Method for branching cable joint and structure of ring support for spacing wire

A branch and power cable technology, applied in the direction of electrical components, etc., can solve the problems of cable core insulation performance decline, branch joint volume growth, and longer opening length, etc., to facilitate construction and installation, use less wire, and seal reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

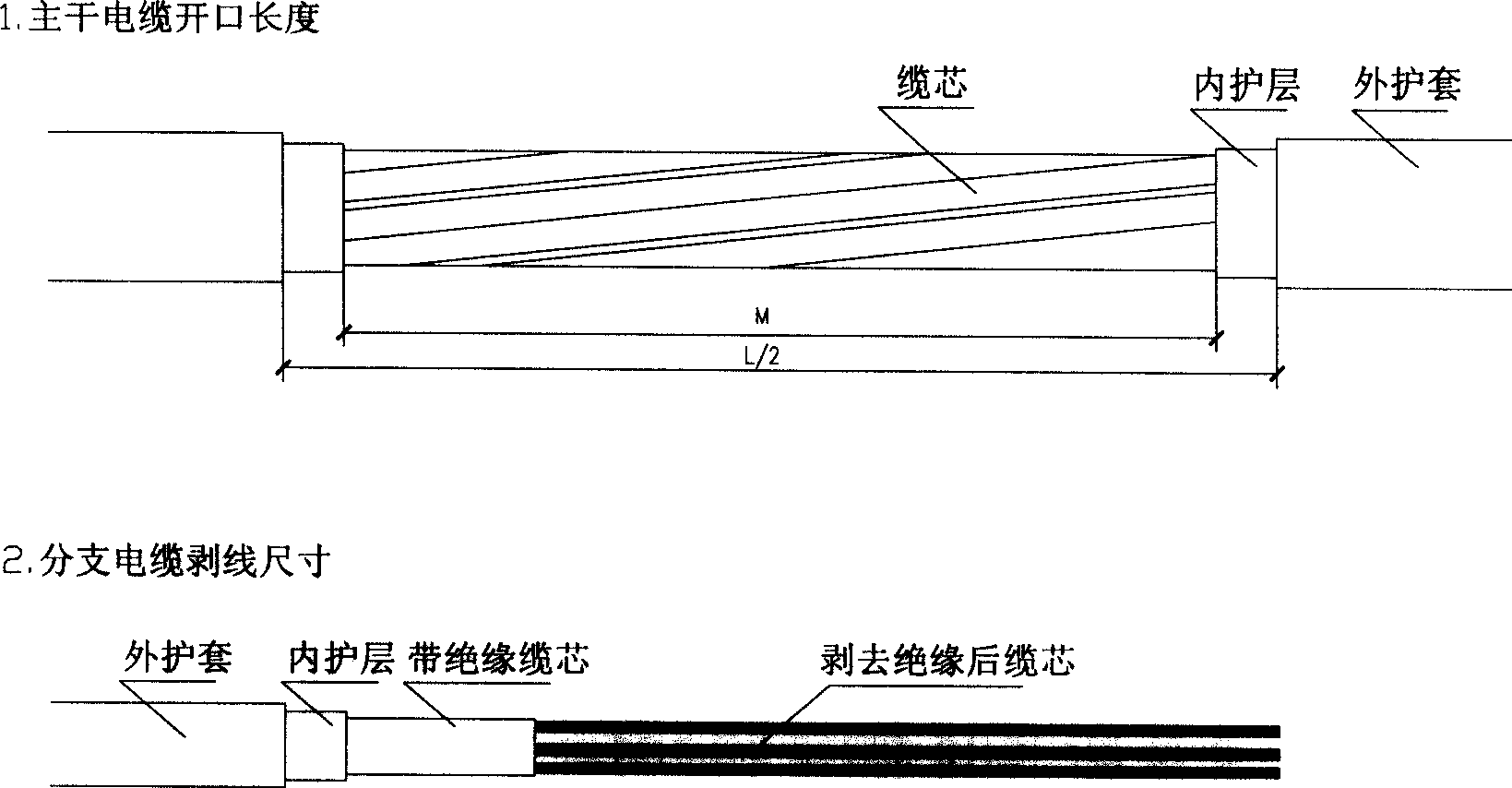

[0012] Branching method of railway tunnel lighting power cable joint;

[0013] As shown in Figure 1(a),

[0014] 1) On the main cable determined to be a branch, use a wet rag to wipe off the dirt on the surface of the branch, and then dry it with a dry rag, the length is L;

[0015] 2) Cut and strip the outer sheath of L / 2 at its center;

[0016] 3) Then cut and strip the inner sheath with m<L / 2;

[0017] 4) Peel off the binding tape and filler at the cable core, and reveal the core wire group including the control cable core wire, intermediate cable core wire, and power core wire;

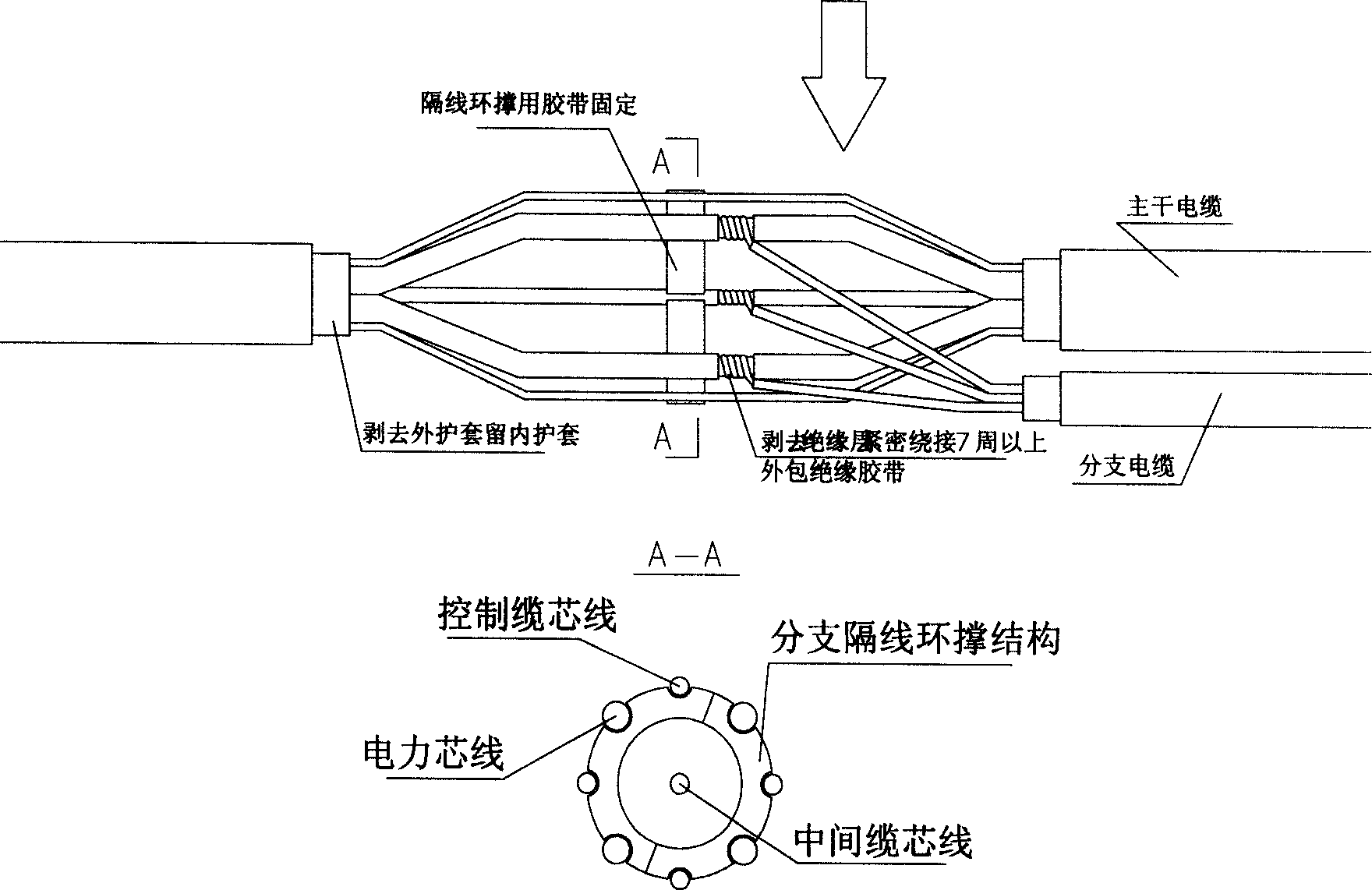

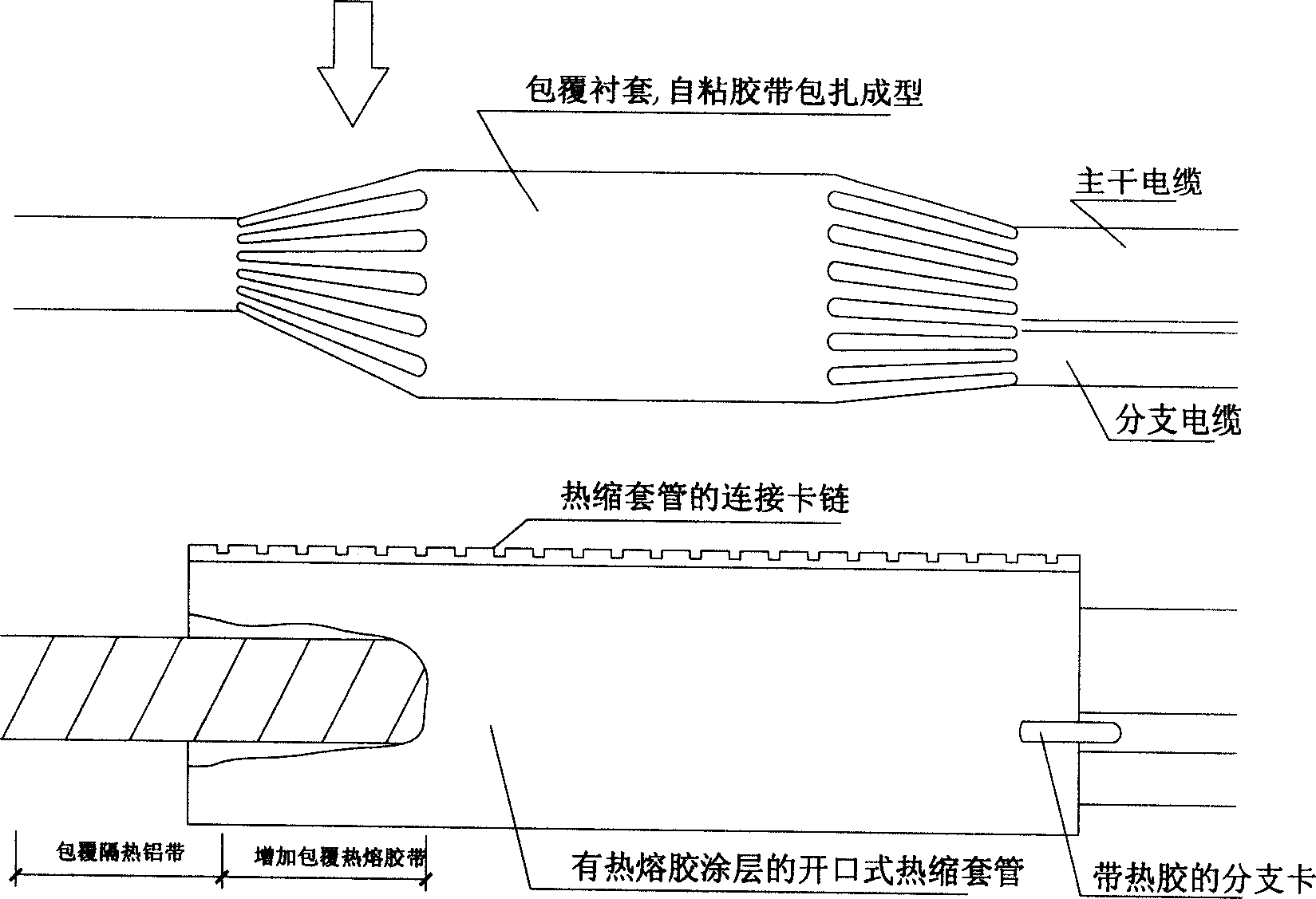

[0018] As shown in Figure 1(b),

[0019] 5) According to the diameter of the main cable, put the appropriate branch spacer ring support structure into the core wire group, and snap each core wire into the corresponding groove on the surface of the ring support, and the middle core wire of the cable passes through the ring support. The opening gap enters the middle of the ring support, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com