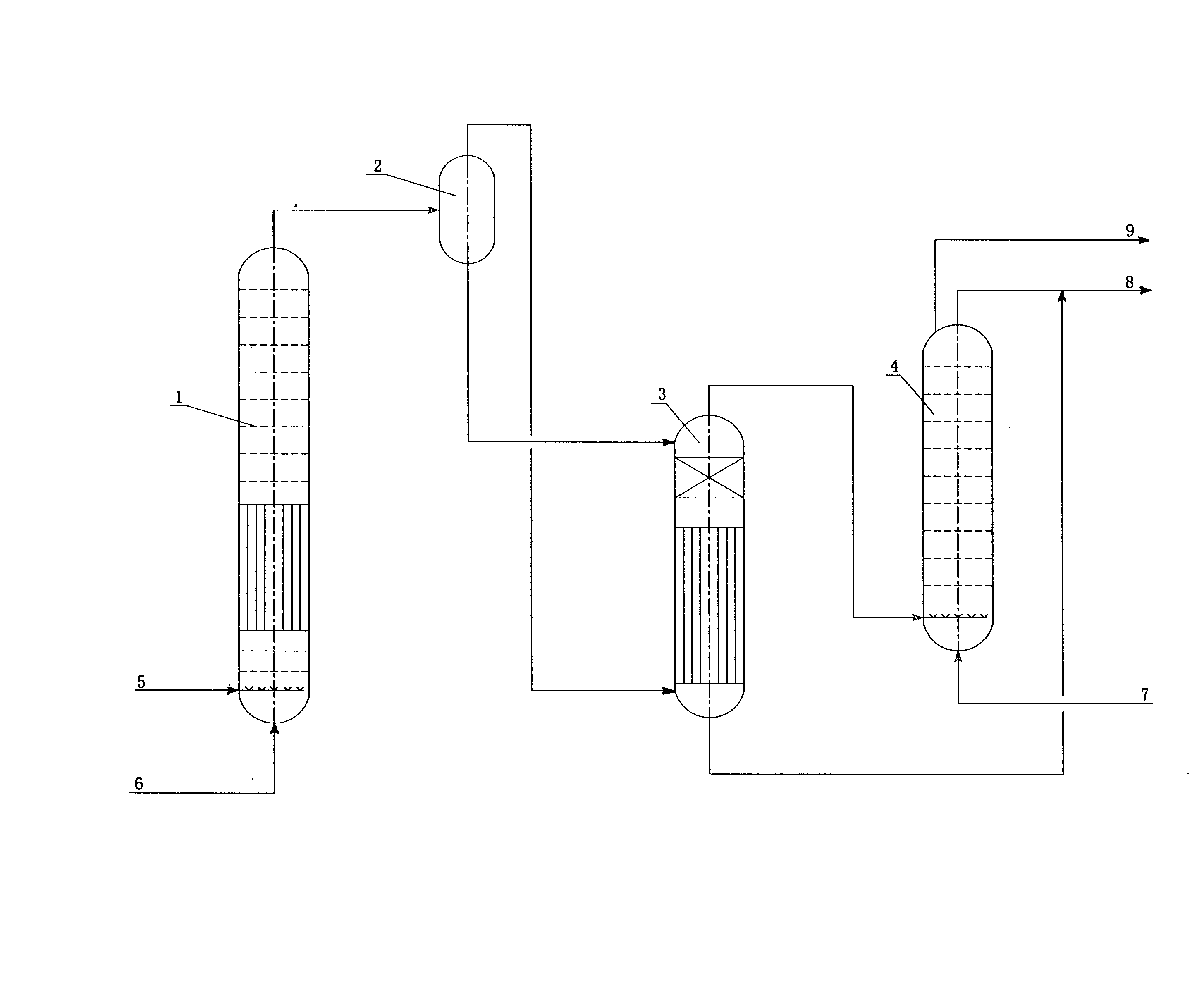

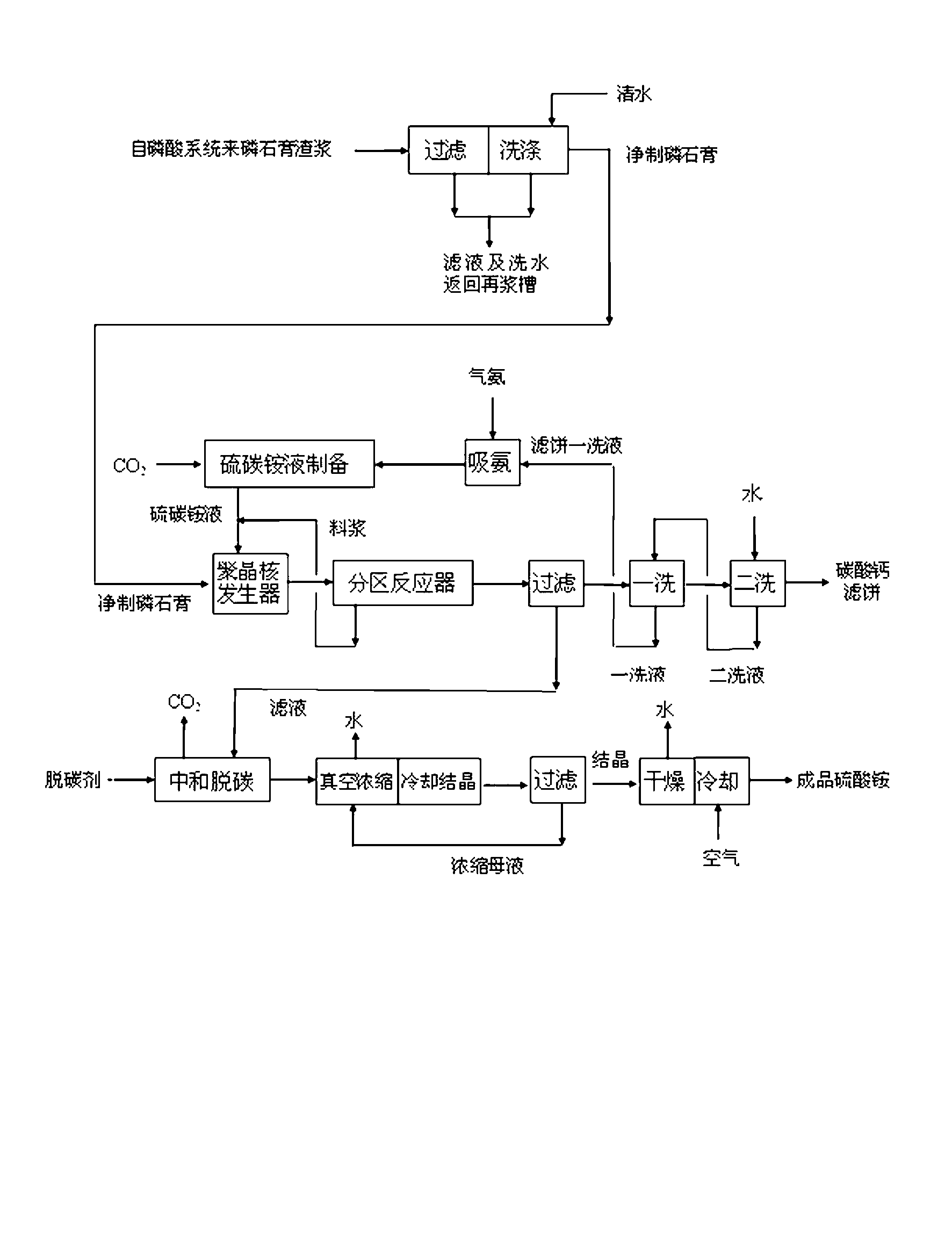

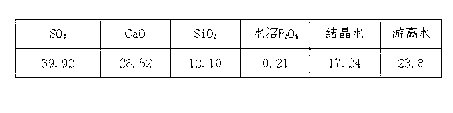

Method for preparing ammonium sulfate by conversion of phosphogyspum with polycrystalline method

ActiveCN102303874AImprove filter strengthEmission reductionAmmonium sulfatesChemical industryO-Phosphoric Acid

The invention relates to a method for preparing ammonium sulfate by continuous conversion of phosphogyspum with a polycrystalline method, belonging to the technical fields of resource comprehensive utilization and chemical industry, and relates to a method for producing ammonium sulfate by conversion of phosphogyspum with a polycrystalline method based on a byproduct phosphogyspum in a (sulfuric acid) wet phosphoric acid industry as a main raw material. The production process comprises the following steps: (1) pretreating the raw material of phosphogyspum discharged in the wet phosphoric acidindustry so as to obtain purified phosphogyspum; (2) absorbing ammonia and carbon dioxide with a ammonia-sulfate-containing primary lotion which is produced by washing a calcium carbonate filter cakewith water in a filtration process in a carbonation tower so as to produce an ammonia sulfate and carbonate solution; (3) connecting a calcium carbonate polycrystalline nucleus generator with a multiple-tank or multiple-partition groove type reactor with a stirrer in series to constitute a conversion crystallizer; (4) filtering a reaction material slurry discharged from the conversion crystallizer so as to obtain a filter cake and filtrate containing 38-40% by weight of ammonium sulfate; (5) carrying out secondary countercurrent washing on the filter cake obtained in the step (4) with clear water, and feeding the ammonia-sulfate-containing primary lotion to the carbonation tower for absorbing gas ammonia and carbon dioxide so as to produce an ammonia sulfate and carbonate liquid; and (6) neutralizing and decarburizing the filtrate containing ammonium sulfate from the step (4) with sulfuric acid, then centrifugally separating so as to obtain a crystal containing wet ammonium sulfate, separating out a mother liquid, carrying out cycle concentration on the mother liquid, and drying the crystal containing wet ammonium sulfate so as to obtain a finished product ammonium sulfate.

Owner:YUNNAN CHEM RES INST

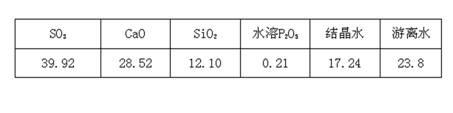

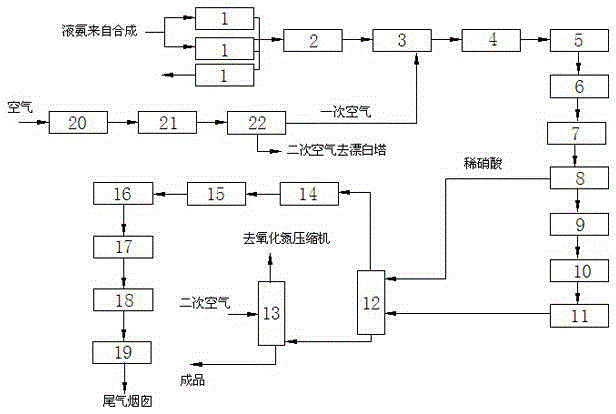

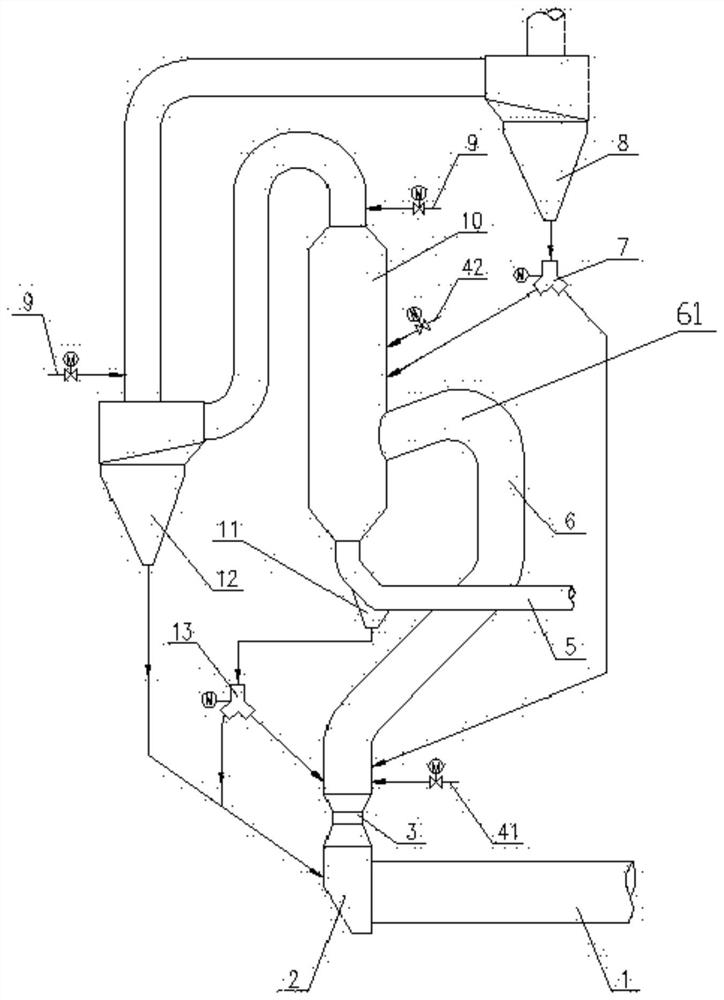

Medium-pressure nitric acid production process and equipment

PendingCN110540178AReduce ammonia consumptionCompact processChemical industryNitric oxideMolecular sieveDecomposition

The invention discloses a medium-pressure nitric acid production process. The medium-pressure nitric acid production process is characterized in that the ammoxidation and absorption pressure is 0.5-0.6 MPa; tail gas of an absorption tower passes through a carbon molecular sieve temperature swing adsorption (TSA) treatment device, so that the content of nitrogen oxides in the tail gas is reduced tobe less than 100 mg / Nm<3>; air compressor process air is used as regeneration desorption air of the carbon molecular sieve TSA treatment device, and the regeneration desorption air containing the nitrogen oxides can be returned to an oxidation reactor for reuse; a layer of N2O decomposition catalyst is added in the oxidation reactor to reduce the content of the N2O to 50-100 PPM through reaction;and a nitric acid bleaching tower is arranged at the bottom of the absorption tower, and the nitric acid bleaching tower and the absorption tower are integrated, so that the process is shortened, andthe equipment investment is reduced.

Owner:CHINA CHENGDA ENG

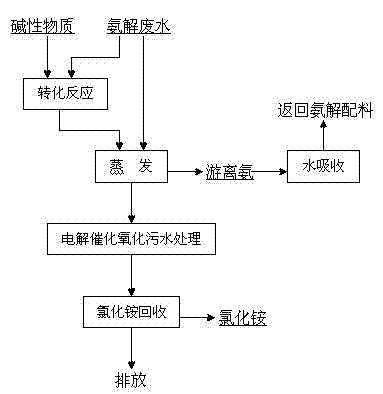

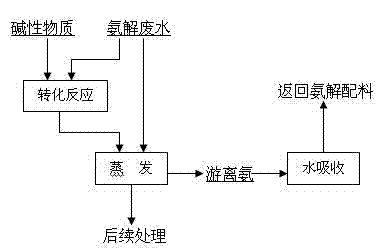

Process and system for treating nitrochlorobenzene ammonolysis wastewater

InactiveCN103359862AReduce consumptionReduce ammonia consumptionWater contaminantsMultistage water/sewage treatmentIonChemistry

The invention discloses a process and system for treating nitrochlorobenzene ammonolysis wastewater. According to the process, ammonolysis wastewater is evaporated by using ammonia distilling equipment so as to liberate free ammonia; or an alkaline substance is added firstly so as to convert ammonium ions in the ammonolysis wastewater into the free ammonia, and then, evaporation is carried out; the free ammonia in vapor is absorbed by water and then returns to a material proportioning process of nitrochlorobenzene ammonolysis; and the evaporated wastewater enters an electrolysis and catalytic oxidation sewage treatment device for degradation, enters an ammonium chloride recovery device for ammonium chloride recovery and then can be discharged. Compared with the prior art, the process and the system have the advantages that the free ammonia is recovered and utilized in a cycling manner, so that the consumption of ammonia is reduced; after the free ammonia is recovered, the consumption of neutralizing acid is reduced, the volume of the wastewater is reduced, and the load of the sewage treatment device is reduced; and by adopting the process and the system, the recovery ratio of ammonia and ammonium chloride can be adjusted randomly according to the market price of liquid ammonia and ammonium chloride.

Owner:杜惠红

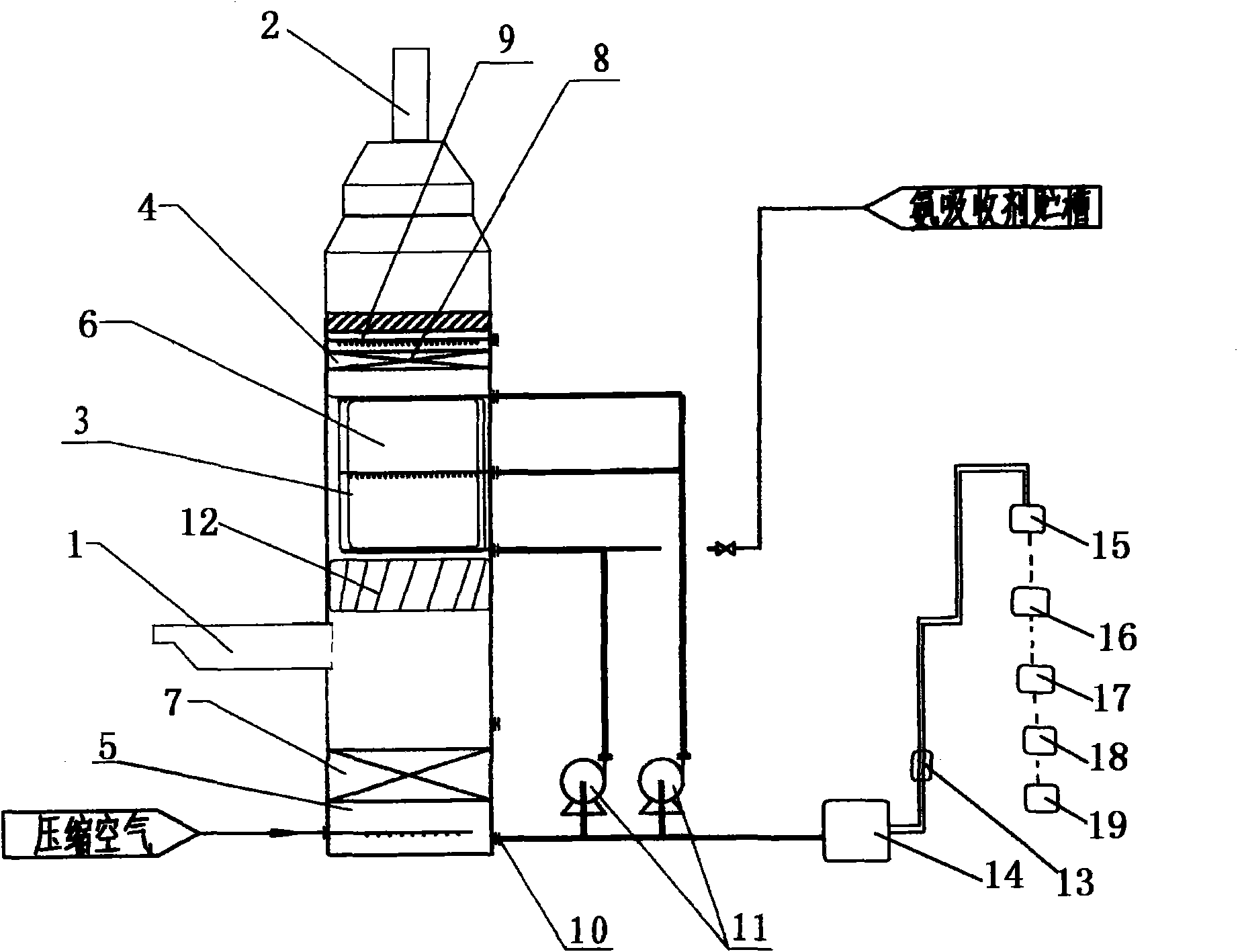

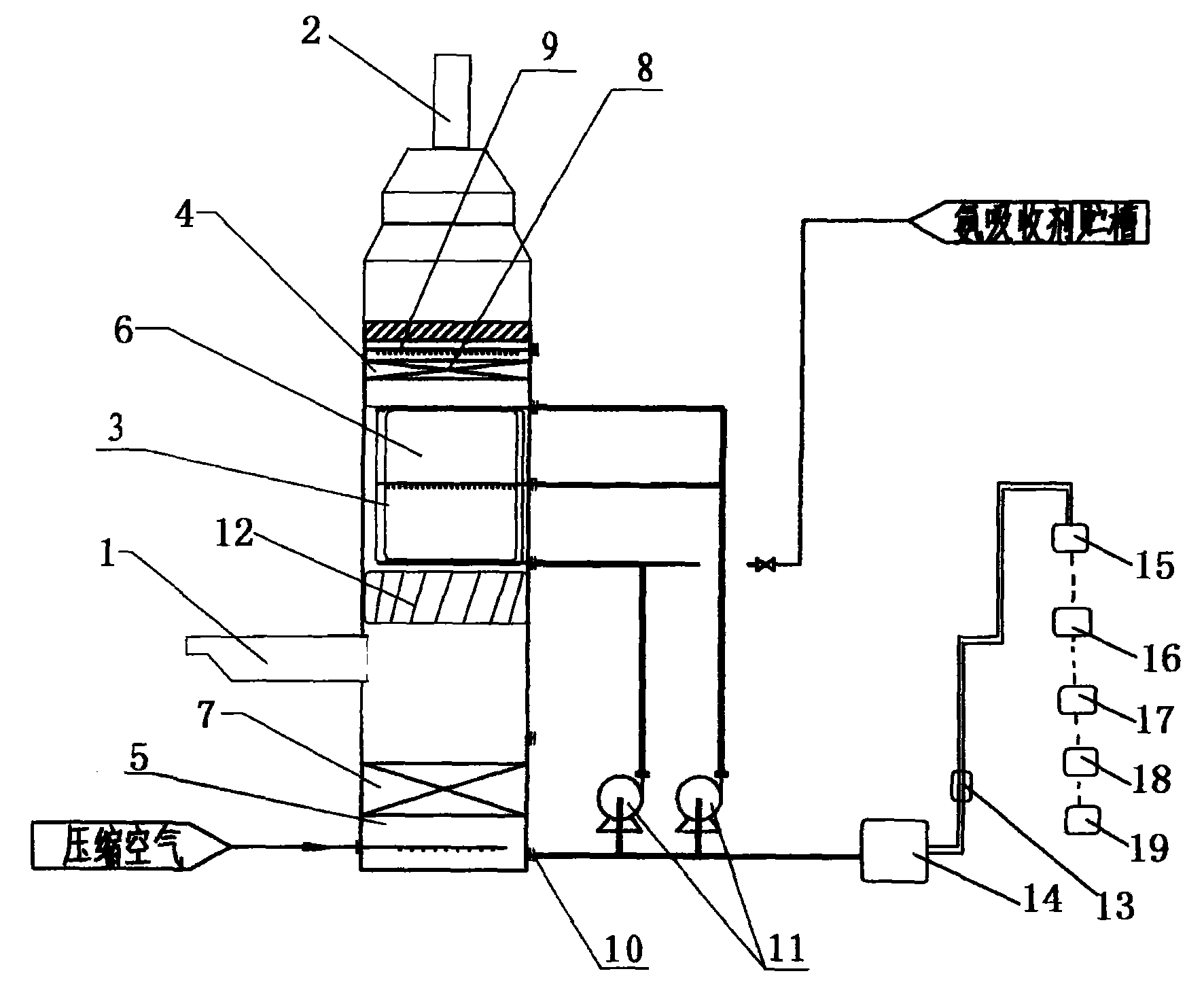

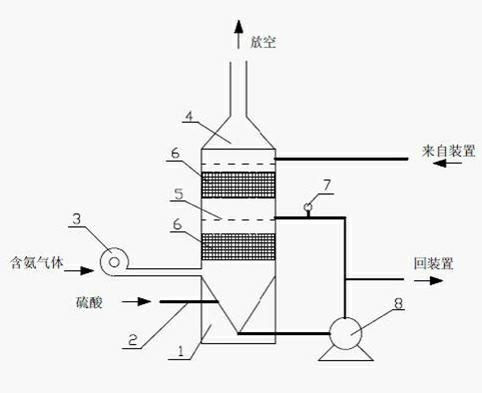

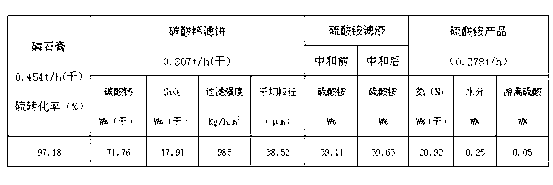

Double-oxidation, double-loop and double-demisting desulfurization tower and processing device

InactiveCN101884872ASimple structureEasy maintenance and operationDispersed particle separationWater vaporDesorption

The invention relates to the technical field of environmental protection equipment, in particular to a double-oxidation, double-loop and double-demisting desulfurization tower and a processing device for carrying out desorption and recovery treatment for sulfur dioxide in flue gas from a boiler, wherein the tower body is divided into four sections, comprising an oxidation section, an oxidation evaporation saturation section, a purification absorption section and a demisting section from bottom to top; a flue gas inlet is arranged at the middle of the tower; the top of the tower is provided with a flue gas outlet and a dewatering and demisting section for desorbing water vapor; the bottom of the tower is provided with the oxidation section for collecting reaction products and carrying out ventilation oxidation for the reaction products; the dewatering and demisting section is provided with a device for demisting, filling and spraying process water; and the oxidation section is provided with a circulating liquid outlet which is connected to a spray system through a circulating pump. The invention has the beneficial effects of simple structure, convenient operation and maintenance, environmental protection, good double demisting effect, and low ammonia consumption; and in the invention, double oxidation efficiency reaches 99%, double circulation desulfuration efficiency is more than 98%, demisting effect is good, ammonia consume is low and the product ammonium sulfate reaches the standard.

Owner:张波

Water solution all-circulation aquadrate high pressure system energy-saving and production-increasing process

InactiveCN1463964AIncrease production capacityEasy to installUrea derivatives preparationOrganic compound preparationTowerHigh pressure

Owner:CHINA HUANQIU CONTRACTING & ENG CO LTD

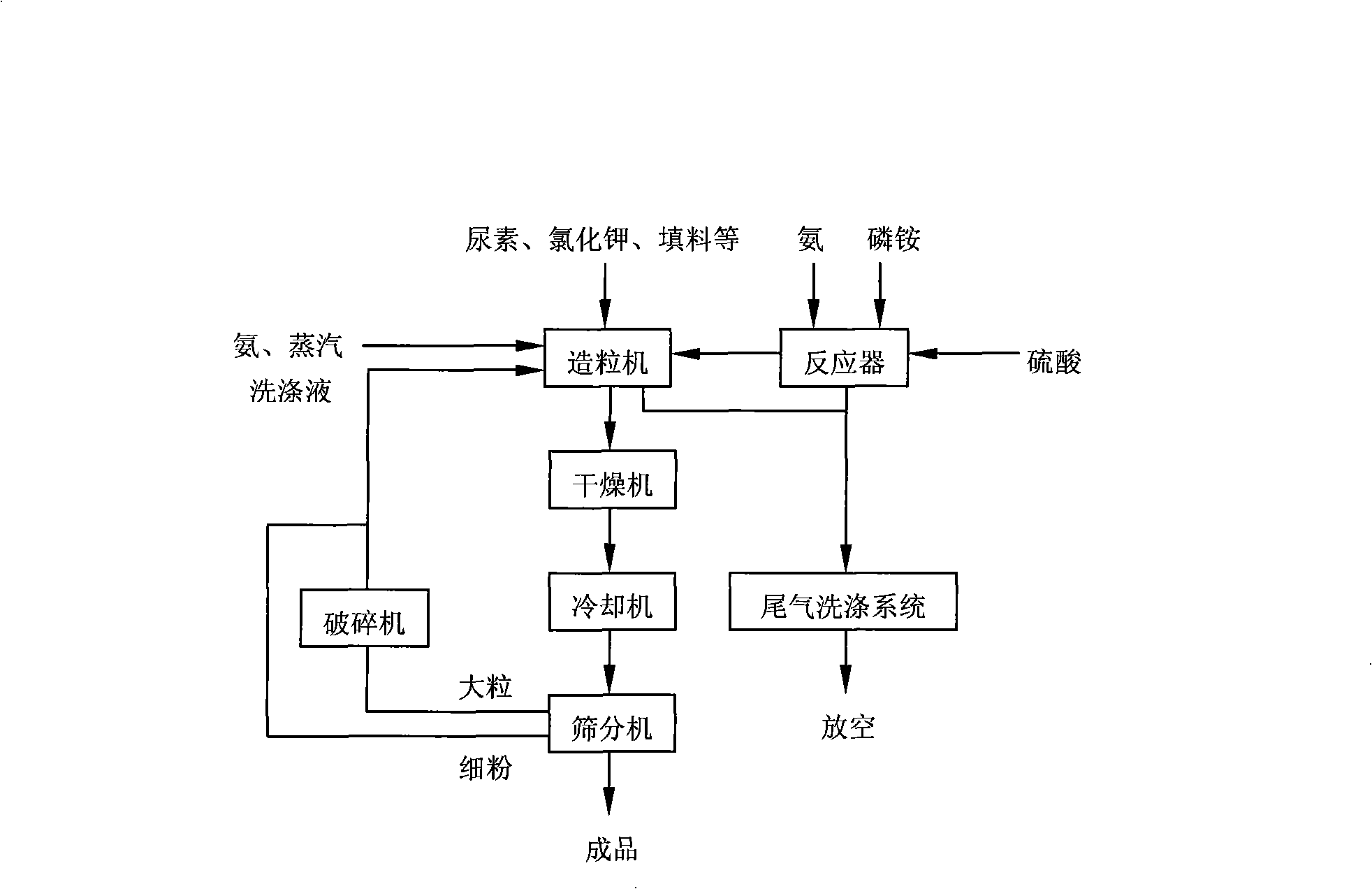

Process for preparing complex fertilizer using sulfuric acid and ammine as partial raw material

ActiveCN101284743AInhibit side effectsIncrease temperatureAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersPhosphatePotassium

The invention relates to a method which takes sulfuric acid and ammonia as partial materials to produce a compound fertilizer; the method arranges raw materials used in the production of the compound fertilizer into a reactor, and the sulfuric acid is added for reaction, thereby generating ammonium sulphate phosphate and phosphoric acid slurry, wherein, the raw materials contain phosphorus elements, and the addition amount of the sulfuric acid is 30 to 150 kilograms per ton of products; then, the ammonium sulphate phosphate and the phosphoric acid slurry are sprayed on a material bed in a granulator, so as to be mixed and granulated with other solid materials and return products, and then the ammonia is used for neutralizing phosphoric acid therein into ammonium phosphate, wherein, the addition amount of the ammonia is 20 to 80 kilograms per ton of products; furthermore, all materials are simultaneously mixed and granulated, and are cooled and screened to obtain the compound fertilizer product. Compared with the prior art, the method has the advantages that the side reactions of the sulfuric acid and other materials in the compound fertilizer such as potassium chloride, ammonium chloride, etc. can be effectively prevented, the heat discharged from the reaction is utilized to the greatest extent, the temperature of the granulating material is increased, and the water content required by the particle formation of the granulating material is reduced.

Owner:SHANGHAI RES INST OF CHEM IND

Flue gas conditioning agent for flue gas mercury removal and composite flue gas purifying method thereof

ActiveCN103223290AImprove efficiencyReduce usageLighting and heating apparatusDispersed particle separationGas phaseSorbent

The invention discloses a flue gas conditioning agent for flue gas mercury removal and a composite flue gas purifying method thereof. The flue gas conditioning agent is ammonium bromide powder or ammonium bromide solution. The flue gas conditioning agent is put into a flue of a combustion system at 150-450 DEG C and activated by use of the temperature of the flue gas; the activated flue gas conditioning agent reinforces conversion of the elemental mercury steam to mercury oxide and particle mercury in a flue gas environment, and the activation of the flue gas conditioning agent and the oxidation and adsorption of mercury are performed at the same time; and then the flue gas mercury removal is realized by use of the existing flue gas purifying equipment of the system. According to the flue gas conditioning agent and the composite flue gas purifying method disclosed by the invention, the flue gas is subjected to trace conditioning at specific temperature, and the gas-phase oxidation or gas-solid catalytic oxidation process of the mercury steam in the flue gas environment is reinforced so as to change the state of mercury in the flue gas; and finally, the flue gas mercury removal is realized by use of the existing purifying equipment of the system. The use of an activated carbon-based adsorbent can be avoided, and the flue gas mercury removal is realized by use of the existing equipment while maintaining the reusing value of fly ash.

Owner:BEIJING GUODIAN LONGYUAN ENVIRONMENTAL ENG

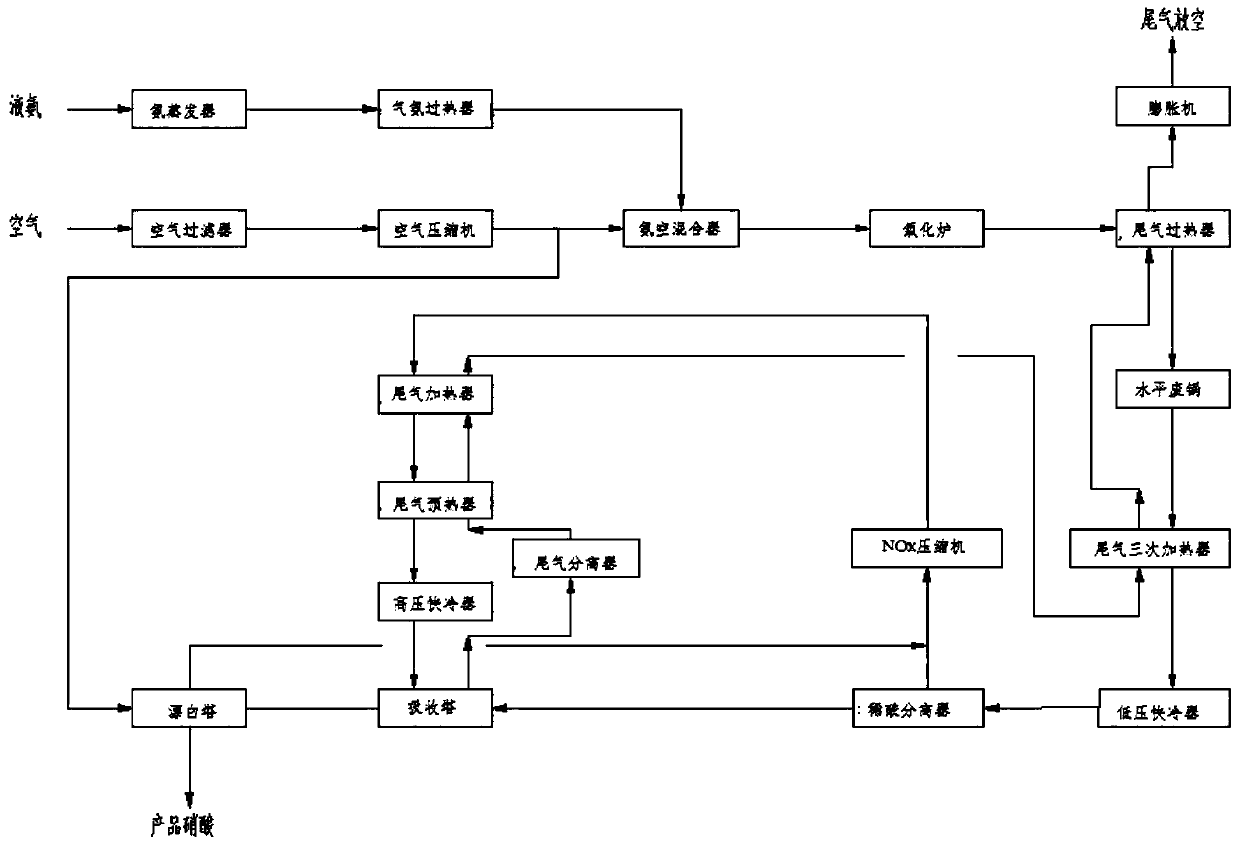

Dilute nitric acid production process

ActiveCN110550614AReduce emission concentrationImprove absorption rateEnergy inputNitric oxideChemical industryEvaporation

The invention belongs to the field of chemical industry, and in particular, relates to a dilute nitric acid production process. The process includes the following steps: after ammonia evaporation andheating, adjusting the flow quantity, allowing gas ammonia to enter an ammonia-air mixer and uniformly mixing the gas ammonia with compressed air; allowing the ammonia-air mixture after mixing to enter an oxidation furnace, carrying out catalytic oxidation reaction on a platinum mesh surface, oxidizing ammonia into nitric oxide, recycling waste heat from process gas leaving the catalyst through awaste heat boiler and tail gas respectively, and then condensing by a low-pressure quick cooler, after separation of dilute acid, mixing the process gas with air from a bleaching tower, and then allowing the mixed gas to enter an oxidation nitrogen compressor; further increasing the temperature of gas through the compressed process gas; recycling waste heat of the compressed process gas, cooling,and then allowing the cooled process gas to enter an absorption tower; and carrying out a reaction of oxide of nitrogen in the absorption tower after absorption with water to generate nitric acid. Theprocess has the advantages of high nitrogen oxide absorption rate, low ammonia consumption, high acid concentration and low tail gas emission concentration, and can reach the standard without furthertreatment.

Owner:SICHUAN GOLDEN ELEPHANT SINCERITY CHEM CO LTD

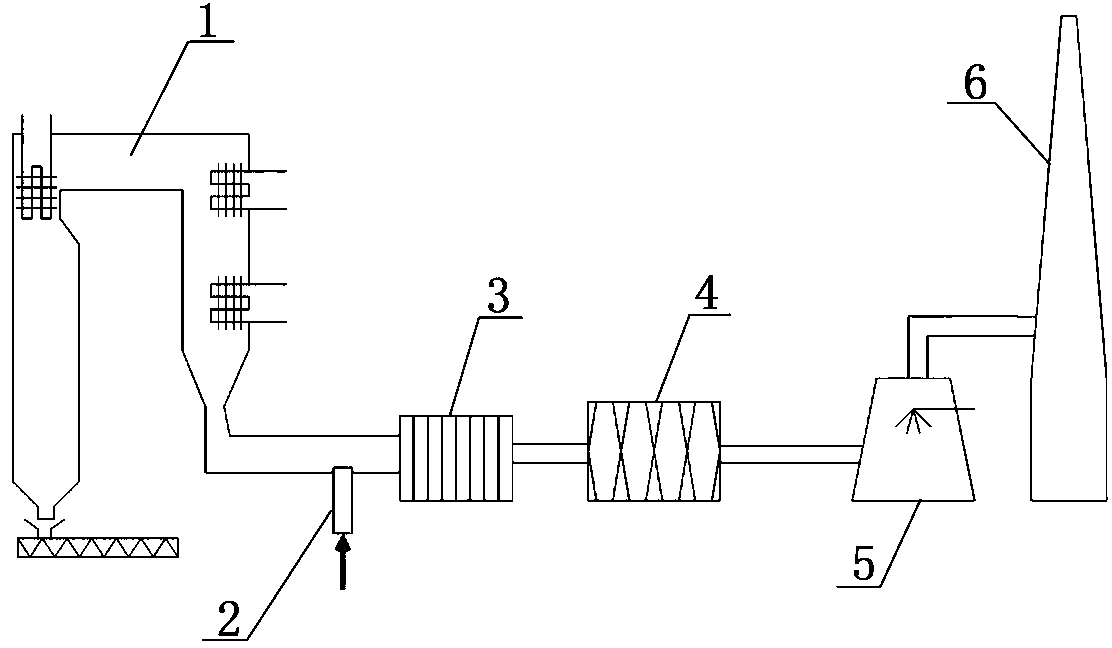

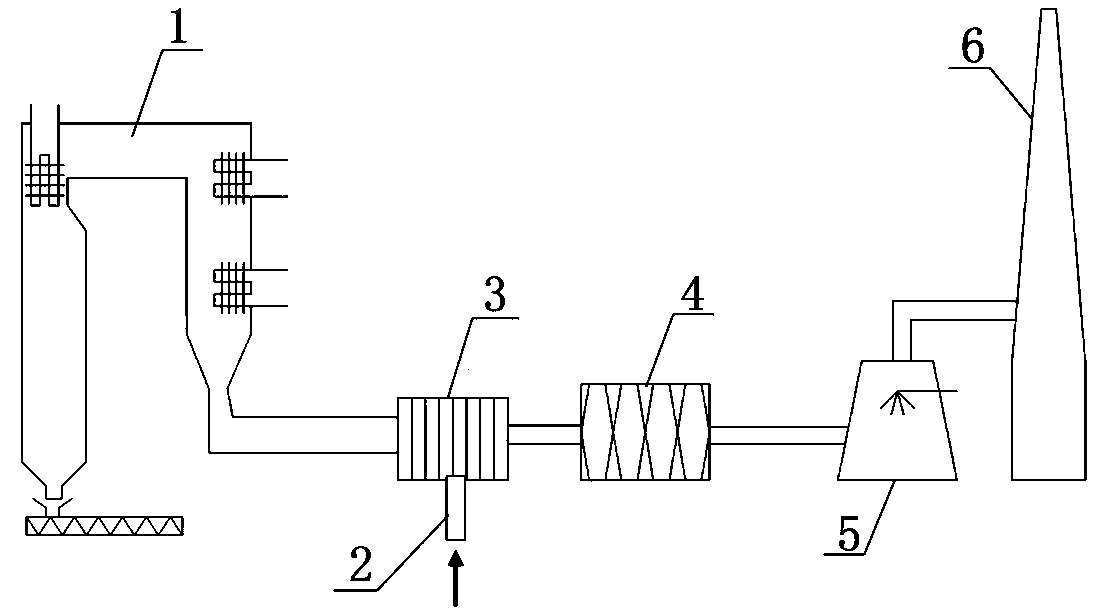

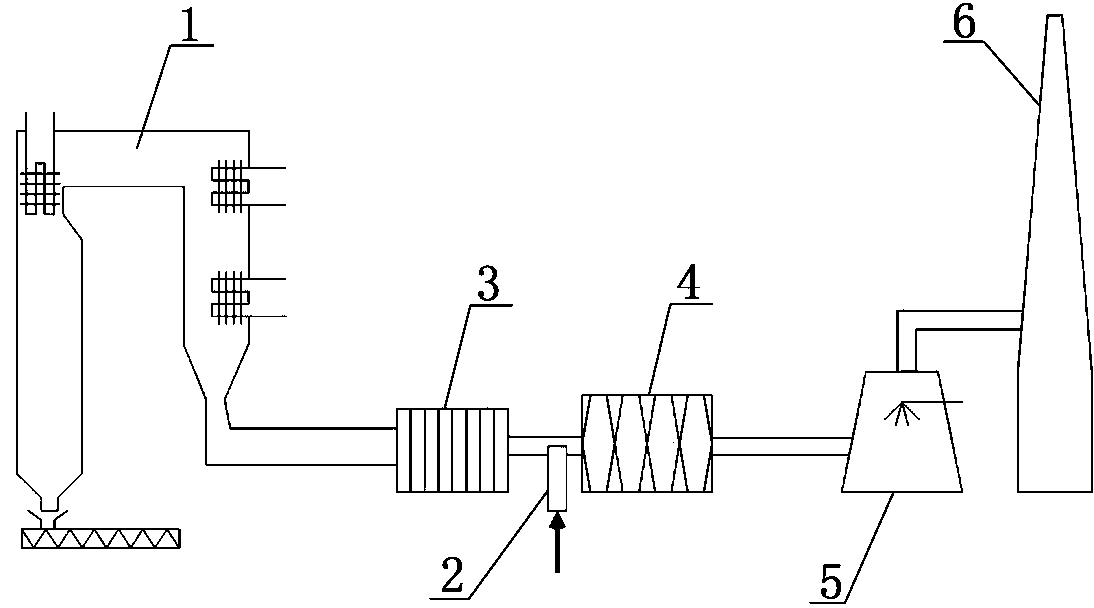

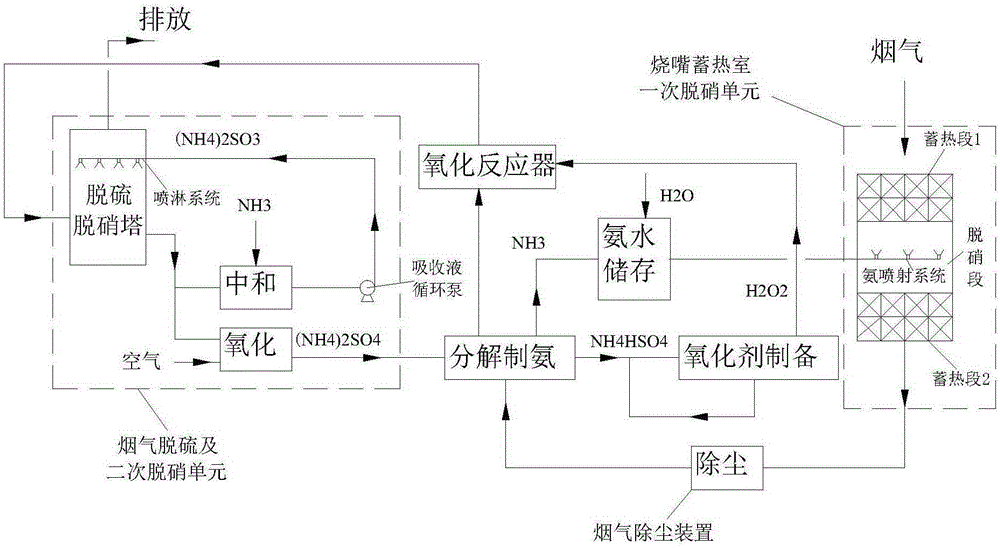

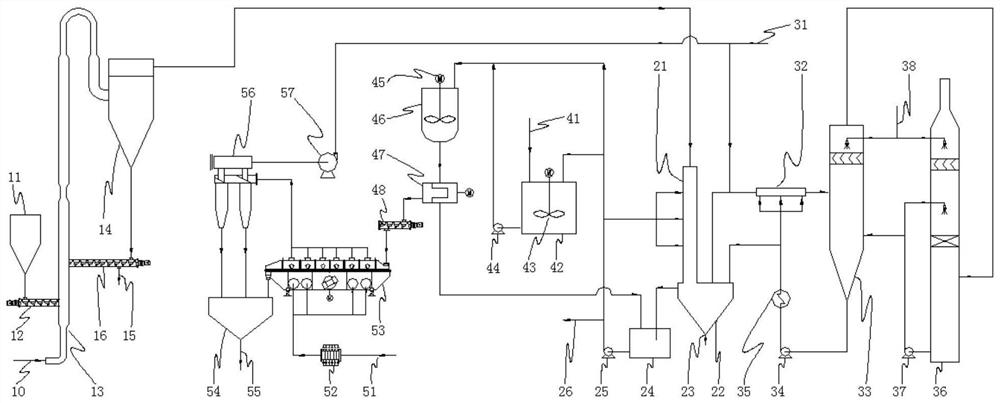

Glass furnace flue gas desulfurization and denitrification system and process

ActiveCN105194991AAchieve secondary denitrificationAvoid consumptionDispersed particle separationAir quality improvementHydrogen SulfateGlass furnace

The invention discloses a glass furnace flue gas desulfurization and denitrification system and process. The system comprises a glass furnace burner regenerative chamber primary denitrification unit, a flue gas dust removal device, a decomposition-process ammonia production device and a flue gas desulfurization and secondary denitrification unit. Primary denitrification of flue gas is completed in a glass furnace burner regenerative chamber by using ammonia as a denitrification agent, secondary denitrification can be realized during subsequent ammonia desulfurization, ammonia and ammonium hydrogen sulfate are produced by using a desulfurization product ammonium sulfate, the ammonia can be used as a primary denitrification absorbent, hydrogen peroxide is further produced by using the ammonium hydrogen sulfate and is used as an oxidant of NOx in the flue gas, residual liquid can be cyclically utilized, thereby the ammonia does not need to be externally supplied during the primary denitrification in the invention, and the secondary removal of the remaining NOx in the flue gas is realized in the subsequent ammonia desulfurization process. The glass furnace flue gas desulfurization and denitrification system and process disclosed by the invention are simple and the desulfurization and denitrification efficiency are high.

Owner:SHENWU TECH GRP CO LTD

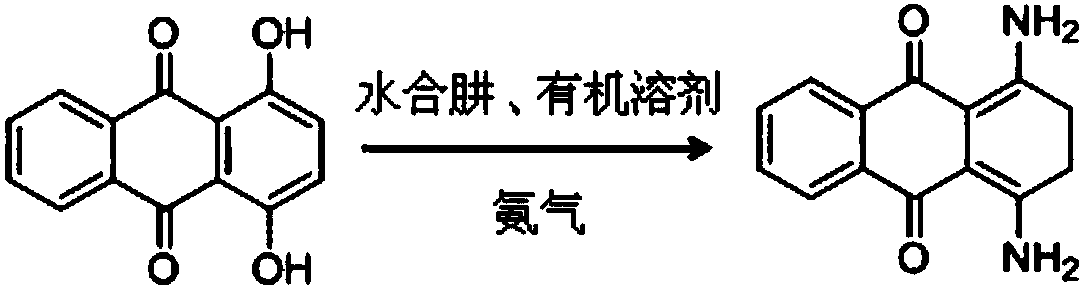

Synthesis method of 1,4-diamino-anthraquinone leuco body

ActiveCN108395381AReduce ammonia consumptionHigh product yieldOrganic chemistryOrganic compound preparationChemical synthesisOrganic solvent

The invention belongs to the field of chemical synthesis, and particularly relates to a synthesis method of a 1,4-diamino-anthraquinone leuco body. The synthesis method comprises the following steps:adopting 1,4-diamino-anthraquinone as a raw material to mix with hydrazine hydrate and an organic solvent; reacting with ammonia gas for 3-4 hours under the conditions of the reaction pressure being 0.2-0.5 Mpa and the reaction temperature being 50-100 DEG C; exhausting ammonia gas after finishing reaction; and cooling, crystallizing, filtering and drying a reaction product to obtain the 1,4-diamino-anthraquinone leuco body. The synthesis method has the advantages of no high-COD (chemical oxygen demand), high-ammonia nitrogen and high-salinity waste water in the synthesis process, recyclability of filtrated stock, reduction of ammonia consumption, efficient reduction of production cost and high-purity and high-yield products, and is suitable for scale production.

Owner:大连傲视化学有限公司

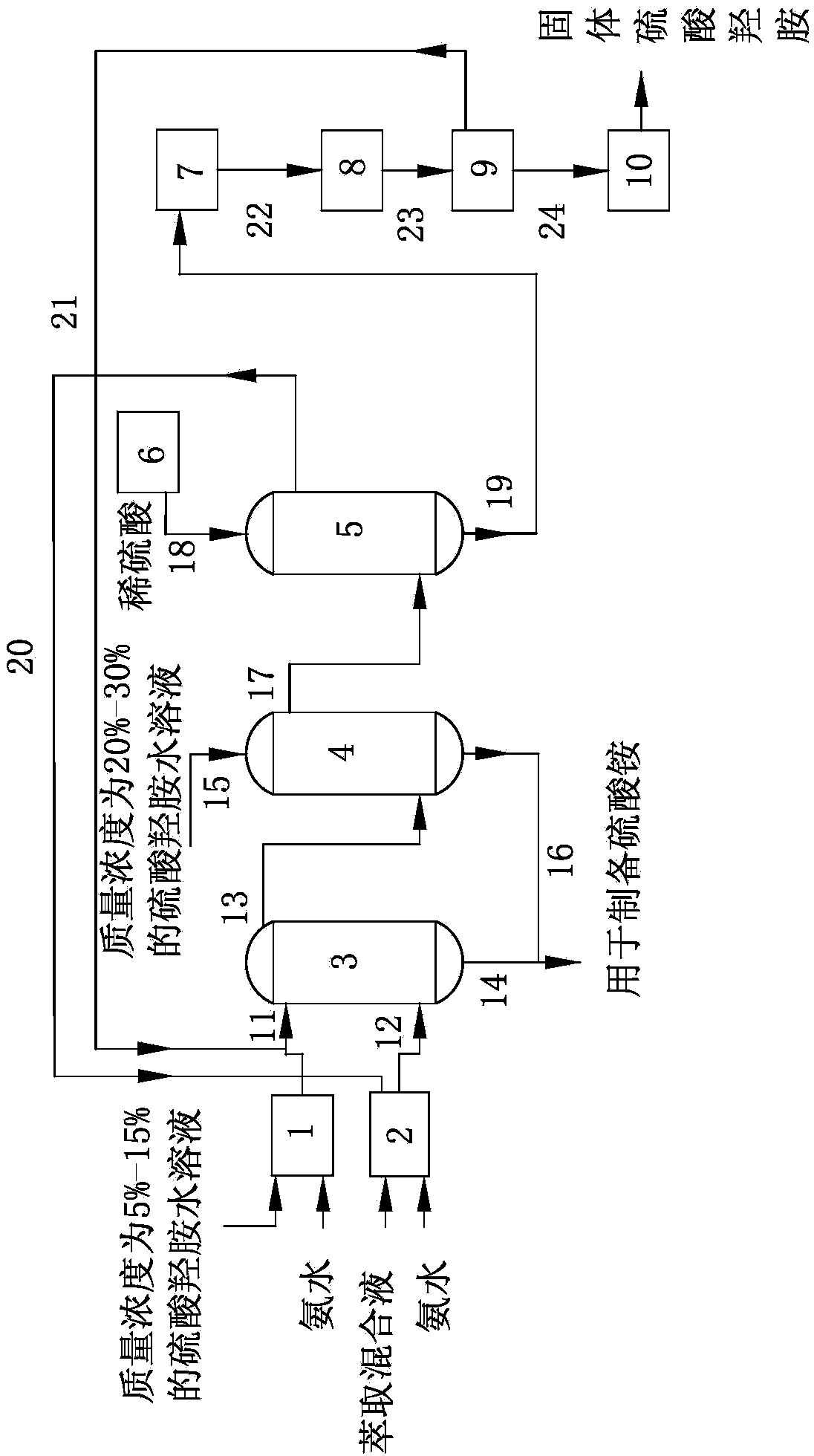

Preparation method of high-purity solid hydroxylamine sulphate

The invention discloses a preparation method of high-purity solid hydroxylamine sulphate. The preparation method of the high-purity solid hydroxylamine sulphate comprises the following steps: adding a 5-15% hydroxylamine sulphate aqueous solution into a first reactor, mixing the hydroxylamine sulphate aqueous solution with 18-23% ammonia water, controlling the temperature of the first reactor to 20-30 DEG C, and regulating the pH value of the solution to 5.8-6.5, so that a first reaction product is obtained; fully mixing an extracting agent, a diluter and a stabilizer in a volume ratio of 1:(3-3.5):(0.001-0.002), putting the obtained mixture into a second reactor, regulating the pH value to 7.0-7.8 by adopting 18-23% ammonia water, and controlling the temperature of the second reactor to 20-30 DEG C, so that a second reaction product is obtained; carrying out extraction, concentration, cold crystallization, centrifugation and vacuum drying on the first reaction product and the second reaction product, so that the target product high-purity solid hydroxylamine sulphate is obtained. The preparation method of the high-purity solid hydroxylamine sulphate has the advantages of simple temperature, mild reaction conditions, high yield and low cost.

Owner:QUZHOU JUHUA POLYAMIDE FIBER

Processing method for tail gas generated in preparation of ammonium sulfate from phosphogypsum

InactiveCN102631825AImprove the on-site operating environmentReduce ammonia consumptionDispersed particle separationEconomic benefitsPhosphogypsum

The invention discloses a processing method for tail gas generated in preparation of ammonium sulfate from phosphogypsum, and the method comprises the following steps: additionally arranging a washing tower, an exhaust fan and a circulating pump in a device for preparing ammonium sulfate from phosphogypsum.; connecting the circulating pump and the washing tower to form a circulating loop by virtue of a pipeline; feeding acid filtered fluid, utilized as circulating absorption liquid, from the device into the washing tower to backflush gas containing ammonia and absorb the ammonia in the gas, enabling the acid filtered fluid to flow to the bottom of the tower, then pumping out the acid filtered fluid by virtue of the circulating pump so as to be used as absorption liquid, and recycling and absorbing; returning part of the absorption liquid back into the device so as to be used as a reaction replenisher, wherein the ammonia in the liquid can be used for producing the ammonium sulfate; feeding the tail gas in the device for preparing ammonium sulfate from phosphogypsum and the volatized gas containing ammonia into the washing tower by virtue of the exhaust fan; and when the pH value of the circulating absorption liquid is overhigh, adding sulfuric acid from the bottom of the tower. The processing method can be used for sufficiently absorbing the tail gas in the device for preparing ammonium sulfate from phosphogypsum and the volatized gas containing ammonia, improving a field operation environment, recovering the ammonia for producing ammonium sulfate and reducing the ammonia consumption of products, and has economic benefits, thus being applicable to manufacturers for producing ammonium sulfate from phosphogypsum.

Owner:WENGFU (GRP) CO LTD

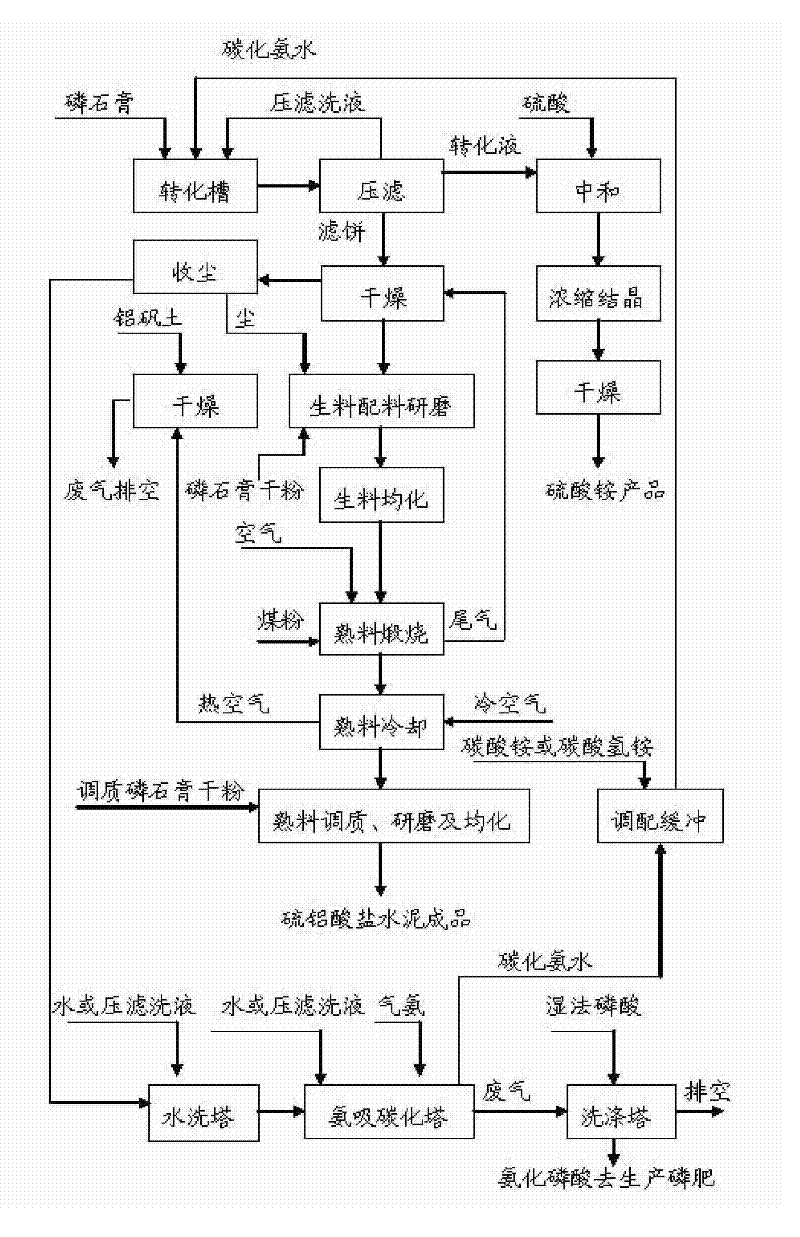

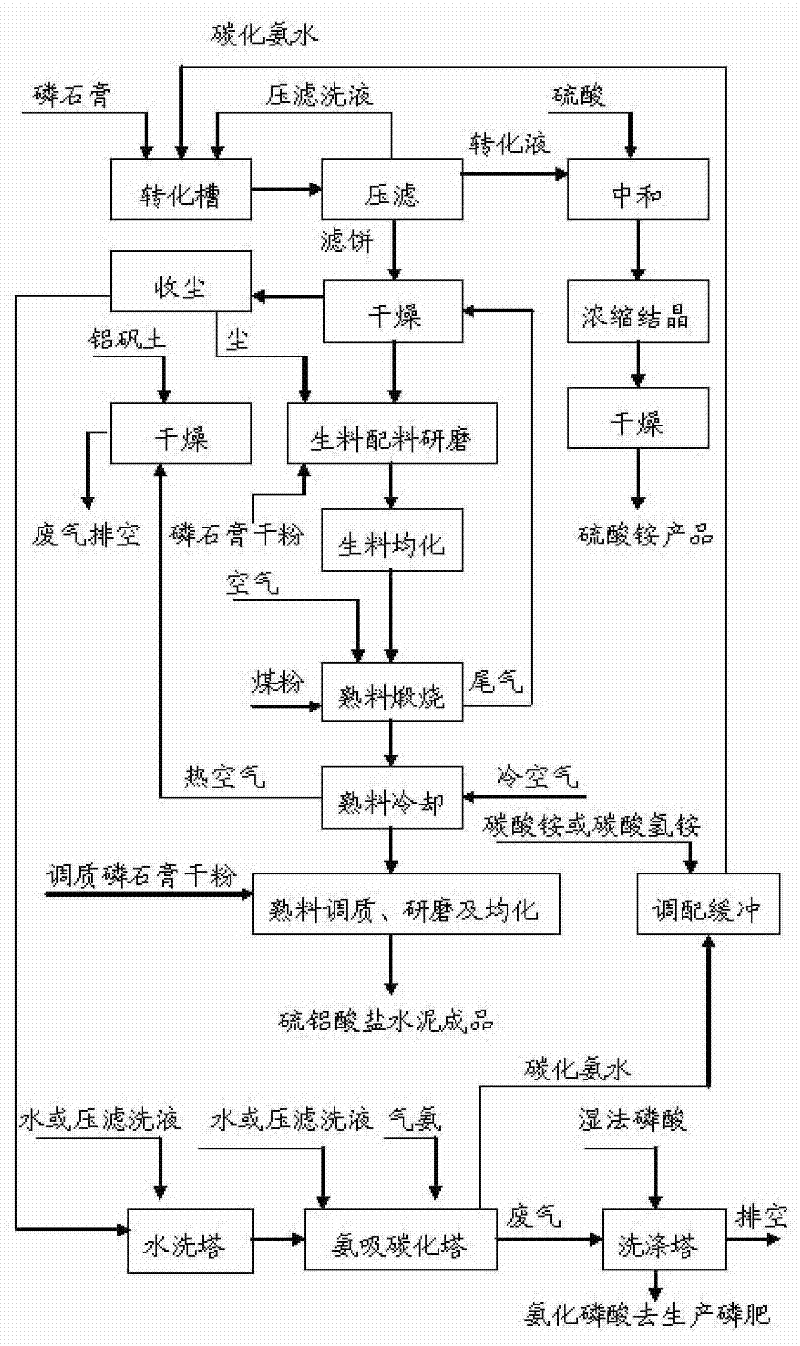

Method for preparing sulphoaluminate cement by-product ammonia sulfate by partly converting phosphogypsum

InactiveCN101481222BBroaden control and operational flexibilityAvoid dischargeDispersed particle separationAmmonium sulfatesThermal energyPhosphogypsum

The invention discloses a method of partially converting phosphorous plaster to prepare side product ammonium sulfate of aluminum sulfate, which has the main steps of converting phosphorous plaster, filtering and separating converted substances, neutralizing converted liquid, concentrating, crystallizing and drying aluminum sulfate solution, drying filtrated cake and bauxite, blending and homogenizing raw material, calcining and cooling grog, modifying, grinding and homogenizing grog, processing calcination tail gas and the like. The mixed material satisfying materials required by the production of aluminum sulfate cement is achieved by partially converting the phosphorous plaster which does not need to be preprocessed. No limestone is required to be additionally added, the application range of the phosphorous plaster with high ferric and aluminum impurity contents is widened, the procedures and the converting equipment are simplified, ammonia consumption and operation difficulty are reduced, the cost is saved, the discharge of secondary polluting substances is eliminate, the heat and the carbon dioxide carried out by the calcination tail gas are recovered and utilized, and the energy consumption can be effectively reduced to further save the cost. In addition, the method does not have high requirements on the impurity content of the phosphorous plaster and has strong suitability on the raw material.

Owner:SICHUAN HONGDA

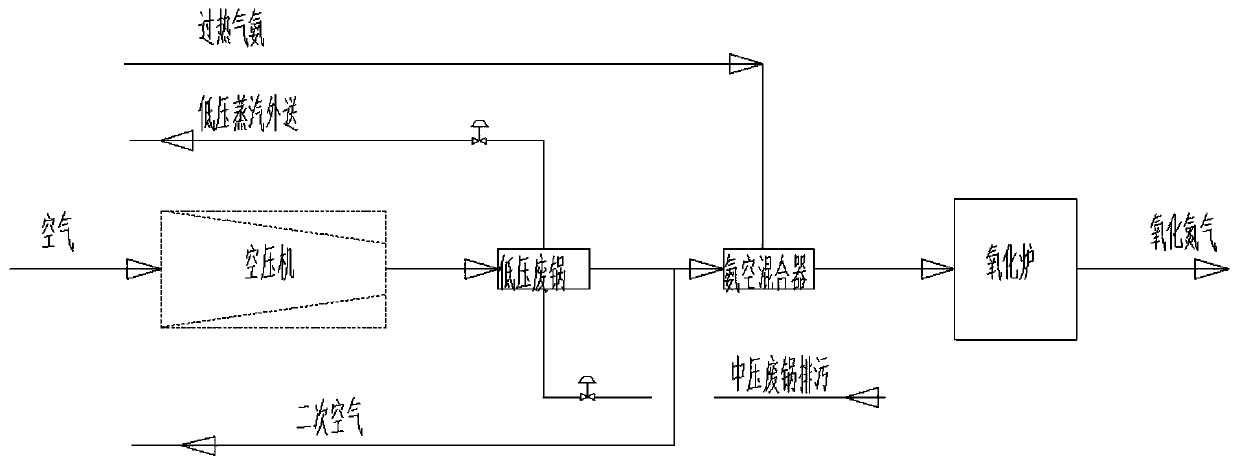

Dilute nitric acid device adopting double pressure method

ActiveCN105314611AIncrease annual outputIncrease air intakeEnergy inputNitric acidAir filterSuperheater

The invention relates to a dilute nitric acid device adopting a double pressure method, and the device can increase output at the high temperature season and improve heat energy recovery efficiency. The device is characterized in that a gaseous ammonia outlet of an ammonia evaporator is communicated with a cold fluid inlet of a second ammonia superheater; a cold fluid outlet of the second ammonia superheater is communicated with a cold fluid inlet of a first ammonia superheater; the gaseous ammonia outlet of the ammonia evaporator is communicated with the cold fluid inlet of the first ammonia superheater; a gaseous ammonia inlet of an ammonia filter is communicated with a cold fluid outlet of the first ammonia superheater; a tail gas outlet of a tail gas expansion machine is communicated with a thermal fluid inlet of the second ammonia superheater; an air filter, an air blast dehumidification device and an axial flow compressor are sequentially connected; a gas outlet of the air filter is communicated with a gas inlet of an air blower; a gas outlet of the air blower is communicated with a thermal fluid inlet of a heat exchanger; a thermal fluid outlet of the heat exchanger is communicated with an inlet of a demister; an outlet of the demister is communicated with an inlet of the axial flow compressor; a cold fluid outlet of the heat exchanger, a cold water pump, a refrigerating unit and a cold fluid inlet of the heat exchanger are sequentially communicated.

Owner:HANGZHOU LONGSHAN CHEM CO LTD

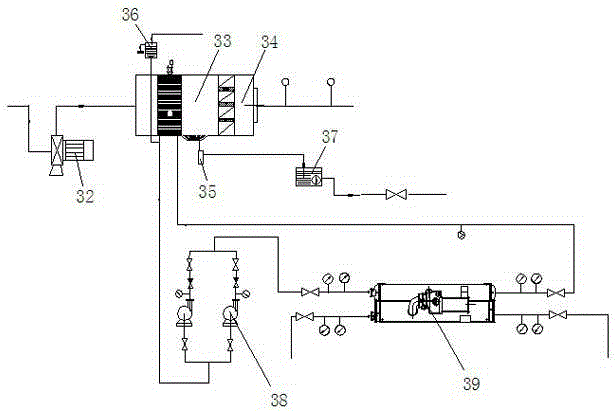

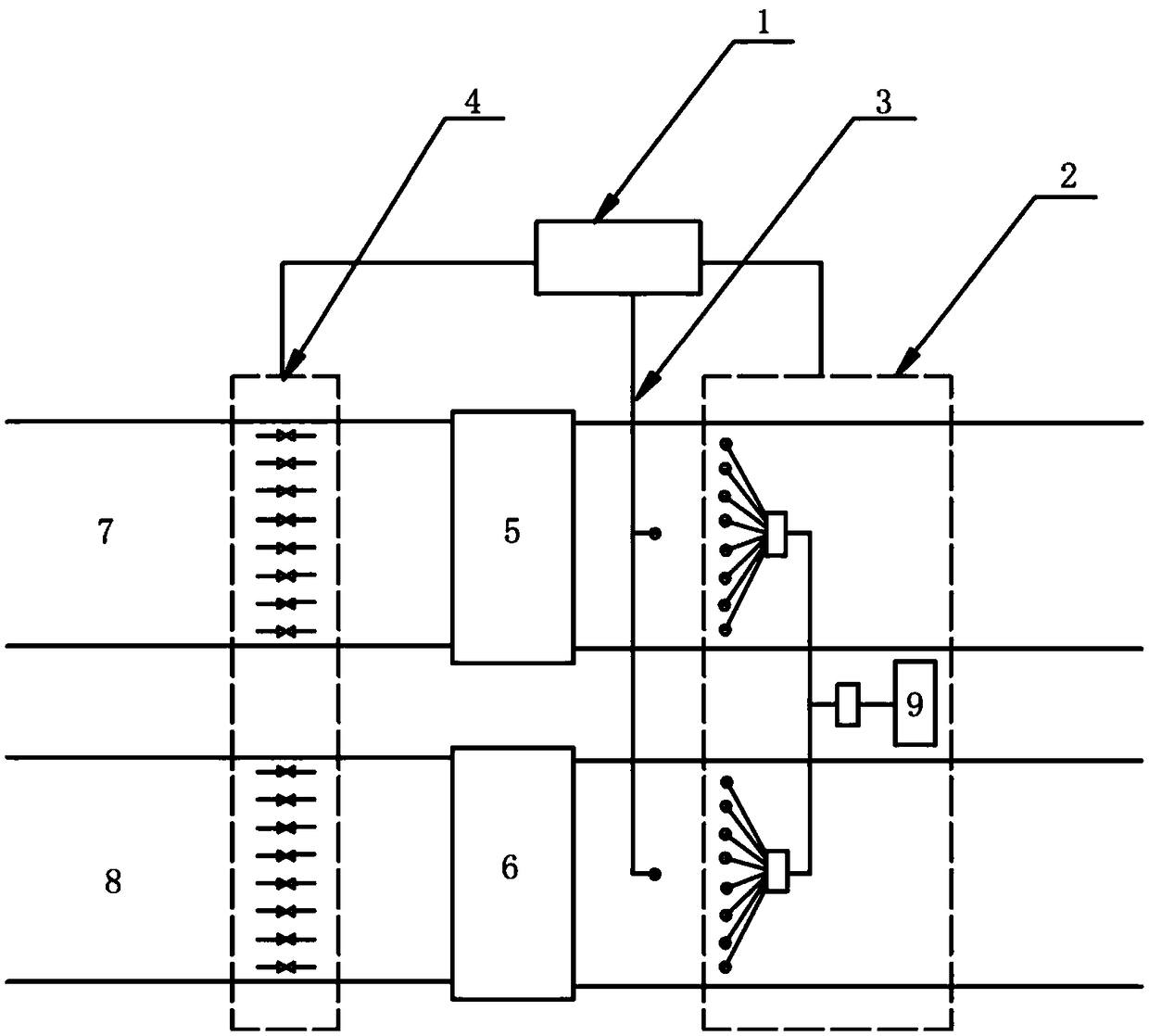

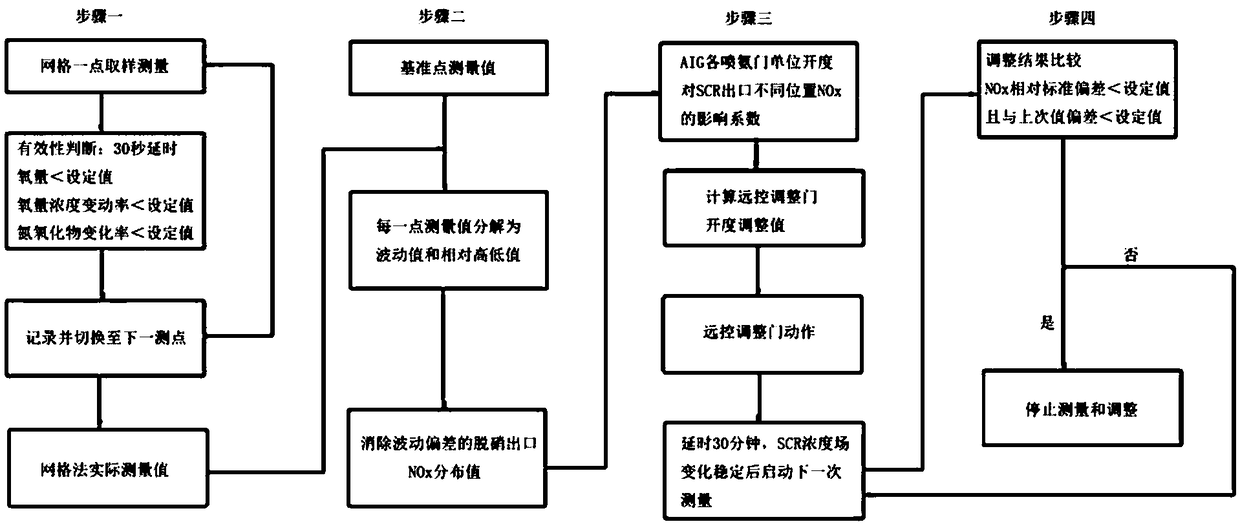

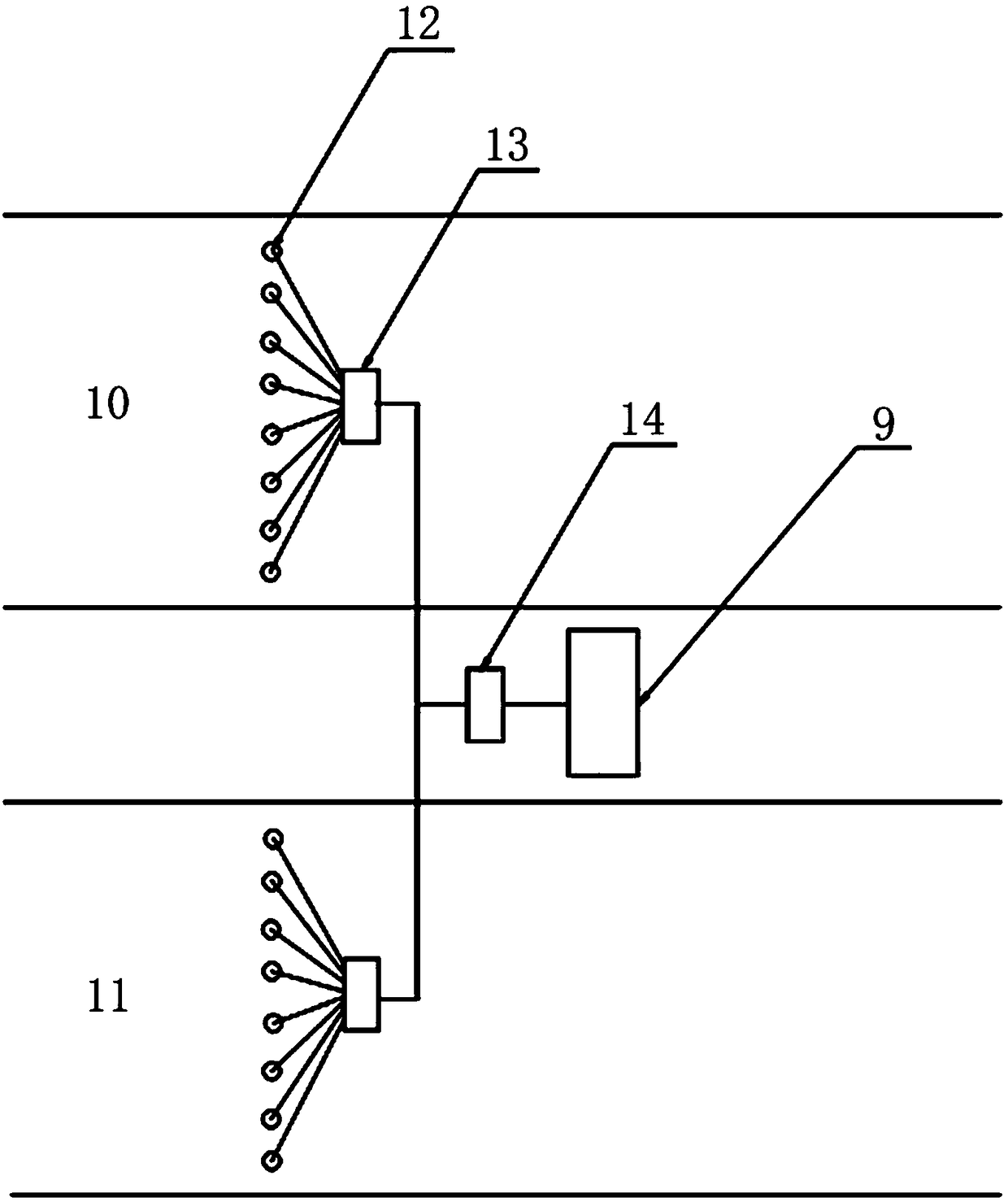

Denitration uniformity measurement optimizing system and method under fluctuating loads

InactiveCN109260948AEliminate the bias effects of fluctuationsEliminate bias effectsGas treatmentControlling ratio of multiple fluid flowsControl systemRemote control

The invention relates to a denitration uniformity measurement optimizing system and method under fluctuating loads. The system comprises two flue inlets formed in a side A and a side B respectively and two SCR reactors arranged between two flue outlets, remote control adjusting doors (4) are formed between the two flue inlets and the two SCR reactors, grid method tour measuring devices (2) are arranged between the two flue outlets and the two SCR reactors, reference point calibration loops (3) are arranged between the two flue outlets and the two grid method tour measuring devices, and a uniformity analysis control system (1) is further arranged and connected with the remote control adjusting doors (4), the reference point calibration loops (3) and the grid method tour measuring devices (2) separately. According to the system and method, through the reference point calibration loops, the deviation influence of NOx overall fluctuation is removed, through the uniformity measurement result, the relative amplitude of NOx values at different position points is accurately reflected, and misjudgment and wrong adjustment caused by the influence of fluctuation are avoided.

Owner:HUADIAN POWER INTERNATIONAL CORPORATION LTD +1

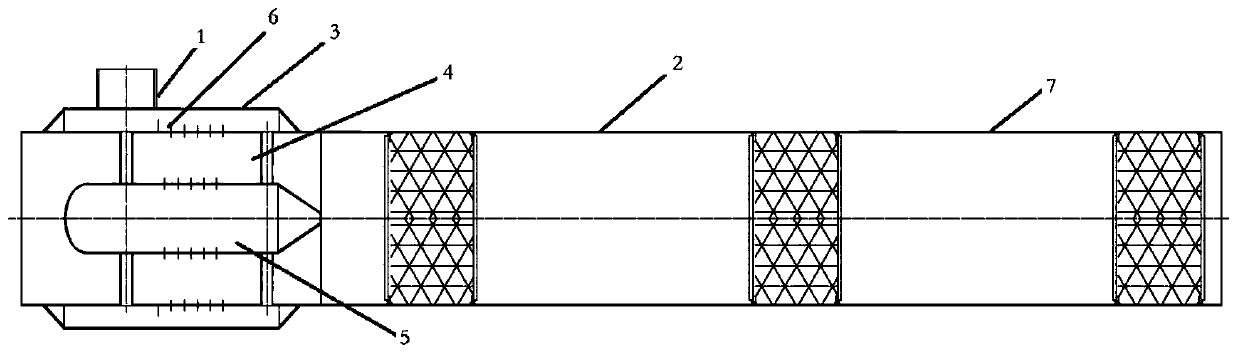

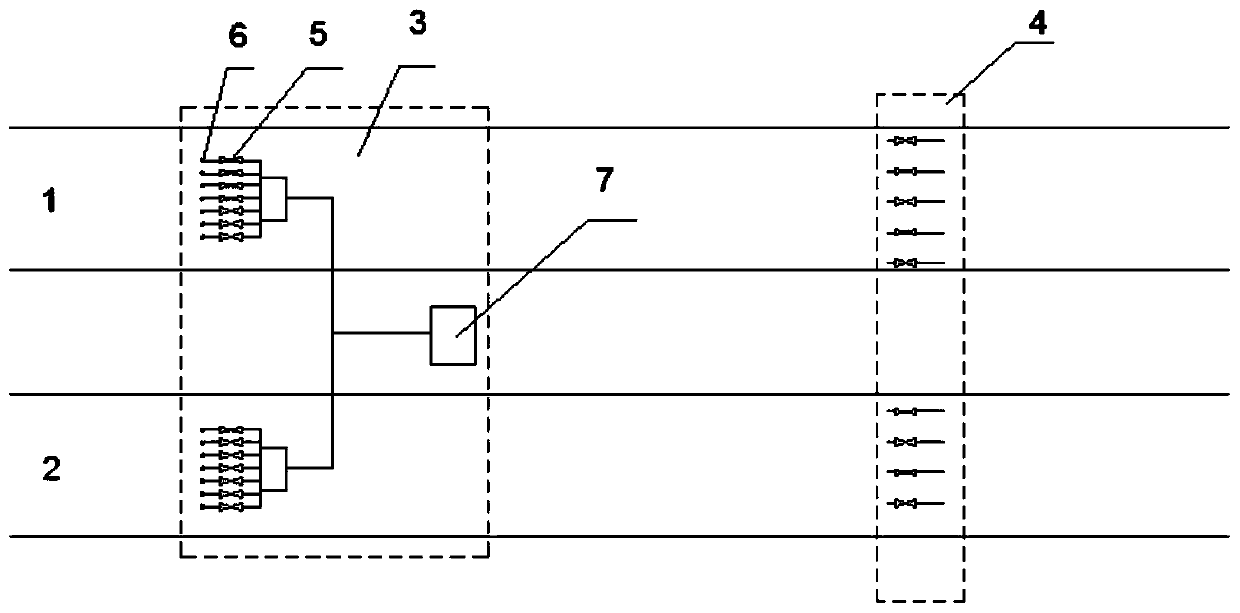

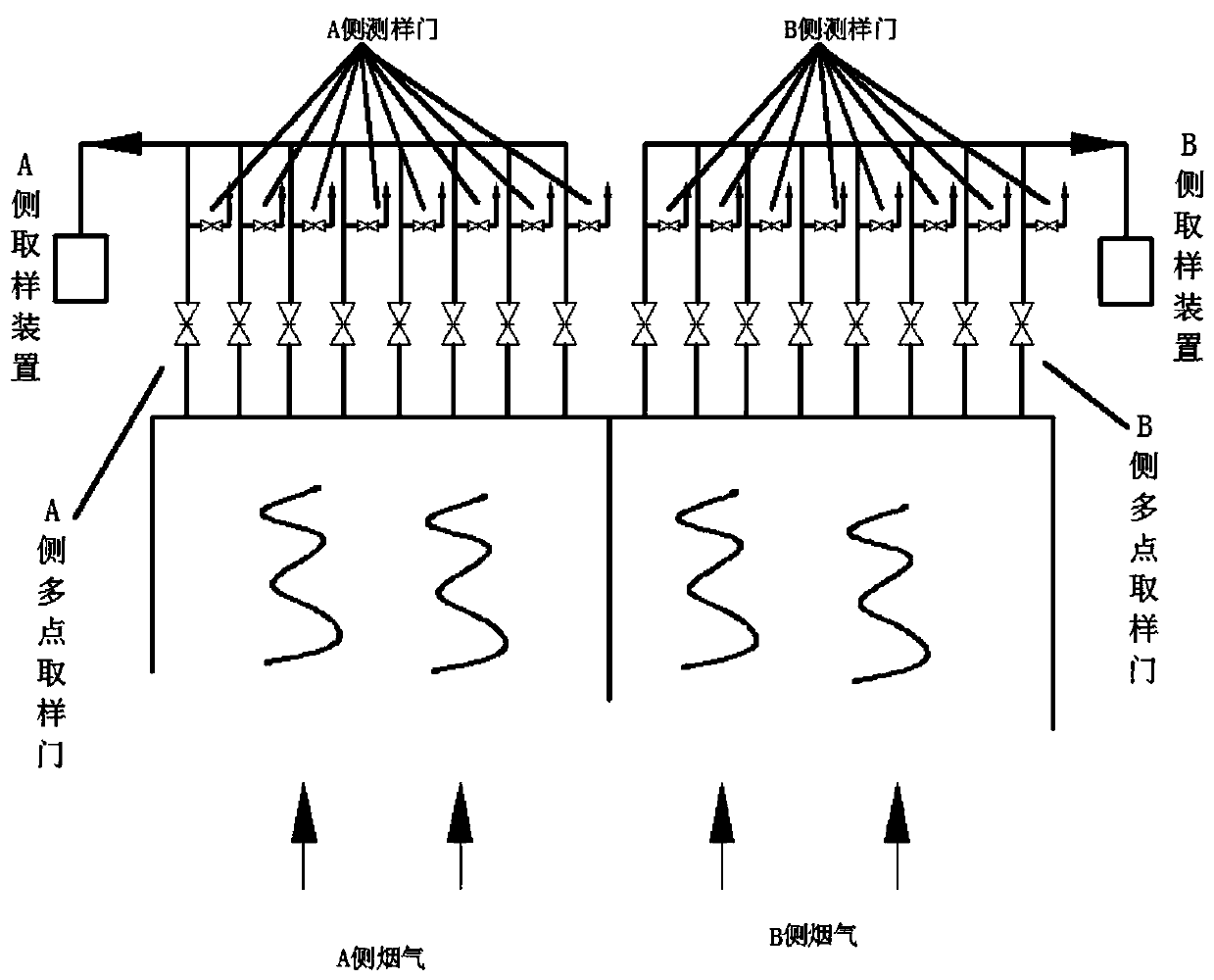

Optimizing system and method for denitration-system ammonia injection grating

InactiveCN109821417AEvenly distributedImprove mixing uniformityDispersed particle separationPtru catalystEnvironmental engineering

The invention provides an optimizing system and method for a denitration-system ammonia injection grating. The optimizing system comprises an A-side smoke outlet, a B-side smoke outlet, a sampling device and an ammonia injection control valve group; the ammonia injection control valve group is arranged in the A-side smoke outlet and the B-side smoke outlet, the sampling device is installed in theA-side smoke outlet and the B-side smoke outlet and located on the outer side of the ammonia injection control valve group, and comprises multiple sampling doors, and the sampling doors are evenly arranged in the A-side smoke outlet and the B-side smoke outlet. According to the optimizing system and method for the denitration-system ammonia injection grating, the multiple sampling doors are evenlyarranged at multiple sampling door outlets from the A side and the B side of a denitration outlet; through the adjusted denitration-reactor ammonia injection grating (AIG), the mixing uniformity of ammonia and smoke is improved, the using rate of a catalyst is increased, and the unit ammonia injection amount is decreased. By optimizing and adjusting the ammonia injection grating (AIG), outlets NOx are more evenly distributed, and denitration efficiency is better guaranteed; meanwhile, the ammonia consumption amount is decreased, the running cost is reduced, and the forming risk of ammonium bisulfate (ABS) is also reduced.

Owner:DATANG GUIZHOU FAER POWER GENERATION

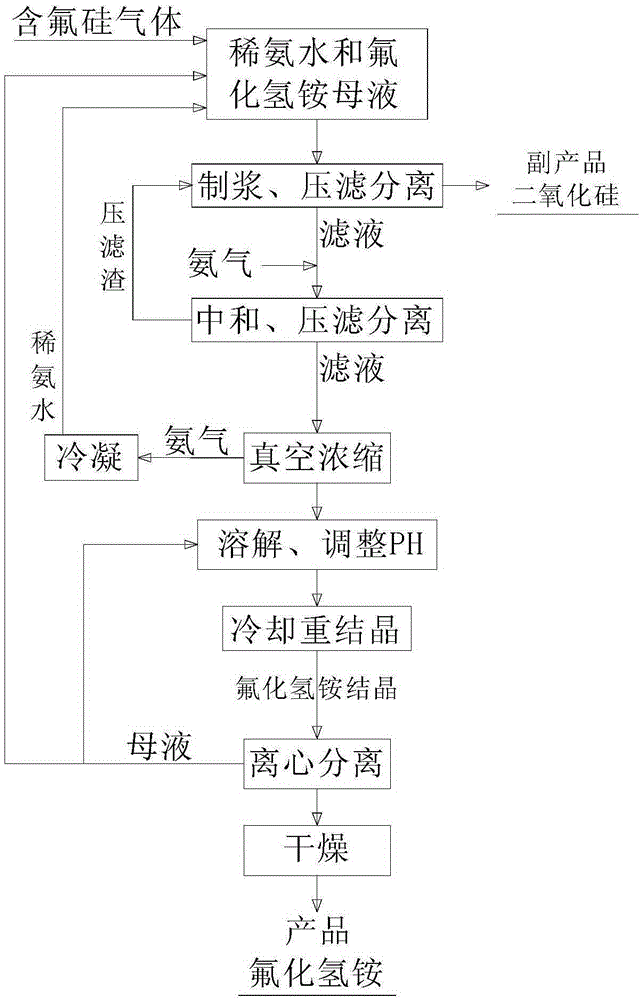

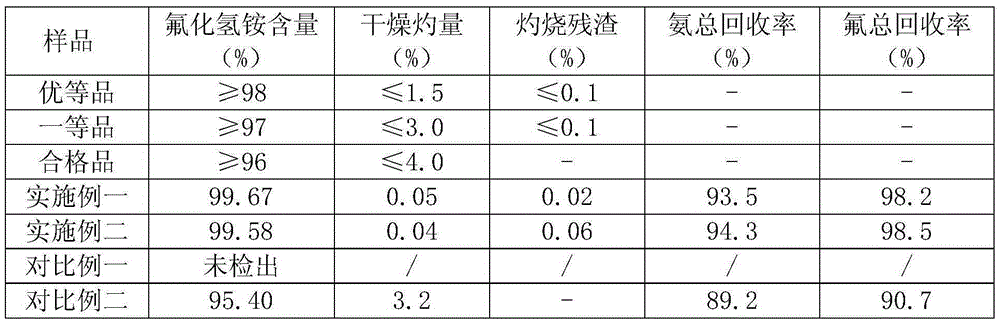

Preparation method of ammonium bifluoride

The invention discloses a preparation method of ammonium bifluoride. The method comprises steps as follows: a, dilute ammonia water and ammonium bifluoride mother liquor are mixed to adsorb gas containing fluorine and silicon, and a mixed solution is obtained; b, the mixed solution and filter-press residues obtained in Step d are mixed for slurry making and filter-press separation, and a filtrate and a silica by-product are obtained; c, ammonia is introduced into the filtrate; d, slurry is subjected to filter-press separation, and an ammonium fluoride filtrate and filter-press residues are obtained; e, the ammonium fluoride filtrate is subjected to vacuum concentration; f, concentrated slurry is dissolved, the pH value of the solution is adjusted with hydrogen fluoride, and cooling crystallization is performed; g, ammonium bifluoride crystals are filtered, separated and dried, and the ammonium bifluoride product is obtained. With the adoption of the method, the utilization rate of fluorine and ammonia is increased, the gas containing fluorine and silicon is changed into the ammonium bifluoride product with the high economic value in the phosphoric acid production process, the production cost is low, the economic benefit is significant, meanwhile, the purity and other indexes of the product meet the requirement for superior products, and the method is suitable to be popularized and applied in the field.

Owner:GUIZHOU CHANHEN CHEM CO LTD

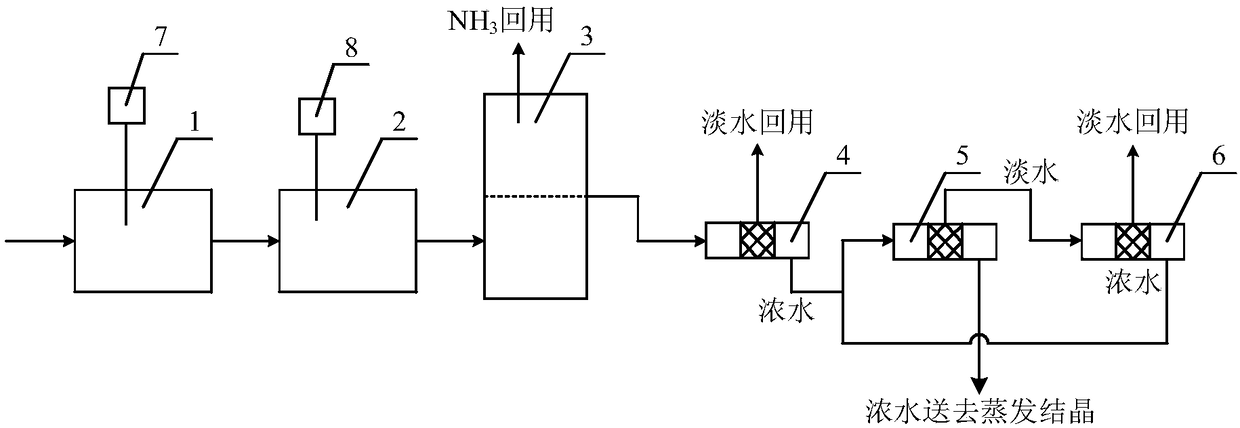

Low-energy-consumption desulfurization wastewater zero emission technology and device

InactiveCN108383308ASimplified Dissolved Salt CompositionAvoid foulingMultistage water/sewage treatmentWater/sewage treatment by neutralisationSludgeFresh water organism

The invention discloses a low-energy-consumption desulfurization wastewater zero emission technology and device. The technology comprises the following steps: (1) conveying desulfurization wastewaterinto an adjusting tank and adjusting the pH (Potential of Hydrogen) value; (2) then conveying the desulfurization wastewater into a sedimentation tank; adjusting the pH of the wastewater to be 10 to 13; after carrying out sedimentation, conveying supernatant into a denitrification tower; conveying bottom sludge into a sludge treatment unit; (3) removing ammonia nitrogen pollutants in the wastewater in the denitrification tower through a blowing-off technology; (4) conveying the blown-off wastewater into a primary reverse osmosis membrane device to obtain primary freshwater for direct recycling; conveying concentrated water into an electric ion membrane device; (5) conveying the concentrated water into the electric ion membrane device and separating to obtain concentrated water and freshwater; conveying the concentrated water into an evaporation curing and crystallization system for separating and crystallizing and conveying the freshwater into a secondary reverse osmosis membrane. According to the low-energy-consumption desulfurization wastewater zero emission technology and device, disclosed by the invention, the pre-treatment problems of slightly high operation pressure and largeenergy consumption in a desulfurization wastewater membrane treatment technology are solved; heavy metal and suspended matters are removed and the ammonia nitrogen pollutants also can be removed; furthermore, the quality of recycled water is improved, and the aims of improving the wastewater recycling rate and reducing the wastewater emission are realized.

Owner:ZHEJIANG TIANLAN ENVIRONMENTAL PROTECTION TECH

Device and method for preparing sulfite

PendingCN111792651AReduce manufacturing costFull recoveryDispersed particle separationAmmonium sulfitesProcess equipmentFluid phase

The invention discloses a device for preparing sulfite. SO2-containing feed gas passes through a flue gas conditioning unit, then enters an acidic sulfite preparation unit and a basic sulfite slurry preparation and residual SO2 re-absorption unit in sequence, and is discharged out of the system; the synthesized intermediate slurry passes through an acidic sulfite conditioning and target product separating unit and a product drying unit in sequence, and finally a solid-phase target product or a liquid-phase target product is obtained. Ammonia in the feed gas can be fully recycled by the deviceand method, the ammonia consumption of a unit product can be reduced by 1 / 4-1 / 2, and the production cost of a target product is lower. The primary purity of the target product is high, secondary separation and purification are not needed, the loss in a purification step is avoided, and the yield of the target product can be increased by 0.8%-2.3% according to empirical analysis. The primary purityof the target product reaches 98.5-99.3%, one set of process equipment can be used for producing various products, and the market requirements can be better met.

Owner:NANJING LIUYAN ENVIRONMENTAL PROTECTION TECH CO LTD

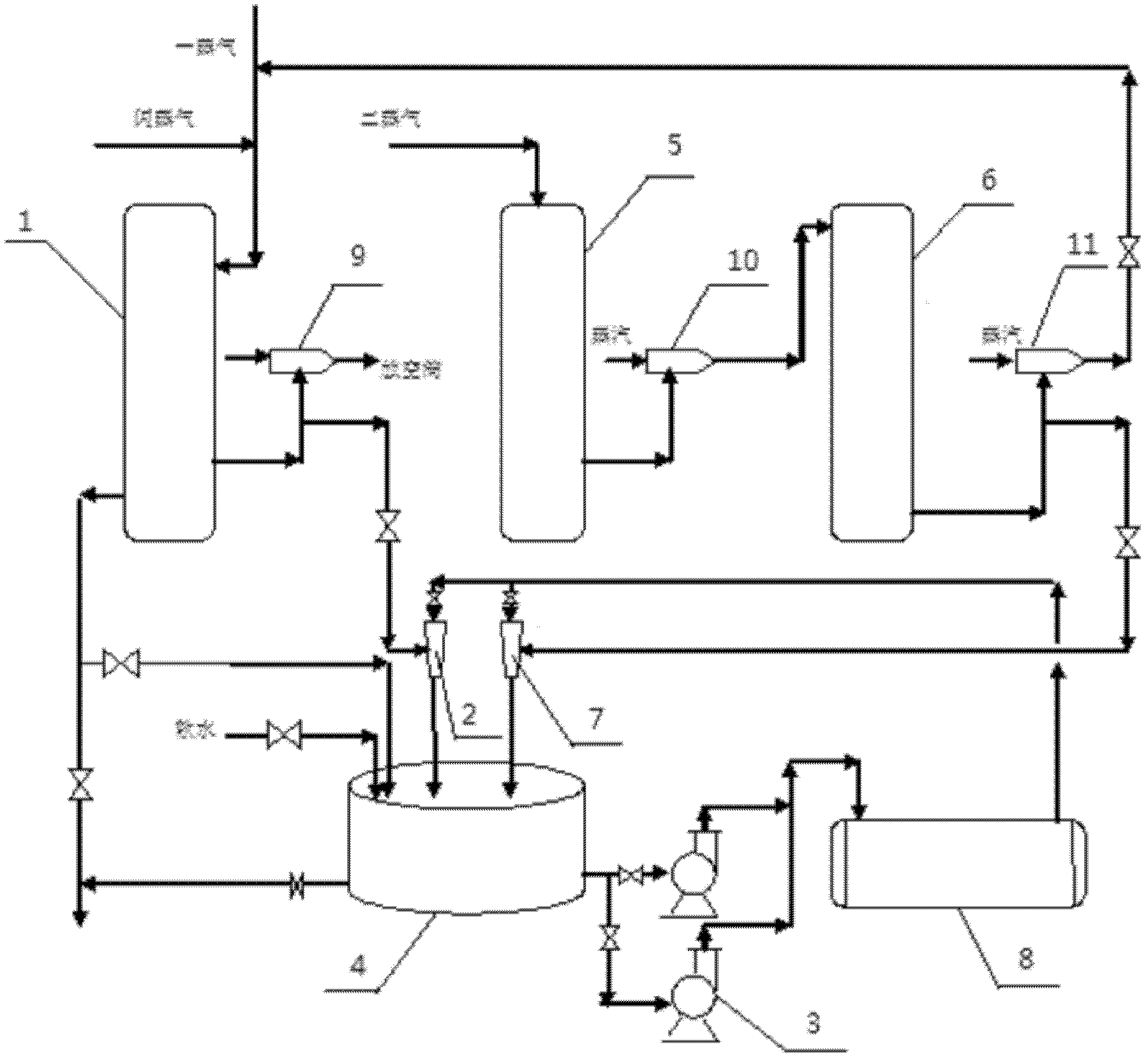

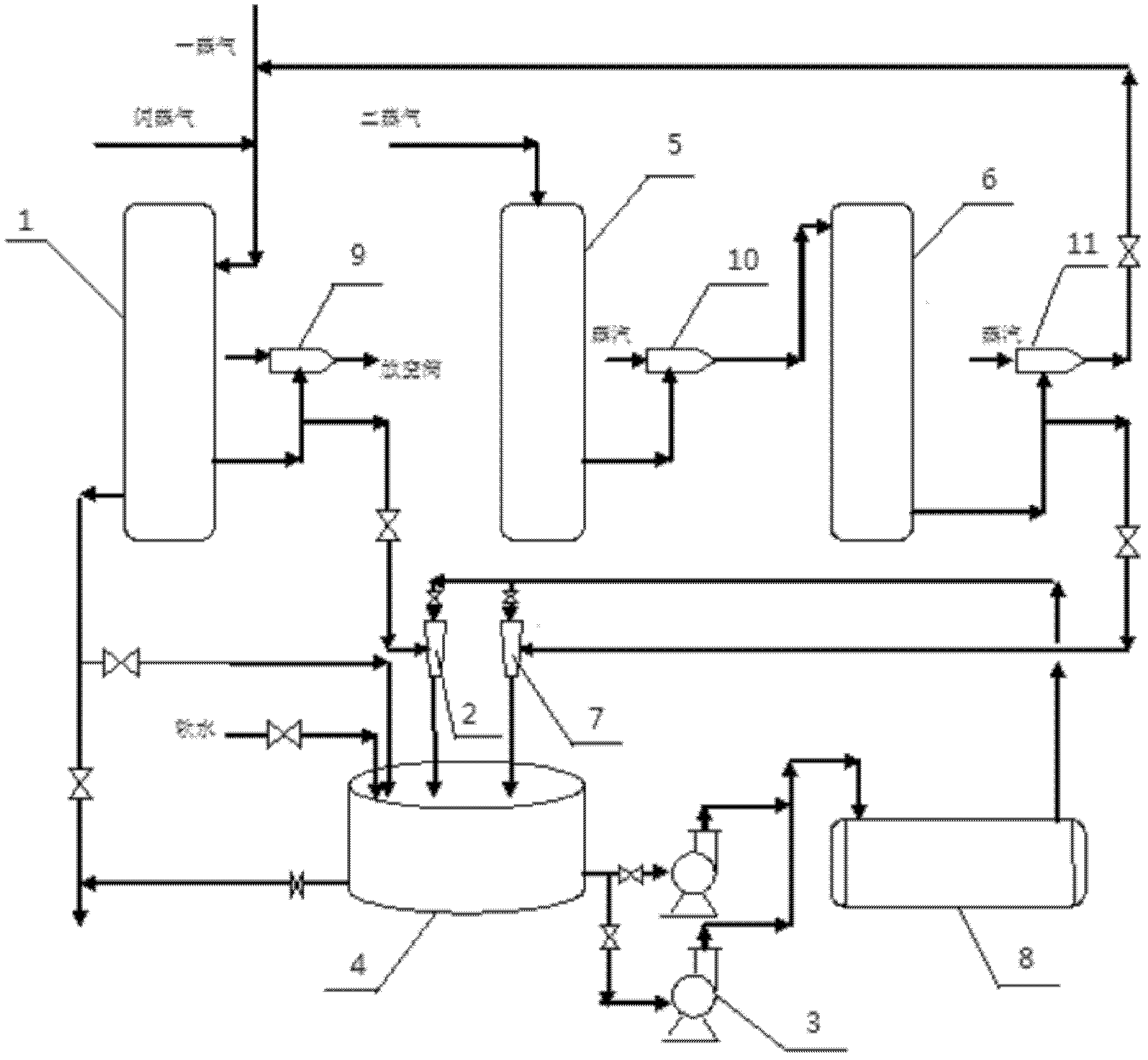

Water vacuumizing method and water vacuumizing system in urea production

InactiveCN102606545AReduce consumptionEmission reductionJet pumpsMachines/enginesEvaporationEnvironmental engineering

The invention discloses a water vacuumizing method and a water vacuumizing system in urea production. The method is used for vacuumizing a urea evaporation system with circulating water by the aid of a circulating system formed by sequentially connecting a hydraulic jet pump, a circulating water tank and a water pump through pipelines. The method and the system utilize water as media to vacuumize the urea evaporation system, so that consumption of vapor is reduced, and energy sources are saved. When the water is utilized as the vacuumizing media, uncondensed gases dissolve in water, and as the uncondensed gases generally refer to NH3 (ammonia) and CO2 (carbon dioxide), when concentration reaches to a specific value after the uncondensed gases dissolve in water, the circulating water is delivered to a subsequent process so that NH3 and CO2 are analyzed and utilized as raw materials for urea synthesis. The water vacuumizing system is simple in design and small in investment and has an active role in reduction of vapor and ammonia consumption, and urea waste gas emission is reduced.

Owner:XISHUI COUNTY FURUIDE CHEM ENG

Method for preparing ammonium sulfate by conversion of phosphogyspum with polycrystalline method

ActiveCN102303874BImprove filter strengthEmission reductionAmmonium sulfatesChemical industryO-Phosphoric Acid

The invention relates to a method for preparing ammonium sulfate by continuous conversion of phosphogyspum with a polycrystalline method, belonging to the technical fields of resource comprehensive utilization and chemical industry, and relates to a method for producing ammonium sulfate by conversion of phosphogyspum with a polycrystalline method based on a byproduct phosphogyspum in a (sulfuric acid) wet phosphoric acid industry as a main raw material. The production process comprises the following steps: (1) pretreating the raw material of phosphogyspum discharged in the wet phosphoric acid industry so as to obtain purified phosphogyspum; (2) absorbing ammonia and carbon dioxide with a ammonia-sulfate-containing primary lotion which is produced by washing a calcium carbonate filter cake with water in a filtration process in a carbonation tower so as to produce an ammonia sulfate and carbonate solution; (3) connecting a calcium carbonate polycrystalline nucleus generator with a multiple-tank or multiple-partition groove type reactor with a stirrer in series to constitute a conversion crystallizer; (4) filtering a reaction material slurry discharged from the conversion crystallizer so as to obtain a filter cake and filtrate containing 38-40% by weight of ammonium sulfate; (5) carrying out secondary countercurrent washing on the filter cake obtained in the step (4) with clear water, and feeding the ammonia-sulfate-containing primary lotion to the carbonation tower for absorbing gas ammonia and carbon dioxide so as to produce an ammonia sulfate and carbonate liquid; and (6) neutralizing and decarburizing the filtrate containing ammonium sulfate from the step (4) with sulfuric acid, then centrifugally separating so as to obtain a crystal containing wet ammonium sulfate, separating out a mother liquid, carrying out cycle concentration on the mother liquid, and drying the crystal containing wet ammonium sulfate so as to obtain a finished product ammonium sulfate.

Owner:YUNNAN CHEM RES INST

Ammonia-spillage amount control method in ammonia-process desulfurization

InactiveCN101422697ASolve the problem of controlling the amount of ammonia slipReduce utilizationDispersed particle separationFlue gasTower

The invention relates to an ammonia escaping amount controlling method that is used in ammonia desulphurization, belongs to the technical field of chemical engineering and environmental protection, and comprises following steps: a high-efficiency flue gas desulfurizing defogger (2) is arranged at the upper part of a washing and absorbing tower, sulphureous flue gas passes through an absorbing section and is chemically absorbed by an absorbing liquor then forms fog drops that contain ammonia salt and free ammonia, the fog drops rise into the region of the defogger (2) along with the flue gas, and the defogger (2) catches the ammoniac fog drops; the upper and lower ends of the defogger (2) that is arranged at the upper part of the washing and absorbing tower are assorted with technical watery regions for program controlling washing devices (1) and (3) sequentially, and the ammonia fog caught by the defogger (2) is washed and recycled; and the water supplement of a desulfurizing system is supplemented by technical washing water (4), thus satisfying water balance problem of the system. The method can lead the ammonia escaping amount in ammonia desulphurization to be much lower than GB14555-93 discharge limit value, solve the ammonia escaping amount control problem in ammonia desulphurization, lead the ammonia escaping amount to reach standards, improve the utilization rate of ammonia, and simultaneously avoid the corrosion of surrounding devices that is caused by wet ammoniac flue gas drops in the desulphurization, and is favorable for environmental protection.

Owner:ASIA PACIFIC ENVIRONMENTAL CORP

Circulating spouting type NOx emission reduction system and working method thereof

PendingCN112058064AAvoid local high temperatureAvoid or reduceGas treatmentDispersed particle separationEnvironmental engineeringMechanical engineering

The invention relates to a circulating spouting type NOx emission reduction system and a working method thereof. The circulating spouting type NOx emission reduction system comprises a rotary kiln, asmoke chamber, a spouting ring, a fuel system, a tertiary air pipe, a reactor, a first material distribution valve, a first cyclone cylinder, a denitration system, a decomposing furnace, a hopper anda second cyclone cylinder. An air inlet of the smoke chamber is connected with an air outlet of the rotary kiln, an air outlet of the reactor is connected to one side of the decomposing furnace and communicated with the interior of the decomposing furnace, and an air inlet of the reactor is connected with an air outlet of the smoke chamber through the spouting ring. An air outlet of the tertiary air pipe is connected to the bottom of the decomposing furnace, a feeding port of the hopper is connected to the lower portion of the air outlet of the tertiary air pipe, and an air inlet of the secondcyclone is connected with an air outlet of the decomposing furnace; The formation of NOX is effectively avoided or reduced so that the emission reduction efficiency of NOX is improved, and the ammonia water consumption of the denitration system is greatly reduced to save the production cost; meanwhile, the problem of serious material accumulation at the bottom of the decomposing furnace is solved, and secondary pollution can be avoided.

Owner:NANJING KISEN INT ENG

A kind of flue gas desulfurization and denitrification process method

ActiveCN103768919BConsume moreReduce consumptionUsing liquid separation agentAir quality improvementGas phaseFlue gas

The invention discloses a flue gas desulfurization and denitrification process method. The method comprises the following steps: (1) spraying and washing flue gas containing NOx and SOx; (2) allowing a gas phase exhausted in step (1) to enter a desulfurization tower to be subjected to desulfurization treatment, wherein the desulfurization treatment adopts the ammonia desulphurization technology, part of NOx is removed during desulphurization, a low-concentration ammonia water desulfurization section is arranged at the upper part of the 0.5%-1.0%; (3) performing selective reduction denitrification reaction on gas exhausted from the top of the desulfurization tower. Compared with the prior art, the flue gas desulfurization and denitrification are combined organically, so that the overall effectiveness and economic efficiency of flue gas treatment are improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

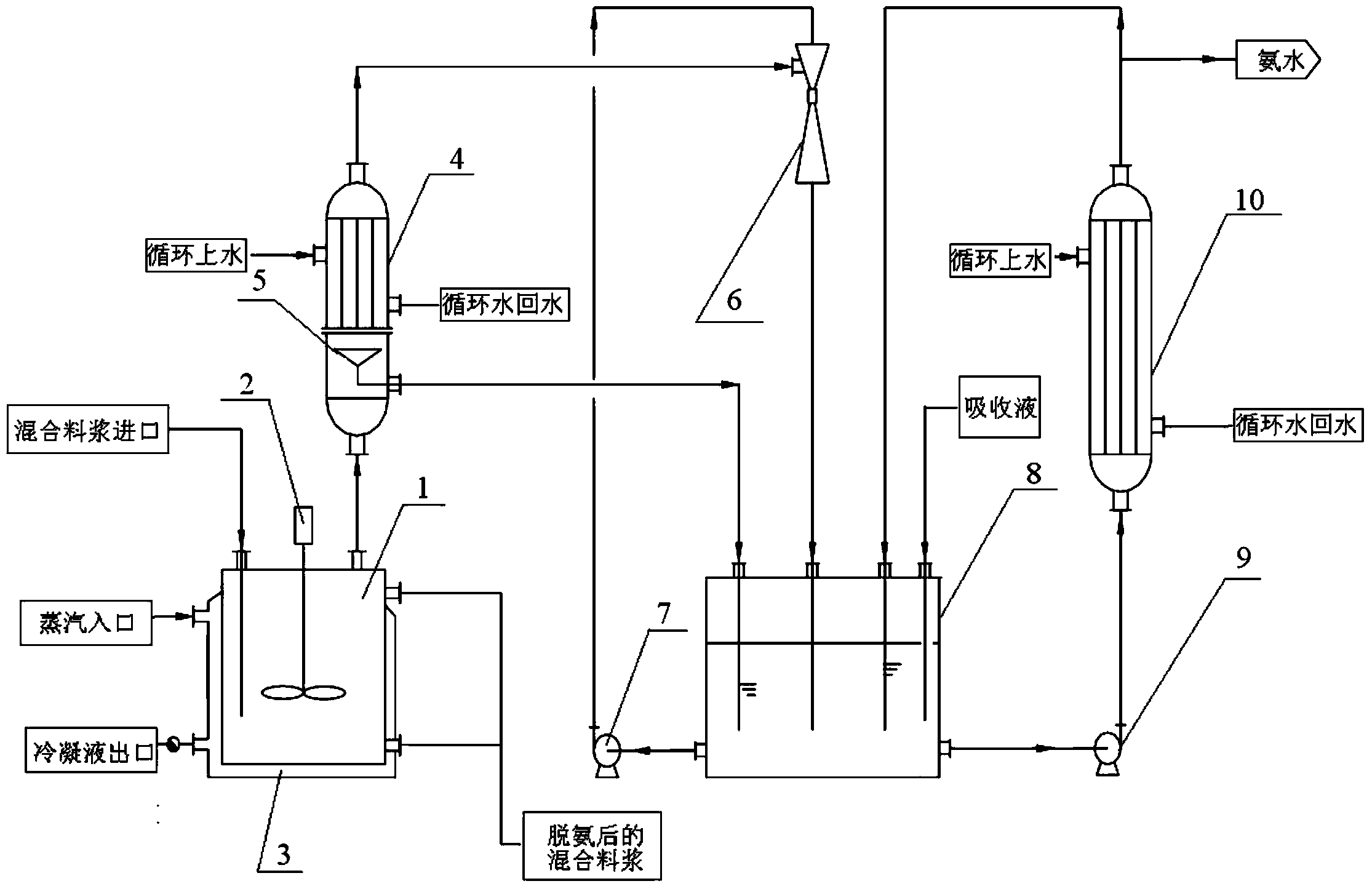

Device and method for removing free ammonia from mixed slurry of ammonium sulfate and calcium carbonate

ActiveCN104003418AIncrease production intensityReduce steam consumptionAmmonium sulfatesAmmonia preparation/separationAmmonium sulfateWater content

The invention discloses a device and a method for removing free ammonia from mixed slurry of ammonium sulfate and calcium carbonate, and belongs to the technical field of deamination. The method adopts the following technical scheme: feeding mixed slurry of ammonium sulfate and calcium carbonate to a deamination tank; and heating the slurry to be in a boiling state by steam under a negative pressure condition, and then feeding the generated mixed gas into a condenser; conveying an absorption liquid to an ammonia tank after the generated ammonia gas is absorbed by the absorption liquid in a hydraulic ejector. By adopting the technical scheme, the removal rate for removing the free ammonia from the slurry is over 90%, the removed free ammonia is recycled to prepare ammonium hydroxide, and the recovery rate can be up to 100%. In addition, a sulfuric acid does not need to be added in the technical scheme, the moisture content of the mixed slurry is reduced in deamination, the problem of unorganized emission of ammonia in the process of preparing ammonium sulfate from phosphogypsum is solved, the production intensity of a filter separator in the process for preparing ammonium sulfate from phosphogypsum is improved, ammonia consumption of the system is reduced, the production cost is reduced, and the production and operation environment is improved.

Owner:SINOPEC NANJING ENG & CONSTR +1

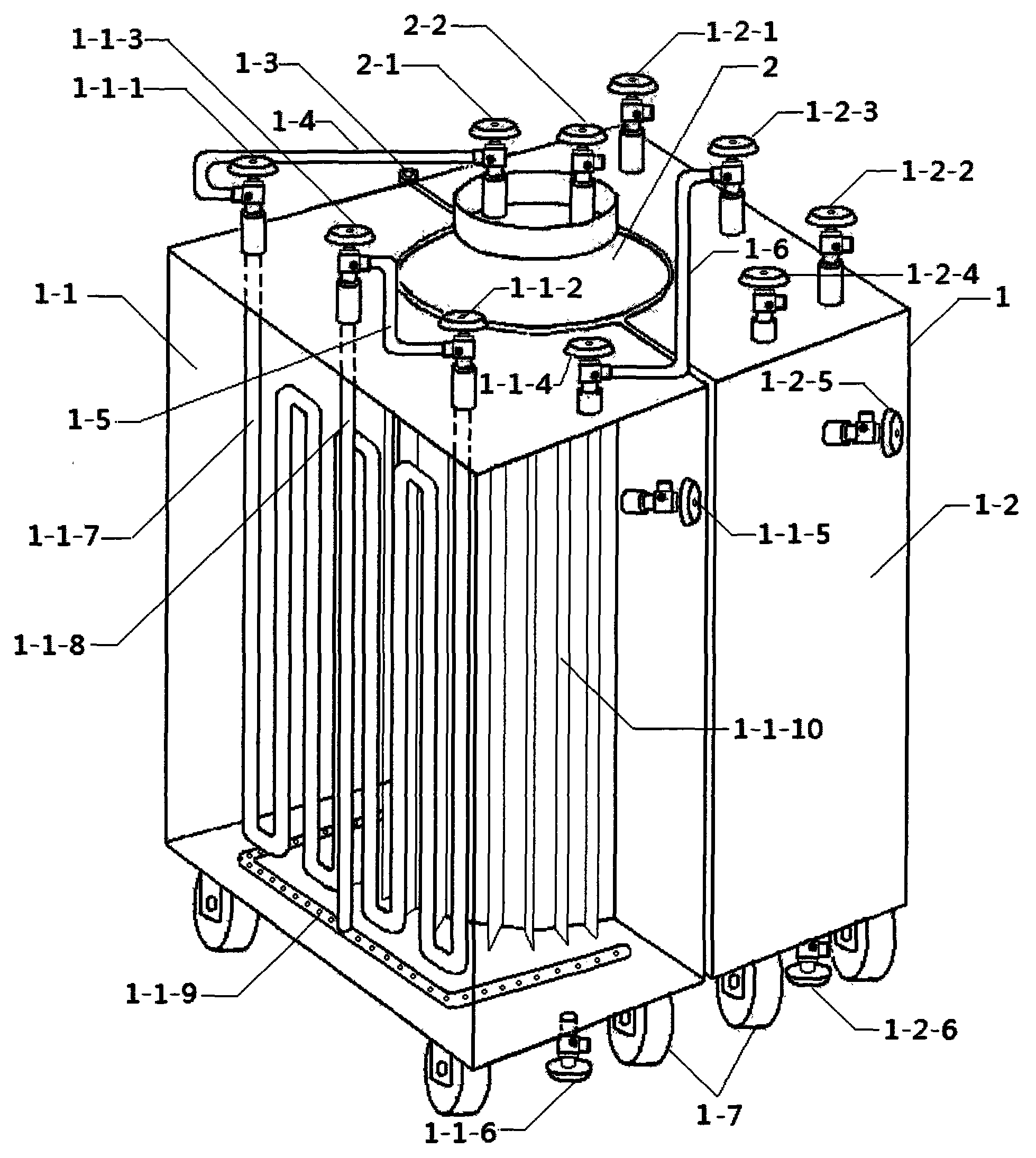

Heat self-exchange tube array fin dual ammonia preparation device

InactiveCN104016373AStable productionAvoid the effects of temperature changesAmmonia preparation/separationElectricityEngineering

The invention discloses a heat self-exchange tube array fin dual ammonia preparation device, which is mainly composed of two absorption reactors. The inside of each absorption reactor can closely contact with the outer wall of a liquid ammonia steel cylinder, so that the liquid ammonia steel cylinder can be contained between the two absorption reactors; and array tubes and fins are arranged in the two absorption reactors. In the ammonia preparation process, the heat released from the absorption reaction can simultaneously absorbed by the liquefied ammonia gasification process through the array tubes and fins in the reactors, so as to reach the purpose of dual exchange of array tubes and fins; heat released from the reaction process is effectively removed, and heat required by liquid ammonia gasification is supplied, so as to facilitate the proceeding of the reaction towards the product generation direction as well as supply stable gasification temperature for liquid ammonia; and heat direct self-exchange of heat released in the absorption reaction and heat absorbed by liquid ammonia gasification in the system is realized, so that the ammonia preparation process is carried out and completed under efficient and stable conditions without the need of cooling water and electricity.

Owner:李景峰 +1

Method and device for recovering ammonia from nitrochlorobenzene ammonolysis wastewater

InactiveCN103359802AReduce consumptionReduce ammonia consumptionDispersed particle separationWater/sewage treatment by heatingRecovery methodElectrolysis

The invention discloses a method and device for recovering ammonia from nitrochlorobenzene ammonolysis wastewater. According to the method, ammonolysis wastewater is evaporated by using ammonia distilling equipment so as to liberate free ammonia; or an alkaline substance is added firstly so as to convert ammonium ions in the ammonolysis wastewater into the free ammonia, and then, evaporation is carried out; the free ammonia in vapor is absorbed by water, then returns to a material proportioning process of nitrochlorobenzene ammonolysis and is cyclically reused in a manner of serving as an ammonolysis raw material; and then, the treated wastewater is subjected to electrolysis and catalytic oxidation treatment and ammonium chloride recovery. Compared with the prior art, the method and the device have the advantages that the free ammonia is recovered and utilized in a cycling manner, so that the consumption of ammonia is reduced; after the free ammonia is recovered, the consumption of neutralizing acid is reduced, the volume of the wastewater is reduced, and the load of the sewage treatment device is reduced; and by adopting the method and the device, the recovery ratio of ammonia and ammonium chloride can be adjusted randomly according to the market price of liquid ammonia and ammonium chloride.

Owner:杜惠红

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com