Patents

Literature

258results about How to "Increase floor space" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

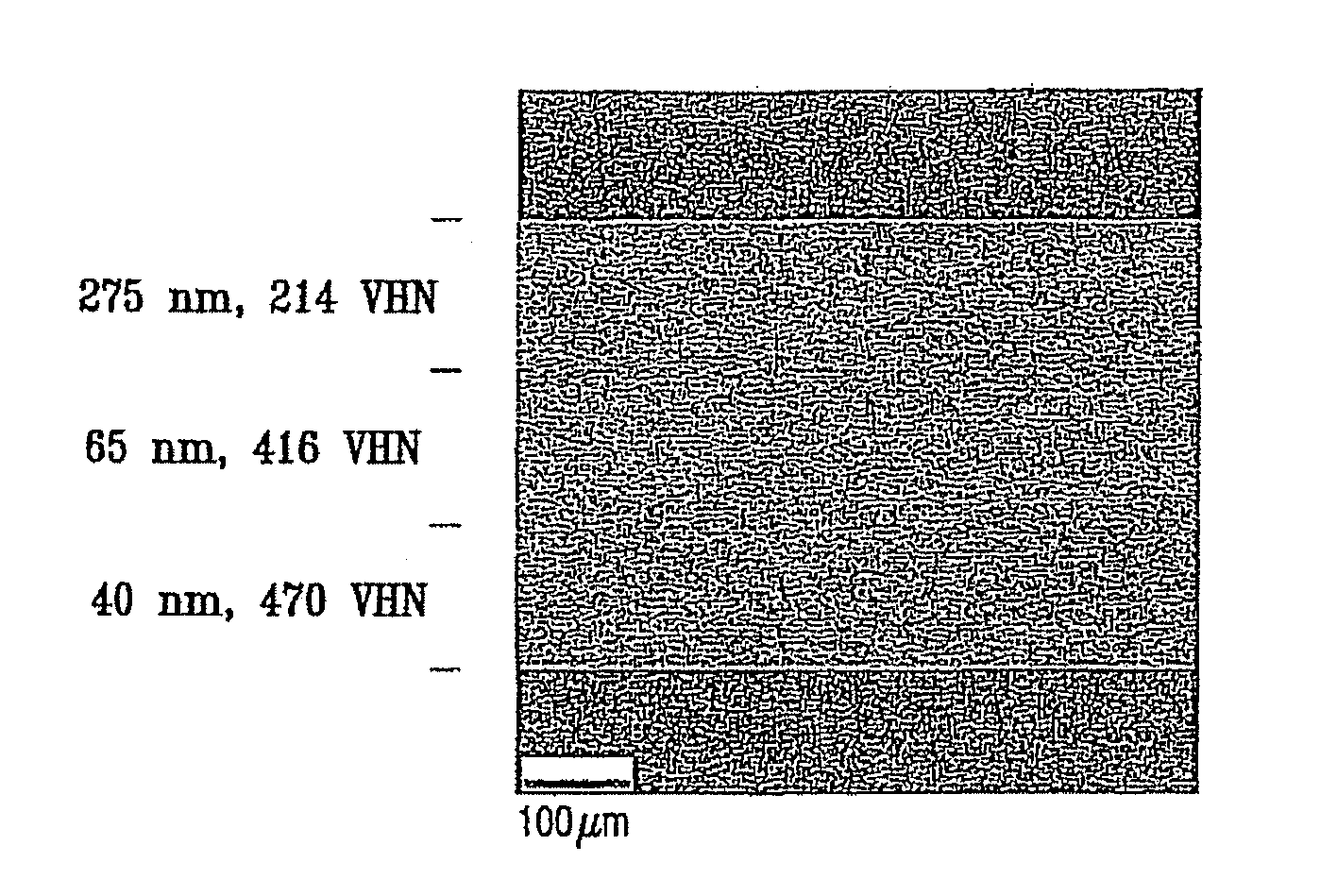

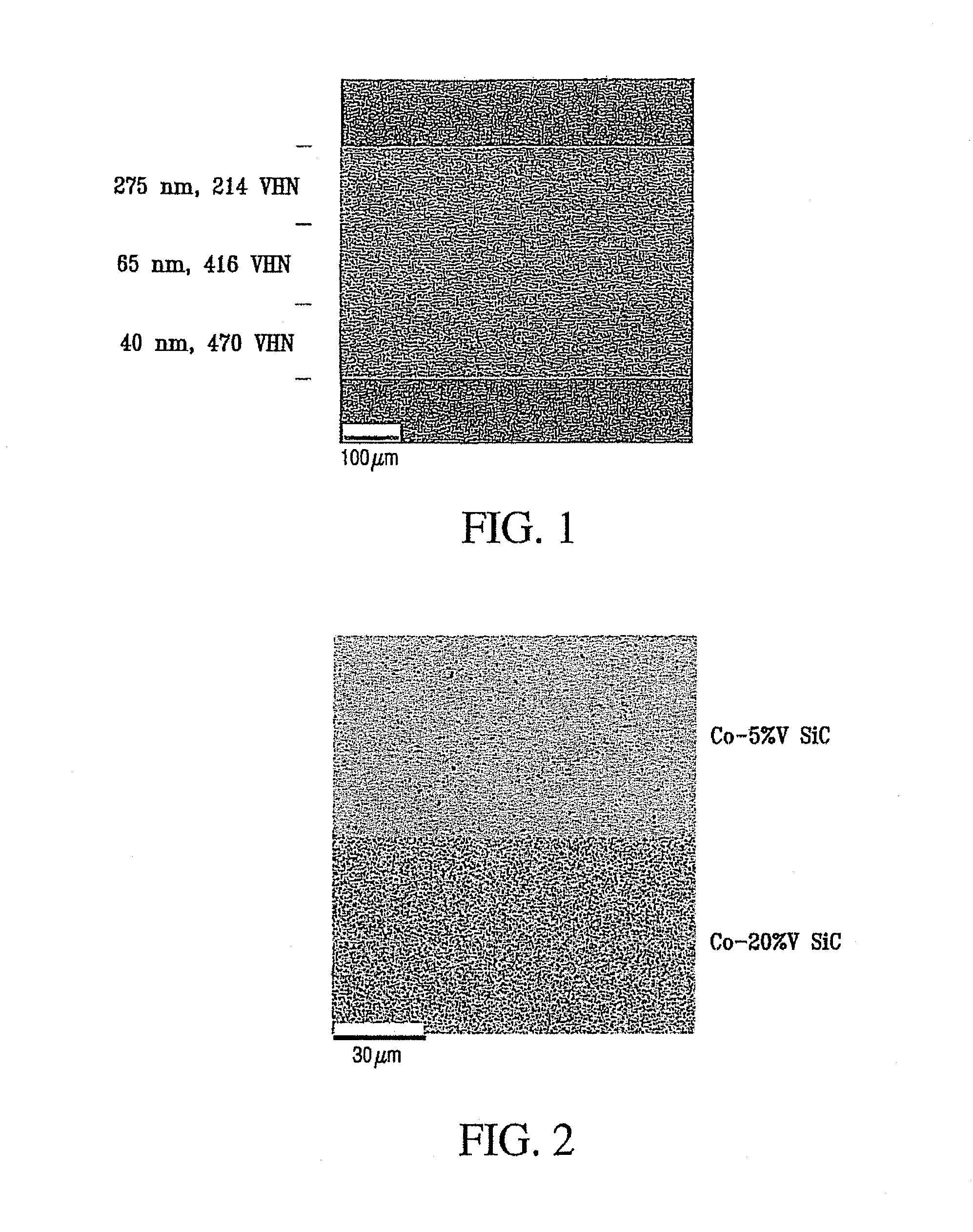

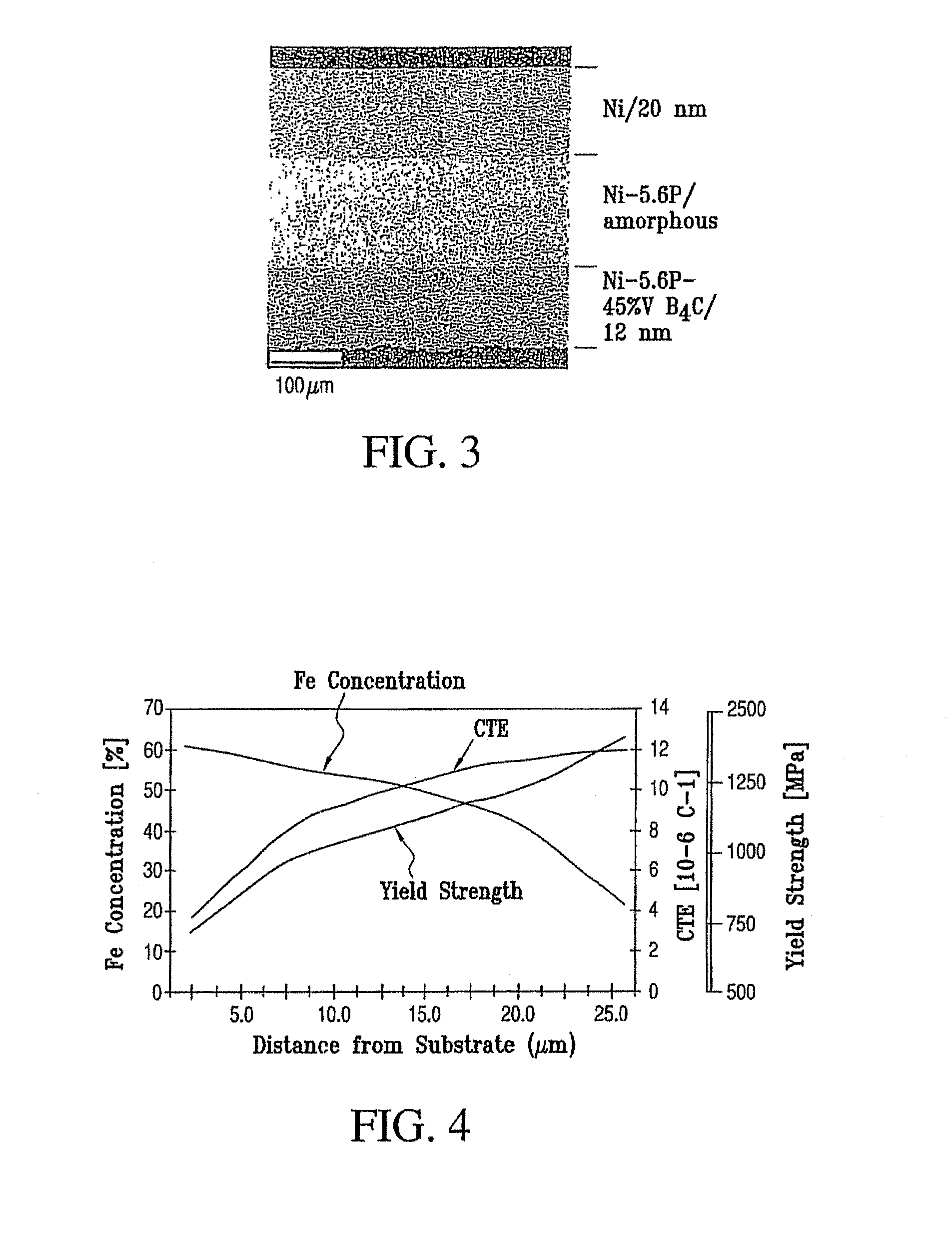

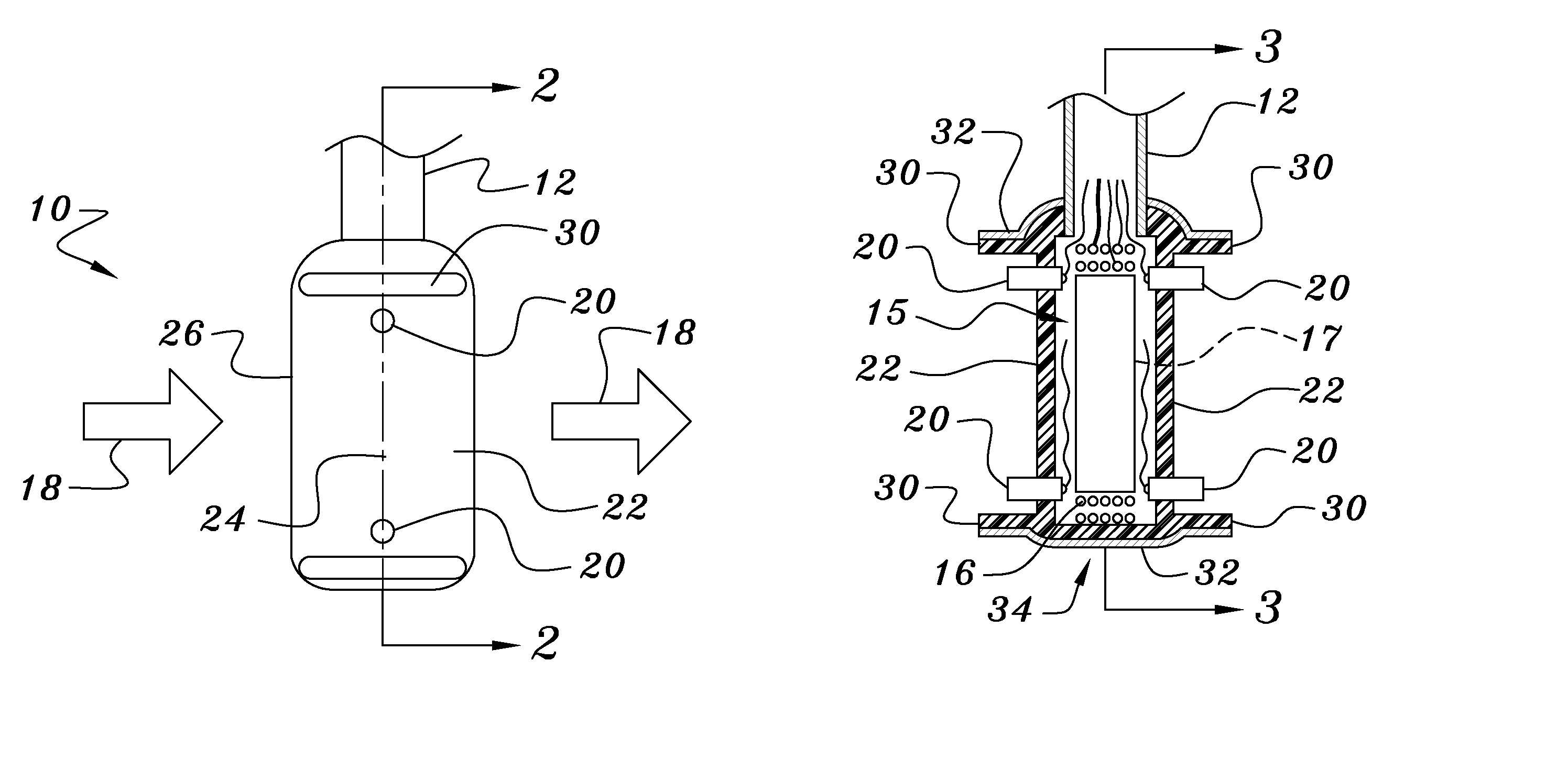

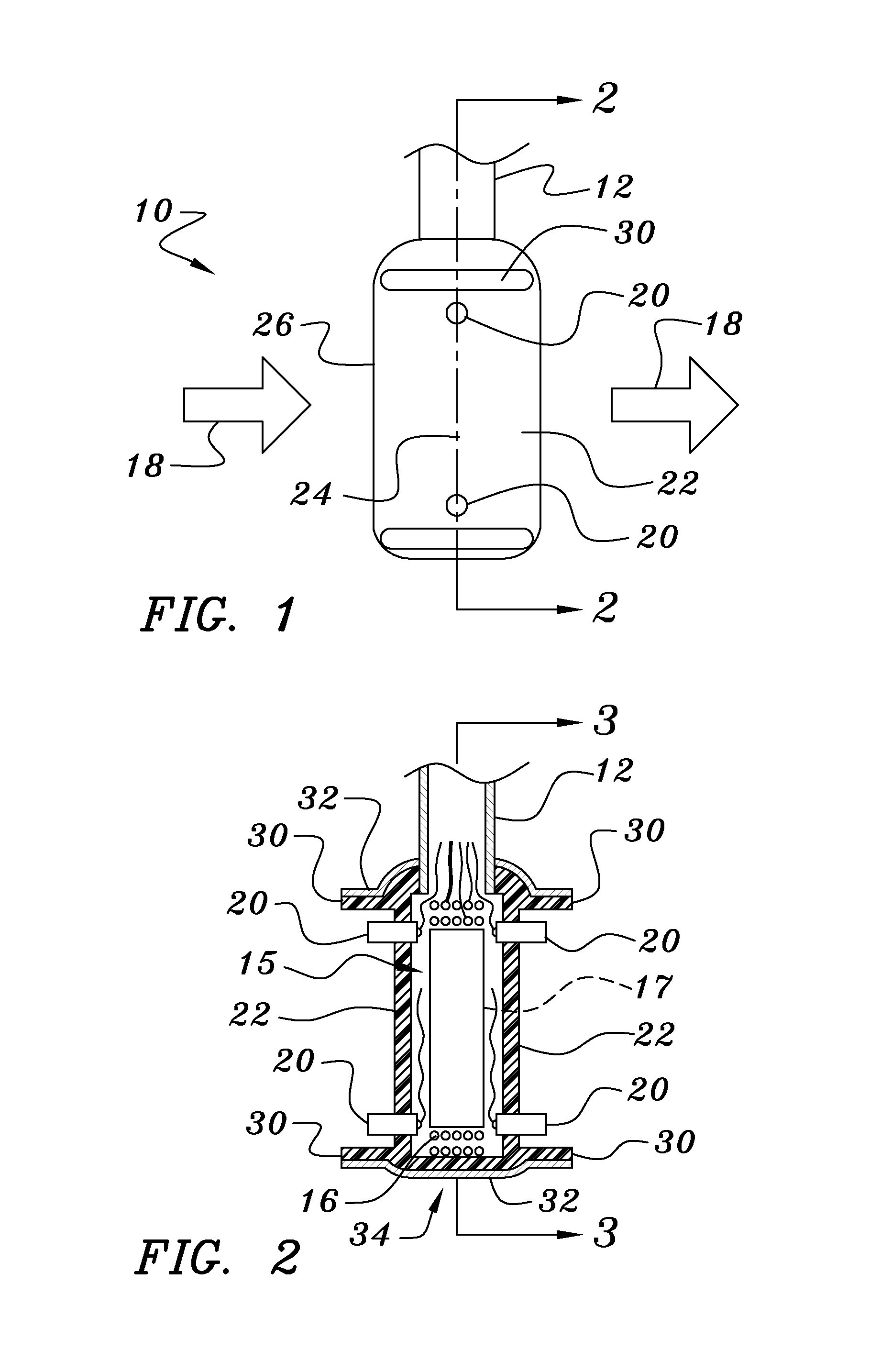

Variable property electrodepositing of metallic structures

ActiveUS20090159451A1Increase floor spaceAdd equipmentCellsElectrolytic coatingsParticulatesMetallic materials

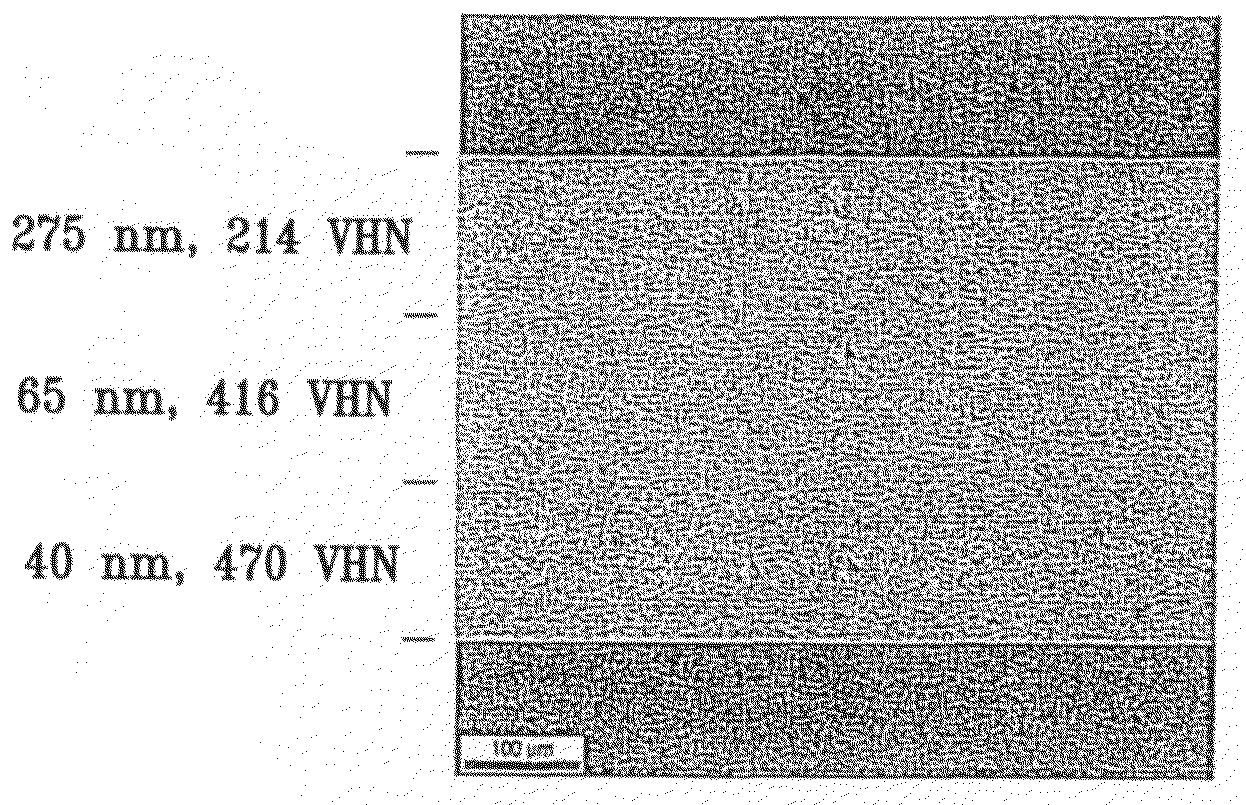

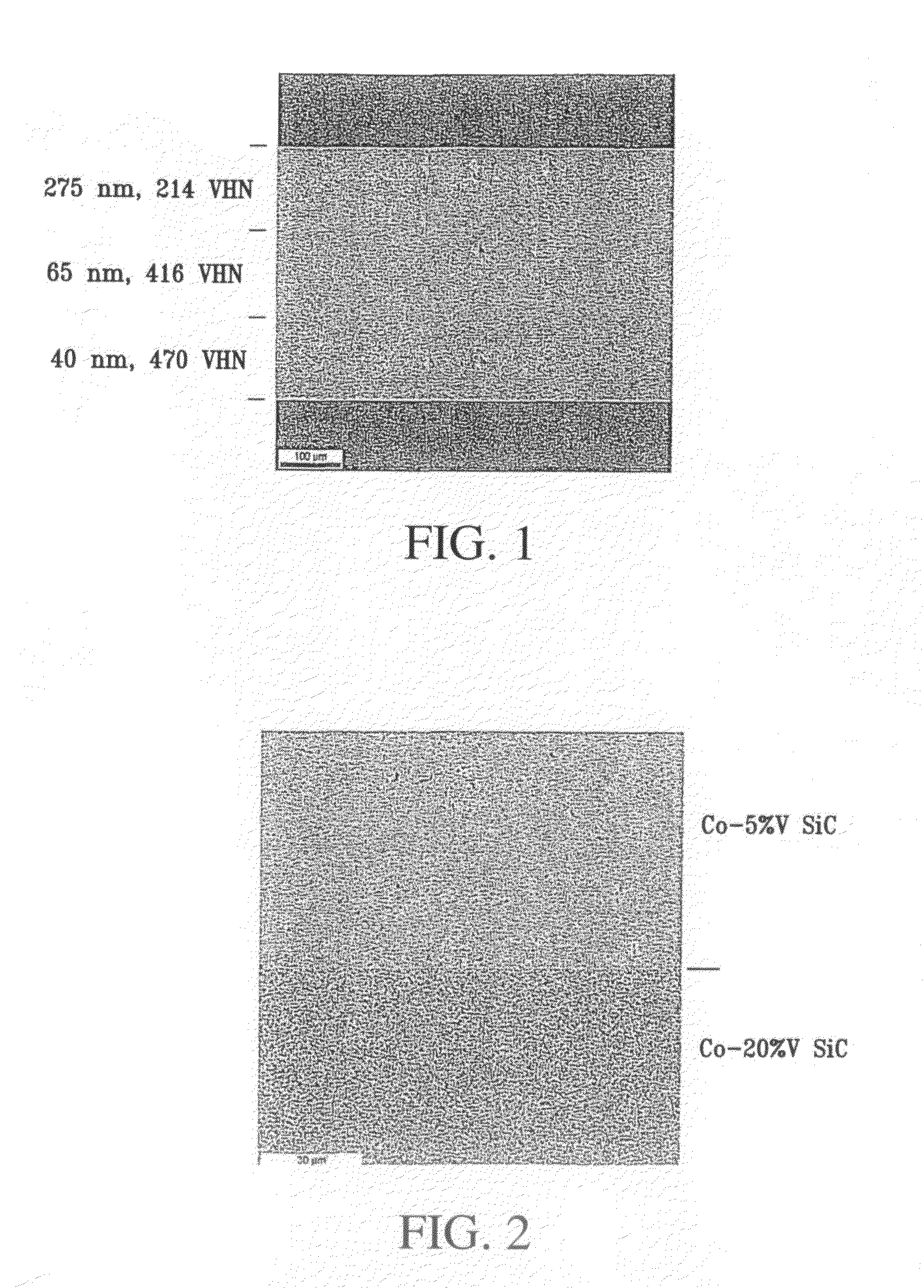

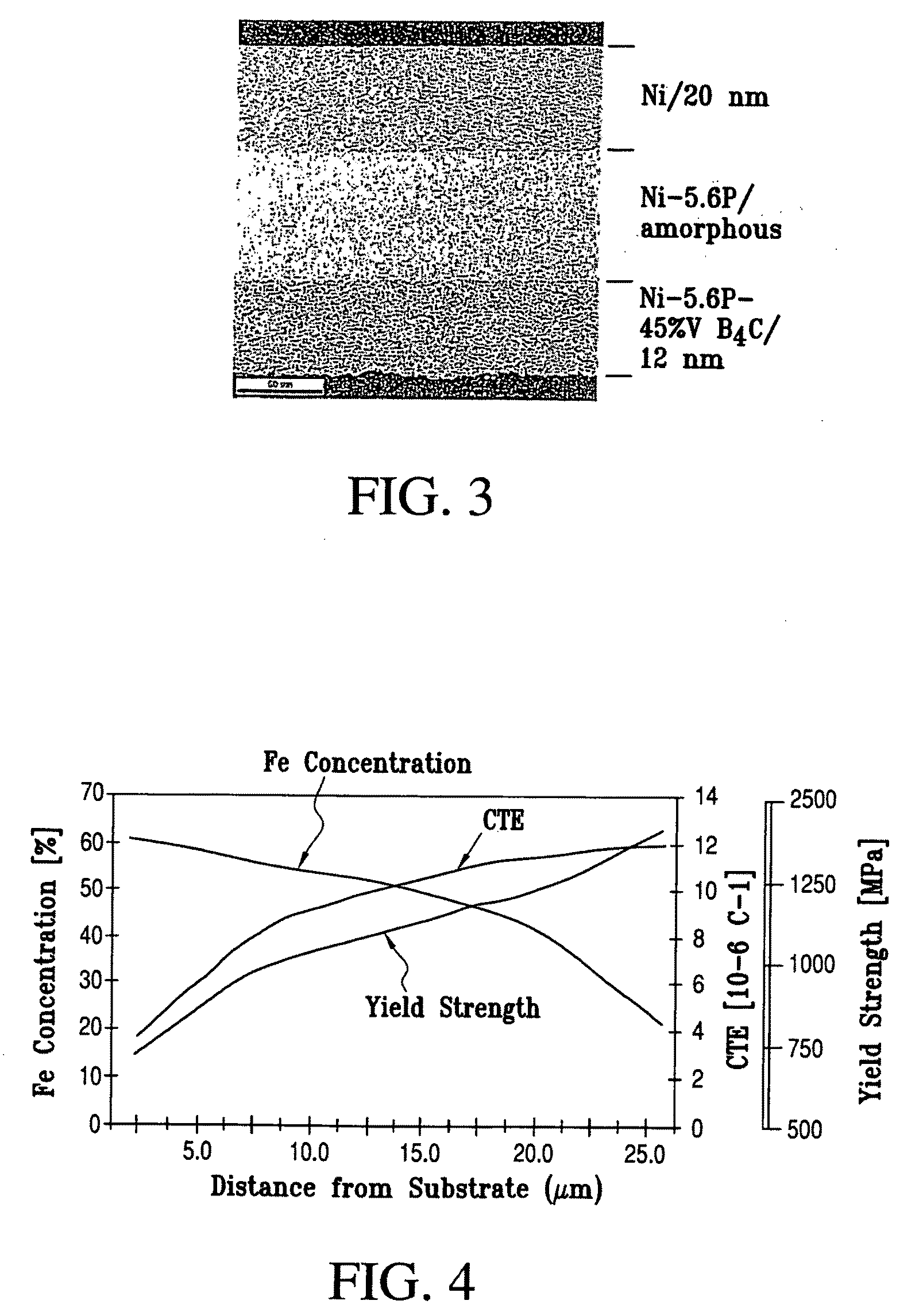

Variable property deposit, at least partially of fine-grained metallic material, optionally containing solid particulates dispersed therein, is disclosed. The electrodeposition conditions in a single plating cell are suitably adjusted to once or repeatedly vary at least one property in the deposit direction. In one embodiment denoted multidimension grading, property variation along the length and / or width of the deposit is also provided. Variable property metallic material deposits containing at least in part a fine-grained microstructure and variable property in the deposit direction and optionally multidimensionally, provide superior overall mechanical properties compared to monolithic fine-grained (average grain size: 2 nm-5 micron), entirely coarse-grained (average grain size: >20 micron) or entirely amorphous metallic material deposits.

Owner:INTEGRAN TECH

Comprehensive treating system for domestic wastes

InactiveCN102527701AIncrease productionImprove qualityBio-organic fraction processingWaste processingSludgeOrganic manure

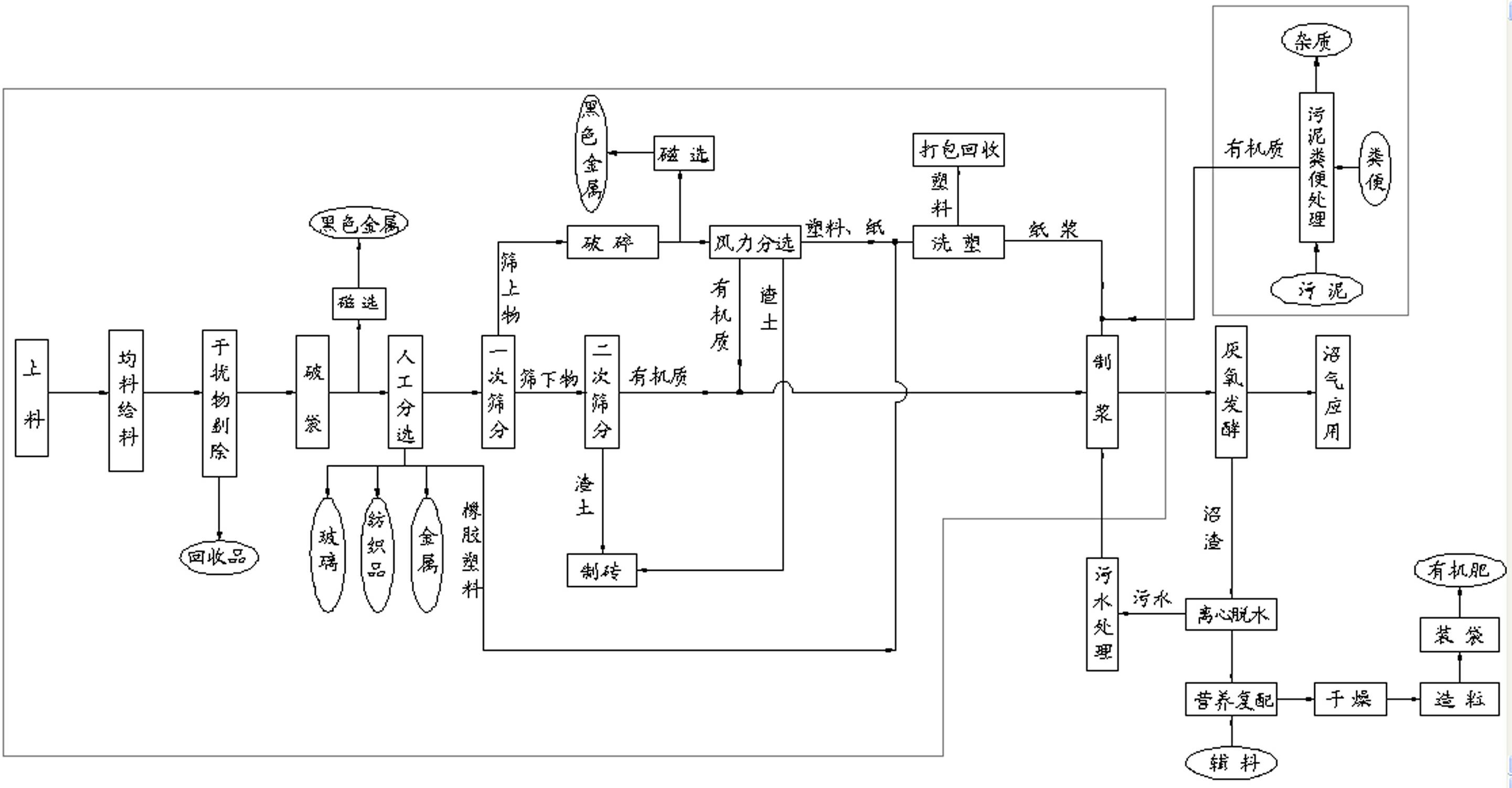

The invention discloses a comprehensive treating system for domestic wastes. Reutilizing comprehensive treatment for mixed wastes is realized by the system according to a comprehensive sorting technology and a combined anaerobic fermentation technology, wherein the advanced sorting techniques, such as, crushing, magnetic separating, sieving, air classifying, and the like, are adopted in the comprehensive sorting technology; reutilized products, such as metal, plastics, organic matters, and the like, are screened out; the screened organic matters are prepared into slurry together with sludge and excrements and are then subjected to the combined anaerobic fermentation; the reutilized products, such as methane, organic fertilizer, and the like, can be produced under the action of anaerobic fermentation; and after the methane is purified, the methane is used for generating power, domestic fuel or vehicle-mounted fuel. According to the technology, the intensified treatment for organic wastes, such as domestic wastes, sludge, excrements, kitchen wastes, and the like, can be realized. The comprehensive treating system is high in mechanical and automated degree. Compared with the prior art, the comprehensive treating system has the advantages of simplification, effectiveness, less labor power, and the like.

Owner:BEIJING HAOHAI TIANJI TECH +1

Metallic Structures with Variable Properties

InactiveUS20110256356A1Increased durabilityIncrease floor spaceVacuum evaporation coatingSputtering coatingParticulatesMetallic materials

Variable property deposit, at least partially of fine-grained metallic material, optionally containing solid particulates dispersed therein, is disclosed. The electrodeposition conditions in a single plating cell are suitably adjusted to once or repeatedly vary at least one property in the deposit direction. In one embodiment denoted multidimension grading, property variation along the length and / or width of the deposit is also provided. Variable property metallic material deposits containing at least in part a fine-grained microstructure and variable property in the deposit direction and optionally multidimensionally, provide superior overall mechanical properties compared to monolithic fine-grained (average grain size: >20 micron) or entirely amorphous metallic material deposits.

Owner:INTEGRAN TECH

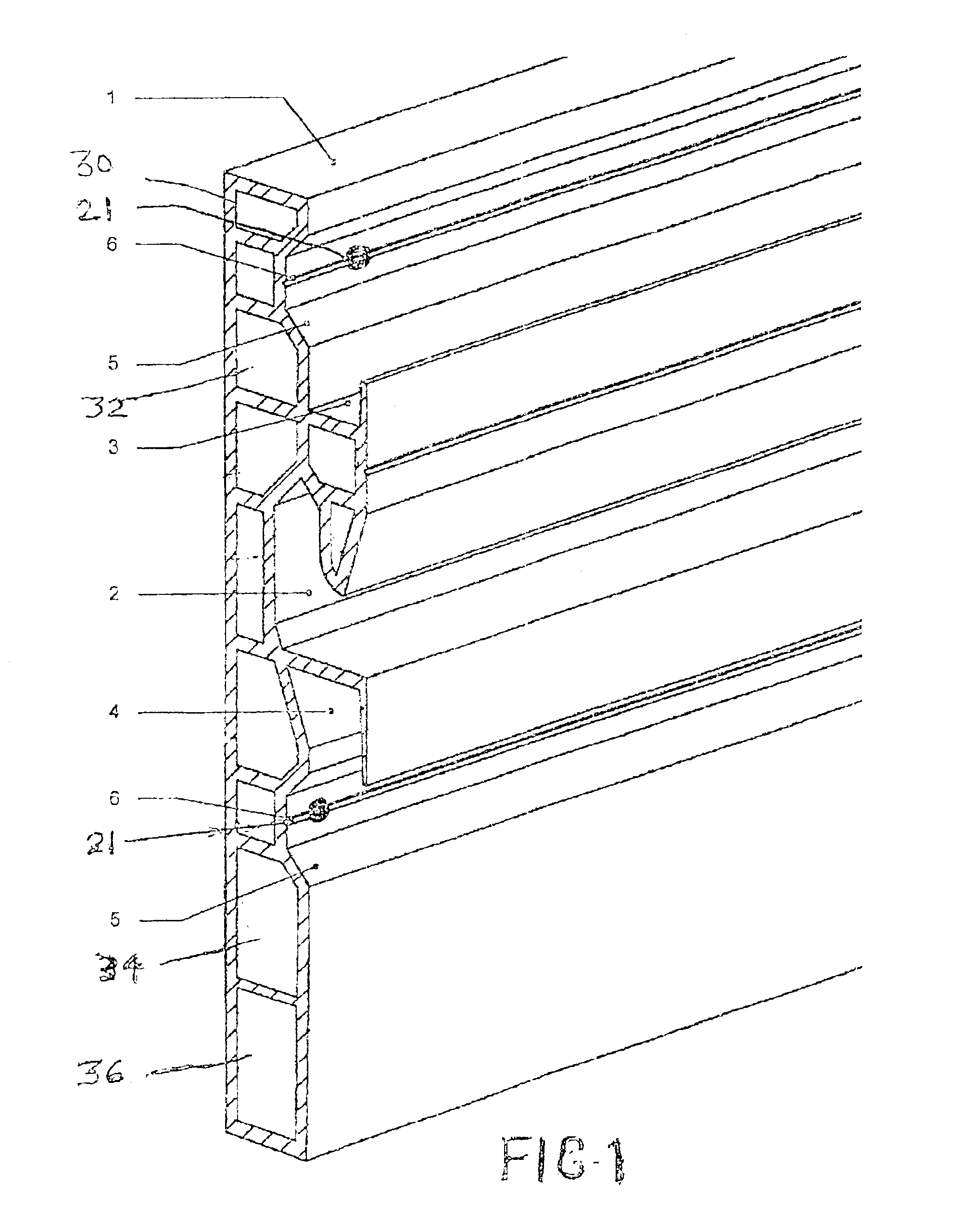

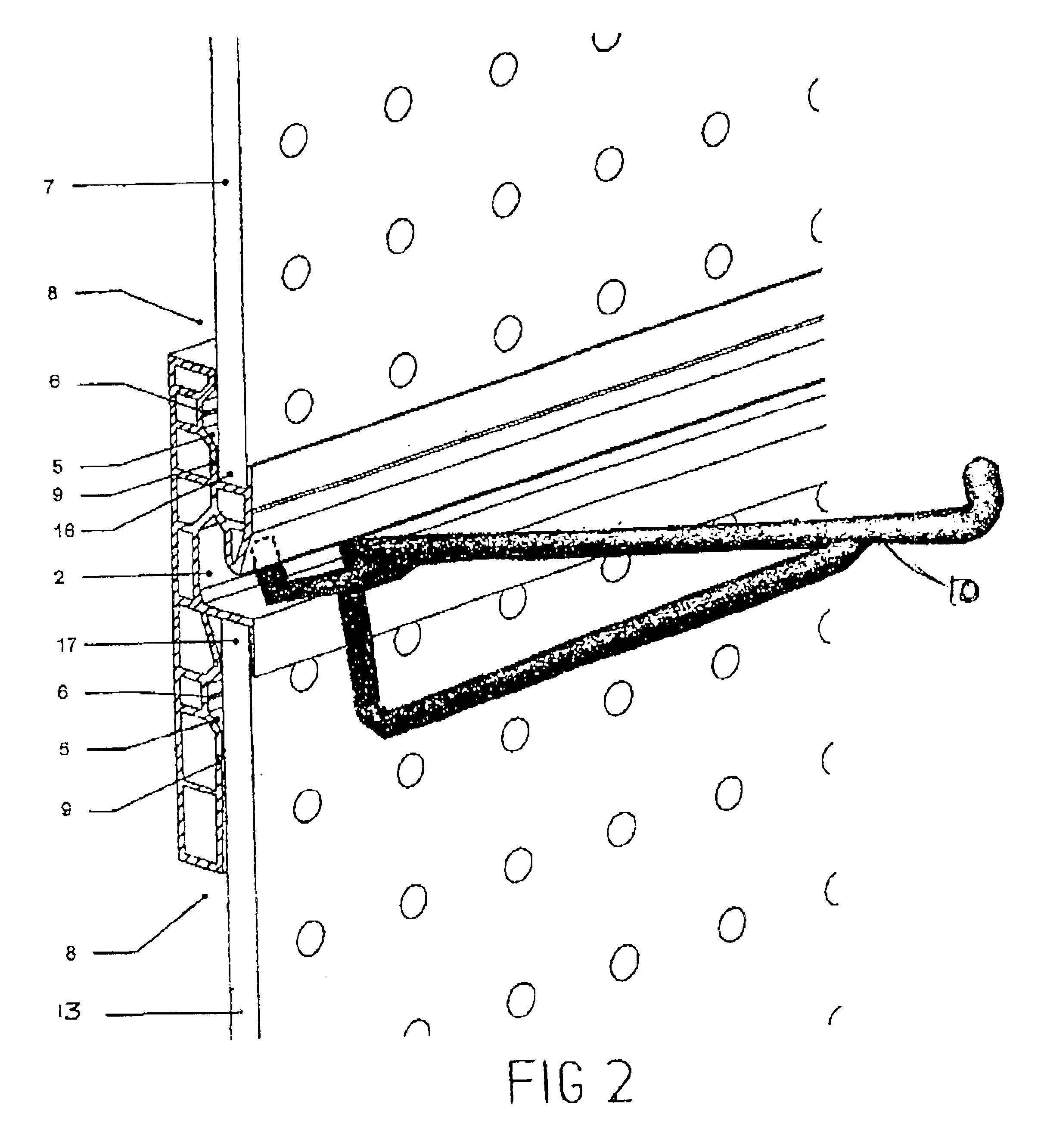

Storage track

InactiveUS6837384B2Effectively and efficiently display/merchandiseIncrease floor spaceBuilding constructionsShow shelvesEngineeringSurface plate

Owner:ACCLAIM DESIGN & PROFILES

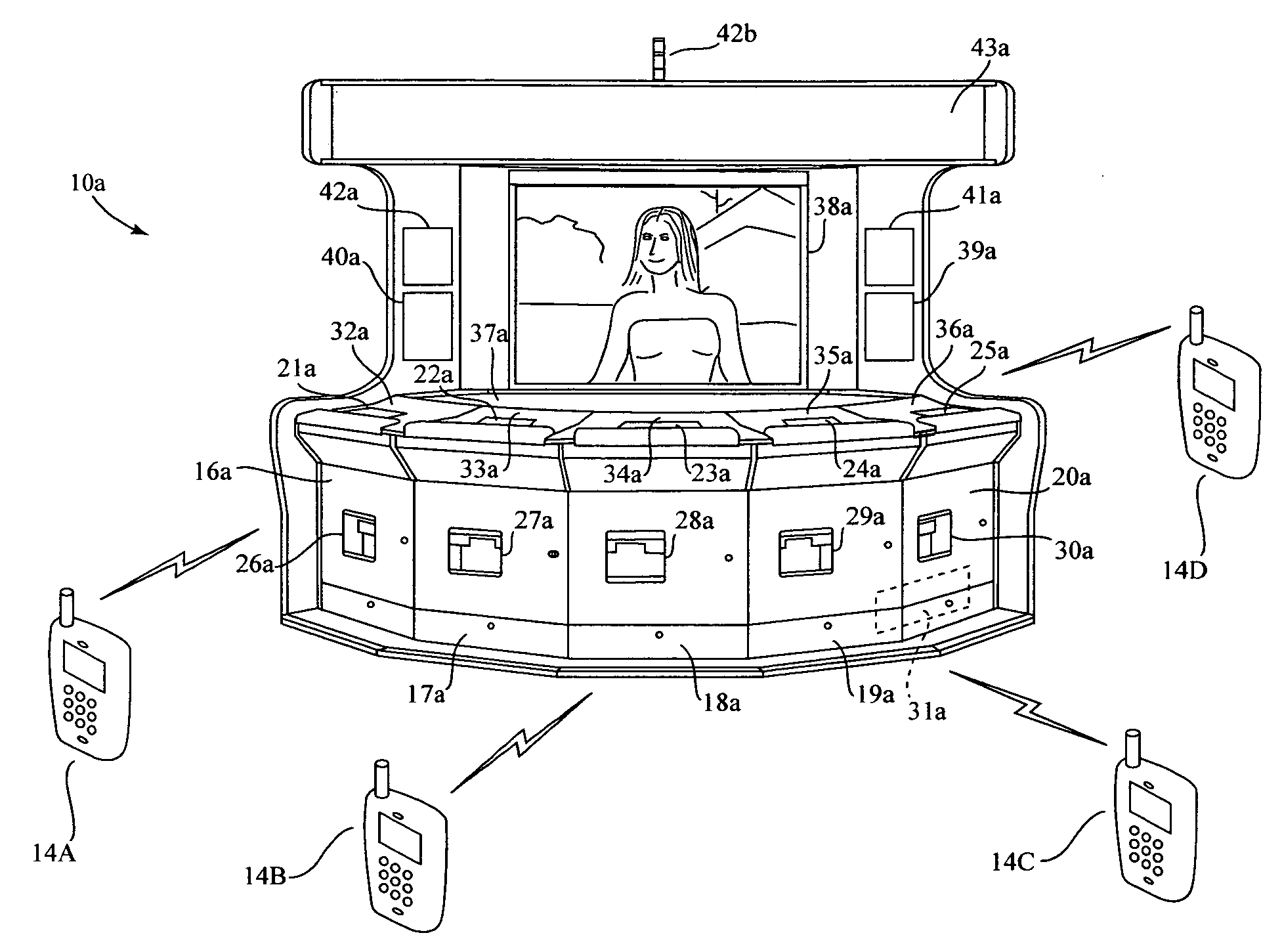

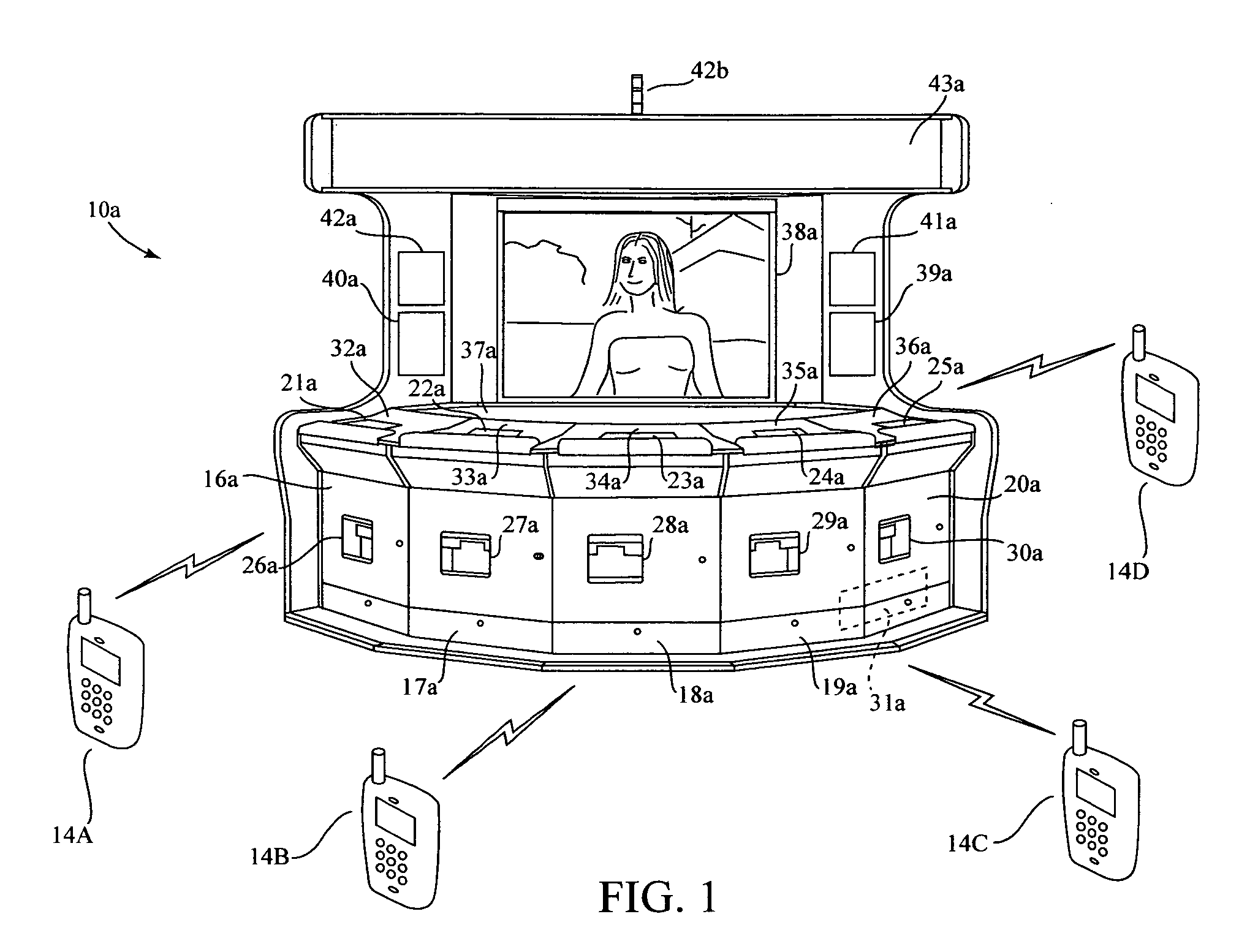

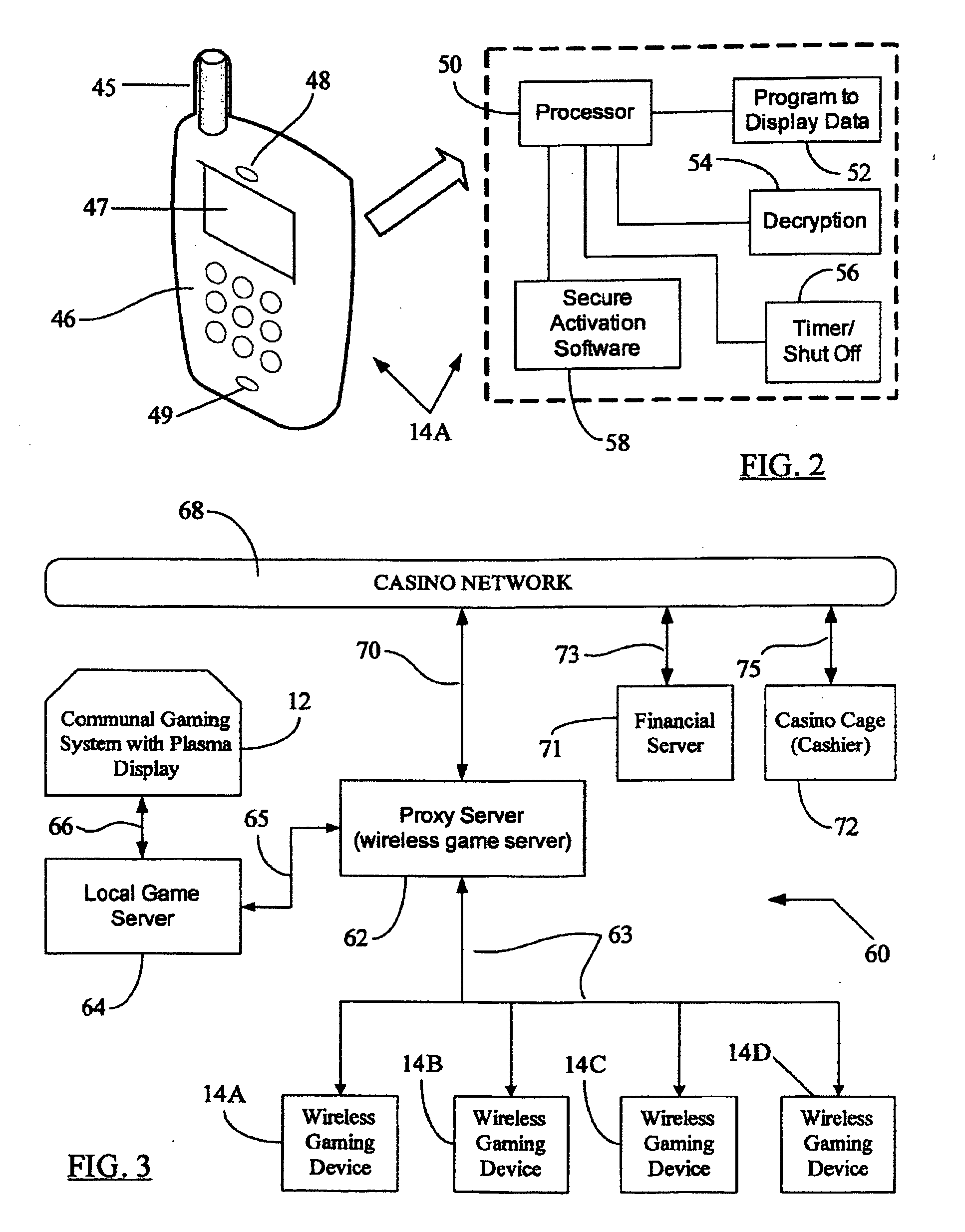

Wireless bet withdrawal gaming system

InactiveUS20090075724A1Improve mobilityWithout reducing speed of playBoard gamesCard gamesWireless transmissionUser input

A system for wireless gaming comprises a central game processor having wireless transmission and reception ability. The game processor has a device server and a local game server. Multiple user input devices having a visual display and wireless transmission and reception ability are provided. The wireless devices are used to play a game in which a player places a multiple part wager comprising at least two distinct wagers to participate in a game. At least a partial hand of cards is provided to each player, and at least one common card is provided. Players are given an opportunity to withdraw a portion of the wager after viewing the player cards. The at least one common card is revealed and play is resolved. All wagers not withdrawn by the player are resolved

Owner:BALLY GAMING INC

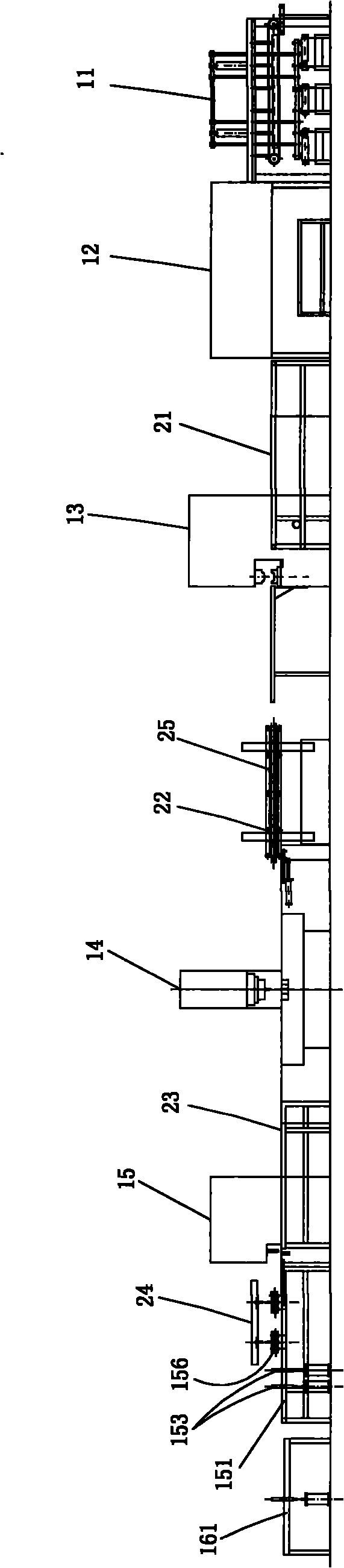

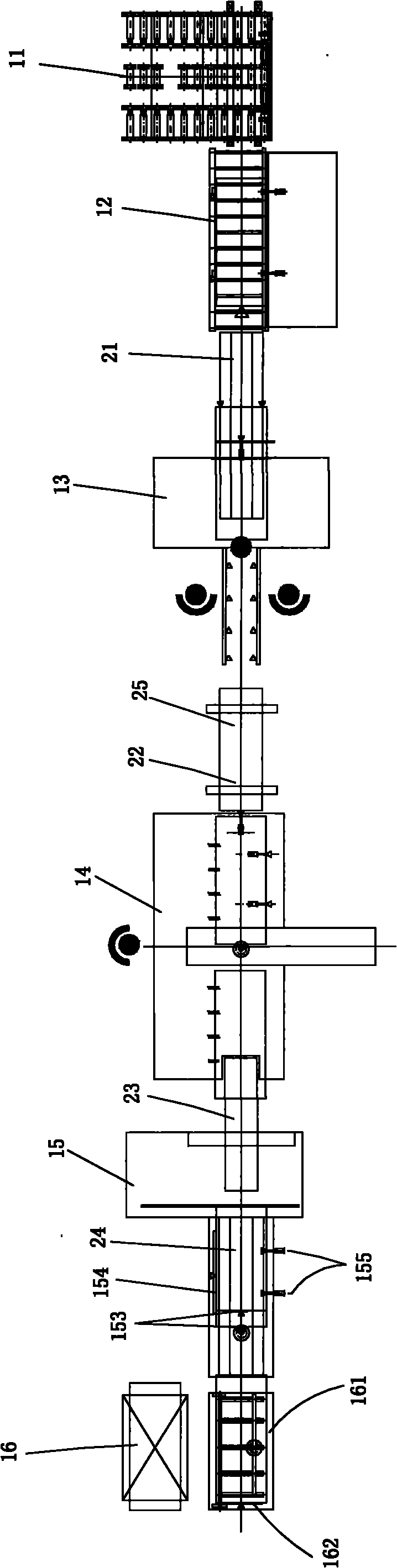

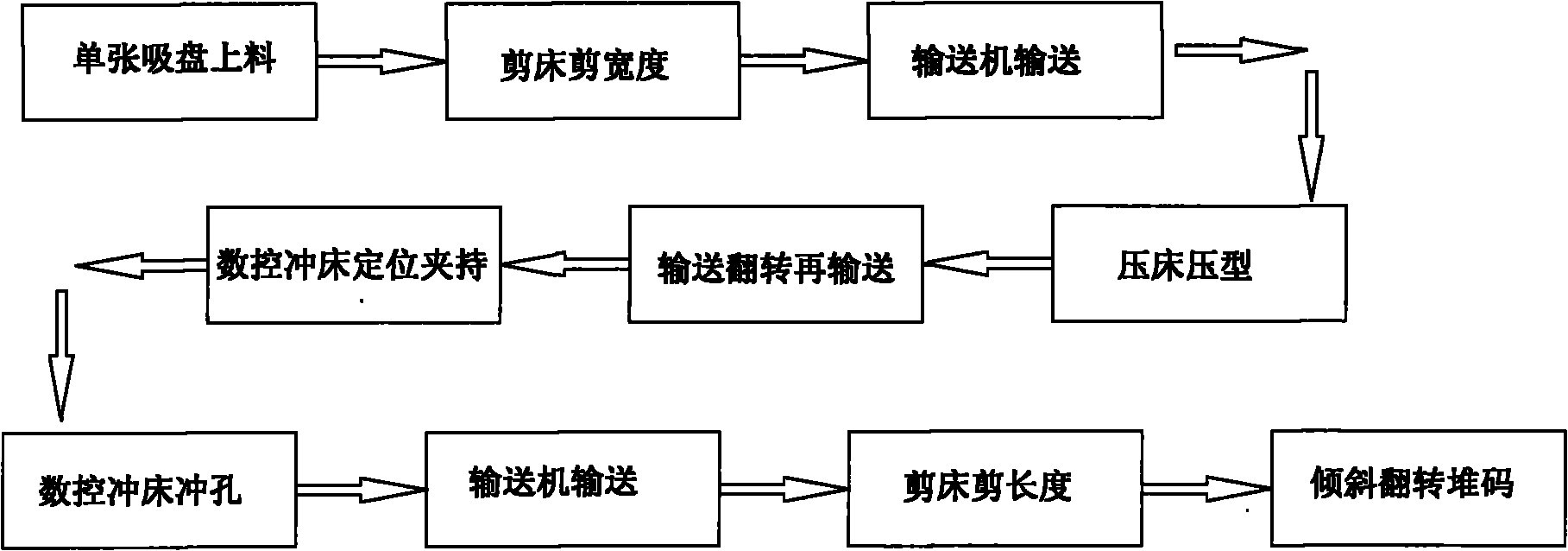

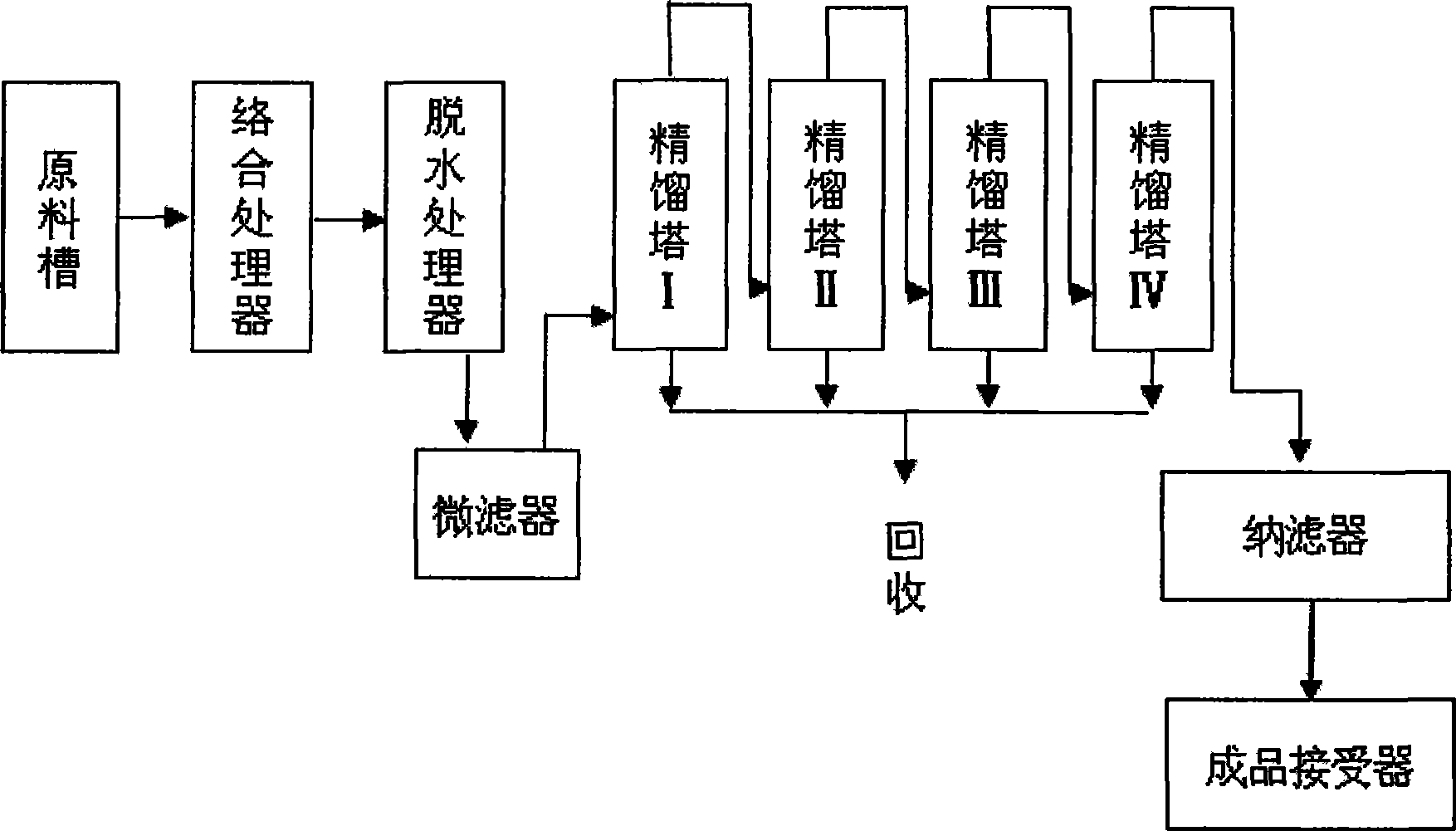

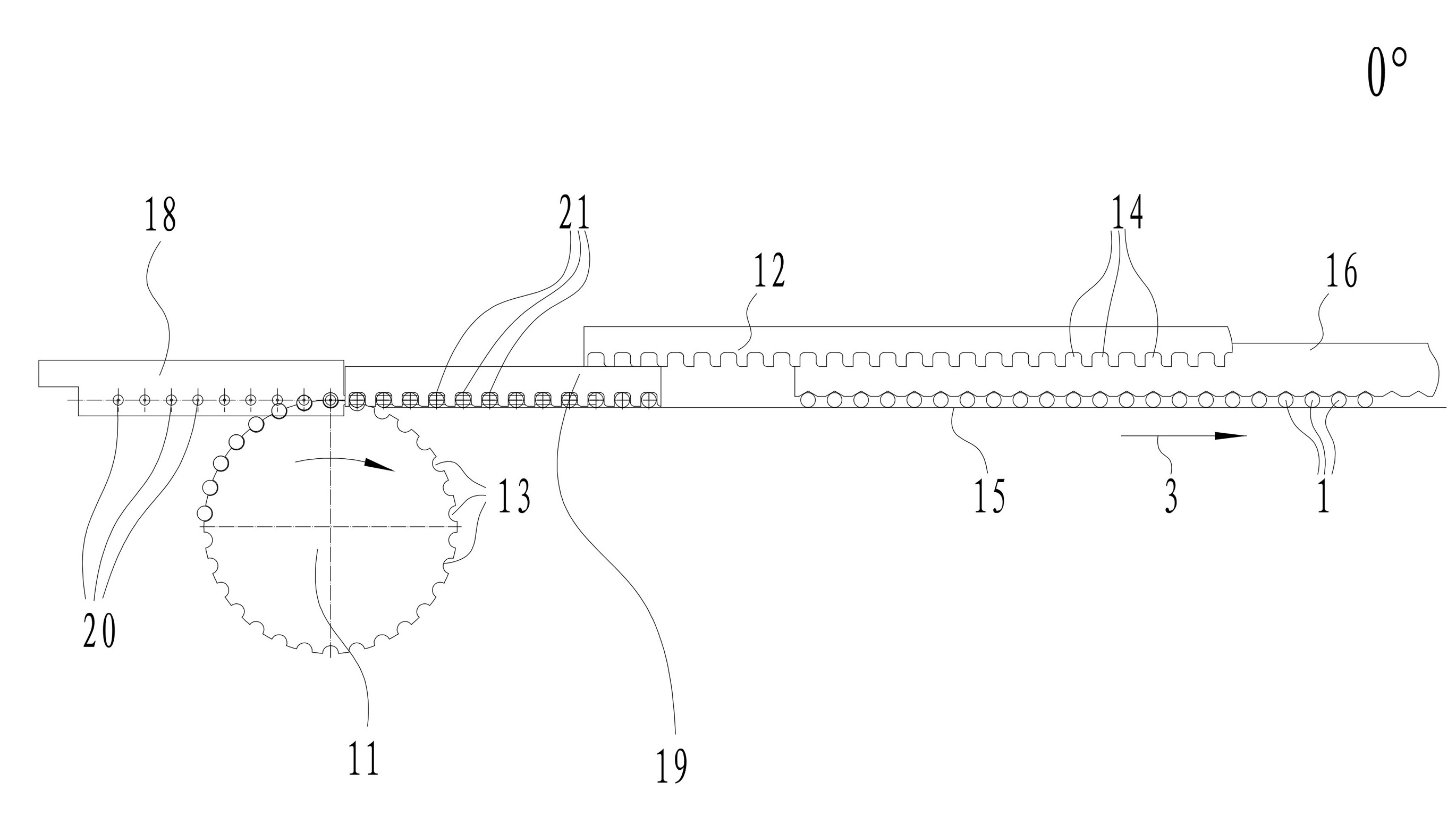

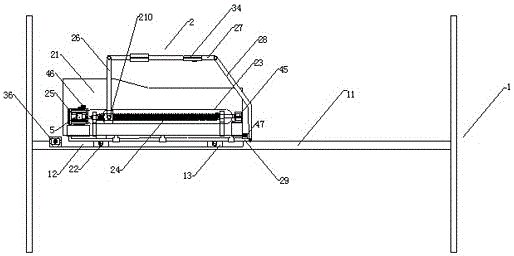

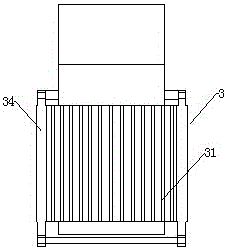

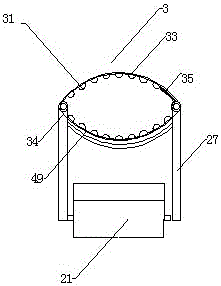

Production method and production system of container door panel

ActiveCN101875170AImprove quality controlIncrease productivityOther manufacturing equipments/toolsNumerical controlEngineering

The invention relates to a production method and a production system of container door panels. The method comprises the following steps sequentially: (1) after the whole stack of panels are fed, an automatic feeding device sucks single panel one by one according to set pace, and sends the panels to a shearing machine width shearing device for shearing the width of the panels; (2) a conveyer automatically conveys the panels with sheared width to a press machine, and the panels are pressed and formed after being conveyed to a mould of the press machine and being positioned by a positioning device of the press machine; (3) the pressed panels are punched after being turned over and then conveyed to a numerical control press; when the door panels are conveyed to the worktable of the numerical control press, the numerical control press automatically carries out initial positioning to the door panels to be machined, and the panels to be machined are clamped with clamps after being positioned, and then punched according to the set program; (4) the punched panels are conveyed to a shearing machine length shearing device to be sheared into qualified door panels; (5) the qualified door panels with sheared length are stacked. The production method has the advantages of high production efficiency, cost saving and the like.

Owner:CHINA INTERNATIONAL MARINE CONTAINERS (GROUP) CO LTD

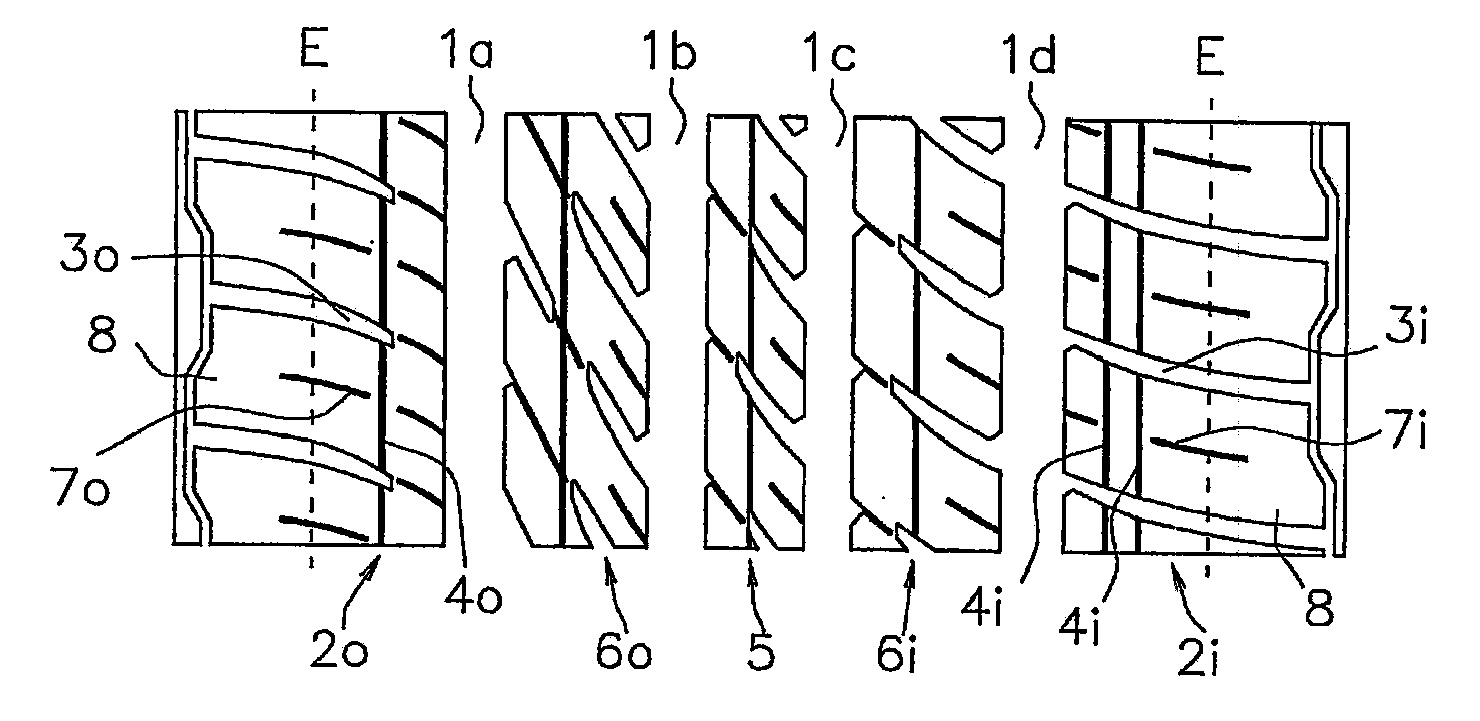

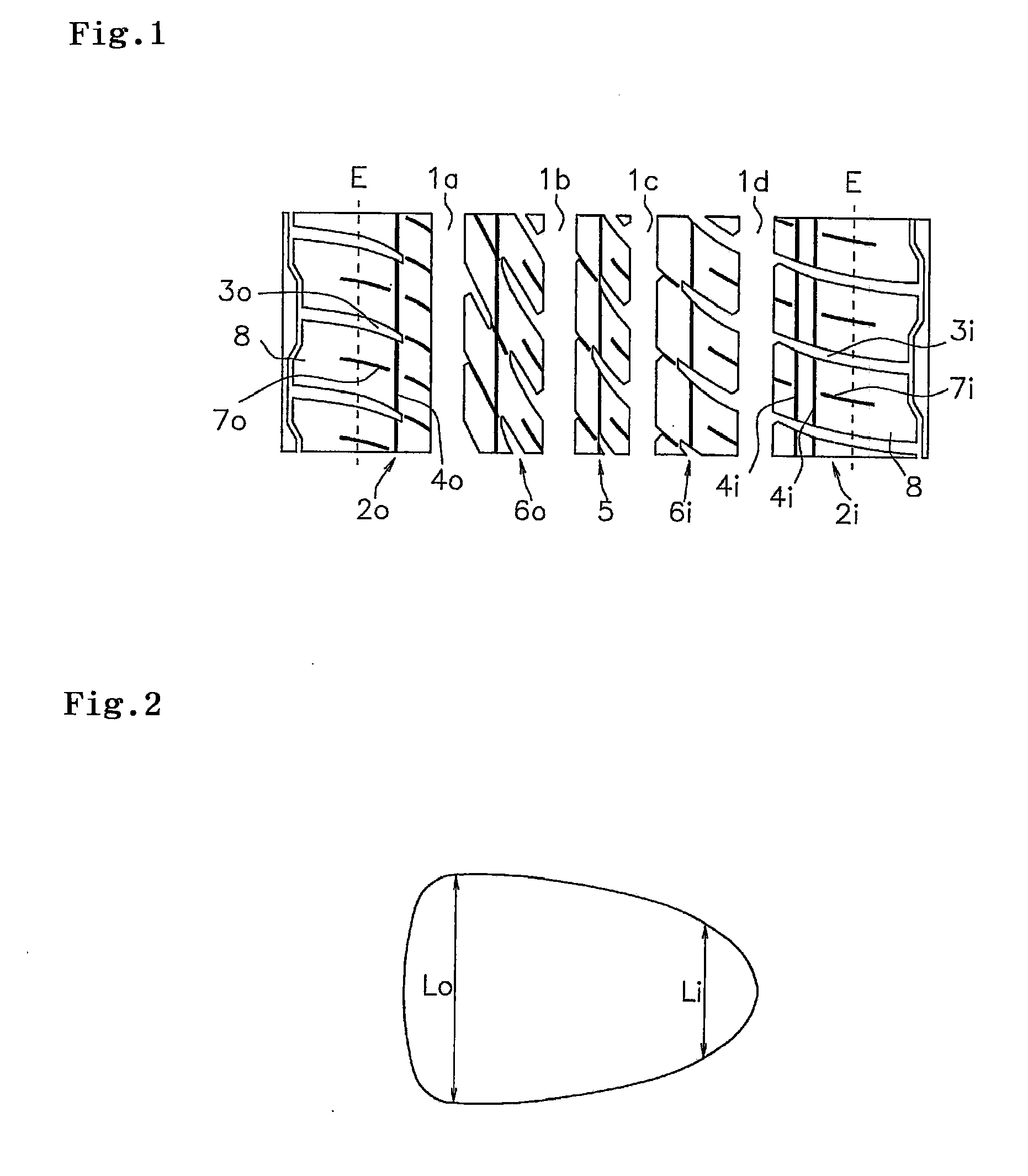

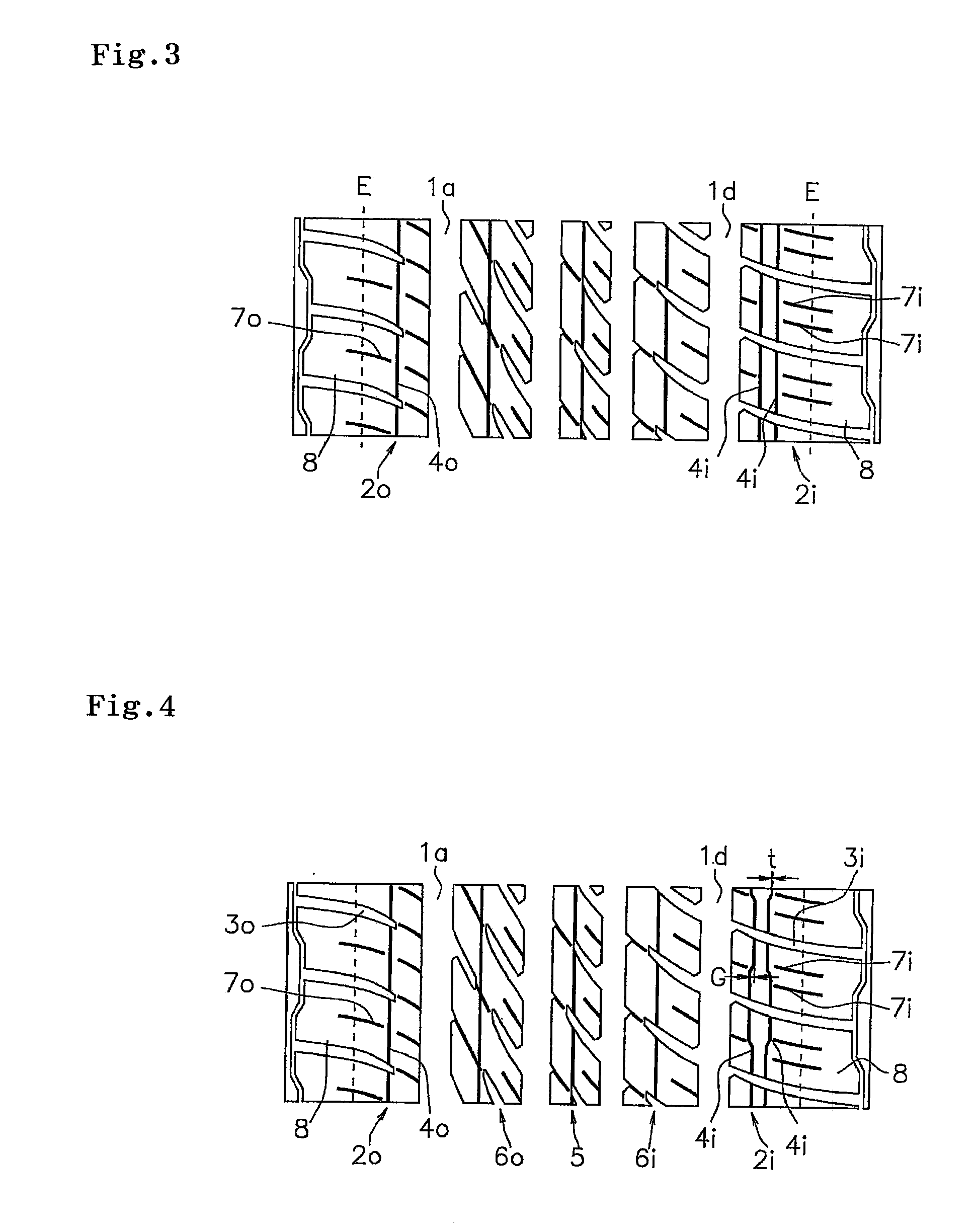

Pneumatic Tire

ActiveUS20100116393A1Improve rigidityImprove braking effectTyre tread bands/patternsNon-skid devicesTreadAutomotive engineering

A pneumatic tire has a tread pattern including a plurality of main grooves extending along a tire circumferential direction, and a shoulder land portion constructed by a rib or a block row formed in an outer side in a tire width direction of the main groove positioned in an outermost side. A circumferential sipe is provided in each of the shoulder land portions in both sides in the tire width direction. The number of the circumferential sipes provided in the shoulder land portion in a vehicle inner side is larger than the number of the circumferential sipes provided in the shoulder land portion in a vehicle outer side.

Owner:TOYO TIRE & RUBBER CO LTD

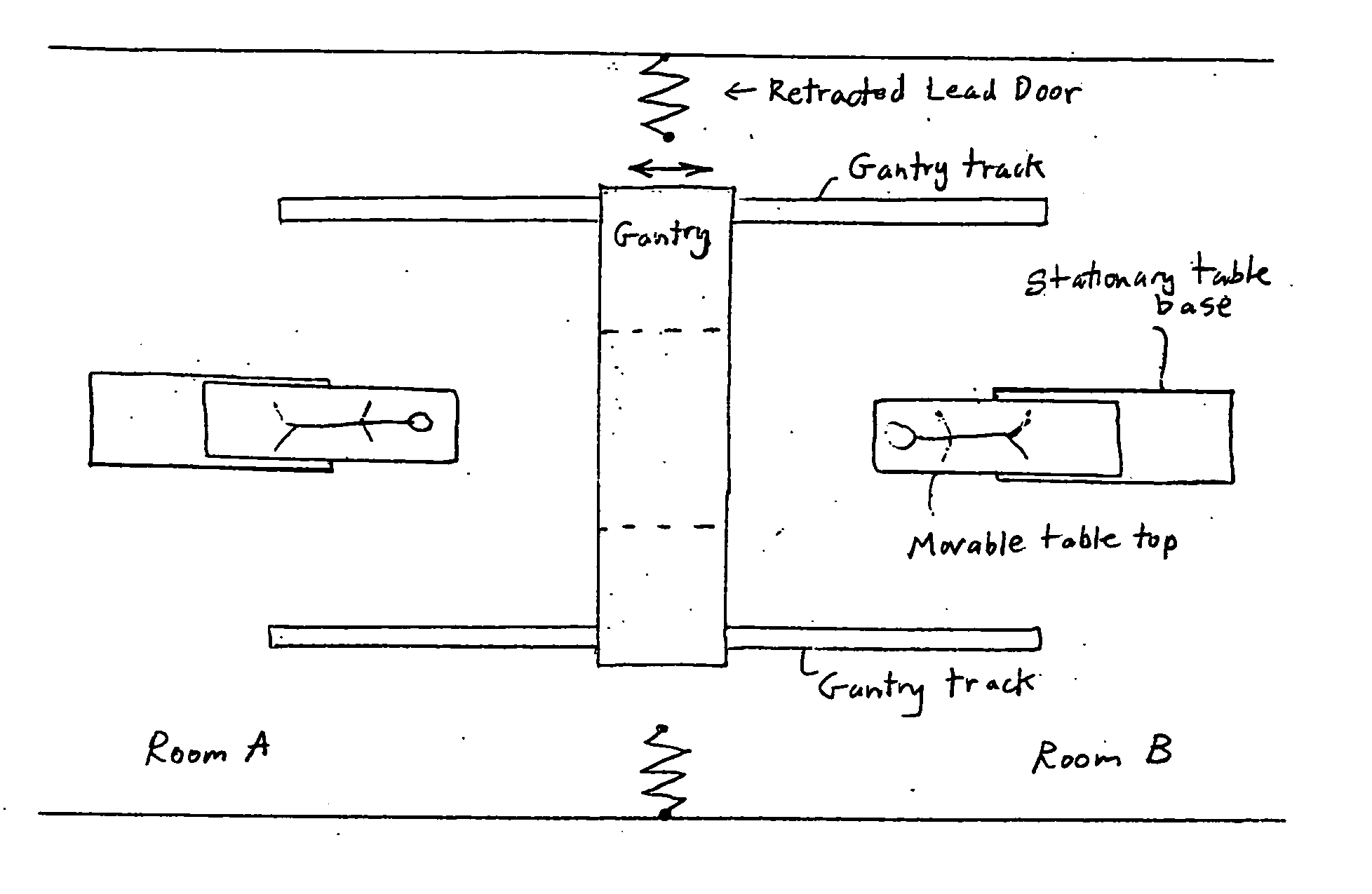

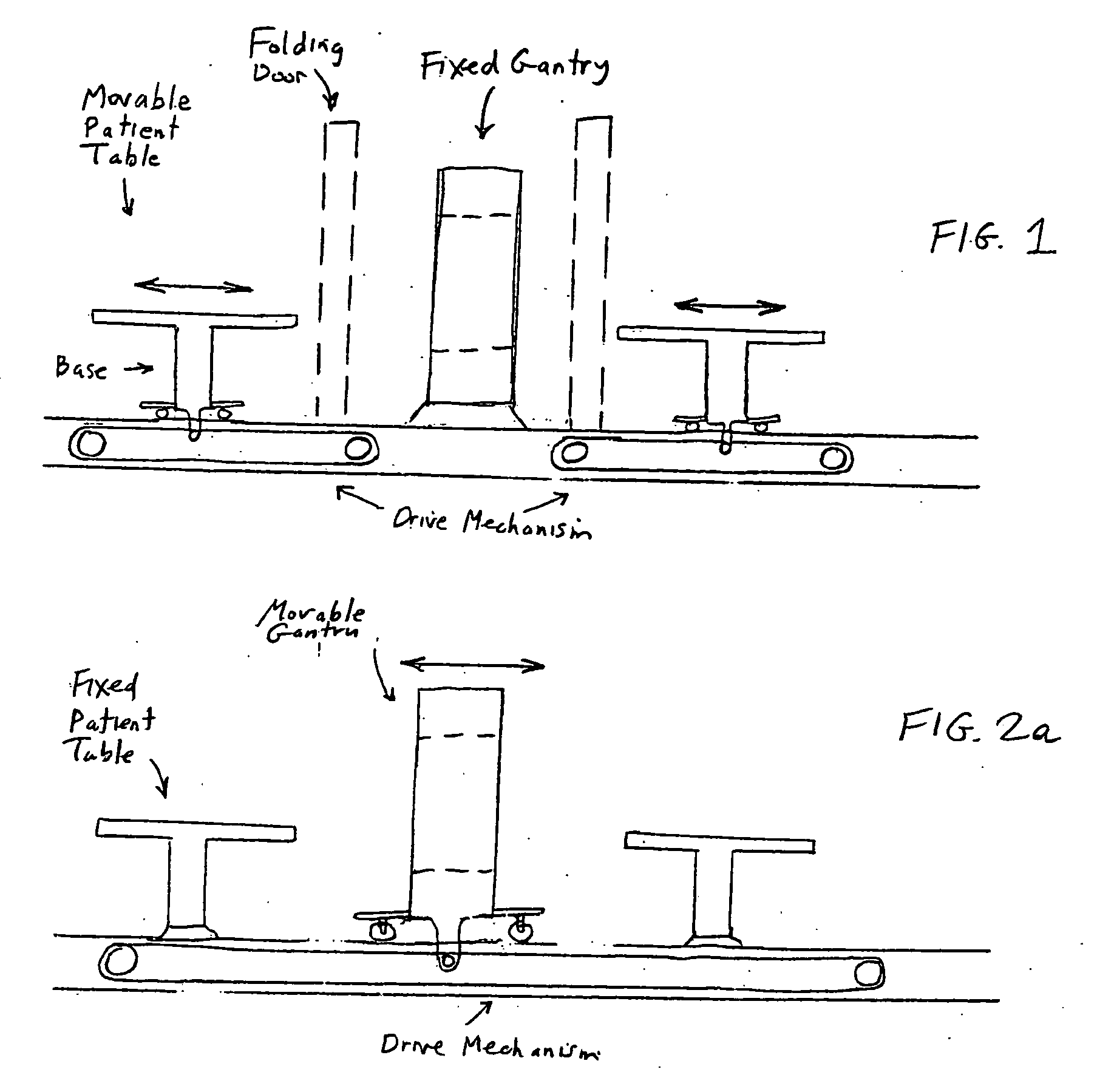

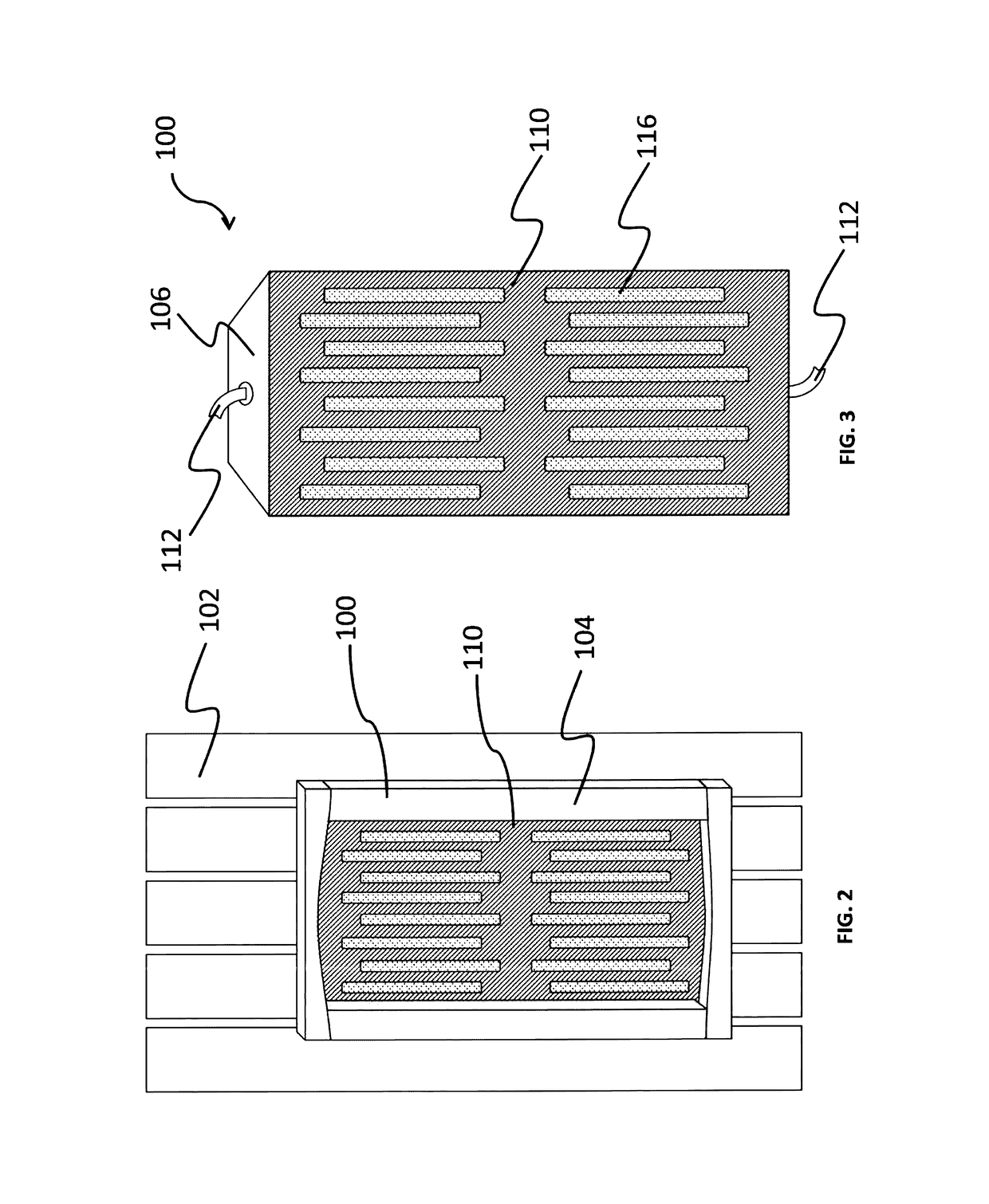

Multi-table CT or MRI scanner arrangement for increasing patient throughput

InactiveUS20060260050A1Increased scan productivityImprove throughputWheelchairs/patient conveyanceNursing bedsImaging processingMedical imaging

A medical imaging system with increased scan productivity or throughput. The invention allows hospitals and other medical facilities to ameliorate the high cost of imaging devices such as CT or MRI scanners while improving patient care and lowering per-patient costs. A single imaging device is arranged so that pre- or post-imaging processing of one or more patients and patient tables / tabletops can be performed simultaneously with imaging of another patient. The imaging device can be stationary, while patient tables / tabletops are movably guided by tracks on both sides of the imaging device. The imaging device can also be movable relative to the patient tables / tabletops. An overhead or floor track system can be used such as a circuit, or multiple track branches that merge at a junction. Or, the imaging device can be located at the center, or outside, of a carousel on which the patient tables are loaded and unloaded.

Owner:RES FOUND OF STATE UNIV OF N Y THE

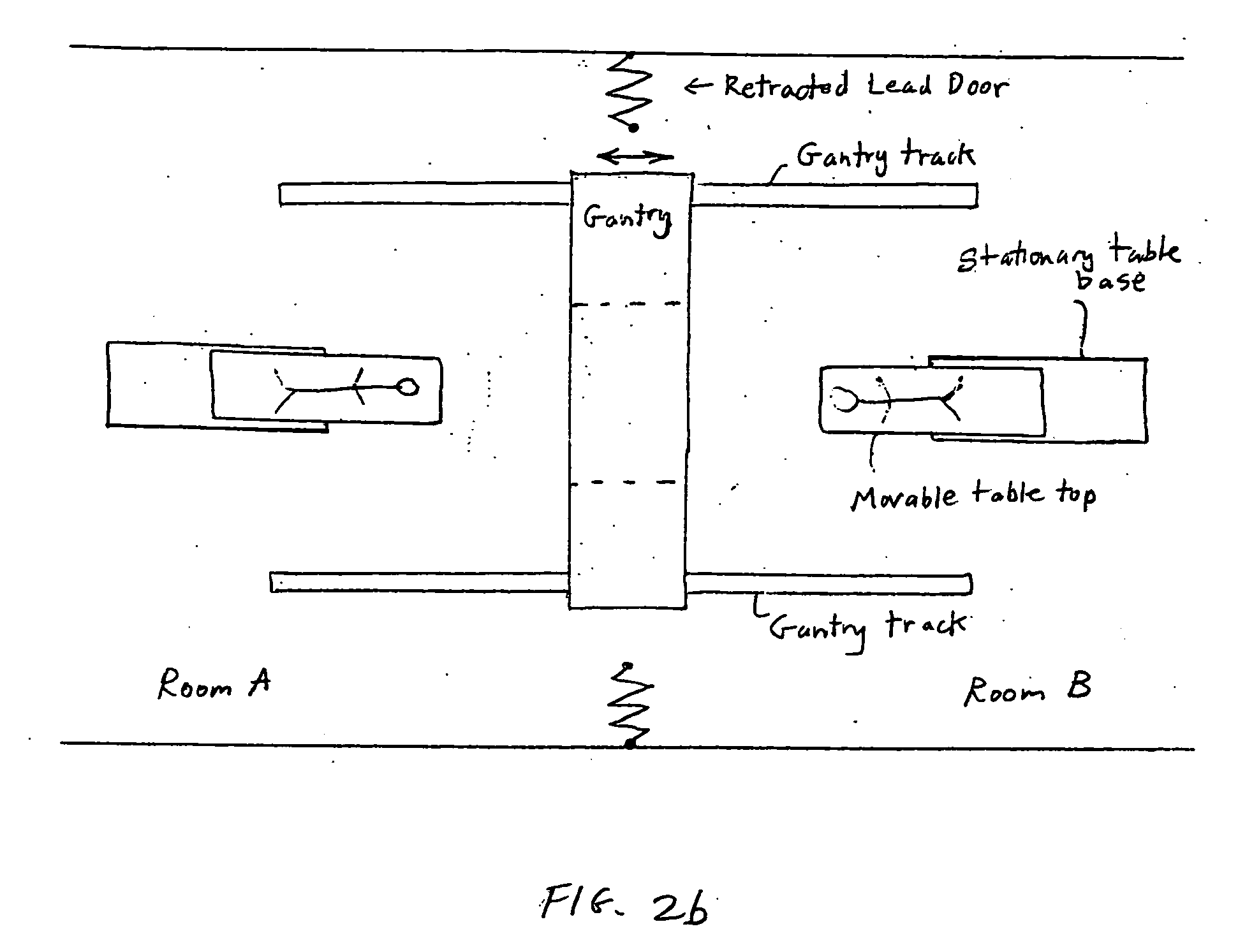

Method for preparing super-clean and high-purity isopropanol and apparatus thereof

ActiveCN101362675AEasy to processLow priceOrganic compound preparationHydroxy compound preparationSmall footprintImpurity

The invention relates to a method for preparing super-clean and high-purity isopropanol and a device thereof, and the high-purity isopropanol is mainly suitable for cleaning in the manufacture industry of large scale integrated circuit semiconductor devices in the microelectronic industry. The method is as follows: firstly, the industrial grade isopropanol material with mass percentage to be 98 percent is mixed with a metal ion complexing agent with 0.5-5 percent of the weight of the isopropanol material in a complexing processor, under the normal temperature and pressure, after 30-120 minutes, the mixture is fed into a dehydrating processor, and then mixed for 60-150 minutes with a dehydrating agent with 0.1-15 percent of the weight of the isopropanol material under the temperature of 60 DEG C to 100 DEG C in the dehydrating processor, and then the mixture is filtered by the microfiltration membrane under the operation pressure of 0.1-0.2MPa, the filtrate enters into a multilevel rectification tower, and the semi-finished product from the tower is filtered by a nanofiltration membrane under the purifying environment and the operation pressure of 0.5-0.8MPa, and then is fed into a finished product acceptor. The method has the advantages of strong continuity, good separation effect, high purity and low impurity content. The device has the advantages of small occupied area, convenient automatic operation, stable quality and continuous production.

Owner:JIANGYIN RUNMA ELECTRONICS MATERIAL

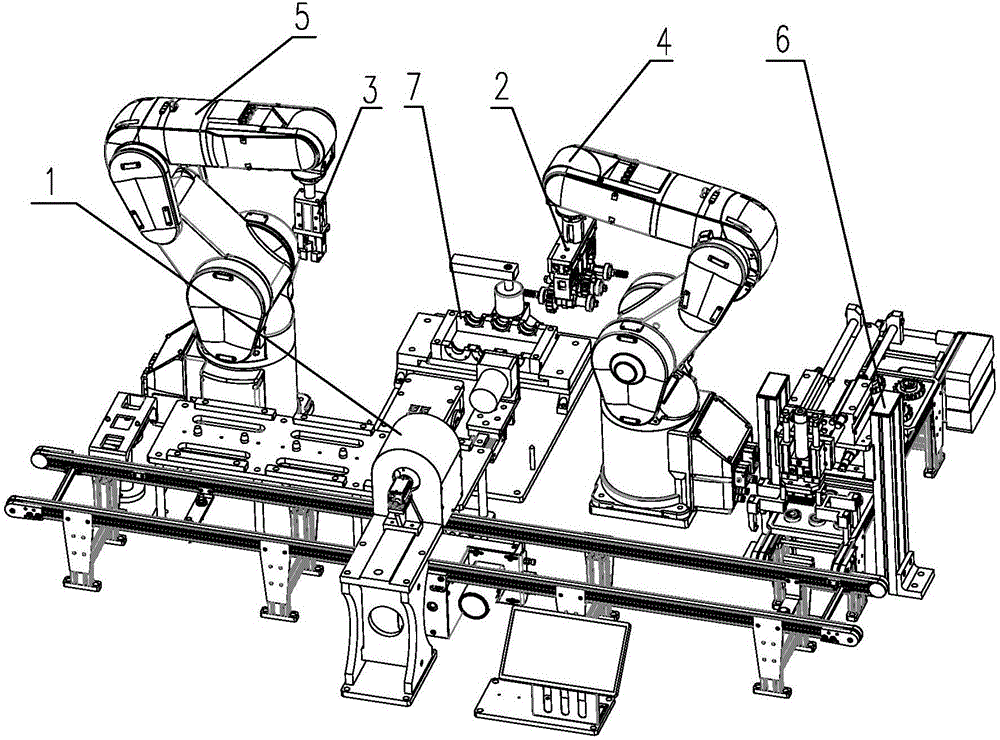

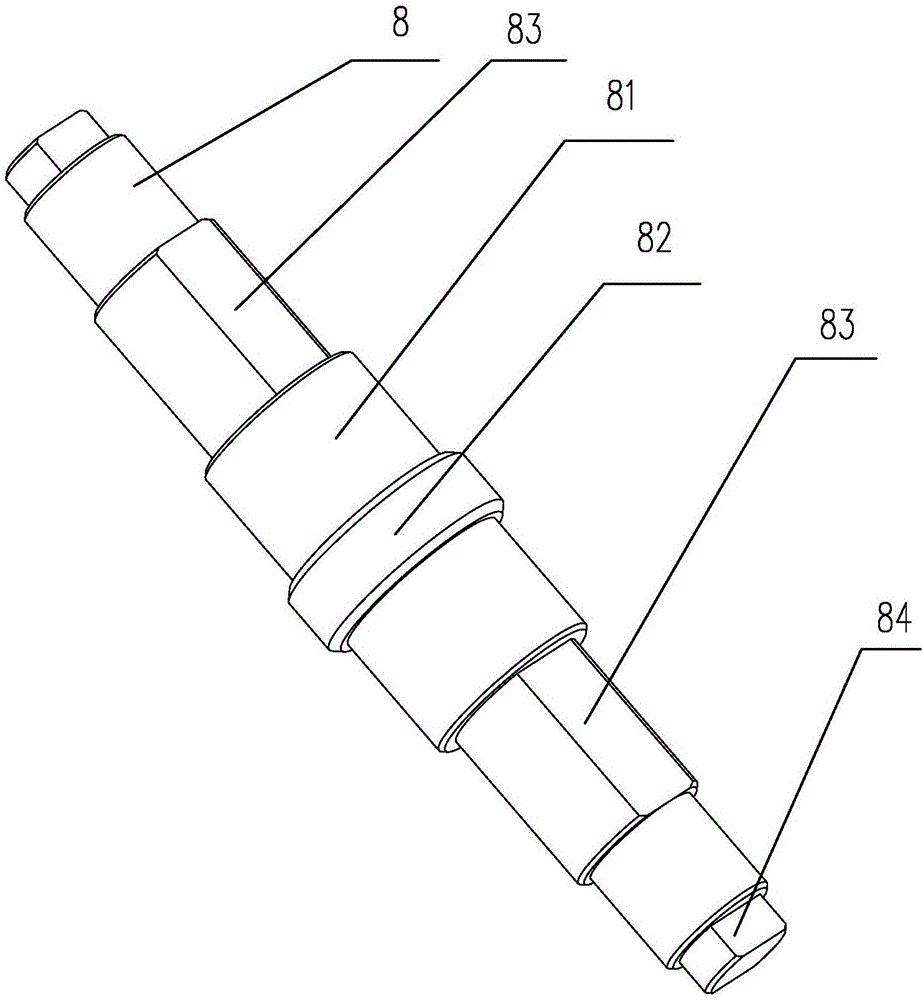

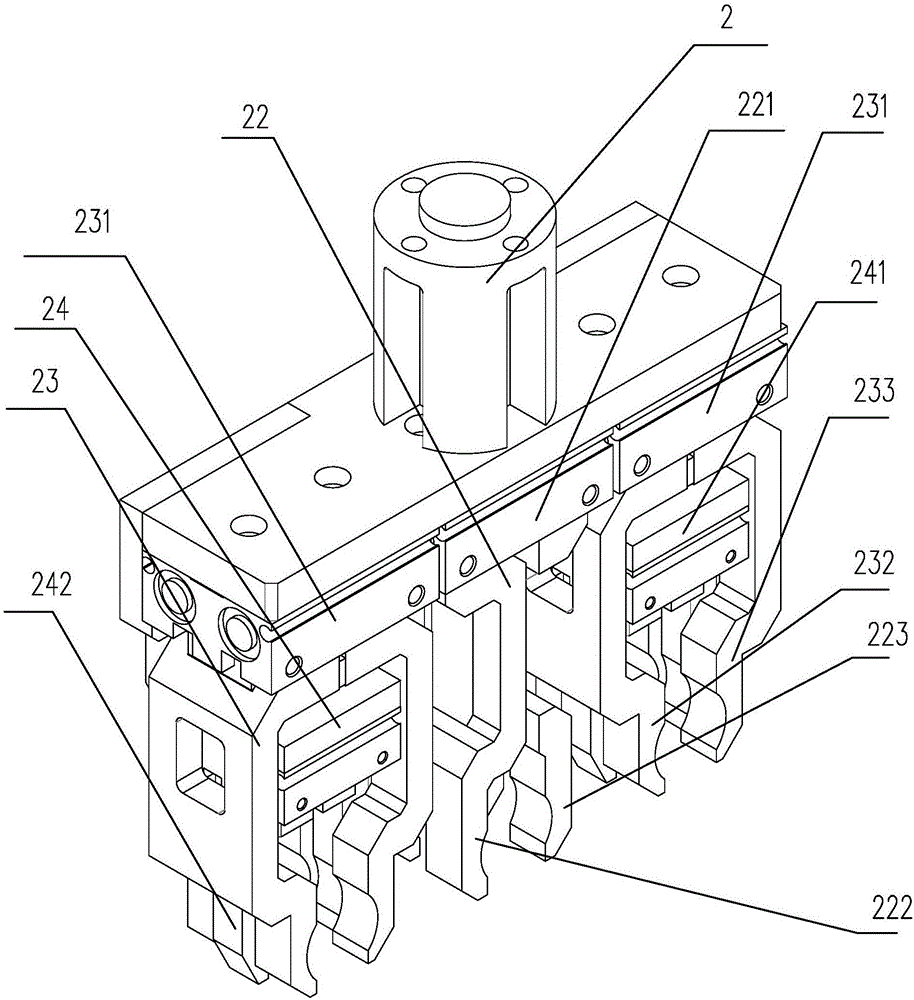

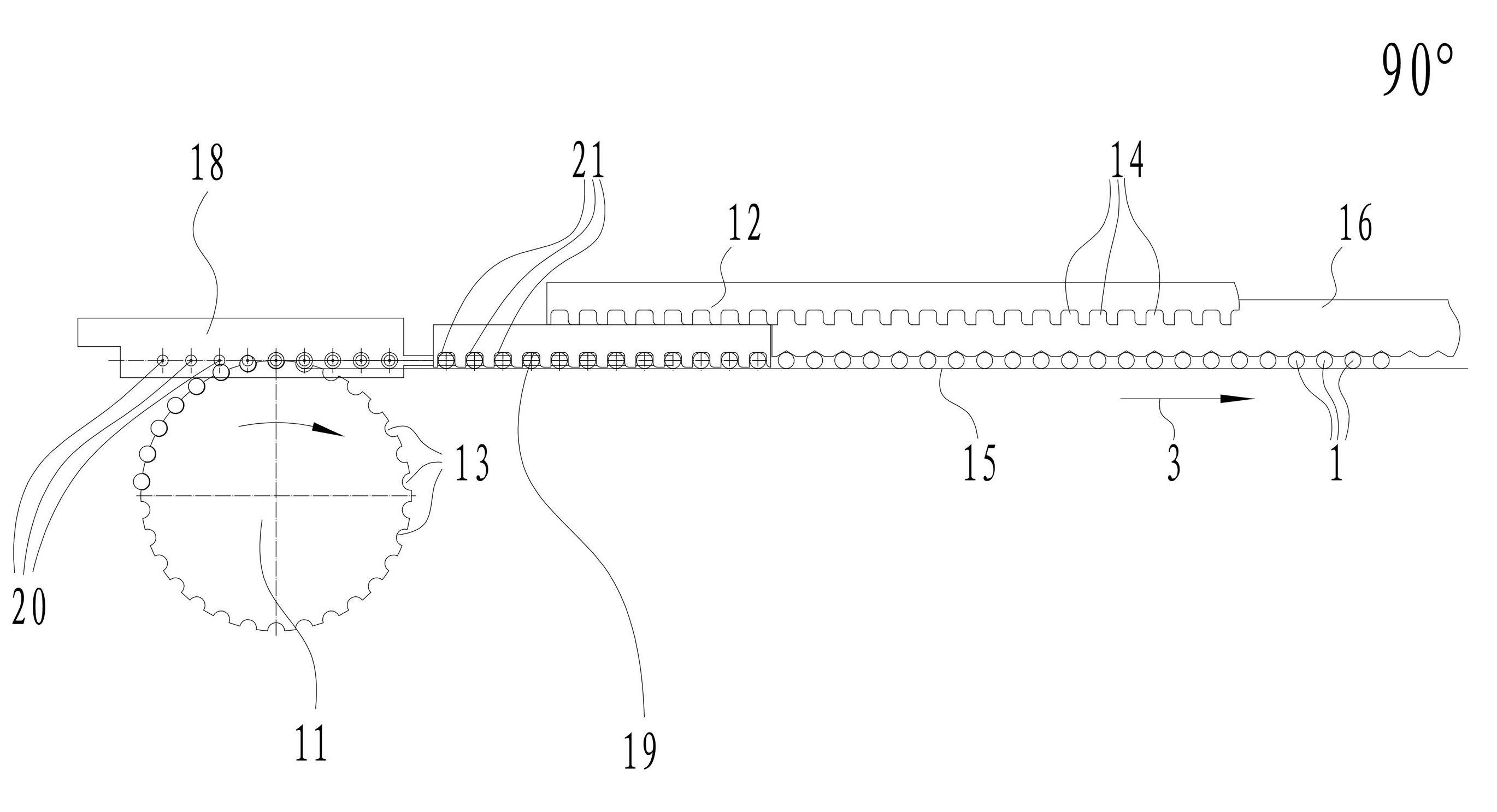

Assembling machine for assembling gears, bearings and gear shafts

Owner:YALONG INTELLIGENT EQUIP GRP CO LTD

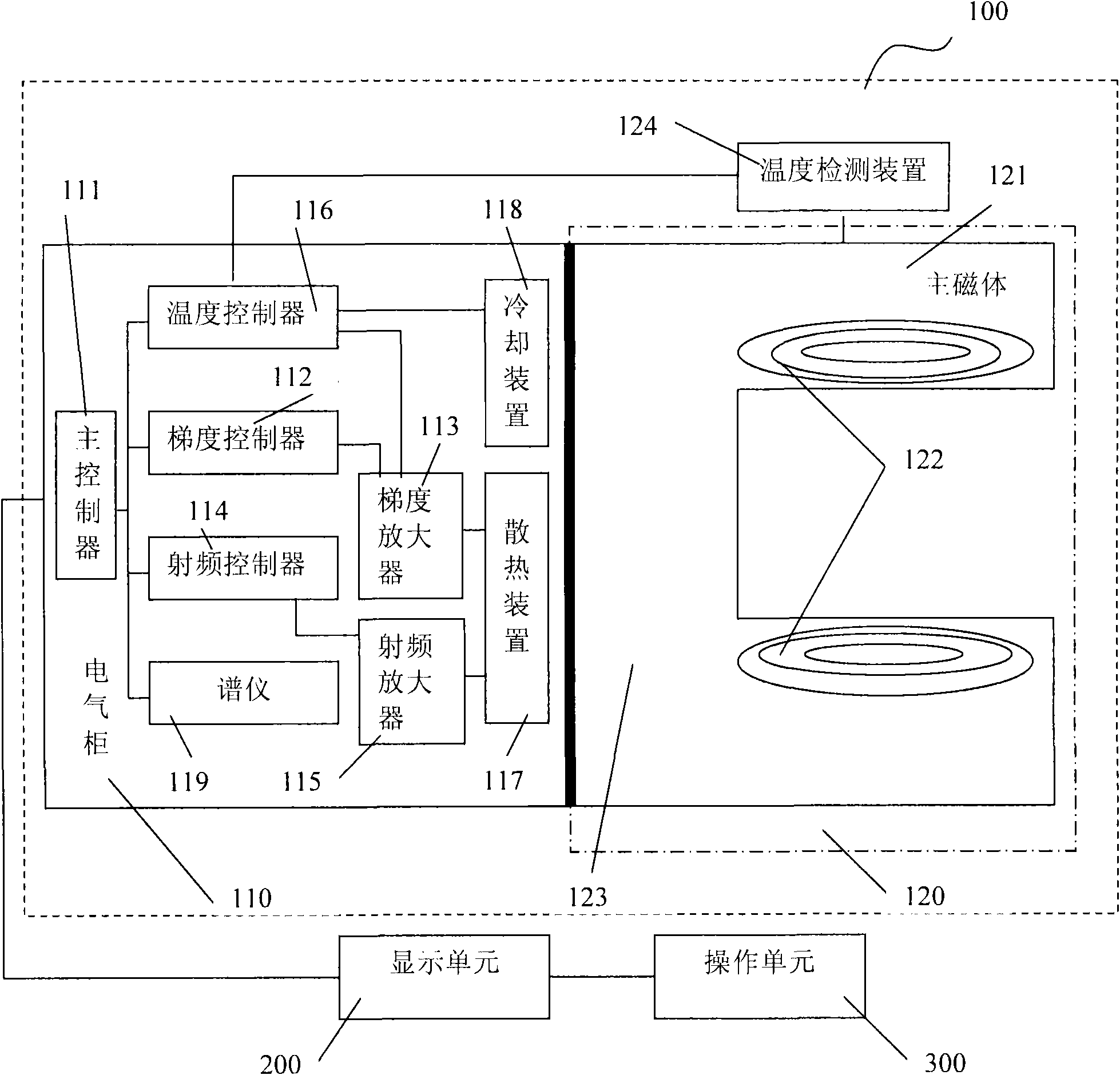

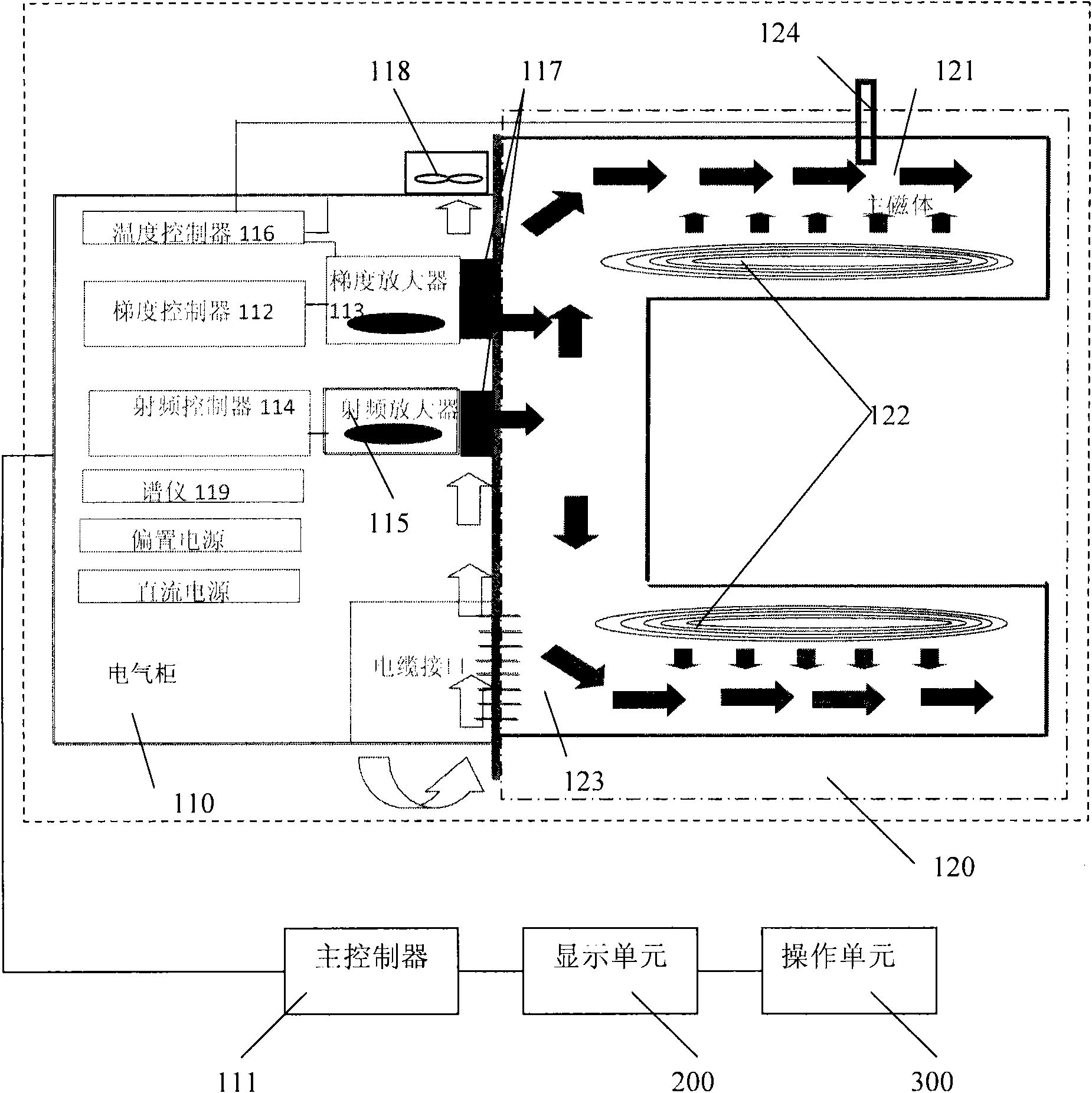

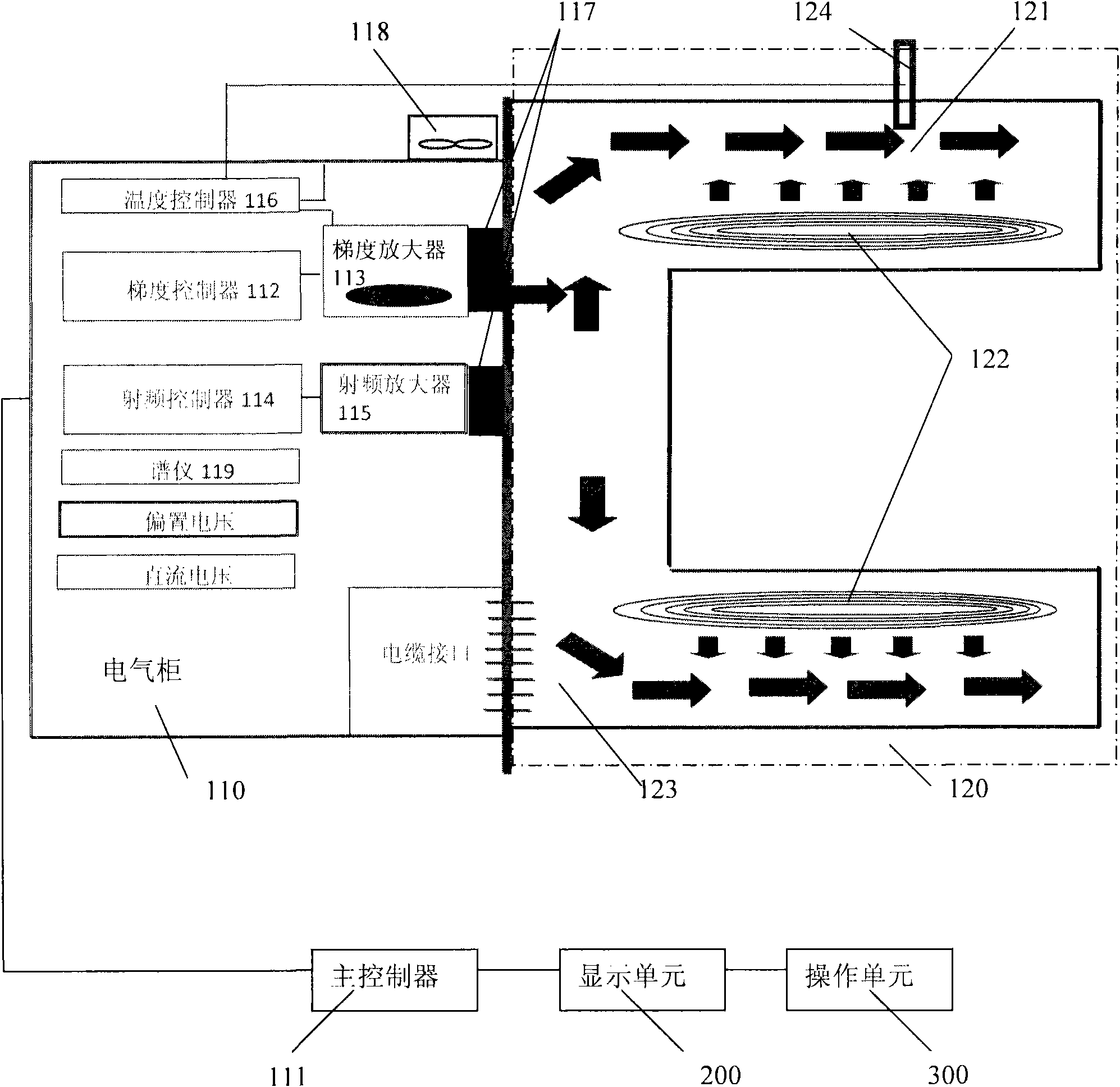

Magnetic resonance imaging system and method for stabilizing temperature of main magnet in same

InactiveCN101788655ASimple structureSave energyMeasurements using magnetic resonanceMiniaturizationEngineering

The invention relates to a magnetic resonance imaging system and a method for stabilizing the temperature of a main magnet in the magnetic resonance imaging system. By mutually approaching an electric cabinet and magnetic field generating equipment, the heat generated by the electric cabinet can be used for heating the main magnet, and meanwhile, the electric cabinet can be cooled without mounting a heater on the main magnet and specially mounting a cooling system on the electric cabinet. The magnetic resonance imaging system has simplified structure and miniature design, energy saving, cost reduction and reliability increase. In addition, the invention is easy for application.

Owner:GE MEDICAL SYST GLOBAL TECH CO LLC

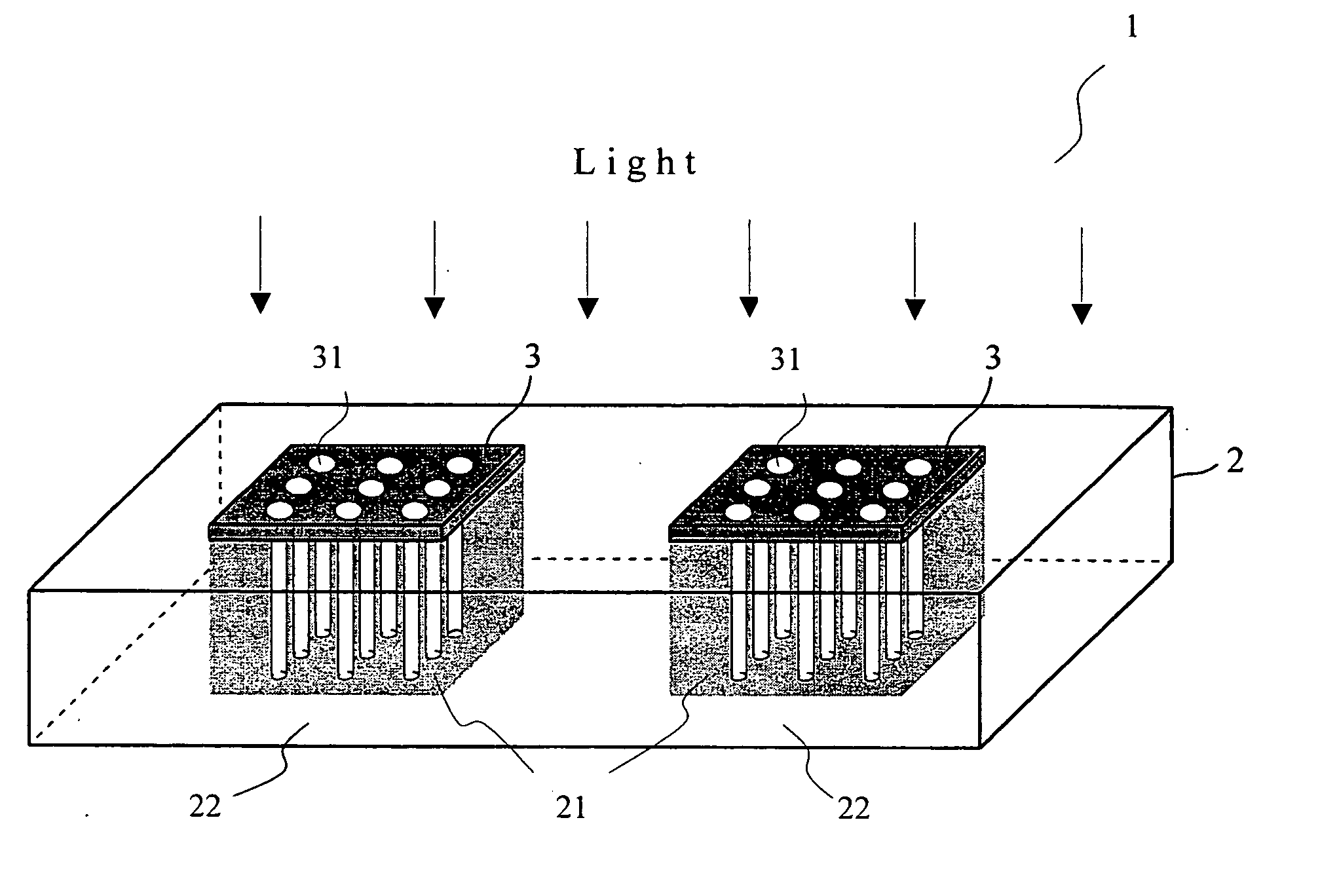

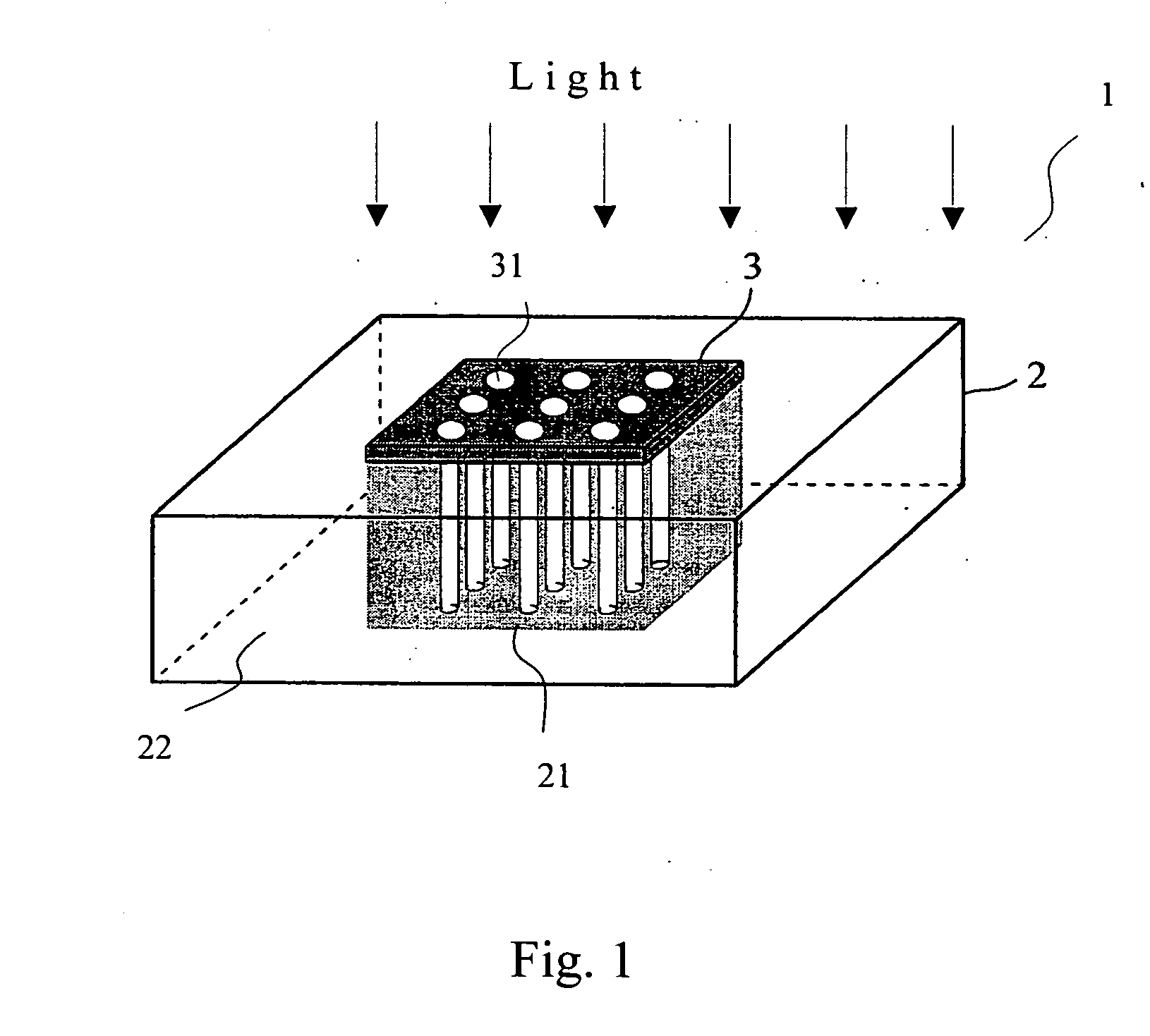

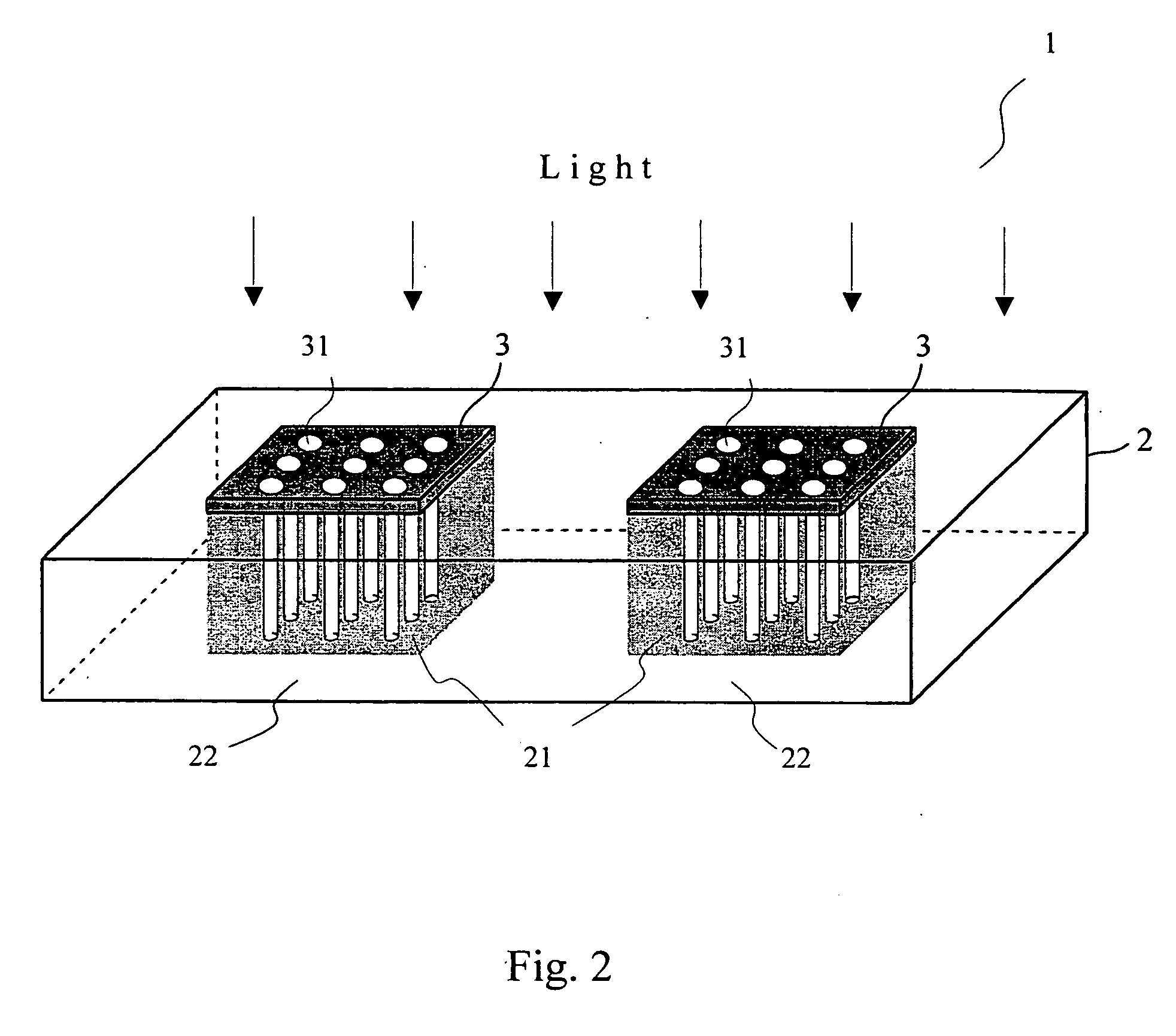

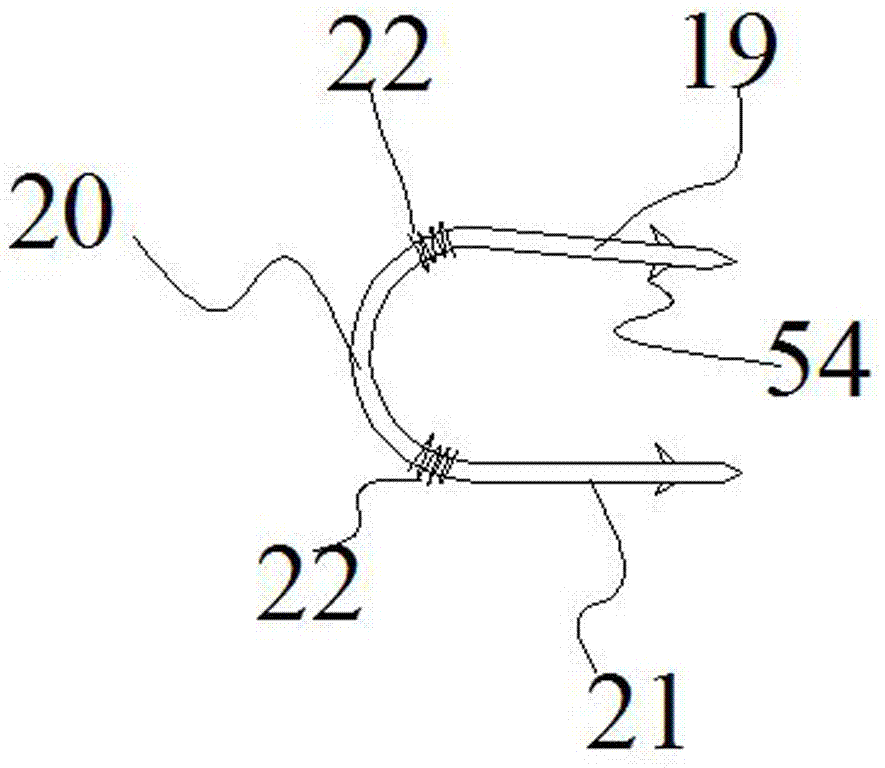

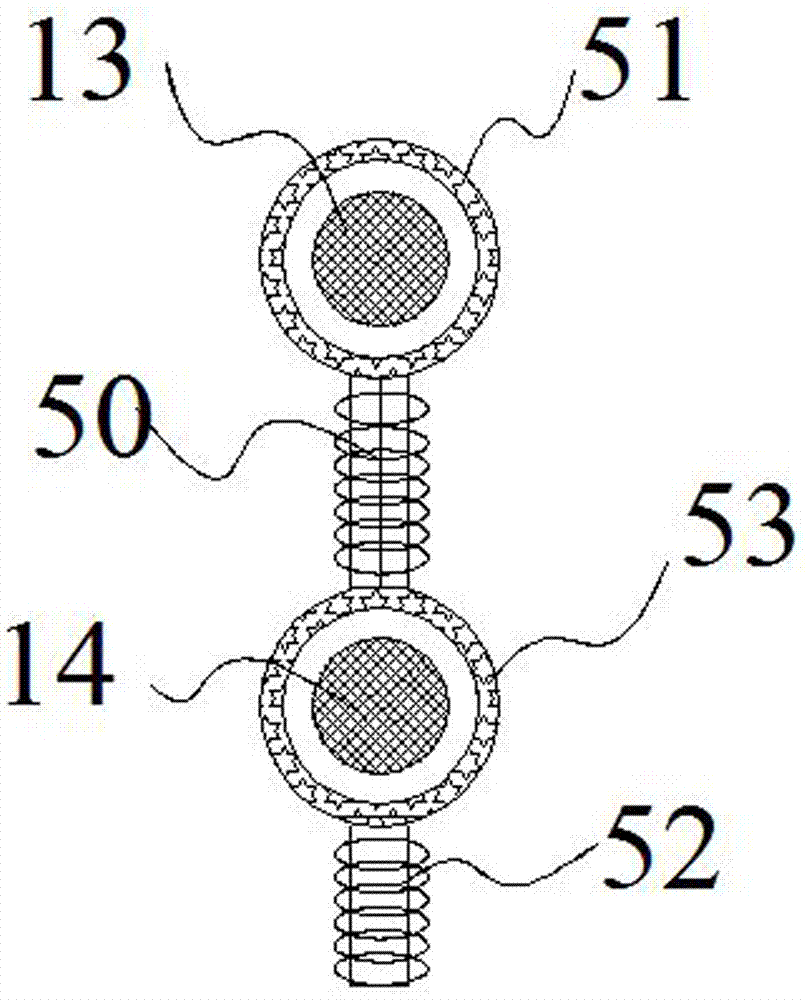

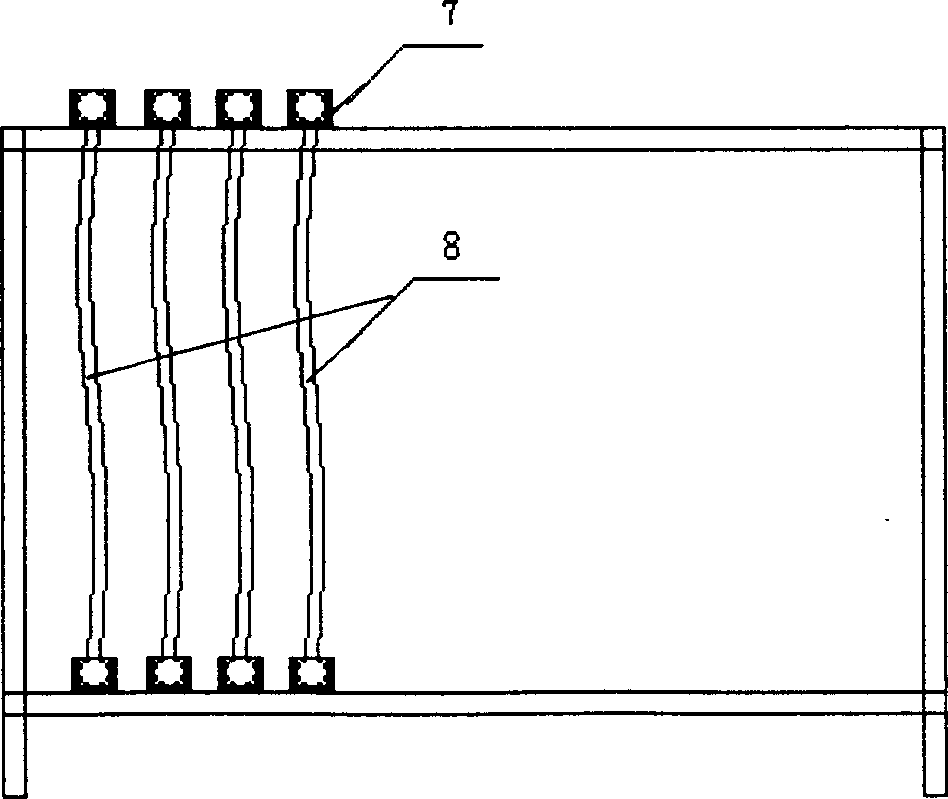

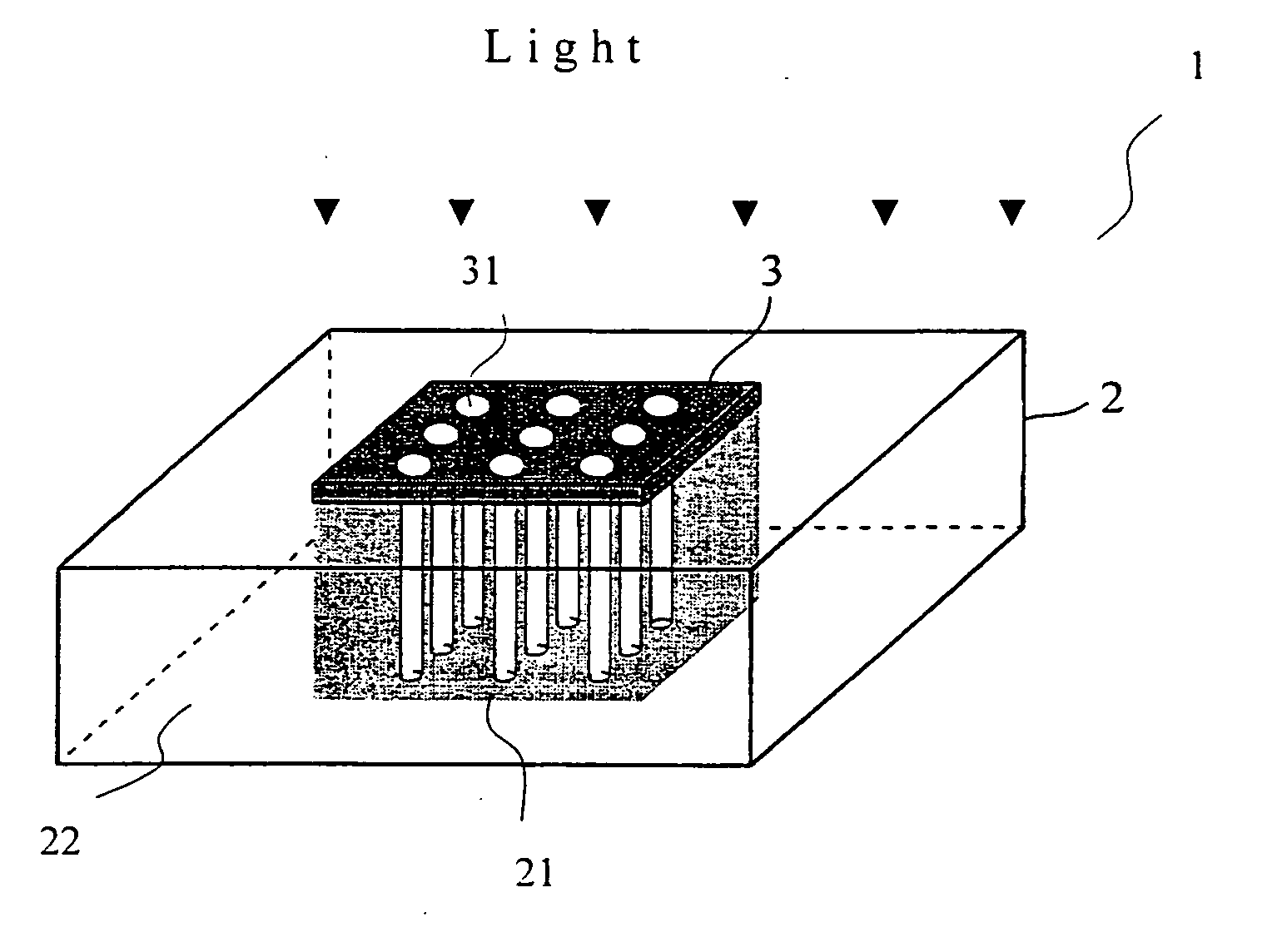

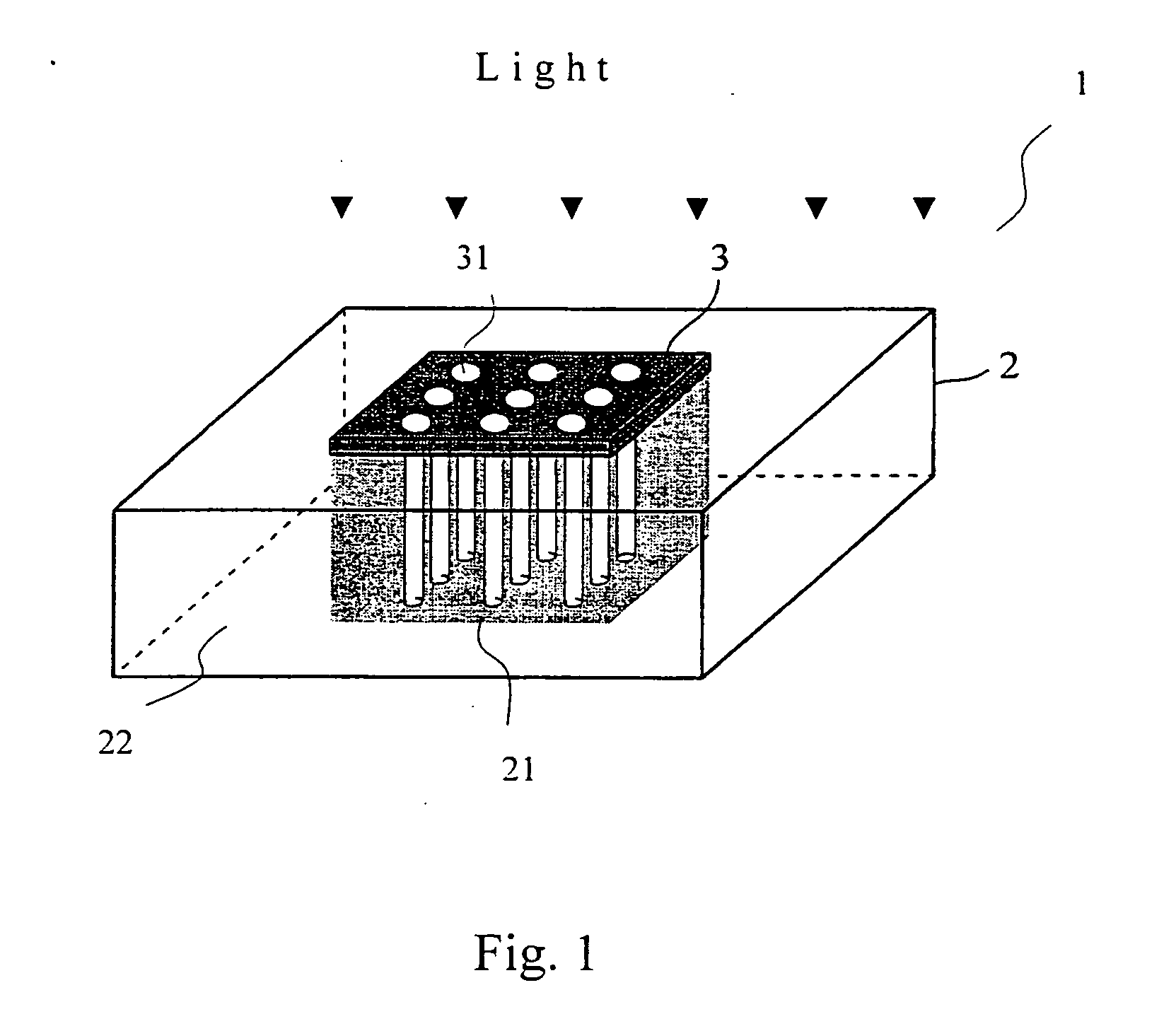

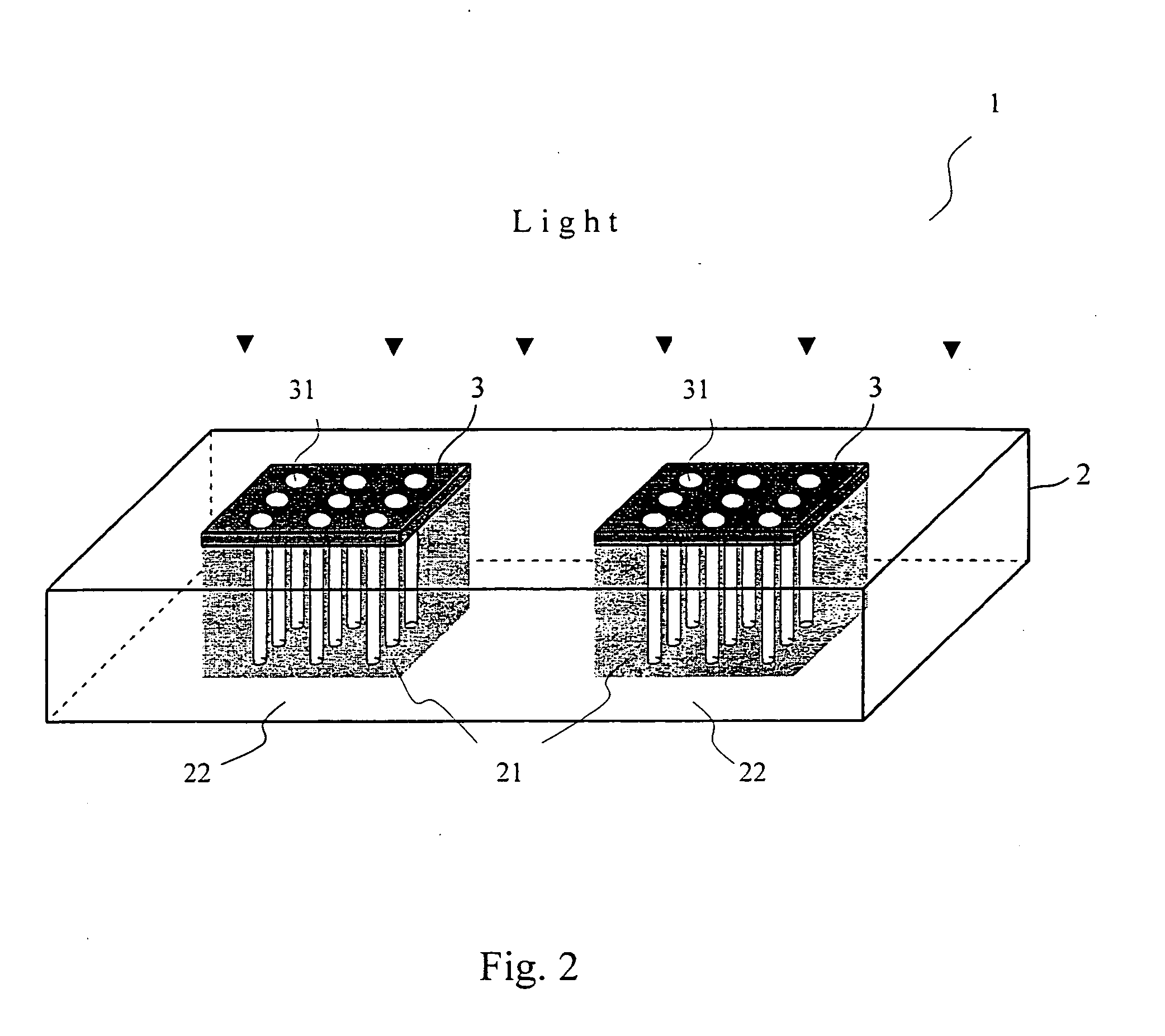

Method and device for cultivating and maintaining aquatic crustaceans

InactiveUS20050072368A1Efficient inductionAvoid deathClimate change adaptationPisciculture and aquariaHigh densityTactile sensation

A device for cultivating and maintaining aquatic crustaceans and the method for the same are provided, whereby aquatic crustaceans are cultured in a culture tank having at least one effective resting and / or hiding area that provides visual only or both visual and tactile sensations for aquatic crustaceans. The present invention creates effective resting and / or hiding areas by utilizing the sensitivity of aquatic crustaceans to physical environment, thereby allowing aquatic crustaceans to live within confined spaces in high densities without cannibalizing those fall outside the effective resting and / or hiding areas (the non-effective habitat areas). The device of the present invention can cultivate and maintain aquatic crustaceans successfully in shallow waters and a plurality of which may be vertically incorporated into a multi-layered culture system to bring about higher culture and maintenance densities per unit floor area.

Owner:IND TECH RES INST

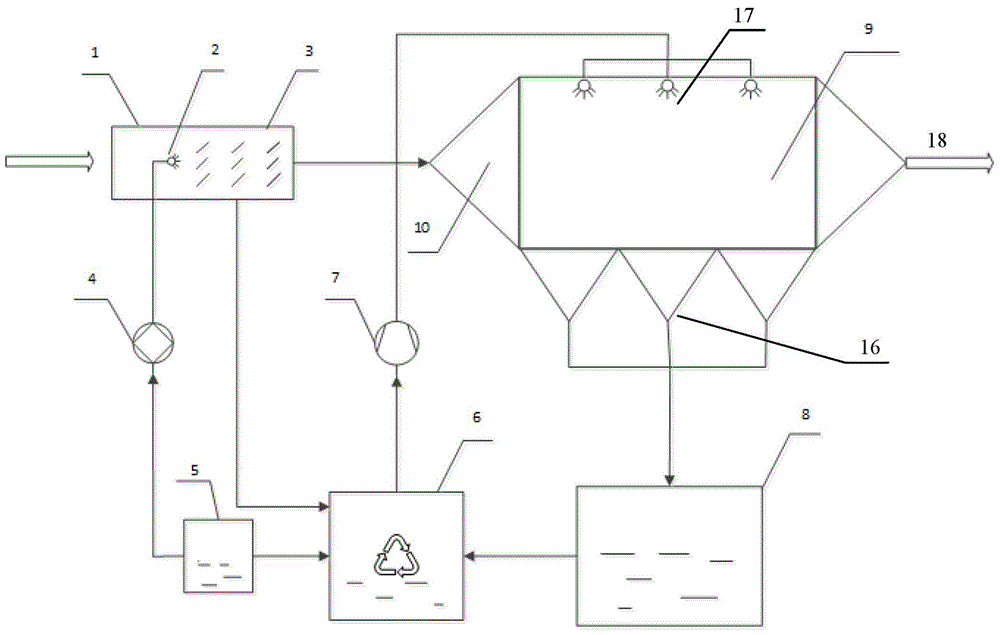

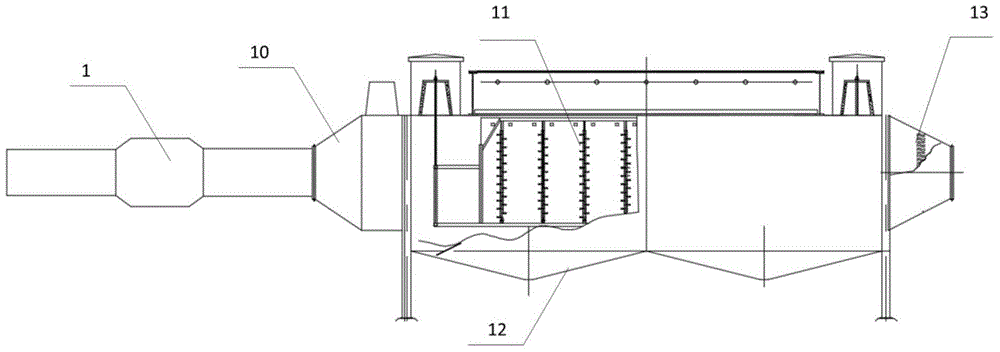

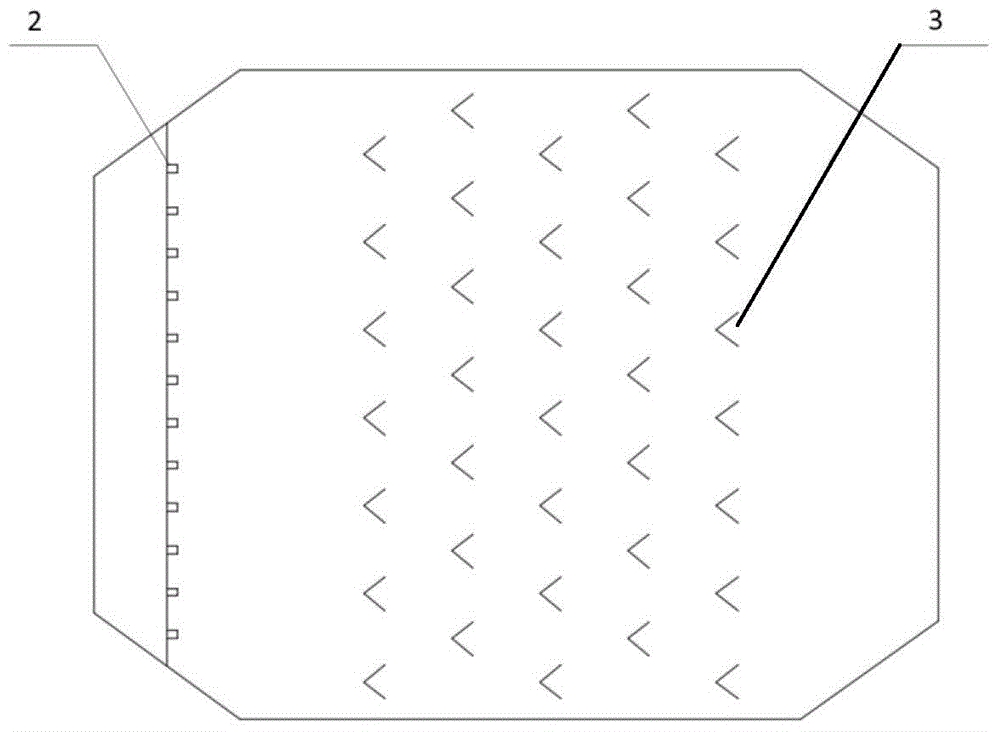

Deep control system for multiple pollutants through wet static electricity and reinforced by pre-charging

InactiveCN105032611AImprove work performanceEmission reductionExternal electric electrostatic seperatorElectrostatic separation detailsPre-chargeDust particles

The invention relates to dust removing equipment for coal-fired flue gas, particularly to a deep control system for multiple pollutants through wet static electricity and reinforced by pre-charging. The system comprises an alkali liquor atomizing mixer, a pre-charger and a wet static electricity reactor which are sequentially connected, wherein the pre-charger is mounted at the inlet of the wet static electricity reactor; double-fluid atomizing nozzles and turbulent flow mixing plates are mounted in the alkali liquor atomizing mixer; water outlets are formed in the lower part of the wet static electricity reactor and are connected with pipelines of a waste water tank, then a circulating water tank, an alkali liquor tank and an alkali liquor pump are sequentially connected to the waste water tank, the alkali liquor pump is connected with the double-fluid atomizing nozzles, sprinkling devices are arranged in the wet static electricity reactor, the circulating water tank is additionally provided with a water outlet pipeline which is connected with the sprinkling devices of the wet static electricity reactor, and a circulating filter pump is mounted on the water outlet pipeline. The system organically integrates the pre-charger and a wet electrostatic dust remover so as to realize the purpose of efficiently removing plaster fluid drops, dust particles, SO3, NOx, SO2 and the like behind a desulfurizing tower.

Owner:ZHEJIANG UNIV

Device for transmitting ampoule or bottle-like container

The invention relates to a device for transmitting an ampoule or bottle-like container. The device comprises a first conveying device, a second conveying device, a transmitting element and a vacuum adsorption transmitting element, wherein the first conveying device is used for continuously conveying the ampoule or bottle-like container, the second conveying device is used for periodically driving and transmitting the ampoule or bottle-like container, the transmitting element is used for transmitting the ampoule or bottle-like container from the first conveying device to the second conveying device, and the vacuum adsorption transmitting element can synchronously move with the first conveying device in partial regions; and the movement route of the transmitting element overlaps with the that of the vacuum adsorption transmitting element in the region of the first conveying device, and the transmitting element synchronously moves with the first conveying device in the overlapping region to take up the ampoule or bottle-like container from the containing part of the first conveying device. The invention has the advantages of simple and compact structure, low cost, wide application range, high reliability, small occupied area and the like.

Owner:TRUKING TECH LTD

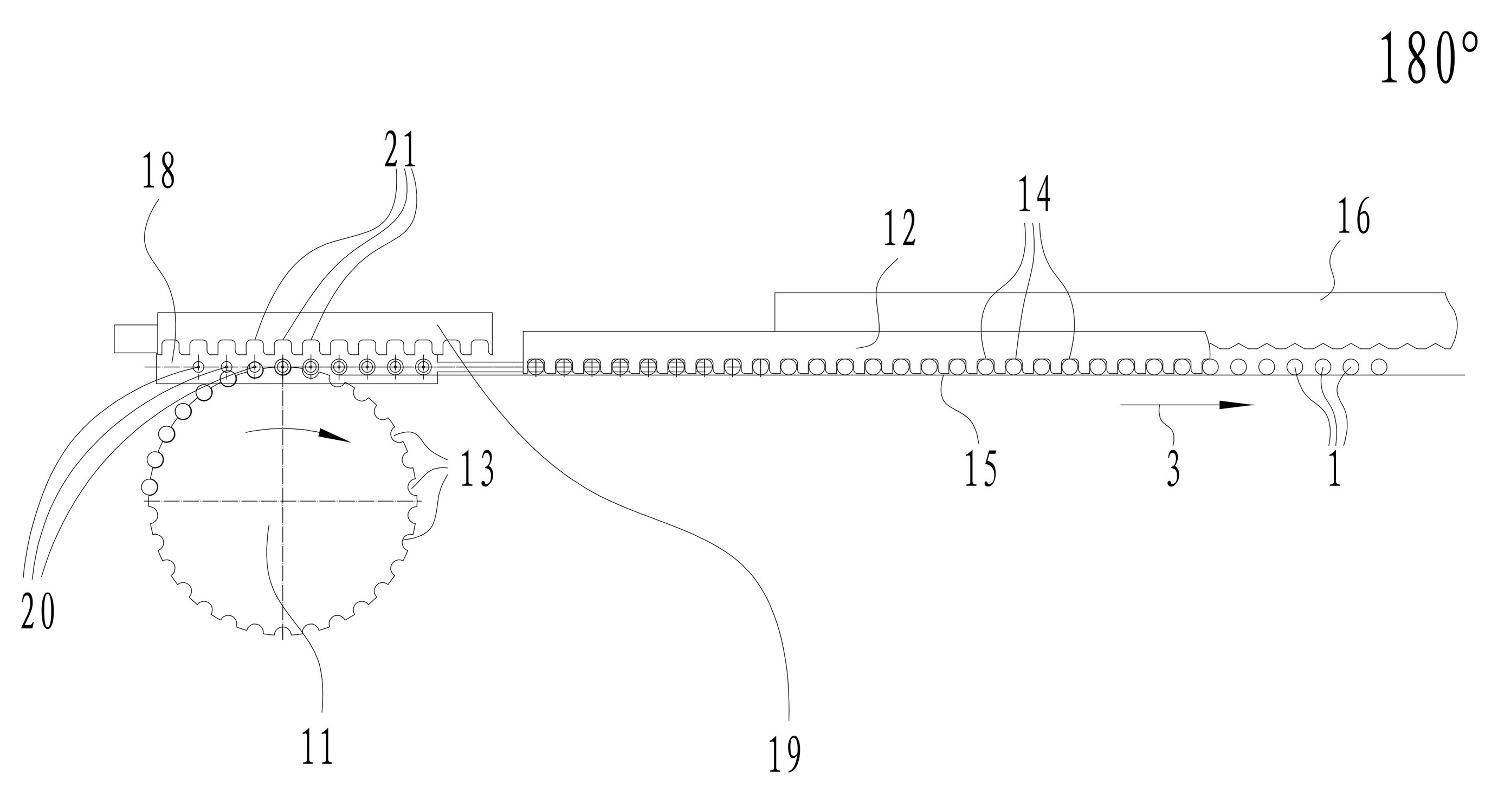

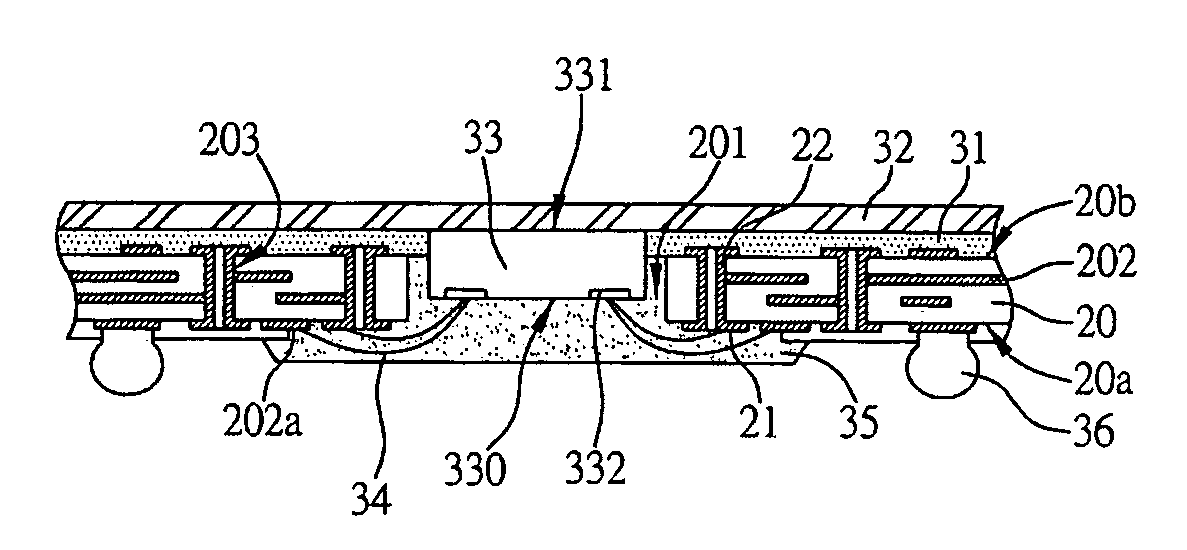

Substrate structure of semiconductor package

InactiveUS20060273458A1Quality improvementReduce manufacturing costSemiconductor/solid-state device detailsSolid-state devicesSemiconductor packageEngineering

A substrate structure of a semiconductor package is proposed. The structure includes a substrate with at least one opening; a grounding ring formed on the substrate and around the opening; and a plurality of plating through holes (PTH) formed in the substrate and corresponding to the grounding ring. The grounding area is increased by the grounding ring, so that the grounding quality of the substrate in package is improved. Meanwhile, it also simplifies the process, increases process yield and reduces cost of the process.

Owner:PHOENIX PRECISION TECH CORP +1

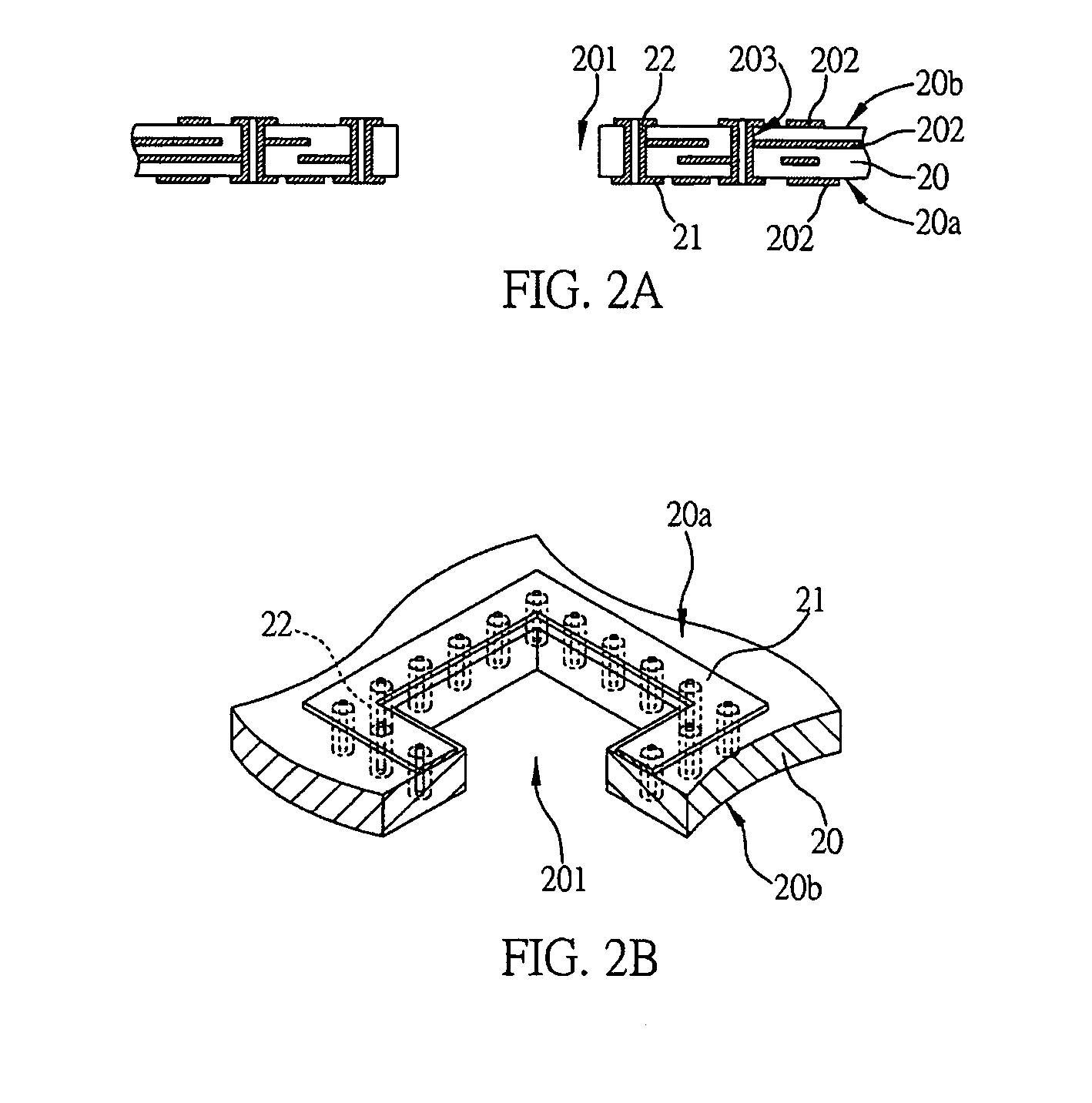

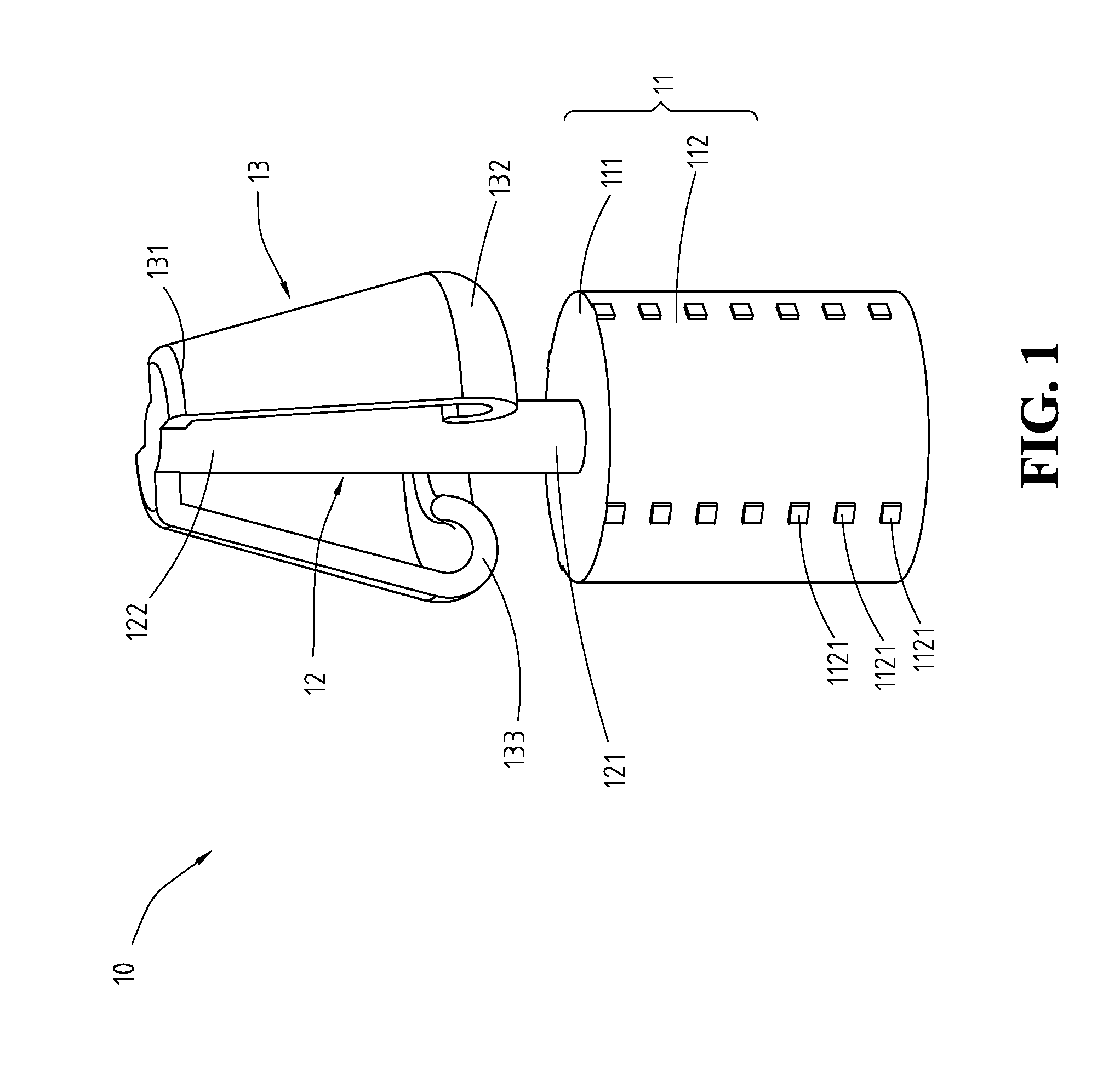

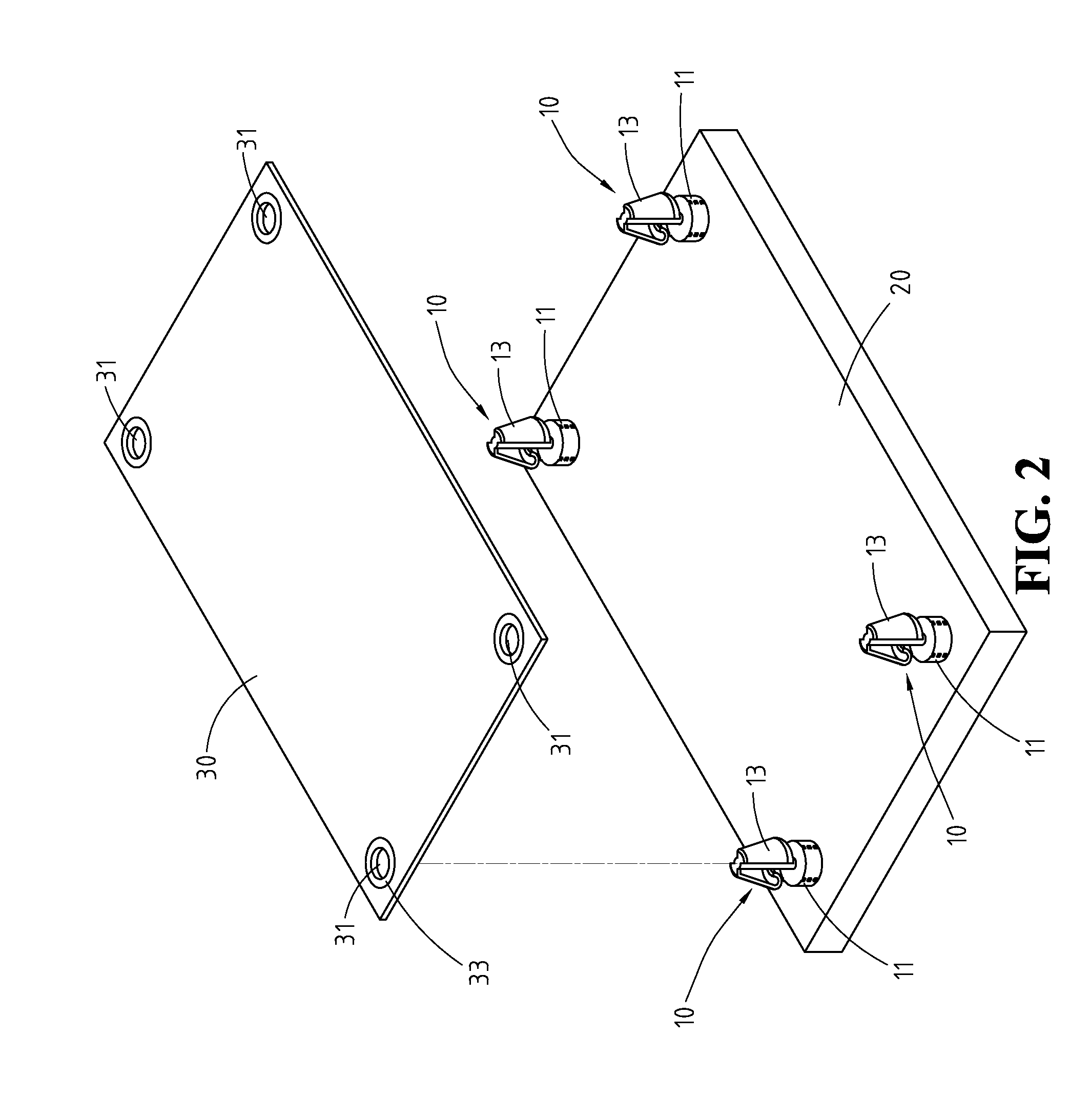

Flexible positioning post

A flexible positioning post includes a base, a metal post and a plurality of metal elastic pieces. The base has an upper surface. The metal post has a first end and a second end opposite to each other, and the first end is connected to the upper surface of the base. Each of the metal elastic pieces has a fixed end and a free end opposite to each other. The fixed end is securely assembled at the second end of the metal post, and the free end is adjacent to the upper surface of the base and bent toward the metal post to form a bending portion. Consequently, upon receiving a foreign force, the free end of each of the metal elastic pieces is moved toward the metal post; conversely, once the foreign force is removed, the free end of each of the metal elastic pieces is moved resiliently.

Owner:WISTRON CORP

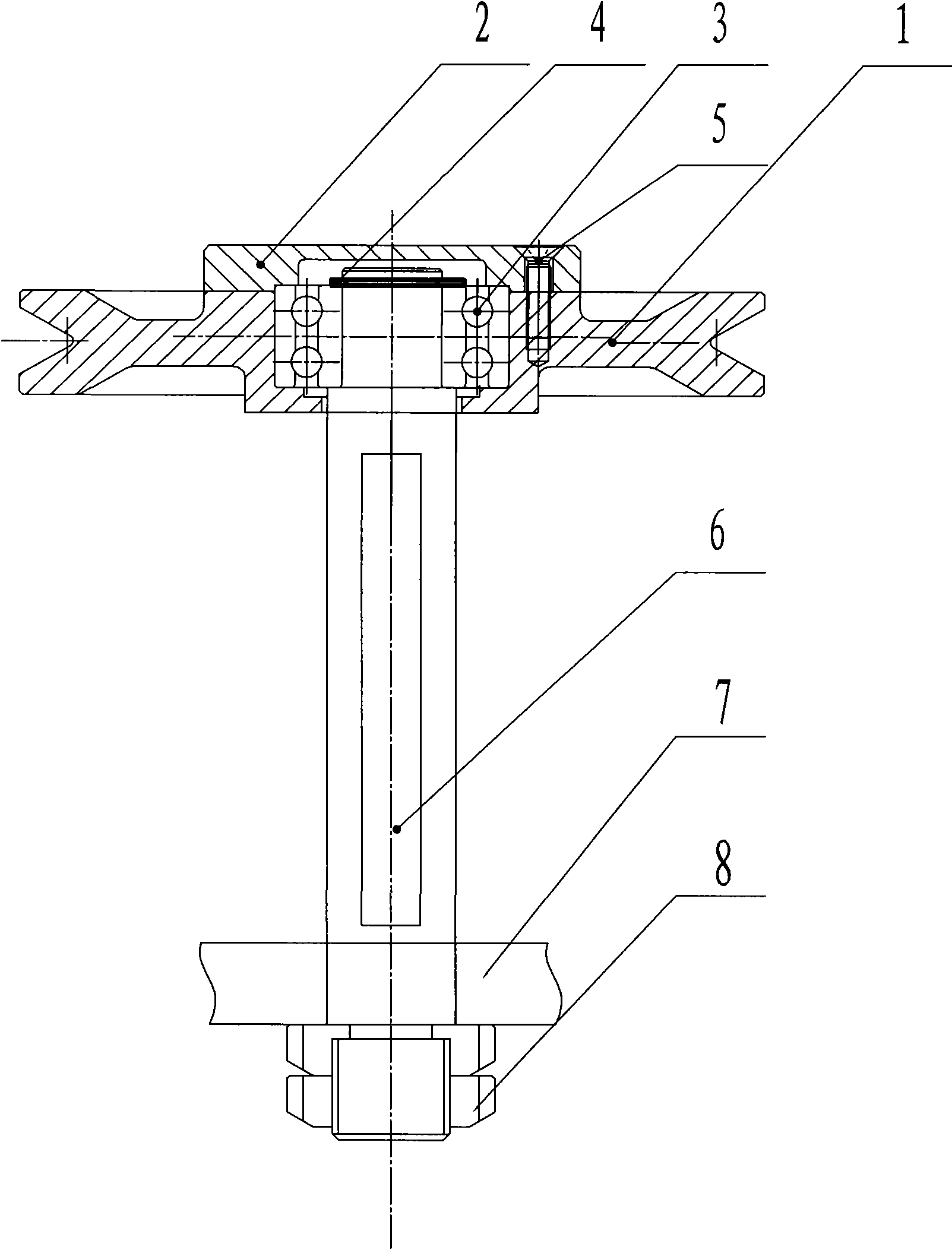

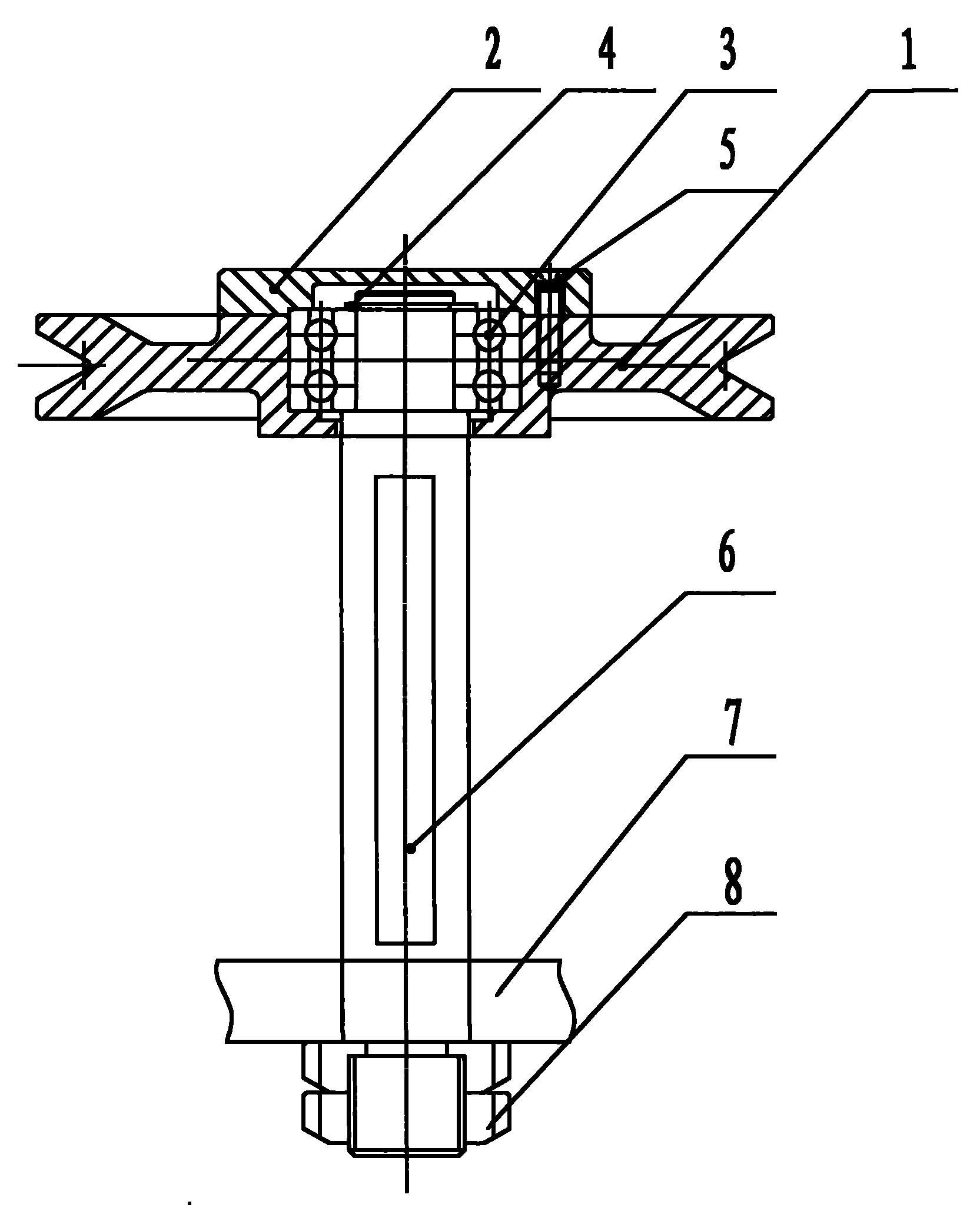

Finished product guide wheel mechanism on wire drawing machine

The invention relates to a finished product guide wheel mechanism on a wire drawing machine, which plays the role of guiding and belongs to the wire drawing field of metal product manufacture. The guide wheel mechanism comprises a guide wheel, a guide wheel cover, a bearing, a retainer ring for a shaft, sunk screws and a guide wheel shaft, wherein the guide wheel is fixed on the guide wheel shaft by using the bearing and the retainer ring for the shaft, the guide wheel cover is tightly fixed on the guide wheel by using the sunk screws, and the guide wheel shaft is mounted on a stand and tightly locked by round nuts. The invention has simple, compact and reasonable structure, convenient repairs and replacements, convenient use and favorable interchangeability, and can improve anti-carrying capabilities without increasing the occupied space and prolong the service life.

Owner:WUXI PINGSHENG SCI & TECH

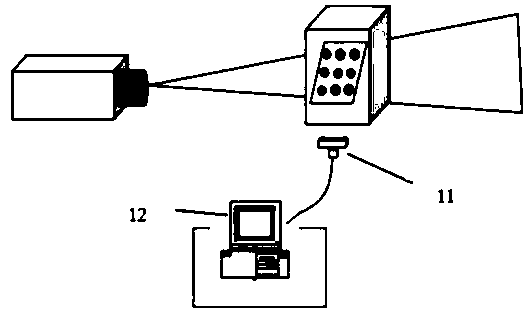

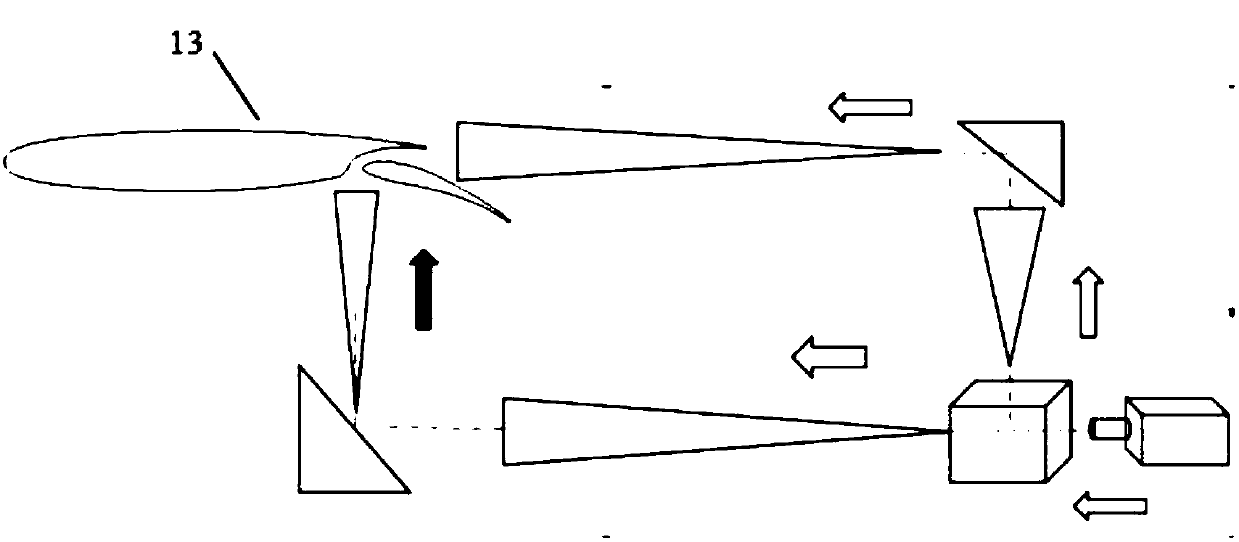

Device for measuring flow of flap gap based on PIV method

ActiveCN107748052AMeet the requirements of the experimentGuaranteed accuracyAerodynamic testingBeam splittingOptoelectronics

The invention belongs to the technical field of wind tunnel tests, and in particular relates to a device and method for measuring the flow of a flap gap based on a PIV method. The method comprises thesteps of emitting a laser sheet from an emitting end of a laser, and dividing the laser sheet into two laser sheets through a light path device; coarsely tuning reflectors in the light path device and making the two laser sheets radiating respectively from two directions into a flap gap; and finely tuning the reflectors and making the two laser sheets overlap, that is, completing the constructionof a light path. The device includes a beam splitting cube, reflectors, and an optical clamping member. The device also includes a PIV unit. The device is simple and practical in structural principle, well solves the problem of light path limitation on the PIV shooting of a flow field like a flap gap environment, and greatly improves the efficiency of PIV shooting.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

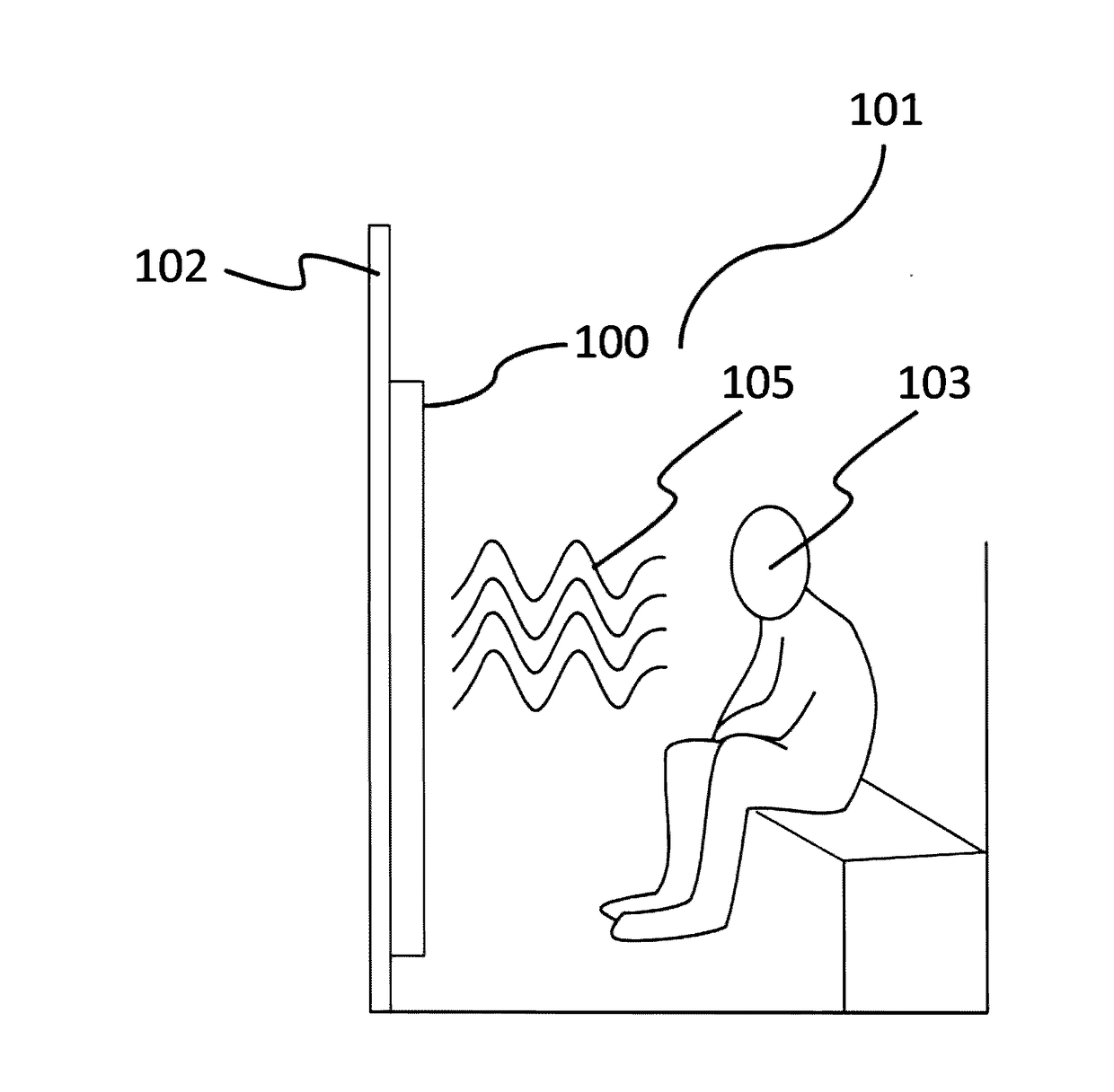

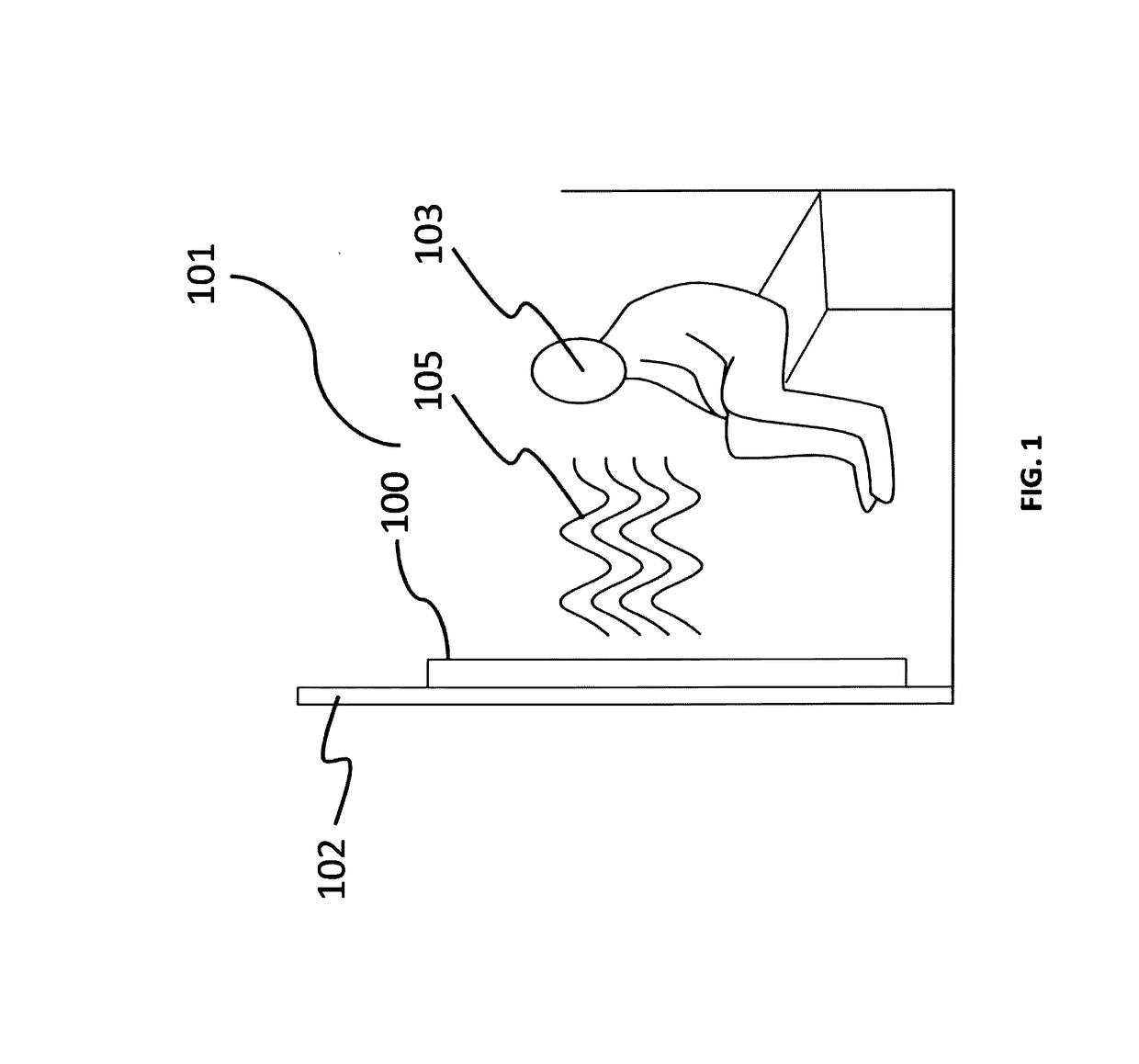

Exercise Sauna Having Far Infrared Heating Elements and Configurable Seating

InactiveUS20170131693A1Accelerated settlementIncrease floor spaceProgramme controlComputer controlHuman bodyEngineering

A far infrared (“FIR”) sauna cabin equipped with a far infrared (“FIR”) heating elements constructed of ceramic, carbon, and / or light emitting diodes (“LED”), designed for therapeutic use in a sauna, capable of emitting far infrared energy, and heating an individual's skin for purposes of rejuvenation, anti-aging, weight loss, and acne therapy. The FIR heating element emits IR energy in a wavelength and frequency optimum for resonant absorption by the human body, resulting in the release of toxins stored within subcutaneous fatty deposits, which are then carried out of the person's system as he or she sweats. The FIR sauna is operated by a system comprising a local control system and a remote computer running access control software. A user account is configured containing a user's allowed privileges. When a user swipes an access card, the remote computer verifies the requested privilege. If allowed, the local system energizes the sauna system.

Owner:SHURTLEFF DAVID FLOYD

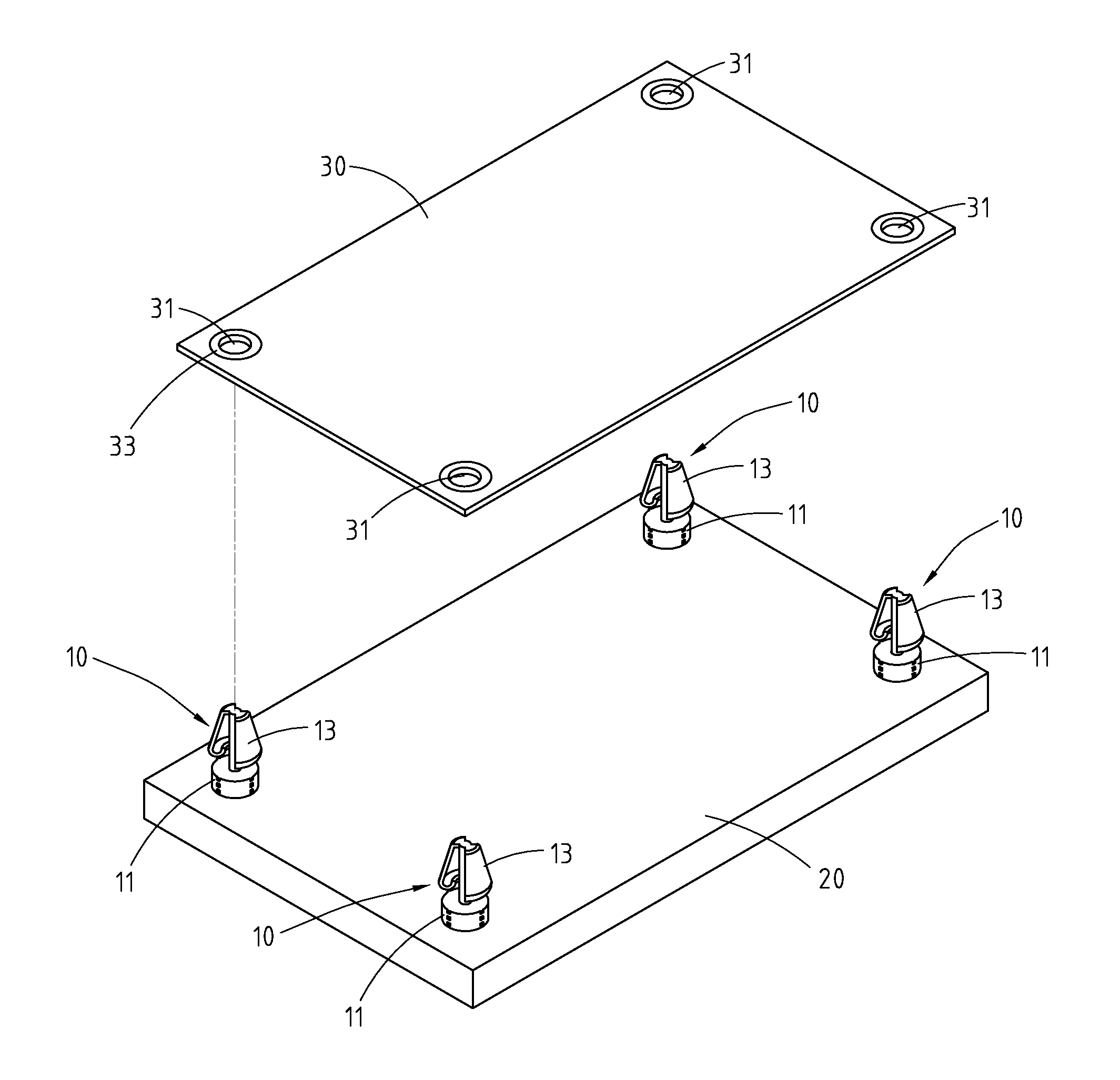

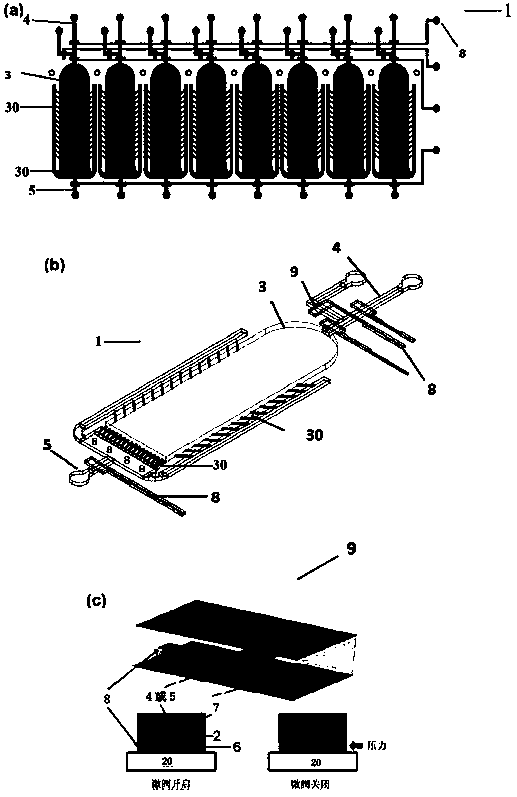

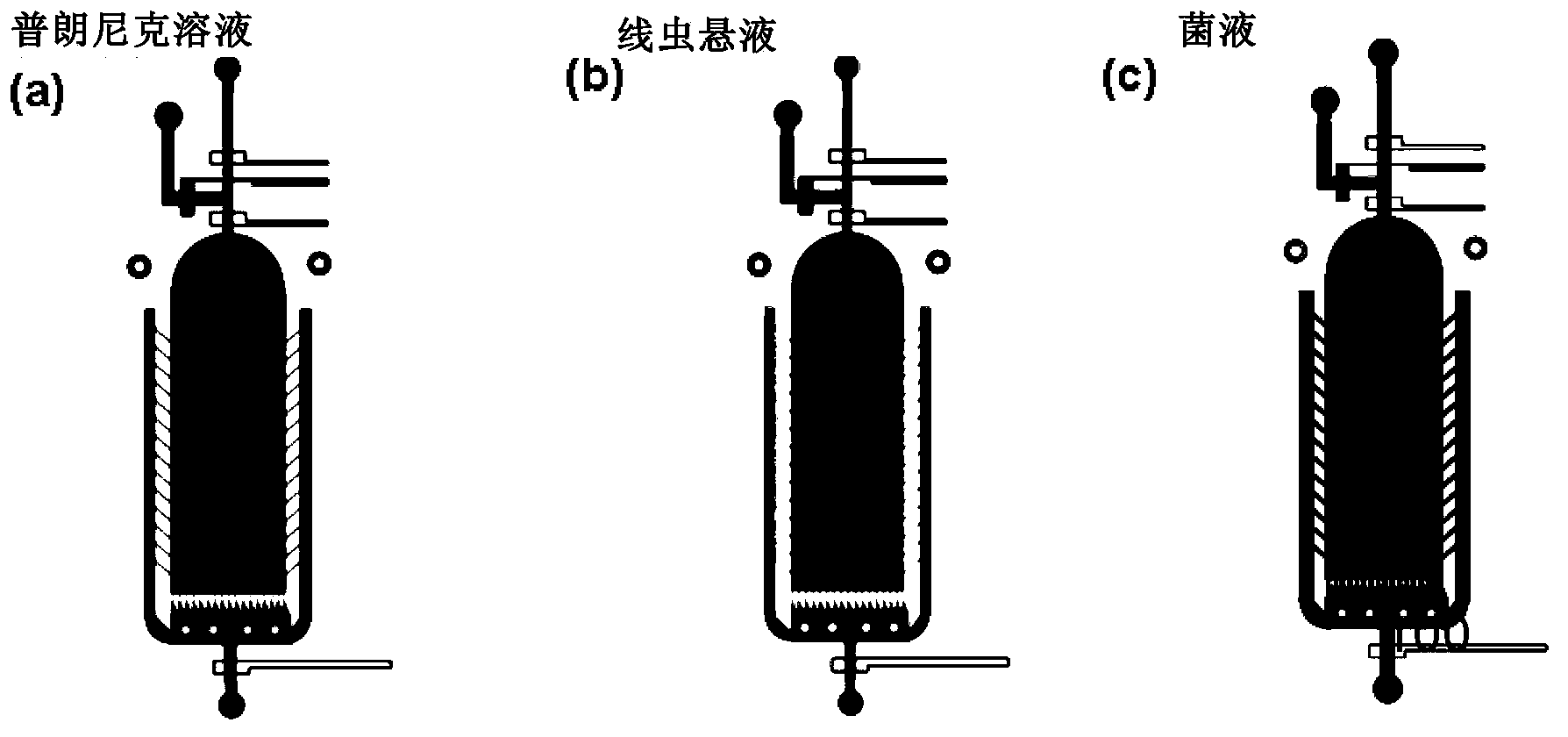

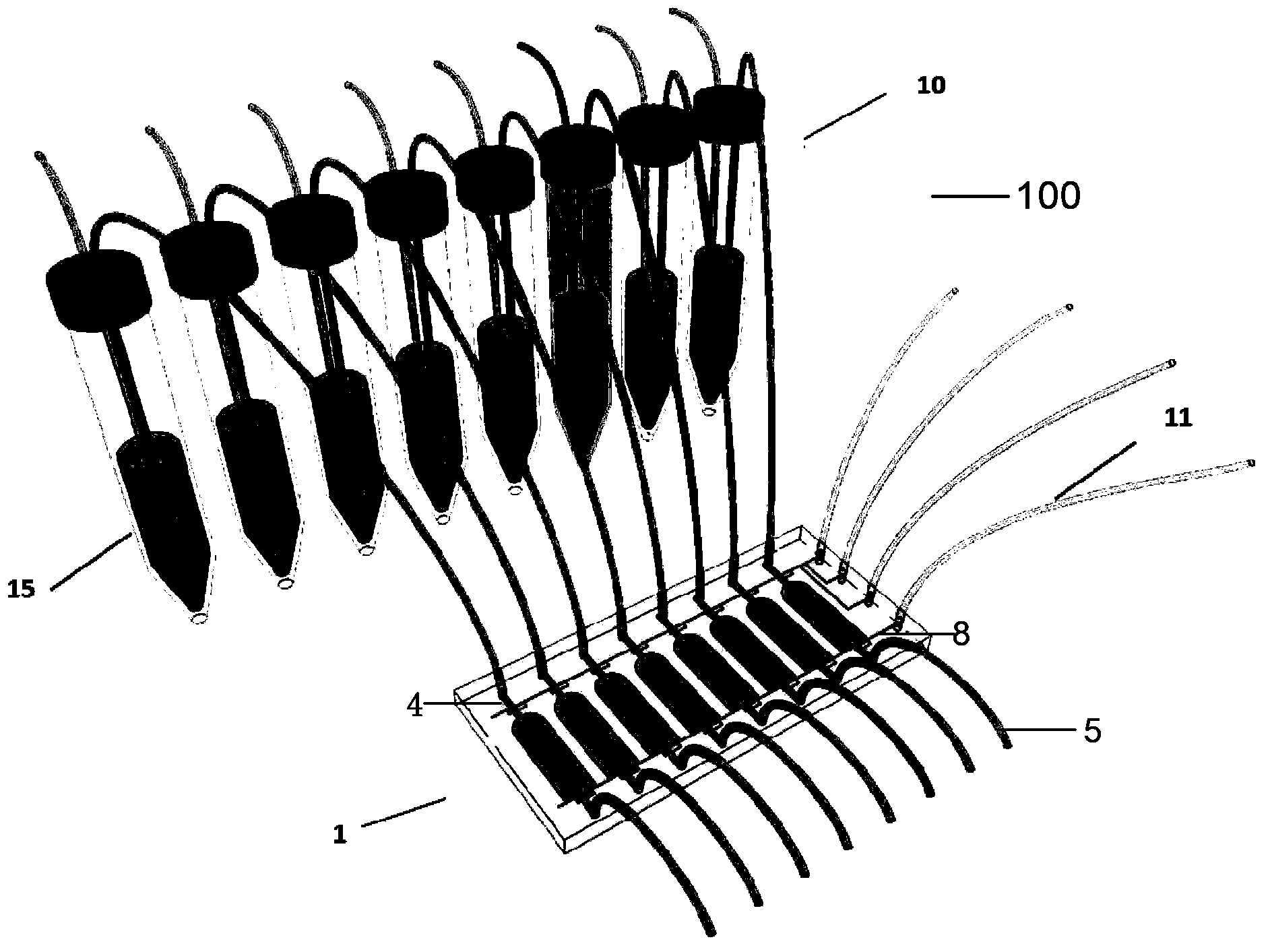

Micro-fluidic chip and device for elegans cultivation and/or observation and application of micro-fluidic chip and device

ActiveCN103461279AImprove throughputIncrease floor spaceLaboratory glasswaresAnimal husbandryEngineeringReagent

The invention relates to a micro-fluidic chip and a device for elegans cultivation and / or observation and application of the micro-fluidic chip and the device, and specifically provides the micro-fluidic chip for elegans cultivation, observation and / or research, the device comprising the micro-fluidic chip and the application of the micro-fluidic chip and the device. According to the micro-fluidic chip and the device, which are provided by the invention, high throughput and high resolution can be both considered, the growth of larvas is prevented from being restrained by the use of an additional chemical reagent, the manufacturing and using cost is low, the operation automation degree is high, and the application prospect is wide.

Owner:SHANGHAI INST OF BIOLOGICAL SCI CHINESE ACAD OF SCI +1

Hand-operated double-fork sheller for small bamboo shoots

InactiveCN107212433AThe efficiency of peeling bamboo shoots is lowNovel and compact structureVegetable peelingBiochemical engineeringBamboo shoots

The invention relates to and provides a hand-operated double-fork sheller for small bamboo shoots, comprising a housing and a frame; the housing is arranged on the frame; a shelling device is arranged on the frame and includes a shelling unit, a scraping unit and a pushing unit; the shelling unit is arranged on the housing; the pushing unit is arranged on the frame; the scraping unit is arranged on the pushing unit. The hand-operated double-fork sheller for small bamboo shoots is high in shelling efficiency and shelling speed, requires low labor intensity, saves time and labor, and is novel in structure and suitable for large-scale production, popularization and use.

Owner:长沙联博科技咨询有限公司

Magnetic flow probe

InactiveUS7437945B1Increase floor spaceReduce vibrationVolume/mass flow by electromagnetic flowmetersElectrical conductorProbe type

Problems of instability and non-linearity in probe-type magnetic flow meters are ameliorated by either or both of a conductor coating connecting a tip portion of the probe with a supporting probe stem and flat end plates parallel to the flow direction that are arranged adjacent to the sensing electrodes and that act to straighten and confine fluid flowing past the electrodes.

Owner:ONICON INC

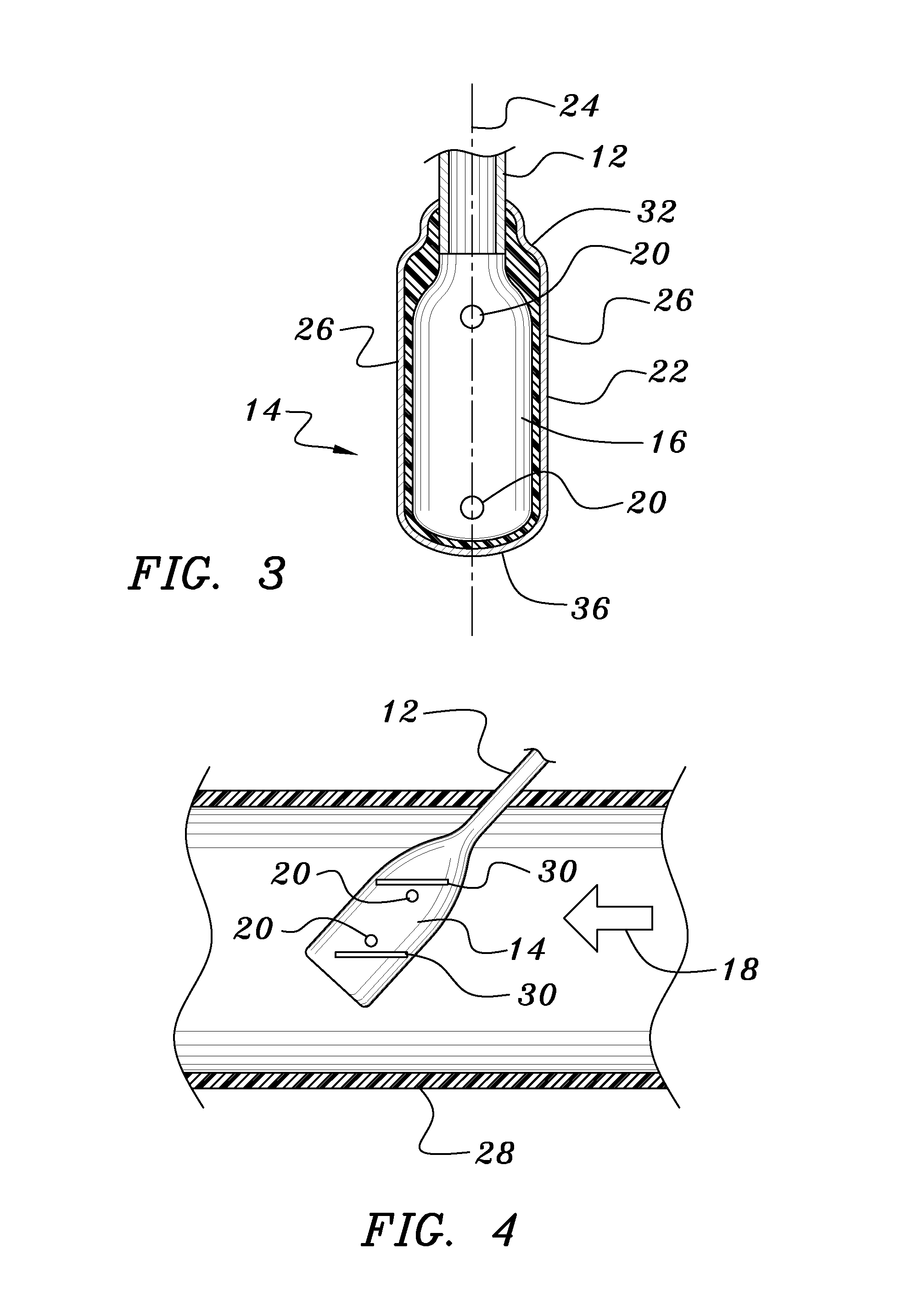

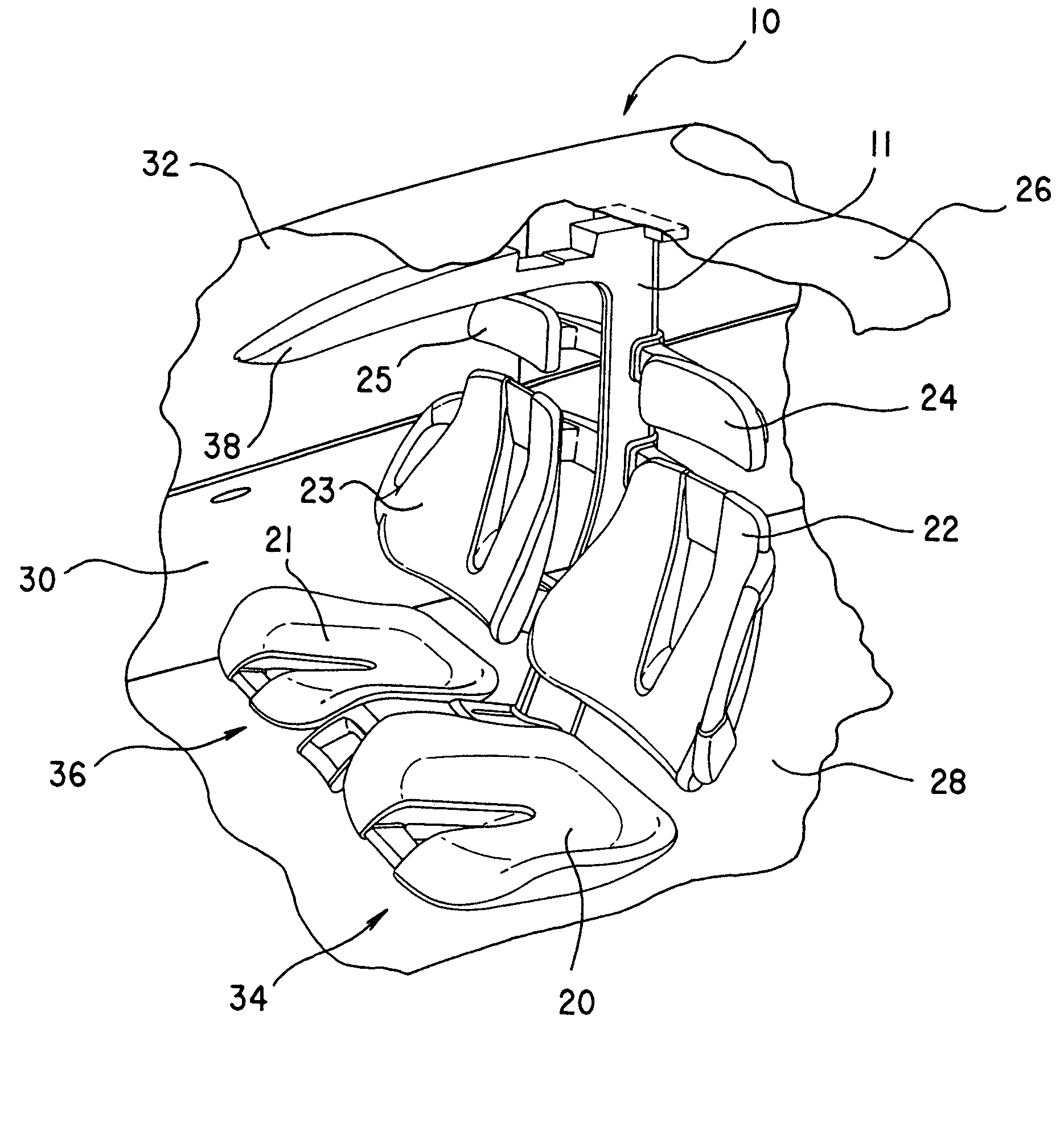

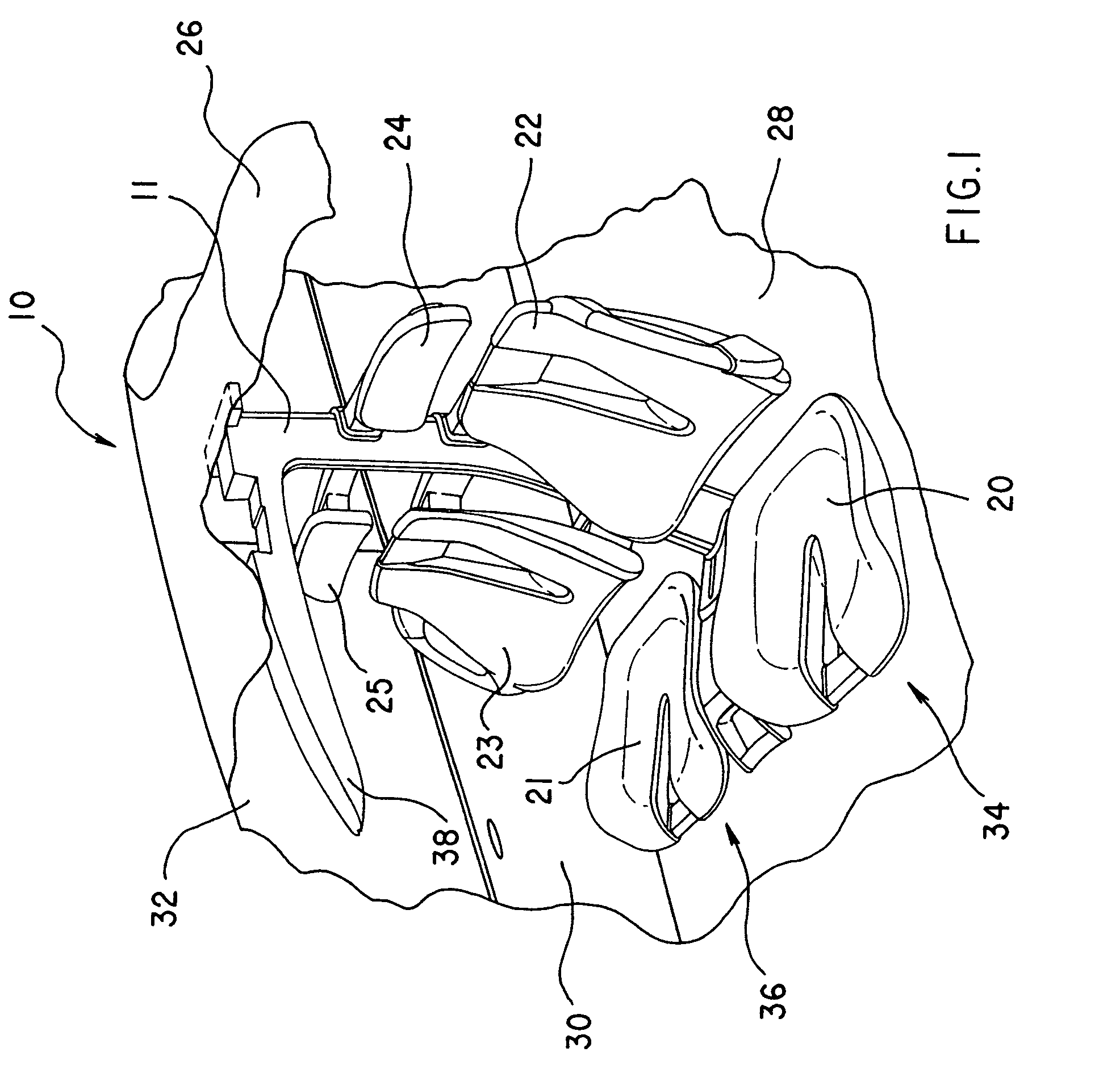

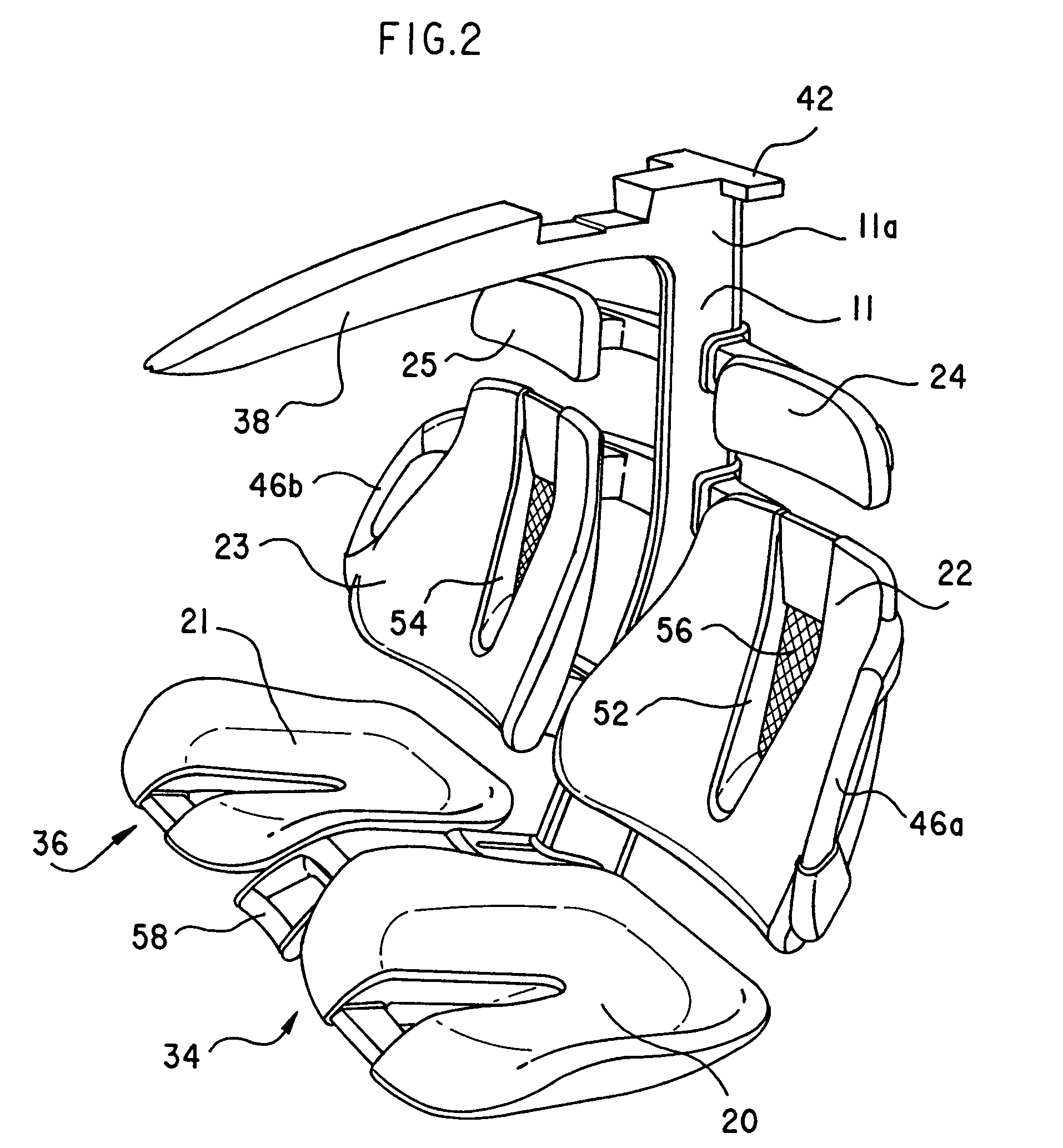

Vehicle seat

InactiveUS7597395B2Additional floor spaceIncrease foot roomSeat framesSeating furnitureAutomotive engineeringMajor and minor

Owner:HONDA MOTOR CO LTD

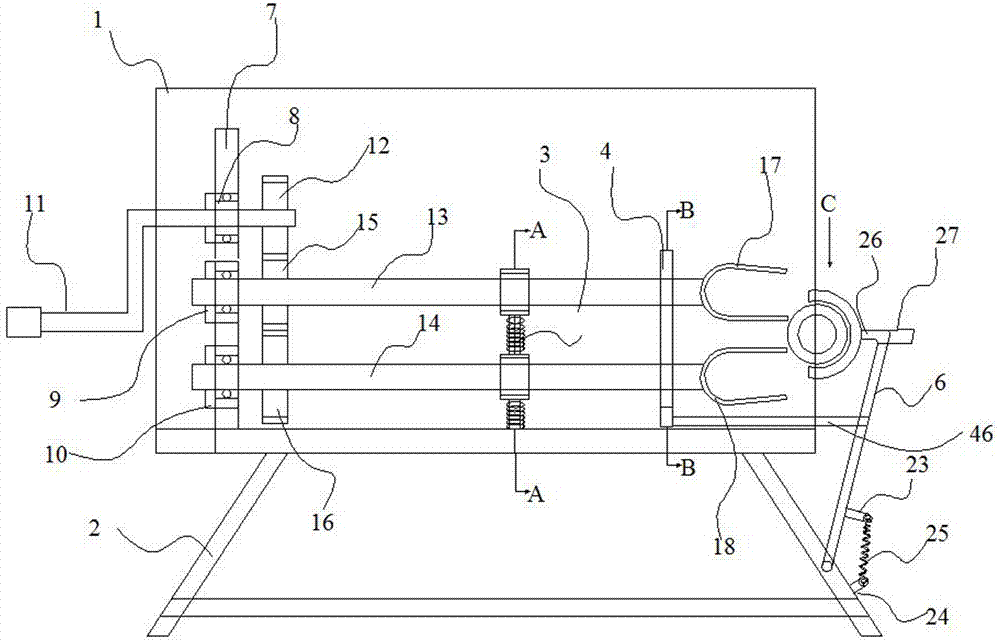

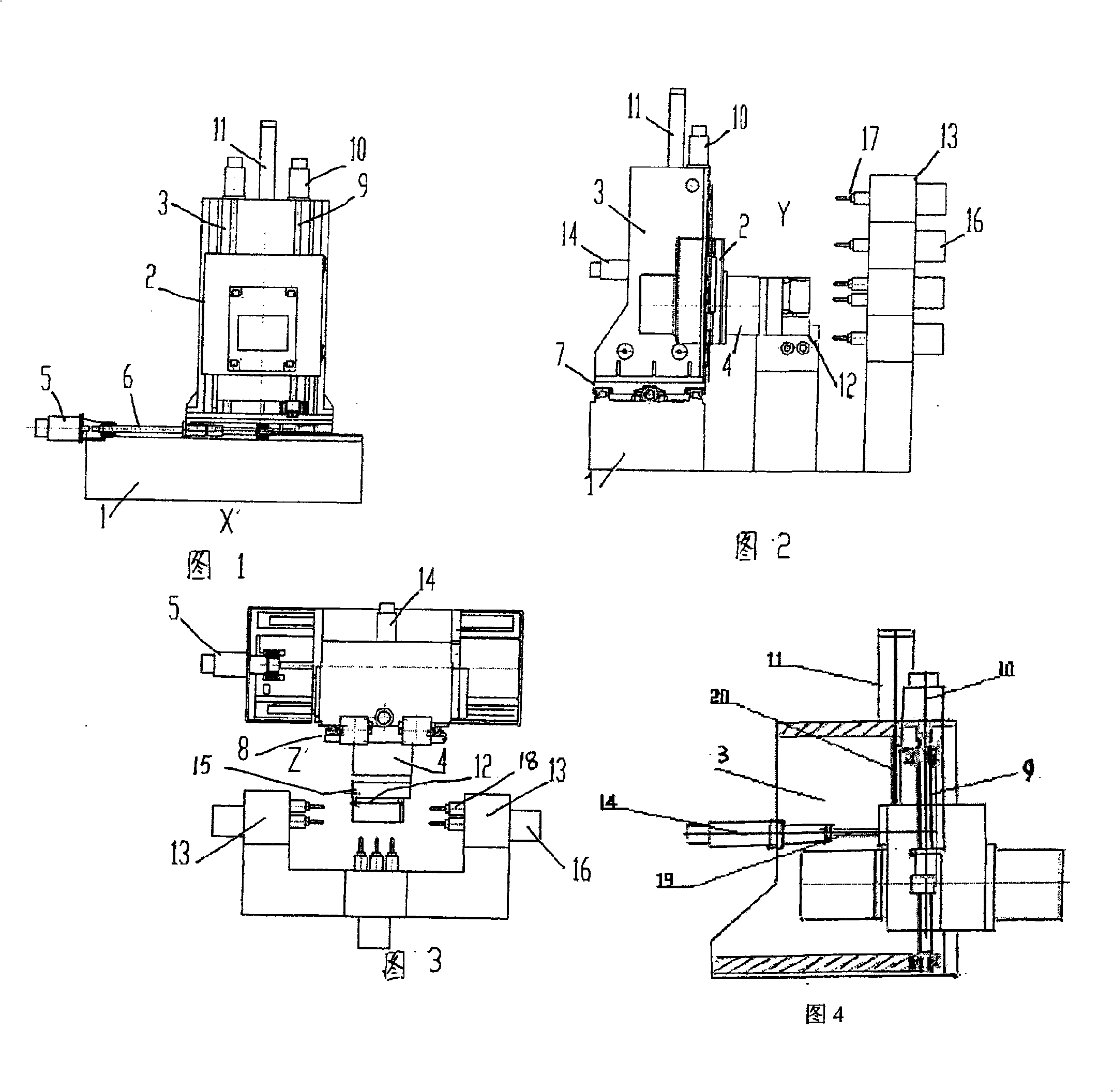

Numerical control reverse direction machining aggregate machinery

InactiveCN101347911AImprove processing efficiencyImprove machining accuracyLarge fixed membersMetal working apparatusNumerical controlSlide plate

The invention relates to a numerical control reverse processing combined machine tool which is composed of a work fixture unit for fixing a part to be processed, a motor, an X axis direction guide way, a Y axis direction guide way, a Z axis direction guide way, a spindle box module for fixing tools, a sliding plate, a ram, an upright post and a base; the upright post and the base are provided with the X axis direction guide way, and the upright post is arranged on the base and can move along the X axis direction guide way; the upright post is provided with the Y axis direction guide way, and the sliding plate is arranged on the upright post and can move along the Y axis direction guide way; the sliding plate and the ram are provided with the Z axis direction guide way, and the ram is arranged on the sliding plate and can move along the Z axis direction guide way; the work fixture can be arranged on a revolving axle of a B axis; the upright post does horizontal linear movement oppositely to the base along the X axis direction; the sliding plate does vertical linear movement oppositely to the upright post along the Y axis direction; the sliding plate is arranged along the Z axis direction and internally provided with the ram, and square holes on the sliding plate and the ram longitudinally stretch back and forth to form the longitudinal and horizontal movement of the Z axis; the work fixture can be directly installed on the end face of the ram of the Z axis, or placed on the revolving axle of the B axis and then mounted on the end face of the ram, and the tool is installed on the spindle of a multi-spindle box.

Owner:JIANGSU HENGLI MACHINE TOOL

Compound rehabilitation system

ActiveCN106137504AHigh activitySave human effortPneumatic massageChiropractic devicesMotor speedThree vessels

The invention relates to a compound rehabilitation system. The rehabilitation system comprises a rehabilitation training bed, a lower-limb pulling muscle joint training module in the accommodating cavity and a control system, wherein the rear half part of the rehabilitation training bed is provided with an accommodating cavity; a lower limb blood circulation rehabilitation module is fixed on the lower-limb pulling muscle joint training module; and the control system comprises a microprocessor, a memory, an input module, an output module, a rotary coder, a pulling motor speed-regulation controller, an overload torque sensor, an air pressure sensor, a temperature sensor and a communication module. The compound rehabilitation system integrates joint motion, muscle extension, blood vessel function and blood circulation into a whole, is used for controlling motion of the rehabilitation system by means of the control system, and is intelligent since spontaneous determination can be carried out according to the rehabilitation training condition of a patient; and rehabilitation training condition of a patient can be carries safety and efficiency.

Owner:杨如山

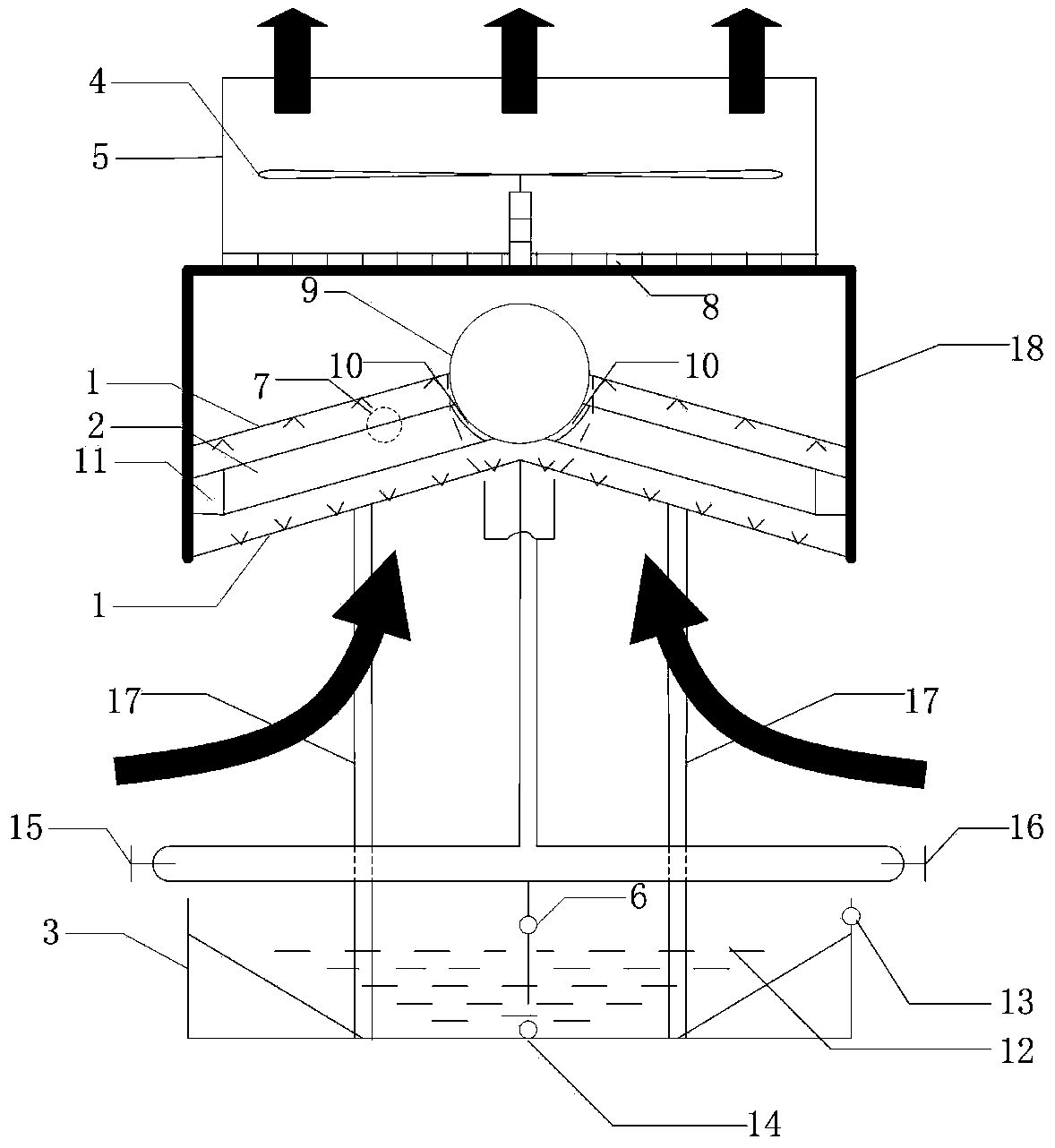

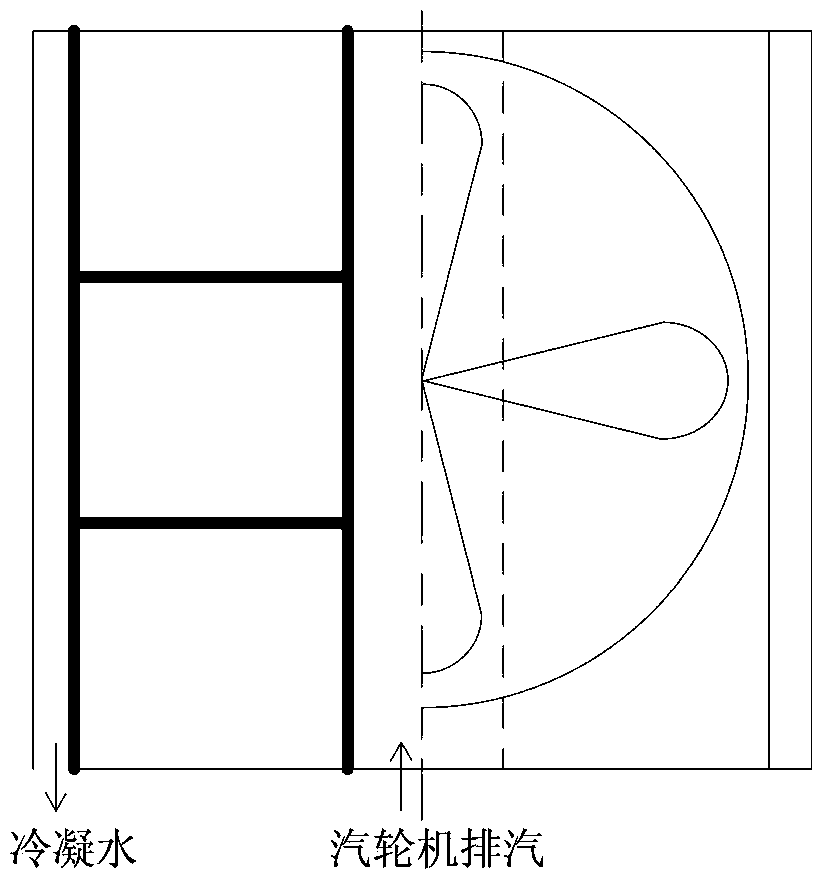

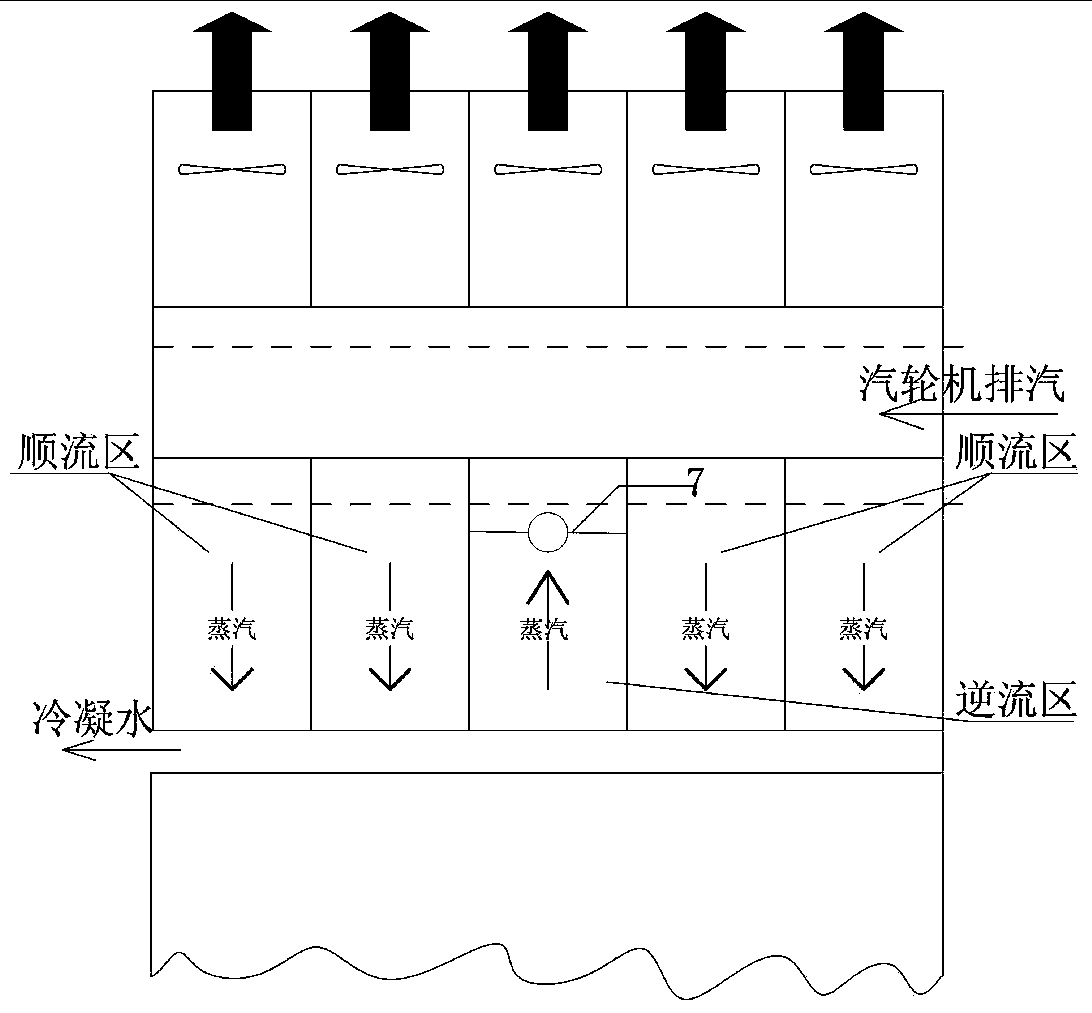

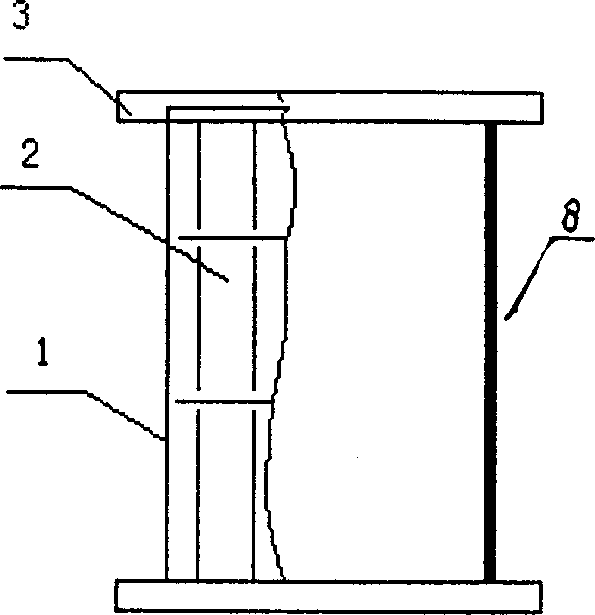

Plate-type evaporation air-cooling condenser

InactiveCN104034178ASpeed up the flowSpeed up evaporationEnergy industrySteam/vapor condensersCondensed waterEngineering

The invention belongs to the technical field of heat exchange, in particular relates to a plate-type evaporation air-cooling condenser which comprises heat exchange plate bundles, a fan, a vapor distribution tube, a spraying device, a water baffle plate and a circulation pump, wherein two heat exchange plate bundles take the shape of an inverted V; vapor inlets and condensed water outlets are respectively formed in the upper ends and the lower ends of the heat exchange plate bundles; the vapor inlets are connected with the vapor distribution tube; the condensed water outlets are connected with a condensed water pipeline; a group of spraying devices parallel to the heat exchange plate bundles are respectively arranged above and below the heat exchange plate bundles; an upper surface partitioned from the positions of the heat exchange plate bundles is covered with the water baffle plate; the fan is arranged inside an air outlet cylinder; the water baffle plate is arranged below the fan; the fan is arranged at the upper parts of the heat exchange plate bundles. Due to adoption of an air sucking structure, the structure is more compact, with the cooperation of two groups of upper and lower groups of the spraying devices, the working condition of a machine set can be flexibly adapted, and the heat exchange coefficient is about 50 times that of direct air cooling, so that not only is the heat exchange efficiency greatly improved, but also the number of condensation units is reduced, then the occupied space is reduced, and modular design is facilitated.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

High-pass flexible bionic dynamic membrane assembly and its production method and uses

InactiveCN1807279ALow costEasy to processTreatment using aerobic processesSustainable biological treatmentHigh fluxEngineering

The disclosed high-flux flexible bionic dynamic membrane module for solid-liquid separation comprises: a membrane module with a piece of cord fabric constituted by some porous material nets or filter cloth, a flow-guide cavity, and two catch-water pipes; a valve, a loose joint, and a membrane frame welded a stationary block to fix the catch-water pipes. Wherein, modifying the module surface with collagen; arranging a cavity with long and wide size, sticking or sewing two sides of long direction, opening two sides of wide direction; arranging the flexible flow-guide grid to form the former flow-guide cavity; inserting two opening ends of the cord fabric into the grooves of two catch-water pipes with one end be sealed and another end connected to the total outlet pipe by the valve and loose joint.

Owner:NANJING UNIV OF TECH

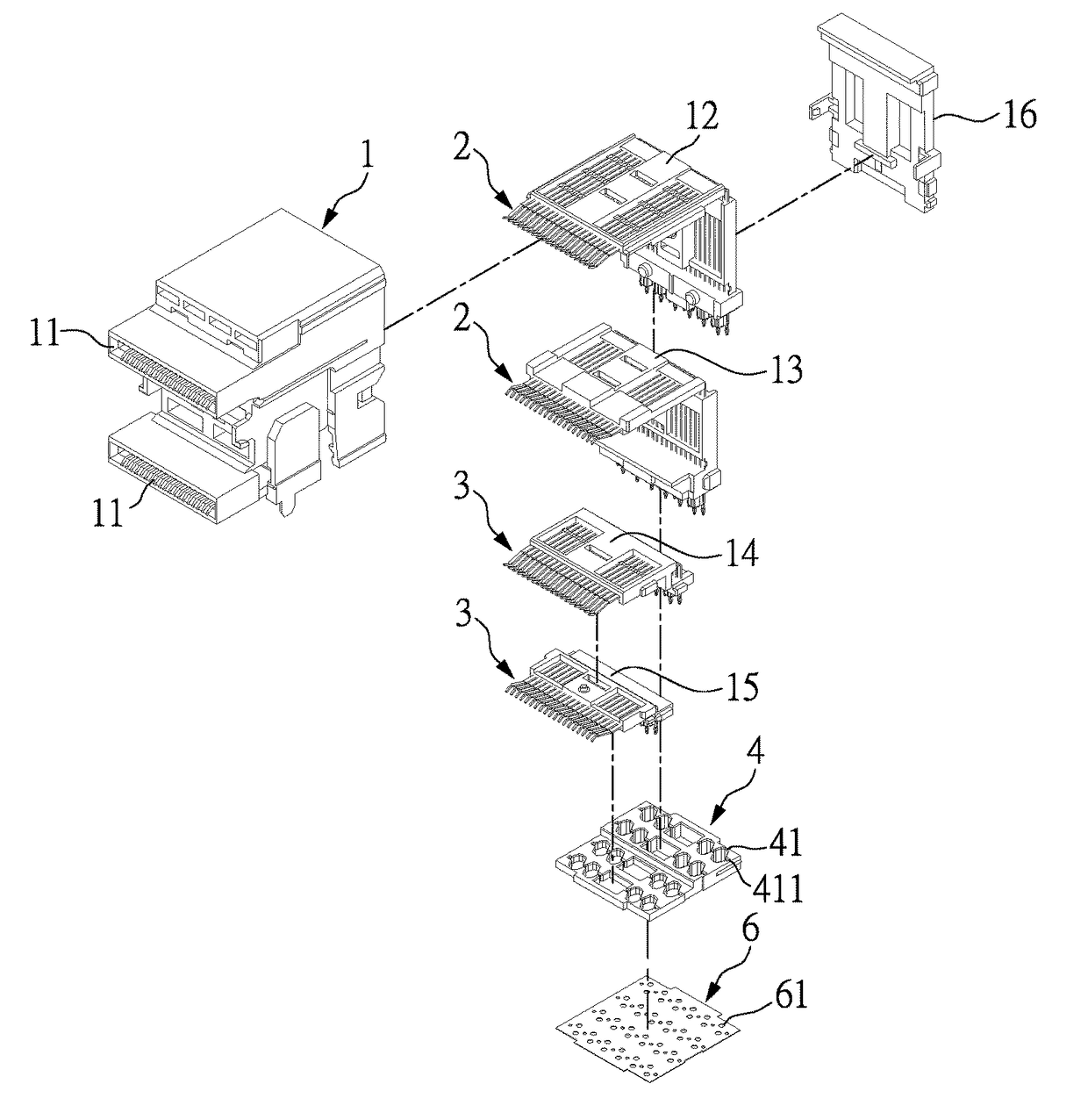

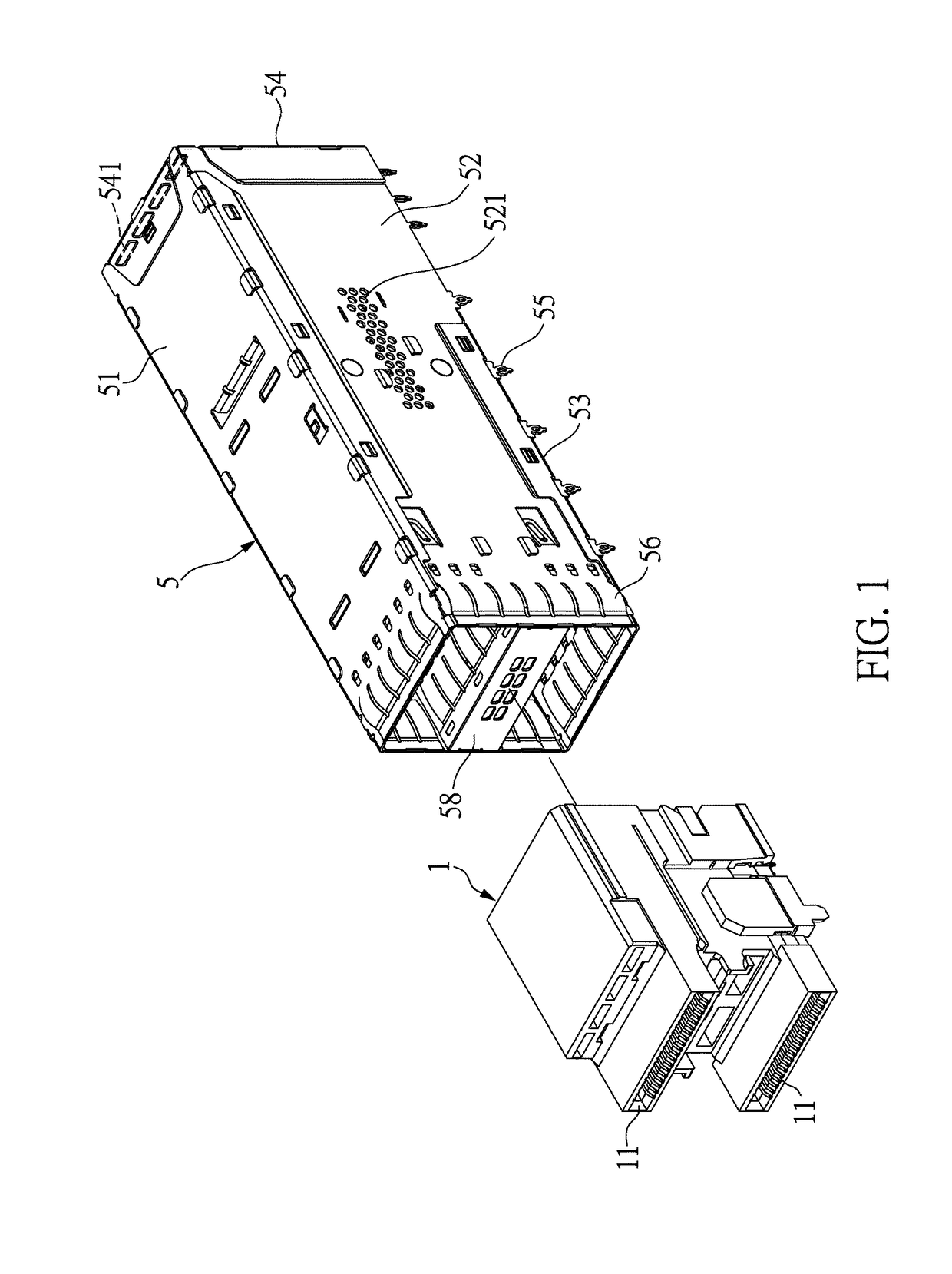

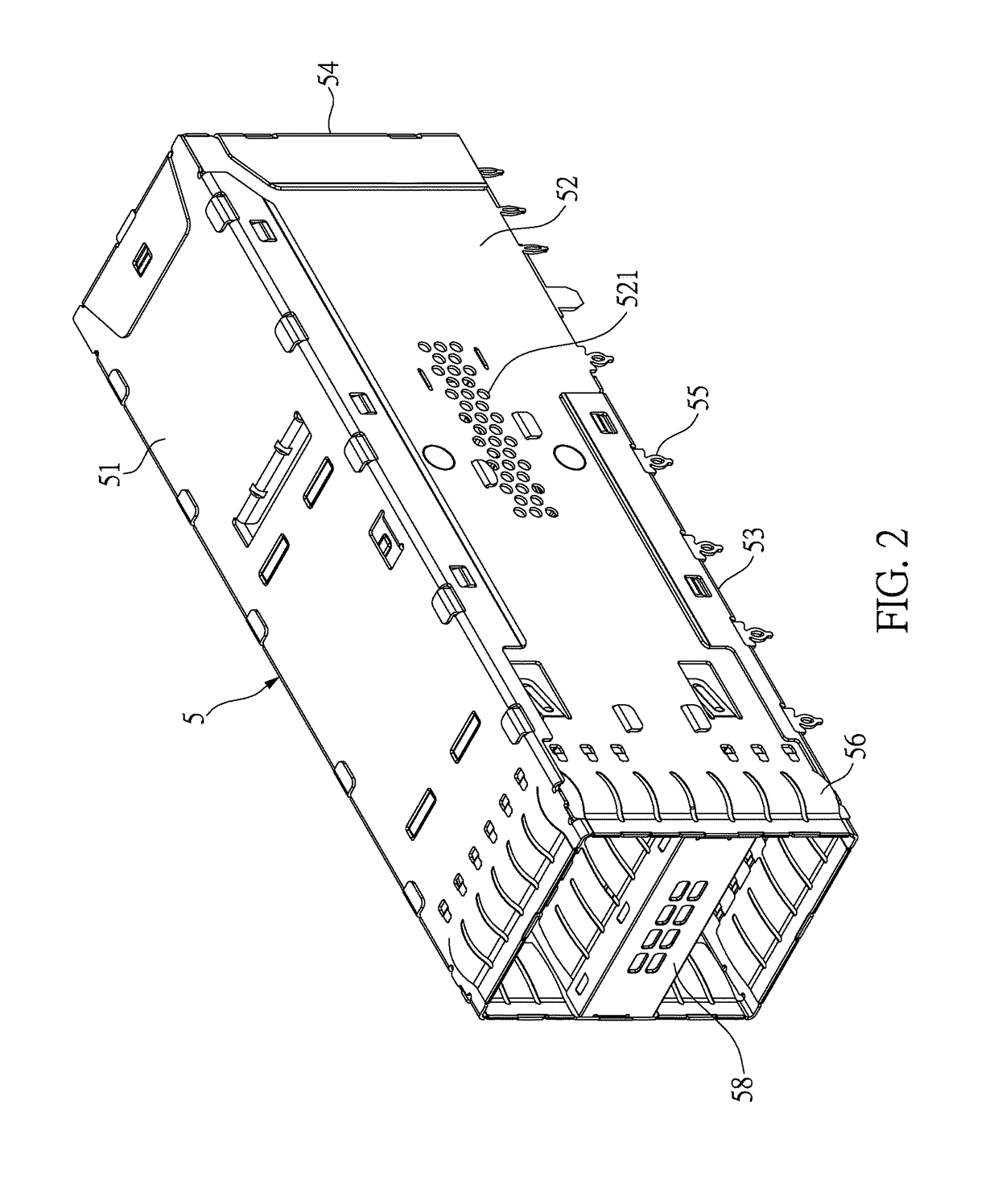

High frequency signal communication connector with improved crosstalk performance

ActiveUS9774143B1Improved crosstalk performanceReduce crosstalk interferenceTwo-part coupling devicesCoupling protective earth/shielding arrangementsCrosstalk interferenceEngineering

A high frequency signal communication connector with improved crosstalk performance includes an insulated housing, a plurality of first terminals, a plurality of second terminals, a conductive shielding layer, and a metal shell. The insulated housing has two inserting slots. The first and second terminals are disposed in the insulated housing, and have front ends respectively extending into the two inserting slots, and rear ends respectively extending outside a bottom of the insulated housing. The conductive shielding layer is provided on the insulated housing, and is disposed with a plurality of through holes. The first and second terminals respectively pass through the through holes, so that the conductive shielding layer covers a part of the first and second terminals. The first and second terminals have grounding terminals contacting with the conductive shielding layer, so that the terminals have better shielding effectiveness to reduce crosstalk interference.

Owner:NEXTRONICS ENG CORP

Method and device for cultivating and maintaining aquatic crustaceans

InactiveUS20060005778A1Efficient inductionAvoid deathClimate change adaptationPisciculture and aquariaHigh densityTactile sensation

A device for cultivating and maintaining aquatic crustaceans and the method for the same are provided, whereby aquatic crustaceans are cultured in a culture tank having at least one effective resting and / or hiding area that provides visual only or both visual and tactile sensations for aquatic crustaceans. The present invention creates effective resting and / or hiding areas by utilizing the sensitivity of aquatic crustaceans to physical environment, thereby allowing aquatic crustaceans to live within confined spaces in high densities without cannibalizing those fall outside the effective resting and / or hiding areas (the non-effective habitat areas). The device of the present invention can cultivate and maintain aquatic crustaceans successfully in shallow waters and a plurality of which may be vertically incorporated into a multi-layered culture system to bring about higher culture and maintenance densities per unit floor area.

Owner:IND TECH RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com