Preparation method of composite membrane

A composite membrane and membrane hole technology, applied in the field of separation membranes, can solve the problems of difficulty in reducing the thickness of the composite layer, difficulty in controlling the supply volume and supply speed, difficulty in achieving stable control of the concentration, etc., and achieve lower technical requirements and high removal rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

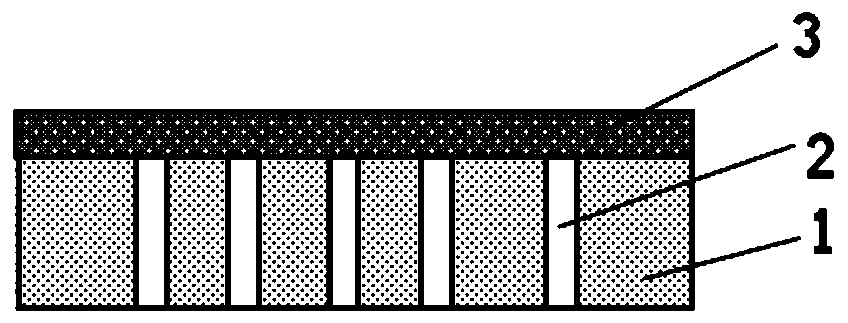

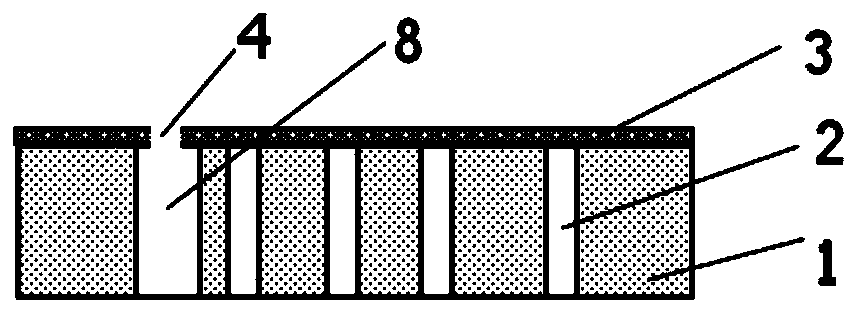

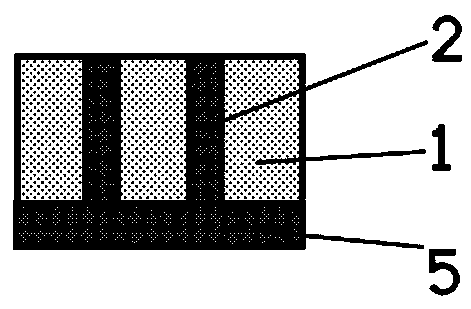

Embodiment 1

[0045] First, pure water is coated on the permeable side of the polysulfone flat porous base membrane to wet the porous base membrane, and the membrane pores are filled with liquid water, and then continuously coated on the surface (front) of the porous base membrane containing 0.10wt% homogeneous The n-hexane oil phase solution of benzene tricarboxylic acid chloride, the 3rd step, the aqueous phase solution that contains 0.40wt% p-xylylenediamine is coated on the permeation side of porous base membrane continuously for 15 minutes, makes the terephthalic diamine in the aqueous phase solution The amine diffuses into the membrane pores, contacts with the trimesoyl chloride reactive monomer in the oil phase solution at the opening of the membrane pores, and interfacial polymerization occurs, forming a cap-shaped cross-linked layer at the openings of the membrane pores to block the membrane pores , so as to prepare flat reverse osmosis membrane. Under the test pressure of 1.5MPa, ...

Embodiment 2

[0047] Using 0.08wt% concentration of trimesoyl chloride in n-hexane oil phase solution, 0.20wt% concentration of p-xylylenediamine, and other preparation conditions Example 1, a flat reverse osmosis membrane was prepared. Under the test pressure of 1.5MPa, the rejection rate of 1000mg / L sodium chloride aqueous solution is 98%, and the pure water membrane flux is 38L / m2.h. Compared with Example 1, the concentration of the reaction monomer is reduced, and the membrane flux is further improved.

Embodiment 3

[0049] First, pure water is coated on the permeable side of the polysulfone flat porous base membrane to wet the porous base membrane, and the membrane pores are filled with liquid water, and then continuously coated on the surface (front side) of the porous base membrane containing 0.08wt% homogeneous The n-hexane oil phase solution of trimellitic acid chloride, the 3rd step, the water phase solution that contains 0.25wt% piperazine is continuously coated on the permeation side of the porous base membrane, the piperazine in the water phase solution is diffused into the membrane hole, in The openings of the membrane pores are in contact with the trimesoyl chloride reactive monomer in the oil phase solution, interfacial polymerization occurs, and a cap-shaped cross-linked layer is formed at the openings of the membrane pores to block the membrane pores, thereby preparing a flat nanofiltration membrane. Under the test pressure of 0.3MPa, the rejection rate of 1000mg / L sodium sul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com