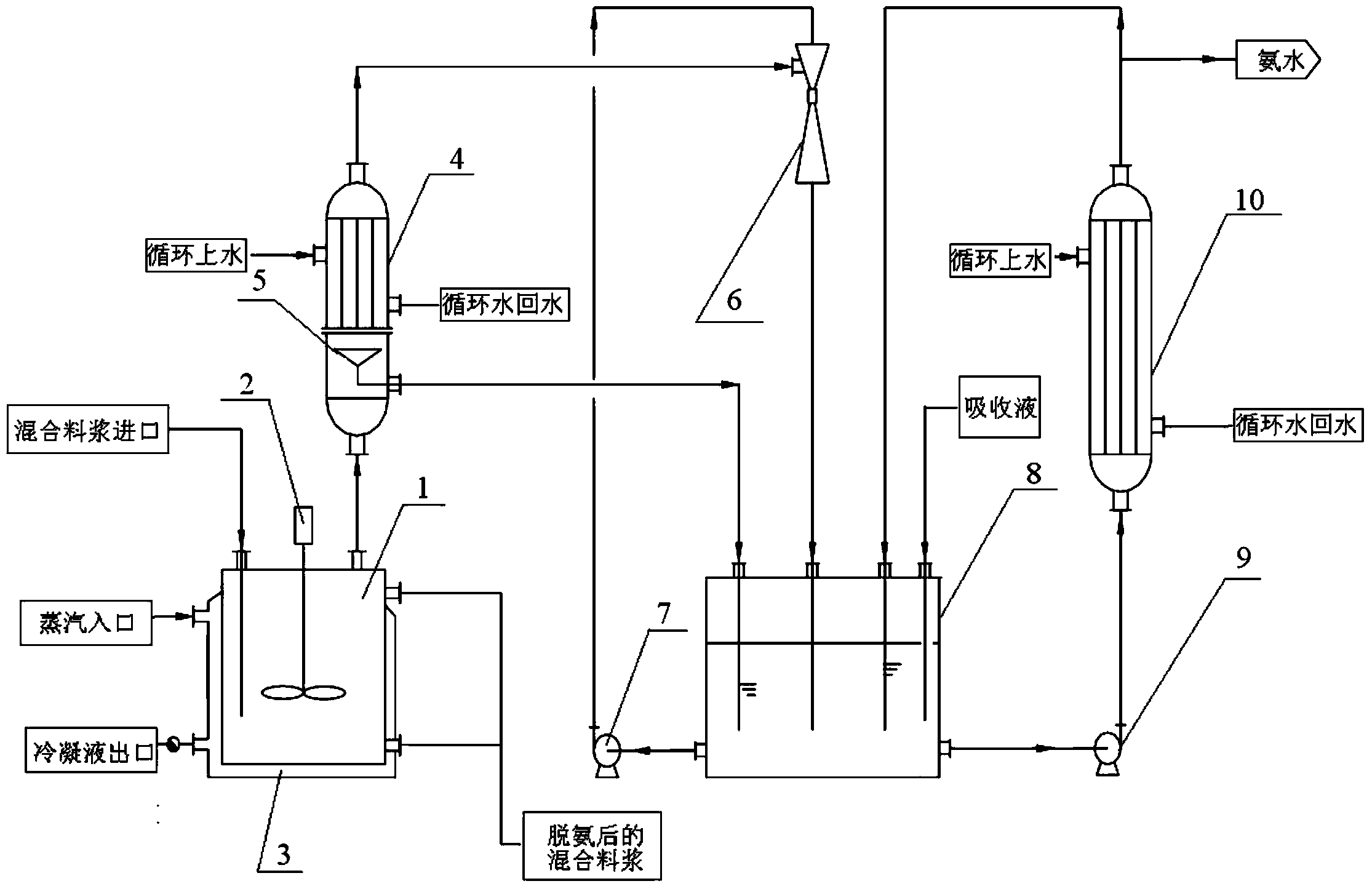

Device and method for removing free ammonia from mixed slurry of ammonium sulfate and calcium carbonate

A mixed slurry and calcium carbonate technology, applied in the field of ammonia removal, can solve the problems of unorganized ammonia emissions affecting the operating environment, affecting production costs, increasing ammonia consumption, etc., to improve the production operating environment, reduce production costs, and reduce steam consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The slurry of 66 kilograms / hour ammonium sulfate scale, utilizes above-mentioned device to realize the method for removing free ammonia in ammonium sulfate and calcium carbonate mixed slurry, the concrete steps of this method are as follows, and operating conditions are as shown in table 1.

[0033] The ammonia water tank is first fed with the absorption liquid, the ammonia water pump and the circulating cooling pump are started, and the circulating cooling water is introduced. Send the mixed slurry of ammonium sulfate and calcium carbonate into the deamination tank, maintain the tank in a fully mixed flow state through the agitator, maintain the absolute pressure inside the deamination tank at 20-50KPa, and use the steam jacket of the deamination tank to heat ( Saturated steam of 0.2-0.4Mpa) makes the slurry in a boiling state (65-110°C). After heating and boiling, the gas (ammonia and water vapor) generated in the deamination tank enters the condenser and condenses to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com