Method for treating concrete by utilizing copper plating wastewater

A technology for wastewater treatment and concrete, applied in the field of corrosion resistance treatment of concrete structures, can solve problems such as corrosion, reduce pollution, prevent the production of biological sulfuric acid, and realize the effect of recycling waste resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The concentration of copper ions in the electrolyte is configured to be 5000mg / L.

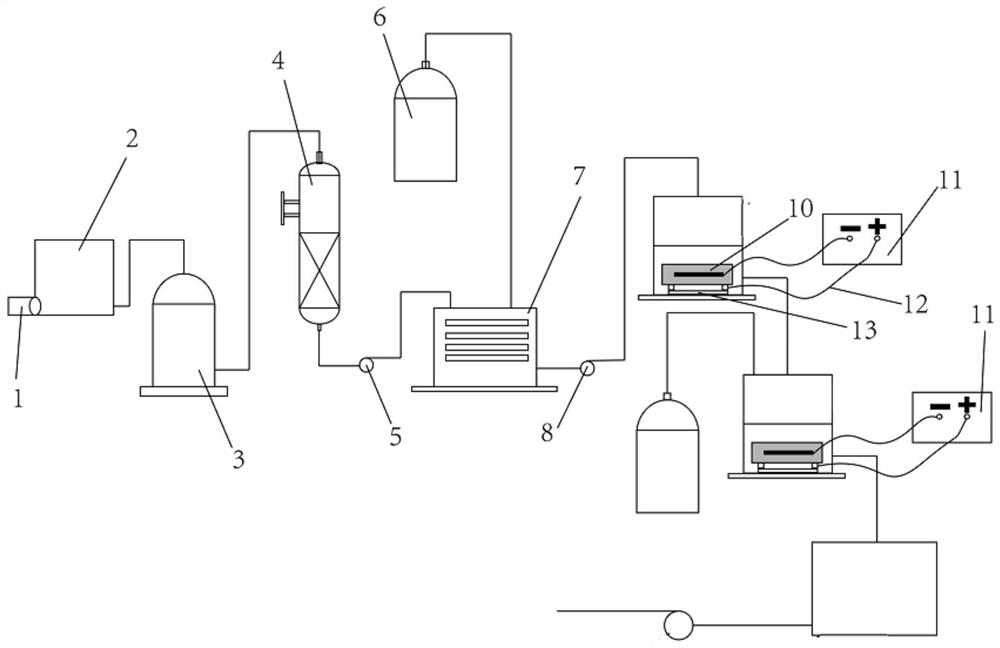

[0042] Submerge the concrete with built-in steel bars 10 in the electrolyte, use the steel bars built in the concrete as cathodes, and use 13 pieces of titanium mesh as anodes, connect the electrochemical workstation 11 through copper wires 12, and perform electrodeposition, wherein the anode and concrete The distance is 30mm, the output voltage of the DC power supply is 30V, and the current density applied to the cathode by the DC power supply is 1.5mA / cm 2 , the first step of electrodeposition time is 48 hours. A layer of copper plating is deposited on the surface of the concrete by the first step of electrodeposition.

[0043] After the first step of electrodeposition, the concentration of copper ions in the electrolyte is reduced to 485mg / L, and lactic acid solution is added to the electrolyte. The concentration of lactic acid is 5 times the concentration of copper ions (molar ratio...

Embodiment 2

[0046] The concentration of copper ions in the electrolyte is configured to be 2000mg / L.

[0047] Immerse the concrete with built-in steel bars in the electrolyte, use the steel bars built in the concrete as the cathode, and use the titanium mesh as the anode to conduct electrodeposition. The distance between the anode and the concrete is 30mm, and the output voltage of the DC power supply is 30V. , the current density applied to the cathode by DC power supply is 1.5mA / cm 2 , the first step of electrodeposition time is 48 hours.

[0048] After the first step of electrodeposition, the concentration of copper ions in the electrolyte is reduced to 265mg / L, and lactic acid solution is added to the electrolyte. The concentration of lactic acid is 5 times the concentration of copper ions (molar ratio), and 1mol / L of NaOH is added to adjust the solution The pH is 11. Afterwards, pulse power supply was used for electrodeposition for 12 hours, the pulse frequency of the pulse power s...

Embodiment 3

[0050] Embodiment 3: The concentration of copper ions in the electrolyte is configured to be 500 mg / L.

[0051] Immerse the concrete with built-in steel bars in the electrolyte, use the steel bars built in the concrete as the cathode, and use the titanium mesh as the anode to conduct electrodeposition. The distance between the anode and the concrete is 30mm, and the output voltage of the DC power supply is 30V. , the current density applied to the cathode by DC power supply is 1.5mA / cm 2 , the first step of electrodeposition time is 48 hours.

[0052] After the first step of electrodeposition, the concentration of copper ions in the electrolyte is reduced to 95 mg / L, and lactic acid solution is added to the electrolyte. The concentration of lactic acid is 5 times the concentration of copper ions (molar ratio), and 1mol / L of NaOH is added to adjust the solution The pH is 11. Afterwards, pulse power supply was used for electrodeposition for 12 hours, the pulse frequency of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com