Zero-discharge advanced treatment method of desulfurized wastewater

A technology for advanced treatment and desulfurization of wastewater, which is applied in gaseous discharge wastewater treatment, multi-stage water treatment, water/sewage treatment, etc. and other problems, to achieve the effect of simple and easy design and processing, harmless desulfurization effect, and not easy to block

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

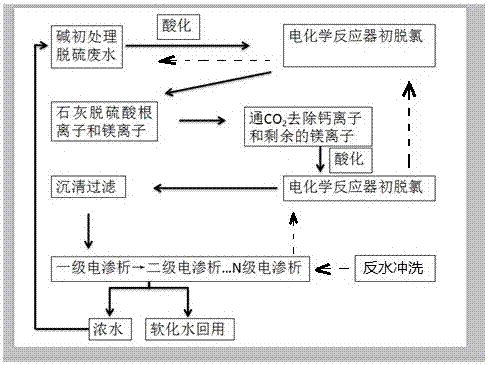

[0043] Example (see attached figure 1 )

[0044] Prepare the wastewater to be treated: the high-salt water after the tail end of the limestone-gypsum desulphurization process of a power plant has a PH value of about 8. The test indicators are as follows:

[0045] Serial number project unit Raw water Remarks 1 pH / 8.67 2 Conductivity us / cm8395 3 total hardnessmg / L as CaCO 3

216793 4 Calcium ion mg / L1943.41 5 Magnesium ions mg / L3987.89 6 Total alkalinitymg / L as CaCO 3

287.05 End with methyl orange 7 Chloride mg / L11787.23 8 Sulfate mg / L4332.66

[0046] 1. The first acidification treatment: add sulfuric acid solution to the wastewater and adjust the pH value of the wastewater to 3-5;

[0047] 2. The first initial dechlorination of electrochemical reactor: the method of electrochemical reactor dechlorination is in accordance with the method in "Electrochemical reactor and electrocatalytic method for removing chloride ions" provided by the patent number 201611243285.7 or other existin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com