Toughening FRP spiral connecting piece and manufacturing method thereof

A spiral connection and toughening technology, which is applied in the direction of connecting components, threaded fasteners, screws, etc., can solve the problems of no FRP connectors and patented technology of FRP connectors, etc., so as to reduce the loss of raw materials and reduce the difficulty of production , The effect of improving installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Below in conjunction with accompanying drawing and example describe in detail:

[0043] 1. Structure of Toughened FRP Spiral Connector

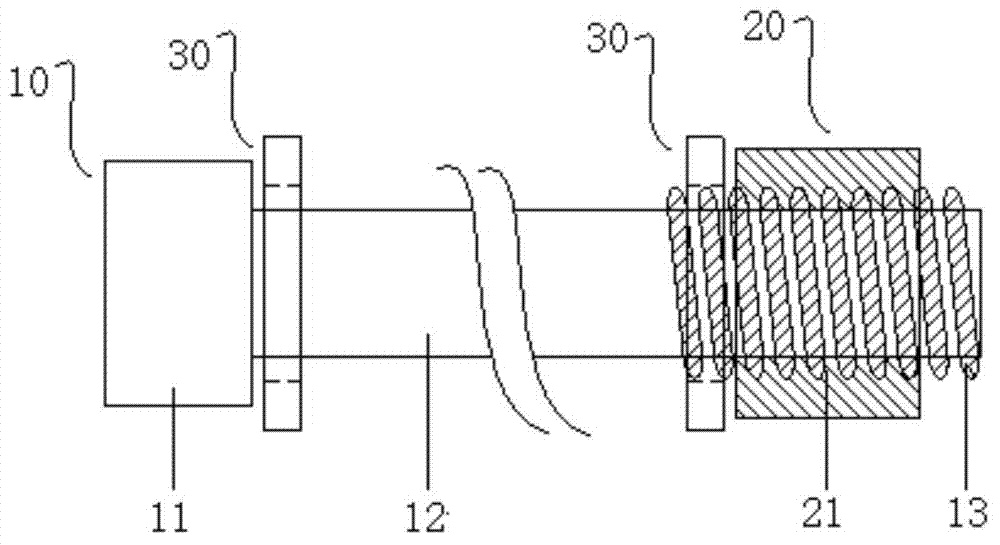

[0044] Such as figure 1 , the connector includes a bolt 10, a nut 20 and a gasket 30;

[0045] The bolt 10 includes a screw head 11 and a screw rod 12 connected as one, and the screw rod 12 is provided with an external thread 13;

[0046] An internal thread 21 is provided on the nut 20;

[0047] The external thread 13 and the internal thread 21 are compatible with each other;

[0048] The washer 30 is sleeved on the screw rod 12 , and the nut 20 is tightened on the screw rod 12 .

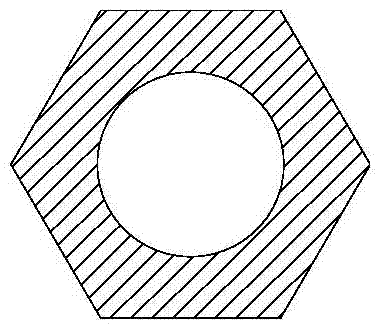

[0049] Described screw head 11 is polygonal, is preferably with regular hexagon, as figure 2 ;

[0050] Described nut 20 is polygonal, preferably with regular hexagon, as figure 2 ;

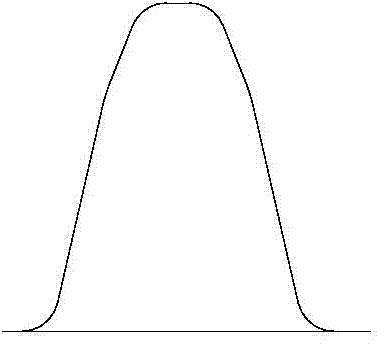

[0051] The thread shape is triangular, trapezoidal, trapezoidal or zigzag, preferably trapezoidal; described trapezoidal as image 3 , that is, the side of the trape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com