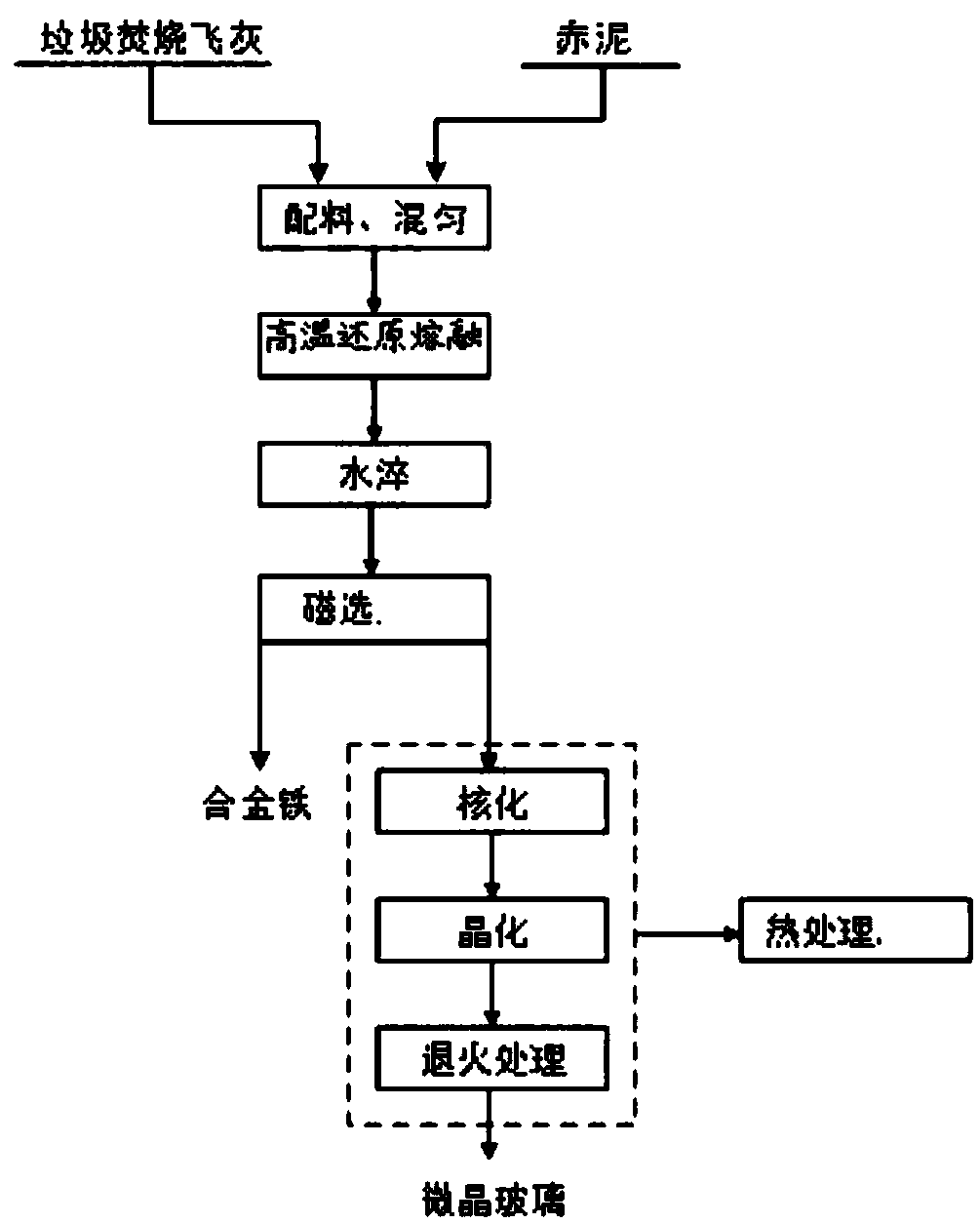

Method for preparing alloy iron and glass ceramics

A technology of glass-ceramics and alloy iron, which is applied in the field of solid waste recycling, can solve the problems of low utilization rate and inability to realize resource utilization of waste incineration fly ash and red mud, achieve high economic value, improve comprehensive utilization rate of resources, The effect of excellent comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

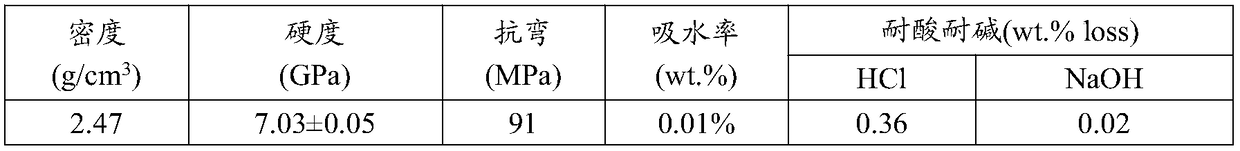

Embodiment 1

[0052]The process conditions for preparing alloy iron and glass-ceramic from waste incineration fly ash and red mud are as follows: the amount of waste incineration fly ash is 33%, and the amount of red mud is 67%; the waste incineration fly ash and red mud are mixed evenly in proportion and put into the crucible , place the crucible in an induction furnace at 1300°C for reduction and melting for 120 minutes; quench it with water, crush it to -2mm with a crusher, and separate it by magnetic separation at a magnetic field strength of 110kA / m. The iron grade of 94.56% and the iron recovery rate of 85.47% can be obtained. Direct reduction alloy iron of trace ferrophile metals such as Ni and Cu; dry the crushed glass slag and place it in a crystallization furnace for heat treatment. 1200℃, until the glass slag completely slumps, and finally cools with the furnace. The glass-ceramic product was taken out from the crystallization furnace, and polished to obtain glass-ceramics. The p...

Embodiment 2

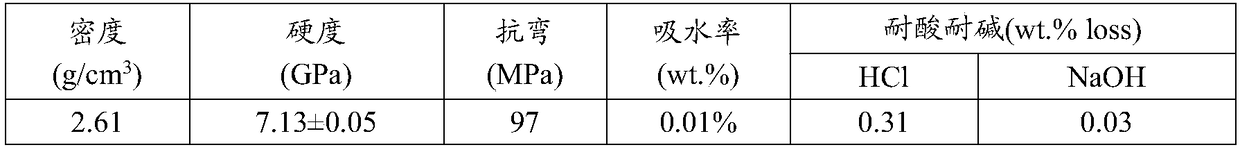

[0059] The process conditions for preparing alloy iron and glass-ceramics from waste incineration fly ash and red mud are as follows: the amount of waste incineration fly ash is 36%, the amount of red mud is 64%, and the waste incineration fly ash and red mud are mixed evenly in proportion and put into the crucible , place the crucible in an induction furnace at 1400°C for reduction and melting for 100 minutes; quench it with water, crush it to -2mm with a crusher, and separate it by magnetic separation at a magnetic field strength of 110kA / m. The iron grade of 93.94% and the iron recovery rate of 87.11% can be obtained. Direct reduction of alloy iron with trace amounts of Ni, Cu and other iron-loving metals; dry the water-quenched broken glass slag and place it in a crystallization furnace for heat treatment. Raise the temperature to 1200°C until the glass slag completely collapses, and finally cool down with the furnace. The glass-ceramic product is taken out from the crysta...

Embodiment 3

[0067] The process conditions for preparing alloy iron and glass ceramics from waste incineration fly ash and red mud are as follows: the amount of waste incineration fly ash is 40%, and the amount of red mud is 60%; the waste incineration fly ash and red mud are mixed evenly according to the proportion and put into the crucible , place the crucible in an induction furnace at 1600°C for reduction and melting for 90 minutes; quench it with water, crush it to -2mm with a crusher, and separate it by magnetic separation at a magnetic field strength of 110kA / m. Direct reduction alloy iron with trace amounts of ferrophilic metals such as Ni and Cu; dry the water-quenched broken glass slag and place it in a crystallization furnace for heat treatment. Raise the temperature to 1180°C until the glass slag completely collapses, and finally cool down with the furnace. The glass-ceramic product is taken out from the crystallization furnace, and the glass-ceramic product can be obtained by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com