Patents

Literature

1156results about How to "Strong anti-pollution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Complete-oil synthetic base drilling fluid

InactiveCN101215461AGood water loss wall building performanceStrong anti-pollutionDrilling compositionReducerHigh pressure

The invention discloses whole-oil synthetic base drilling fluid which mainly comprises following components: base liquid 100 parts, histosol 2-5 parts, viscosity increaser 0.5-3 parts, filtrate reducer 2-5 parts, wetting agent 0.5-2 parts, emulsifier 1-3 parts, calcium oxide 0.5 part and weighting agent 27-180 parts. The invention has the advantages that firstly, the rheological property is good and the plastic viscosity is low, secondly, the anti-temperature performance is good and anti-temperature can reach 150 DEG C, thirdly, the invention is provided with good water loss wall building performance with API filter loss content<5ml and high temperature and high pressure filter loss content <= 10 ml, fourthly, the anti-pollution ability is strong and the anti-poor soil ability and the anti-water invasion ability respectively reach 20%, and fifthly, reservoir has good protective effects and the permeability recovery value is over 85%.

Owner:CHINA NAT OFFSHORE OIL CORP +1

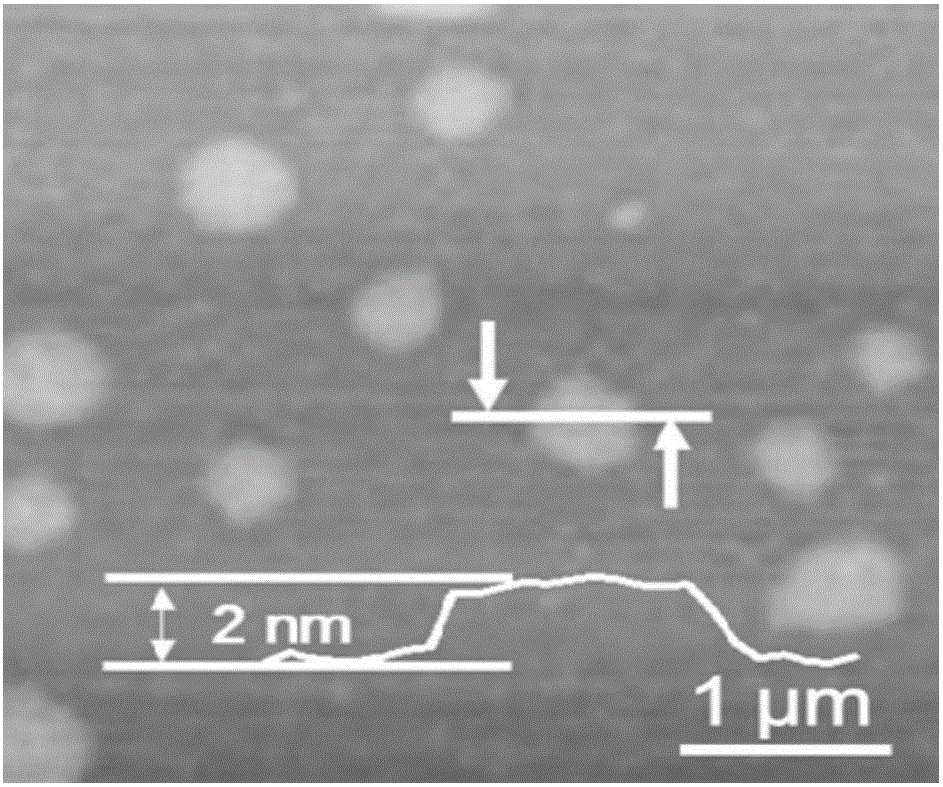

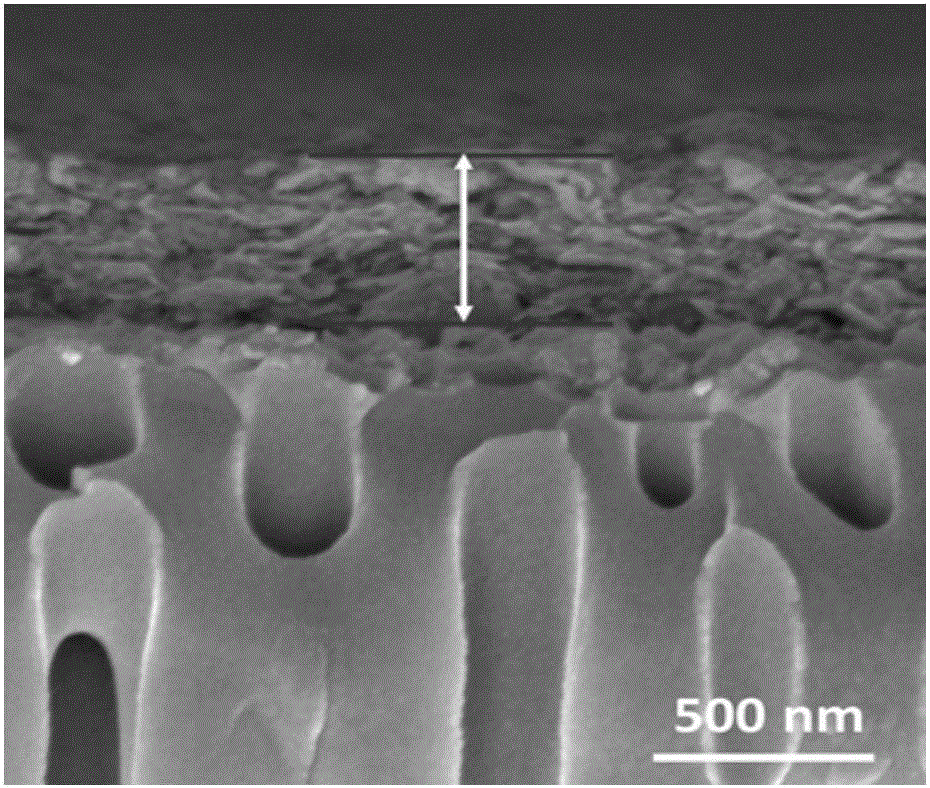

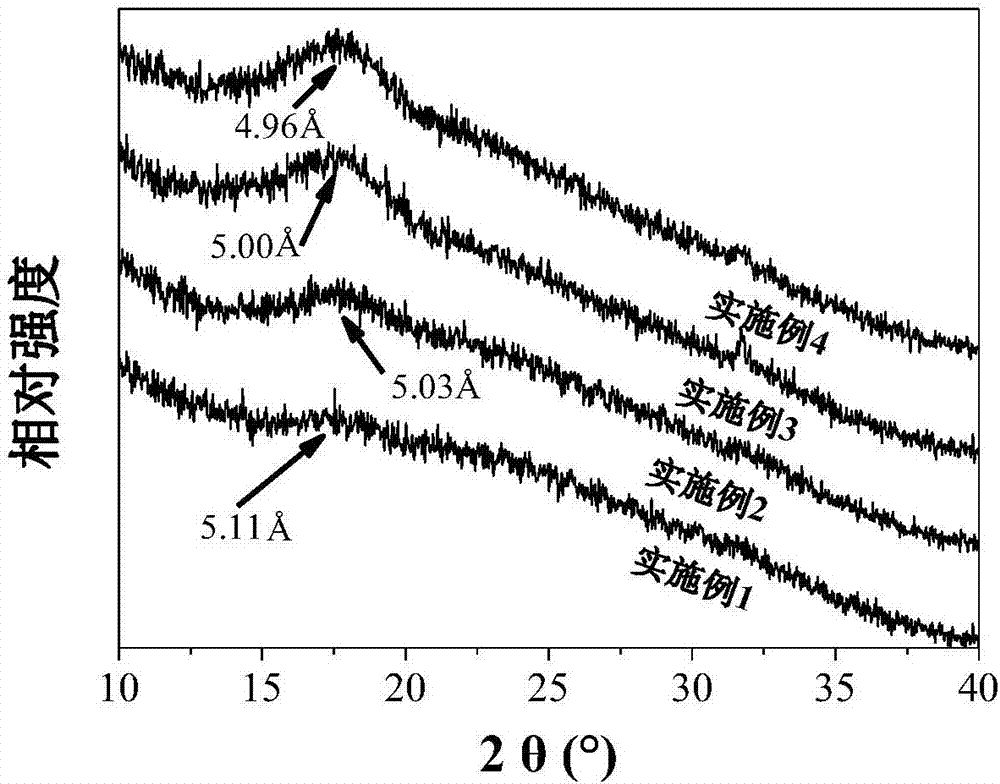

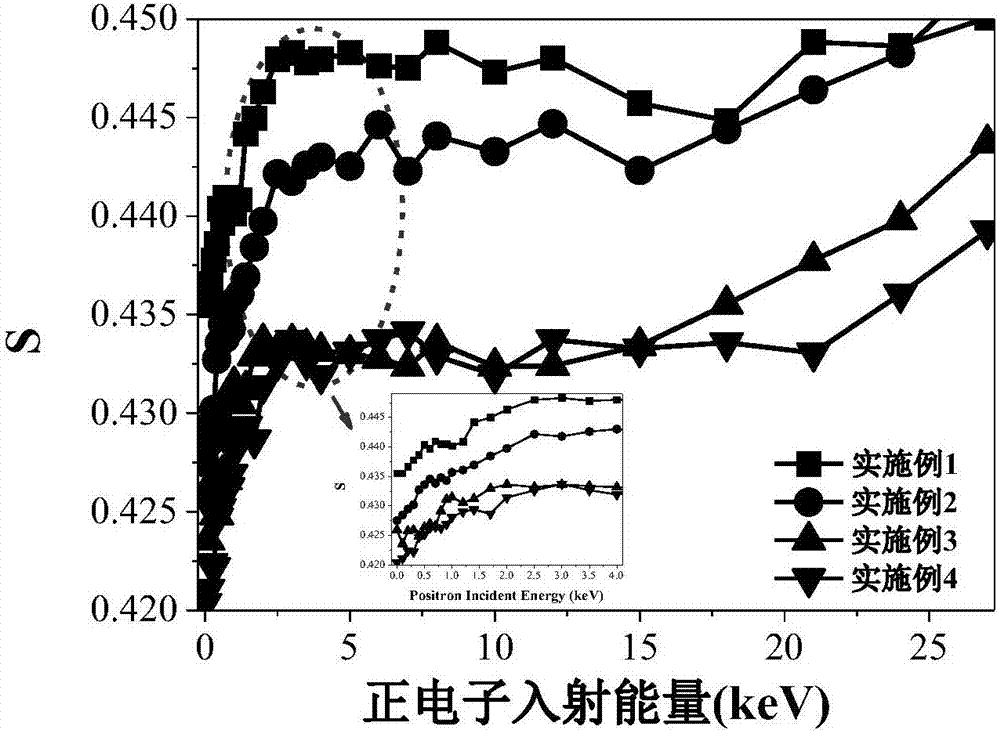

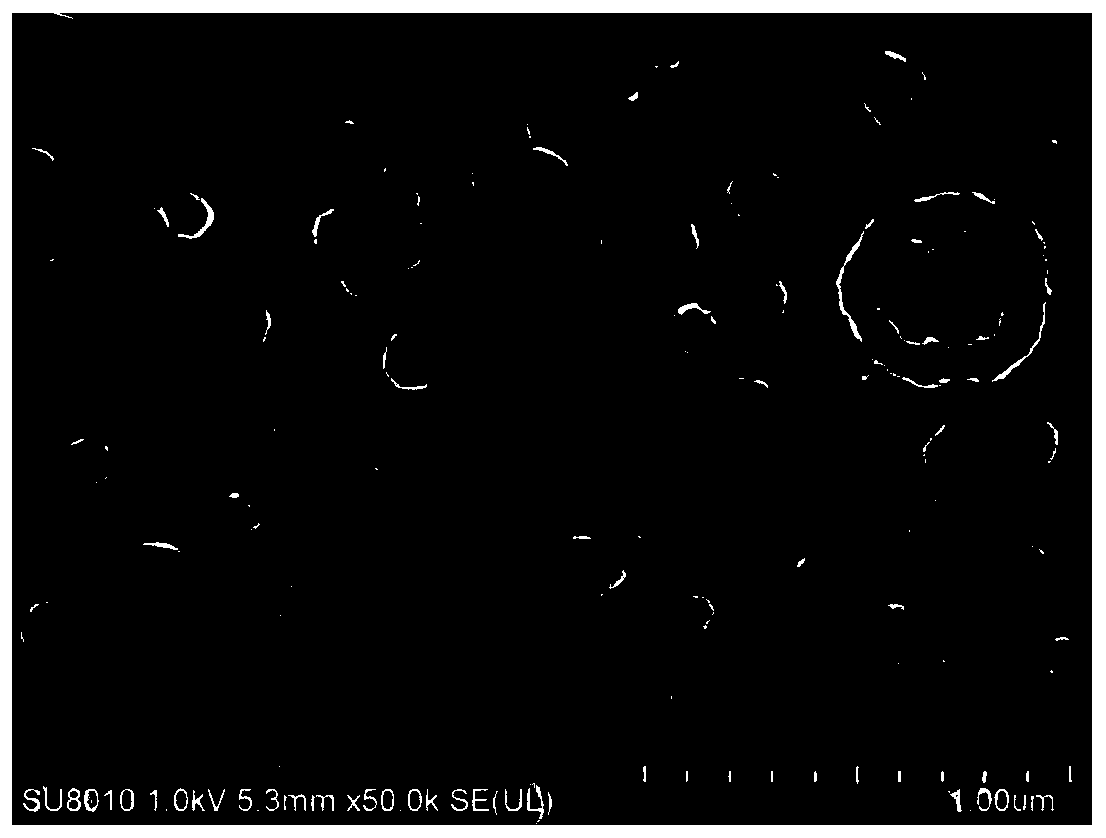

High-performance two-dimensional layered Ti3C2-MXene membrane, preparation method thereof and application of membrane in water treatment

ActiveCN106178979AIncrease water fluxHigh selectivitySemi-permeable membranesWater/sewage treatment bu osmosis/dialysisPorous substrateCentrifugation

The invention belongs to the technical field of membrane preparation and water purification and discloses a high-performance two-dimensional layered Ti3C2-MXene membrane, a preparation method thereof and an application of the Ti3C2-MXene membrane in water treatment. The method comprises steps as follows: (1), Ti3AlC2 powder and an HF solution are mixed, stirred for a reaction, centrifugally washed and dried, and Ti3C2 powder is obtained; (2), the Ti3C2 powder and a solvent are mixed, stirred for the reaction, washed and dried, and treated powder is obtained; (3), the treated powder is dissolved in the solvent and subjected to ultrasonic treatment and centrifugation, a liquid supernatant is taken and dried, and a two-dimensional nanosheet is obtained; (4), a solution is prepared from the two-dimensional nanosheet and deposited on a porous substrate with a nano self-assembly technology, and the high-performance two-dimensional layered Ti3C2-MXene membrane is obtained. The membrane has ultrahigh water flux, higher selectivity and good mechanical property and stability; the method is simple, low in energy consumption and cost, good in repeatability and wide in applicability.

Owner:SOUTH CHINA UNIV OF TECH

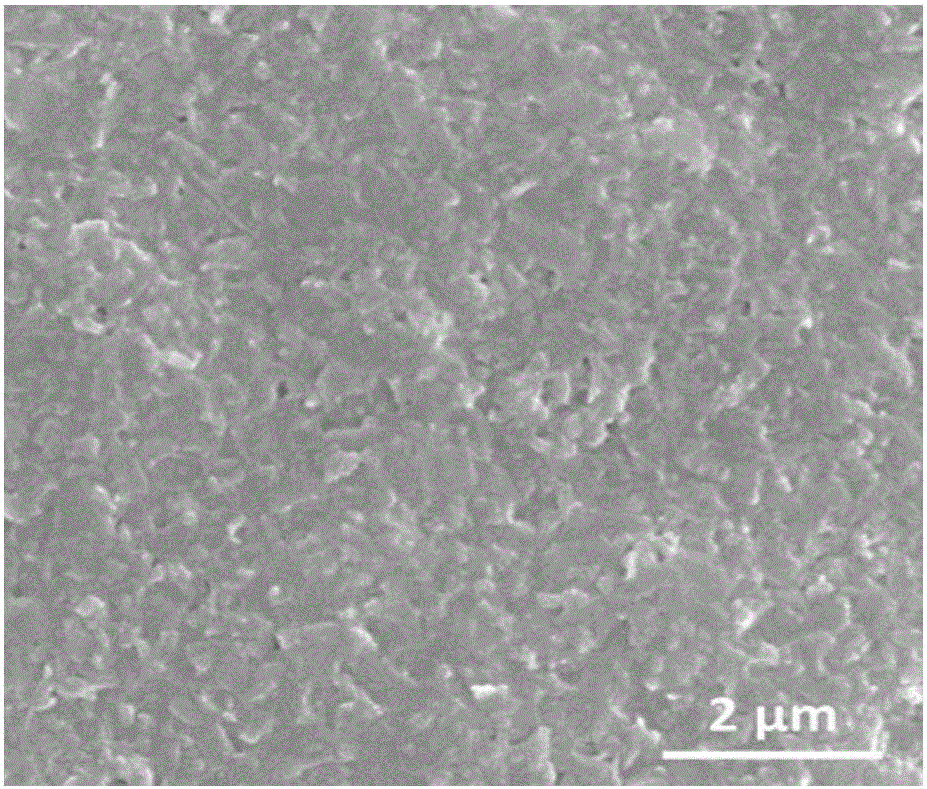

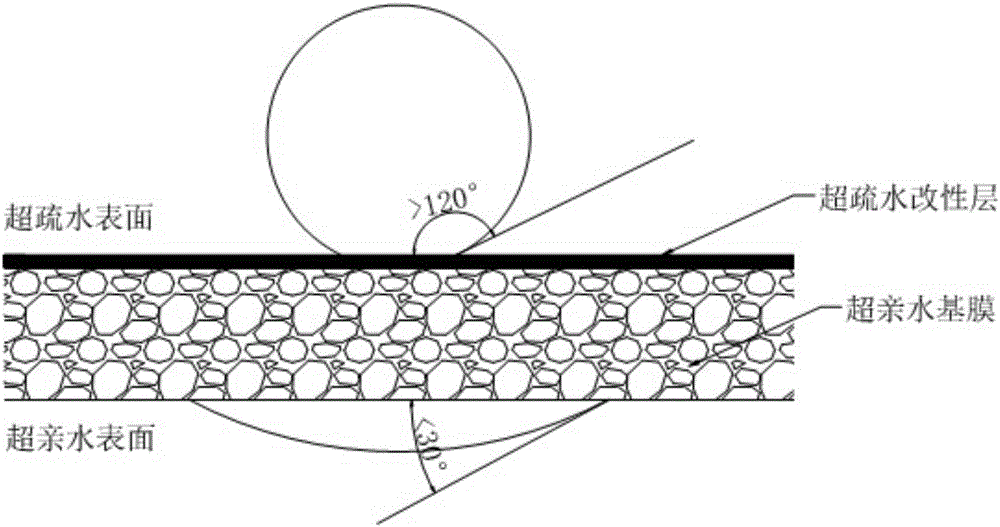

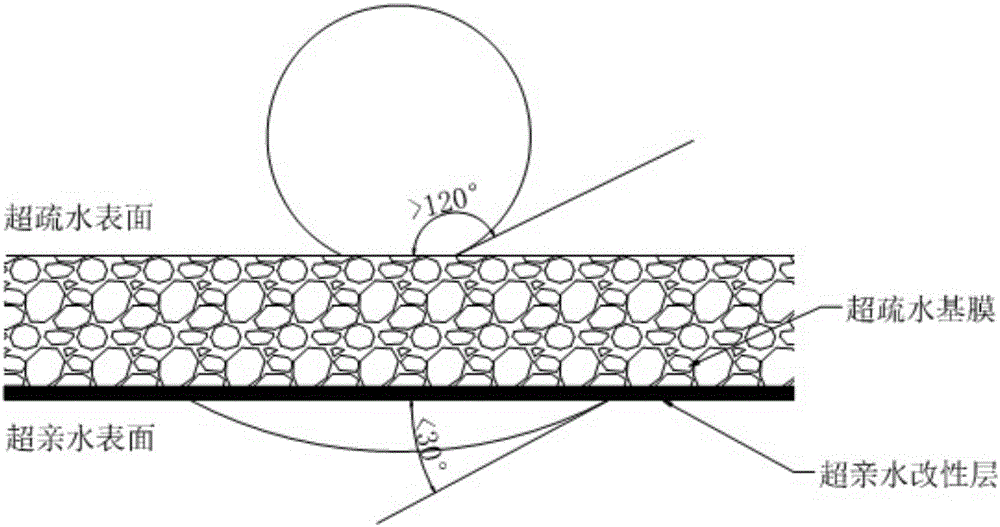

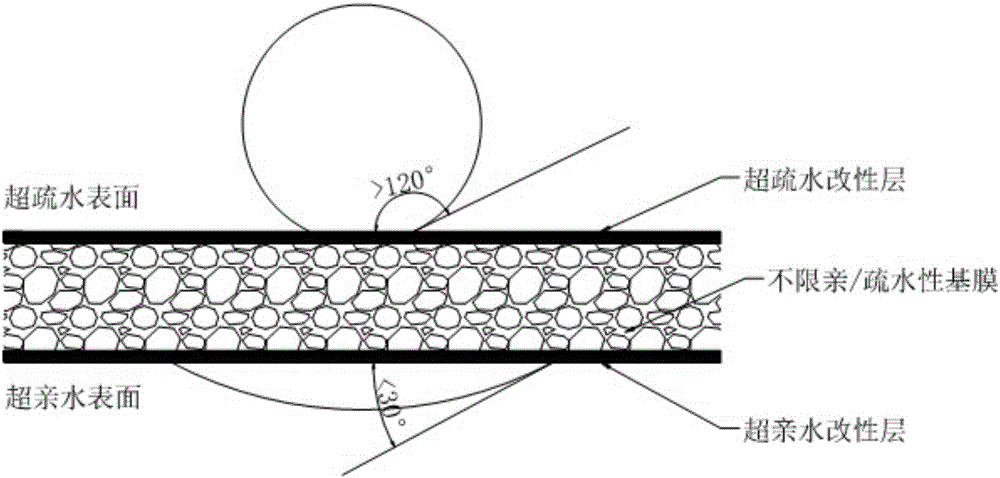

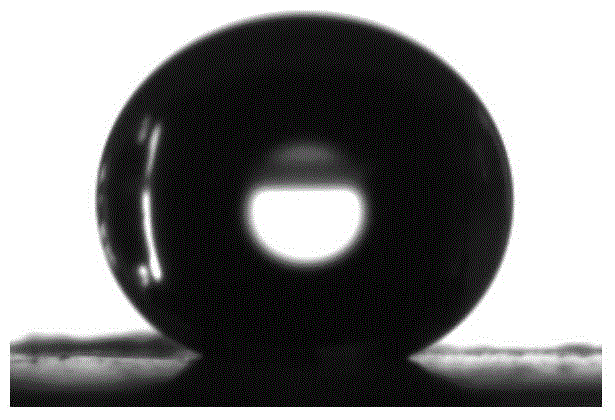

Asymmetric ultra-hydrophilic/hydrophobic dual-property polymer membrane and preparation method thereof

ActiveCN106268355AImprove anti-pollution performanceReduce adhesionMembranesSemi-permeable membranesPore diameterHollow fiber membrane

The invention relates to a membrane separation technique and aims at providing an asymmetric ultra-hydrophilic / hydrophobic dual-property polymer membrane and a preparation method thereof. According to the asymmetric ultra-hydrophilic / hydrophobic dual-property polymer membrane, a base membrane is a flat sheet membrane or a hollow fiber membrane, one side of the base membrane is a hydrophilic side, the water contact angle of the hydrophilic side is not greater than 30 degrees, the other side of the base membrane is a hydrophobic side, and the water contact angle of the hydrophobic side is not smaller than 120 degrees. The prepared asymmetric ultra-hydrophilic / hydrophobic dual-property polymer membrane is of the type of the flat sheet membrane or the hollow fiber membrane and belongs to an ultra-micro filter membrane category, and the pore diameter range of the membrane is 0.01-2.0 microns. Therefore, the hydrophilic and hydrophobic properties on double sides are different, one side is hydrophilic, the other side is hydrophobic, and the asymmetric ultra-hydrophilic / hydrophobic dual-property polymer membrane shows asymmetric hydrophilic / hydrophobic properties and is a novel water treatment membrane.

Owner:ZHEJIANG UNIV

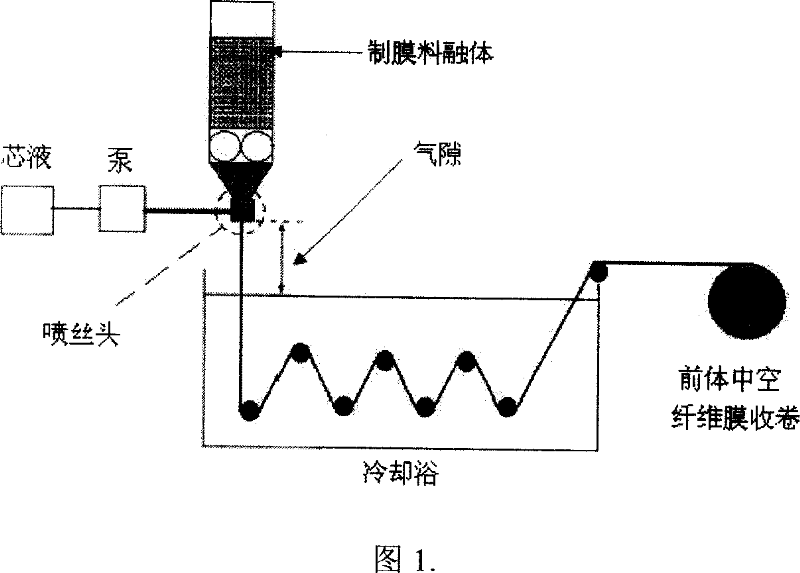

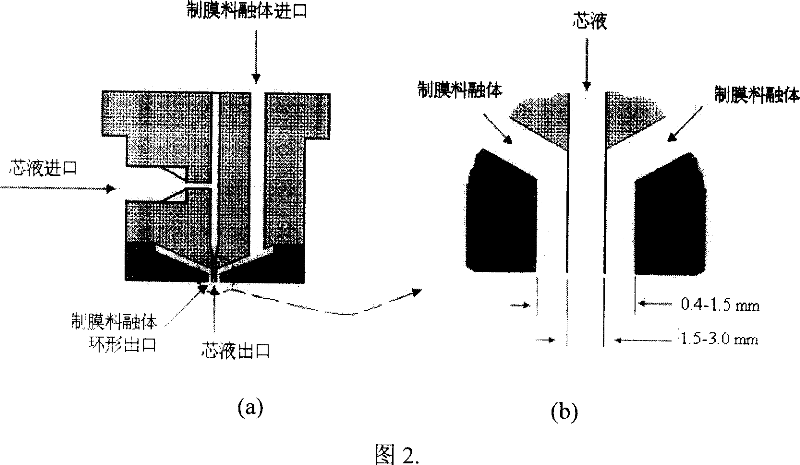

Hydrophilicity polyethylene hollow fiber micro-hole film and the preparation method

InactiveCN101036861AExtended cleaning cycleHydrophilic realizationSemi-permeable membranesFiberMolten state

The invention discloses hydrophilic polyethylene hollow fiber microporous membrane and preparation process thereof. Said membrane is characterized in that it mainly comprises polyethylene, amphoteric copolymer containing polyethylene oxide, and inorganic nano particles. The membrane preparing process is carried out based on thermally induced phpase separation and surface segregation principles, comprising the steps of (1) preparing membrane blank by fusion and blending of amphoteric copolymer containing polyethylene oxide, diluent, and inorganic nano particles; (2) preparing hollow fiber membrane precursor by hollow process spinning of membrane blank in molten state; (3) extracting diluent in hollow fiber membrane precursor by using organic solvent to obtain said hydrophilic polyethylene hollow fiber microporous membrane, wherein the porosity of said membrane is between 40% and 80%, and average pore diameter is between 0.1mum and 5.0mum. The microporous membrane in the invention has the characteristics of high hydrophilicity, narrow pore size distribution, high strength, and good chemical stability, and serves as micro-filtration and ultra-filtration membrane material with high performance, low cost, pollution resistance, and long serve life for water treatment.

Owner:ZHEJIANG UNIV

Preparation method of high-throughput anti-pollution composite nanofiltration membrane

ActiveCN104667759AImprove performanceImprove throughputSemi-permeable membranesGlycerolSurface-active agents

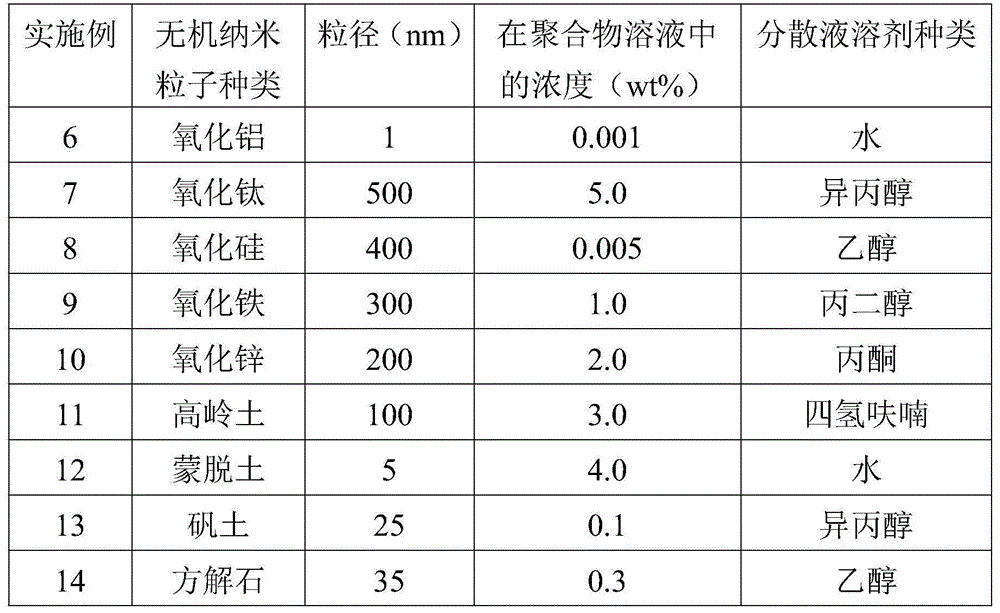

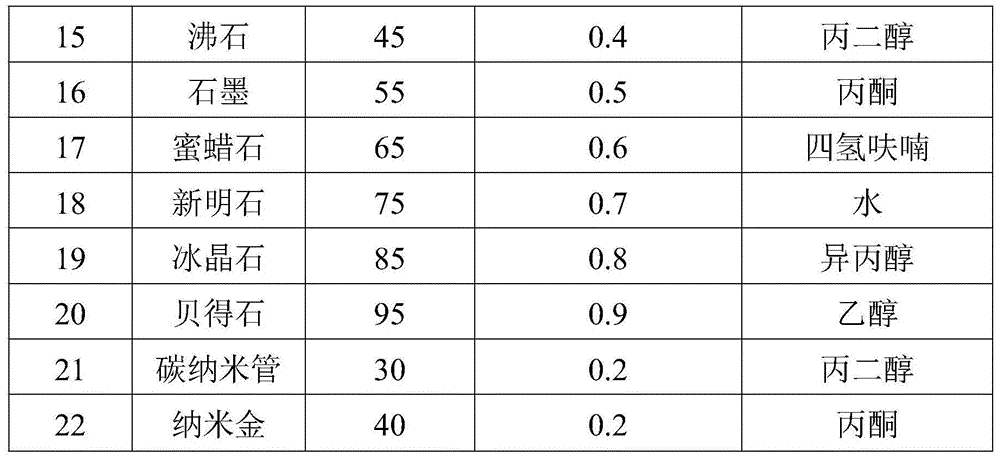

The invention discloses a preparation method of a high-throughput anti-pollution composite nanofiltration membrane. The preparation method comprises the following steps: inorganic nanoparticles are uniformly dispersed in a porous polymer supporting layer, a surface active agent is added in solution A, a polyamide layer is prepared on the porous polymer supporting layer through interfacial polymerization, hot water soaking treatment and glycerol moisturization treatment are adopted, and then drying is performed, and thus, the high-throughput anti-pollution composite nanofiltration membrane is prepared. According to the method, the porous supporting layer microstructure is changed by inorganic nano particles, the surface active agent is added in the solution A, and the flux and the antifouling property of the composite nanofiltration membrane are improved. The preparation method is easy, the raw material is cheap, the preparation process is simple and the method has good industrial applicability.

Owner:VONTRON TECH CO LTD

Hydrophobic film with self-cleaning function, preparation method thereof and application thereof

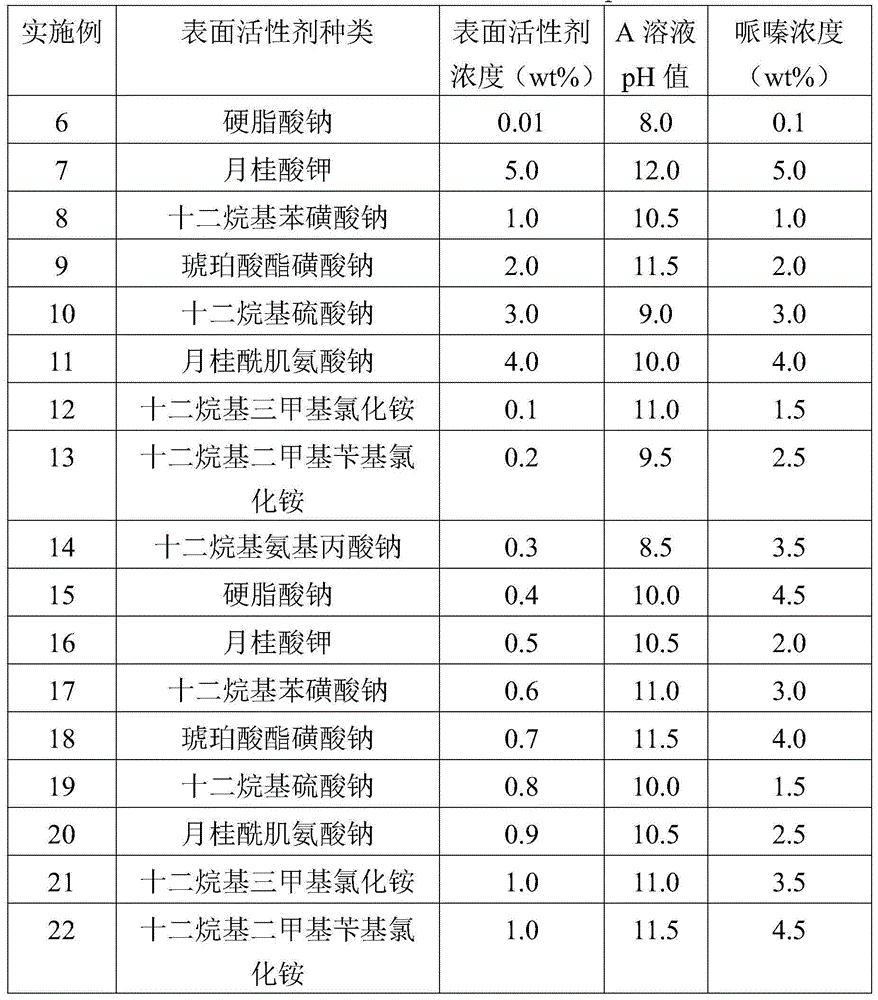

ActiveCN105002656AHigh porosityWith self-cleaning functionSemi-permeable membranesFilament/thread formingPorosityFiber

The invention relates to a hydrophobic film, and specifically relates to a hydrophobic film with a self-cleaning function, and a preparation method thereof and an application thereof. The hydrophobic film is a polymer nanofiber film prepared through an electrospinning fiber technique, the surface of the hydrophobic film is subjected to nanocrystallization modification to improve the surface hydrophobicity, and the contact angle between the hydrophobic film and water is 140-180 DEG. According to the invention, the electrospinning fiber technique and the surface nanocrystallization technique are combined, the preparation technology is simple, and the prepared hydrophobic film has the self-cleaning function and a high porosity factor, and can be applied to fields of air purifying filters, film distillation and oil-water separation and the like.

Owner:YANTAI LVSHUIFU MEMBRANE MATERIAL

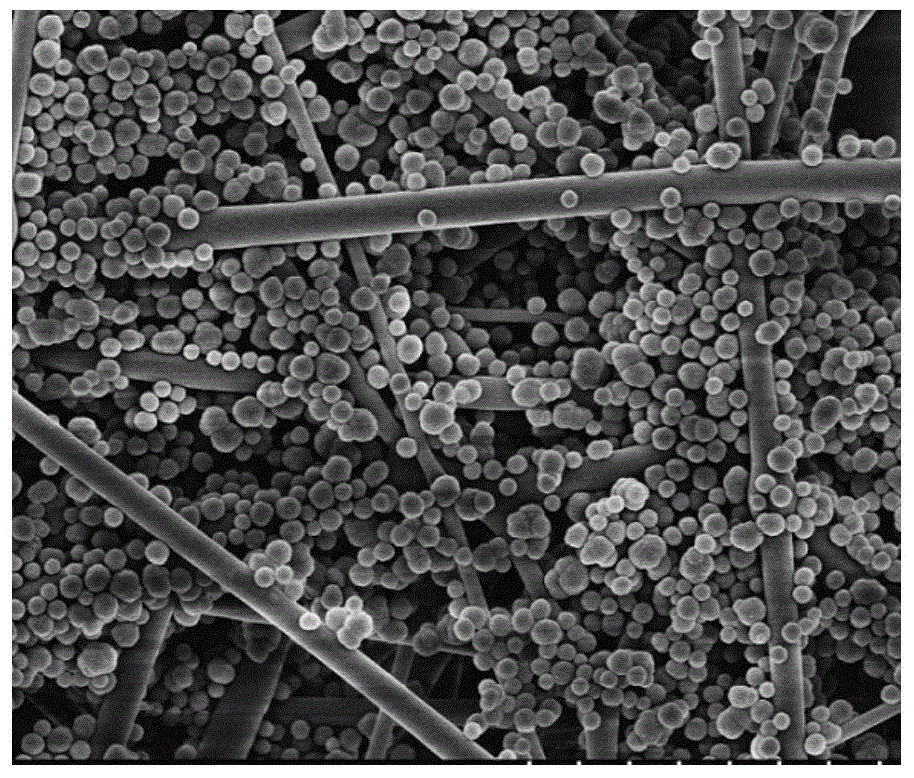

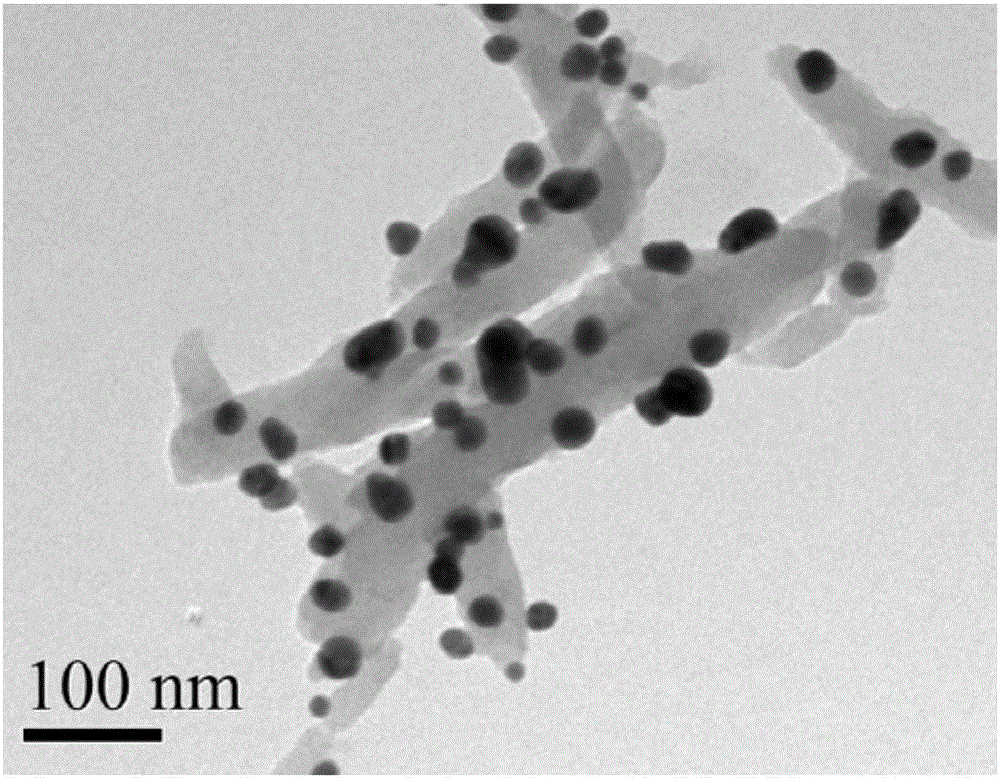

Method of preparing antibacterial anti-pollution ultrafiltration membrane by adopting silver-loaded nano composite material

ActiveCN105195025AImprove hydrophilicityImprove antibacterial propertiesBiocideSemi-permeable membranesUltrafiltrationPollution

The invention discloses a method of preparing an antibacterial anti-pollution ultrafiltration membrane by adopting a silver-loaded nano composite material. The method comprises the following steps: preparing a nano material water dispersion solution, adding trihydroxymethyl aminomethane and dopamine hydrochloride, stirring and reacting for 2 to 12 hours, centrifugally washing, then drying to obtain a polydopamine-modified nano material; preparing a mixed solution containing the polydopamine-modified nano material, a silver-ammonium solution, a stabilizer and water, stirring for 2 to 12 hours, centrifugally washing, and then drying to obtain the silver-loaded nano composite material; dispersing the silver-loaded nano composite material in an organic solvent, adding a membrane material, stirring, completely dissolving the membrane material, and standing to obtain a membrane casting solution; and scraping the membrane casting solution into a flat membrane by utilizing a flat membrane scraping machine, immersing in a coagulating bath, and carrying out a phase conversion to obtain the antibacterial anti-pollution ultrafiltration membrane. The ultrafiltration membrane has good hydrophilia, durable antibacterial performance and excellent anti-pollution performance, has good antibacterial and sterilization effect for colibacillus, bacillus subtilis and the like; moreover, the silver nano particles stably exist in the antibacterial anti-pollution ultrafiltration membrane.

Owner:TIANJIN UNIV

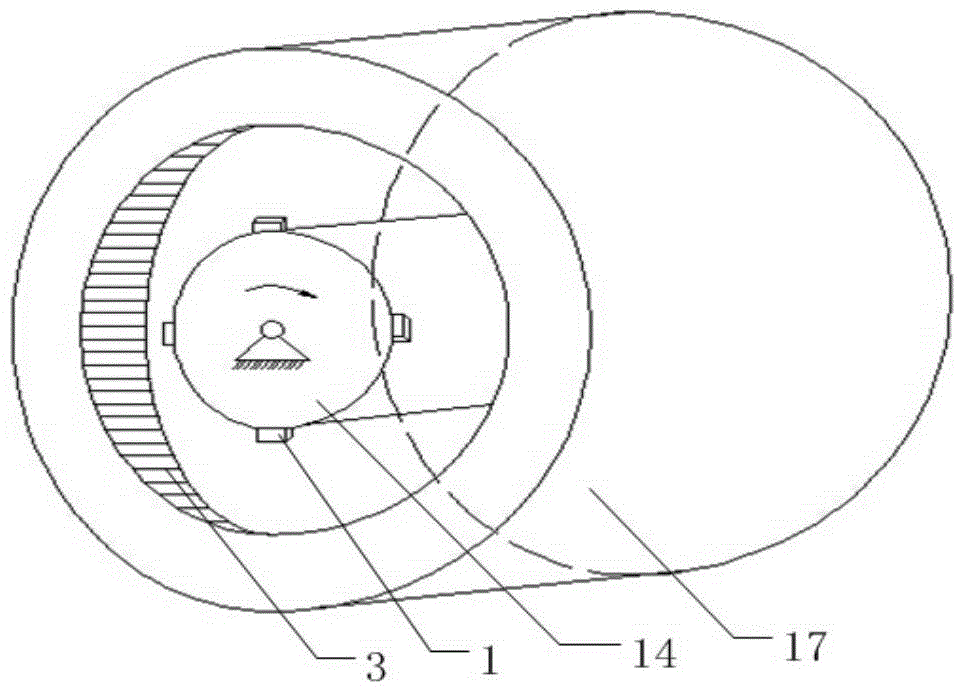

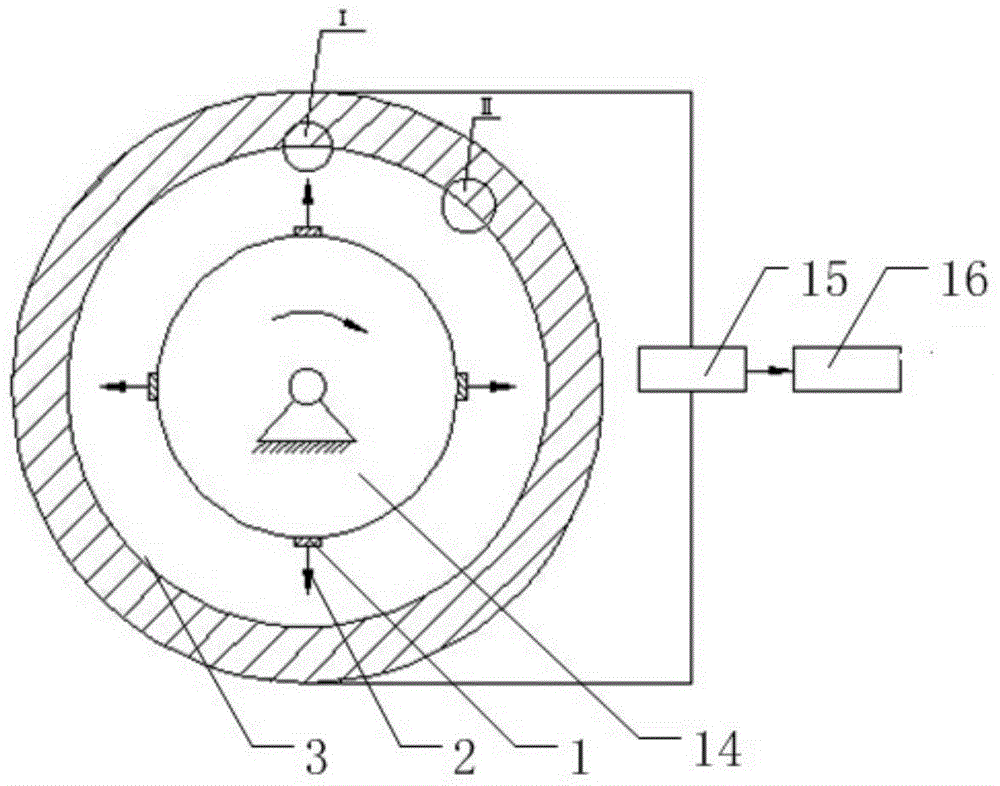

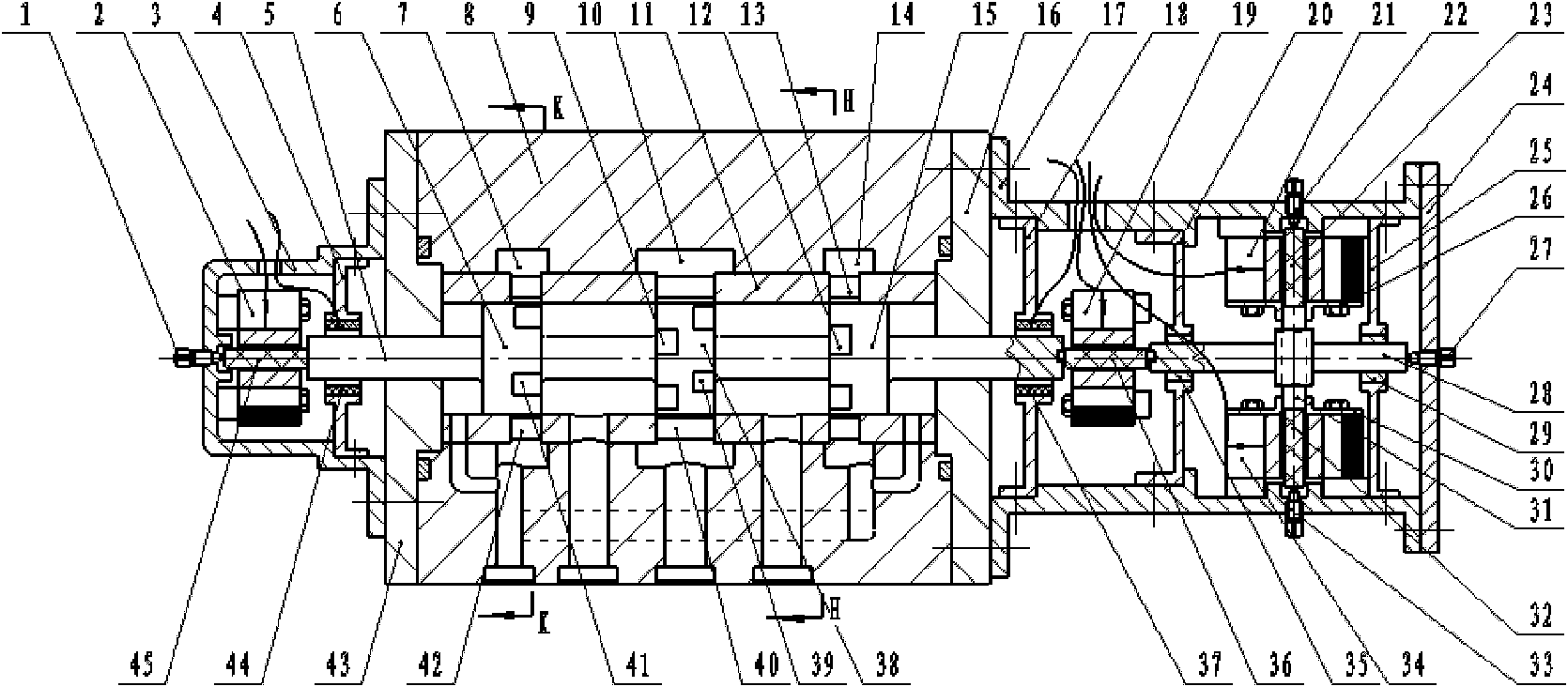

Mine-hoist constant deceleration safety braking system and braking method thereof

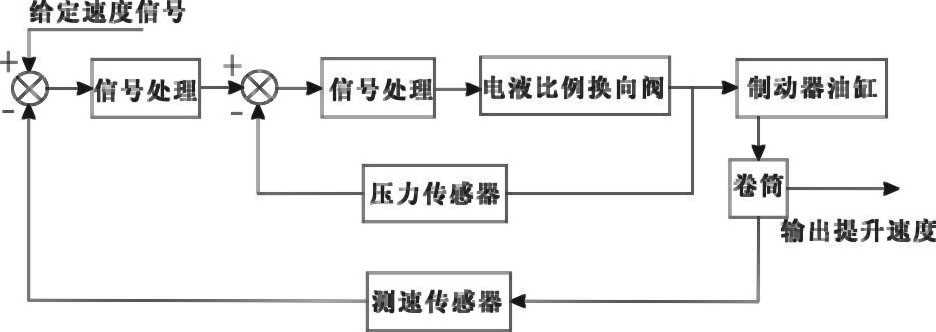

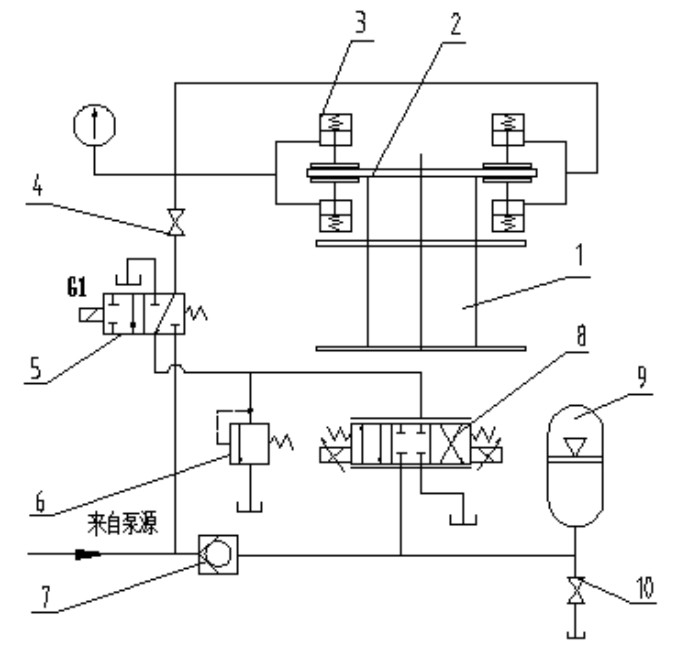

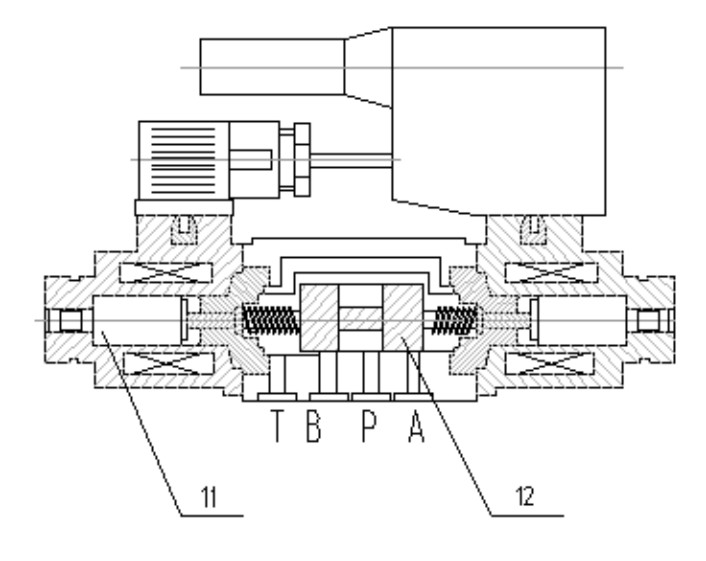

ActiveCN102030280AEasy to operateReduce stepsServomotor componentsHoisting equipmentsInput controlElectric control

The invention discloses a mine-hoist constant deceleration safety braking system and a braking method thereof, and relates to the technical field of mine-hoist safety braking control. The system comprises a disk brake, a hydraulic station, an electric control device and a detection feedback device which are arranged on a drum brake disk, wherein a speed sensor arranged on the drum acquires a hoist deceleration signal and inputs the hoist deceleration signal into the electric control device; the electric control device receives the signal and compares the signal with the given speed value to send out a control command; after the control command is processed into an electric signal and compared with an oil pressure signal which is fed back by a pressure sensor on the hydraulic pipeline arranged between the outlet end of an electrohydraulic proportion reversing valve and the disk brake cylinder, an electric signal control command is sent out; and the electrohydraulic proportion reversingvalve of the hydraulic station outputs a hydraulic pressure signal, which varies as the input control command varies, so as to control the motion state of the hoist by the disk brake, thereby realizing constant deceleration safety braking of the mine hoist.

Owner:CITIC HEAVY INDUSTRIES CO LTD +1

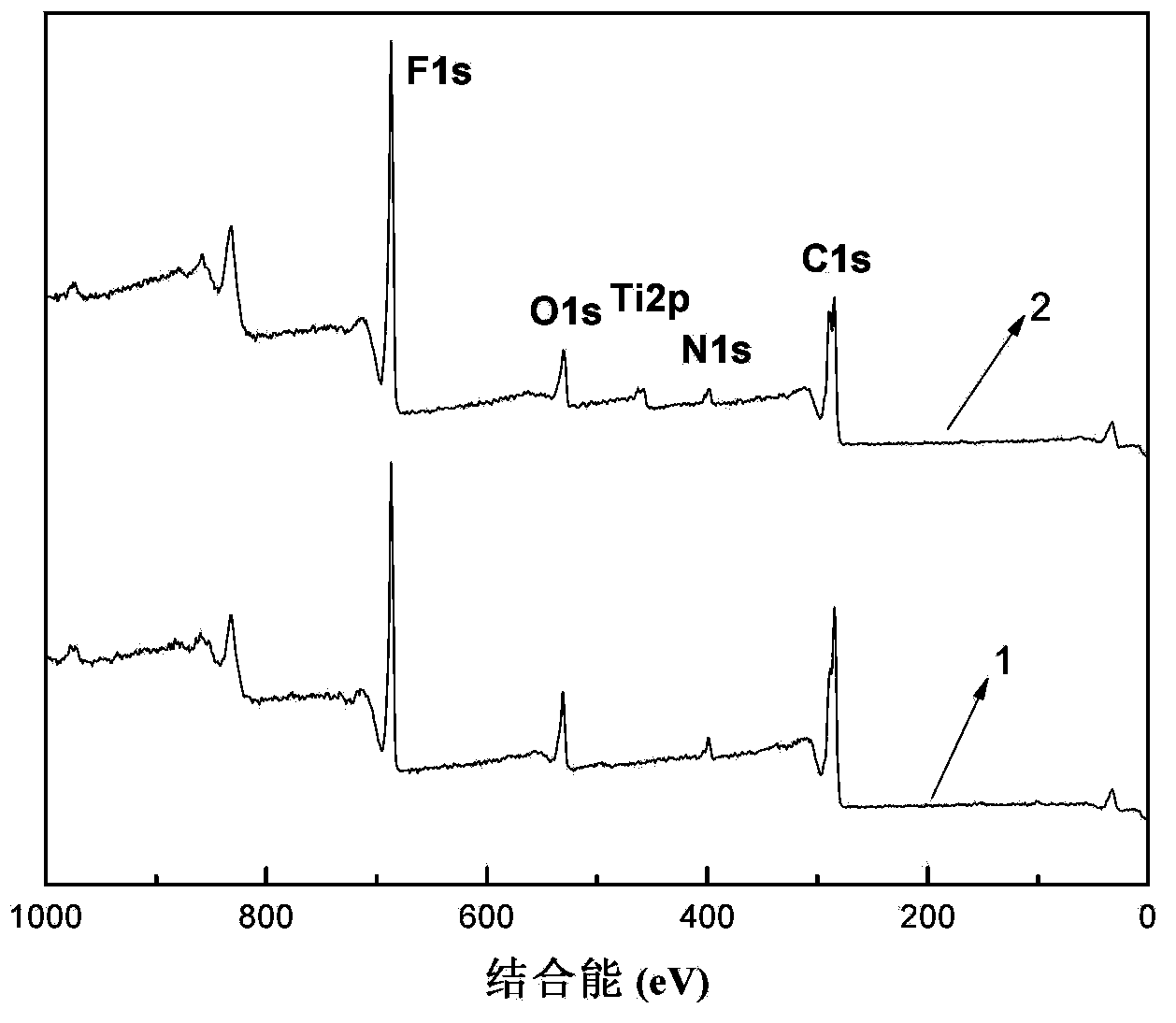

Preparation method of high-performance PVDF composite ultrafiltration membrane with surface loaded with TiO2 thin membrane

InactiveCN103394294AImprove stabilityEasy to manufactureSemi-permeable membranesThin membraneRejection rate

A preparation method of a high-performance PVDF composite ultrafiltration membrane with the surface loaded with a TiO2 thin membrane is provided. The invention is used for solving the problems of complex process, high membrane preparing cost, and difficult industrialized production existing in a conventional method for improving membrane hydrophilicity so as to improve membrane flux, anti-fouling performance and the like. The preparation method comprises the steps: 1, preparing a PVDF polymer membrane casting solution, and preparing an ultrafiltration basement membrane by an immersion-precipitation method; 2, preparing an auxiliary agent solution; 3, soaking the basement membrane in the auxiliary agent solution, taking out and swashing with water, and soaking in deionized water; 4, preparing a titania precursor solution; 5, immersing the basement membrane in the titania precursor solution, hydrolyzing a precursor, taking out and swashing with water, and thereby obtaining the high-performance ultrafiltration membrane with the surface firmly loaded with the TiO2 thin membrane. The method of the invention has the advantages of simple operation and low cost; and the obtained ultrafiltration membrane has large permeation flux, high rejection rate, strong hydrophilicity and outstanding anti-fouling performance. The preparation method is used for the membrane processing field.

Owner:HARBIN INST OF TECH

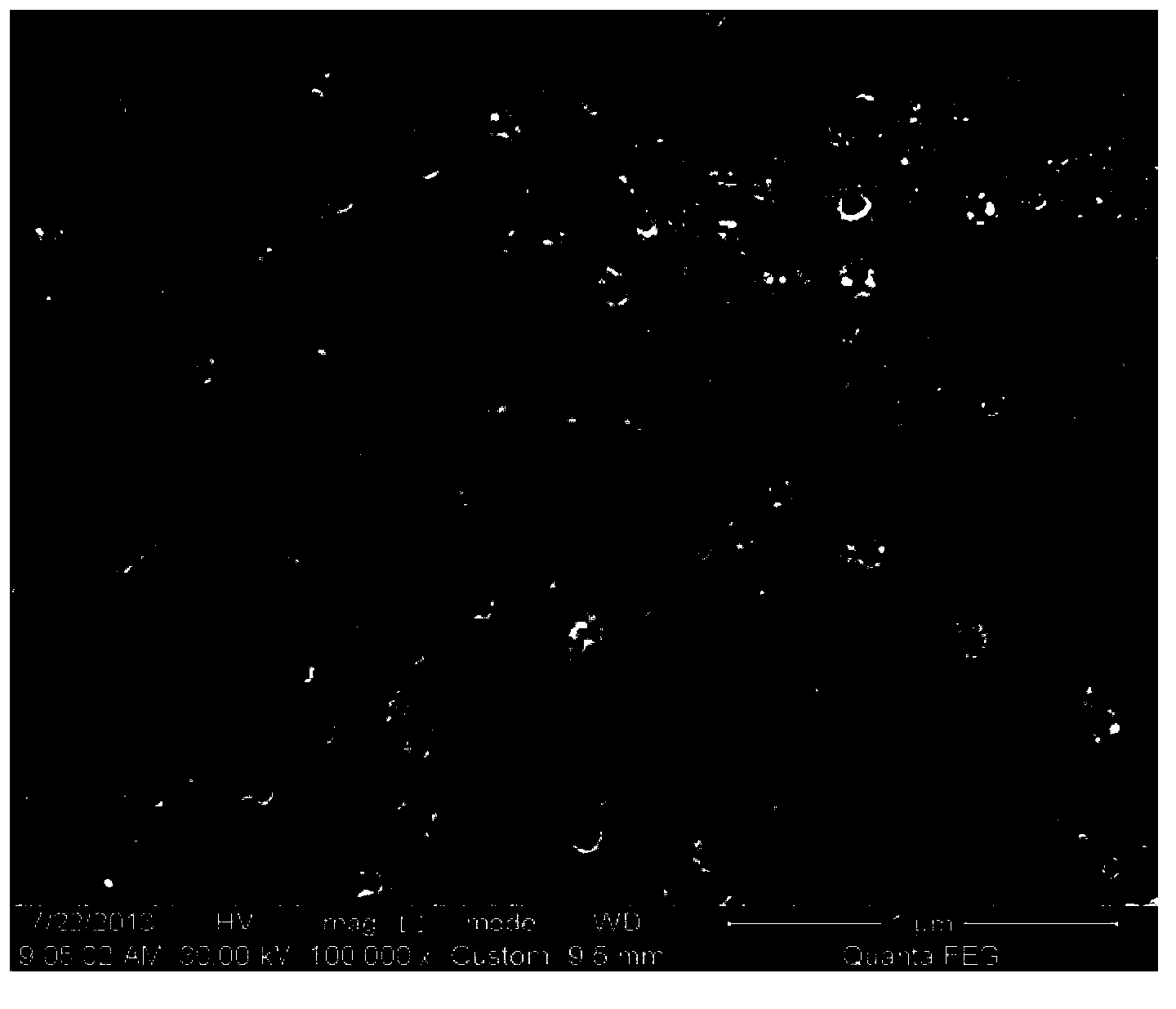

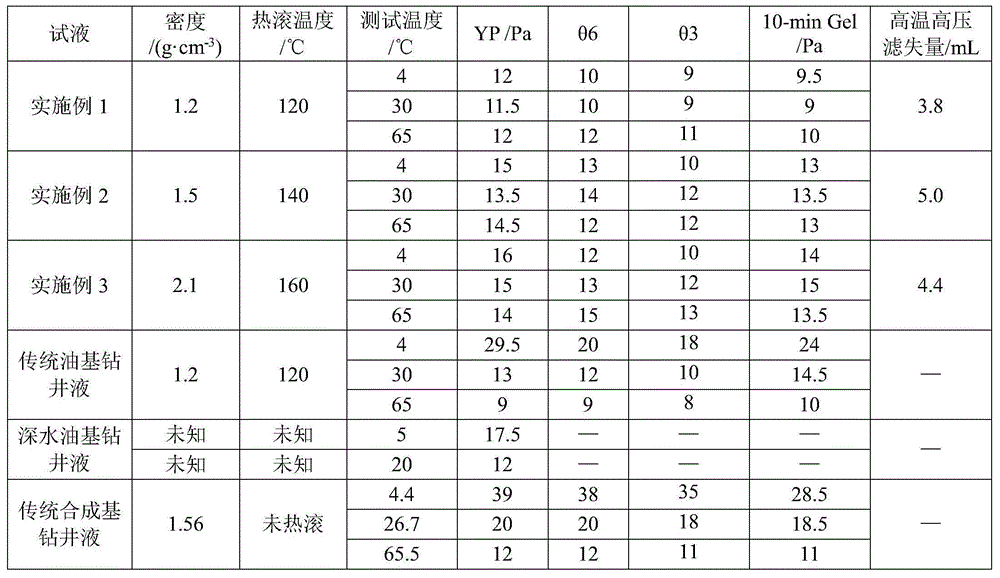

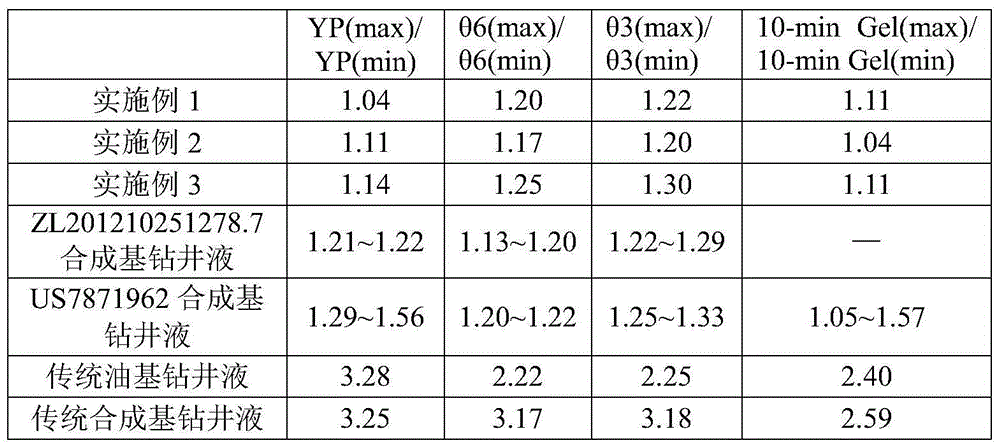

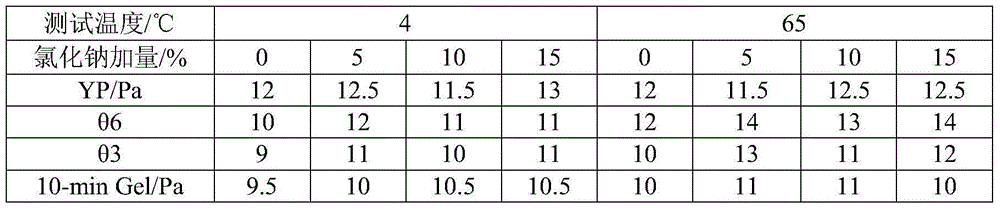

Deepwater constant-rheology oil base drilling fluid

ActiveCN104861944ARaw material requirements are relaxedLow costDrilling compositionDimer acidWhite oil

The invention discloses a deepwater constant-rheology oil base drilling fluid applicable for deep sea drilling. The deepwater constant-rheology oil base drilling fluid applicable for deep sea drilling comprises the following components in parts by weight: 70-100 parts of white oil, 0-30 parts of a calcium chloride aqueous solution, 1.5-5 parts of a fluid type conditioning agent, 1-4 parts of an emulsifying agent, 0.5-2.5 parts of a wetting agent, 1-3.5 parts of organic soil used for drilling fluid, 1.5-5 parts of a filtrate reducer, 0.2-0.6 parts of calcium oxide and 0-260 parts of a weighting agent. The fluid type conditioning agent is at least one of ethylene-propylene copolymer, polymethacrylate, trimeric acid, phenolic resin, copolymer generated from reaction of dimer acid, cholamine and polyethylene polyamine and copolymer generated from reaction of acrylamide, styrene and methacrylic acid. The movable shearing force and six-speed viscometer of the oil base drilling fluid is respectively less than 6 r / min and 3 r / min, and the 10-min static shearing force can be kept steady within 4-65 DEG C; constant eheology is realized in the temperature range of the barrel of the deepwater drilling, technical demands on sea deepwater drilling can be satisfied, requirements on base oil raw material are loose, and the cost is low.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

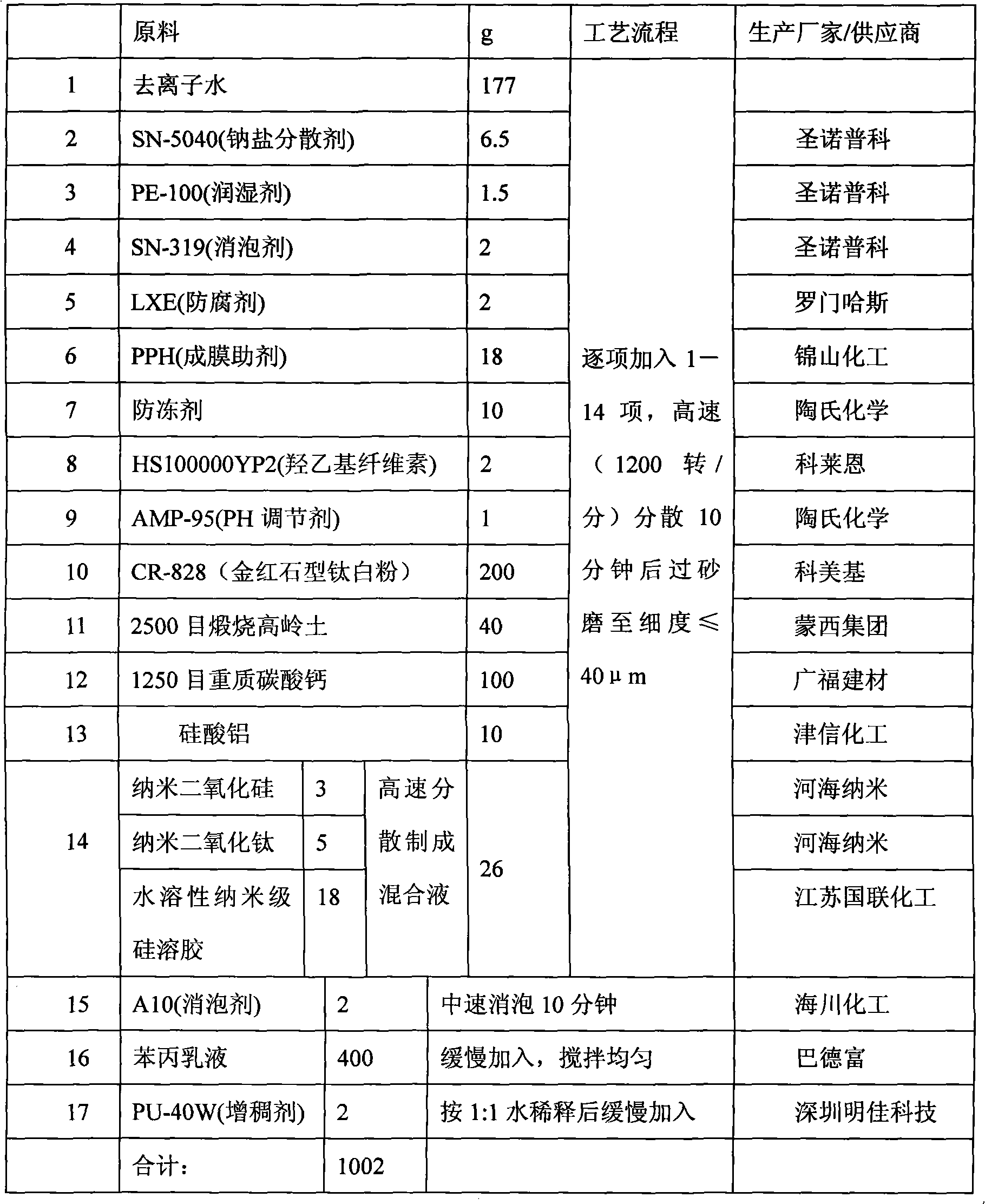

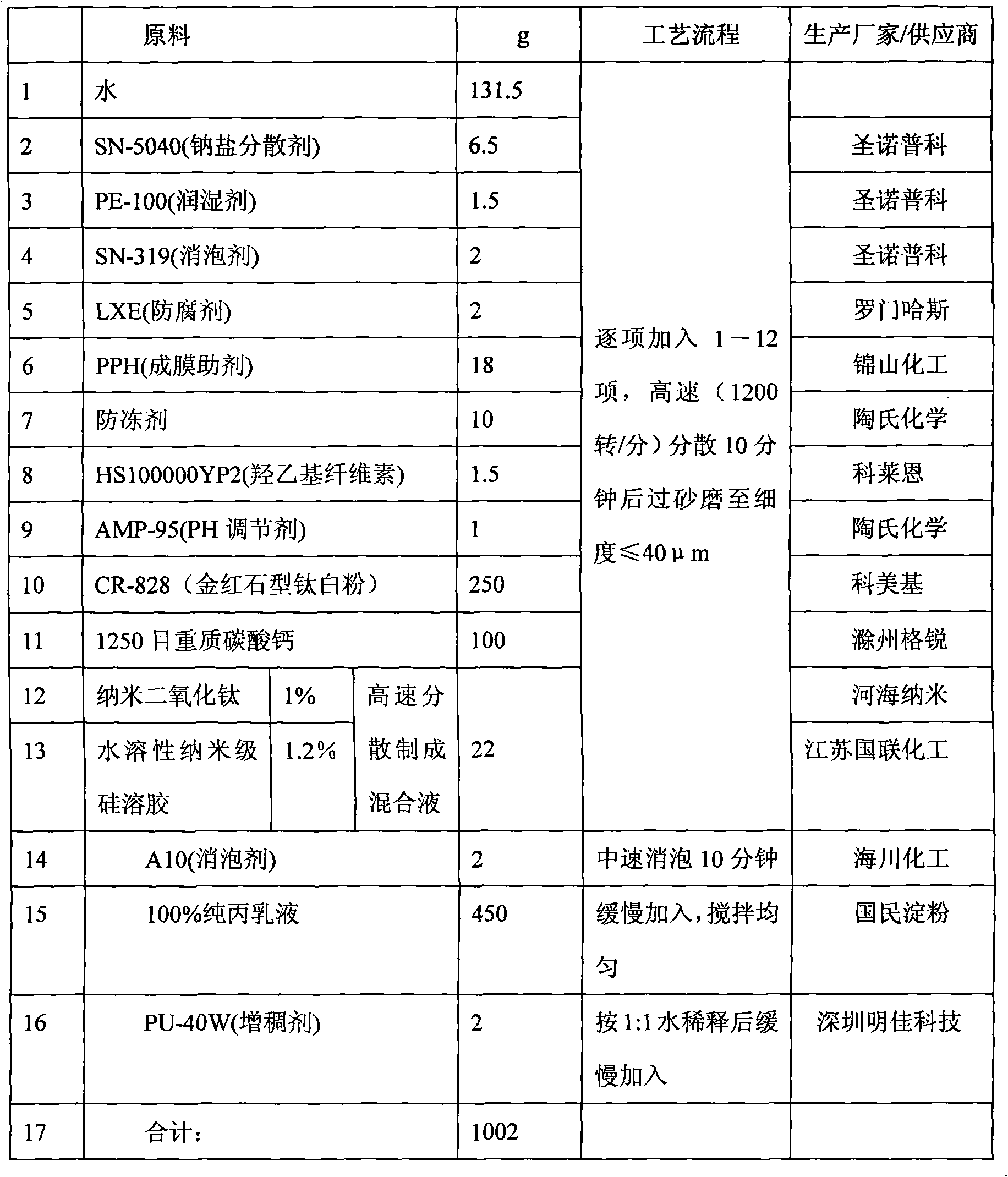

Nanometer interior wall coating g

InactiveCN101338101AImprove performanceImprove pollution resistanceEmulsion paintsMetallurgyAluminum silicate

The invention relates to a nano interior wall coating; the composition by the weight percent is as follows: 35 percent to 45 percent of film-forming material, 28 percent to 42 percent of pigment and filler, 4 percent to 7 percent of assistant, 0.6 percent to 1.2 percent of nano powdery material, 1.0 percent to 2.0 percent of water-soluble nano silica sol, and 10 percent to 30 percent of deionized water. The film-forming material can be styrene-acrylic latex or acrylic latex; the pigment and filler is one or more than one type among rutile titanium dioxide powder, calcined kaolin, heavy calcium carbonate and super-fine aluminum silicate; the assistant comprises one or more than one type among dispersant, wetting agent, foam killer, preservative, thickener, anti-freezing agent, ph regulator and film-forming assistant. The coating of the invention can continuously release negative ions under the radiation of a fluorescent lamp, and can effectively degrade the dissociative TVOC and formaldehyde content in the air; the washing resistant times reaches 20000 to 50000 times, and the manual aging resistance reaches more than 1000 hours. In addition, the coating saves the consumption of nano powdery material and reduces the production cost.

Owner:广州市星冠化工涂料有限公司

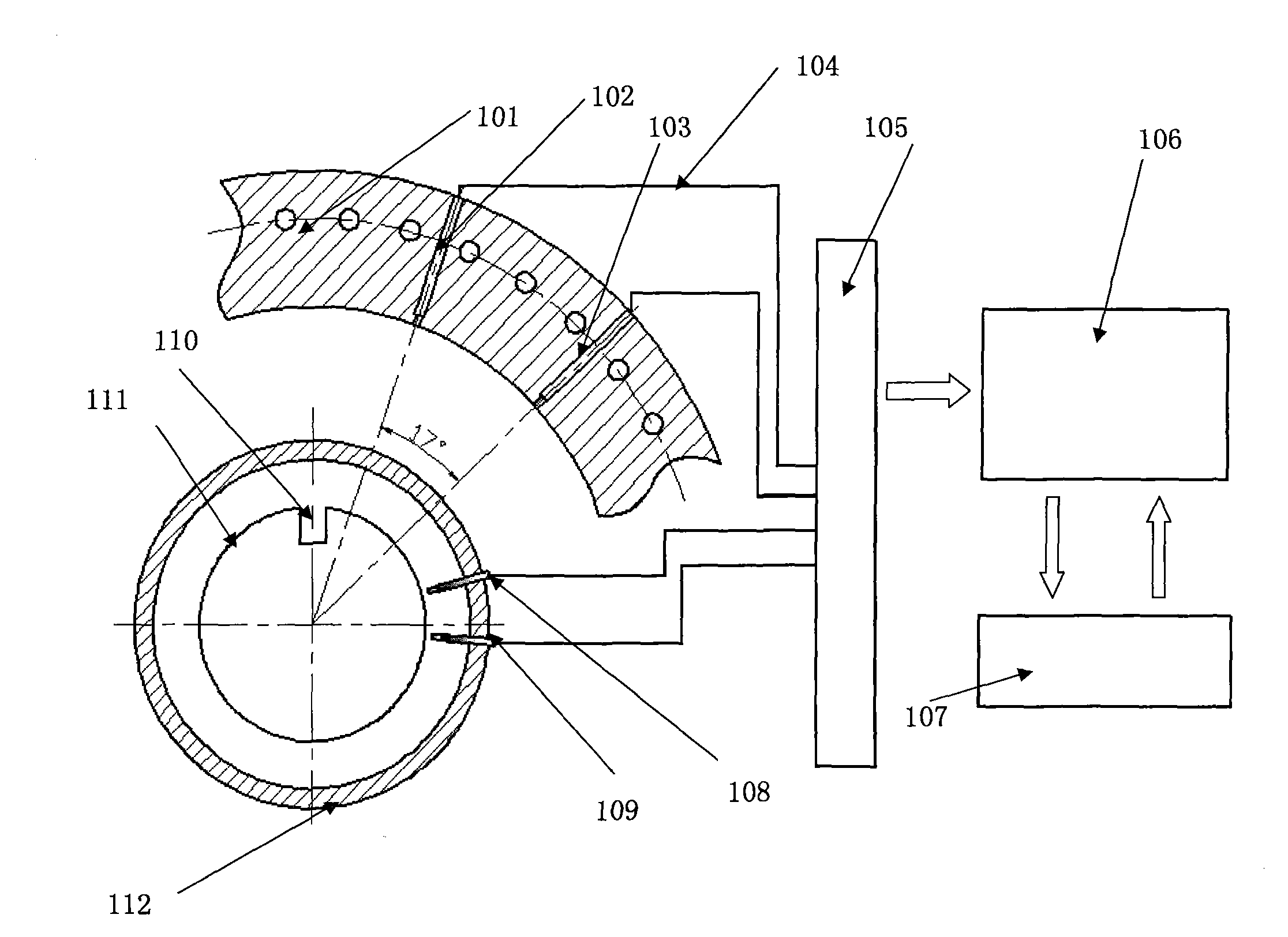

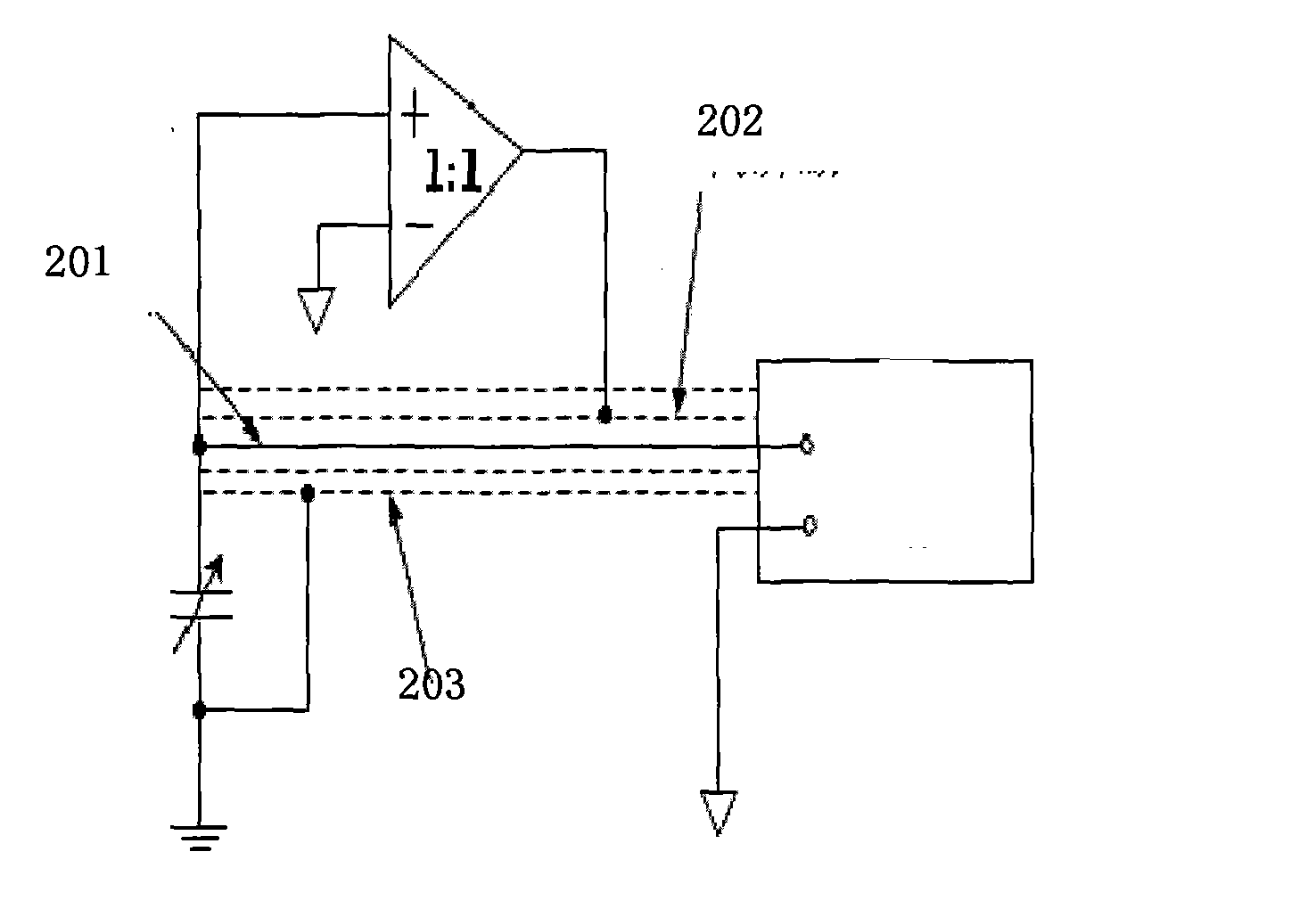

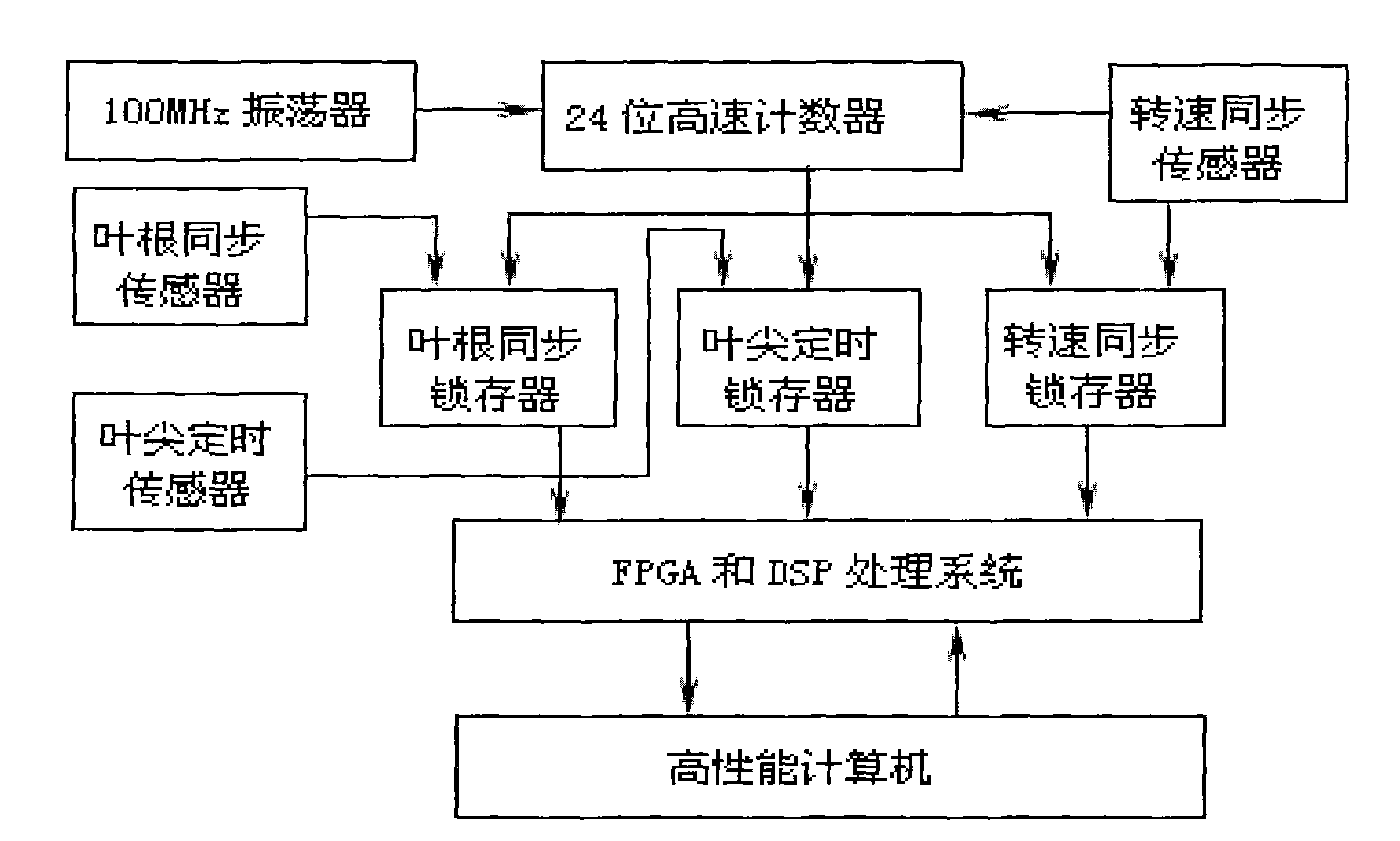

Real-time on-line monitoring apparatus of blade vibration of flue gas turbine

InactiveCN102735326AReal-time monitoring of vibrationHigh precisionSubsonic/sonic/ultrasonic wave measurementUsing electrical meansCapacitanceFlue gas

The invention relates to a real-time on-line monitoring apparatus of blade vibration of a flue gas turbine. The monitoring apparatus comprises blade tip timing sensors, an angle reference sensor, a rotating speed synchronization sensor, a preprocessing system, a data integrated processing card, and a computer. The blade tip timing sensors, the angle reference sensor, and the rotating speed synchronization sensor are connected with the preprocessing system that is connected with the data integrated processing card; and the data integrated processing card is connected with the computer. According to the invention, the sensors employ double-shielded capacitance impulsers; single-core double-shielded wires are utilized as transmission lines of output signals; and a driving cable technology is utilized to effectively reduce a random error introduced by an environmental interference; and a charge amplification circuit is used to extract a capacitance pulse signal, thereby eliminating the system error basically and improving the measurement accuracy of the system.

Owner:CHINA SPECIAL EQUIP INSPECTION & RES INST

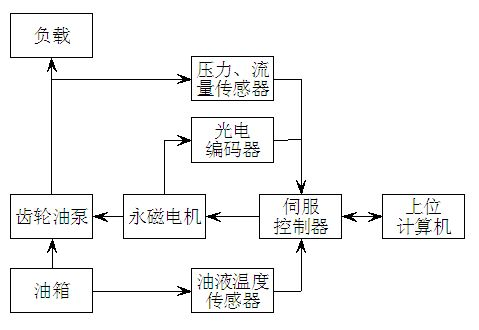

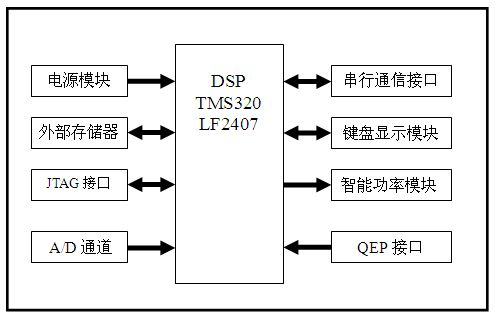

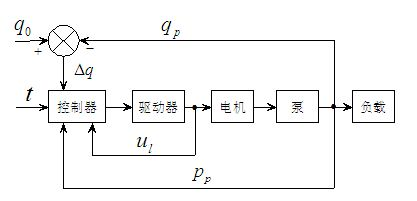

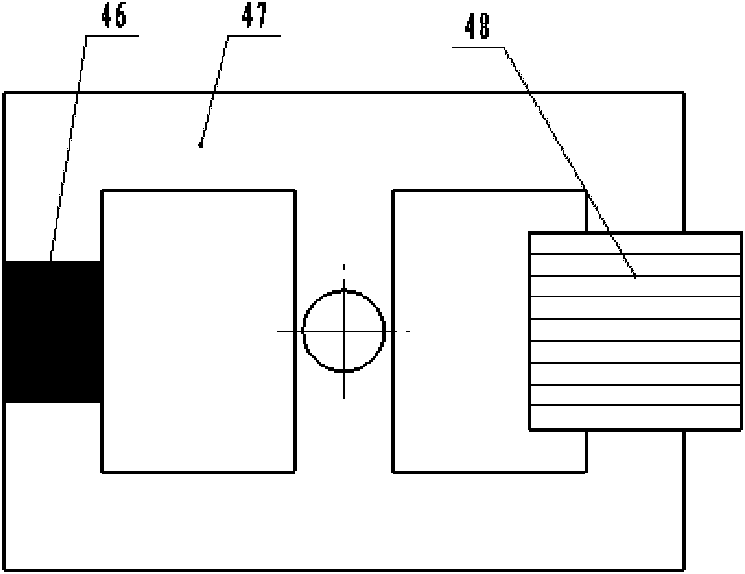

Energy-efficient hydraulic power supply driven by permanent magnet servo motor

InactiveCN101900153ALarge overload multipleQuick responseFluid-pressure actuator testingFluid-pressure actuator componentsLow speedClosed loop

The invention discloses an energy-efficient hydraulic power supply driven by a permanent magnet servo motor, which comprises the permanent magnet servo motor, a servo controller, a hydraulic oil pump (comprising a gear oil pump, a vane pump, and a plunger pump), a sensor and the like. An oil pump is driven by the high-efficiency permanent magnet servo motor which has good mechanical characteristic, large overload magnification, and high speed regulation performance; a system for redundancy monitoring of system flow and pressure by pressure-flow double closed loop control and the voltage and current of the motor is adopted; and an oil temperature compensation function is realized. According to different hydraulic pressure load working conditions, three working modes of pressure self-adaption, flow self-adaption, and power self-adaption are provided, and each working mode is optimized by adopting different control strategies. Therefore, the energy-efficient hydraulic power supply has the advantages of wide application range, high system efficiency, high low-speed stability, quick response, accurate speed regulation and the like.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

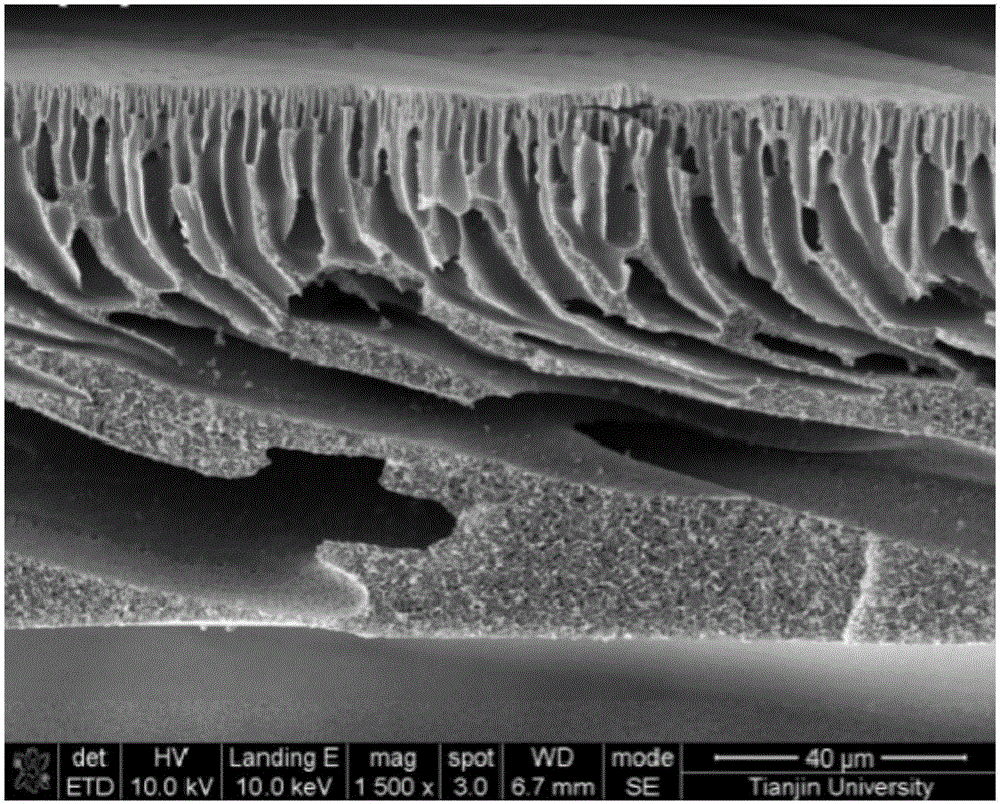

Novel method for amphiphilic copolymer modified PVDF (Polyvinylidene Fluoride) hollow fiber ultra-filtration membranes

InactiveCN103007787AStrong anti-pollutionImprove throughputSemi-permeable membranesFiltration membraneFoaming agent

The invention relates to a novel method for amphiphilic copolymer modified PVDF (Polyvinylidene Fluoride) hollow fiber ultra-filtration membranes, and belongs to the technical field of preparation of PVDF membranes. The method comprises the following steps: (1) PVDF, amphiphilic copolymer, pore-foaming agent, nonsolvent and solvent are fully mixed, and are dissolved to obtain membrane casting liquid; (2) the membrane casting liquid is fed in a hollow fiber membrane spinning machine for extruding, is condensed and formed in a coagulating bath, and is wound and collected to obtain the PVDF hollow fiber membranes; (3) the PVDF hollow fiber membranes are dipped in hot water; and (4) finished products are obtained after cleaning and drying. The amphiphilic copolymer modified PVDF hollow fiber ultra-filtration membranes, prepared by the method, have the characteristics of permanent hydrophilcity, excellent pollution resistance, high throughput and high reject rate.

Owner:SHAOXING REEYEE ENVIRONMENTAL PROTECTION TECH

Anti-pollution high efficiency isolation liquid and preparing method

The present invention relates to anti-pollution high efficiency isolating liquid for shaft wall cementing operation and its preparation process. The isolating liquid is compounded through adding suspension stabilizer, water reducing agent, tackifier, diluent, viscosity and shearing force increasing agent, weight additive and pH regulator in certain weight proportion into water. One compounding process is a water base process through throwing the said components successively into water in a slurry tank apparatus. One other compounding process is one dry mixture process in a cementing tank apparatus. The isolating liquid has flexible compounding process, high anti-pollution capacity and effective eliminating effect on well wall interface pollutant.

Owner:SOUTHWEST PETROLEUM UNIV

Normal-temperature sealer for anodic oxide film of aluminum and aluminum alloy and sealing method thereof

InactiveCN101665970AQuick sealImprove sealing efficiencySurface reaction electrolytic coatingTetramineDodecylsulfonic acid

The invention provides a normal-temperature sealer for an anodic oxide film of aluminum and aluminum alloy. The sealer is characterized by comprising the following components in concentration (g / L): Ni<2+>0.8-1.3, F<-> 0.4-0.8, triethanolamine 0.1-5.0, hexamethylene tetramine 0.1-1.0, sodium dodecanesulphonate0.001-0.1, bloom inhibitor 0.01-2.0 and the balance of water. The invention also discloses a sealing method for the sealer. Compared with the prior art, the sealer has the advantages of low cost, easy preparation, easy operation, and great improvement on the surface anti-pollution ability, the anti-corrosion property and the electric insulativity of the anodic oxide film of the aluminum alloy.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

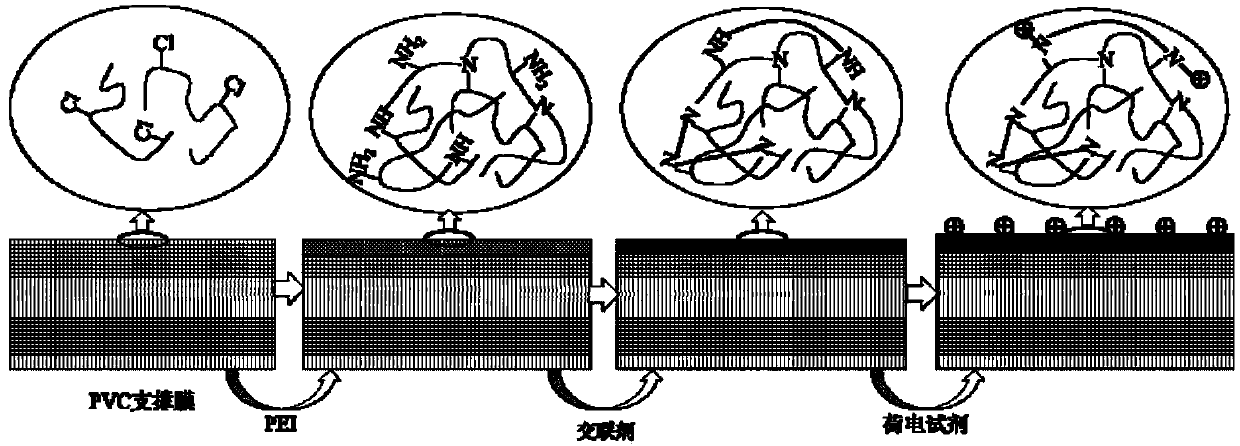

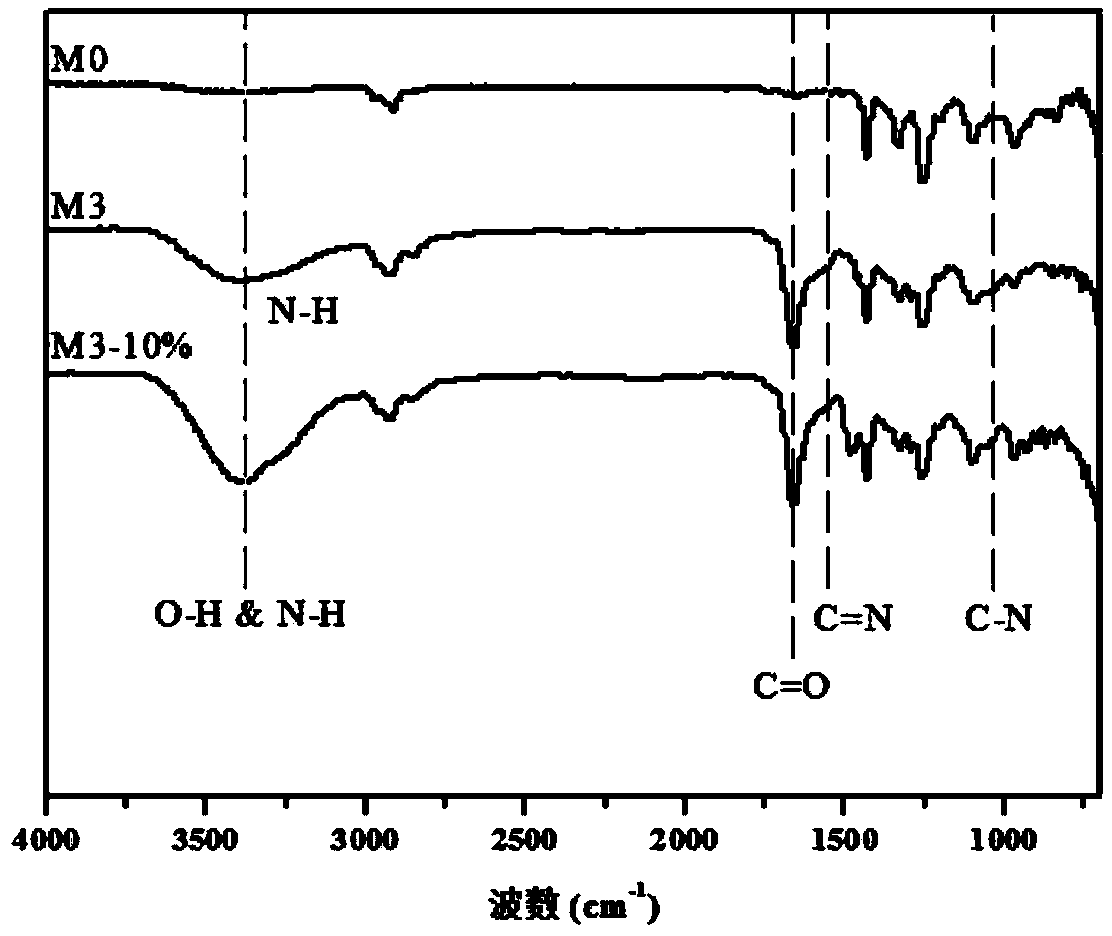

Low-pressure high-flux chlorine-containing polymer nanofiltration membrane with stable separation layer and preparation method thereof

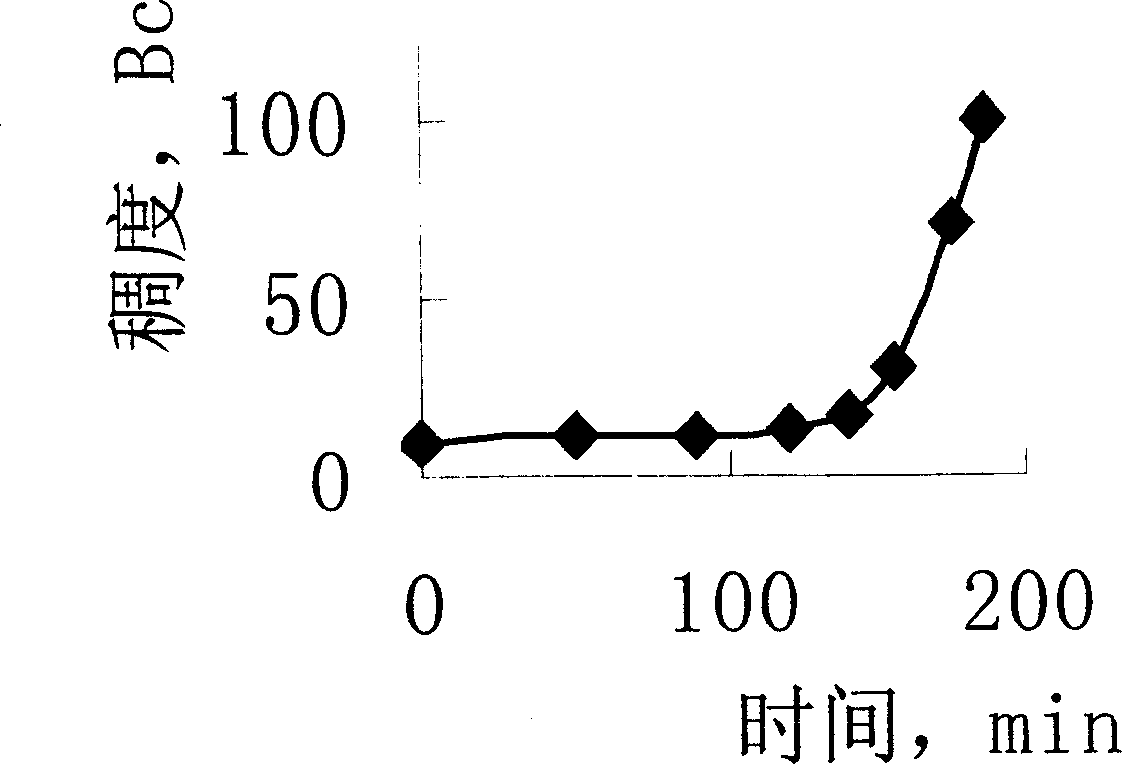

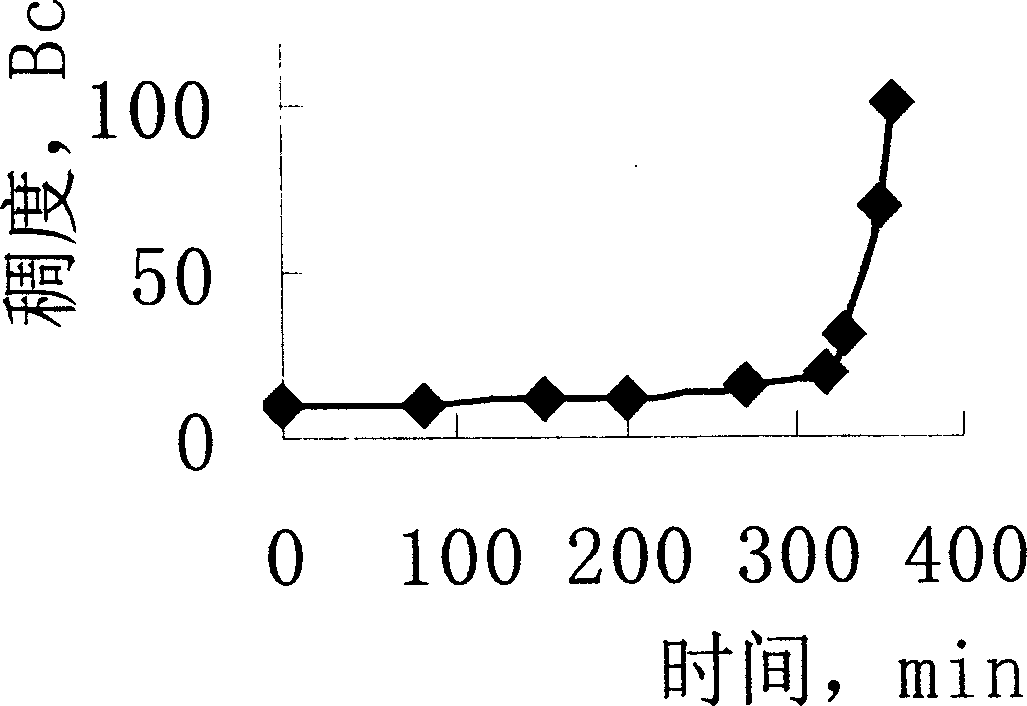

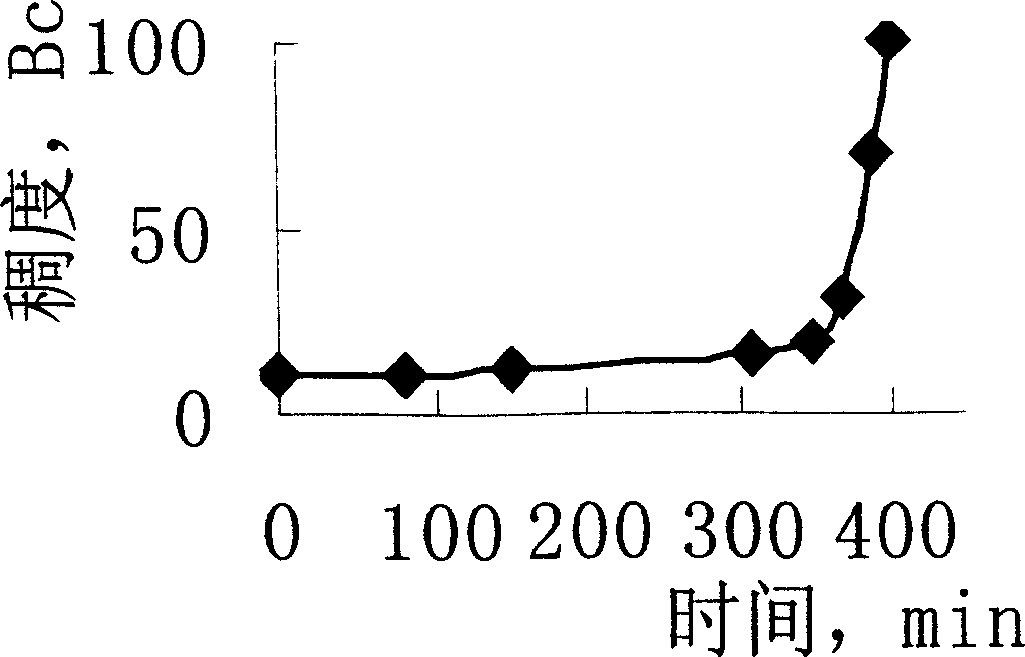

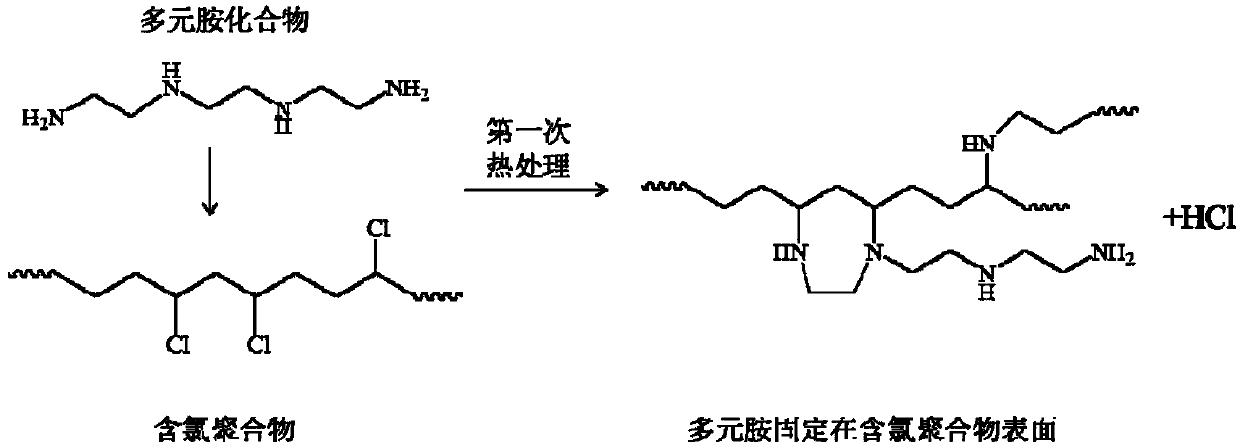

The invention discloses a low-pressure high-flux chlorine-containing polymer nanofiltration membrane with a stable separation layer and a preparation method thereof. The nanofiltration membrane comprises a macroporous support layer and a dense function layer, wherein the macroporous support layer and the dense function layer are connected with each other by virtue of a C-N bond; the dense function layer is made of a positive, charged or amphoteric ionic cross-linking polyamine compound; the macroporous support layer is made of a chlorine-containing polymer. The preparation method of the filtration membrane comprises the following steps: firstly coating the surface of a chlorine-containing polymer ultrafiltration membrane with the polyamine compound, carrying out heat treatment, washing the ultrafiltration membrane, then dipping the ultrafiltration membrane in a mixed solution of a cross-linking agent and a charge reagent and carrying out heat treatment again. The membrane flux of the prepared polymer nanofiltration membrane can reach 60L / m<2>.h under the pressure of 0.3MPa; the retention rate on micromolecule dye and high-valence inorganic salt can reach 90%; the chlorine-containing polymer nanofiltration membrane can be in a flat fiber ultrafiltration membrane form or a hollow fiber ultrafiltration membrane form, and has good practical prospect.

Owner:ZHEJIANG UNIV

Composite type rotary encoder and measurement method thereof

InactiveCN104457806AHigh precisionAvoid measurement errorsUsing optical meansConverting sensor outputObservational errorEngineering

The invention discloses a composite type rotary encoder and a measurement method of the composite type rotary encoder. The composite type rotary encoder comprises an optical system, a circular coding ring, a rotating shaft, a data collecting module and a data processing unit. The optical system comprises a plurality of light source modules evenly distributed on the surface of the rotating shaft, the circular coding ring and the rotating shaft are coaxially installed, and a plurality of relative code ways and a plurality of absolute code way sets are sequentially arranged on the circular ring inner side face of the circular coding ring. The distances between photoelectric sensors of the relative code ways are equal, the distances between photoelectric sensors of a plurality of absolute code ways of each absolute code way set are equal, and the distances between the photoelectric sensors of the absolute code way sets are gradually increased according to position relations. The relative code ways and each absolute code way are independently connected with the data collecting module, and the data collecting module is connected with the data processing unit. The composite type rotary encoder and the measurement method of the composite type rotary encoder are capable of avoiding measurement errors caused by radial jumps, high in measurement precision, high in anti-interference capability and anti-pollution capability, high in reliability and capable of being widely applied to the field of measurement of rotating angles.

Owner:NANTONG DUOQIAN NEW MATERIAL SCI & TECH CO LTD

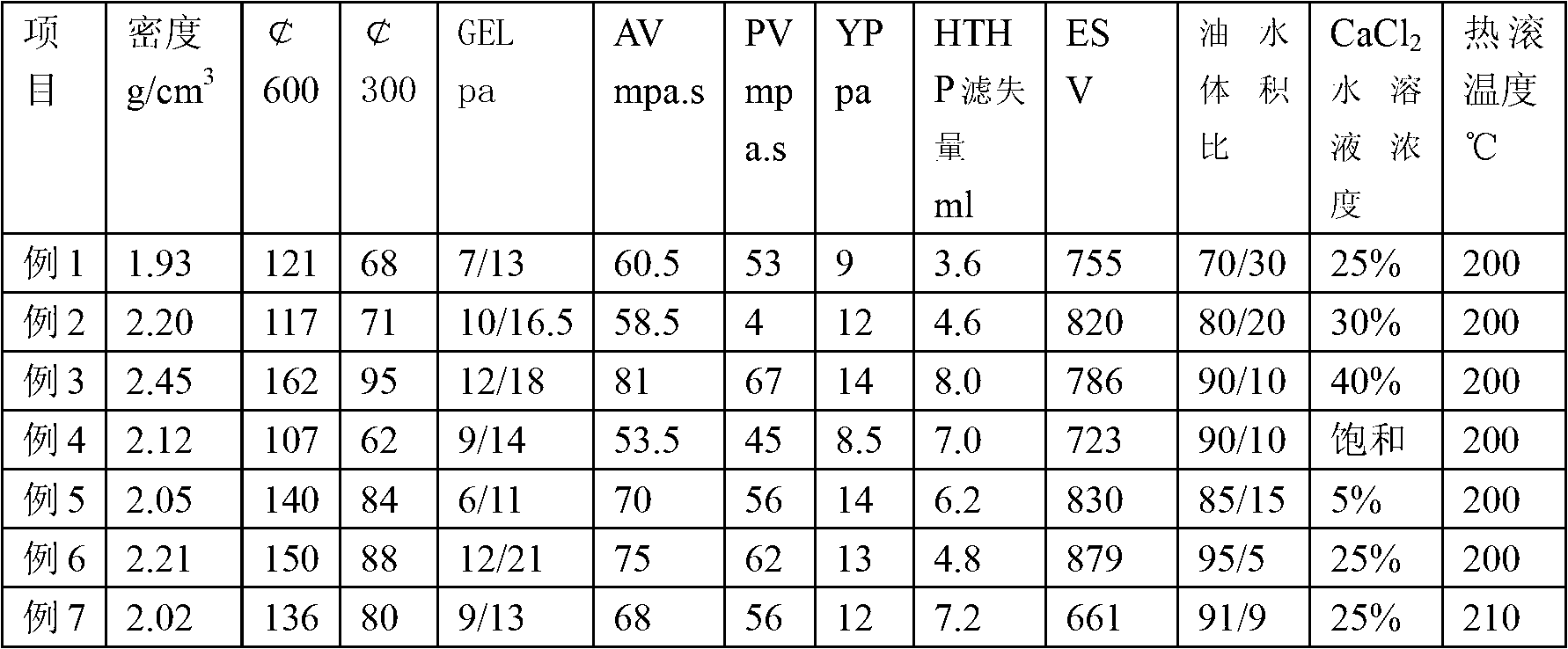

Gas oil base invert oil-emulsion drilling fluid and preparation method

InactiveCN102796497AStrong salt resistanceGood temperature resistanceDrilling compositionTemperature resistanceChemistry

The invention relates to a gas oil base invert oil-emulsion drilling fluid and a preparation method, wherein the total volume of gas oil and calcium chloride aqueous solution is 100 parts: the volume ratio of oil phase to water phase is between 95:5 and 70:30, and the concentration of calcium chloride aqueous solution is 5%-saturation; the required gas oil, primary emulsion, auxiliary emulsion and wetting agent are added into a high speed mixing beaker, and are mixed at high speed for 2-5 minutes; the calcium chloride aqueous solution is added and mixed at high speed for 15 minutes; organic soil, calcium oxide and a fluid loss agent are added and mixed at high speed for 10 minutes; and the required amount of barite is added according to density, and is mixed at high speed for 25 minutes. The gas oil base invert oil-emulsion drilling fluid is used for overcoming the defects of the existing gas oil base drilling fluid and solving the problems of the salt resistance and temperature resistance of the gas oil base drilling fluid, and can resist the temperature above 200 DEG C.

Owner:COSL CHEM TIANJIN +1

Livestock and poultry breeding wastewater treating technology

InactiveCN106007201AReduce SS contentEasy to settleSludge treatment by de-watering/drying/thickeningTreatment using aerobic processesPig farmsFeces

The invention discloses a livestock and poultry breeding wastewater treating technology and belongs to the technical field of treatment of livestock and poultry breeding waste. The method comprises the following steps of gravity sedimentation pretreatment, flocculation treatment, special ultrafiltration treatment, nanofiltration treatment, reverse osmosis treatment and aeration biological filter treatment. The membrane technology is used as the core, and a whole set of complete-process technology, which has the good separation and removal effect on organic matter, nitrogen, phosphorus and the like in livestock and poultry breeding wastewater, makes the processed waste water reach the pollution discharge standards in livestock and poultry breeding industry, and is wide in application range and suitable for livestock and poultry breeding wastewater zero discharge of various feces removal, is provided, wherein effluent can be recycled for washing hog houses, pig farm landscape water and toilets and the like.

Owner:嘉兴悟净环保科技有限公司

Polyamide film composite membrane and preparation method and application thereof

InactiveCN106914152AIncrease water fluxLow reverse salt fluxSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisPolyamideActive layer

The invention discloses a polyamide film composite membrane and a preparation method and application thereof. The composite membrane comprises a polymer support layer and a polyamide active layer. The polyamide active layer is obtained by a reaction of a multielement acyl chloride solution and a polyamine aqueous solution containing a tertiary amine additive. In the preparation process, the polyamine aqueous solution containing the tertiary amine additive and the multielement acyl chloride solution undergo an interfacial polymerization reaction to produce the modified polyamide active layer so that the film-forming process is greatly simplified. The composite membrane has a high crosslinking degree and high compactness, and has a high water flux in membrane separation, a low reverse salt flux and good anti-fouling properties.

Owner:HUAZHONG UNIV OF SCI & TECH

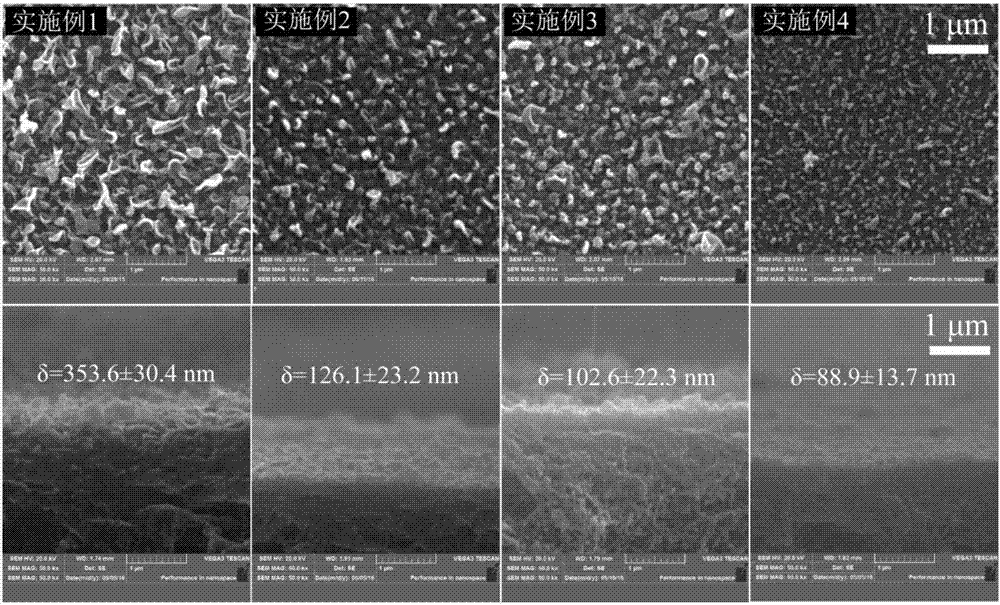

Polyvinylidene fluoride organic-inorganic hybrid membrane and preparation method thereof

InactiveCN102430352AImprove hydrophilicityIncrease membrane fluxSemi-permeable membranesSolventPolyvinylidene fluoride

The invention relates to a polyvinylidene fluoride membrane and a preparation method thereof, and specially, relates to a polyvinylidene fluoride organic-inorganic hybrid membrane and a preparation method thereof. A casting solution of the polyvinylidene fluoride organic-inorganic hybrid membrane comprises 14 to 25% of polyvinylidene fluoride, 3 to 12% of one or more mixed polymers, 0.2 to 5% of one or more inorganic nanometer additives, 4 to 12% of one or more hydrophilic pore-forming agents, 0.05 to 3% of a surfactant and 50 to 80% of one or two solvents. The casting solution is prepared and then is processed into a polyvinylidene fluoride organic-inorganic hybrid membrane finished product through a dry-wet spinning technology. Compared with the prior art, the preparation method adopts hydrophilic mixtures and hydrophilic inorganic nanometer particles simultaneously and thus further improving membrane wire hydrophily, membrane flux and membrane contamination resistance.

Owner:SANDA FILM SCI & TECH XIAMEN

Preparation method of anti-pollution composite nanofiltration membrane

ActiveCN110052179AEasy to separateWater flux effectSemi-permeable membranesHydrophilic polymersSalt bridge

The invention provides a preparation method of an anti-pollution composite nanofiltration membrane. The preparation method includes subjecting a polysulfone ultrafiltration membrane to primary interfacial polymerization by a first aqueous phase solution and an oil phase solution, pouring a second aqueous phase solution containing nonionic hydrophilic polymers onto the surface of the ultrafiltration membrane to conduct secondary interfacial polymerization, removing the second aqueous phase solution, conducting heat treatment, and taking out the membrane for washing to obtain the composite nanofiltration membrane. The preparation method has the advantages that the nonionic hydrophilic polymers containing ether bonds in main chains are embedded in a polyamide layer through the secondary interfacial polymerization, the surface of the modified membrane is smooth, and the surface roughness is lowered; through introduction of nonionic hydrophilic groups, the number of residual carboxyl groupson the surface can be remarkably decreased, pollutant adsorption and salt bridge effect can be effectively reduced, and the anti-pollution performance of the nanofiltration membrane is improved; theoperation process is simple and convenient, and the preparation method is convenient for industrial production and has a broad application prospect in anti-pollution modification of the composite nanofiltration membrane.

Owner:WANHUA CHEM GRP CO LTD +1

Method for preparing Kefir sour milk

The invention discloses a method for preparing Kefir sour milk which comprises water, sugar and sour milk prepared from the fermentation of two different Kefir grains; the preparing method comprises the follow steps: 1. raw milk is sterilized and then cooled to the temperature of 20 DEG C to 30 DEG C; 2. the two different Kefir grains are activated and cultured separately; 3. the activated and cultured Kefir grains with inoculum size of 2 percent to 5 percen are respectively inoculated to the sterilized raw milk; 4. the raw milk is fermented for 15 hours to 24 hours at the temperature of 20 DEG C to 30 DEG C; 5. the Kefir grains are filtered out to obtain two filtrates which are fermentation agents; 6. the two fermentation agents are mixed; 7. the mixed fermentation agents with the inoculum size of 2 percent to 5 percent are inoculated to the sterilized original milks and then fermented at the variable temperature ranging from 20 DEG C to 45 DEG C for 4 hours to 6 hours; and 8. the fermented milk are blended, homogenized and canned. With the adoption of the fermentation agents for fermenting at the variable temperature, the flavor of Kefir milk is well improved. The ferment time of the product is short, the yeasts in the mixed fermentation agents are more stable and the difference between flavors of Kefir sour milk prepared in different batches is small. The product has health-care functions of regulating beneficial bacteria in intestinal canals, lowering blood lipids, resisting tumors and the like, thus being a low-cost functional beverage.

Owner:于岚 +2

Hydrophilic and oleophobic easy-to-clean organic coating and preparation method thereof

ActiveCN102585664AImprove wettabilityEasy to replaceEpoxy resin coatingsOrganic solventFluorine containing

The invention discloses a hydrophilic and oleophobic easy-to-clean organic coating and a preparation method thereof. The organic coating is obtained by curing an organic solution by a curing agent, the organic solution is a fluorine-containing polyurethane modified epoxy resin solution formed by carrying out a reaction on fluorine-containing polyurethane and an epoxy resin in an organic solvent, and the fluorine-containing polyurethane and the epoxy resin form a semi-interpenetrating network structure formed through the bonding of chemical bonds. A micro area with uniformly distributed hydrophilicity and oleophobicity is constructed on the surface of an object to be coated through the semi-interpenetrating structure and low surface performances of fluorine, so the hydrophilic and oleophobic easy-to-clean organic coating is formed. Experiments prove that the lowest contact angle between the organic coating and water can reach 15DEG, and the highest contact angle between the organic coating and oil can reach 90DEG, so water can thoroughly displace oil stains on the surface of an original solid, and an easy-to-clean effect is reached.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Composite high-efficiency high-flow servo valve

InactiveCN102213243ASmall excitation powerHigh frequency responseOperating means/releasing devices for valvesServomotor componentsControl engineeringAlloy

The invention relates to a composite high-efficiency high-flow servo valve. The technical scheme is as follows: the servo valve consists of a composite flow valve and a composite magnetic control motor, two ends of the composite flow valve are respectively connected with a left haft part and a right half part of the composite magnetic control motor. A first electromagnetic converter [2] and a displacement sensor [44] are concentrically arranged in a left shell [3] from left to right in sequence; a valve core [5] is movably arranged in a valve sleeve [11] that is fixed in a valve body [8]; an angle displacement sensor [37], a second electromagnetic converter [19], a left sliding bearing [35], a gear shaft [28] and a right sliding bearing [29] are concentrically arranged in a right shell [17] from left to right in sequence; one side of the gearing shaft [28] is provided with a rack [31] that is meshed with the gear shaft [28]; and one end of the valve core [5] of the composite flow valve is in contact with an end surface of a first electromagnetic memorial alloy [45], and the other end of the valve core [5] is fixedly connected with a second magnetic control memorial alloy [36]. The servo valve has the characteristics of high frequency response, high reliability, high flow, small volume, small leakage, compact structure and high precision.

Owner:WUHAN UNIV OF SCI & TECH

Antifouling and antibacterial coating paint and applications thereof

InactiveCN104327663ADurable antifouling and antibacterial abilityStrong antibacterial activityAntifouling/underwater paintsPaints with biocidesMethacrylateBetaine

The invention discloses an antifouling and antibacterial coating paint, which is prepared by taking methanol as a solvent through carrying out quaterisation reaction on copolymers methoxy polyethylene glycol-b-poly(ethyl methacrylate) dimethyl sulfo-propane betaine-b-poly dimethylaminoethyl methacrylate and 3-triethoxysilane. The invention also discloses applications of the paint in preparing coatings on the surfaces of ships, marine engineering machineries and sewage treatment equipment so as to implement antifouling and antibacterial treatment. Experiments show that a polymer coating prepared by using the paint disclosed by the invention has excellent protein adsorption and microbial contamination resistance, and has lasting antifouling and antibacterial abilities, and therefore, the paint has a board market prospect, and has significant social and economic values.

Owner:SHANDONG JIAOTONG UNIV

Nano self-crosslinked acrylate paint for external wall and method for making same

InactiveCN1632015AImprove surface energyLow film forming temperatureCoatingsHydrophilic coatingLow speed

The invention relates to a method to prepare a new hydrophilic coating for outside wall containing nmself-crosslinking acrylic ester latices and nm inorganic powder. Its dispensation is:nm indoor crosslinking acrylic ester latex(5-40%), indoor crosslinking acrylic ester latex(20-50%),inorganic nm powder(0.1-20%),inorganic filler(10-50%),film-forming assistant(0.05-5.0%) and the other is water without ion. Its preparing method is:firstly use high speed dispersion and sand grinding method to prepare nm disperseion and filler color which are then mixed with nm self-crosslinking acrylic ester latex and general acrylic ester latex, add into assistant and stir them by media-low speed for 0.5-1.5h,filter and package. The coating has good stability and film-forming performance,strong adhesive force and resistance to pollution, outstanding thermo insulating property, as well as self-cleaning performance.

Owner:上海梅盛企业发展有限公司

Method for preparing homogeneous-phase anion exchange film

InactiveCN1978038ASafe homogeneous performanceHomogeneous performance is stableSemi-permeable membranesAnion exchangersDialysis membranesFuel cells

The present invention relates to a preparation method of homogeneous anion-exchange membrane. Said method includes three processes of membrane-casting liquor preparation, membrane-forming and amination. Said invention also provides the concrete steps of above-mentioned every process. Said homogeneous anion-exchange membrane has extensive application field, it can be used for making concentration or desalination of dilute brine solution in electrodialysis method, can be used as electrolytic diaphragm in metallurgical industry, can be used as diffusive dialysis membrane for recovering acid and can be used as anionic selective electrode, etc.

Owner:UNIV OF SCI & TECH OF CHINA

Bacillus subtillis strain containing ramie degumming activity, preparation and application thereof

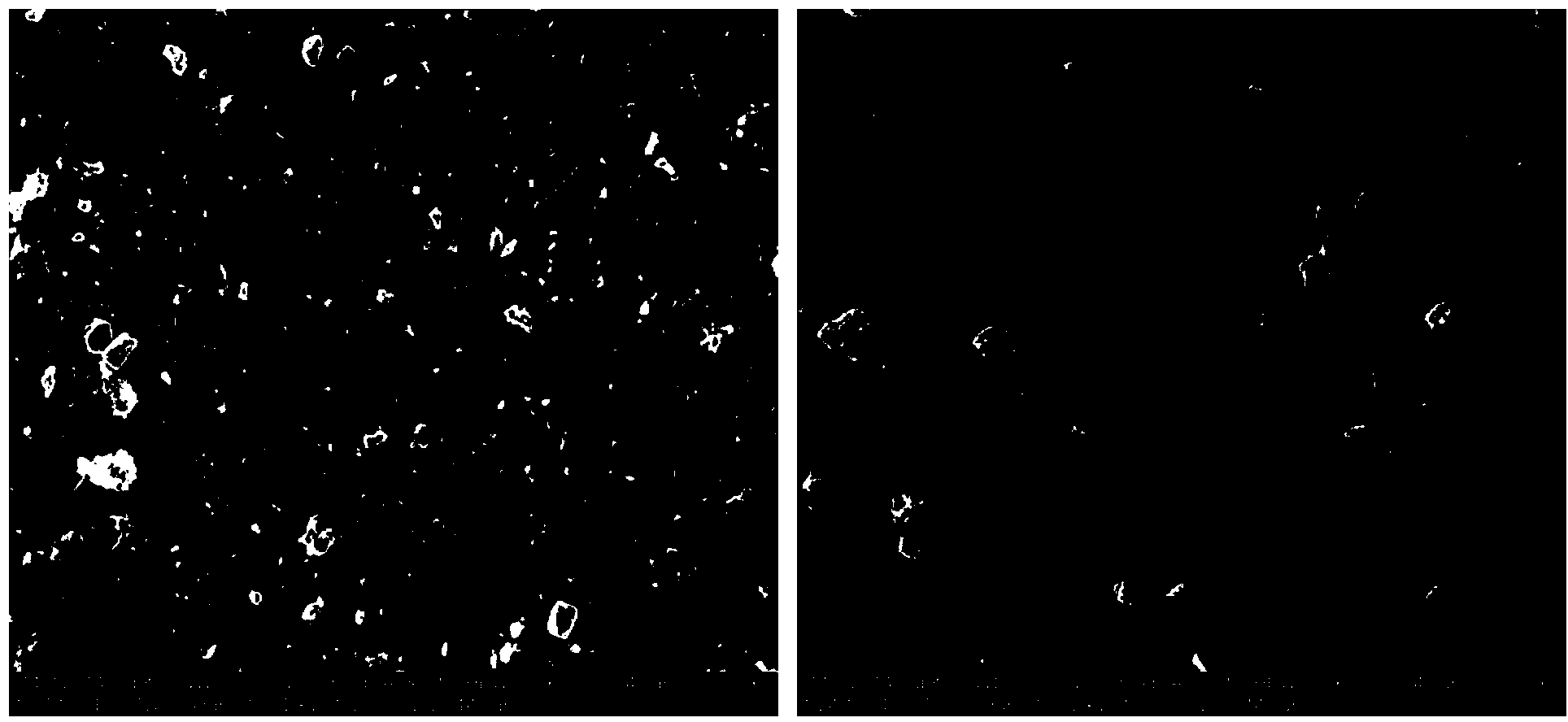

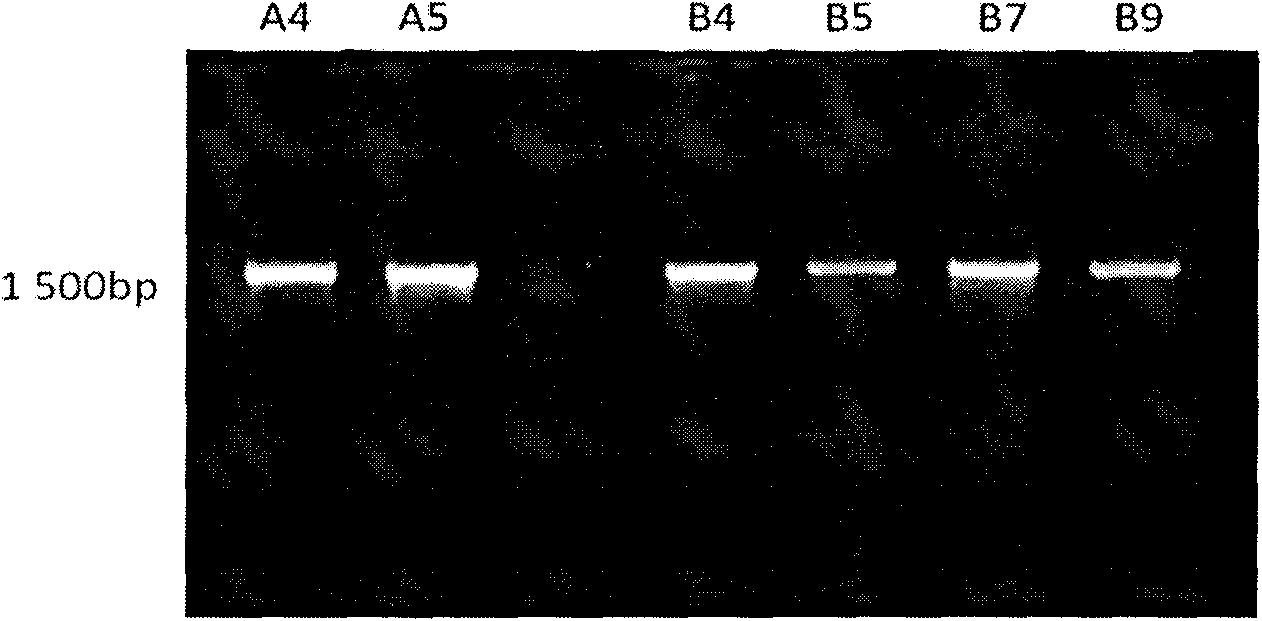

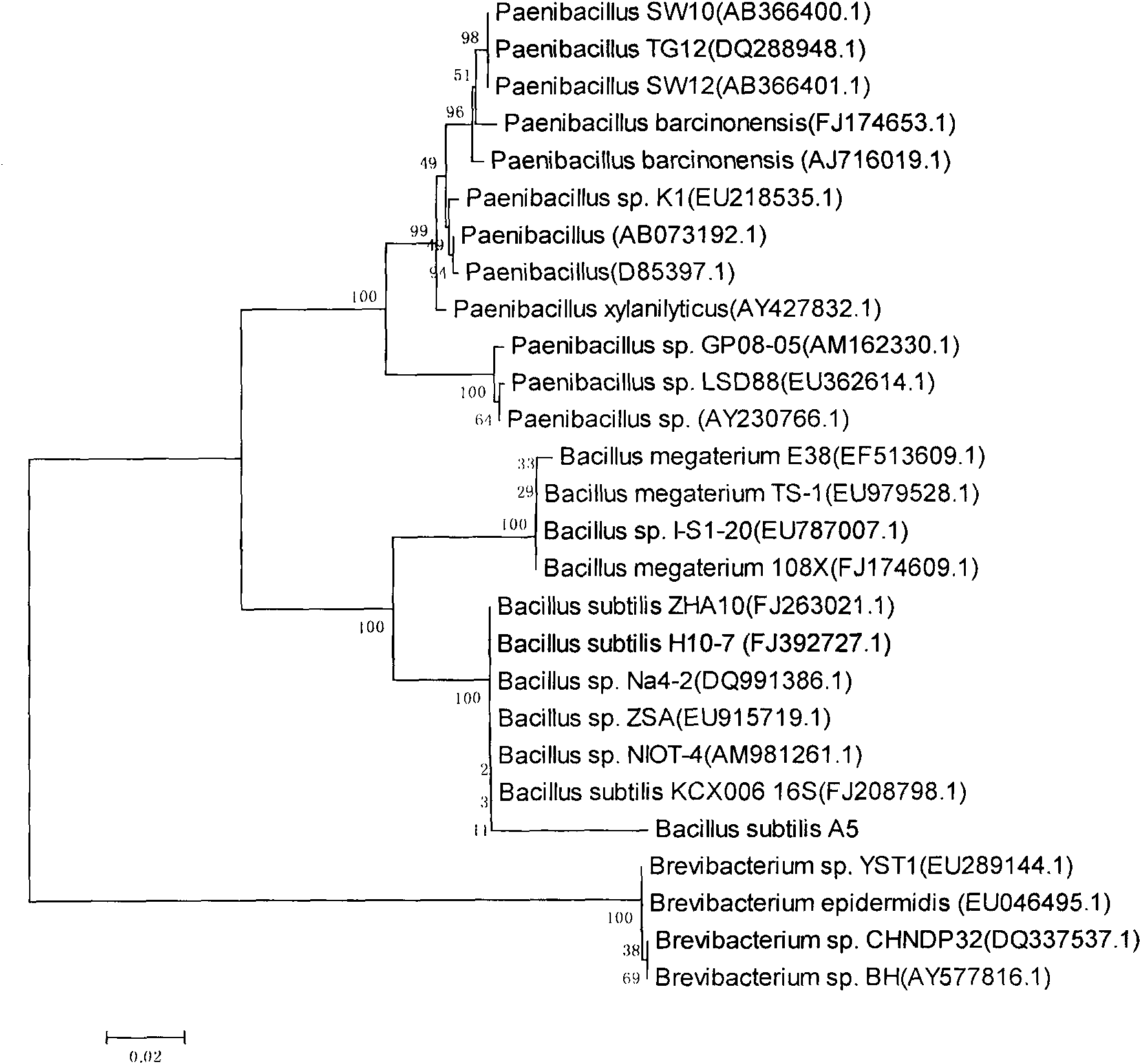

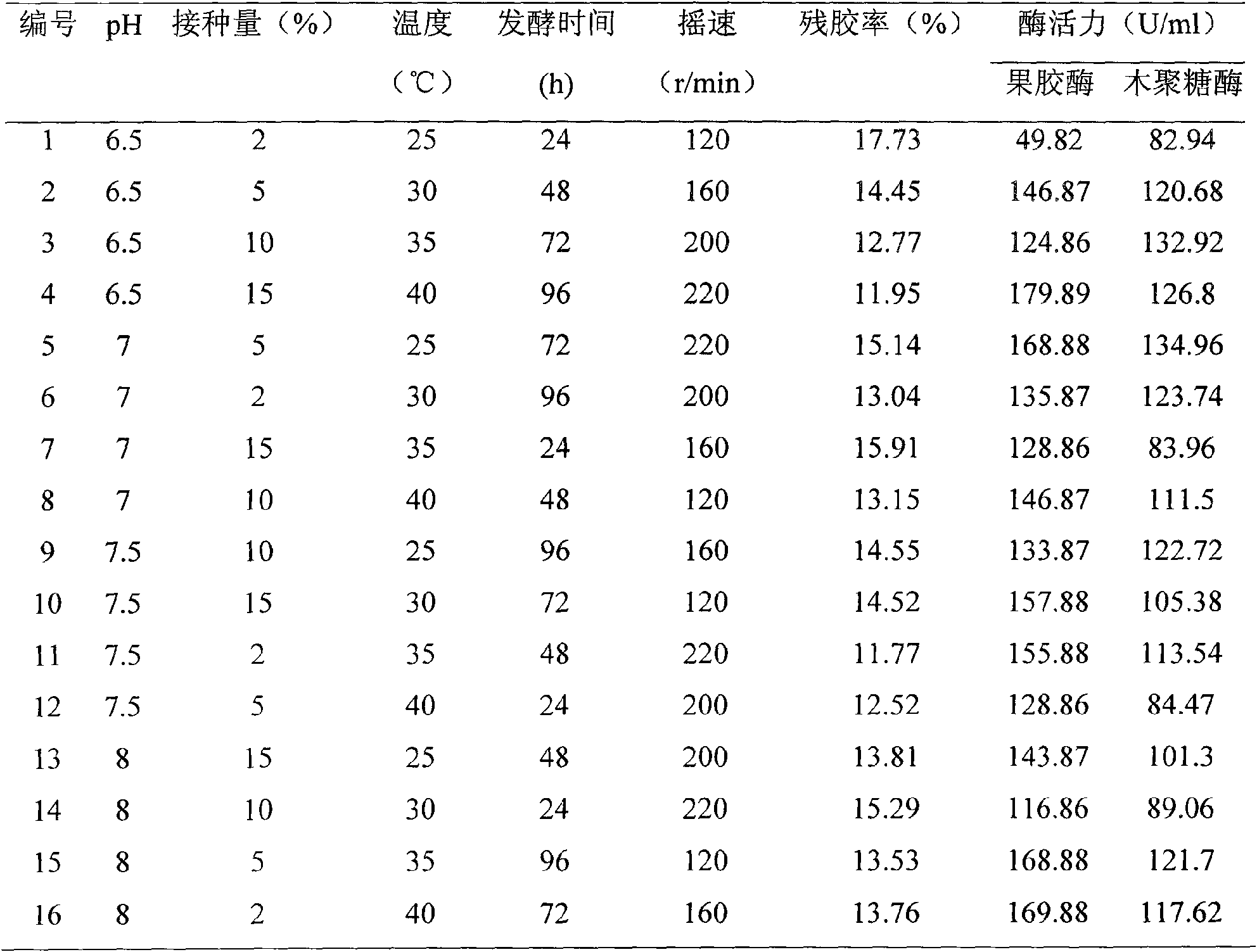

InactiveCN101654660ANot easy to polluteNo pollution in the processBacteriaMicrobiological testing/measurementPectinaseBiotechnology

The invention relates to a bacillus subtillis strain containing ramie degumming activity, preparation and application thereof, which uses a system taking the strain as the core for ramie degumming. The strain of the system has high reproductive rate, high yield of pectase and xylanase, short production period, strong contamination resistance and favorable heat-resistant quality. The system and thecultivating process are safe to operate, have no toxicity and pollution no environment. Compared with the prior art, the invention has simple technology, is suitable for large-scale industrial production and the like. When the system is used for ramie degumming, degumming time is short, the dispersion coefficient of ramie fiber can reach 100%, degumming ratio can reach above 90%, and the qualityof refined dry ramie can reach the standard of chemical degumming.

Owner:DONGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com