Multiplex compound ejector

A technology of ejector and mixing tube, applied in the field of multiplex composite ejector, can solve the problem of low efficiency of single ejection, and achieve the effect of wide work adaptability, large work flow, and high suction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

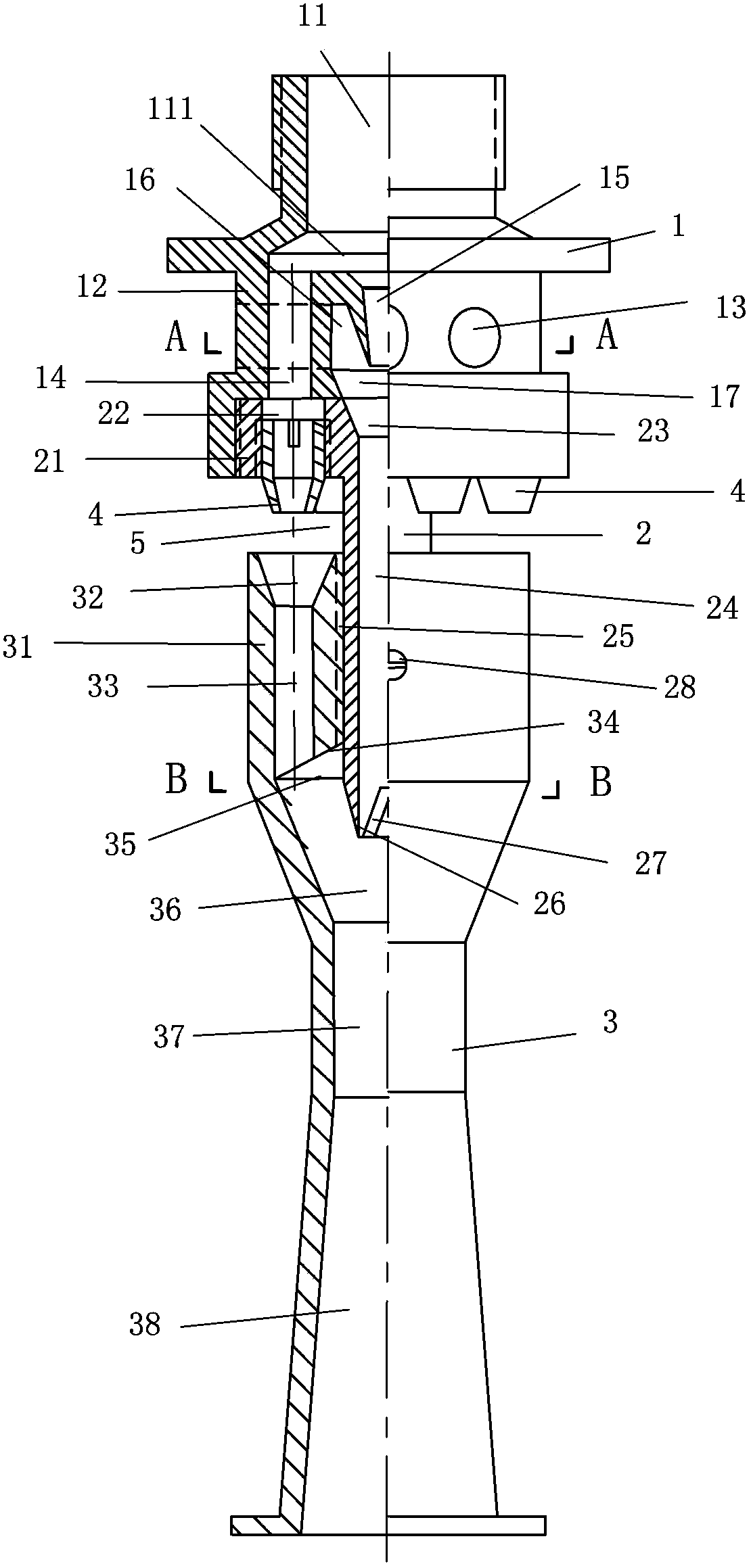

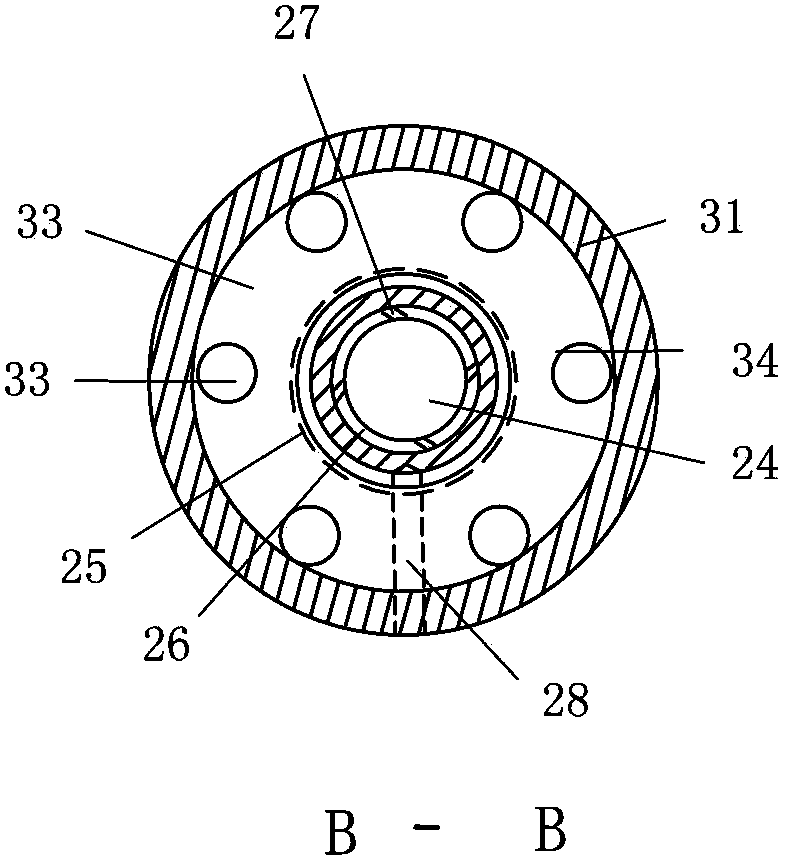

[0036] One embodiment of the multi-channel composite injector of the present invention adopts a high-pressure primary fluid input from the front end, a low-pressure or no-pressure secondary fluid input from the side, and a pressurized mixed flow output from the tail. Its structure, such as figure 1 As shown, it includes a main fluid assembly 1 , an inner pipe assembly 2 , an outer pipe collar 3 and six peripheral nozzles 4 .

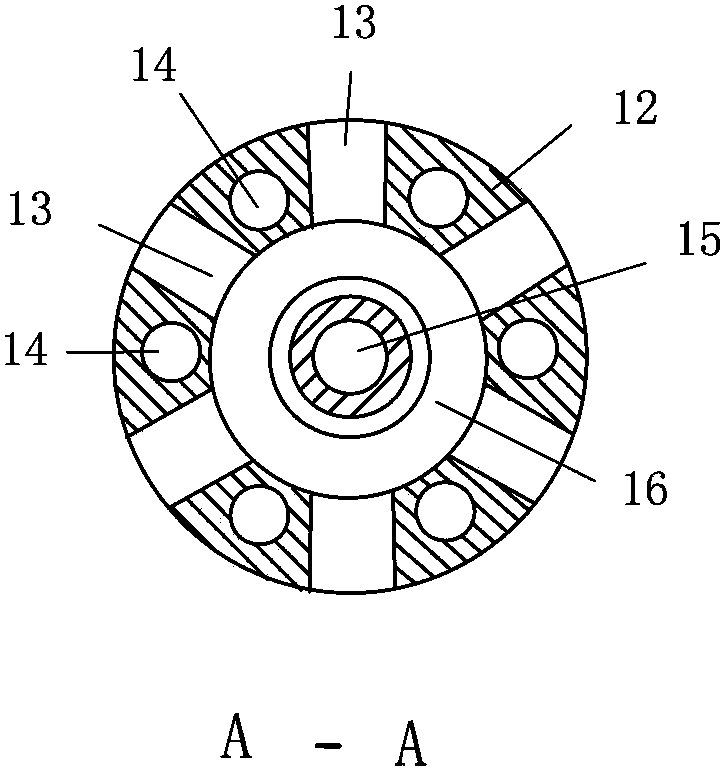

[0037] The center of the top (front end) of the main fluid assembly 1 is provided with a main fluid inlet pipe 11 upwards and a central nozzle 15 downwards. The lower part of the main fluid assembly 1 is provided with an annular distribution sleeve 12, see figure 2 A plurality of horizontal secondary fluid holes 13 and a plurality of vertical primary fluid holes 14 are provided on the peripheral wall of the annular distribution sleeve 12 , and the secondary fluid holes 13 and the primary fluid holes 14 are cross-isolated. The inner cavity of the annula...

Embodiment 3

[0060] In this embodiment, a high-pressure main fluid is input from the front end, a low-pressure or no-pressure secondary fluid is injected from the side, and a mixed flow is output from the tail. Its structure is as follows Figure 5 As shown, it includes the main fluid assembly 100, the inner pipe assembly 200, an outer pipe collar 300 and its extension extension pipe 300' and a central nozzle assembly 1500.

[0061]The main fluid inlet pipe 1100 is arranged at the center of the top (front end) of the main fluid assembly 100, and an annular flange is arranged at its lower end; The peripheral flanges provided are sealed butt-connected, and a diameter-expanding cavity 11100 is formed in the flared jacket 21100 at the top of the annular flow distribution sleeve 2100 . Six lateral secondary fluid holes 1300 and six vertical primary fluid holes 1400 are provided on the peripheral wall of the annular distribution sleeve 2100 , and the secondary primary fluid holes 21300 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com