Metallic Structures with Variable Properties

a technology of variable properties and metal structures, applied in the direction of electrolysis components, climate sustainability, electrolysis coatings, etc., can solve the problems of inability to easily scale, process energy intensive, and limited method practical utility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

working example i

Grading of Pure Ni Electrodeposit to Grade Grain Size and Hardness in the Deposit Direction with Electrodeposition Condition Modulation

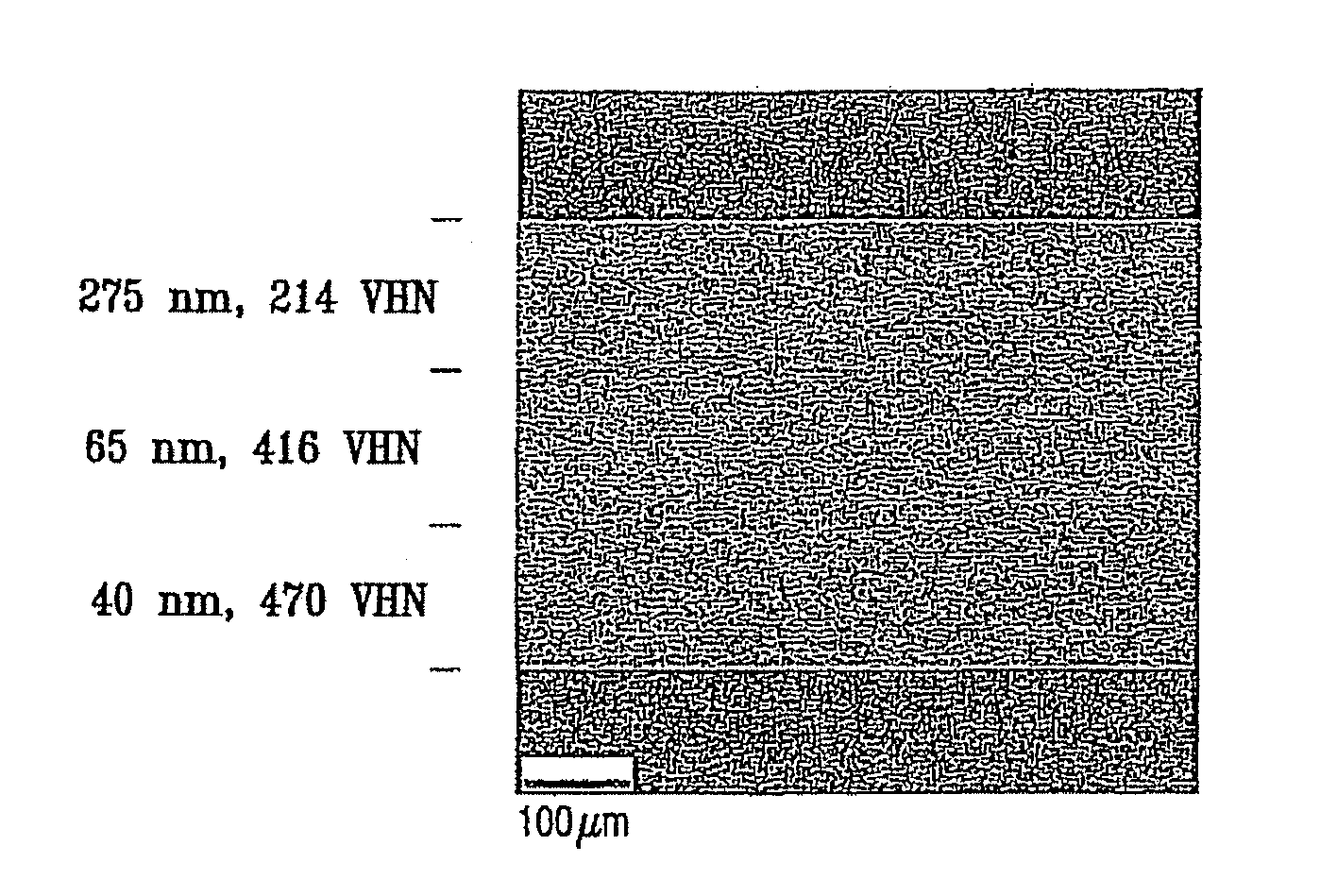

[0158]Free-standing Ni-layers with variable property and multilayered grain size were electrodeposited on a polished Ti cathode (10 cm2) in a modified Watts nickel bath (40 l tank) using grain refiners, levelers, brighteners, stress relievers and chelating agents (Integran Technologies Inc, Toronto, Ontario, Canada). Nickel “R”-rounds (Inco Ltd., Sudbury, Ontario, Canada) were used as anode material. NPA-91 wetting agent was provided by Atotech USA (Rock Hill, S.C.). The plating current was supplied by a Dynatronix (Amery, Wis., USA, Dynanet PDPR 40-100-400) pulse power supply. The electrolyte and the electroplating conditions used are indicated in Table 2. The variation in grain size of the metallic layers was achieved by modulating the electroplating conditions as set forth in Table 2. Resulting variable property structure is shown in FIG. 1. FIG. ...

working example ii

Composite Golf Shafts comprising Pure Ni Plated Layers of Different Grain Size in the Deposit Direction with Electrodeposition Condition Modulation

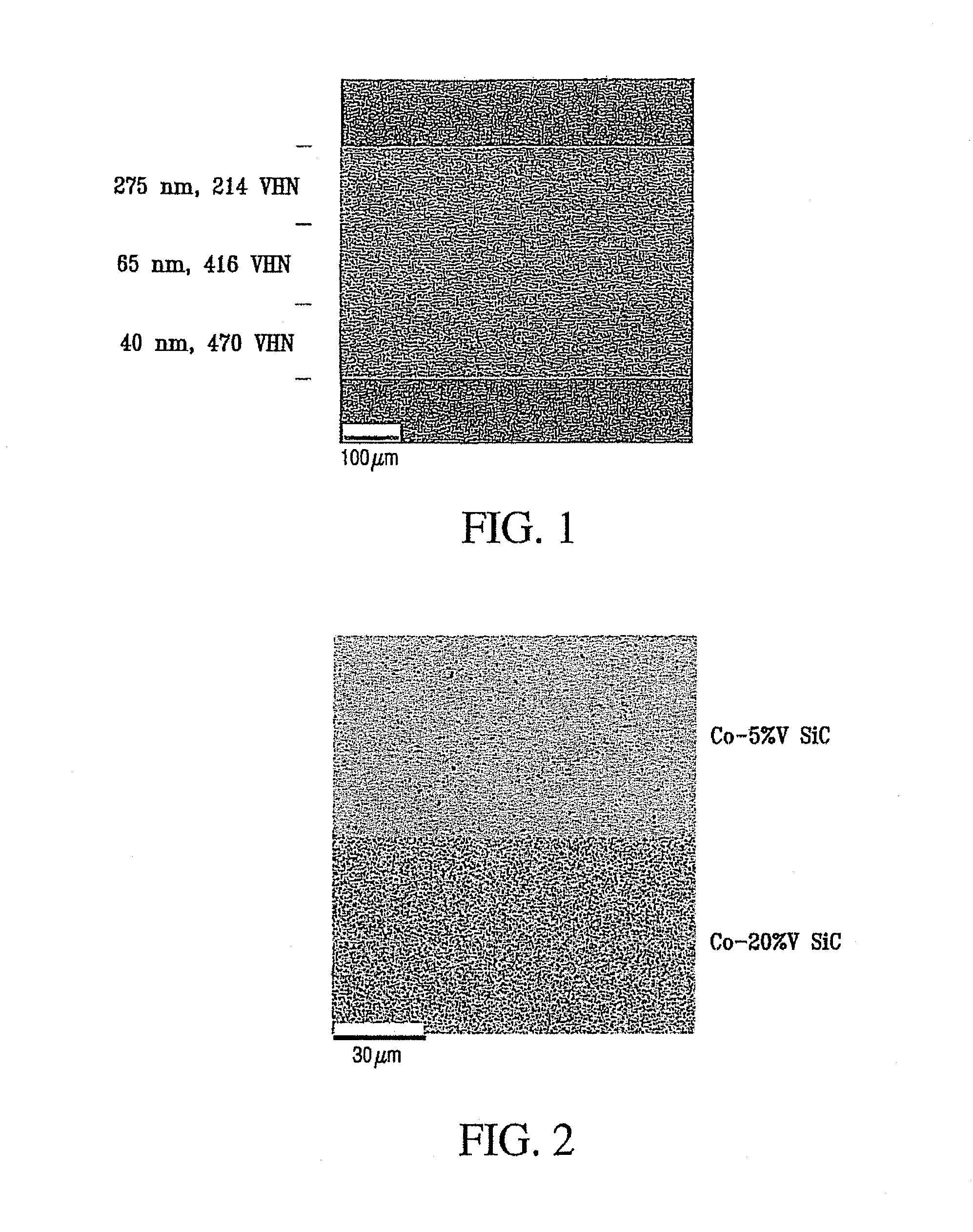

[0160]95 cm long, ˜1.25 cm outer diameter graphite / epoxy golf shafts (400 cm2 surface area) were coated with fine-grained Ni in a tubular tank (125 cm high, ID: 30 cm, electrolyte volume: ˜90 liter) equipped with a heater, recirculation system and a single anode basket. Golf shaft precursor tubes were mounted on a stainless steel feeder which was attached to a rotator. The modified Watts nickel bath illustrated in Table 2 of Example I was employed and precursor tubes were rotated at 15 RPM. Nickel “R”-rounds (Inco Ltd., Sudbury, Ontario, Canada) were used as anode material and the plating current was supplied by a pulse power supply (Dynatronix, Amery, Wis., USA), Before electroplating, graphite / epoxy precursor tubes were metalized with amorphous Ni-10P (Elnic 101, MacDermid Americas, Waterbury, Conn., USA) to a thickness of around 1 micr...

working example iii

Composite Golf Shafts Comprising Pure Ni Plated Layers of Mfferent Grain Size in the Denosit Direction with Electrodeposition Condition Modulation and Along its Length using Shielding

[0161]95 cm long, ˜1.25 cm outer diameter graphite / epoxy golf shafts (400 cm2 surface area) were coated with fine-grained Ni as illustrated in Example H except that the anode was shielded to impart a tapered thickness profile and grade the grain size along the surface of the shaft. Employing anode shielding and current thieves the thickness profile was adjusted to gradually decrease the thickness of the nickel coating metallic layer from 200 microns to 85 microns over the lower 30 cm of the 95 cm long tube while the Ni coating thickness of the remaining 65 cm of the tube was maintained at 85 microns. Specific to the shielding, ˜65% of the anode surface was covered with a polypropylene sheet to reduce the local current density along the aforementioned 65 cm-long section of the tube intended to have a uni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

| reverse current density | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com