Detection and braking integrated robot joint driver

A technology of robot joints and drives, which is applied in the direction of program control manipulators, manipulators, manufacturing tools, etc., can solve the problem that is not conducive to the simplification of structure and the improvement of reliability of compact system, and is not conducive to the improvement of reliability of system simplification and compaction , unable to accurately detect the actual output angle of the driver, etc., to achieve perfect reliability, compact and simple mechanical structure, simple electrical design and layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with specific embodiments.

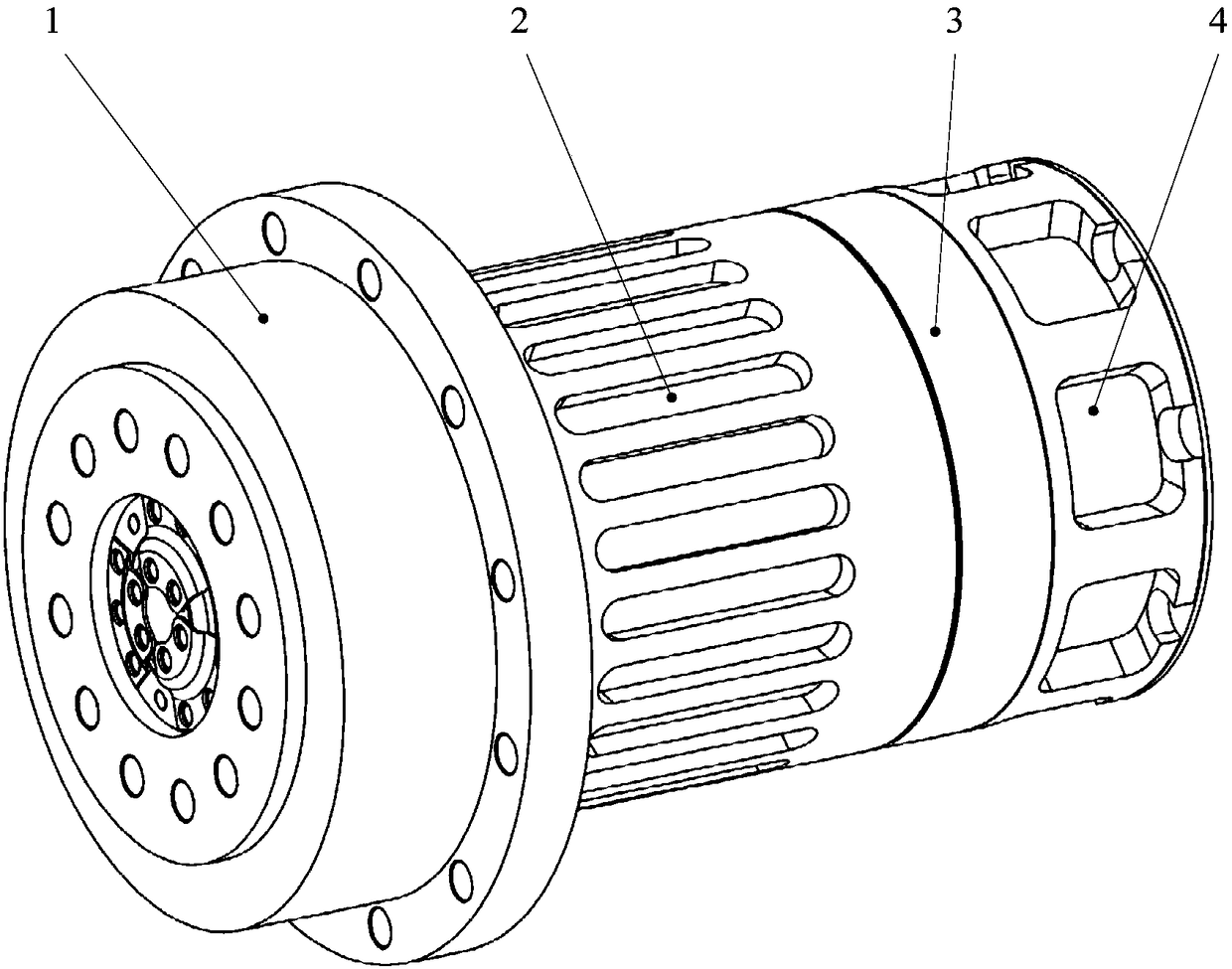

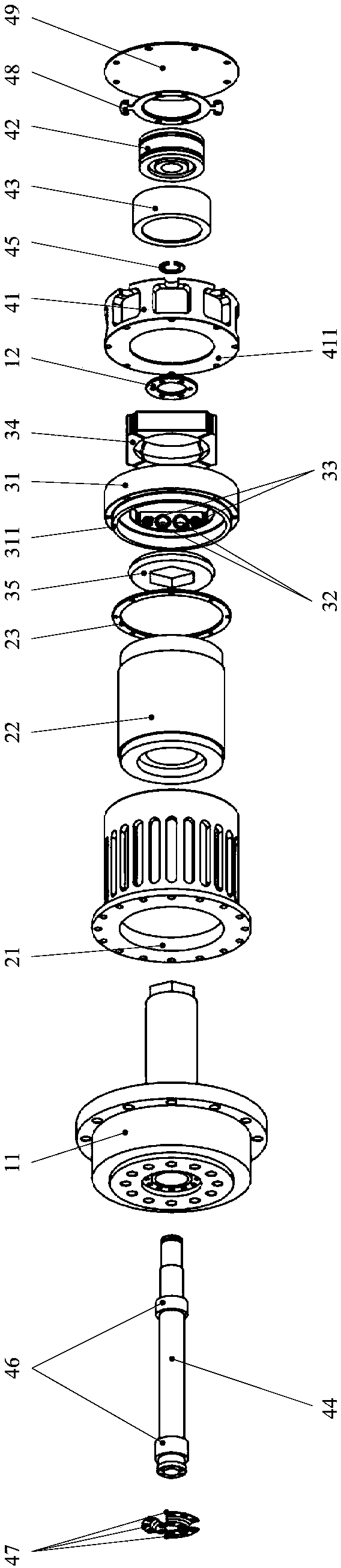

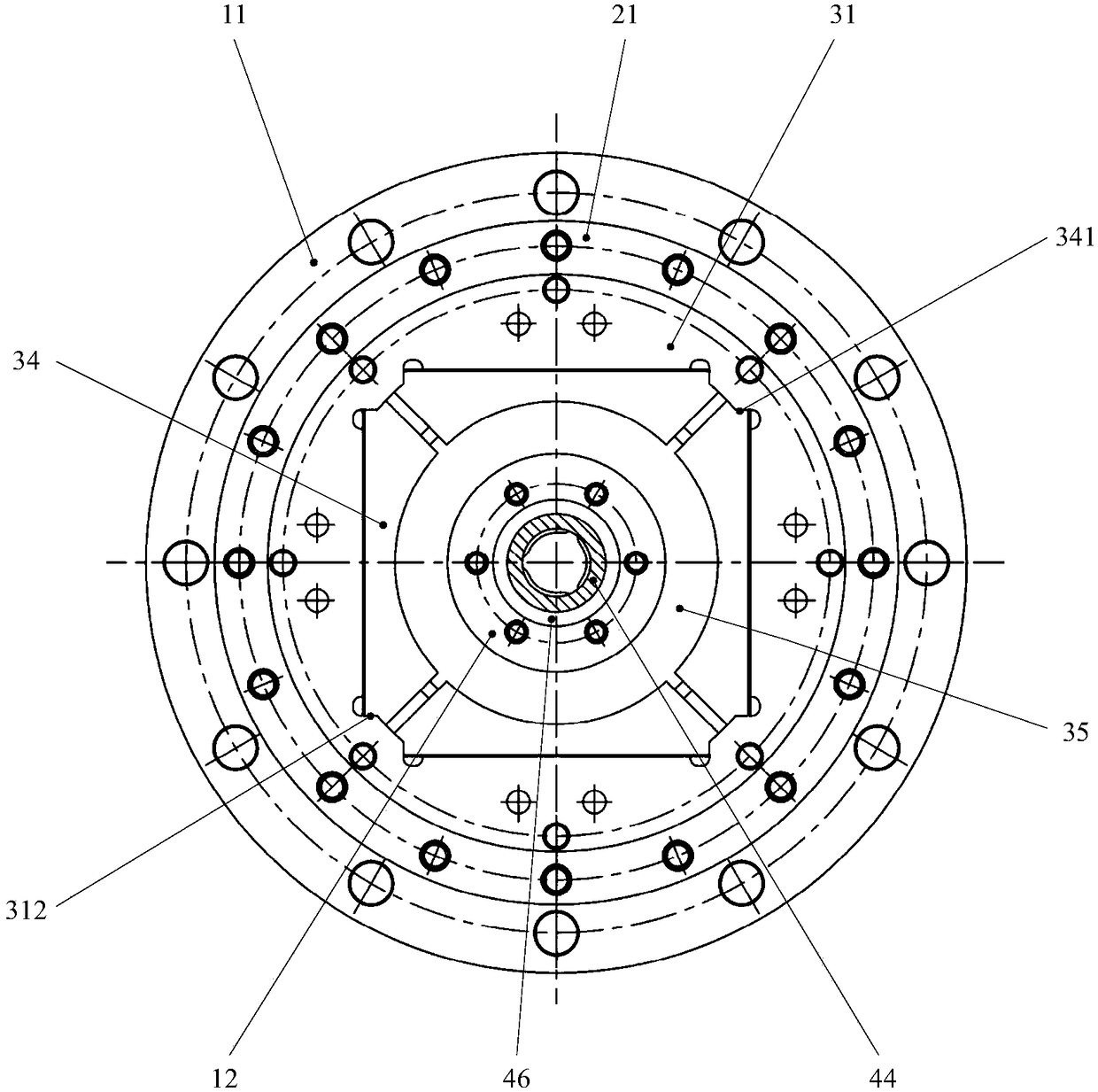

[0033] Embodiments of the present invention provide a detection and braking integrated robot joint driver, such as figure 1 with figure 2 As shown, it includes: a deceleration assembly 1 , a driving assembly 2 , a braking assembly 3 and an angle detection assembly 4 .

[0034] The deceleration assembly 1 includes a decelerator 11 and a friction block retaining ring 12 . The reducer input shaft 111 is a hollow structure, and its end section is a regular polygon, and threaded holes are evenly arranged on the end face along the circumferential direction. The friction block retaining ring 12 and the reducer input shaft 111 are connected through screws and threaded holes.

[0035] Drive assembly 2 comprises motor housing 21, motor 22 and motor fixing sn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com