Patents

Literature

218results about How to "Improved braking stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Carbon-ceramic composite brake disc and preparation method thereof

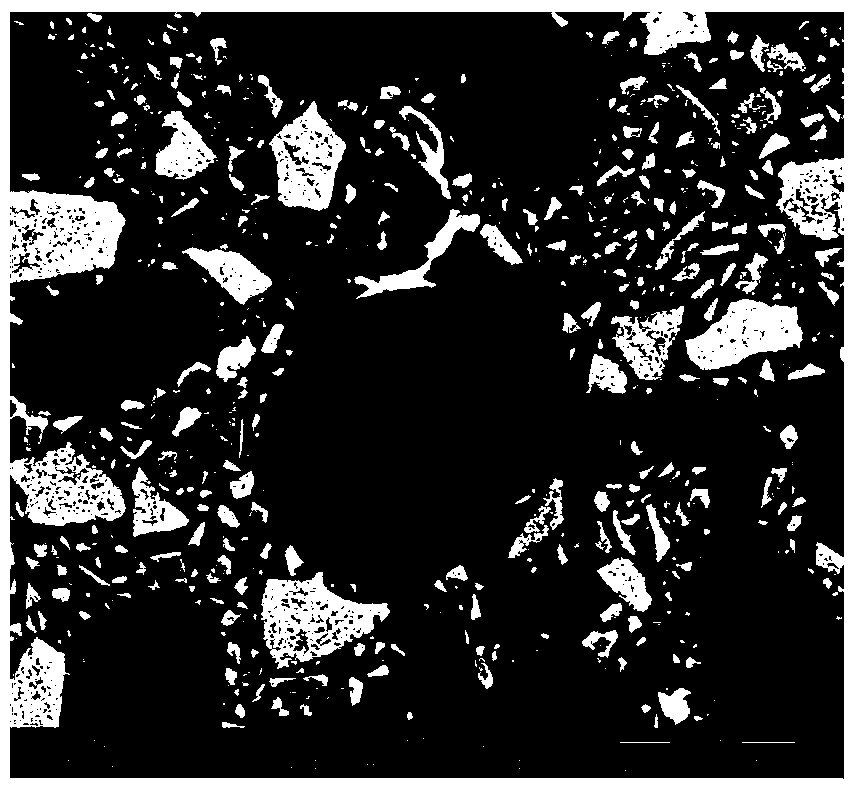

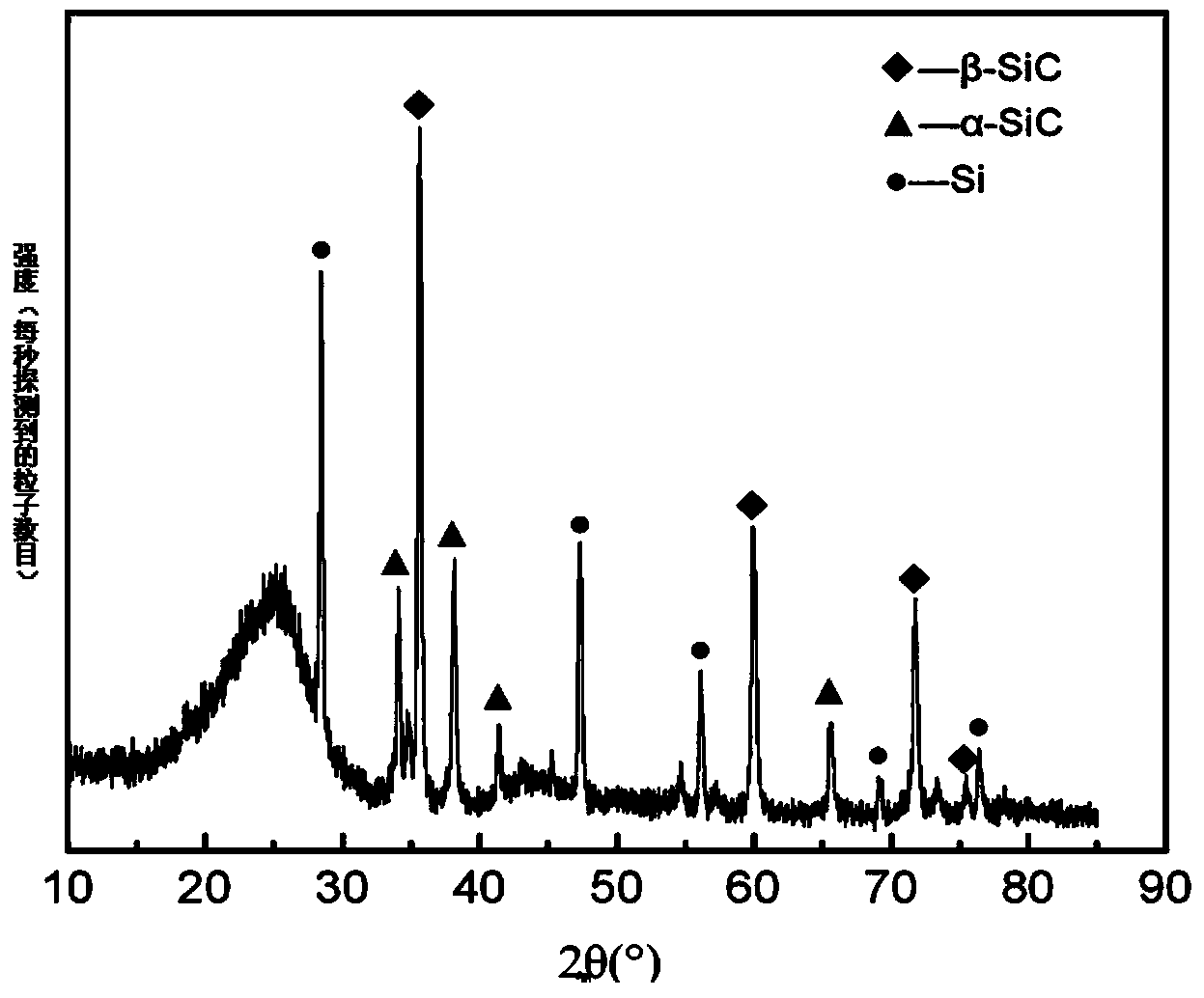

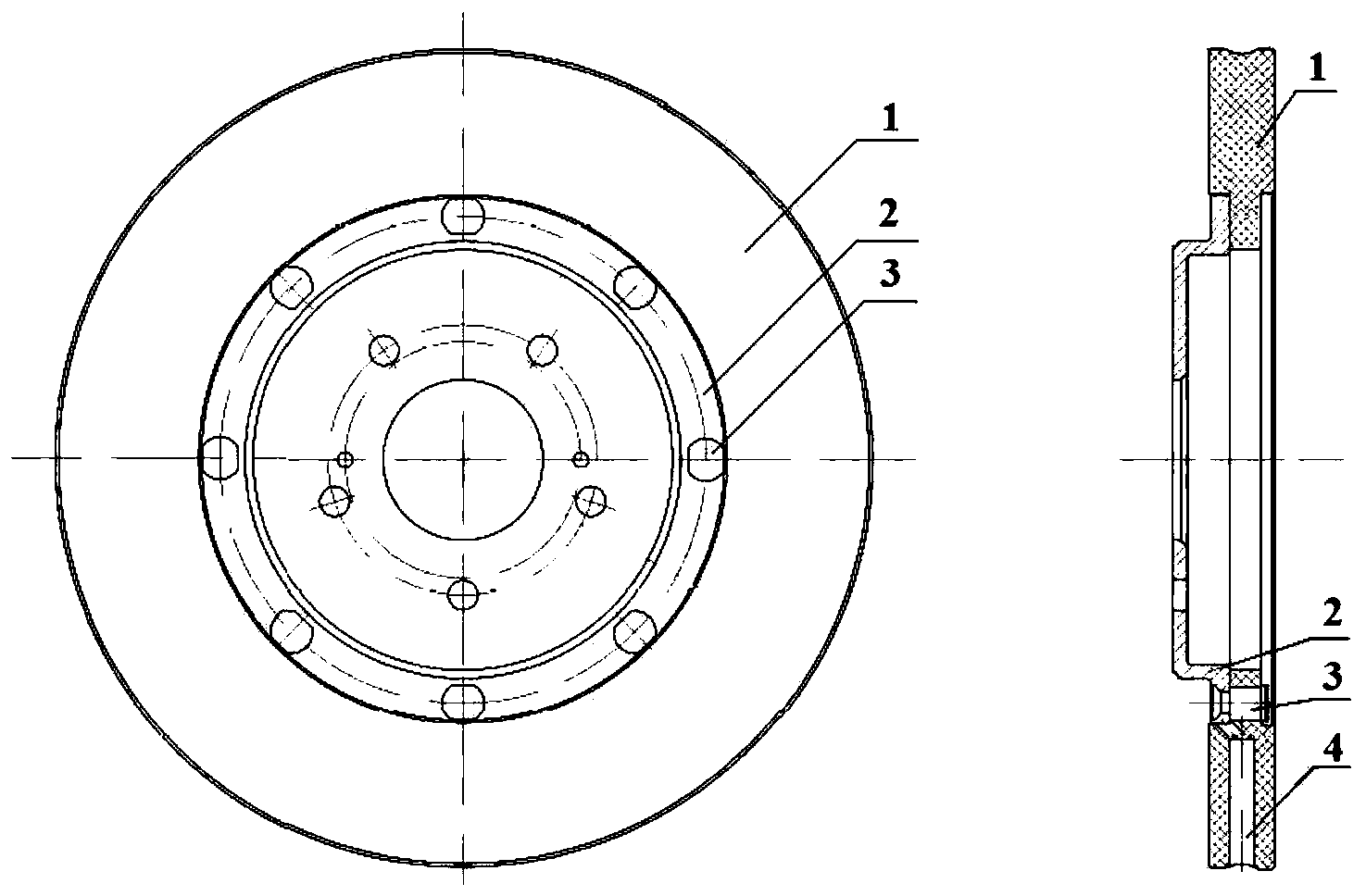

The invention relates to a carbon-ceramic composite brake disc and a preparation method thereof and belongs to the technical field of preparation of carbon-ceramic composites and brake discs. The carbon-ceramic composite brake disc comprises the following components by mass percent: 12% to 20% of short carbon fiber, 20% to 45% of matrix carbon, 30% to 55% of SiC and 2% to 6% of Si, wherein the short carbon fiber is 15-30mm in length. The method comprises the following steps: carbonizing a carbon fiber-reinforced blank body with the density of 0.9g / cm<3> to 1.3g / cm<3> so as to obtain a porous carbon / carbon (C / C) body; then performing dipping on the porous C / C body, cross-linking solidification and splitting decomposition so as to generate a SiC base body on the matrix carbon; performing the dipping, the cross-linking solidification and the splitting decomposition again until the density of an obtained C / C-SiC composite blank body reaches 1.6-1.9g / cm<3>; and performing silicon leaching treatment on the C / C-SiC composite blank body and anti-oxidation treatment and assembling, thus obtaining the carbon-ceramic composite brake disc. According to the method provided by the invention, the difficult problem that a metal brake disc is poor in thermal dissipation and abrasion resistance and heavy in weight in the prior art is effectively solved. The preparation method is simple; and the obtained carbon-ceramic composite brake disc is high in thermal stability, light in weight and resistant to abrasion, and cannot generate thermal vibration.

Owner:HUNAN SHIXIN NEW MATERIALS CO LTD

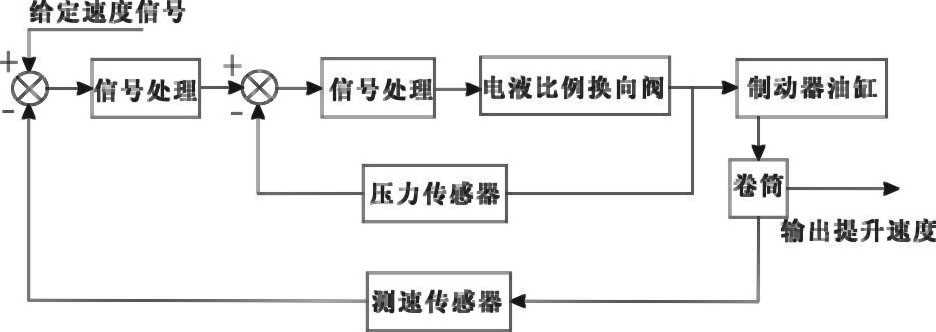

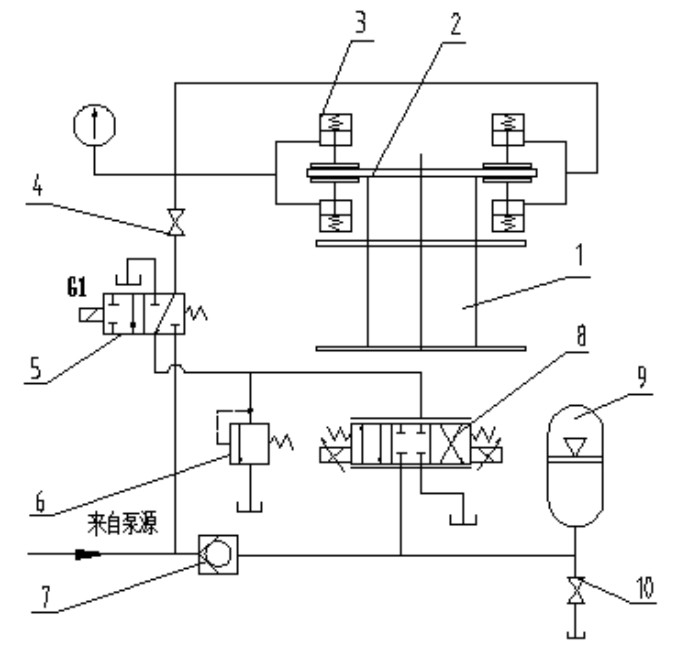

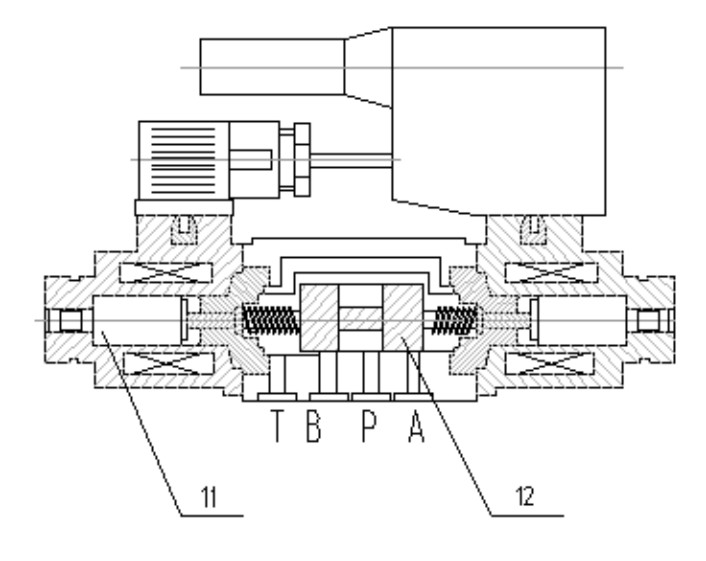

Mine-hoist constant deceleration safety braking system and braking method thereof

ActiveCN102030280AEasy to operateReduce stepsServomotor componentsHoisting equipmentsInput controlElectric control

The invention discloses a mine-hoist constant deceleration safety braking system and a braking method thereof, and relates to the technical field of mine-hoist safety braking control. The system comprises a disk brake, a hydraulic station, an electric control device and a detection feedback device which are arranged on a drum brake disk, wherein a speed sensor arranged on the drum acquires a hoist deceleration signal and inputs the hoist deceleration signal into the electric control device; the electric control device receives the signal and compares the signal with the given speed value to send out a control command; after the control command is processed into an electric signal and compared with an oil pressure signal which is fed back by a pressure sensor on the hydraulic pipeline arranged between the outlet end of an electrohydraulic proportion reversing valve and the disk brake cylinder, an electric signal control command is sent out; and the electrohydraulic proportion reversingvalve of the hydraulic station outputs a hydraulic pressure signal, which varies as the input control command varies, so as to control the motion state of the hoist by the disk brake, thereby realizing constant deceleration safety braking of the mine hoist.

Owner:CITIC HEAVY INDUSTRIES CO LTD +1

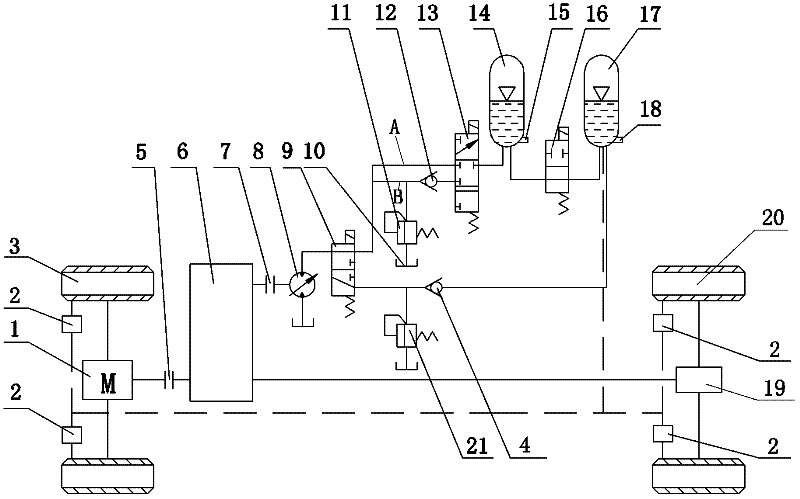

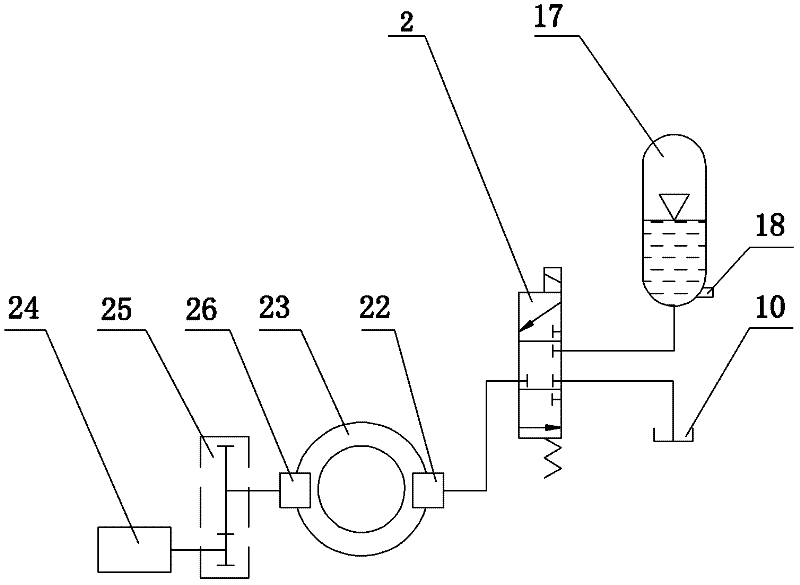

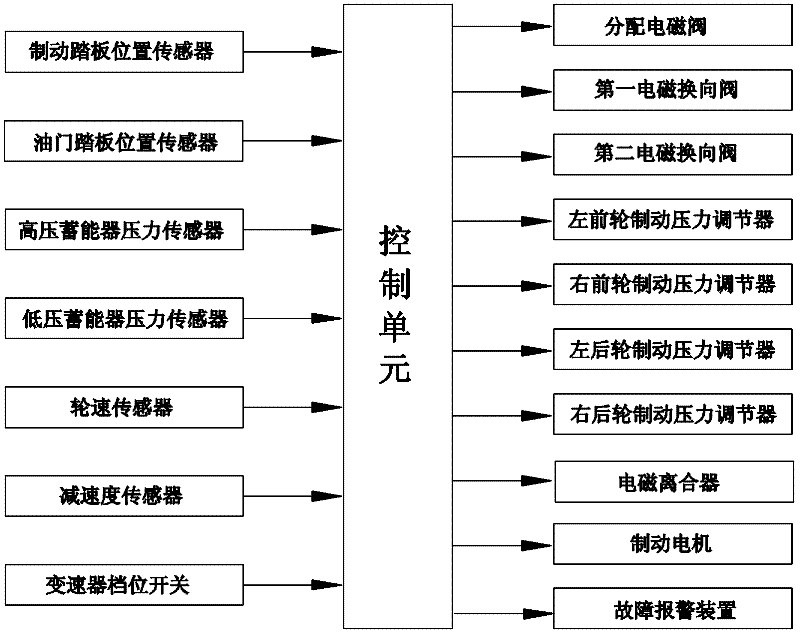

Energy regeneration device of drive-by-wire braking system and control method of braking system

ActiveCN102442286AImprove starting performanceImprove acceleration performanceAuxillary drivesBraking element arrangementsElectric machineElectromagnetic clutch

An energy regeneration device of a drive-by-wire braking system comprises a gearbox, an oil tank, an electromagnetic clutch, a hydraulic oil pump / motor, an electromagnetic distributing valve, a first electromagnetic reversing valve, a high-pressure energy accumulator, a second electromagnetic reversing valve and a low-pressure energy accumulator. A hydraulic brake is additionally arranged on a brake disc of each wheel, and an increasing gear mechanism is additionally mounted on an output shaft of the gearbox. By the aid of a method for accumulating and releasing braking energy, accumulated energy of the high-pressure energy accumulator can be released when an automobile starts and accelerates, a starting performance and an acceleration performance of the automobile are improved, accumulated energy in the low-pressure energy accumulator can also be directly applied to the wheels during braking and used with a braking motor of the drive-by-wire braking system to realize braking of the automobile, and braking energy recycle efficiency is improved. When the drive-by-wire braking system fails and cannot work normally, the device can be used as an emergency braking system, and the accumulated energy in the energy accumulators is used for realizing parking braking of the automobile. The energy regeneration device is particularly suitable for pure electric automobiles.

Owner:江苏久通汽车零部件有限公司

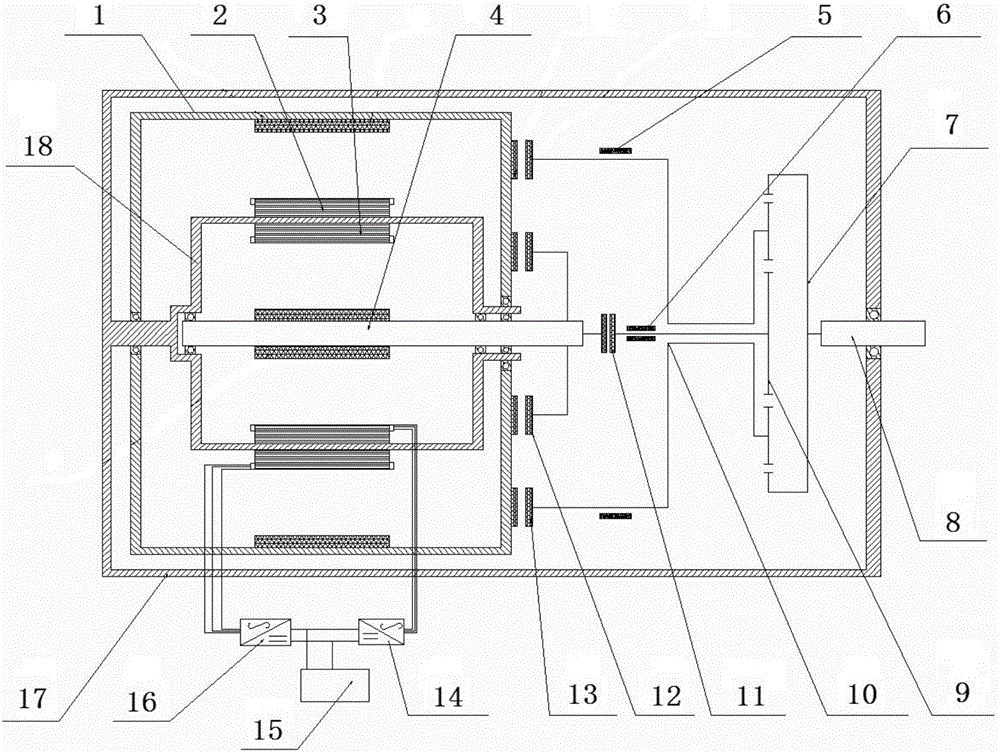

Dual-rotor wheel hub motor for four-wheel drive electric automobile and power transmission method of dual-rotor wheel hub motor

ActiveCN105024509ACompact layoutSimple structureMagnetic circuit rotating partsMechanical energy handlingCouplingControl theory

The invention provides a dual-rotor wheel hub motor for a four-wheel drive electric automobile and a power transmission method of the dual-rotor wheel hub motor. The dual-rotor wheel hub motor comprises a planetary gear mechanism and a motor group formed by an inner motor and an outer motor. The motor group and the planetary gear mechanism are connected via a clutch and are arranged in a machine shell. The outer motor is formed by an outer rotor and a stator outer winding, and the inner motor is formed by an inner rotor and a stator inner winding. The planetary gear mechanism is composed of a gear ring, an output shaft, a sun wheel, a planet wheel and a planet carrier. The dual-rotor motor could achieve torque coupling, rotational speed coupling and speed differing by combining with the planetary gear mechanism, so that different vehicle condition requirements could be met under the condition that the motor with relative small power is selected, thereby reducing automobile arrangement space and cost. As the dual-rotor wheel hub motor has a single motor braking mode and a dual-motor braking mode, the braking energy can be effectively recovered, slow braking can be achieved, and the braking stability of the motor is improved.

Owner:JIANGSU UNIV

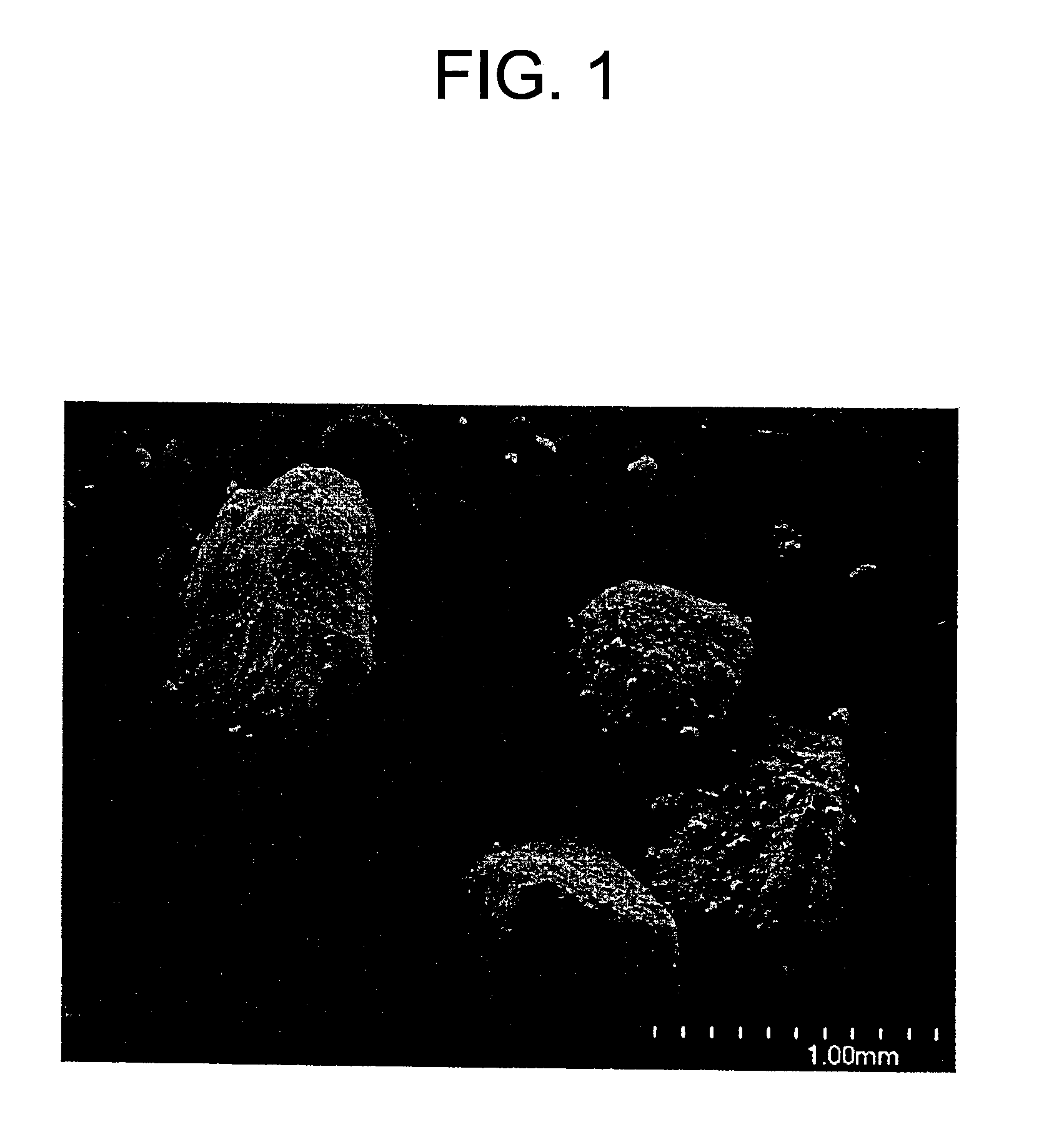

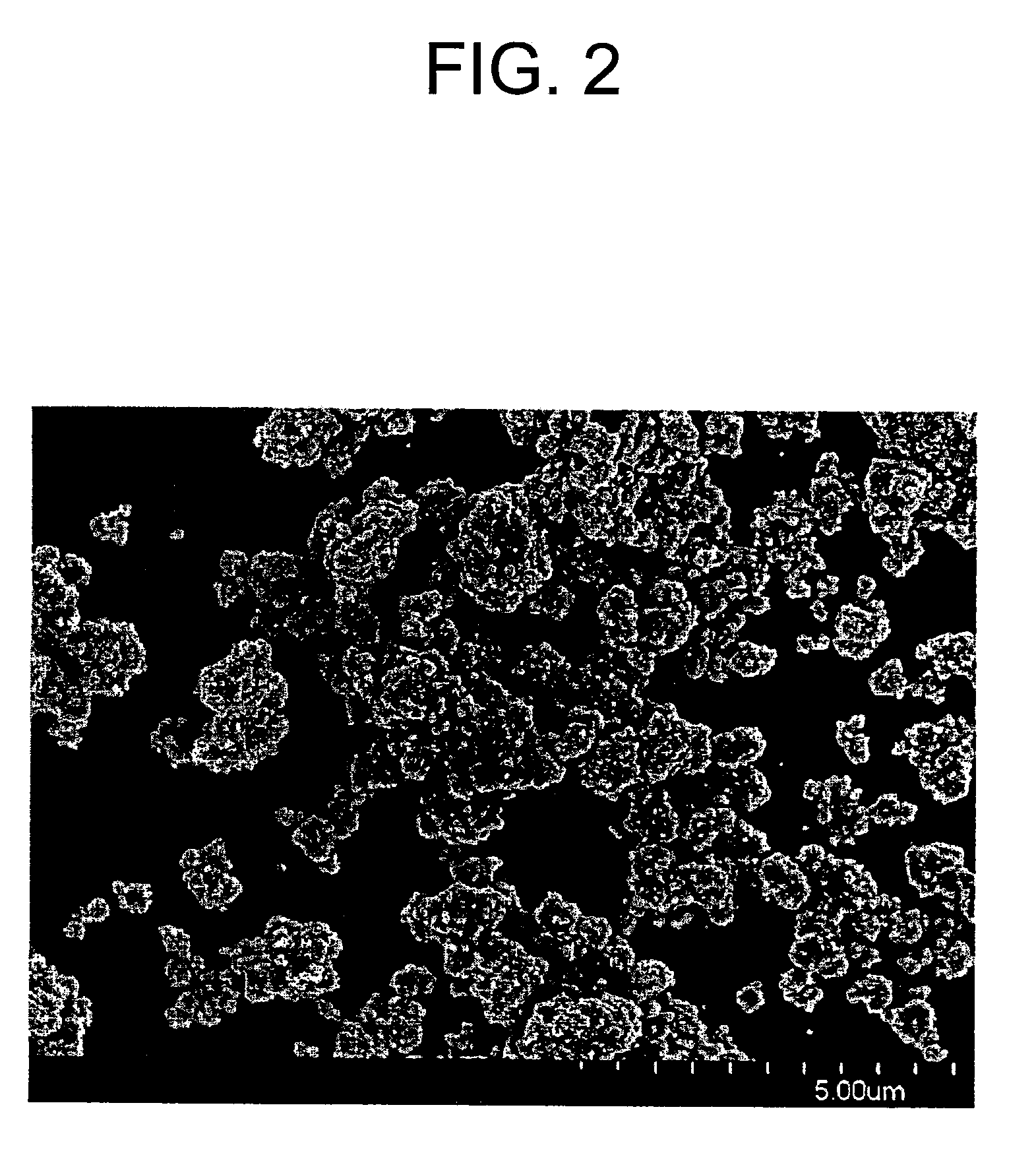

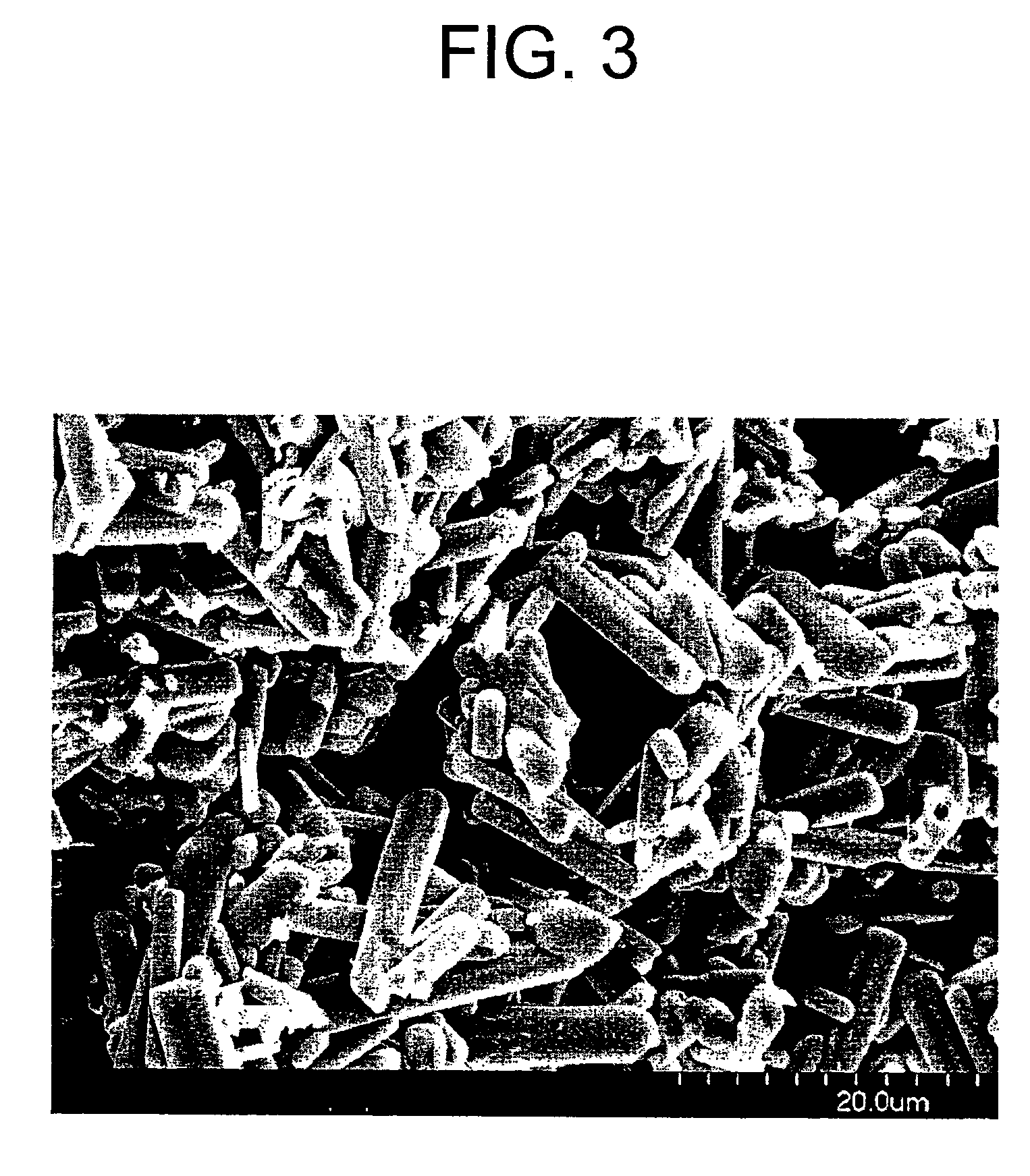

Method of manufacturing alkali metal titanate and hollow body particle thereof, product thereof, and friction material containing the product

ActiveUS20100112350A1Improve braking performanceImproved braking stabilityAlkali titanatesZirconium compoundsPotassiumTitanium

The present invention is to provide a method of manufacturing a potassium titanate adapted for a friction material of a friction slide member. The present invention includes the steps of uniformly mixing an aggregate or a granulation of a titanium compound and a potassium compound with a vibration rod mill to form a mixture and sintering the mixture for reaction one another in order to manufacture a desired potassium titanate with ease and low cost.

Owner:TOHO TITANIUM CO LTD

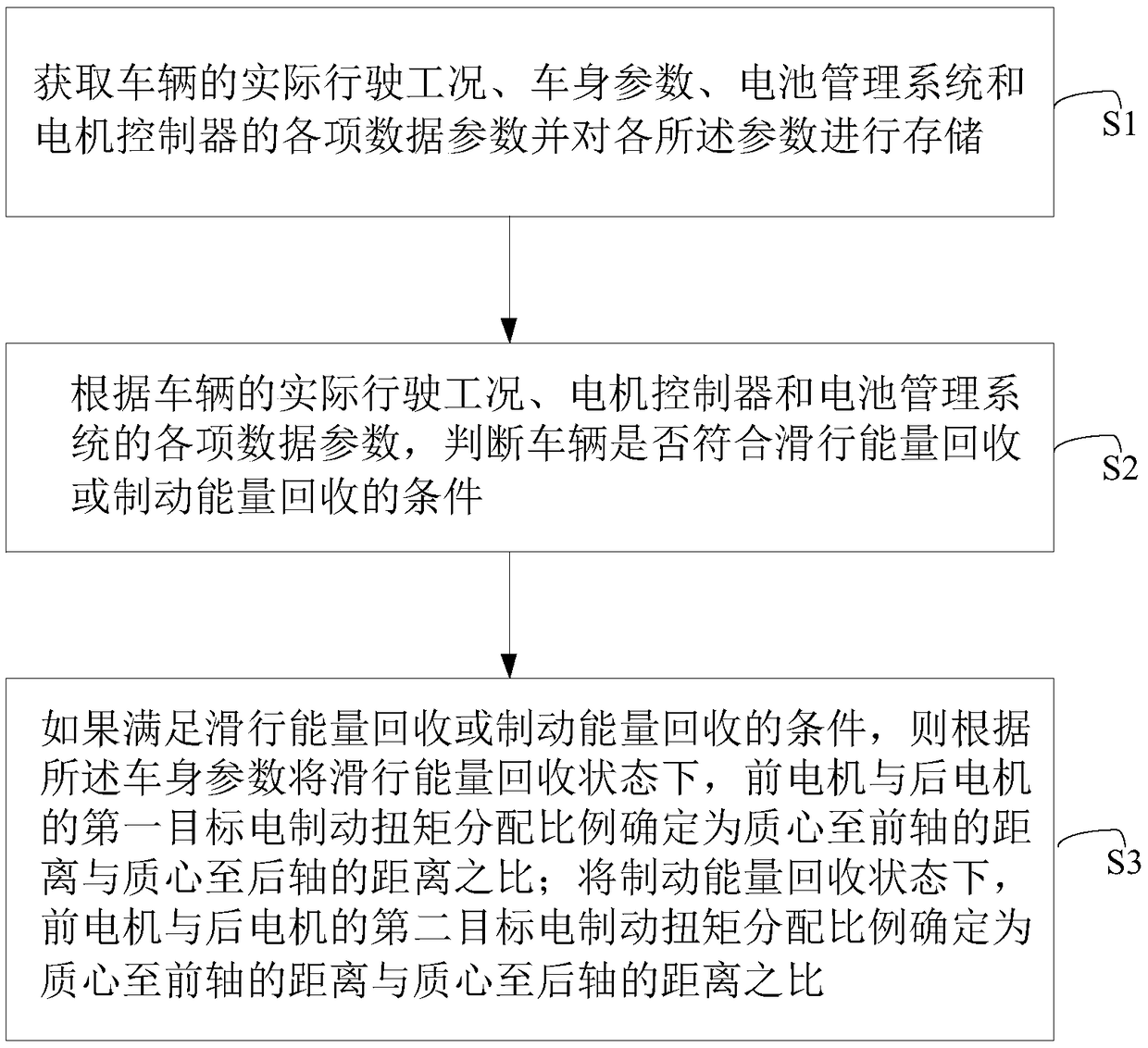

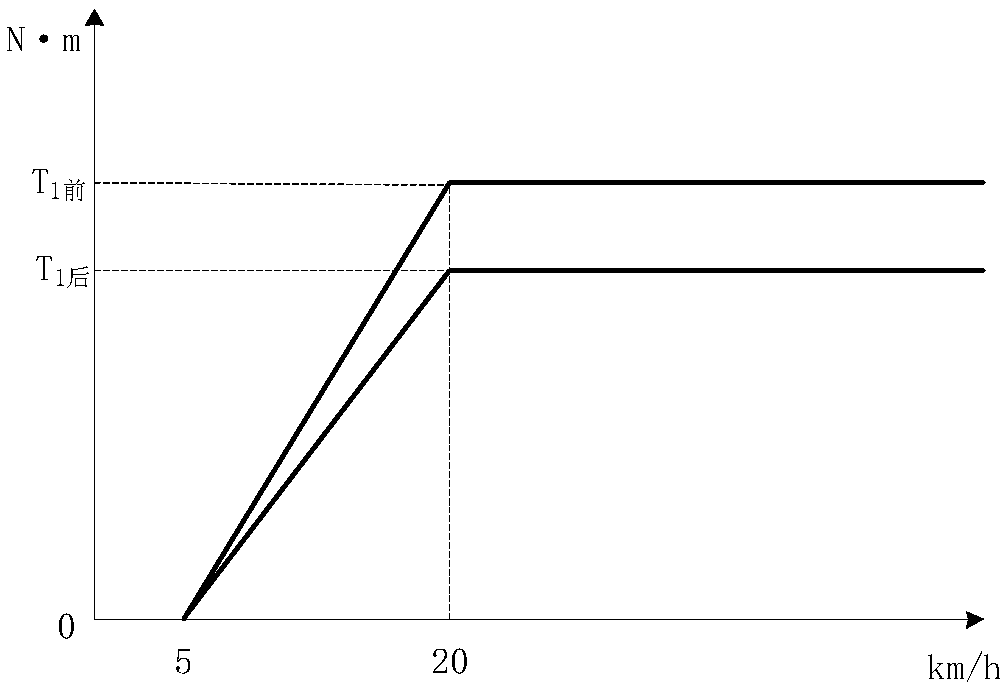

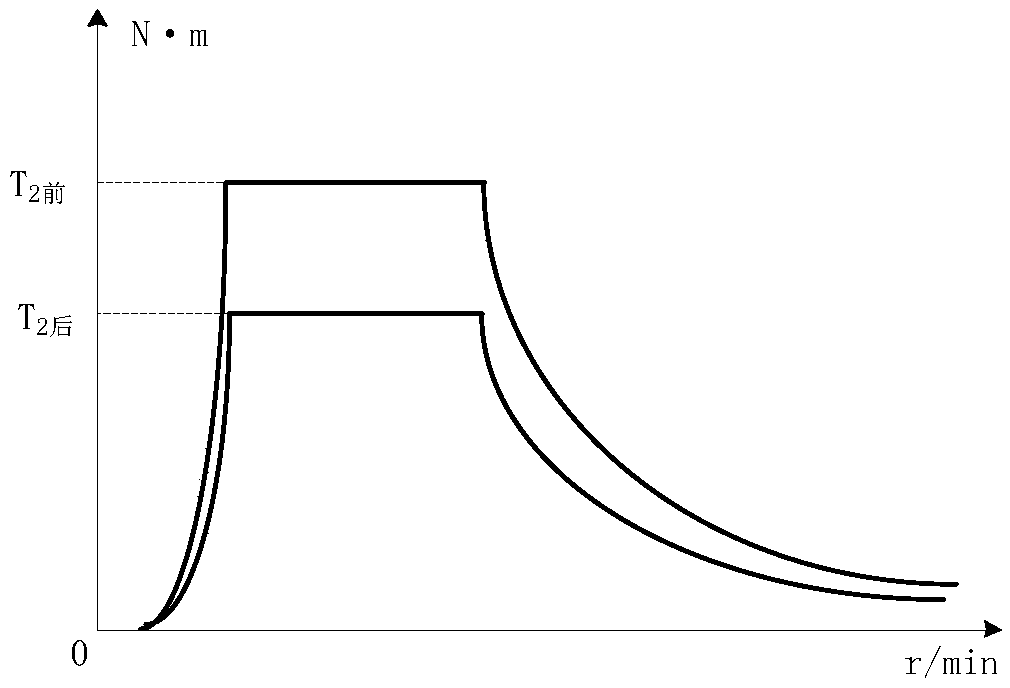

Electric braking torque distribution method and device for vehicle

InactiveCN109305044APrevent deviationImproved braking stabilitySpeed controllerElectrodynamic brake systemsElectricityBrake torque

The invention provides an electric braking torque distribution method and device for a vehicle. The electric braking torque distribution method comprises the steps that all data parameters of the travelling work condition, vehicle body parameters, a battery management system and a motor controller of a vehicle are obtained and stored; according to all the data parameters of the actual travelling work condition, the motor controller and the battery management system of the vehicle, whether the vehicle meets the conditions of sliding energy recovery or braking energy recovery or not is judged; and in a sliding energy recovery state, the target electric braking torque distribution ratio of a front motor and a rear motor is determined to the ratio of the distance from the mass center to a front shaft to the distance from the mass center to a rear shaft. According to the electric braking torque distribution method, sliding energy recovery electric braking torque and braking energy recoveryelectric braking torque are distributed qualitatively to the front motor and the rear motor; and the energy recovery rate is increased, the driving intention of a driver is easier to achieve, the phenomena of off tracking of the vehicle due to braking and sideslip of the rear shaft are effectively prevented, and the vehicle braking stability is improved.

Owner:CH AUTO TECH CORP CO LTD

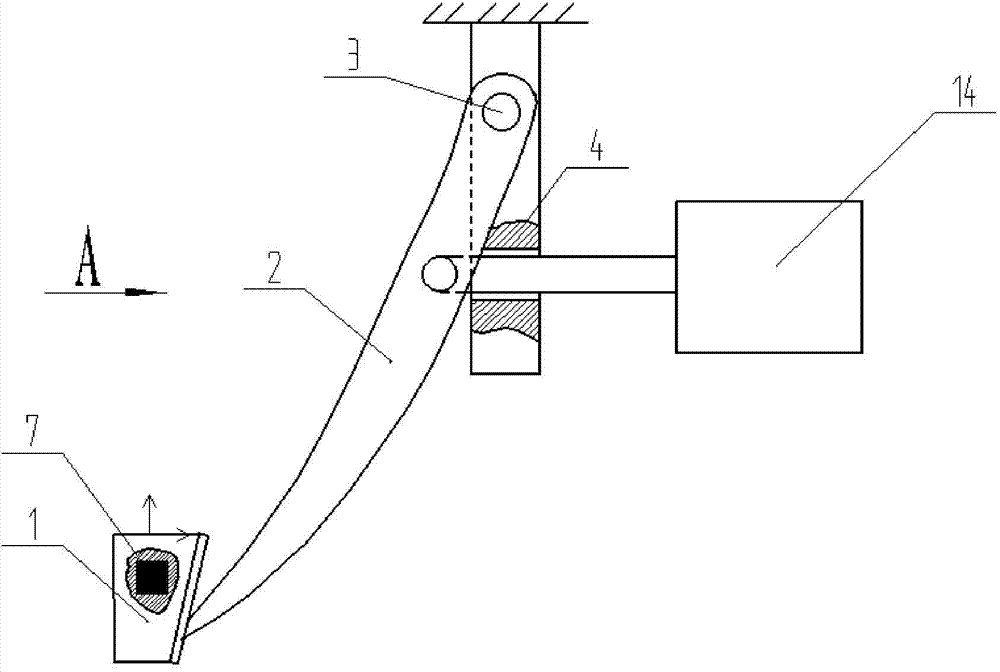

Automobile brake pedal mechanism and pedal feel simulator thereof

The invention relates to an automobile brake pedal mechanism and a pedal feel simulator thereof. The brake pedal mechanism comprises a brake pedal, a pedal displacement sensor, the pedal feel simulator, a microwave distance-measuring radar, a central processing unit and the like, wherein the pedal displacement sensor adopts two variable resistors for identifying the brake intention of a driver; the pedal feel simulator is based on a magnetorheological fluid principle; the central processing unit can controls the voltage volume of a coil and adjusts the damp of the simulator according to the pedal speed or distance information of front vehicles, people or barriers provided by the microwave distance-measuring radar, so that the driver has excellent operation feel, and the stability, comfortand safety of brake can be improved. Meanwhile, by changing the set value in the central processing unit, the damp output curve of the pedal feel simulator can be adjusted to meet requirements of different vehicle models or drivers. The automobile brake pedal mechanism and the pedal feel simulator thereof have the advantages of simple structure, quick response, good adaptability and the like, andis convenient in operation,.

Owner:南通特力锻压机床有限公司 +1

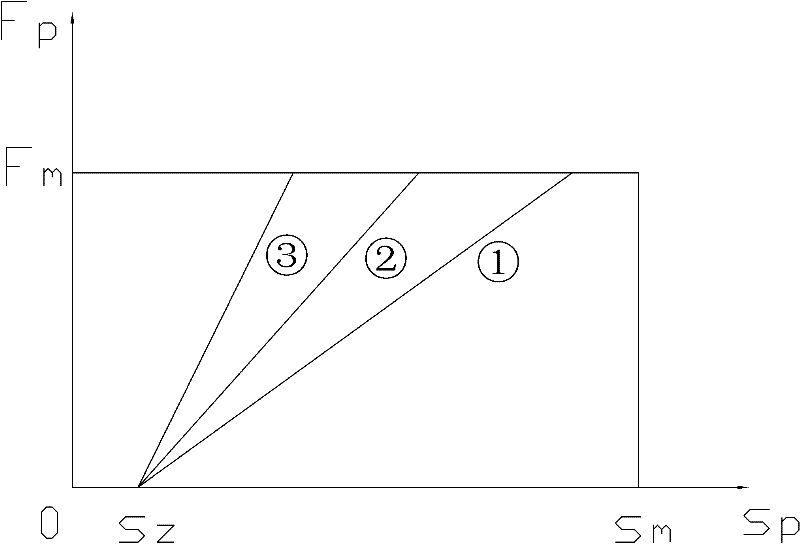

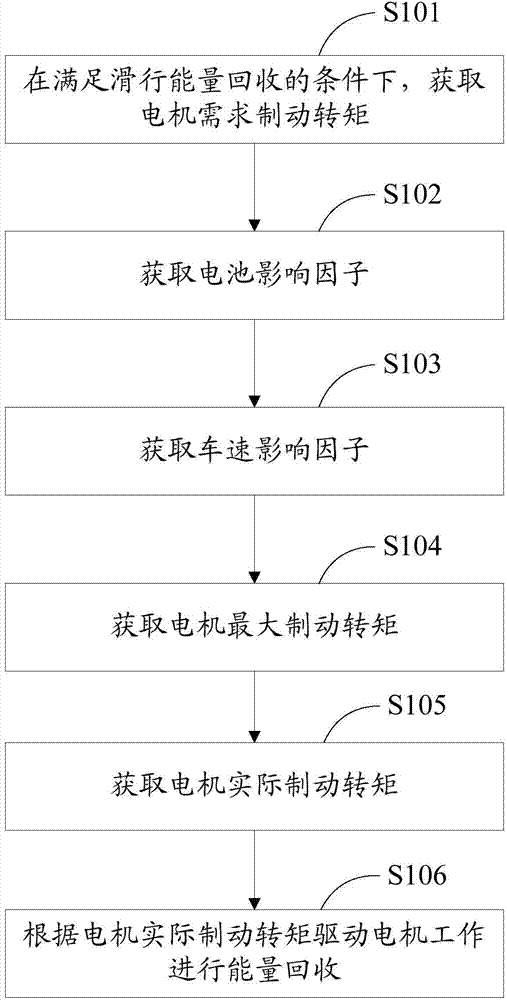

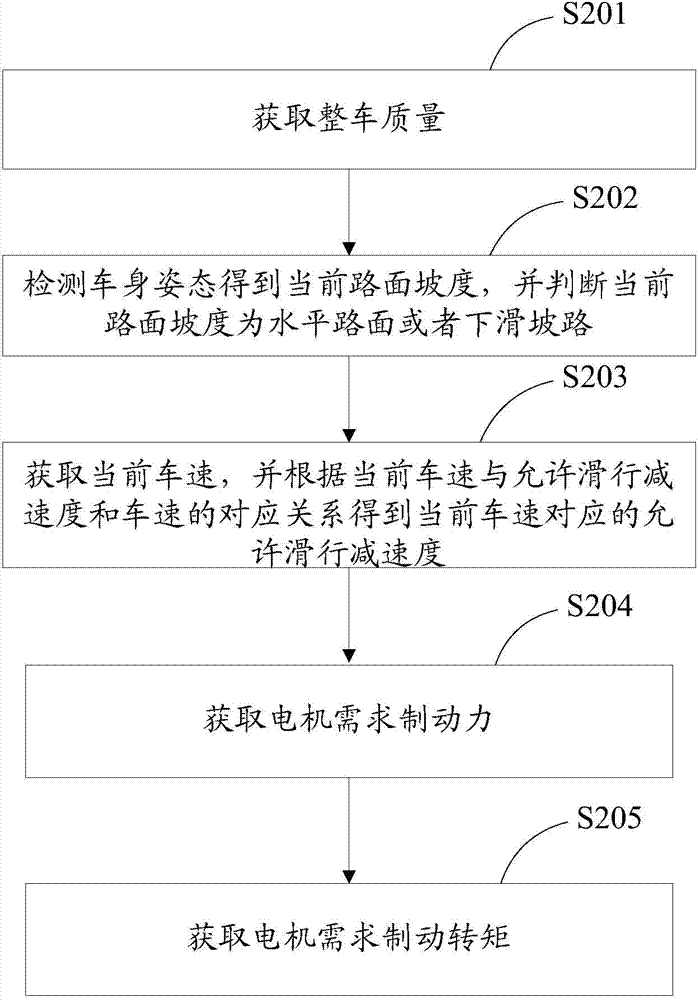

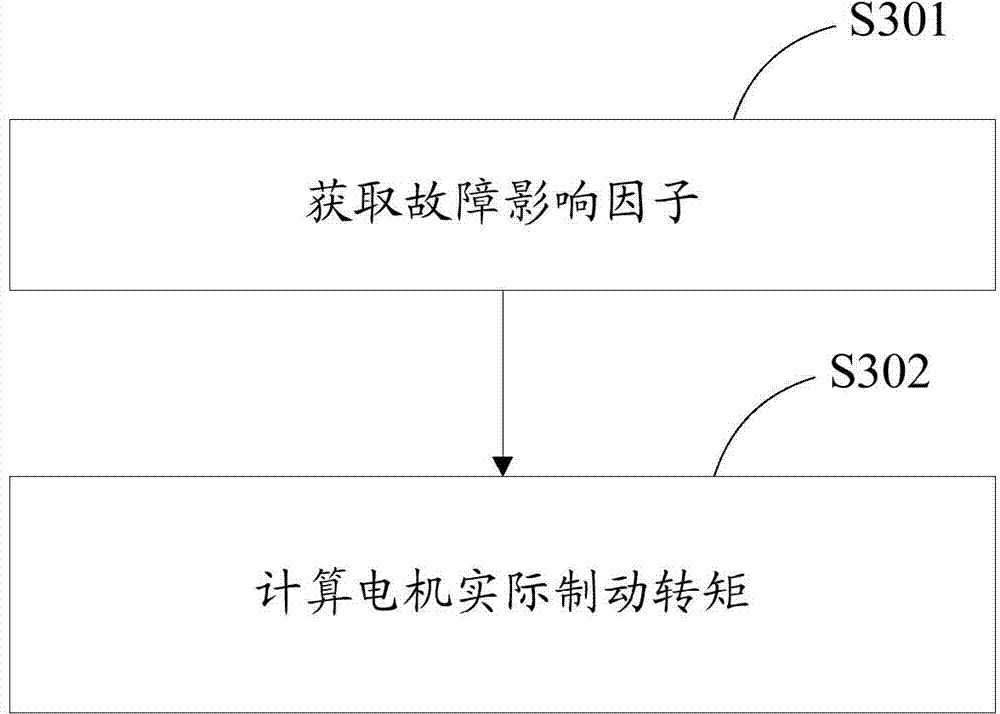

Vehicle and vehicle slide energy recycling method and system

ActiveCN103921795AImprove securityAll application scenariosExternal condition input parametersVehicle condition input parametersBrake torqueRecovery method

The invention provides a vehicle and a vehicle slide energy recycling method and system. The method includes: acquiring required motor brake torque when a slide energy recycling condition is satisfied; acquiring a battery influence factor; acquiring a vehicle speed influence factor; acquiring maximum motor brake torque; acquiring actual motor brake torque, selecting the smaller one of the required motor brake torque and the maximum motor brake torque, and multiplying the smaller one by the battery influence factor and the vehicle speed influence factor to obtain the actual motor brake torque; driving a motor to operate for energy recycling according to the actual motor brake torque. The v vehicle and the vehicle slide energy recycling method and system have the advantages that overall vehicle mass and current road slope can be detected in real time to adjust the required motor brake torque, compatibility of road slope variation and vehicle mass variation during vehicle energy recycling is achieved, the method is widely applicable, brake stability is increased by adding the current vehicle speed influence factor, and vehicle slide energy recycling safety is increased by adding a fault influence factor.

Owner:ZOOMLION HEAVY IND CO LTD

Self-locking electronic mechanical braking device

PendingCN107289043AReduce volumeHighly integratedAxially engaging brakesBrake actuating mechanismsGear driveBall screw

The invention provides a self-locking electronic mechanical braking device. The braking device consists of a box, a first motor, a planet gear transmission mechanism, a lead screw shaft, a second motor, a ball screw pair nut, a spring, friction plates and a brake disc; the first motor is mounted on the box; a sun gear of the planet gear transmission mechanism is arranged on a motor output shaft; a gear ring is fixed in the box; a planet carrier is coaxially connected with the lead screw shaft; the muddle part of the lead screw shaft and a second motor rotor are mounted to form a slide lead screw pair; a second motor stator is fixedly mounted on the inner side of the box; the other end of the lead screw shaft and the ball screw pair nut are mounted to form a ball screw pair; the ball screw pair nut penetrates through the box; the spring is mounted between the ball screw pair nut and the box; two friction plates are respectively mounted on separation plates on the outer sides of the ball screw pair nut and the box; and the brake disc is mounted between the two friction plates. The braking device can effectively save the volume in overall vehicle arrangement, and can stably realize self-locking function.

Owner:JILIN UNIV

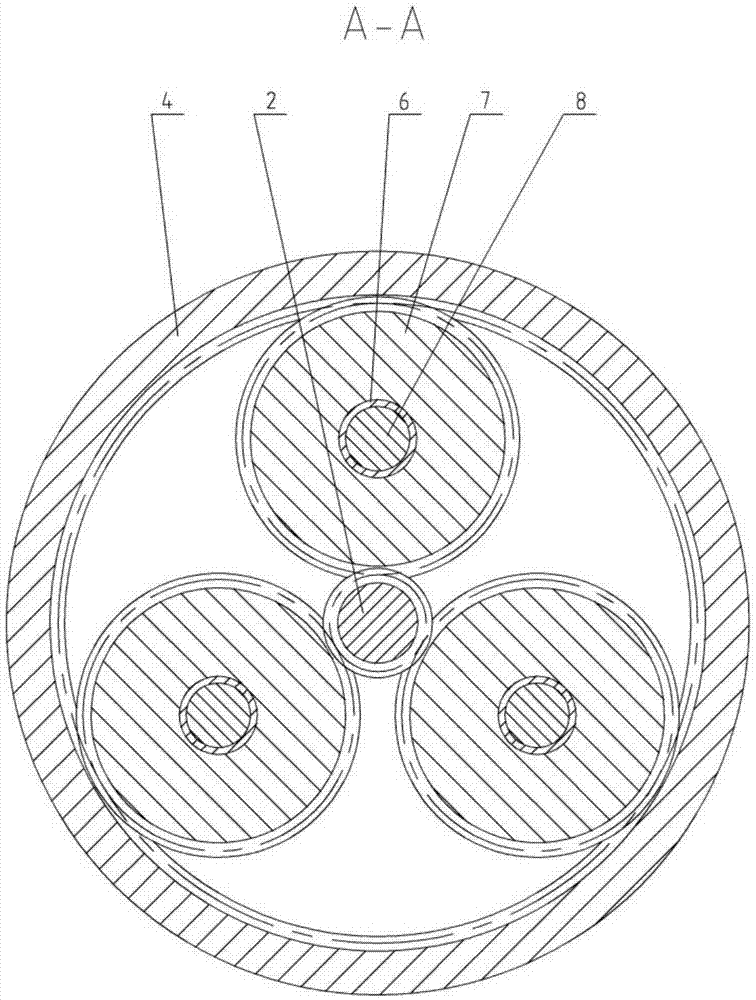

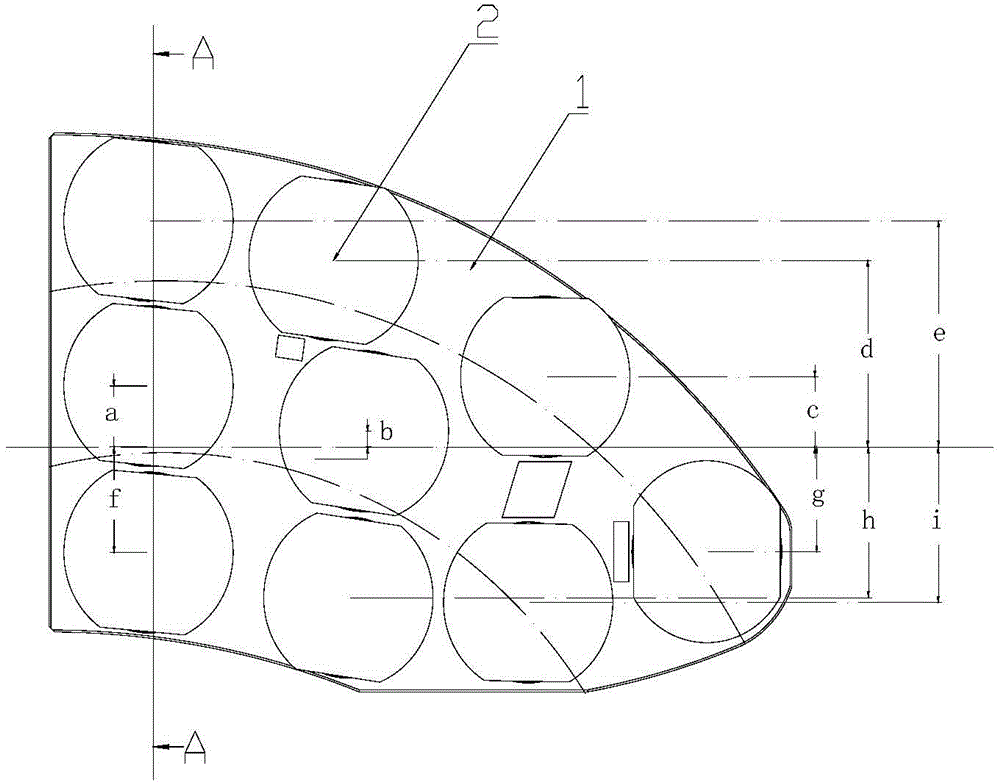

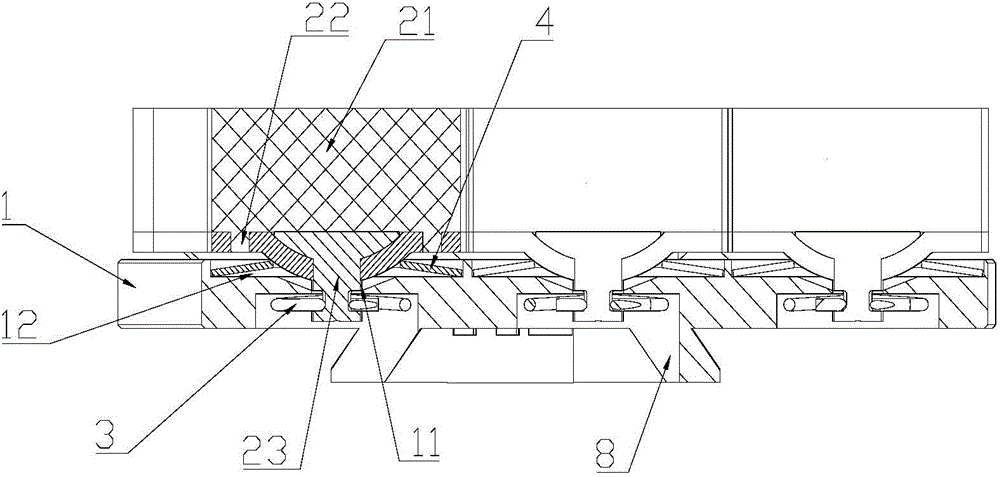

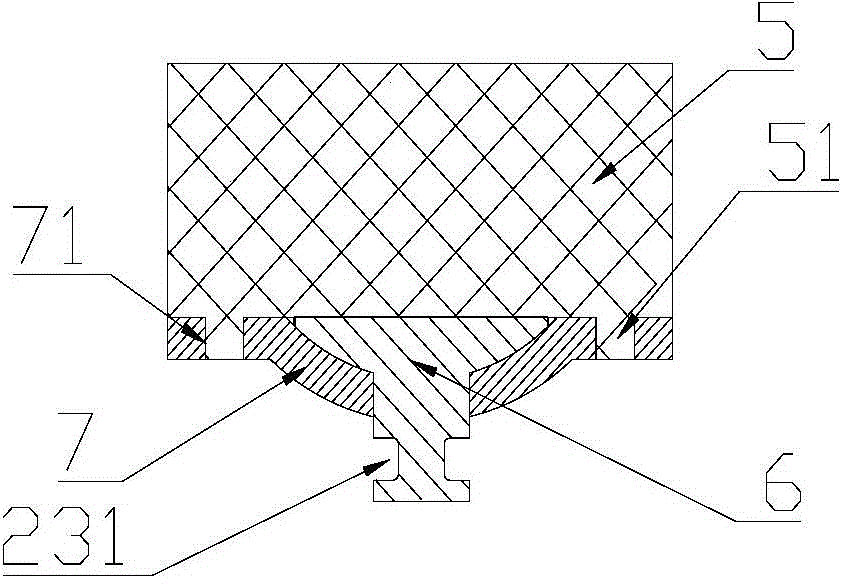

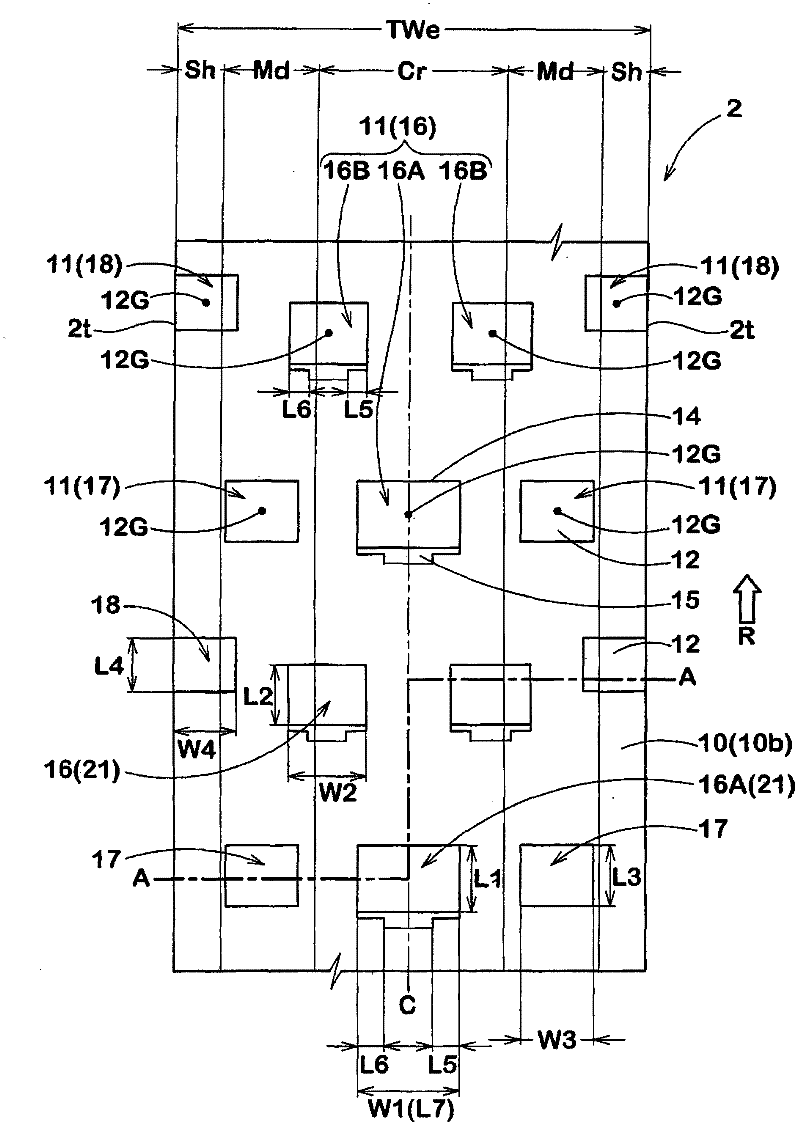

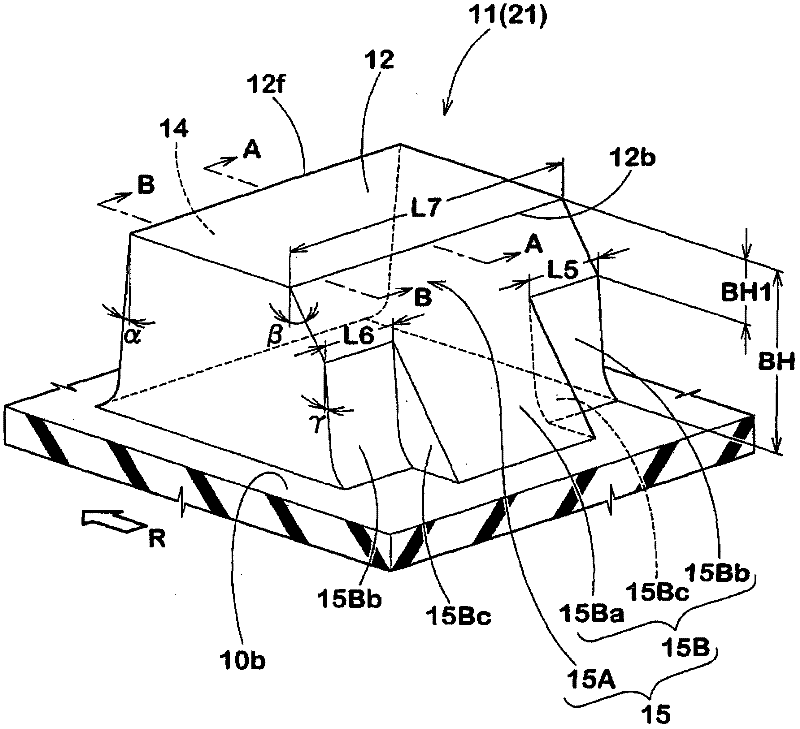

Floating type brake pad

InactiveCN104455105AConsistent heat fluxExtended service lifeBraking membersFriction liningStress concentrationEngineering

The invention discloses a floating type brake pad. The floating type brake pad comprises a back plate, a plurality of friction blocks, disc springs and clamping springs, wherein the friction blocks are arranged on the back plate, the disc springs are arranged between the friction blocks and the back plate, and the friction blocks are connected to the first back plate in a floating mode through the clamping springs. Positioning grooves are formed in the back plate, and the disc springs are arranged inside the positioning grooves. The back plate is divided into a plurality of concentric circular rings by using the circle center of a brake disc matched with the brake pad as the circle center. The circular rings are equal in radial length. The friction area of the friction block inside each circular ring is not larger than 15% of the standard average friction area compared with the standard average friction area. According to the floating type brake pad, the problem of fatigue cracks caused by instantaneous stress concentration during braking of existing disc springs is solved, meanwhile, gaps between the back plate and the friction blocks are reduced, oscillation of the friction blocks is small, meanwhile, the problem of eccentric abrasion of the friction blocks is avoided, and the brake stability is greatly improved.

Owner:BEIJING TIANYISHANGJIA NEW MATERIAL

Construction method for rubber grain asphalt concrete pavement

InactiveCN101153478AImprove deformation abilityGood flexibilityIn situ pavingsSnowpackWear resistant

A method for constructing rubber particles asphalt concrete road surfaces relates to a method for constructing asphalt concrete road surfaces, aiming to resolve the problems that: the asphalt concrete road surfaces have weak wear-resistant, and the attachment coefficient and the adhesive force are reduced and vehicles have the problem of braking stability when the road surfaces are covered by snow and ice. The construction method comprises the following steps that: compositions by weigh percentage of the following materials are adopted: 76.5 to 91.5 percent of mineral aggregate, 2.5 to 7.5 percent of asphalt, 4 to 10 percent of mineral powder and 2 to 6 percent of rubber particles; the mineral aggregate is heated up to 190 to 200 DEG C, the rubber particles are added into the mineral aggregate with mixing about 20 to 25 seconds, the asphalt heated up in advance and the mineral powder are added into the rubber particles and the mineral aggregate with mixing lasting for 70 to 80 seconds, and then the road surfaces are subject to the pavement, the first stage initial pressure, the first and the second stage re-pressure and the second stage final pressure. The invention can increase the deformation capabilities of the road surfaces effectively, improve the bond state between the road surfaces and snow, and the invention can improve the attachment coefficient, increase the adhesive force, and improve the braking and turning operation stability of vehicles when the road surfaces are cover by snow and ice.

Owner:HARBIN INST OF TECH

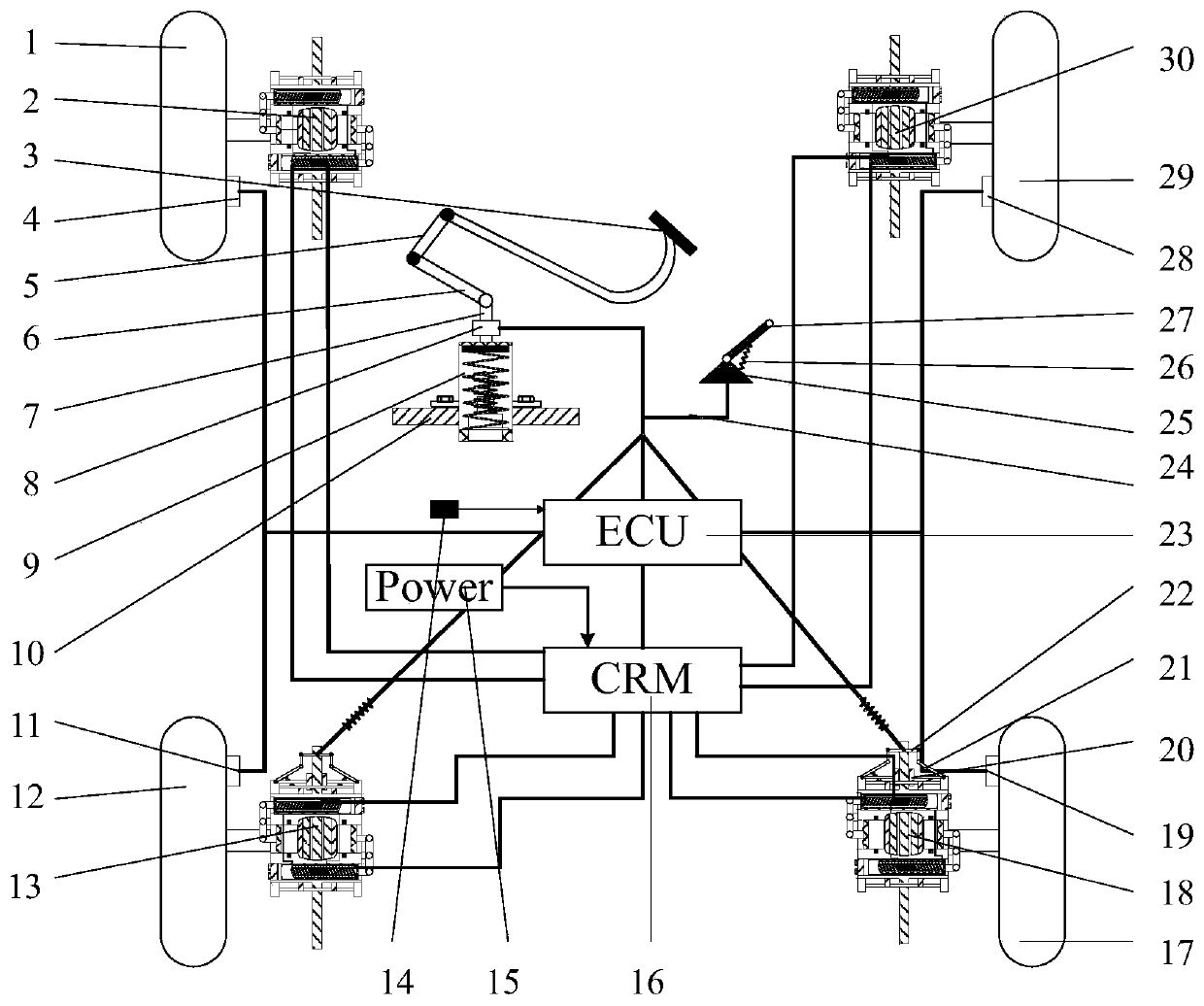

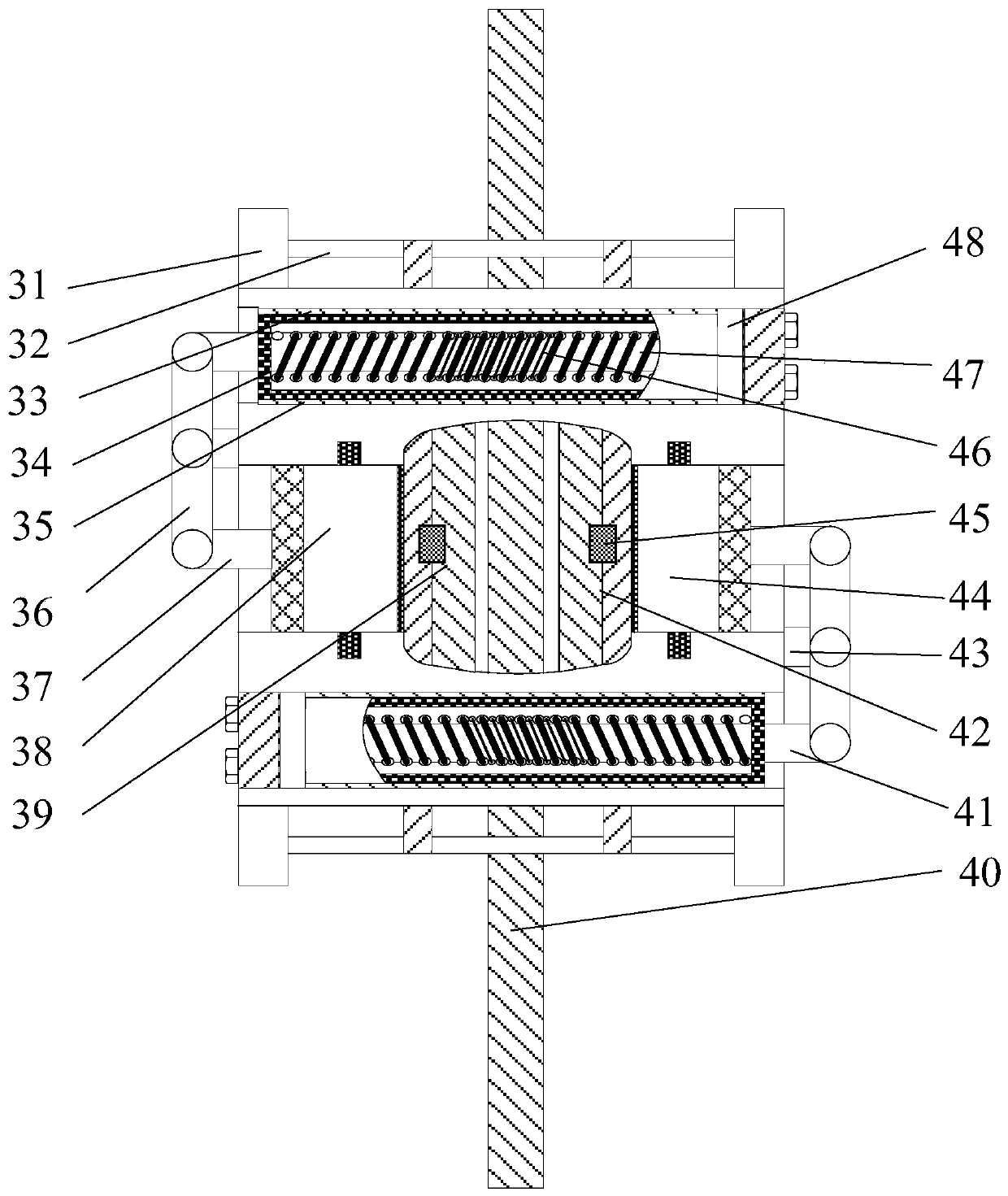

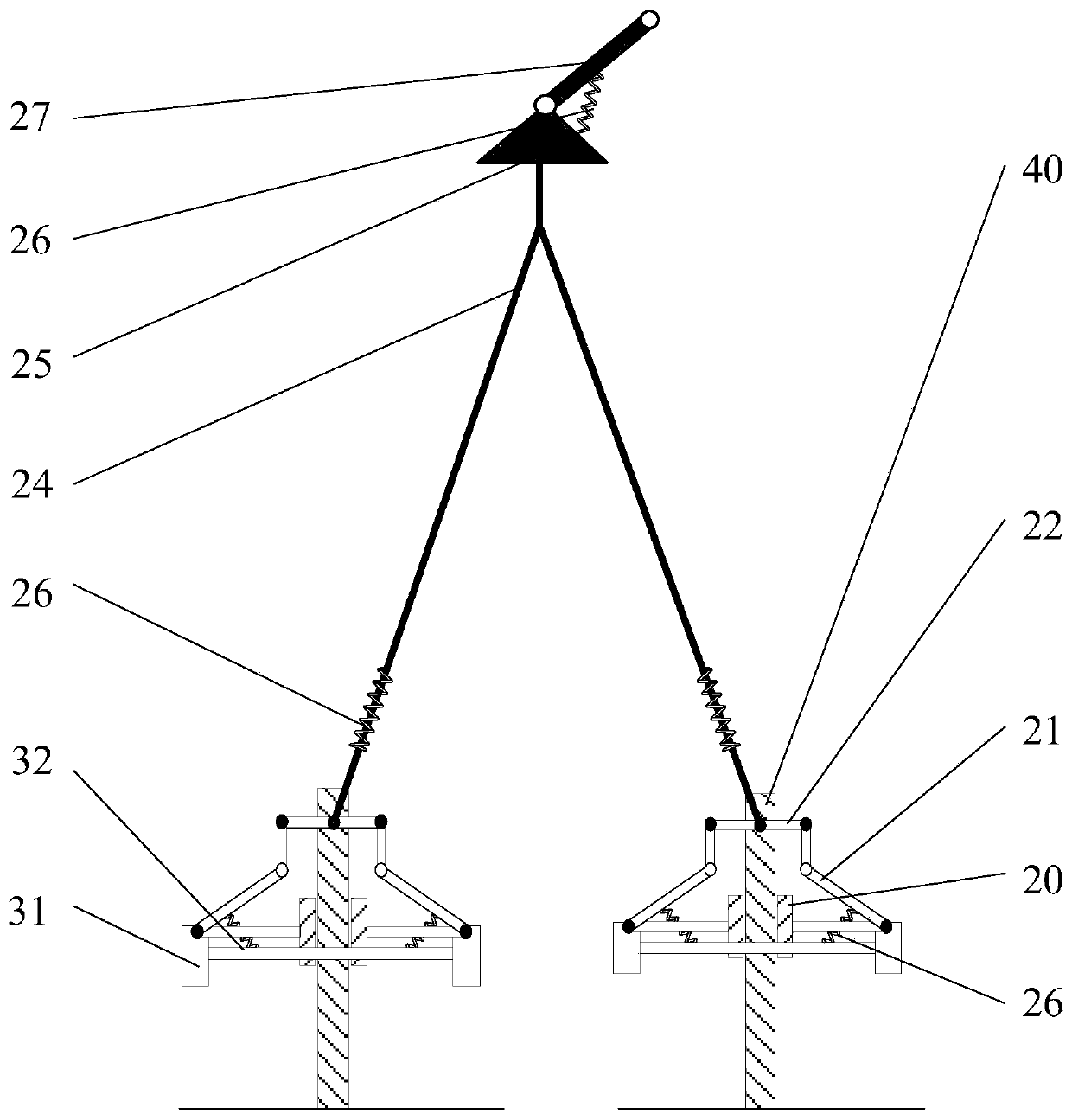

Disc type brake-by-wire system based on magnetostrictive material and control method thereof

PendingCN110962825AEasy to control electronicallyEasy to integrateBraking element arrangementsBraking action transmissionElectric controlControl theory

The invention discloses a disc type brake-by-wire system based on magnetostrictive material and a control method thereof. The disc type brake-by-wire system comprises a brake pedal module, a left front brake, a right front brake, a left rear brake, a right rear brake, a left front wheel, a right front wheel, a left rear wheel, a right rear wheel, a control module, a power source, a current adjusting module and a parking brake module. According to the system, by means of the characteristics of a magnetostrictive material, the magnetostrictive material serves as a driving source and controls thebraking system by controlling the current in a magnet exciting coil. Due to the fact that traditional hydraulic drive is replaced by magnetostriction drive, the defects of an electric control hydraulic brake system are eliminated. Compared with a mechanical brake-by-wire system, the brake-by-wire system is simple in structure, light in weight, small in size, low in energy consumption and beneficial to control.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Line control brake system pedal force simulation and braking force control system of electric car

InactiveCN103481879AUniform braking decelerationSmall throttling resistanceElectrodynamic brake systemsFoot actuated initiationsDriver/operatorTorsion spring

The invention relates to a line control brake system pedal force simulation and a braking force control system of an electric car. The braking force control system comprises a braking operation mechanism, a pedal feel simulator, torsion springs, a pedal angular displacement sensor, a pedal force sensor and an electro-hydraulic composite braking control system. A pedal operating arm of the braking operation mechanism is connected with the front end of a push bar of the pedal feel simulator through hinge rotation. The torsion spring are loosely sleeved on a pedal shaft of the braking operation mechanism, one end of the pedal shaft is fixedly connected on a pedal fixing support, and the other end of the pedal shaft is fixedly connected with the pedal operating arm. The pedal angular displacement sensor is mounted in a round hole of the upper end of the pedal operating arm. The pedal force sensor is mounted on the braking pedal. Pedal angular displacement sensor signals and pedal force sensor signals are input to a control unit of the electro-hydraulic composite braking control system. By the aid of the braking force control system, feeling of a braking pedal can be simulated, a good response is brought to acting force of the pedal, and braking forces of front and rear shafts of the electric car are controlled by identifying braking intention of a driver and calculating braking intensity.

Owner:BEIHANG UNIV

Brake block of environment friendly composite material and its making process

InactiveCN1887939AGood vibration and noise reduction performanceAvoid harmFriction liningFiberGraphite

The present invention relates to automobile braking system technology, and discloses one kind of brake block of environment friendly composite material and its making process. The present invention features that the brake block is made with nanometer modified resin, composite mineral fiber, organic fiber, mineral fiber, ceramic fiber, artificial graphite, baritite and other materials in certain weight proportion, and through mixing, hot pressing and heat treatment. The brake block has the advantages of no pollution, good damping and noise reducing performance, low cost, long service life, high braking stability, etc.

Owner:NANYANG BROADCASTING TV UNIV

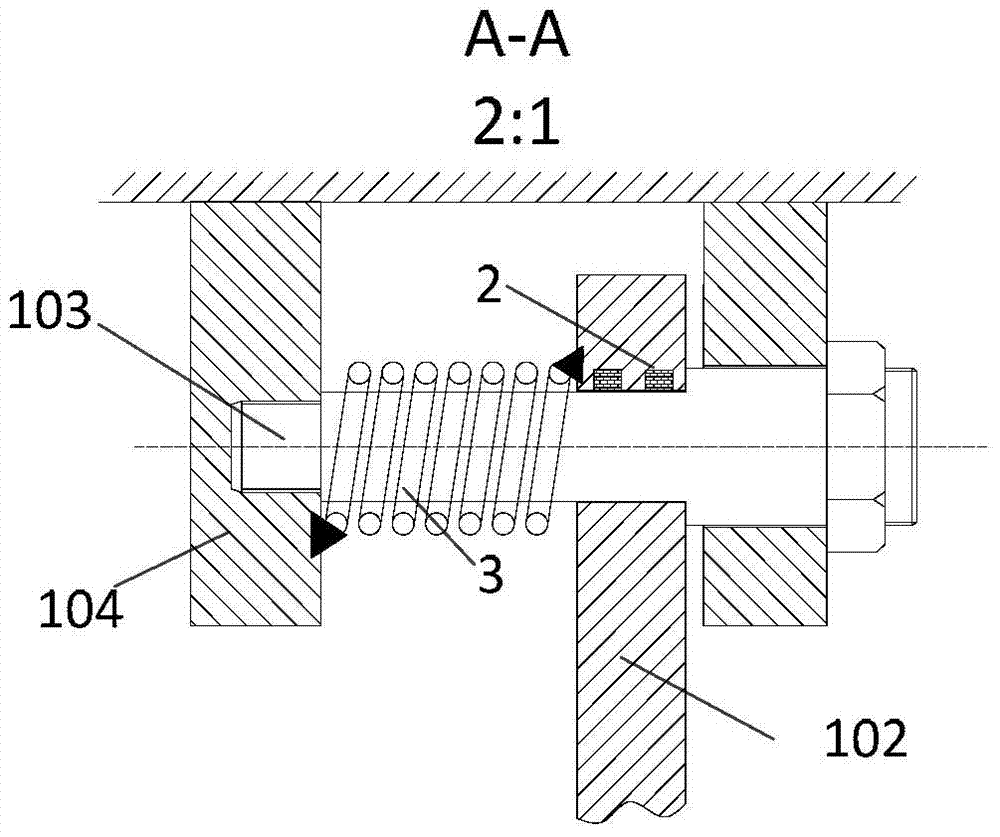

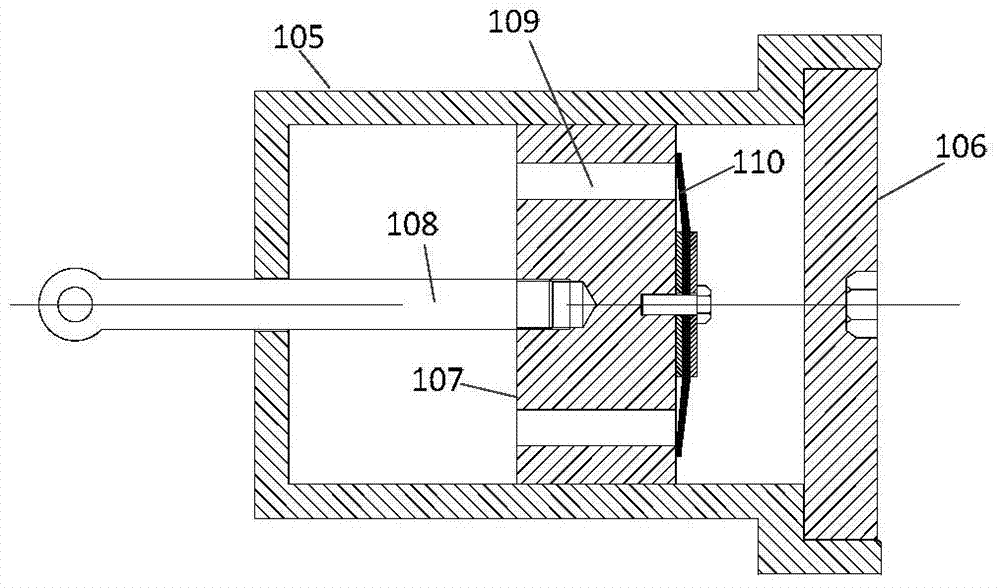

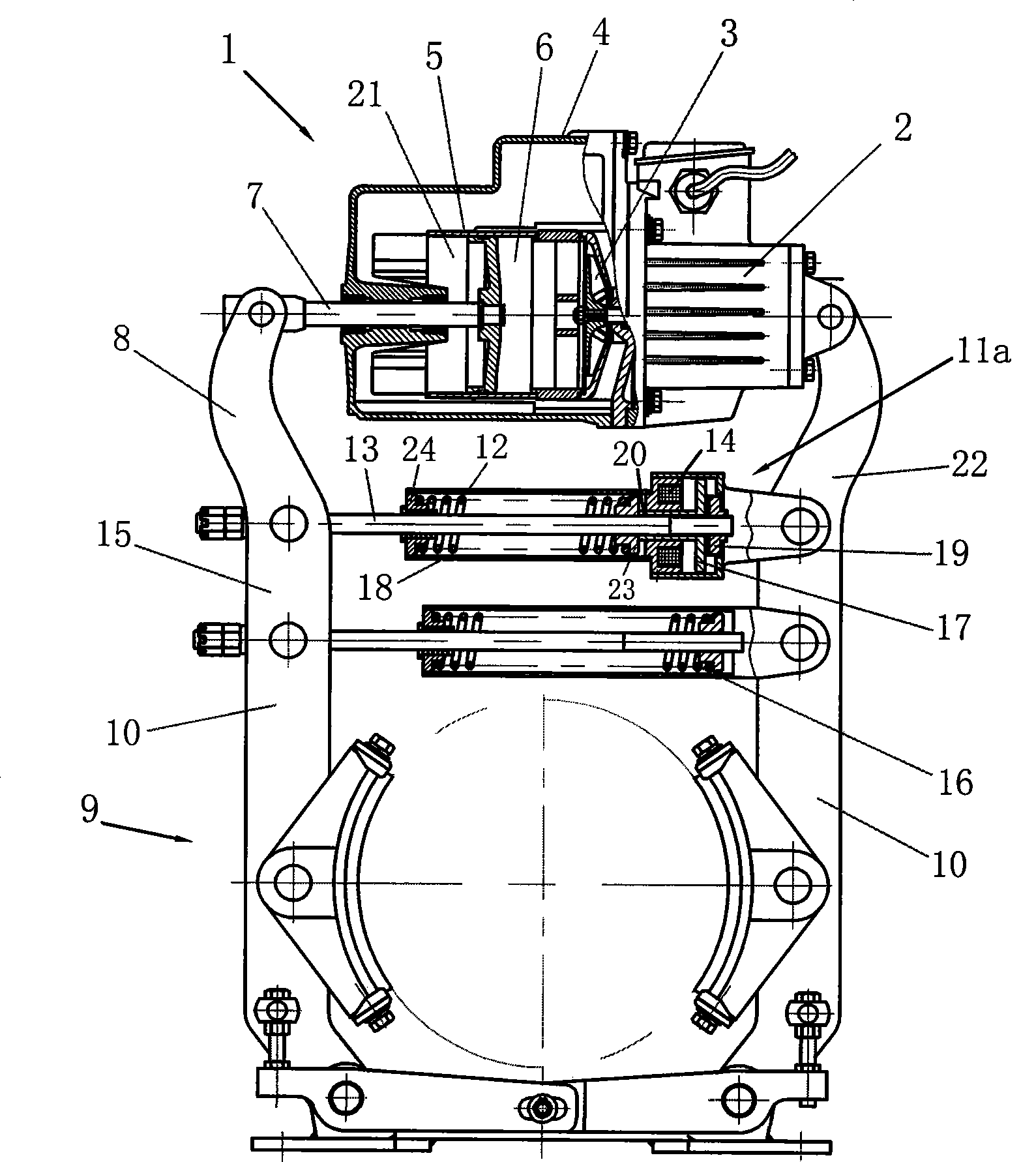

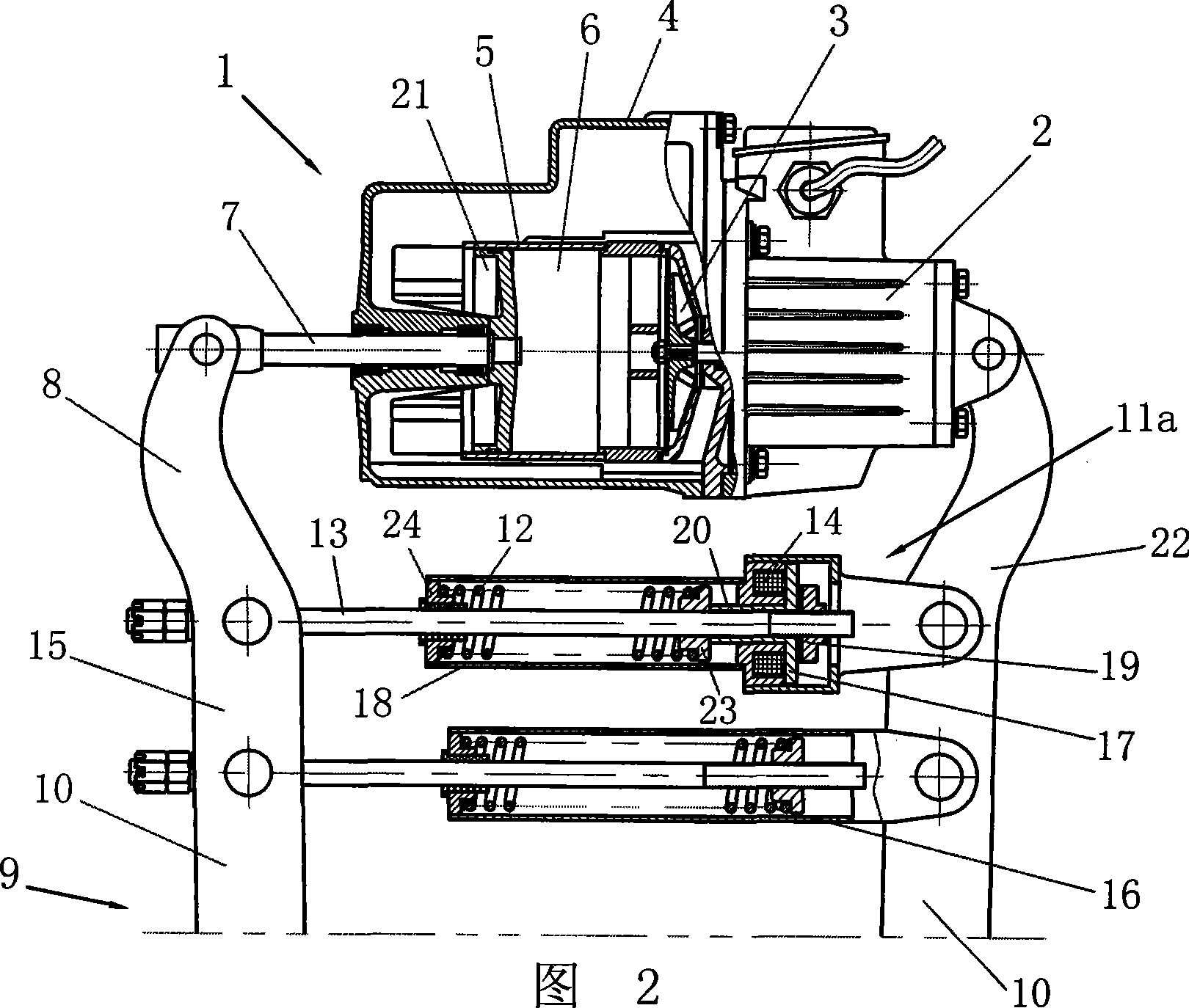

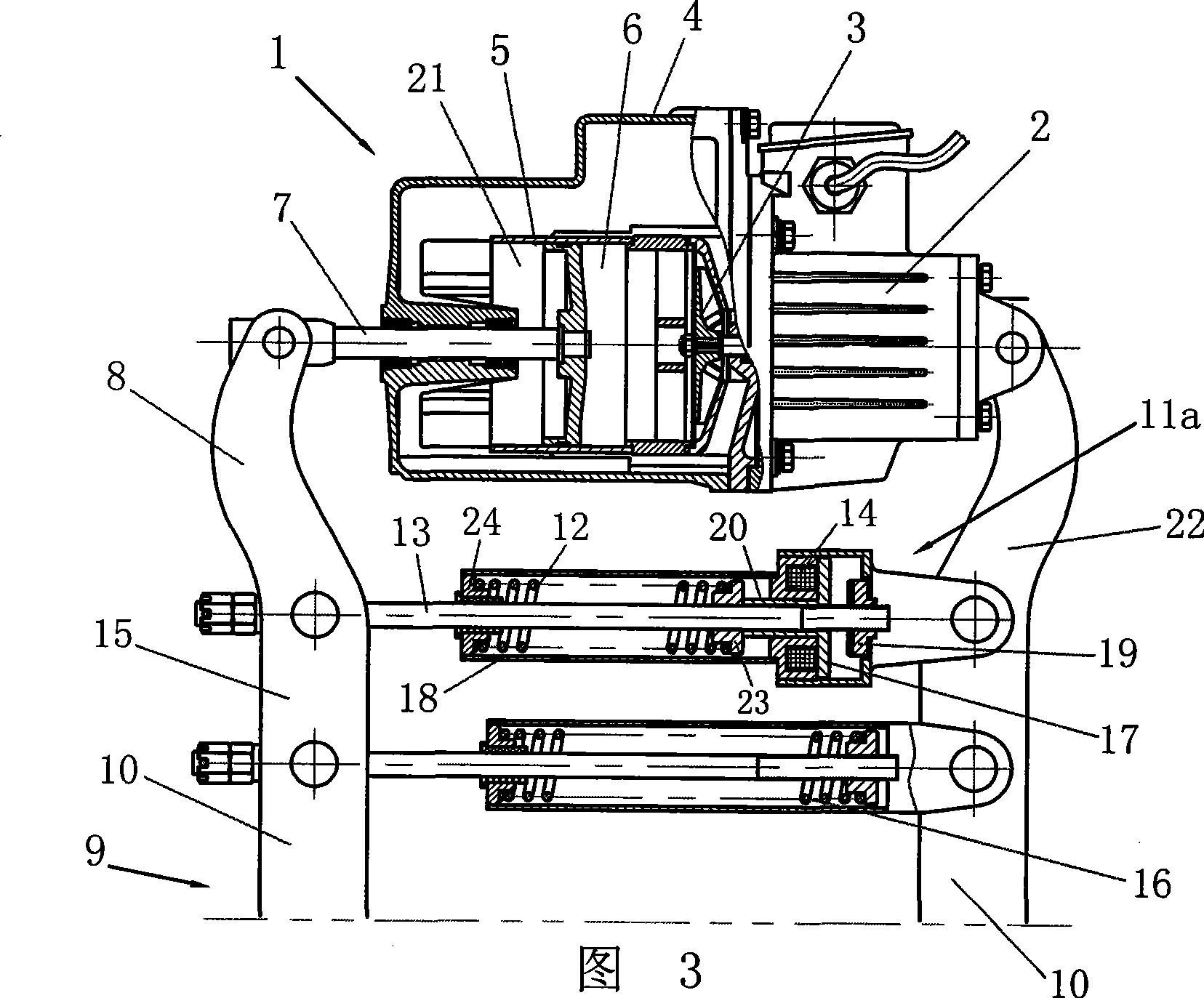

Stacked braking thrust unit of normally closed brake

InactiveCN101463874AReliable brakingMeet braking requirementsDrum brakesBrake actuating mechanismsAutomotive engineeringHinge angle

A superimposed braking driver of a normally closed type brake comprises a driver (1), the external end of a push rod (7) is used for connecting a driving arm (8) in a braking part by hinge shaft so as to act on the braking part (9), a superimposed braking mechanism which can lead the braking part to realize superimposed braking is arranged, and the superimposed braking mechanism acts on the braking arm (10) in the braking part (9) by a corresponding component; the superimposed braking mechanism can adopt a plurality of structures like a superimposed braking mechanism (11a) or a superimposed braking mechanism (11b) or a superimposed braking mechanism (11c). By operating the driver (1) individually, the openness and restoration of the normally closed brake can be realized, and according to requirement, the superimposed braking mechanism can be operated individually to realize the superimposed brake; and the working process of the openness and restoration of the normally closed brake can be applied to a working condition with frequent braking individually to lead the normally closed brake and the superimposed brake to be in a working process of a braking mode, and can be applied to a more stable and reliable braking.

Owner:谢兴云

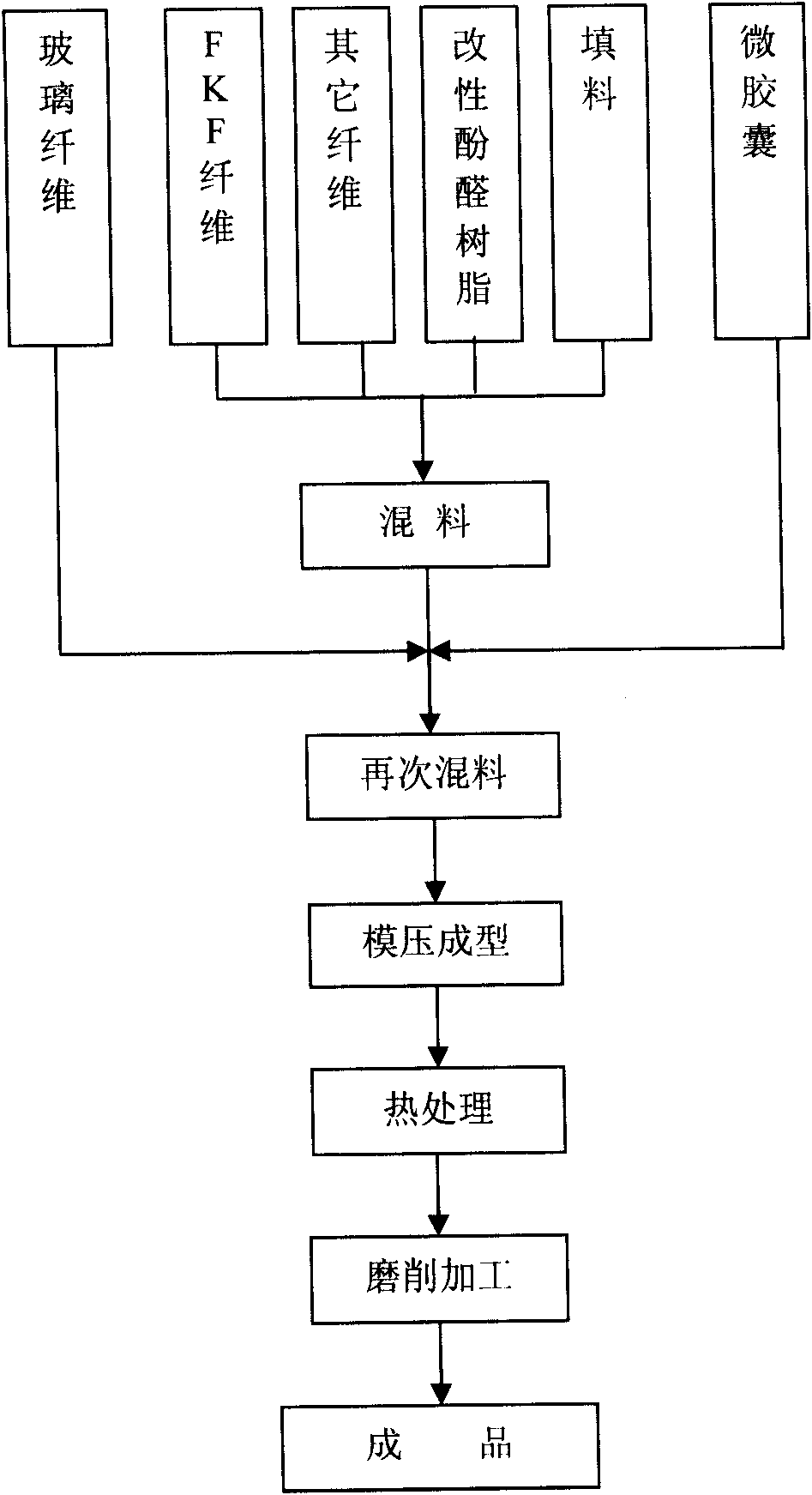

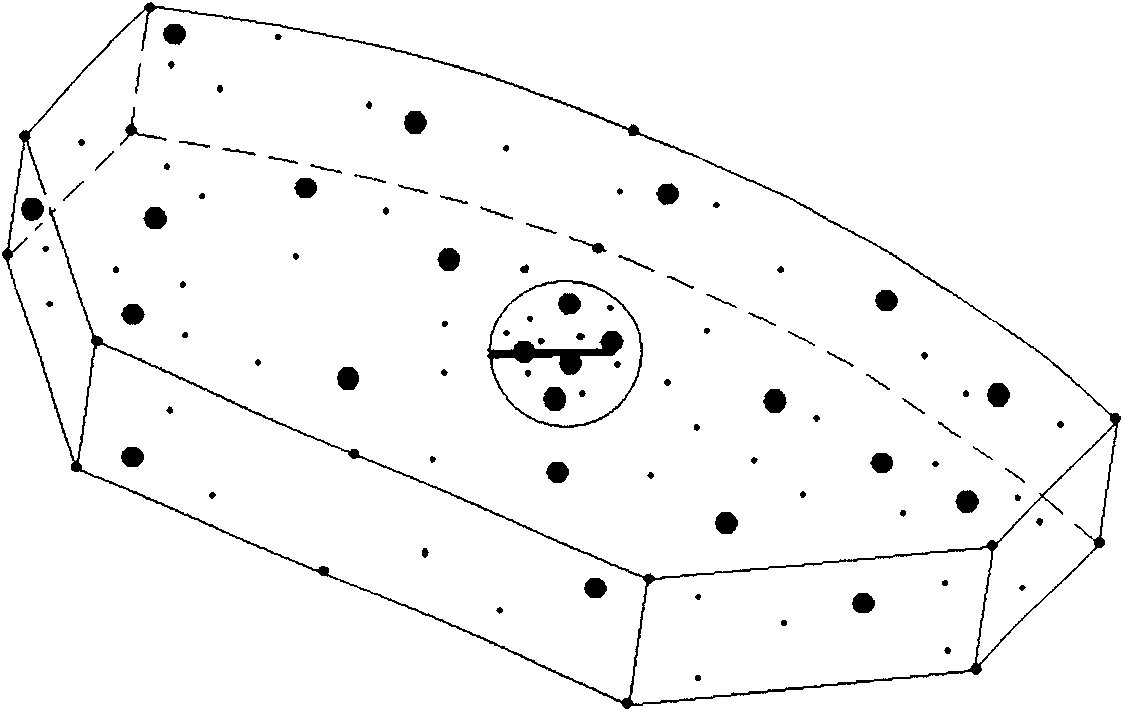

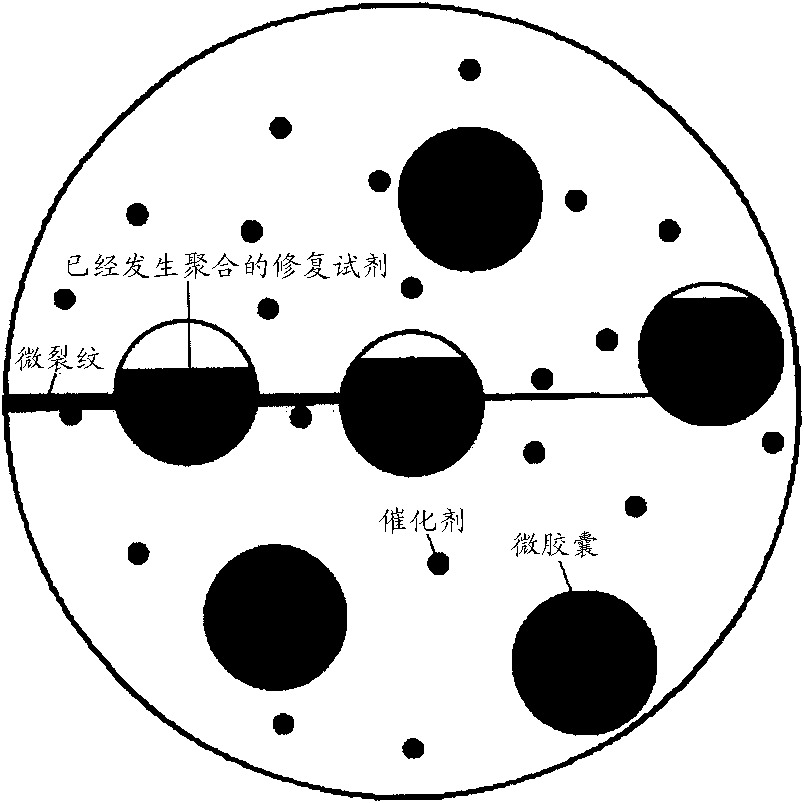

Application of micro-capsule self-repair technology in automobile brake shoe made of composite material

InactiveCN101619156ANo pollution in the processGood vibration and noise reductionFiberStress concentration

The invention discloses application of micro-capsule self-repair technology in automobile brake shoe made of a composite material. The novel automobile brake shoe made of the composite material which contains self-repair micro-capsules selects dicyclpentadiene (DCPD) microcapsules coated with poly(urea-formaldehyde) as the self-repair micro-capsules, takes an inorganic nano-modified phenolic resin as a matrix and composite mineral fiber (FKF fiber) as main reinforced fiber, is added with a small amount of other fiber-assisted enhanced hybrid reinforcements such as glass fiber and Dutch rock wool at the same time, selects ten materials such as flaky vermiculite, barite, chromite powder, fluorite, calcium carbonate and the like as friction-increasing fillers, selects three materials such as grain graphite and the like as friction-reducing fillers, selects three materials such as cashew nut shell oil friction powder and the like as organic fillers, and is developed according to preferable process conditions. When the brake shoe produces a micro-crack during the friction and wear, the stress concentration of the tip of the crack can cause the rupture of the micro-capsules, a repair agent is released to the surface of the crack by capillary action, and then a polymerization reaction is triggered through a catalyst to ensure that fractured surfaces are adhered together, thereby repairing the surface of the crack.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

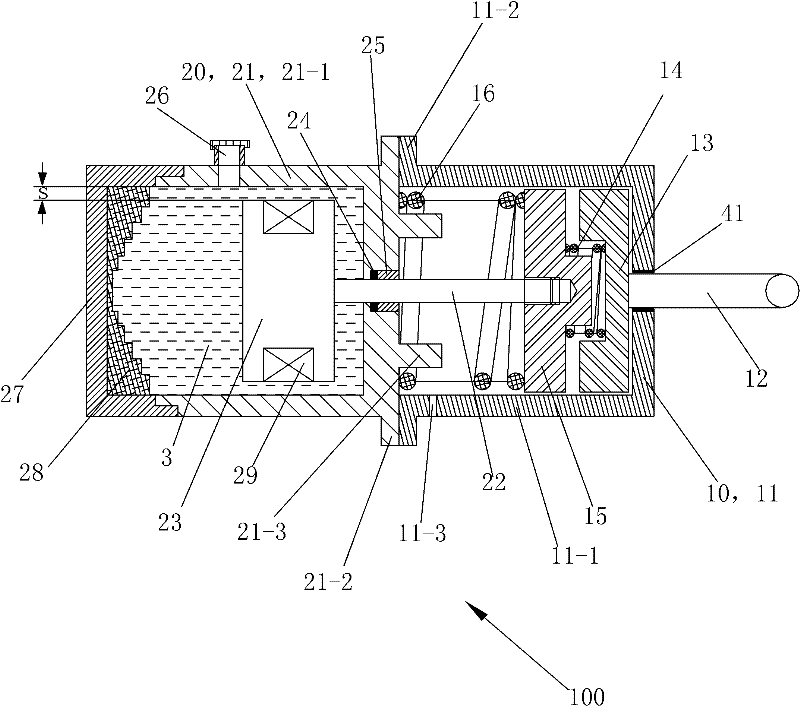

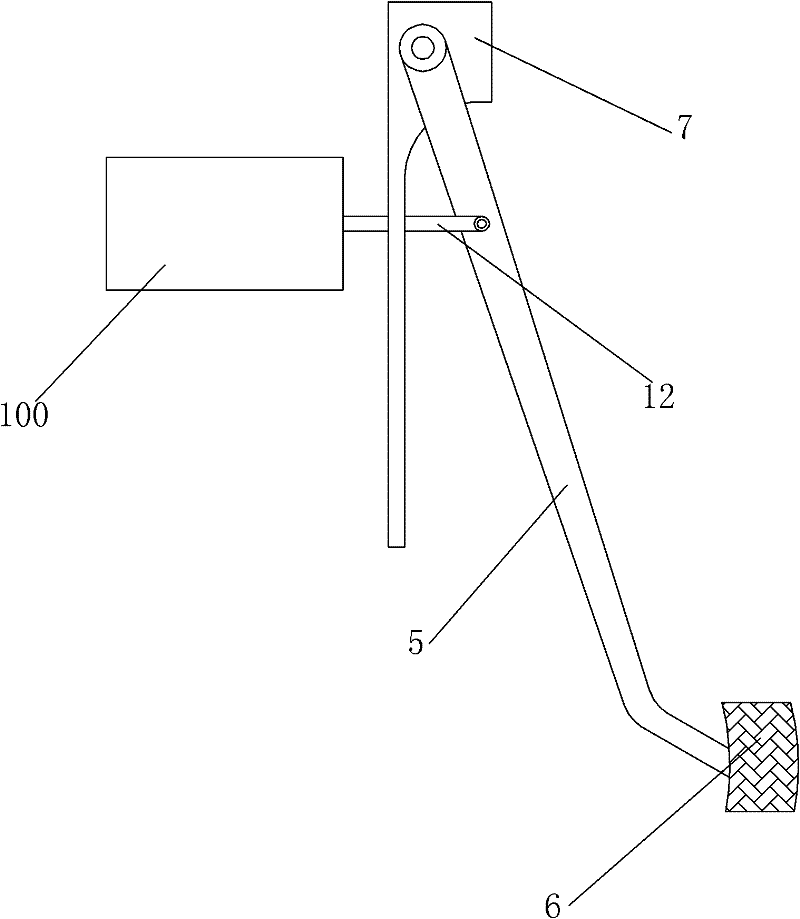

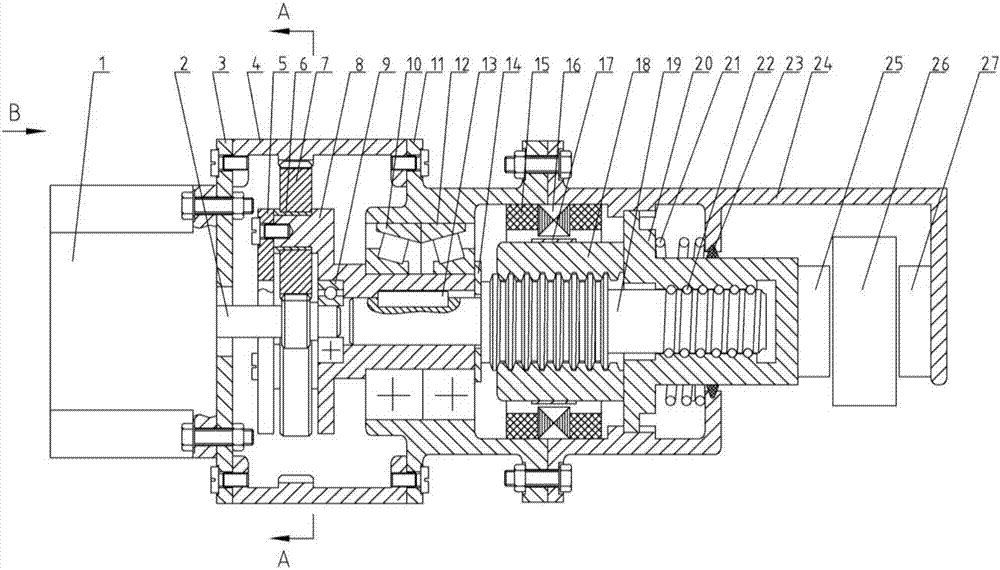

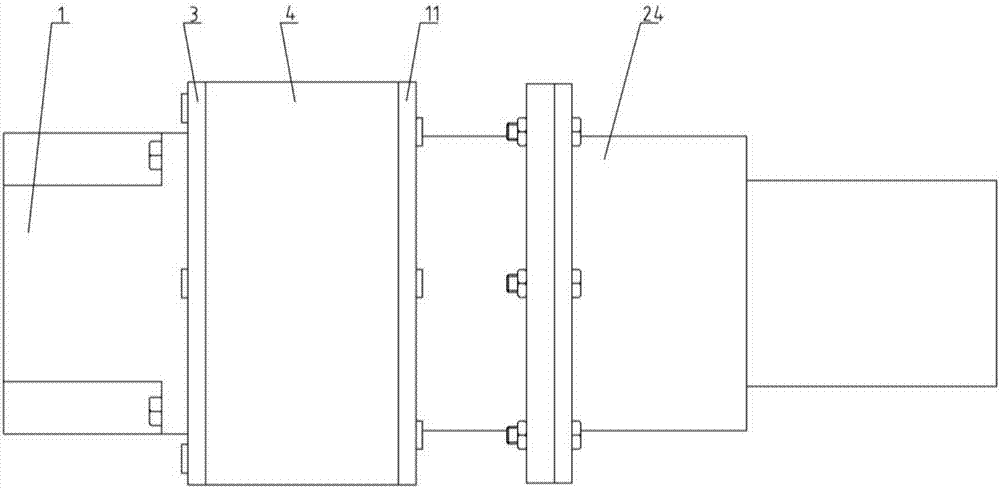

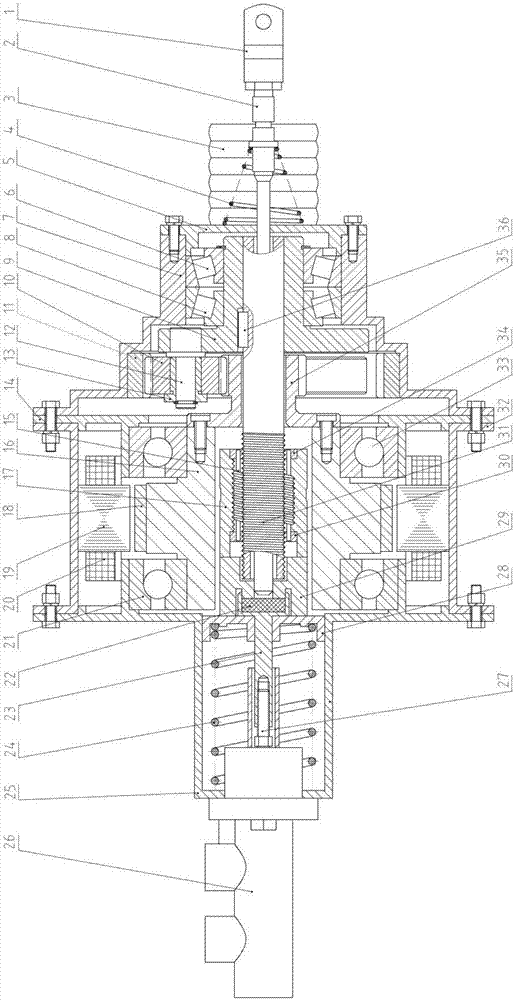

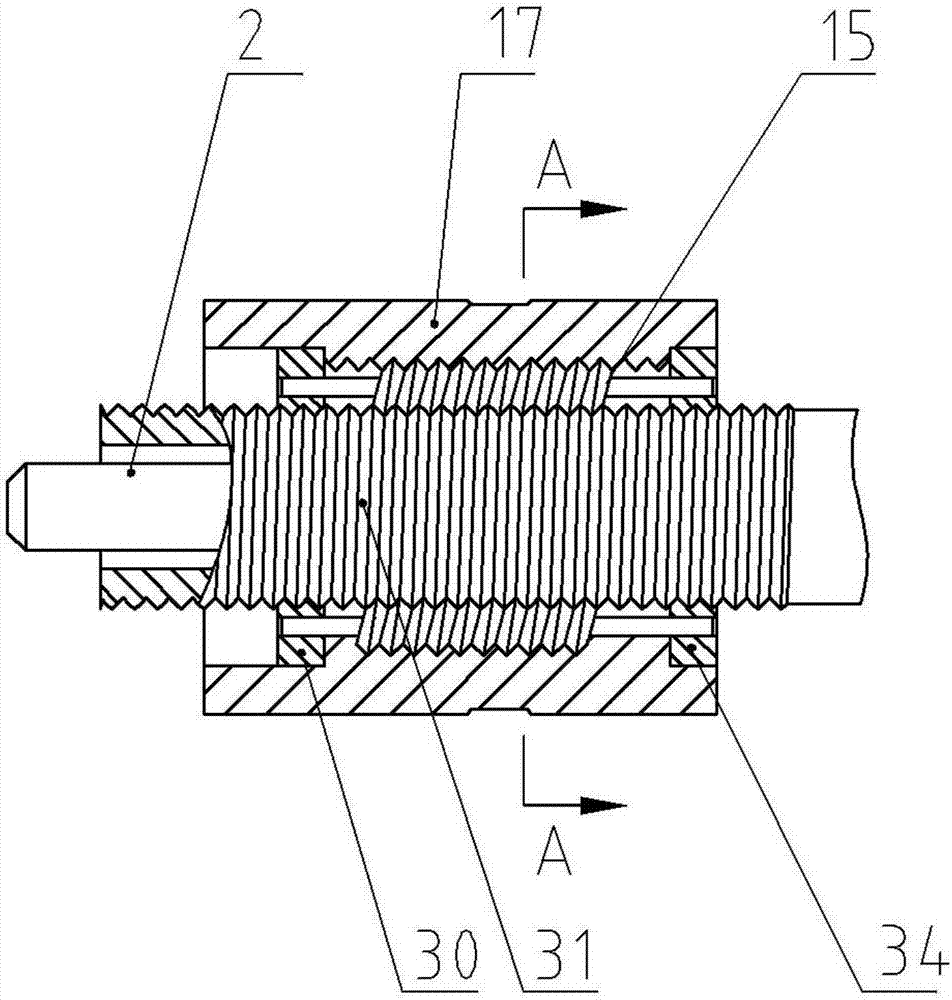

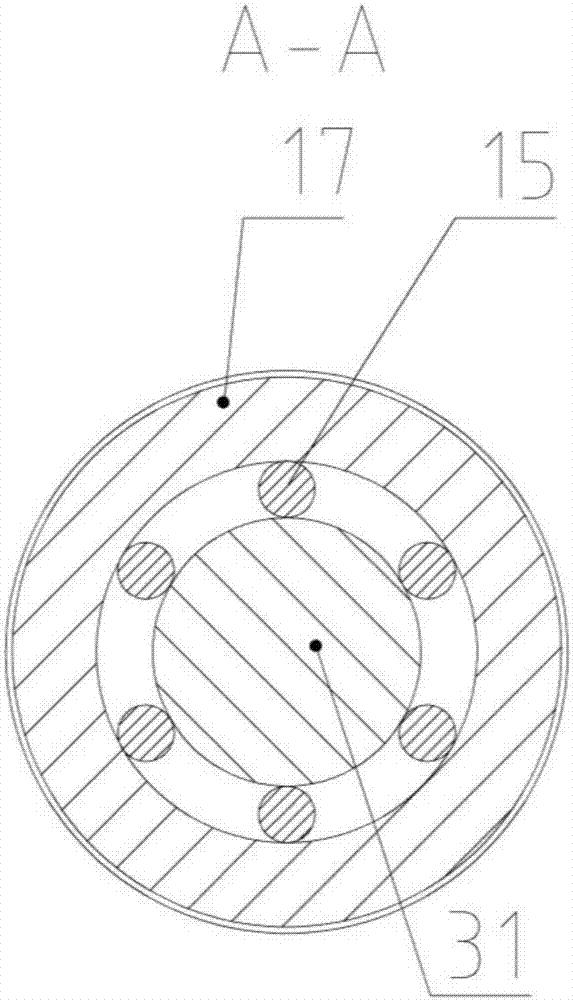

Integrated type drive-by-wire hydraulic braking device

InactiveCN107444380AReduce volumeHighly integratedBraking action transmissionDrive by wireEngineering

The invention provides an integrated type drive-by-wire hydraulic braking device. The integrated type drive-by-wire hydraulic braking device is composed of a braking main cylinder connecting assembly, a braking pedal connecting assembly, a end cover shell body assembly, a motor assembly, a planetary rolling column lead screw mechanism and a planetary gear mechanism. The motor assembly is next to the braking main cylinder connecting assembly. The planetary gear mechanism is next to the braking pedal connecting assembly. The planetary rolling column lead screw mechanism is located in a central hole of motor rotor magnetic steel in the motor assembly. A sun wheel of the planetary gear mechanism is coaxially connected with the motor rotor magnetic steel. A planetary frame of the planetary gear mechanism is coaxially connected with a hollow lead screw of the planetary rolling column lead screw mechanism. When the motor assembly works, the motor rotor magnetic steel drives the sun wheel to rotate, the planetary frame is further driven to rotate, the hollow lead screw is driven by the planetary frame, and a planetary rolling column lead screw nut of the planetary rolling column lead screw mechanism is driven to output displacement towards a braking main cylinder through the braking main cylinder connecting assembly. By means of the integrated type drive-by-wire hydraulic braking device, the size of the braking device is reduced, the integration level is improved, and arranging on a whole vehicle is achieved conveniently.

Owner:JILIN UNIV

Wear-proof brake pad

ActiveCN106015411AImprove toughnessImprove wear performanceOther chemical processesFriction liningSodium titanateAramid

The invention discloses a wear-proof brake pad. The wear-proof brake pad comprises a steel plate, a thermal-insulating layer and a friction block. The friction block is fixed to the steel plate through the thermal-insulating layer. The raw materials of the friction block comprise, by weight, 10-20 parts of phenolic resin, 3-12 parts of nitrile rubber, 2-10 parts of butadiene rubber, 5-10 parts of carbon fiber, 3-8 parts of aramid fiber, 2-5 parts of glass fiber, 10-30 parts of potassium titanate lamella crystals, 5-20 parts of iron sodium titanate lamella crystals, 20-40 parts of barium sulfate, 2-5 parts of nano-silica, 2-5 parts of sepiolite, 2-8 parts of alumina powder, 0.2-1.5 parts of accelerant D, 0.1-0.5 part of zinc oxide, 1-4 parts of vermiculite powder, 2-5 parts of petroleum coke, 1-5 parts of synthetic graphite and 3-10 parts of bamboo charcoal. The wear-proof brake pad is excellent in wear resistance and impact resistance, good in heat resistance and small in curing shrinkage.

Owner:WUHU DONGZHENG AUTOMOTIVE IND

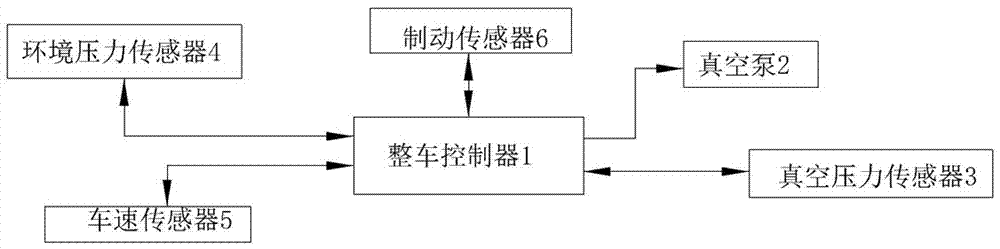

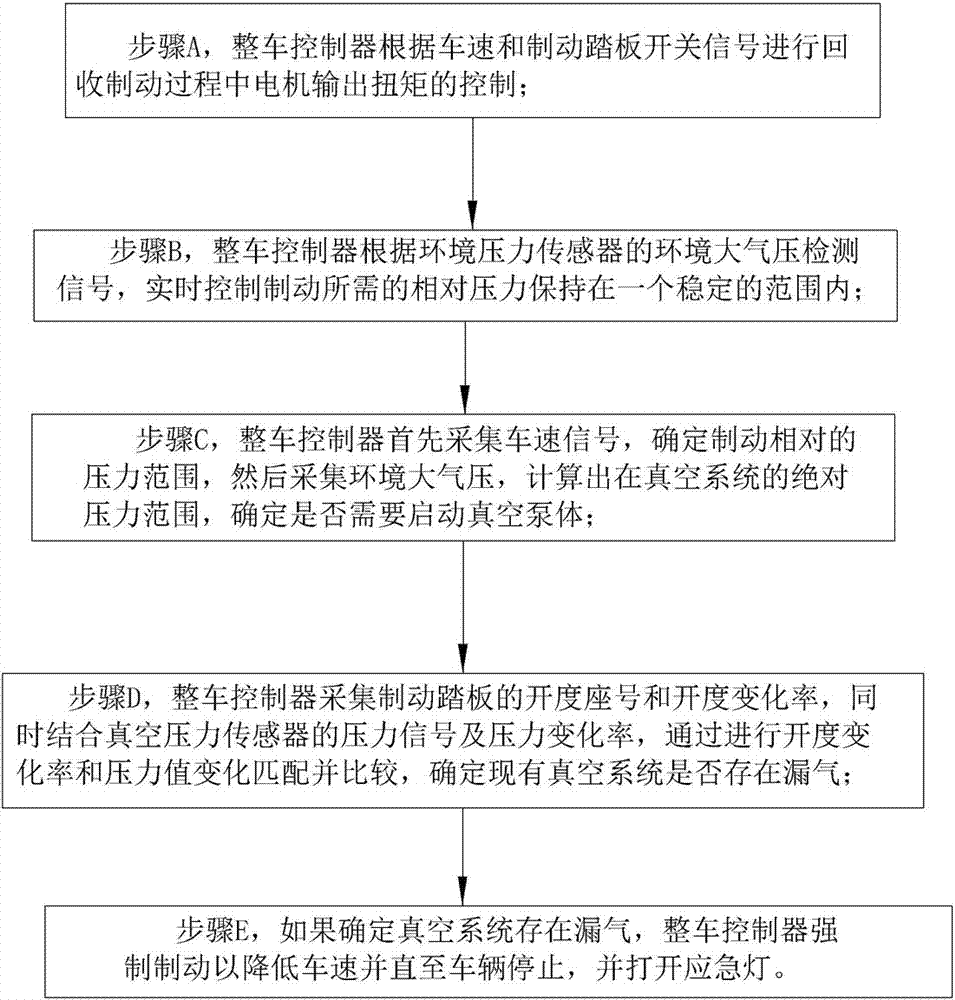

Electric vehicle with vacuum pump control system

InactiveCN107444196AImprove basic performanceImproved braking stabilitySpeed controllerBraking action transmissionAmbient pressureElectric vehicle

The invention discloses an electric vehicle with a vacuum pump control system. The electric vehicle with the vacuum pump control system comprises a vehicle controller, a vacuum pump, a vacuum pressure sensor, an ambient pressure sensor, a speed sensor and a braking sensor. A controlling method for the electric vehicle with the vacuum pump control system comprises the following steps that step A, the vehicle controller controls the motor output torque in the recycling and braking process according to speed and braking pedal switch signals; step B, signals are detected according to the ambient atmospheric pressure; step C, the relative pressure range of braking is determined, the absolute pressure range in a vacuum system is calculated, and whether starting the vacuum pump body is needed or not is determined; step D, opening degree signals and the changing rate of the opening degree of the braking pedal are collected to determine whether gas leaking is existed in the prior vacuum system or not; and step E, if gas leaking in the vacuum system is determined, the vehicle controller brakes enforcedly to reduce the speed until the vehicle is stopped, and an emergency light is turned on. According to the electric vehicle with the vacuum pump control system, the basic performance of the vacuum pump can be improved, running braking stability and reliability of the electric vehicle can be improved, running safety of the vehicle is ensured, applicability is high, and practicability is good.

Owner:中汽院智能网联科技有限公司 +1

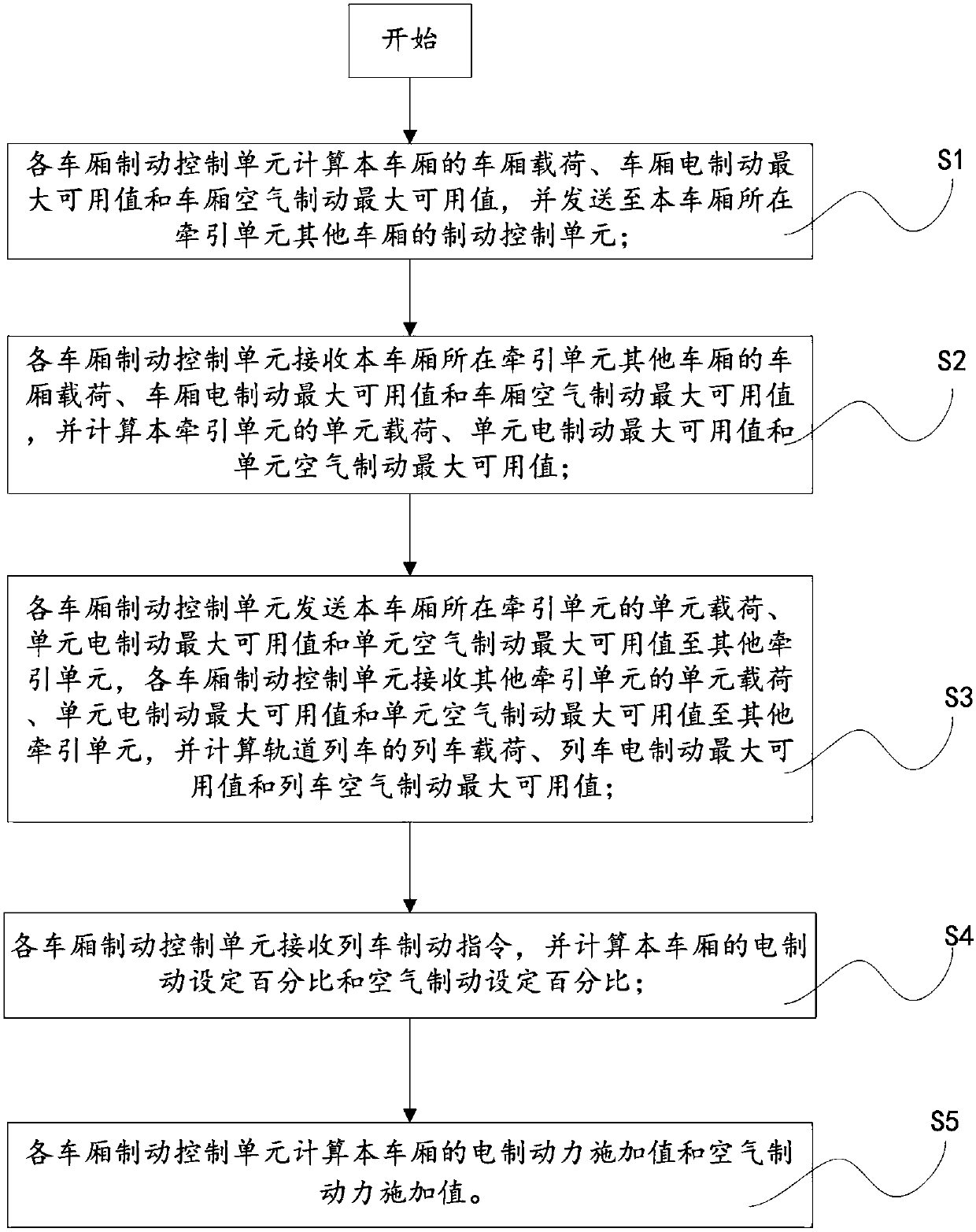

Rail train brake control system and method

ActiveCN107697056AAvoid technical problems of brake failureImproved braking stabilityBraking action transmissionElectricityControl system

The invention provides a rail train brake control system and a rail train brake control method. Brake control units in each compartment are arranged for receiving train brake commands and respectivelycalculating the load, the electric brake maximum available value and the air brake maximum available value of the compartment, the load, the electric brake maximum available value and the air brake maximum available value of a traction unit in which the compartment is located, and the load, the electric brake maximum available value and the air brake maximum available value of the train, and finally performing calculating to obtain an electric brake force applying value and an air brake force applying value of the compartment. According to the control system and the control method disclosed by the invention, the unit electric brake maximum available value and the unit air brake maximum available value of the traction unit in which each compartment is located, and the train electric brakemaximum available value and the train air brake maximum available value of the rail train can be updated in real time according to the condition of the compartment, so that the technical problem thatin the prior art, the brake of the rail train fails caused by that a head train brake control unit or an end train brake control unit is broken down, the brake stability of the rail train brake control system is improved, and the travelling safety of the rail train is further improved.

Owner:CRRC QINGDAO SIFANG ROLLING STOCK RES INST +1

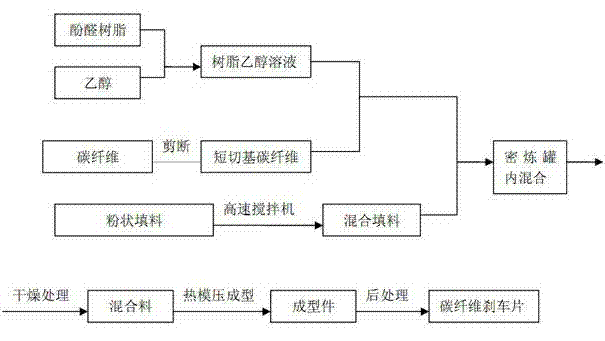

Preparation method of carbon fiber brake block

InactiveCN102206482AEffective use of wear-resistant and heat-resistantLow costOther chemical processesFriction liningFiberCarbon fibers

The invention relates to a preparation method of a carbon fiber brake block, relating to the technical field of automobile brake systems. Aiming at the problems of thermal conductivity and high-temperature controllability existing in the current asbestos-free organism-type (NAO type) automobile brake block, the invention provides the preparation method of the carbon fiber brake block which is prepared from the following raw materials including the following components in percentage by weight: 35-55% of carbon fiber, 15-35% of phenolic resin and 20-40% of powdery packing. The prepared carbon fiber brake block has thermal conductivity and electrical conductivity as well as thermal resistance and corrosion resistance of a metal material; and as the rise of temperature, the friction coefficient is kept constant and even is slightly increased, therefore, the carbon fiber brake block has very excellent brake stability.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

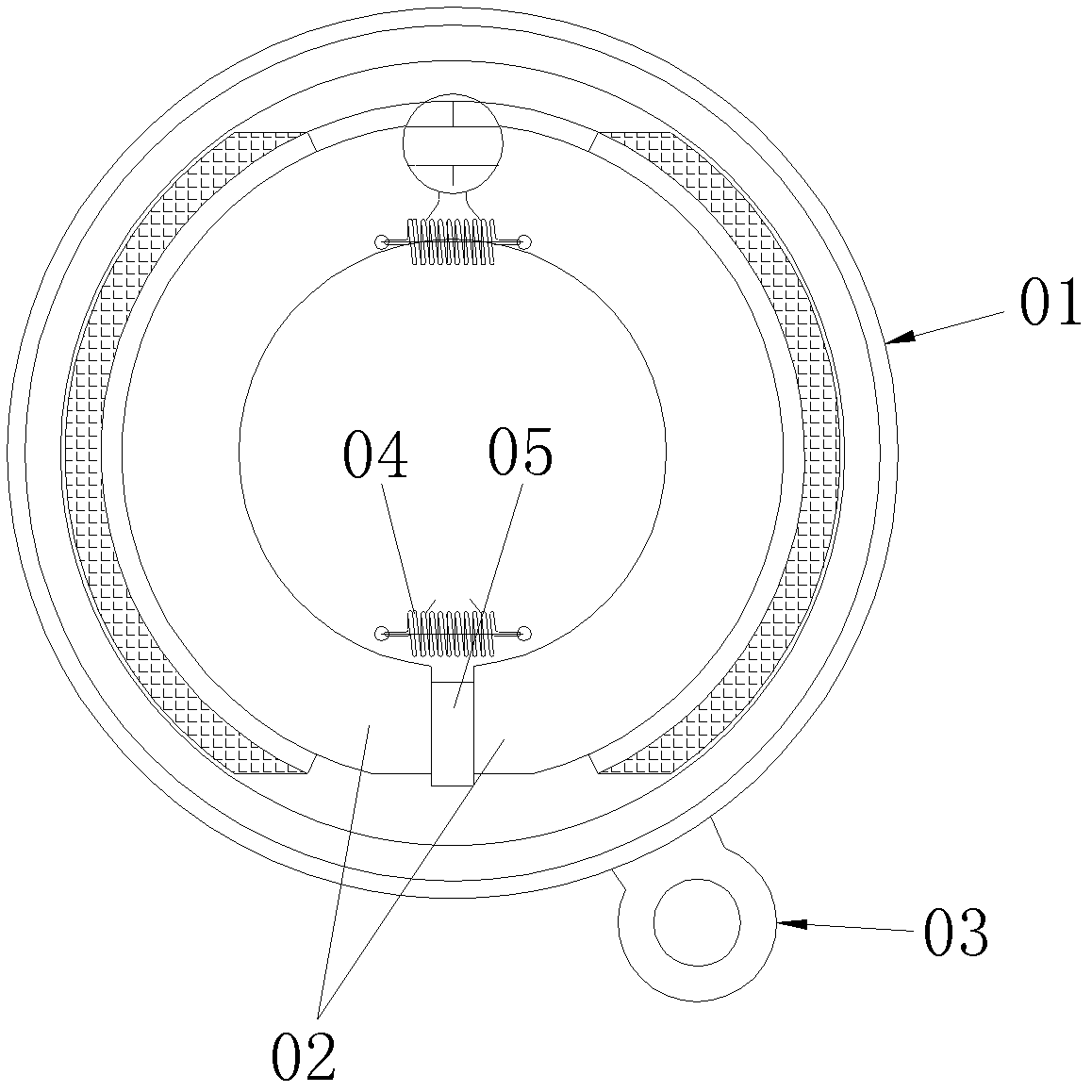

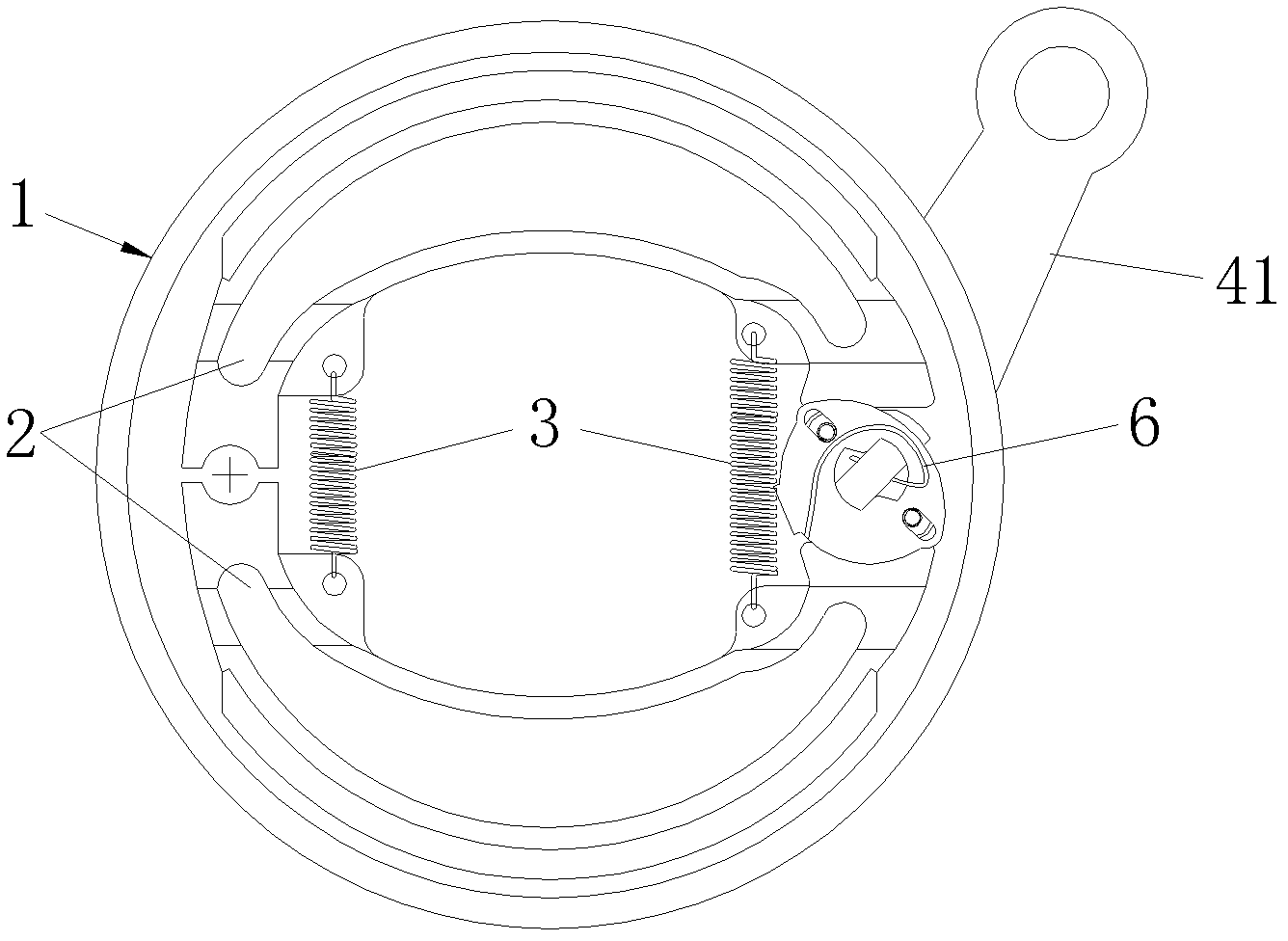

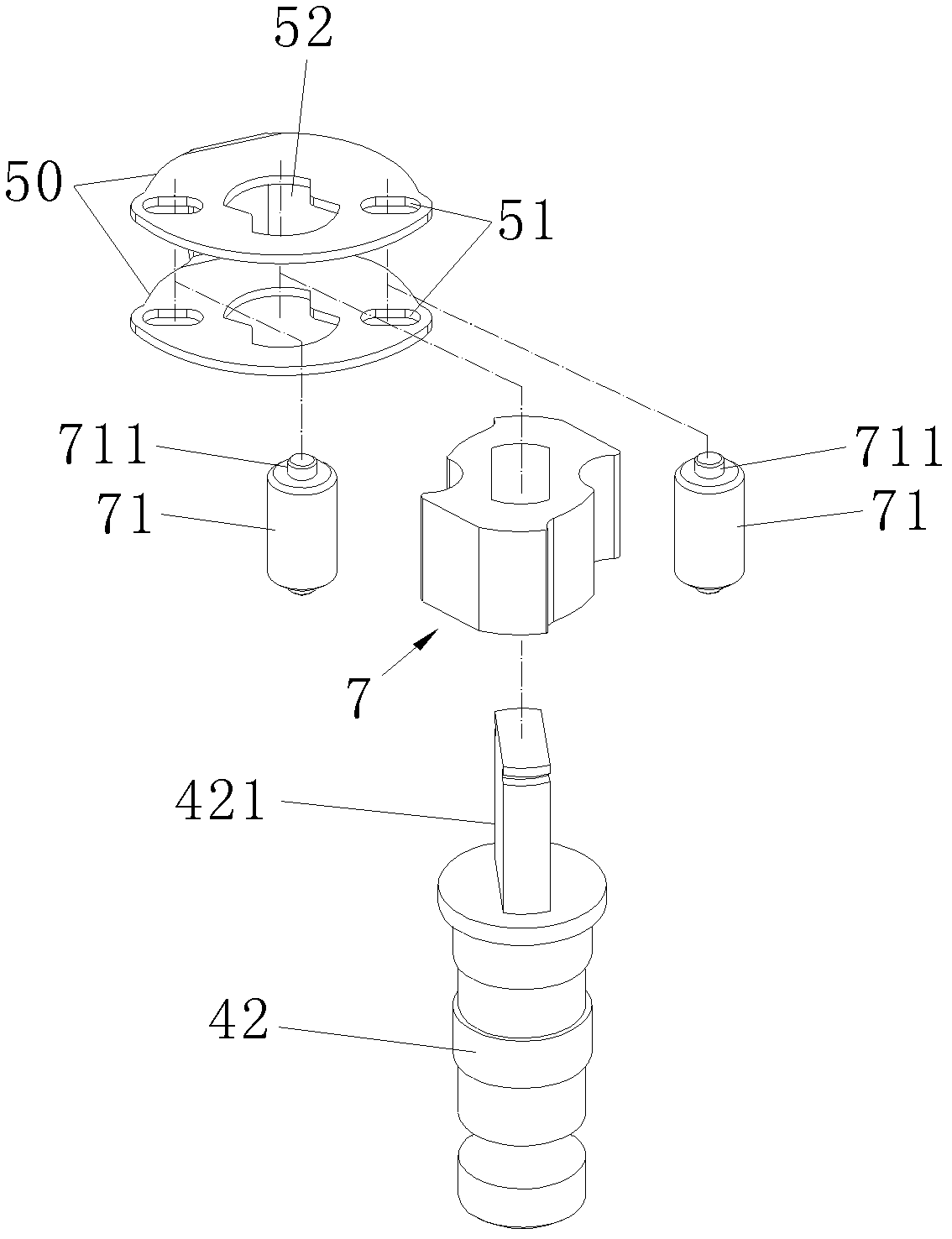

Improved drum brake structure

ActiveCN102305252AReduced service lifeExtended service lifeBrake actuating mechanismsMechanically actuated drum brakesEngineeringCam

The invention discloses an improved drum brake structure which comprises a shell, a pair of brake shoes arranged in the shell, a resetting element and a brake arm assembly, wherein the resetting element is connected with the pair of brake shoes; one end of each brake shoe is rotatably positioned in the shell, and a gap between the other ends of the brake shoes is provided with a brake wheel driven to rotate by the brake arm assembly; a pin roller is respectively abutted and connected between the brake wheel and the end surfaces of the brake shoes on two sides; locating plates are arranged on the two axial end surfaces of the brake wheel, and the pin roller is rotatably positioned between the two locating plates; the edge of the brake wheel is provided with a limiting edge face which is matched with the end surface of the brake shoes to be abutted with the pin roller; and a rolling meshing structure is arranged between the limiting edge face and the pin roller. According to the improved structure provided by the invention, the phenomenon that the original drum brake adopts the working mode of directly driving the brake shoes to expand by a cam is changed, and the shortages of poor brake effect and long vehicle brake sliding distance of the existing drum brake can be effectively improved.

Owner:CHANGXING HUAYI ELECTROMECHANICAL

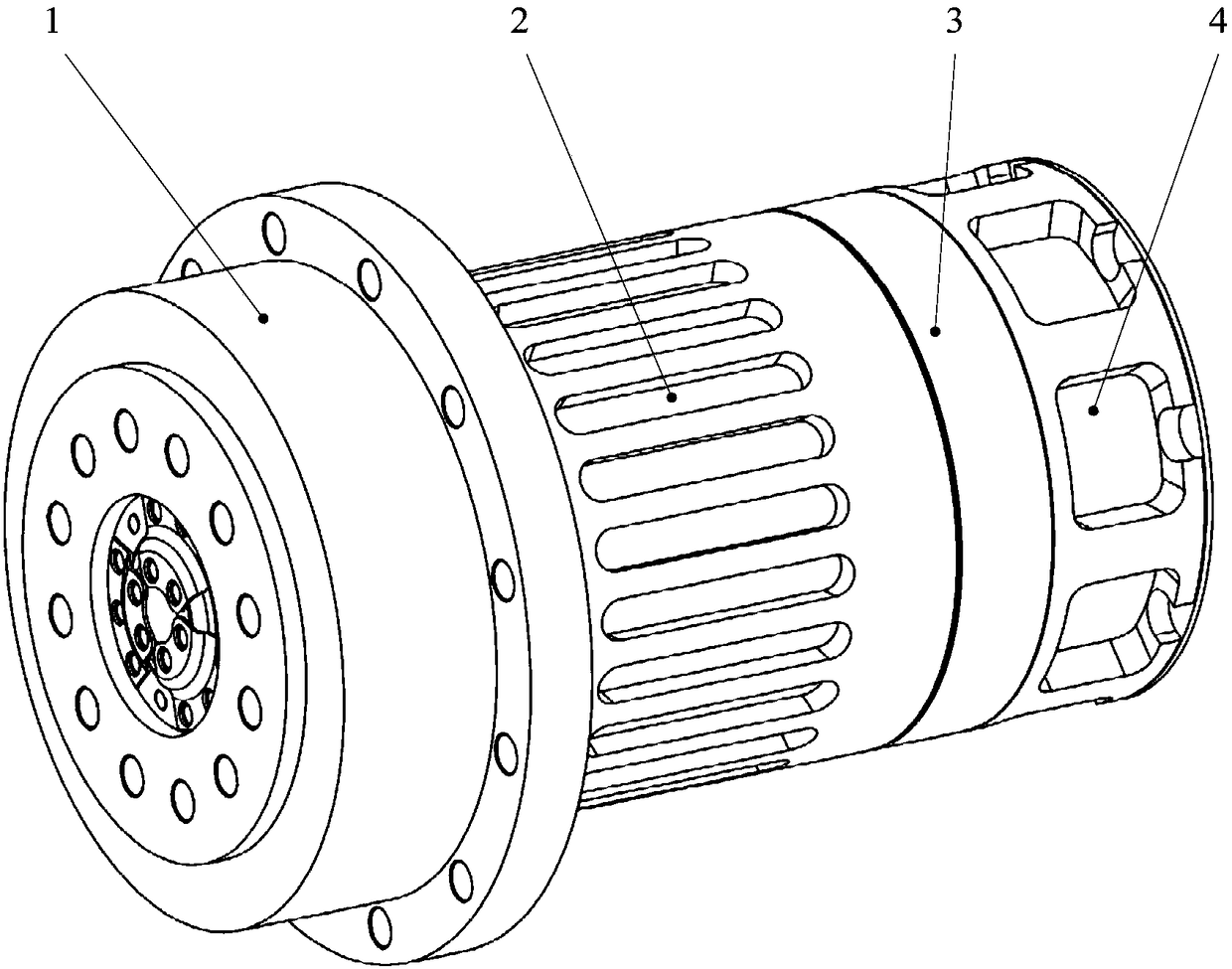

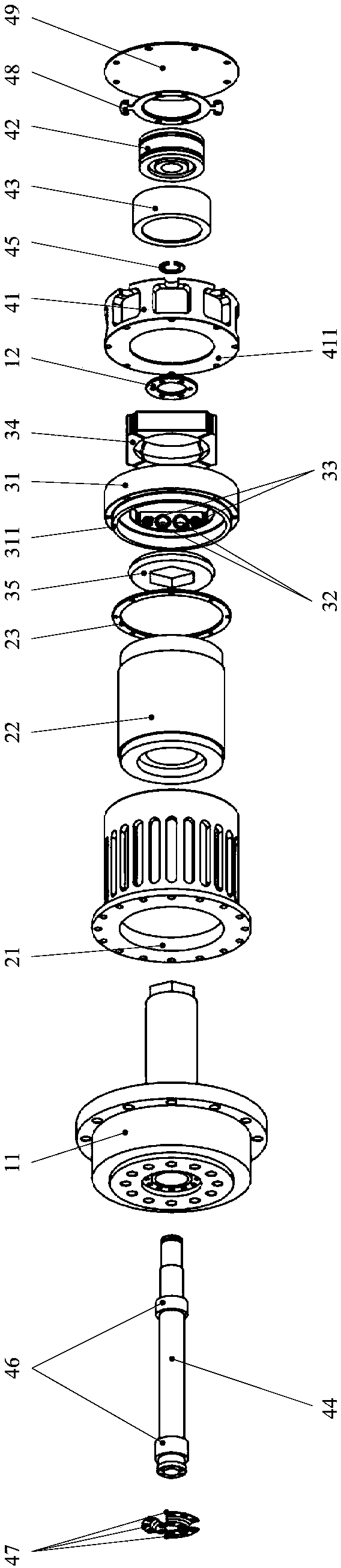

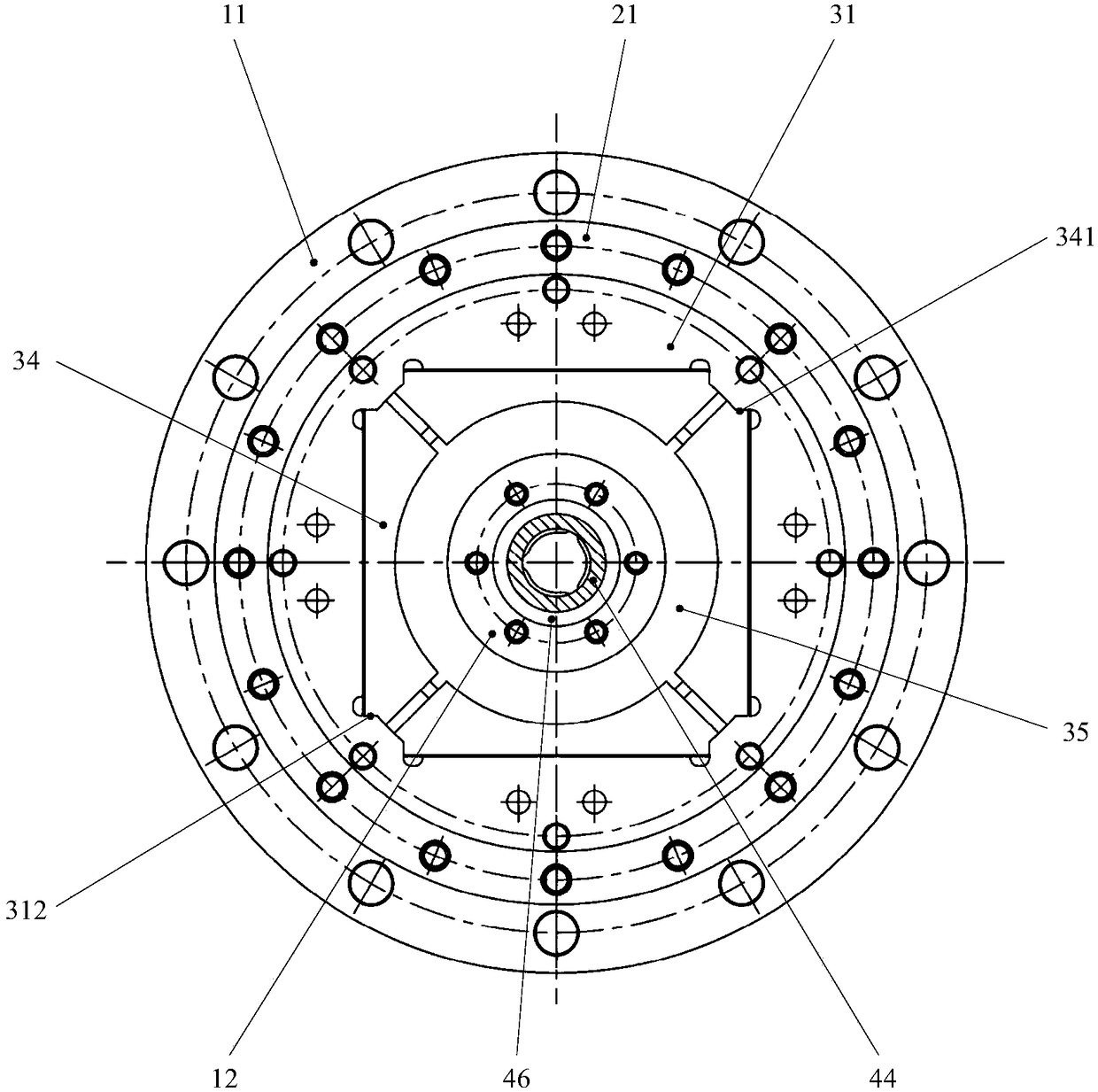

Detection and braking integrated robot joint driver

PendingCN108081256AMechanically compactSimple Electrical DesignProgramme-controlled manipulatorJointsElastic componentReduction drive

The invention discloses a detection and braking integrated robot joint driver and relates to the field of industrial control. The detection and braking integrated robot joint driver comprises a speedreducing assembly, a driving assembly, a braking assembly and an angle detection assembly, and a reducer input shaft in the speed reducing assembly penetrates through and integrates the driving assembly, the braking assembly and the angle detection assembly, so that a mechanical structure of the detection and braking integrated robot joint driver is compact and concise; the compact mechanical structure allows electrical design and configuration of the detection and braking integrated robot joint driver to be relatively simple; with the adoption of a speed reducer input shaft coaxial mounting manner, an angle sensor detects more precisely, braking force of a friction block is applied more directly and uniformly, the braking stability is better, and the reliability of the detection and braking integrated robot joint driver is improved integrally; through the use of an elastic component in the detection and braking integrated robot joint driver, an unavoidable error in use and assembly ofthe detection and braking integrated robot joint driver is compensated smartly, and the reliability of the detection and braking integrated robot joint driver is further perfected; in conclusion, themechanical structure assembly mode of the detection and braking integrated robot joint driver can be integrated, the electrical design is simplified and the integrated level and reliability are improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

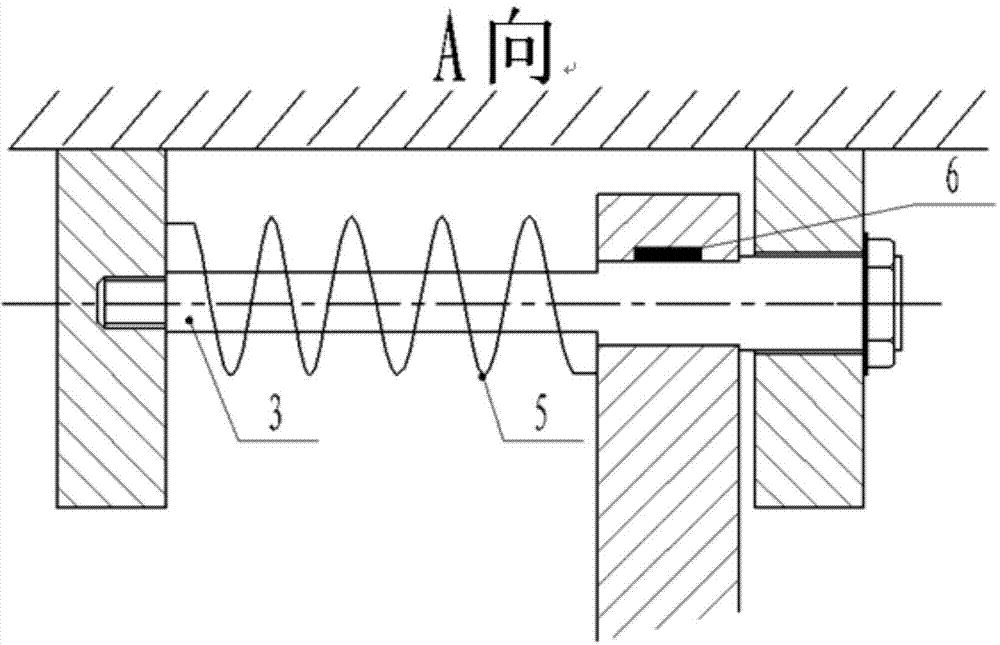

Braking pedal feel simulating device of automobile brake-by-wire system

InactiveCN103481878AReduce pressure differenceThe small pressure difference is very small, and the force exerted by the push rod on the control armMechanical braking transmissionInterference fitSpring force

A braking pedal feel simulating device of an automobile brake-by-wire system comprises a braking pedal, a pedal controlling arm, a pedal shaft, a pedal fixing support, a torsion spring, a pedal angle displacement sensor, a pedal force sensor and a pedal feel simulator. The braking pedal is fixedly connected with the pedal controlling arm, a round hole is processed at the upper end of the pedal controlling arm which is rotatably connected with the pedal shaft, the pedal shaft is mounted in a mounting hole of the pedal fixing support, a guide small hole is formed in the pedal fixing support, the diameter of the guide small hole is in interference fit with the outer diameter of a pushing rod, the torsion spring is cylindrical and is sleeved on the pedal shaft in a hollow manner, one end of the torsion spring is fixedly connected on the pedal fixing support while the other end of the same is connected on the pedal controlling arm, the torsion spring reverses and generates spring force along with rotating of the pedal controlling arm, the pedal angle displacement sensor is mounted in the round hole at the upper end of the pedal controlling arm, the pedal force sensor is mounted on the braking pedal, and the front end of a pushing rod of the pedal feed simulator is rotatably connected with the pedal controlling arm.

Owner:BEIHANG UNIV

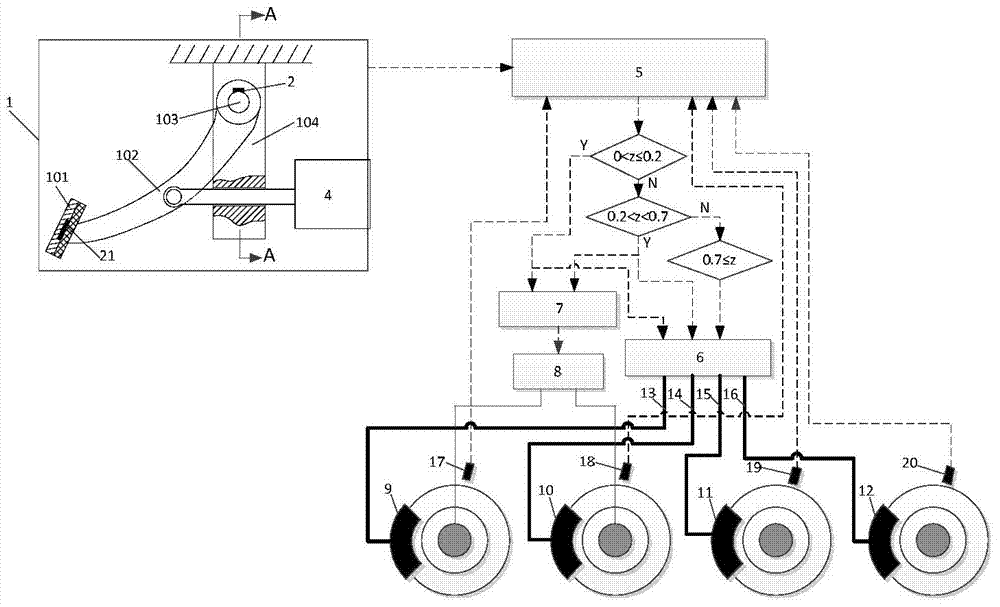

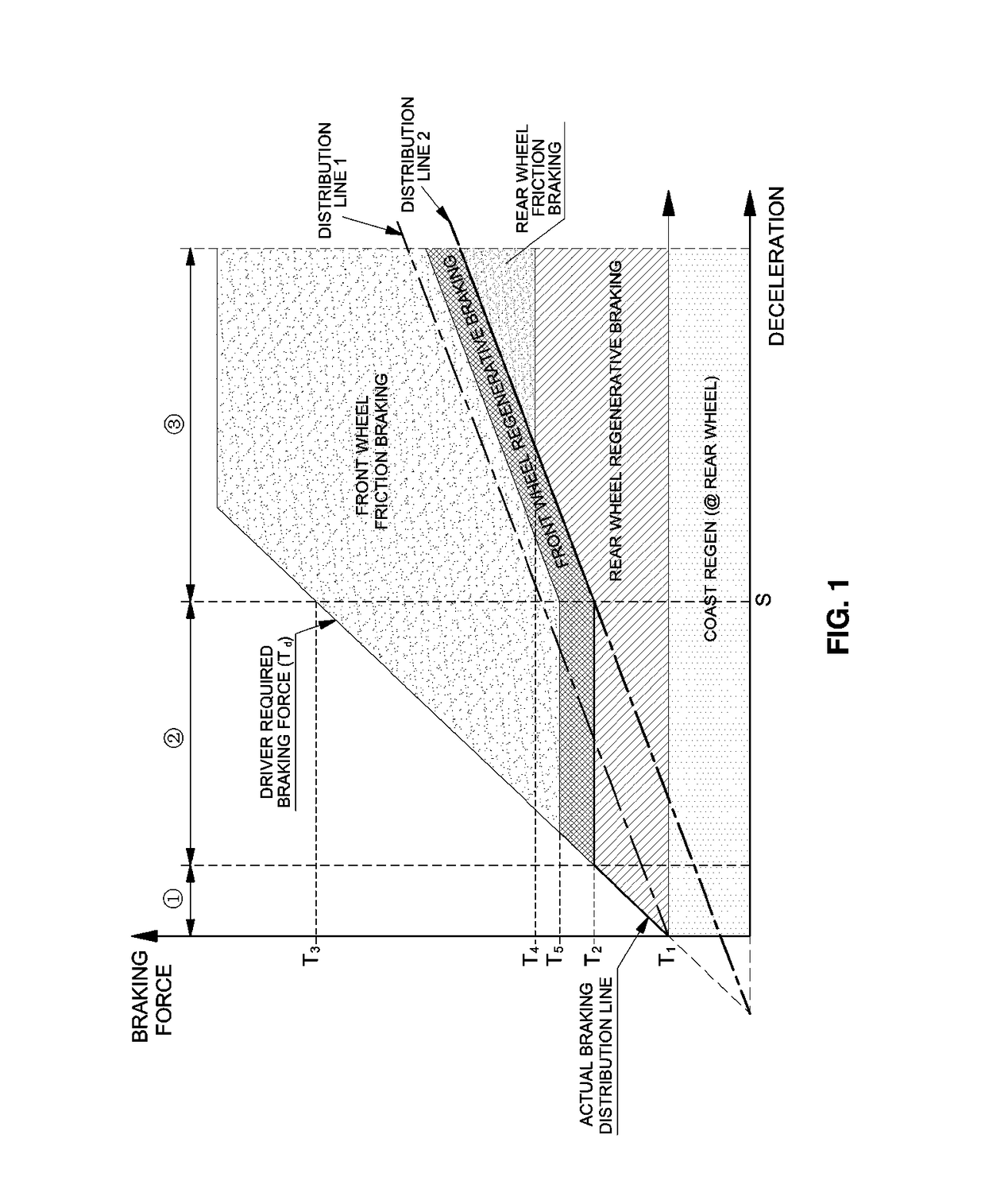

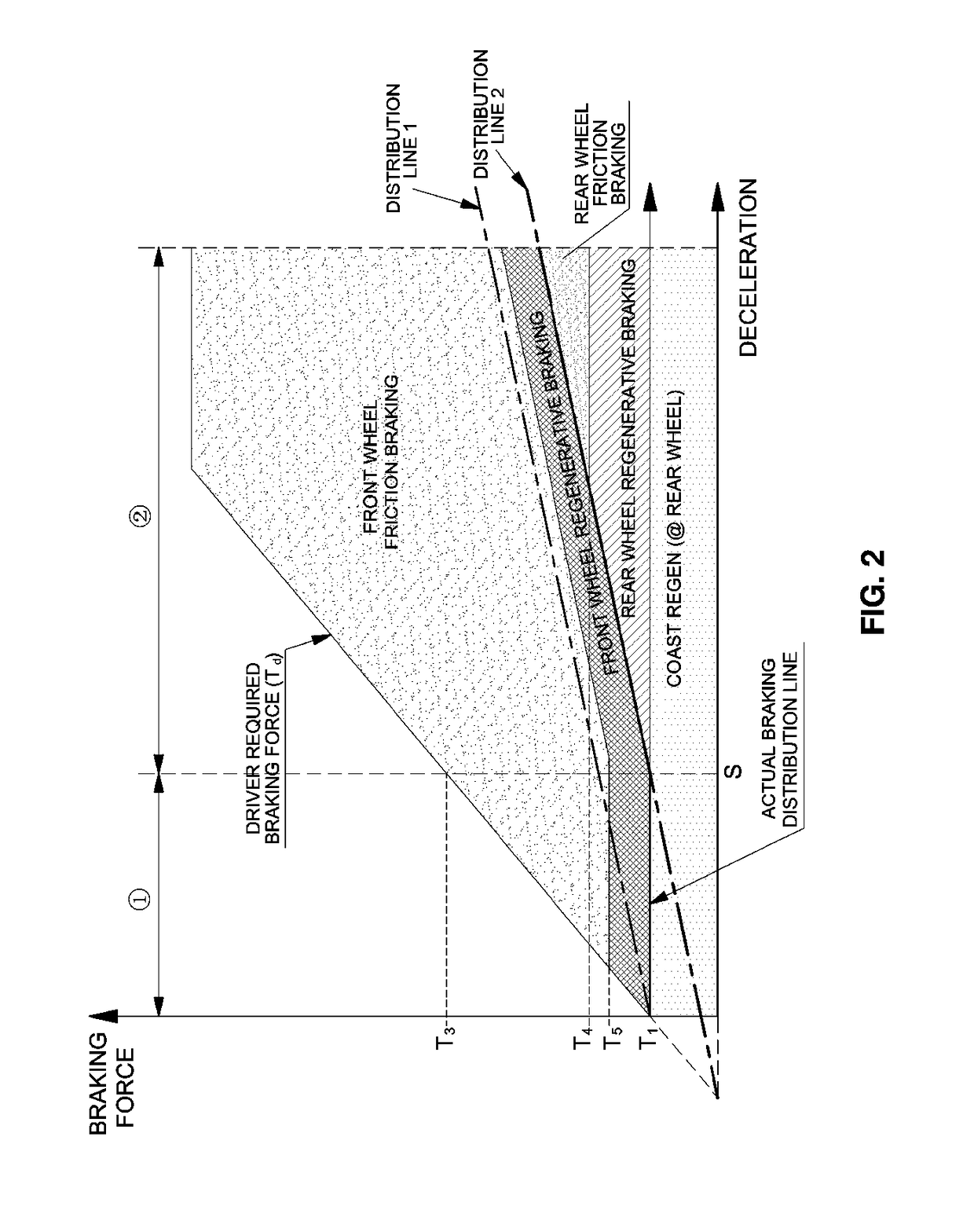

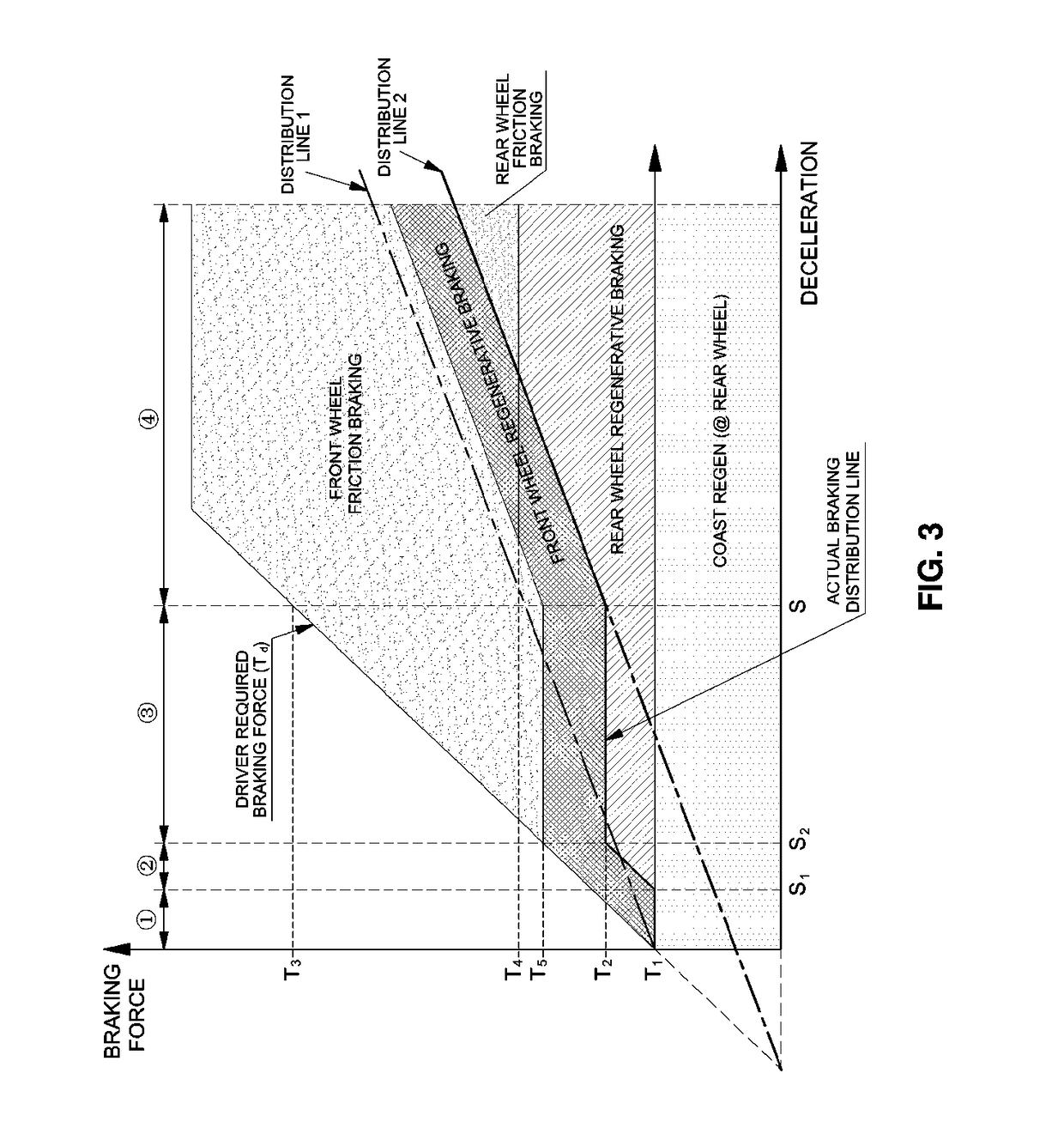

Method for controlling braking force in regenerative brake cooperation control system

ActiveUS20180086209A1Improving vehicular braking stabilityImproved braking stabilitySpeed controllerBraking element arrangementsRegenerative brakeControl system

A method for controlling braking force in a regenerative brake cooperation control system can maximally use regenerative braking force of a rear wheel simultaneously while improving vehicular braking stability by preventing the rear wheel from being locked earlier than a front wheel. The method includes controlling braking forces of the front wheel and the rear wheel by considering a distribution of total vehicular braking force including a coasting regenerative braking force in the regenerative brake cooperation control system in an eco-friendly vehicle which can perform regenerative braking in the rear wheel or both the front wheel and the rear wheel.40

Owner:HYUNDAI MOTOR CO LTD

Electric vehicle control method based on left and right electric wheel differential motion/braking control

InactiveCN104276155AReduce lossReduce braking energy consumptionBraking action transmissionEnergy recoveryElectric vehicle

The invention relates to an electric vehicle control method based on left and right electric wheel differential motion / braking control. A control system is used for judging a steering intention of a driver according to the steering direction of a steering wheel and then judging an acceleration or deceleration intention of a vehicle; as a mode of acceleration of the vehicle, voltages of a left motor and a right motor are distributed according to the requirements of steering angles, so that the rotating speeds of a left electric wheel and a right electric wheel reach the requirements of the steering angles; as another mode of deceleration of the vehicle, braking forces applied to the left electric wheel and the right electric wheel are distributed according to the requirements of the steering angles; in the process of distributing the braking forces, in accordance with the difference of the braking strengths, different braking modes are adopted, i.e., magnetic fields of the motors are independently used for braking, the magnetic fields of the motors and a hydraulic braking system are jointly used for braking, and the hydraulic braking system is independently used for braking. The electric vehicle control method disclosed by the invention has the characteristics of protecting braking pieces, reducing power consumption, acquiring energy recovery, ensuring that the vehicle stably operates, saving energy, protecting environment, reducing cost and the like, and is convenient to operate.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

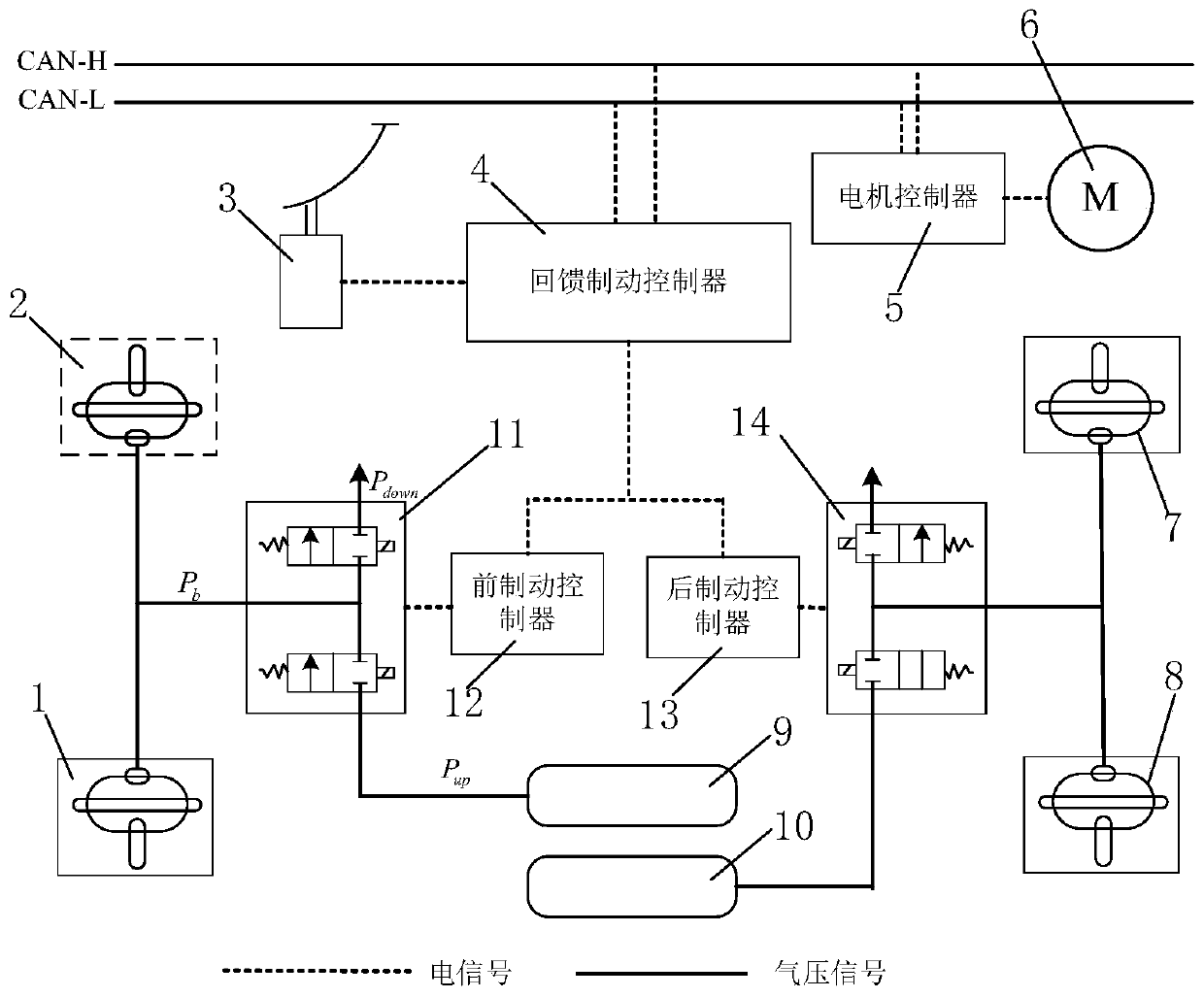

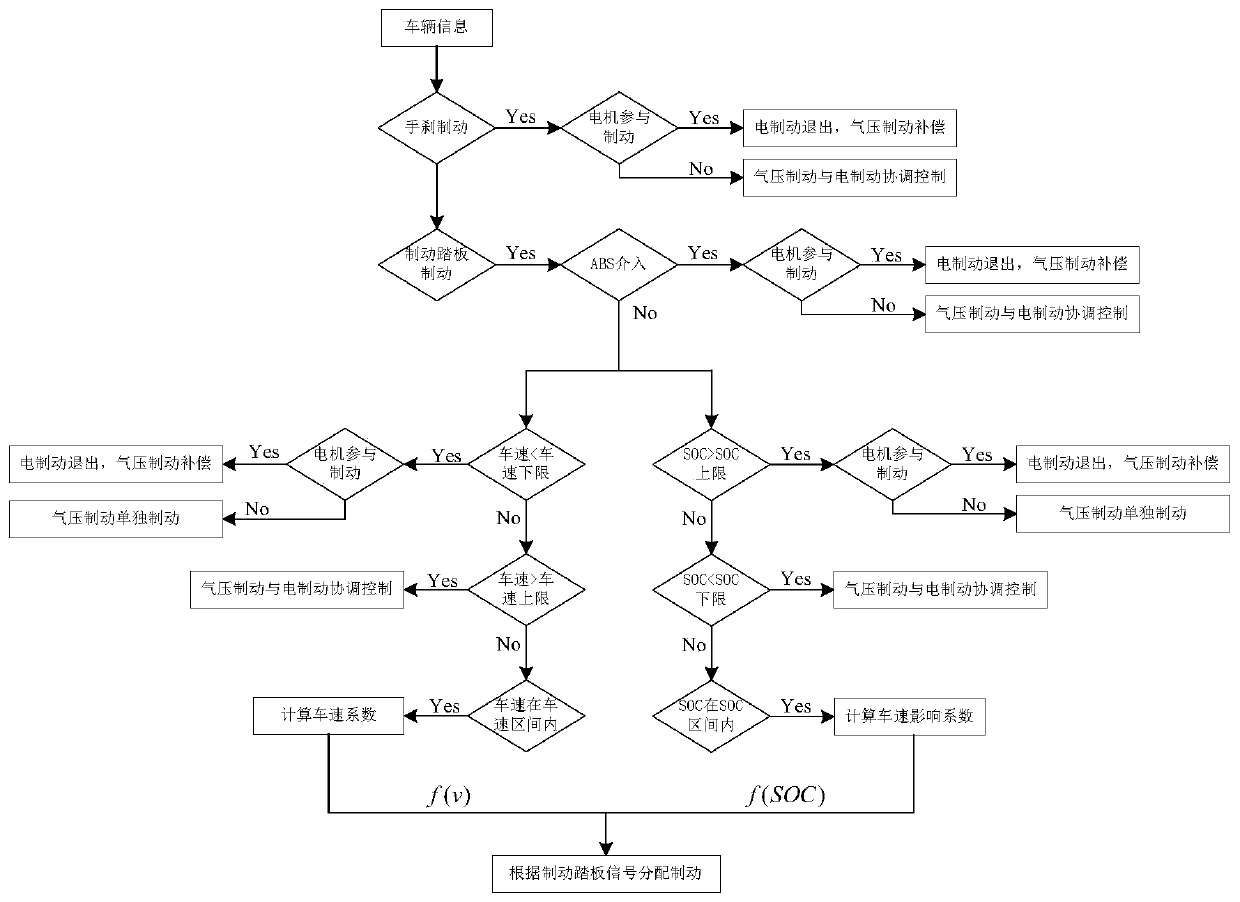

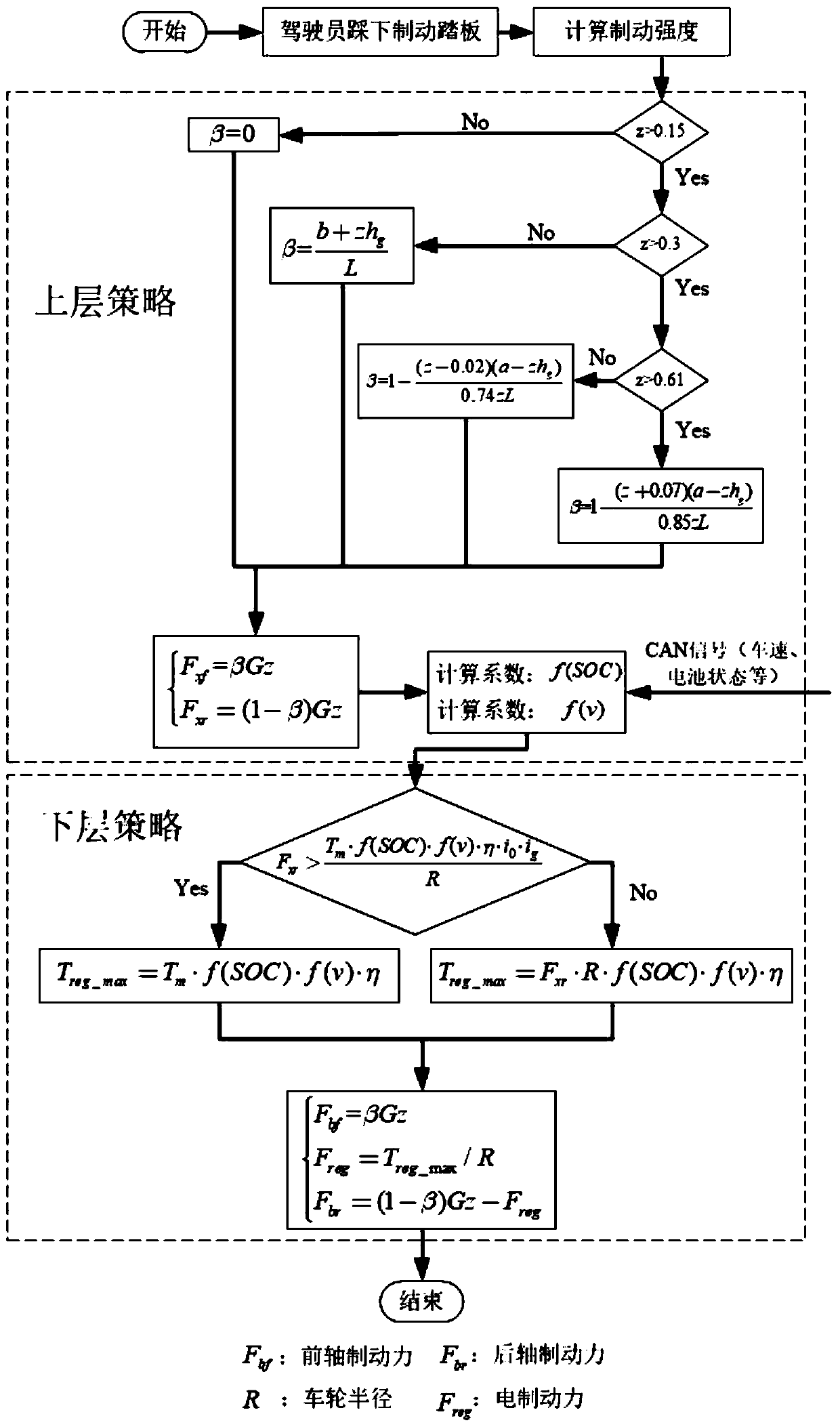

Electric commercial vehicle brake energy recovery system and control method

ActiveCN110614921ALow priceSimple structureElectrodynamic brake systemsElectric energy managementEnergy recoveryElectric vehicle

The invention belongs to the field of vehicle brake, and particularly relates to an electric commercial vehicle brake energy recovery system and a control method. The system comprises a control systemand a pneumatic brake system, the control system comprises a brake controller, a brake bridge valve controller, a motor controller and a motor, and the pneumatic brake system comprises a brake pedal,a high-pressure air storage barrel, a front brake axle valve, a rear brake axle valve, a front wheel brake cylinder and a rear wheel brake cylinder; the brake controller comprises a communication module and a brake force distribution module, the brake bridge valve controller comprises a pressure acquisition module, a control module and a driving module, and the air brake bridge valve comprises anair pressure combination valve, a left brake air path and a right brake air path. The method comprises the steps of obtaining the current vehicle information through a vehicle-mounted CAN bus and a vehicle-mounted sensor; judging the participation condition of a brake source in the current scene; and the brake controller formulating a brake strategy according to the vehicle state and the brake pedal information. According to the scheme provided by the invention, the coordination control method of the air pressure brake and the electric brake of the electric vehicle under the conventional brake working condition is comprehensively considered, so that the brake force distribution is more reasonable.

Owner:NANJING UNIV OF SCI & TECH

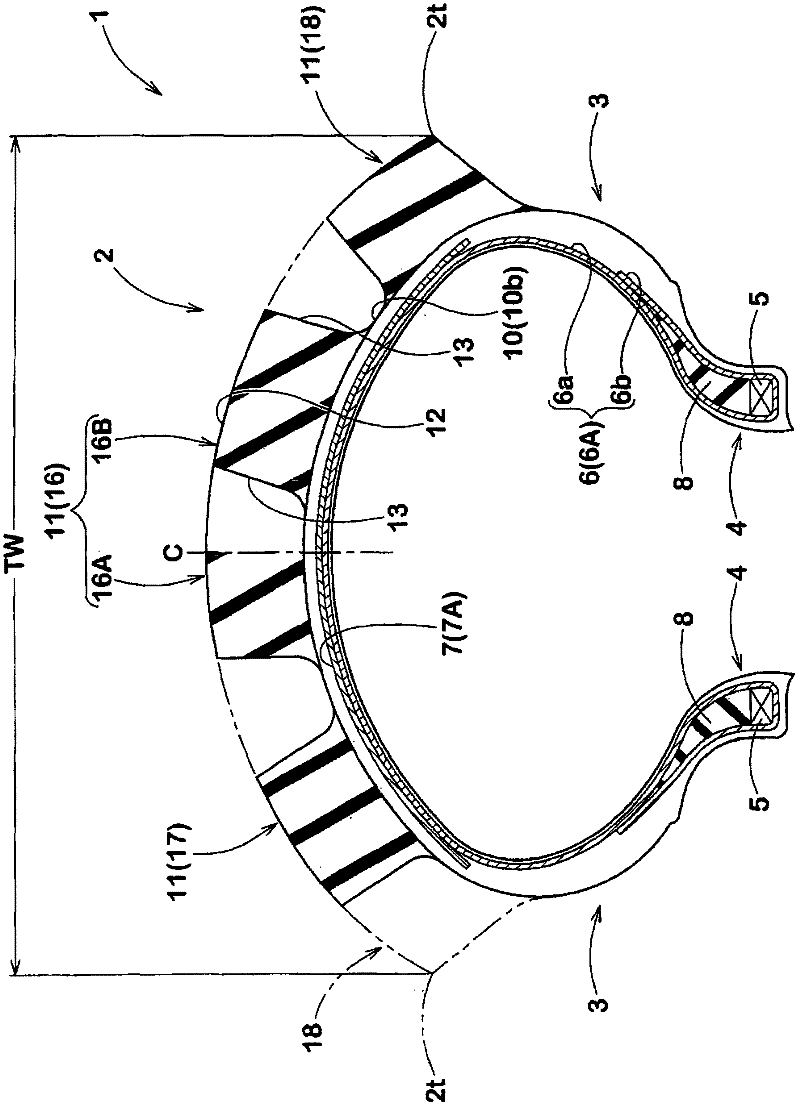

Motorcycle tire for running on rough terrain

InactiveCN102381141AMake sure to sink into the amountGreat tractionOff-road vehicle tyresMotorcycle tyresTerrainLeading edge

A motorcycle tire for running on rough terrain is provided, the rotation direction of the motorcycle tire is specified, and the motorcycle tire can maintain traction force and improve brake stability. At least one of pattern blocks comprises a first pattern block, the first pattern block comprises a tread portion, a first ground-touching side wall surface extending from a front edge of the tread portion toward the internal side, and a back ground-touching sidewall surface extending from a back edge toward the internal side. The first ground-touching side wall surface of the pattern block is formed by a steeply inclined surface inclining toward the first ground-touching side. The back ground-touching sidewall surface comprises: a front end side region and a root side region connected with the front end side region and extending toward the internal side. The front end side region is formed by a gently inclined surface inclining toward the back ground-touching sidewall side. The root side region is provided with: a middle surface extending in the same angle with the front end side region; a pair of side part surfaces formed by steeply inclined surfaces disposed respectively at two sides of the pattern block width direction of the middle surface and inclining toward the back ground-touching side; and a step surface connecting the side part surfaces and the middle surface.

Owner:SUMITOMO RUBBER IND LTD

Power device for air jet loom

InactiveCN103966731AHigh transmission efficiencySimple structureLoomsElectric machineryAerospace engineering

The invention discloses a power device for an air jet loom. The power device for the air jet loom comprises a servo motor, wherein a primary driving gear is arranged on the output shaft of the servo motor and is in mesh transmission with a beating-up transmission gear and an open transmission gear simultaneously, the open transmission gear is arranged on an open transmission gear shaft, a power-off brake is arranged on the open transmission gear shaft, the beating-up transmission gear is arranged on a transmission shaft, and a beating-up conjugate cam is arranged on the transmission shaft. By means of the gear transmission structure formed by the primary driving gear, the beating-up transmission gear and the open transmission gear, transmission efficiency is increased, the structure is simplified, and regulation and maintenance are convenient.

Owner:HANGZHOU CHUANGXING WEAVING EQUIP TECH

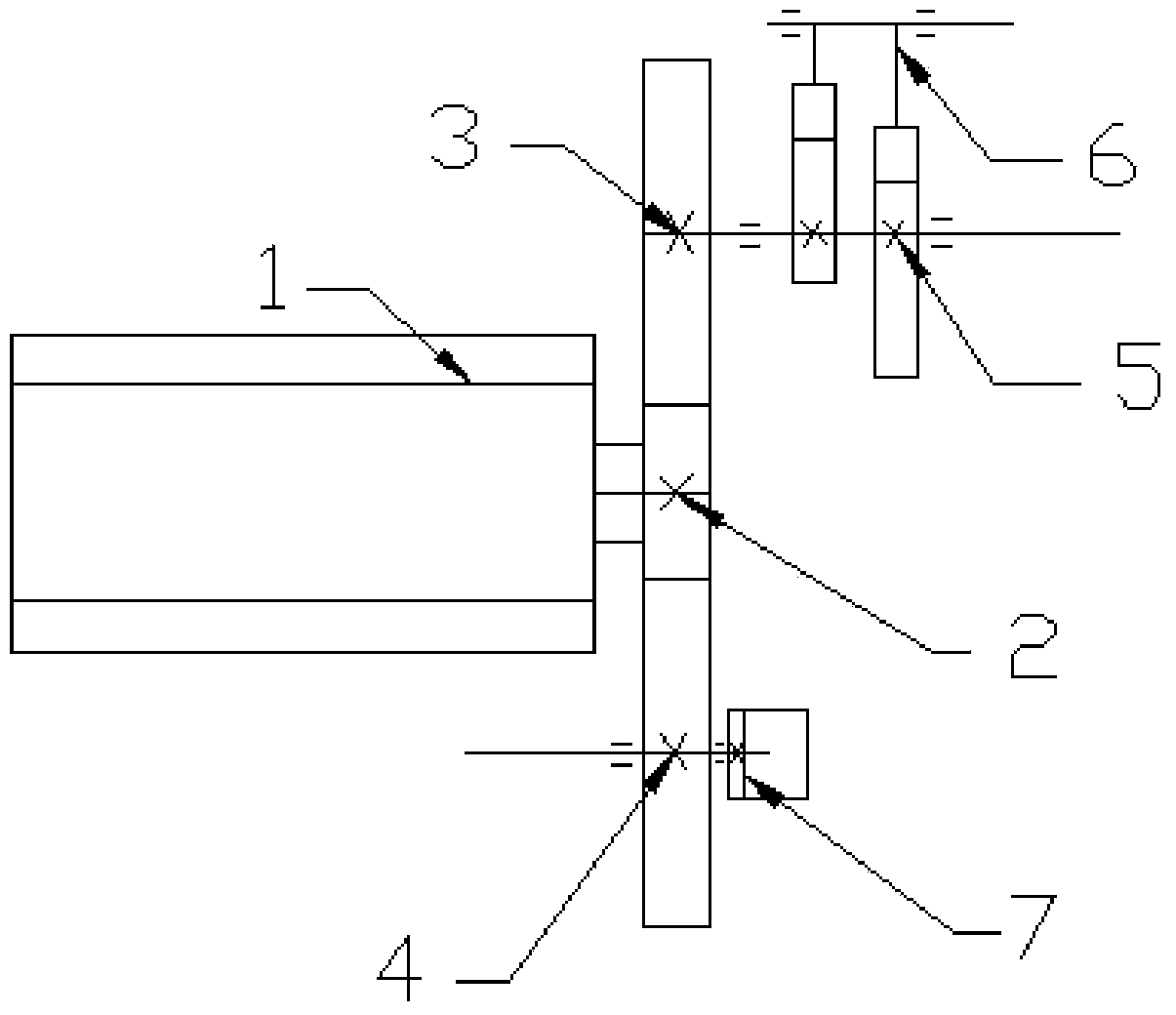

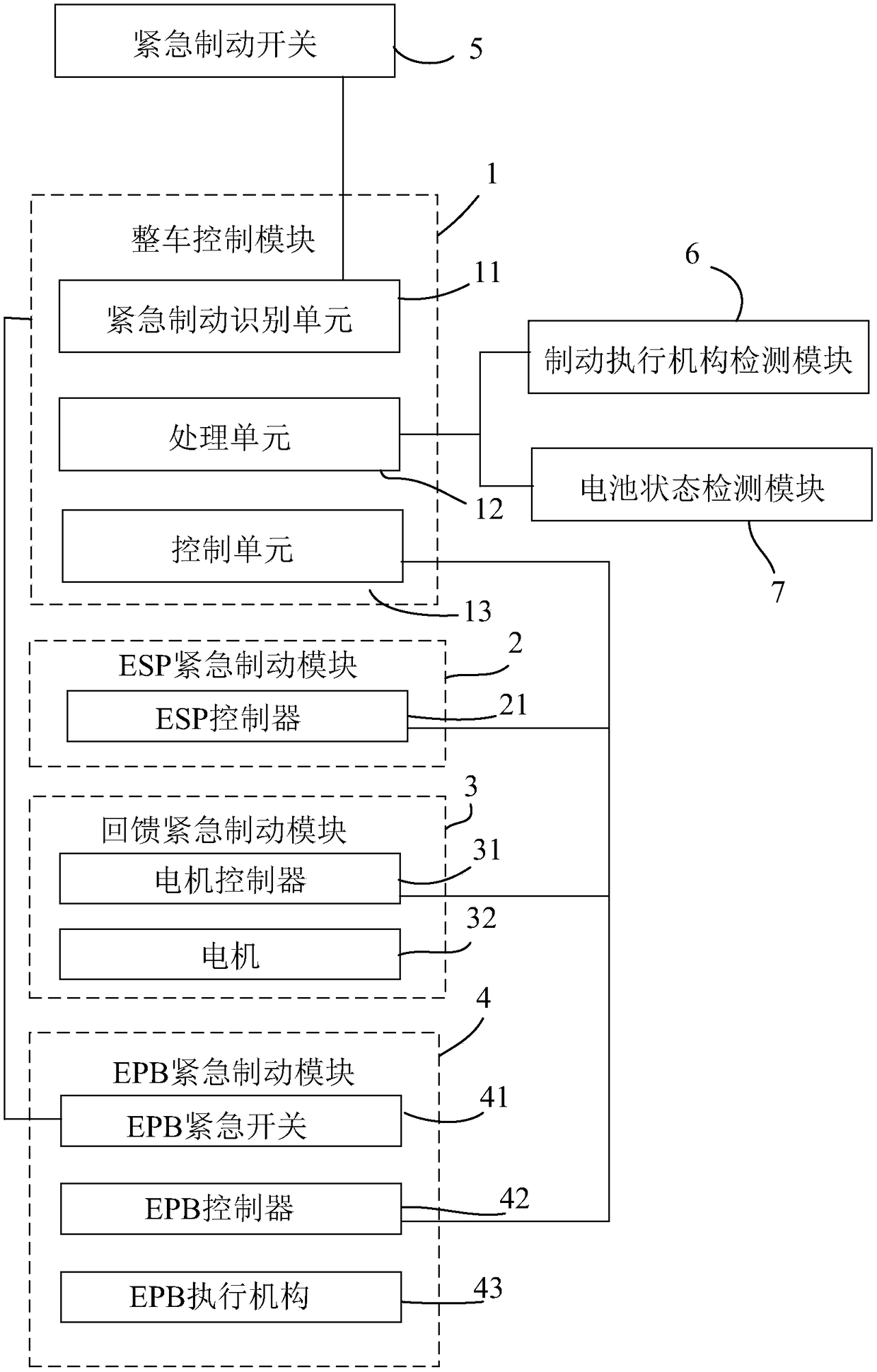

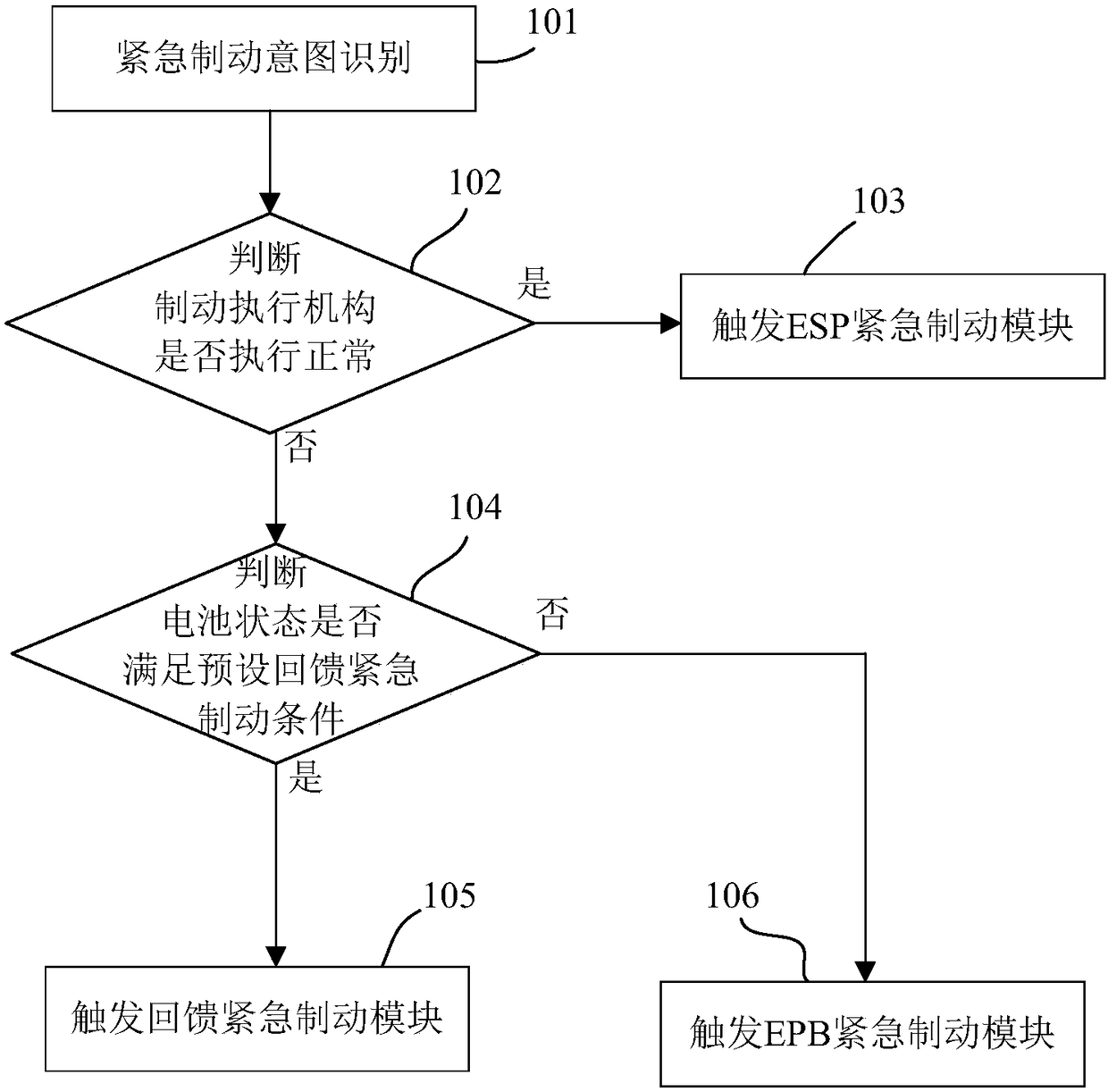

Emergency braking system and method used for electric automobile and electric automobile

ActiveCN108177639AImprove securityImproved braking stabilityBraking action transmissionDecision schemeEmergency brake

The invention discloses an emergency braking system and method used for an electric automobile and the electric automobile. The emergency braking system comprises a vehicle control module, an ESP emergency braking module, a feedback emergency braking module and an EPB emergency braking module. When the electric automobile is in an emergency braking state, the vehicle control module judges whethera braking execution mechanism of the electric automobile executes braking normally or not, if the braking execution mechanism executes braking normally, the ESP emergency braking module is triggered to conduct emergency braking, if the braking execution mechanism does not execute braking normally, the vehicle control module judges whether the battery state of the electric automobile meets a presetfeedback emergency braking condition or not, if the battery state meets the preset feedback emergency braking condition, the feedback emergency braking module is triggered to conduct feedback braking, and if the battery state does not meet the preset feedback emergency braking condition, the EPB emergency braking module is triggered to conduct EPB braking. A complete decision scheme for emergencybraking is supplied and can be well applied to the electric automobile, so that the safety and braking stability of the electric automobile are improved, and the user experience level is improved.

Owner:WM SMART MOBILITY (SHANGHAI) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com