Patents

Literature

383results about How to "Improve plating efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

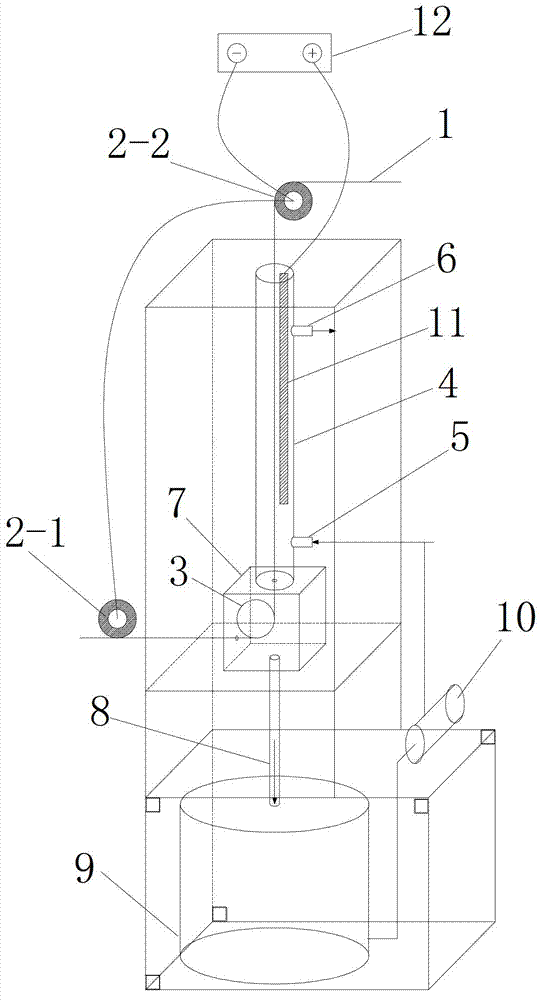

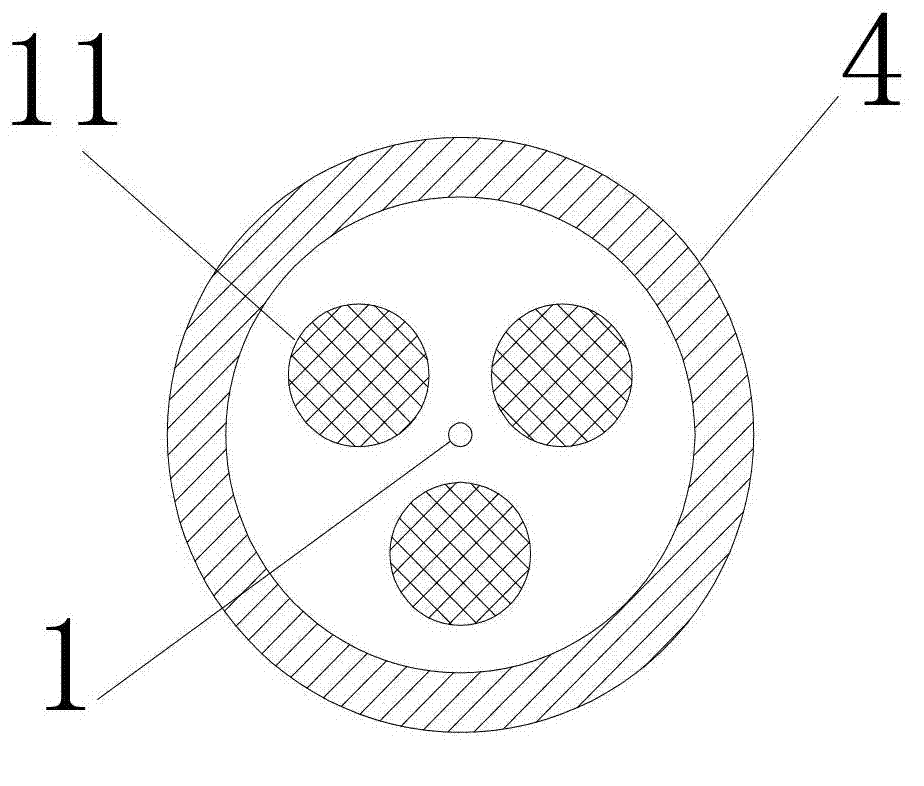

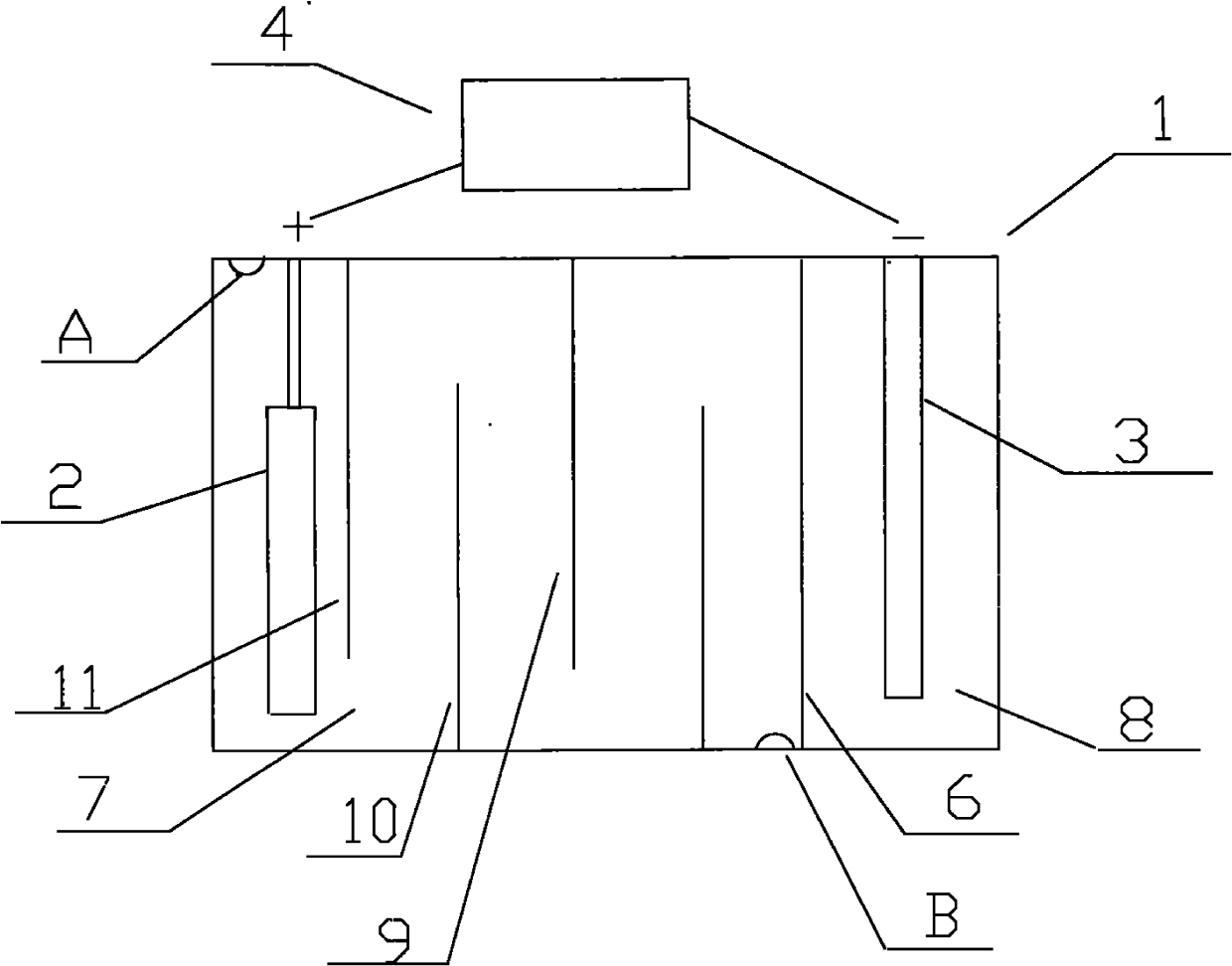

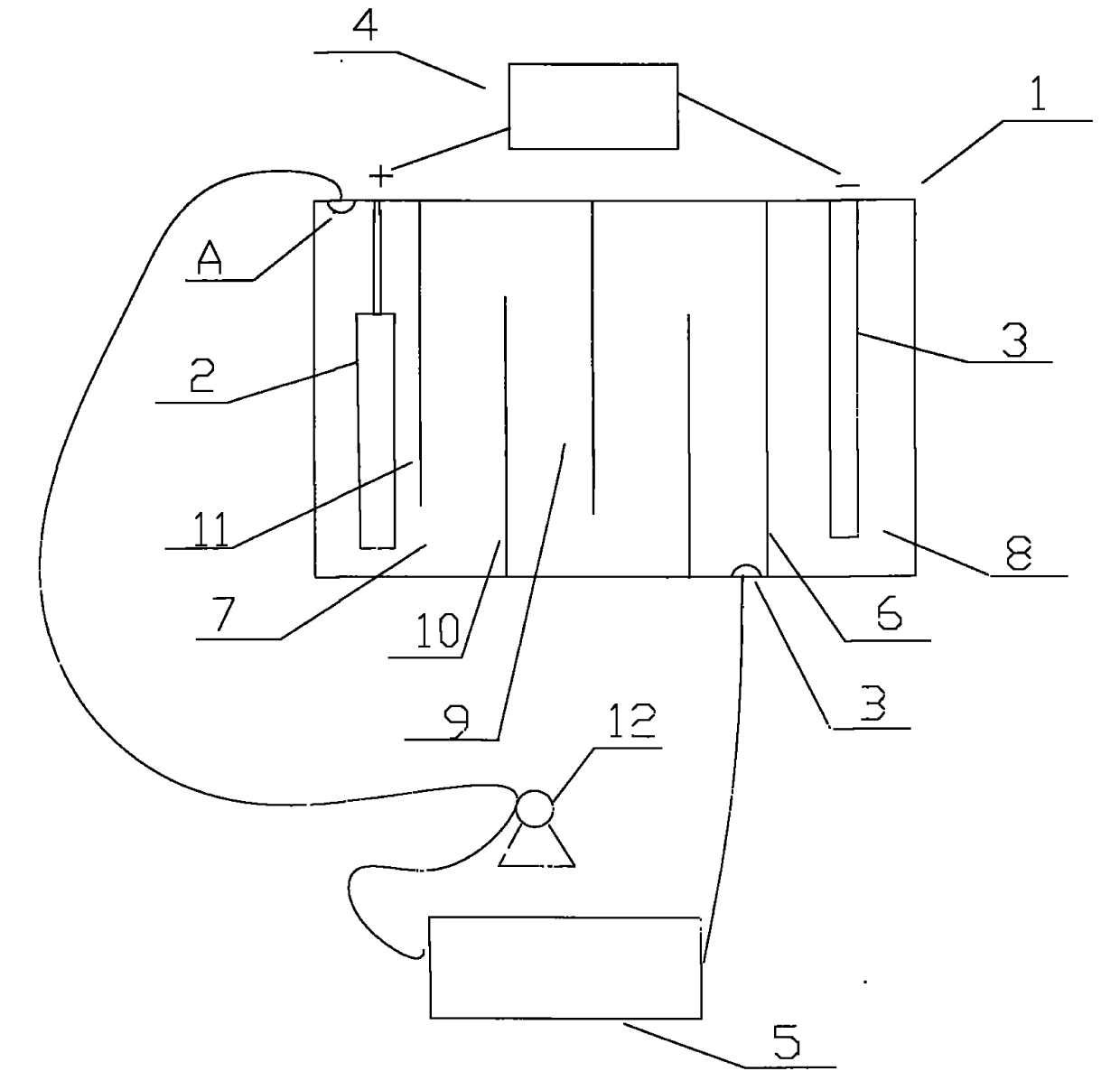

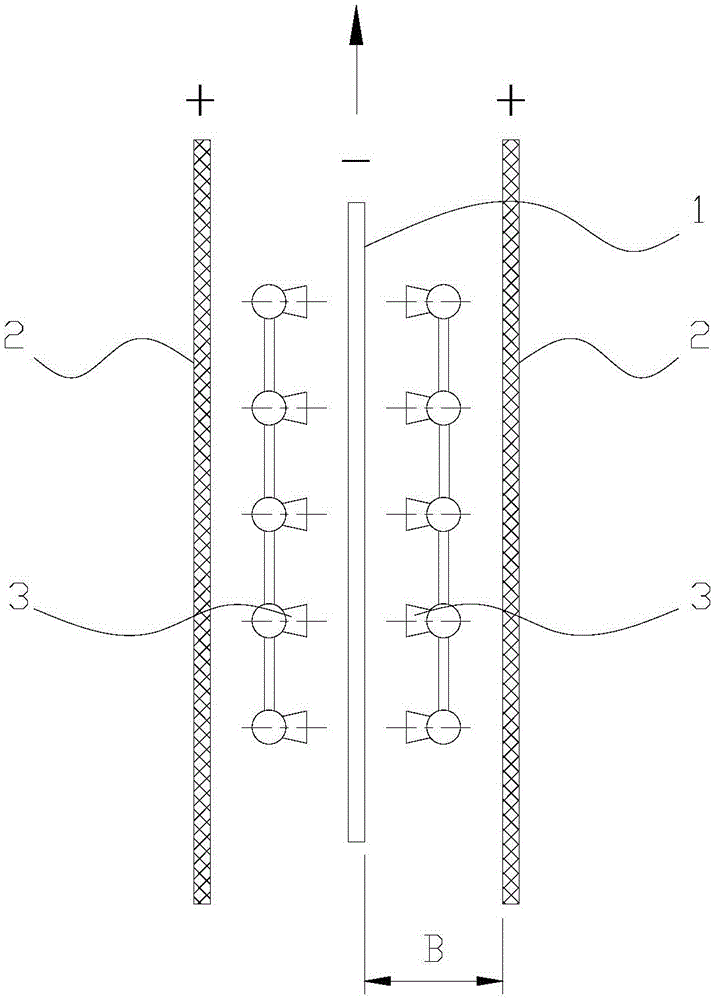

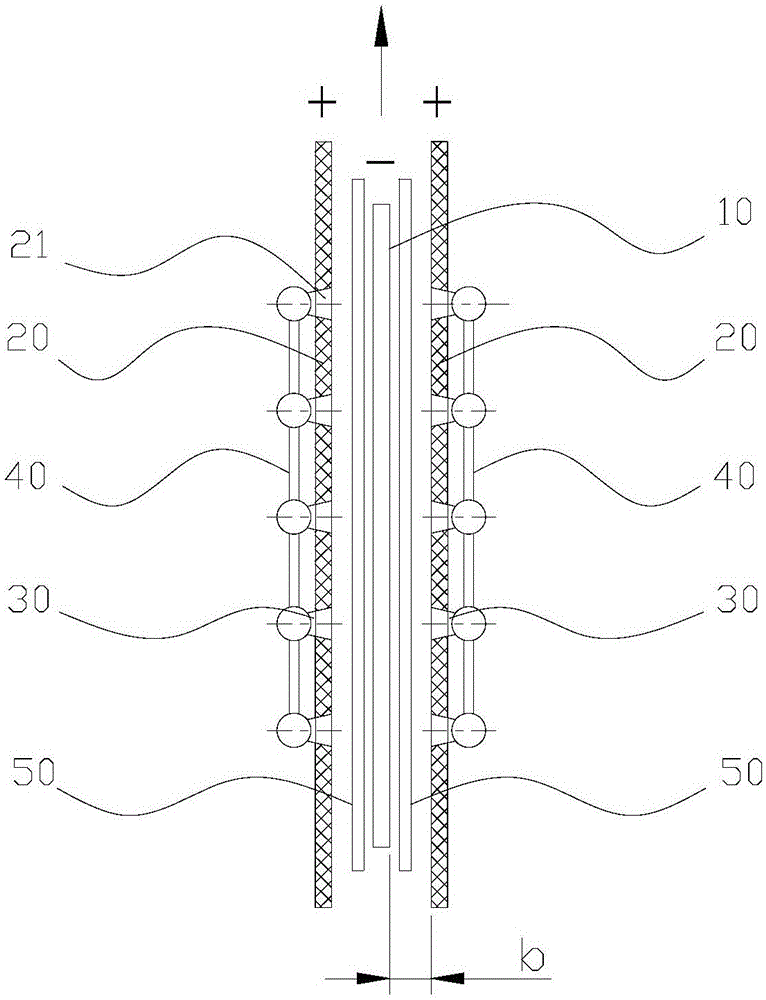

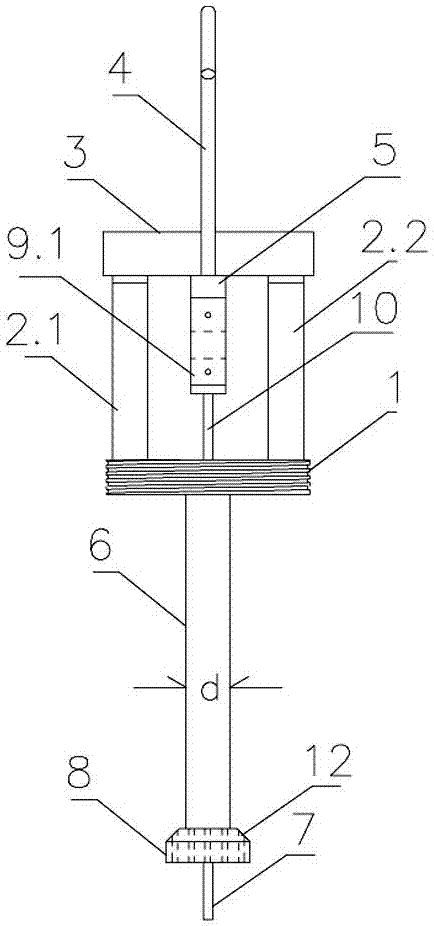

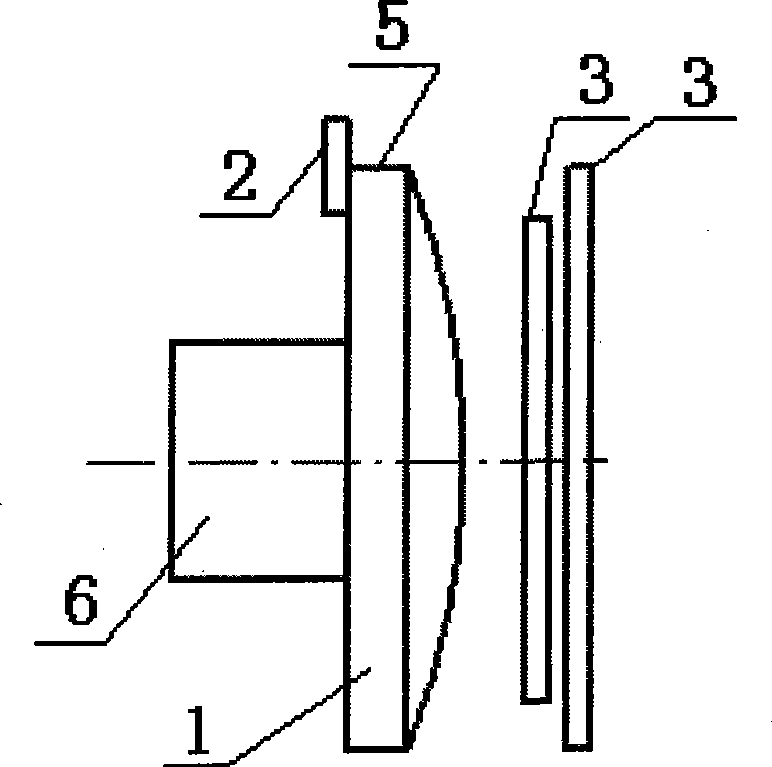

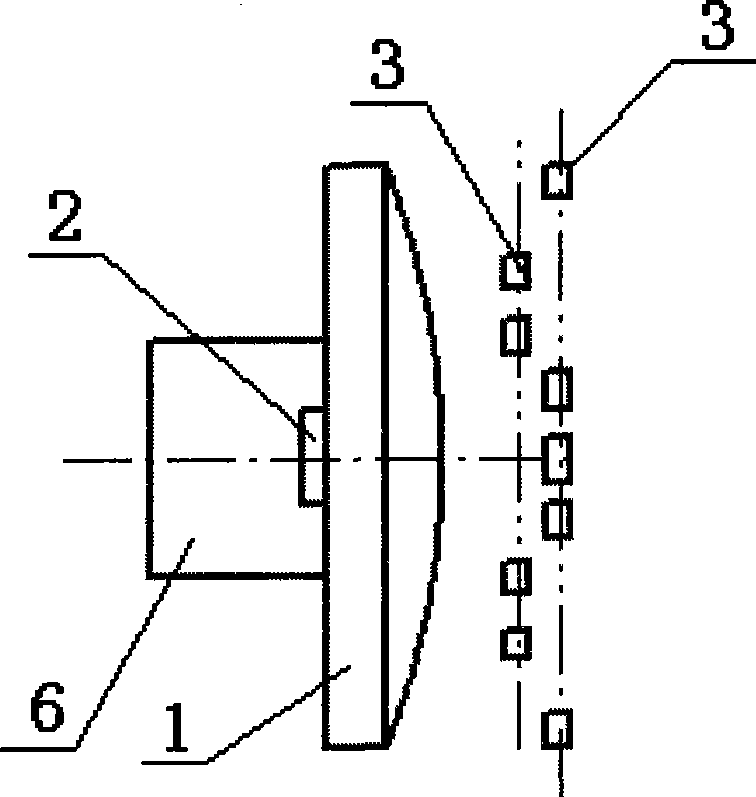

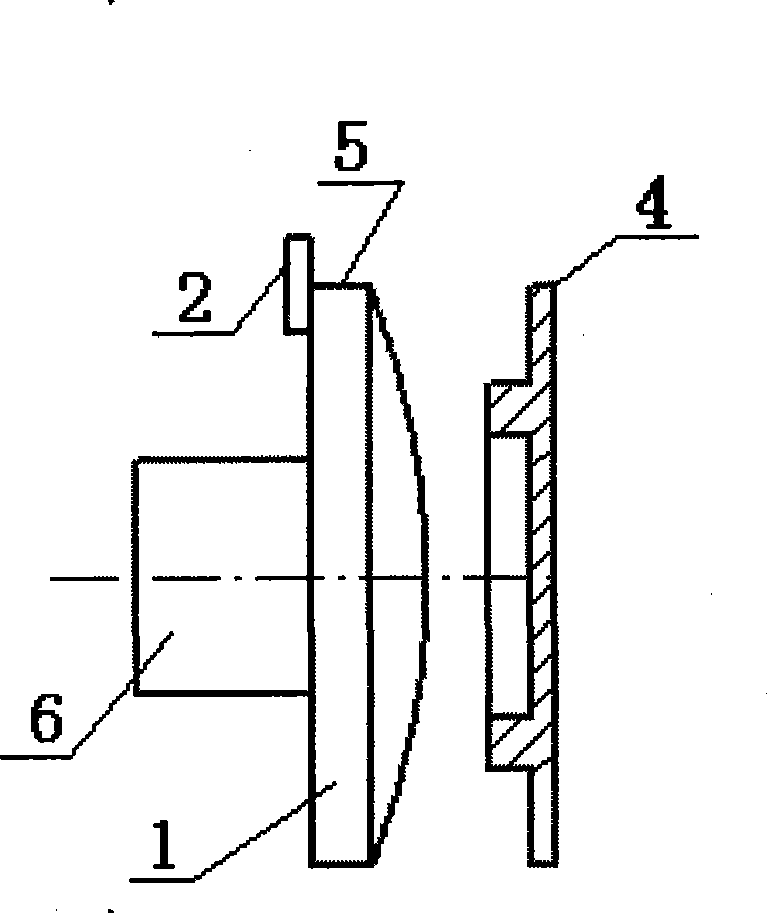

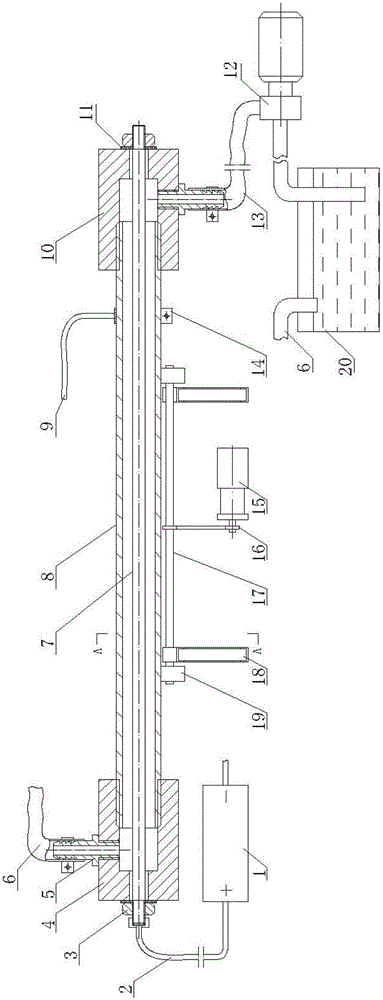

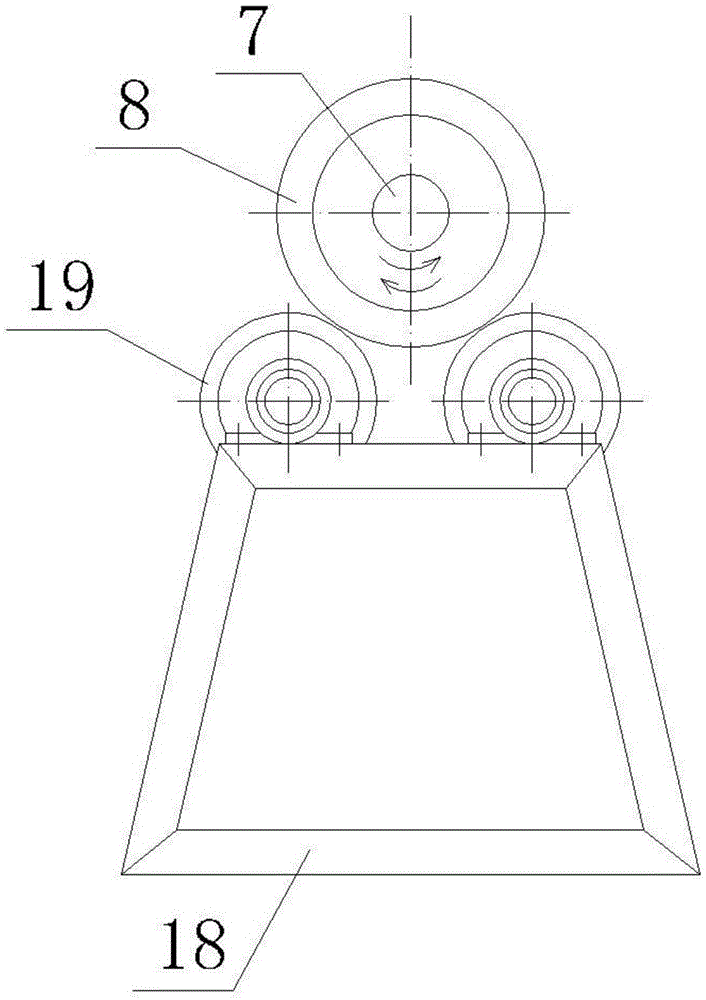

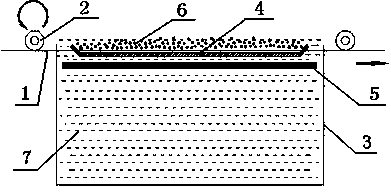

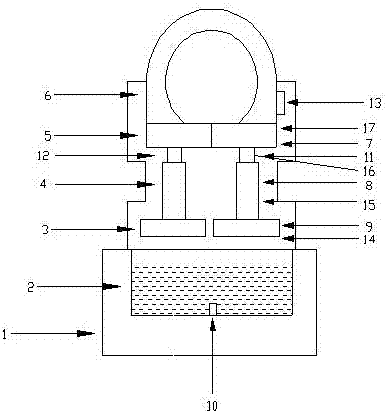

Electroplated diamond wire saw sand-applying device

The invention discloses an electroplated diamond wire saw sand-applying device. The device sequentially comprises the components, from top to bottom: a vertical tubular sand-applying sub tank, a liquid-returning box, and a plating solution master tank. A guide wheel is fixed in the liquid-returning box. A core wire is sequentially wound on a wire-feeding conductive wheel on the bottom of the vertical tubular sand-applying sub tank and the guide wheel. The core wire then penetrates the vertical tubular sand-applying sub tank, and is finally wound on a wire-discharging conductive wheel on the top of the vertical tubular sand-applying sub tank. The wire-feeding conductive wheel and the wire-discharging conductive wheel are connected in parallel, and are then connected to the negative electrode of an electroplating power supply. Metal anodes are arranged around the core wire in the vertical tubular sand-applying sub tank. The metal anodes are connected with positive electrodes of the electroplating power supply. Through a water pump above the plating solution, the plating solution is lifted from the plating solution master tank into the vertical tubular sand-applying sub tank. With the device provided by the invention, sand-application of produced diamond wire is uniform and good. During the production process, current density is high, efficiency is high, internal stresses of the plating and the substrate are small, plating solution application amount is low, and wire breakage probability is low.

Owner:无锡超亚环保设备有限公司

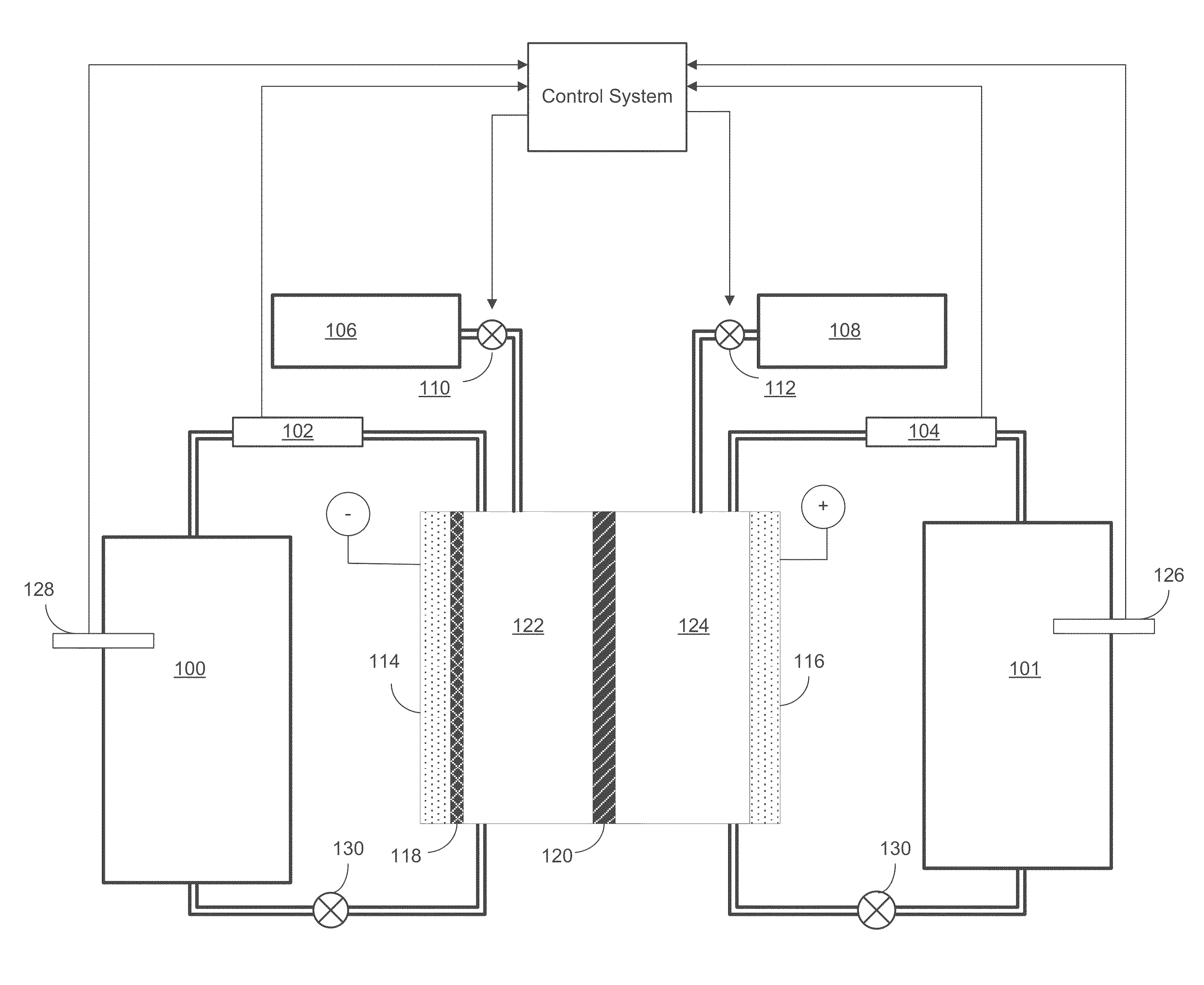

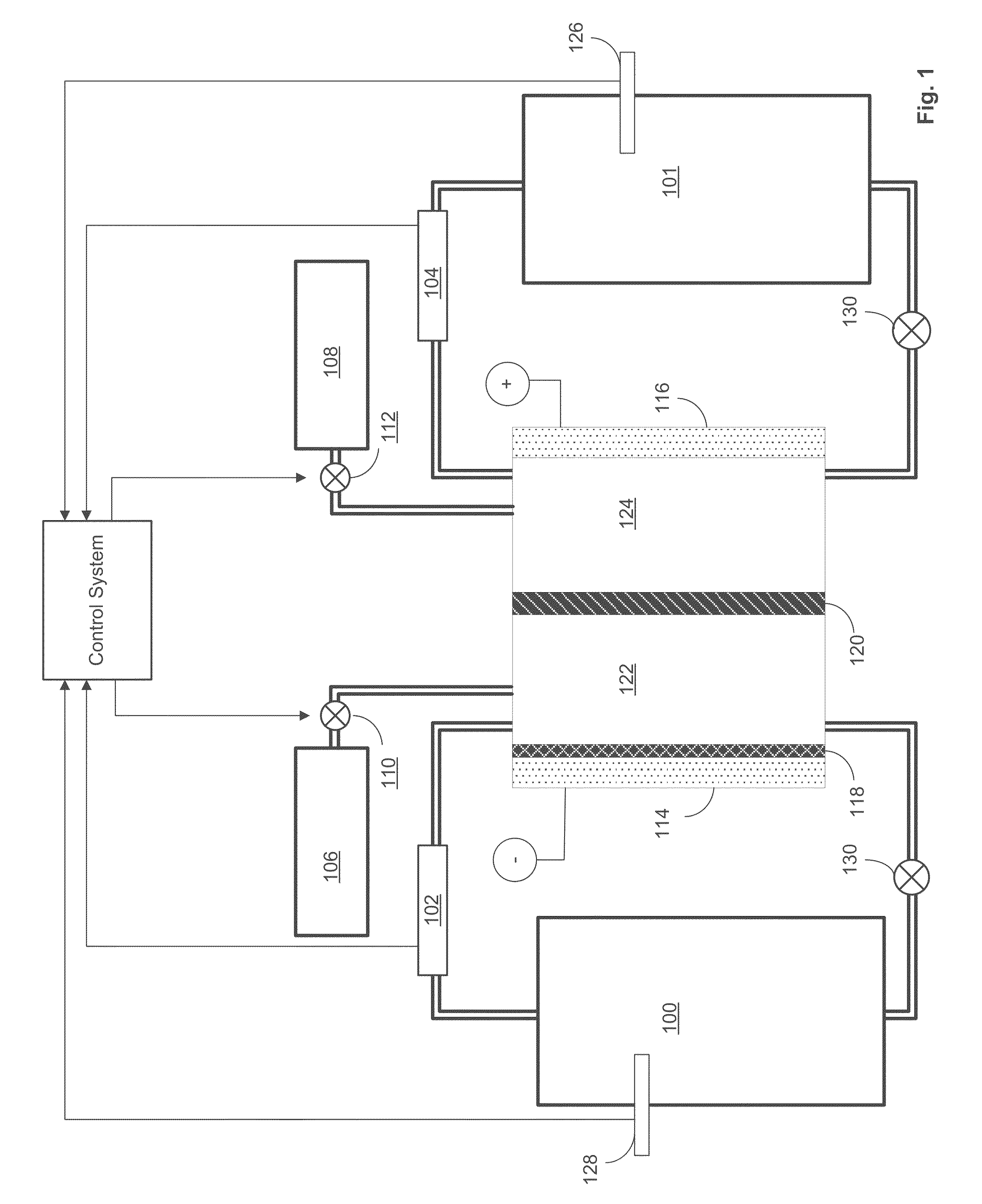

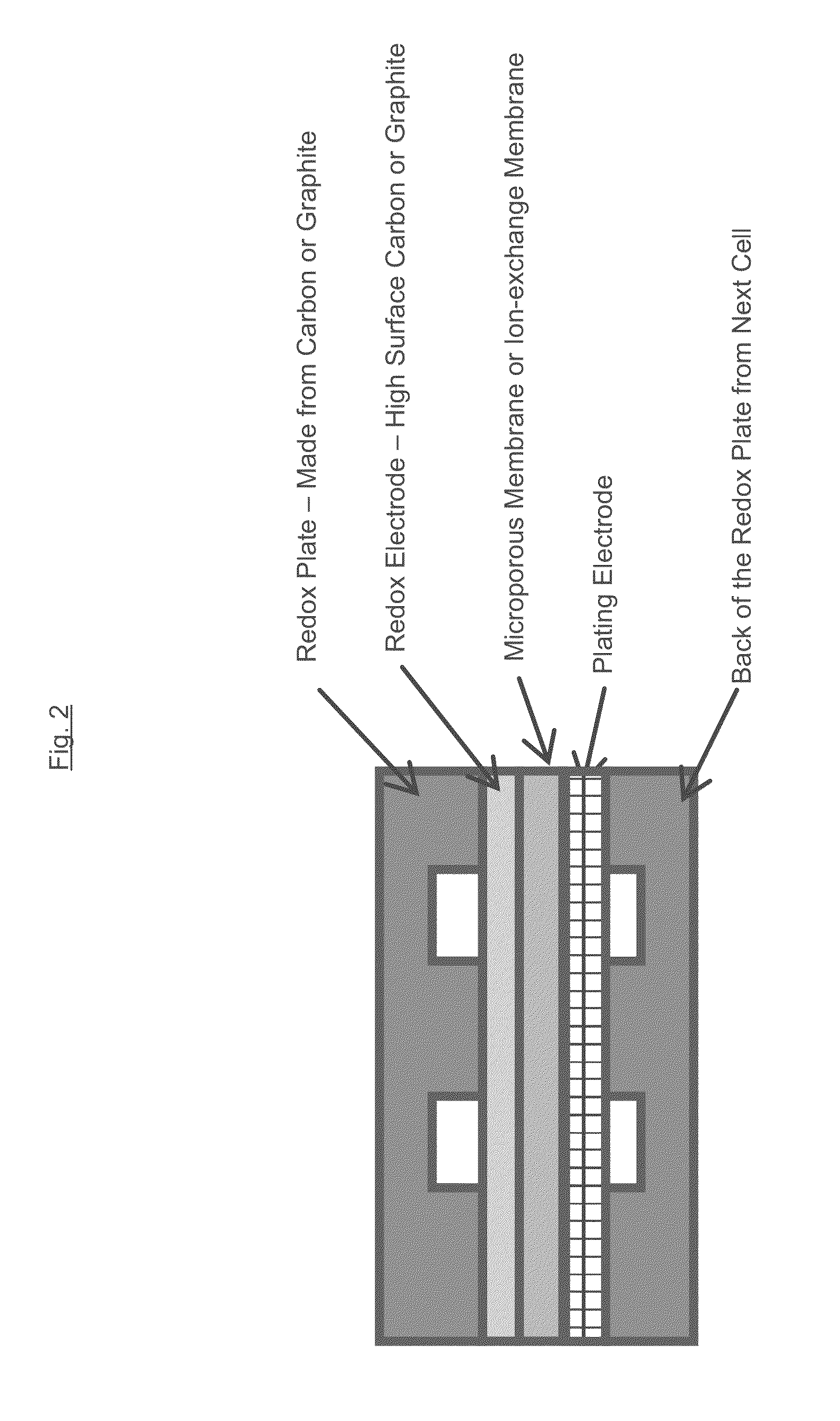

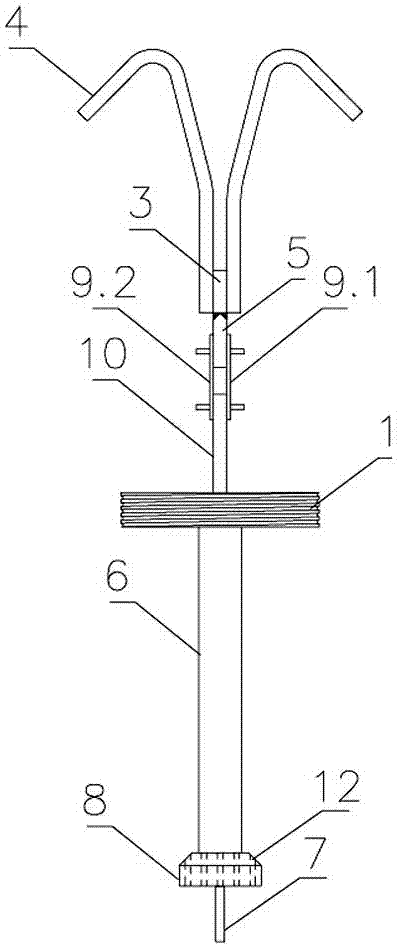

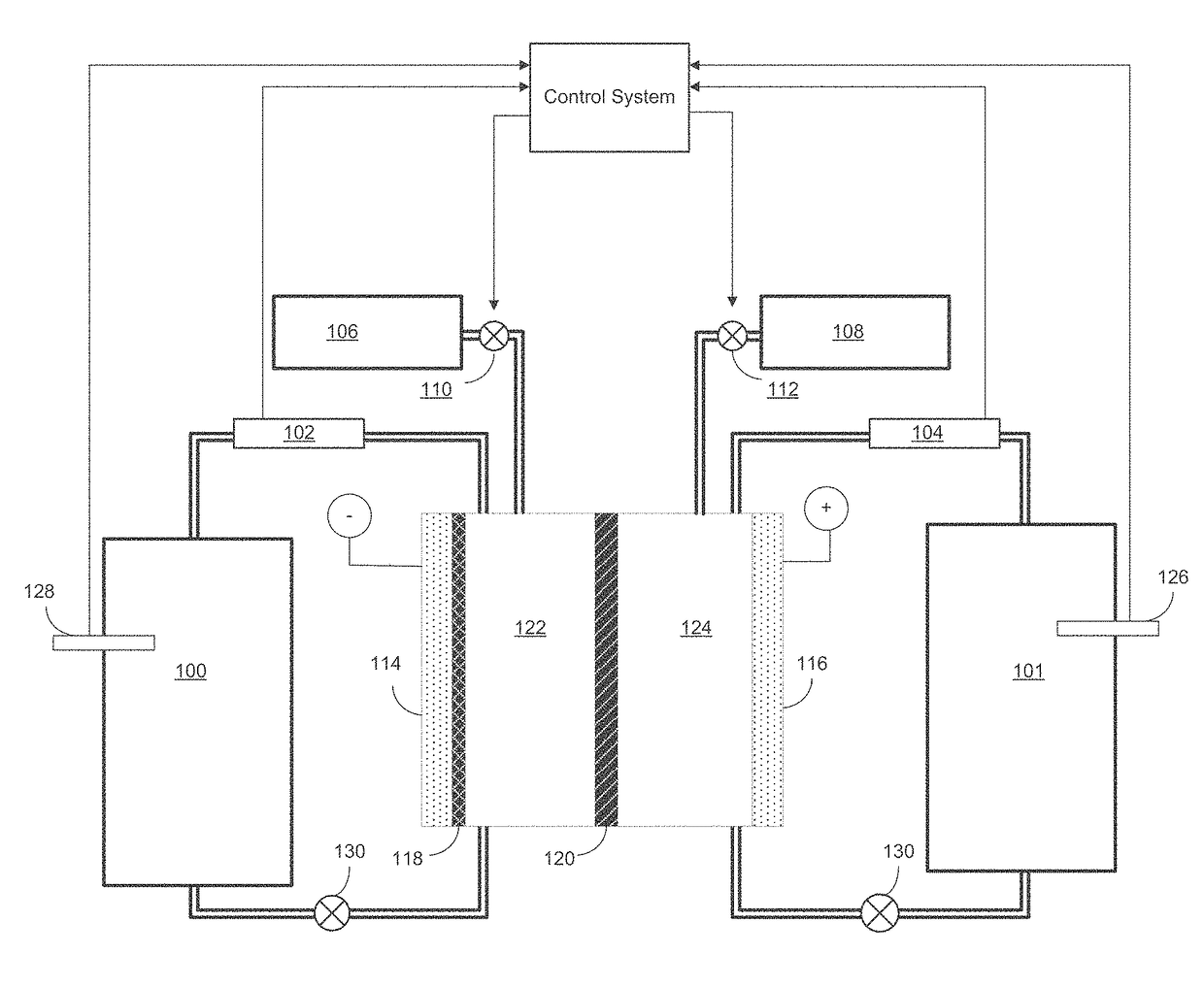

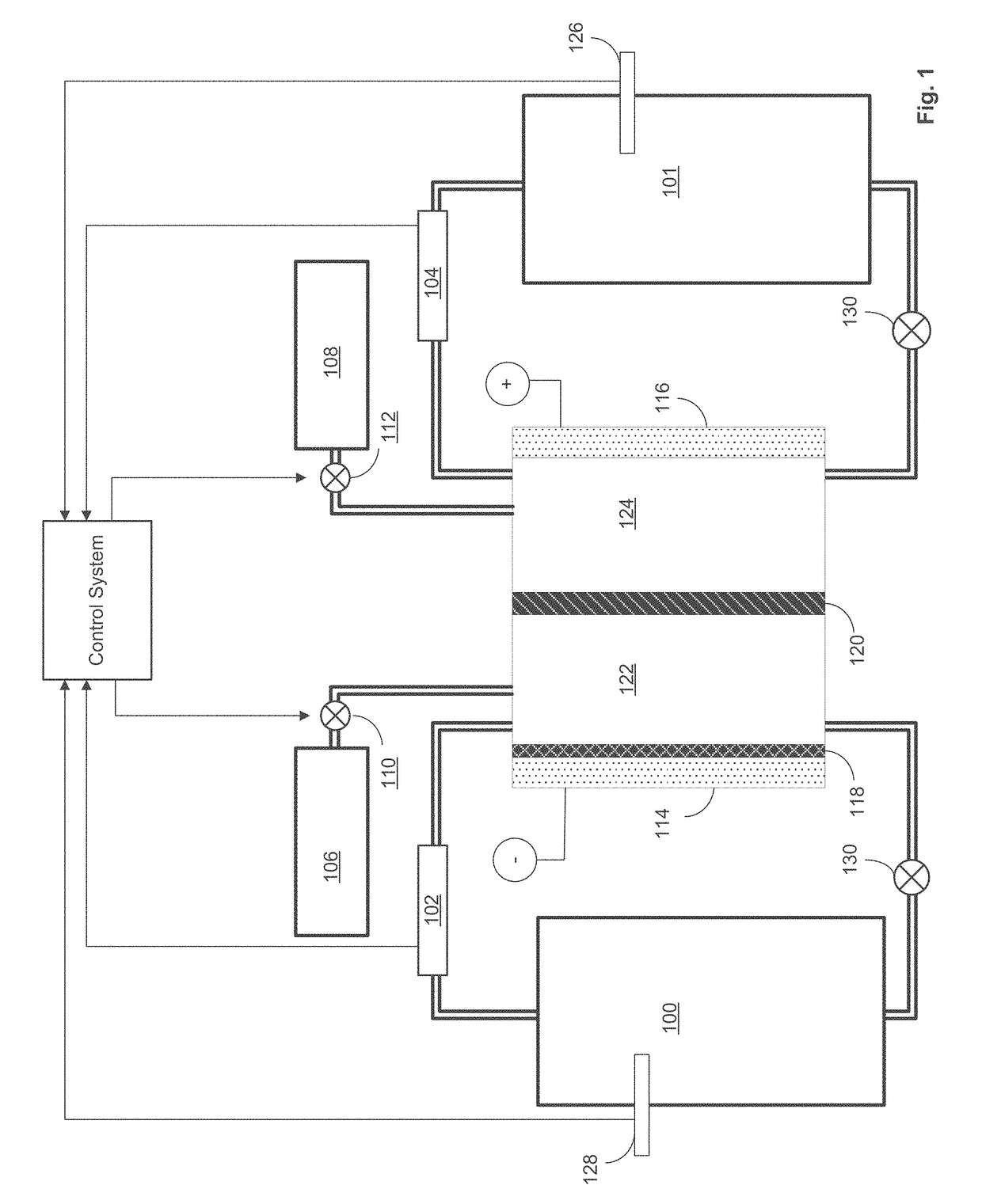

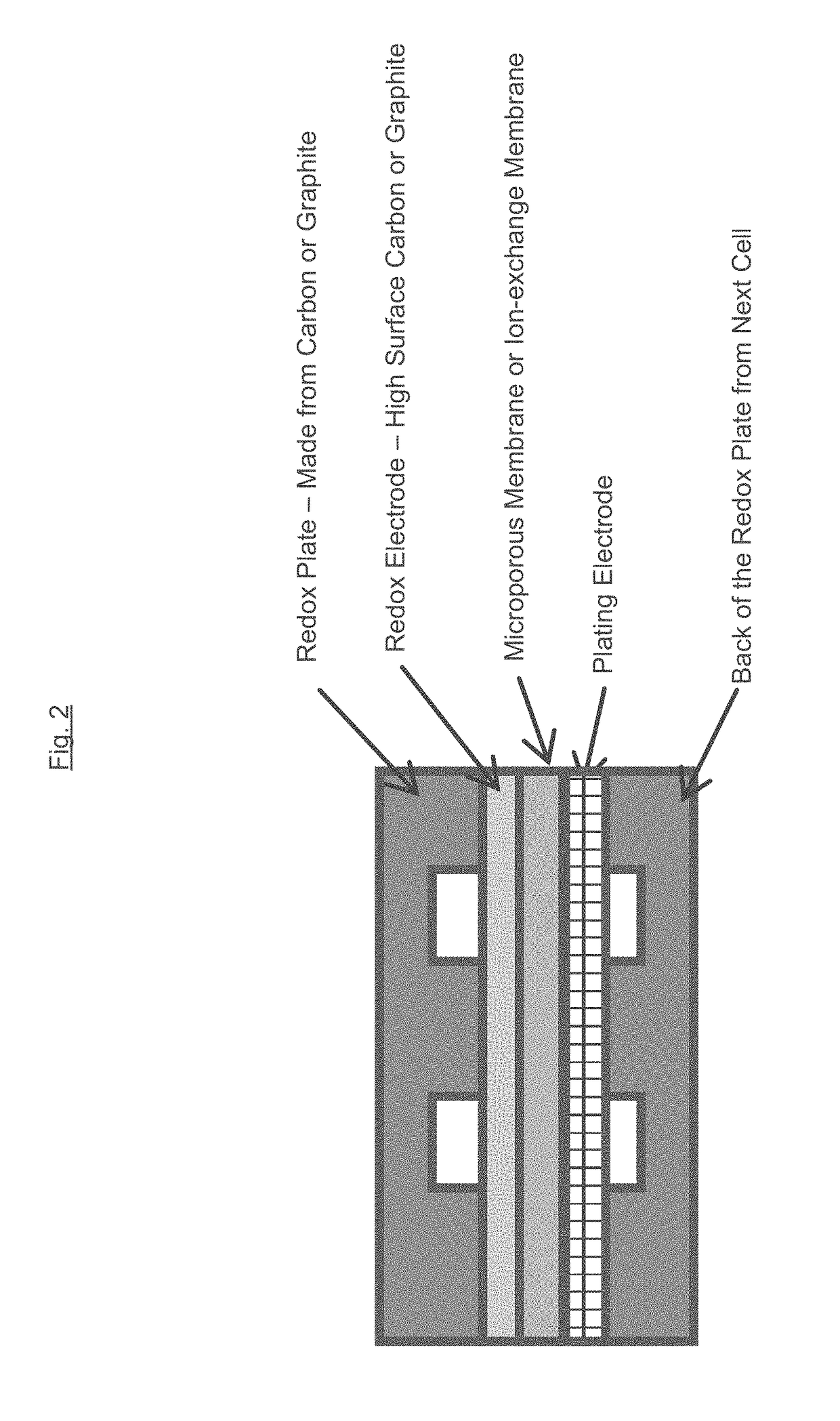

Methods to prepare stable electrolytes for all iron redox flow batteries

ActiveUS20140272493A1Low costHigh recycling valueRegenerative fuel cellsIndirect fuel cellsChemical reactionOxidation-Reduction Agent

An iron redox flow battery system, comprising a redox electrode, a plating electrolyte tank, a plating electrode, a redox electrolyte tank with additional acid additives that may be introduced into the electrolytes in response to electrolyte pH. The acid additives may act to suppress undesired chemical reactions that create losses within the battery and may be added in response to sensor indications of these reactions.

Owner:ESS TECHNOLOGY

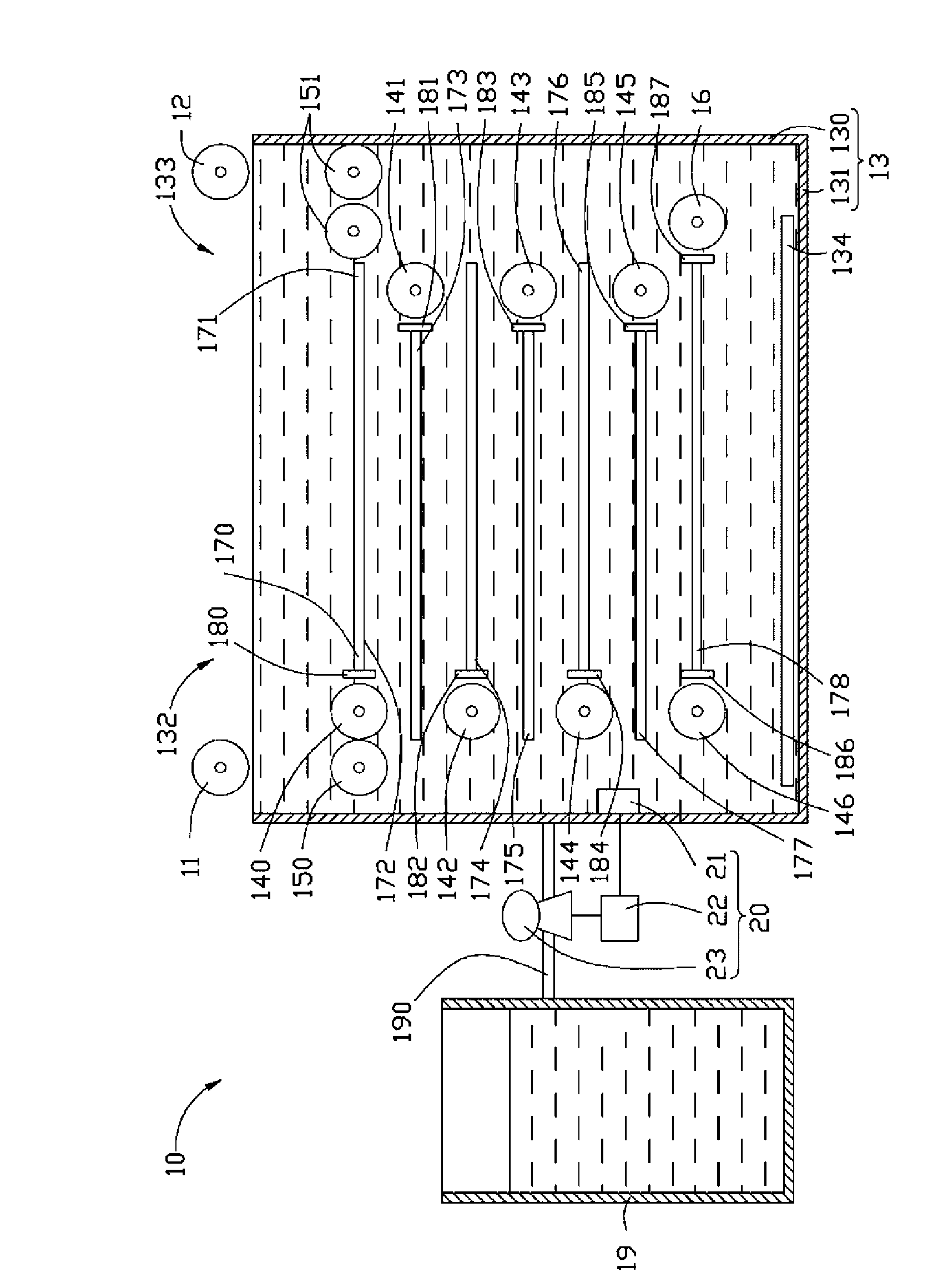

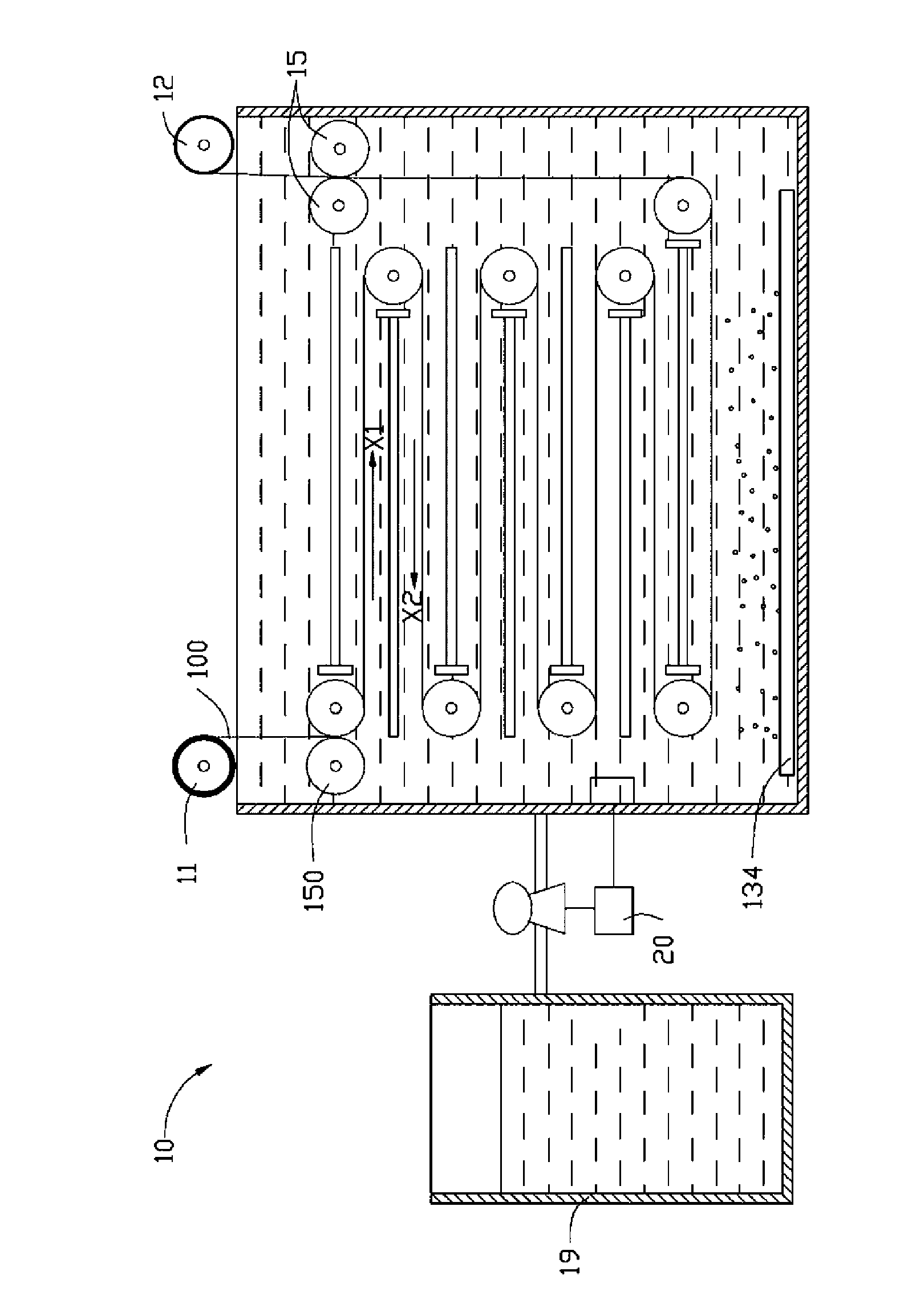

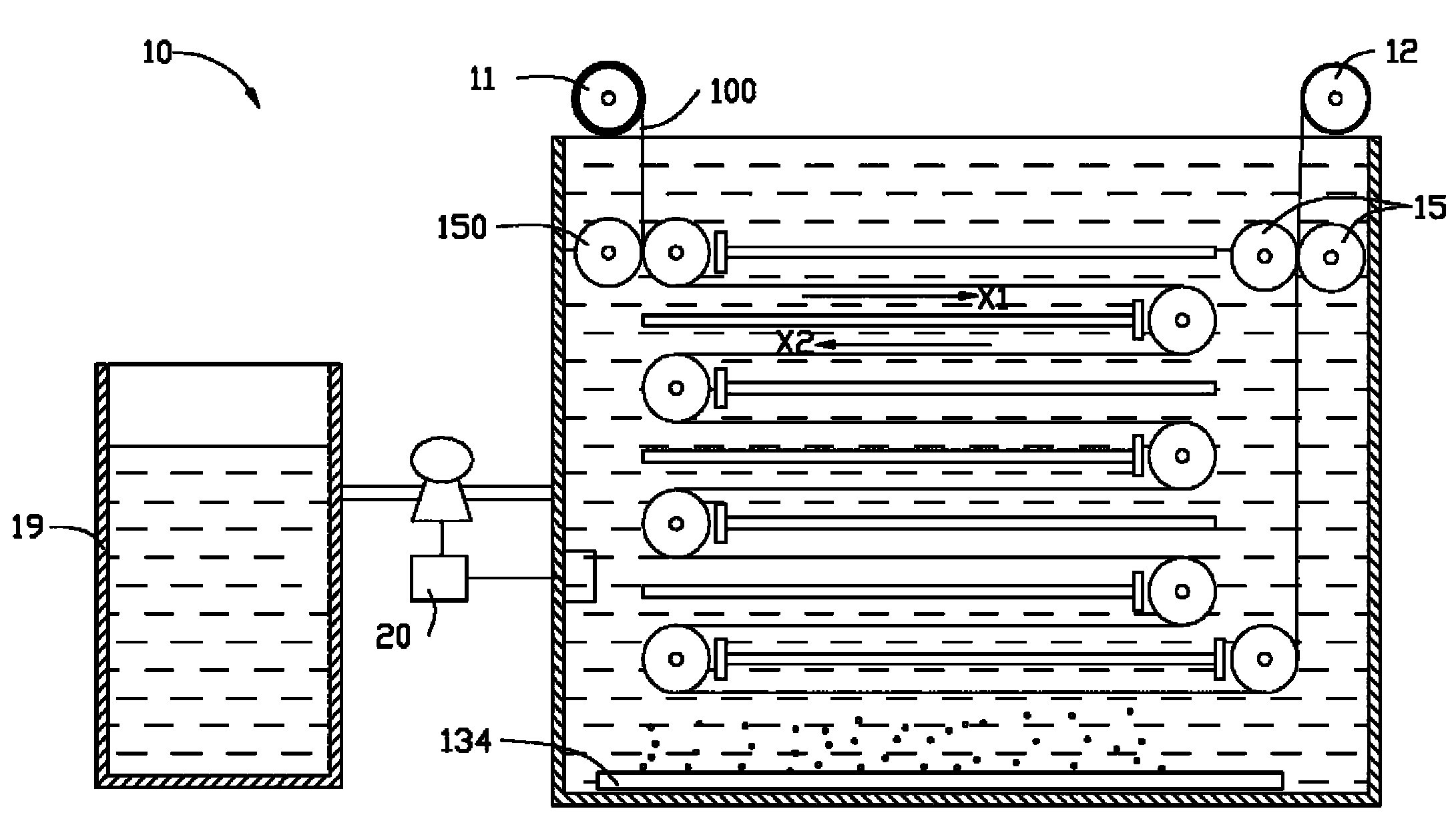

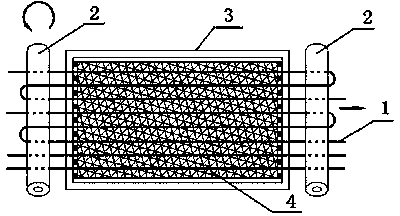

Electroplating device

InactiveCN102140661AImprove uniformityImprove plating efficiencyCellsPrinted circuit manufactureEngineeringMechanical engineering

The invention relates to an electroplating device for electroplating continuously delivered flexible substrates. The electroplating device comprises a sending wheel, a coiling wheel, an electroplating tank containing electroplating solution, a plurality of conductive delivery wheels and a plurality of anode plates, wherein the sending wheel and the coiling wheel are both arranged outside the electroplating tank; the plurality of delivery wheels and the plurality of anode plates are all arranged in the electroplating tank; the plurality of anode plates and the plurality of conductive delivery wheels are all immersed in the electroplating solution; the sending wheel is used for sending the flexible substrates to the electroplating tank; the plurality of delivery wheels are used for delivering the flexible substrates sent by the sending wheel to the coiling wheel by rotation and conducting power to the delivered flexible substrate; the plurality of anode plates are basically arranged in parallel; the flexible substrates are delivered between the neighboring two anode plates when being delivered by the two delivery wheels; and the coiling wheel is used for coiling the electroplated flexible substrates from the plurality of delivery wheels.

Owner:AVARY HLDG (SHENZHEN) CO LTD +1

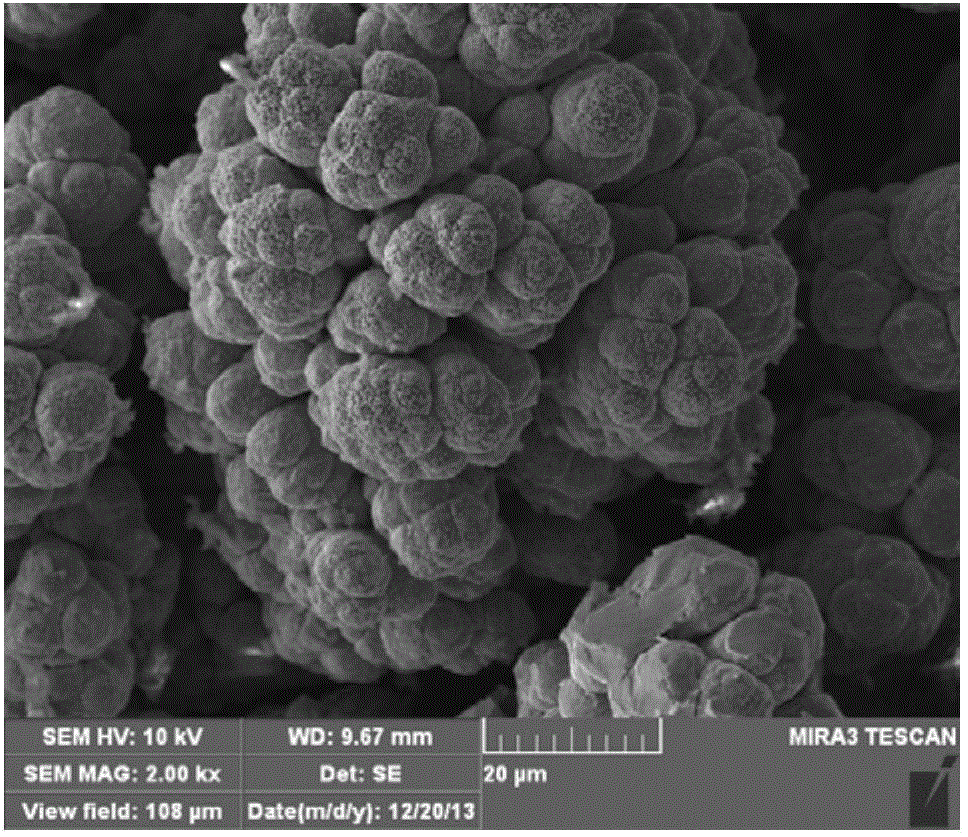

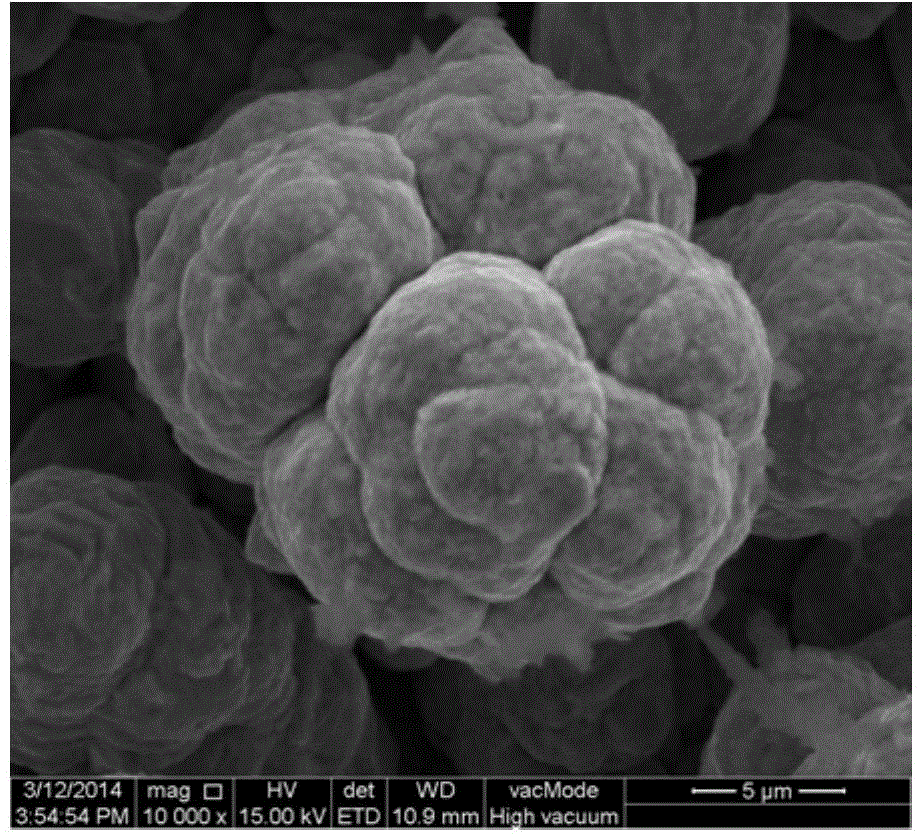

Preparation method for super-hydrophobic metal surface

InactiveCN103981547AEliminate differencesImprove general performanceLiquid/solution decomposition chemical coatingChemical platingAlloy

The invention discloses a preparation method for a super-hydrophobic metal surface. The method comprises the following steps: constructing a micrometer structure on the surface of a frequently used engineering material (such as copper, iron, stainless steel, nickel, aluminum, an aluminum alloy and a high-molecular section covering the above-mentioned metal through chemical plating) by using an electrocoppering process; then constructing a nanometer structure by using a chemical silvering process; and carrying out modification with low-surface energy substances like octadecanethiol so as to obtain excellent and stable super-hydrophobicity. The method has a wide application scope and can be used on pure metal, alloys and metalized high-molecular sections; an obtained surface has stable and reliable surface performance, strong film-substrate bonding force and good corrosion resistance, especially good acid resistance, can be extensively applied in fields like self-cleaning, water prevention and dehumidification, corrosion prevention, fluid drag reduction, frost prevention and condensation and heat exchange, and has an industrialization value.

Owner:RESEARCH INSTITUTE OF TSINGHUA UNIVERSITY IN SHENZHEN

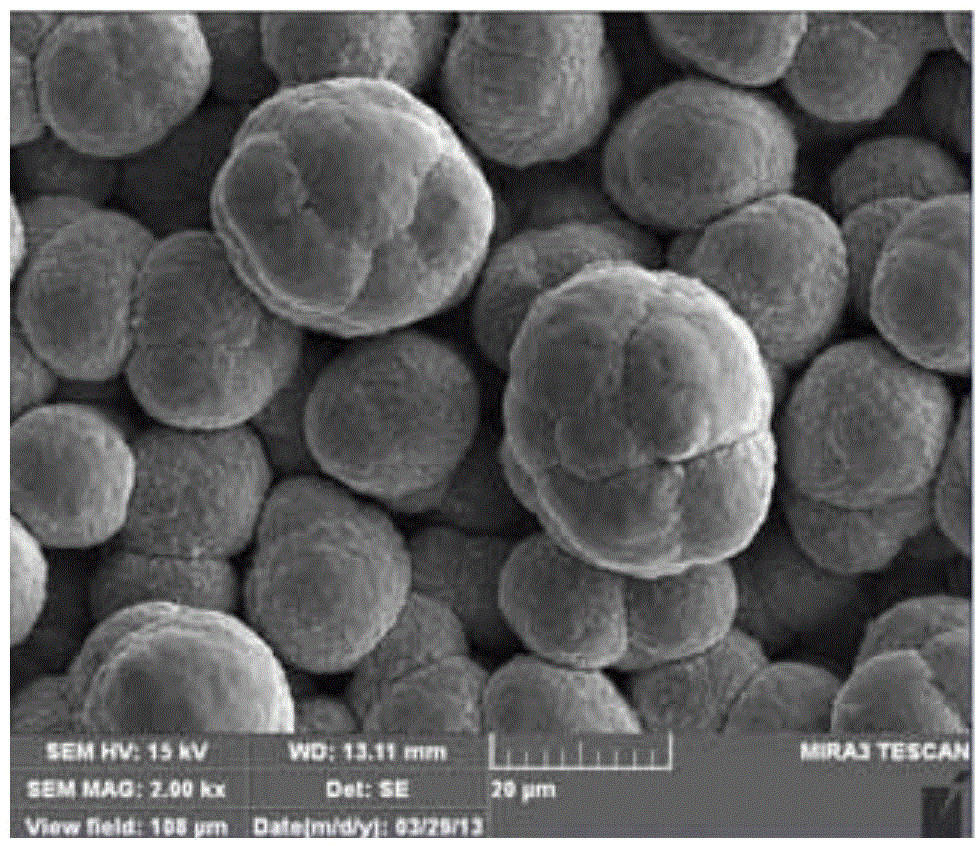

Production method of oversized-diameter anode phosphorus copper ball

InactiveCN102615482AAvoid effectivenessEasy to controlMetal-working apparatusCrystal structureUltra fine

The invention belongs to the technical field of phosphorus copper balls for electroplating and particularly relates to a production method of an oversized-diameter anode phosphorus copper ball. The method comprises the following steps of: firstly melting pure copper and phosphorus copper intermediate alloy to obtain a phosphorus copper alloy solution and producing a phosphorus copper alloy rod by utilizing the uniformly mixed phosphorus copper alloy solution through an upward casting method; feeding the obtained phosphorus copper alloy rod into a continuous extruding machine for extrusion, wherein the phosphorus copper alloy rod is driven by an extrusion wheel to be forcedly pressed into an extrusion cavity and is extruded according to the designed size so as to obtain an ultra-fine grain phosphorus copper rod blank; and finally performing cold heading and molding on the obtained ultra-fine grain phosphorus copper rod blank by utilizing a cold header, so as to form phosphorus copper ball of design specification. The phosphorus copper ball obtained by utilizing the production method has a smooth, round and complete surface and a compact internal crystal structure, and has the advantage of obviously improved appearance and internal quality compared with the phosphorus copper ball obtained by utilizing an existing technology.

Owner:铜陵有色股份铜冠电工有限公司

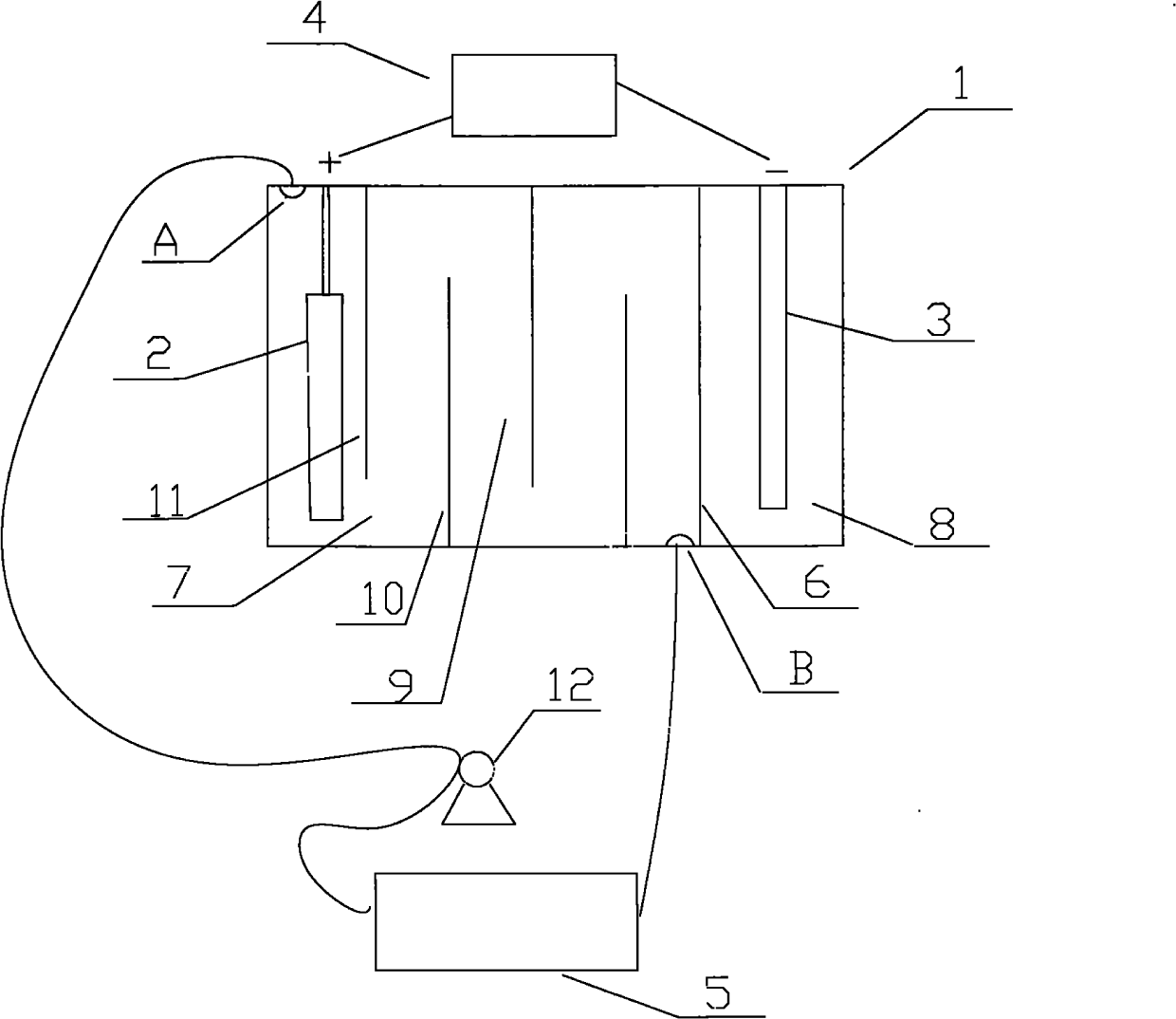

Method for sustainably complementing metallic cations in plating solution

The invention discloses a method for sustainably complementing metallic cations in plating solution. In the process of plating, the plating solution in a plating device is delivered into a cation generator; the cation generator can generate coated metal cations during working; the plating solution containing the metal cations is delivered back to the plating device; and the steps are circulated so as to complement the metallic cations consumed in the plating solution of the plating device. The method can sustainably complement the metallic cations consumed in the plating solution, so as to avoid pouring the plating solution lacking the cations and preparing new plating solution again. By the method, the plating solution can be continuously used, the service life of the plating solution is prolonged, the plating solution does not be wasted so as to reduce production cost, and environmental pollution is reduced to achieve the aims of saving energy and reducing emission.

Owner:SUZHOU QUANLI PLATING HANGERS

Electroplating device for printed circuit board

ActiveCN105063709AReduce spacingImprove thickness uniformitySemiconductor devicesElectrodesEngineeringPrinted circuit board

The invention provides an electroplating device for a printed circuit board. The electroplating device comprises a plating tank the middle part of which is used for passing through of the printed circuit board, one or more anode plates arranged at any one side or two sides of the printed circuit board, and nozzles which are arranged in the planting tank and are opened towards the printed circuit board, wherein through holes penetrating through along the thickness direction thereof are formed in the anode plate; the nozzles are fixedly arranged on the anode plate; and the openings of the nozzles are matched with the through holes. Compared with the prior art, on the premise of not changing the distance between the nozzles and the printed circuit board, the distance between the printed circuit board serving as a cathode and the anode plate is greatly shortened to 2-3cm, on the one hand, the thickness uniformity of a surface electroplated coating of the printed circuit board is effectively improved, and on the other hand, the electroplating efficiency is greatly enhanced, and the energy consumption is lowered.

Owner:AKM ELECTRONICS TECH SUZHOU

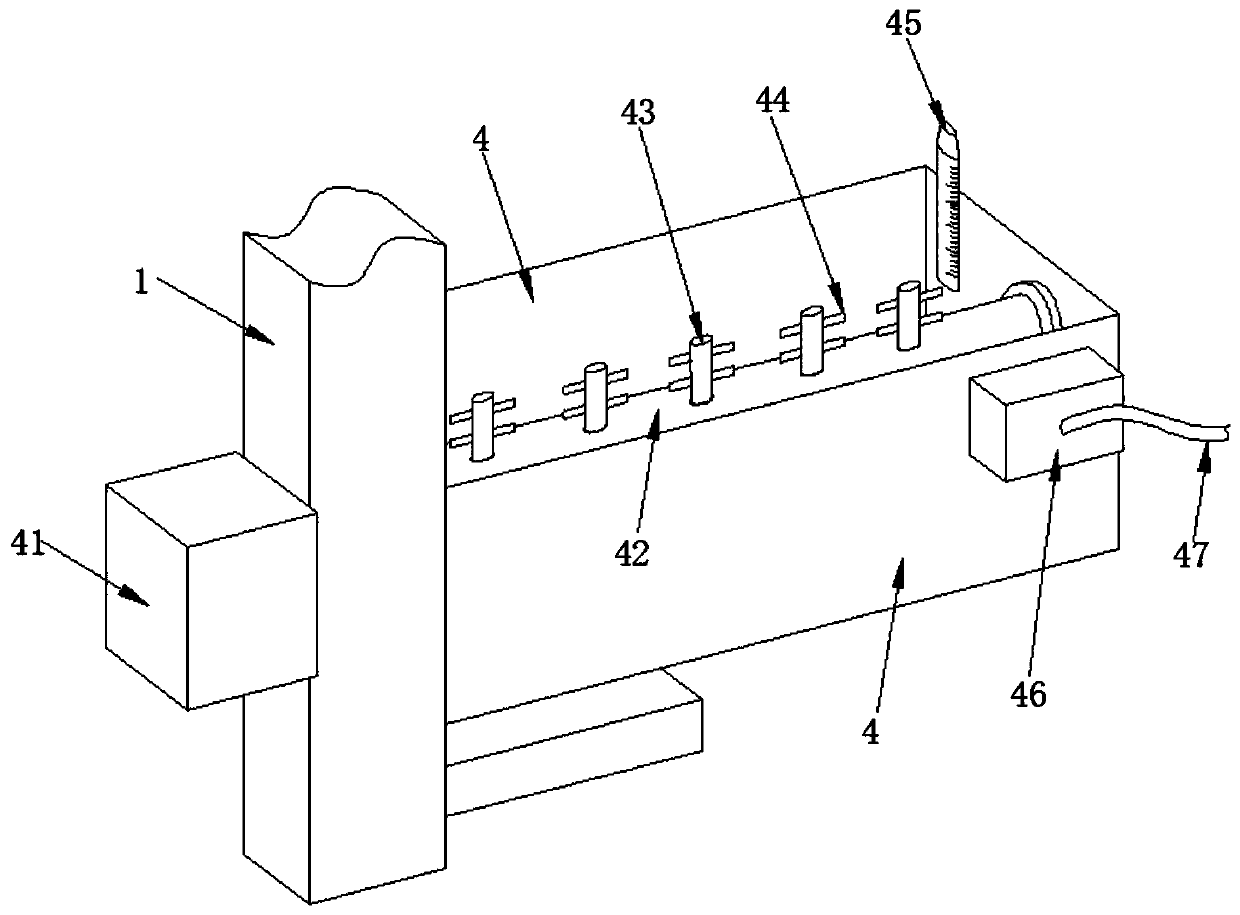

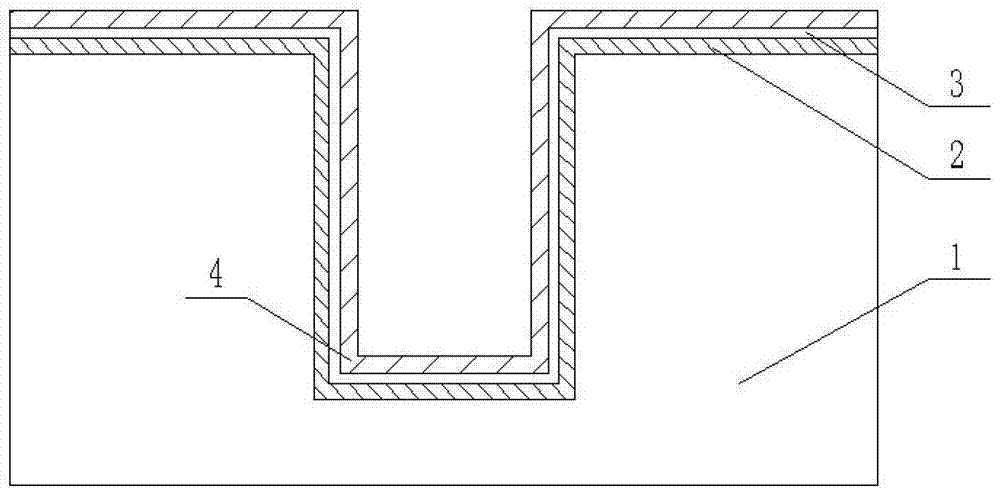

Copper plating tank

The invention discloses a copper plating tank. The copper plating tank comprises a tank body, a spraying pipe array arranged in the tank body, anode hangers and an anode array, wherein the tank body is used for accommodating an electroplating solution and consists of a U-shaped tank body unit or a plurality of the U-shaped tank body units connected in sequence; the spraying pipe array is provided with a plurality of spraying pipes arranged side by side, a plurality of spray nozzles for spraying a plating solution are arranged on the front surface of each of the spraying pipes in the height directions of the spraying pipes, and shielding grooves are formed in two side edges of the spraying pipes; the anode hangers are used for supplying anode currents and comprise conductive flat plates arranged in the length direction of the U-shaped tank body unit; the anode array is provided with a plurality of anode monomers, anode strips immersed in the electroplating solution are arranged at the lower parts of the anode monomers, and the left lateral edges and the right lateral edges of the anode strips are inserted into shielding grooves between every two adjacent spraying pipes. According to the copper plating tank disclosed by the invention, the distribution of electric power lines in the plating solution can be effectively improved, so that an edge effect is eliminated; the electric currents which do not exceed the upper limit of current density can also be effectively supplied, so that the uniformity of a copper layer is improved, and the electroplating efficiency is improved; the copper plating tank is suitable for various printed circuit boards such as a back board, a base board, and a flexible board .

Owner:江新德

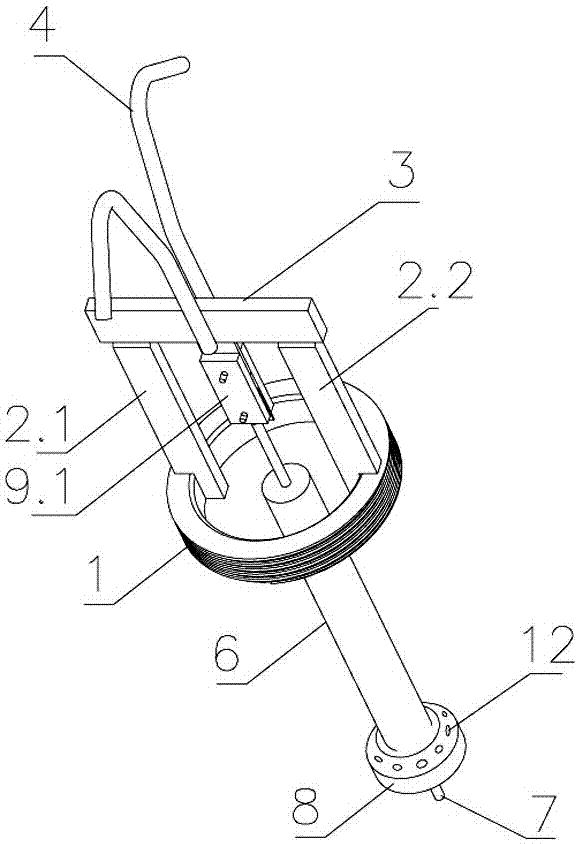

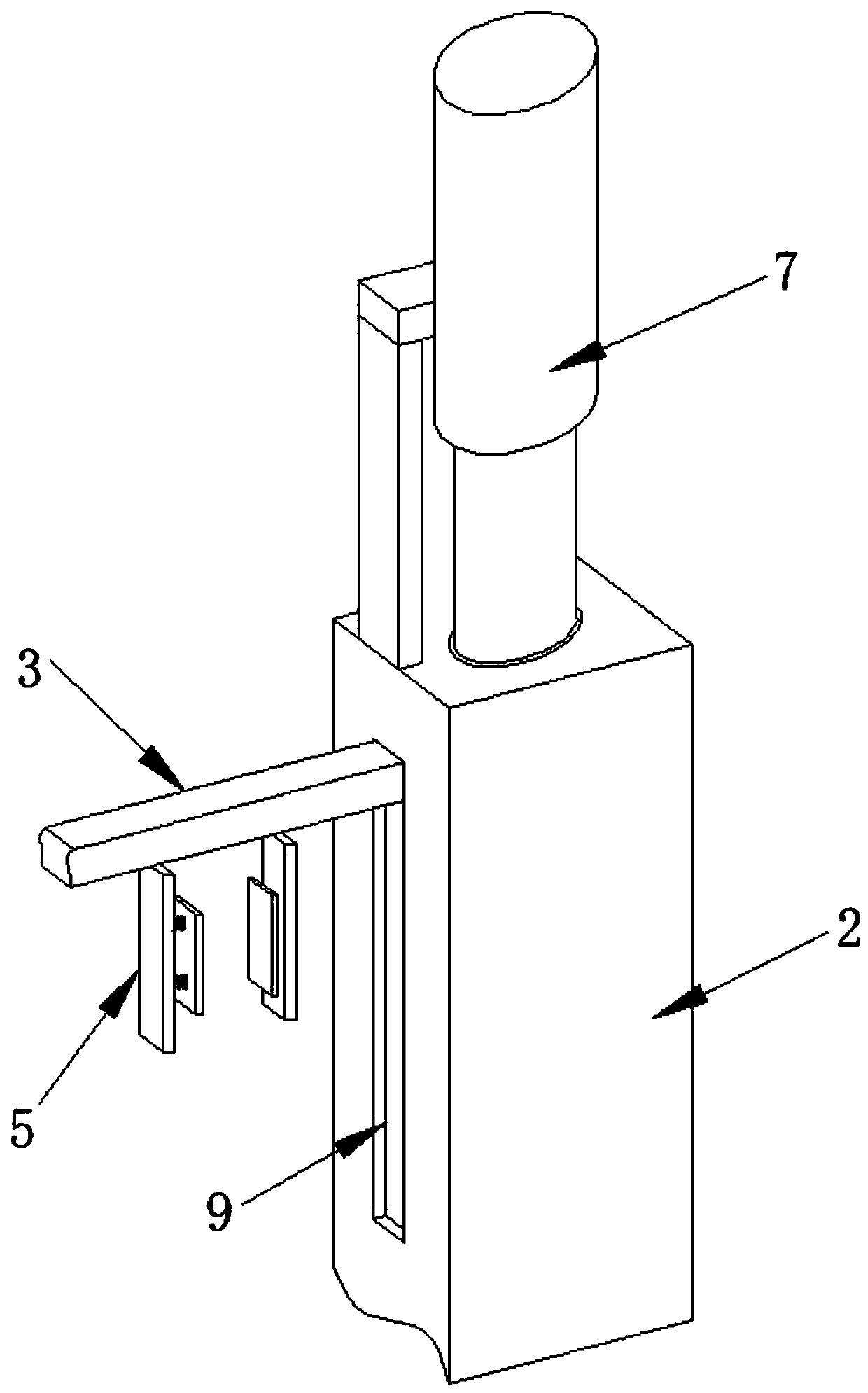

Tooling for simultaneously electroplating inner and outer surfaces of hydraulic oil cylinder and use method

ActiveCN107022787AReduce transshipmentReduce frequent transfersElectrolysis componentsProduction lineHydraulic cylinder

The invention discloses a use method of a tooling for simultaneously electroplating the inner and outer surfaces of a hydraulic oil cylinder. The use method comprises the following steps: first, a conducting column is put in the cylinder body of the hydraulic oil cylinder, and a bolt arranged on the lower end surface of the conducting column penetrates through a valve hole formed in the cylinder bottom of the hydraulic oil cylinder; then, an external thread ring sleeve is connected with an internal thread formed on the cylinder mouth of the hydraulic oil cylinder, and an insulating sleeve is connected onto the bolt; and finally, a lifting hook is hung on a cathode bar of an electroplating bath, the cylinder body of the hydraulic oil cylinder is placed in the electroplating bath, and the conducting column is connected with the anode of the electroplating bath through a lead wire. The use method disclosed by the invention has the advantages that a conventional process for electroplating a hydraulic oil cylinder with a copper-tin alloy is changed, so that the hydraulic oil cylinder machining frequency and transfer frequency can be reduced, the hydraulic oil cylinder can be electroplated with the copper-tin alloy through one-step operation in an electroplating production line, the hydraulic oil cylinder electroplating efficiency and transfer efficiency can be improved by 50% or above, and the production cost can be reduced by about 30%; and meanwhile, the defect that the valve hole formed in the cylinder bottom of the hydraulic oil cylinder cannot be electroplated with the copper-tin alloy is overcome, and the product service life is prolonged.

Owner:ZHENGZHOU COAL MINING MACHINERY GRP +1

Methods to prepare stable electrolytes for iron redox flow batteries

ActiveUS9865895B2Low costHigh recycling valueRegenerative fuel cellsIndirect fuel cellsChemical reactionOxidation-Reduction Agent

Owner:ESS TECHNOLOGY

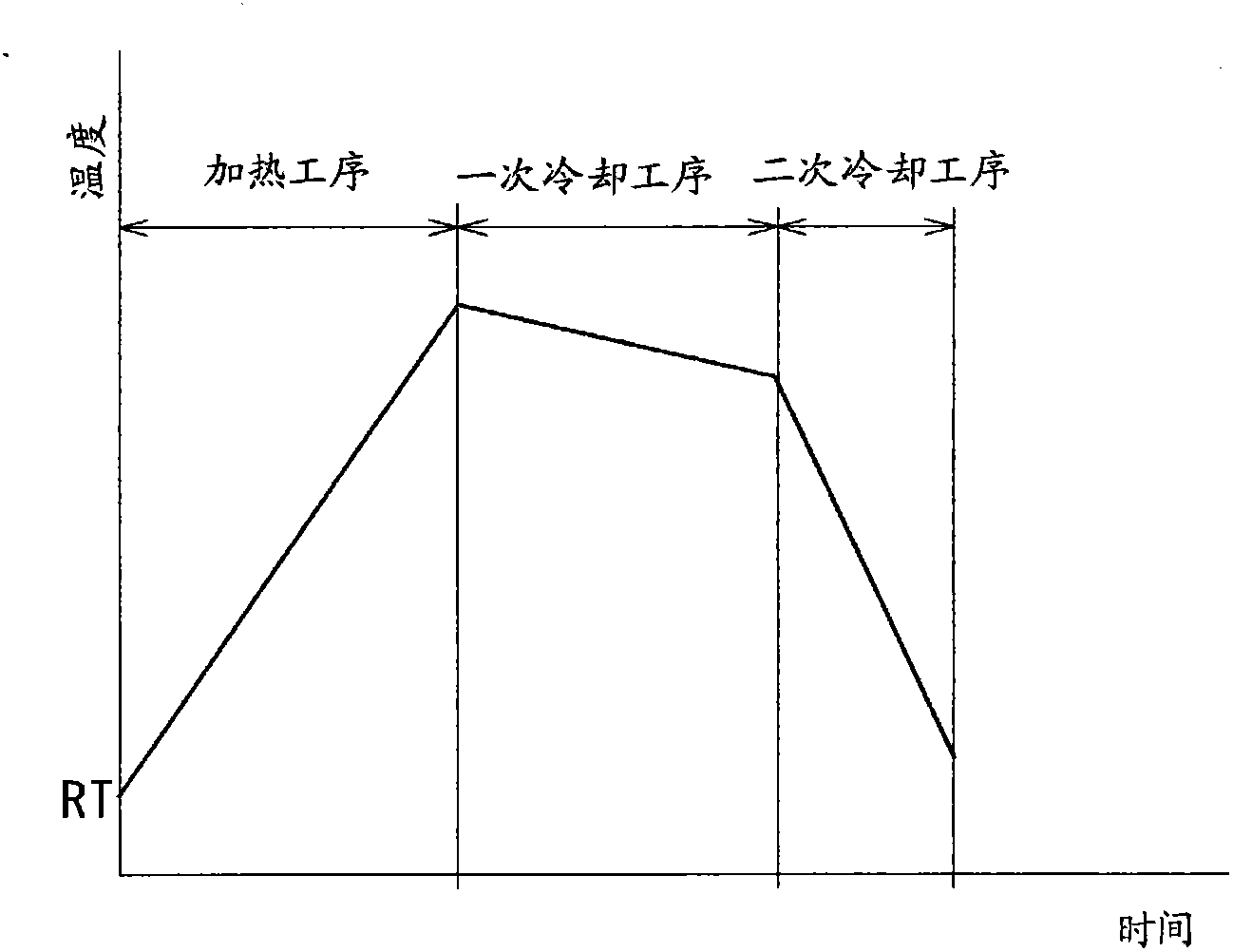

Chrome plating method for spherical crown surface of major diameter spherical crown workpiece

The invention provides a method for plating chromium on a spherical cap surface of a large-diameter spherical cap workpiece. In a step of immersing and positioning, the arrangement mode or structure of an anode strap or an anode plate is changed; in a step of plating chromium, opacified chromium is plated under the conditions that the temperature of the plating solution is 70 to 75 DEG C and the current density is 20 to 25A / decimeter<2>; and then, hard chromium is plated under the conditions that the temperature of the plating solution is 50 to 55 DEG C and the current density is 25 to 30A / decimeter<2>. The polishing processing is carried out on the spherical cap surface of the workpiece, which has the advantages of good evenness of chromium plated coating, defect prevention, high electroplating efficiency, fast speed of cladding deposit, high surface finish of the spherical cap surface after chromium is plated, and subsequent mechanical processing workload reduction.

Owner:LUOYANG SUNRUI SPECIAL EQUIP

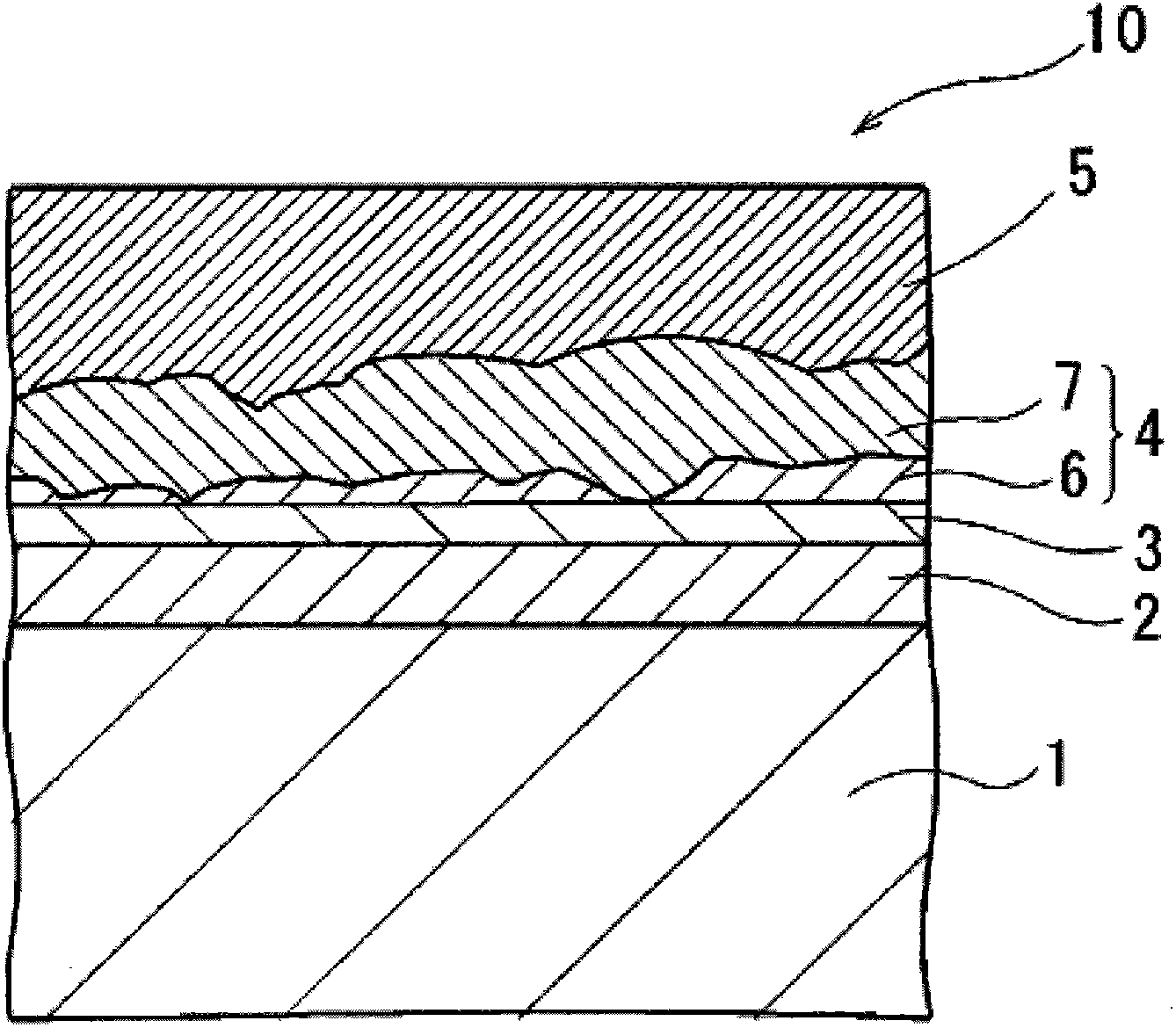

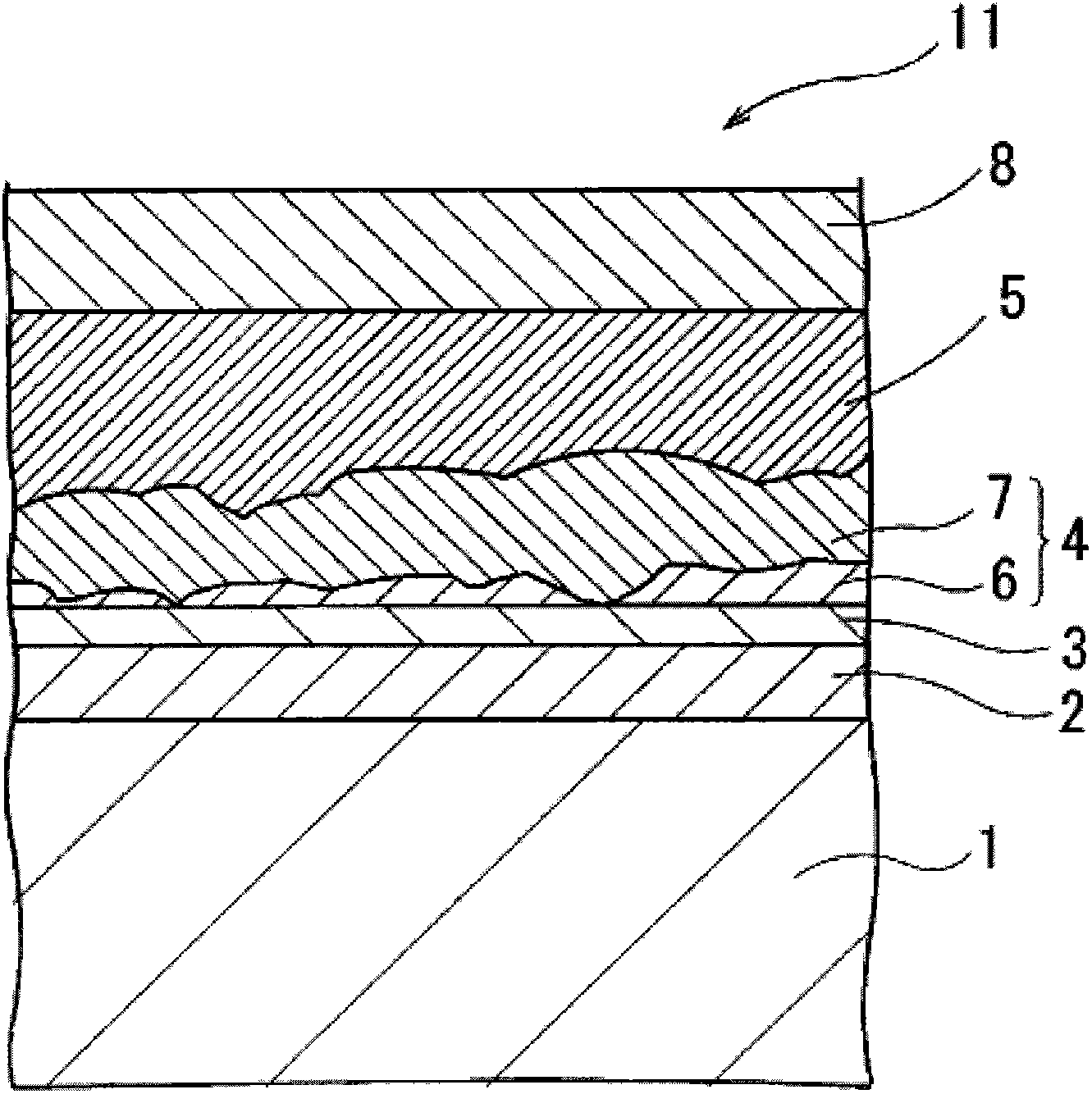

Conductive member and manufacturing method thereof

ActiveCN102395713AEfficient removalImprove plating efficiencyCoupling contact membersEmergency protective devicesOptoelectronicsIntermetallic

The conductive member has a stable contact resistance, resists peeling, displays a low insertion / removal force and is stable when used as a connector, and has an excellent fusing characteristic when used as a fuse. A Cu-Sn intermetallic compound layer (4) is formed between a Ni-based underlayer (3) formed on a Cu-based base material (1), and a Sn-based surface layer (5) that forms the surface. In addition, the Cu-Sn intermetallic compound layer (4) comprises a Cu3Sn layer (6) disposed on the Ni-based underlayer (3) and a Cu6Sn5 layer (7) that is disposed on the Cu3Sn layer (6). The surface roughness of the contact face between the Sn-based surface layer (5) and the Cu-Sn intermetallic compound layer (4) combining the Cu3Sn layer (6) and Cu6Sn5 layer (7) has an arithmetic mean roughness Ra of 0.05-0.25 [mu]m, and the maximum valley depth Rv of the roughness curve is 0.05-1.00 [mu]m. Furthermore, the Cu3Sn layer covers the Ni-based underlayer with a surface coverage of 60-100%.

Owner:MITSUBISHI SHINDOH CO LTD

Swinging-type long-pipe inner wall electroplating method and electroplating equipment applying same

InactiveCN105002539AImprove plating qualityImprove plating efficiencyCellsLiquid storage tankEngineering

The invention discloses a swinging-type long-pipe inner wall electroplating method and electroplating equipment applying the same. The electroplating process comprises the following steps that an inner anode penetrates through a cathode long pipe to be electroplated; the two ends of the cathode long pipe are separately connected to a liquid inlet connector and a liquid outlet connector; the liquid inlet connector and the liquid outlet connector are communicated with a liquid storage tank; the two ends of the inner anode are separately fixed on the liquid inlet connector and the liquid outlet connector; then one end of the inner anode and the outer wall of the cathode long pipe are separately connected to the positive electrode and negative electrode of a power source through flexible conductors; an electroplating solution is circularly injected into the cathode long pipe through a liquid inlet in the liquid inlet connector and a liquid outlet in the liquid outlet connector, and the inner cavity of the cathode long pipe is fully filled with the electroplating solution; the power source is started, and the cathode long pipe and the inner anode are driven to swing in a reciprocating manner by a swinging mechanism, so that an electroplating layer is formed on the inner wall of the cathode long pipe. The swinging-type long-pipe inner wall electroplating method has the beneficial effects that a recovery groove does not need to be arranged; the electroplating layer is uniform in thickness; the electroplating quality is ensured; and moreover, a liquid conveying mechanism and a power delivery mechanism of the equipment are greatly simplified.

Owner:黄激扬 +1

Postnatal neural crest stem cells

ActiveUS20040110288A1Reduced neuronal subtype potentialAffects determinationCulture processNervous system cellsNeural crestIn vivo

The present invention relates to compositions and methods employing postnatal (e.g., adult) neural crest stem cells. The stem cells are multipotent and differentiate when transplanted in vivo. Transplantation methods are provided for therapeutic, diagnostic, and research applications.

Owner:RGT UNIV OF MICHIGAN

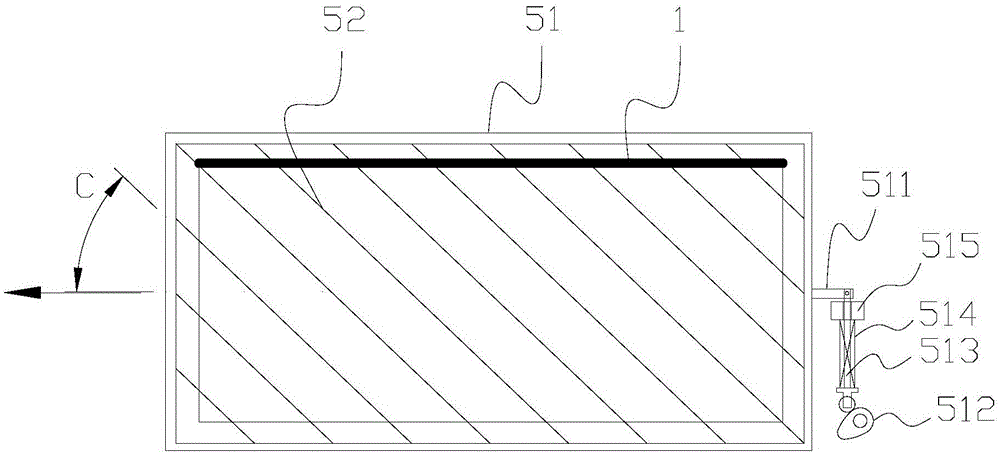

Automatic electroplating device and method for bolts

InactiveCN111394762AEasy to clamp and fixEasy to PlatingCellsElectric machineryStructural engineering

The invention discloses an automatic electroplating device and method for bolts, and relates to the technical field of electroplating. The automatic electroplating device comprises a first stand column, a second stand column, a movable plate, an electroplating box, a clamp mechanism, a filter box and a hydraulic telescopic rod, wherein the first stand column and the second stand column are arranged in parallel; the movable plate is movably arranged between the first stand column and the second stand column; the clamp mechanism used for clamping the bolts is fixedly arranged at the bottom of the movable plate; the electroplating box positioned between the first stand column and the second stand column is arranged under the clamp mechanism; and electroplating liquid is filtered, when a filter screen needs to be cleaned regularly, two clamping blocks are lifted upwards, then the filter screen can be taken out and cleaned, and thus the using effect is improved. The structure is simple, theelectroplating liquid can be filtered and cleaned easily, a motor is used for driving a rotary shaft to rotate, then stirring blades on the rotary shaft are driven to rotate, thus the electroplatingliquid can be fully and evenly stirred, the concentration of the electroplating liquid is uniform, the electroplating quality is improved, and the electroplating efficiency is improved easily.

Owner:GUIYANG BAIYUN AVIATION FASTENERS

Barrel-plating device and barrel-plating system

The invention discloses a barrel-plating device and a barrel-plating system. The barrel-plating device comprises a first tank, a barrel-plating barrel and a circulating device. The first tank is provided with an inner cavity. The barrel-plating barrel is rotationally arranged in the inner cavity of the first tank, a feeding opening and a discharging opening are formed in the two side end faces in the axial direction of the barrel-plating barrel, and overflow holes located below the feeding opening and the discharging opening are formed in at least one end face. One end of the circulating device is connected to the overflow holes, the other end of the circulating device is located in the barrel-plating barrel, and the circulating device is used for recycling and filtering electroplate liquid at the position higher than the overflow holes in the barrel-plating barrel through the overflow holes and inputting the filtered electroplate liquid into the barrel-plating barrel again. The barrel-plating system comprises at least two above barrel-plating devices. The circulating device can recycle and filter matter floating on the surface of the electroplate liquid, the filtered electroplate liquid is input into the barrel-plating barrel again, so that the circulating mode of the electroplate liquid is formed, it is guaranteed that few impurities are contained in the electroplate liquid in the barrel-plating barrel, the electroplating quality of plated workpieces is improved, and the plated workpieces can be continuously electroplated.

Owner:KUNSHAN DONGWEI MACHINERY CO LTD

Copper and nickel preprocessing technology in ion implantation before polymer surface chemical plating

InactiveCN1952209AReduce porosityGood lookingVacuum evaporation coatingSputtering coatingPolymeric surfacePorosity

An ion implanted copper, nickel pretreatment process of before polymer surface chemical plating, belongs to pretreating process of polymer surface chemical plating. Adding high molecular polymer into ion implanter, adding electrode to the polymers, switching on the energy injecting switch of the ion implanter, with a accelerating voltage of 10 kV-45 kV, injected dose of 2*10e17-5*10e17ions / cm2. The method combines the ion implantation and chemical plating, adopts injecting metal ion different from or the same as the chemical coating metal, make full use of the advantages of chemical plating and ion implantation, thus creats a uniform coating with small porosity, good appearance, improves bonding tightness of the coating and substrate, has simple process and does not need repeated treatment; there is no plating liquid during the pretreatment Process, no secondary pollution; no noble metals injection, reduces costs, enhances self-catalysis in chemical plating, improves the plating efficiency.

Owner:CHINA UNIV OF MINING & TECH

Photovoltaic cell horizontal electroplating equipment and method

PendingCN113930831AImprove coating qualityReduce length dimensionCellsTanksElectrical batteryEngineering

The invention is applicable in the technical field of photovoltaic cell electroplating, and provides photovoltaic cell horizontal electroplating equipment and method. The photovoltaic cell horizontal electroplating equipment comprises an electroplating bath which is filled with electroplating liquid and is provided with an inlet and an outlet opposite to the inlet, an anode piece which is arranged in the electroplating bath and is located below the liquid level of the electroplating liquid, a cell moving mechanism which is used for driving a cell to move from the inlet to the outlet so as to enable the cell to move relative to the anode piece in the electroplating liquid to realize electroplating, and a cathode conductive assembly; the cathode conductive assembly comprises a rotary moving piece and a plurality of cathode conductive probes arranged on the rotary moving piece, and the rotary moving piece can drive the plurality of cathode conductive probes to synchronously rotate, so that at least one cathode conductive probe makes contact with the cell and keeps synchronous movement with the cell. According to the photovoltaic cell horizontal electroplating equipment, the coating quality of the photovoltaic cell can be effectively improved, and the overall length size of the photovoltaic cell horizontal electroplating equipment can be greatly reduced.

Owner:ZHEJIANG AIKO SOLAR ENERGY TECH CO LTD +3

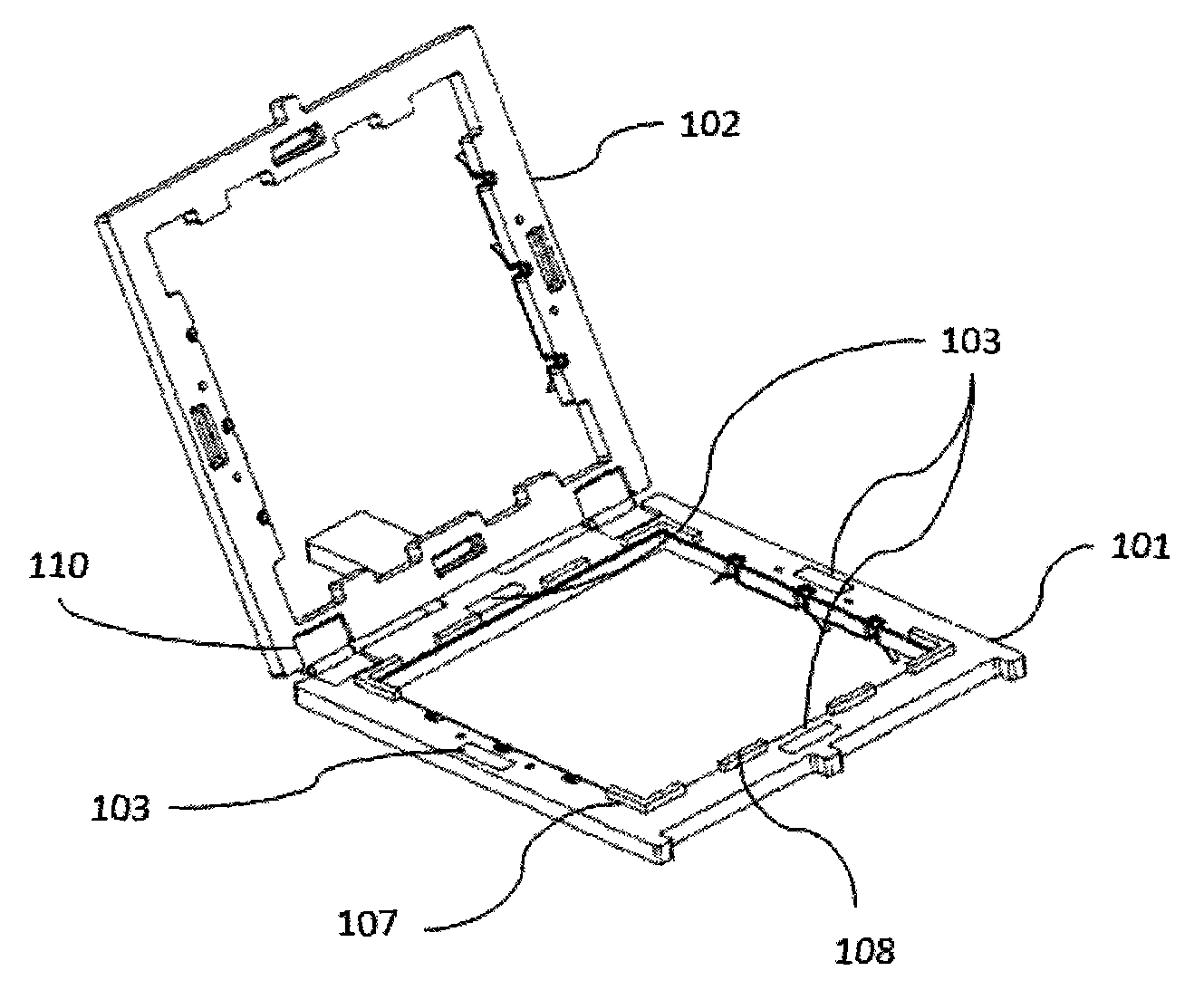

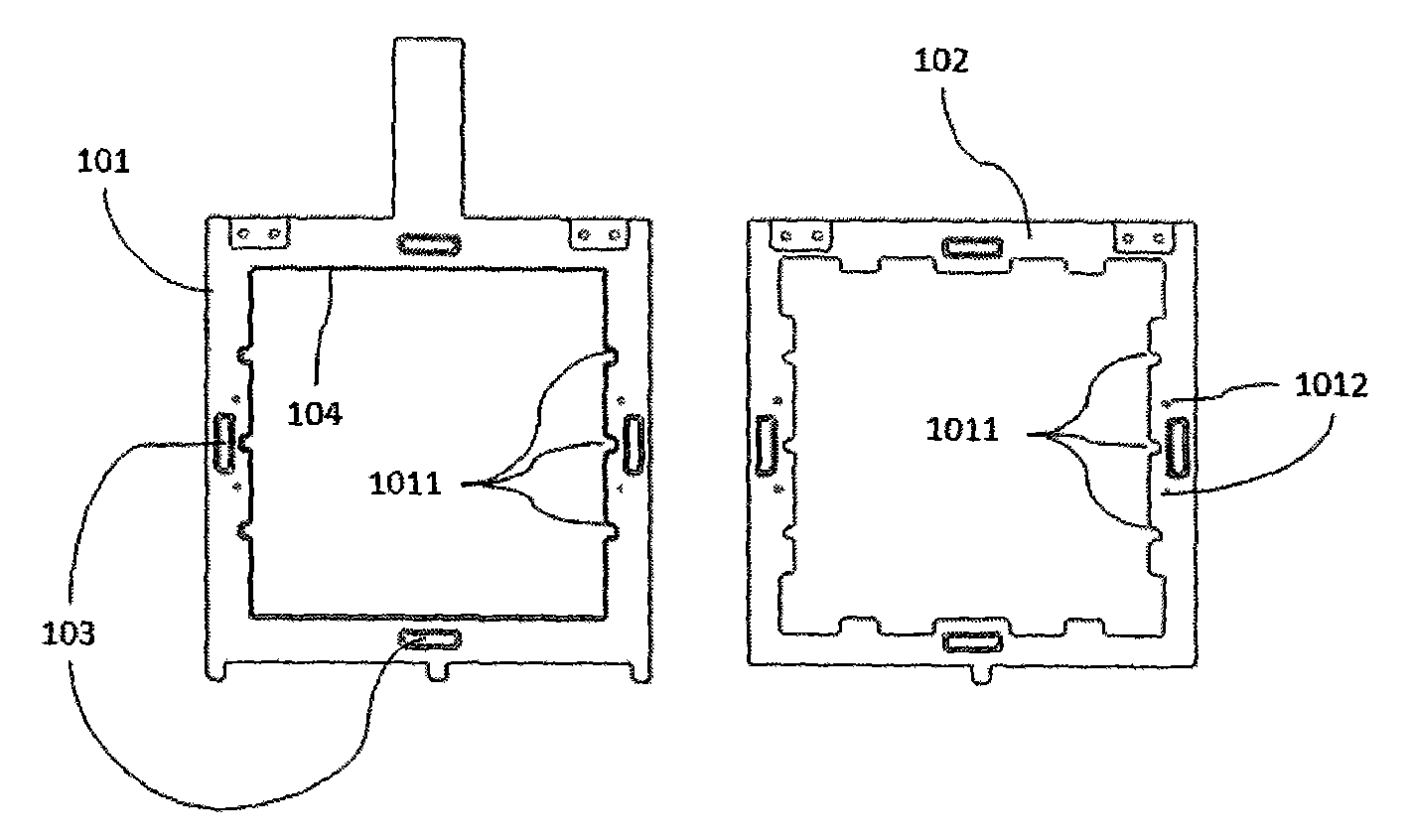

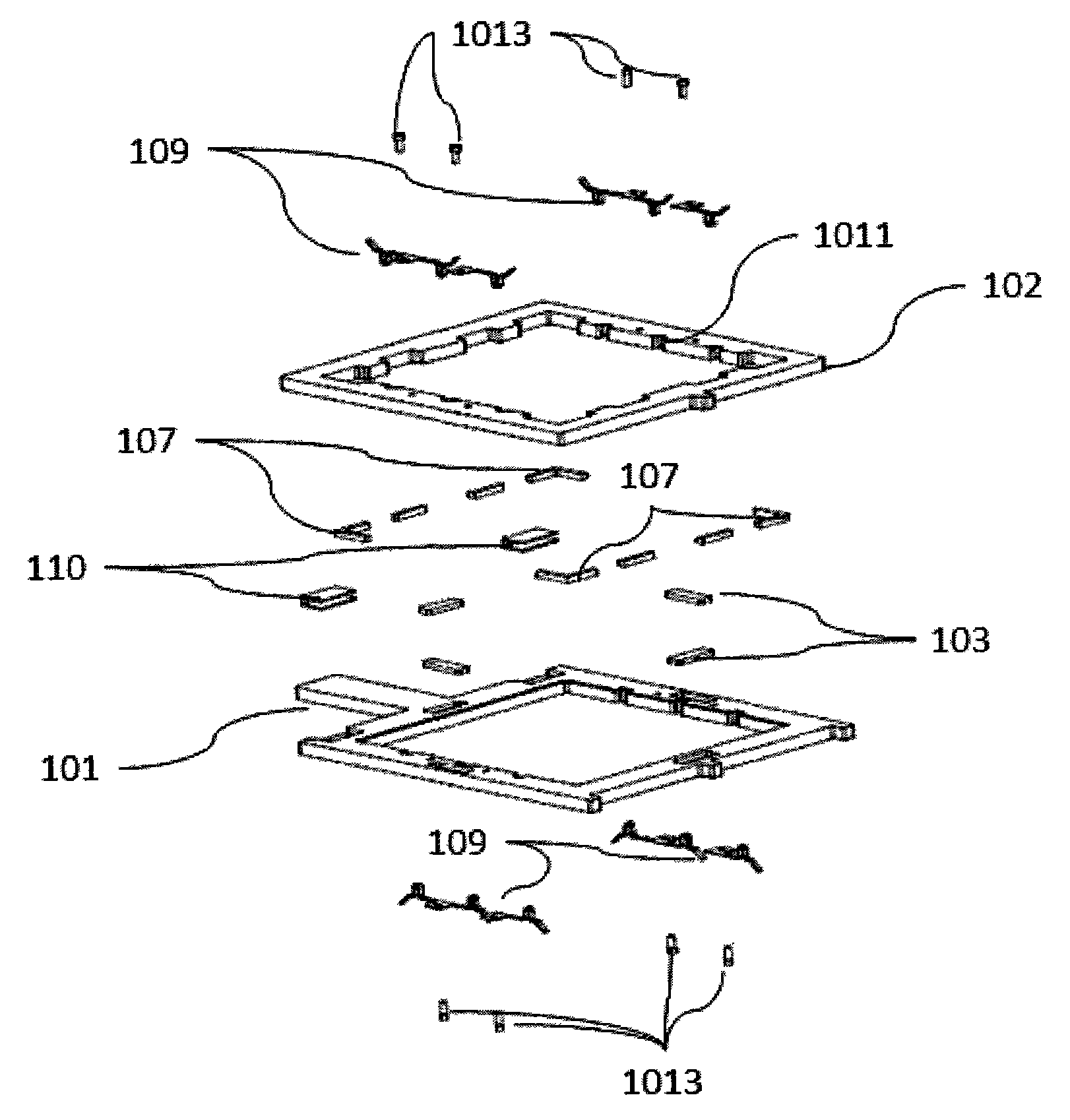

Electroplating clamp of solar cell

ActiveCN104032360AFast positioning and assemblyReduce broken rateElectrolysis componentsSemiconductor devicesMagnetEngineering

The invention provides an electroplating clamp of a solar cell. The electroplating clamp of the solar cell, provided by the invention, comprises a first frame, a second frame and a plurality of magnets, wherein the first frame and the second frame are of a hollow shape, edge parts of the first frame and the second frame are in contact and clamp the cell; and the plurality of magnets are respectively symmetrically fixed on the first frame or second frame, and the first frame and the second frame are jointed by using a magnetic force. The electroplating clamp of the solar cell, provided by the invention, is capable of rapidly locating the cell, quick in assembly, and continuous in production, ensures that the cell is uniformly conducted, and is capable of reducing the breakage rate of the cell.

Owner:平邑经济开发区投资发展有限公司

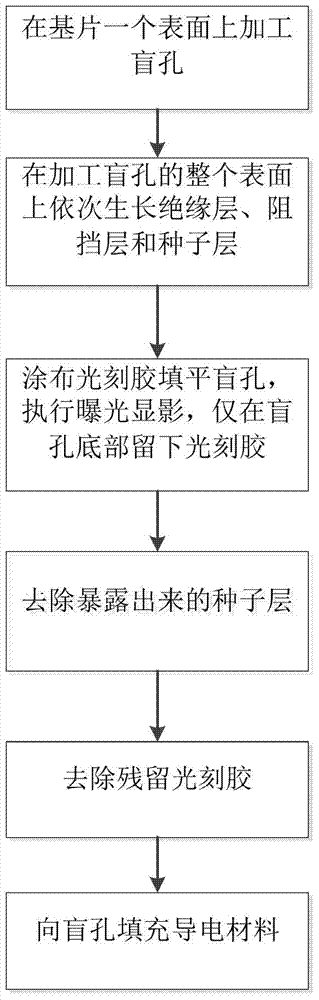

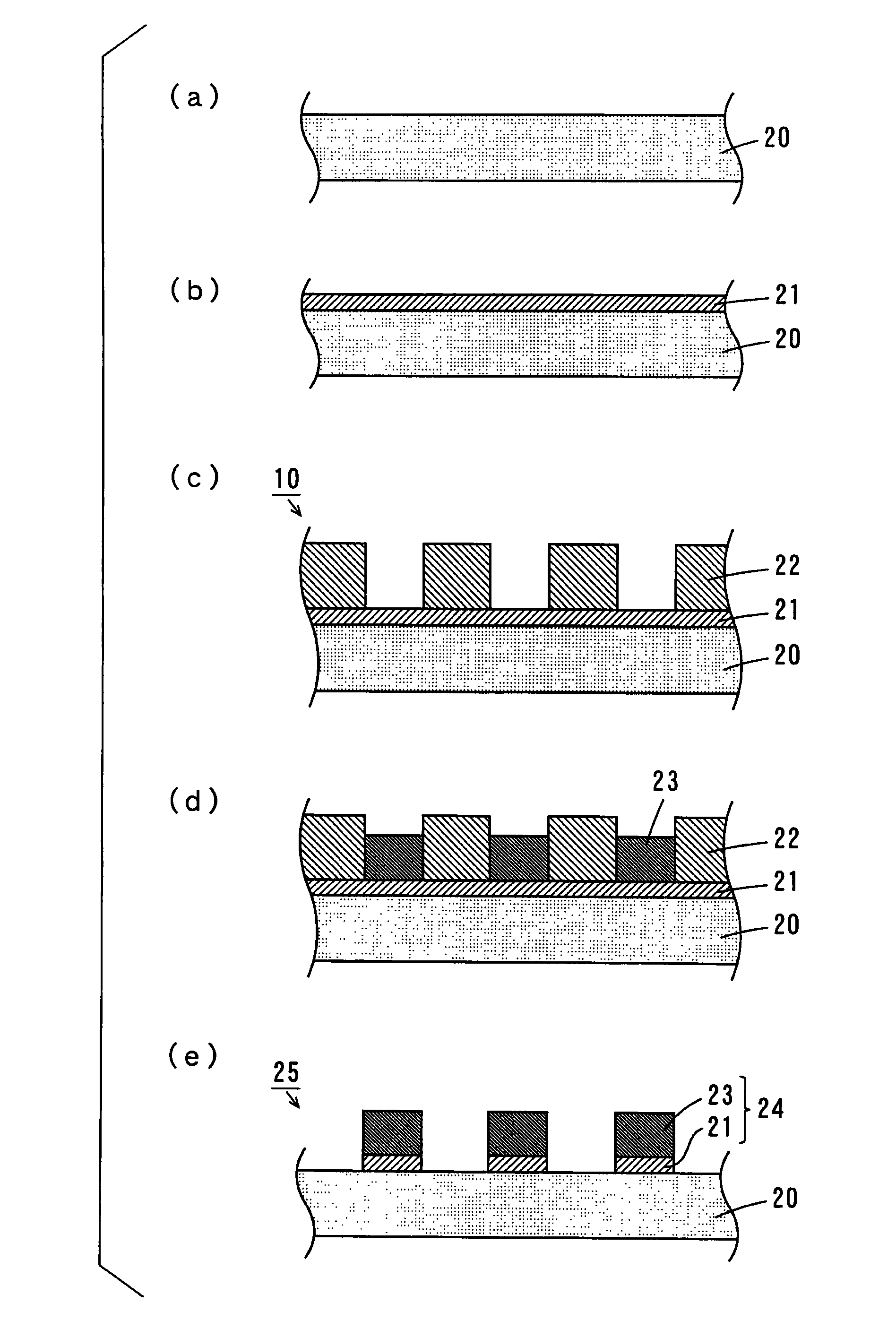

Method for achieving through hole interconnection by filling through hole from bottom to top and product thereof

InactiveCN103325700AQuality improvementFilling high speedSemiconductor/solid-state device detailsSolid-state devicesInterconnectionPhotoresist

The invention discloses a method for achieving through hole interconnection by filling a through hole from bottom to top. The method includes the steps that (a) a blind hole is machined in one surface of a substrate; (b) an insulating layer, a barrier layer and a seed layer are sequentially formed on the surface, provided with the blind hole, of the substrate; (c) the surface of the seed layer is coated with photoresist, the blind hole is filled and leveled up, and then exposure and development treatment is carried out so that the photoresist can only remain on the portion, at the bottom of the blind hole, of the surface of the seed layer; (d) the portion, not covered with the photoresist, of the seed layer is removed, wherein the portion, at the bottom of the blind hole, of the seed layer is not affected; (e) the residual photoresist is removed; (f) conducting materials are filled into the blind hole to achieve generation from bottom to top; (g) the surface, not provided with the blind hole, of the substrate is thinned so that a through hole can be formed, and then the process of through hole interconnection is finished. The invention further discloses a corresponding through hole interconnection structure product. By means of the method, the process of through hole electroplating can be carried out with convenient control, low cost and high efficiency, and the through hole interconnection structure product with better filling effects can be obtained.

Owner:HUAZHONG UNIV OF SCI & TECH

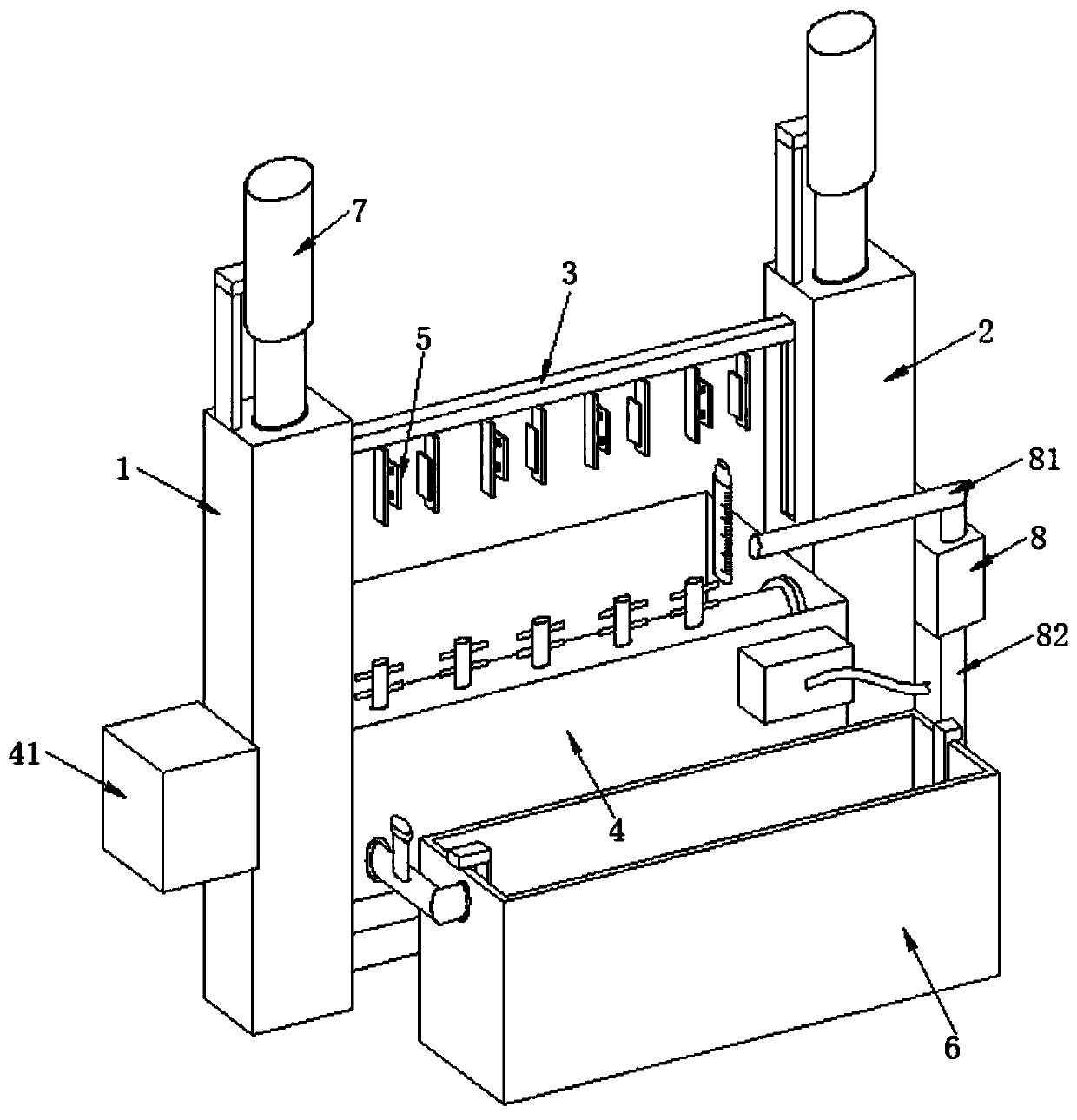

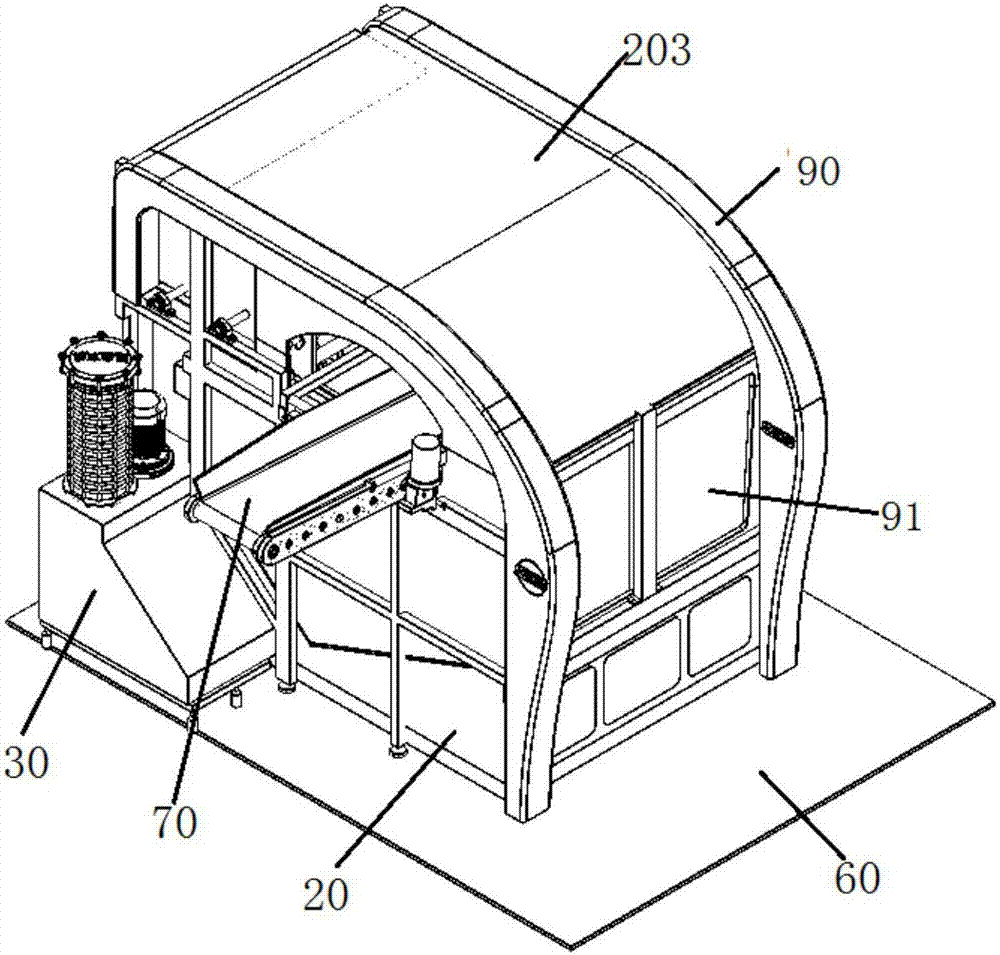

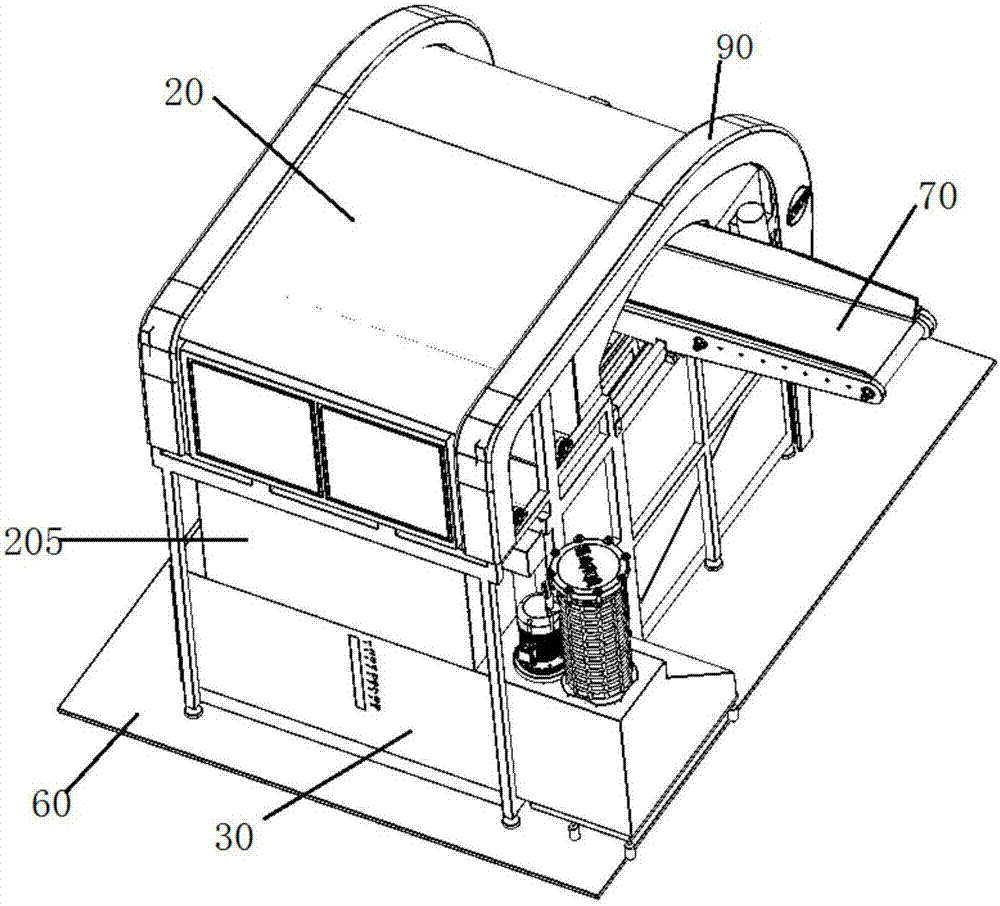

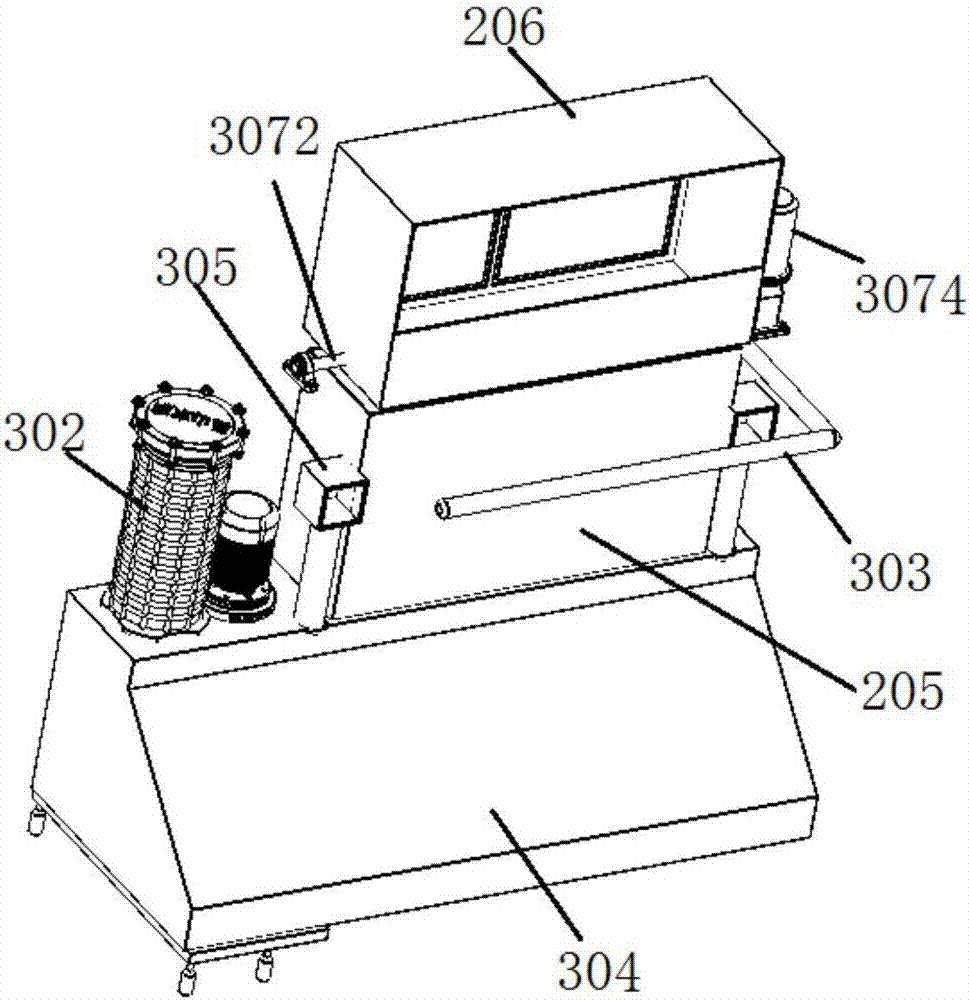

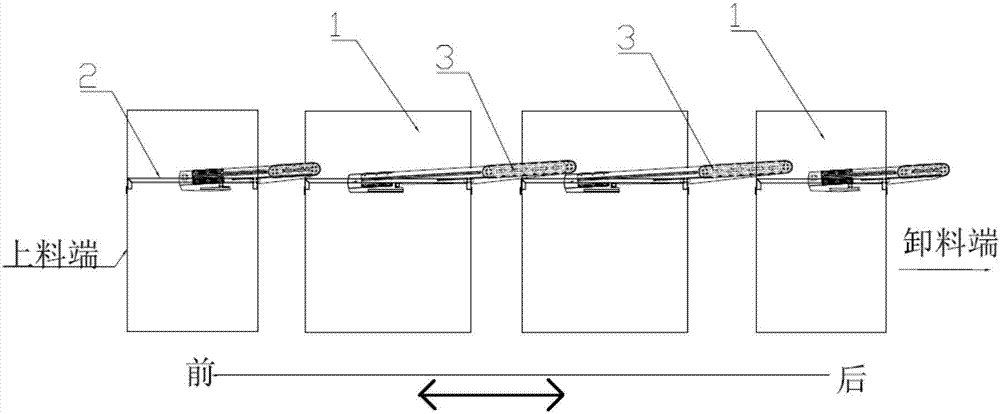

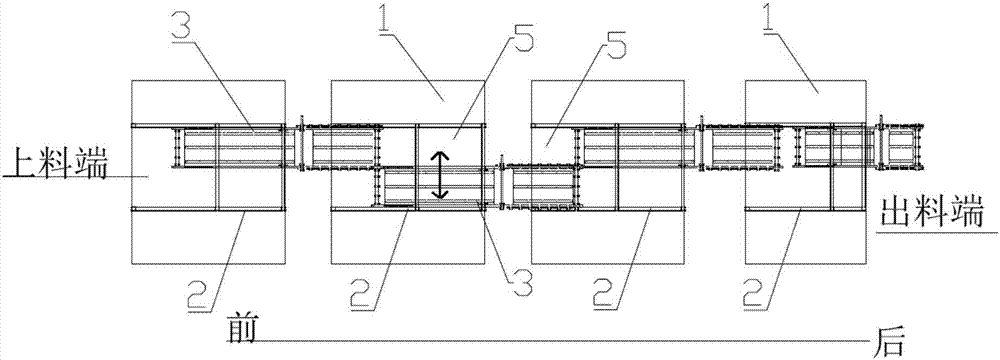

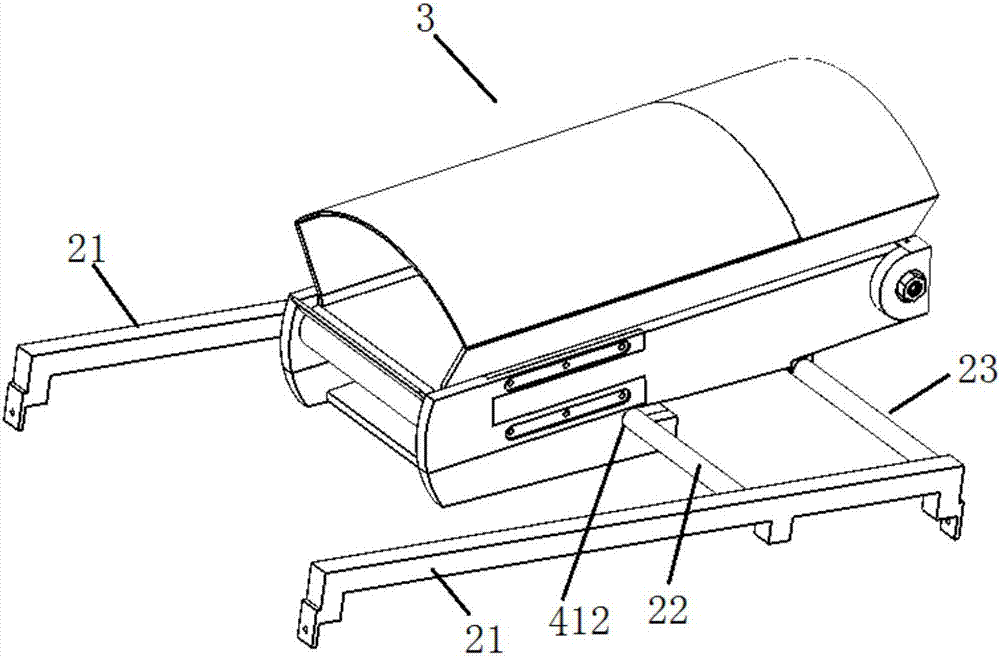

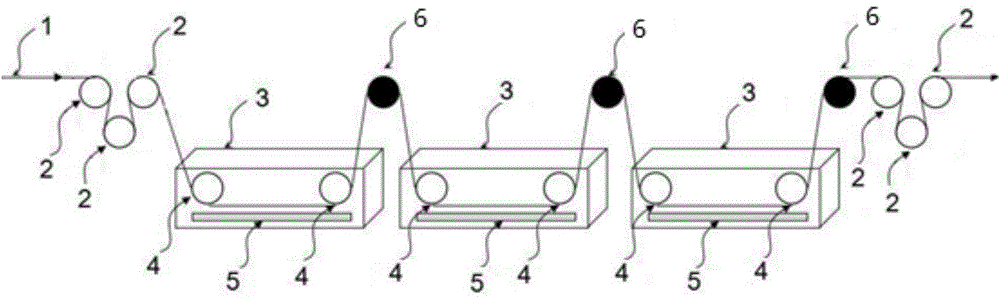

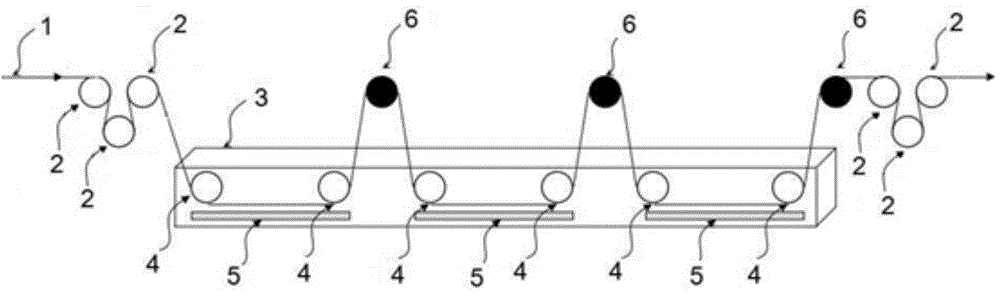

Barrel plating production line

ActiveCN106892250ARealize the function of barrel platingImprove barrel plating qualityElectrolysis componentsSupporting framesProduction lineEngineering

The invention discloses a barrel plating production line. The barrel plating production line comprises multiple barrel plating devices arranged in sequence; in the arrangement length direction of all the barrel plating devices, feed ports and discharge ports are respectively formed in the two end surfaces of all the barrel plating devices; conveying mechanisms are slidingly arranged on the adjacent end surfaces of two adjacent barrel plating devices; one ends of the conveying mechanisms extend into the barrel plating devices by the discharge ports of the barrel plating devices on the front sides, and the other ends of the conveying mechanisms extend into the barrel plating devices by the feed ports of the barrel plating devices on the back sides; connecting positions for enabling two adjacent ends to be positioned in overlapped areas and separation positions for enabling two adjacent ends to be positioned in staggered areas are vertically arranged at any one adjacent ends or two adjacent ends in at least one set of two adjacent conveying mechanisms; and any one adjacent ends or two adjacent ends in two adjacent conveying mechanisms move between the connecting positions and the separation positions to form the overlapped or staggered areas, so that plated workpieces are selectively input in the barrel plating devices for treatment by needed procedures according to the demands.

Owner:KUNSHAN DONGWEI MACHINERY CO LTD

Metal nano injection molding air tightness electric connector and manufacturing process thereof

ActiveCN105098439ABoost power loadReduce weightLine/current collector detailsCouplings bases/casesHigh intensityTitanium

The invention discloses a metal nano injection molding air tightness electric connector manufacturing process. The process comprises the following steps: S1, an outer shell and a contact piece are molded through mechanical processing; S2, the surface of the contact piece matched with the stainless steel or titanium shell for use is plated with nickel and gold, and the contact piece matched with the aluminum alloy or copper alloy shell is not plated; S3, the sealing interface of the nickel and gold-plated contact piece is processed mechanically to remove the plating layer, nano modified treatment is then carried out, nano modified treatment is directly carried out on the stainless steel or titanium alloy shell, and surface nano modified treatment is directly carried out on the aluminum alloy or copper alloy shell and the matched contact piece; and S4, the contact piece is assembled in the outer shell through a nano injection molding process. High strength for the contact piece of the air-tightness connector can be kept, and plug-pull contact reliability can be improved; the electroplating efficiency and the electroplating layer quality can be improved; the weight of the connector is reduced greatly to reduce load of an aircraft; and power load of the air tightness electric connector is greatly enhanced.

Owner:SICHUAN HUAFENG ENTERPRISE GRP

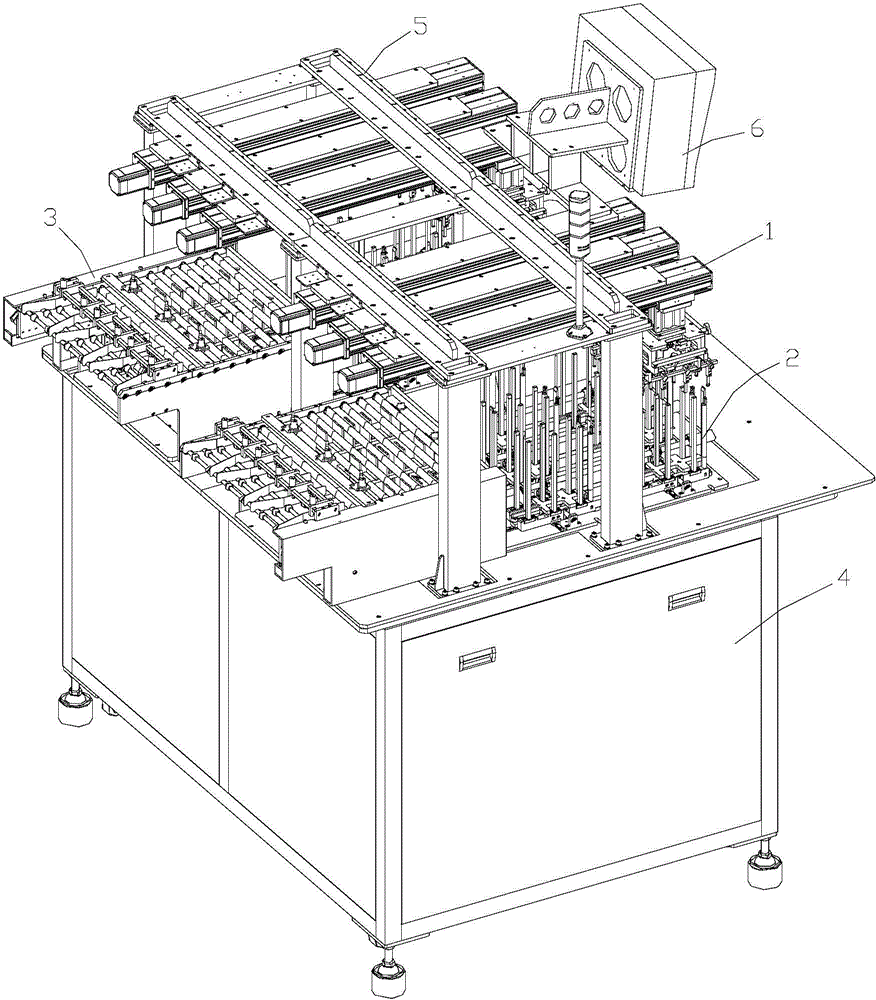

Collecting device for sheet type integrated circuit plating equipment

ActiveCN104562125ARealize automatic receivingImprove plating efficiencyElectrolysis componentsSemiconductor devicesEngineeringFront and back ends

The invention discloses a collecting device for sheet type integrated circuit plating equipment. The collecting device comprises a base and further comprises a sorting frame assembly, a collecting box assembly, a stand and a collecting clamp assembly which are arranged on the base; the collecting clamp assembly is arranged above the collecting box assembly; the front end and the rear end of the sorting frame assembly are respectively provided with a feeding hole and a temporary storage area, wherein the temporary storage area of the sorting frame assembly is arranged near the front end of the collecting box assembly and extends to the position below the collecting box assembly; the collecting clamp assembly comprises a horizontal guide rail mechanism, an adsorbing component and two clamping components, wherein the adsorbing component and the two clamping components can be arranged on the horizontal guide rail mechanism in a horizontal sliding way and a vertical lifting way; and the collecting box assembly comprises a collecting box mounting support, a collecting box and an auxiliary box, wherein the collecting box and the auxiliary box are arranged on the collecting box mounting support. The collecting device for the sheet type integrated circuit plating equipment can be used for collecting sheets automatically in the process of plating the sheets, thus the integral plating efficiency of the sheets can be improved effectively.

Owner:东莞奥美特科技有限公司

Continuous metal electroplating method and device for carbon fiber tows

The invention provides a continuous metal electroplating method for carbon fiber tows. According to the method, after cleaning treatment by a surfactant solution, a carbon fiber is used as a cathode and plated metal is used as an anode for electroplating, and then cleaning, drying and tow winding are carried out. The continuous metal electroplating method provided by the invention has the advantages of high safety, good deoxidation effect, less investment, high convenience in operation and low operating cost.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

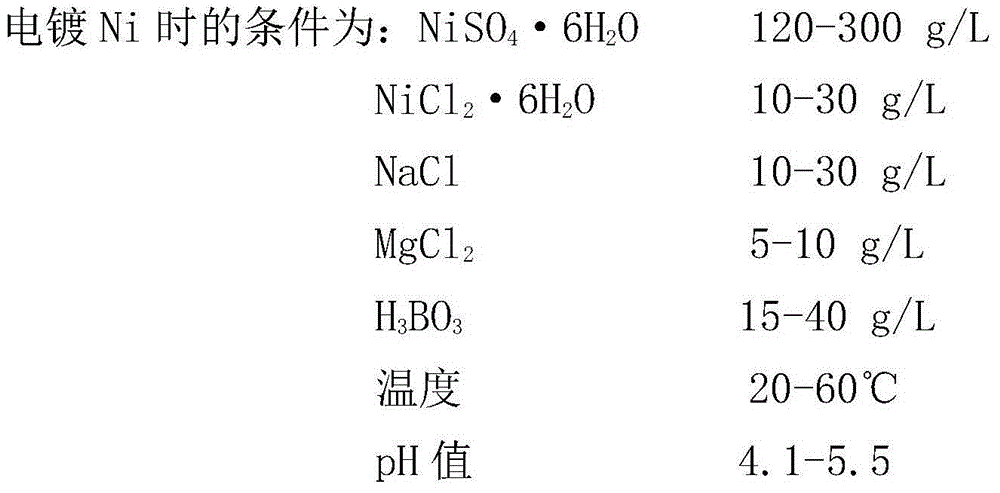

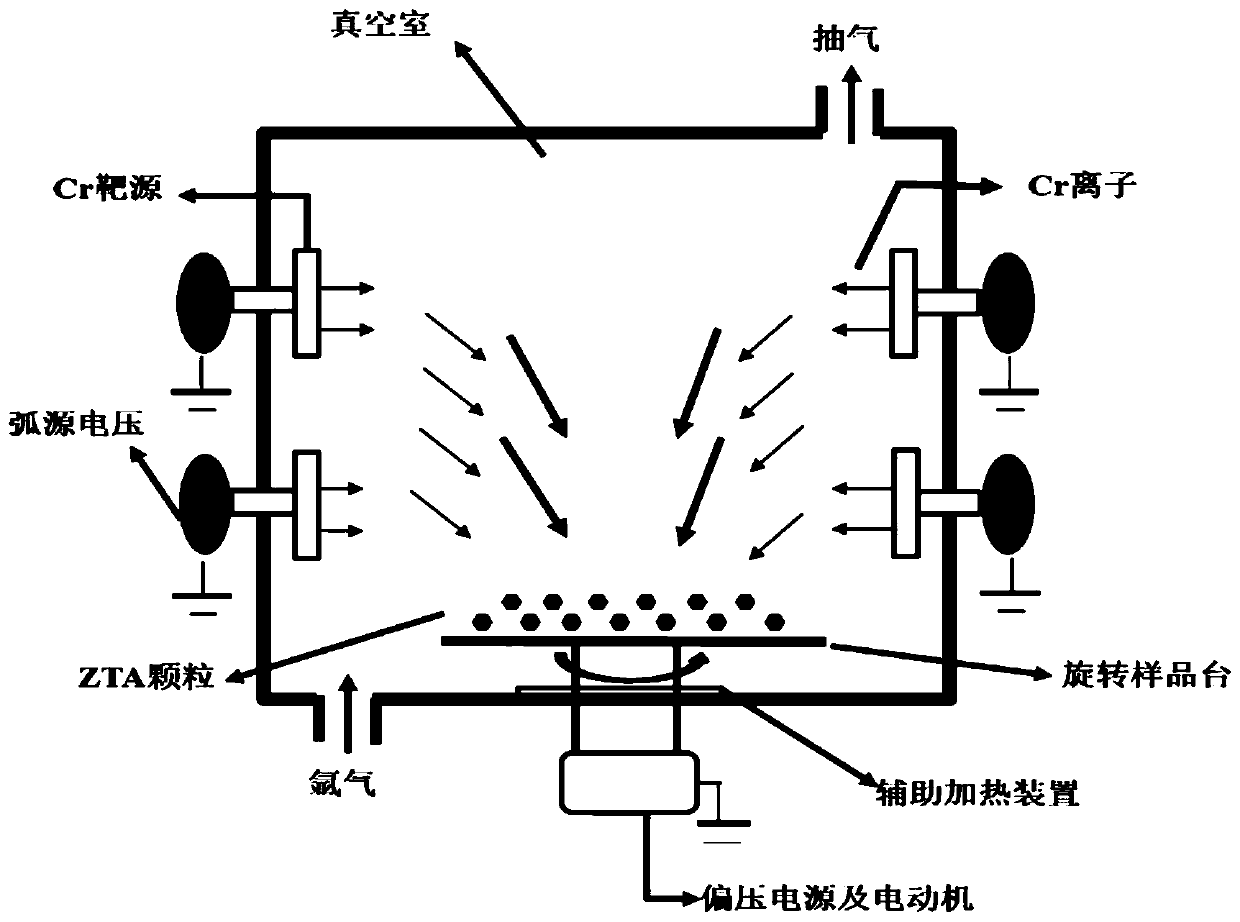

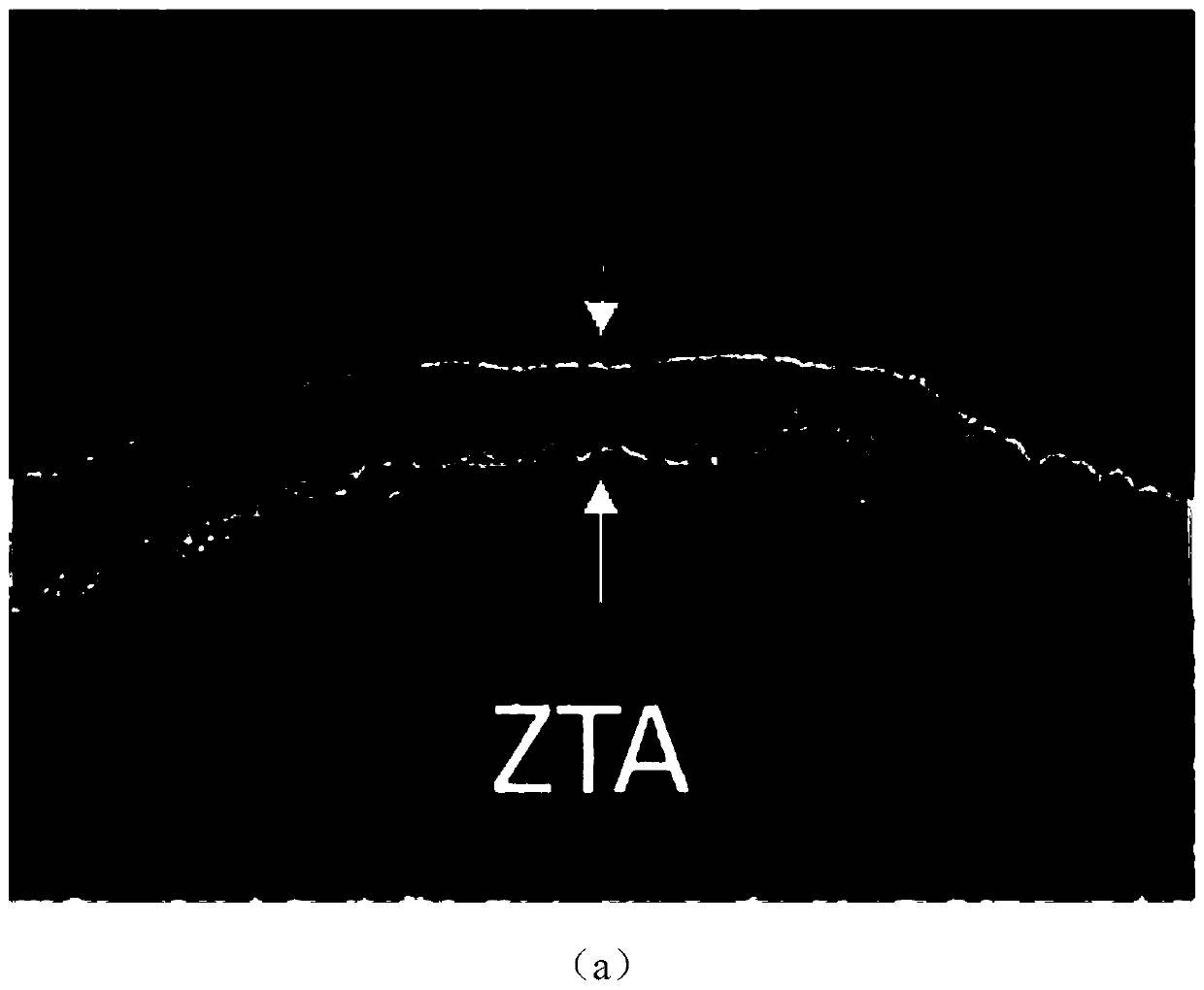

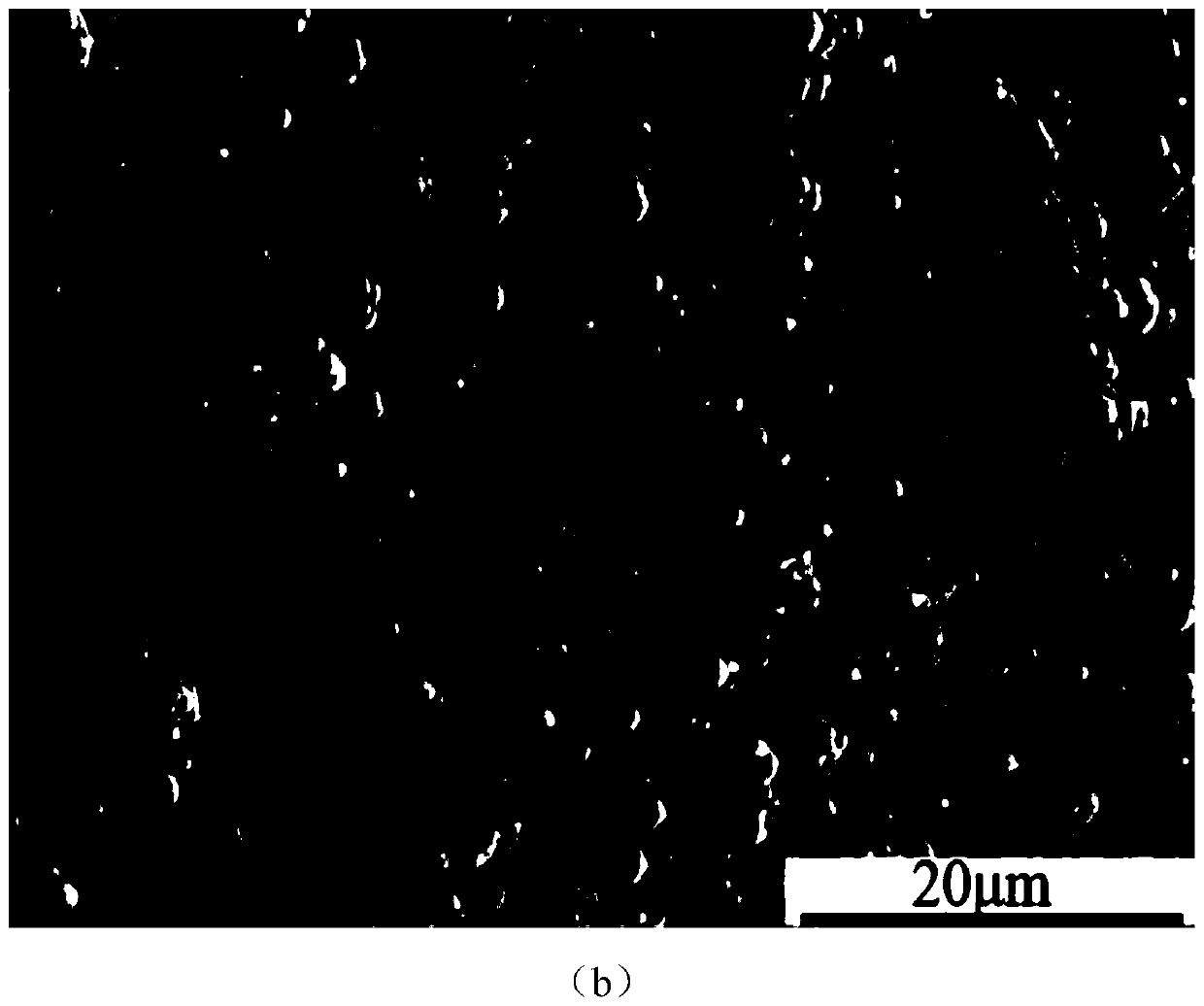

Preparation method for surface treatment ZTA particle enhanced steel-based composite grinding roller

ActiveCN110935864AEnhanced interface bindingHigh bonding strengthVacuum evaporation coatingSputtering coatingHoneycomb likeHeat treating

The invention discloses a preparation method for a surface treatment ZTA particle enhanced steel-based composite grinding roller. The surfaces of ZTA particles are subjected to micro roughening; attachment points of the ZTA particles during Cr plating are improved, the plating efficiency is improved, and the surfaces of the ZTA particles are subjected to metallization modifying by adopting a micro-arc ion plating method; then a self-made adhering agent is added for sizing, drying treatment is performed so that a prefabricated body of a honeycomb-shaped structure is obtained, and then heat treatment is performed on the honeycomb-shaped prefabricated body so that the bonding strength of the prefabricated body can be improved; and the prefabricated body is placed into a sand box for molten metal casting, and after cooling, the grinding roller with high abrasion resistance is obtained. According to the preparation method, Cr element plating is performed through physical vapor deposition sothat the bonding manner between the ZTA particles and metal can be improved, interface bonding is converted into metallurgical bonding from simple mechanical bonding, and high bonding and impacting strength is achieved. An abrasion-resistant composite material prepared through the technology of the preparation method has high impacting abrasion resisting performance, and the service safety underharsh working conditions is also guaranteed.

Owner:XI AN JIAOTONG UNIV +1

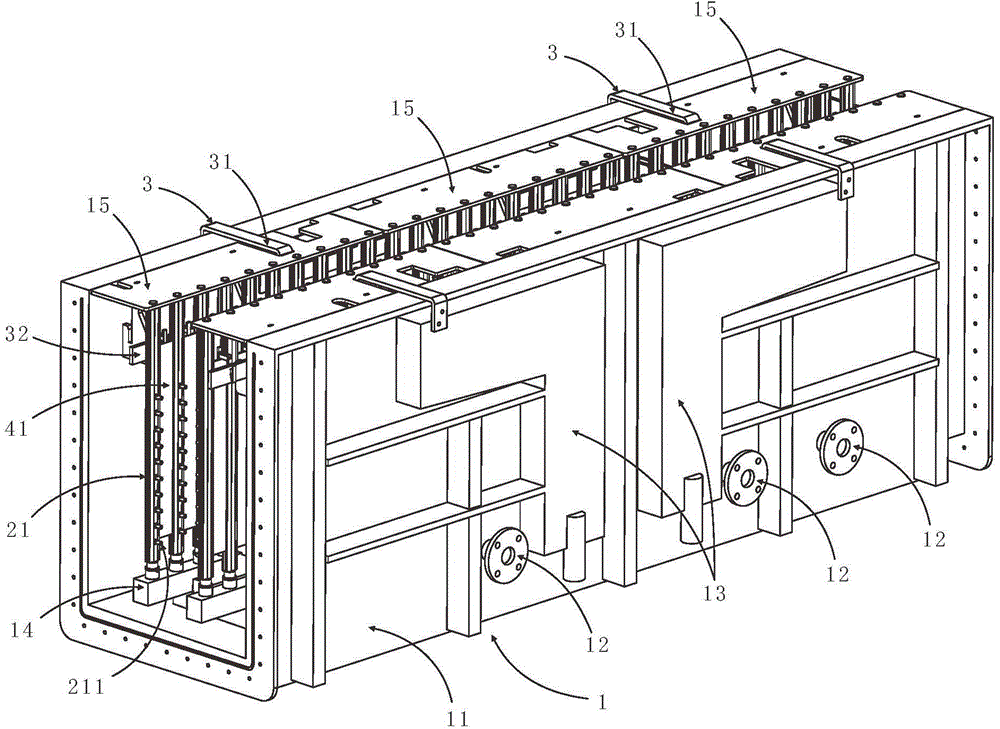

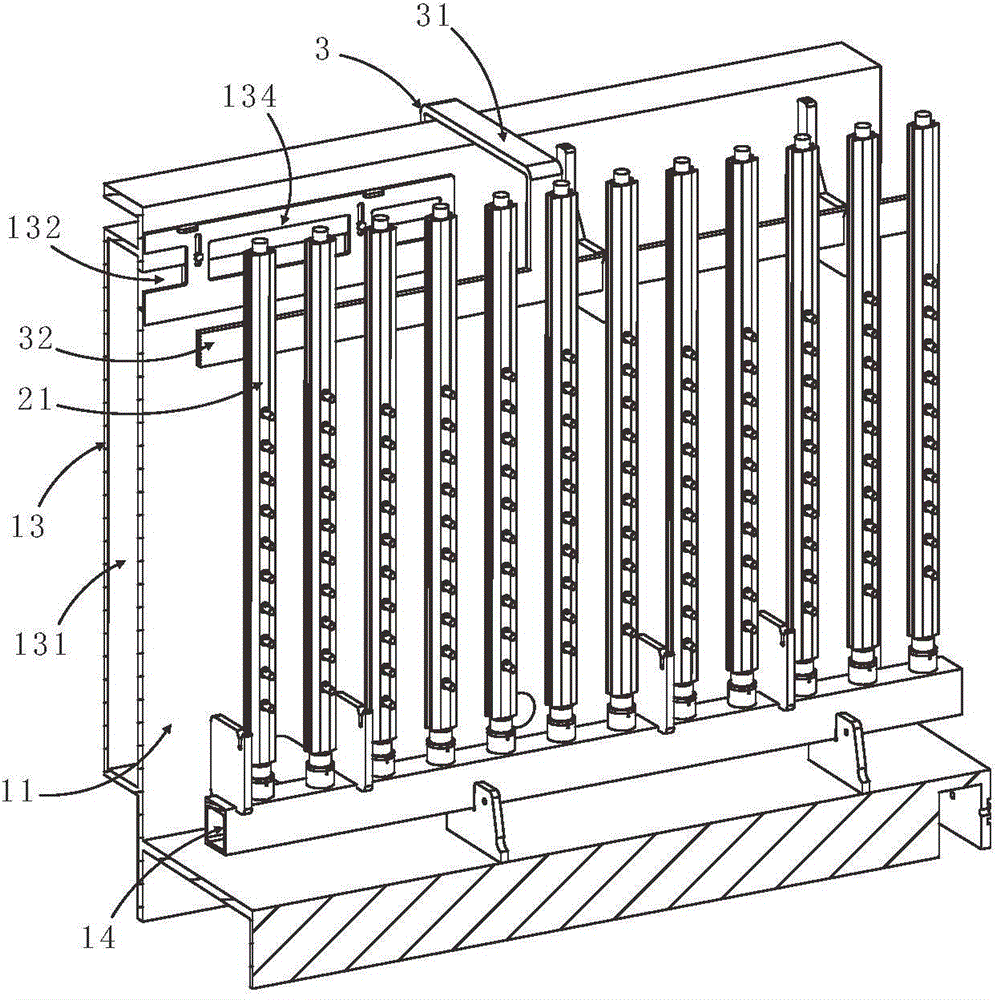

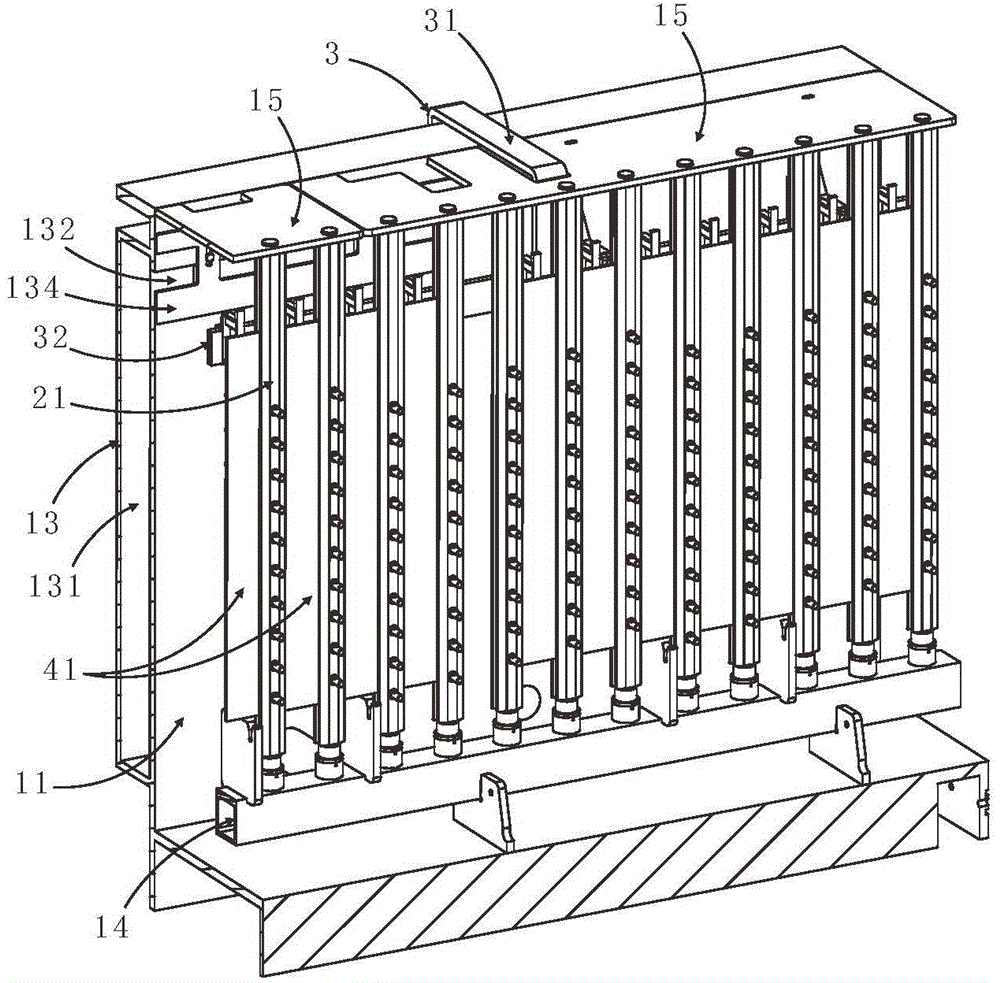

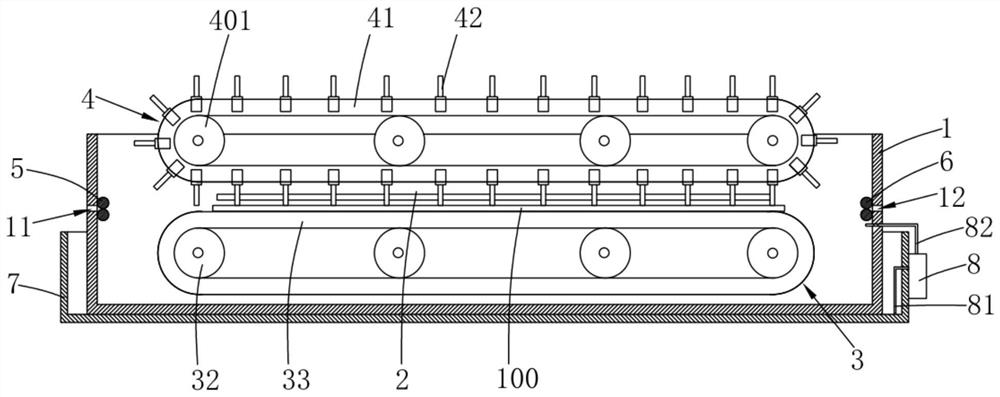

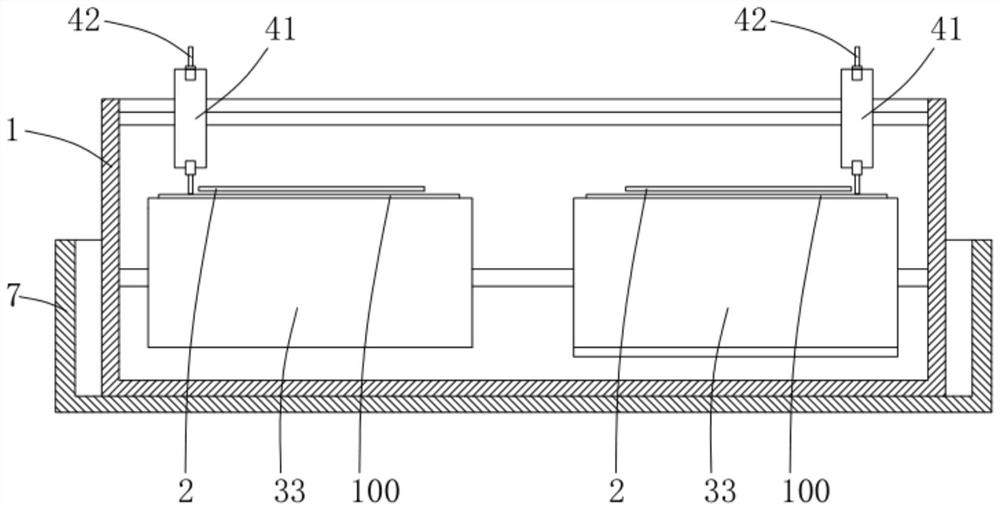

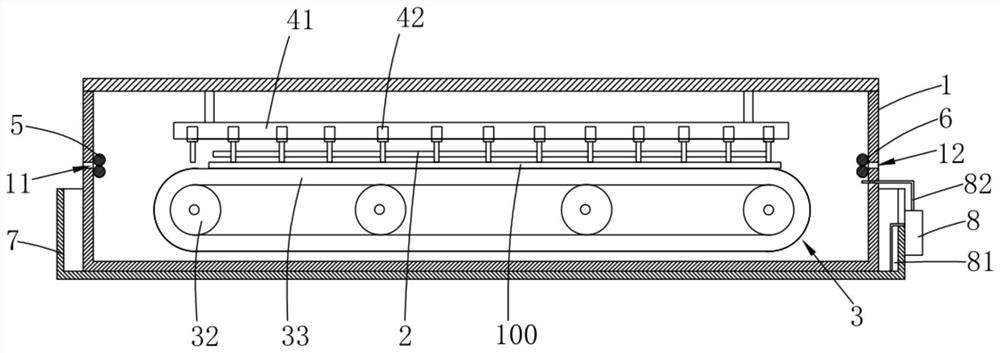

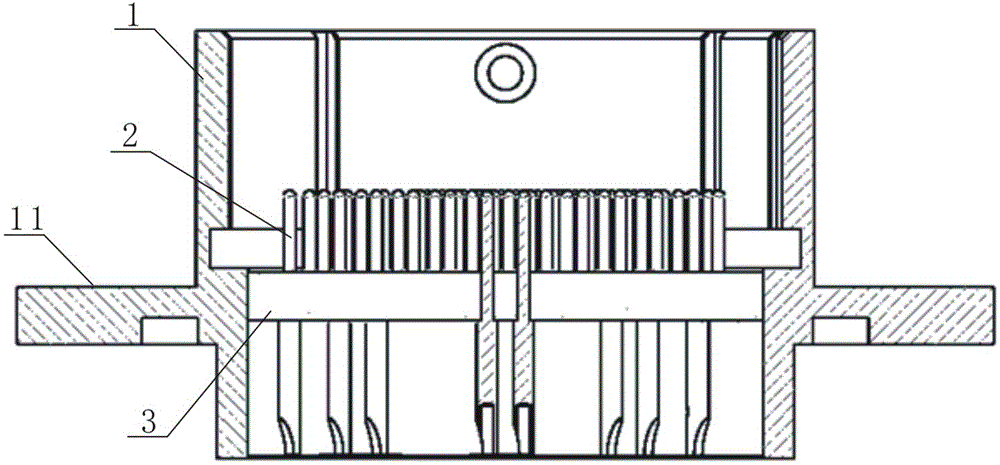

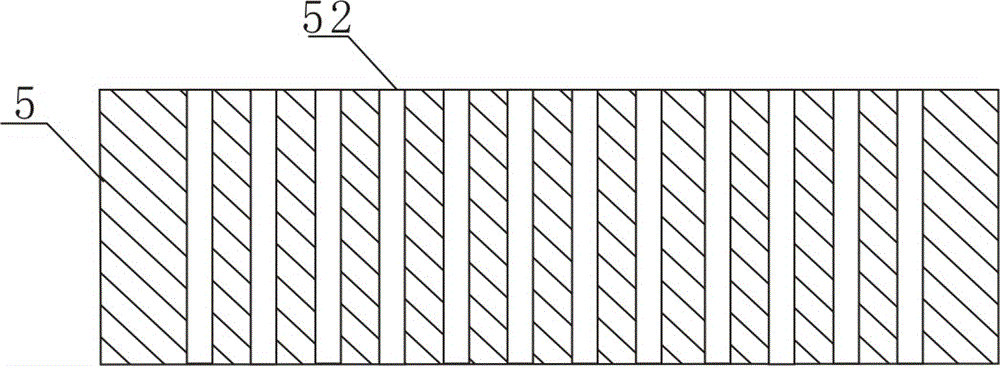

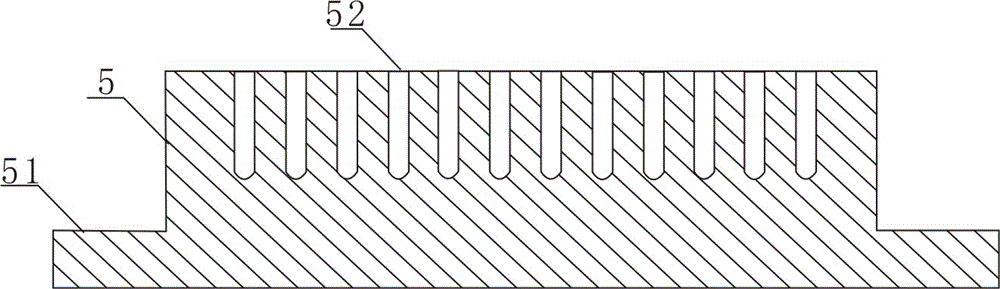

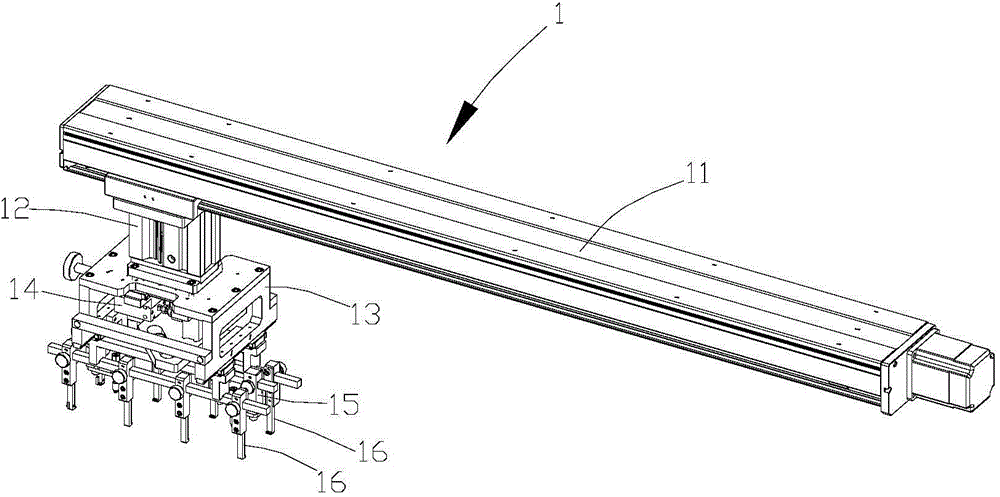

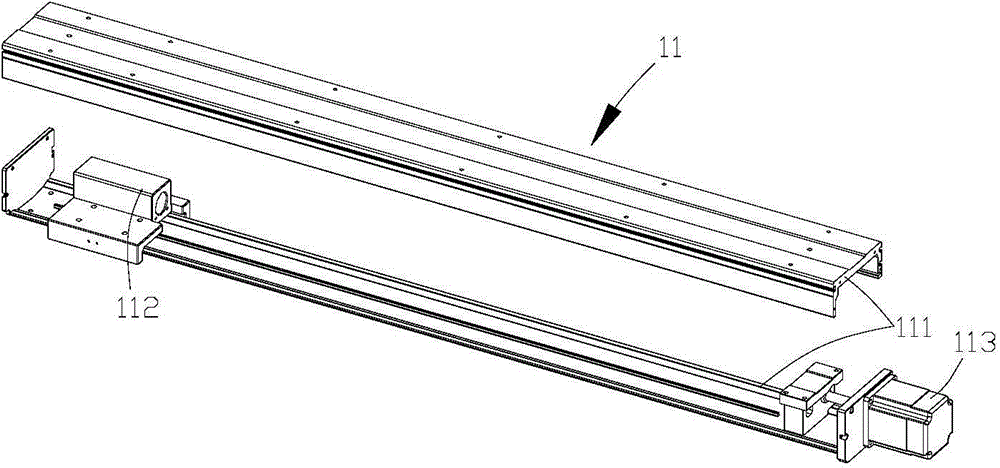

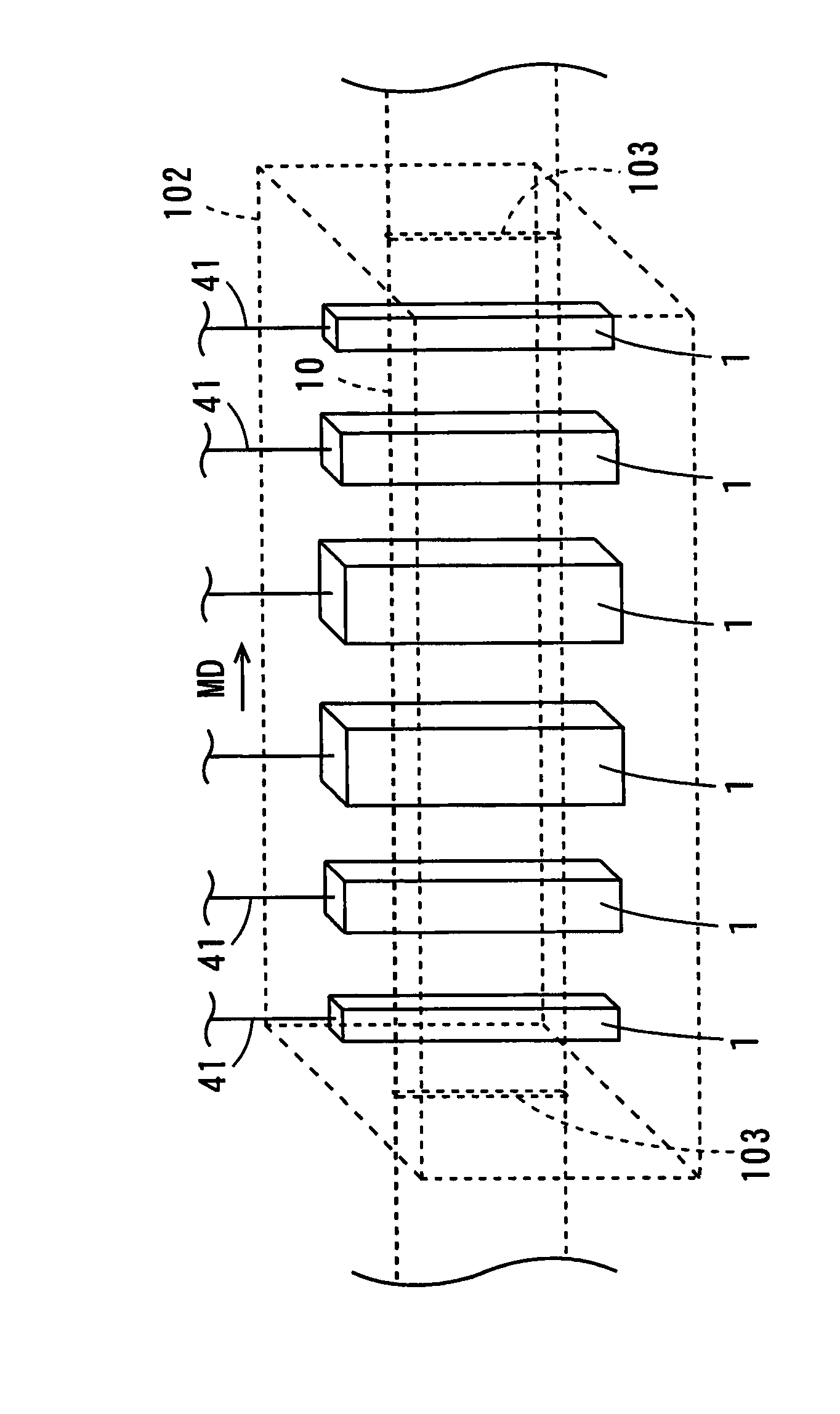

Continuous composite plating sand overlying tank for diamond cutting line

ActiveCN103898595AImprove plating efficiencyHigh controllability of coating qualityElectrolysis componentsElectrolytic coatingsDiamond cuttingElectroplating

The invention discloses a continuous composite plating sand overlying tank for a diamond cutting line. The continuous composite plating sand overlying tank comprises an electroplating bath body, a cathode roller, an anode rack, a sand loading tank and a wire guiding wheel, wherein the cathode roller is connected with the cathode of a power supply, and the anode rack is connected with the anode of the power supply; the cathode roller is arranged on the outer side of the electroplating bath body; a plating solution is filled in the electroplating bath body; diamond micro-powder is loaded by the sand loading tank; the anode rack, the sand loading tank and a cutting steel wire wound at the upper part and lower part of the cathode roller are submerged in the plating solution; the anode rack is fixed below the sand loading tank; the cutting steel wire below the cathode roller is buried in the diamond micro-powder. The composite plating sand overlying tank has the characteristics of high electroplating efficiency, high controllability on the length of the needed electroplating bath body and the plating quality, strong binding force of cutting line diamond with a base body, good heat-resisting and abrasion-resisting properties and high cutting efficiency.

Owner:JIANGSU XINGDA STEEL TYPE CORD

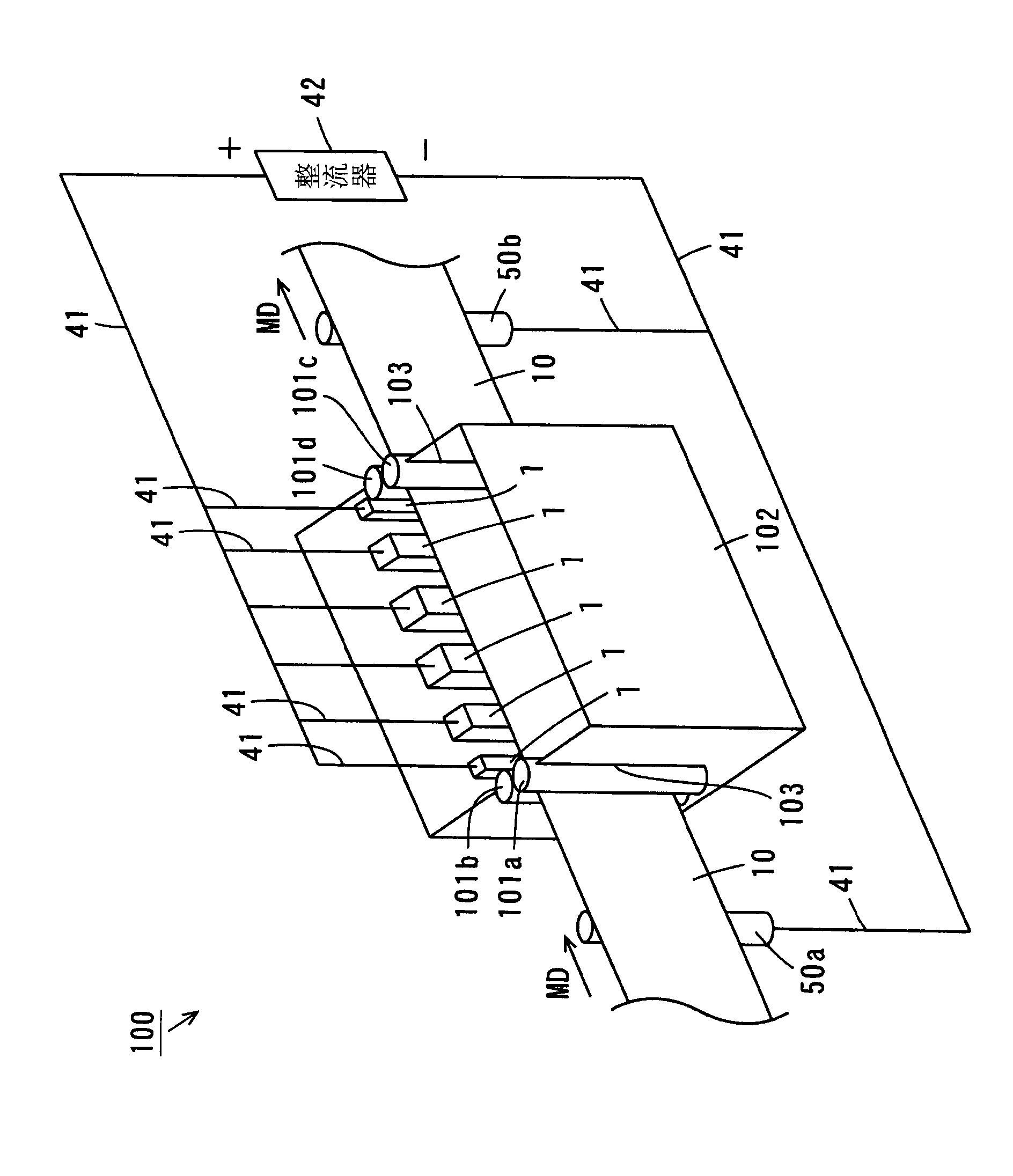

Plating apparatus and method of manufacturing printed circuit board

InactiveCN102127785AImprove plating efficiencyAvoid burnsCellsPrinted circuit manufactureEngineeringPrinted circuit board

The invention provides a plating apparatus and a method of manufacturing printed circuit board. The plating apparatus includes a plating tank. The plating tank contains a plating solution. A long-sized substrate is transported by transport rollers to pass through inside of the plating tank. Three or more bar-shaped anodes are provided in the plating tank to line up along the long-sized substrate. A surface area of each of the anodes arranged at both ends is smaller than a surface area of another anode.

Owner:NITTO DENKO CORP

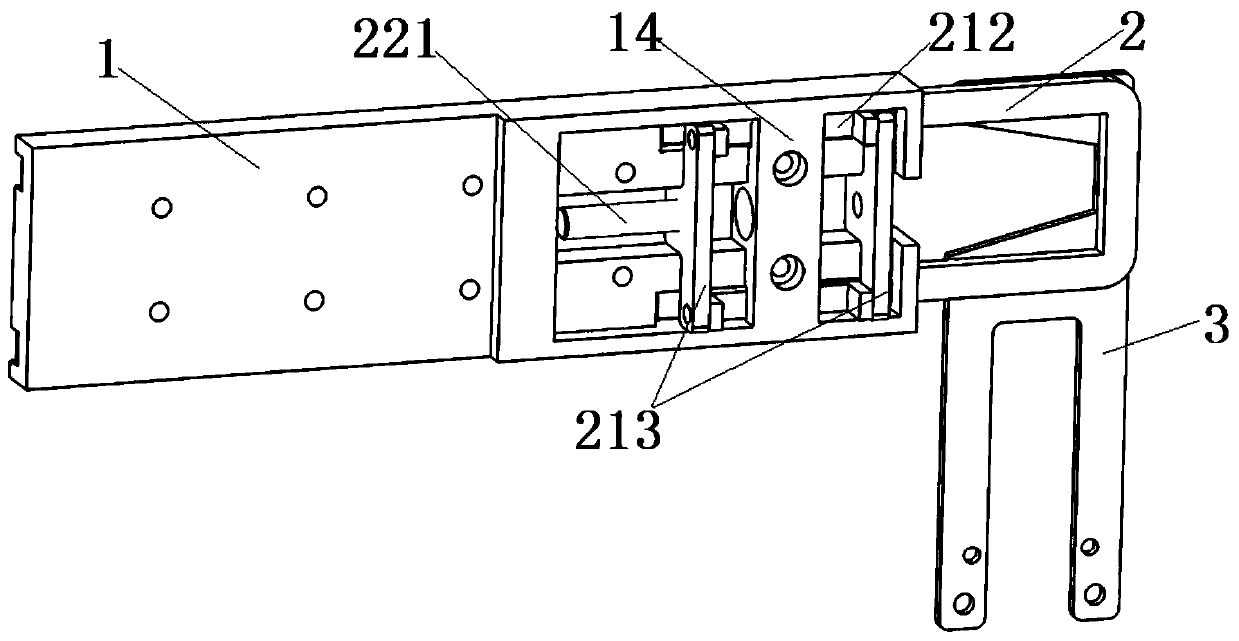

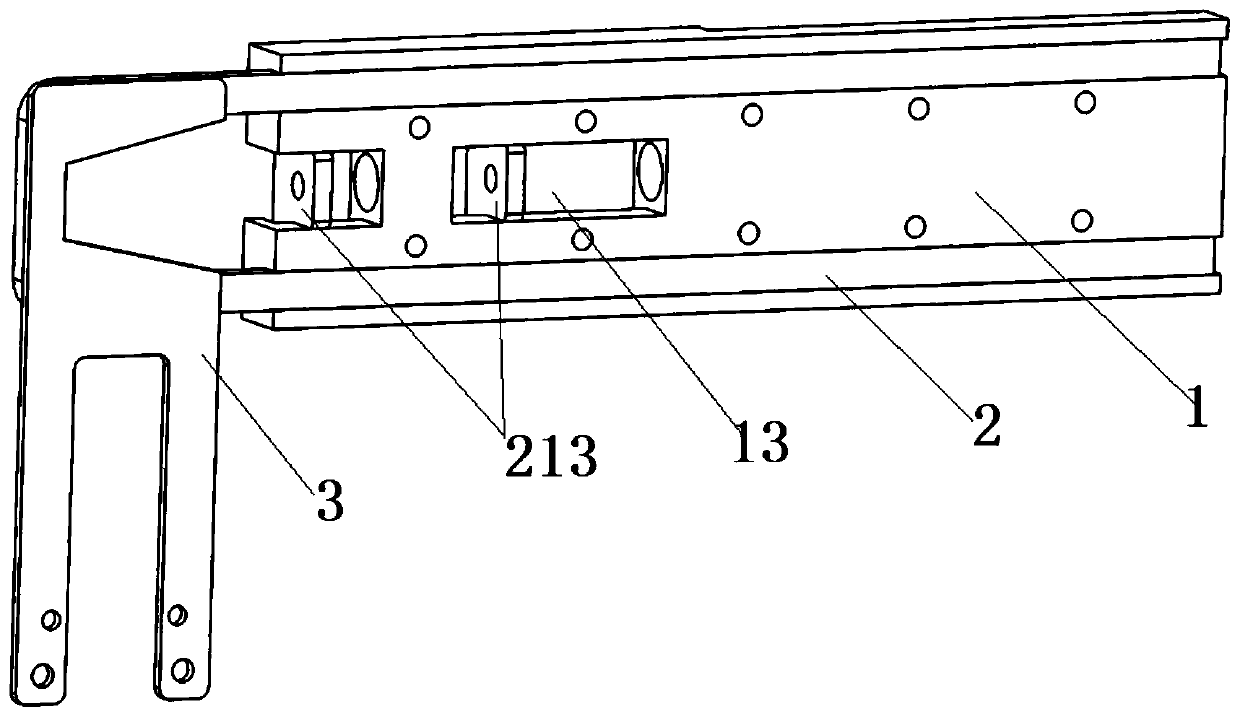

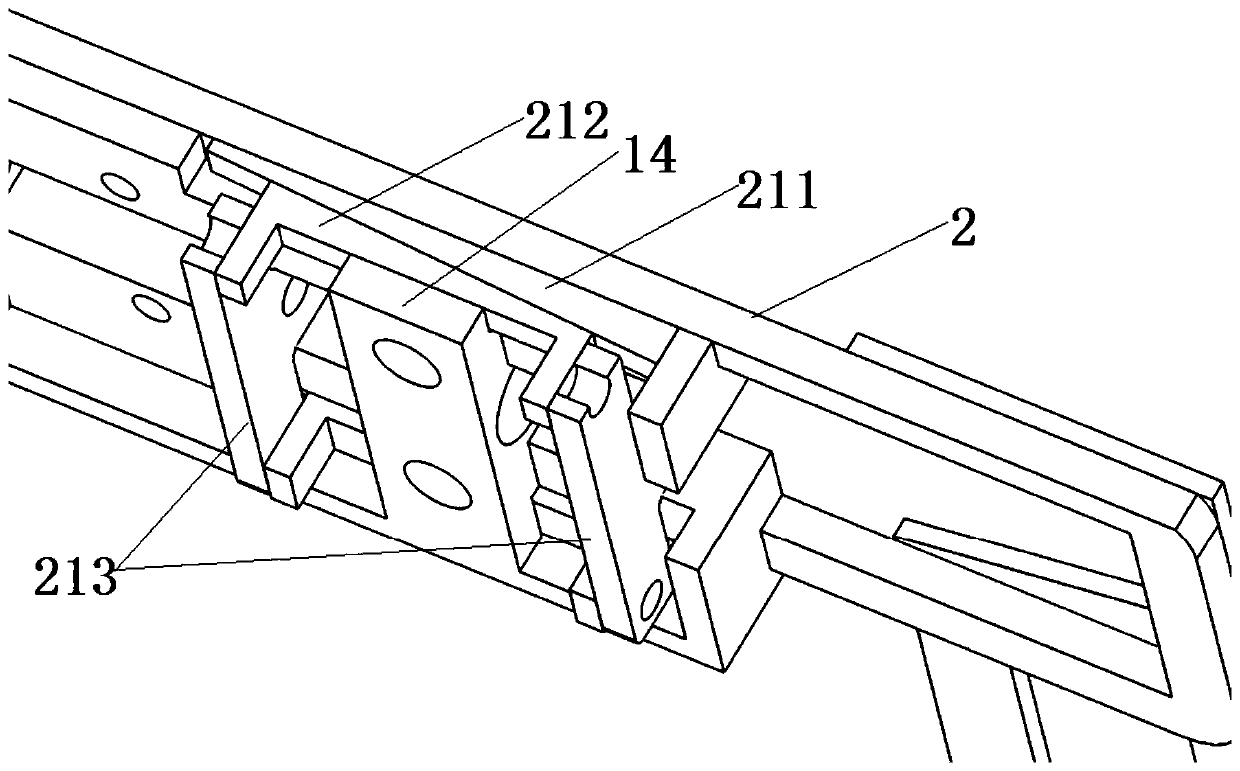

Adjustable fixed plate and hanging fixture

PendingCN111441076AStable clampingIncrease contact areaElectrolysis componentsPrinted circuit manufactureStructural engineeringMechanical engineering

The invention provides an adjustable fixed plate and a hanging fixture. The adjstable fixed plate comprises a main body, a conductive slide rod and a locking mechanism. The hanging fixture comprises the adjustable fixed plate. The main body is arranged on a conductive plate; the conductive slide rod is slidably arranged between the main body and the conductive plate; sliding clamping jaws are connected to one side of the condutive slide rod; and the locking mechanism is provided with an extrusion structure arranged between the main body and the conductive slide rod so as to tightly press the conductive slide rod onto the conductive plate. Acording to the adjustable fixed plate with the structure, the sliding clamping jaws can adapt to clamping circuit boards with different widths; the conductive slide rod is tightly pressed on the condutive plate through the extrusion structure, and the conductive slide rod is tightly pressed on the condutive plate through an extrusion way so as to bepositioned, so that the contact area of the extrusion structure and the conductive slide rod is large; and meanwhile, a pressing force acted on the conductive slide rod is stable, the condutive sliderod is positioned firmly through thelocking mechanism after sliding in place, and the conductive slide rod stably contacts the conductive plate so as to conduct electricity stably, so that the slidingclamping jaws can be ensured to conduct electricity stably.

Owner:KUNSHAN DONGWEI MACHINERY CO LTD

Oscillating diode electroplating machine

InactiveCN107541766AIncrease rotation speedNot easy to bendCellsSemiconductor devicesPower flowEngineering

The invention discloses an oscillating diode electroplating machine which is composed of an electroplating machine body, an electroplating tank, a variable resistance box, hydraulic transmission shafts, two oscillators, oscillation-transmitting shafts, an oscillating electroplating motor, oscillating screens and a conductive nail. The electroplating tank is arranged at the lower end of the electroplating machine body; the conductive nail is arranged at the bottom of the electroplating tank; the oscillating electroplating motor is arranged at the upper end of the electroplating machine body andfixedly connected with the oscillators; the lower ends of the oscillators are connected with the upper ends of hydraulic lifting shafts, and the lower ends of the hydraulic lifting shafts are connected with the upper ends of the oscillation-transmitting shafts; and the lower ends of the oscillation-transmitting shafts are connected with the oscillating screens, and the variable resistance box ismounted on the oscillating electroplating motor. The oscillating diode electroplating machine has the beneficial effects that the oscillating electroplating motor, the two oscillators, the two hydraulic lifting shafts and the variable resistance box are arranged, the lifting shafts drive the oscillating screens to move from top to bottom, a lead is not prone to be bent, the quality of the lead isguaranteed, the electroplating thickness can be uniform, the variation coefficients are few, the rotating speed of the oscillating electroplating motor can further be increased by increasing a current, and thus the electroplating efficiency is improved.

Owner:张晓宇

Through hole electroplating and filling method and preparation method of printed circuit board

ActiveCN112030203AImprove plating efficiencyIncreasing the thicknessPrinted element electric connection formationOrganic sulfonic acidSulfonate

The invention discloses a through hole electroplating and filling method and a preparation method of a printed circuit board. The through hole electroplating and filling method comprises the followingsteps: S1, carrying out reversing pulse electroplating on a to-be-plated substrate with a through hole by utilizing pulse electroplating liquid; and S2, carrying out hole filling treatment on the through hole treated in the step S1. Wherein the pulse electroplating solution contains metal ions to be plated, halogen ions and an accelerator, the accelerator comprises organic sulfonate, and the concentration c of the organic sulfonate meets the following relational expression: c is equal to or more than 1 ppm and less than 8 ppm; and the reversing pulse electroplating adopts PPR square wave current with at least one turn-off time, and the single turn-off time ranges from 20 ms to 80 ms. According to the scheme, the pulse electroplating liquid is combined with PPR electroplating to realize the situation that the electroplating efficiency in the middle of the hole is higher than that in a hole opening and surface copper in the electroplating process, so that protrusions exist on the surface of the copper in the hole, plating starting points are provided for hole filling lotion, and then electroplating hole filling is achieved.

Owner:DONGGUAN SHENGYI ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com