Chrome plating method for spherical crown surface of major diameter spherical crown workpiece

A workpiece ball and large-diameter technology, applied in the direction of the electrode, etc., can solve the problems of complex process, the surface finish of the spherical crown cannot meet the requirements, and the uniformity of the coating layer is difficult to control, so as to achieve high surface finish, reduce follow-up workload, and deposit deposition fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with accompanying drawing description and specific embodiment:

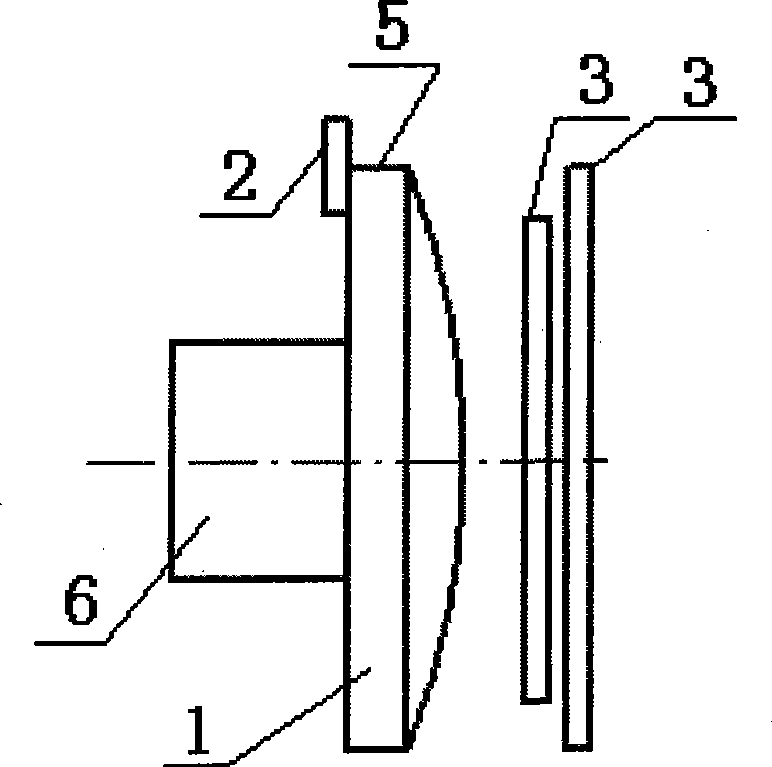

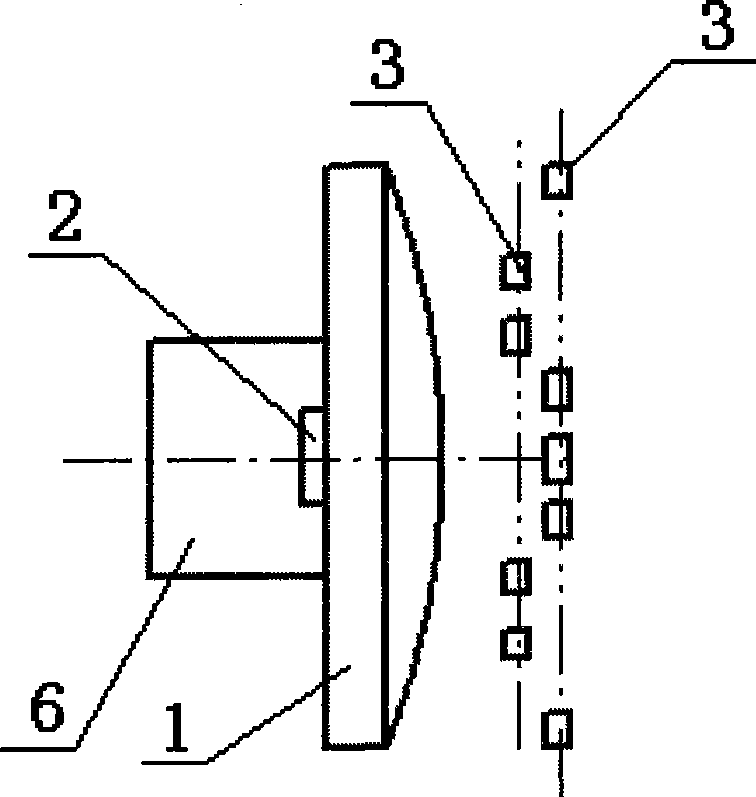

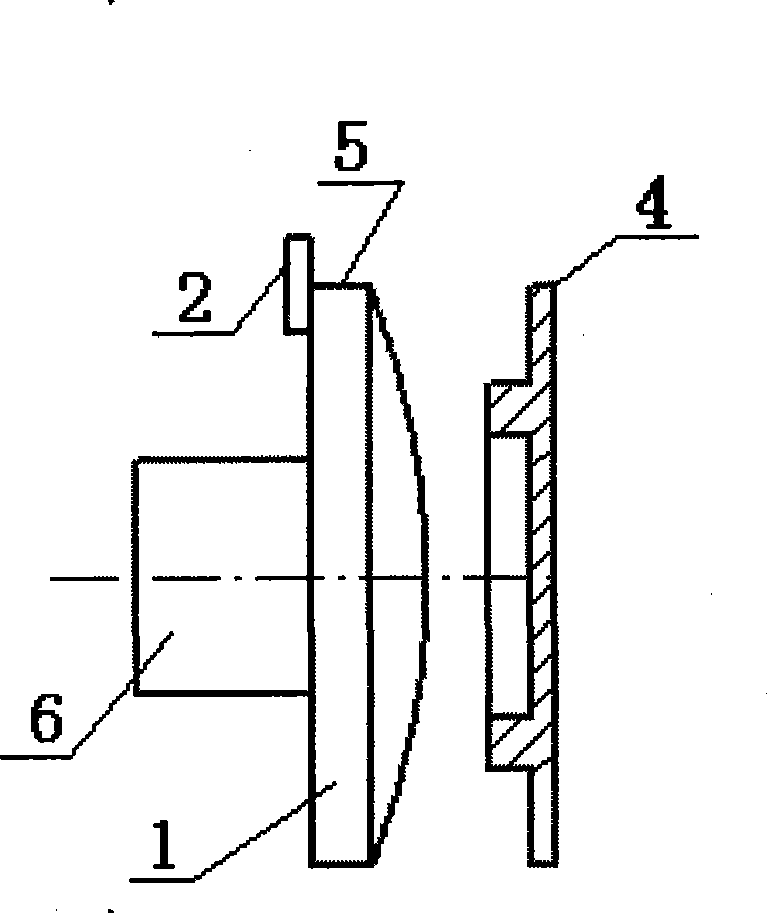

[0027] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , the chromium-plating method of a spherical crown surface of a large-diameter spherical crown workpiece of the present invention, comprising the process steps of degreasing and pickling, positioning in the groove, preheating, chrome plating, water washing, unloading and dehydrogenation,

[0028] A. In the described positioning step of entering the groove, a conductive plate 2 is set on the aspherical end face of the workpiece 1, the spherical crown surface of the workpiece 1 is vertically placed in the plating solution, and the anode strip 3 or the anode plate 4 are also vertically placed in the plating solution Among them, its anode strip 3 or anode plate 4 are arranged as follows:

[0029] A1. The anode strips 3 are arranged in two layers. The inner anode...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com