Reclaimed copper smelting process and device

A process device and recycled copper technology, applied in the direction of improving process efficiency, etc., can solve the problems of low production scale and efficiency, limited amount of recycled copper, etc., and achieve the effect of high production intensity, high production efficiency and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

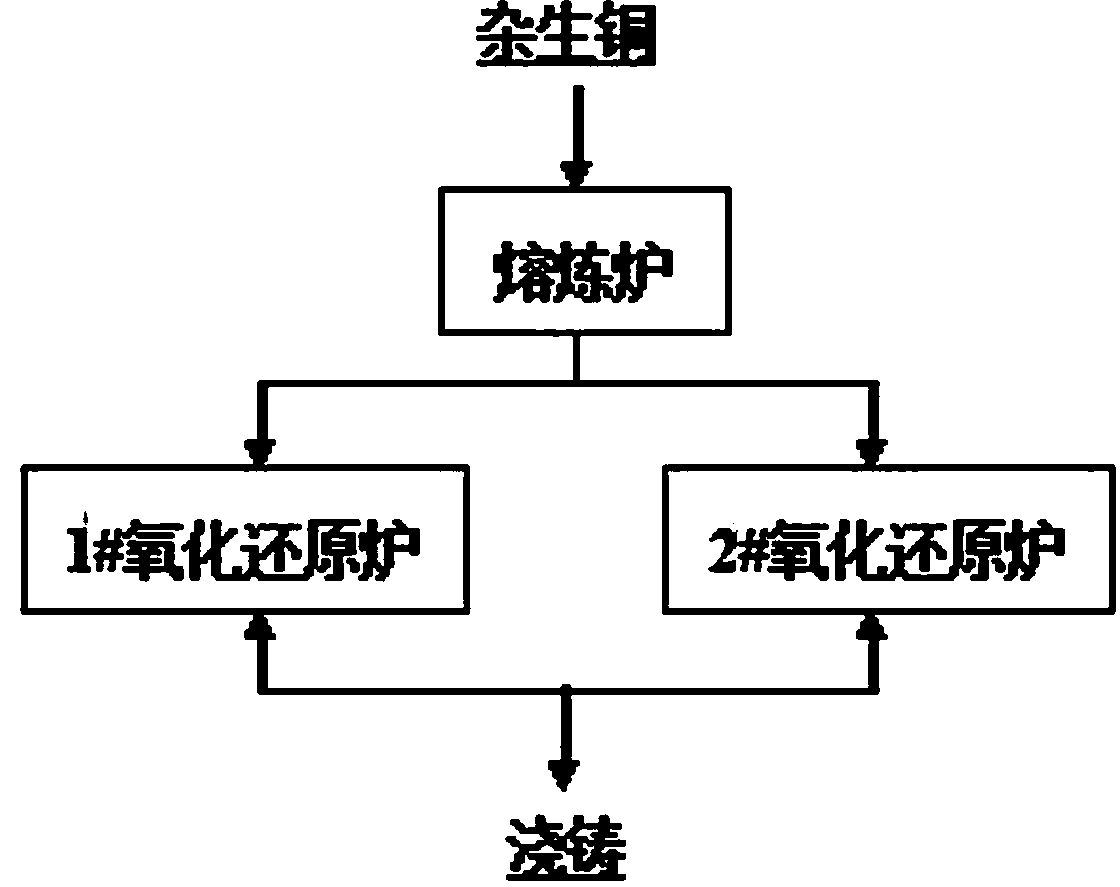

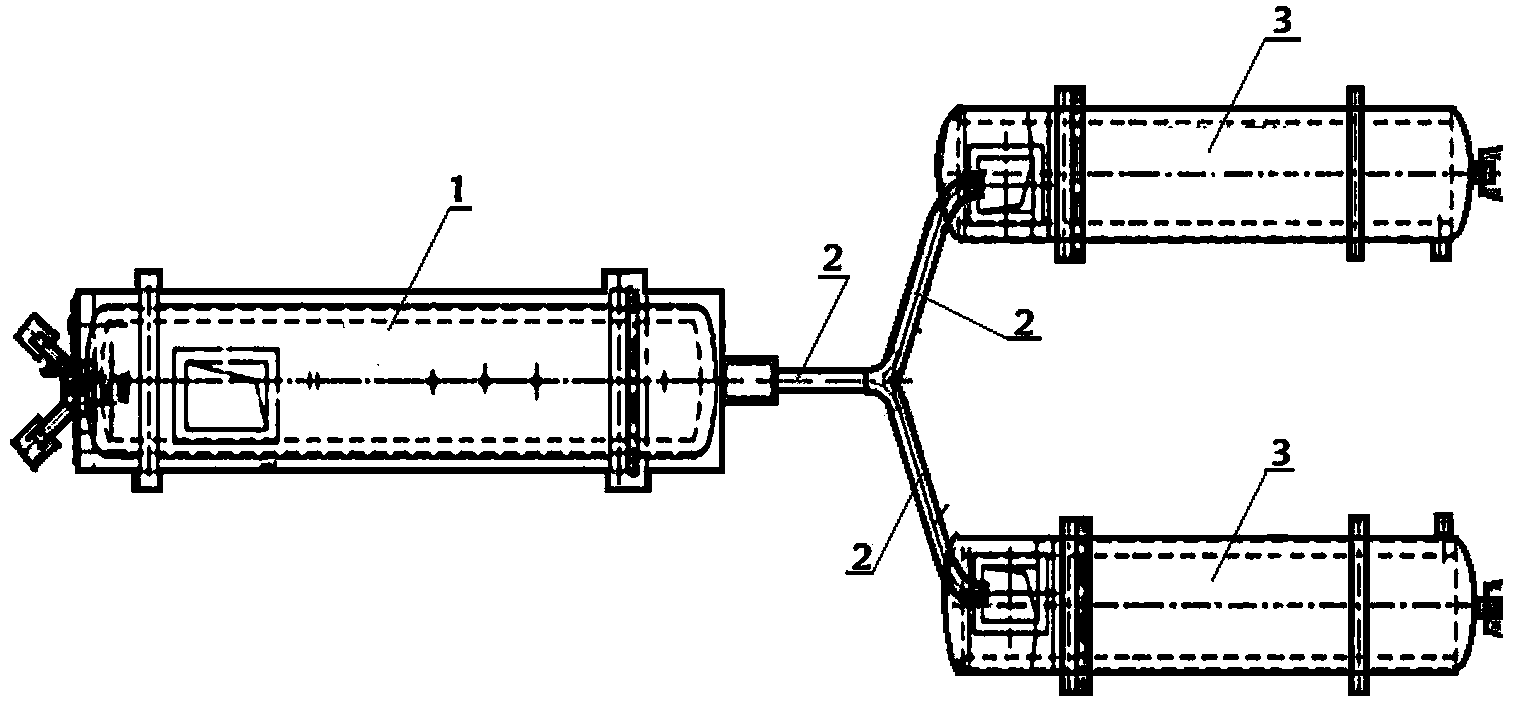

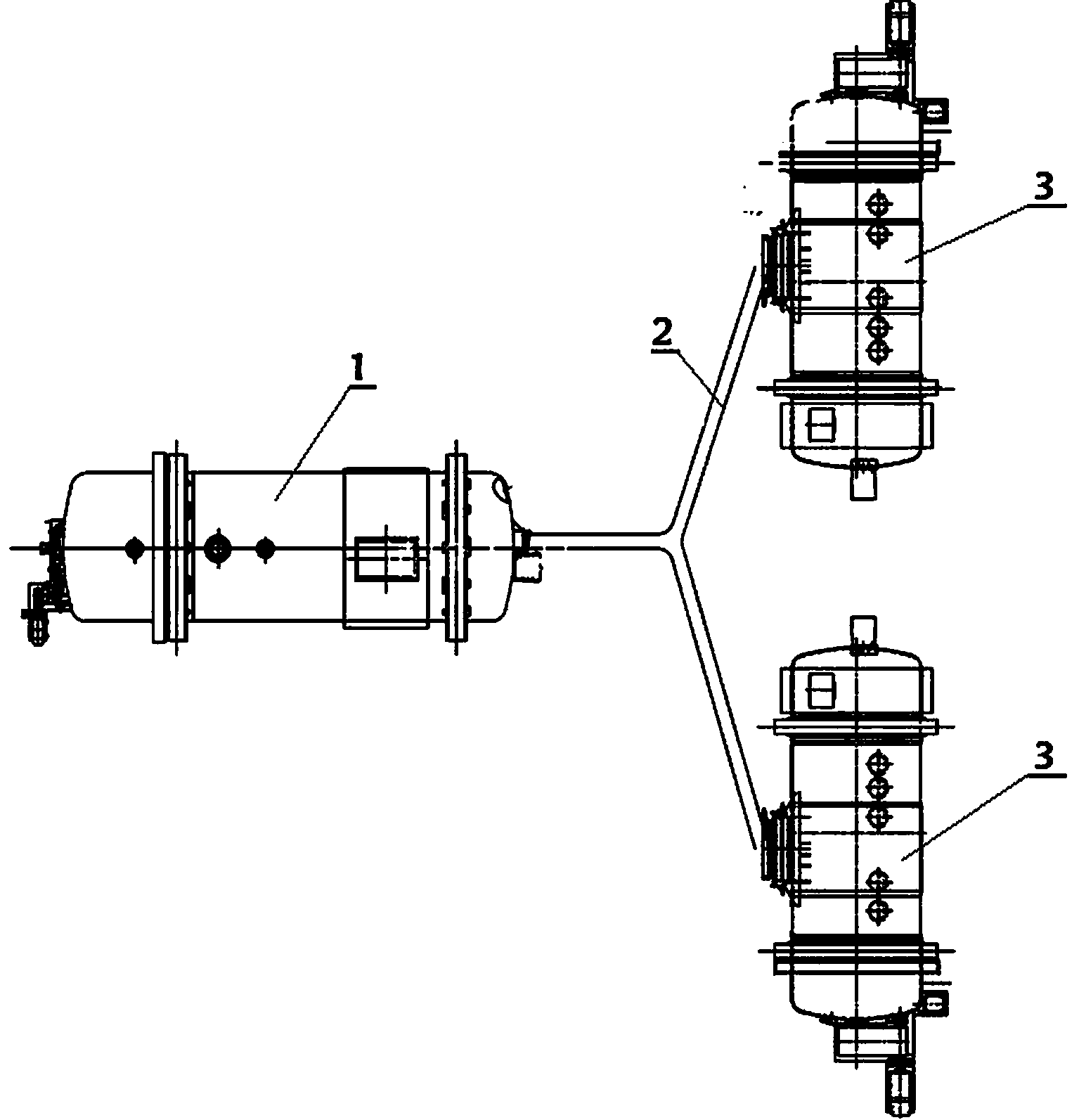

[0016] Recycled copper smelting process and equipment, the process equipment is composed of a smelting furnace 1 and two redox furnaces 3, the two redox furnaces 3 are arranged in parallel, and are connected with the smelting furnace 1 through a main chute 2 and two sub-chutes 2 , the three furnaces are arranged in the shape of "product"; the furnace body includes the feeding port, the flue gas outlet, the copper matte outlet, the slag discharge port, the side wall socket at the side of the furnace body and the spray gun socket at the bottom of the furnace body; the slag discharge The mouth is located on the end face of the furnace body, and the copper discharge port is located on the end face of the furnace body at one end of the slag mouth or the lower part of the side of the furnace body; the furnace body is cylindrical and rotatable, and the furnace cavity has a circular cross section and the radial dimension The axial direction is consistent; the spray gun is in the form o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com