Numerical control reverse direction machining aggregate machinery

A technology of combined machine tools and fixtures, applied in metal processing machinery parts, metal processing, metal processing equipment, etc., can solve the problems of large area of the automatic line of combined machine tools, inability to convert production models, and high investment costs, saving auxiliary The effect of time, uniform force and improved processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

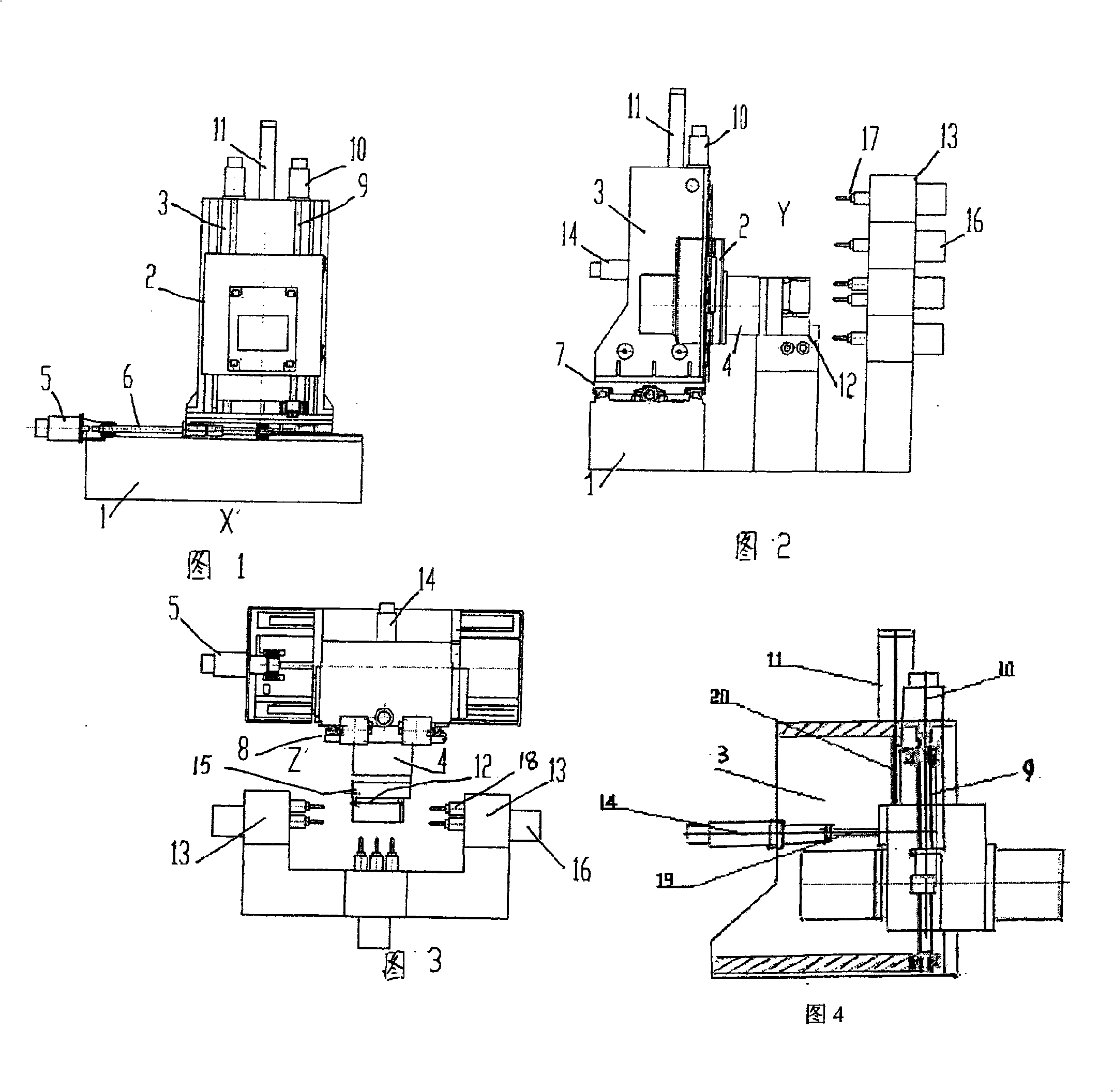

[0032] Embodiment of the present invention: the column 3 and the base 1 are provided with an X-axis guide rail 7, the column 3 is provided on the base 1, driven by the X-axis servo motor 5, driven by the X-axis ball screw 6, and moves along the X-axis guide rail 7 ; The slide plate 2 and the column 3 are provided with a Y-axis guide rail 8, the slide plate 2 is arranged on the column 3, and two Y-axis servo motors 10 are driven at the same time, driven by the Y-axis ball screw 9, moving along the Y-axis guide rail 8, and on the column 3) A hydraulic balance oil cylinder 11 is installed at the center position of the top, and one end of the piston rod 20 is connected with the slide plate 2; the slide plate 2 and the ram 4 are provided with a Z-axis guide rail 14, the ram 4 is provided on the slide plate 2, and the Z-axis servo motor 14 The drive is driven by the Z-axis ball screw and moves along the Z-axis guide rail 14; the tooling fixture 12 can be set on the B-axis rotary shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com