Patents

Literature

31results about How to "No eddy current loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

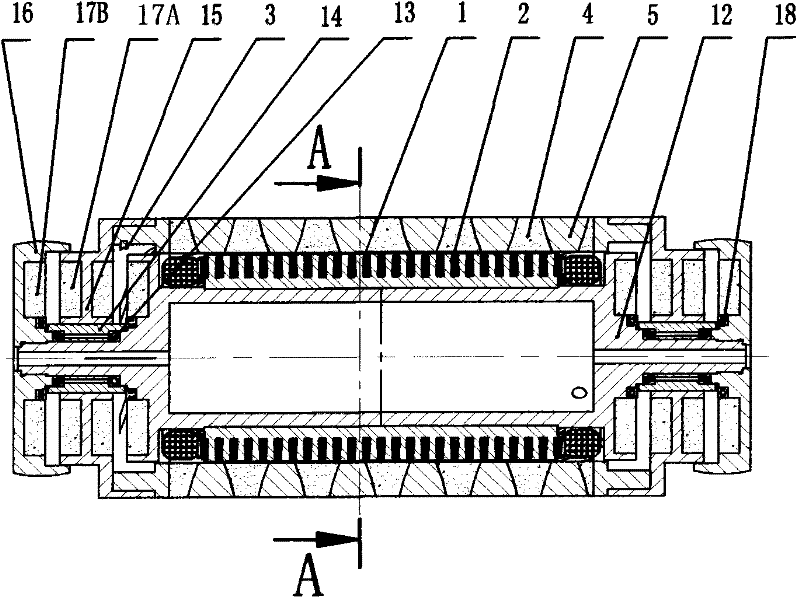

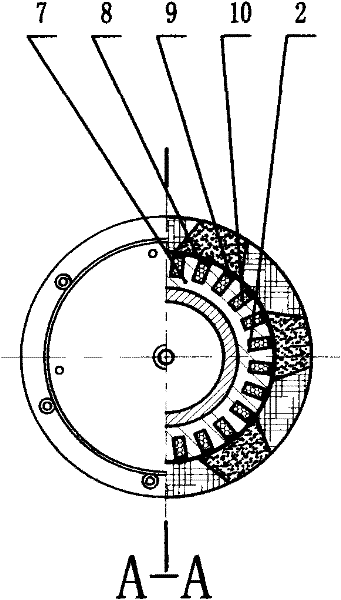

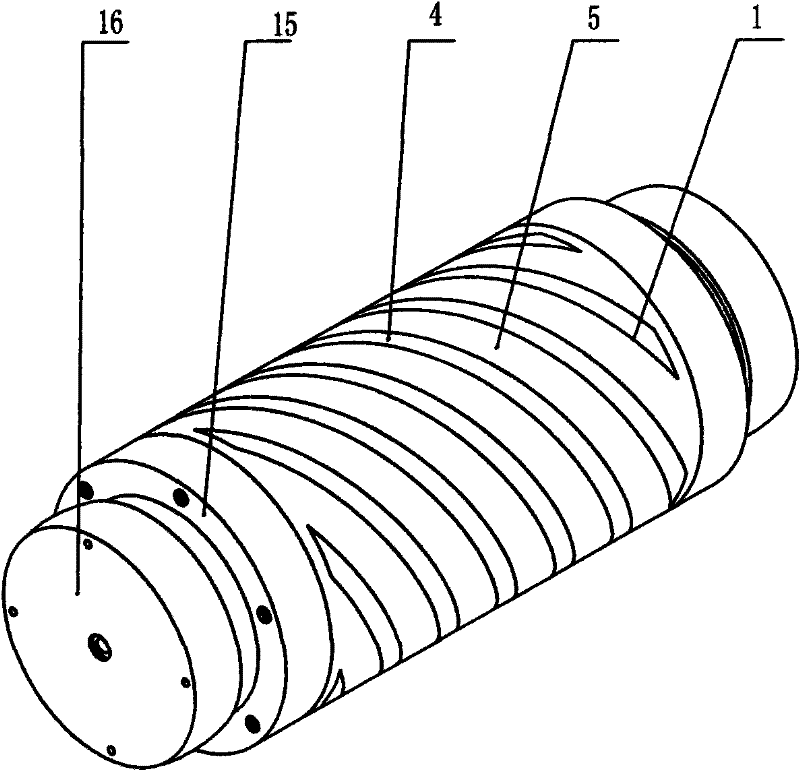

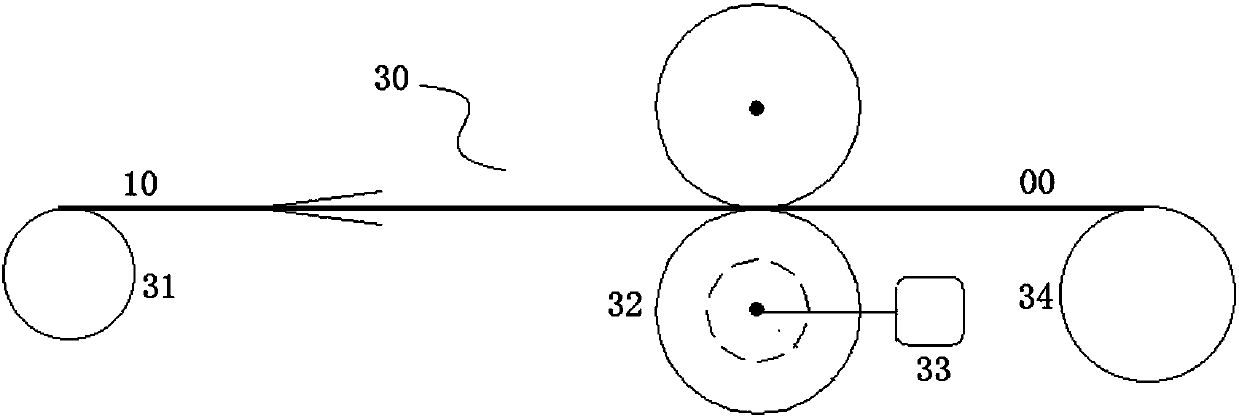

Permanent magnet motor with external spiral rotor and permanent magnet suspension wheeltrack vehicular access system

InactiveCN102447365AEfficient use ofCompact structureDynamo-electric brakes/clutchesMagnetic circuit rotating partsRailway passenger carPermanent magnet motor

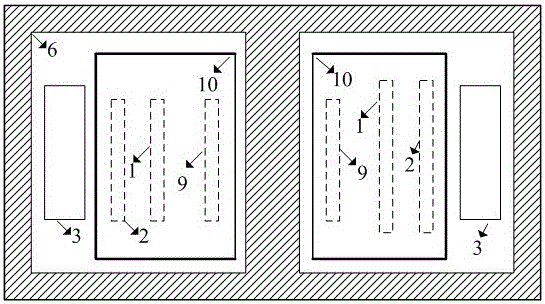

The invention provides a permanent magnet motor with an external spiral rotor and a permanent magnet suspension wheeltrack vehicular access system. The external part of the motor is provided with the external spiral rotor, so that larger output power is obtained with the same external diameter. The permanent magnet motor with the external spiral rotor is applied to efficient drive and efficient power generation recovery brake kinetic energy of a magnetic suspension train, can be used for driving a permanent magnet suspension wheeltrack subway, a permanent magnet suspension vehicle and a four-channel elevated railway passenger car, and is used for elevated permanent magnet suspension towing machine to convey cars or trucksin an enegy saving way. Due to the adoption of the elevated bidirectional four-channel permanent magnet suspension wheeltrack high-speed rail, the constructing cost of a permanent magnet suspension high-speed rail can be lower than that of the existing high-speed rail, and a realistic significance is realized on energy conservation of transportation sector and national energy-saving emission reduction.

Owner:刘忠臣

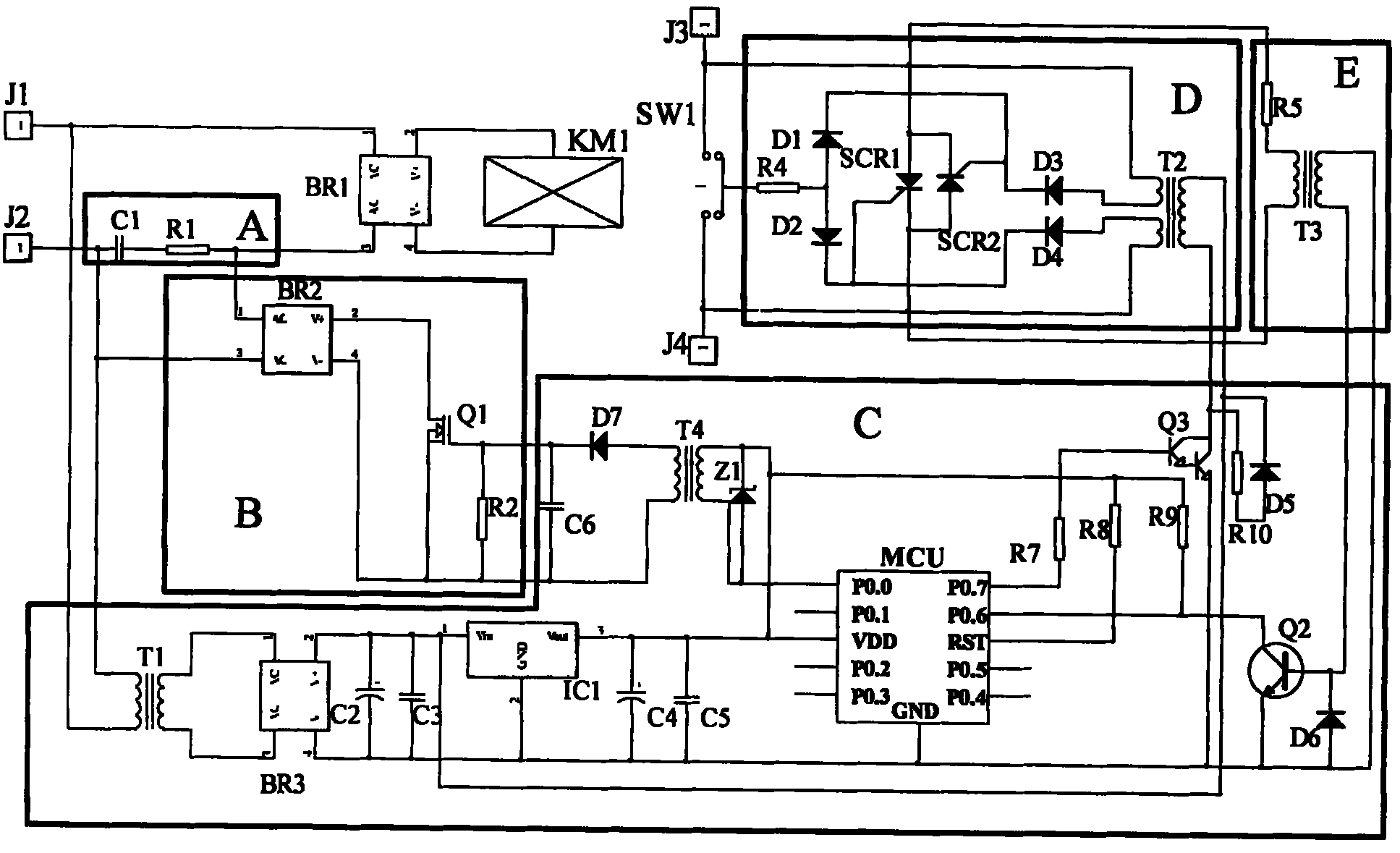

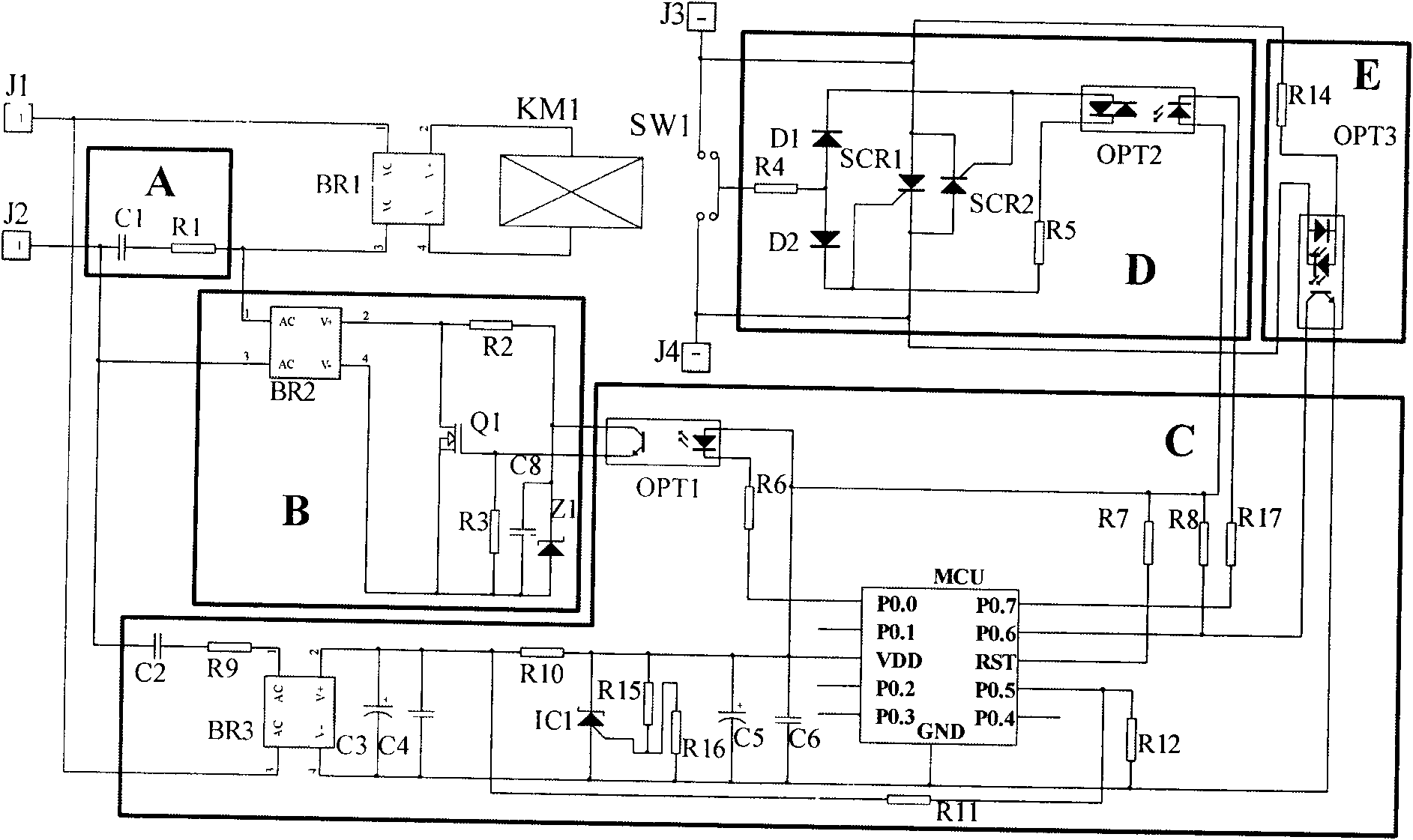

Composite contactor

InactiveCN101951249AShort on-timeStrong anti-interferenceElectronic switchingRelaysCapacitanceElectricity

The invention relates to a composite contactor which belongs to the field of electric switches, in particular to a contactor suitable for powering on and off a power capacitor. In the invention, an input power supply is subjected to current limit by a capacitor voltage drop circuit and rectification by a rectifying circuit and used for supplying power to a control coil of the contactor; the capacitor voltage drop circuit is connected with a starting electronic switch in parallel, the control end of the starting electronic switch is connected to a control circuit, and the control circuit is connected with a working power supply; a voltage zero passage detection circuit and a controllable silicon circuit are connected to two ends of a mechanical contact of the contactor in parallel; and the output end of the voltage zero passage detection circuit and one on control end of the controllable silicon circuit are connected to the control circuit, while the other on control end of the controllable silicon circuit is connected to a contact bridge of the contactor. The control coil of the composite contactor adopts a capacitor voltage drop direct current working manner, and the controllable silicon circuit adopts a design with multiple control ends, so that the composite contactor has the advantages of environmental protection, energy saving, strong anti-jamming, power on work, power on with voltage zero passage, power off with current zero passage, short controllable silicon on time, high reliability and long operation service life.

Owner:GUANGZHOU JINSHI ELECTRONICS

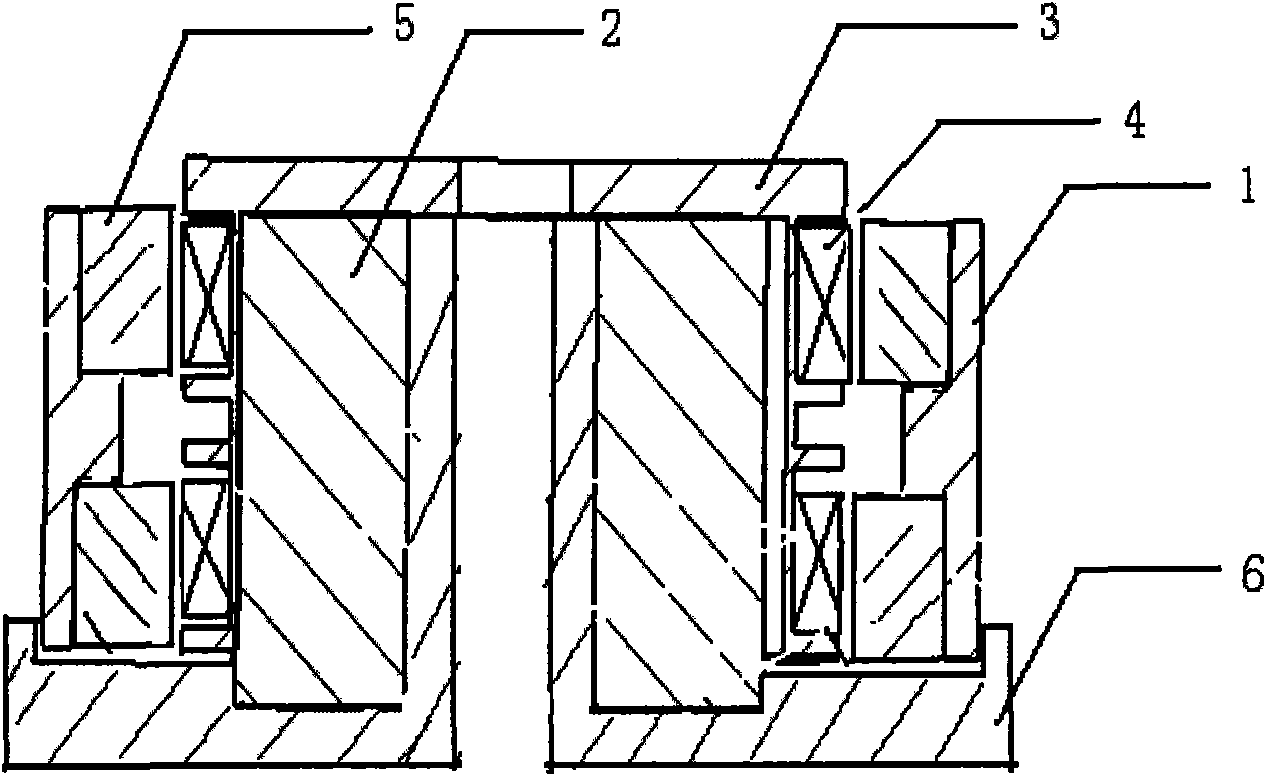

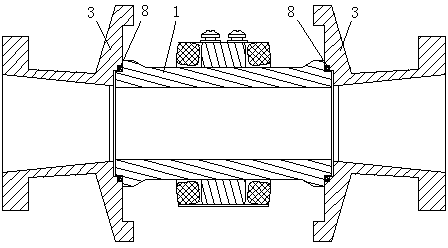

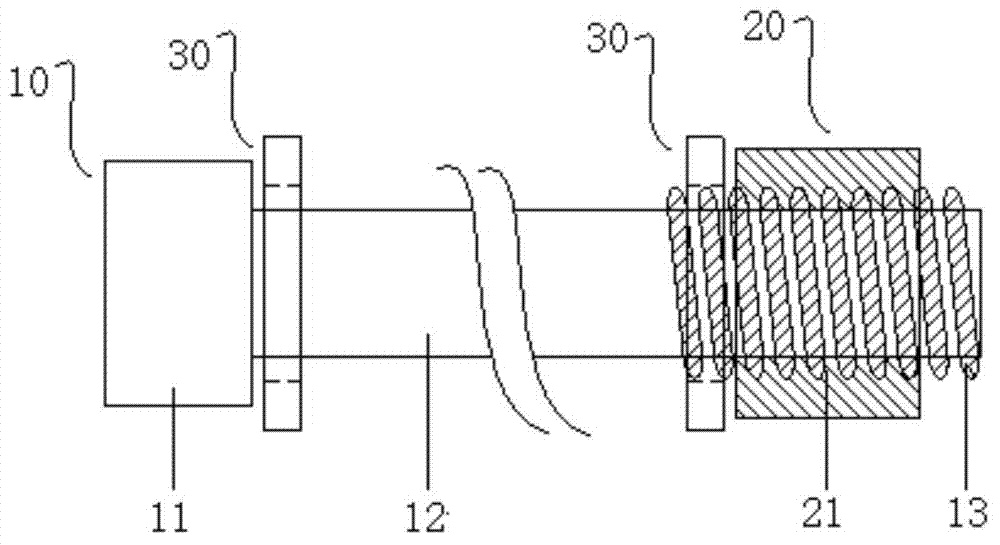

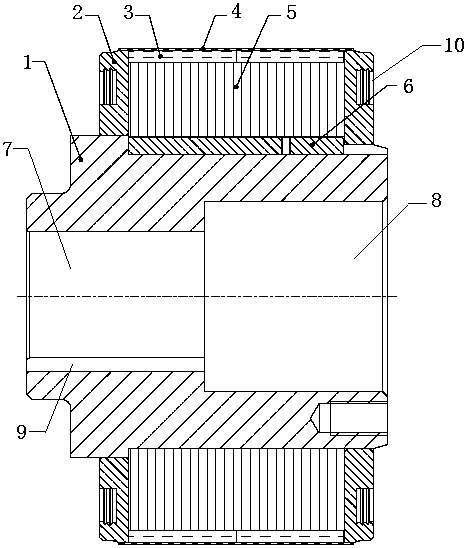

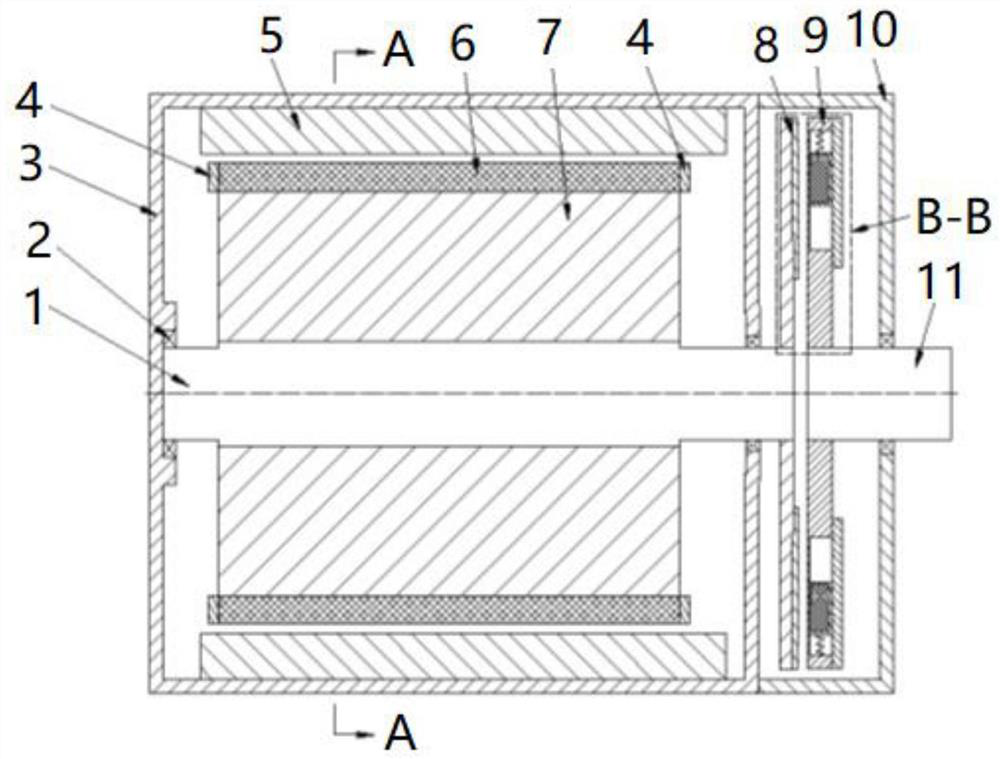

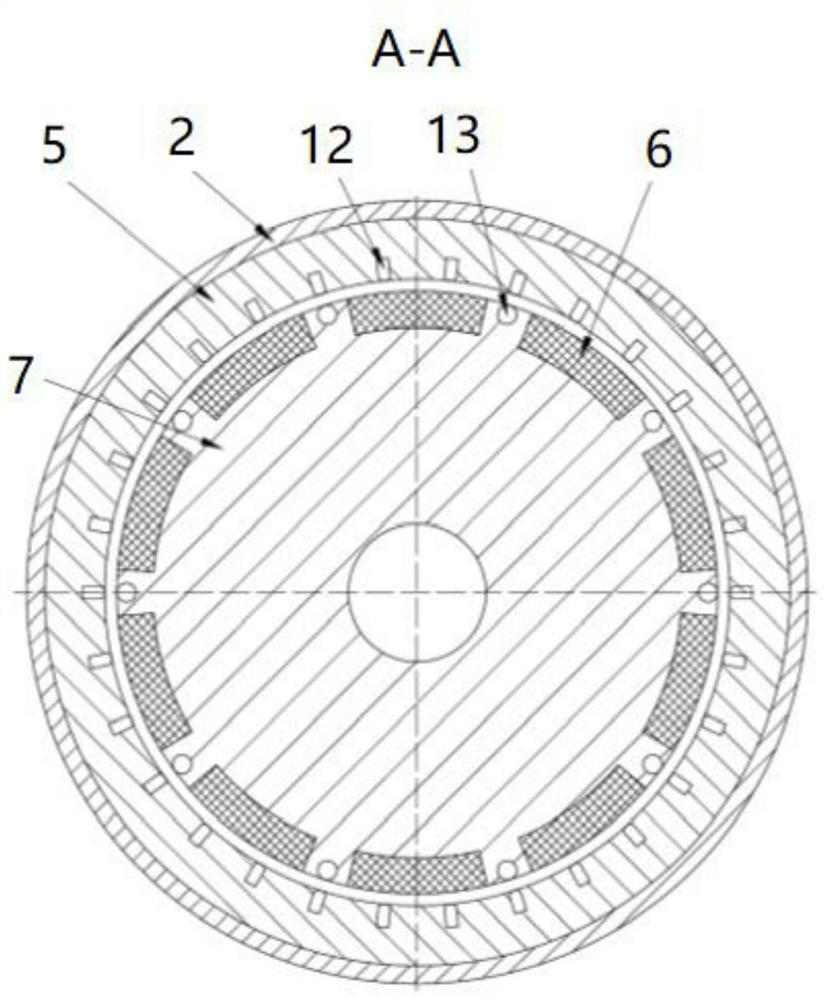

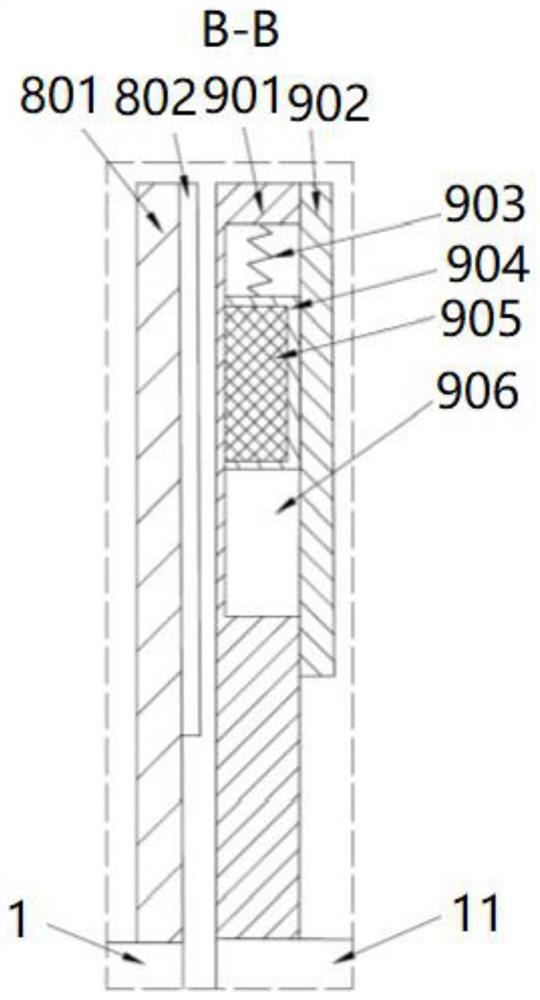

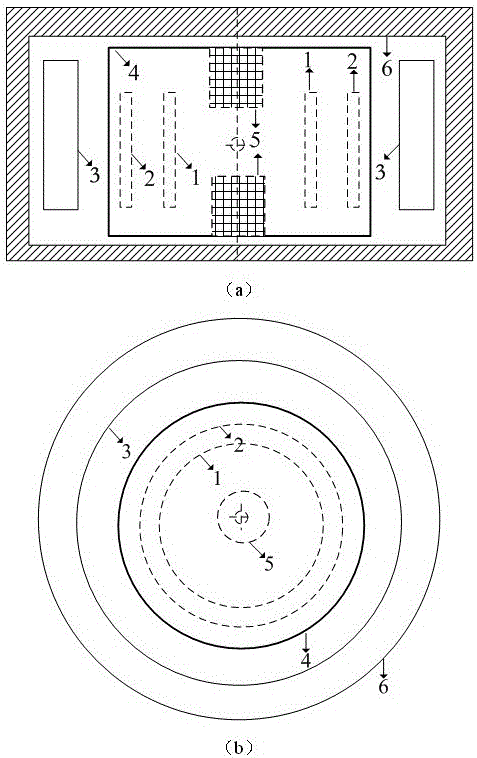

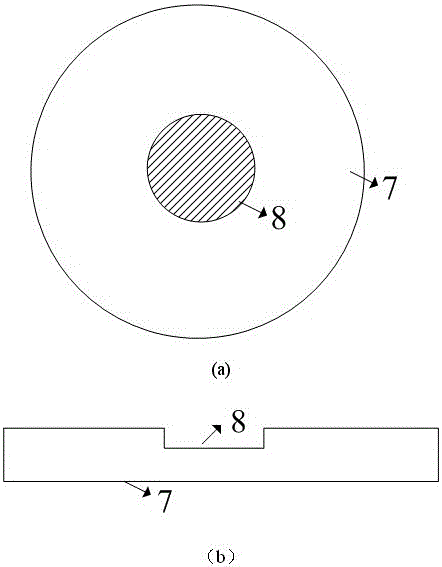

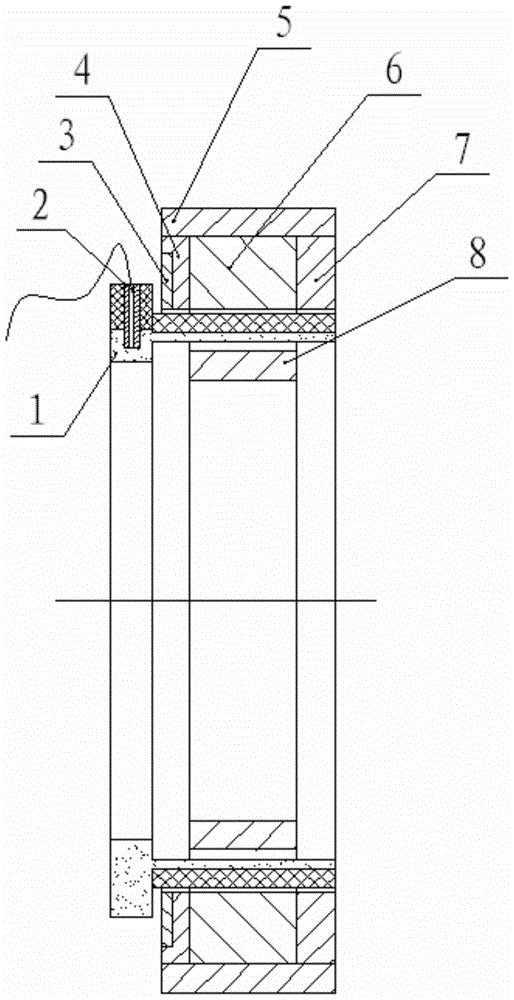

Permanent magnet linear voice coil motor with high thrust-weight ratio for direct drive valve

The invention relates to a permanent magnet linear voice coil motor with high thrust-weight ratio for a direct drive valve, comprising an inner stator, an outer stator, a magnetic steel component, a moving coil winding, a moving coil support and an end cover. The permanent magnet linear voice coil motor is characterized in that the magnetic steel component is two circular magnetic steel components which are bonded on the inner wall of the outer stator by a high-strength adhesive; the inner and the outer stators are both bonded on the end cover by adopting the high-strength adhesive; a spigot is processed on the end cover for realizing the mechanical positioning of the inner and the outer stators with the end cover; two annular air gaps are formed between the inner and the outer stators and the two annular magnetic steel components; the moving coil winding adopts two sets of windings, the numbers of turns of the two sets of windings are equivalent, and the winding directions are opposite, each set of winding is respectively arranged in the two annular air gaps constituted by the inner and the outer stators and the two annular magnetic steel components; the moving coil winding adopts a copper clad aluminum enameled wire, the wire winding method of the moving coil winding adopts the multi-layer flat winding; the moving coil support adopts a nylon rod with light weight, high strength and high temperature resistance; and a through hole is formed on the end cover.

Owner:BEIHANG UNIV

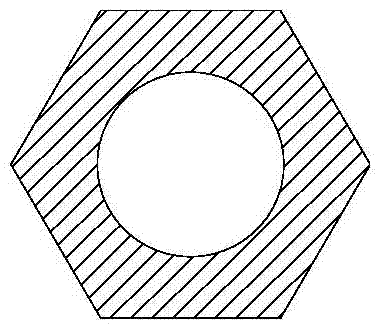

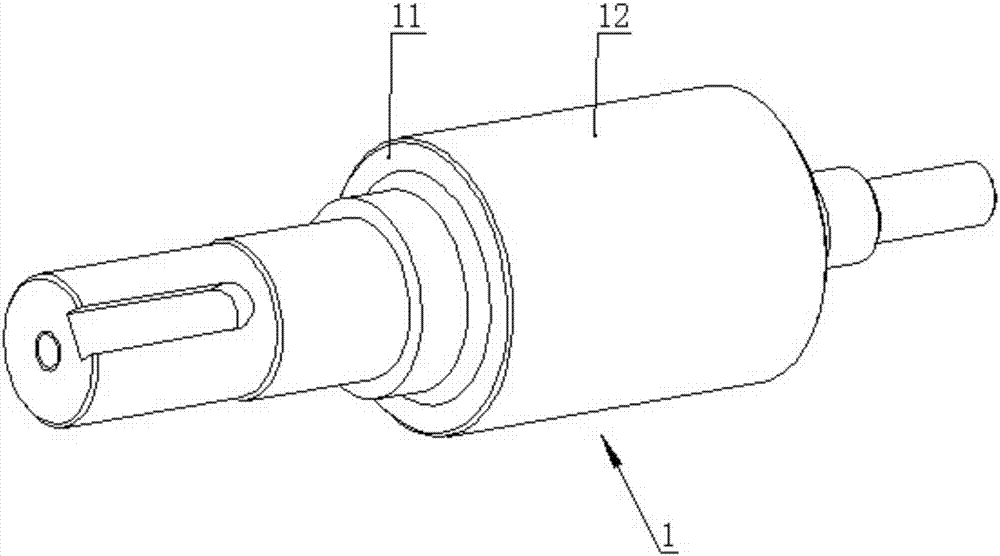

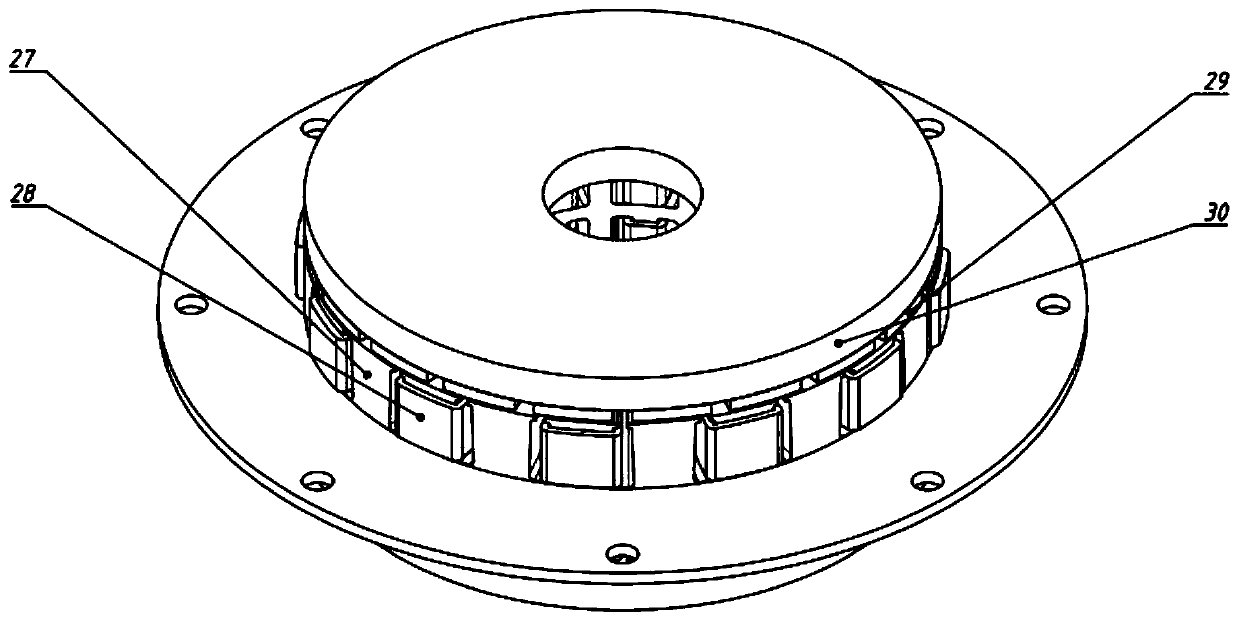

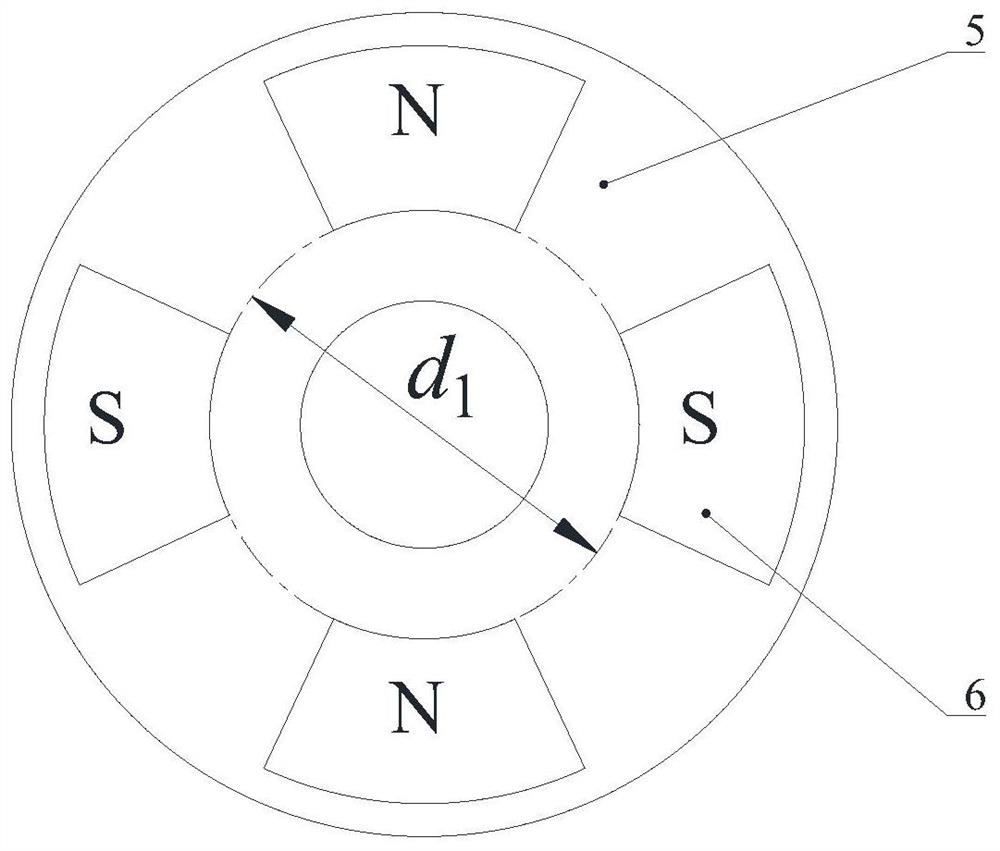

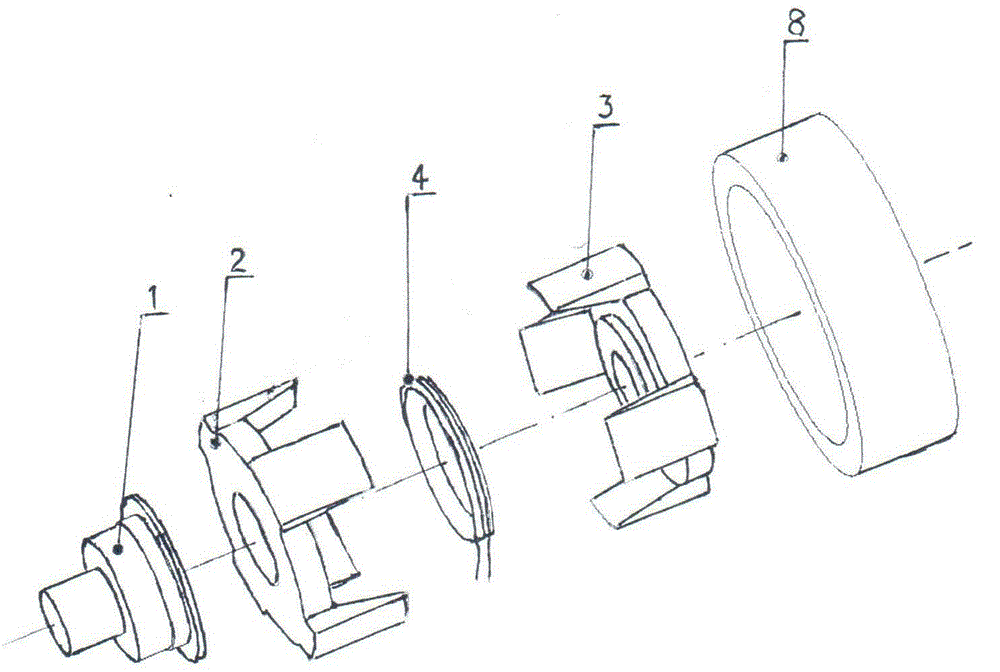

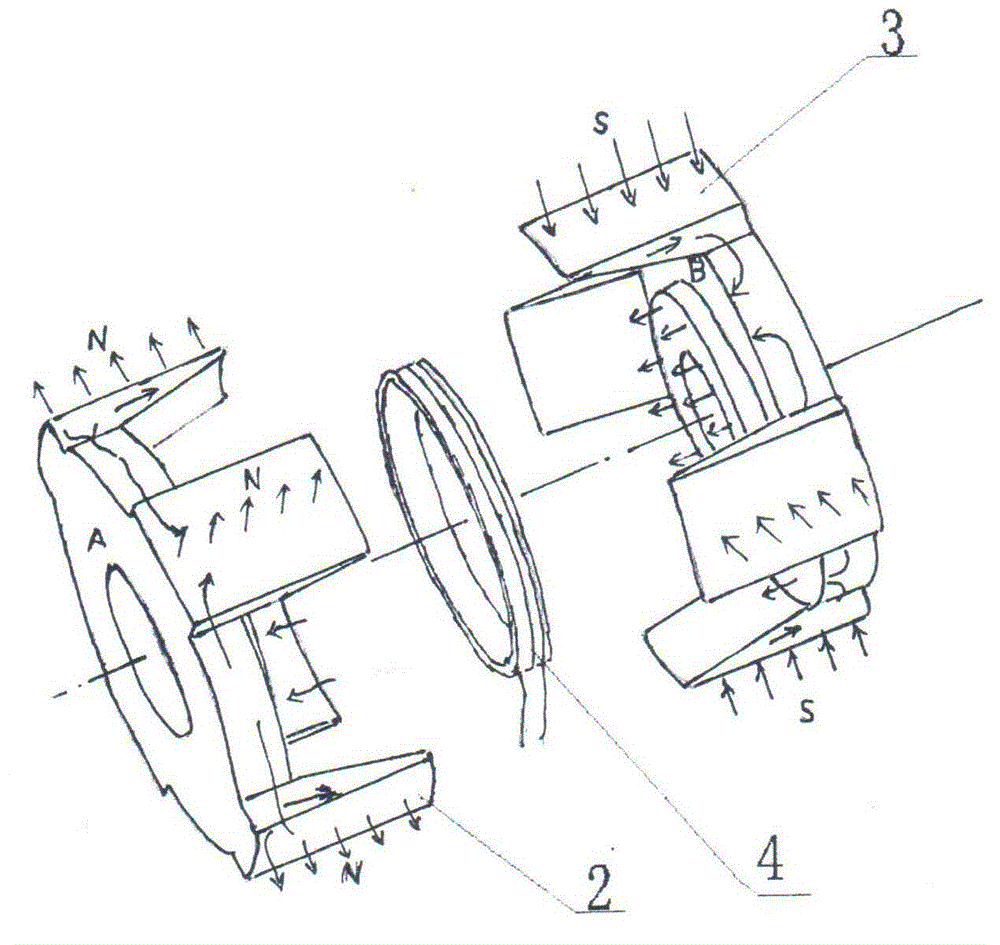

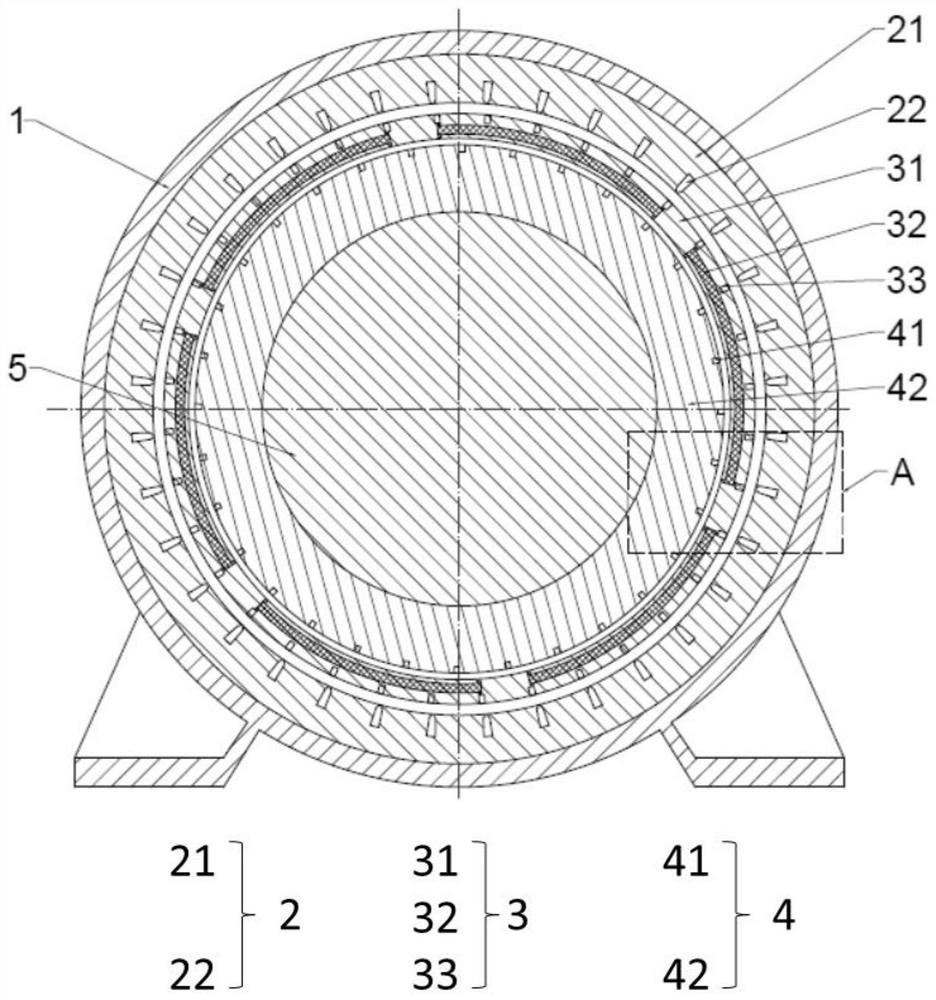

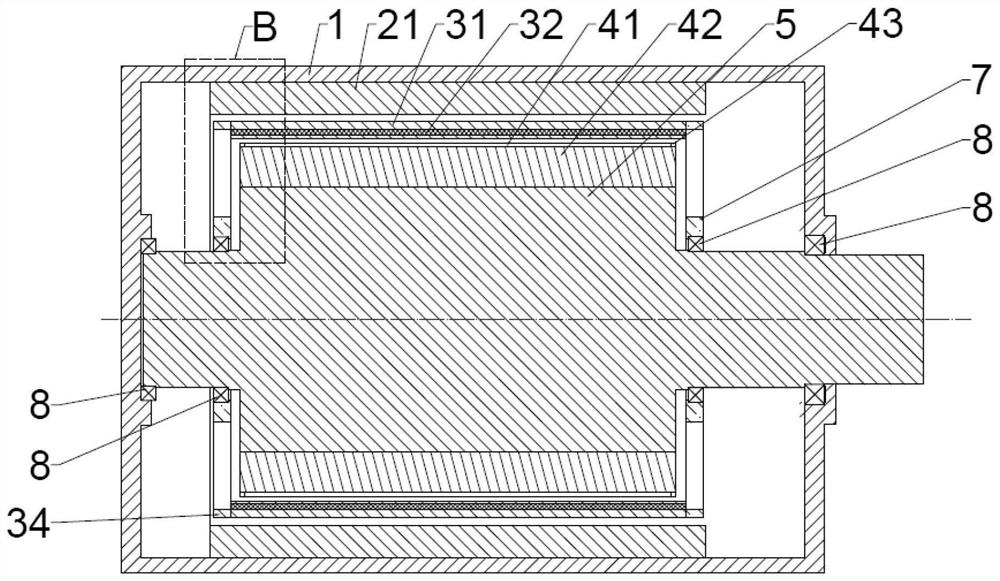

Field element

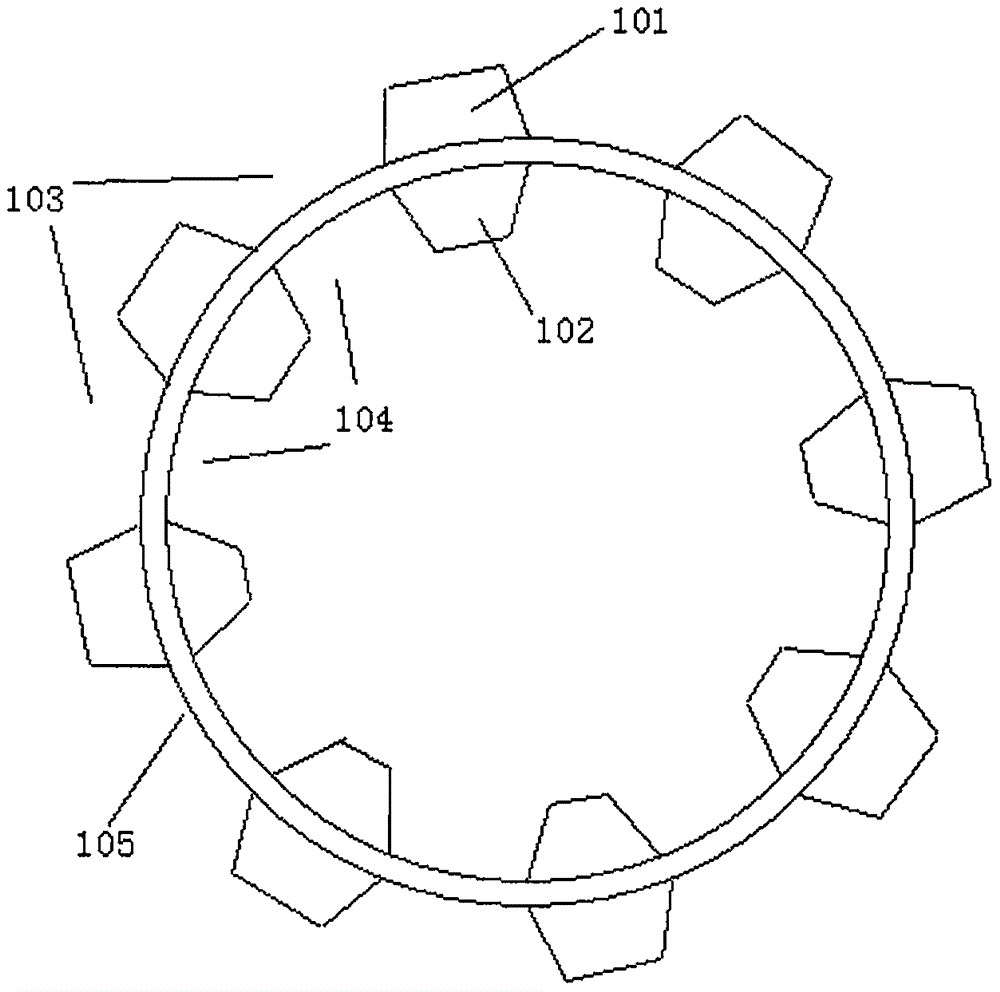

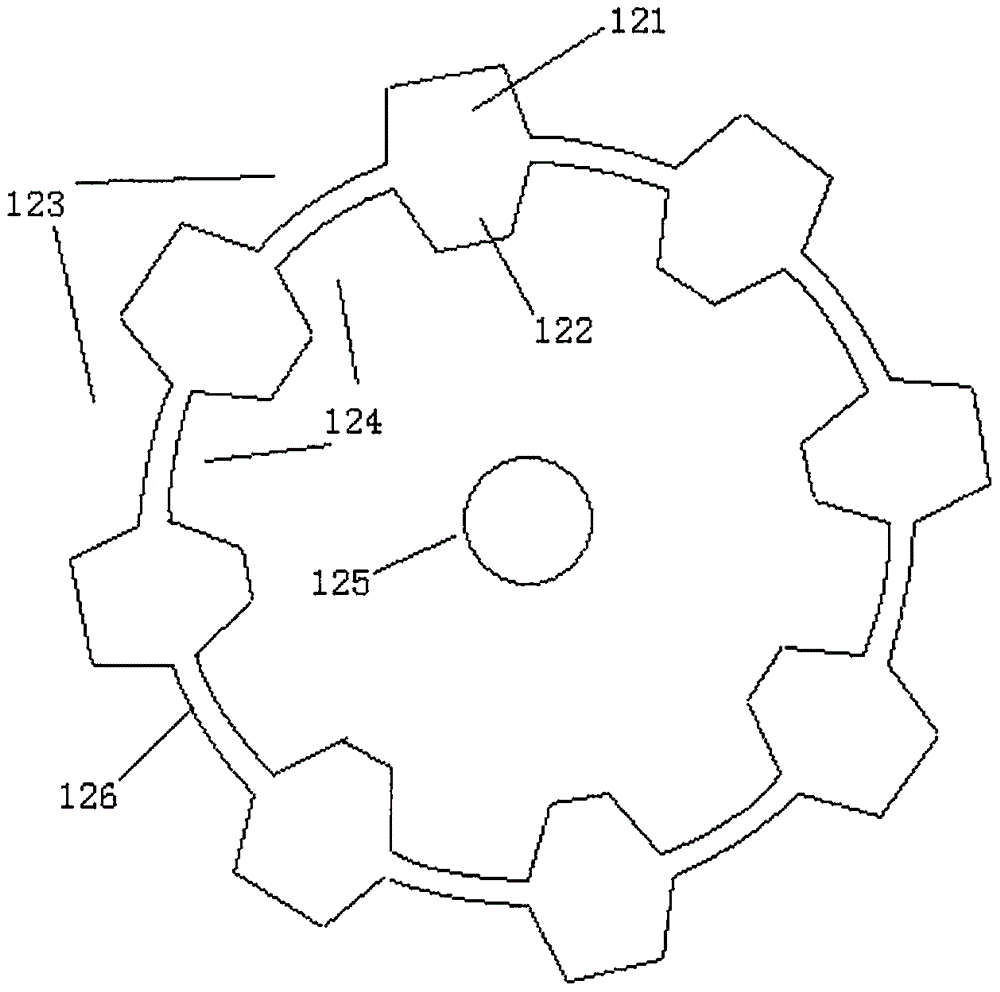

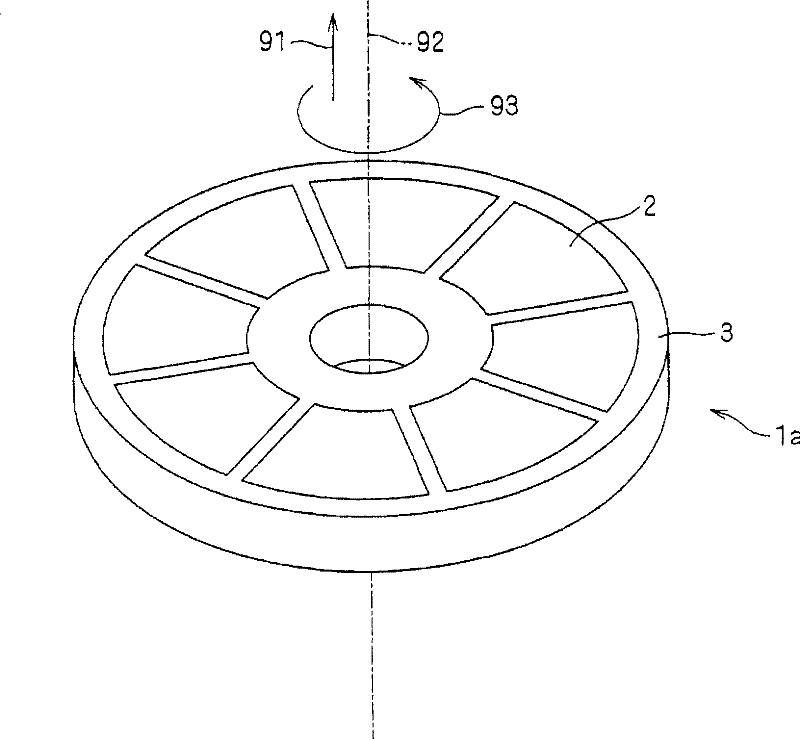

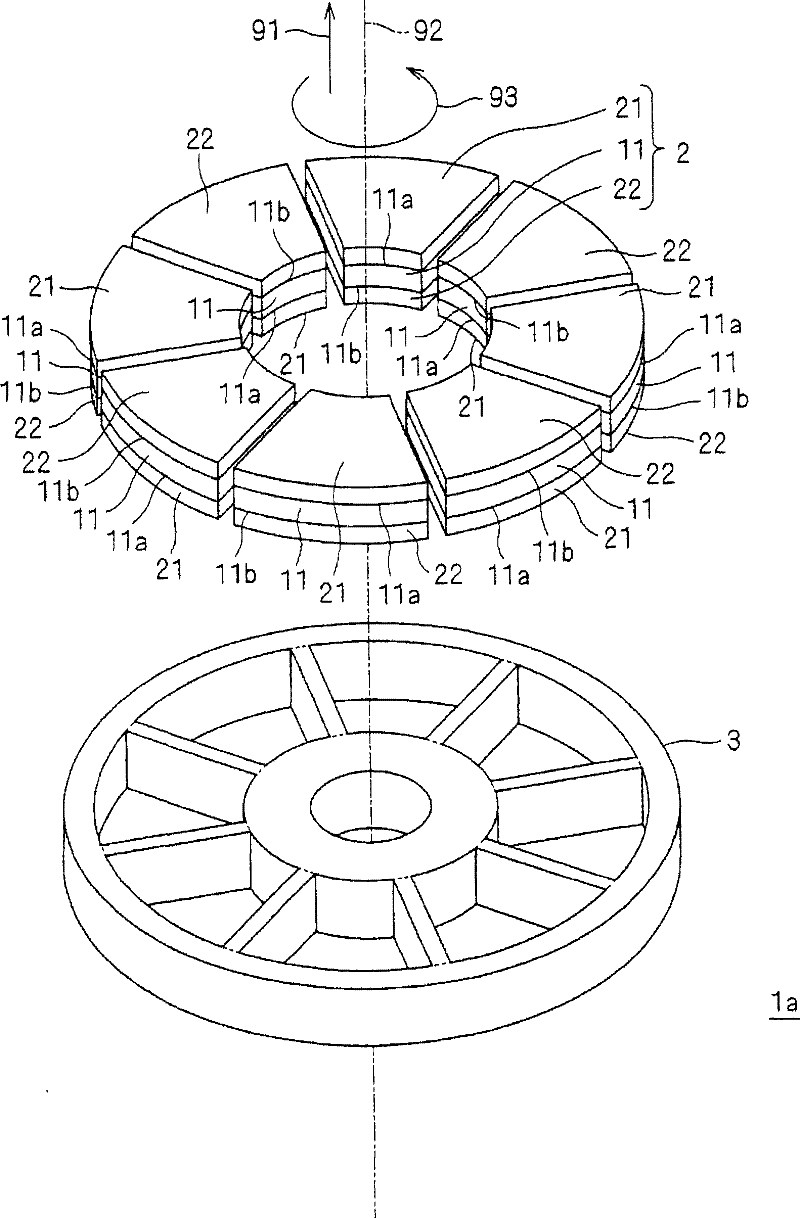

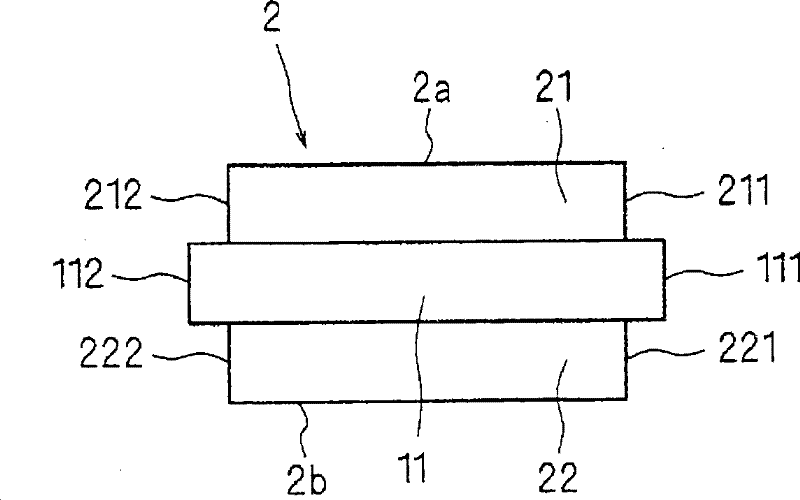

InactiveCN101454961AAvoid demagnetizationHigh strengthMagnetic circuit rotating partsMagnetic circuit characterised by magnetic materialsMagnetField element

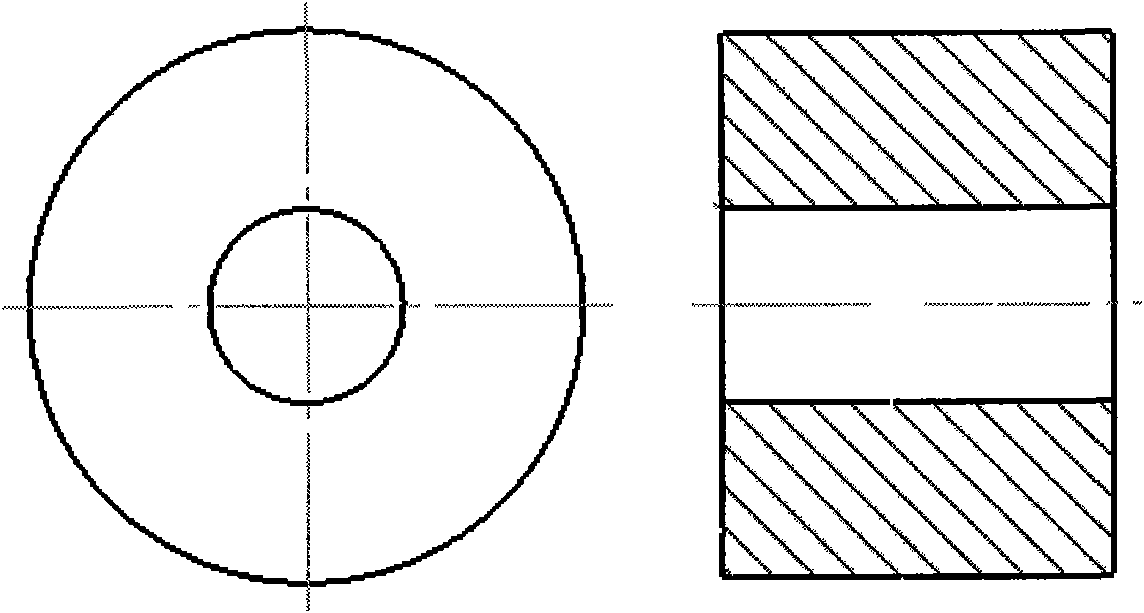

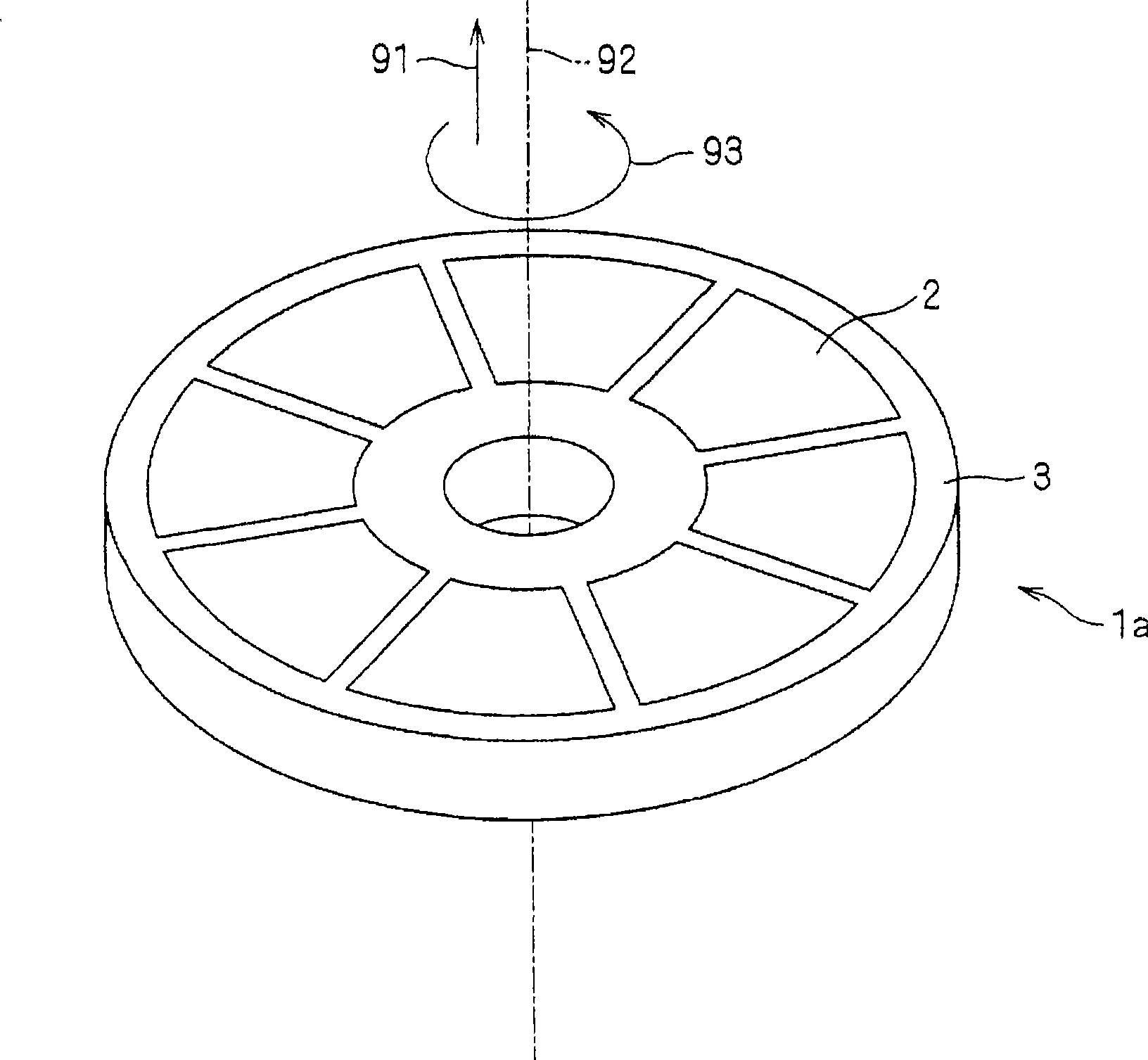

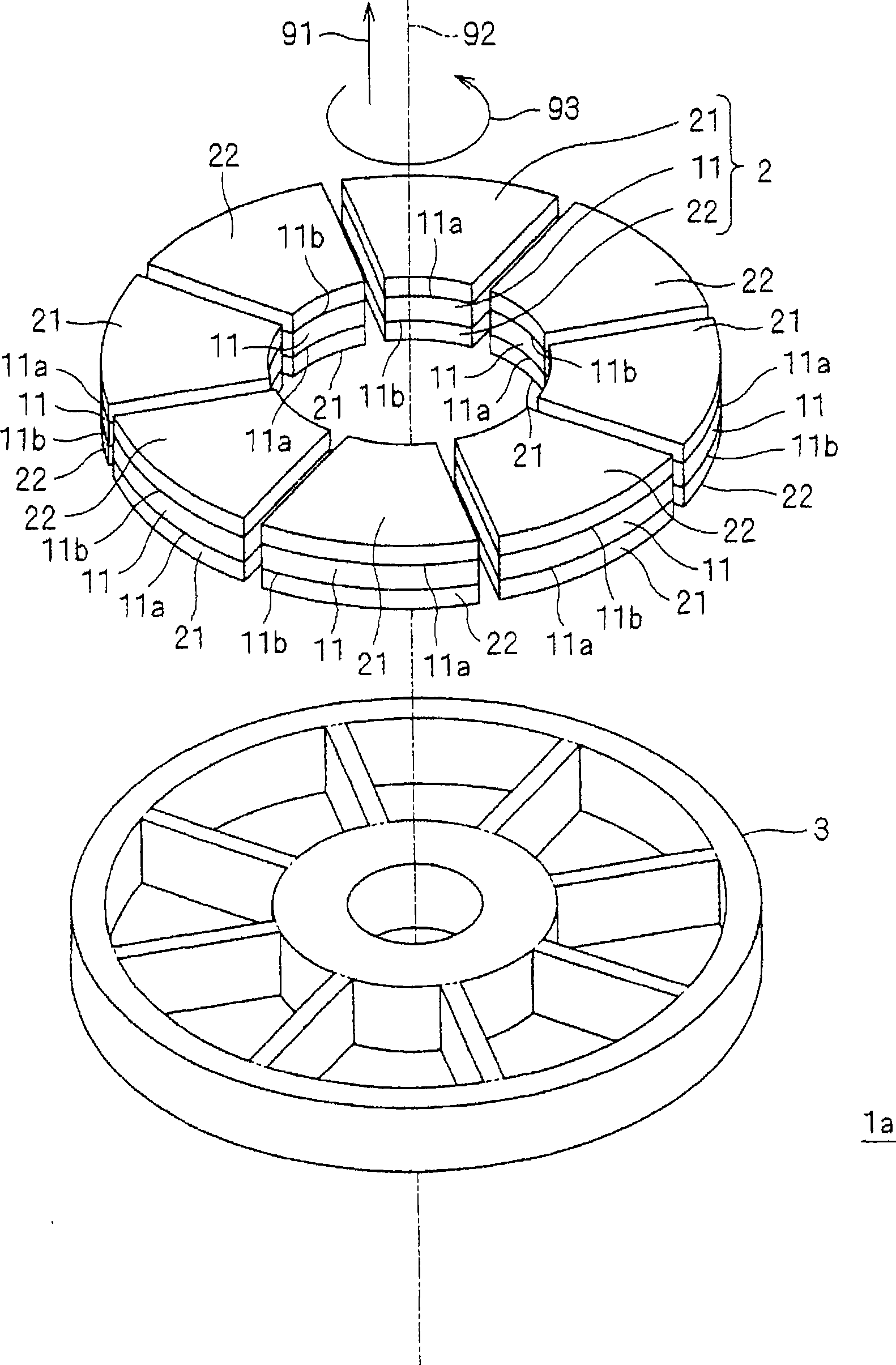

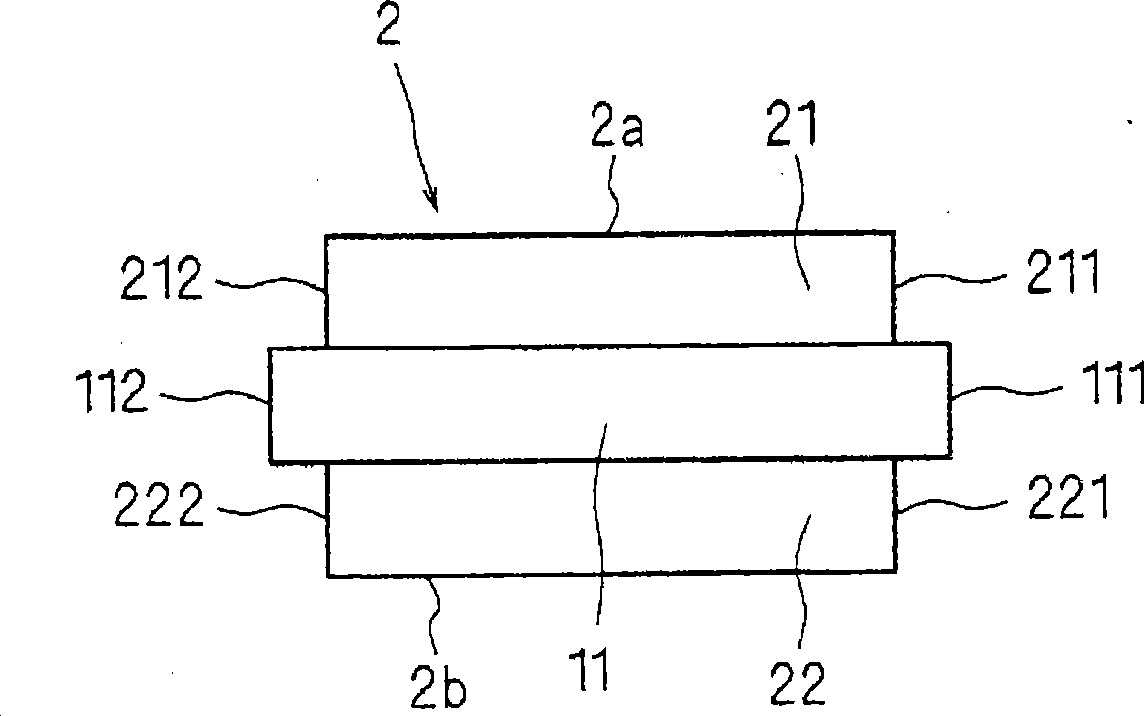

The invention provides a magnetic field element. It is an object to prevent demagnetization of magnets. A magnetic field element 1a includes magnetic field portions 2 and a coupling portion 3 and is rotatable on a rotation axis 92 along a given direction 91. Each magnetic field portion 2 includes a magnet 11 and magnetic plates 21 and 22. The magnet 11 includes first and second pole faces 11a and 11b having different polarities from each other in the given direction 91. The magnetic-material plates 21 and 22 are provided on the first and second pole faces 11a and 11b, respectively. The magnetic field portions 2 are annularly arranged along a circumferential direction 93 around the rotation axis 92 and spaced in the circumferential direction 93 from one another. The coupling portion 3 is made of a non-magnetic material and couples the magnetic field portions 2 to one another.

Owner:DAIKIN IND LTD

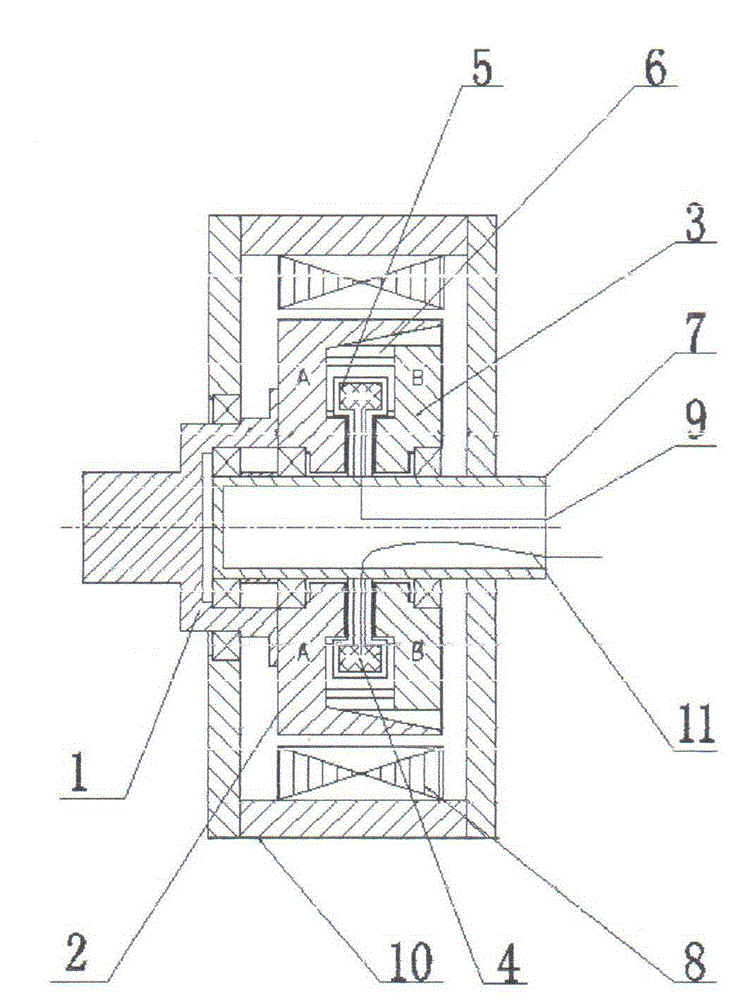

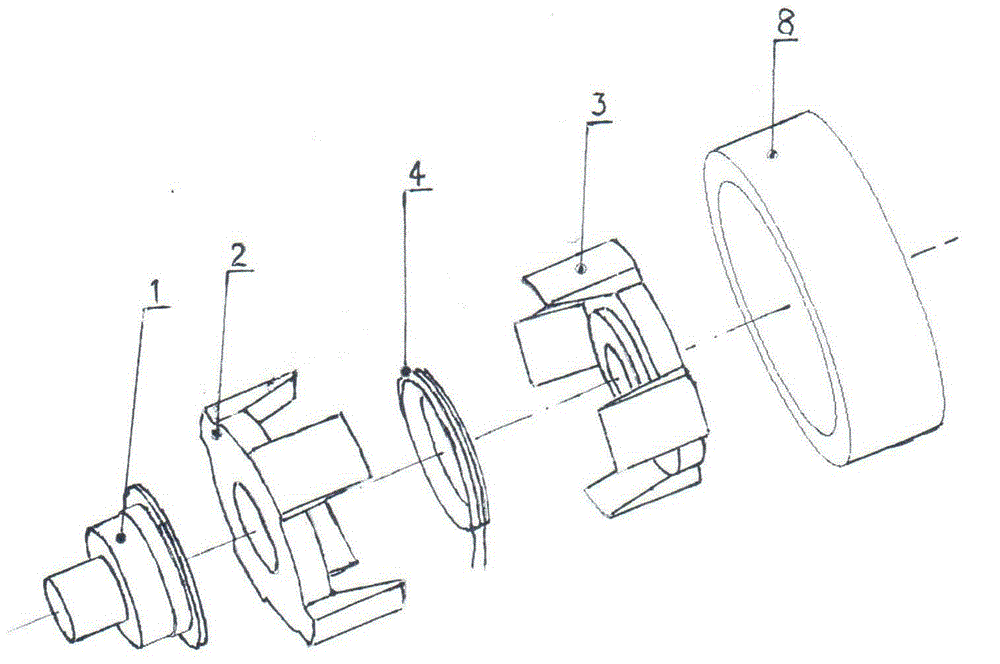

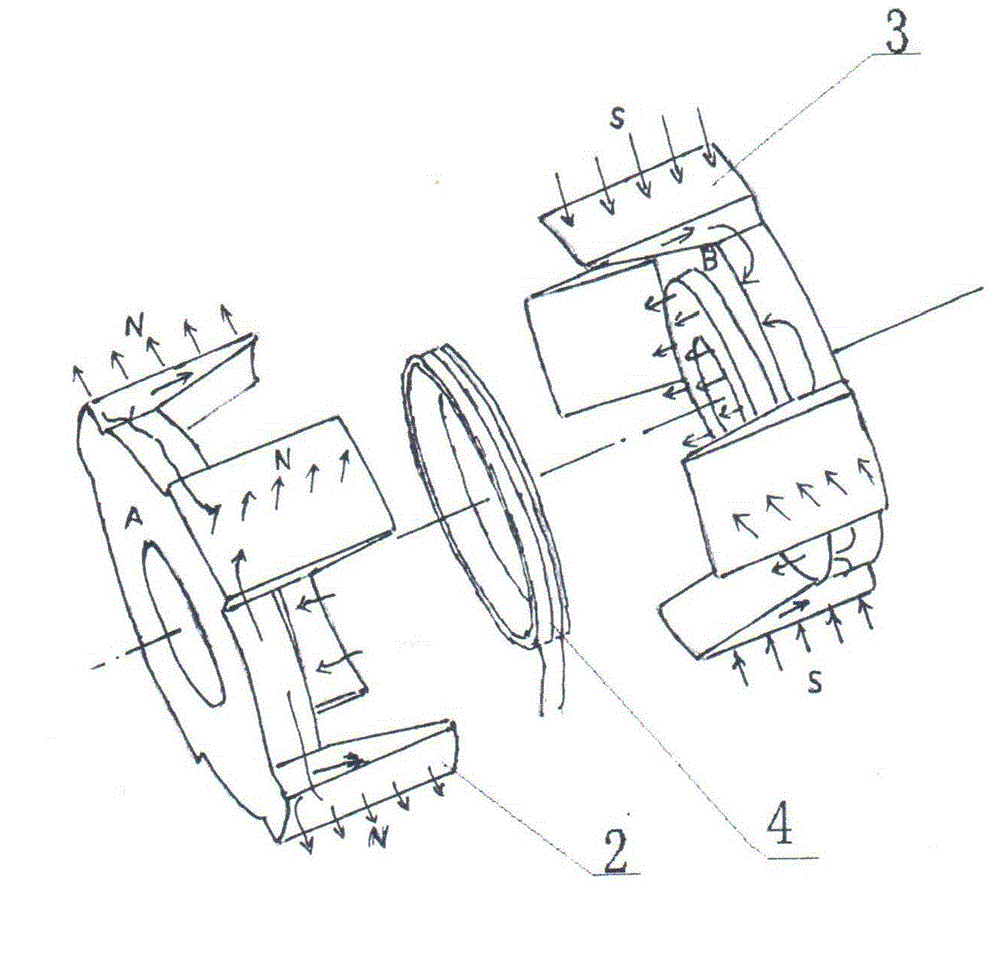

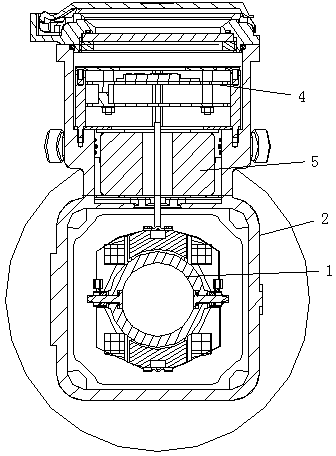

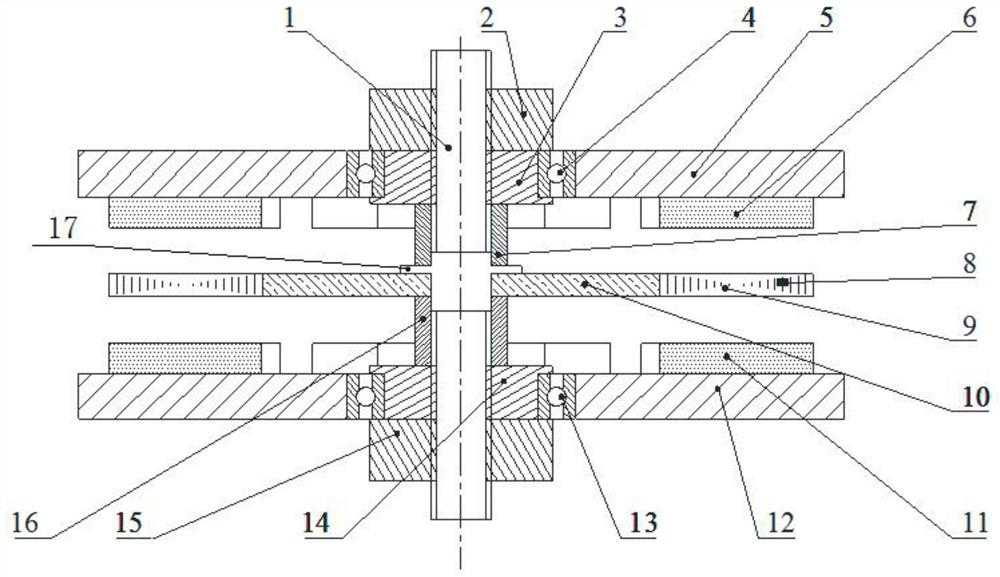

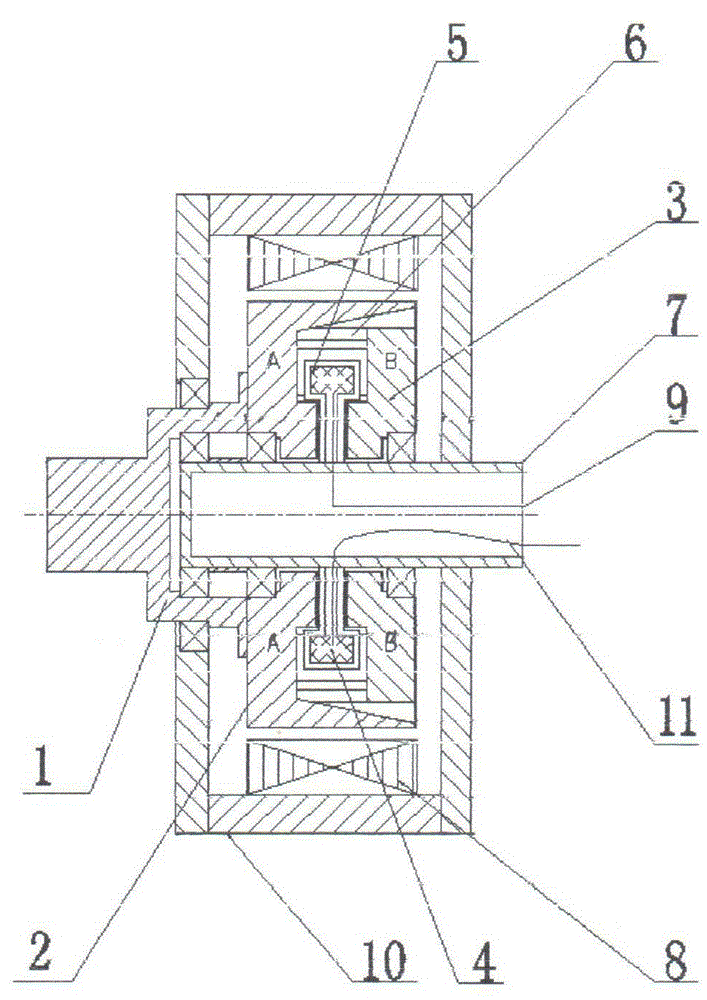

Superconducting claw-pole motor

ActiveCN102882352ASimple structureSolve the problem of longevityMagnetic circuit rotating partsWindings conductor shape/form/constructionRotor magnetsElectric machine

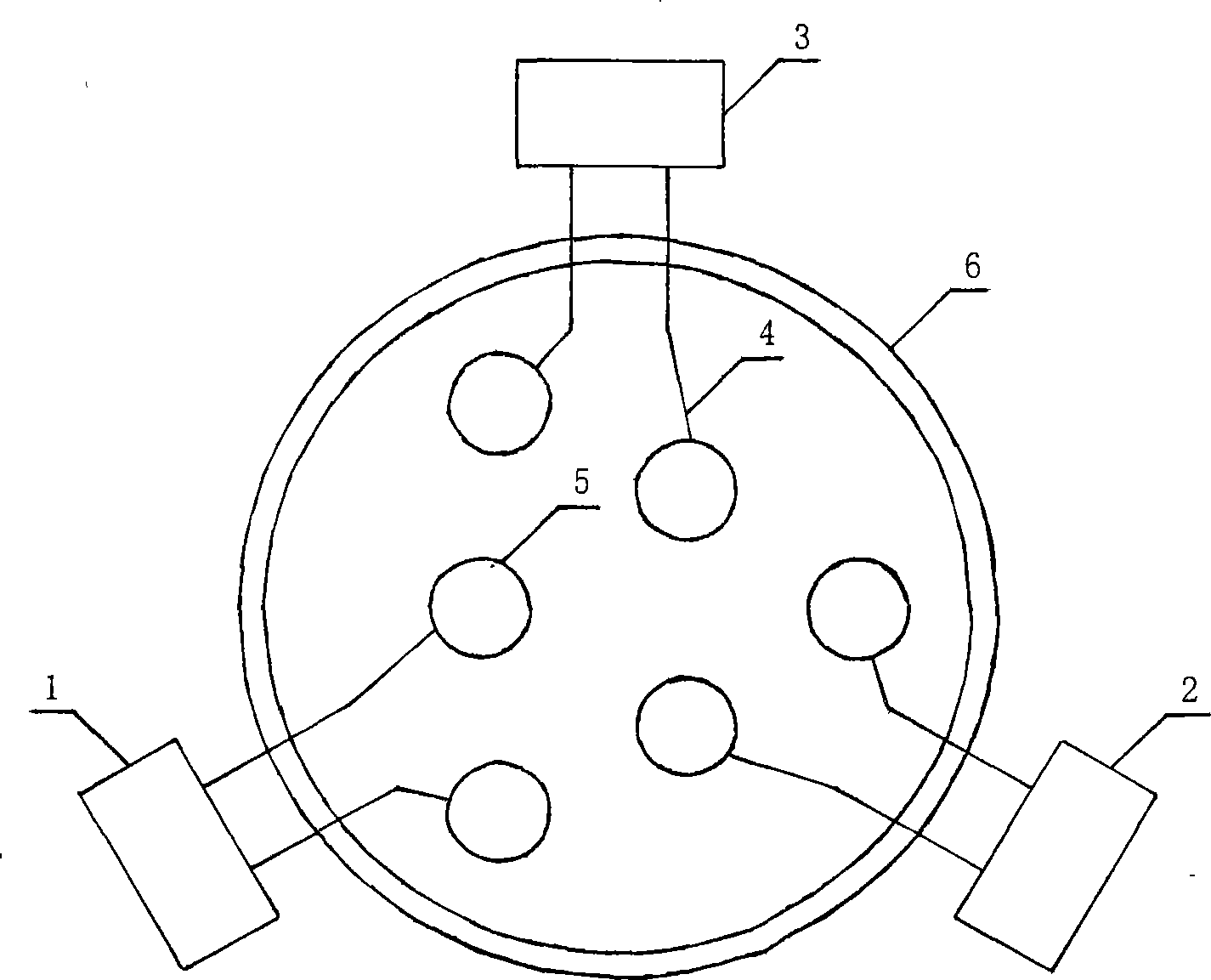

The invention provides a superconducting claw-pole motor. A stator part comprises a hollow support shaft, n superconducting exciting winding supports and a Dewar structure, wherein the n superconducting exciting winding supports and the Dewar structure are fixed on the hollow support shaft, a superconducting exciting winding is arranged in each exciting winding support, and a refrigerant pipe and a superconducting outgoing line are arranged in the hollow support shaft; a rotor part comprises a rotor shaft and n rotor magnet yoke sets; and each rotor magnet yoke set comprises an A magnet yoke and a B magnet yoke, claw poles on the two magnet yokes are distributed in a staggered mode and oppositely buckled on the two sides of a corresponding superconducting exciting winding, and the rotor shaft and the n rotor magnet yoke sets can rotate synchronously around the central axis of the rotor shaft. Motors in different power levels can be implemented through expanding the diameters along the radial direction or increasing the number of superposed claw pole assemblies along the axial direction. According to the invention, under the premise of meeting the operation of superconducting motors, the superconducting claw-pole motor disclosed by the invention has the characteristics of simple structure, low cost, easy machining, direct power-supply connection of exciting windings, no carbon brush or induced circuit required, small weight and size, and the like, and improves the reliability and efficiency of systems.

Owner:陕西捷普控制技术有限公司

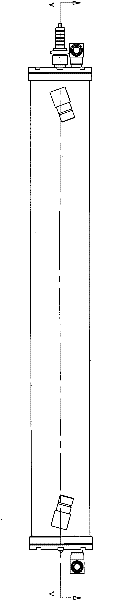

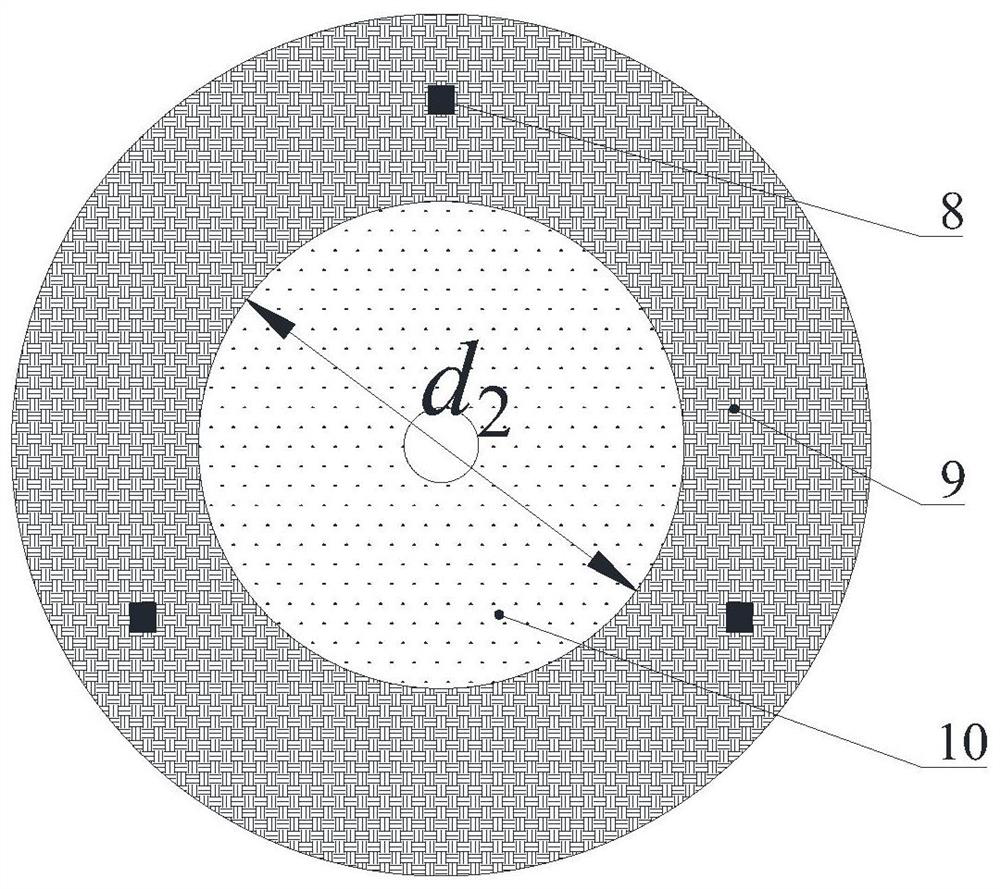

Unlined pipeline type necking electromagnetic water meter

InactiveCN104165662ANo lossAvoid lossVolume meteringVolume/mass flow by electromagnetic flowmetersButt jointMeasuring instrument

The invention discloses an unlined pipeline type necking electromagnetic water meter and relates to the technical field of measuring instruments. The unlined pipeline type necking electromagnetic water meter achieves the technical purposes that measuring errors are reduced and the reliability of measuring results is improved. The unlined pipeline type necking electromagnetic water meter comprises a measuring pipe, a water meter shell and two flanges. The unlined pipeline type necking electromagnetic water meter is characterized in that the water meter shell is fixedly provided with two diversion conical pipes, pipe openings in the two ends of the measuring pipe are coaxially in butt joint with pipe openings in the narrow ends of the two diversion conical pipes, and the pipe openings in the two ends of the measuring pipe and the pipe openings in the narrow ends of the two diversion conical pipes are fixed. The joint parts of the two ends of the measuring pipe are sealed and the two diversion conical pipes are sealed through sealing rings respectively. The two flanges are installed on the outer walls of the two diversion conical pipes respectively through clamp springs. The unlined pipeline type necking electromagnetic water meter is suitable for measuring the flow of media in pipelines.

Owner:上海肯特仪表股份有限公司

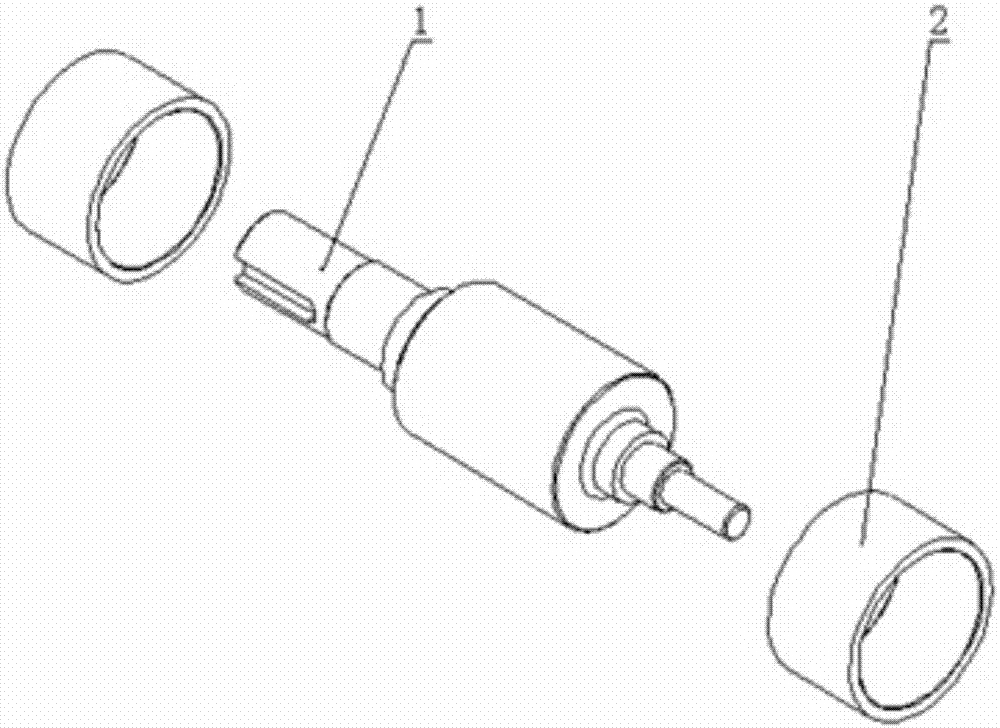

Production technology of coreless micro brushless DC (Direct Current) motor

ActiveCN102611256ANo eddy current lossExtend your lifeManufacturing stator/rotor bodiesElectric machineWork in process

The invention discloses a production technology of a motor and particularly relates to a production technology of a coreless micro brushless DC (Direct Current) motor. The production technology comprises the following steps of: winding and integrating a varnished wire into a coil with the diameter of 10mm-100mm by a coil winding mold, adding glue to solidify and bake the coil, mounting the coil in a coil fixing base, and then, mounting a bearing on the fixing base to get a semi-finished stator; placing an inner shell in an end cover clamp, adding the glue to form an end cover pressed inner shell with the diameter of 10mm-60mm, pasting a magnet on an outer circle of the inner shell by a magnet grading mold; reinforcing the outer circle of the magnet; placing an outer shell in the end cover clamp, and adding the glue to form an end cover pressed outer shell with the diameter of 10mm-100mm; adding the glue to paste the magnet on an inner circle of the outer shell by the magnet grading mold; reinforcing the magnet on the inner circle of the outer shell, then, baking in a roaster at 60-200 degrees centigrade for 1-4 hours; placing the end cover pressed outer shell into a pressing shaft branch by an end cover mold to obtain a semi-finished rotor with the diameter of 10mm-100mm; and assembling the stator and the rotor with other components to form the coreless micro brushless DC motor.

Owner:胡景威

Low-heat-leakage and low-temperature container

ActiveCN107477352AEasy to take outEasy to put inVessel wallsContainer filling methodsEngineeringRadiant heat

The invention discloses a low-heat-leakage and low-temperature container. The low-heat-leakage and low-temperature container comprises a basin body ground support, a container body and a sealing cover; the container body comprises a cylindrical inner cylinder and a cylindrical outer cylinder, wherein the upper part of the cylinder wall of the cylindrical inner cylinder is bent outwards to form a fly edge, the cylindrical inner cylinder is bonded with the cylindrical outer cylinder through the flash edge to form a double-layer vacuum cavity sealing space; the sealing cover comprises a lower pot body and an upper pot body, wherein an upper opening flange is arranged at the upper end of the upper pot body, and the lower pot body and the upper pot body are bonded with each other to form the double-layer vacuum cavity sealing space; and the container body is arranged on the bottom surface of the basin body ground support, the sealing cover is in contact with the container body and is arranged inside the cylindrical inner cylinder, and a supporting platform is arranged on the inner bottom surface of the cylindrical inner cylinder. According to the low-heat-leakage and low-temperature container, the basin body ground support, the container body, the sealing cover and the supporting platform are made of insulating non-metal materials so that eddy current loss is not prone to be generated, the double-layer vacuum cavity structure of the sealing cover and the container body can reduce the heat leakage generated during use, a plurality of layers of anti-radiation screens in the sealing cover can reduce the radiation heat of outside, so that the eddy current loss under the alternating-current magnetic field condition is reduced.

Owner:YUNNAN POWER GRID CO LTD ELECTRIC POWER RES INST

Toughening FRP spiral connecting piece and manufacturing method thereof

InactiveCN103939446AReduce production difficultyImprove installation efficiencyNutsScrewsCorrosionFiber

The invention discloses a toughening FRP spiral connecting piece and a manufacturing method of the toughening FRP spiral connecting piece. The toughening FRP spiral connecting piece comprises a bolt, a nut and a gasket. The bolt comprises a bolt head and a threaded rod, wherein the bolt head and the threaded rod are connected into a whole, and external threads are arranged on the threaded rod. Internal threads are arranged on the nut. The external threads and the internal threads are matched with each other. The threaded rod is sleeved with the gasket. The nut is tightly screwed on the threaded rod. According to the method, an epoxy resin substrate serves as a main body, flexibilizers are then added, and resin adhesive materials, short fiber and fiber cloth are formed according to vacuum molding. Mechanical and semi-automatic molding forming is adopted for the FRP connecting piece, and therefore large-scale production can be achieved; the FRP connecting piece is used for connection of FRP components, and the overall corrosion-free function, the non-magnetic function, the electric insulation function, the vortex-loss-free function, the vortex-interference-free function and other functions are given into full play; when the FRP connecting piece is used, the large FRP component can be resolved into multiple small FRP parts, and the energy saving effect and the emission reduction effect are achieved.

Owner:湖北金力工程复合材料有限公司

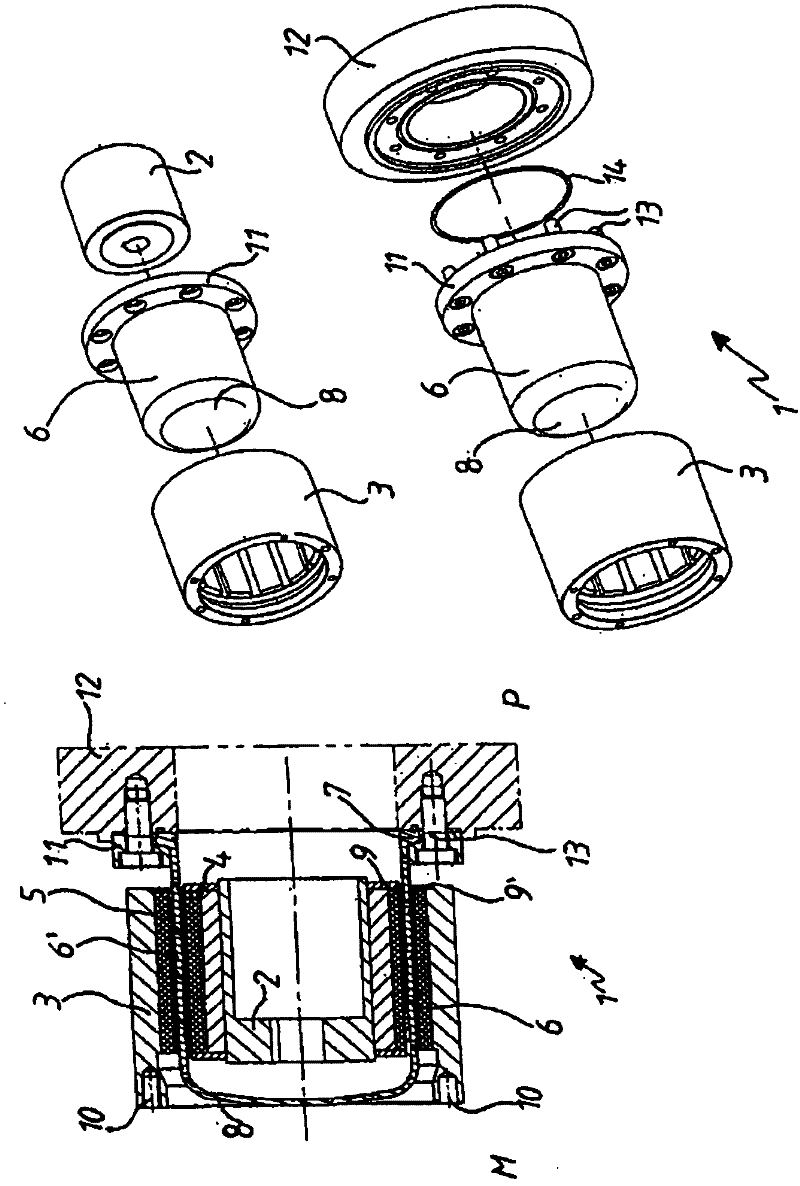

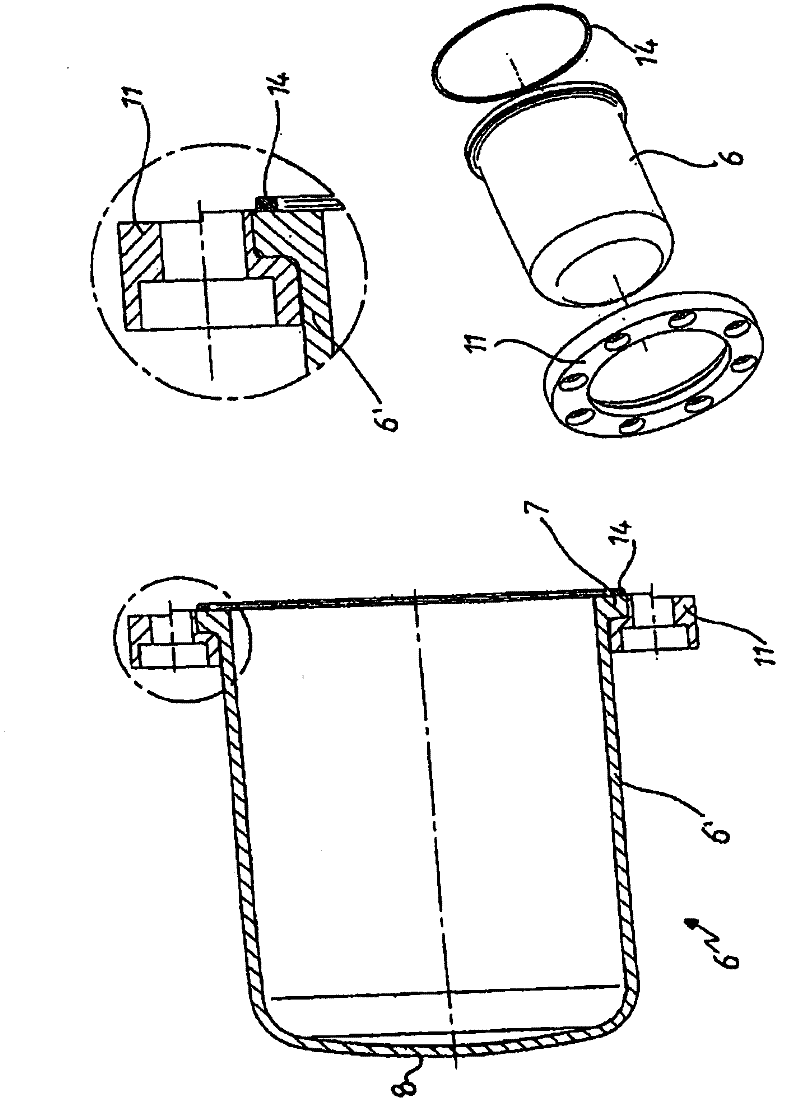

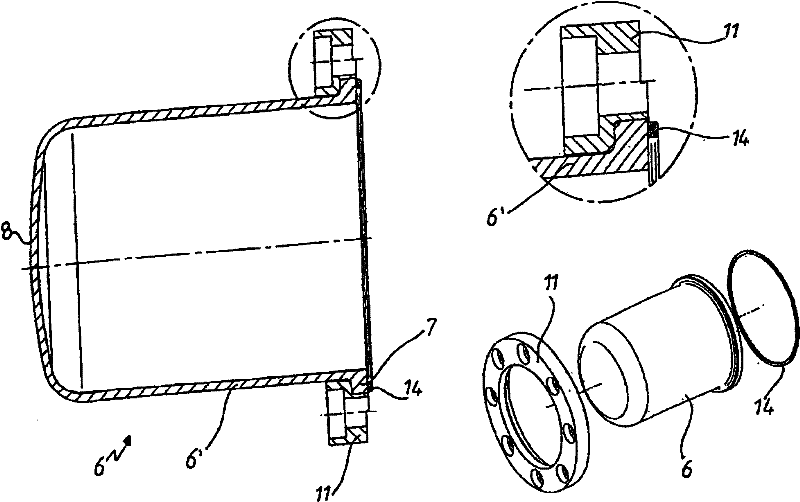

Magnetic coupler and gap tank for magnetic coupler

InactiveCN102301572ANo eddy current lossInexpensive and high-quality manufacturingPermanent-magnet clutches/brakesSupports/enclosures/casingsCouplingConductive materials

Owner:DST DAUERMAGNET SYST TECHN

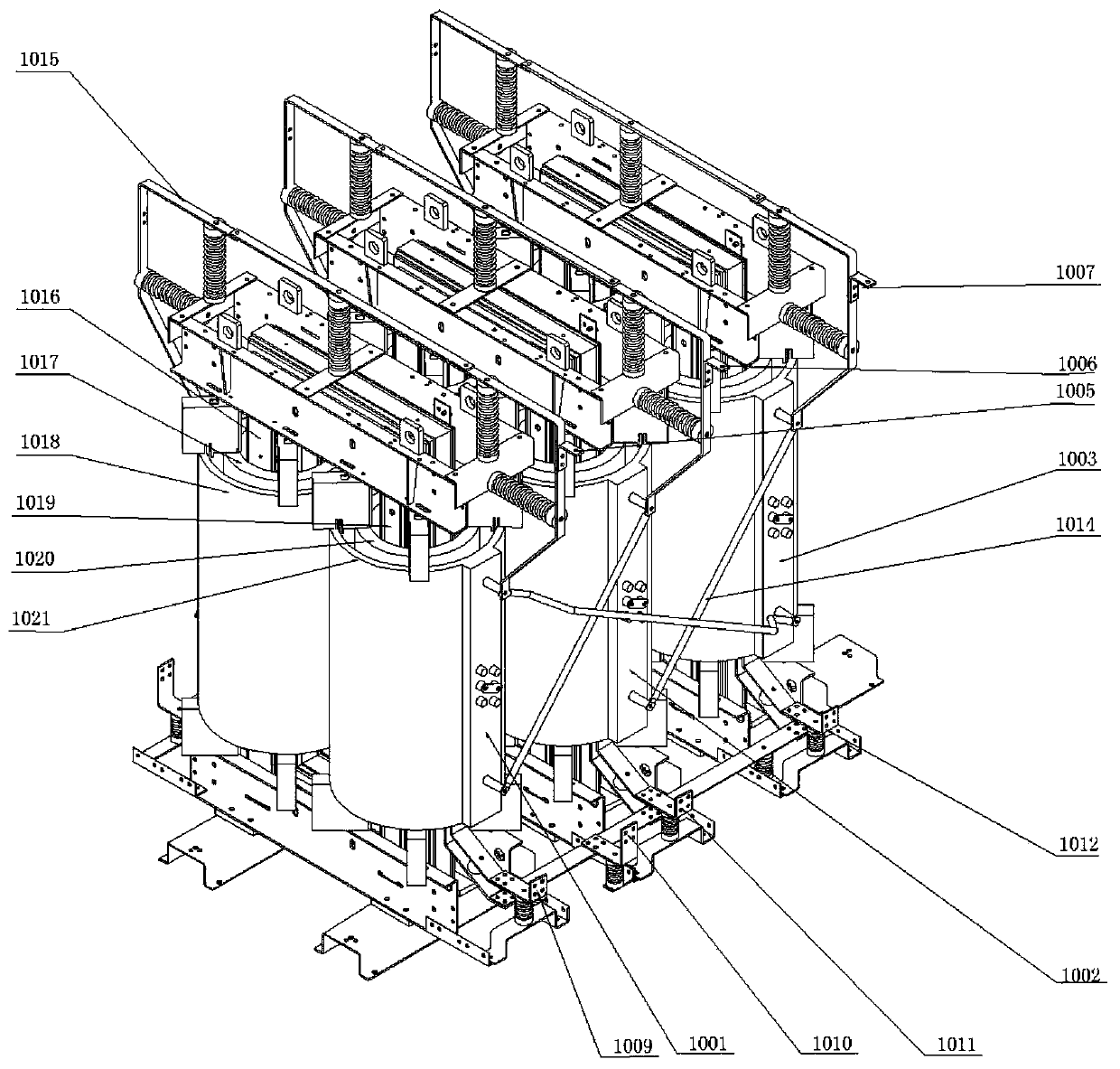

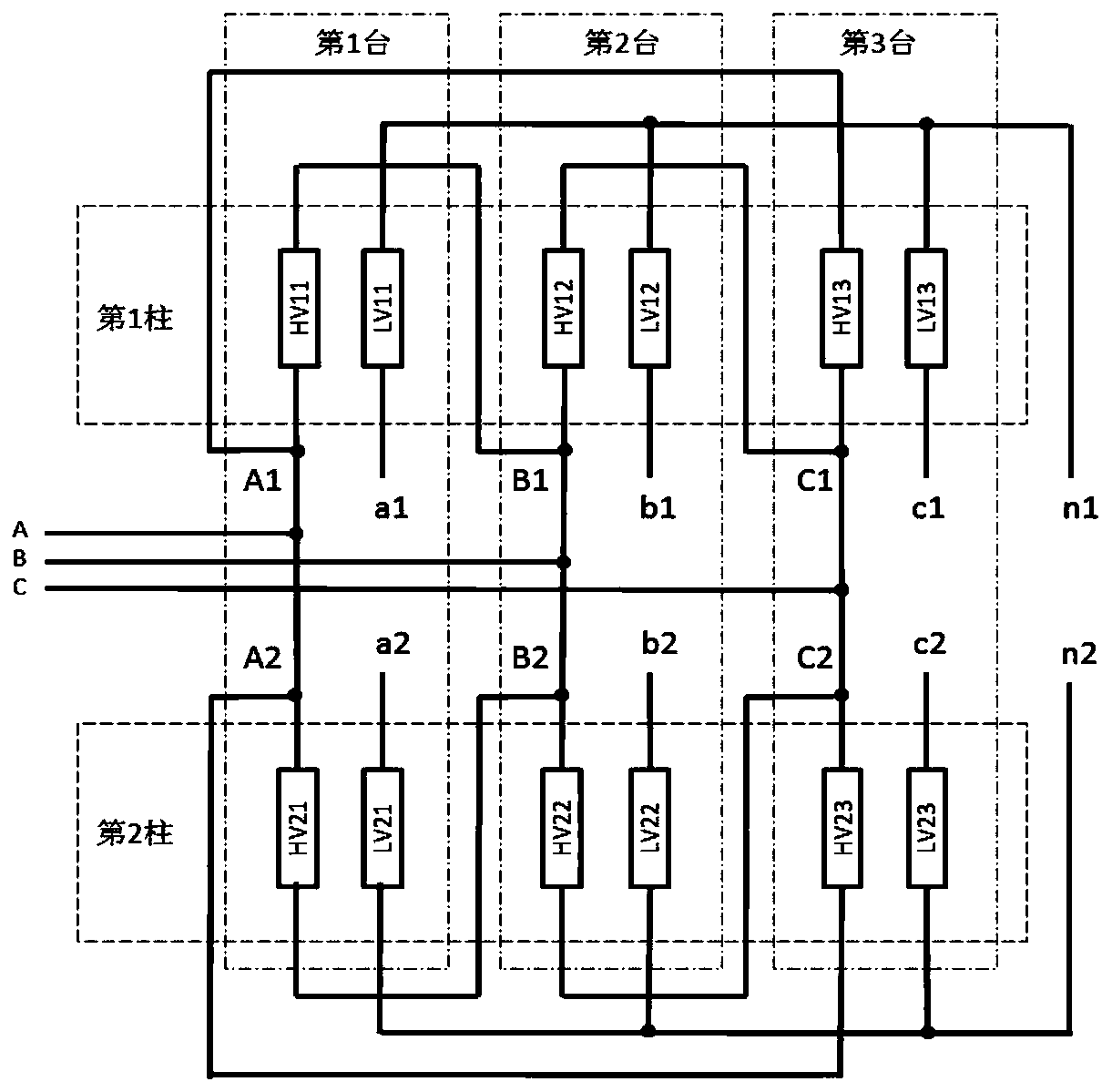

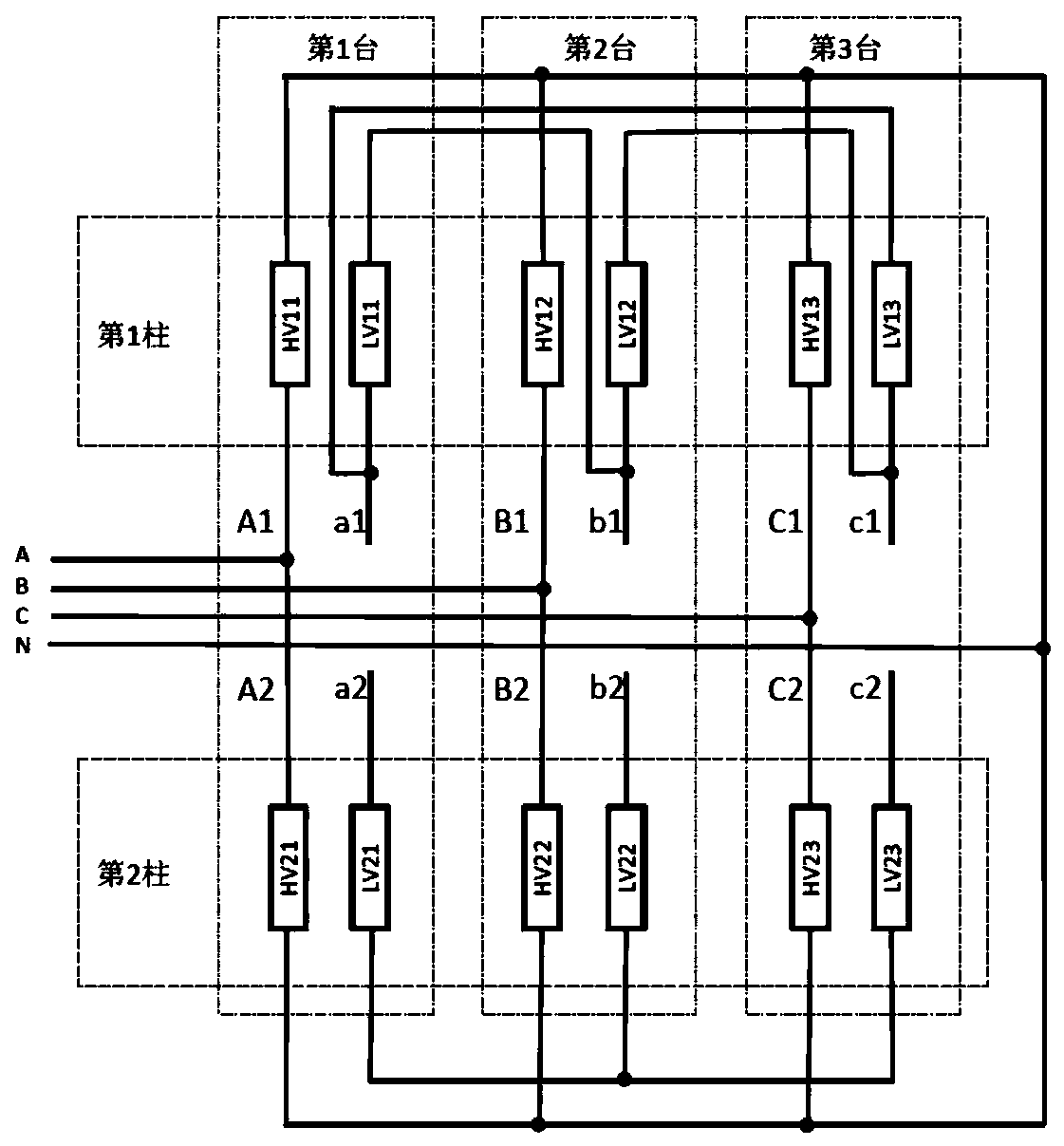

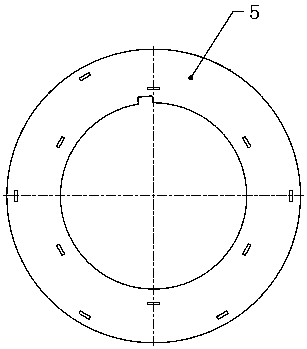

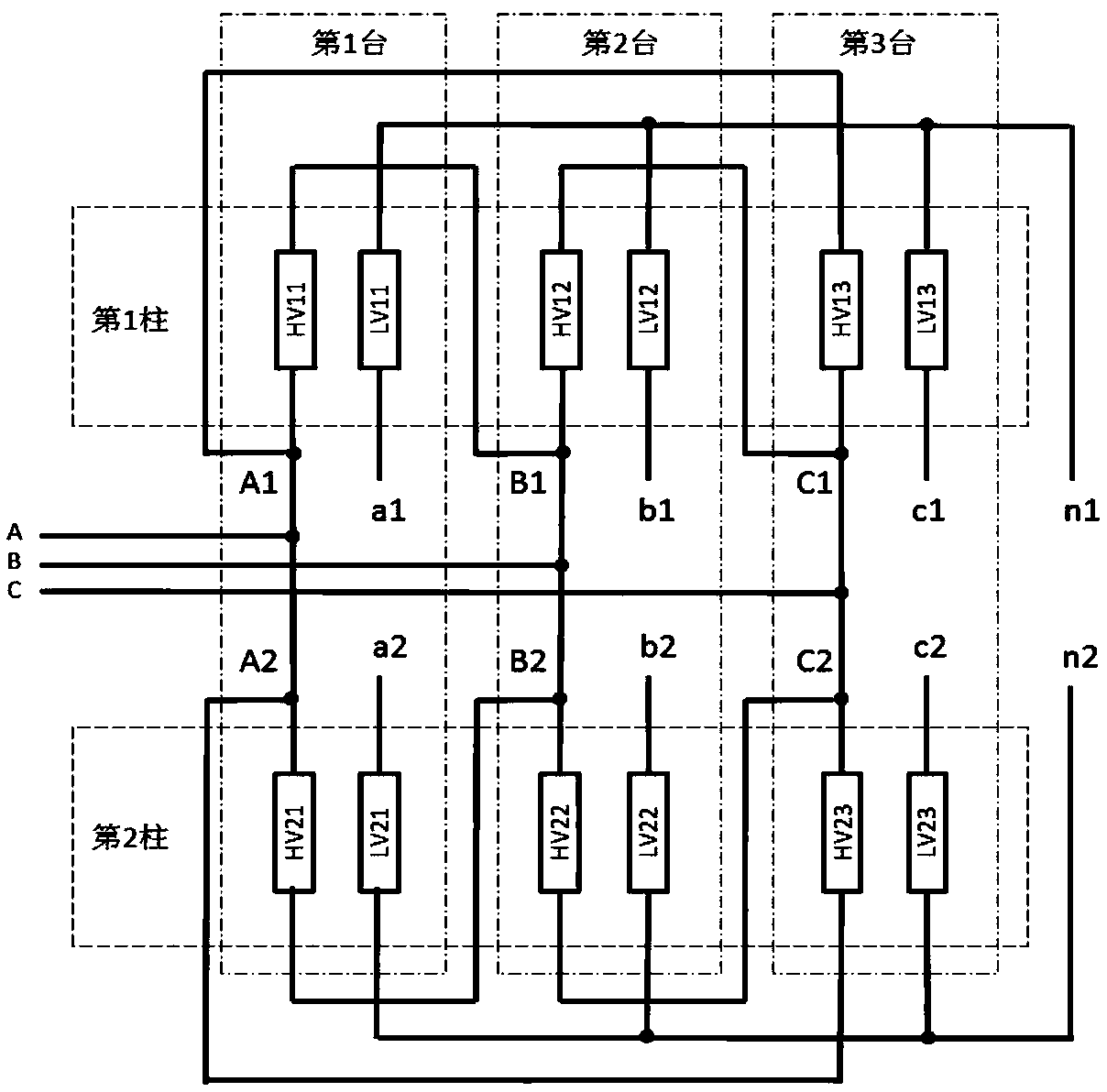

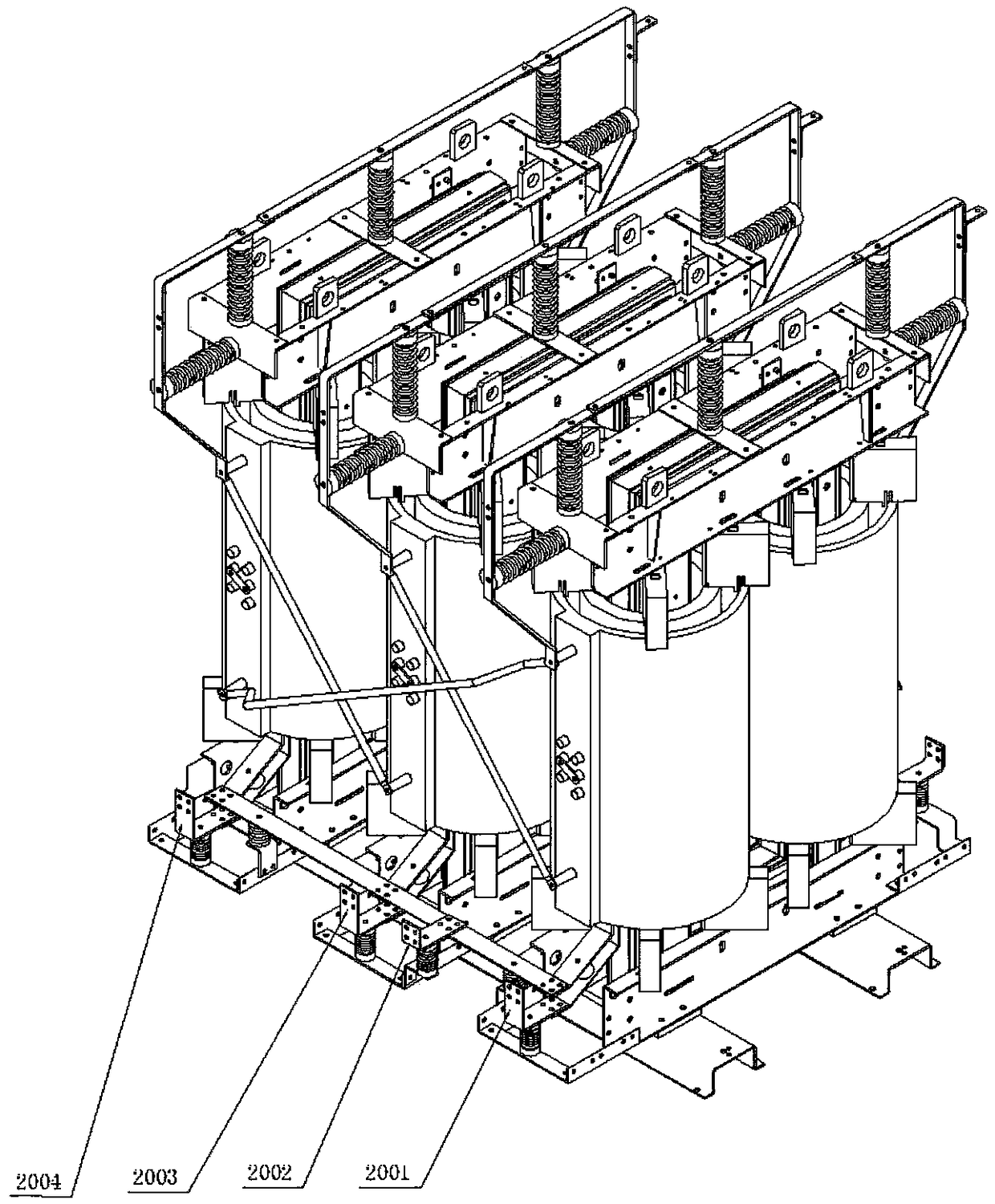

Transformer set

PendingCN110111985AAvoid failureNo eddy current lossTransformers/inductances coils/windings/connectionsUnwanted magnetic/electric effect reduction/preventionCouplingDual column

The invention discloses a transformer set. The transformer set includes three dual-column single-phase transformers, wherein the dual-column single-phase transformers respectively include a first corecolumn of a rectangular frame core, a second core column, a high voltage coil and a low voltage coil disposed on the first core column, and a high voltage coil and a low voltage coil disposed on thesecond core column. The transformer set is advantaged in that each core column includes only one low voltage coil, the magnetic coupling relationship along the low voltage coils is avoided, so leakageof a magnetic field due to unbalanced loads is avoided, eddy current loss is further avoided, and a problem of transformer fault caused by the unbalanced loads is avoided, moreover, compared with a three-phase axial dual-split transformer in the prior art, the three-phase dual-column dual-split transformer set is utilized, and the transformer set is safer and more reliable.

Owner:HAINAN JINPAN INTELLIGENCE TECH CO LTD

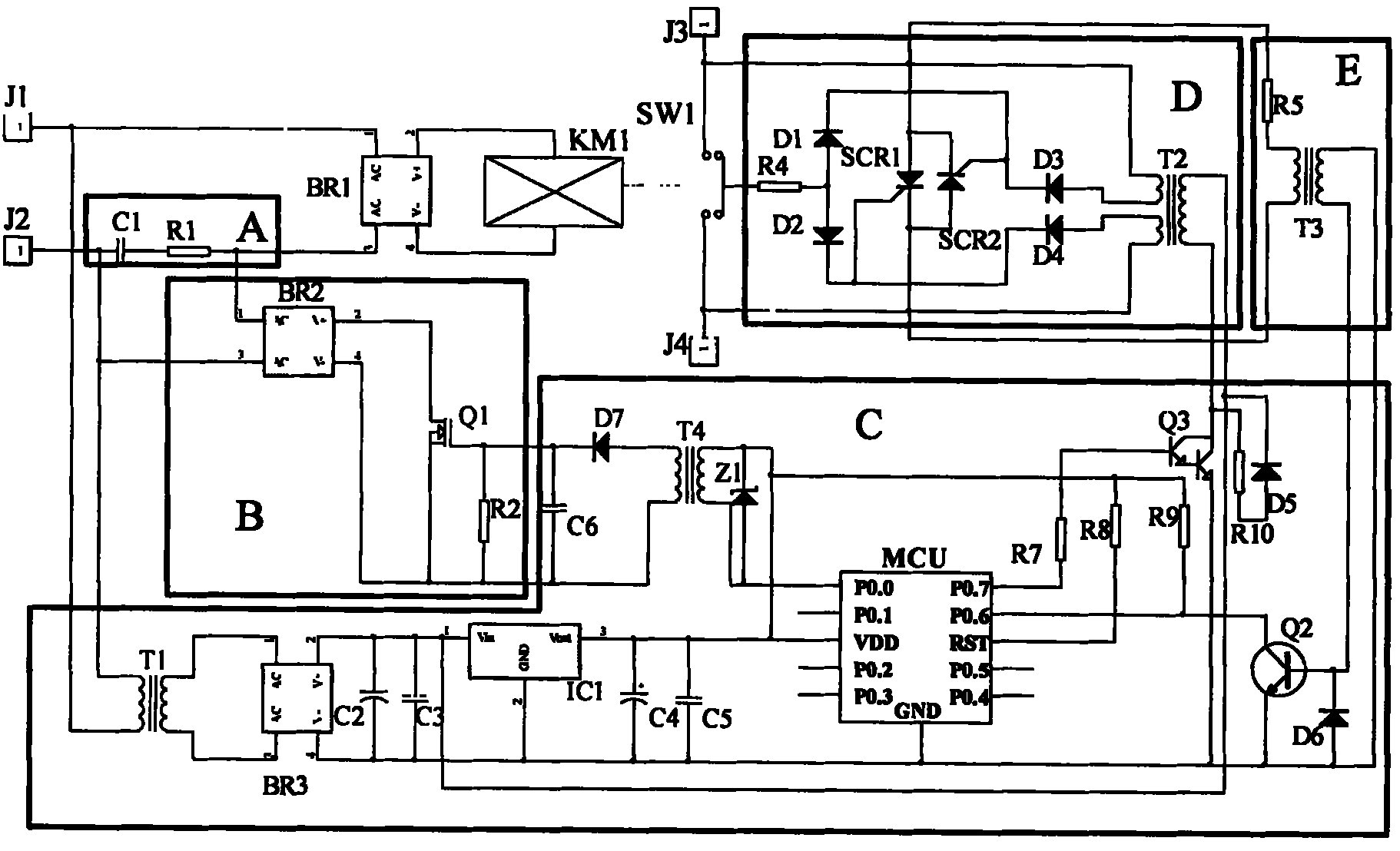

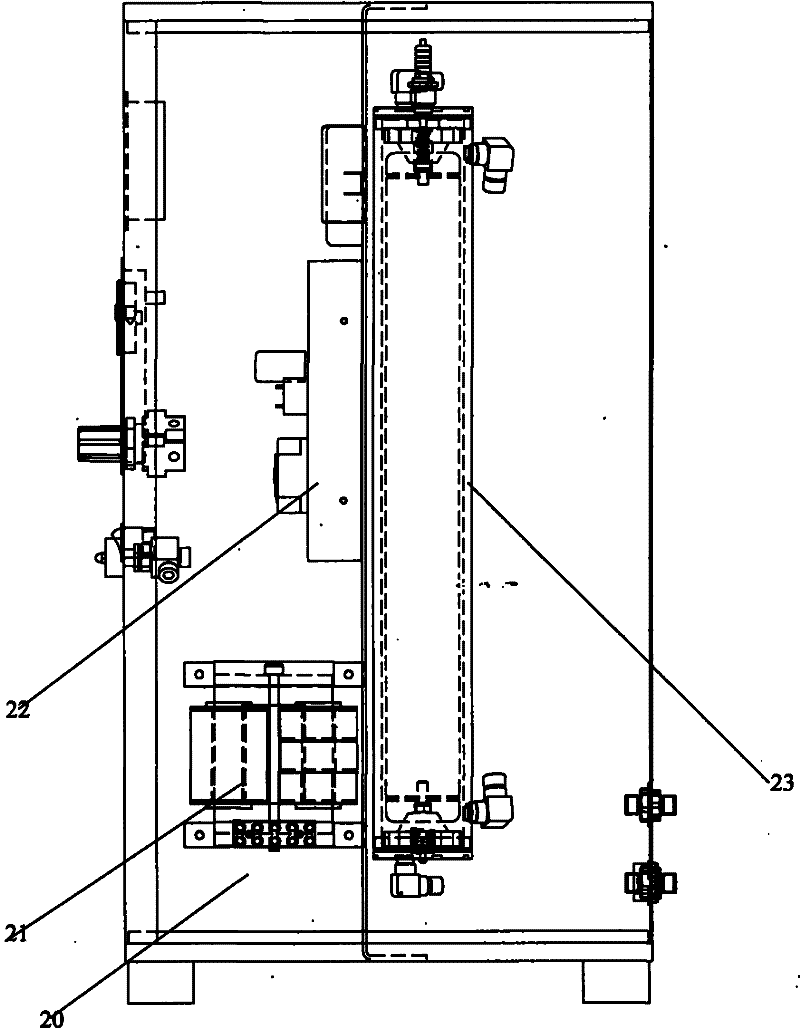

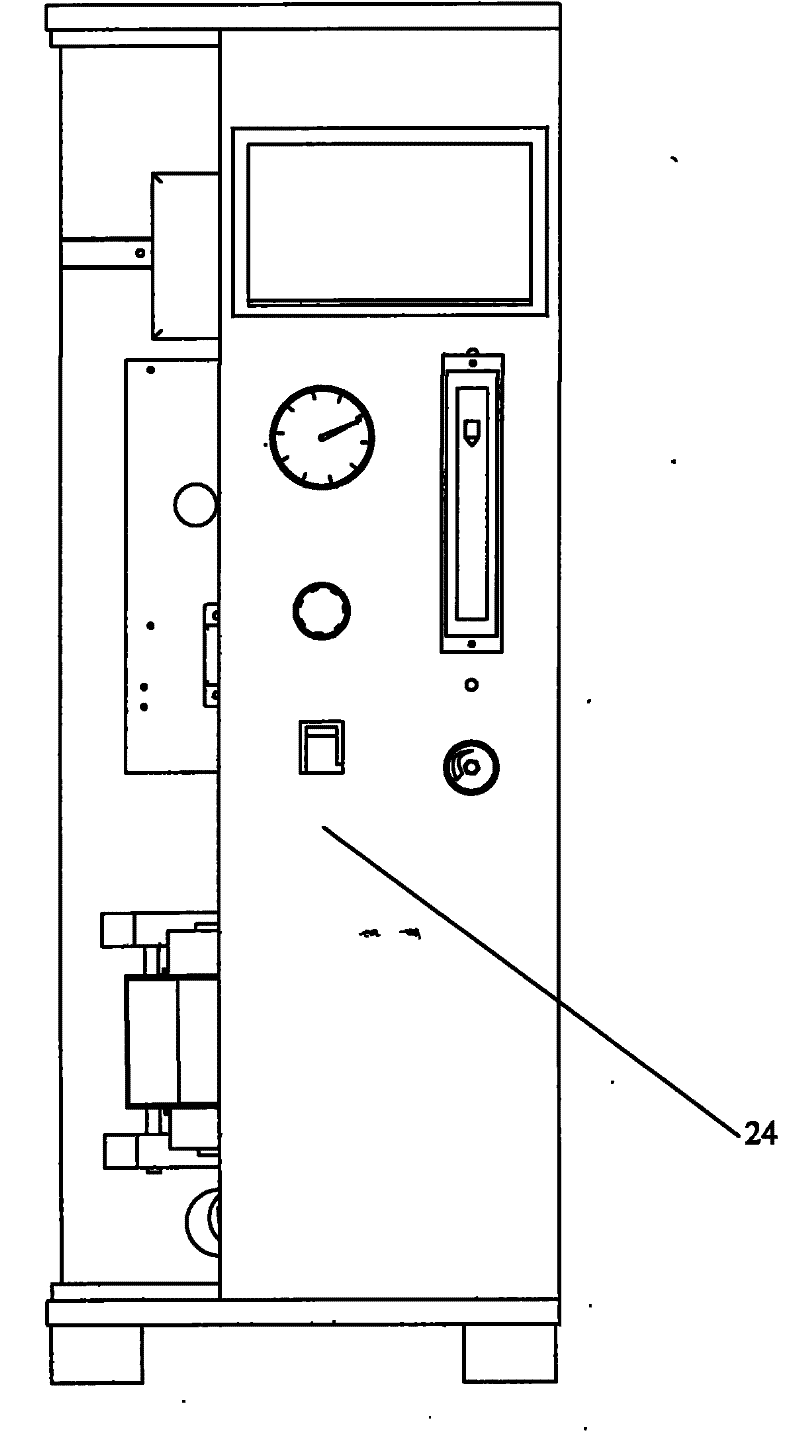

Intelligent ozone generator

The invention discloses an intelligent ozone generator, which consists of a case, an ozone generating tube, a circuit control system, a transformer and a control panel, wherein the ozone generating tube in the case is connected with the circuit control system; the circuit control system comprises a rectifying circuit, a half-bridge inverter circuit, a control power supply circuit, a voltage stabilizing circuit, a constant current regulating circuit and a high-frequency driving circuit, wherein the rectifying circuit is connected with the voltage stabilizing circuit and the half-bridge inverter circuit respectively; the control power supply circuit is connected with the constant current regulating circuit and the driving circuit respectively; the driving circuit is connected with the half-bridge inverter circuit which is connected with the transformer; and the transformer is connected with the ozone generating tube and is a step-up transformer with adjustable frequency. The intelligentozone generator has the advantages of simple, convenient and reliable whole gas circuit design, reliable equipment operation, low power loss and equipment security, reliability and anti-interference property.

Owner:HANGZHOU CHENGJIE ENVIRONMENTAL PROTECTION

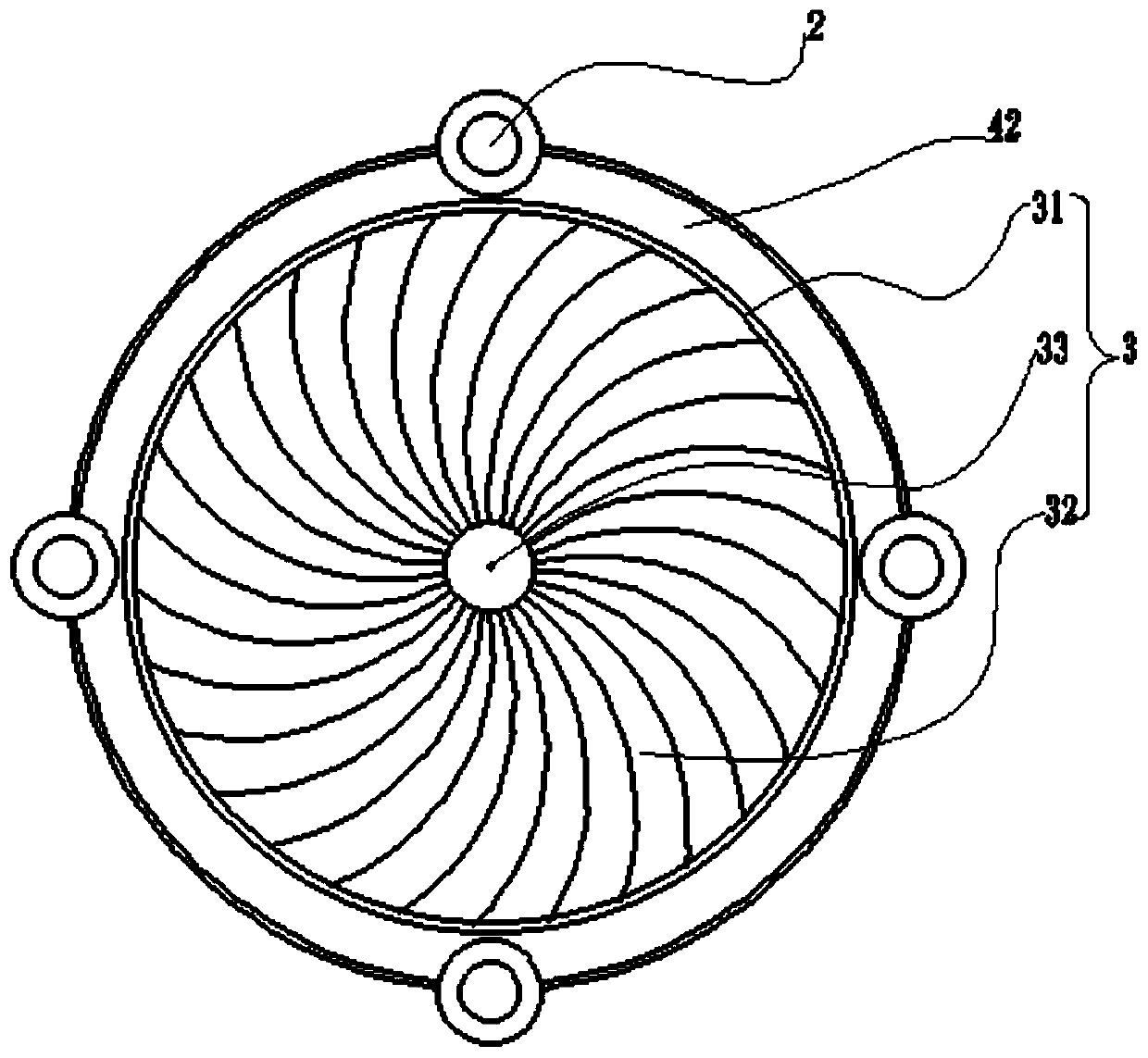

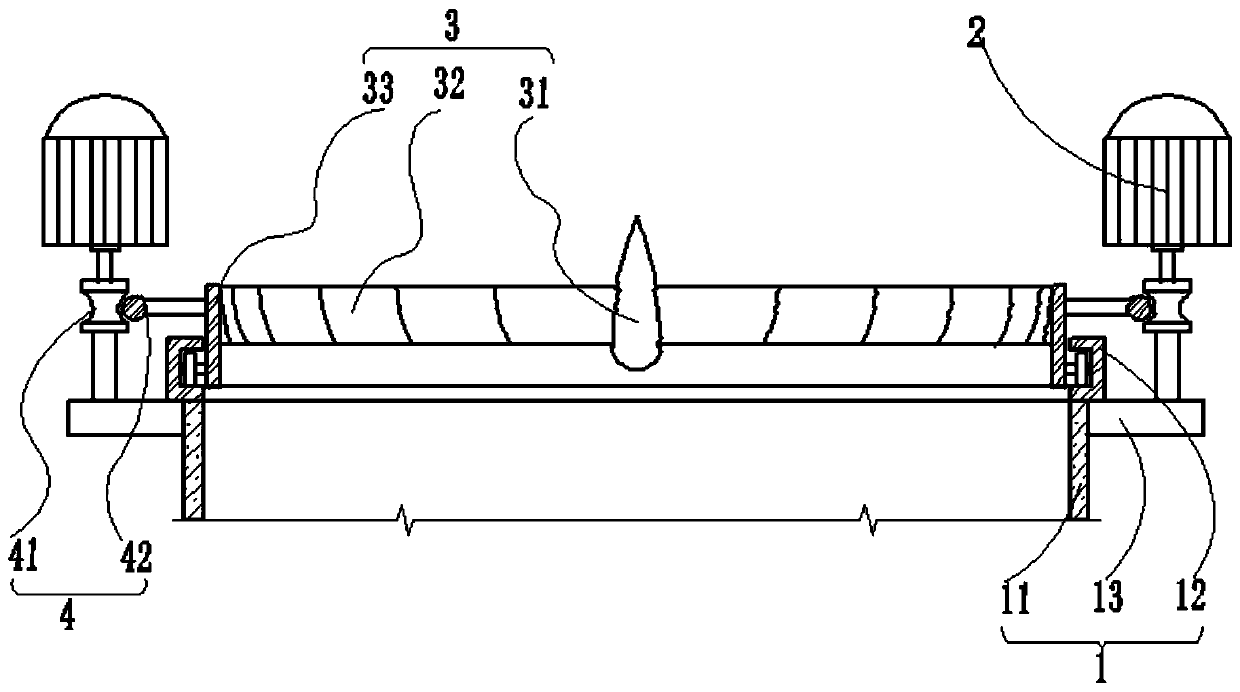

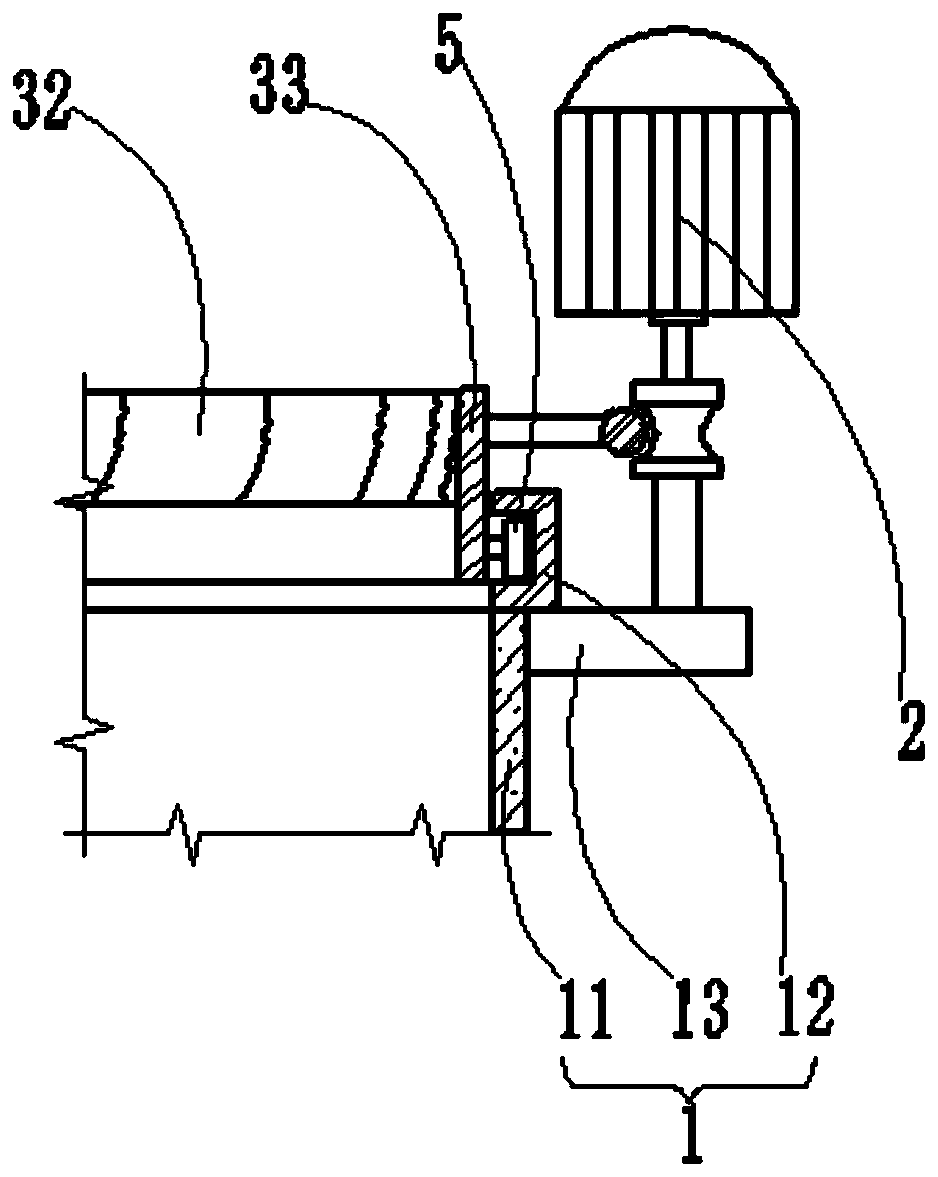

Switching type turbine machine

InactiveCN110030200AImplement switchable usageAchieve flowPump componentsWind motor combinationsElectricityElectric machine

The invention provides a switching type turbine machine. The switching type turbine machine comprises a supporting sleeve, electromechanical devices, a rotating part and transmission parts, wherein the electromechanical devices are arranged on the supporting sleeve, the rotating part is suspended at the top end of the supporting sleeve, the rotating part comprises a mounting shaft, a rotating surrounding wall and rotating blades, the rotating surrounding wall is arranged around the mounting shaft, the rotating blades are connected with the mounting shaft and the rotating surrounding wall, thetransmission parts are used for being in transmission connection with the rotating surrounding wall and the electromechanical devices, when the switching type turbine machine is switched to an air outlet state, the electromechanical devices are driving motors, the electromechanical devices drive the rotating surrounding wall to rotate through the transmission parts so as to realize the effect thatthe rotating blades accelerate flowing of a fluid, when the switching type turbine machine is switched to a power generating state, the electromechanical devices are generators, and the flowing fluiddrives the rotating blades to rotate so as to realize the effect that the rotating surrounding wall drives the electromechanical devices to generate electricity through the transmission parts. The switching type turbine machine can be used as power generation equipment and wind power equipment correspondingly, and is low in energy consumption, strong in energy-saving performance and low in noise.

Owner:HUNAN CHUANGHUA LOW CARBON ENVIRONMENTAL PROTECTION TECH

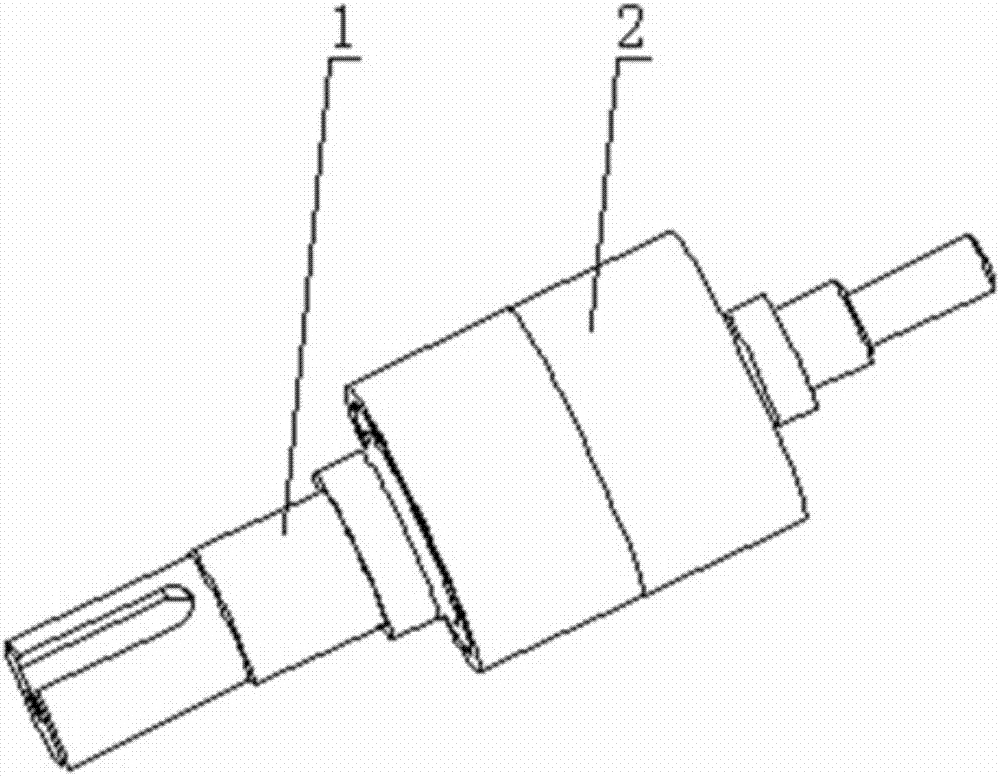

Permanent magnet synchronous motor rotor component and manufacturing method thereof

PendingCN107863830ASimple structureSimple processing technologyMagnetic circuit rotating partsMechanical energy handlingFiberCarbon fibers

The invention discloses a permanent magnet synchronous motor rotor component and a manufacturing method thereof. The permanent magnet synchronous motor rotor component comprises a rotating shaft, a balance ring, a magnetic steel, a carbon fiber sleeve, a rotor core and a flat key, a first U-shaped groove is formed in the outer circle surface of the rotating shaft, the flat key is arranged in the first U-shaped groove, the rotor core is arranged on the outer surface of the rotating shaft in a sleeved manner and in interference fit with the rotating shaft, the balance ring is arranged at the endof the rotating shaft in a sleeved manner and in interference fit with the rotating shaft and the rotor core, the magnetic steel is pasted on the outer surface of the rotor core, the carbon fiber sleeve is arranged on the outer surfaces of the magnetic steel and the balance ring in a sleeved manner, a first cylindrical shaft hole and a second cylindrical shaft hole are mutually communicated and formed in the rotating shaft, and the first cylindrical shaft hole is larger than the second cylindrical shaft hole. The component is simple in structure, convenient to assemble, disassemble and maintain, high in qualification rate, small in size and less in consuming material and not easy to break and generates less heat in operation.

Owner:NINGBO PHASE MOTION CONTROL

Transformer bank

InactiveCN109448975AAvoid failureNo eddy current lossTransformers/inductances coils/windings/connectionsUnwanted magnetic/electric effect reduction/preventionLow voltageCoupling

The invention discloses a transformer bank. The transformer bank comprises three double-column single-phase transformers; and each double-column single-phase transformer comprises a first iron core column, a second iron core column, and a high-voltage coil and a low-voltage coil arranged on the first iron core column, and a high-voltage coil and a low-voltage coil arranged on the second iron corecolumn. Each iron core column only comprises one low-voltage coil, so that no magnetic coupling relation exists between the low-voltage coils, a leakage magnetic field cannot be generated between thelow-voltage coils due to load imbalance, the eddy current loss cannot be generated, and the problem of transformer faults caused by the load imbalance is avoided; and meanwhile, compared with a three-phase axial double-split transformer in the prior art, the transformer bank adopted by the invention is safer to apply and more reliable.

Owner:HAINAN JINPAN INTELLIGENCE TECH CO LTD

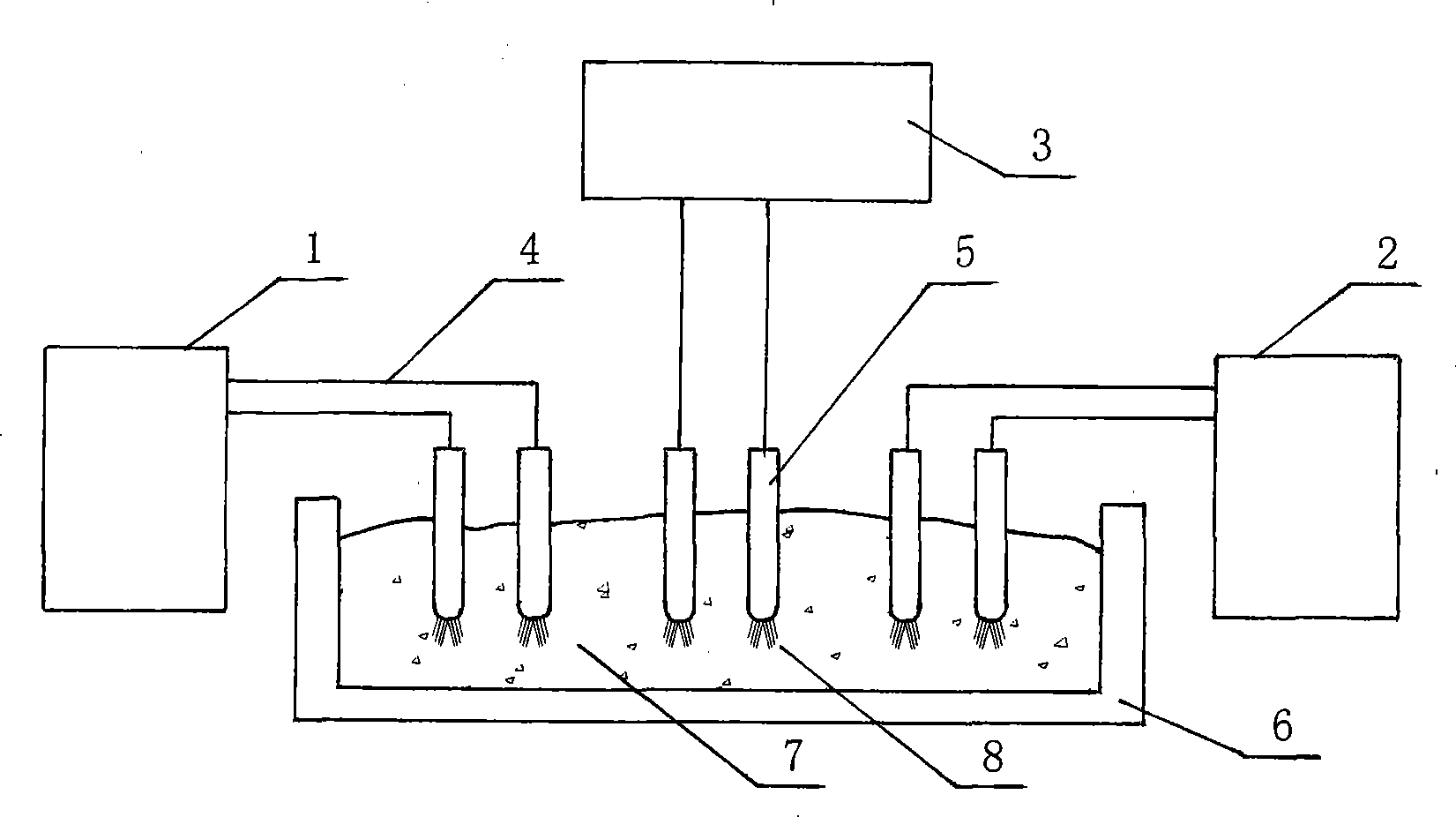

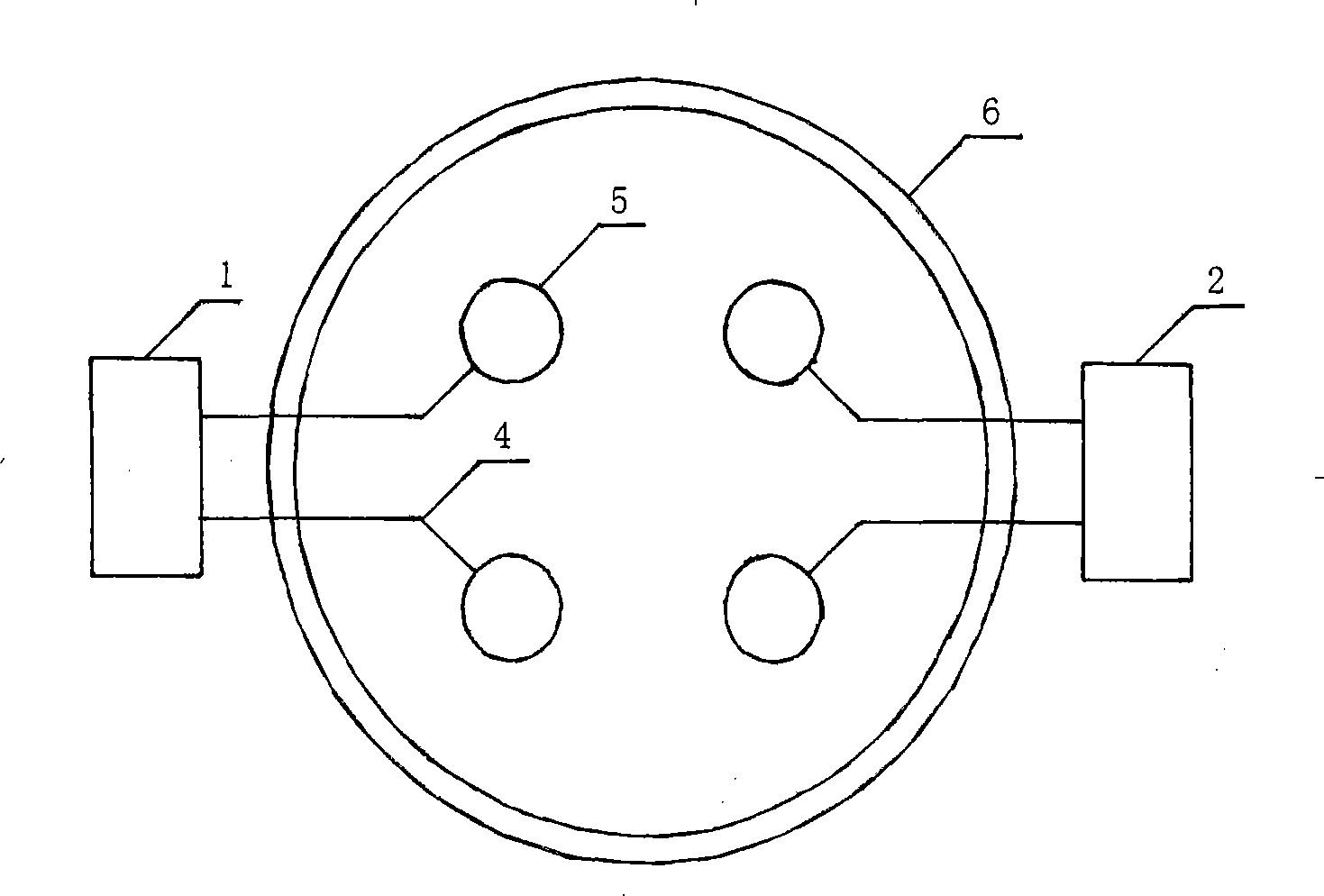

Multi-loop direct-current power supply smelting ore furnace

InactiveCN101251337AShort network reactance zeroNo eddy current lossElectric heating for furnacesTransformerEddy current

The invention relates to a submerged arc furnace with a multi-loop direct current power supply, wherein, an alternating current power supply becomes a plurality of direct current power supplies after transforming of a transformer and commutating of a rectifier, the direct current power supplies are connected with one end of a corresponding positive negative carbon electrode bar through a short network, the other end of the positive negative carbon electrode bar inserts into the charging in the hearth, the positive negative electrode instantly produces the arc to melt the charging to obtain ferrous alloy products. The submerged arc furnace has the advantages of steady smelting arc, big melting pot, exact electrode control and remarkable energy saving effect, and is applicable to industrialization; the reactance of the short network is zero and the device does not have the eddy current loss.

Owner:丁长桂

Permanent magnet servo motor rotor and manufacturing method of the same

InactiveCN107040066AReduce assembly processIncrease profitMagnetic circuit rotating partsMagnetic circuit characterised by magnetic materialsCooking & bakingGlass fiber

The invention provides a permanent magnet servo motor rotor. The permanent magnet servo motor rotor includes an integrated member of rotating shaft and iron core, and magnet rings, wherein the magnet rings are arranged on the integrated member of rotating shaft and iron core. The invention also provides a manufacturing method of the permanent magnet servo motor rotor. The permanent magnet servo motor rotor has the advantages that the integrated structure of rotating shaft and iron core is utilized so that the assembling process of the rotor and the iron core can be saved; as glass fibres and other protection sleeves are not added on the outside of the magnetic rings, the assembling relation is simple and the production cost is saved; a steel protective device is not required to add on the outside of each magnetic ring, so that eddy current loss is not generated; only the outside of the integrated member of rotating shaft and iron core is required to be coated with adhesive uniformly, and then the magnetic rings which are not magnetized are put in the integrated member of rotating shaft and iron core, and when the rotor is baked to become solid and reliable in a baking box, the rotor can be magnetized integrally with a desired magnetic field wave form; and the rotor structure enables the air gap to be smaller, so that the utilization rate of permanent magnet can be improved.

Owner:深圳市百晟传动有限公司

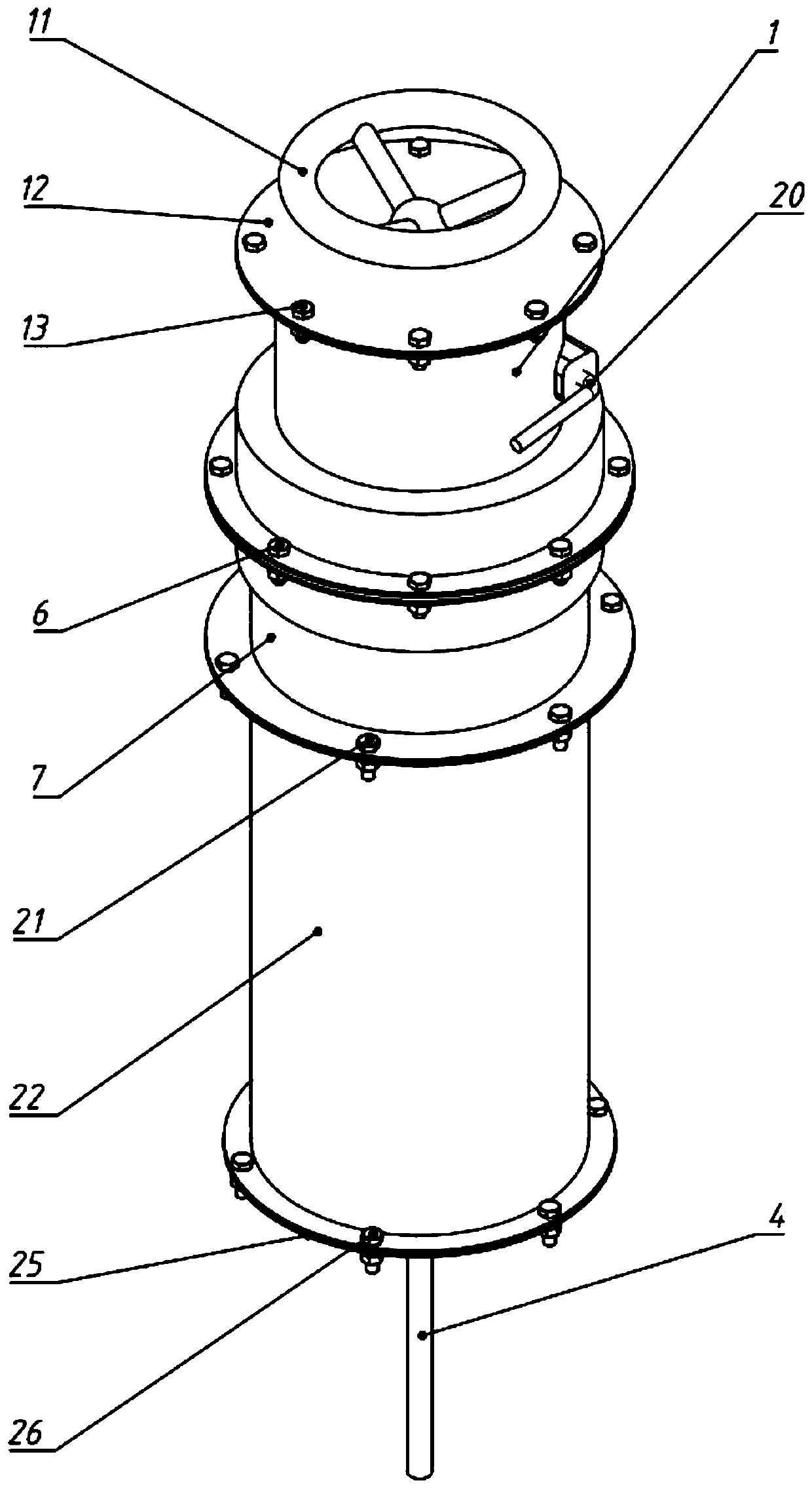

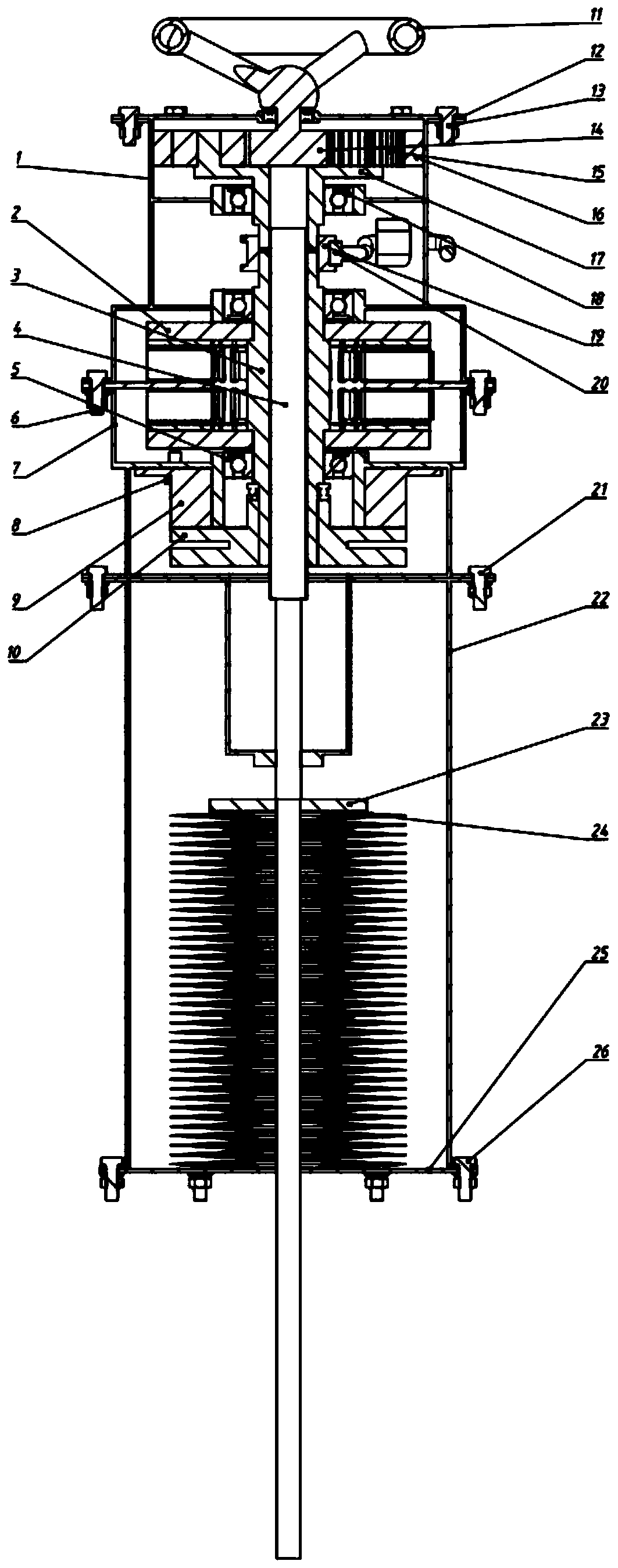

Direct-drive type disc spring energy storage and return type linear-motion quick shut-off performing mechanism

InactiveCN111425645AAvoid casualtiesAvoid property damageWindingsOperating means/releasing devices for valvesElectric machinePower switching

The invention discloses a direct-drive type disc spring energy storage and return type linear-motion quick shut-off performing mechanism. The direct-drive type disc spring energy storage and return type linear-motion quick shut-off performing mechanism comprises a power mechanism, a power switching mechanism, a transmission system and an energy storage and return mechanism, wherein the power mechanism drives the transmission system to realize motion output; the power mechanism comprises an electric drive system and a manual operation system; the power switching mechanism is used for realizingswitching between the electric drive system and the manual operation system; and the energy storage and return mechanism is used for performing shut-on and shut-off on an electric performing mechanismwhile the electric drive system is shut off. An alternating-current servo motor drives a nut to rotate under a shut-on condition, so that a lead screw moves up and down; and under a sudden power-losing condition, the motor and an electromagnetic brake are shut off, the lead screw nut is in a free moving station, a disc spring energy storage mechanism releases elastic potential energy to push thelead screw to move upwards, so that quick shut-off is realized.

Owner:CHINA PETROLEUM & CHEM CORP +2

Integrated PCB winding disc type motor system

ActiveCN112134429AImprove performanceAdjustable upper and lower air gapAssociation with control/drive circuitsWindings conductor shape/form/constructionPull forceElectric machine

The invention discloses an integrated PCB winding disc type motor system. According to the integrated PCB winding disc type motor system, the upper rotor disc, the lower rotor disc and the stator discform a double-side permanent magnet disc type motor structure, single-side magnetic pull force can be overcome, magnetic flux leakage is reduced, permanent magnet materials are fully utilized, the motor performance is improved, the cost is reduced, the size is reduced, the axial size is short, and the structure is compact; and the system is suitable for occasions with strict requirements on placement space. According to the disc type motor system, the stator and the rotor are arranged in a peer-to-peer mode, heat dissipation is good, and high power density can be obtained. In addition, the adjustable mechanism additionally arranged on the rotating shaft can realize the adjustability of the upper and lower air gaps of the motor, and can facilitate the expansion and adjustment of the numberof layers of the integrated PCB winding structure, so that the performance of the motor is optimal.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

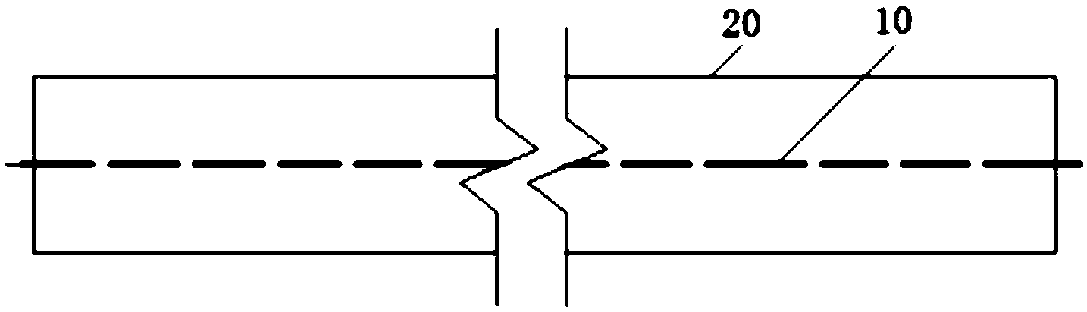

High-performance micro-prestressing-force thermoplastic intelligent fiber rod and manufacturing method thereof

The invention, which relates to fields of the building composite material, the sensor, the engineering detection, and solid mechanics, discloses a high-performance micro-prestressing-force thermoplastic intelligent fiber rod and a manufacturing method thereof. The fiber rod comprises a sensing fiber (10) and a thermoplastic rod body (20). The outside of the sensing fiber (10) is coated with the thermoplastic rod body (20). The sensing fiber (10) is a communication fiber with an applied micro-prestressing force; and the thermoplastic rod body (20) is a high-polymer-material-based coating element. The intelligent fiber rod has the following advantages: firstly, the weight is light, the density is 1900kg / m<3>, the rigidity and flexibility are high, and the fiber rod also has corrosion-resistant, magnetism-free, electric insulation, eddy-loss-free, and eddy-interference-free functions; secondly, the intelligent fiber rod belongs to the passive sensor field and does not need a power supply, so that a problem of electrode corrosion can be solved; and thirdly, the service life is long; the base material thermoplastic unit is arranged inside the structure and isolated from the fiber and air, so that the service life is prolonged; and the functional material fiber is a piece of glass essentially and has the service life equal to the structure.

Owner:湖北同广和新材料有限公司

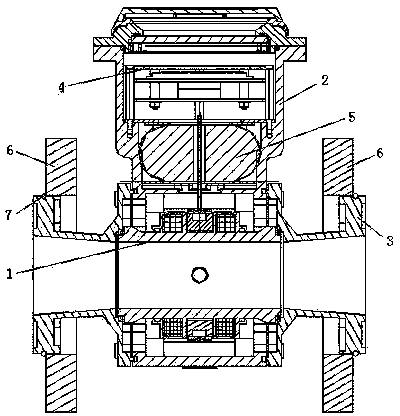

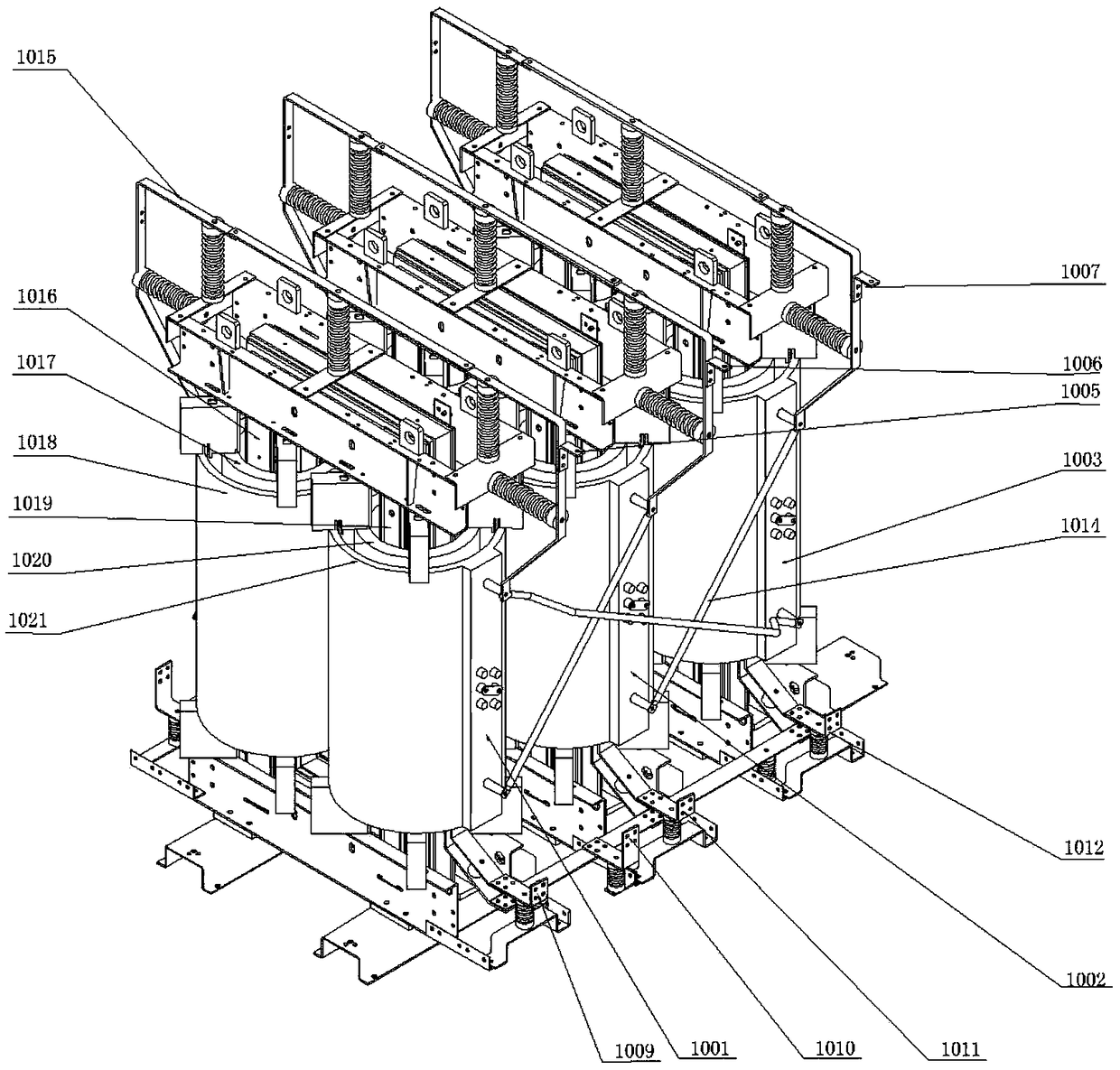

Buffer starting type permanent magnet coupling direct drive device

PendingCN113162357ASolve the problem that additional electronic components are required for buffered startupSolve the problem that additional electronic components need to be addedMagnetic circuit rotating partsPermanent-magnet clutches/brakesElectrical conductorEngineering

The invention discloses a buffer starting type permanent magnet coupling direct drive device which comprises a machine shell and a stator assembly, a rotor assembly, a conductor disc assembly, a permanent magnet disc assembly, a main shaft and an output shaft which are set in the machine shell; the main shaft and the output shaft are rotationally connected with the machine shell and are concentrically arranged, and a gap is formed between the main shaft and the output shaft. The rotor assembly and the conductor disc assembly respectively sleeve and are fixedly connected to the main shaft. The conductor disc assembly is arranged on one side, close to the output shaft, of the rotor assembly. The stator assembly is sleeved on the rotor assembly, and the stator assembly is fixedly connected to the machine shell. The permanent magnet disc assembly sleeves and is fixedly connected to the output shaft. External multi-phase alternating current is introduced into the stator assembly to generate a rotating magnetic field, the rotating magnetic field interacts with a first permanent magnetic field generated by the rotor assembly, and the rotor assembly is driven to rotate to drive the main shaft and the conductor disc assembly to rotate. The conductor disc assembly cuts a second permanent magnetic field on the permanent magnetic disc assembly so as to induce and generate torque to drive the permanent magnetic disc assembly and the output shaft to rotate.

Owner:SHANGHAI ORIENTAL MARITIME ENG TECH CO LTD

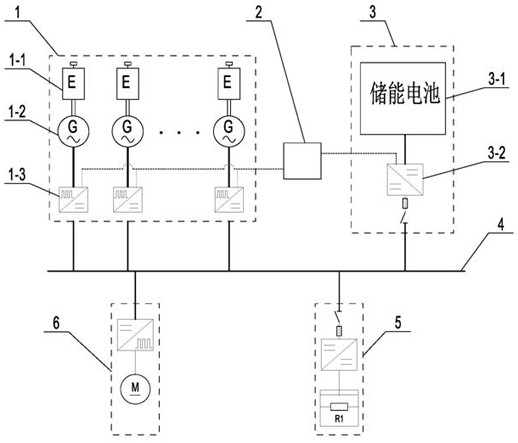

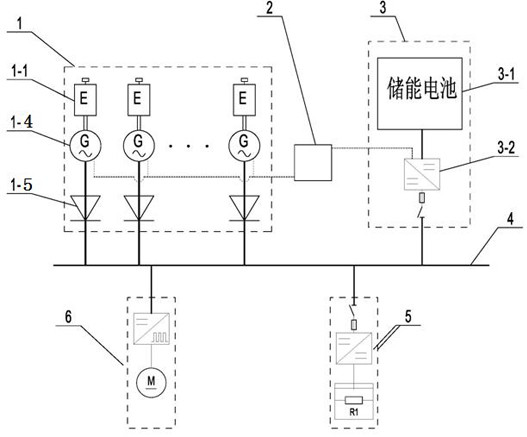

Direct-current micro-grid power transmission system applied to petroleum drilling machine

PendingCN113991637ASolve the problem of AC harmonic pollutionImprove efficiencyAc-dc conversion without reversalLoad balancing in dc networkHarmonicsControl theory

The invention discloses a direct-current micro-grid power transmission system applied to a petroleum drilling machine. The system comprises a power generation rectification unit, a central controller, an energy storage unit, a common direct-current bus, a braking unit and a load unit; the power generation rectification unit is connected to a common direct current bus, the energy storage unit is connected to the common direct current bus, the control end of the central controller is connected with the controlled ends of the power generation rectification unit and the energy storage unit, and the brake unit and the load unit are connected to the common direct current bus in parallel; the system solves the problem of AC harmonic pollution of a well site power device, greatly improves the motor efficiency and the service life of equipment, is good in power grid quality, and does not need to treat cost; and meanwhile, an energy storage device is configured to bear an impact load when the load suddenly changes, maintain the DC bus voltage stable, and guarantee the normal operation of the system.

Owner:华兴智控(北京)能源有限公司

A superconducting controllable reactor

ActiveCN104425118BImprove permeabilityNo eddy current lossTransformersFixed transformers or mutual inductancesEngineeringMagnetic powder

The invention discloses a superconduction controllable reactor. Superconduction control coils, working coils, a low-temperature cryostat and a magnetic shielding iron core are respectively in a hollow cylinder shape, a high-magnetic-conductivity iron core consists of an upper magnetic conducting iron core and a lower magnetic conducting iron core, the upper magnetic conducting iron core and the lower magnetic conducting iron core are respectively in a cylinder shape and are respectively and fixedly arranged on an upper cover plate and a lower cover plate of the low-temperature cryostat, a space between the two iron cores is filled and supported by epoxy resin material, the filling height of the epoxy resin is equal to 1 / 2 to 1 / 3 of the height of each working coil, the superconduction control coils are positioned in the low-temperature cryostat, and are arranged in a coaxial or similarly coaxial way from interior to exterior, the working coils sleeve the low-temperature cryostat, and are respectively positioned in the magnetic shielding iron core, and the high-magnetic-conductivity iron core is made of iron powder cores or magnetic powder cores. The superconduction controllable reactor has the advantages that the usage amount of superconduction wires is reduced, the technical complexity of the manufacturing of the low-temperature cryostat is decreased, the additional heat load on a low-temperature system caused by the vortex loss of the high-magnetic-conductivity iron core is effectively reduced, the refrigerating cost is reduced, and the safety and stability of the low-temperature system are improved.

Owner:HUAZHONG UNIV OF SCI & TECH +1

High-efficiency motor with full-circumference magnetic flux polarized circumferential winding and new-energy electric vehicle

PendingCN106385125AEliminate magnetic flux leakageIncrease powerMagnetic circuit rotating partsMagnetic circuit stationary partsNew energyMagnetic poles

A motor with a full-circumference magnetic flux polarized three phase circumferential windings comprises three phase circumferential windings and six U-shaped stator magnetic poles which perform full-circumference magnetic flux polarization on the circumferential winding and have different orientations. A rotor shaft (200) is connected with rotor magnetic poles (202,203), (206,207), (212,213), (216,217), (222,223), (226,227) with a first orientation to a sixth orientation through rotor discs (201,211,221,231). The number of stator magnetic poles in a random orientation is same with that of the rotor magnetic poles in the orientation. Each phase circumferential winding controls two stator magnetic fields which performs polarization on the full circumference and in two orientations. The three phase circumferential windings (204,214,224) respectively control three phase stator and rotor magnetic fields which are at 120 DEG electric angle to one another. An electronic control system controls current of the three phase circumferential windings through testing the position of a rotor and is used as a motor or a power generator. The motor has advantages of small amount of magnetic flux leakage and high efficiency.

Owner:杨明

A superconducting claw pole motor

ActiveCN102882352BSimple structureSolve the problem of longevityMagnetic circuit rotating partsWindings conductor shape/form/constructionRotor magnetsSuperconducting electric machine

The invention provides a superconducting claw-pole motor. A stator part comprises a hollow support shaft, n superconducting exciting winding supports and a Dewar structure, wherein the n superconducting exciting winding supports and the Dewar structure are fixed on the hollow support shaft, a superconducting exciting winding is arranged in each exciting winding support, and a refrigerant pipe and a superconducting outgoing line are arranged in the hollow support shaft; a rotor part comprises a rotor shaft and n rotor magnet yoke sets; and each rotor magnet yoke set comprises an A magnet yoke and a B magnet yoke, claw poles on the two magnet yokes are distributed in a staggered mode and oppositely buckled on the two sides of a corresponding superconducting exciting winding, and the rotor shaft and the n rotor magnet yoke sets can rotate synchronously around the central axis of the rotor shaft. Motors in different power levels can be implemented through expanding the diameters along the radial direction or increasing the number of superposed claw pole assemblies along the axial direction. According to the invention, under the premise of meeting the operation of superconducting motors, the superconducting claw-pole motor disclosed by the invention has the characteristics of simple structure, low cost, easy machining, direct power-supply connection of exciting windings, no carbon brush or induced circuit required, small weight and size, and the like, and improves the reliability and efficiency of systems.

Owner:陕西捷普控制技术有限公司

A high stability permanent magnet torquer

ActiveCN104362777BHigh Moment Coefficient StabilityImprove stabilityMagnetic circuit rotating partsMagnetic circuit stationary partsBobbinPigtail

The invention relates to a high-stability permanent magnet torque device, which belongs to the field of electromagnetic components. The torque device includes: shell, permanent magnet steel, coil and skeleton, etc. The torque device of the present invention uses permanent magnetic steel as the excitation magnetic field source, and the coil rotates in the magnetic field after being energized. High linearity and stability; the sensitivity of the torque device is high; the rotor is output through soft wires, and the disturbance torque is very small.

Owner:BEIJING PULIMEN ELECTRO MECHANICAL HIGH TECHN CO

Permanent magnet coupling direct drive device

PendingCN111799981AAvoid overheating and burningMitigate start-up shockAsynchronous induction clutches/brakesPermanent-magnet clutches/brakesPermanent magnet rotorElectrical conductor

The invention discloses a permanent magnet coupling direct drive device. The device comprises a casing, and a stator assembly, a permanent magnet rotor assembly, a conductor rotor assembly and an output shaft which are coaxially arranged in the casing in sequence from outside to inside. The output shaft is rotatably connected to the casing, and the conductor rotor assembly is fixedly connected tothe output shaft. The stator assembly is fixedly connected with the casing, and is used for communicating with external multi-phase alternating currents and generating a rotating magnetic field. The permanent magnet rotor assembly is rotationally connected with the casing or the output shaft and drives the permanent magnet rotor assembly to rotate through interaction of a permanent magnet field and a rotating magnetic field. The conductor rotor assembly cuts the rotating permanent magnetic field and generates torque, and the torque drives the conductor rotor assembly to rotate so as to drive the output shaft to rotate. The advantages of a permanent magnet synchronous motor and an asynchronous induction motor are integrated, and the problems that an existing permanent magnet synchronous motor is large in starting impact, locked-rotor is prone to demagnetization and the like and the problems that an asynchronous motor is low in efficiency, large rotational inertia loads are difficult todirectly start, locked-rotor is prone to burning and the like can be solved.

Owner:SHANGHAI ORIENTAL MARITIME ENG TECH CO LTD

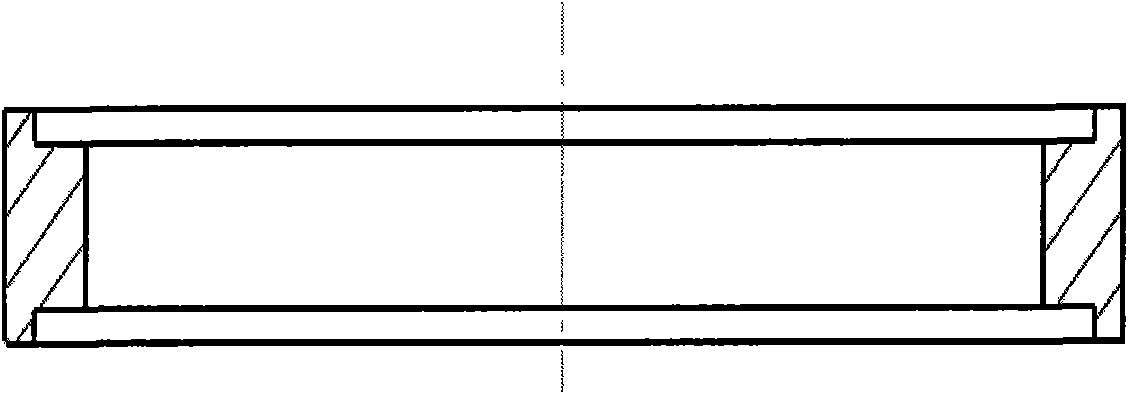

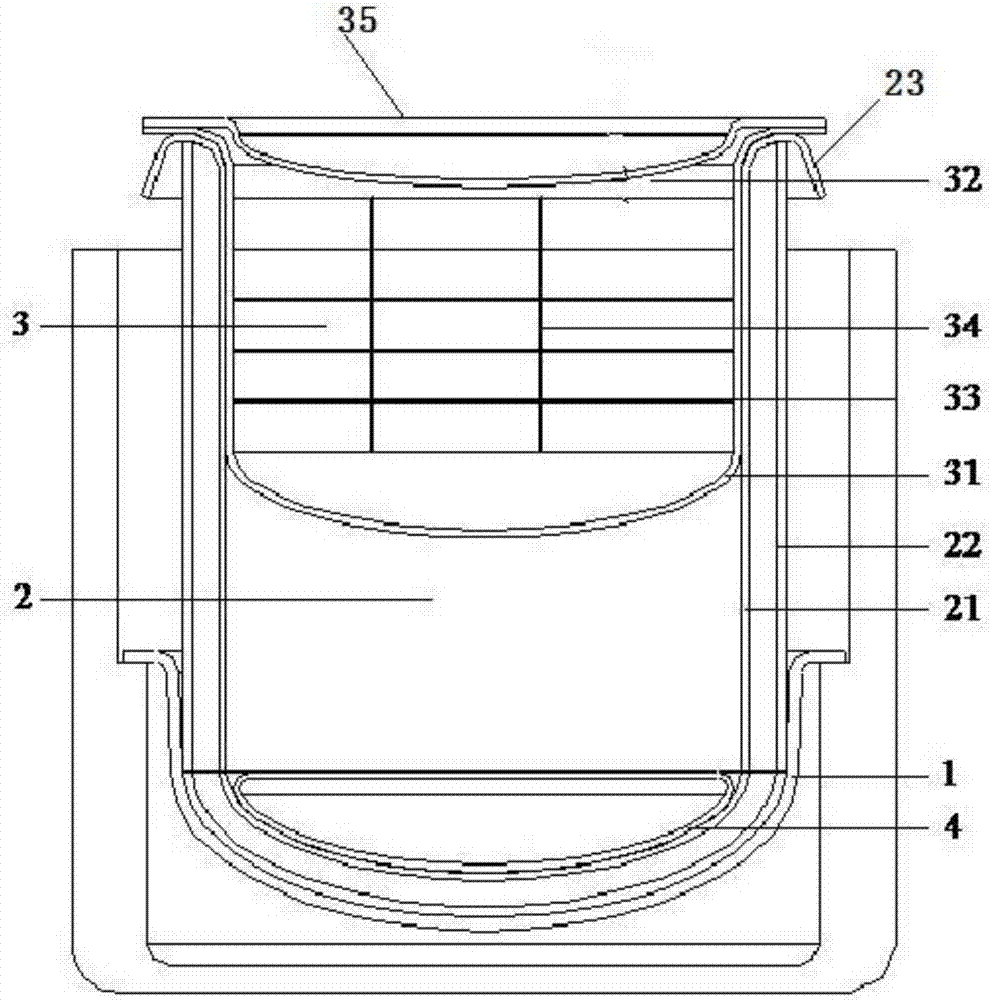

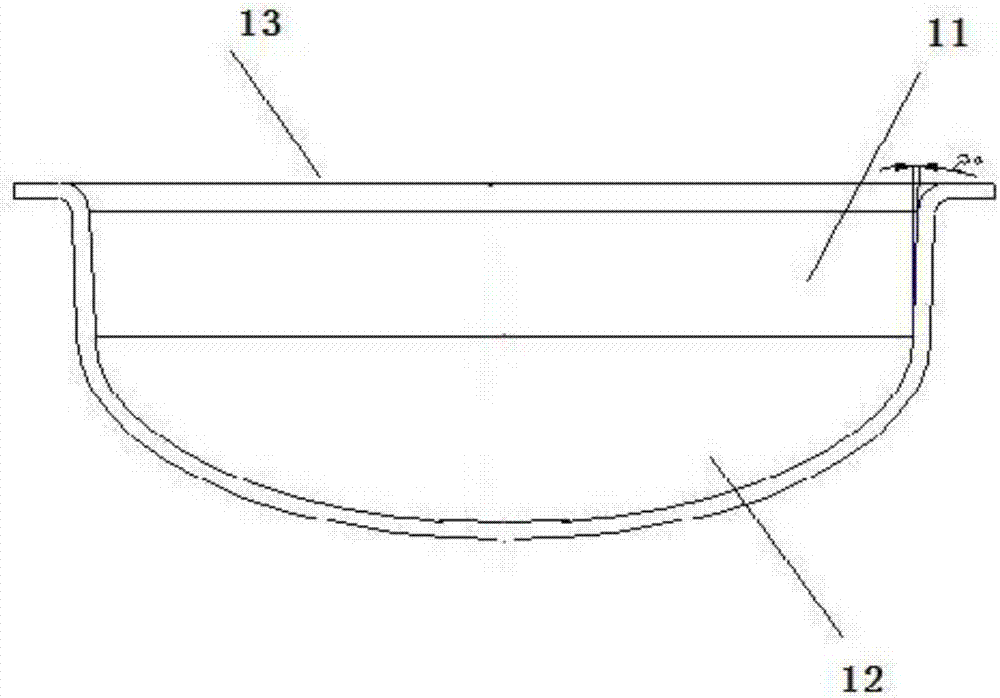

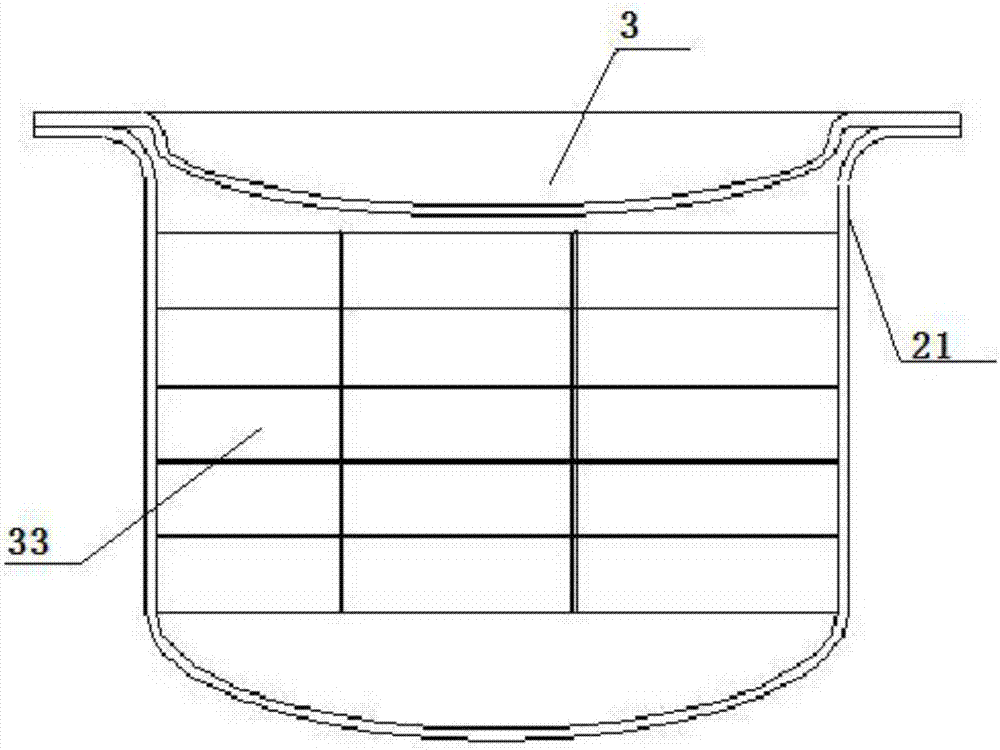

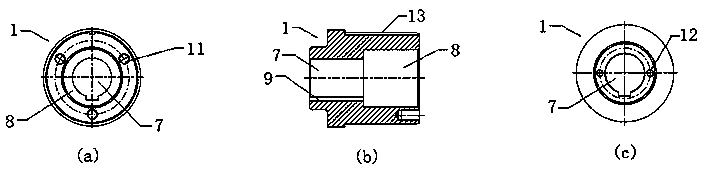

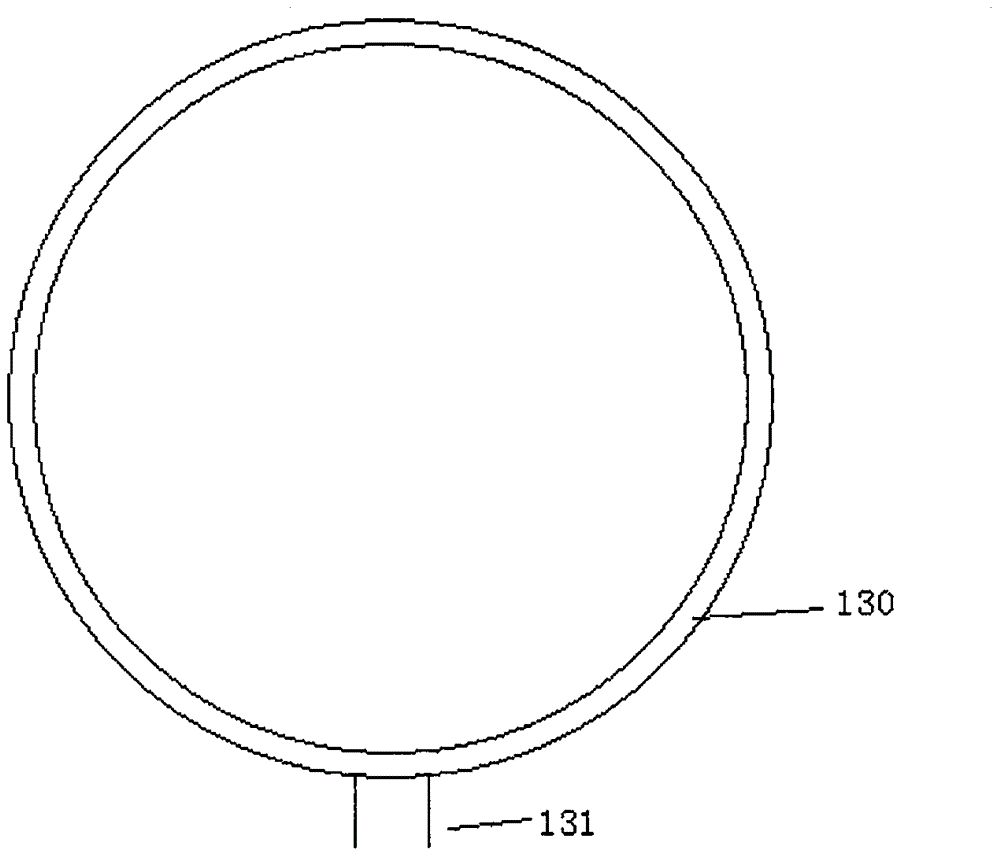

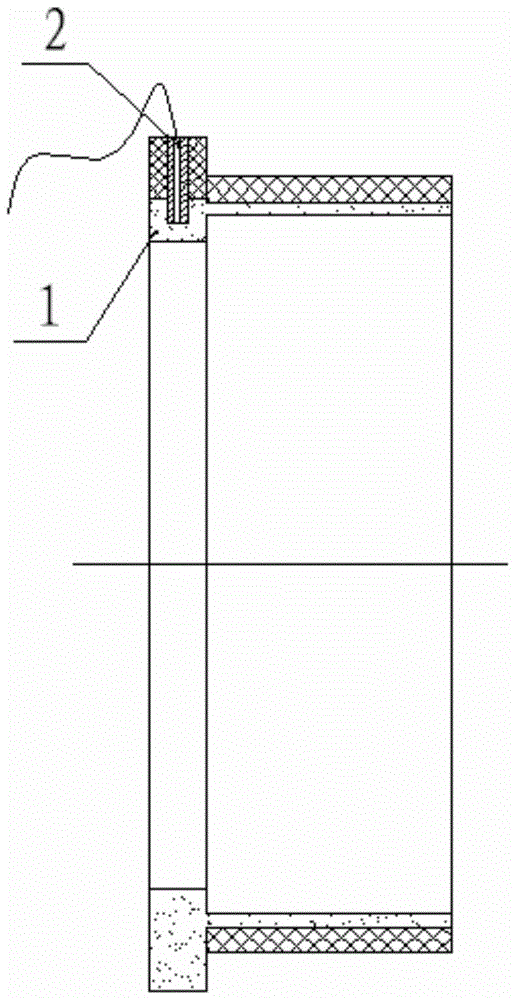

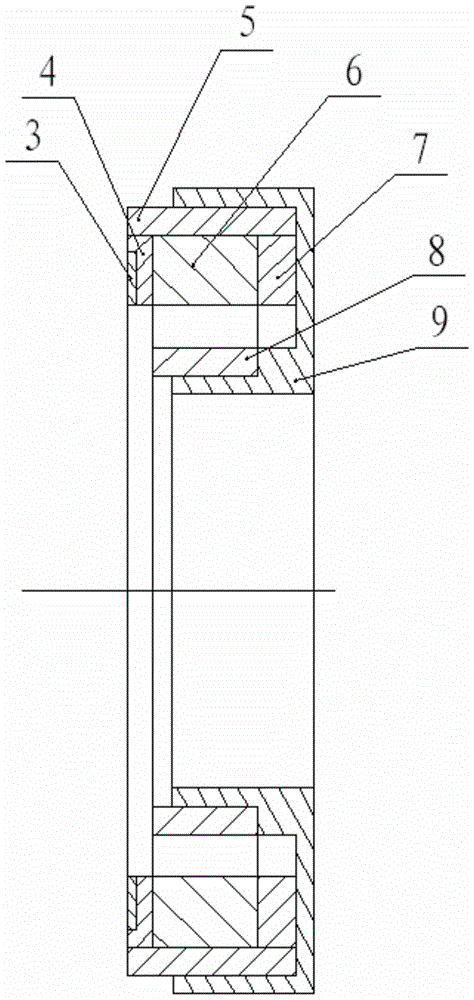

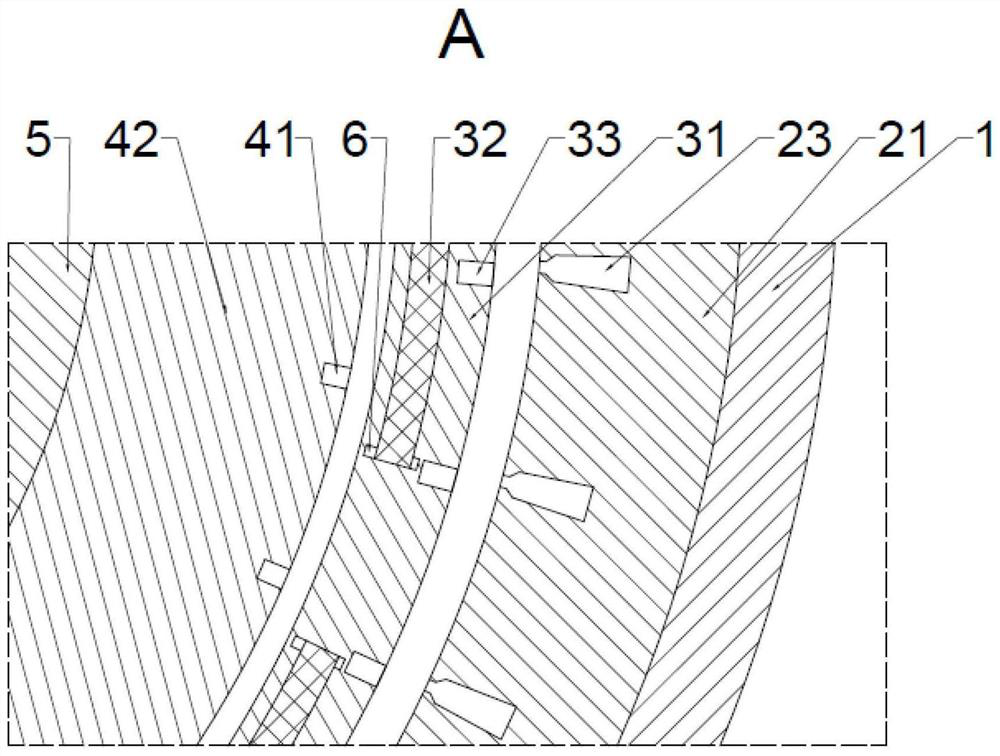

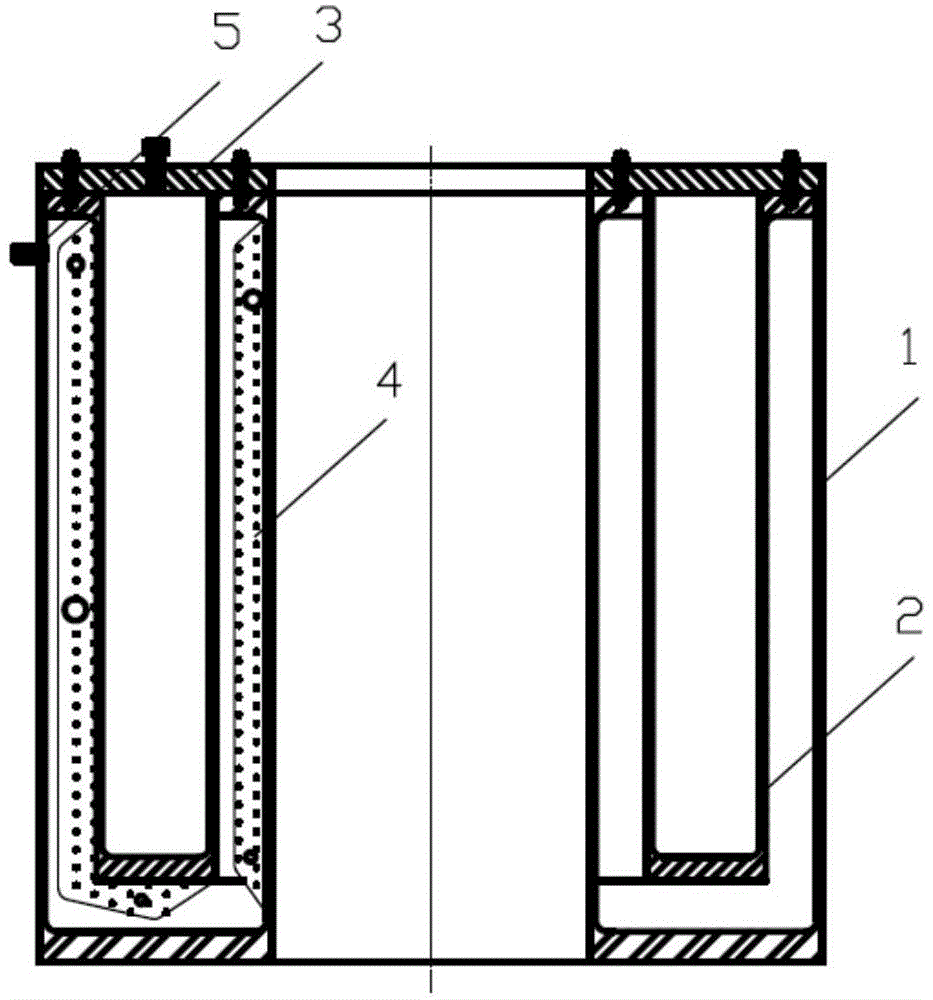

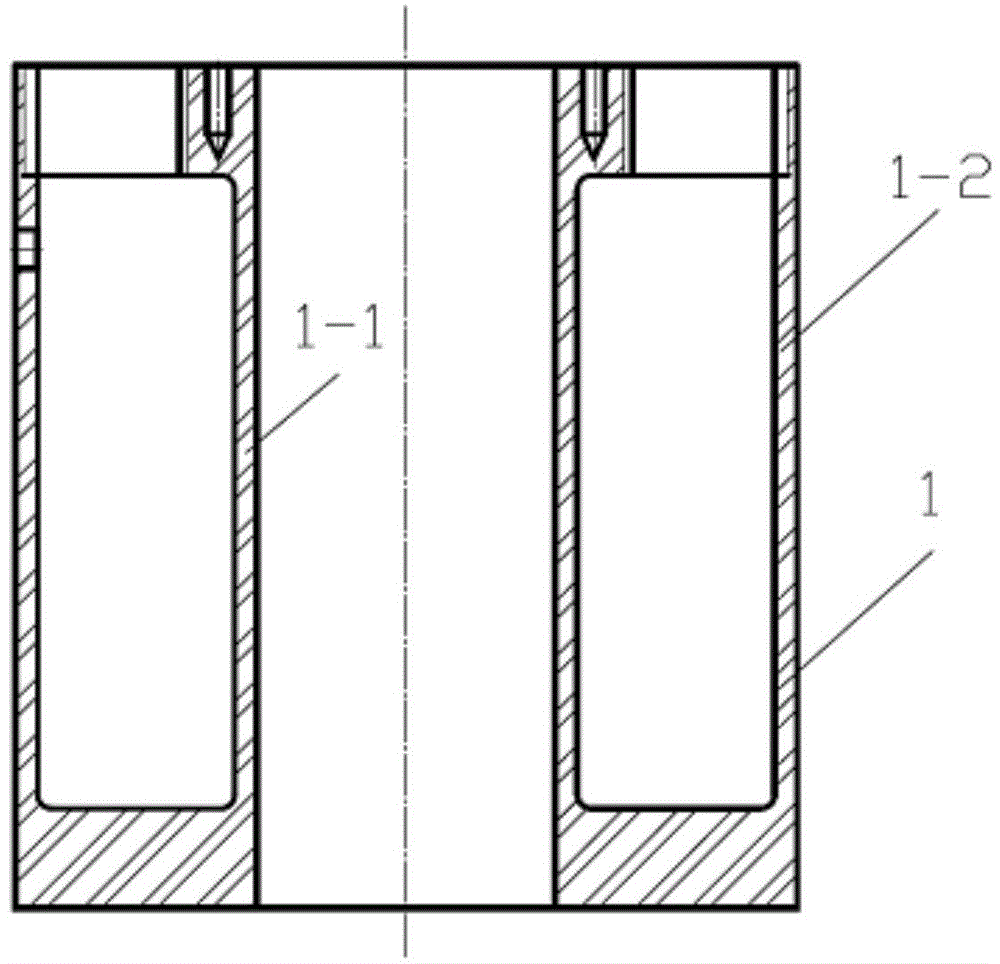

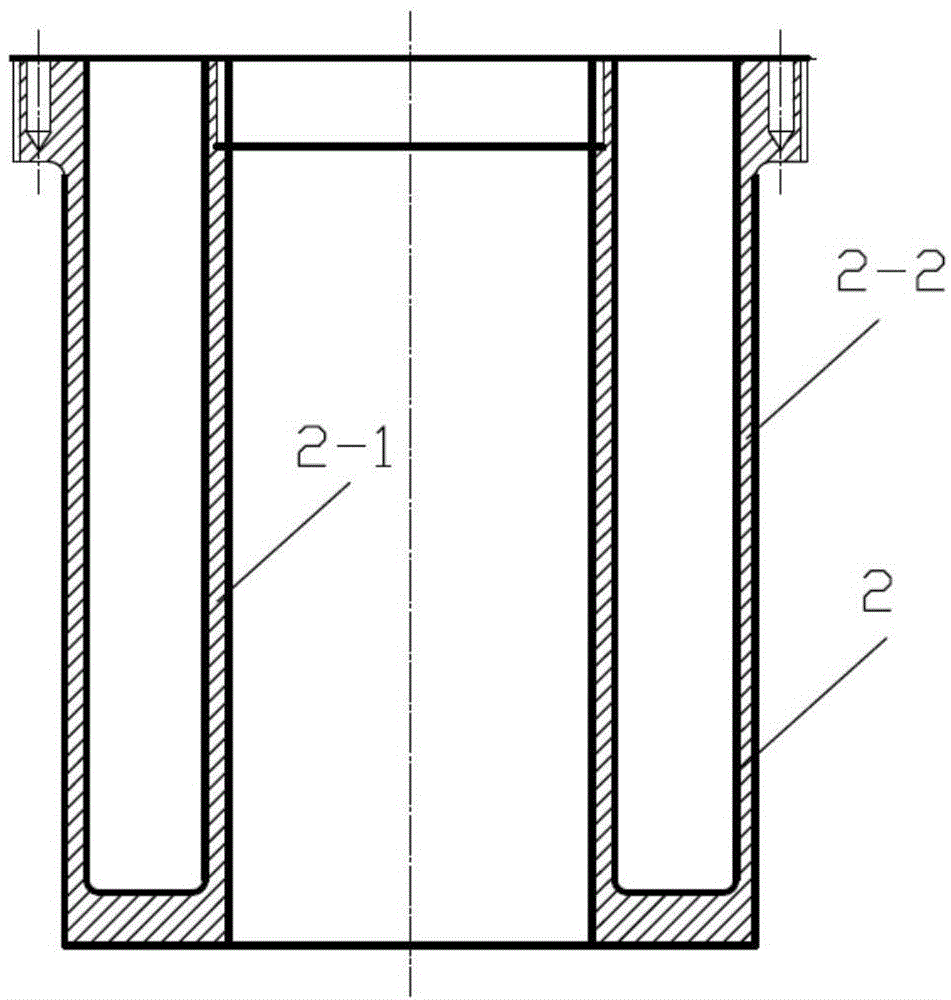

A hollow-structured non-metallic Dewar for AC superconducting magnets

InactiveCN103277662BNo eddy current lossImprove air tightnessContainer filling methodsPressure vesselsEpoxyGlass fiber

The invention discloses a hollow-structure nonmetal Dewar type barrel for an alternating-current superconducting magnet, which comprises an inner-outer barrel (1), a middle barrel (2), a Dewar type cover plate (3), a vacuum interlayer (4) and a vacuum suction nozzle (5), wherein the nonmetal Dewar type barrel adopts a hollow structure with indoor temperature holes; and the Dewar type barrel comprises the inner-outer barrel (1) and the middle barrel (2) which are made of epoxy resin and glass fibre in an integrated and curing forming manner, wherein the vacuum interlayer (4) is arranged between the inner-outer barrel (1) and the middle barrel (2) and is subjected to vacuumizing by the vacuum suction nozzle (5), and a molecular sieve is adopted as an adsorbent for keeping the high vacuum degree. A plurality of layers of thermal insulation materials are pasted on the side walls and the bottom of the barrel of the vacuum interlayer (4), so that conduction heat and radiant heat are reduced; and in the plurality of layers of thermal insulation materials, a reflecting screen is cut off along the peripheral direction, so that the vortex is reduced. The Dewar type cover plates are positioned above the inner-outer barrel (1) and the middle barrel (2), and the magnet and a low-temperature medium are contained in the middle barrel (2).

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

A kind of production process of ironless micro brushless DC motor

ActiveCN102611256BNo eddy current lossExtend your lifeManufacturing stator/rotor bodiesWork in processEngineering

The invention discloses a production technology of a motor and particularly relates to a production technology of a coreless micro brushless DC (Direct Current) motor. The production technology comprises the following steps of: winding and integrating a varnished wire into a coil with the diameter of 10mm-100mm by a coil winding mold, adding glue to solidify and bake the coil, mounting the coil in a coil fixing base, and then, mounting a bearing on the fixing base to get a semi-finished stator; placing an inner shell in an end cover clamp, adding the glue to form an end cover pressed inner shell with the diameter of 10mm-60mm, pasting a magnet on an outer circle of the inner shell by a magnet grading mold; reinforcing the outer circle of the magnet; placing an outer shell in the end cover clamp, and adding the glue to form an end cover pressed outer shell with the diameter of 10mm-100mm; adding the glue to paste the magnet on an inner circle of the outer shell by the magnet grading mold; reinforcing the magnet on the inner circle of the outer shell, then, baking in a roaster at 60-200 degrees centigrade for 1-4 hours; placing the end cover pressed outer shell into a pressing shaft branch by an end cover mold to obtain a semi-finished rotor with the diameter of 10mm-100mm; and assembling the stator and the rotor with other components to form the coreless micro brushless DC motor.

Owner:胡景威

Field element

InactiveCN101454961BAvoid demagnetizationReduce short circuitMagnetic circuit rotating partsMagnetic circuit characterised by magnetic materialsCouplingElectrical polarity

The invention provides a magnetic field element. It is an object to prevent demagnetization of magnets. A magnetic field element 1a includes magnetic field portions 2 and a coupling portion 3 and is rotatable on a rotation axis 92 along a given direction 91. Each magnetic field portion 2 includes a magnet 11 and magnetic plates 21 and 22. The magnet 11 includes first and second pole faces 11a and11b having different polarities from each other in the given direction 91. The magnetic-material plates 21 and 22 are provided on the first and second pole faces 11a and 11b, respectively. The magnetic field portions 2 are annularly arranged along a circumferential direction 93 around the rotation axis 92 and spaced in the circumferential direction 93 from one another. The coupling portion 3 is made of a non-magnetic material and couples the magnetic field portions 2 to one another.

Owner:DAIKIN IND LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com