Triaxial seepage stress temperature creep coupling experimental device based on digital image

A technology of digital images and experimental devices, applied in the field of rock mechanics, can solve the problems of difficult and accurate measurement, complicated testing process, etc., and achieve the effect of reducing labor consumption and automatic measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

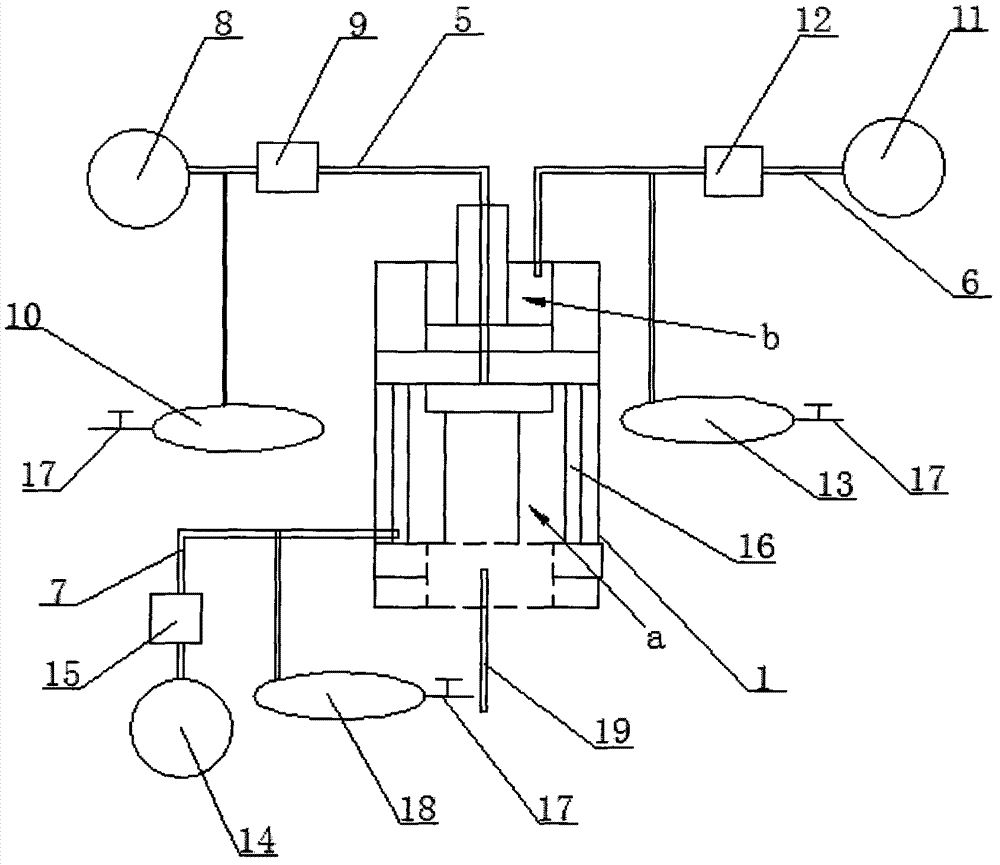

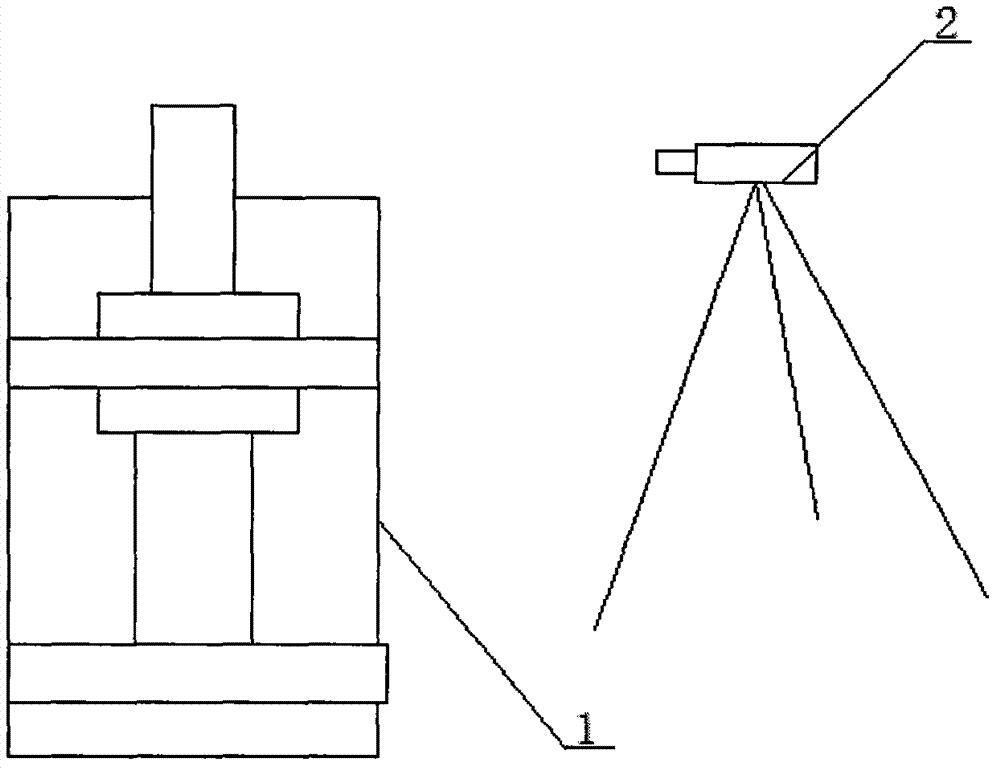

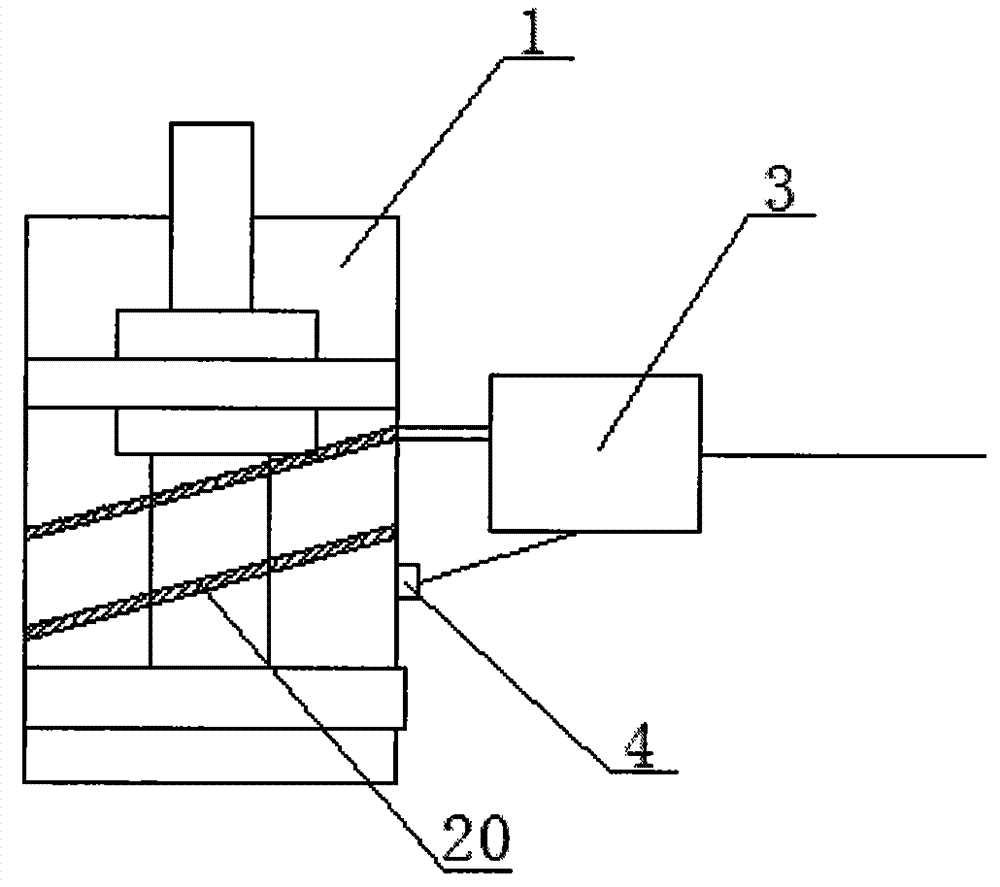

[0028] see Figure 1-3 , using this experimental device to complete the stress-seepage-temperature coupling experiment process: after installing the test piece, apply the confining pressure and axial pressure to predetermined values, then heat the triaxial pressure chamber 1 to the predetermined temperature, and then apply pore pressure to measure different confining pressure, axial pressure Permeability under pressure and temperature.

Embodiment 2

[0030] see Figure 1-3 , using this experimental device to complete the stress-seepage-creep coupling experiment process: after installing the specimen, apply confining pressure and axial pressure to the predetermined value, after a period of time, use the digital image observation system to test the axial strain value, and then apply the pore pressure, using The steady flow method is used to test the permeability, and then after a period of time, the above process is repeated to obtain the permeability at different creep times.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com