Oil-based fluid loss additive for drilling fluid and preparation method thereof

A technology of oil-based drilling fluid and fluid loss control agent, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of poor dispersion, environmental pollution, poor dispersion, etc., and achieve good compatibility and preparation technology. Simple, environmentally friendly effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

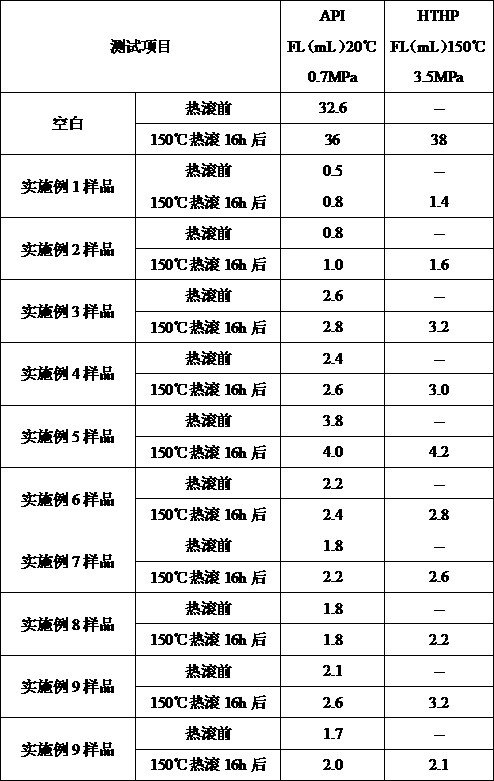

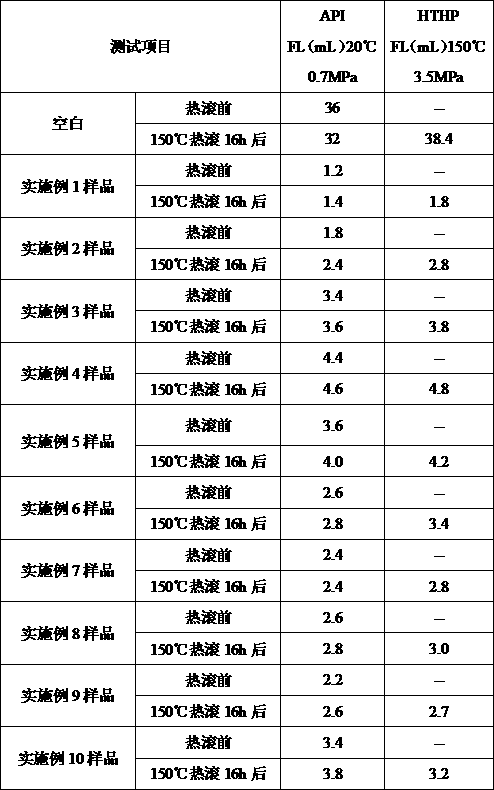

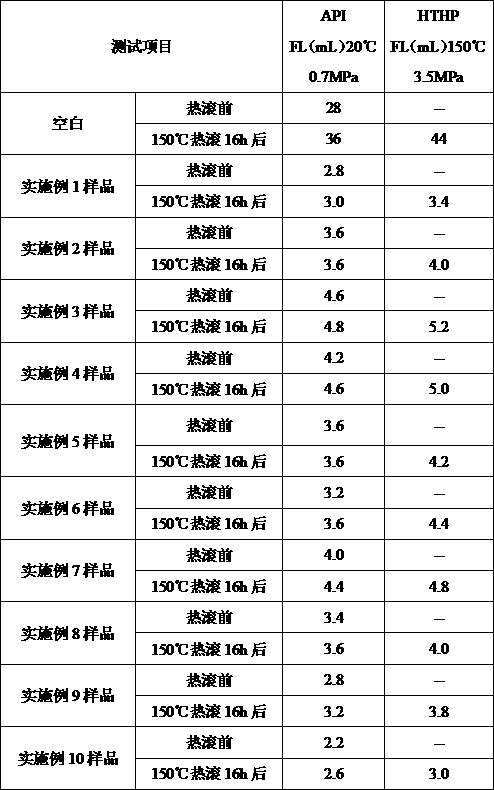

Examples

Embodiment 1

[0014] Under the protection of nitrogen, add 120 parts of 45% NaOH solution, 500 parts of isopropanol, 50 parts of refined cotton to the reaction kettle, stir well, alkalinize at 20°C for 1 hour, add 100 parts of chloroacetic acid, and heat up to 50 After reacting at ℃ for 1 hour, adjust the pH value to 4-6 with glacial acetic acid, add 100 parts of octadecyl primary amine, raise the temperature to 140 ℃ and react for 1 hour, and press filter to obtain the oil-based drilling fluid fluid loss reducer.

Embodiment 2

[0016] Under the protection of nitrogen, add 100 parts of 47% NaOH solution, 400 parts of isopropanol, 50 parts of refined cotton to the reaction kettle, stir thoroughly, alkalinize at 20°C for 1 hour, add 137 parts of chloroacetic acid, and heat up to 50 After reacting at ℃ for 1 hour, adjust the pH value to 4-6 with glacial acetic acid, add 200 parts of tetradecyl primary amine, raise the temperature to 140 ℃ and react for 1 hour, and press filter to obtain the oil-based drilling fluid fluid loss reducer.

Embodiment 3

[0018] Under the protection of nitrogen, add 100 parts of 46% NaOH solution, 400 parts of toluene, 50 parts of refined cotton to the reaction kettle, stir thoroughly, alkalinize at 20°C for 1.5h, add 120 parts of chloroacetic acid, and heat up to 50°C After reacting for 2 hours, adjust the pH value to 4-6 with glacial acetic acid, add 150 parts of cetyl primary amine, raise the temperature to 150° C. and react for 2 hours, and press filter to obtain the oil-based drilling fluid fluid loss additive.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com