Patents

Literature

931 results about "Axial compressor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An axial compressor is a gas compressor that can continuously pressurize gases. It is a rotating, airfoil-based compressor in which the gas or working fluid principally flows parallel to the axis of rotation, or axially. This differs from other rotating compressors such as centrifugal compressor, axi-centrifugal compressors and mixed-flow compressors where the fluid flow will include a "radial component" through the compressor. The energy level of the fluid increases as it flows through the compressor due to the action of the rotor blades which exert a torque on the fluid. The stationary blades slow the fluid, converting the circumferential component of flow into pressure. Compressors are typically driven by an electric motor or a steam or a gas turbine.

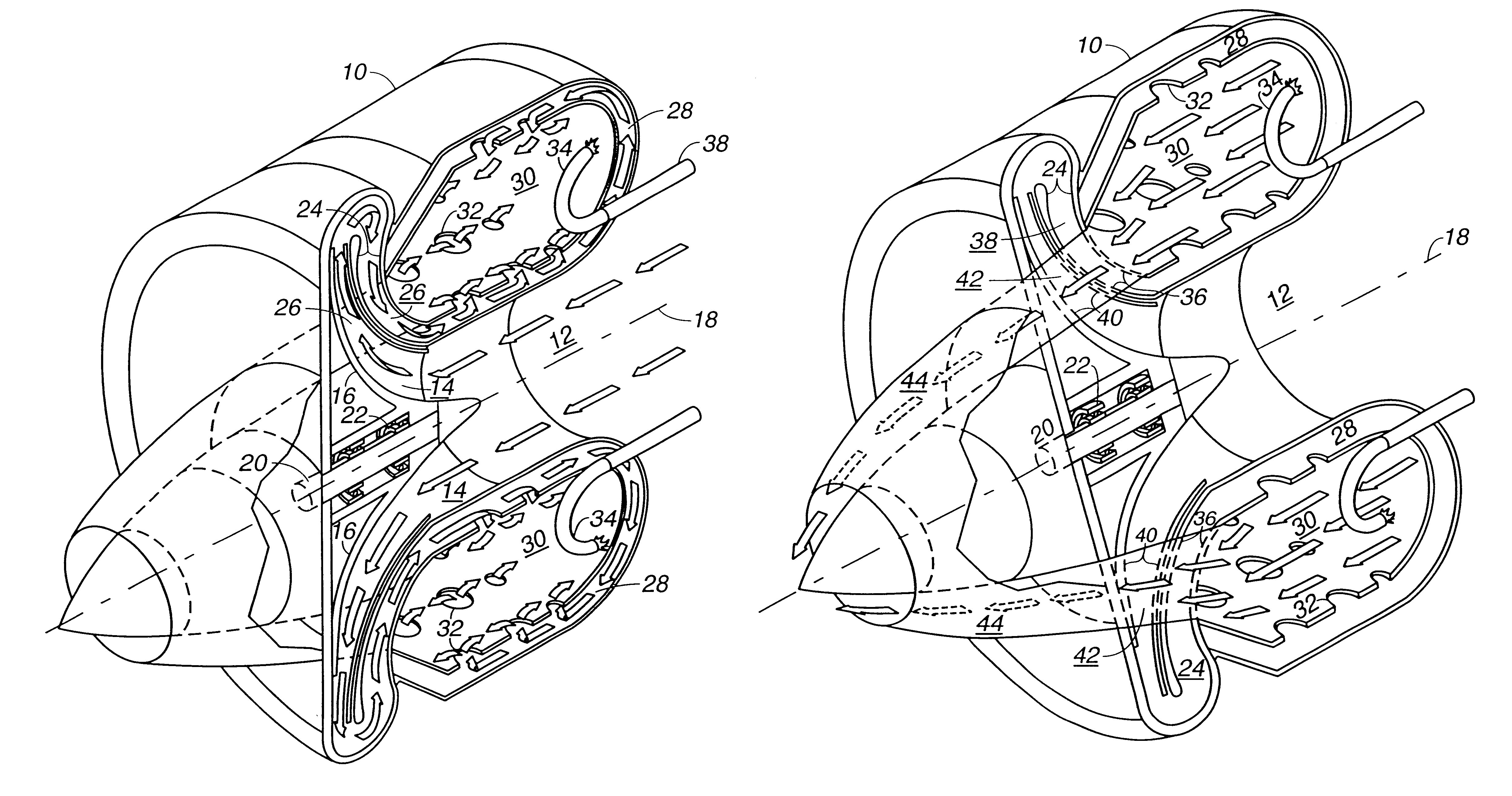

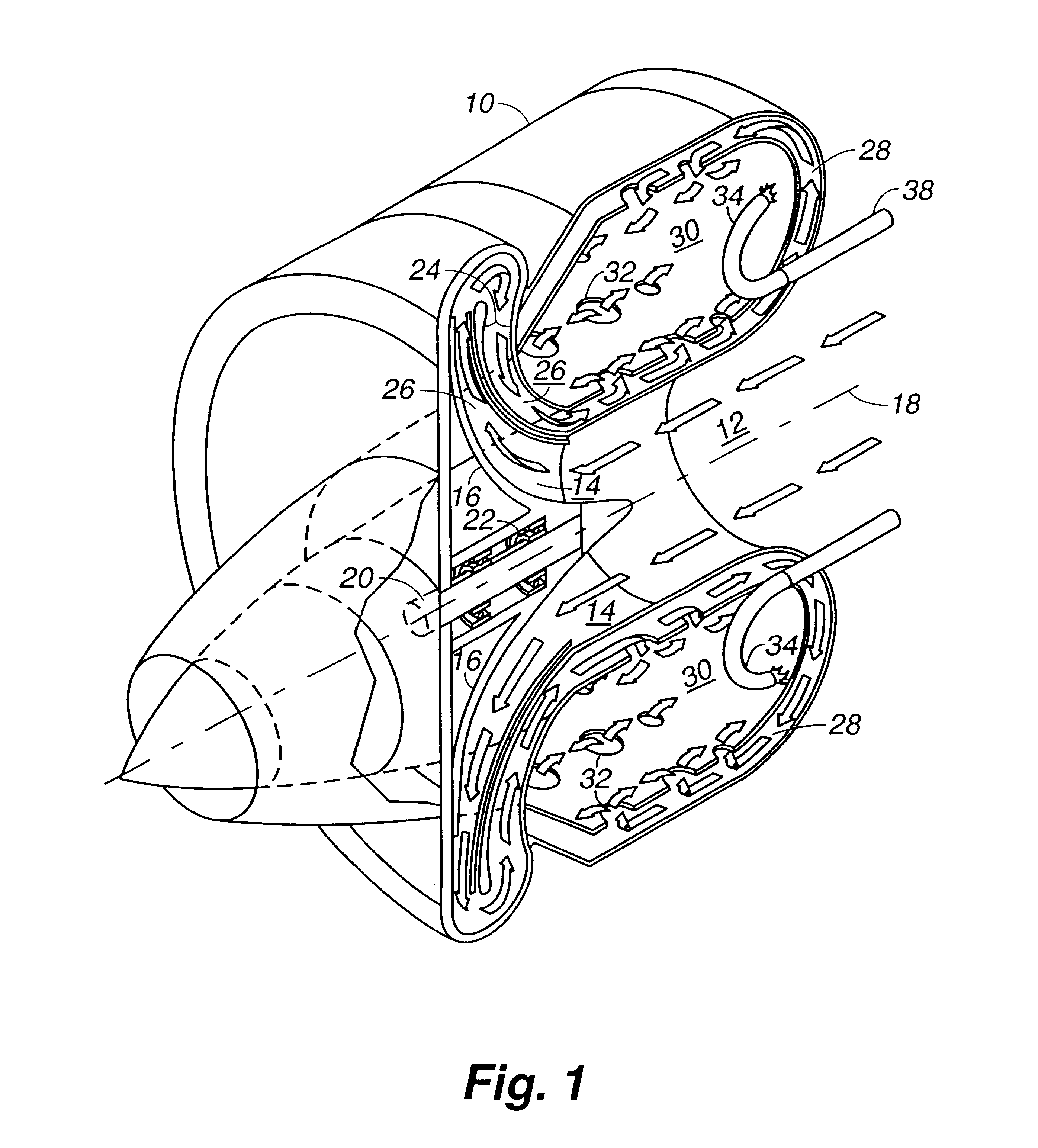

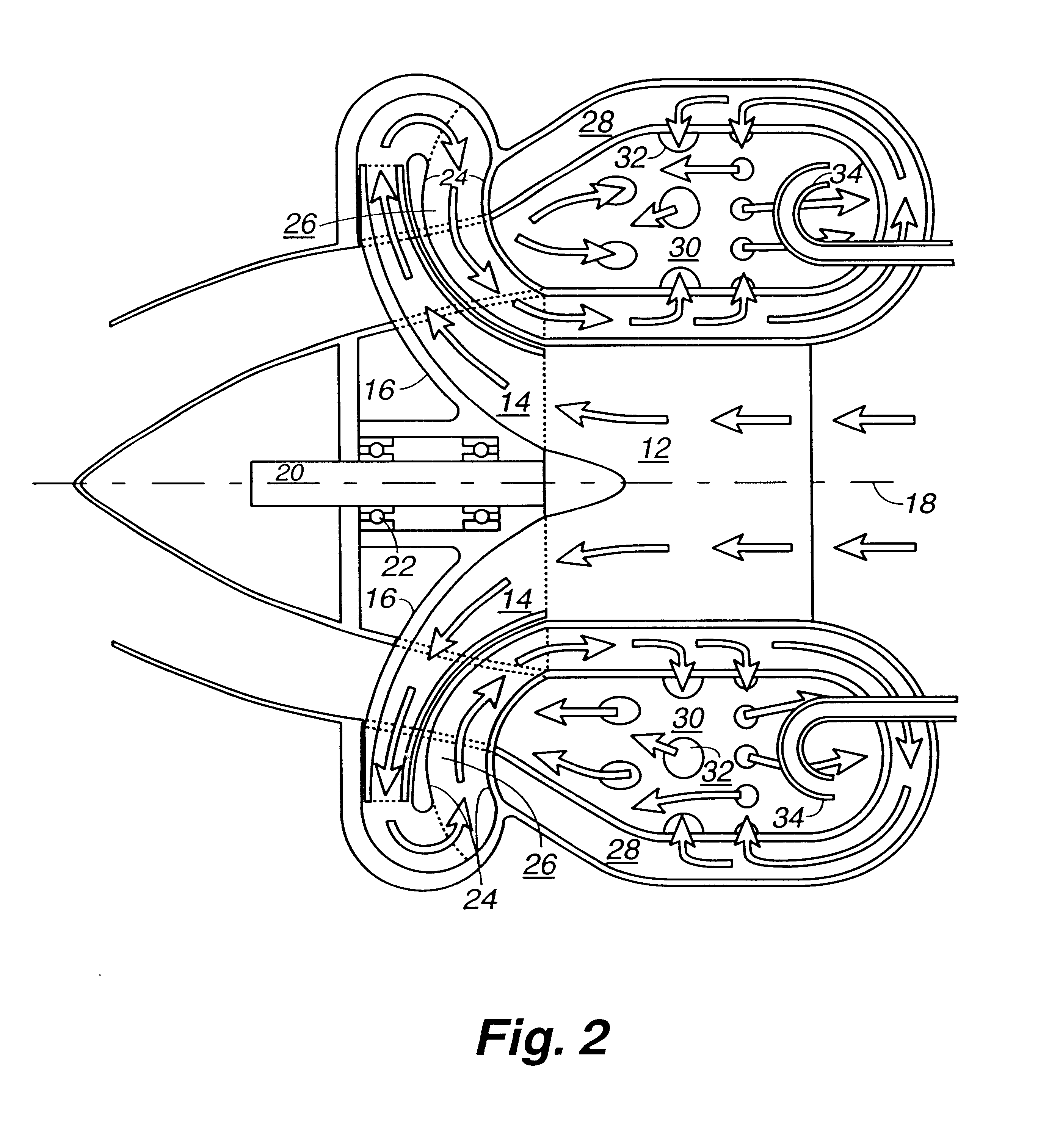

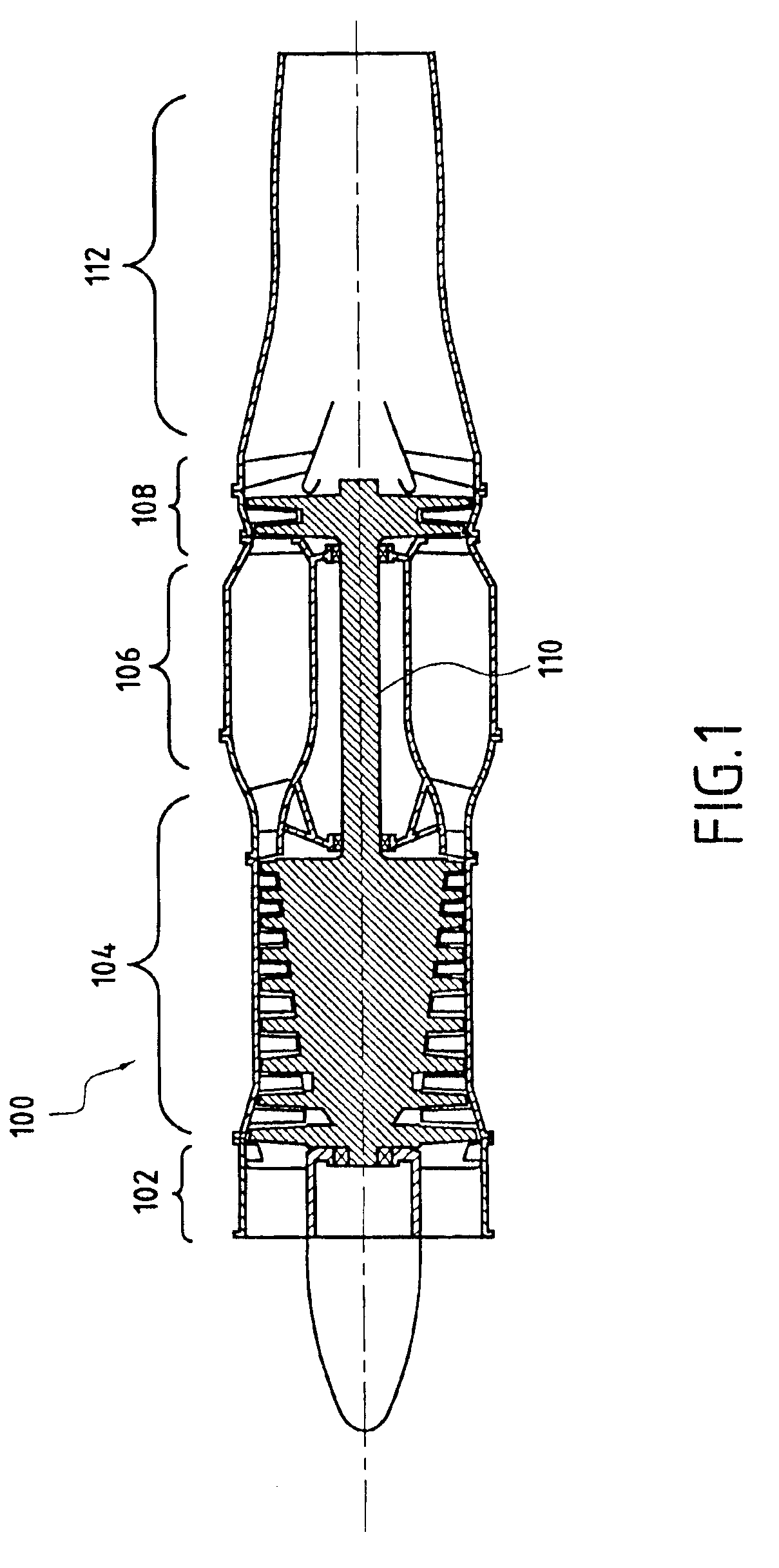

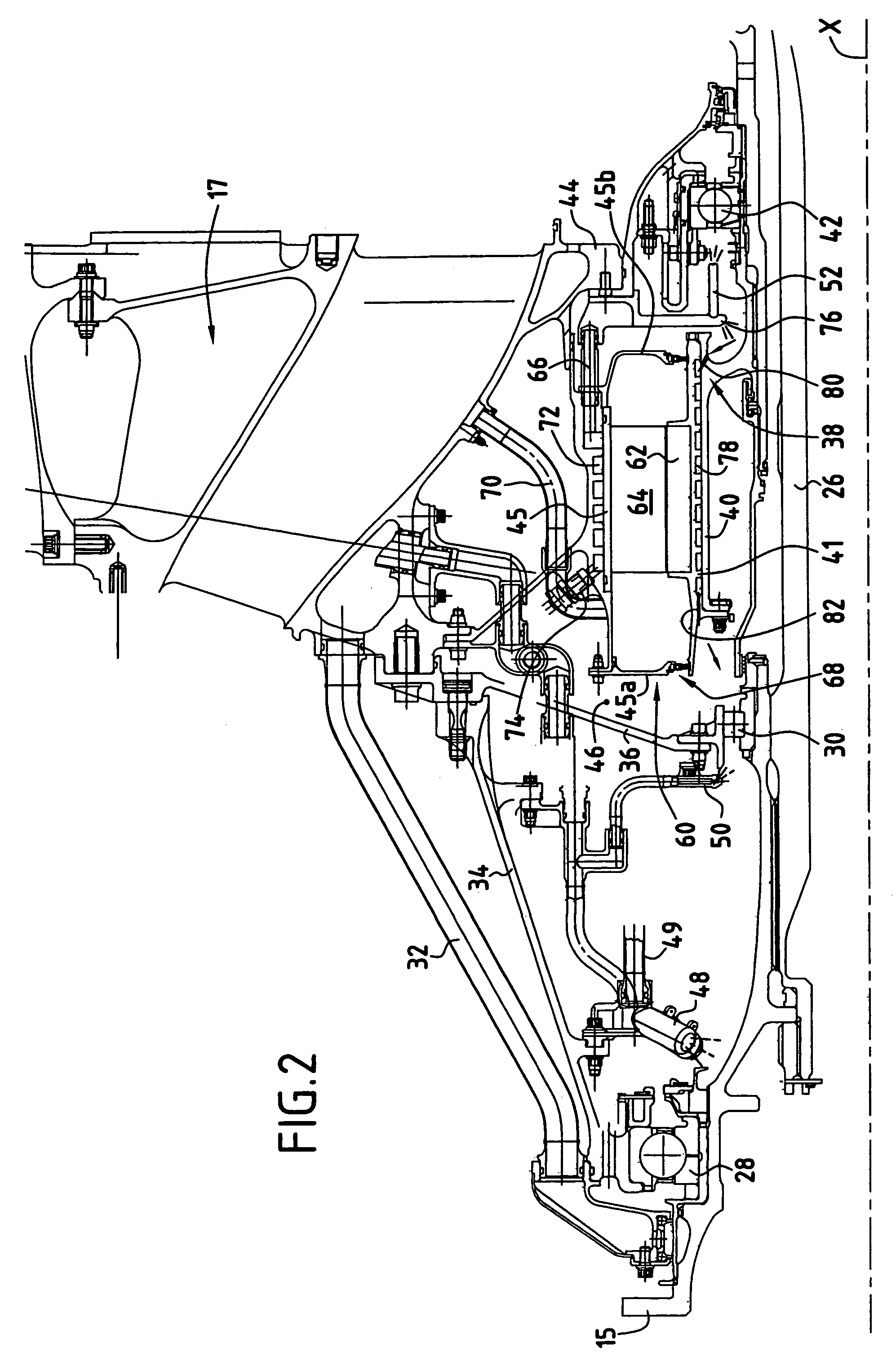

Single rotor turbine engine

There has been invented a turbine engine with a single rotor which cools the engine, functions as a radial compressor, pushes air through the engine to the ignition point, and acts as an axial turbine for powering the compressor. The invention engine is designed to use a simple scheme of conventional passage shapes to provide both a radial and axial flow pattern through the single rotor, thereby allowing the radial intake air flow to cool the turbine blades and turbine exhaust gases in an axial flow to be used for energy transfer. In an alternative embodiment, an electric generator is incorporated in the engine to specifically adapt the invention for power generation. Magnets are embedded in the exhaust face of the single rotor proximate to a ring of stationary magnetic cores with windings to provide for the generation of electricity. In this alternative embodiment, the turbine is a radial inflow turbine rather than an axial turbine as used in the first embodiment. Radial inflow passages of conventional design are interleaved with radial compressor passages to allow the intake air to cool the turbine blades.

Owner:LOS ALAMOS NATIONAL SECURITY

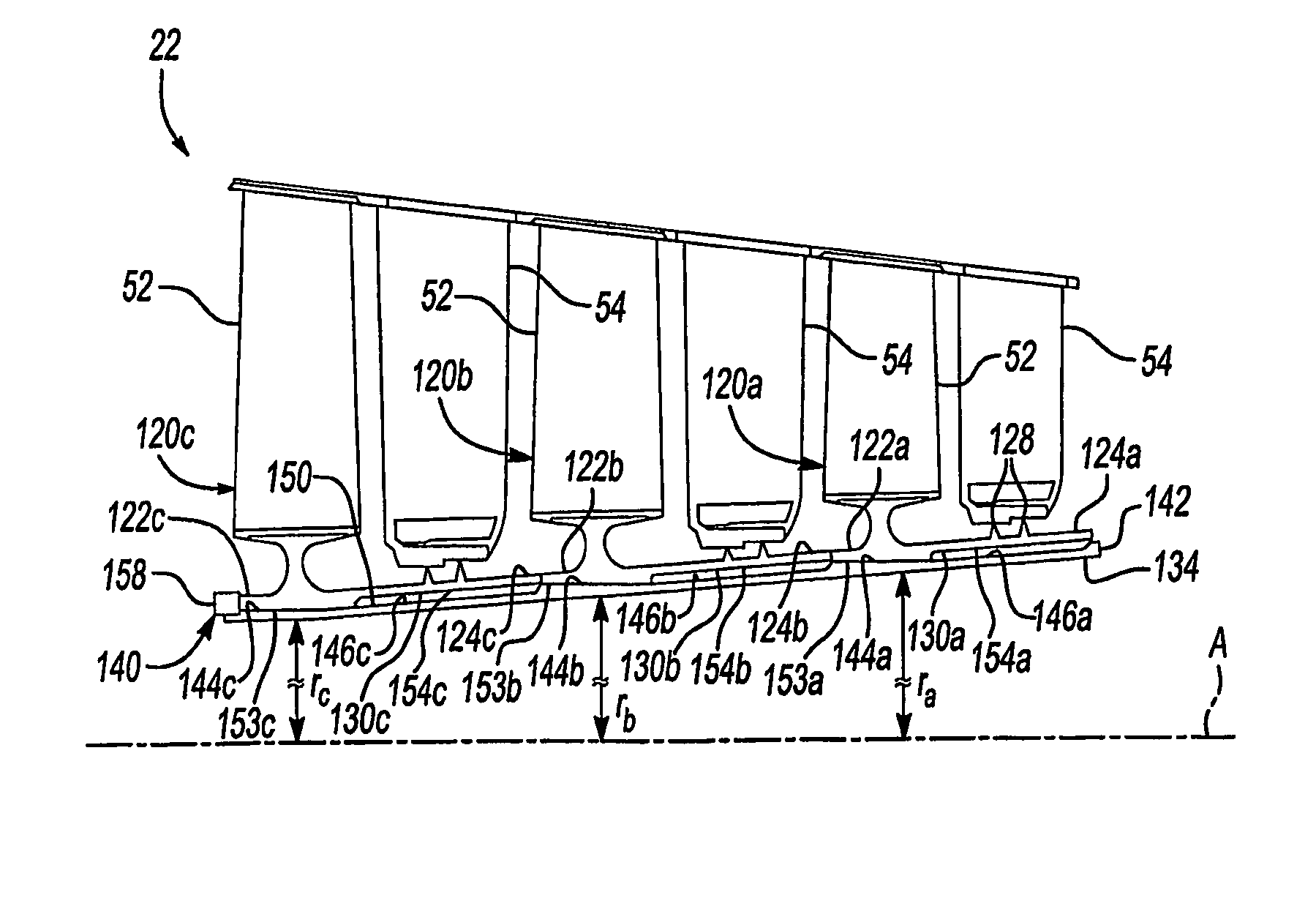

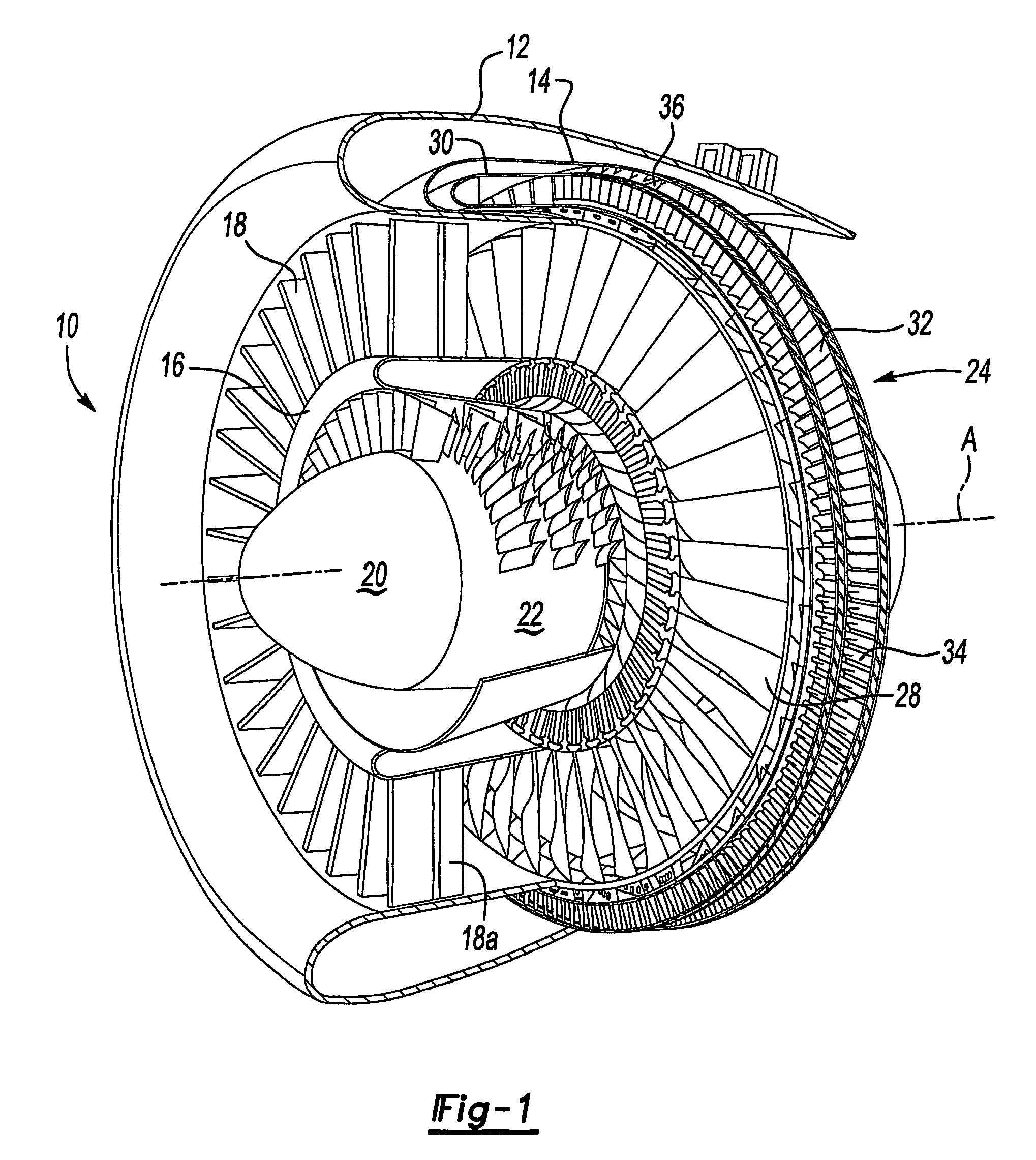

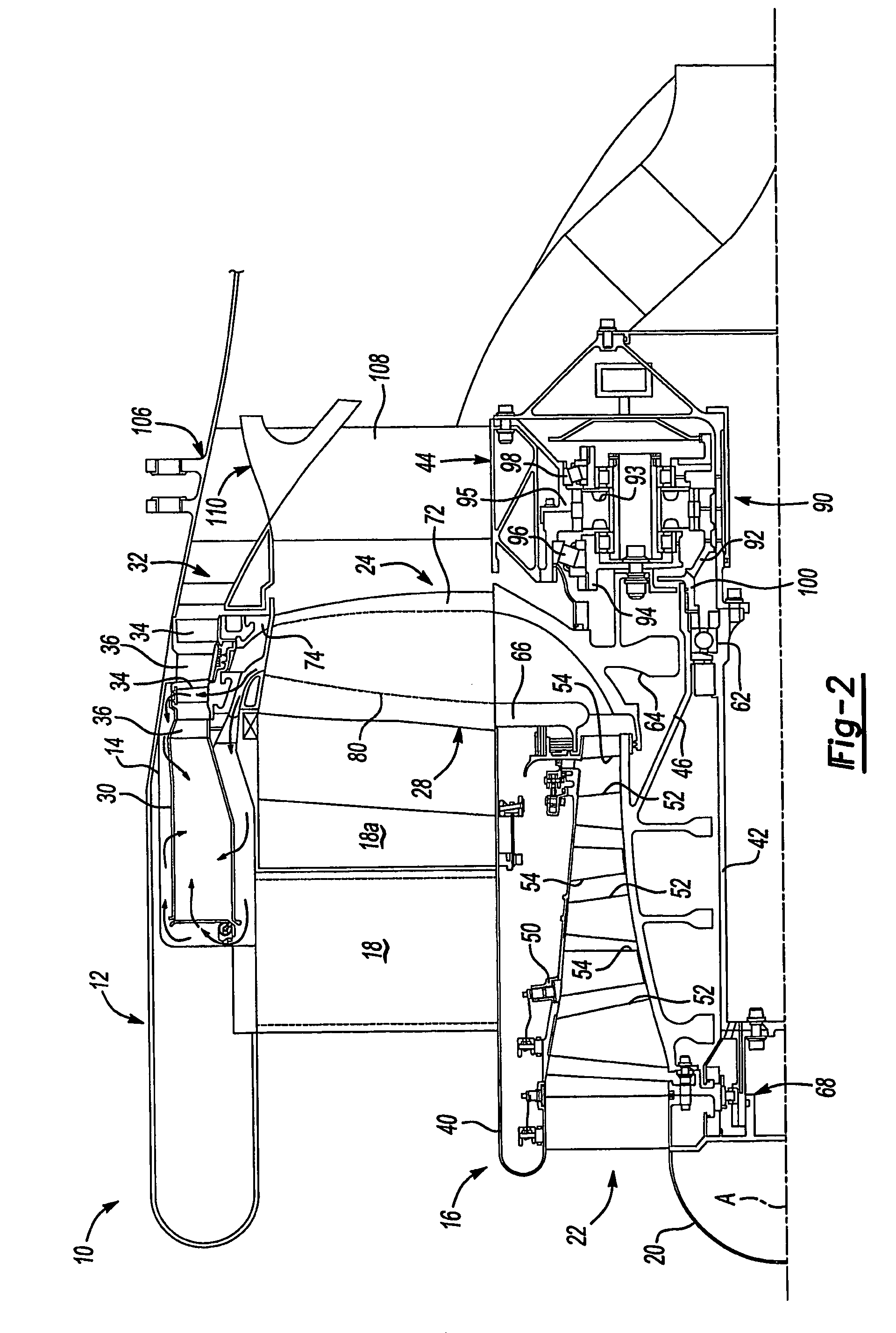

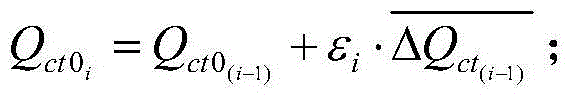

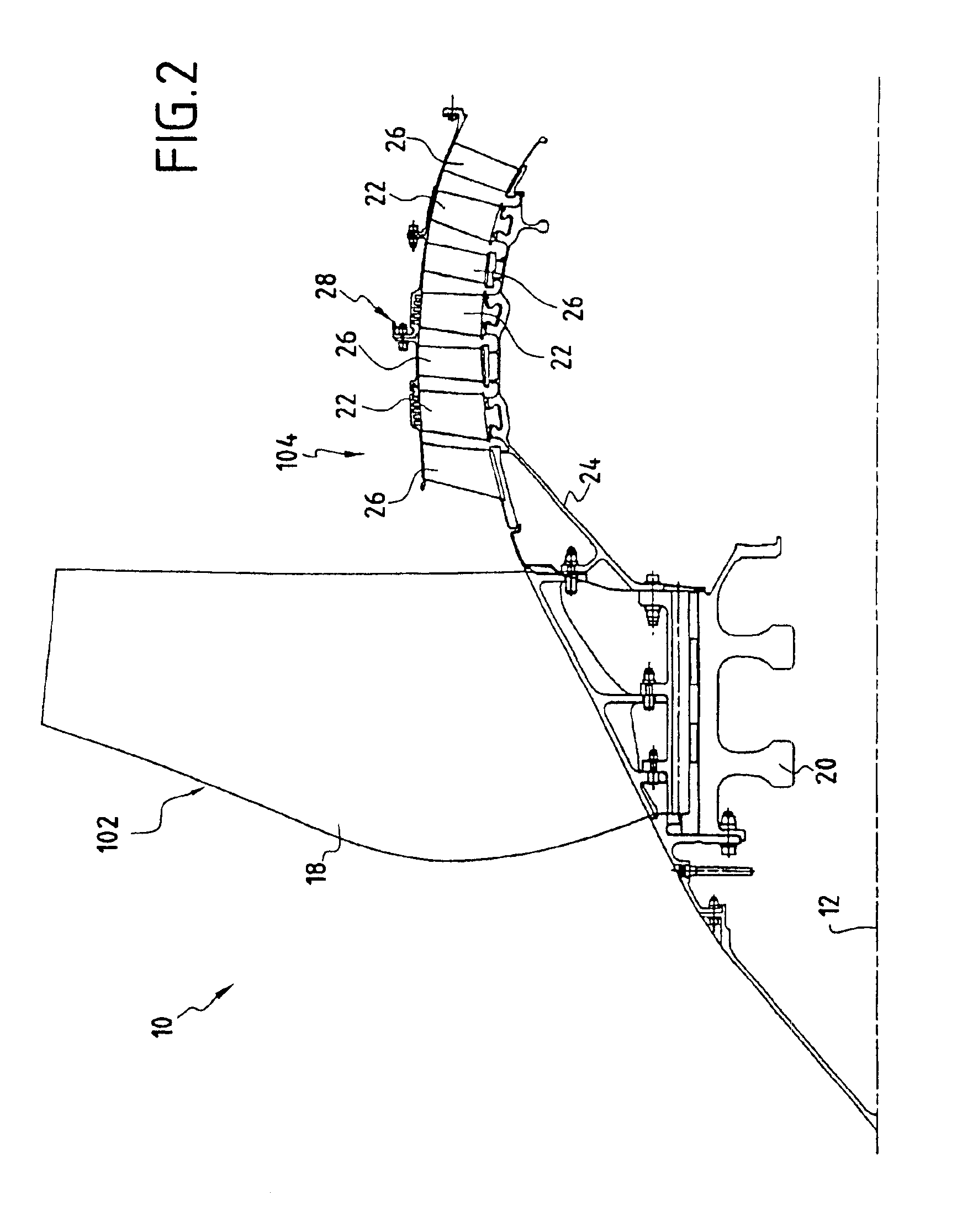

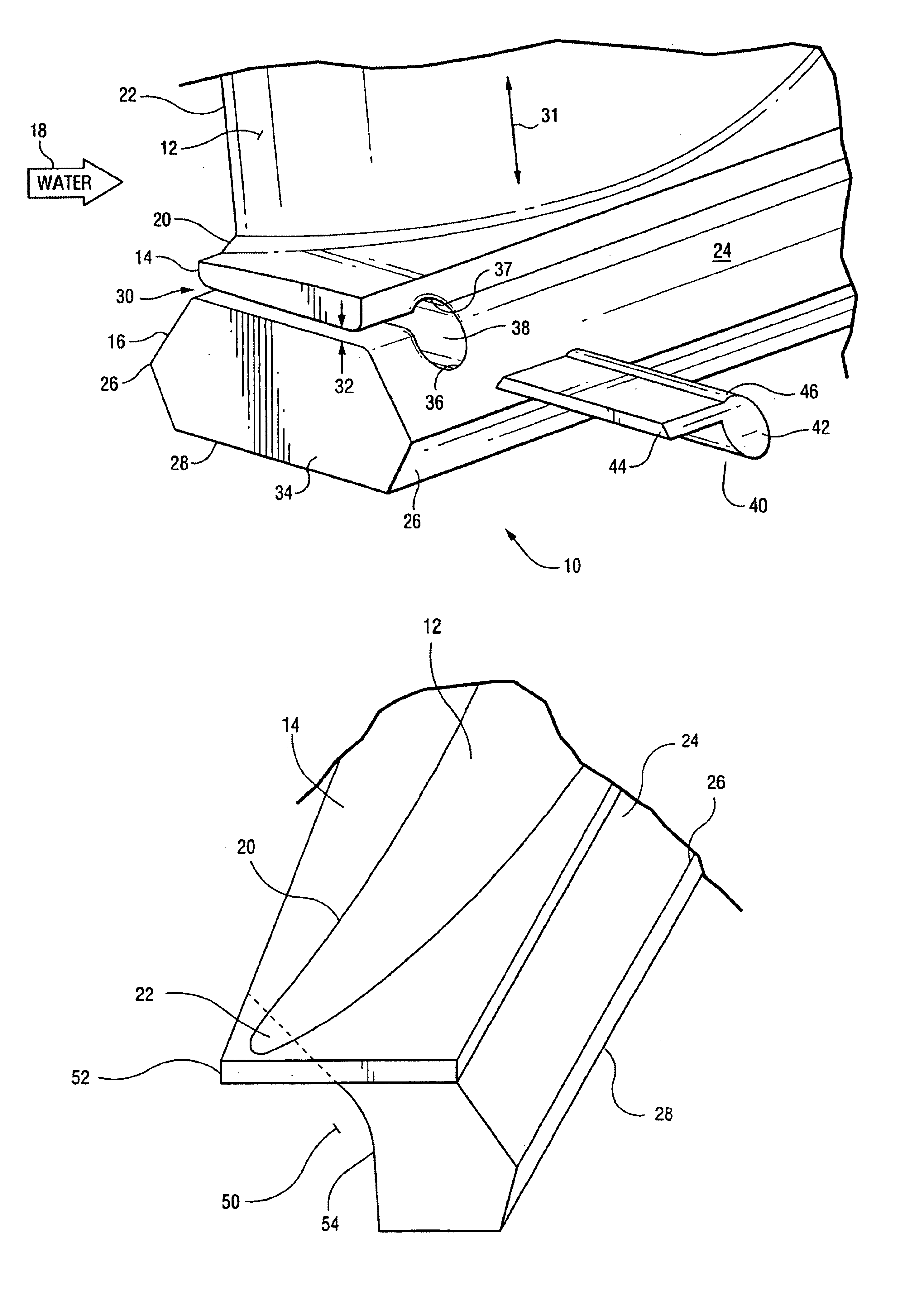

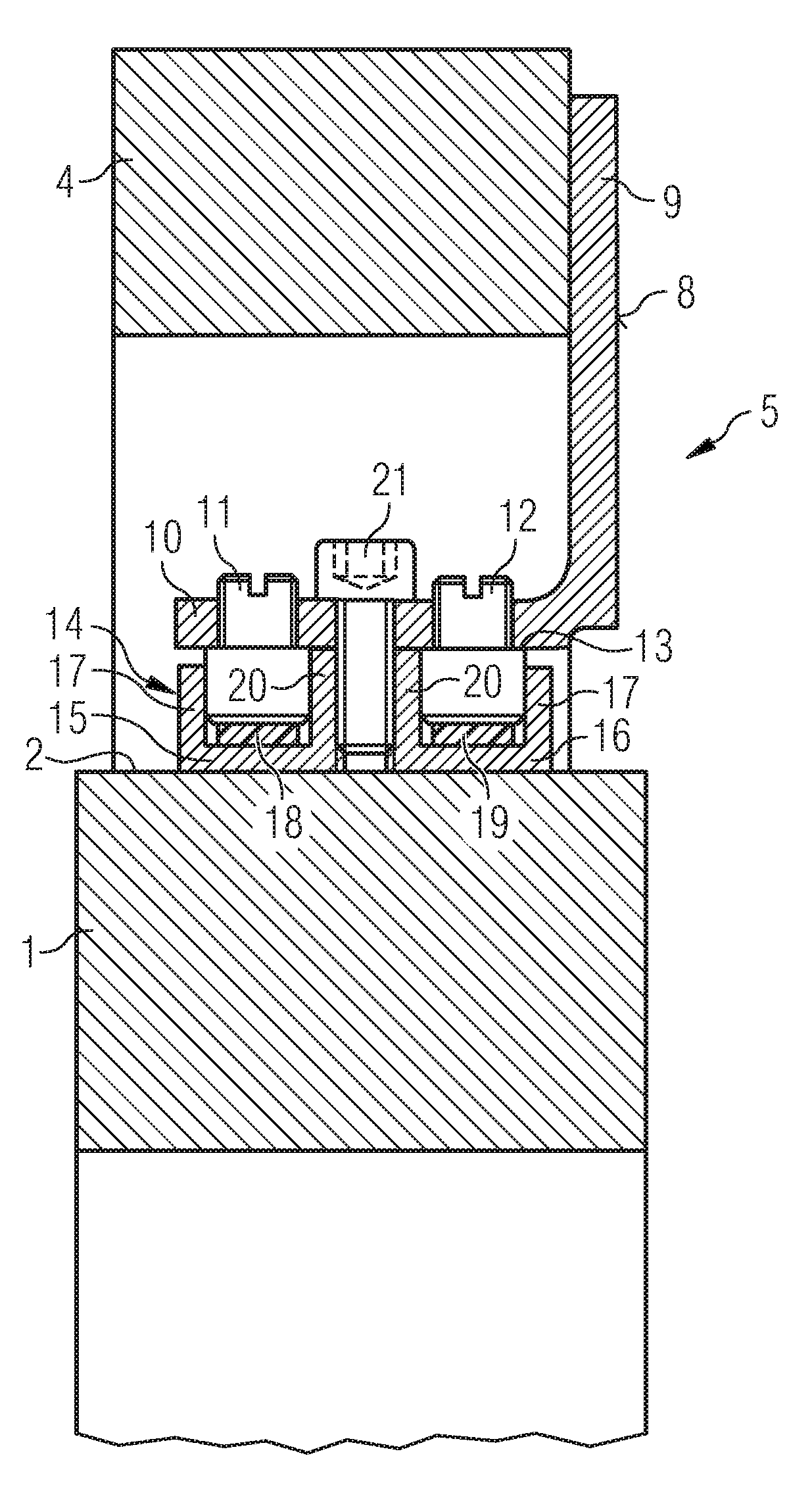

Stacked annular components for turbine engines

ActiveUS8087885B2Reduces weight and costPump componentsGas turbine plantsAxial compressorEngineering

Owner:RTX CORP

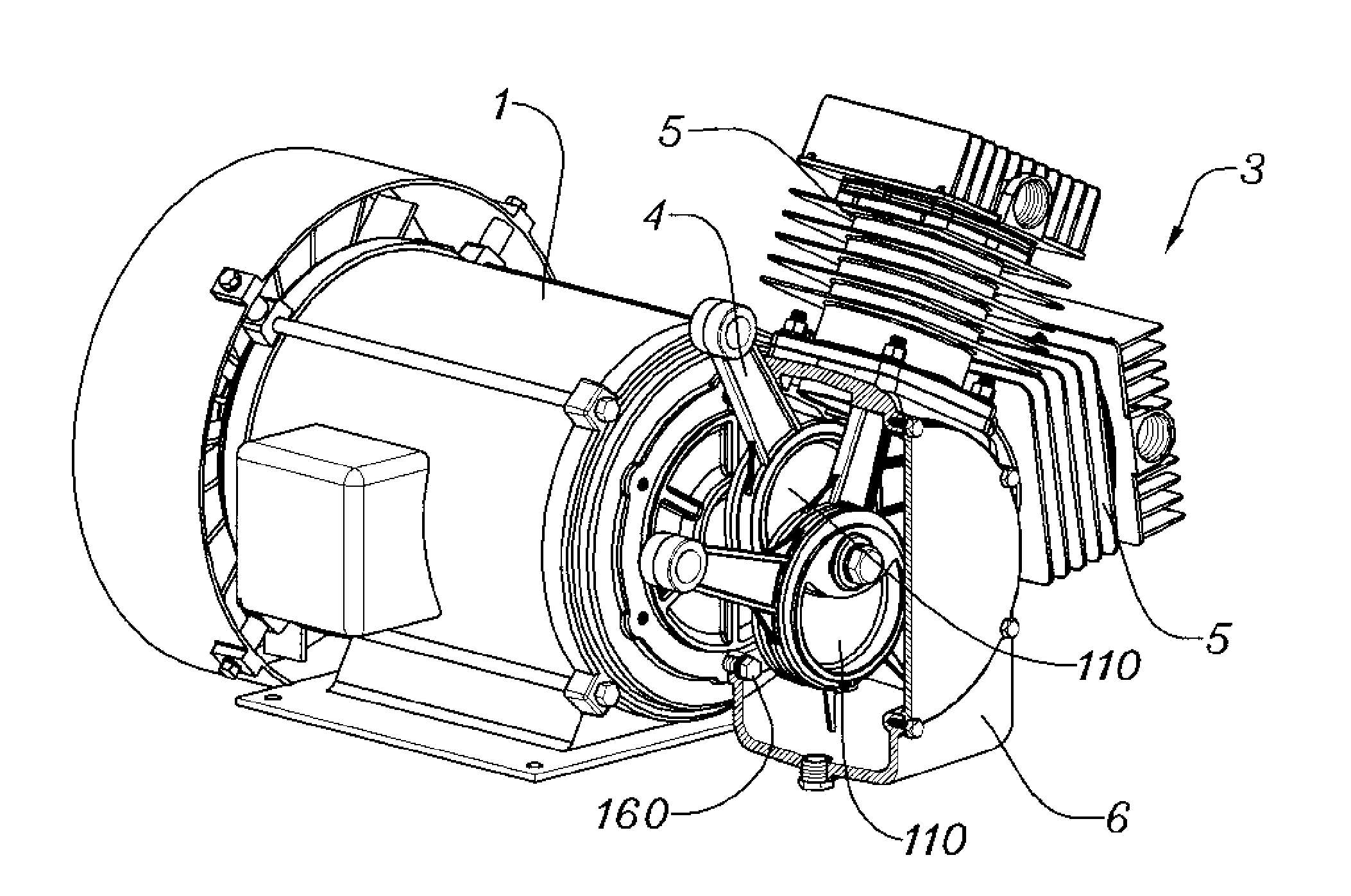

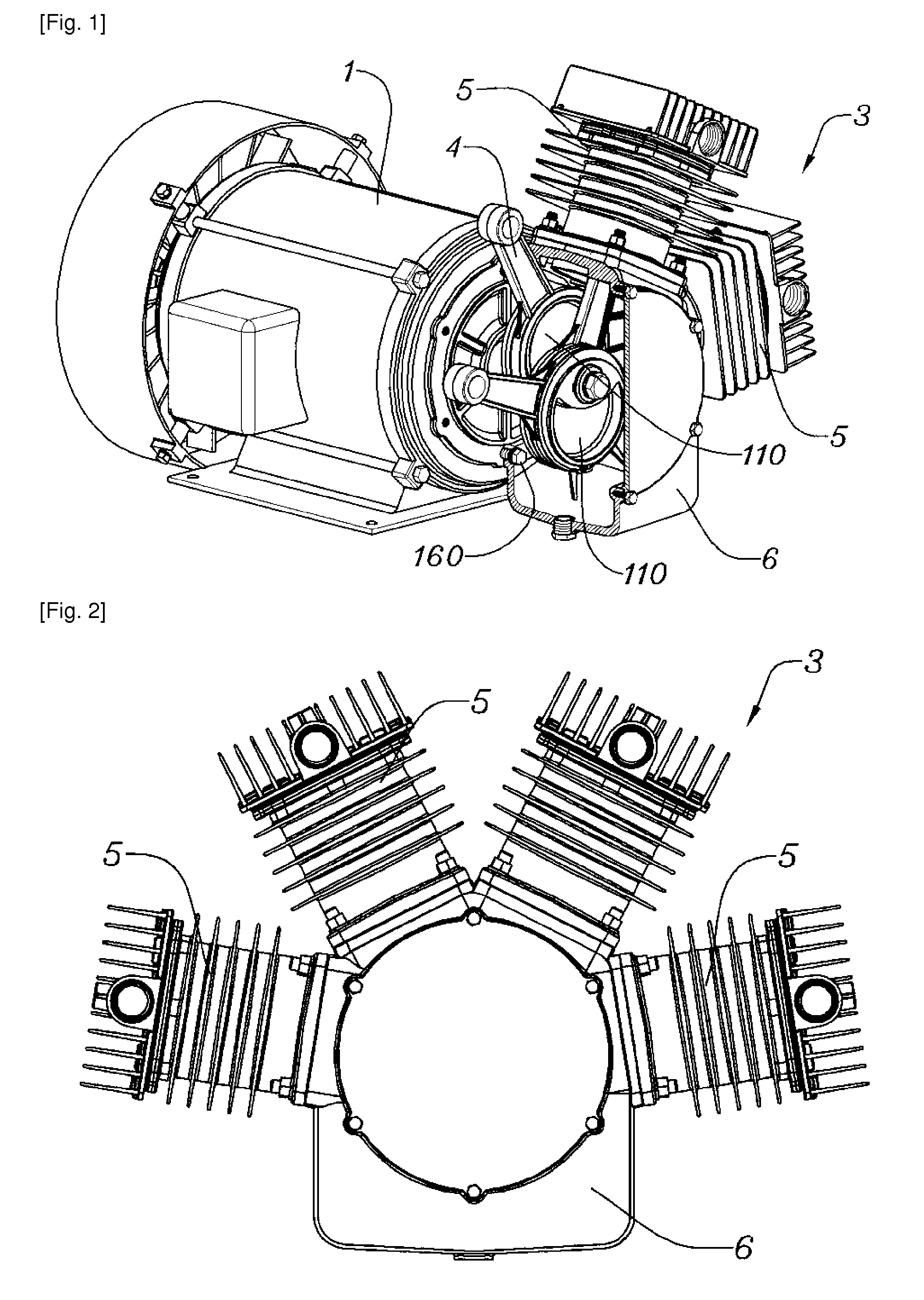

Direct crankshaft of air compressor

InactiveUS8388317B2Configured more compactlyCompact configurationPositive displacement pump componentsPortable liftingCompression PumpEngineering

There is provided a direct crankshaft of an air compressor for producing compressed air in which a crankshaft is implemented by two crank plates integrally overlapped with each other so that compression cylinders can be arranged in the radial direction to exhibit an excellent air cooling performance, top dead centers and bottom dead centers of the compression cylinders are symmetrically arranged so that the cancellation between pressurizing and vacuuming phenomena and the running of a motor can be smoothly performed, and the motor is integrated with a compression pump so that various driving components such as belts, pulleys, covers, and the like are eliminated and manufacturing costs are remarkably reduced. The direct crankshaft includes crank plates integrated with each other to form an overlapping unit. The overlapping unit has a shaft coupling hole through which a motor shaft penetrates such that the direct crankshaft is directly coupled with a motor.

Owner:KOHANDS CO LTD

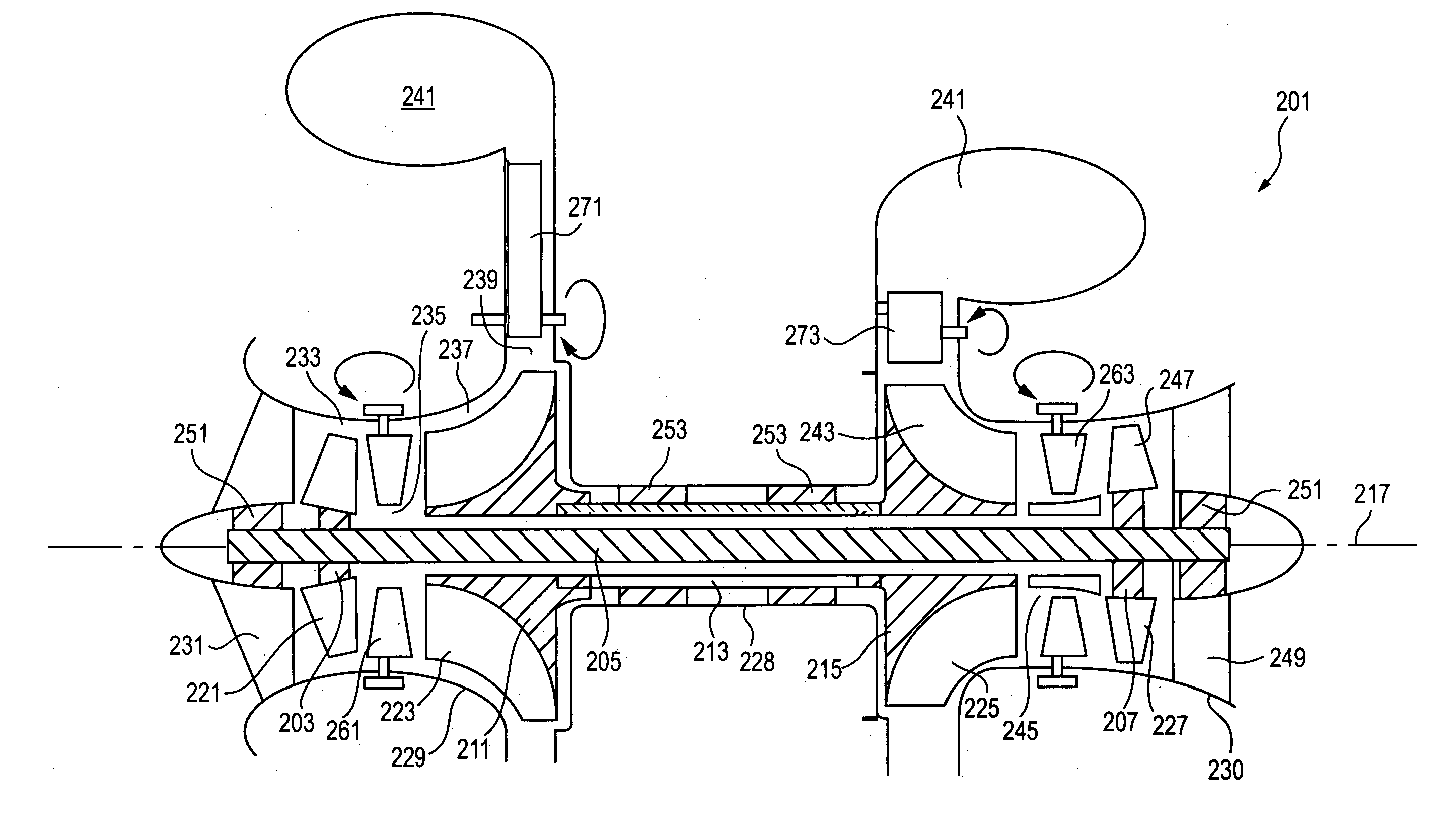

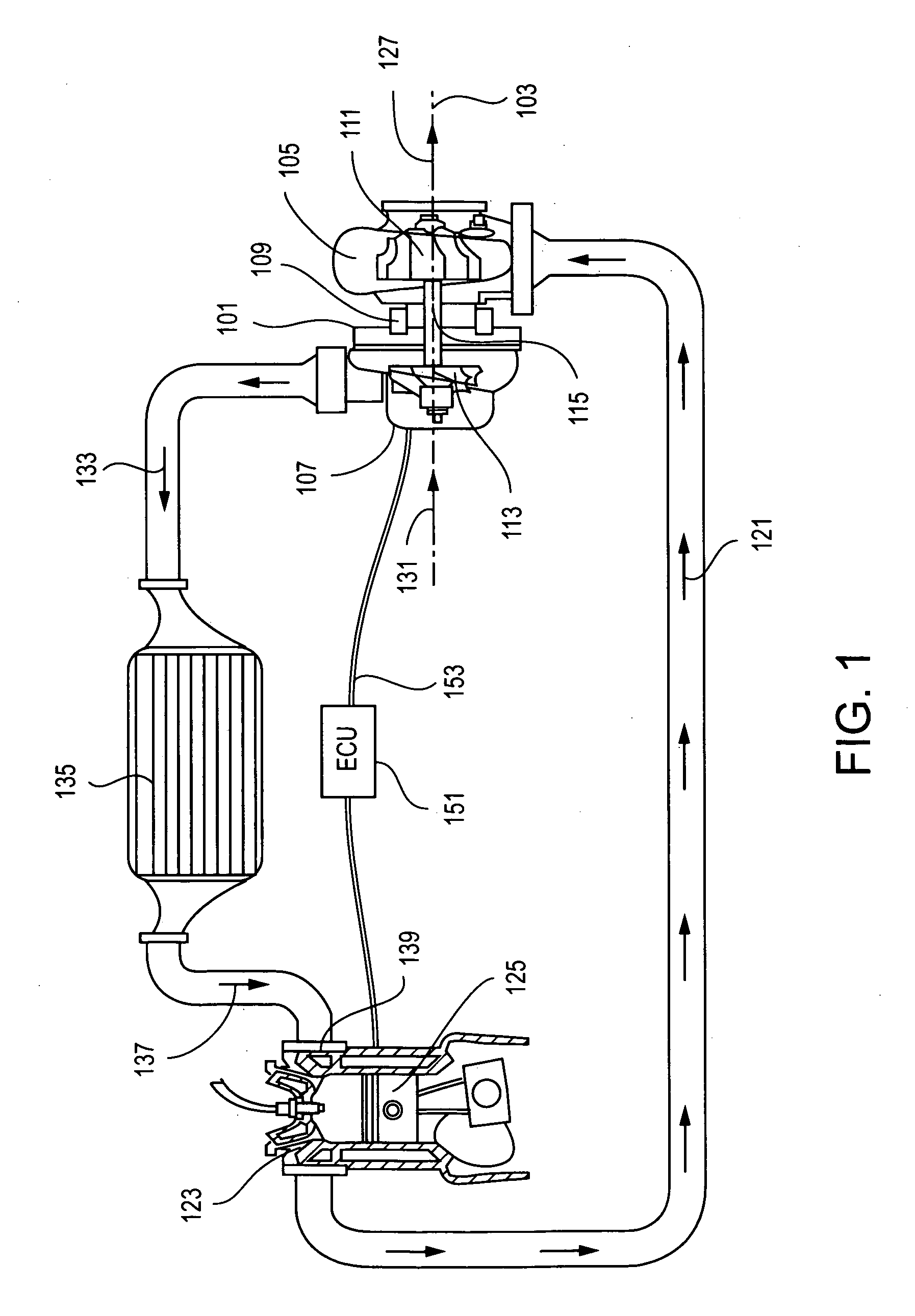

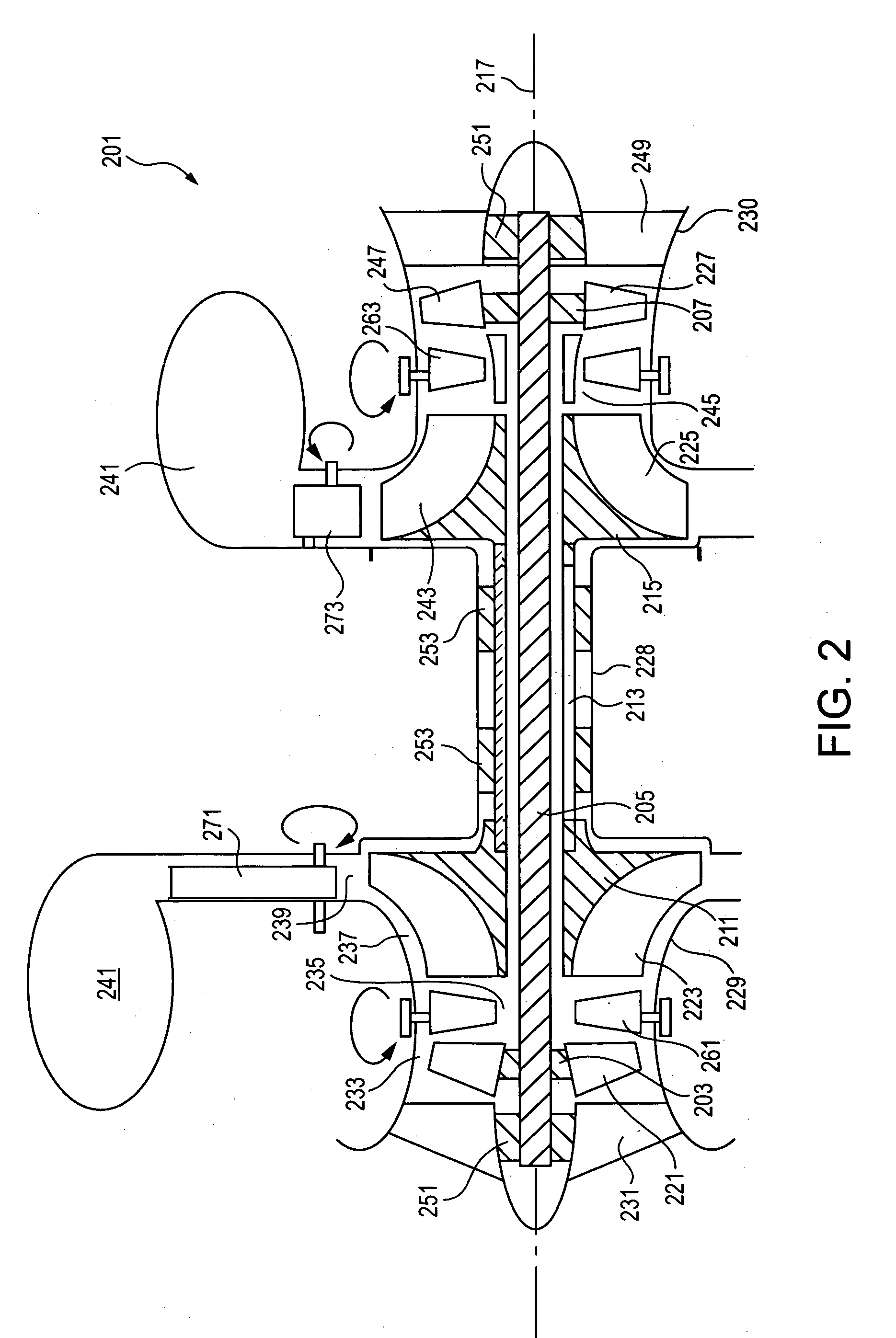

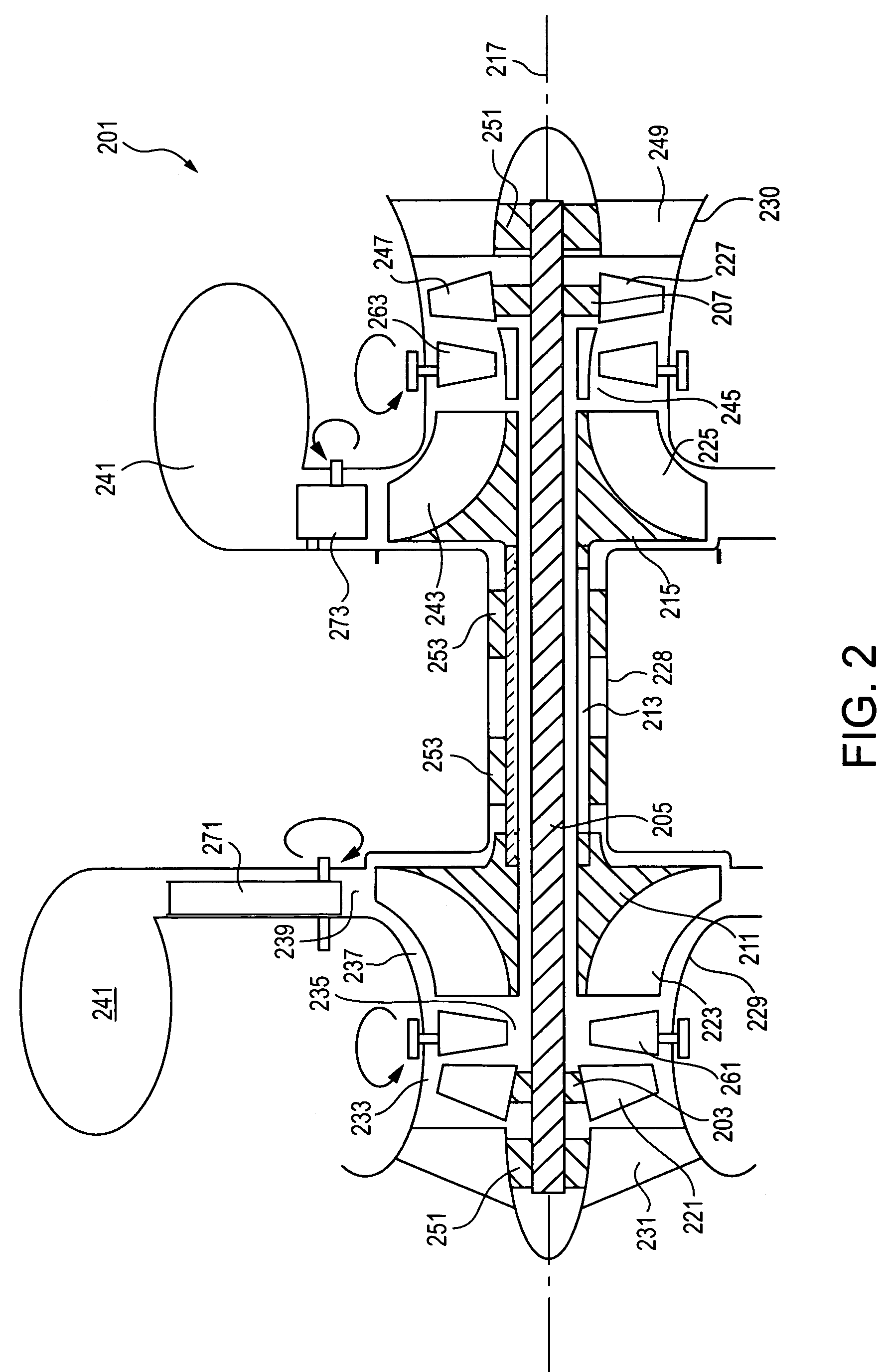

Two-shaft turbocharger

InactiveUS20070204615A1Improve transient response timeReduce morbidityInternal combustion piston enginesCombination enginesAxial compressorTurbine blade

A turbocharger, having an axial compressor wheel and an axial turbine wheel mounted on a first shaft supported by a housing, and a radial compressor wheel and a radial turbine wheel mounted on a second shaft, the second shaft concentrically extending around the first shaft and being supported by the housing. The housing defines a first duct extending axially from the exducer of the axial compressor to the inducer of the radial compressor, and a second duct extending axially from the exducer of the radial turbine to the inducer of the axial turbine. A plurality of controllable compressor guide vanes extend through the first duct, and a plurality of controllable turbine stator vanes extend through the second duct. The housing is provided with variable diffuser vanes at the exducer of the radial compressor, and with variable turbine vanes at the inducer of the radial turbine. The variable turbine vanes and the turbine stator vanes are controlled to accurately control the rotation rate of the radial and axial turbines. The compressor guide vanes are controlled to minimize surge and maximize choke flow rate.

Owner:HONEYWELL INT INC

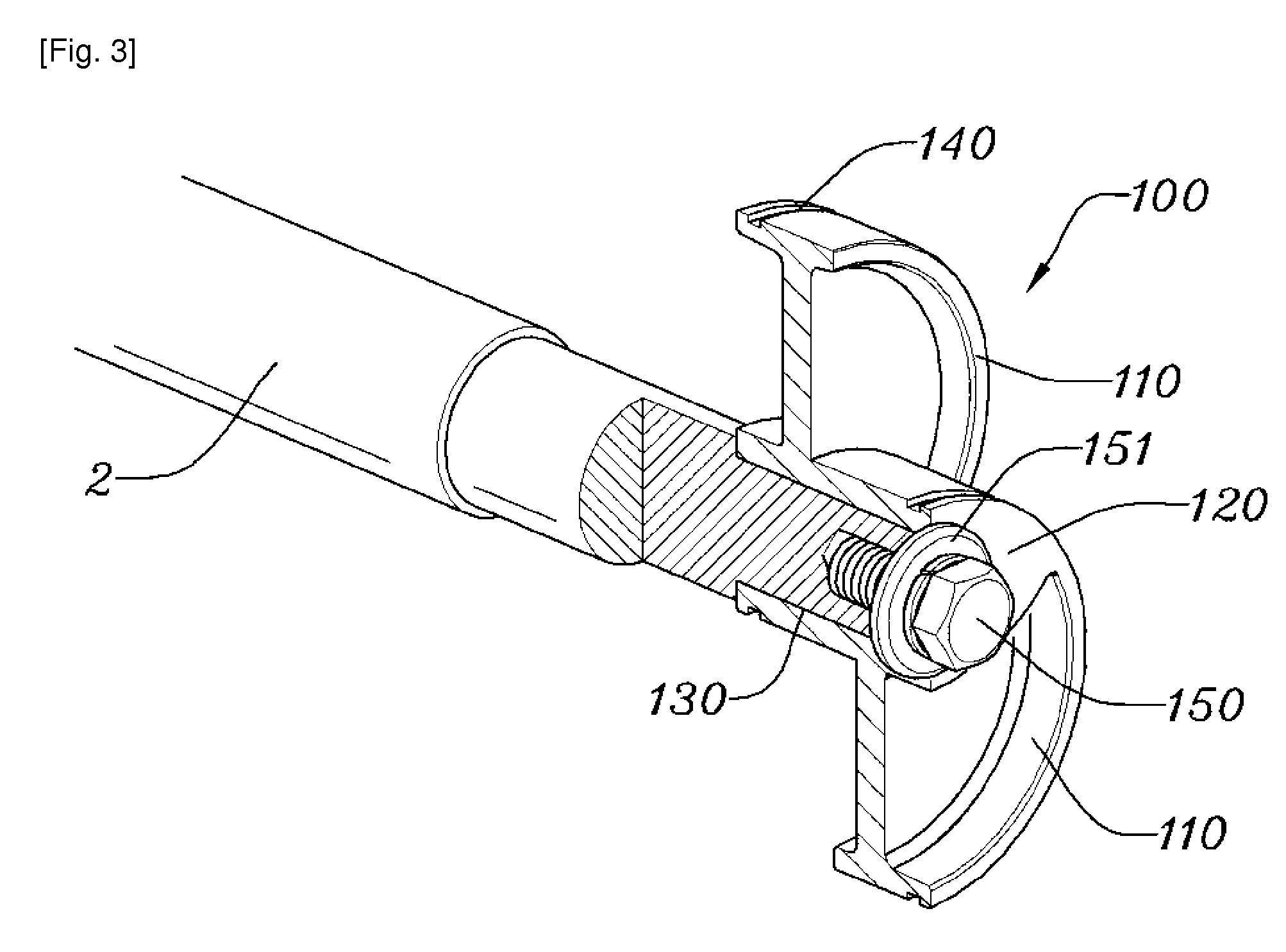

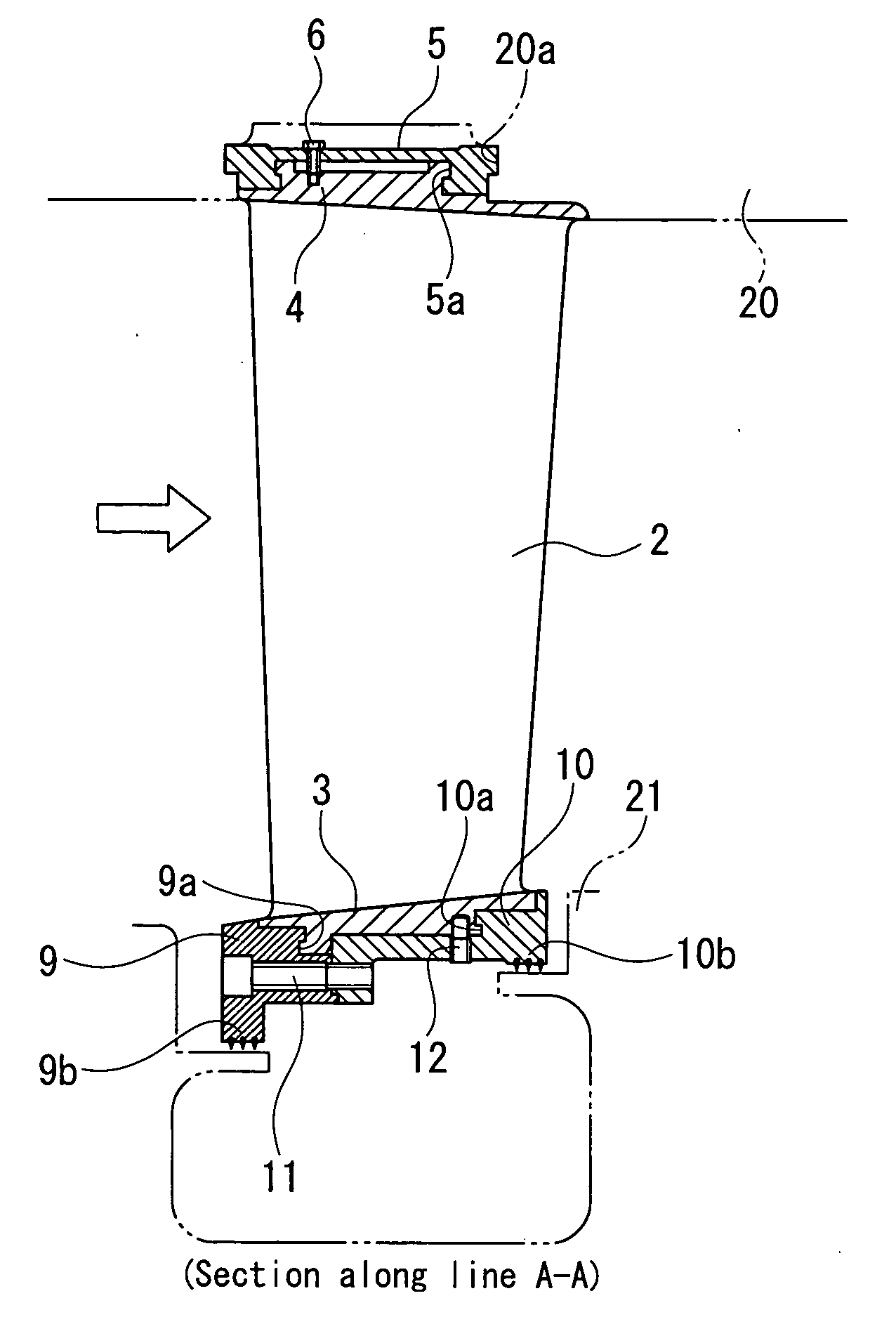

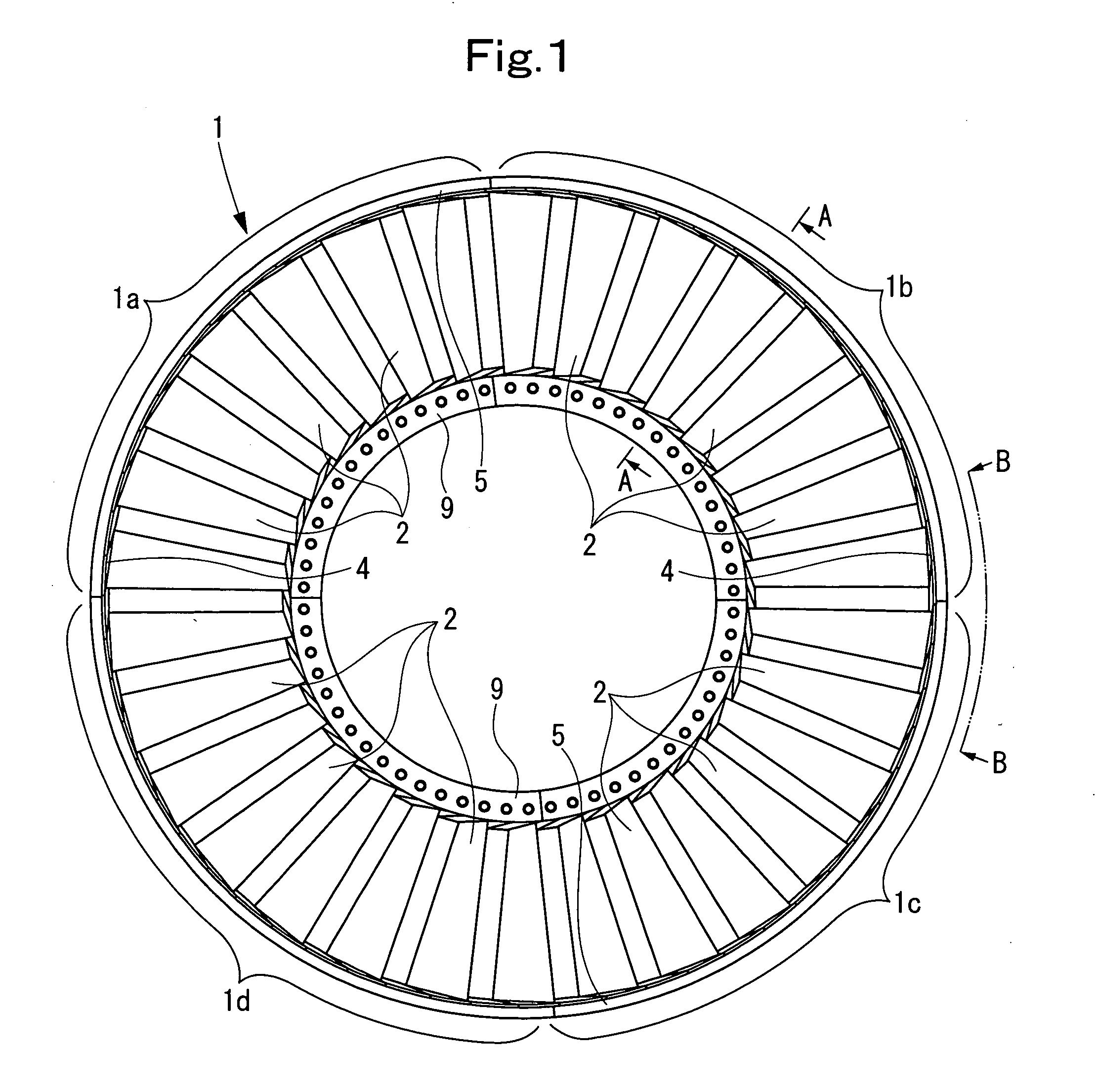

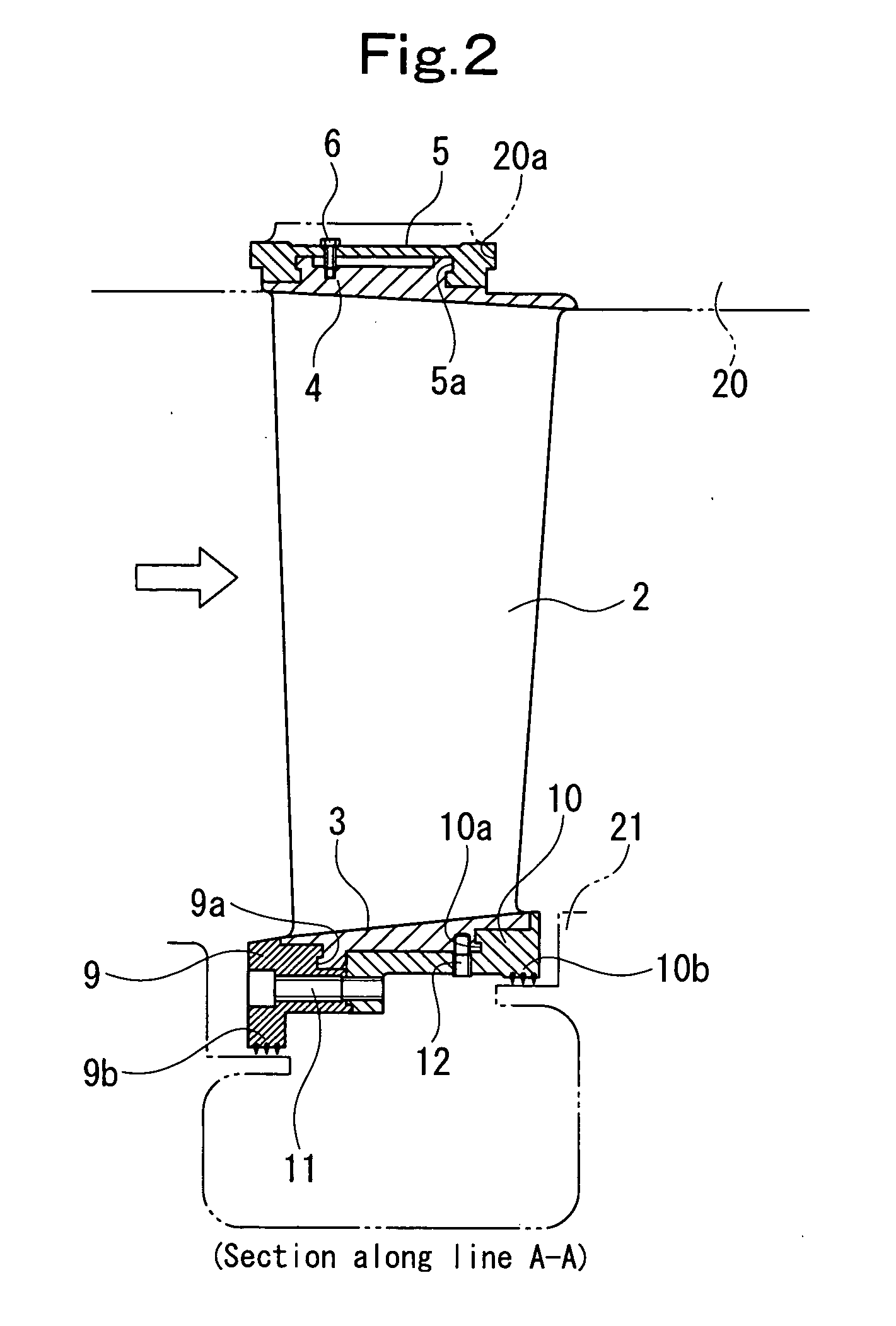

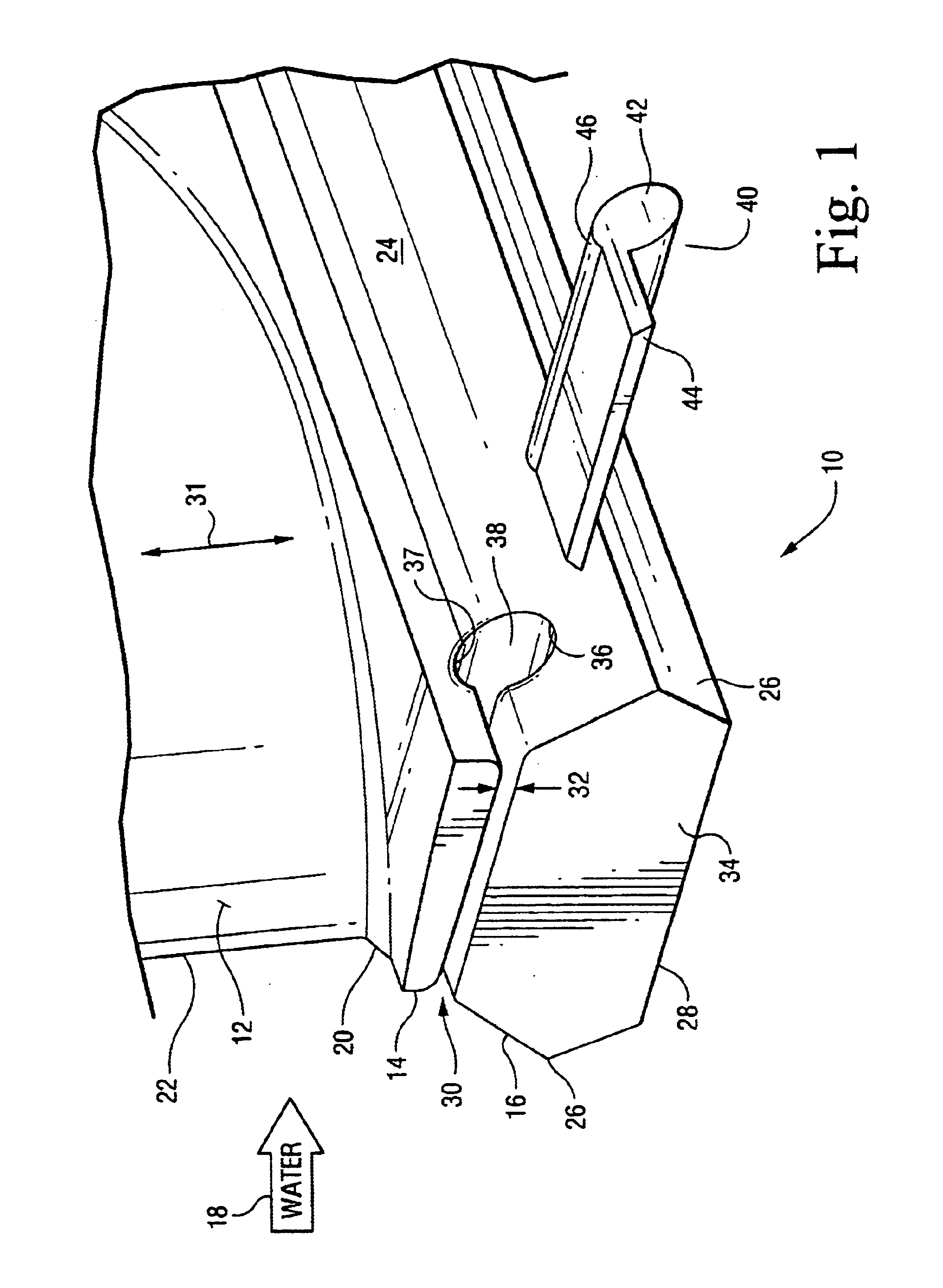

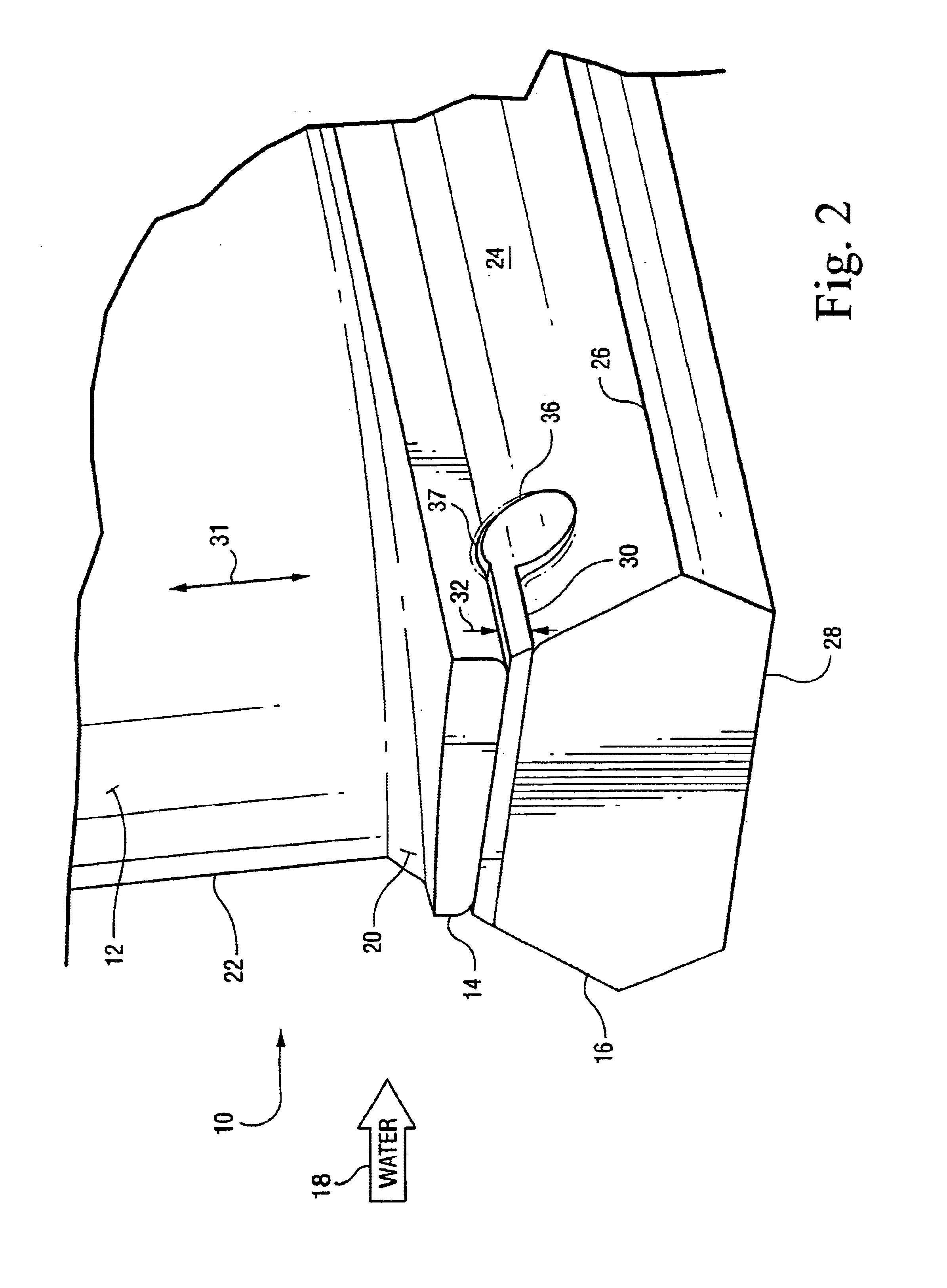

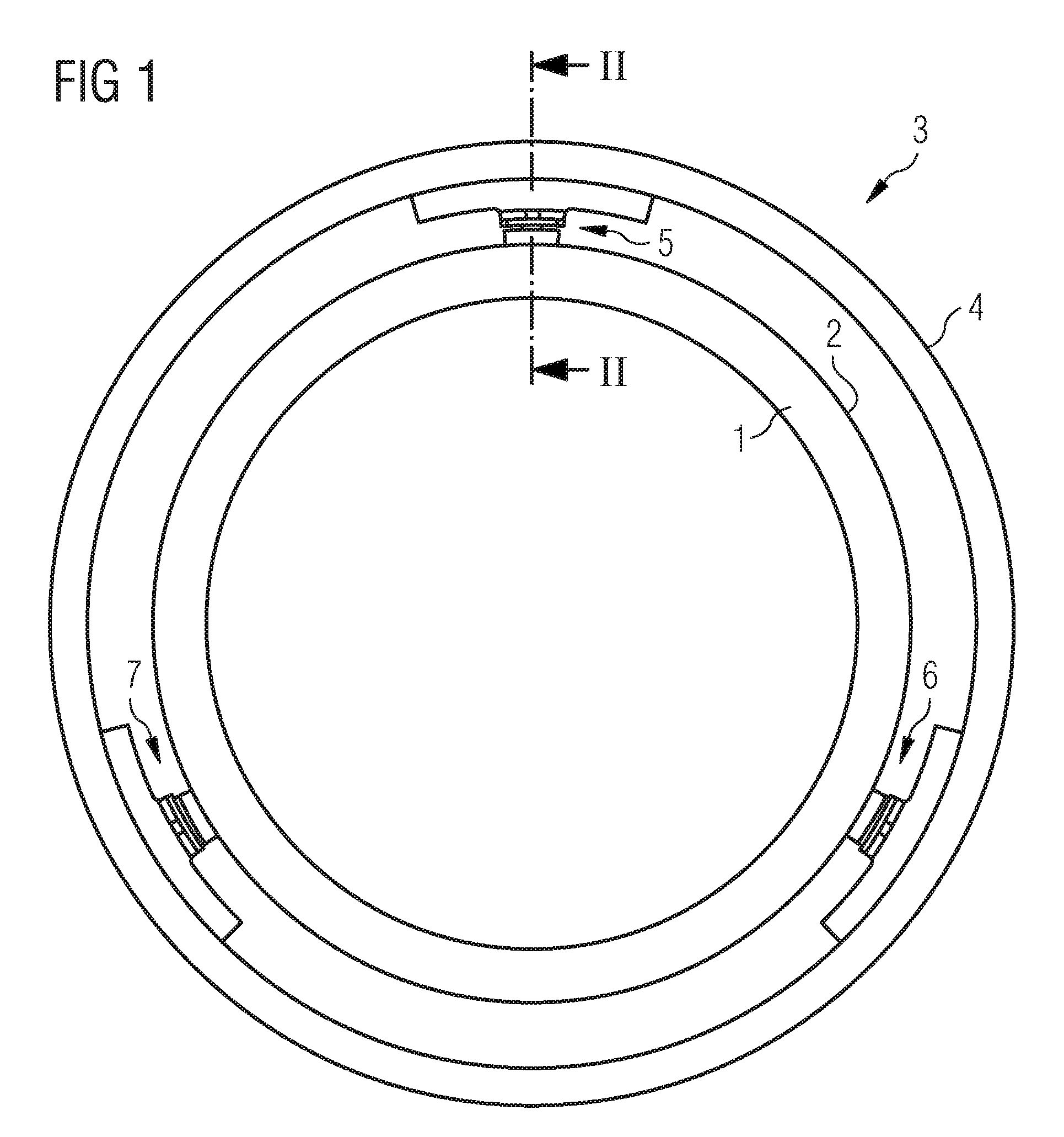

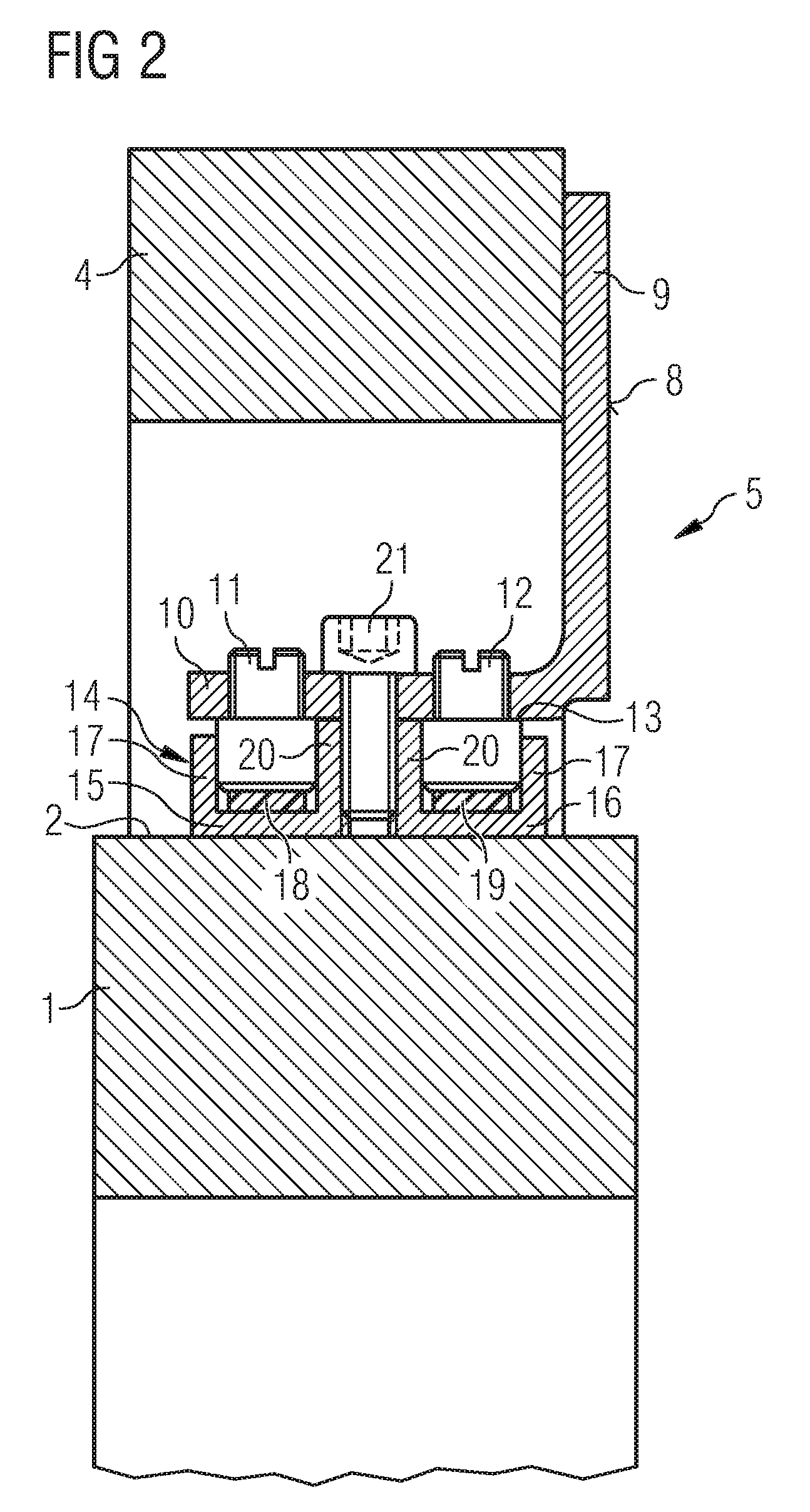

Stationary blade ring of axial compressor

ActiveUS20070177973A1Rule out the possibilityImprove reliabilityPump componentsEngine fuctionsAxial compressorWorking fluid

An inner shroud portion and an outer shroud portion dividedly formed per stationary blade are formed integrally with each stationary blade. A plurality of the stationary blades adjacent to each other in a circumferential direction are coupled together by a band member at the outer shroud portions. The inner shroud portions are held between seal holders which are formed as two divided members in the flowing direction of a working fluid, which are fastened by a bolt, and which have a length corresponding to the plurality of the stationary blades. The plurality of stationary blades, the inner and outer shroud portions, the band member, and the seal holders assembled in this manner constitute a unit. A plurality of the units are connected in the circumferential direction to constitute a stationary blade ring of an axial compressor.

Owner:MITSUBISHI POWER LTD

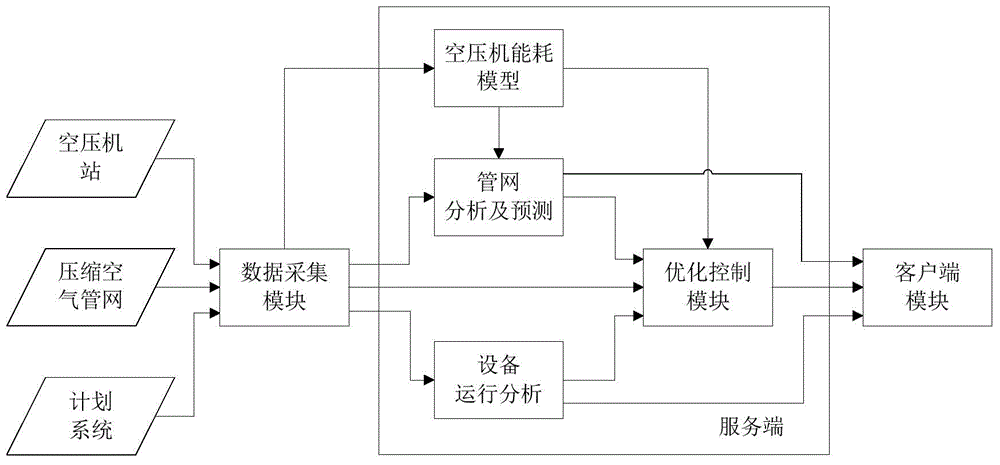

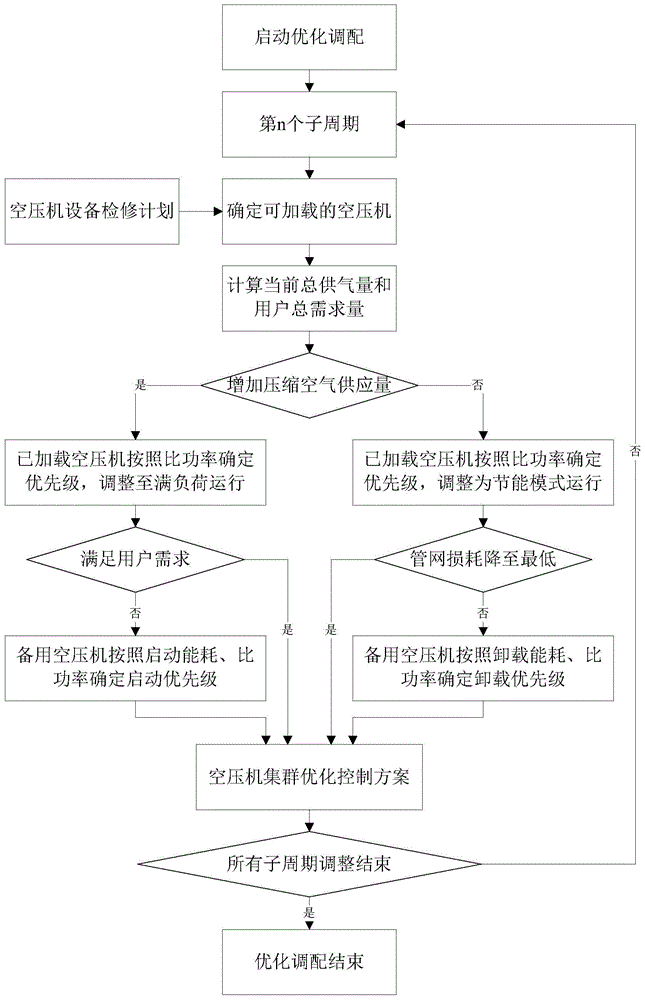

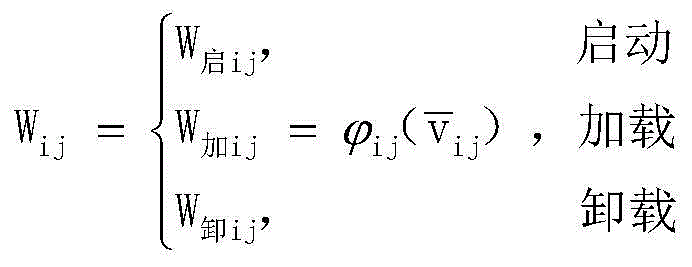

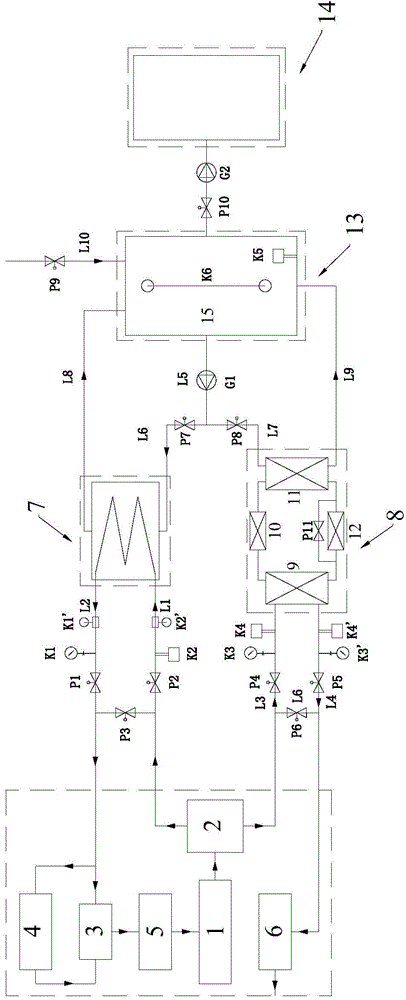

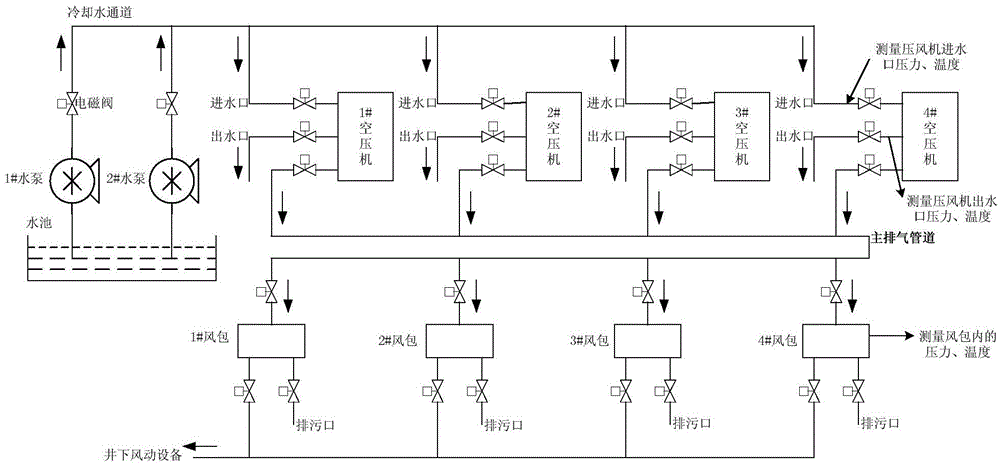

Cluster optimization control system for air compressor

InactiveCN104635684AReduce emptyingAccurate theoretical dataEnergy industryTechnology managementData informationData acquisition

The invention discloses a cluster optimization control system for an air compressor and belongs to the field of air-operated system energy saving. The cluster optimization control system comprises a data acquisition module, an air compressor energy consumption model, a pipeline network analysis and prediction module, an equipment operation analysis module, an optimization control module, four server-side modules and a client-side module; the data acquisition module is deployed on a data acquisition server; the four server-side modules are deployed on an application server; the client-side module is deployed on a client; the data acquisition server and the application server are connected through the Ethernet; the application server and the client are connected through the Ethernet; data information exchange is performed between the data acquisition module and the server-side module through inter-process message call; the data information exchange is performed between the data acquisition module and the server-side module through network message call; the client-side module is connected with the server-side module through a network message. The cluster optimization control system has the advantages that the cluster energy consumption of the air compressor is minimum under the condition that the demands of compressed air users change, and on the premise that the normal running of the air compressor equipment is ensured, the equipment efficiency is increased, the service life of the equipment is prolonged, energy consumption can be reduced to a certain degree, and the production running cost is reduced.

Owner:AUTOMATION RES & DESIGN INST OF METALLURGICAL IND

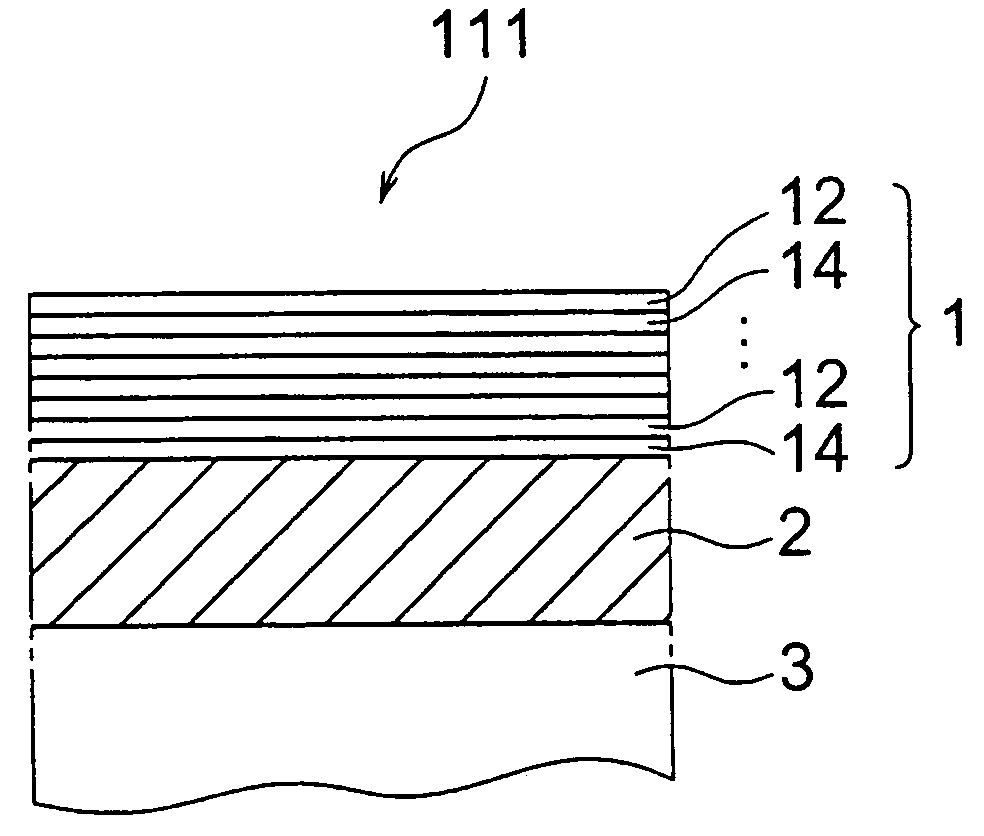

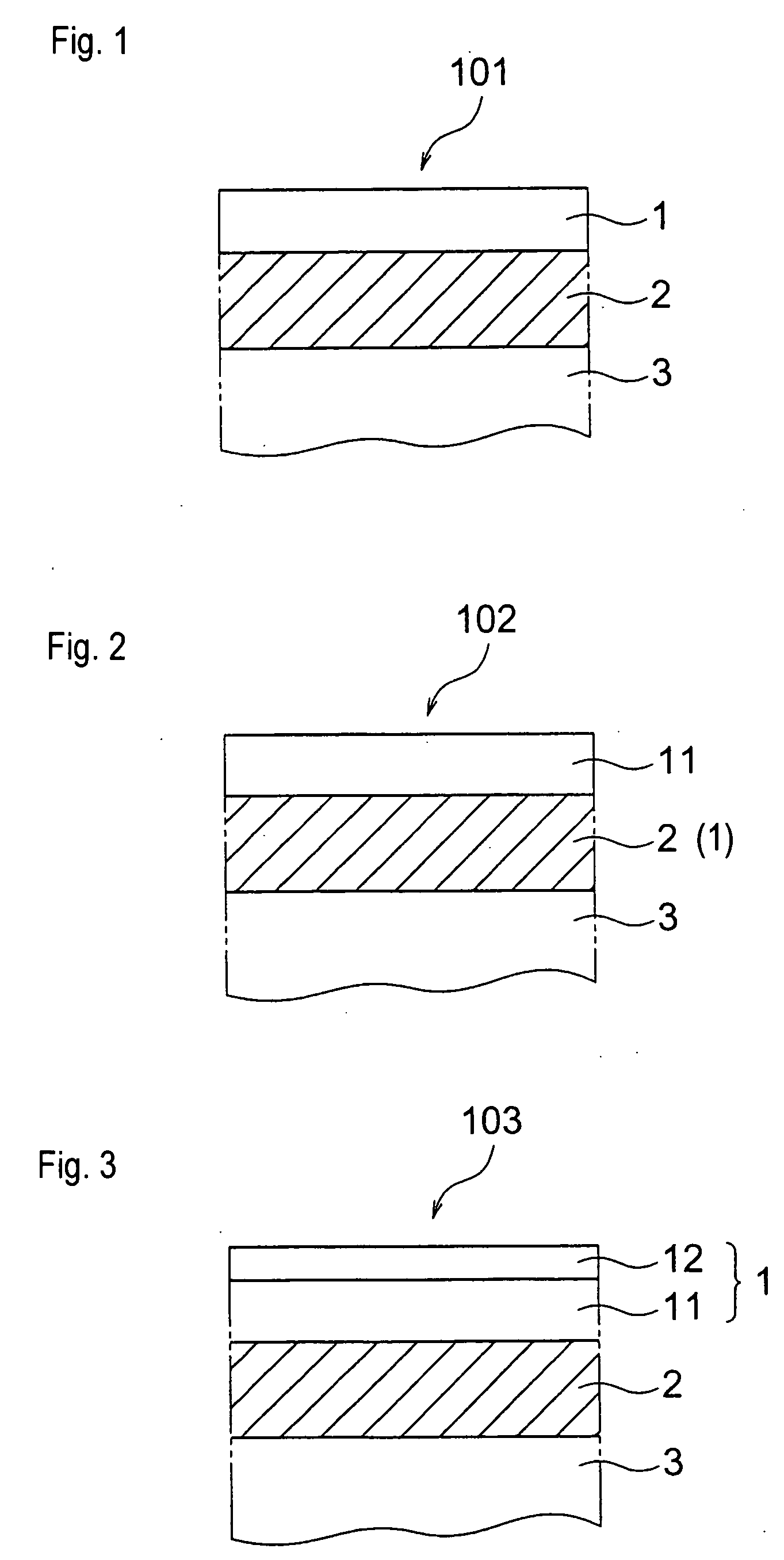

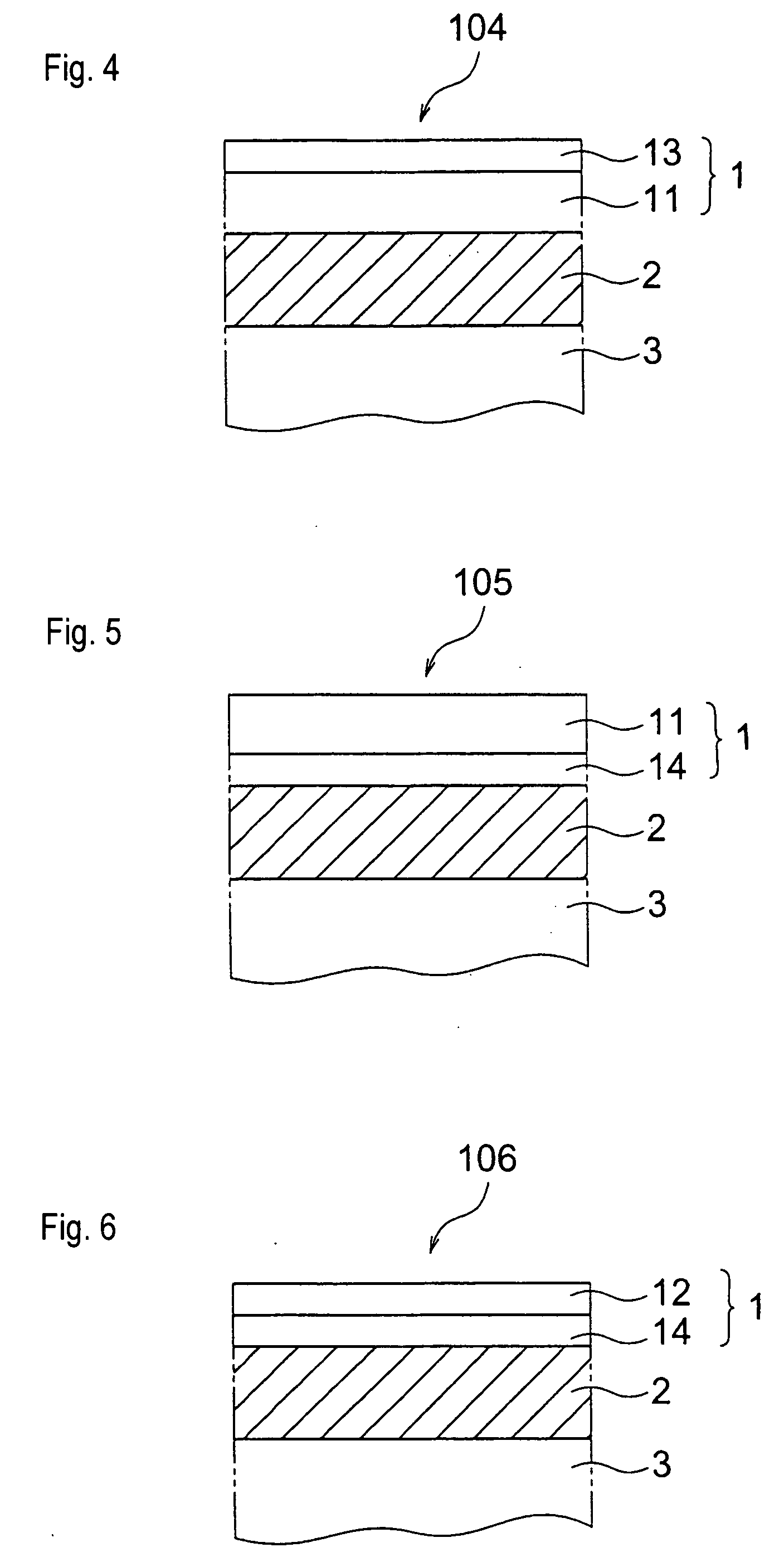

Solid Particle Erosion Resistant Surface Treated Coat and Rotating Machine Applied Therewith

ActiveUS20090123737A1Improve fatigue strengthHigh erosion resistance and oxidation resistance and fatigue strengthLiquid surface applicatorsPump componentsAxial compressorSolid particle

A solid particle erosion resistant surface treated coat is provided by which a solid, particle erosion resistance is largely enhanced and a rotating member is given with an oxidation resistance without deteriorating a fatigue strength. Also, a rotating machine, such as a steam turbine, axial compressor or the like, applied with this coat is provided. The solid particle erosion resistant surface treated coat comprises a nitrided hard layer formed on a surface of base material and a PVD (physical vapor deposition) hard layer of at least one layer formed on the nitrided hard layer by a PVD method. The nitrided hard layer has a thickness of at least 30 μm. The PVD hard layer has a total thickness of at least 10 μm. Deformation of the base material by collisions by solid particles is prevented and crack of the coat comprising the nitrided hard layer formed on the base material and the PVD hard layer formed on the nitrided hard layer is prevented. Thereby, the solid particle erosion resistance is secured, life of the solid particle erosion resistant surface treated coat can be elongated and the oxidation resistance and fatigue strength are enhanced.

Owner:MITSUBISHI HEAVY INDUSTIES COMPRESSOR CORP

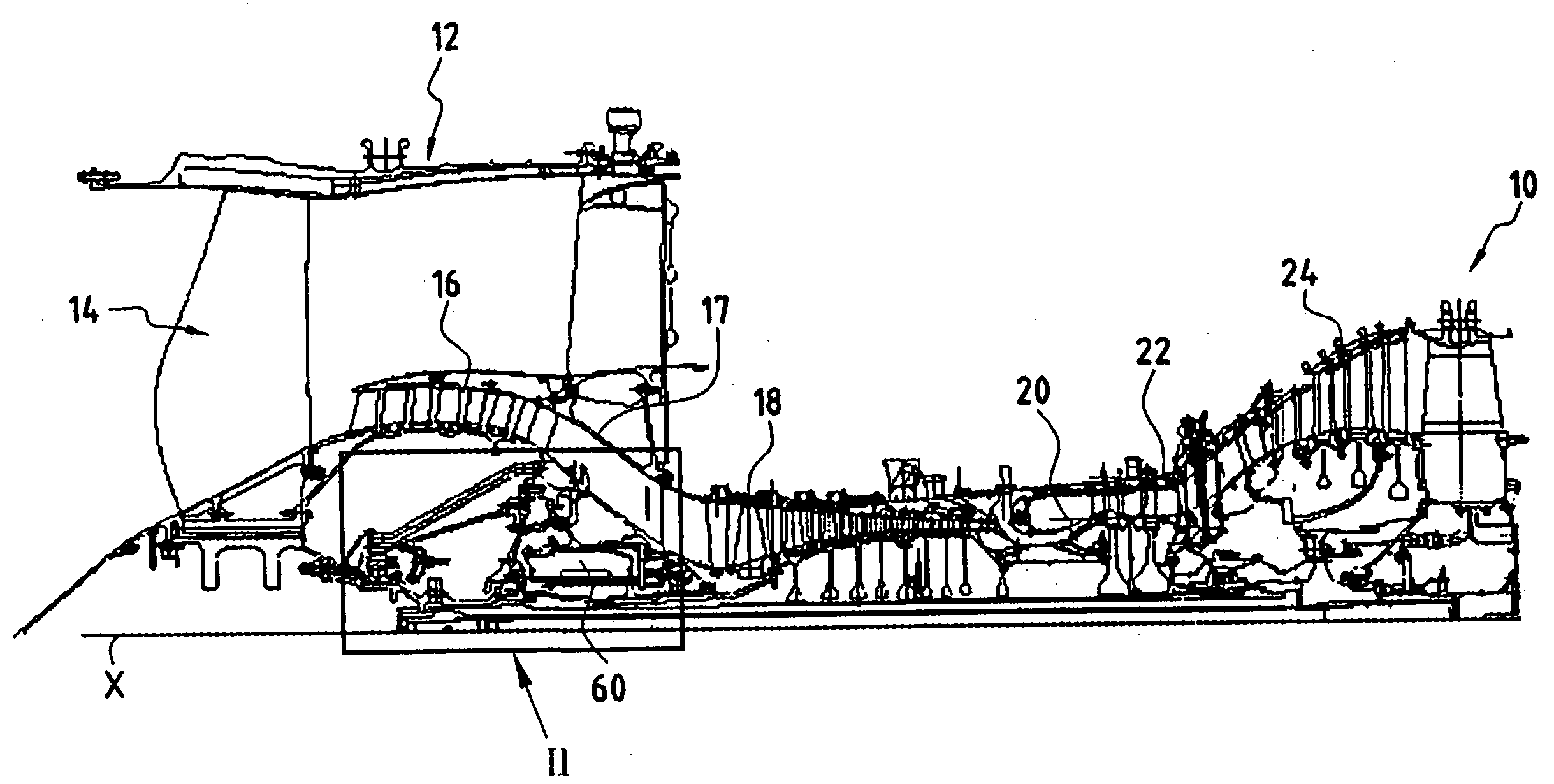

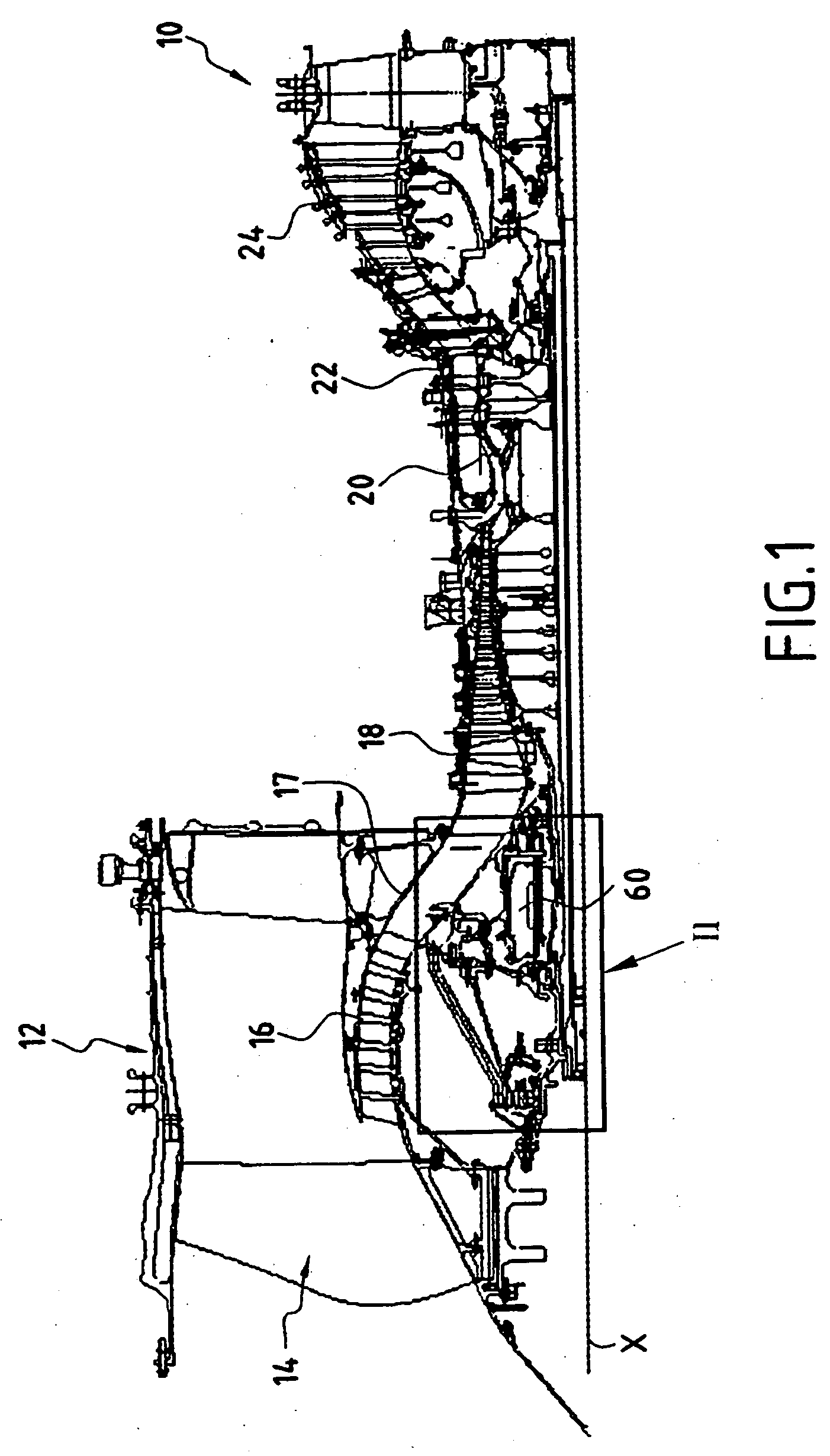

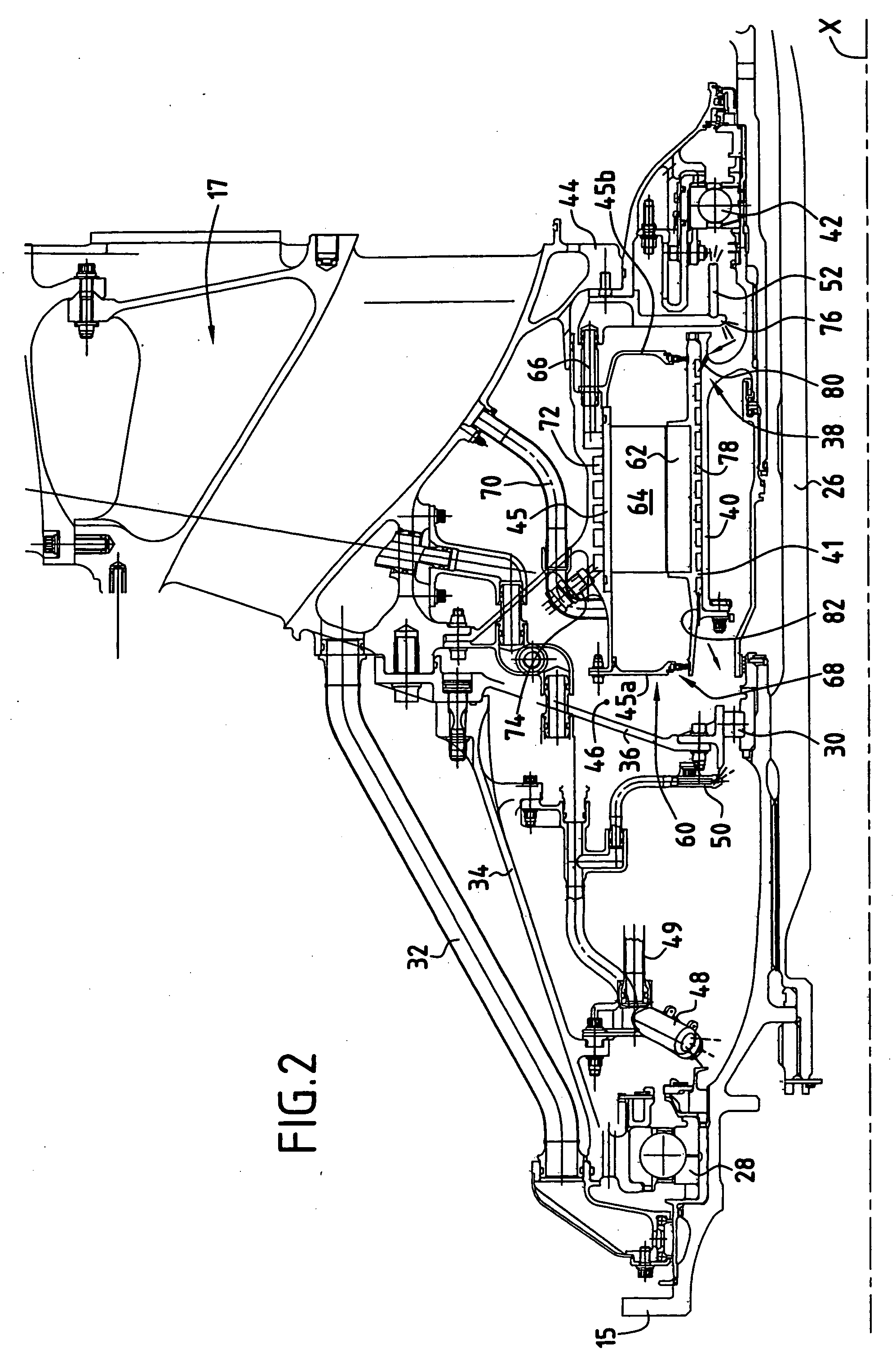

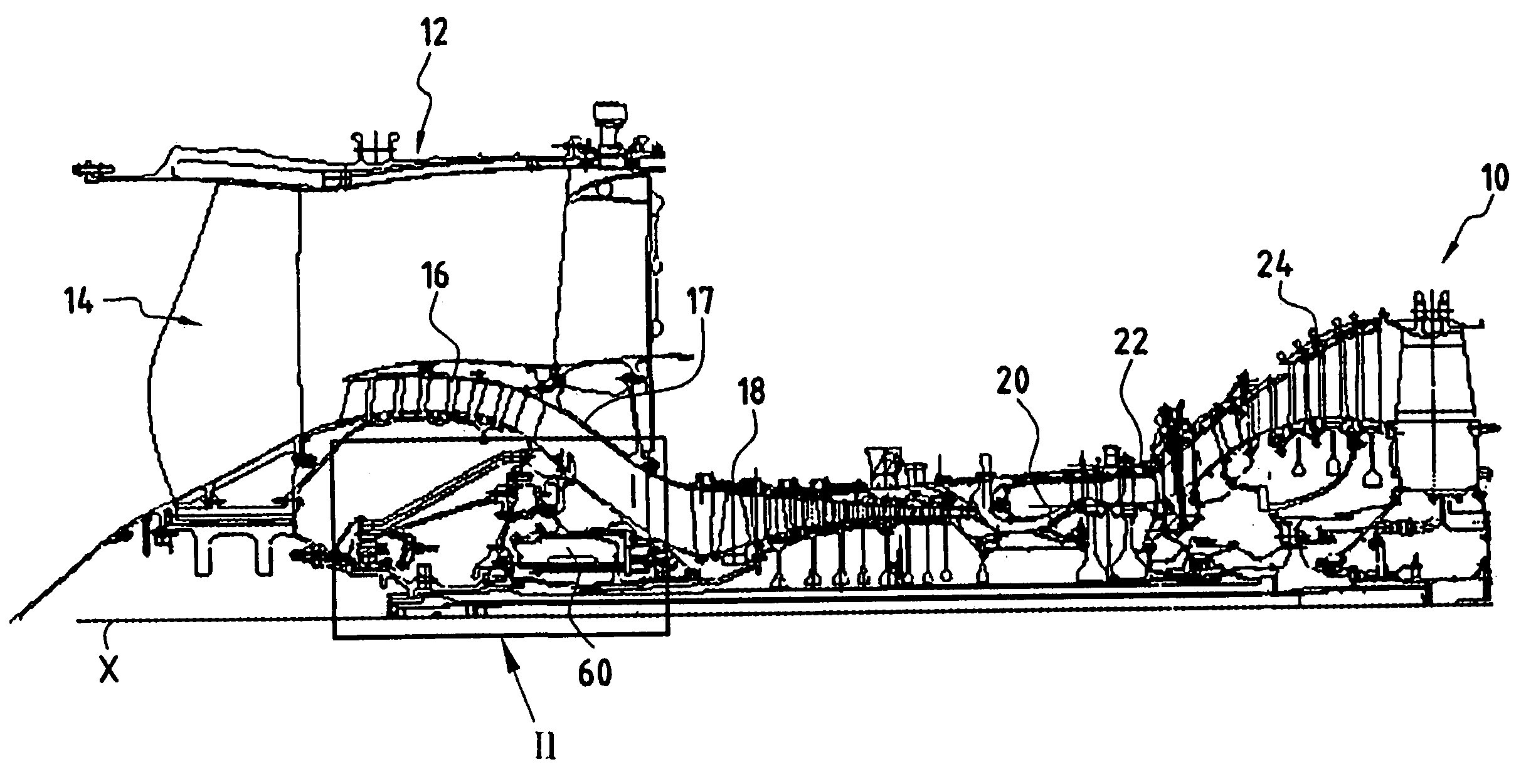

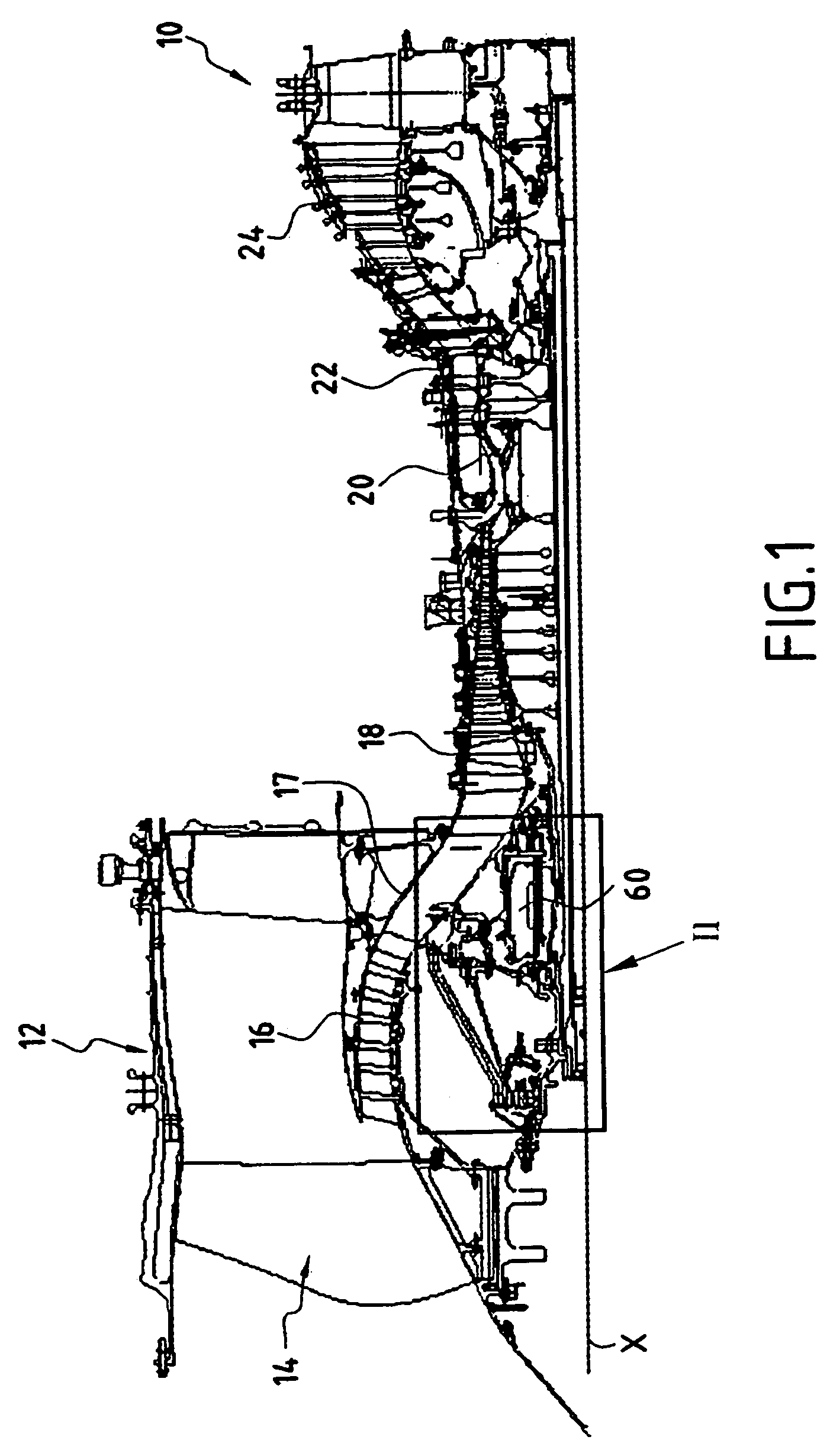

Turbomachine including an integrated electricity generator

ActiveUS20060108807A1Eliminates mechanical connectionsEliminate angle takeoffEngine fuctionsEfficient propulsion technologiesElectricityAxial compressor

The invention relates to a turbomachine comprising a high-pressure spool, an axial compressor of axis X mounted on a rotor and comprising a casing and at least one rear bearing disposed between the casing and the rotor of said compressor, said turbomachine further comprising an electricity generator coaxial with said spool and including a primary magnetic circuit that is constrained to rotate with said rotor of the compressor and a secondary magnetic circuit that is secured to said casing. In characteristic manner, said electricity generator is disposed upstream from said rear bearing and includes at least a first cooling circuit surrounding said secondary magnetic circuit and extended by a nozzle for lubricating said rear bearing.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

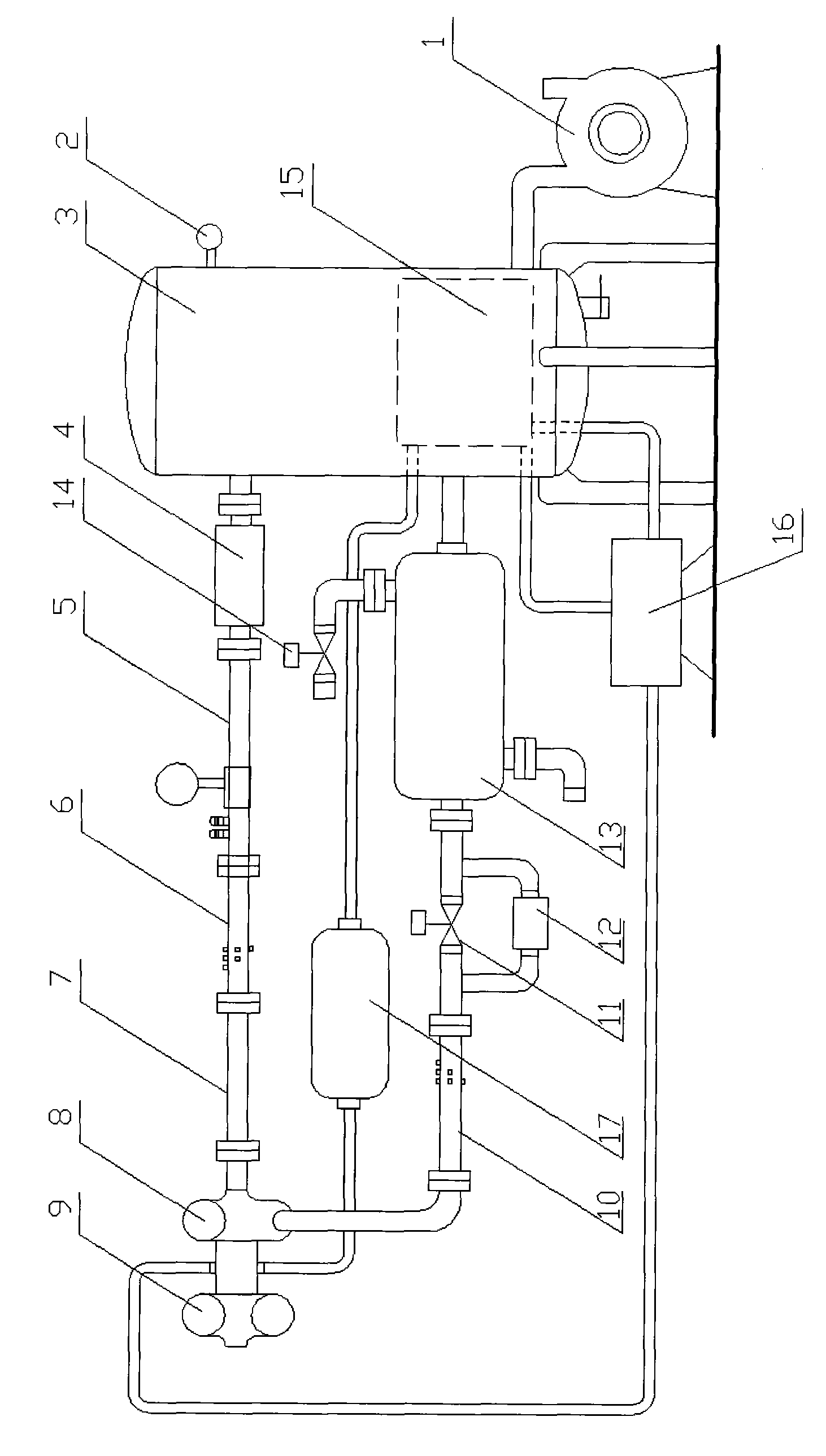

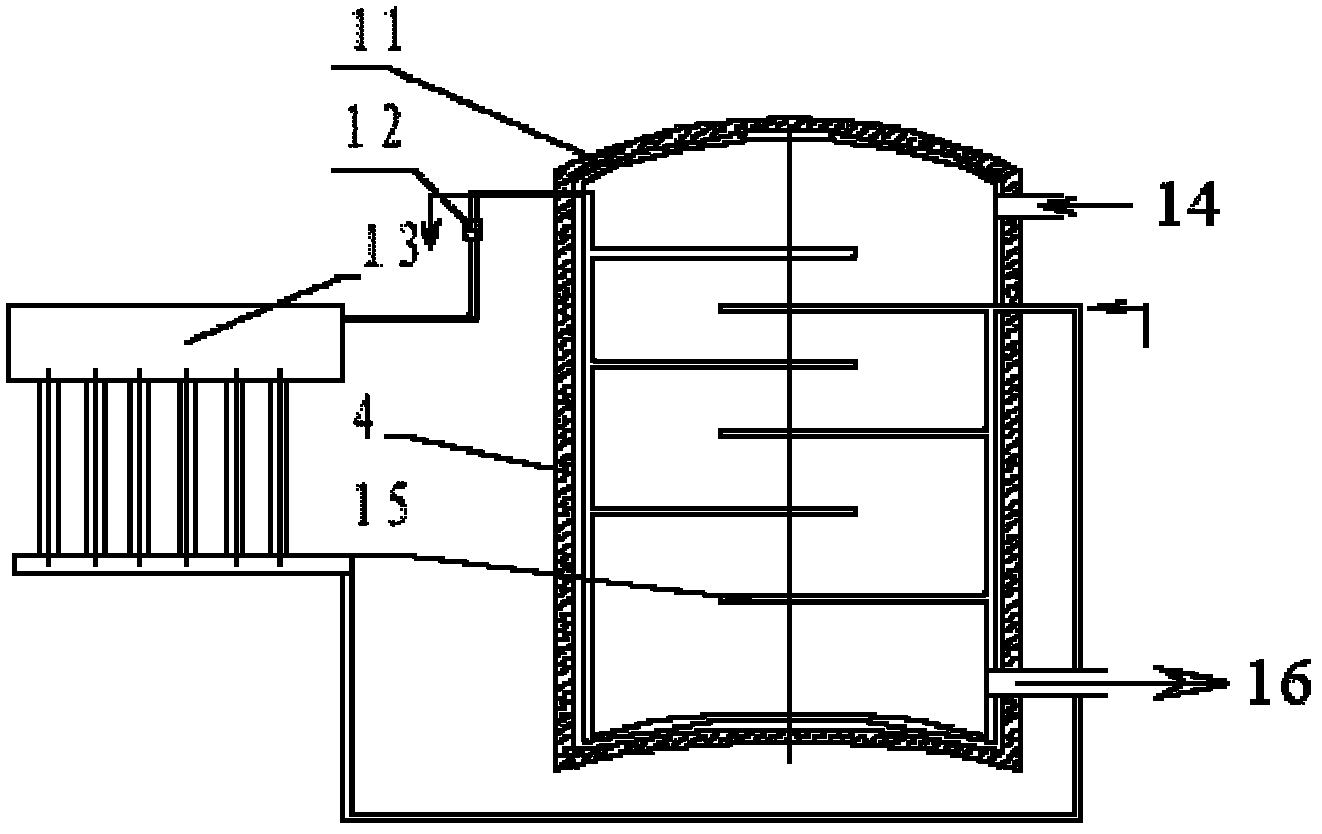

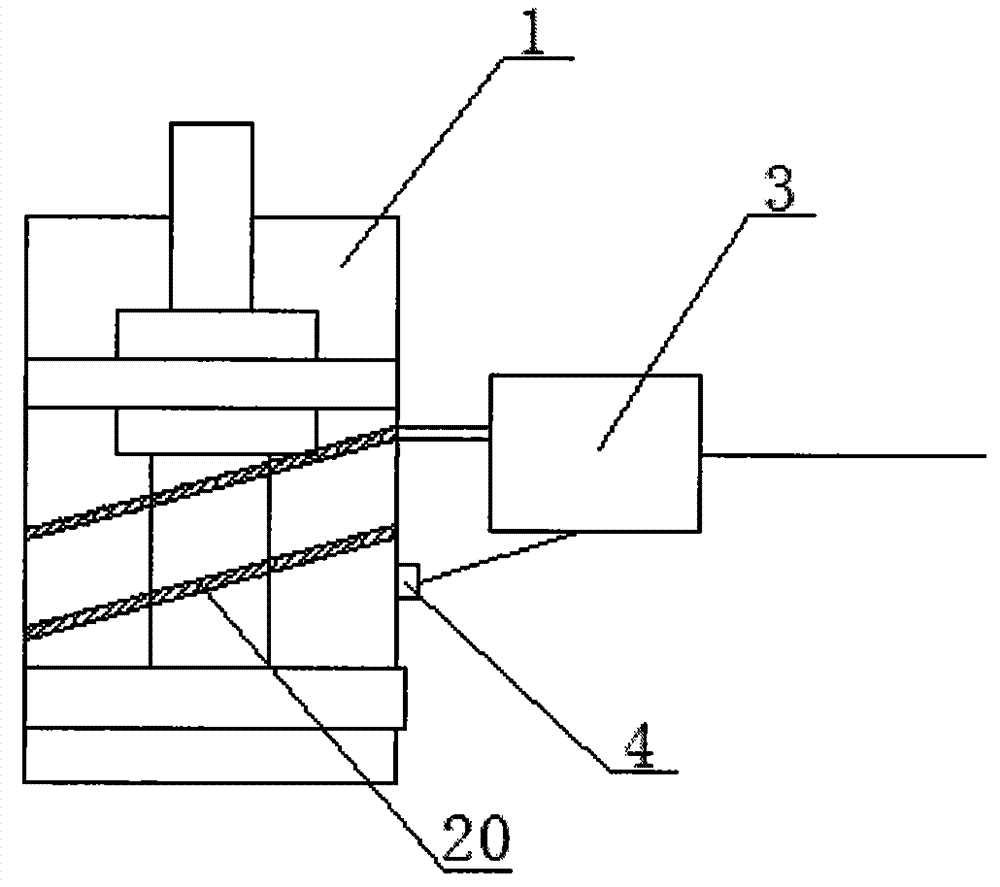

Waste heat recovery device of air compressor and control method of waste heat recovery device

ActiveCN104061680AGuaranteed heat exchange effectEfficient use ofHeat pumpsPositive displacement pump componentsAxial compressorWaste heat recovery unit

The invention discloses a waste heat recovery device of an air compressor and a control method of the waste heat recovery device. The waste heat recovery device comprises heat exchanging modules and enhanced heat exchanging modules, wherein the heat exchanging modules are arranged in parallel at the two ends of an oil-channel electric valve; the reinforcing heat exchanging modules are arranged in parallel at the two ends of the air-channel electric valve; the heat exchanging modules and the reinforcing heat exchanging modules are utilized to recover and store the heat energy in circulating oil and the heat energy in compressed air lost and wasted when the air compressor operates; the heat energy of the compressed air can be recycled at highest efficiency under the premise that the operation of the air compressor is not impacted. According to the waste heat recovery device of the air compressor and the control method of the waste heat recovery device, the collected data are analyzed and operated so as to realized effective high intelligent control; not only is the efficiency of the operation of the air compressor improved, but also the energy input of the heat energy utilizing modules can be reduced, the energy consumption or fuels for heating are lowered, and energy comprehensive utilizing degree is improved. Therefore, the waste heat recovery device has the advantages that the energy-saving effect is good, the intelligent degree is high, and the stability is excellent.

Owner:ZHEJIANG UNIV

Two-shaft turbocharger

InactiveUS7571607B2Easy to controlIncrease pressure ratioInternal combustion piston enginesCombination enginesAxial compressorImpeller

Owner:HONEYWELL INT INC

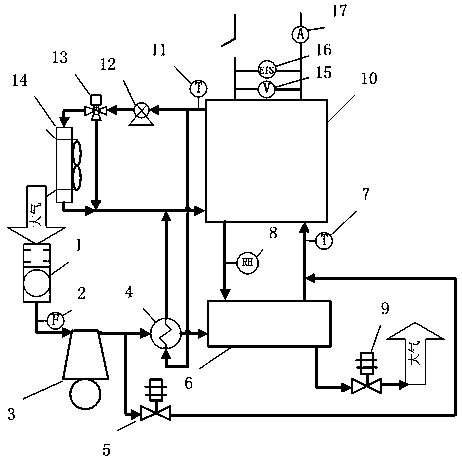

High-altitude and low-pressure characteristic simulation test station of air compressor in internal-combustion engine

The invention discloses a high-altitude and low-pressure characteristic simulation test station of an air compressor in an internal-combustion engine, relating to a characteristic simulation test station of an air compressor in an internal-combustion engine, and comprising an air pipeline system and a lubricating system, wherein the air pipeline system comprises a vacuum pump, a pressure stabilizing box, and an air filter, a flow testing section, an air inlet parameter testing section, a flow stabilizing section and an air compressor sequentially connected with an outlet of the pressure stabilizing box, and an air exhaust parameter testing section, a back pressure regulating valve, a stopping valve and an air exhaust intercooler sequentially connected with an outlet of the air compressor;the lubricating system comprises an oil tank, an oil supplying system and a lubricant intercooler; an outlet of the air exhaust intercooler is connected with the pressure stabilizing box so that an air pipeline of the test station forms a sealed air circulation system; and the oil tank is arranged inside the pressure stabilizing box so as to improve the sealing property of the test station. The test station can simulate the environmental pressure at the altitude of 0-30,000 meters and performs the high-altitude simulation characteristic test of the air compressor in the turbo-charged internal-combustion engine, therefore, the sealing property and simulated altitude of the test station are higher than those of the existing simulation test station of the same type.

Owner:TSINGHUA UNIV

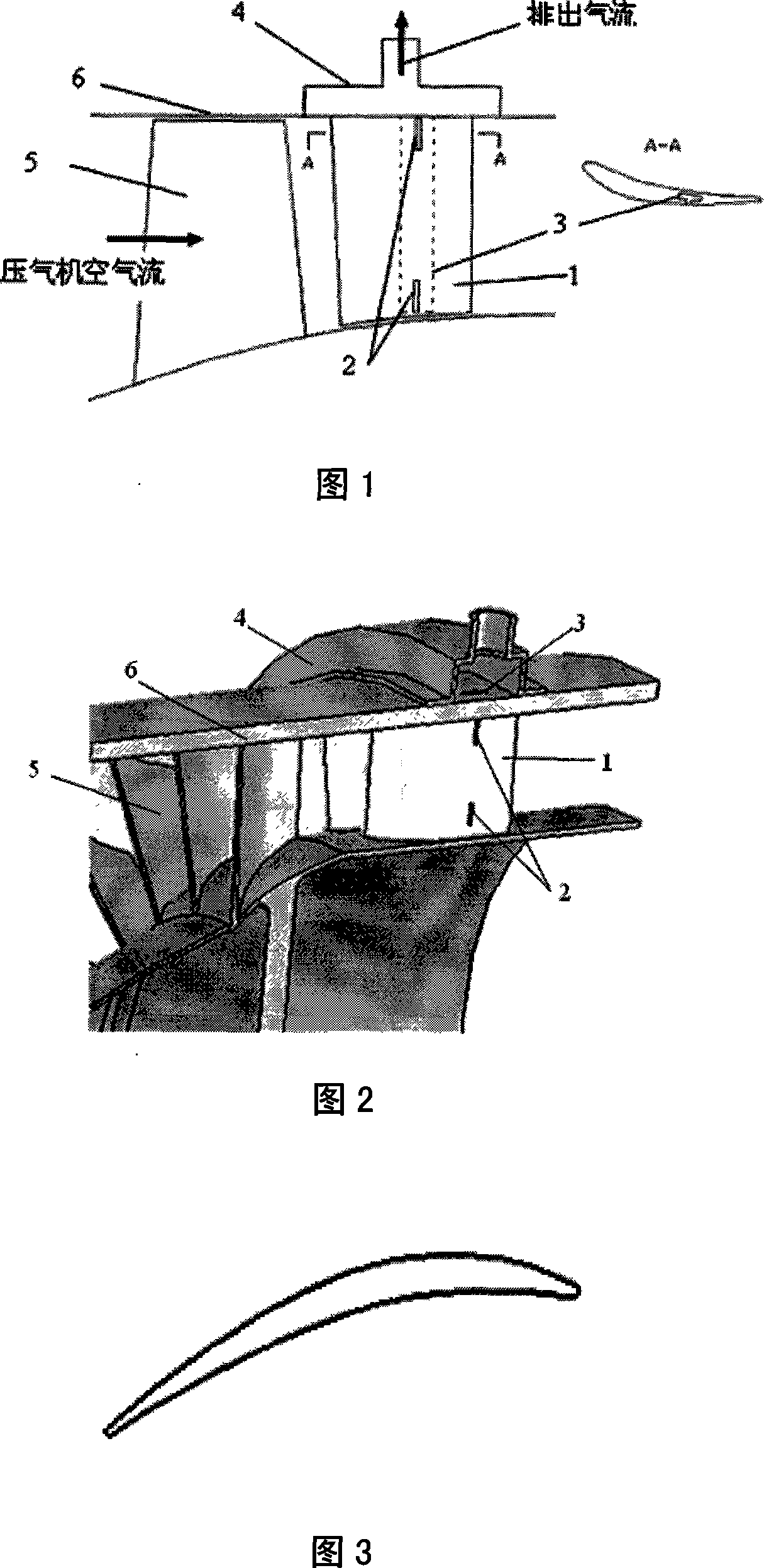

Synergic action device of preventing breath heavily and expanding stability of airbleed inside stator of multistage axial flow air compresdsor

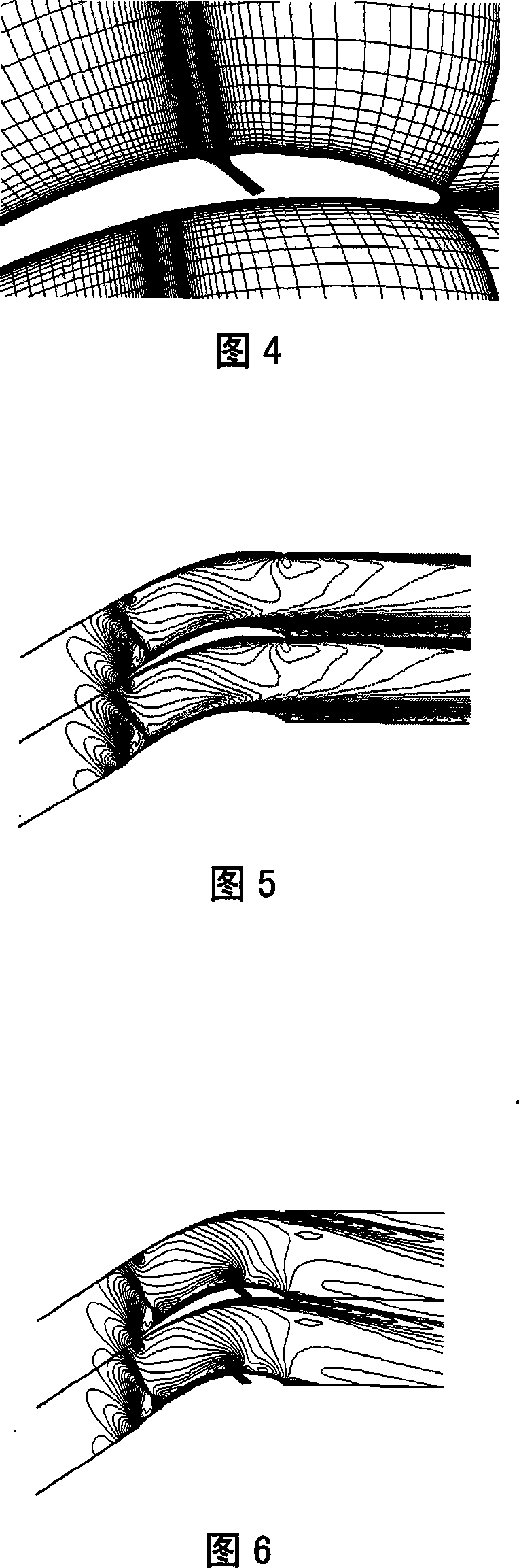

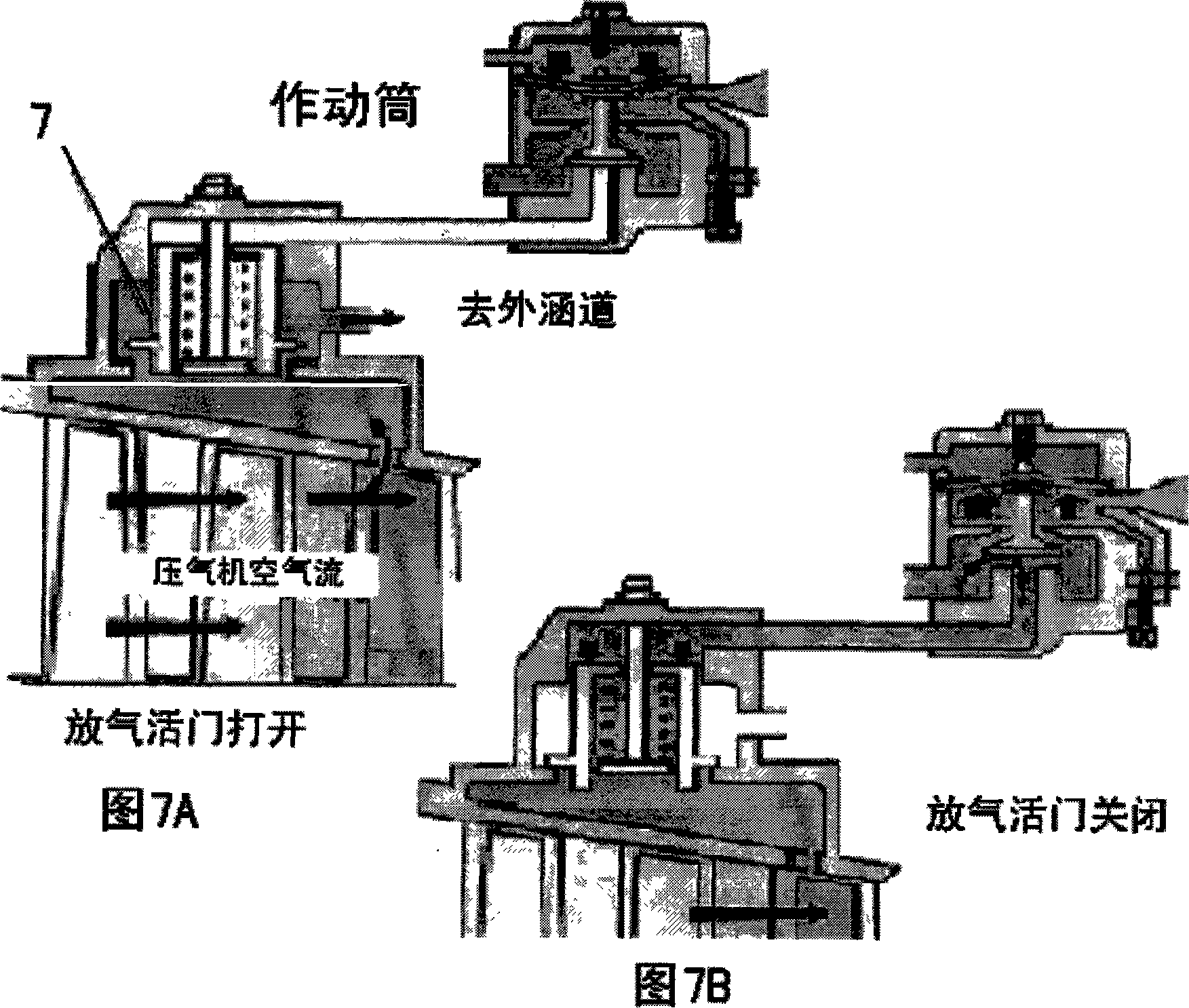

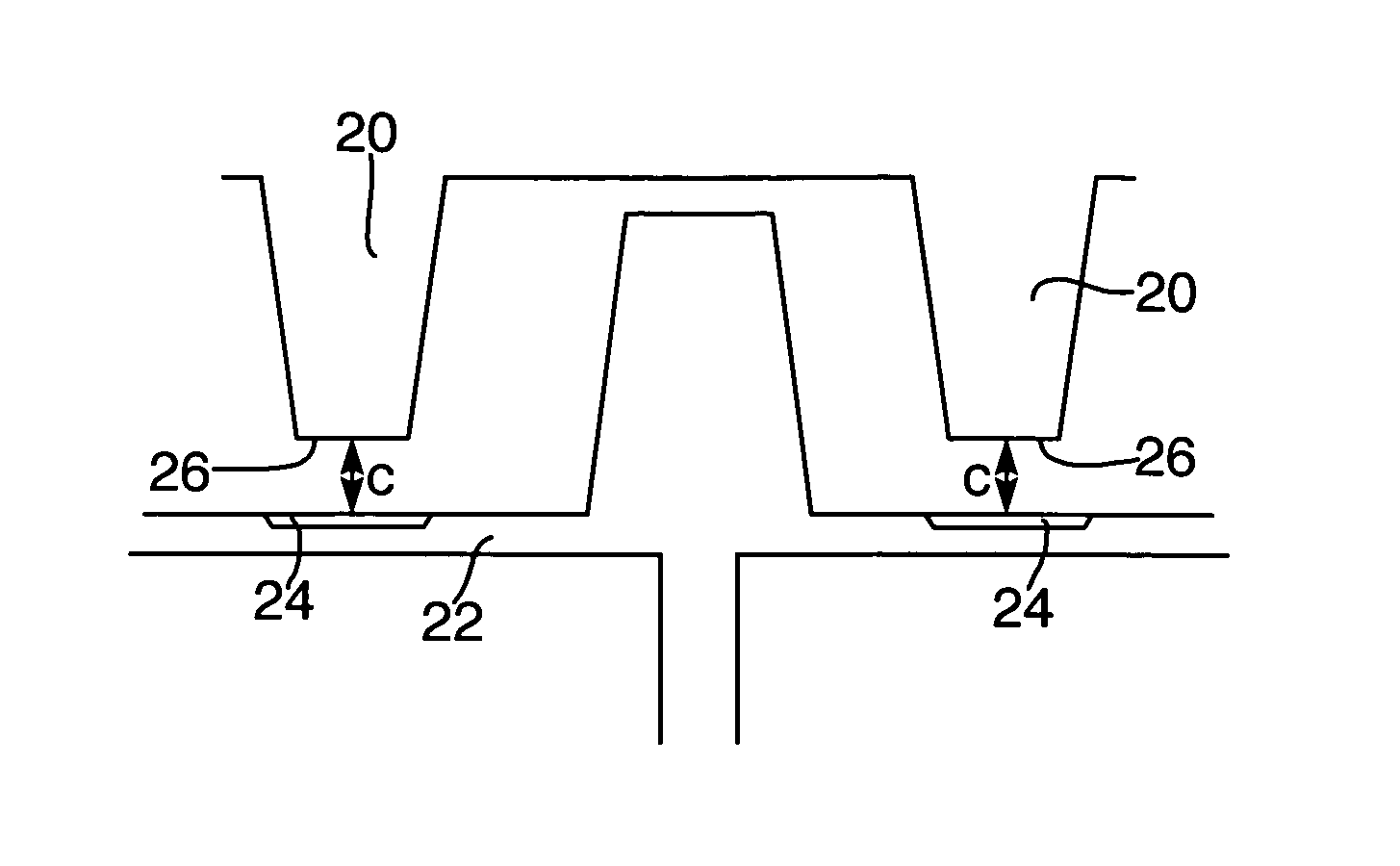

InactiveCN101092978AEasy to processReduce structural design requirementsPump componentsPumpsAxial compressorSuction stress

This invention discloses a stator internal gas-inducing efficient anti-surge steady expansion device of a multi-stage axial compressor composed of a stator, a gas-suction groove, a gas-inducing pipe and a gas-collecting chamber, in which the stator is stator blade in the multi-stage axial compressor, the groove, one or many, is placed in a region adjacent to flow separation existing on the surface of the stator suction face, the gas inducing pipe is in the stator blade and a ventilation pipe connecting suction pipes, the collecting chamber is set outside of the runner box and collects gas flows induced by the gas-inducing pipe after the suction groove absorbs small low energy gas flows, and the suction groove absorbs fluids of low energy on the surface of the stator suction side and transports them to the chamber and discharges them out of the system after mixed press.

Owner:BEIHANG UNIV

Cantilevered stator stage

ActiveUS7241108B2Easy to GrindReduce thicknessEngine manufacturePump componentsAxial compressorCantilever

Owner:ROLLS ROYCE PLC

Casing, a compressor, a turbine, and a combustion turbine engine including such a casing

ActiveUS6881029B2More energyMinimize and avoid usePump componentsBlade accessoriesAxial compressorCombustion

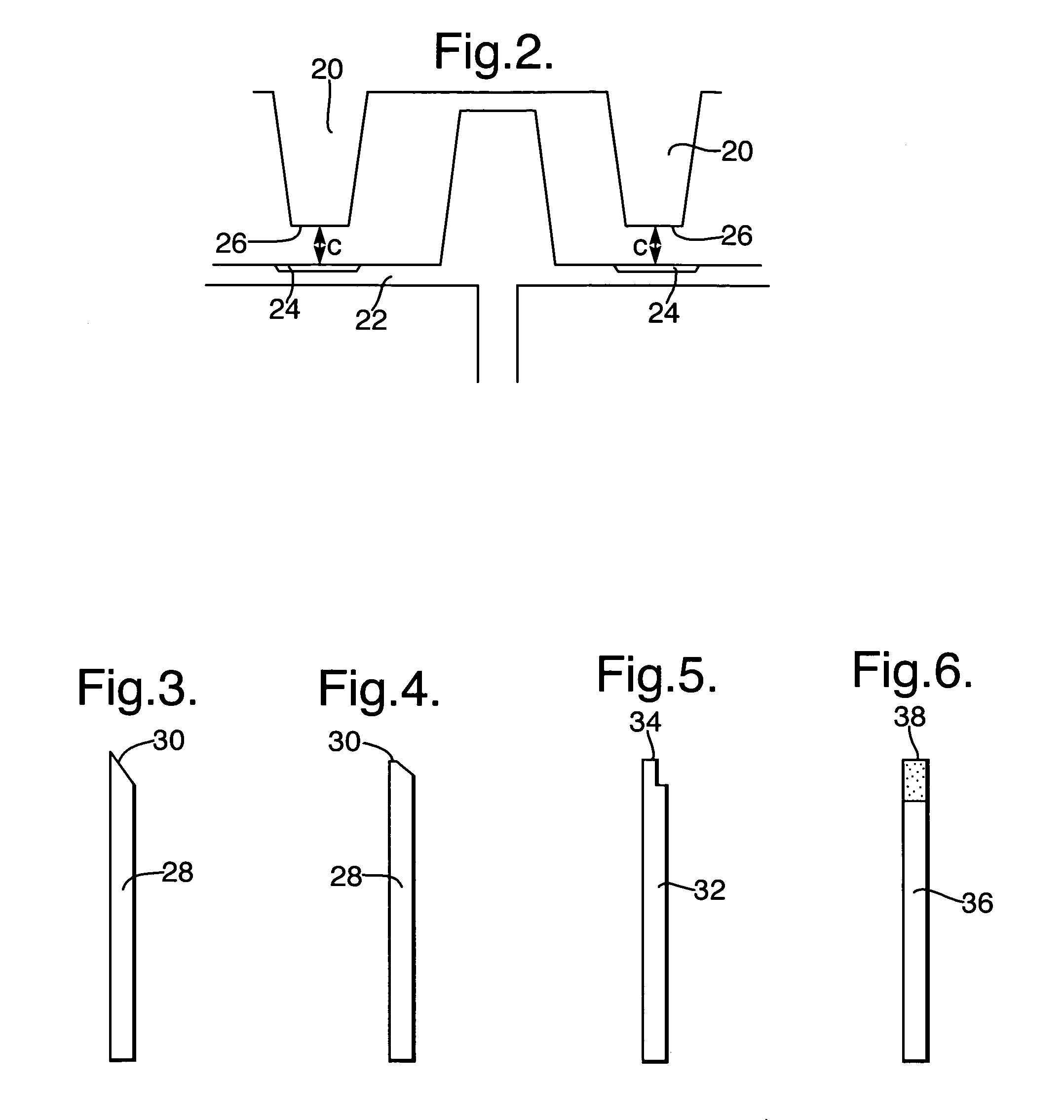

The casing of the invention is of the type supporting series of stationary blades having disposed between them series of blades that are movable in rotation about a longitudinal axis. In characteristic manner, said casing comprises a main element and, at least facing one of the series of moving blades, an assembly comprising a plate made of a honeycomb material and a covering disposed on the face of the plate facing away from the blades so that said cells are open towards the blades, said covering being provided with holes that open out into cells of the plate, thereby forming open cells, said covering closing other cells of the plate, thereby forming closed cells, a cavity being formed between said plate and the inside face of said main element. Preferably, the casing forms the casing of an axial compressor operating at low pressure in a turbojet engine.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

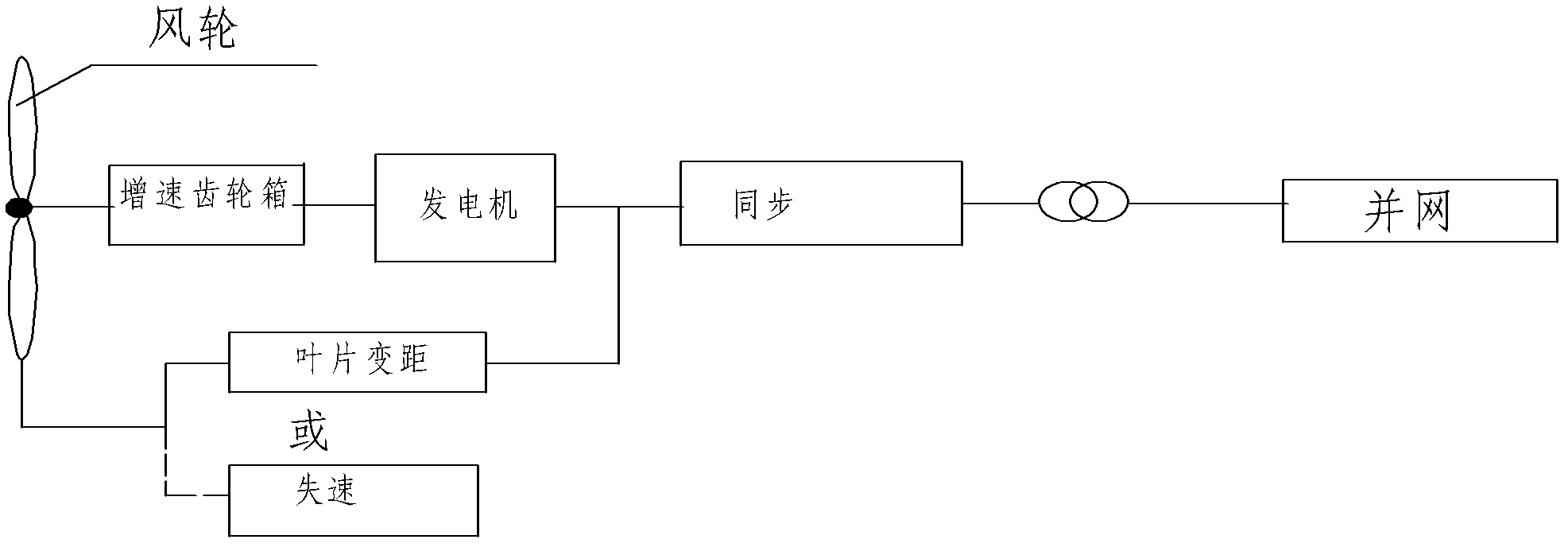

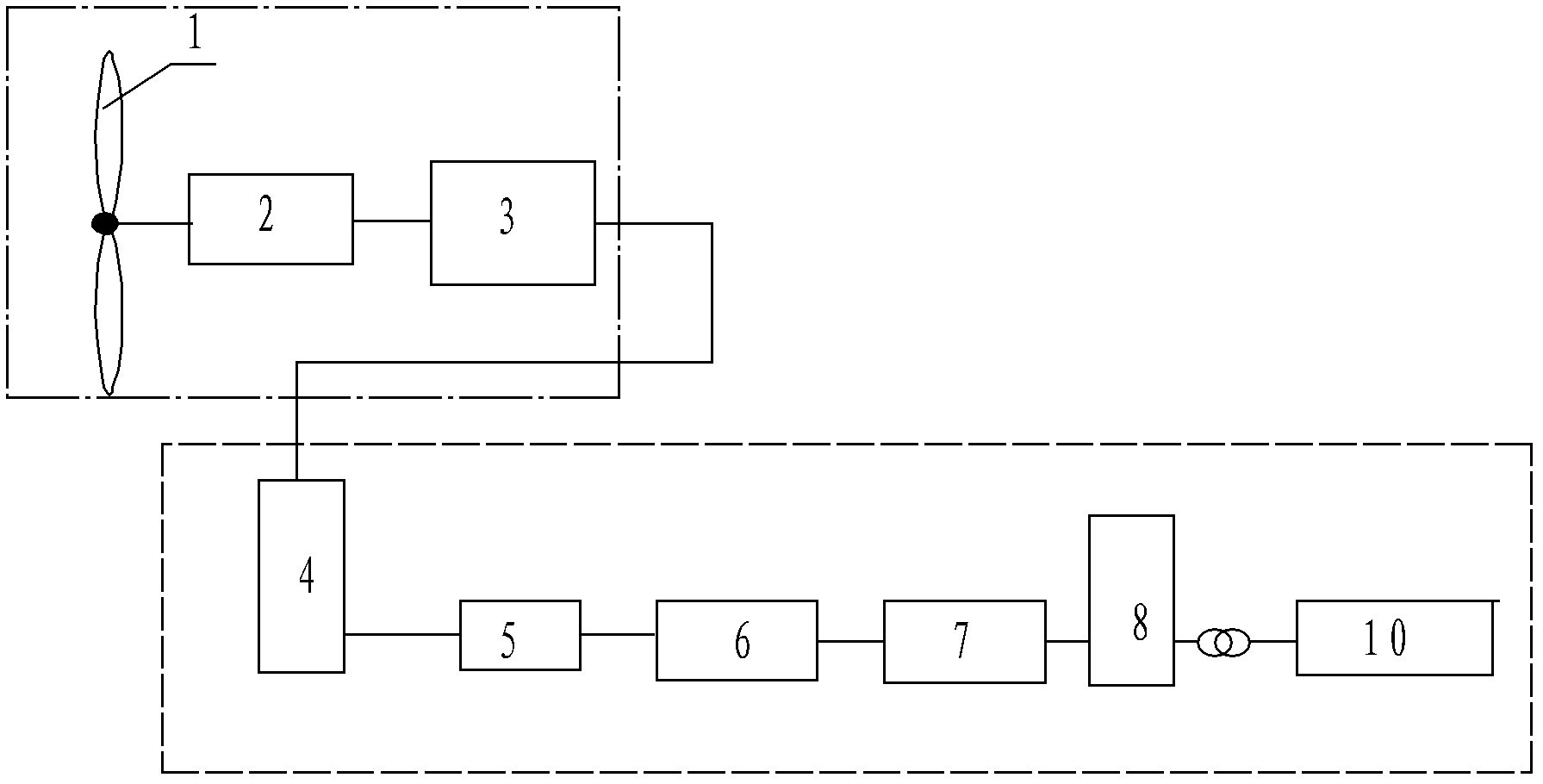

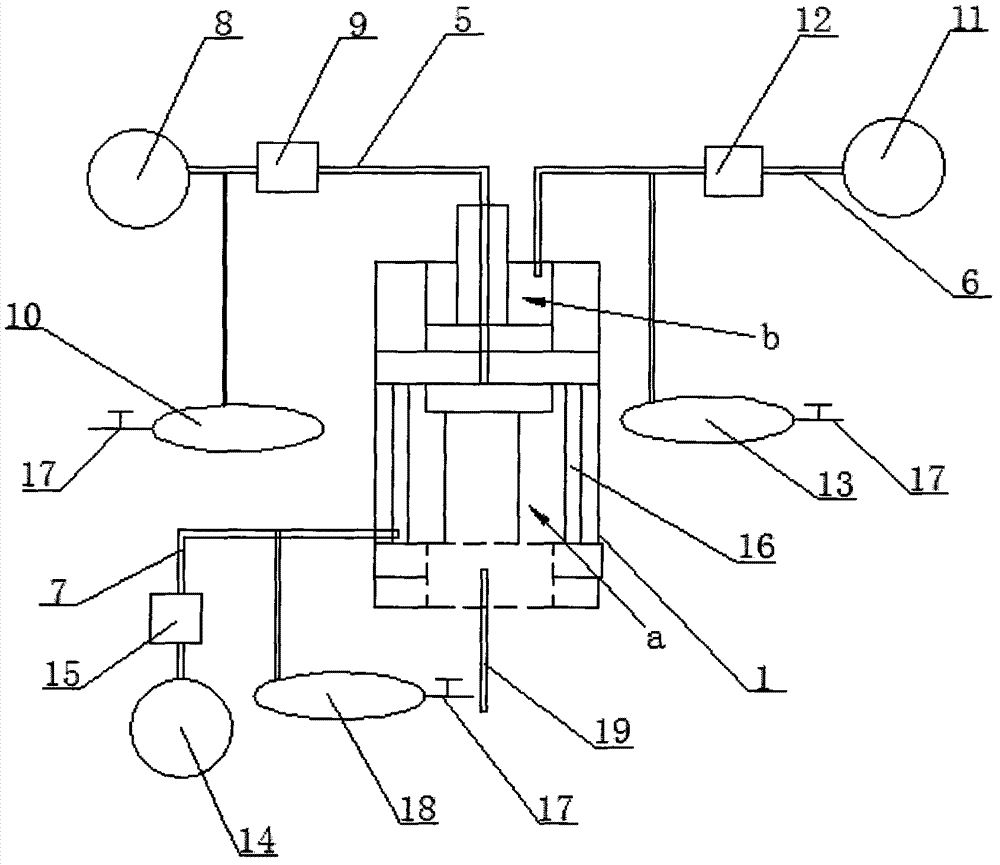

Air compression energy storage wind power generation method and generating set thereof

InactiveCN102305193AImprove efficiencySmall radius of rotationFrom solar energyFinal product manufactureMechanical energyAir compressor

The invention discloses an air compression energy storage wind power generation method and a generating set thereof for overcoming the rotation rate limitation and the problems of a rigid drive system in the prior art. The air compression energy storage wind power generation method comprises the following steps: 1, wind wheels convert the kinetic energy of wind into mechanical energy; 2, the wind wheels drive an air compressor to work so as to generate compressed air; 3, an air storage tank stores the compressed air; 4, the compressed air drives an air motor or a steam turbine; 5, the air motor or the steam turbine drives the generator to generate electricity; and 6, the surplus electric energy is stored. The invention also provides an air compression energy storage wind power generating set and a surplus electric energy storage device. The air compression energy storage wind power generating set comprises wind wheels, a speed increasing gear case, an air compressor, an air storage tank, an electric control valve, an air motor or a gas turbine and a generator. In the surplus electric energy storage device, the wind wheels and the speed increasing gear case of the air compression energy storage wind power generating set are replaced by electromotors, and other parts are the same as those of the air compression energy storage wind power generating set.

Owner:初立森

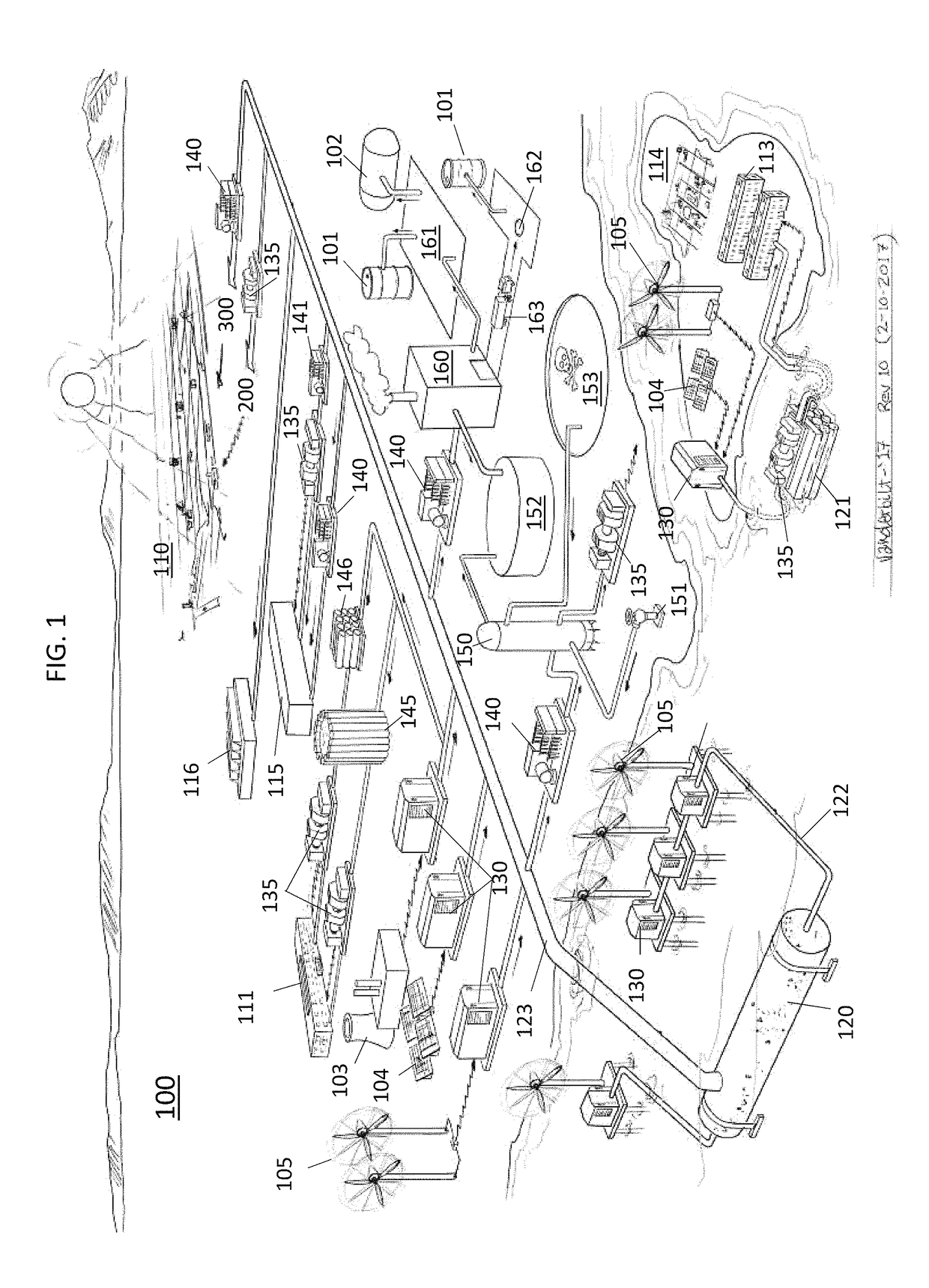

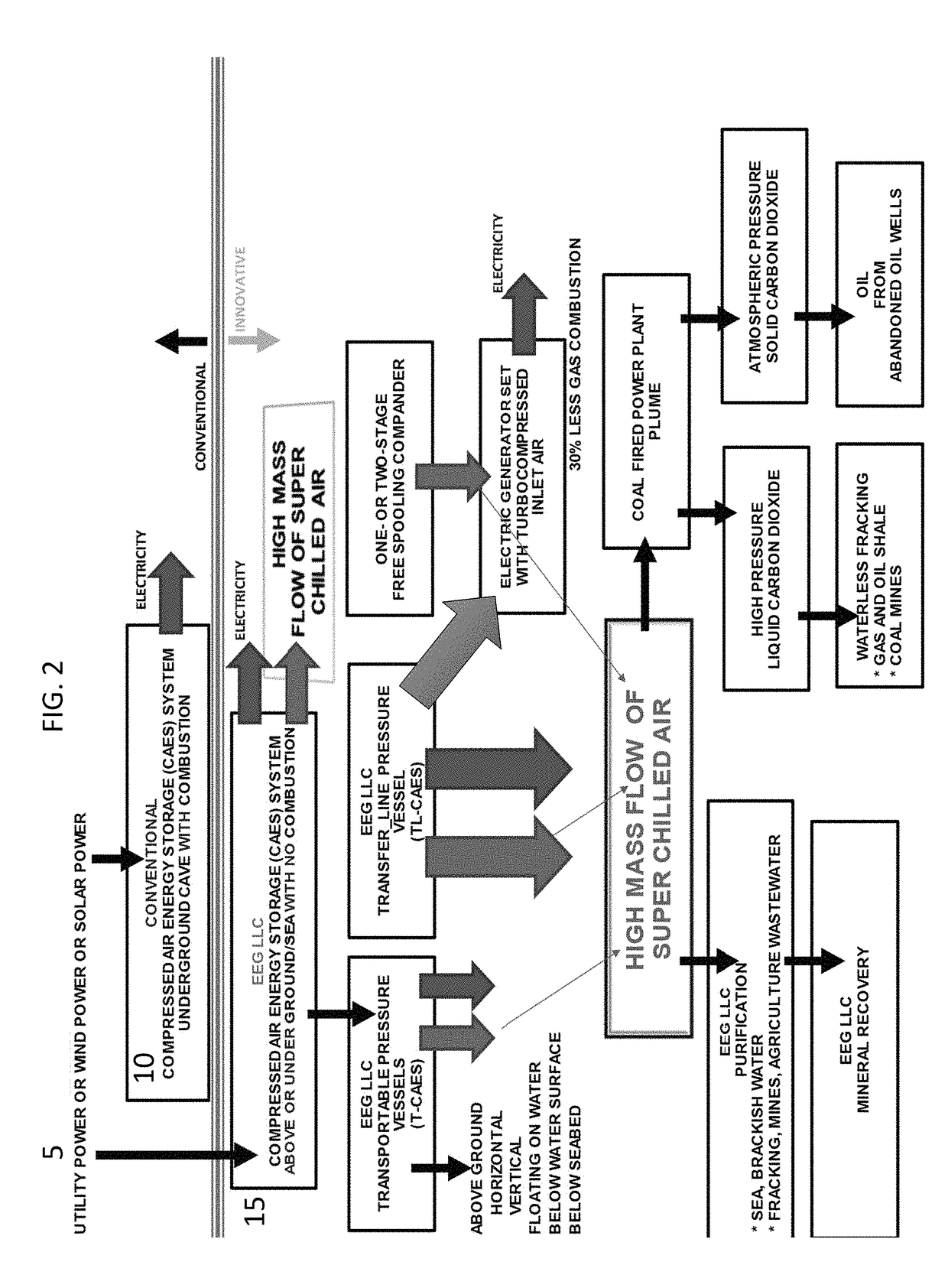

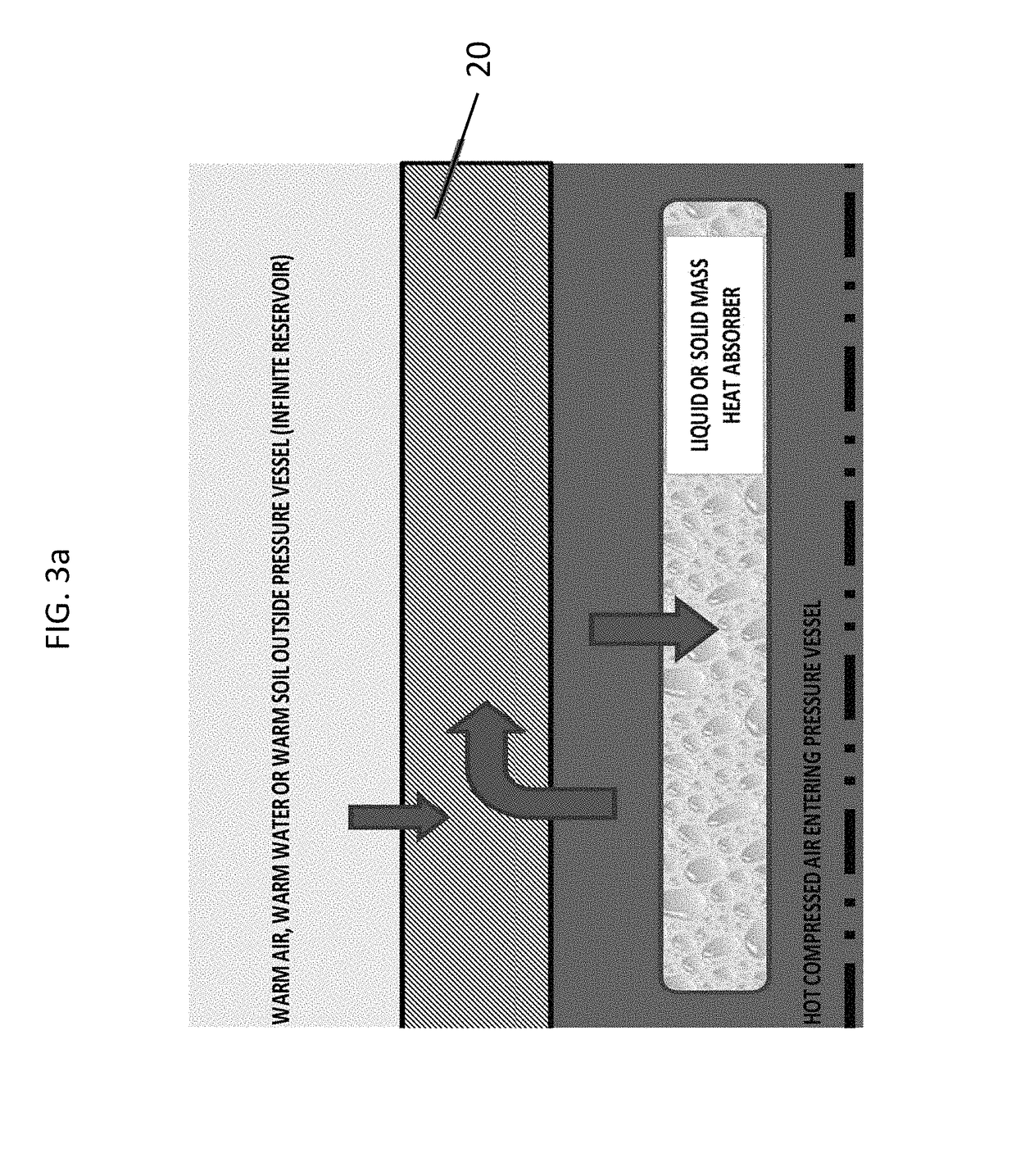

Green communities

InactiveUS10184465B2Improve heat transfer efficiencyImprove efficiencyPositive displacement pump componentsHeat storage plantsCommunity systemEngineering

Owner:ENISENERGEN LLC

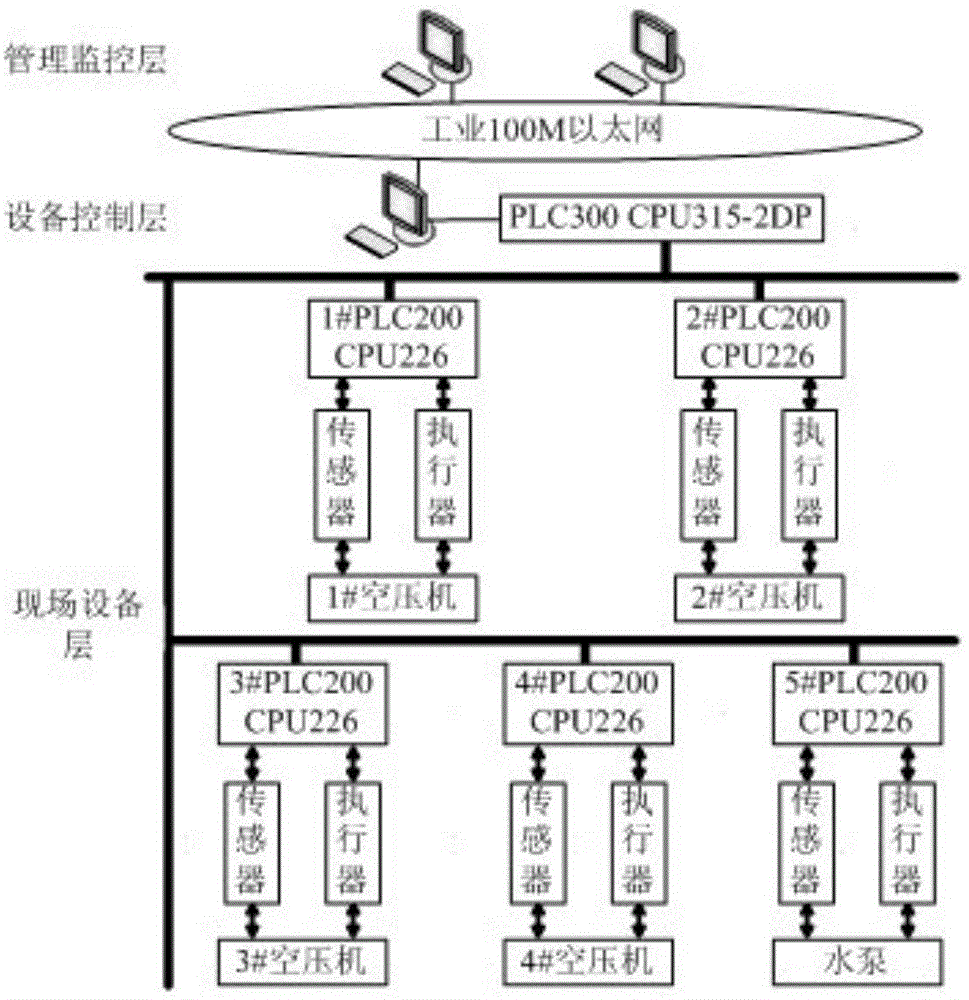

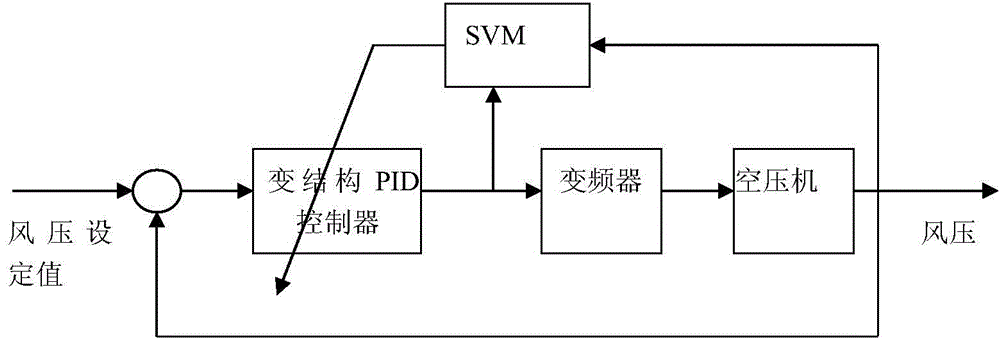

Air compressor monitoring diagnosis system and method adopting adaptive kernel Gaussian hybrid model

InactiveCN104595170AHigh degree of automationRealize remote and short-range monitoringPump controlPositive-displacement liquid enginesControl layerEngineering

The invention discloses an air compressor monitoring diagnosis system and method adopting an adaptive kernel Gaussian hybrid model, and relates to the field of air compressor control technologies. The system comprises a site equipment layer, an equipment control layer and a management and monitoring layer. The site equipment layer is composed of PLCs200, sensors, air compressors, actuators and a water pump, and with the PLCs200 as slave stations, control over the site equipment layer is completed. The equipment control layer comprises an upper computer and a PLC300, with the PLC300 as a master station, the whole air compressor system is controlled through a variable-structure adaptive PID controller based on a support vector machine, and the upper computer monitors the air compressor system. The equipment control layer is in communication with the management and monitoring layer through the industrial Ethernet, and then remote monitoring and data transmission of the upper computer are achieved. The Gaussian hybrid model and the kernel principal component analysis method are integrated in the fault diagnosis method adopted in the upper computer, optimal kernel function parameters are solved through the iterative optimization method, and the purpose of distinguishing different mode data is achieved. The air compressor monitoring diagnosis system and method have higher diagnosis precision and higher practical value.

Owner:CHINA UNIV OF MINING & TECH

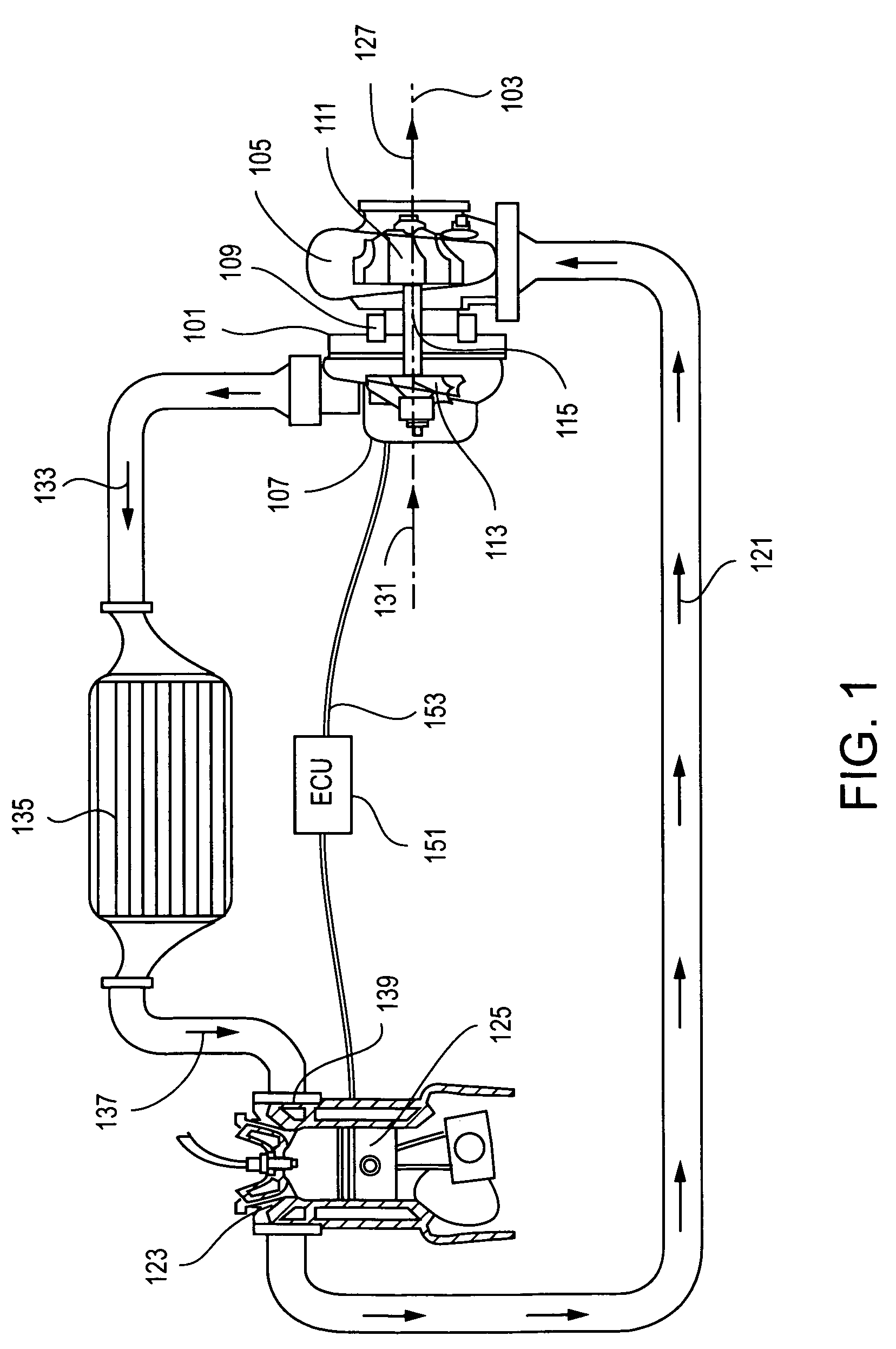

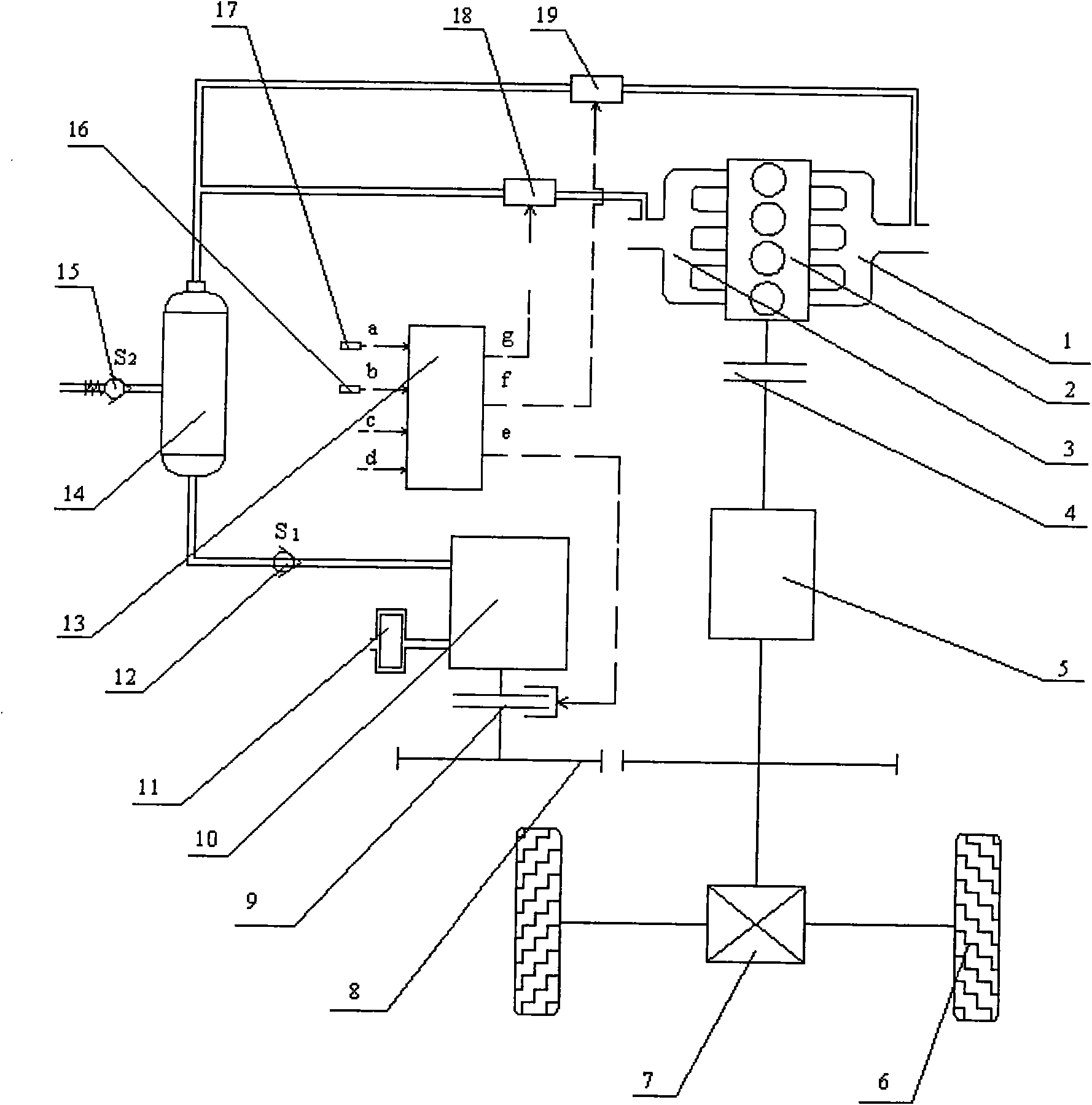

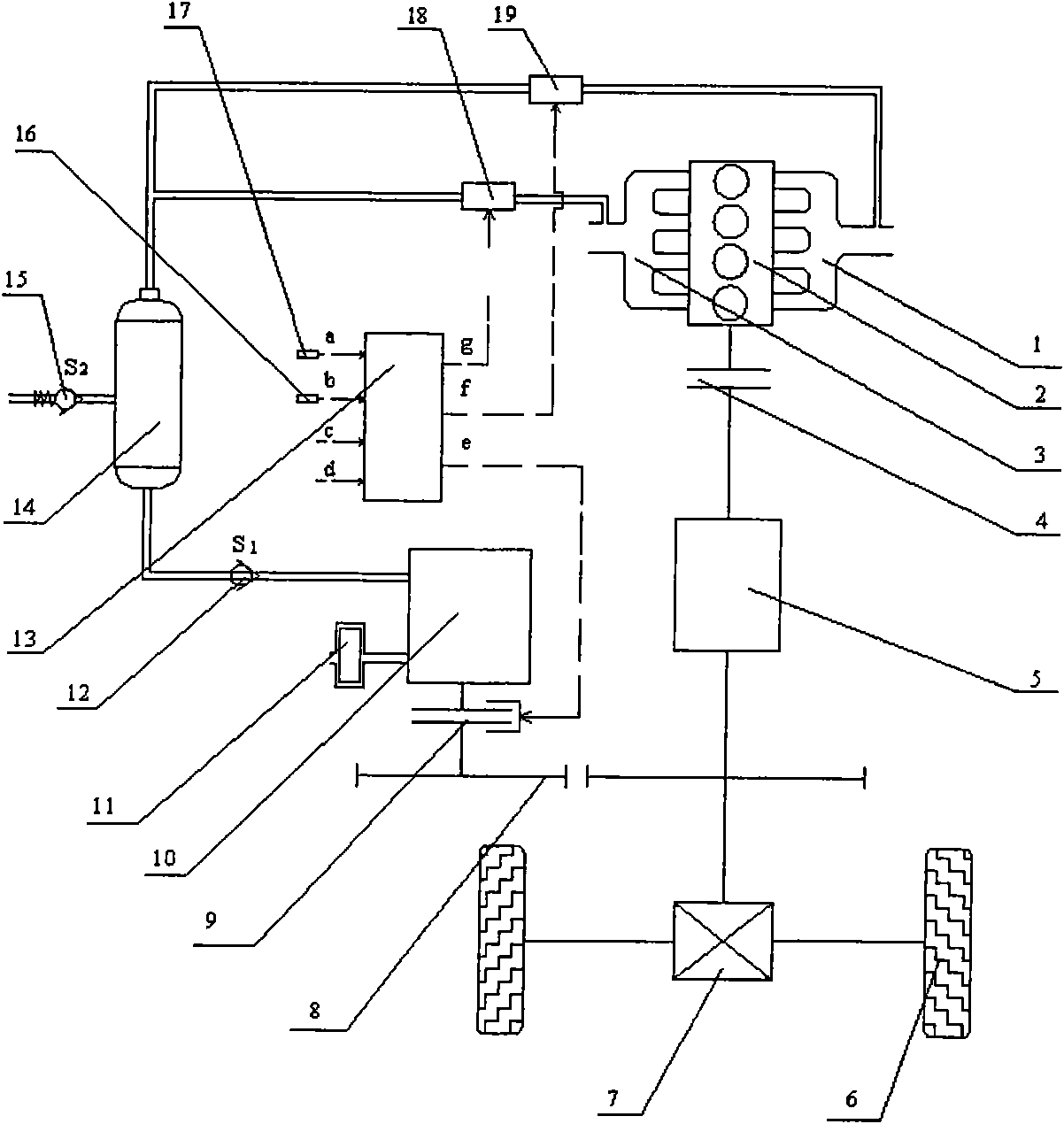

Pneumatic vehicular braking energy recovery and recycling device and control method

InactiveCN102069788AImprove powerImprove acceleration performanceBraking action transmissionExhaust apparatusDrivetrainGas cylinder

The invention provides a pneumatic vehicular braking energy recovery and recycling device and a control method, which belong to the technical field of energy conservation and emission reduction of vehicles. The device provided by the invention is characterized in that in the checking brake process of a vehicle, an air compressor is connected with a drivetrain system of the vehicle by an electromagnetic clutch, the air compressor is driven to operate by using the inertia of the vehicle so as to recover the braking energy of the vehicle, and the high pressure air produced by the air compressor is stored in a high pressure gas cylinder; when a vehicle is accelerated, the high pressure air stored in the high pressure gas cylinder can carry out air-intake compensation on an internal-combustion engine, which facilitates the sufficient air acquisition of the internal-combustion engine under instantaneous conditions, and improves the dynamic property and acceleration performance of the internal-combustion engine, especially can shorten the air-intake response delay of a turbocharged internal-combustion engine when the internal-combustion engine is accelerated; and when the internal-combustion engine is started, the high pressure air can carry out additional air compensation on the air exhaust of the internal-combustion engine (in particular to a hybrid electric vehicle with an internal-combustion engine frequently controlled to start and stop) so as to reduce the discharge of noxious substances in a starting process of the internal-combustion engine.

Owner:BEIJING UNIV OF TECH

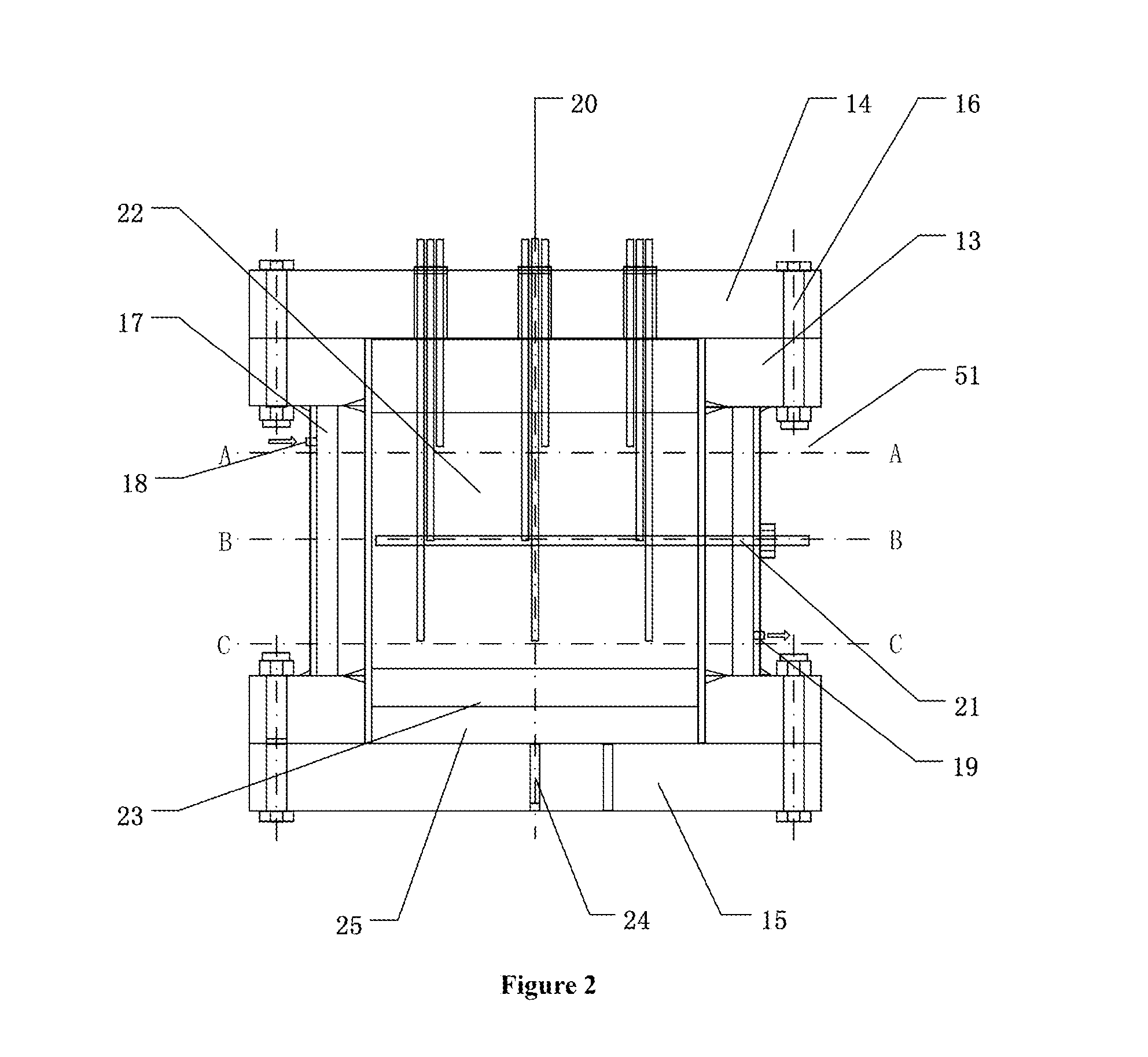

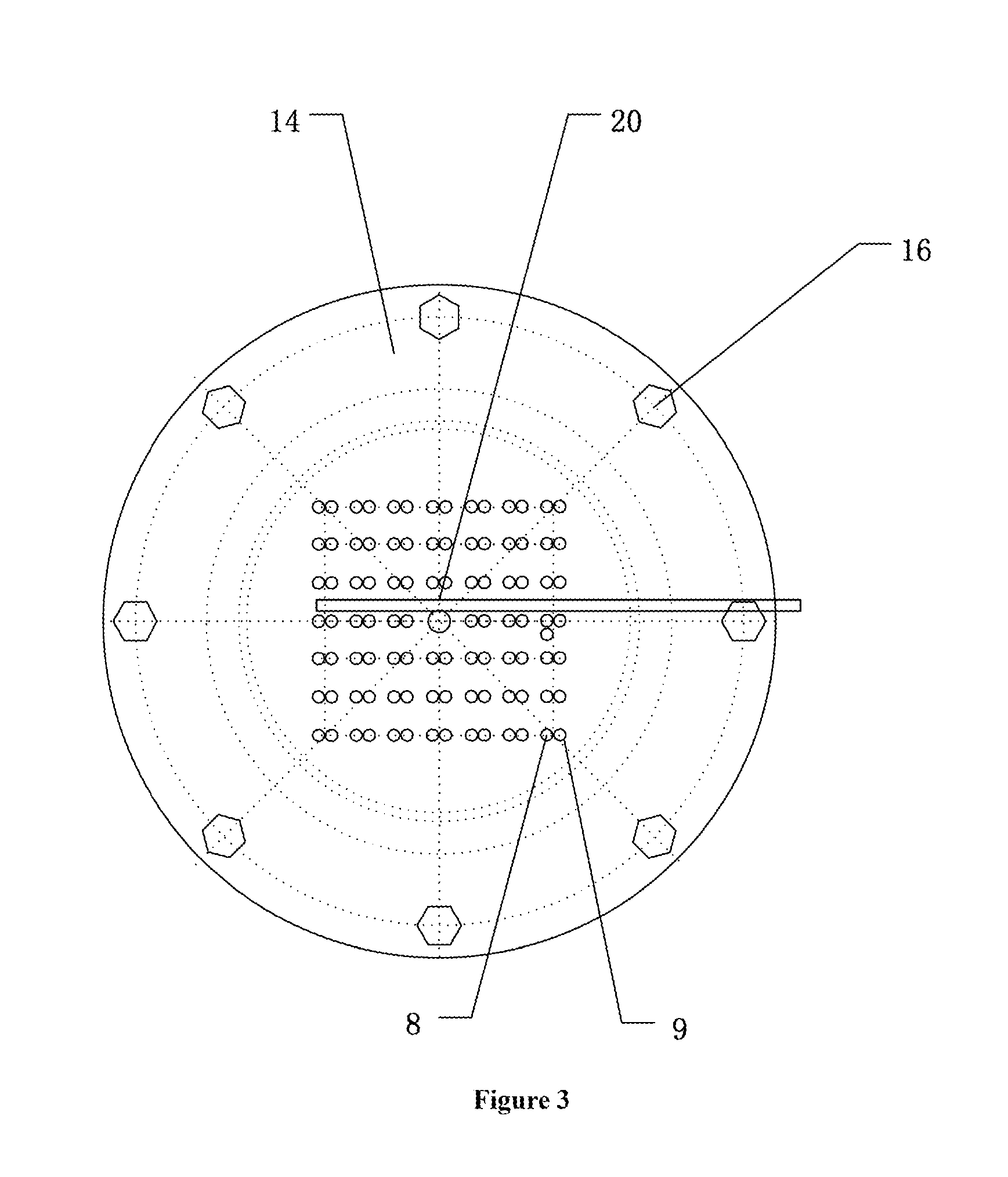

Three-dimensional simulating device for the stratum stability in the natural hydrate exploitation

ActiveUS20150205004A1Improve reliabilityImprove accuracyFluid removalGeomodellingAxial compressorElectricity

A three-dimensional simulating device for the stratum stability in natural gas hydrate exploitation includes a three-dimensional model located in an environmental control unit, an axial pressure control unit, and a post-processing unit. An inner cavity of the three-dimensional model is divided into a sealed simulating cavity and a sealed axial pressure sealing cavity by an axial pressure sealing piston arranged in the inner cavity. A vertical well and a horizontal well stretch into the simulating cavity. The axial pressure control unit, the environmental control unit, and a plurality of sensors in the three-dimensional model are electrically connected to the post-processing unit. This simulating device simulates the external environment and combines in-situ synthesis and decomposition of a hydrate with stratum stability, thereby achieving high reliability and high accuracy, comprehensively evaluating mechanical characteristic change of the stratum and the stratum stability to provide guidance in natural gas hydrate exploitation.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

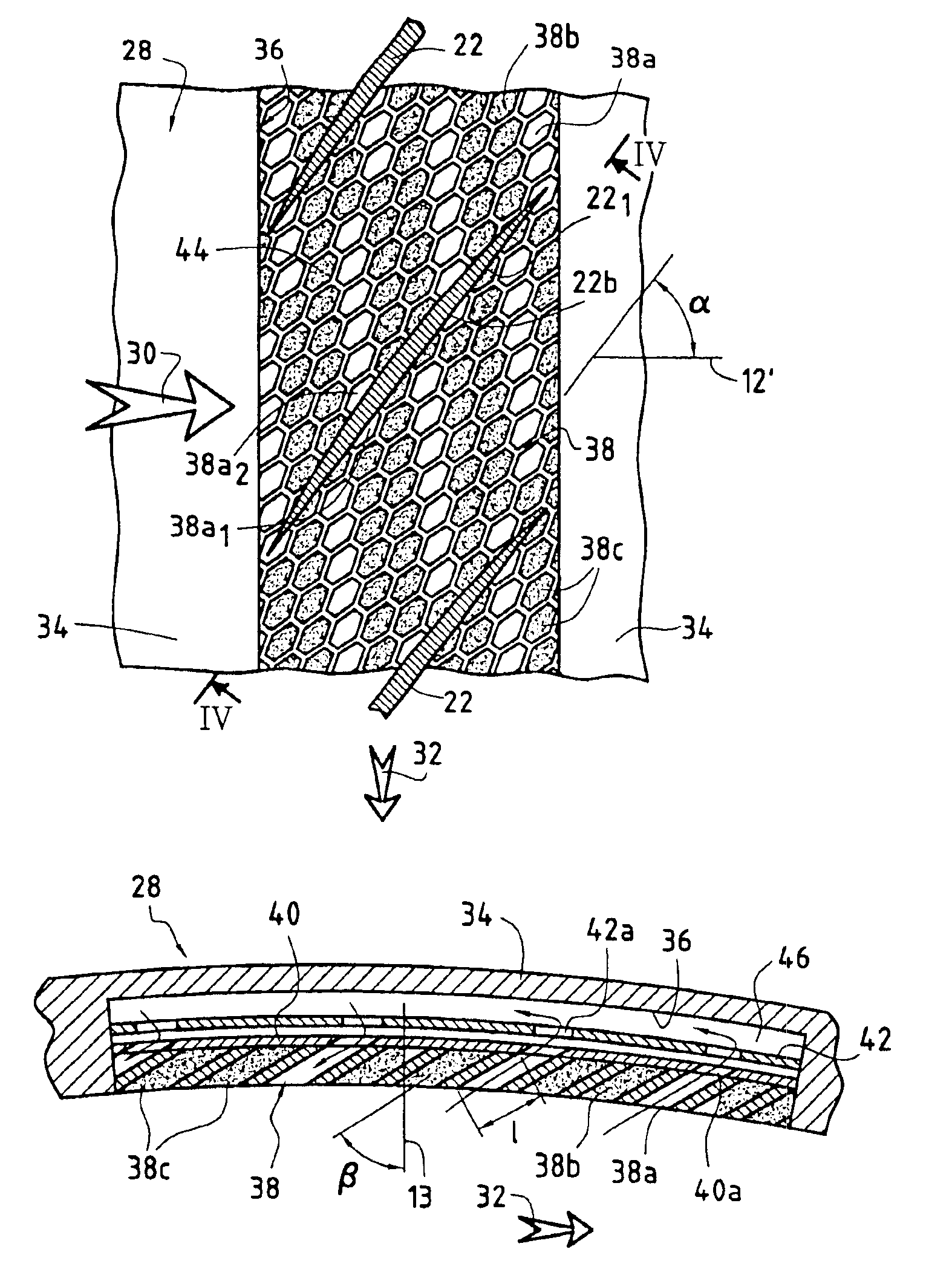

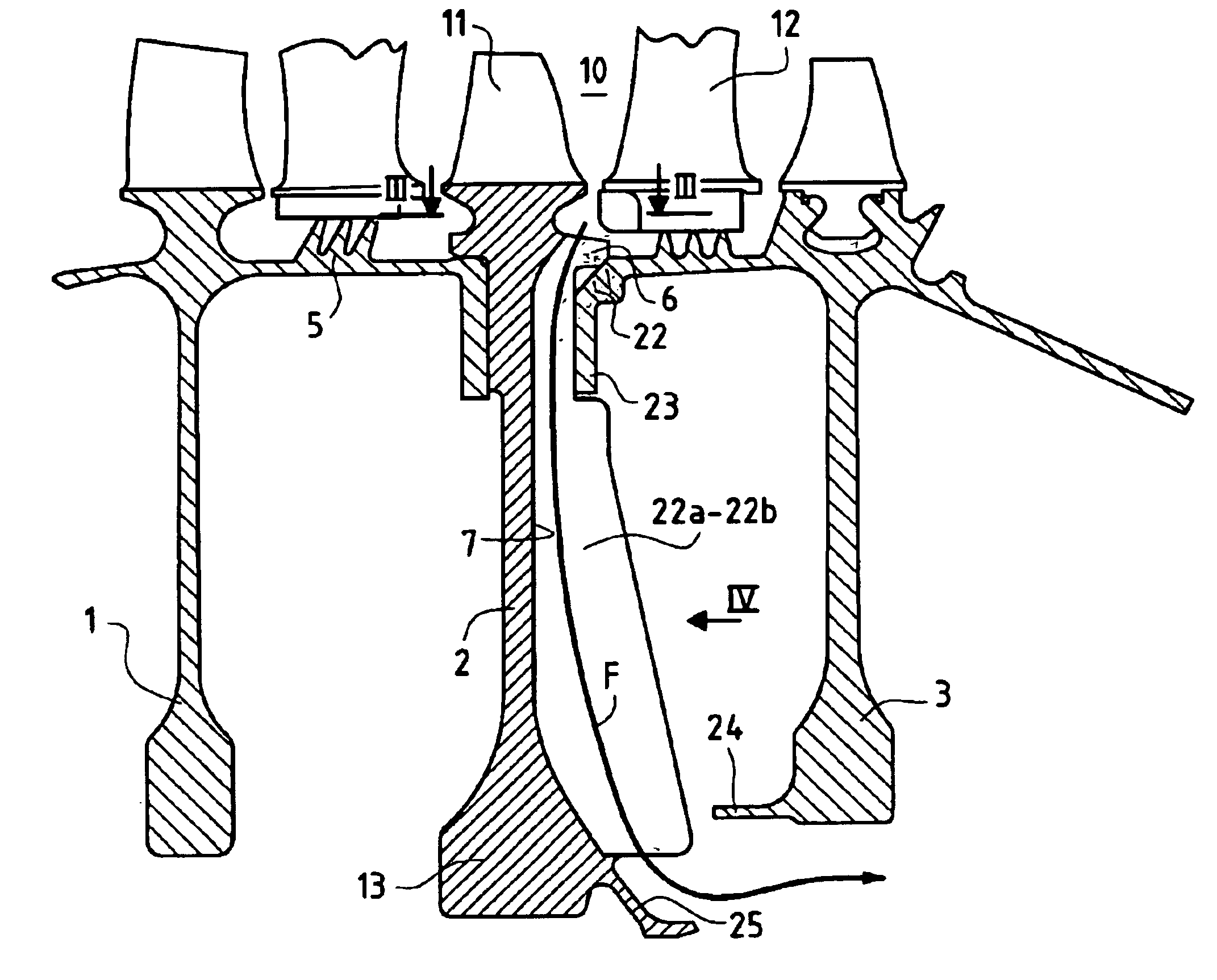

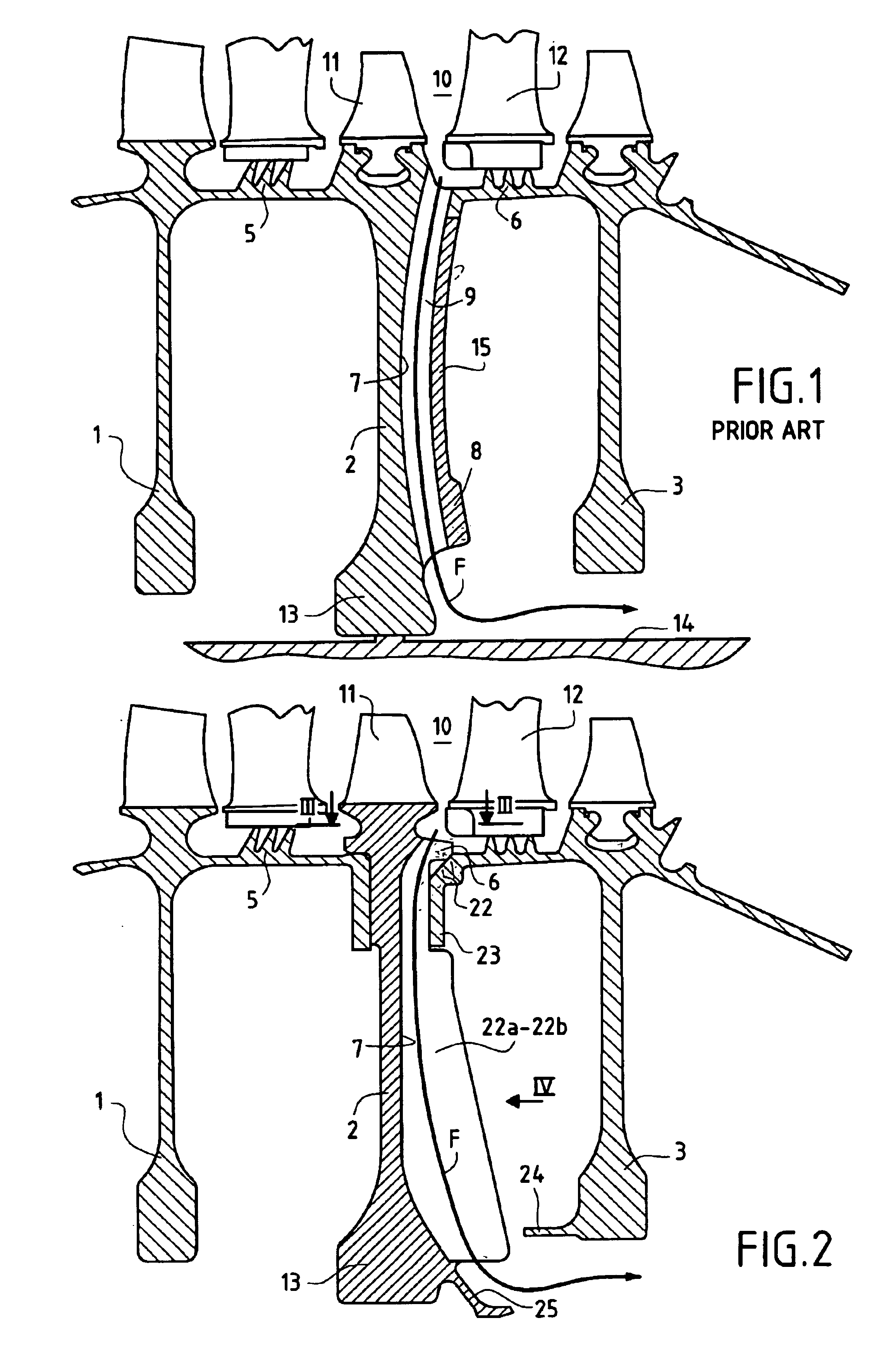

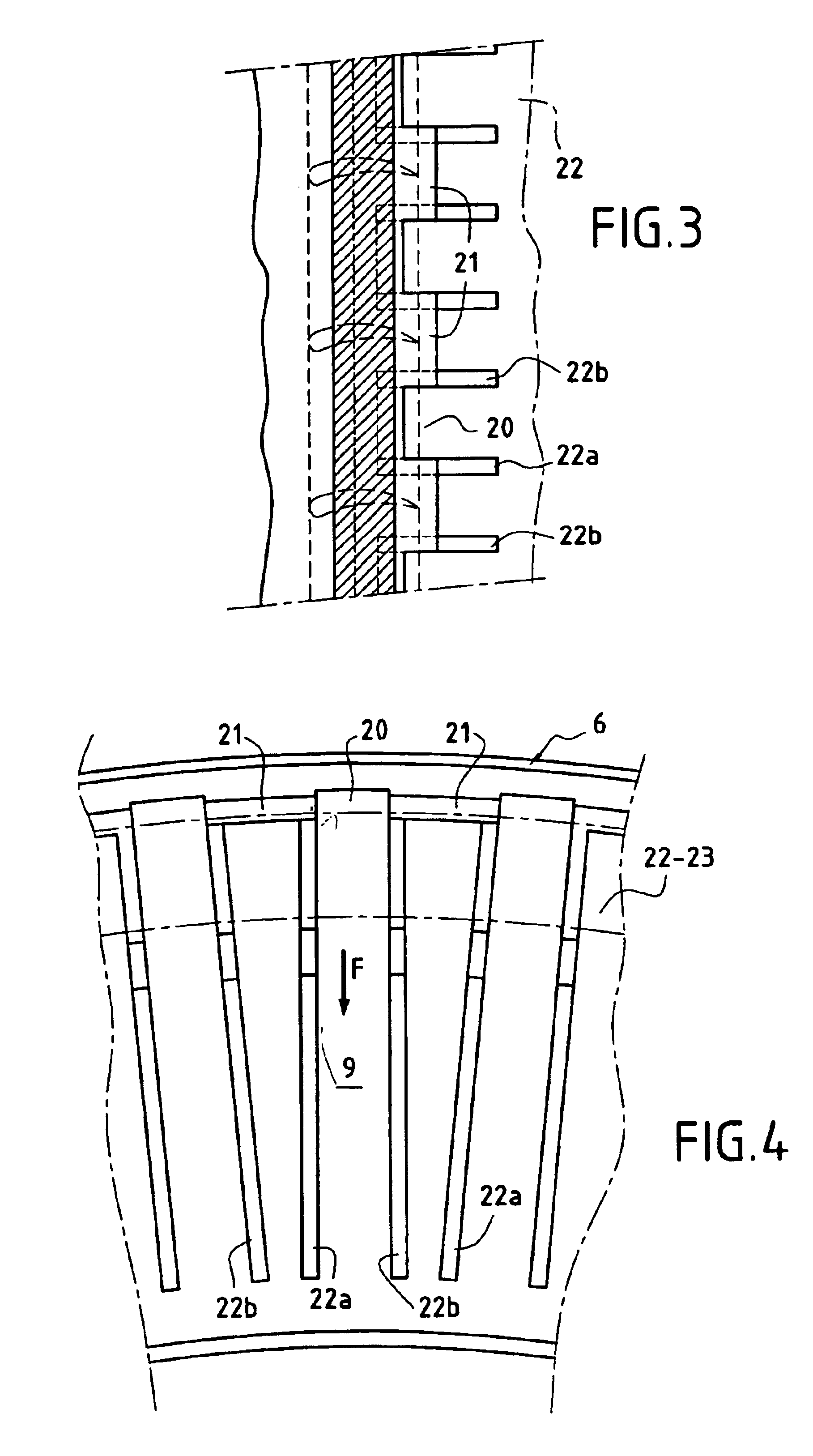

Axial compressor disk for a turbomachine with centripetal air bleed

The invention relates to an axial compressor disk for a turbomachine, the disk including a bleed system for bleeding air centripetally from the compressor stream in order to cool a turbine, said bleed system comprising channels formed outside the working section of the disk and parallel to said section in an extra thickness projecting away from said working section on a face of said disk, wherein the bleed channels are axially open over substantially their entire radial extent.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

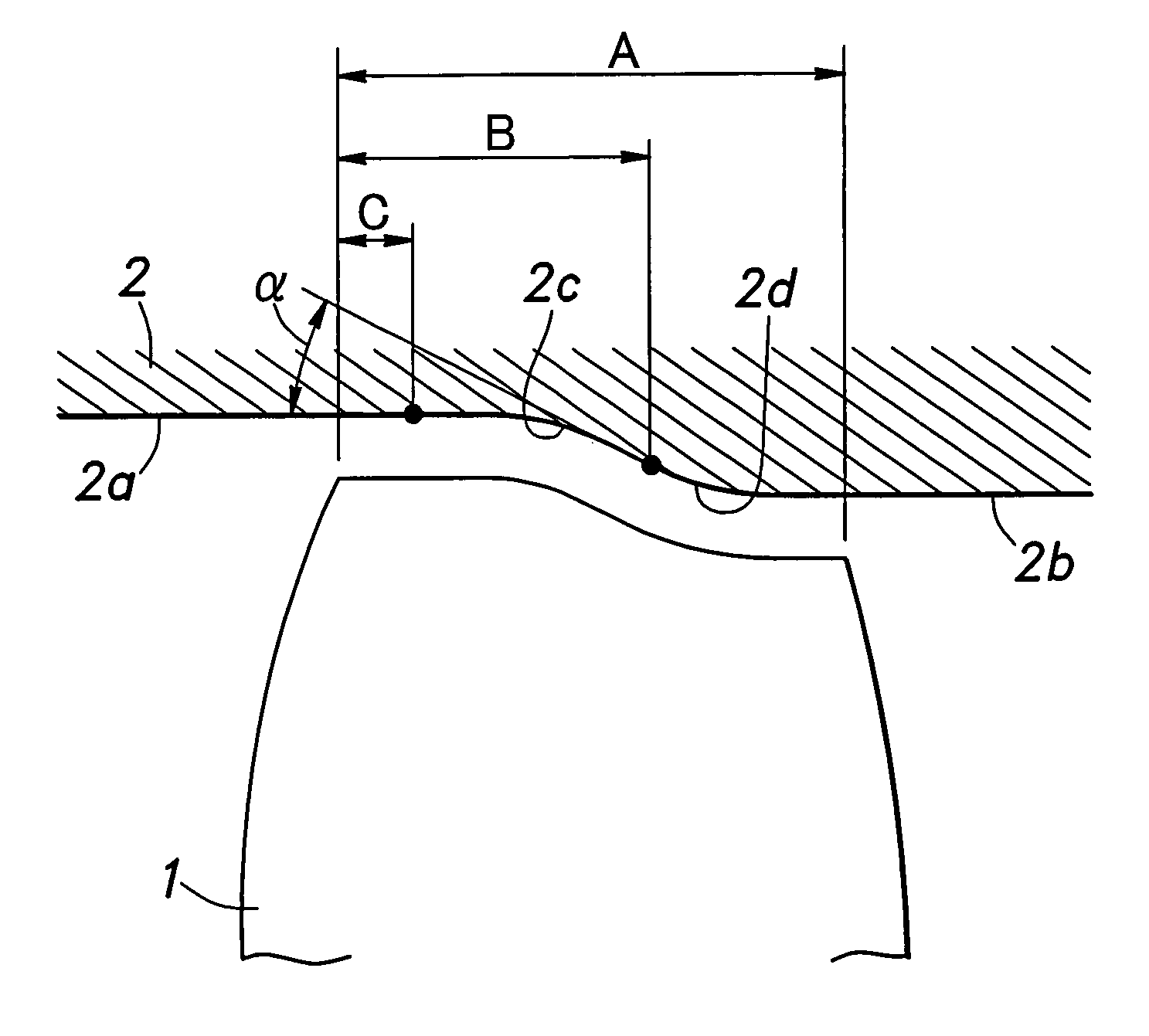

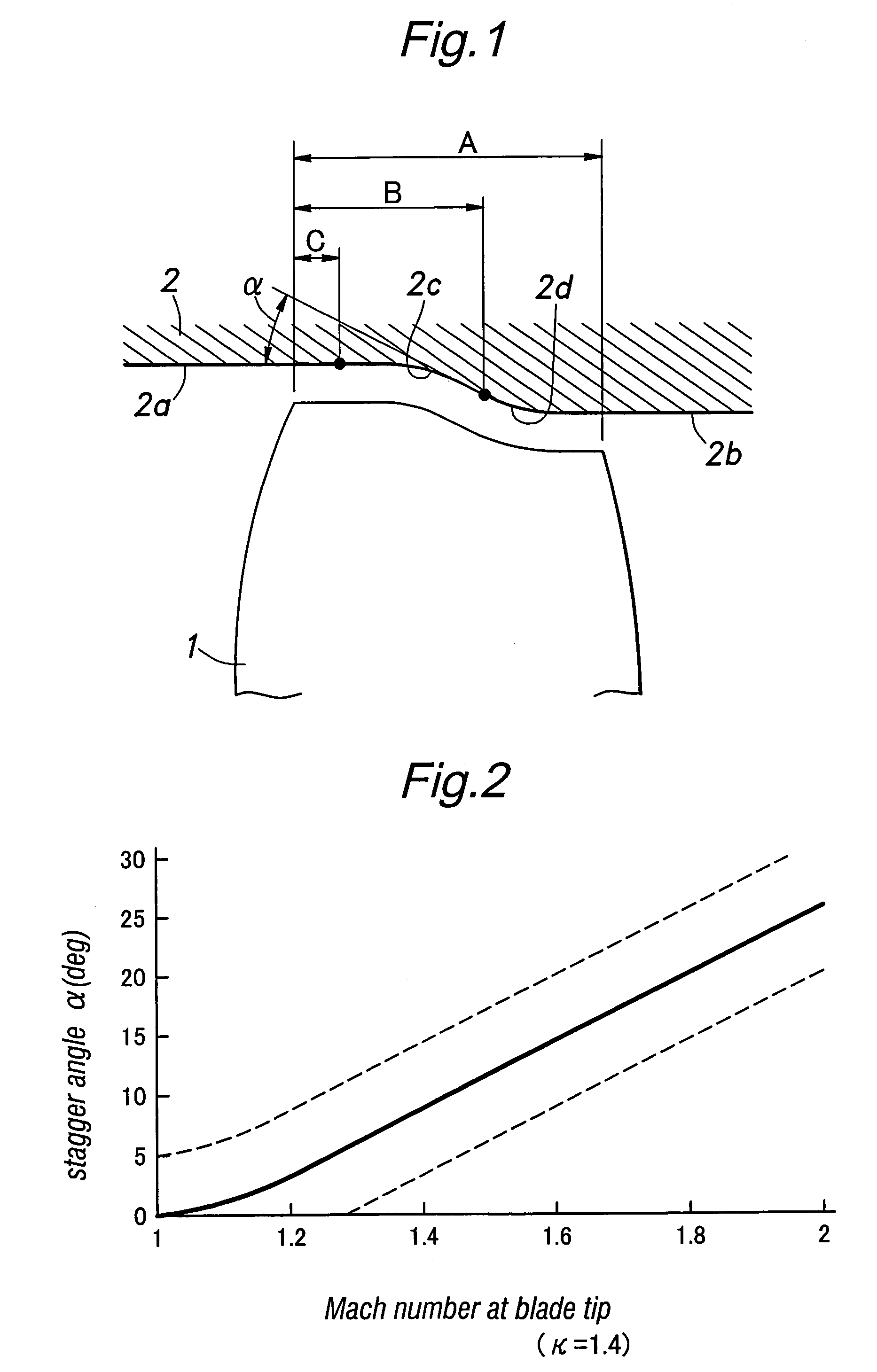

Axial flow compressor

InactiveUS7004722B2Improve efficiencyWide operatingSupersonic fluid pumpsPump componentsAxial compressorEngineering

At least part of the inner circumferential wall of the outer casing is provided with a concave surface opposing the rotor blade tips as seen in a longitudinal section. Typically, each of the rotor blades is provided with aerofoil section, and the compressor is designed as a transonic axial flow compressor. Thereby, a compressive wave is produced upstream of the shockwave so that the Mach number of the flow entering the shockwave can be reduced. As a result, the shockwave is made less severe, and the shockwave loss can be reduced. In particular, because the concave surface is provided in the casing wall as opposed to the case where the concave surface is provided in the negative pressure side of the rotor blade, the reduction in the performance owing to the change in the angle of the airflow entering the passage defined by the concave surface under a partial load condition can be avoided.

Owner:HONDA MOTOR CO LTD

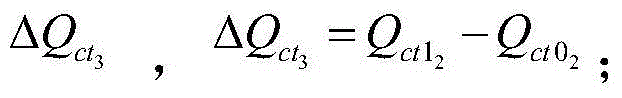

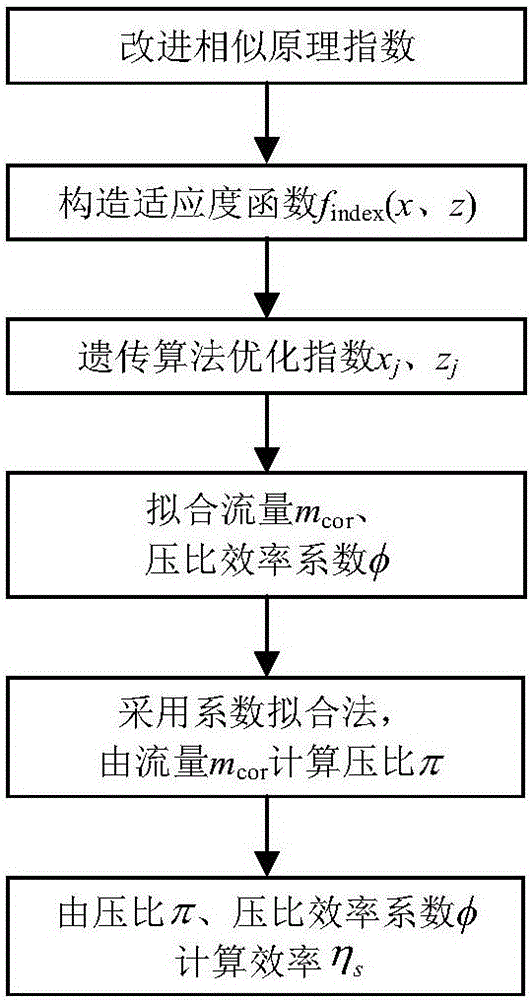

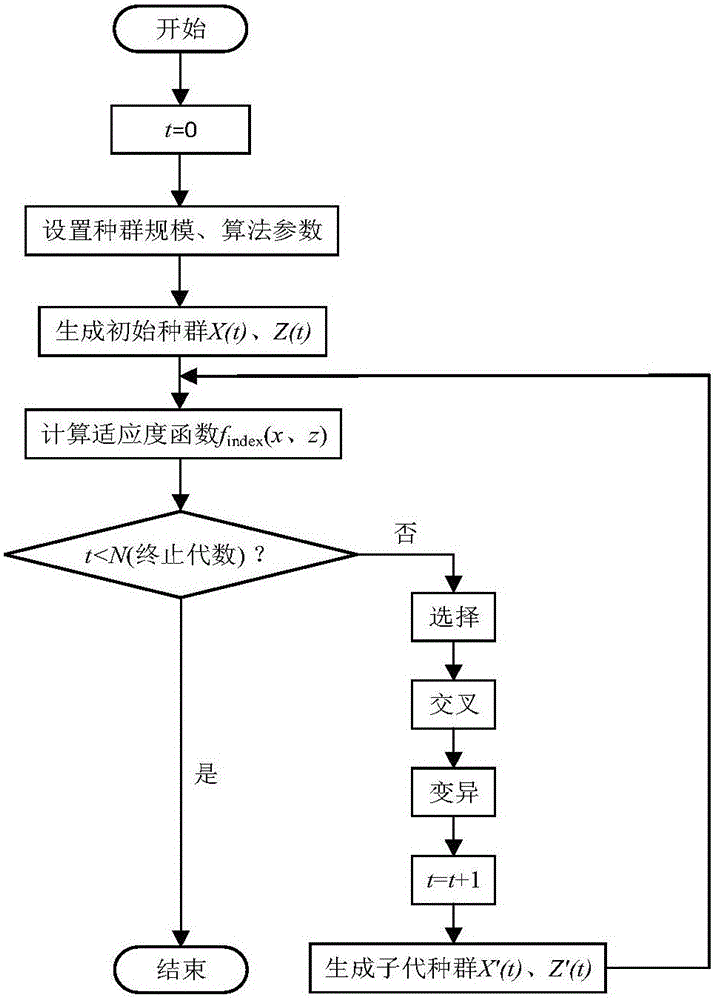

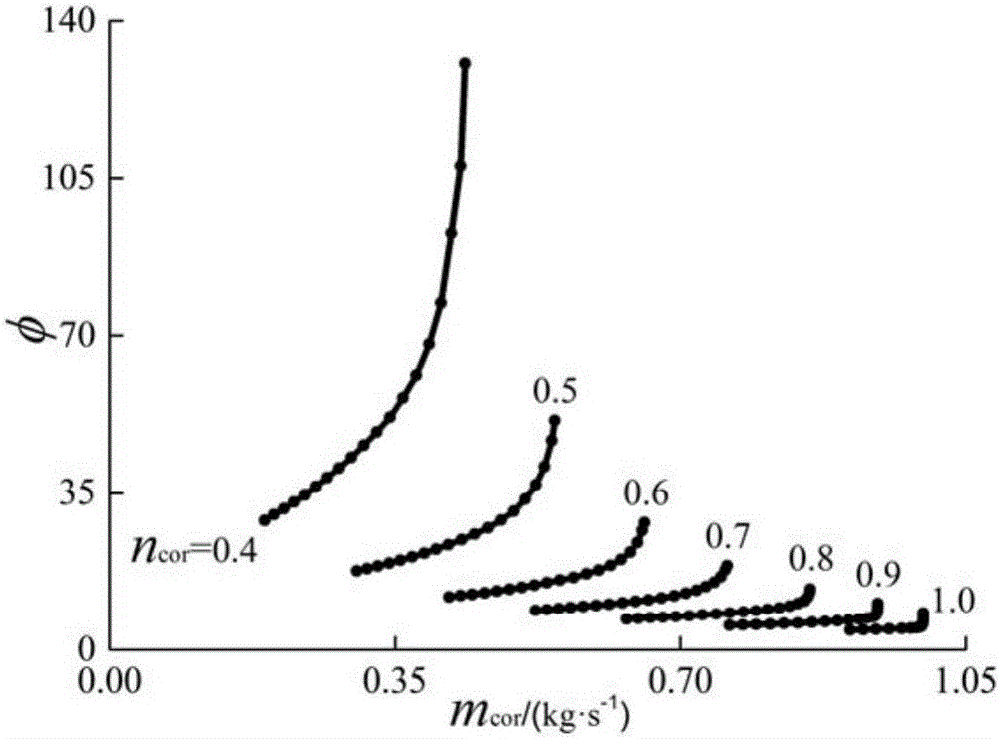

Low-speed characteristic extrapolation method for gas compressor

ActiveCN105930662AQuick acquisition of low speed characteristicsEngine fuctionsPump controlAviationAxial compressor

The invention discloses a low-speed characteristic extrapolation method for a gas compressor to solve the problem that an existing low-speed characteristic extrapolation method for the gas compressor does not consider the influence of compressibility of a working medium on a low-speed characteristic. The method is suitable for obtaining gas compressor low-speed characteristics of a ground gas turbine and an aero-engine. The method is characterized in that the low-speed characteristic extrapolation method considers application conditions of a similar principle and the low-speed condition characteristic of the gas compressor, an index of the similar principle is improved, an optimal index is obtained through an optimization algorithm, and a coefficient fitting method for variable condition calculation of the gas turbine is applied to the low-speed characteristic extrapolation of the gas compressor so as to obtain the low-speed characteristic. The low-speed characteristic extrapolation method for the gas compressor, adopted in the invention, and the method for obtaining the optimal index of the similar principle through a genetic algorithm have wide application values.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

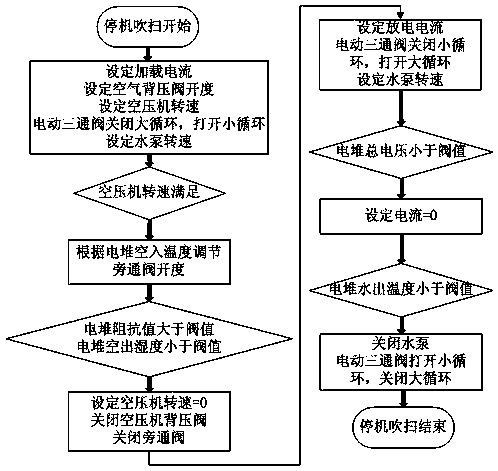

Fuel cell auxiliary system and shutdown cathode rapid purging method

The invention discloses a fuel cell auxiliary system and a shutdown cathode rapid purging method. The auxiliary system includes an air filter, an air flowmeter, an air compressor, an intercooler, an air bypass valve, a humidifier, an electric pile air incoming temperature sensor, an electric pile air outgoing humidity sensor, an air back pressure valve, an electric pile, an electric pile water outgoing temperature sensor, a water pump, an electric three-way valve, a radiator, a voltage sensor, an AC impedor and a current sensor. The auxiliary system is advantaged in that change of the system is little, parts are simple, and integration is facilitated; when a fuel cell is shutdown, an electric pile can be rapidly dried through purging, normal start at the next time is facilitated, and the auxiliary system can play the important role in the fuel cell vehicle field.

Owner:河南豫氢动力有限公司

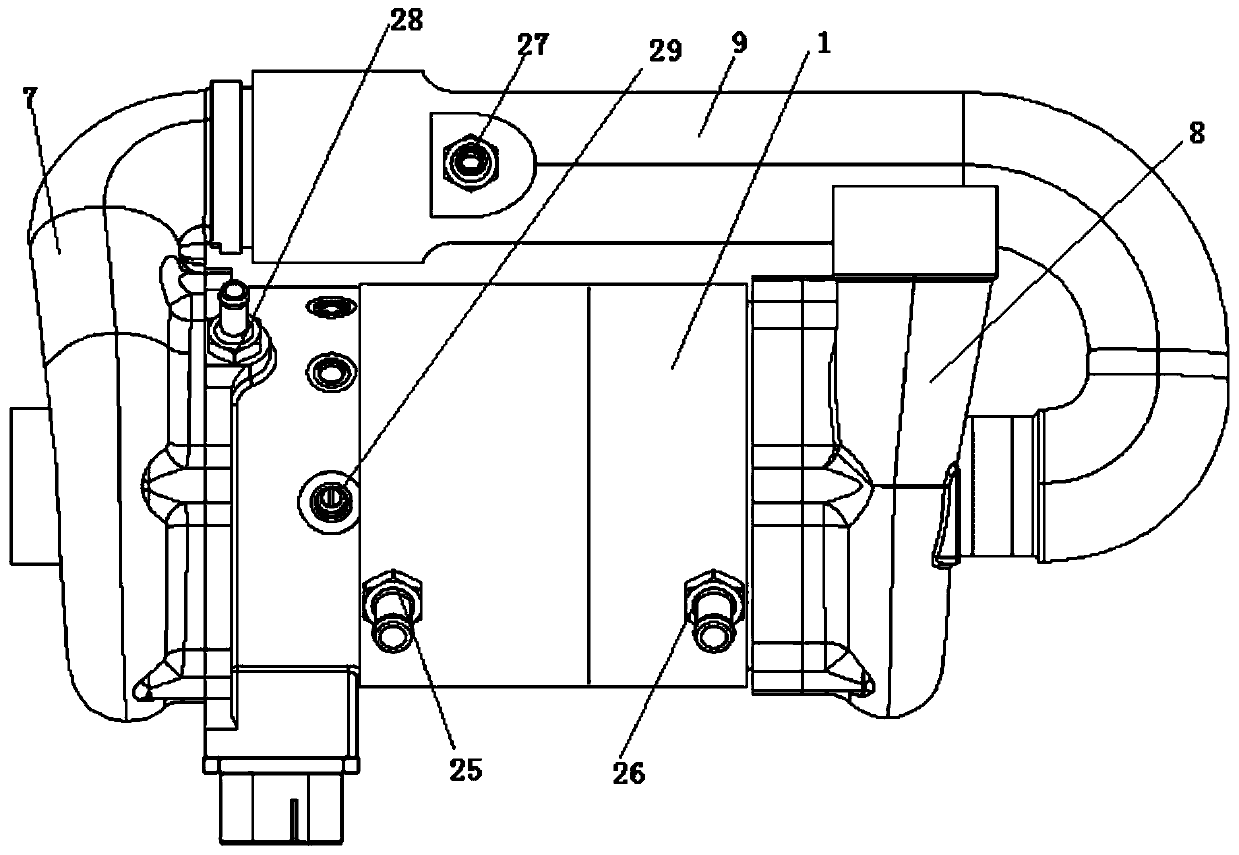

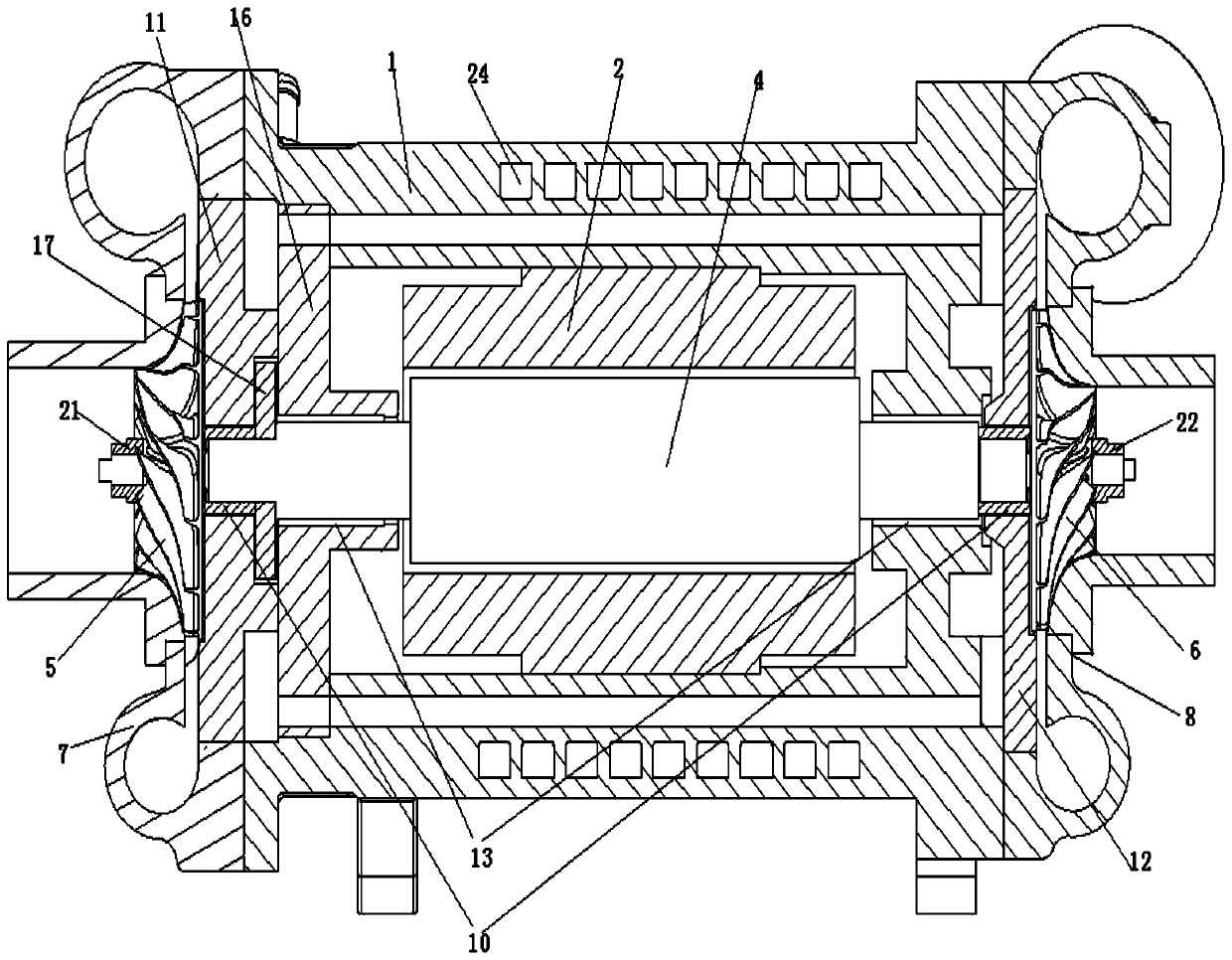

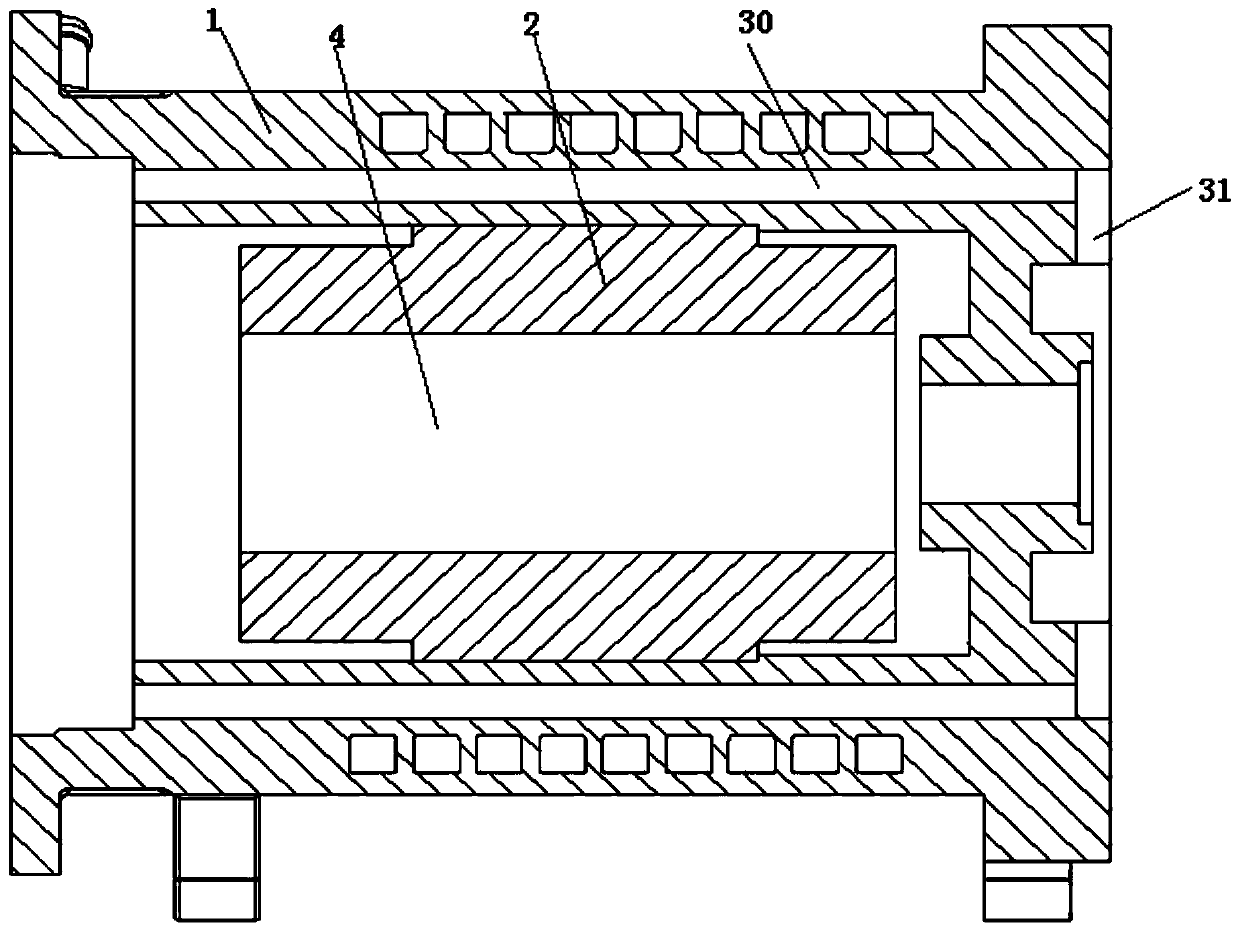

Two-stage air-suspending centrifugal electric direct drive air compressor

The invention discloses a two-stage air-suspending centrifugal electric direct drive air compressor. The two-stage air-suspending centrifugal electric direct drive air compressor comprises a shell, amotor stator, a spindle, impellers, lock nuts, volutes and a cooling system, wherein the shell, the motor stator and the spindle are sequentially arranged from outside to inside, the impellers, the lock nuts and the volutes are arranged on the two sides of the spindle, and the cooling system is arranged on the shell. The two-stage air-suspending centrifugal electric direct drive air compressor hasthe beneficial effects that the shell, the motor stator, the spindle, the impellers and the volutes are integrally designed, and the size and the weight of the whole machine are reduced. The two stages of impellers are connected in series through a middle pipeline, and small flow and the high-pressure ratio are achieved. Axial thrust of the two stages of impellers can be mutually offset, and axial force applied by thrust bearings is reduced. Radial and axial air bearings are adopted, gas films are formed through high-pressure gas generated by the bearings, friction between the bearings and arotor is reduced, air-suspending motor high-speed direct drive is formed, and mechanical losses are reduced. Part of compressed gas is introduced into a machine shell assembly through the middle pipeline, the motor stator, the spindle, the radial bearings and the thrust bearings are cooled, and the service life of the air compressor is prolonged.

Owner:势加透博洁净动力如皋有限公司

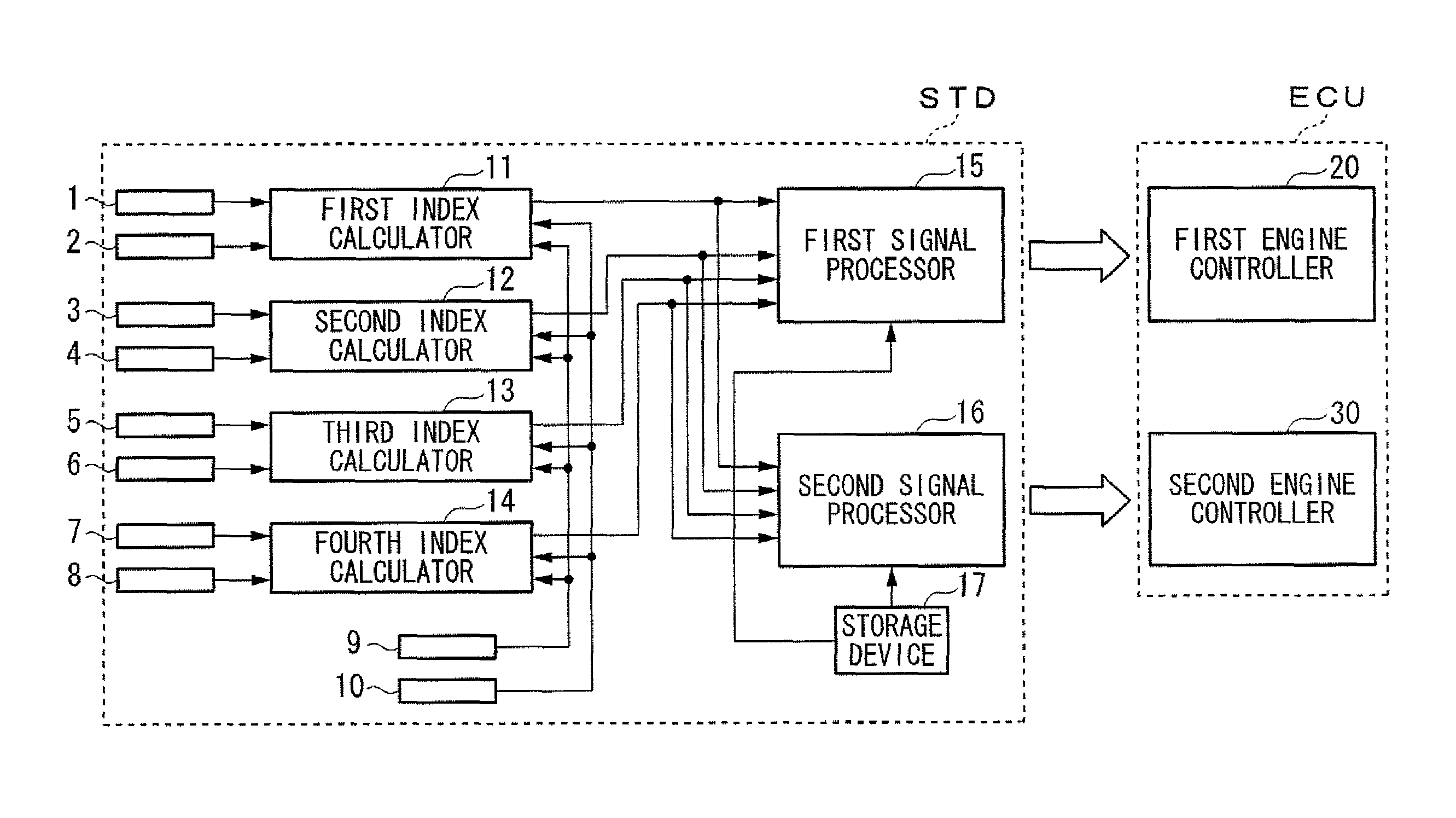

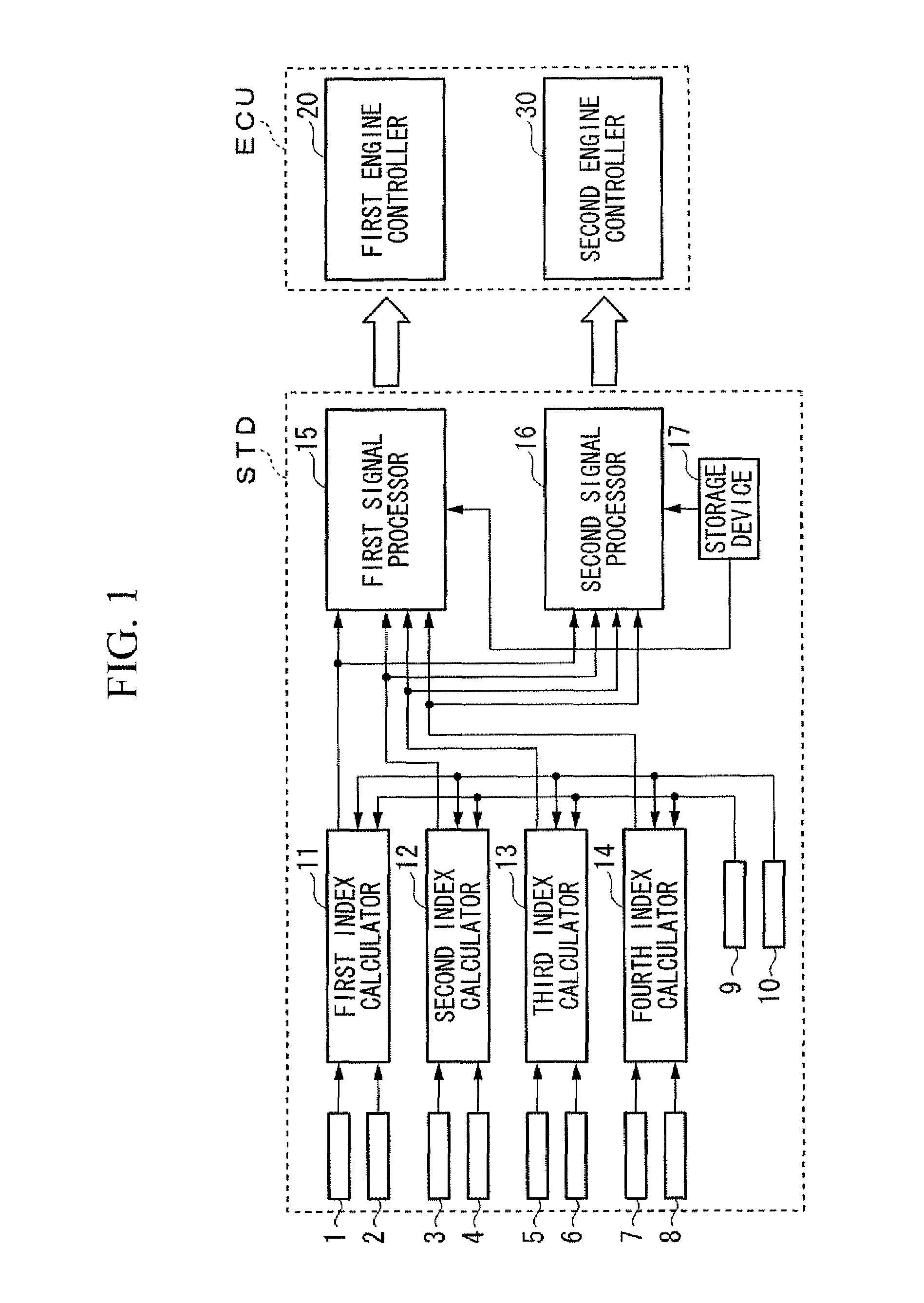

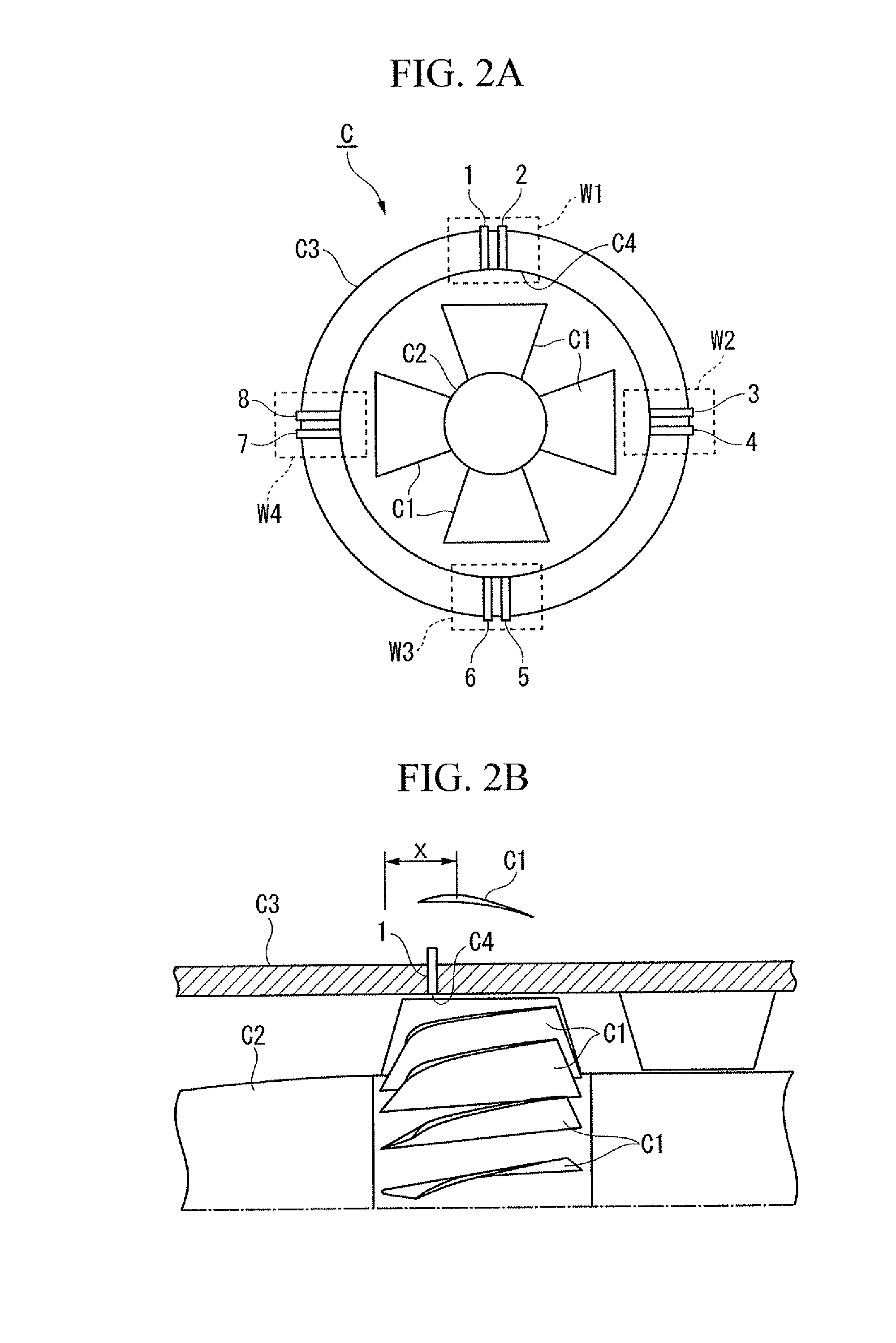

Stall prediction apparatus, prediction method thereof, and engine control system

ActiveUS20090312930A1Improve reliabilityEliminate fluctuationsVehicle testingAnalogue computers for vehiclesAxial compressorControl system

A stall prediction apparatus of an axial compressor provided with: a rotor provided with a plurality of rotor blades; and a cylindrical casing facing the rotor blades and provided so as to cover the outer circumference of the rotor, comprising: pressure sensors provided in equal numbers at a plurality of locations in a circumferential direction of an inner wall surface of the casing, an index calculator for calculating an index (stall risk index) for evaluating the stall risk based on time-series data detected by each of the pressure sensors, and a signal processor for predicting the stall occurrence based on the stall risk indexes obtained corresponding to said each of the pressure sensors. In accordance with the present invention, it is possible to obtain a stall risk index which is highly accurate (supersensitive) and stable necessary for the active stall control, and to realize an engine control system with high reliability.

Owner:IHI CORP +1

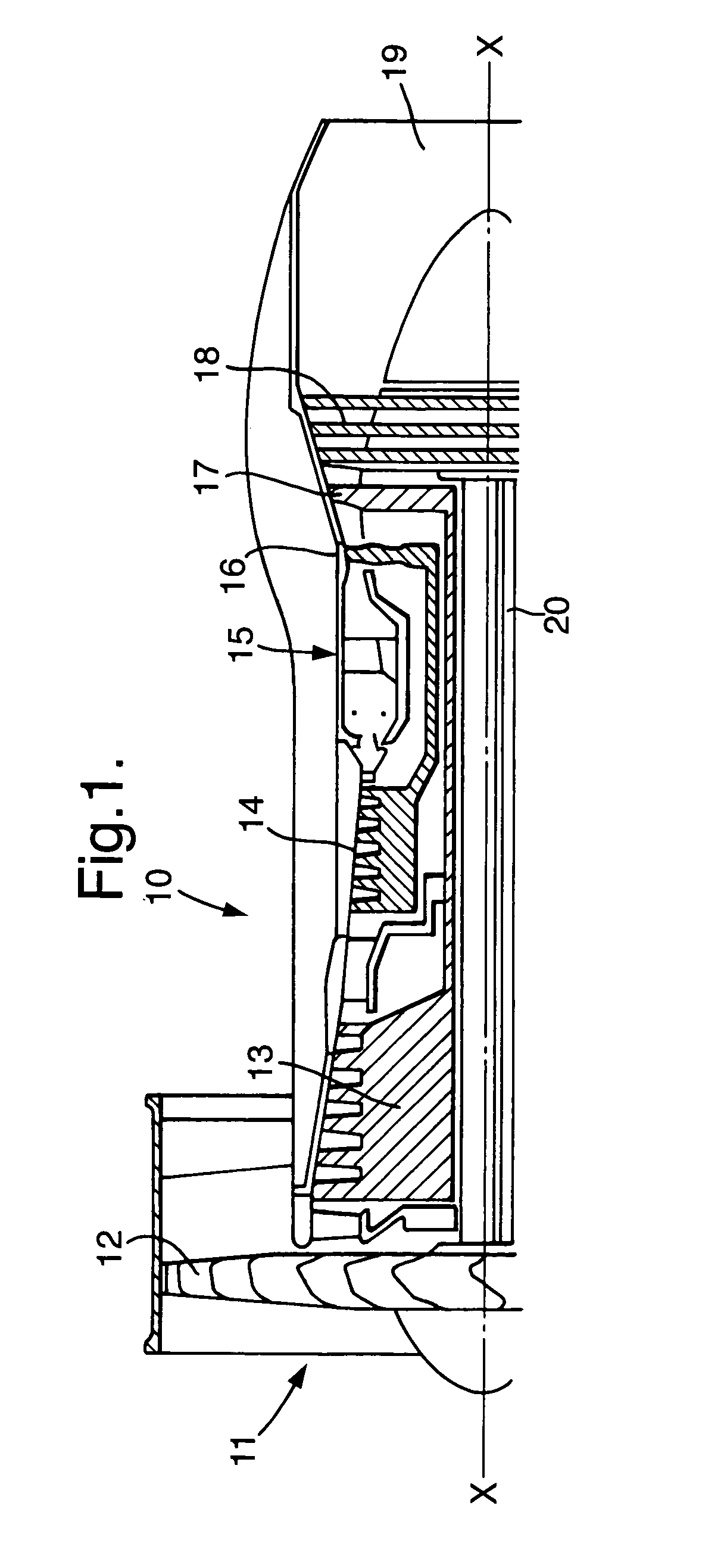

Compressor blade with dovetail slotted to reduce stress on the airfoil leading edge

InactiveUS6902376B2Reducing centrifugalReducing vibratory loadPropellersOther chemical processesLeading edgeAxial compressor

A blade of an axial compressor comprising: an airfoil is disclosed that has a leading edge and a root; a platform attached to the root of the airfoil; a dovetail attached to a side of the platform opposite to the airfoil; a neck of the dovetail adjacent the platform, and a slot in the neck and generally parallel to the platform, and the slot extends from a front of the neck to position in the neck beyond a line formed by the leading edge of the blade.

Owner:GENERAL ELECTRIC CO

Turbomachine including an integrated electricity generator

ActiveUS7224082B2Overcomes drawbackOptimization pathEngine fuctionsEfficient propulsion technologiesAxial compressorElectricity

A turbomachine includes a high-pressure spool, an axial compressor of axis X mounted on a rotor and including a casing and at least one rear bearing disposed between the casing and the rotor of the compressor. The turbomachine further includes an electricity generator coaxial with the spool and including a primary magnetic circuit that is constrained to rotate with the rotor of the compressor and a secondary magnetic circuit that is secured to the casing. The electricity generator is disposed upstream from the rear bearing and includes at least a first cooling circuit surrounding the secondary magnetic circuit and extended by a nozzle for lubricating the rear bearing.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Unison ring assembly for an axial compressor casing

InactiveUS8123472B2Minimal frictionSlide freelyWind motor controlPump componentsAxial compressorMechanical engineering

Owner:SIEMENS AG

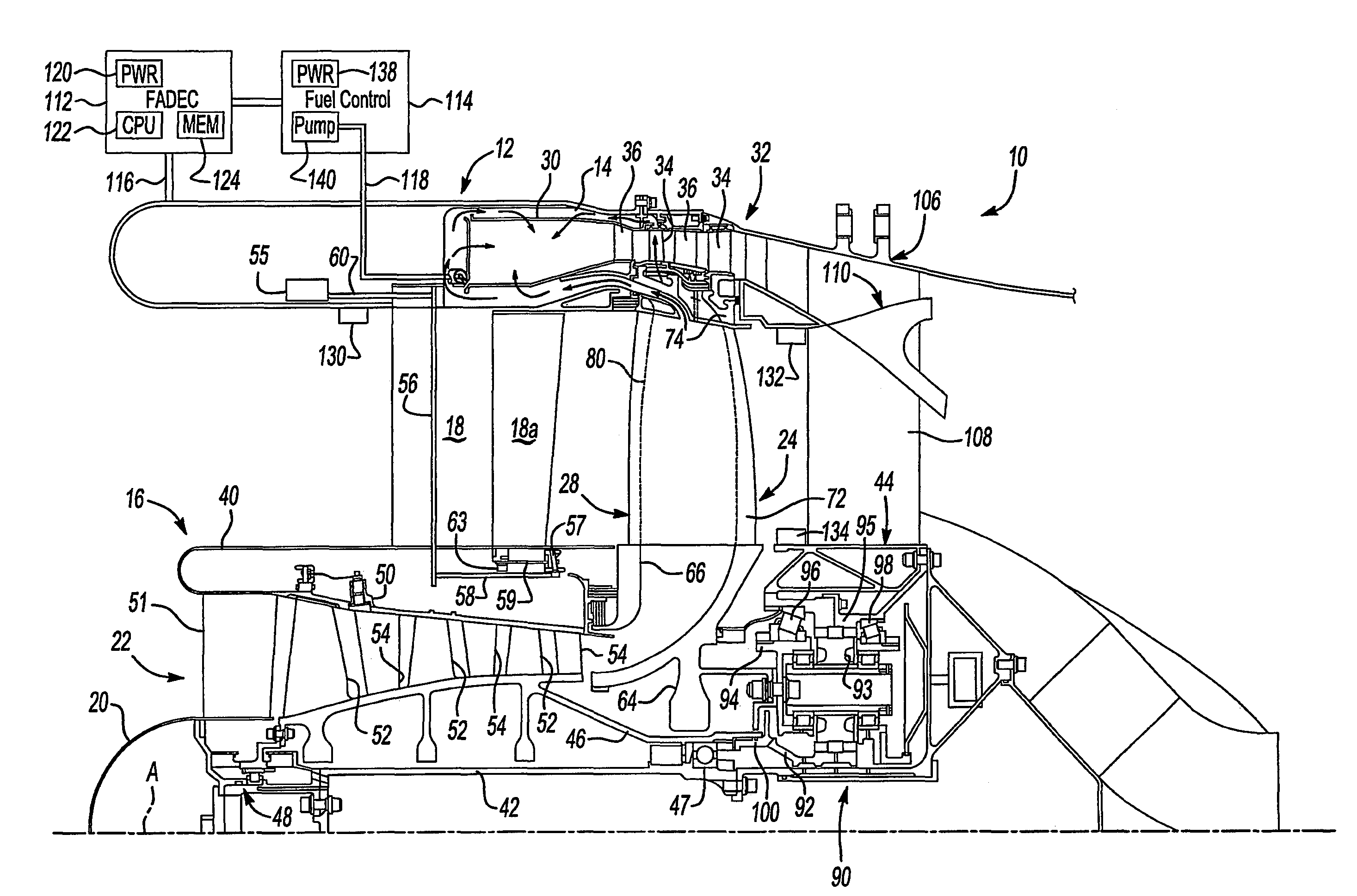

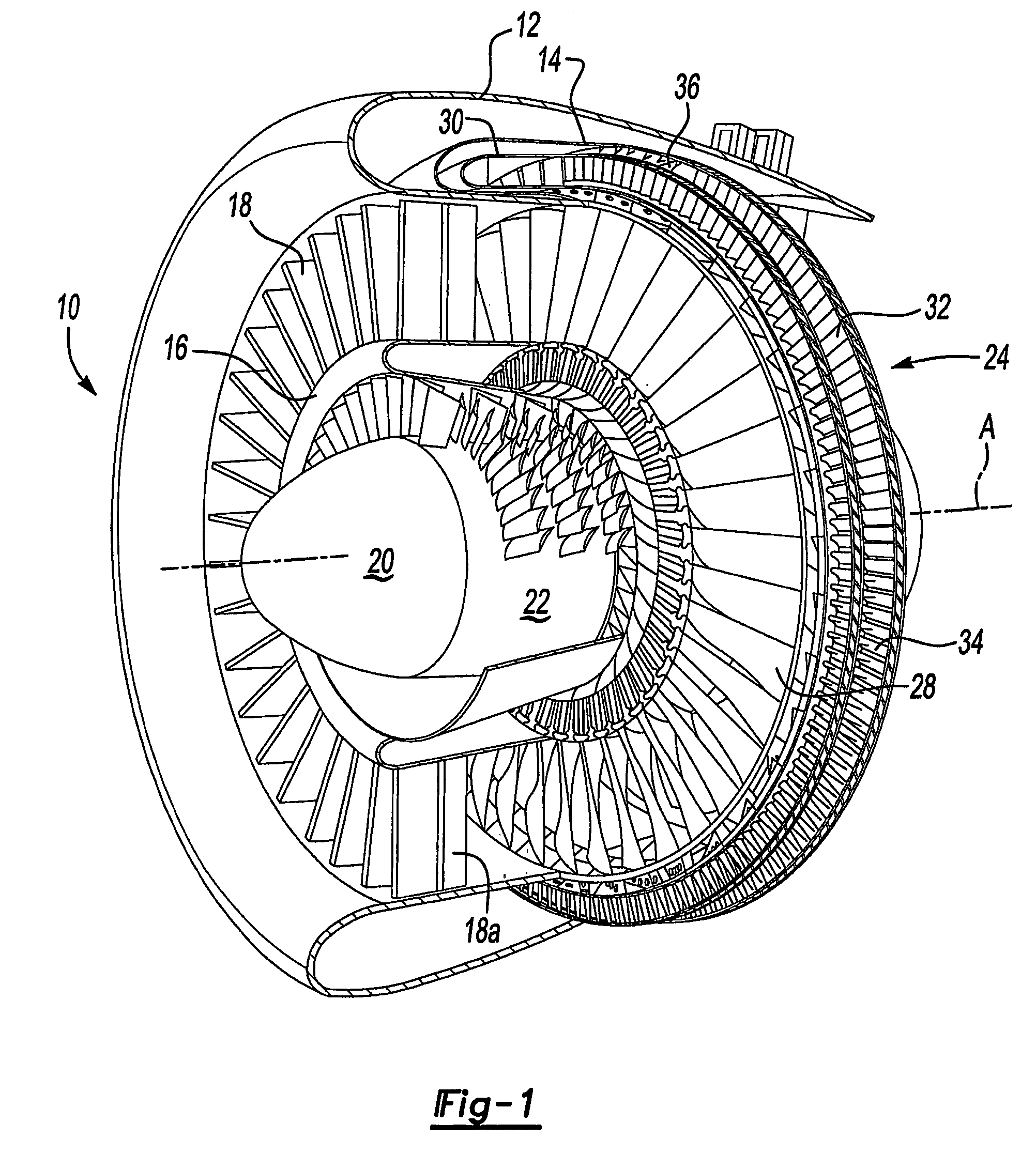

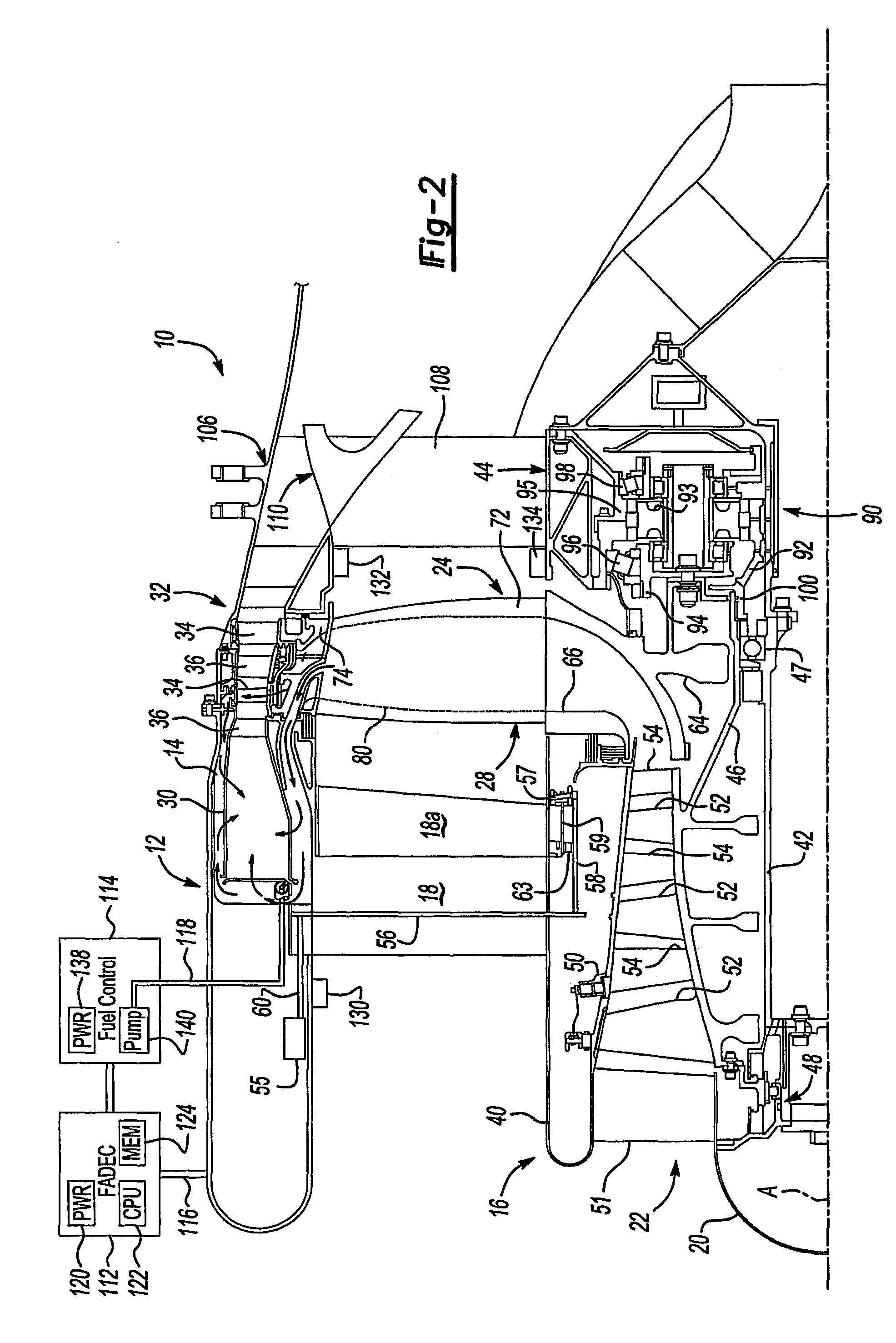

Variable fan inlet guide vane assembly for gas turbine engine

ActiveUS7882694B2Reduced stabilityReduced Power RequirementsPump componentsWind motor controlAxial compressorGas turbines

A turbine engine includes a plurality of variable fan inlet guide vanes. Where the turbine engine is a tip turbine engine, the variable fan inlet guide vanes permit the ability to control engine stability even though the fan-turbine rotor assembly is directly coupled to the axial compressor at a fixed rate. The fan inlet guide vanes may be actuated from an inner diameter of the fan inlet guide vanes.

Owner:RTX CORP

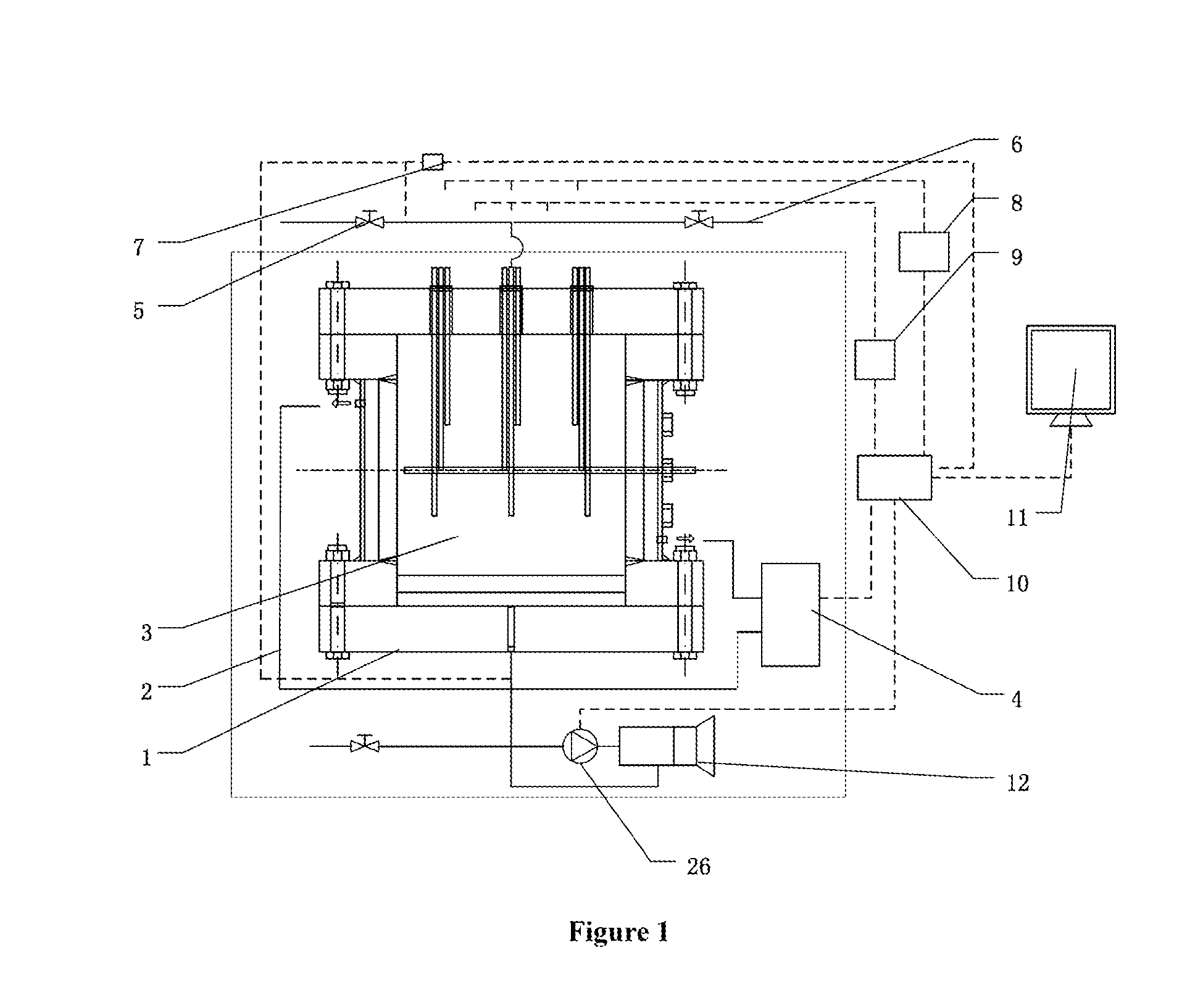

Triaxial seepage stress temperature creep coupling experimental device based on digital image

InactiveCN104849194APrecise creep deformationReduce manpower consumptionPermeability/surface area analysisAxial compressorAxial pressure

The invention discloses a triaxial seepage stress temperature creep coupling experimental device based on a digital image. The triaxial seepage stress temperature creep coupling experimental device comprises a triaxial pressure chamber (1), a digital image observing system and a triaxial pressure chamber heating system, wherein a pore pressure applying system, a stable-pressure axial applying system and a surrounding pressure applying system are mounted on the triaxial pressure chamber (1); the pore pressure applying system comprises a pore pressure fluid injection tube (5), one end of the pore pressure fluid injection tube is connected with a first pressure pump (8); the first pressure pump (8) is used for providing pore pressure energy, the pressure value is measured by a digital pressure meter (9), and the pressure meter (9) is mounted on the pore pressure fluid injection tube (5). The triaxial seepage stress temperature creep coupling experimental device can be used for accurately and automatically measuring creep deformation by searching the influences of the surrounding pressure, the axial pressure, the hole pressure, the temperature and the creep deformation on coal permeability.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com