Patents

Literature

136results about How to "Less prone to defects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

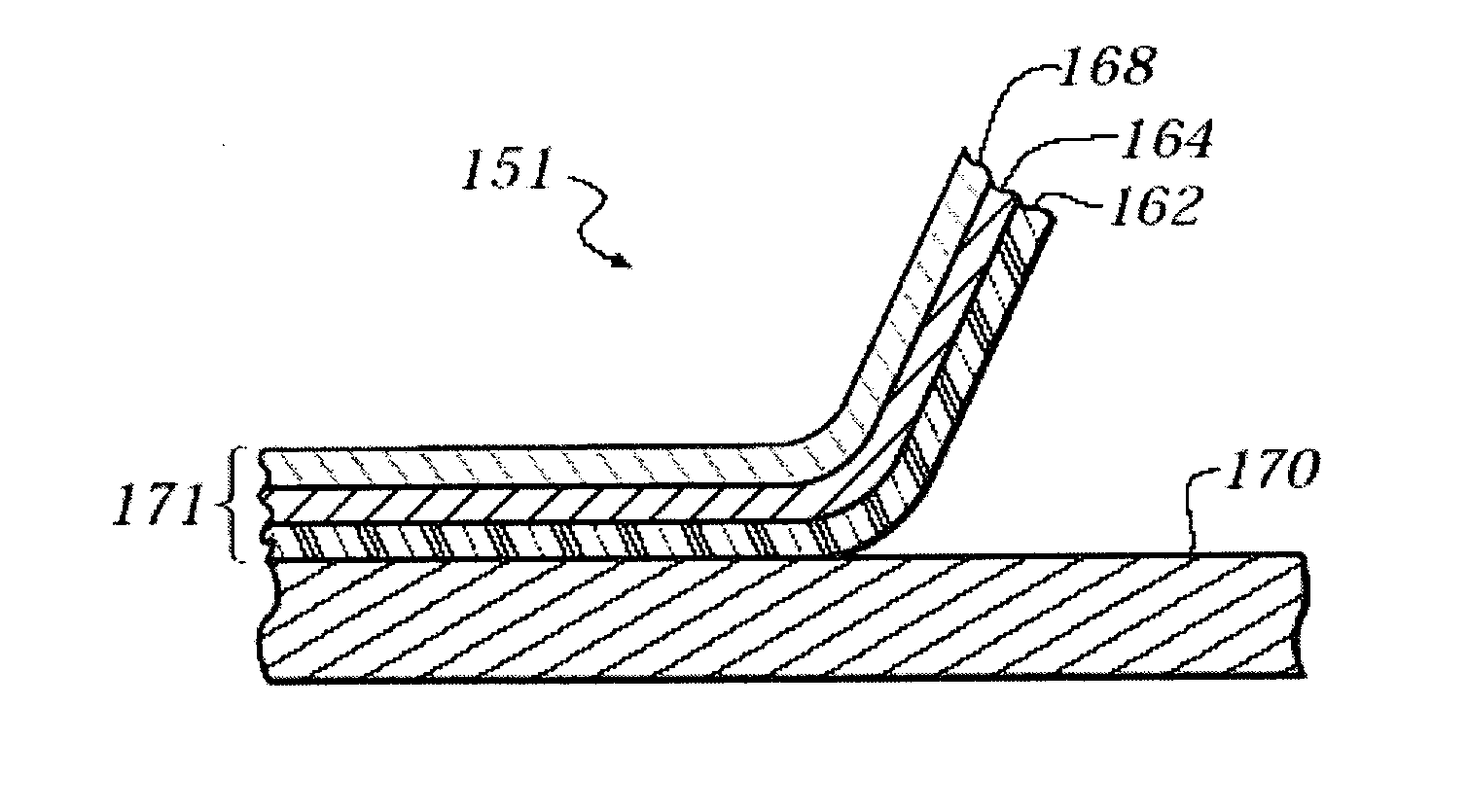

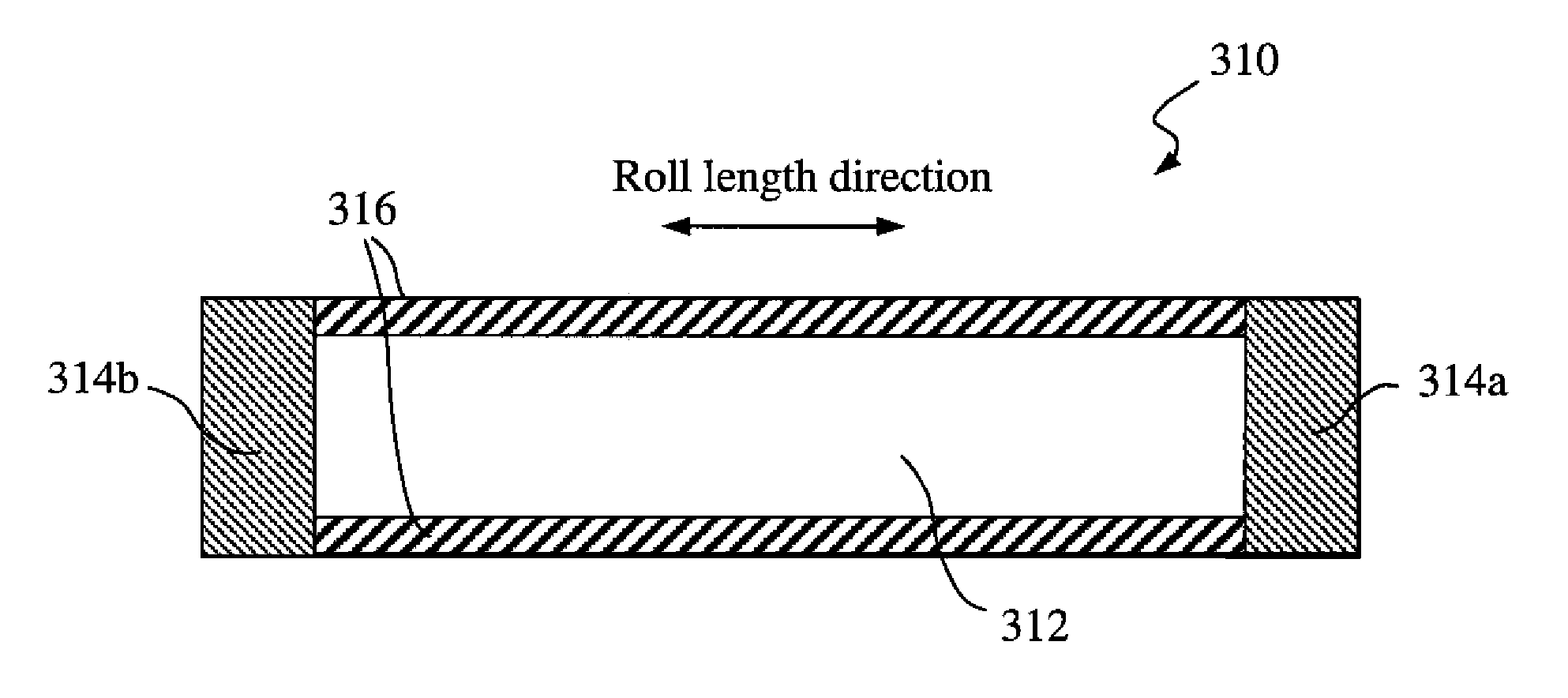

Optical film composite having spatially controlled adhesive strength

InactiveUS20070134459A1Improve handlingSimple processLamination ancillary operationsLayered product treatmentLiquid-crystal displayPolarizer

The present invention generally relates to optical films useful in the manufacture of polarizer plates, an improved method for producing polarizing plates, and a Liquid Crystal Display employing the same. More particularly, the invention relates to an optical film composite comprising a temporary carrier substrate having a center area and an edge area, said substrate having coated thereon an optical film wherein the adhesive strength between the optical film and the substrate is greater at the edge area than at the center area of the substrate.

Owner:EASTMAN KODAK CO

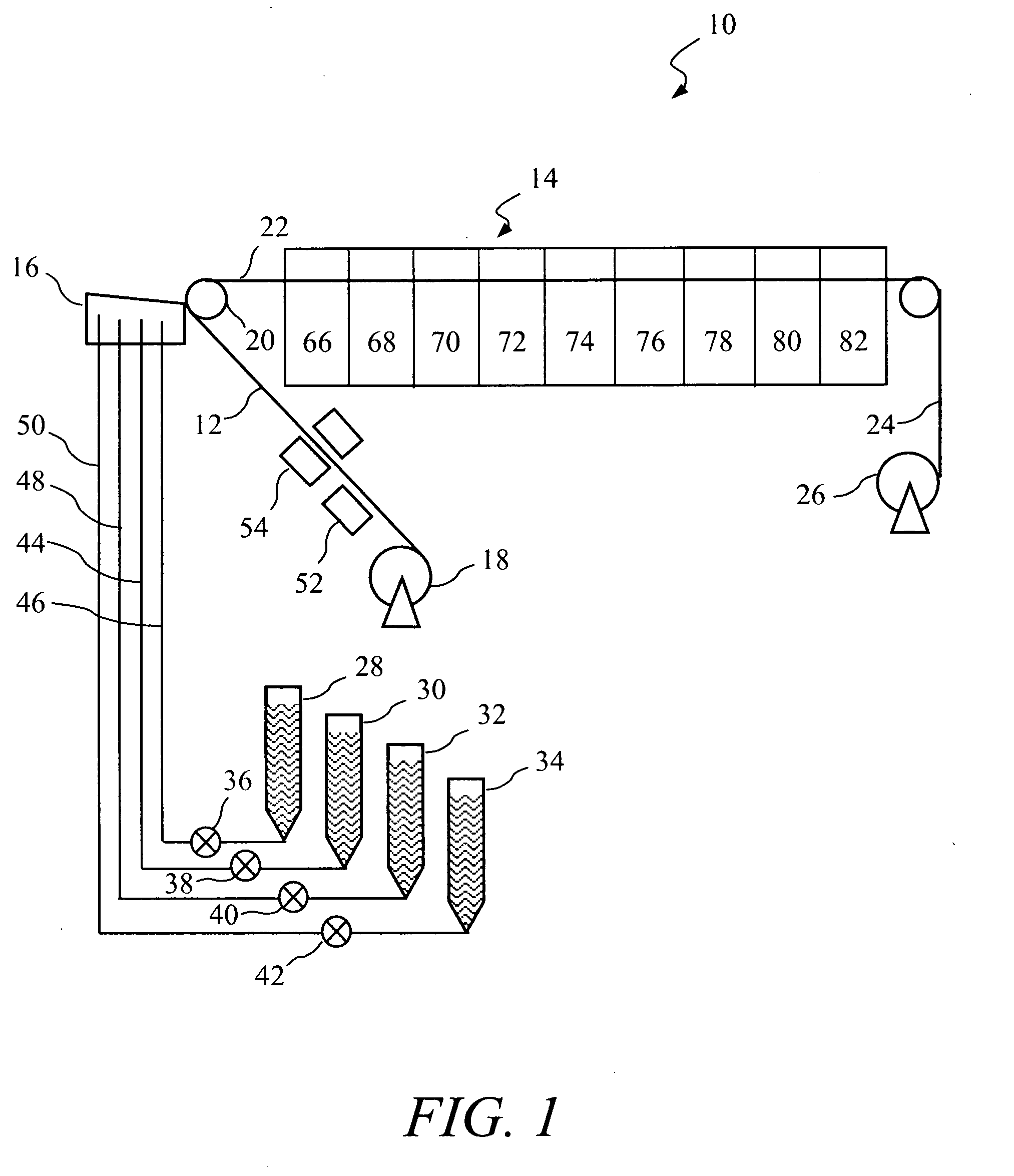

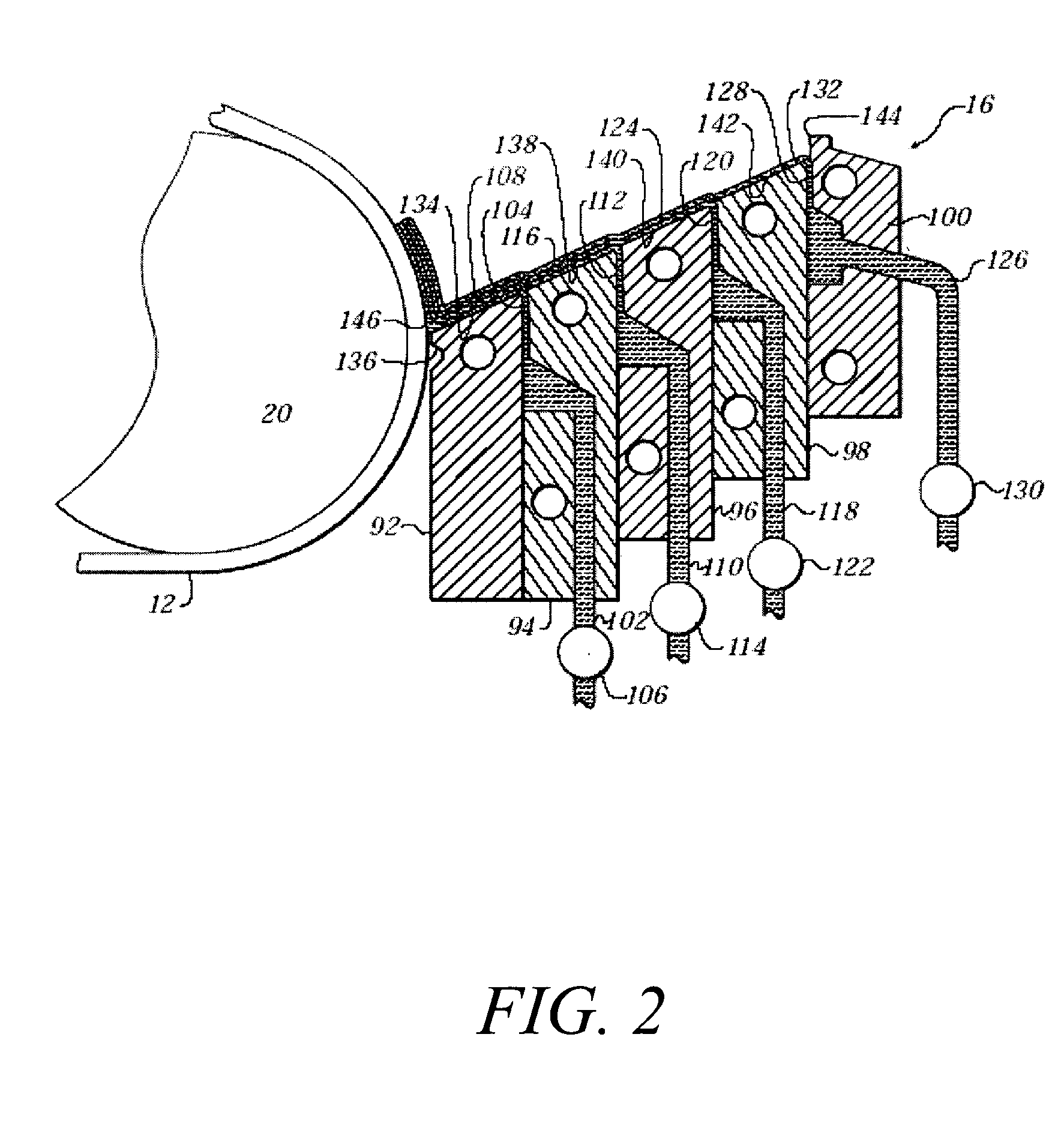

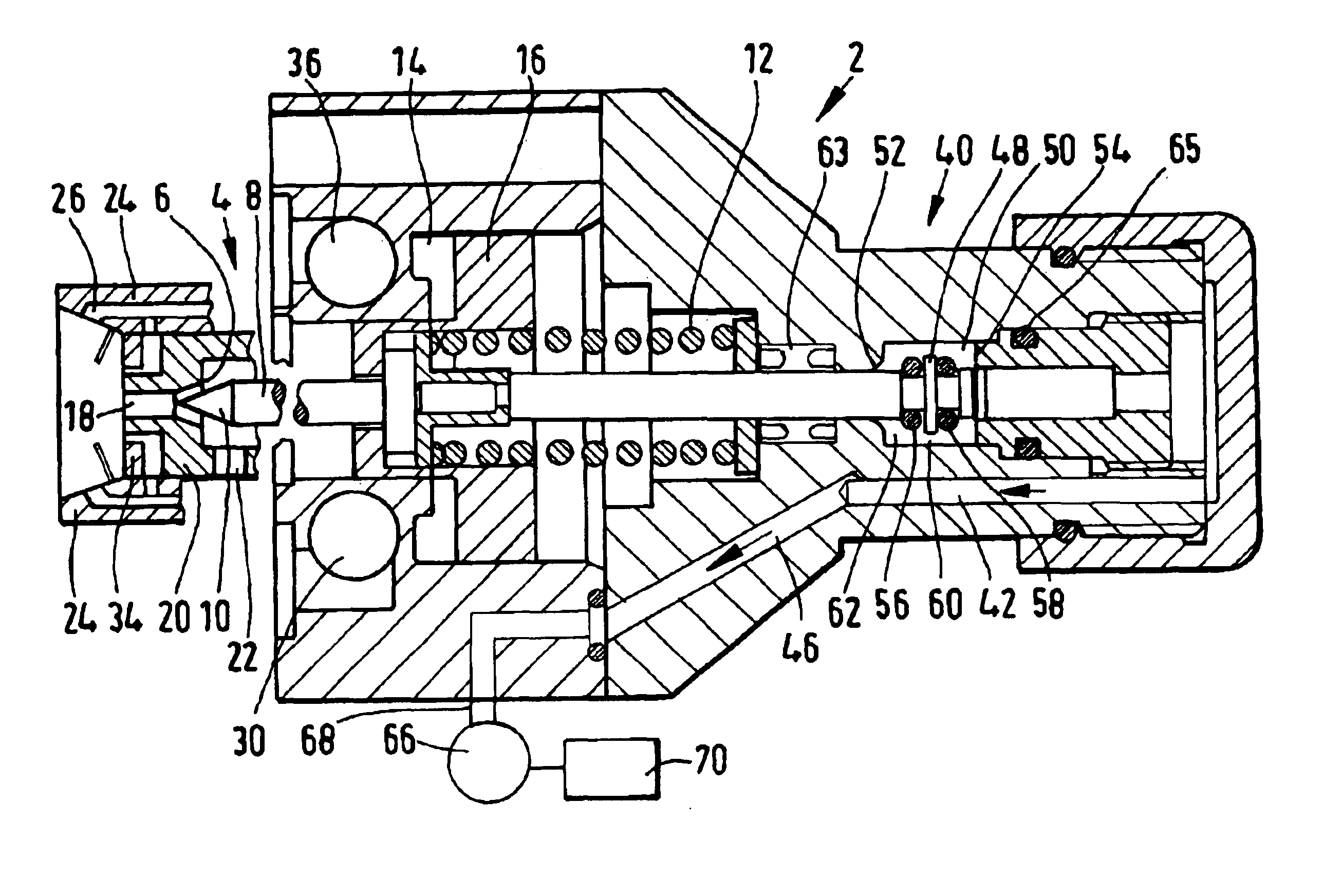

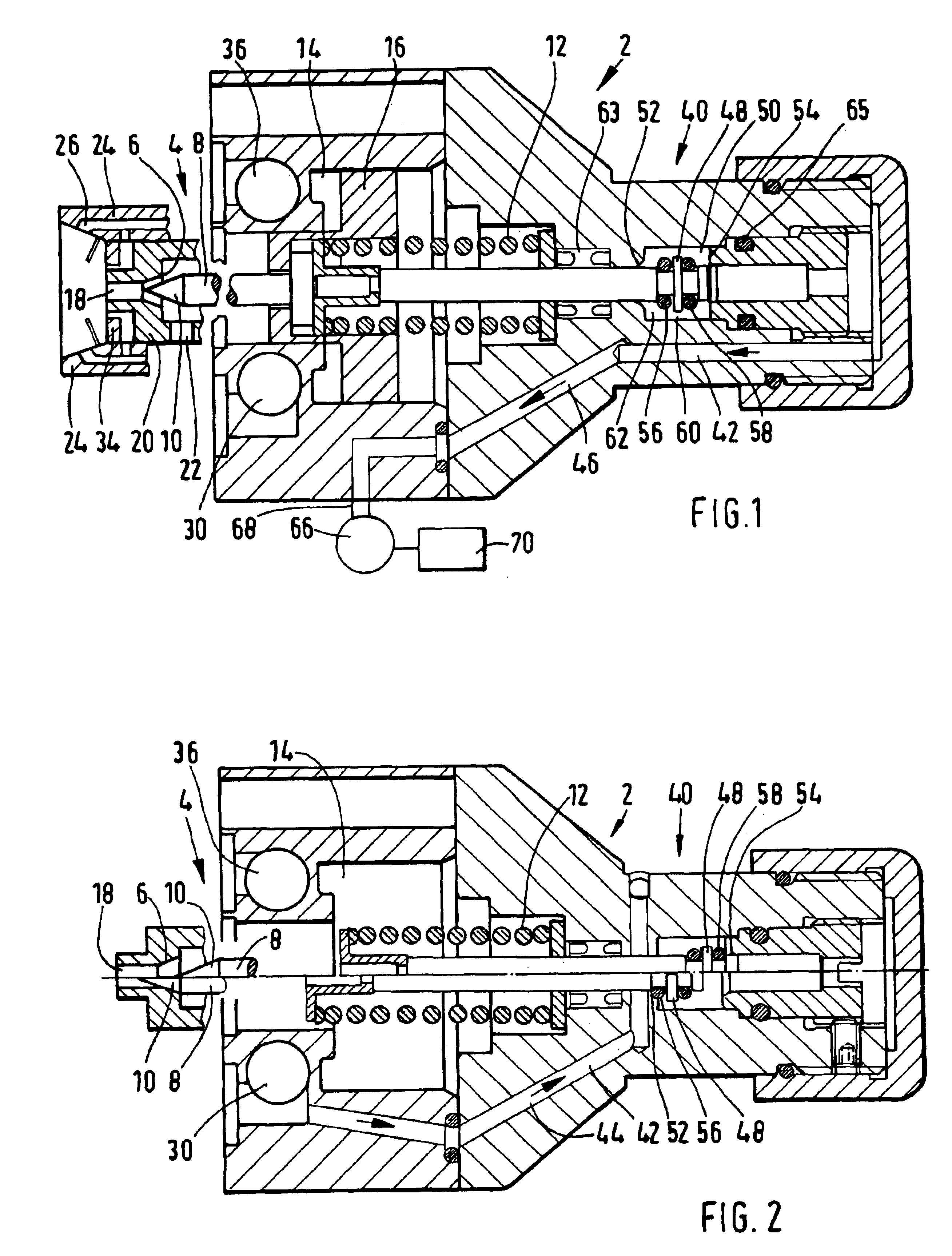

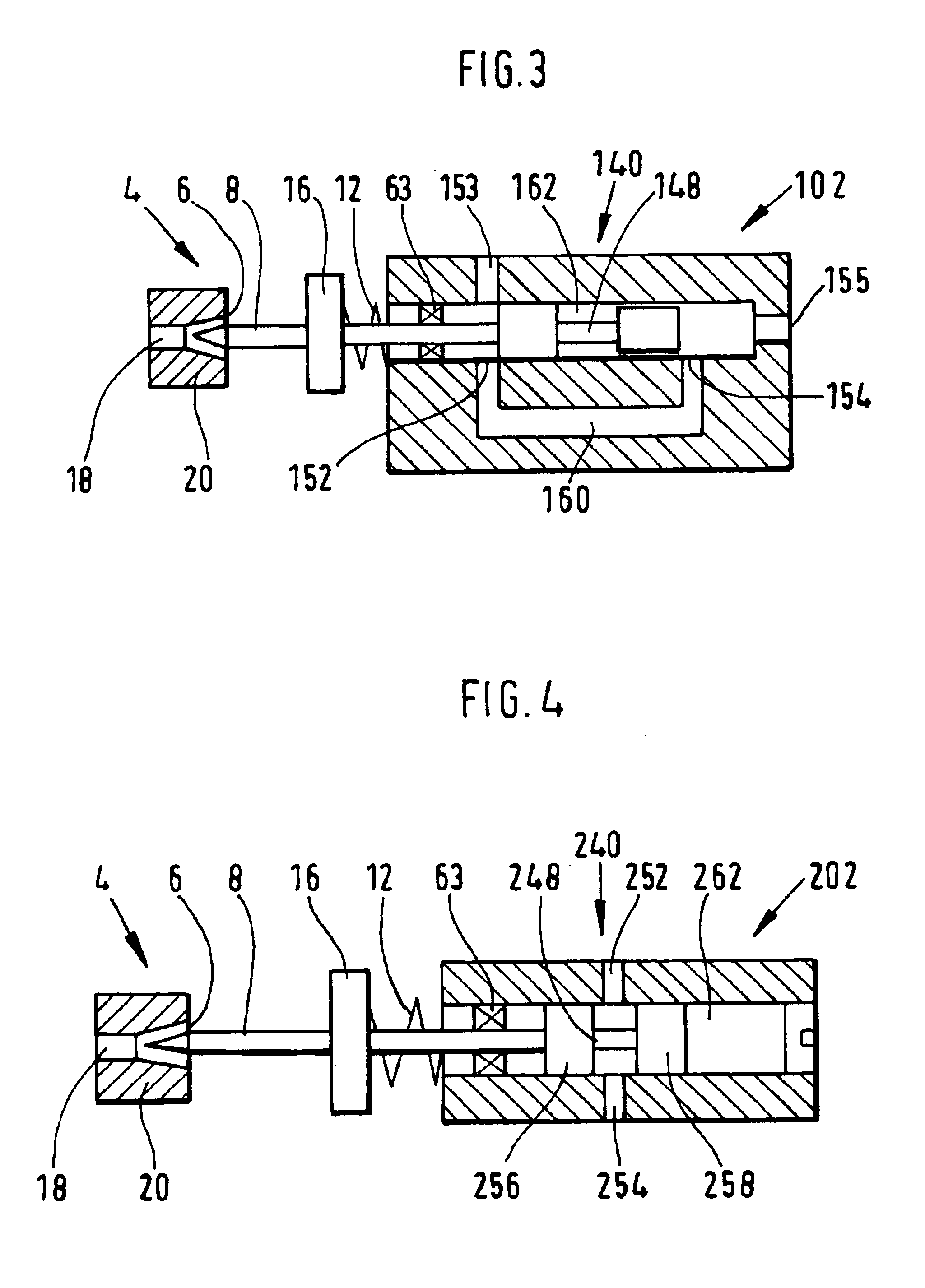

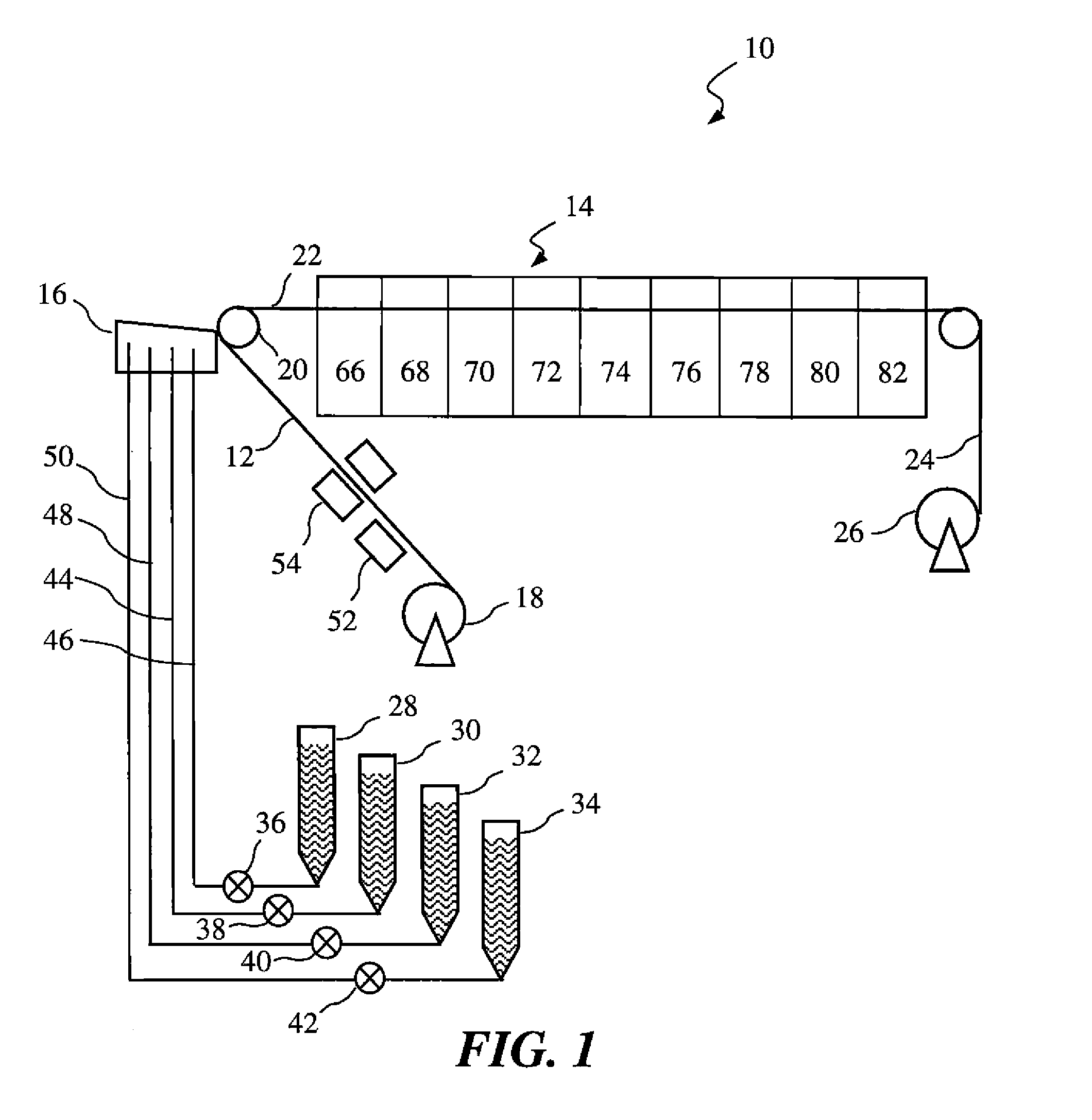

Spray-coating device for a coating liquid

InactiveUS6955724B2Less susceptibleAccurate operationBurnersValve arrangementsSpray coatingProduct gas

A spraycoating device includes at least one coating liquid spray gun (2) which contains a measuring valve device (40) opening or closing a compressed gas measuring valve flow path (42) depending on the positions of a liquid feed valve (4). The measurement of the compressed gas flow allows automatically determining whether the liquid feed valve (4) is situated in a fully close or a fully open position or in an arbitrary intermediate position thereto.

Owner:FINISHING BRANDS GERMANY

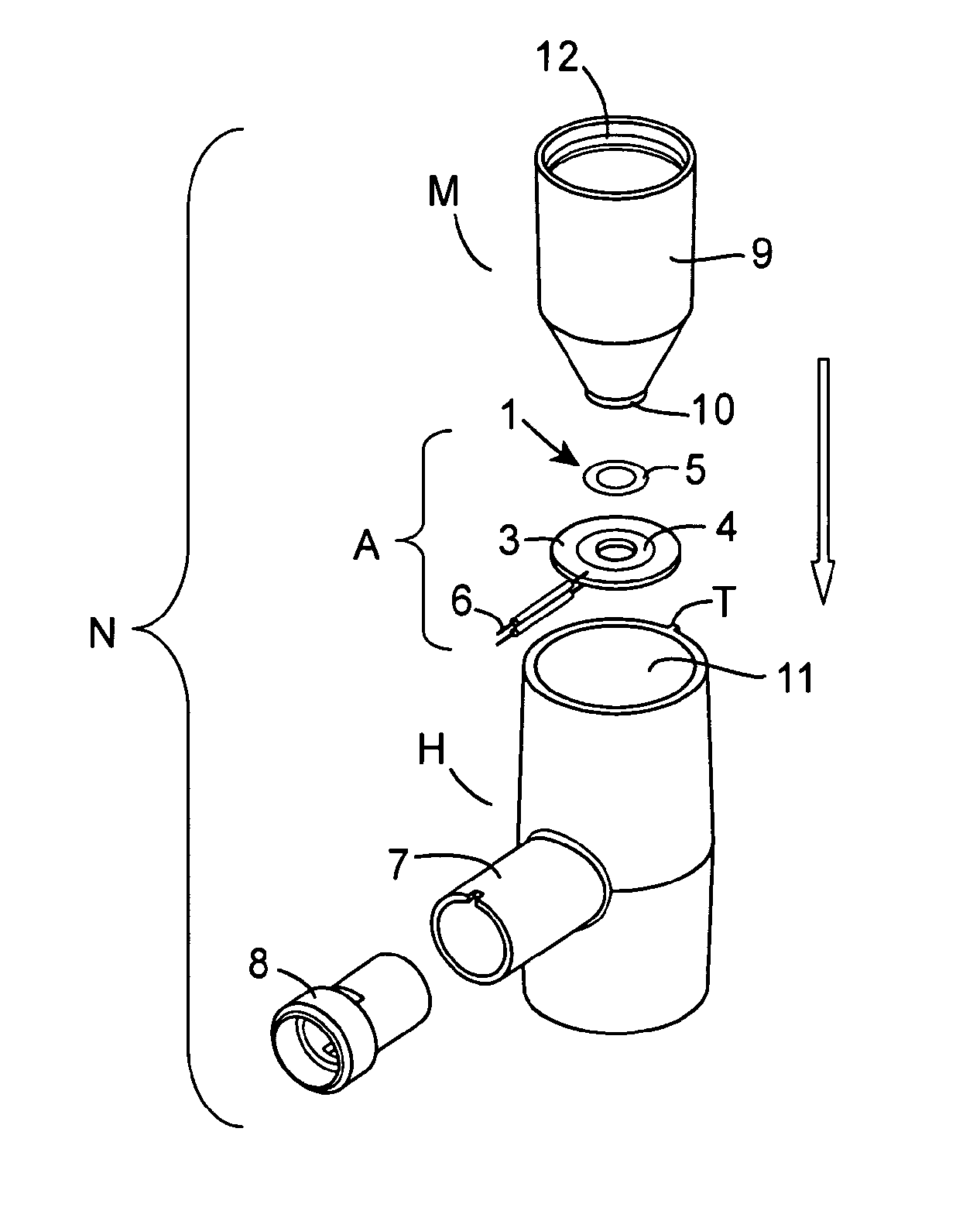

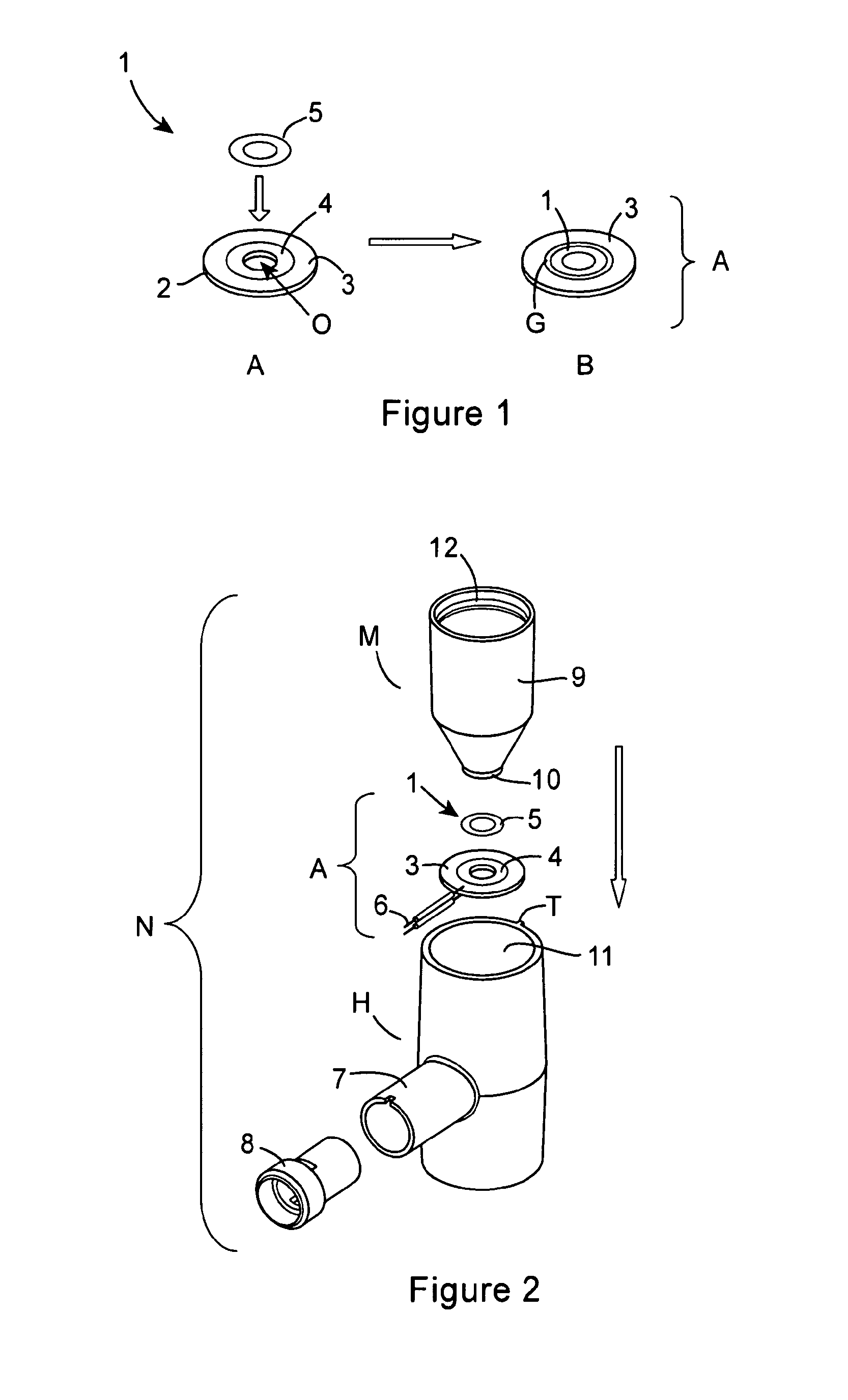

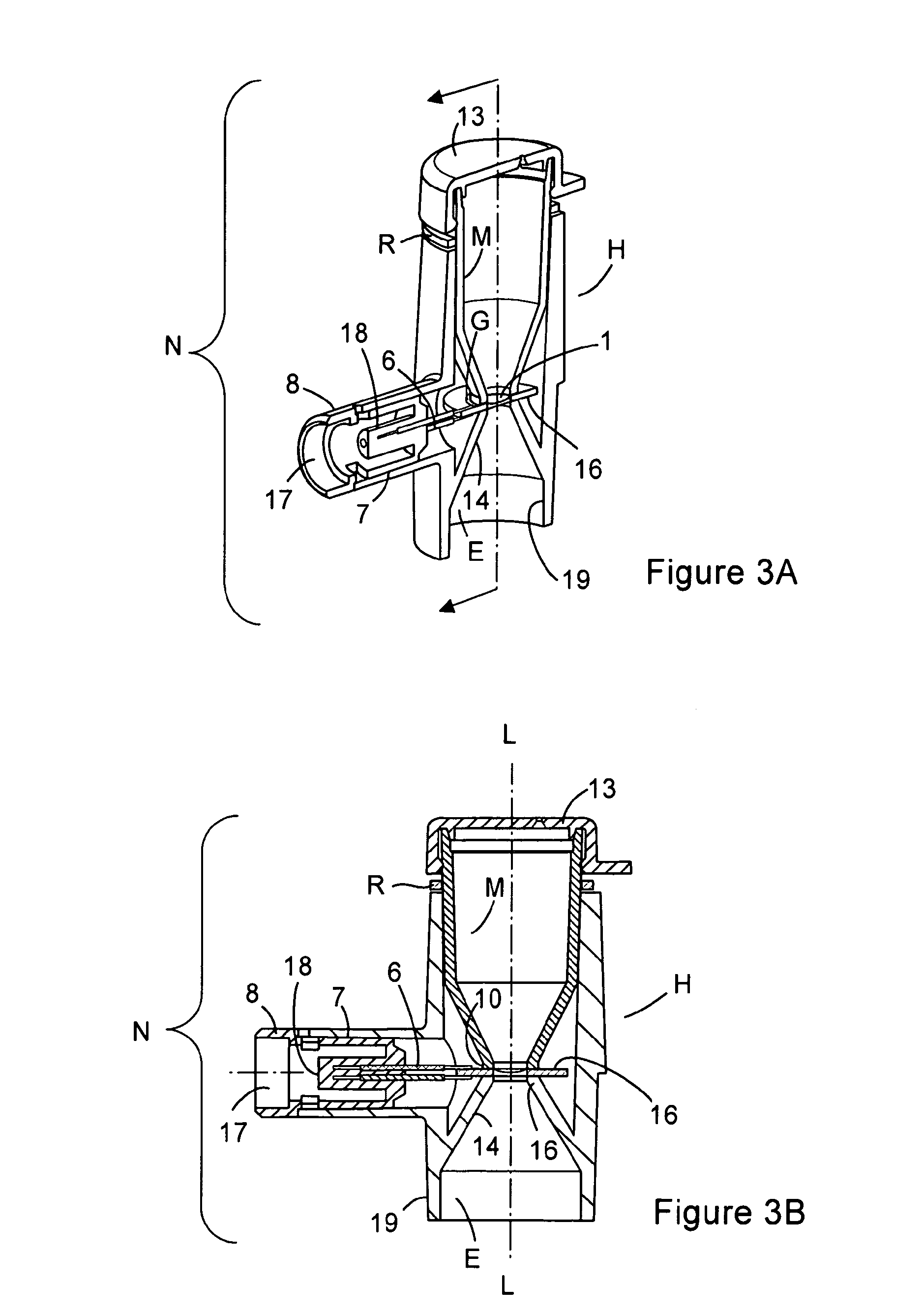

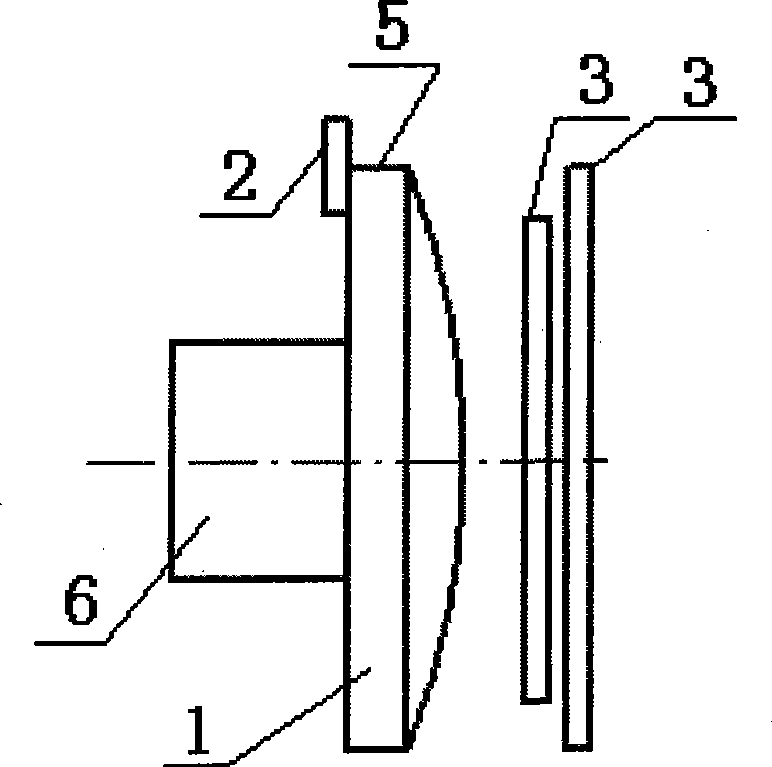

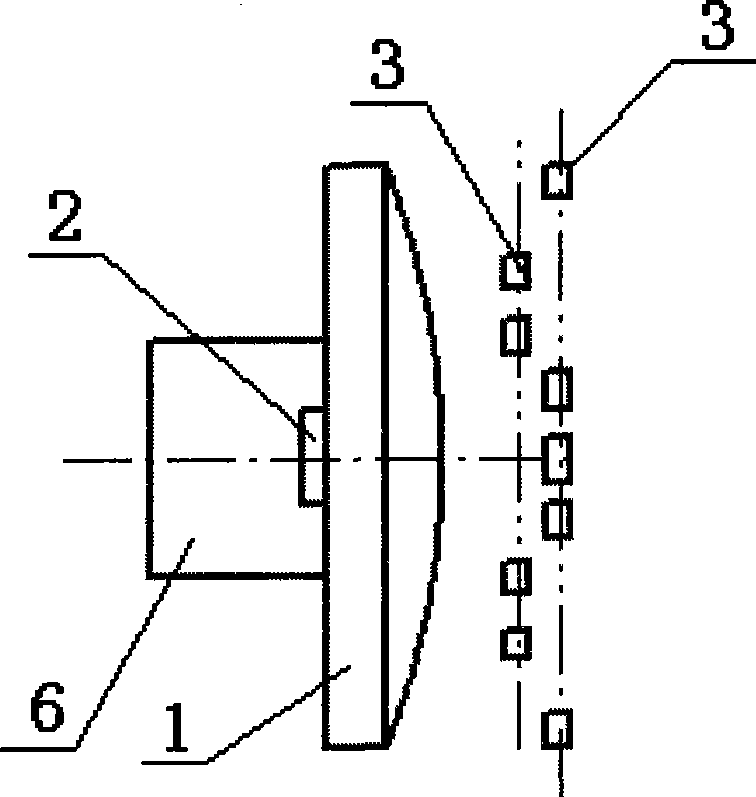

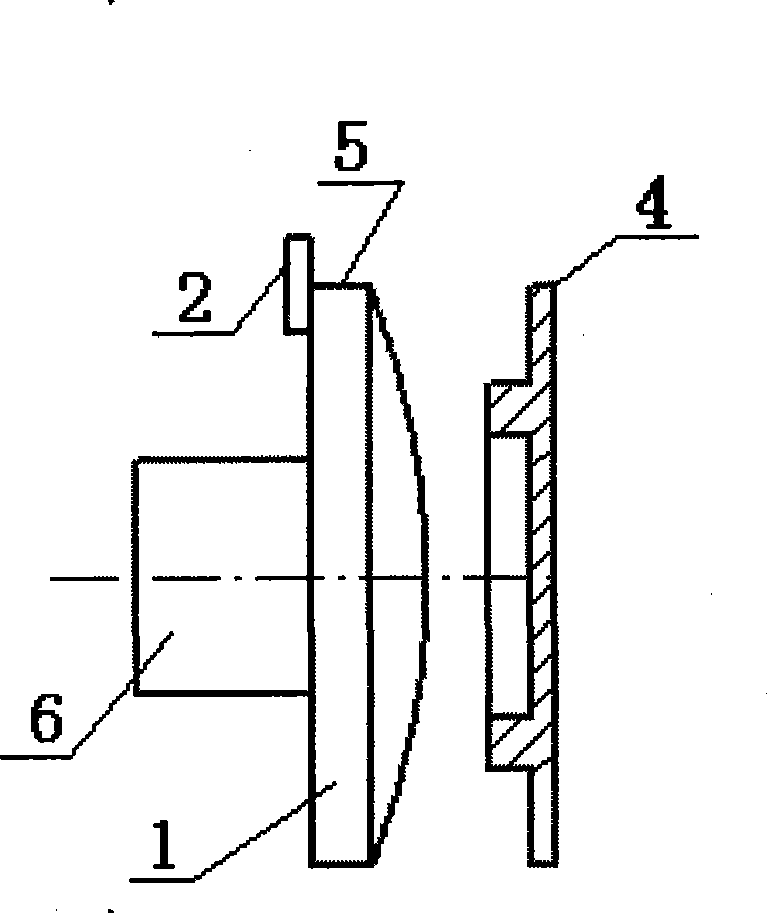

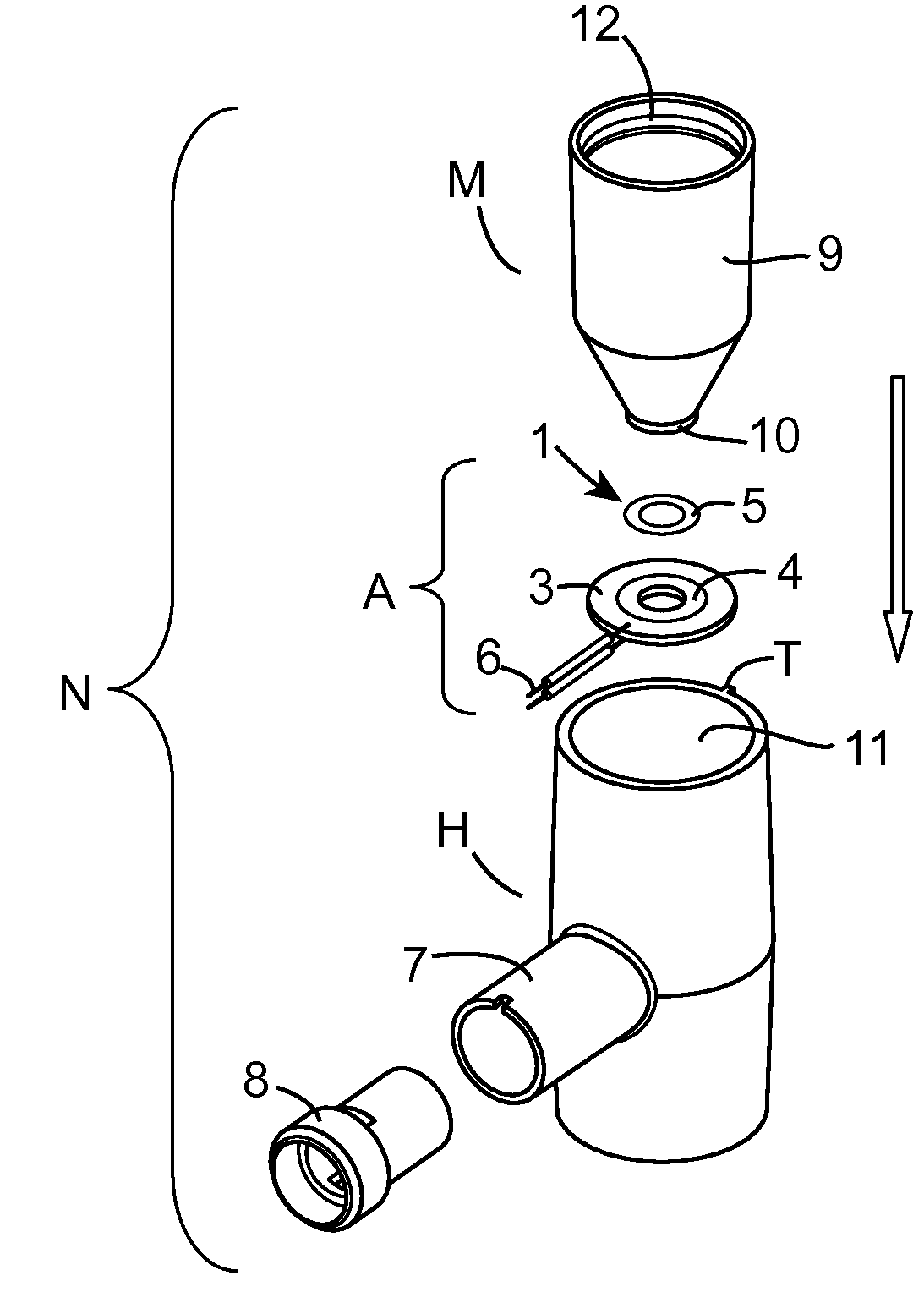

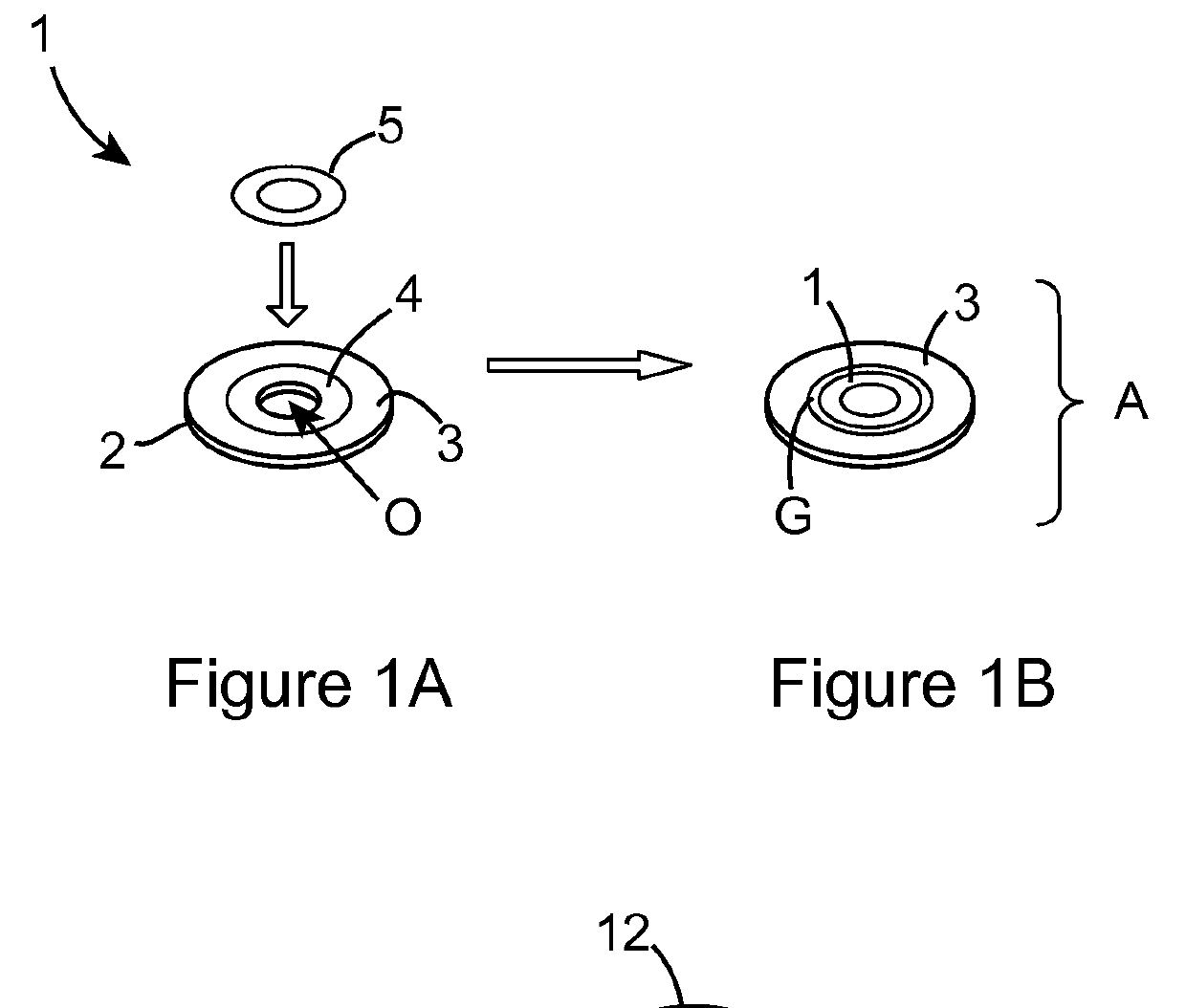

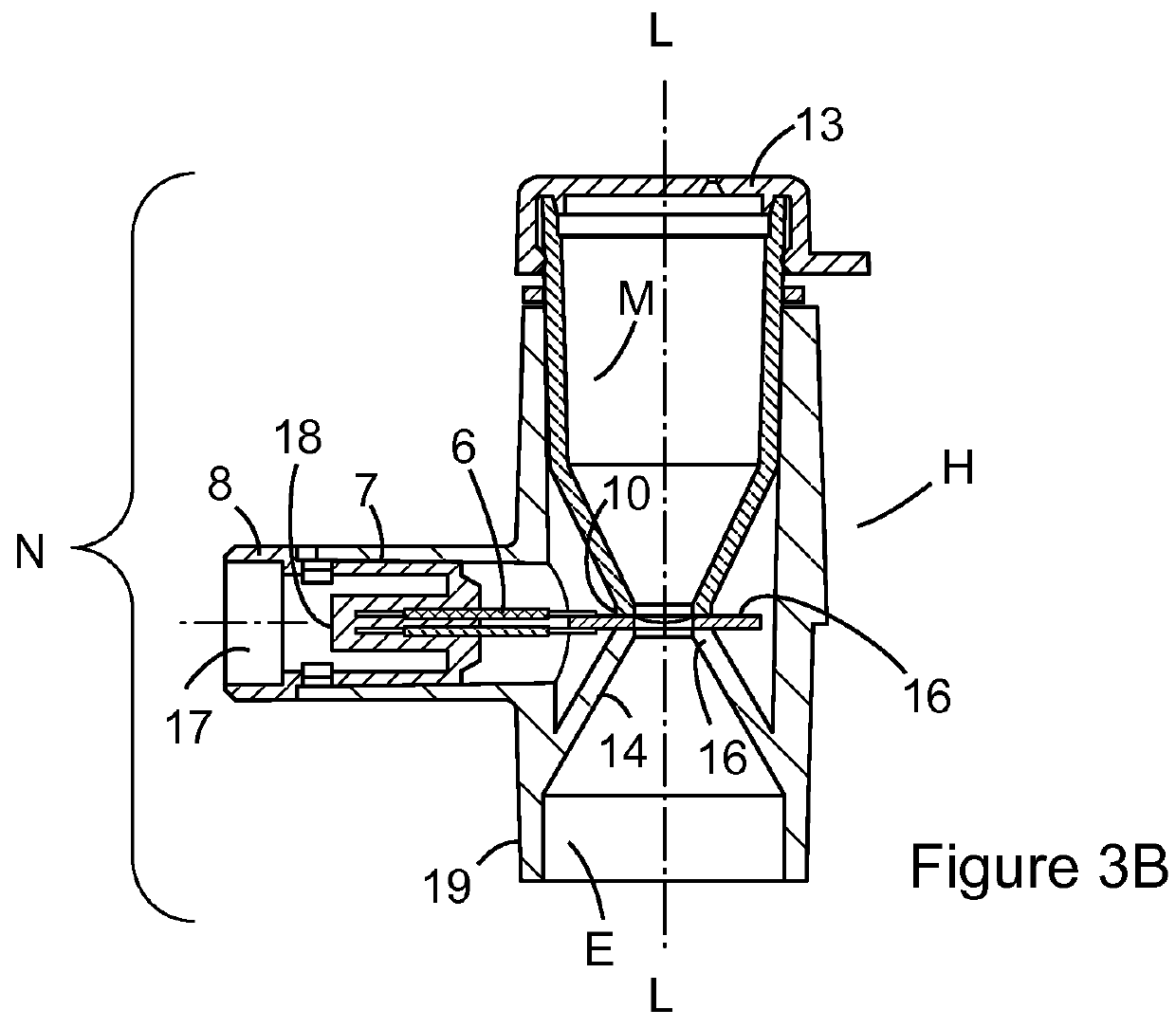

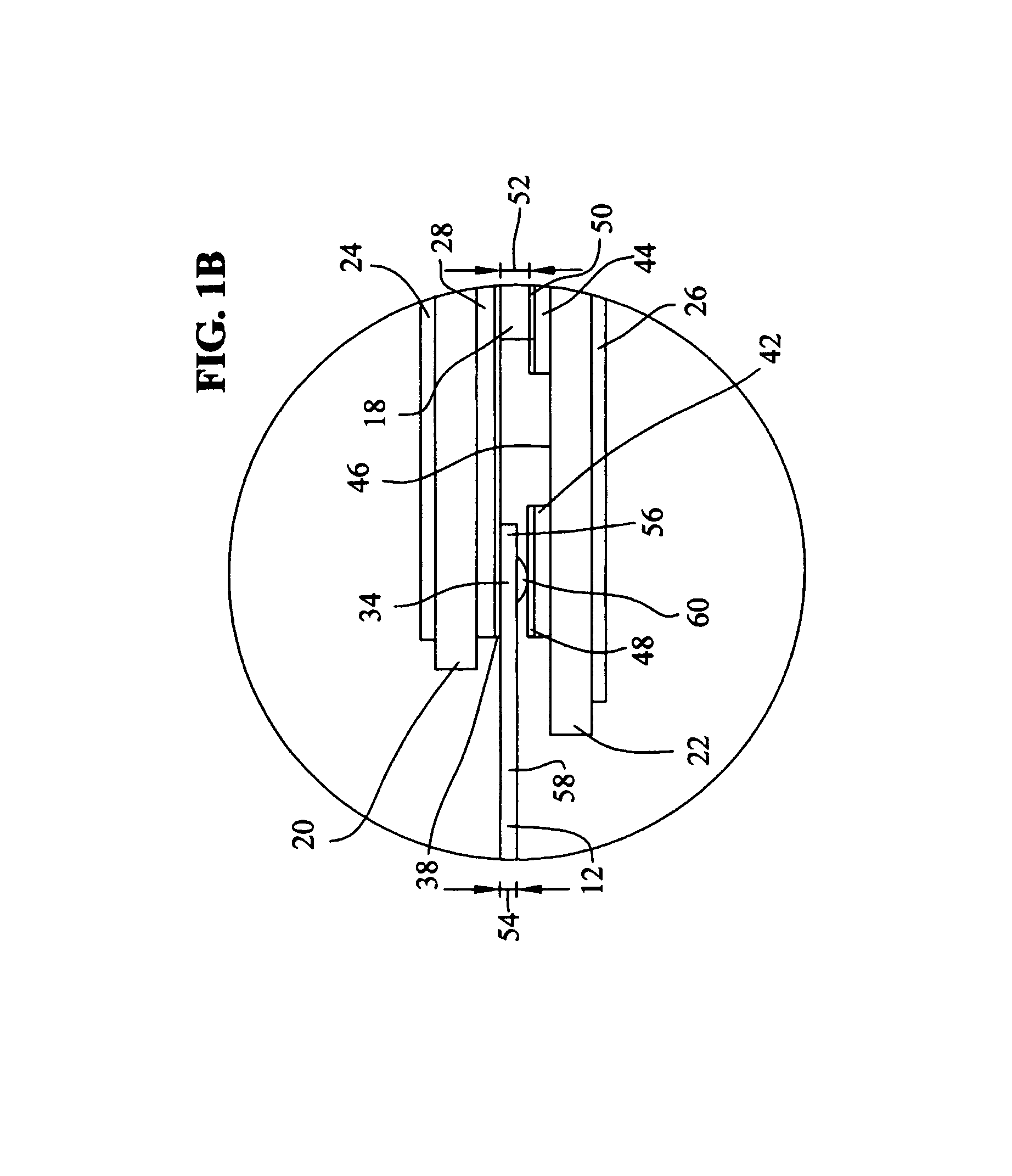

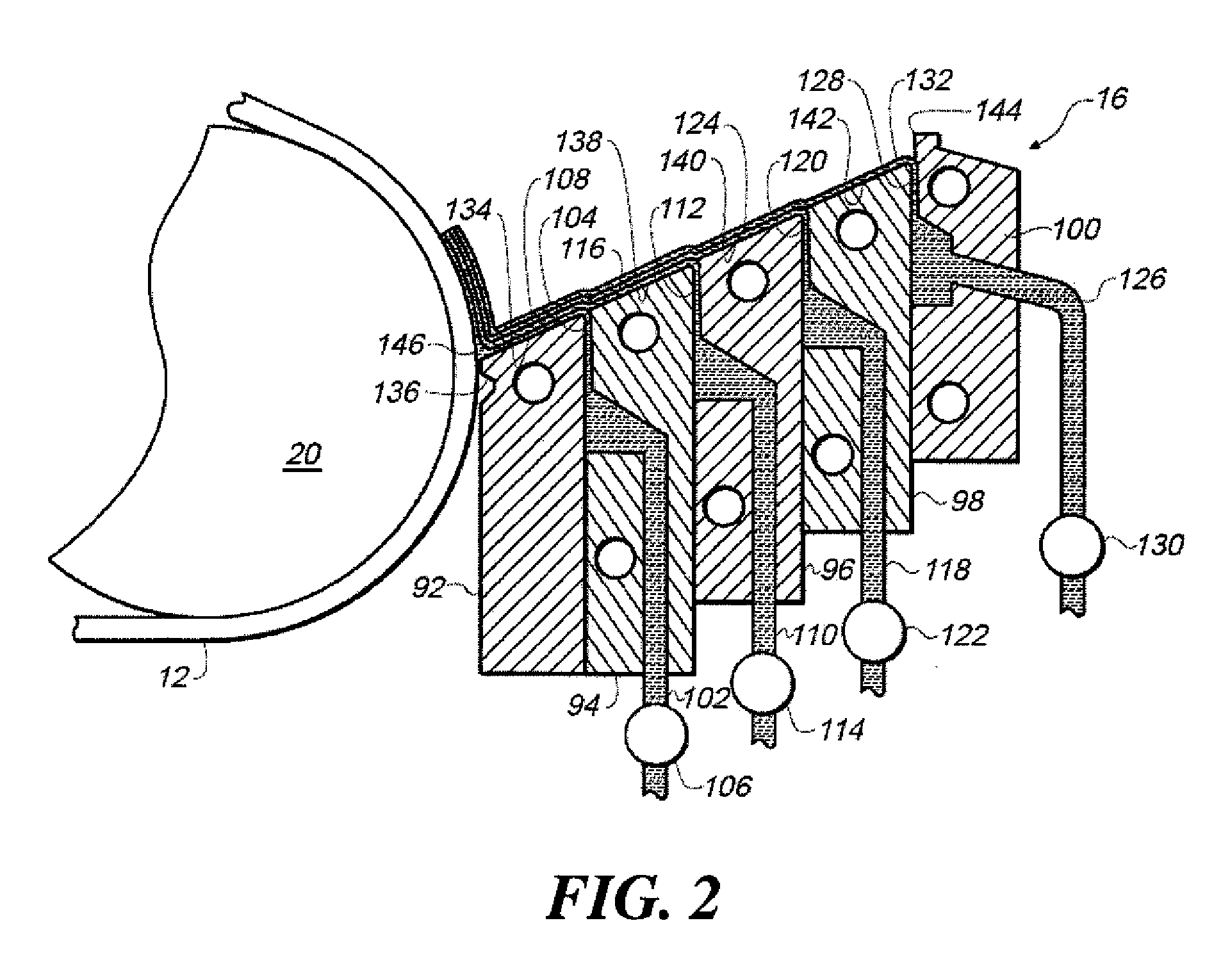

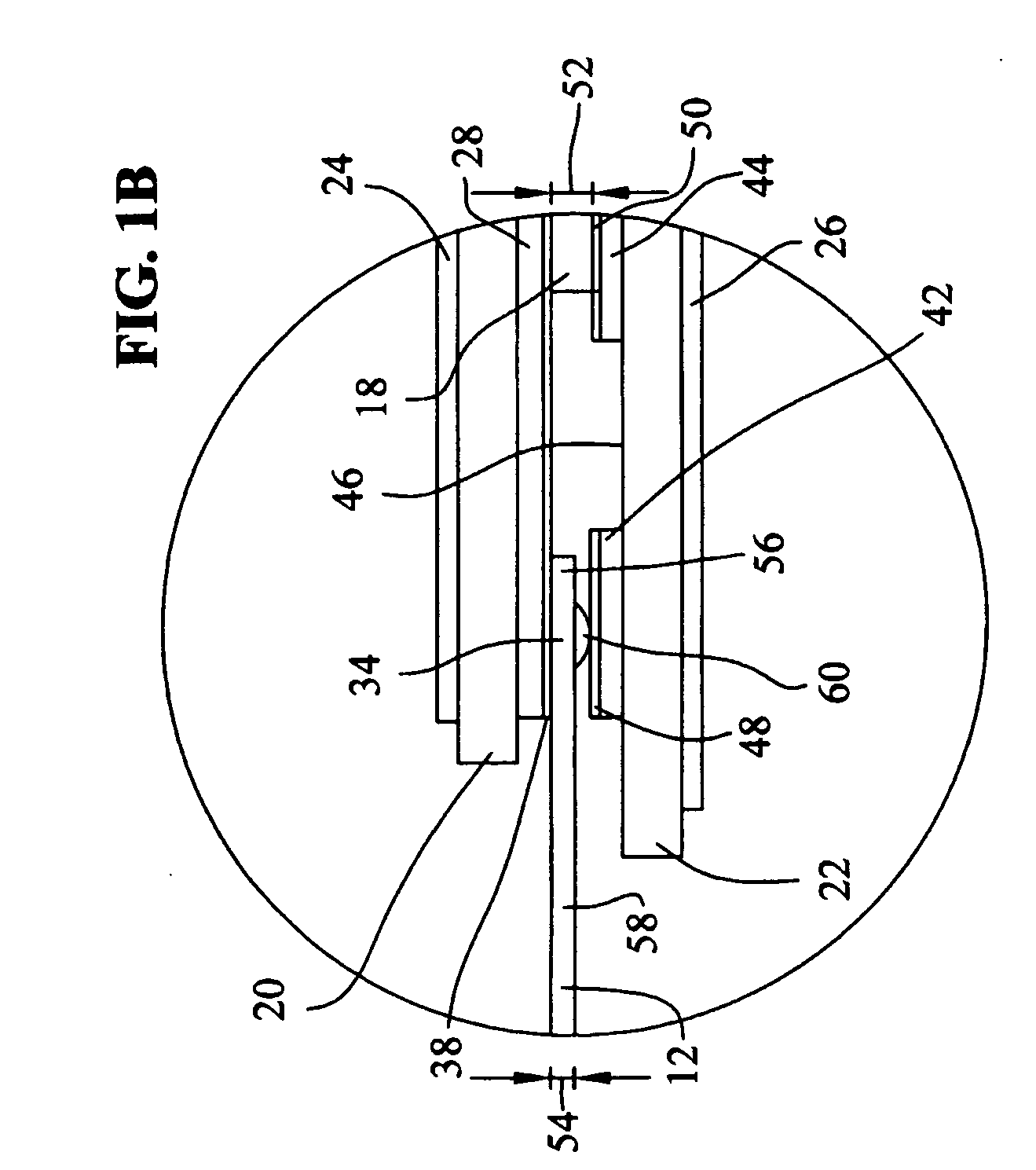

Aerosol generator assembly

ActiveUS20130119151A1Less prone to defectsReduce riskMovable spraying apparatusMedical devicesElectricityFree zone

An aerosol generator assembly comprising a vibratable piezo ceramic body (2) having first and second opposing sides, an aperture (o) defined in the vibratable body and extending through the body from the first side to the second side and having a layer of electrical contact material on each side of the vibratable body, the vibratable body being vibratable by application of an electrical signal thereto; a vibratable member (1) with pores defined therein, the vibratable member mounted across the aperture; and an electrical contact material free-zone (4) is provided on at least one side of the body about the aperture, characterised in that the electrical contact material free-zone and the vibratable member are dimensioned so that the vibratable member is mountable directly onto the vibratable body on top thereof within the electrical contact material free-zone such that a gap area free of electrode contact material is formed between the terminating edge of the electrical contact material and the periphery of the vibratable member.

Owner:NORTEV

Method used for manufacturing multi-layer circuit board by employing 3D printing technology

InactiveCN104486910ALess prone to defectsReduced responseConductive pattern formationInsulation layerCam

The invention provides a method used for manufacturing a multi-layer circuit board by employing the 3D printing technology. The method is additionally provided with a heatproof insulation layer on the basis of an original printed circuit board. Raw material powder of the circuit comprises copper alloy powder and tin powder which are in a certain proportion, the heatproof insulation layer is ceramic powder, the 3D molding method is a laser irradiation molding method. During processing, the computer auxiliary manufacturing (CAM) technology is firstly utilized, circuit board design is accomplished on computer software and is transmitted to a 3D printer. The ceramic powder is fixed on the circuit board to form the heatproof insulation layer by utilizing the laser 3D printer, circuit molding of the powder is directly carried out on the heatproof insulation layer base body by utilizing the 3D printing technology, the steps above are repeated, and thereby the multi-layer circuit board is formed. Compared with a traditional printed circuit board, the multi-layer circuit board can be rapidly produced in a lab or under the small-batch production condition, moreover, the circuit does not easily generate defects, cost is low, response is rapid, equipment investment is small, and the method employing the 3D printing technology provides feasible small-batch customized production.

Owner:ANHUI NEOFOUND TECH +2

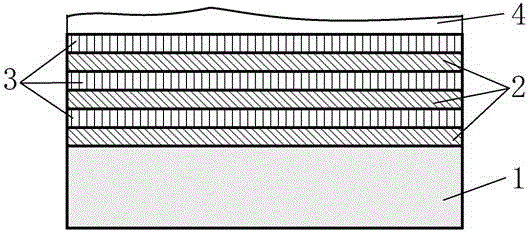

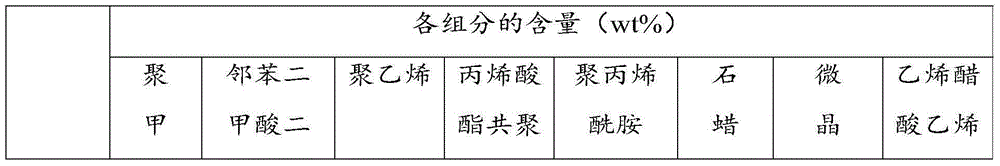

Binding agent for powder injection moulding, preparation method and application method of binding agent

The invention provides a binding agent for powder injection moulding, a preparation method of the binding agent and an application method of the binding agent. The binding agent is mainly prepared from the following components in percentage by mass: 65 to 75 percent of polyformaldehyde, 4 to 9 percent of dioctyl phthalate, 6 to 13 percent of polyethylene, 1 to 3 percent of acrylate copolymer, 3 to 8 percent of polyacrylamide, 1.5 to 4 percent of paraffin, 2 to 6 percent of microcrystalline wax and 0.5 to 2 percent of ethylene vinyl acetate copolymer. In the binding agent provided by the invention, multiple types of components are combined through scientific compatibility, so that the compatibility between metal powder or ceramic powder and the binding agent can be obviously improved, and meanwhile, the binding agent can be quickly removed in a degreasing process without causing the defects of bubbling and cracking of a green body, so as to guarantee the quality of the green body.

Owner:王有才

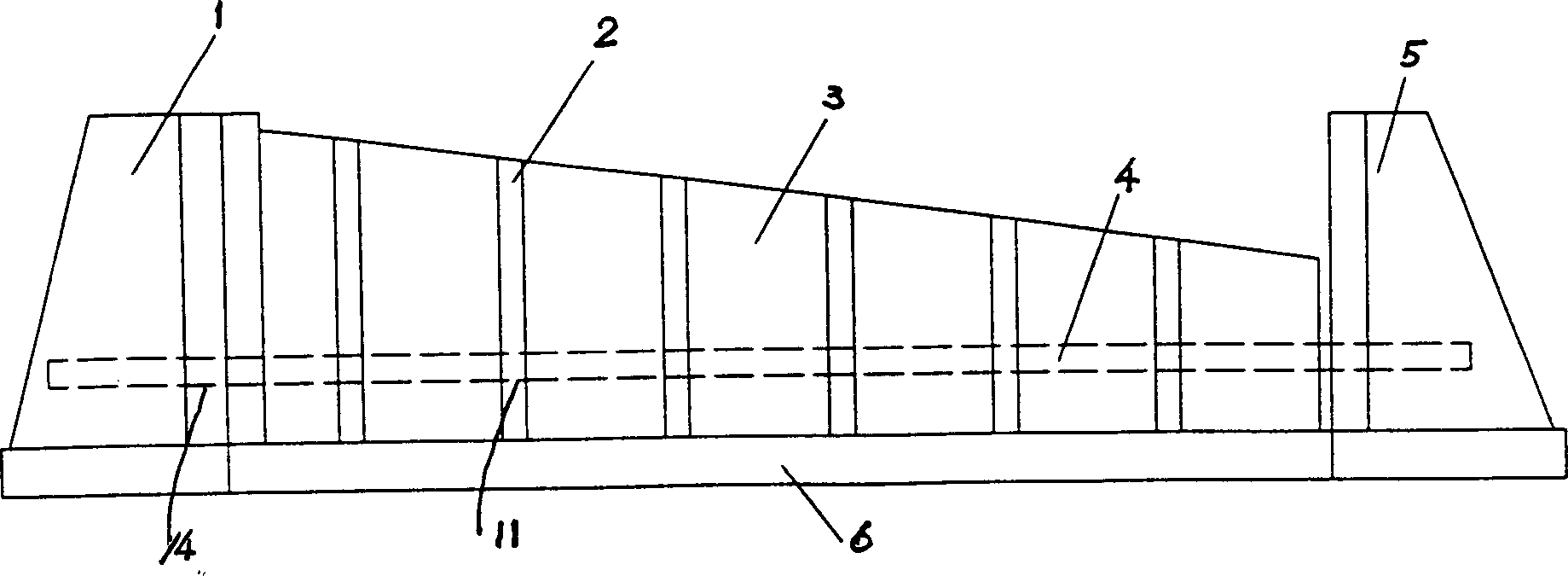

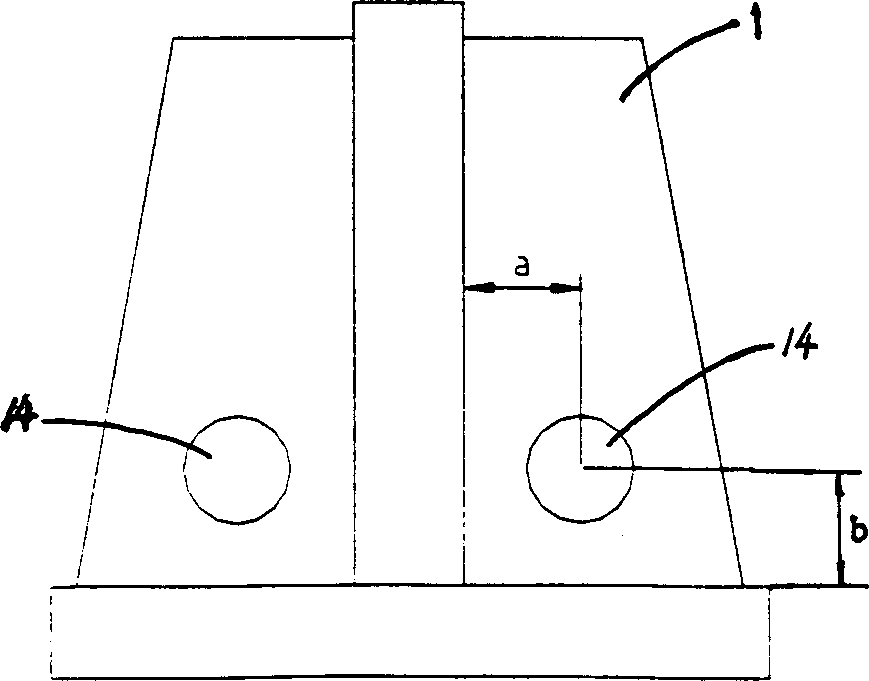

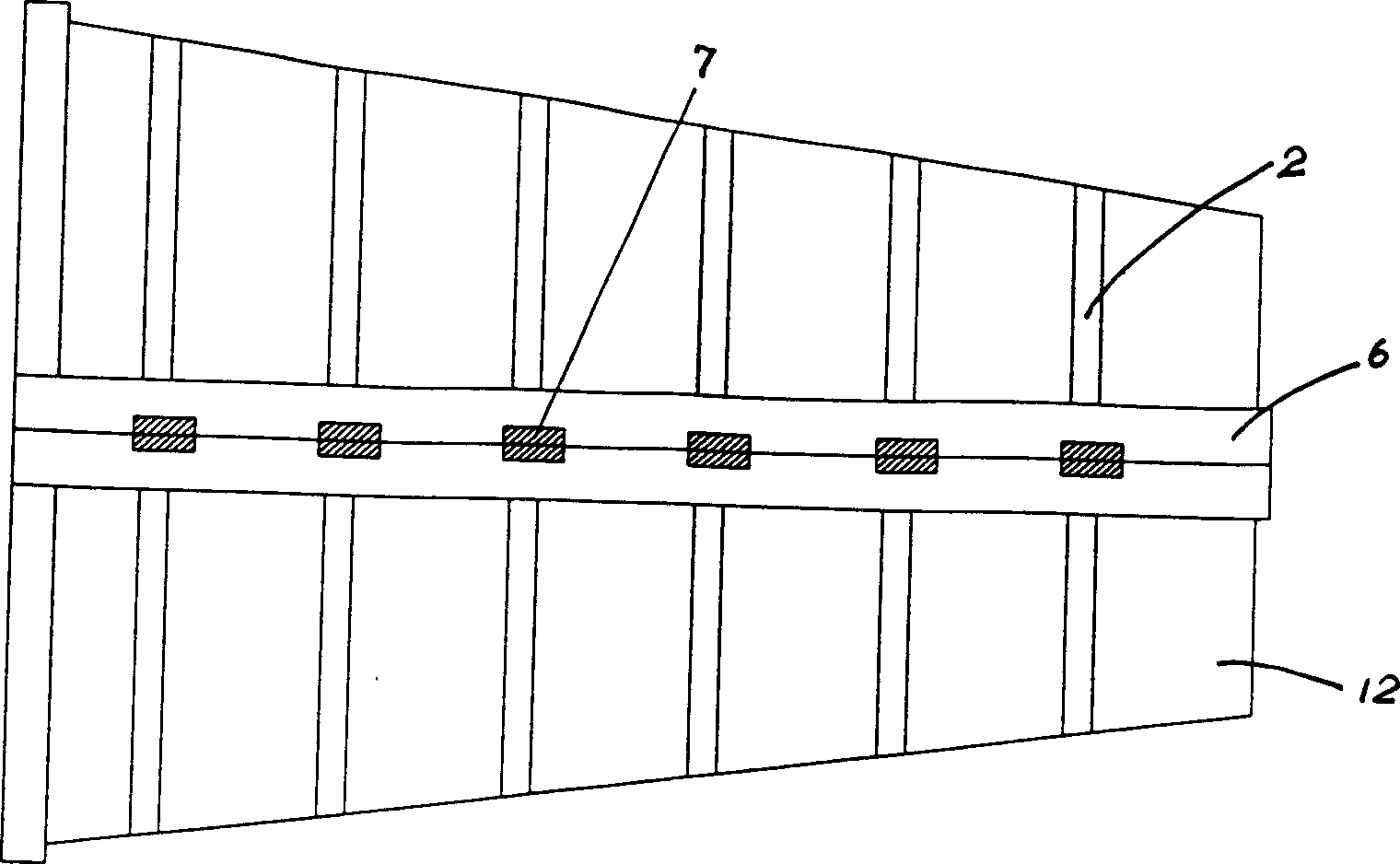

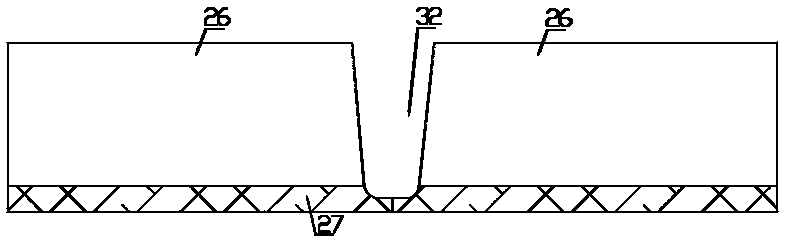

Low-speed diesel engine frame welding method

InactiveCN1405482ASolving Concentricity ProblemsSolve the deformationMachine framesWelding apparatusLow speedEngineering

A method for welding the frame of a low speed diesel engine. It includes the following steps: 1) By passing locating iron pipes through the screw holes in small iron plates, a number of small iron paltes are located between two bed-jigs according to the requirements of design, and spot welded on a guide plate and a triangle plate to form guide plate components. 2) The bilateral symmetric and located guide plate components are put symmetrically side by side and located by butt strap welding. 3) The welded and located bilateral guide plate component are welded in symmetry. 4) After welding, butt straps are removed, and the bila-teral guide plate components are separated. 5) with the help of the bed-jig, the bilateral guide plate components and a division plate are located on a cast-iron platform.

Owner:HUDONG HEAVY MACHINERY +1

Electrode production of fuel battery membrane with proton exchange membrane

ActiveCN1713424AIncrease contactTightly boundCell electrodesFinal product manufacturePtru catalystNafion

The method includes following steps: 1) the carbon paper or carbon fabric is dipped in PTFE latex, and then dried to get conduction base; 2) the VXCÊ72 carbon black or acetylene black is mixed with PTFE latex to form synthetic size that is coated on the conducting base; after drying, forms a gas diffusion layer; 3) prepares catalyst slurry; 4) the catalyst slurry is coated on the diffused layer; after hot pressing, it is cooled at the condition of keeping pressure, and the gas diffusion electrode is formed; 5) the Nafion film is set between two gas diffusion electrodes with catalysis layer; after hot pressing, it is cooled at the condition of keeping pressure.

Owner:BYD CO LTD

Chip-level bottom filling adhesive and preparation method thereof

InactiveCN102559115ADoes not affect memoryCuring shrinkage is smallSemiconductor/solid-state device detailsSolid-state devicesCross-linkEpoxy

The invention relates to a chip-level bottom filling adhesive, which comprises following components by weight percentage: 15 to 50 percent of epoxy resin, 1 to 20 percent of toughening agent, 0.1 to 1 percent of dispersing agent, 0.01 to 1 percent of defoaming agent, 0.8 to 10 percent of cross-linking agent, 0.1 to 0.5 percent of pigment, 40 to 70 percent of filler, 3 to 30 percent of curing agent and 1 to 20 percent of diluting agent. A preparation method of the chip-level bottom filling adhesive comprises the steps that the epoxy resin, toughened resin, the dispersing agent, the defoaming agent, the cross-linking agent and the pigment are weighed according to the proportion, thrown into reaction kettle and mixed to form a homogeneous solution; and afterwards, the filler, the curing agent and the diluting agent are weighed according to the proportion, thrown into the reaction kettle in sequence and evenly mixed with the homogeneous solution, and then the chip-level bottom filling adhesive is obtained. The bottom filling adhesive prepared by adopting the method has the characteristics of low curing shrinkage rate, high reliability, and the like, simultaneously satisfies the requirement of low radioactivity and is suitable for primary high-density packaging of memory chips.

Owner:YANTAI DARBOND TECH

Welding process for red copper and stainless steel dissimilar materials

ActiveCN102962543AMeet the use requirementsImprove mechanical propertiesArc welding apparatusFurnace typesForeign matterDehydrogenation

The invention discloses a welding process for red copper and stainless steel dissimilar materials. The welding process comprises the following steps of: (A) machining grooves on the opposite sides of a red copper component and a stainless steel component, cleaning foreign matters on the edges of the grooves, placing the red copper component and the stainless steel component on the same plane for pairing, and reserving a gap; (B) performing before-welding preheating on one side of the red copper component at 600 to 680 DEG C; (C) tackingperforming point fixing in a plurality of positions between the red copper component and the stainless steel component according to a tacking sequence; (D) welding the red copper component and the stainless steel component by adopting shielded metal arc welding direct current electrode positive; (E) heating a welding joint to 130 to 180 DEG C after the red copper component and the stainless steel component are welded, cooling the welding joint to room temperature, and performing dehydrogenation treatment to reduce hydrogen content in a welding seam; and (F) after the dehydrogenation treatment and cooling, performing stabilization treatment on one side of the stainless steel component at 840 to 890 DEG C, and quickly cooling the stainless steel component to reduce the formation of chromium carbide and improve the plasticity and toughness of the welding seam.

Owner:PETROCHINA CO LTD

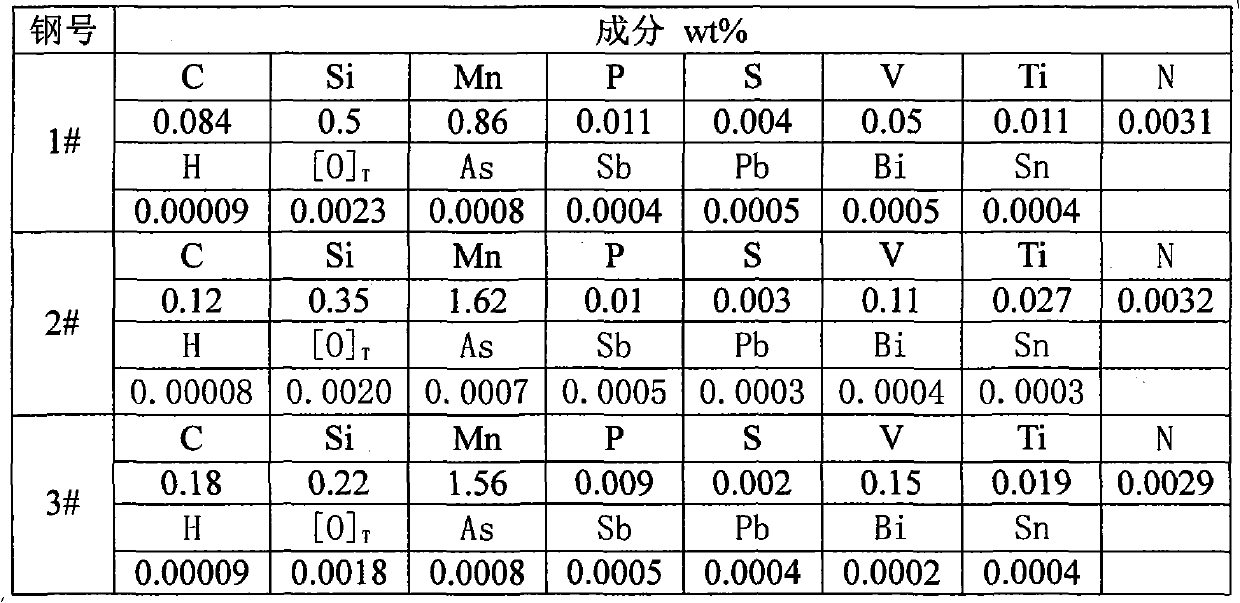

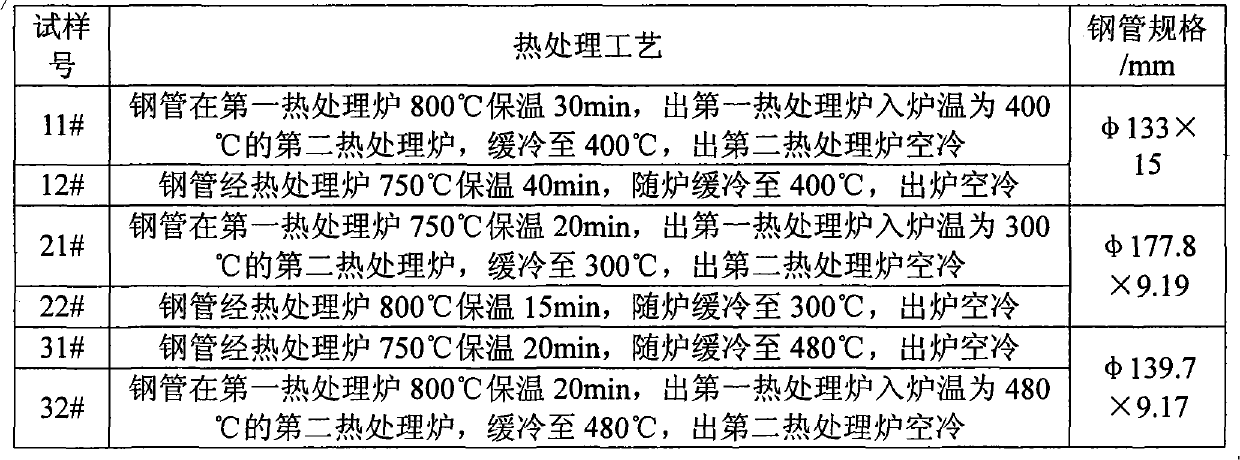

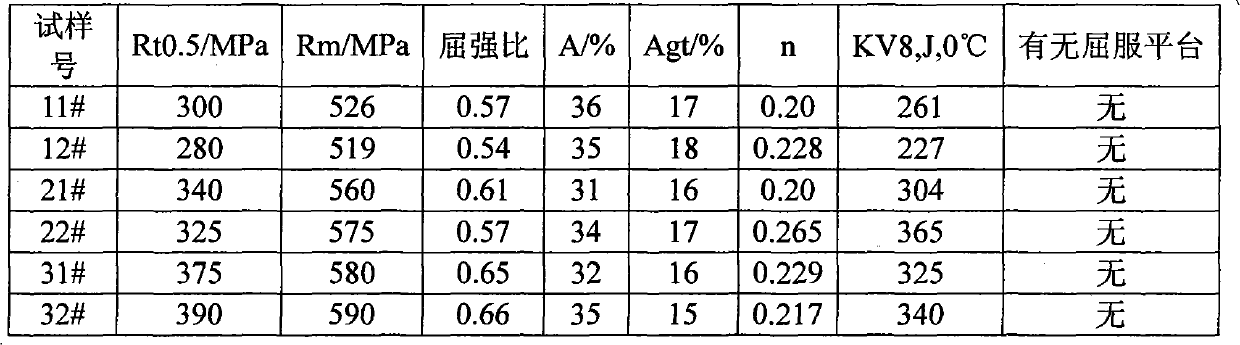

Economical seamless oil well pipe for expansion pipe and manufacturing method thereof

ActiveCN102022086AHigh elongationUniform elongationDrilling rodsManufacturing convertersChemical compositionHeat penetration

The invention provides an economical seamless oil well pipe for an expansion pipe and a manufacturing method thereof. The oil well pipe comprises the following chemical components in percentage by weight: 0.08 to 0.18 percent of C, 0.2 to 0.5 percent of Si, 0.6 to 1.7 percent of Mn, less than or equal to 0.012 percent of P, less than or equal to 0.005 percent of S, 0.04 to 0.15 percent of V, 0.01to 0.03 percent of Ti and the balance of Fe and inevitable impurities. A heat treatment process in the manufacturing method comprises the following steps of: incompletely quenching a hot-rolled seamless pipe, controlling the temperature of a heating furnace at 750 to 800 DEG C, keeping the temperature of the steel pipe in the range of 30 to 40 DEG C higher than Ac1 and 30 to 40 DEG C lower than Ac3 between the two phase regions of ferrite and austenite, performing calculation at the heat penetration speed of 1mm / min, preserving the heat of the oil well pipes for 10 to 60 min after the hot-rolled oil well pipes with different wall thicknesses reach the temperature of the furnace, and then cooling the oil well pipes at the speed of not higher than 0.2 DEG C per second. In the economical seamless oil well pipe and the manufacturing method thereof, the manufacturability and expandability performance of the steel pipe, the mechanical properties of the expanded steel pipe and the manufacturing cost are taken into account.

Owner:ANGANG STEEL CO LTD

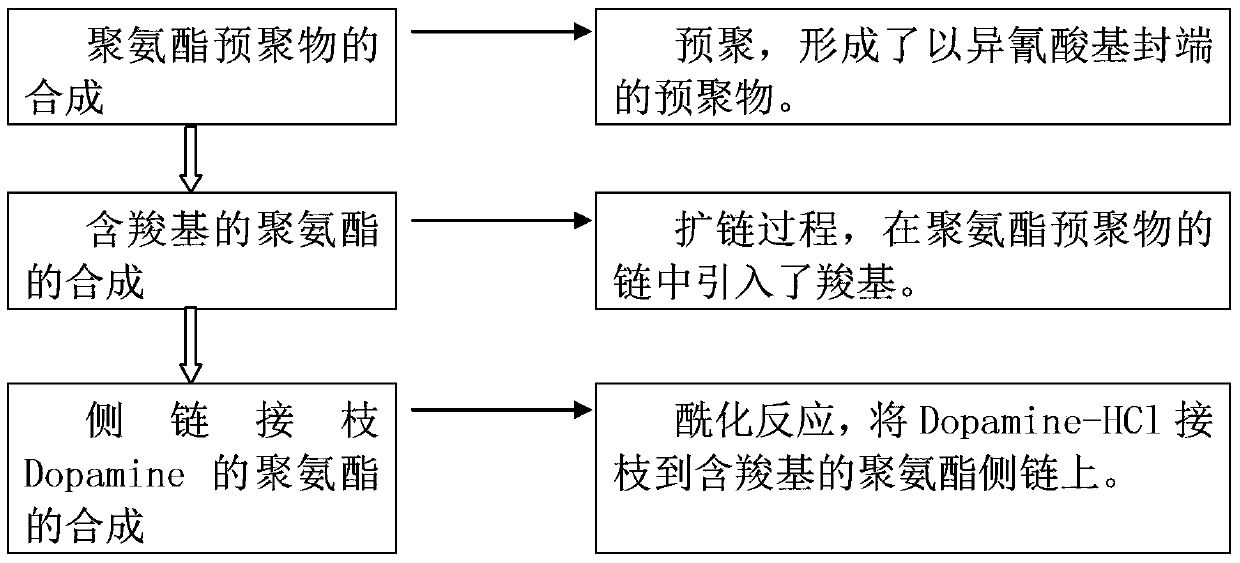

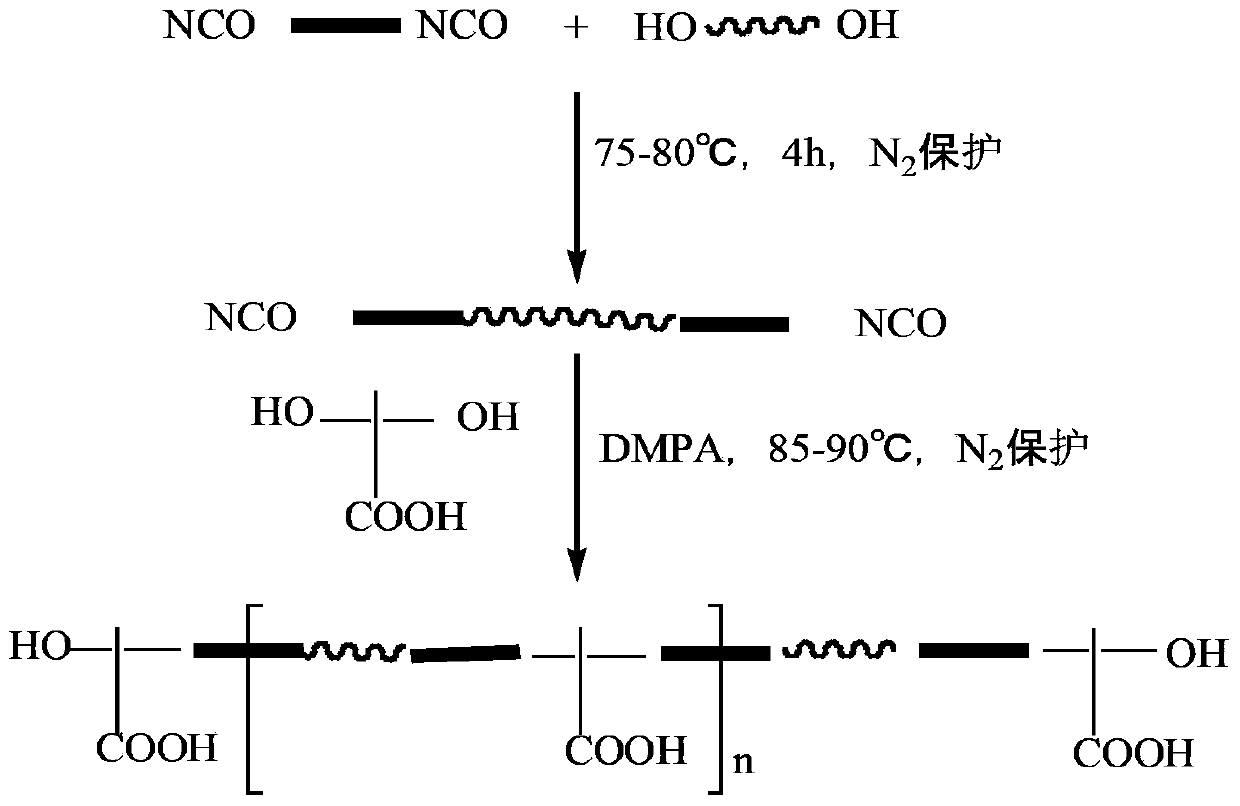

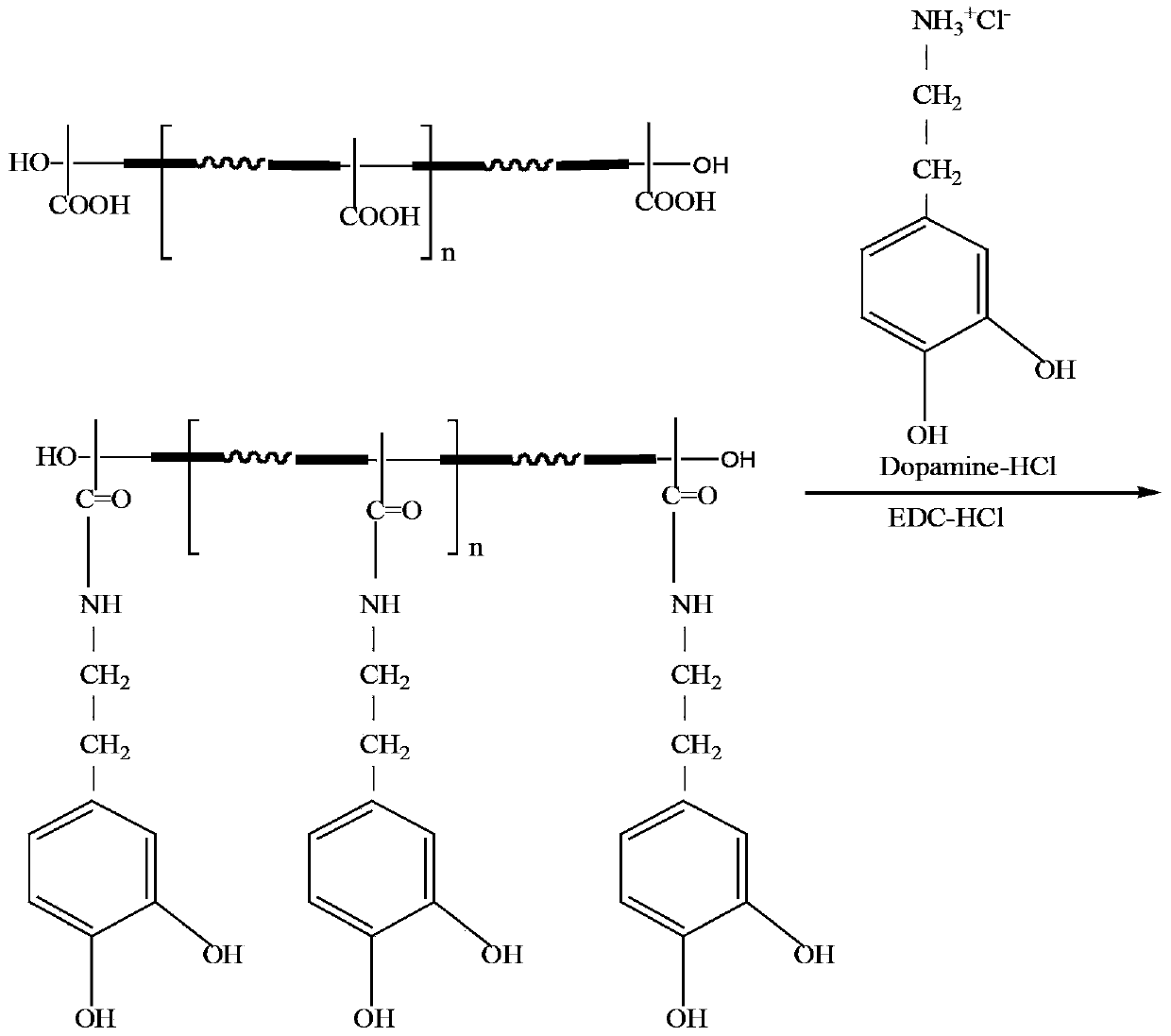

Borehole wall stabilizing agent and preparation method thereof

InactiveCN103361037AHigh affinityReduce penetrationDrilling compositionPolypropylene glycolRoom temperature

The invention specifically relates to a borehole wall stabilizing agent capable of plugging and reinforcing borehole wall rocks, which belongs to the field of oilfield chemistry. The borehole wall stabilizing agent comprises, by weight, 15 to 30% of isophorone diisocyanate, 25 to 60% of polypropylene glycol, 5 to 20% of dimethylolpropionic acid and 10 to 30% of dopamine hydrochloride. The borehole wall stabilizing agent provided by the invention is capable of plugging and cementing micro-cracks near a borehole wall, reducing permeability of shale and bonding with the shale on the borehole wall to form a compound which can harden the borehole wall; molecules of the borehole wall stabilizing agent have a small size, are easy to diffuse and can penetrate into the shale, so bonding among the shale is benefited and bonding capability is enhanced; the borehole wall stabilizing agent is convenient to use, has excellent operation performance, can be cured through heating or at room temperature and meets environmental requirements during outdoor drilling operation; and due to no side reaction during curing, a bonding layer hardly has defects.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

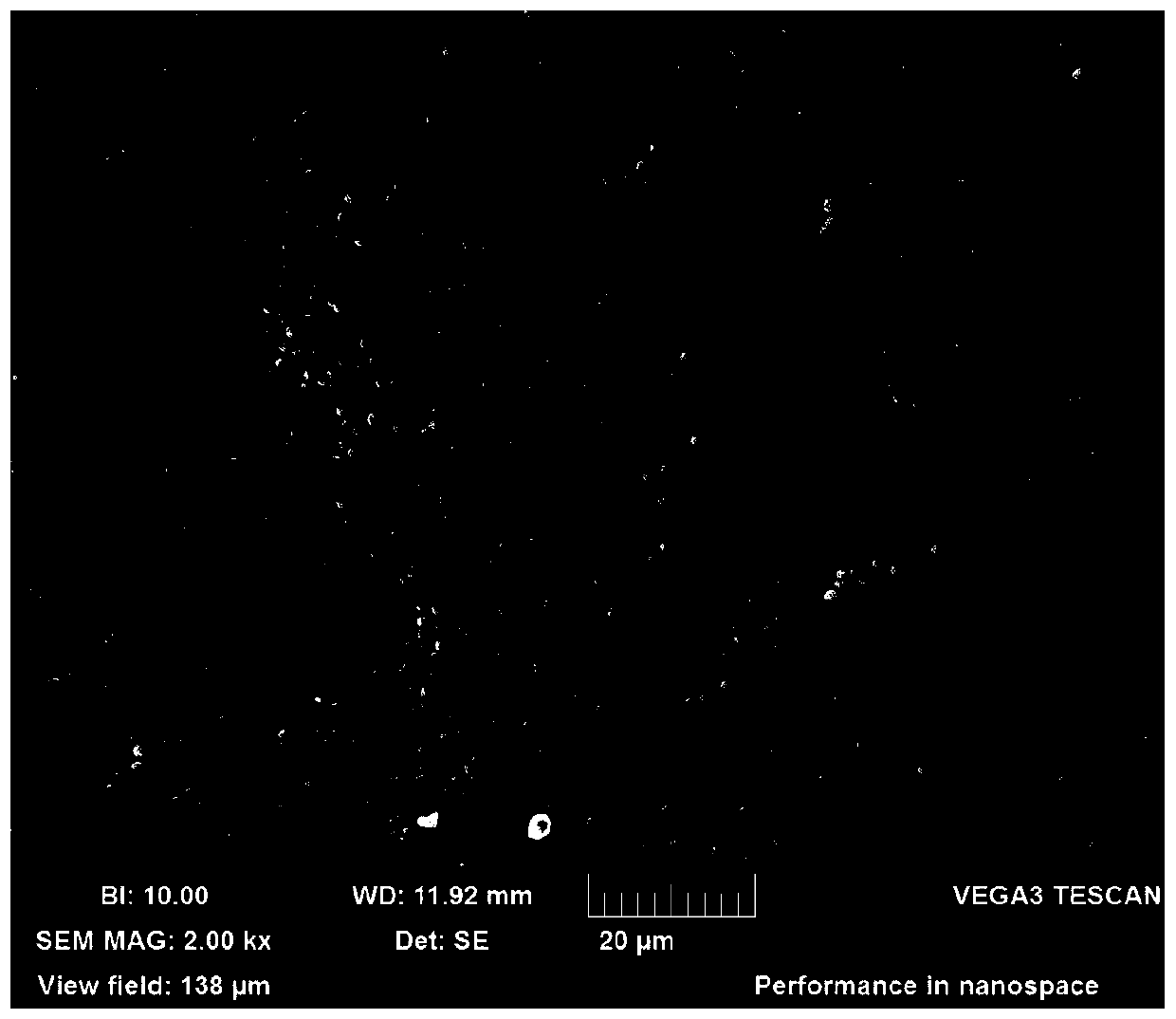

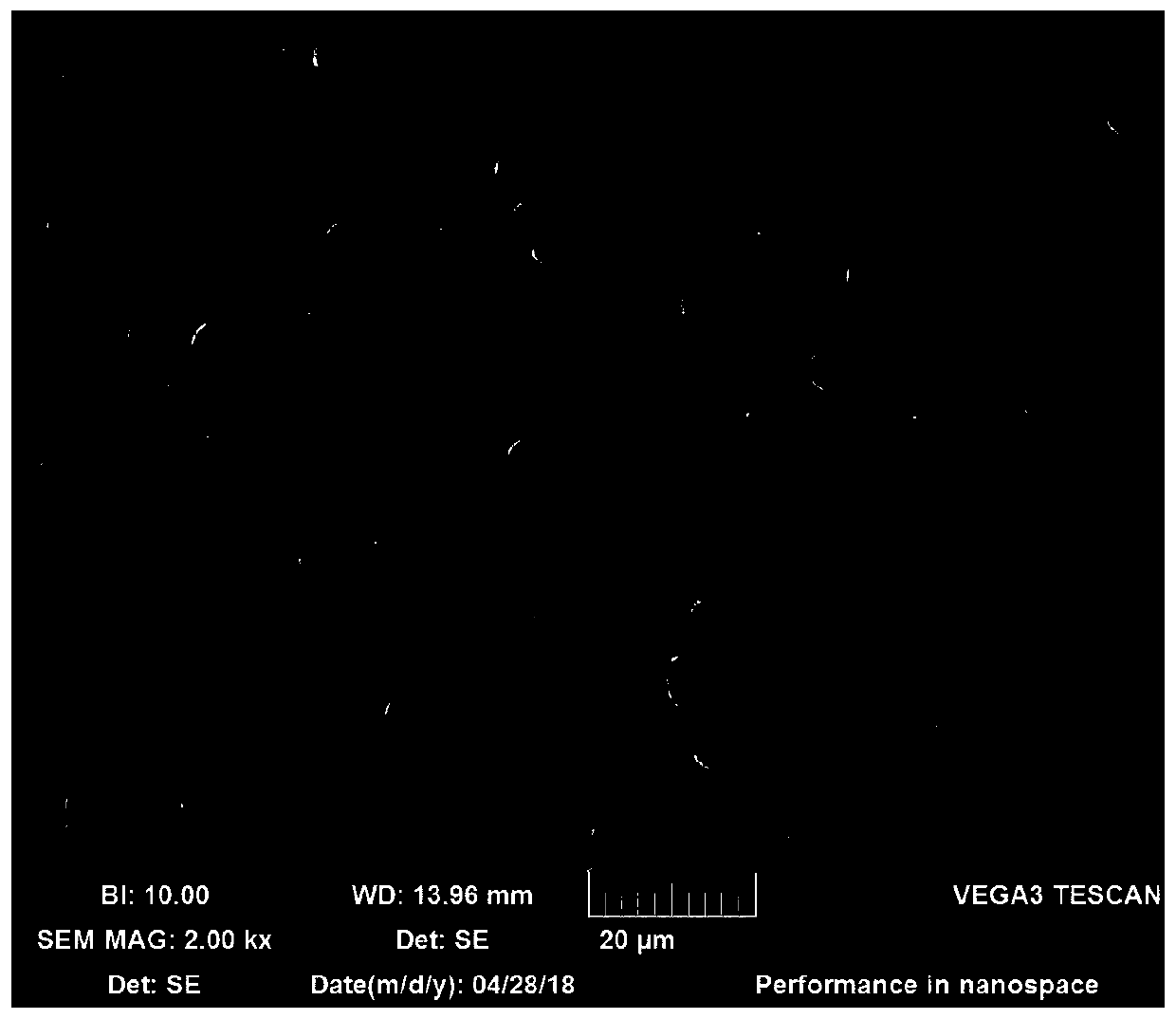

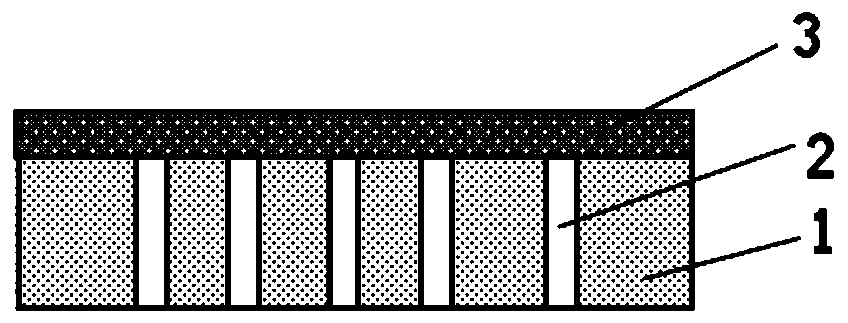

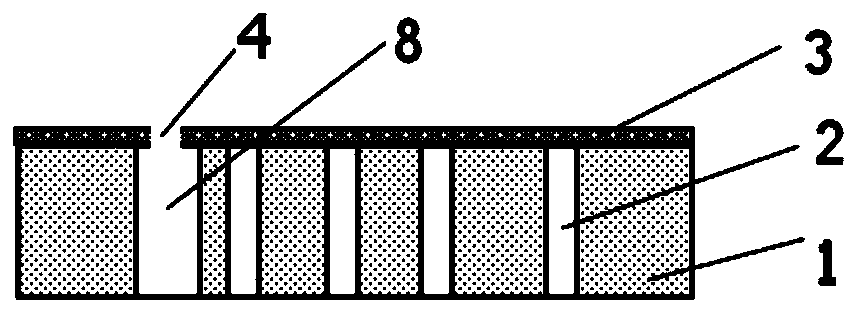

Preparation method of porous metal film

InactiveCN109745870AStrengthen the bridging effectLess prone to defectsSemi-permeable membranesFoaming agentMass ratio

The invention relates to a preparation method of a porous metal film. The preparation method specifically comprises the following steps: respectively weighing 3-10 percent by weight of bonding agent,0.45-1 percent by weight of dispersing agent, 0.05-0.3 percent of a de-foaming agent and the balance of deionized water, wherein the sum of the mass percents of the components is 100 percent; mixing and dissolving the weighted bonding agent, dispersing agent, de-foaming agent and deionized water to prepare slurry; pouring metal powder and the prepared slurry into a stirring tank according to the mass ratio of 1:(0.8-1.5) and uniformly mixing to prepare mixed liquid; spraying the prepared mixed liquid onto the surface of a rotary tubular porous metal supporting body by adopting a spray gun, disassembling a metal film after the completion of absorption and successively performing drying, degreasing and sintering treatment on the metal film to prepare the porous metal film. The porous metal film prepared by the preparation method provided by the invention is high in permeability, good in film layer uniformity, high in filtering precision and high in finished product rate.

Owner:WESTERN BAODE TECH CO LTD

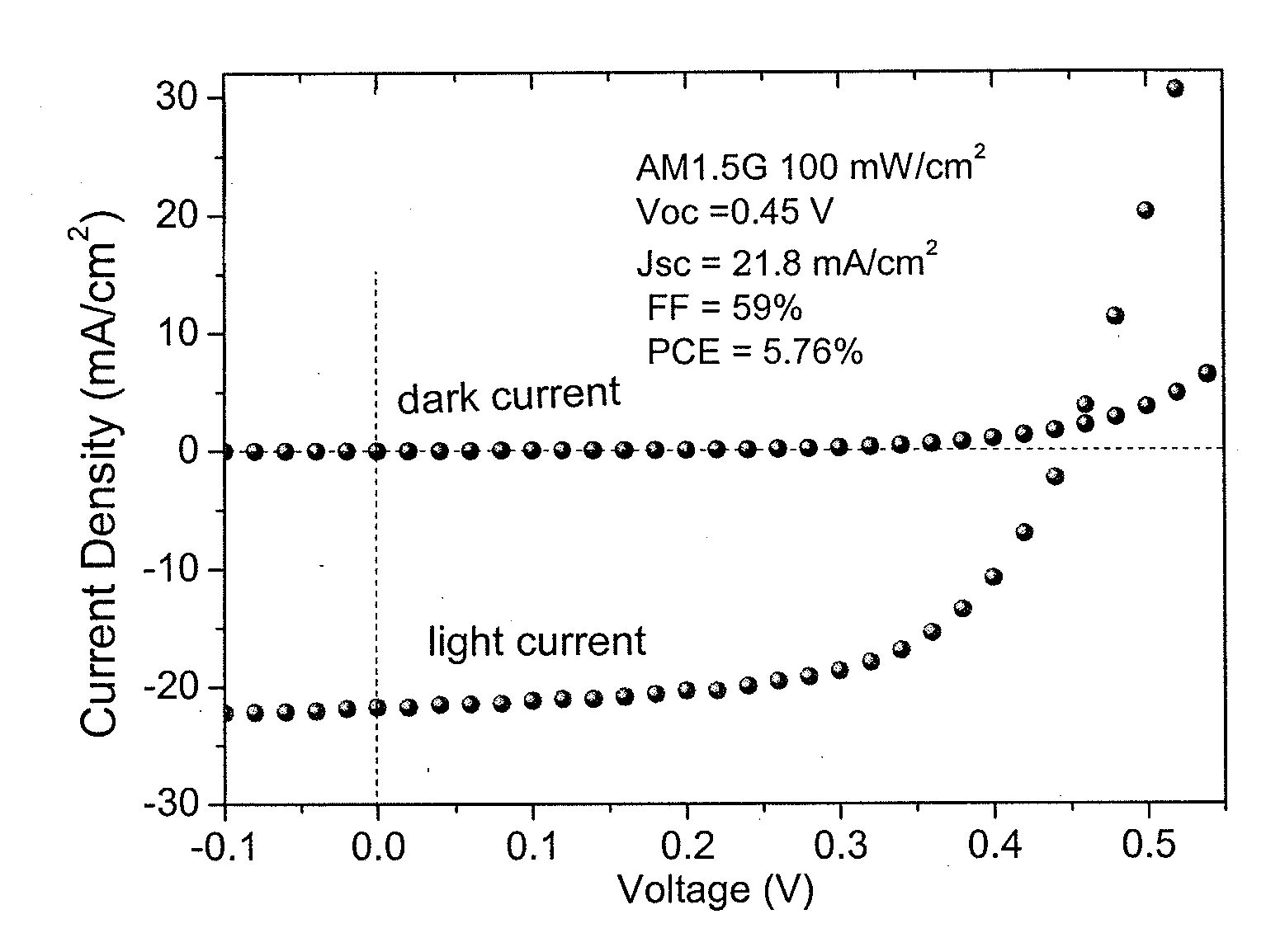

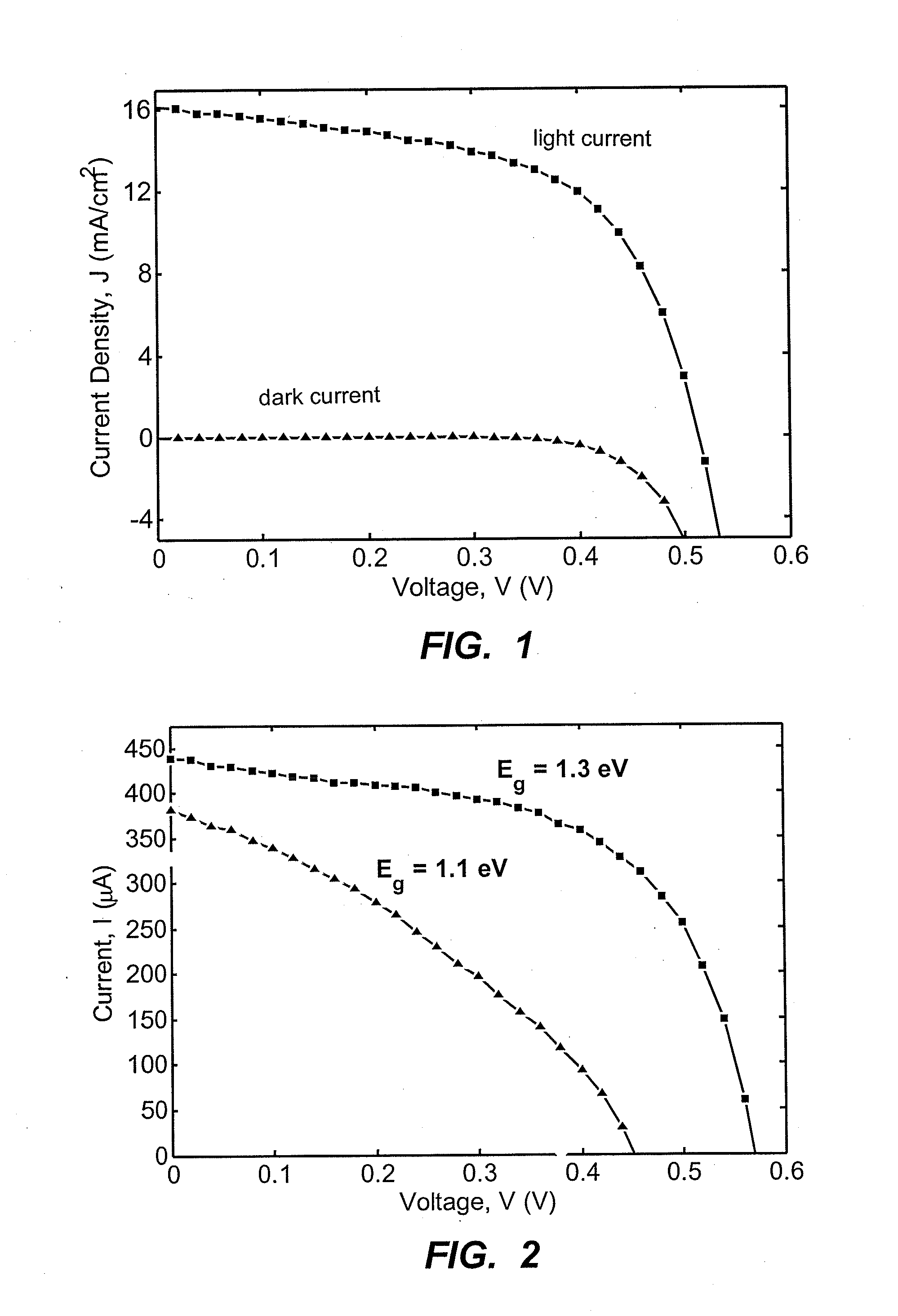

Photovoltaic devices with depleted heterojunctions and shell-passivated nanoparticles

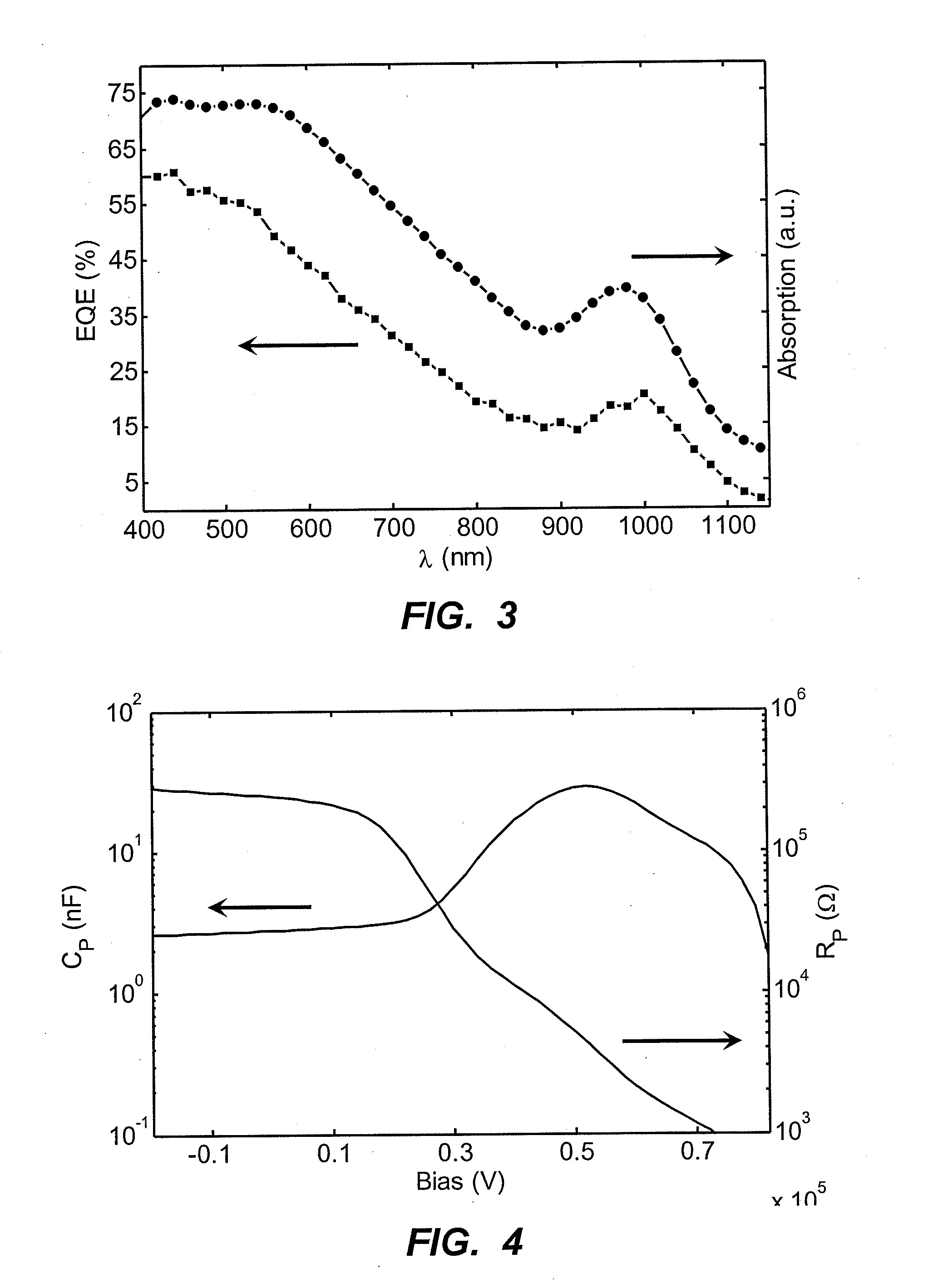

ActiveUS20110240106A1Well definedSimple passivation processSemiconductor/solid-state device manufacturingNanoopticsHeterojunctionCharge carrier

Photovoltaic cells are fabricated in which the compositions of the light-absorbing layer and the electron-accepting layer are selected such that at least one side of the junction between these two layers is substantially depleted of charge carriers, i.e., both free electrons and free holes, in the absence of solar illumination. In further aspects of the invention, the light-absorbing layer is comprised of dual-shell passivated quantum dots, each having a quantum dot core with surface anions, an inner shell containing cations to passivate the core surface anions, and an outer shell to passivate the inner shell anions and anions on the core surface.

Owner:THE GOVERNINIG COUNCIL OF THE UNIV OF TORANTO

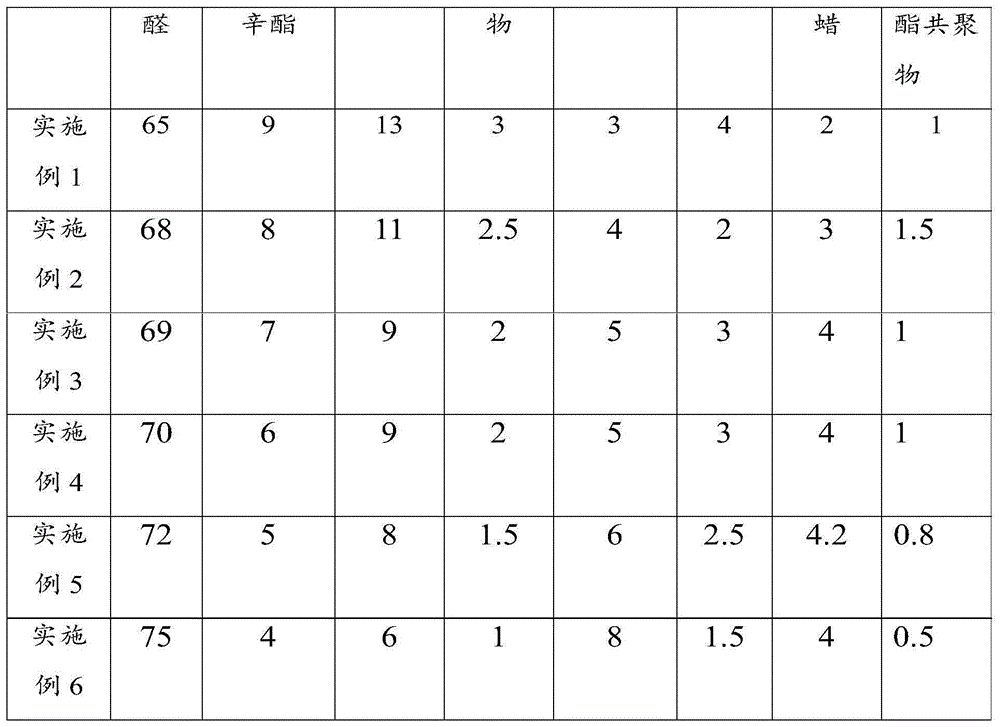

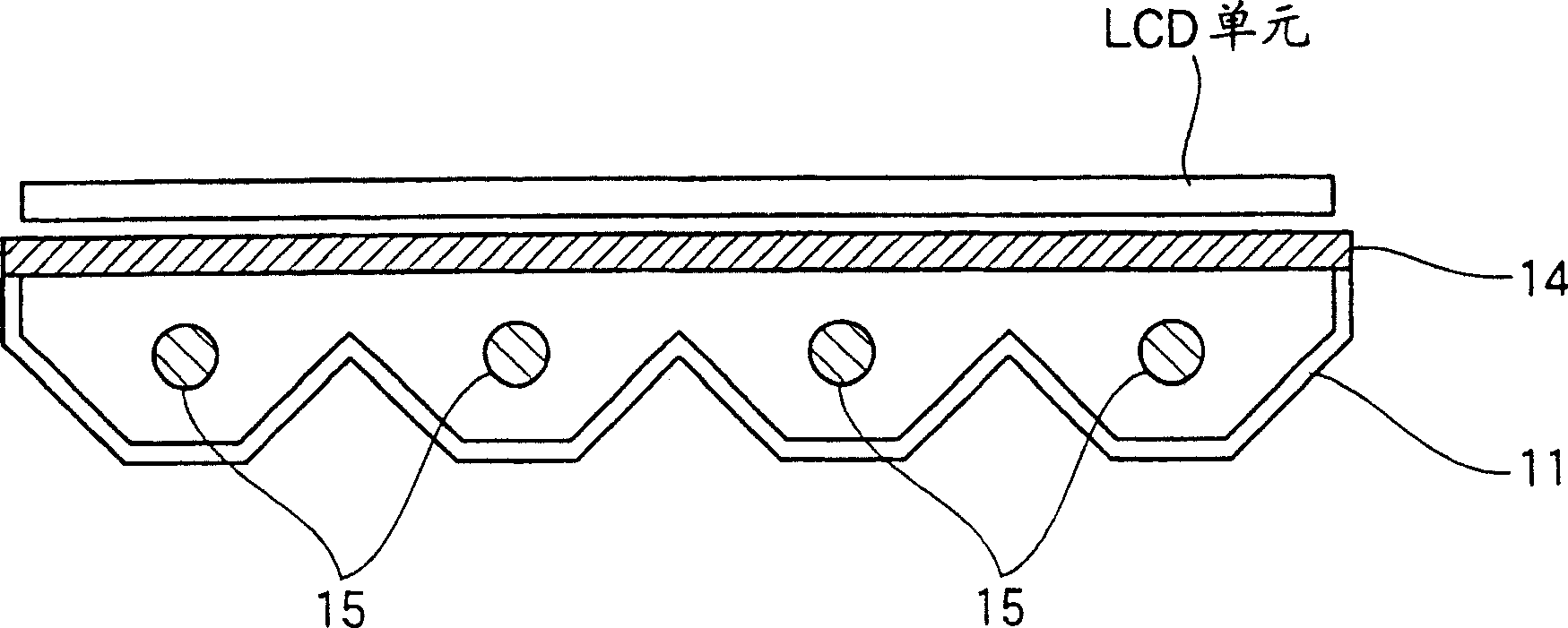

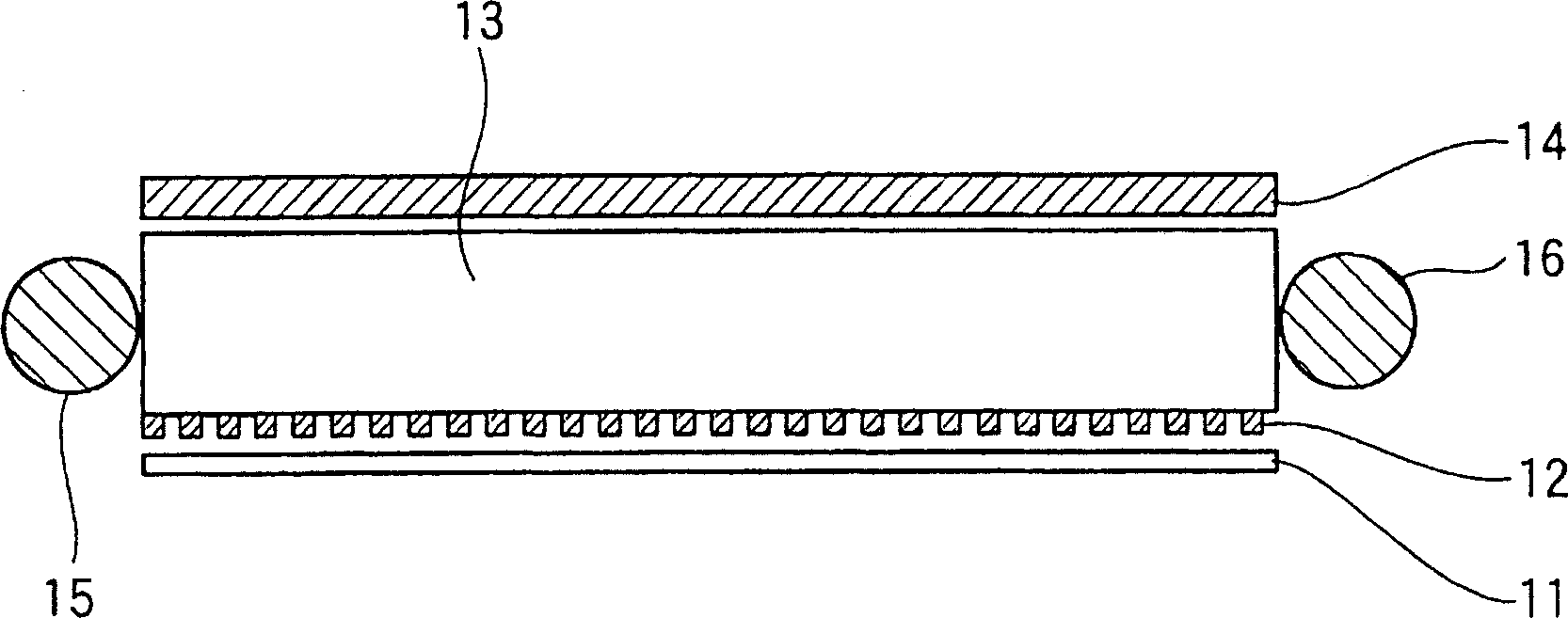

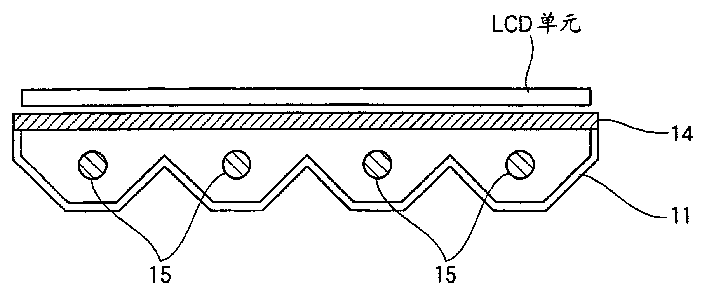

Light reflector

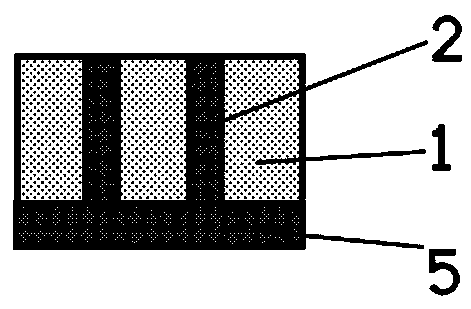

InactiveCN1672067ALess prone to defectsLess prone to decrease in brightnessMechanical apparatusMirrorsPolyesterFoaming agent

An object of the present invention is to provide a light reflector, which causes no unevenness in luminance in the surface direction due to deflection in use. The present invention is a light reflector comprising: an olefin-based resin film 1 comprising a filler and having a total ray reflectance of 90% or more, which is stretched at least monoaxially at an area stretch ratio of from 1.5 to 80; and at least one of the following substrates (1) to (4): (1) Film 2 comprising at least one of olefin-based resin and polyester-based resin as a main component; (2) Woven cloth 3 or non-woven cloth 4; (3) Metal plate 5; and (4) Molded material 6 comprising a thermoplastic resin composition (a1) containing a foaming agent and having a foaming ratio of from 1.05 to 10 as calculated by the following equation (1): <DF NUM="(1)">Foaming ratio = rho o / rho < / DF> where po represents the density before foaming; and rho represents the density after foaming.

Owner:YUPO CORP

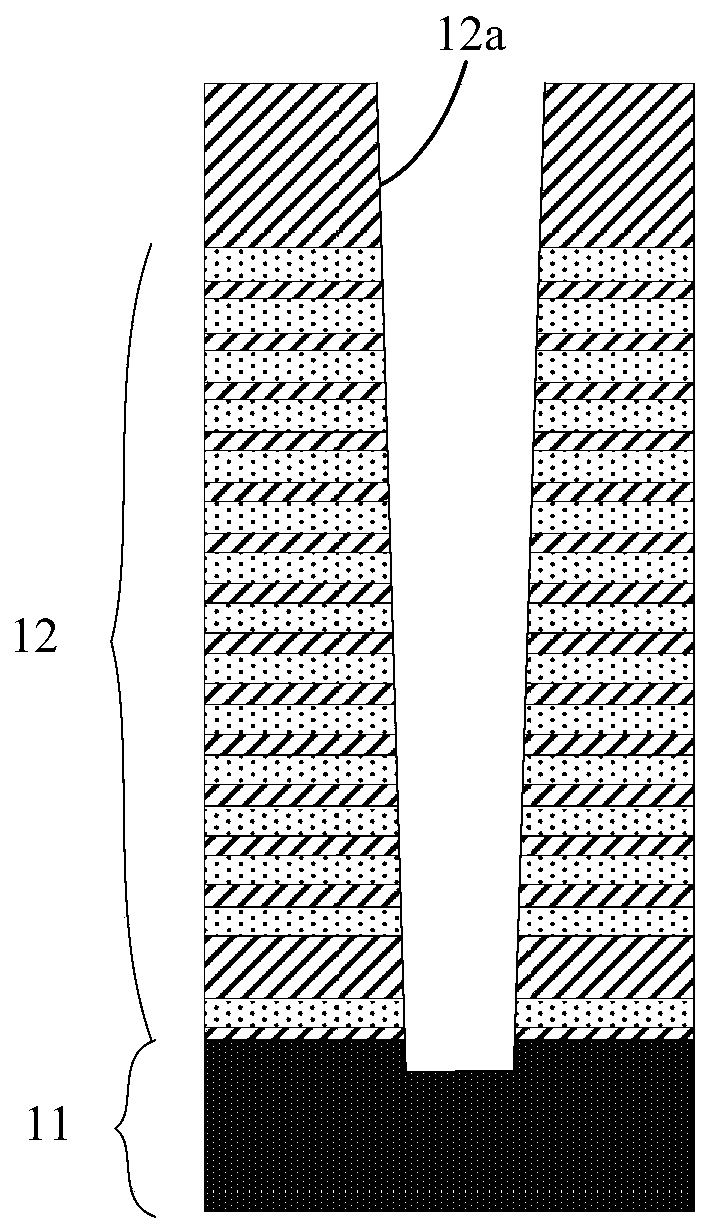

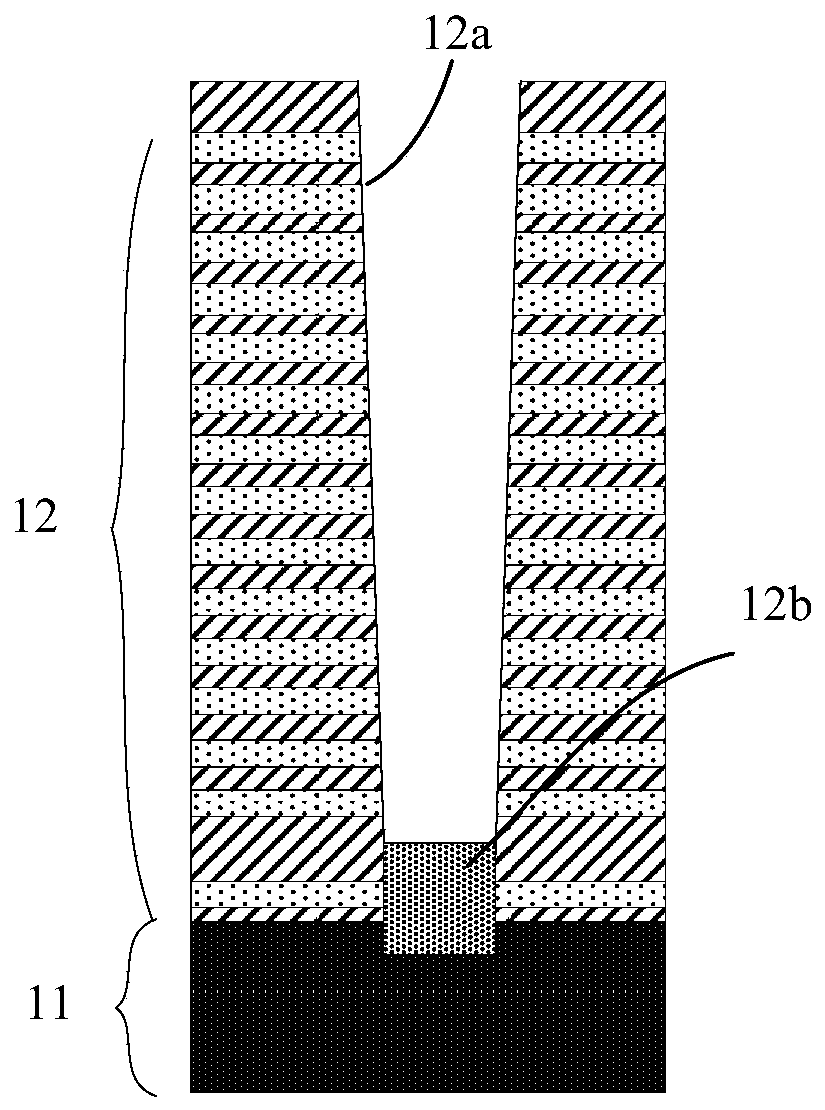

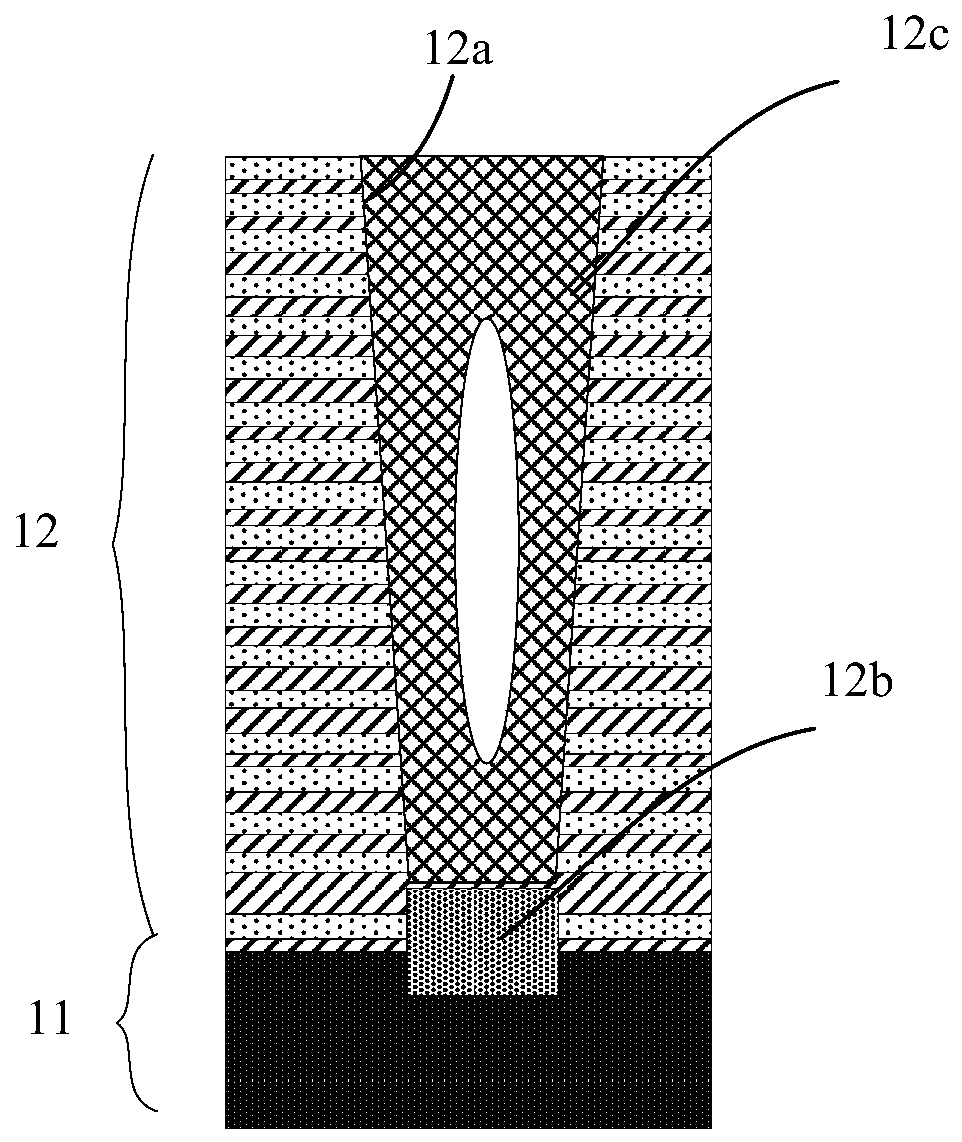

Method of forming three-dimensional memory and three-dimensional memory

ActiveCN109887918ALess prone to defectsSimple methodSolid-state devicesSemiconductor devicesSemiconductor structureEngineering

The present invention relates to a method of forming a three-dimensional memory and a three-dimensional memory. The method includes the steps of: providing a semiconductor structure having a substratelocated on a back side of the semiconductor structure and a first stack located on the substrate, wherein the first stack located on a front side of the semiconductor structure; forming a plurality of first channel holes passing through the first stack from the front side; putting a sacrificial layer in the first channel hole; overturning the semiconductor structure and thinning the substrate; forming a second stack stacked on the first stack from a back side; forming a plurality of second channel holes passing through the second stack and reaching the sacrificial layer; removing the sacrificial layer; and forming a plurality of vertical channel structures in the plurality of first channel holes and the plurality of second channel holes.

Owner:YANGTZE MEMORY TECH CO LTD

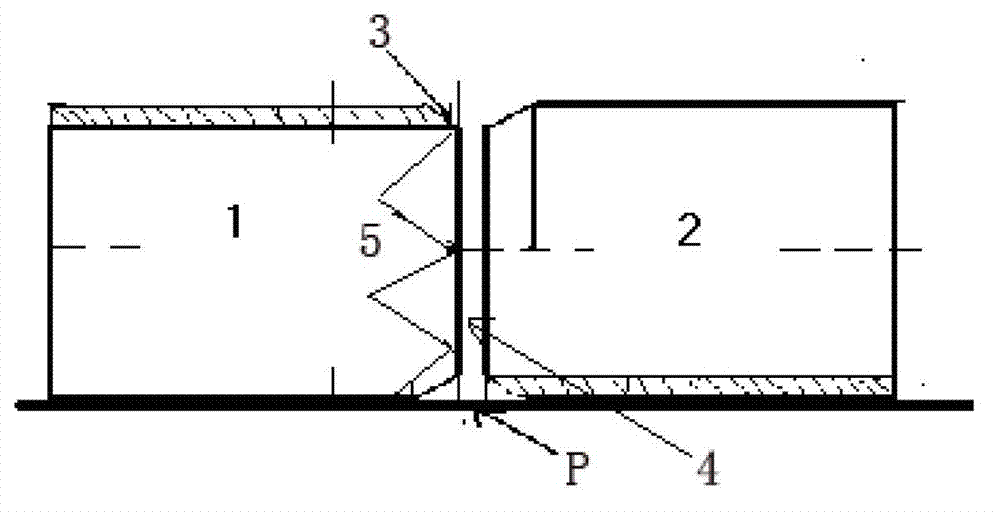

Chrome plating method for spherical crown surface of major diameter spherical crown workpiece

The invention provides a method for plating chromium on a spherical cap surface of a large-diameter spherical cap workpiece. In a step of immersing and positioning, the arrangement mode or structure of an anode strap or an anode plate is changed; in a step of plating chromium, opacified chromium is plated under the conditions that the temperature of the plating solution is 70 to 75 DEG C and the current density is 20 to 25A / decimeter<2>; and then, hard chromium is plated under the conditions that the temperature of the plating solution is 50 to 55 DEG C and the current density is 25 to 30A / decimeter<2>. The polishing processing is carried out on the spherical cap surface of the workpiece, which has the advantages of good evenness of chromium plated coating, defect prevention, high electroplating efficiency, fast speed of cladding deposit, high surface finish of the spherical cap surface after chromium is plated, and subsequent mechanical processing workload reduction.

Owner:LUOYANG SUNRUI SPECIAL EQUIP

Preparation method of composite membrane

ActiveCN111229050AControl concentrationEasy to control aggregate structureMembranesUltrafiltrationPolymer scienceOil phase

The invention relates to a preparation method of a composite membrane, which comprises the following steps: respectively introducing an oil-phase reaction monomer and a water-phase reaction monomer participating in a polymerization reaction from two sides of a porous base membrane, and contacting at openings of membrane holes through the membrane holes to cause an interfacial polymerization reaction. The concentrations and the supply amounts of the two reaction monomers are convenient to control, the reaction speeds and the reaction degrees of the two reaction monomers can be respectively controlled, and the bottleneck of the prior art is broken through, so that the aggregation state structure of the cross-linking layer is easy to regulate and control, and the composite membrane with a higher removal rate is obtained.

Owner:吕剑阳

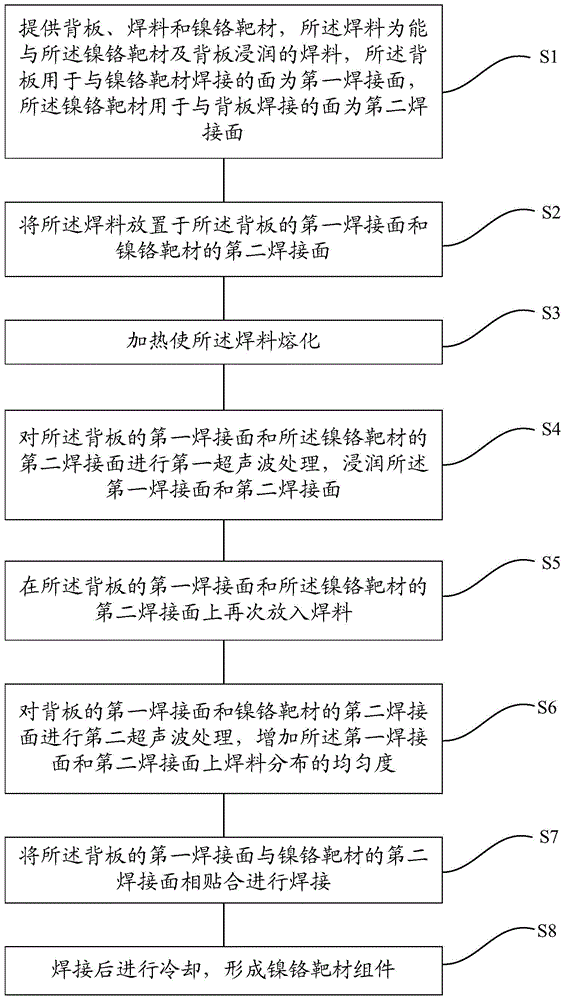

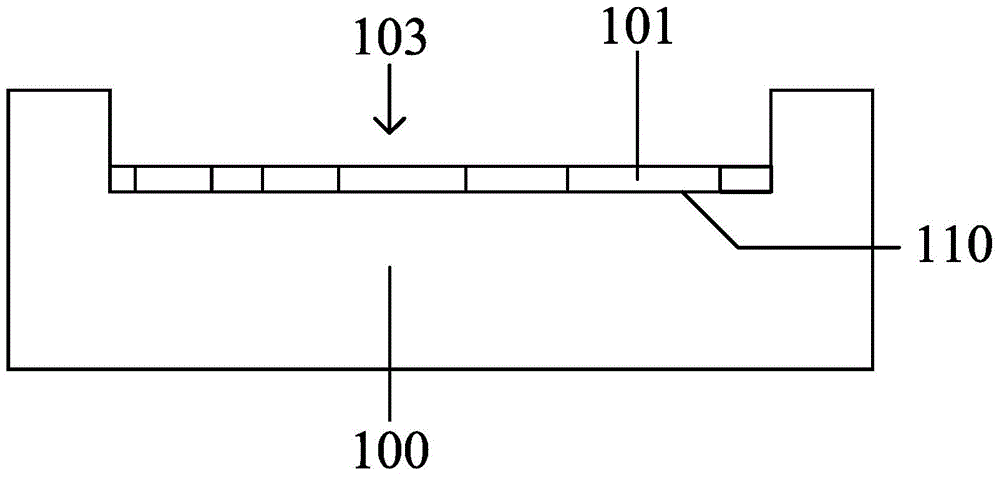

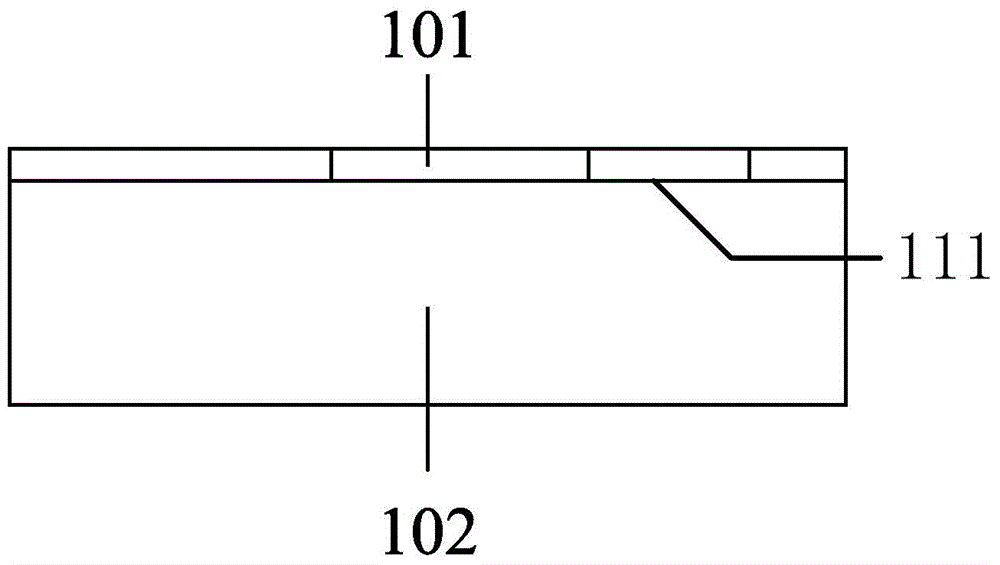

Method for manufacturing nickel-chromium target material component

ActiveCN106695109AEvenly distributedIncrease contactNon-electric welding apparatusNichromeEngineering

The invention provides a method for manufacturing a nickel-chromium target material component. The method comprises the following steps: placing a solder on welding faces of both a back panel and a nickel-chromium target material; heating to enable the solder to be molten; performing first ultrasonic treatment on the welding faces of both the back panel and the nickel-chromium target material, and soaking the welding faces; re-placing the solder on the welding face of the back panel, and performing second ultrasonic treatment on the welding faces of both the back panel and the nickel-chromium target material; laminating the welding faces of the back panel and the nickel-chromium target material and welding; and cooling after welding to form the target material component. According to the method, welding is assisted by twice ultrasonic treatment methods, twice ultrasonic treatment can enable alloy layers to form on the surfaces of the back panel and the nickel-chromium target material and can also ensure that the solder is uniformly distributed on the welding faces of both the back panel and the nickel-chromium target material, and accordingly, the high-welding-strength, high-welded-rate and low-defect-rate welding effects of the nickel-chromium target material and the back panel are achieved.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

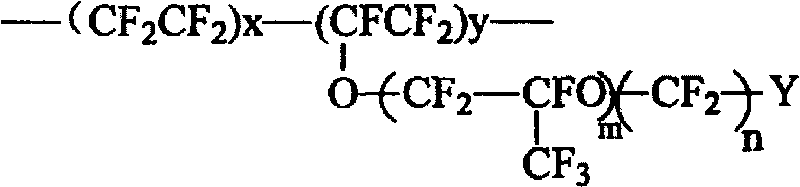

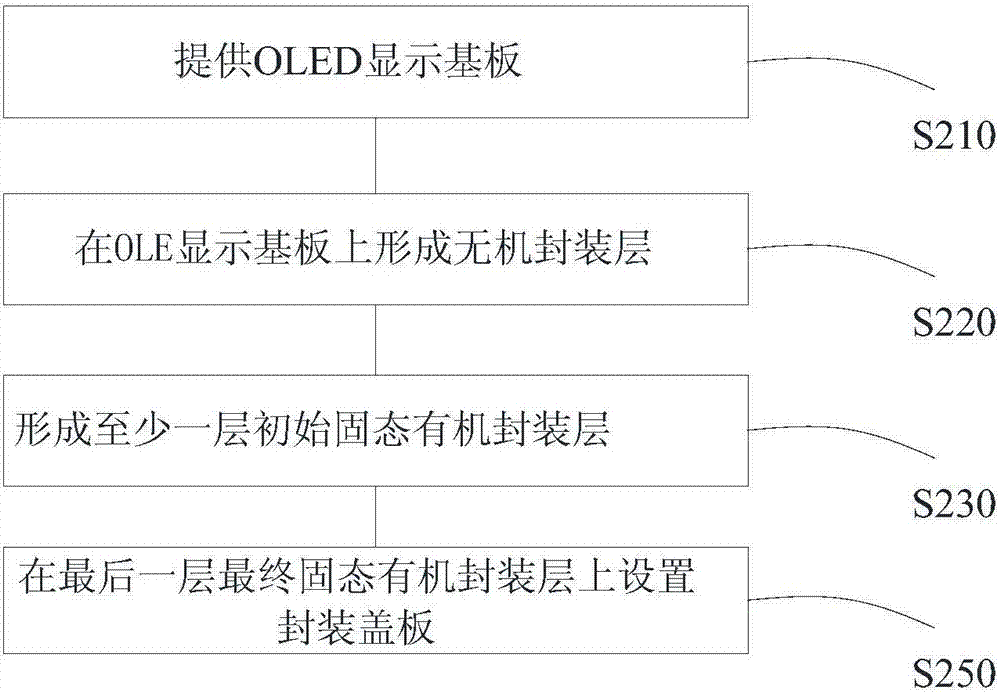

Method for preparing perfluorocarboxylic acid ion membranes by liquid surface tape casting method

ActiveCN101759864AImprove uniformitySimplify cumbersome operationsFinal product manufactureSolid electrolyte fuel cellsHigh densityThin layer

The invention relates to a method for preparing perfluorocarboxylic acid ion membranes, which is characterized in that the method comprises the following steps: (1) dissolving perfluorocarboxylic acid resin into a solvent for forming a uniform perfluorocarboxylic acid resin solution A; (2) adding materials with low melting point and high density into a heatable container, heating the container for dissolving the materials, and forming uniform liquid B in the container; (3) preheating the perfluorocarboxylic acid resin solution A and pouring the perfluorocarboxylic acid resin solution A onto the surface of the liquid B protected by nitrogen gas so that a thin layer solution is formed on the surface of the liquid B through casting; (4) heating the liquid B, then carrying out program temperature reduction, and continuously introducing the nitrogen gas for protection in the whole process; and (5) evaporating most or all of the solvent in the perfluorocarboxylic acid resin solution A to obtain the perfluorocarboxylic acid ion membrane on the surface of the liquid B. The perfluorocarboxylic acid ion membrane prepared by the invention can be applied to composite layers of sodium hudroxide use ion membranes, and has the advantages of uniform thickness, difficult bubble generation and stable performance, and the invention provides reliable carboxylic acid layer ion membranes for producing the sodium hudroxide use ion membranes.

Owner:SHANDONG DONGYUE POLYMER MATERIAL

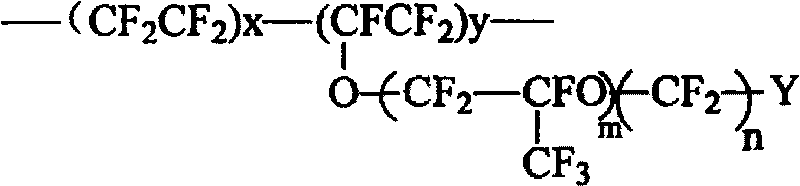

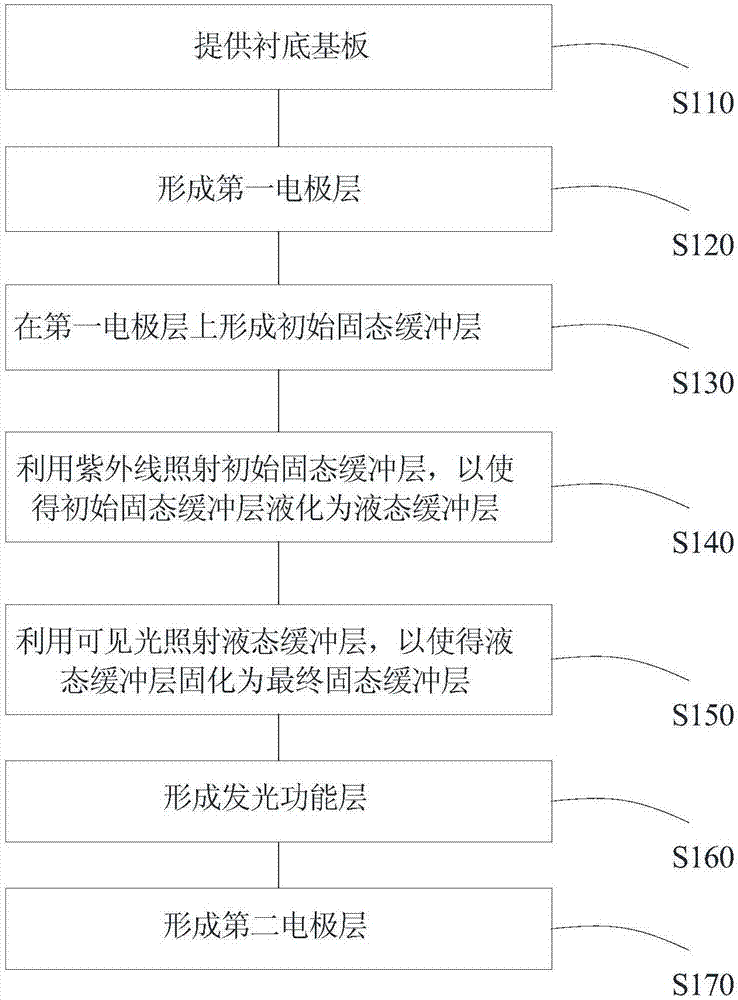

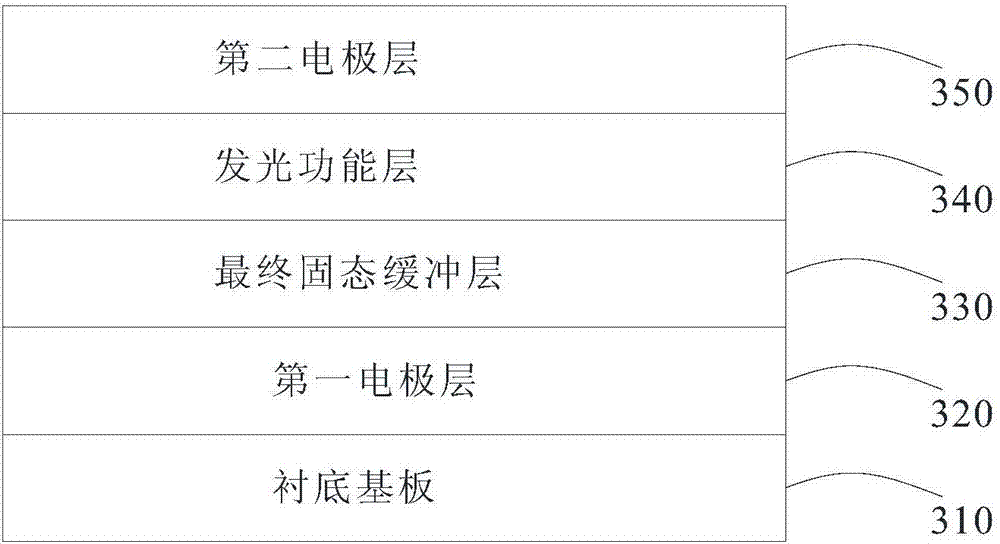

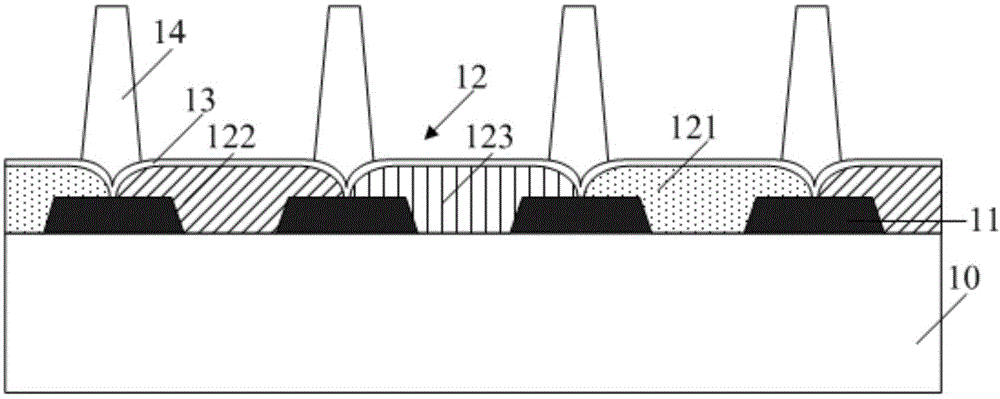

OLED display substrate, manufacturing method of OLED display substrate, display apparatus and encapsulating method of display apparatus

ActiveCN106920902ALess prone to defectsImprove yieldFinal product manufactureSolid-state devicesLiquid stateUltraviolet

The invention provides a manufacturing method of an OLED display substrate. The method comprises the following steps: providing an underlayer substrate; forming a first electrode layer; forming an initial solid buffer layer on the first electrode layer, wherein a molecular formula of a material of the initial solid buffer layer has an azobenzene group, a HOMO energy level of the initial solid buffer layer is between -6eV and 4.5eV, and a LUMO energy level of the initial solid buffer layer is between -3eV and 2eV; illuminating the initial solid buffer layer by utilizing ultraviolet, so that the initial solid buffer layer is liquefied to a liquid buffer layer; illuminating the liquid buffer layer by utilizing visible light, so that the liquid buffer layer is solidified into a final solid buffer layer; and forming a luminescent functional layer by virtue of the final solid buffer layer. The invention also provides an OLED display substrate, an encapsulation method of a display apparatus and a display apparatus. The display apparatus is relatively high in yield.

Owner:BOE TECH GRP CO LTD

Aerosol generator assembly

ActiveUS9339838B2Less prone to defectsReduce riskMovable spraying apparatusSpray nozzlesElectricityFree zone

Owner:NORTEV

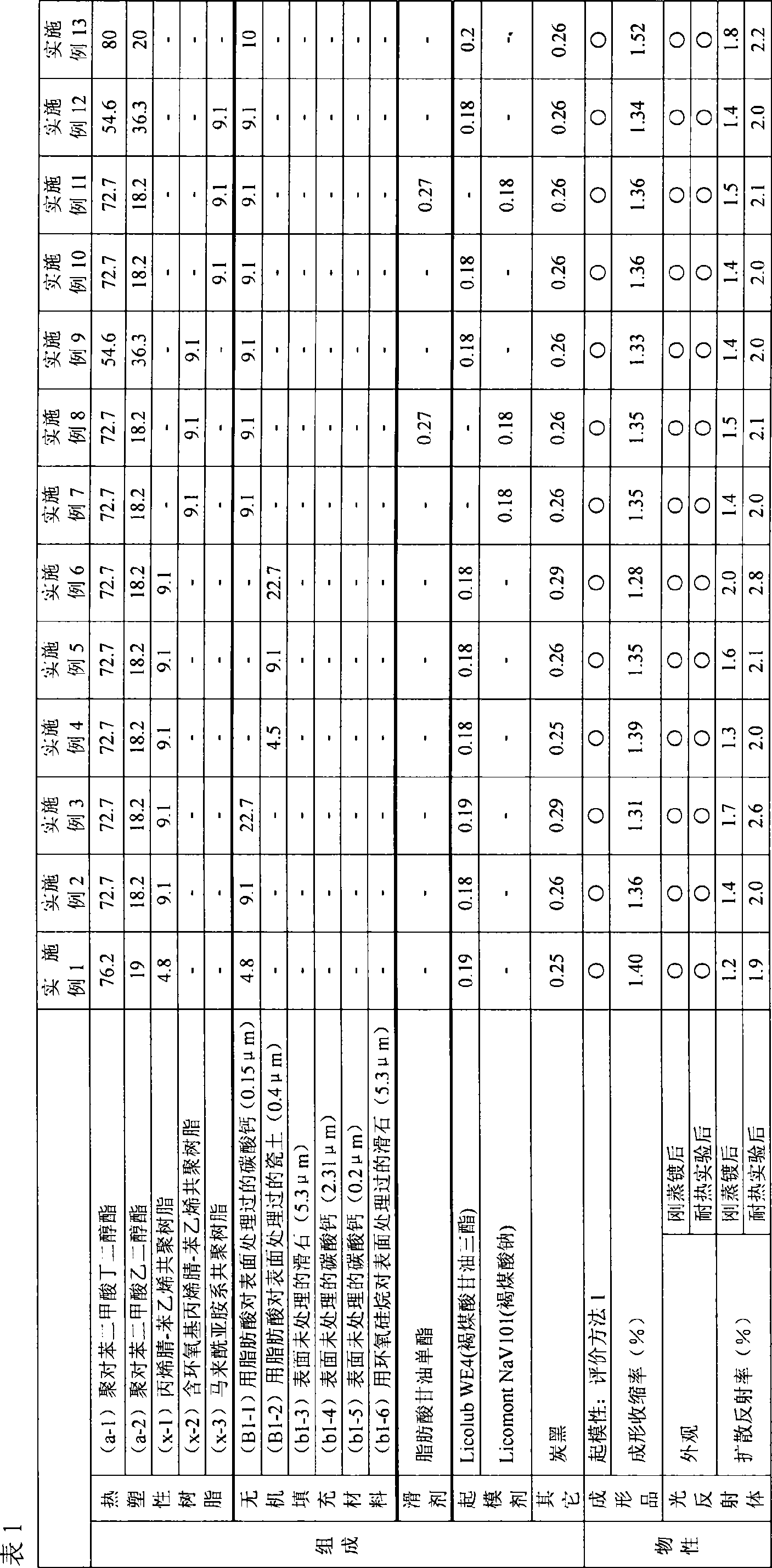

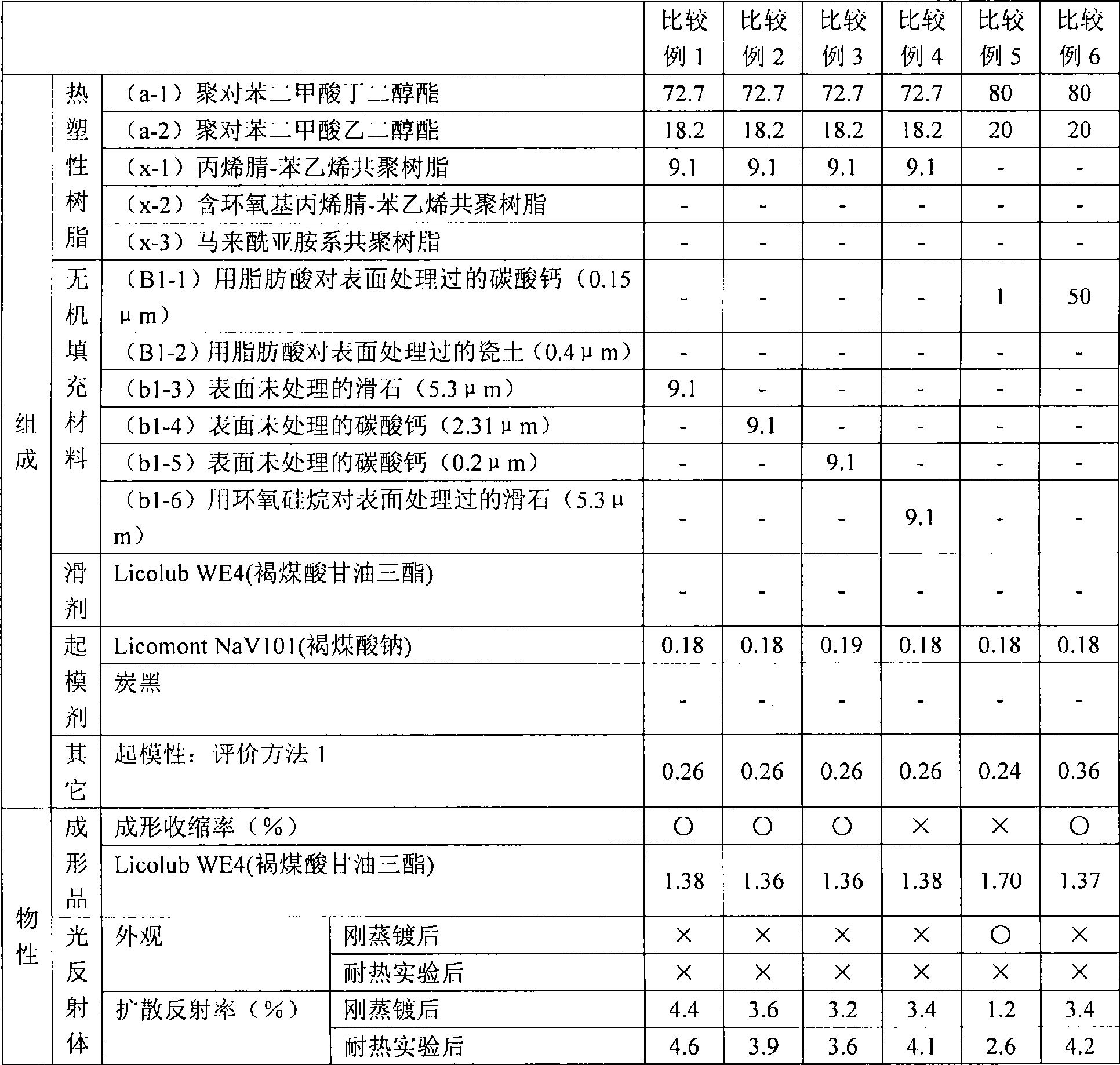

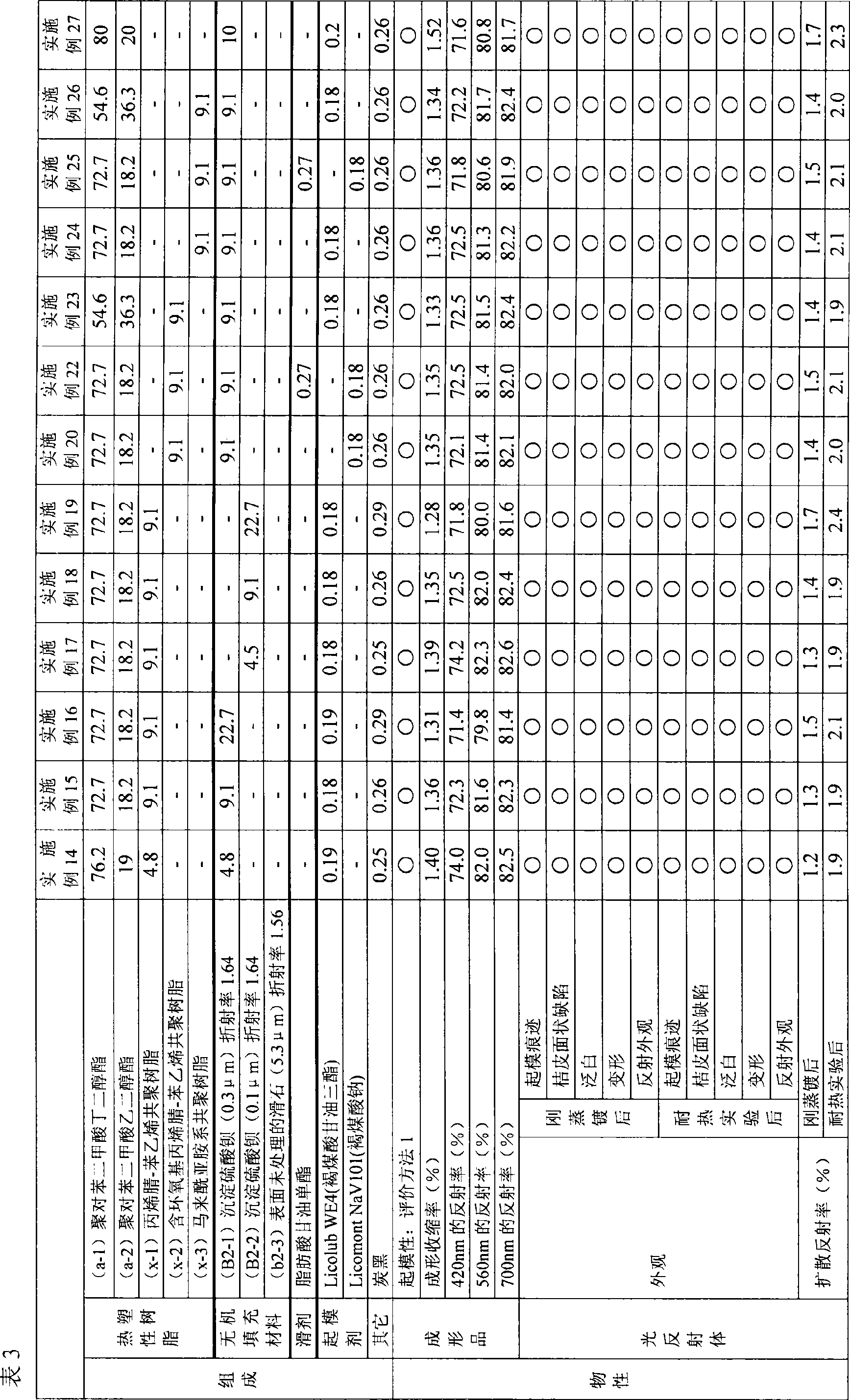

Thermoplastic resin composition, light reflector and method for producing molded article for light reflector

ActiveCN101428478AGood formabilityImprove surface smoothnessOptical articlesReflectorsSurface finishFilling materials

Disclosed are a thermoplastic resin composition for light reflectors which contains 2-45 parts by mass of an inorganic filler (B1) which is treated with a fatty acid based surface-finishing agent and has an average particle diameter of not more than 3 mum, per 100 parts by mass of a thermoplastic resin (A); a thermoplastic resin composition for light reflectors which contains 2-45 parts by mass of an inorganic filler (B2) with an average particle diameter of not more than 3 mum whose refractive index alpha is 1.61 <= alpha <= 2.5, per 100 parts by mass of a thermoplastic resin (A); and a thermoplastic resin composition for light reflectors which contains 0.01-3 parts by mass of a fatty acid glycerol triester and / or a fatty acid glycerol diester (C1) and 0.01-3 parts by mass of a fatty acid glycerol monoester (C2) per 100 parts by mass of a thermoplastic resin (A). Also disclosed are a formed article for light reflectors which is made of one of such thermoplastic resin compositions and a light reflector obtained by directly forming a light-reflecting metal layer on at least a part of the surface of such a formed article for light reflectors.

Owner:MITSUBISHI CHEM CORP

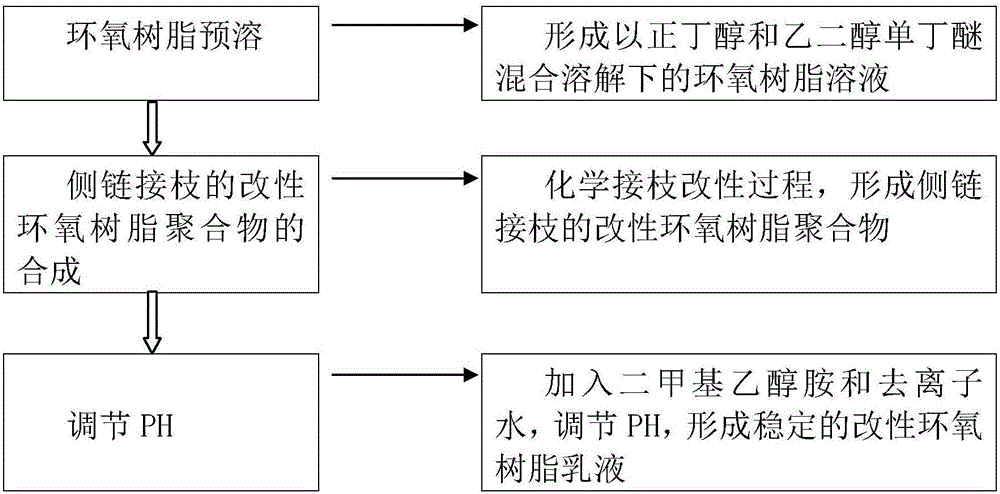

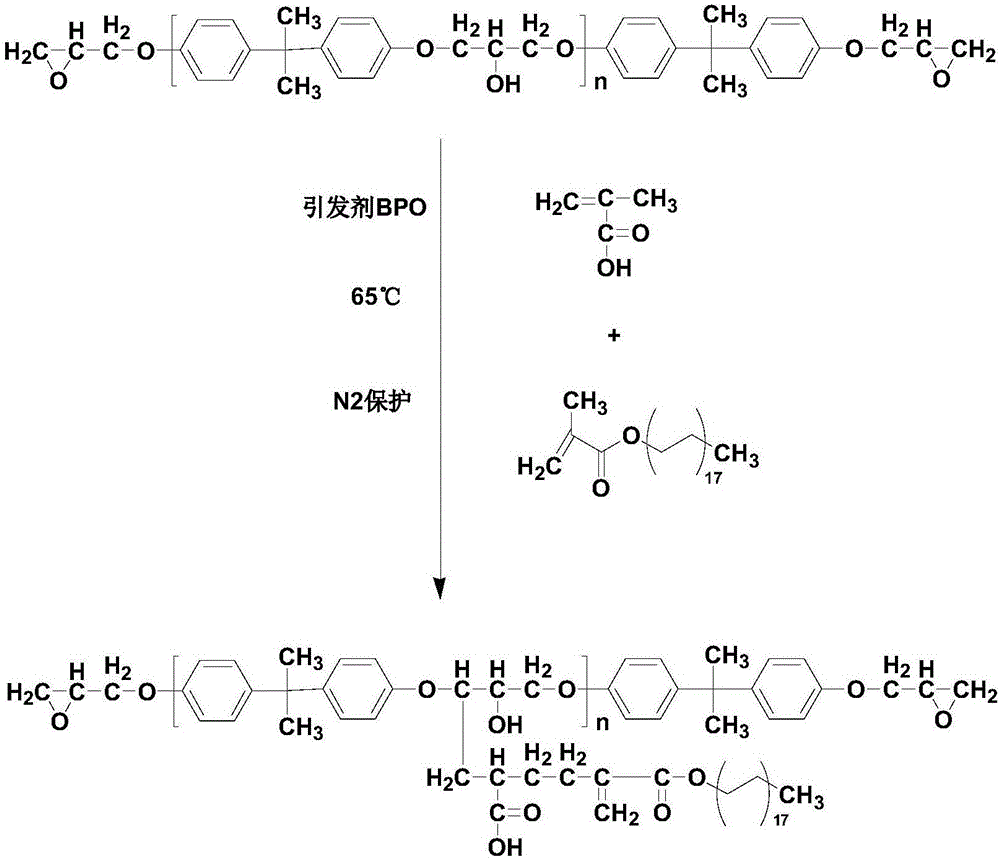

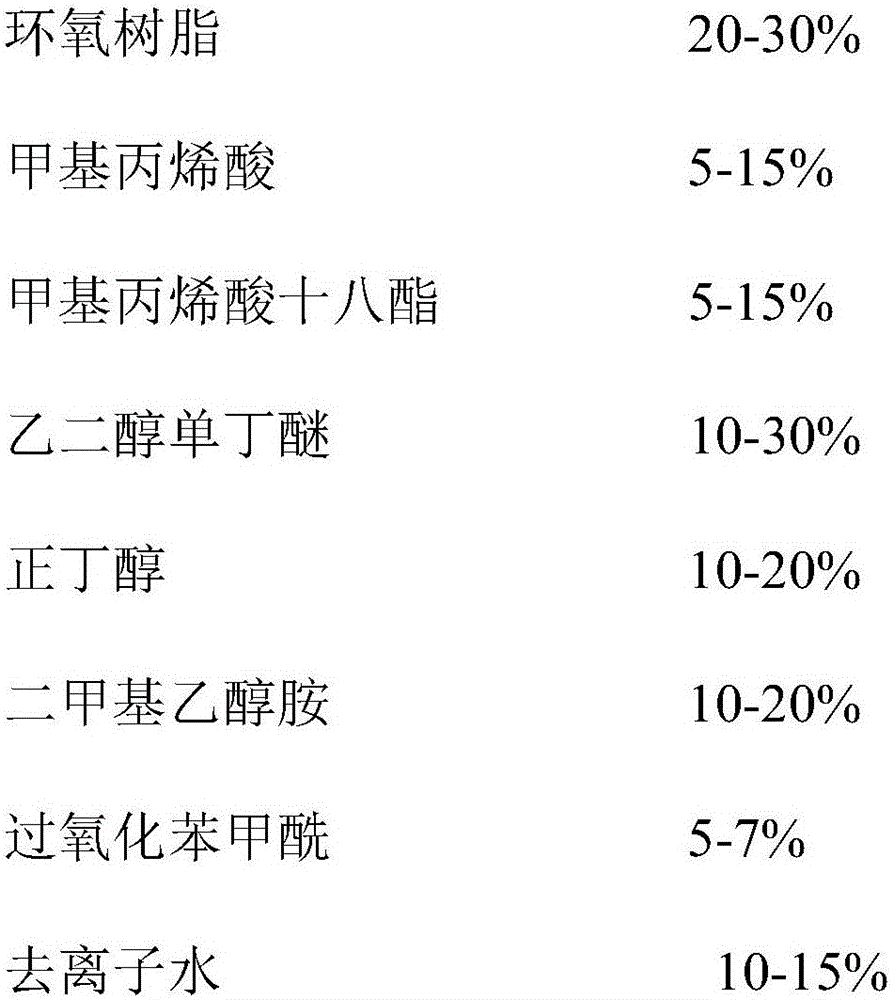

Active oil-washing sand consolidating agent and preparation method and application thereof

The invention relates to an active oil-washing sand consolidating agent. The active oil-washing sand consolidating agent is prepared from the following components in percentage by weight: 20 percent to 30 percent of epoxy resin, 5 percent to 15 percent of methacrylic acid, 5 percent to 15 percent of octadecyl methacrylate, 10 percent to 30 percent of ethylene glycol monobutylether, 10 percent to 20 percent of n-butanol, 10 percent to 20 percent of dimethylethanolamine, 5 percent to 7 percent of benzoyl peroxide and 10 percent to 15 percent of de-ionized water. A mixed solution of the n-butanol and the ethylene glycol monobutylether is used for pre-dissolving the epoxy resin, and the octadecyl methacrylate and the methacrylic acid are grafted onto the epoxy resin under the initiation of the benzoyl peroxide; a proper amount of the dimethylethanolamine and the de-ionized water are added to regulate the pH (Potential of Hydrogen), so as to obtain the active oil-washing sand consolidating agent. The active sand consolidating agent provided by the invention can be rapidly cured at a temperature lower than 60 DEG C, and a coupling agent can also be used for enhancing the cohesive property of the resin and a surface of a sandstone, so that the strength of a resin consolidated matter is guaranteed; meanwhile, the active sand consolidating agent has an extremely high oil-absorption capability and the permeability of the consolidated sandstone is kept, so that a stratum structure is stabilized or an artificial borehole wall with certain strength and permeability is formed.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

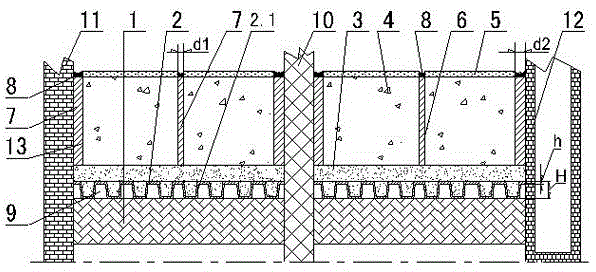

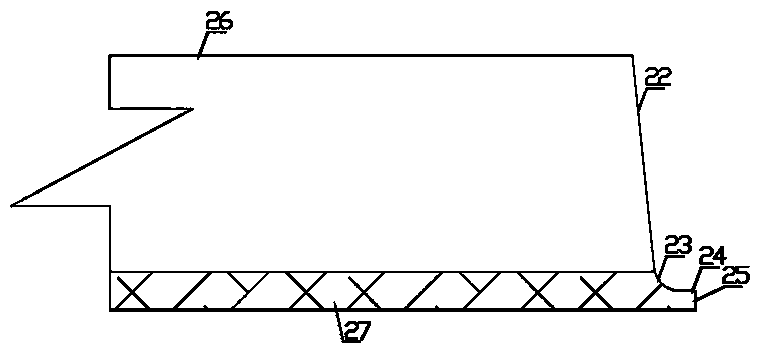

Manufacturing method and structure for basement floor without crack, leakage and with oversized area

InactiveCN104060628AAvoid crackingImprove waterproof qualityArtificial islandsProtective foundationReinforced concreteFloor slab

The invention discloses a manufacturing method and a structure for a basement floor without crack, leakage and with an oversized area. According to the method and the structure, disclosed by the invention, a concrete self waterproof floor board layer is firstly poured, and the concrete self waterproof floor layer is poured by adopting leakage resisting concrete; a drain board layer made from high impact polystyrene (HIPS) is paved on the concrete self waterproof floor board layer; then, a plain concrete leveling layer is poured on the drain board layer; a reinforced concrete layer of which the thickness is from 160 to 260mm is poured on the plain concrete leveling layer, the reinforced concrete layer is divided into small integrated reinforced concrete layers by expansion joints, and extruded polystyrene board materials are filled in the expansion joints; a polyurethane coating layer is painted on each small integrated reinforced concrete layer of the reinforced concrete layer, and silicone weather-proof glue is filled in a gap between every two adjacent polyurethane coating layers. The structure has the advantages of difficulty in sinking, no crack, no leakage and the like.

Owner:CHINA CONSTR FOURTH ENG DIV

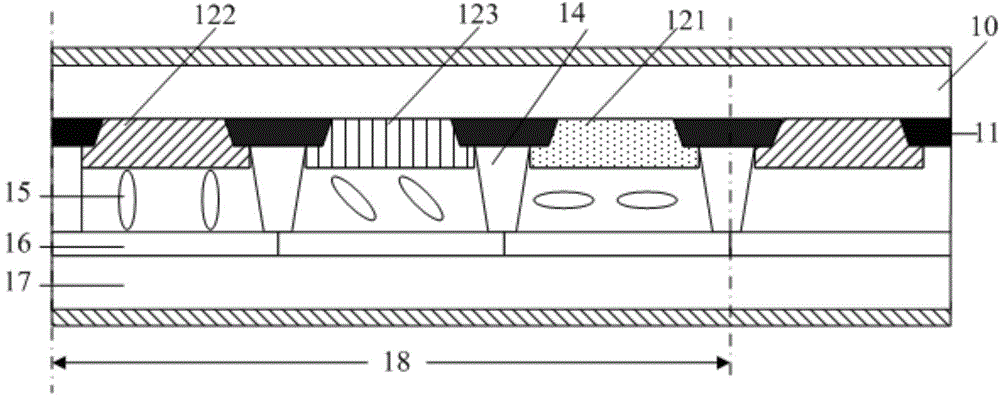

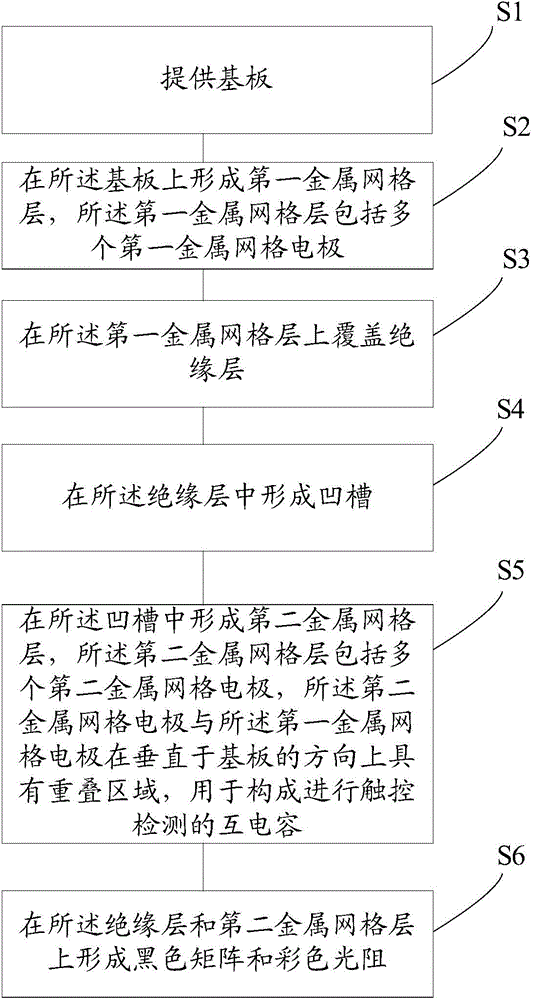

Manufacture method of color filter, color filter and liquid crystal display device

ActiveCN105807351AImprove yieldReduce noiseOptical filtersNon-linear opticsManufacturing technologyLiquid-crystal display

The invention provides the manufacture method of a color filter, the color filter and a liquid crystal display device. The manufacture method of the color filter comprises the steps that a first metal grid layer is formed on a substrate, wherein the first metal grid layer comprises a number of first metal grid electrodes; the first metal grid layer is covered by an insulating layer; a groove is formed in the insulating layer; and a second metal grid layer is formed in the groove, wherein the second metal grid layer comprises a number of second metal grid electrodes. The second metal grid electrodes and the first metal grid electrodes are used to form mutual capacitance used for touch detection. The first metal grid electrodes and the second metal grid electrodes are made of metal, and have lower impedance compared with a touch detection electrode of an ITO material. The noise of touch detection is reduced. The sensitivity of touch monitoring is improved. Compared with the existing color filter manufacture technology, the color filter manufacture method provided by the invention has the advantages of great compatibility, high yield of manufactured color filter and reduced color filter cost.

Owner:INESA DISPLAY MATERIALS

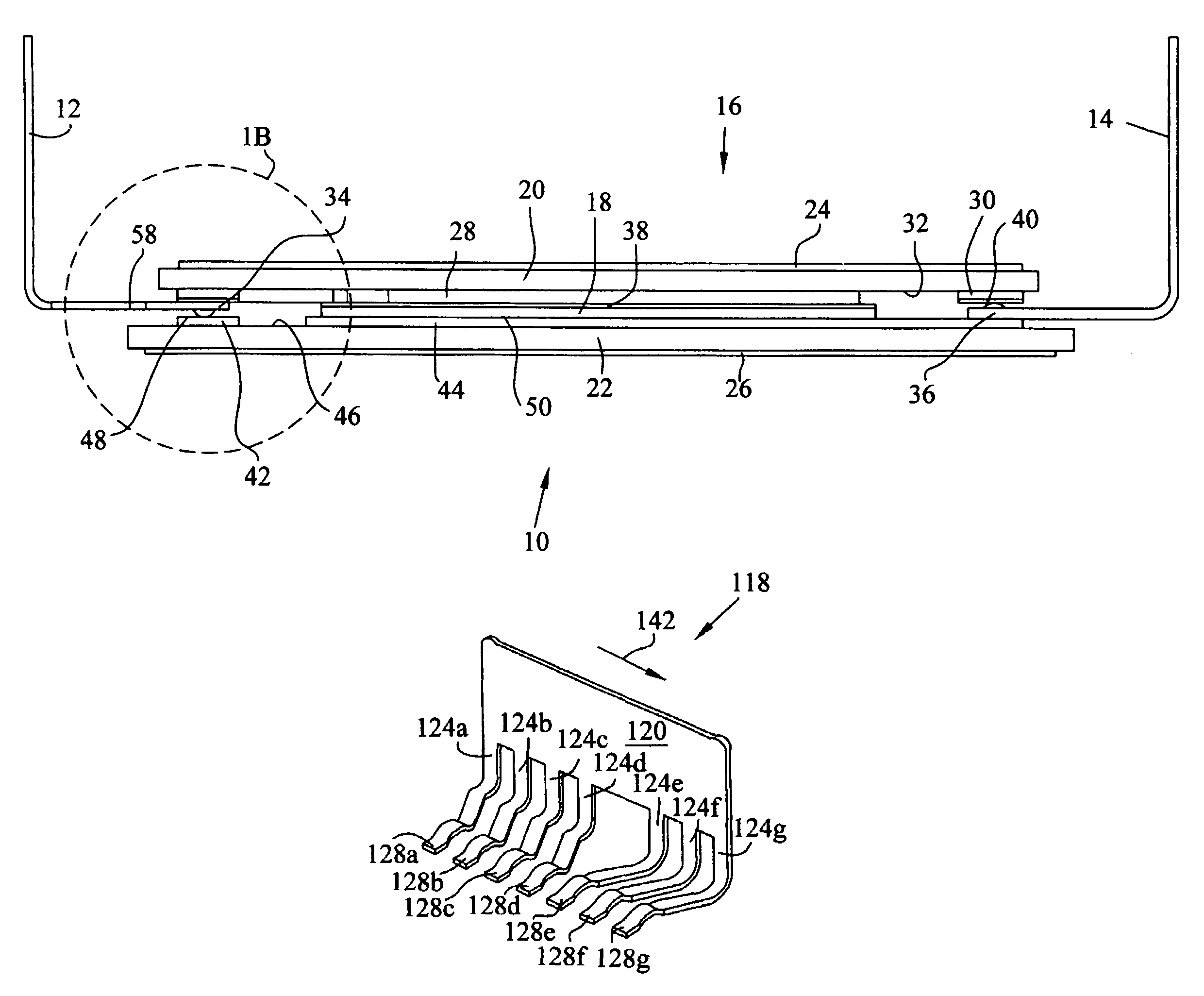

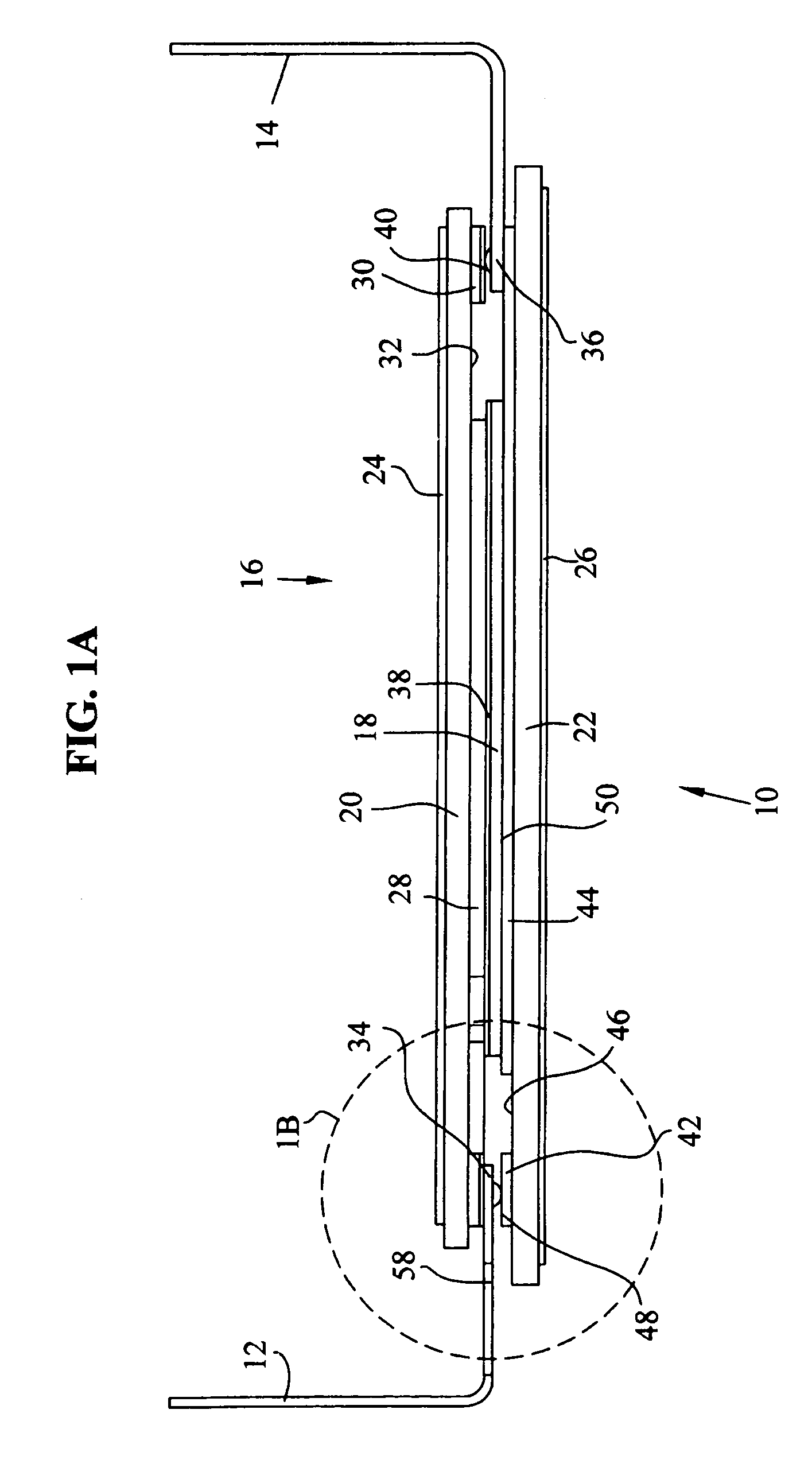

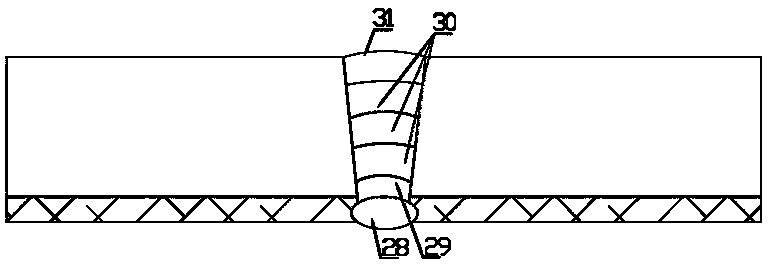

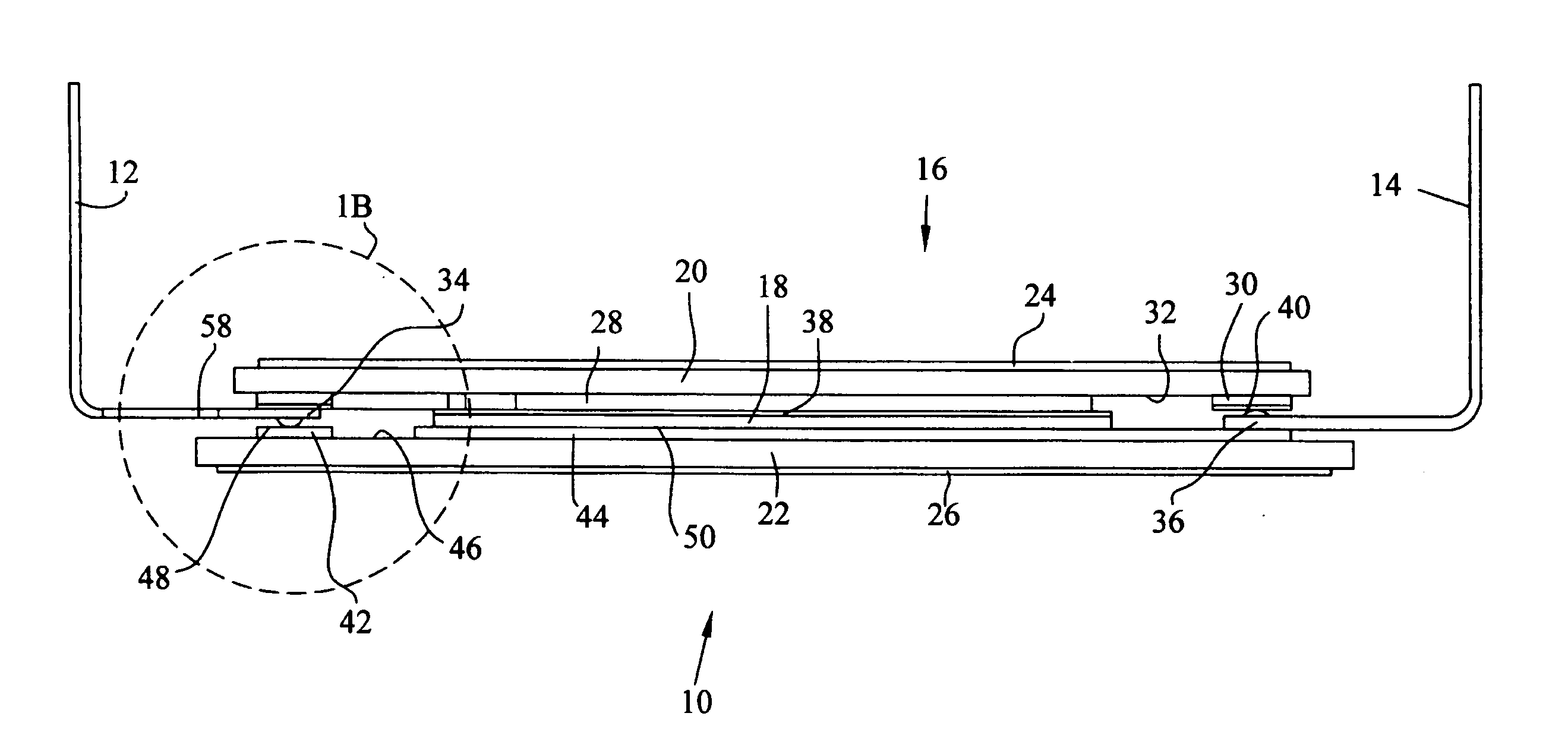

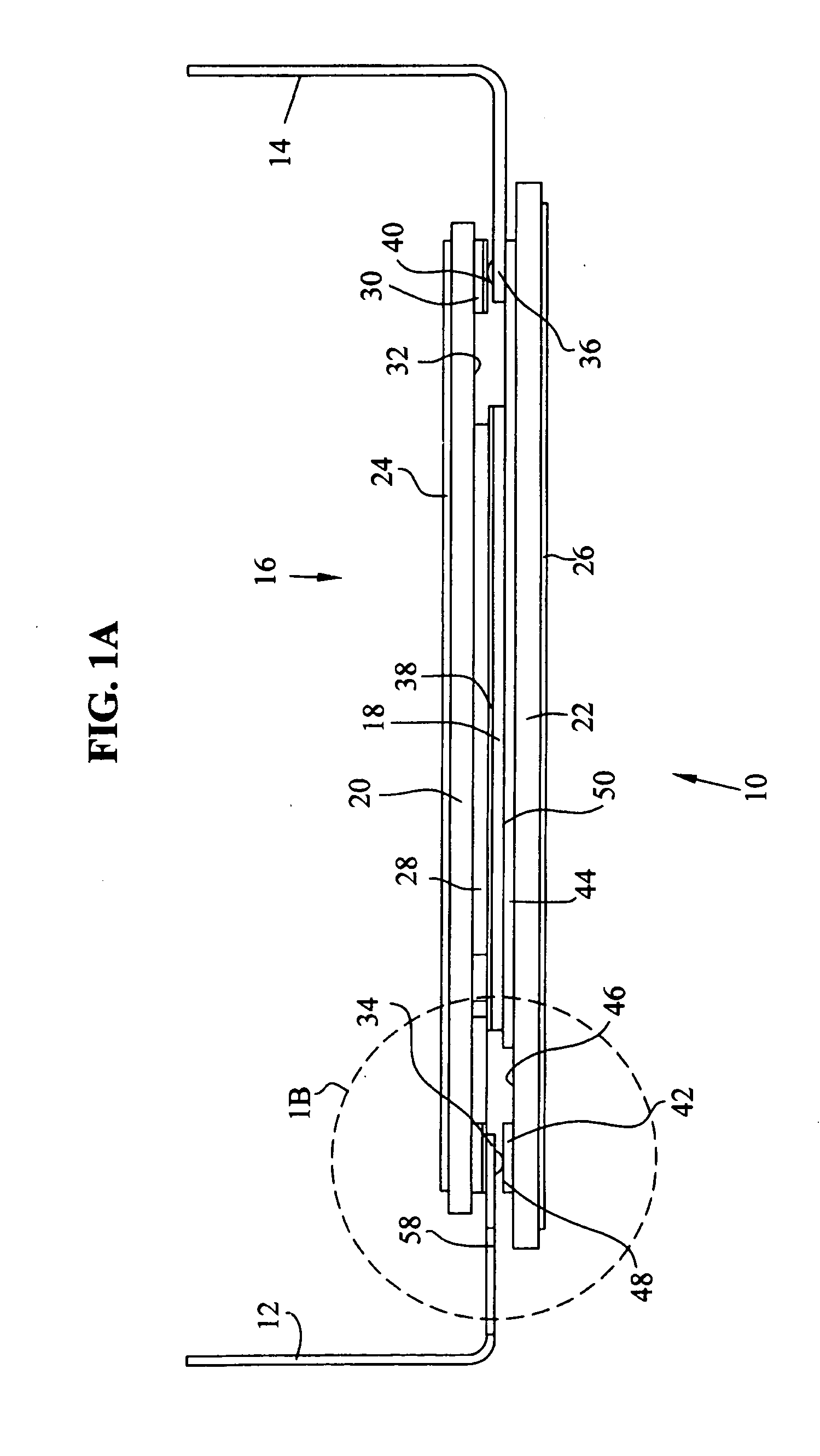

Dual-sided substrate integrated circuit package including a leadframe having leads with increased thickness

ActiveUS7148564B2Less prone to defectsEasy to manufactureSemiconductor/solid-state device detailsSolid-state devicesBiomedical engineeringIncreased thickness

An integrated circuit package includes a first non-conductive substrate having a first inner surface and a second non-conductive substrate having a second inner surface. A die having a first thickness is disposed between the first and second inner surfaces. A leadframe includes a member having a proximal end and a distal end. The proximal end has a second thickness less than the first thickness. The distal end is disposed between the first and second inner surfaces. The distal end is undulated such that the distal end has an effective thickness greater than the second thickness.

Owner:DELPHI TECH IP LTD

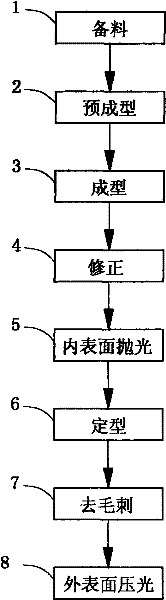

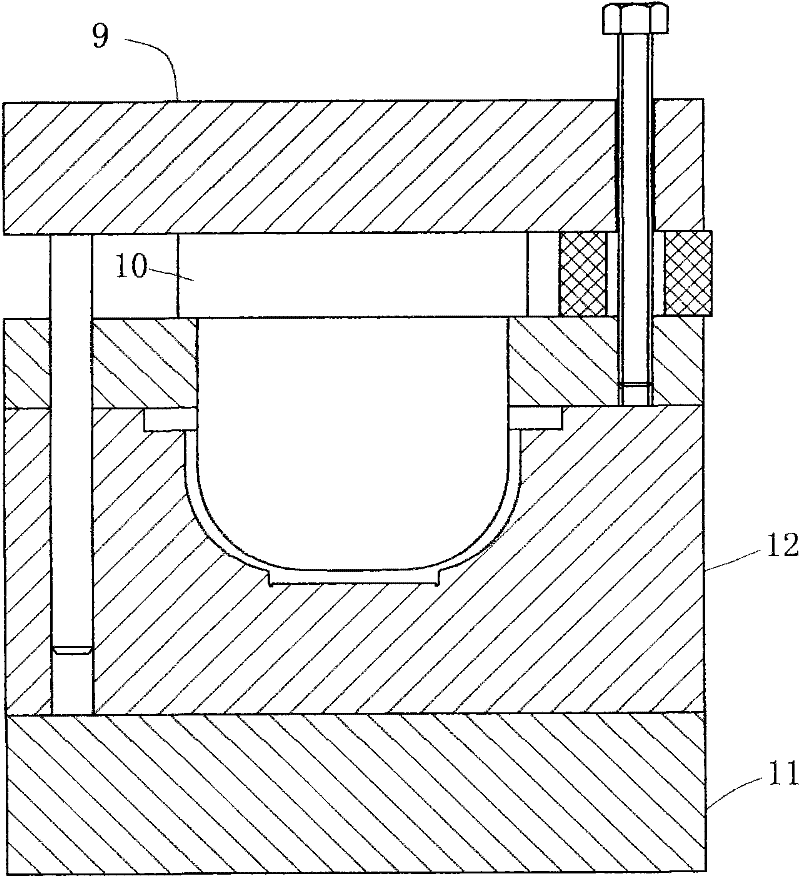

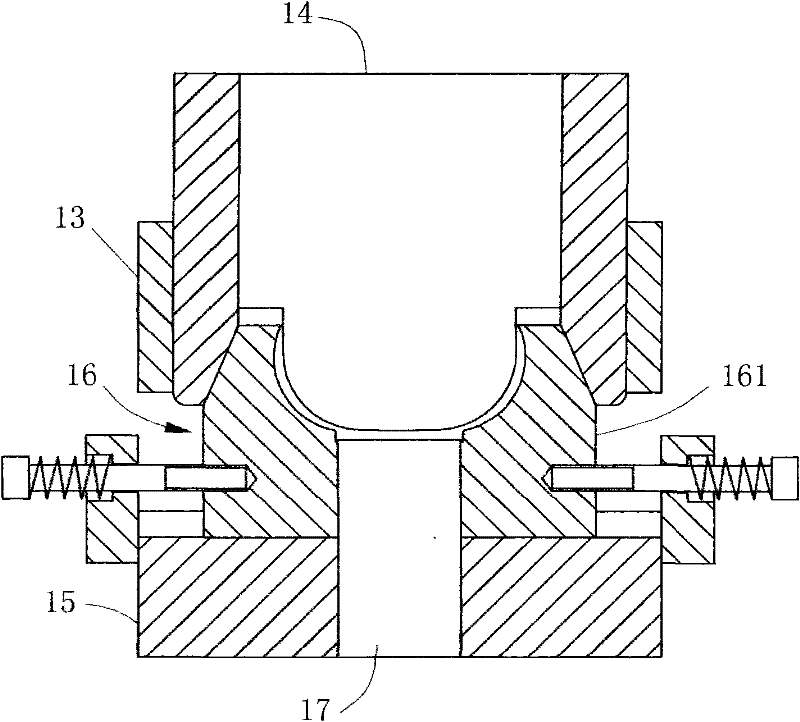

Bowl type ornament manufacturing method

ActiveCN102172303AIncrease productivityEvenly polishedEdge grinding machinesShaping toolsSizingManufacturing engineering

The invention discloses a bowl type ornament manufacturing method and belongs to the technical field of ornament manufacturing methods. The bowl type ornament manufacturing method mainly comprises the following steps: preparing raw materials, pre-forming, forming, correcting, polishing internal surface, sizing, deburring and polishing external surface, wherein a sizing die is used for sizing, thesizing mold comprises a sizing upper die holder and a sizing lower die holder, the sizing upper die holder is sleeved with a sizing male die, the sizing lower die holder is provided with a sizing female die, an impression die hole is formed on the sizing lower die holder, an impression die is restrained and arranged in the impression die hole, the sizing female die comprises a plurality of femaledie segmental bodies which are arranged in an array around the center of the impression die hole and is arranged on the sizing lower die holder in a way of being capable of sliding along the radial direction of the impression die hole. In the invention, the technical problem of processing workpieces, of which the maximum sizes of the molding cavities are greater than the sizes of openings, by using a drawing die is solved, and the method can be widely used in ornament processing industry.

Owner:SHANDONG MOKINGRAN JEWELRY

Optical film composite having spatially controlled adhesive strength

InactiveUS7655289B2Improve handlingSimple processLamination ancillary operationsLayered product treatmentLiquid-crystal displayPolarizer

Owner:EASTMAN KODAK CO

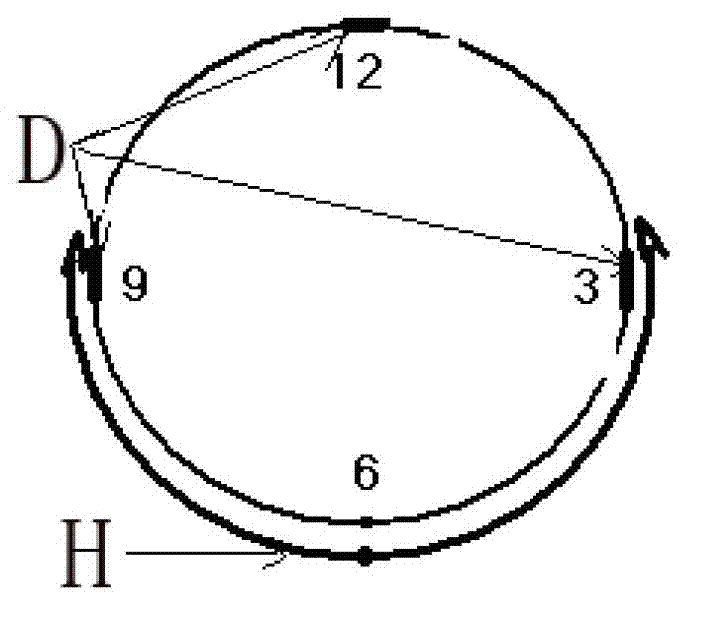

Full-automatic argon arc welding method of circumferential weld of large-caliber bimetal composite pipe

PendingCN110576244AEliminates the problem of unmelted sidewallsStrong penetrating powerShielding gas supply/evacuation devicesElectrode holder supportersSmall amplitudeShielding gas

The invention relates to the technical field of a full-automatic welding method of a circumferential weld of a large-caliber bimetal composite pipe, and discloses a full-automatic argon arc welding method of a circumferential weld of a large-caliber bimetal composite pipe. The method includes the following steps of firstly, making a preparation before welding; secondly, conducting root welding, wherein the root welding is conducted through a full-automatic argon tungsten-arc welding machine in the upward direction from the 6 o'clock position to the 12 o'clock position, the protection gas introduced into a welding gun is argon or mixed gas of argon and helium, the volume percentage of the helium in the mixed gas is 15-20%, the purity of the argon is larger than 99.99%, the purity of the argon for welding is not lower than 99.99%, the dew point is not higher than -50 DEG C, and the oxygen content is not larger than 500 ppm. The method has the advantages that root welding is conducted bymeans of the welding gun small-amplitude swinging process, so the back of the weld is well formed, grasping is easy, and defects can hardly appear; and hot welding and filling welding are conducted through U-type swinging adaptive to the groove type, so an electric arc can more easily reach a groove face, and the side wall non-welding problem easily appearing in an existing welding process is eliminated.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

Dual-sided substrate integrated circuit package including a leadframe having leads with increased thickness

ActiveUS20050179123A1Less prone to defectsEasy to manufactureSemiconductor/solid-state device detailsSolid-state devicesBiomedical engineeringIntegrated circuit

An integrated circuit package includes a first non-conductive substrate having a first inner surface and a second non-conductive substrate having a second inner surface. A die having a first thickness is disposed between the first and second inner surfaces. A leadframe includes a member having a proximal end and a distal end. The proximal end has a second thickness less than the first thickness. The distal end is disposed between the first and second inner surfaces. The distal end is undulated such that the distal end has an effective thickness greater than the second thickness.

Owner:DELPHI TECH IP LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com