Patents

Literature

31 results about "Copper industry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Copper is one of the essential metals required for developing industrial economy. Globally, the copper mining industry is one of the leading markets of the metal mining market. Most of the available copper is distributed over large areas, mixed with mineralized materials and rocks.

Process for treating wastewater in copper industry by using polymeric ferric sulfate

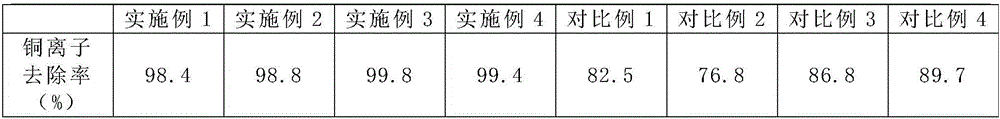

ActiveCN105692833AEfficient removalHigh removal rateWater/sewage treatment by flocculation/precipitationSodium BentoniteEmission standard

The invention belongs to the field of wastewater treatment and discloses a process for treating wastewater in the copper industry by using polymeric ferric sulfate. The process comprises steps as follows: firstly, a flocculant, namely, polymeric ferric sulfate, is mixed with bentonite to form a compound treating agent; the prepared compound treating agent is added to the wastewater in the copper industry and stirred for a reaction, precipitation is performed after the reaction ends, and finally, solid-liquid separation is performed. The process has the benefits as follows: through compounding of bentonite and polymeric ferric sulfate, copper in the wastewater in the copper industry can be effectively removed under the synergistic effect of bentonite and polymeric ferric sulfate; compared with the single effect of bentonite or polymeric ferric sulfate, the removal rate is high, and the emission standard is met.

Owner:JIANGSU GUOSONG ENVIRONMENT SCI & TECH DEV CO LTD +1

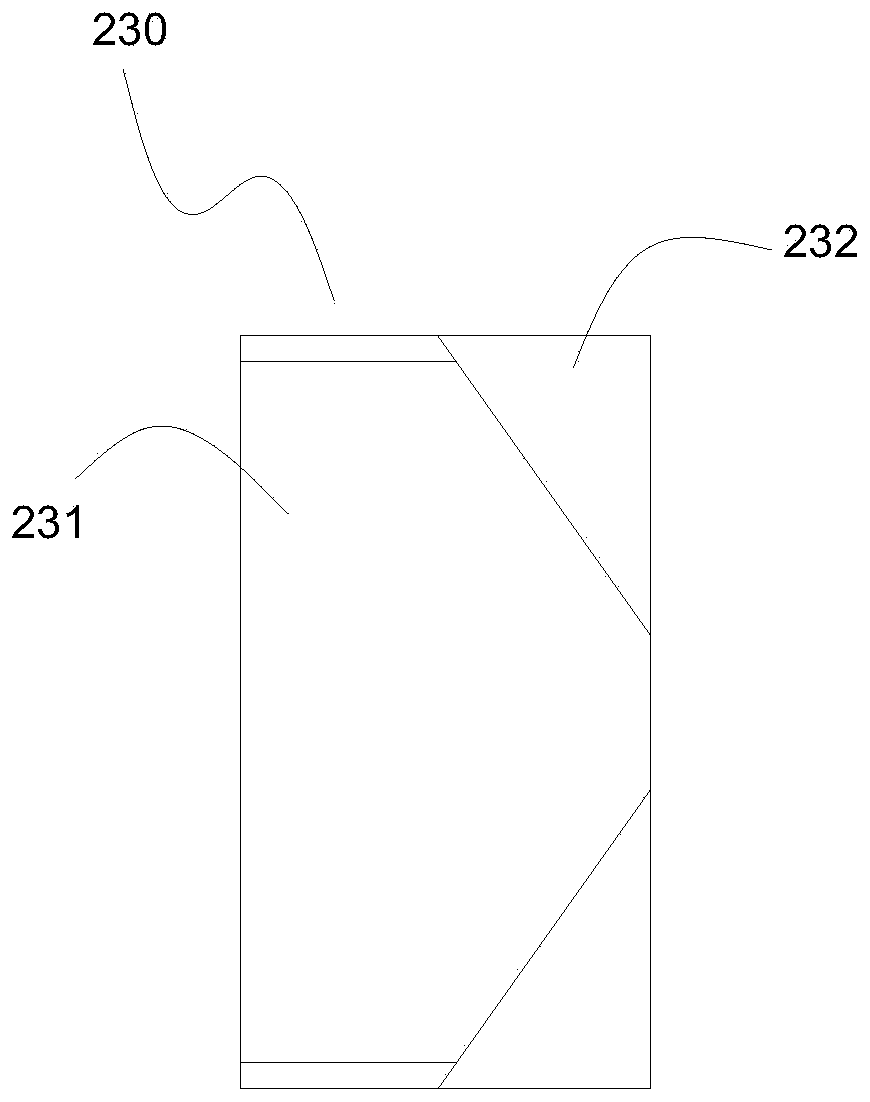

Soft magnetic alloy powder and preparation method thereof, magnetic ring inductor and production method thereof

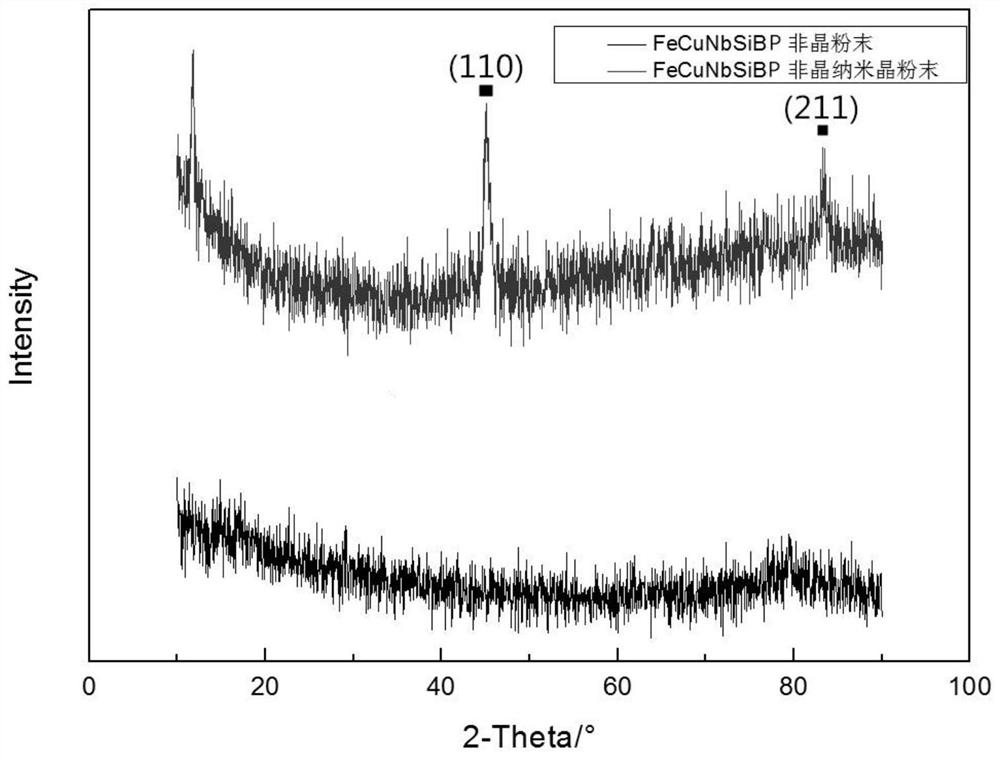

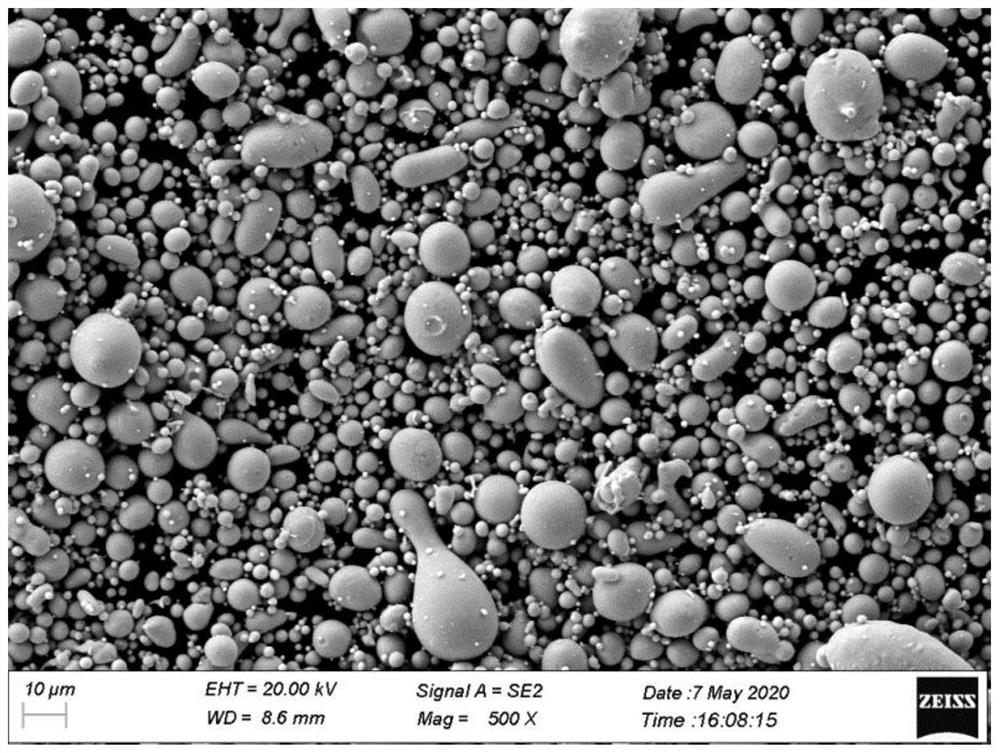

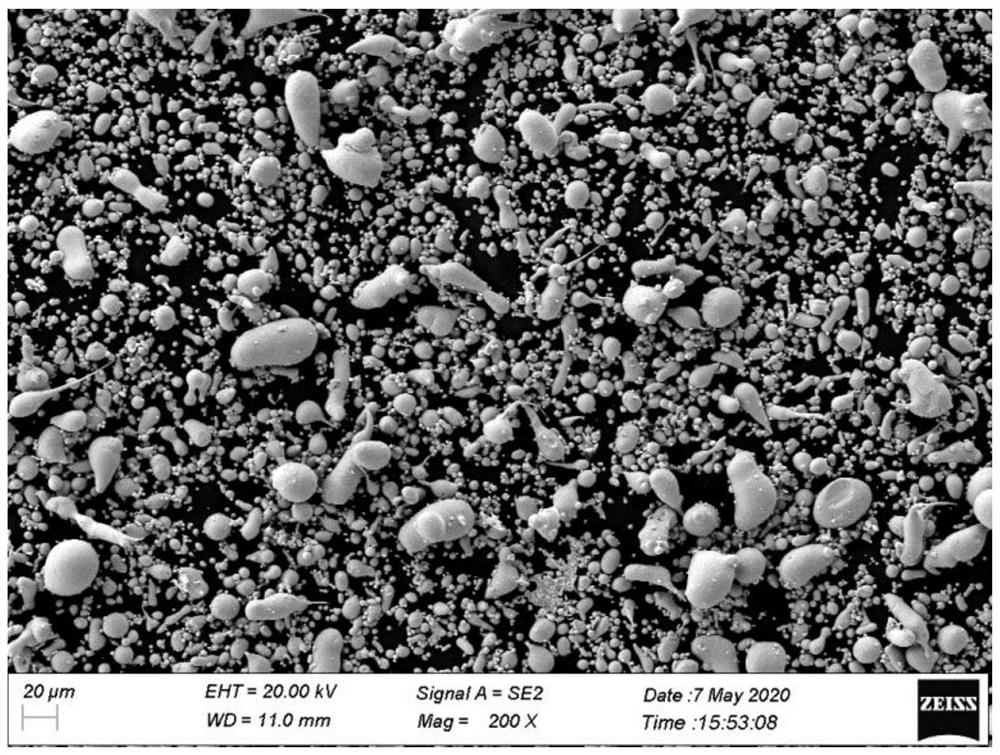

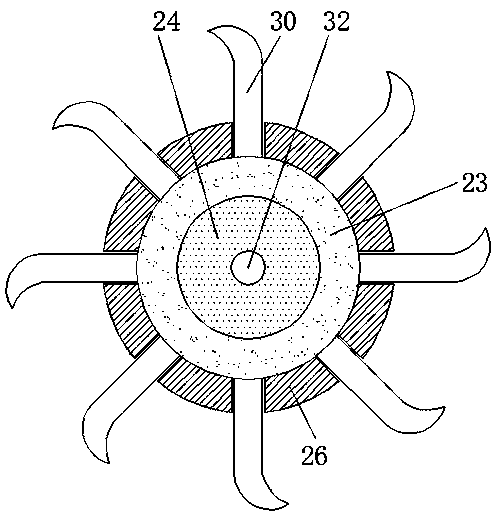

PendingCN111968821AGood sphericityHigh tap densityTransformers/inductances detailsInductances/transformers/magnets manufactureFerroniobiumAtomizer nozzle

The invention discloses a soft magnetic alloy powder and a preparation method thereof, and a magnetic ring inductor and a produciton method thereof, and belongs to the field of alloy materials. The method comprises the steps of selecting industrial pure iron with a purity of 99.9%, pure copper, industrial ferroboron, monocrystalline silicon, ferroniobium and ferrophosphorus as raw materials, adding into a corundum crucible, carrying out steel burning, adopting a supersonic speed gas atomization nozzle, carrying out water-powder separation on the powder obtained through atomization, and carrying out vacuum drying to obtain the required amorphous powder precursor; and acquiring a required amorphous nano soft magnetic alloy powder through batch treatment of crystallization annealing treatment, powder grading and screening. The powder and the preparation method, and the inductor and the method have beneficial effects that through medium-frequency induction melting, gas-water spraying, water cooling and atomization, in cooperation with the procedures of later-period water-powder separation, vacuum drying, crystallization annealing treatment, powder grading, screening and the like, the prepared powder is good in sphericity degree, low in oxygen content, reasonable in particle size distribution and the like.

Owner:TIZ ADVANCED ALLOY TECH CO LTD

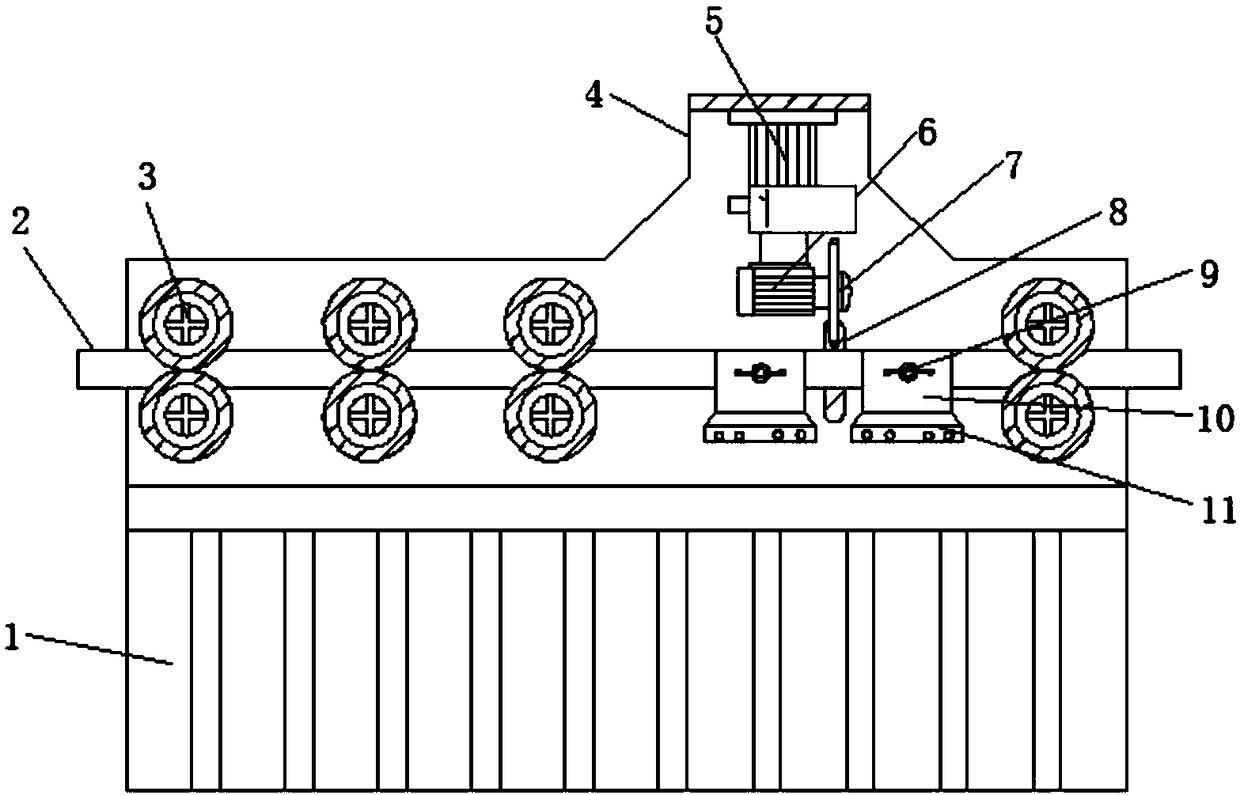

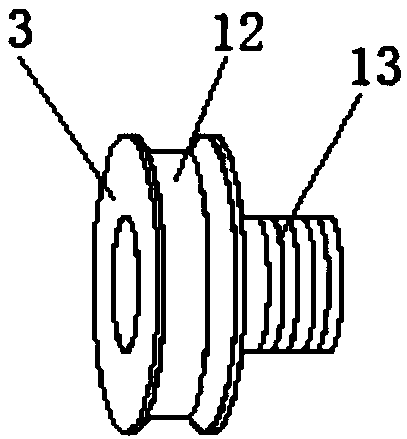

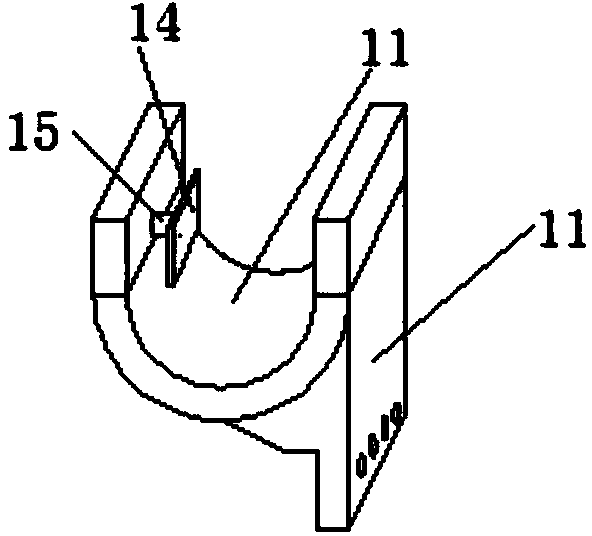

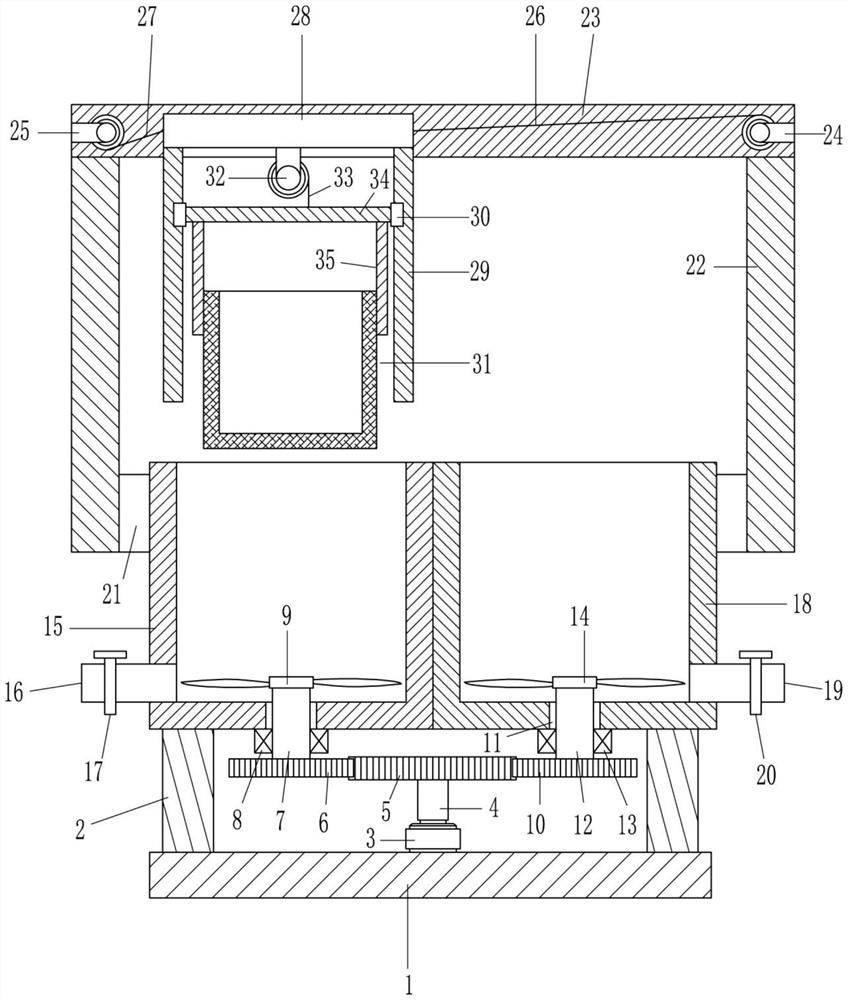

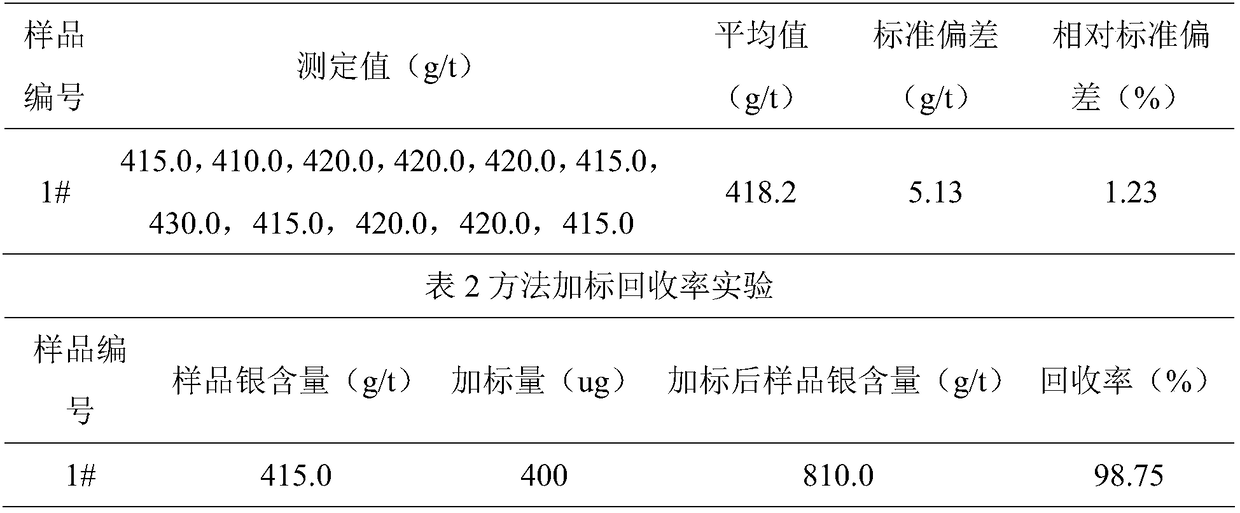

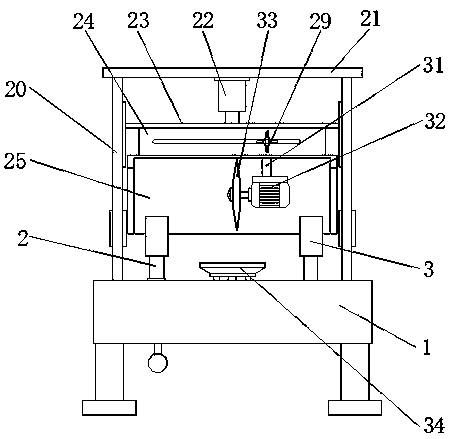

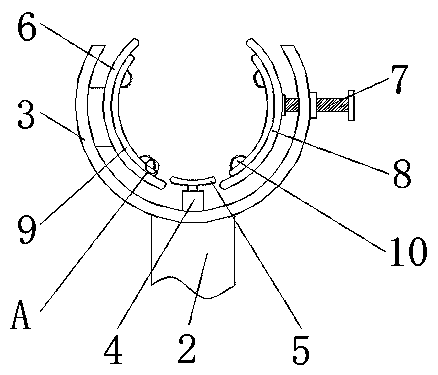

Copper bar cutting-off machine for copper industry

InactiveCN108526982AStable deliveryPrevent vibration from falling offPositioning apparatusMetal working apparatusFixed frameEngineering

The invention discloses a copper bar cutting-off machine for a copper industry. The copper bar cutting-off machine for the copper industry comprises a cutting-off machine body. The cutting-off machinebody is rotationally connected with two sets of copper bar conveying rotating shafts through rotating connection shafts, and a copper bar is embedded to the part between the two sets of copper bar conveying rotating shafts through arc-shaped grooves. The top of the cutting-off machine body is provided with a fixing support in a welded manner. The bottom of the fixing support is spirally connectedwith a cutting motor through an extensible and retractable rod. The cutting motor is in transmission connection with a cutting wheel through a motor rotating shaft. The position, corresponding to thecutting wheel, on the cutting-off machine body is provided with a cutting groove. The parts, on the two sides of the cutting groove, of the cutting-off machine body are spirally and fixedly providedwith copper bar fixing frames through an installation frame. A outer side shell of the copper bar fixing frame is connected with a spiral adjusting shaft in a spirally embedded manner. According to the copper bar cutting-off machine for the copper industry, the arc-shaped grooves in the copper bar conveying devices can conduct embedding fixation on the copper bar, and the copper bar is prevented from shaking and disengaging during conveying, so that copper bar conveying is more stable.

Owner:CHENGDU YIRUIXIN TECH CO LTD

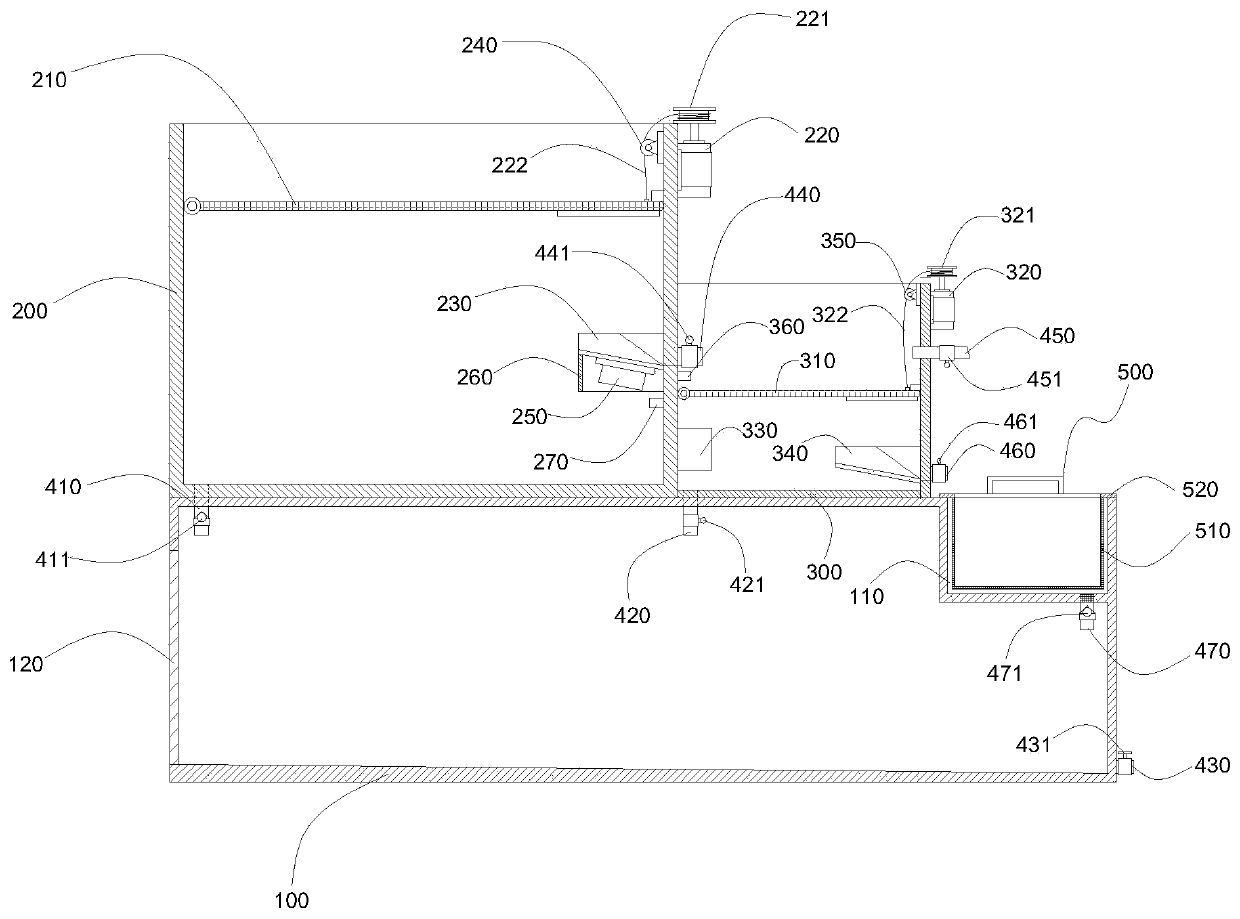

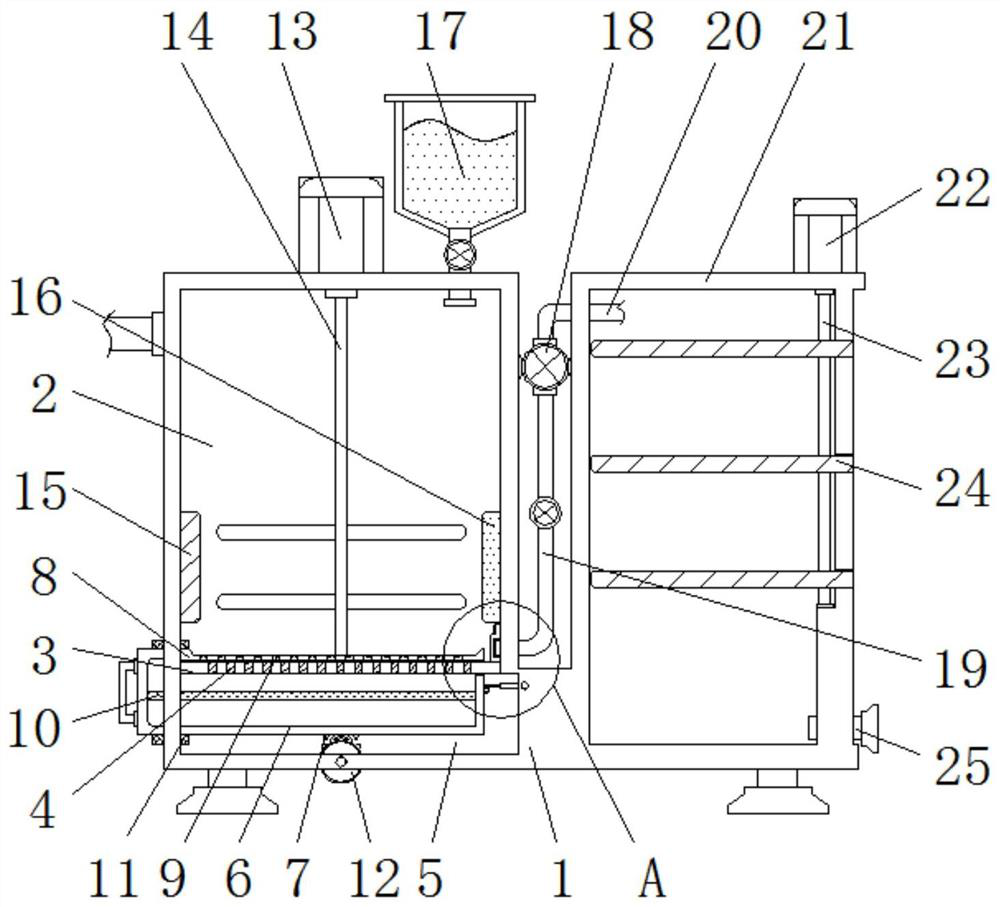

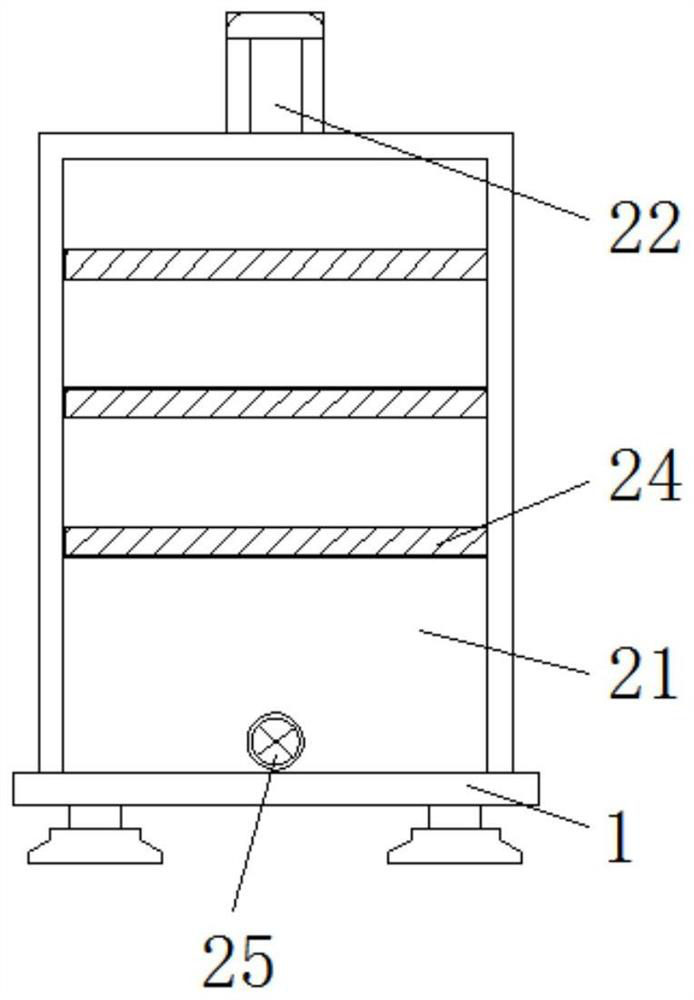

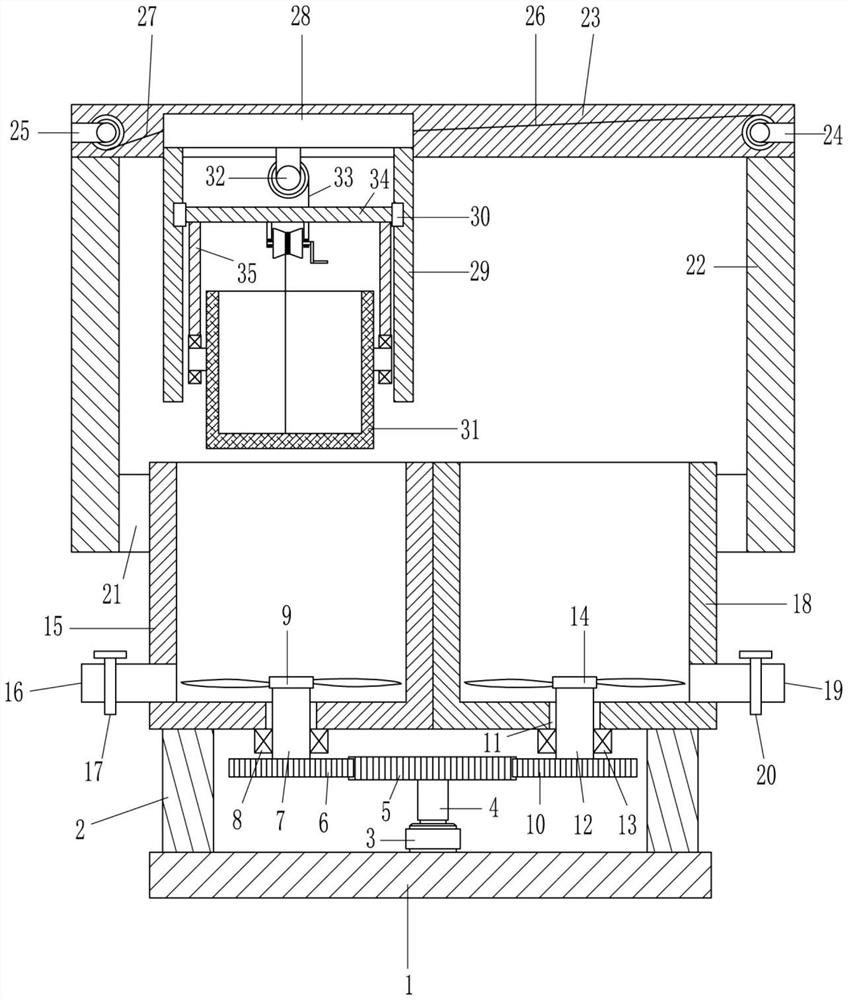

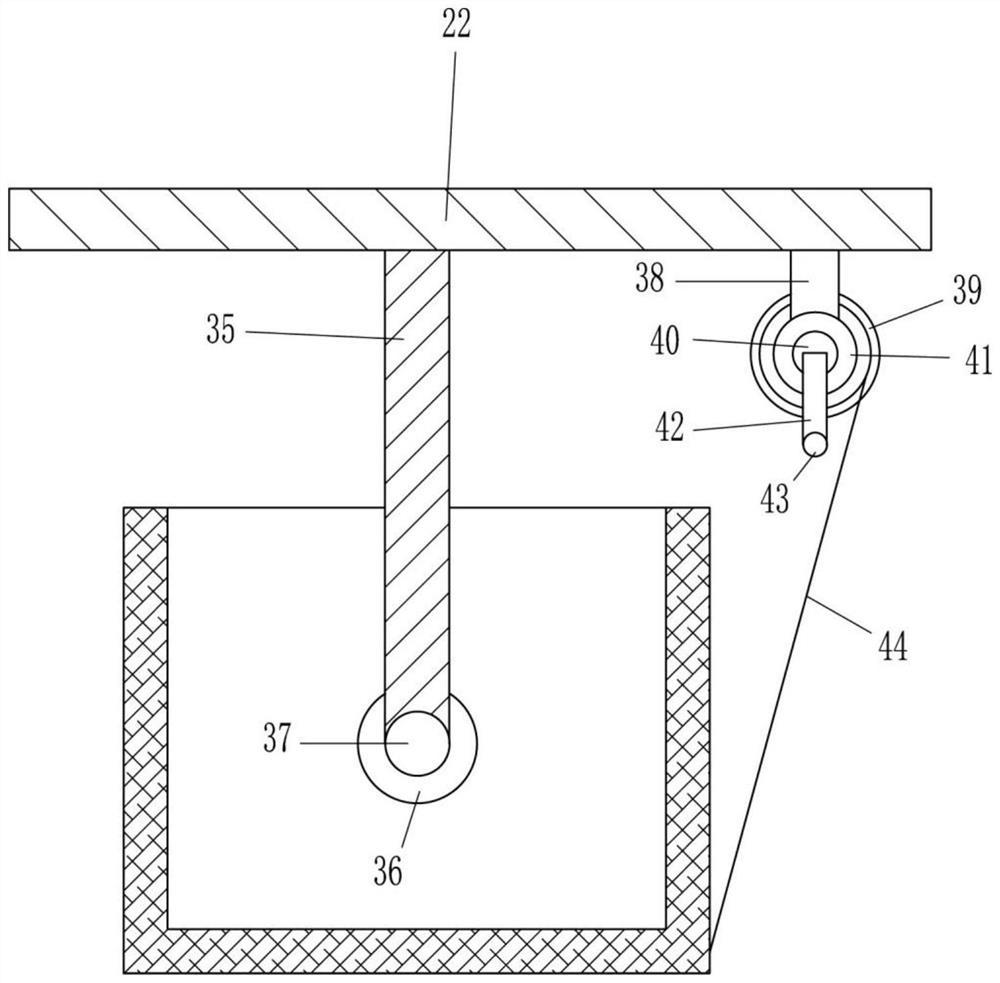

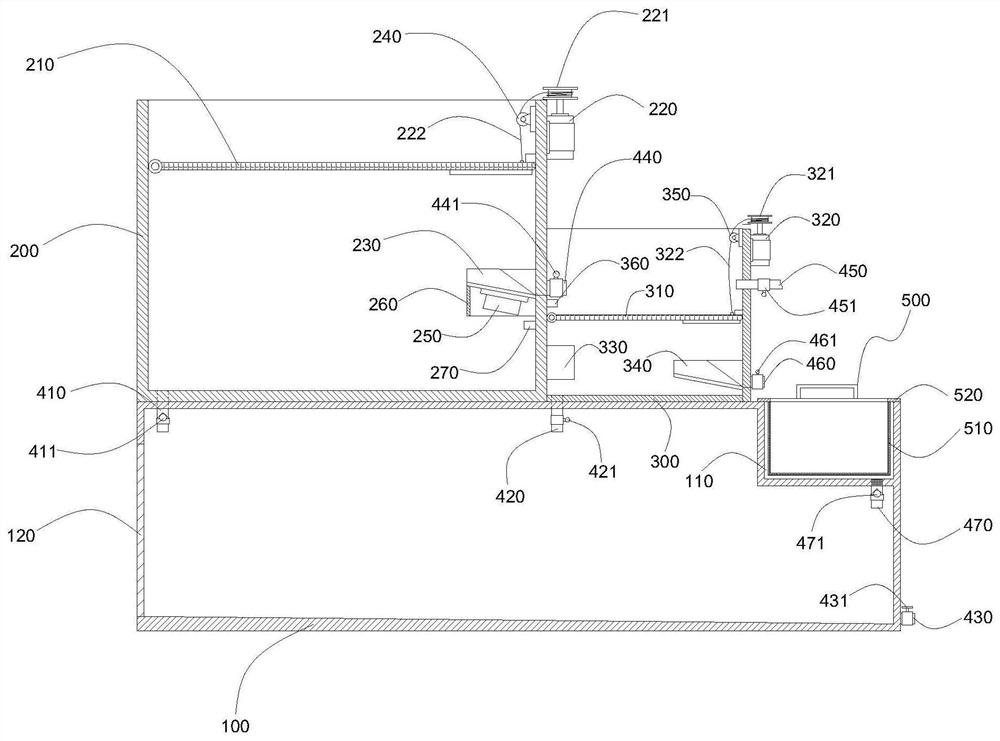

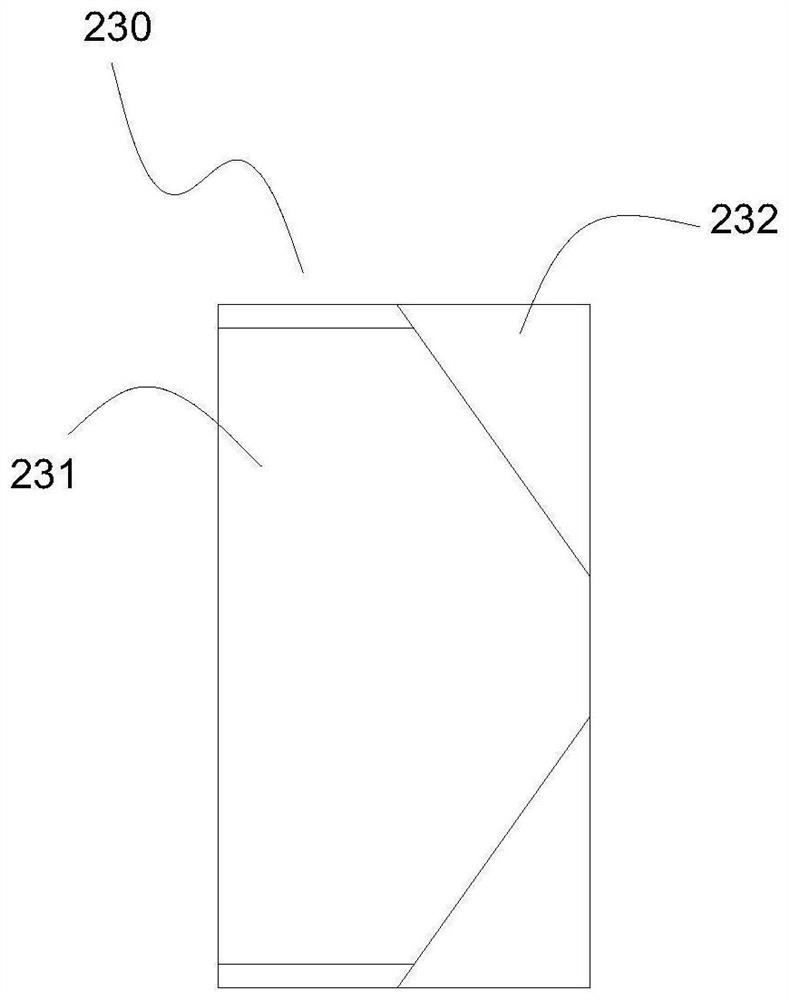

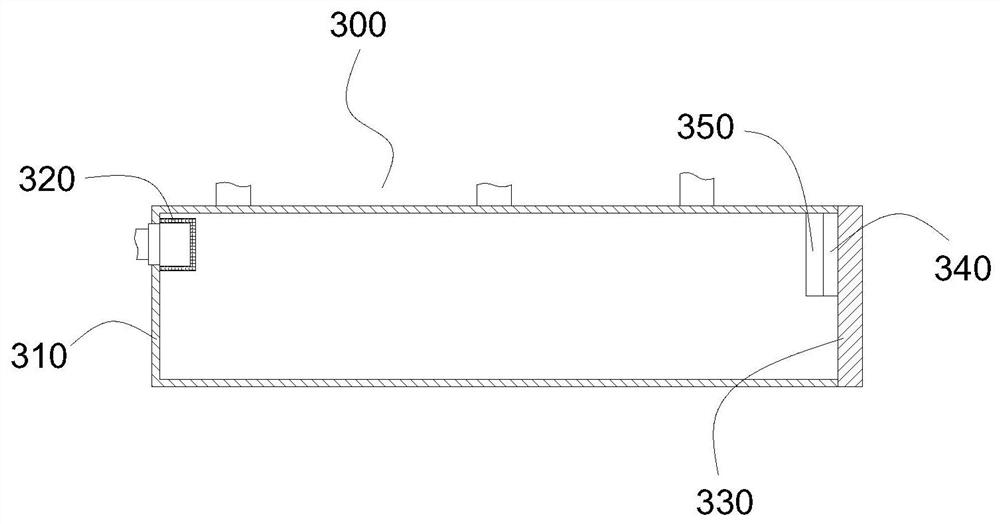

Copper industry production wastewater treatment device

ActiveCN110743225ANovel structureEasy to carry and transferCleaning using liquidsStationary filtering element filtersElectric machineryWater processing

The invention provides a copper industry production wastewater treatment device comprising a filter box and a cleaning box; a first filter plate is arranged in the filter box, one side of the first filter plate is pivoted with the inner wall of the filter box, the other side of the first filter plate is driven by a first motor to lift and fall and rotate around a pivoting part, a first flow guideframe is arranged on one side of the filter box, and a first discharge pipe is arranged on the inner wall of the cleaning box corresponding to the first flow guide frame; a second filter plate is arranged in the cleaning box; one side, close to the filter box, of the second filter plate is pivoted with the inner wall of the cleaning box, and the other side of the second filter plate is driven by asecond motor to lift and fall and rotate around a pivoting part; the side wall of the cleaning box communicates with a water inlet pipe communicating with an external water source, an ultrasonic generator is arranged on the inner wall of the cleaning box; a second flow guide frame is arranged on one side, away from the filter box, of the cleaning box; a second discharging pipe is arranged on theouter wall of the cleaning box corresponding to the second flow guide frame, and a collecting frame is arranged outside the second discharging pipe; wastewater can be effectively filtered and treated,and collected precipitates are cleaned, so that subsequent recovery of the precipitates is facilitated.

Owner:清远楚江高精铜带有限公司

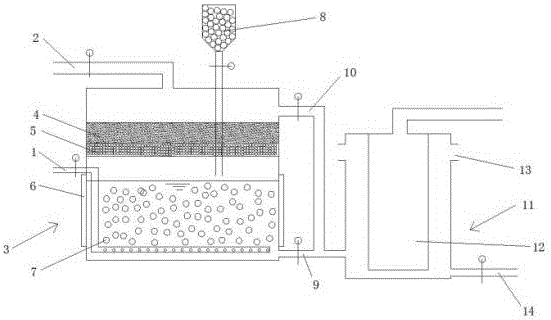

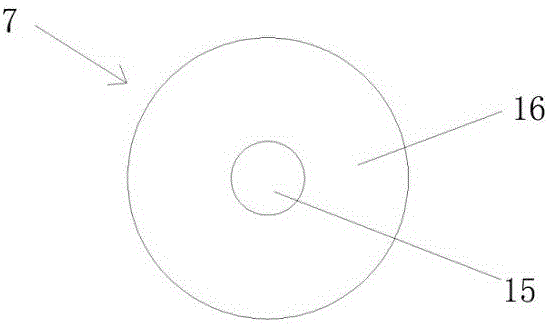

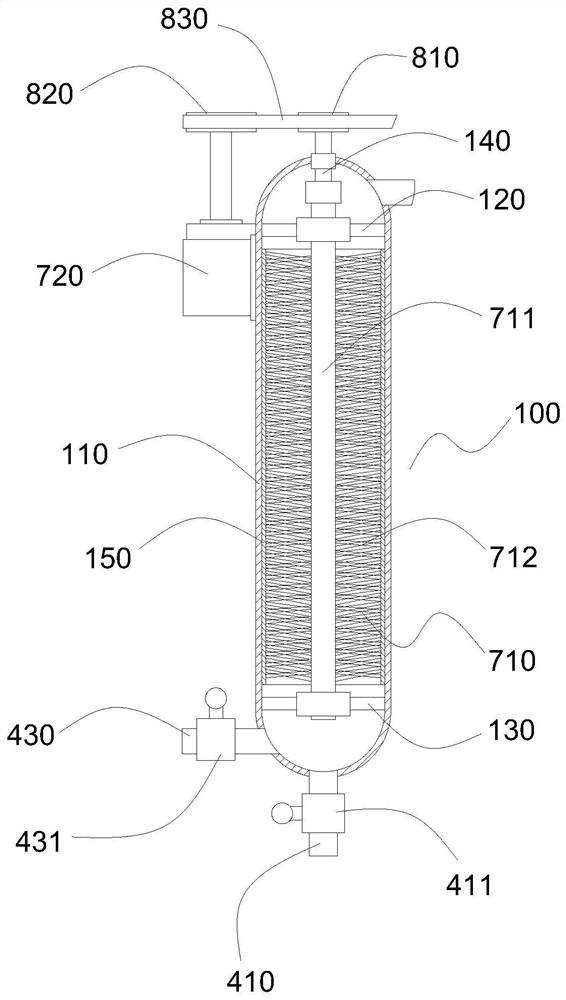

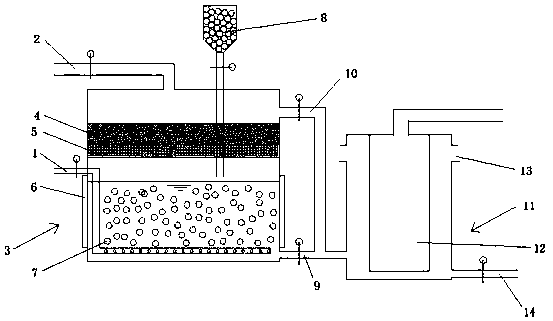

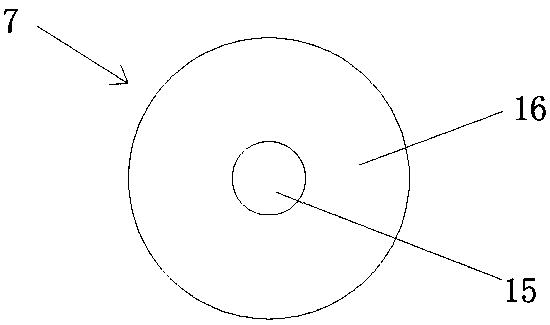

Purifying device for copper-industry wastewater and waste gas

ActiveCN106139836AStop pollutionExtended service lifeGas treatmentDispersed particle separationParticulatesSorbent

The invention discloses a purifying device for copper-industry wastewater and waste gas. The purifying device comprises a gas inlet pipe, a water inlet pipe, a treating box, a water outlet pipe, a gas outlet pipe and a film pool. The inside of the treating box sequentially comprises a heavy metal adsorption layer, an SDG adsorbent layer and a purifying layer from top to bottom, and the purifying layer comprises immobilized microorganism balls; a magnetic field generator is arranged outside the treating box; in the purifying device for copper-industry wastewater and waste gas, the purified wastewater and waste gas are mixed and enter the film pool, wastewater can be purified through a film assembly in the film pool, film pollution can be prevented through scouring of waste gas, the proportion of wastewater to waste gas ranges from 1:2.5 to 1:2, and the effect of the a waste-gas scouring film assembly is best; nitrogen oxide and particulate matter in wastewater and nitrogen oxide and particulate matter in waste gas can be removed through the immobilized microorganism balls; heavy metal matter can be removed through the heavy metal adsorption layer arranged in the treating box, and sulfuric acid mist can be removed through the SDG adsorbent layer.

Owner:广西东兴市富佳五金皮具有限公司

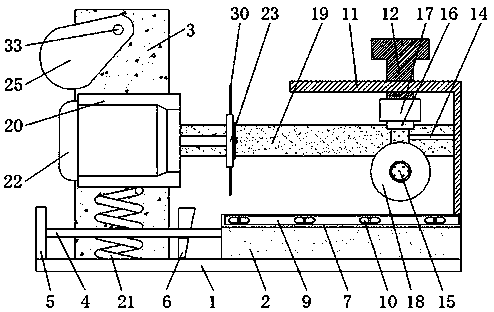

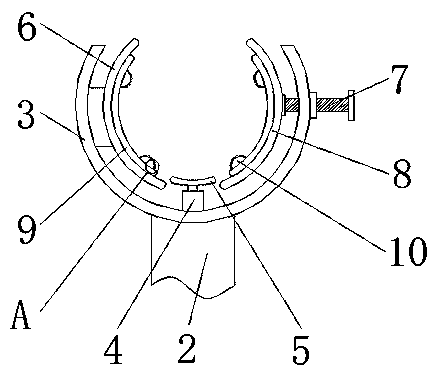

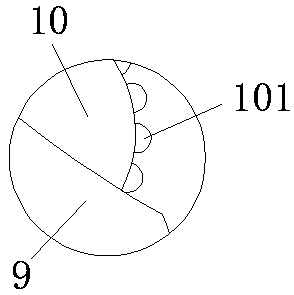

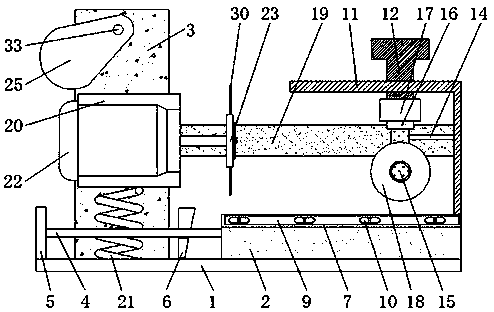

Copper rod adjustable type rapid cut-off machine used for copper industry

ActiveCN108907333ATo achieve the adjustment effectSolve the problem of troublesome blade replacementShearing machine accessoriesShearing toolsArchitectural engineeringCopper industry

The invention discloses a copper rod adjustable type rapid cut-off machine used for the copper industry, and relates to the technical field of cut-off machines. The copper rod adjustable type rapid cut-off machine comprises a base, a work table and a fixed table. The work table and the fixed table are both fixedly connected to the upper surface of the base. The fixed table is located behind the left portion of the work table. The left side of the work table is fixedly connected with a threaded rod. The left end of the threaded rod is fixedly connected with a fixed plate. The fixed plate is fixedly connected to the upper surface of the base. The fixed plate is located on the front face of the fixed table. The surface of the threaded rod is movably connected with a limiting block in a sleeving manner. A groove is formed in the upper surface of the work table. The inner wall of the groove is fixedly connected with a spring. The end, away from the inner wall of the groove, of the spring isfixedly connected with a baffle. According to the copper rod adjustable type rapid cut-off machine used for the copper industry, by means of pawls and blades, the problem that because none of bladesof an existing copper rod adjustable type rapid cut-off machine can be regulated for copper rods of different diameters and cutting lengths, blade change is troublesome when the copper rods of different diameters are cut.

Owner:芜湖市海源铜业有限责任公司

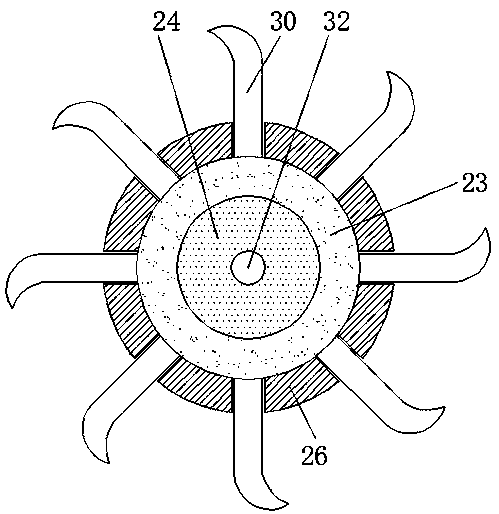

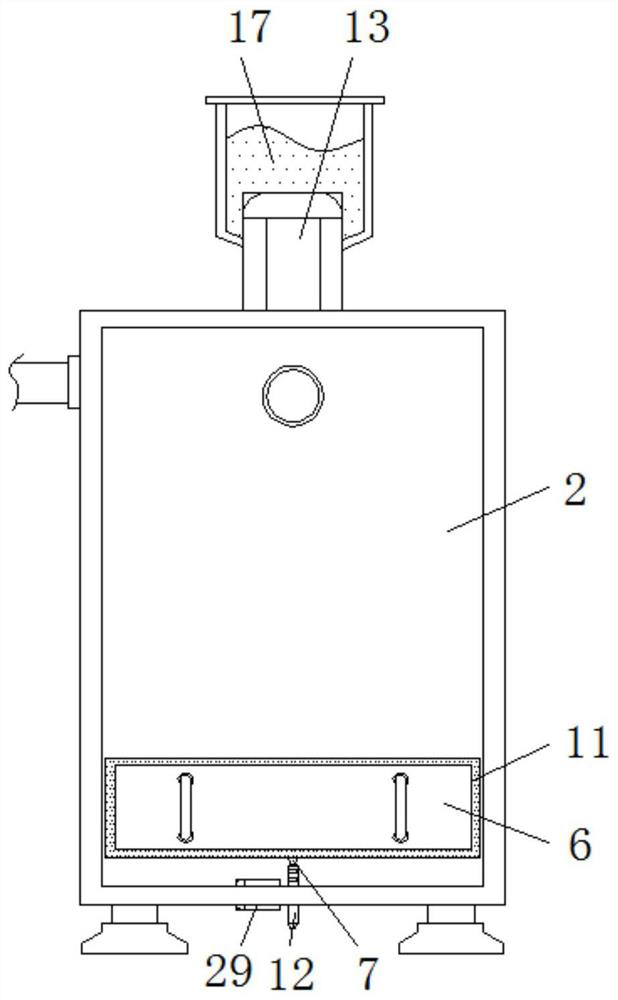

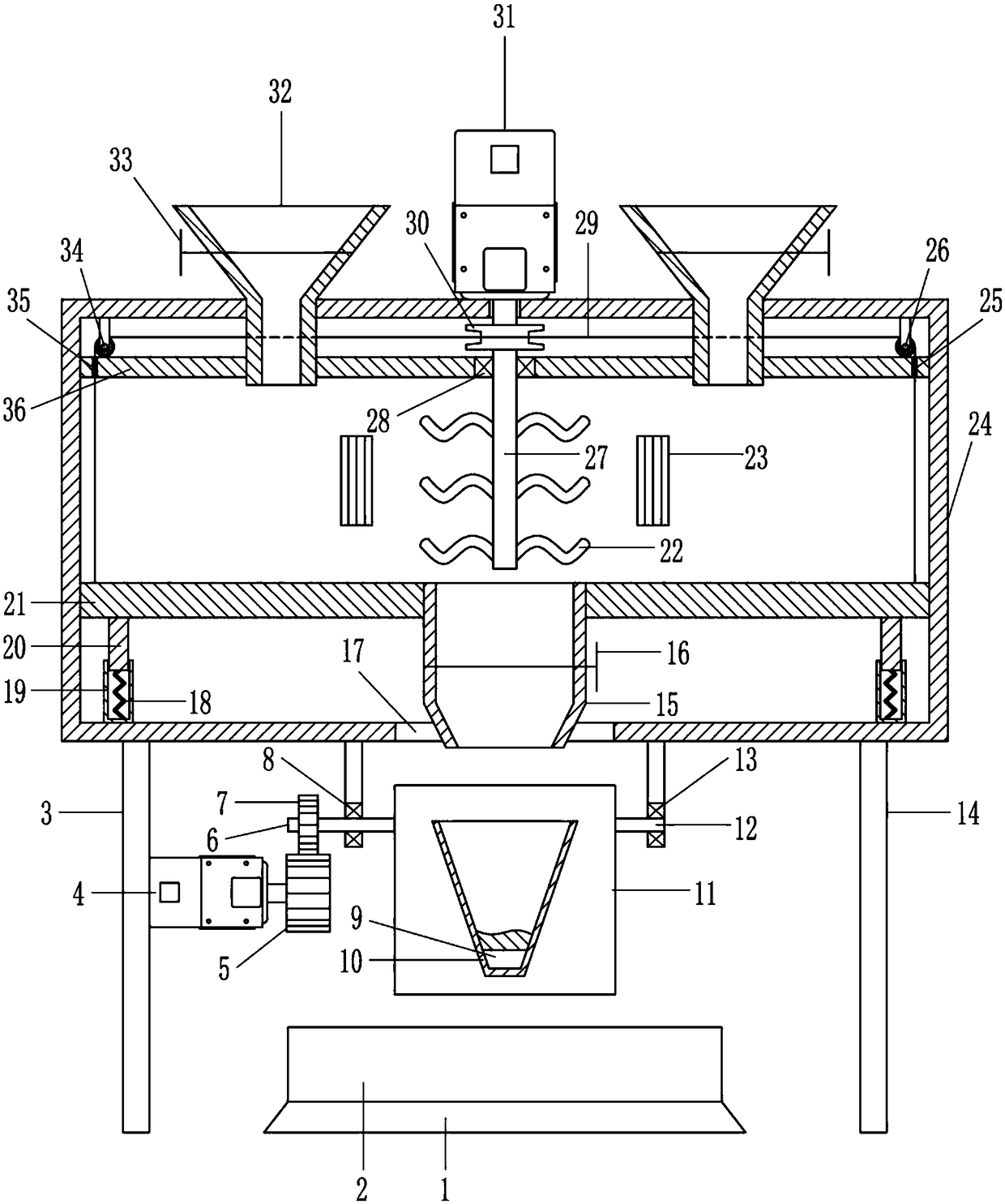

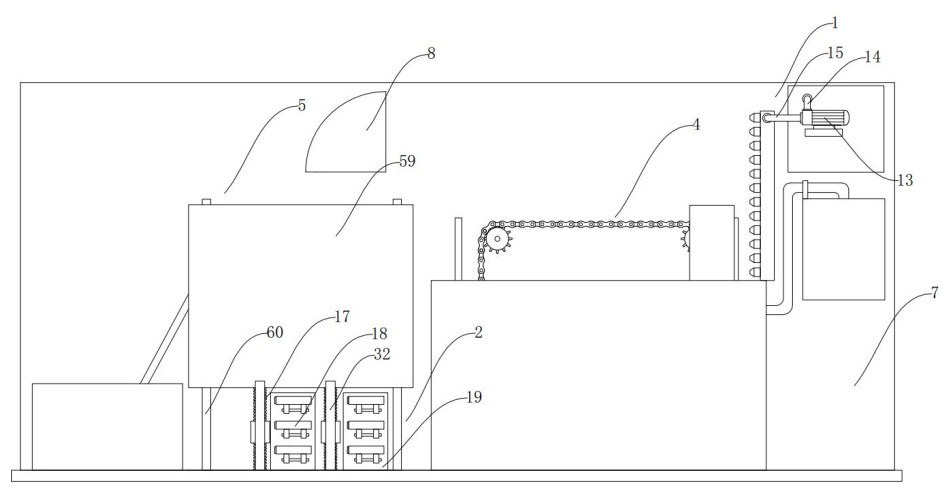

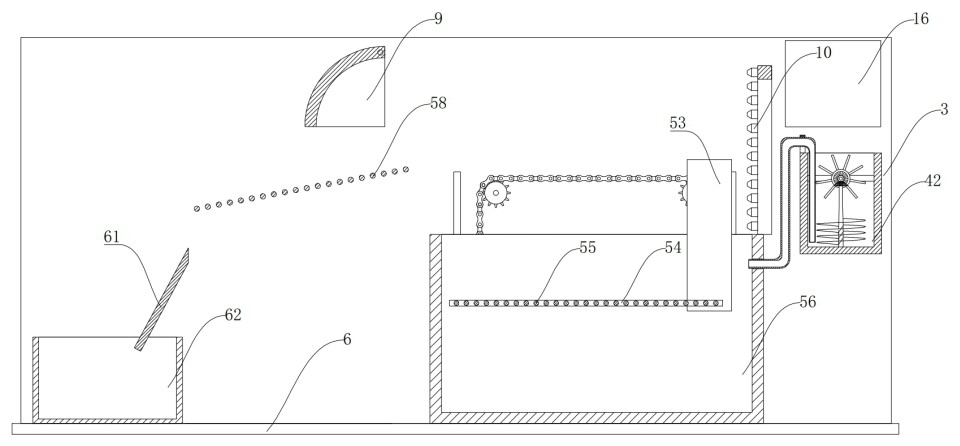

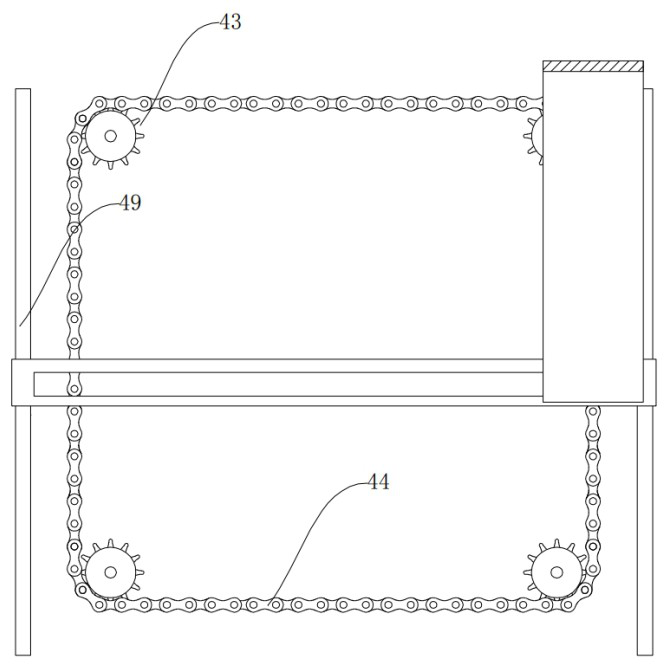

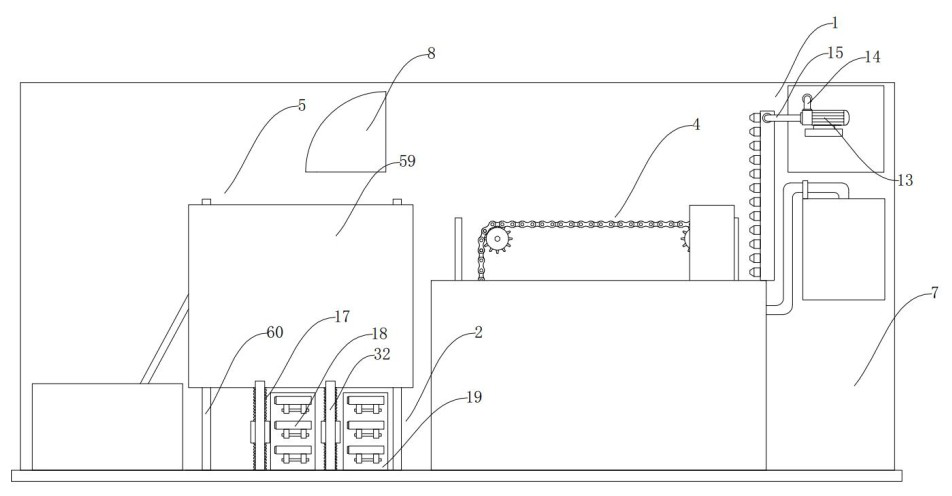

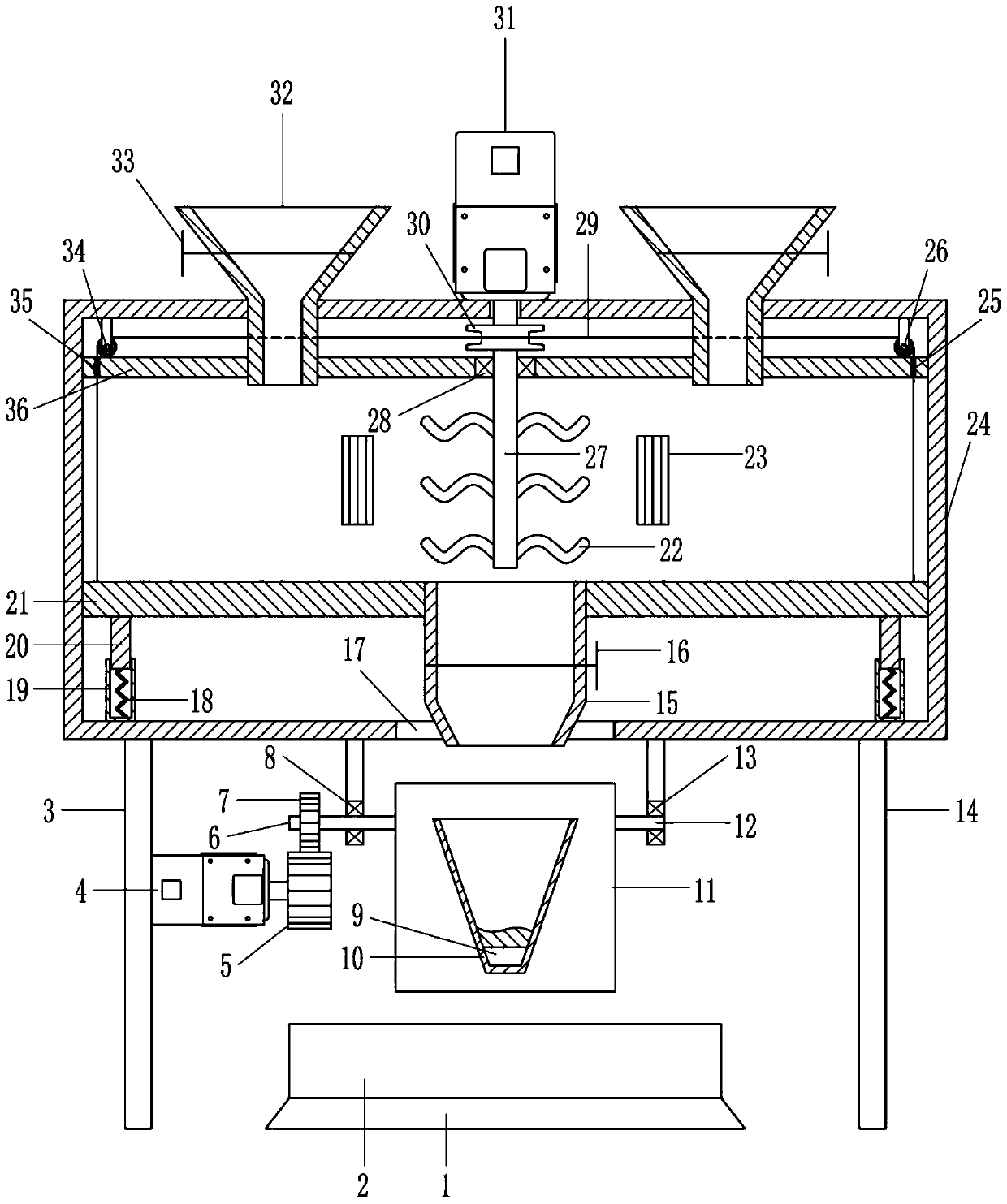

Chemical polishing and soaking machine for copper industry production

The invention relates to the field of copper industry, in particular to a chemical polishing and soaking machine for copper industry production, and aims to provide the chemical polishing and soakingmachine which is used for the copper industry production and capable of sufficiently corroding the surface of a copper product for polishing and prevents a corrosive agent from adhering to the copperproduct and damaging the copper product. The chemical polishing and soaking machine for copper industry production comprises a mounting plate, a support frame, a motor, a first rotating shaft, a firstgear and the like, wherein the support frame and the motor are fixedly connected to the top surface of the mounting plate in sequence; a mixing box and a cleaning box are both fixedly connected to the top of the support frame; the first rotating shaft is in transmission connection with the output end of the motor; the first gear is fixedly connected to the top of the first rotating shaft; a firstbearing seat is fixedly connected to the outer bottom surface of the mixing box, and a second bearing seat is fixedly connected to the outer bottom surface of the cleaning box. The chemical polishingand soaking machine has the effects of sufficiently corroding the surface of the copper product for polishing and preventing the corrosive agent from adhering to the copper product and damaging the copper product.

Owner:安徽友进冠华新材料科技股份有限公司

Copper industry sewage treatment device with metal recovery function

ActiveCN112028374AEasy to handleEasy to separateTreatment involving filtrationWater/sewage treatment by magnetic/electric fieldsElectrochemical responseFiltration

The invention discloses a copper industry sewage treatment device with a metal recovery function, wherein the copper industry sewage treatment device comprises a base, a first motor, a dosing tank, awater pump, a second motor and a third motor, a treatment box is fixedly mounted on the left side of the upper portion of the base, a partition plate is fixed to the lower portion of the treatment box, and first screen holes are formed in the surface of the partition plate; a bottom cavity is formed in the lower portion of the treatment box, a recycling box is connected to the interior of the bottom cavity, a tooth block is fixed to the middle of the lower portion of the recycling box, a water plugging plug is arranged at the bottom of a filtering box, a connecting block is fixed to the rightend of the recycling box, and a protective net is arranged on the right side of the interior of the treatment box. According to the copper industry sewage treatment device with the metal recovery function, metal oxides in sewage can be subjected to a reinforced alkali electrochemical reaction, metal ions can be conveniently separated, metal materials in the sewage can be effectively recovered, meanwhile, the sewage can be subjected to stepped filtration, and the sewage treatment effect is improved.

Owner:江西绿色盾牌环境工程有限公司

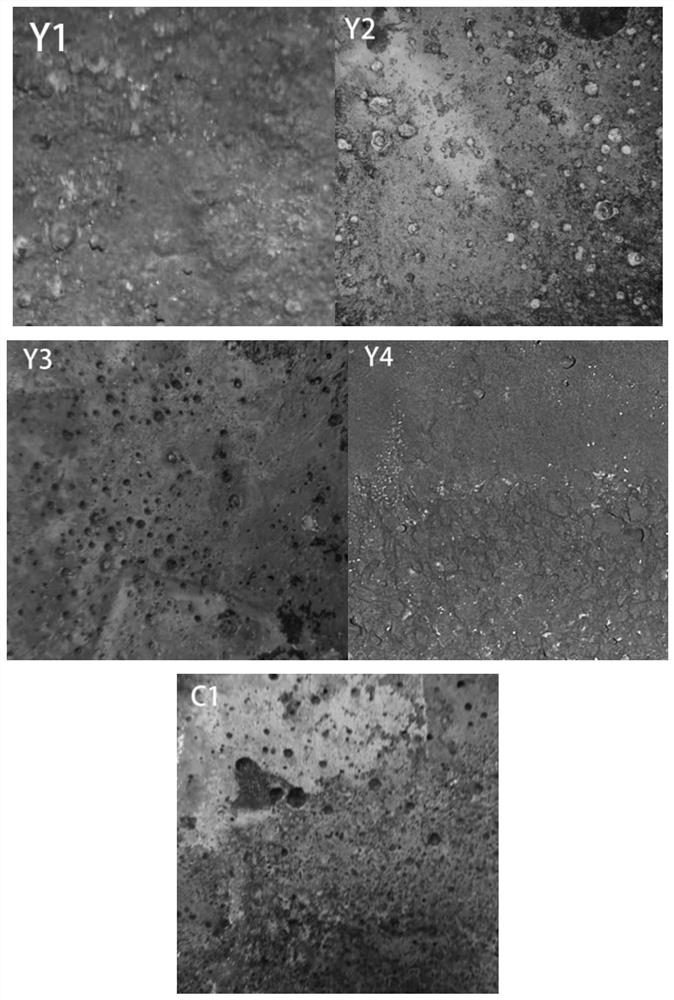

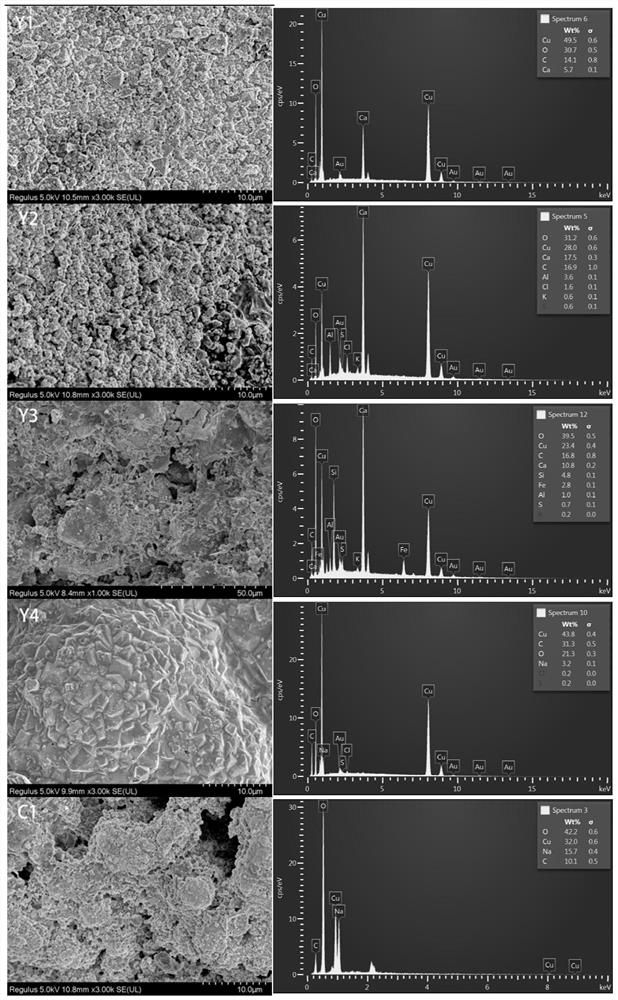

Method for treating concrete by utilizing copper plating wastewater

The invention discloses a method for treating concrete by utilizing copper plating wastewater. The method comprises the following steps of: A, sequentially carrying out sedimentation, acidification or alkalization treatment on copper industrial wastewater, adjusting the pH value of the waste liquid to 5-7, purifying and concentrating; B, adding a surfactant into the obtained wastewater treatment liquid according to the concentration of 100-200mg / L to prepare an electrolyte, wherein the concentration of copper ions in the electrolyte is 2000mg / L-5000mg / L; C, immersing a concrete test piece into the electrolyte, connecting an electrochemical device, and taking the electrochemical device as a cathode to carry out first-step electrodeposition; and D, after the first-step electrodeposition is finished, adding a lactic acid solution into the electroplating solution, adjusting the pH value to 10-12, and carrying out second-step electrodeposition. The bonding force between the prepared electrodeposition and the concrete matrix is higher; and the formed sediment has good sterilization performance, and the microbial corrosion resistance of the concrete is improved.

Owner:HOHAI UNIV

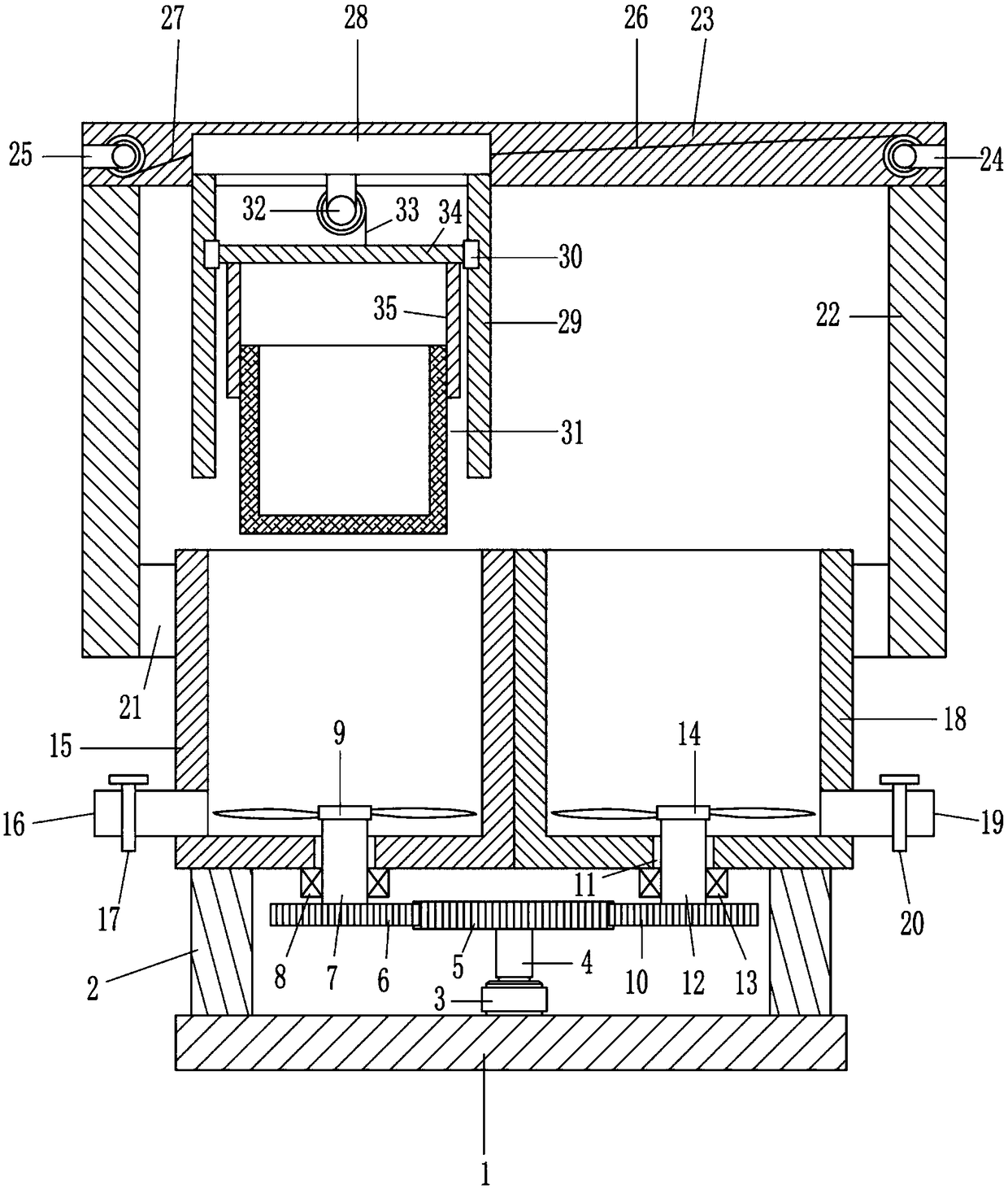

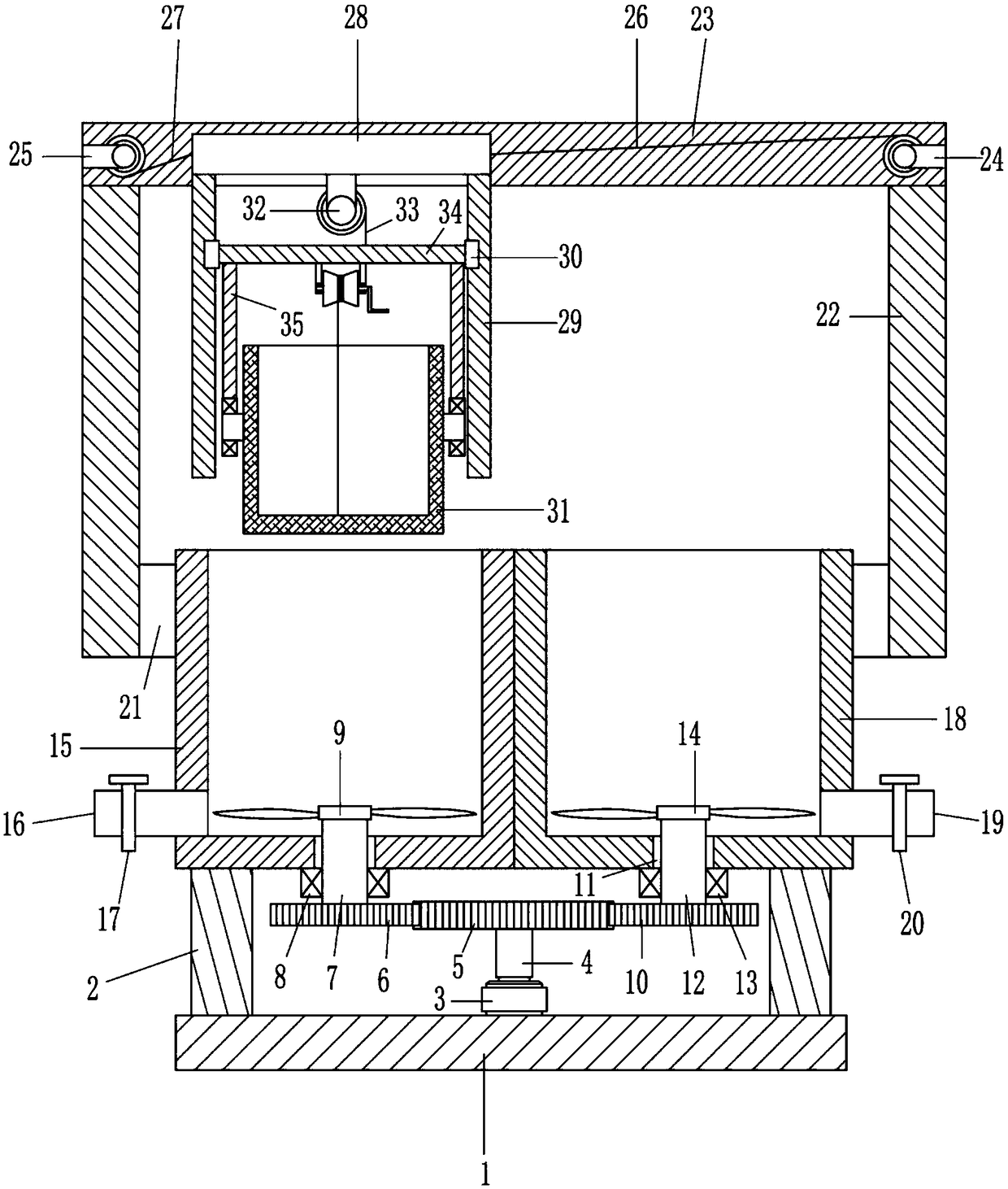

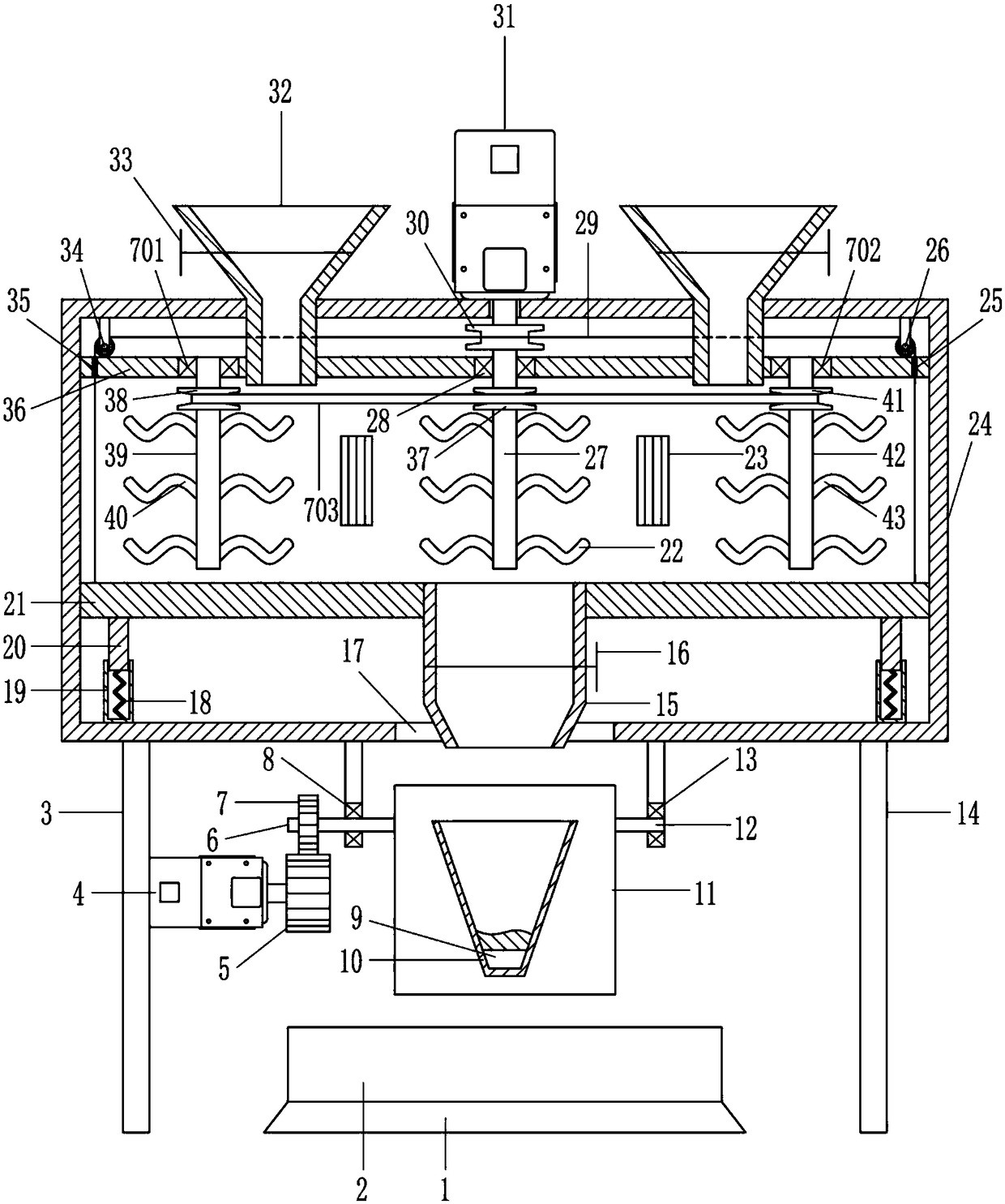

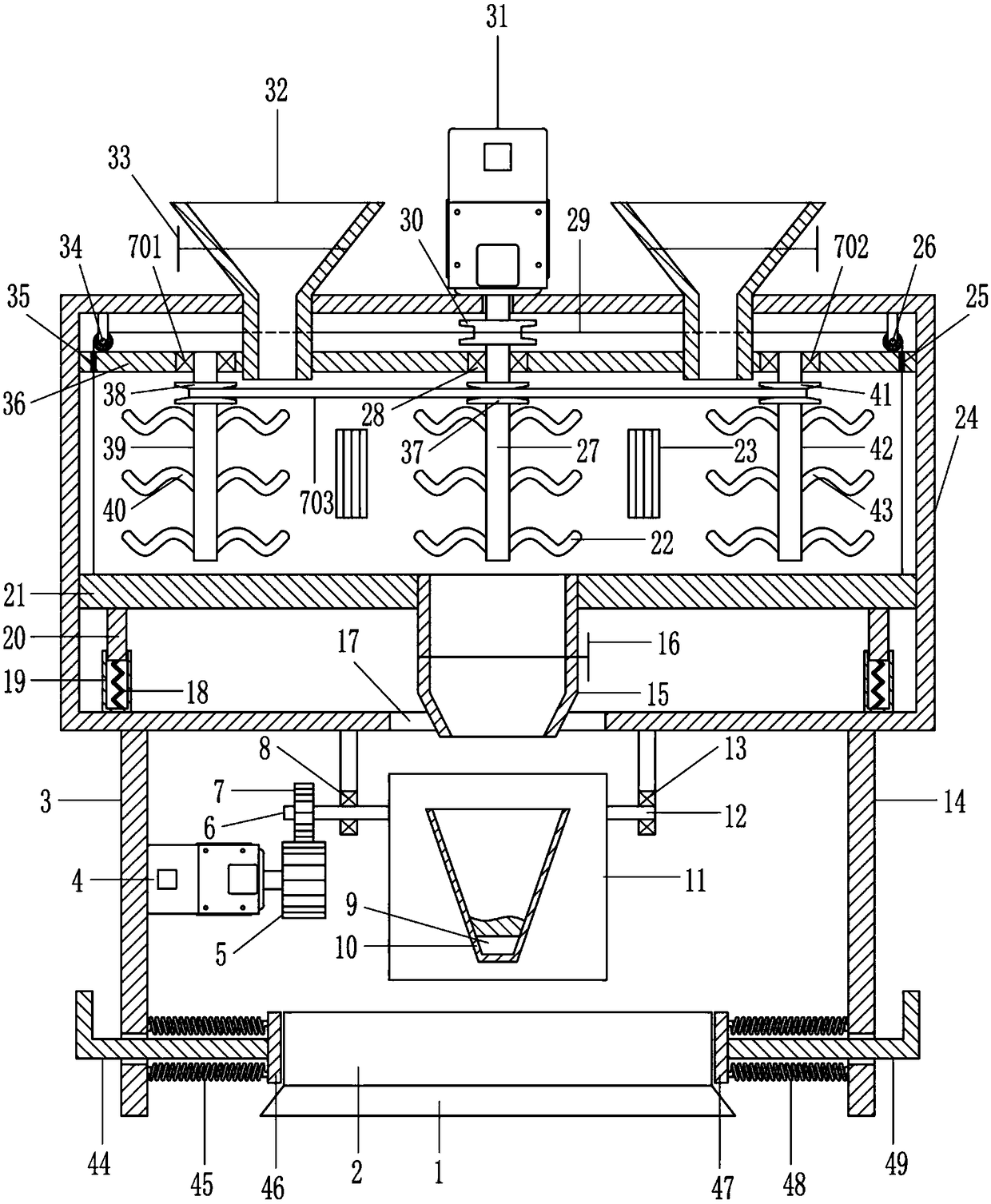

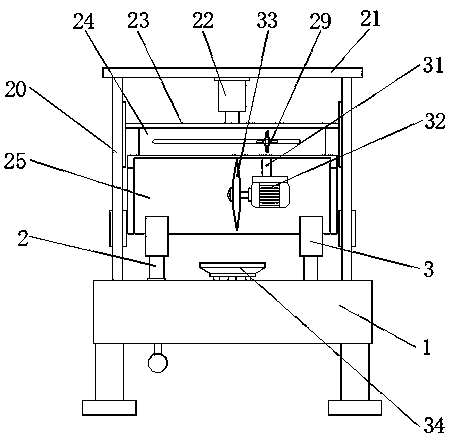

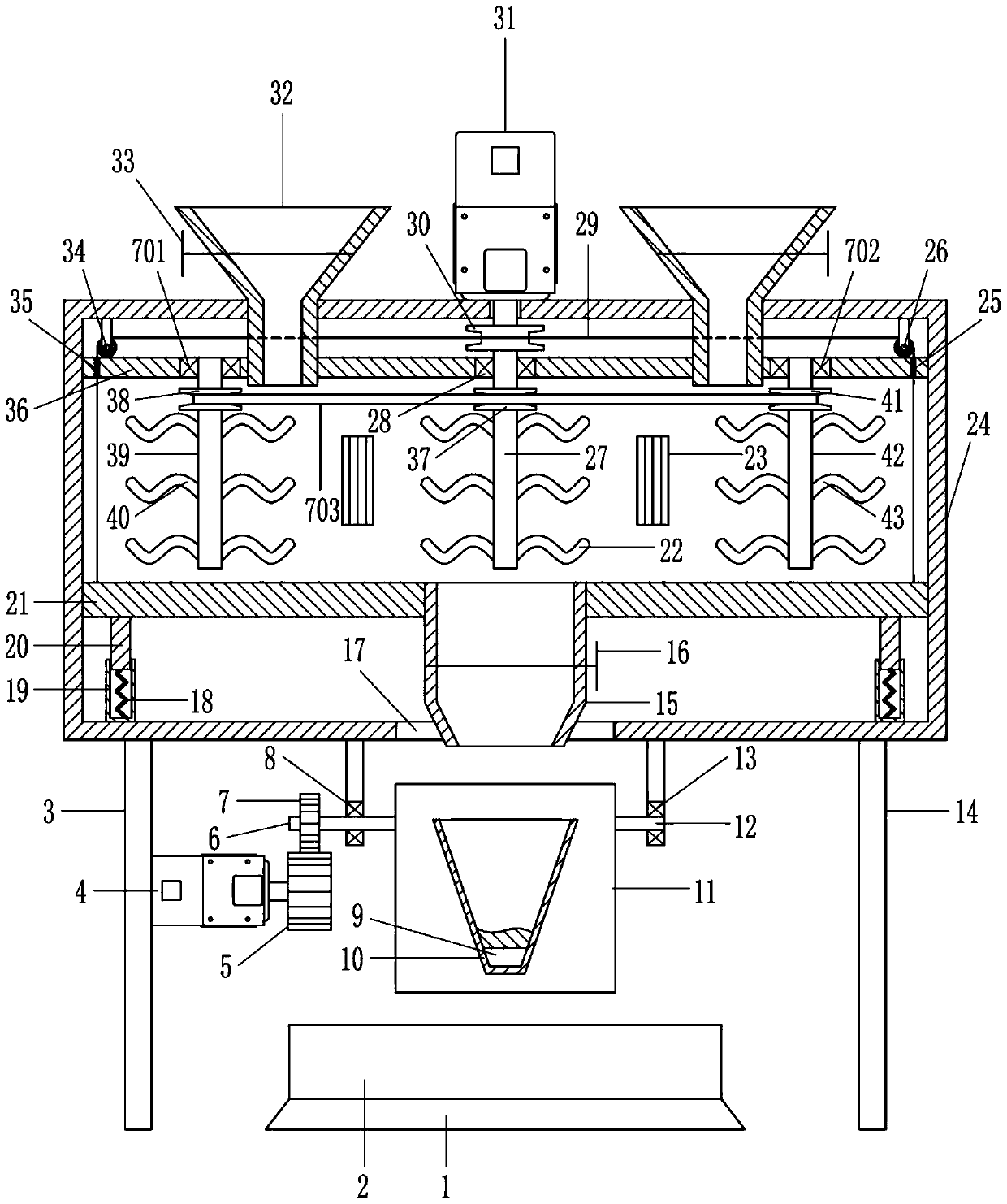

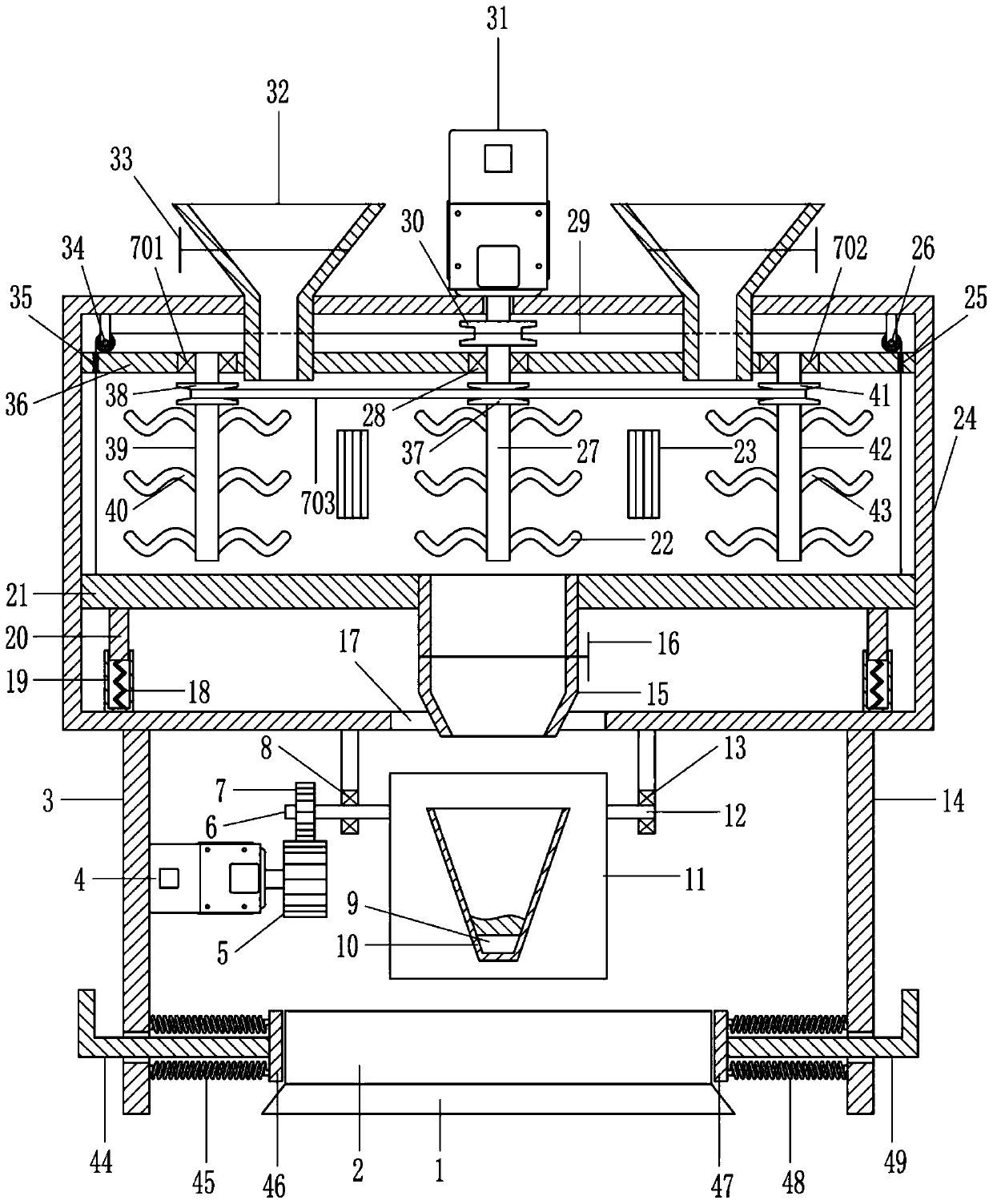

High-precision type casting equipment for copper industry machining

ActiveCN109317654AQuality improvementImprove securityMolten metal pouring equipmentsElectric dischargeSlide plate

The invention relates to the field of copper industry machining, in particular to high-precision type casting equipment for the copper industry machining. According to the high-precision type castingequipment for the copper industry machining, the casting efficiency is high, the casting product quality is high, the labor intensity is low, the safety is high, and steel material quantity supply isaccurate. The high-precision type casting equipment for the copper industry machining comprises a placing seat, a casting device, a first supporting column, a first motor, a first gear, a first rotating shaft, a second gear, a first bearing block, a discharging hopper, a material receiving frame, a second rotating shaft, a second bearing block, a second supporting column, a discharging frame, an electric discharging valve, a first elastic part, a guiding rod, a lifting rod, a sliding plate, first mixing rods and the like. According to the high-precision type casting equipment, the casting efficiency is high, the casting product quality is high, the labor intensity is low, and steel material quantity supply is accurate.

Owner:临沂市凯星水表有限公司

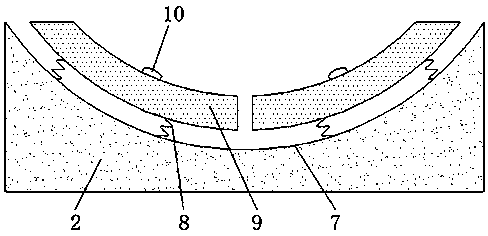

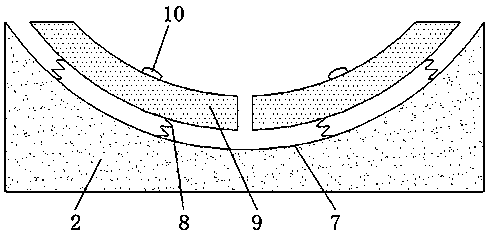

Copper bar cutting machine for copper industry

ActiveCN108907332AImprove cutting effectImprove practicalityLarge fixed membersMaintainance and safety accessoriesEngineeringCopper industry

The invention discloses a copper bar cutting machine for the copper industry. The copper bar cutting machine comprises a box body, wherein a movable block is connected to the top of the inner wall ofthe box body in a sliding mode, arc-shaped blocks are fixedly connected to the top of the movable block and the other side of the top of the box body respectively, an elastic telescopic rod is fixedlyconnected to the bottoms of the inner walls of the arc-shaped blocks, a cushion block is fixedly connected to the top of the elastic telescopic rod, and first arc-shaped clamping blocks are fixedly connected to one side of the inner walls of the arc-shaped blocks by virtue of support blocks. The copper bar cutting machine relates to the technical field of copper bar cutting equipment. According to the copper bar cutting machine for the copper industry, friction blocks and antiskid blocks are arranged, so that the friction between fixtures and copper bars is increased, the copper bars are preferably prevented from moving during cutting, the copper bar cutting effect is greatly increased, the distance between the fixtures can be preferably adjusted through the movement of the movable block,a clamping block can be preferably clamped with a bulged block through the movement of the clamping block, the stable fixture position adjustment is guaranteed, and the practicability of the cuttingmachine is greatly increased.

Owner:芜湖市海源铜业有限责任公司

Smelting copper slag accretion agent and preparing method thereof

InactiveCN104928496ALow costWill not polluteRotary drum furnacesCrucible furnacesPyrophyllitePotassium

A smelting copper slag accretion agent is characterized by comprising, by mass, 74%-78% of perlite, 5%-12.0% of pyrophyllite, 3%-5% of calcium aluminate, 10%-14% of albite and 5%-15% of kaliophilite. A preparing method comprises the steps that firstly, weighing and mixing are carried out, raw materials are weighed according to the formula and weight, and the weighed raw materials are evenly mixed; secondly, crushing is carried out, the mixture obtained in the first step is placed in a crusher to be crushed, and the crushing granularity ranges from 80 meshes to 100 meshes; thirdly, packaging is carried out, powder obtained through crushing is bagged and packaged, and then a finished product is obtained. According to the smelting copper slag accretion agent, the vacancy of the domestic smelting copper industry in the field of the slag accretion field is filled up, the smelting copper slag accretion agent has the advantages of being low in cost, good in slag accretion effect, short in slag drossing time and small in copper loss, and in the using process, toxicity, dust and foreign smell do not exist, and the environment cannot be polluted.

Owner:万燕杰

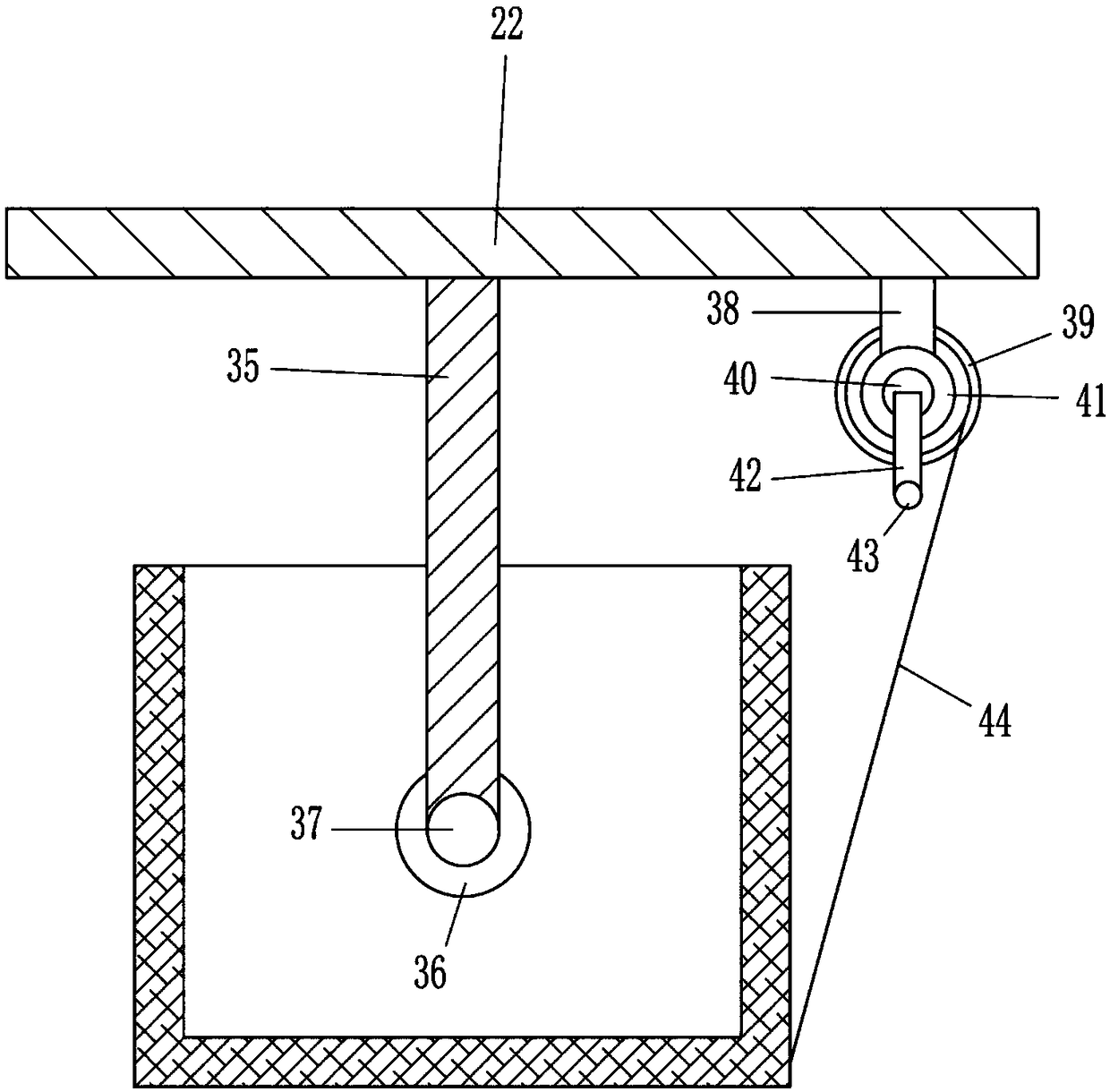

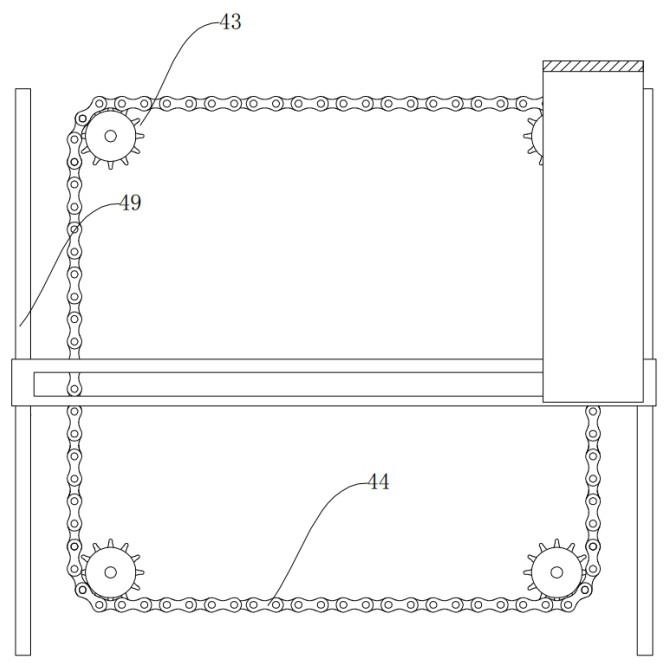

Self-resetting intrusive and passive operation metal recycling machine for copper industry sewage treatment

ActiveCN113415865AAchieve automatic shutdownOvercoming contradictory technical problems of increased energy consumptionSpecific water treatment objectivesWater contaminantsProcess engineeringSewage treatment

The invention discloses a self-resetting intrusive and passive operation metal recycling machine for copper industry sewage treatment. The metal recycling machine comprises an intrusive all-dimensional peculiar smell isolation and vibration power source integrated unit, a self-resetting maintenance-free dynamic and static state switching unit, an element removal type passive stirring and self-conveying integrated unit, an exclusive heavy metal fishing unit, an exclusive heavy metal collecting unit, a supporting base, a rear side supporting vertical plate, an impact force reversing frame and an impact force reversing cavity. The invention belongs to the field of heavy metal wastewater treatment, and particularly relates to the self-resetting intrusive and passive operation metal recycling machine for copper industry sewage treatment. Through the arrangement of the intrusive all-dimensional peculiar smell isolation and vibration power source integrated unit, the self-resetting maintenance-free dynamic and static state switching unit and the element removal type passive stirring and self-conveying integrated unit, multiple effects of intervention type all-directional odor isolation and vibration power source integration, self-resetting maintenance-free dynamic and static state switching, element removal type passive stirring and self-conveying integration and the like are achieved.

Owner:徐州欧润泵业有限公司

A chemical polishing soaking machine for copper production

The invention relates to the field of copper industry, in particular to a chemical polishing and soaking machine for copper industry production, and aims to provide the chemical polishing and soakingmachine which is used for the copper industry production and capable of sufficiently corroding the surface of a copper product for polishing and prevents a corrosive agent from adhering to the copperproduct and damaging the copper product. The chemical polishing and soaking machine for copper industry production comprises a mounting plate, a support frame, a motor, a first rotating shaft, a firstgear and the like, wherein the support frame and the motor are fixedly connected to the top surface of the mounting plate in sequence; a mixing box and a cleaning box are both fixedly connected to the top of the support frame; the first rotating shaft is in transmission connection with the output end of the motor; the first gear is fixedly connected to the top of the first rotating shaft; a firstbearing seat is fixedly connected to the outer bottom surface of the mixing box, and a second bearing seat is fixedly connected to the outer bottom surface of the cleaning box. The chemical polishingand soaking machine has the effects of sufficiently corroding the surface of the copper product for polishing and preventing the corrosive agent from adhering to the copper product and damaging the copper product.

Owner:安徽友进冠华新材料科技股份有限公司

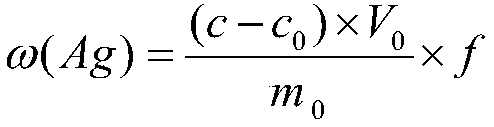

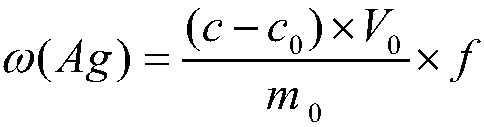

Method for determining silver content in crude copper

InactiveCN108444926AEasy to masterProtect your healthPreparing sample for investigationColor/spectral properties measurementsPhysical well beingDigestion

The invention relates to a method for determining a silver content in crude copper, which belongs to the field of analytical chemistry. According to the invention, lefort aqua regia is used for digestion of a sample, hydrochloric acid is added for complexation of silver in the crude copper, and a flame atomic absorption spectrometry is used for determining the silver content. The method uses two reagents of the hydrochloric acid and nitric acid for digestion of the sample, the reagent is saved, and the experiment cost is reduced; the experiment steps are simple, and are easily grasped by inspectors, and are adapted to detection of large-batch samples; the accuracy is high, and the precision is good. The method avoids the poisonous and harmful medicines such as lead oxide, health of the inspectors can be protected, a purpose of protecting environment can be achieved, the method provides technical support and guarantee for the crude copper industry analysis tests, and popularization andapplication of the method in the industry can be promoted, the method has the advantages of high accuracy, short determination period, and environmental protection, and achieves a purpose of reducingcost and improving effect for enterprises.

Owner:CHANGCHUN GOLD RES INST

Self-resetting type intrusive and passive operation metal recovery machine for copper industry sewage treatment

ActiveCN113415865BAchieve automatic shutdownOvercoming contradictory technical problems of increased energy consumptionSpecific water treatment objectivesWater contaminantsProcess engineeringSewage treatment

The invention discloses a self-resetting type interventional and passive operation metal recovery machine for copper sewage treatment, which includes an interventional all-round odor isolation and vibration power source integrated unit, a self-resetting maintenance-free dynamic and static state switching unit, and an element-removing type non-recycling unit. Source stirring and self-conveying integrated unit, exclusive heavy metal fishing unit, exclusive heavy metal collection unit, support base, rear support vertical plate, impact force reversing frame and impact force reversing chamber. The invention belongs to the field of heavy metal wastewater treatment, and specifically refers to a self-resetting type interventional and passive operation metal recovery machine for copper sewage treatment, which is integrated with an interventional all-round odor isolation and vibration power source, self-resetting maintenance-free dynamic and static state The setting of switching unit, element-eliminating passive stirring and self-conveying integrated unit realizes the integration of interventional all-round odor isolation and vibration power source, self-resetting maintenance-free dynamic and static state switching, element-eliminating passive stirring and self-conveying integration, etc. multiple effects.

Owner:徐州欧润泵业有限公司

A reducing agent nfa for deep deoxidation in copper industry

Owner:云南泉凯冶金材料有限公司

A kind of copper production wastewater treatment equipment

ActiveCN110743225BNovel structureEasy to carry and transferCleaning using liquidsStationary filtering element filtersElectric machineEngineering

Owner:清远楚江高精铜带有限公司

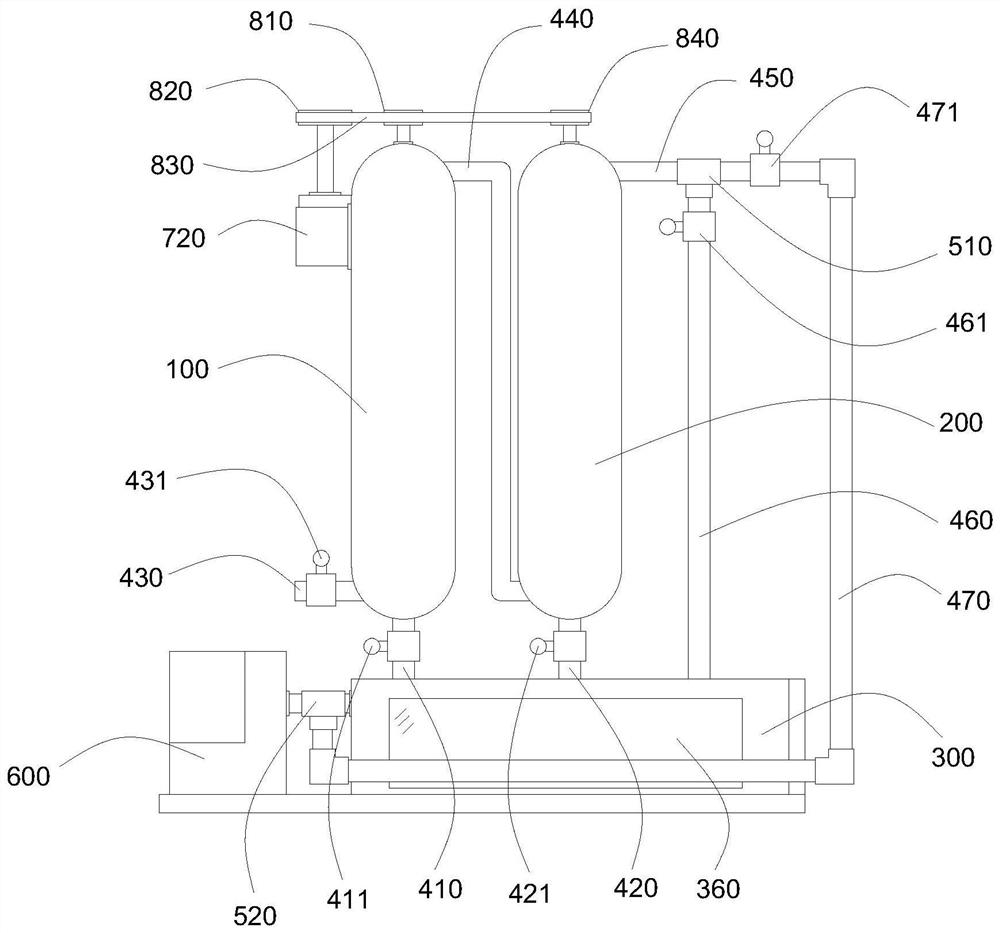

An easy-to-clean waste gas and fume treatment equipment for copper furnaces

ActiveCN110711442BNovel structureEasy to cleanDispersed particle filtrationTransportation and packagingAir pumpExhaust fumes

The invention provides a waste gas and smoke treatment equipment for copper furnaces that is easy to clean. The first filter bottle communicates with the collection box through the first discharge pipe, the second filter bottle communicates with the collection box through the second discharge pipe, and the first filter bottle The bottom of the side wall of the filter bottle is provided with an air intake pipe, the top of the side wall of the first filter bottle is connected with the bottom of the side wall of the second filter bottle through an air pipe, and the top of the side wall of the second filter bottle is connected with an exhaust pipe, and the exhaust pipe The end is provided with a first three-way valve, an interface of the first three-way valve communicates with the collection box through the first pipeline, the air inlet of the air pump is connected with a second three-way valve, and an interface of the second three-way valve It communicates with the collection box, the second three-way valve communicates with the first three-way valve through the second pipeline, the first filter bottle is provided with the first filter element, the second filter bottle is provided with the second filter element, the first filter element and the second filter element The filter elements are all driven by the drive motor; they can carry out effective dust suction and filtration, which greatly improves the filtration effect; and it is easy to clean and remove dust, which is convenient for operation.

Owner:清远楚江高精铜带有限公司

A copper bar adjustable fast cutting machine for copper industry

ActiveCN108907333BTo achieve the adjustment effectSolve the problem of troublesome blade replacementShearing machine accessoriesShearing toolsArchitectural engineeringCopper industry

The invention discloses a copper rod adjustable type rapid cut-off machine used for the copper industry, and relates to the technical field of cut-off machines. The copper rod adjustable type rapid cut-off machine comprises a base, a work table and a fixed table. The work table and the fixed table are both fixedly connected to the upper surface of the base. The fixed table is located behind the left portion of the work table. The left side of the work table is fixedly connected with a threaded rod. The left end of the threaded rod is fixedly connected with a fixed plate. The fixed plate is fixedly connected to the upper surface of the base. The fixed plate is located on the front face of the fixed table. The surface of the threaded rod is movably connected with a limiting block in a sleeving manner. A groove is formed in the upper surface of the work table. The inner wall of the groove is fixedly connected with a spring. The end, away from the inner wall of the groove, of the spring isfixedly connected with a baffle. According to the copper rod adjustable type rapid cut-off machine used for the copper industry, by means of pawls and blades, the problem that because none of bladesof an existing copper rod adjustable type rapid cut-off machine can be regulated for copper rods of different diameters and cutting lengths, blade change is troublesome when the copper rods of different diameters are cut.

Owner:芜湖市海源铜业有限责任公司

A high-hardness zinc-copper-aluminum alloy

Owner:CHANGZHOU UNIV

Purification equipment for sewage and waste gas in copper industry

ActiveCN106139836BStop pollutionExtended service lifeGas treatmentDispersed particle separationParticulatesSorbent

The invention discloses a purifying device for copper-industry wastewater and waste gas. The purifying device comprises a gas inlet pipe, a water inlet pipe, a treating box, a water outlet pipe, a gas outlet pipe and a film pool. The inside of the treating box sequentially comprises a heavy metal adsorption layer, an SDG adsorbent layer and a purifying layer from top to bottom, and the purifying layer comprises immobilized microorganism balls; a magnetic field generator is arranged outside the treating box; in the purifying device for copper-industry wastewater and waste gas, the purified wastewater and waste gas are mixed and enter the film pool, wastewater can be purified through a film assembly in the film pool, film pollution can be prevented through scouring of waste gas, the proportion of wastewater to waste gas ranges from 1:2.5 to 1:2, and the effect of the a waste-gas scouring film assembly is best; nitrogen oxide and particulate matter in wastewater and nitrogen oxide and particulate matter in waste gas can be removed through the immobilized microorganism balls; heavy metal matter can be removed through the heavy metal adsorption layer arranged in the treating box, and sulfuric acid mist can be removed through the SDG adsorbent layer.

Owner:广西东兴市富佳五金皮具有限公司

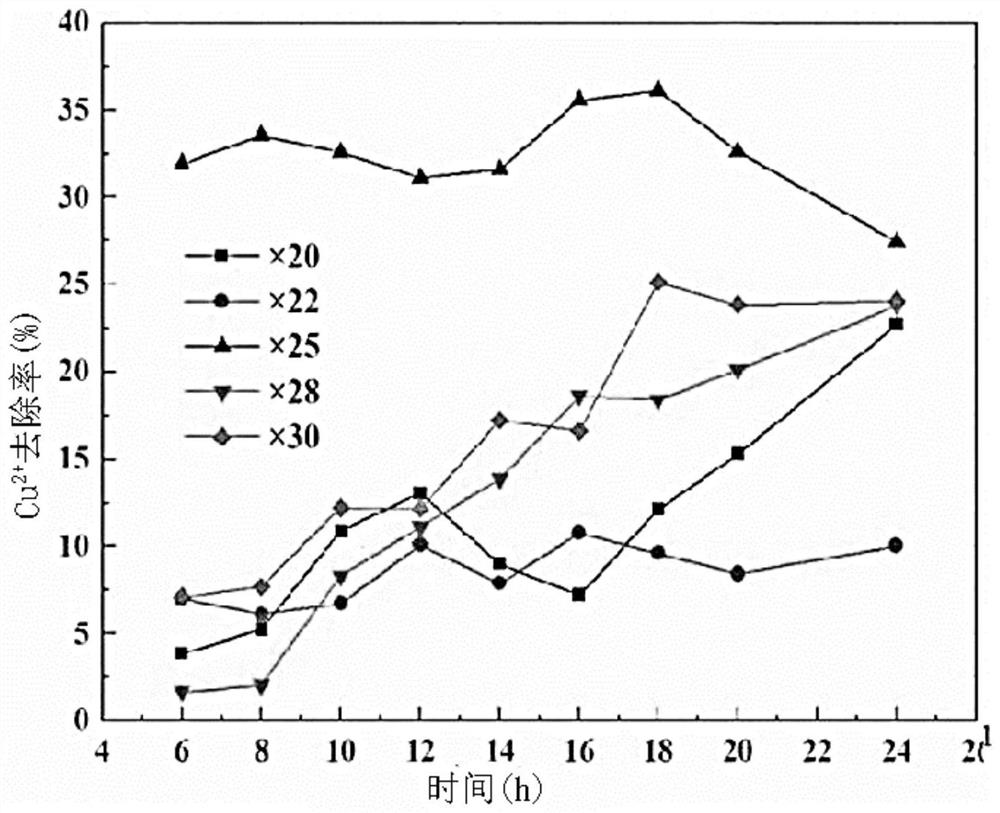

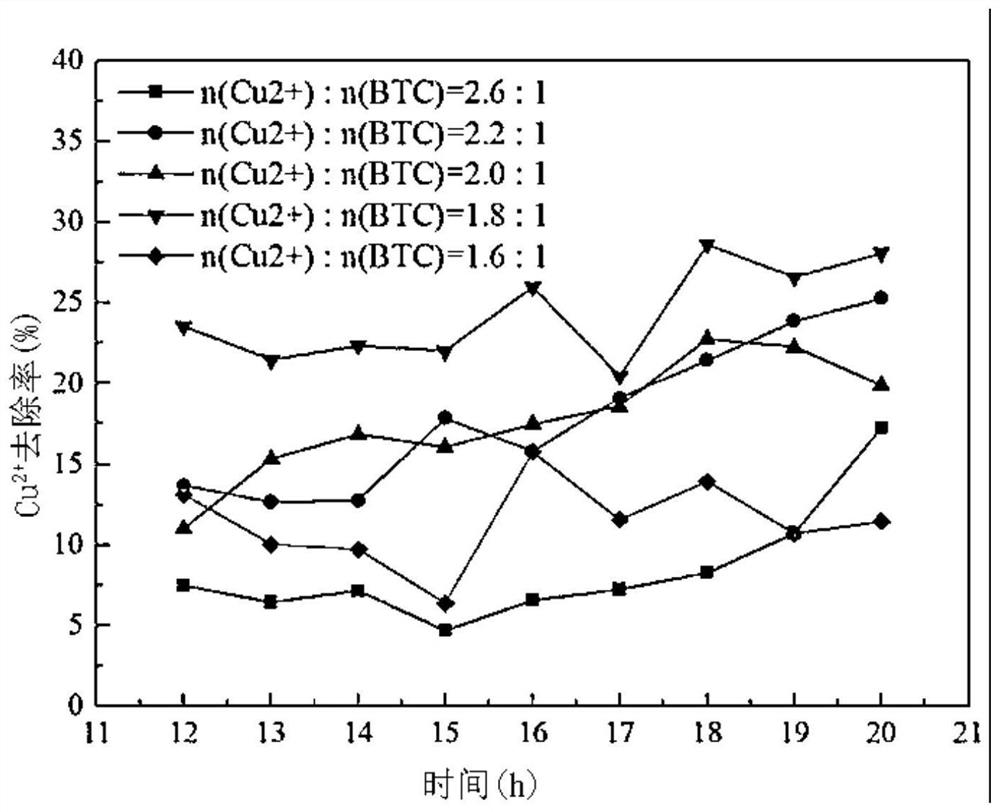

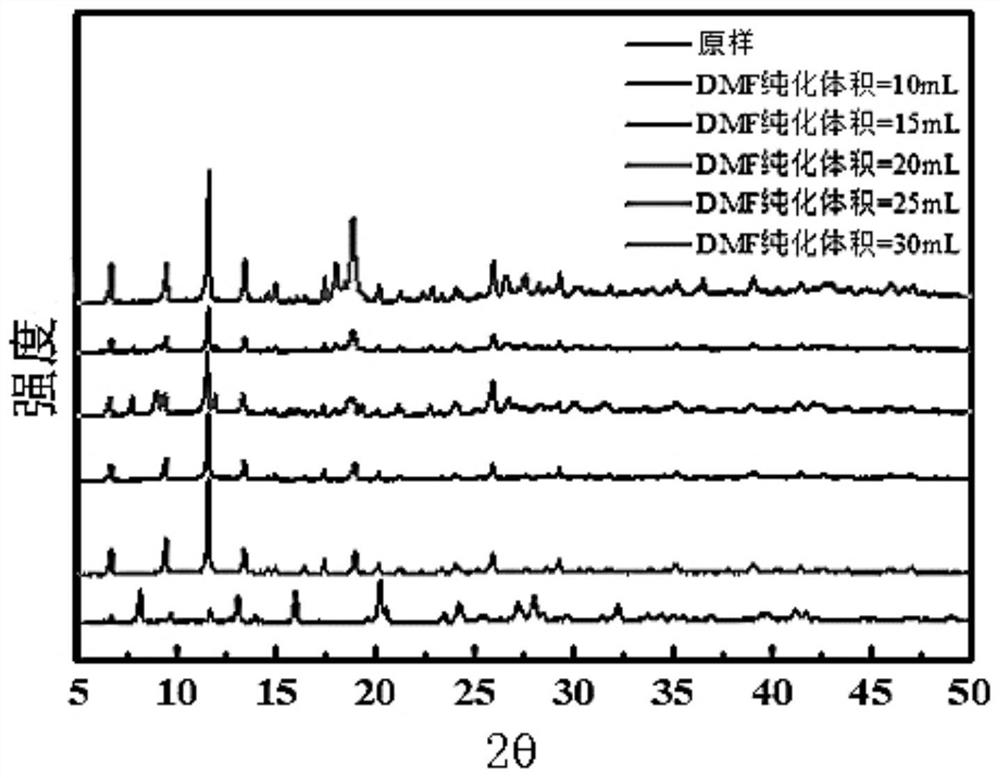

Method for preparing metal-organic framework material HKUST-1 from copper-containing industrial wastewater

The invention provides a method for preparing a metal-organic framework material HKUST-1 from copper-containing industrial wastewater, belonging to the technical field of wastewater utilization. The method comprises the following steps: mixing the copper-containing industrial wastewater with trimesic acid, and carrying out a coordination reaction to obtain a crude reaction product, wherein the pH value of the copper-containing industrial wastewater is 0.4 to 1.5; and mixing the obtained crude reaction product with an activating agent, and carrying out activating treatment to obtain the metal-organic framework material HKUST-1. The metal-organic framework material HKUST-1 is prepared from the copper-containing industrial wastewater, so cost is low, copper ions in the industrial wastewater can be removed, and environmental pollution is reduced. A result of an embodiment shows that the HKUST-1 is successfully prepared by the method disclosed by the invention.

Owner:NANCHANG HANGKONG UNIVERSITY

A new type of stripping solution for copper process in panel industry

ActiveCN107942625BModerate peeling speedImprove corrosion resistancePhotosensitive material processingPhotoresistCopper metal

The invention relates to a high-recycling rate and environmental-friendly stripping liquid for copper processing of TFT industry. The high-recycling rate and environmental-friendly stripping liquid comprises the following constituents based on percent by mass: 1-2% of alcohol, 40-50% of ether, 3-8% of mixed amine, 40-50% of organic solvent with a low boiling point, 1-5% of corrosion inhibitor and1-5% of non-ionic surfactant with the balancing being pure water. The stripping liquid is moderate in striping speed, no photoresist is resided on a surface of a stripped wafer under a 1,000-rate microscope, and no corrosion to a copper metal layer is generated. The photoresist removal capability is improved by using the alcohol and ether in a mixed way, and the corrosion-resistant performance ofcopper metal is improved by combining the mixed amine; while the corrosion of the copper metal can be improved when the dosage of a conventional amine substance is increased; in the stripping liquid,the mixed amine substance is used, namely, (hydrochloric acid mixed amine and monohydrate mixed amine) are used in a combination and are combined with other amine substances, thus, the photoresist removal capability can be improved, and the protection of the copper metal is improved; and moreover, since the mixed amine composition is very easy to dissolve in water and is convenient to remove, theaddition of an imidazole substance can be reduced, and a relatively small amount of additive is resided.

Owner:江苏中德电子材料科技有限公司

Reductant NFA used for deep deoxidization in the copper industry

The invention relates to a reductant NFA used for deep deoxidization in the copper industry and belongs to the technical field of non-ferrous metallurgy. The reductant NFA is obtained by removing impurities of anthracite or petroleum coke and pitch coke, subjecting oxidized ore of Al, Si, Ca and Mg to strong reduction to obtain elementary substances or alloys, separately smashing and sieving the abovementioned two raw materials to obtain particles having a size of 0.1-5 mm, and mixing the two kinds of materials according to the requirements of the refining process to obtain the reductant NFA. The reductant NFA can also be obtained by directly mixing the two raw materials, subjecting the mixture to strong reduction at high temperature, smashing and sieving. In a reduction stage in the later period of fire refining of crude copper, single adoption of the reductant NFA or combination of the reductant NFA with a traditional reductant can achieve the objective of deep deoxidization of fire-refined copper and can make the resident oxygen lower than 30-1500 ppm. The reductant NFA is suitable for the cooper smelting industry and the copper processing industry.

Owner:云南泉凯冶金材料有限公司

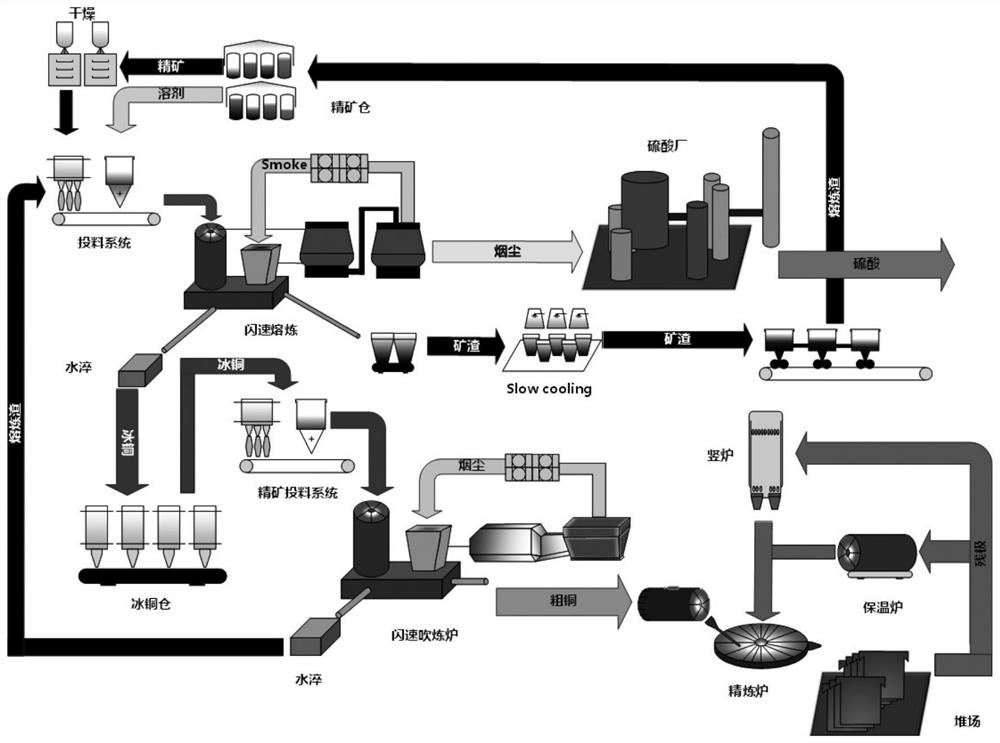

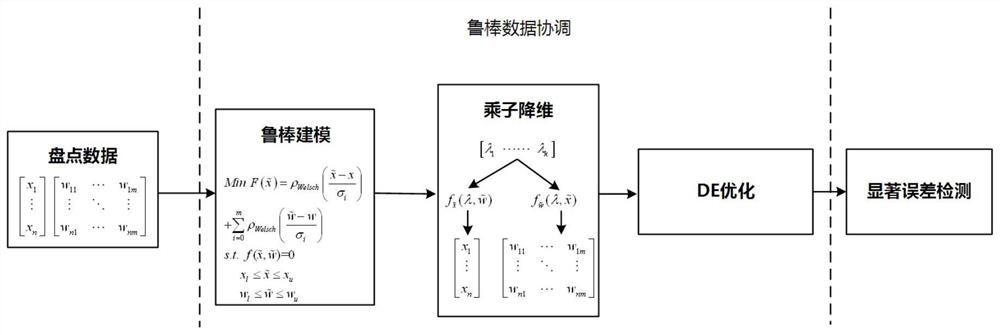

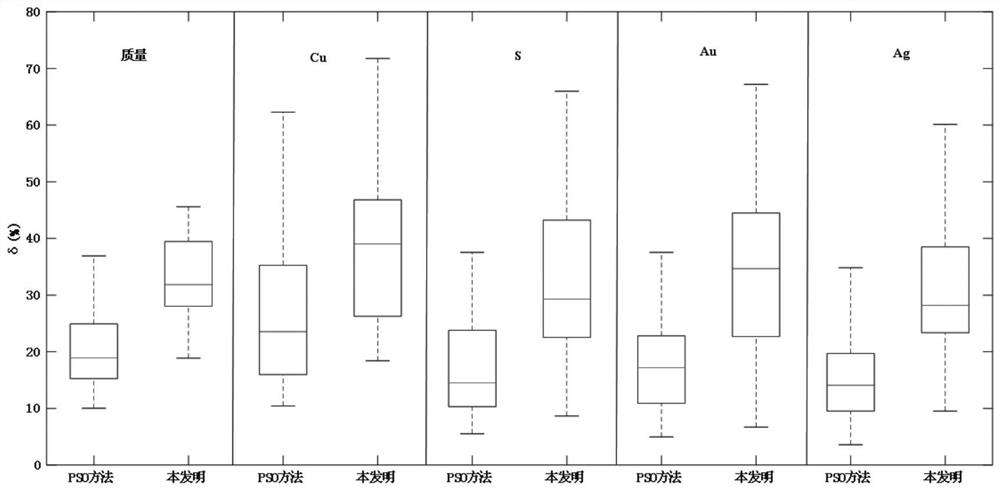

Copper industry data robust coordination and significant error detection method

PendingCN112734166AOvercoming the problem of data reconciliation being affected by significant error termsNarrow down the search spaceResourcesComplex mathematical operationsIndustrial engineeringConversion method

The invention provides a copper industry data robust coordination and significant error detection method, and relates to the technical field of information, and the method comprises the steps: employing real material inventory data, and roughly calculating the inventory data standard deviation of each data item according to the inventory data; According to the copper, sulfur, gold and silver metal amount recovery rate of a smelting plant of a copper production enterprise, in order to prevent significant errors in inventory data from interfering with other data items during data coordination, robust data coordination model is established; in order to realize rapid data coordination and significant error detection of all material attributes for inventory data of materials of a smelting plant, a Lagrange multiplier conversion method is adopted, and a high-dimensional variable space is represented by a low-dimensional constraint multiplier space. And in addition, a differential evolution algorithm is adopted to carry out optimization iterative solution. The result obtained by the method is more accurate in significant error detection, the coordinated data is more stable, the calculation efficiency meets the actual requirements, and the method can also be popularized and applied in copper production enterprises and other production enterprises.

Owner:DUT ARTIFICIAL INTELLIGENCE INST DALIAN +1

A high-precision casting equipment for copper industry processing

ActiveCN109317654BQuality improvementImprove securityMolten metal pouring equipmentsGear wheelElectric machinery

The invention relates to the field of copper industry machining, in particular to high-precision type casting equipment for the copper industry machining. According to the high-precision type castingequipment for the copper industry machining, the casting efficiency is high, the casting product quality is high, the labor intensity is low, the safety is high, and steel material quantity supply isaccurate. The high-precision type casting equipment for the copper industry machining comprises a placing seat, a casting device, a first supporting column, a first motor, a first gear, a first rotating shaft, a second gear, a first bearing block, a discharging hopper, a material receiving frame, a second rotating shaft, a second bearing block, a second supporting column, a discharging frame, an electric discharging valve, a first elastic part, a guiding rod, a lifting rod, a sliding plate, first mixing rods and the like. According to the high-precision type casting equipment, the casting efficiency is high, the casting product quality is high, the labor intensity is low, and steel material quantity supply is accurate.

Owner:临沂市凯星水表有限公司

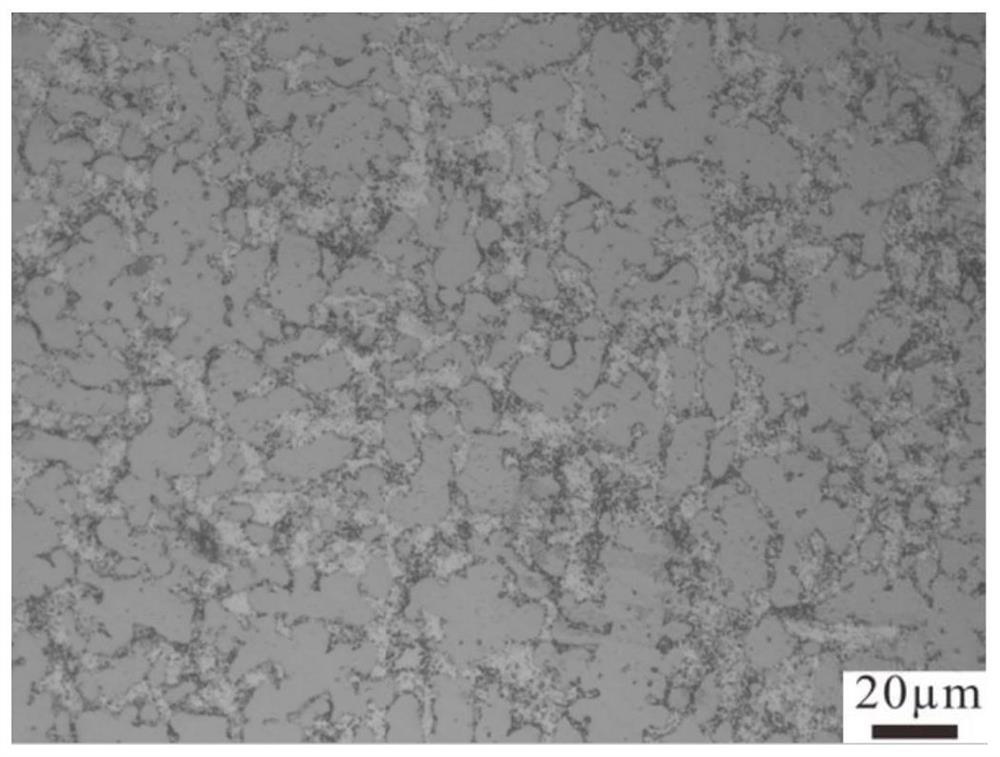

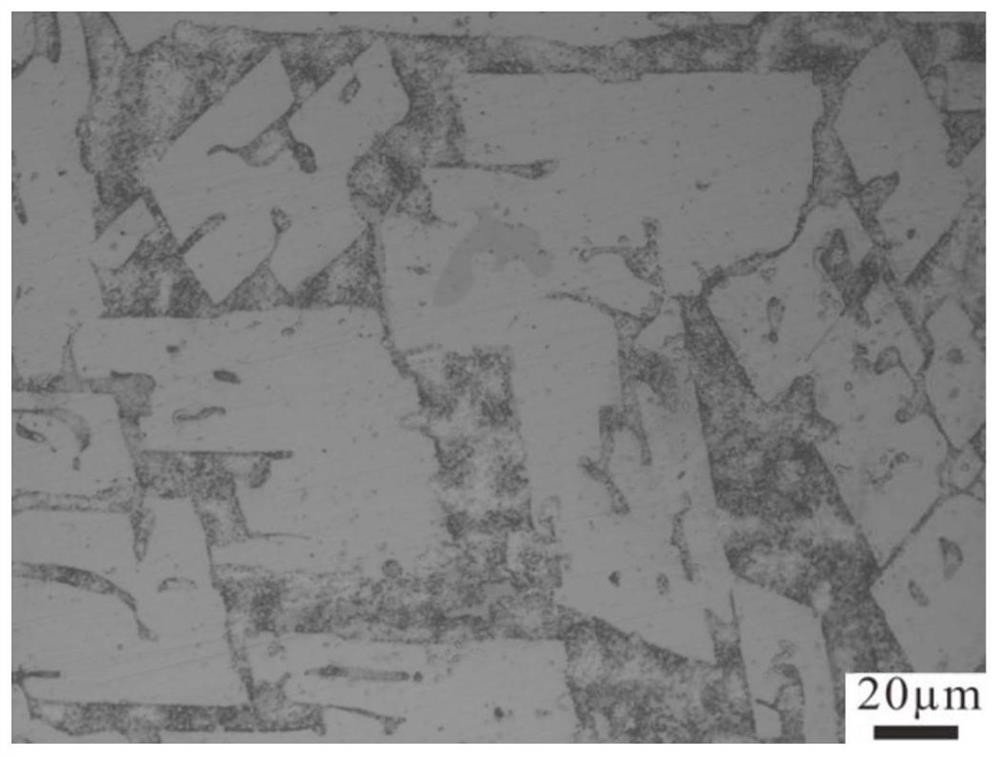

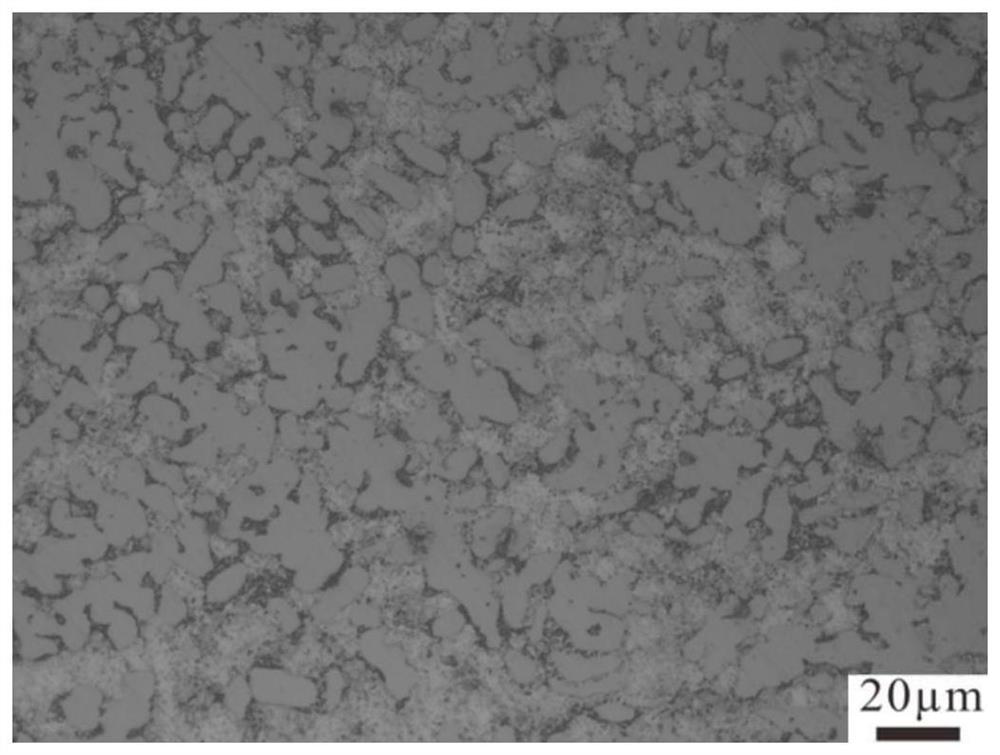

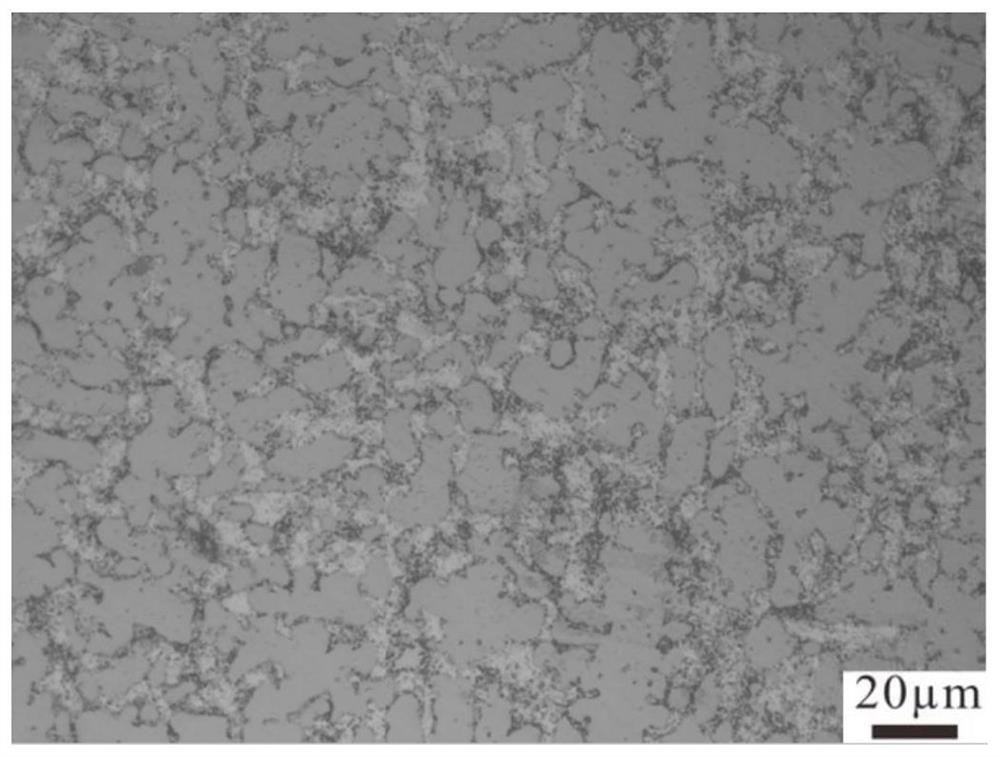

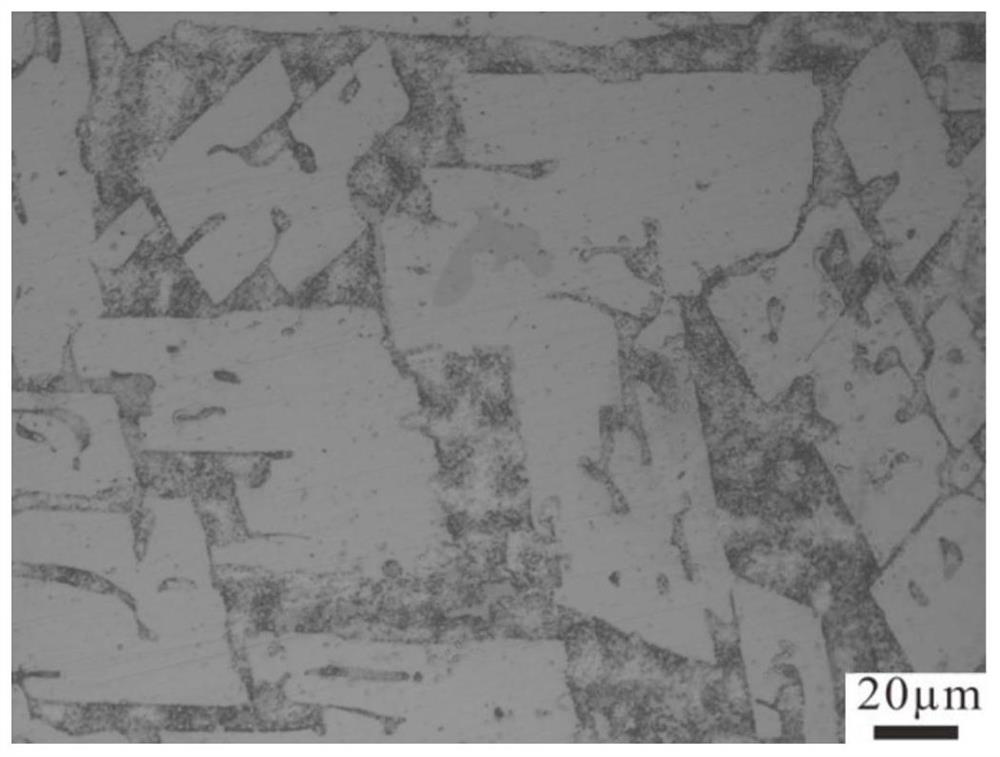

High-hardness zinc-copper-aluminum alloy

The invention belongs to the field of nonferrous metal processing, and particularly relates to a high-hardness zinc-copper-aluminum alloy. The high-hardness wear-resistant zinc-copper-aluminum alloy is prepared from an Al-50Cu intermediate alloy, industrial pure copper, industrial pure aluminum and industrial pure zinc by adopting a smelting casting and natural cooling method. The alloy comprises,by mass, 30-38% of Zn, 30-38% of Cu, 30-38% of Al and less than 0.8% of inevitable impurities. The preferable alloy component is copper-aluminum-zinc metal component with equal mass percentage, and has the optimal hardness and wear-resistant effect. The high-hardness zinc-copper-aluminum alloy can be applied to the industrial fields of machinery, mines and the like.

Owner:CHANGZHOU UNIV

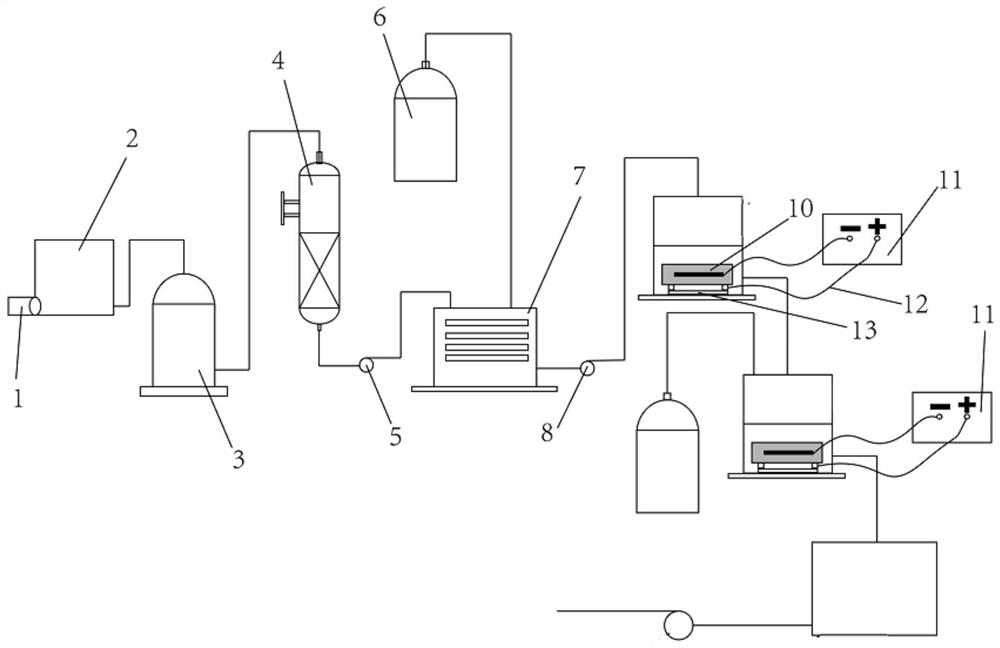

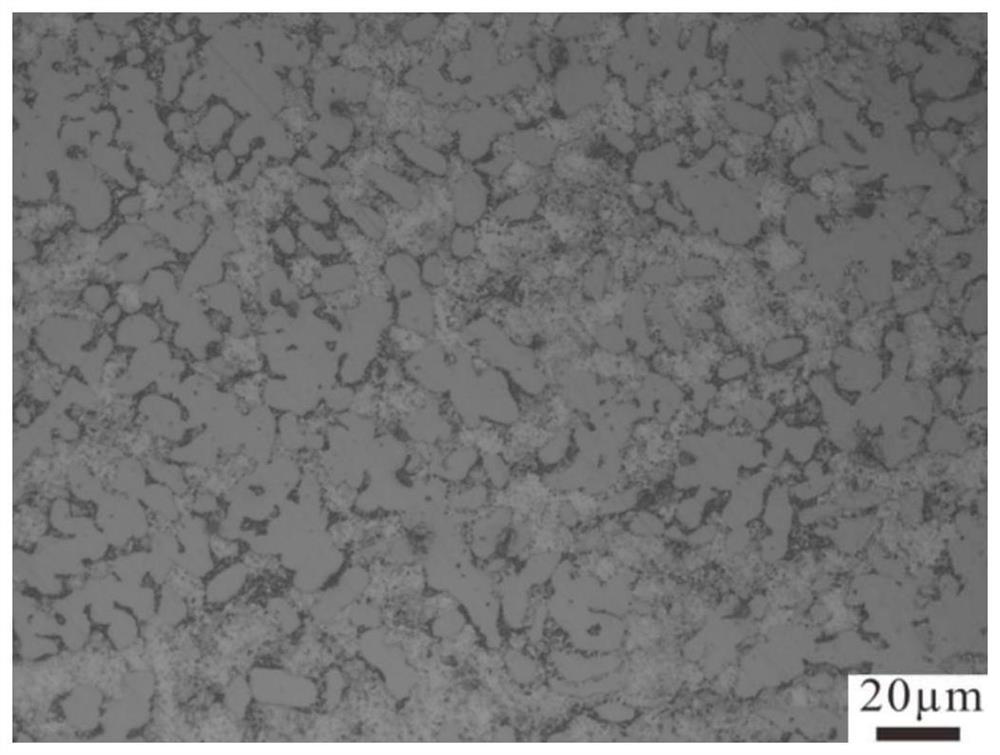

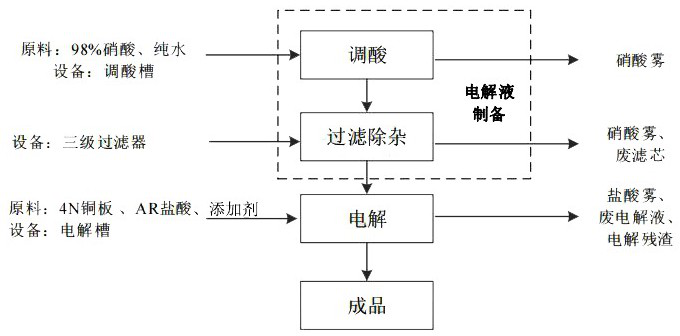

Processing technology of high-purity copper product for space flight and aviation

PendingCN114293227AReduce manufacturing costEfficient removalPhotography auxillary processesElectrolysis componentsElectrolytic agentAviation

The invention discloses a processing technology of a high-purity copper product for space flight and aviation, which comprises the following steps: acid regulation: 68% electronic-grade nitric acid and pure water are pumped into an acid regulation tank according to a certain proportion, the pH value is regulated to 3, a nitric acid electrolyte is prepared, and then the nitric acid electrolyte is pumped into a liquid pouring storage tank; filtering to remove impurities, namely removing impurities from the nitric acid electrolyte of which the pH is adjusted through a three-stage filter; electrolysis is conducted, specifically, a 4N high-purity copper plate serves as an anode plate, a titanium plate serves as a cathode plate, the nitric acid electrolyte obtained after filtering and impurity removal is pumped into an electrolytic bath, electrolysis circulation is started, direct-current electrolysis is conducted, and 7N high-purity copper is obtained on the cathode plate; and vacuum packaging is conducted, specifically, the cathode plate with copper deposited is cleaned and conveyed to a stripping unit to be stripped, stripped cathode copper is inspected, and vacuum packaging and warehousing are conducted after the cathode copper is inspected to be qualified. Impurities in the production process of the high-purity copper can be effectively removed, the electrolyte can be purified, the quality requirement of the high-purity copper is met, and meanwhile the industrial production cost of the high-purity copper is further reduced.

Owner:CHENGDU HONGHUA ENVIRONMENTAL SCI & TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com