Patents

Literature

113 results about "Plating efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Plating efficiency ("PE") is a measure of the number of colonies originating from single cells. It is a very sensitive test and is often used for determining the nutritional requirements of cells, testing serum lots, measuring the effects of growth factors, and for toxicity testing.

Efficient Gallium Thin Film Electroplating Methods and Chemistries

InactiveUS20070272558A1Improve plating efficiencyGood repeatabilityAnti-corrosive paintsLiquid/solution decomposition chemical coatingElectrical conductorEngineering

The present invention relates to gallium (Ga) electroplating methods and chemistries to deposit uniform, defect free and smooth Ga films with high plating efficiency and repeatability. Such layers may be used in fabrication of electronic devices such as thin film solar cells. In one embodiment, the present invention provides a solution for application on a conductor that includes a Ga salt, a complexing agent, a solvent, and a Ga-film having submicron thickness is facilitated upon electrodeposition of the solution on the conductor. The solution may further include one or both of a Cu salt and an In salt.

Owner:SOLOPOWER

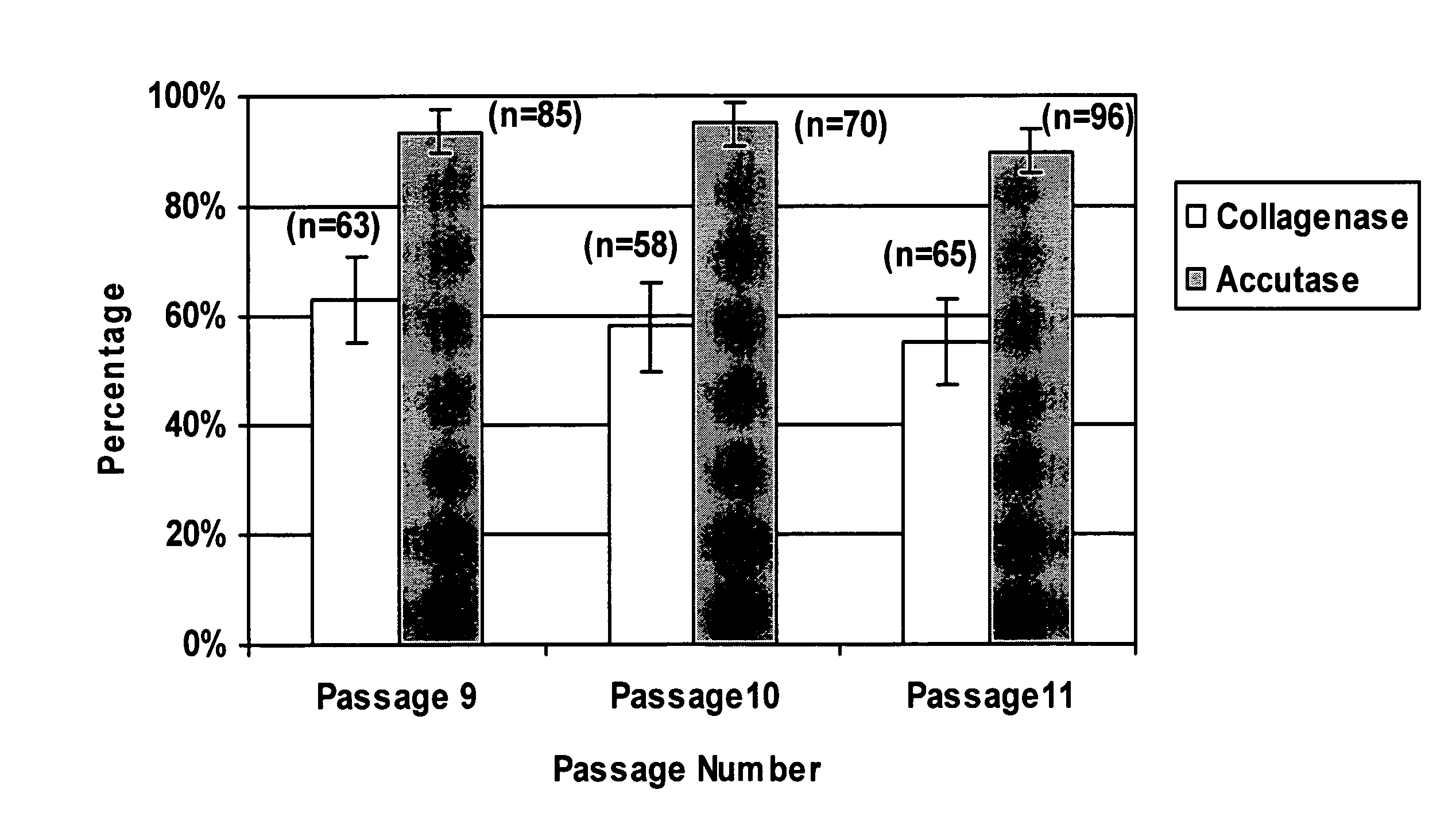

Methods for culture and production of single cell populations of human embryonic stem cells

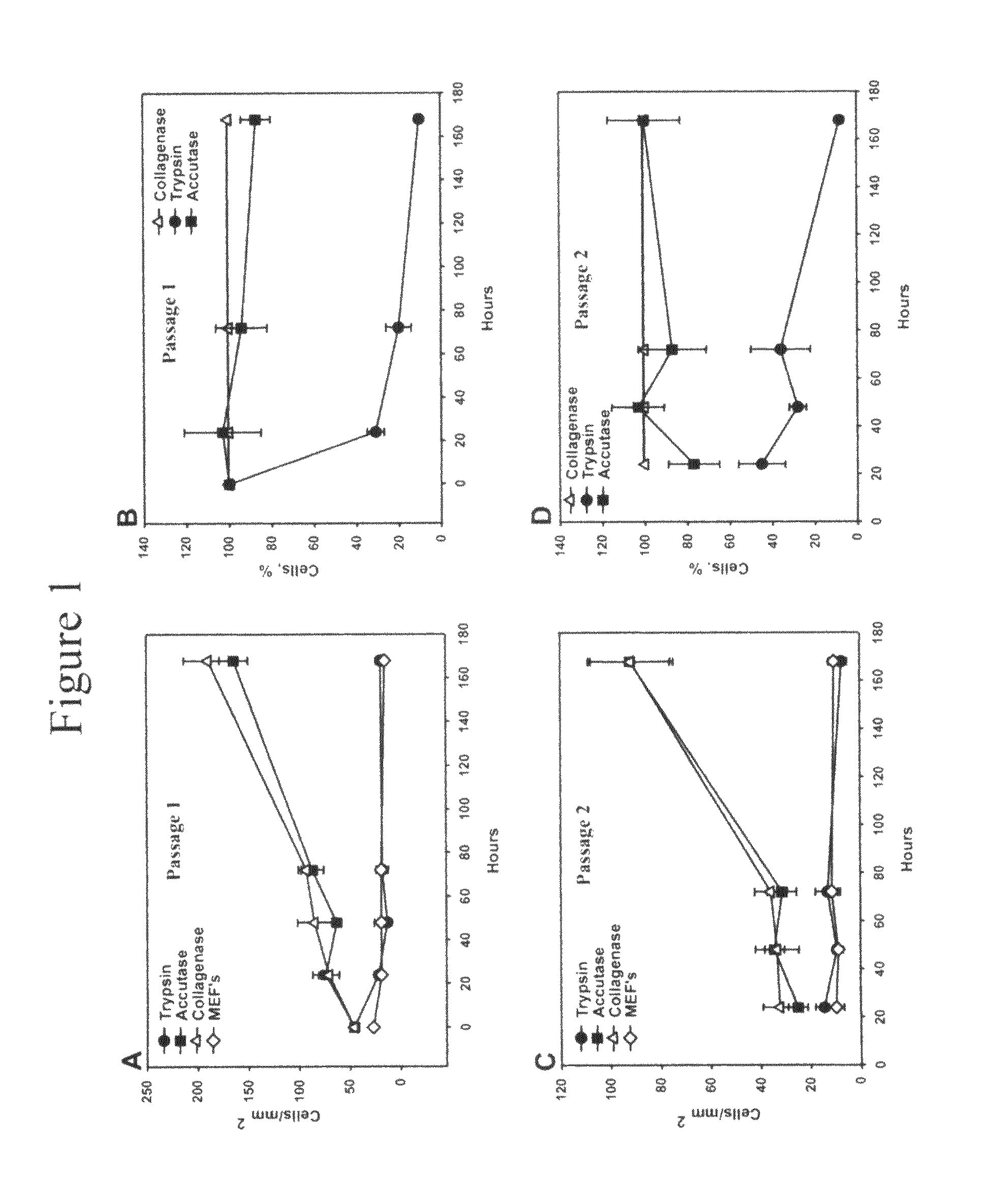

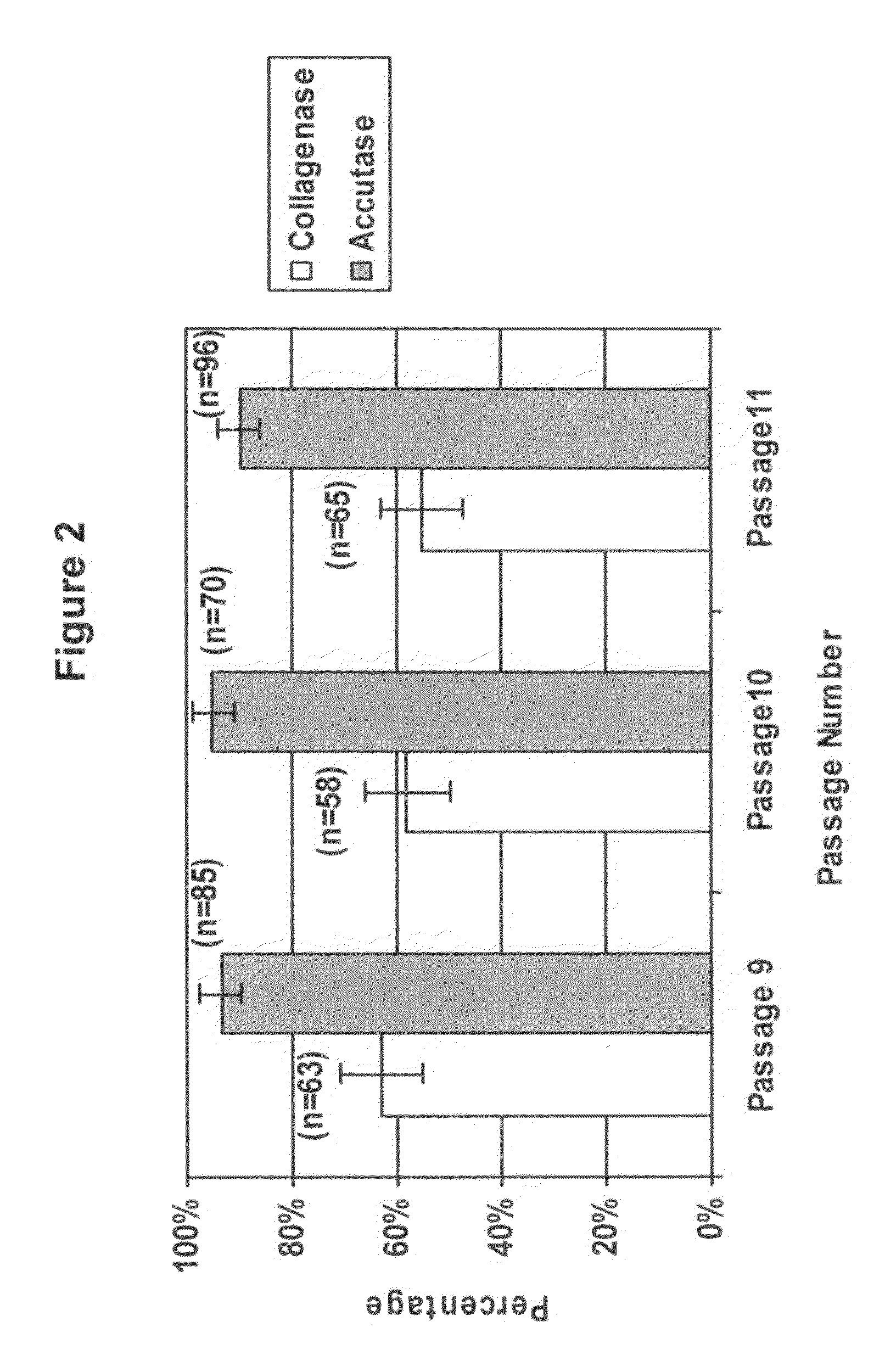

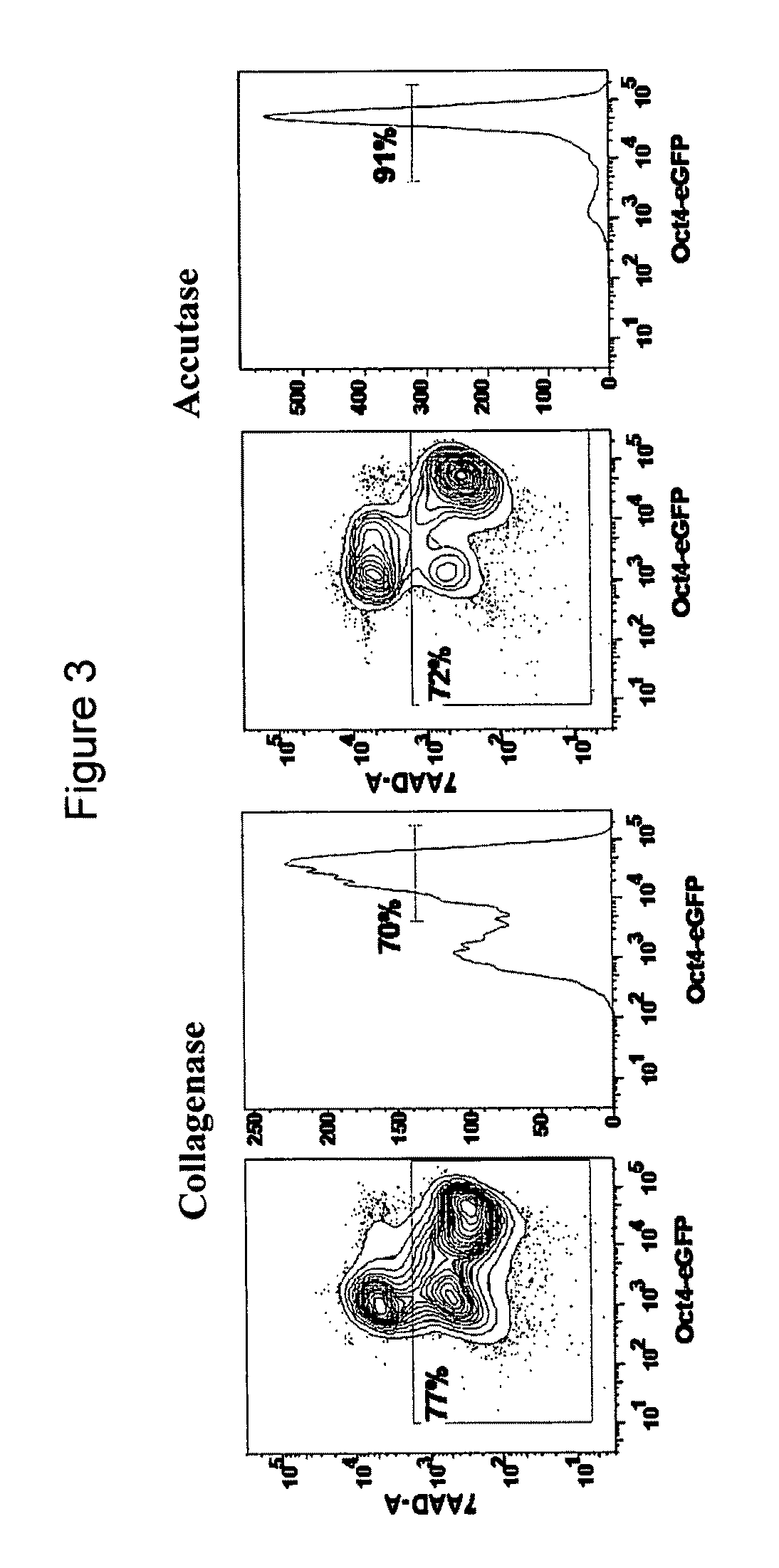

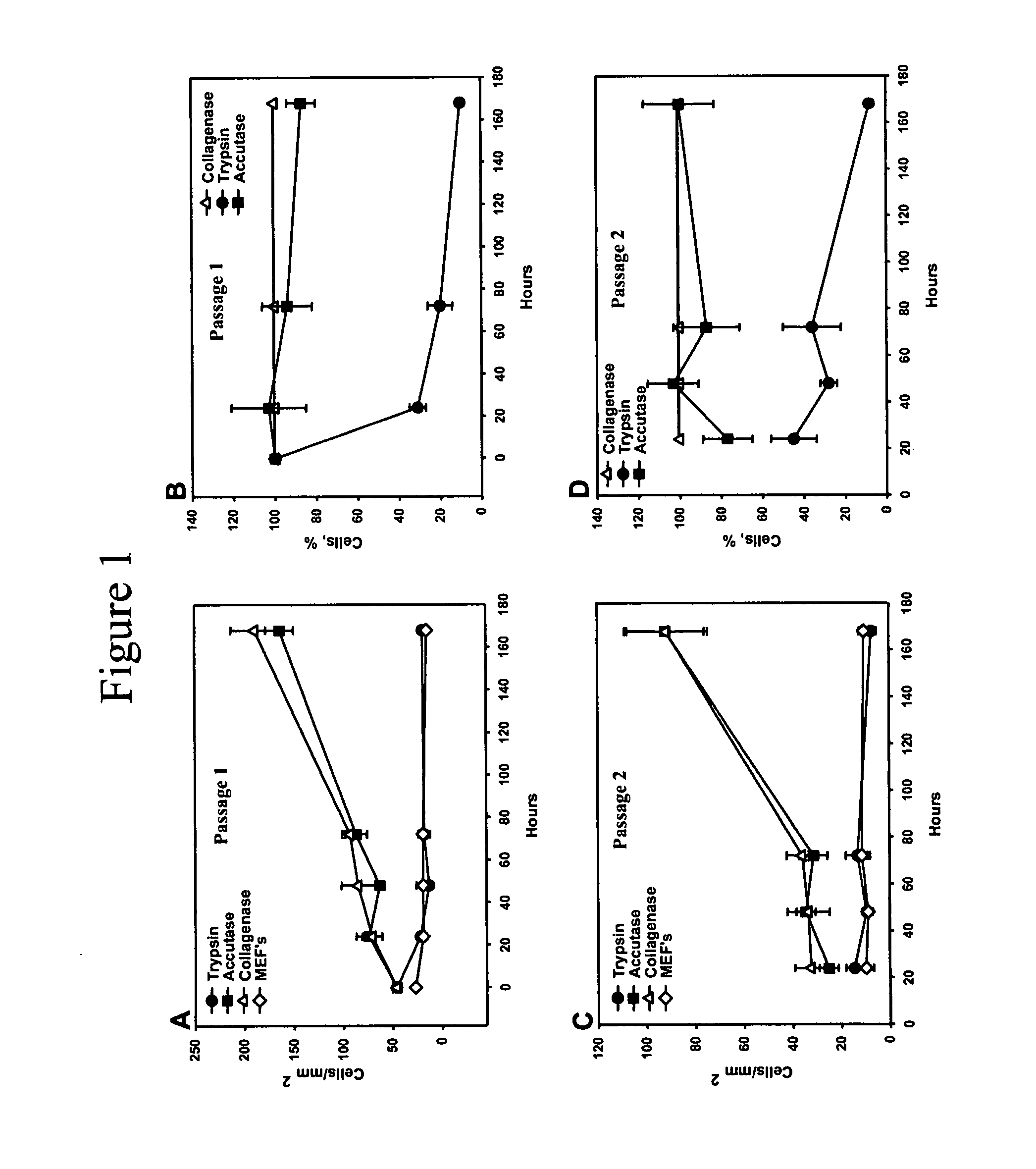

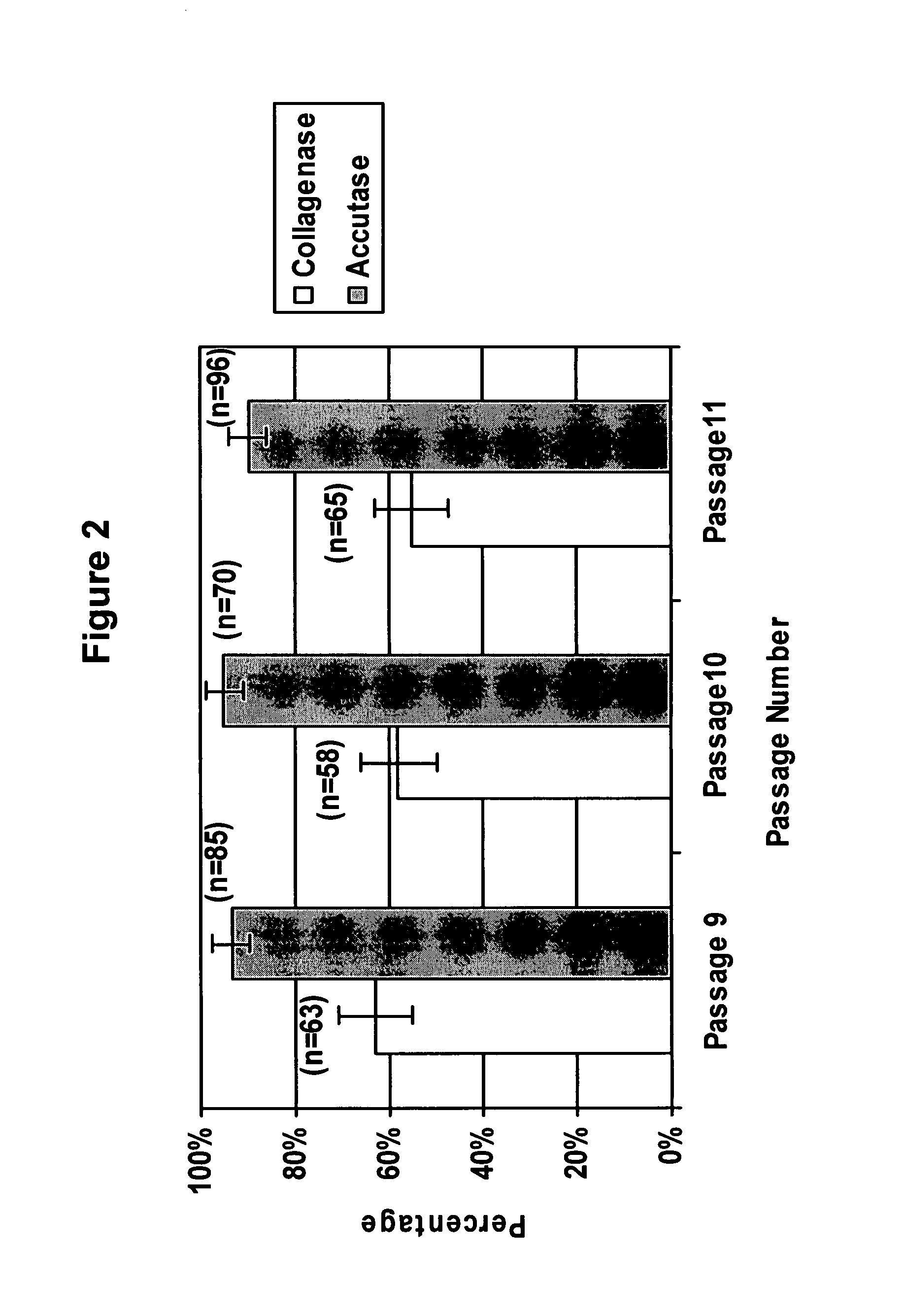

We used Accutase™, a commercially available cell detachment solution, for single cell propagation of pluripotent hESCs. Unlike trypsin dissociation, Accutase treatment does not significantly affect the plating efficiency of hESC dissociation into single cells. Cultures dissociated with Accutase to single cells at each passage maintain a higher proportion of pluripotent cells as compared to collagenase-passaged hESCs. Accutase-treated hESCs can be grown to a high density as monolayers, and yet retain their pluripotency.

Owner:BURNHAM INST FOR MEDICAL RES

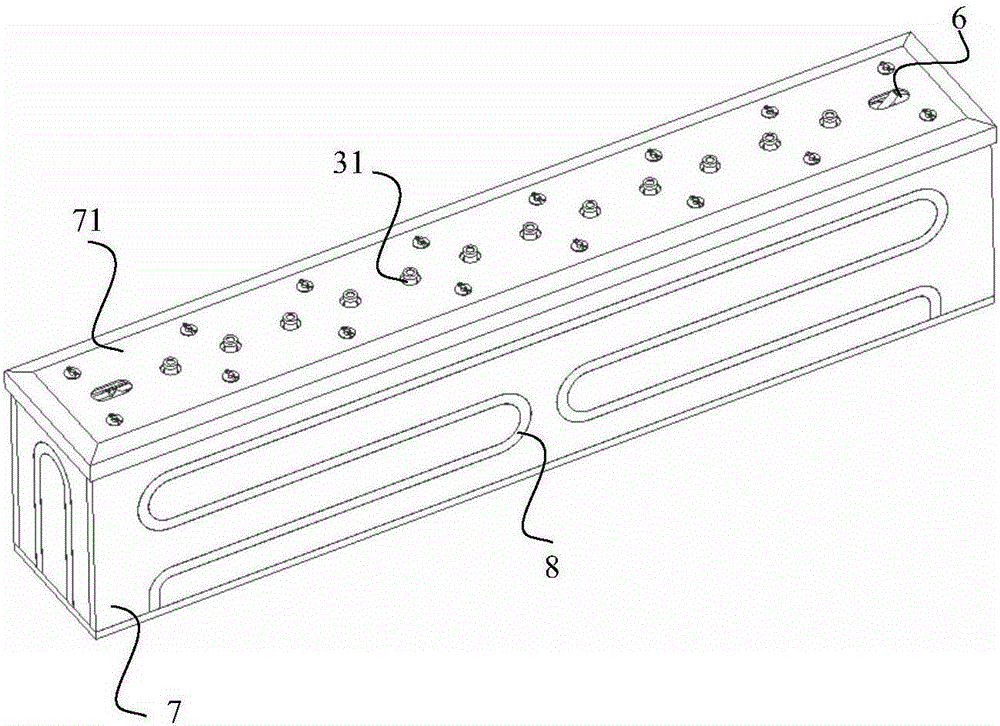

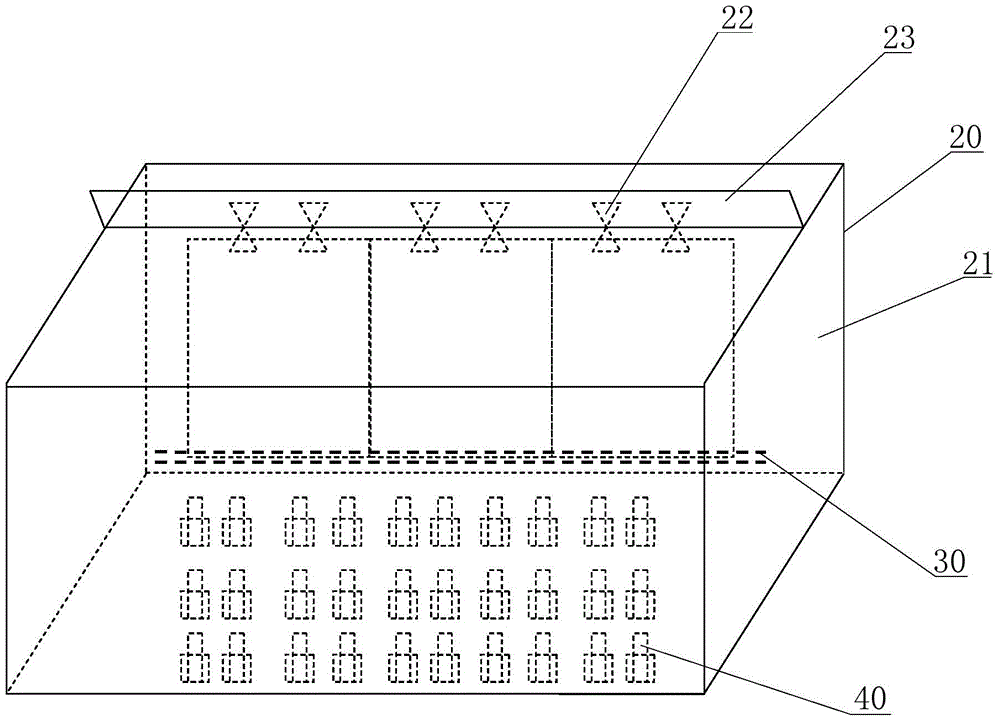

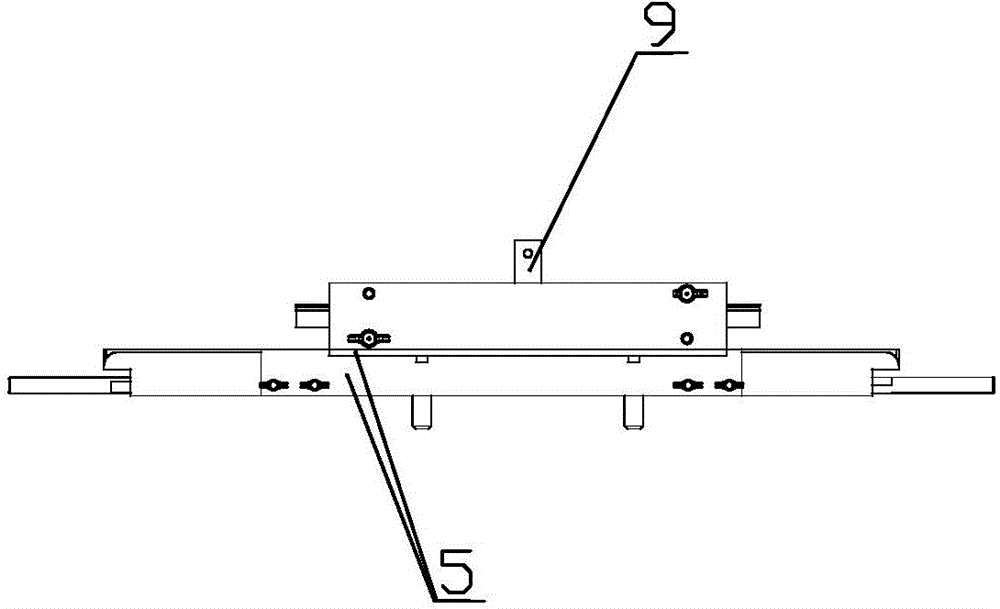

Linear evaporation source and evaporation plating device

ActiveCN105296934AUniform temperatureAvoid clogged nozzlesVacuum evaporation coatingSputtering coatingCrucibleEvaporation

The invention discloses a linear evaporation source and an evaporation plating device in order to reduce the phenomenon that nozzles are blocked and improve the evaporation plating efficiency. The linear evaporation source comprises a crucible with one end open, a first heater and a top cover, wherein a hollow cavity used for containing evaporation plating materials is arranged in the crucible, the first heater surrounds the outer side of the crucible and provides heat for the crucible, the open end of the crucible is covered with the top cover, and the top cover is provided with a plurality of nozzles used for jetting gasified evaporation plating materials to a substrate to be plated. The linear evaporation source further comprises a second heater providing the same heat for each nozzle, and the second heater comprises heating ends corresponding to the nozzles one to one and wrapping the outer surfaces of the corresponding nozzles.

Owner:合肥欣奕华智能机器股份有限公司

Method for painting fluoro resin inside slender metal tube

InactiveCN1765526AReduce dispersionLow dispersion and low dispersion; use thinner for spraying high solids coatingsHollow article cleaningPretreated surfacesDiffusion functionRoom temperature

The invention discloses a method for plating fluoro-resin in the elongated metal pipe. The invention uses the method for high pressure airless spraying or static plating to plate the polytetrafluoroethylene or fusible polytetrafluoroethylene on the inner wall of elongated metal pipe, while the invention has high plating efficiency, the spray fog without compressed airflow, wider application of paint viscidity, high paint availability ratio, and lower environmental pollution. Since the airflow diffusion function of air spraying is avoided, the plating fog has lower diffusion; since the thinner when spraying solid coating is used little, the volatilization of solvent is lower, therefore, the working condition is improved, the invention can be processed in room temperature, the availability ratio of paint can be above 95%, and the plating film is thinner (50-100ª–m). The invention can form a continuous smooth paint film on the surface of work-piece and it can be automatically produced.

Owner:EAST CHINA UNIV OF SCI & TECH

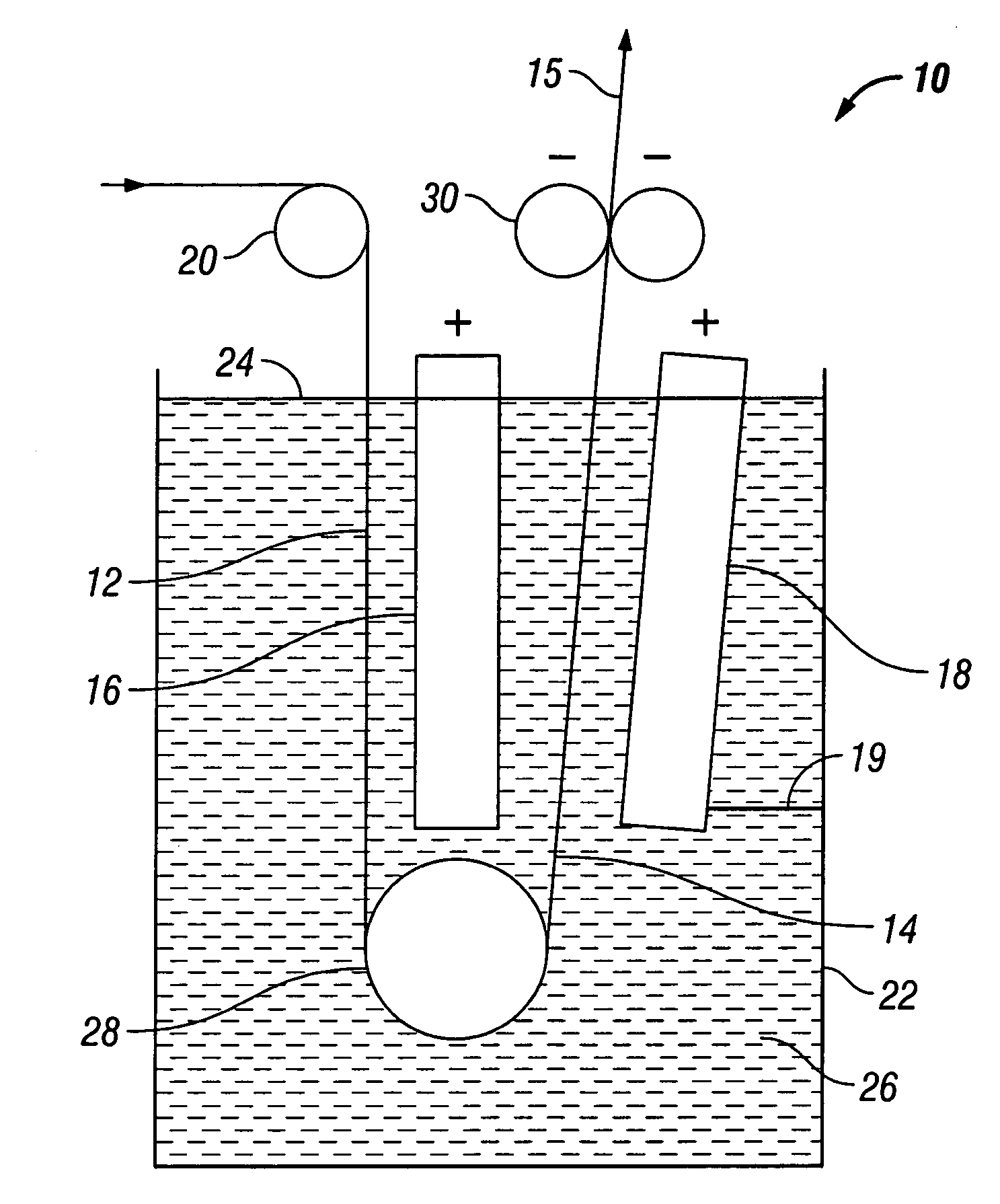

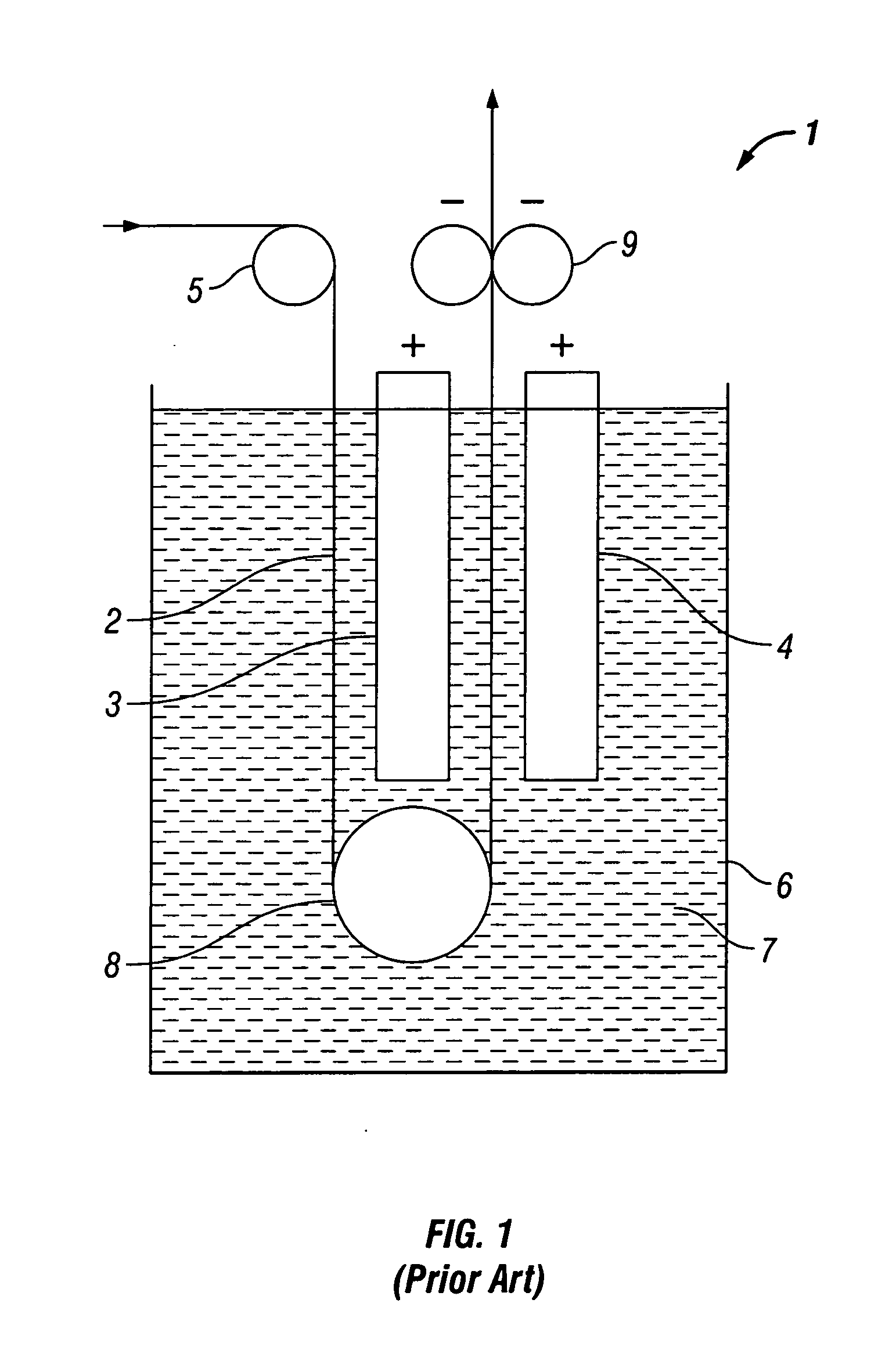

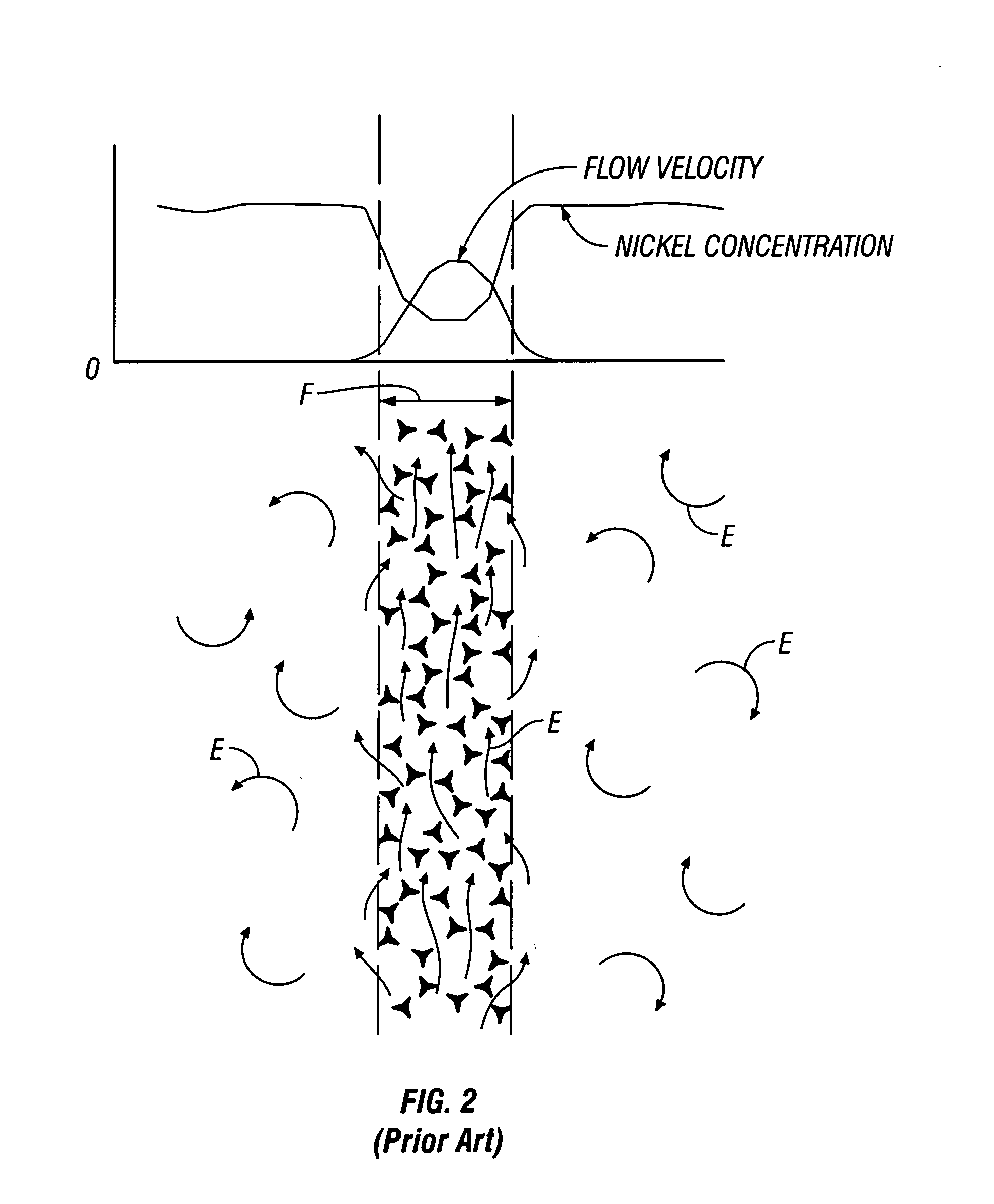

Apparatus and foam electroplating process

InactiveUS20070278105A1Increasing mass transportReduce current densityCurrent insulating devicesElectroforming processesNatural convectionMetal foam

An improved apparatus and method of producing metal foam is provided which involves optimizing the natural convection of electrolyte through a foam being electroplated by inclining the foam during plating. A diagonal flow of electrolyte though the foam enhances electrolyte turnover within the foam while increasing electroplating efficiency. Further increases in plating efficiency are provided by shifting current density from higher plating zones to lower plating zones.

Owner:INCO

Additive for heat zinc coating auxiliary agent

InactiveCN101126142AHigh activityIncrease profitHot-dipping/immersion processesSlagSurface-active agents

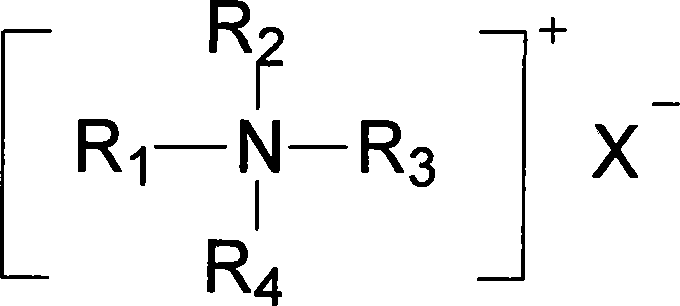

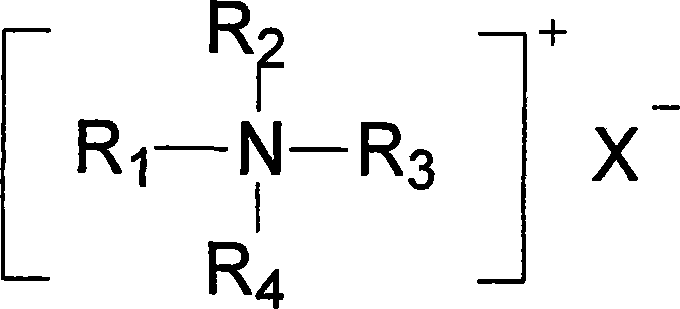

The invention provides an additive used in hot-dip galvanizing assistant plating agent, belonging to the technical field of metal material plating. The invention is used for solving the problem of assistant plating efficiency. The technical proposal of the invention is that the additive is a de-ionized water solution; the water solution contains cation surface active agent and organic solvent of the long chain alkyl; the content of the long chain alkyl cation surface active agent is 100 to 800 gram per liter; the organic solvent can be ethanol, isopropyl alcohol, acetone or one of nickel and N-dimethyl formamide, with adding content of 30 to 160 gram per liter. The invention has the advantages that the assistant plating agent is made and the made element have a plating face with excellent wettability and compatibility, which can increase the activity and the utilization rate, improve the assistant plating efficiency, prevent plated element from escaping, prevent the plated element which is assistant plated from being secondarily oxidized in air, reduce zinc slag, prevent the zinc liquid from splashing and increase the surface quality of the made element. Furthermore, the invention can be directly added into the assistant agent, and then is evenly mixed, with the character of easy operation. The invention is not limited by the temperature of the assistant plating agent so that the invention can be used under room temperature.

Owner:陈冬

Plating limit device, plating equipment using same and plating method using same

InactiveCN101608328AImprove plating efficiencyImprove appearance qualitySlide fastenersEngineeringElectroplating

The invention discloses a plating limit device, plating equipment using the same and a plating method using the same. The plating limit device is used for limiting a moving zipper in a plating process and comprises a plating cathode and a tensioning mechanism, wherein the top face of the plating cathode is provided with an opening, cloth belts of the zipper runs through the opening of the plating cathode; and the tensioning mechanism is used for applying a tensile force toward the plating cathode onto the zipper to allow the bottom of zipper teeth on the cloth belts of the zipper to be pressed against and connected with two sides of the opening of the plating cathode and to be electrically connected with the plating cathode. The plating equipment using the plating limit device and the plating method using the plating limit device have the advantages of high plating quality and high plating efficiency.

Owner:FUJIAN SBS ZIPPER SCI & TECH CO LTD

Film spray no-back mixing column plate

ActiveCN101507883AAvoid backmixingIncrease mass transfer driving forceDispersed particle separationFractional distillationEngineeringPlating efficiency

The invention relates to a film spray non-back-mixing column plate, which comprises two spray covers, a column tray ring and a down-flow plate. A column plate is provided with a raise steam hole, and a down-flow pipe is formed between the down-flow plate and the column plate, wherein a position opposite to the raise steam hole of the column plate is fixedly provided with a top cover through a supporting plate. The bottoms of the spray covers and the column plate are reserved with a gap which forms a channel for liquid to enter the spray cover, and both side walls of the spray covers are provided with spray holes. The film spray non-back-mixing column plate is characterized in that the raise steam hole on the column plate is rectangular, and the part of the raise steam hole is welded with a rectangular raise steam pipe, wherein the upper end of the raise steam pipe is provided with a nozzle; the top cover, the raise steam pipe and the supporting plate form the spray covers; and the space between the two spray covers and the outside of the edges of the spray covers are provided with a liquid guide groove, wherein three surfaces of the liquid guide groove are provided with walls, and one surface of the liquid guide groove is provided with an opening which extends into the down-flow pipe. The film spray non-back-mixing column plate can prevent the liquid from back mixing, and greatly improve mass transfer driving force and the column plate efficiency.

Owner:TIANJIN CHUANGJU TECHNOLGOY +1

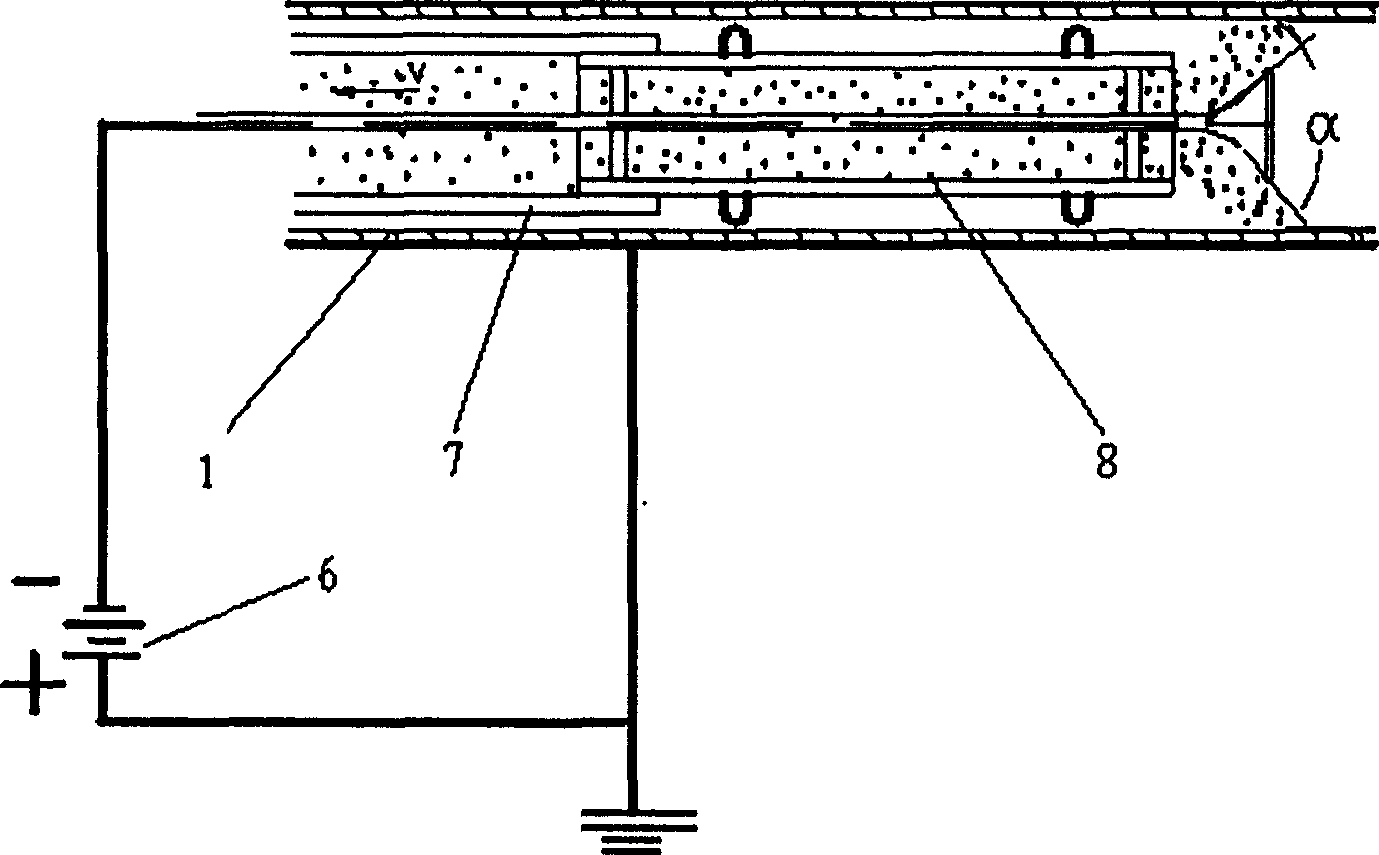

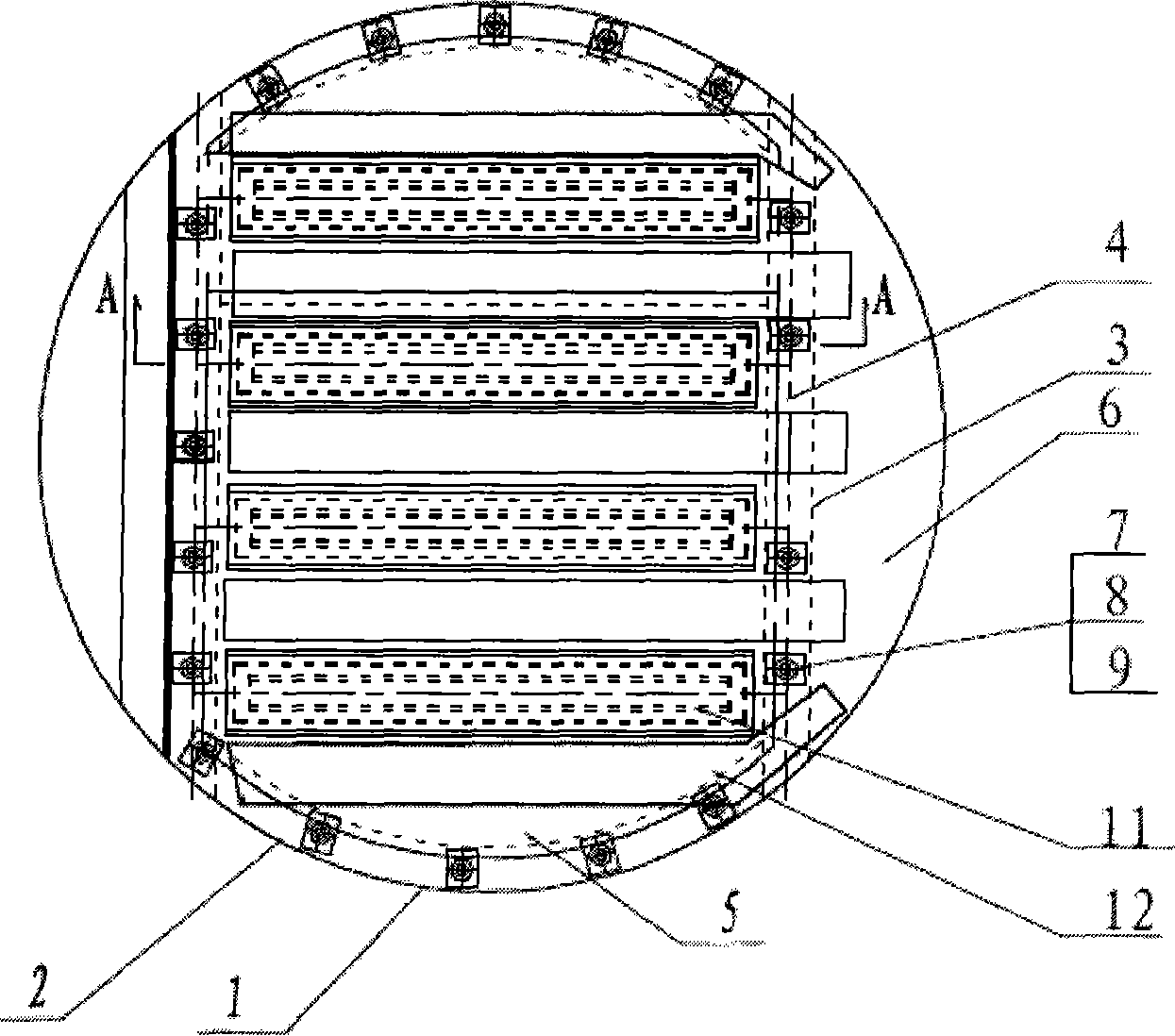

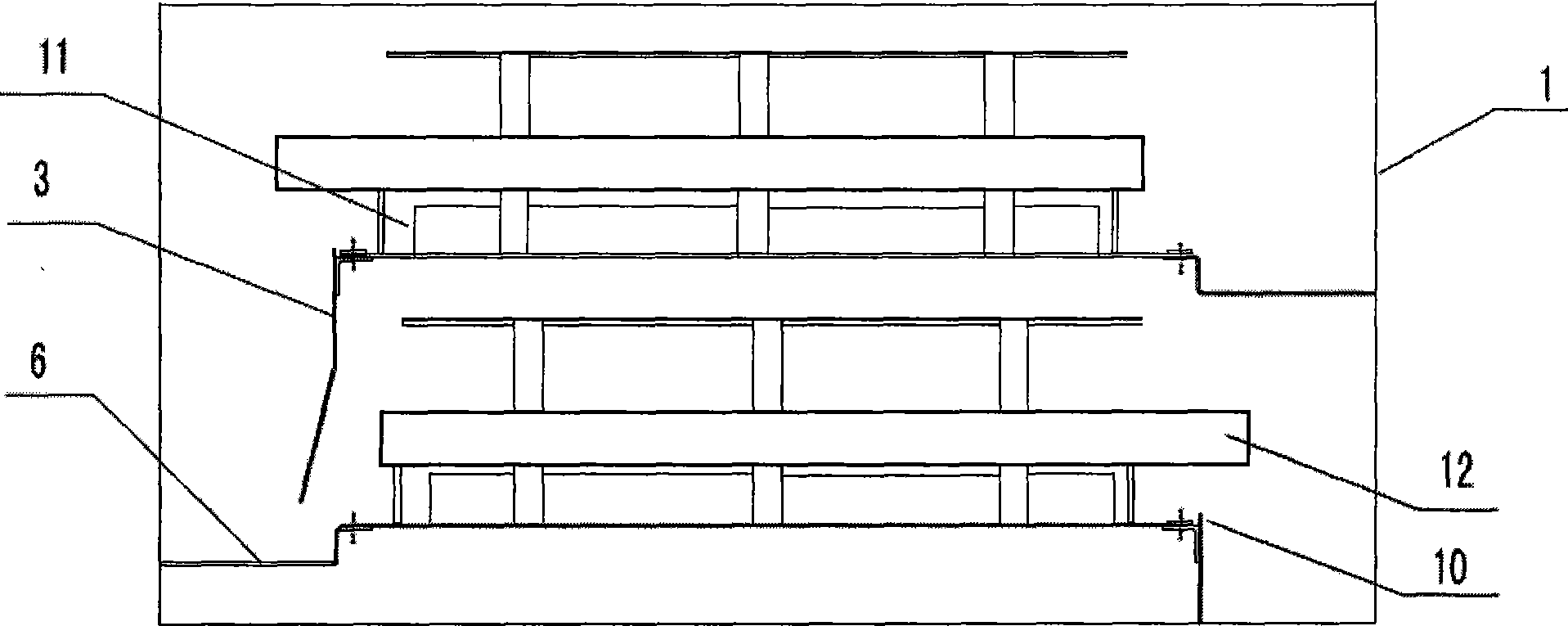

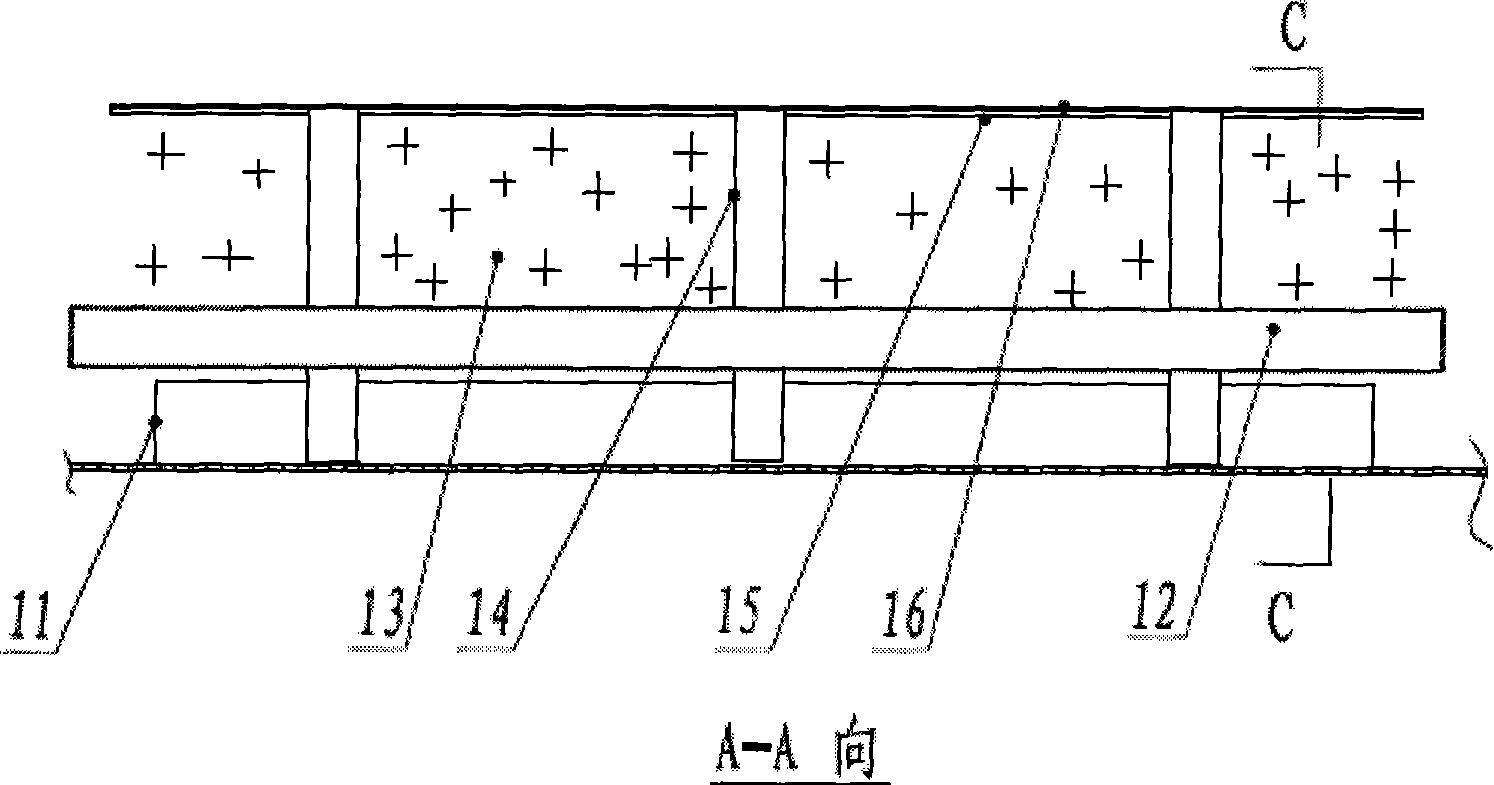

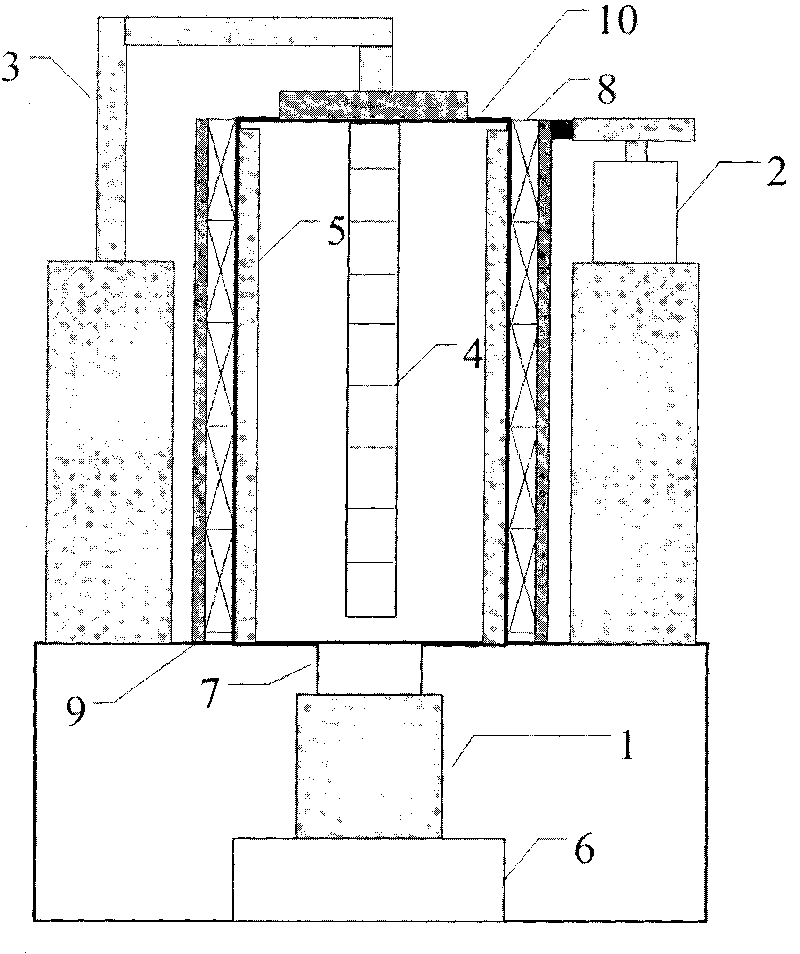

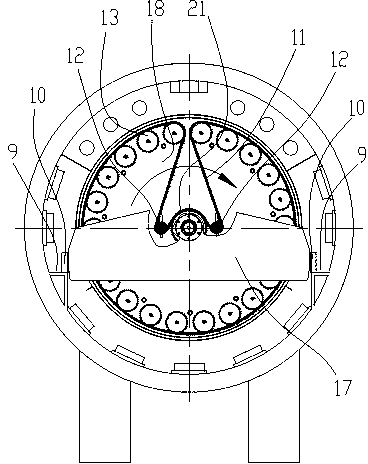

Hollow cathode electric arc ion coating plating system

InactiveCN101698934AIncrease deposition rateImprove uniformityVacuum evaporation coatingSputtering coatingVacuum chamberElectromagnetism

The invention discloses a hollow cathode electric arc ion coating plating system, comprising a vacuum chamber provided with a vacuumizing port. A cathode electric arc target and a work rest are arranged in the vacuum chamber; the vacuum chamber is isolated from earth; the inner wall of the vacuum chamber is provided with a target material which is connected with a power cathode to form a hollow cathode electric arc target; and the work rest is located in the central zone of space surrounded by the hollow cathode electric arc target. The invention is different from the common electric arc ion plating technology. The invention adopts a rotatable electromagnetism coil to produce a controlled arc magnetic field, and the rotation speed of the coil can be adjusted by adjusting the rotation speed of the motor. The invention substantially improves common electric arc ion plating technology, proposes hollow cathode electric arc ion plating technology for the first time, greatly improves the deposition efficiency of the coating and simplifies coating equipment. The invention has the characteristics of high plating efficiency, low cost, convenient operation and the like, can satisfy the requirements of industrial ultra-thick coating and has better application prospect.

Owner:WUHAN UNIV

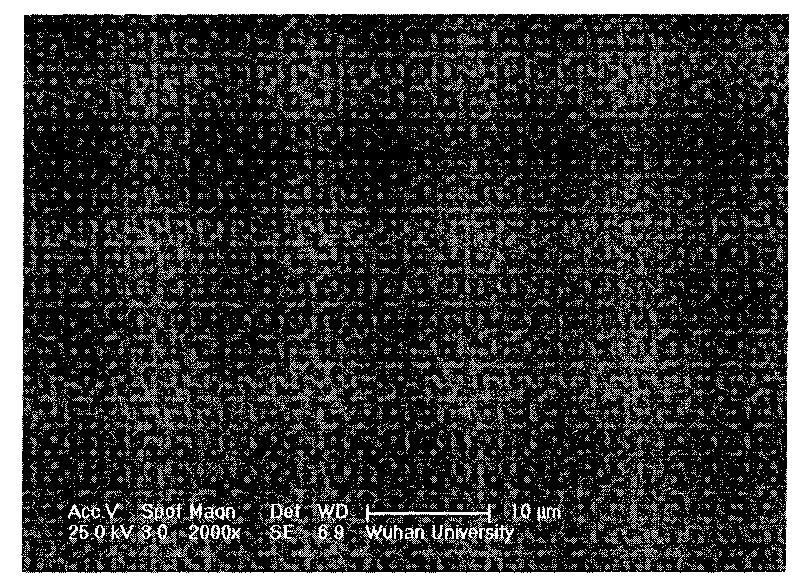

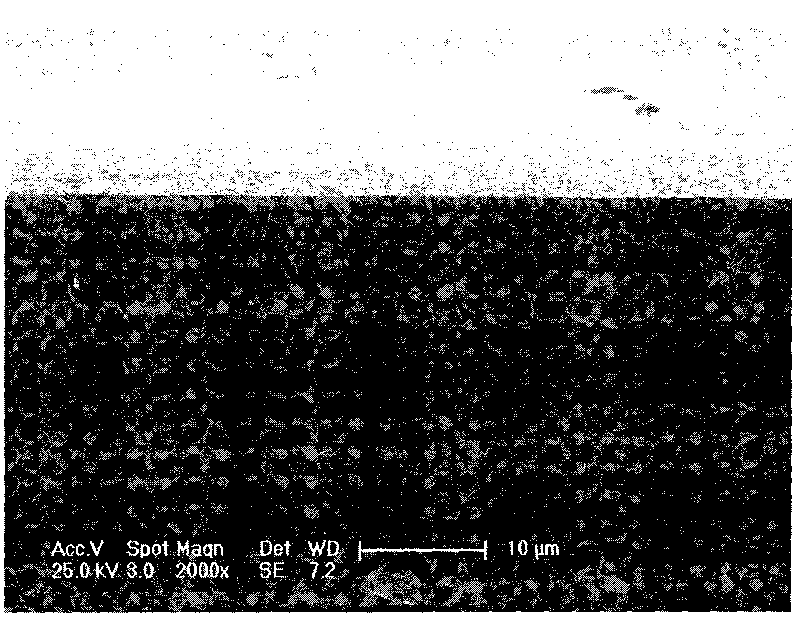

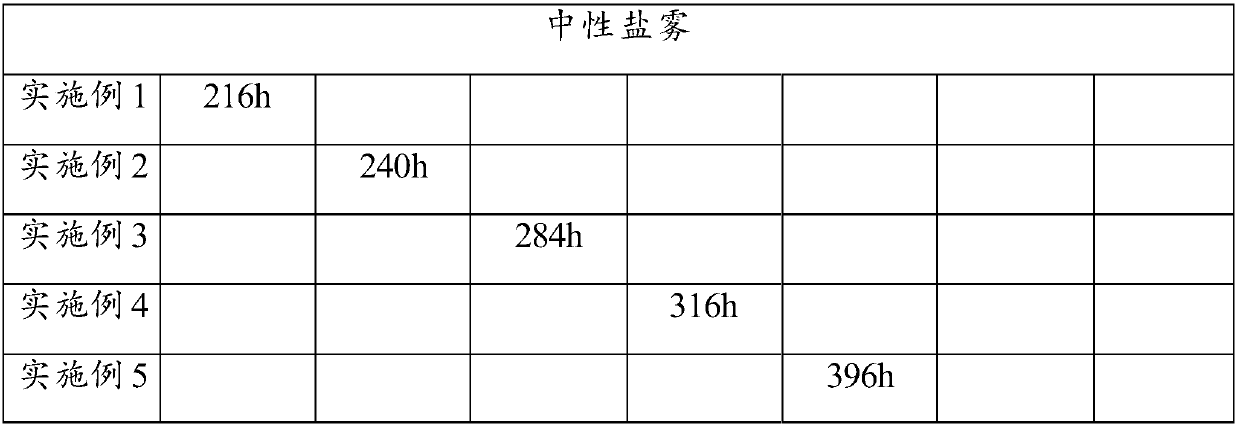

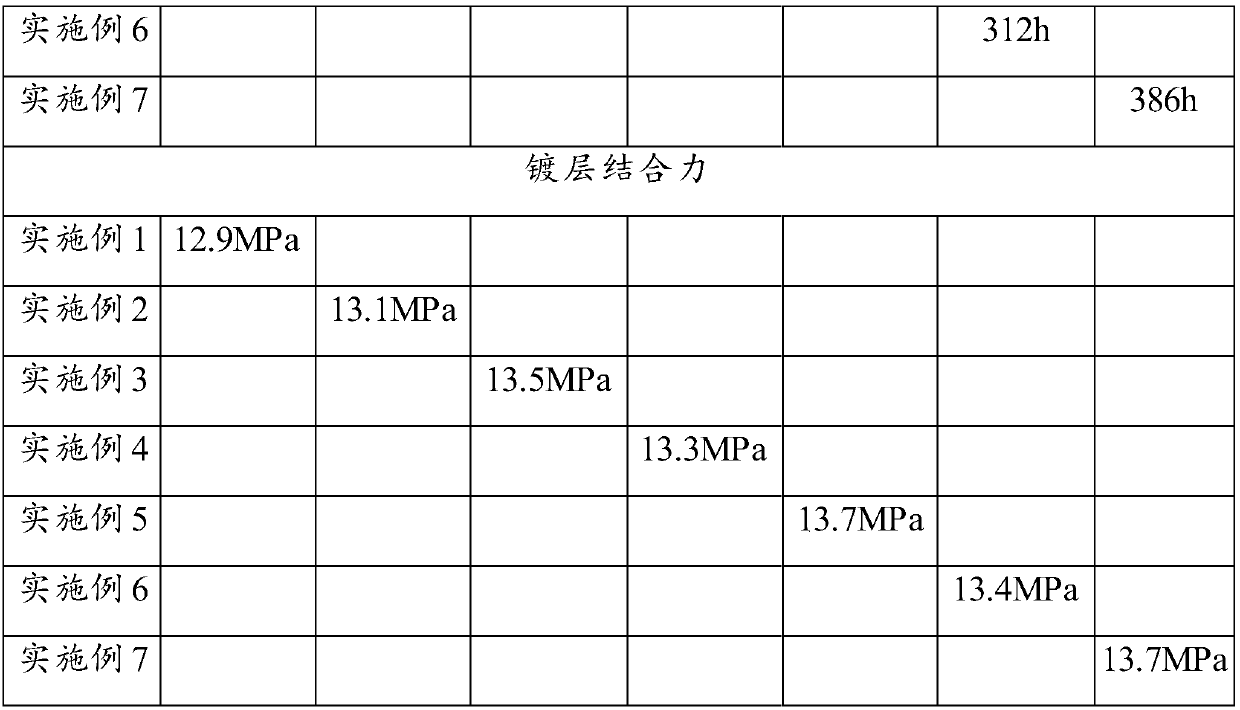

Neodymium iron boron magnet and neodymium iron boron magnet surface plating method

ActiveCN107937879AImprove corrosion resistanceGuaranteed compactnessVacuum evaporation coatingSputtering coatingSputteringMetallurgy

The invention provides a neodymium iron boron magnet with the surface plated with an anti-corrosion layer. The neodymium iron boron magnet comprises a neodymium iron boron magnet body, a multi-arc ionclad layer compounded on the surface of the neodymium iron boron magnet body, and a magnetron sputtering clad layer compounded on the surface of the multi-arc ion clad layer. The invention further provides a method for neodymium iron boron magnet surface plating. Multi-arc ion plating is only adopted in the magnet surface firstly, bottoming flattening is conducted on the magnet surface, the manner of secondary plating through magnetron sputtering is adopted, the multi-arc plating efficiency is high, good film combining and magnetron sputtering film density are effectively combined, the density of the clad layer is improved, the anti-corrosion performance of the film is improved, and the neodymium iron boron magnet with the surface plated with the anti-corrosion layer is obtained. The provided method for neodymium iron boron magnet surface plating, the technology is simple, and the method is suitable for large-scale industry production.

Owner:金力永磁(宁波)科技有限公司

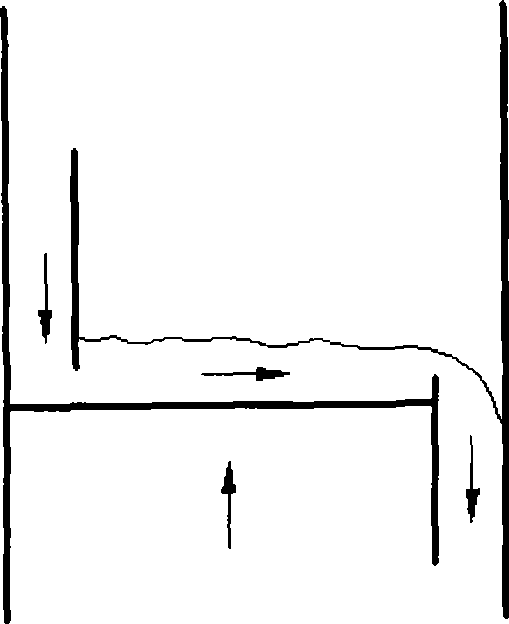

Float valve fixing column plate

A fixed float valve plate, comprising orifice valve and valve block, the valve block is a quadrangle similar to diamond with macro-diagonal line as bilateral symmetry, the separation angle of the long line points to the overflow dam, the length of the valve block long line a is 10-80 mm, the width of the valve block b is 8-60 mm, the width of the valve leg c is 4-20 mm, the length of the valve block d is 15-90 mm, the height of the valve leg h is 3-8 mm, the length of the valve pore I is 15-100 mm, the valve leg connects the valve block with the valve plate. The fixed float valve plate in this invention can push the liquid to the overflow dam to decrease the liquid level drop height, and eliminate the convolution and back-mix-flow effectively, thus increase the valve plate efficiency. The side edge of broken line similar to diamond is longer than that of rectangular straight line and circular arcuate path, which makes the outlet of air passage be larger, and increase the pass amount effectively and the contacting area of the gas-liquid mass transfer, which can not only increase the transferring efficiency but the pore speed of the gas decreases under the same treating amount, thus decreasing the valve plate resistance force.

Owner:NANJING UNIV

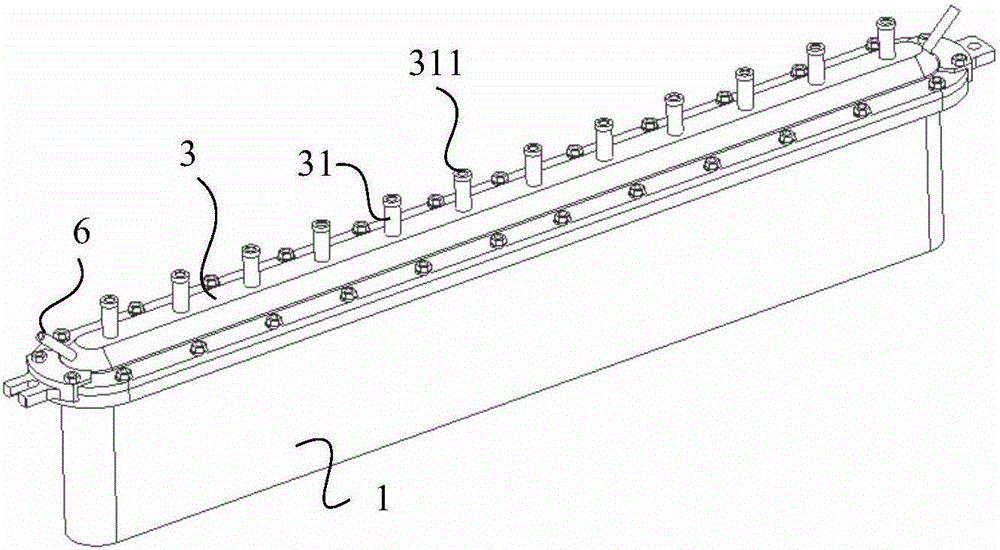

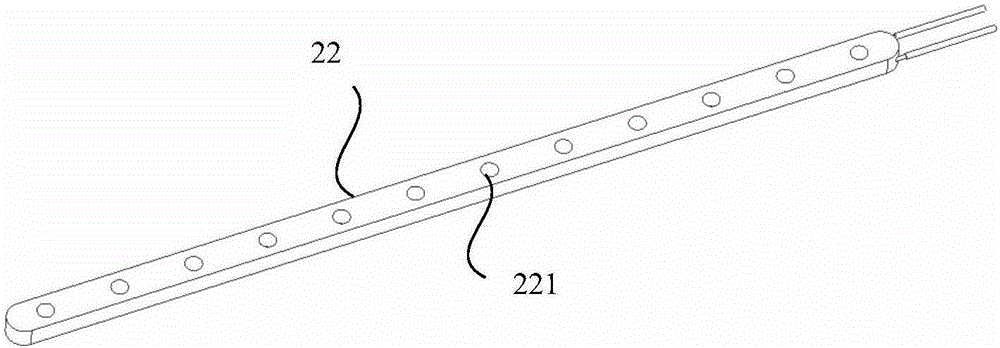

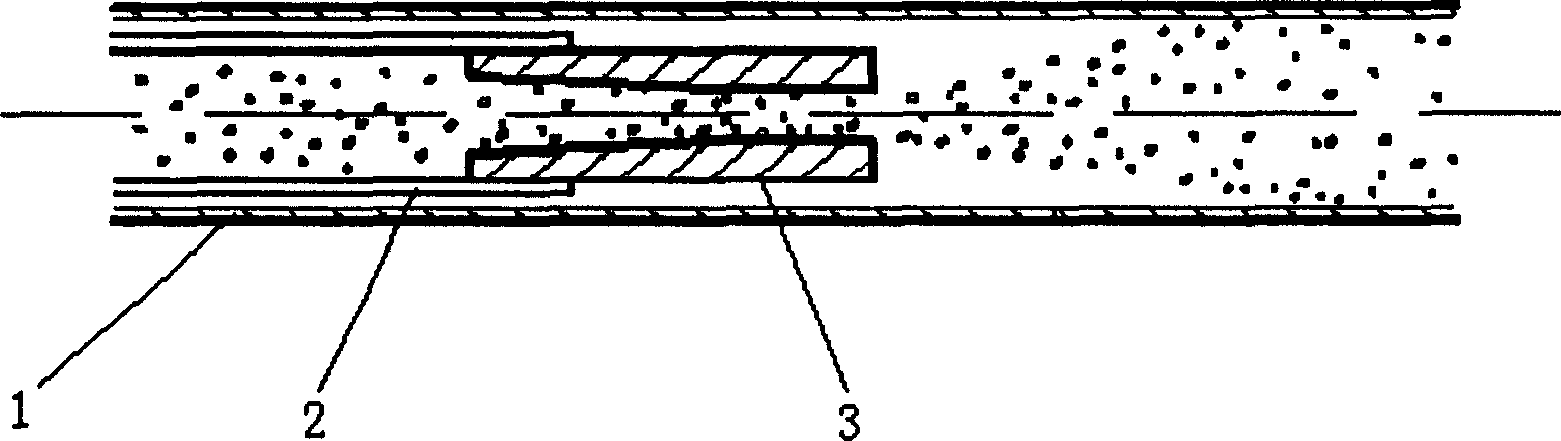

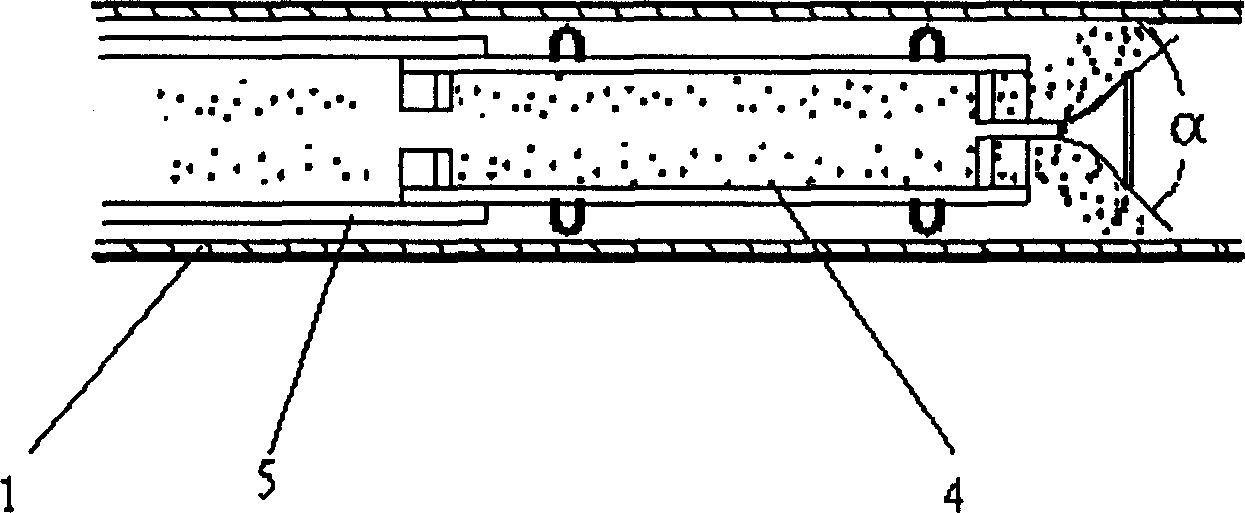

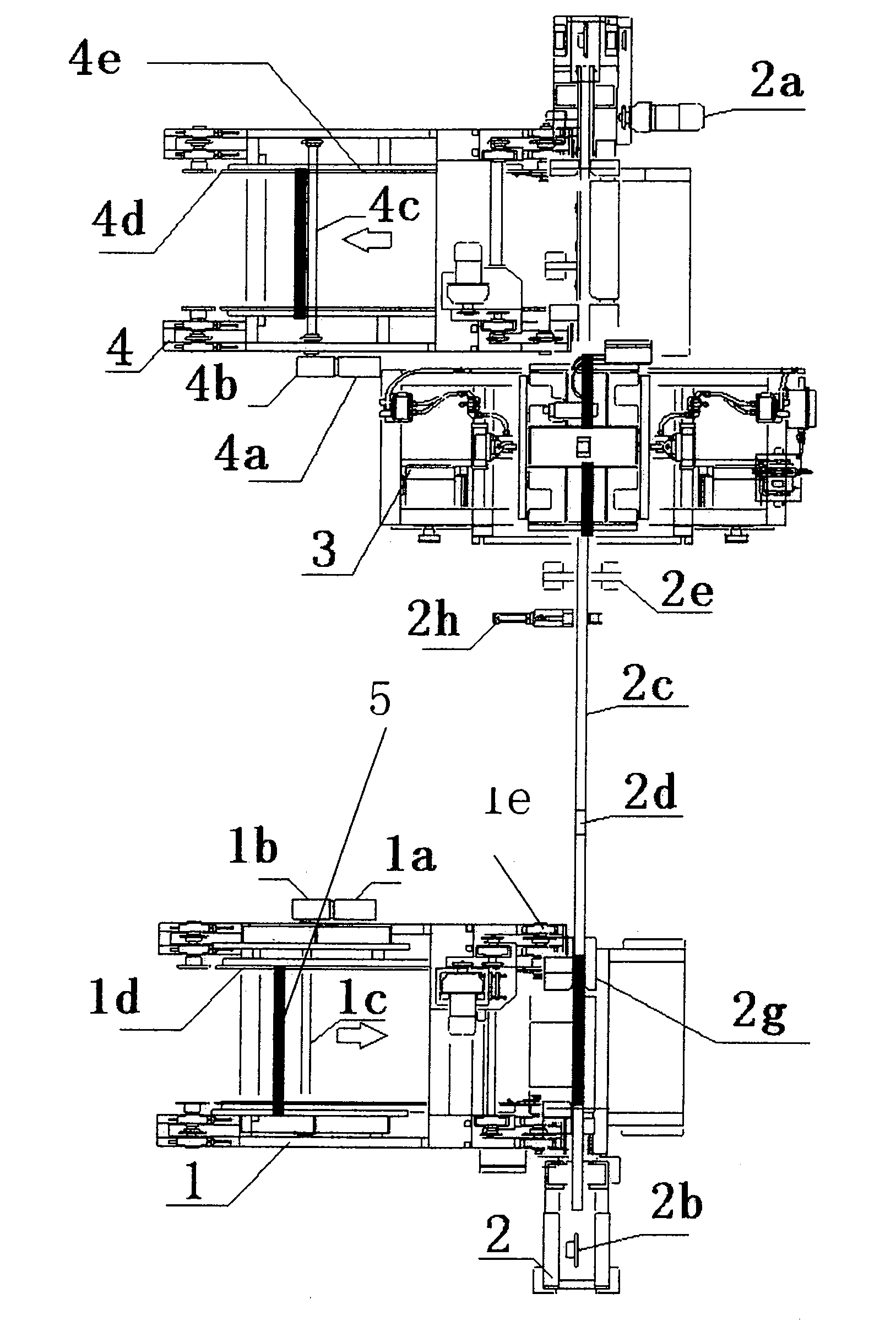

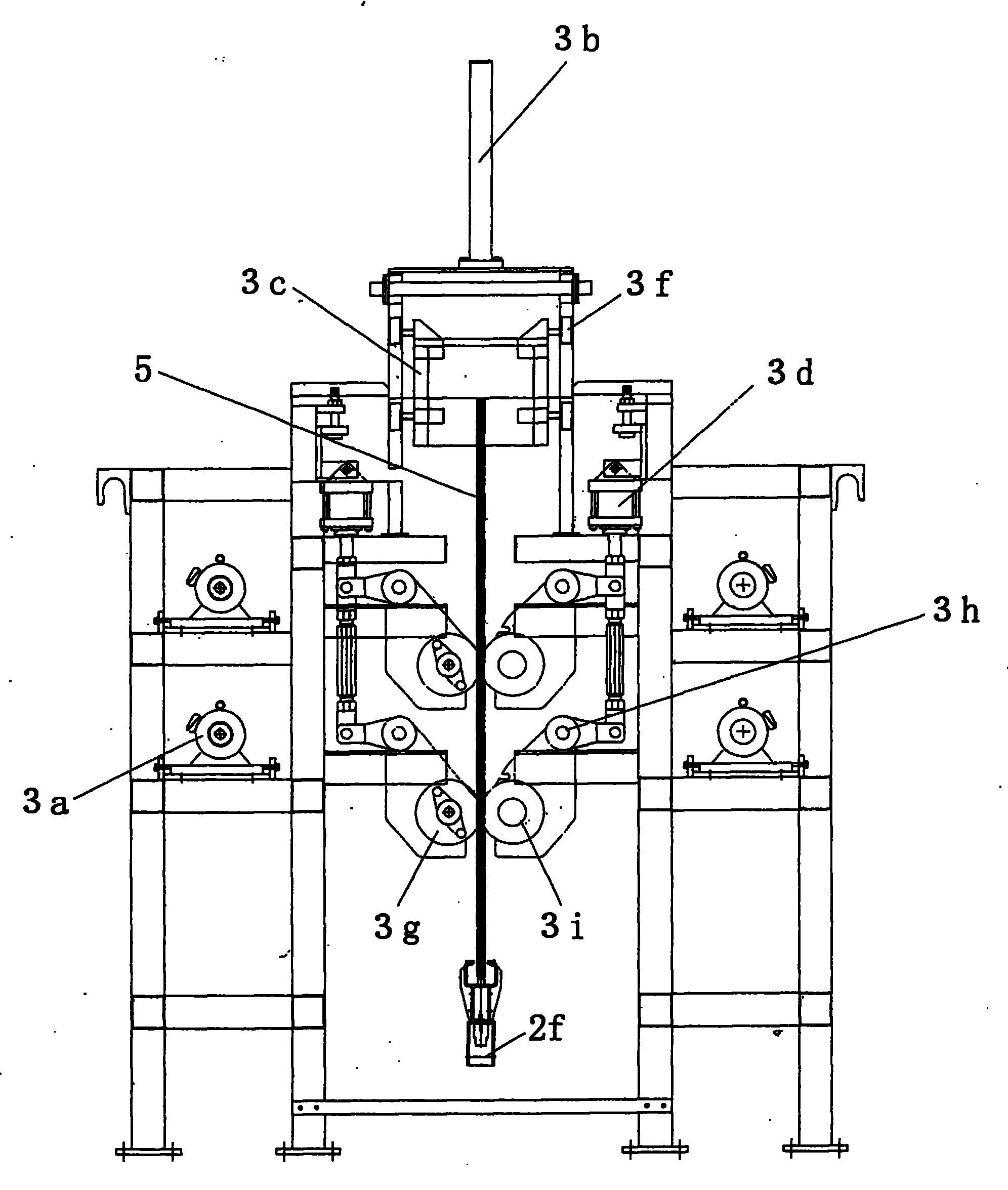

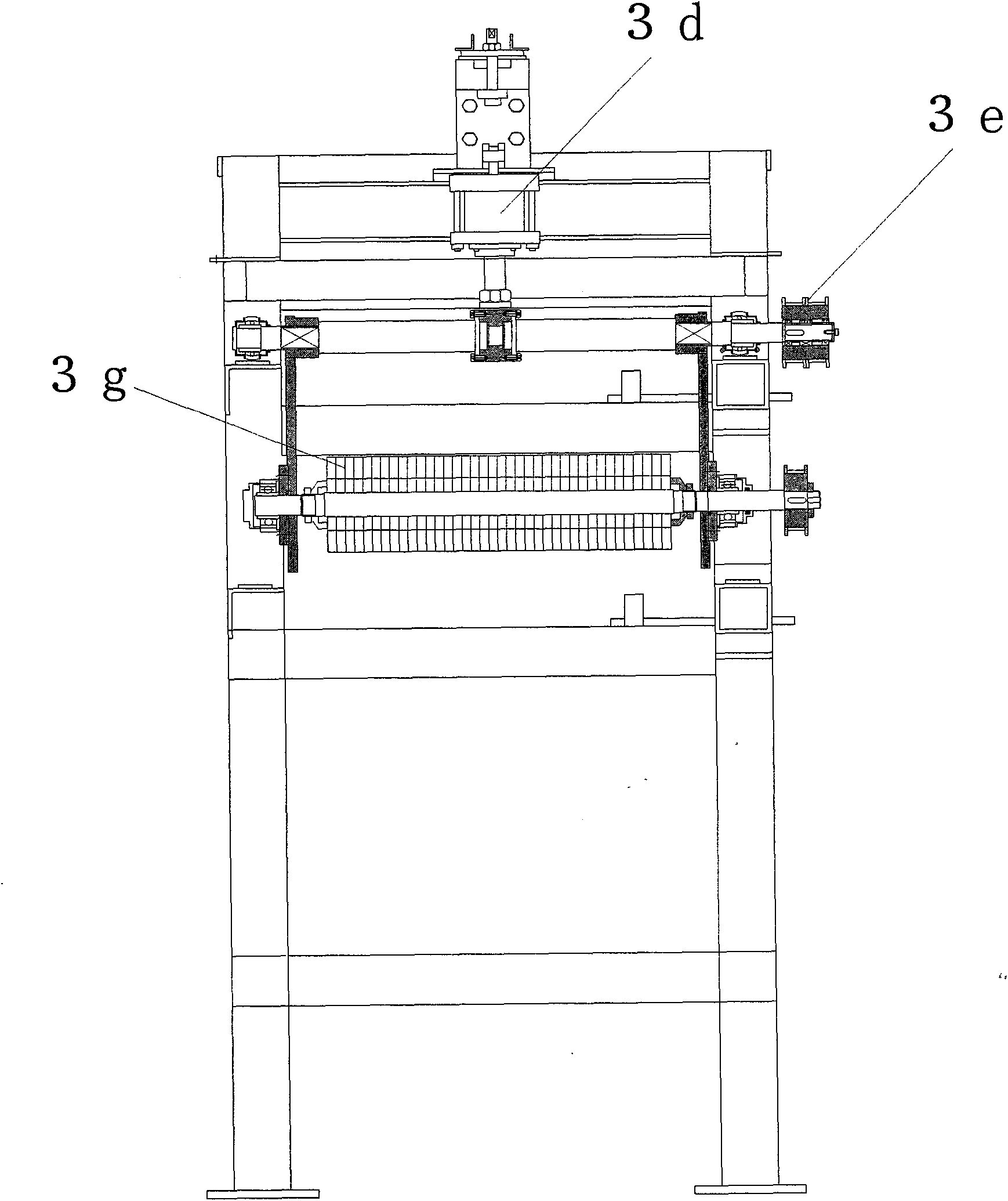

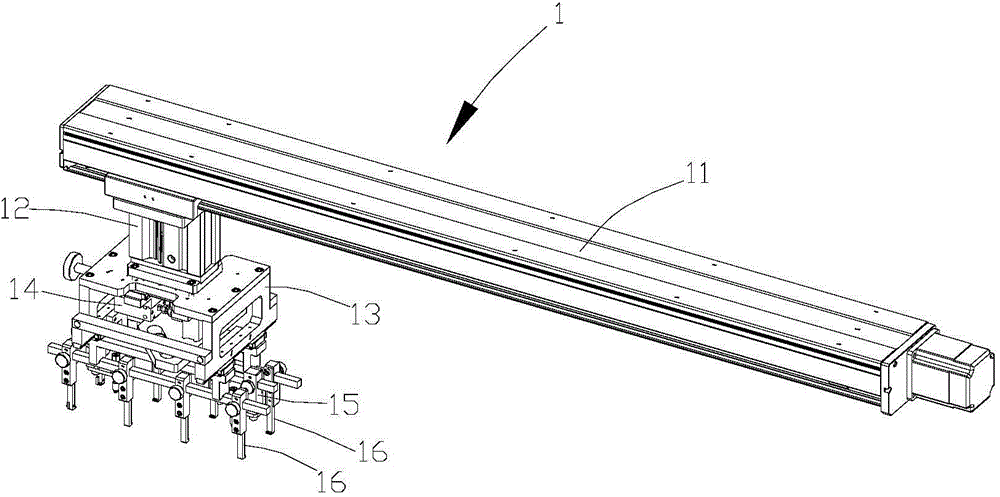

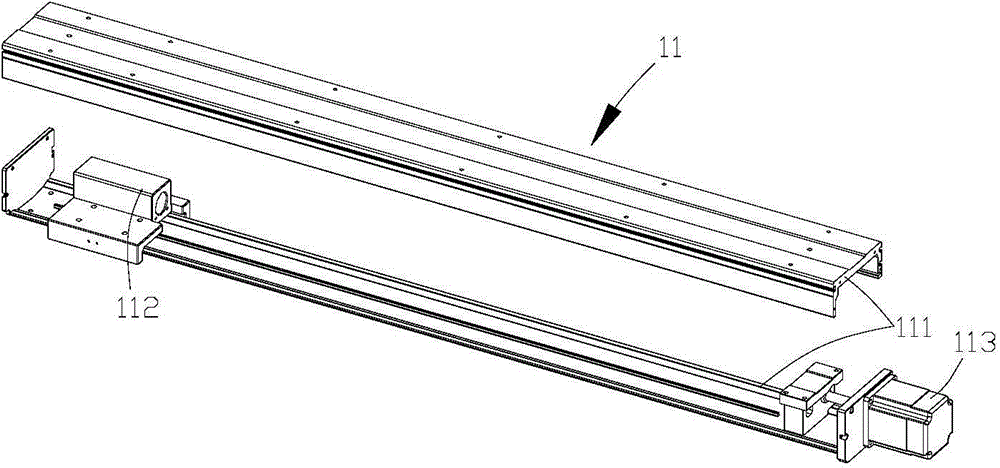

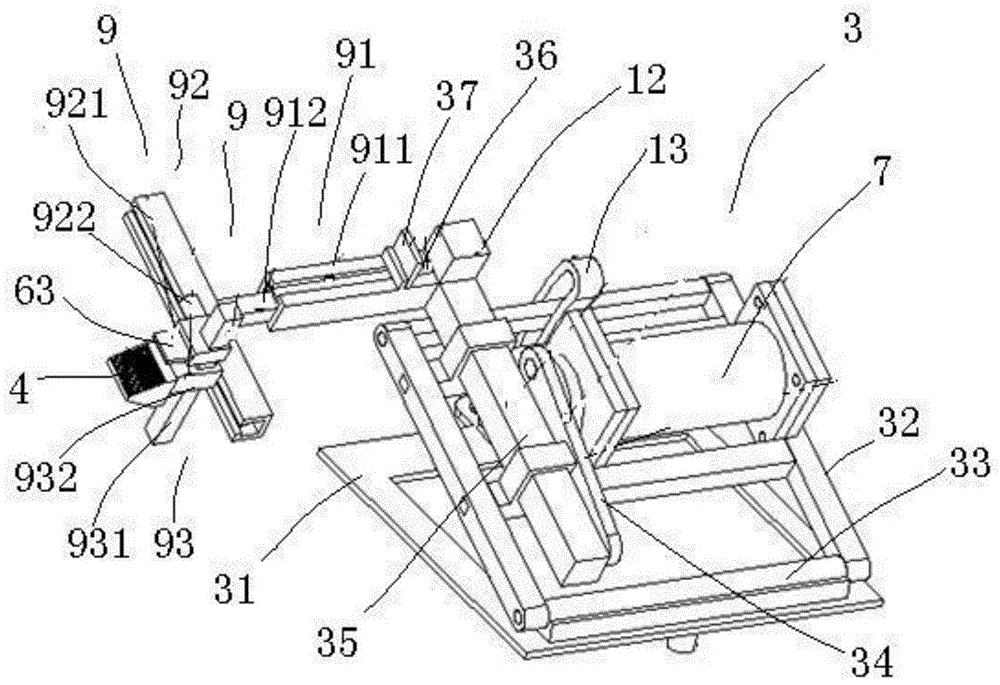

Automatic brush plate machine of zinc electrolysis cathode plate

The invention discloses an automatic brush plate machine of a zinc electrolysis cathode plate, comprising an intaking-plate distance-arranging device (1) and a chain transmission device (2) which are sequentially arranged, a roller brush-plate device (3) and an unloading plate release device (4) which are sequentially arranged along a transmission chain (2d) of the chain transmission device (2), wherein, the roller brush-plate device (3) is located above the chain transmission device (2). The invention can continuously clean a plurality of cathode plates, and has advantages of simple operation, high brush-plate efficiency, and reliable working.

Owner:YUNNAN CHIHONG ZINC & GERMANIUM

Methods for culture and production of single cell populations of human embryonic stem cells

We used Accutase™, a commercially available cell detachment solution, for single cell propagation of pluripotent hESCs. Unlike trypsin dissociation, Accutase treatment does not significantly affect the plating efficiency of hESC dissociation into single cells. Cultures dissociated with Accutase to single cells at each passage maintain a higher proportion of pluripotent cells as compared to collagenase-passaged hESCs. Accutase-treated hESCs can be grown to a high density as monolayers, and yet retain their pluripotency.

Owner:BURNHAM INST FOR MEDICAL RES

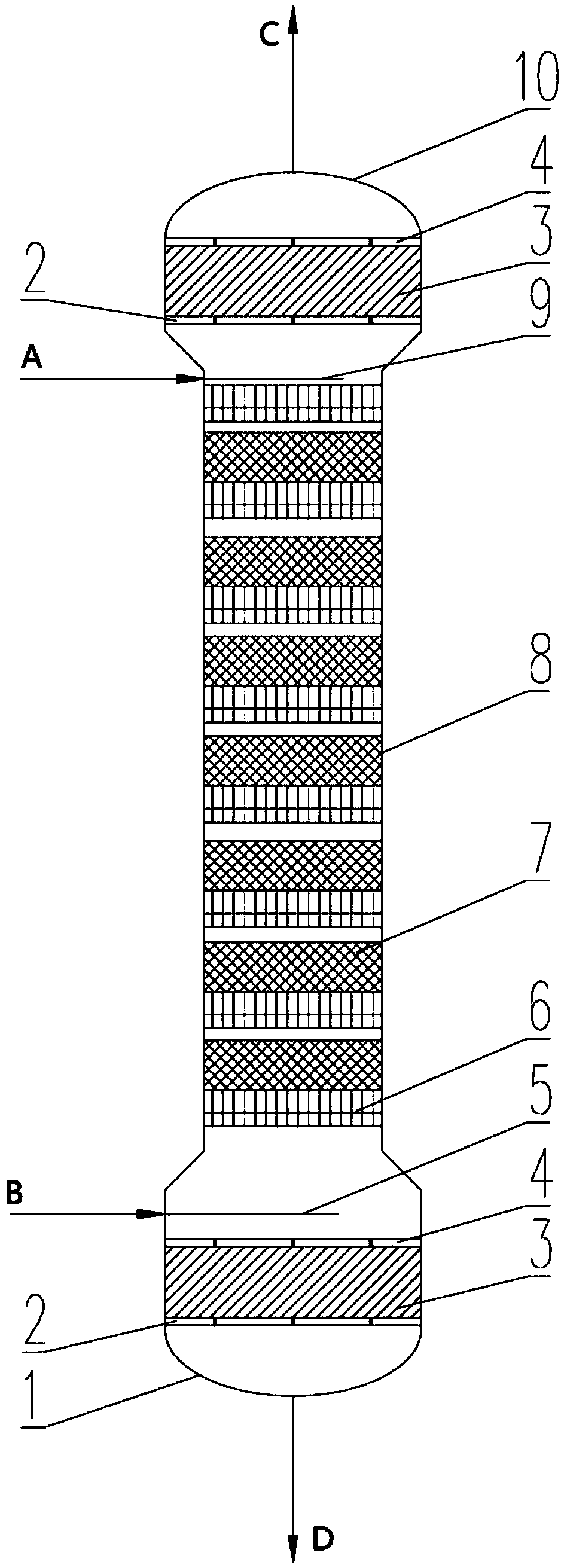

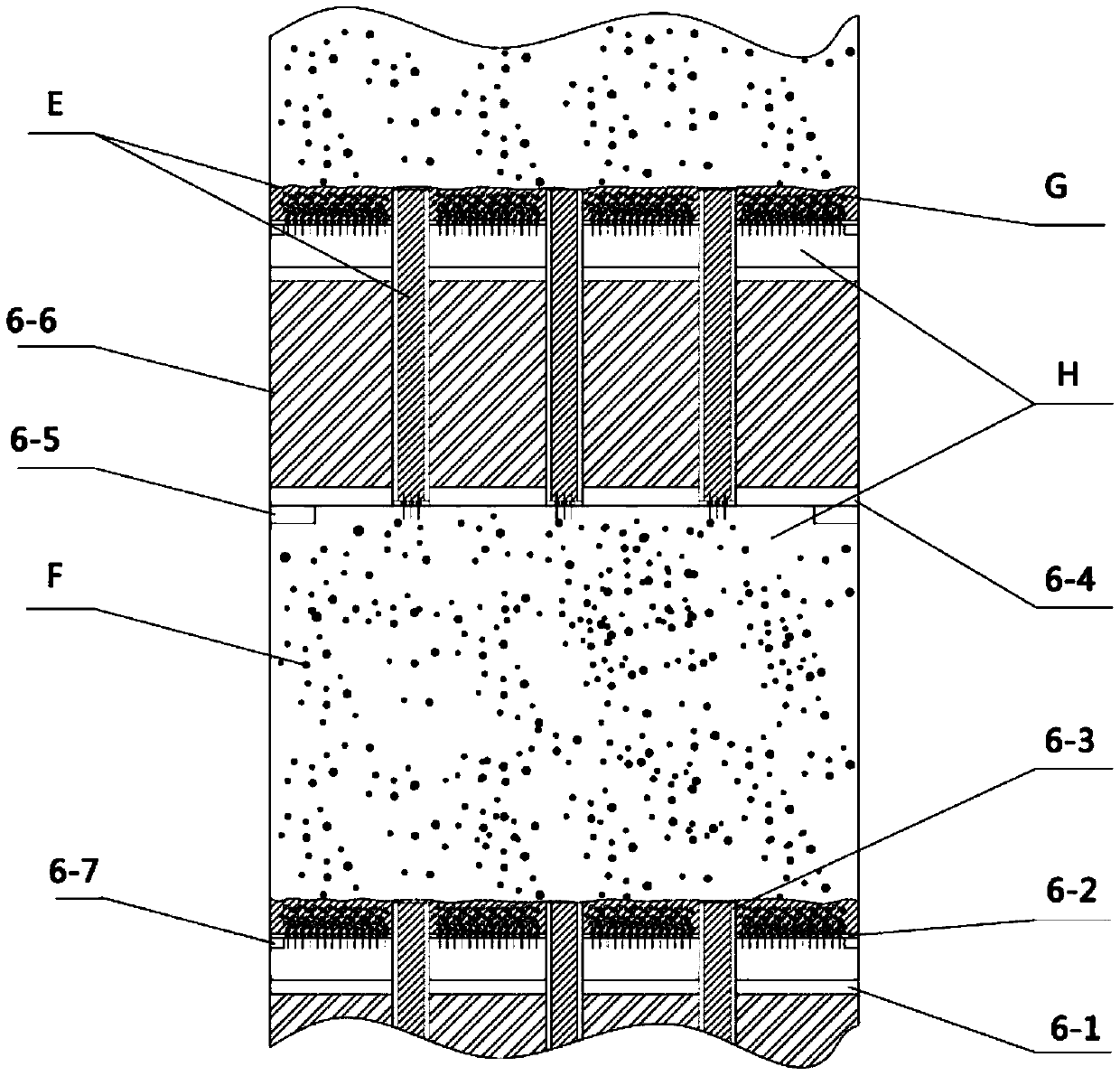

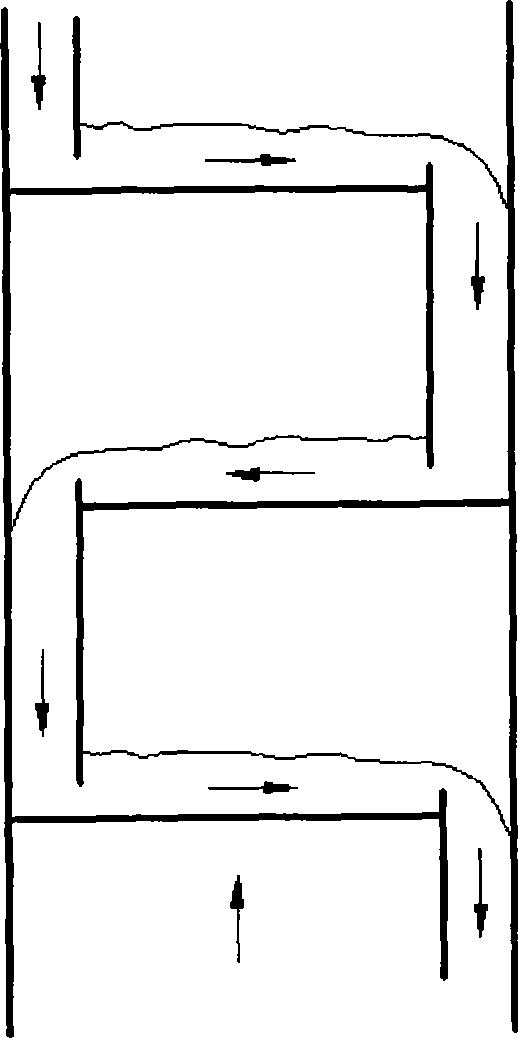

Extracting tower for liquid-liquid heterogeneous separation

ActiveCN105498284AAchieving bi-dispersionImprove extraction and separation tray efficiencyLiquid solutions solvent extractionEngineeringTower

An extracting tower for liquid-liquid heterogeneous separation comprises an extracting tower bottom separating chamber, an extracting tower top separating chamber, a tower body, a heavy phase feeding distributor and a light phase feeding distributor, wherein the extracting tower bottom separating chamber is connected with the bottom end of the tower body, the extracting tower top separating chamber is connected with the top end of the tower body, the heavy phase feeding distributor is mounted at the top of the tower body, the light phase feeding distributor is mounted at the bottom of the tower body, an extracting tower disk is distributed in the tower body and comprises a connecting rib plate, an upper distribution disk and a liquid lowering structure, the connecting rib plate is mounted on a support on the inner side of the tower body, the upper distribution disk is mounted above the connecting rib plate through a tower ring, the upper distribution disk, the connecting rib plate and the tower body define a space, and the liquid lowering structure is mounted on the connecting rib plate and the upper distribution disk in a through manner. The extracting tower has the benefits as follows: dual-dispersion of a light phase and a heavy phase is realized, advantages of a pulsed packed tower and a sieve-plate tower are combined, the extracting separation tower plate efficiency is greatly improved, and the tower height is reduced, so that the equipment investment and the civil engineering cost are reduced.

Owner:CHINA TIANCHEN ENG +2

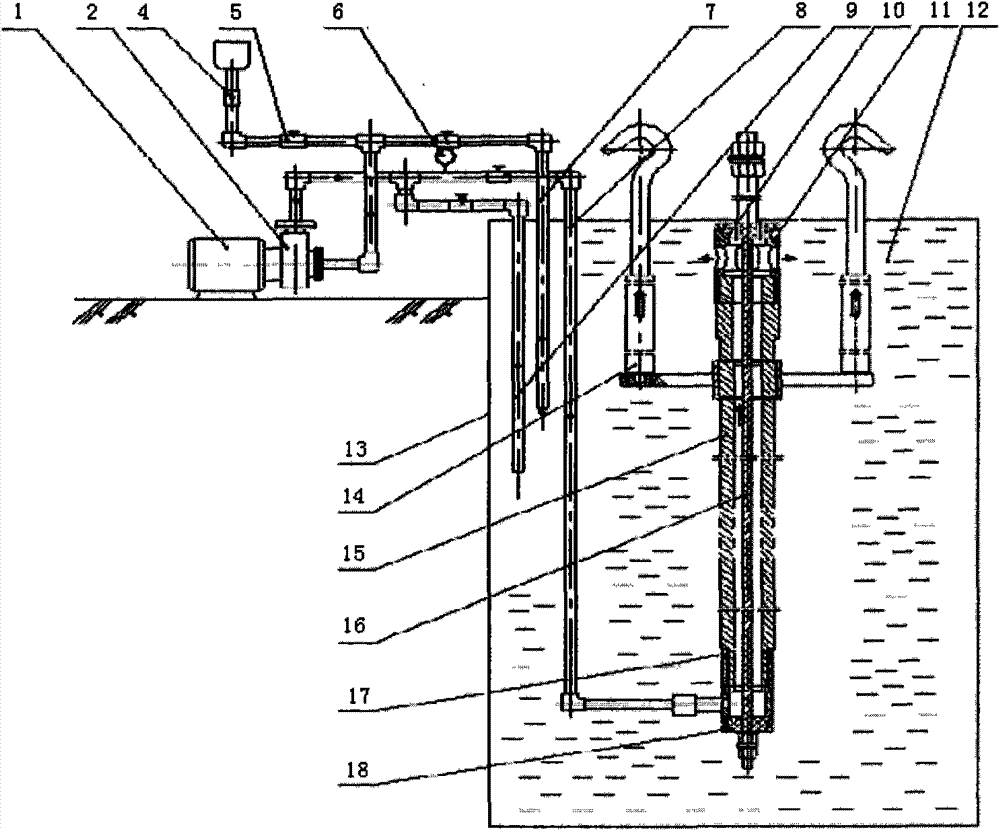

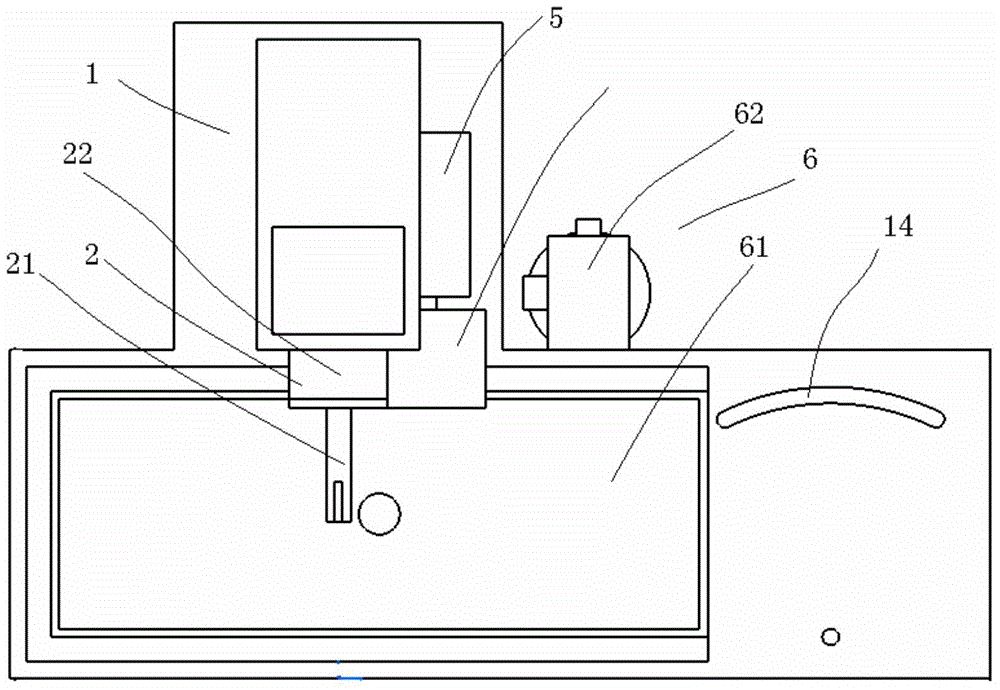

Liquid plating device for inner hole of slender pipe fitting

The invention belongs to the technical field of electroplating and relates to a liquid plating device for an inner hole of a slender pipe fitting. The liquid plating device is characterized in that an upper cap and a lower cap are respectively in threaded connection with the upper and lower ends of the slender pipe fitting, wherein an upper insulating plate is inserted into a step table at the upper end of the upper cap, and a lower insulating plate is inserted into a step table at the lower end of the lower cap; an anode plate simultaneously penetrates through the upper insulating plate and the lower insulating plate, and a nut is in threaded connection with the lower end of the anode plate; the upper end of the anode plate is connected to the anode of a power supply through a nut lead-out lead; a cathode suspension frame is fixed at the outer wall of the slender pipe fitting, and hangers of the cathode hanging frame are connected with the cathode of the power supply and are used for hanging the slender pipe fitting in a liquid plating box; a rotating shaft of a pump body is driven by a motor, an output port of the pump body is communicated with a plating trough liquid inlet of the lower cap through a plating trough liquid inlet pipeline, and an input port of the pump body is communicated with the part below the liquid surface of the liquid plating box through a liquid return pipeline. According to the liquid plating device, the circulation of the plating liquid in the inner hole of the slender pipe fitting can be accelerated, the deposition velocity of a plating layer can be improved, the liquid plating efficiency can be increased, the liquid plating workload can be reduced, and the production cost can be lowered.

Owner:SHANXI NORTH MACHINE BUILDING

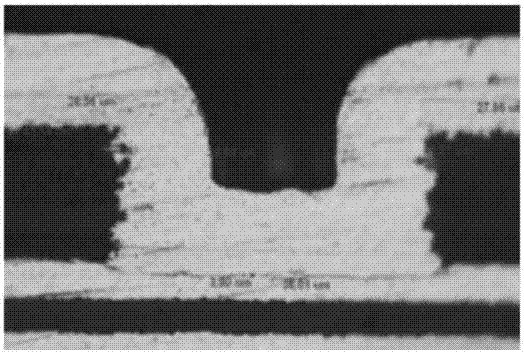

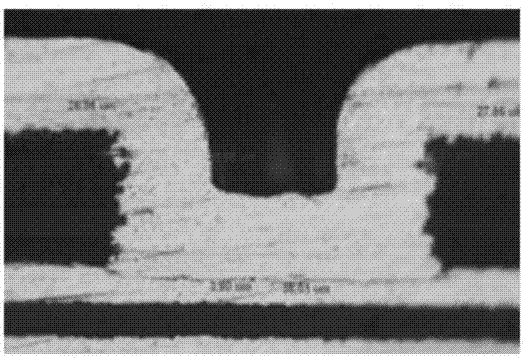

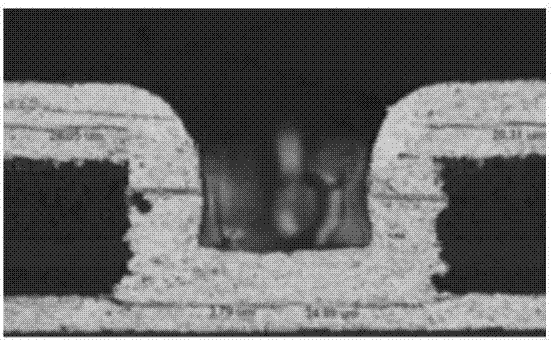

Electroplate liquid for jointly plating through hole and blind hole and electroplating method

InactiveCN107313081AImprove ductilityImprove reliabilityPrinted element electric connection formationSulfonateCopper

The invention provides a co-plating electroplating solution and an electroplating method for through-blind holes. In the through-blind hole co-plating electroplating solution of the present invention, the electroplating solution comprises A-D components, wherein the A component is anhydrous copper sulfate; the B component is sulfuric acid; the C component is chlorine compound; the D component is selected from sodium polydithiodipropanesulfonate, sodium 3-mercaptopropanesulfonate, sodium N,N-dimethyldithiocarbonylpropanesulfonate, internal salt of isothioureapropanesulfonate and 3-(benzothiazole-2-mercapto)-sodium propanesulfonate or a mixture of at least two of them. The total organic carbon content of the through-blind hole co-plating electroplating solution of the present invention is low, the ductility and thermal shock reliability of electroplated copper are high, the electroplating time is short, the process is simple, the electroplating efficiency is high, and the through hole and blind hole are effectively improved. plating reliability.

Owner:SUZHOU TIANCHENG CHEM

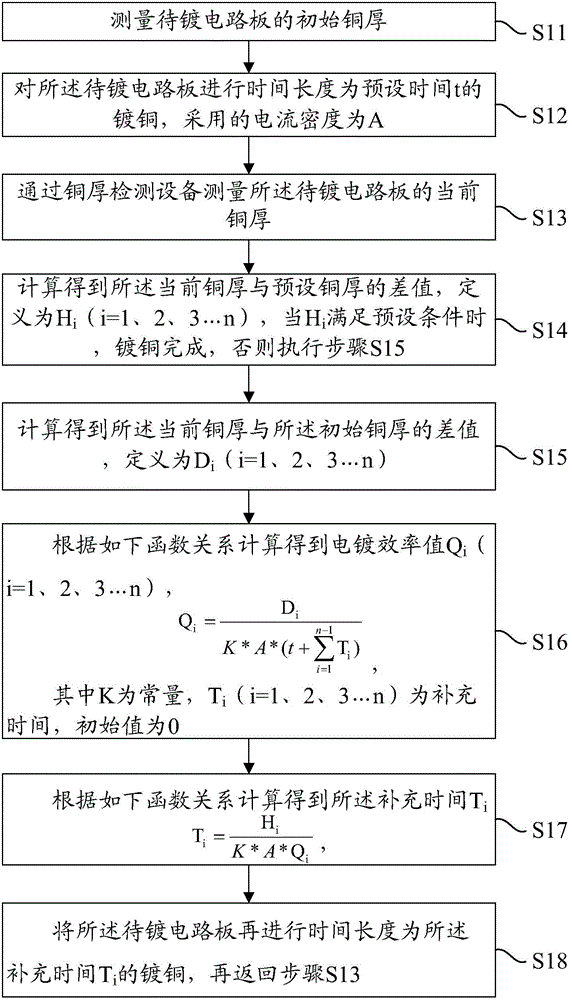

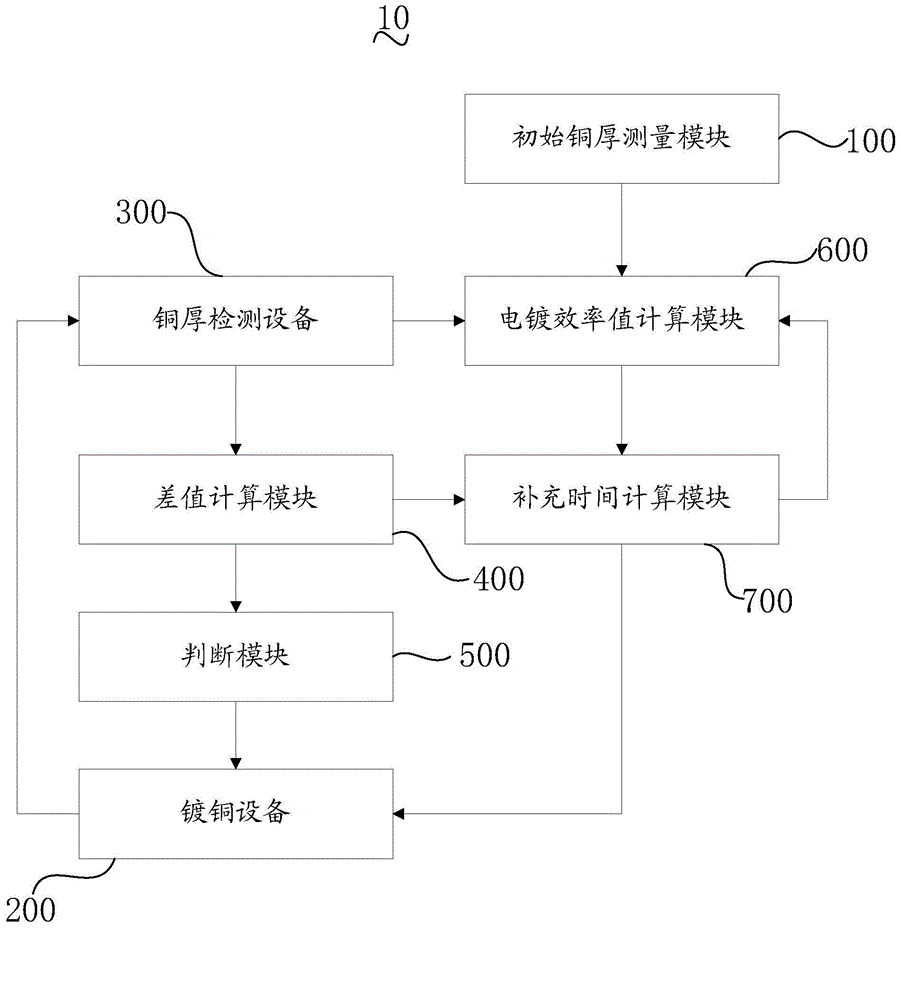

Delay compensation method and system of copper plating thickness

The invention discloses a delay compensation method and system of copper plating thickness, wherein the method comprises the following steps: measuring the initial copper thickness of a circuit board to be plated; plating copper on the circuit board to be plated for preset time t; measuring the current copper thickness of the circuit board to be plated by copper thickness detection equipment; calculating a difference value Hi between the current copper thickness and the preset copper thickness, finishing plating copper when Hi meets preset conditions, or else, continuing to compensate copper plating for time Ti; calculating a difference value Di between the current copper thickness and the initial copper thickness; calculating a plating efficiency value Qi; calculating the compensation time Ti; plating copper on the circuit board to be plated for the compensation time Ti. According to the delay compensation method of copper plating thickness, the compensation time Ti is calculated by modifying and calculating the plating efficiency value Qi, and the copper plating is performed on the circuit board to be plated for the compensation time Ti, so that the thickness of a copper plated layer is more accurate and controllable.

Owner:HUIZHOU TECHUANG ELECTRONIC TECH CO LTD

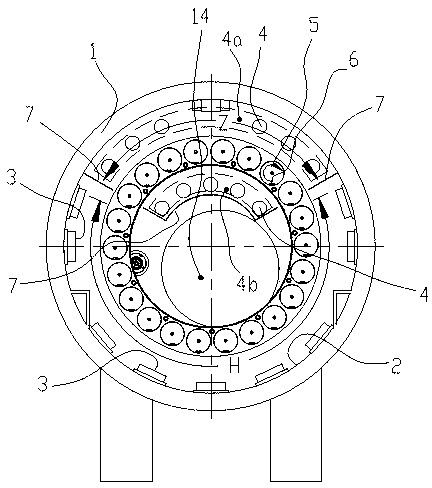

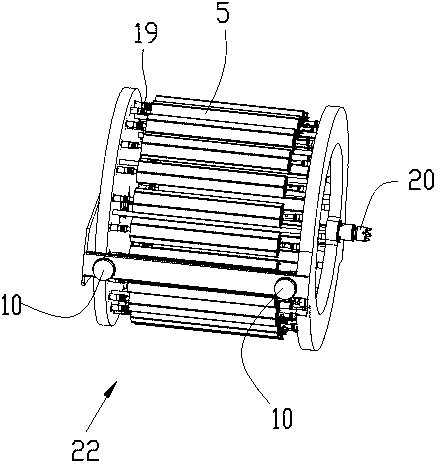

Horizontal type multi-target vacuum sputtering or ion plating machine

ActiveCN103290373AEasy accessFast feedingVacuum evaporation coatingSputtering coatingSputteringEngineering

A horizontal type multi-target vacuum sputtering or ion plating machine comprises a plating machine furnace body, a transmission output component in the plating machine, arc-shaped targets, sputtering targets, a vacuum pump-out slot and a workpiece rack, wherein the interior of the plating machine furnace body is divided into two areas, a plurality of arc-shaped targets are distributed in the area I and arranged below the plating machine furnace body and close to the inner wall of the plating machine furnace body, a plurality of sputtering targets are distributed in the area II and arranged above in the inner cavity of the plating machine furnace body at a hollow position of the corresponding workpiece rack above the center of the plating machine furnace body, a rotating part for placing workpieces and a power input mechanism are arranged on the workpiece rack, when the workpiece rack enters the plating machine furnace body, the rotating part can pass through between the arc-shaped targets and the sputtering targets, the power input mechanism of the workpiece rack and the transmission output component in the plating machine are coupled so as to drive the rotating part to rotate, and the vacuum pump-out slot is arranged at the center or close to the center of the plating machine furnace body. According to the horizontal type multi-target vacuum sputtering or ion plating machine, the mutual pollution of the arc-shaped targets and the sputtering targets can be effectively prevented, and the plating efficiency and the plating quality can be improved.

Owner:宁波韵升装备技术有限公司 +2

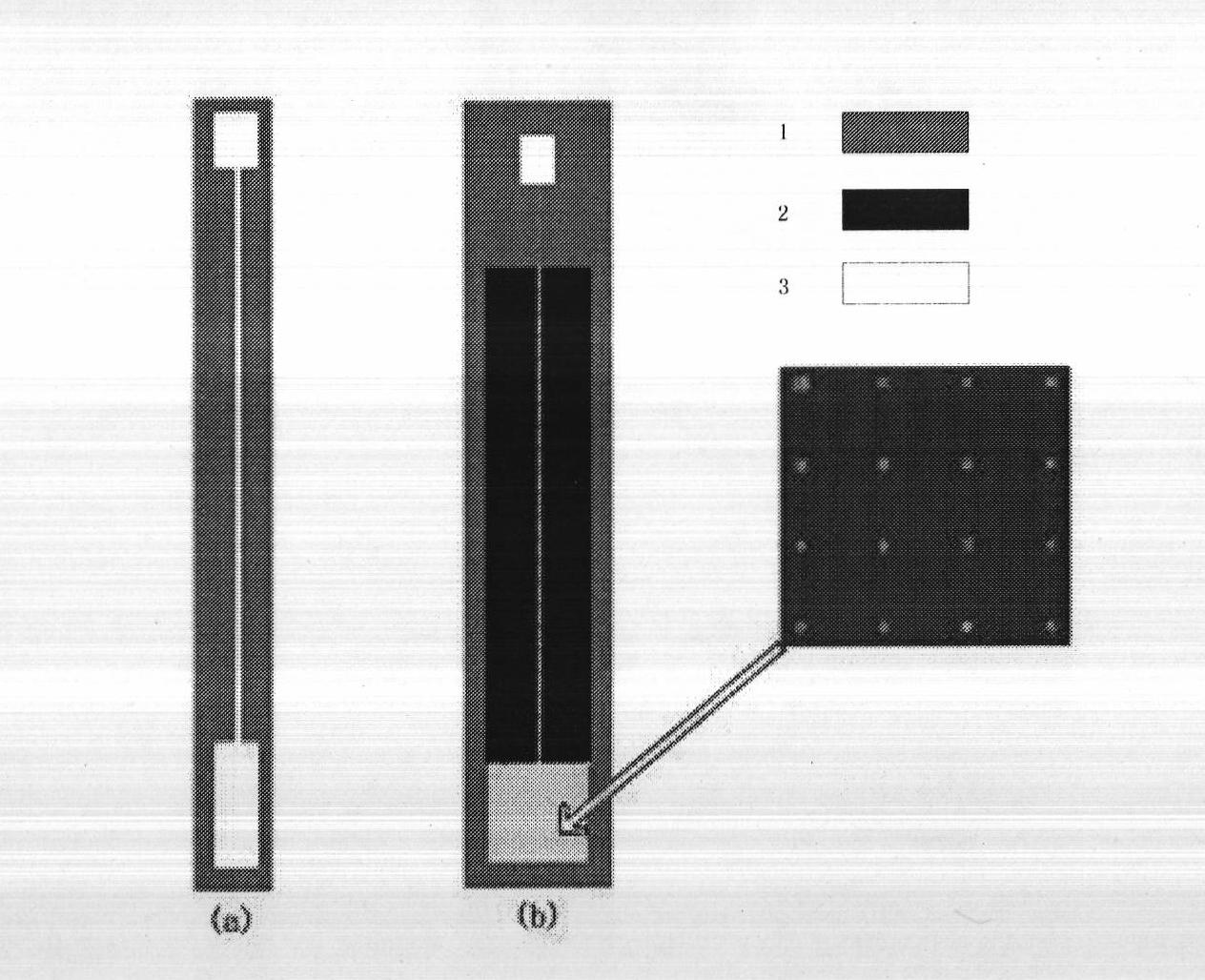

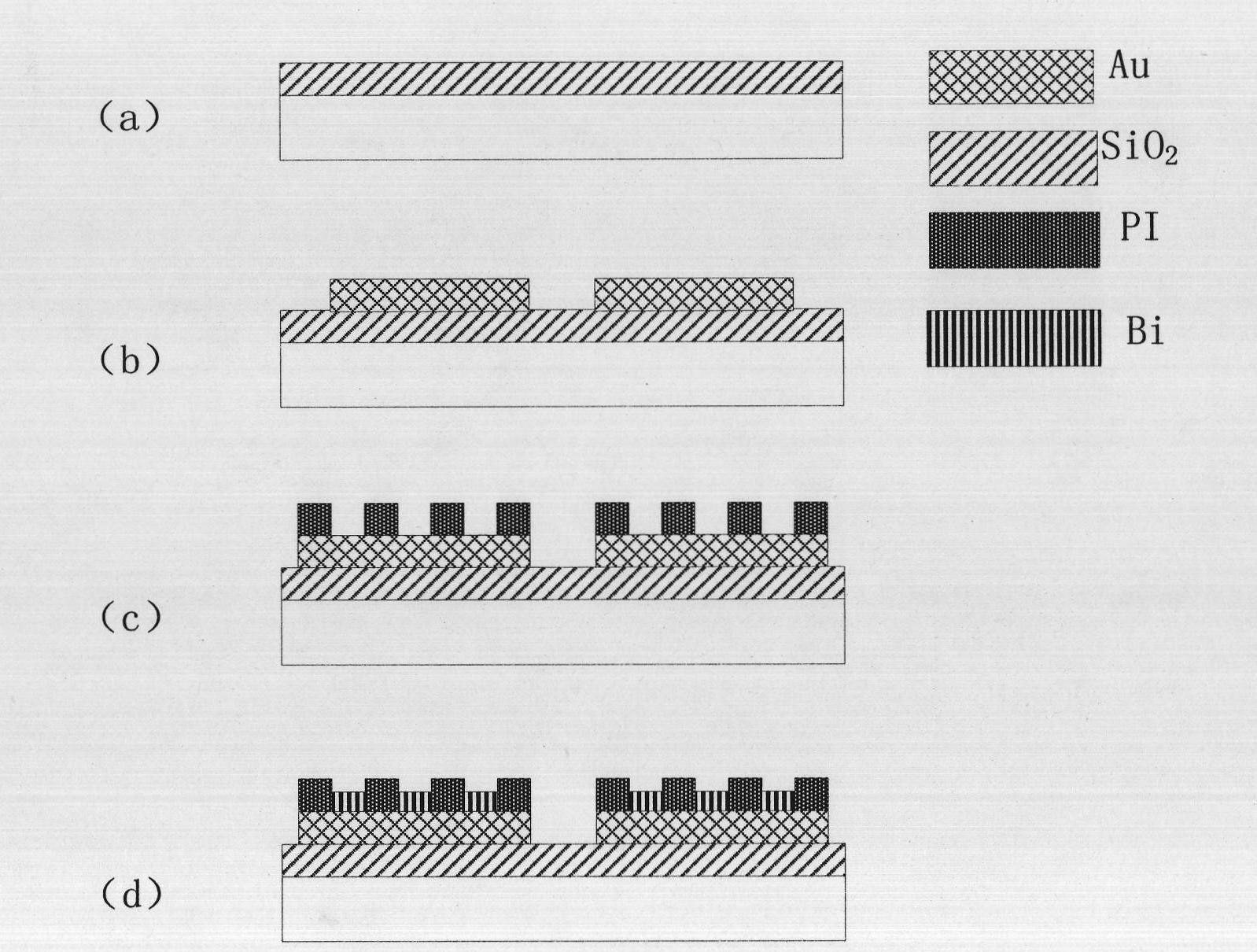

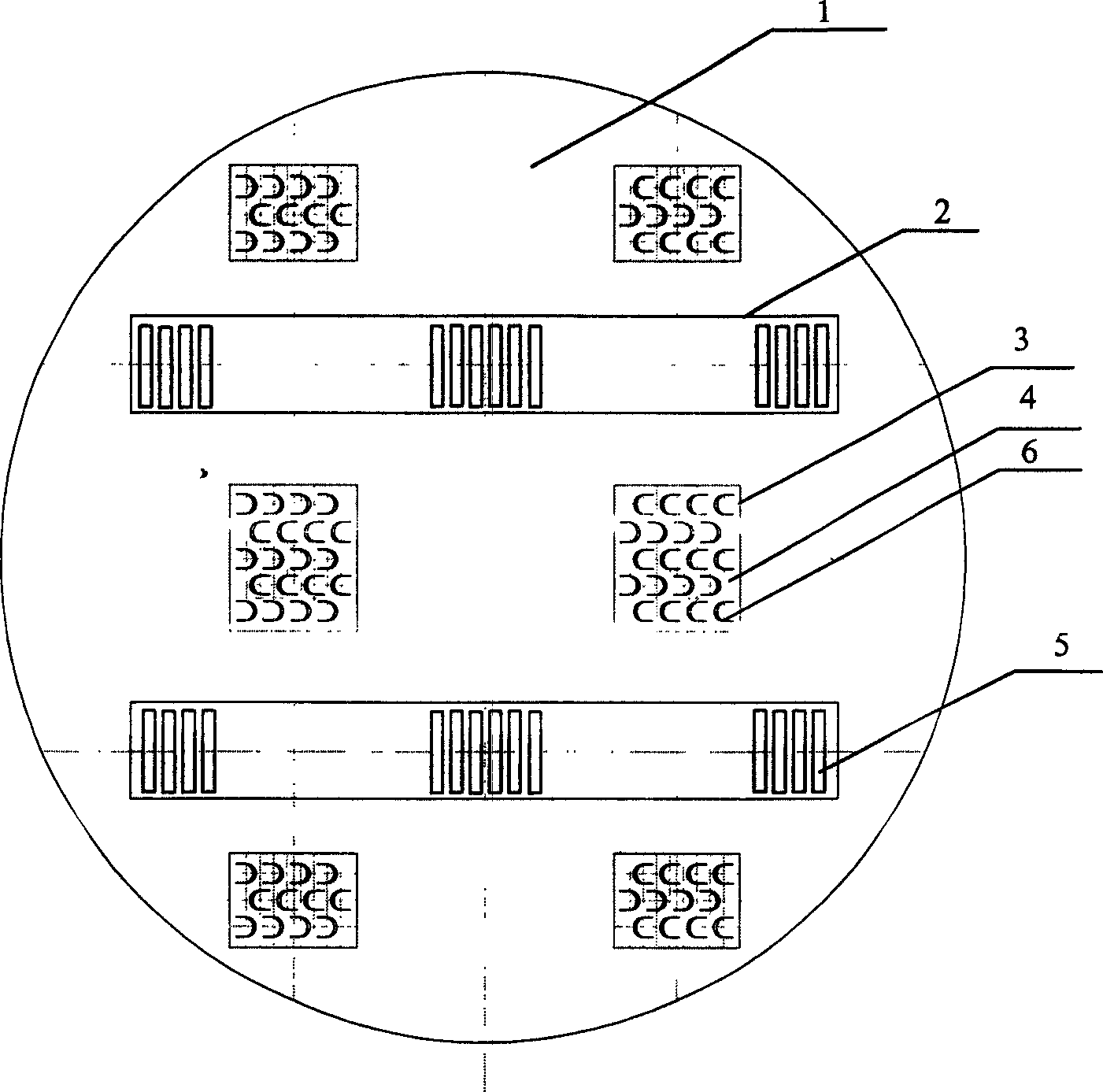

Production and detection method of plated bismuth gold micro-array electrode for detecting heavy metals

ActiveCN102323314ARich sourcesMature processing technologyDecorative surface effectsChemical vapor deposition coatingBismuthElectroplating

The invention relates to a production and detection method of a plated bismuth gold micro-array electrode for detecting heavy metals, which is characterized in that: in a bismuth plating process of a production machine of a gold micro-array electrode, when 0.015mol / L Bi (NO3) 3 . 5H2O, 1 mol / L KNO3 and 1% HNO3 are used to plate heavy metals, magnetic stirring is added to improve the plating efficiency. The micro-array electrode is used as a wok electrode of stripping voltammetry to form a sensor for detecting the heavy metals, liquid is prepared, and parameter values of the voltammetry are set to complete the detection of the heavy metals lead, cadmium or nickel, and the sensitivity is up to the national drinking water standards.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

Copper and nickel preprocessing technology in ion implantation before polymer surface chemical plating

InactiveCN1952209AReduce porosityGood lookingVacuum evaporation coatingSputtering coatingPolymeric surfacePorosity

An ion implanted copper, nickel pretreatment process of before polymer surface chemical plating, belongs to pretreating process of polymer surface chemical plating. Adding high molecular polymer into ion implanter, adding electrode to the polymers, switching on the energy injecting switch of the ion implanter, with a accelerating voltage of 10 kV-45 kV, injected dose of 2*10e17-5*10e17ions / cm2. The method combines the ion implantation and chemical plating, adopts injecting metal ion different from or the same as the chemical coating metal, make full use of the advantages of chemical plating and ion implantation, thus creats a uniform coating with small porosity, good appearance, improves bonding tightness of the coating and substrate, has simple process and does not need repeated treatment; there is no plating liquid during the pretreatment Process, no secondary pollution; no noble metals injection, reduces costs, enhances self-catalysis in chemical plating, improves the plating efficiency.

Owner:CHINA UNIV OF MINING & TECH

Technological method for electro-coppering of PCB (printed circuit board)

InactiveCN106149018AGuaranteed smoothKeep aliveTanksLiquid/solution decomposition chemical coatingEtchingSpecial design

The invention provides a technological method for electro-coppering of a PCB (printed circuit board). The technological method mainly comprises the following steps: (1) deburring: PCB feeding, PCB grinding, high-pressure washing, oven-drying and then PCB discharging are performed; (2) copper deposition: PCB loading, swelling, first washing, desmear, second washing, pre-neutralization, third washing, neutralization, ultrasonic washing, deoiling, post-deoiling, fourth washing, mild etching, fifth washing, pre-impregnation, activation, acceleration, sixth washing, chemical copper deposition, acid pickling and seventh washing are performed; and (3), copper intensification: PCB loading, deoiling, washing, acid leaching, plating thickening, high-position washing and PCB discharging. According to the technological method provided by the invention, a vibrating device is added to the copper deposition process, so that the circumstance of no copper in holes can be obviously improved; through the special design for a plating tank in the cooper intensification process, not only can the activity of a plating solution be guaranteed, but also the plating uniformity can be facilitated; and meanwhile, through synergistic action between the plating solution and the plating tank, the highest plating uniformity and plating efficiency can be achieved.

Owner:安徽广德威正光电科技有限公司

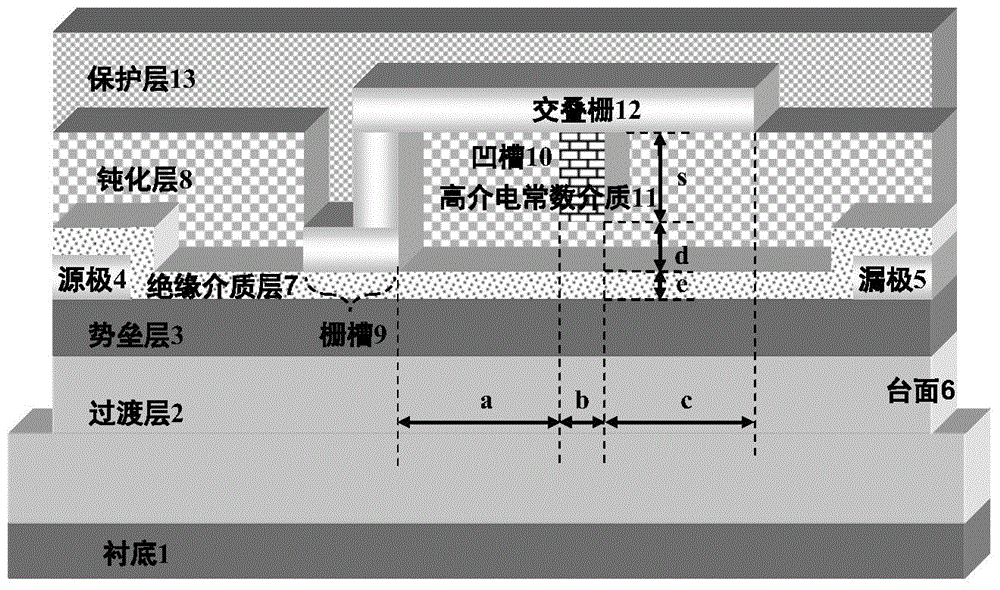

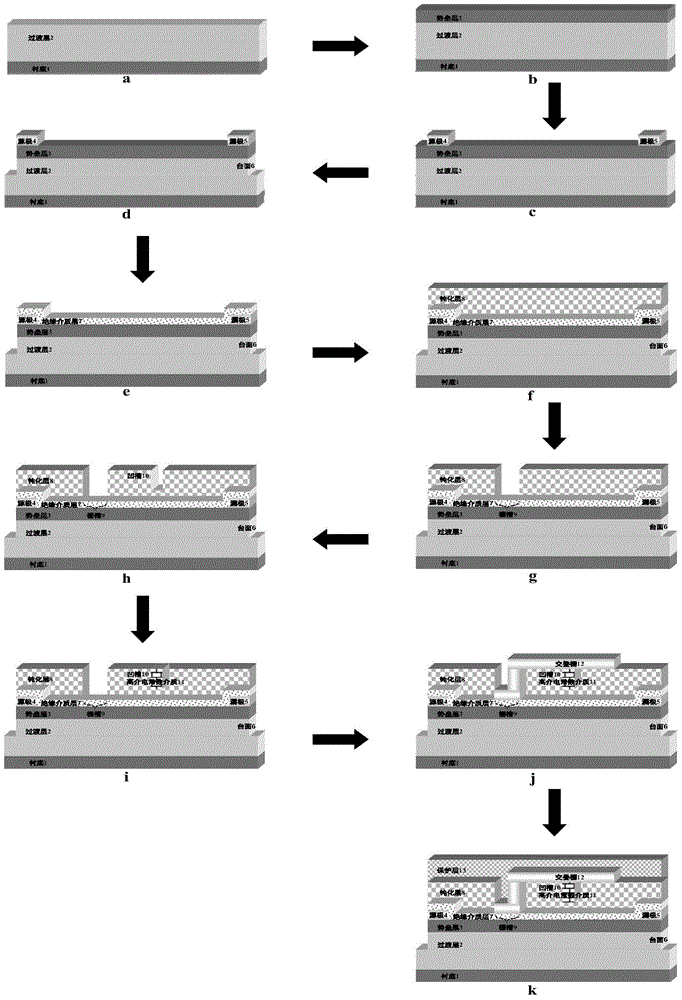

Medium-modulation power device of composite overlapping gate

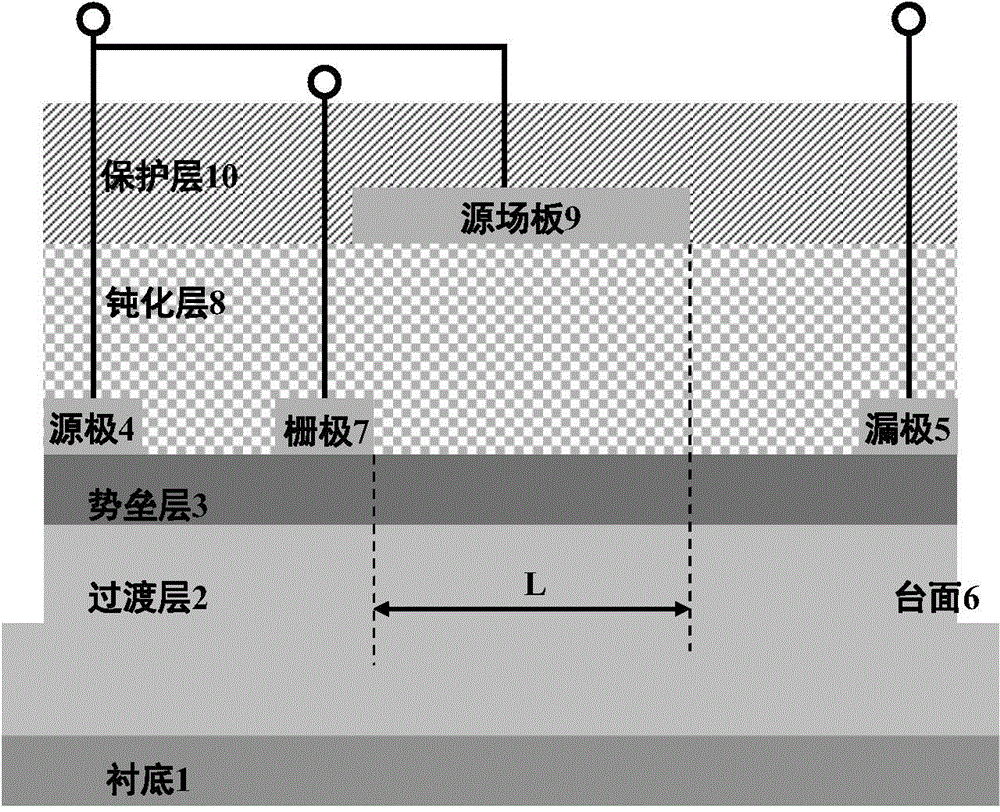

ActiveCN104393048AImprove breakdown voltageImprove distributionSemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringMedia layer

The invention discloses a medium-modulation power device of a composite overlapping gate. The medium-modulation power device of the composite overlapping gate is mainly used for solving the problem that the process for realizing high breakdown voltage is complex in the existing field plate technology. The medium-modulation device of the composite overlapping gate comprises a substrate (1), a transition layer (2), a barrier layer (3), a table board (6), an insulating medium layer (7), a passivation layer (8) and a protective layer (13), wherein a source electrode (4) and a drain electrode (5) are deposited on the barrier layer (3); a gate slot (9) and a groove (10) are etched in the passivation layer (8); the grid slot is close to the source electrode, the groove is close to the drain electrode, the depth of the grid slot is equal to the thickness of the passivation layer; a high dielectric constant medium (11) is completely filled in the groove (10); overlapping gates (12) are deposited on the upper part of the passivation layer in the grid slot between the grid slot and the drain electrode, and on the upper part of the high dielectric constant medium; the high dielectric constant medium and the overlapping gates form a composite overlapping gate. The medium-modulation power device of the composite overlapping gate has the advantages of a simple process, high breakdown voltage, high field plate efficiency, high reliability and high yield.

Owner:XIDIAN UNIV

Vehicle interior decoration surface electroplating treatment process

ActiveCN106835220AImprove the effect of surface treatmentImprove efficiencyTreatment effectResource saving

The present invention discloses a vehicle interior decoration surface electroplating treatment process, which comprises: 1) ultrasonic wave degreasing; 2) coarsening; 3) palladium activation; 4) peptization; 5) chemical nickel achieving; 6) nickel pre-plating, 7) acid-copper treatment; 8) semi-bright nickel achieving; 9) pearl nickel achieving; 10) nickel sealing; 11) chromium decoration; and 12) electrolytic retreating. According to the present invention, the process is fine, the setting of the steps is detailed and reasonable, and the operation is ordered and simple so as to improve the vehicle interior decoration surface treatment effect, improve the yield, and provide advantages of god aesthetics, long use cycle, cost saving and resource saving; and after the boric acid in the electroplating process is rationally treated, the nickel plating efficiency and the nickel plating effect are significantly improved.

Owner:宣城托新精密科技有限公司

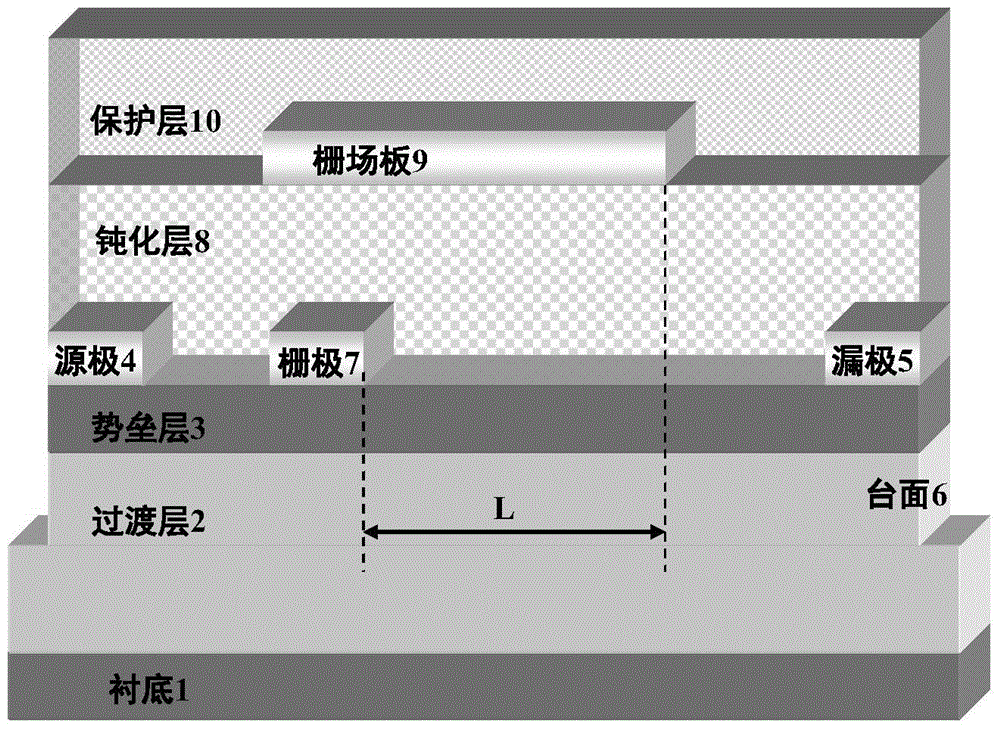

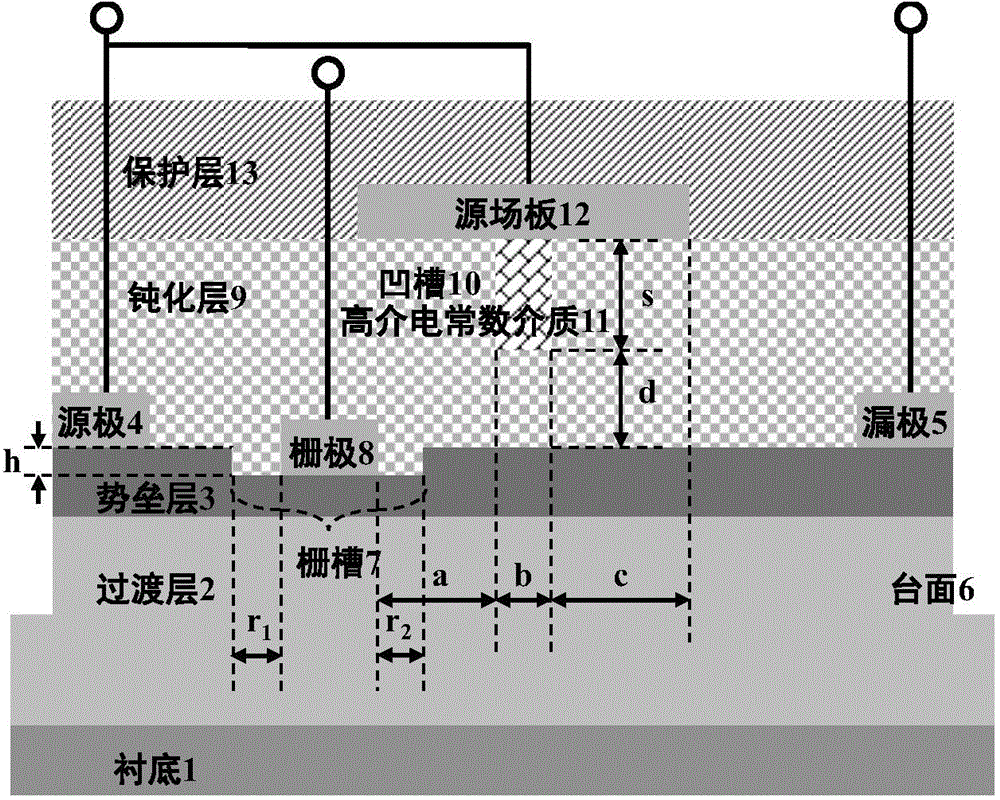

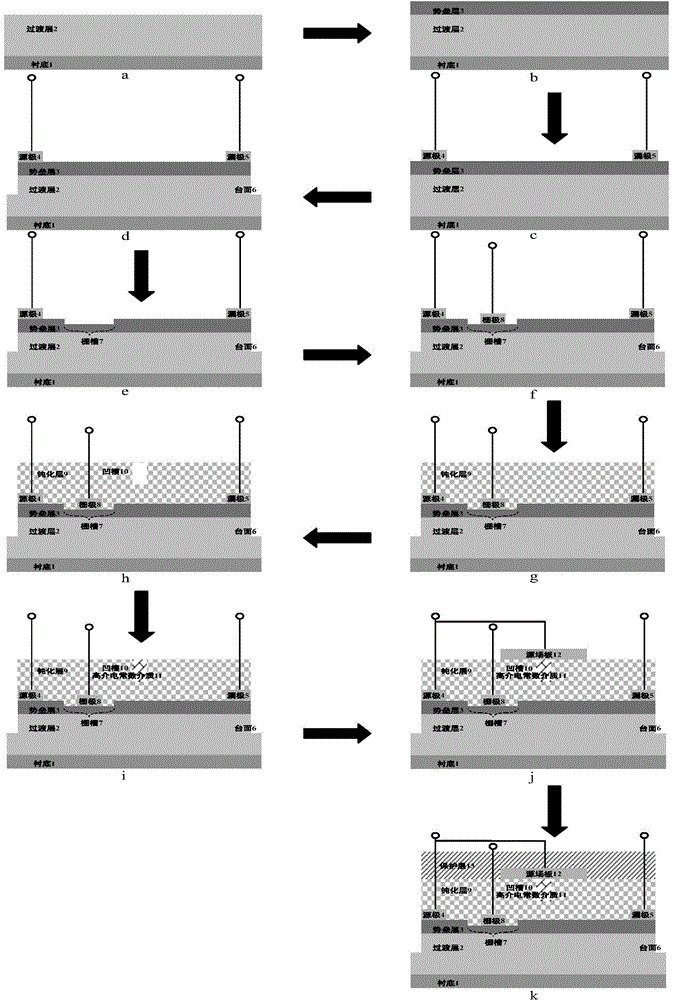

Heterojunction field effect transistor of composite source field plate based on medium modulation

The invention discloses a heterojunction field effect transistor of a composite source field plate based on medium modulation. The heterojunction field effect transistor of the composite source filed plate based on the medium modulation is mainly used for solving the problem that the process for realizing high breakdown voltage in the existing field plate technology is complex. The heterojunction field effect transistor comprises a substrate (1), a transitional layer (2), a barrier layer (3), a source electrode (4), a drain electrode (5), a table board (6), a passivation layer (9) and a protective layer (13), wherein a gate slot (7) is etched in the barrier layer between the source electrode and the drain electrode; a grid electrode (8) is deposited in the grid slot (7); a groove (10) is etched in the passivation layer (9) between the grid electrode and the drain electrode; a high dielectric constant medium (11) is completely filled in the groove (10); a source field plate (12) is deposited between the passivation layer (9) and the protective layer (13); the source field plate is electrically connected with a source electrode; and the source field plate (12) and the high dielectric constant medium (11) form a composite source field plate. The heterojunction field effect transistor of the composite source filed plate based on the medium modulation has the advantages of a simple manufacturing process, high breakthrough voltage, high field plate efficiency, high reliability and high yield.

Owner:XIDIAN UNIV

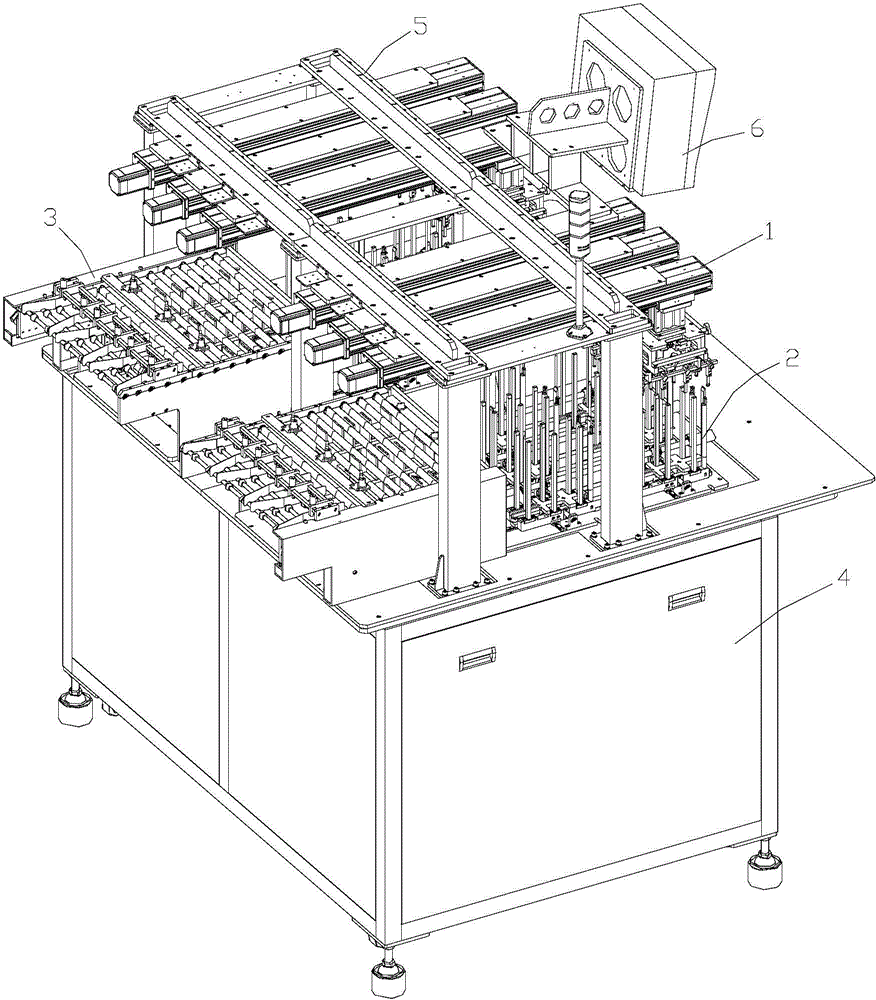

Collecting device for sheet type integrated circuit plating equipment

ActiveCN104562125ARealize automatic receivingImprove plating efficiencyElectrolysis componentsSemiconductor devicesEngineeringFront and back ends

The invention discloses a collecting device for sheet type integrated circuit plating equipment. The collecting device comprises a base and further comprises a sorting frame assembly, a collecting box assembly, a stand and a collecting clamp assembly which are arranged on the base; the collecting clamp assembly is arranged above the collecting box assembly; the front end and the rear end of the sorting frame assembly are respectively provided with a feeding hole and a temporary storage area, wherein the temporary storage area of the sorting frame assembly is arranged near the front end of the collecting box assembly and extends to the position below the collecting box assembly; the collecting clamp assembly comprises a horizontal guide rail mechanism, an adsorbing component and two clamping components, wherein the adsorbing component and the two clamping components can be arranged on the horizontal guide rail mechanism in a horizontal sliding way and a vertical lifting way; and the collecting box assembly comprises a collecting box mounting support, a collecting box and an auxiliary box, wherein the collecting box and the auxiliary box are arranged on the collecting box mounting support. The collecting device for the sheet type integrated circuit plating equipment can be used for collecting sheets automatically in the process of plating the sheets, thus the integral plating efficiency of the sheets can be improved effectively.

Owner:东莞奥美特科技有限公司

Efficient gallium thin film electroplating methods and chemistries

InactiveUS20090173634A1Improve efficiencyPhotovoltaic energy generationSemiconductor devicesElectrical conductorEngineering

The present invention relates to gallium (Ga) electroplating methods and chemistries to deposit uniform, defect free and smooth Ga films with high plating efficiency and repeatability. Such layers may be used in fabrication of electronic devices such as thin film solar cells. In one embodiment, the present invention provides a solution for application on a conductor that includes a Ga salt, a complexing agent, a solvent, and a Ga-film having submicron thickness is facilitated upon electrodeposition of the solution on the conductor. The solution may further include one or both of a Cu salt and an In salt.

Owner:SOLOPOWER

Selective plating fixture

InactiveCN104894622AHigh control precisionReduce consumptionElectrolysis componentsIridiumCurrent distribution

The invention discloses a selective plating fixture which comprises a rear cover, a cathode plate, cathode fixing blocks, a pressing plate, guide posts, a material strap, an anode, a material passing plate and a liquid leakage plate, wherein the liquid leakage plate is arranged on the rear cover; the material passing plate is arranged on the liquid leakage plate; the anode is arranged between the liquid leakage plate and the material passing plate; the pressing plate is arranged above the material passing plate; the pressing plate and the material passing plate are elastically connected through butterfly bolts and springs; the guide posts are arranged between the pressing plate and the material passing plate; the vertical cathode fixing block and the material passing plate are fixedly screwed; the horizontal cathode fixing block and the cathode plate are fixedly screwed; cathode handles are correspondingly arranged at two ends of the cathode plate; the material strap horizontally passes through a part between the material passing plate and the pressing plate and is arranged between the material passing plate and the pressing plate. According to the selective plating fixture disclosed by the invention, a selective plating structure is optimized, a titanium material is used as an anode base material, and the surface of the titanium material is coated with iridium, so that current distribution and plating efficiency are improved, the control precision of a selective plating area is improved, the plating quality is improved, the consumption of potion is reduced, precious metals are saved, the plating production cost is reduced, and the selective plating efficiency is improved.

Owner:KUNSHAN YIDING IND TECH CO LTD

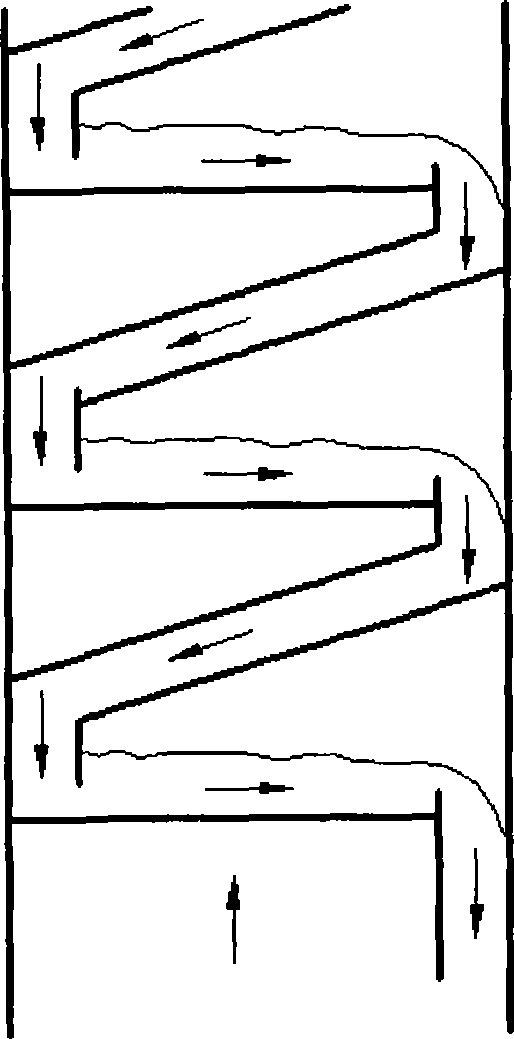

Multi-overflow circle tower plate

ActiveCN101444678AImprove efficiencyReduce pressure dropFractional distillationDistillationEngineering

The invention provides a multi-overflow circle tower plate, comprising at least a circle tower disc. The center of the circle tower disc is provided with a central supporting pipe which forms a circle tower disc; the circle tower disc is equally divided into sector blocks according to the overflow number; each sector block is divided into three blocks: a liquid receiving disc, a sector tower disc and a liquid falling area; the liquid falling area of the next layer of tower plate is arranged right below the liquid falling area of the circle tower disc; the liquid falling area is connected with the liquid receiving disc of the lower layer of tower plate by a slope; a circle liquid communicating vessel is arranged in the middle of the central supporting pipe of the circle tower disc; the bottom surface of the communication vessel is aligned to the bottom surface of the liquid receiving disc, the top surface thereof is about 50mm higher than the maximum liquid level of the liquid receiving disc, and the external side surface is communicated with the liquid falling pipe. The multi-overflow circle tower plate has the advantages of improving the tower plate efficiency, reducing the pressure reduction of the tower plate, reducing the separation energy dissipation, shortening the dimension of distillation column, reducing the cost of equipment, meeting the high requirement on separation performance of the tower plate during the modernized separation process, and the like.

Owner:HANGZHOU HANGYANG

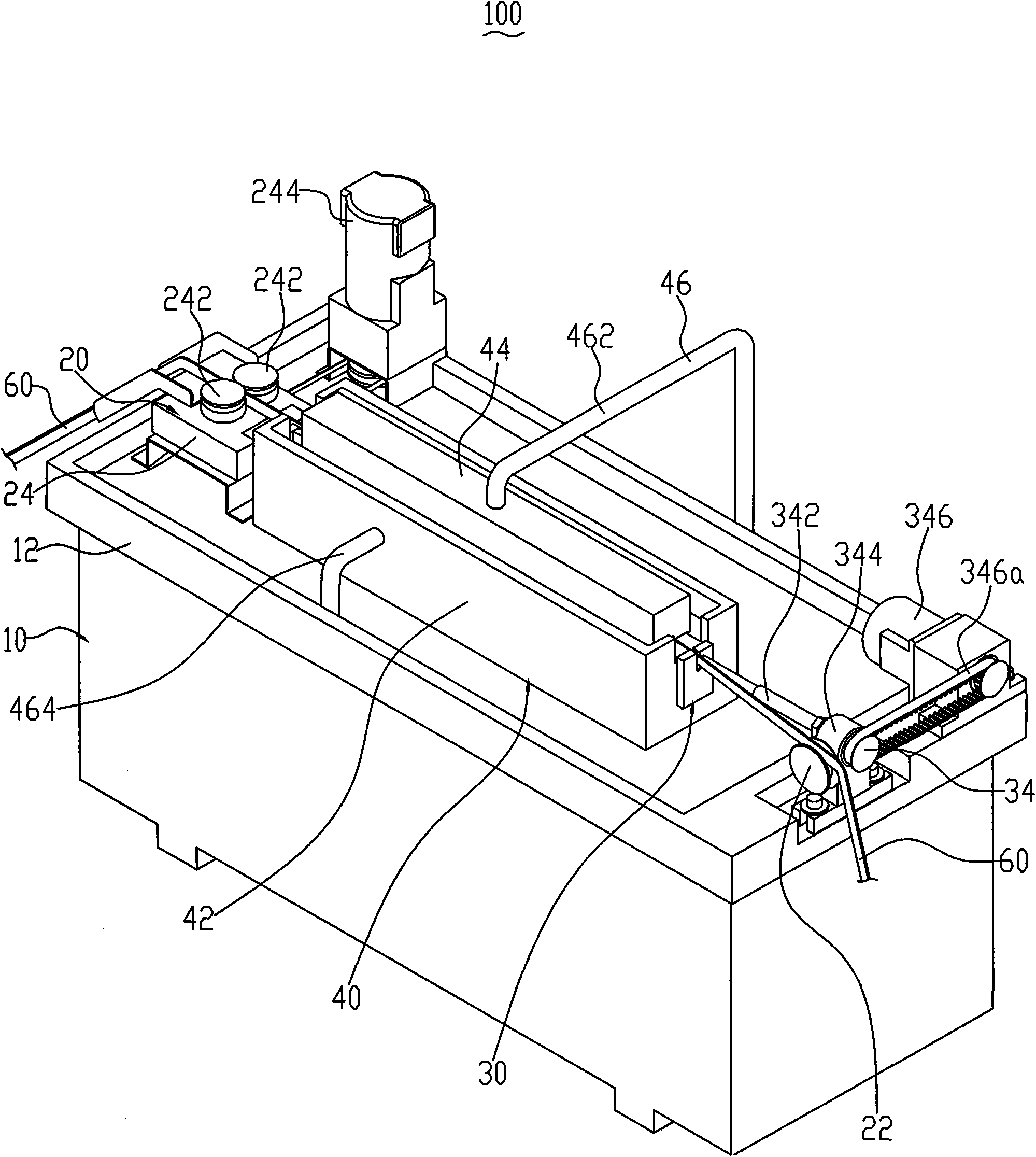

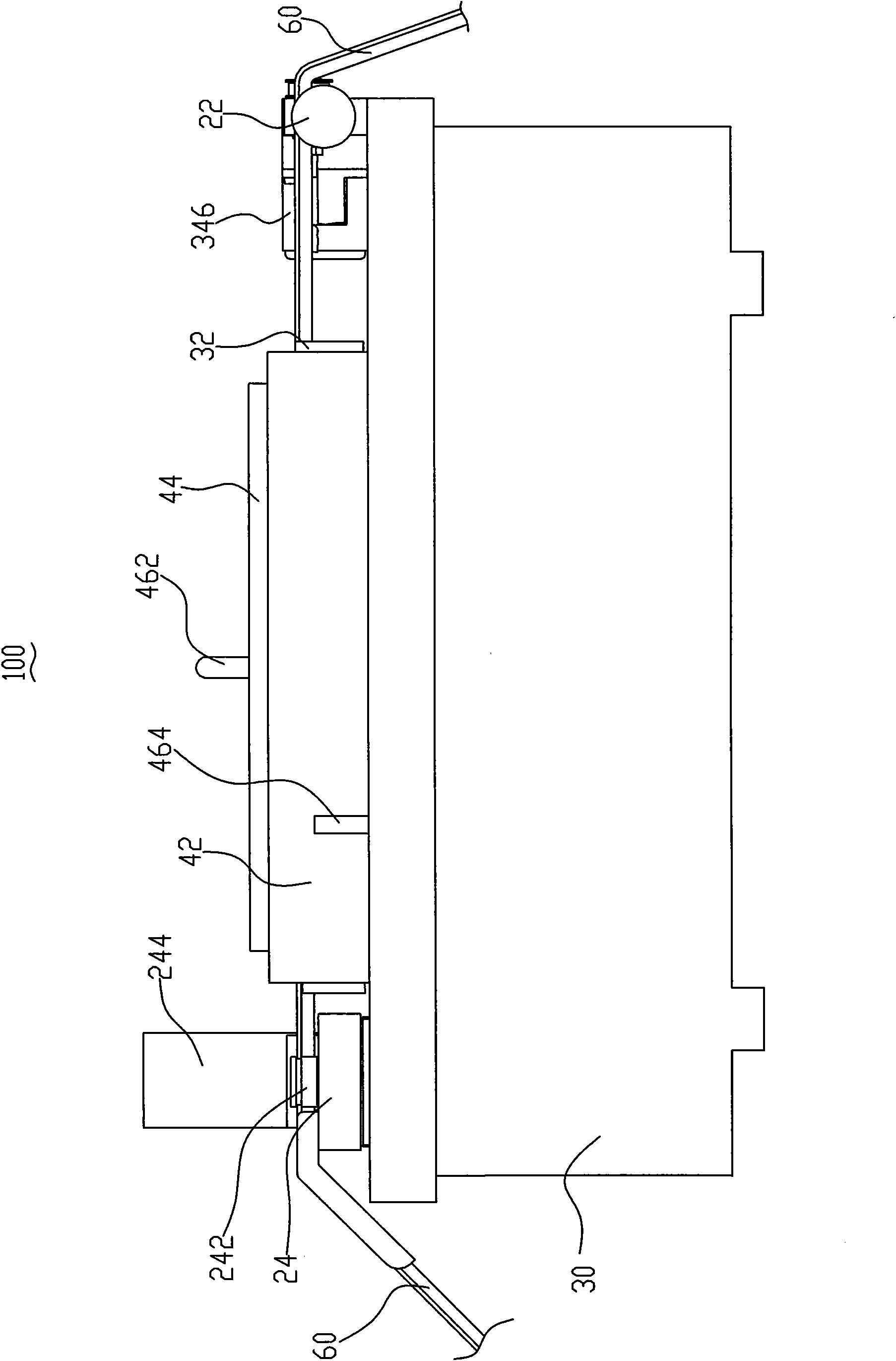

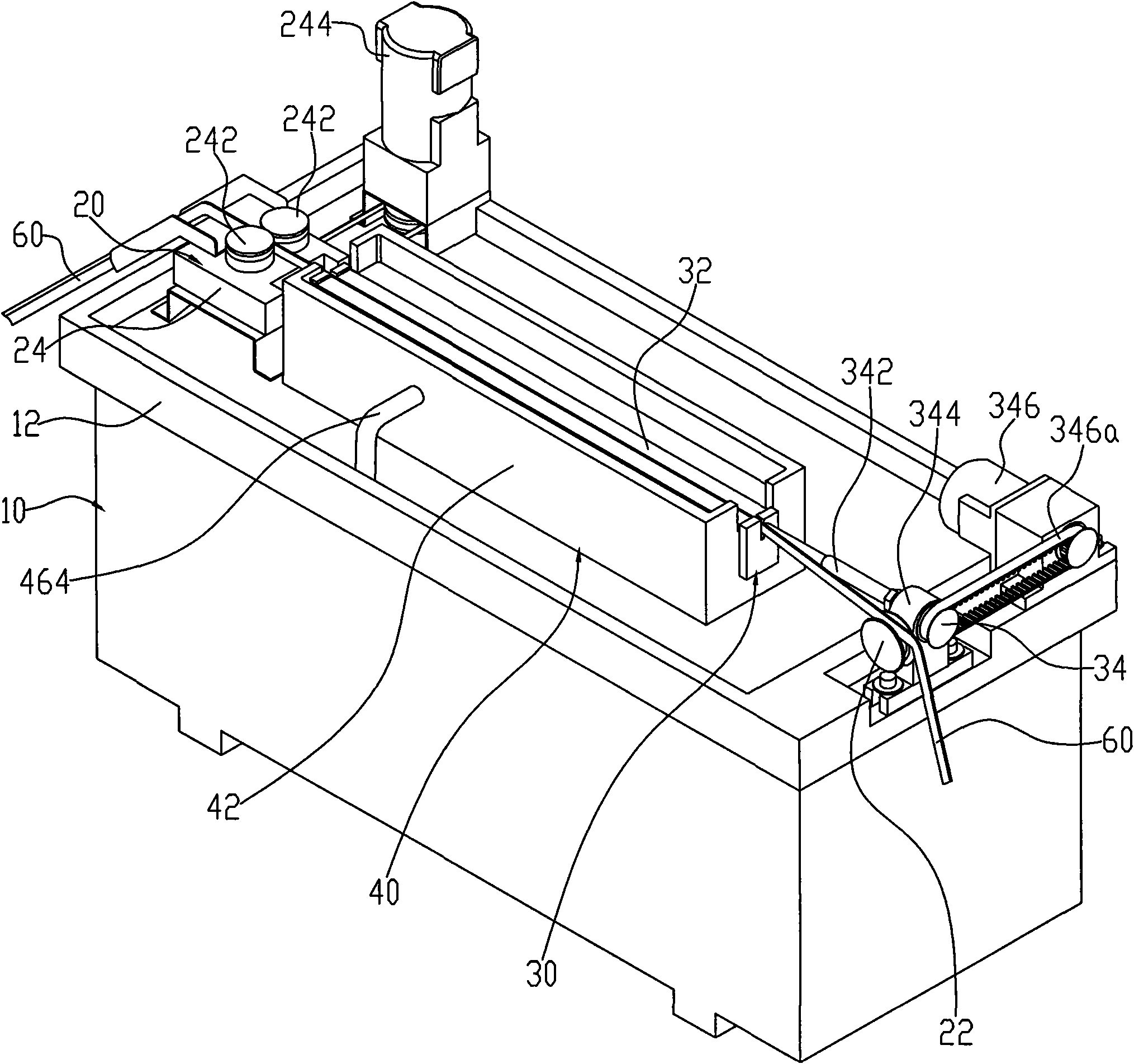

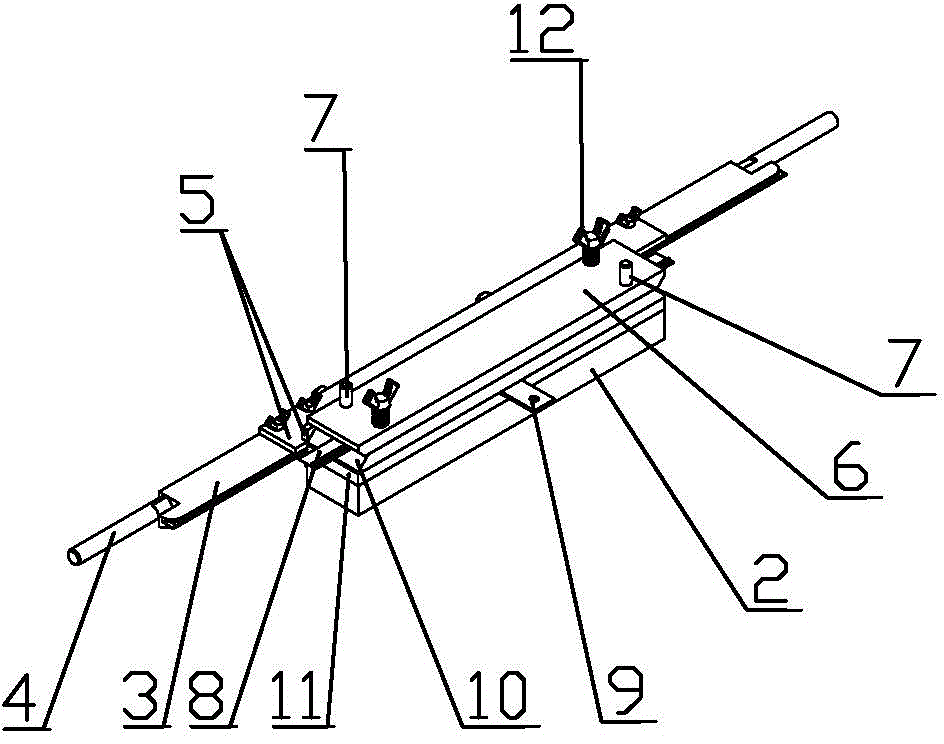

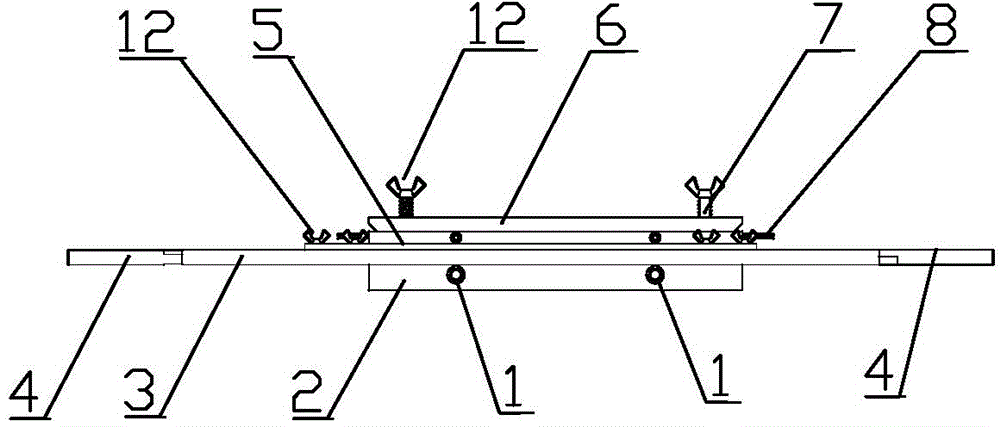

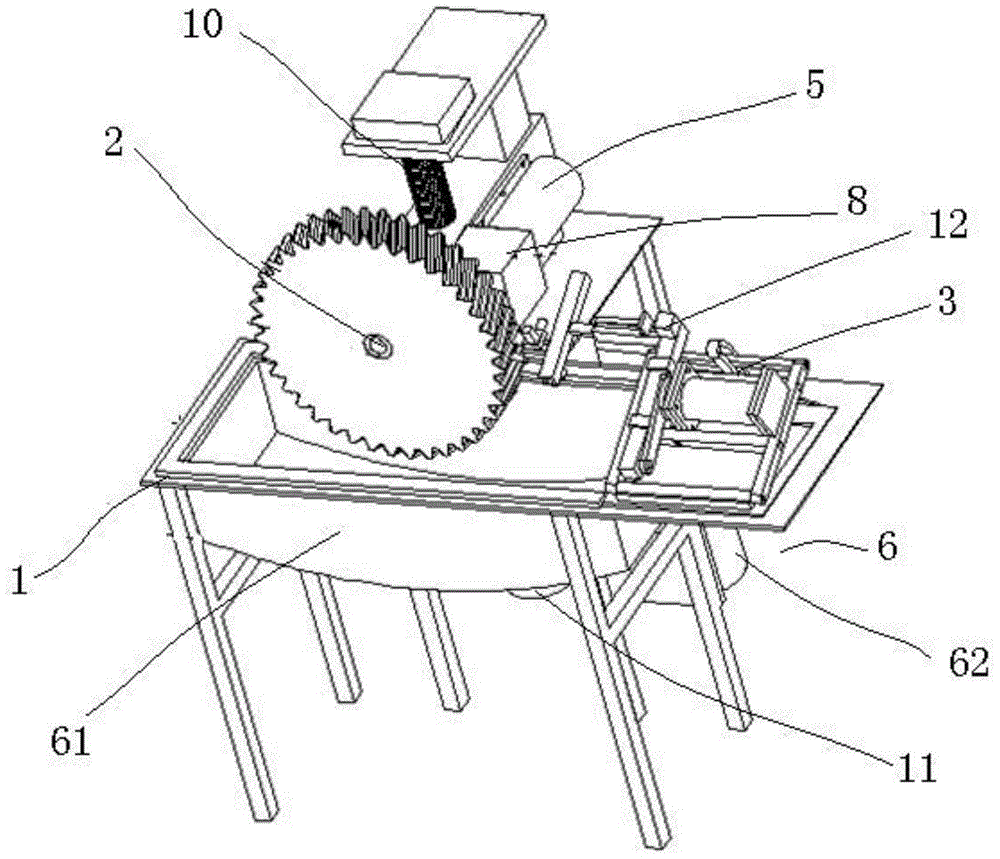

Gear tooth electric brush plating experiment platform

The invention discloses a gear tooth electric brush plating experiment platform which comprises a worktable, a gear fixing device, a brush plating pen machine frame and a plating solution conveyor, wherein the gear fixing device is arranged on the worktable and used for driving the gear arranged on the gear fixing device to move; the brush plating pen machine frame comprises a base and a supporting frame, the base is moveably arranged on the worktable, the supporting frame is moveably arranged on the base, the brush plating pen is corresponding to the gear teeth and arranged on the supporting frame, and the position of the brush plating pen can be adjusted in the X axis, Y axis or Z axis according to the shape of the gear teeth; and in the brush plating process, a power mechanism drives the brush plating pen to reciprocate along the tooth socket of the gear. The electric brush plating experiment platform can regulate the direction of the brush plating pen in a multivariant way, and can implement brush plating on different types of gears. The electric brush plating experiment can implement automatic brush plating on the gear teeth, thereby enhancing the brush plating efficiency and implementing uniform brush plating. The electric brush plating experiment can perform brush plating on spur gears, helical gears and bevel gears, and has the advantages of favorable brush plating effect and high work efficiency.

Owner:GUANGXI UNIV

Impact leakage preventing device of suspending downspout column plate

The impact leakage preventing device is set in the liquid accepting bubble region of suspending downspout column plate, and has several rows of inclined holes for gas to pass through. It consists of two parts of inclined holes in the same number and opposite inclined directions, and the two parts of inclined holes may be several rows arranged alternately. The device can guide the direction of the impact liquid leakage, reduce the amount of impact liquid leakage to the next layer of column plate downspout by over 80 %, improve the gas-liquid contact state in the column plate and raise column plate efficiency by 5-10 %.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com