Patents

Literature

37 results about "Alkalization - Treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

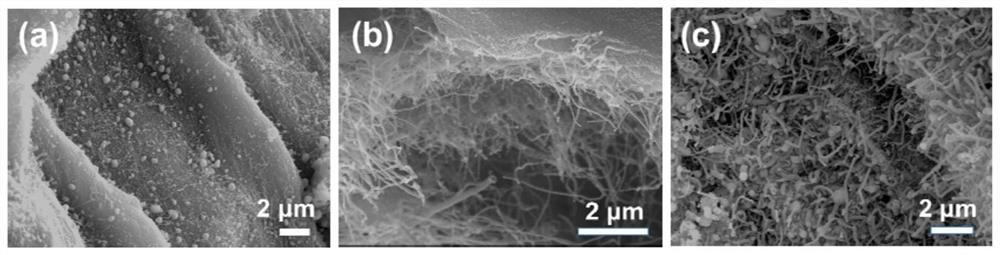

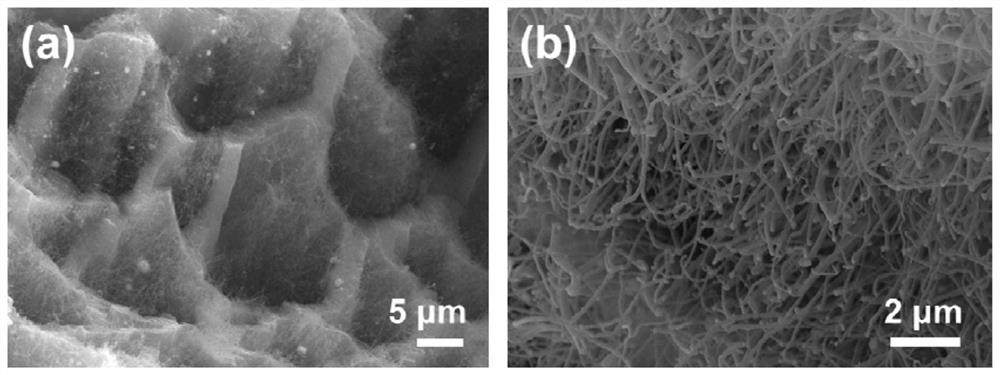

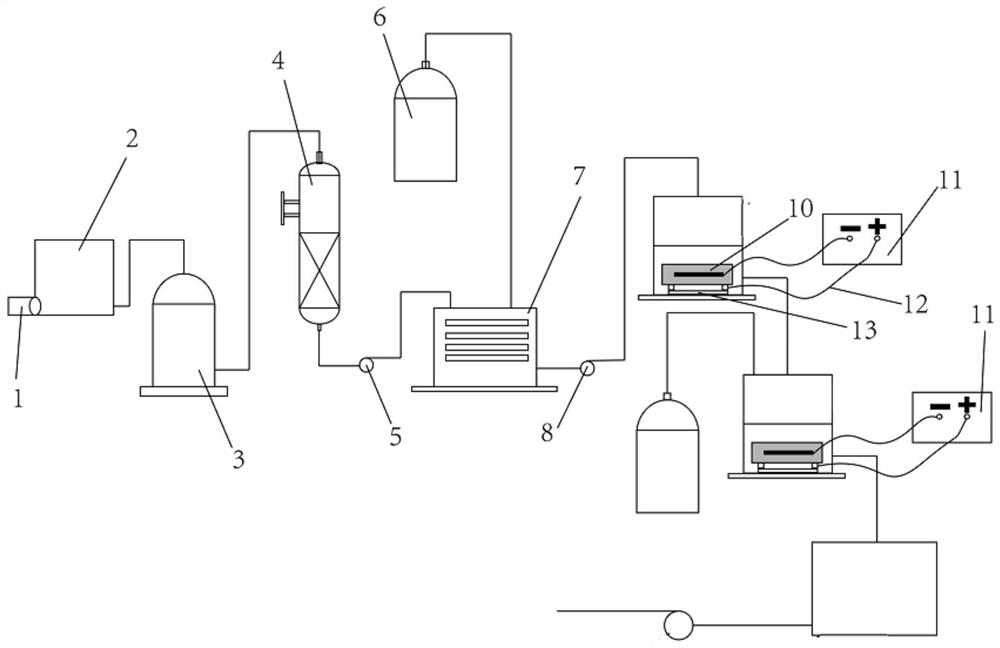

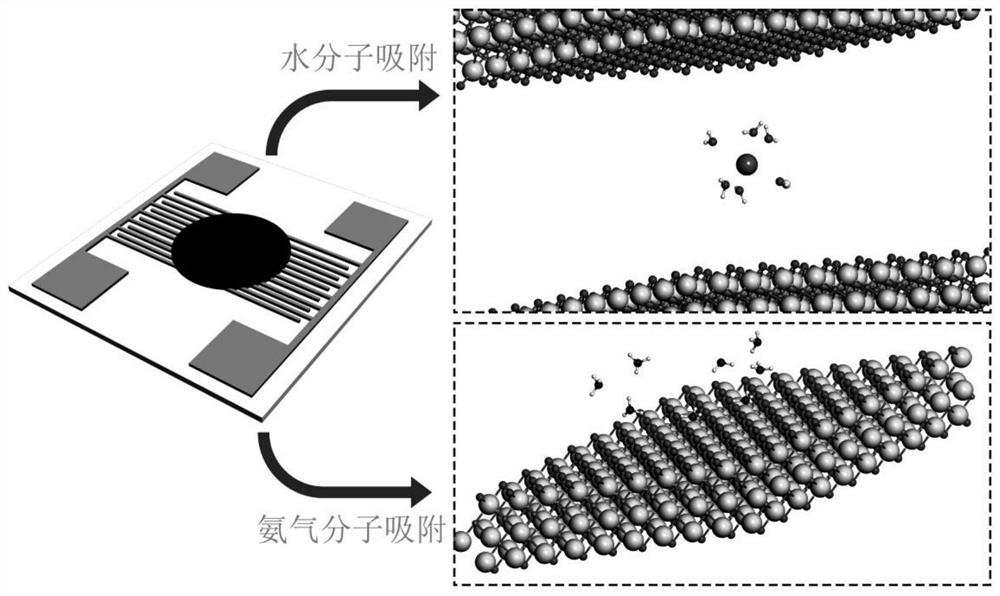

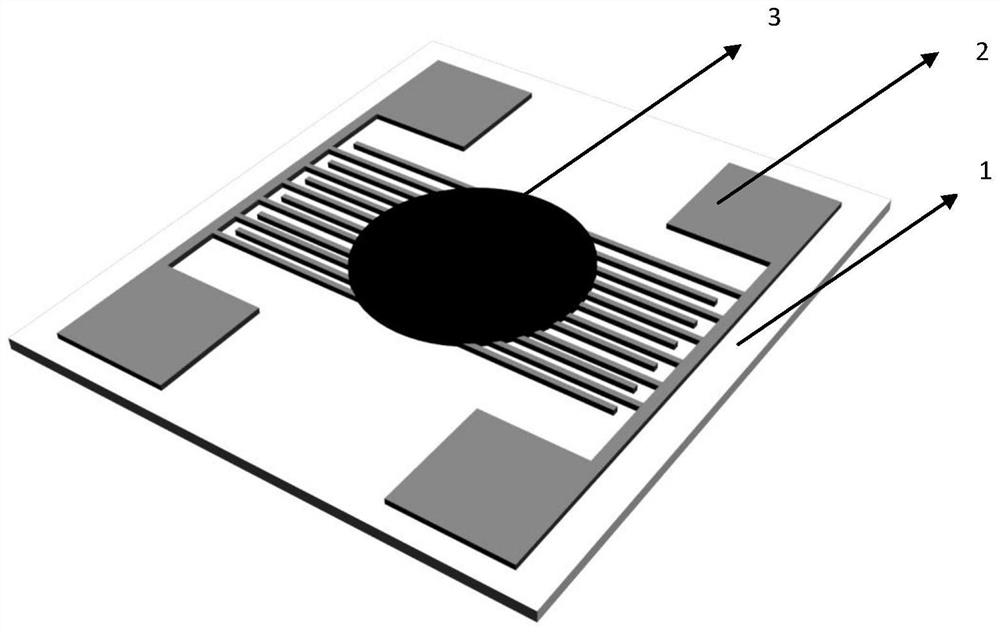

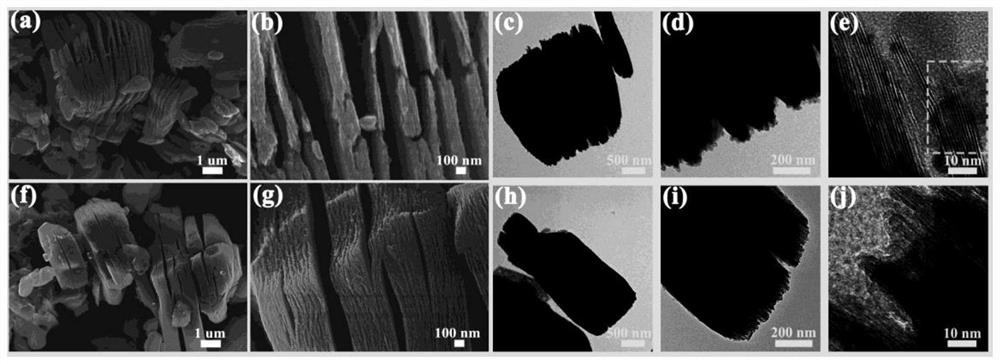

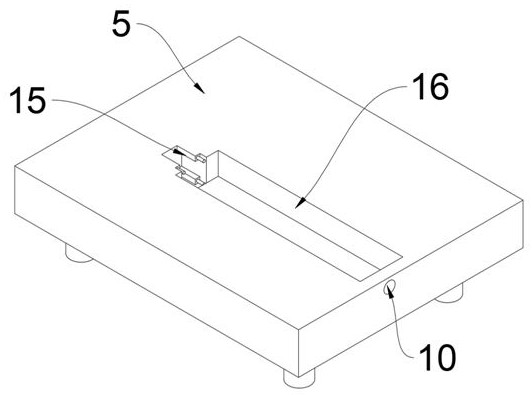

Planar humidity-ammonia gas sensor based on alkalized organ-like MXene sensitive material and preparation method thereof

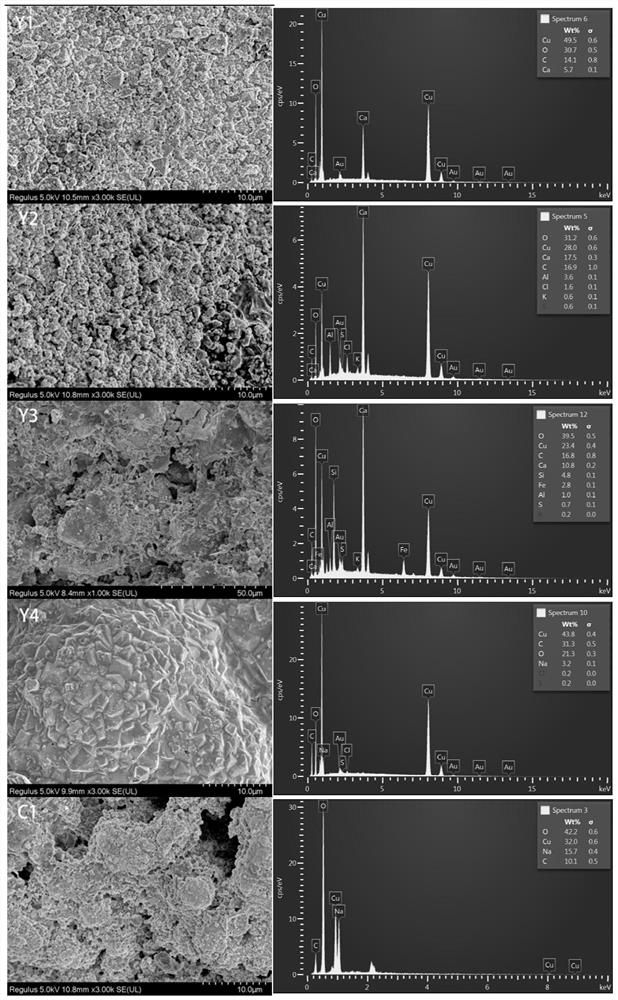

ActiveCN109799267AImprove humidity sensitivityImproving Ammonia Sensing PerformanceMaterial resistanceAmmonia gasMaterials science

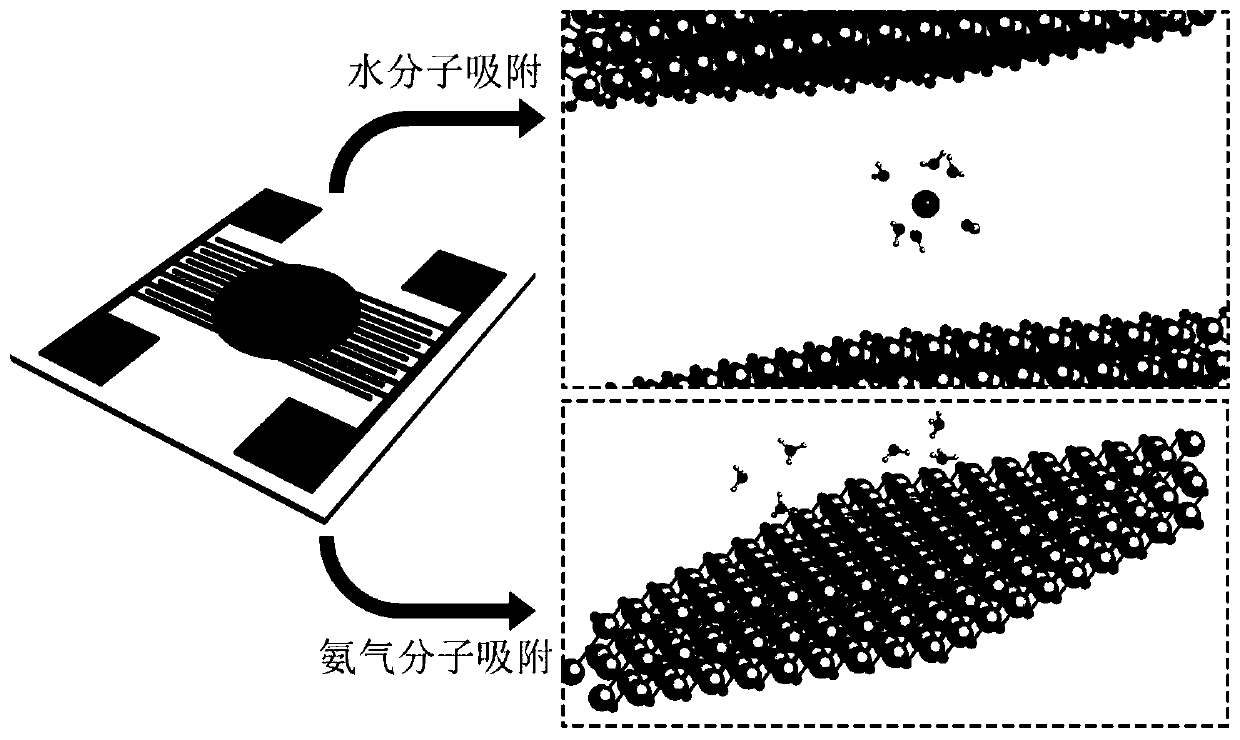

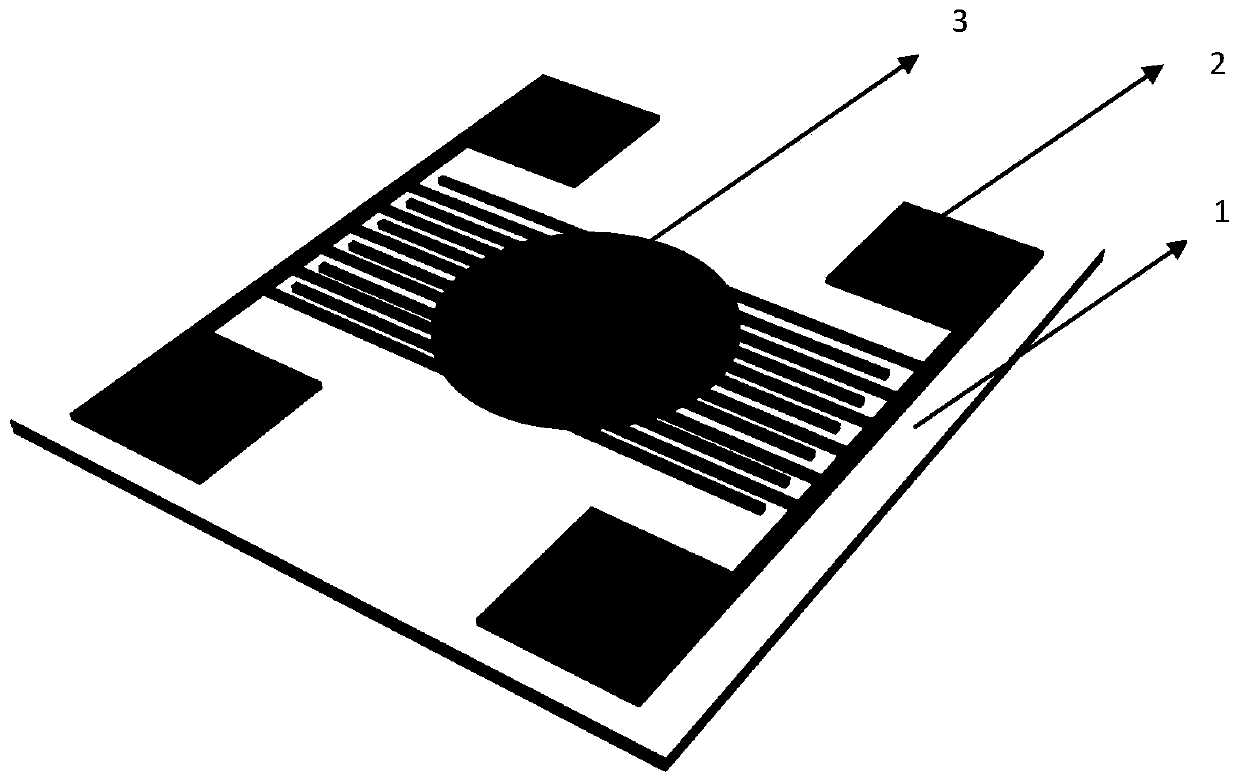

The invention belongs to the technical field of gas-humidity sensitive sensors and relates to a planar humidity-ammonia gas sensor based on alkalized organ-like MXene (Ti3C2Tx, with T representing surface basic group terminals and x valuing from a ratio of surface terminals) sensitive material and preparation method thereof. The planar humidity-ammonia gas sensor is composed of an Al2O3 ceramic base plate with an Au / Ni interdigital electrode and an alkalized organ-like MXene (Ti3C2Tx) sensitive material applied evenly to the interdigital electrode and the ceramic base plate by dripping. Basedon the organ-like MXene material, surface F terminals are removed and sodium ions are inserted by alkalizing the organ-like MXene material. pre-alkalization and post-alkalization gas-humidity sensitivities are compared to obtain a device having better humidity and ammonia gas sensitivities. The sensor prepared herein has MXene gas-humidity sensitive response which is the highest up to now, and hasgood selectivity.

Owner:JILIN UNIV

Method of using crop straw to produce acidic wastewater adsorbent for mine

InactiveCN102600804AEfficient removalNo secondary pollutionOther chemical processesWater/sewage treatment by sorptionSulfate radicalsSorbent

The invention discloses a method of using crop straws to produce an acidic wastewater adsorbent for a mine, which comprises the following steps of: A1, cleaning, drying and crushing the crop straws to 20-40 meshes; A2, alkalizing straw particles after crushing; A3, dehydrating the straws after alkalization; A4, mixing dehydrated and alkalized straws with excessive epichlorohydrin for crosslinking reaction; A5, mixing solid products prepared in the crosslinking reaction and trimethylamine alcoholic solution for quaternization reaction to prepare a solid-phase product; and A6, cleaning the solid-phase product, and drying to obtain the adsorbent. Compared with the traditional sulfate removal method, sulfate radical can be effectively removed, no secondary pollution can be caused, and no post-processing equipment is needed. The used adsorbent can be recycled after regeneration in NaOH solution, and the removal rate of SO4<2-> remains more than 75 percent after the adsorbent is recycled multiple times.

Owner:XIAN UNIV OF SCI & TECH

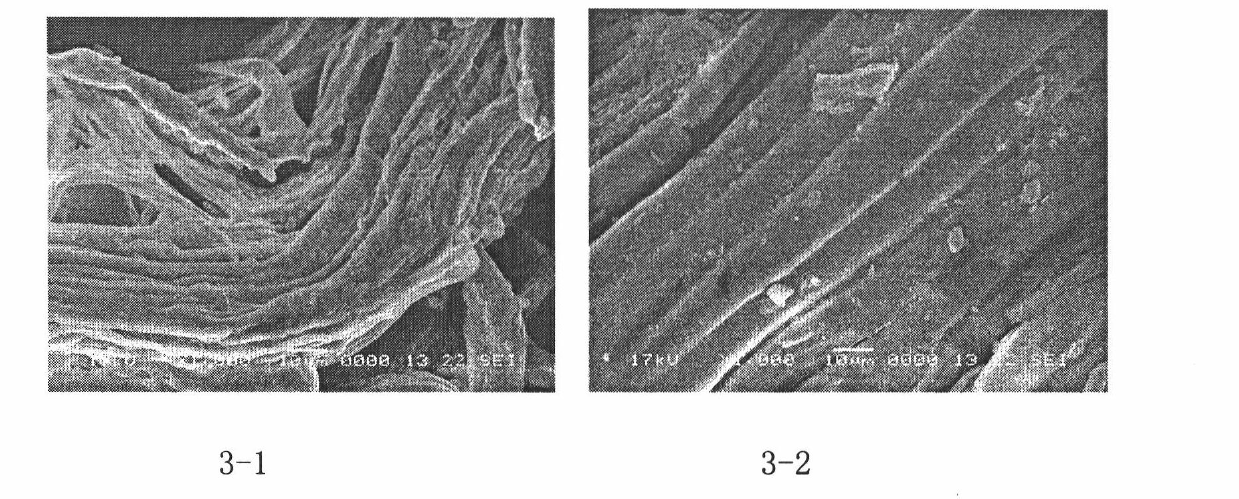

Zero-discharge advanced treatment method of desulfurized wastewater

ActiveCN107089744ASolve severe foulingSolve processingWater contaminantsTreatment involving filtrationElectrochemical responseFiltration

The invention provides a zero-discharge advanced treatment method of desulfurized wastewater. The method comprises the following steps: 1, primary acidizing treatment; 2, primary dechlorination with an electrochemical reactor; 3, alkalization treatment; 4, elimination of calcium and magnesium ions; 5, secondary acidizing treatment; 6, secondary dechlorination with the electrochemical reactor; 7, settling and filtration; 8, first-stage electrodialysis, second-stage electrodialysis...N-stage electrodialysis; and 9, reclamation of clear water. The method solves a series of problems such as high treatment cost, high requirements on pretreatment, short service life of products, high replacement cost, serious scaling of an evaporator and pipelines, difficulty in treatment of solid mixture wastes and the like in the prior arts such as chemical softening plus hyperfiltration plus reverse osmosis, chemical softening plus multiple-effect evaporation, and the like, and the treatment cost of the method is about 1 / 3 of that of the existing methods.

Owner:HUBEI UNIV

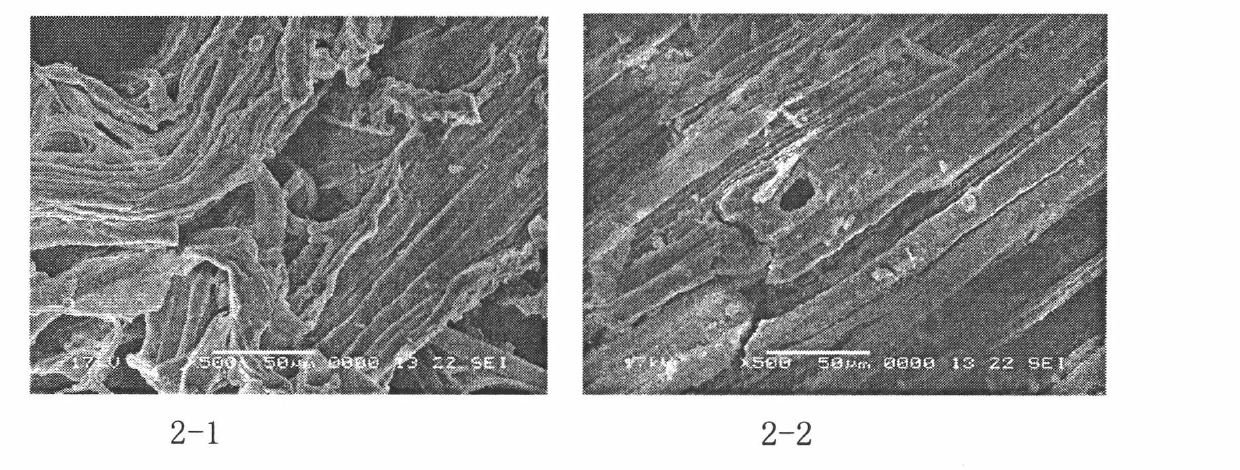

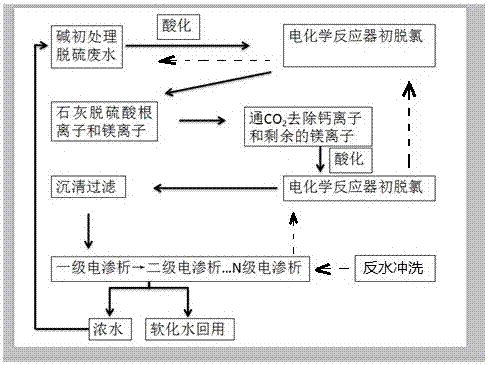

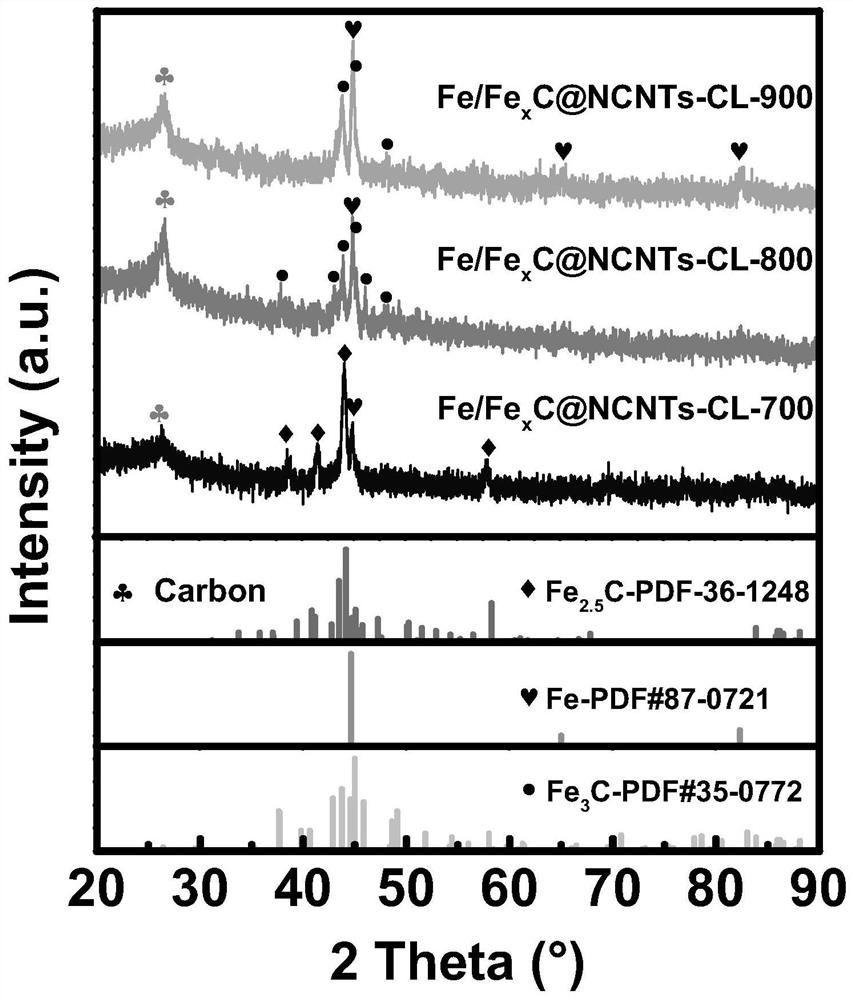

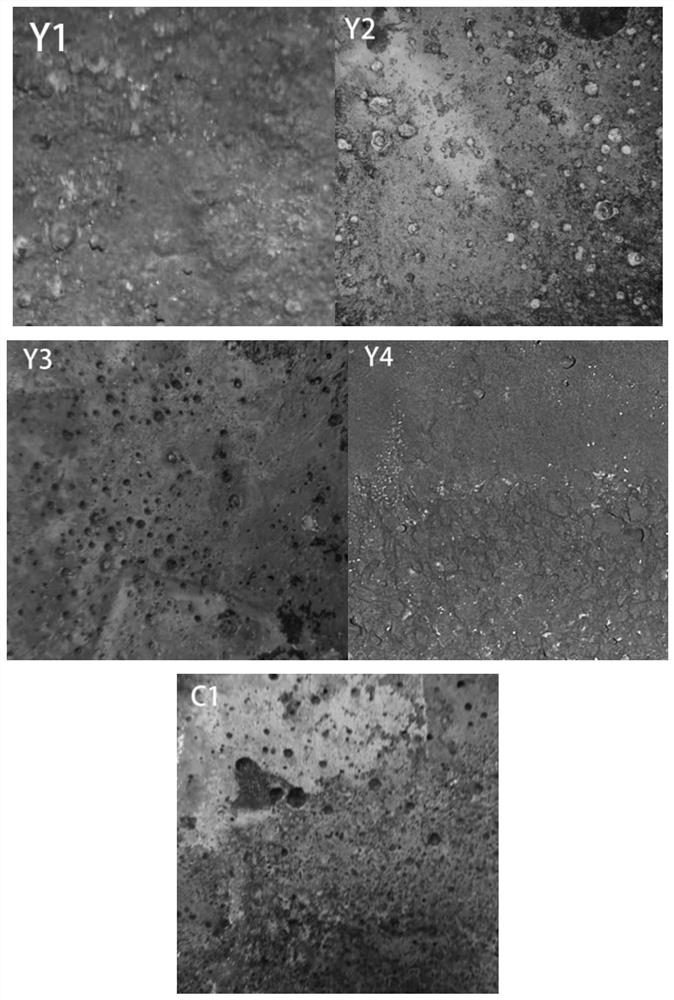

Preparation method and application of loofah sponge biomorphic supported nitrogen-doped carbon nanotube coated iron nanoparticle Fenton-like catalyst

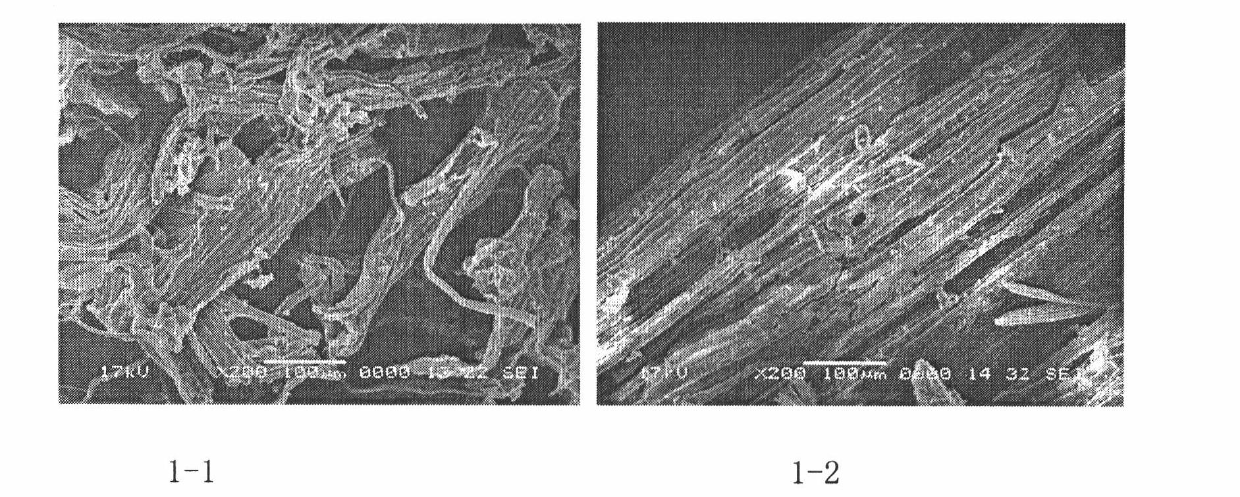

ActiveCN112121843AUnique porous vascular bundle structureGood dispersionPhysical/chemical process catalystsWater treatment compoundsPtru catalystTetracycline Hydrochloride

The invention discloses a preparation method and application of a loofah sponge biomorphic supported nitrogen-doped carbon nanotube coated iron nanoparticle Fenton-like catalyst, relates to a preparation method and application of a Fenton-like catalyst, and aims to solve the problems of easy agglomeration of active components, ion leaching, slow Fe < 3 + > / Fe < 2 + > conversion under a neutral condition and poor cycling stability of the existing Fenton-like catalyst. The method comprises the following steps: 1, preparing dried loofah sponge with the particle size of 8-10mm; 2, alkalization treatment; 3, precipitating Fe < 3 + > on the surface of the loofah sponge; 4, doping a nitrogen source; 5, carrying out pyrolysis; 6, cleaning and drying. The loofah sponge biomorphic supported nitrogen-doped carbon nanotube coated iron nanoparticle Fenton-like catalyst is used for degrading tetracycline hydrochloride in sewage. The method is suitable for degrading antibiotics.

Owner:HARBIN INST OF TECH

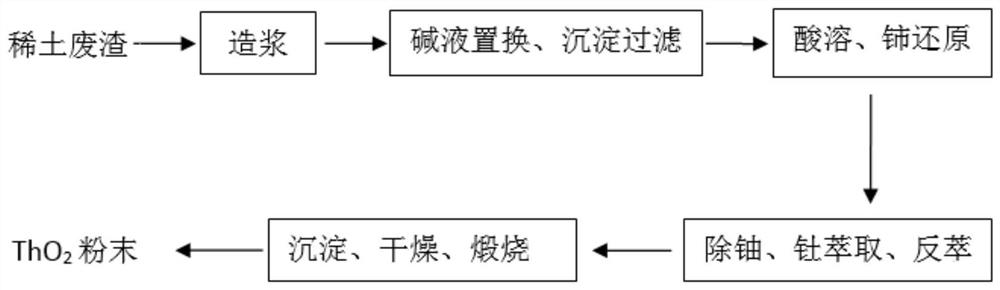

Method for extracting and preparing nuclear-grade ThO2 powder from rare earth waste residues

PendingCN112593099AReduce dosageEasy extractionProcess efficiency improvementRare-earth elementEngineering

The invention belongs to the technical field of radioactive waste treatment, and particularly relates to a method for extracting and preparing nuclear-grade ThO2 powder from rare earth waste residues.The method is used for alkalization treatment of the rare earth waste residues, not only can realize preliminary separation of thorium elements and part of impurity elements, but also can effectivelysolve the problem of equipment corrosion, meanwhile, the generated thorium hydroxide is easily converted into a thorium nitrate solution, and the next extractive purification process is carried out.According to the method, the thorium nitrate is extracted and purified by adopting a centrifugal extraction technology, the method has the characteristics of high recovery rate, continuous operation,low energy consumption and the like, the thorium elements are efficiently separated from other rare earth elements, and therefore the method has important significance in extracting and preparing nuclear-grade ThO2 powder from the rare earth waste residues.

Owner:CHINA NUCLEAR BAOTOU GUANGHUA CHEM IND

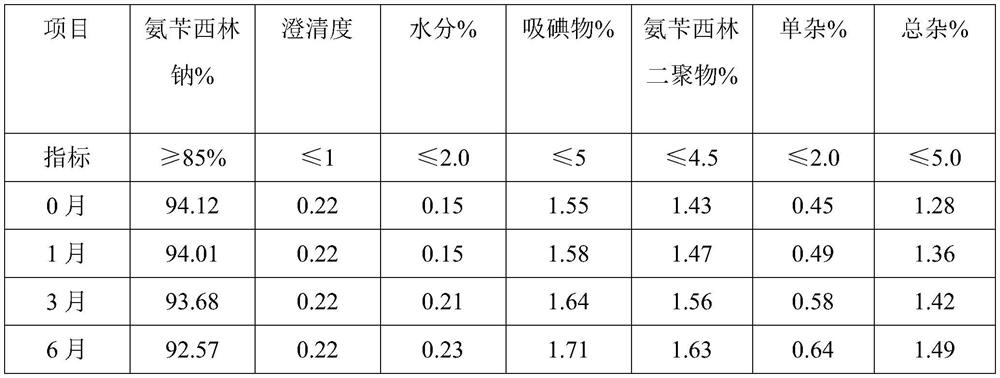

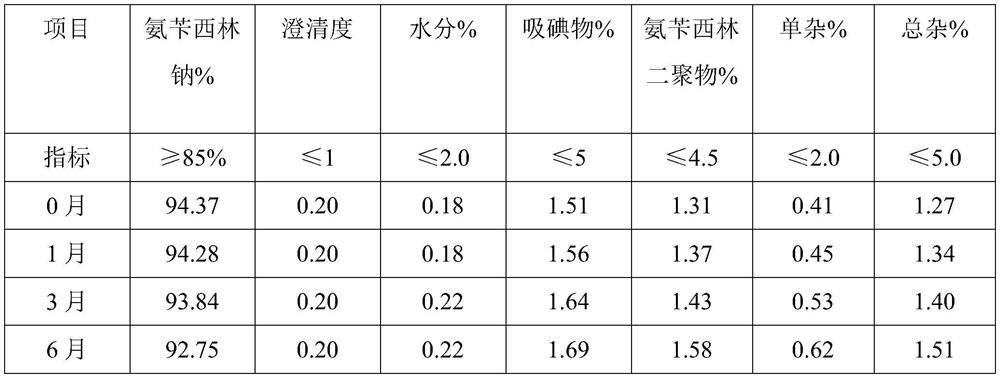

Preparation method of ampicillin sodium for injection

ActiveCN114796131ALower the eutectic point temperatureReduce generationAntibacterial agentsPowder deliveryPhysical chemistryMesoporous silica

The preparation method comprises the following steps: S1, dissolving an ampicillin sodium crude product in deionized water, and adding a proper amount of alkali liquor to adjust the pH value of the solution to 6.7-6.9; s2, adding a magnetic nanotube into the alkalized solution, and stirring and adsorbing in a vacuum environment; s3, separating the magnetic nanotubes by using a magnetic field, and dispersing the magnetic nanotubes into deionized water for oscillation desorption; wherein the magnetic nanotube comprises a multi-layer structure, and the multi-layer structure sequentially comprises a compact silicon dioxide nanotube layer, a Fe3O4 layer and a mesoporous silicon dioxide layer from inside to outside; and S4, merging and crystallizing the ampicillin sodium solution obtained by oscillation desorption to obtain refined ampicillin sodium. The ampicillin sodium molecules are reversibly adsorbed by adopting the special structure of the magnetic nanotube in a weak acid environment, and the inner layer of the silicon dioxide nanotube and the outer layer of the mesoporous silicon dioxide layer can be subjected to physical adsorption reaction with the ampicillin sodium molecules through hydrogen bonds, surface atomic coordination and the like.

Owner:SICHUAN PHARMA

Method for high-temperature alkalization treatment of solid hazardous waste and co-treatment in a cement kiln

ActiveCN111825357AEffective burnoutSimple methodRotary drum furnacesCement productionClinker (waste)Physical chemistry

The invention discloses a method for high-temperature alkalization treatment of solid hazardous waste and co-treatment in a cement kiln. In the pretreatment process of the solid or plastic or slurry hazardous waste, a modification treatment agent is added for modification treatment to serve as a substitute raw material for cement production, and the modified solid hazardous waste is fed into a discharging pipeline at the conical part of a C5 or C6 preheater for high-temperature alkalization and enters a rotary kiln for high-temperature calcination to form clinker minerals. The method is easy to operate, low in investment, low in treatment energy consumption, low in treatment cost and free of secondary pollution. According to the invention, organic matters in the solid hazardous wastes canbe effectively burnt out, silicon-aluminum / calcium inorganic minerals in the solid hazardous wastes are converted into mineral components of the cement clinker, heavy metal and most of alkali are fused through silicon-aluminum root group / silicate group / aluminate group lattices, fluorine, chlorine and sulfur are converted into early-strength calcium fluoroaluminate, calcium chloroaluminate and calcium sulphoaluminate clinker minerals, accumulated materials of a kiln tail smoke chamber are prevented from being stuck and blocked, and cost reduction and efficiency improvement are facilitated.

Owner:长沙紫宸科技开发有限公司

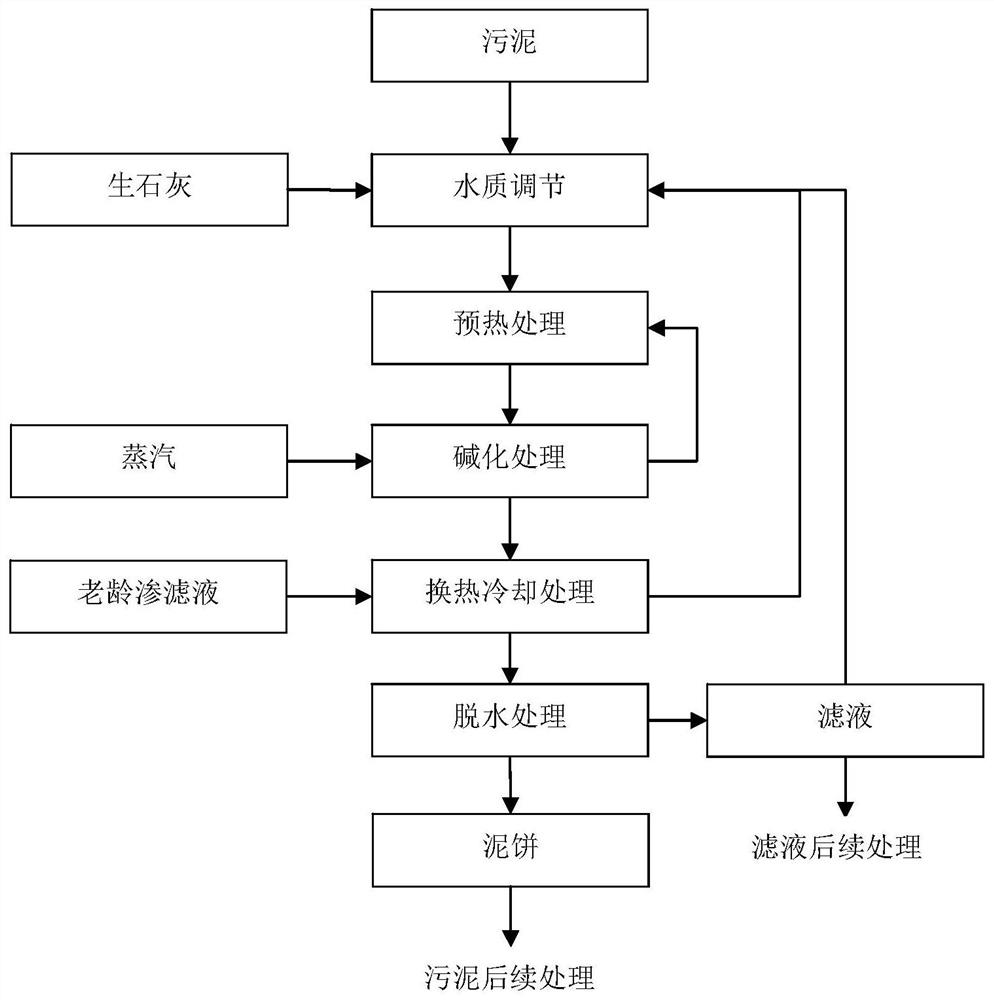

Method and system for synergistic sludge dewatering treatment of aged leachate of refuse landfill

ActiveCN112661366AImprove the breaking effectImprove dehydration effectSludge treatment by de-watering/drying/thickeningWaste based fuelLeachateDehydration

The invention discloses a method and system for synergistic sludge dewatering treatment of aged leachate of a refuse landfill, and the method comprises the following steps: mixing sludge and aged leachate, adding alkali for alkalization treatment and dewatering treatment, and completing the synergistic treatment of aged leachate and sludge. The system comprises an alkalization device and a dehydration device. According to the method for synergistic sludge dewatering treatment of the aged leachate of the refuse landfill, the aged leachate of the refuse landfill is used as dilution water for sludge dewatering treatment, alkali is added for alkalization treatment and dewatering treatment, and resource utilization of the aged leachate can be achieved while the wall breaking effect and dewatering performance of sludge are improved; and the method has the advantages of simple process, short flow, convenience in operation, high treatment efficiency, low medicament dosage, low energy consumption, low cost, good dehydration effect, less secondary pollution and the like, and meanwhile, the pH of the obtained filtrate is easy to adjust back, the conductivity is proper, the subsequent advanced treatment is easy, and the method has very good use value and very good application prospect.

Owner:HUNAN JUNXIN ENVIRONMENTAL PROTECTION CO LTD

Method for treating concrete by utilizing copper plating wastewater

The invention discloses a method for treating concrete by utilizing copper plating wastewater. The method comprises the following steps of: A, sequentially carrying out sedimentation, acidification or alkalization treatment on copper industrial wastewater, adjusting the pH value of the waste liquid to 5-7, purifying and concentrating; B, adding a surfactant into the obtained wastewater treatment liquid according to the concentration of 100-200mg / L to prepare an electrolyte, wherein the concentration of copper ions in the electrolyte is 2000mg / L-5000mg / L; C, immersing a concrete test piece into the electrolyte, connecting an electrochemical device, and taking the electrochemical device as a cathode to carry out first-step electrodeposition; and D, after the first-step electrodeposition is finished, adding a lactic acid solution into the electroplating solution, adjusting the pH value to 10-12, and carrying out second-step electrodeposition. The bonding force between the prepared electrodeposition and the concrete matrix is higher; and the formed sediment has good sterilization performance, and the microbial corrosion resistance of the concrete is improved.

Owner:HOHAI UNIV

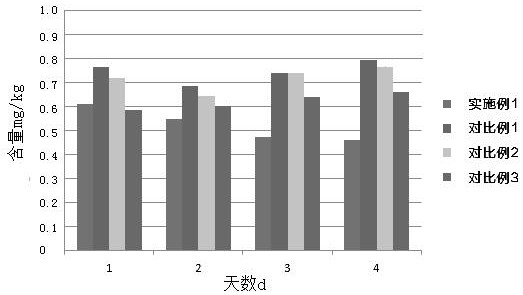

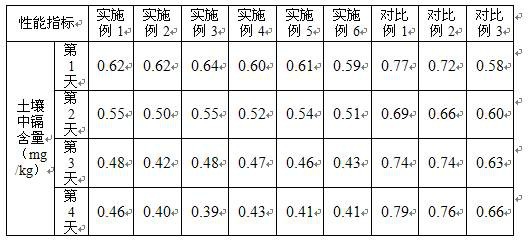

Slow-release alkali particles for long-acting fixation of soil heavy metals and preparation method thereof

InactiveCN112676333AGood slow-release alkaline propertiesGood effectContaminated soil reclamationOrganic fertilisersSoil sciencePhosphate

The invention relates to the field of soil remediation, and discloses slow-release alkali particles for long-acting fixation of soil heavy metals and a preparation method thereof. The preparation method comprises the following steps: (1) uniformly mixing and grinding sodium sulfide, iron sulfide and colloid, and then spraying water to aggregate, so as to obtain sulfide slow-release particles; and (2) crushing artemisia selengensis, uniformly mixing the crushed artemisia selengensis with fly ash, expanded perlite, kaolin, stone powder, phosphate and cement, adding the sulfide sustained-release particles, spraying water to aggregate, and drying to obtain the sustained-release alkali particles for long-acting fixation of soil heavy metals. The prepared soil heavy metal immobilizing particles have a good slow-release alkaline effect, an alkaline environment is only formed inside and outside the particles during heavy metal stabilization, soil alkalinization is not needed, the effect of long-acting heavy metal immobilizing and stabilizing is achieved, heavy metal is in a stable state for a long time, the defect that soil needs to be alkalized when sulfide is directly adopted for fixing heavy metal in the prior art is effectively overcome, and meanwhile large particles can be removed at any time.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

Planar humidity and ammonia sensor based on alkalized organ-shaped mxene sensitive material and preparation method thereof

ActiveCN109799267BLower working temperatureReduce power consumptionMaterial resistanceHigh humidityEngineering

The invention belongs to the technical field of gas-humidity sensitive sensors and relates to a planar humidity-ammonia gas sensor based on alkalized organ-like MXene (Ti3C2Tx, with T representing surface basic group terminals and x valuing from a ratio of surface terminals) sensitive material and preparation method thereof. The planar humidity-ammonia gas sensor is composed of an Al2O3 ceramic base plate with an Au / Ni interdigital electrode and an alkalized organ-like MXene (Ti3C2Tx) sensitive material applied evenly to the interdigital electrode and the ceramic base plate by dripping. Basedon the organ-like MXene material, surface F terminals are removed and sodium ions are inserted by alkalizing the organ-like MXene material. pre-alkalization and post-alkalization gas-humidity sensitivities are compared to obtain a device having better humidity and ammonia gas sensitivities. The sensor prepared herein has MXene gas-humidity sensitive response which is the highest up to now, and hasgood selectivity.

Owner:JILIN UNIV

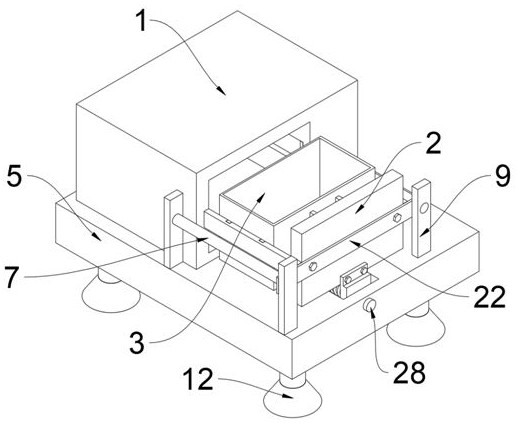

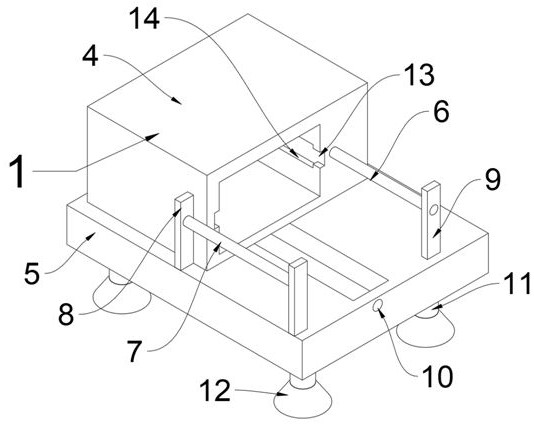

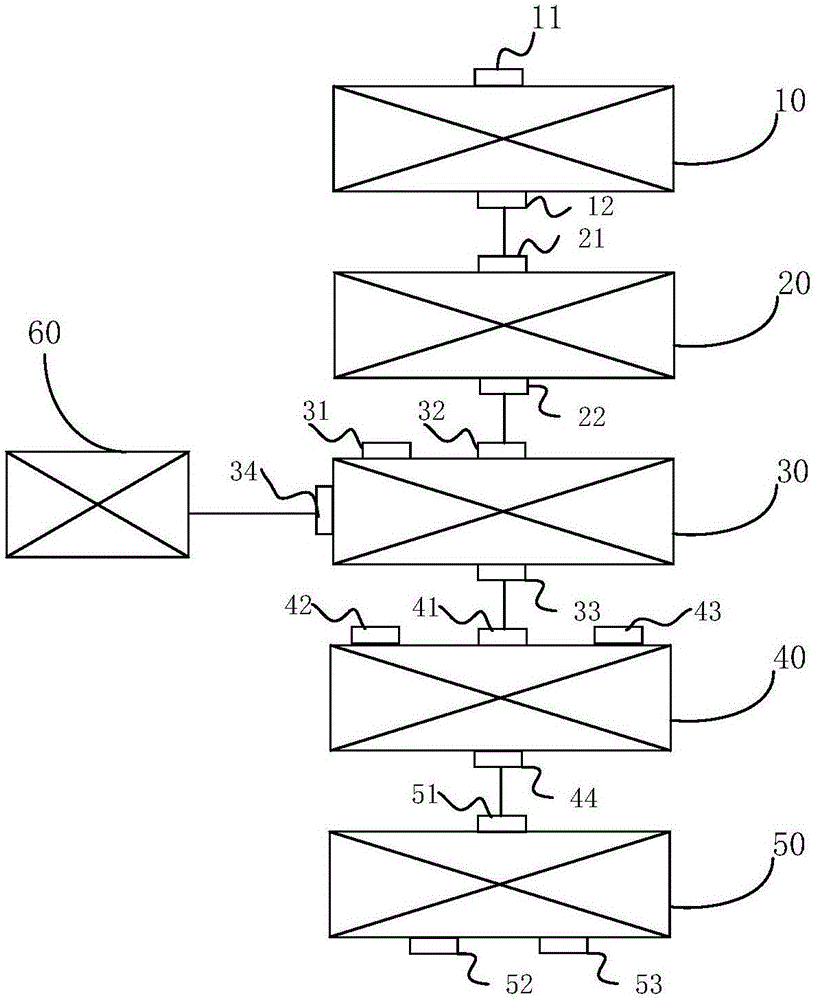

Pressurized carbonization device for bulk solid waste after alkalization treatment

InactiveCN113231441ARealize clean upInstallation helpSolid waste disposalTransportation and packagingCarbonizationProcess engineering

The invention discloses a pressurized carbonization device for bulk solid waste after alkalization treatment. The pressurized carbonization device comprises a fixing device, the interior of the fixing device is slidably connected with a pushing device, and the interior of the pushing device is fixedly clamped with a loading device. The fixing device comprises a pressurizing carbonization box, a bottom plate, a first connecting column, a second connecting column, a first positioning plate, a second positioning plate, a first positioning hole, supporting columns, a base, a first moving groove, a second moving groove, a mounting groove and a positioning groove, the bottom plate is arranged in the fixing device, and the supporting columns are fixedly connected to the four corners of the lower end face of the bottom plate. The bases are fixedly connected to the lower end faces of the supporting columns, the first positioning plates are symmetrically and fixedly connected to one side of the front end of the bottom plate, and the second positioning plate is fixedly connected to the other side of the front end of the bottom plate. The invention relates to the pressurized carbonization device for bulk solid waste after alkalization treatment, and the bulk solid waste is eliminated through the fixing device.

Owner:张军强

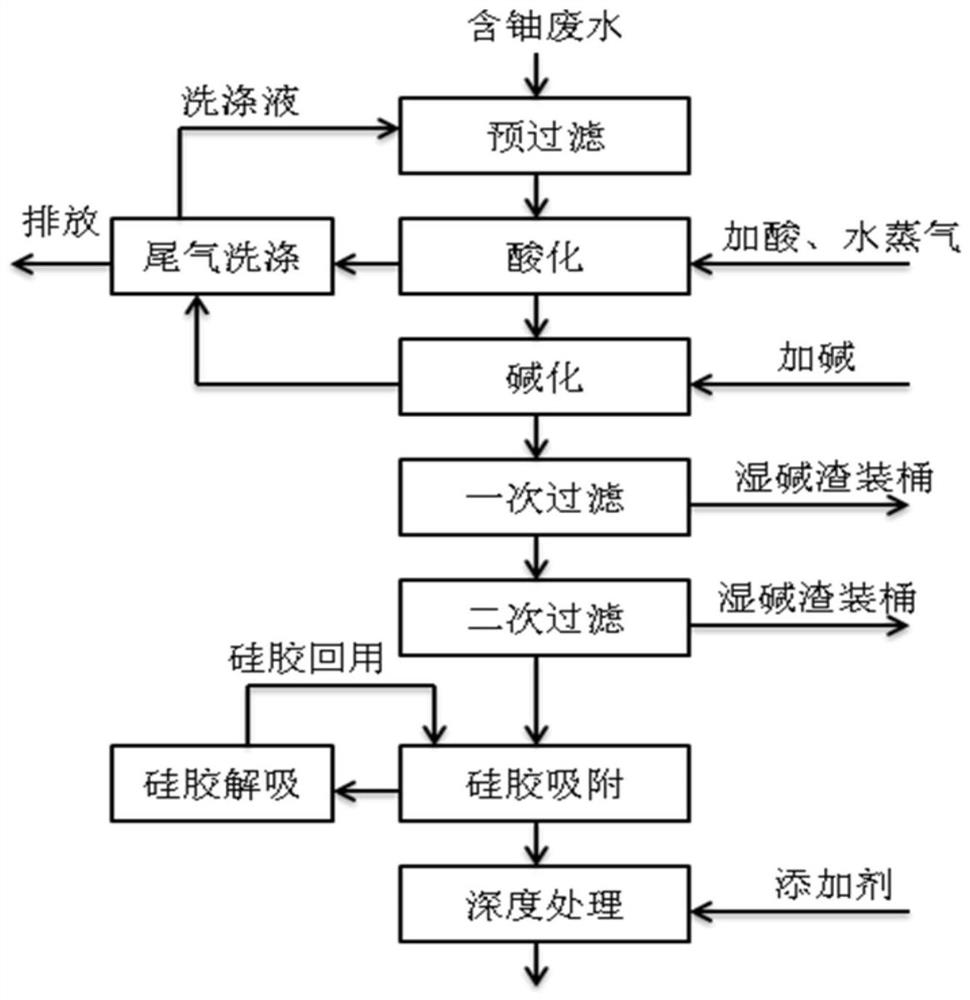

A kind of uranium-containing wastewater treatment method

ActiveCN108257706BAvoid affecting adsorptionAvoid pollutionRadioactive decontaminationParticulatesFiltration

The invention belongs to nuclear fuel circulation technologies, and specifically discloses a uranium-containing wastewater treatment method. The treatment method is characterized in that firstly uranium-containing wastewater is subjected to pre-filtration, and followed by acidification treatment and alkalization treatment; and after being filtered again, the wastewater is subjected to silica gel adsorption uranium removing, after the wastewater reaches standards, deep treatment is performed, and if the wastewater does not reach the standards, deep treatment is performed after silica gel desorption. According to the treatment method, particulate matters in the wastewater are removed through pre-filtration firstly, thereby avoiding high temperature acidification making the uranium concentration of the wastewater increased to bring critical safety problems; with the help of the high temperature acidification, acid gases are driven off, and organic matters are destroyed, thereby avoiding affecting the adsorption of the silica gel on uranium; after the acidification, ammonia water, sodium hydroxide or the like is added to precipitate most of the uranium in the wastewater, thereby reducing the uranium concentration in the wastewater, and the precipitated wastewater is subjected to two stage filtration to make most of uranium-containing particles intercepted, thereby avoiding the uranium-containing particles polluting the silica gel, and improving the service life and the adsorption effect of the silica gel.

Owner:CNNC JIANZHONG NUCLEAR FUEL

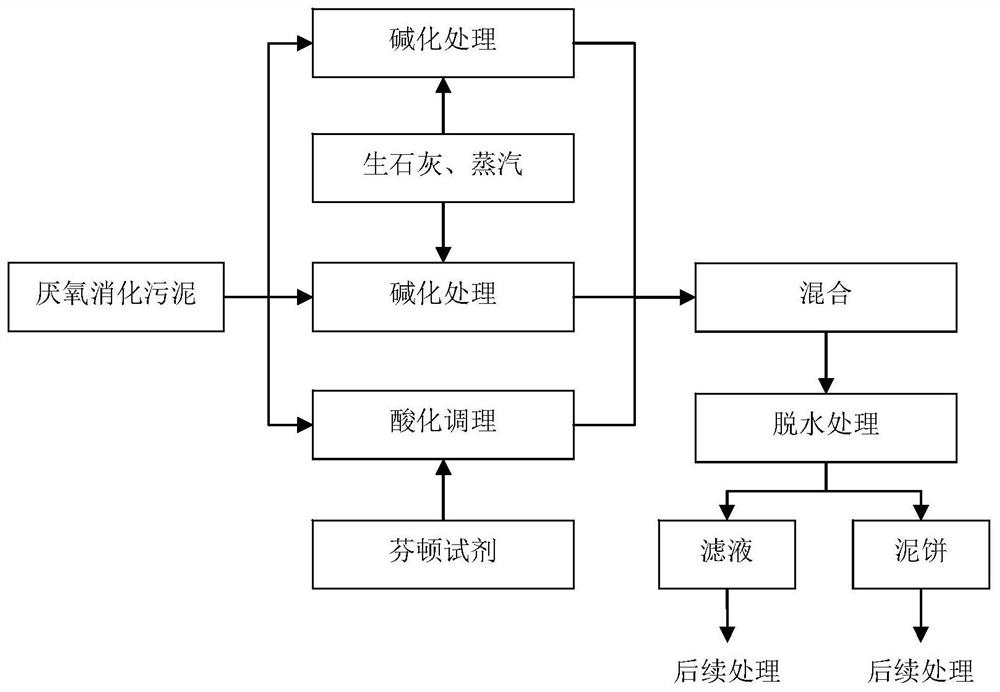

Anaerobic digestion sludge treatment method and treatment system

PendingCN112624545AReduce dosageModerate conductivitySludge treatment by oxidationWater contaminantsDehydrationTreatment system

The invention discloses an anaerobic digestion sludge treatment method and treatment system. The treatment method comprises the following steps: anaerobic digestion sludge is divided into two parts, one part is subjected to alkalization treatment to obtain alkalized sludge, and the other part is subjected to acidification conditioning to obtain acidified sludge; and the alkalized sludge and the acidified sludge are mixed for dehydration treatment. The treatment system comprises at least two sets of alkalization devices, acidification devices and dehydration devices. According to the treatment method, through alkalization treatment and acidification conditioning of the anaerobic digestion sludge, the dehydration performance and physicochemical properties are improved, high-quality and low-cost dehydration of the anaerobic digestion sludge is achieved, and the treatment method has the advantages of being simple in process, convenient to operate, high in treatment efficiency, low in agent dosage, low in energy consumption, low in cost, good in dehydration effect, little in secondary pollution and the like; and the filtrate which is proper in temperature, slightly neutral in pH value and capable of meeting biochemical requirements in C / N ratio is obtained, subsequent treatment of the filtrate is facilitated, and the method has very good use value and very good application prospect.

Owner:HUNAN JUNXIN ENVIRONMENTAL PROTECTION CO LTD

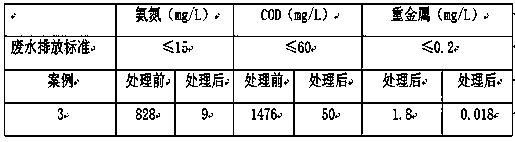

Process method for treating rare earth wastewater

InactiveCN111018184AIncrease reduction rateWater treatment parameter controlWater contaminantsAmmoniacal nitrogenCatalytic oxidation

The invention provides a technological method for treating rare earth wastewater. The technological method comprises the steps of rare earth wastewater preparation, acidification treatment, catalyticoxidation, alkalization treatment and filter pressing. In the catalytic oxidation process, the ammonia nitrogen reduction rate is 100 ppm / kg, and an ammonia nitrogen remover is 13-15 ppm / kg of sodiumhypochlorite; in the step of alkalization treatment, calcium oxide is added, the PH value is controlled to be about 9, a reaction is conducted for 30 min, and the reaction time is 90-120 min. After treatment, the concentration of ammonia nitrogen is 9-13 mg / L, the concentration of COD is 42-50 mg / L, and the concentration of heavy metal is 0.011-0.04 mg / L. According to the process method for treating the rare earth wastewater, COD, ammonia nitrogen and heavy metal ions in the wastewater generated in the rare earth extraction process can be effectively removed at the same time, when the ammonianitrogen is removed, the ammonia nitrogen reduction rate is high, and the process method has the characteristics of being remarkable in treatment effect and large in application range.

Owner:中稀(寿光)资源科技有限公司

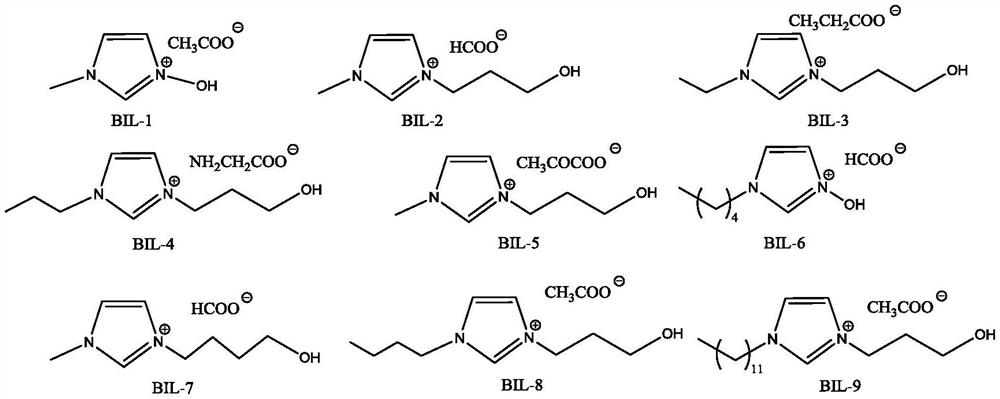

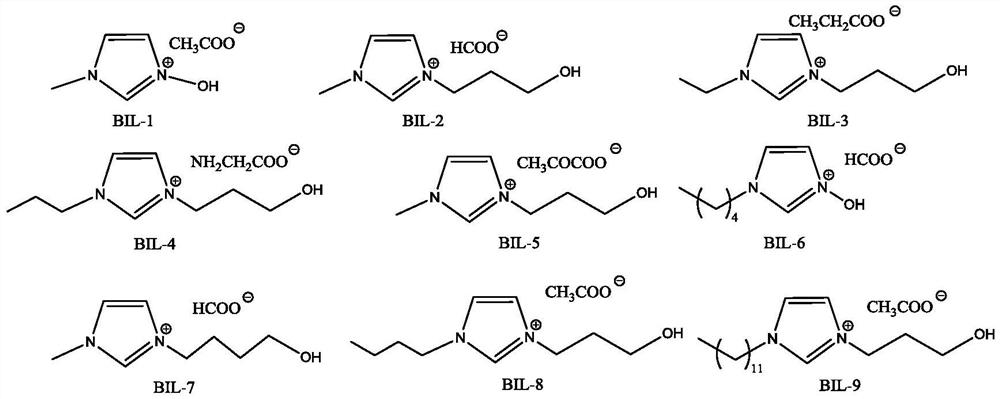

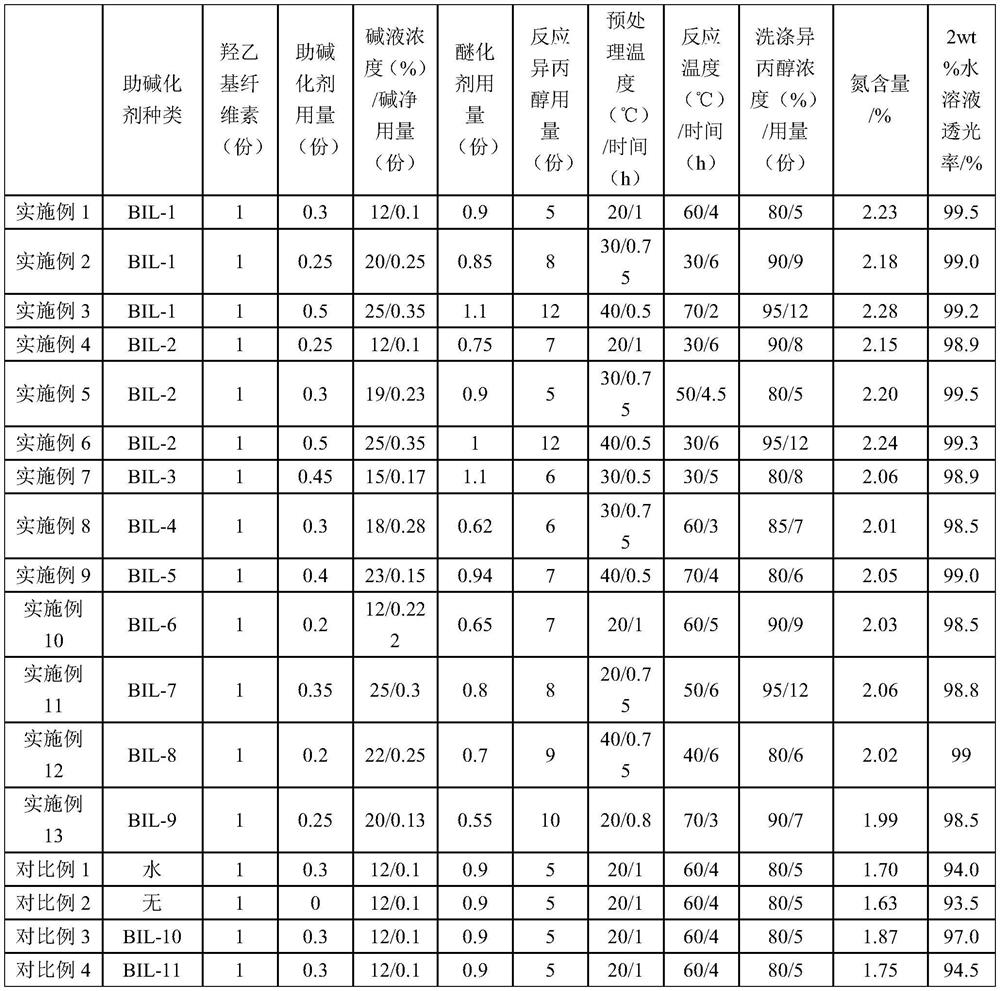

Method for preparing polyquaternium-10

ActiveCN114292340AHigh nitrogen contentHigh light transmittanceBulk chemical productionOrganosolvAqueous solution

The invention discloses a method for preparing polyquaternium-10, which comprises the following steps: (1) dispersion: adding an organic solvent into a reactor, adding hydroxyethyl cellulose under a stirring condition, and fully dispersing; (2) alkalization: adding an aqueous solution of alkali and alkalescence ionic liquid serving as an auxiliary alkalizer into the hydroxyethyl cellulose mixed solution in the step (1) for alkalization treatment; (3) etherification reaction: adding a cationic etherifying agent into the mixed solution in the step (2) for reaction under rapid stirring; and (4) washing and purifying: filtering, washing, filtering, drying and crushing the substance obtained in the step (3) to obtain the polyquaternium-10. According to the method, the auxiliary basifier is added in the reaction to increase the phase interface of the solid-liquid heterogeneous reaction, so that the reaction efficiency is effectively improved, the generation of byproducts and the degradation of the raw material hydroxyethyl cellulose are reduced, the post-treatment difficulty is reduced, the raw material consumption and the energy consumption are reduced, and the obtained product is relatively high in nitrogen content, high in light transmittance and suitable for industrial production.

Owner:WANHUA CHEM GRP CO LTD

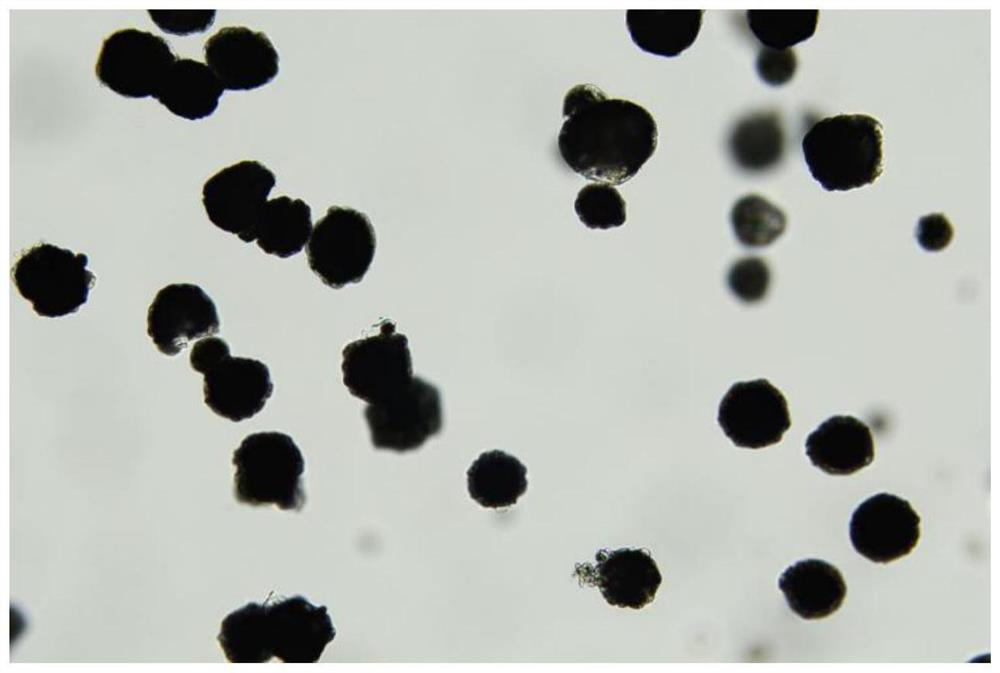

Starch-absorbable hemostatic material and preparation method thereof

PendingCN114848888AImprove water absorptionImprove water absorption speedSurgical adhesivesPharmaceutical delivery mechanismCelluloseInorganic salts

The invention provides an absorbable starch hemostatic material which is prepared by taking composite starch as a raw material, carrying out alkali and inorganic salinization treatment and then carrying out reversed-phase microemulsion reaction, the composite starch comprises one or more of modified starch and cellulose, and natural starch. Two starch-based materials, namely modified starch and natural starch, particularly potato starch and sodium carboxymethyl starch are compounded as main raw materials, the main raw materials are subjected to alkalization treatment and reversed-phase microemulsion reaction to obtain hemostatic microspheres in a certain particle range, and the hemostatic microspheres are refined, purified, endotoxin-removed and sterilized to obtain a final product. The obtained product has high water absorption capacity and water absorption speed, is good in biocompatibility, can be used for rapid hemostasis of various wounds, can be completely degraded, and is safe, non-toxic and convenient to operate. The method has the advantages of being simple in production process, mild in condition, low in production cost, rapid in hemostasis, short in in-vivo degradation time and the like.

Owner:上海威高医疗技术发展有限公司 +1

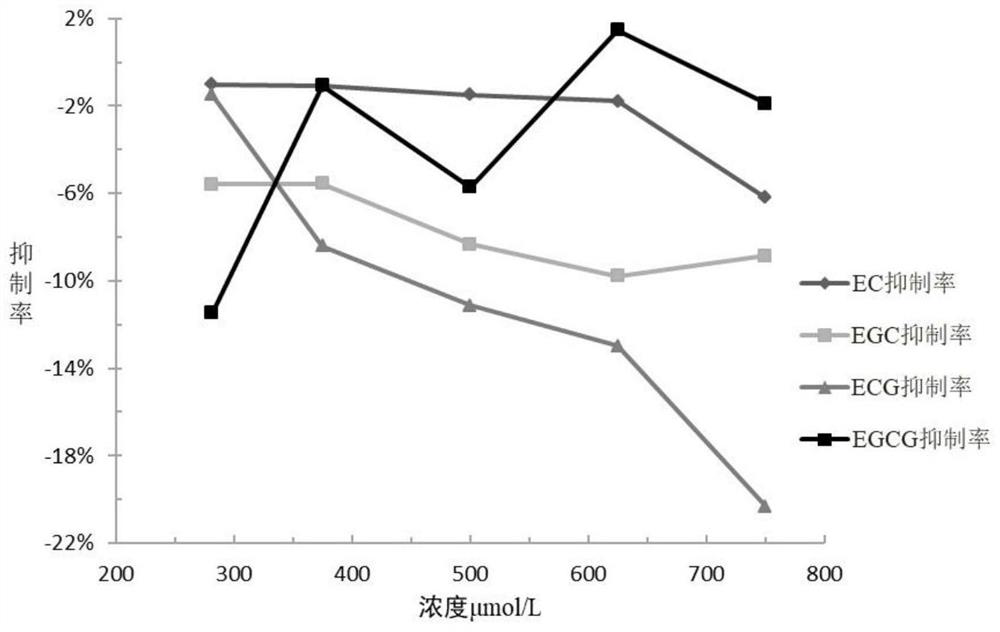

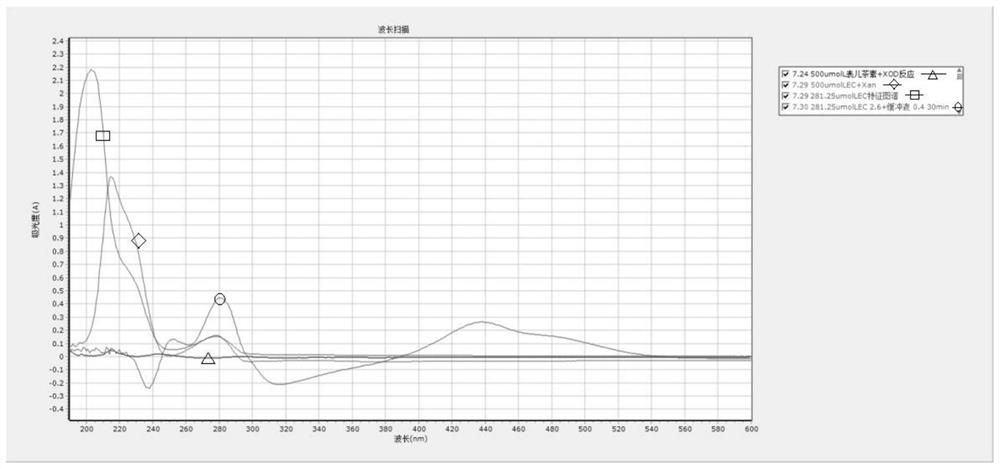

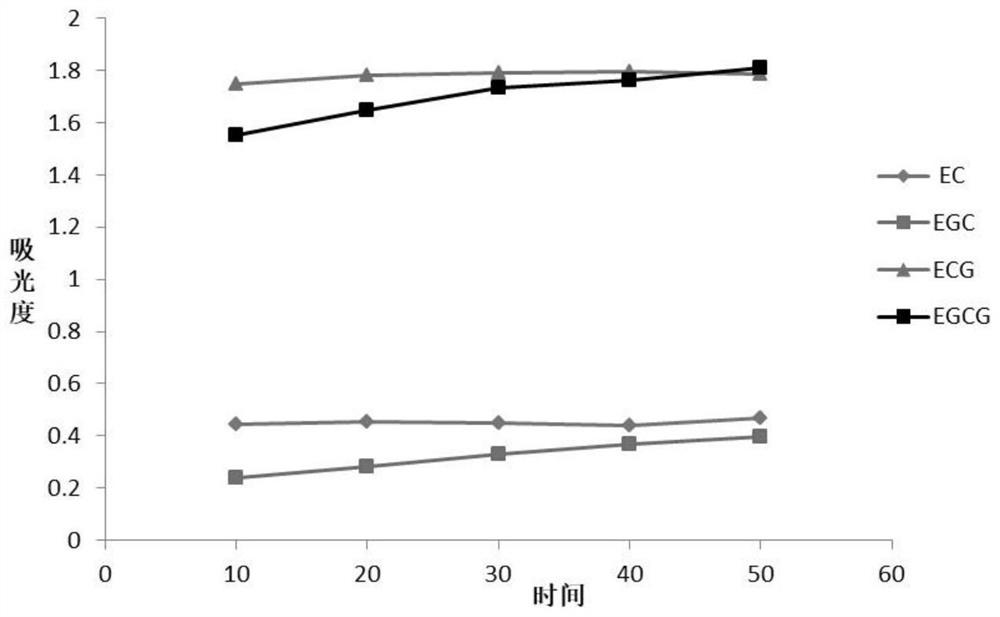

Process for inhibiting xanthine oxidase activity in vitro by using alkalized catechin monomer

PendingCN114848630AWide variety of sourcesHas inhibitory effectOrganic active ingredientsSkeletal disorderPurine-Xanthine OxidaseSodium phosphates

The invention discloses a process for inhibiting the activity of xanthine oxidase in vitro by using an alkalized catechin monomer, and belongs to the technical field of catechins, and the process comprises the following steps: S1, preparing materials: preparing a sodium pyrophosphate buffer solution with the pH value of 7.5, and preparing a xanthine oxidase mother solution, a xanthine solution and a catechin monomer diluent for later use; s2, alkalizing catechin monomers: adding an alkaline solution into the catechin monomer diluent, and reacting in a water bath kettle at 35 DEG C for 30 minutes to obtain alkalized catechin monomers; s3, taking a mixture of the xanthine oxidase solution, the xanthine solution and the buffer solution as a solvent I, mixing the solvent I with the alkalized catechin monomer by adopting a compatible solvent method, and reacting in a water bath kettle at 35 DEG C for 30 minutes, so as to inhibit the activity of the xanthine oxidase in vitro; the catechin monomers are subjected to alkalization treatment, so that the alkalized catechin monomers have an inhibition effect on the activity of xanthine oxidase.

Owner:TONGREN UNIV

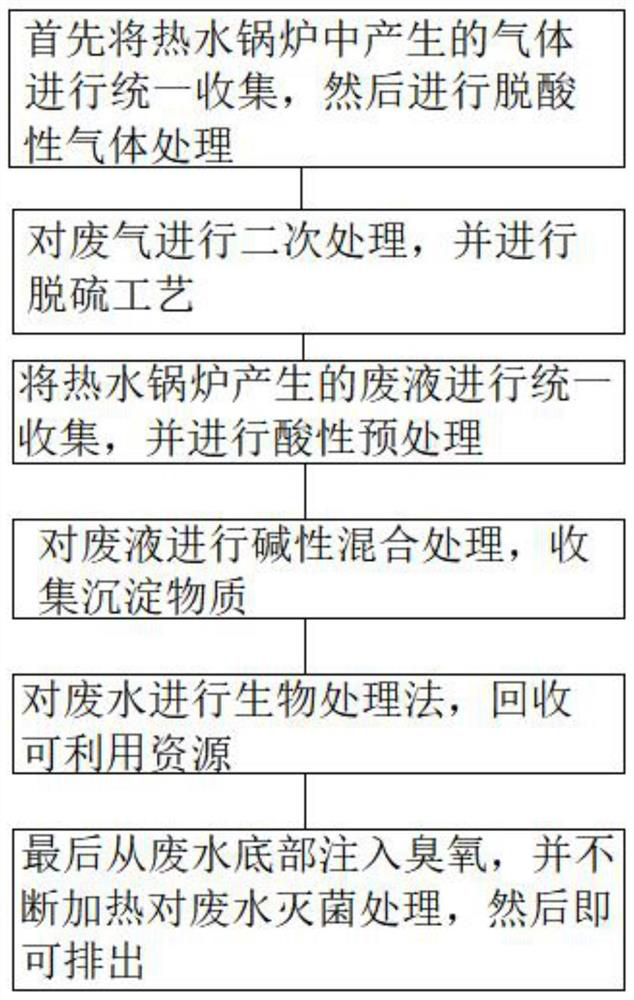

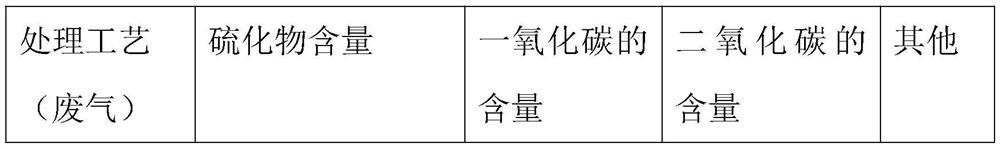

Blowdown treatment process for thermodynamic system of hot water boiler

InactiveCN113149354AReduce sulfideCombination devicesSpecific water treatment objectivesExhaust fumesProcess engineering

The invention discloses a blowdown treatment process for a thermodynamic system of a hot water boiler, and the specific manufacturing method comprises the following steps: S1, firstly, uniformly collecting gas generated in the hot water boiler, and then carrying out acid gas removal treatment; s2, carrying out secondary treatment on the waste gas, and carrying out a desulfurization process; s3, uniformly collecting the waste liquid generated by the hot water boiler, and performing acid pretreatment; s4, carrying out alkaline mixing treatment on the waste liquid, and collecting precipitates; and S5, carrying out biological treatment on the wastewater, and recycling available resources. By means of the method, waste gas and waste liquid generated by the hot water boiler can be collected and treated in a unified mode, dust in the waste gas and sulfide in the gas can be effectively reduced, acidification and alkalization treatment can be conducted in the waste liquid treatment process, more calcium and iron compounds can be precipitated and recycled, meanwhile, phosphorus can be treated through a biological method, and the injected ozone can be used for disinfection and sterilization treatment, so that the whole process is relatively comprehensive, energy-saving and environment-friendly.

Owner:扬州华大锅炉有限公司

Pretreatment process of zeolite molecular sieve for synthesis of hydroxypropyl methacrylate

PendingCN111450873AEfficient removalImprove Catalytic Synthesis EfficiencyMolecular sieve catalystsOrganic compound preparationMolecular sieveHydroxypropyl methacrylate

Owner:CHIZHOU FANGDA SCI & TECH CO LTD

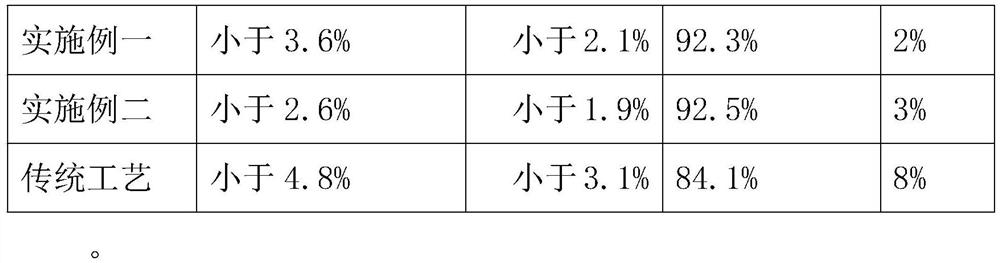

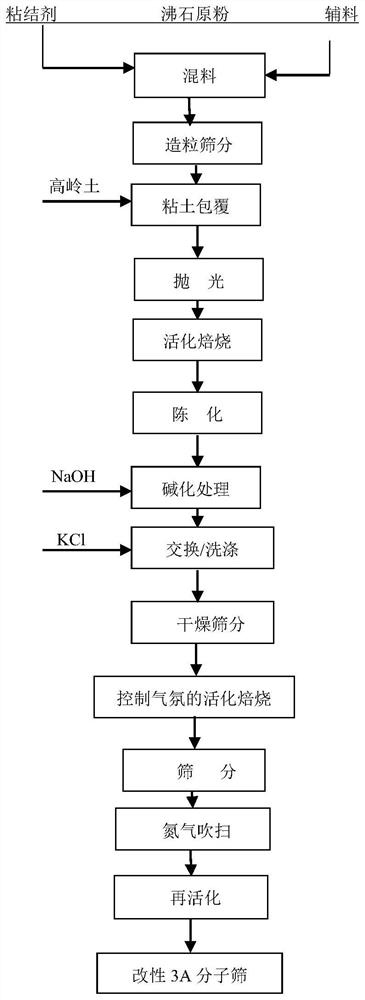

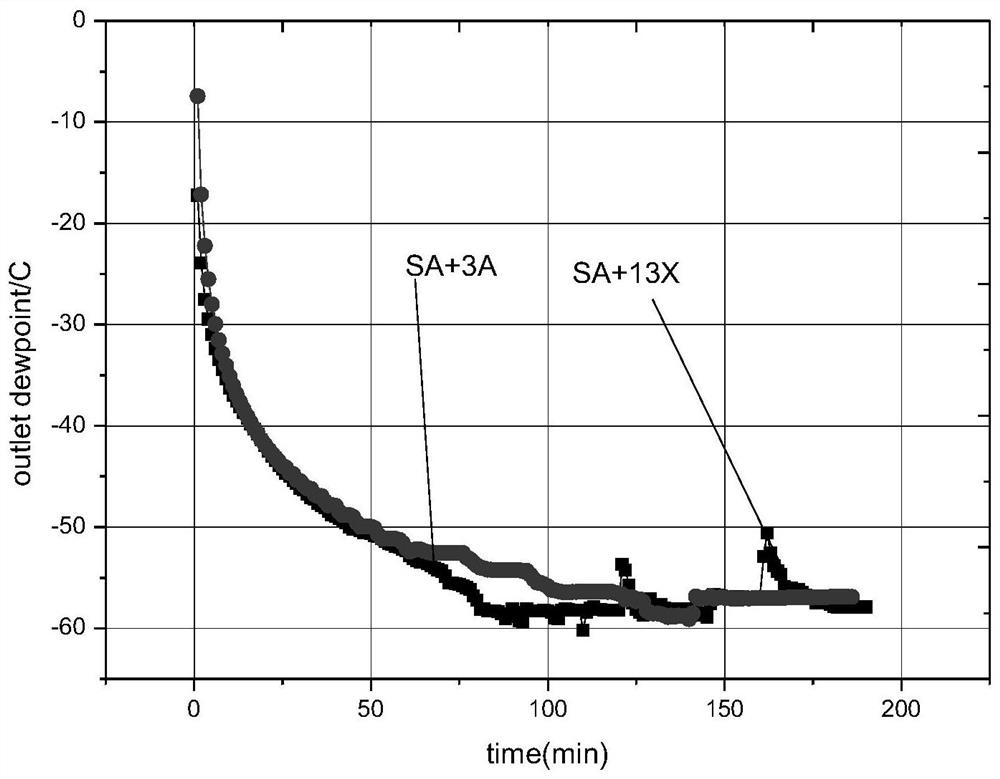

Preparation process and application of modified 3A molecular sieve

PendingCN113697824AEfficient separationImprove removal efficiencyProductsReagentsMolecular sievePotassium

The invention belongs to the field of molecular sieves, and particularly relates to a preparation process and application of a modified 3A molecular sieve. The preparation method of the modified 3A molecular sieve comprises the following steps: preparing molecular sieve particles; coating with clay, activating and roasting to obtain a roasted molecular sieve; carrying out alkalization treatment, and converting into an unbonded molecular sieve; carrying out potassium exchange, controlling the potassium exchange degree to be 30-60%, and drying to obtain a potassium exchange molecular sieve; subjecting the potassium exchange molecular sieve to primary roasting, dust removal through blowing and secondary roasting, wherein the primary roasting and the secondary roasting are carried out in a controlled atmosphere, and the controlled atmosphere is air with the dew point temperature of -20 DEG C to 10 DEG C. According to the preparation method of the modified 3A molecular sieve disclosed by the invention, the prepared molecular sieve has relatively high water absorption and extremely low CO2 interception; the strength and wear resistance are further improved, and the special requirements of a four-bed molecular sieve carbon dioxide removal system on the drying bed molecular sieve are met.

Owner:ZHENGZHOU MINERALS COMPOSITIVE UTILIZATION RES INST CHINESE GEOLOGICAL ACAD +1

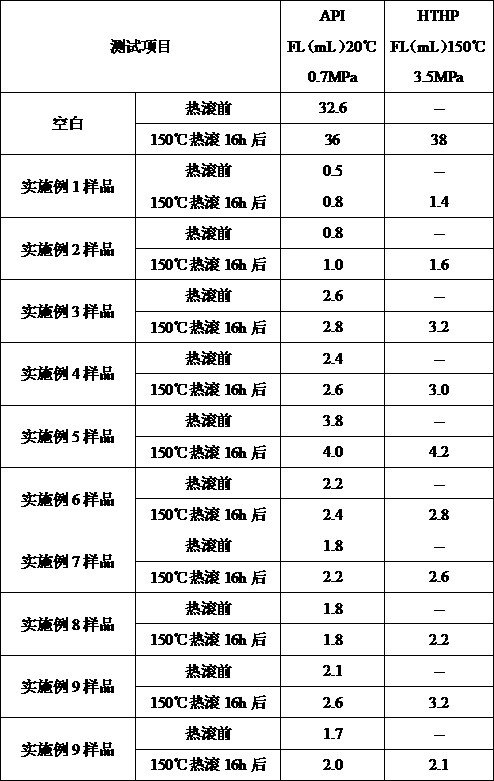

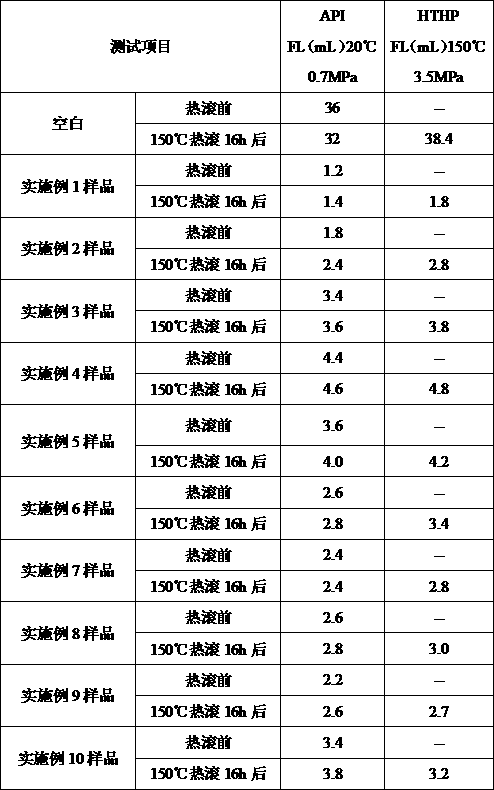

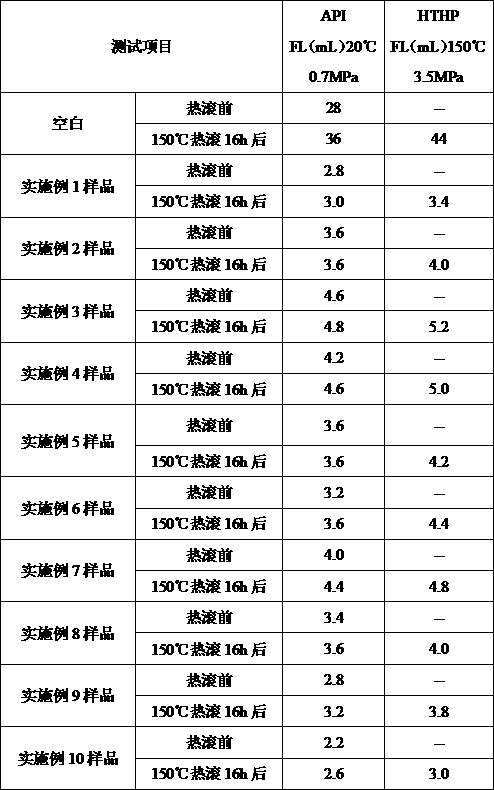

Oil-based fluid loss additive for drilling fluid and preparation method thereof

ActiveCN108728054ARaw materials are easy to getSimple preparation processDrilling compositionAcetic acidOrganosolv

The invention relates to an oil-based fluid loss additive for drilling fluid and a preparation method thereof. Under the nitrogen gas protection, NaOH solution, organic solvents and refining cotton are sequentially added into a reaction kettle; alkalization treatment is performed for 1 to 2h at 20 to 25 DEG C; chloroactic acid is added; the temperature is raised to 50 to 80 DEG C; after the reaction for 1 to 2h, the pH value is regulated to 4 to 6 by glacial acetic acid; organic amine is added; the temperature is raised to 140 to 180 DEG C; after the reaction for 1 to 2h, materials are discharged to obtain the oil-based fluid loss additive for drilling fluid. The oil-based fluid loss additive for drilling fluid can be applied to diesel oil, white oil and synthetic drilling fluid system; the product achieves the environment-friendly effects; the fluid loss reduction effect is obvious; the preparation method and the required equipment conditions are simple; the implementation is easy.

Owner:CHINA PETROLEUM & CHEM CORP +1

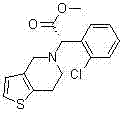

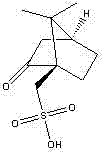

Recycling method of levorotation camphorsulfonic acid serving as clopidogrel resolving agent

InactiveCN102093263BSolving Recycling ProblemsOvercome the high proportion of the costOrganic chemistryOrganic compound preparationStrong acidsEthyl acetate

The invention discloses a recycling method of levorotation camphorsulfonic acid serving as a clopidogrel resolving agent, which belongs to the technical field of fine chemistry industry. The method comprises the following steps of: 1) adding clopidogrel camphorsulfonate into a certain amount of ethyl acetate and water mixed solution, mixing fully and uniformly, and performing alkaline treatment with saturated inorganic salt solution; 2) acidifying a water layer with strong acid, concentrating and evaporating to dryness to obtain a solid, adding an organic solvent, heating until concentrated solution is dissolved, and filtering to remote inorganic salt; and 3) cooling and crystallizing filtrate for 5 to 12 hours and performing suction filtration to obtain the levorotation camphorsulfonic acid. The method has a simple recycling process and short time. Further resolution indicates that an obtained product has high optical purity, recovery ratio of over 89 percent, low production cost anda good economic benefit, is easy to operate, is nontoxic and environmentally-friendly, and is suitable for mass industrial production.

Owner:ZHEJIANG LANGHUA PHARMA

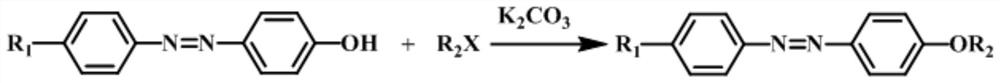

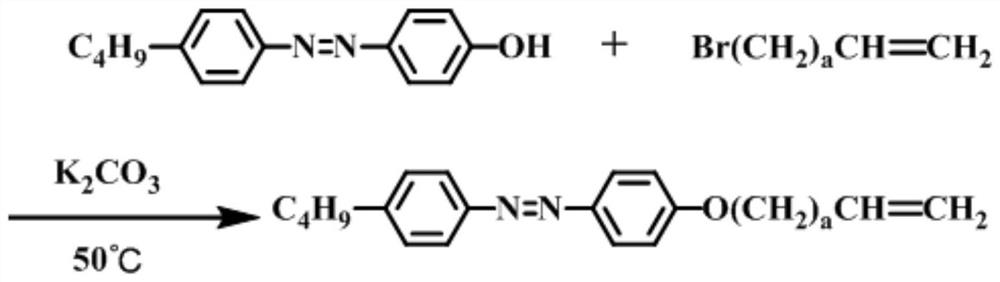

Etherification method of para-alkane azophenol and halogenated alkane

PendingCN114213277AImprove reaction efficiencyMild reaction conditionsOrganic chemistryAlkaneCombinatorial chemistry

The invention relates to an etherification method of para-alkane azophenol, in particular to an etherification method of para-alkane azophenol and halogenated alkane. The invention aims to solve the problem of low conversion rate of the existing p-alkane azophenol etherification method. The preparation method comprises the following steps: 1, alkalization treatment; 2, performing an etherification reaction; 3, removing the basifier; and 4, refining a crude product. The method provided by the invention is used for the etherification of the para-alkane azophenol and the halogenated alkane.

Owner:NORTHEAST FORESTRY UNIVERSITY

A kind of processing method of s-(-)-lipoic acid recycling

ActiveCN109942426BAchieve recyclingSolve the aggregation problemPreparation from carboxylic acid halidesOrganic compound preparationOctanoic AcidsOrganosolv

The invention discloses a processing method for recycling S-(-)-lipoic acid, which comprises the following steps: (1) dissolving S-(-)-lipoic acid in an organic solvent, and then adding alkali for alkalization treatment, Obtain S-(-)-lipoic acid reaction solution; (2) carry out aeration treatment with described S-(-)-lipoic acid reaction solution, then carry out acidification treatment to obtain yellow paste; (3) described yellow The paste is dissolved in an organic solvent, and after adding thionyl chloride for chlorination reaction, adding ethanol to continue the esterification reaction to obtain ethyl 6,8-dichlorooctanoate. The present invention realizes the recycling of S-(-)-lipoic acid, obtains the raw material 6,8 dichlorooctanoic acid ethyl ester for the synthesis of α-lipoic acid, not only solves the recycling problem of S-(-)-lipoic acid, Material waste is avoided, and the cost of raw materials for synthesizing R-lipoic acid is greatly reduced, which provides a new way for industrial production of R-lipoic acid.

Owner:TECHNO (FUJIAN) FOOD INGREDIENTS CO LTD

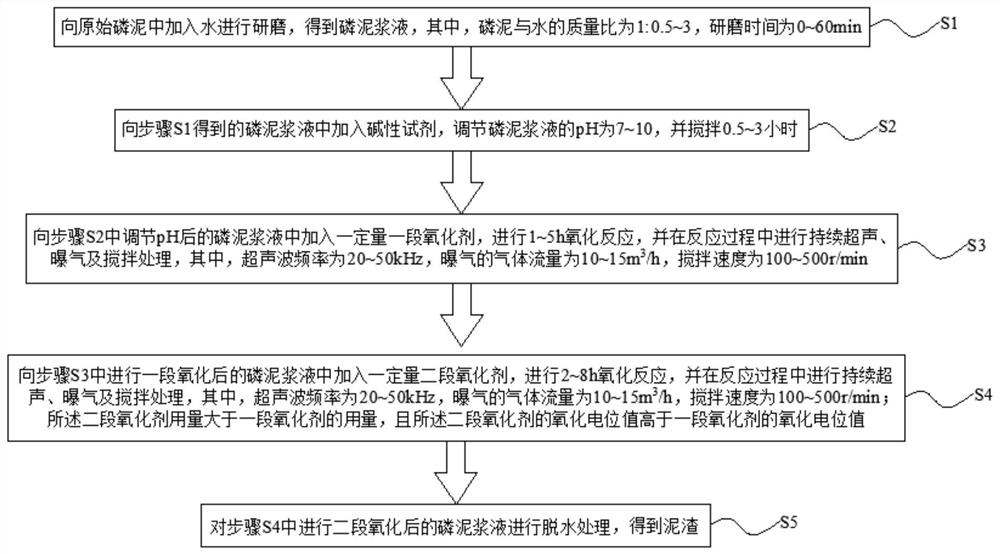

Double-stage oxidation treatment process for weak-phosphorus flammable sludge under synergistic effect of ultrasonic aeration

InactiveCN113429100AImprove mass transfer efficiencyFacilitate chemical reactionsShaking/oscillating/vibrating mixersSludge treatment by oxidationSludgeSlurry

The invention discloses a double-stage oxidation treatment process for weak-phosphorus flammable sludge under the synergistic effect of ultrasonic aeration. The double-stage oxidation treatment process comprises the following steps: preparing phosphorus slurry; carrying out alkalization treatment on the phosphorus slurry; carrying out first-stage oxidation treatment on the phosphorus slurry; carrying out second-stage oxidation treatment on the phosphorus slurry; carrying out dehydration treatment on the phosphorus slurry. According to the technical scheme, an efficient and thorough innocent treatment mode is provided for the weak phosphorus sludge which is difficult to recycle.

Owner:深圳星河环境股份有限公司

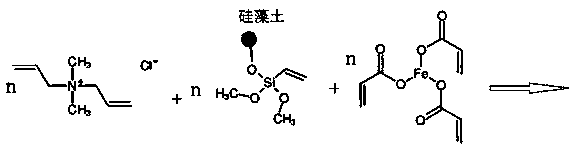

Treatment method of arsenic-fluorine-containing industrial wastewater

InactiveCN111573902ASimple processLow costWater contaminantsMultistage water/sewage treatmentIndustrial waste waterIndustrial wastewater treatment

The invention relates to the field of environmental protection, in particular to a treatment method of arsenic-fluorine-containing industrial wastewater. The method includes acidification treatment, medicament addition, alkalization treatment and settling separation; the invention provides a treatment method of the arsenic-fluorine-containing industrial wastewater. The modified reinforced diatomite is applied to a treatment process of arsenic- fluorine-containing industrial wastewater; in the wastewater treatment process, only a wastewater treatment agent is added after the wastewater is acidified; the modified reinforced diatomite provided by the invention is applicable to treatment of industrial wastewater with medium and low contents of arsenic and fluorine; optimal process conditions such as the addition amount or the treatment flow of a medicament are provided, and a treatment process which is innovative, low in investment, low in cost and easy to manage and protect is provided for treatment of the arsenic-fluorine-containing industrial wastewater; the method has the advantages of simple and easily available raw materials, low cost and simple wastewater treatment process.

Owner:东阳市前途工业设计有限公司

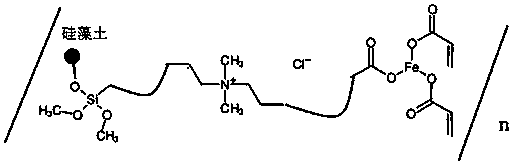

Easy-welding electrode connection piece blank treatment process

InactiveCN109967437AEasy to weldWeld firmlyCell component detailsCleaning using liquidsFailure rateChromium free

The invention discloses an easy-welding electrode connection piece blank treatment process. The process comprises the steps of alkalization treatment, wherein NaHO with the purity being 99 to 99.6% and water are mixed according to the proportion of 1:10 to form a NaHO solution, the material is cleaned, and during cleaning, the temperature is controlled between 50 and 55 DEG C; primary material cleaning treatment, wherein purified water is used for cleaning the material at the normal temperature; acidification treatment, wherein nitric acid with the purity being 99.2 to 99.7% and water are mixed according to the proportion of 1:9 to form a HN03 solution, and the solution is used for cleaning; secondary material cleaning treatment; passivation treatment, wherein chromium-free environment-friendly Alodine and water are mixed according to the proportion of 1.5:10 to form an Alodine solution to clean the material; third-time material cleaning treatment; and oven treatment, wherein an oven is used for drying the water beads on the surface of the material, and the drying temperature is controlled to range from 90 to 110 DEG C. An oil layer on an electrode connection piece blank can be thoroughly removed, the electrode connection piece obtained after treatment is easy to weld, meanwhile, welding is firm, the battery set assembling cost is greatly reduced, the battery set safety is improved, and the failure rate of the battery set is reduced.

Owner:深圳市德惠电池材料有限公司

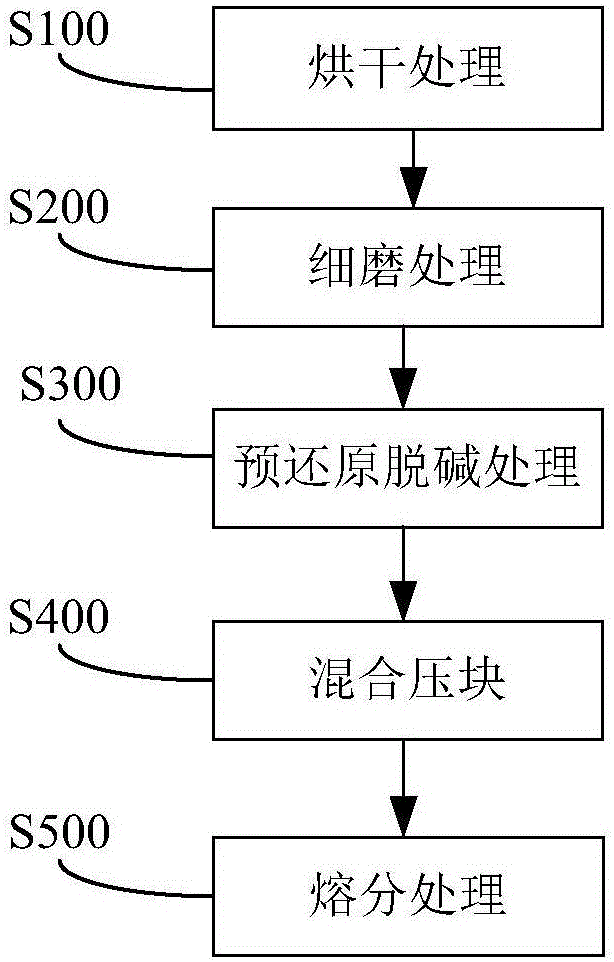

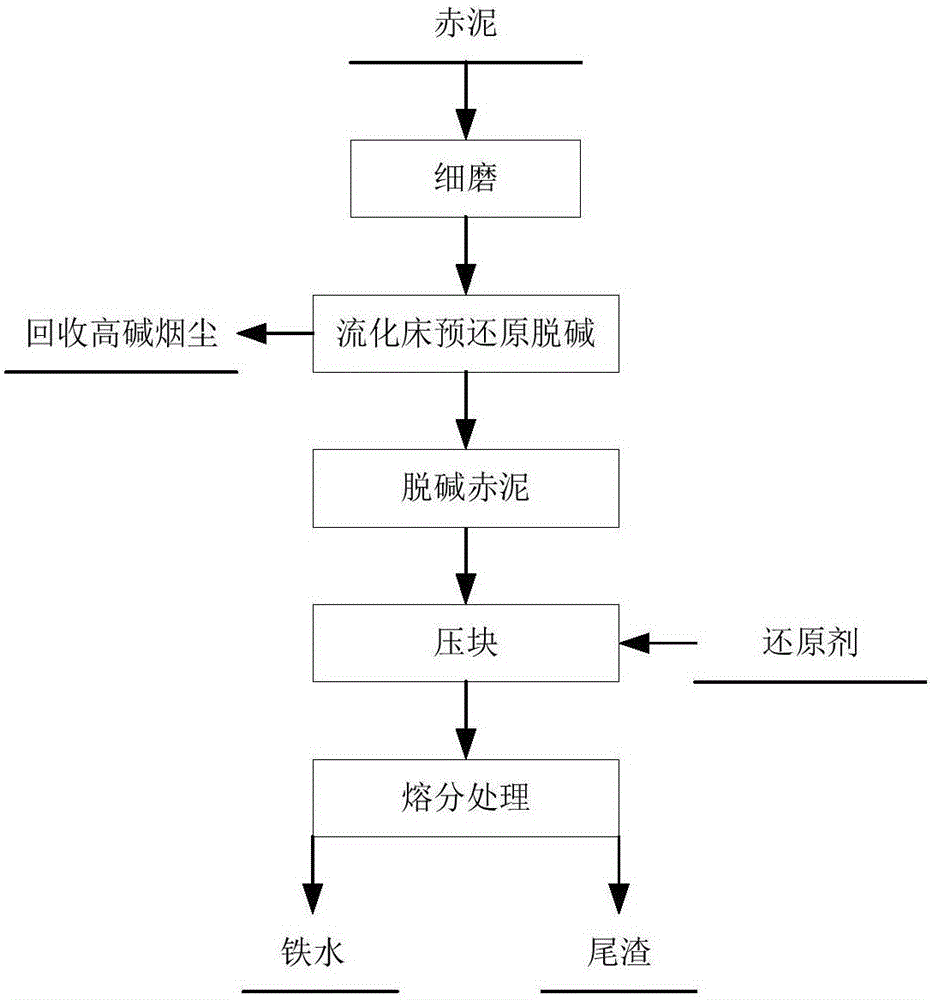

Method and system for treating red mud

PendingCN106148718AHigh dealkalization rateGood iron reduction effectProcess efficiency improvementSlagRed mud

The invention discloses a method and a system for treating red mud. The method for treating the red mud comprises the following steps: drying water-containing red mud to obtain dry red mud; finely grinding the dry red mud to obtain superfine red mud powder; carrying out pre-reduction de-alkalization treatment on the superfine red mud powder in a fluidized bed under the reducing atmosphere to obtain de-alkalized red mud and high-alkali smoke dust; mixing and briquetting the de-alkalized red mud with the a reducing agent to obtain red mud briquette; and melting and separating the red mud briquette in a melting and separating furnace to obtain melted iron and tailings. Through application of the method, the alkali metals in the red mud can be effectively removed; the reducibility of the subsequent red mud iron is improved; the technical problems that the red mud is low in de-alkalization rate, the iron reducing effect is poor and the iron is difficult to recycle are solved; meanwhile, the melting and separating furnace is used for deeply reducing and separating slag iron; the products with higher recycling rate and metalizing rate can be further obtained; the method has important economic benefits.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

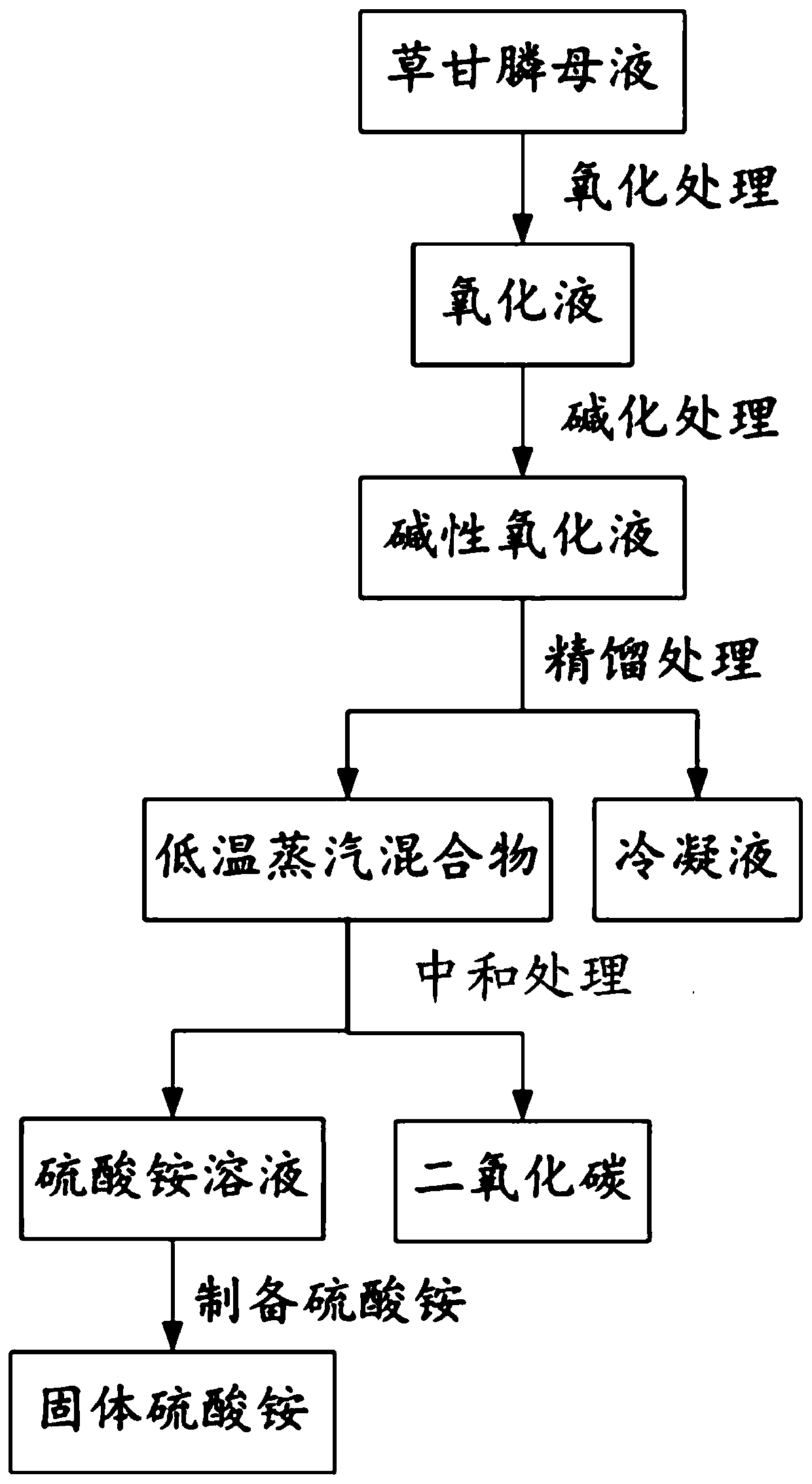

A kind of technology that reclaims ammonium sulfate from glyphosate mother liquor

ActiveCN108483462BPromote sustainable developmentEasy to operateAmmonium sulfatesEconomic benefitsPulp and paper industry

Belonging to the field of recycling of nitrogen resources in glyphosate mother liquor, the invention discloses a process for recovery of ammonium sulfate from glyphosate mother liquor. The process iscarried out according to the steps of: S1 oxidation treatment, S2 alkalization treatment, S3 rectification treatment, S4 neutralization treatment and S5 preparation of ammonium sulfate. The process for recovery of ammonium sulfate from glyphosate mother liquor disclosed by the invention fully recovers and utilizes the nitrogen resources of glyphosate mother liquor, achieves production recycling utilization, and then further improves the economic benefits.

Owner:JIANGXI JINLONG CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com