Ejector with adjustable structure parameters

A technology of structural parameters and injectors, applied in jet pumps, machines/engines, mining fluids, etc., can solve problems such as injection performance limitations, adjustments, and shortened injector life cycles, and achieve the effect of improving energy saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

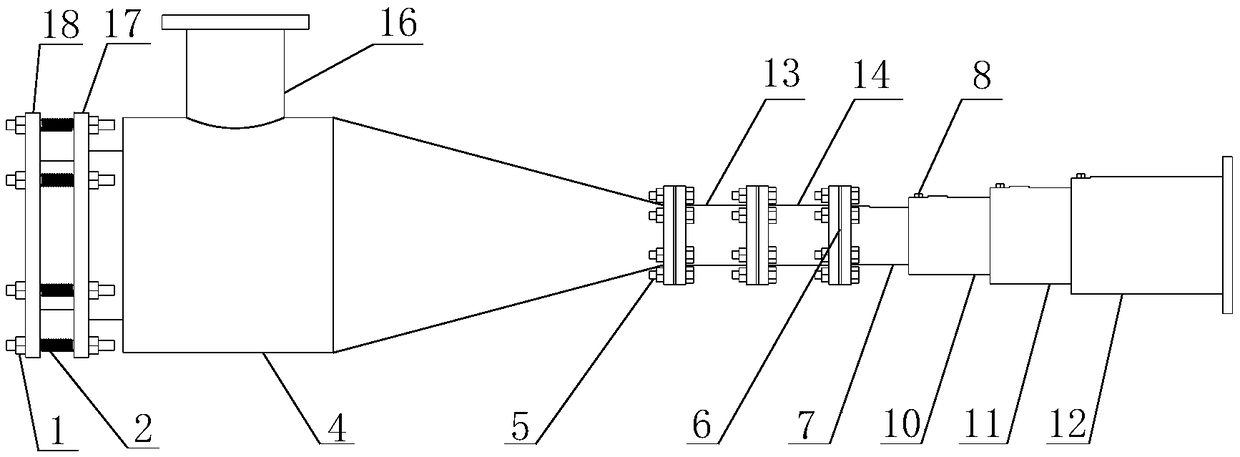

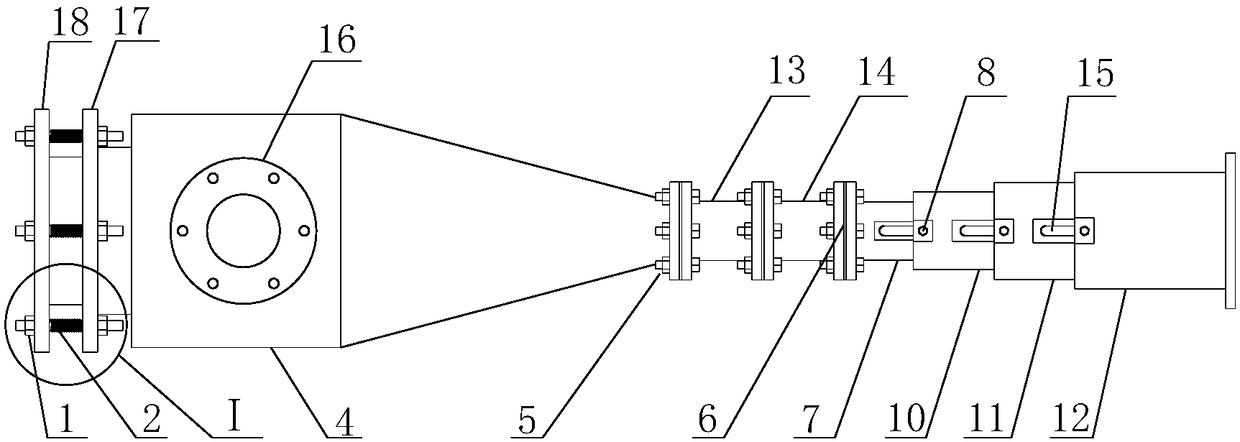

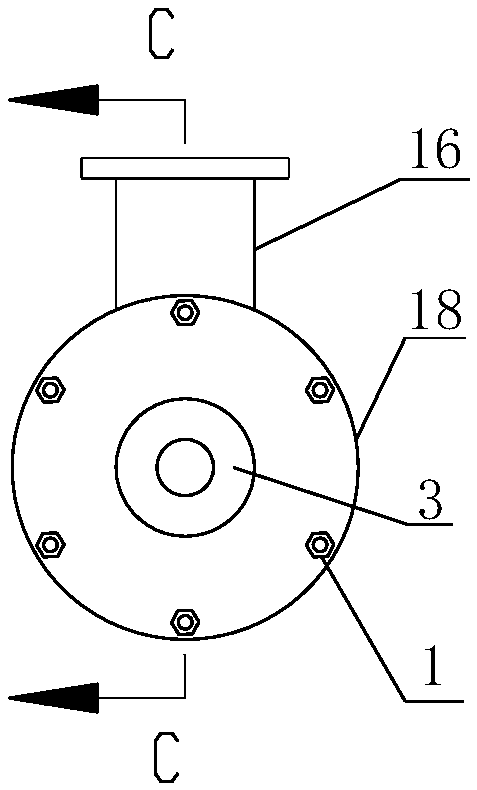

[0026] figure 1 , figure 2 , image 3 and Figure 4 These are the front view, top view, left side view and isometric view of an injector with adjustable structural parameters according to the present invention. Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a kind of ejector with adjustable structural parameters of the present invention comprises a working nozzle 3, a low-pressure inlet chamber 4, a straight pipe section, a diffuser chamber, and a low-pressure inlet chamber inlet pipeline 16, and the diffuser chamber consists of a first-stage The diffuser tube a10, the secondary diffuser tube b11, and the tertiary diffuser tube c12 are nested with each other, and the adjacent diffuser tubes, the primary diffuser tube a10 and the basic straight pipe section 7 are all sealed with a sealing ring 9 . The present...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com