Electroplating device

An electroplating device and electroplating tank technology, which is applied to electrodes, electrolysis process, electrolysis components, etc., can solve the problems of uneven thickness of the surface of the circuit board to be plated, low cation concentration, and the electroplating device occupies a large space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

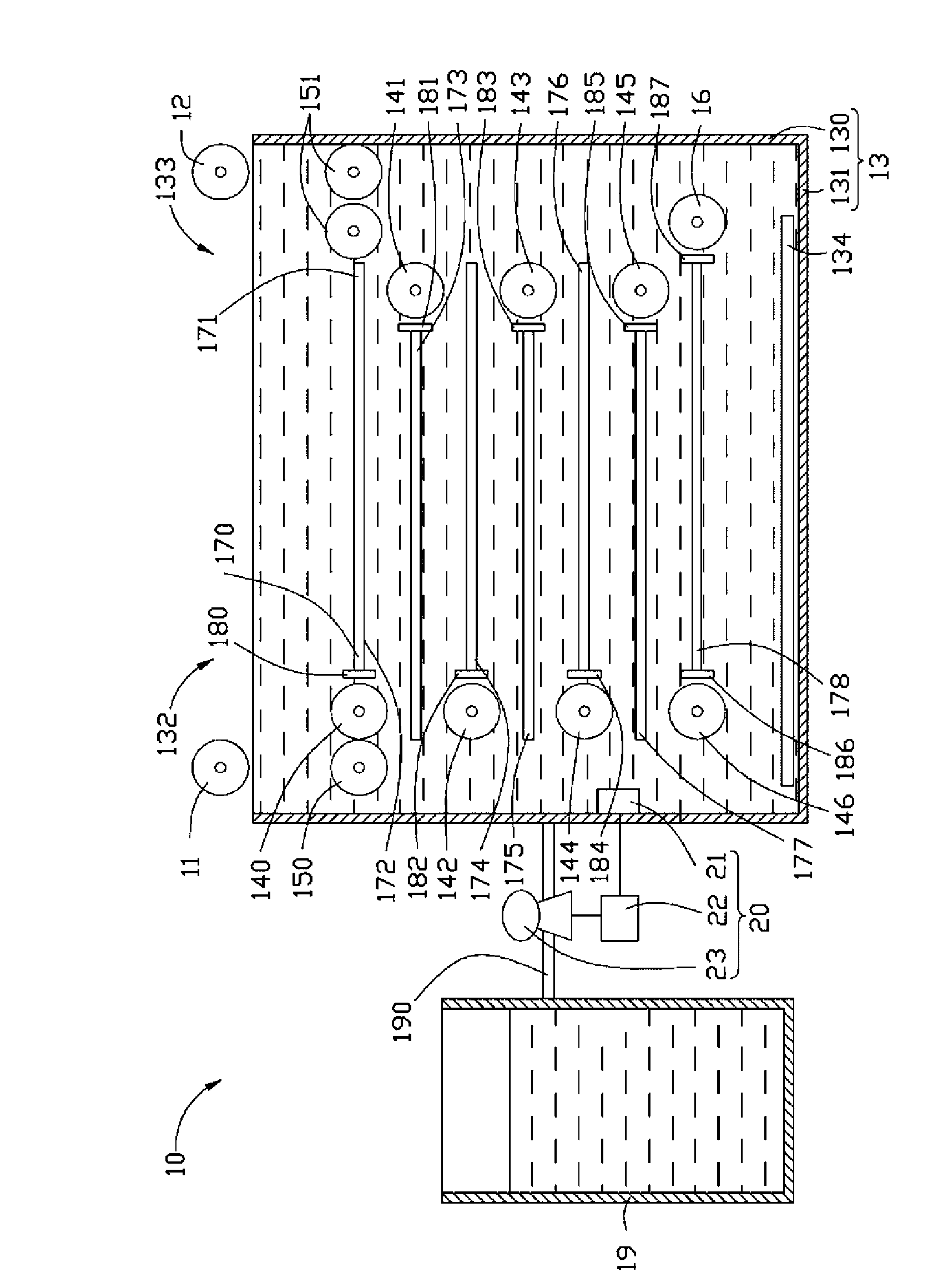

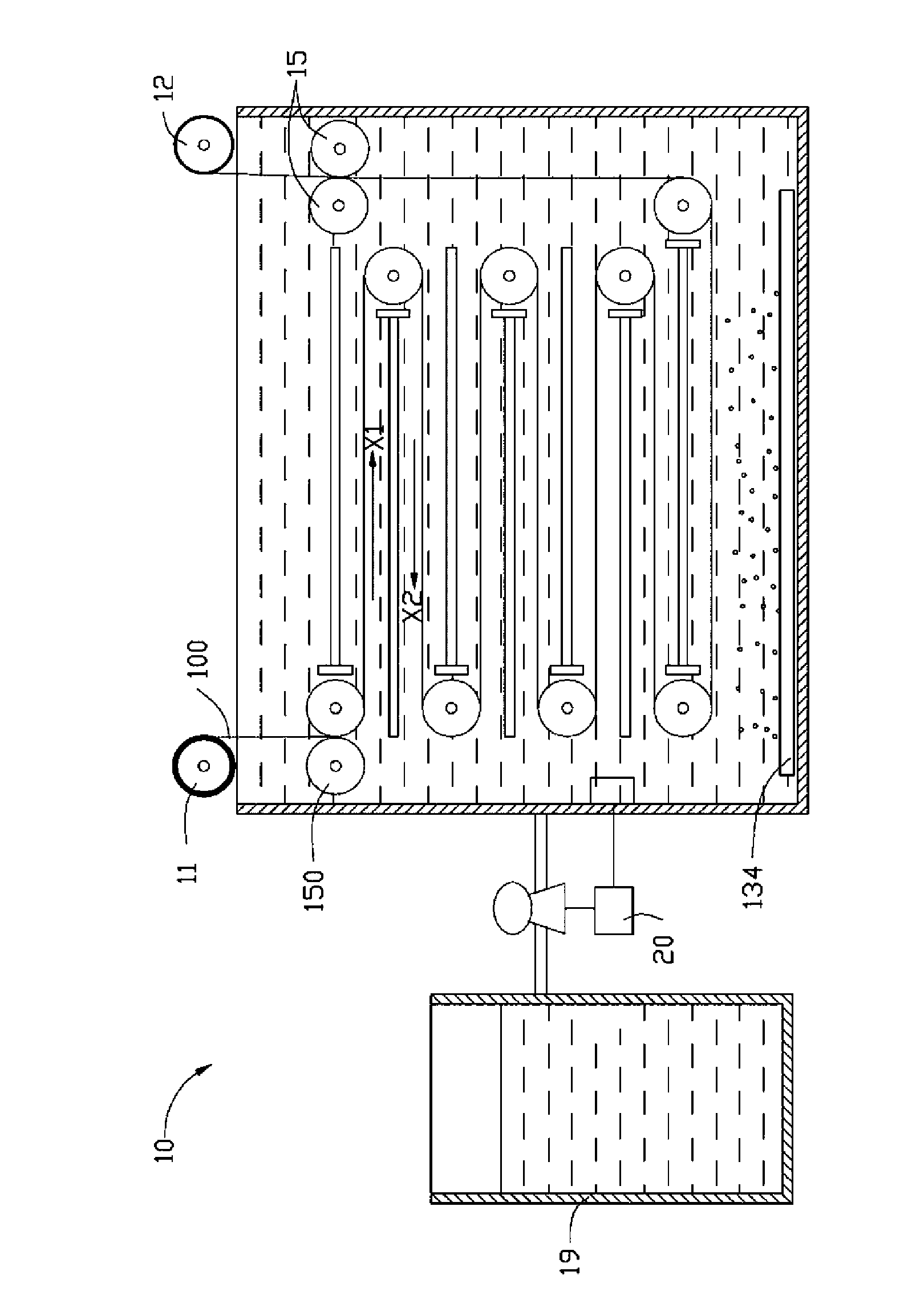

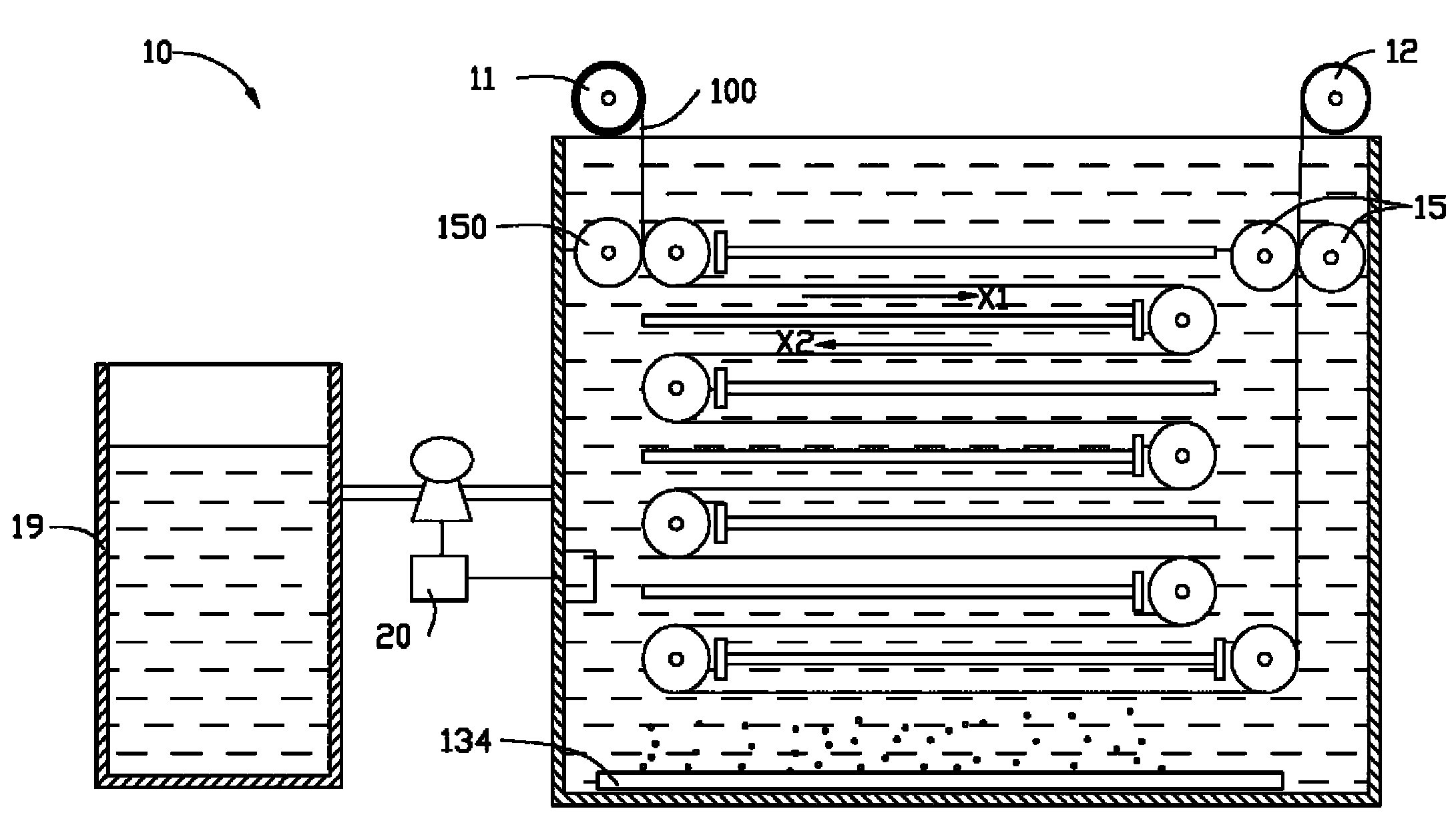

[0012] The electroplating device of the technical solution will be described in detail below with reference to the drawings and embodiments.

[0013] see figure 1 , the technical solution provides an electroplating device 10 for electroplating continuously conveyed flexible substrates. The flexible substrate is a flexible material. Described electroplating device 10 comprises a delivery wheel 11, a take-up wheel 12, an electroplating tank 13 that fills electroplating solution, a plurality of conductive transmission wheels, a plurality of insulated transmission wheels, a conductive transmission roller, multiple An anode plate, a plurality of insulating partitions, a cation replenishment tank 19 and a cation automatic replenishment system 20. The electroplating solution may be a mixed solution containing copper sulfate, sulfuric acid, hydrochloric acid and the like.

[0014] Both the delivery wheel 11 and the take-up wheel 12 are located outside the electroplating tank 13 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com