Polyvinylidene fluoride organic-inorganic hybrid membrane and preparation method thereof

A polyvinylidene fluoride and hybrid membrane technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of unsatisfactory hydrophilicity and low flux of PVC blended ultrafiltration membranes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

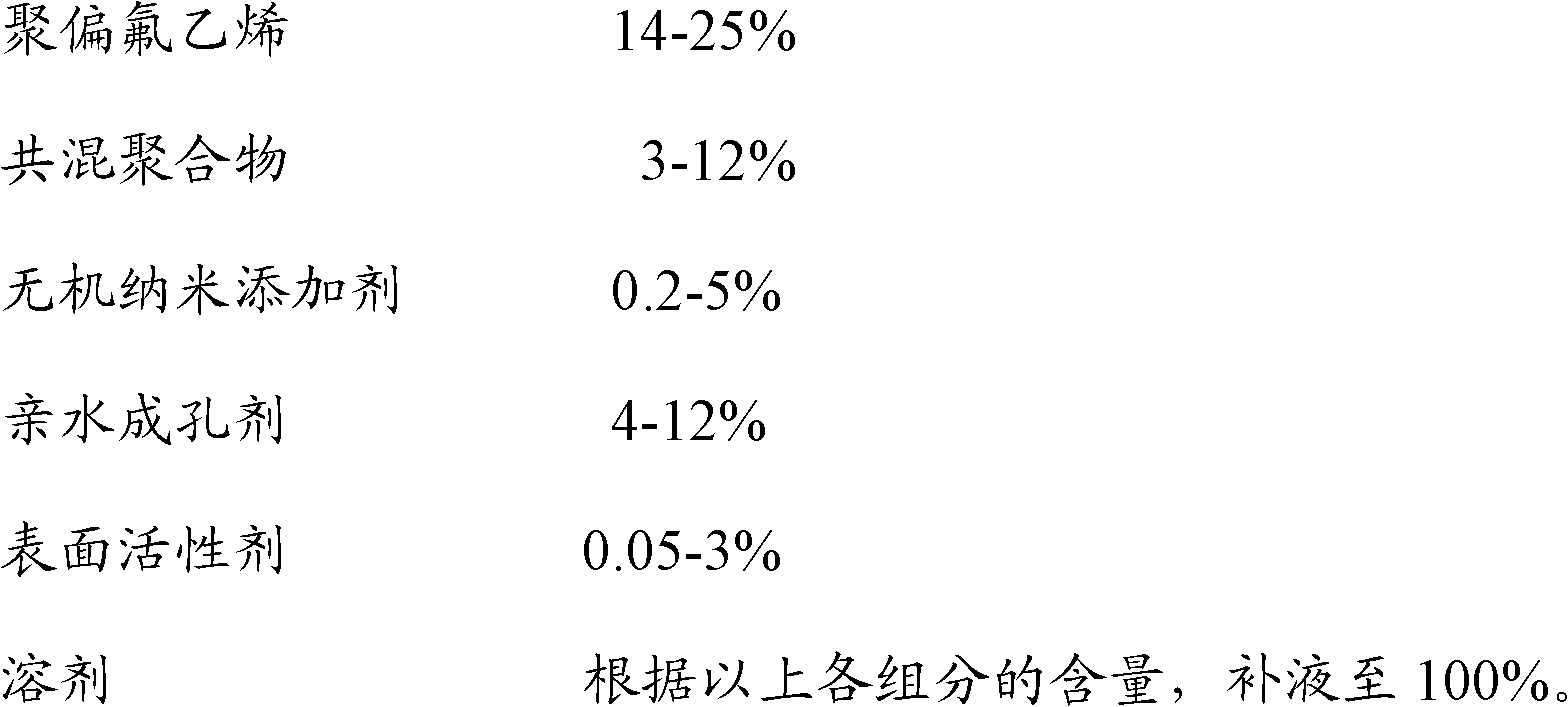

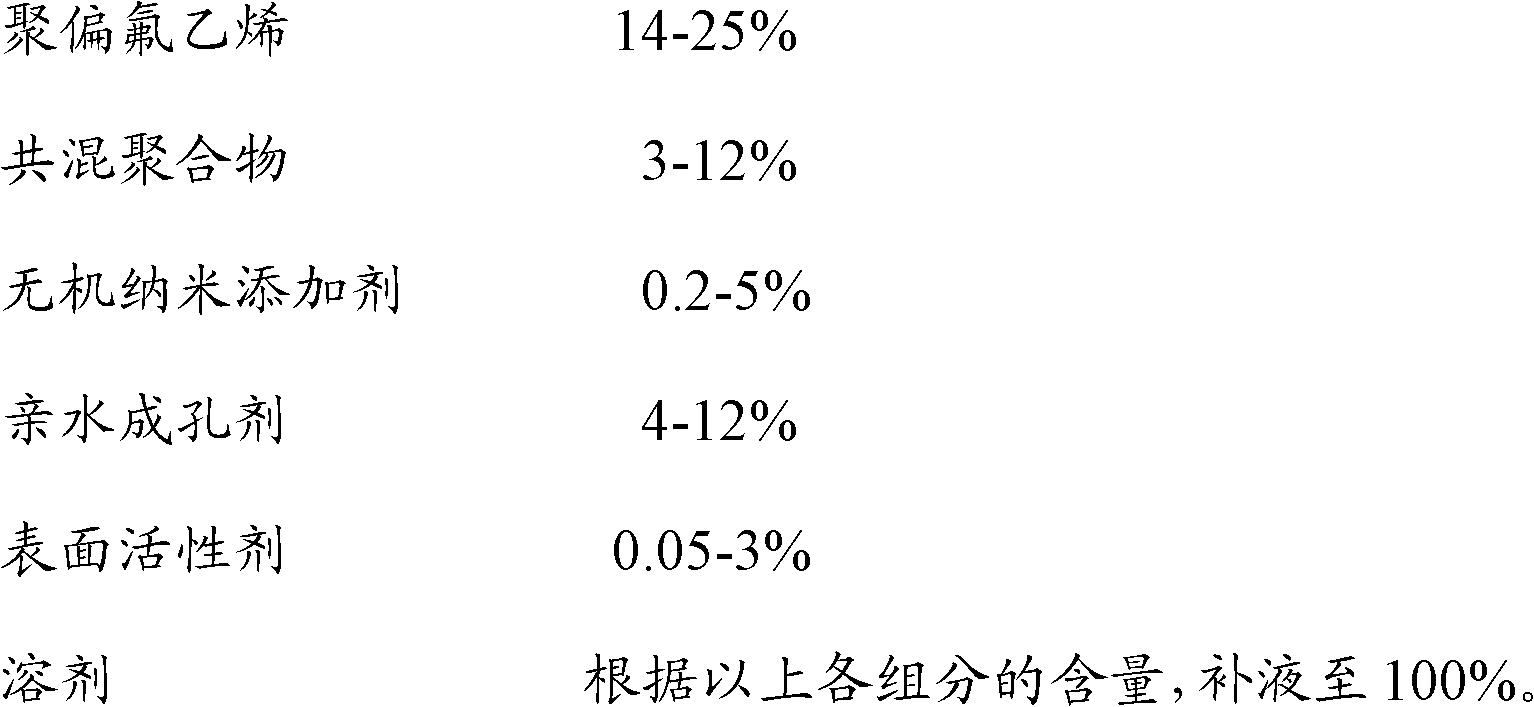

Method used

Image

Examples

Embodiment 1

[0021] Under high-speed stirring, dissolve 25 grams of silicon dioxide and 5 grams of Tween-20 in 3 kilograms of N-methylpyrrolidone. After stirring evenly, add 570 grams of N-methylpyrrolidone and 720 grams of polyvinylidene fluoride. Powder (polymerization degree 250,000), 180 grams of polyvinyl butyral, 500 grams of polyethylene glycol 10000, stirring and dissolving evenly, the stirring temperature is 70 ° C, standing for defoaming for 24 hours; spinning, spinning core liquid and outer The coagulation bath is water at 25°C. After passing through the filter screen, the casting film is extruded from the spinneret together with the core liquid. After walking 15cm in the air, it enters the external coagulation bath for forming and is wound by the winding wheel. The thus obtained polyvinylidene fluoride organic-inorganic hybrid membrane is soaked in pure water (15-35° C. at room temperature) for 48 hours, and then soaked in glycerin water (20-35% by mass of glycerol) for 12 hours...

Embodiment 2

[0023] Under high-speed stirring, dissolve 200 grams of alumina and 125 grams of Tween-80 in 3 kilograms of dimethylacetamide, stir well, then add 125 grams of dimethylacetamide and 1150 grams of polyvinylidene fluoride powder (Polymerization degree 150,000), 200 grams of polymethyl methacrylate, 200 grams of polyvinyl pyrrolidone, stirring and dissolving evenly, the stirring temperature is 85 ℃, stand for defoaming for 24 hours; It is a mixture of water and solvent at 40°C (water is 80%; solvent is dimethylacetamide, accounting for 20%). After the casting liquid passes through the filter screen, it is extruded from the spinneret together with the core liquid. After walking 5cm in the air, it enters the outer coagulation bath to form, and is wound by the winding wheel. The thus obtained polyvinylidene fluoride organic-inorganic hybrid membrane is soaked in pure water (15-35° C. at room temperature) for 48 hours, and then soaked in glycerin water (20-35% by mass of glycerol) fo...

Embodiment 3

[0025] Under high-speed stirring, 100 grams of titanium dioxide and 100 grams of Tween-60 were dissolved in 2560 grams of dimethylacetamide. After stirring evenly, 640 grams of dimethylformamide and 750 grams of polyvinylidene fluoride powder were added ( The degree of polymerization is 155,000), 500 grams of polypropylmethacrylate, 250 grams of polyethylene glycol 6000, and 100 grams of polyvinylpyrrolidone, stir and dissolve evenly, the stirring temperature is 75 ° C, and stand for defoaming for 24 hours; spinning, spinning Both the core liquid and the external coagulation bath are water at 45°C. After passing through the filter screen, the casting film liquid is extruded from the spinneret together with the core liquid. winding. The thus obtained polyvinylidene fluoride organic-inorganic hybrid membrane is soaked in pure water (15-35° C. at room temperature) for 48 hours, and then soaked in glycerin water (20-35% by mass of glycerol) for 12 hours. The obtained high-flux po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pure water flux | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com