Patents

Literature

117results about How to "Improve ejection ability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

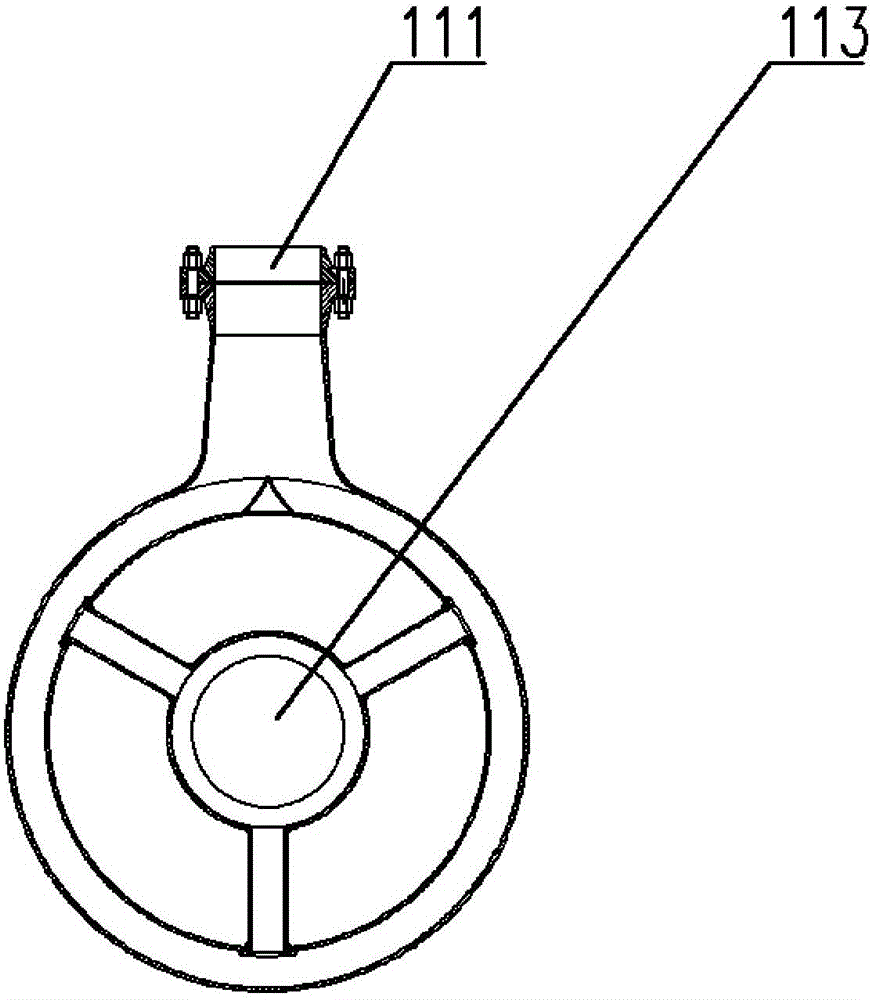

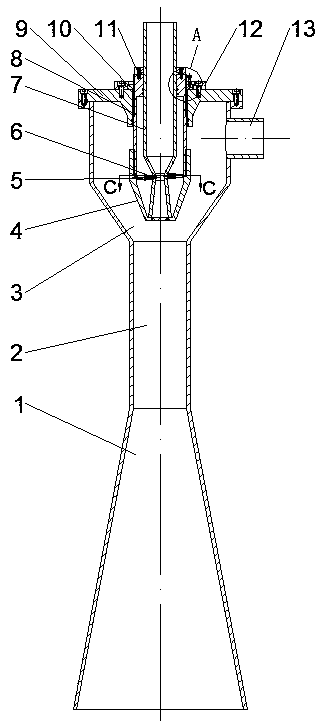

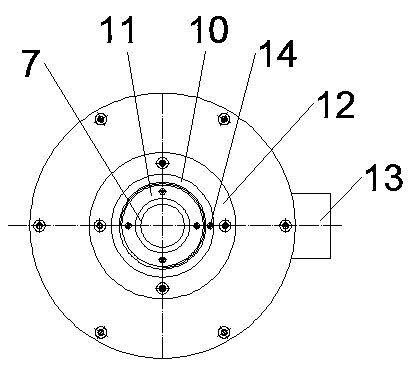

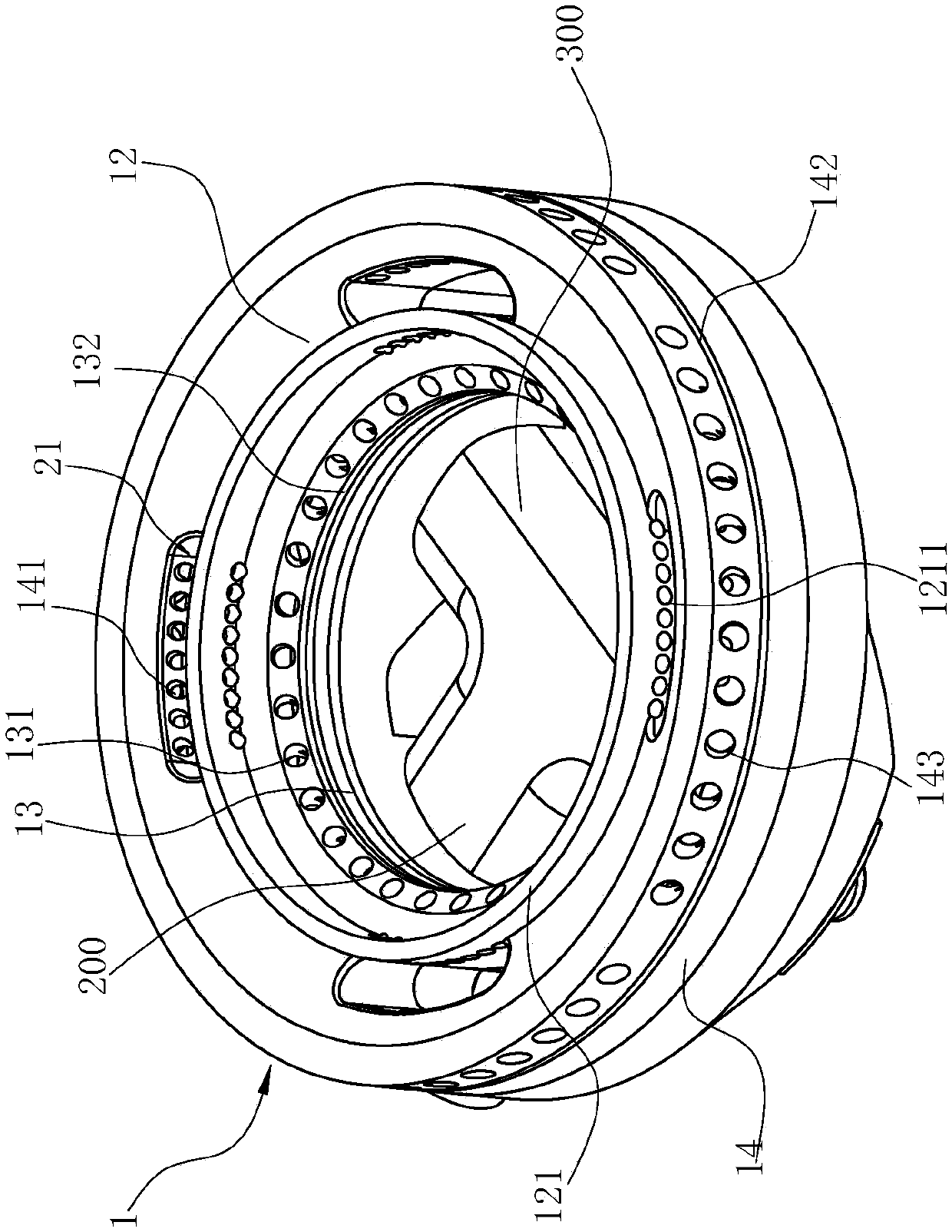

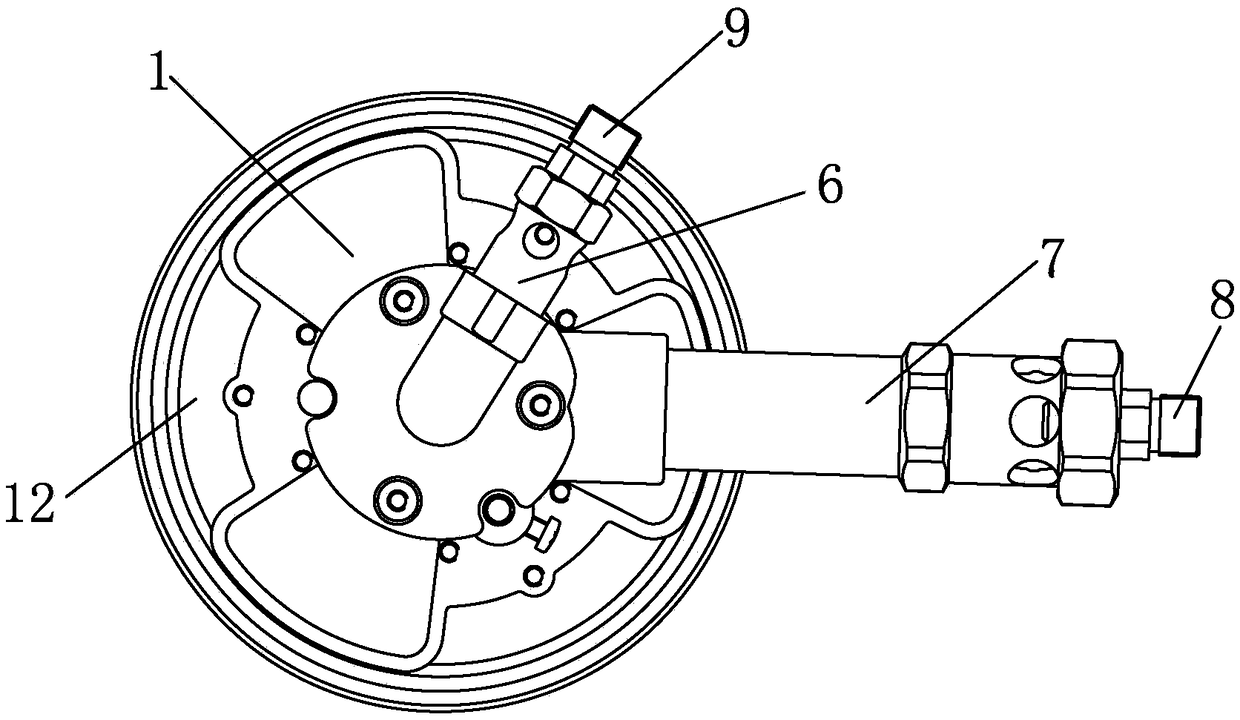

Ejecting pipe

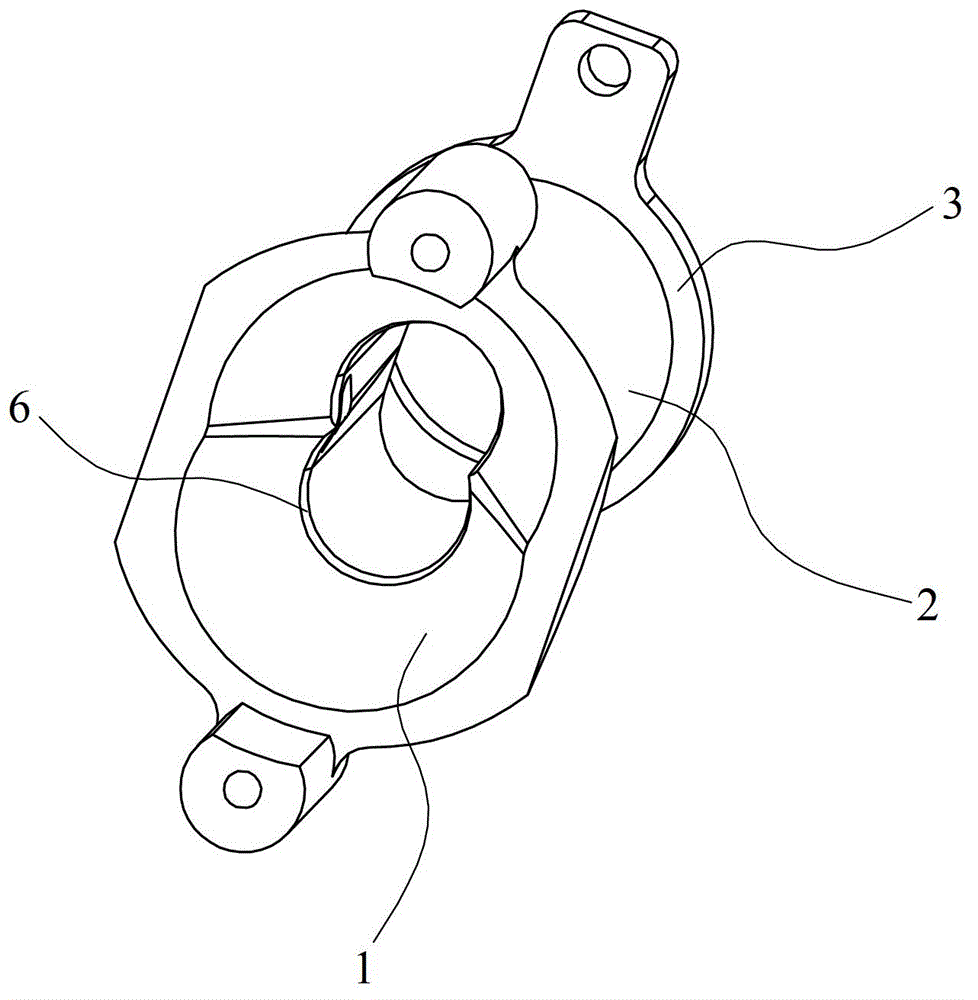

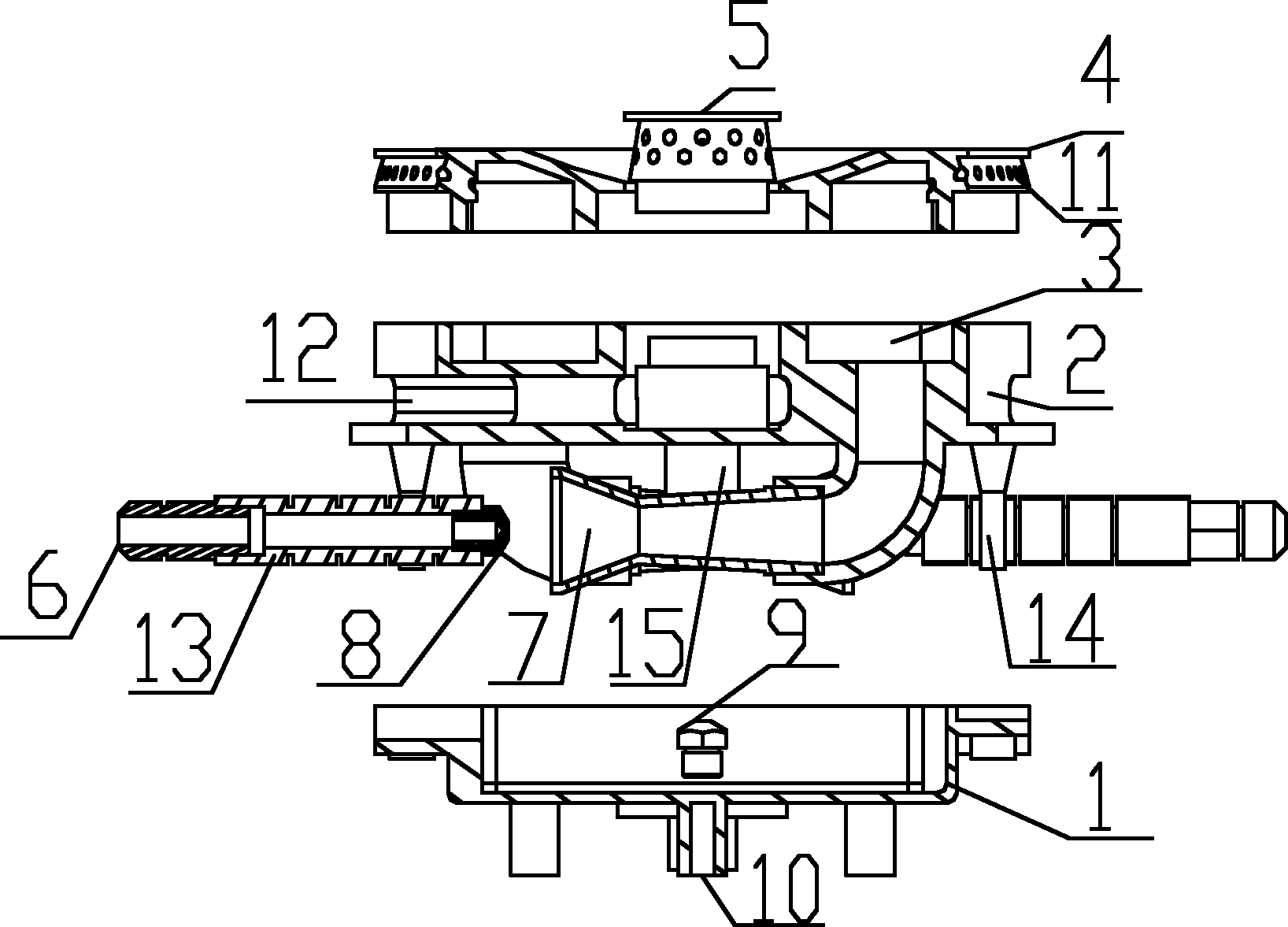

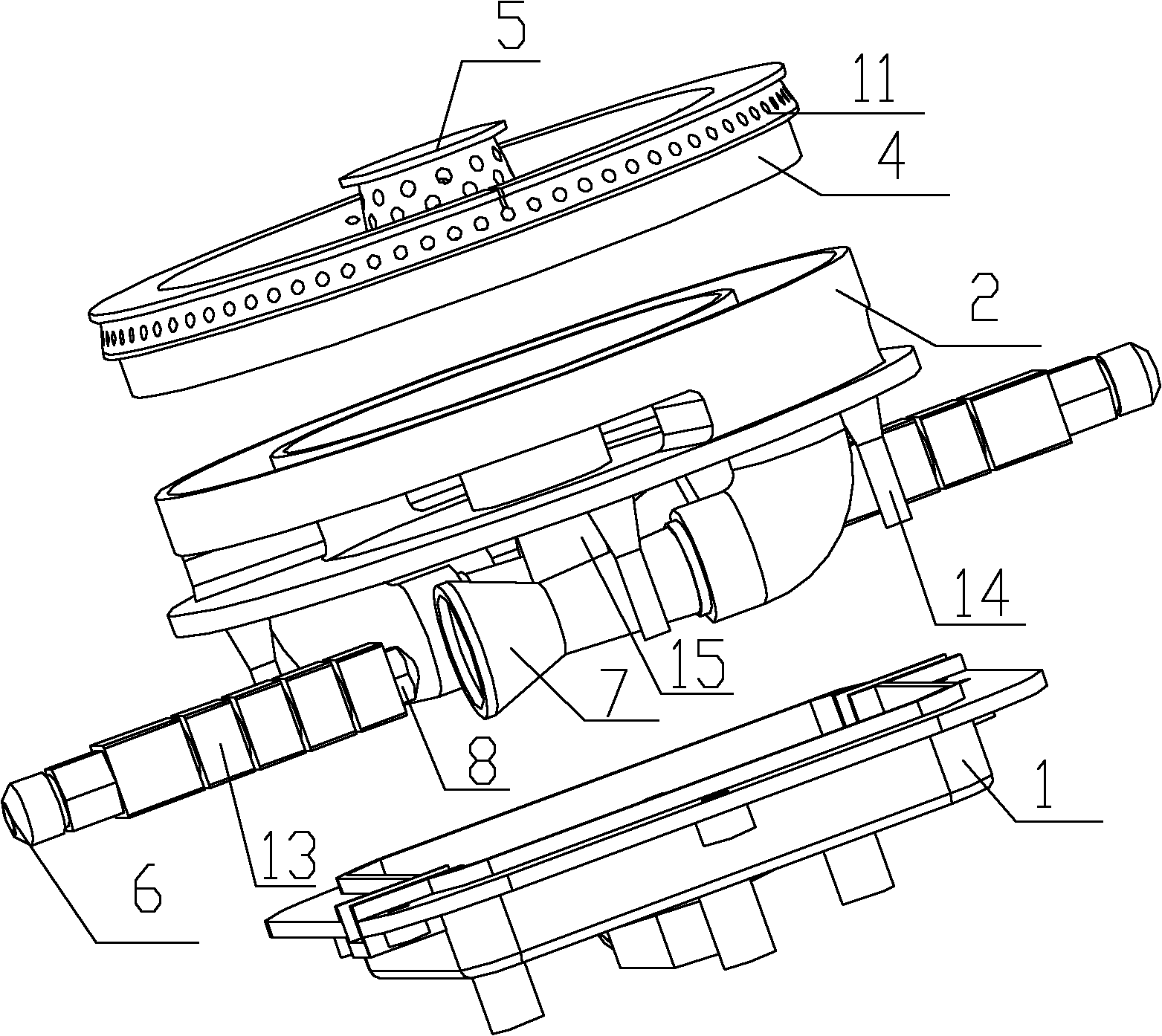

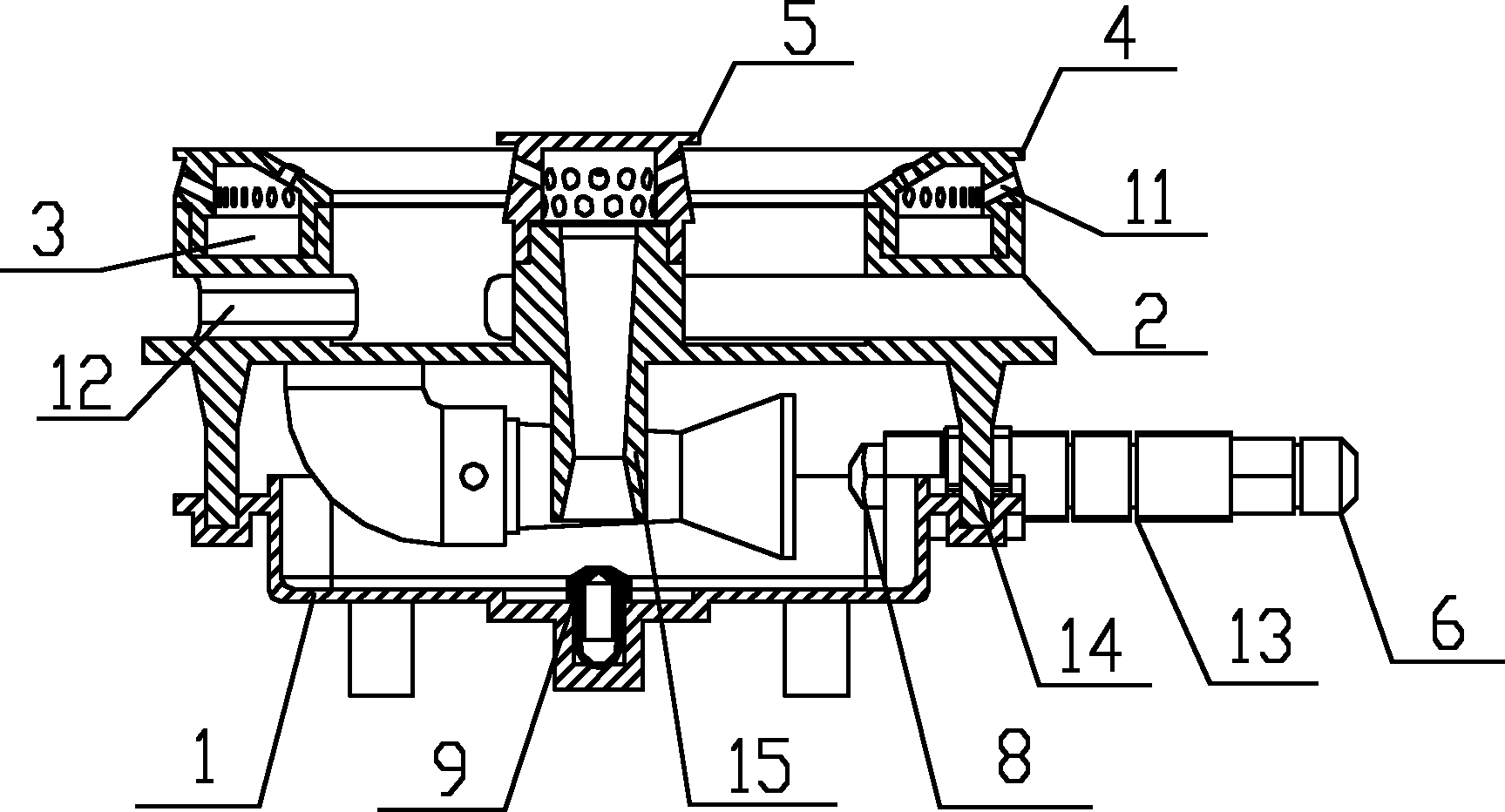

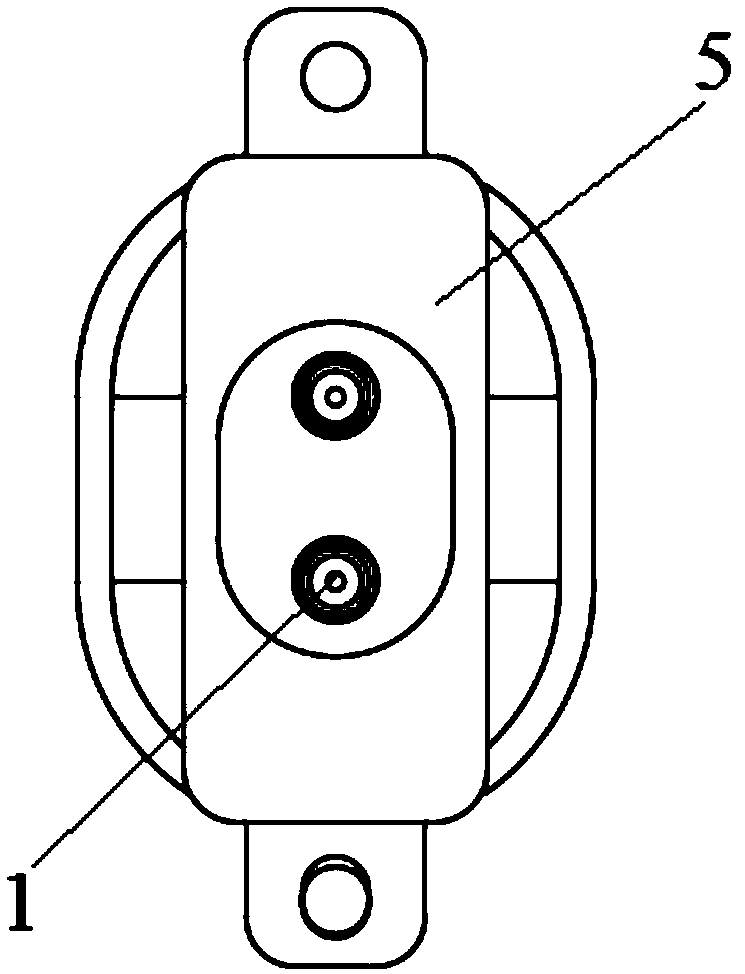

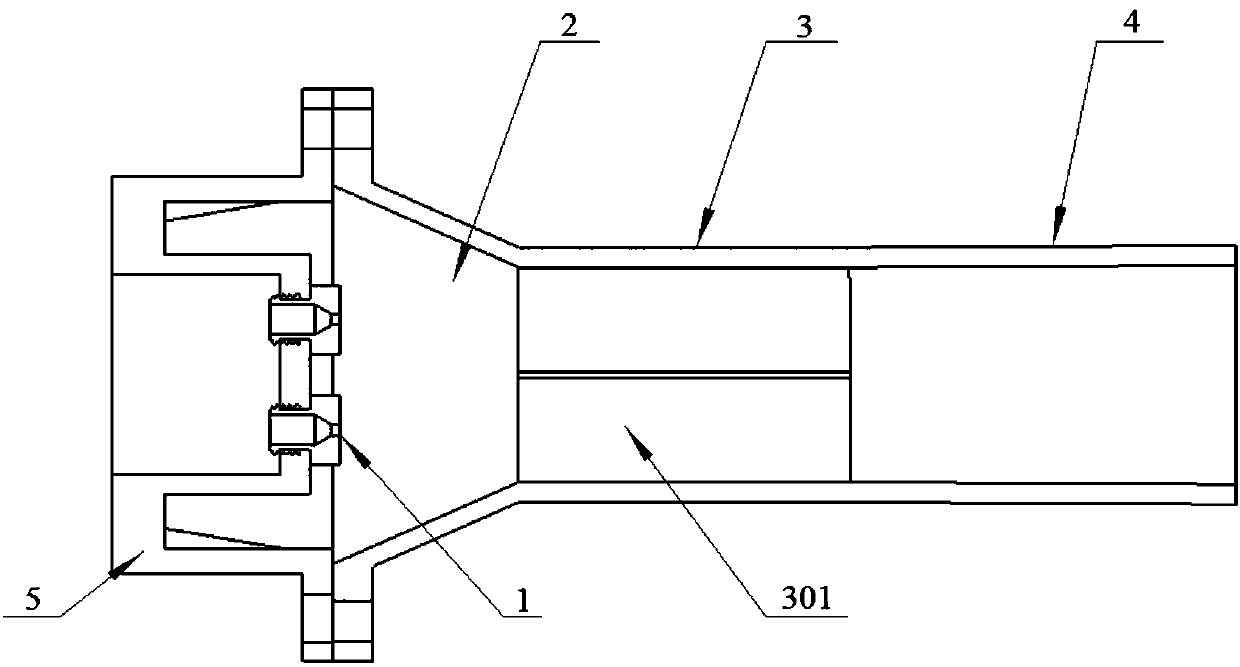

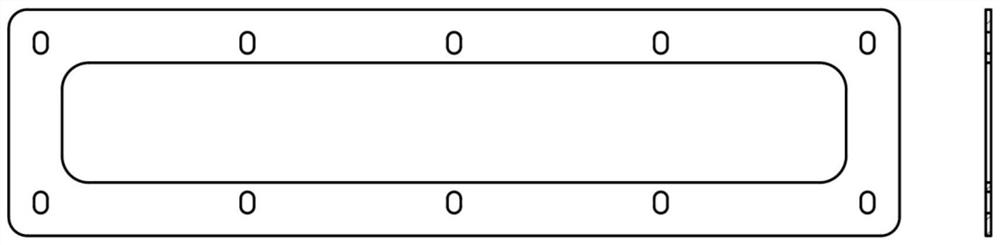

ActiveCN103234201AImprove ejection abilityAvoid mutual interferenceGaseous fuel burnerCombustorEllipse

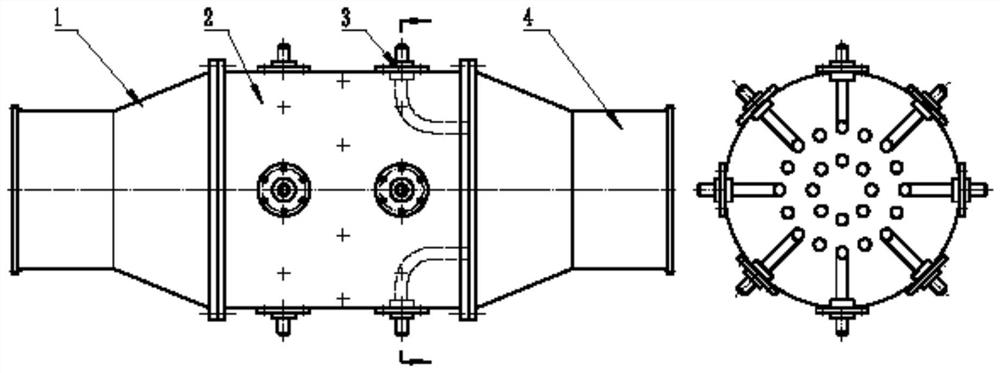

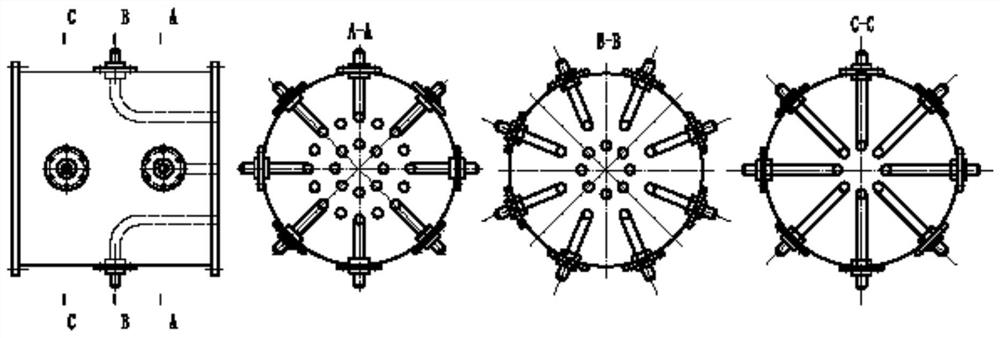

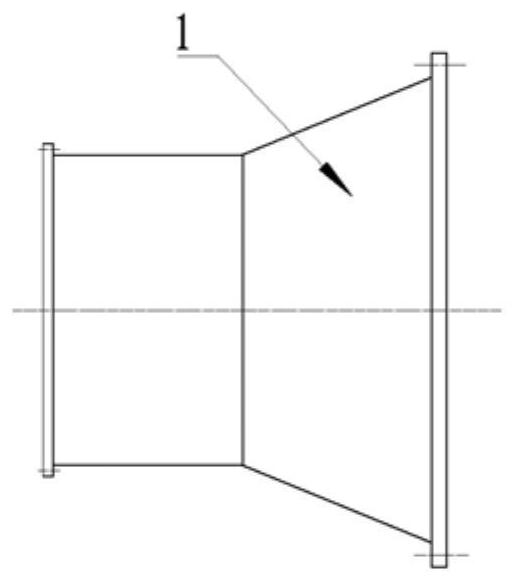

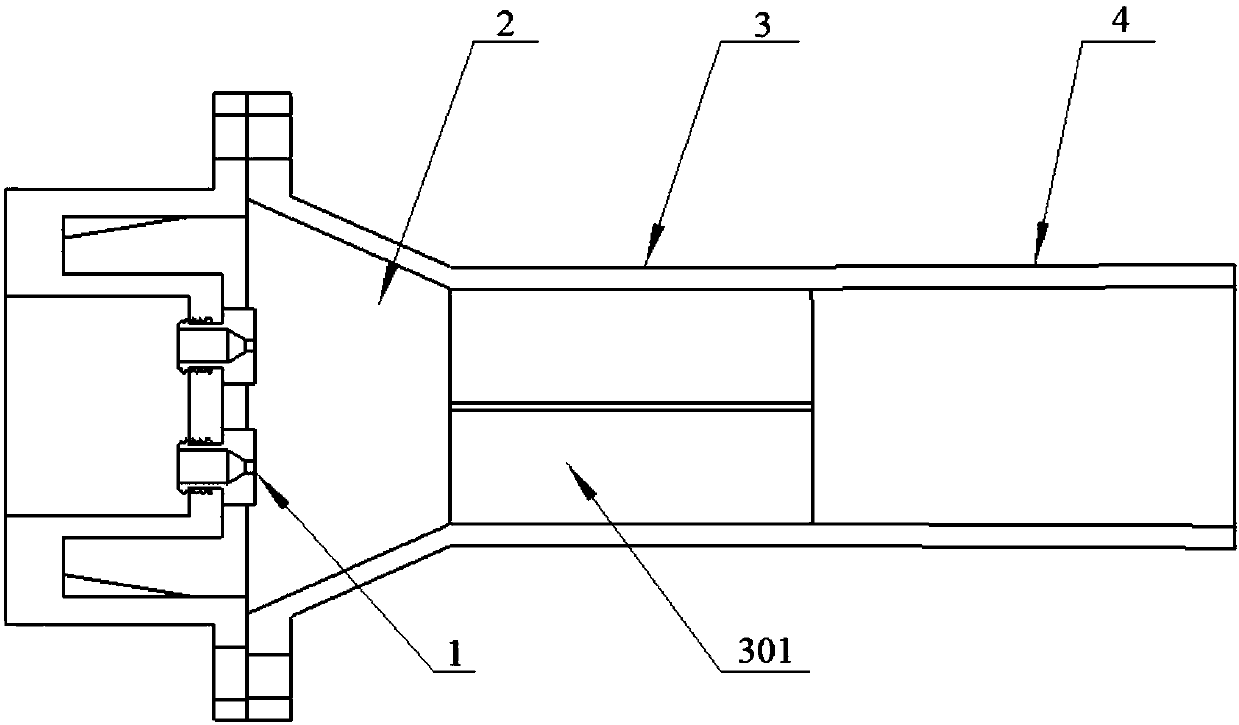

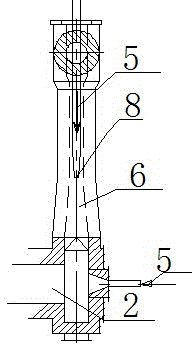

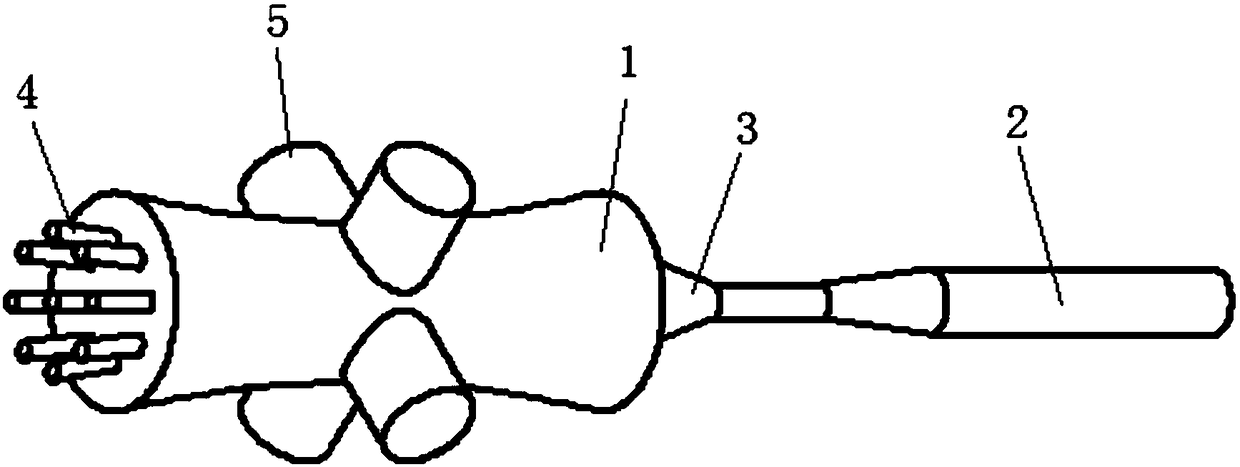

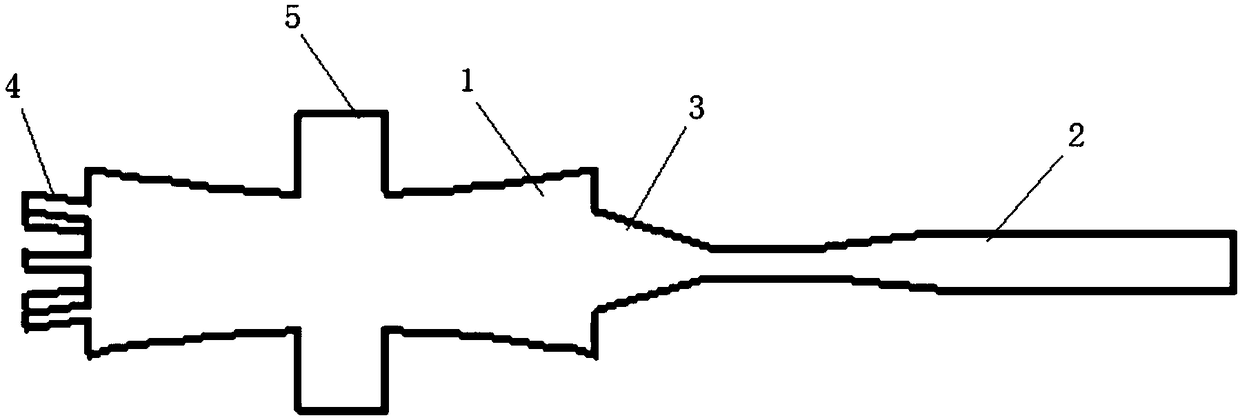

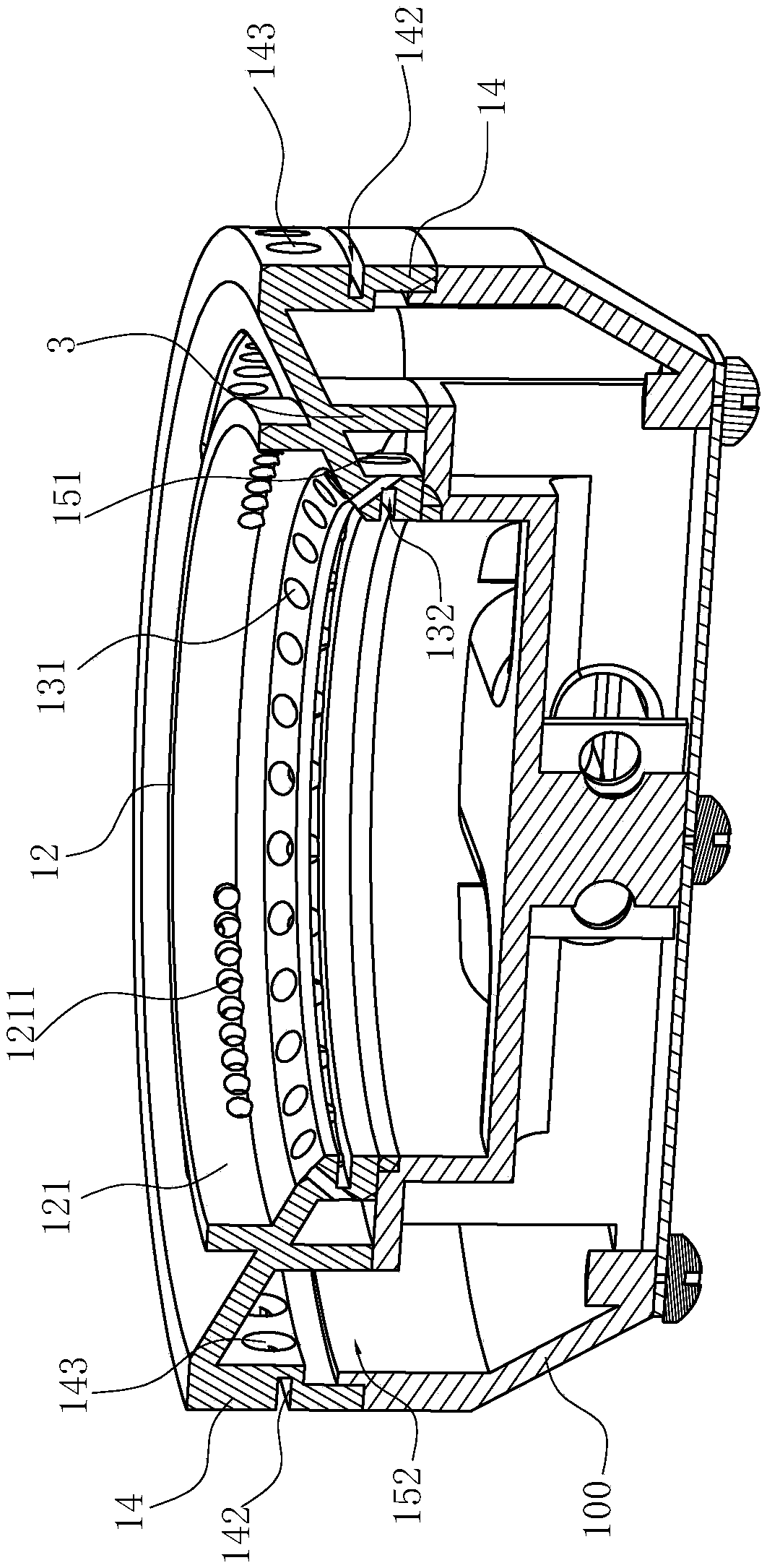

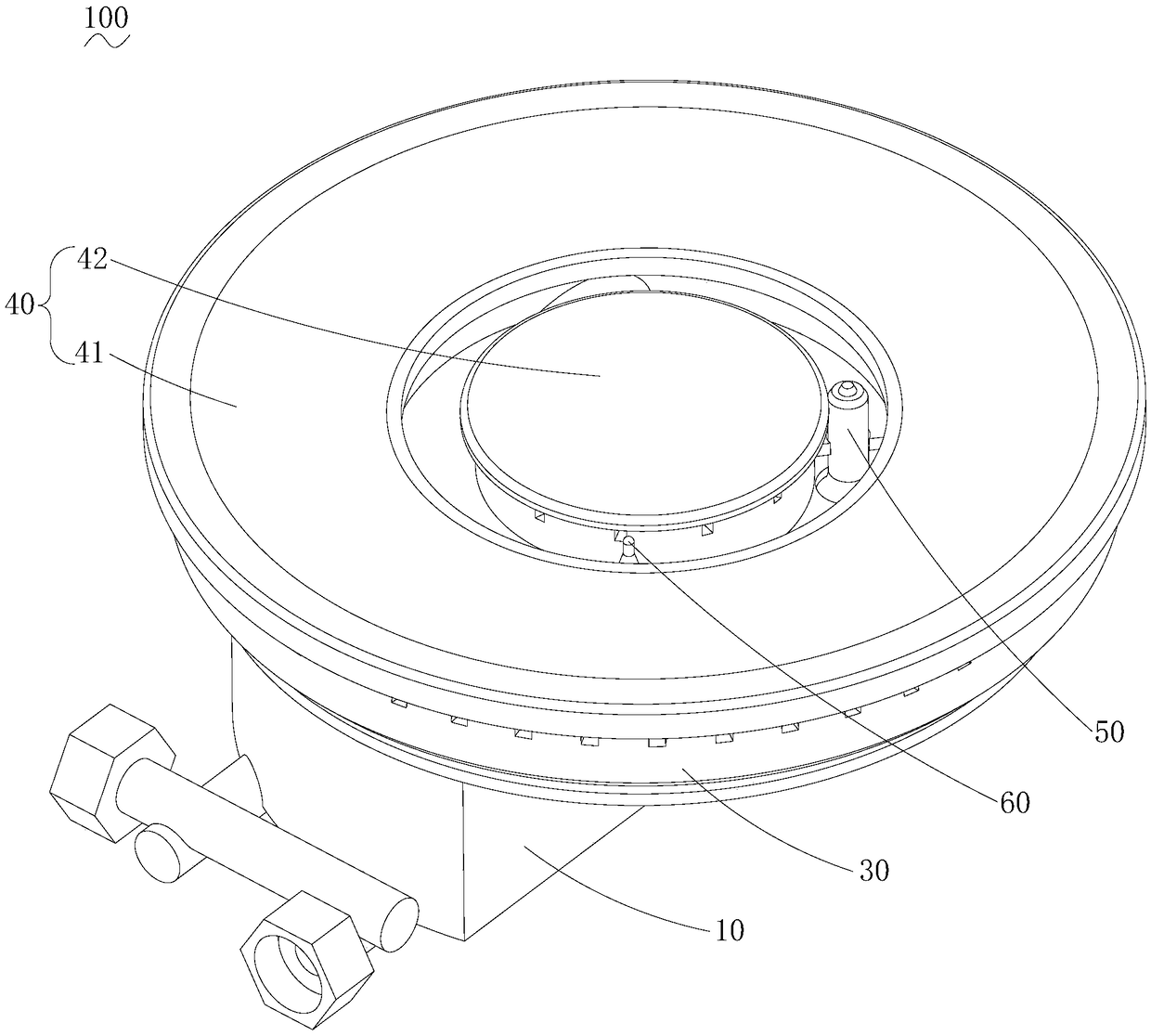

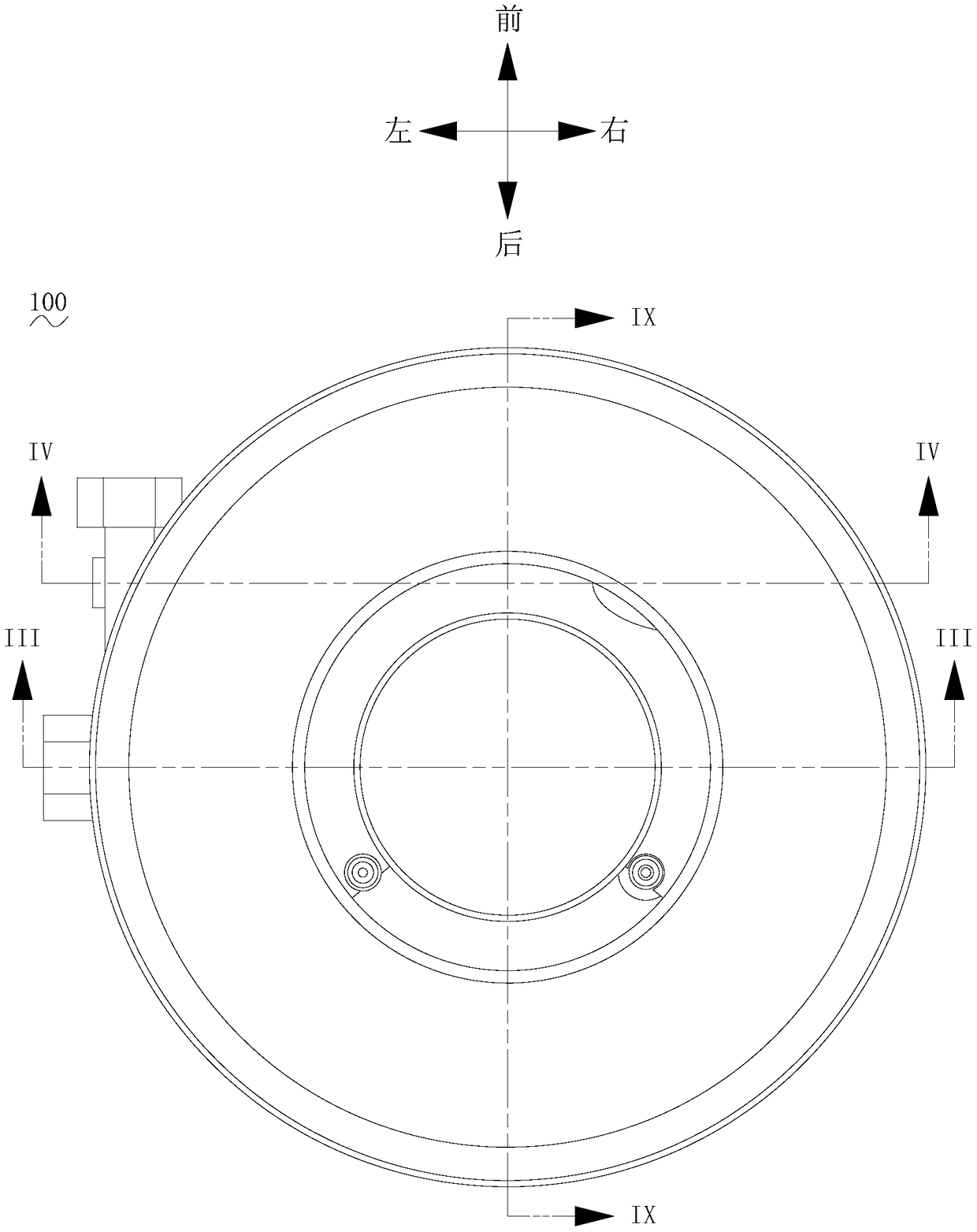

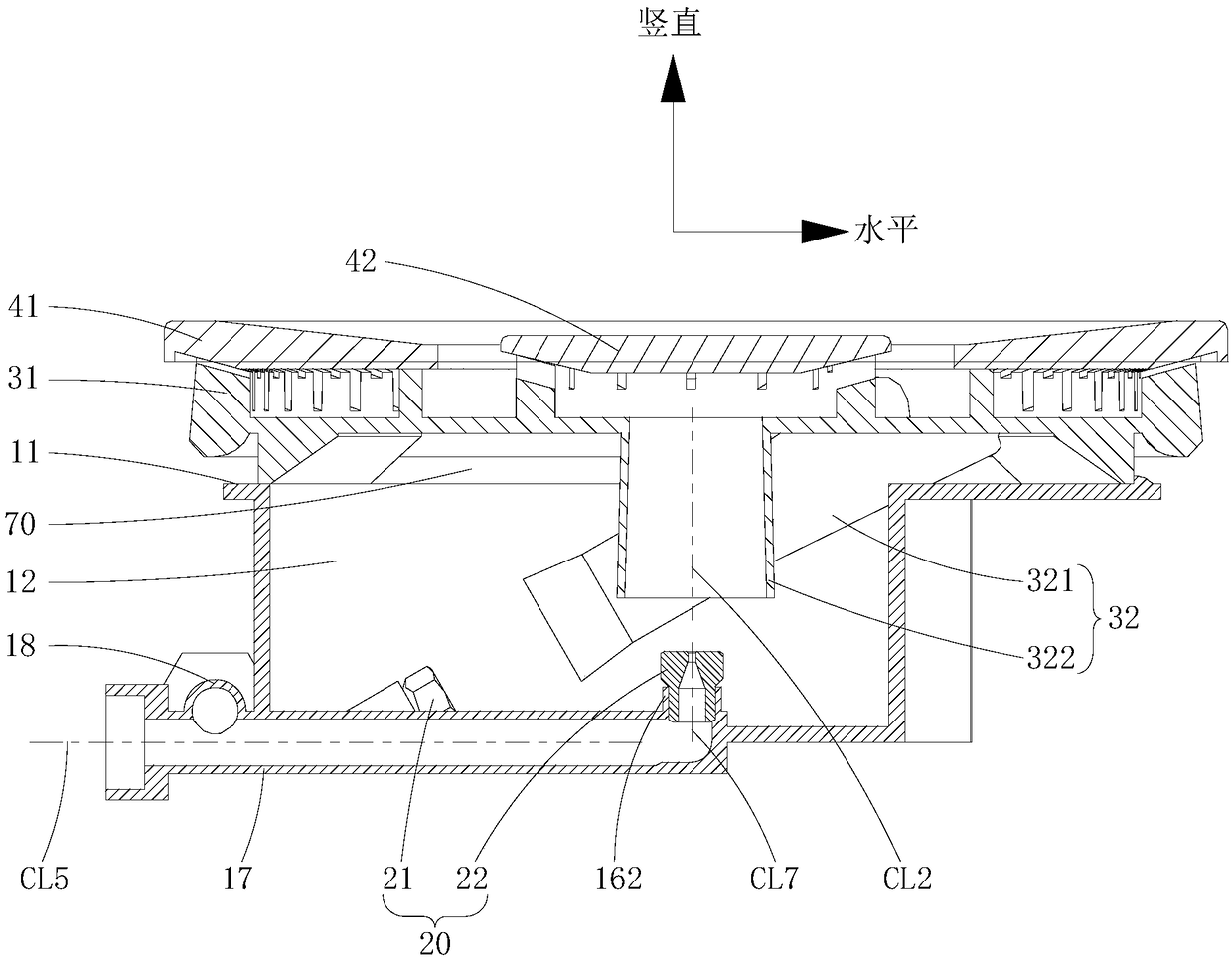

The invention relates to an ejecting pipe. A horn section, a transition section and a tail interface which is matched with a combustor furnace head are sequentially arranged in an internal chamber of the ejecting pipe along the direction from an inlet to an outlet. A throat opening is formed between the horn section and the transition section; an outer contour of the horn section is formed by a plurality of circles or a plurality of ellipses in an intersecting mode; the ellipses are approximate to circles; centers of the circles or centers of the ellipses are arranged in a same first circle and are uniformly distributed relative to a center of the first circle; nozzles which are matched with the ejecting pipe are arranged on centers of the circles or centers of the ellipses; the number of the nozzles is equal to the number of the circles or the number of the ellipses; a cross section of the horn section is gradually decreased; a shape of a cross section of the throat opening is the same with that of the horn section; the cross section area of the transition section is gradually increased from a cross section area the same as that of the throat opening to a cross section area the same as that of the tail interface. The ejecting pipe has the advantages of avoiding mutual interferences among airflows at the beginning of ejection, adding primary air supplementary amount, promoting mutual mixing of the airflows entering into the internal chamber of the ejecting pipe and the air, improving primary air coefficient, increasing ejecting capability and accordingly improving energy efficiency of a combustor.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Ejecting pipe

ActiveCN103234201BImprove ejection abilityAvoid mutual interferenceGaseous fuel burnerCombustorEllipse

The invention relates to an ejecting pipe. A horn section, a transition section and a tail interface which is matched with a combustor furnace head are sequentially arranged in an internal chamber of the ejecting pipe along the direction from an inlet to an outlet. A throat opening is formed between the horn section and the transition section; an outer contour of the horn section is formed by a plurality of circles or a plurality of ellipses in an intersecting mode; the ellipses are approximate to circles; centers of the circles or centers of the ellipses are arranged in a same first circle and are uniformly distributed relative to a center of the first circle; nozzles which are matched with the ejecting pipe are arranged on centers of the circles or centers of the ellipses; the number of the nozzles is equal to the number of the circles or the number of the ellipses; a cross section of the horn section is gradually decreased; a shape of a cross section of the throat opening is the same with that of the horn section; the cross section area of the transition section is gradually increased from a cross section area the same as that of the throat opening to a cross section area the same as that of the tail interface. The ejecting pipe has the advantages of avoiding mutual interferences among airflows at the beginning of ejection, adding primary air supplementary amount, promoting mutual mixing of the airflows entering into the internal chamber of the ejecting pipe and the air, improving primary air coefficient, increasing ejecting capability and accordingly improving energy efficiency of a combustor.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

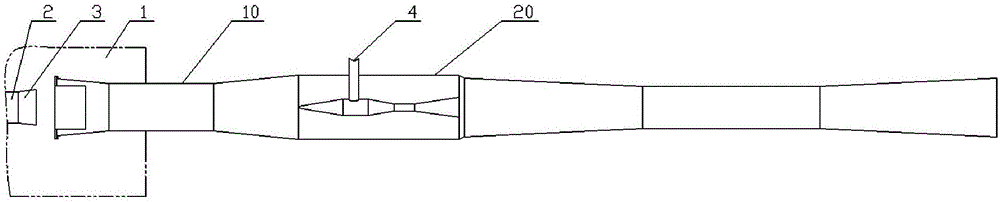

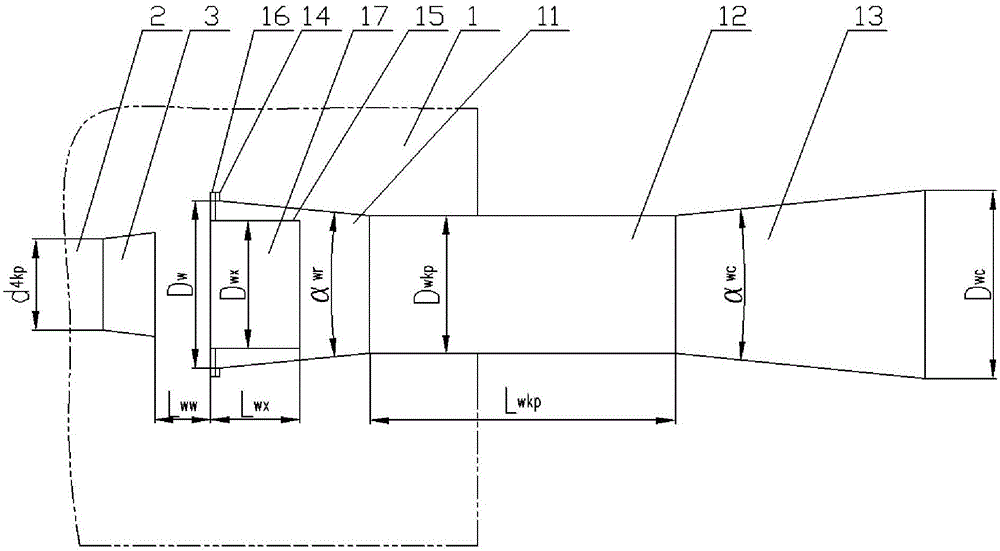

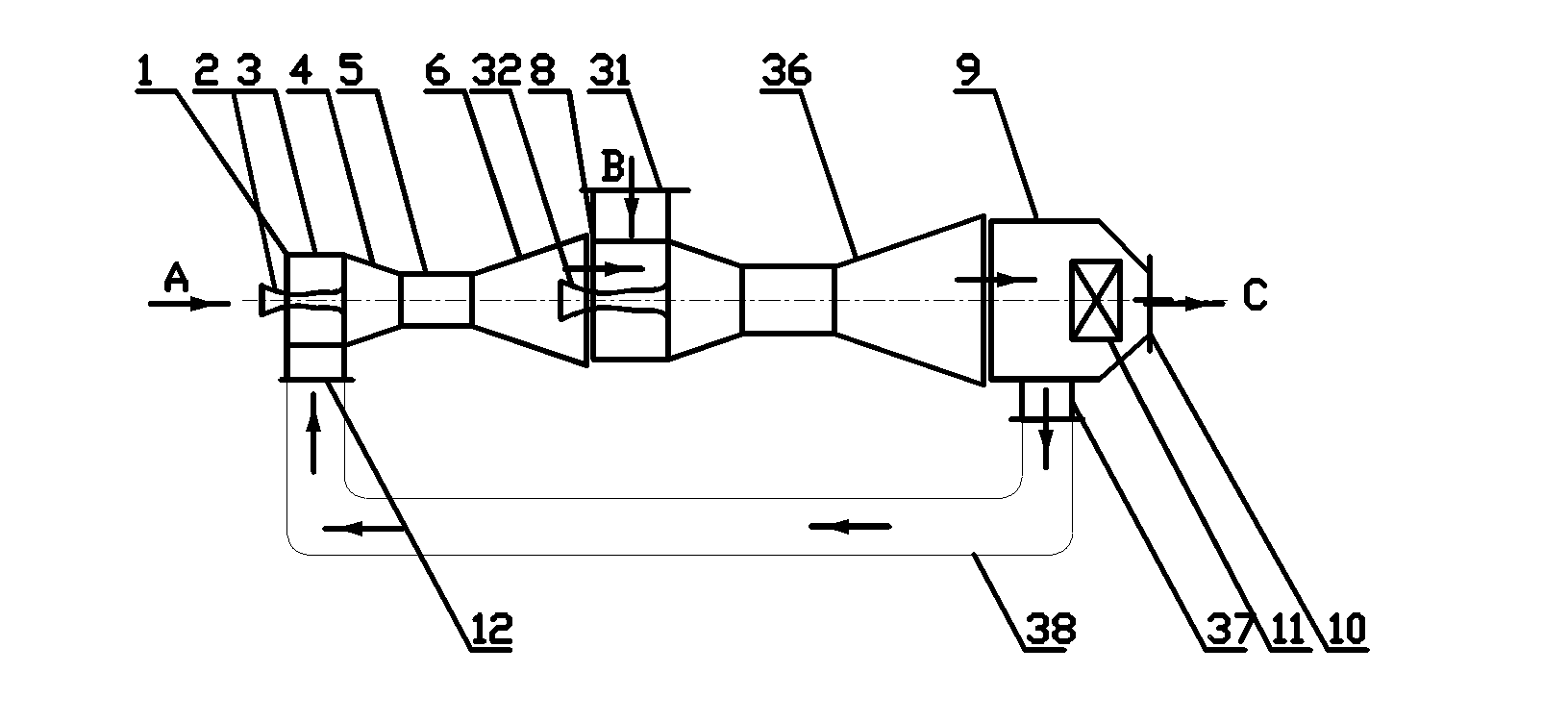

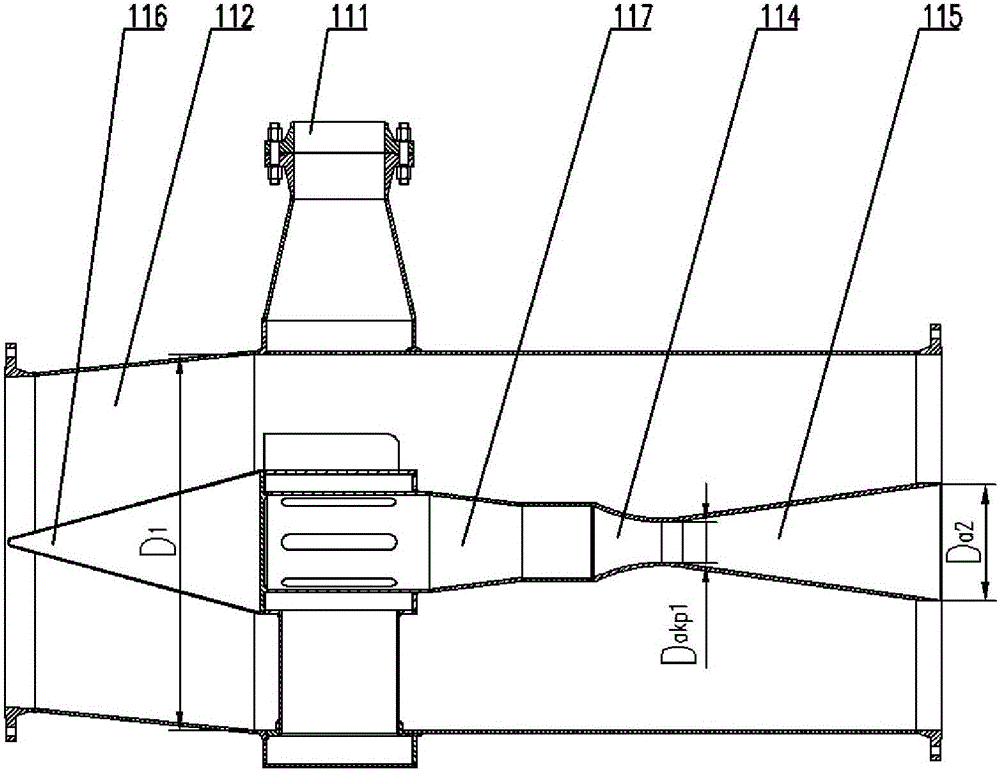

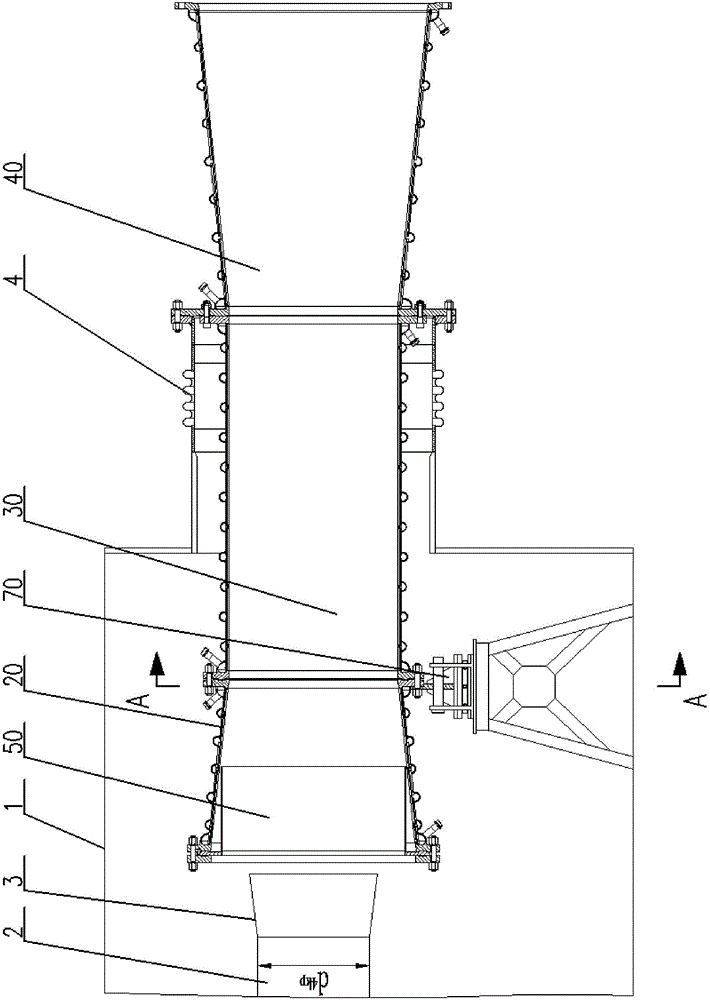

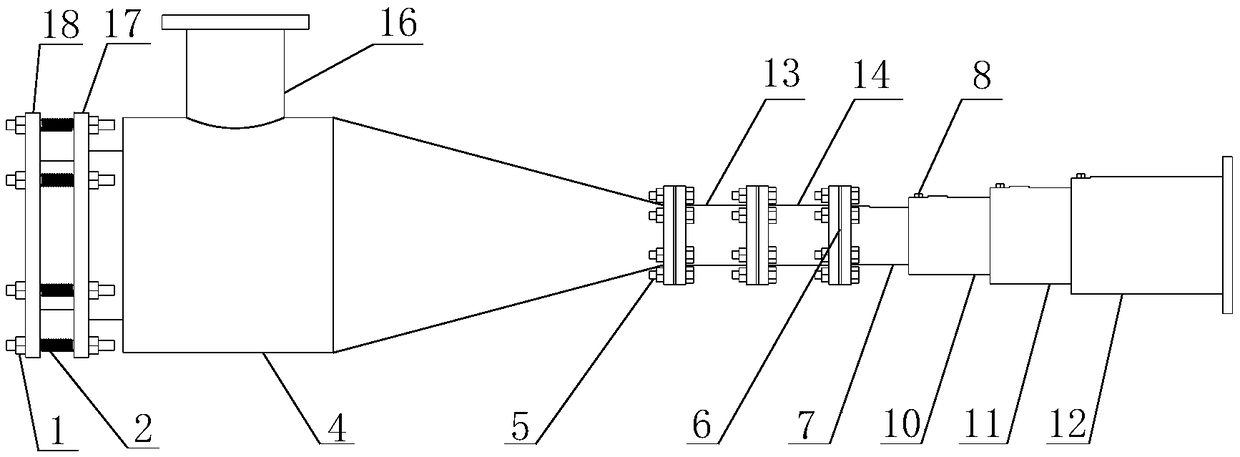

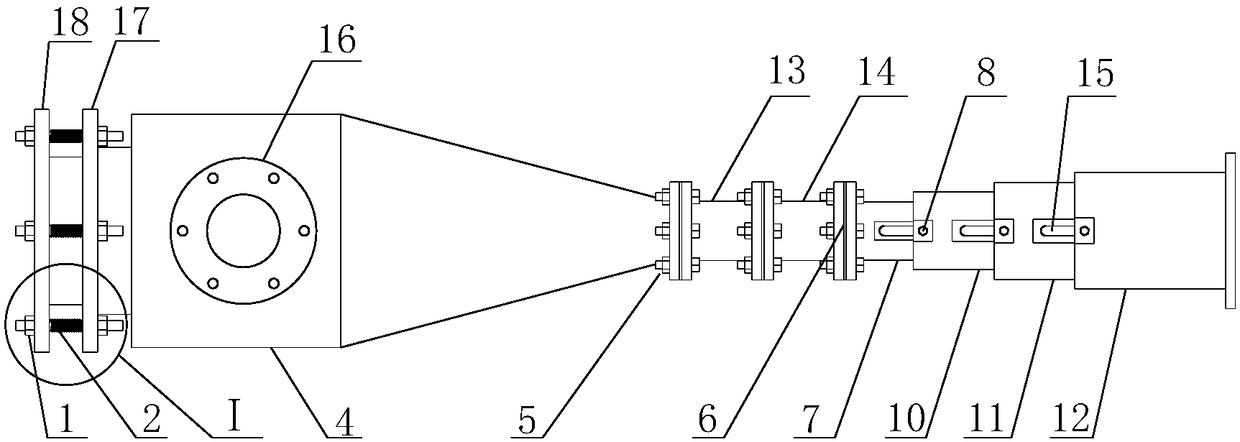

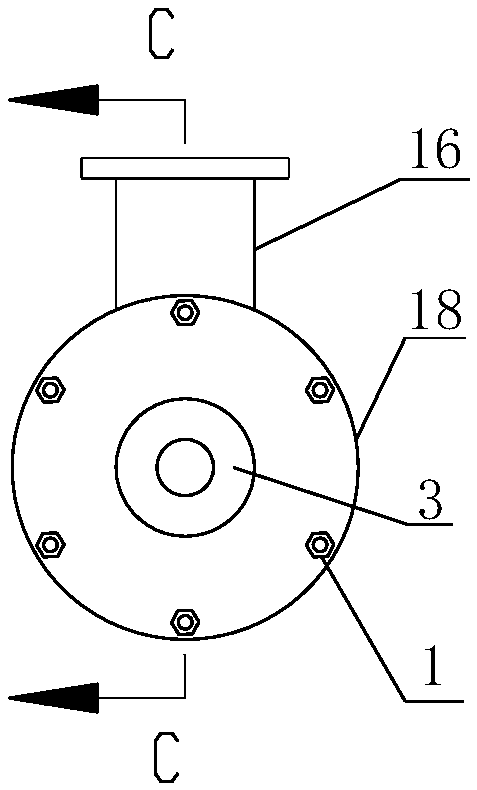

Exhaust apparatus for exhaust simulation test of exhaust nozzle of supersonic engine

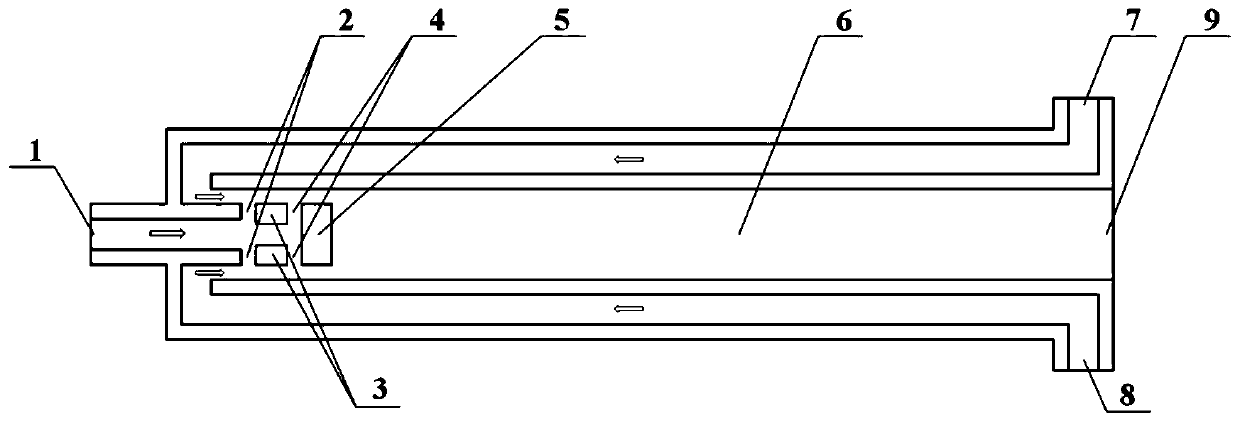

ActiveCN106441916ABoost ratio reductionReduce the number of ejector stagesMachine part testingInternal-combustion engine testingVertical planeTest requirements

The invention discloses an exhaust apparatus for an exhaust simulation test of an exhaust nozzle of a supersonic engine. The exhaust apparatus comprises a tail chamber and an ejector, the tail chamber comprises a fixed large tail chamber and a replaceable small tail chamber, the fixed large tail chamber comprises a tail chamber convergence segment, a tail chamber equal-diameter segment, and a tail chamber expansion segment, the replaceable small tail chamber comprises a small tail chamber flange and a small tail chamber cylinder body, the small tail chamber cylinder body is arranged in the tail chamber convergence segment, the fixed large tail chamber is provided with a circulating cooling water device and a cooling water spraying device, the ejector comprises a low-pressure chamber, a transition segment, a blending convergence segment, a blending equal-diameter segment and a blending expansion segment, the inner part of the low-pressure chamber is fixedly connected with a circular ring diversion and guiding device, an ejection airflow conveying pipeline, an ejection airflow convergence segment and an ejection airflow expansion segment, and cross sections of an outlet of the low-pressure chamber and an outlet of the ejection airflow expansion segment are located in the same vertical plane. According to the exhaust apparatus, test requirements for simulating high-altitude flight states of different supersonic engines on the ground can be met.

Owner:BEIJING AEROSPACE SANFA HIGH TECH

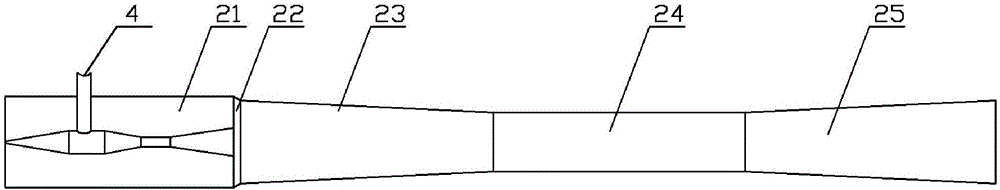

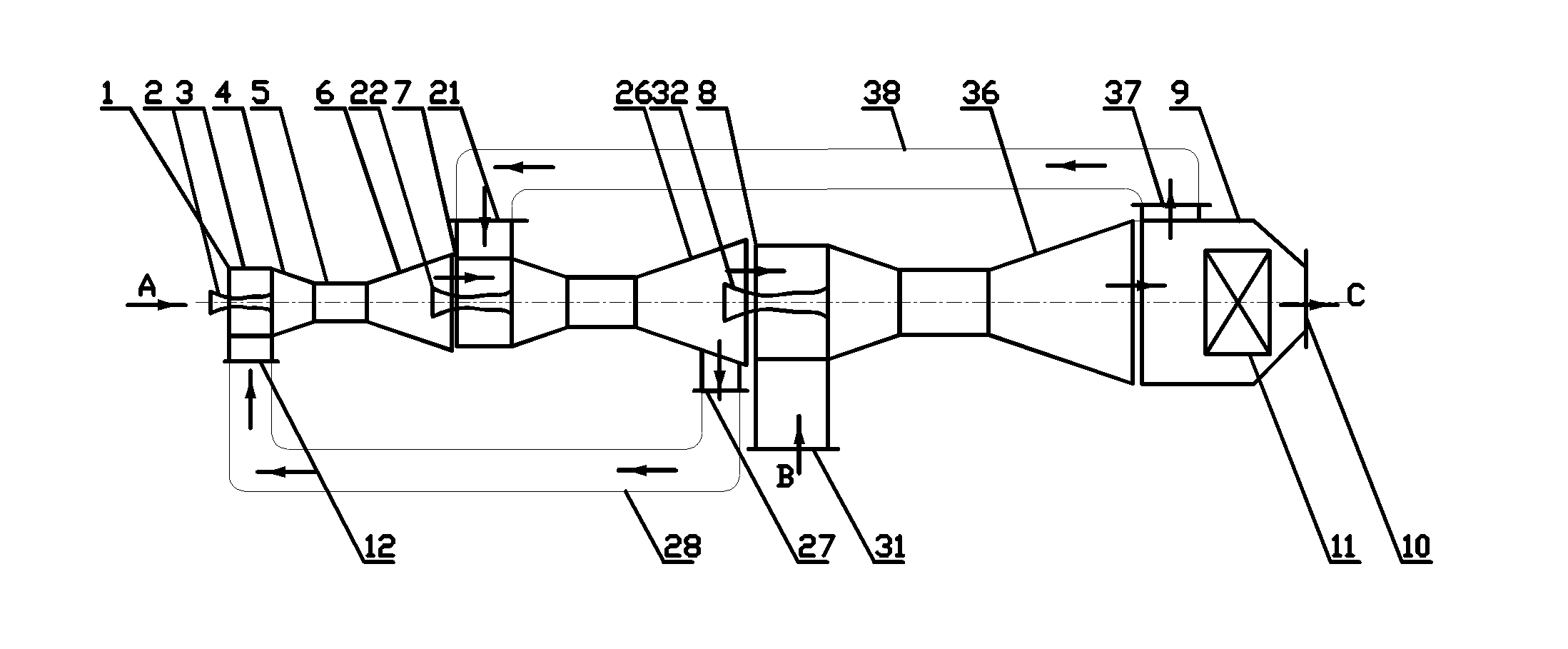

Ultrasonic engine jet pipe exhaust simulation test exhaust device

ActiveCN106370432ABoost ratio reductionReduce the number of ejector stagesMachine part testingInternal-combustion engine testingTest requirementsEngineering

The invention discloses an ultrasonic engine jet pipe exhaust simulation test exhaust device. The device comprises poop houses and an injector which are coaxially and sequentially connected, wherein the poop houses comprise a large poop house and a replaceable small poop house, the large comprises a poop house convergence segment, a poop house linear segment and a poop house expansion segment which are coaxially connected, the replaceable small poop house is coaxially arranged in the poop house convergence segment, the injector comprises a low pressure house, a transition segment, a blending convergence segment, a blending linear segment and a blending expansion segment which are coaxially connected, the low pressure house is internally and coaxiallly connected with an injection flow input segment, an injection flow convergence segment and an injection flow linear segment, an outlet cross section of the low pressure house and an outlet cross section of an injection flow expansion segment are on one same vertical surface, an outlet of the poop house expansion segment and an inlet of the low pressure house are connected, the poop house convergence segment is arranged in a high-altitude boiler-plate, and the blending expansion segment is arranged outside the high-altitude boiler-plate. The device is advantaged in that test requirements of different ultrasonic engines simulating high-altitude flight states on the ground can be satisfied.

Owner:BEIJING AEROSPACE SANFA HIGH TECH

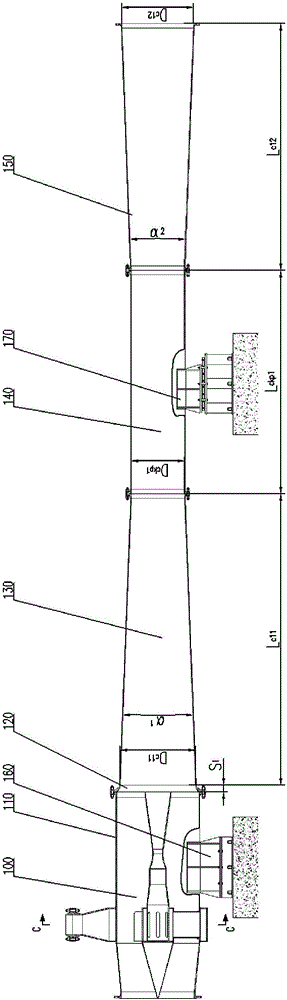

Jet type heat pump adopting multi-effect cascade ejecting mode and large pressure ratio vacuum pump

InactiveCN102435017AIncrease ejection ratioLow impossibility lossHeat pumpsEnergy industrySpray nozzleEngineering

The invention relates to a jet type heat pump adopting a multi-effect cascade ejecting mode and a large pressure ratio vacuum pump and belongs to the fields of industrial waste heat recovery and vacuum pumps. The jet type heat pump and the large pressure ratio vacuum pump adopt a multi-effect cascade structure which is in multi-level series-parallel connection and drives fluid to perform grading work; the structure comprises a first-level ejector, a last-level ejector and a last-level flow distributor, wherein the first-level ejector, the last-level ejector and the last-level flow distributor are in cascaded connections in turn; the first-level ejector and the last-level ejector are respectively formed by an inlet section with a nozzle, a mixed section, a throat section and a diffusion section which are connected in turn; the last-level flow distributor is provided with a last-level mixed outlet and a mixed fluid outlet; and a first-level ejecting opening of the first-level ejector is connected with the last-level mixed outlet of the diffusion section of the last-level ejector through an ejecting connecting pipe. In the jet type heat pump adopting the multi-effect cascade ejecting mode and the large pressure ratio vacuum pump, the new designed multi-effect cascade ejecting mode is adopted, so that the ejecting rate is greatly improved; the total ejecting rate is improved above 2-5 times. The multi-effect cascade ejecting mode can be used for a high-efficient large pressure ratio ejecting type heat pump and the vacuum pump.

Owner:BEIJING ZHONGKE HUAYU ENERGY TECH DEV

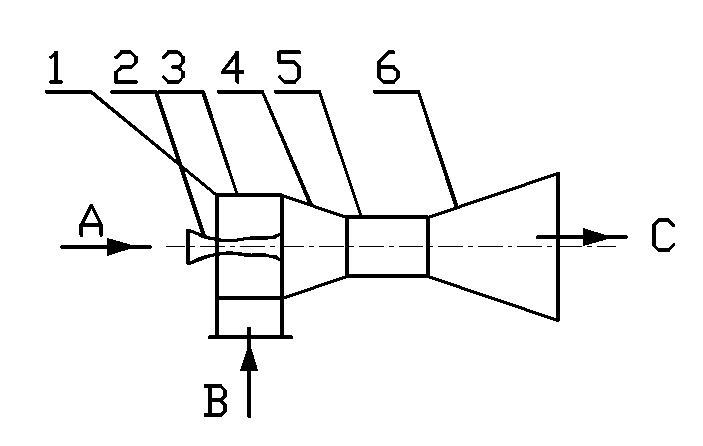

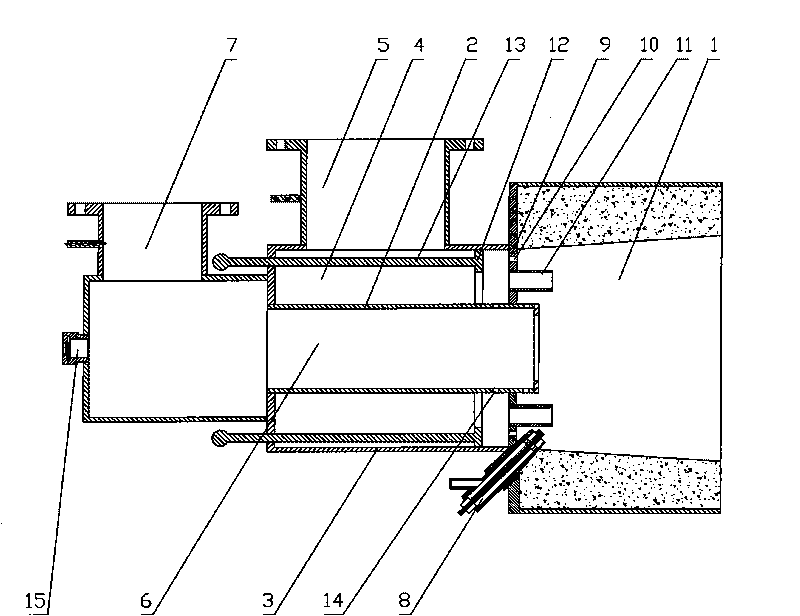

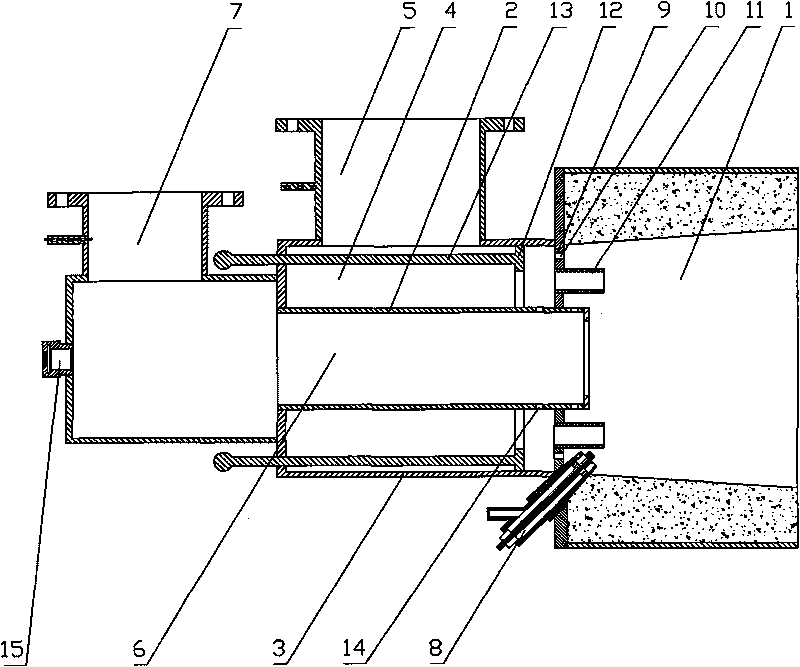

Ejector for engine test bed exhaust system

The invention discloses an ejector for an engine test bed exhaust system. The ejector comprises a low-pressure chamber, a transition section, a mixing convergence section, a mixing equal-straight section and a mixing expansion section, all of which are sequentially and coaxially connected. The low-pressure chamber comprises a low-pressure chamber shell and a flange. An annular flow diverting and guiding device, an ejecting airflow conveying pipeline, an ejecting airflow convergence section and an ejecting airflow expansion section are sequentially and coaxially connected into the low-pressure chamber. An inlet of the annular flow diverting and guiding device is connected with an ejecting airflow intake manifold, the center line of the ejecting airflow conveying pipeline coincides with that of the low-pressure chamber shell, an outlet of the low-pressure chamber and an outlet section of the ejecting airflow expansion section are located on the same vertical plane, the low-pressure chamber is connected with an ejector fixed support, and the mixing equal-straight section is connected with an ejector movable support. The ejector is high in ejection performance, testing efficiency is improved, the testing cost is reduced, and the ejector movable support absorbs the axial length change caused by thermal expansion and cold shrinkage of the ejector in a connected mode.

Owner:BEIJING AEROSPACE SANFA HIGH TECH

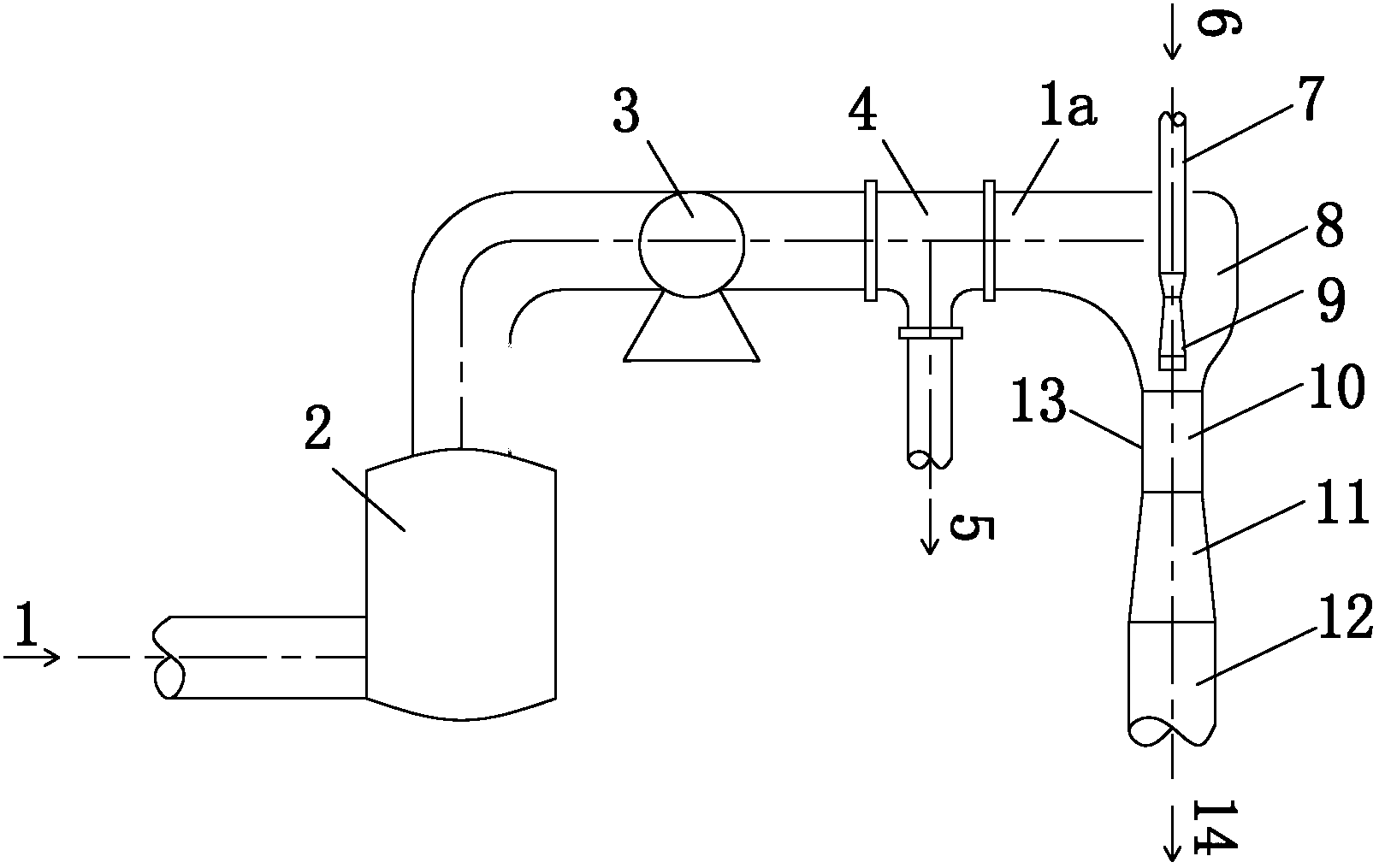

Combustion method of low-pressure and low-concentration methane gas and device

InactiveCN101713538AEfficient combustionImprove ejection abilityIndirect carbon-dioxide mitigationGaseous fuel burnerCombustion chamberProduct gas

The invention discloses a combustion method of low-pressure and low-concentration methane gas. In the combustion method, an inner pipe and an outer pipe which are communicated with a combustion chamber are adopted as an air inlet pipe, wherein the inner pipe is a fuel gas channel, and a channel between the inner pipe and the outer pipe is an air channel; air inside the air channel enters the combustion chamber at high speed and forms negative pressure at the outlet of the fuel gas channel; and the low-pressure and low-concentration methane gas inside the fuel gas channel is absorbed into the combustion chamber and combusts in the combustion chamber in a mixing mode. The invention also provides a combustion device for realizing the combustion method. By utilizing the negative pressure formed at the outlet of the inner pipe when the air enters into the combustion chamber through the air channel and a great injection action generated by the negative pressure on the low-pressure low-concentration methane gas inside the inner pipe, the invention promotes the low-pressure and low-concentration methane gas to enter into the combustion chamber to mix with the air for combustion, and has the advantages of low combustion cost and less discharged pollution of the combustion.

Owner:CHONGQING UNIV

Tread rubber filled with environment-friendly white carbon black and butadiene styrene rubber and preparation method of tread rubber

InactiveCN107903458AImproved wet grip performanceImprove wear resistanceSpecial tyresRolling resistance optimizationRolling resistanceMicrocrystalline wax

The invention relates to tread rubber filled with environment-friendly white carbon black and butadiene styrene rubber and a preparation method of the tread rubber. The tread rubber comprises the following components in parts by weight: 25-40 parts of natural rubber, 60-75 parts of butadiene styrene rubber, 25-45 parts of carbon black, 15-35 parts of white carbon black, 2-4 parts of aromatic oil,1.5-2.5 parts of stearic acid, 3-4 parts of zinc oxide, 1-2 parts of tackifying resin, 1.5-2 parts of anti-cracking resin, 1.5-2.5 parts of an anti-ager 4010NA, 1.5-2 parts of microcrystalline wax, 1.2-1.5 parts of an accelerator NOBS, 0.3-0.5 part of an accelerator TMTD, 1.5-2 parts of sulfur and 0.1-0.3 part of a scorch retarder. The components are subjected to primary mixing, secondary mixing and final mixing to obtain the tread rubber. The preparation method is simple and easy to operate in step; owing to modified rice-husk-source white carbon black, clustering in basic rubber can be reduced; the machinability and the wear resistance of the tread rubber are improved; rolling resistance of a tire can be effectively reduced; and the wet-skid resistance is improved.

Owner:JIANGSU GENERAL SCI TECH

Air exhaust device for ultrasonic engine jet pipe exhaust simulation experiment

ActiveCN106441915ABoost ratio reductionReduce the number of ejector stagesMachine part testingInternal-combustion engine testingVertical planeWater spray

The invention discloses an air exhaust device for an ultrasonic engine jet pipe exhaust simulation experiment. The air exhaust device comprises a tail chamber, an injector and a two-stage injector. The tail chamber comprises a fixed large tail chamber and a replaceable small tail chamber. The fixed large tail chamber comprises a tail chamber convergent segment, a tail chamber equal-diameter segment and a tail chamber expanding segment. The replaceable small tail chamber comprises a small tail chamber flange and a small tail chamber cylinder. The small tail chamber cylinder is arranged in the tail chamber convergent segment. The fixed large tail chamber is provided with a circulated cooling water device and a cooling water spraying device. The injector comprises a low-pressure chamber, a transition segment, a blending convergent segment, a blending equal-diameter segment and a blending expanding segment. The low-pressure chamber is internally and fixedly connected with an annular shunting flow guiding device, an injected air current conveying pipe, an injected air current convergent segment and an injected air current expanding segment. The outlet of the low-pressure chamber and the outlet cross section of the injected air current expanding segment are in the same vertical plane. The air exhaust device can satisfy an experiment requirement for simulating high-altitude flight states of different ultrasonic engines on ground.

Owner:BEIJING AEROSPACE SANFA HIGH TECH

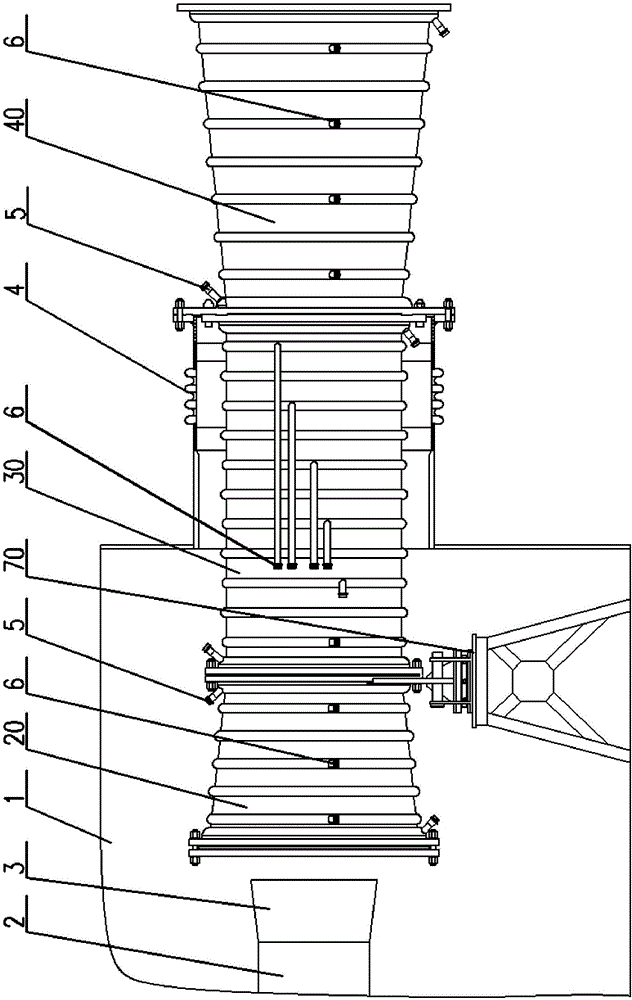

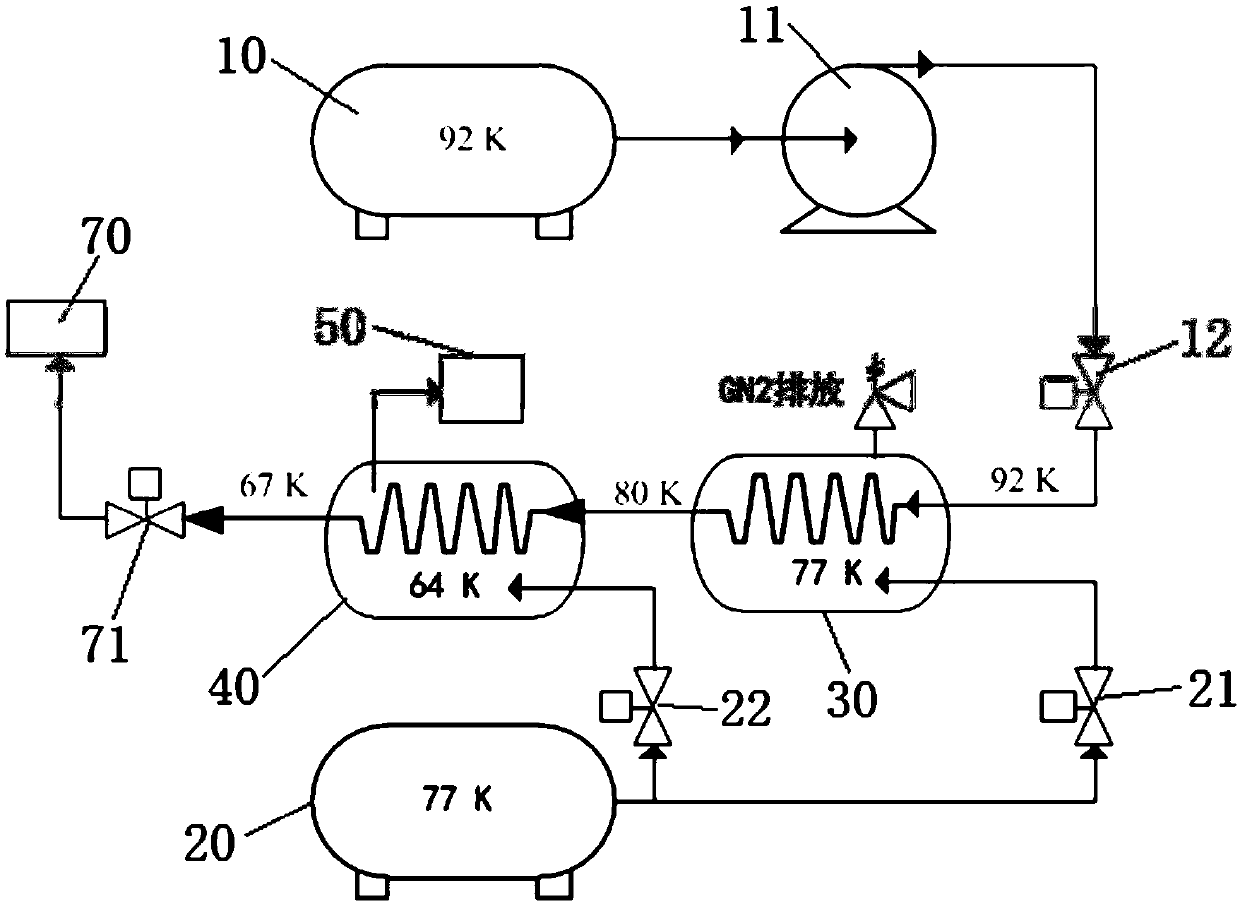

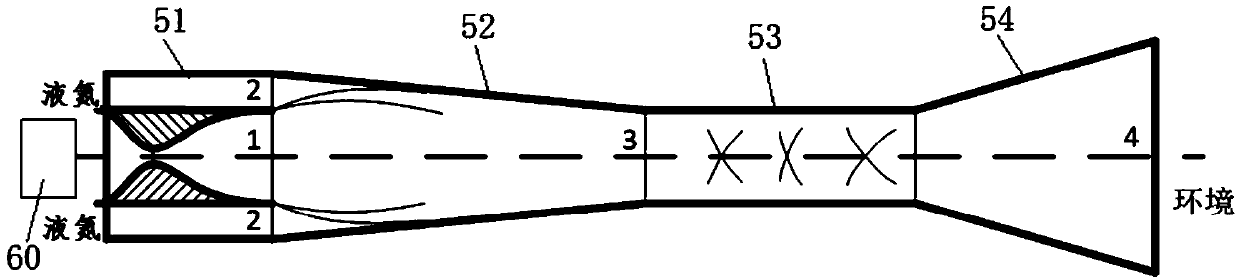

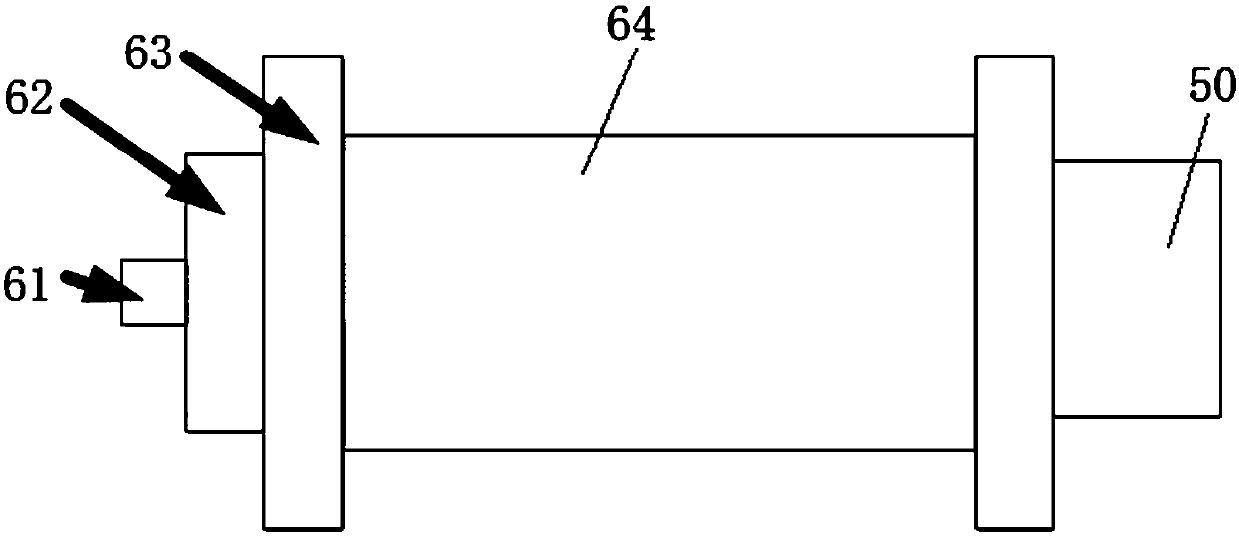

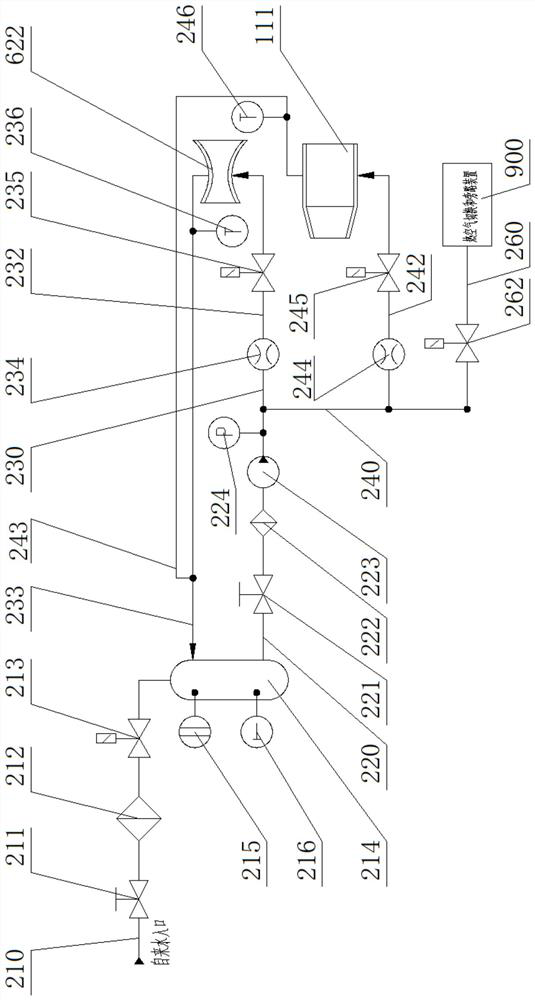

Large flow liquid oxygen supercooling method based on supersonic ejector

InactiveCN109579351ALarge supercooling flowStorage stabilityMechanical apparatusFluid circulation arrangementLiquid nitrogenLiquid oxygen

The invention discloses a large flow liquid oxygen supercooling method based on a supersonic ejector. The large flow liquid oxygen supercooling method comprises the steps that a heat exchanger used inconventional saturated liquid nitrogen supercooling liquid oxygen is used as a primary heat exchanger, and the liquid oxygen with a supercooling flow rate greater than 4500 L / min can be supercooled from 92K to 80K; a secondary heat exchanger is arranged at the downstream position of the primary heat exchanger to supercool the liquid oxygen which is supercooled to 80K and with the supercooling flow rate greater than 4500L / min to below 67K; the secondary heat exchanger is filled with liquid nitrogen in a saturated state, the temperature of the liquid nitrogen in the secondary heat exchanger isno more than 64K, and an air outlet of the secondary heat exchanger is connected with an ejected airflow inlet of the supersonic ejector; an ejector airflow inlet of the supersonic ejector is connected to a gas outlet of a gas generator; the supersonic ejector sequentially includes a mixing section, a super-expansion section and a sub-expansion section which are arranged coaxially in the directionof the airflow; and the mixing section is a conical isobaric mixing chamber with a contracted cross section. The large flow liquid oxygen supercooling method can meet the needs of rapid cooling and filling of large-flow liquid oxygen before launching such as CZ-5. In addition, the pumping capacity of the supersonic ejector can be matched with the load, and more security and reliability are achieved.

Owner:PLA PEOPLES LIBERATION ARMY OF CHINA STRATEGIC SUPPORT FORCE AEROSPACE ENG UNIV

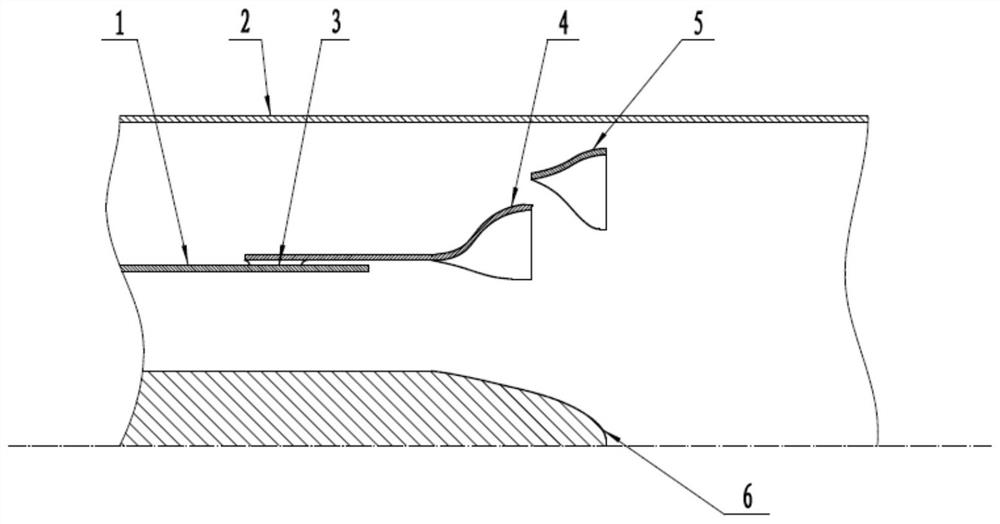

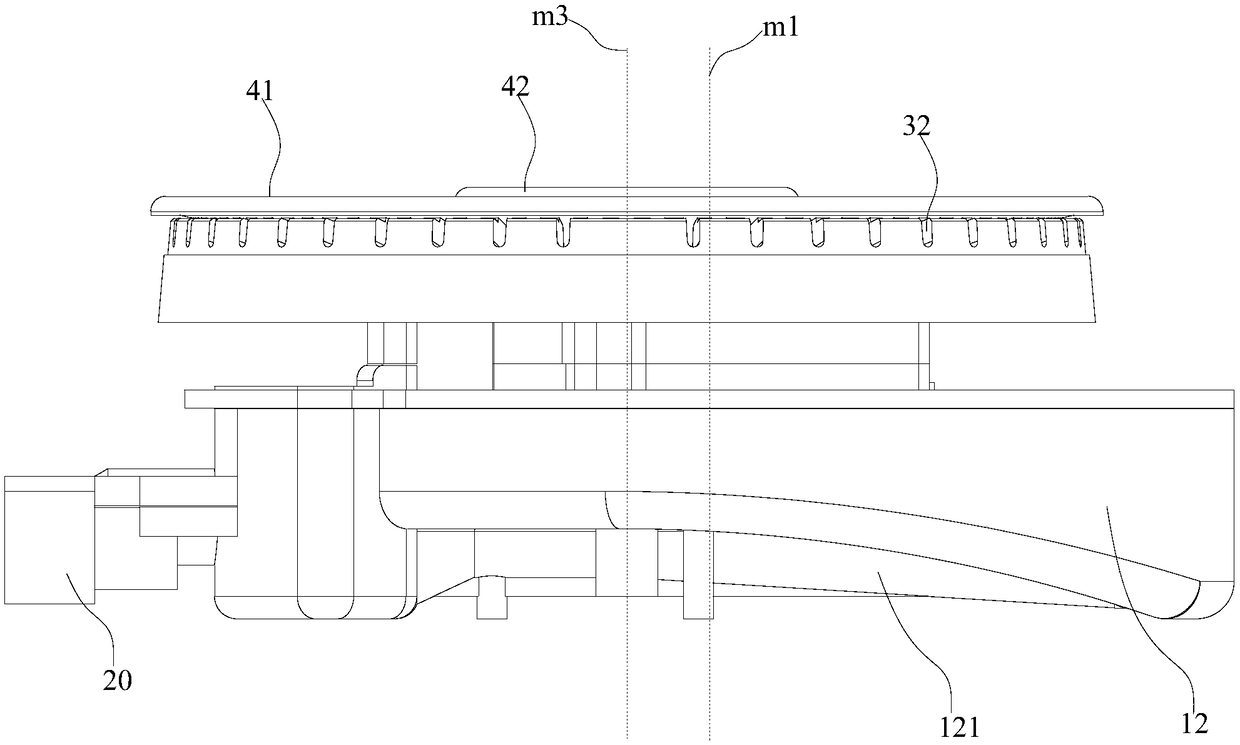

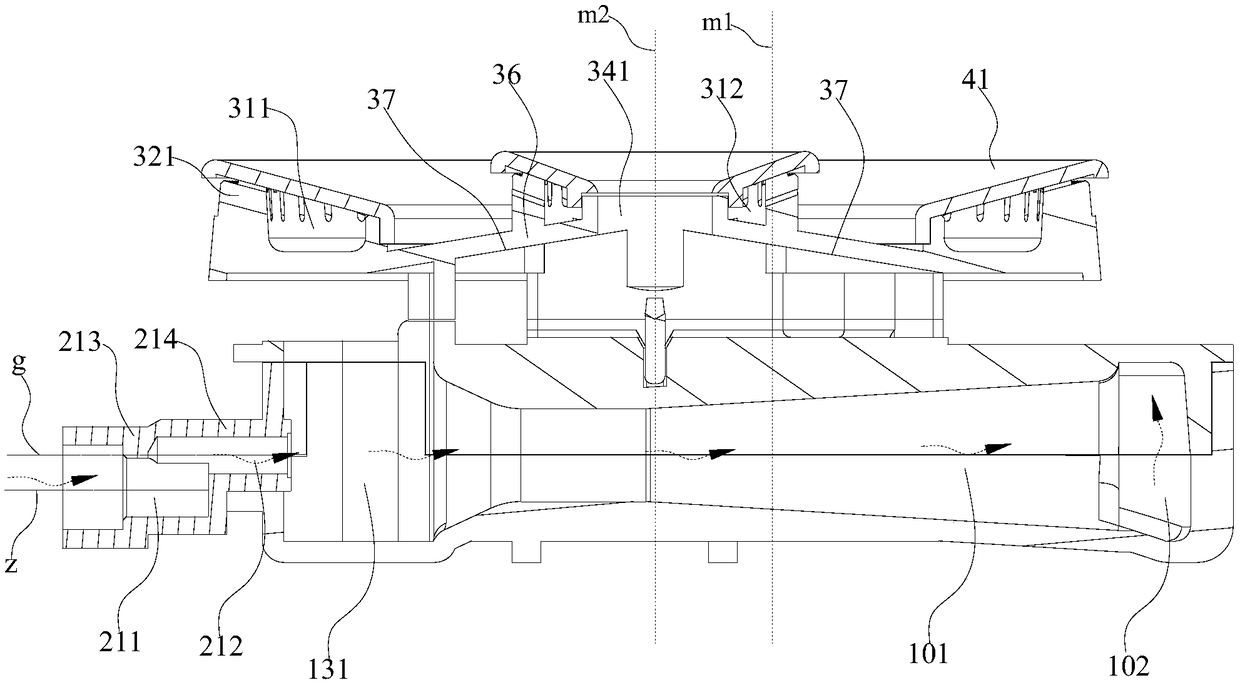

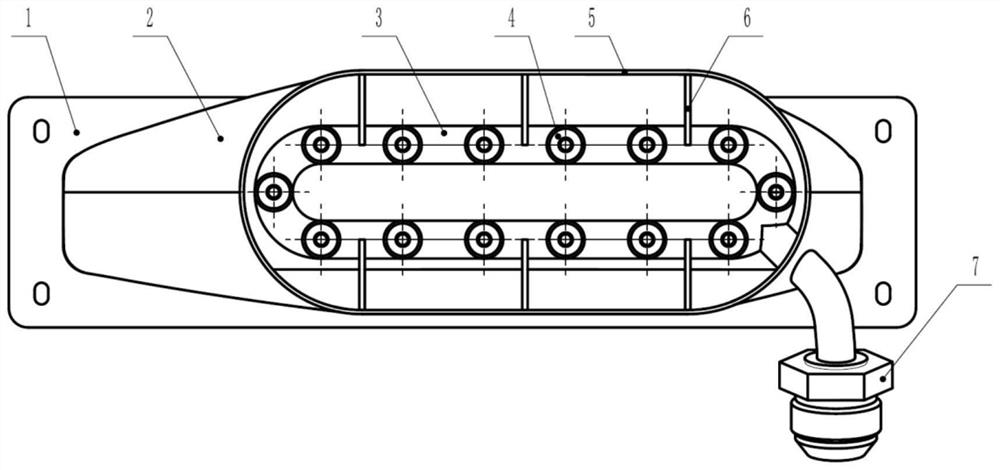

Upper air inlet gas cookware

InactiveCN101936548BImprove ejection abilityIncrease air contentGaseous fuel burnerDomestic cooking appliancesForeign matterCombustor

The invention discloses upper air inlet gas cookware, belongs to gas cookware and solves the problems of inadequate combustion, low efficiency and small power caused by poor ejection capacity of the conventional gas cookware. In the upper air inlet gas cookware, a burner base is provided with a central ejector pipe and is connected with two side ejector pipes, an annular groove is formed on the upper surface of the burner base, an air admission hole is formed on one side face of the burner base and legs are arranged at the bottom of the burner base; a circular path is formed on the lower end face of an outer ring fire cover, fire holes are formed on the outer circumference of the outer ring fire cover and a central fire cover is arranged in the center of the outer ring fire cover; and a central gas nozzle and a central gas interface are arranged at the bottom of the gas ejection base and two spray pipes aligned with two side ejector pipe inlets respectively are arranged on the upper surface of the gas ejection base. The upper air inlet gas cookware improves gas inlet capacity, mixes gas uniformly, has adequate combustion and increases power; and foreign matters cannot enter a shell, so that the health of consumers is facilitated. By the upper air inlet gas cookware, the heat absorption efficiency of a pot can reach 55 percent; the emissions of CO and NOx is lower than 400ppm and 300ppm respectively which are far below the national energy-saving environmental protection index.

Owner:HUAZHONG UNIV OF SCI & TECH

Ejector with adjustable structure parameters

InactiveCN108266411ASatisfy the requirements of injector performanceGood energy saving effectJet pumpsFluid removalThree stageEngineering

The invention relates to an ejector with adjustable structure parameters. The ejector comprises a working nozzle, a low-pressure air inlet chamber, a straight pipe section, a diffusion chamber and a low-pressure air inlet chamber inlet pipeline. The diffusion chamber is formed by nesting three stages of diffusion pipes, so that a structure of the diffusion chamber can be changed through adjustingrelative positions of the diffusion pipes. The straight pipe section is formed by a basic straight pipe section and two stages of detachable straight pipe sections, so that the length of the straightpipe section can be adjusted through disassembling or installing detachable parts. A low-pressure air inlet chamber wheel disc and a working nozzle wheel disc are connected with the low-pressure air inlet chamber and the working nozzle into a whole; and during assembling, a main body of the working nozzle stretches into the low-pressure air inlet chamber, and a distance between the low-pressure air inlet chamber wheel disc and the working nozzle wheel disc is changed through adjusting an adjustable bolt, so that an outlet position of the working nozzle is adjusted. According to the ejector with the adjustable structure parameters provided by the invention, the structure parameters of the ejector can be correspondingly adjusted according to the change of an operation condition, so that an ejecting performance of the ejector under varying duty operation situations such as natural gas extraction is improved.

Owner:苟千舟

Throat area adjustable static momentum-enhanced ejector

ActiveCN108672117ARapid positioningImprove seismic performanceLiquid spraying apparatusThroatFully developed

The invention provides a throat area adjustable static momentum-enhanced ejector and belongs to the technical field of fluid jet pressurization. The ejector is subjected to operation optimization andcan realize adjustment of the large-scale working condition through an adjusting mechanism. The throat area corresponds to the rotating angle. The optimum condition under different parameters can be rapidly located through stepless adjustment of the throat area and the axial position of a spray nozzle. A rigid metal insertion sheet is fixedly constrained between a driving spray nozzle through holeand an adjustable base groove. The throat area adjustable static momentum-enhanced ejector is concise, firm, high in shock resistance and more suitable for fluid flowing. A static momentum-enhanced structure is added to a driving spray nozzle outlet. Generated disturbance can fully develop to induce fluid to conduct circumferential and radial momentum exchange, momentum exchange of driving fluidand driven fluid is enhanced, the length of a mixing chamber is shortened, and the ejecting performance is improved. Different types of rigid metal insertion sheets and static rotational flow structures can be selected to adapt to different requirements. An operator just needs to exchange different rigid metal insertion sheets and adjustable bases. The throat area adjustable static momentum-enhanced ejector is convenient to adjust.

Owner:艾肯(江苏)工业技术有限公司

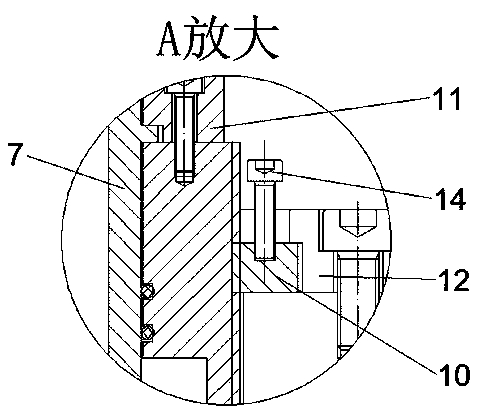

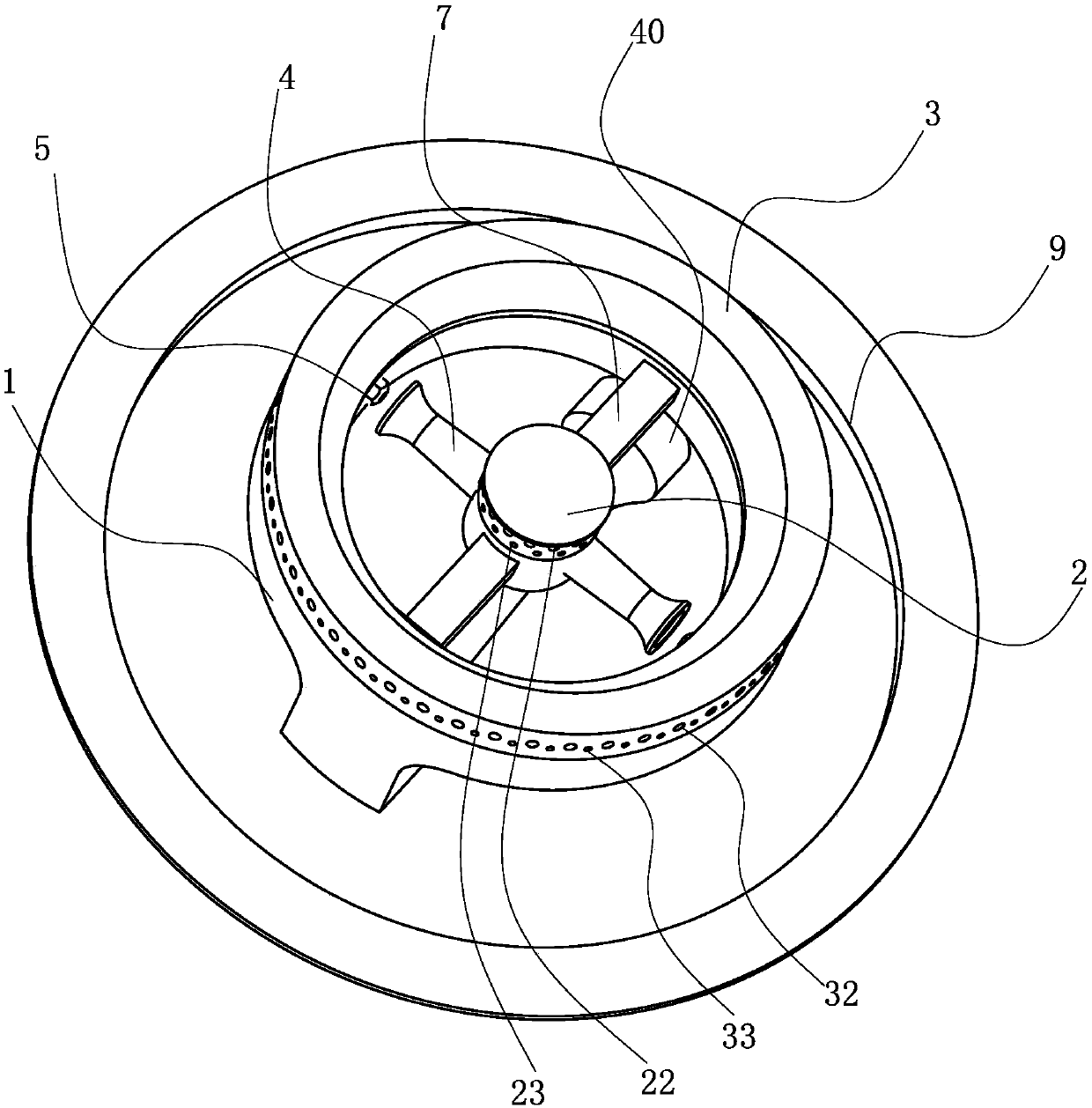

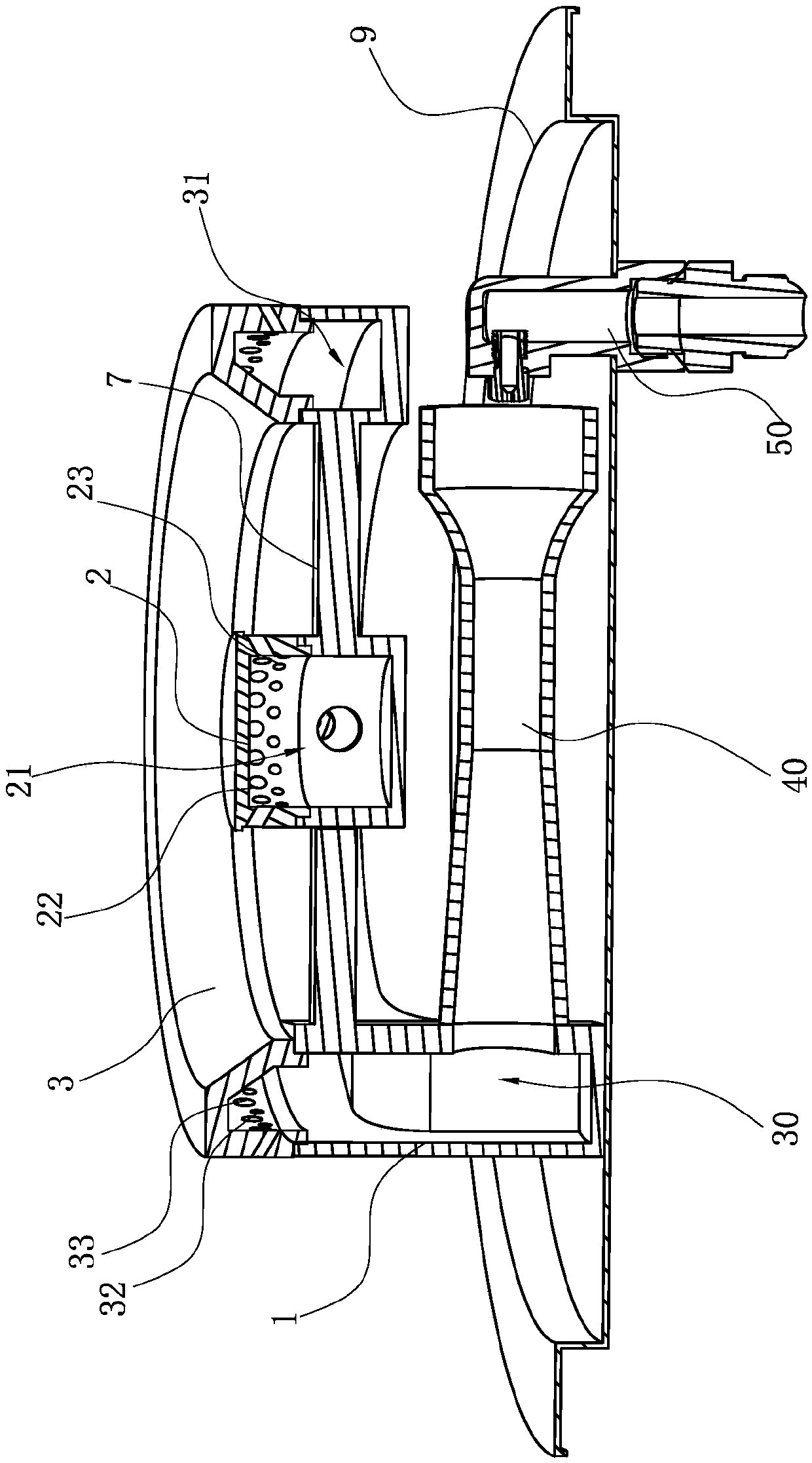

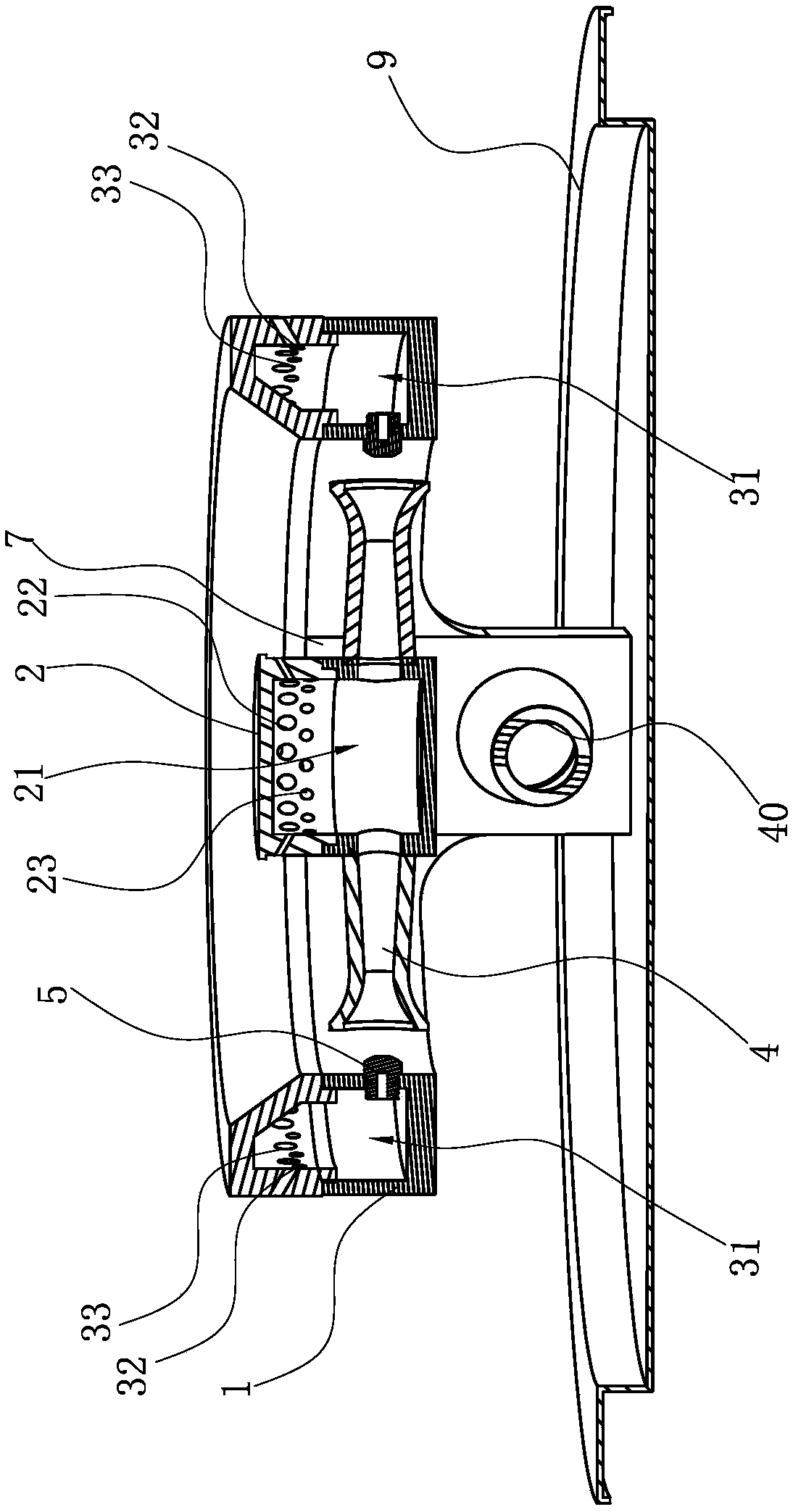

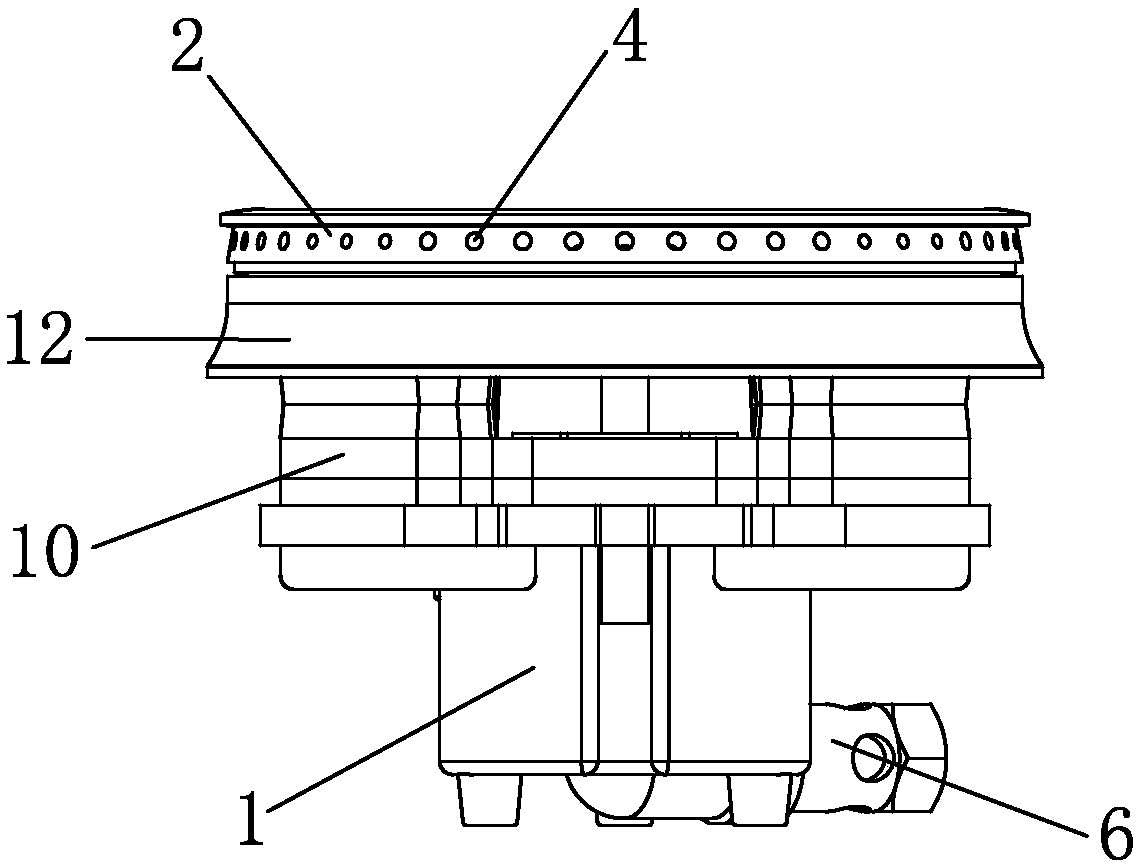

Burner for gas stove

PendingCN109959004ASolve the problem of insufficient ejection volumeEnsure uniformity of combustionGaseous fuel burnerEngineeringGas mixing

The invention relates to a burner for a gas stove. The burner for the gas stove comprises a base, an inner ring burner cap and an outer ring burner cap, wherein the inner ring burner cap and the outerring burner cap are connected to the base. The top face inner wall and annular inner wall of the inner ring burner cap form a central gas mixing chamber, and an inner ring burner port communicating with the central gas mixing chamber is formed in the annular inner wall of the inner ring burner cap. The top face inner wall and annular inner wall of the outer ring burner cap form an outer ring gasmixing chamber, and a plurality of outer ring burner ports are formed in the annular peripheral wall of the outer ring burner cap. The burner for the gas stove is characterized in that at least one ejector pipe is arranged on the outer circumferential wall of the central gas mixing chamber, and nozzles matched with the gas inlet ends of the ejector pipes are arranged on the circumferential wall ofthe outer ring gas mixing chamber correspondingly. Compared with the prior art, the burner for the gas stove has the advantages that fuel gas in the outer ring gas mixing chamber is ejected to the central gas mixing chamber through at least two ejector pipes, the combustion condition can be changed through the ejection amount of the ejector pipes, and combustion homogeneity is guaranteed; and moreover, a plurality of strands of gas jet flow are arranged and can be mixed with primary air more sufficiently, ejection capacity is enhanced, and thus combustion efficiency is improved.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

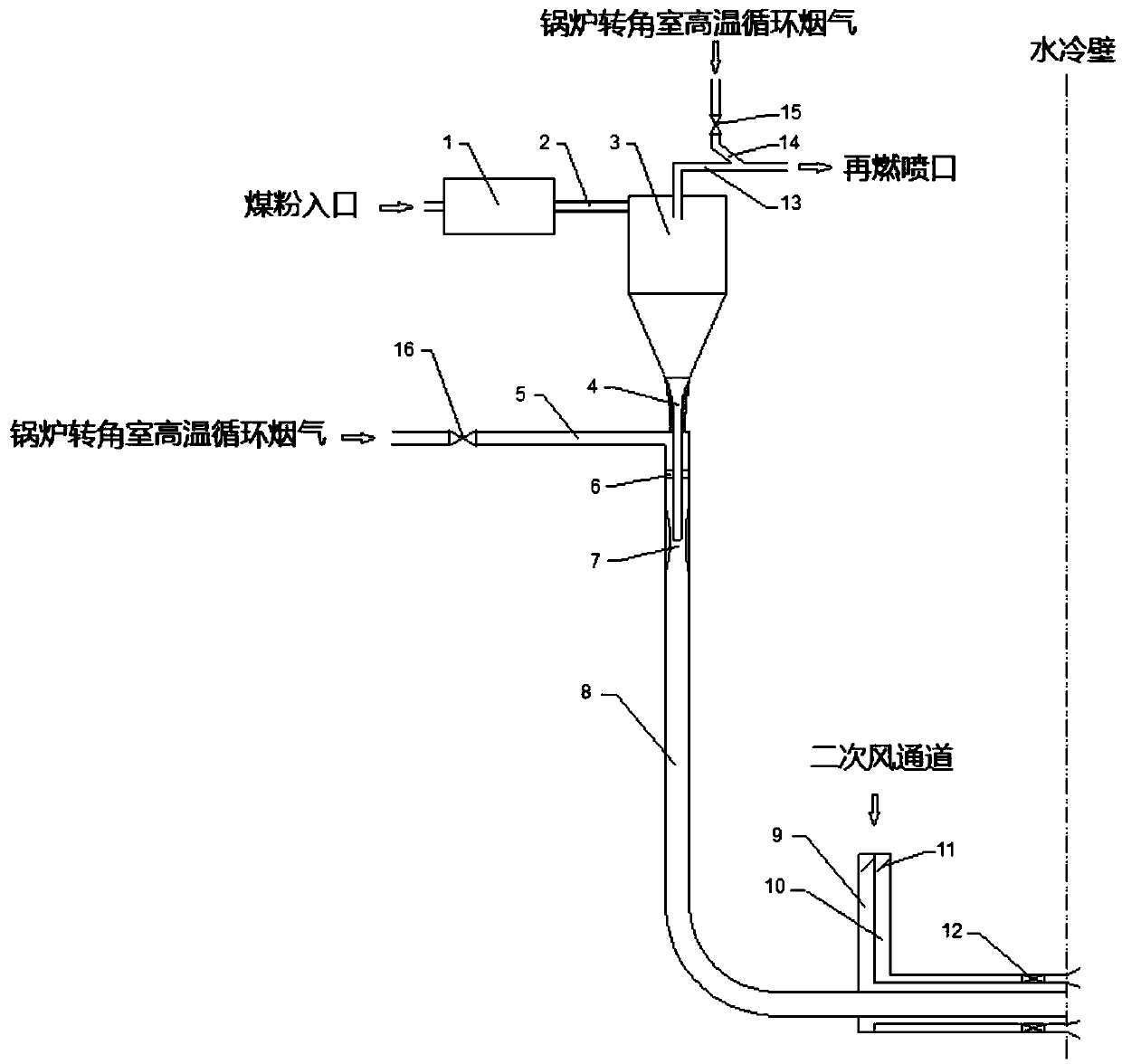

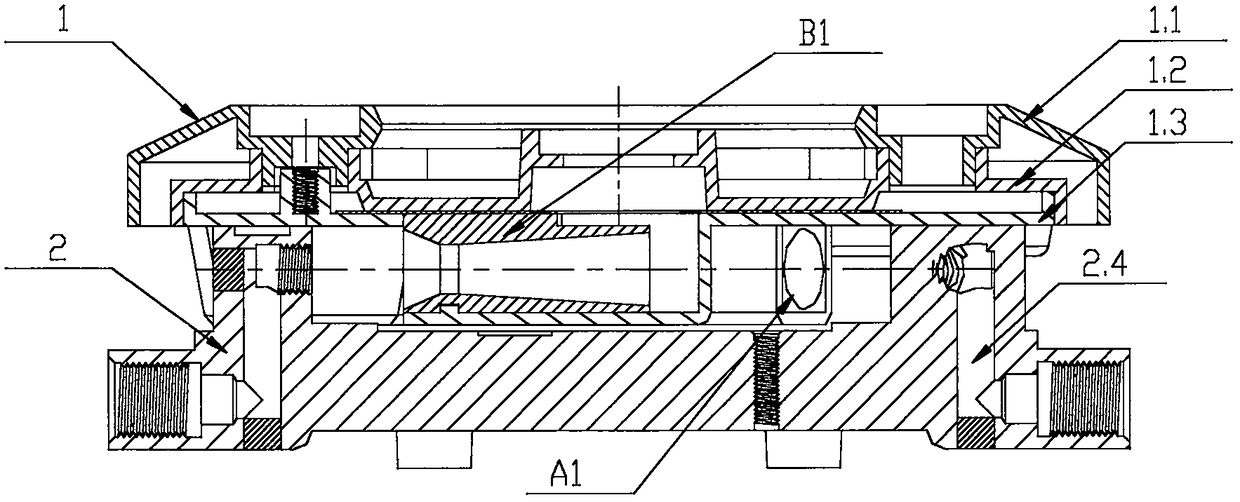

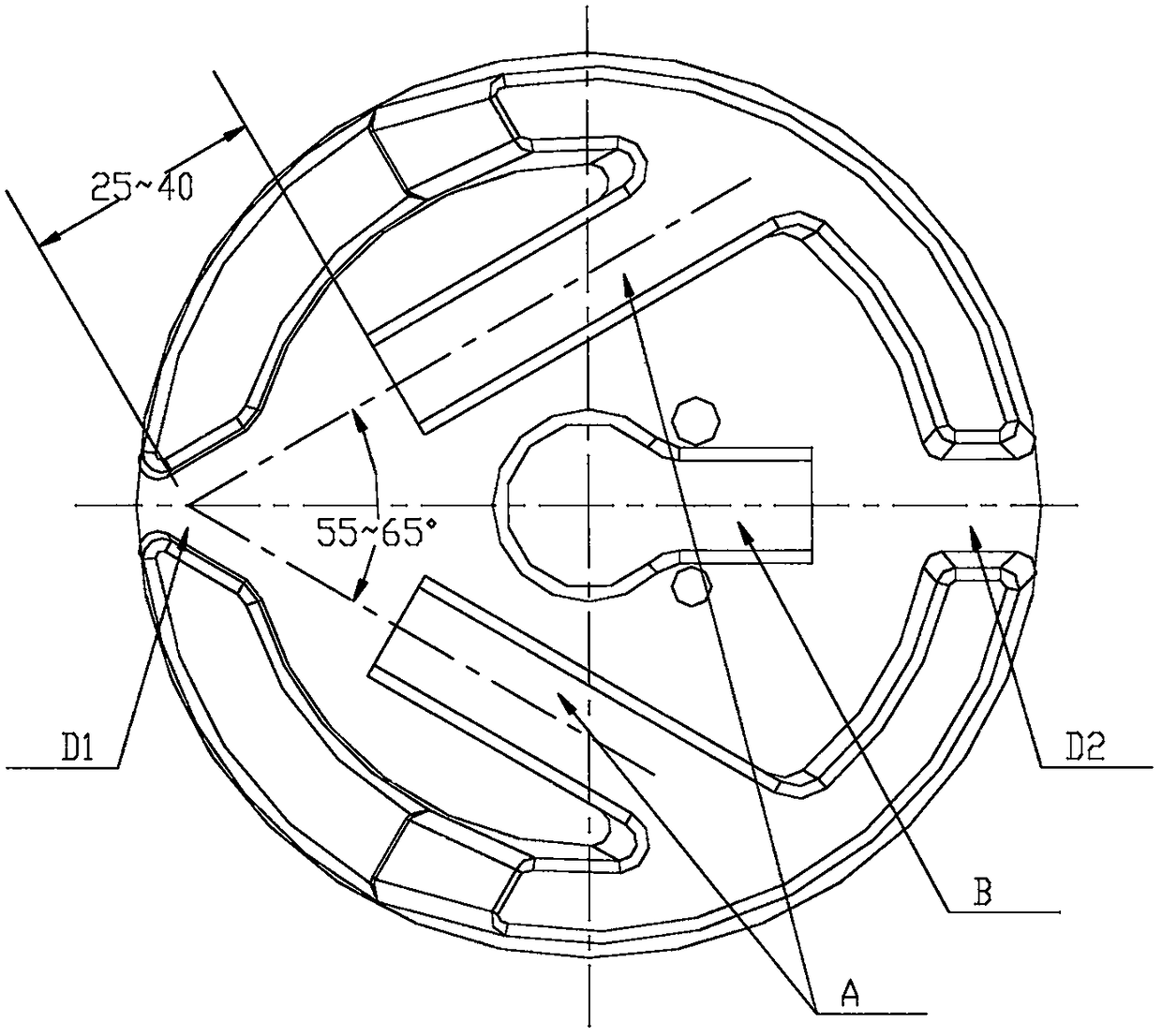

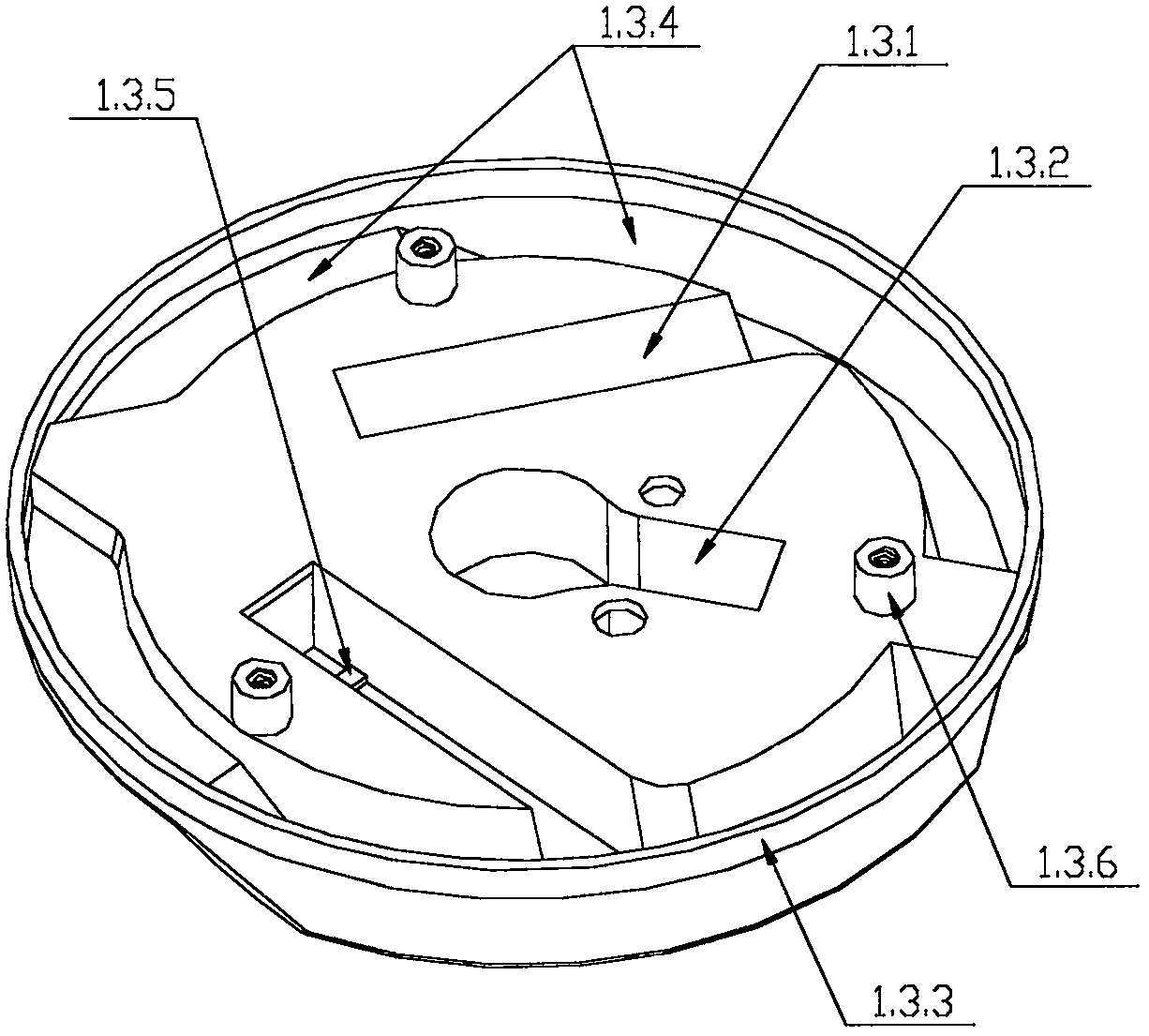

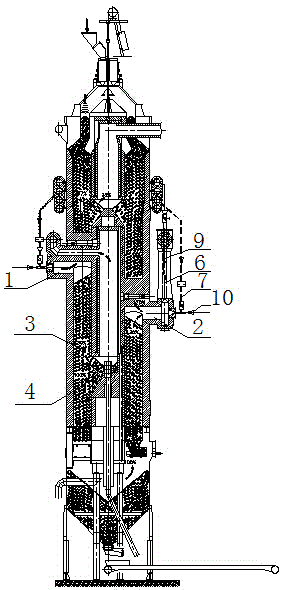

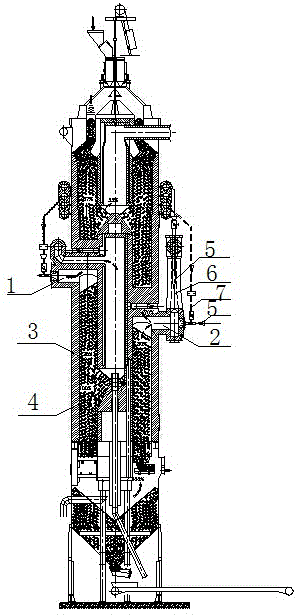

Pulverized coal pre-pyrolyzation decoupling combustion device

ActiveCN109539245AHigh reactivityEfficient combustionNon-combustible gases/liquids supplyDraught inductionProcess engineeringCoal

The invention discloses a pulverized coal pre-pyrolyzation decoupling combustion device comprising a pyrolysis chamber, a cyclone separator, an ejector device and a particle burning device; the pyrolysis chamber is provided with a raw material inlet and a product outlet; the cyclone separator is provided with a product inlet, a volatile component outlet and a particle outlet; the product inlet ofthe cyclone separator communicates with the product outlet of the pyrolysis chamber through a pyrolysis product transport passage; a reburning fuel pipe is arranged at the volatile component outlet ofthe cyclone separator; a discharging pipe is arranged at the particle outlet of the cyclone separator; the reburning fuel pipe is used for being led into a hearth; the discharging pipe communicates with a particle combustion device through the ejector device; ejector gas flow is led into the ejector device; a particle combustion device comprises an air duct; and the air duct is led into the hearth. The pulverized coal pre-pyrolyzation decoupling combustion device is based on the decoupling idea, is suitable for pulverized coal decoupling combustion, can achieve the higher pulverized coal combustion rate, is relatively good in combustion stability, and can effectively suppress NOx generation.

Owner:XI AN JIAOTONG UNIV

Upper air inlet combustor and gas stove equipped with upper air inlet combustor

PendingCN109028060AIncrease the lengthImprove ejection effectDomestic stoves or rangesGaseous fuel burnerSpray nozzlePrimary energy

The invention discloses an upper air inlet combustor. The upper air inlet combustor at least comprises a combustor main body and a combustor mounting base, wherein a ring-shaped gas mixing cavity is additionally arranged at the outer side of the combustor main body; an included-angle type outer ring ejector is arranged on the bottom non-center part of the combustor, so that the length of the outerring ejector is remarkably increased; and on the combustor mounting base, two outer ring spray nozzles share one spray nozzle mounting base and one fuel gas channel, so that flow loss, in the spray nozzle base, of gas is reduced, and the outer ring spray nozzle mounting base is more compact in structure. According to the gas stove disclosed by the invention, two openings which correspond to the spray nozzle mounting base on the combustor mounting base are formed in a liquor containing disc. The upper air inlet combustor has the beneficial effects that: combustion performances are remarkably improved, thermal load of the gas stove can be 4.0-4.5 kW, and heating efficiency can meet primary energy efficiency requirements; and the combustor main body adopts aluminum die casting or plate stretch-forming. The gas stove can realize an ultrathin structure, is free of holes in a stove surface; and the combustor is convenient to dismount, and is easier to clean and maintain.

Owner:吴钰

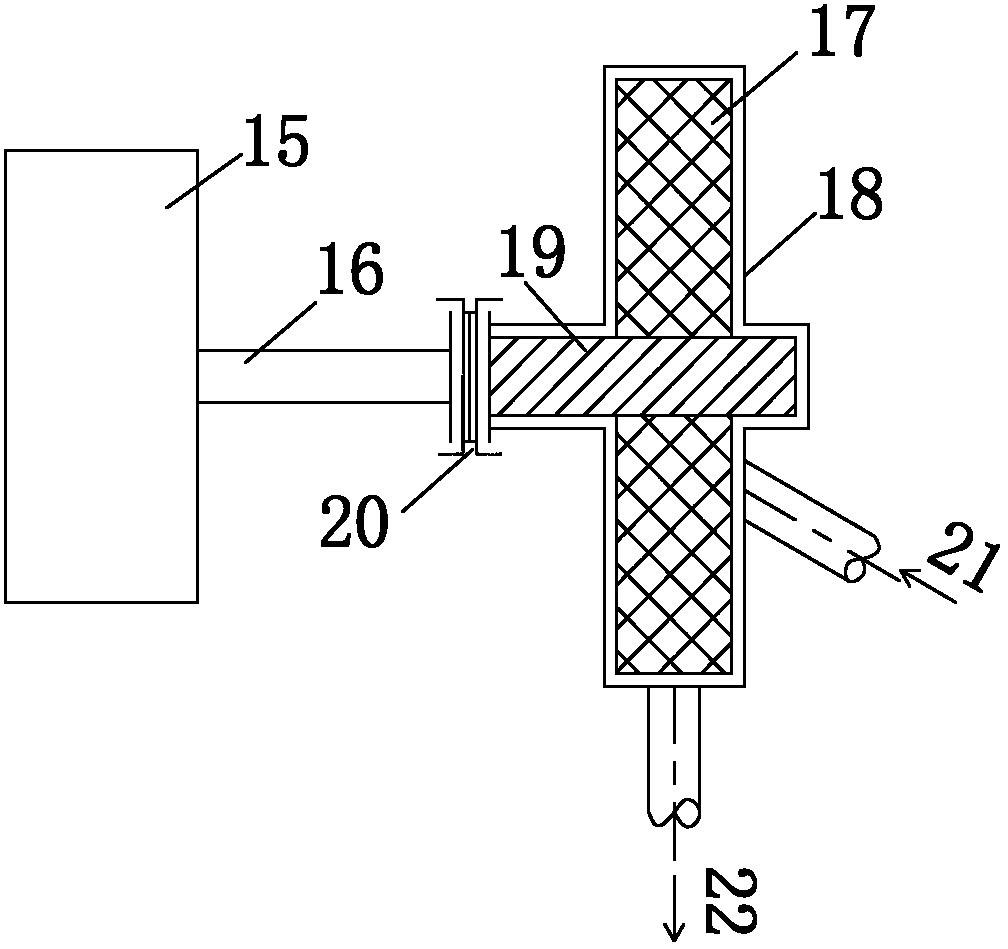

Supersonic-speed air ejector

PendingCN112443518AReduce length dimensionReduce friction lossAerodynamic testingJet pumpsEngineeringPhysics

The invention provides a supersonic-speed air ejector. The supersonic-speed air ejector comprises an air inlet pipe, a pressure-resistant shell and a mixed diffuser pipe which are connected in sequence, and further comprises a plurality of sets of ejection pipes, wherein the plurality of sets of ejection pipes are installed at different cross section positions of the pressure-resistant shell, andthe ejection pipes are evenly distributed in an ejection channel coaxial with the air inlet pipe; Laval nozzles are arranged at the outlet ends of the ejection pipes and evenly distributed on the inlet cross section of the mixed diffuser pipe; and the air source of each set of ejection pipes is one path, and a plurality of paths of air sources are independently controlled. According to the supersonic-speed air ejector, by adopting a method of installing the ejection pipes, the Laval nozzles are evenly distributed, different numbers of ejection pipes are selected according to flow requirementsso as to form ejectors with different flow specifications, the area ratio of the ejector is changed by selectively opening the Laval nozzles, an ejection coefficient and a pressurization ratio of theejector are maintained, airflow parameters are adjusted to maintain the ejector to work near a design point, the highest efficiency is achieved, and standardization is easy to achieve.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

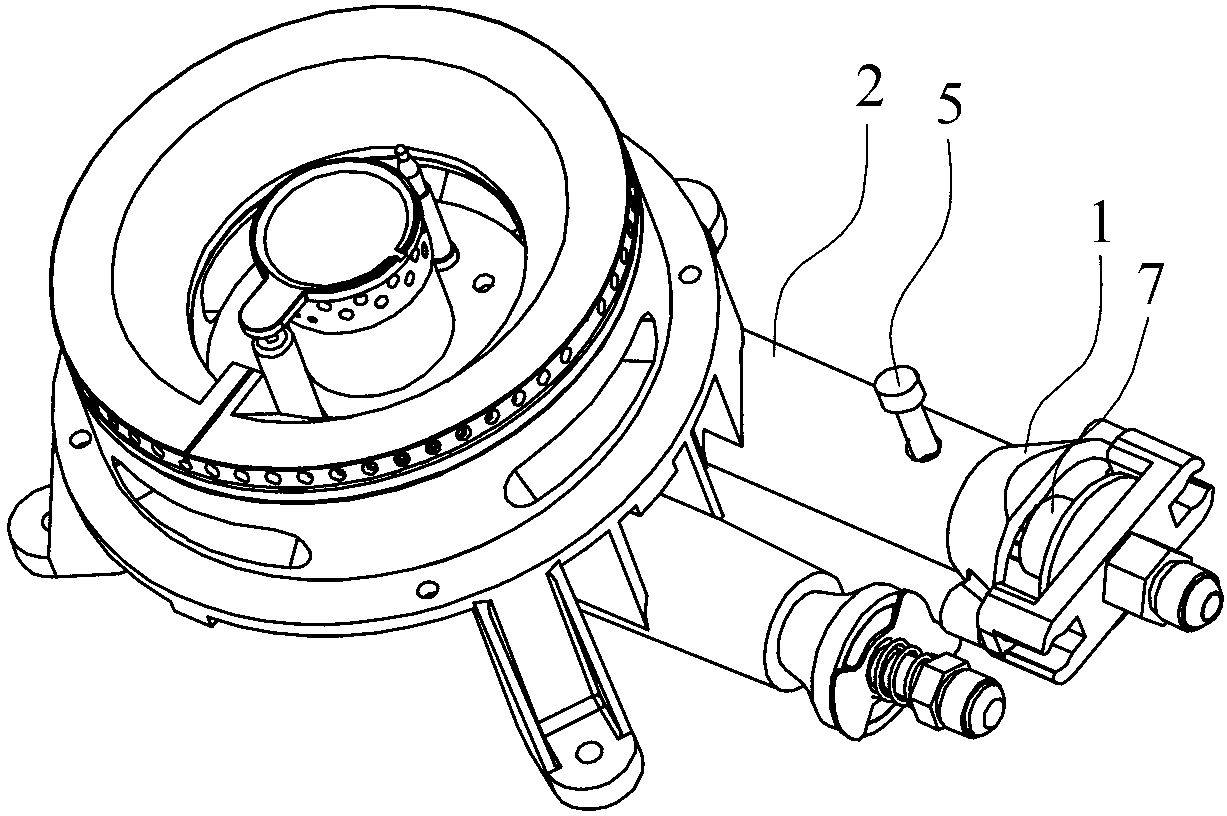

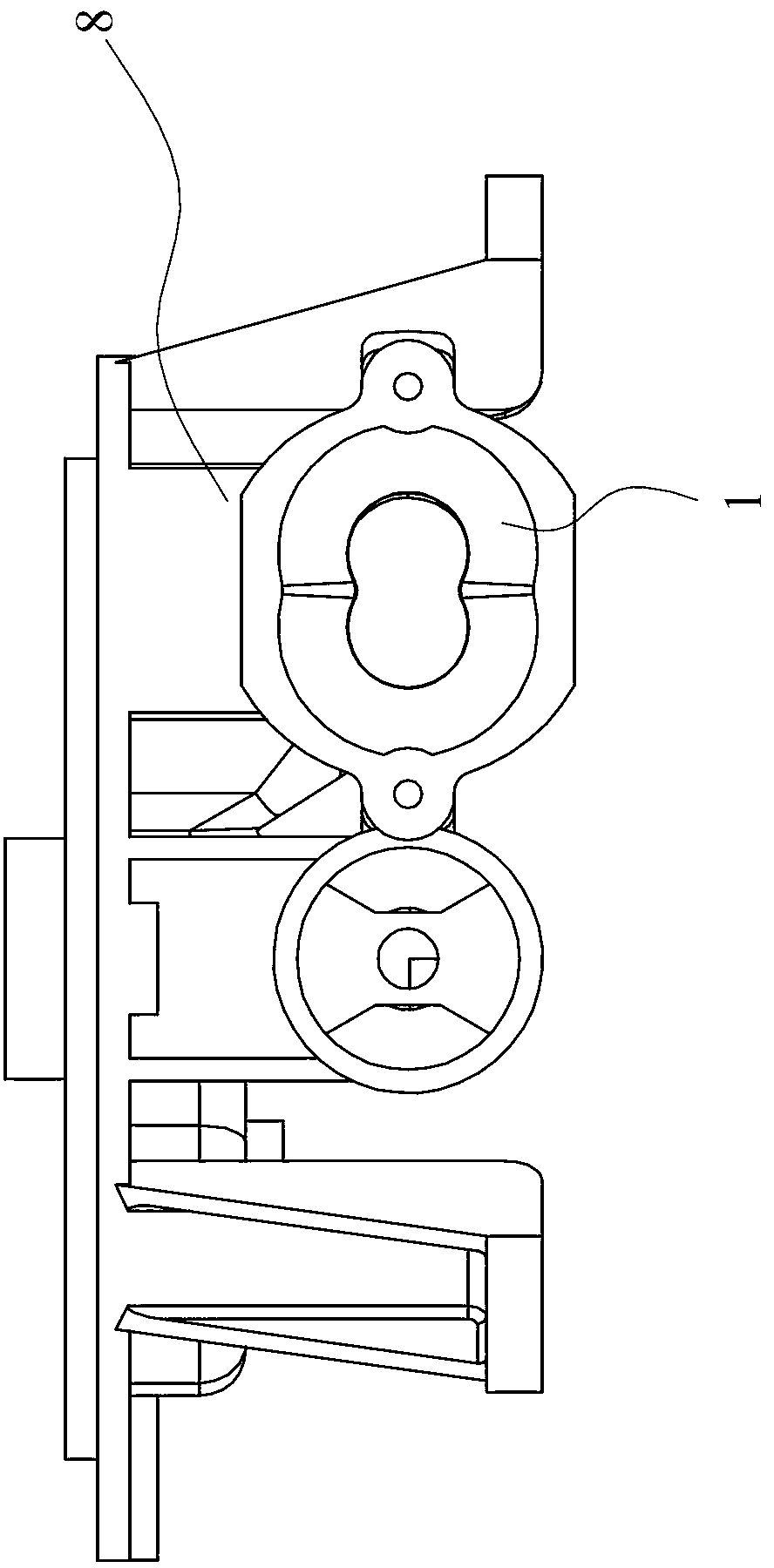

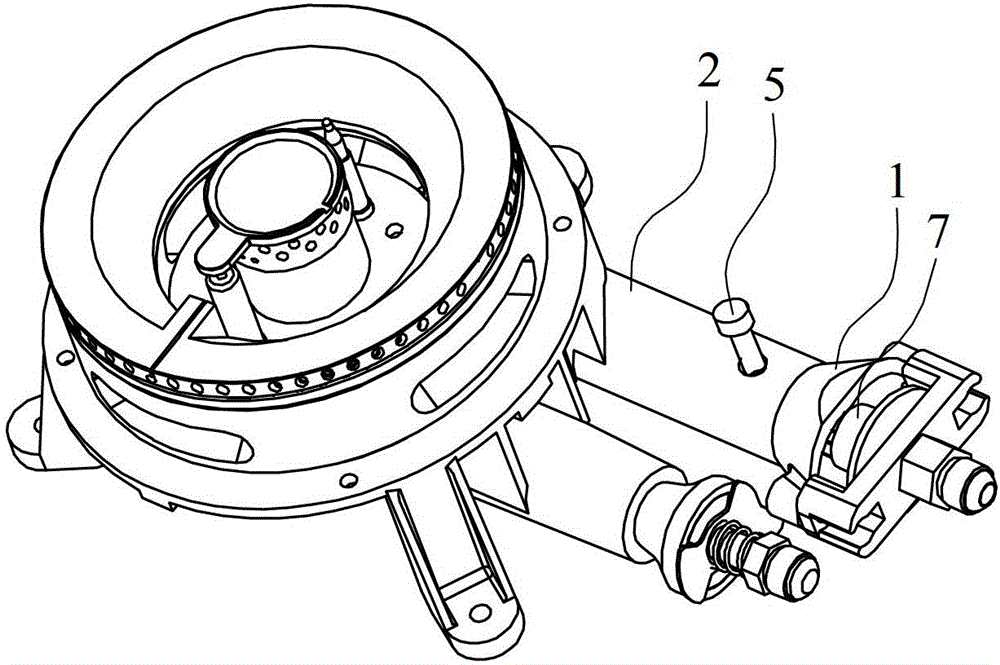

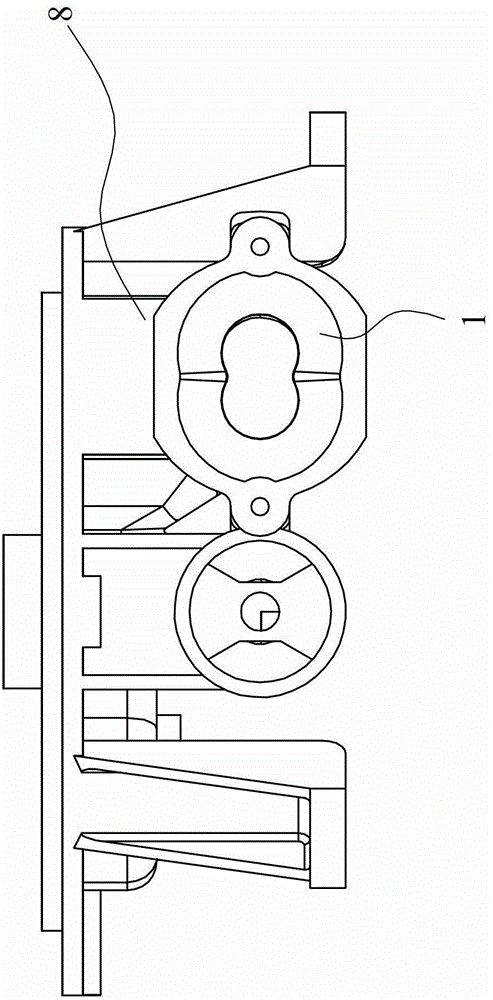

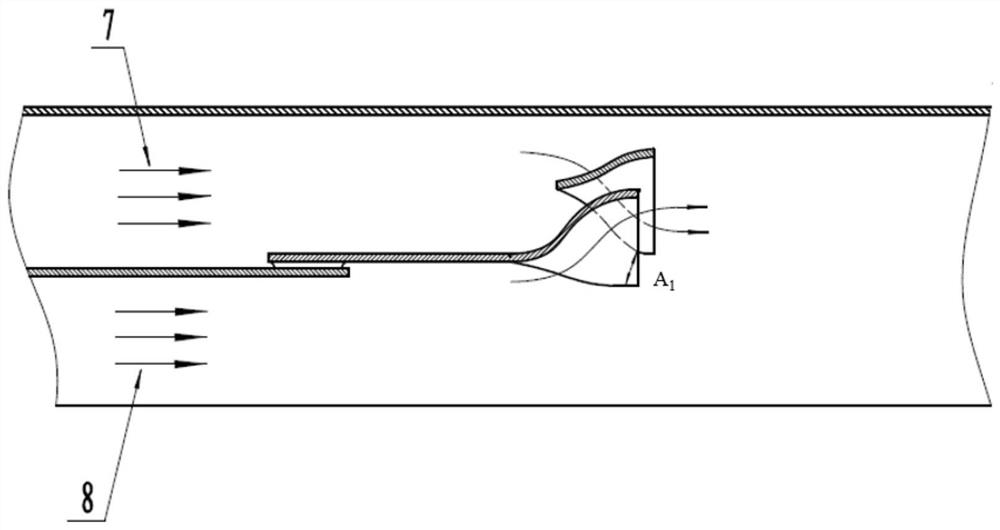

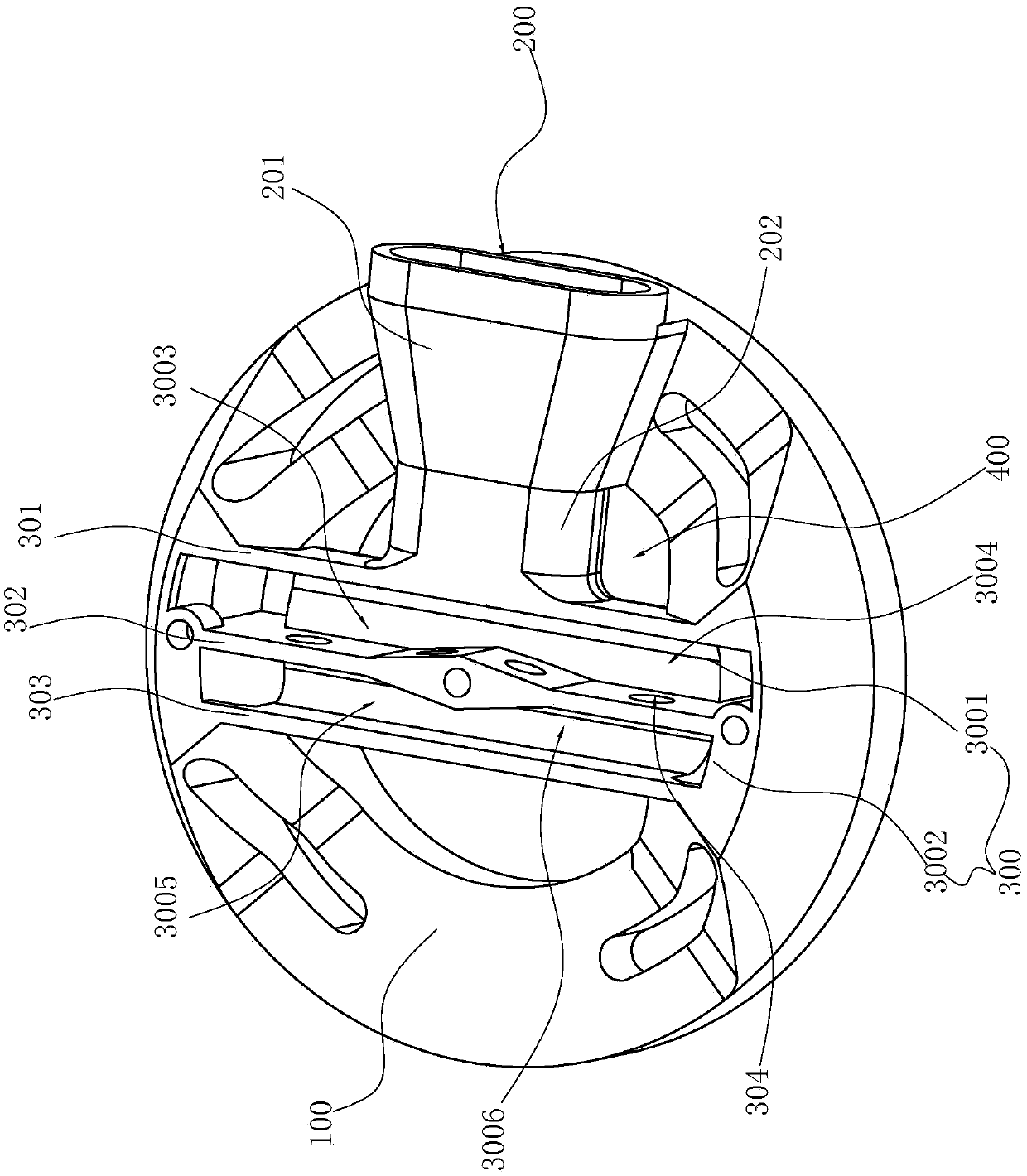

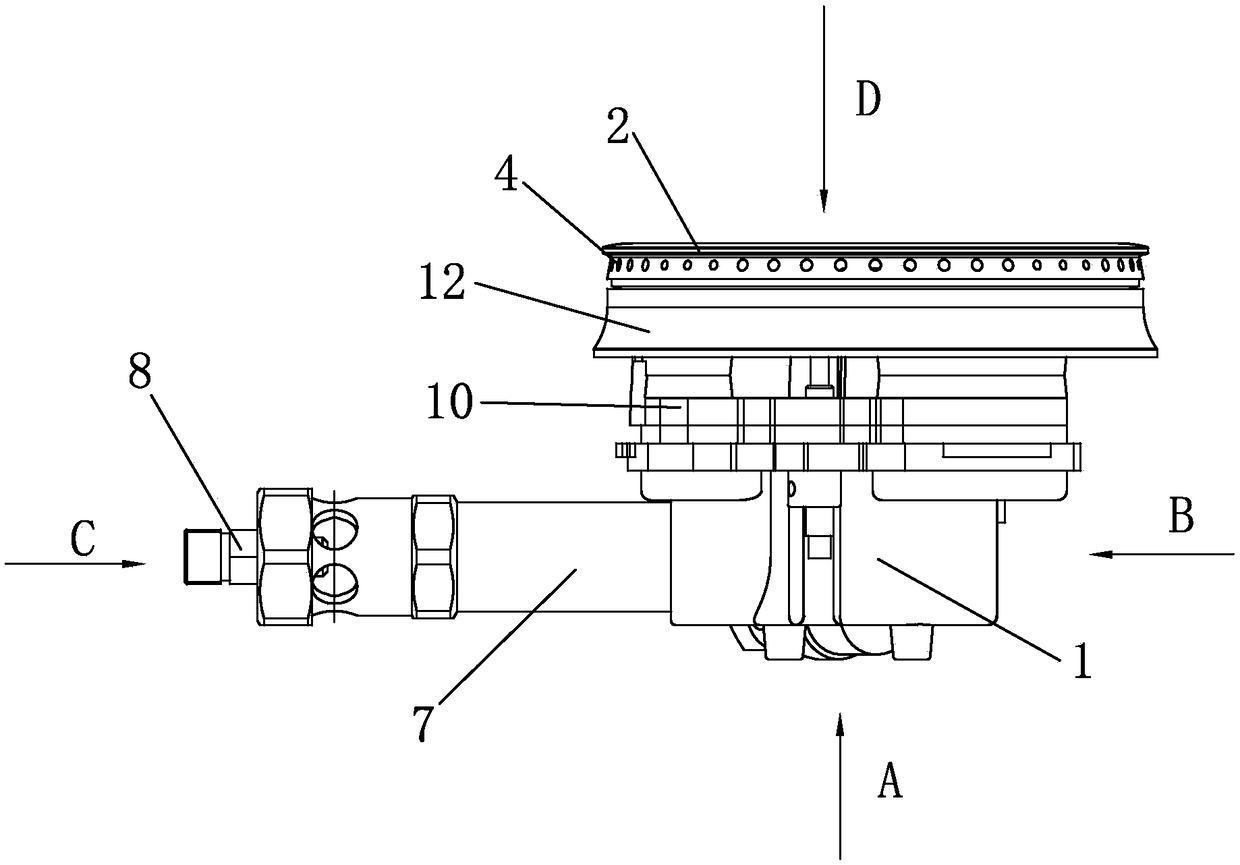

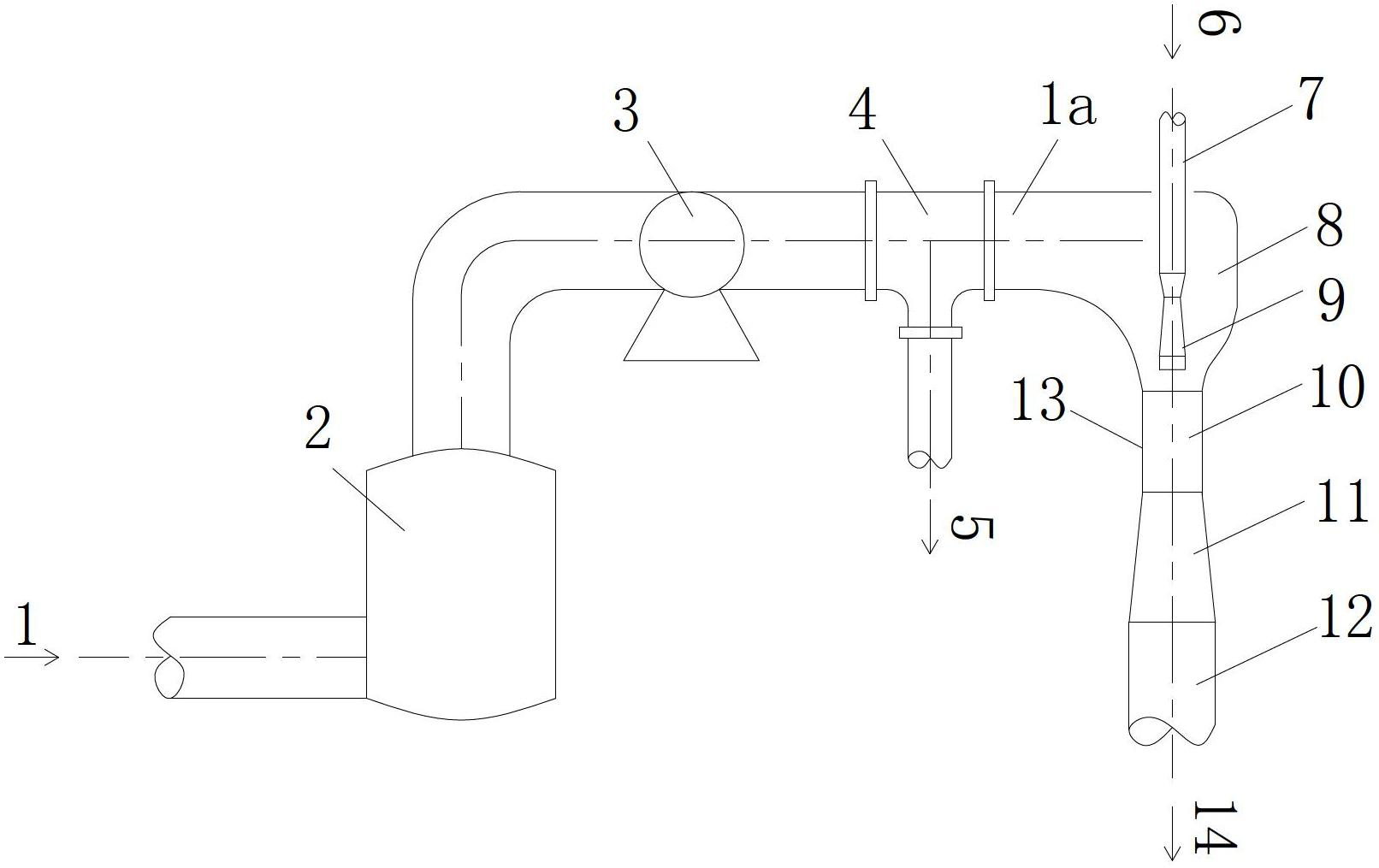

Multi-channel ejector for gas cooker, burner and gas cooker

PendingCN109798521AWell mixedImprove the mixing effectDomestic stoves or rangesGaseous fuel burnerCombustorButt joint

The invention discloses a multi-channel ejector for a gas cooker, and provides a burner and a gas cooker. The multi-channel ejector for the gas cooker comprises at least two nozzles and an ejecting pipe, wherein the nozzles and the ejecting pipe are sequentially arranged along the air flow direction; the nozzles are in butt joint with the ejecting pipe; the ejecting pipe is composed of a suction shrink tube, a mixing pipe and a diffuser pipe which are sequentially connected according to the air flow direction and changes of the cross sections; the mixing pipe is composed of branch mixing pipeswith same quantity of nozzles; and each nozzle corresponds to one branch mixing pipe. According to the multi-channel ejector for a gas cooker, the mixing pipe is divided into multiple branch mixing pipes, multiple nozzles are arranged, and each of the nozzles corresponds to one branch mixing pipe, so that the gas and the air are mixed more uniformly, the mixing effect of the gas and the air is improved, and the ejection ability is improved as well.

Owner:VATTI CORP LTD

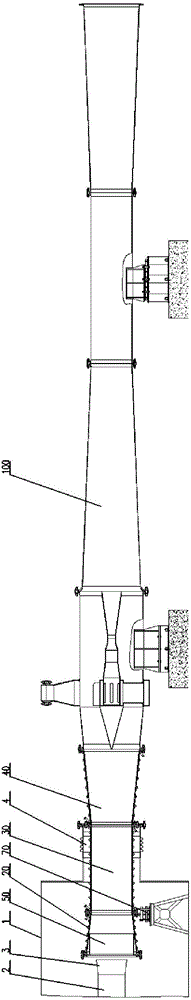

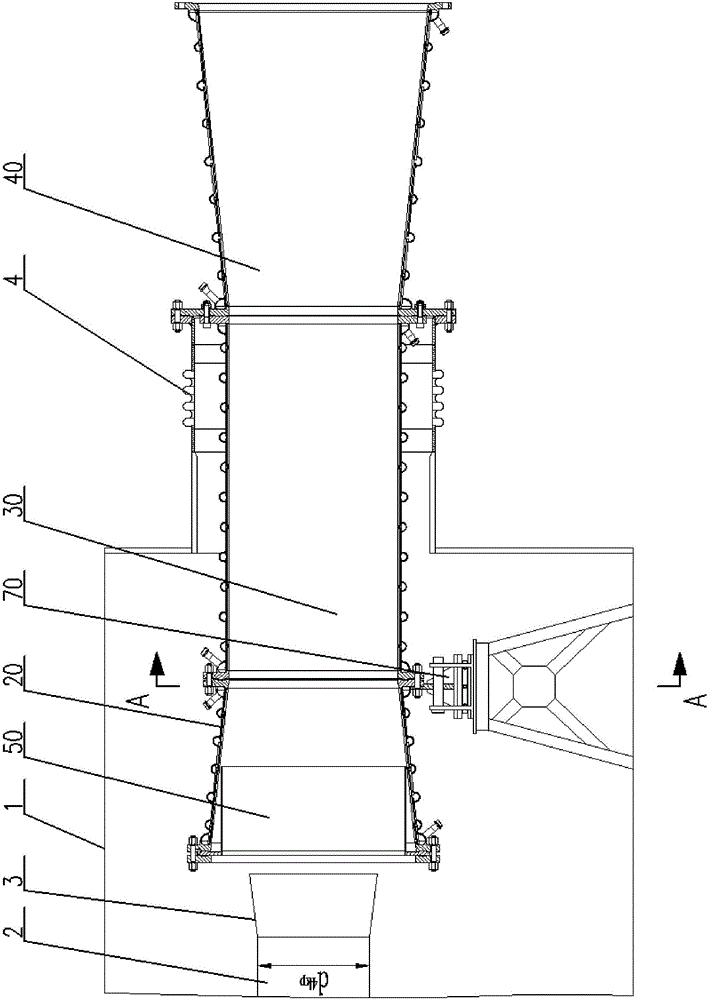

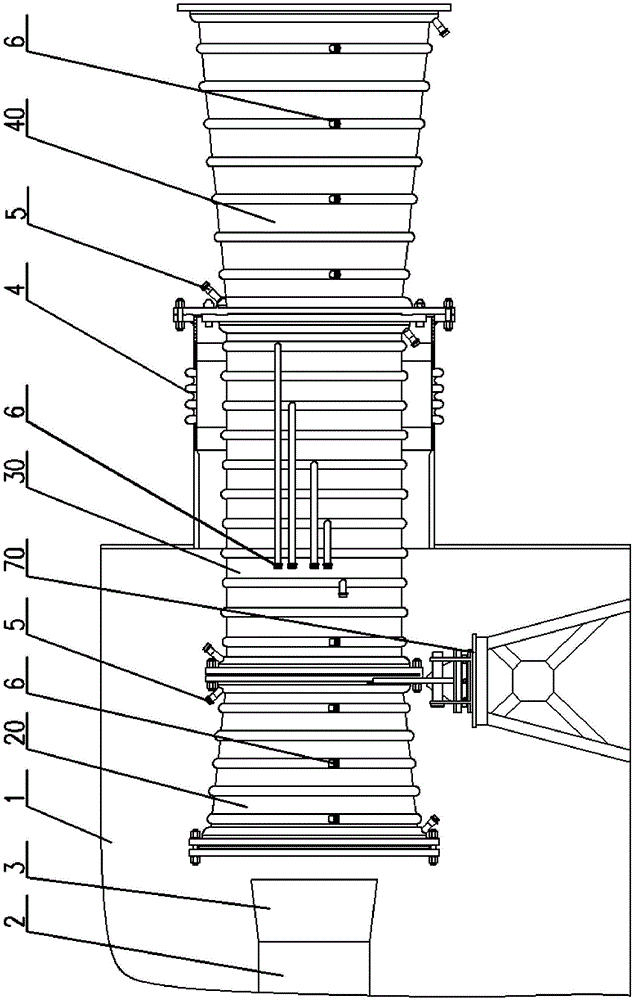

Method for roasting lime with blast furnace gas in sleeve lime kiln

The invention belongs to the technical field of lime kiln roasting and relates to a method for solving the problem that a sleeve lime kiln cannot active lime with low-calorific-value gas, in particular to a method for roasting lime with blast furnace gas in the sleeve lime kiln. According to the method, driving air for injection in an injector is replaced with low-calorific-value blast furnace gas, an injection effect is realized, conditions that low-calorific-value gas combustion temperature cannot meet the lime roasting requirement and driving air causes excessive combustion-supporting wind are eliminated, and the sleeve kiln is more energy-saving. Other parameters are optimized and configured, the method can effectively use the low-calorific-value blast furnace gas to roast lime in the sleeve kiln, the lime quality can be guaranteed, and the lime production cost can be reduced.

Owner:江苏宇力节能科技有限公司

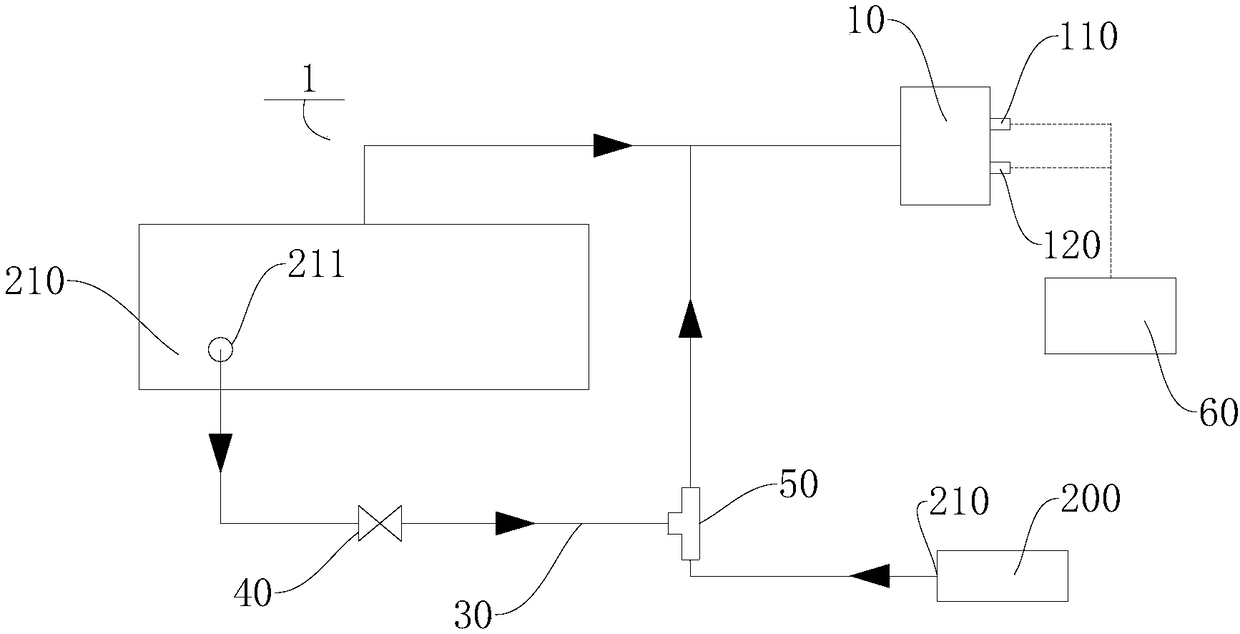

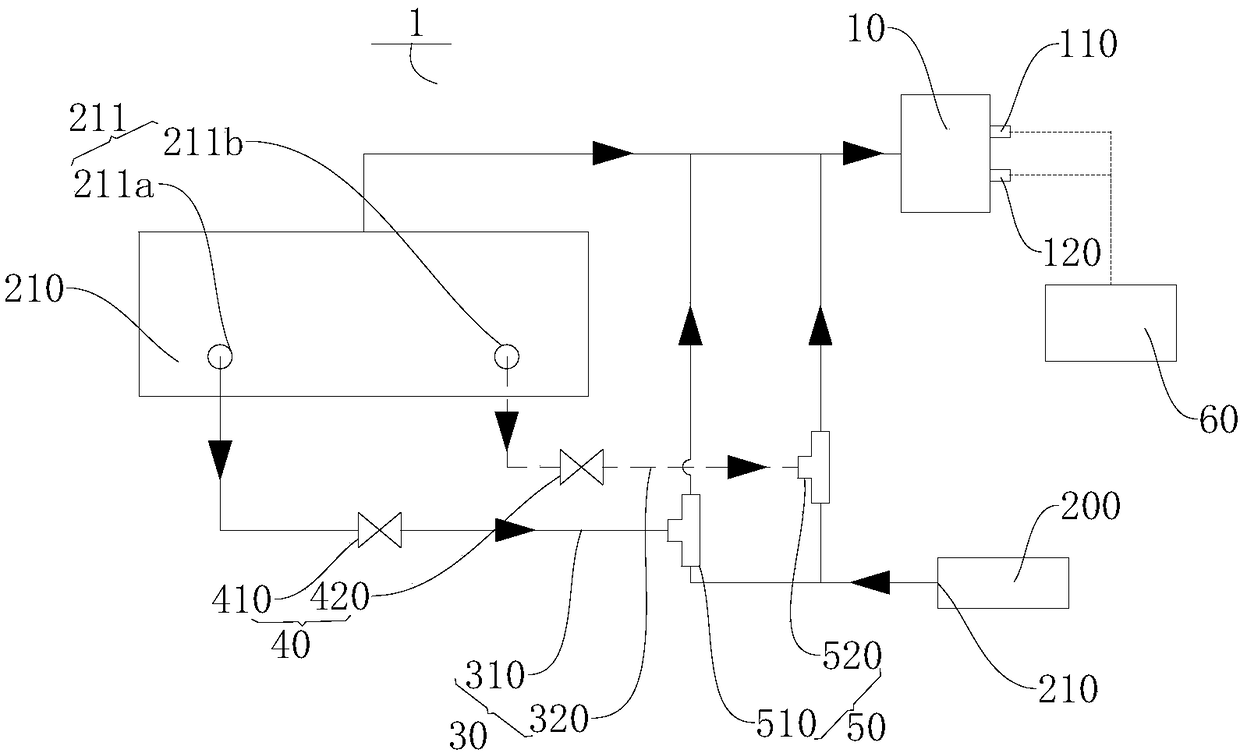

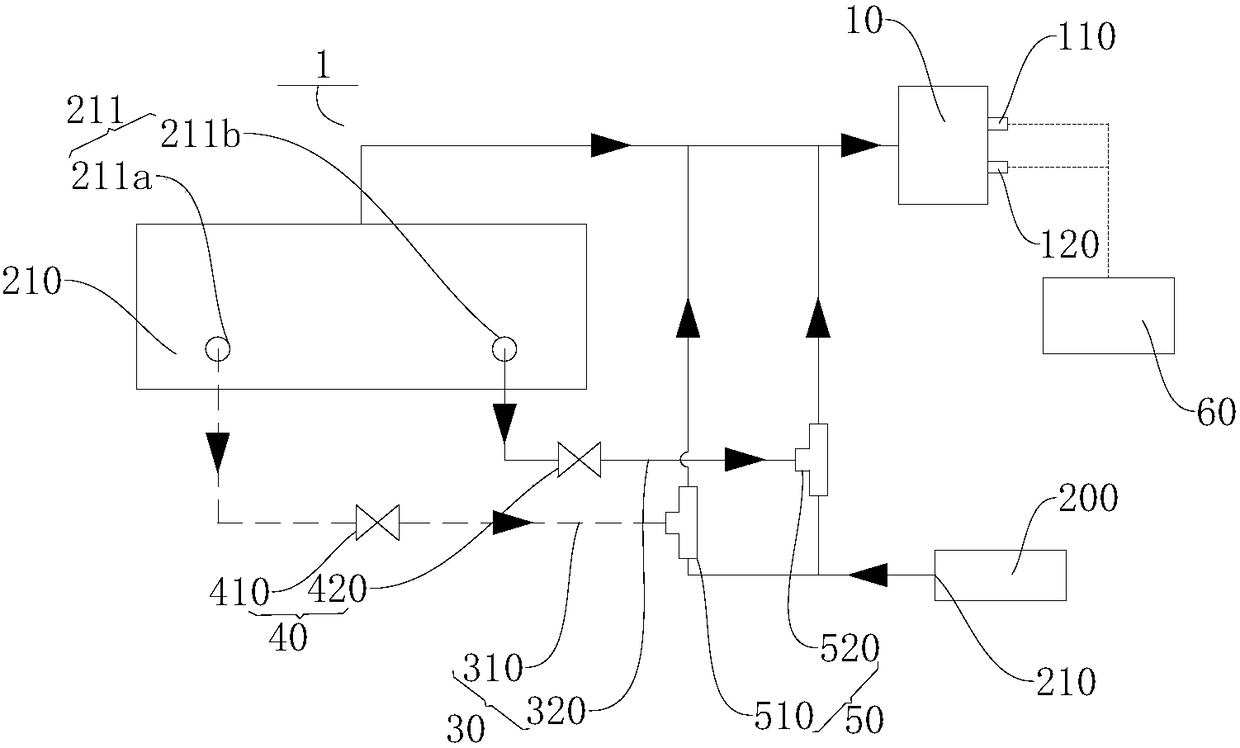

Refrigeration system and control method thereof

InactiveCN108151347AImprove controllabilityImprove reliabilityCompressorCompression machines with non-reversible cycleEngineeringControl valves

The invention discloses a refrigeration system and a control method of the refrigeration system. The refrigeration system comprises a compressor, a heat exchanger assembly, an ejection pipeline, a control valve and a controller. The compressor is provided with a first oil level detection part and a second oil level detection part, and the first oil level detection part and the second oil level detection part are used for detecting oil levels at different positions in the compressor. The heat exchanger assembly is provided with an ejection port. One end of the ejection pipeline communicates with the ejection port, and the other end of the ejection pipeline communicates with the compressor. The control valve is arranged on the ejection pipeline to control on-off of the ejection pipeline. Thefirst oil level detection part, the second oil level detection part and the control valve are all connected with the controller. According to the refrigeration system, the controller judges the stateof the oil level in the compressor by combining the detection results of the first oil level detection part and the second oil level detection part so as to control the state of the control valve forcontrolling on-off of the ejection pipeline, and therefore controllability of ejection and oil return of the heat exchanger assembly for the compressor can be achieved.

Owner:CHONGQING MIDEA GENERAL REFRIGERATING EQUIP +1

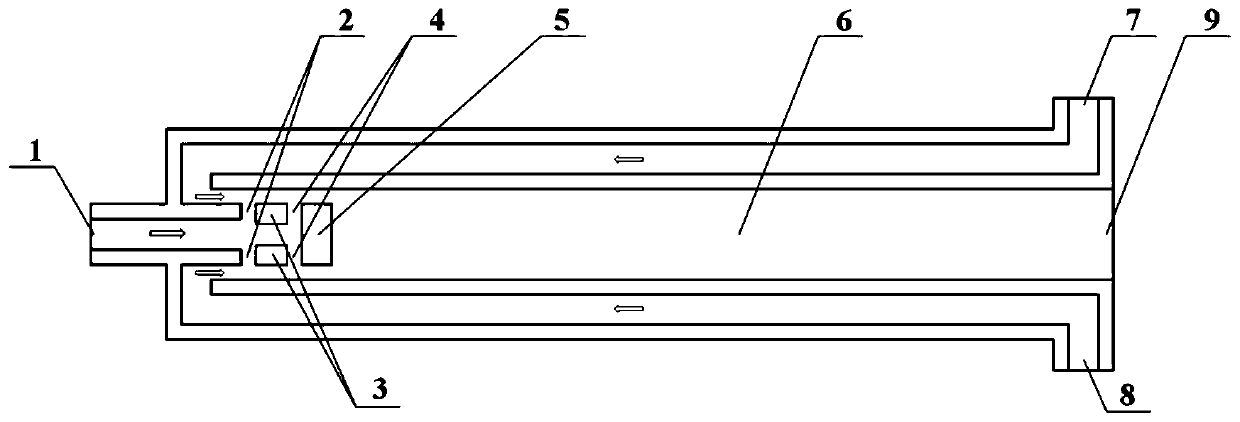

Ejection mixer and control method thereof

PendingCN114183272AImprove blending effectImprove uniformityJet propulsion plantsCombustion chamberAxial distance

The invention provides an injection mixer which is applied to a variable cycle engine and mainly structurally comprises a two-stage lobe mixer driven by an actuating device and used for strengthening mixing of inner culvert airflow and outer culvert airflow. The two stages of lobe mixers are arranged in a series connection mode, and the axial distance between the two stages of lobe mixers is changed through the actuating device, so that the interstage flow area of the lobe mixers is changed, and the function that the duct flow capacity is adjusted through the rear variable-area duct ejector is achieved. Compared with an annular mixer, the characteristic that the lobe mixer has higher mixing capacity on airflow is utilized, under the condition that the function that the rear variable ejector changes the circulation area of the outer culvert is achieved, the mixing quality of the inner culvert airflow and the outer culvert airflow behind the turbine is improved, the outlet temperature distribution of the ejection mixer is more uniform, and the mixing efficiency is improved. And favorable conditions are provided for combustion organization of a downstream afterburner. The invention further provides a control method of the injection mixer.

Owner:BEIHANG UNIV

A Small Diffusion Burner with Separate Preheating

ActiveCN110195862BSimple structureImprove the mixing effectIndirect carbon-dioxide mitigationGaseous fuel burnerThermodynamicsCombustor

The invention belongs to the technical field of micro-dimension combustion, and particularly discloses a separated type preheating small diffusion combustor. The combustor comprises a combustor body.The combustor body comprises a fuel channel, a combustion chamber and a flue gas outlet which are sequentially communicated and share the center line. A first J-shaped preheating channel and a secondJ-shaped preheating channel are symmetrically arranged at the outer side wall of the combustion chamber, a spreader plate is arranged at a gas inlet of the combustion chamber, and a flow baffle is arranged at the side, away from the fuel channel, of the spreader plate for performing second-time flow division on fuel gas introduced through the fuel channel to achieve secondary mixing of fuel gas and an oxidizing agent. The oxidizing agent can be sufficiently preheated, two-time flow dividing and three-level mixing can be achieved, the problems that the flame stability is poor, the combustion efficiency is low, tempering easily happens, and the structure is complex can be effectively solved, and the combustor has the advantages of being simple in structure, good in mixing effect, wide in combustion range, high in combustion efficiency, safe and reliable.

Owner:HUAZHONG UNIV OF SCI & TECH

Combined jet ejection type steam-water hybrid heating device

PendingCN108267030AIncrease temperatureImprove performanceDirect contact heat exchangersCondensed waterDiffusion chamber

The invention discloses a combined jet ejection type steam-water hybrid heating device suitable for a low-pressure working condition. The device comprises a zooming arc-shaped mixing chamber, a diffusion chamber, a steam-water mixing reinforcement chamber, a plurality of condensed water ejection type inlets and at least two steam inlets, wherein one end face of the zooming arc-shaped mixing chamber is connected with one end face of the steam-water mixing reinforcement chamber in a coaxial way, and the other end face of the steam-water mixing reinforcement chamber is connected with the diffusion chamber in a coaxial way; the plurality of condensed water ejection type inlets are connected with the other end face of the zooming arc-shaped mixing chamber; the pipe wall of the throat part of the zooming arc-shaped mixing chamber is connected with the at least two steam inlets. The ratio of the end face diameter to the tube length of the zooming arc-shaped mixing chamber is equal to 0.2-0.5;the ratio of the total cross-sectional area of the plurality of condensed water ejection type inlets to the cross-sectional area of a throat pipe of the steam-water mixing reinforcement chamber is equal to 0.008-0.02; the ratio of the total cross-sectional area of the plurality of condensed water ejection type inlets to the total cross-sectional area of the steam inlets is equal to 0.03-0.07; theratio of the cross-sectional area of the throat part of the steam-water mixing reinforcement chamber to the cross-sectional area of an outlet of the diffusion chamber is equal to 2-5; the ratio of the diameter of the throat part to the diameter of the end face of the zooming arc-shaped mixing chamber is equal to 0.50-0.99.

Owner:CHONGQING UNIV

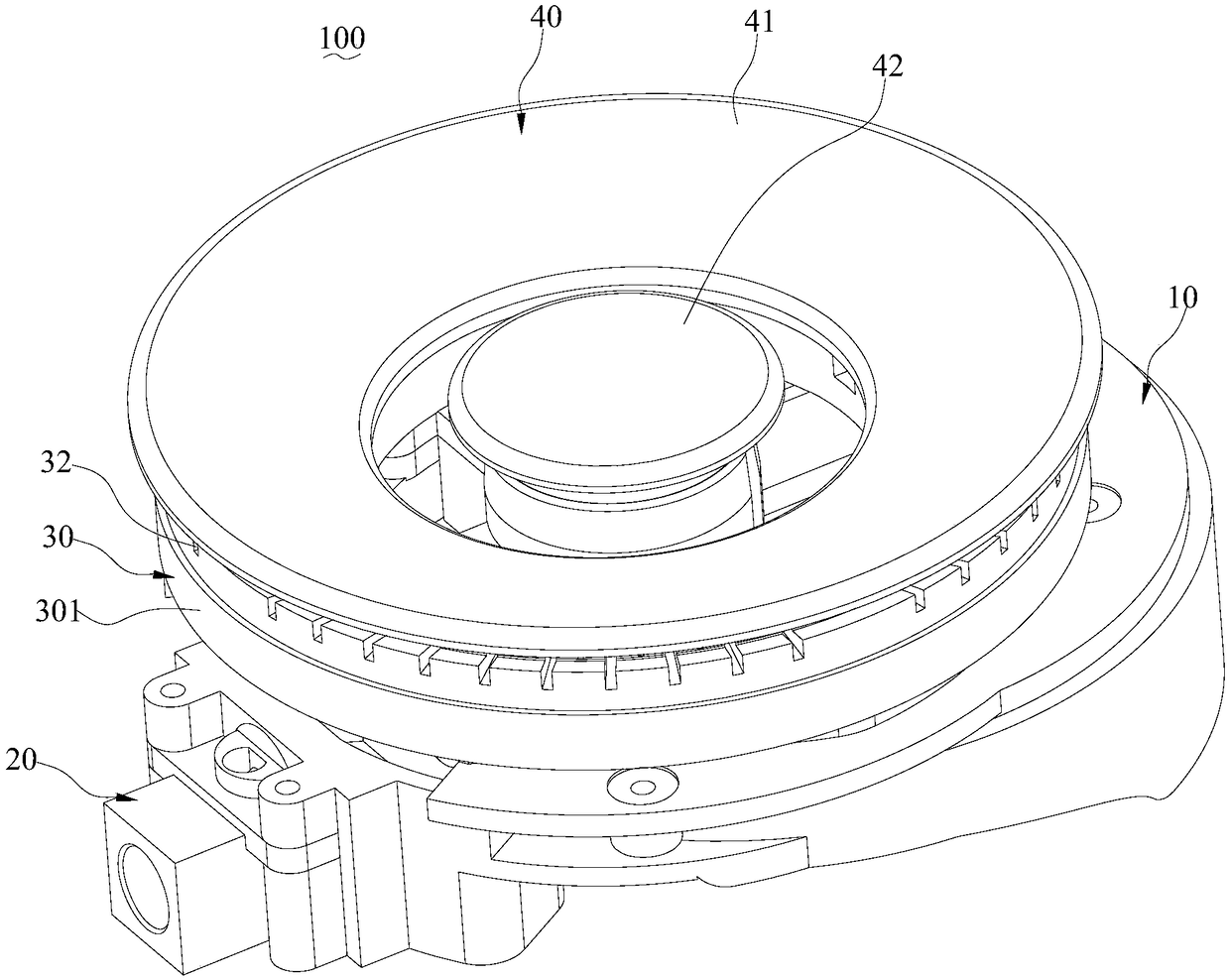

Burner and gas cooker

The invention discloses a burner and a gas cooker. The burner comprises a flamethrower and a bottom cup. The flamethrower is provided with a first center. A gas mixing cavity and a fire hole communicating with the gas mixing cavity are formed in the flamethrower. The bottom cup is provided with a second center. An ejection channel with a Venturi effect is formed in the bottom cup. The flamethroweris installed on the bottom cup. The first center and the second center are arranged eccentrically. The ejection channel communicates with the gas mixing cavity. The first center of the flamethrower and the second center of the bottom cup are arranged eccentrically, thus the bottom cup can have more space for the longer ejection channel, the ejection channel has large ejection ability, the heat load of the burner can be improved, the amount of mixed gas of gas and air entering the gas mixing cavity can be ensured, and then stability of burning of the burner is ensured.

Owner:FOSHAN SHUNDE MIDEA WASHING APPLIANCES MFG CO LTD

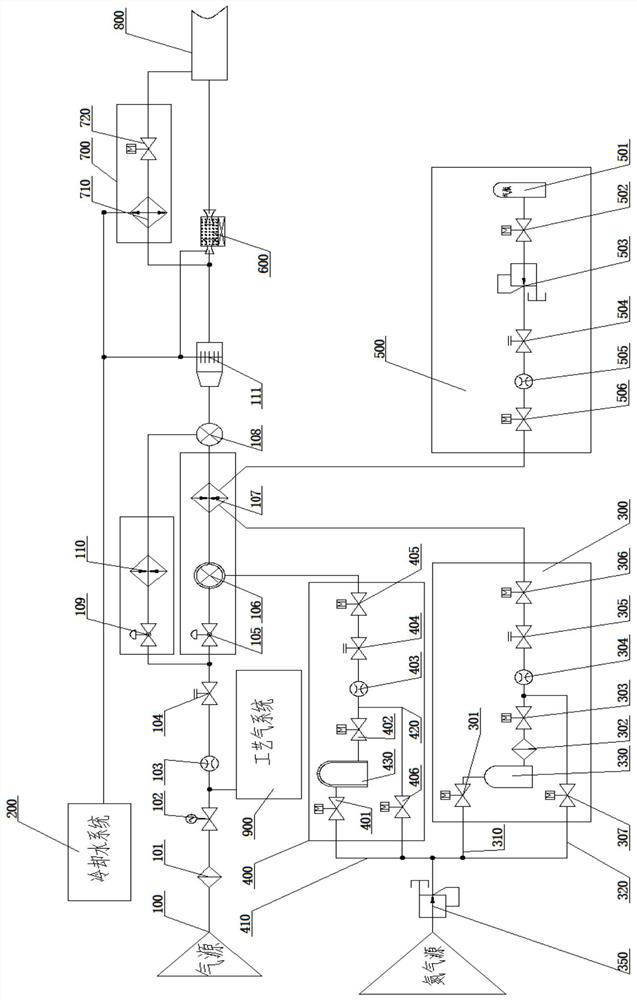

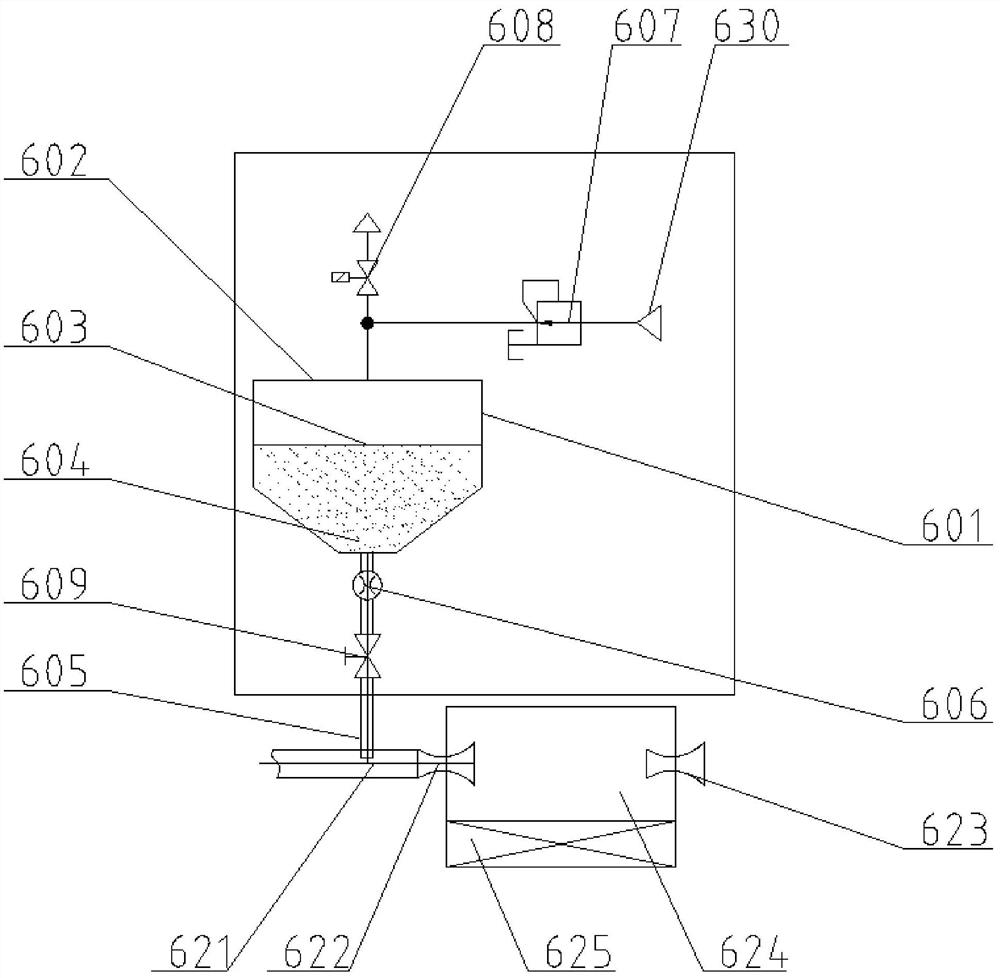

Small-flow incoming flow parameter simulation air inlet system and test bed

PendingCN112763220ASave waterTaking into account economy and practicalityEngine testingSimultaneous control of multiple variablesFuel supplyLiquid oxygen

A small-flow incoming flow parameter simulation system is characterized in that a cooling water system is respectively communicated with a stable measurement section, an air inlet spray pipe, a hot air switching and bypass device, a cooling device and a tail chamber, and provides cooling water for cooling the components; a liquid fuel supply system and a gas fuel supply system provide fuel for the main gas inlet path fuel heating device; an oxygen supplementing system provides liquid oxygen for the main gas inlet path oxygen supplementing mixer and is used for combustion of fuel in the main gas inlet path fuel heating device; a particle loading system is used for loading particles for a test; and a process gas system is communicated with an operation gas source of a pneumatic valve of the system. According to the small-flow incoming flow parameter simulation system, accurate simulation of small-flow incoming flow parameters can be effectively achieved, the mass flow of particles can be accurately and effectively controlled, an effective closed-loop control system is formed, and the test state is effectively observed.

Owner:BEIJING AEROSPACE SANFA HIGH TECH

Burner for gas stove

The invention relates to a burner for a gas stove. The burner is characterized by comprising a pedestal. The pedestal is provided with an injection pipe, a burner cap and a gas channel, wherein the injection pipe is arranged at the bottom of the pedestal; the burner cap is arranged on the pedestal and forms an independent gas mixing chamber with the pedestal; and the gas channel is arranged at thebottom of the pedestal and penetrates the center position of the pedestal longitudinally. The gas channel comprises a runner communicating to the gas mixing chamber and the injection pipe. Compared with the prior art, the burner has the advantages that the conventional gas mixing chamber, injection pipe and pedestal are integrated, and meanwhile, the conventional inner and outer ring burner capsare integrated, so that the whole burner is minimized; in addition, the runner of the gas channel can replace an expanded segment of an existing injection pipe, and meanwhile, the runner is designed to prolong the injection pipe, so that the injection ability can be also enhanced while the integral height of the burner is reduced so as to generate a good gas and primary air mixing effect. Therefore, the integral burner is in a good burning working condition.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Combustor

The invention discloses a combustor. The combustor comprises a distributor, the distributor comprises a body and at least two injection pipes, at least two mixed gas tanks are formed in the body, at least two injection pipes are located below the body and communicate with at least two mixed gas tanks respectively, when the combustor is horizontally placed, the included angle between at least one of at least two injection pipes and the horizontal direction is 15-75 degrees, and at least one injection pipe is basically perpendicular to the horizontal direction. According to the combustor in theembodiment, the inclined and vertical injection pipes are matched with each other, the ejection capacity of the injection pipes can be enhanced through the inclined injection pipe, so that fuel gas iscombusted more sufficiently, while the vertical injection pipe can be used for auxiliary heating, under the condition that the injection capacity required by the mixed gas tanks is met, a material ofthe injection pipes can be saved, and the manufacturing difficulty of the distributor can be reduced.

Owner:FOSHAN SHUNDE MIDEA WASHING APPLIANCES MFG CO LTD

Lower air inlet gas burner for cooking appliance

PendingCN109340749AAchieve finishingFlat surfaceGaseous fuel burnerHome appliance efficiency improvementDie castingEngineering

The invention discloses a lower air inlet gas burner for a cooking appliance. The lower air inlet gas burner comprises a base and a fire cover, and the fire cover comprises an outer fire cover and aninner fire cover; the outer fire cover is provided with outer fire holes, and the inner fire cover is provided with inner fire holes; both the outer fire cover and the inner fire cover are arranged onthe base, and the base is provided with ejector pipes including an inner fire ejector pipe and an outer fire ejector pipe; the outer fire ejector pipe is provided with an outer fire nozzle, and the inner fire ejector pipe is provided with an inner fire nozzle; the base and the ejector pipes are of separate structures, and the ejector pipes are in threaded connection with the base; the base is manufactured through an aluminum die casting technology, and the ejector pipes are manufactured through a machining technology; finish machining of the ejector pipes is achieved, so that the surfaces ofthe inner walls of the ejector pipes are smooth, and the resistance of the ejector pipes to mixing flow is reduced; the ejection effect is improved, and the expected primary air coefficient can be achieved; and combustion is more sufficient.

Owner:浙江森歌智能厨电股份有限公司

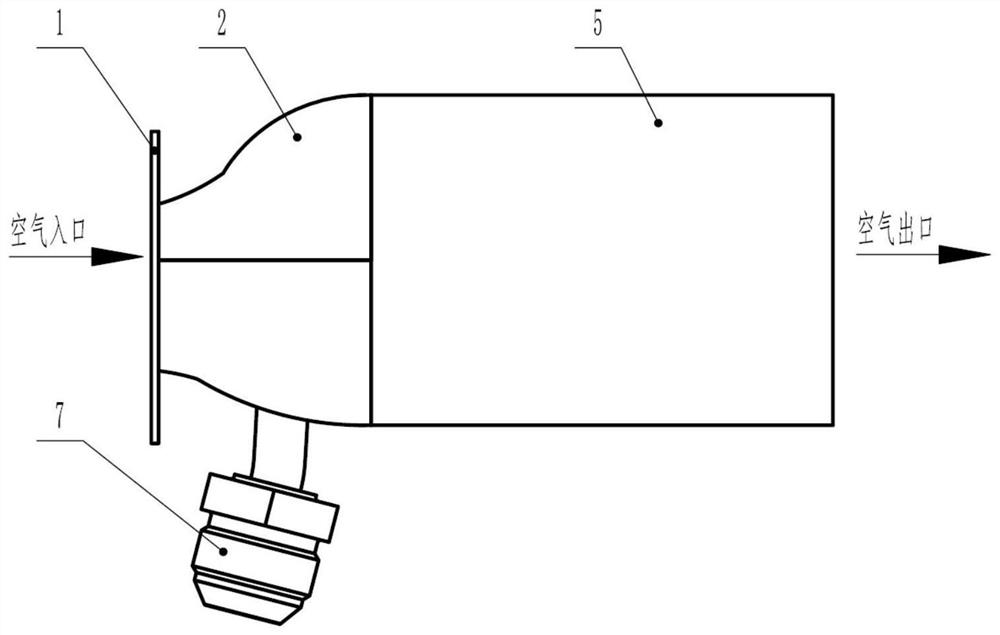

Supersonic air injection device

The invention discloses a supersonic air injection device. The supersonic air injection device is mainly composed of a mounting plate, an air duct transition section, an injection pipe, spray pipes, a secondary cooling air duct, a supporting plate and an inlet pipe nozzle. The injection pipe is arranged in the middle of the air duct transition section, and the spray pipes are symmetrically arranged Laval spray pipes. High-temperature and high-pressure gas enters through the inlet pipe nozzle, flows through the injection pipe and is sprayed out from the spray pipes, a negative pressure area is formed, and low-temperature air is sucked in from an air inlet, passes through the mounting plate and the air duct transition section, is mixed at the secondary cooling air duct and flows out from an air outlet. The supersonic air injection device is used for injecting the low-temperature air through the high-temperature and high-pressure gas, and the injected low-temperature air can serve as a cold source to be supplied to equipment for heat dissipation. The layout of the spray pipes and flow channels is more reasonable, the mixing uniformity of injection airflow and injected airflow is improved, and therefore the injection effect can be effectively improved.

Owner:GUIZHOU YONGHONG AVIATION MACHINERY

Method and device for mechanically pressurizing, injecting and recovering waste steam for suction section

InactiveCN102705273AImprove qualityIncrease pressureJet pumpsMachines/enginesSteam pressureWorking fluid

The invention relates to a method and a device for mechanically pressurizing, injecting and recovering waste steam for a suction section. The waste steam is injected and aspirated by utilizing working steam; a pressurizing machine is arranged on a waste steam pipeline; and the waste steam is sent into an injector after being pressurized. Water is utilized as a working fluid; after being pressurized by using a water pump, the water is sent into the injector and is used for aspirating the waste steam; the pressurizing machine is arranged on the waste steam pipeline; and the waste steam is sent into the injector after being pressurized by the pressuring machine. By using the method and the device, the pressure of the waste steam is improved by utilizing mechanical pressurization; the injection propelling force is increased; the injection effect is obviously improved; and the recovery and utilization rate of the energy of the waste steam is improved drastically. By using the method and the device, not only are the problems of the energy loss and the atmospheric environmental pollution caused by the waste of the waste steam of an ordinary evaporation operation unit solved, but also the method and the device, compared with a conventional steam saving technique, have the characteristics that equipment is simple, the recovery rate of the energy is high, and the economical efficiency is good.

Owner:TIANJIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com