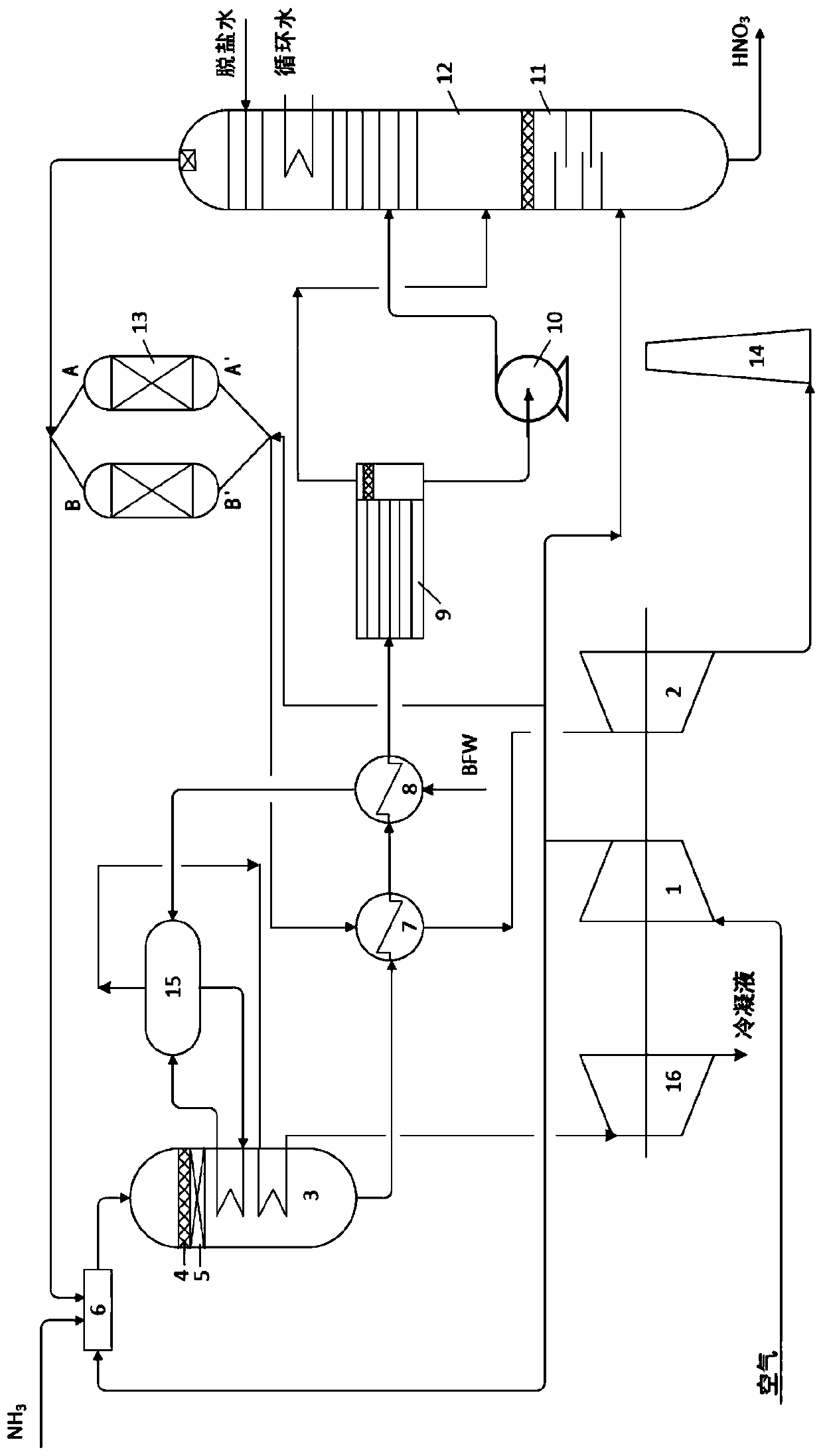

Medium-pressure nitric acid production process and equipment

A production process and production equipment technology, applied in the field of medium-pressure nitric acid production process and production equipment, to achieve the effects of reducing equipment, saving investment costs, and low ammonia consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] This embodiment specifically relates to a medium-pressure nitric acid production process. Taking the production of nitric acid with an annual output of 200,000 tons as an example, the process steps are as follows:

[0046] S1: Using air compressor to 102100Nm 3 / h rate compresses air to 0.5~0.6Mpa, of which 75600Nm 3 / h of process air and 93300Nm 3 / h of ammonia is mixed in the ammonia air mixer, and then the mixed gas is passed into the oxidation reactor;

[0047] S2: The mixed gas sequentially passes through the platinum catalyst layer and N in the oxidation reactor from top to bottom 2 O decomposes the catalyst layer to carry out the catalytic oxidation reaction of ammonia. The reaction temperature is 860℃~900℃, and the production contains NO x The primary gas;

[0048] Among them, the mixed gas reacts to generate NO when passing through the platinum catalyst layer x , Then pass N 2 O decomposition catalyst layer will N 2 O decomposes to generate nitrogen, making N 2 The O c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com