Patents

Literature

1232results about How to "Increase processing cost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

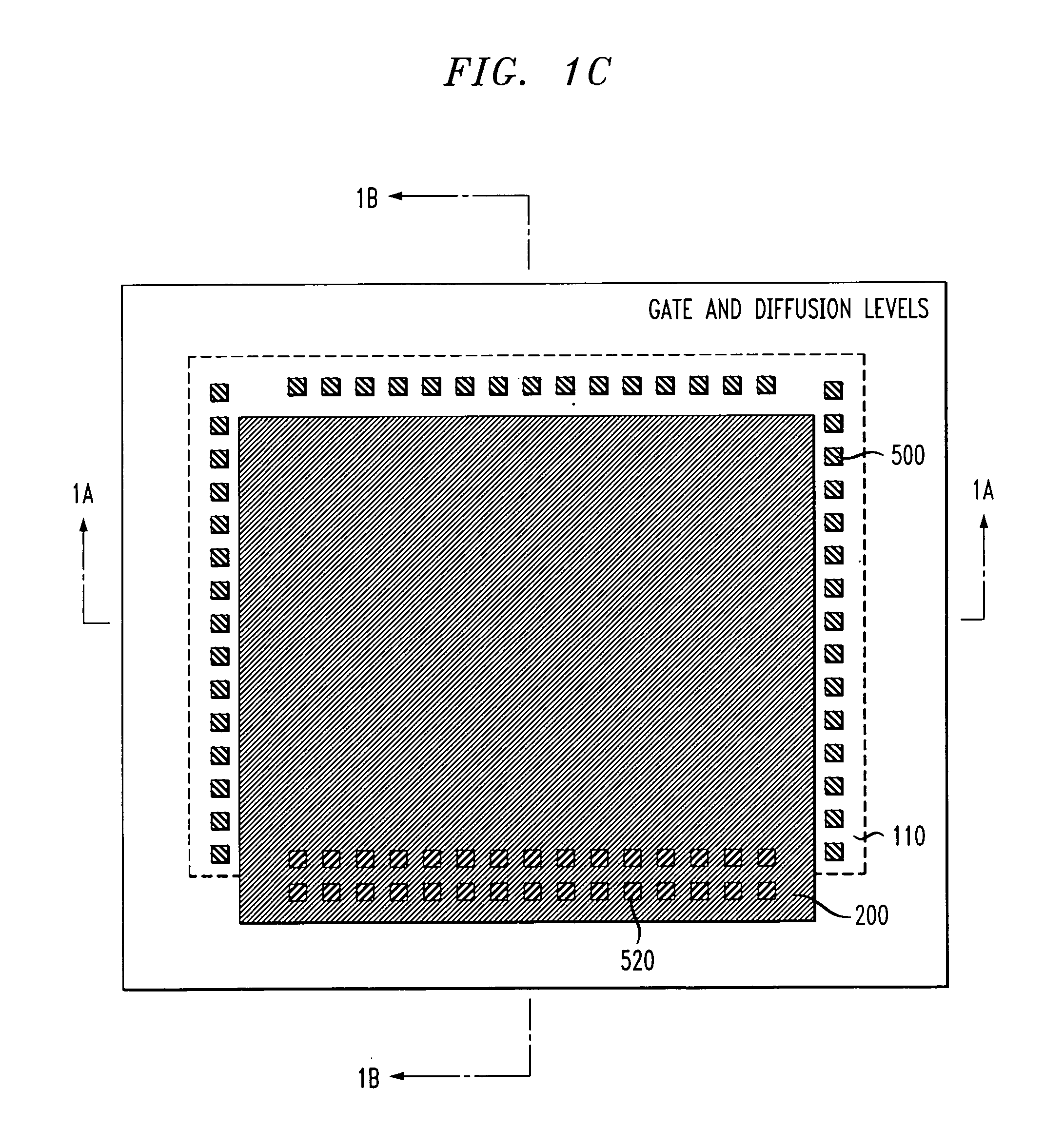

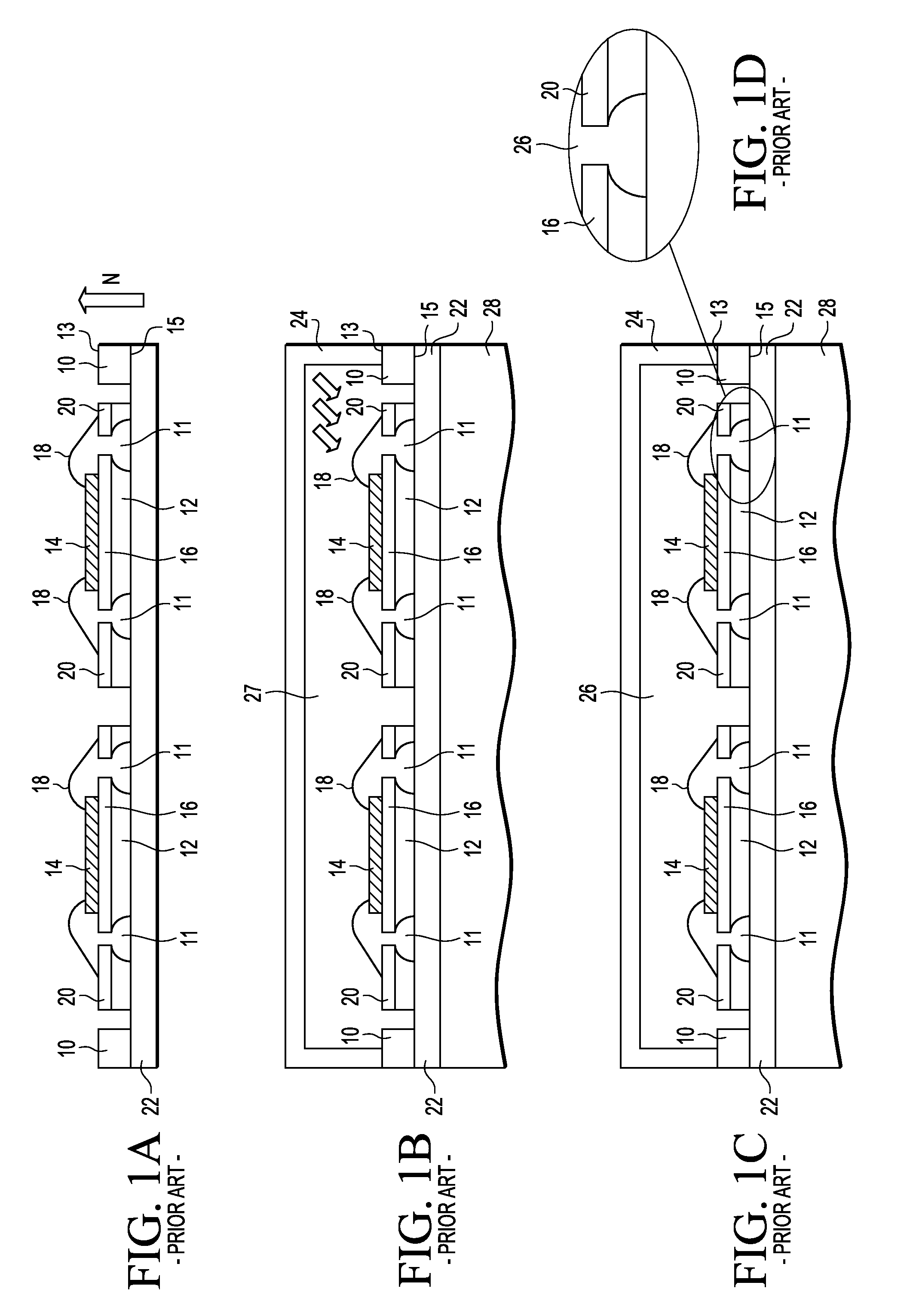

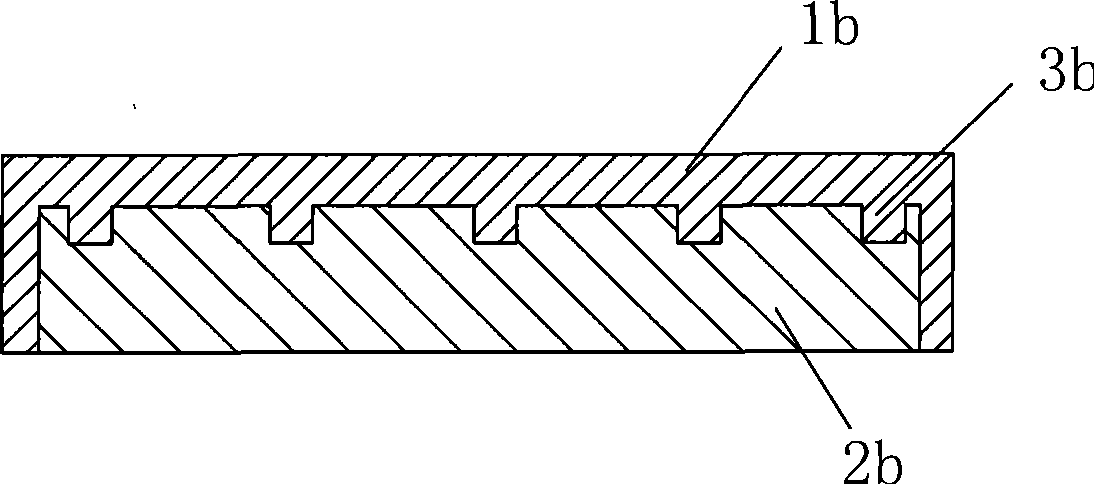

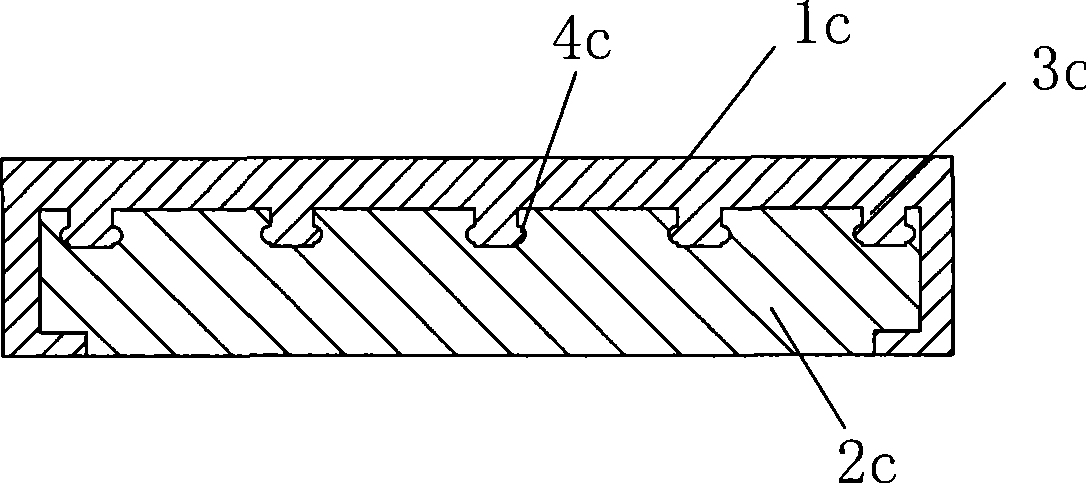

Hard mask arrangement

InactiveUS20060234138A1Reduce spacingIncrease processing costSemiconductor/solid-state device manufacturingOriginals for photomechanical treatmentCarrying capacityLateral region

An interconnect connection structure having first and second interconnects and multiple connection elements that electrically connect the first interconnect to the second interconnect is described. The multiple connection elements are formed laterally in a lateral region of the first and second interconnects relative to an overlay orientation of the interconnects. A central region may be free of connection elements so that electro-migration properties of the connection structure are improved and the current-carrying capacity is increased.

Owner:FEHLHABER RODGER +1

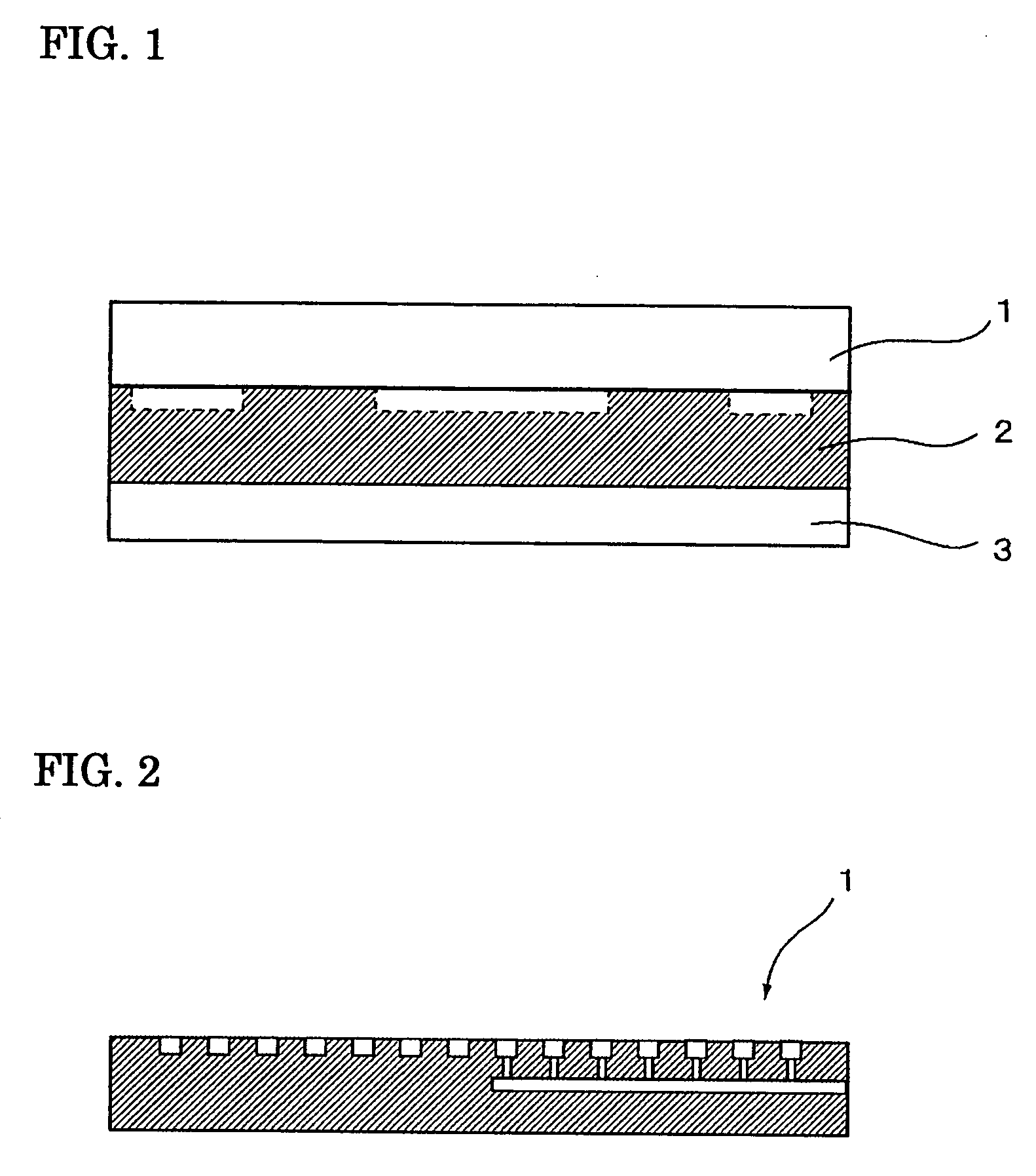

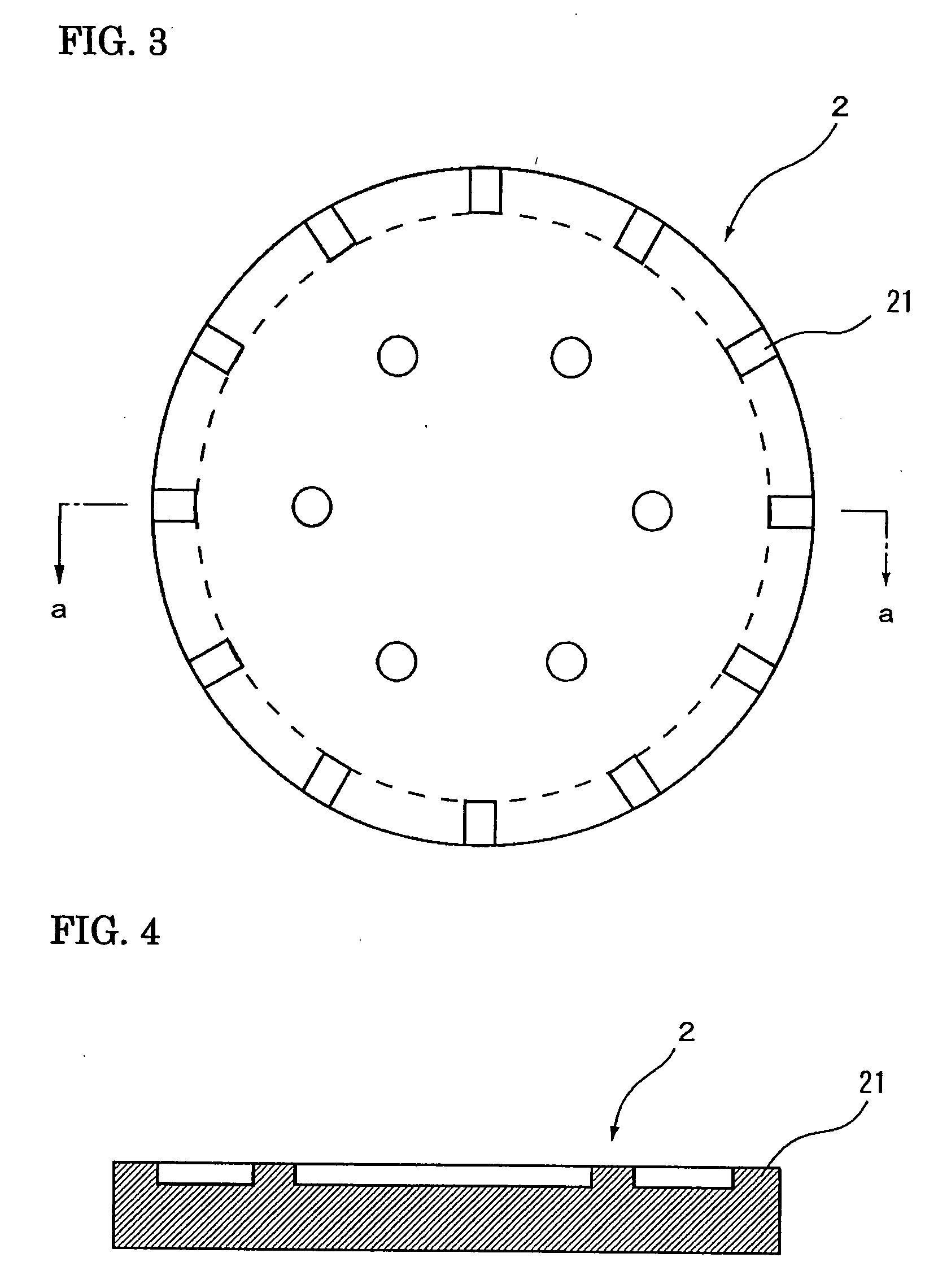

Wafer holder, and wafer prober provided therewith

InactiveUS20070205788A1Good effectIncrease speedSemiconductor/solid-state device manufacturingHot plates heating arrangementsYoung's modulusEngineering

A wafer holder is provided having high rigidity and an enhanced heat-insulating effect that allow positional accuracy and heating uniformity to be improved, a chip to be rapidly heated and cooled, and the manufacturing cost to be reduced, and a wafer prober apparatus on which the wafer holder is mounted. The wafer holder of the present invention includes a chuck top for mounting a wafer, a support member for supporting the chuck top, and a stand for supporting the support member. The chuck top has a thermal conductivity K1 and a Young's modulus Y1; the support member has a thermal conductivity K2 and a Young's modulus Y2; and the stand has a thermal conductivity K3 and a Young's modulus Y3. K1>K2 and K1>K3; and Y3>Y1 and Y3>Y2.

Owner:SUMITOMO ELECTRIC IND LTD

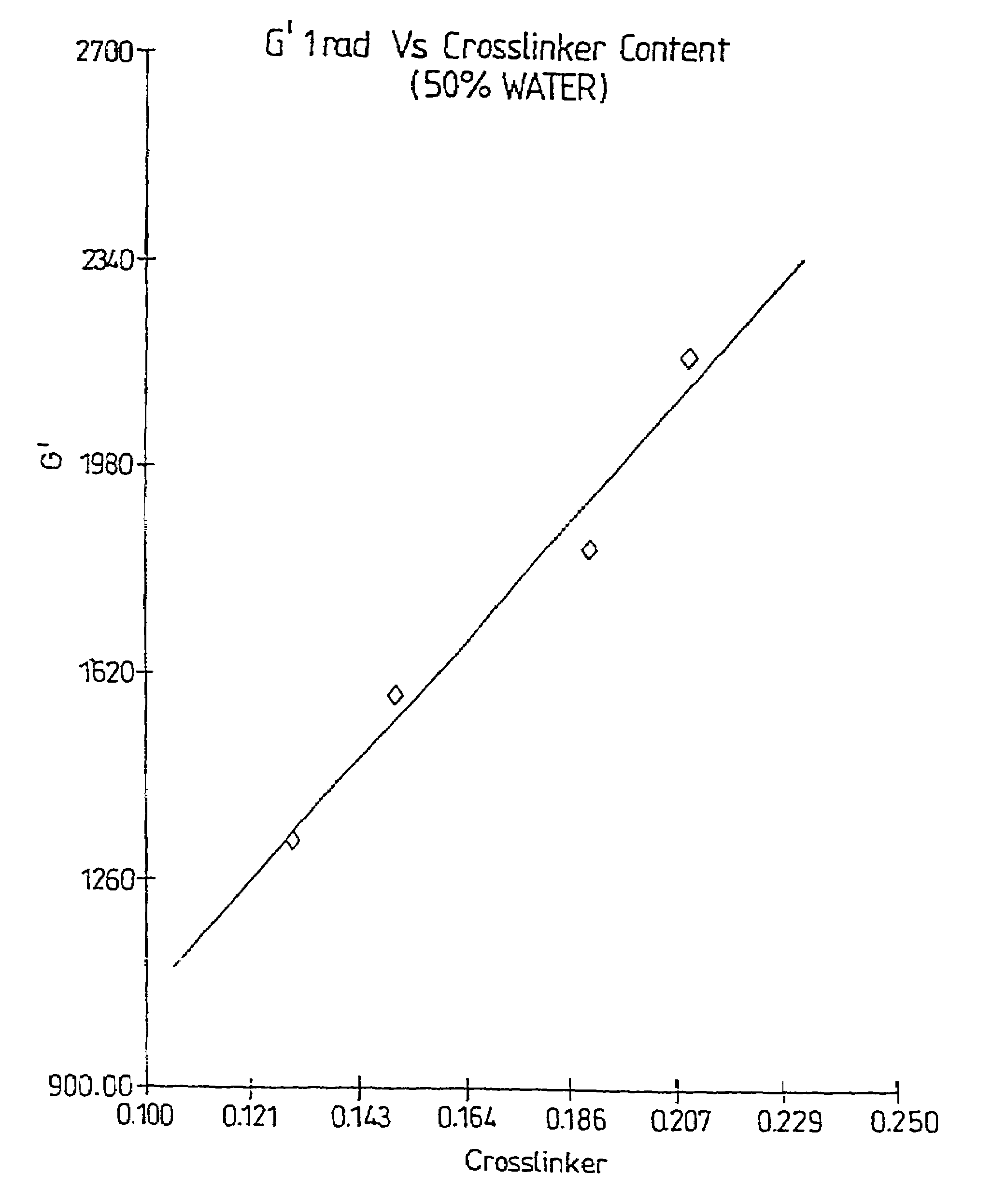

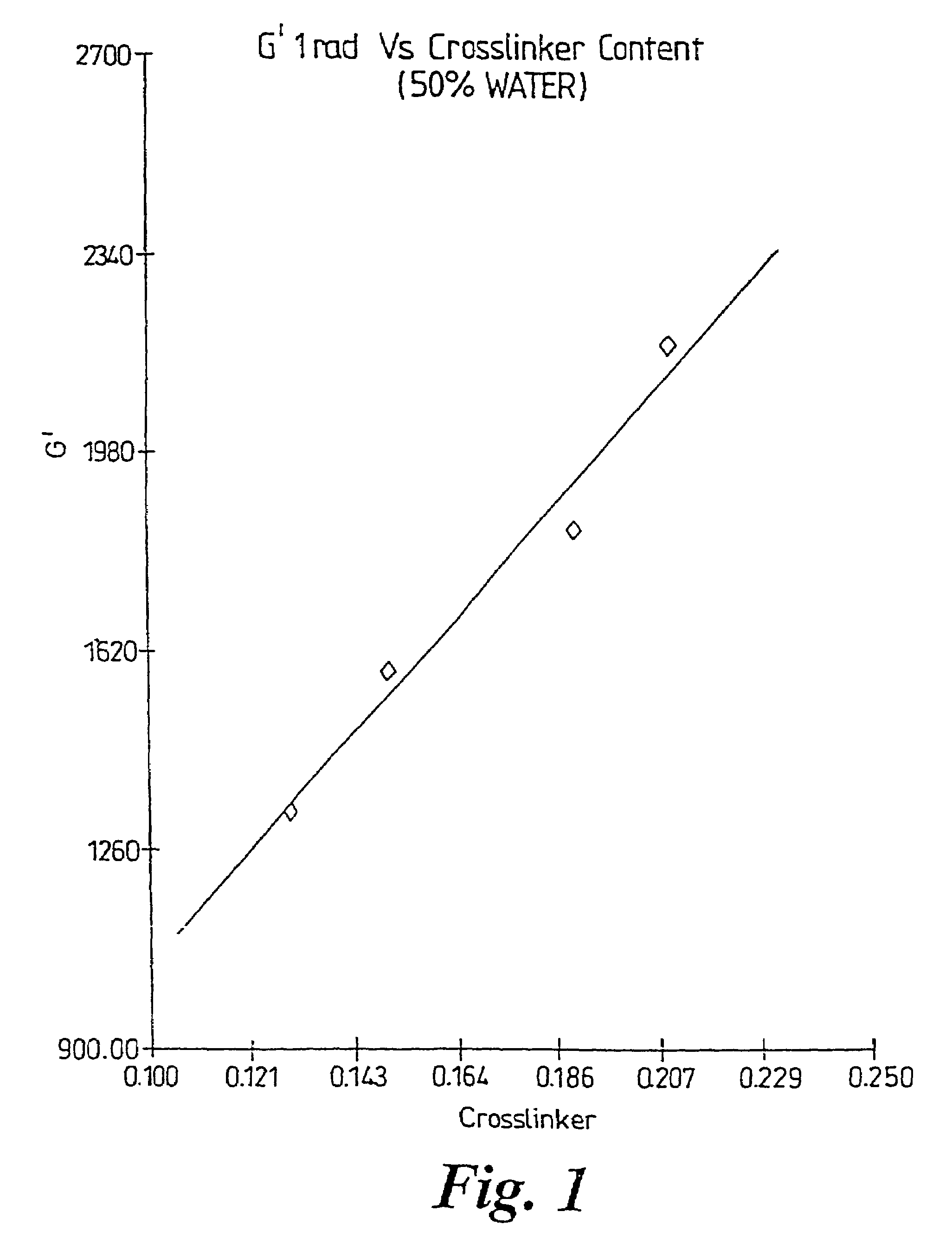

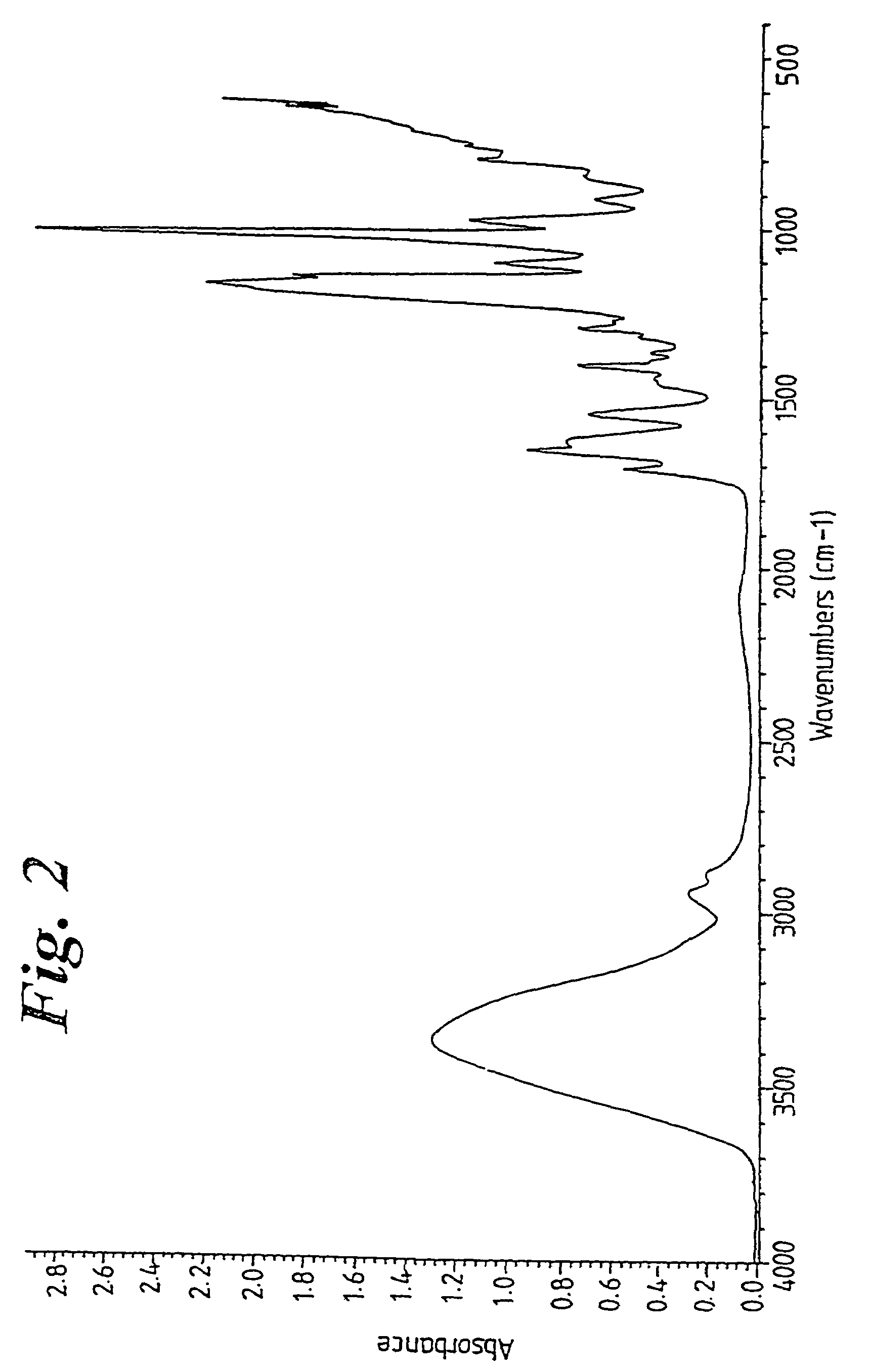

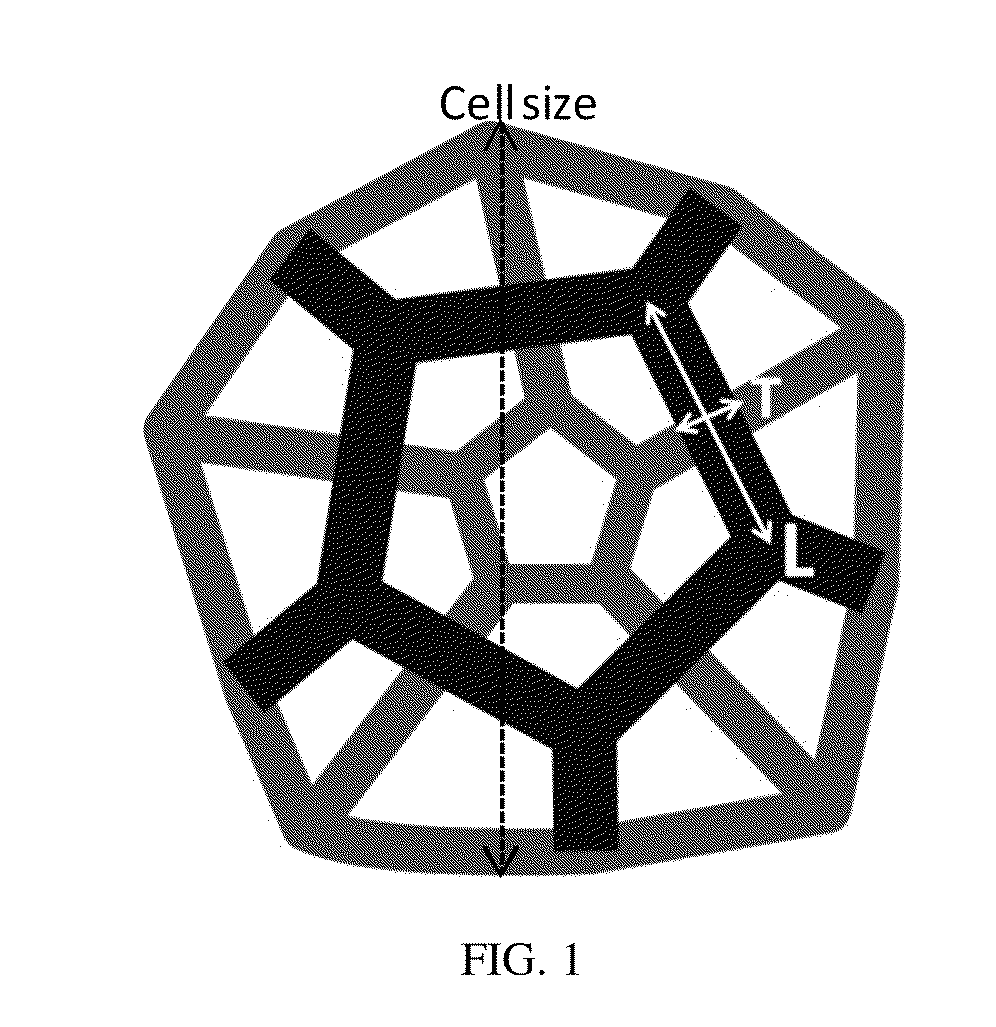

Cellular plastic material

An improved cellular plastic material comprises a urethane foam that is the reaction product of soy oil, an isocyanate, and a cross linker. The soy oil replaces the polyol typically generally required in the production of urethanes. Because the replaced polyol is a petrochemical, use of a renewable and environmentally friendly material such as soy oil is most advantageous. Further, plastic materials of many final qualities may be formed using a single vegetable oil. In addition to cellular foams, solid plastic elastomers may be formed.

Owner:URETHANE SOY SYST +1

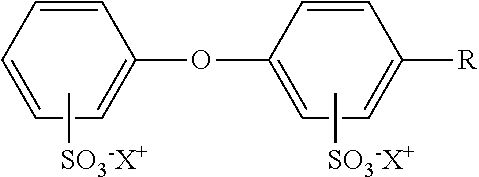

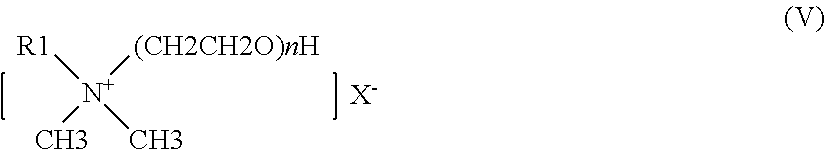

Bioadhesive compositions and biomedical electrodes containing them

InactiveUS7076282B2Good bioadhesionHigh mechanical strengthElectrocardiographySurgical adhesivesWound dressingHydrophobic polymer

Owner:FIRST WATER

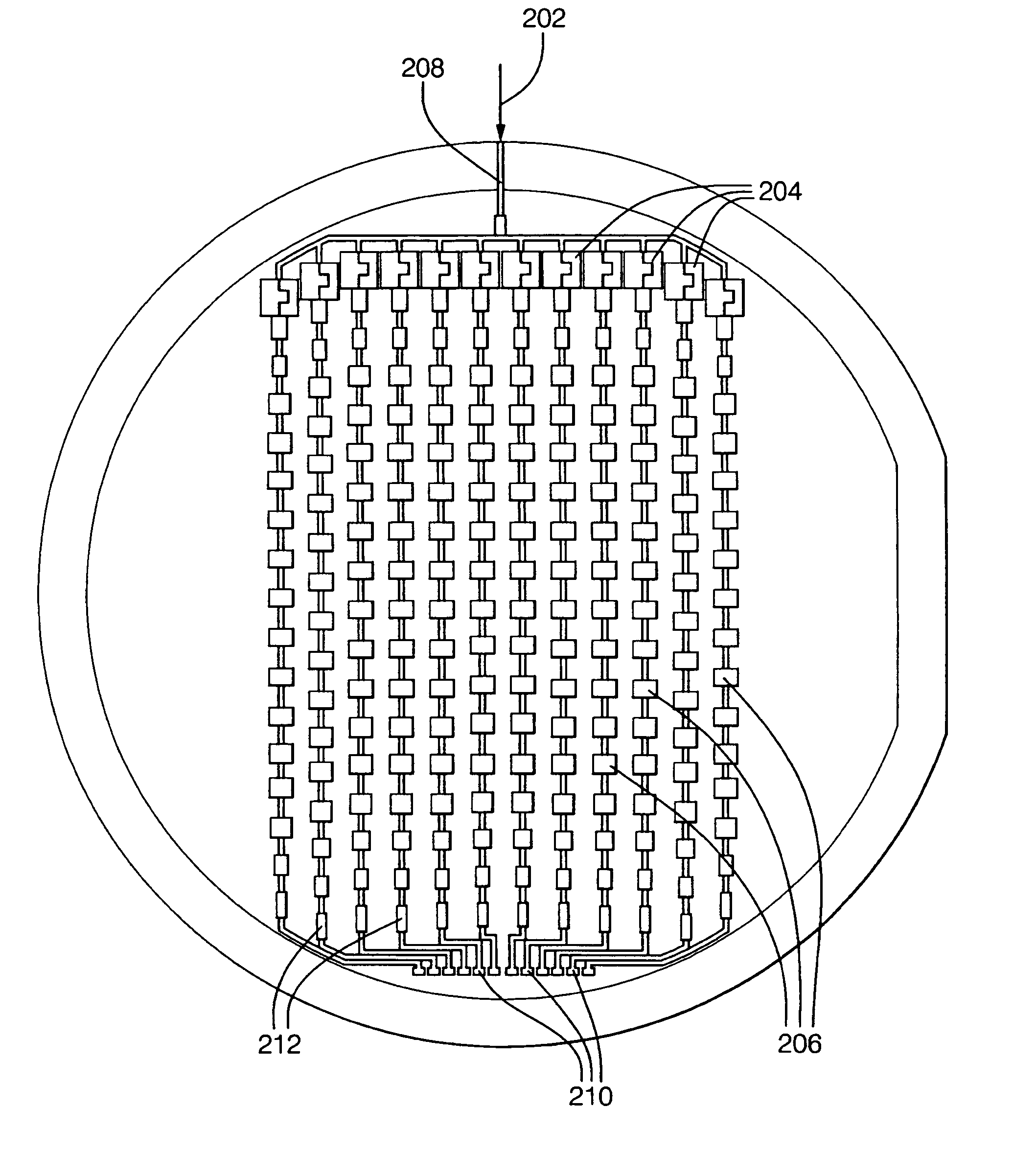

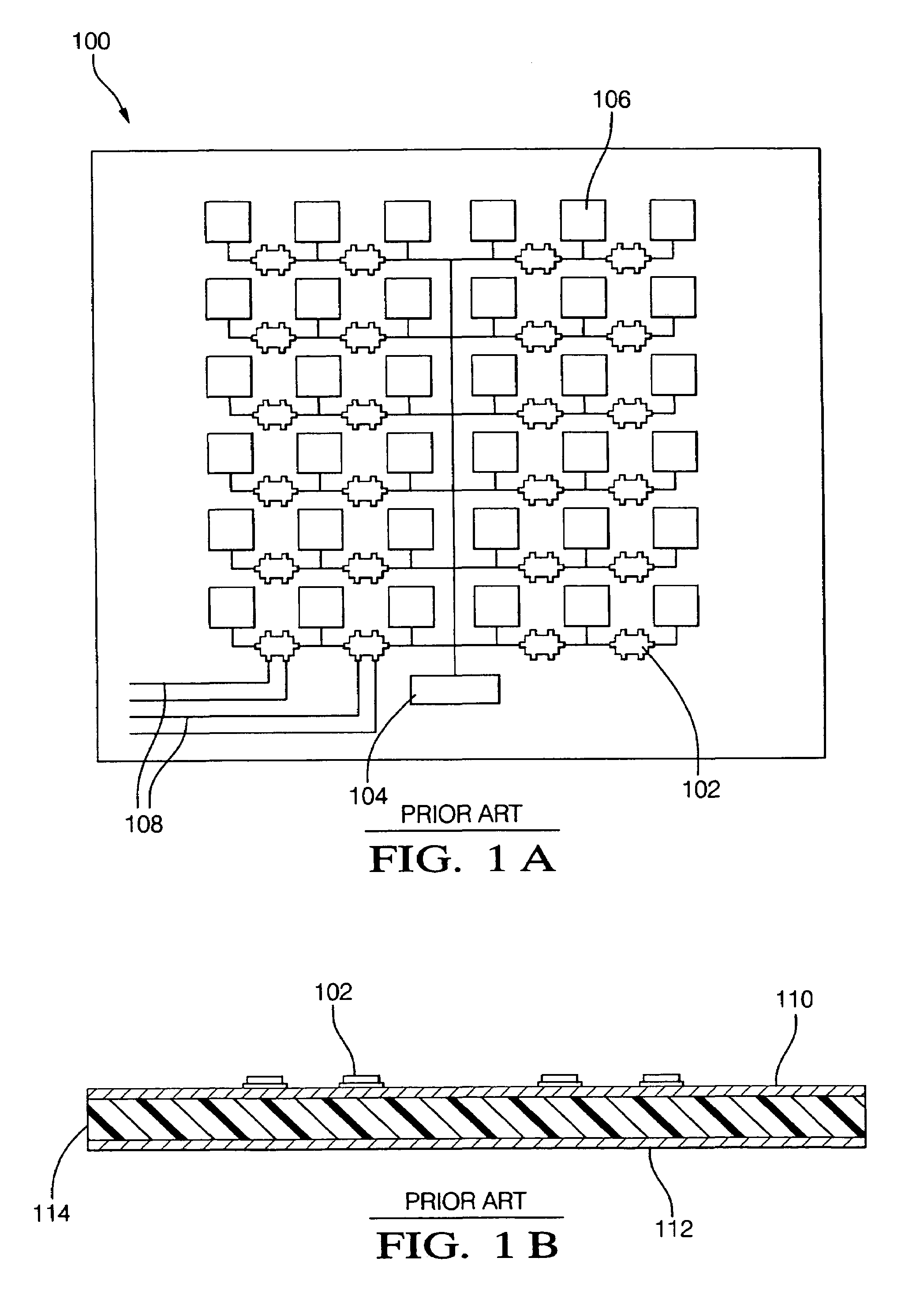

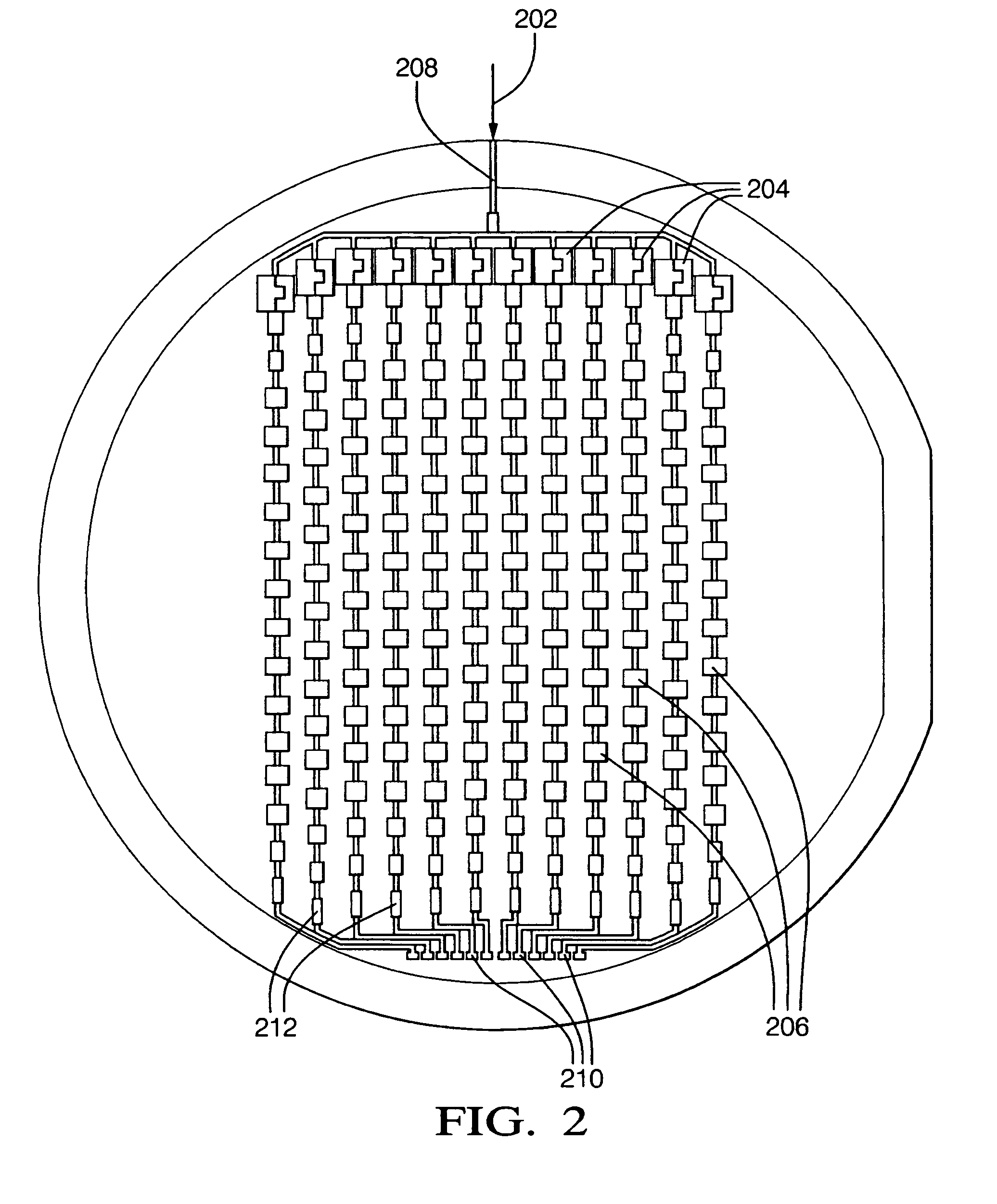

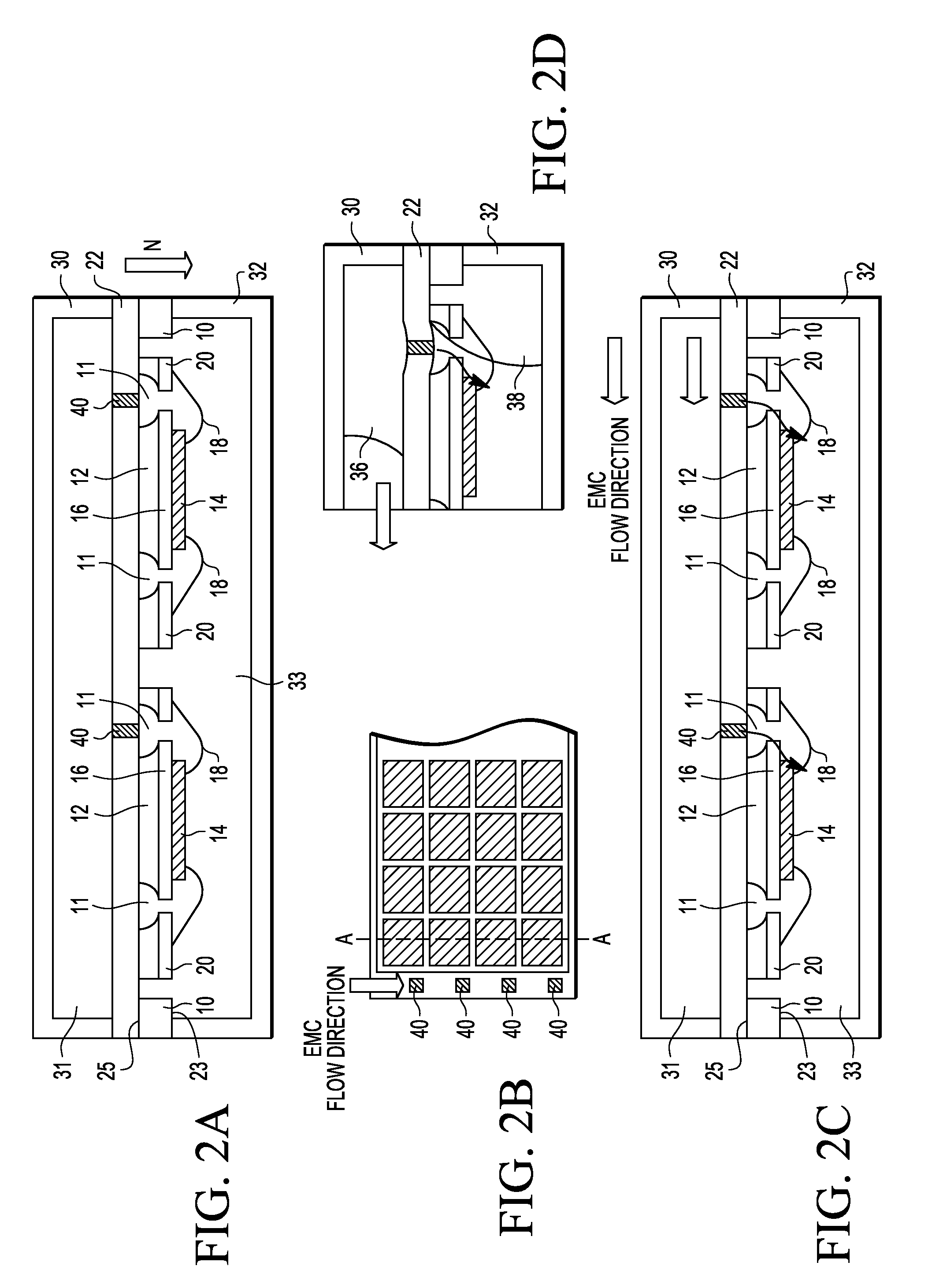

Phase shifters deposited en masse for an electronically scanned antenna

ActiveUS7324043B2Increase processing costPatterning of backsideSimultaneous aerial operationsRadiating elements structural formsDielectricEngineering

A system and method for an electronically scanned antenna is provided in which phase shifters are deposited en masse along with other electronically scanned antenna components on a wafer scale substrate using a thin film process. Alternative wafer scale sizes may be utilized to furnish a required antenna aperture area. Significant processing costs for radar and communication systems are saved utilizing the present invention as compared with contemporary discrete phase shifters that are individually mounted on an antenna. In an aspect, the phase shifter is made up of a base electrode, a barium strontanate titanate (BST) ferroelectric varactor and a top electrode. The BST ferroelectric material is a voltage variable dielectric, which generates a radiation phase. The radiation phase is regulated by a phase shifter control. The radiation phase generates an electromagnetic field about a radiating element and electromagnetic radio waves are radiated from the radiating element.

Owner:APTIV TECH LTD

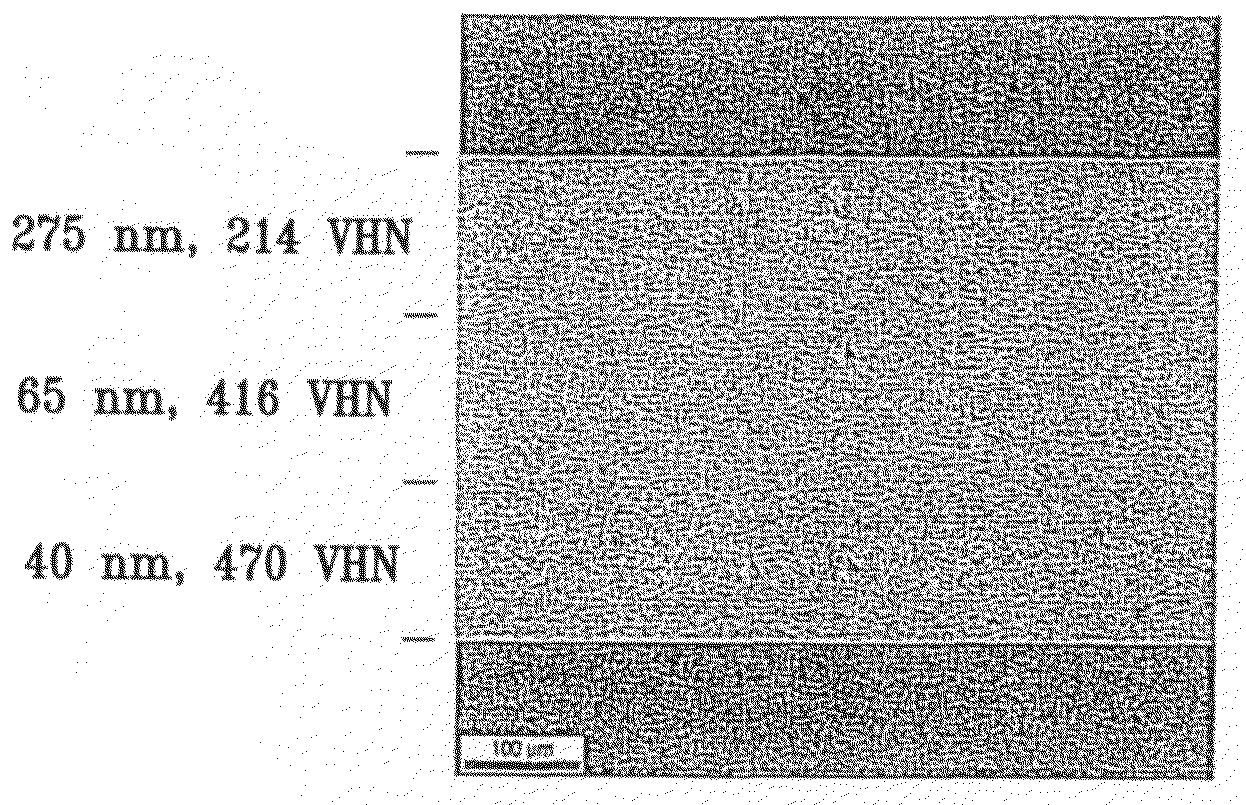

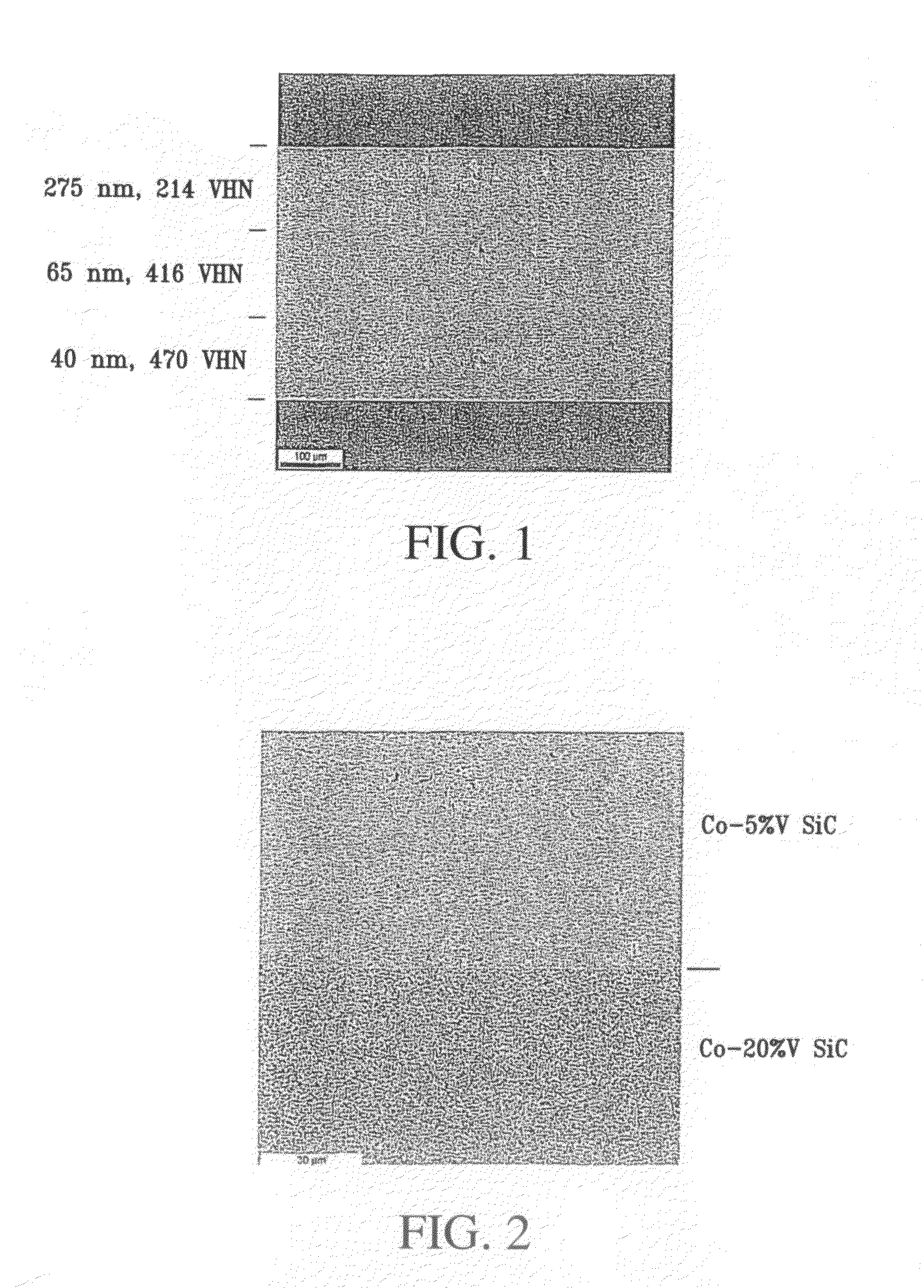

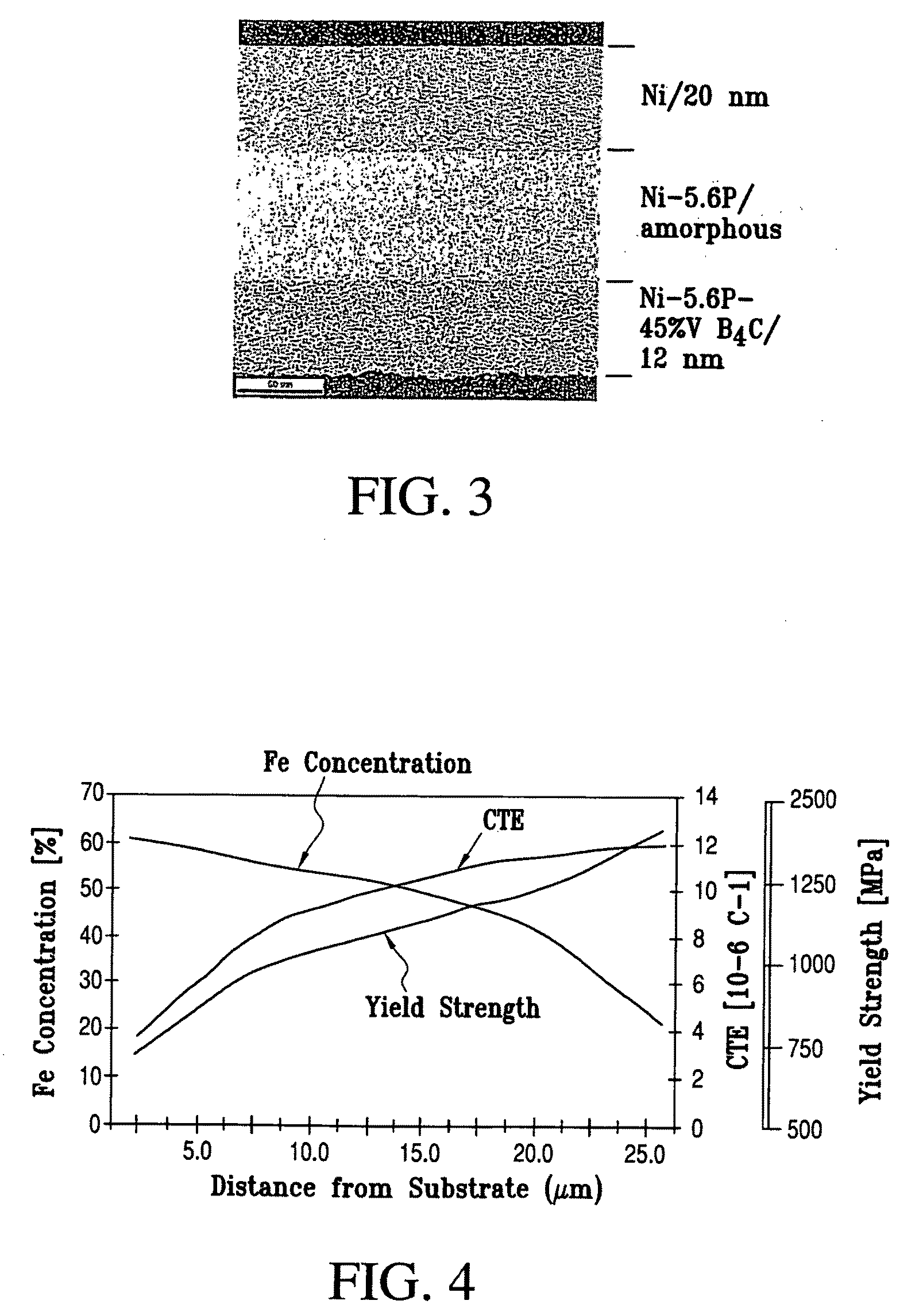

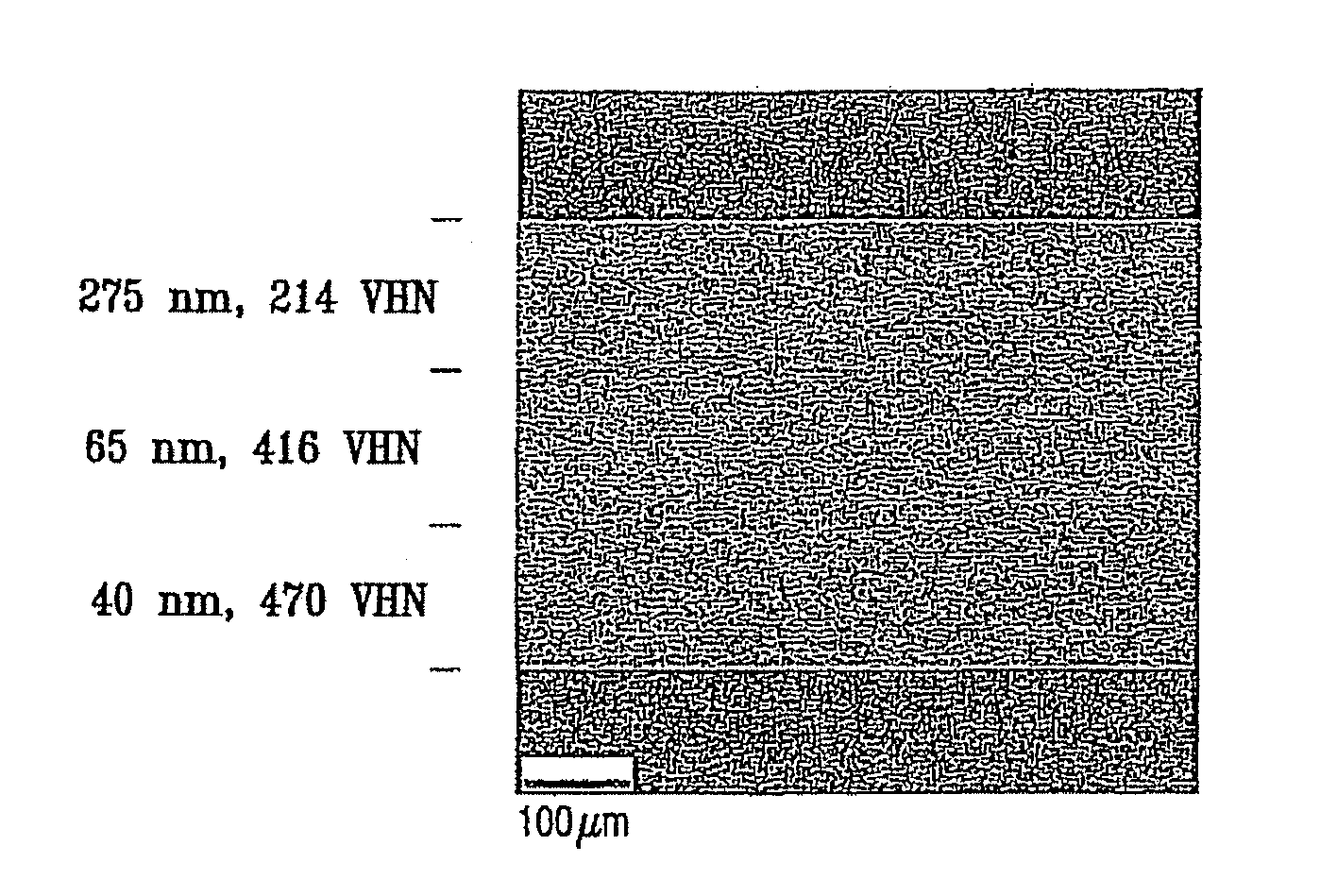

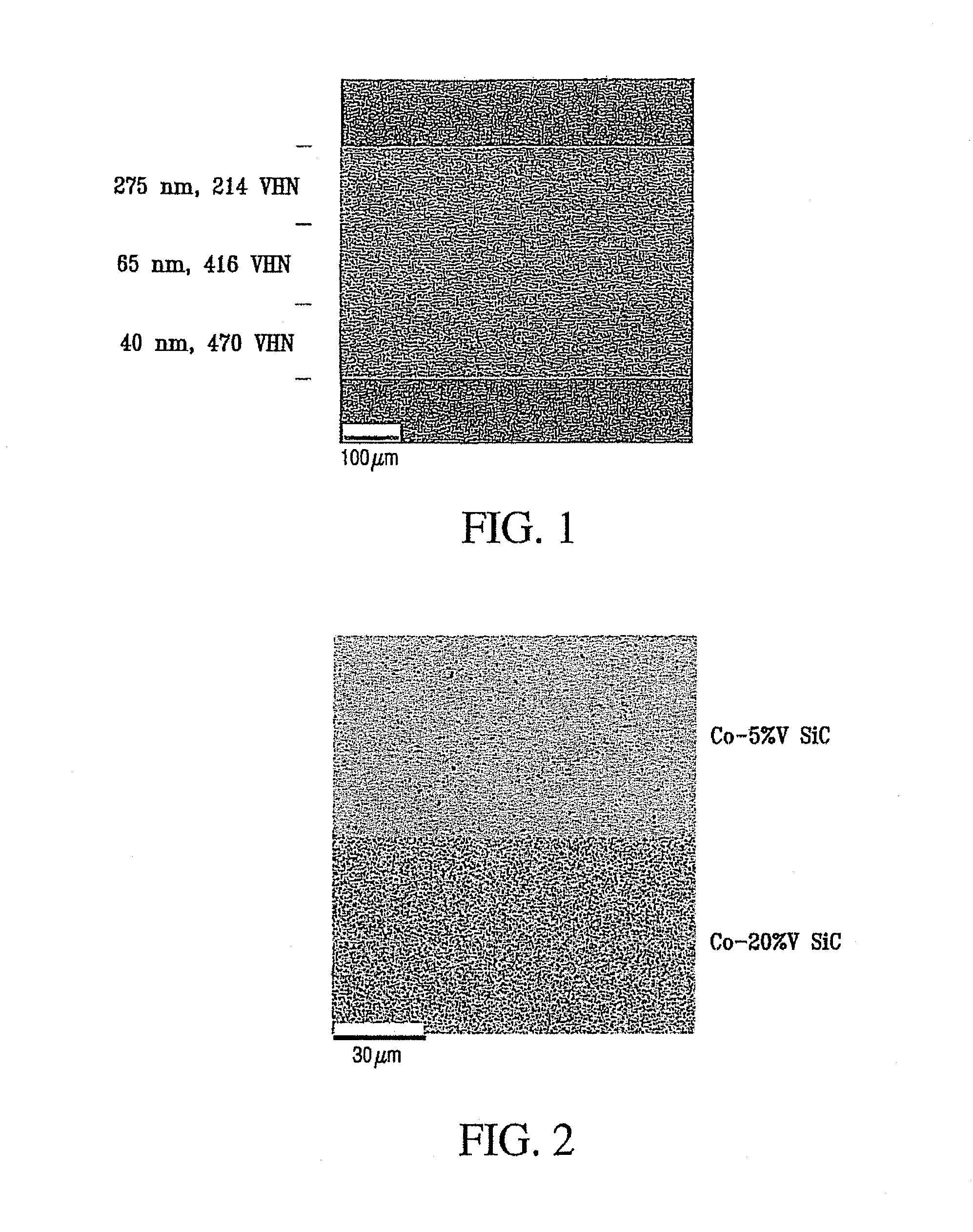

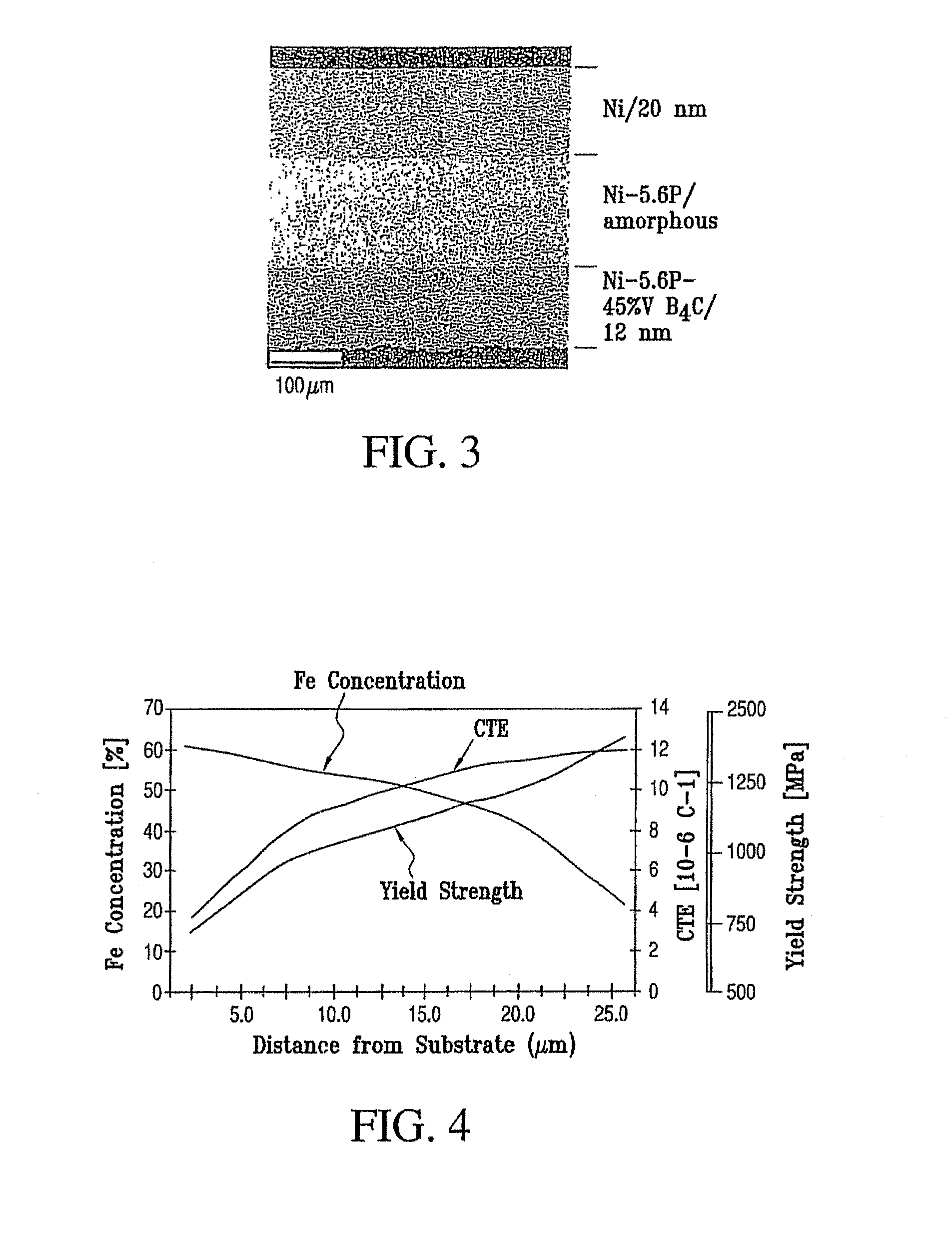

Variable property electrodepositing of metallic structures

ActiveUS20090159451A1Increase floor spaceAdd equipmentCellsElectrolytic coatingsParticulatesMetallic materials

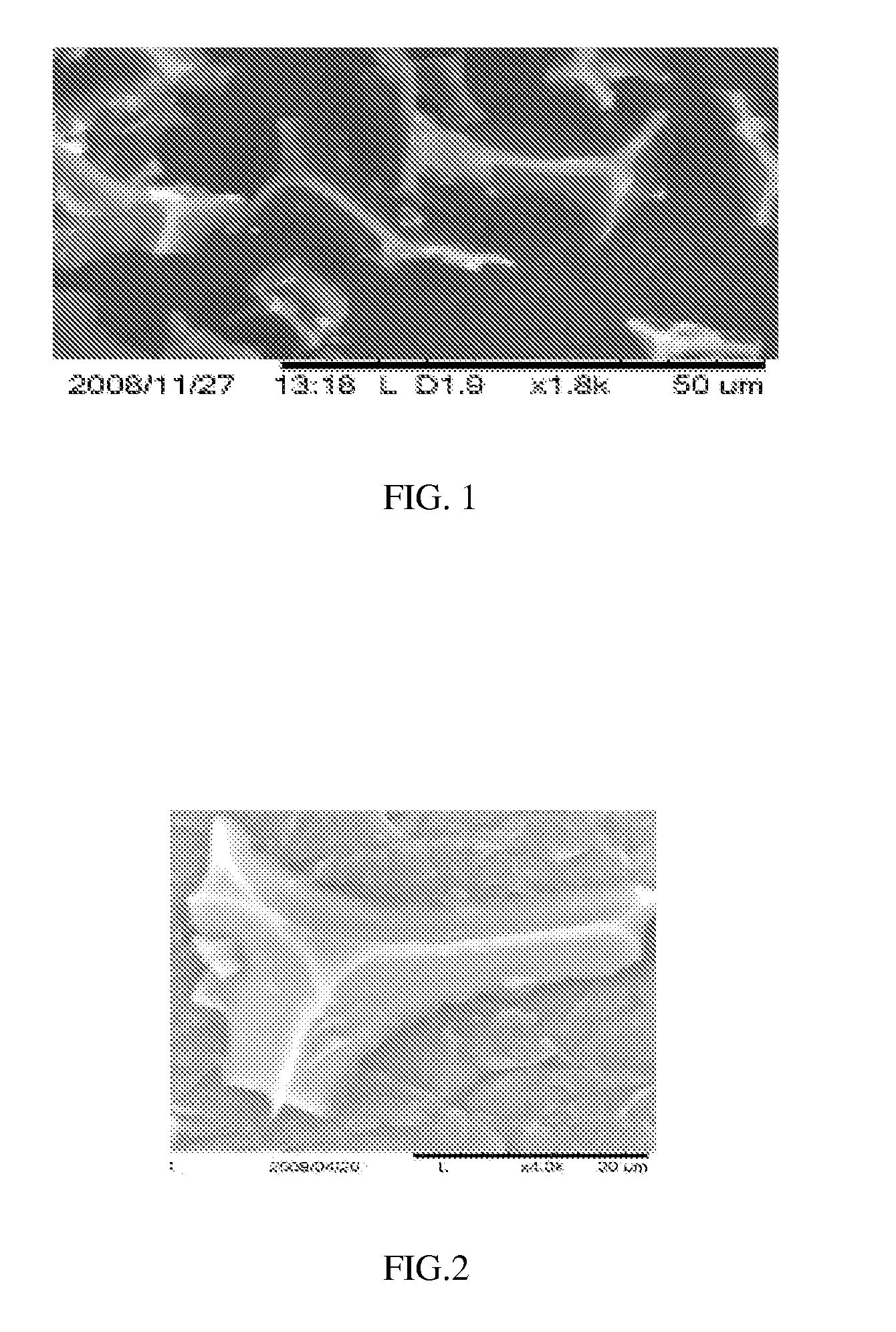

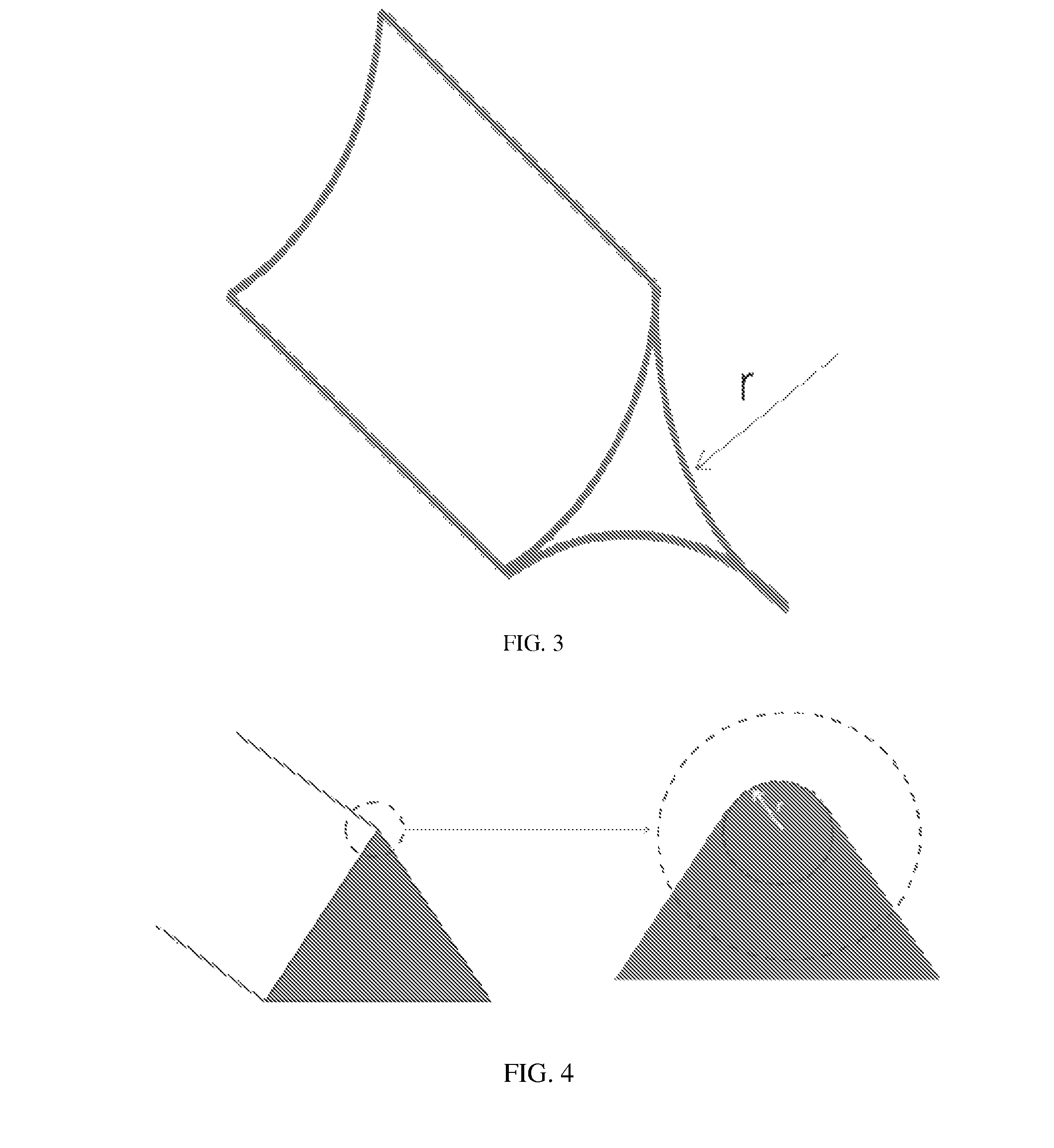

Variable property deposit, at least partially of fine-grained metallic material, optionally containing solid particulates dispersed therein, is disclosed. The electrodeposition conditions in a single plating cell are suitably adjusted to once or repeatedly vary at least one property in the deposit direction. In one embodiment denoted multidimension grading, property variation along the length and / or width of the deposit is also provided. Variable property metallic material deposits containing at least in part a fine-grained microstructure and variable property in the deposit direction and optionally multidimensionally, provide superior overall mechanical properties compared to monolithic fine-grained (average grain size: 2 nm-5 micron), entirely coarse-grained (average grain size: >20 micron) or entirely amorphous metallic material deposits.

Owner:INTEGRAN TECH

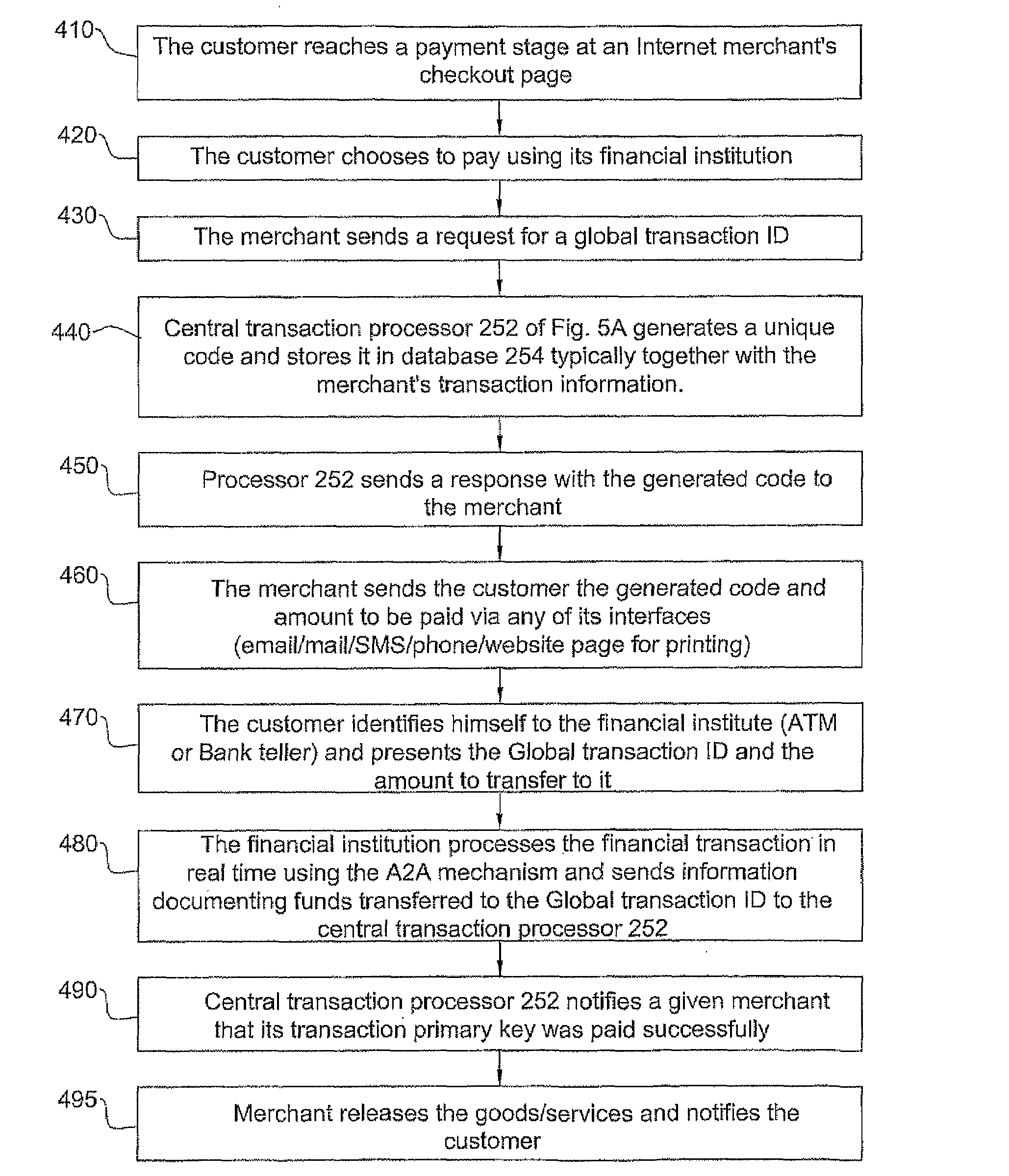

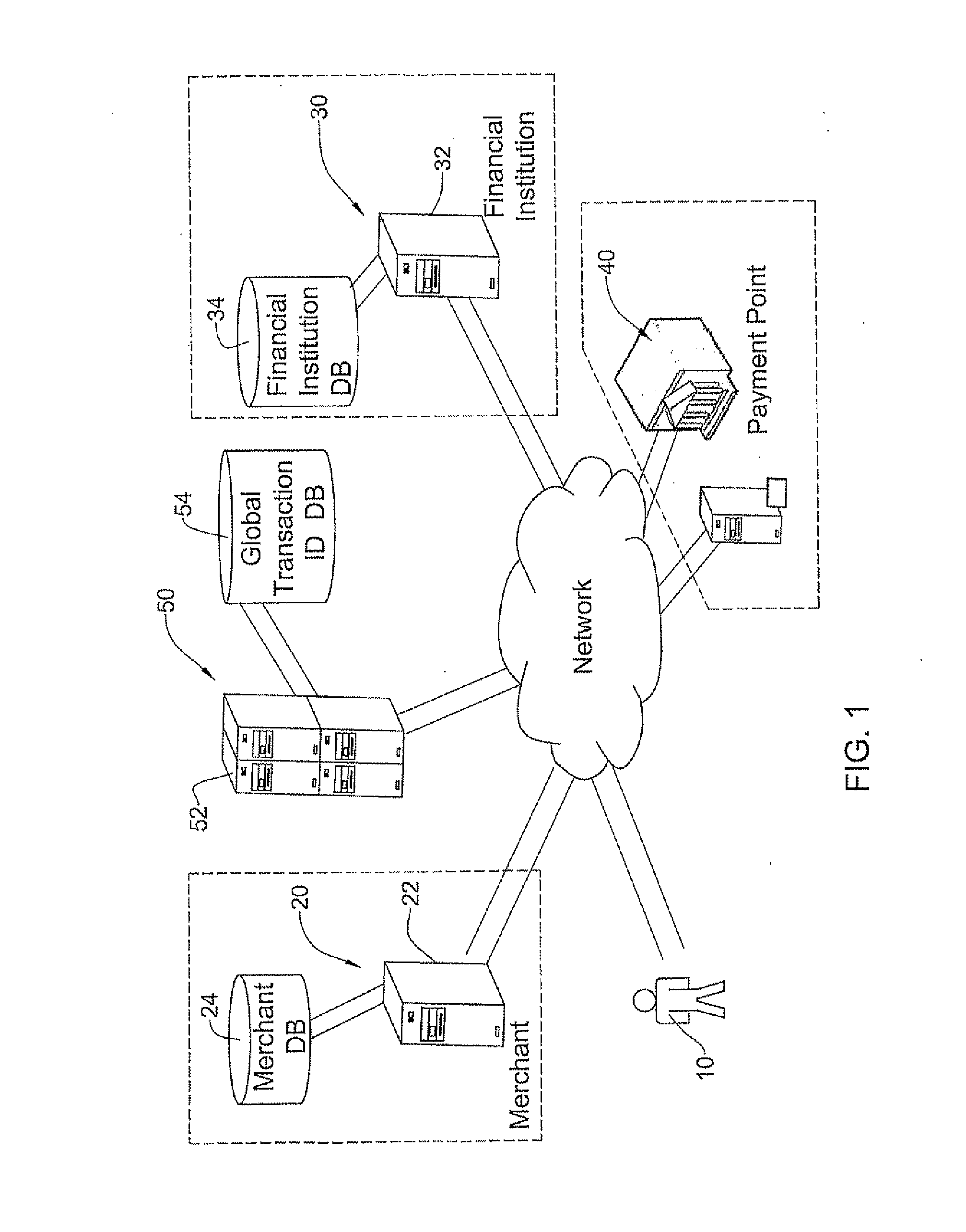

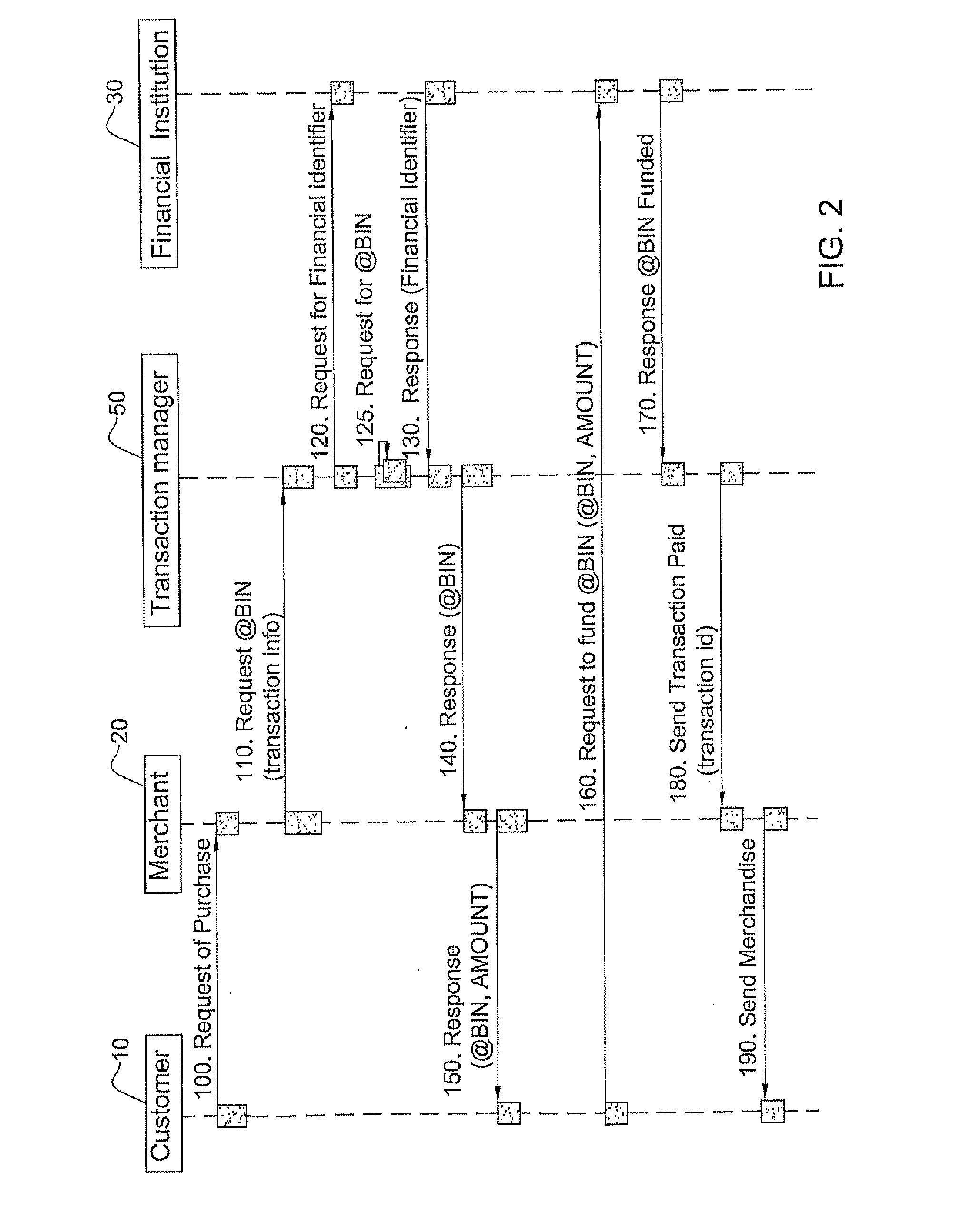

Secure mechanism and system for processing financial transactions

InactiveUS20090327133A1Raise security concernsImproved and highly secureFinanceDebit schemesPayment transactionFinancial transaction

A system for secure processing payment transactions between merchants and customers, via financial institutions, the system comprising apparatus for generating global transaction identifiers each of which is recognized by the merchants as a transaction ID and by the financial institutions as a fundable entity, and methods useful in conjunction therewith.

Owner:SEERGATE

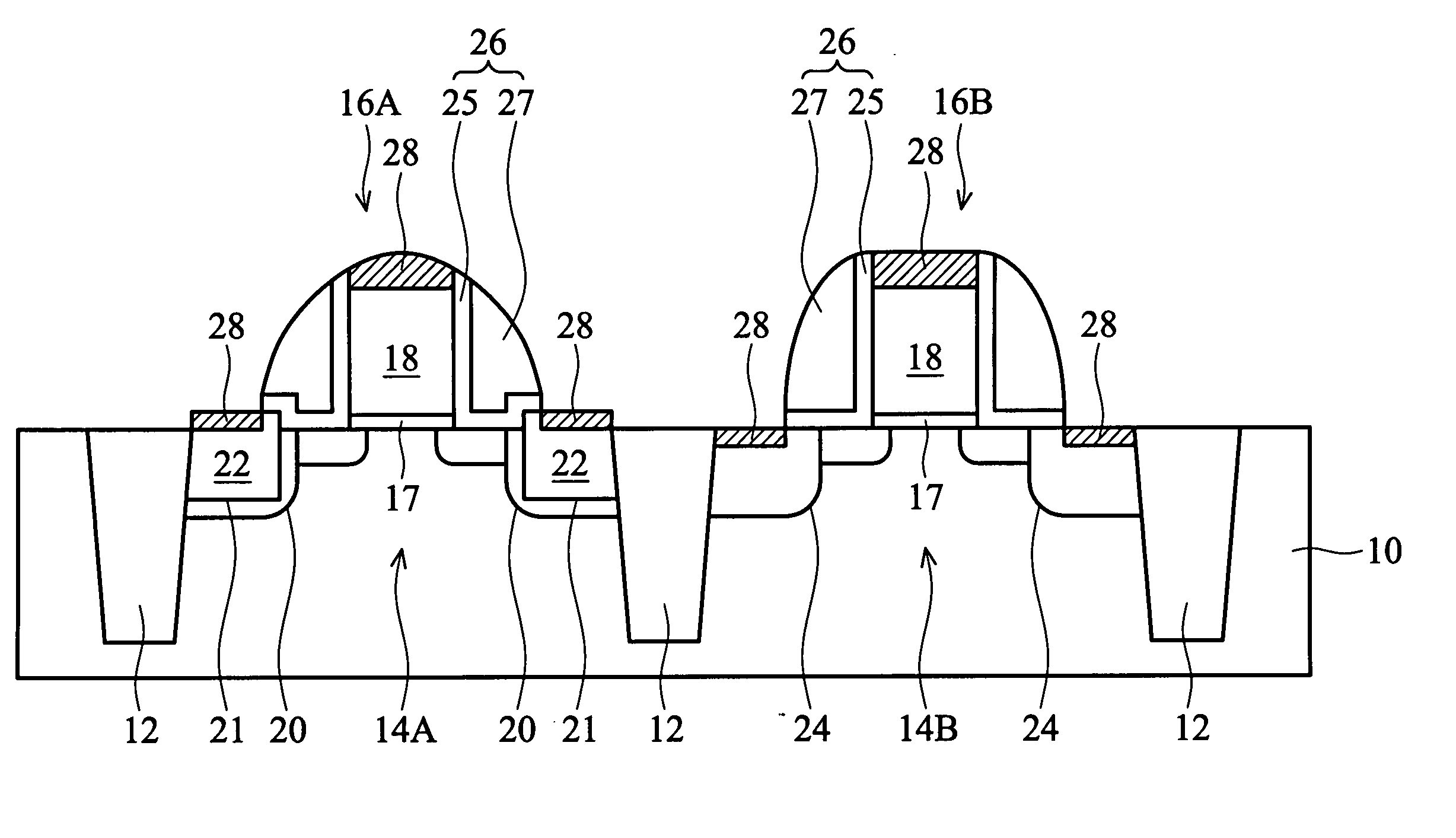

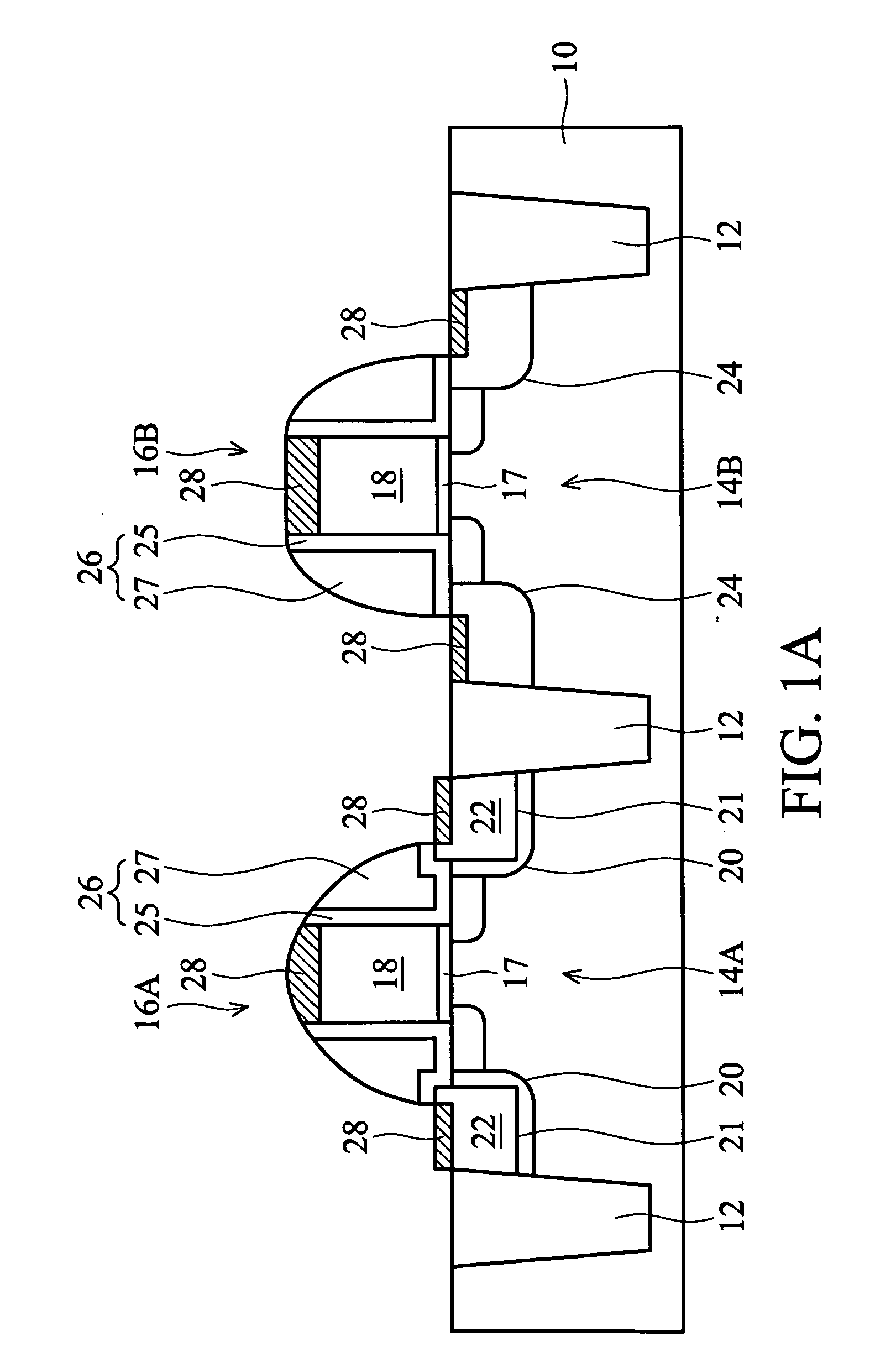

Strain enhanced CMOS architecture with amorphous carbon film and fabrication method of forming the same

InactiveUS20070200179A1High carrier mobilityImprove mobilitySemiconductor/solid-state device manufacturingSemiconductor devicesCMOSComposite material

A strain enhanced CMOS device using amorphous carbon films and fabrication methods of forming the same. The amorphous carbon (a-C) film, such as fluorinated amorphous carbon (a-C:F), is formed of a tensile film or a compressive film to act a stress capping film on the pMOS device region or the nMOS device region. The amorphous carbon film also acts a contact etching stop layer during a contact hole etching process.

Owner:TAIWAN SEMICON MFG CO LTD

Metallic Structures with Variable Properties

InactiveUS20110256356A1Increased durabilityIncrease floor spaceVacuum evaporation coatingSputtering coatingParticulatesMetallic materials

Variable property deposit, at least partially of fine-grained metallic material, optionally containing solid particulates dispersed therein, is disclosed. The electrodeposition conditions in a single plating cell are suitably adjusted to once or repeatedly vary at least one property in the deposit direction. In one embodiment denoted multidimension grading, property variation along the length and / or width of the deposit is also provided. Variable property metallic material deposits containing at least in part a fine-grained microstructure and variable property in the deposit direction and optionally multidimensionally, provide superior overall mechanical properties compared to monolithic fine-grained (average grain size: >20 micron) or entirely amorphous metallic material deposits.

Owner:INTEGRAN TECH

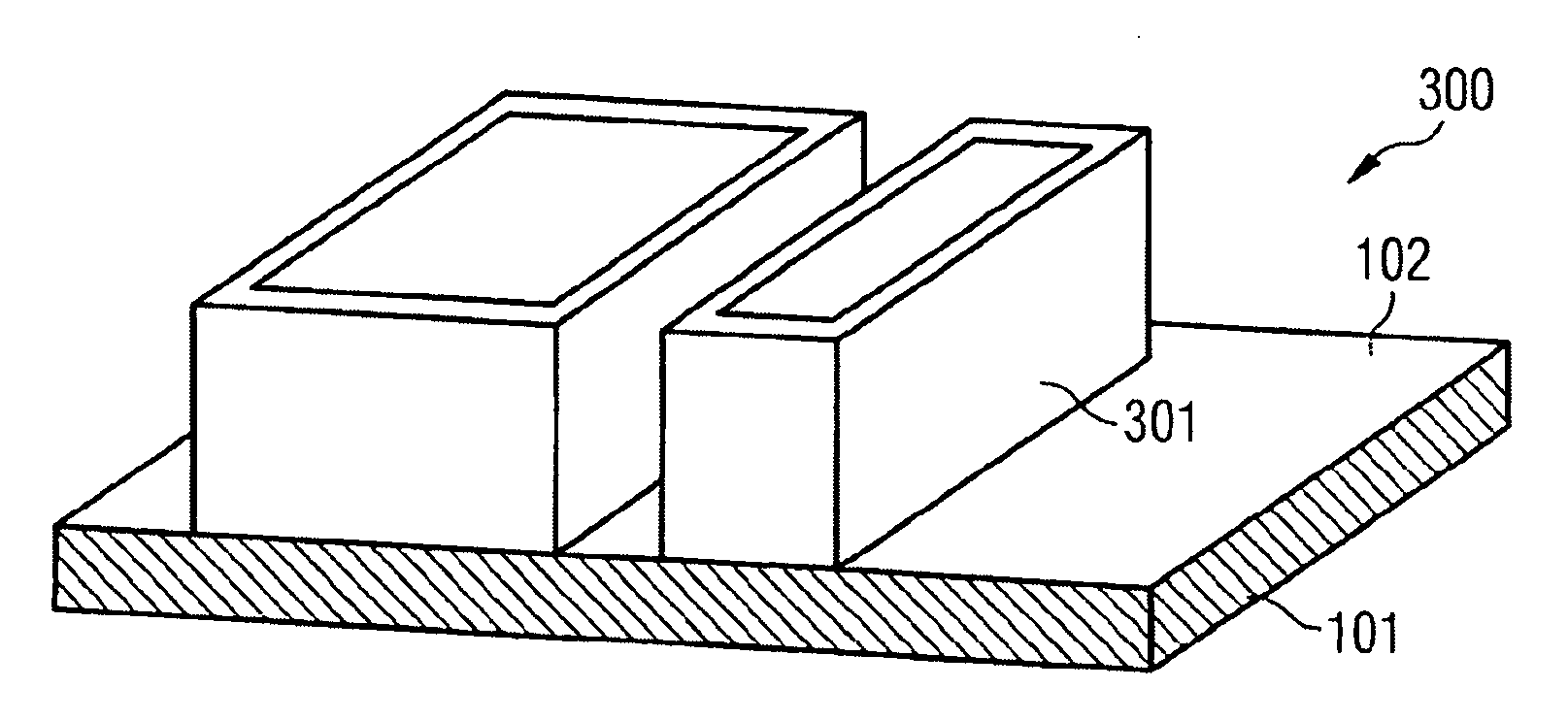

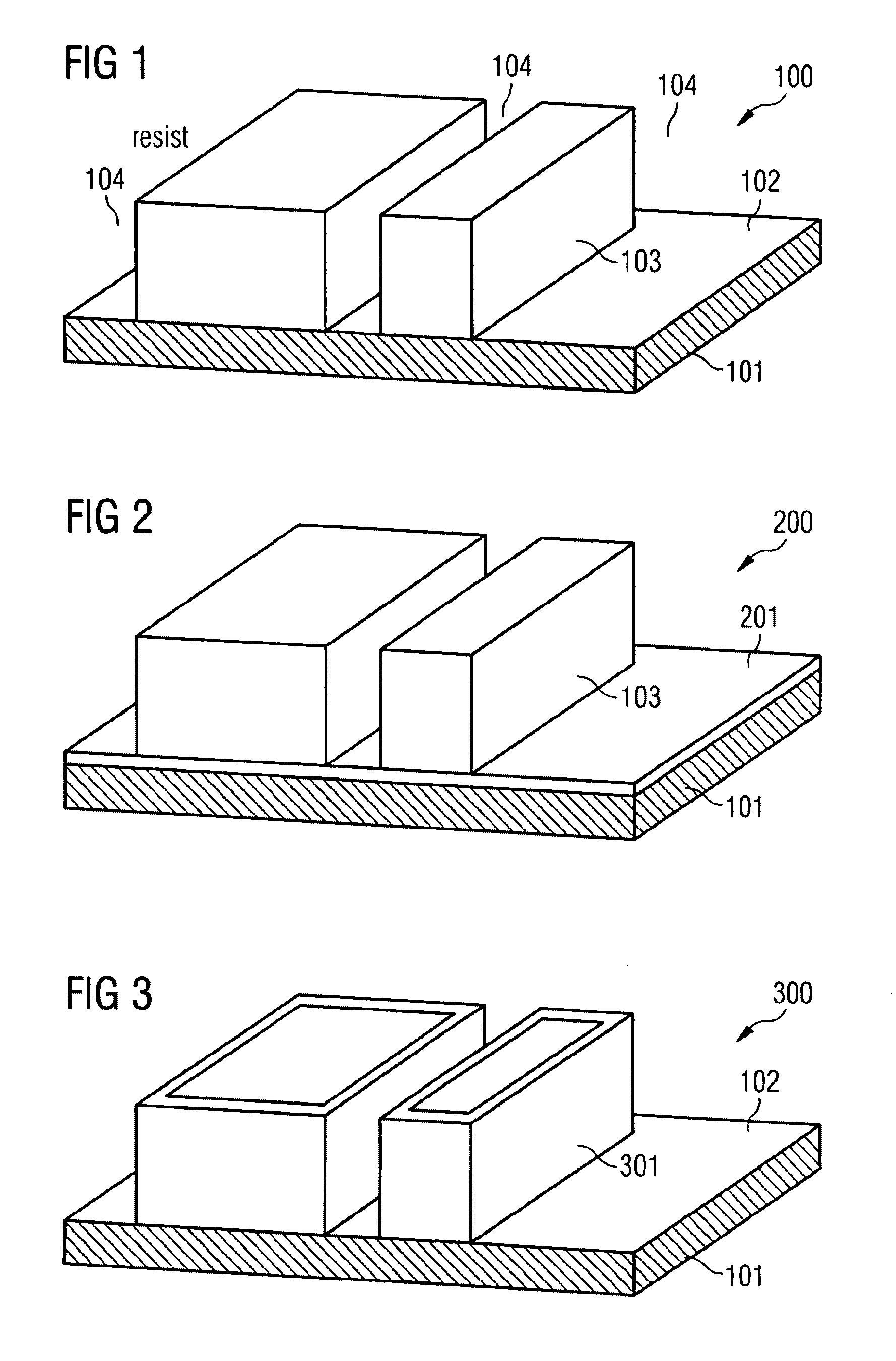

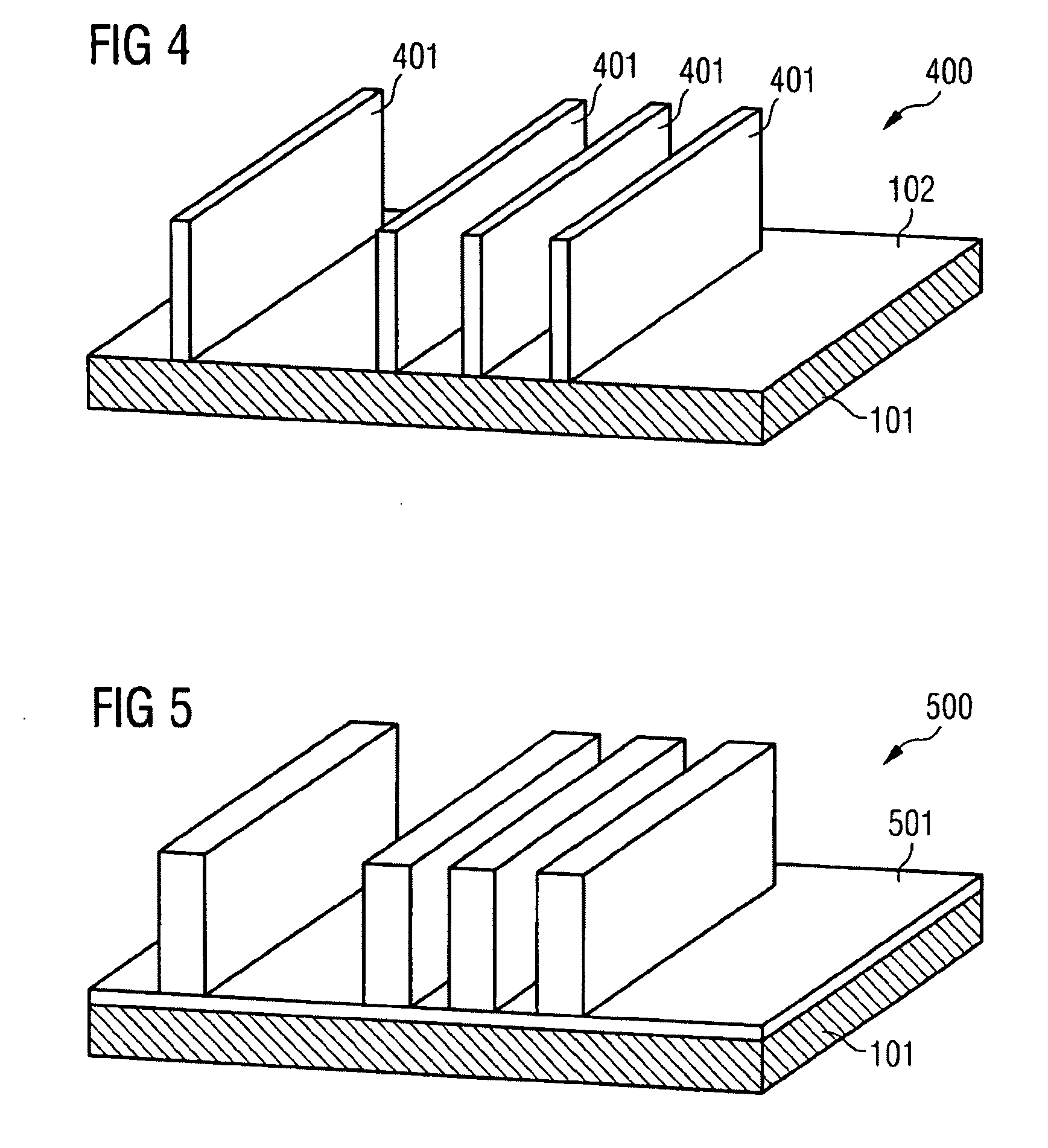

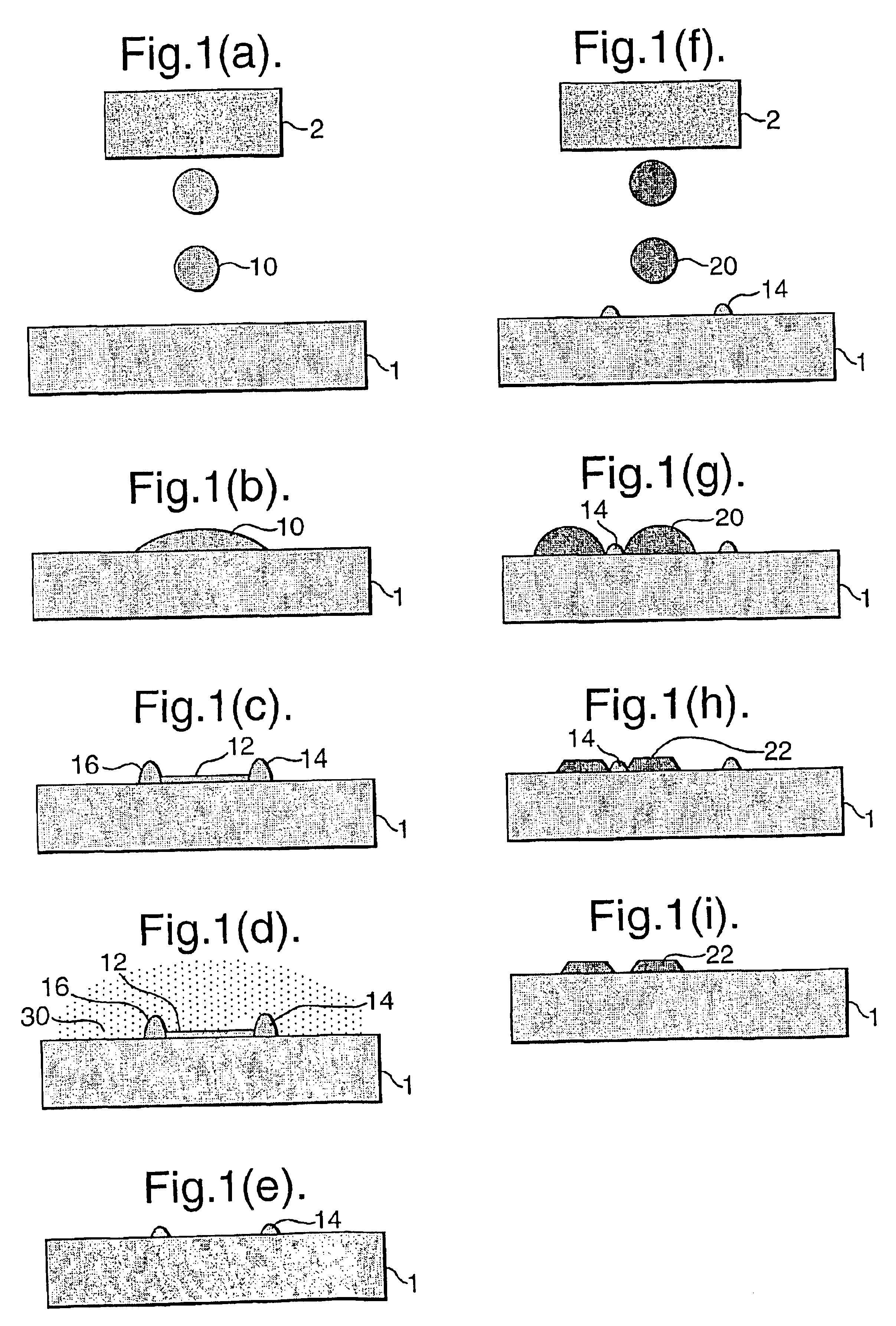

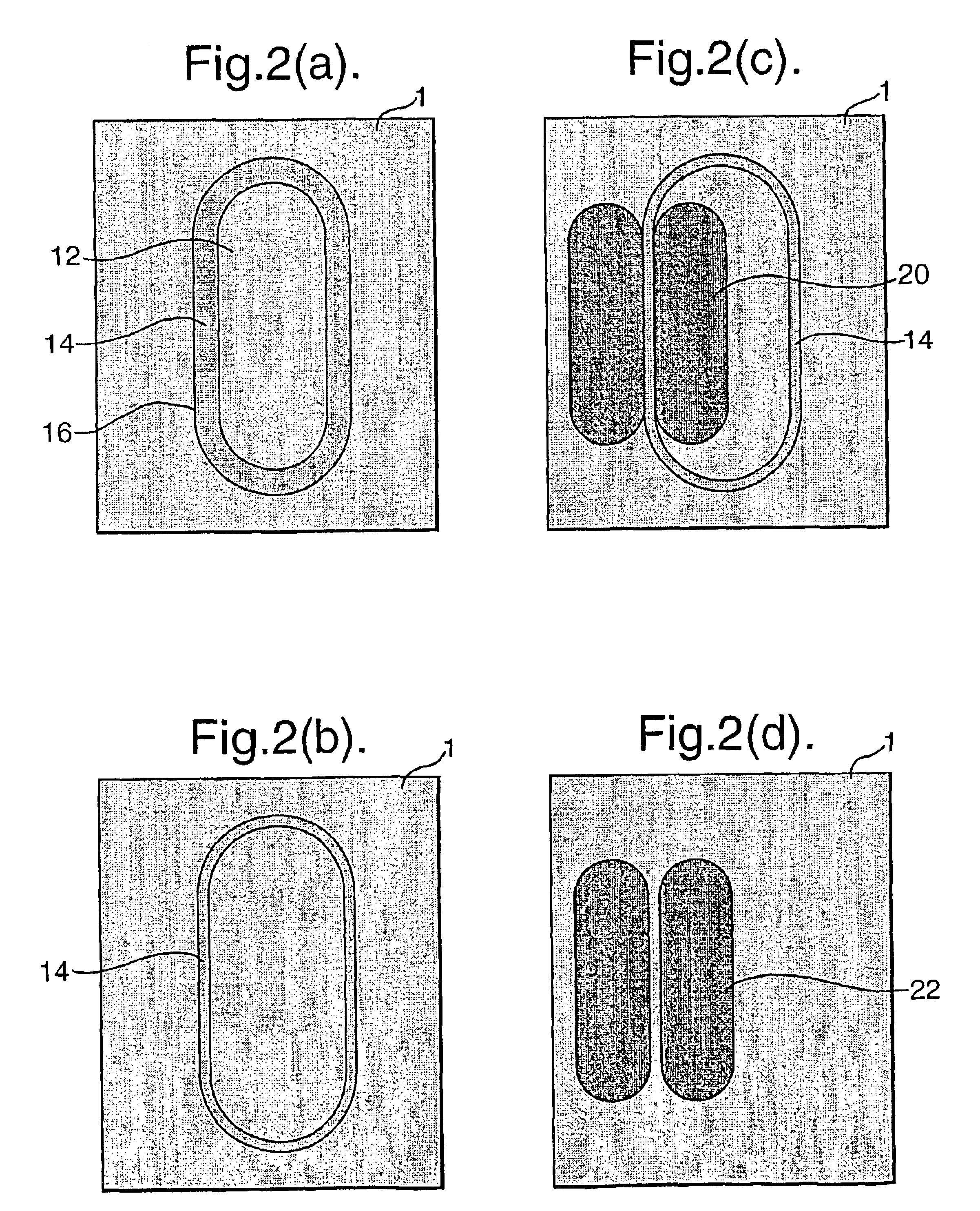

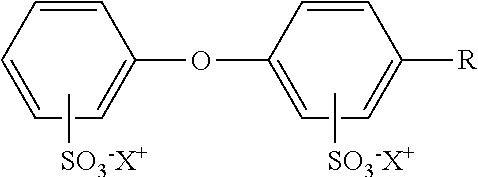

Method of patterning a substrate

InactiveUS6838361B2Increase processing costFew stepsTransistorElectroluminescent light sourcesAqueous solutionPolymer chemistry

The invention provides a method of pattering a substrate, in which a first material in solution is deposited on the substrate. The composition of the solution of the first material is selected so it dries to leave a residue of the first material on the substrate, the residue comprising a thin film in the centre and a ridge around the perimeter. The residue is etched to remove the thin film, leaving the ridge on the substrate. After etching the ridge is hydrophobic and the substrate is hydrophilic. An aqueous solution of a second material is then deposited on both sides of the ridge. After the aqueous solution has dried, the ridge is removed, leaving a layer of the second material on the substrate, the layer having a narrow gap therethrough. The layer may be used for the source and drain electrodes of an organic thin film transistor.

Owner:SEIKO EPSON CORP

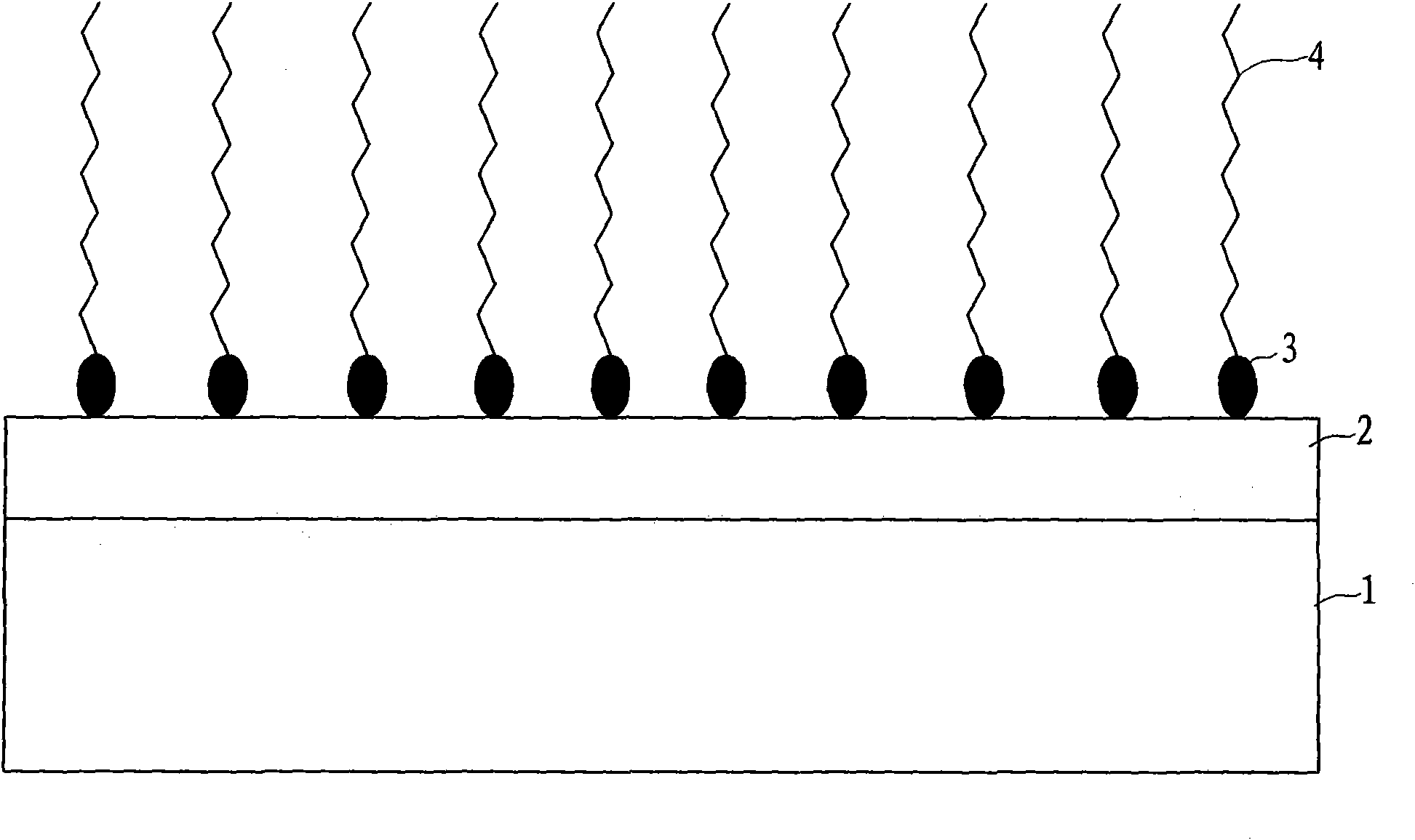

Preparation method of photovoltaic glass surface antireflection film

The invention discloses a preparation method of a photovoltaic glass surface antireflection film, which is characterized by comprising the following steps of firstly, preparing inorganic-organic hybrid silicasol; secondly, coating; thirdly, hydrophobic treatment; and fourthly, solidification treatment. Compared with the prior art, the invention has the advantages that the film-substrate cohesion between an antireflection film and substrate photovoltaic glass is stronger, and therefore, the wiping resistance of the coated photovoltaic glass surface antireflection film is enhanced; a layer of hydrophobic group with low surface energy is formed on the surface of the antireflection film, and therefore, the corrosion of moisture to a film microstructure is reduced, and the long service life of the coated photovoltaic glass is ensured; and the invention has low whole process cost and simple technical route and is suitable for industrial and large-scale application.

Owner:CHANGZHOU ALMADEN

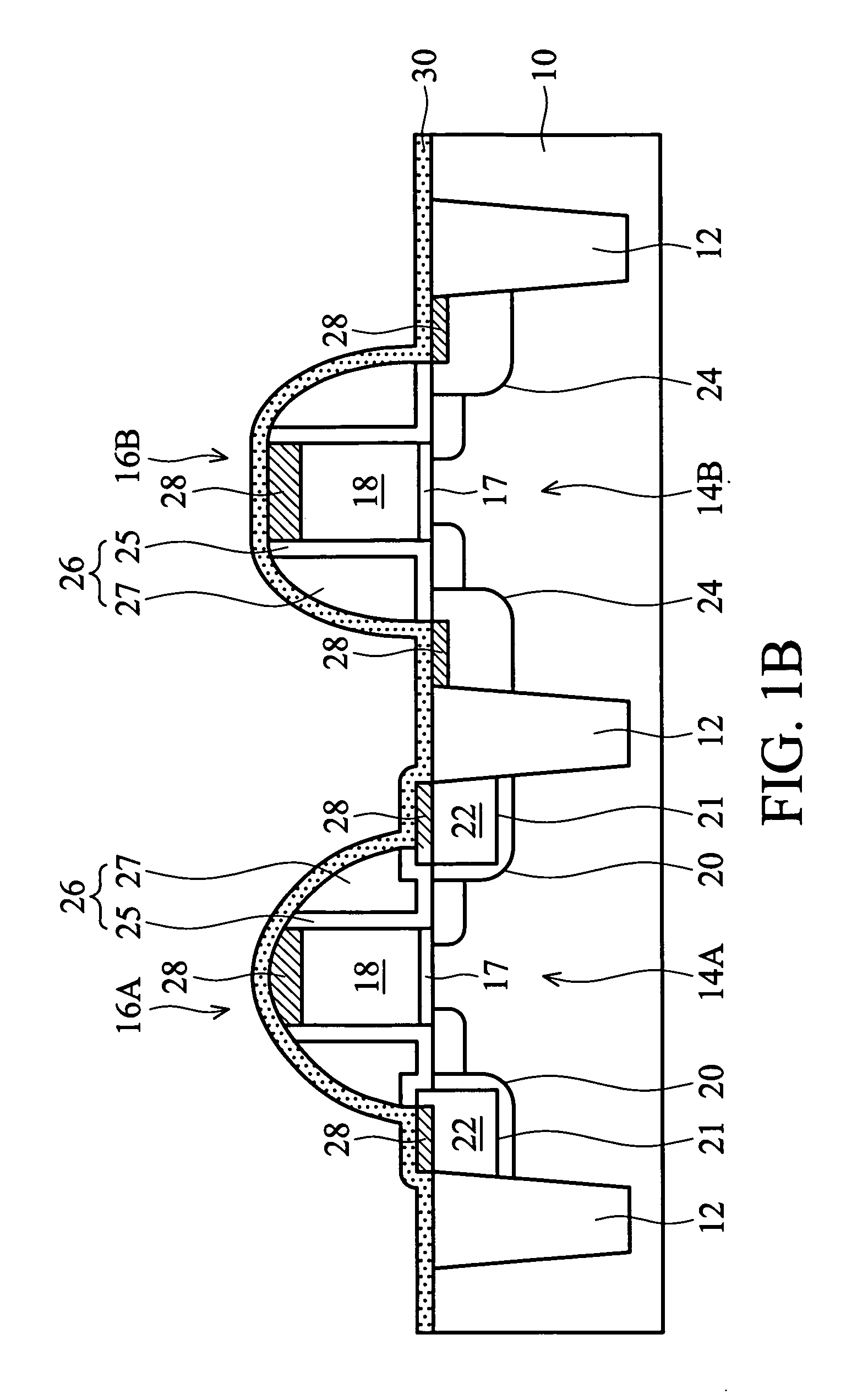

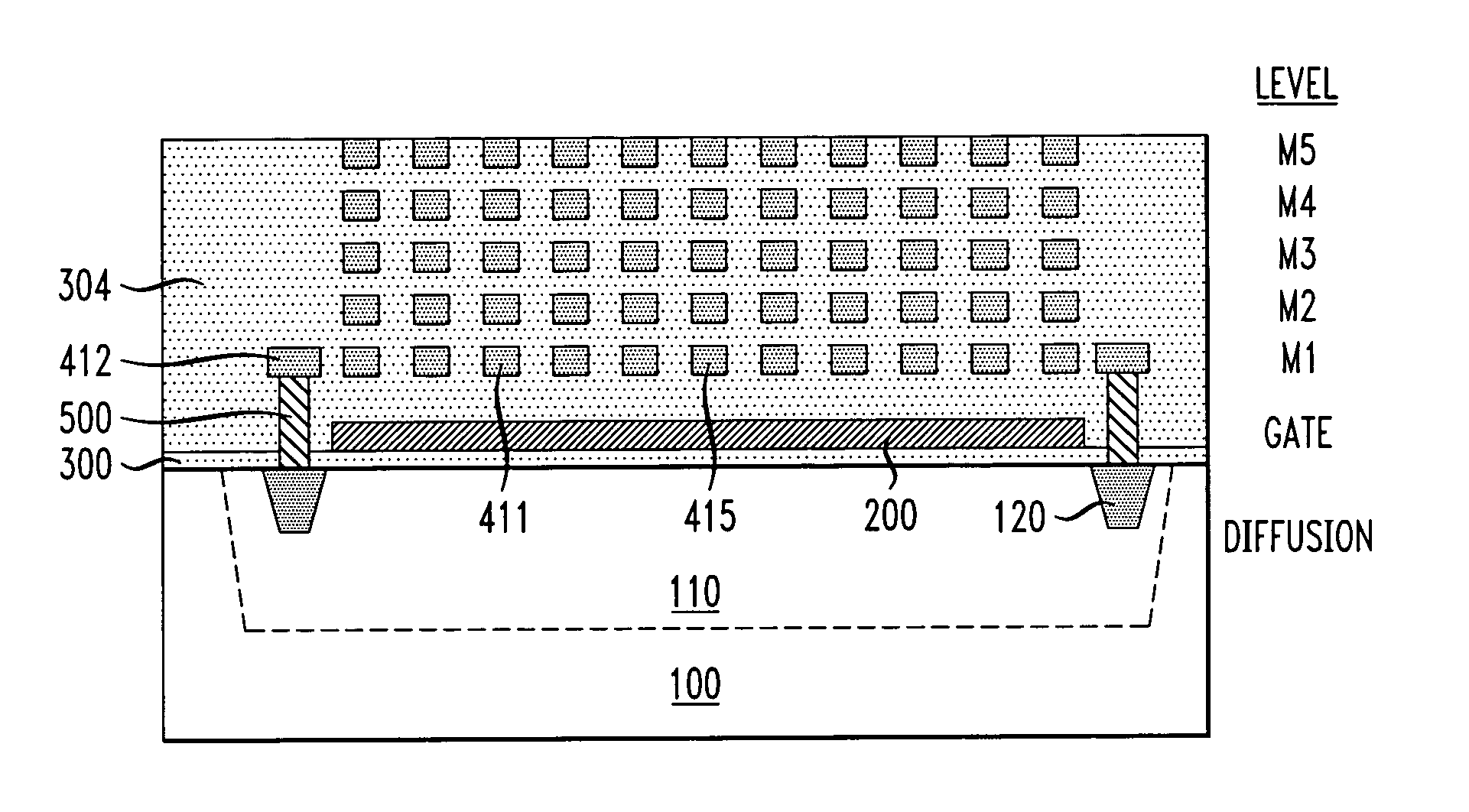

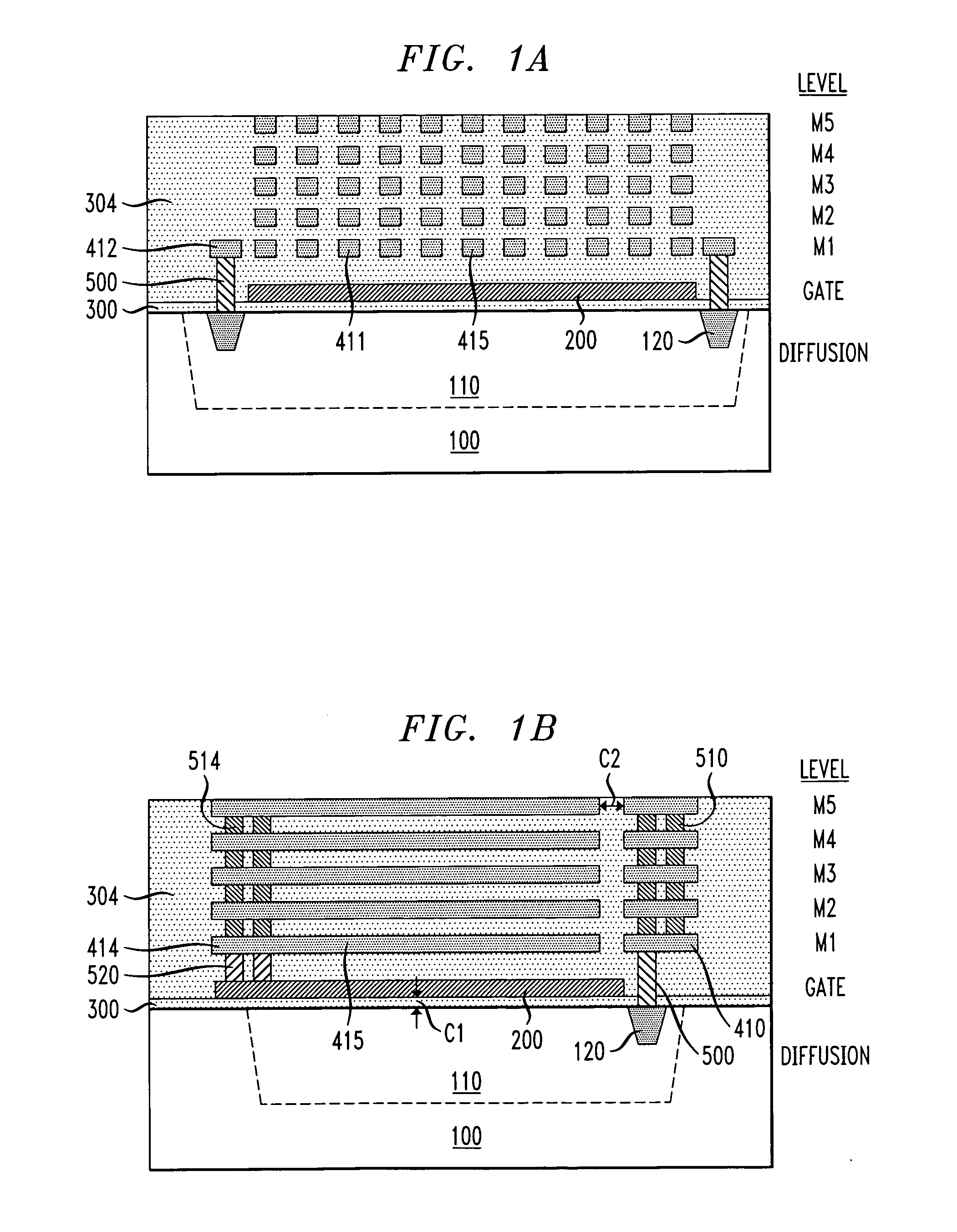

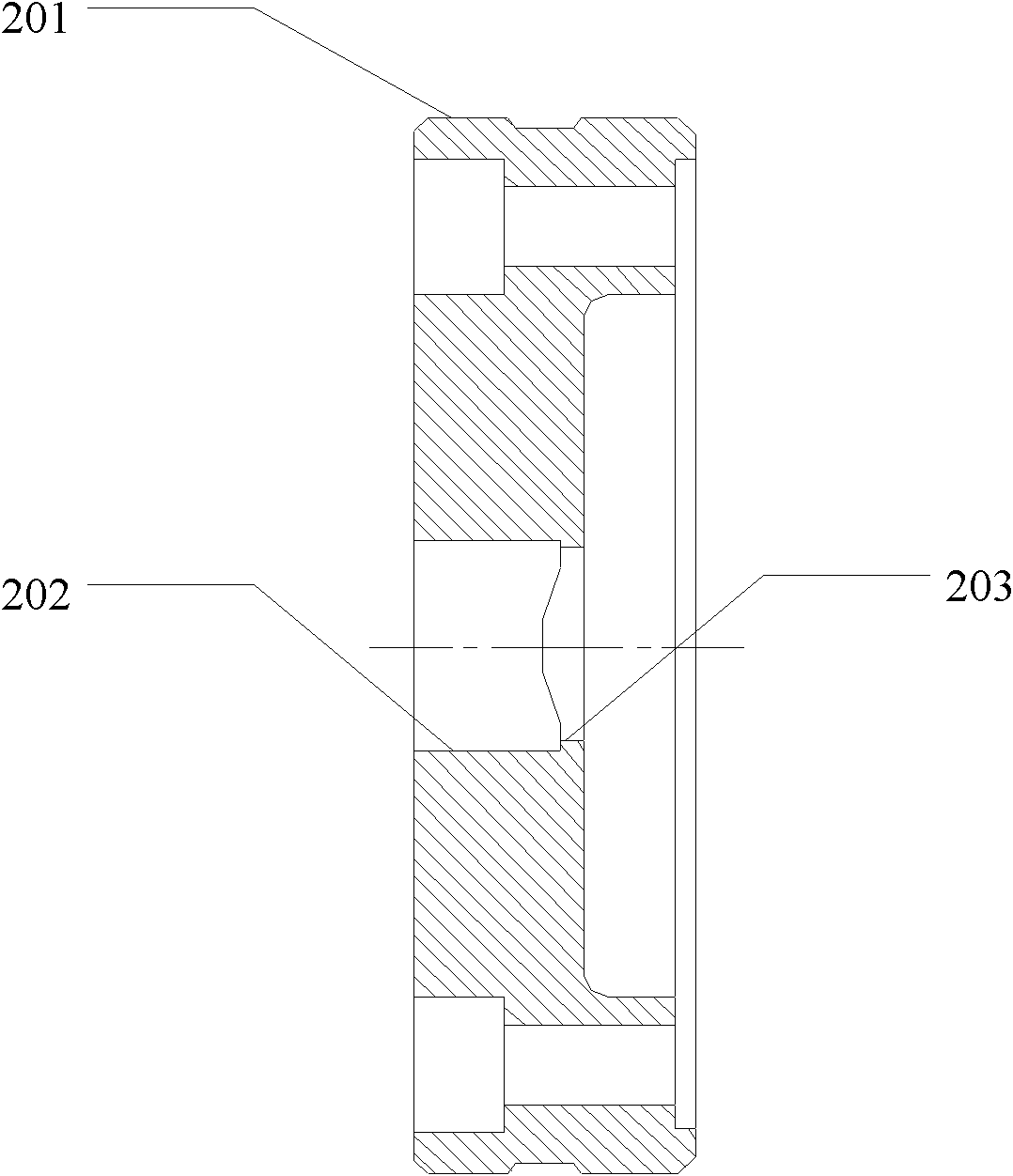

Metal capacitor stacked with a MOS capacitor to provide increased capacitance density

InactiveUS20060024905A1Increase capacitance densityIncrease processing costTransistorSemiconductor/solid-state device detailsCapacitanceMetal interconnect

An on-chip capacitive device comprises a semiconductor substrate, a MOS capacitor formed on the semiconductor substrate, and a metal interconnect capacitor formed at least in part in a region above the MOS capacitor. The MOS capacitor and the metal interconnect capacitor are connected in parallel to form a single capacitive device. The capacitance densities of the MOS capacitor and the metal interconnect capacitor are, thereby, combined. Advantageously, significant capacitance density gains can be achieved without additional processing steps.

Owner:BELL SEMICON LLC

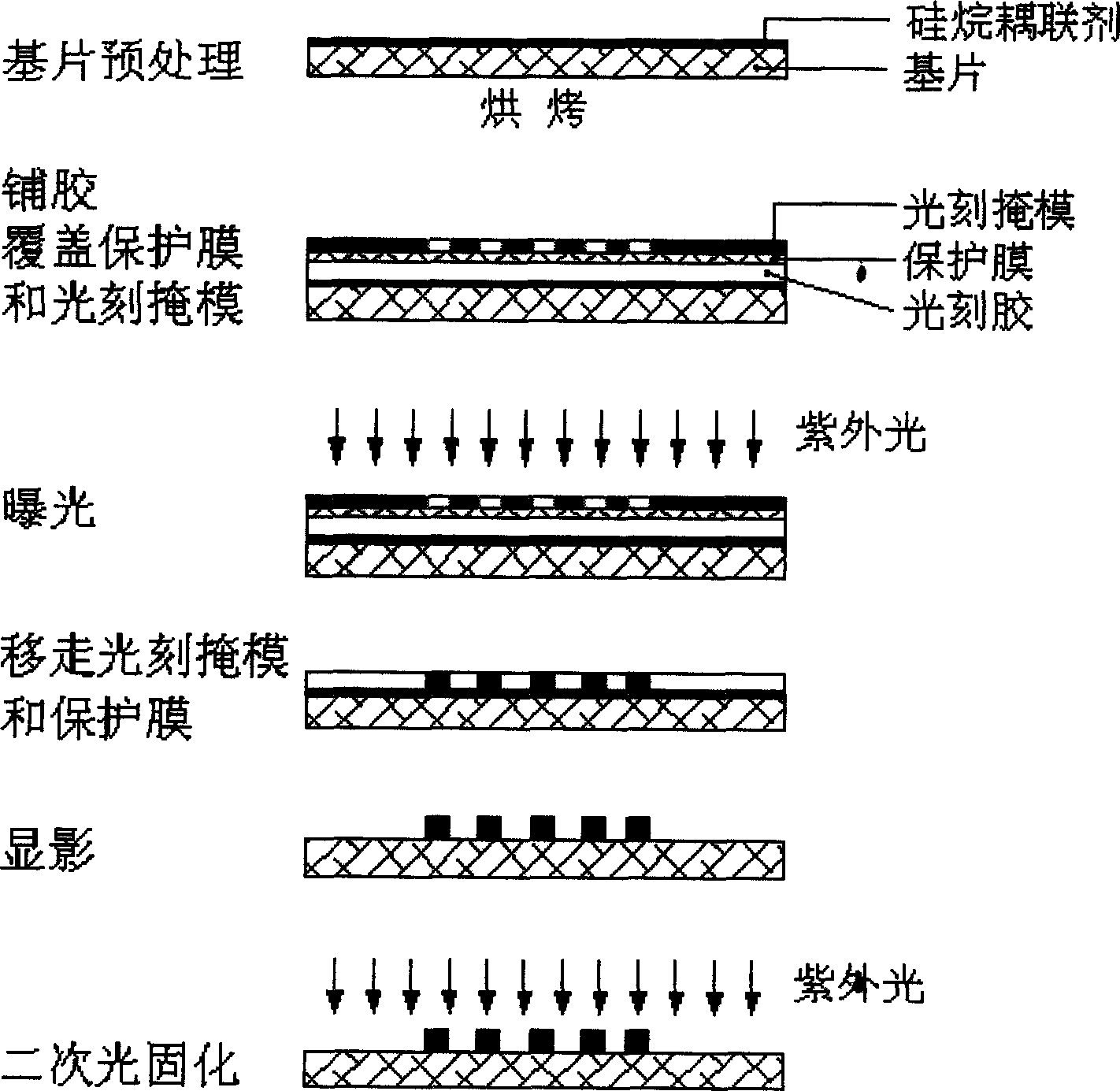

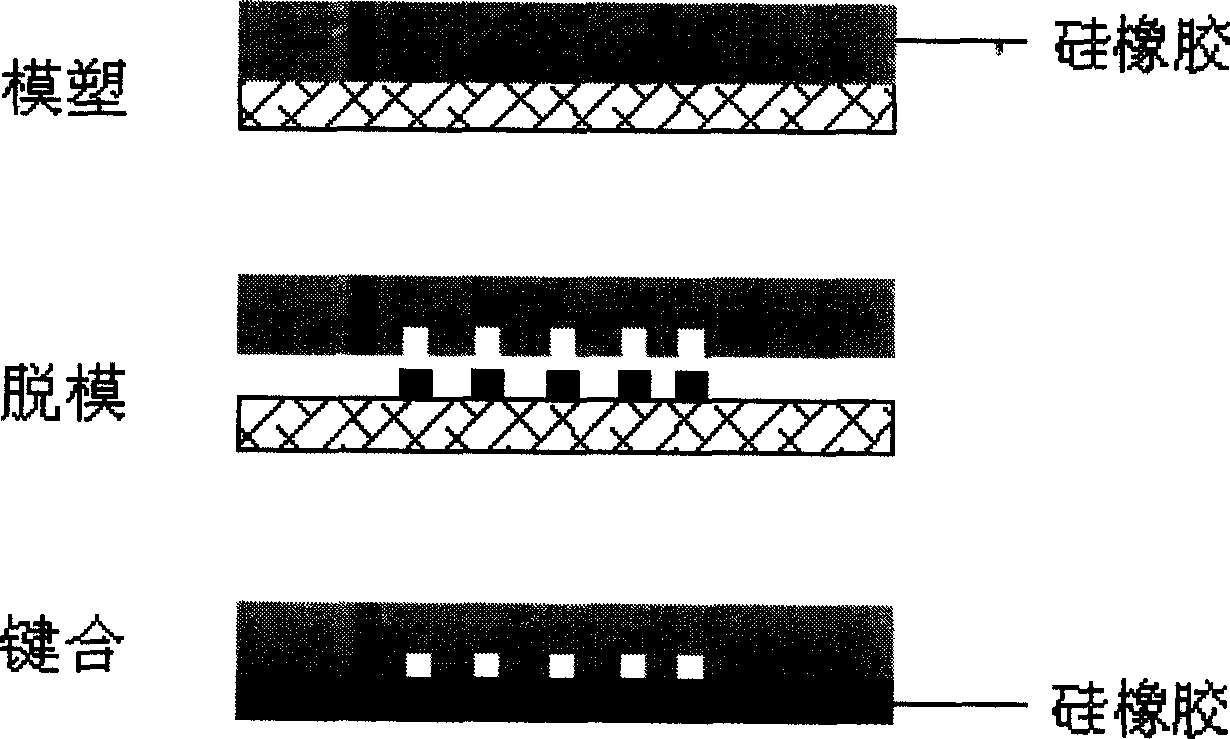

Method for making dimethyl silicone polymer micro flow control chip composite type optical cured resin die arrangement

InactiveCN1621945ASolve sticking problemsHigh speedPhotomechanical exposure apparatusMicrolithography exposure apparatusEtchingSilanes

The present invention discloses the making process of composite photocuring resin mold for preparing microfluid controlling chip of polydimethyl siloxane. The present invention adopts liquid photoresist of photosensitive epoxy resin as micro mold material, quartz glass as substrate, silane coupler coating on the substrate to increase the binding force between the mold structure and the substrate, plastic film of different thickness adhered around the substrate to control the thickness of photoresist, photoetching mask of photosensitive film from laser photoset, common ultraviolet lamp or ultraviolet laser as exposure light source, F46 film as exposure protecting film, absolute alcohol as developer, vibration for clear development contour and secondary photocuring after development to raise structure strength and structure-substrate binding force. The mold is used in copying microfluid control chip, biochip, soft mold for impression etching, etc.

Owner:XI AN JIAOTONG UNIV

Semiconductor integrated circuit package and method of packaging semiconductor integrated circuit

InactiveUS20090236713A1Reduce the possibilityEasy to flow outTailstocks/centresSemiconductor/solid-state device detailsShell moldingSurface mounting

In a method of packaging a semiconductor IC, a tape is attached to a back surface of a lead frame array, and the lead frame array is held between an upper mold chase and a lower mold chase of a mold, with the back surface of the lead frame array upward. The upper and lower mold chases form an upper cavity and a lower cavity with respect to the lead frame array respectively. A mold compound is injected into the upper and lower cavities respectively. With respect to clearances between leads, between die pads and / or between the leads and the die pads, the mold compound injected into the upper cavity covers the portion of the tape over the clearances before the mold compound injected into the lower cavity fills the clearances, so that the tape is depressed. After curing the mold compound, removing the mold and de-taping, the mold compound filled in the clearances is recessed inward from the back surface, which increases the solderability in the subsequent surface mount process and decreases the possibility of the occurrence of lead short-circuits.

Owner:NXP USA INC

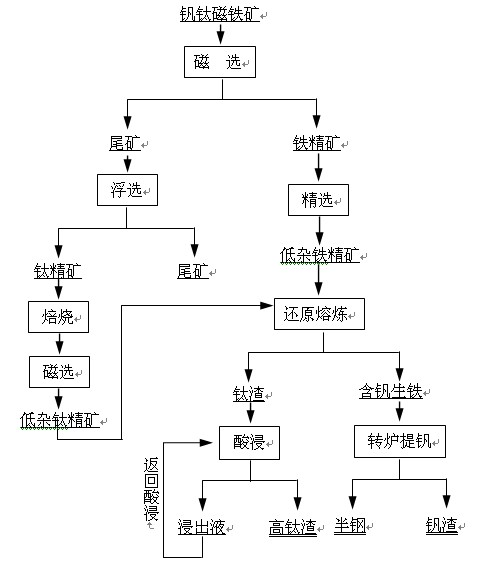

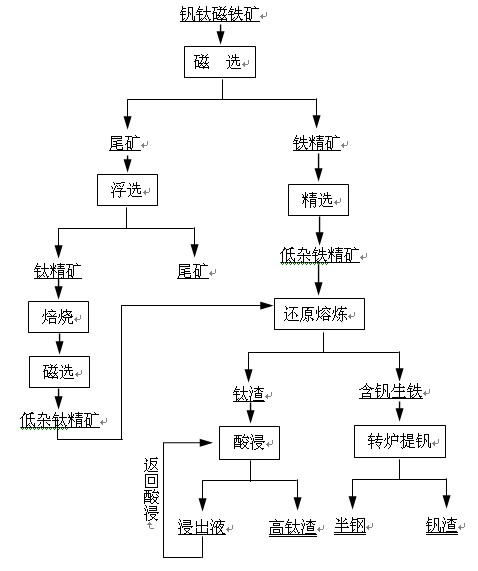

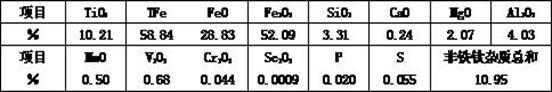

Method for separating vanadium-titanium magnetite to extract iron, vanadium and titanium

InactiveCN102179292AHigh technical difficultyIncrease processing costWet separationSmelting processMagnetite

The invention discloses a method for separating vanadium-titanium magnetite to extract iron, vanadium and titanium, comprising the following steps of: magnetically selecting raw magnetite, that is, acquiring iron-vanadium concentrate and tail magnetite after performing magnetic selection on the vanadium-titanium magnetite; sorting titanium concentrate from the tail magnetite, that is, acquiring the titanium concentrate after performing floating selection on the obtained tail magnetite; roasting and magnetically selecting the titanium concentrate, that is, performing enriched-titanium impurity-removing magnetic selection after roasting the titanium concentrate; finely selecting the iron-vanadium concentrate, that is, performing the magnetic selection and fine section again on the iron-vanadium concentrate obtained from magnetic selection; reducing and smelting, that is, mixing the titanium concentrate obtained from the impurity-removing process with the iron concentrate according to the beneficiation yield, adding in a reducer and soda ash to perform reduced iron and vanadium smelting process; purifying vanadium slag, that is, removing the impurity of the vanadium slag obtained by reducing and smelting by using the acidic dipping to obtain the high-quality titanium slag product with the content of TiO2 larger than 92%; and extracting vanadium from pig iron, that is, performing vanadium extraction by converter blowing on the vanadium-containing pig iron obtained by reducing and smelting to obtain the semi-steel and vanadium slag. The method not only improves the utilization ratio of titanium, iron and vanadium but also obtains the high-titanium slag product with the content of TiO2 larger than 92% so as to widen the application field of titanium.

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

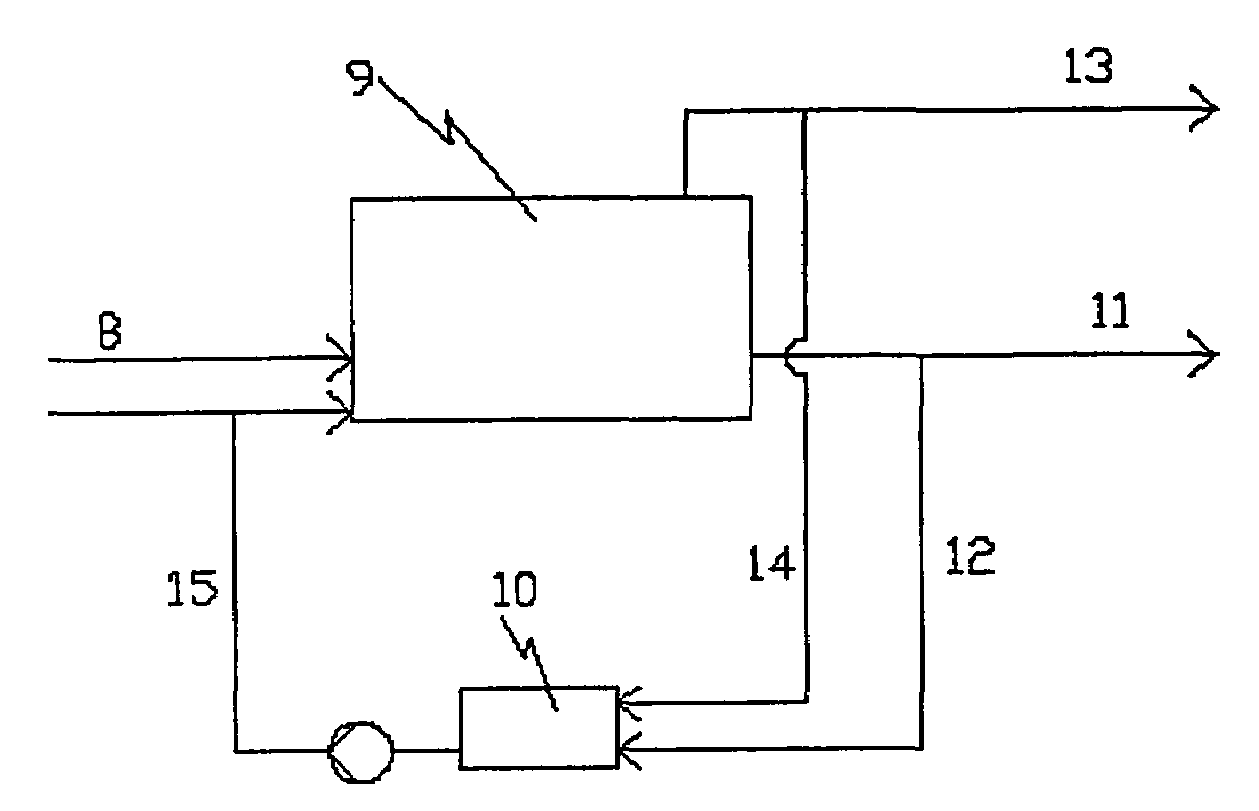

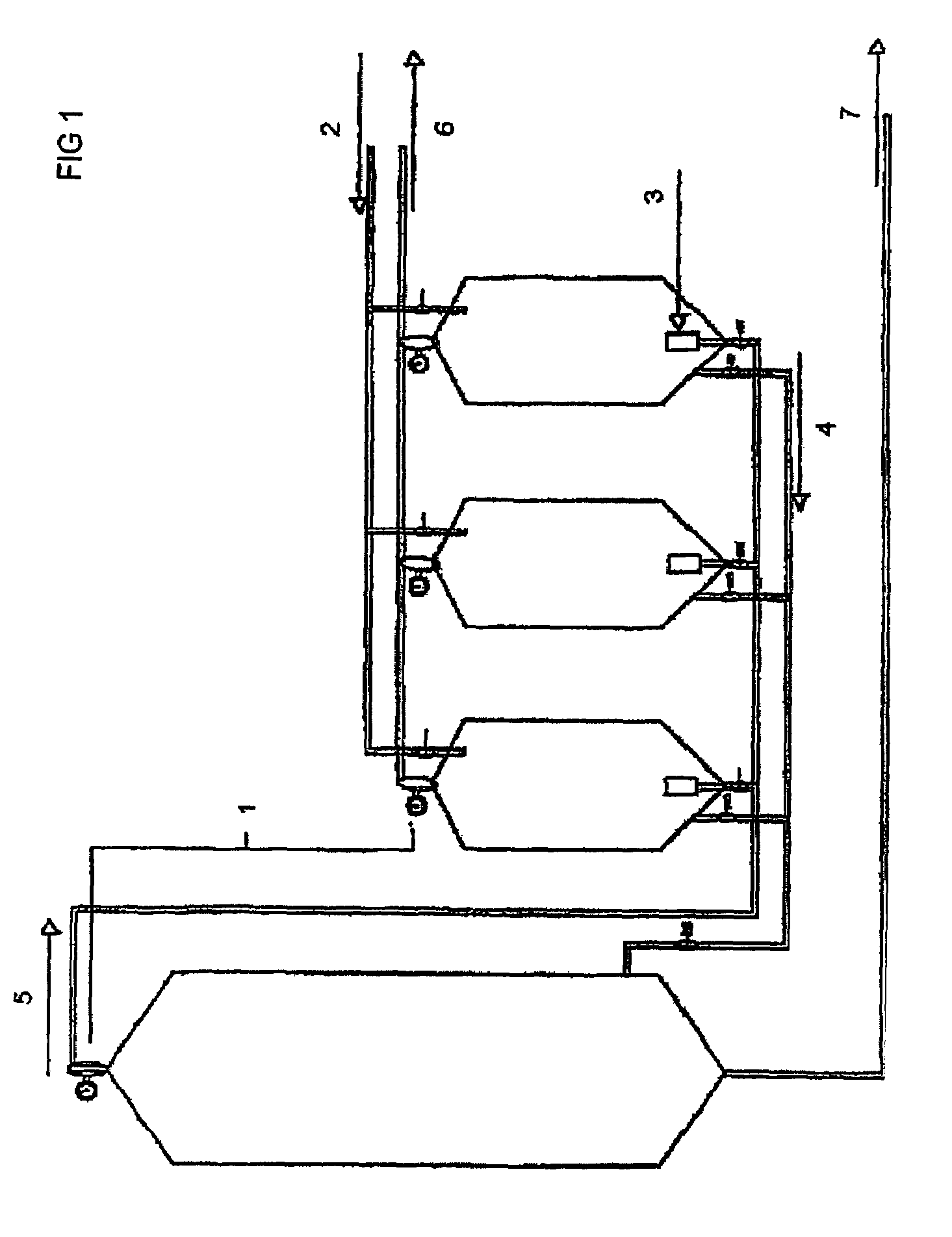

Method and equipment for processing organic material

InactiveUS7160456B2Organic material longerEasy to storeBio-organic fraction processingAnimal corpse fertilisersBuffer solutionAmmonia

A method for processing organic material, in which method bioconversion is performed on the organic material in at least one first reactor, the biogas formed in the bioconversion is treated with ammonia in at least one second reactor and buffer solution produced in the second reactor is recycled to the bioconversion in the first reactor. Thus, the carbon dioxide of the mixed methane / carbon dioxide gas reacts with the ammonia and forms a buffer compound, such as ammonium bicarbonate and / or ammonium carbonate.

Owner:PRESECO

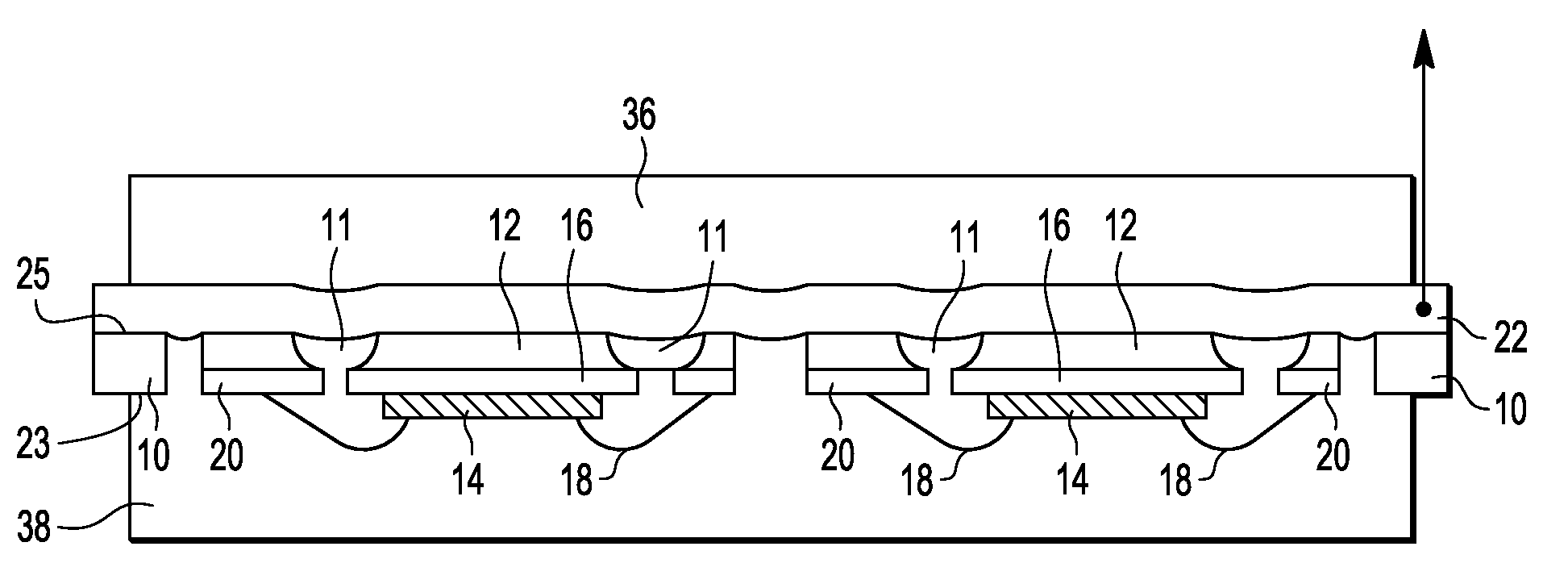

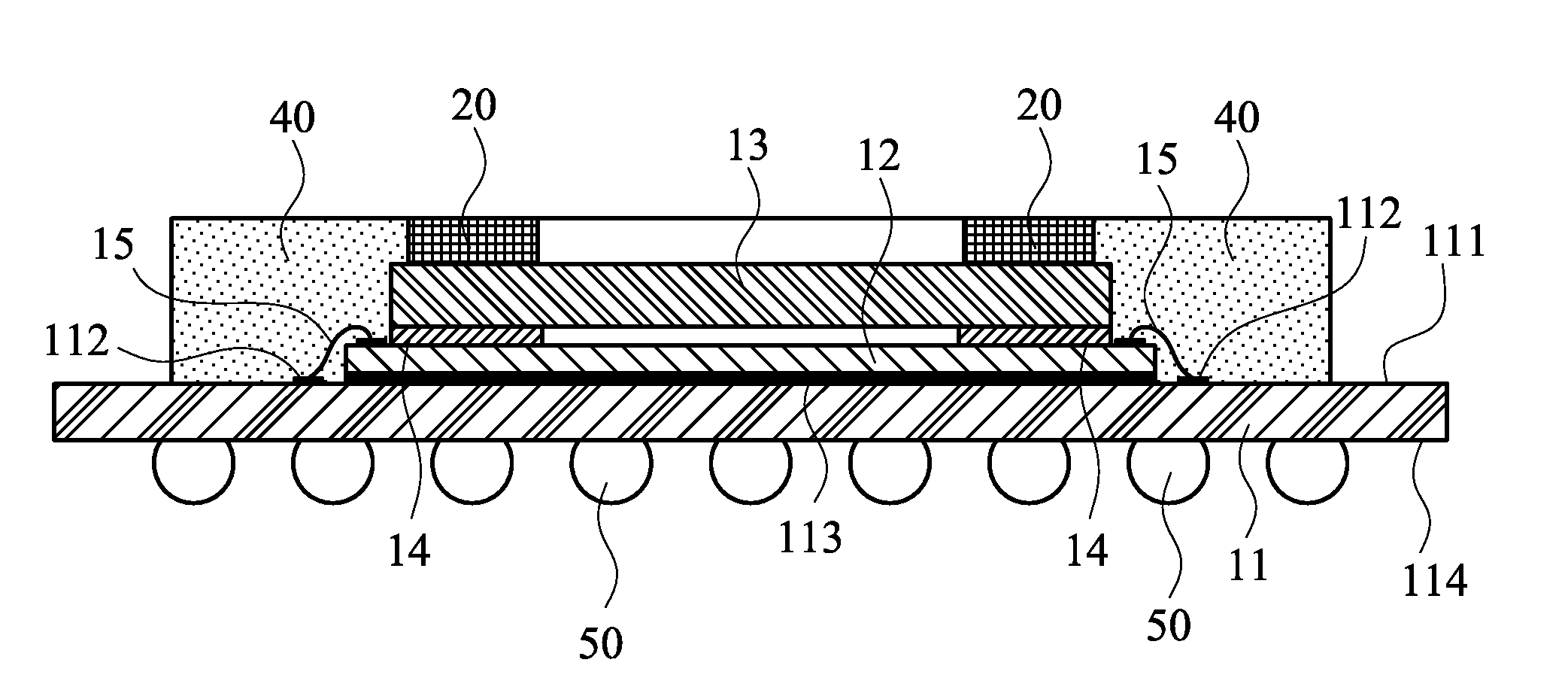

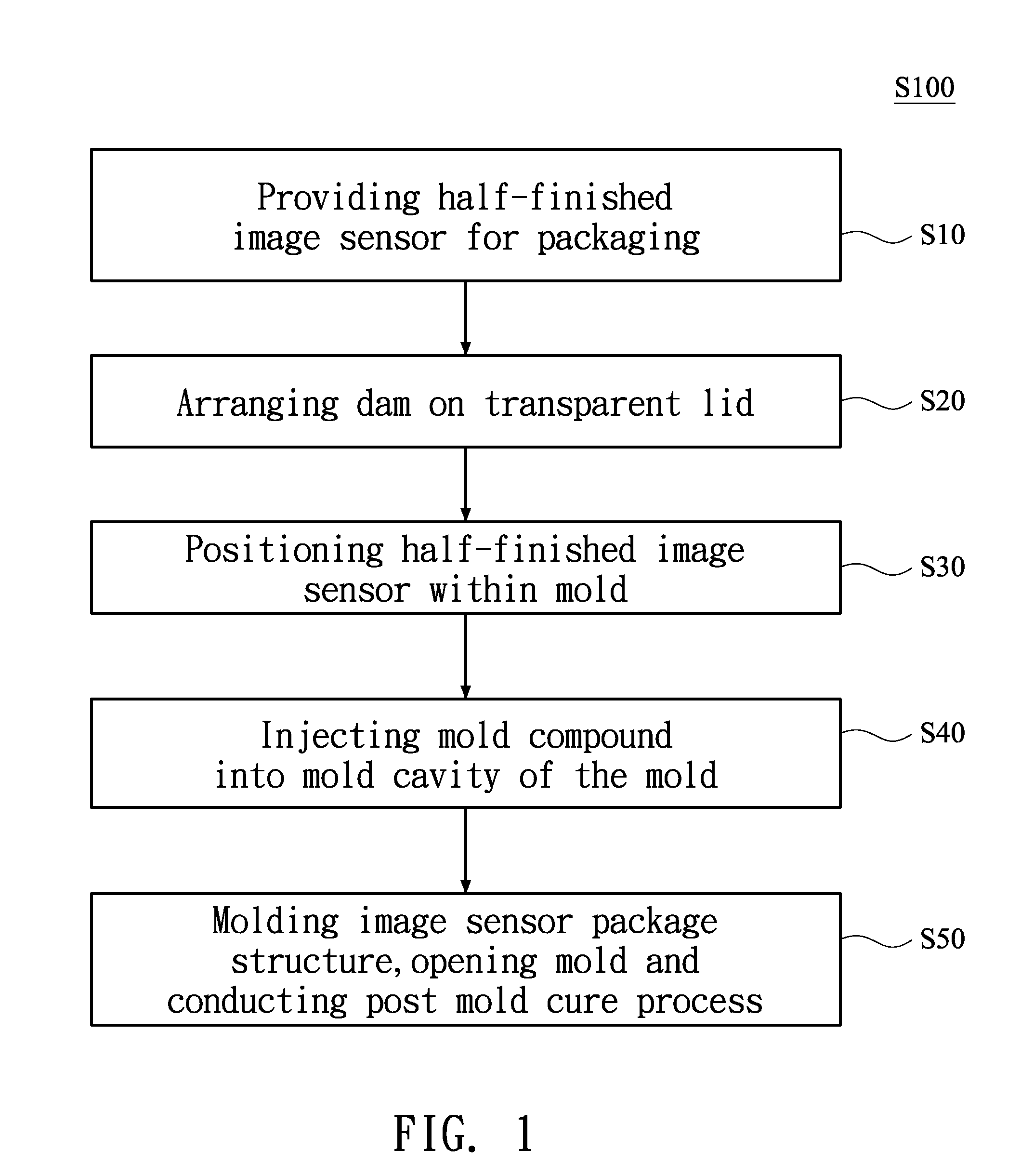

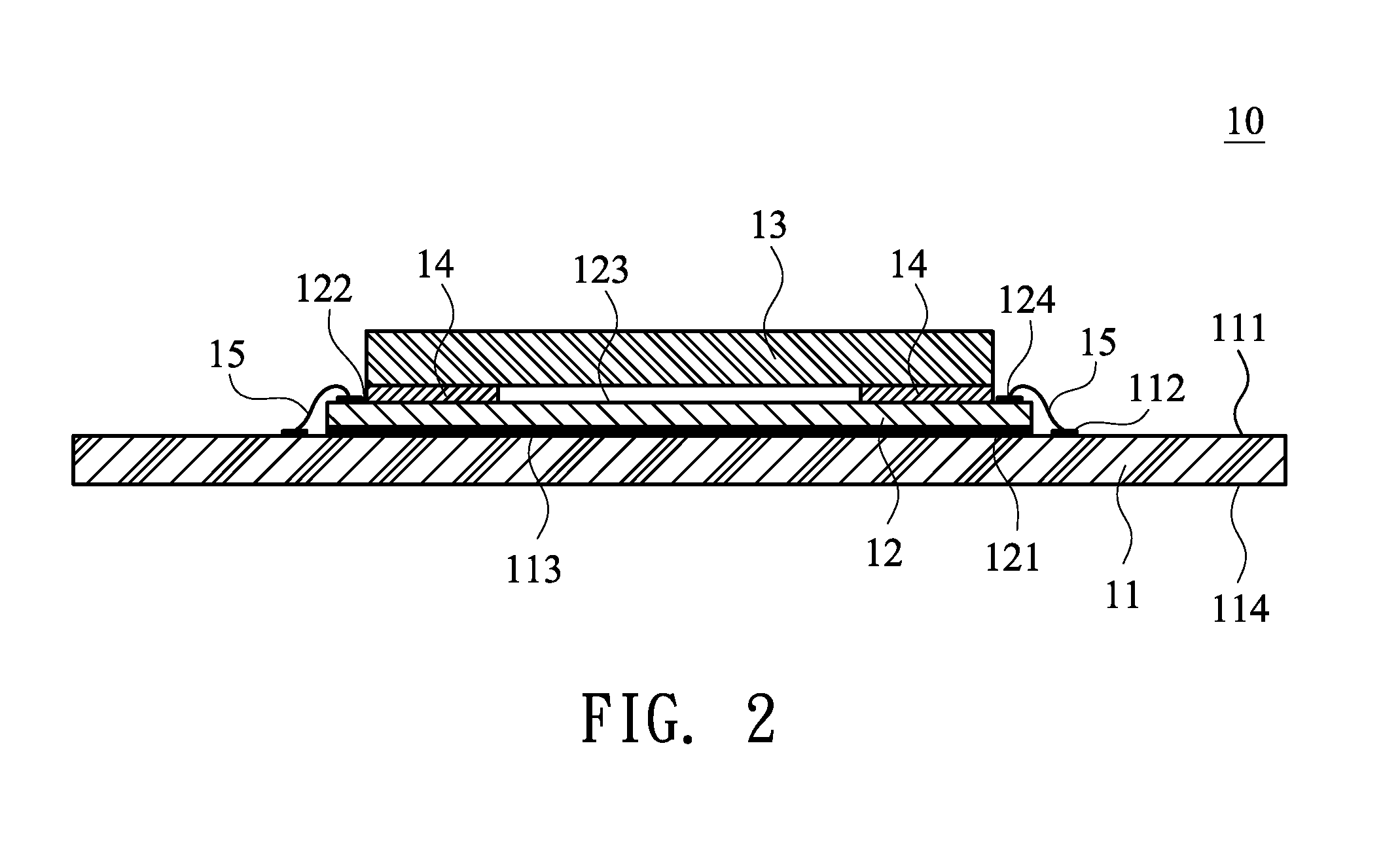

Manufacturing method for molding image sensor package structure and image sensor package structure thereof

ActiveUS20110024861A1Low costImprove reliabilitySolid-state devicesSemiconductor/solid-state device manufacturingEngineeringWork in process

A manufacturing method for molding an image sensor package structure and the image sensor package structure thereof are disclosed. The manufacturing method includes following steps of providing a half-finished image sensor for packaging, arranging a dam on the peripheral of a transparent lid of the half-finished image sensor, positioning the half-finished image sensor within a mold, and injecting a mold compound into the mold cavity of the mold. The dam is arranged on the top surface of the transparent lid and the inner surface of the mold can exactly contact with the top surface of dam so that the mold compound injected into the mold cavity is prevented from overflowing to the transparent lid by the dam. Furthermore, the arrangement of the dam and the mold compound can increase packaged areas and extend blockage to invasive moisture so as to enhance the reliability of the image sensor package structure.

Owner:TONG HSING ELECTRONICS INDS

Liquid Cleaning And/Or Cleansing Composition

InactiveUS20110150949A1Difficult rinseDifficult end cleaning profileInorganic/elemental detergent compounding agentsCosmetic preparationsCross-linkOrganic solvent

The present invention relates to a liquid, cleaning and / or cleansing composition comprising abrasive cleaning particles, wherein said abrasive cleaning particles comprise a divinyl benzene cross-linked styrene polymer, wherein said abrasive cleaning particles are non-spherical and have a mean particles size D(v,0.9) of at least about 10 μm and wherein said liquid, cleaning and / or cleansing composition comprises from about 0% to about 30% by weight of the composition of an organic solvent.

Owner:THE PROCTER & GAMBLE COMPANY

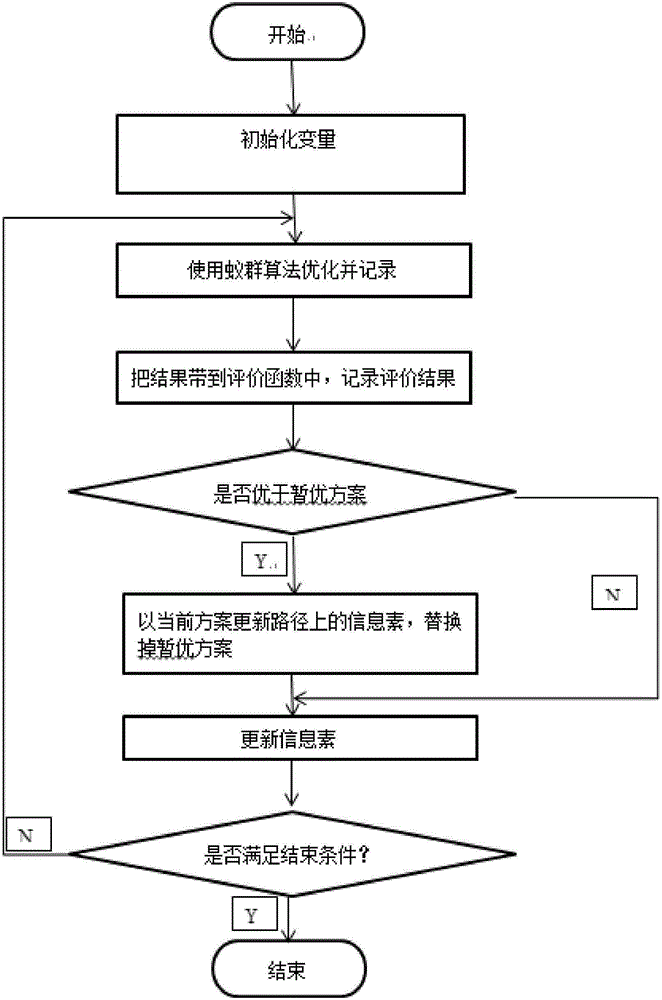

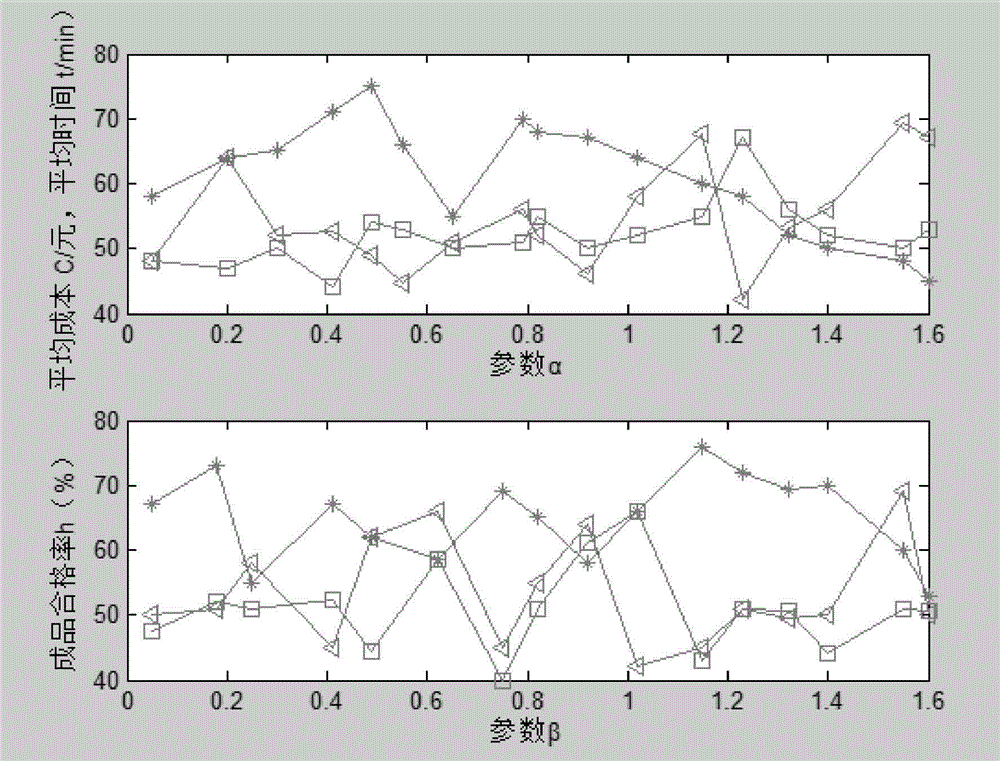

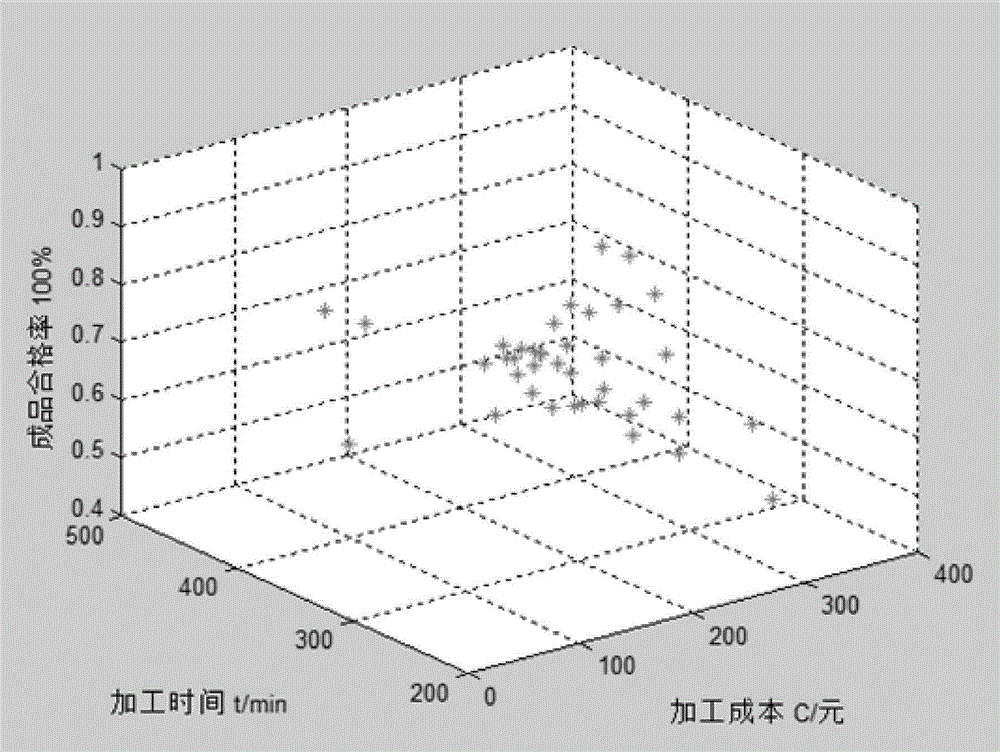

Flexible job-shop scheduling multi-objective method

InactiveCN104914835AReduce manufacturing costGood effectProgramme total factory controlJob shop schedulingJob shop scheduling problem

The invention discloses a flexible job-shop scheduling multi-objective method. The specific implementation procedures of the flexible job-shop scheduling multi-objective method are that: establishing a model for a multi-objective flexible job shop; optimizing the model by using an ant colony algorithm, and evaluating the result to check whether the scheme is the optimal scheme; and improving a pheromone updating rule according to the optimal scheme, and increasing convergence rate of the algorithm to obtain a Pareto optimal solution of a multi-objective flexible job shop scheduling problem. Compared with the prior art, the flexible job-shop scheduling multi-objective method effectively reduces workshop production cost, shortens the processing time, improves qualified rate of products, is high in practicability, and is easy to popularize.

Owner:QILU UNIV OF TECH

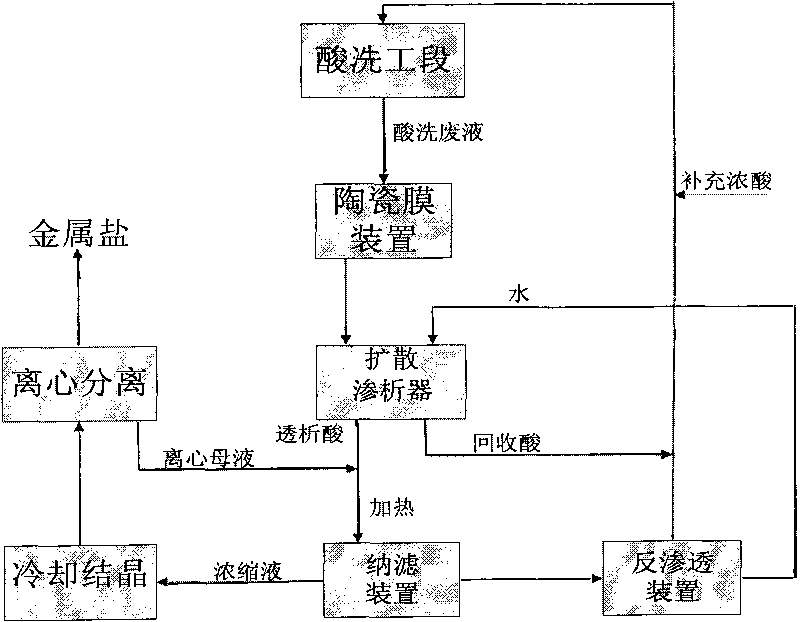

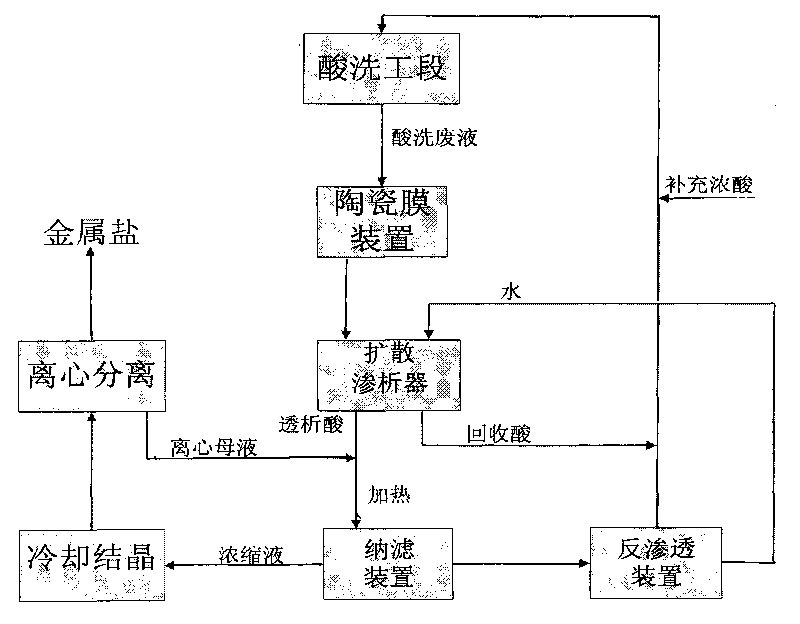

Process for recovering heavy metallic salt and inorganic acid in pickling waste liquid

ActiveCN101759250AOptimizing the integration processReduce pollutionSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisLiquid wasteIron salts

The invention relates to a process for separating and recovering heavy metallic salt and inorganic acid in pickling waste liquid by a membrane method, which comprises the following concrete steps: filtering and removing solid suspended substances in pickling waste liquid through an inorganic ceramic membrane; separating acid from salt in the ceramic membrane penetrating liquid through diffusion dialysis; and heating the dialysis liquid of a diffusion dialyzer, then introducing the dialysis liquid into a nanofiltration membrane, and cooling and crystallizing the concentrated liquid of a nanofiltration device and then centrifuging the crystal of the concentrated liquid to obtain iron salt, wherein the penetrating liquid of the nanofiltration device passes through a reverse osmosis membrane device, the concentrated liquid of the reverse osmosis device returns to a pickling section, and the water discharged from the reverse osmosis device enters a diffusion dialysis section for recycling. The invention has the characteristics that the pickling waste liquid is completely used as resources, the recovery process is simple, the recovery ratio of metallic salt and acid is high, and water is recycled. The process of the invention can be coupled with various pickling sections to realize continuous and stable automated operation, and the supplemented acid amount can be quantitatively controlled according to the acid amount consumed by the crystallized metallic salt.

Owner:NANJING UNIV OF TECH +1

Liquid cleaning composition

ActiveUS20120071380A1Difficult rinseDifficult end cleaning profileInorganic/elemental detergent compounding agentsSoap detergents with inorganic compounding agentsChemistryPhysical chemistry

The present invention relates to a liquid, cleaning composition comprising coloured abrasive cleaning particles.

Owner:THE PROCTER & GAMBLE COMPANY

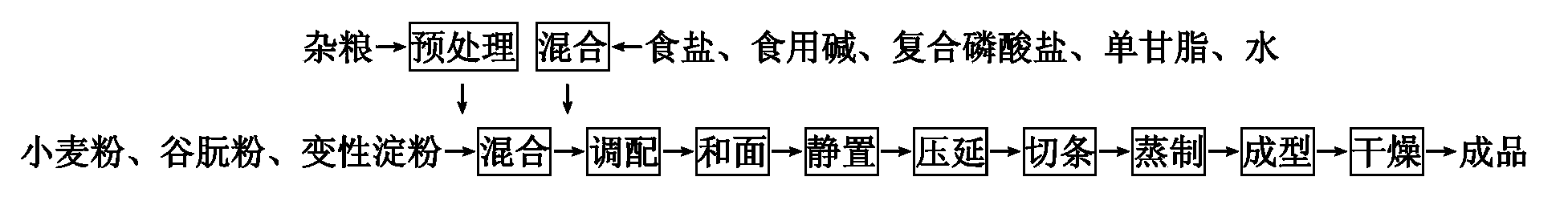

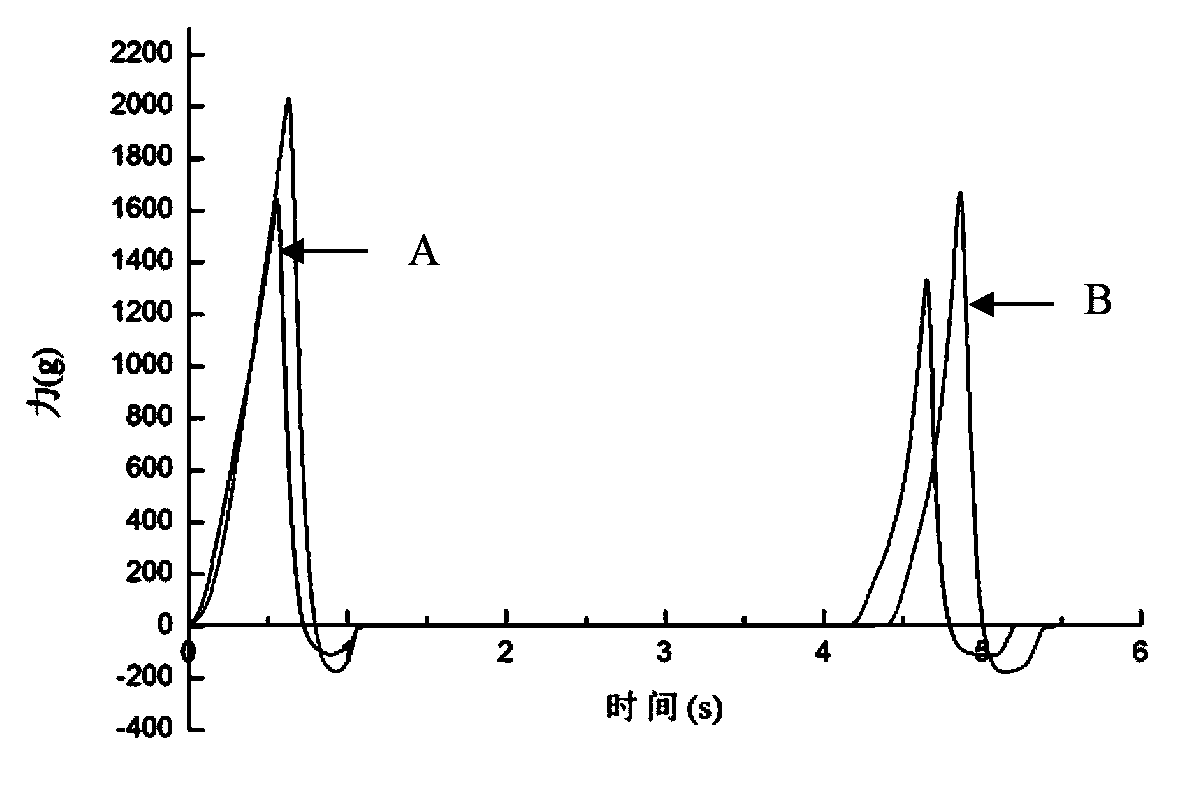

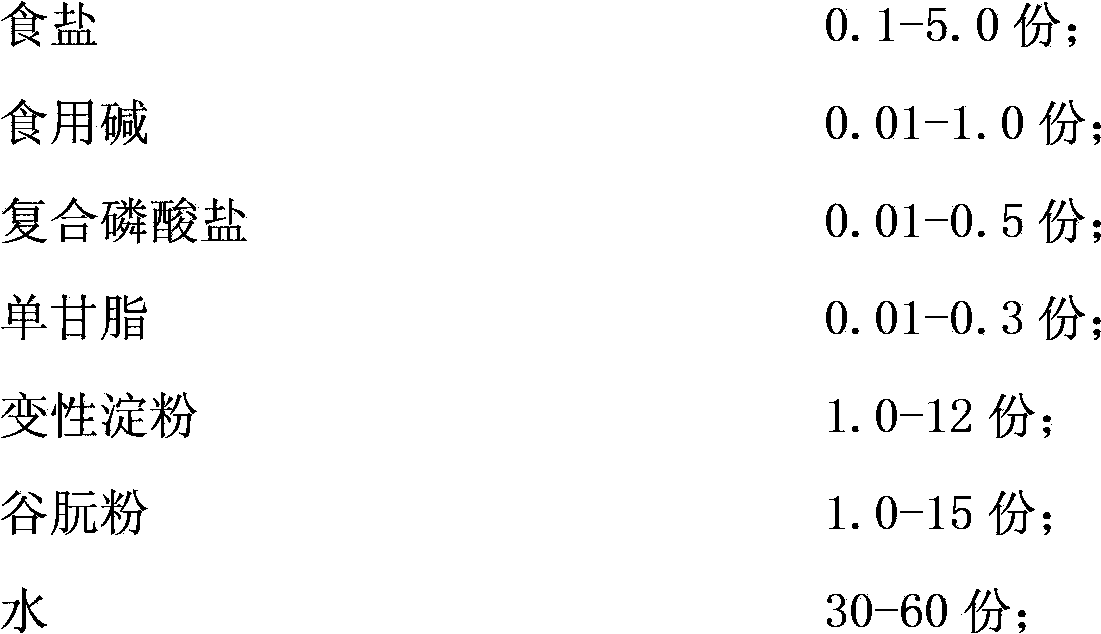

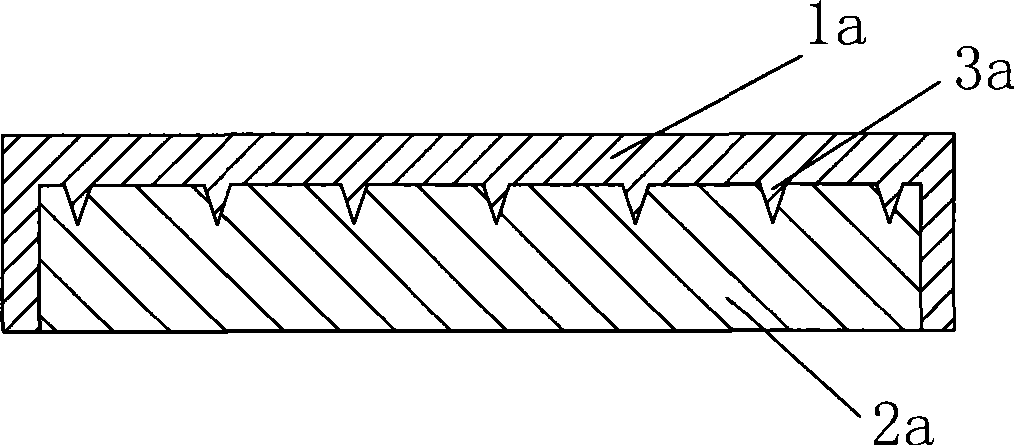

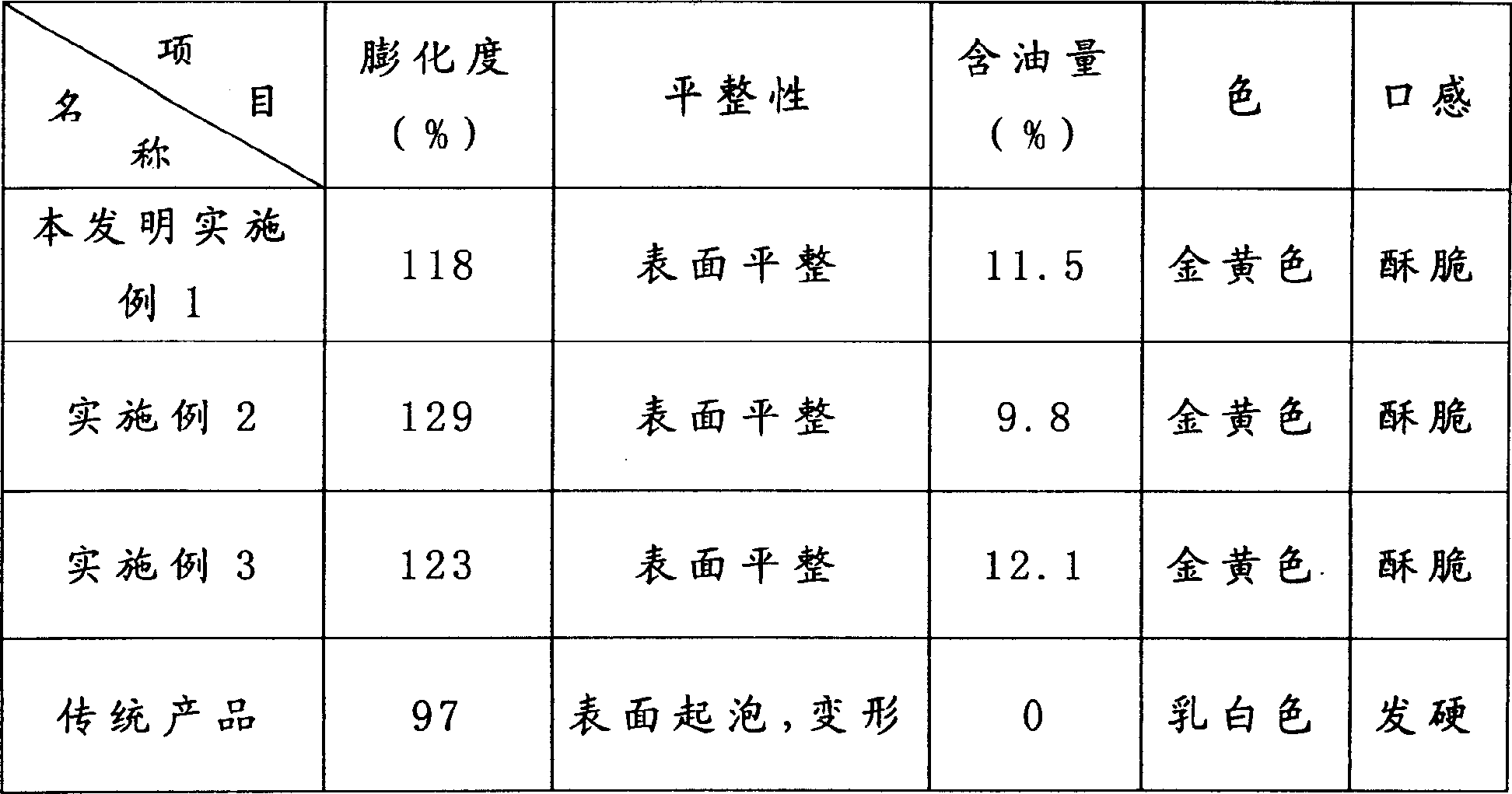

Multi-grain instant noodle and manufacturing method thereof

The invention belongs to the technical field of flour food processing, and particularly relates to a multi-grain instant noodle and a manufacturing method thereof. The preparation method comprises the following steps: multi-grain flour and high gluten wheat flour are used as main raw materials and are manufactured into the multi-grain instant noodle with modified starch, vital gluten, salts, dietary alkali, composite phosphate, and monoglyceride through processes of dough making, still standing, calendering, cutting, steaming, forming, drying and the like, wherein the multi-grain flour is a flour material sieved by a sieve of 100-150 meshes and is manufactured by one or the combination of mung beans, black soya beans, kidney beans, peas, broad beans, ormosia, maize, potatoes, and sweet potatoes being subjected to ultrahigh pressing, enzymolysis, germinating and / or superfine grinding and then drying and smashing. The multi-grain instant noodle manufactured by the method has the outstanding advantages of well nutrition and flavor, high raw material utilization ratio, low nutrient loss, good reconstitution property, modest crunch and elasticity, low fat content and the like.

Owner:湖北金银丰粮食储备有限责任公司

Magnalium composite board and method for producing the same

The invention discloses a magnesium-aluminum composite board and a method for manufacturing the same. The magnesium-aluminum composite board comprises at least one layer of magnesium or magnesium alloy plate and at least one layer of aluminum or aluminum alloy plate which are cast together by vacuum die-casting, and at least one two-layer joint surface which is provided with a mutually occlusive zigzag structure, namely the magnesium-aluminum composite board consists of a magnesium plate and an aluminum plate, or the magnesium alloy plate and the aluminum plate, or the magnesium plate and the aluminum alloy plate, or the magnesium alloy plate and the aluminum alloy plate by vacuum die-casting, and can be a structure with two layers, three layers or more than three layers. The method for manufacturing the composite board comprises the following steps: preheating a manufactured aluminum or aluminum alloy plate finished product as an insert of a die to certain temperature, and then putting the insert into a magnesium or magnesium alloy vacuumized die; matching the die in a vacuum pressure casting machine; pouring the molten magnesium or magnesium alloy molten; performing vacuumizing injection; and finally forming the magnesium-aluminum composite board. The joint surface of the composite board is provided with the mutually occlusive zigzag structure so that the layers are closely connected with each other sequentially and the combined strength is higher.

Owner:青岛地恩地材料科技有限公司

Potato crisp utilizing micro wave processing and its processing method

InactiveCN1891072AEasy to storePreserve nutrientsFood preservationFood preparationChipped potatoesMicrowave

The present invention discloses a kind of potato crisps processed by microwave and its processing method. Said processing method includes the following steps: washing potato flakes, scalding said potato flakes in boiling edible salt water, cooling, draining, freezing, drying, adding palm oil and egg yolk powder, mixing them with potato flakes, uniformly stirring them, roasting them by using microwave and spraying flavouring material so as to obtain the invented product.

Owner:HUNAN AGRICULTURAL UNIV

Liquid cleaning composition

InactiveUS20120071379A1Difficult rinseDifficult end cleaning profileInorganic/elemental detergent compounding agentsNon-surface-active detergent compositionsChemistryMetallurgy

The present invention relates to a liquid, cleaning composition comprising abrasive cleaning particles.

Owner:THE PROCTER & GAMBLE COMPANY

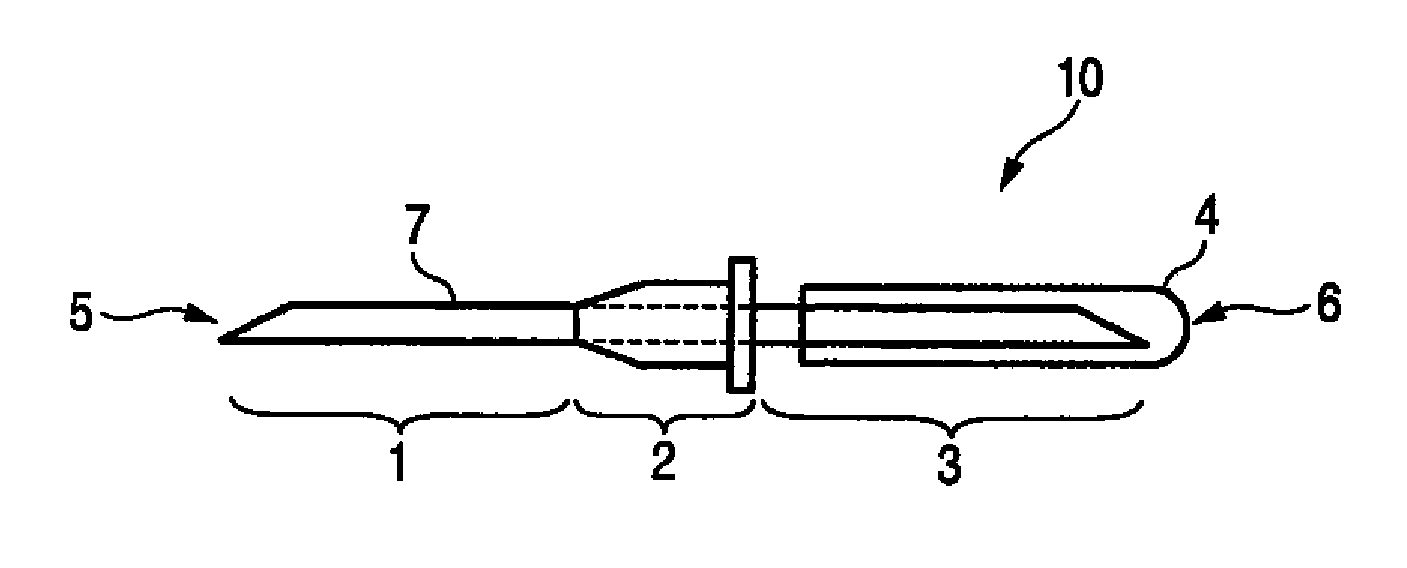

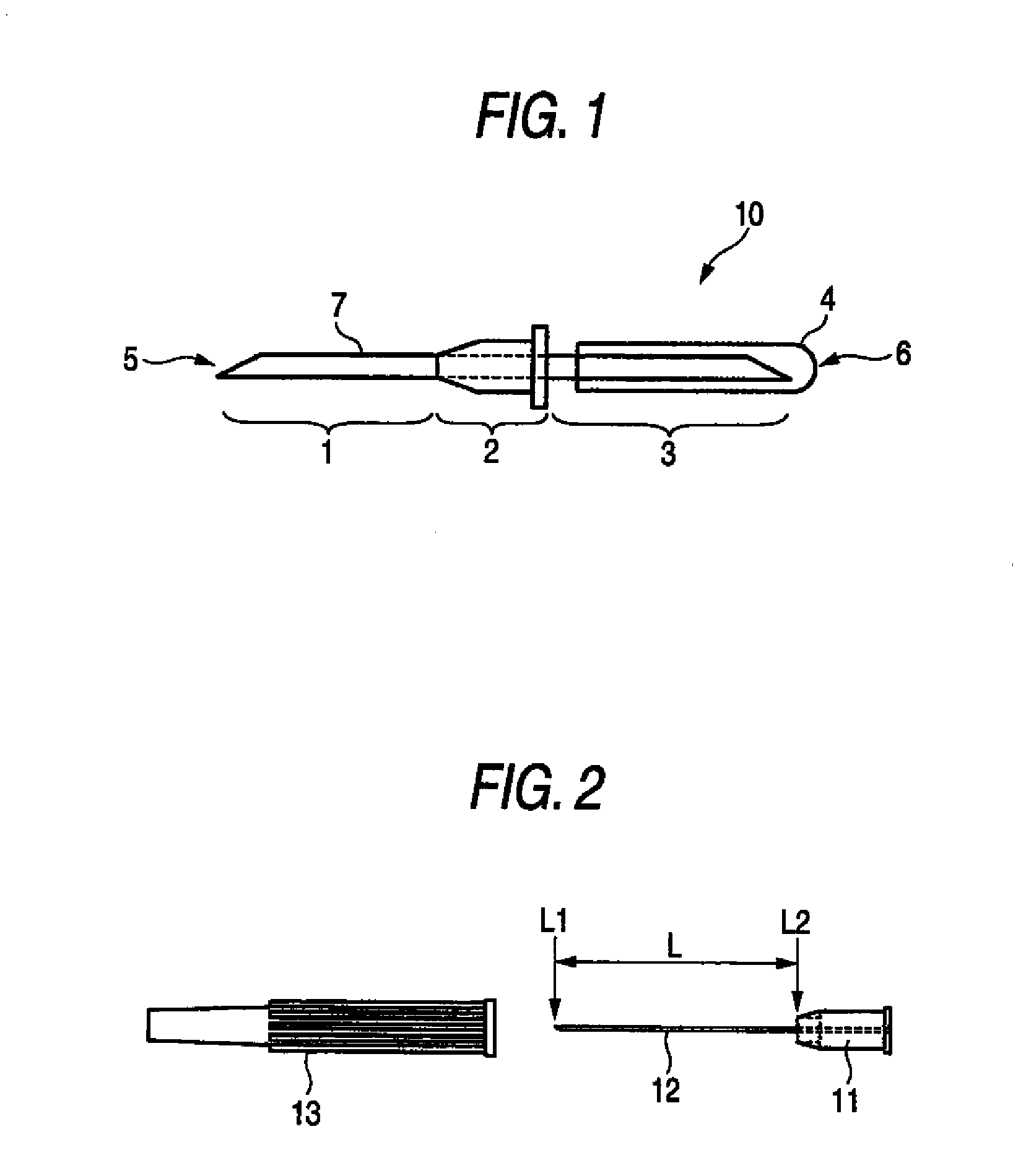

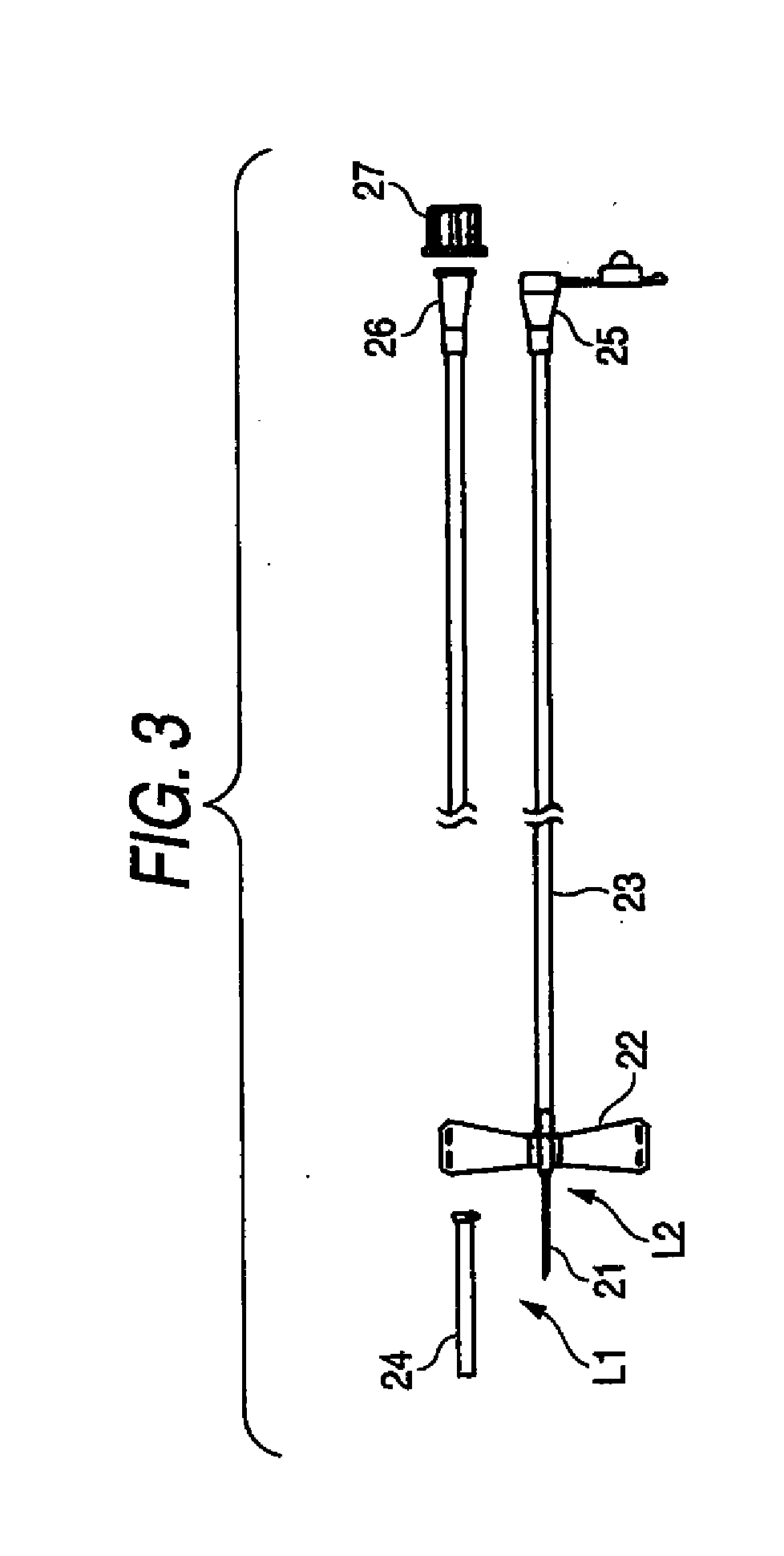

Blood collecting needle, syringe needle, winged needle, test kit and blood collecting kit

InactiveUS20070219509A1Shorten puncture timeRelieve painCatheterDiagnostic recording/measuringSurgerySyringe needle

A blood collecting needle, which comprises: a needle tube having a human-body puncturing needle tube and a stopper-body puncturing needle tube, wherein the needle tube has an outer diameter having substantially the same dimension from a tip of the human-body puncturing needle tube to a tip of the stopper-body puncturing needle tube, the needle tube has an inner diameter having substantially the same dimension from the tip of the human-body puncturing needle tube to the tip of the stopper-body puncturing needle tube, and the blood collecting needle satisfies equation (1):0.35≦D1<0.70 (equation 1) wherein D1 represents the outer diameter (mm) of the needle tube.

Owner:FUJIFILM CORP

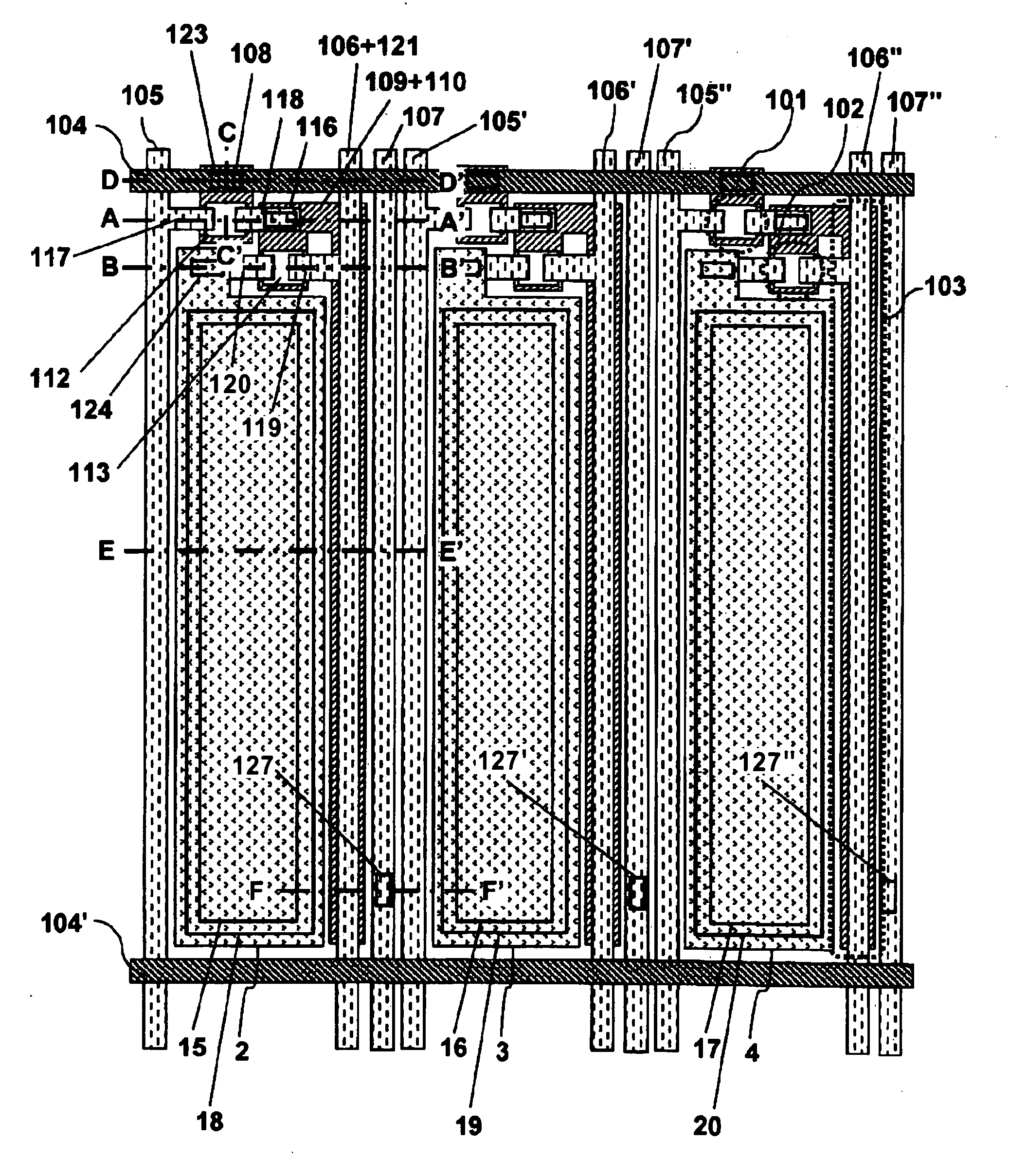

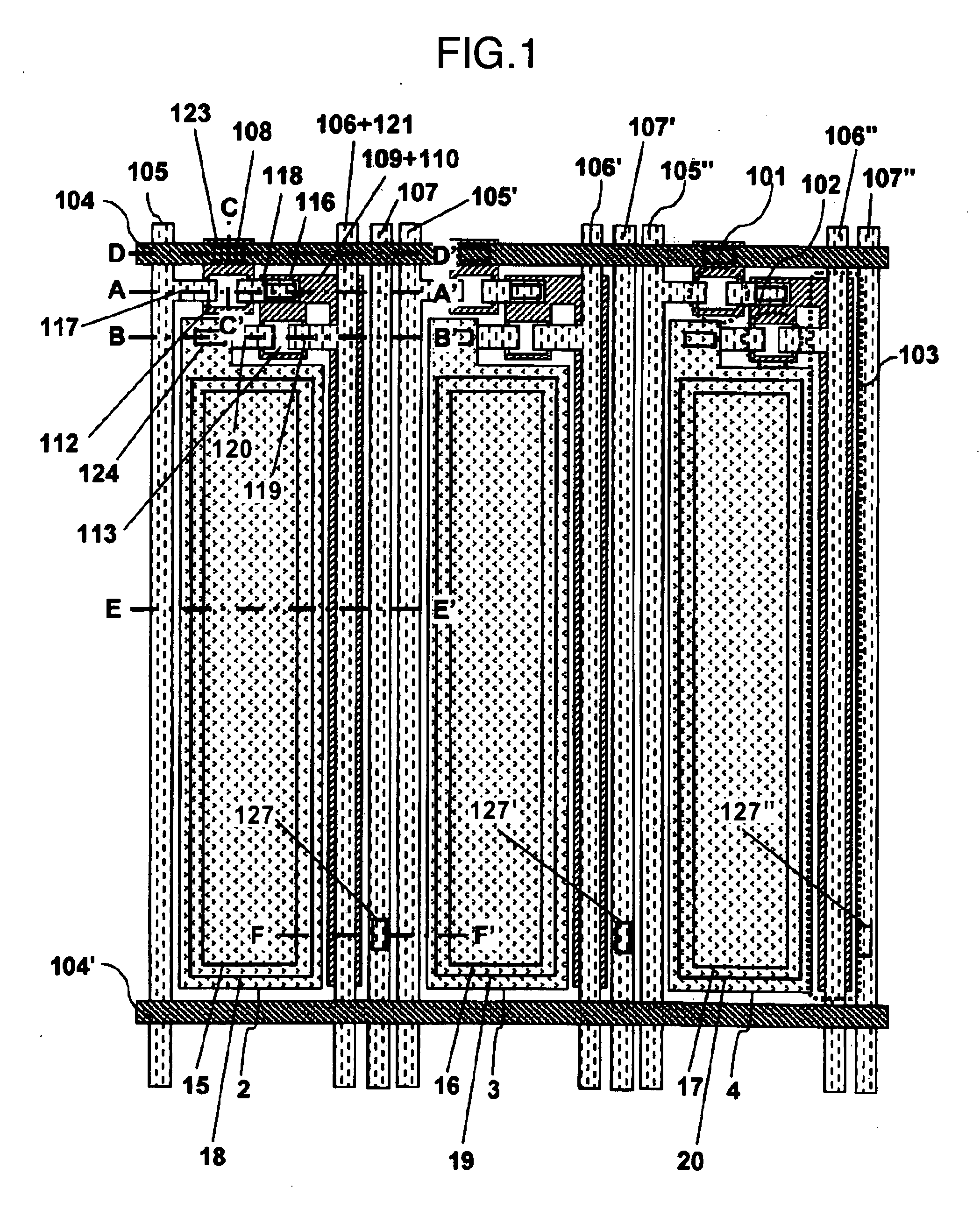

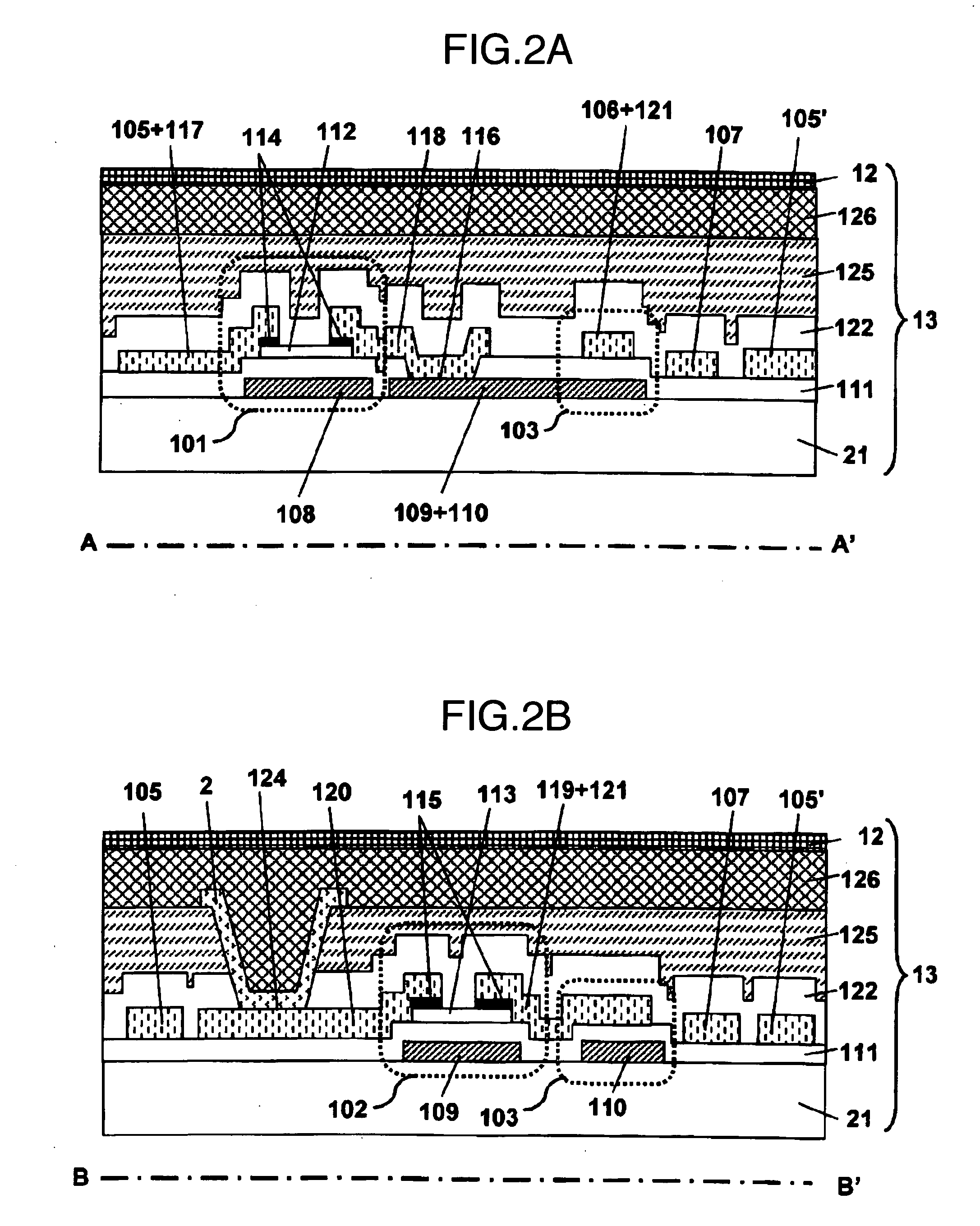

Organic electro-luminescent display apparatus

InactiveUS20090146930A1Avoid heat damageIncrease processing costStatic indicating devicesSolid-state devicesOrganic electroluminescencePolycrystalline silicon

Each TFT for driving each of a plurality of pixels arranged in a matrix-like configuration is configured using a stagger-type polycrystalline-Si TFT. A gate electrode, which is composed of a high-heat-resistant material capable of resisting high temperature at the time of polycrystalline-Si film formation, is disposed at a lower layer as compared with the polycrystalline-Si layer that forms a channel of each TFT. A gate line, which is composed of a low-resistance material, is disposed at an upper layer as compared with the polycrystalline-Si layer. The gate electrode and the gate line are connected to each other via a through-hole bored in a gate insulation film. Respective configuration components of each organic electro-luminescent element are partially co-used at the time of the line formation, thereby suppressing an increase in the steps, processes, and configuration components.

Owner:HITACHI LTD

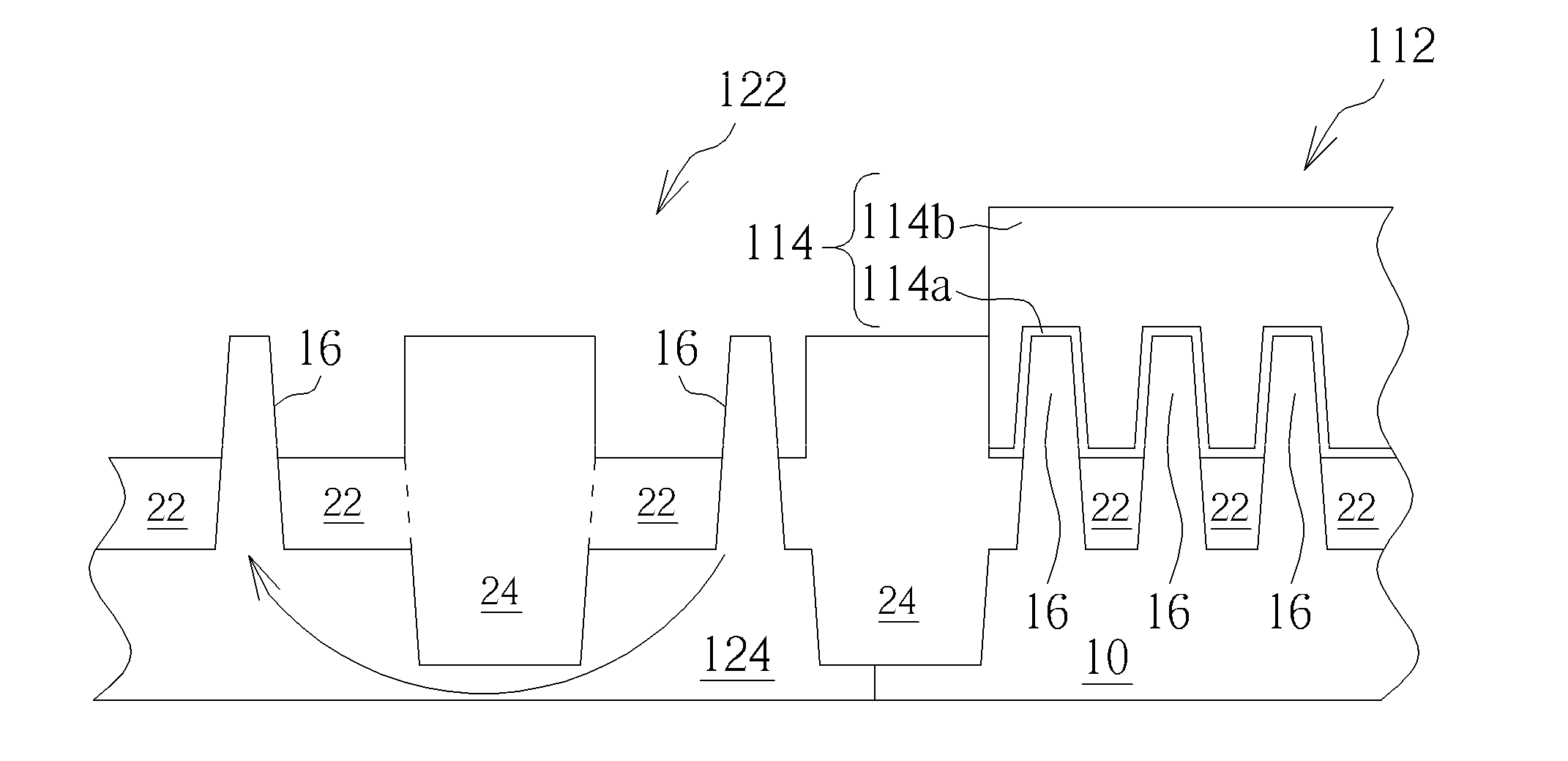

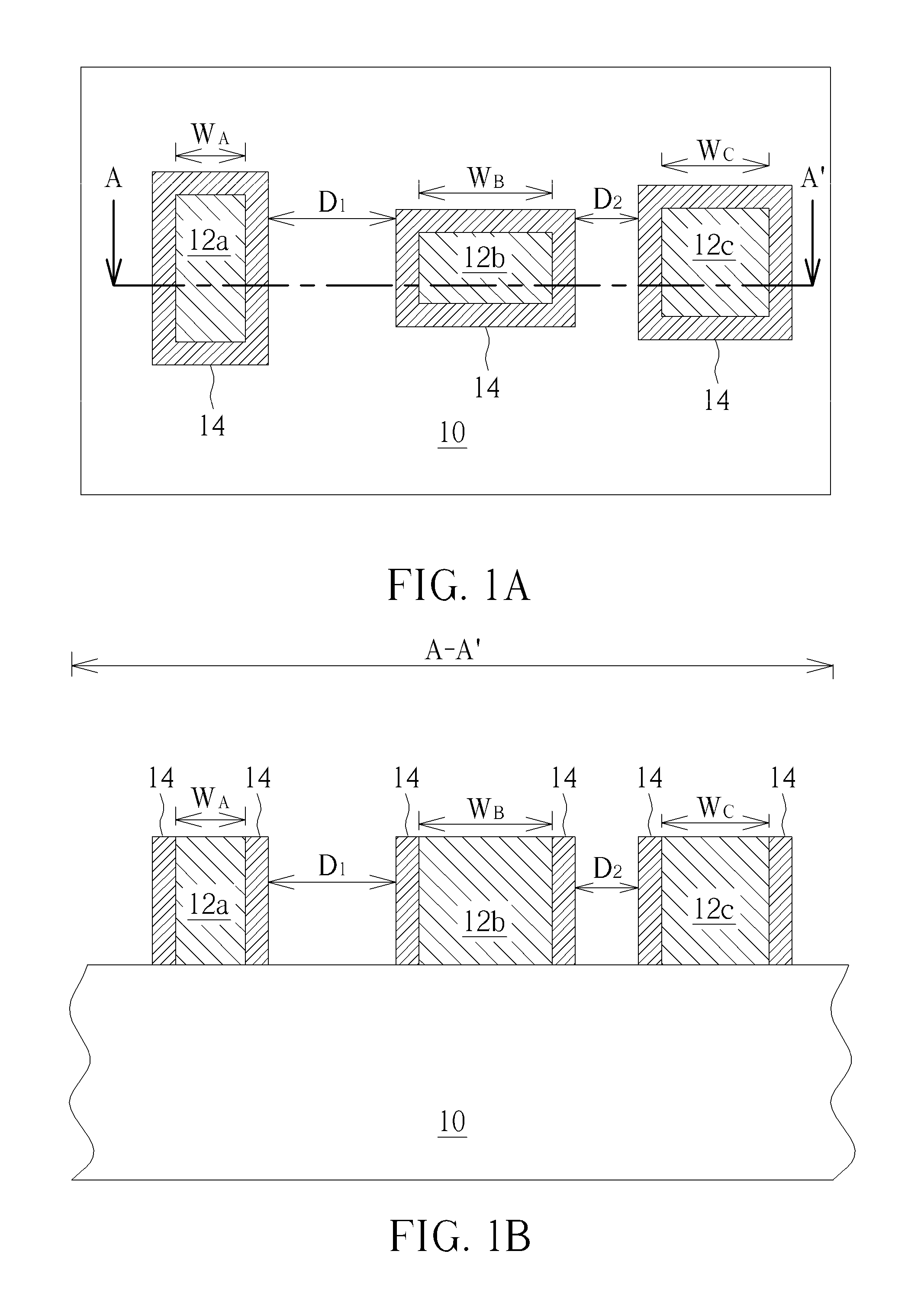

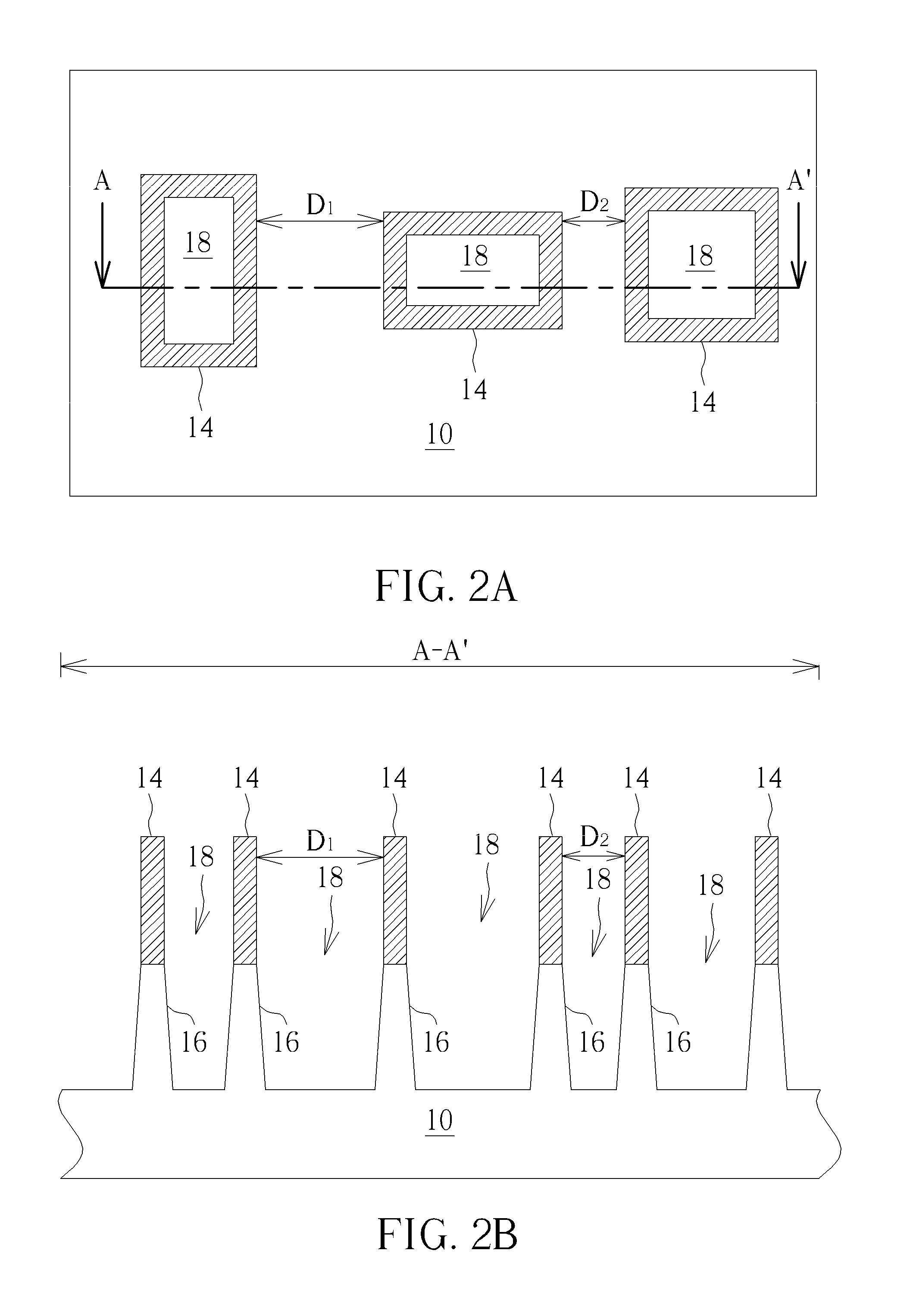

Semiconductor integrated circuit

ActiveUS20140327074A1Good flexibilityIncrease processing costTransistorSolid-state devicesDevice formEngineering

A semiconductor integrated circuit includes a substrate, a multi-gate transistor device formed on the substrate, and an n-well resistor formed in the substrate. The substrate includes a plurality of first isolation structures and at least a second isolation structure formed therein. A depth of the first isolation structures is smaller than a depth of the second isolation structure. The multi-gate transistor device includes a plurality of fin structures, and the fin structures are parallel with each other and spaced apart from each other by the first isolation structures. The n-well resistor includes at least one first isolation structure. The n-well resistor and the multi-gate transistor device are electrically isolated from each other by the second isolation structure.

Owner:UNITED MICROELECTRONICS CORP

Liquid cleaning and/or cleansing composition

ActiveUS20110150788A1Difficult rinseDifficult end cleaning profileInorganic/elemental detergent compounding agentsCosmetic preparationsChemistry

The present invention relates to a liquid, cleaning and / or cleansing composition comprising abrasive cleaning particles.

Owner:THE PROCTER & GAMBLE COMPANY

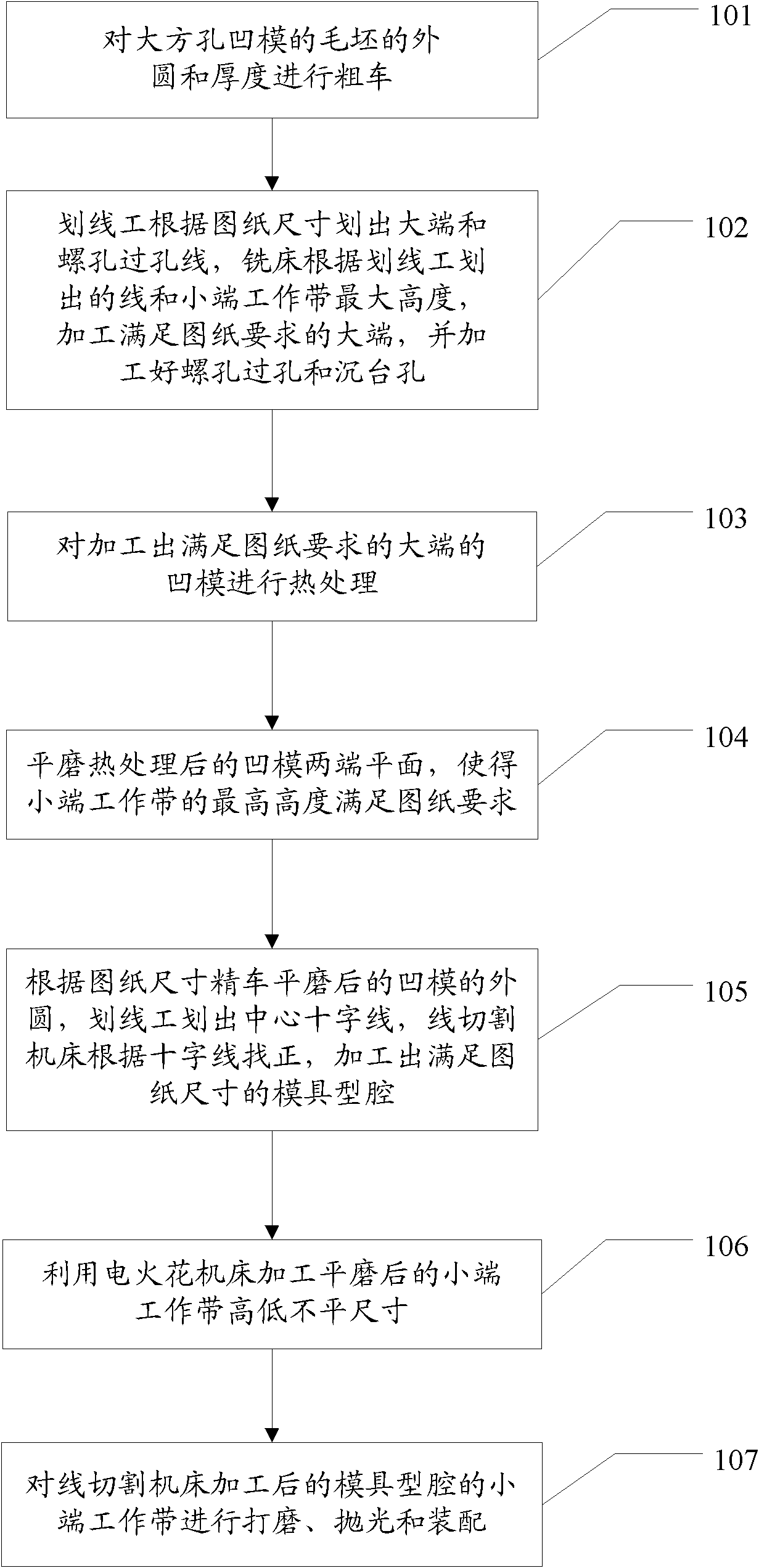

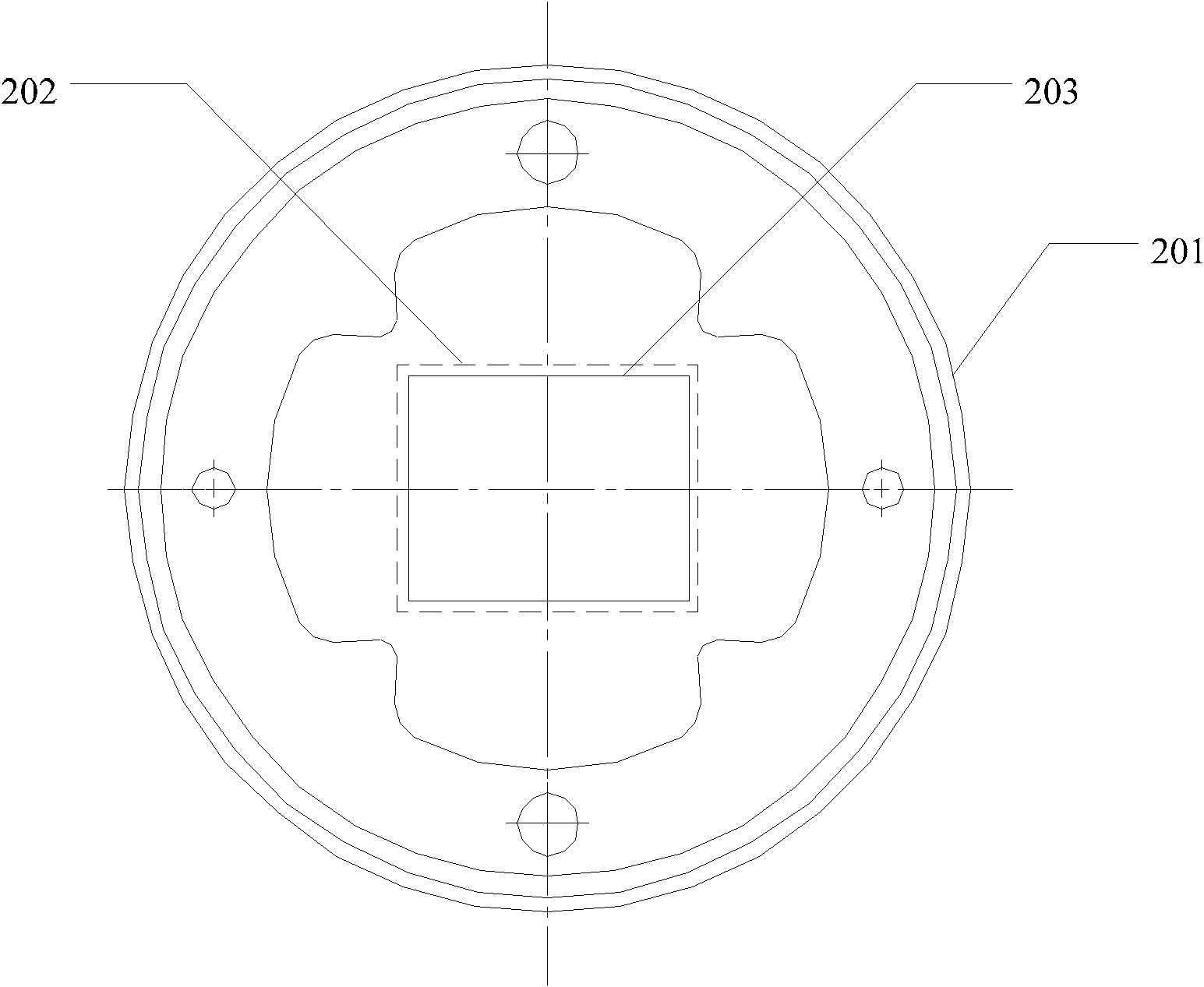

Method for processing female die with large square hole

ActiveCN102303221AHigh concentricityIncrease productivityMilling equipment detailsEngineeringMachine tool

The embodiment of the invention discloses a method for processing a female die with a large square hole. The method comprises the following steps of: roughly turning the excircle and thickness of a blank of the female die with the large square hole; processing the blank by using a milling machine, and thus obtaining a large end which meets requirements of a drawing; semi-finishing a small end by using a numerically controlled milling machine, and thus obtaining a small-end working tape which meets the requirements of the drawing; processing a screw through hole and a sunk table hole, and reserving an allowance for the size of a cavity of the small-end working tape; performing heat treatment on the female die, and flatly grinding planes at two ends of the female die to make the largest height of the small-end working tape meet the requirements of the drawing; performing finish turning on the excircle of the female die which is flatly ground; performing finish machining, and thus obtaining a mold cavity which meets the size of the drawing; processing an uneven part of the small-end working tape which is flatly ground by using an electric spark machine tool; and grinding, polishing and assembling the small-end working tape of the mold cavity which is subjected to finish machining by the numerically controlled milling machine. By adoption of the method provided by the embodiment of the invention, production efficiency can be improved, and production cost is reduced.

Owner:SOUTHWEST ALUMINUM GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com