Multi-grain instant noodle and manufacturing method thereof

A technology for instant noodles and miscellaneous grains, applied in application, food preparation, food science and other directions, can solve the problems of unutilized bioactive components, increased skin residue processing costs, and difficulty in exerting special nutrients of miscellaneous grains.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

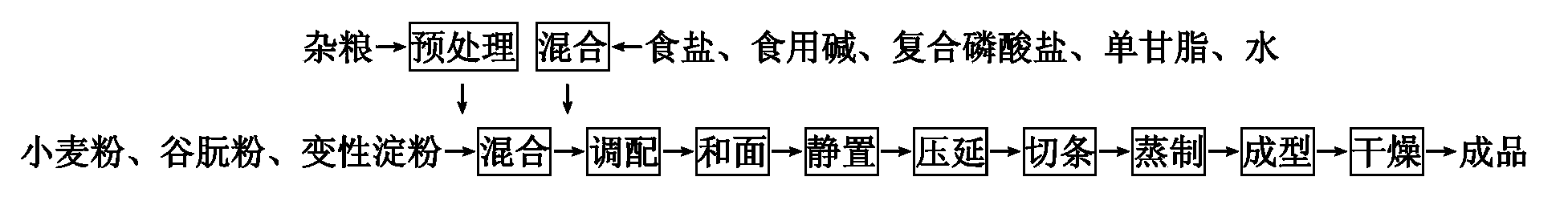

Method used

Image

Examples

Embodiment 1

[0076] Example 1: General Example

[0077] Step 1: Take 220 kilograms of broad beans purchased commercially and cleaned and dried, pulverize them with a pulverizer, and pass through a 100-mesh sieve to obtain 200 kilograms of broad bean powder;

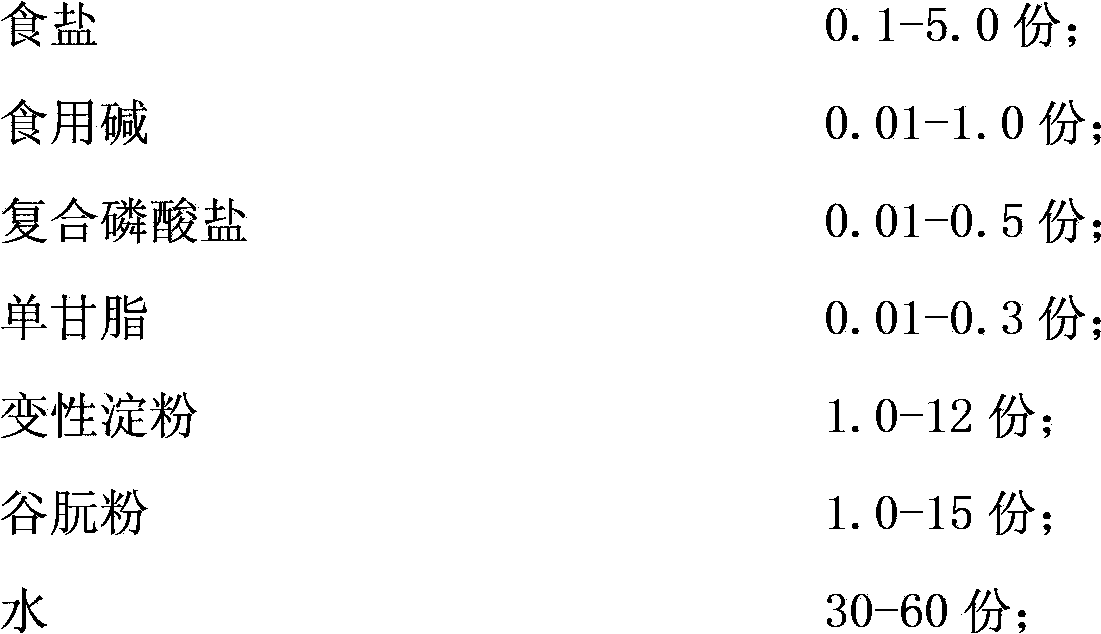

[0078] Step 2:: mix 5 kilograms of salt, 1.5 kilograms of edible alkali (Na 2 CO 3 , Wuhan Chengda Food Co., Ltd.), 1 kg of compound phosphate (product of Xuzhou Hengshi Food Co., Ltd.) was dissolved in 190 kg of water, and then 10 kg of hydrated molecularly distilled monoglyceride (product of Guangdong Jialishi Food Co., Ltd.) was added to fully Stir to obtain a composite solution;

[0079] Step 3: Mix the broad bean flour obtained in step 1 with 300 kg of high-gluten wheat flour (product of Hunan Jinjian Rice Industry Co., Ltd.), 30 kg of gluten powder (product of Taikang Grain Deep Processing Co., Ltd.), 30 kg of modified starch (Hangzhou Pro Star Starch Co., Ltd. product) mixed evenly;

[0080] Step 4: Mix the compound solutio...

Embodiment 2

[0090] Example 2 Example of the application effect of pretreatment process 1 (ultra-high pressure treatment process) on products

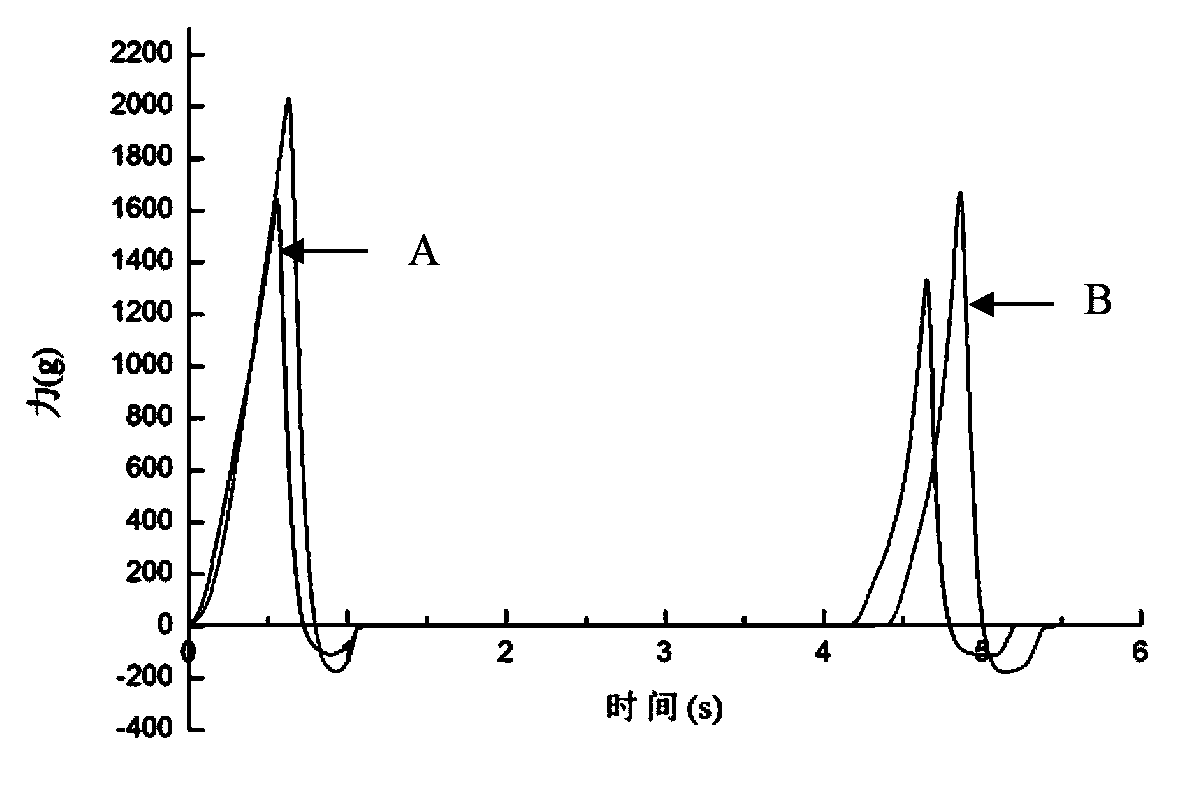

[0091] Follow the steps of Example 1. The miscellaneous grains of the present embodiment are red beans. The pretreatment process adopts ultra-high pressure method. Wash the red beans with water, then add three times the volume of water to soak, filter out the soaking water, add 1.2 times the volume of water to refine the slurry, and treat the slurry with 0.1MPa, 100MPa, 200MPa, 300MPa, 400MPa, 500MPa, 600MPa for 15 minutes, and then centrifuge , the precipitate was dried and crushed at 40°C and passed through a 100-mesh sieve. The experiments in this example only compared the effects of the ultra-high pressure treatment process on the sensory quality, texture, dietary fiber and water-soluble protein content of the product. The texture test is carried out in TPA mode, the compression probe P / 36 is selected, the speed before the test is 2mm / s, the...

Embodiment 3

[0096] Example 3 Example of the application effect of pretreatment process 2 (enzymatic treatment process) on the product

[0097] Follow the steps of Example 1. The miscellaneous grains of this embodiment are kidney beans. After washing the kidney beans with water, add three times the volume of water to soak, filter out the soaking water, and then add 1.2 times the volume of water to refine the slurry. Use 80U cellulase (commercially available), 170U pectinase (commercially available), and 40U nectar Glycanase (commercially purchased) was reacted at 50°C and pH 5 for 0h, 4h, 5h, 6h, 7h, and 8h, and then centrifuged, and the precipitate was dried and crushed at 40°C and passed through a 150-mesh sieve. The experiments in this example only compared the effects of the enzymatic treatment process on the product sensory quality, dietary fiber and water-soluble protein content. The effects of enzymatic hydrolysis on product sensory, dietary fiber and water-soluble protein content...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com