Patents

Literature

122results about How to "Improve ejection effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

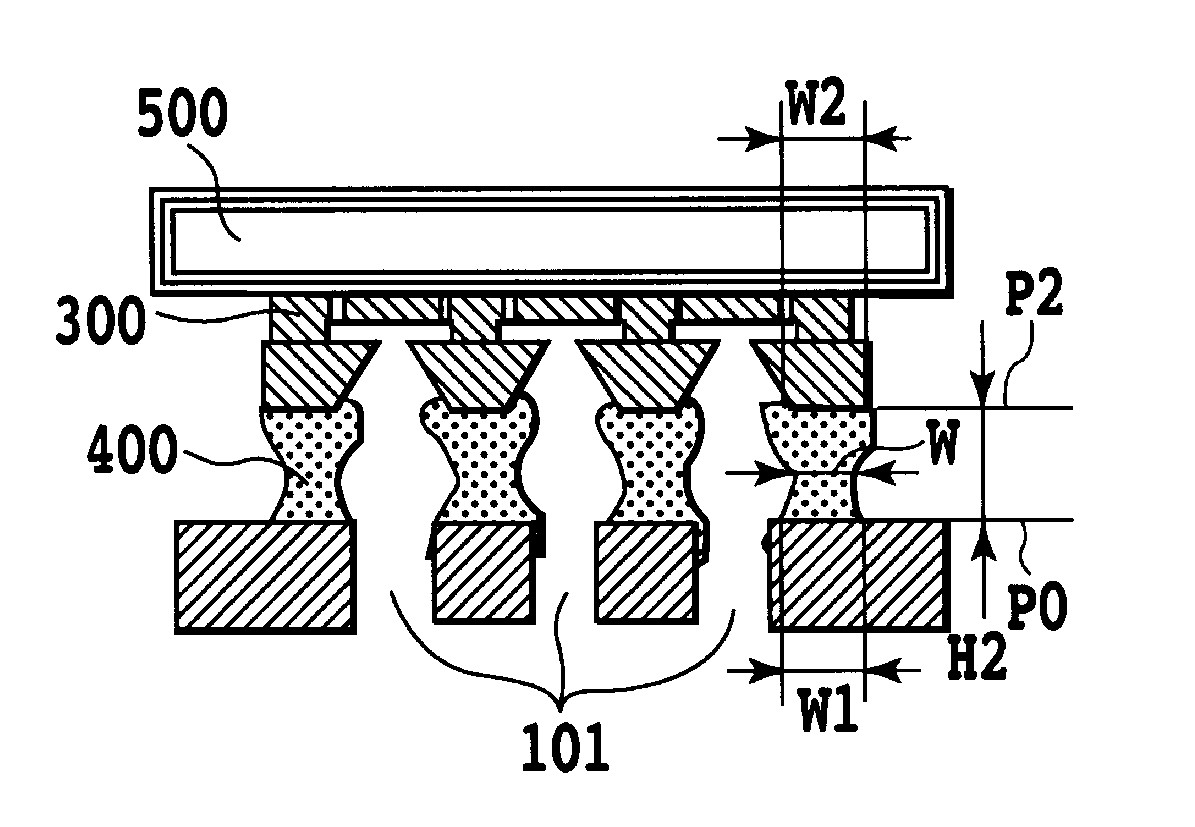

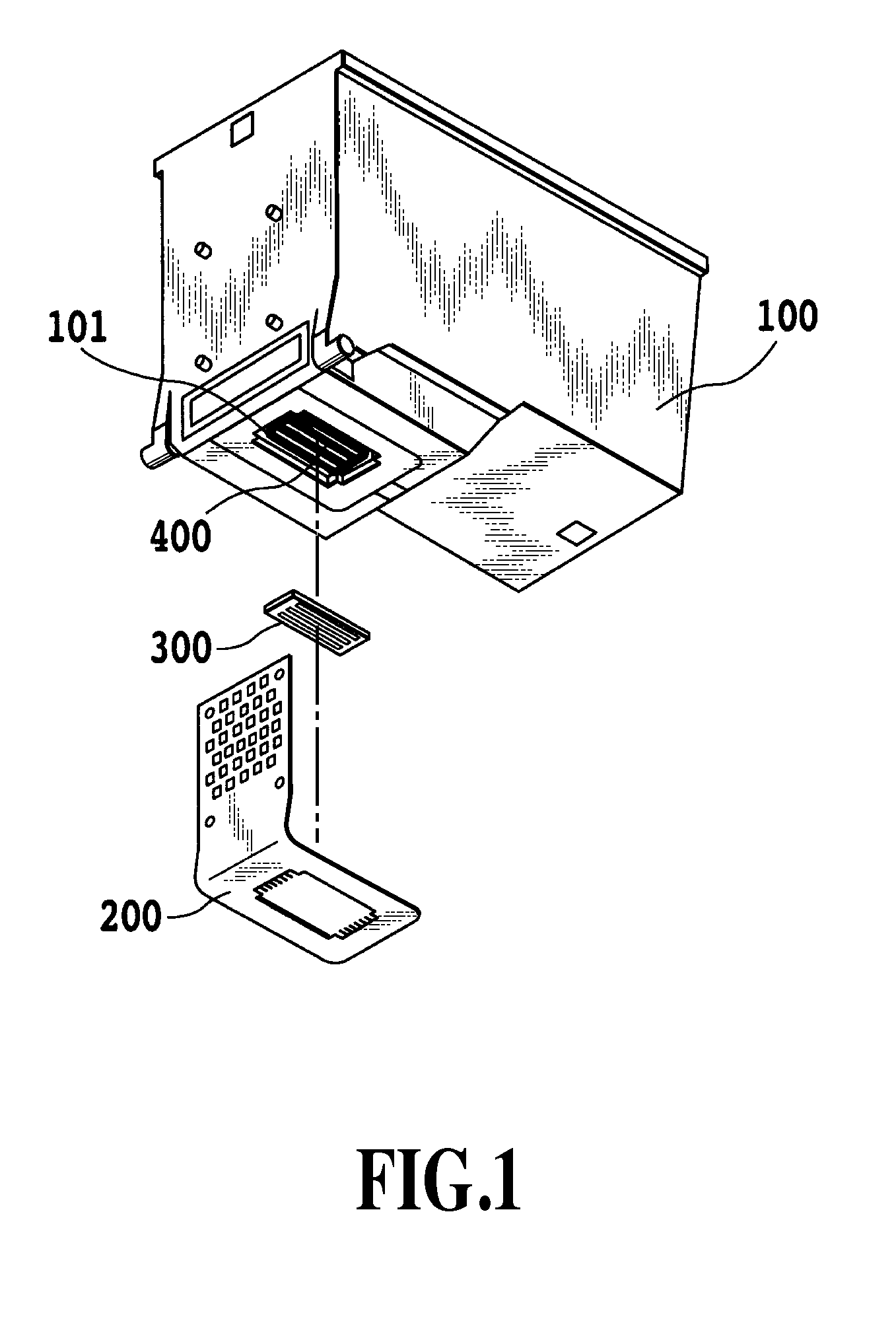

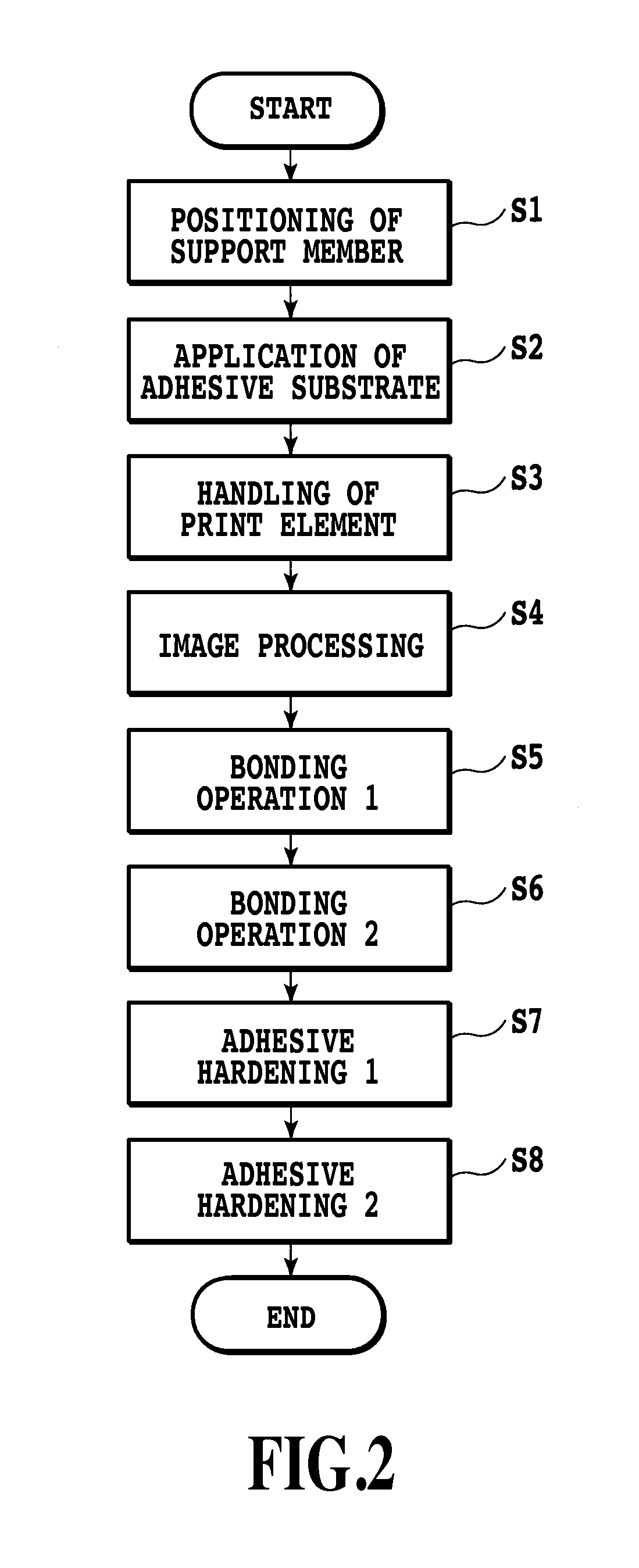

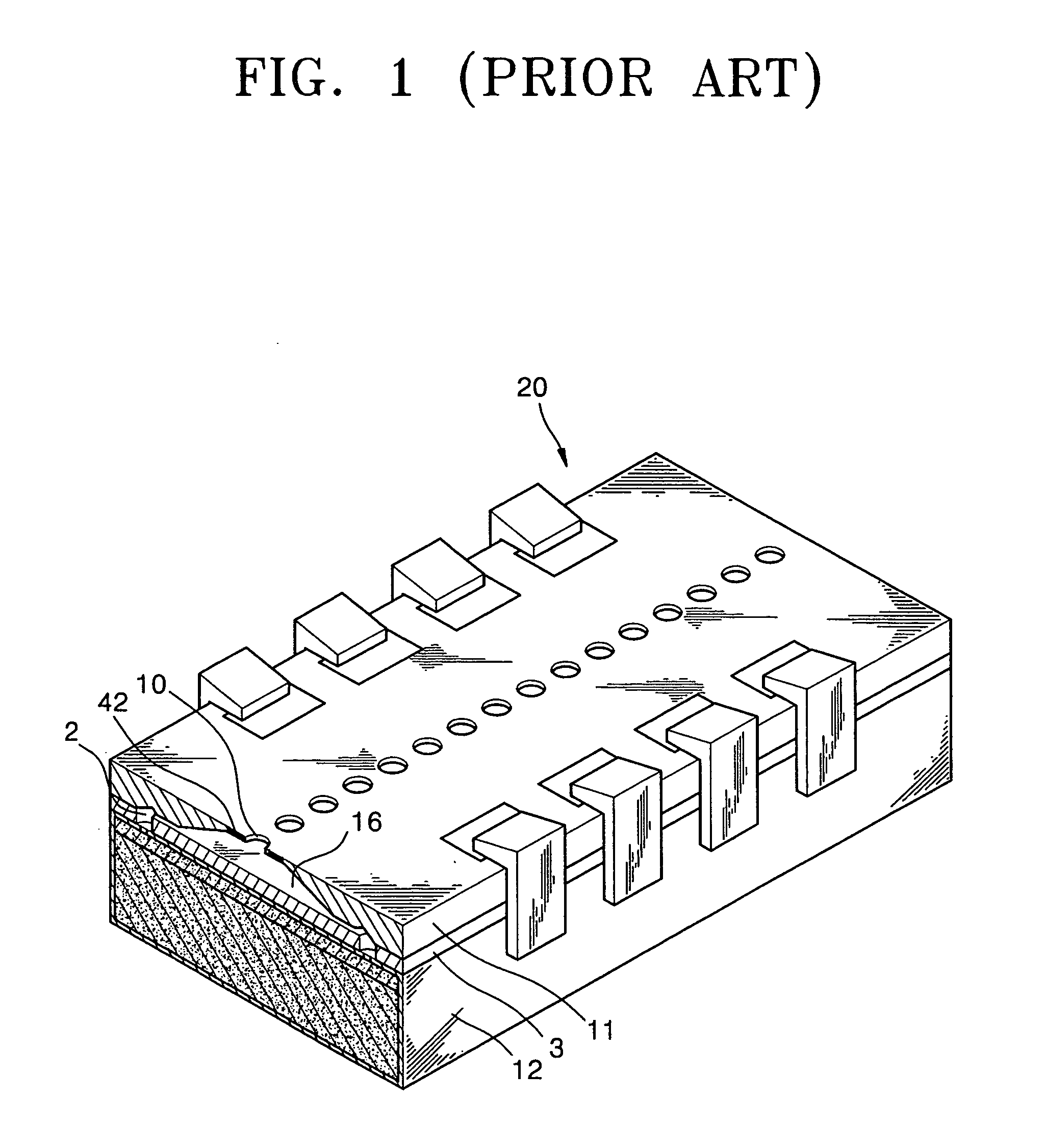

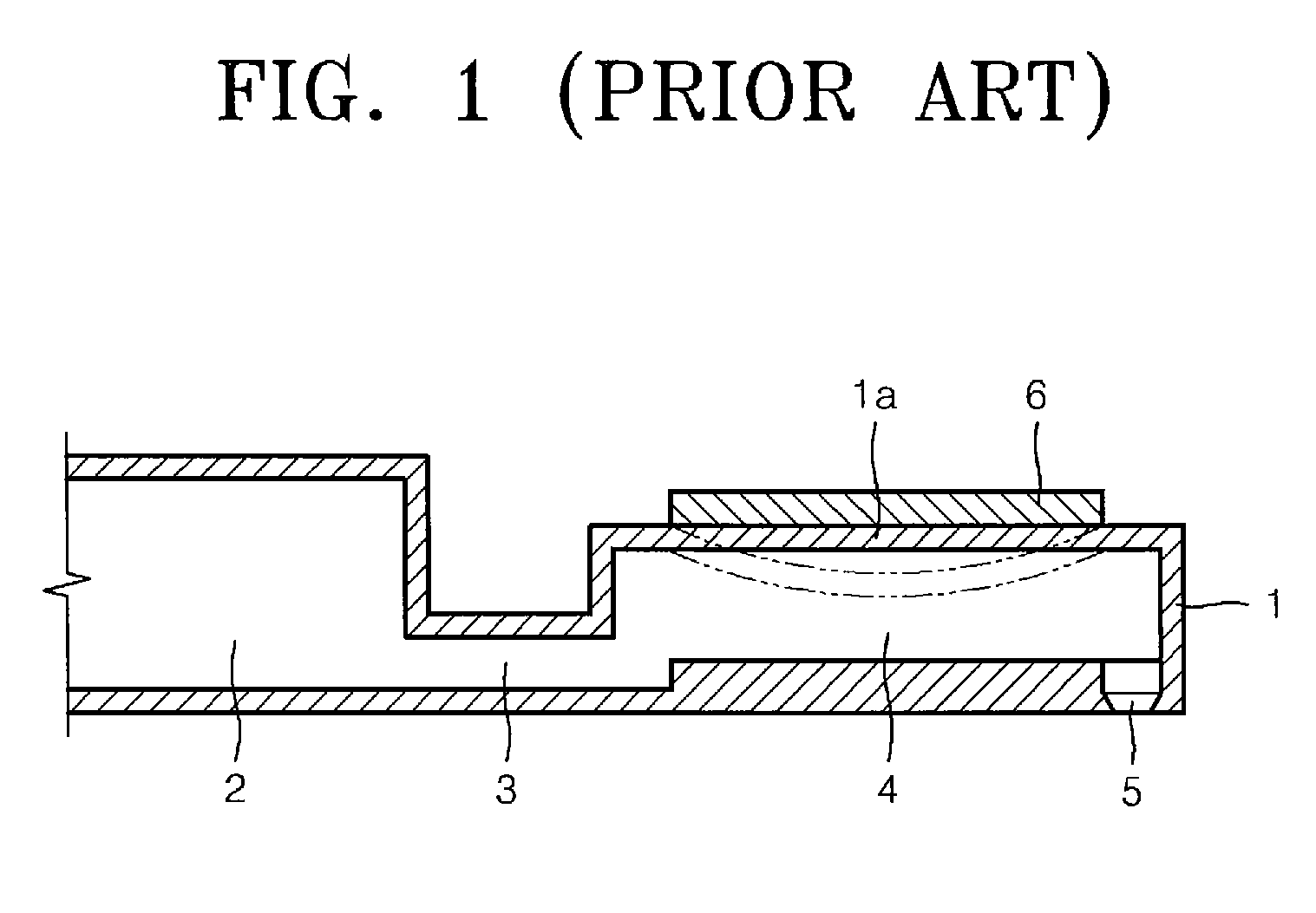

Ink jet print head manufacturing method and ink jet print head

InactiveUS20090309938A1Good inkjet effectImprove ejection effectLaminationLamination apparatusEngineeringMechanical engineering

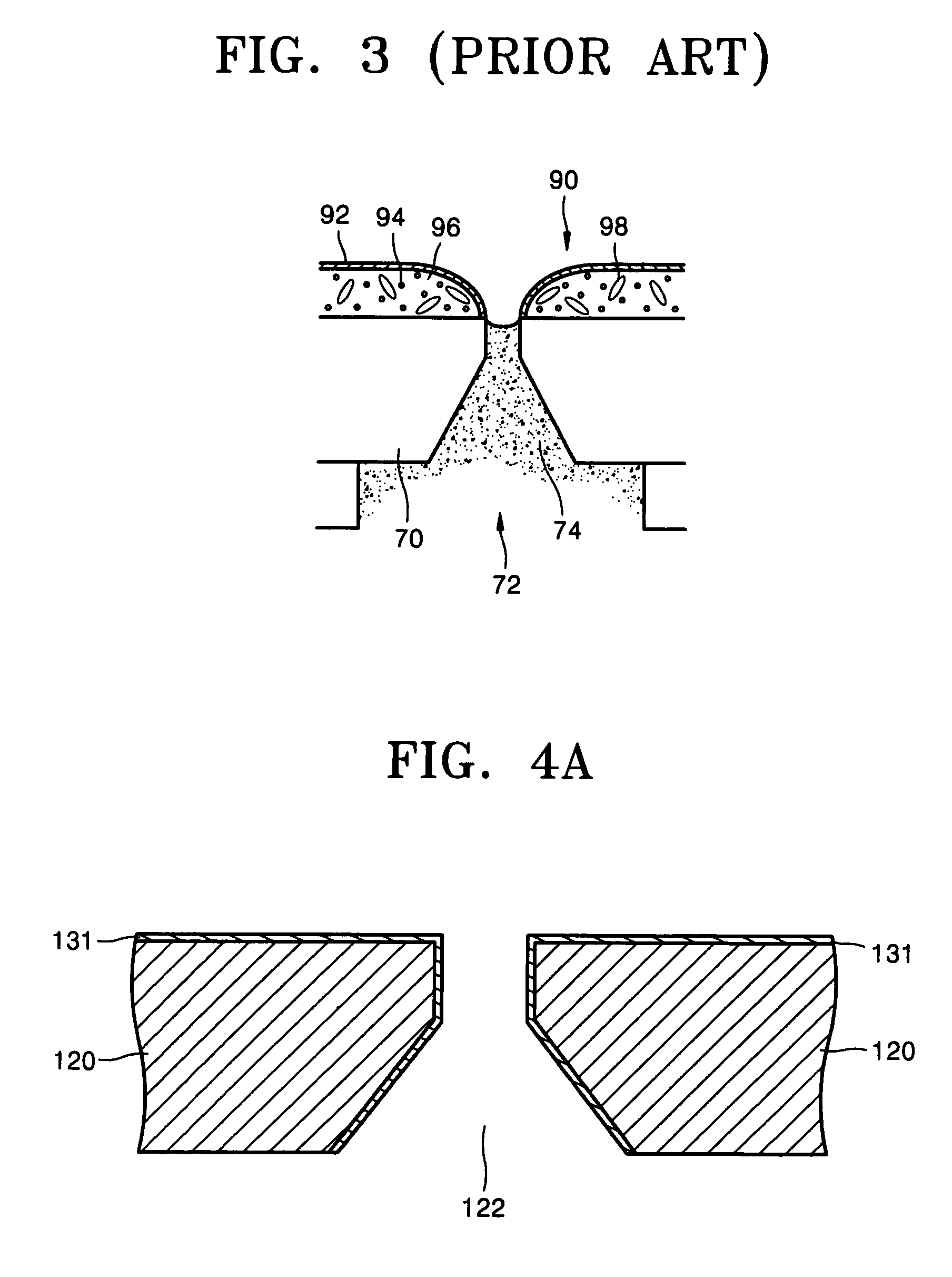

An ink jet print head manufacturing method and an ink jet print head are provided in which a shape of an adhesive that bonds a support member and a print element substrate together is controlled to maintain a high level of ink ejection performance even if the print element substrate is reduced in size. The adhesive, after being disposed between the support member and the print element substrate, is elongated and then hardened. This process allows the shape of the adhesive to be controlled, securing a sufficient ink path between an ink supply port on the support member side and an ink introducing port on the print element substrate side.

Owner:CANON KK

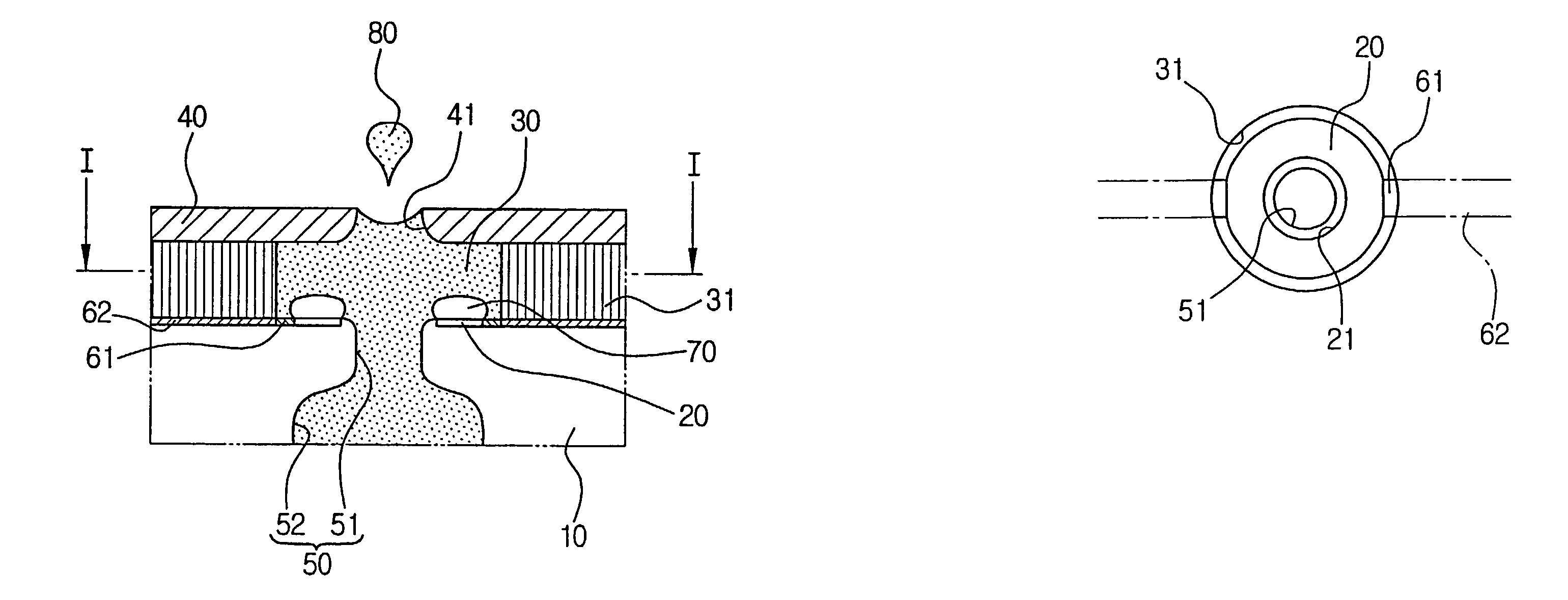

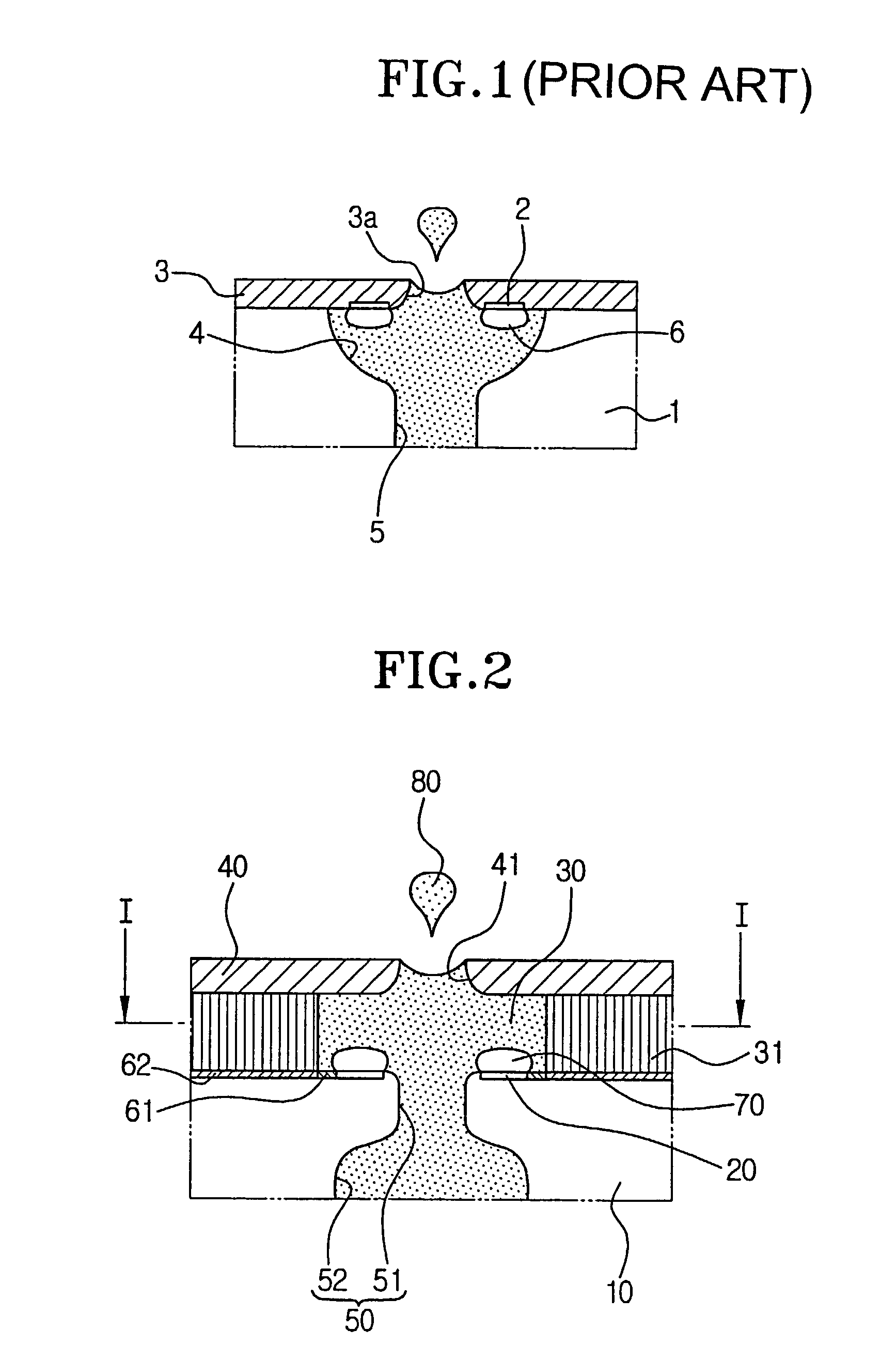

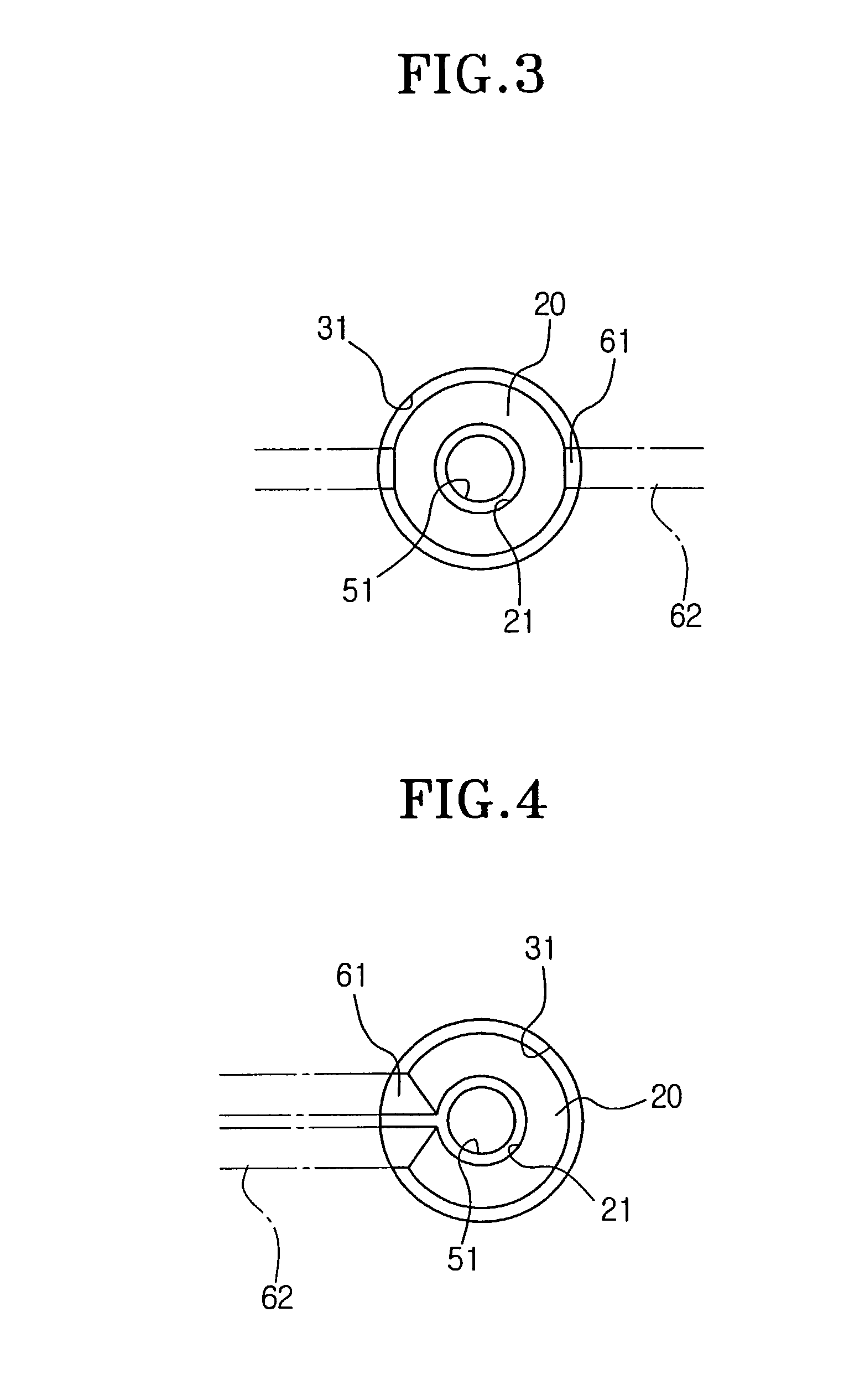

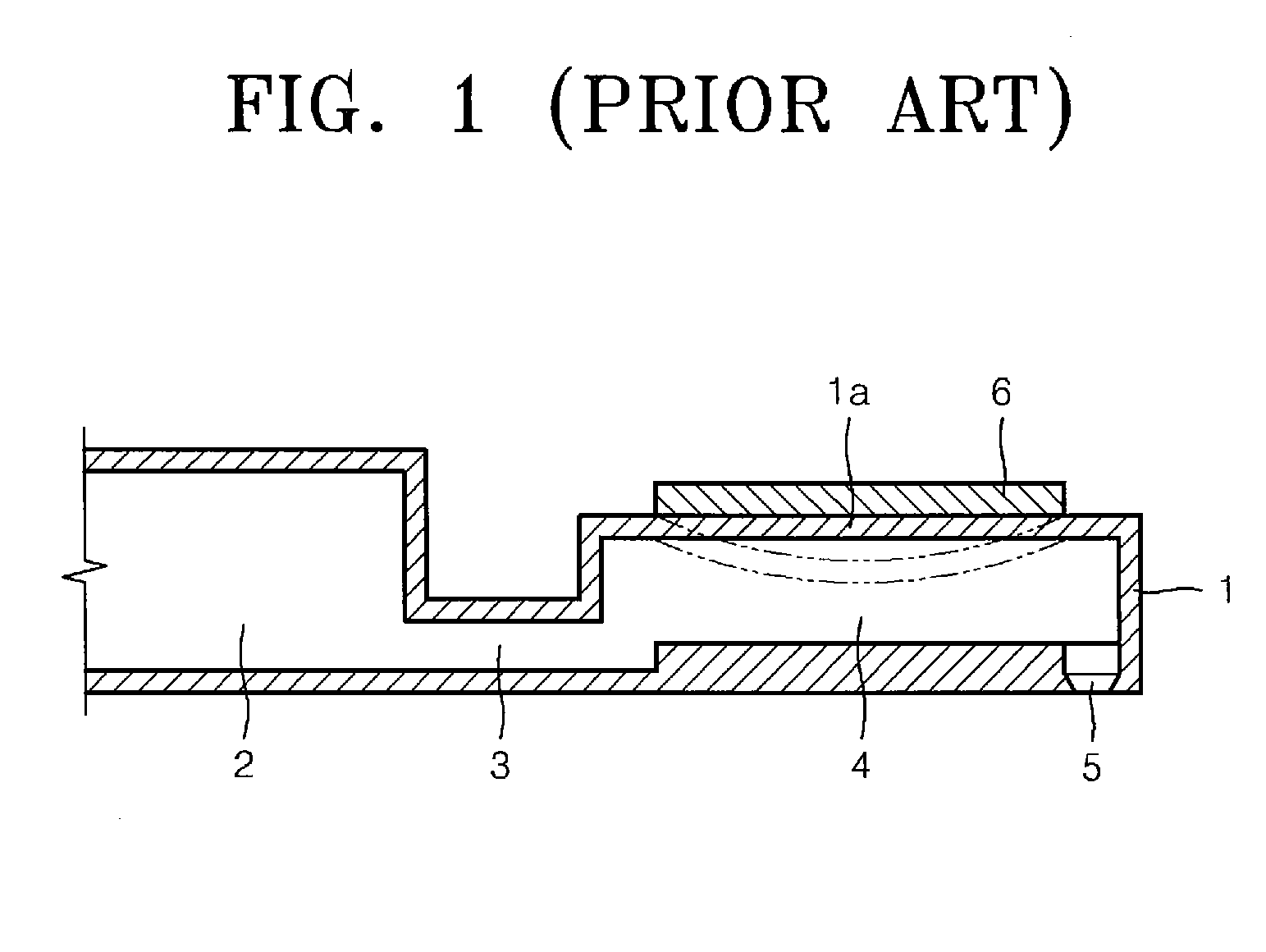

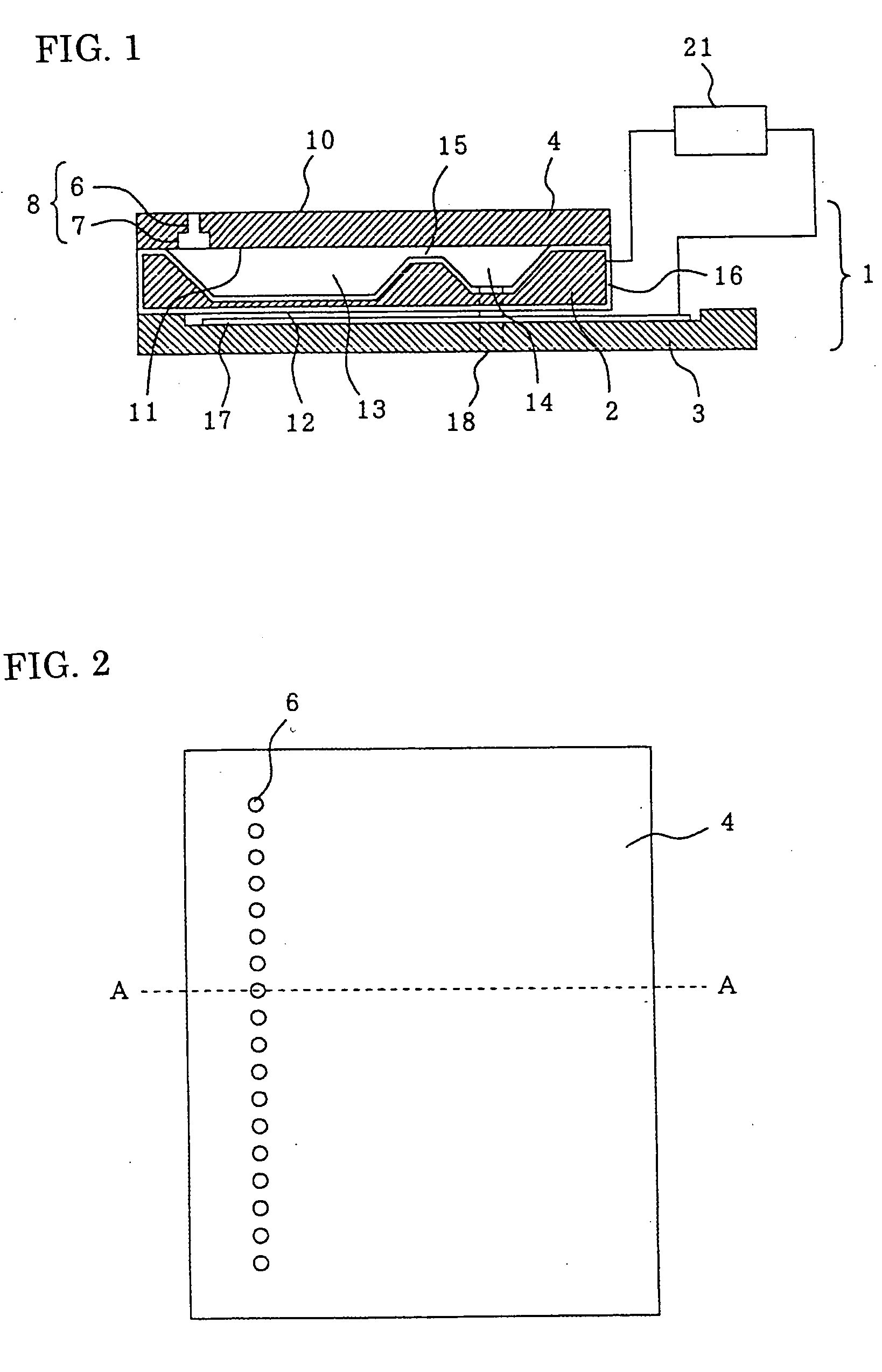

Ink-jet head and ink-jet printer

Owner:BROTHER KOGYO KK

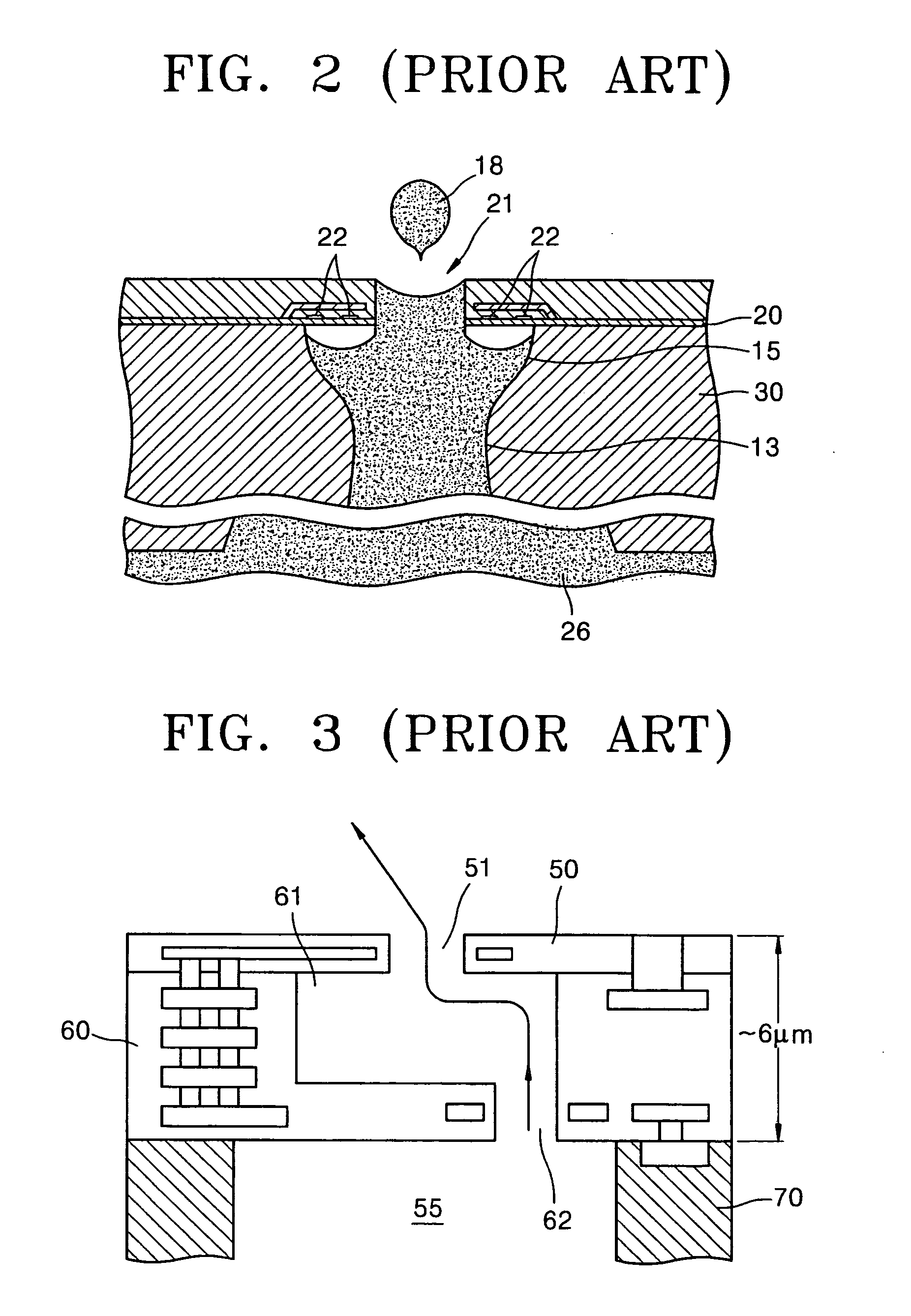

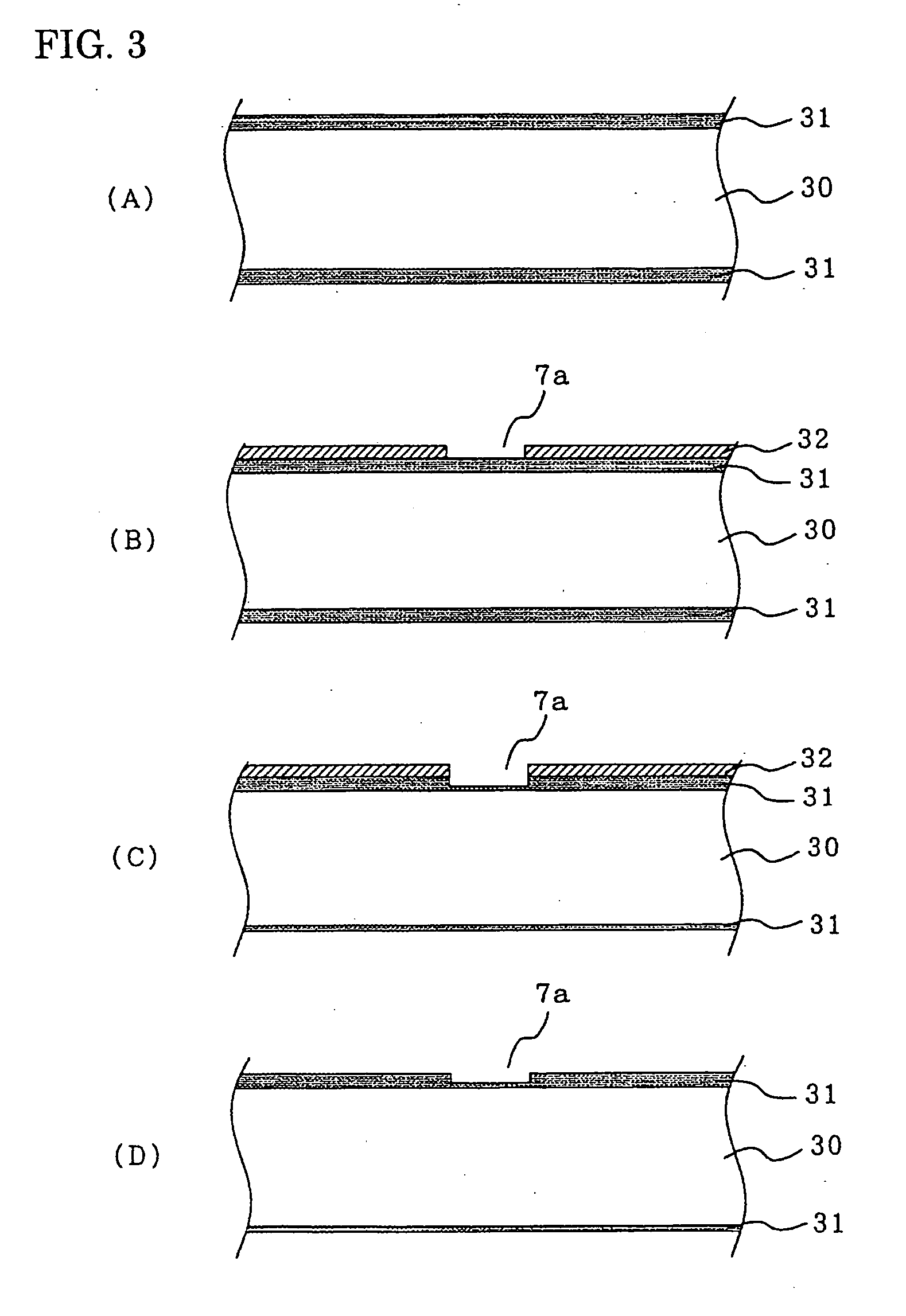

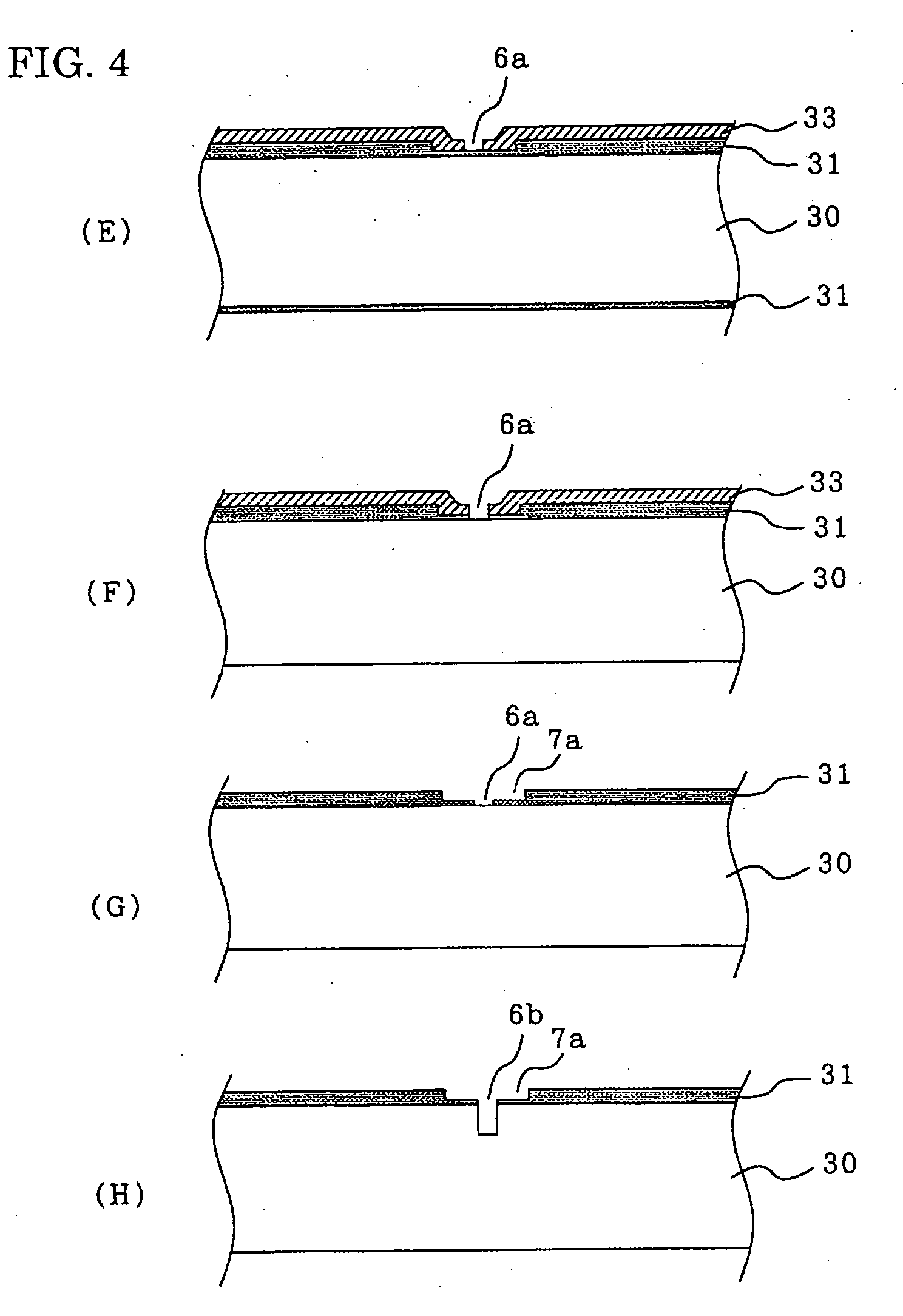

Inkjet printer head and method of manufacturing the same

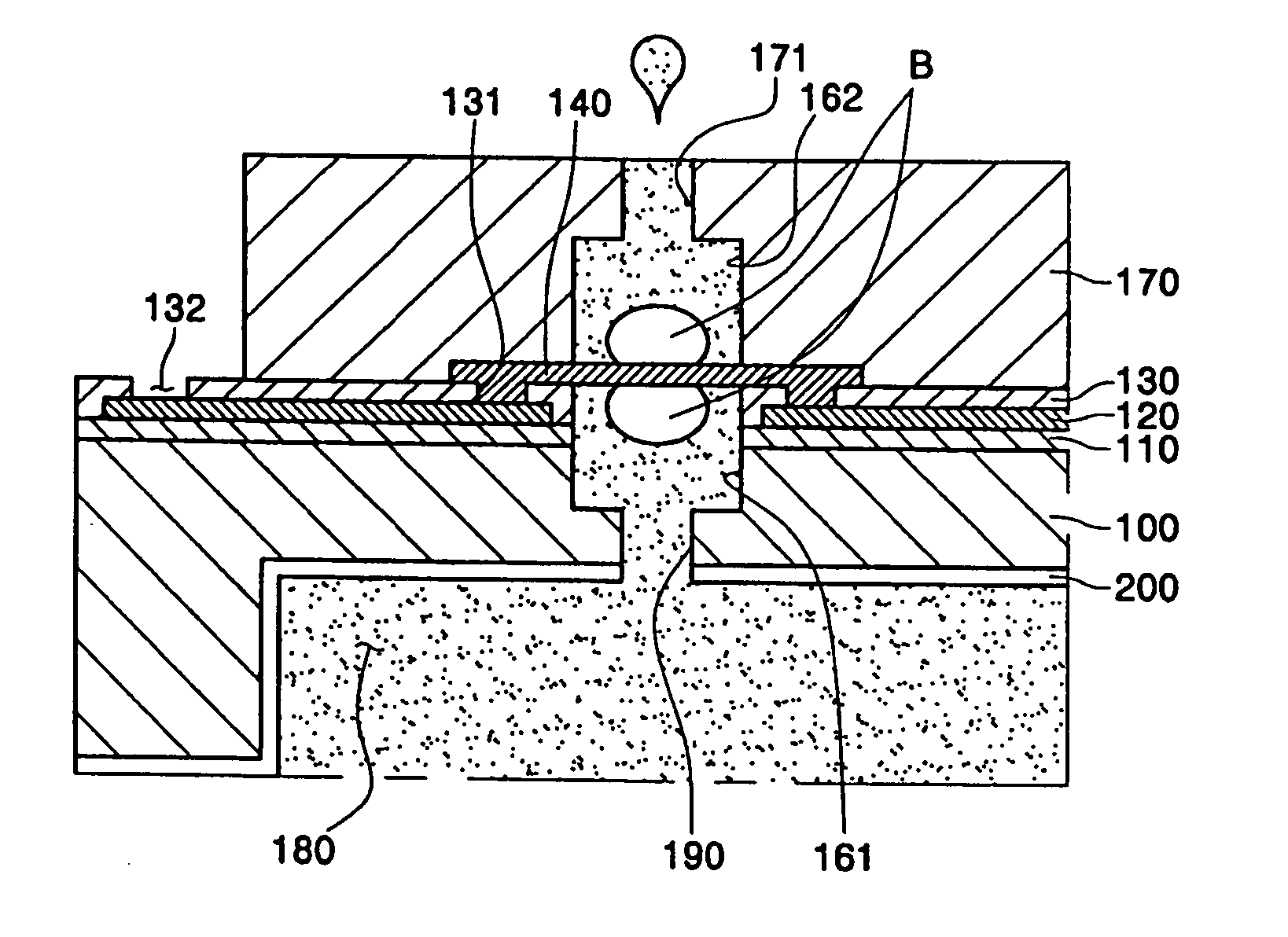

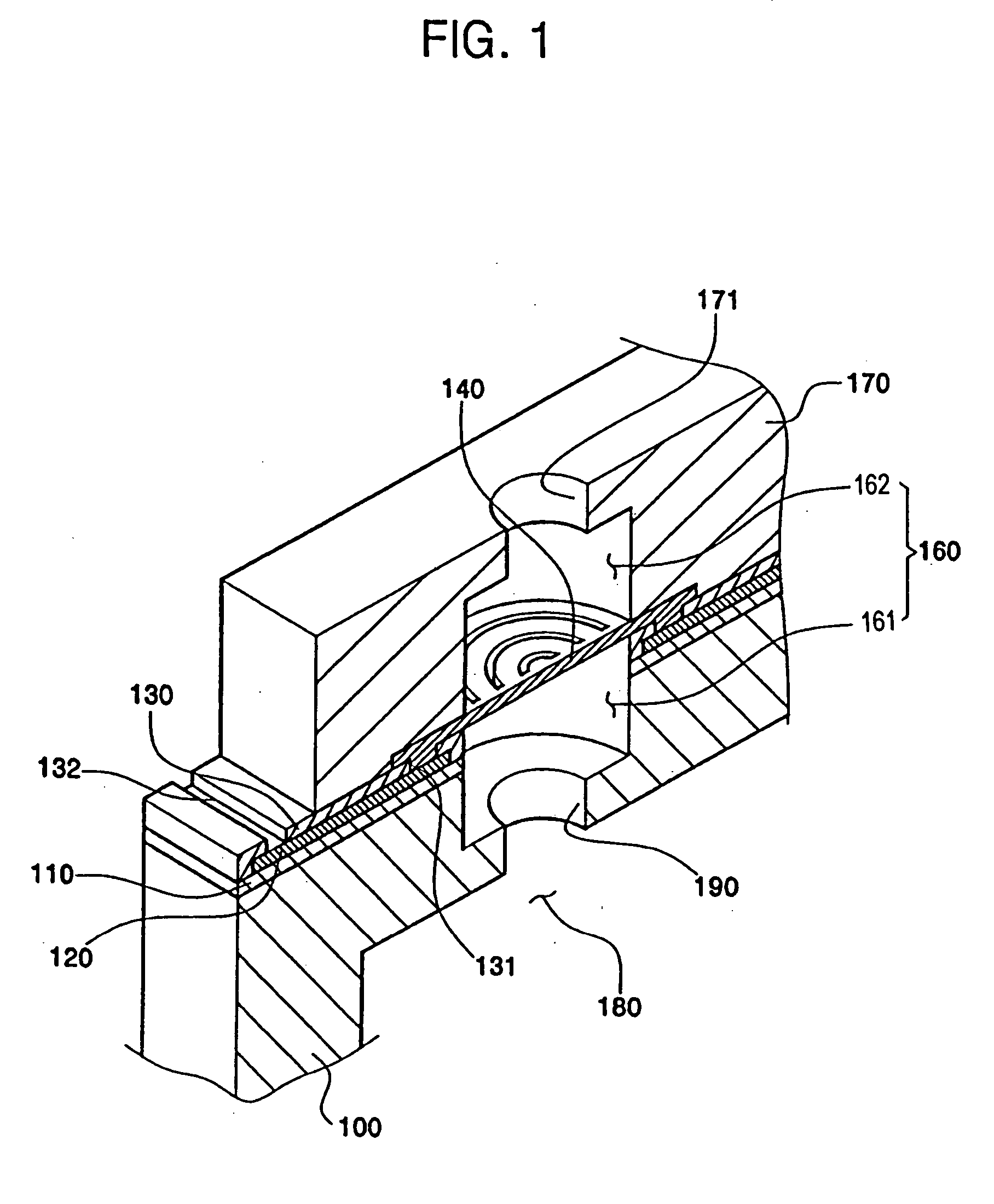

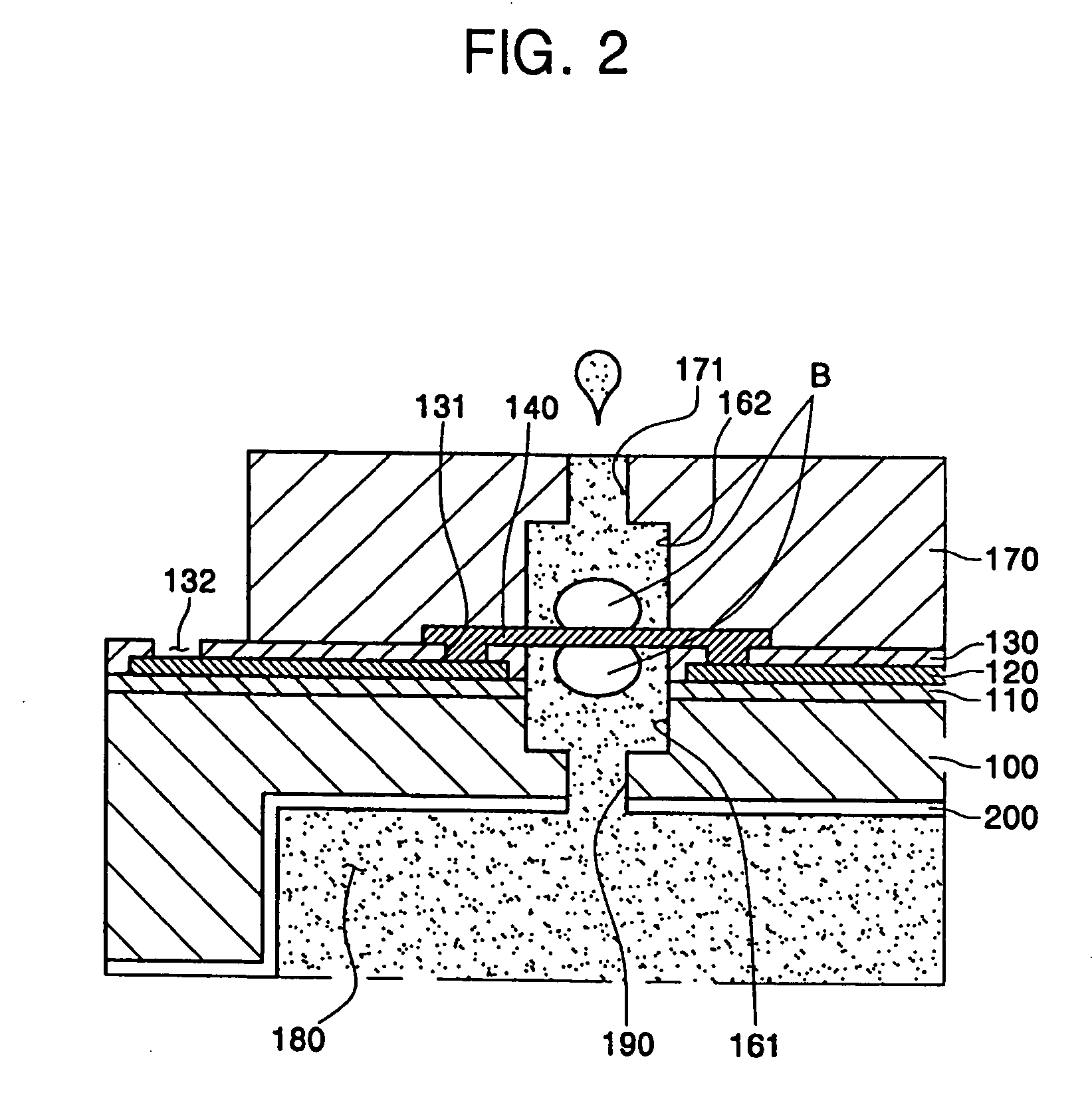

InactiveUS20060061629A1Good inkjet effectImprove ejection effectPrintingManufacturing technologyEngineering

An inkjet printer head includes a substrate having a manifold and an ink channel to supply ink, a nozzle plate formed on the substrate, a chamber formed between the substrate and the nozzle plate and extending toward the substrate and the nozzle plate, an electrode formed at an interface between the substrate and the nozzle plate and around the chamber, and a heater having both ends extending in contact with the electrode to be suspended on the chamber in direct contact with the ink and to generate bubbles from both surfaces thereof. The inkjet printer head is capable of improving manufacturing process efficiency by omitting a process of separately forming a heater passivation layer, operating the heater at low electric power by omitting the heater passivation layer, improving integrity of a nozzle by lowering a working voltage, and improving reliability in manufacturing processes by locating the suspended heater to be in parallel with the substrate and the electrode.

Owner:SAMSUNG ELECTRONICS CO LTD

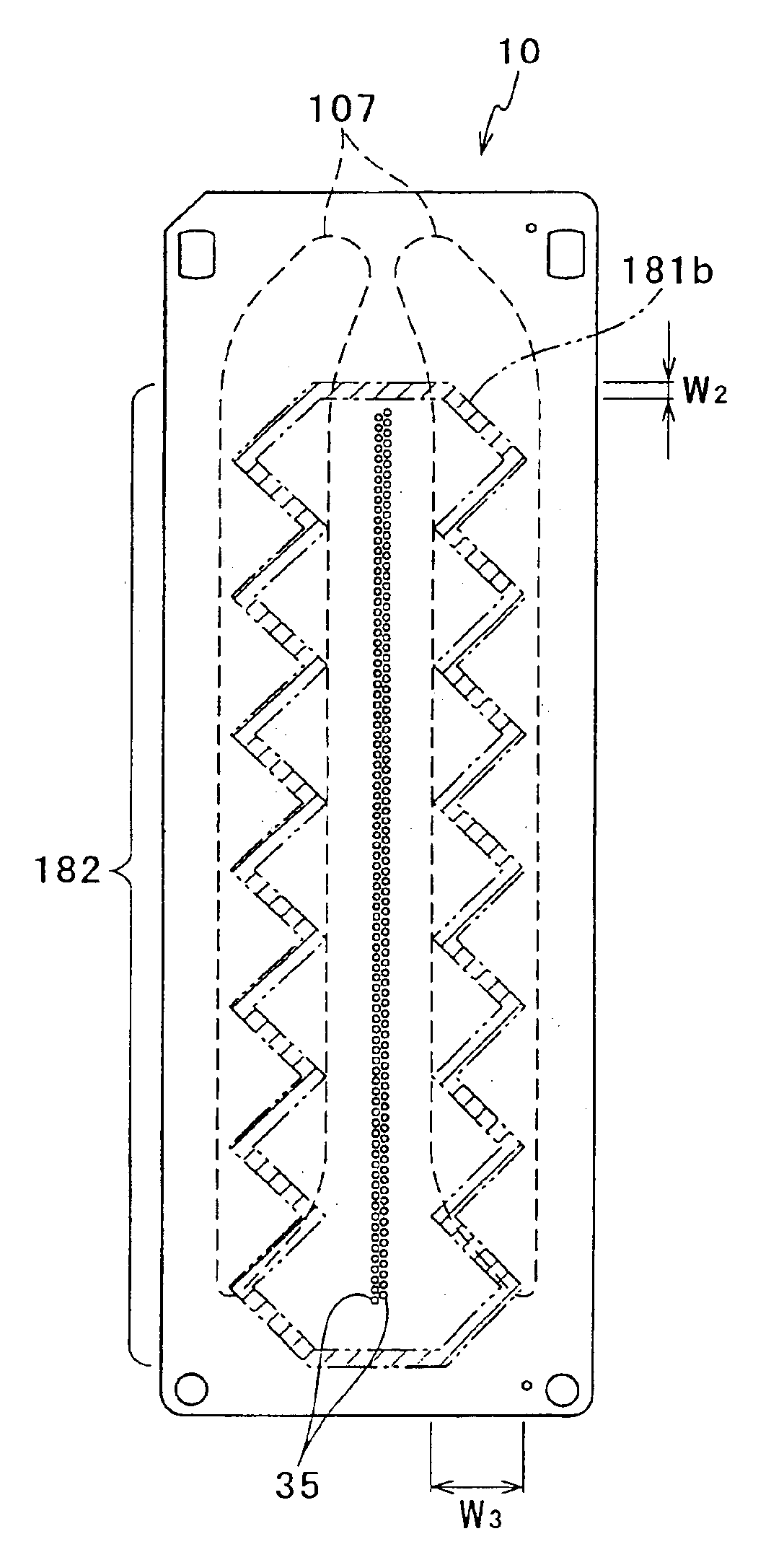

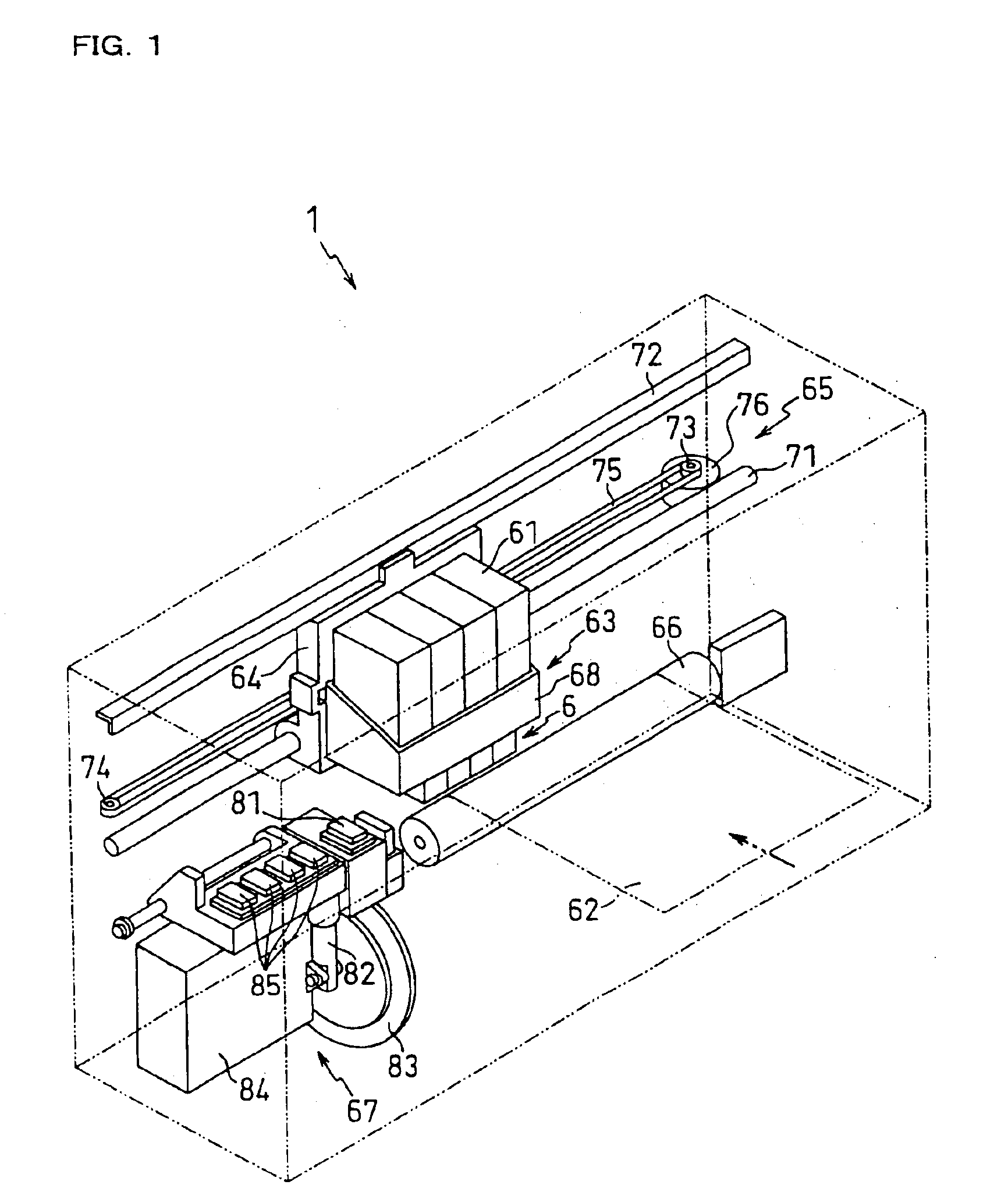

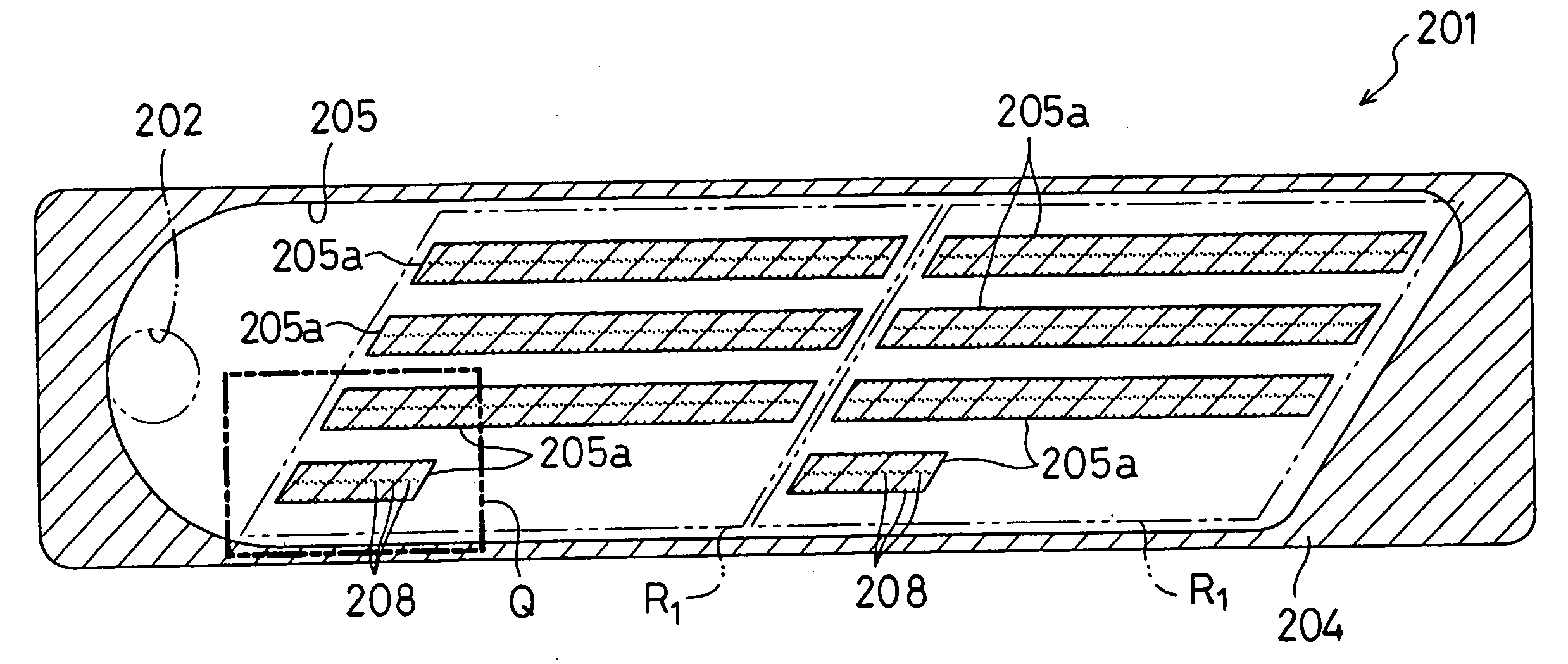

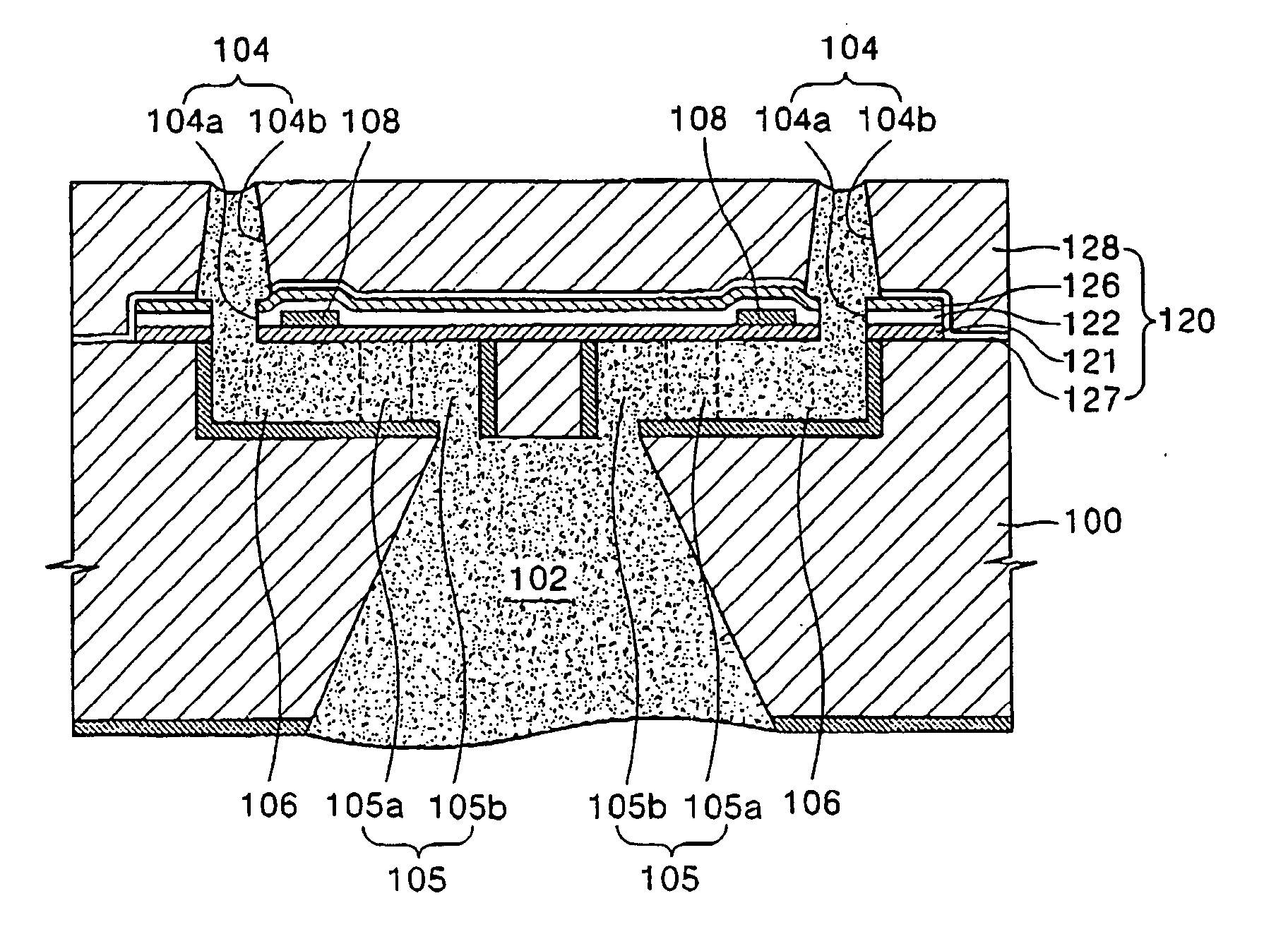

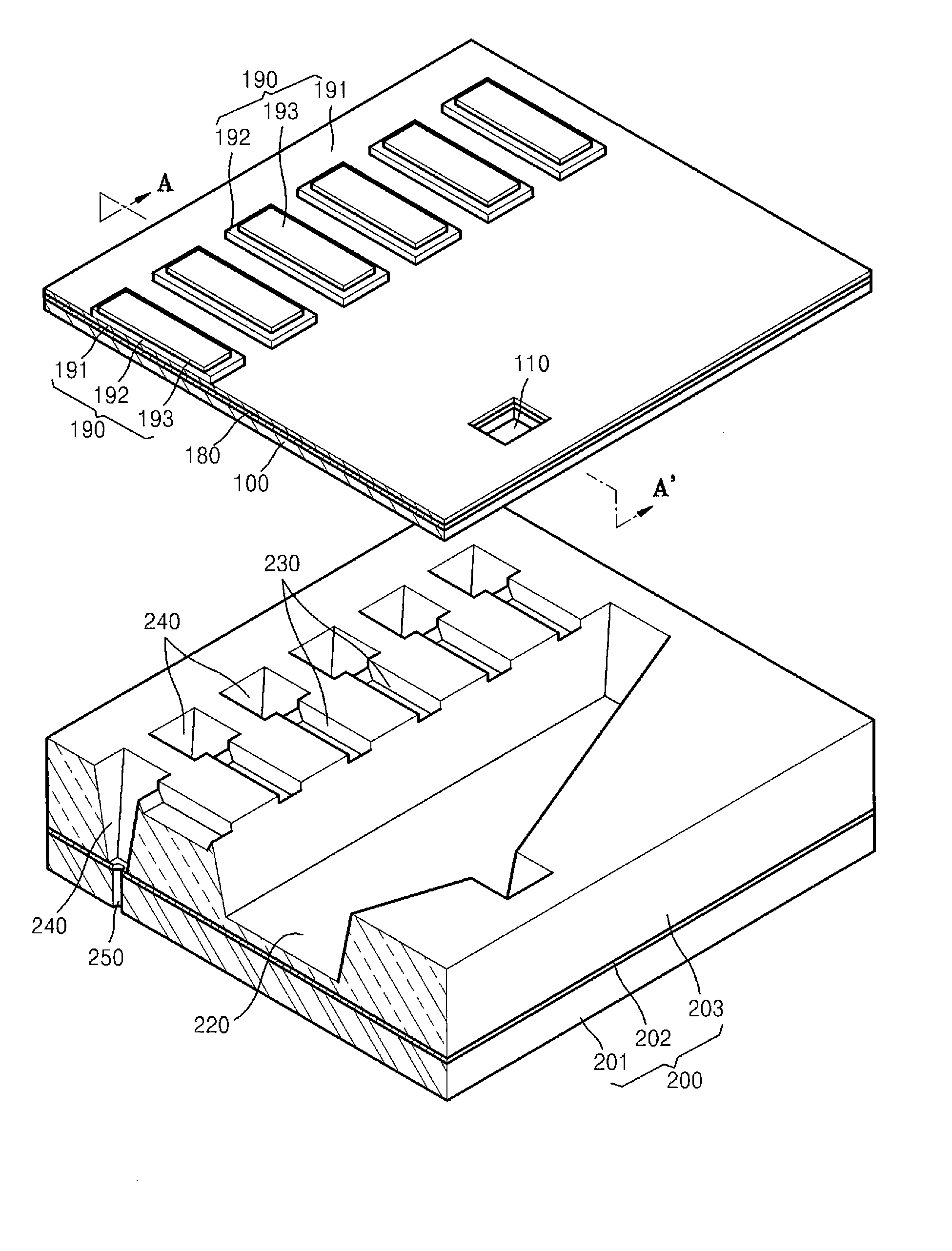

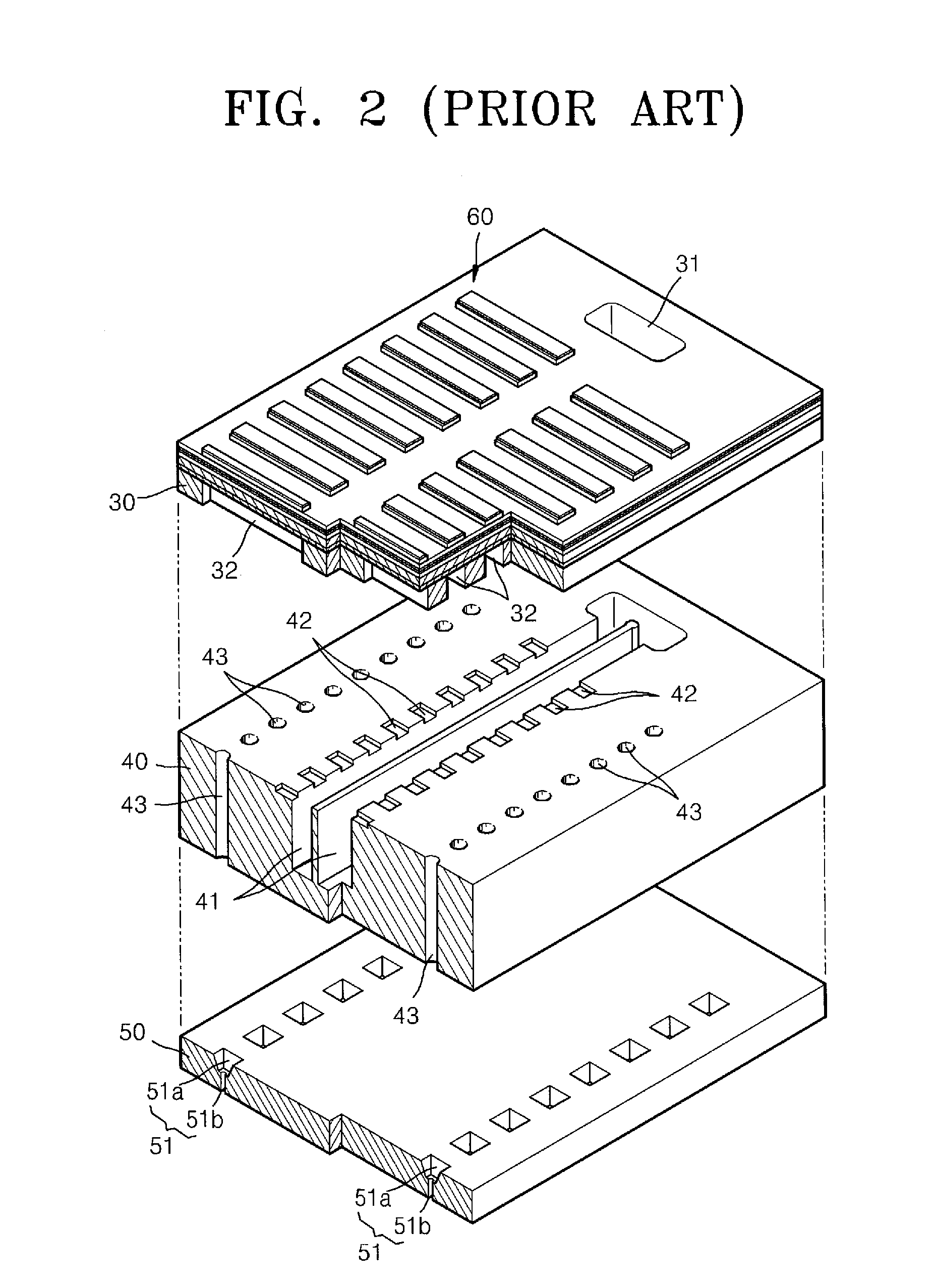

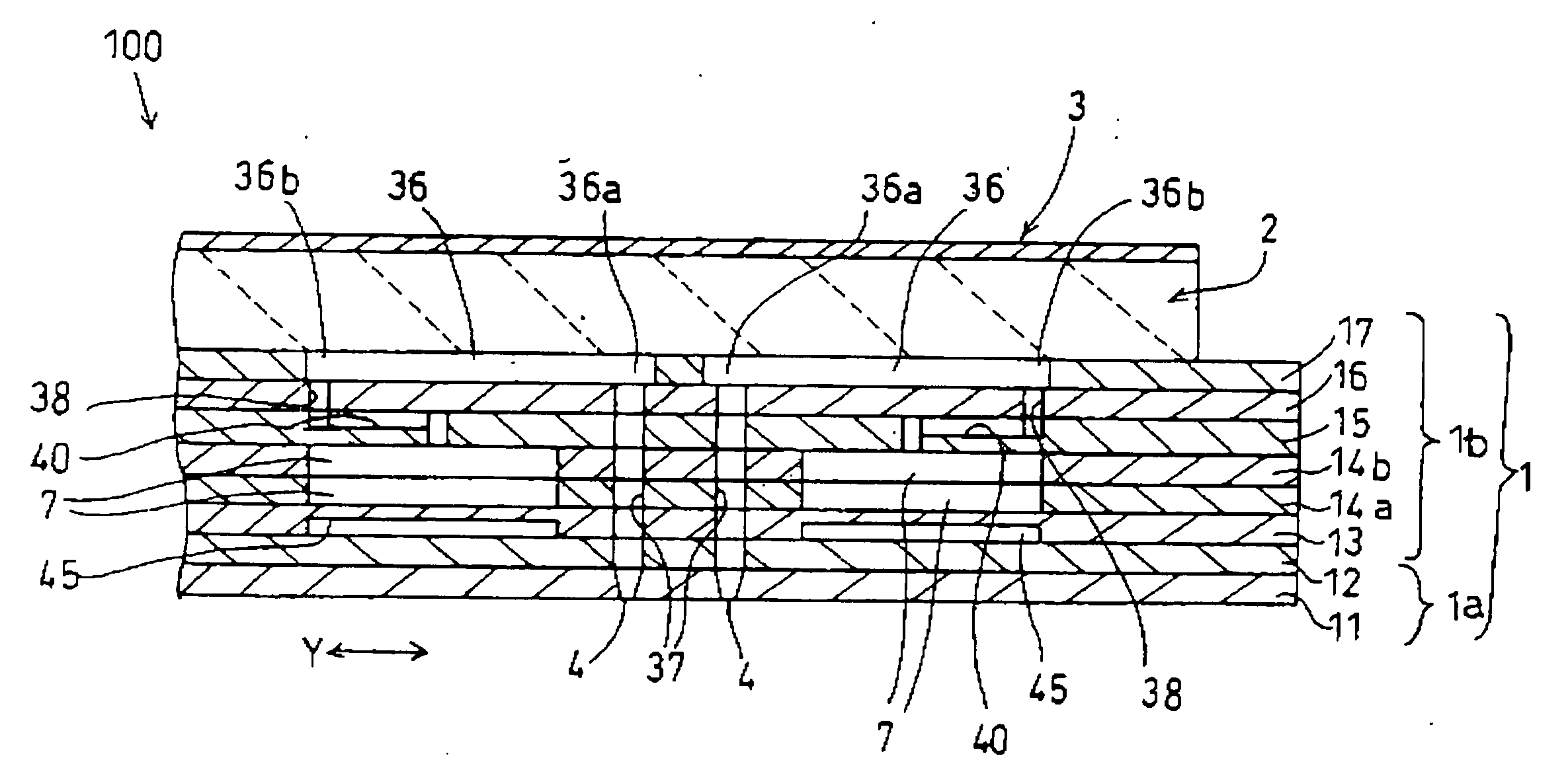

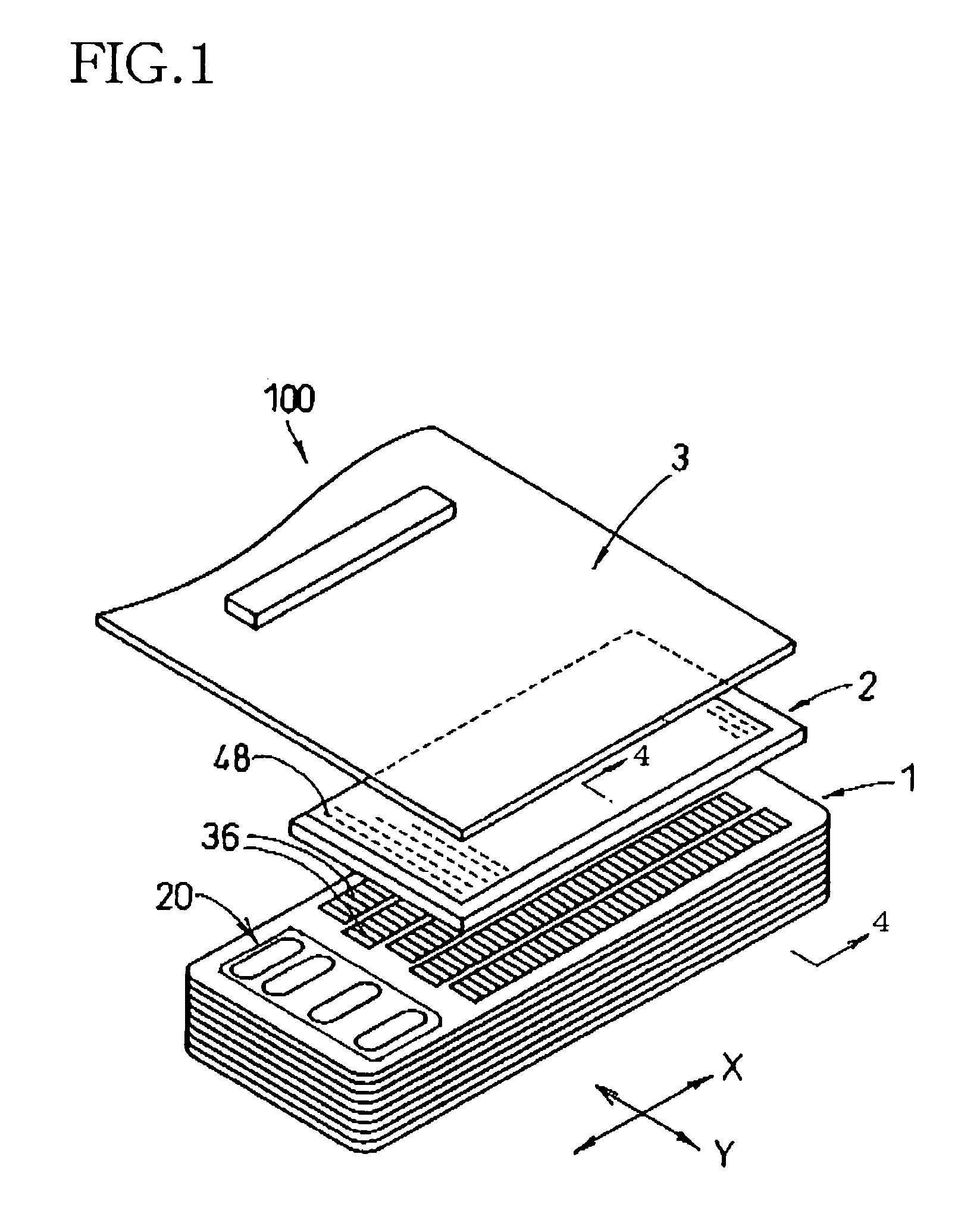

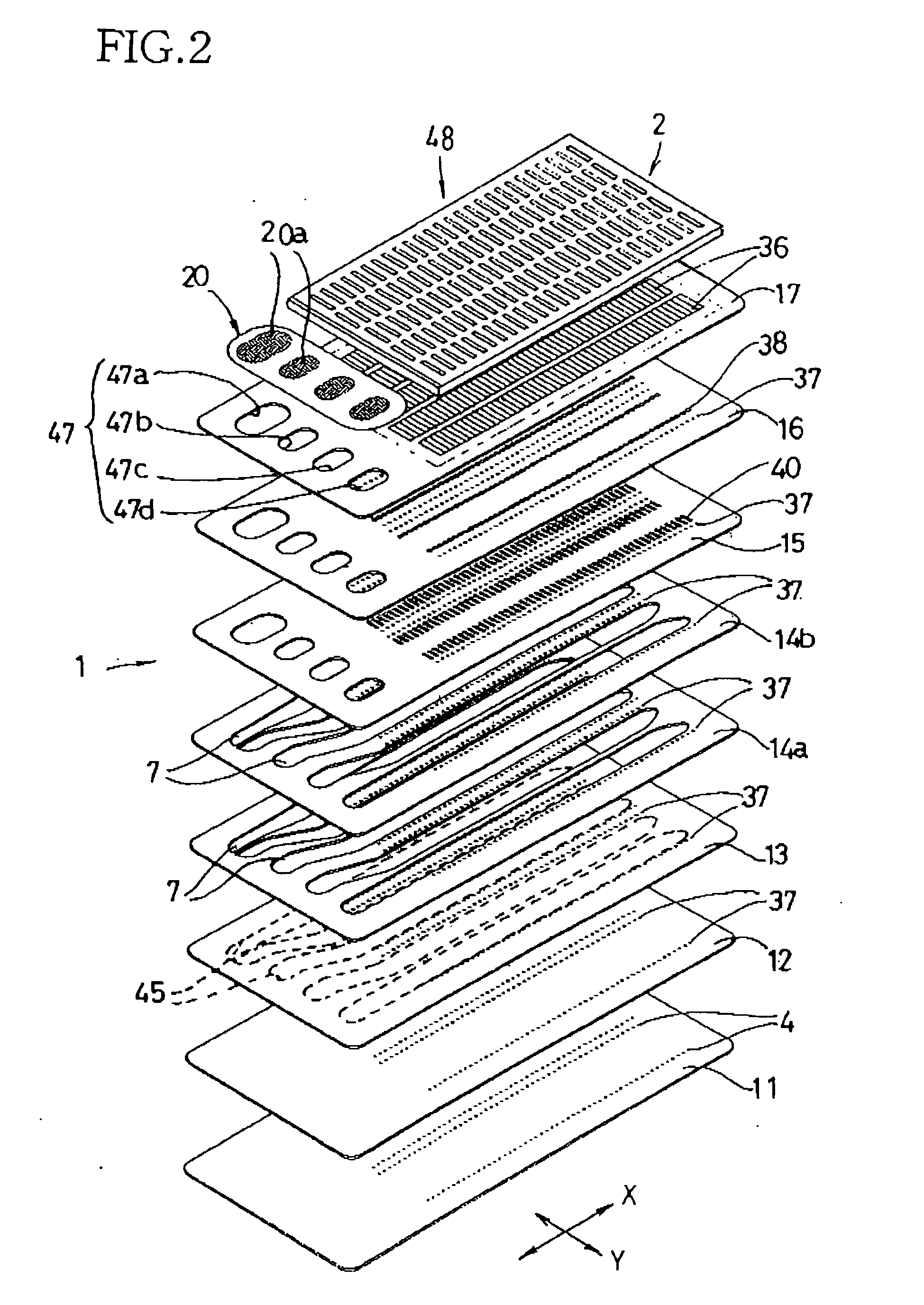

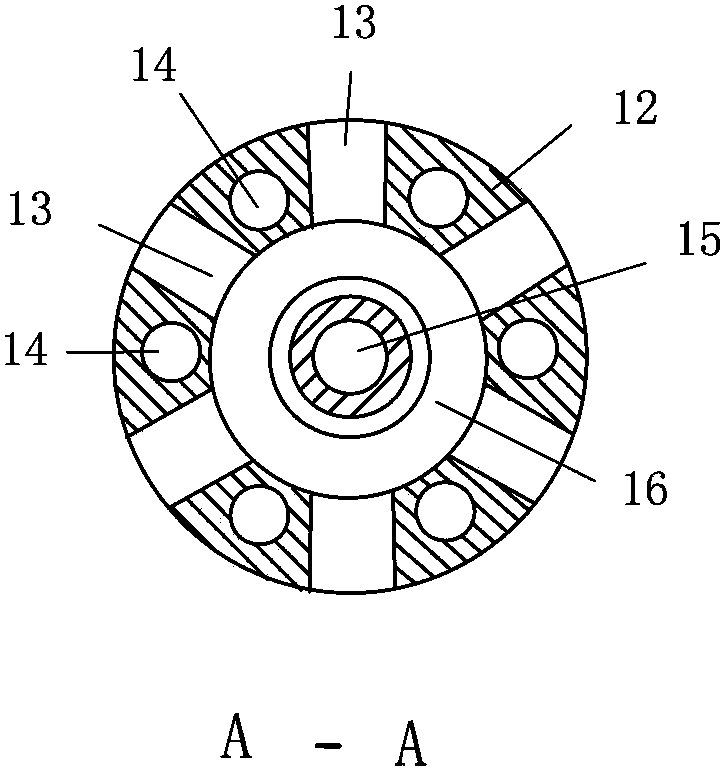

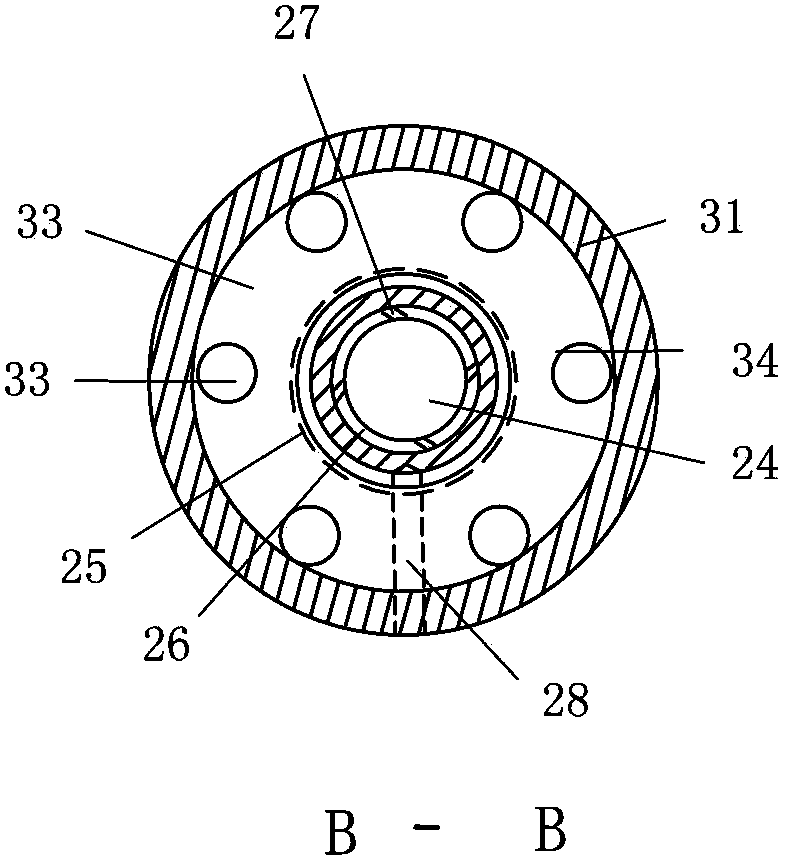

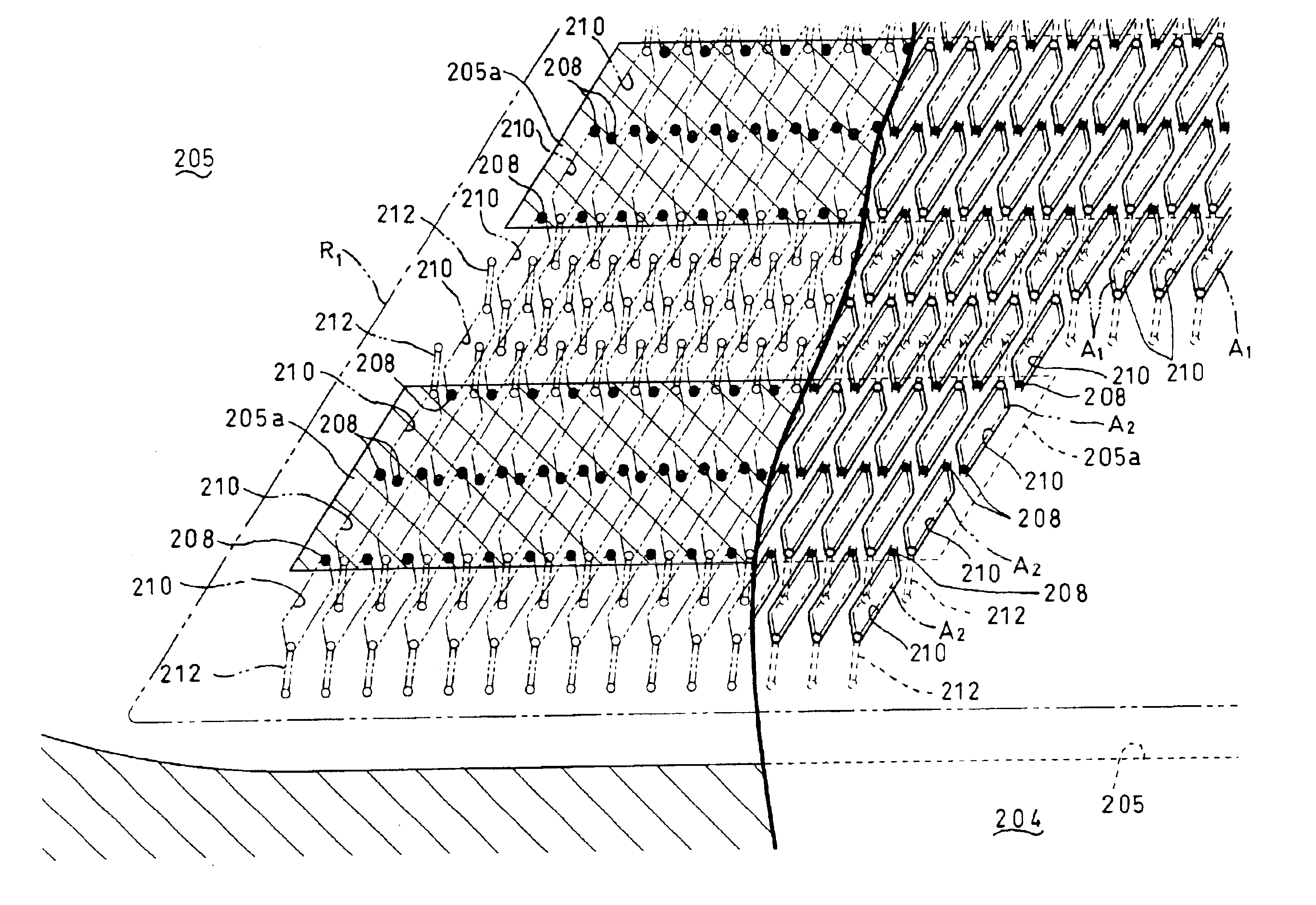

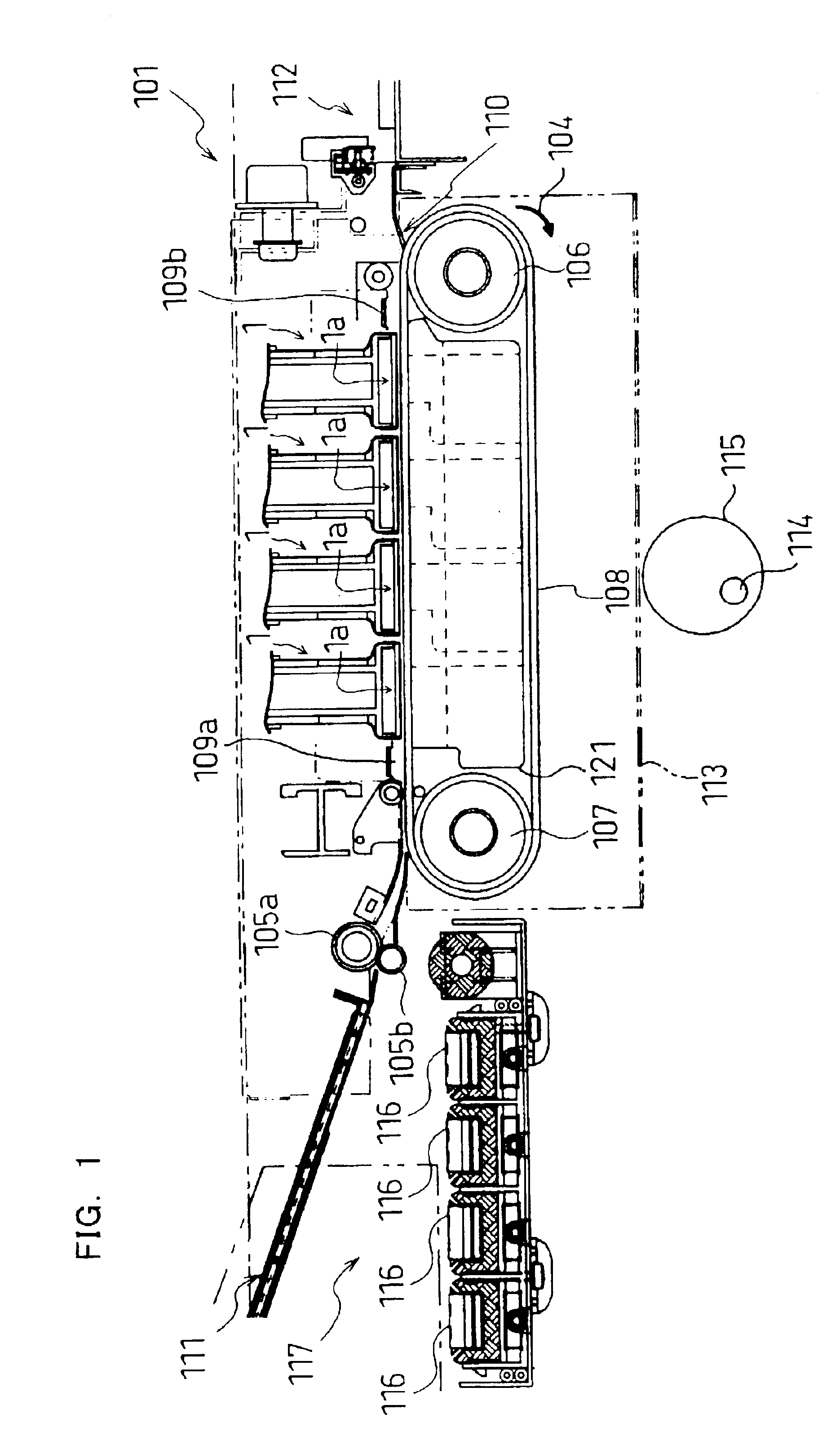

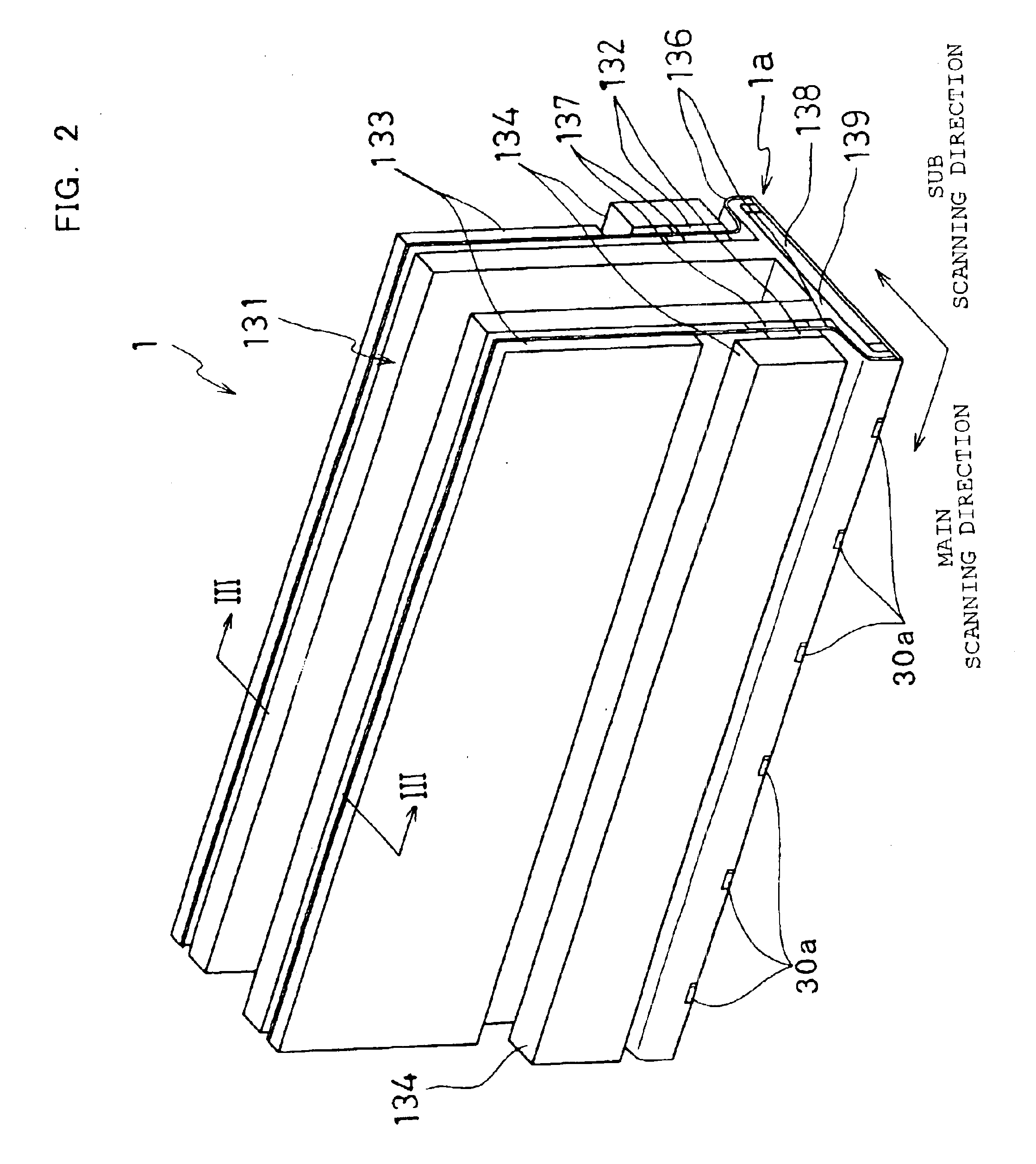

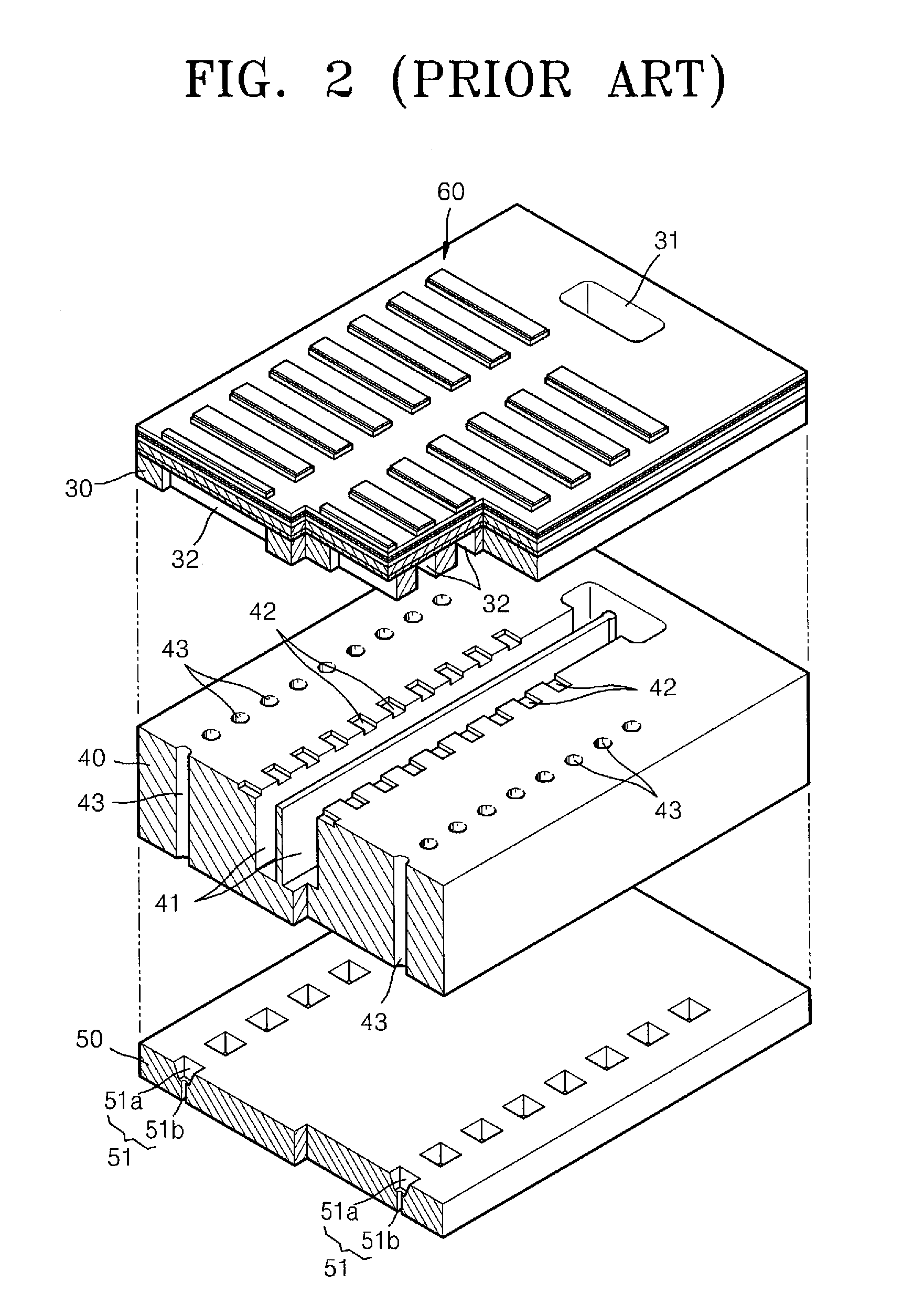

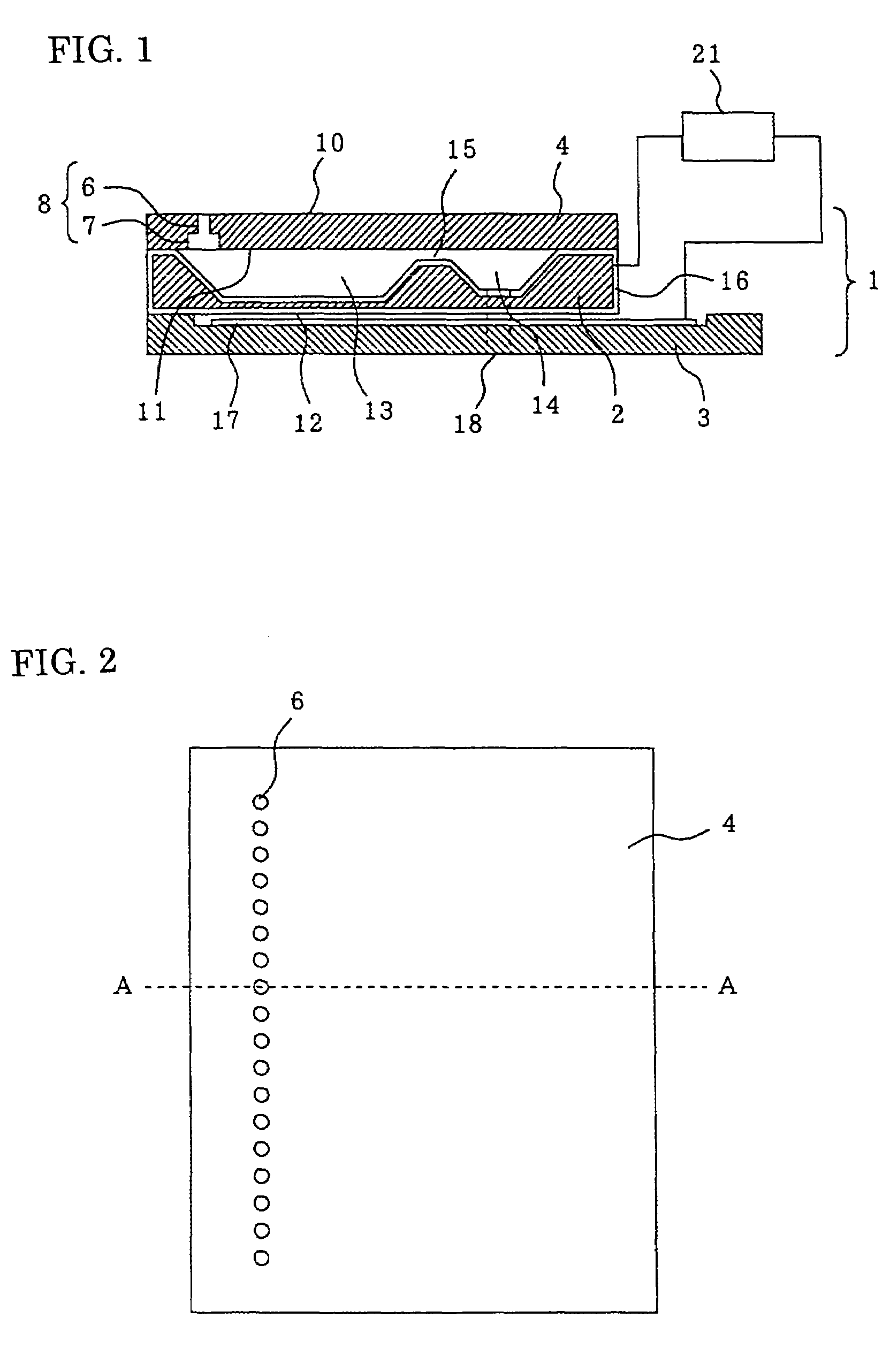

Ink-jet head having passage unit and actuator units attached to the passage unit, and ink-jet printer having the ink-jet head

ActiveUS20050231554A1Precise positioningImprove positionInking apparatusPressure generationInk printer

An ink-jet head having a passage unit including pressure chambers each having one end coupled to a nozzle and the other end to be coupled to an ink supply source. The pressure chambers are arranged along a plane to neighbor each other. The ink-jet head further includes actuator units attached to a surface of the passage unit for changing the volume of each pressure chamber. Each actuator unit includes pressure generation portions respectively corresponding to pressure chambers, and is formed to extend over the pressure chambers. The actuator units are arranged along the longitudinal direction of the passage unit so that each neighboring actuator units partially overlap each other in the lateral direction of the passage unit. Each actuator unit has a basic region where many pressure generation portions are formed in a matrix, and an additional region neighboring the basic region in the lateral direction of the passage unit. In the additional region, pressure generation portions are formed to correspond to a gap portion between the pressure generation portions in the basic region of the actuator unit and the pressure generation portions in the basic region of another actuator unit neighboring that actuator unit.

Owner:BROTHER KOGYO KK

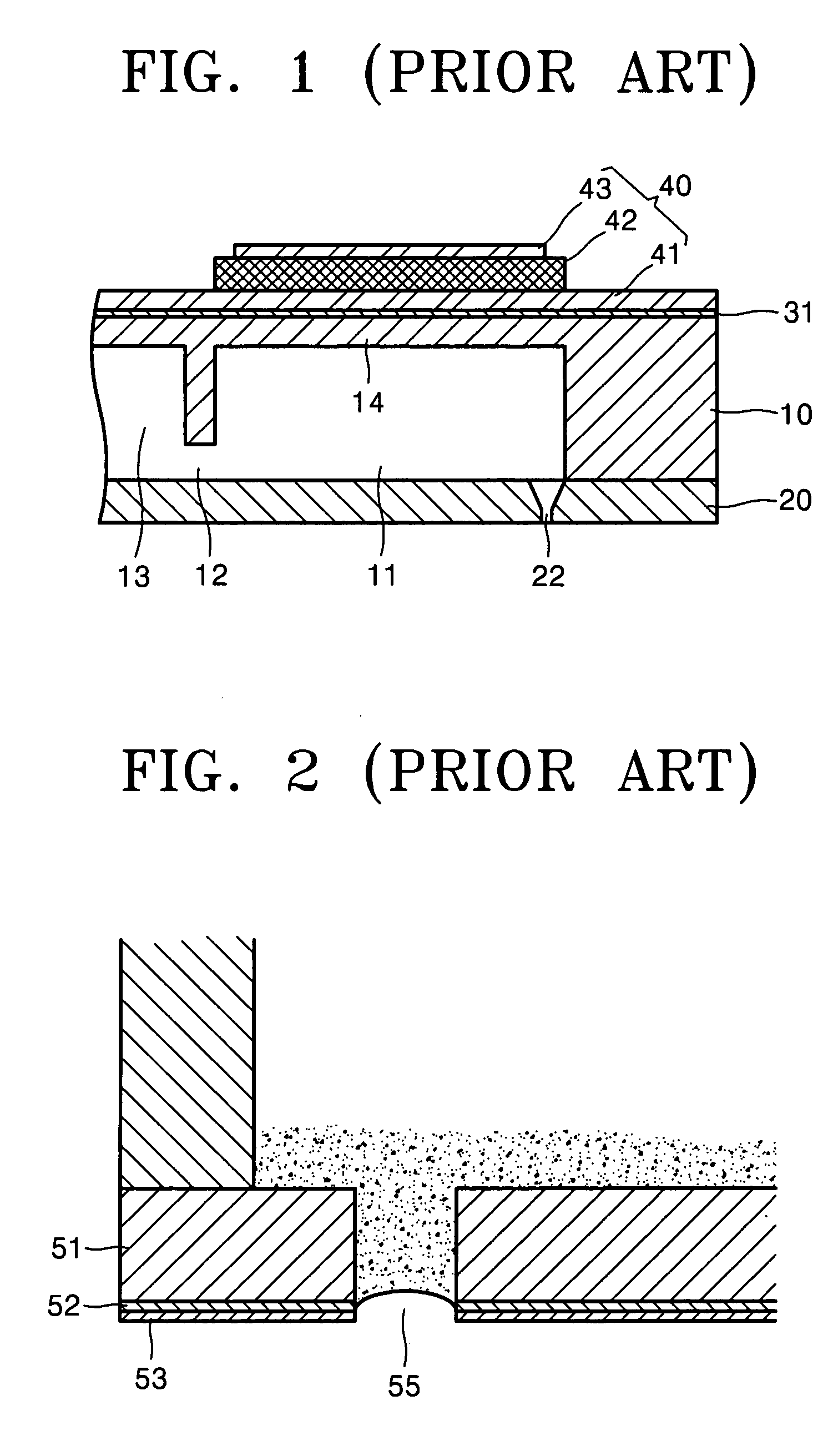

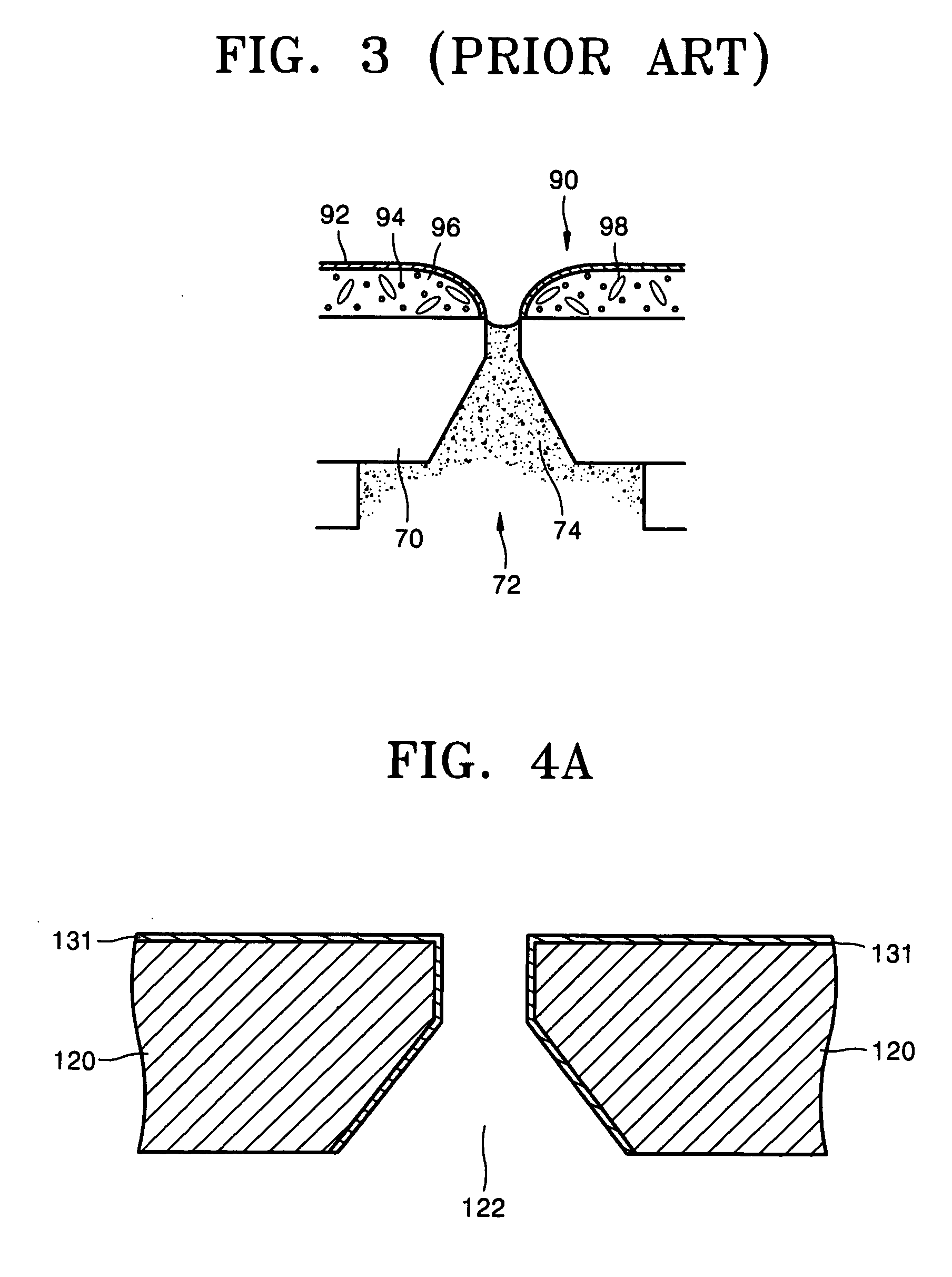

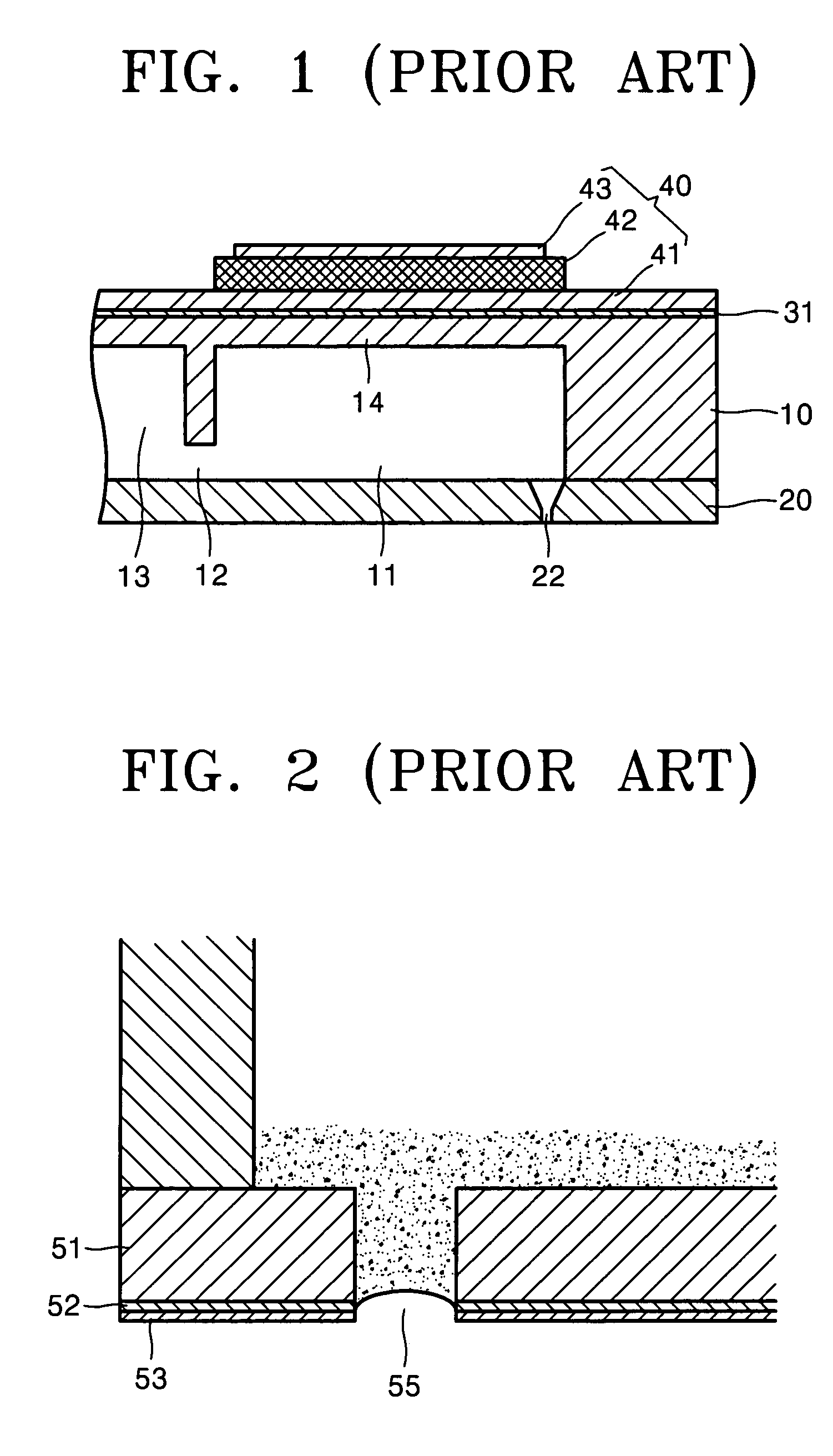

Method of manufacturing an ink-jet printhead

InactiveUS7086142B2Improve ejection effectImprove productivityRecording apparatusOhmic-resistance electrodesEngineeringElectric wire

A method of manufacturing an ink-jet printhead, including forming an insulation film on a substrate, depositing a metal layer onto said insulation film and patterning said metal layer to form a heater, forming an electrical wire on said substrate, etching said substrate at a predetermined depth from a top surface of said substrate in a direction perpendicular to a major surface of said heater to form a narrow passage, depositing an ink chamber barrier layer on said top surface of said substrate and patterning said ink chamber barrier layer to form an ink chamber, stacking a nozzle plate having a nozzle on said ink chamber barrier layer and disposed on an upper portion of said ink chamber barrier layer, and applying predetermined pressure and temperature onto said nozzle plate to bond said nozzle plate and said substrate, and etching said substrate from a bottom surface thereof to form a wide passage communicating with said narrow passage.

Owner:S PRINTING SOLUTION CO LTD

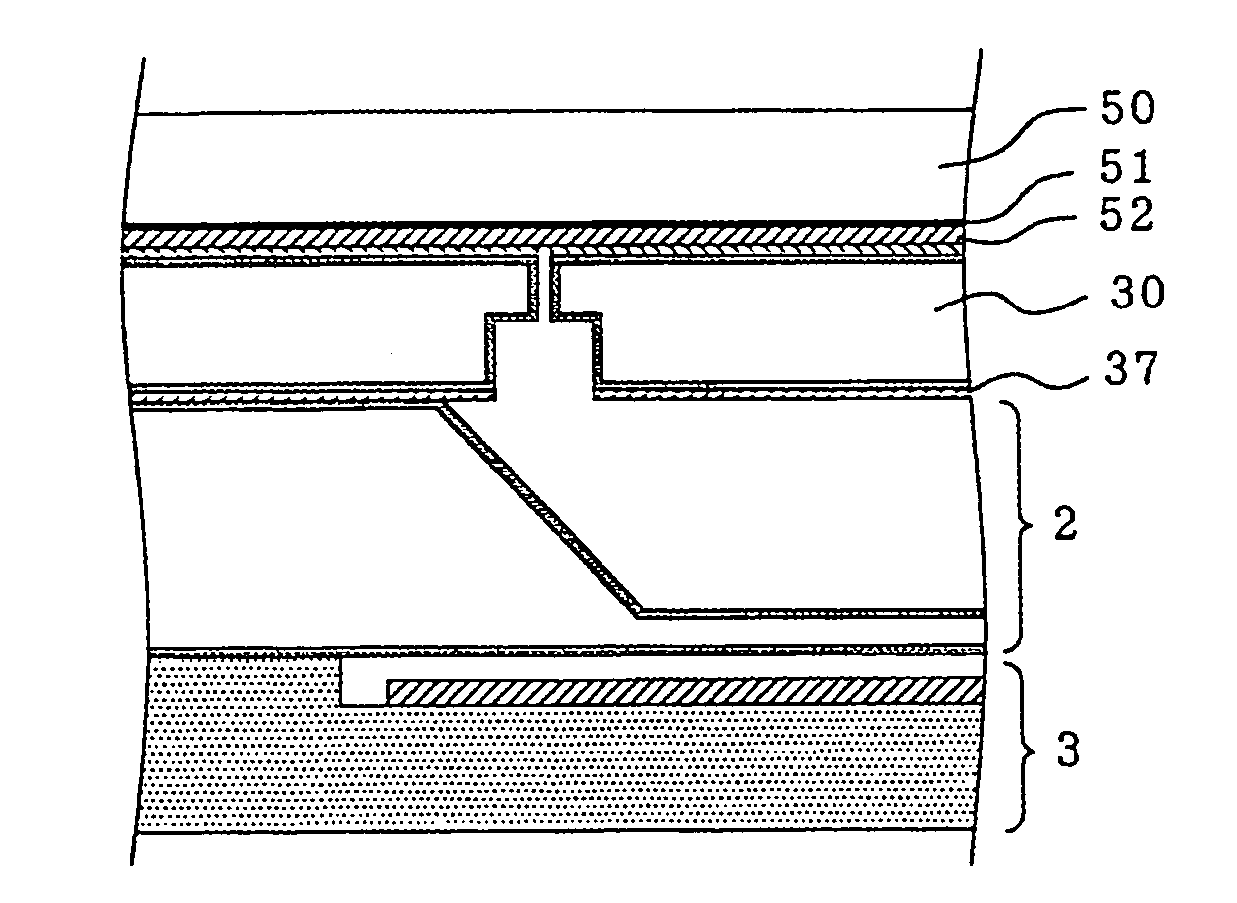

Method for manufacturing ink-jet printhead

InactiveUS20060146102A1Simple structureIncrease drive frequencyRecording apparatusDecorative surface effectsElectrical conductorMetallic materials

In an ink-jet printhead and a method for manufacturing the same, the ink-jet printhead includes a substrate, an ink chamber to be filled with ink formed on a front surface of the substrate, a manifold for supplying ink to the ink chamber formed on a rear surface of the substrate, and an ink passage in flow communication with the ink chamber and the manifold formed parallel to the front surface of the substrate; a nozzle plate including a plurality of passivation layers formed of an insulating material on the front surface of the substrate, a heat dissipating layer formed of a metallic material, and a nozzle in flow communication with the ink chamber; and a heater and a conductor, the heater being positioned on the ink chamber and heating ink in the ink chamber, and the conductor for applying a current to the heater.

Owner:HEWLETT PACKARD DEV CO LP

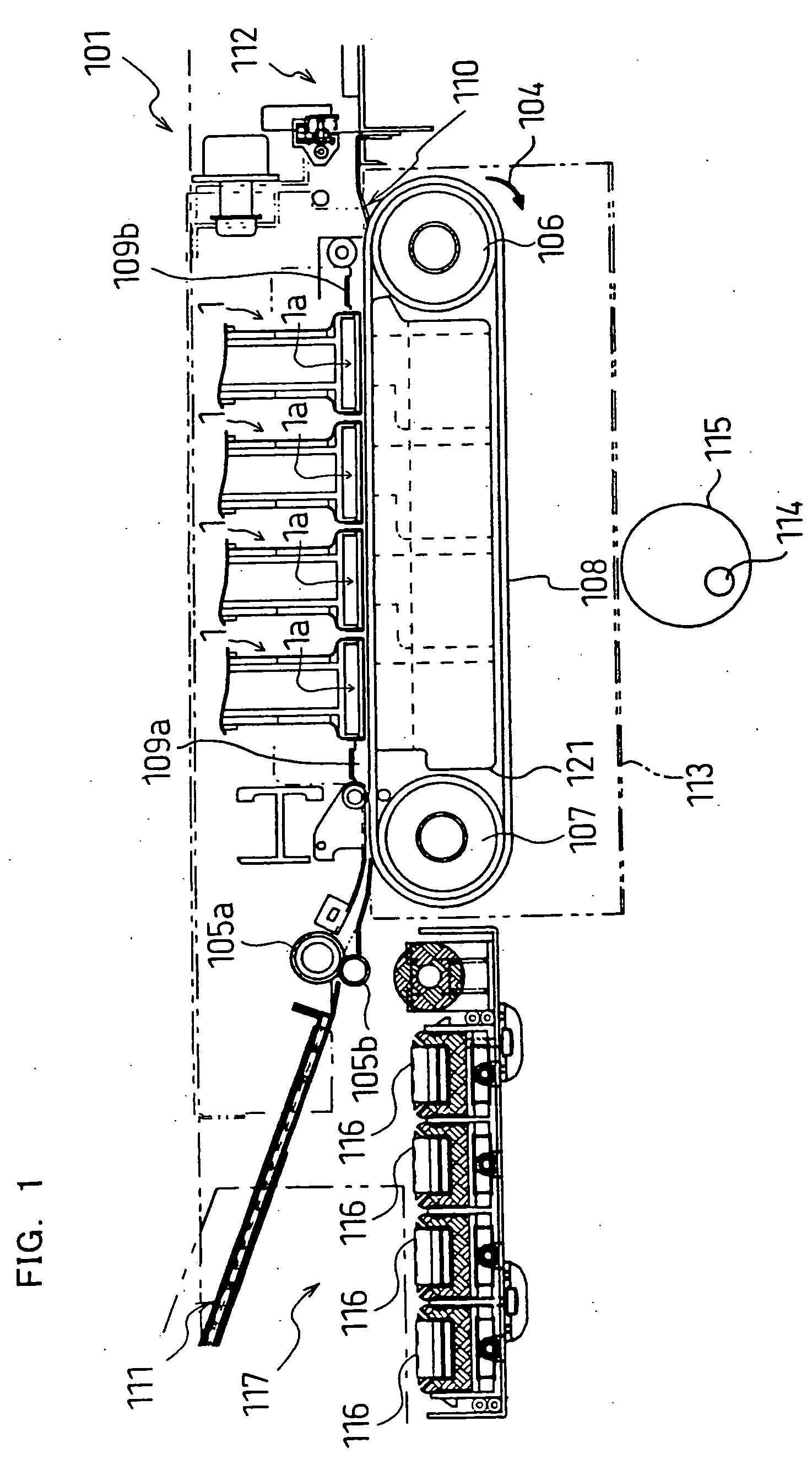

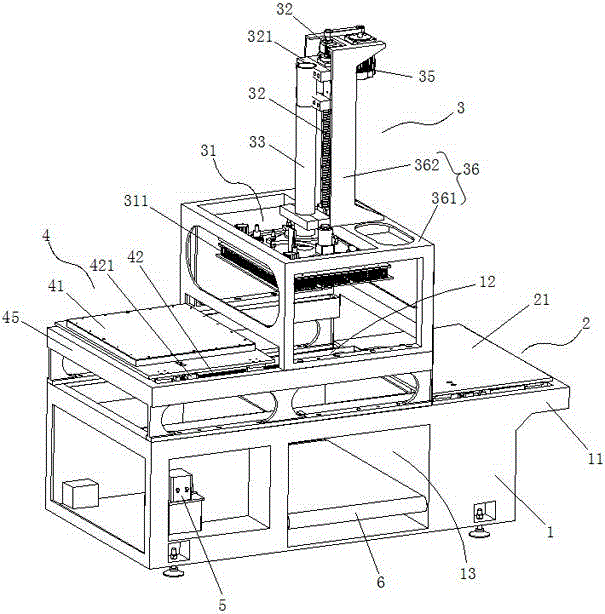

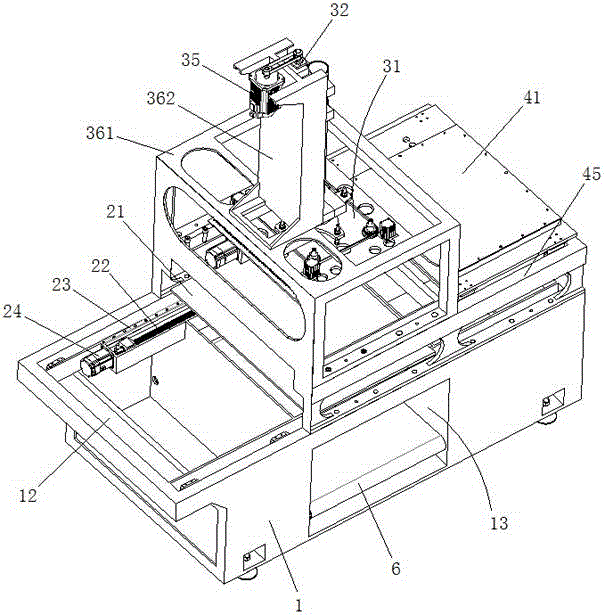

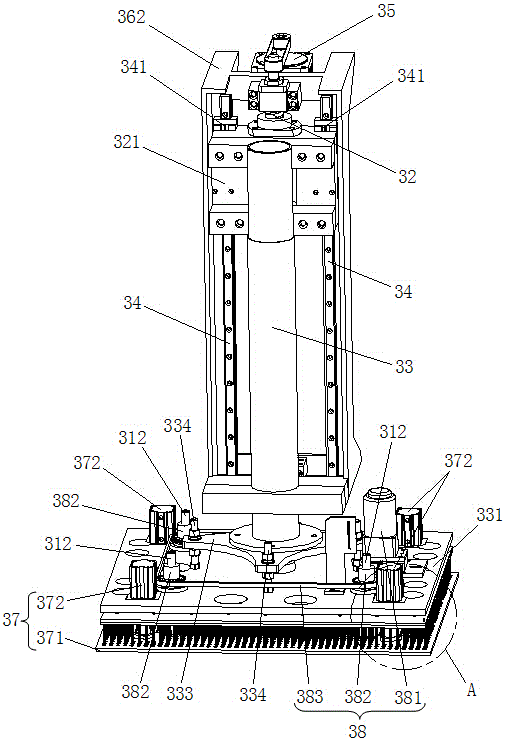

Automatic fusing machine for EPE pearl wool

The invention relates to an automatic fusing machine for EPE pearl wool. The automatic fusing machine for the EPE pearl wool comprises a cabinet, a material conveying device, a material taking device and a heating and ironing device, wherein the material conveying device is horizontally arranged on a material discharging station of the cabinet, and a material conveying plate of the material conveying device can horizontally move to a processing station of the cabinet; the heating and ironing device is horizontally arranged on the cabinet, and a heating and ironing plate of the heating and ironing device can horizontally move to the processing station of the cabinet and is positioned over the material conveying plate moved to the processing station; the material taking device is perpendicular to the cabinet, and a material taking plate of the material taking device is arranged right above the processing station and can perpendicularly move up and down to the material conveying plate and the heating and ironing plate on the processing station; material taking needles are arranged on the bottom surface of the material taking plate at intervals. Therefore, fusing of an upper material and a bottom material of a pearl wool sheet can be automatically finished; the automatic fusing machine is suitable for fusing large-area pearl wool sheets, and the material taking needles can be used for guaranteeing stable taking and loading of the pearl wool sheet; the moving and conveying precision is high, the fusing speed is high, heating is uniform, and the fusing effect is good.

Owner:珠海市柏泉精密制造有限公司

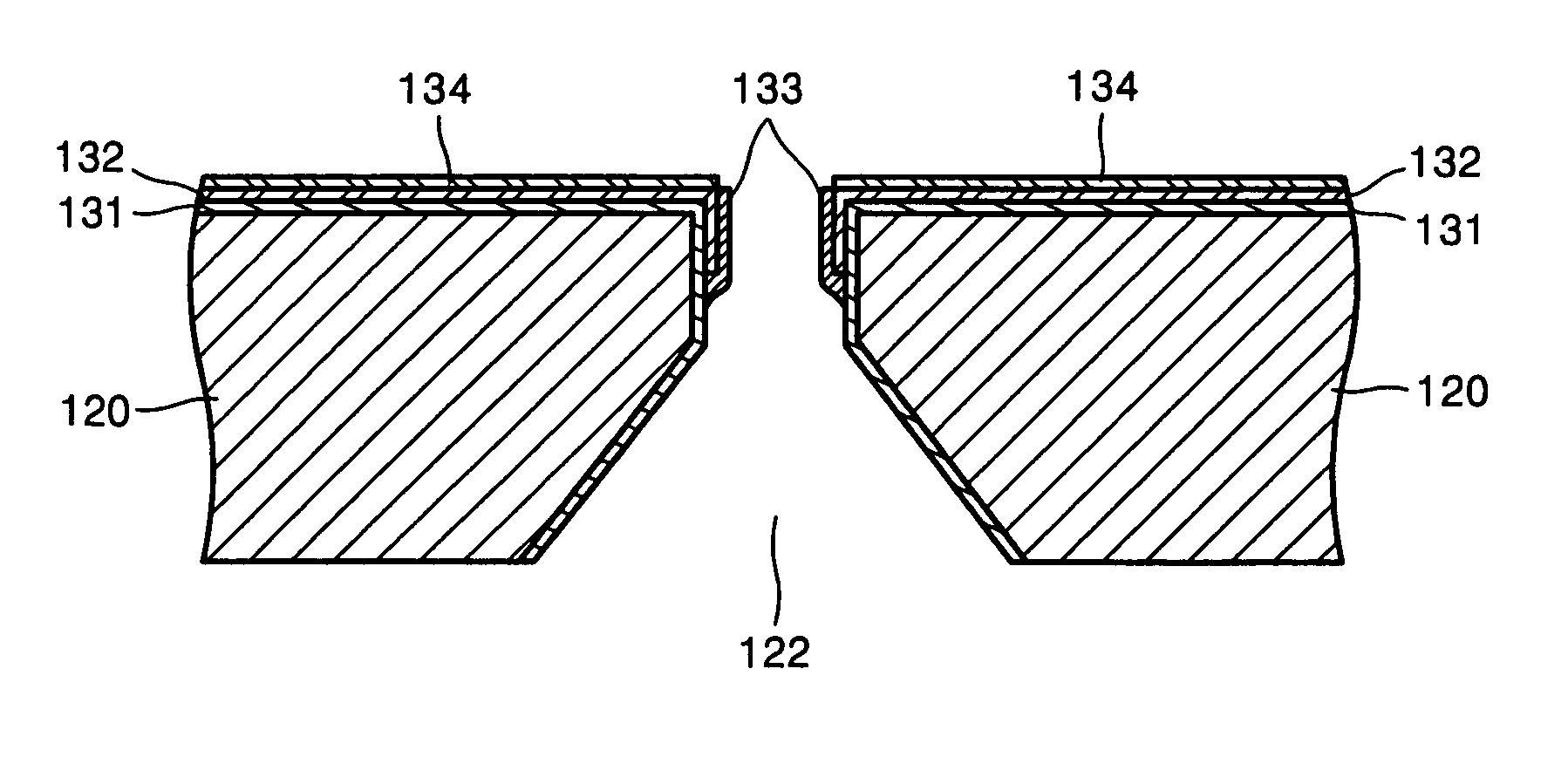

Piezoelectric inkjet printhead and method of manufacturing the same

InactiveUS20070171260A1Simple manufacturing processImprove ejection effectPrintingSoi substrateDry etching

A piezoelectric inkjet printhead including an upper substrate formed of a single crystal silicon substrate or an SOI substrate and having an ink inlet therethrough, and a lower substrate formed of an SOI substrate having a sequentially stacked structure with a first silicon layer, an intervening oxide layer, and a second silicon layer in which a manifold, pressure chambers, and dampers are formed in the second silicon layer by wet or dry etching, and nozzles are formed through the intervening oxide layer and the first silicon layer by dry etching, and a method of manufacturing the same.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

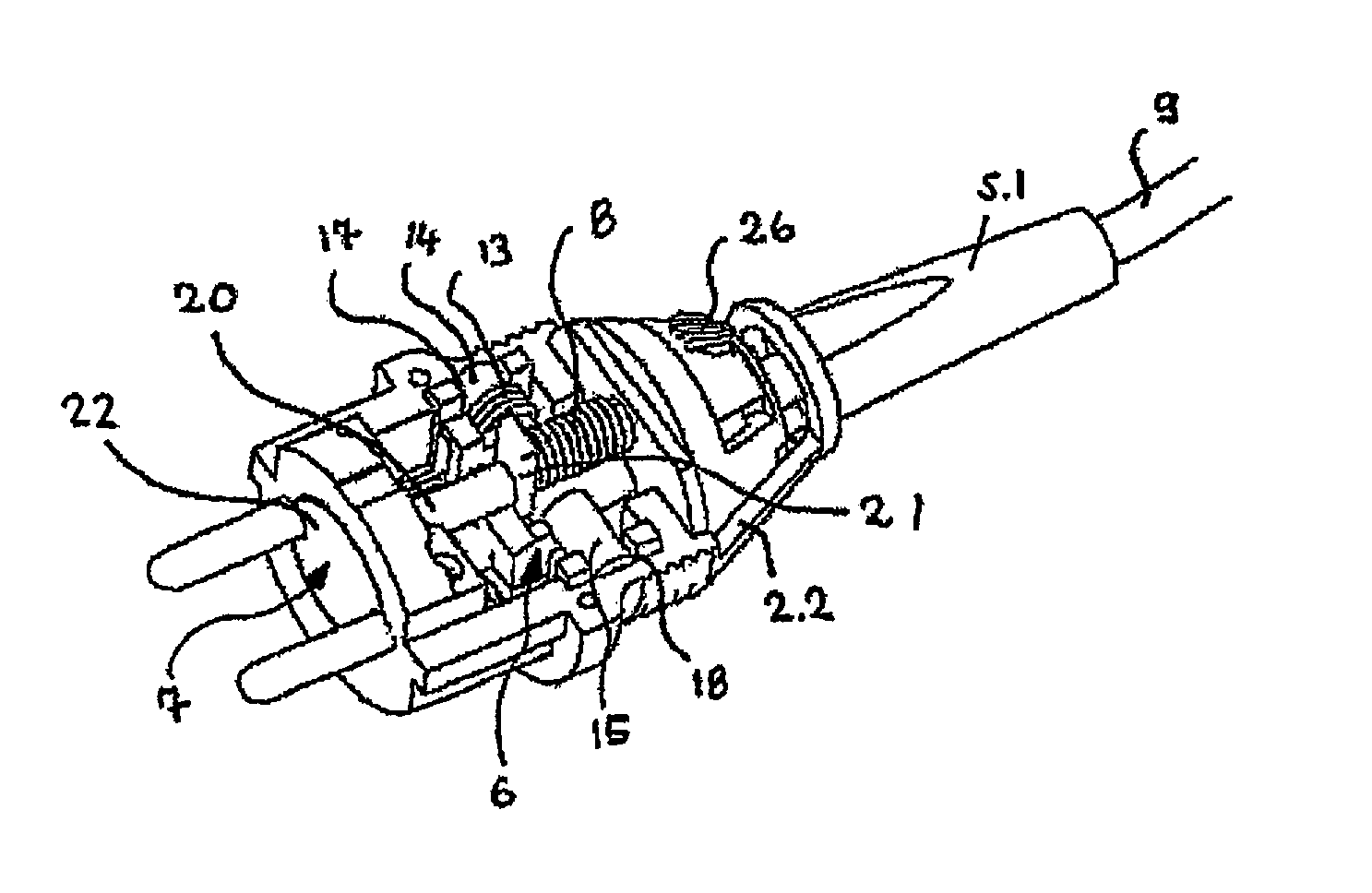

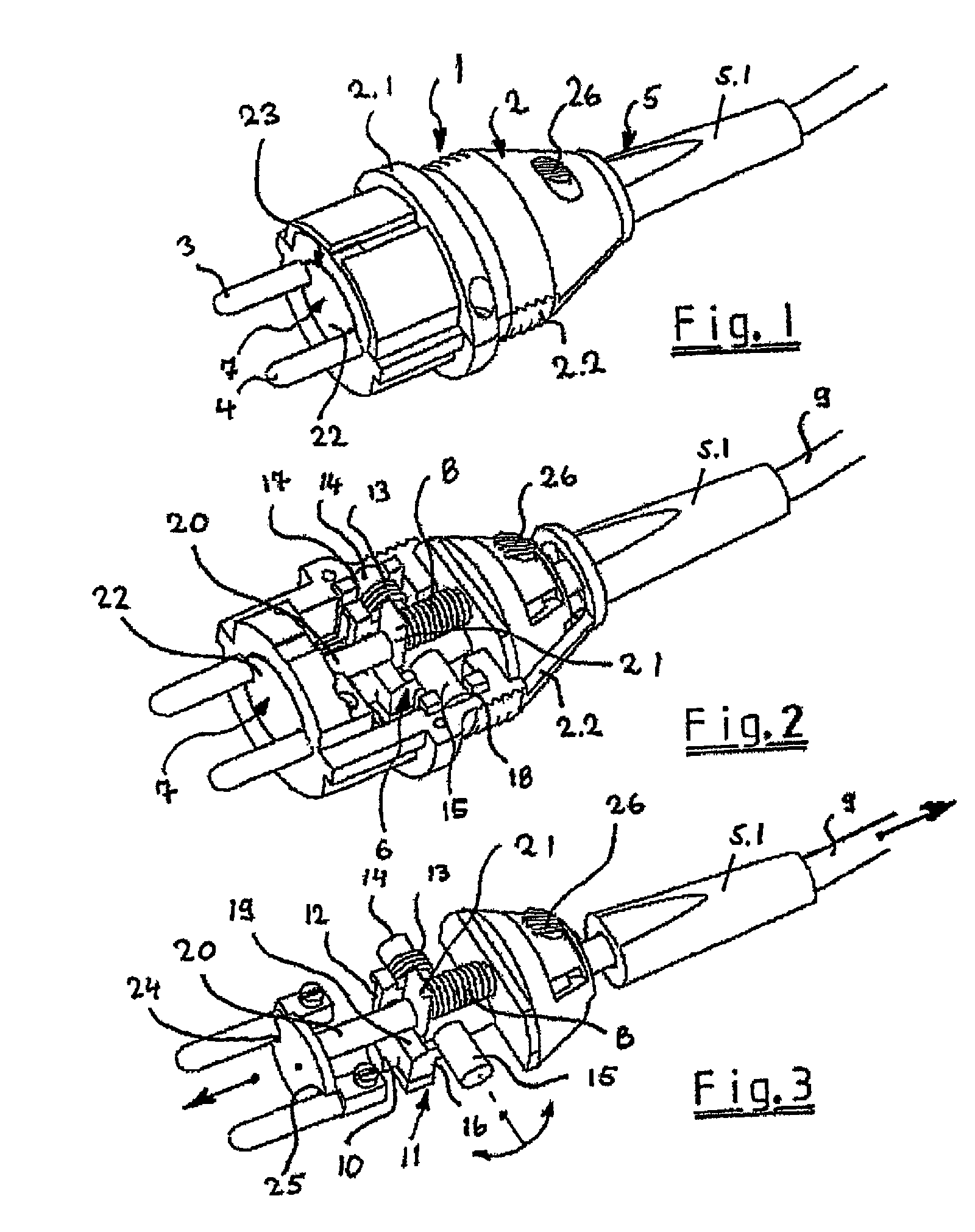

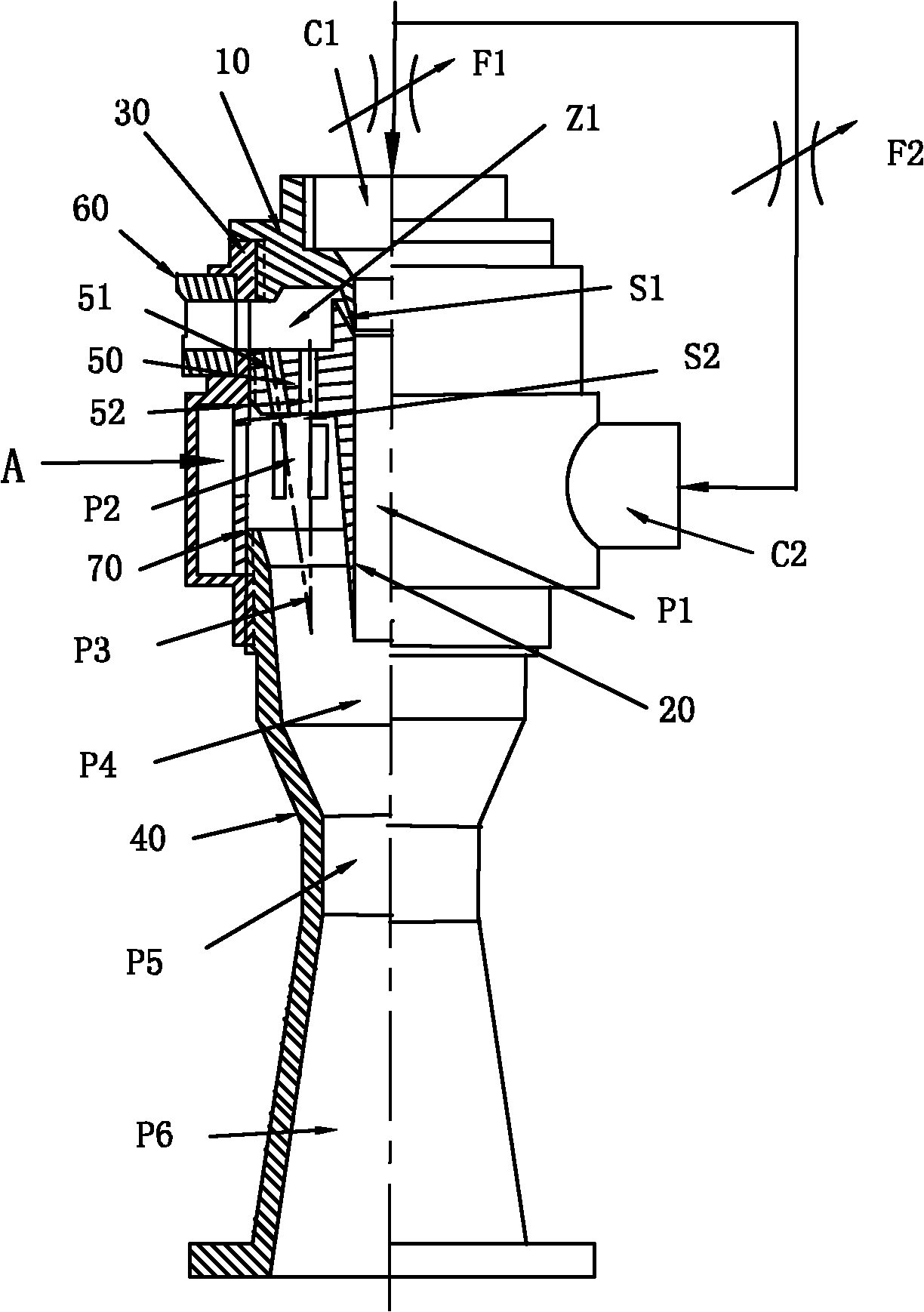

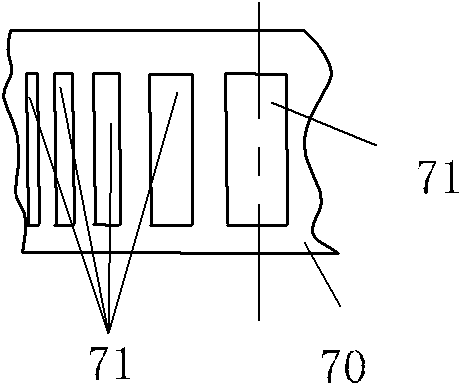

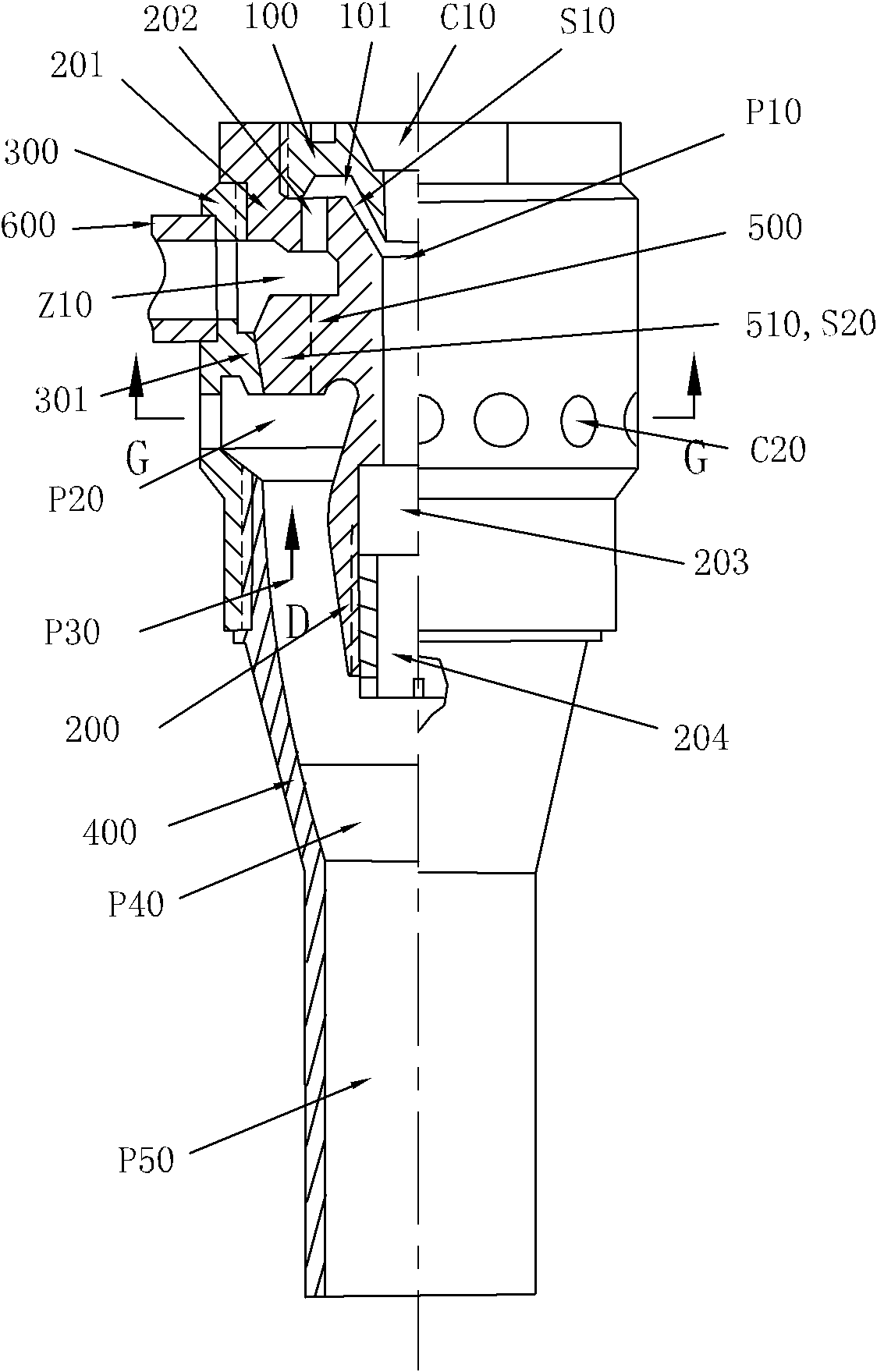

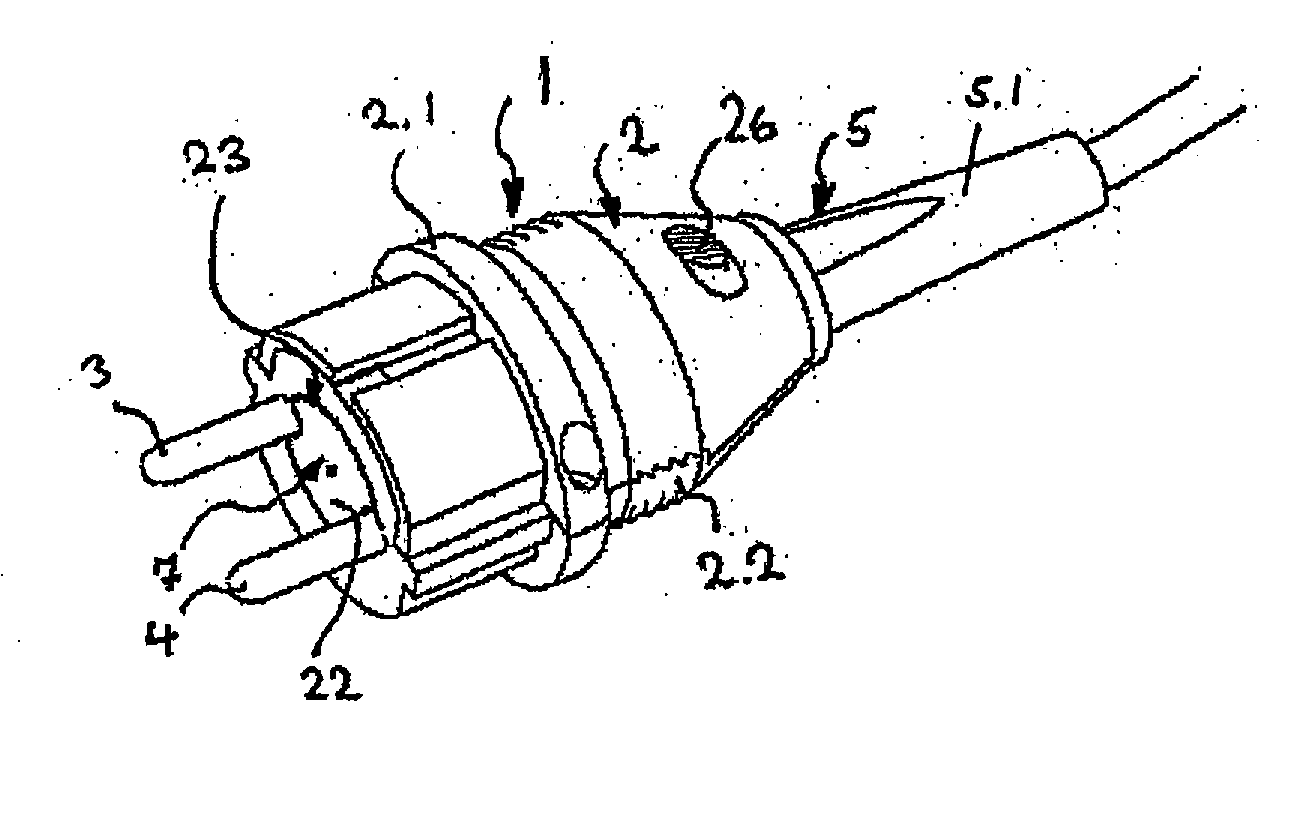

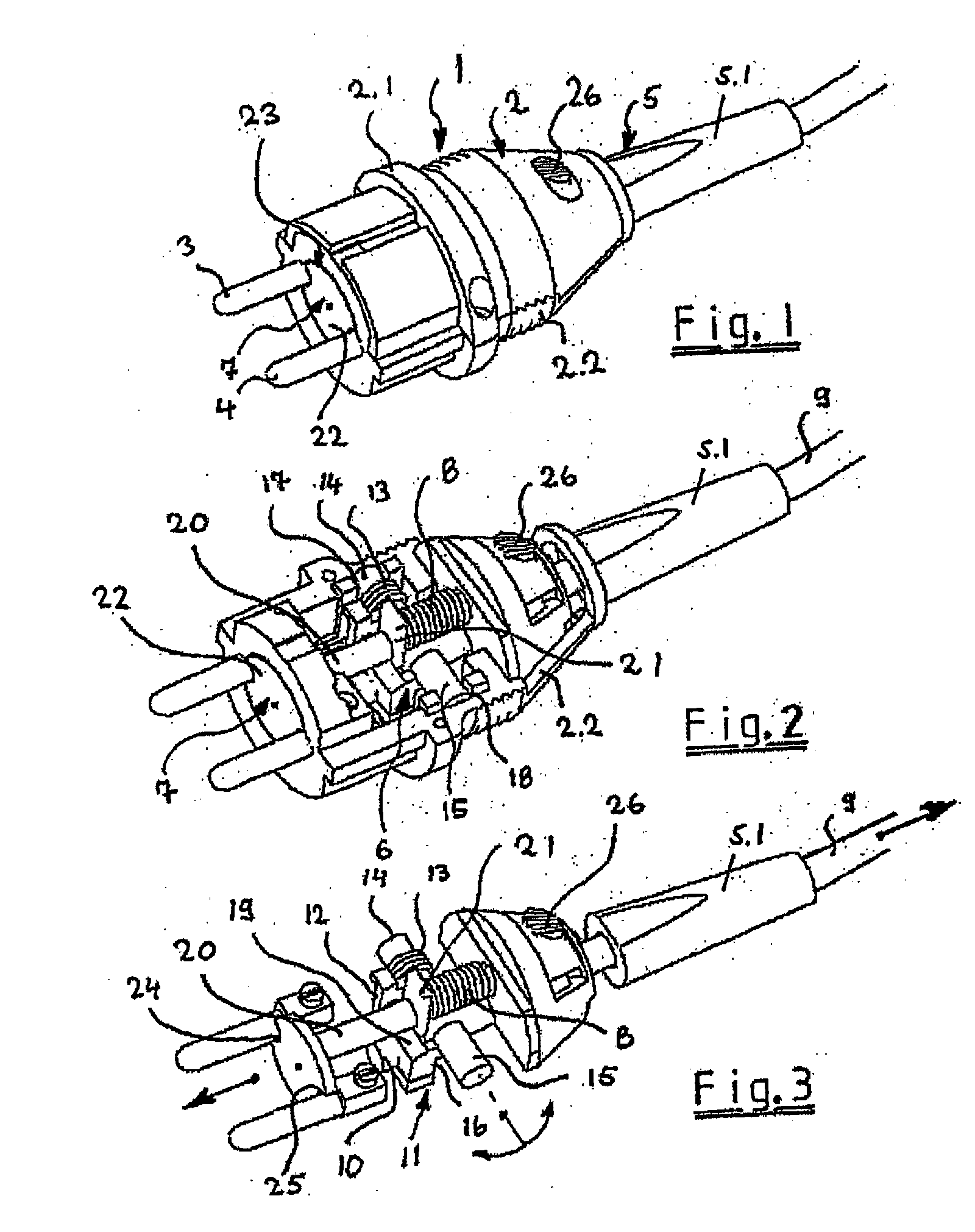

Electric plug comprising a plug housing and at least two integrated plug-in contacts with an ejection mechanism

InactiveUS7344393B2Good effectImprove ejection effectEngagement/disengagement of coupling partsTwo pole connectionsPush outTriggering device

An electric plug includes a plug housing, at least two incorporated plug-in contacts that are to be inserted into corresponding jacks of an outlet, and a cable feeder. A manually actuated ejection mechanism encompassing a push-out device is disposed in the plug housing. The push-out device cooperates with a spring in such a way that the spring is biased in the plugged-in state of the plug in order to allow the plug to be automatically removed from the outlet by means of the push-out device when the ejection mechanism is actuated. In order to actuate the ejection mechanism, the same is automatically triggered by pulling on the cable, the tensile force being effective on a strain relief device for the cable, which is located in the plug housing and cooperates with triggering device for actuating the spring-biased push-out device.

Owner:MIELE & CO KG

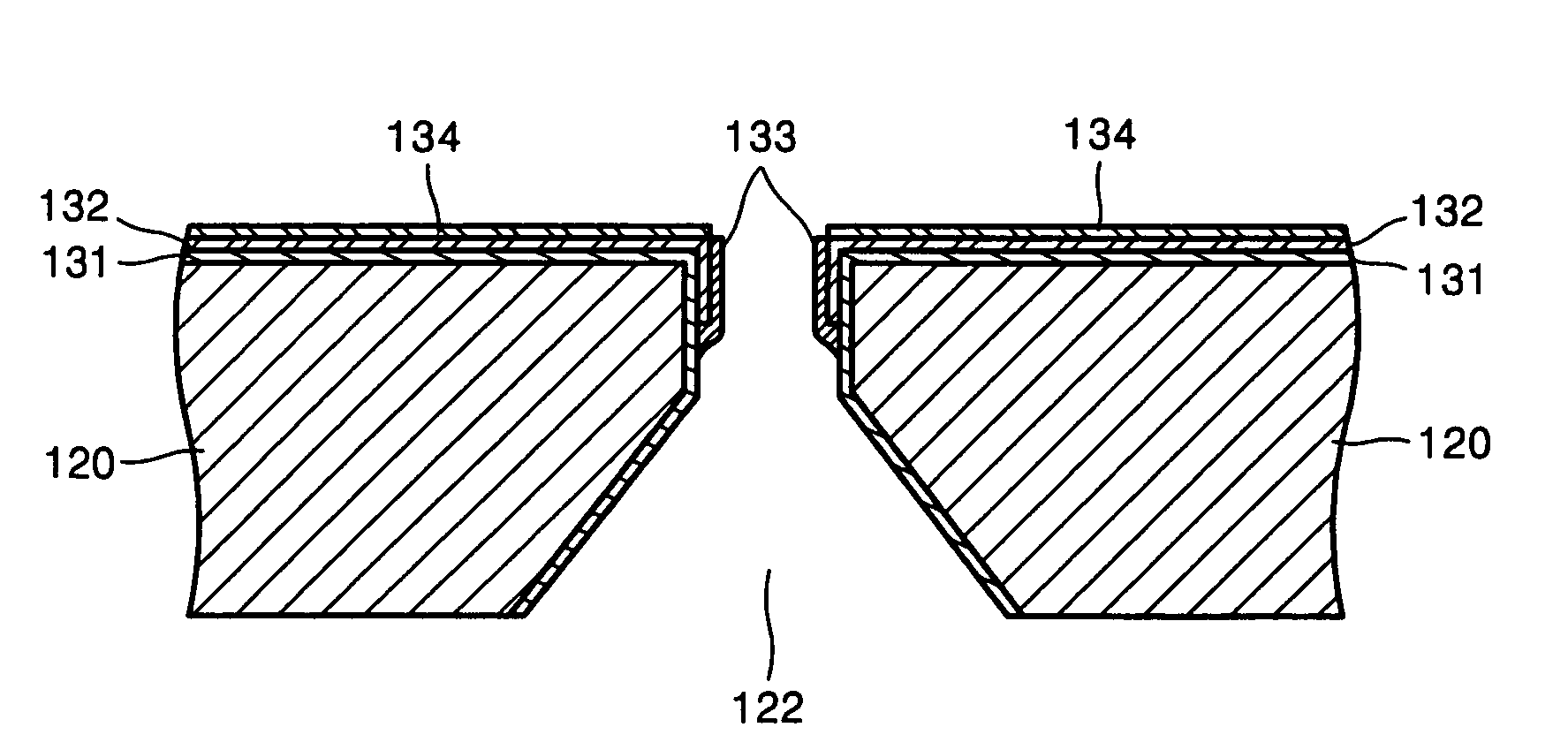

Method of forming a hydrophobic coating layer on a surface of a nozzle plate for an ink-jet printhead

InactiveUS20050190231A1Improve ejection effectImprove printing qualityRecording apparatusDecorative surface effectsSulfurCompound (substance)

A method of forming a hydrophobic coating layer on a surface of a nozzle plate for an ink-jet printhead includes preparing a nozzle plate having a nozzle, forming a metal layer on a surface of the nozzle plate, forming a material layer covering the metal layer, selectively etching the material layer to expose a portion of the metal layer formed on an outer surface of the nozzle plate, and forming the hydrophobic coating layer of a sulfur compound on the exposed portion of the metal layer by dipping the nozzle plate in a sulfur compound-containing solution.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

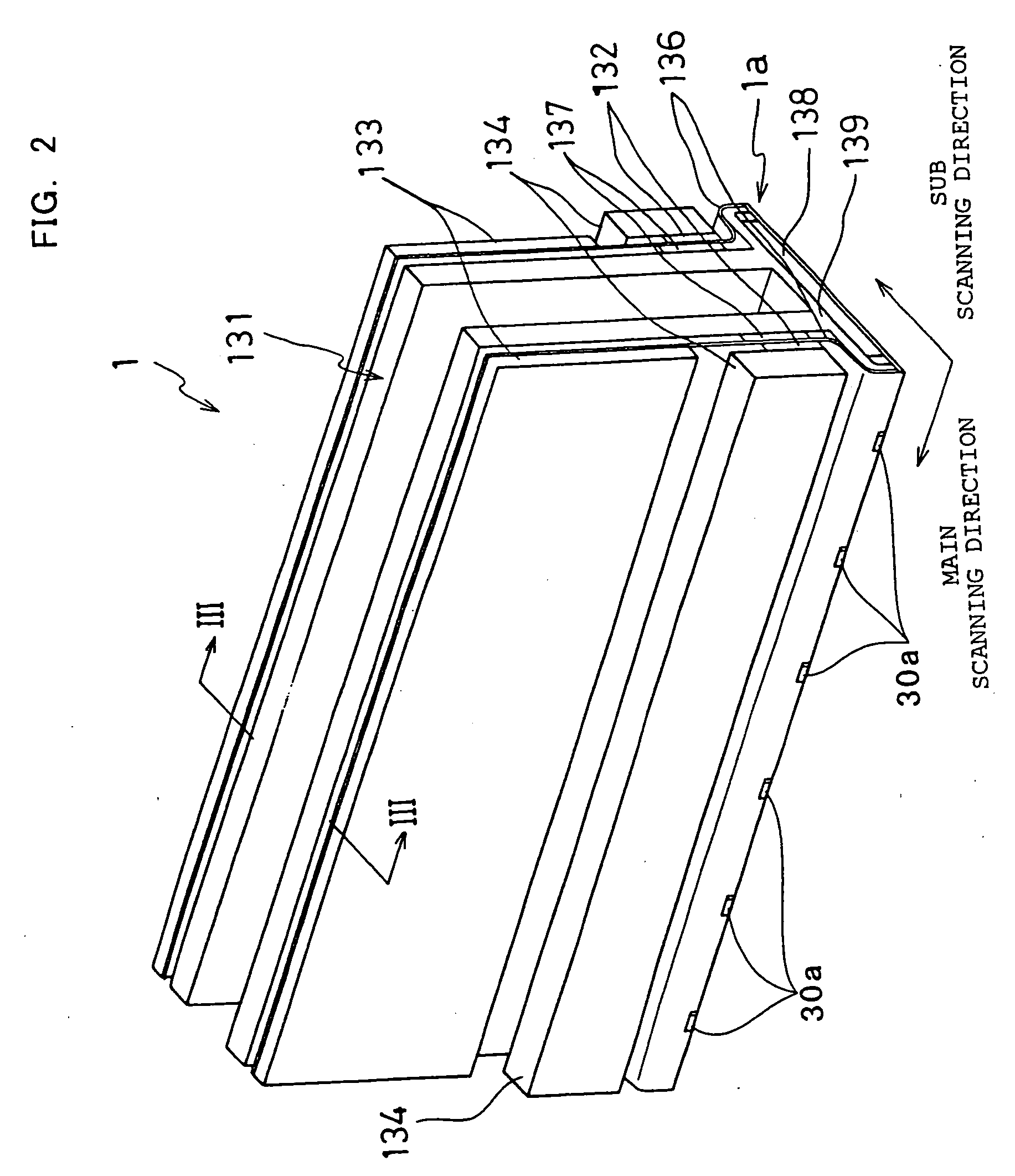

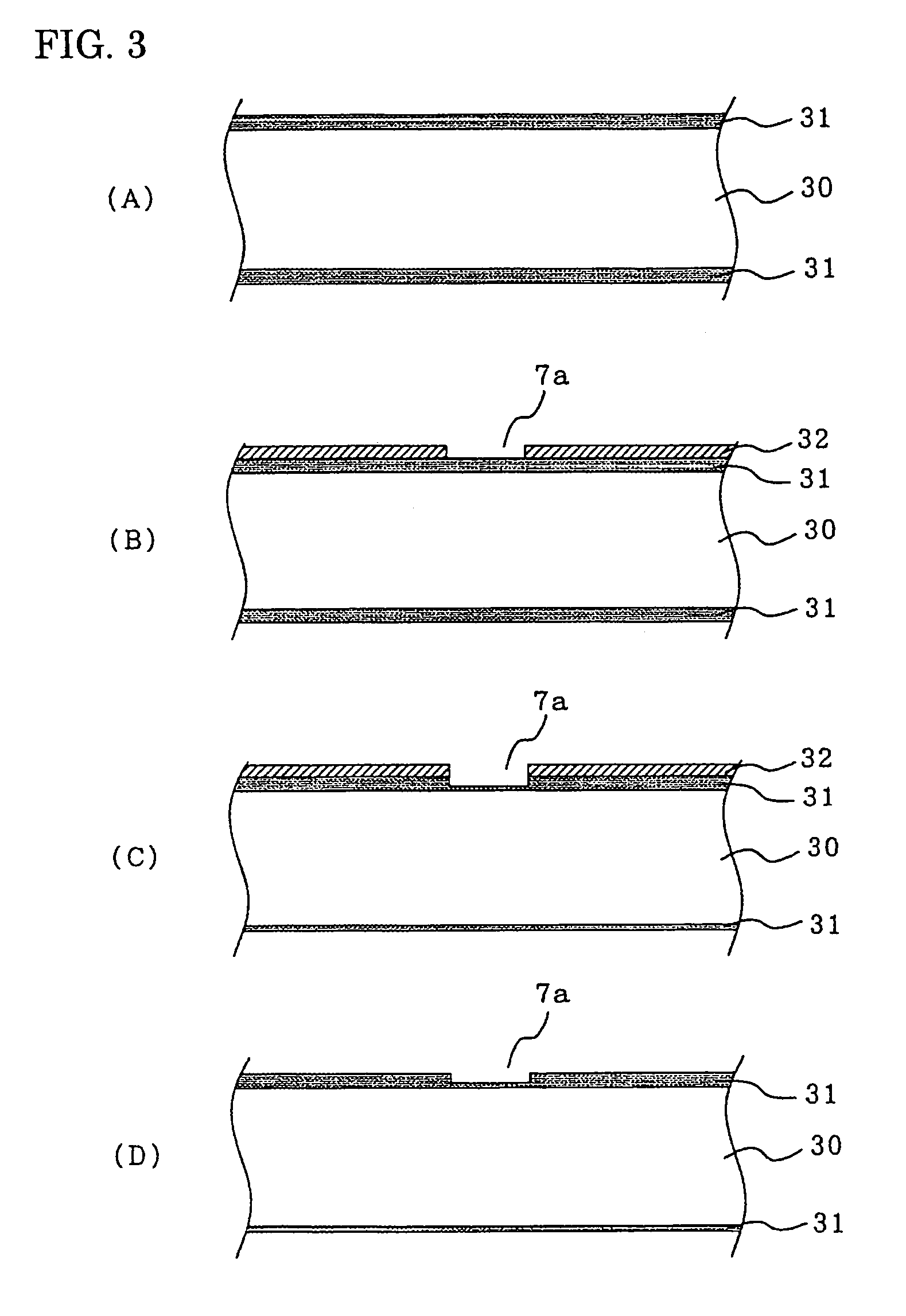

Method for manufacturing droplet ejection head, droplet ejection head, and droplet ejection apparatus

ActiveUS20060118512A1High yieldAvoid crackingRecording apparatusPiezoelectric/electrostrictive device manufacture/assemblySiliconNozzle

A method for manufacturing a droplet ejection head includes a step of forming recessed sections for forming nozzles by etching a first face of a silicon substrate, a step of bonding a support substrate to the first face of the silicon substrate, a step of reducing the thickness of the silicon substrate by processing a second face of the silicon substrate that is opposite to the first face thereof, and a step of removing the support substrate from the silicon substrate after the reduction of the thickness of the silicon substrate. A droplet ejection head manufactured by the method is provided. A droplet ejection apparatus includes the droplet ejection head.

Owner:SEIKO EPSON CORP

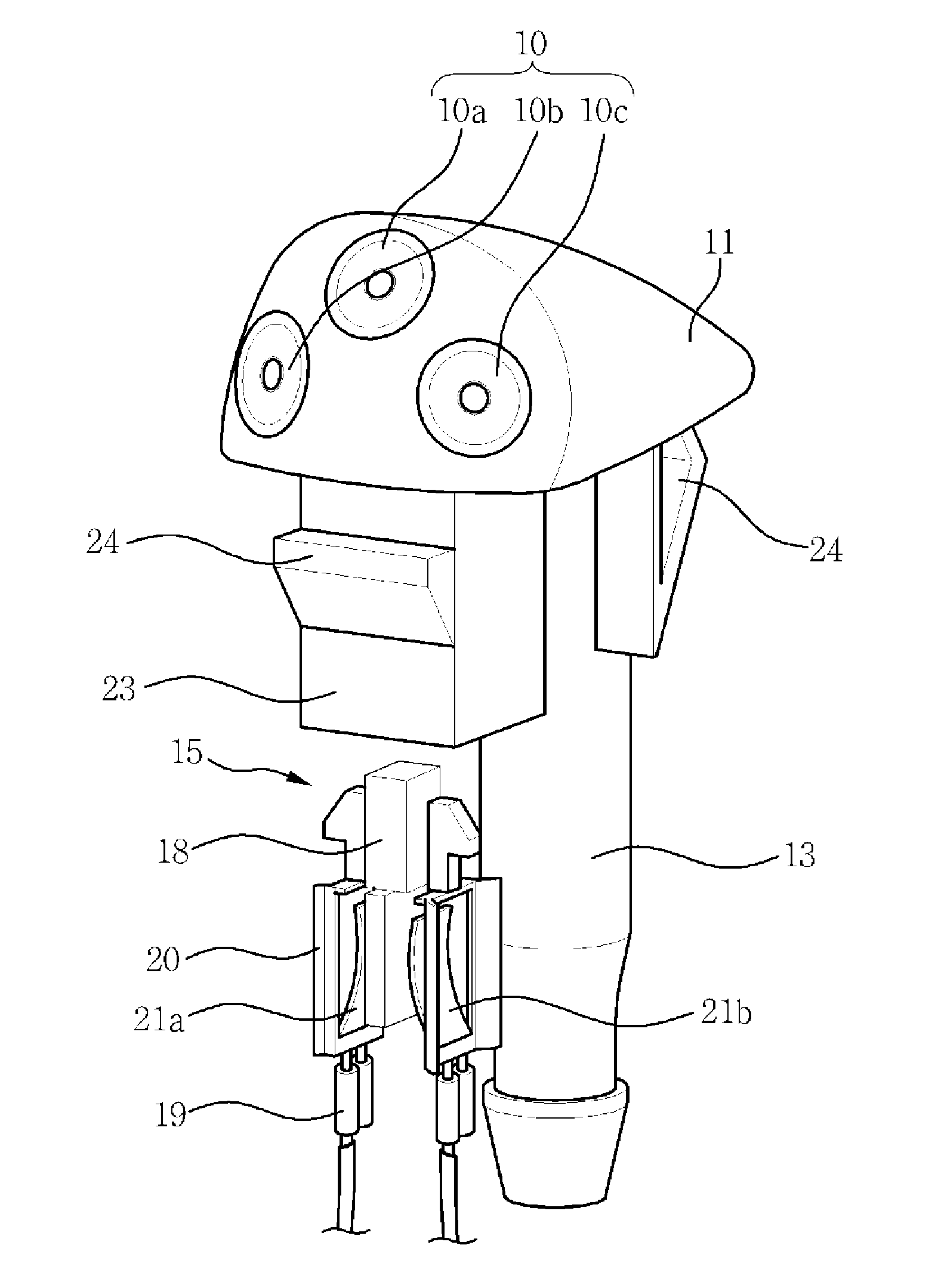

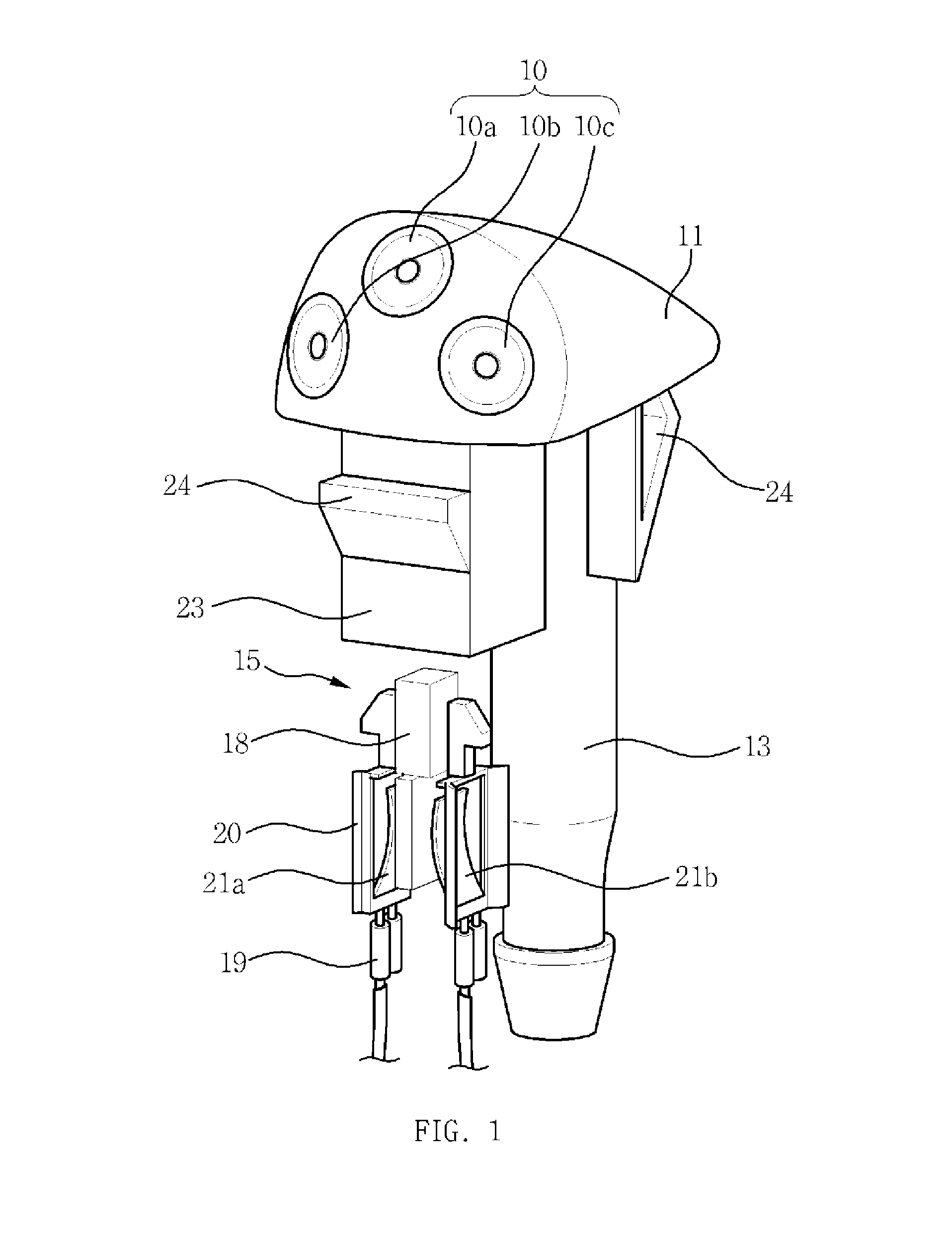

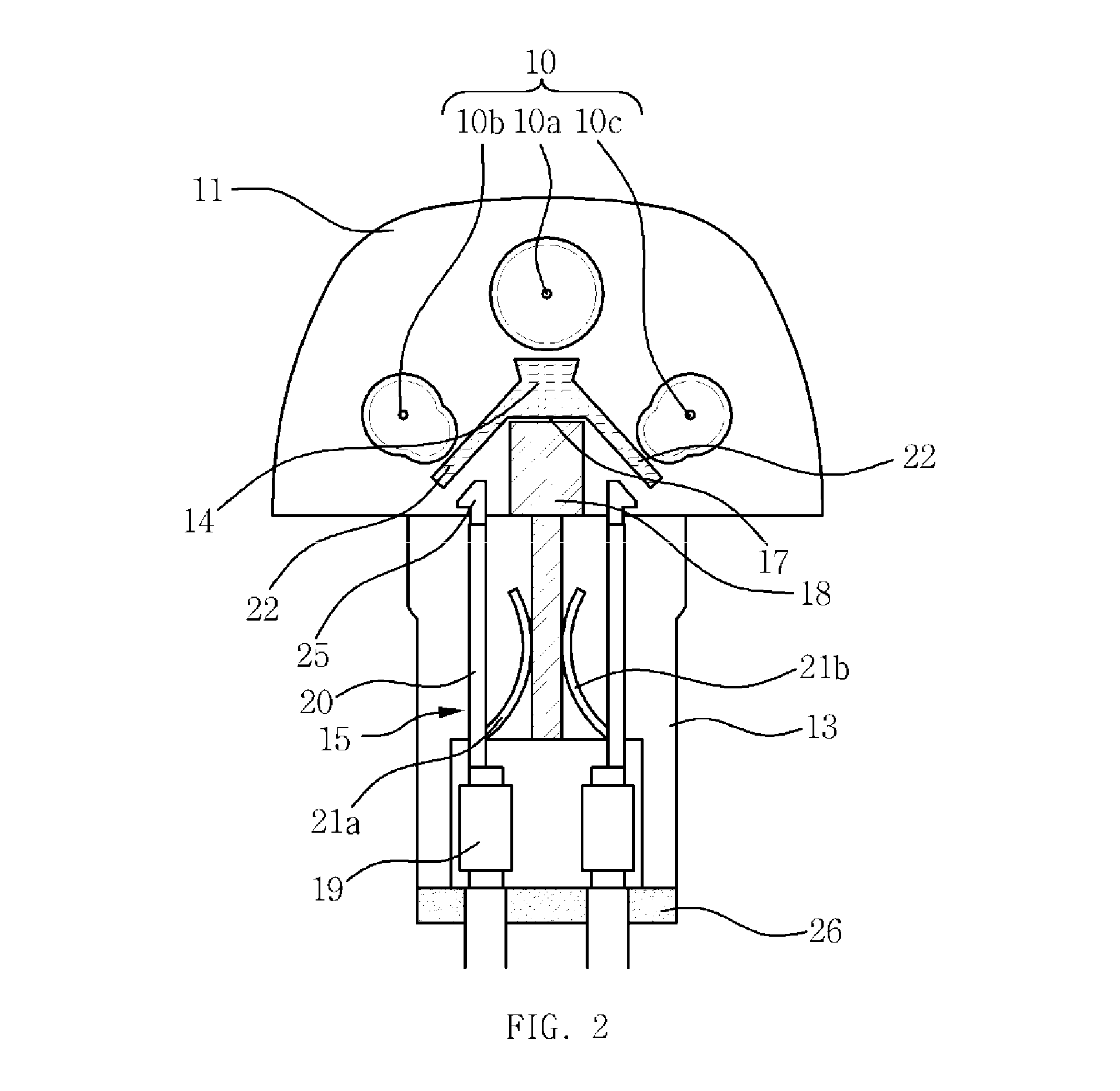

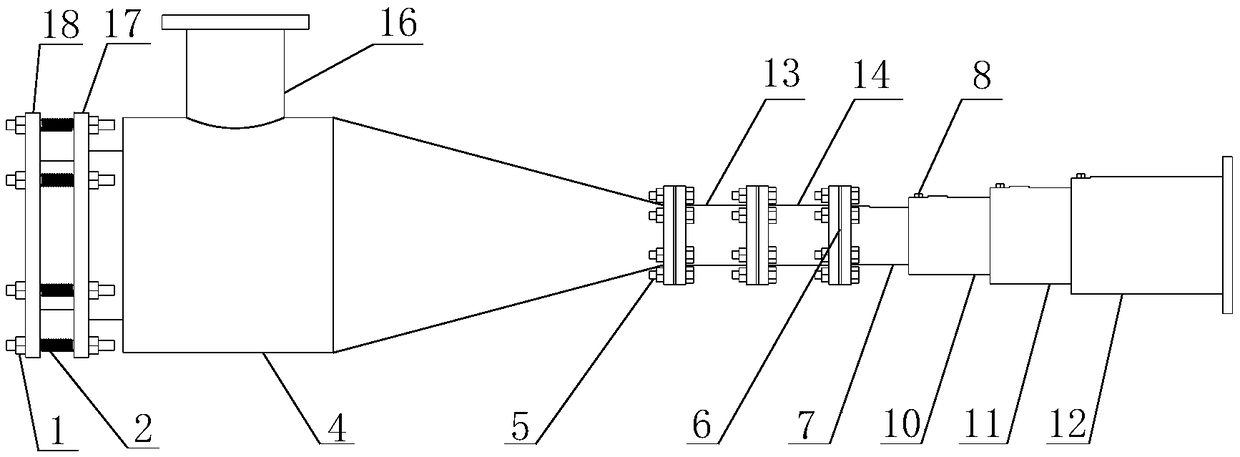

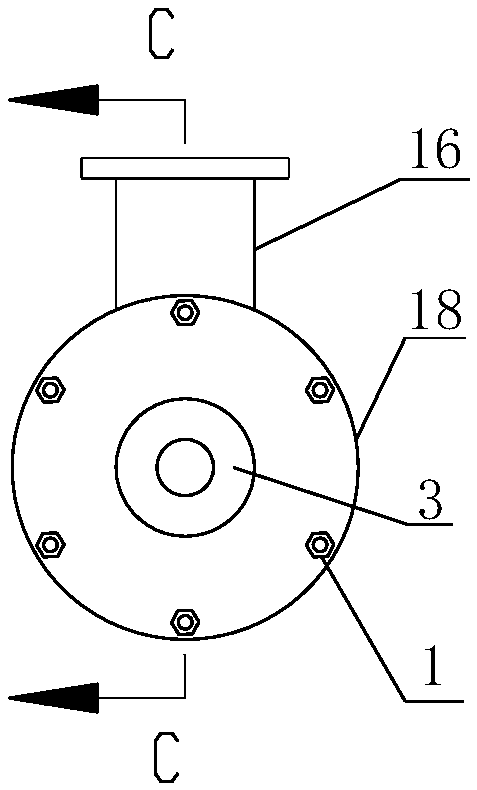

Dual ring ejector

InactiveCN102678634ASpeed up or enhance mixingSolve the problem of low ejection efficiencyJet pumpsMachines/enginesEngineeringInjector

The invention provides to a dual ring ejector, and relates to a fluid pump. An inner ring ejector apparatus is sequentially provided with a central time fluid inlet sleeve, an inner ring nozzle and a center mixing tube along an axle wire, a main stream annular cavity, an outer ring nozzle, an annular mixing room and an annular mixing tube are sequentially arranged on the periphery of the inner ring ejector apparatus along the axle wire by an outer ring ejector apparatus, a main stream inlet tube is communicated with an inner ring nozzle inlet and an outer ring nozzle inlet through the main stream annular cavity, the annular mixing room is communicated with an outer ring stream inlet tube and the annular mixing tube, an outer ring nozzle outlet is convex and protrudes into the annular mixing room and faces to the annular mixing tube, the two outlets of the mixing tubes are jointly communicated with a general mixing output tube, the same main stream is used by the inner ring ejector and the outer ring ejector for pumping time fluid, and after being mixed, the pumped time fluid enters the general mixing output tube for outputting. According to the dual ring ejector, the weight is light, the size in axial direction is small, the absorbing and ejecting rate is high, and the ejector performs well with mass flow and has various structure forms. The main stream can be used for injecting and mixing one or two time fluids, so as to realize output under uniform pressure.

Owner:韩铁夫

Droplet ejecting head

ActiveUS20050285910A1Excellent in ink ejection performanceImprove ejection effectPrintingEngineeringHead parts

A droplet ejecting head including a nozzle plate having nozzle holes each ejecting a droplet and comprising: a jetting end open at a first surface of the plate; an inflow end open at a second surface of the plate; a taper portion between the jetting end and a vicinity of the inflow end, where a diameter of the nozzle hole linearly increases from the jetting end to the vicinity so as to have a taper angle; a connecting portion comprising a surface connecting the taper portion and the inflow end, at the connecting portion the diameter increasing more greatly than at the taper angle; and where D1 and D2 respectively represent the diameter of the nozzle hole at the inflow end and at an imaginary inflow end obtained if the taper portion extends at the taper angle up to the second surface, D2<D1<1.2×D2.

Owner:BROTHER KOGYO KK

Electric plug comprising a plug housing and at least two integrated plug-in contacts with an ejection mechanism

InactiveUS20070155191A1Relieve pressureLarge actionEngagement/disengagement of coupling partsRotary current collectorEngineeringPush out

An electric plug includes a plug housing, at least two incorporated plug-in contacts that are to be inserted into corresponding jacks of an outlet, and a cable feeder. A manually actuated ejection mechanism encompassing a push-out device is disposed in the plug housing. The push-out device cooperates with a spring in such a way that the spring is biased in the plugged-in state of the plug in order to allow the plug to be automatically removed from the outlet by means of the push-out device when the ejection mechanism is actuated. In order to actuate the ejection mechanism, the same is automatically triggered by pulling on the cable, the tensile force being effective on a strain relief device for the cable, which is located in the plug housing and cooperates with triggering device for actuating the spring-biased push-out device.

Owner:MIELE & CO KG

Washer nozzle for vehicle

ActiveUS20140042243A1Improve performanceImprove heat transfer performanceLiquid surface applicatorsSpray nozzlesElectrical conductorHeat transfer efficiency

A washer nozzle includes a heat emitting unit for smoothly washing a glass in a winter season is installed. The washer nozzle for a vehicle which, by realizing a new type of washer nozzle to which an integral structure of a heat conductor and a nozzle cover is applied through insert injection-molding of the heat conductor is applied and to which a structure where a heat emitter is firmly fastened to the housing by using a structure in the housing is applied, can improve a washer liquid ejecting performance through an increase in a heat transfer efficiency inside the nozzle and reduce the number of processes and a defect rate through fixing of the heat emitter at an optimum location, thereby improving quality.

Owner:HYUNDAI MOTOR CO LTD

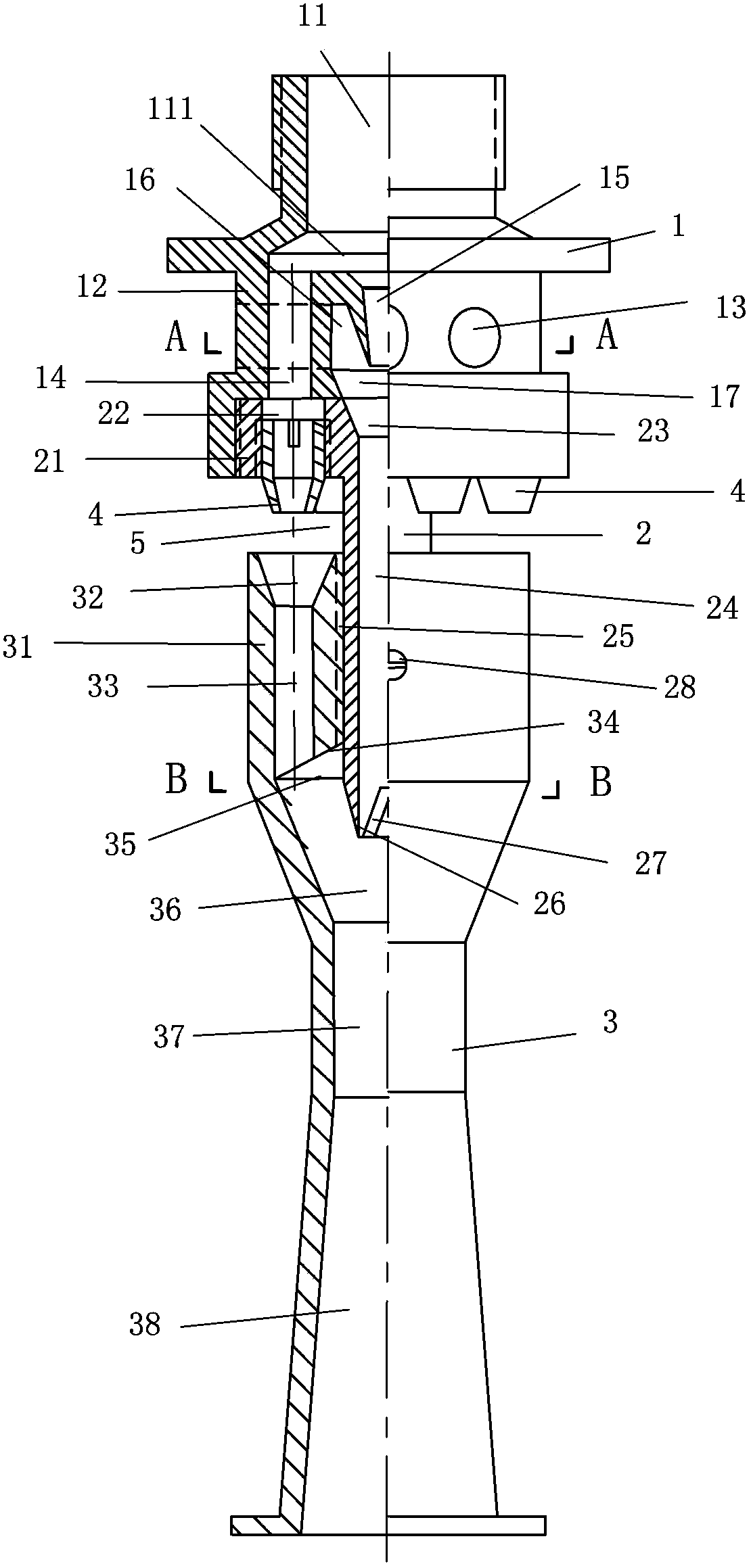

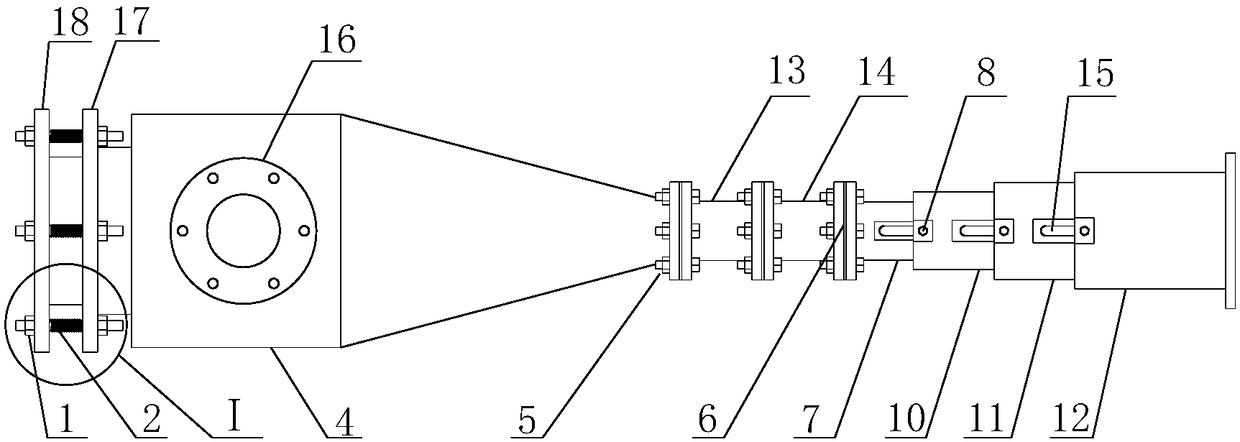

Multiplex compound ejector

InactiveCN103423215APrevent failbackShorten the lengthJet pumpsPositive-displacement liquid enginesMixed flowButt joint

The invention relates to a mixed flow injection device, in particular to a multiplex compound ejector which comprises a forestage compound annular ejector, a middle ejector and a rear-stage main ejector. The middle ejector is coaxially arranged in the compound annular ejector, incoming ends of the middle ejector and the compound annular ejector share a main fluid inlet pipe, and the main ejector is arranged behind the compound annular ejector and the middle ejector and concentrically connected with the compound annular ejector and the middle ejector in series to achieve integral butt joint. The multiplex compound ejector solves the technical problem that the existing ejector is simple in structure, low in ejection efficiency and insufficient in flow, and is compact in size, light in weight, high in volley rate and good in perform during mass flow.

Owner:韩铁夫 +1

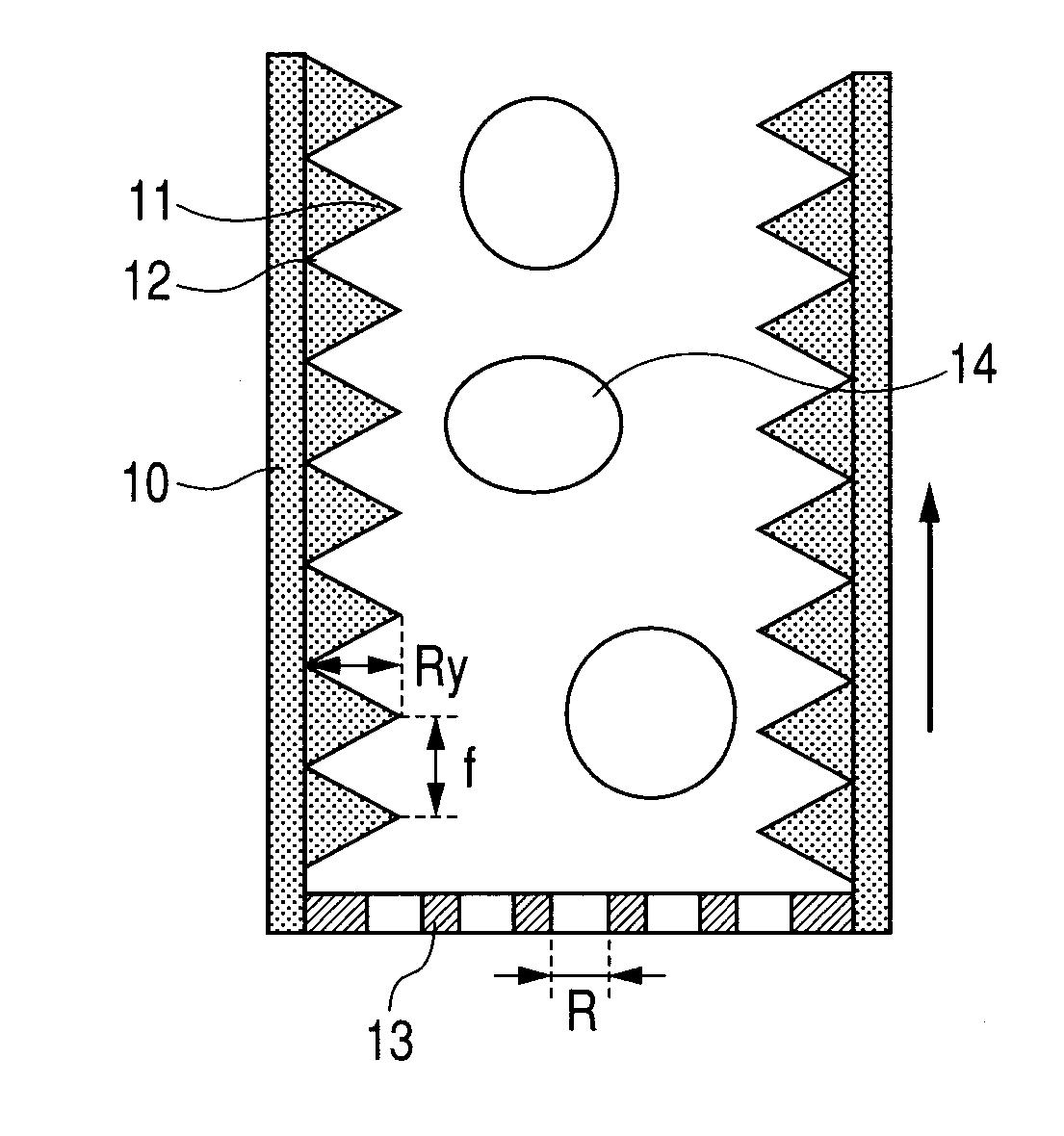

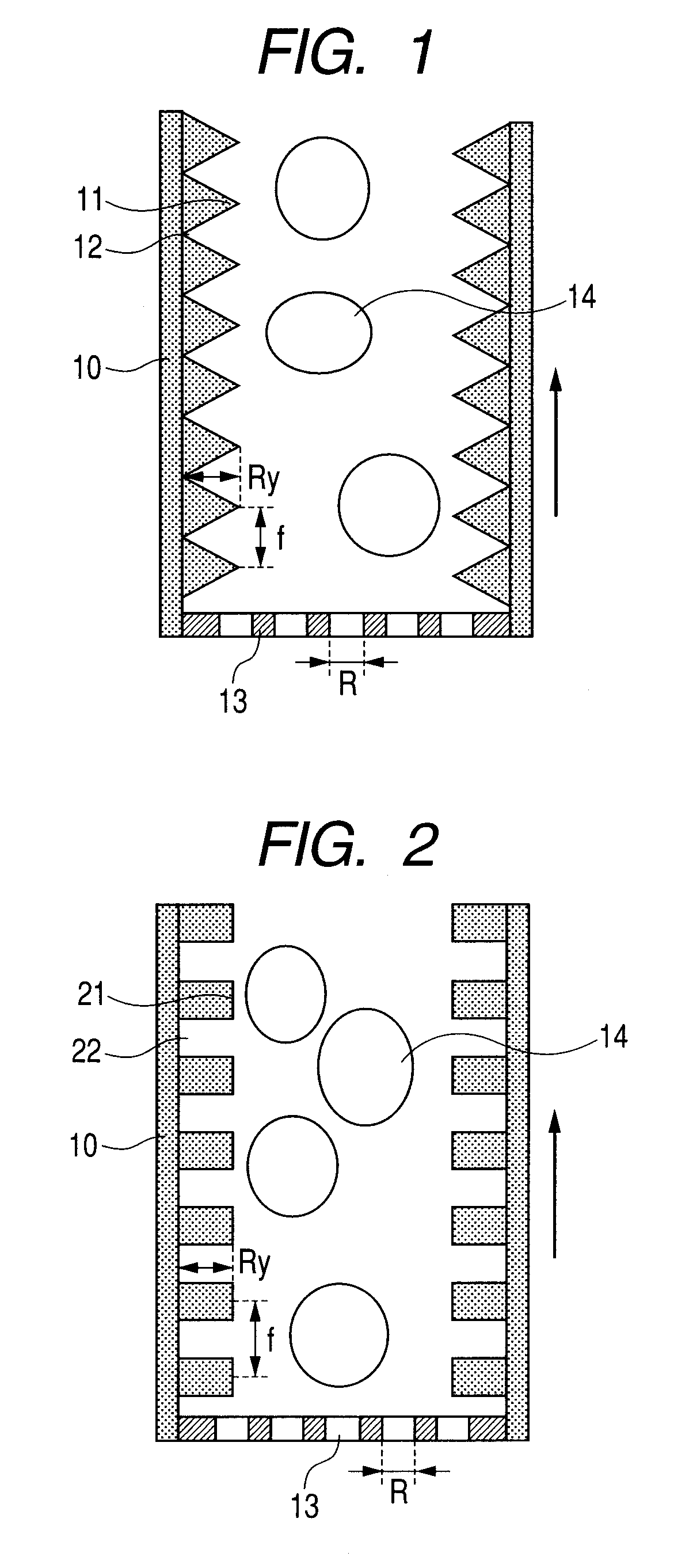

Liquid supplying member, negative pressure unit, and liquid discharging apparatus

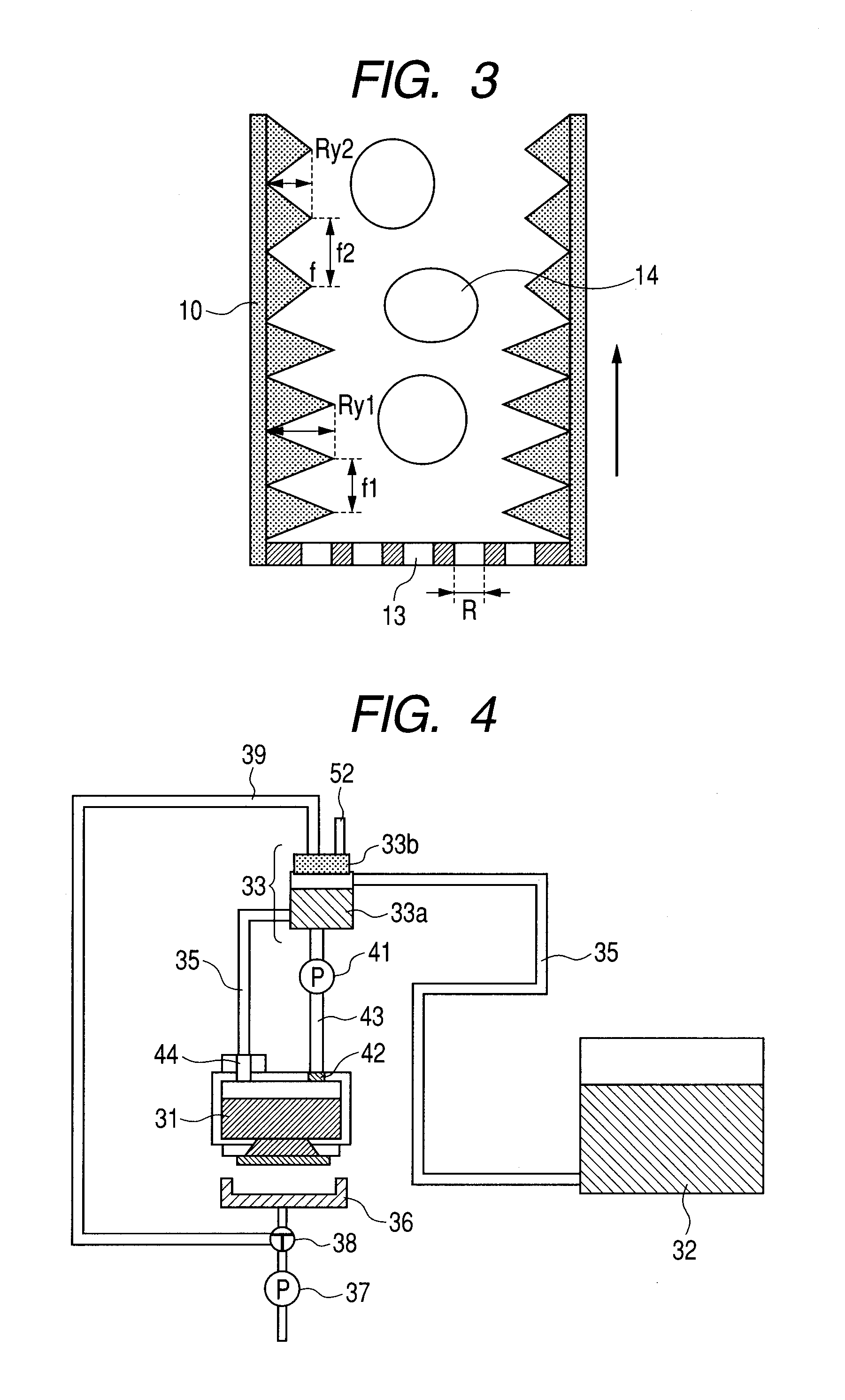

InactiveUS20100282342A1Improve ejection effectAvoid depositionLarge containersService pipe systemsEngineeringSpatial frequency

A deposition of bubbles or foams to an inner wall of a liquid supplying member is prevented, thereby improving ejecting performance of the bubbles or foams. In the liquid supplying member which forms a flow path for supplying a liquid to a liquid discharging apparatus, the inner wall surface has a concave / convex shape in which a mountain portion and a valley portion are repeated at a predetermined spatial frequency. Assuming that an opening diameter of a filter provided for the liquid discharging apparatus is equal to R (μm), one period f (μm) of the spatial frequency lies within a range from R or more to √{square root over (2)}·R or less and a maximum height Ry (μm) of the mountain portion is equal to √{square root over (2)}·R / 2 or more.

Owner:CANON KK

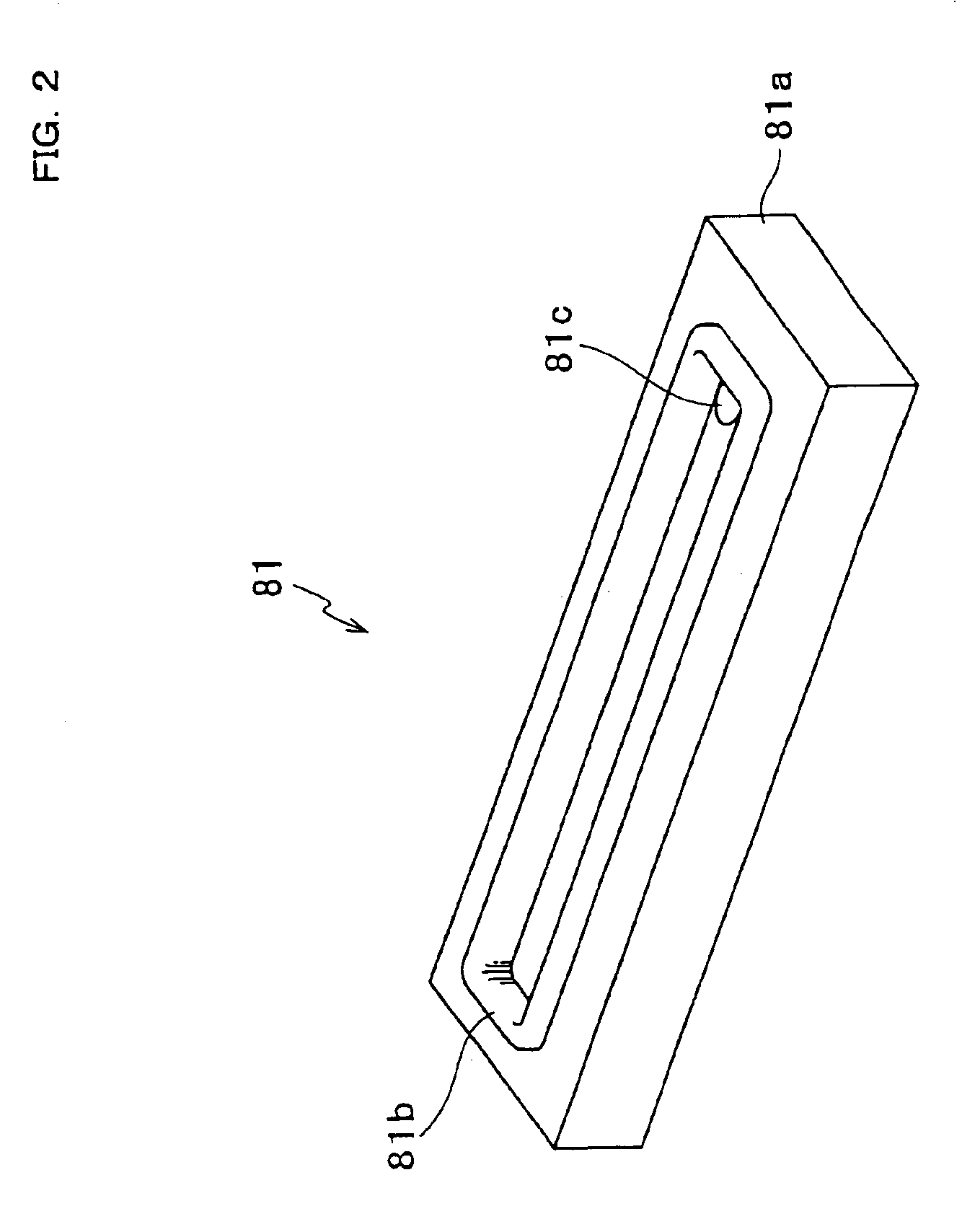

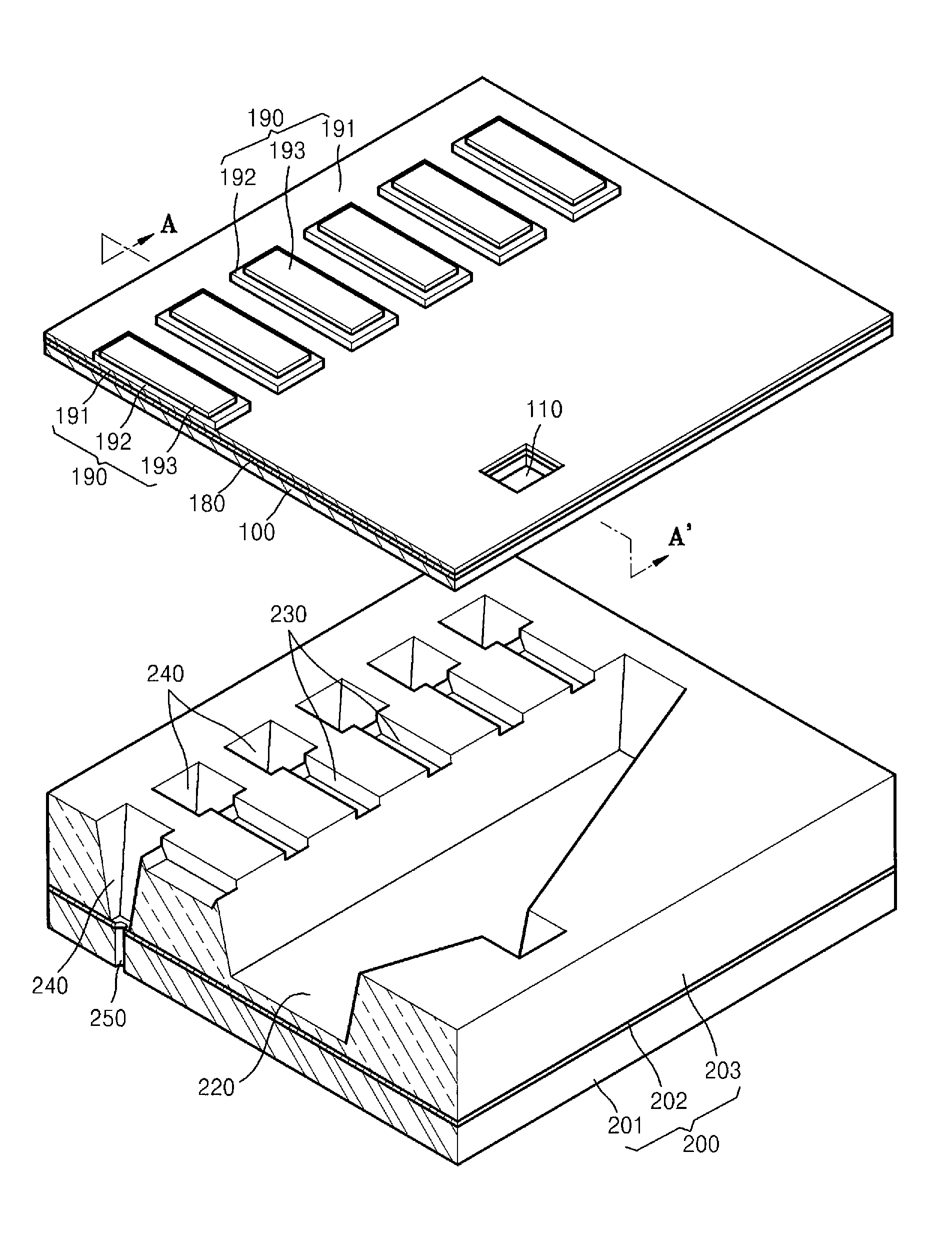

Ink-jet head having passage unit and actuator units attached to the passage unit, and ink-jet printer having the ink-jet head

InactiveUS6953241B2Increase in positional shiftPrecise positioningInking apparatusPressure generationActuator

An ink-jet head having a passage unit including pressure chambers each having one end coupled to a nozzle and the other end to be coupled to an ink supply source. The pressure chambers are arranged along a plane to neighbor each other. The ink-jet head further includes actuator units attached to a surface of the passage unit for changing the volume of each pressure chamber. Each actuator unit includes pressure generation portions respectively corresponding to pressure chambers, and is formed to extend over the pressure chambers. The actuator units are arranged along the longitudinal direction of the passage unit so that each neighboring actuator units partially overlap each other in the lateral direction of the passage unit. Each actuator unit has a basic region where many pressure generation portions are formed in a matrix, and an additional region neighboring the basic region in the lateral direction of the passage unit. In the additional region, pressure generation portions are formed to correspond to a gap portion between the pressure generation portions in the basic region of the actuator unit and the pressure generation portions in the basic region of another actuator unit neighboring that actuator unit.

Owner:BROTHER KOGYO KK

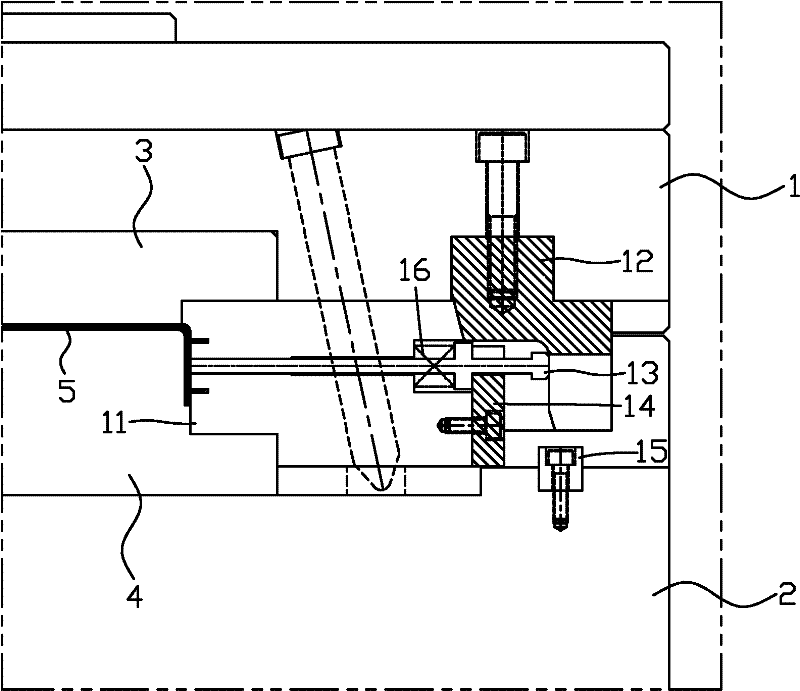

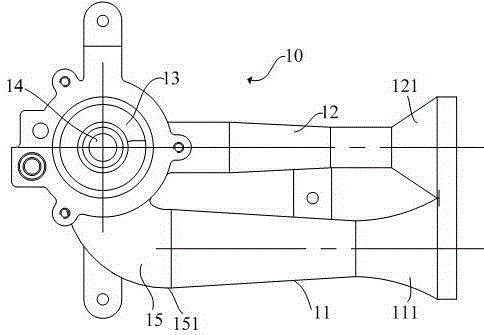

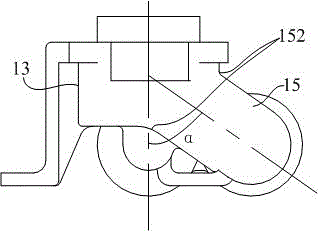

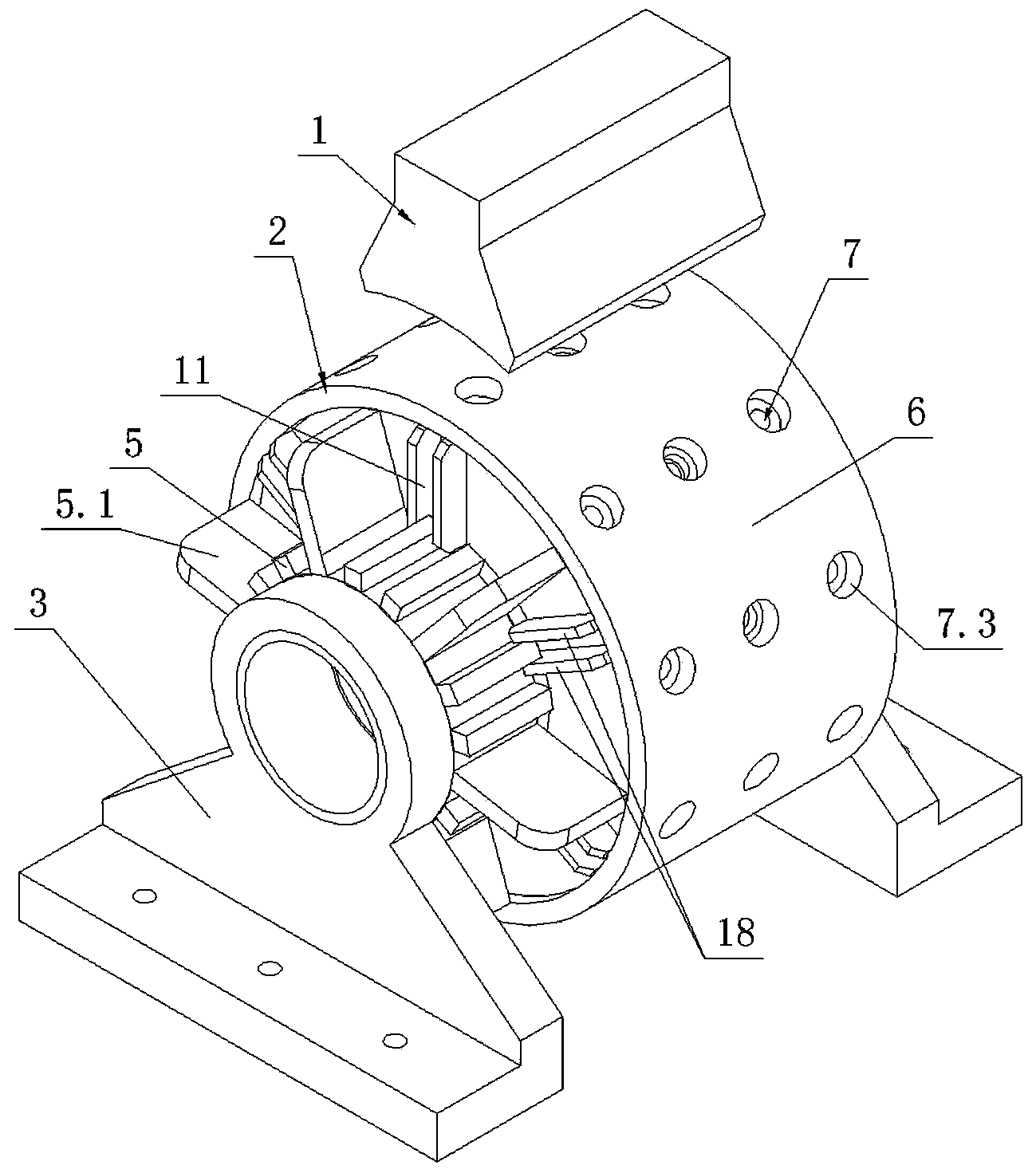

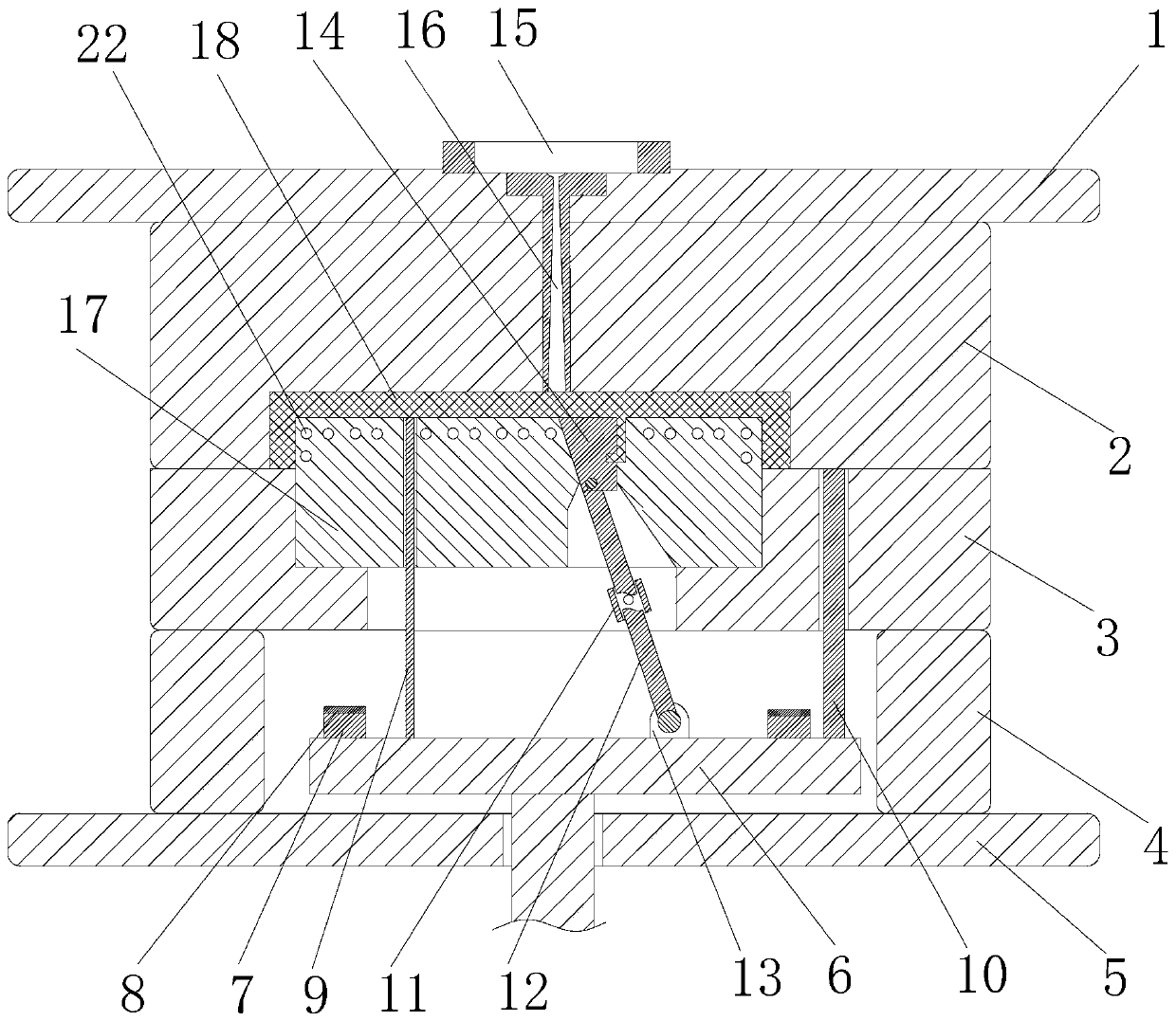

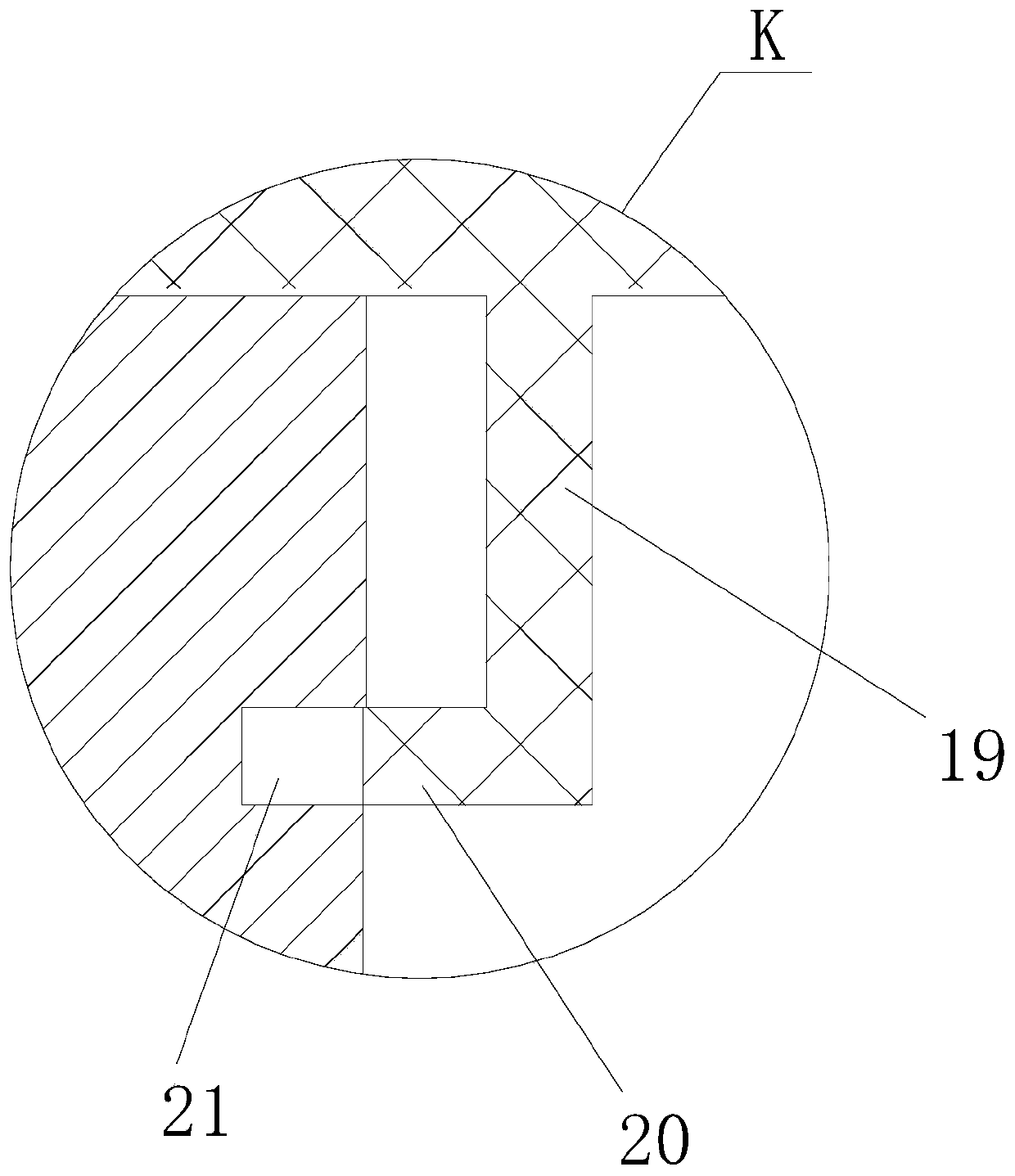

Die possessing twice exit mode slide block

The invention provides a die possessing a twice exit mode slide block which is used for injection moulding of a product. The die comprises a female template, a male template, a female mold core and a male mold core, the die comprises an inclined guide pillar, a slide block body and a slide block pin. The slide block pin is placed in a groove of the slide block body, and the clearance amount between the slide block body and the inclined guide pillar is larger than the clearance amount between the slide block pin and the inclined guide pillar, the inclined guide pillar drives the slide block pin to move for certain distance when die-opening, thereby the inclined guide pillar is contacted with the slide block body, then the inclined guide pillar drives the slide block body to move for exiting the product. According to the invention, the die possessing twice exit mode slide block forms a twice exit mode through relative movement of the slide block body and the slide block pin. The product has good ejection effect, and the product has no ejector pin mark after being ejected.

Owner:MITAC PRECISION TECH(KUNSHAN) CORP

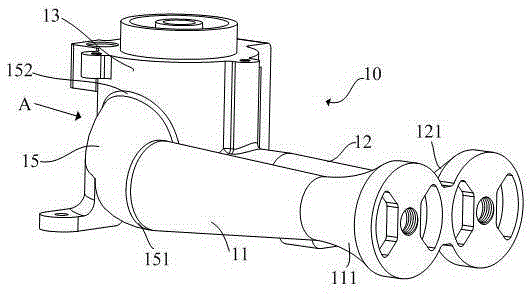

Burner, combustor and gas stove

The invention provides a burner, a combustor and a gas stove. The burner comprises a main ejection pipe, a sub ejection pipe, a main mixing cavity and a sub mixing cavity, wherein the sub mixing cavity and the main mixing cavity are coaxially arranged; the main ejection pipe and the sub ejection pipe are positioned at the outer part of the main mixing cavity; the axis of the sub ejection pipe and the axis of the sub mixing cavity are in the same plane, and the sub ejection pipe is positioned below the main mixing cavity; a main ejection transition pipe is connected between the main ejection pipe and the main mixing cavity; and the main ejection transition pipe is an oblique pipe oblique upwards from the connection end of the main ejection transition pipe and the main ejection pipe to the connection end of the main ejection transition pipe and the main mixing cavity. According to the burner, the resistance to air flow can be greatly reduced, the ejection effect is improved, the combustion efficiency is improved, and the flue gas emission is reduced; through the adoption of a combustor with the burner and a gas stove, the ejection effect can be further improved, the combustion efficiency is improved, and the glue gas is reduced.

Owner:GUANGDONG HISENSE HOME APPLIANCES CO LTD

Ink and ink jet recording method

InactiveUS7926931B2Improve ejection effectEnhance the imageMeasurement apparatus componentsDuplicating/marking methodsThermal energyLiquid medium

An ink used in an ink jet recording method in which ink droplets are ejected from a recording head by the action of thermal energy to record an image on a recording medium; the ink being characterized by containing (a) a pigment, (b) a dispersing agent, (c) a liquid medium, (d) a polyglycerol and (e) at least one selected from a potassium salt of a carboxylic acid, a rubidium salt of a carboxylic acid and a cesium salt of a carboxylic acid.

Owner:CANON KK

Method of forming a hydrophobic coating layer on a surface of a nozzle plate for an ink-jet printhead

InactiveUS7329363B2Improve ejection effectImprove printing qualityRecording apparatusDecorative surface effectsSulfurMetal

A method of forming a hydrophobic coating layer on a surface of a nozzle plate for an ink-jet printhead includes preparing a nozzle plate having a nozzle, forming a metal layer on a surface of the nozzle plate, forming a material layer covering the metal layer, selectively etching the material layer to expose a portion of the metal layer formed on an outer surface of the nozzle plate, and forming the hydrophobic coating layer of a sulfur compound on the exposed portion of the metal layer by dipping the nozzle plate in a sulfur compound-containing solution.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

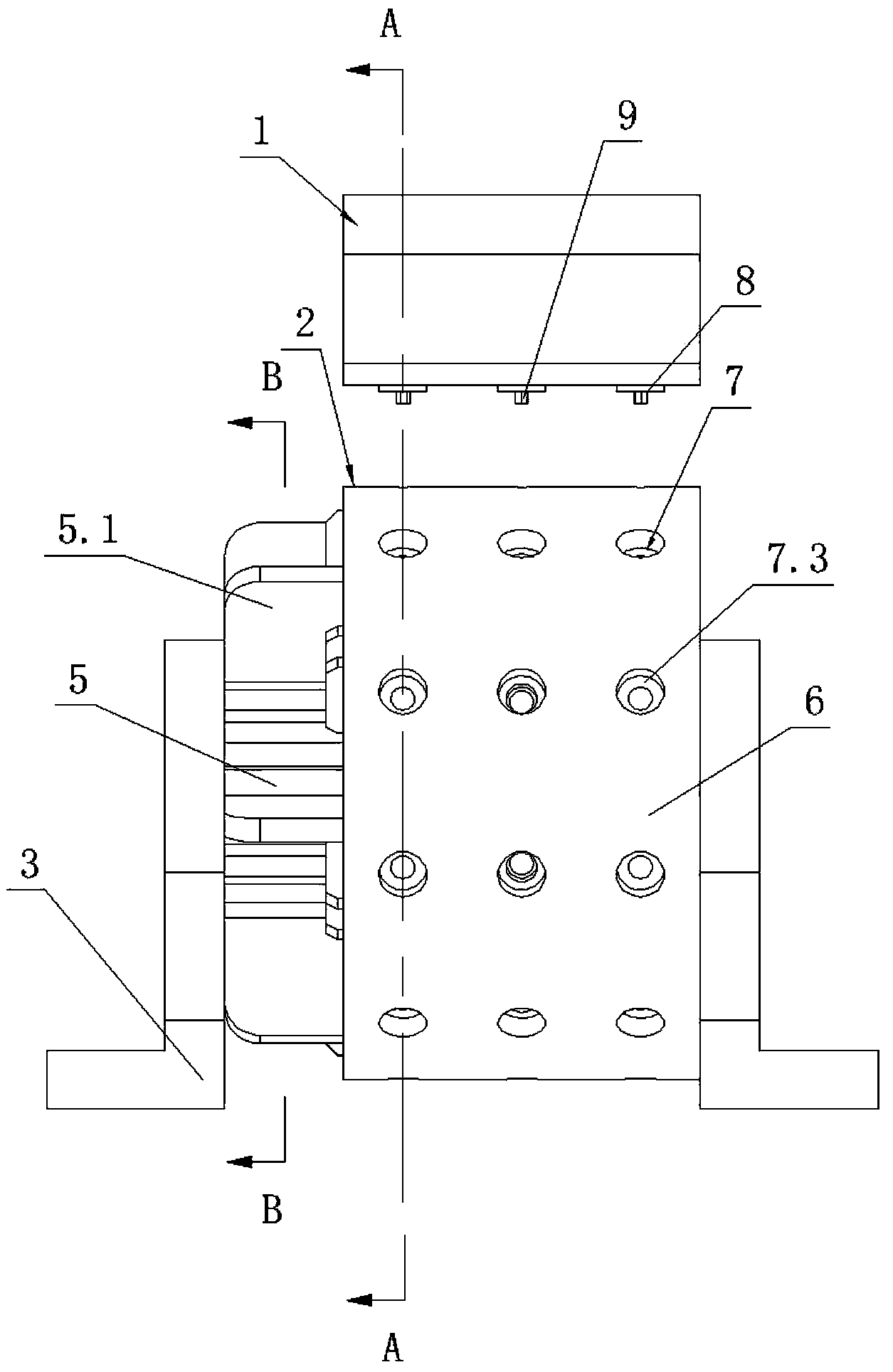

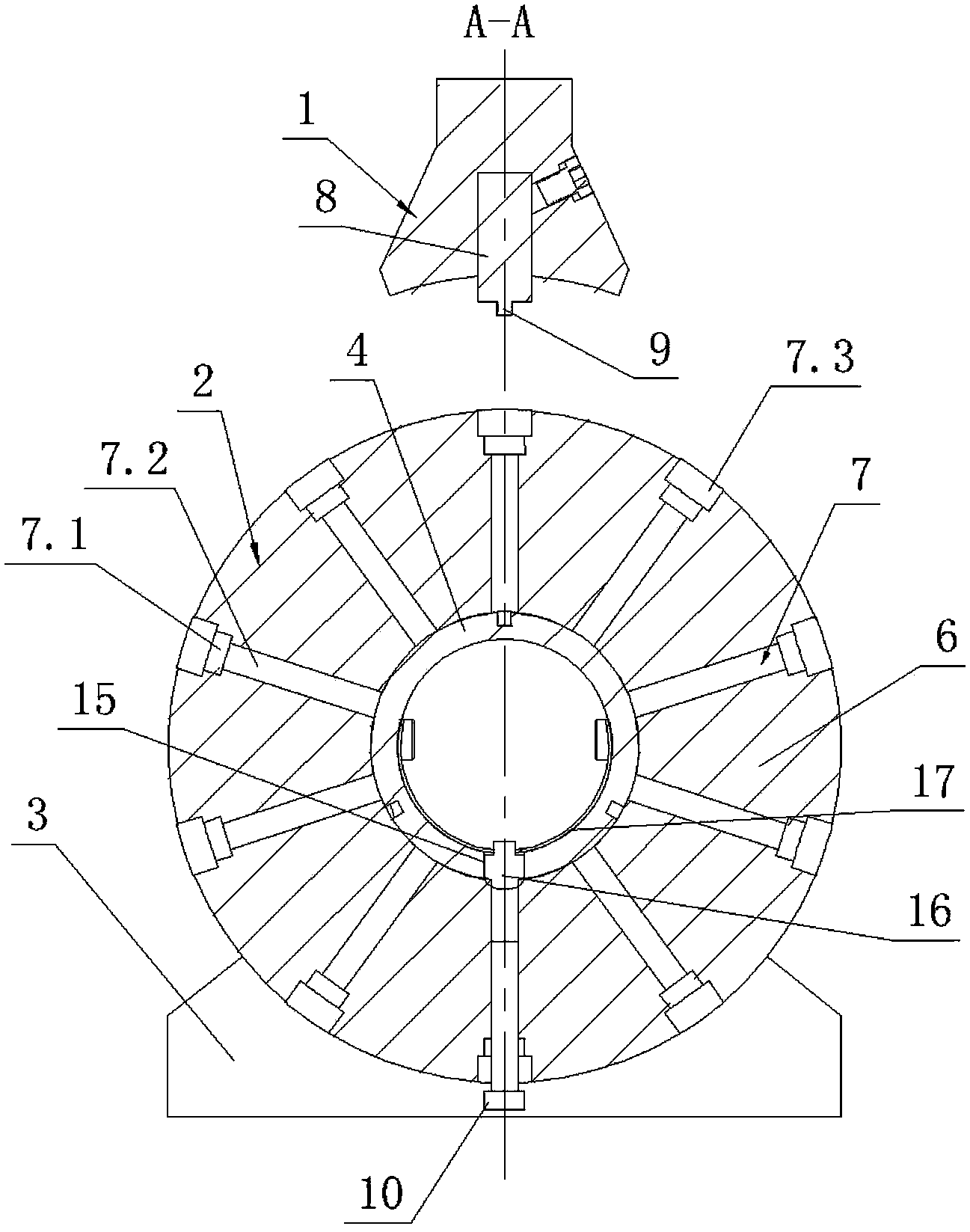

Punching die

InactiveCN103480732AShort tripPut an end to the safety hazard of smashing and injuring people's handsShaping toolsNutsPunchingGear wheel

The invention discloses a punching die, which comprises a punch (1) and a die shell (2), wherein the die shell (2) comprises two supports (3), a rotating shaft (4), a shifting gear and a rotating barrel (6), the two ends of the rotating shaft (4) are fixed with the two supports (3), the shifting gear and the rotating shaft (4) are registered, a ratchet gear is arranged between the shifting gear and the rotating shaft (4), the rotating barrel (6) is rotatably registered on the rotating shaft (4), a plurality of radial through holes (7) are formed in the rotating barrel (6), the outer openings of the radial through holes (7) are arrayed in the outer circumferential surface of the rotating barrel (6) in rows along the axial direction, the punch (1) is provided with a plurality of rams (8), all of the row of rams (8) are over against the row of radial through holes (7) on the highest position of the rotating barrel (6), and the rotating shaft (4) is also provided with a device for releasing a punching forming screw (10) from the radial through holes (7) in an ejecting manner. The punching die enables the speed of a punching process to be high, the efficiency is high, and safety and convenience are realized.

Owner:TAIZHOU XINGYU SPORTS TACKLE

Ink and ink jet recording method

InactiveUS20080260948A1Improve ejection effectHigh fastnessMeasurement apparatus componentsDuplicating/marking methodsThermal energyLiquid medium

An ink used in an ink jet recording method in which ink droplets are ejected from a recording head by the action of thermal energy to record an image on a recording medium; the ink being characterized by containing (a) a pigment, (b) a dispersing agent, (c) a liquid medium, (d) a polyglycerol and (e) at least one selected from a potassium salt of a carboxylic acid, a rubidium salt of a carboxylic acid and a cesium salt of a carboxylic acid.

Owner:CANON KK

Ejector with adjustable structure parameters

InactiveCN108266411ASatisfy the requirements of injector performanceGood energy saving effectJet pumpsFluid removalThree stageEngineering

The invention relates to an ejector with adjustable structure parameters. The ejector comprises a working nozzle, a low-pressure air inlet chamber, a straight pipe section, a diffusion chamber and a low-pressure air inlet chamber inlet pipeline. The diffusion chamber is formed by nesting three stages of diffusion pipes, so that a structure of the diffusion chamber can be changed through adjustingrelative positions of the diffusion pipes. The straight pipe section is formed by a basic straight pipe section and two stages of detachable straight pipe sections, so that the length of the straightpipe section can be adjusted through disassembling or installing detachable parts. A low-pressure air inlet chamber wheel disc and a working nozzle wheel disc are connected with the low-pressure air inlet chamber and the working nozzle into a whole; and during assembling, a main body of the working nozzle stretches into the low-pressure air inlet chamber, and a distance between the low-pressure air inlet chamber wheel disc and the working nozzle wheel disc is changed through adjusting an adjustable bolt, so that an outlet position of the working nozzle is adjusted. According to the ejector with the adjustable structure parameters provided by the invention, the structure parameters of the ejector can be correspondingly adjusted according to the change of an operation condition, so that an ejecting performance of the ejector under varying duty operation situations such as natural gas extraction is improved.

Owner:苟千舟

Piezoelectric inkjet printhead and method of manufacturing the same

InactiveUS7695118B2Simple manufacturing processImprove ejection effectPrintingSoi substrateDry etching

A piezoelectric inkjet printhead including an upper substrate formed of a single crystal silicon substrate or an SOI substrate and having an ink inlet therethrough, and a lower substrate formed of an SOI substrate having a sequentially stacked structure with a first silicon layer, an intervening oxide layer, and a second silicon layer in which a manifold, pressure chambers, and dampers are formed in the second silicon layer by wet or dry etching, and nozzles are formed through the intervening oxide layer and the first silicon layer by dry etching, and a method of manufacturing the same.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

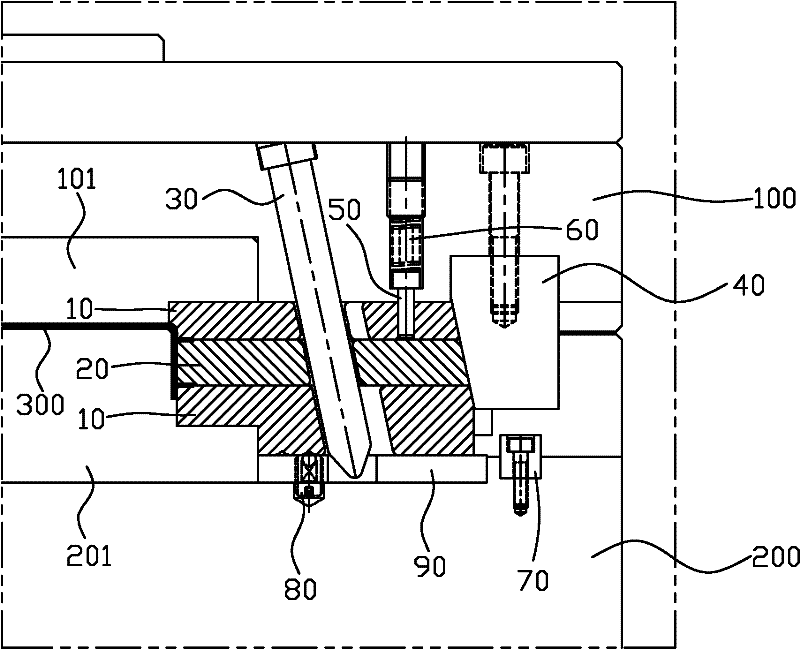

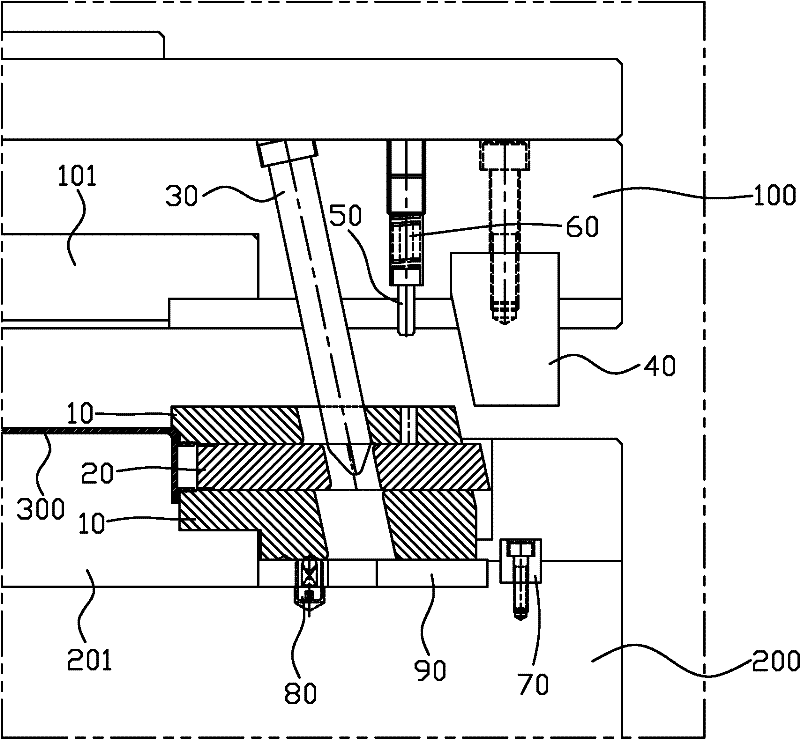

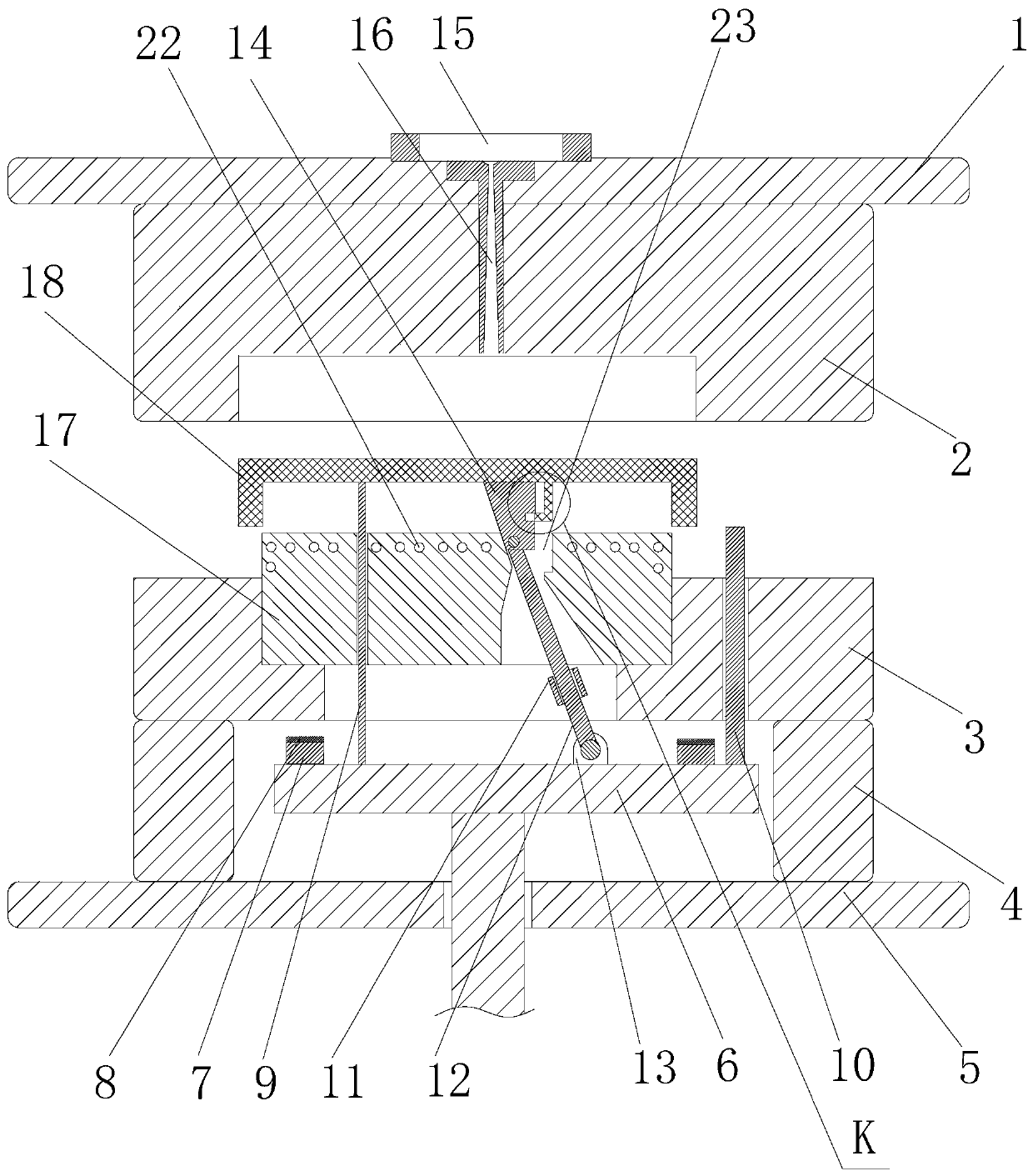

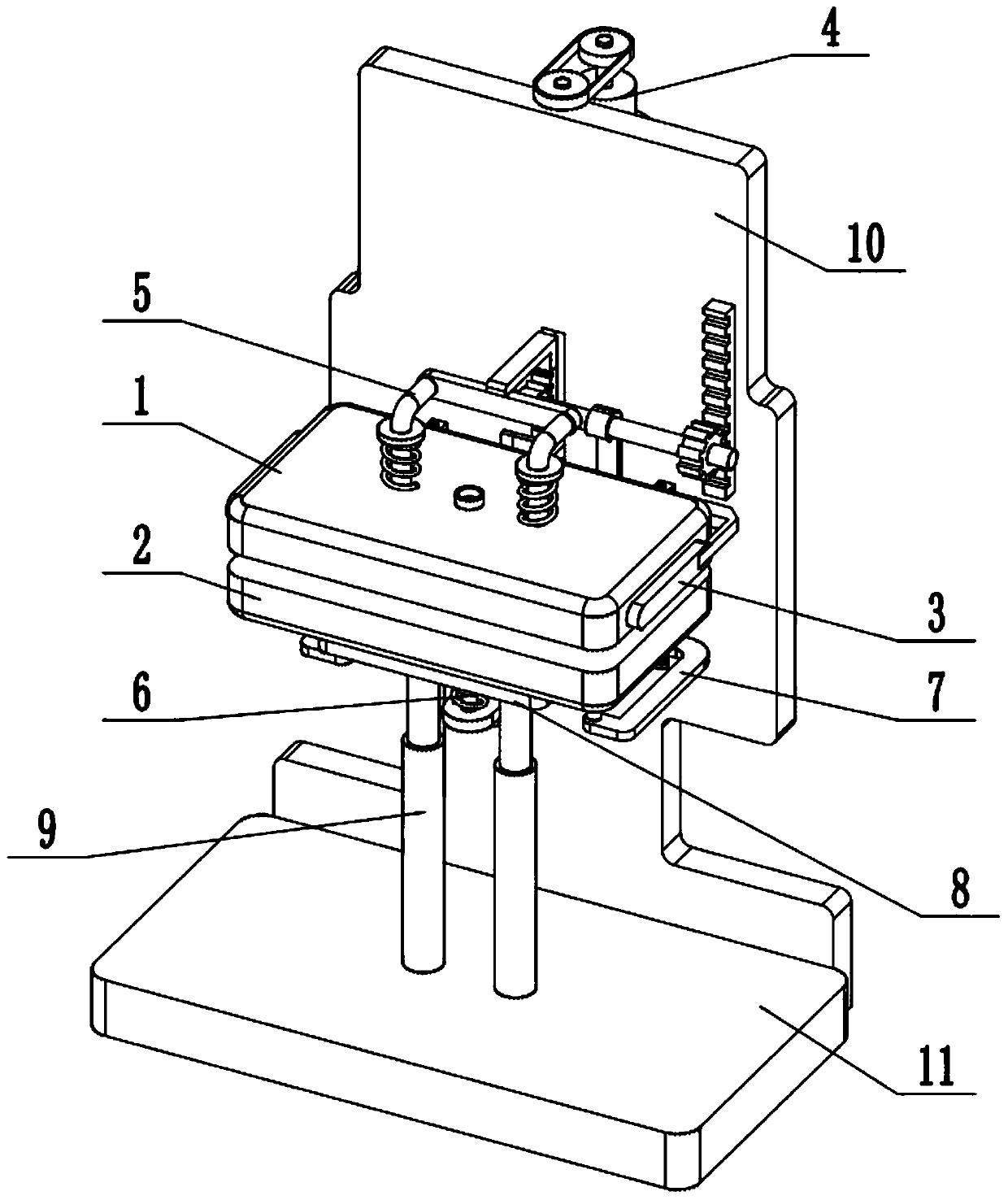

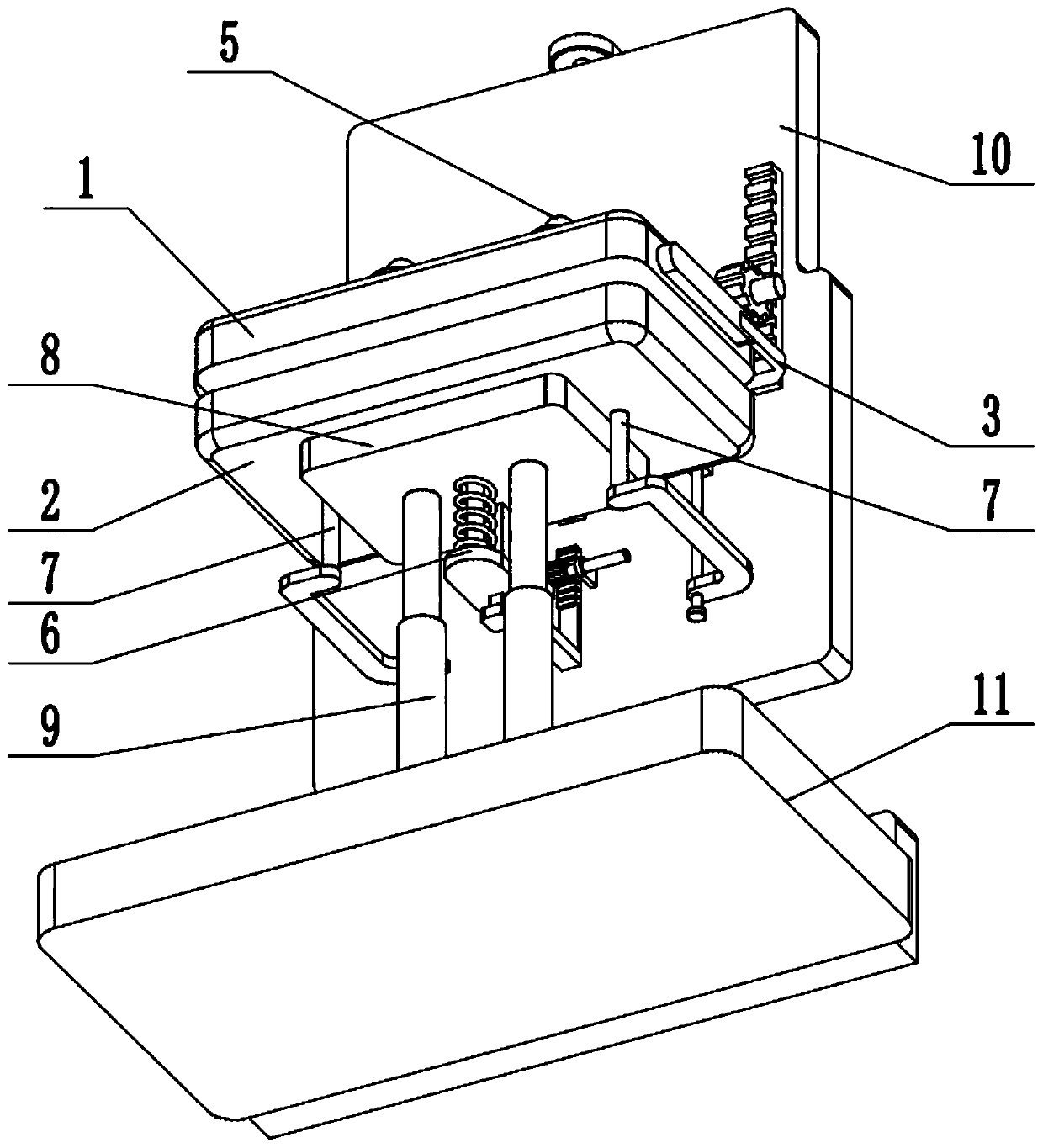

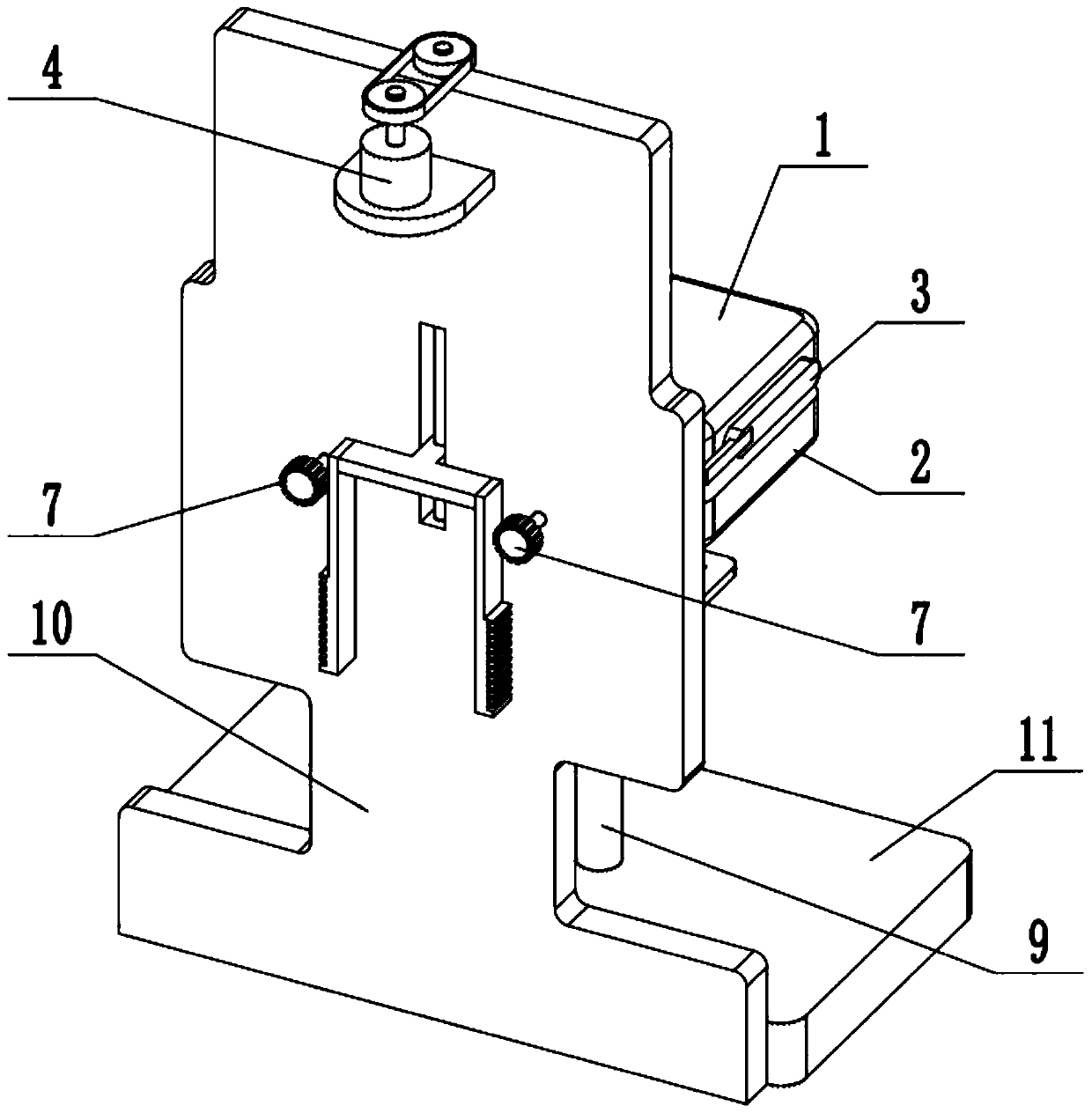

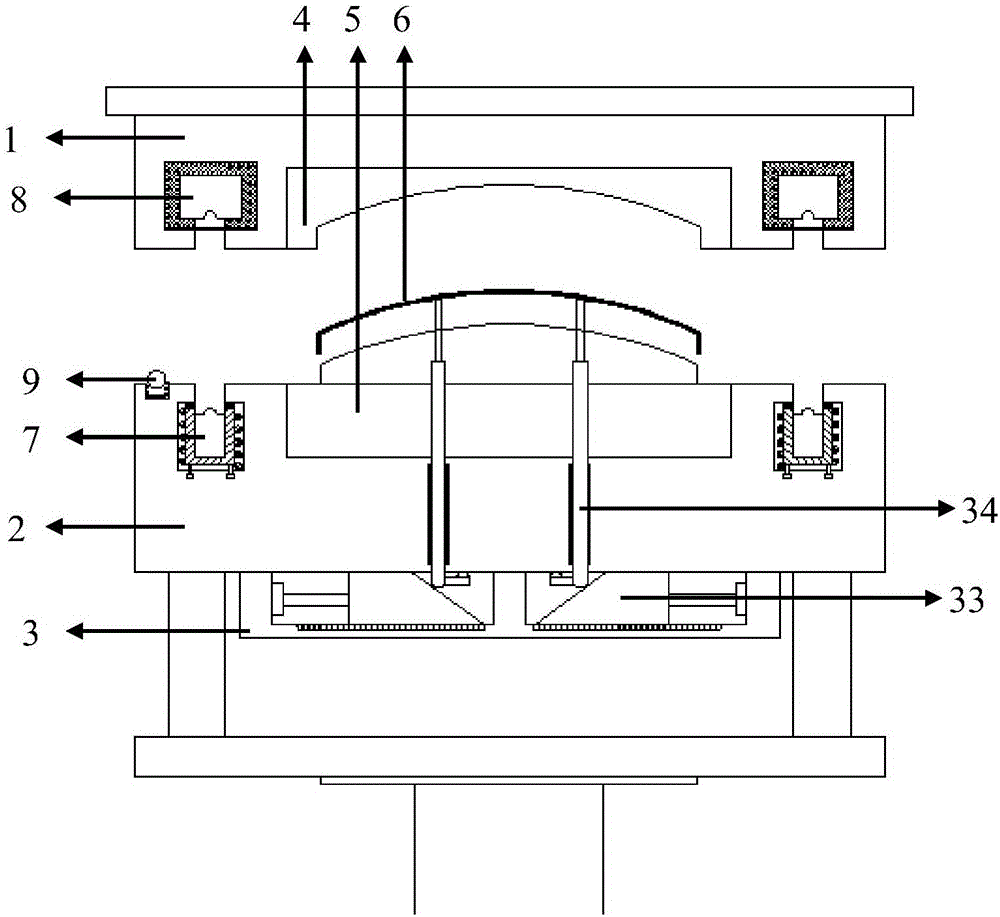

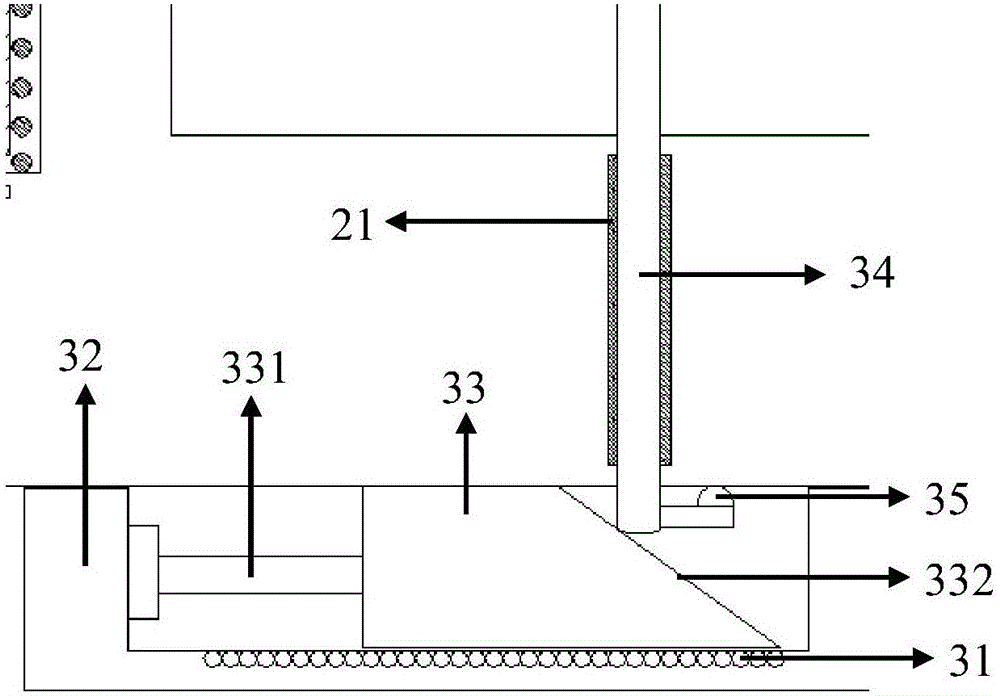

Injection mold with good ejection effect

InactiveCN110722747AAvoid sticking to the top wedgeImprove stabilityStructural engineeringMechanical engineering

Owner:苏州丰硕模具有限公司

Method for manufacturing a droplet ejection head

ActiveUS7536785B2High yieldAvoid crackingRecording apparatusPiezoelectric/electrostrictive device manufacture/assemblySpray nozzleEngineering

A method for manufacturing a droplet ejection head includes a step of forming recessed sections for forming nozzles by etching half way through a first face of a silicon substrate, a step of bonding a first support substrate to the first face of the silicon substrate, a step of reducing the thickness of the silicon substrate by processing a second face of the silicon substrate that is opposite to the first face thereof, and making the recessed sections through holes, and a step of removing the first support substrate from the silicon substrate after the reduction of the thickness of the silicon substrate.

Owner:SEIKO EPSON CORP

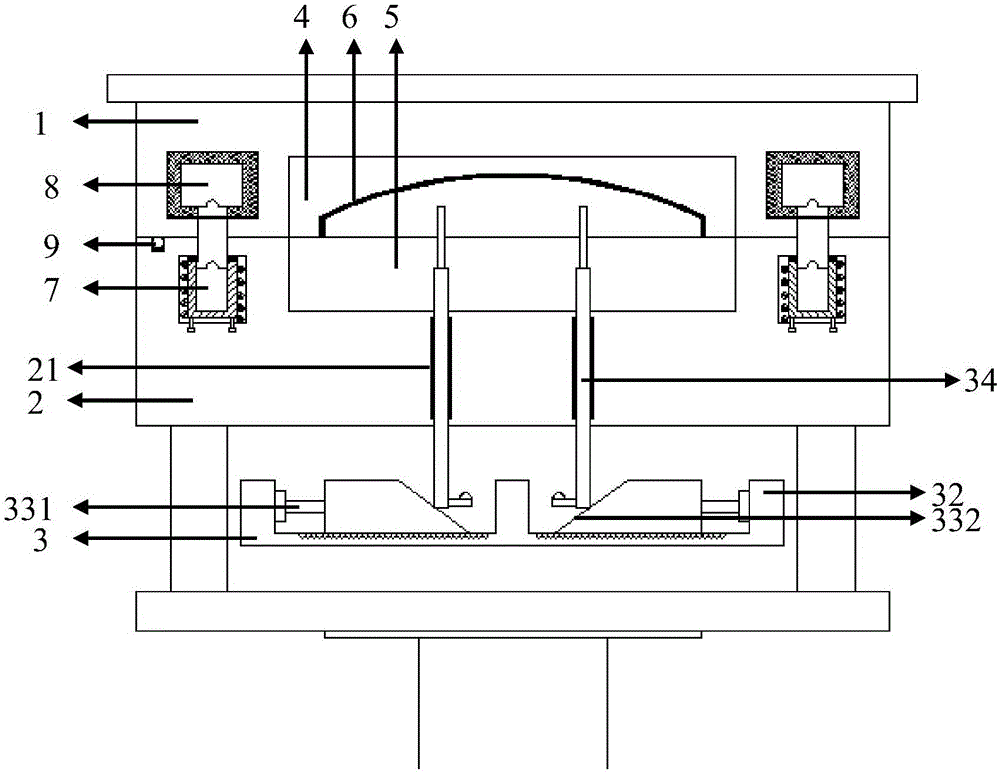

Automobile injection mold

ActiveCN110039733AGuarantee product qualityImprove ejection effectDomestic articlesEngineeringSpare part

The invention relates to the field of injection molds, in particular to an automobile injection mold. The automobile injection mold comprises a movable mold core, a fixed mold core, a movable frame, amold opening and closing controller, an upper micro ejector demolding device, a lower micro ejector demolding device, ejectors, a support plate, a stand column, a back plate and a base; the movable mold core is fixed to the front end of the movable frame; the middle of the movable frame is connected with the back plate; the rear end of the movable frame is in drive connection with the two ejectors; the middles of the two ejectors are connected to the back plate; and the front ends of the two ejectors are slidably mounted at the two ends of the bottom surface of the fixed mold core in a sealedmode correspondingly. Automobile spare parts subjected to injection molding can be quickly and smoothly ejected, and the production and processing efficiency can be improved while the quality of automobile spare parts is ensured.

Owner:深圳市嘉森模具实业有限公司

Injection mold capable of achieving cylinder core pulling ejection

The invention provides an injection mold. The injection mold comprises a fixed mold, a movable mold, a top plate, a fixed mold core and a movable mold core, wherein the top plate and the fixed mold are relatively fixed; core pulling sliding blocks are fixed inside the top plate; the core pulling sliding blocks are connected with cylinders; the inner sides of the core pulling sliding blocks are inclined planes; at least one ejector rod is arranged on each inclined plane; and ejection channels for allowing the ejector rods to perform reciprocating motion in the vertical direction are arranged inside the fixed mold and the movable mold. According to the injection mold, a product can be stably demolded more quickly.

Owner:TIANJIN CITY JIUYUE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com