Reusing system and processing method for byproduct carbon dioxide in synthetic ammonia process

A technology for synthesizing ammonia and CO2, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve problems affecting device stability, long-term operation, increasing wastewater treatment capacity and environmental protection pressure, methanol recovery effect is not obvious, etc., to achieve The effect of reducing sewage treatment costs, saving equipment and maintenance costs, and reducing environmental pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

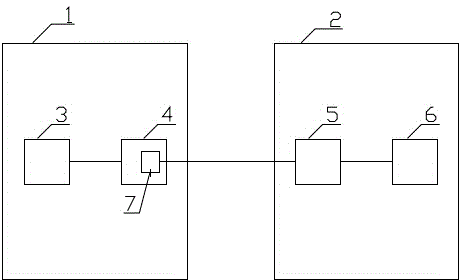

[0011] Example. A kind of synthetic ammonia process by-product CO 2 The reuse system, constituted as figure 1 As shown, it includes a pre-processing unit 1, which is connected to a pulverized coal pressurized gasification device 2; the pre-processing unit 1 includes a CO conversion device 3, and the CO conversion device 3 is connected to a low-temperature methanol washing device 4; the The pulverized coal pressurized gasification device 2 includes CO 2 Compressor 5, CO 2 The compressor 5 is connected with the fly ash filter 6 .

[0012] Aforesaid low-temperature methanol washing device 4 is provided with flash evaporator 7, and flash evaporator 7 is connected with CO 2 Compressor 5 is connected.

[0013] CO by-product of ammonia synthesis process 2 The reuse treatment method is: in the CO con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com