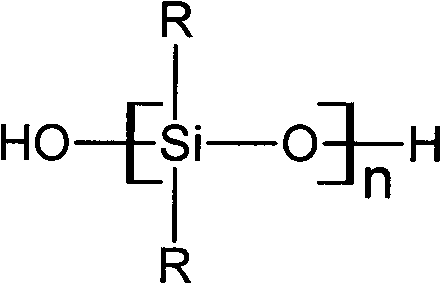

Silicone fireproof sealant for construction and preparation method thereof

A technology for fireproof sealant and construction, applied in the direction of chemical instruments and methods, adhesives, and other chemical processes, can solve the problems of reducing the mechanical processing performance and mechanical properties of sealants, environmental secondary pollution, and limiting the scope of application, etc., to achieve Improved machinability, high flame retardant efficiency, and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

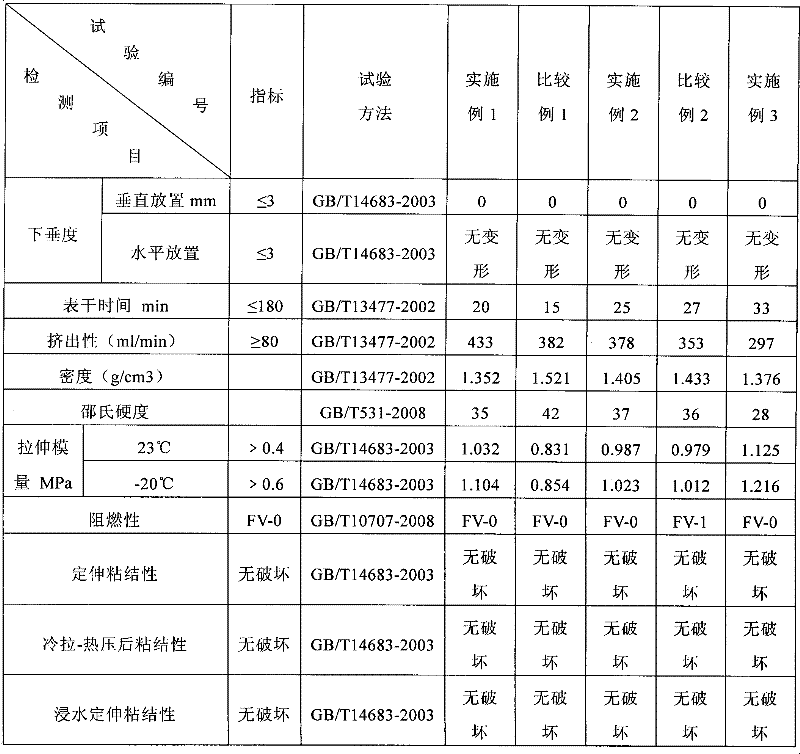

[0032] Add 100 parts of α, ω-dihydroxypolysiloxane, 30 parts of aluminum hydroxide, 50 parts of melamine cyanurate, and 0.01 part of kaolin into the kneader, knead and dehydrate for 0.5 hours at a temperature of 180°C and a vacuum degree of 0.1MPa , the base material is obtained after cooling. At room temperature, add the base material into the planetary mixer, and then add 0.01 part of polydimethylsiloxane, 0.1 part of carbon black, 2 parts of methyltrimethoxysilane, 3-glycidylpropyltrimethoxysilane 2 parts, 2 parts N-(β-aminoethyl)-α-aminopropyltrimethoxysilane, 2 parts isopropyl titanate were added to the planetary mixer together with the base material at a vacuum degree of 0.1MPa, and the rotation speed was 80 rpm The chemical reaction is carried out for 0.5 hours at the time of / minute to make a silicone fireproof sealant for construction. The product performance test results are shown in Table 1.

Embodiment 2

[0034] Add 100 parts of α,ω-dihydroxypolysiloxane, 80 parts of zinc borate, 10 parts of melamine cyanurate, and 20 parts of silicon micropowder into the kneader, knead and dehydrate for 2.5 hours at a temperature of 100°C and a vacuum degree of 0.08MPa. , the base material is obtained after cooling. At room temperature, the base material was added to the planetary mixer, and then 20 parts of polydimethylsiloxane, 10 parts of iron red, 8 parts of vinyl tributyl ketoximo silane, and 7 parts of methyl tributyl ketoximo silane were added. parts, 0.2 parts of N-(β-aminoethyl)-α-aminopropyltrimethoxysilane, and 5 parts of titanate chelate were added to the planetary mixer together with the base material at a vacuum degree of 0.06MPa, and the rotation speed was 20 rpm The chemical reaction is carried out for 6 hours at the temperature of / min to make a silicone fireproof sealant for construction. The product performance test results are shown in Table 1.

Embodiment 3

[0036] 100 parts of α, ω-dihydroxypolysiloxane, 30 parts of ultrafine calcium carbonate, 60 parts of magnesium hydroxide, and 30 parts of melamine were added to the kneader, kneaded and dehydrated for 4 hours at a temperature of 150°C and a vacuum degree of 0.06MPa, The base material is obtained after cooling. At room temperature, the base material was added to the planetary mixer, and then 50 parts of polydimethylsiloxane, 5 parts of iron red, 6 parts of methyltributyl ketoximinosilane, N-(β-aminoethyl) - 3 parts of α-aminopropyltrimethoxysilane and 0.5 part of dibutyltin dilaurate were added to the planetary mixer together with the base material, and the chemical reaction was carried out for 3 hours under the vacuum degree of 0.08MPa and the rotation speed of 30 rpm. Silicone fireproof sealant for construction. The product performance test results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com