Electromagnetic switching apparatus

A technology of electromagnetic switches and equipment, applied in the direction of electromagnetic relays, electromagnetic relay details, circuits, etc., can solve problems affecting electronic components and electromagnetic switching equipment, coil noise, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

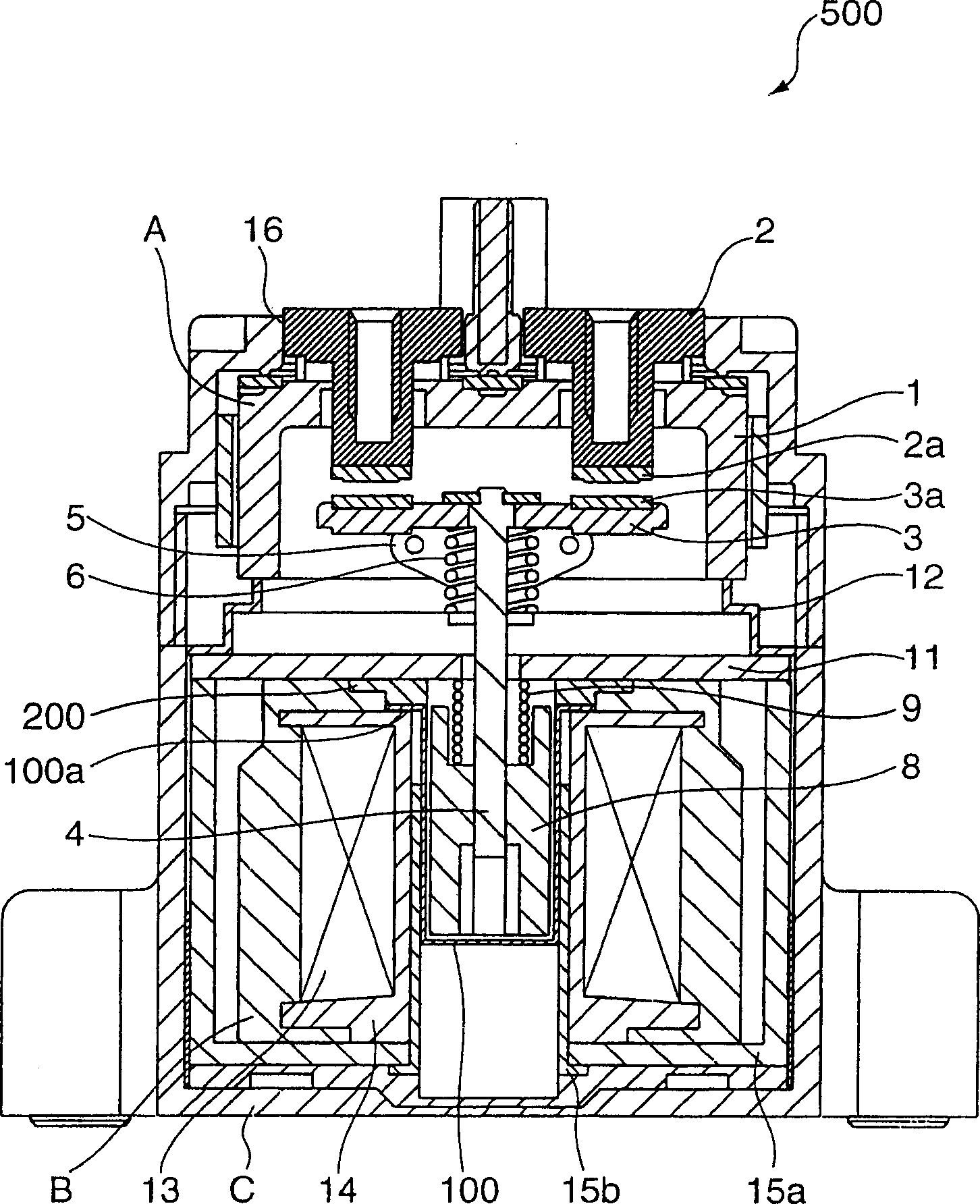

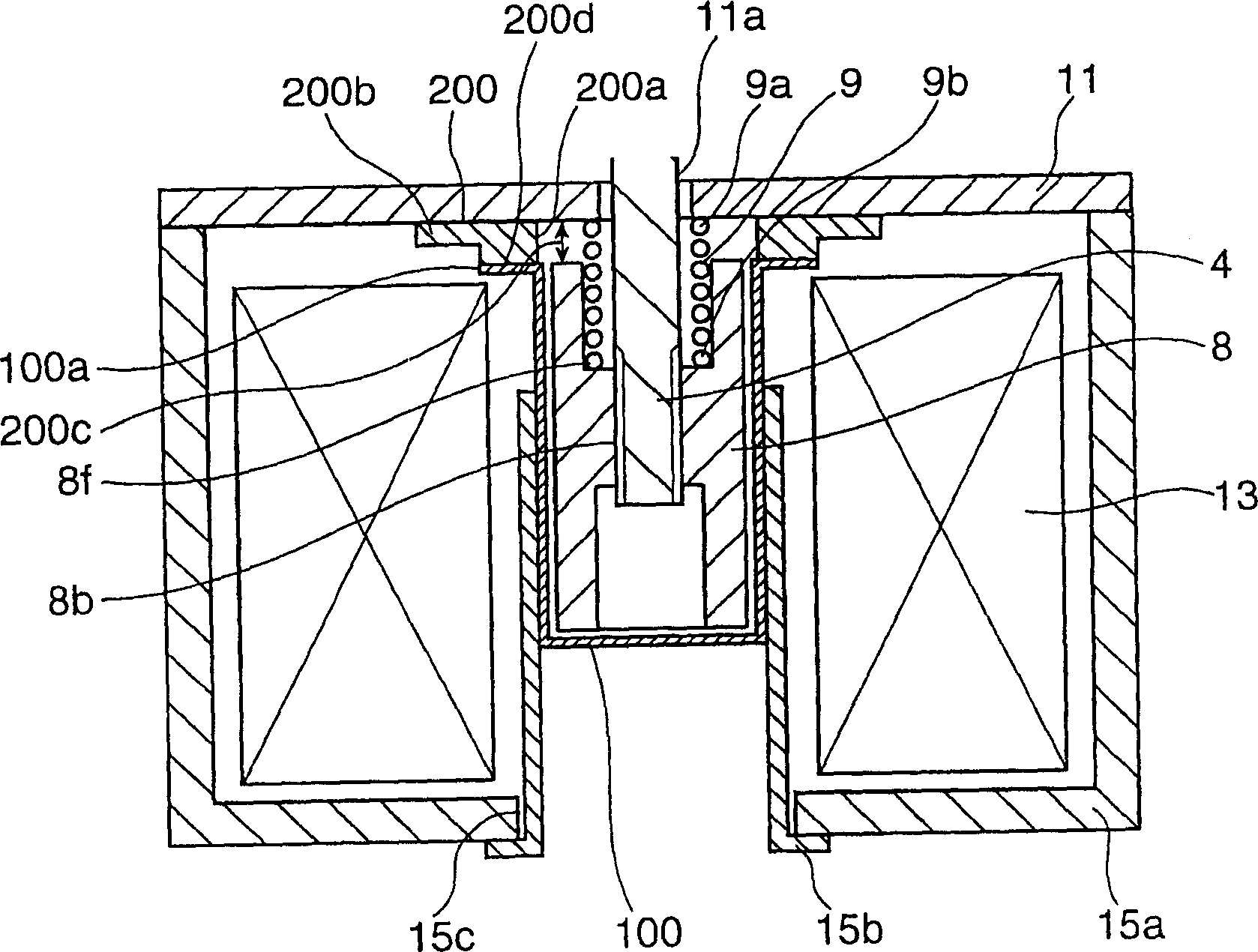

[0051] figure 1 It is a side sectional view of the electromagnetic switch device as the first embodiment of the present invention. Since the basic structure of the first electromagnetic switch device is the same as that of the conventional device, only the characteristic parts of the first electromagnetic switch device are described here. In particular, the first electromagnetic switch device 500 including the sealed contact device is different from the conventional electromagnetic switch device 1000 including the conventional sealed contact device in that: Figure 21 The fixed iron core 7; provide a cylindrical member 100 made of magnetic material and with a closed bottom instead of Figure 21 The cylindrical member 10 made of a non-magnetic material is shown; a metal plate 200 made of a non-magnetic material is arranged between the cylindrical member 100 and the first joining member 11; and the various components are connected to each other by laser welding and other methods. ...

no. 2 example

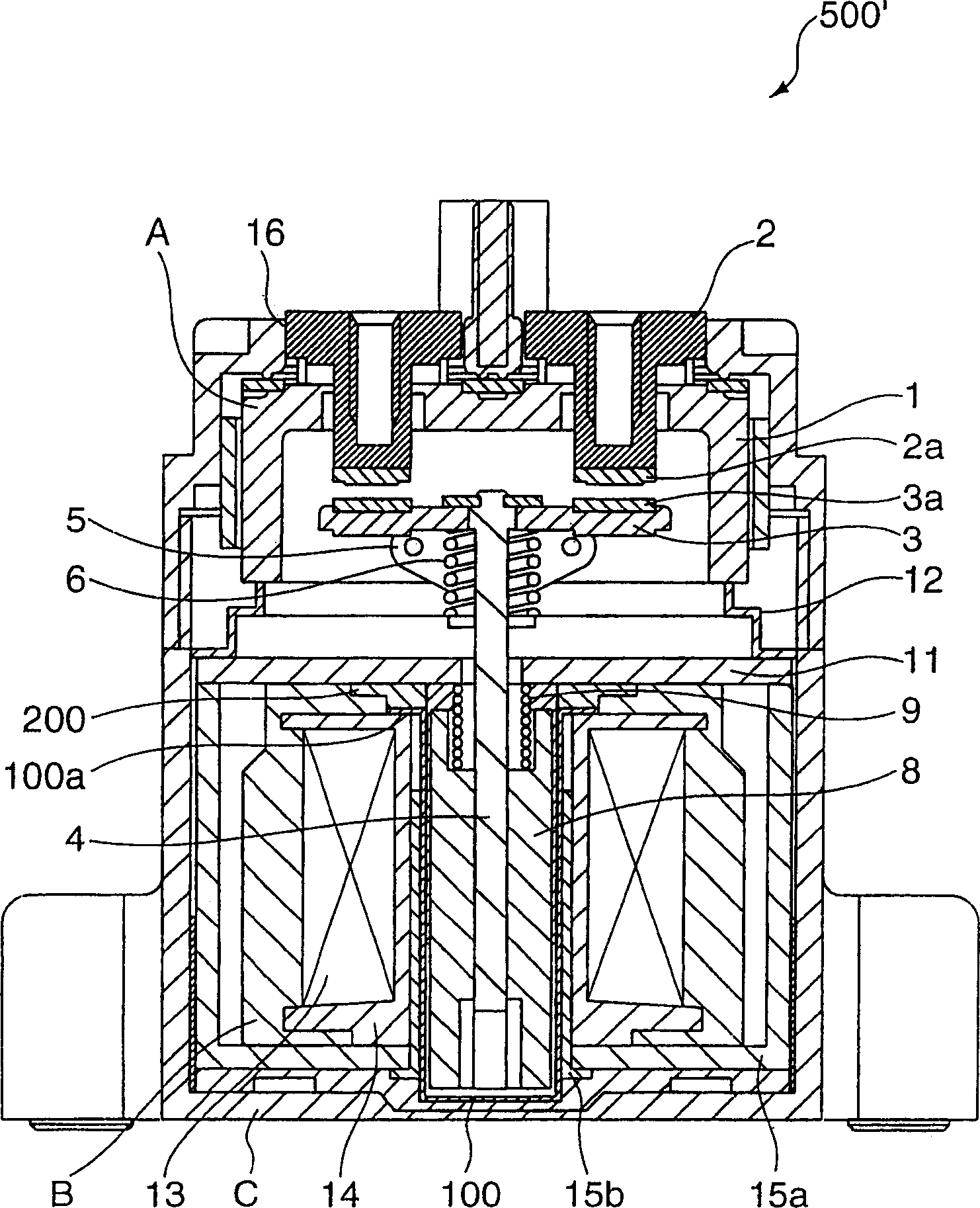

[0058] Figure 4 It is a side sectional view showing the main components of the electromagnetic switch device as the second embodiment of the present invention. Since the basic structure of the second electromagnetic switch device is the same as that of the conventional device, only the characteristic parts of the second electromagnetic switch device are described here. In particular, the second electromagnetic switch device including the sealed contact device is different from the conventional electromagnetic switch device 1000 including the conventional sealed contact device in that: Figure 21 The fixed iron core 7; is provided with a cylindrical member 100 made of magnetic material and has a closed bottom instead of Figure 21 The cylindrical member 10 made of a non-magnetic material is shown; a metal plate 300 made of a non-magnetic material is provided between the cylindrical member 100 and the first joining member 11; and the various components are mutually connected by la...

no. 3 example

[0064] Figure 5 to Figure 8 It is an electromagnetic switch device as the third embodiment of the present invention. Figure 5 with Figure 6 These are a front cross-sectional view and a side cross-sectional view showing the third device, respectively. Figure 7 It is a top cross-sectional view of the coil. Figure 8 It is a circuit diagram illustrating the circuit used in the third device.

[0065] The third electromagnetic switchgear 501 including a sealed contact device includes: a sealed container 1 made of insulating material; fixed terminals 2, 2 having fixed contacts 2a, 2a to be airtightly joined to the sealed container 1; Contacts 2a, 2a movable movable contact piece 3; movable iron core 8 movable in one direction; cylindrical member 10 having a closed bottom for placing the movable iron core 8 therein; airtightly joined to The first engaging member 11 on the cylindrical member 10; the movable shaft 4 connected to the movable iron core 8; the movable contact 3a, 3a is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com