Mine-hoist constant deceleration safety braking system and braking method thereof

A mine hoist and safety braking technology, which is applied to mechanical equipment, fluid pressure actuators, servo motor components, etc., can solve the problems of reducing equipment safety performance and service life, high cost, low reliability, etc., and achieve improvement Braking stability and safety reliability, high safety reliability and technical economy, and the effect of improving safety reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

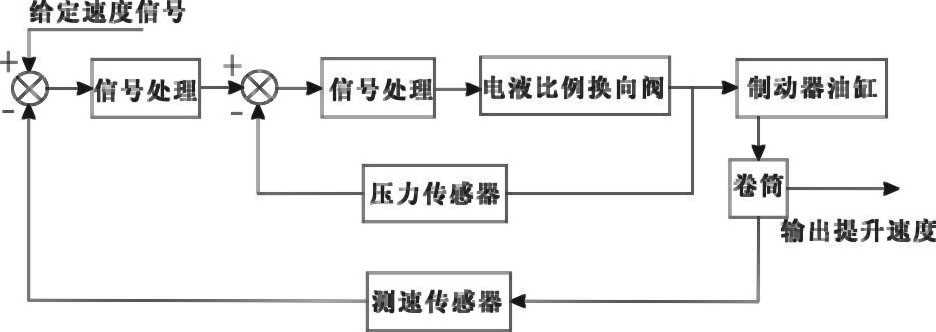

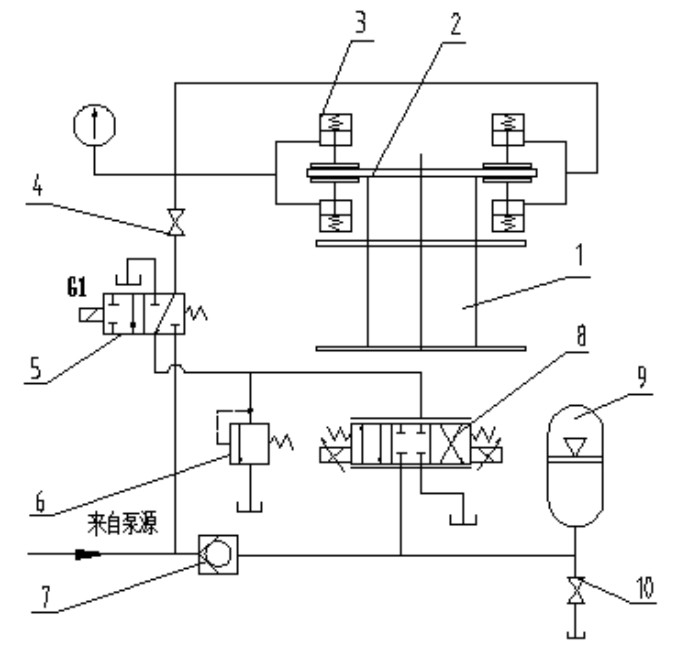

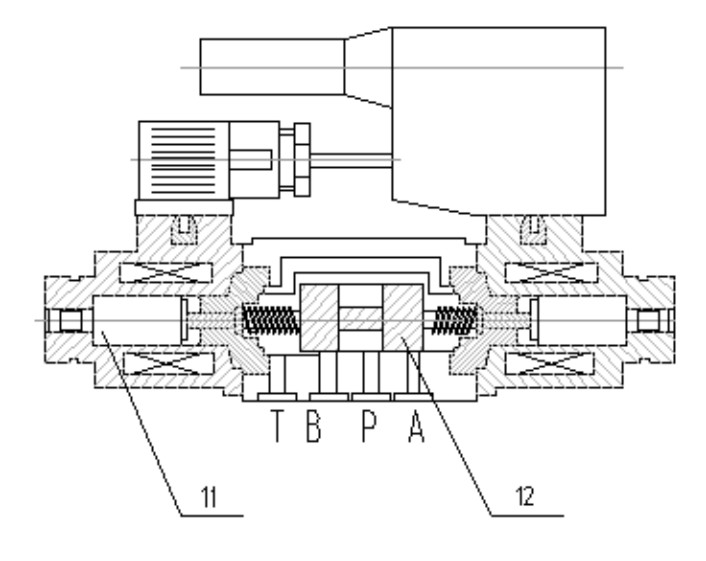

[0035] The mine hoist constant deceleration safety braking system of the present invention includes a disc brake, a hydraulic station, an electric control device and a detection feedback device; the detection feedback device continuously feeds back the detected deceleration signal of the hoist to the electric control device, and the electric control After the device compares the feedback signal with the set signal, it sends a control command to the electro-hydraulic proportional reversing valve of the hydraulic station, and the electro-hydraulic proportional reversing valve outputs the changed hydraulic power oil flow or pressure signal according to the input command to control the disc brake cylinder action.

[0036] combine figure 2As shown, the energy storage device of the hydraulic station "this embodiment selects the accumulator 9", the electro-hydraulic proportional reversing valve 8 and the electromagnetic reversing valve 5 are sequentially connected through pipelines ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com