Air compressor monitoring diagnosis system and method adopting adaptive kernel Gaussian hybrid model

A technology of Gaussian mixture model and diagnostic system, which is applied in pump control, mechanical equipment, machine/engine, etc., can solve the problems of inability to monitor the nonlinear structure of input data, high false alarm rate, and low monitoring accuracy, and achieve online Monitoring and diagnostics, increased automation, and unattended effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

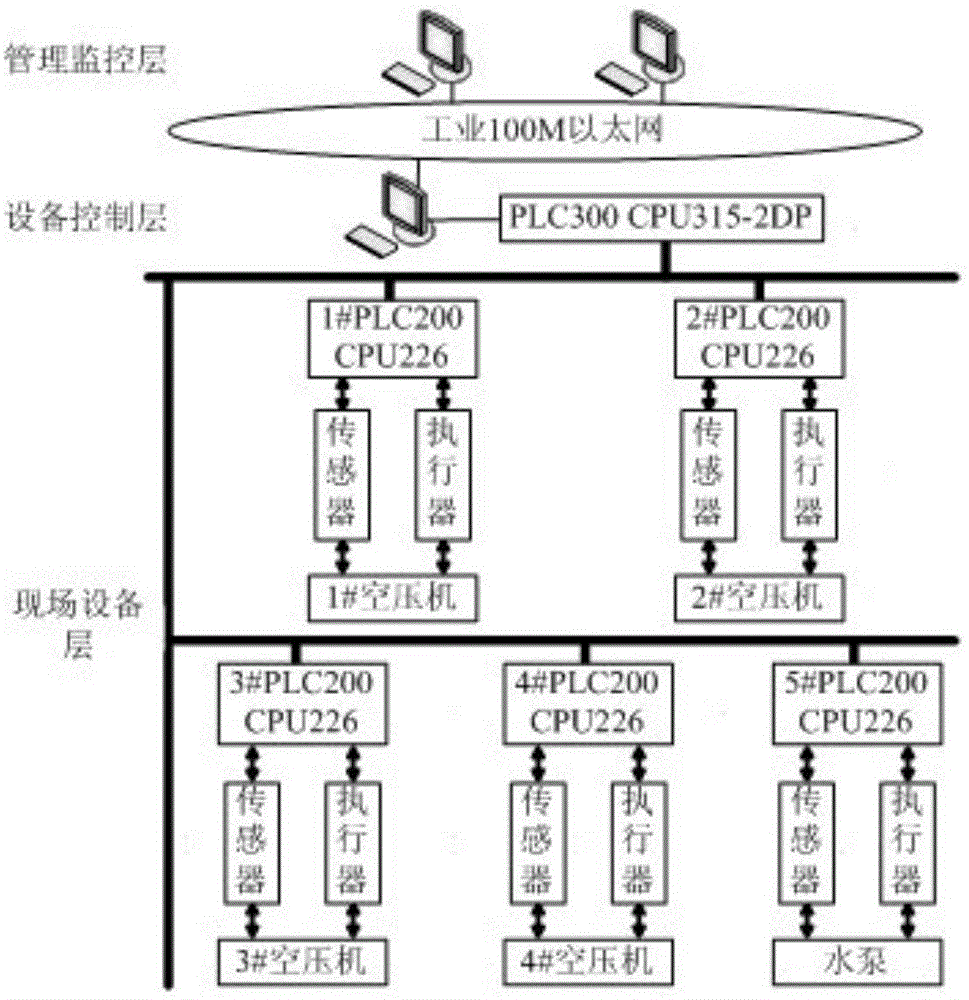

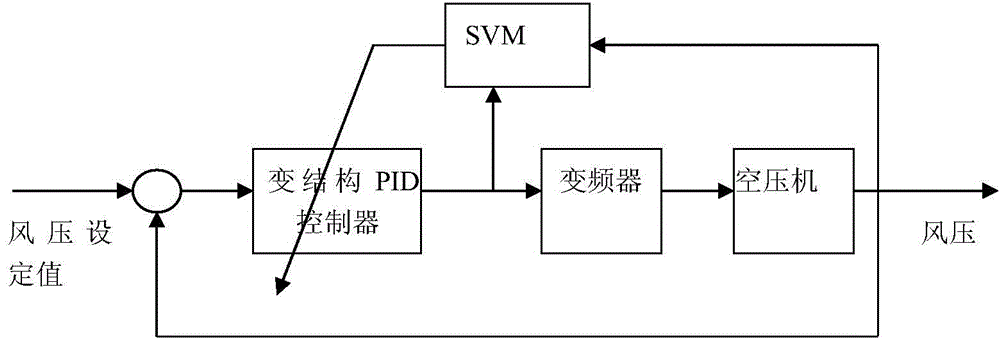

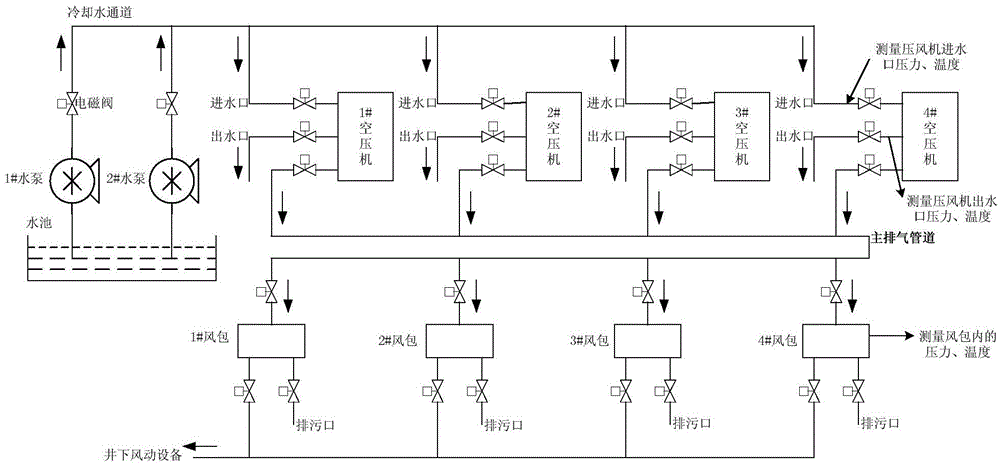

[0027] like figure 1 and figure 2 As shown, an air compressor monitoring and diagnosis system of an adaptive nuclear Gaussian mixture model includes a field device layer, a device control layer and a management monitoring layer. The field device layer is composed of PLC200, sensors, air compressors, actuators and The water pump is composed of PLC200 as a substation to complete the control of the field equipment layer; the equipment control layer includes the upper computer and PLC300, with PLC300 as the master station, and the PROFIBUS-DP master-slave is selected between the master station and 5 slave stations The network communicates to form a distributed I / O system. The input signal from the slave station can be quickly transmitted to the master station, and the instructions and output results issued by the master station can also be sent to the slave station in time to execute the output. PLC is used as the central control unit. , the variable structure adaptive PID contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com