Patents

Literature

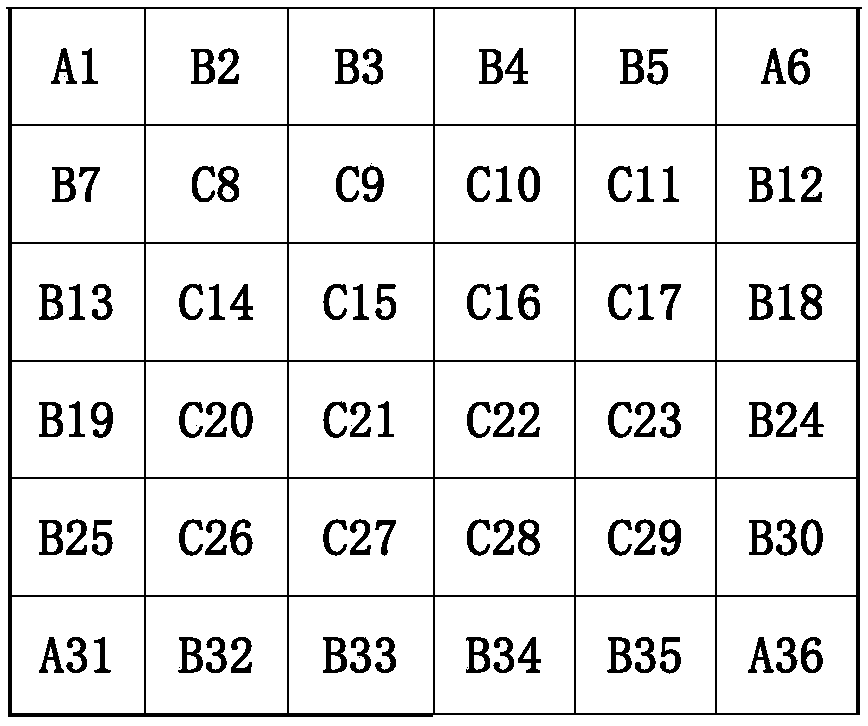

41results about How to "Reduce thread consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

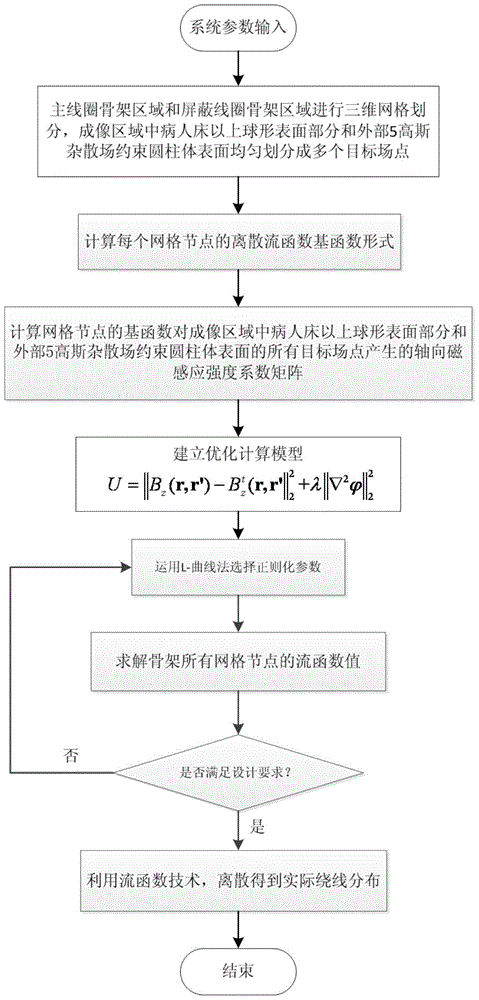

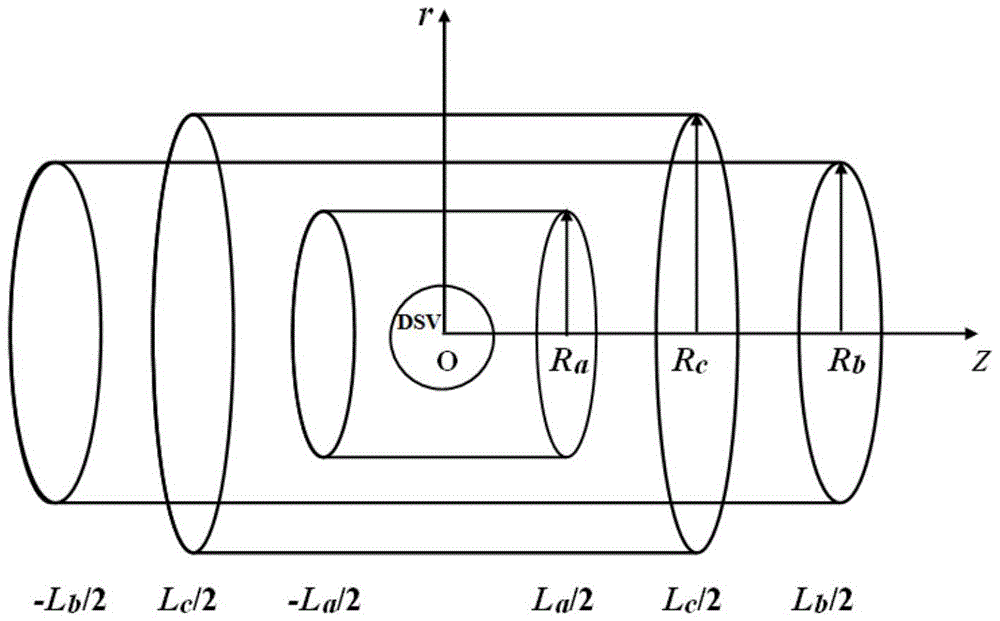

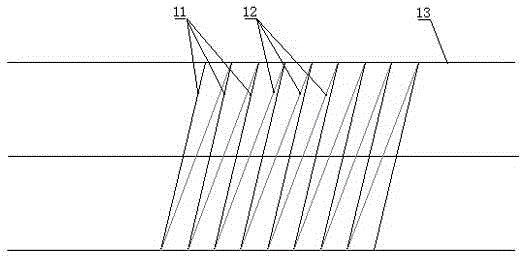

Designing method for gradient coil of self-shielding superconductive nuclear magnetic resonance imaging system

InactiveCN105718677AReduce inductanceLarge line spacingSpecial data processing applicationsNMR - Nuclear magnetic resonanceIntensity coefficient

The invention discloses a designing method for a gradient coil of a self-shielding superconductive nuclear magnetic resonance imaging system.The designing method comprises the steps that firstly, three-dimensional continuous triangular mesh dividing is performed on a main coil framework region and a shielding coil framework region, and an axial magnetic induction intensity coefficient matrix generated by mesh nodes in the main coil framework region and the shielding coil framework region on a target field point is calculated according to a boundary elements method; secondly, an optimization calculation model is built through a regularization method, wherein the optimization calculation model comprises two parts, the first part is deviation between the axial magnetic induction intensity generated by the mesh nodes in the main coil framework region and the shielding coil framework region on a target field point and the expected target magnetic induction intensity, the second part is the quadratic sum of the flow function curvature of the mesh nodes, and flow function values of the mesh nodes in the main coil framework region and the shielding coil framework region are obtained through solution; lastly, actual winding distribution of the gradient coil is obtained through a flow function method.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

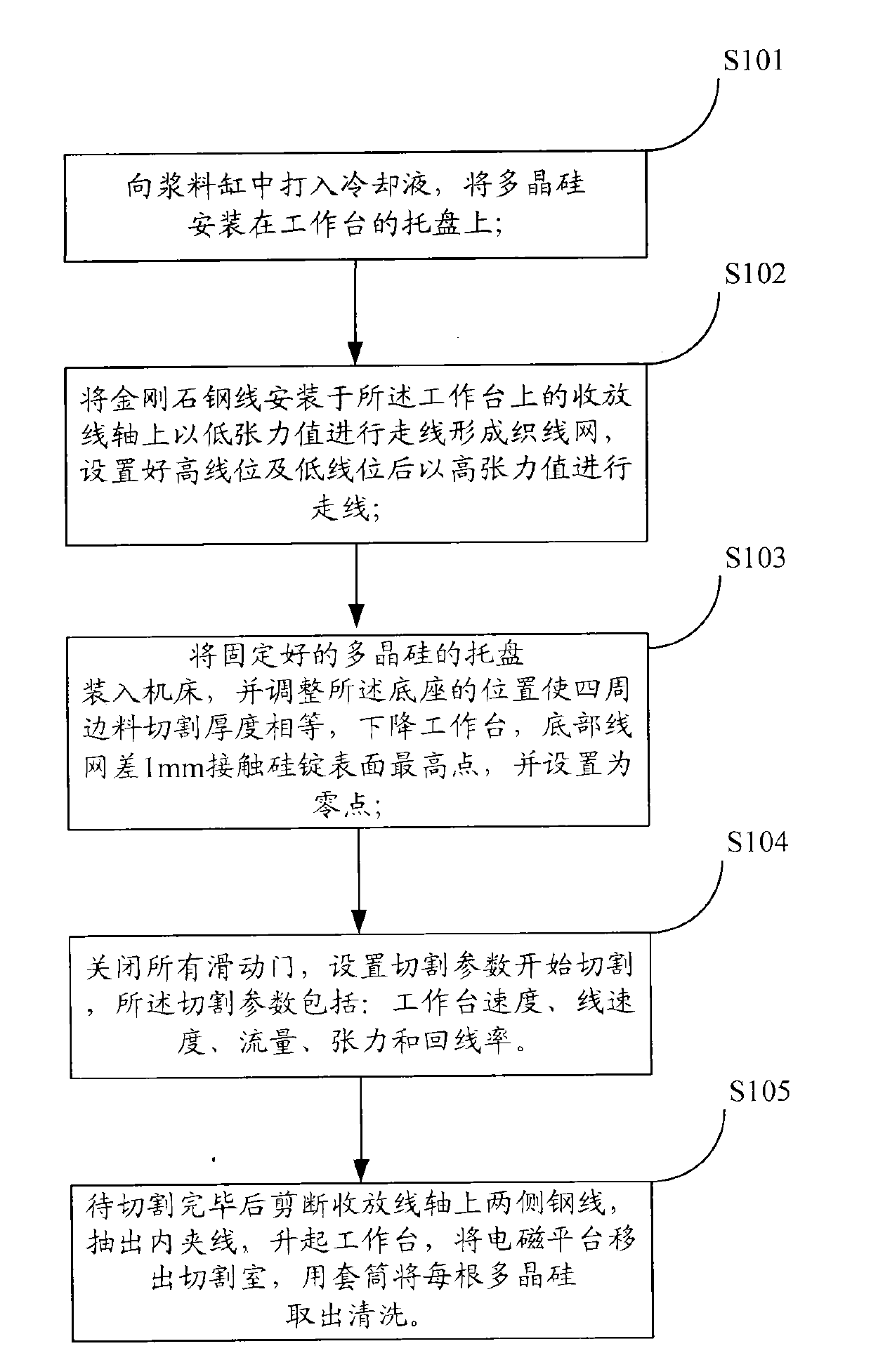

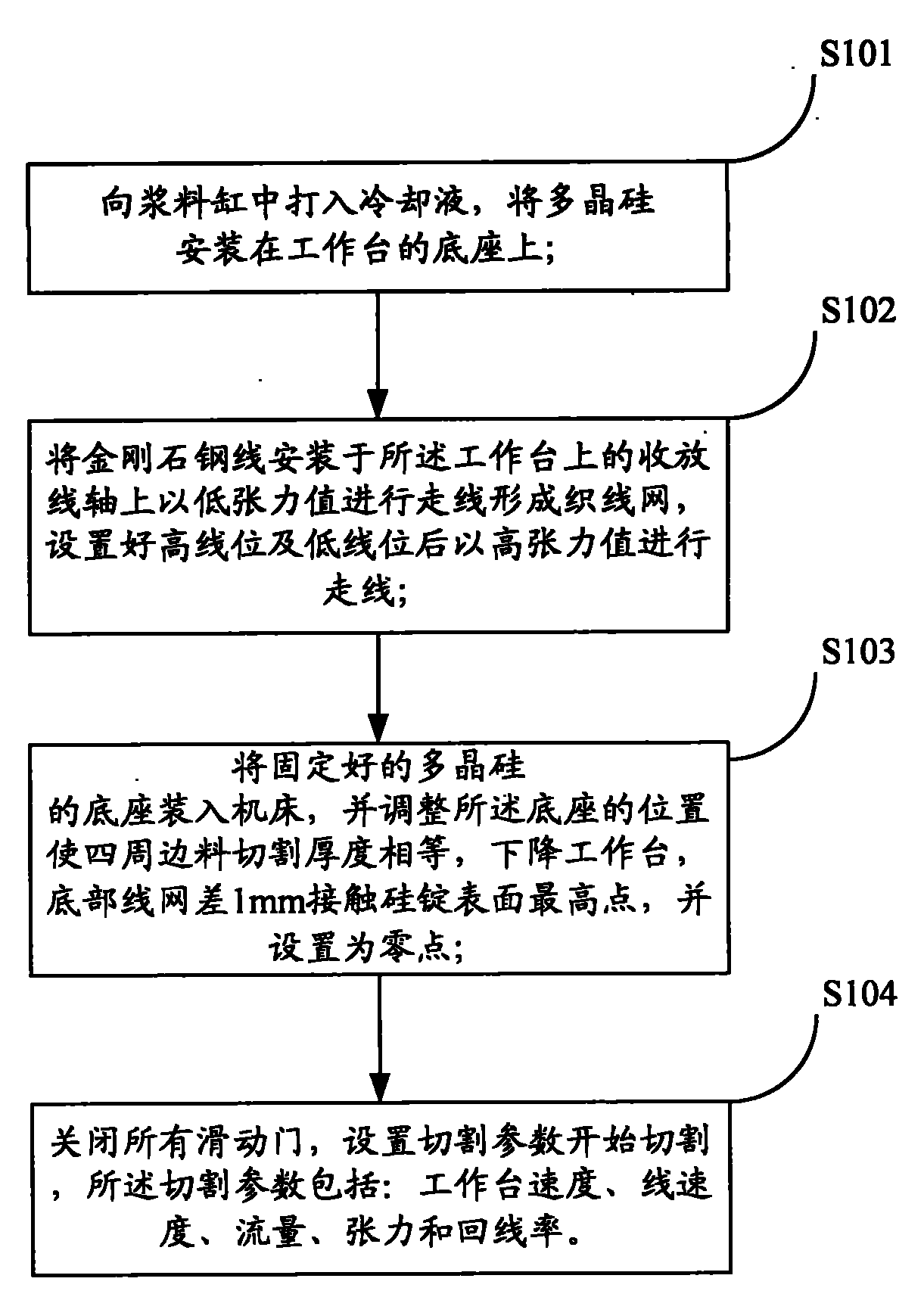

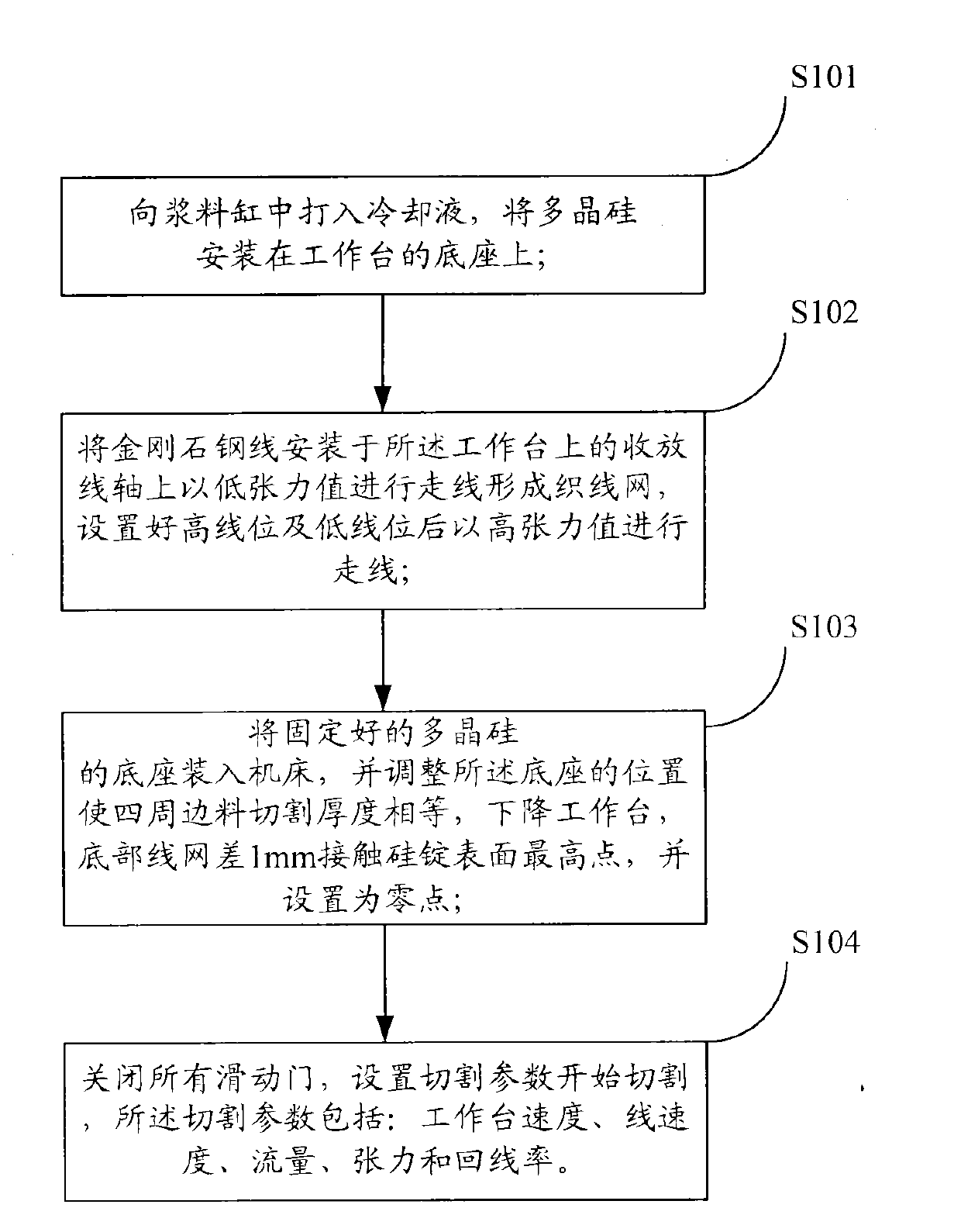

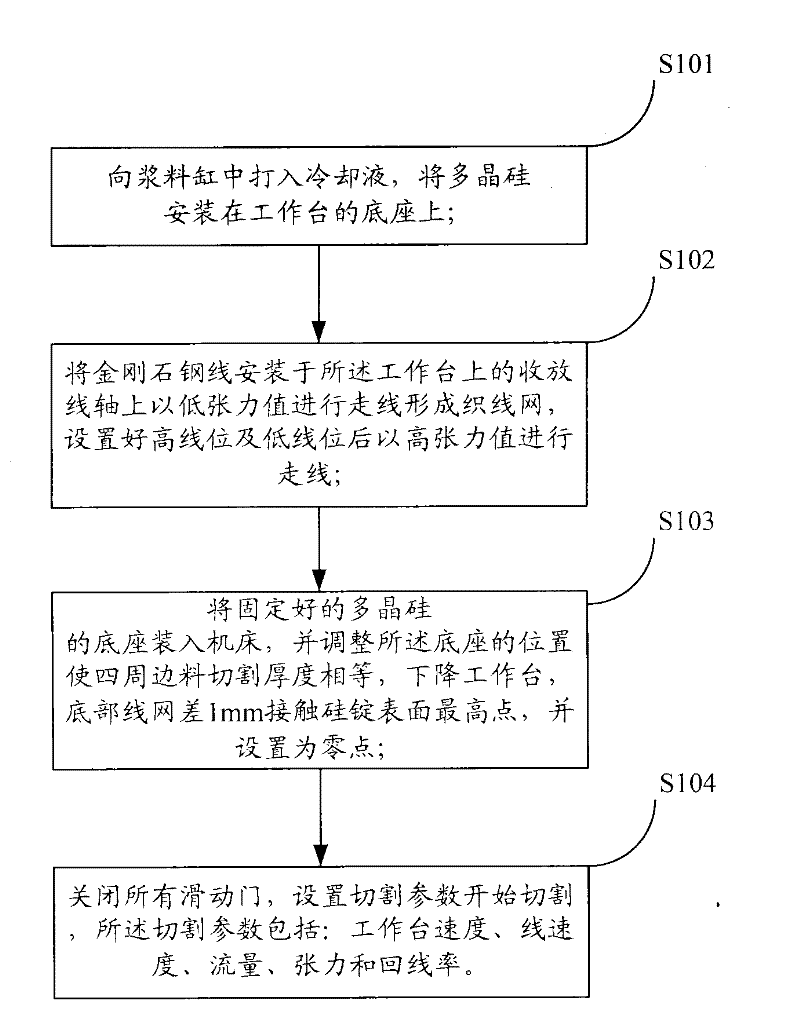

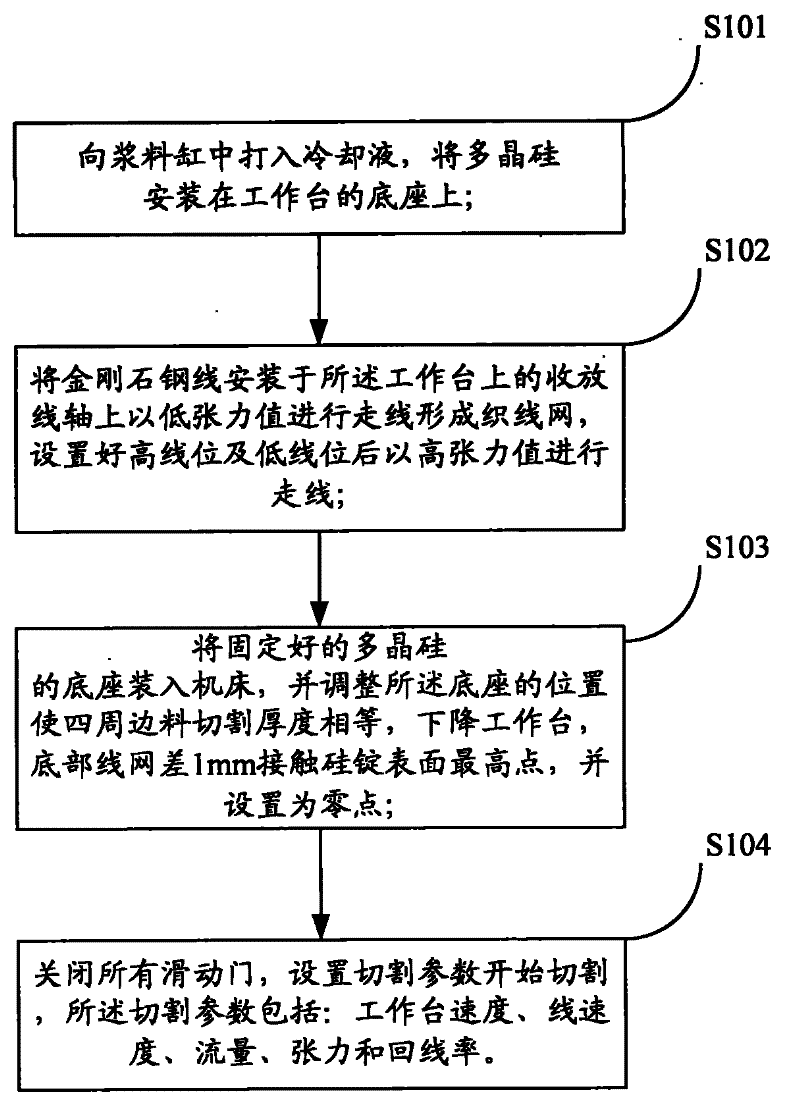

Polycrystalline silicon ingot ripping method

The invention discloses a polycrystalline silicon ingot ripping method, which comprises the following steps of: 1, pouring cooling liquid into a slurry tank and adhering a polycrystalline silicon ingot onto a tray; 2, mounting a diamond steel wire on an unwinding shaft on a workbench to form a wire net by wire laying at a low tension value, and performing wire laying at a high tension value after a high wire level and a lower wire level are set; 3, assembling the tray with the fixed polycrystalline silicon ingot into a machine, adjusting the position of the tray to ensure that the cut thicknesses of offcut on the four sides are equal, lowering the workbench down, allowing the bottom wire net to suspend at a position which is 1mm away from the highest point on the surface of the silicon ingot, and setting the position as a null position; and 4, closing all sliding doors and setting cutting parameters for cutting, wherein the cutting parameters comprise a workbench speed, a linear speed, flow, tension and a wire returning rate. In the embodiment of the invention, the diamond steel wire is adopted, so that the production efficiency of an ingot ripping process is improved, and manufacturing cost in the process is reduced correspondingly.

Owner:YINGLI ENERGY CHINA

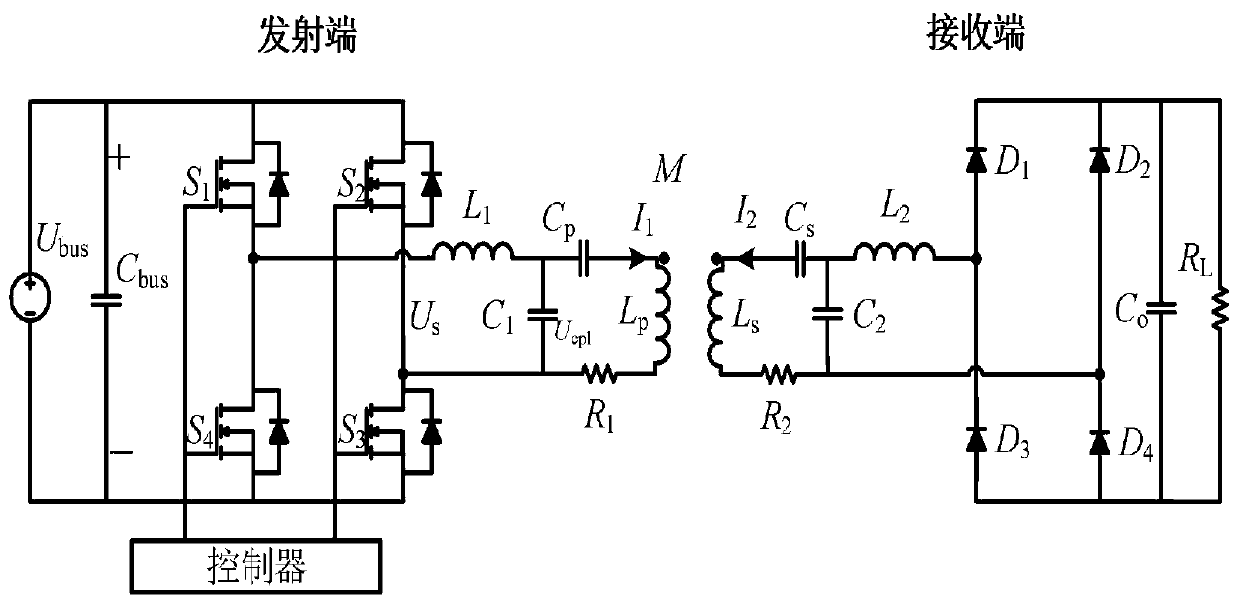

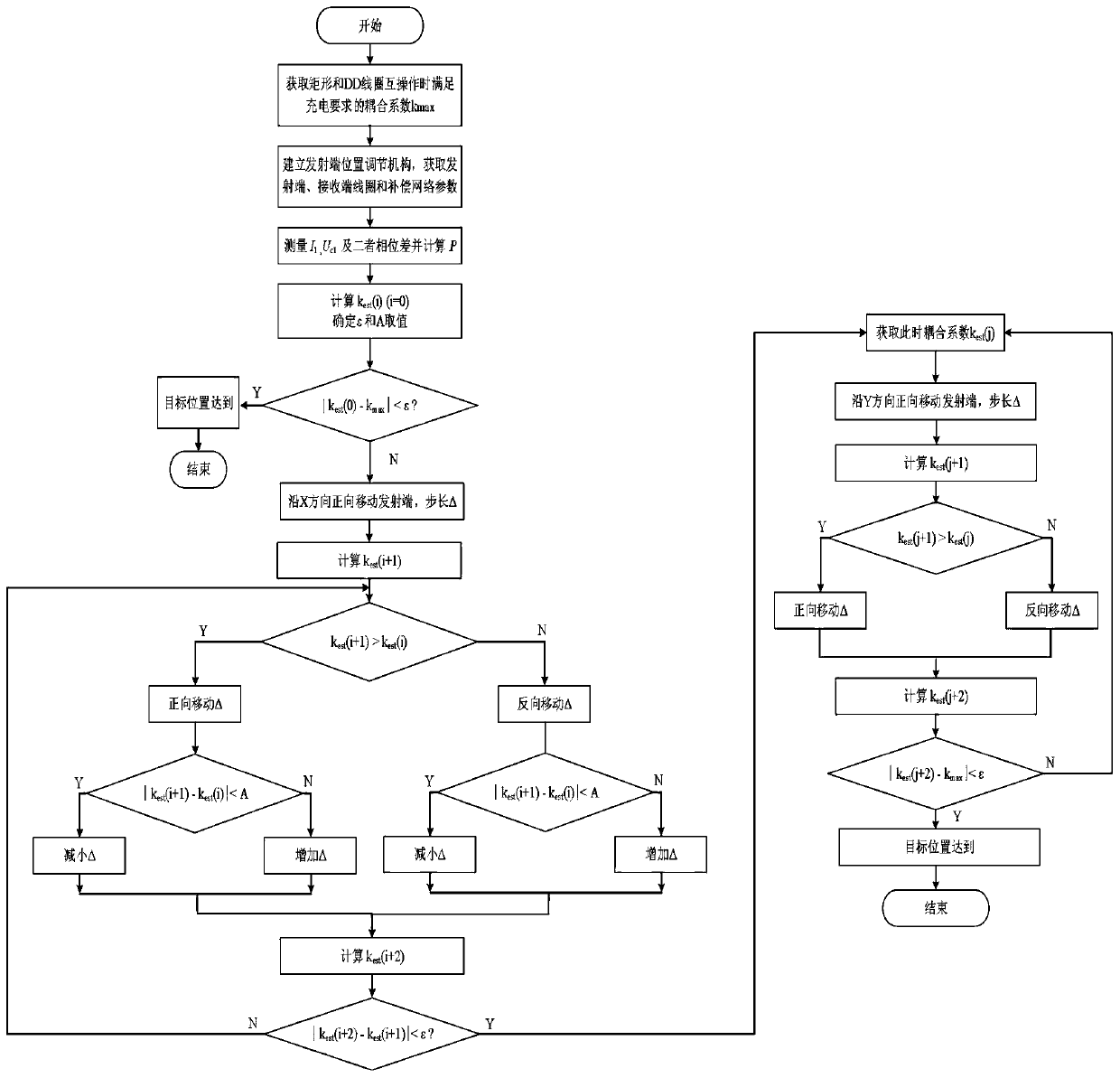

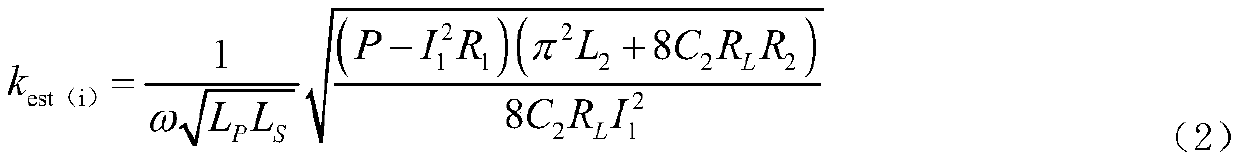

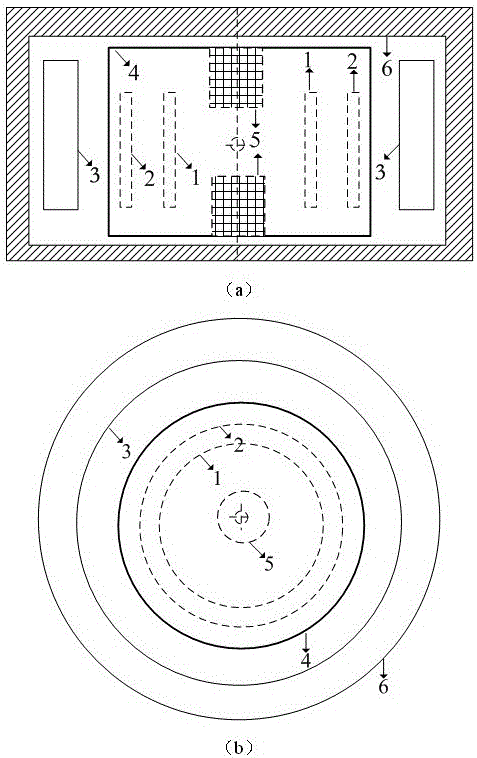

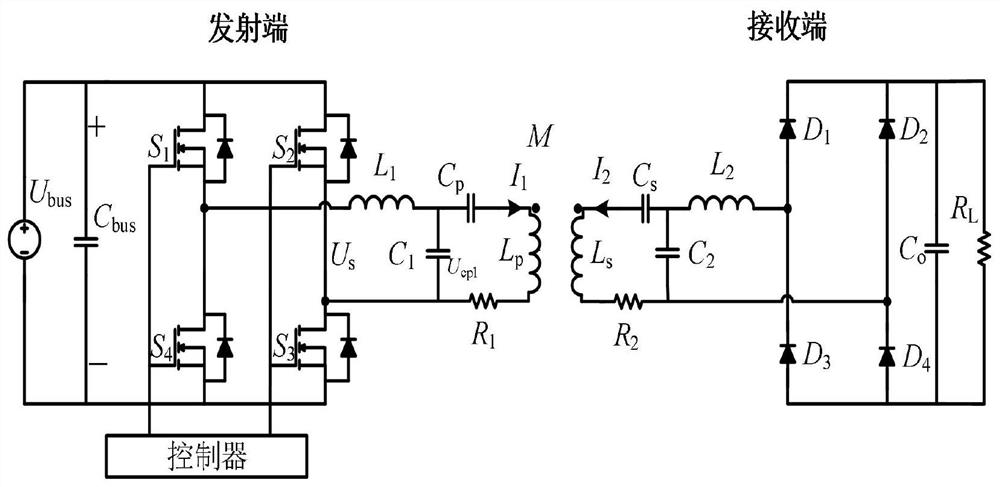

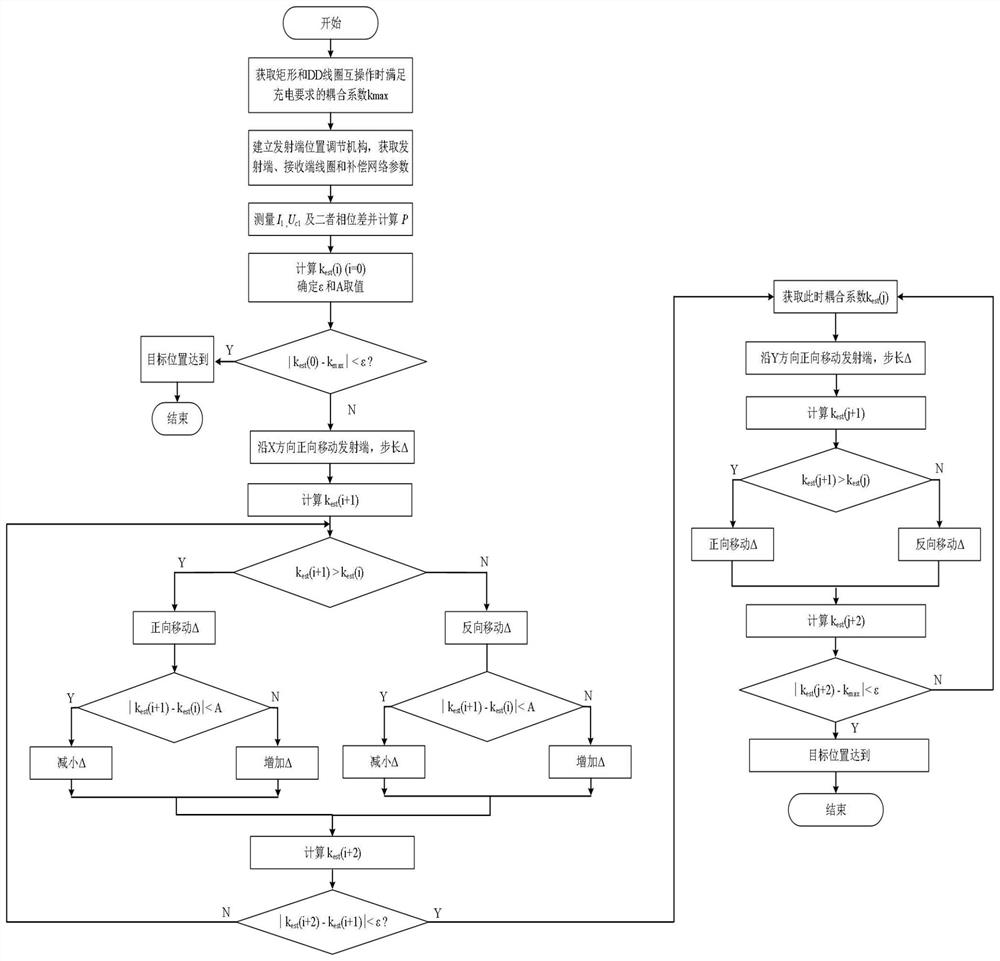

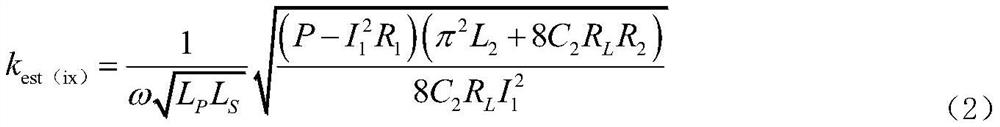

Adaptive transmitting end position adjusting method for improving interoperability of electric vehicle wireless charging coils

ActiveCN109774520AReduce manufacturing difficultyReduce thread consumptionCharging stationsCircuit arrangementsCouplingElectric vehicle

The invention discloses an adaptive transmitting end position adjusting method for improving the interoperability of electric vehicle wireless charging coils. In the method, a controller, a transmitting end and a receiving end are adopted to establish a system circuit model, a coupling coefficient meeting charging requirements in interoperation of a rectangular coil and a DD coil and a coupling coefficient obtained by calculation are acquired to adjust the position of the transmitting end, and then the coupling coefficient in the XY direction infinitely approaches the coupling coefficient meeting the charging requirements in interoperation of the rectangular coil and the DD coil. Based on a variable-step-size 'disturbance-observation' algorithm, no complicated mathematical calculation is needed, no extra communication circuit is needed, the coupling coefficient can be predicted simply by measuring transmitting end or ground equipment parameters and serves as a basis for position adjustment, the system structure is simplified, and the disturbance of a strong magnetic field to wireless communication is avoided.

Owner:HARBIN INST OF TECH

PBO fiber resin diamond wire and preparation method thereof

The invention provides a PBO fiber resin diamond wire. The PBO fiber resin diamond wire comprises a PBO fiber mother wire and a resin coating coated on the surface of the PBO fiber mother wire; the diameter of the PBO fiber mother wire is 65-80 micrometers. The PBO fiber serves as the mother wire of the resin diamond wire, so that the diameter of the PBO fiber resin diamond wire is further reduced compared with a traditional metal base material. Compared with an existing metal base material resin diamond wire, the diameter of the mother wire of the PBO fiber resin diamond wire is only 65-80 micrometers, and a higher strip yield and a higher material utilization rate are achieved in the cutting process of silicon slices. The experiment result shows that when the PBO fiber resin diamond wire is used for cutting silicon rods, the strip yield is 99.7%, the rate of finished products is 96.34%, and the material utilization rate is 67.67%. The invention further provides a preparation method for the PBO fiber resin diamond wire.

Owner:徐州博创建设发展集团有限公司

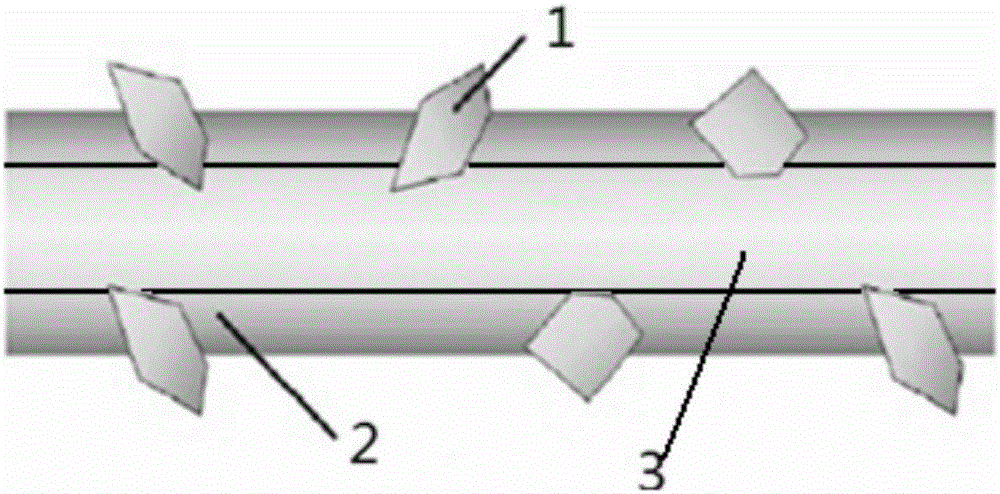

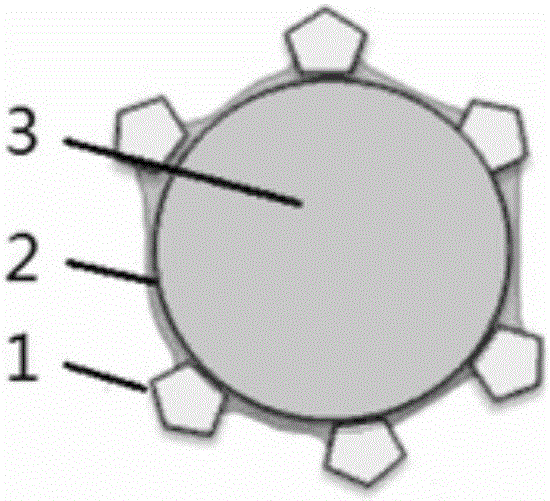

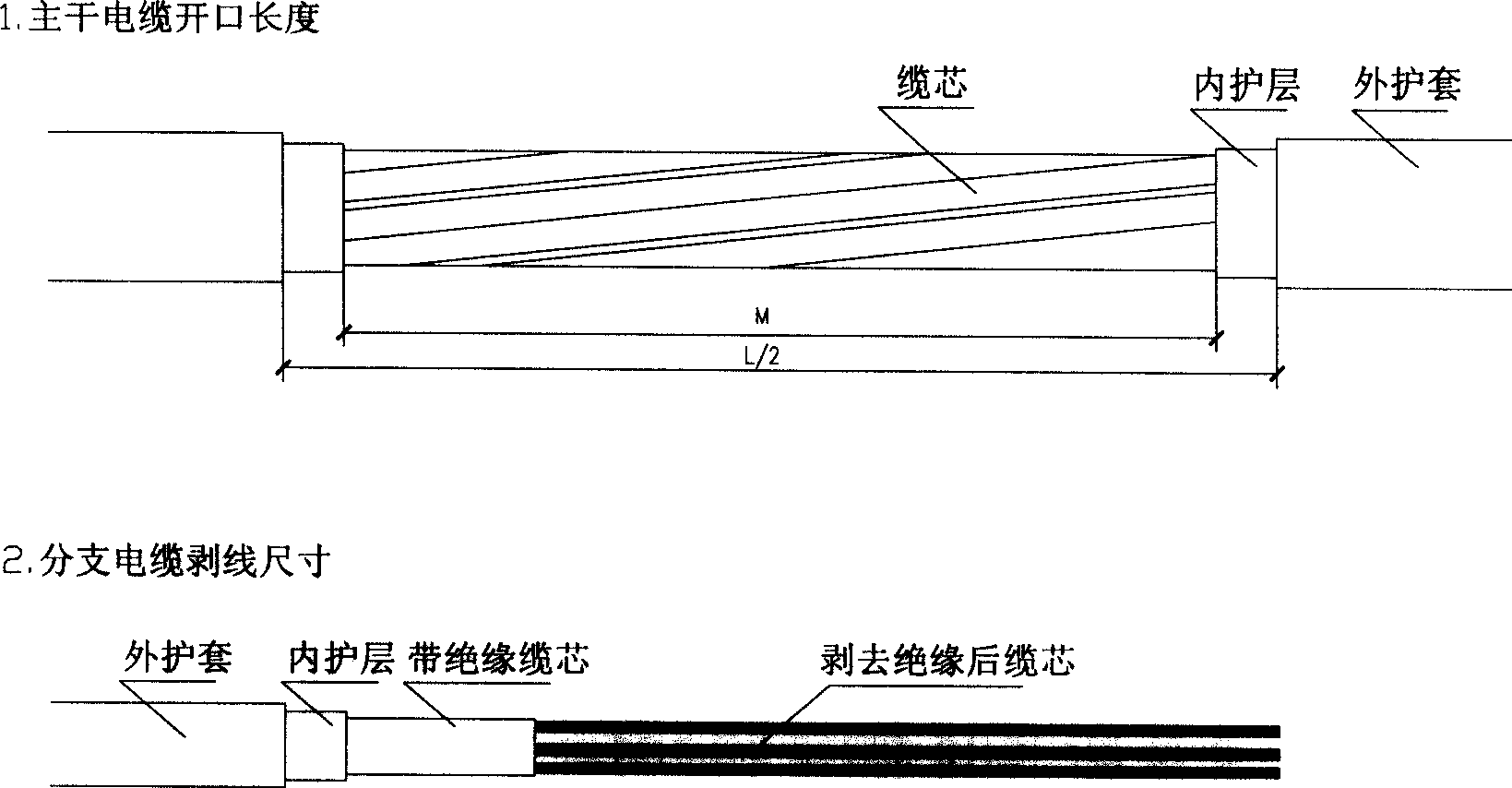

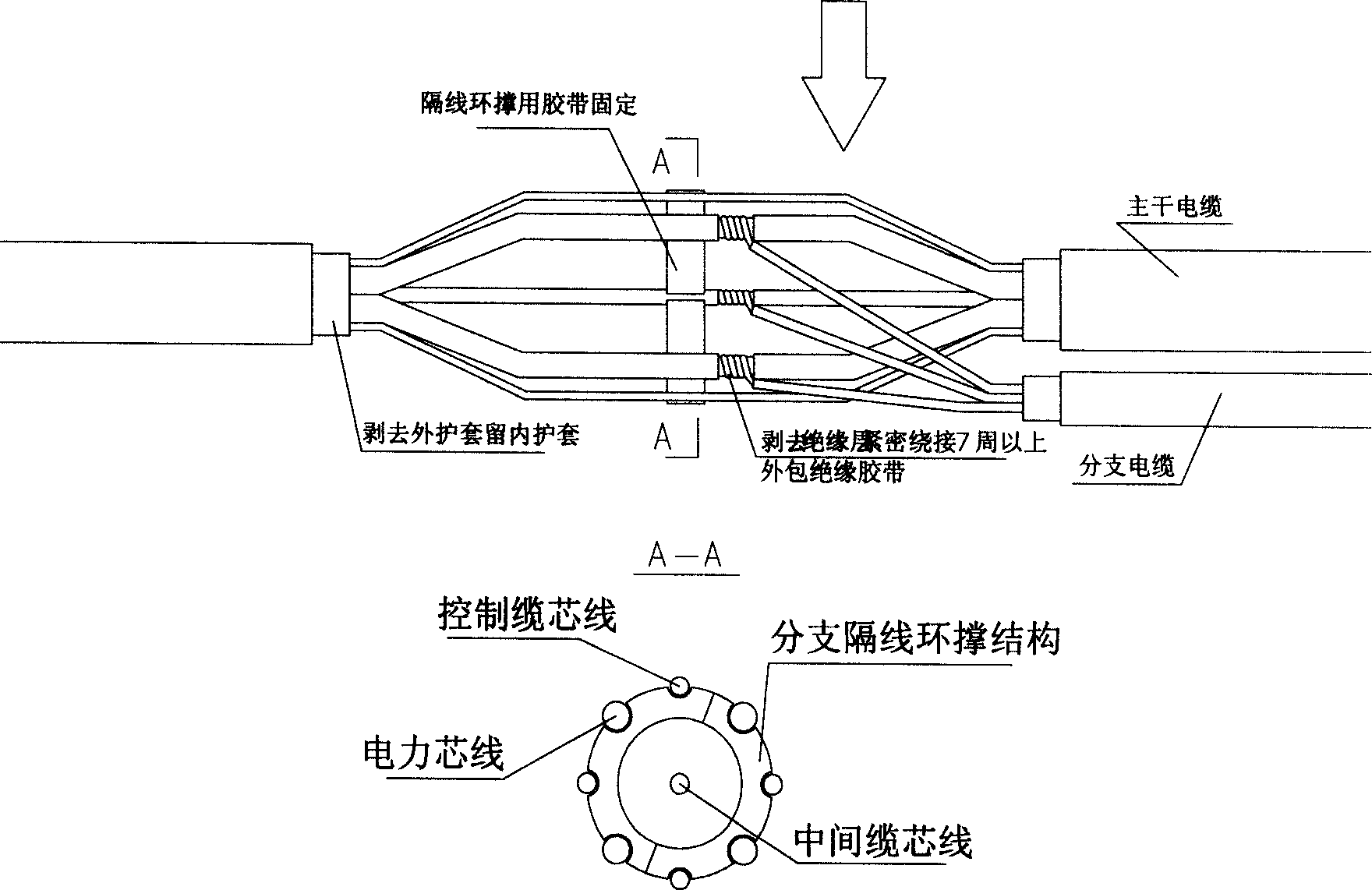

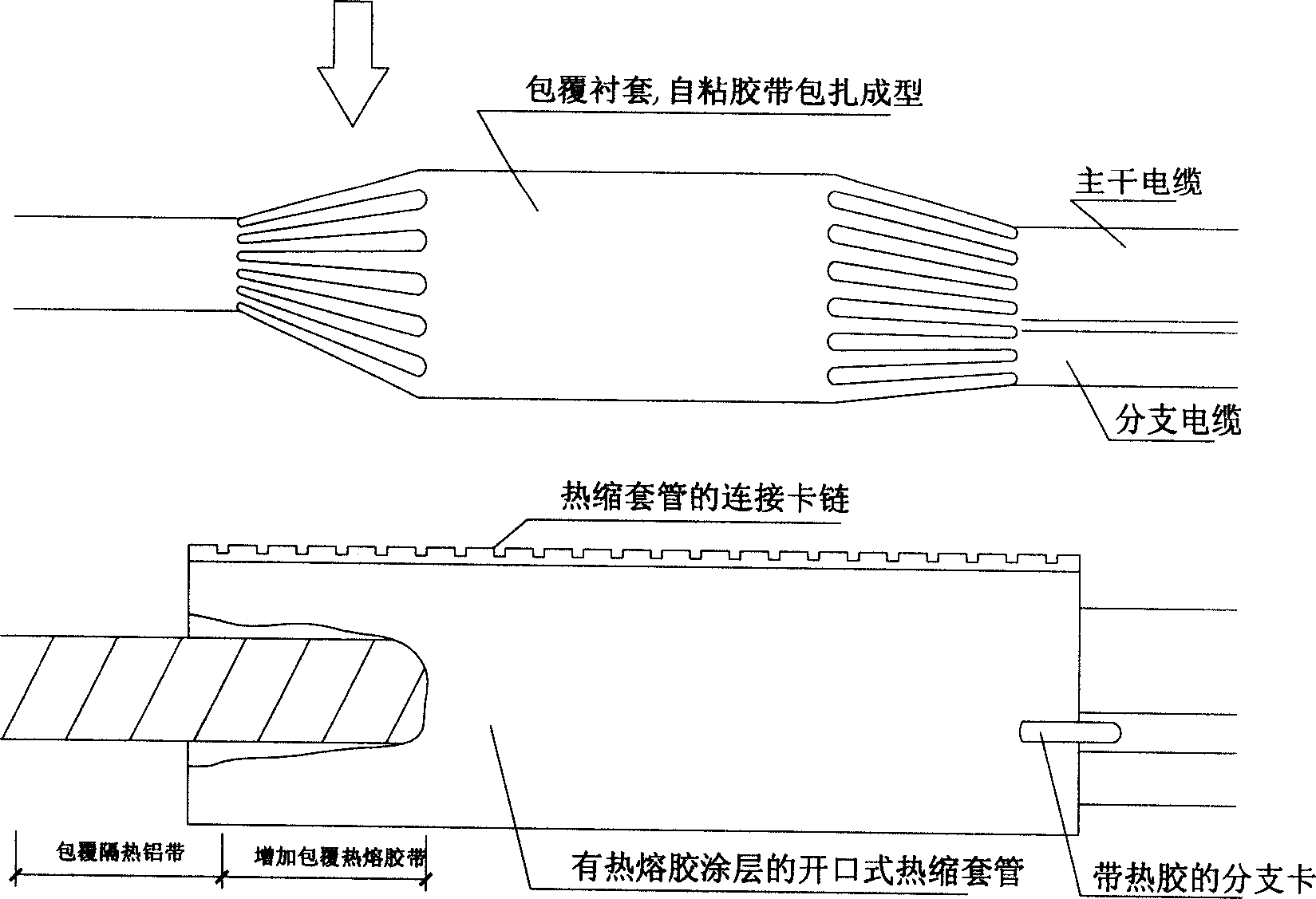

Method for branching cable joint and structure of ring support for spacing wire

InactiveCN1761113AMechanically compactReduce thread consumptionElectrical apparatusRailway tunnelPower cable

The method is in use for power cable for illumining railway tunnel. Based on diameter of main cable, the method places matched ring support for spacing wire to core thread set. Each core thread is clipped to relevant groove on surface of ring support. Through open gap, middle cable enters to center of the ring support. A segment of insulation sheath of power cable to be educed out on one or two sides of the ring support are peeled off. The peeled branching cable and relevant cable are wire wrapped according to requirement, and corresponding binding up is carried out for the joint by using selfadhesive tape of electrician. The ring support for spacing wire is a shaped column. There is a through hole in center of the shaped column, and there are grooves matched to cables on surface. Advantages are: jointing without discontinuity, compact mechanical structure, reliable seal, and good electrical specification.

Owner:达诺尔电气(集团)有限公司

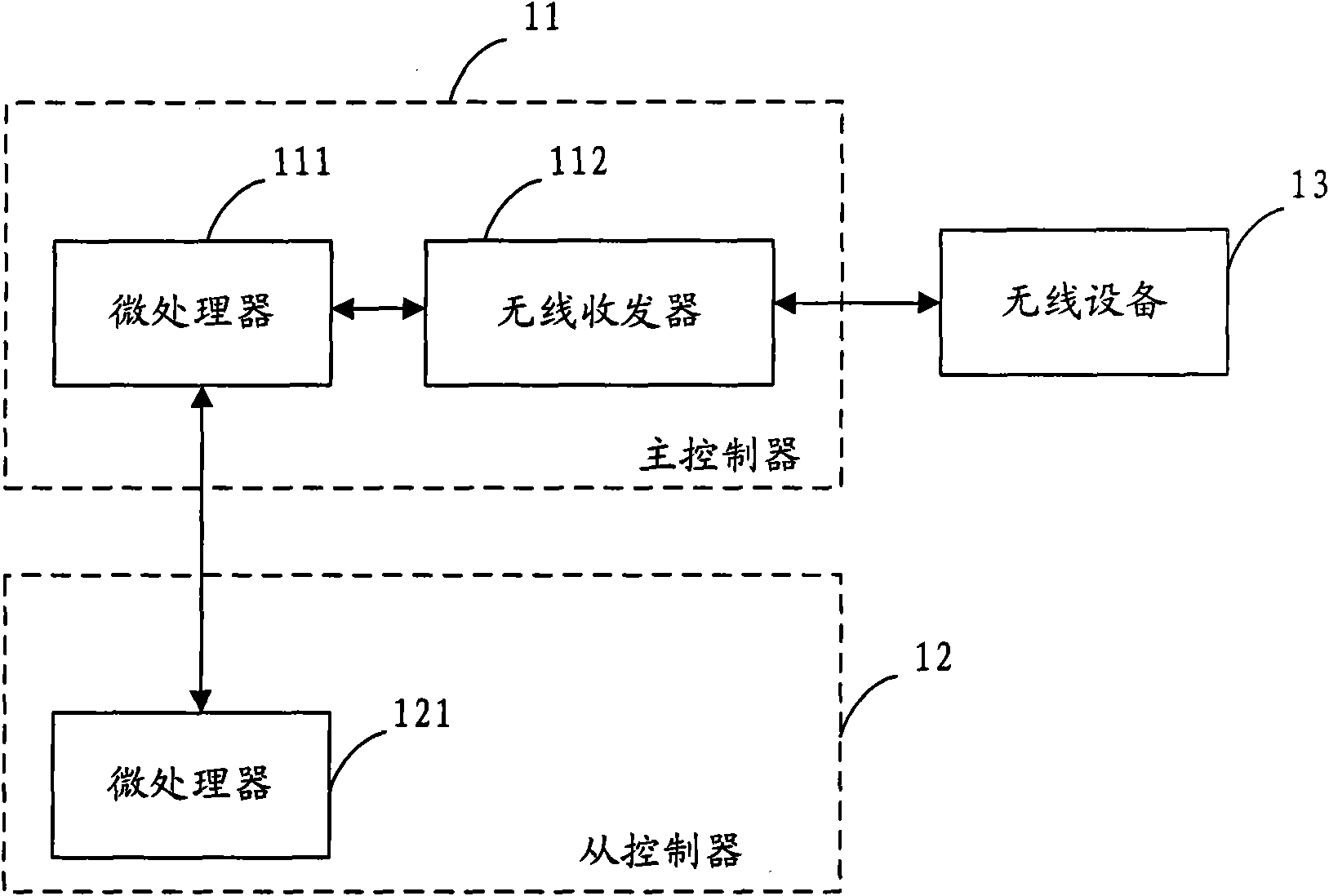

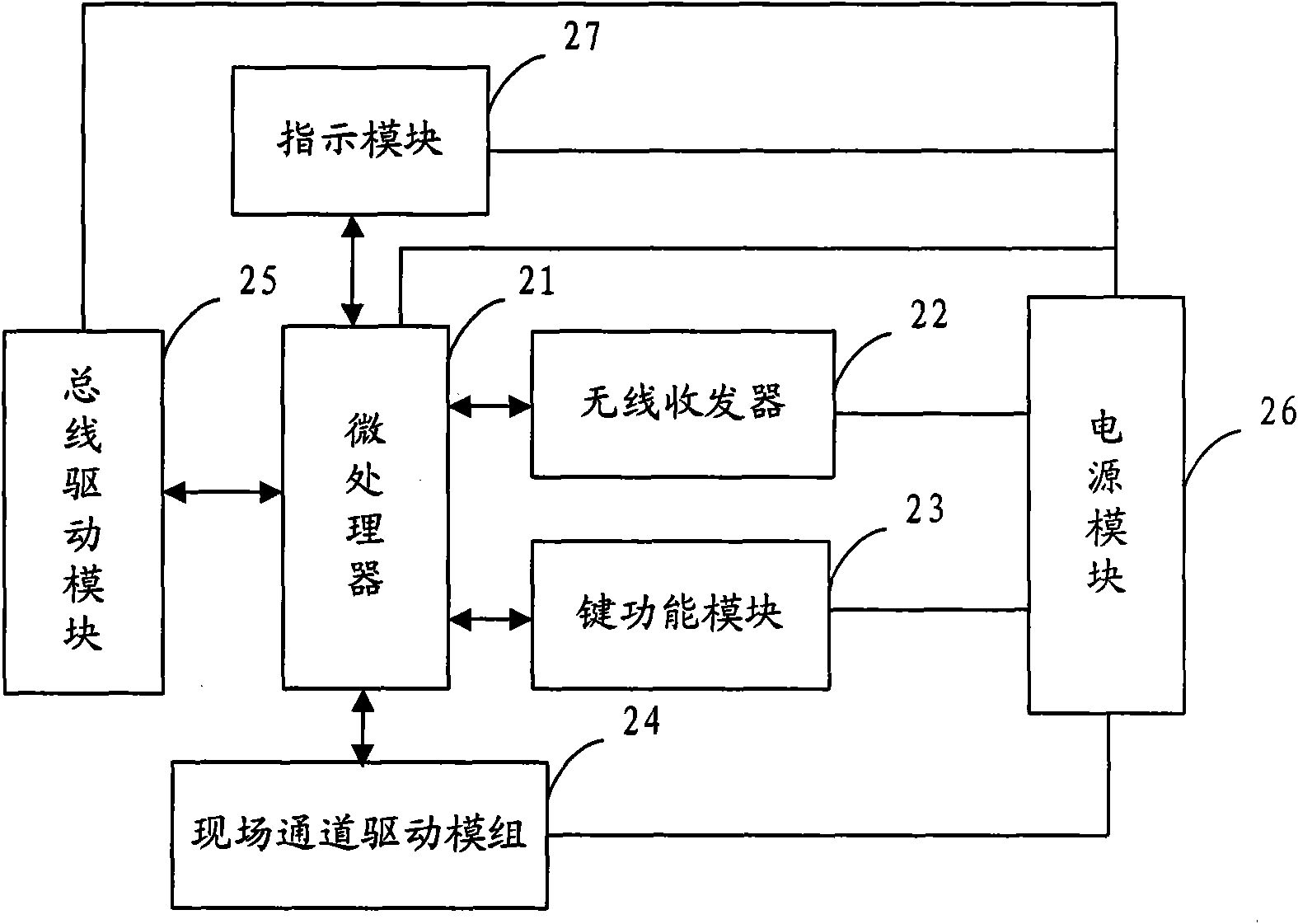

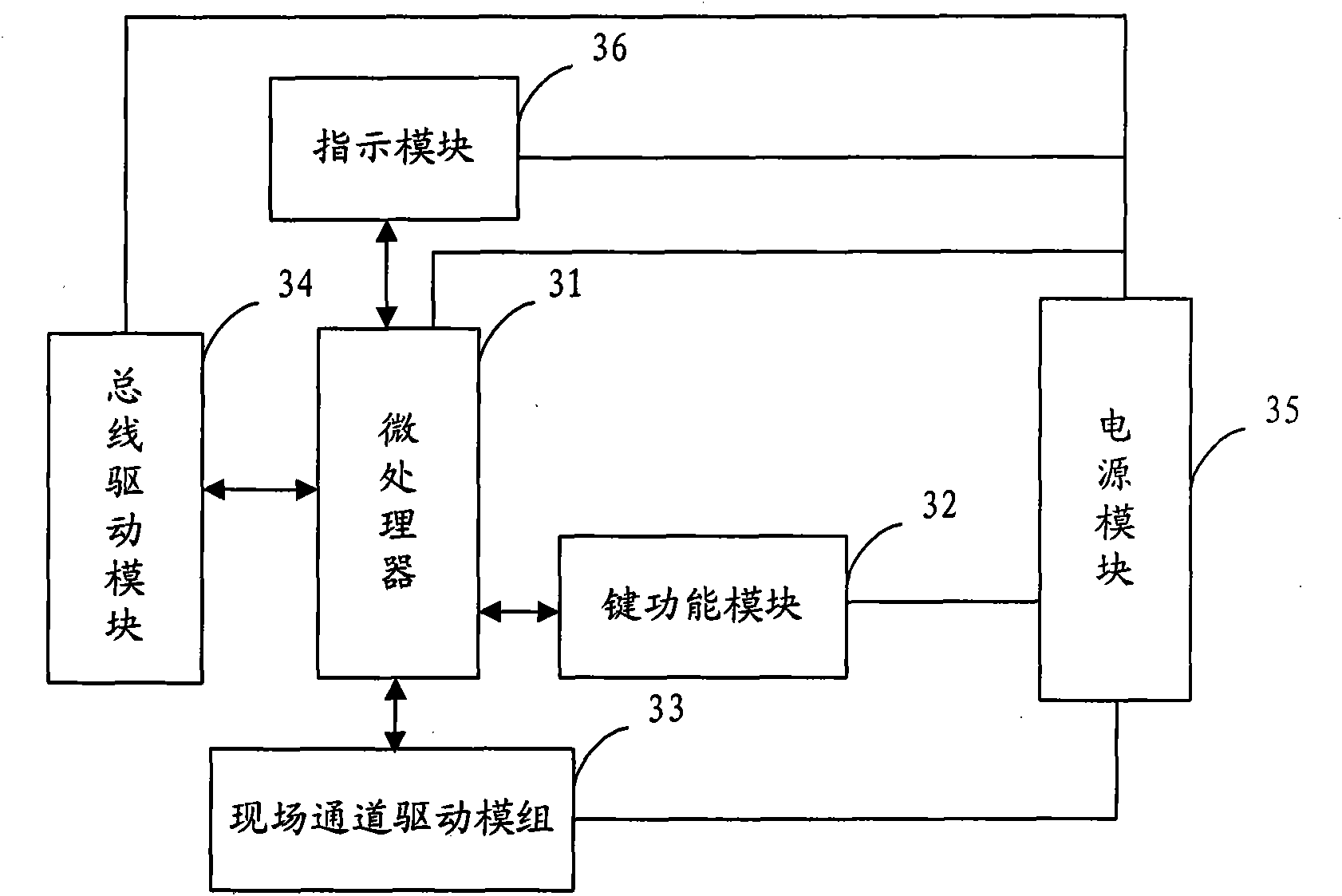

Concentrated-distributed wireless control system and controller

InactiveCN101887256AImplement automatic recoveryEasy maintenanceTotal factory controlProgramme total factory controlWireless controlTransceiver

The invention is suitable for the field of wireless and batteryless technology, and provides a concentrated-distributed wireless control system and a controller. The system comprises a master controller, a plurality of slave controller and a plurality of wireless devices, wherein the master controller and the plurality of slave controller are connected through a local area control bus; and the plurality of wireless devices are communicated with the master controller in a wireless mode. The master controller and the slave controllers all store control code tables and control parameters thereof and the opposite side, so when a failed control code table appears on one side, the opposite side can transmit the control code table and the control parameters of the site to the side through the local area control bus, the automatic restoration of the controllers is realized and the system maintenance is extremely convenient; besides, the system combines 'wireless' and 'wired', so the connecting lines among the control devices are greatly decreased; the local area control bus is a twisted pair, the line consumption is low, and the installation is convenient; and the controllers are not needed to be provided with precious wireless transceivers, so the system cost is low.

Owner:SHENZHEN LUMIUNITED TECH CO LTD

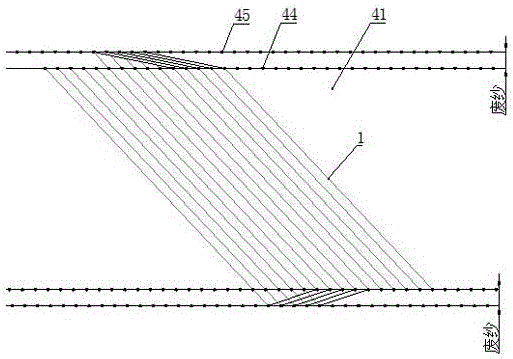

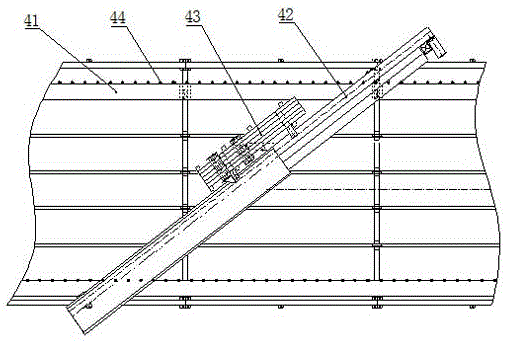

Manufacturing method of multi-axial composite base material

ActiveCN105015105AImprove structural strengthHigh surface finishLamination ancillary operationsLaminationGlass fiberWeft yarn

The invention relates to a manufacturing method of a multi-axial composite base material. The manufacturing method is characterized by comprising steps as follows: a multi-axial glass fiber yarn layer is laid, after a weft yarn laying trolley moves weft yarn layers of the glass fiber yarn layer from one side edge of a conveying belt to the outside of the other side edge of the conveying belt in a fixed direction, weft yarn is hooked on retaining pins of the conveying belt, then the weft yarn laying trolley returns to the starting point in the direction opposite to the original direction, and multiple pieces of continuous Z-shaped weft yarn with the same arrangement are formed on the conveying belt through combination of the weft yarn laying trolley with the direction of the conveying belt during forward and reverse movement; then glass fiber continuous felt is laid, sewn and wound. The manufacturing method has the advantages as follows: glass fiber weft yarn and glass fiber warp yarn are laid on the conveying belt respectively through a weft yarn laying device group and a let-off device, so that the multi-axial glass fiber yarn layer is formed, a layer of the glass fiber continuous felt is laid on the multi-axial glass fiber yarn layer after the multi-axial glass fiber yarn layer passes below a continuous felt unwinding device, then sewing is performed by a multi-needle quilting machine, and finally, the multi-axial composite base material is obtained through winding.

Owner:JIANGSU JIUDING UNIVERSAL WIND ENERGY

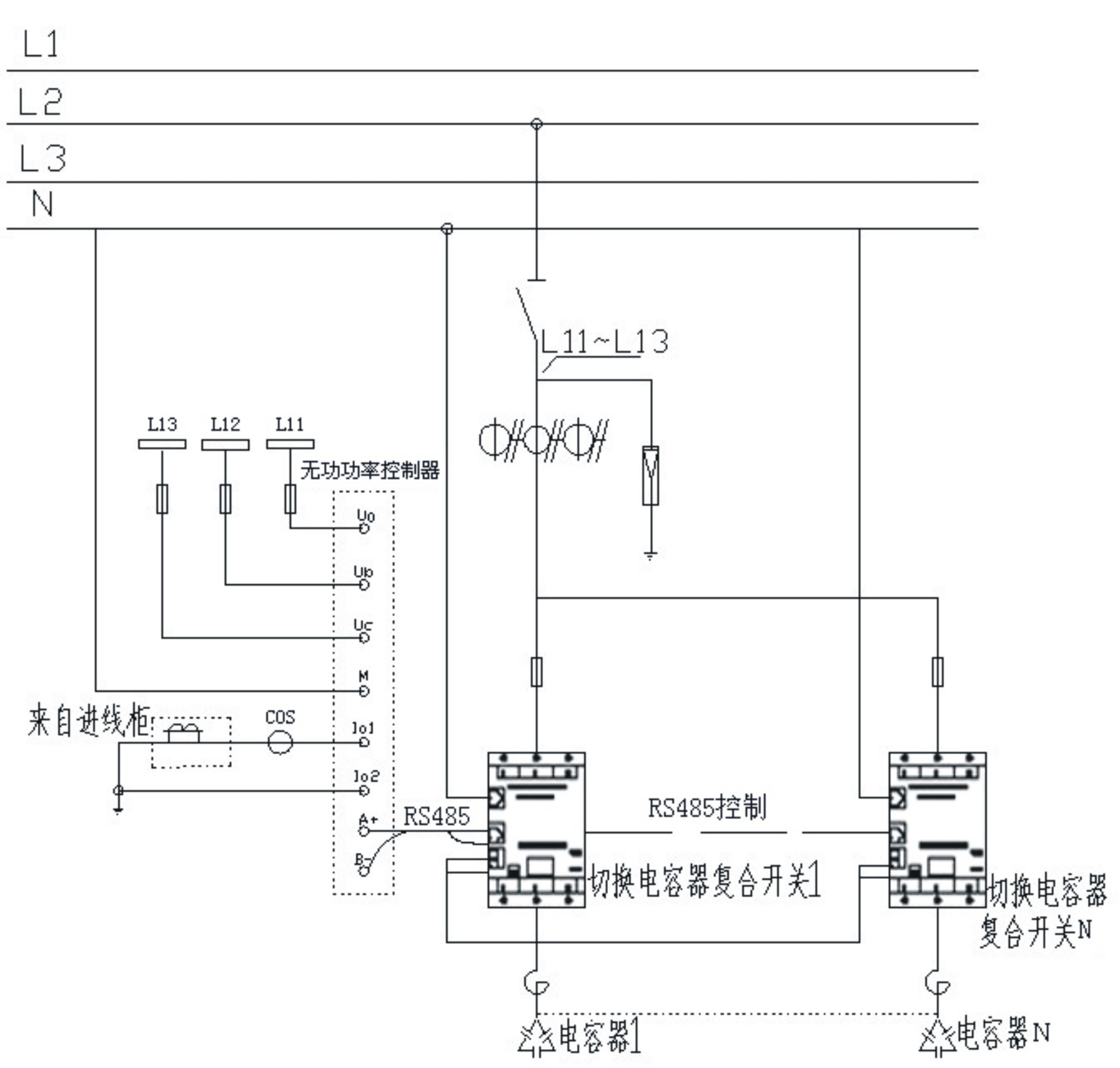

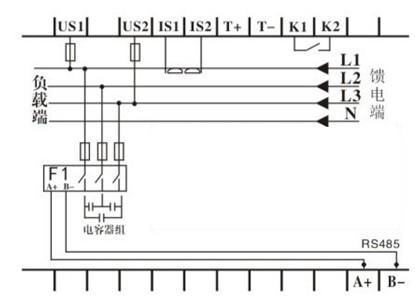

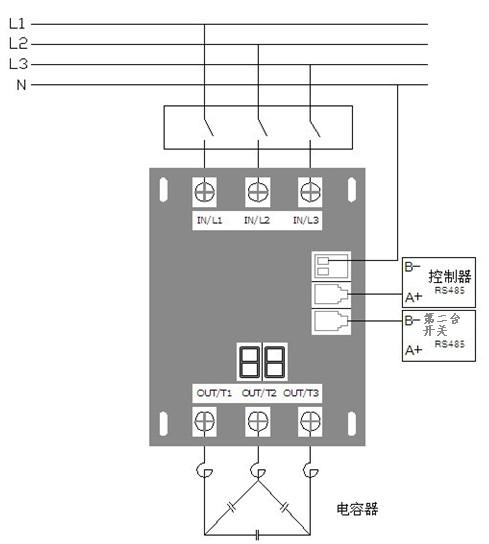

Reactive power compensation device and compensation method

InactiveCN102638050AHigh compensation accuracyReduce labor intensityReactive power adjustment/elimination/compensationReactive power compensationPower controllerPower compensation

The invention relates to a reactive power compensation device and a compensation method, in which an RS485 interface networking communication technology is applied to a control system between a reactive power controller and a combination switch of a switching capacitor. The reactive power compensation device comprises the reactive power controller, the combination switch of the switching capacitor and a power capacitor, wherein a signal output end of the reactive power controller is connected with a signal input end of the combination switch of the switching capacitor respectively through a networking communication module and an RS486 interface, and a signal output end of the combination switch of the switching capacitor is connected with a signal input end of the power capacitor respectively. The reactive power compensation device and the compensation method have the advantages that firstly, the compensation accuracy is improved; secondly, 32-path output is easily realized through one data line of the reactive power controller with the RS485 interface output, for example, by utilizing a specially-made 485 chip, 128 or 256 nodes can be achieved, and 400 nodes can be supported to the maximum degree, therefore, the compensation accuracy of a large-capacity compensation device is solved; thirdly, the compensation reliability is improved; fourthly, the compensation connection is more convenient; fifthly, intelligent compensation is realized; and sixthly, the compensation device has low cost.

Owner:杭州浙泰电气有限公司

Equal-line-loss computation method for multi-line cutting machine

InactiveCN102626959AReduce thread consumptionConsistent amount of wearFine working devicesLine lossEngineering

An equal-line-loss computation method for a multi-line cutting machine is achieved by calculating loop rate of any one point in multi-line cutting. The loop rate of the any one point is calculated through the following formula: K=(1-beta*fw*a-2*beta*Vw*Vw) / (1+beta*fw*a), wherein r is the radius of a cutting material, p is a main roll groove distance, C is set abrasion area, a is linear acceleration, Vw is linear speed, L is the length of the cutting material, h is cutting depth, fw is inlet line quantity, k is loop rate, and V(h) is a function of the feeding speed and the cutting depth. Beta=alpha*V(h)*L*C / (fw*p*a*Vw) / 30. Alpha= sqrt (r*r-(r-h)*(r-h)). The V(h) is set before machining. The equal-line-loss computation method guarantees that a line is scraped until enough area is cut, namely abrasion loss is uniform, optimum abrasion loss is achieved, and a use amount of lines is saved.

Owner:TIANJIN UNIV OF TECH & EDUCATION TEACHER DEV CENT OF CHINA VOCATIONAL TRAINING & GUIDANCE +1

Isovolumetric cutting speed calculation method for multi-line cutting machine

InactiveCN102700015AConsistent amount of wearEasy to wearFine working devicesEngineeringCalculation methods

The invention discloses an isovolumetric cutting speed calculation method for a multi-line cutting machine. The isovolumetric cutting speed calculation method for the multi-line cutting machine is realized by solving a feeding speed of any positional point during the multi-line cutting. The feeding speed of any point is obtained according to the formula as follows: F=C*P / [(R<2>-(R-h)<2>)<1 / 2>*(dw+2*d)*L*K], wherein F is the feeding speed, C is a cutting volume in a unit time, P is a slot pitch of a main roller, R is a radius of a cut material, h is a cutting depth, dw is a diameter of a cutting line, d is a diameter of a cut abrasive material, L is a length of the cut material and K is a safety coefficient. A maximum feeding speed Fmax is set and if the feeding speed F of one positional point, calculated through the formula, is greater than the Fmax, the Fmax is taken as the feeding speed. The isovolumetric cutting speed calculation method for the multi-line cutting machine, disclosed by the invention, has the advantages of guaranteeing the volume amount removed in a unit time as the setting value, adjusting the cutting speed F according to the slot pitch P of the main roller, the cutting position h, the cutting length L, the diameter d of the cut abrasive particle and the like and improving processing efficiency.

Owner:TIANJIN UNIV OF TECH & EDUCATION TEACHER DEV CENT OF CHINA VOCATIONAL TRAINING & GUIDANCE

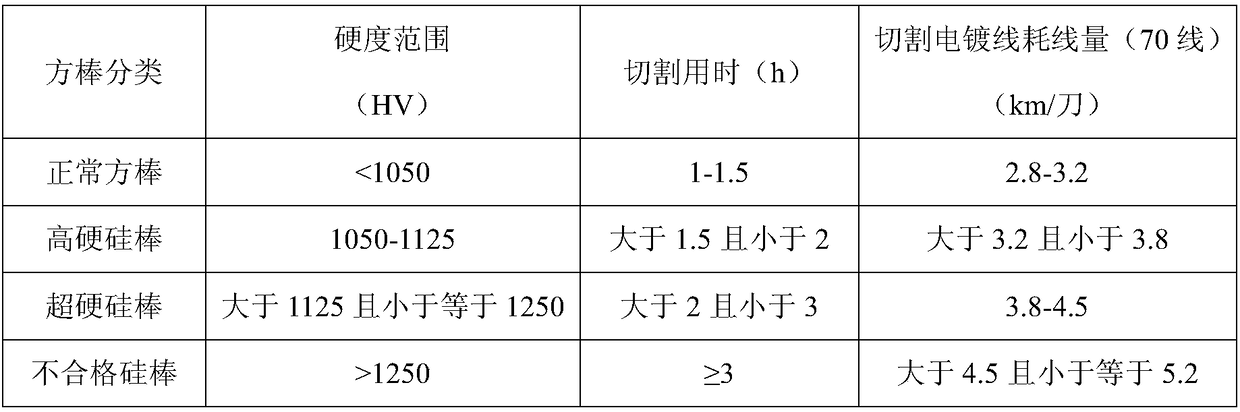

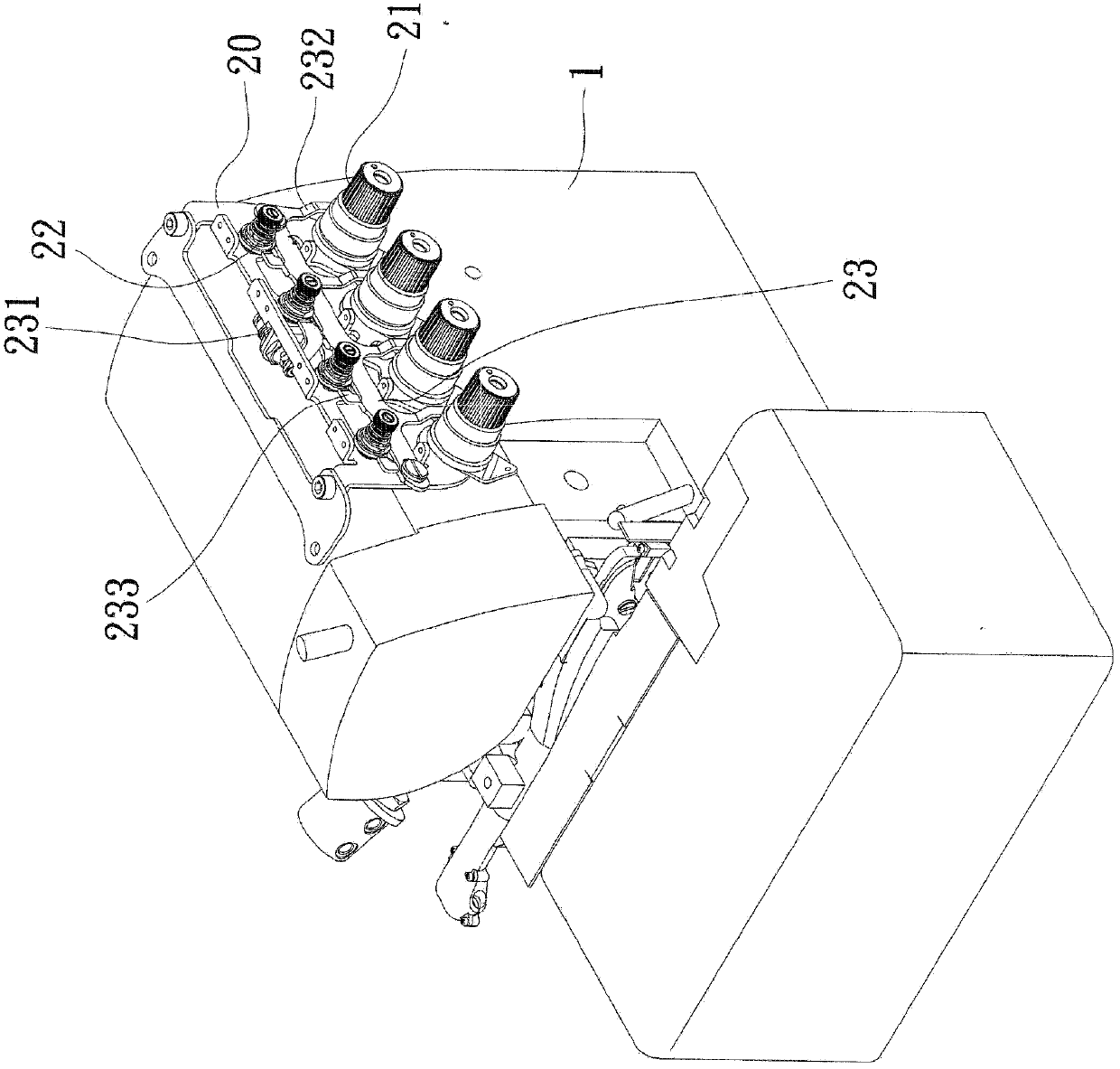

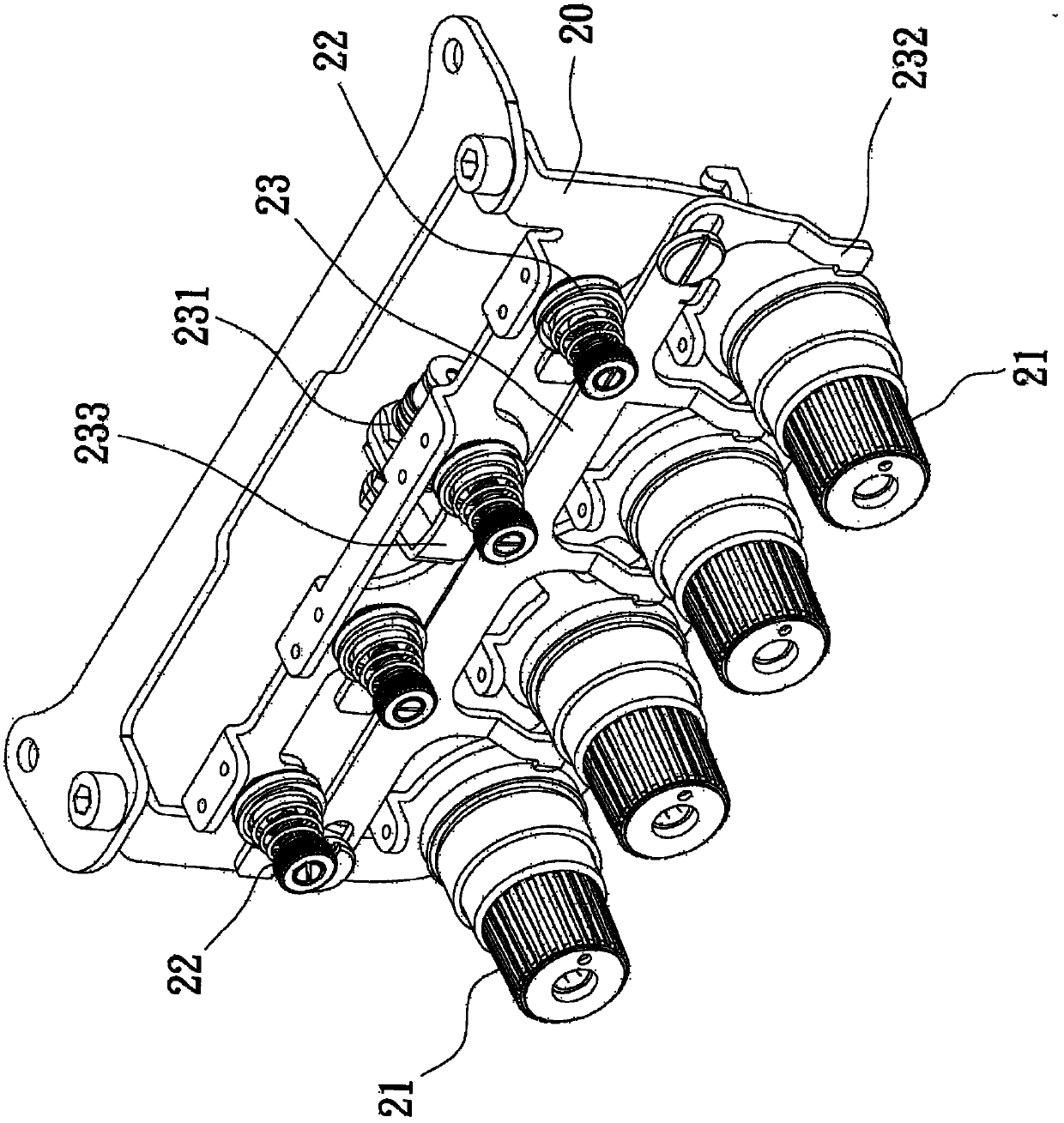

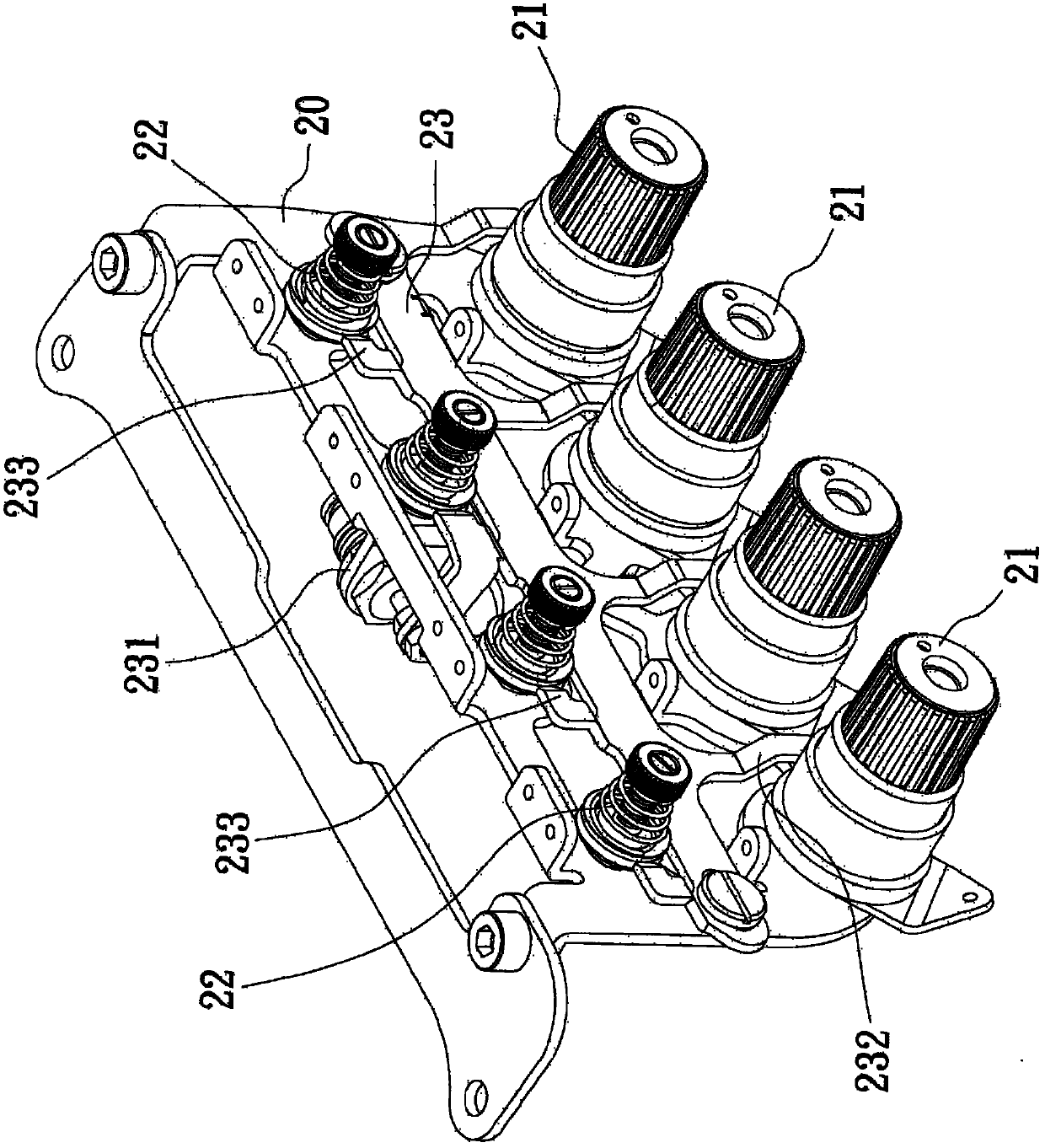

Silicon briquette machining method

PendingCN108162217AReduce the comprehensive lineReduce slicing costsWorking accessoriesFine working devicesPolycrystalline diamondBriquette

The invention discloses a silicon briquette machining method. The method comprises a step of cutting silicon briquettes by adopting a diamond wire slicing method, wherein the silicon briquettes are cut by adopting different cutting processes according to difference of the hardness of the silicon briquettes; and the cutting processes mainly represent the time spent in cutting and the amount of diamond wires consumed for cutting. According to the method disclosed by the invention, the hardness of the silicon briquettes is classified; corresponding cutting wire techniques are adopted according todifferent types of silicon briquettes so as to prevent uneven diamond abrasion caused by different hardness of silicon rods, thus the cutting yield and even the reject ratio of broken wires are not affected, the amount of comprehensive used wires for polycrystalline diamond wire slicing is reduced, the cutting yield is increased, and thus the polycrystalline diamond wire slicing cost is lowered.

Owner:LUOYANG CSI PHOTOVOLTAIC TECH CO LTD

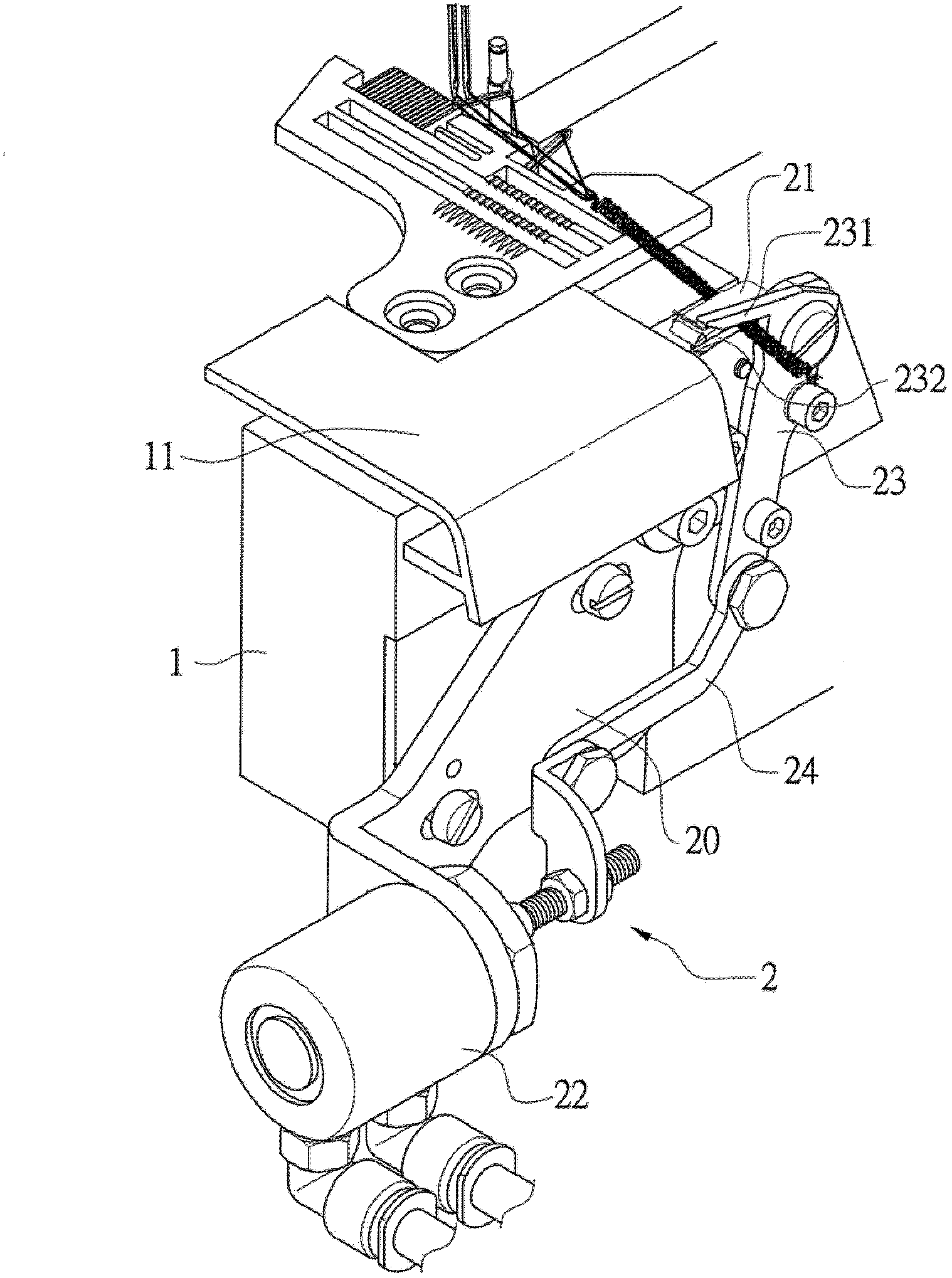

Method for reducing thread using amount during thread shearing of overlock sewing machine

ActiveCN103290625AReduce thread consumptionNo need to waste lengthTensioning devicesEngineeringSewing machine

The invention relates to a method for reducing a thread using amount during thread shearing of an overlock sewing machine. According to the method, after a work piece sewing procedure is finished, external force is applied to the platform of the overlock sewing machine, a tension adjusting knob which is assembled on the platform and used for clamping a fixed sewing thread is expanded and releases the sewing thread, and simultaneously, the sewing thread is pressed and limited by clutching force which is smaller than clamping force of the tension adjusting knob. Accordingly, due to the released sewing thread of the machine, the number of knotted meshes of a knotting chain behind a work piece is reduced, so that the using amount of cut tailing threads is reduced.

Owner:顾飞龙

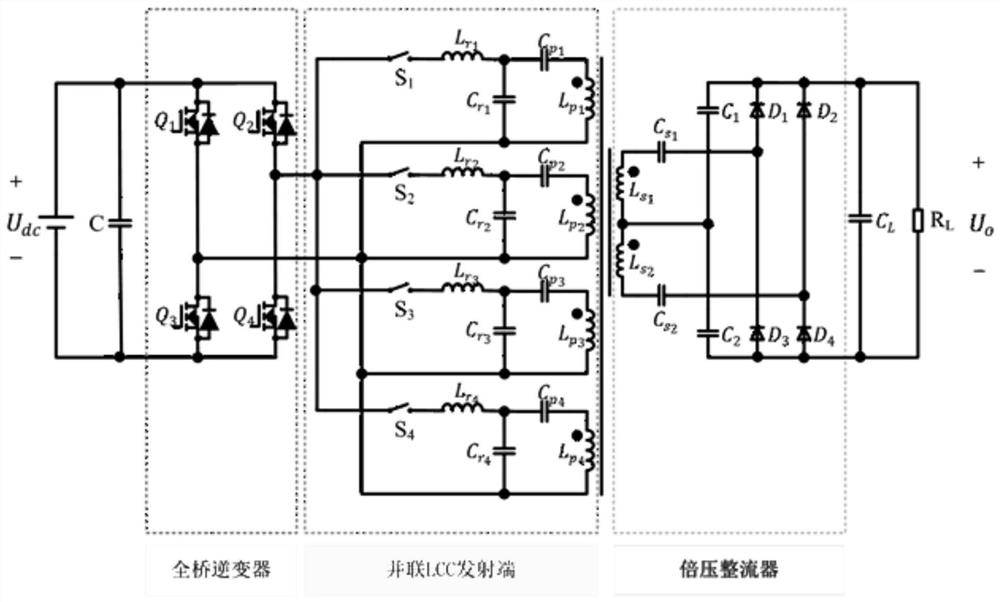

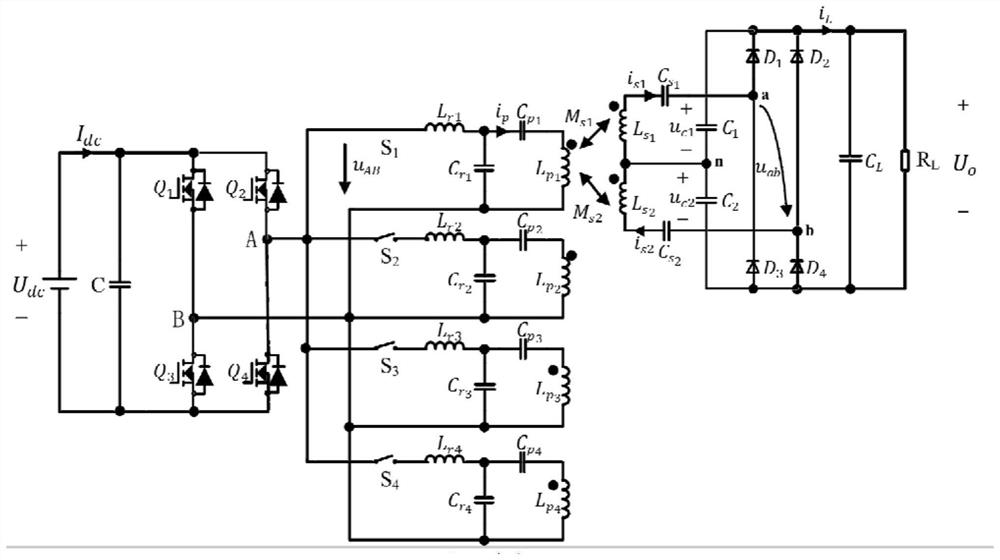

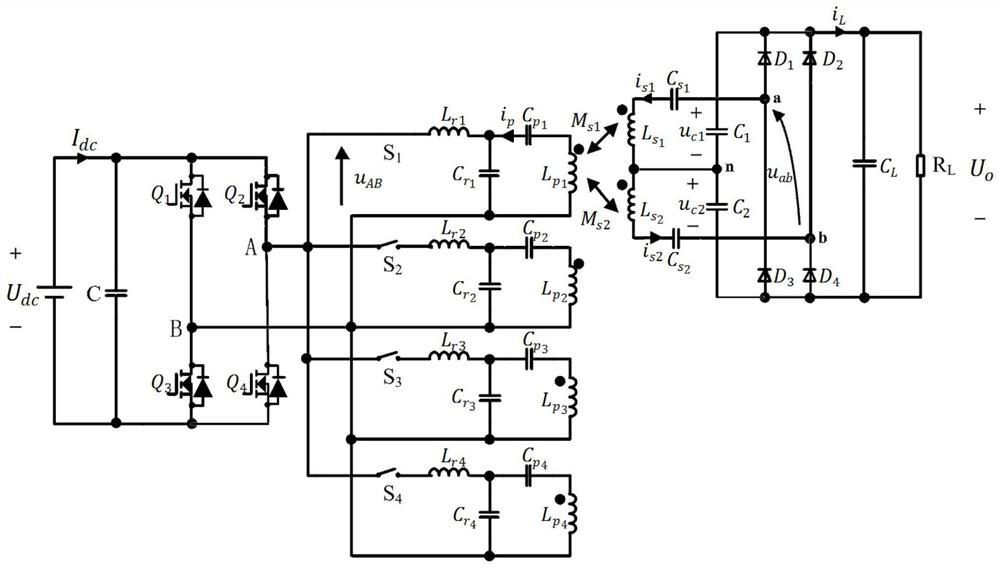

Dynamic wireless power supply system power fluctuation suppression method based on voltage doubling rectifier

ActiveCN111654118AStable power supplyAvoid unpowered areasCircuit arrangementsTransmitter coilLoop control

The invention discloses a dynamic wireless power supply system power fluctuation suppression method based on a voltage doubling rectifier, and belongs to the technical field of dynamic wireless charging. The problem of output voltage and power fluctuation caused by mutual inductance fluctuation of the transmitting coil and the receiving coil in the moving process of the receiving end of the dynamic wireless power supply system is solved. The output voltage of the system is kept at a constant value, a non-power area of the dynamic wireless power supply system is avoided, and the power supply stability and reliability of the system are ensured. The method comprises the following steps: a, constructing a wireless power supply system topological structure based on primary side LCC parallel connection and secondary side dual-decoupling; and b, adjusting the working mode of the wireless power supply system based on primary side LCC parallel connection and secondary side dual-decoupling according to the relative offset state of the topological structure coil, and ensuring that the output voltage U0 is stable. According to the method, the constant output voltage of the dynamic wireless power supply system can be effectively maintained in the moving process of the receiving end, a complex closed-loop control means is not needed, and the method has good applicability and operability.

Owner:SOUTHWEST JIAOTONG UNIV

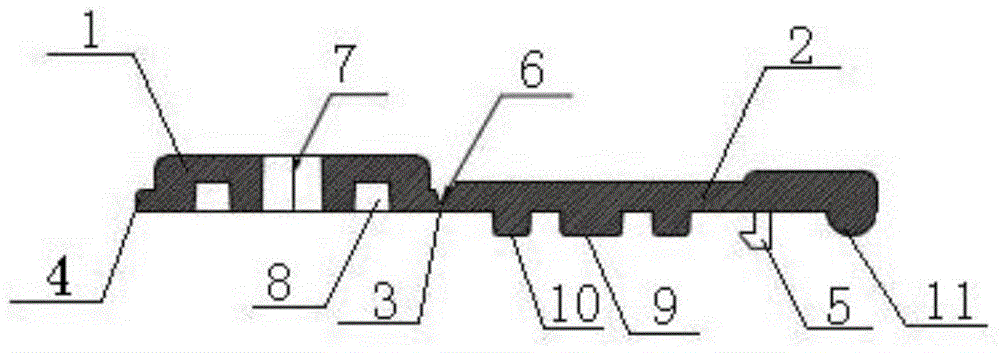

Suture buckle

The invention relates to a suture buckle. The suture buckle comprises a first buckle body and a second buckle body which are matched with each other, wherein an edge is arranged on one side of the first buckle body; the other side of the first buckle body is connected with the second buckle body in a folding manner; the second buckle body is provided with a snap; the edge is detachably connected with the snap; the first buckle is provided with a threading hole and positioning grooves; the second buckle is provided with line fixing bumps which are matched with the threading hole and positioning bumps which are matched with the positioning grooves. According to the suture buckle, the tail end of the suture line can be fixed through matching of the threading hole and the line fixing bumps by only penetrating the tail end of the suture line through the threading hole, folding the first buckle body and the second buckle body and then fixing through the snap and the edge. According to the suture line, the time during knotting of the suture line can be reduced, the using amount of the line during suturing of a cut and a wound is saved, and the reliability and the stability are both superior to those of knotting.

Owner:湖南然元医用高科技蛋白线有限公司

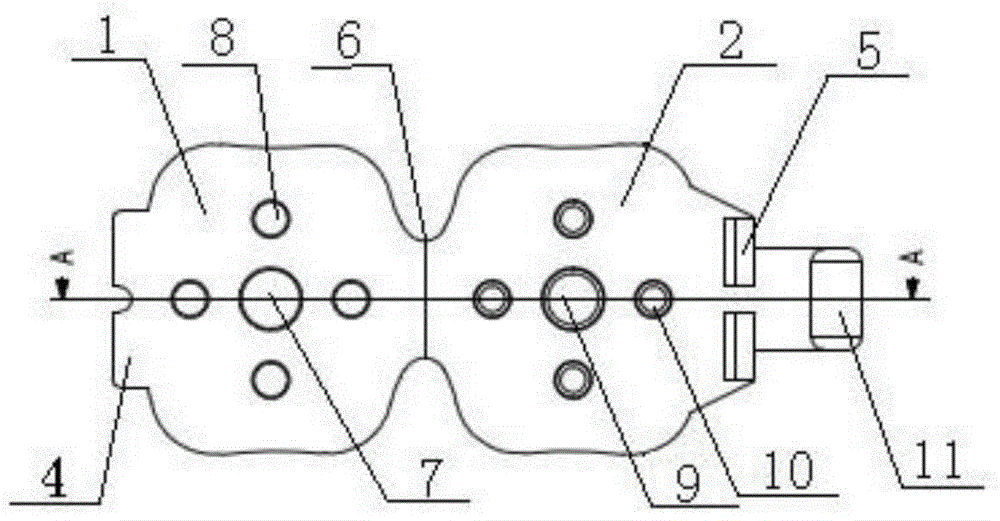

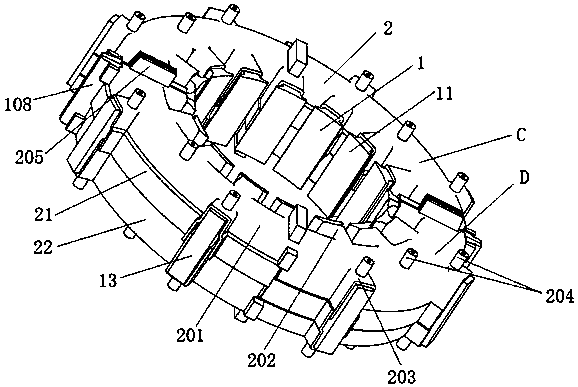

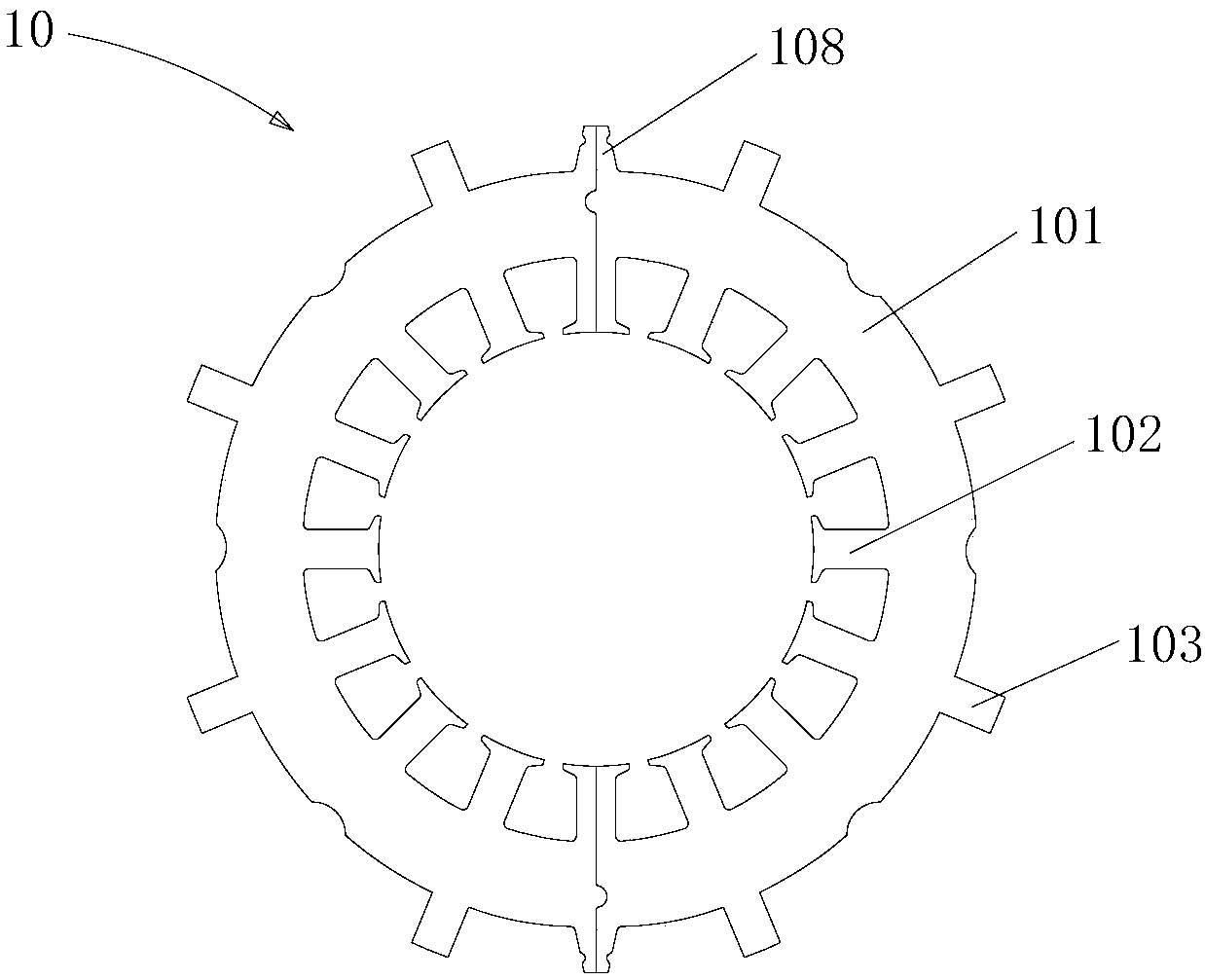

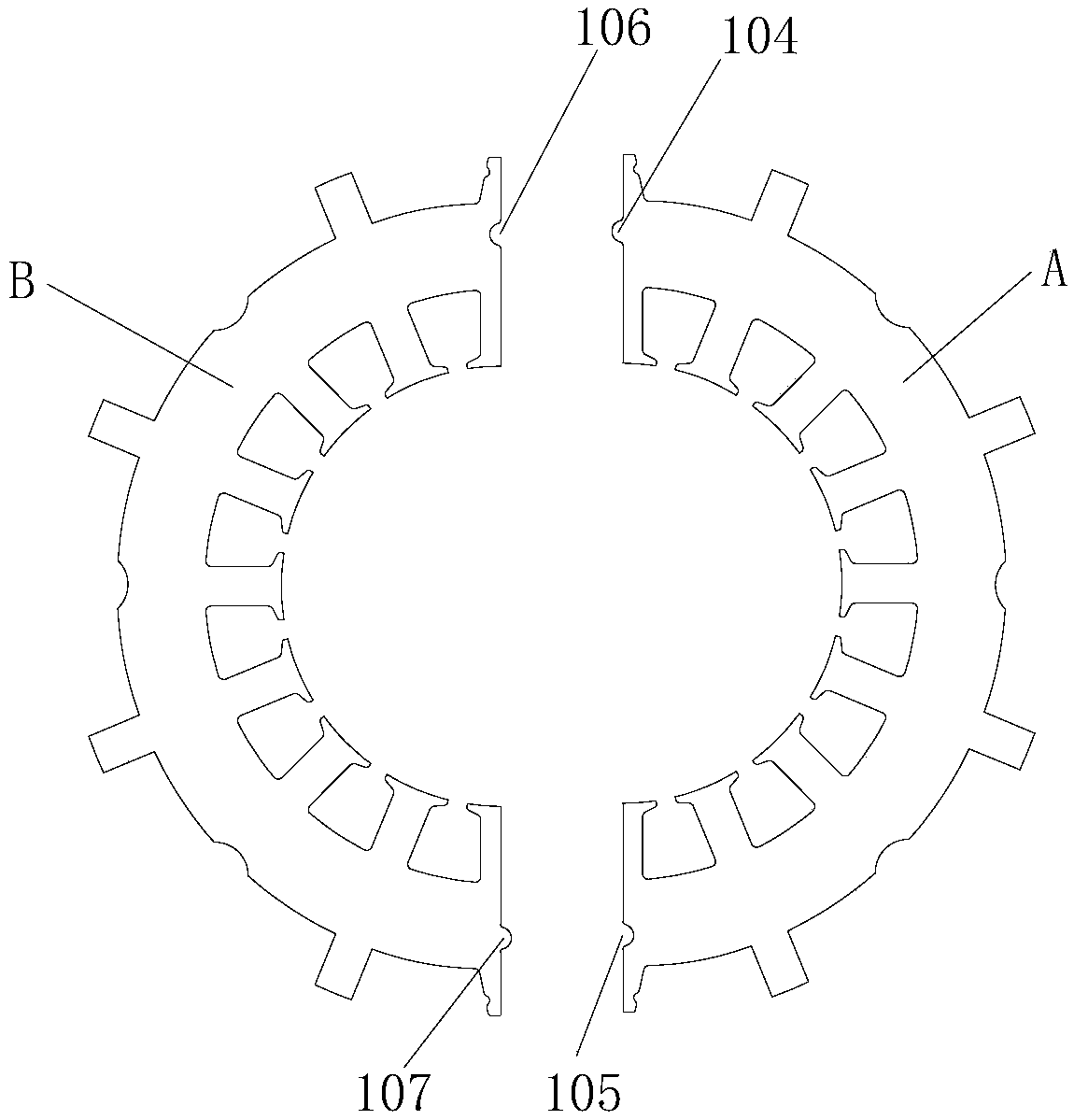

Stator punching plate, stator assembly and motor

ActiveCN108631460AReduce weightImprove effective utilizationMagnetic circuit stationary partsPunchingElectric machine

The invention discloses a stator punching plate, a stator assembly and a motor. The stator punching plate includes a yoke part (101) and a plurality of teeth (102) arranged on the yoke part (101) along the inner periphery at intervals. The state punching plate is characterized in that the outer periphery of the yoke part (101) is provided with a plurality of bosses (103) used for fitting positioning with a housing of the motor at intervals. According to the invention, the effective utilization rate of windings can be improved effectively and material of the windings can be saved and the weightof the windings can be reduced. Besides, implementation of automation can be facilitated, production efficiency of the motor can be improved and labor cost can be saved.

Owner:GUANGDONG WELLING ELECTRIC MACHINE MFG

Method for preparing hexagonal mesh polythene warp-knitting net for deep-water net box and net bag

InactiveCN101445995AImprovement of internal and external water body exchange performance and fishery adaptabilityEnsure safetyWarp knittingMonocomponent polyolefin artificial filamentHigh-density polyethyleneEngineering

The invention provides a method for preparing hexagonal mesh polythene warp-knitting net for a deep-water net box and a deep-water net bag, relating to the preparation of webbing for deep-water net box and net bag; the problem to be solved is to improve strength performance of the polythene warp-knitting net for deep-water net box and net bag, exchange performance of internal and external waters and fishing adaptability. The technical proposal comprises that high-density polyethylene is used as raw material to prepare the high-strength fishing polyethylene monofilament with the diameter of 0.20mm and hexagonal warp-knitting mesh shapes by a high-temperature high-time self-reinforced technique; the method is characterized in that weft-lining wreathing empirical coefficient of hexagonal mesh polyethylene warp-knitting net is 0.160-0.200; the wreathing number is equal to the product of strand number and wreathing empirical coefficient, the weft-lining empirical coefficient is 0.400-0.500, the weft-lining number is equal to the product of the strand number and the weft-lining empirical coefficient and the weft-lining number is an even number. The method is used for preparing hexagonal mesh polythene warp-knitting net for deep-water net box and net bag.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

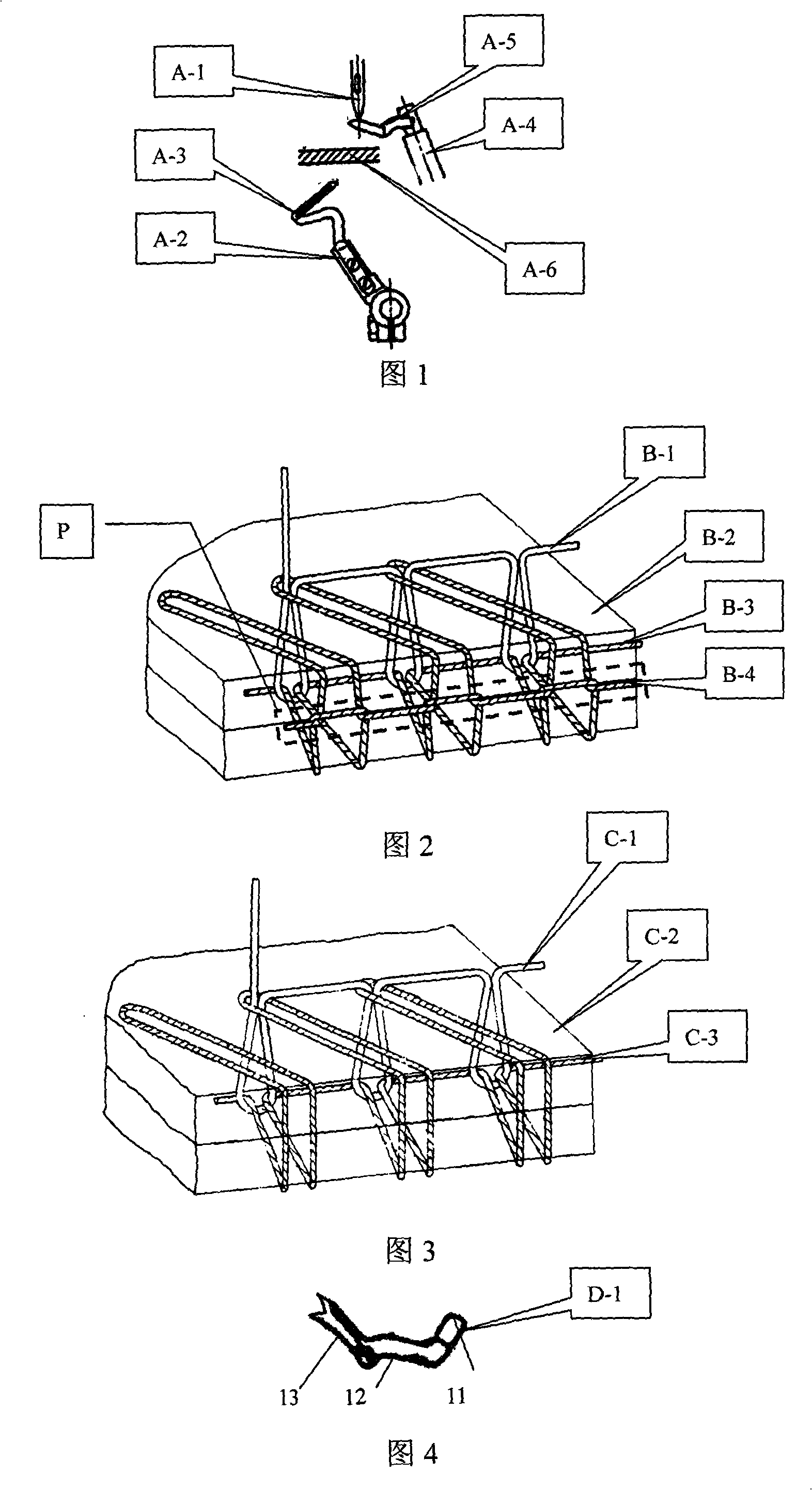

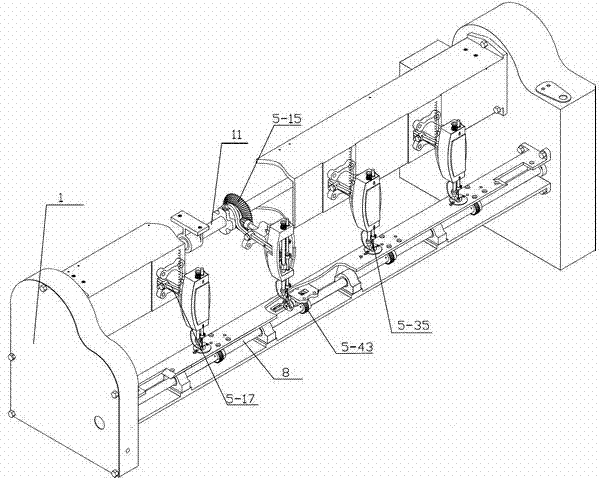

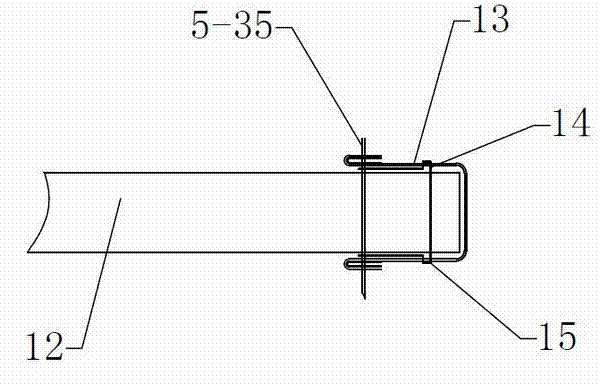

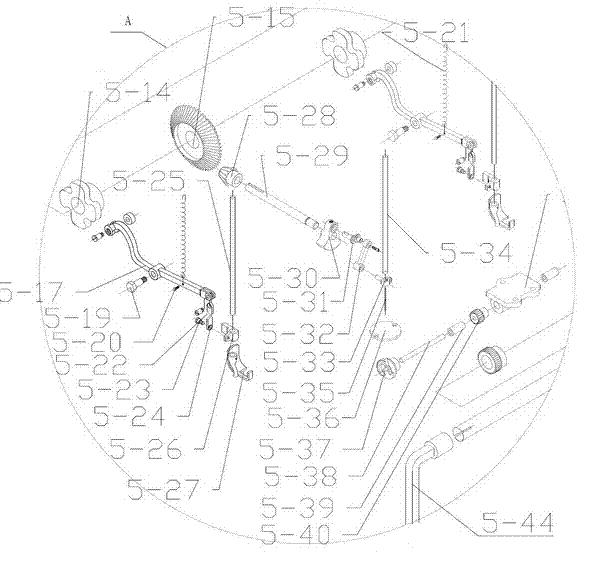

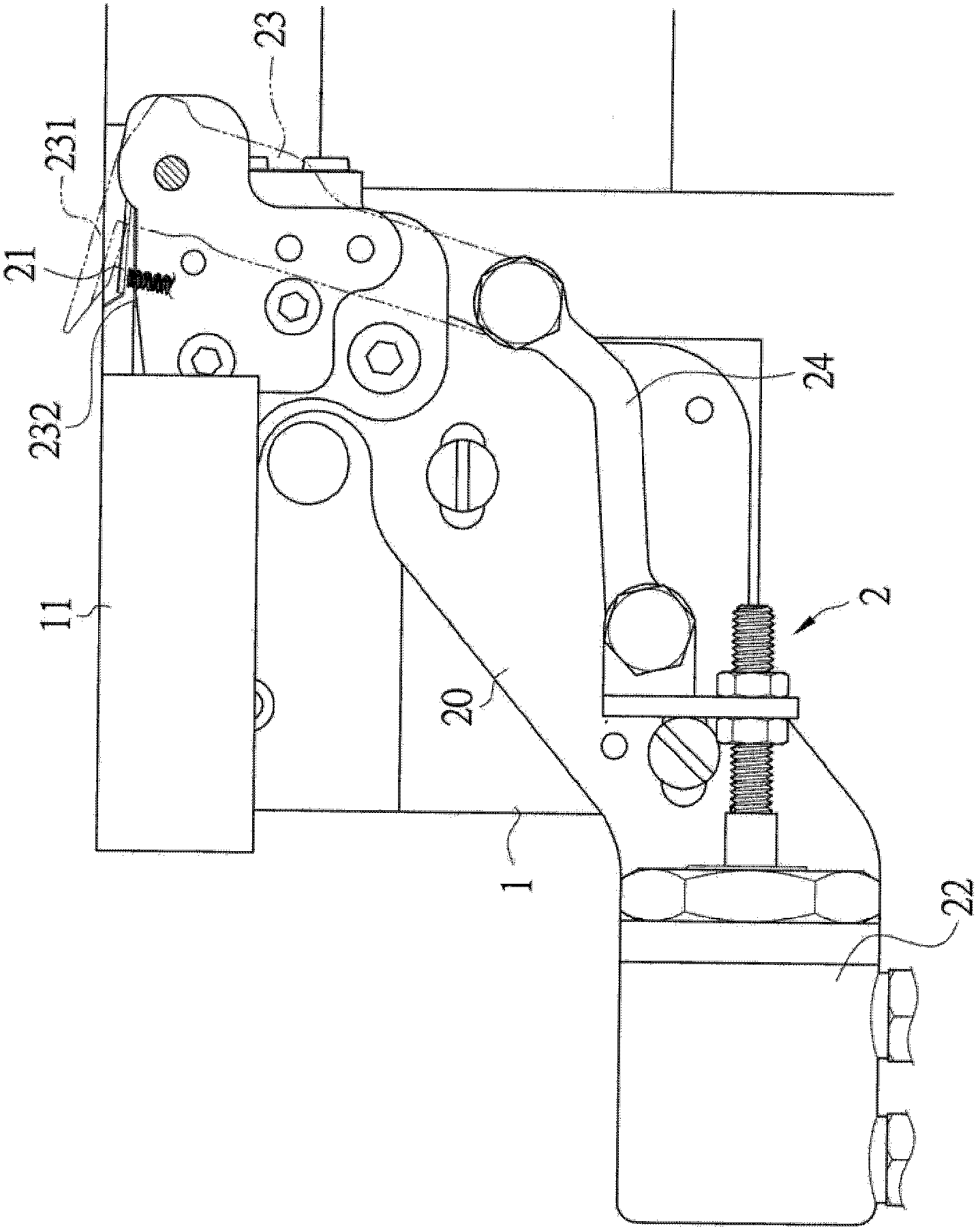

Wrapping executing structure of high-density over lock machine of cup seaming machine

InactiveCN101338494ABeautiful stitchesReduce thread consumptionThread-laying mechanismsNeedle barsHigh densityEngineering

The present invention relates to a tipping structure of a high-density edge processing machine of an overedger. The tipping structure comprises a needle (A-1), a lower bending needle (A-3) arranged on a lower bending needle rocker (A-2), an upper bending needle guide rod (A-4), a needle plate (A-6), and a forked needle (D-1) for thread poking without using stitching; the forked needle (D-1) is arranged on the upper bending needle guide rod (A-4). The beneficial effects of the present invention are that: denser, narrower and more pleasant stitching is realized based on the changes of a few spare parts, and the thread consumption is reduced.

Owner:SHANGHAI GUIYI SEWING EQUIP MFG

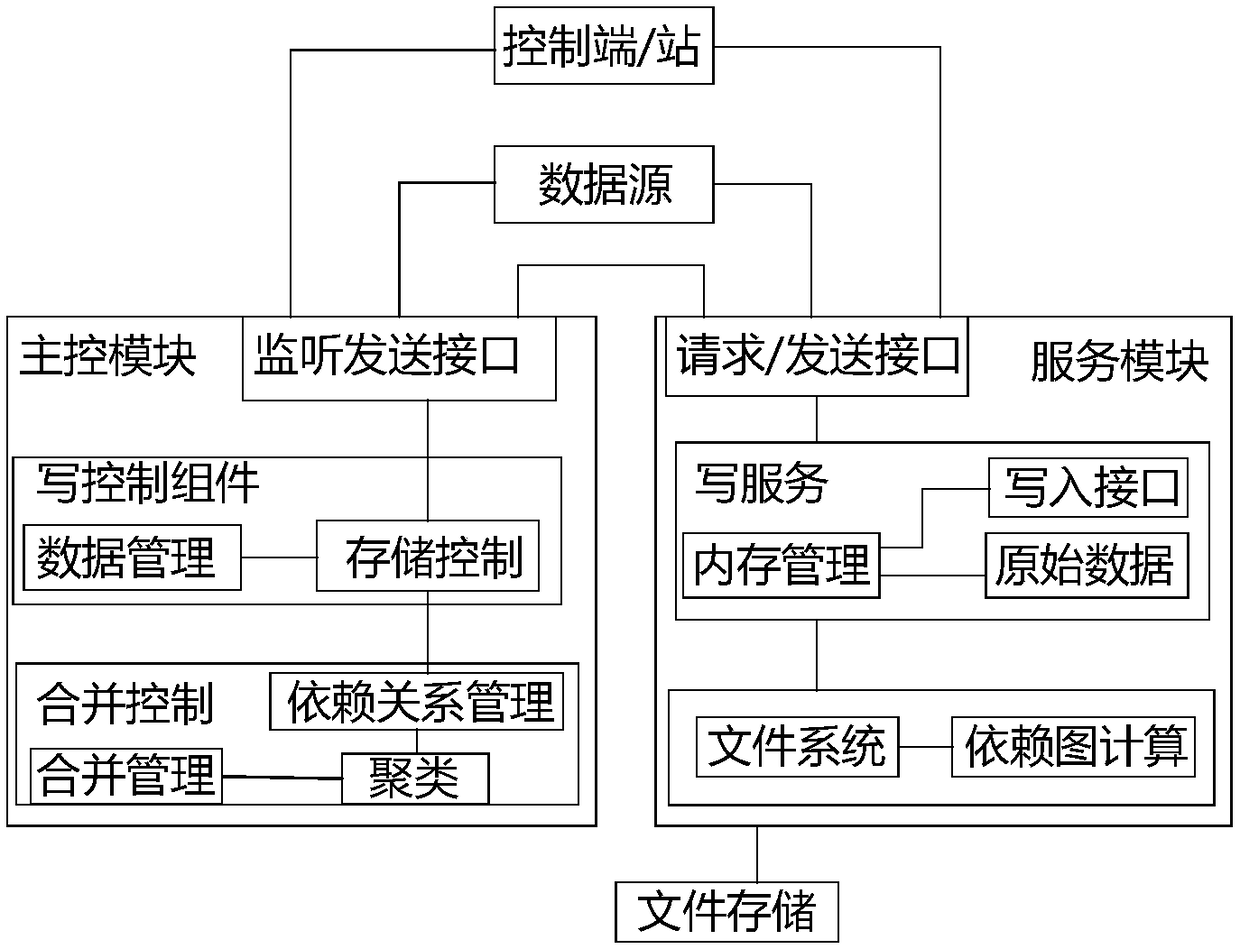

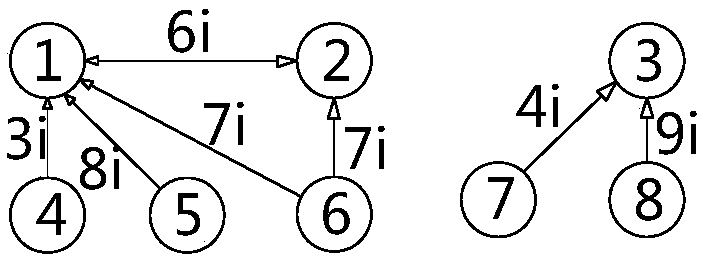

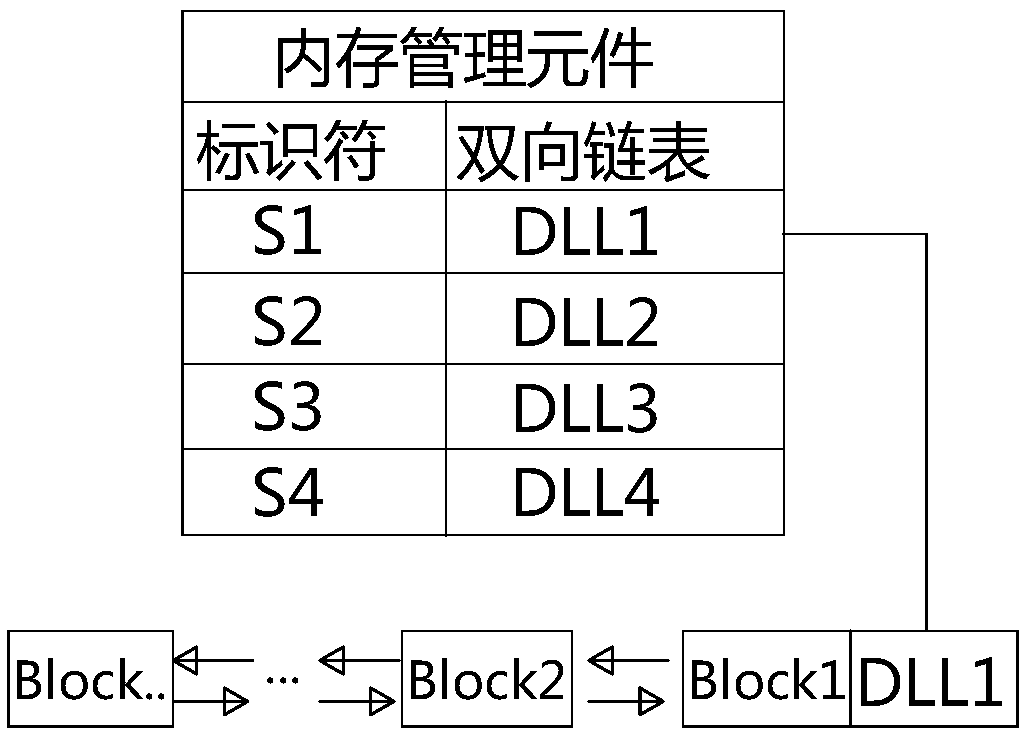

A large capacity data and service management system

ActiveCN109508317AImprove the efficiency of transmission and storageSimplify positioning difficultyFile system administrationFile access structuresData fileStructure of Management Information

The invention belongs to the technical field of data management service, in particular to a large-capacity data and service management system. The large-capacity data and service management device ofthe invention improves the efficiency of file data transmission and storage, Increases resource consumption for data operations such as queries, can significantly reduce the number of nodes in the data file, improve the efficiency of the whole system operation in the large-capacity data system, the burden of system file processing is decreased, the file association structure based on dependency relation simplifies the difficulty of file location and management, simplifies the location operation of dependency node in the process of file location and clustering, reduces the thread consumption offile data reading and writing, and improves the reading and writing speed.

Owner:陕西合友网络科技有限公司

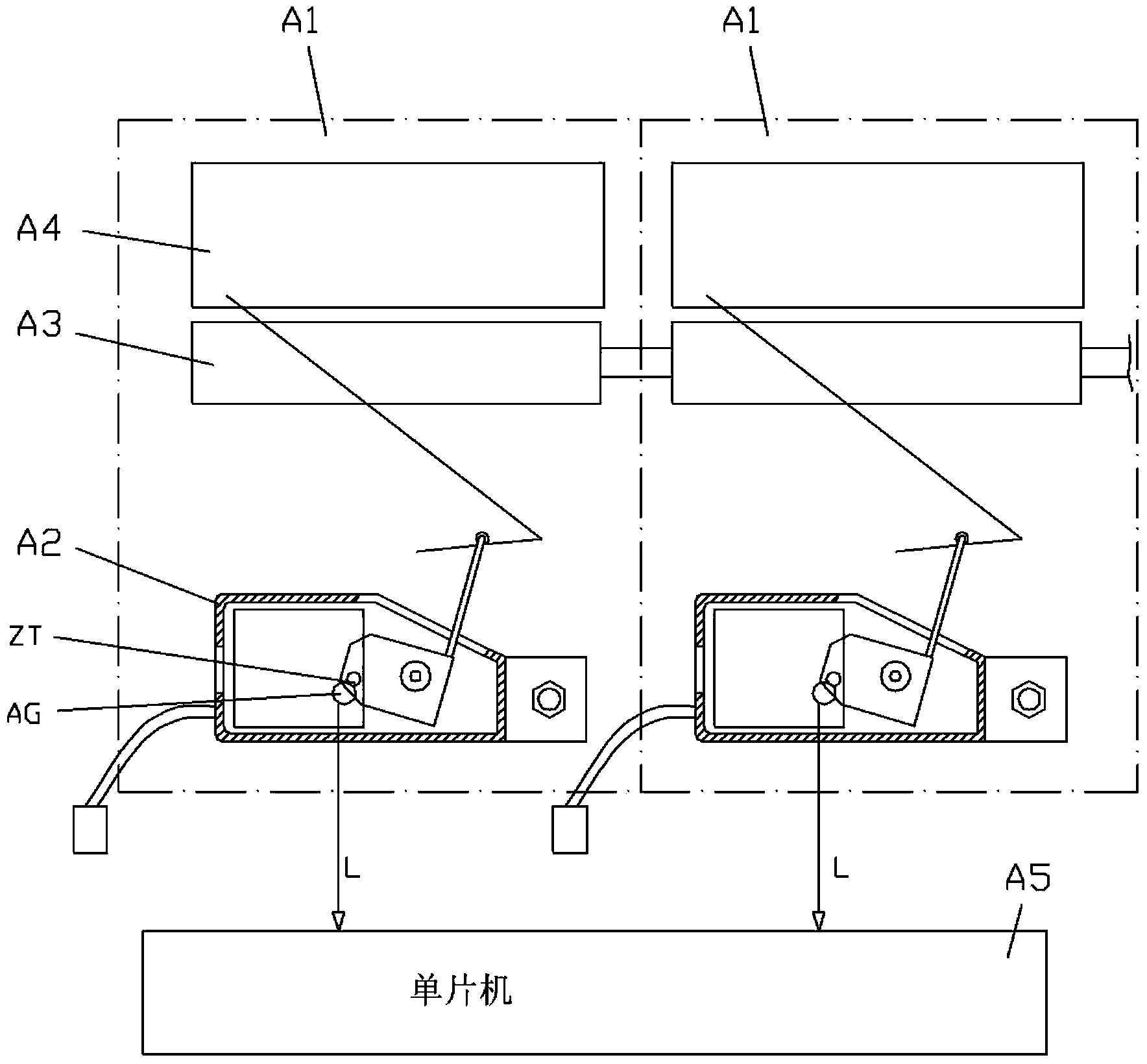

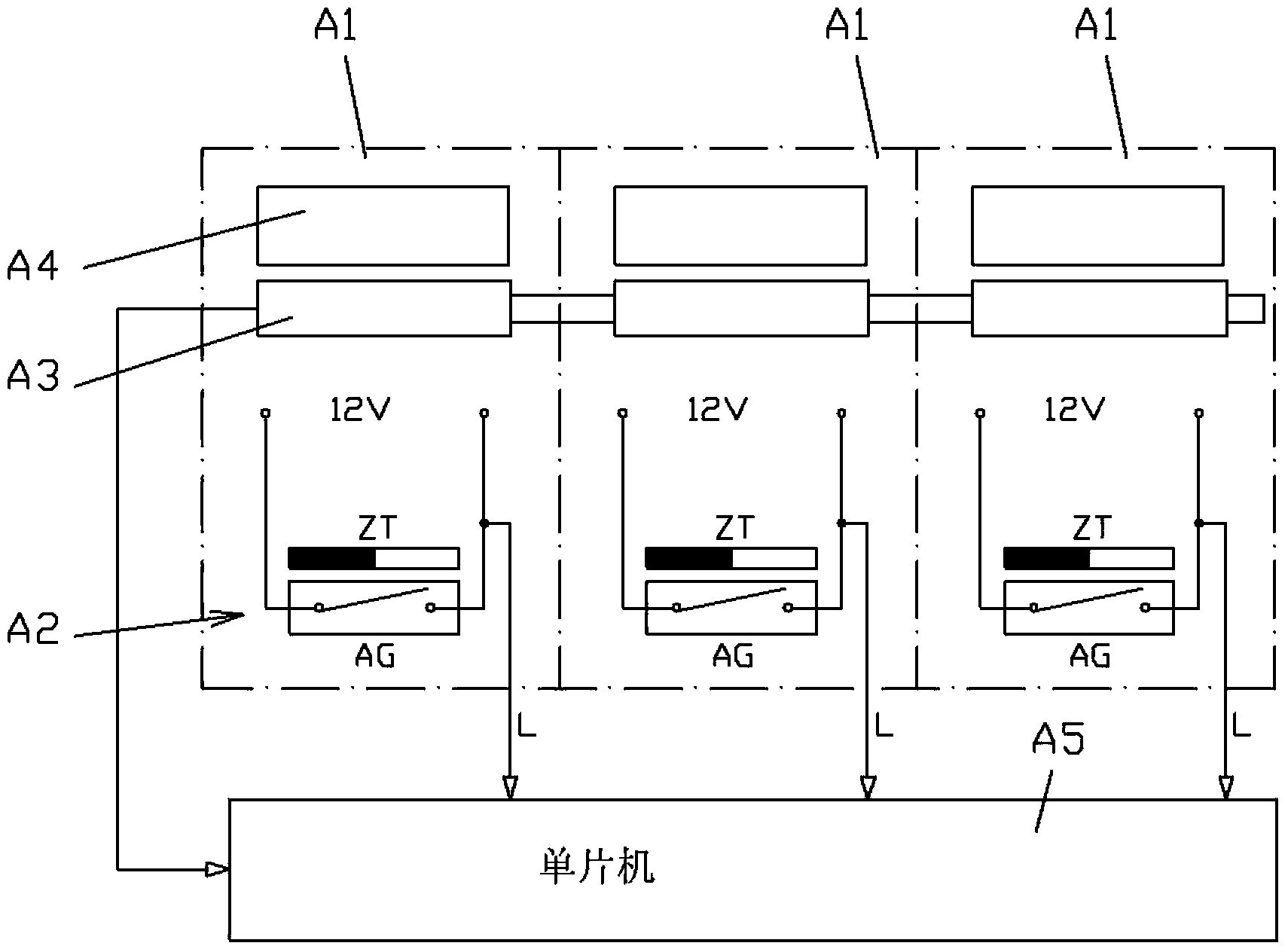

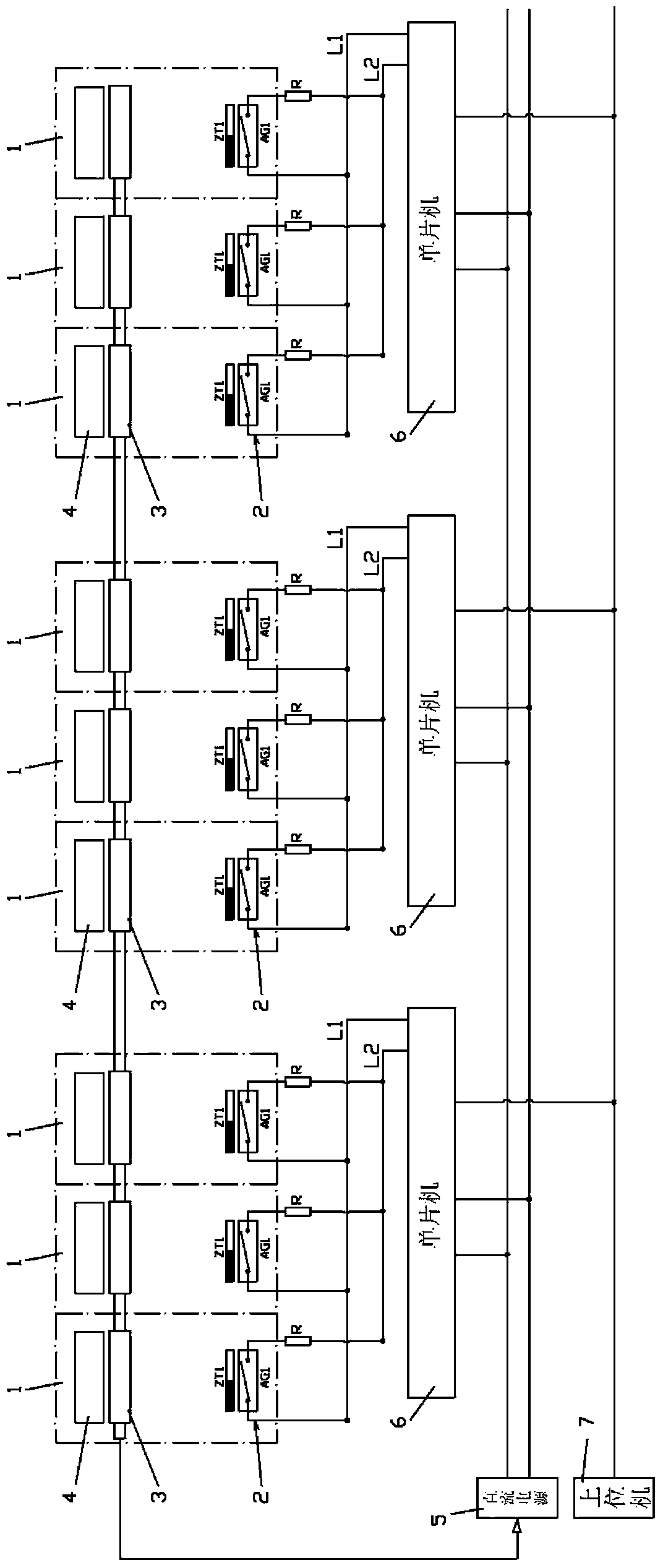

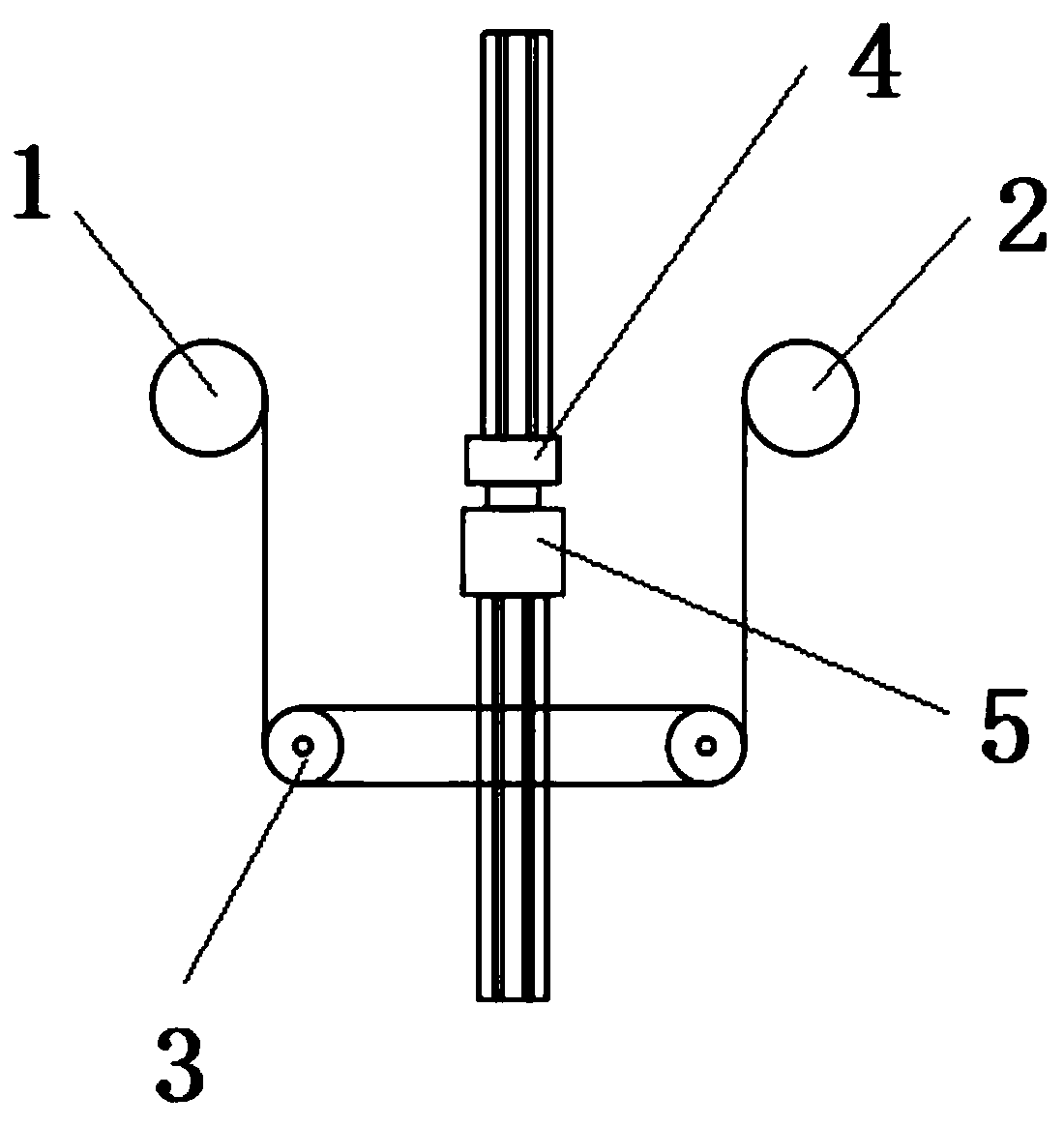

Yield statistic device of textile machine

The invention provides a yield statistic device of a textile machine. The yield statistic device of the textile machine comprises single spindle production units of the textile machine, wherein each single spindle production unit comprises a yarn detector, a winding driving roller and a wire wrapping roller; the winding driving rollers of all single spindle production units are coaxially fixed together; the wire wrapping rollers are elastically pressed onto the winding driving rollers; each yarn detector consists of a magnet and a reed pipe; a direct current power source supplies a plurality of single chip computers with power; each single chip computer is electrically connected with the reed pipe of the yarn detectors of eight to sixteen single spindle production units; a power supply loop of each reed pipe is connected in series with a resistor; the rotation speed signals of the winding driving rollers are transmitted to the single chip computers; the connection / disconnection signals of the reed pipe are transmitted to the single chip computers; the single chip computers transmit the connection signal time of the reed pipe and the rotation speed signals of the winding driving rollers to an upper computer; the upper computer determines the yarn yield of the textile machine according to the connection signal time and the rotation speed signals of the winding driving rollers. The yield statistic device of the textile machine is simpler in wiring; the wire consumption is lowered greatly; the arrangement of wires is easier.

Owner:ZHEJIANG KANGLI AUTOMATIC CONTROL TECH

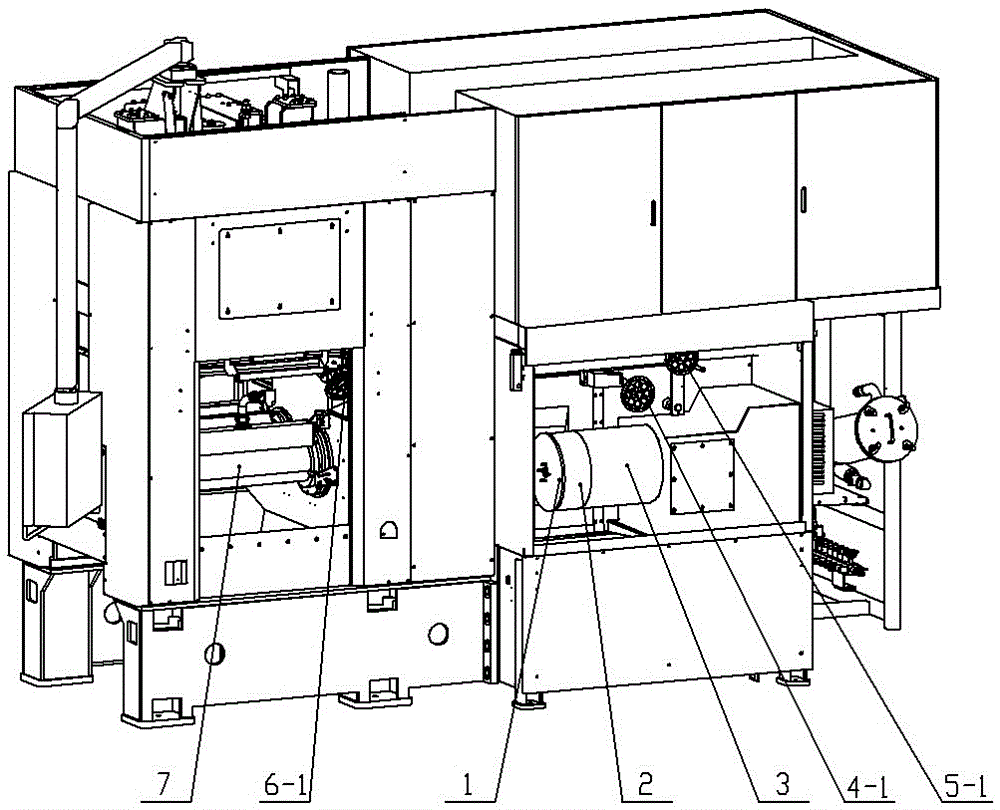

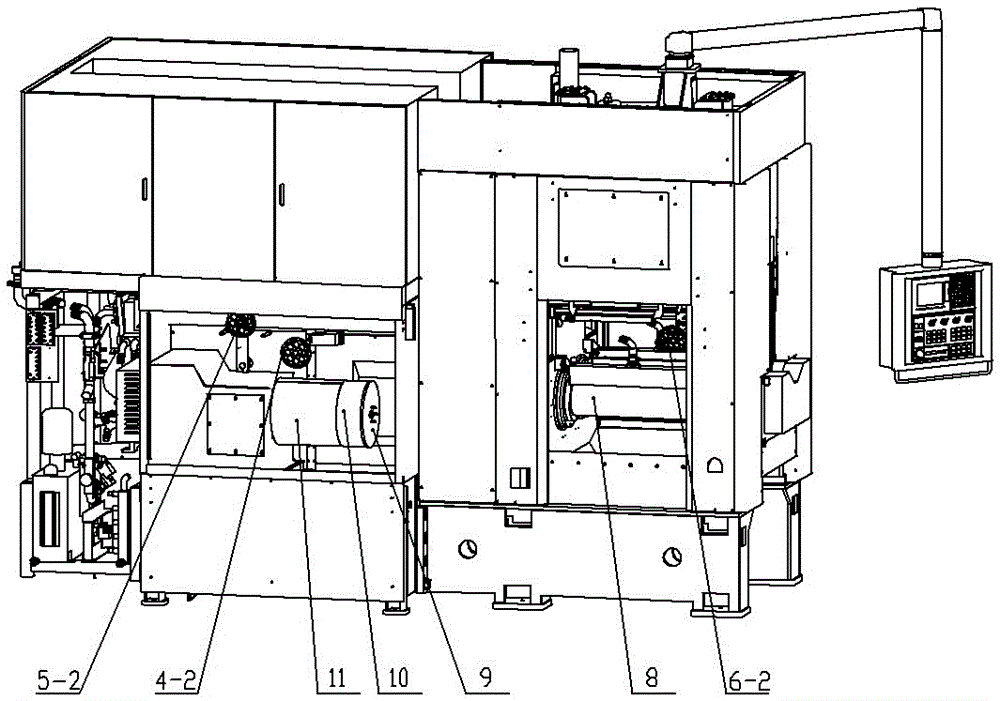

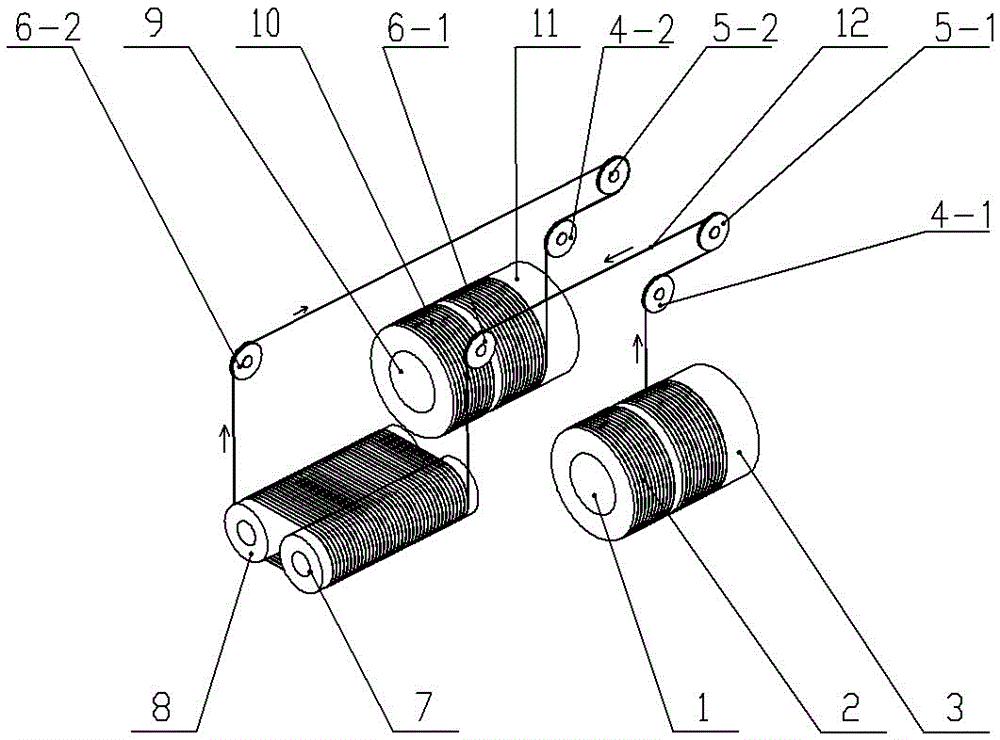

Cutting method of slicing machine with two spindles instead of three spindles

InactiveCN109291268AReduce the number of bendsReduce the risk of disconnectionFine working devicesEngineeringSemiconductor

The invention relates to the technical field of semiconductor machining. A cutting method of a slicing machine with two spindles instead of three spindles includes the following steps that (1) steel wires are winded on the slicing machine, the slicing machine comprises a driving mechanism used for driving steel wires to move, the driving mechanism comprises an unwinding roller, the two parallelly-arranged spindles and a winding roller, the steel wires sequentially pass through the unwinding roller, the two spindles and the winding roller, the two ends of the steel wires are fixed to the unwinding roller and the winding roller correspondingly, the portions, winded on the two spindles, of the steel wires form a wire net which is used for cutting silicon ingots; (2) the silicon ingots are clamped and fixed to a silicon ingot clamping mechanism, and the silicon ingot clamping mechanism is mounted on a translation mechanism; and (3) the driving mechanism drives the steel wires to move, andthe translation mechanism drives crystal ingots to move towards the wire net for down-pressing till the crystal ingots are cut into several pieces by the wire net. The slicing machine with the two spindles is adopted for cutting, the consumption of the wires which are densely distributed on the whole wire net is lowered by 15%-20%, and the wire consumption of a single silicon slice is greatly lowered.

Owner:SHANGHAI SHENHE THERMO MAGNETICS ELECTRONICS CO LTD

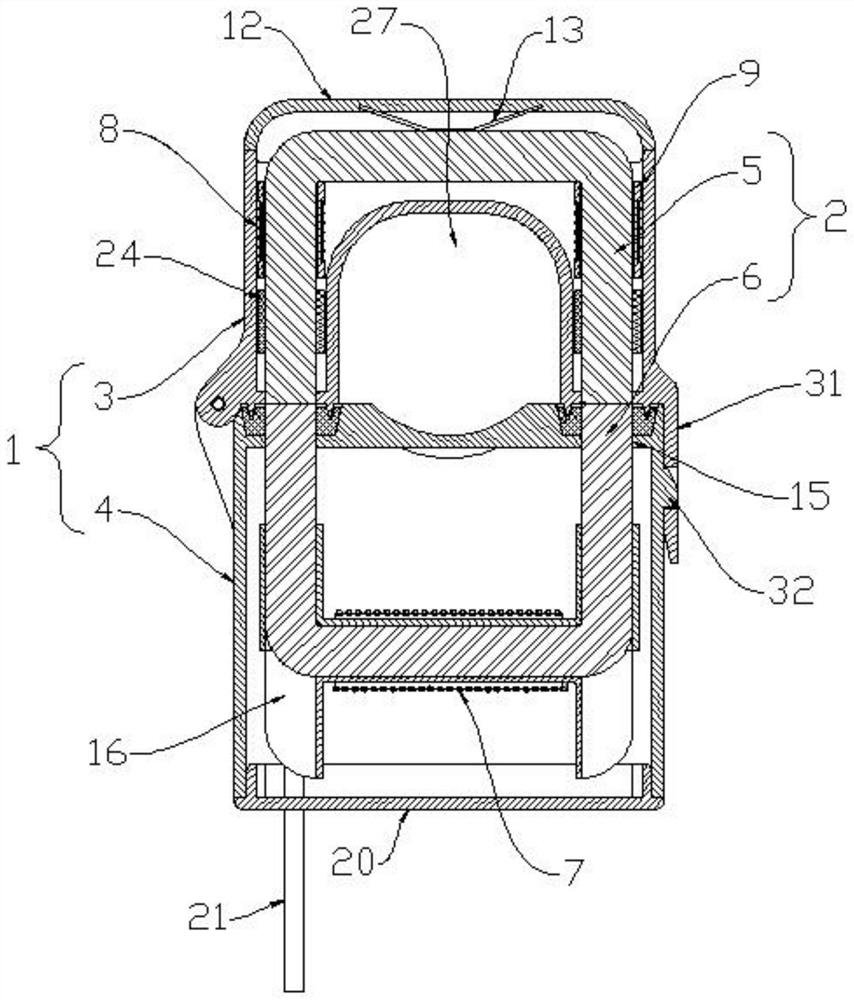

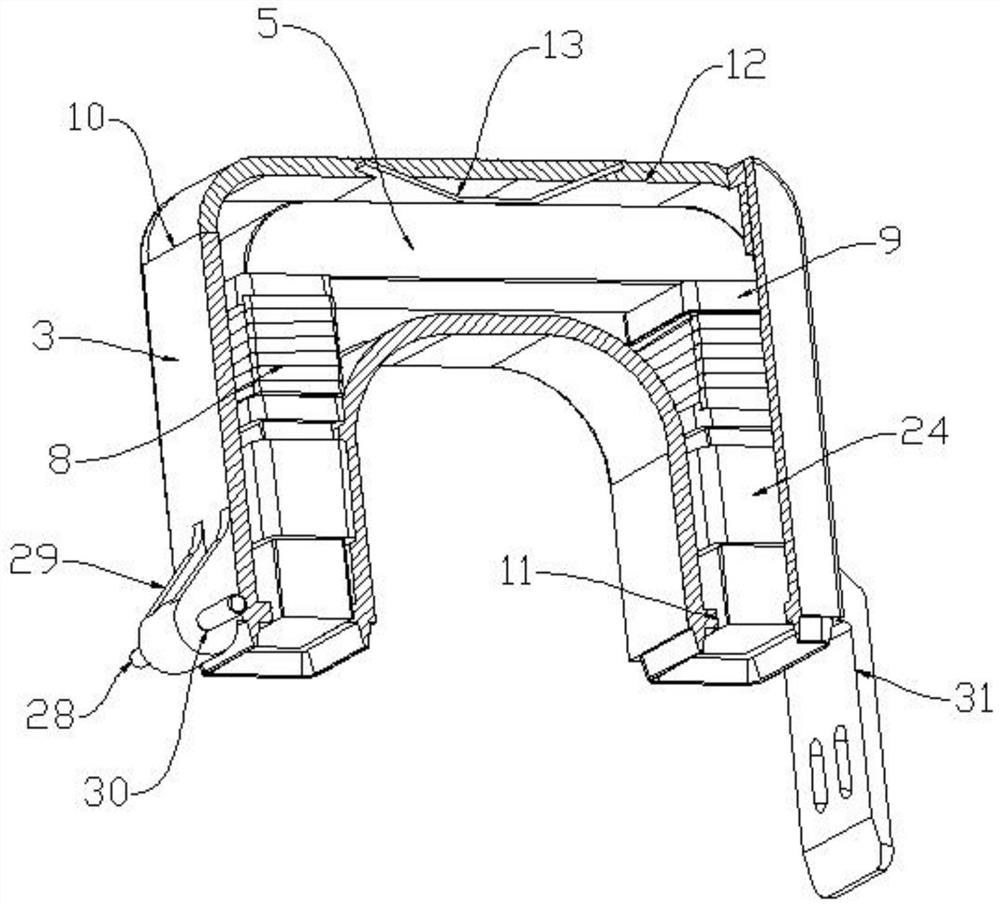

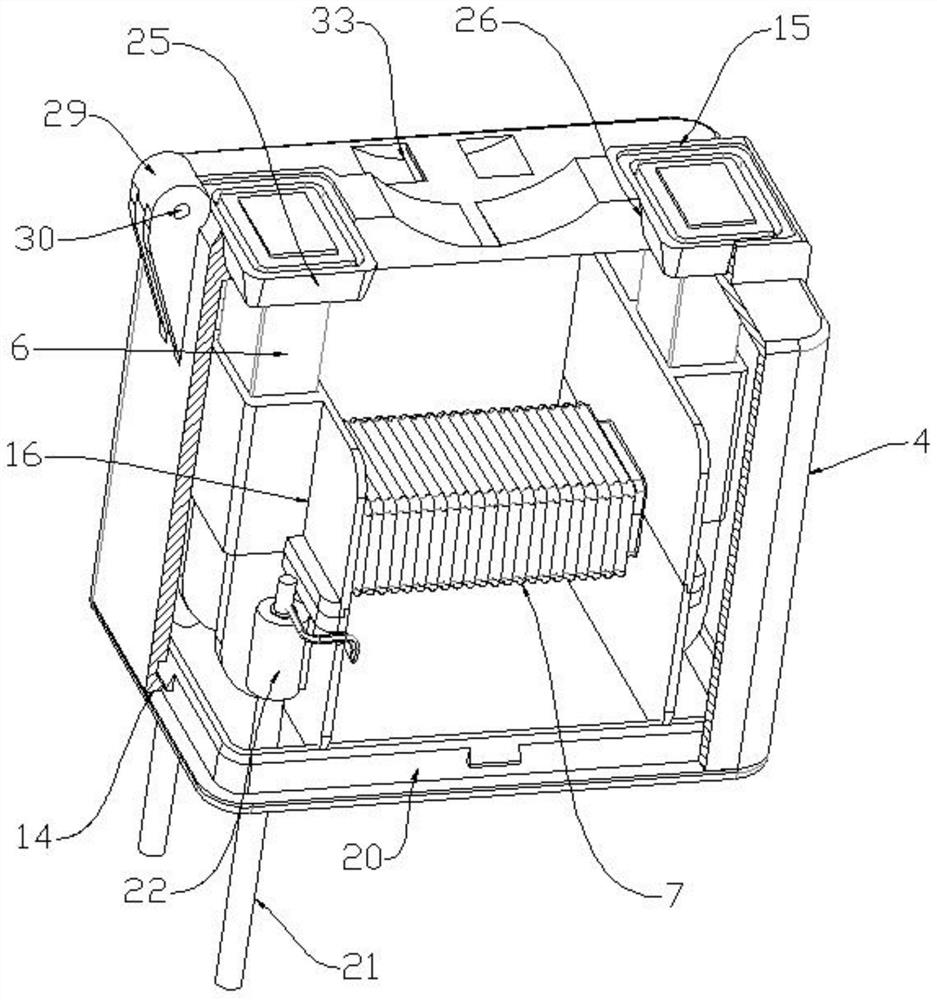

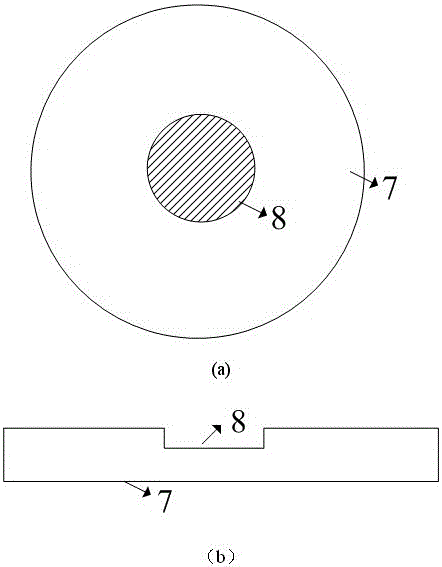

Open-type current transformer and manufacturing method thereof

InactiveCN113593814AReduce thread consumptionLower requirementTransformers/inductances casingsTransformers/inductances magnetic coresInstrument transformerMechanical engineering

The invention relates to an open-type current transformer and a manufacturing method thereof. The open-type current transformer comprises a shell and annular iron cores, wherein the shell comprises an upper shell body and a lower shell body, the upper shell body and the lower shell body are movably connected, the iron cores comprise an upper iron core accommodated in the upper shell body and a lower iron core accommodated in the lower shell body, a secondary winding is wound on the lower iron core, and a compensation winding is arranged on the upper iron core. According to the open-type current transformer, the compensation winding is arranged on the upper iron core without the secondary winding to compensate the secondary winding, so that various parameters of the secondary winding meet parameter requirements, the yield of products is improved, the requirements on iron core materials are reduced, the wire consumption of the secondary winding is reduced, the production efficiency is multiplied, and therefore, the production cost is greatly reduced, and very obvious economic benefits are achieved.

Owner:山东铂晶智能科技有限公司

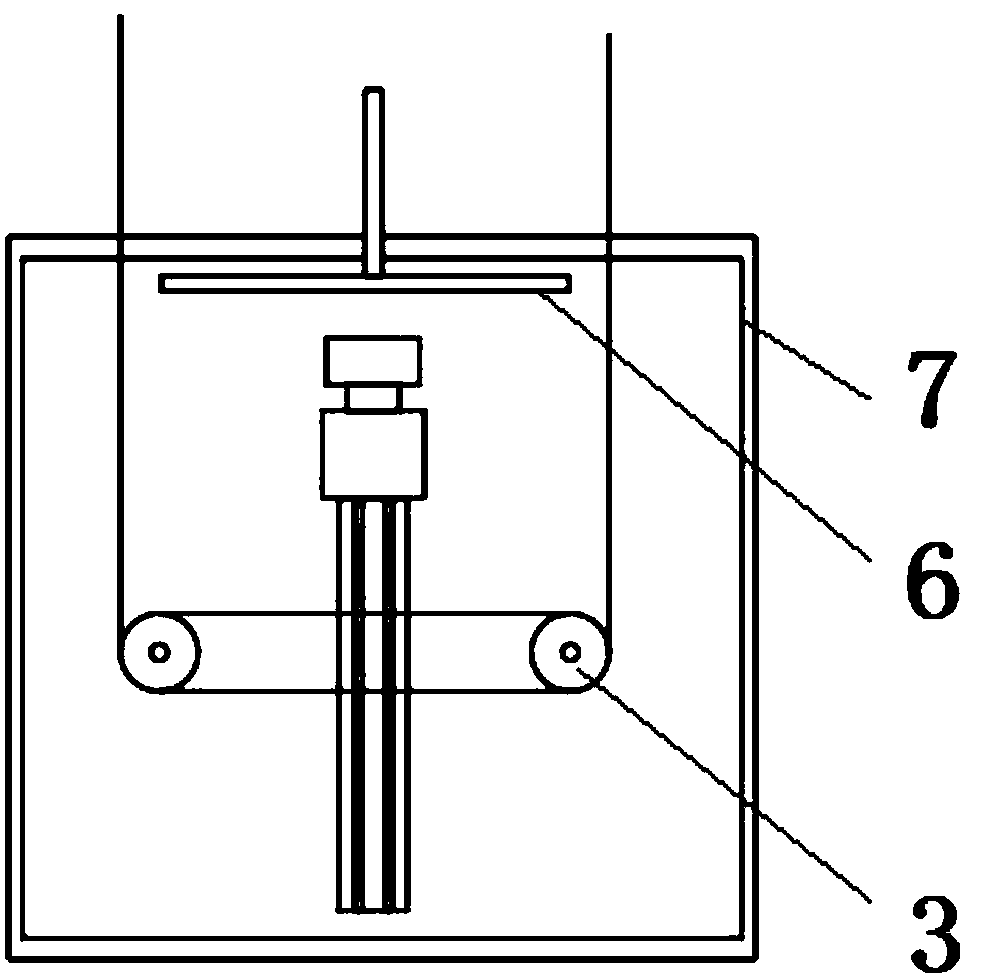

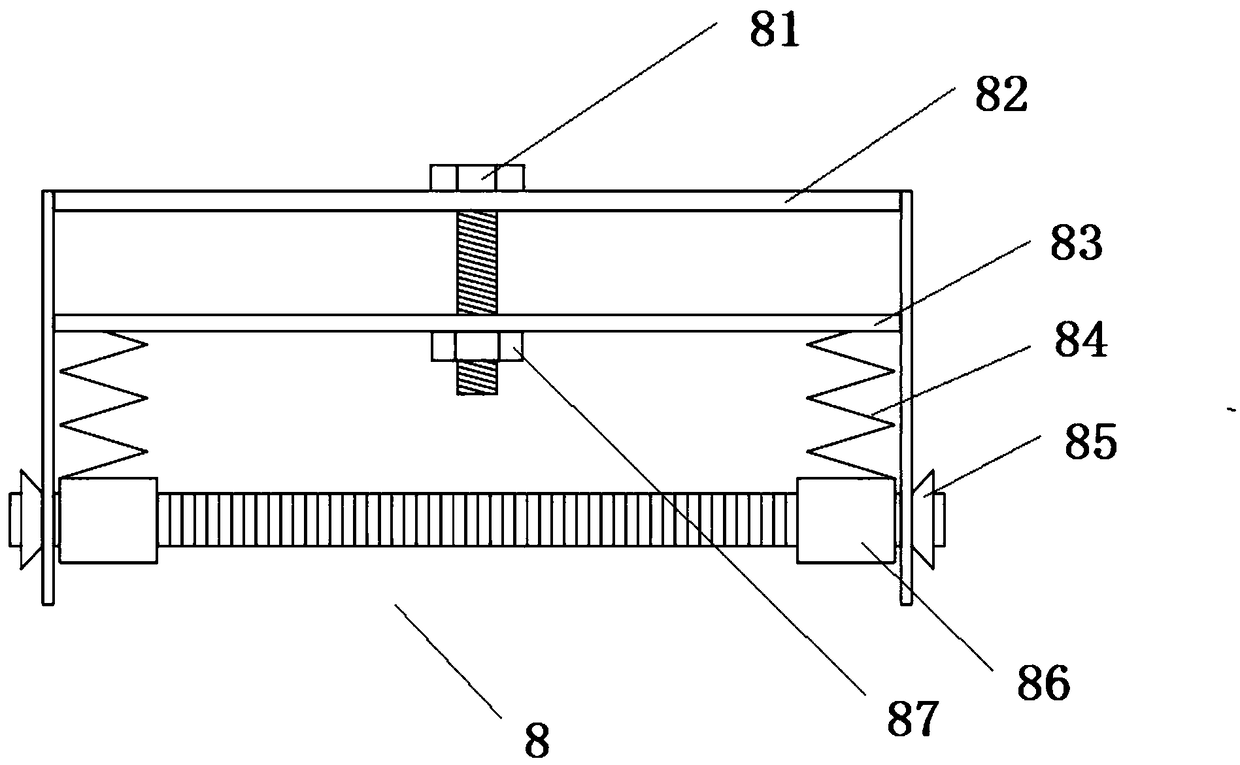

Diamond line numerical control take-up and payoff device

InactiveCN105936096AReduce frictionExtend reciprocating service lifeWorking accessoriesFine working devicesNumerical controlEngineering

The invention provides a diamond line numerical control take-up and payoff device. The device is simple in structure, friction generated between diamond lines can be effectively prevented, carborundum peeling off can be reduced, linear materials are saved, the reciprocated service life of the diamond lines is greatly prolonged, the strength and the machining efficiency of the diamond lines are improved, and therefore the silicon block slicing yield is improved; a take-up management device and a payoff management device are arranged on the two sides of one end inside a machine tool, guide wheels are arranged on the two sides of the other end inside the machine tool, a payoff routing wheel and a payoff tension wheel are arranged above the payoff management device, a take-up routing wheel and a take-up tension wheel are arranged above the take-up management device, a pay-off passing wheel is arranged at the initial end of one guide wheel, and a take-up passing wheel is arranged above the tail end of the other guide wheel; the take-up management device and the payoff management device are each of a segmented integral structure; the payoff management device comprises a payoff turn and a payoff wiring turn, and the take-up management device comprises a take-up turn and a turn-up wiring turn; and diamond lines between the guide wheels, on the payoff wiring turn and the take-up wiring turn are each arranged in a single-layer manner.

Owner:WUXI SHANGJI AUTOMATION

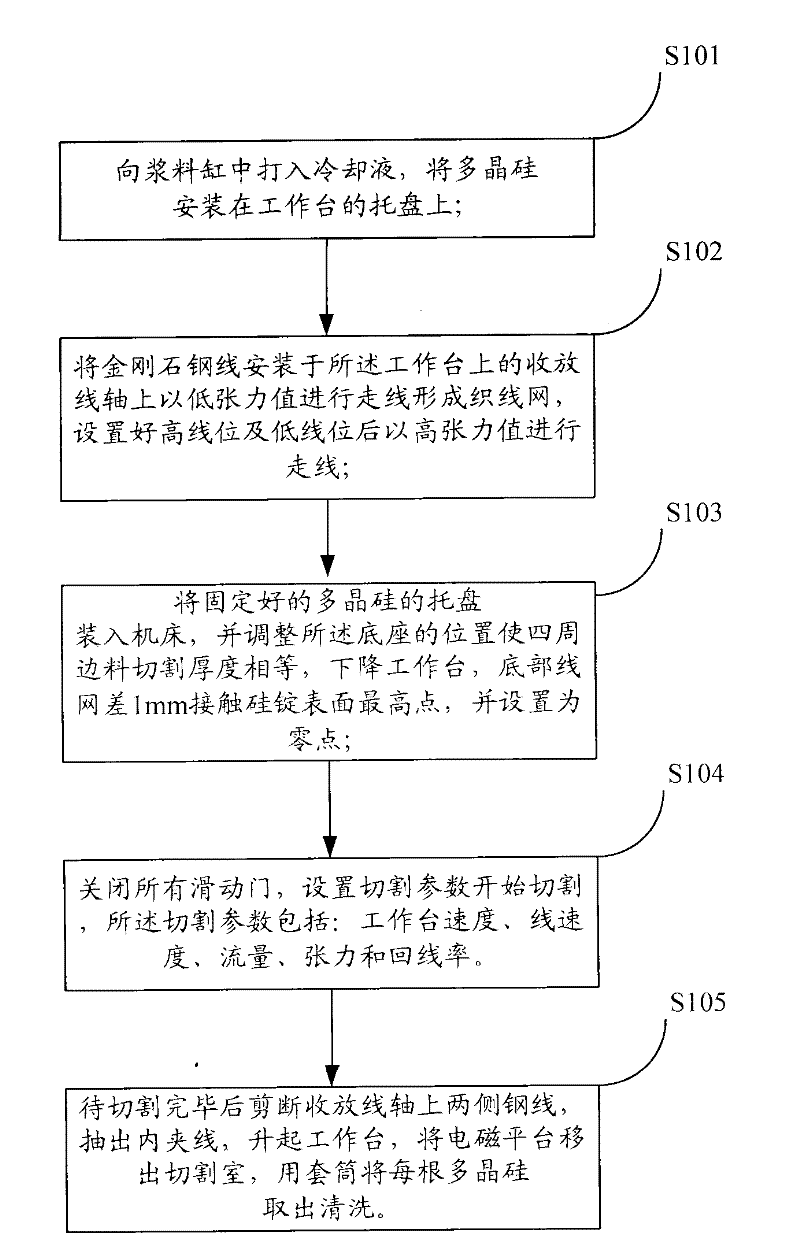

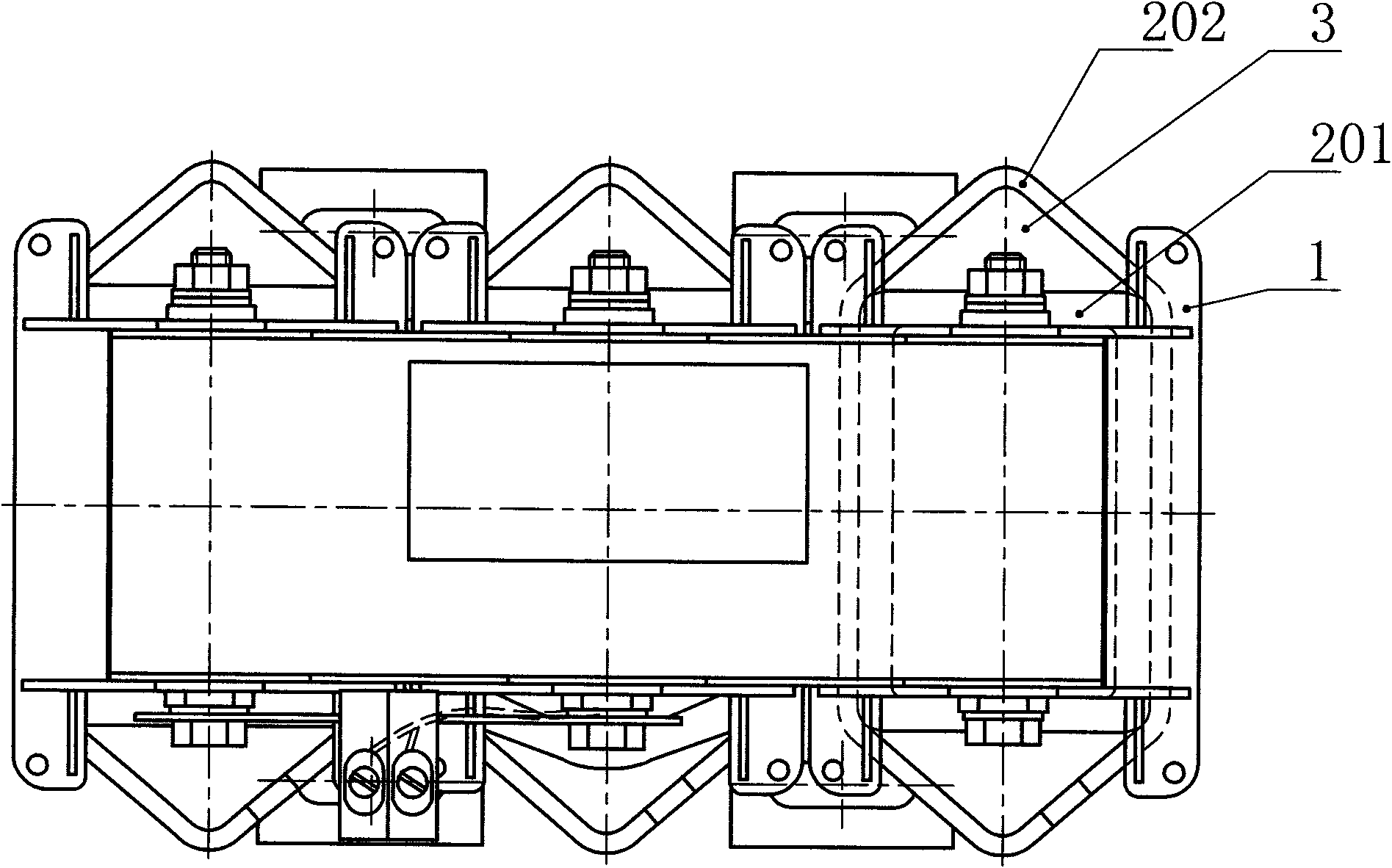

Polycrystalline silicon ingot ripping method

The invention discloses a polycrystalline silicon ingot ripping method, which comprises the following steps of: 1, pouring cooling liquid into a slurry tank and adhering a polycrystalline silicon ingot onto a tray; 2, mounting a diamond steel wire on an unwinding shaft on a workbench to form a wire net by wire laying at a low tension value, and performing wire laying at a high tension value after a high wire level and a lower wire level are set; 3, assembling the tray with the fixed polycrystalline silicon ingot into a machine, adjusting the position of the tray to ensure that the cut thicknesses of off cut on the four sides are equal, lowering the workbench down, allowing the bottom wire net to suspend at a position which is 1mm away from the highest point on the surface of the silicon ingot, and setting the position as a null position; and 4, closing all sliding doors and setting cutting parameters for cutting, wherein the cutting parameters comprise a workbench speed, a linear speed, flow, tension and a wire returning rate. In the embodiment of the invention, the diamond steel wire is adopted, so that the production efficiency of an ingot ripping process is improved, and manufacturing cost in the process is reduced.

Owner:YINGLI ENERGY CHINA

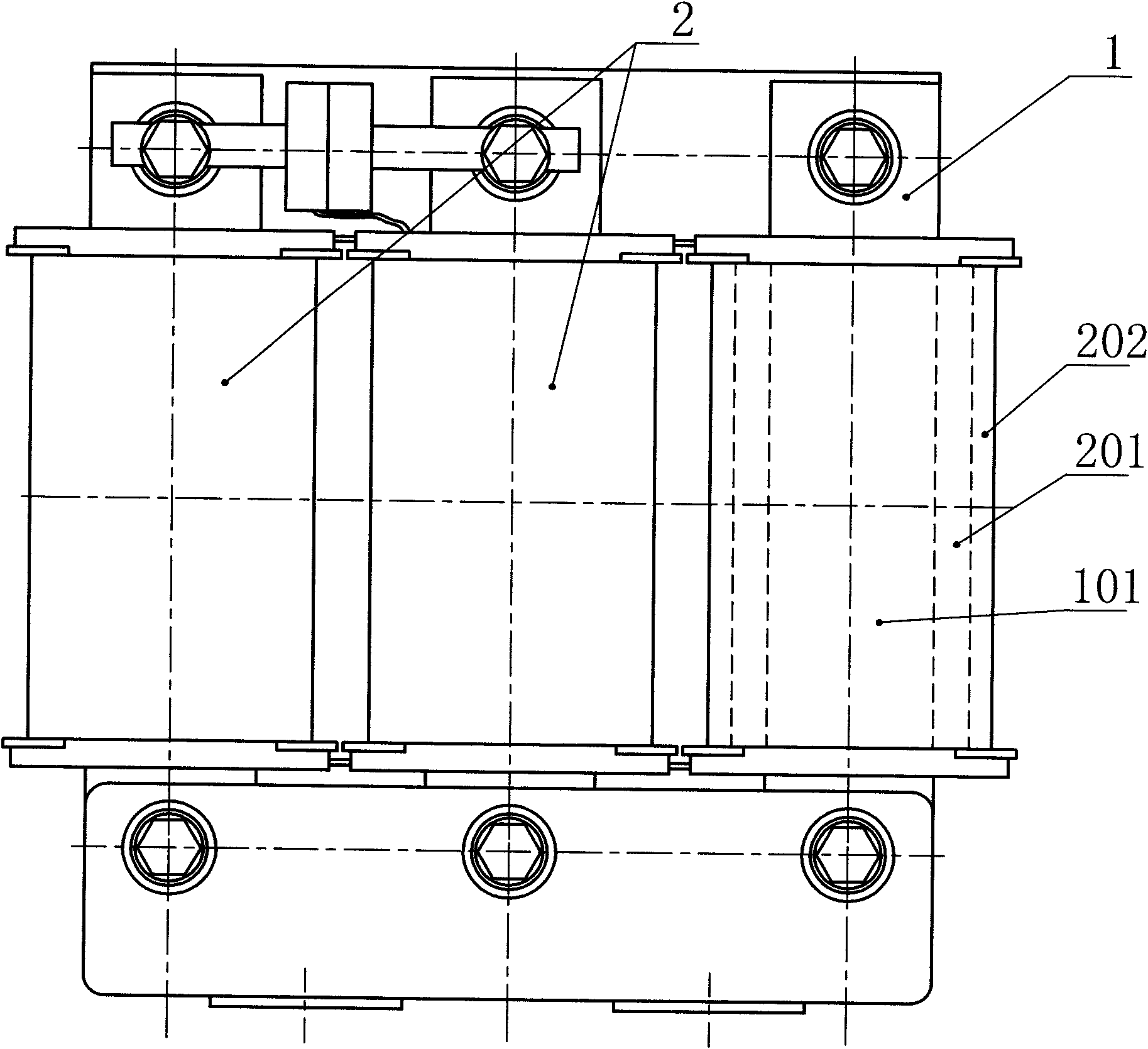

Winding type electric reactor

InactiveCN101640110AGuaranteed not to deformStrong and stable structureTransformers/inductances coils/windings/connectionsCoils manufacturePower gridEngineering

The invention discloses a winding type electric reactor in the technical field of electric reactors, which comprises an upper iron yoke, a lower iron yoke, a core column and a framework, wherein the framework is formed by connecting pulling plates; a coil is wound outside the core column on the framework; the coil comprises an inner-layer coil and an outer-layer coil; both sides of the outer-layercoil and the inner-layer coil form a triangle; and a triangular heat dissipation air passage is retained between the outer-layer coil and the inner-layer coil at both sides; When the winding type electric reactor is wound, a triangular support element is clamped between both sides of the outer-layer coil and the inner-layer coil; after winding is finished, the support element is drawn so that theheat dissipation air passage is in the triangle with stable structure; the heat dissipation air passage can not deform without an air passage support stripe between the outer-layer coil and the inner-layer coil; the triangular structure with same equivalent heat dissipating area has smaller side length than a rectangular structure and can save the coil; the winding type electric reactor has firmstructure, less coil usage and large heat dissipating area; and the invention can be used for a power grid and can improve the power running condition.

Owner:艾博白云电气技术(扬州)有限公司

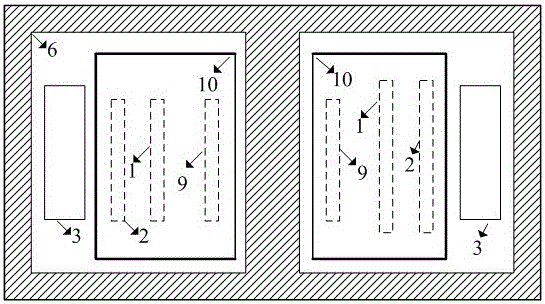

A superconducting controllable reactor

ActiveCN104425118BImprove permeabilityNo eddy current lossTransformersFixed transformers or mutual inductancesEngineeringMagnetic powder

The invention discloses a superconduction controllable reactor. Superconduction control coils, working coils, a low-temperature cryostat and a magnetic shielding iron core are respectively in a hollow cylinder shape, a high-magnetic-conductivity iron core consists of an upper magnetic conducting iron core and a lower magnetic conducting iron core, the upper magnetic conducting iron core and the lower magnetic conducting iron core are respectively in a cylinder shape and are respectively and fixedly arranged on an upper cover plate and a lower cover plate of the low-temperature cryostat, a space between the two iron cores is filled and supported by epoxy resin material, the filling height of the epoxy resin is equal to 1 / 2 to 1 / 3 of the height of each working coil, the superconduction control coils are positioned in the low-temperature cryostat, and are arranged in a coaxial or similarly coaxial way from interior to exterior, the working coils sleeve the low-temperature cryostat, and are respectively positioned in the magnetic shielding iron core, and the high-magnetic-conductivity iron core is made of iron powder cores or magnetic powder cores. The superconduction controllable reactor has the advantages that the usage amount of superconduction wires is reduced, the technical complexity of the manufacturing of the low-temperature cryostat is decreased, the additional heat load on a low-temperature system caused by the vortex loss of the high-magnetic-conductivity iron core is effectively reduced, the refrigerating cost is reduced, and the safety and stability of the low-temperature system are improved.

Owner:HUAZHONG UNIV OF SCI & TECH +1

Quilting device for four-needle quilt quilting machine

The invention discloses a quilting device for a four-needle quilt quilting machine. The quilting device comprises a machine frame, an upper beam shaft which is arranged on the machine frame and is used for controlling a needle frame and a presser foot to act, a lower beam shaft for controlling a rotating shuttle to act and a machine head assembly, wherein a gear is fixed to one end of the upper beam shaft; four bevel gears and four four-tooth cams are distributed on the upper beam shaft uniformly; the four bevel gears are meshed with four bevel pinions; the bevel gears are matched with the bevel pinions, so that the motion is transferred to a machine head shaft on a machine head; the machine head assembly comprises the machine head shaft, a roller rod, a needle frame library and a presserfoot frame library; a groove wheel, a first gear, a sliding sleeve gear and a fixed gear are fixed to one end of the lower beam shaft, and a movable crank handle is arranged at the other end of the lower beam shaft; and four second straight gears are distributed on the full length of the lower beam shaft, and the four second straight gears are matched with four spindle head rod frame bases on themachine frame. By the quilting device, quilts can be quilted quickly, quilting line traces are regular and attractive, and the efficiency and the quality of products are high.

Owner:JIHUA 3502 PROFESSIONAL GARMENT

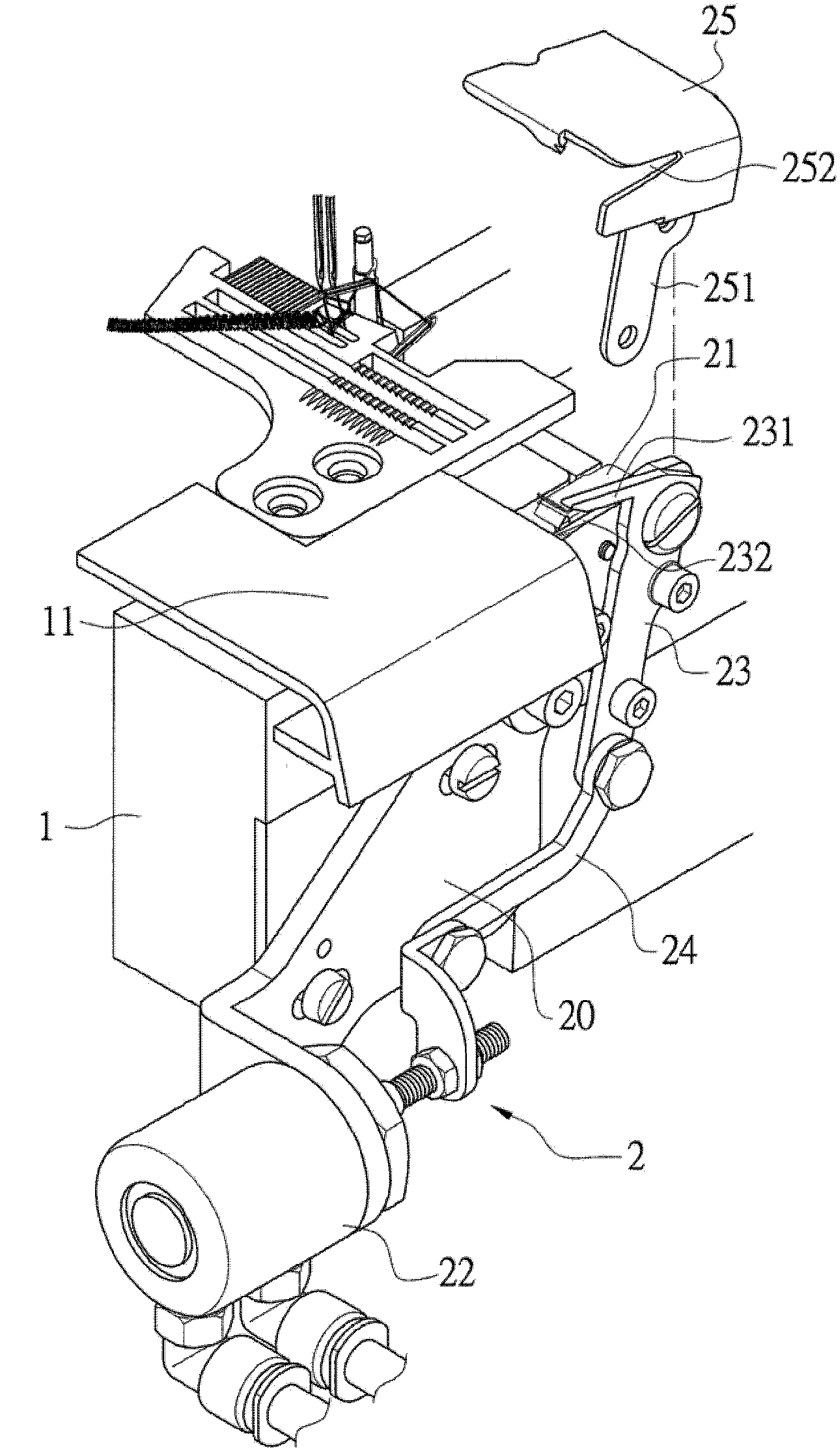

Stitch pressing and cutting device of overlock stitching machine

InactiveCN103806227AEasy to put inConvenient overlock sewing operationNeedle severing devicesMan-hourEngineering

The invention relates to a stitch pressing and cutting device of an overlock stitching machine. The stitch pressing and cutting device of the overlock stitching machine is mainly characterized in that a pressing and cutting device is arranged and connected with an overlock stitching machine table, the pressing and cutting device is provided with an elastic gripping piece on the outer side corresponding to a working platform of the overlock stitching machine, the pressing and cutting device is provided with a pushing power source corresponding to the overlock stitching machine, the pushing power source can drive a cutter to swing, a moving cutting edge is arranged at the upper end of the cutter corresponding to the outer end of the elastic gripping piece and a fixed cutting edge is arranged at a position corresponding to the moving cutting edge. Therefore, the stitch pressing and cutting device of the overlock stitching machine has the advantages that the gripping and cutting action can be automatically performed to a netted section of stitches after an object is stitched, the cut netted section can be kept to be gripped at the front of a needle plate, the overlock stitching operation can be conveniently and directly performed after the next object is put inside, not only is the stitching operation more smooth, simple and convenient, but also the man hour spent in the stitching process can be relatively reduced, the netted section of the stitches after stitching can be kept in a fixed range, the function of saving threads is achieved and the practical effect is more greatly increased in overall implementation and use.

Owner:顾飞龙

Calculation method of equal wire loss for multi-wire cutting machine

InactiveCN102626959BConsistent amount of wearEasy to wearFine working devicesEngineeringCalculation methods

An equal-line-loss computation method for a multi-line cutting machine is achieved by calculating loop rate of any one point in multi-line cutting. The loop rate of the any one point is calculated through the following formula: K=(1-beta*fw*a-2*beta*Vw*Vw) / (1+beta*fw*a), wherein r is the radius of a cutting material, p is a main roll groove distance, C is set abrasion area, a is linear acceleration, Vw is linear speed, L is the length of the cutting material, h is cutting depth, fw is inlet line quantity, k is loop rate, and V(h) is a function of the feeding speed and the cutting depth. Beta=alpha*V(h)*L*C / (fw*p*a*Vw) / 30. Alpha= sqrt (r*r-(r-h)*(r-h)). The V(h) is set before machining. The equal-line-loss computation method guarantees that a line is scraped until enough area is cut, namely abrasion loss is uniform, optimum abrasion loss is achieved, and a use amount of lines is saved.

Owner:TIANJIN UNIV OF TECH & EDUCATION TEACHER DEV CENT OF CHINA VOCATIONAL TRAINING & GUIDANCE +1

Adaptive Adjustment Method of Transmitter Position for Improving the Interoperability of Electric Vehicle Wireless Charging Coils

ActiveCN109774520BReduce manufacturing difficultyReduce thread consumptionCharging stationsCircuit arrangementsControl engineeringElectric vehicle

The invention discloses an adaptive transmitting end position adjusting method for improving the interoperability of electric vehicle wireless charging coils. In the method, a controller, a transmitting end and a receiving end are adopted to establish a system circuit model, a coupling coefficient meeting charging requirements in interoperation of a rectangular coil and a DD coil and a coupling coefficient obtained by calculation are acquired to adjust the position of the transmitting end, and then the coupling coefficient in the XY direction infinitely approaches the coupling coefficient meeting the charging requirements in interoperation of the rectangular coil and the DD coil. Based on a variable-step-size 'disturbance-observation' algorithm, no complicated mathematical calculation is needed, no extra communication circuit is needed, the coupling coefficient can be predicted simply by measuring transmitting end or ground equipment parameters and serves as a basis for position adjustment, the system structure is simplified, and the disturbance of a strong magnetic field to wireless communication is avoided.

Owner:HARBIN INST OF TECH

Isovolumetric cutting speed calculation method for multi-line cutting machine

InactiveCN102700015BConsistent amount of wearEasy to wearFine working devicesEngineeringCalculation methods

The invention discloses an isovolumetric cutting speed calculation method for a multi-line cutting machine. The isovolumetric cutting speed calculation method for the multi-line cutting machine is realized by solving a feeding speed of any positional point during the multi-line cutting. The feeding speed of any point is obtained according to the formula as follows: F=C*P / [(R<2>-(R-h)<2>)<1 / 2>*(dw+2*d)*L*K], wherein F is the feeding speed, C is a cutting volume in a unit time, P is a slot pitch of a main roller, R is a radius of a cut material, h is a cutting depth, dw is a diameter of a cutting line, d is a diameter of a cut abrasive material, L is a length of the cut material and K is a safety coefficient. A maximum feeding speed Fmax is set and if the feeding speed F of one positional point, calculated through the formula, is greater than the Fmax, the Fmax is taken as the feeding speed. The isovolumetric cutting speed calculation method for the multi-line cutting machine, disclosed by the invention, has the advantages of guaranteeing the volume amount removed in a unit time as the setting value, adjusting the cutting speed F according to the slot pitch P of the main roller, the cutting position h, the cutting length L, the diameter d of the cut abrasive particle and the like and improving processing efficiency.

Owner:TIANJIN UNIV OF TECH & EDUCATION TEACHER DEV CENT OF CHINA VOCATIONAL TRAINING & GUIDANCE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com