Patents

Literature

286results about How to "Increase membrane flux" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

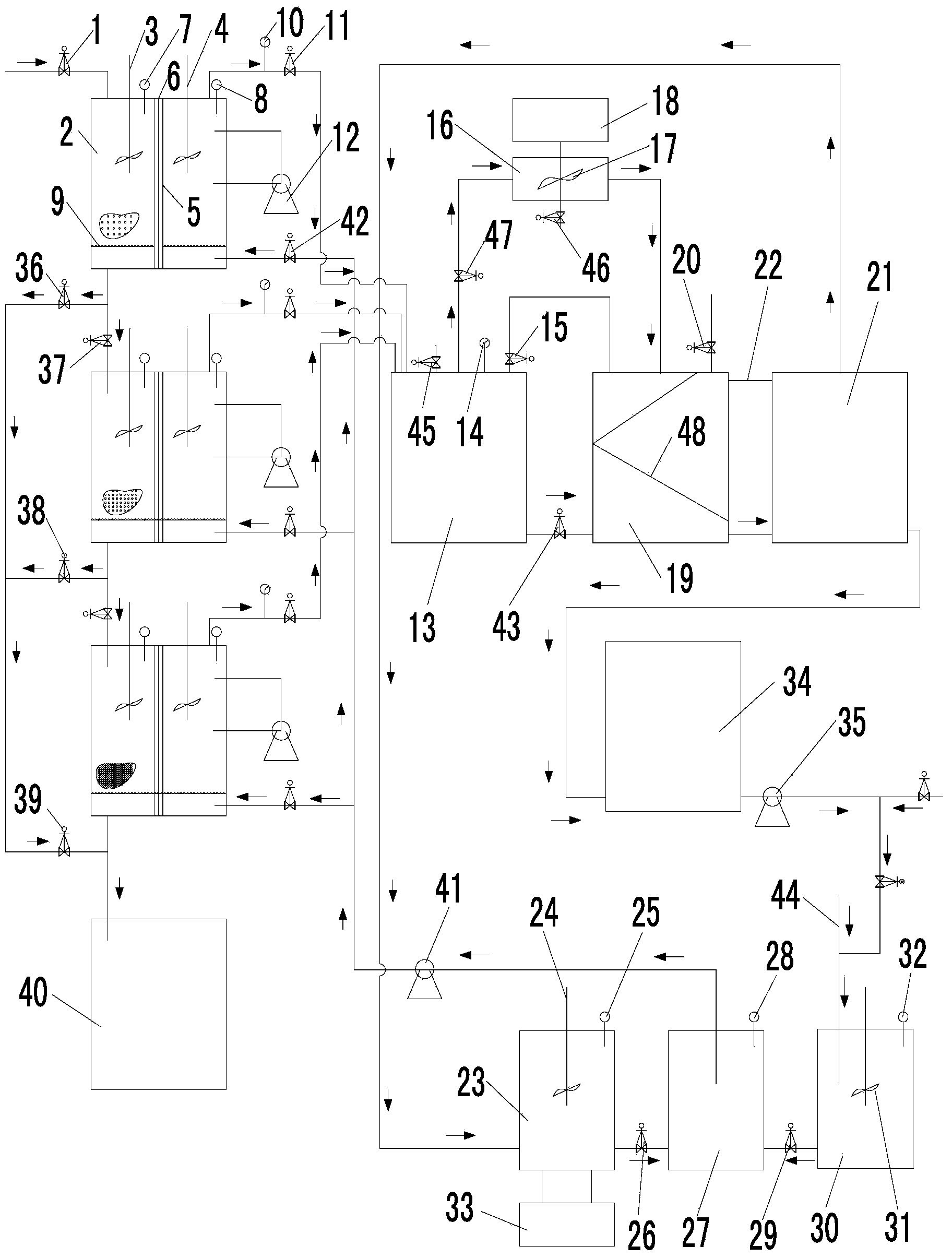

Oil sludge cleaning and processing system for oil tank

InactiveCN102825040ARealize all-round cleaningCompact structureSludge treatmentHollow article cleaningUltrafiltrationResource utilization

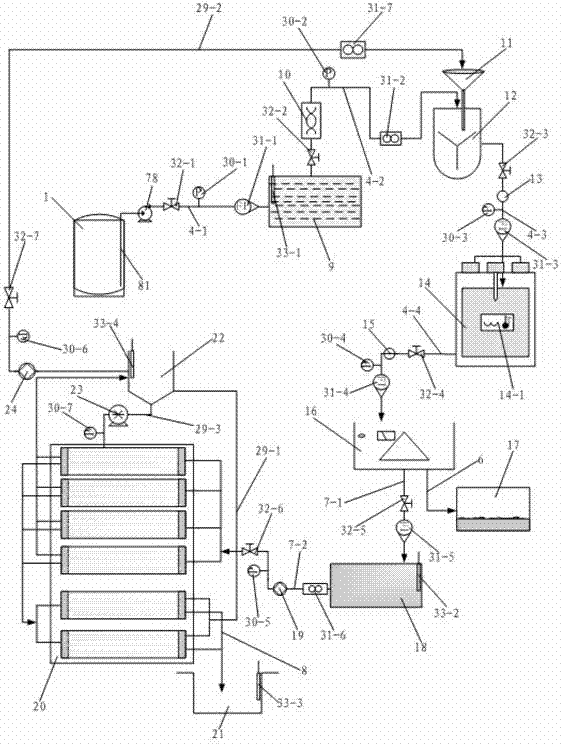

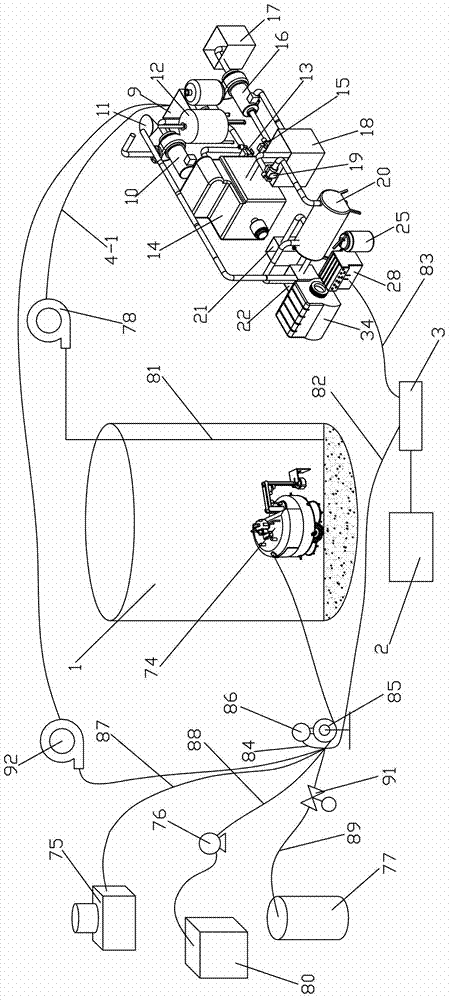

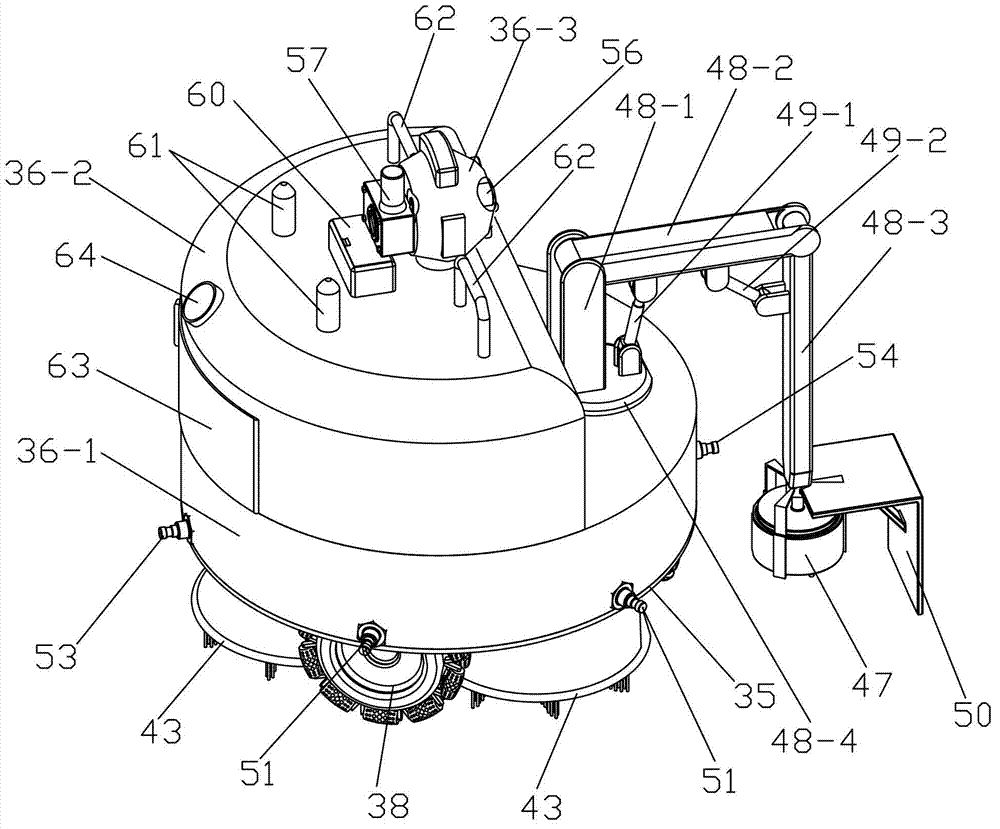

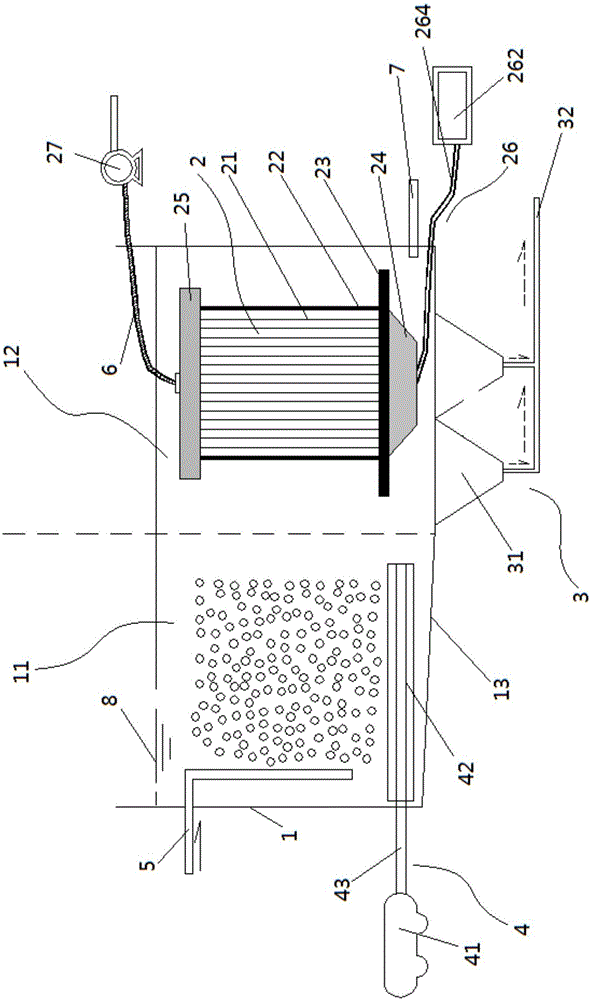

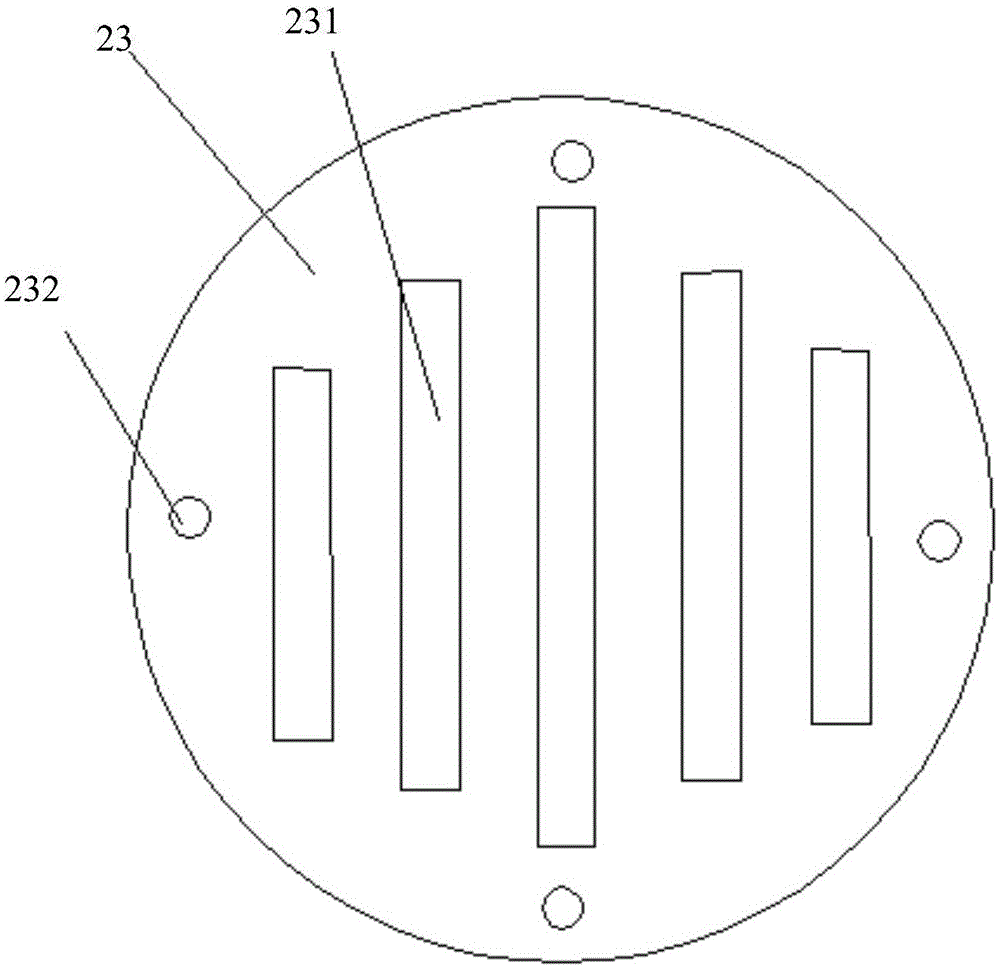

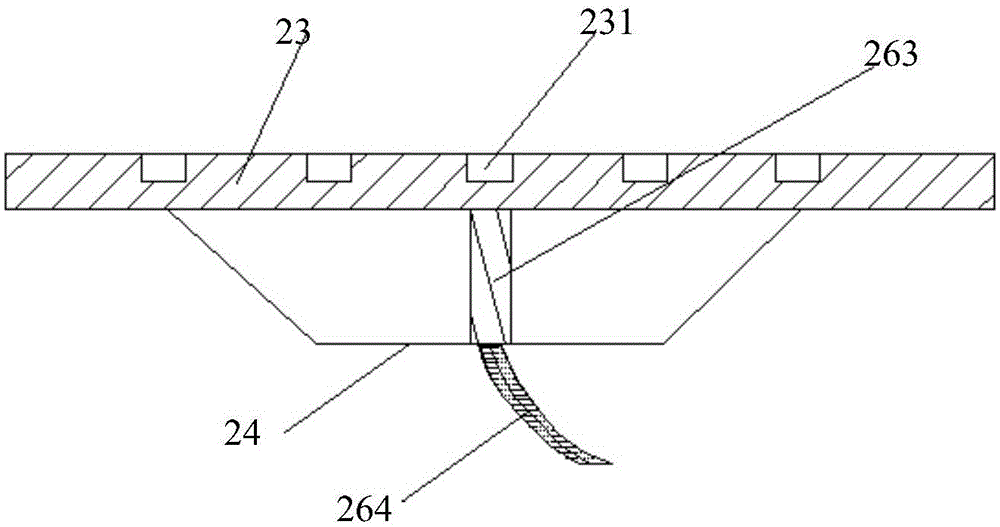

The invention discloses an oil sludge cleaning and processing system for an oil tank. The oil sludge cleaning and processing system comprises a cleaning system, an oil sludge processing system and an integrated control system, wherein the cleaning system comprises a cleaning robot, an electric hydraulic pump, a water pump, an inert gas storage tank and a screw pump; the cleaning robot comprises a machine body, a traveling unit, a cleaning unit, a robot cleaning control unit, a sensing and communication unit and a robot power supply unit; the oil sludge processing system comprises an oil sludge processing device, an oil sludge processing control system and an oil sludge processing power supply device; the oil sludge processing device comprises a stirring machine, an ultrasonic emulsion breaking device, a centrifuge and an ultrafiltration system, as well as an oil sludge storage pool, a sludge pool, a centrifugal liquid storage tank, a concentration tank and a filtrate pool; a funnel is arranged on the stirring machine; and the integrated control system comprises an integrated control computer and a communication circuit module. The oil sludge cleaning and processing system disclosed by the invention has the advantages of reasonable design and high degree of intelligentization, and can realize comprehensive cleaning of the oil tank, good safety, fast oil sludge processing speed and resource utilization of oil sludge, and further reduce environmental pollution and waste of resources.

Owner:周利坤

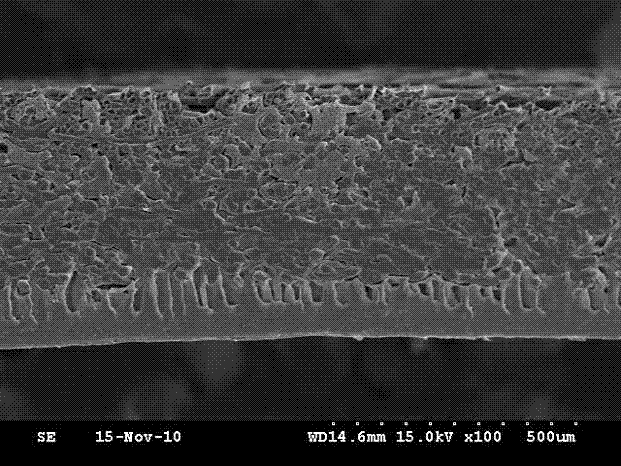

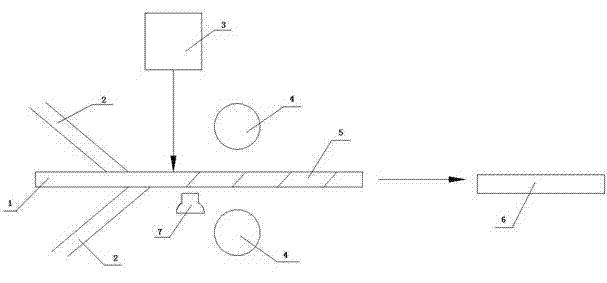

A kind of manufacture method of polytetrafluoroethylene hollow fiber membrane

InactiveCN102284251APrecise control of apertureHigh porositySemi-permeable membranesPorosityAdhesive

The invention provides a method for manufacturing a polytetrafluoroethylene hollow fiber membrane, comprising the following steps: step 1: using a PET fiber braided tube as a support tube, and coating the PET fiber braided tube with an adhesive; step 2: applying a PTFE flat The membrane is continuously wrapped on the PET fiber braided tube, and the adjacent PTFE flat membrane partially overlaps during wrapping; Step 3: Drying. By selecting high-quality PTFE flat membranes and precisely controlling the pore size of PTFE hollow fiber membranes, the porosity of PTFE hollow fiber membranes can be effectively increased, thereby improving the membrane flux of the fiber membranes, and the process is simple, easy to operate, and environmentally friendly. Pollution is small.

Owner:ZHEJIANG DONGDA ENVIRONMENTAL ENG

Water treatment method for catalytic ozonation of refractory organics in water by ceramic membrane

InactiveCN103951028AIncrease profitEnhance its oxidative capacityWater/sewage treatment bu osmosis/dialysisWater/sewage treatment by oxidationHazardous substanceData acquisition

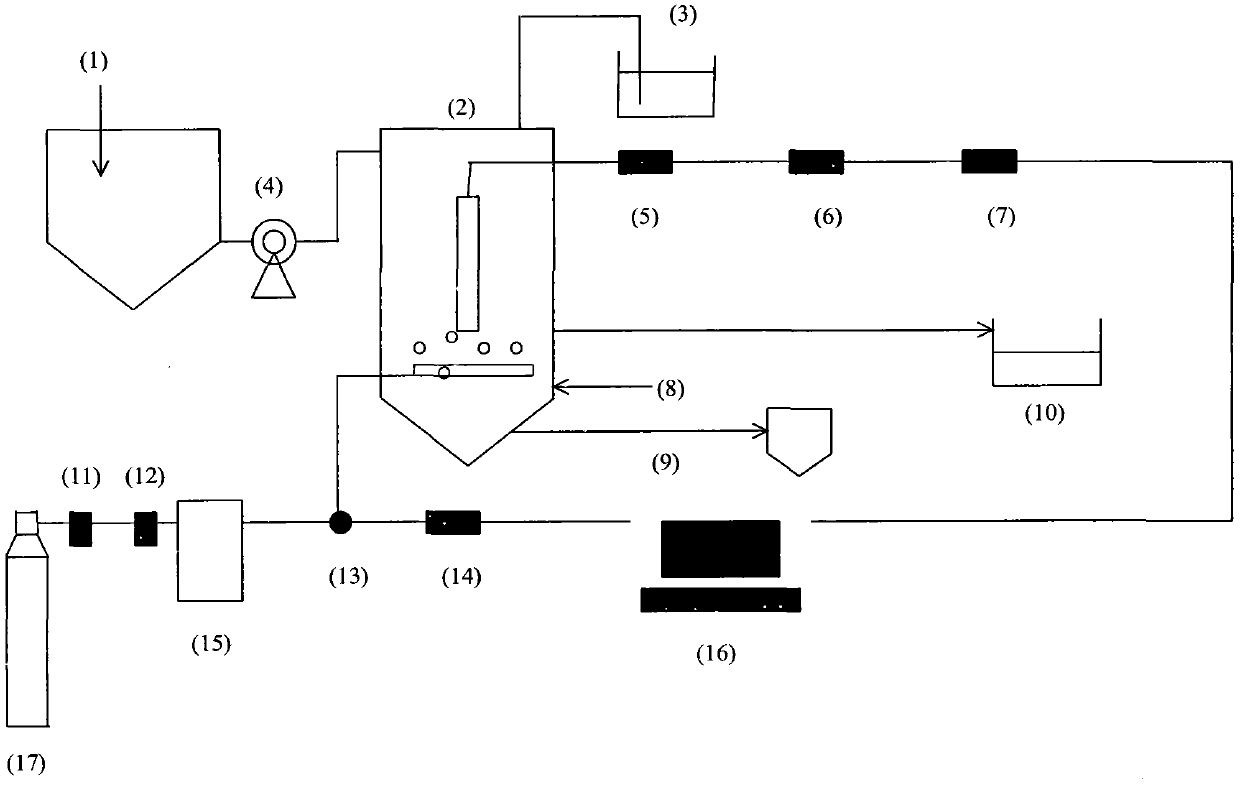

The invention relates to water deep treatment technology of heterogeneous catalytic ozonation depollution. With the combination of catalytic ozonation depollution technology with membrane filtration technology, a novel, high-efficient, and economical catalytic ozonation water deep treatment technology is provided, which combines the advantages of the two technologies, overcomes their disadvantages, effectively improves the ozone utilization rate and the ozone oxidation capability, reduces some toxic and harmful substances generated due to incomplete oxidation, alleviates the problem of ceramic membrane contamination, and prolongs the system operation period. An experiment device mainly comprises three parts: an ozone generation device, a ceramic membrane device, and a computer data acquisition and analysis system; an ozone outlet of the ozone generation device is connected with a water inlet valve of the ceramic membrane assembly through a silicone flexible pipe to realize the coupling of the two system. The method of the invention can improve the purifying effect of routine water treatment technology, and provides novel, high-efficient and cheap water deep treatment technology for enhanced removal of low-concentration high-toxicity refractory organic pollutants in water.

Owner:BEIJING FORESTRY UNIVERSITY

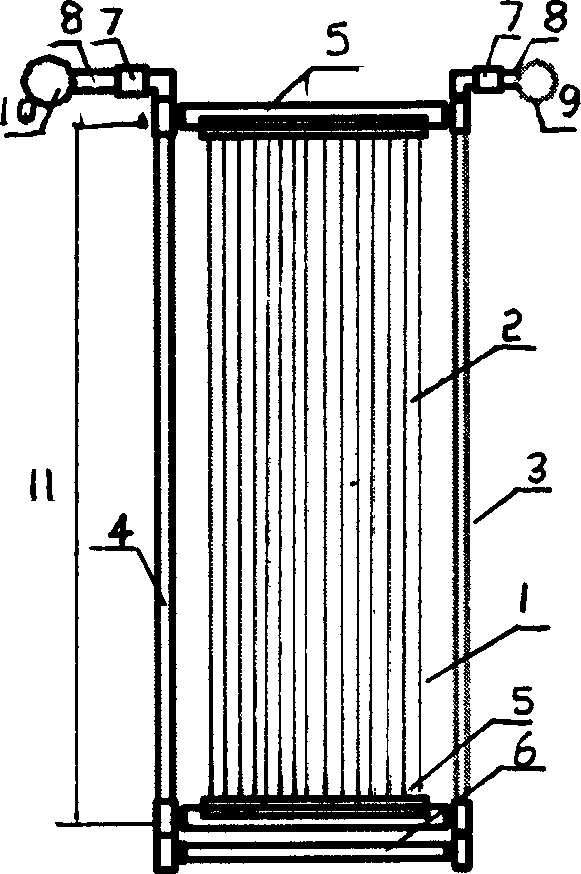

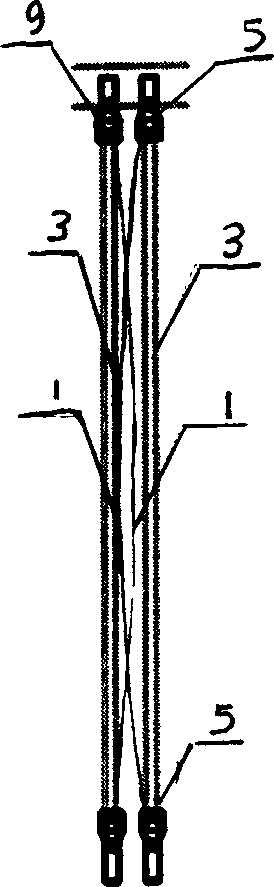

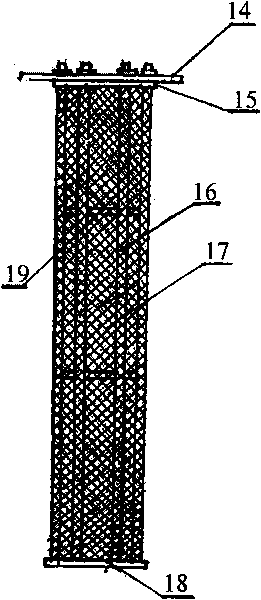

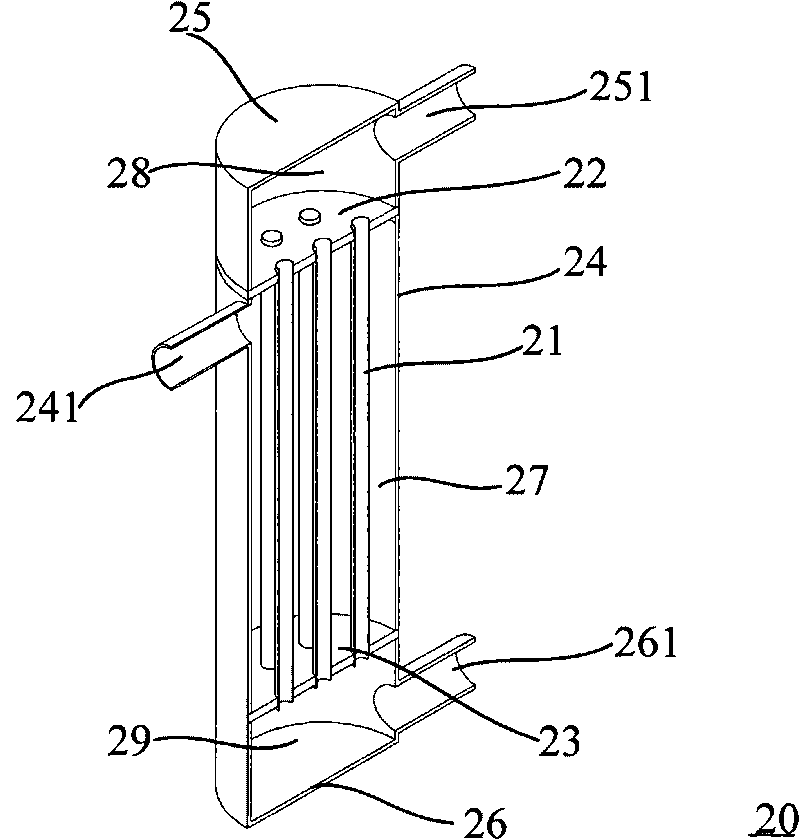

Film assembly cleaned mechanically

InactiveCN1491904AReduce the effective areaEfficient removalSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisHigh fluxMembrane bioreactor

The present invention belongs to the field of membrane bioreactor, and is especially one mechanically cleaned membrane assembly. The membrane assembly includes membrane plate, water outlet branched pipe and aeration pipe. The membrane plate consists of membrane filament, membrane brush and water collecting pipe; the parallel membrane filaments and membrane brushes are arranged alternately; the membrane filament has its two ends connected to upper and lower water collecting pipes separately with the drained water being collected via membrane filament to two water collecting pipes; the water outlet branched pipe has one end connected to the water collecting pipe and the other end to the general water outlet pipe; the aeration pipe is connected to the branch and general aeration pipe; and gas is generated on two sides of the aeration pipe below the membrane plate and raises along the sides of the membrane plate. The membrane assembly is used in treating waste water with high flux.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

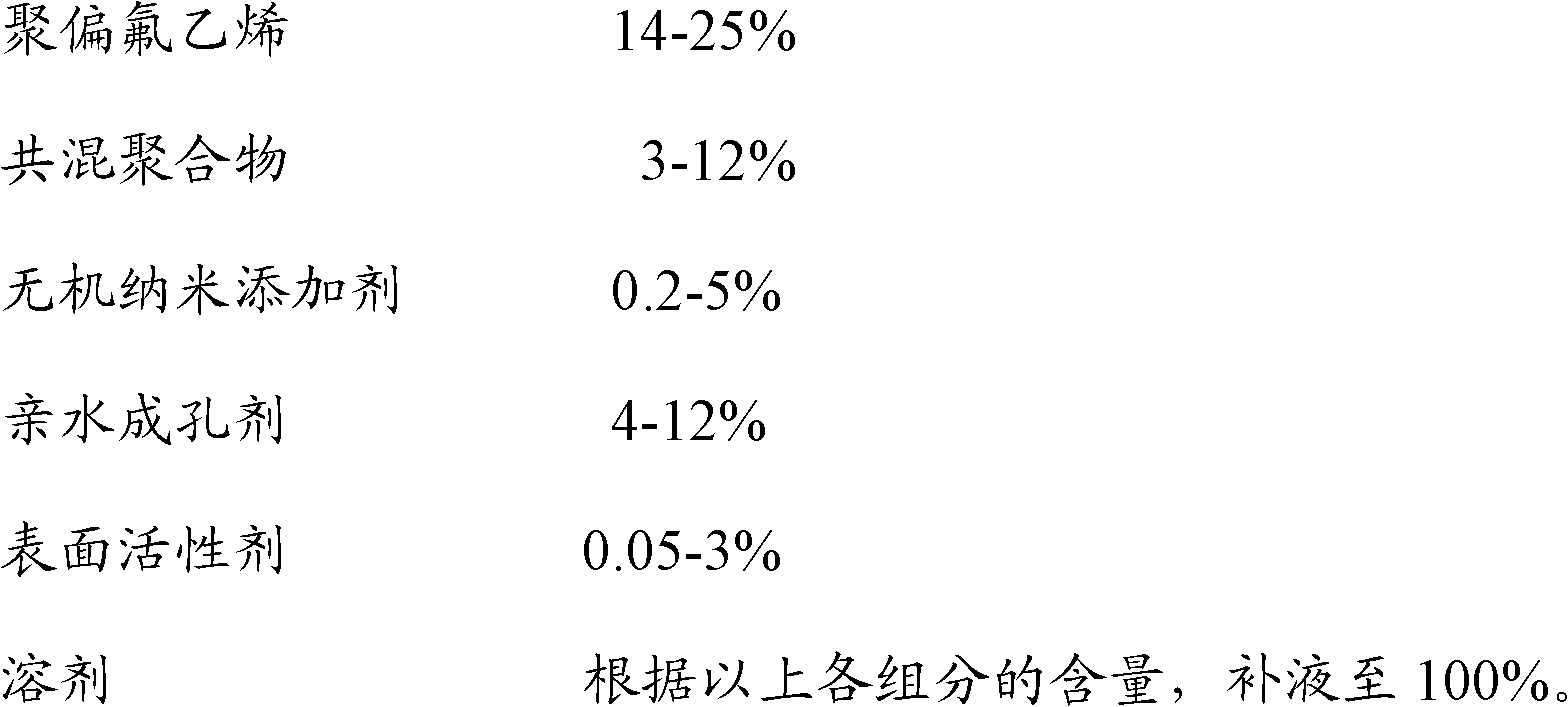

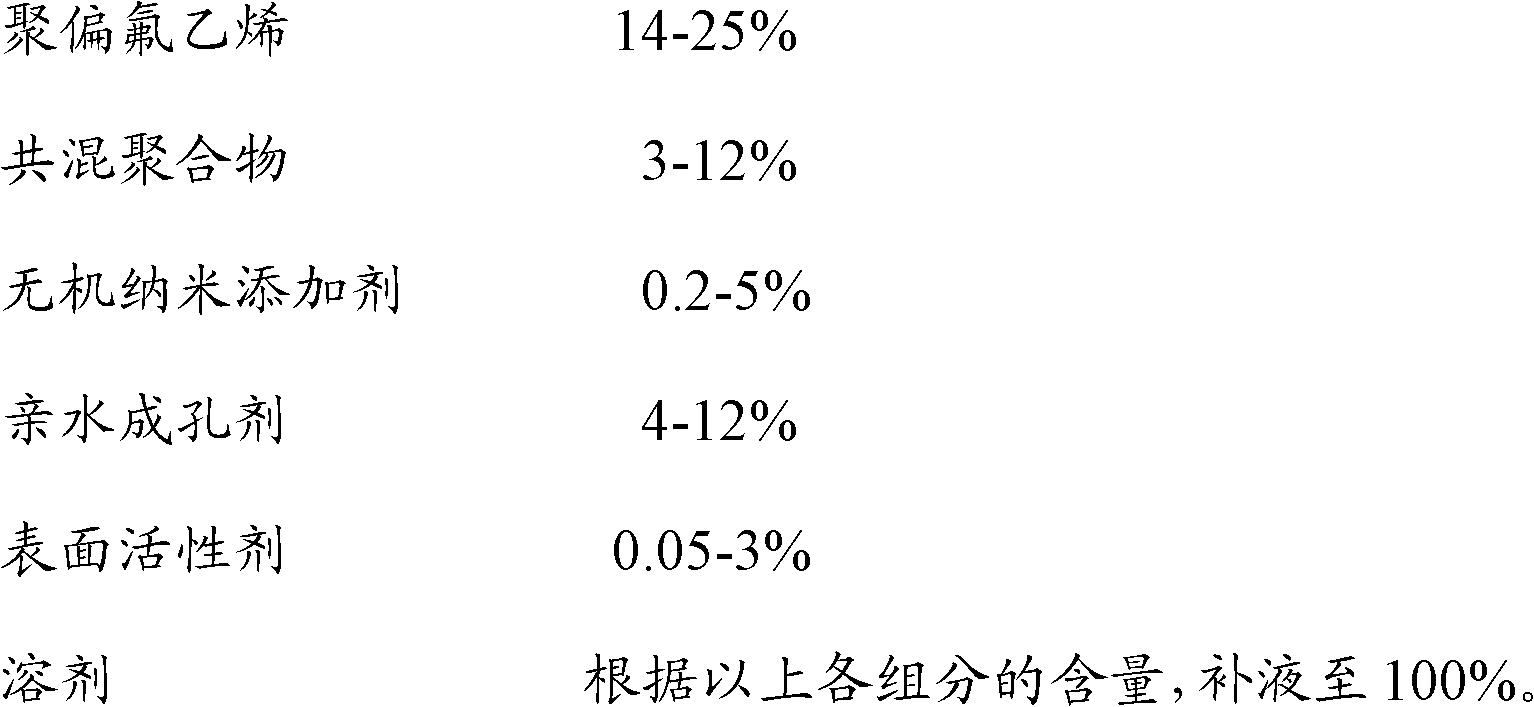

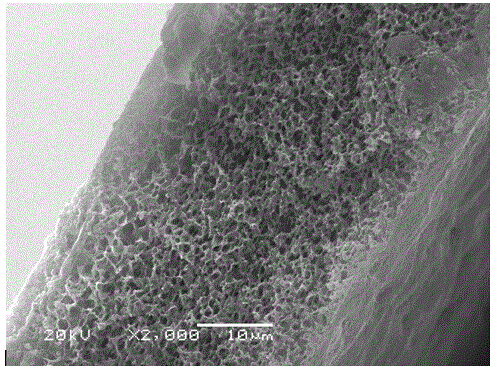

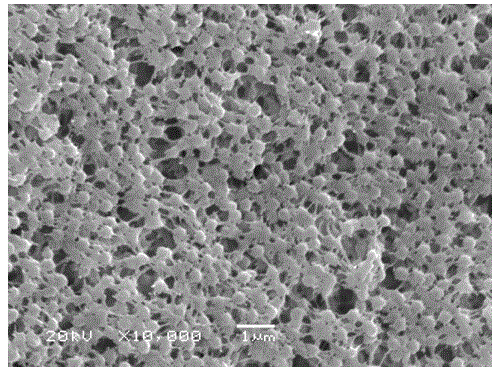

Polyvinylidene fluoride organic-inorganic hybrid membrane and preparation method thereof

InactiveCN102430352AImprove hydrophilicityIncrease membrane fluxSemi-permeable membranesSolventPolyvinylidene fluoride

The invention relates to a polyvinylidene fluoride membrane and a preparation method thereof, and specially, relates to a polyvinylidene fluoride organic-inorganic hybrid membrane and a preparation method thereof. A casting solution of the polyvinylidene fluoride organic-inorganic hybrid membrane comprises 14 to 25% of polyvinylidene fluoride, 3 to 12% of one or more mixed polymers, 0.2 to 5% of one or more inorganic nanometer additives, 4 to 12% of one or more hydrophilic pore-forming agents, 0.05 to 3% of a surfactant and 50 to 80% of one or two solvents. The casting solution is prepared and then is processed into a polyvinylidene fluoride organic-inorganic hybrid membrane finished product through a dry-wet spinning technology. Compared with the prior art, the preparation method adopts hydrophilic mixtures and hydrophilic inorganic nanometer particles simultaneously and thus further improving membrane wire hydrophily, membrane flux and membrane contamination resistance.

Owner:SANDA FILM SCI & TECH XIAMEN

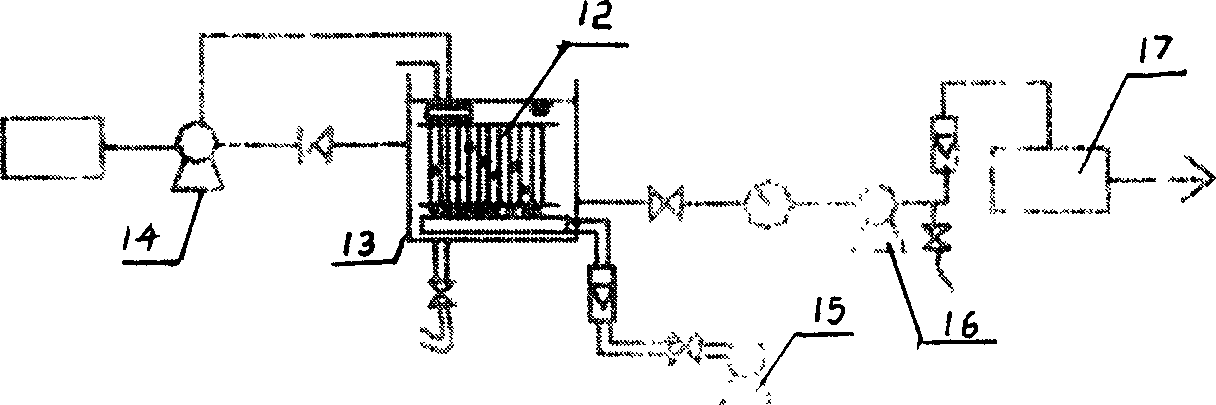

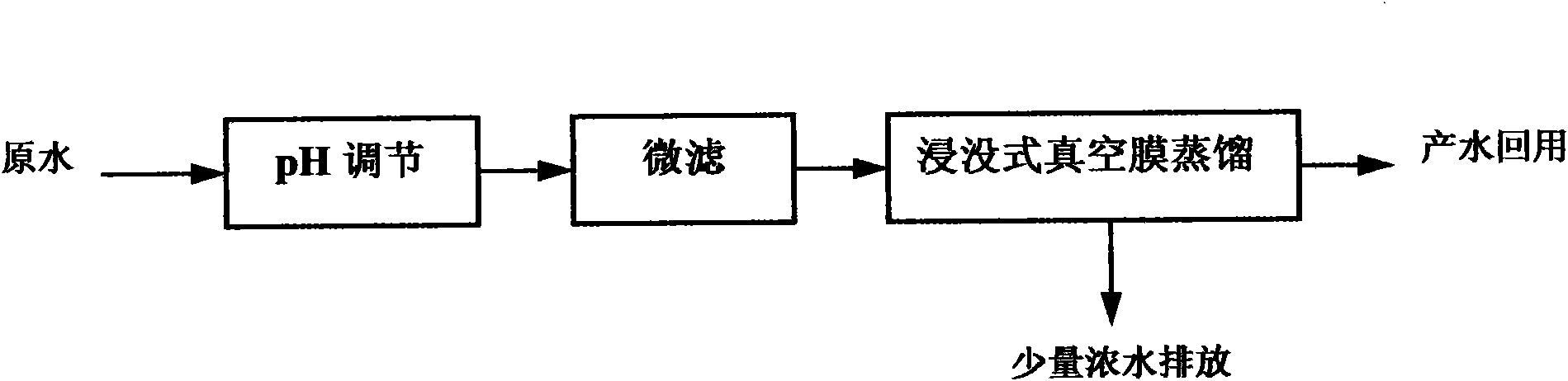

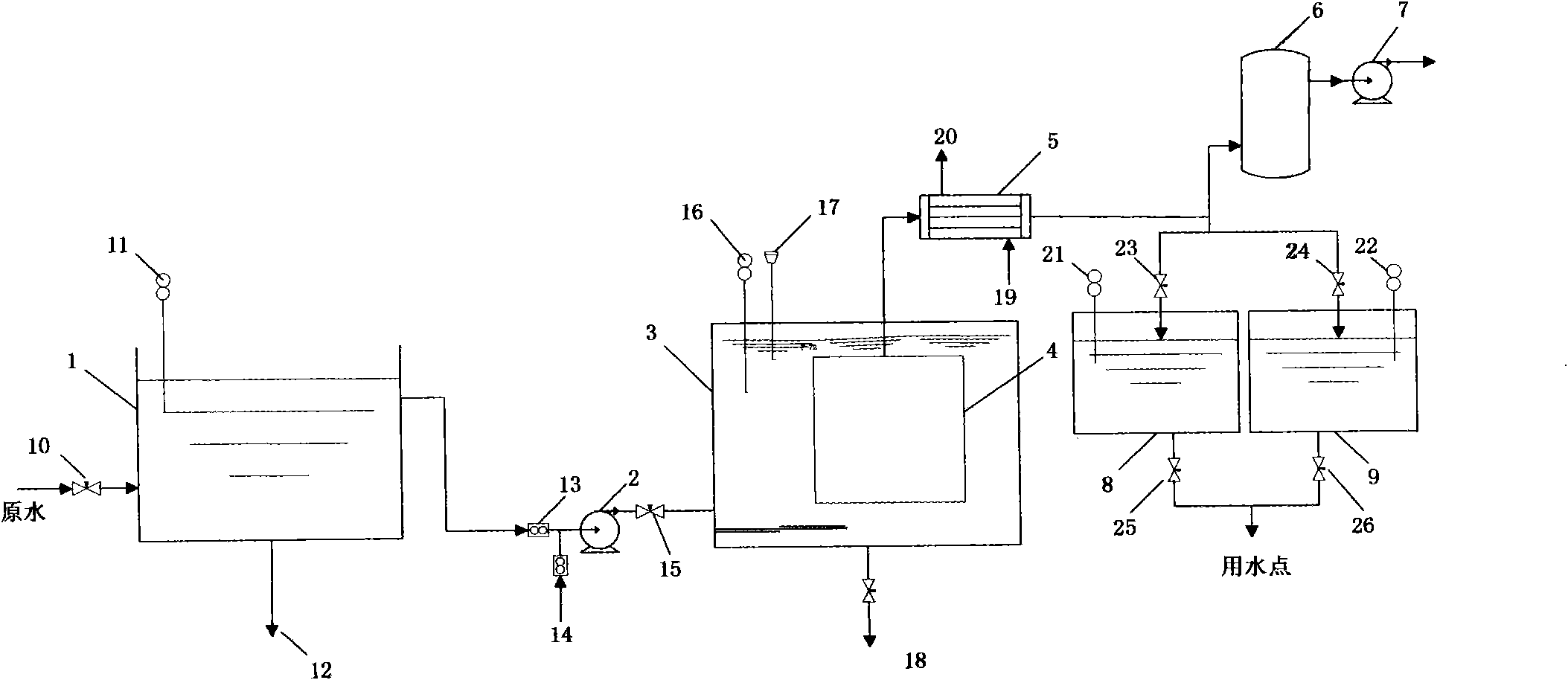

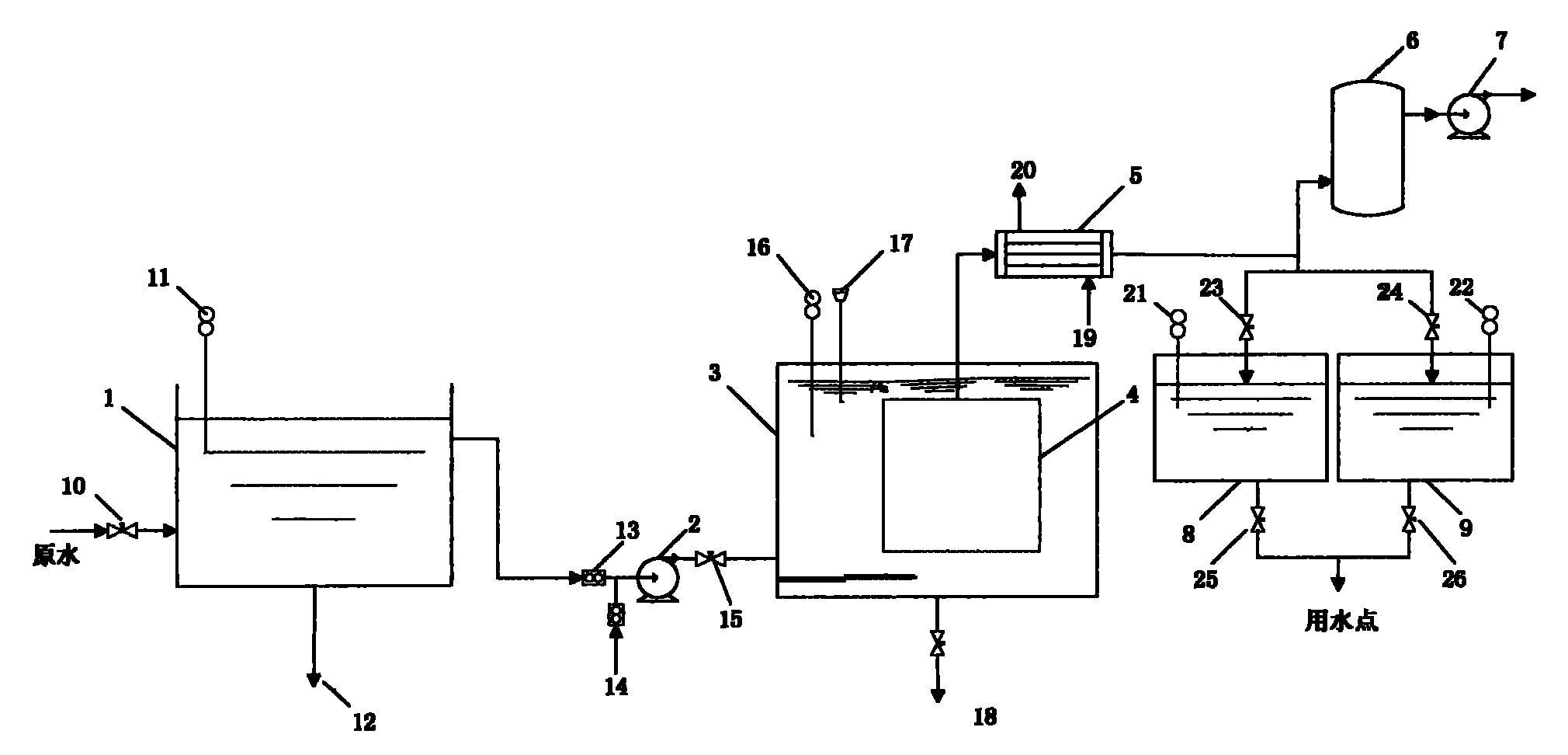

Immersed vacuum membrane distillation plant and sewage treatment technology using the same

ActiveCN102417210AIncreased distillation throughputReduce pollutionWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentConcentration polarizationMeasuring instrument

The invention relates to an immersed vacuum membrane distillation plant and a sewage treatment technology using the same. The immersed vacuum membrane distillation plant comprises a raw water storage tank, a gas dissolving pump, a raw water heating water tank, a membrane distillation hydrophobic membrane module, a condenser, a vacuum buffer tank, a vacuum pump, a water producing tank, a valve, a measuring instrument, and an automatic controller. The sewage treatment technology is characterized in that: raw water is subject to pH regulation, microfiltration and other pretreatment, then the pretreated raw water enters into the raw water storage tank, the sewage in the raw water storage tank is subject to gas-water mixing through the gas dissolving pump, and then the gas-water mixture enters into the raw water storage tank for heating to a specific temperature, membrane distillation is carried out at the specific temperature, the produced water after membrane distillation is directly reused, and a little thick water is treated concentrately. According to the invention, the use of the plant in sewage treatment reduces the effect of concentration polarization and temperature difference polarization in the sewage, reduces membrane pollution, increases the membrane distillation flux, prolongs the operation period of the membrane module, reduces the heat loss of the pipeline, and increases the heat utilization rate.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of high-flux PVDF (polyvinylidene fluoride) porous membrane

ActiveCN104971631AIncrease water fluxImprove hydrophilicitySemi-permeable membranesEngineeringBovine serum albumin

The invention discloses a preparation method of a high-flux PVDF porous membrane. The method comprises the following steps: mixing PVDF, a highly hydrophilic polymer, a pore-forming additive, deionized water, a solvent and graphene powder, curing, stirring, standing, defoaming so as to obtain membrane casting liquid, and forming a wet membrane from the membrane casting liquid in a scraping manner; pre-evaporating the wet membrane in air, putting the pre-evaporated membrane in a solidification bath, and soaking to obtain a primary membrane in the deionized water; putting the primary membrane in the deionized water, performing heating activation, soaking in absolute ethyl alcohol and n-butyl alcohol, and airing in the air. According to the method, graphene nano-particles with two-dimensional structures are used as additives, the pure water flux can be up to 800L*m<-2>*h<-1> or more, and the rejection rate on bovine serum albumin is 98% or more; the hydrophilic polymer is added for performing the activation on the primary membrane, so that the hydrophilia of the PVDF membrane is greatly improved, and the membrane surface contact angle is up to 59.8 degrees; a porous membrane material is adopted, so that the structure is controllable, and the pore diameter range is controlled to be within 0.1-5 microns.

Owner:CENT SOUTH UNIV

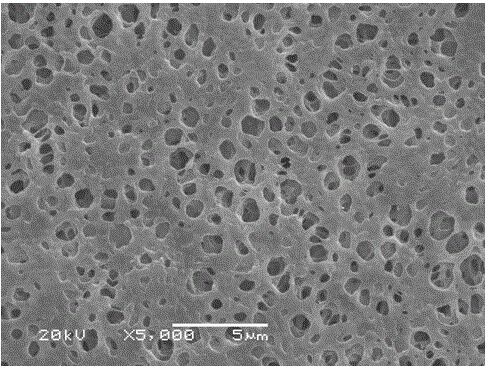

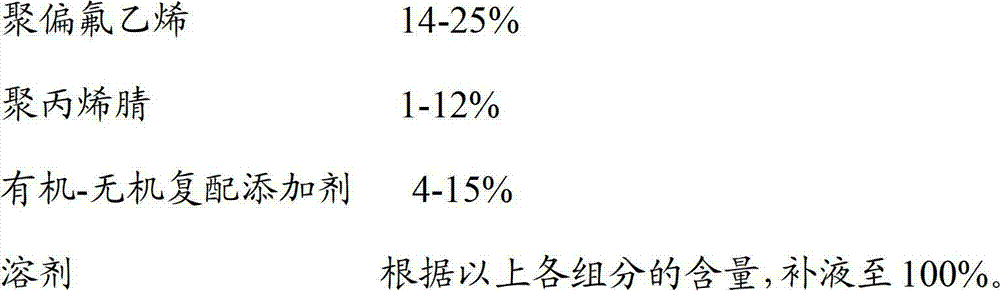

Polyvinylidene fluoride/polyacrylonitrile organic-inorganic hybrid hollow fiber membrane and preparation method thereof

ActiveCN102872729AImprove hydrophilicityIncrease membrane fluxSemi-permeable membranesHollow filament manufactureInorganic compoundPolyvinylidene difluoride

The invention relates to a polyvinylidene fluoride / polyacrylonitrile organic-inorganic hybrid hollow fiber membrane and a preparation method thereof. Membrane-casting liquid of the fiber membrane comprises the following components in percentage by weight: 14 to 25 percent of polyvinylidene fluoride, 1 to 12 percent of polyacrylonitrile, 4 to 15 percent of organic-inorganic compound additive and 50 to 80 percent of solvent. After the membrane-casting liquid is prepared, the finished polyvinylidene fluoride / polyacrylonitrile organic-inorganic hybrid hollow fiber membrane is prepared by a dry-wet spinning process. Compared with the prior art, the preparation method has the advantages that a hydrophilic blend and the novel organic-inorganic compound additive are added, so that the strength and the hydrophilcity of membrane fiber is further improved; and compared with a relatively pure polyvinylidene fluoride membrane, the prepared polyvinylidene fluoride / polyacrylonitrile organic-inorganic hybrid hollow fiber membrane has the advantages that the performance of is greatly improved, and the application field of the membrane is greatly widened.

Owner:SUNTAR MEMBRANE ENVIRONMENT TECH

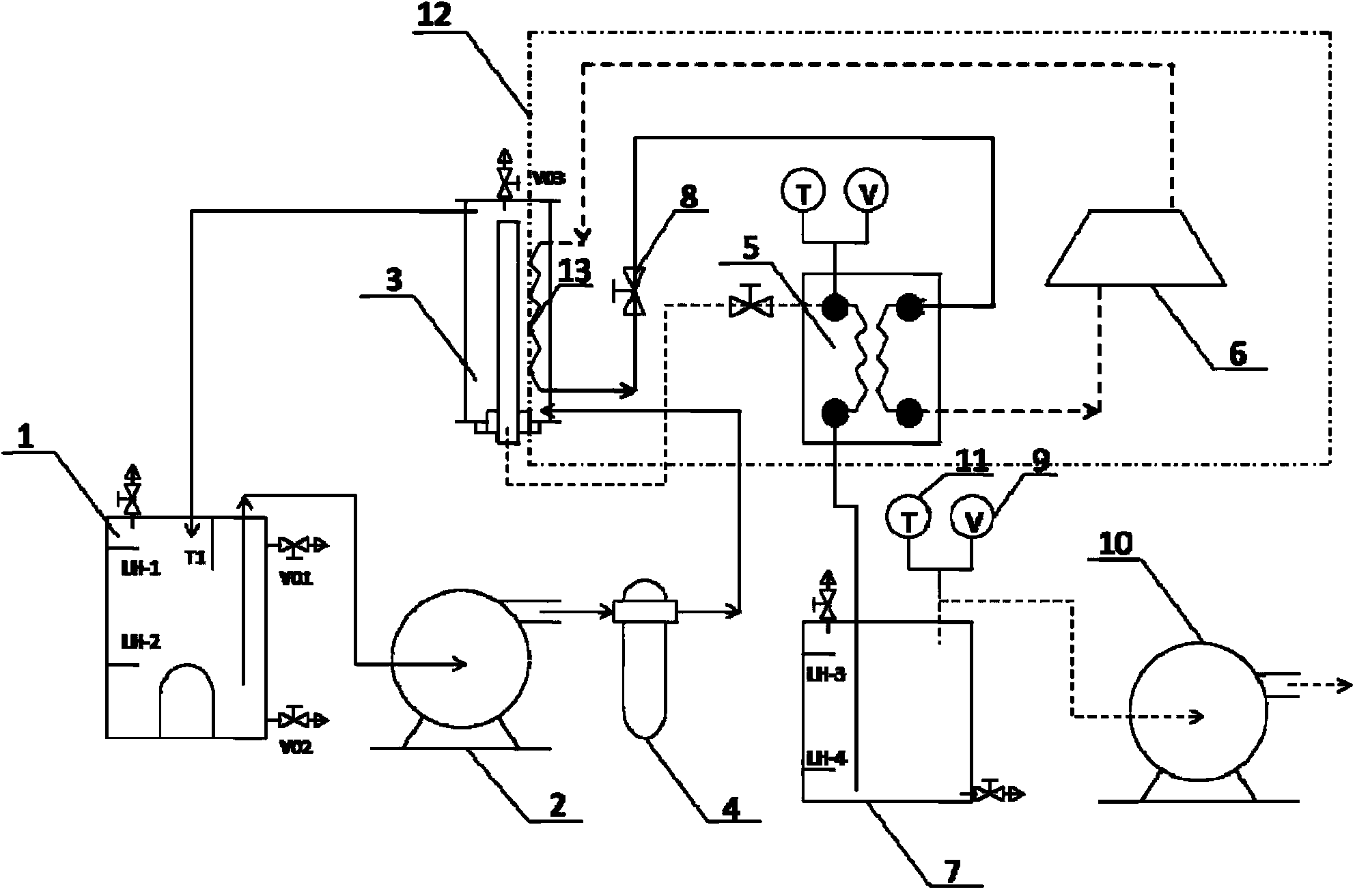

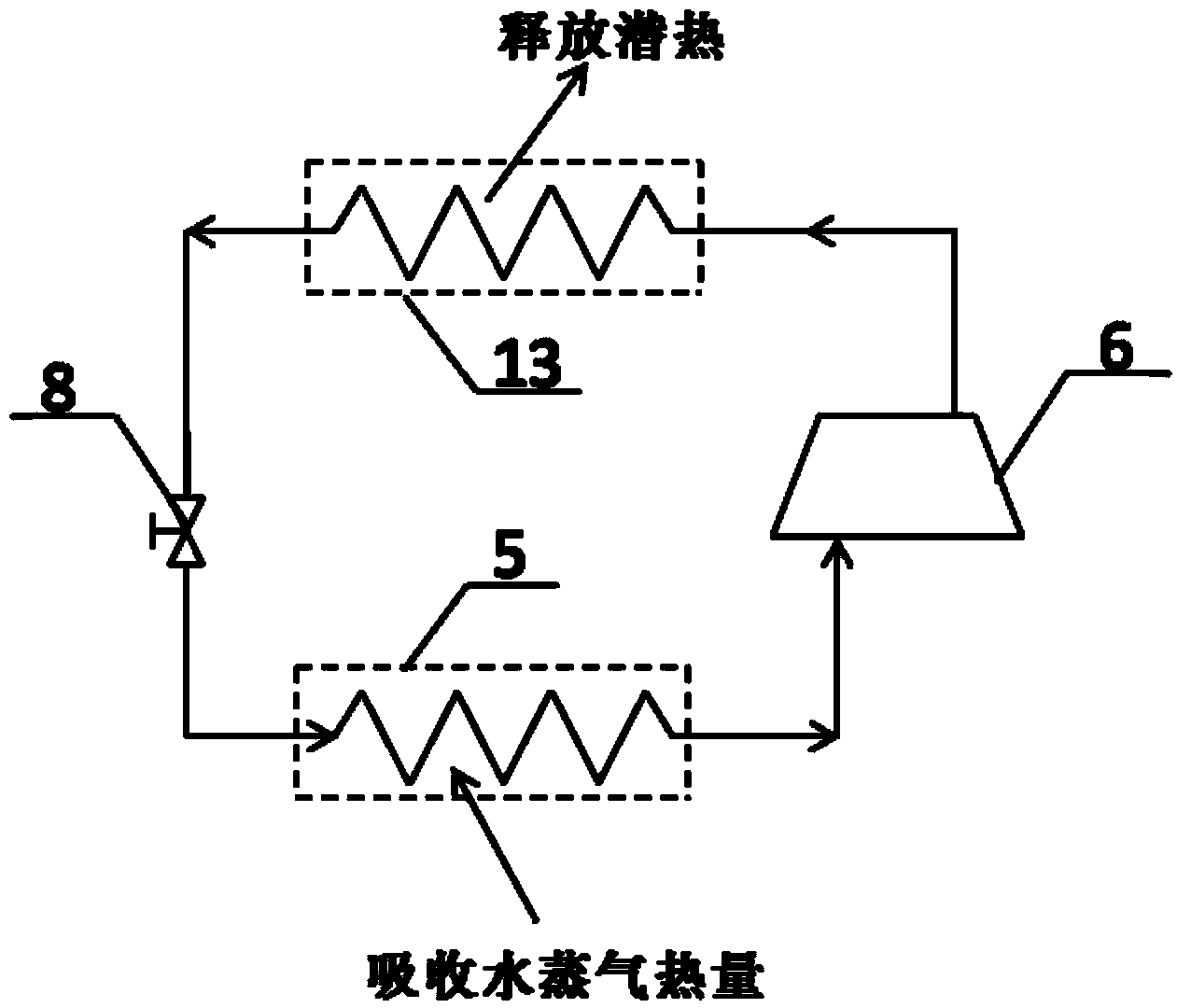

Vacuum membrane distillation type sewage treatment device capable of recycling heat

InactiveCN103663590AImprove cleanlinessIncrease membrane fluxWater/sewage treatment bu osmosis/dialysisWater/sewage treatment by heatingLiquid wasteWater vapor

The invention discloses a vacuum membrane distillation type sewage treatment device capable of recycling heat. The vacuum membrane distillation type sewage treatment device comprises a heating tank which is provided with a heater and used for heating sewage, wherein a sewage outlet of the heating tank is communicated with a sewage inlet of a membrane evaporator through a liquid circulating pump, and a sewage outlet of the membrane evaporator is communicated with a sewage backflow inlet of the heating tank; a refrigerant inlet and a refrigerant outlet of a heat pump condenser in the membrane evaporator are communicated with a refrigerant inlet and a refrigerant outlet of a heat pump evaporator through pipelines; and a steam inlet of the heat pump evaporator is communicated with a steam outlet of the membrane evaporator, a liquid water outlet of the heat pump evaporator is connected with a steam-water separator, and a gas outlet of the steam-water separator is connected with a circulating water vacuum pump, so that a vacuum system is formed. The vacuum membrane distillation type sewage treatment device is suitable for treating waste liquids containing heavy metal ions or purified seawater, has three functions of recycling water, concentrating waste liquid and saving energy and is characterized in that a refrigerant is used for recycling heat emitted by phase change of water steam, and the heat is used for heating sewage in the evaporator, so that the heat recycling effect is realized.

Owner:XI AN JIAOTONG UNIV

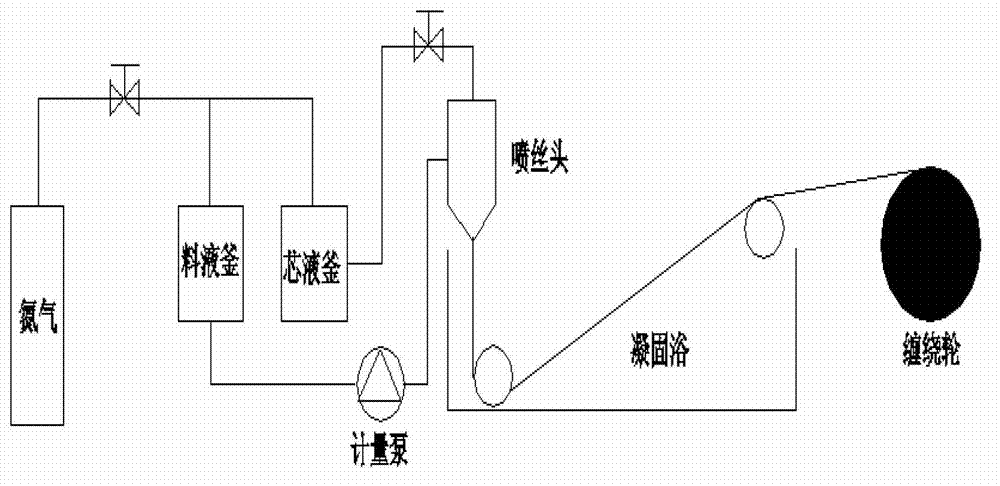

Improved preparation method of polypropylene hollow fiber separation membrane

ActiveCN103007784AThe method is simpleSolve dense problemsSemi-permeable membranesPolypropyleneWinding machine

The invention relates to an improved preparation method of a polypropylene hollow fiber separation membrane. The invention belongs to the field of high-molecular material science. The method comprises the steps that: (1) polypropylene and a diluent are added into a kettle with a stirring device; heating and stirring are carried out, such that a membrane casting liquid is obtained; and when stirring is stopped, the liquid is subjected to standing and defoaming for 0.5-2h; (2) the membrane casting liquid is filtered by using a filter; an inner core liquid is introduced into a spinning nozzle, wherein a nozzle temperature is 145-165 DEG C; the inner core liquid and the membrane casting liquid are extruded by the spinning nozzle; the mixture first passes through air atmosphere, and then enters a multi-stage coagulating bath; the membrane casting liquid is cooled by the multi-stage coagulating bath, and the hollow fiber membrane is obtained by curing; (3) the hollow fiber membrane is wound by using a winding machine, and is extracted in one or a plurality of extraction agents; and (4) the extracted membrane is fetched and dried; and extraction agent is removed, such that the polypropylene hollow fiber separation membrane is obtained. With the method provided by the invention, under a same condition, a membrane flux is improved from 15 / m<2>.h of one-stage water coagulating bath to higher than 1200 / m<2>.h of two-stage coagulating bath.

Owner:CHINA PETROLEUM & CHEM CORP +1

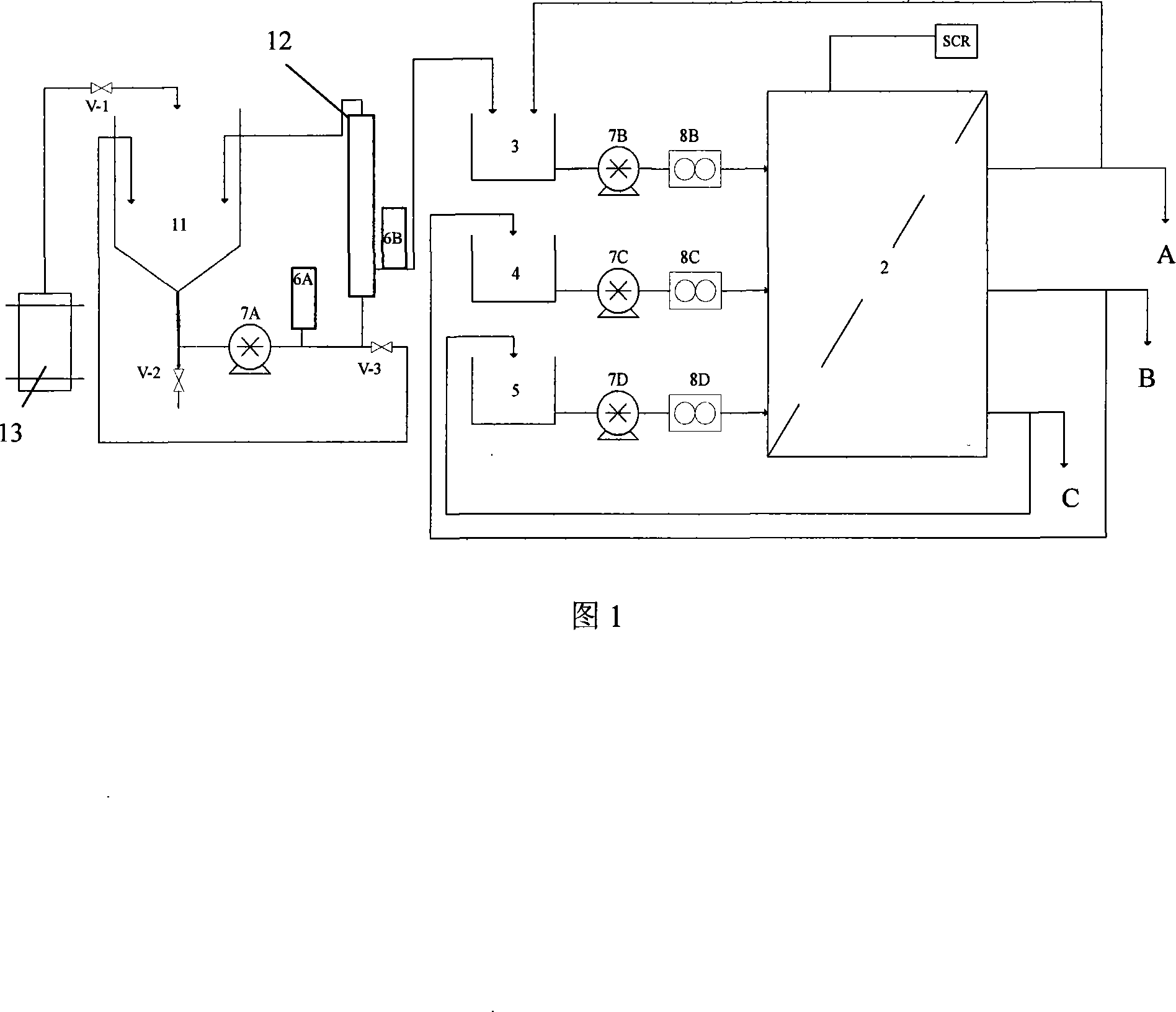

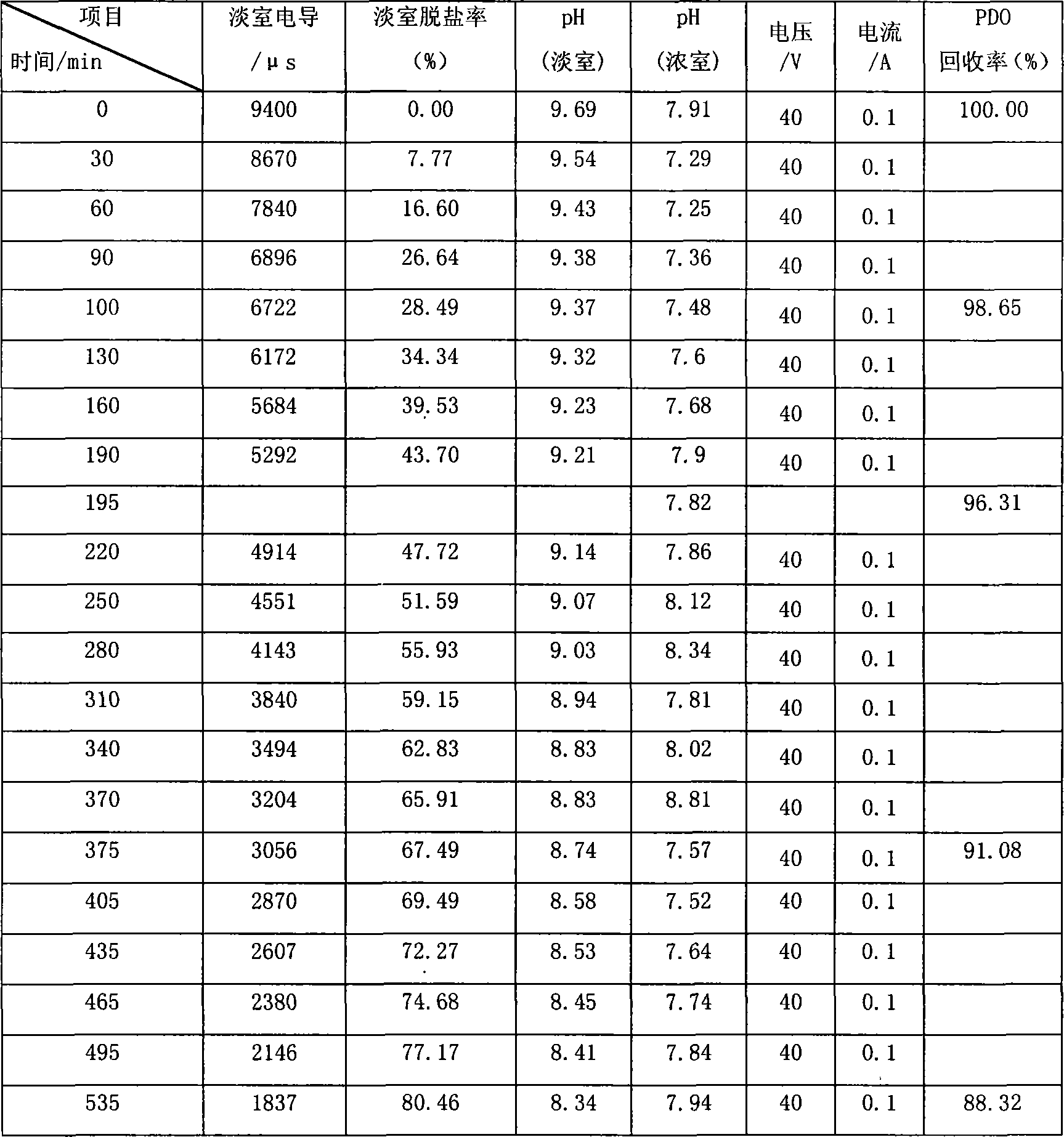

Methods for edulcoration and desalinization of 1,3-methyl glycol fermentation liquor

ActiveCN101117306ASolve the problem of membrane foulingSolve technical problems such as flow channel blockageHydroxy compound separation/purificationLoss rateDistillation

An impurity removing and desalting method for 1, 3-propanediol zymotic fluid relates to a 1, 3-propanediol zymotic fluid, which provides the An impurity removing and desalting method for 1, 3-propanediol zymotic fluid. Micro filtering impurity removing is that the 1, 3-propanediol zymotic fluid with germ is preprocessed by a filtering bag and enters a ceramics film device micro for micro filtering impurity removing. The germ body and protein macromolecular matter are removed from zymotic fluid to get the zymotic filter fluid of the 1, 3-propanediol. The salt removing by electrodialysis is that zymotic filter fluid containing the 1, 3-propanediol is put into an electrodialysis device to remove salt and completes when filtrate conductance is reduced to 2000 us. Therefore, the electrodialysis operation is stopped. The filter fluid enters the following technics for condensation and purification. The invention has a bigger film flux, a good treating effect and light ion exchanging film pollution. The salt removing by electrodialysis has low energy consumption and good treating effect. The conductance of material liquid can be completely reduced to 2000 us to satisfy techincs demand of following concentration and distillation. The loss rate of the 1, 3-propanediol is low with little environment pollution.

Owner:SUNTAR MEMBRANE ENVIRONMENT TECH +1

Preparation method of high-flux tubular microfiltration membrane

InactiveCN102806020AUniform pore size distributionIncrease membrane fluxSemi-permeable membranesFoaming agentMicrofiltration membrane

The invention relates to a preparation method of a high-flux tubular microfiltration membrane. The preparation method comprises preparing a membrane casting liquid and forming a membrane through phase inversion, and comprises the following specific steps of: mixing polyvinylidene fluoride, a pore-foaming agent, an additive and a solvent, heating to 30-80 DEG C, and stirring at the constant stirring speed of 100-1,000 revolutions per minute at a constant temperature for 10-48 hours to obtain a membrane casting liquid; standing the membrane casting liquid under the vacuum condition for defoaming for 10-48 hours, and winding a non-woven fabric into a non-woven fabric support pipe by using an integral tubular coating machine while completing membrane coating to obtain a tubular microfiltration basement membrane; and soaking the tubular microfiltration basement membrane into a coagulating bath, and performing phase inversion to obtain a finished tubular microfiltration membrane. The tubular microfiltration membrane has the characteristics of simple preparation process, high membrane flux, uniform pore diameter distribution, high mechanical strength, high chemical tolerance and the like.

Owner:JIANGSU KAIMI MEMBRANE TECH

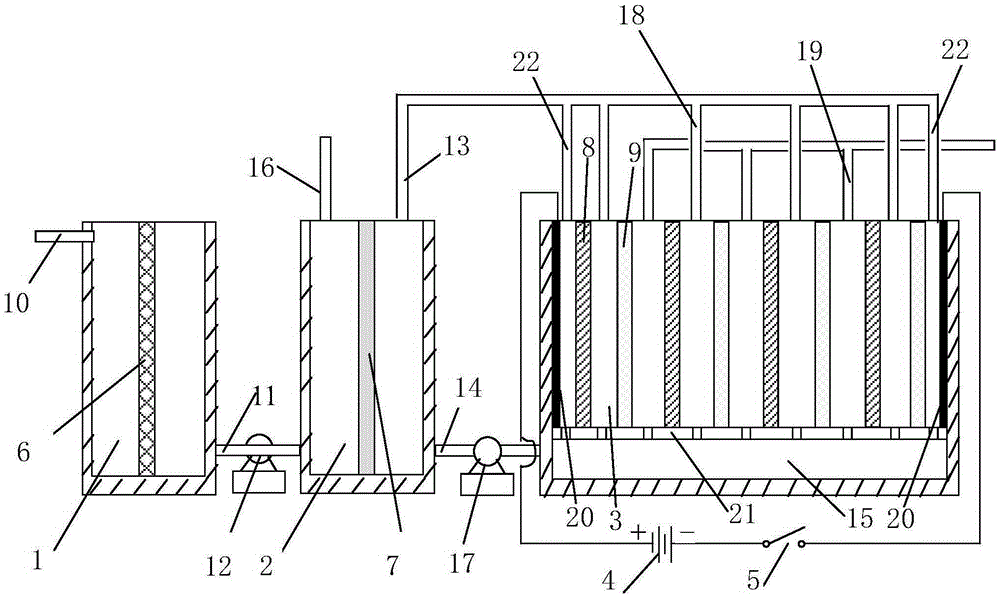

Method and system for extracting fresh water from sewage with synergy of forward osmosis and electrodialysis

InactiveCN105417801AAchieve recyclingIncrease membrane fluxGeneral water supply conservationWater/sewage treatmentHigh concentrationFiltration membrane

The invention provides a method and system for extracting fresh water from sewage with synergy of forward osmosis and electrodialysis. The method comprises the three stages: secondary effluent pretreatment, forward osmotic membrane separation and drawing liquid regeneration; in the secondary effluent pretreatment stage, suspended solids are removed from secondary effluent of an urban sewage treatment plant by utilizing a mechanical filtering function of micro-filtration membrane holes; in the forward osmotic membrane separation stage, the secondary effluent is concentrated, NaCl aqueous solution is diluted; in the drawing liquid regeneration stage, fresh water is collected and the concentrated NaCl aqueous solution is recycled. The system comprises a secondary effluent pretreatment tank, a forward osmotic separation tank and a drawing liquid regenerator. According to the method and system for extracting the fresh water from the sewage with the synergy of the forward osmosis and the electrodialysis, the forward osmosis technique and the electrodialysis technique are combined; on one hand, the fresh water resource can be recycled from the diluted drawing liquid, and one the other hand, the regeneration and utilization of the drawing liquid can be achieved; therefore, the stable and high concentration of the drawing liquid on one side of the drawing liquid in the forward osmotic separation process is ensured, high membrane flux is ensured, and the scaling possibility in the electrodialysis process is reduced.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

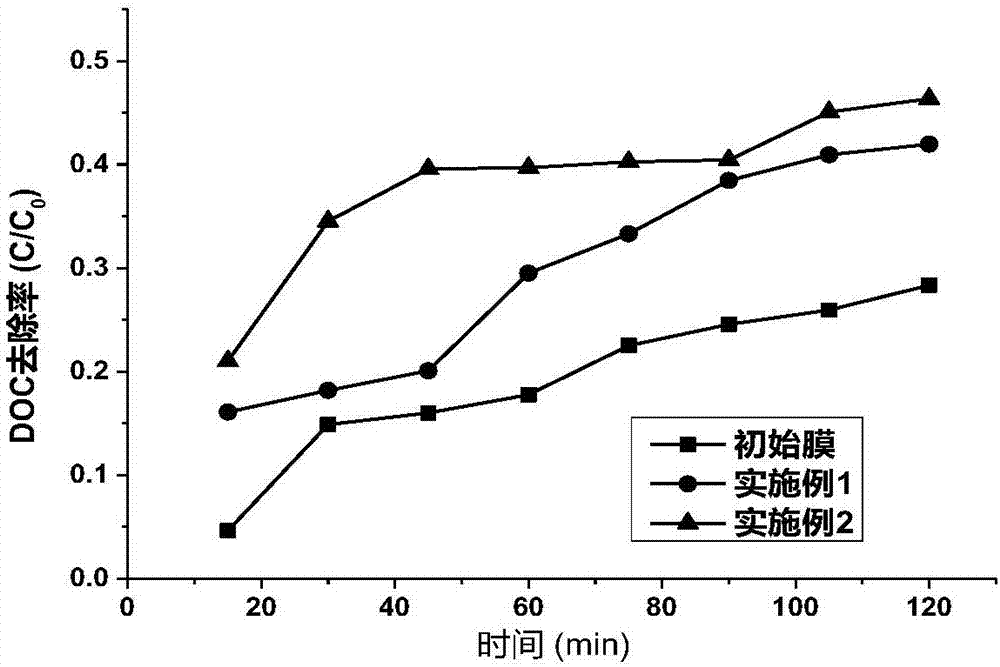

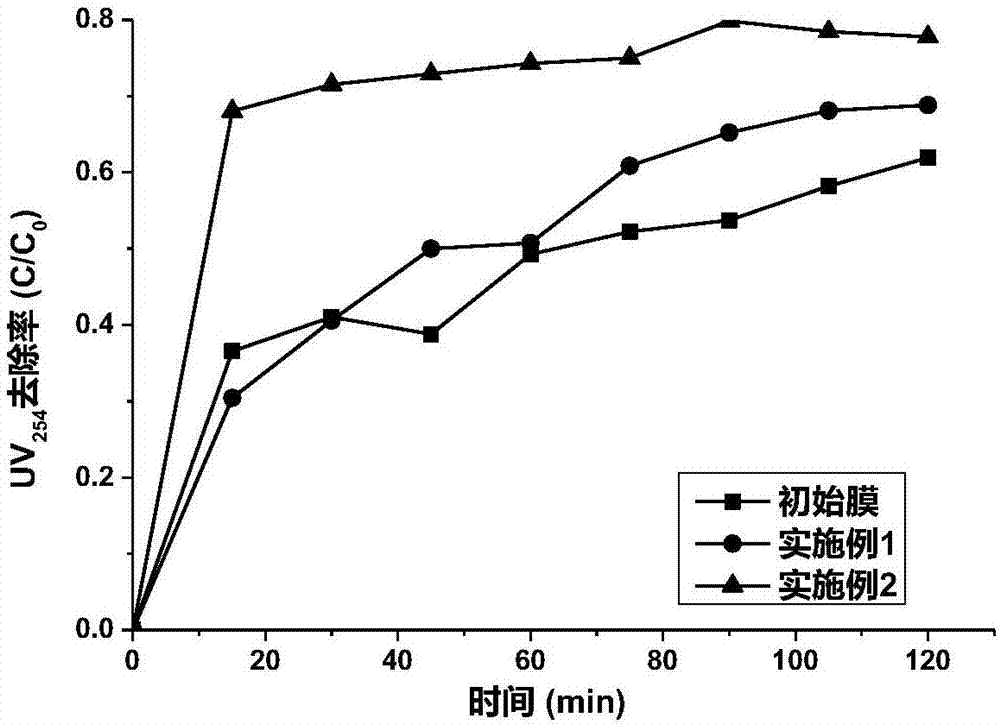

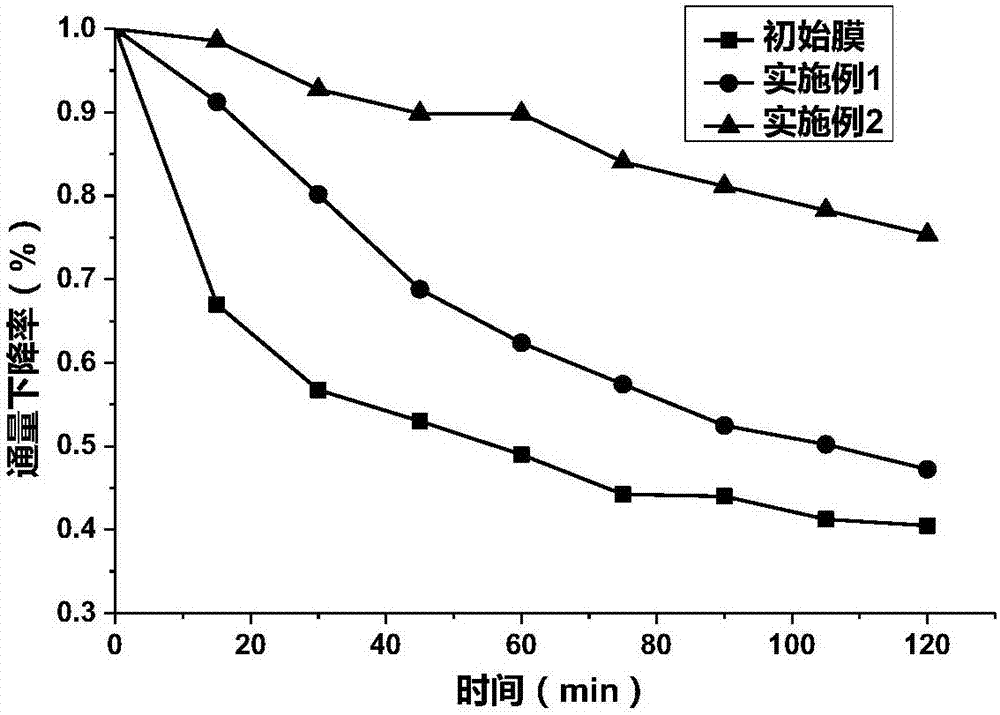

Graphene oxide modified high-temperature ultrafiltration composite membrane and preparation method thereof

ActiveCN106943894AGuaranteed stabilityIncrease membrane fluxMembranesWater contaminantsSolubilityUltrafiltration

The invention discloses a graphene oxide modified high-temperature ultrafiltration composite membrane and a preparation method thereof. The high-temperature ultrafiltration composite membrane is prepared through a chemical immersion method and a layer-by-layer assembling method by utilizing a graphene oxide modified commercial polyvinylidene fluoride ultrafiltration membrane. The preparation method comprises the following modification steps: activating the polyvinylidene fluoride ultrafiltration membrane; immersing in a trimesoyl chloride solution and grafting an acyl chloride group; immersing in a graphene oxide solution; and circularly and alternately immersing in an ethylenediamine solution and the graphene oxide solution to enable graphene oxide to be connected through an ethylenediamine cross-linking agent, and forming a lamellar structure on the surface of the membrane so as to obtain the graphene oxide composite membrane with different layer quantities. The graphene oxide modified high-temperature ultrafiltration composite membrane prepared by the preparation method has the advantages of high flux, high anti-pollution property and high pollutant removing rate; and the water flux can reach 3750kg / m<2>h to 10150kg / m<2>h and the removing rate of soluble organic matters is 36.5%-68% and is improved by 15% when being compared with that of an ultrafiltration membrane before modification.

Owner:BEIJING NORMAL UNIVERSITY +1

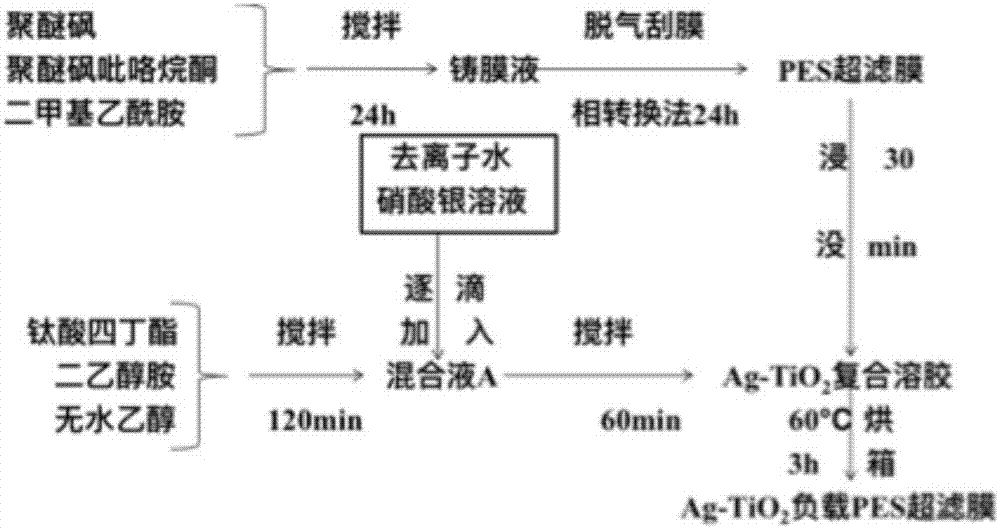

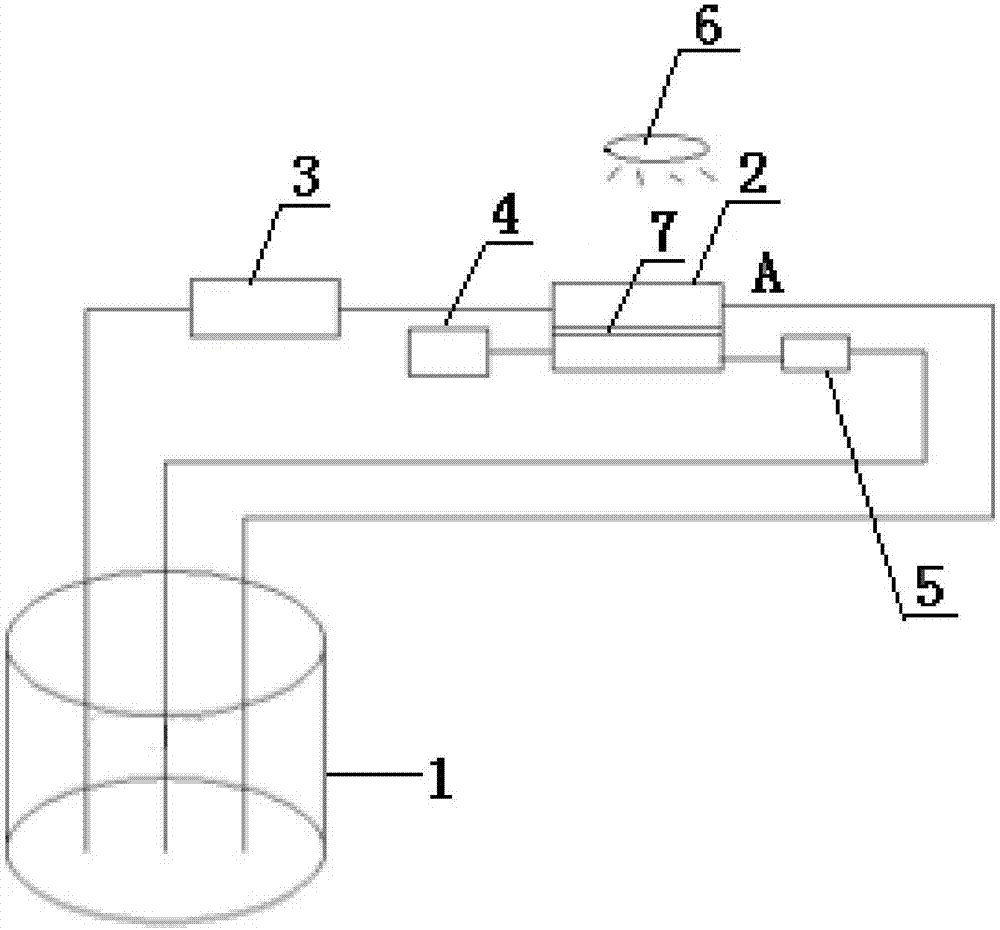

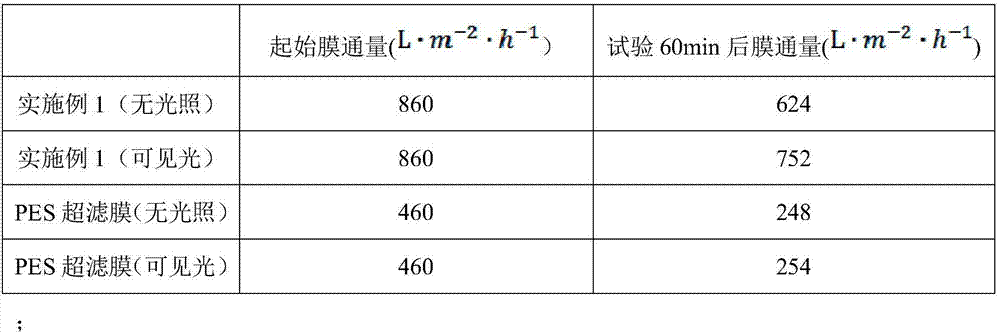

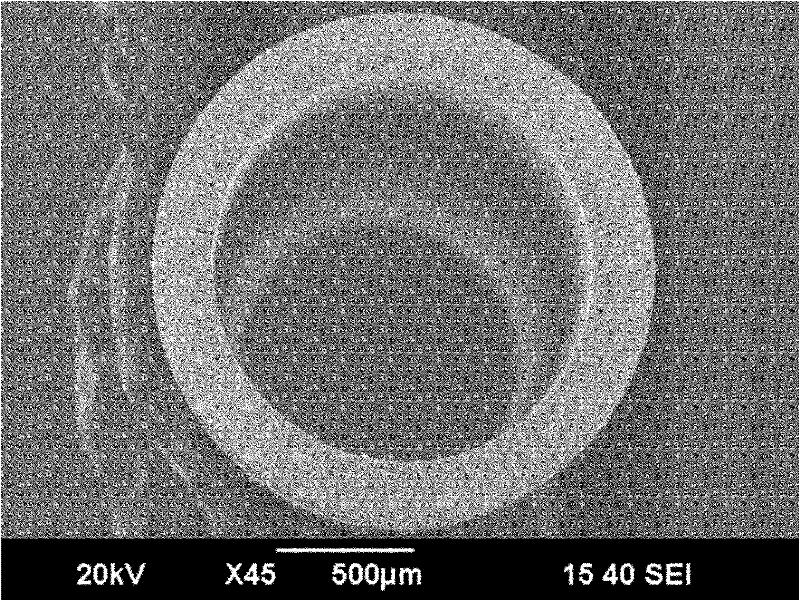

PES ultra-filtration film loaded with Ag-TiO2 and preparation method and application of PES ultra-filtration film

InactiveCN107376658AReduce pollutionGood separation and filtration effectMembranesWater/sewage treatment by irradiationFiltrationIrradiation

The invention discloses a PES ultra-filtration film loaded with Ag-TiO2, and discloses a preparation method and application of the PES ultra-filtration film loaded with Ag-TiO2. A PES ultra-filtration film is soaked in an Ag-TiO2 composite sol to obtain a PES ultra-filtration film loaded with Ag-TiO2 on the surface. Because an Ag-TiO2 photocatalysis material is arranged on the surface of the PES ultra-filtration film loaded with Ag-TiO2, the water contact angle of the ultra-filtration film becomes small; pollution of the film is reduced favorably, and then the flux of the film is increased; and moreover, under irradiation of visible light, the Ag-TiO2 photocatalysis material on the surface of the film can degrade pollutants on the surface of the PES ultra-filtration film, therefore, pollution on the film is further reduced, and the flux of the film is increased.

Owner:HOHAI UNIV

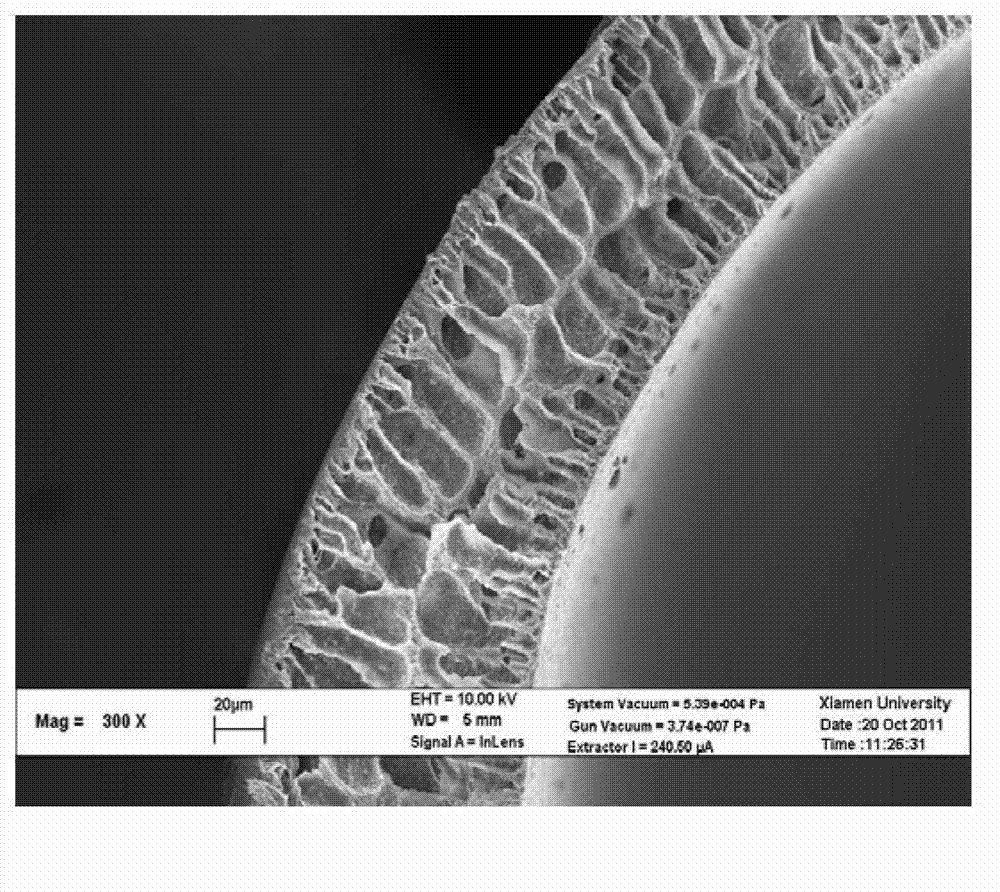

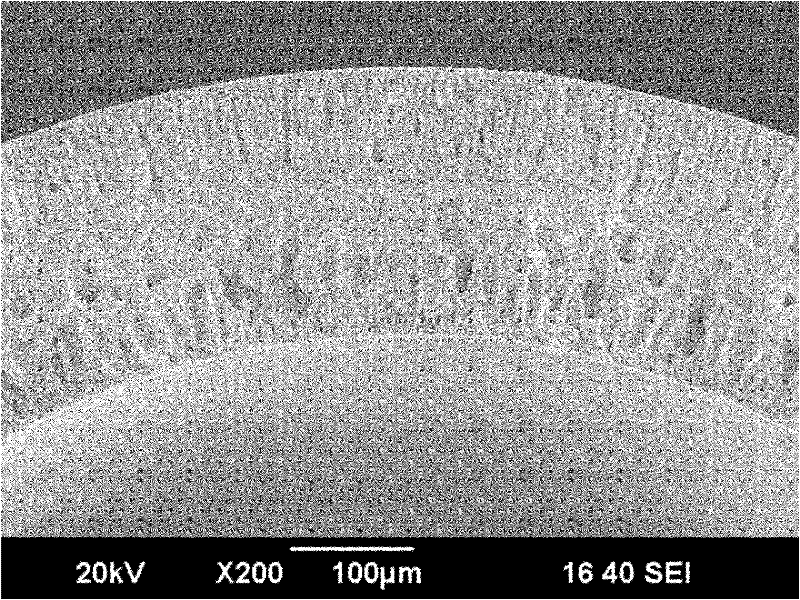

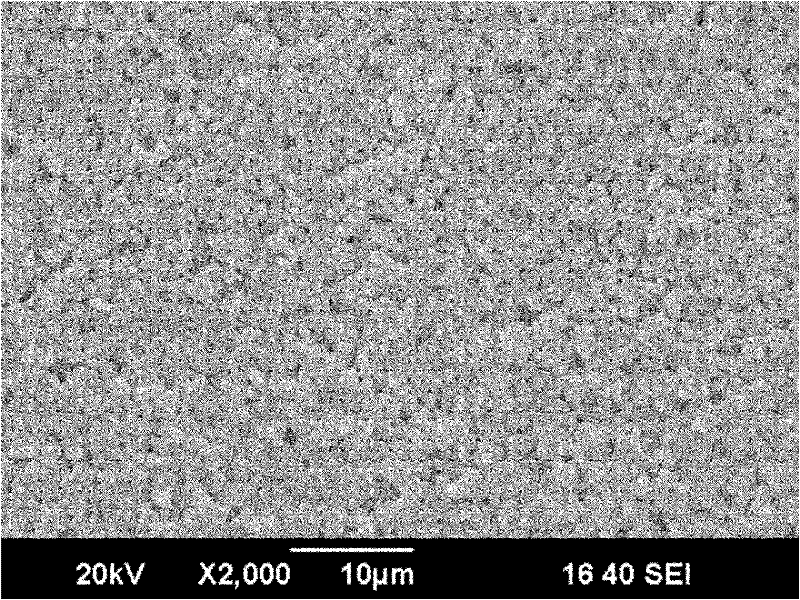

Hydrophobic ceramic hollow fiber membrane applied to membrane distillation and preparation method thereof

InactiveCN102172478AControl sintering temperatureImprove high temperature resistanceSemi-permeable membranesPhase conversionMass transfer resistance

The invention provides a preparation method of a hydrophobic ceramic hollow fiber membrane applied to membrane distillation. The preparation method comprises the following steps of: a) mixing ceramic powder, polyether sulfone, N-methyl-1-ketopyrrolidine and a dispersant and grinding to obtain slurry; b) extruding the slurry out by using a spinning jet and performing phase conversion molding to obtain a hollow fiber blank; c) sintering the hollow fiber blank to obtain a ceramic hollow fiber membrane; and d) modifying the ceramic hollow fiber membrane by taking silane as a modifier to obtain the hydrophobic ceramic hollow fiber membrane. The hydrophobic ceramic hollow fiber membrane has a hollow fiber structure, a thinner membrane wall and small mass transfer resistance, so that a higher membrane flux is achieved, the filling density of a membrane component is high and the separating effect is good during membrane distillation. Moreover, the ceramic hollow fiber membrane is taken as a substrate of the hydrophobic hollow fiber membrane, so that the hydrophobic hollow fiber membrane has high high-temperature resistance, high structural stability and high restoration and regeneration performance, is easy to clean and has a long service life.

Owner:UNIV OF SCI & TECH OF CHINA

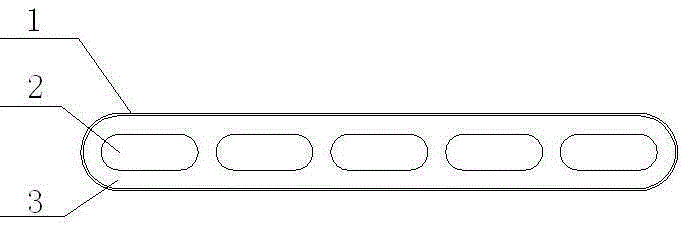

Diatomite-based low-cost ecological environment-friendly type flat ceramic membrane and preparation method thereof

ActiveCN105413484ALow priceLow costMembranesSemi-permeable membranesWater processingCeramic membrane

The invention discloses a diatomite-based low-cost ecological environment-friendly type flat ceramic membrane. The diatomite-based low-cost ecological environment-friendly type flat ceramic membrane comprises a ceramic flat support body and a separating layer membrane coated an outer surface of the ceramic flat support body, the water outlet holes are arranged in the ceramic flat support body; an integral body of the ceramic flat support body is a flat plate, and each corner angle of the flat plate is designed as round corner. The invention also provides a preparation method of the diatomite-based low-cost ecological environment-friendly type flat ceramic membrane, which comprises the steps of preparation of a ceramic flat membrane support body and preparation of a separating flat ceramic membrane. The raw materials have the advantages of low cost and no toxicity, the ceramic membrane is the ecological environment-friendly type filter membrane, is easily decomposed after being discard, and secondary pollution on environment cannot be generated. The ceramic membrane has wide utilization scope, can be used for water processing and gas processing, and especially used for processing and purifying harmful gas due to indoor decoration and processing outdoor environment gas PM2.5.

Owner:安徽名创新材料科技有限公司

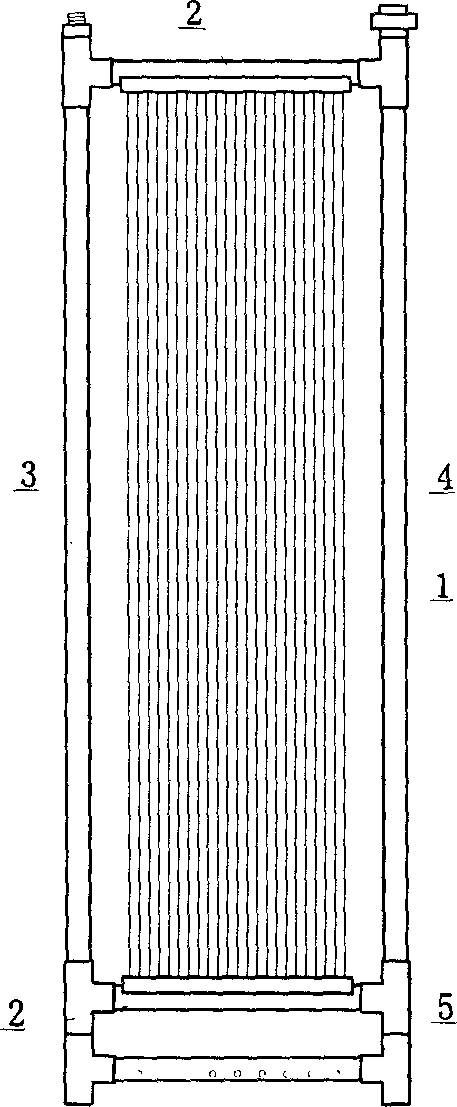

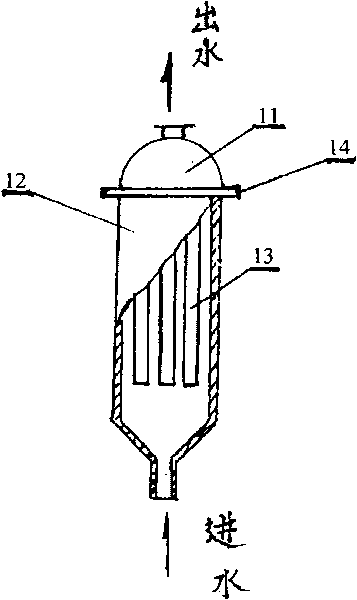

Hollow fiber membrane assembly

InactiveCN1785487AExcellent effective membrane silk densityIncrease working areaSemi-permeable membranesTreatment using aerobic processesHollow fibreHollow fiber membrane

A curtain-type hollow fiber membrane module is composed of membrane fibers, water collecting tube and aerating tubes. It features that the ultrafiltering or microfiltering hollow fiber membrane made of the membrane fibers with 1.5-3.5 m in length integrate the aeration flushing with sucking and collecting water for increasing the flux of membrane and decreasing the energy consumption for flushing.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

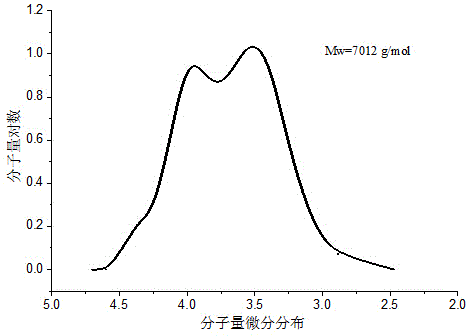

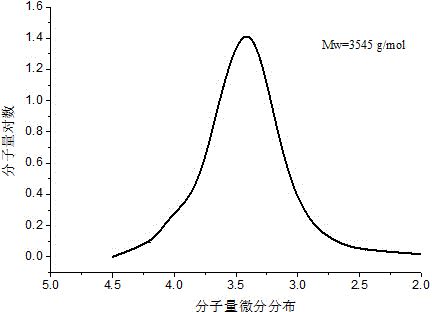

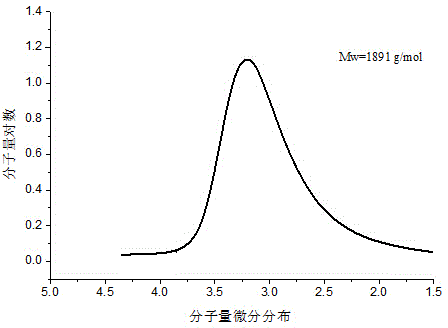

Method of extracting lignins different in molecular weight from bamboo pulping black liquor

The invention discloses a method of extracting lignins different in molecular weight from bamboo pulping black liquor. The method includes: filtering the bamboo pulping black liquor, adjusting pH to 1.5 to 2.0, and acquiring lignin by settling; drying the lignin, dissolving the lignin with 90% acetic acid to obtain lignin acetic acid solution of low viscosity, and subjecting the lignin acetic acid solution to ultrafiltration and grading with ultrafiltration membranes having different cut-off molecular weights; and subjecting ultrafiltrate and cut-off liquid to precipitating with distillate according to the ratio being 1:10 and purifying with dichloroethane / water, diethyl ether and petroleum ether solvents to obtain lignins different in molecular weight distribution range. The pH value of the bamboo pulping black liquor of high viscosity is adjusted with hydrochloric acid to precipitate the lignin therein, the lignin is dissolved with the 90% acetic acid, and the lignin acetic acid solution is of low viscosity and is directly graded with the ultrafiltration membranes to separate the lignins; the method has the advantages that stock liquor needs no dilution, membrane flux is great, attenuating speed is low, a membrane component is simple to maintain, and the industrial applicability is high.

Owner:NANJING FORESTRY UNIV

Multi-pipe internal pressure mechanical circulation forced cross current solid-liquid separation dynamic membrane system and device thereof

InactiveCN101757854AIncrease water pressureUniform thicknessSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisVena contracta diameterWork period

The invention relates to a multi-pipe internal pressure mechanical circulation forced cross current solid-liquid separation dynamic membrane system and a device thereof; wherein the dynamic membrane comprises a tubular shape internal pressure supporting body with plural number of large aperture nets, an upper orifice plate and a lower orifice plate, a shell, an upper cover and a lower cover; the upper orifice plate and the lower orifice plate are respectively provided with plural number of jack sockets, the tubular shape internal pressure supporting body is connected with the jack sockets; the shell is connected with the upper orifice plate and the lower orifice plate to form a water purification chamber; the upper cover and the upper orifice plate are connected to form a cross current backflow chamber, and the upper cover is provided with an water outlet for the cross current backflow water; the lower cover and the lower orifice plate are connected to form a water inlet chamber and the lower cover is provided with a raw water inlet thereupon. The dynamic membrane device of the invention has the advantages of no water power dead angle, short pre-coating time, convenient back wash, continuous work, improved dynamic membrane flux, stable water yield and long work period.

Owner:上海臻泓环境科技工程有限公司

Graphene oxide modified high-performance forward osmosis composite membrane and preparation method

InactiveCN107174950AIncrease membrane fluxLow reverse salt fluxMembranesSemi-permeable membranesPolyamidePolyethylene glycol

The invention discloses a graphene oxide modified high-performance forward osmosis composite membrane and a preparation method and belongs to the technical field of water treatment. The method comprises the steps as follows: firstly, polysulfone, graphene oxide, polyethylene glycol-600, Tween-80 and a solvent are added to a flask through blending, a membrane casting solution is prepared, and a graphene oxide / polysulfone support layer is prepared with a phase conversion method; a polyamide active layer is composited on the surface of the support layer in an interface polymerization manner, and a graphene oxide / polyamide forward osmosis composite membrane is obtained. The prepared graphene oxide modified high-performance forward osmosis composite has the advantages of high flux, low reverse salt flux and high pollution resistance and has the water flux up to 9-12 LMH and the reverse salt flux of 2-4 gMH, and in a pollution resistance test, the flux decrease amplitude caused by pollution is only 30%-50% of that of an unmodified membrane.

Owner:BEIJING NORMAL UNIVERSITY +1

Fabricating method of fiber powder modified polymer microporous film

InactiveCN101224392ASimple preparation processThe preparation process is matureSemi-permeable membranesFiberPolymer science

The invention relates to a macromolecule separation microporous membrane and a preparation method thereof, in particular to a preparation method of modified fiber powder / polymer mixed microporous membrane. The method provided by the invention includes the following steps: the surface of the fiber powder is cleaned and carved; the surface-carved fiber powders, polymer, various additives and solutions are combined to prepare membrane casting liquid, and then the membrane casting liquid is put onto a glass plate for membrane-shaving or spanning and then the liquid membrane is gelatinized into membrane in the coagulation bath process, and finally the membrane is dipped in membrane-dipping liquid and then is dried. The invention can prepare the polymer microporous membrane which has low cost, high strength and better capability through adding various fiber powders into the membrane preparation liquid and changing process conditions.

Owner:WUHAN TEXTILE UNIV

Vacuum membrane distillation water-treatment plant utilizing solar energy

InactiveCN101767841ALow costReduce energy consumptionGeneral water supply conservationEnergy based wastewater treatmentAutomatic controlDistillation

The invention provides a vacuum membrane distillation water-treatment plant utilizing solar energy or waste heat, which belongs to the field of water treatment. The vacuum membrane distillation water-treatment plant comprises a membrane module, a distillation box, a cooling cylinder, a vacuum pump, a control system and a circulating system. The invention uses a vacuum membrane distillation method which has the separation principle that hot raw water to be treated passes through one side of the separation membrane, and the other side is vacuumized so as to form transfer vapor pressure difference on the two sides of the membrane; and the vacuum side only generates water vapor, and the water vapor is condensed into drinking water, thereby separating and purifying the raw water. The invention utilizes cheap energy sources, such as solar energy, low-grade waste heat and afterheat, or the like, and can recycle latent heat of condensation, thereby reducing the energy consumption. The vacuum membrane distillation water-treatment plant has the advantages of simple structure, small occupied area, low cost, high desalination rate, large membrane flux and the like, and can be operated continuously and realize automatic control.

Owner:SHANDONG SHENHUA SHANDA ENERGY ENVIRONMENTAL

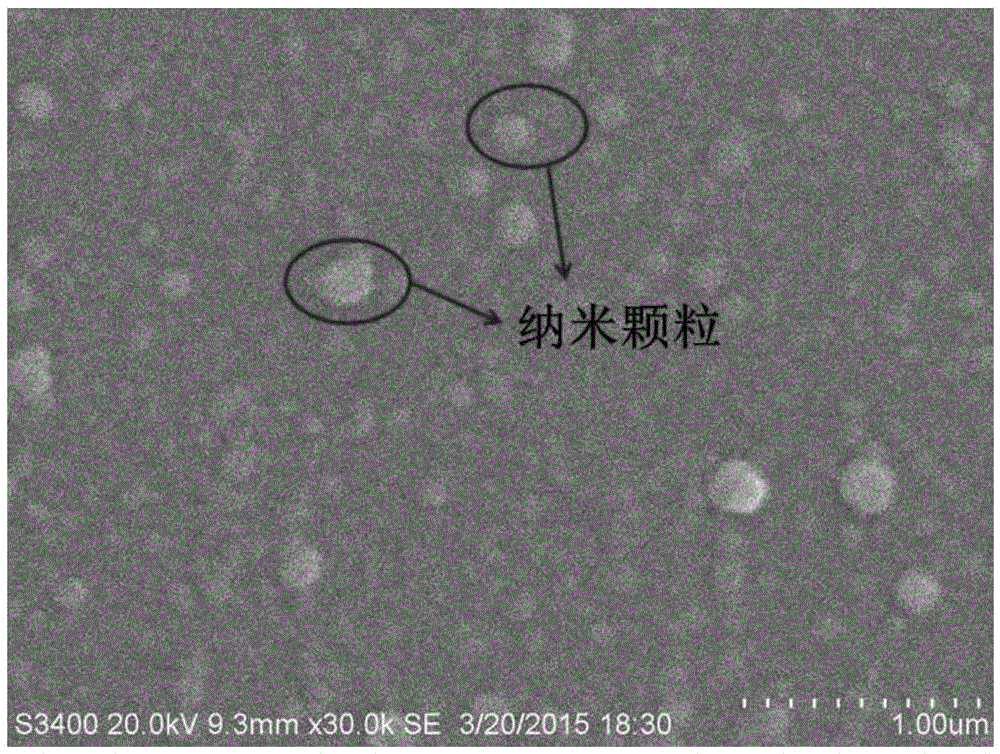

Preparation method of polymer-based nano composite ultrafiltration membrane

ActiveCN105536551AImprove adsorption capacityGood dispersionSemi-permeable membranesMembranesSynthesis methodsUltrafiltration

The invention discloses a preparation method of a polymer-based nano composite ultrafiltration membrane, and belongs to the field of membrane material preparation. The preparation method mainly comprises the steps: a hydrophobic polyvinylidene fluoride ultrafiltration membrane is prepared by a traditional phase transformation method, then the polyvinylidene fluoride ultrafiltration membrane is activated and modified by using potassium permanganate and sodium bisulfite, and the polyvinylidene fluoride ultrafiltration membrane is grafted with hydrophilic groups; and then a metal oxide precursor is introduced, the surface of the polyvinylidene fluoride ultrafiltration membrane is loaded with nano metal oxide by an in-situ deposition method, and thus the polymer-based nano composite ultrafiltration membrane is prepared. The synthesis method disclosed by the invention is simple in process, the problems that the utilization efficiency is low and nano materials are easy to agglomerate because the interior of a membrane piece is easily encapsulated with nanoparticles are solved, and the prepared polymer-based nano composite ultrafiltration membrane has the advantages of high utilization efficiency of nanomaterials, large membrane flux, strong anti-pollution ability, stable separation performance and the like.

Owner:NANJING UNIV

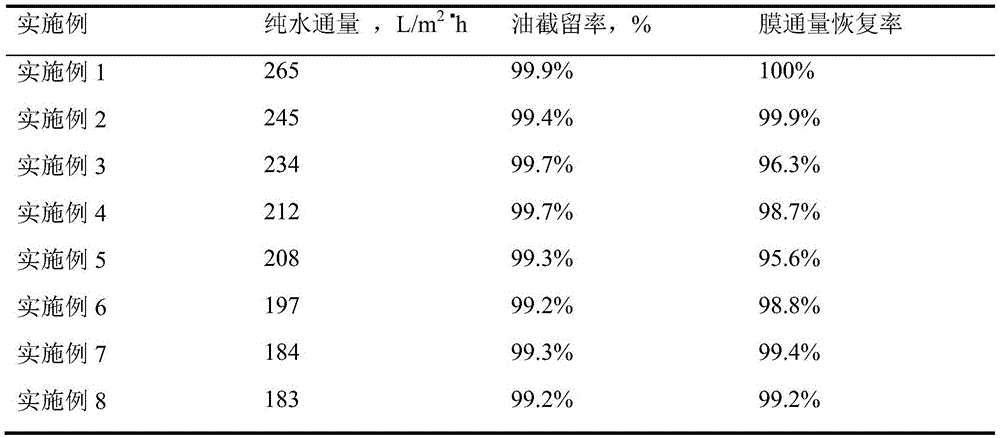

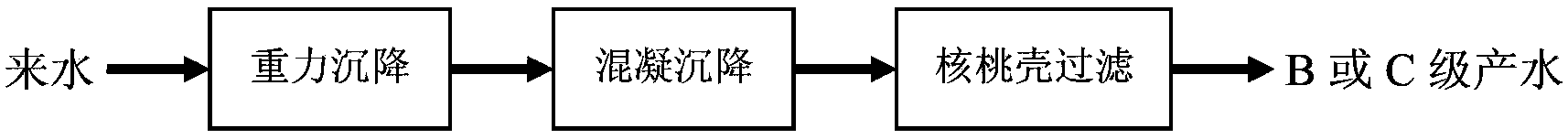

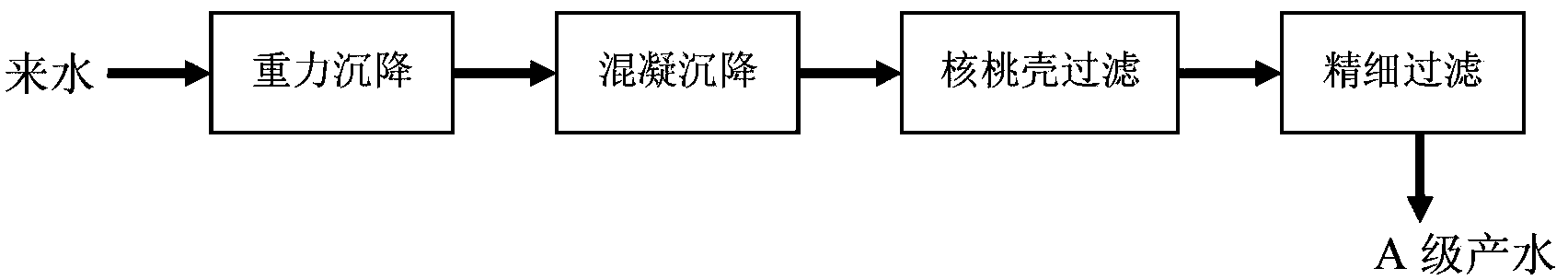

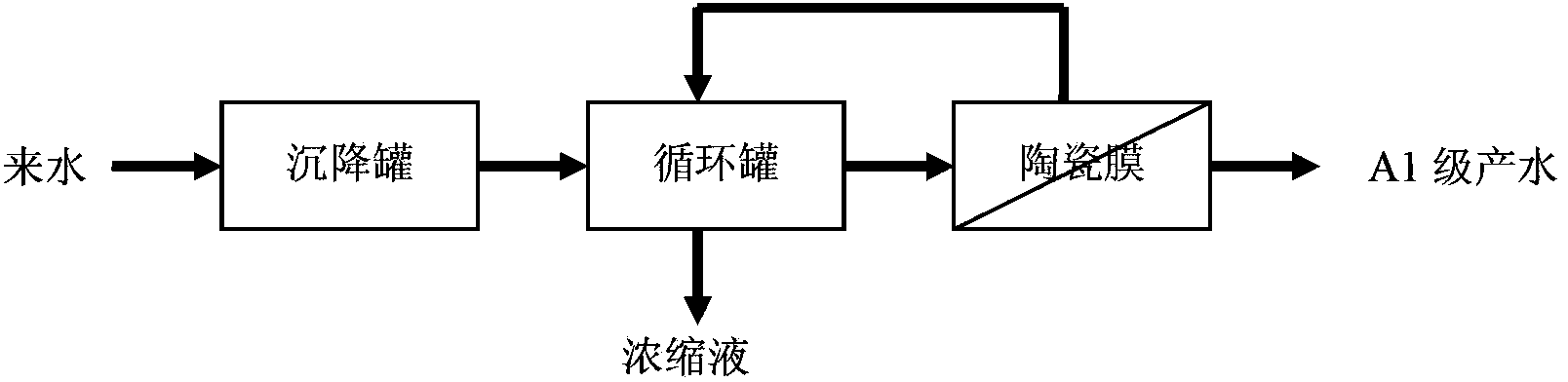

Purification method for oilfield reinjection water

ActiveCN103663624AHigh structural integrationNarrow filter pore size distributionWaste water treatment from quariesWater/sewage treatment bu osmosis/dialysisPurification methodsFiltration

The invention discloses a purification method for oilfield reinjection water. According to the method, at least one level of membrane filtration treatment is carried out on oilfield produced water through a cellular carrier type inorganic carbon membrane component so as to prepare the reinjection water suitable for low permeability and extra-low permeability oil reservoirs, wherein the filter precision of the membrane component for membrane filtration treatment is 0.001-100mu m. The purification method has high filtration accuracy, the membrane flux of the compound carbon membrane carrier is large, the capacity of the membrane in resisting oil contamination is strong, the integration level of the structure of the membrane core is high, the quality of the prepared reinjection water is stable, and fine filtrated oilfield reinjection water meets the requirement of the reinjection water for the oil reservoirs in low permeability and extra-low permeability block, and meets the A-grade standard of 'recommended index and analysis method for quality of oil reservoir injection water of clastic rock' (SY / T 5329-94).

Owner:ZHEJIANG CATHAYRIPE ENVIRONMENTAL ENG

Energy-saving high-salt wastewater treatment system and treatment method

ActiveCN104326615AEfficient ConcentrationEasy to implementMultistage water/sewage treatmentWater/sewage treatment by heatingWastewaterWater resources

The invention discloses an energy-saving high-salt wastewater treatment system and treatment method. The system comprises a forward-osmosis salt concentrating device and a multi-effect evaporator, wherein the forward-osmosis salt concentrating device comprises an FO membrane closed exchange box, an absorbing liquid recycling device and a fresh water recycling device; at least one stage of FO membrane closed exchange box is arranged; the absorbing liquid recycling device is respectively connected with each stage of FO membrane closed exchange box through electric valves; the fresh water recycling device is connected with the absorbing liquid recycling device; all stages of FO membrane closed exchange boxes are sequentially connected through liquid discharging electric valves and all connected with a multi-effect mother liquor evaporator through overrunning electric valves. According to hyperosmosis character of the high-salt wastewater and due to preparation of the absorbing liquid with higher colligative properties and utilization of osmotic pressure difference caused by difference of the colligative properties, the method can be used for efficiently concentrating the high-salt wastewater as well as recycling water resource to generate electric energy; automatic interlock control is realized during a running process, and the running mode can be regulated according to different water charging conditions.

Owner:马涛 +1

Hydrophilic/hydrophobic composite membrane for membrane distillation

InactiveCN103372378AHigh mechanical strengthImprove anti-pollution performanceDistillationPolyesterMembrane distillation

The invention belongs to the technical field of membrane method water treatment and relates to a composite membrane for membrane distillation, which is formed by compounding a hydrophilic layer, a hydrophobic layer and a non-woven fabric supporting layer. The composite membrane is characterized in that a hydrophilic layer membrane casting solution system is DMAC (Dimethylacetamide) / TiO2 / LiCl / PVP / H2O / PVDF (Polyvinylidene Fluoride), a hydrophobic layer membrane casting solution system is DMAC / LiCl / H2O / PVDF, and the non-woven fabric supporting layer is made of a polyester material. The preparation method comprises the following steps of: firstly, uniformly striking a hydrophobic layer membrane casting solution on a clean non-woven fabric, standing, carrying out coagulating bath and airing; and then, uniformly striking a hydrophilic layer membrane casting solution on the just made hydrophobic layer, standing, carrying out coagulating bath and airing to obtain the hydrophilic / hydrophobic composite membrane. The hydrophilic / hydrophobic composite membrane for membrane distillation, provided by the invention, has the characteristics of strong antipollution capability, large membrane flux and high mechanical strength, and can be widely applied to different forms of membrane distilled bitter-brackish water desalination, seawater desalination and high salinity wastewater treatment and recycling processes.

Owner:HEBEI UNIV OF ENG

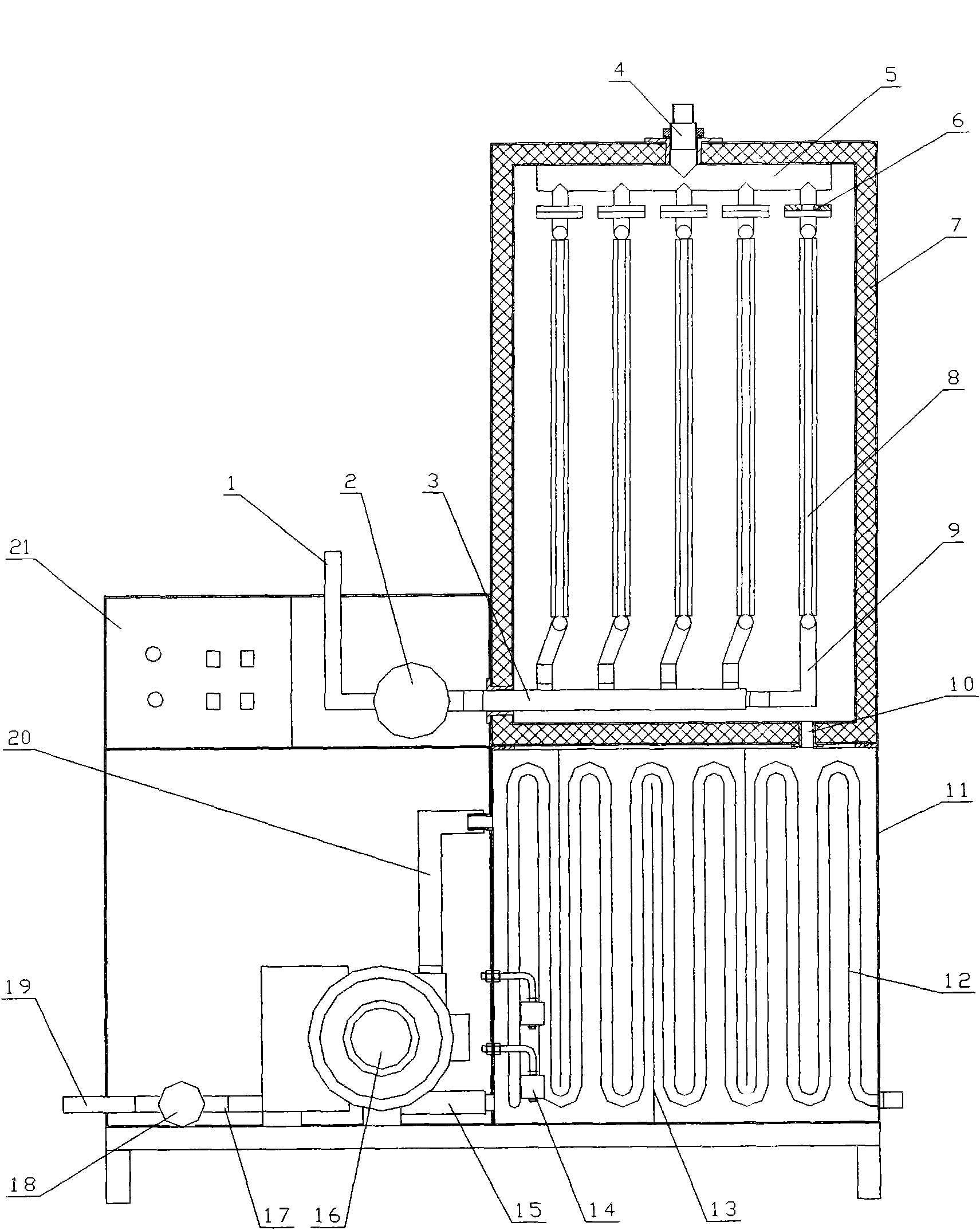

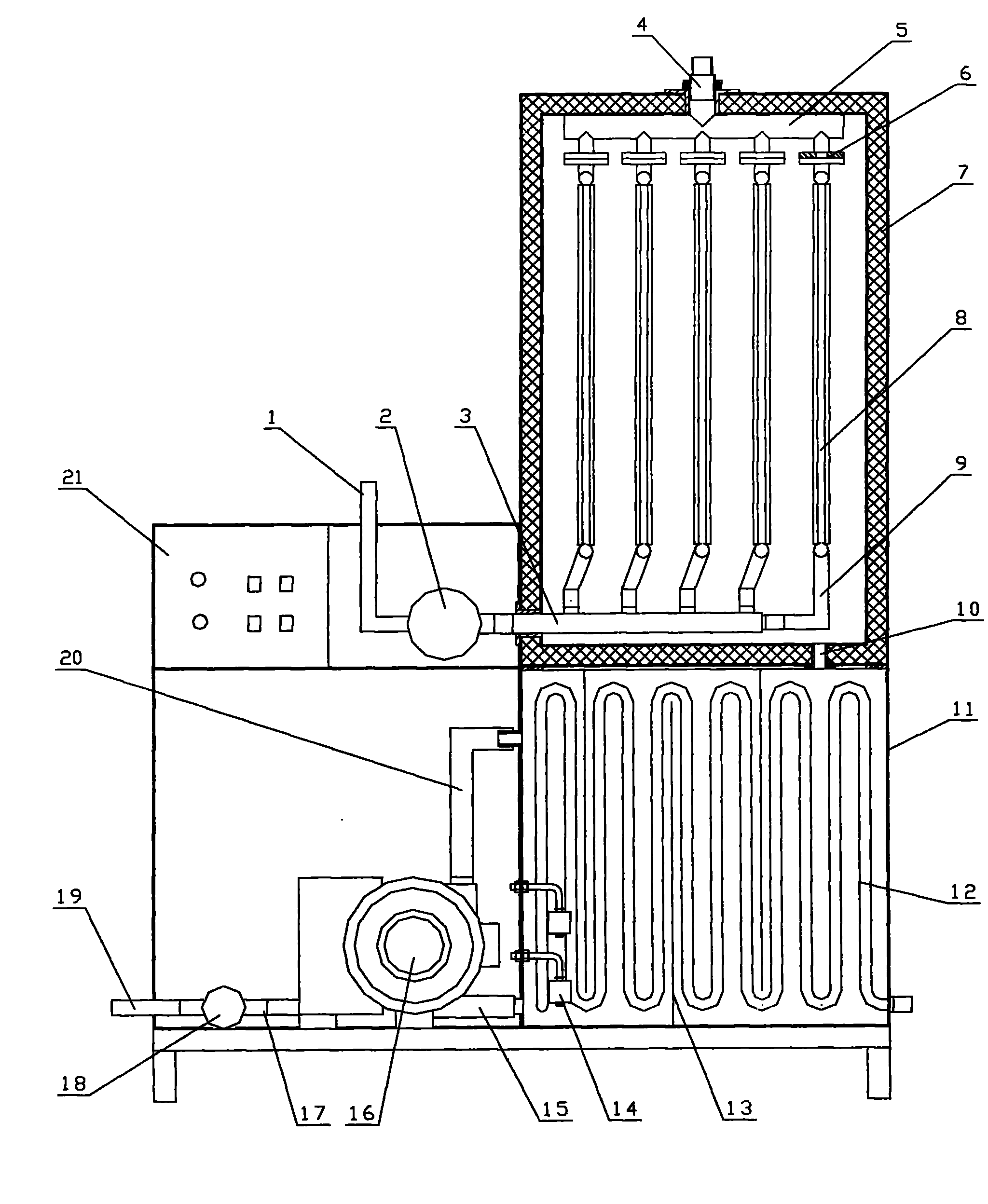

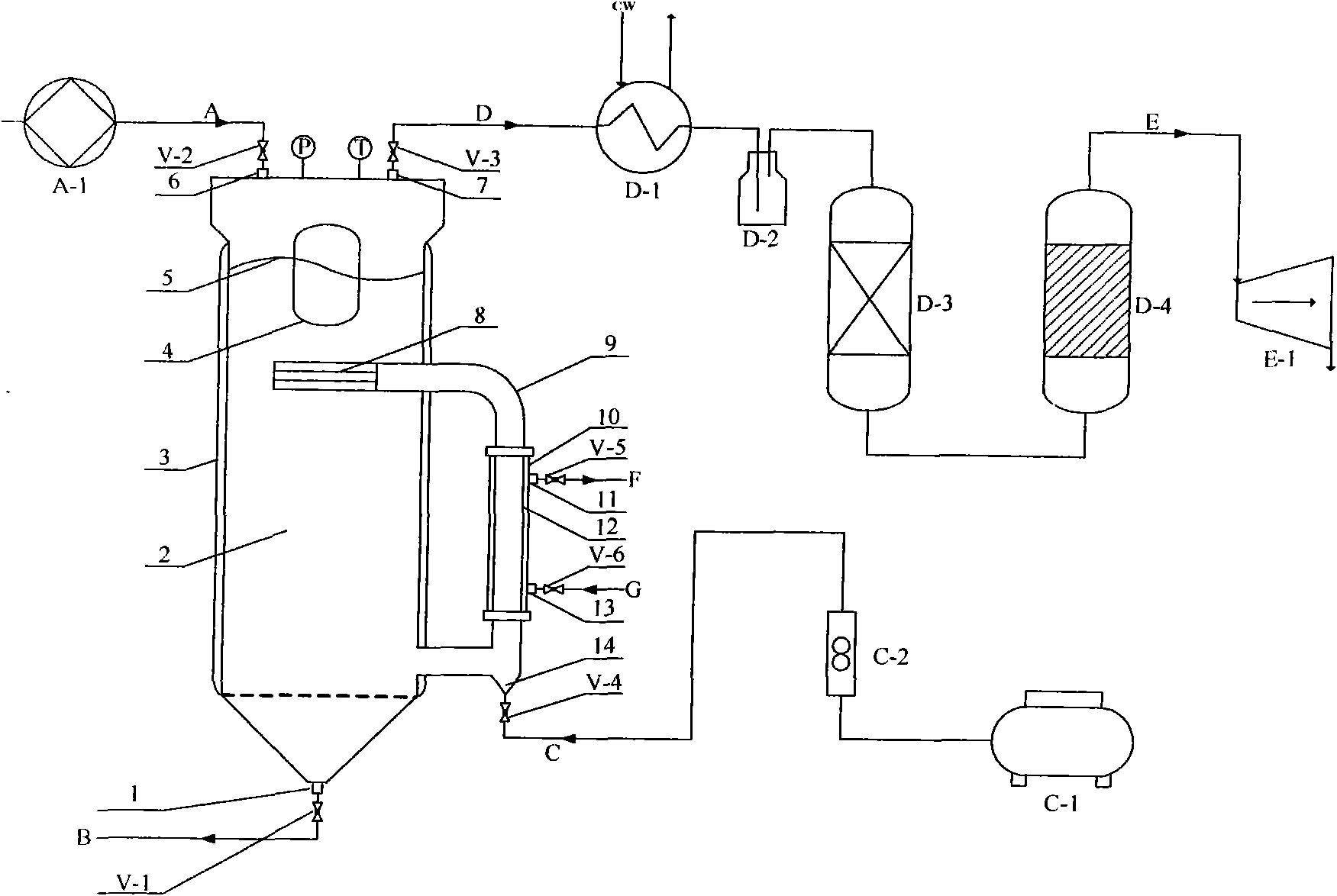

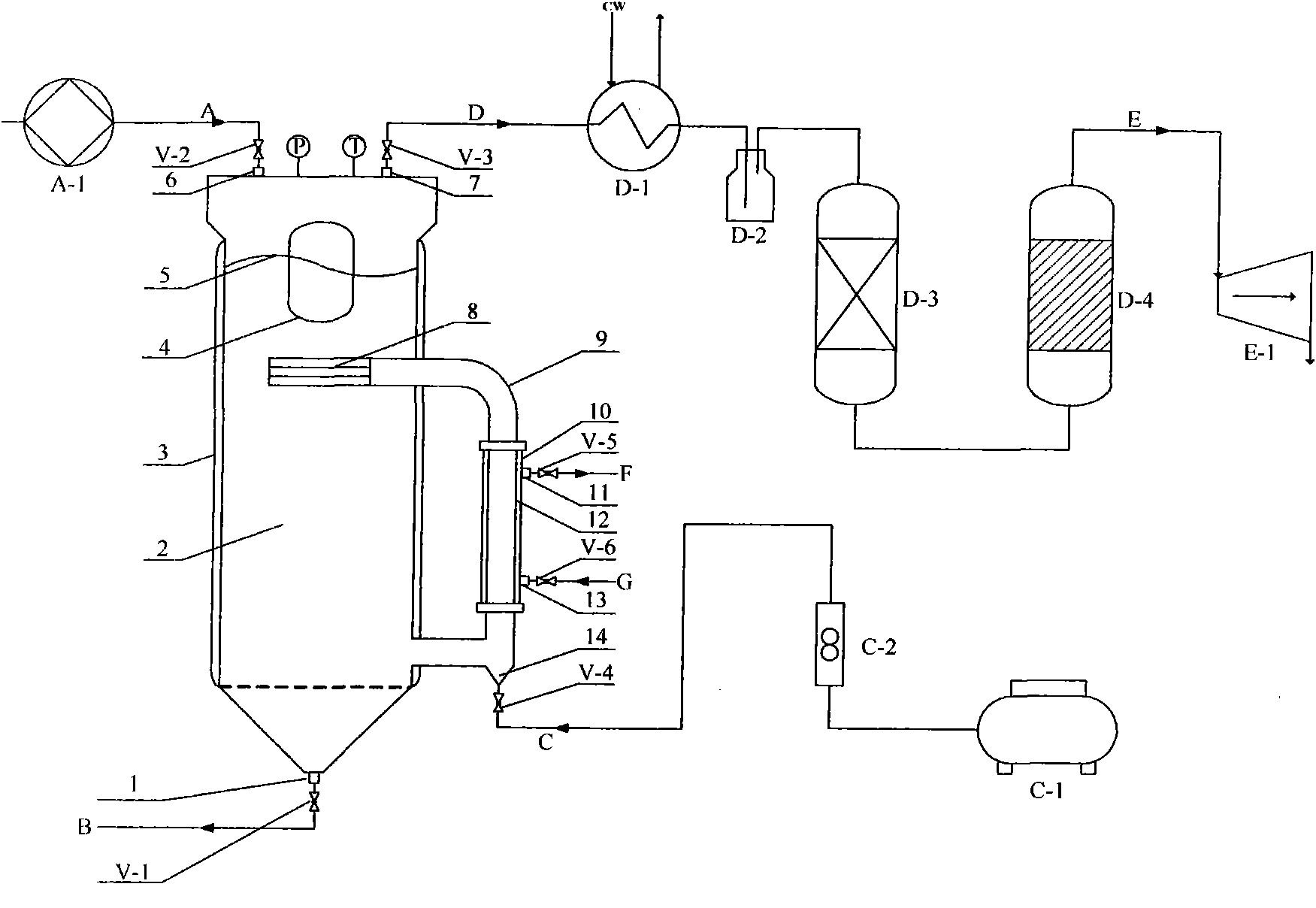

Air-lift membrane filtration complete equipment

The invention relates to air-lift membrane filtration complete equipment. The air-lift membrane filtration complete equipment consists of a membrane filtration system, a feed pump, a gas supply system, a tail gas solvent reclaiming system and an energy reclaimer, wherein the membrane filtration system consists of a kettle body 2, a circulating pipe 9 and a membrane component 10; the gas supply system consists of a compressed gas source and a gas flowmeter; the tail gas solvent reclaiming system consists of a tail gas condenser, a gas-liquid separating tank, an adsorption column and a dryer; in the kettle body, an upper cylinder body is a circulating area and a lower cone body is a sedimentation area; the circulating pipe is arranged on the side wall of the kettle body; the membrane component is encapsulated in the circulating pipe and is connected with the compressed gas source; a transmembrane pressure and a membrane surface gas speed are controlled by adjusting a gas inlet and outlet valve of the kettle body, so that positive pressure filtration concentration is realized; membrane flux is improved through the strengthening effect of gas-liquid two-phase flow; and the tail gas solvent reclaiming system can reclaim air-lift solvent and convert tail gas pressure into electric energy or mechanical energy. The air-lift membrane filtration complete equipment has the advantages of low energy consumption, high reclaiming efficiency, mild filtration condition and the like.

Owner:南京工大釜鼎能源技术有限公司

Reciprocating rotary type membrane bioreactor

ActiveCN105129974AReduce interactionImprove retention efficiencySustainable biological treatmentBiological water/sewage treatmentSurface concentrationPolarization phenomenon

The invention discloses a reciprocating rotary type membrane bioreactor which comprises a sewage treatment pond, a membrane separation device, a sludge discharge device, an aeration device, a water inlet pipe and a water outlet pipe. The membrane separation device is arranged in the sewage treatment pond, and a power driving assembly which drives the membrane separation device to conduct reciprocating rotation movement is installed on the lower portion of the membrane separation device. Due to the fact that the membrane separation device conducts the reciprocating rotation movement under the action of the power driving assembly, the surface concentration polarization phenomenon of a membrane separation assembly is significantly reduced, the membrane flux is kept stable, the service life of the membrane assembly is prolonged, and the sewage treatment efficiency is improved. Meanwhile, rejuvenation of the membrane assembly is conducted by rotating the membrane assembly in a rapid and reciprocating mode, traditional cleaning processes of adding chemical drugs or water or gas or the like are not needed, operation is easy, and the consumption of energy resources is greatly reduced.

Owner:BEIJING SINORICHEN ENVIRONMENTAL PROTECTION

Method for preparing tubular micro-porous filter membrane

ActiveCN104028108AUniform thicknessImprove integritySemi-permeable membranesPolymer scienceNonwoven fabric

The invention discloses a method for preparing a tubular micro-porous filter membrane. The method comprises the following steps: (1) preparing a base membrane casting solution, namely mixing a polymer, an additive and a solvent until each component is completely dissolved, standing in vacuum, and defoaming, thereby obtaining the base membrane casting solution; (2) preparing a separation layer casting membrane solution, namely mixing a polymer, an additive and a solvent until each component is completely dissolved, standing in vacuum, and defoaming, thereby obtaining the separation layer casting membrane solution; (3) preparing a base membrane, namely coating by placing the base membrane casting solution prepared in the step (1) and a non-woven fabric on a tubular coating machine, thereby obtaining the base membrane; and (4) preparing the tubular micro-porous filter membrane, namely putting the separation layer casting membrane solution prepared in the step (2) on the tubular coating machine, uniformly coating the inner surface of the base membrane prepared in the step (3) with the separation layer casting membrane solution to form a polymer seepage filter layer with concentration gradient, standing in air, immersing in a coagulating bath, and performing phase inversion separation. The prepared tubular micro-porous filter membrane is uniform in thickness, uniform in pore size distribution and complete without defects.

Owner:JIANGSU KAIMI MEMBRANE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com