Patents

Literature

35 results about "Crystal plasticity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

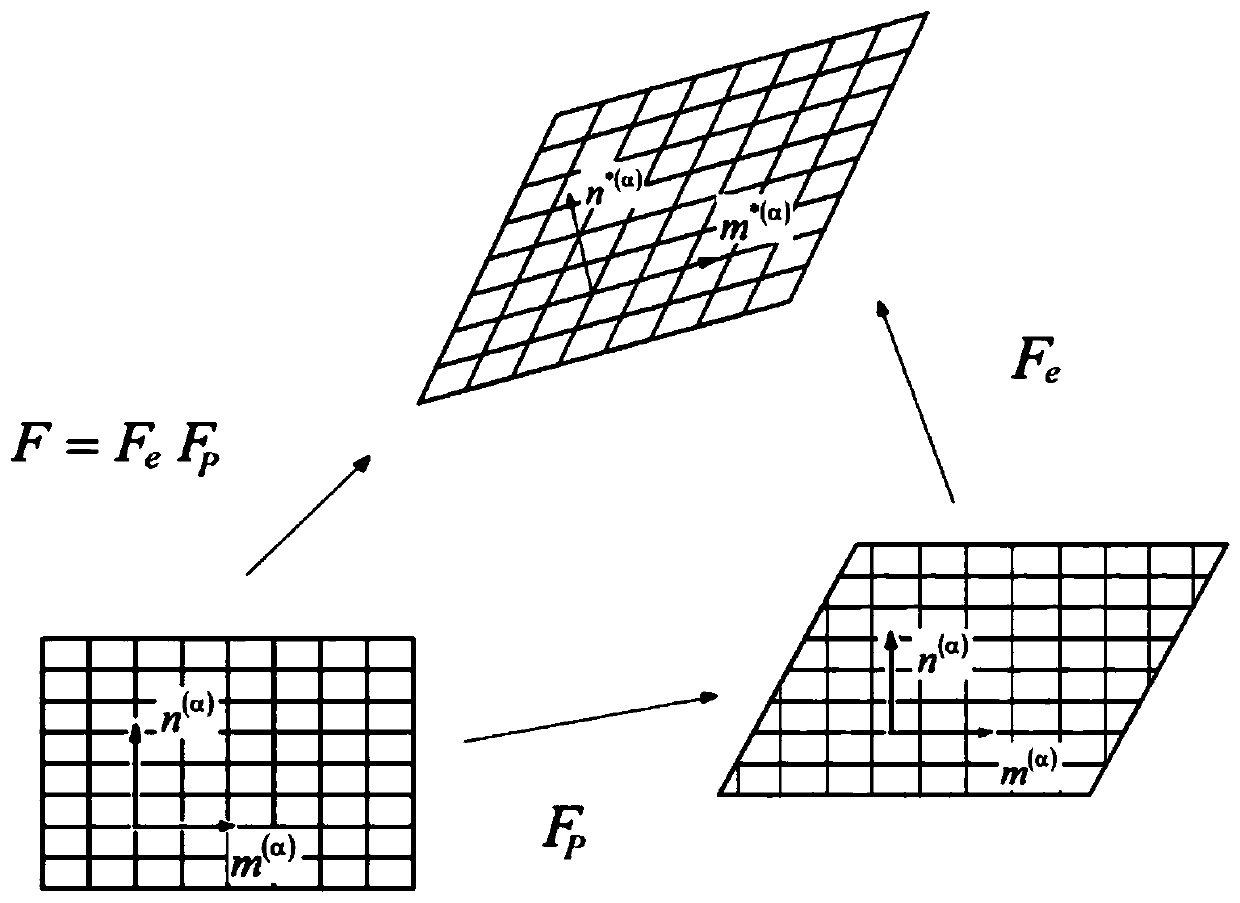

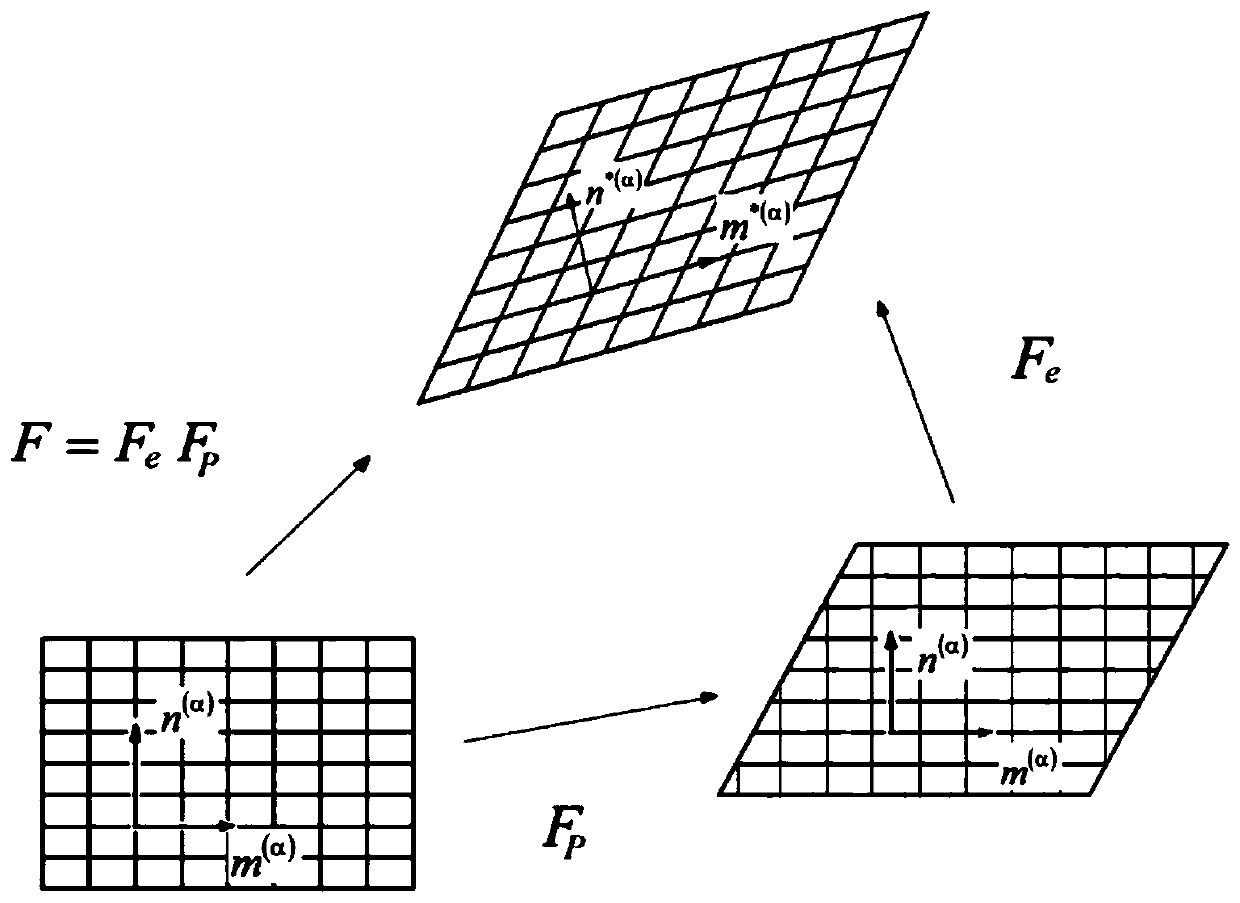

Abstract. Besides Dislocation Dynamics, crystal plasticity can be considered a mesoscale formulation, since the details of the equations start at the scale of the crystal or grain. In this section, the topics of classical crystal plasticity formulations, kinematics, kinetics, and the polycrystalline average methods will be discussed.

Method for predicting coupling responses of isothermal forming and dynamic recrystallization evolution of titanium alloys

ActiveCN106202675AAchieving Unified PredictionTightly deformedDesign optimisation/simulationSpecial data processing applicationsCrystallization kineticsTitanium alloy

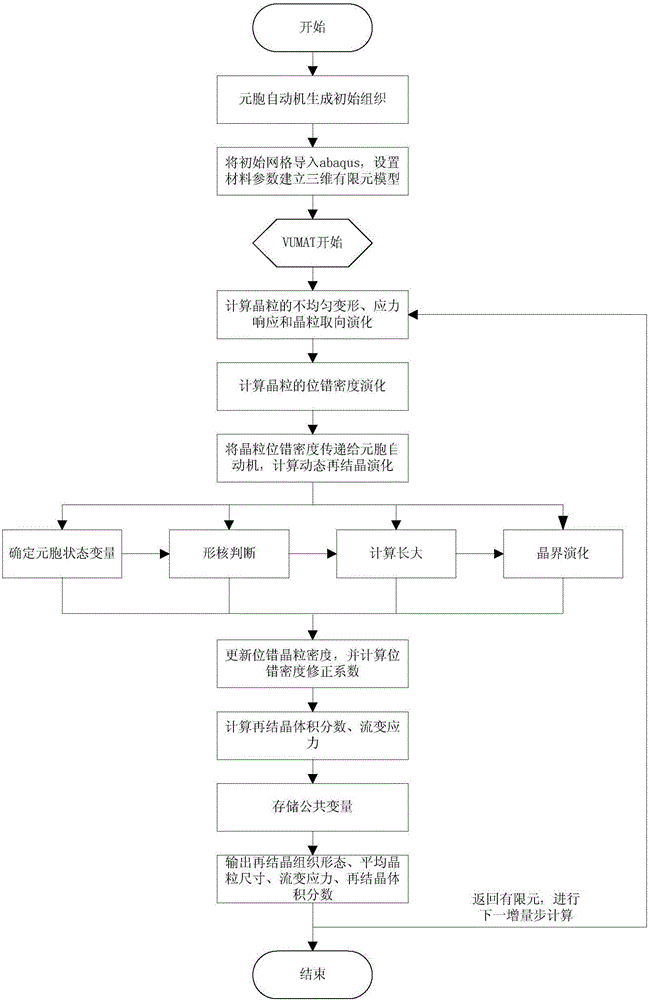

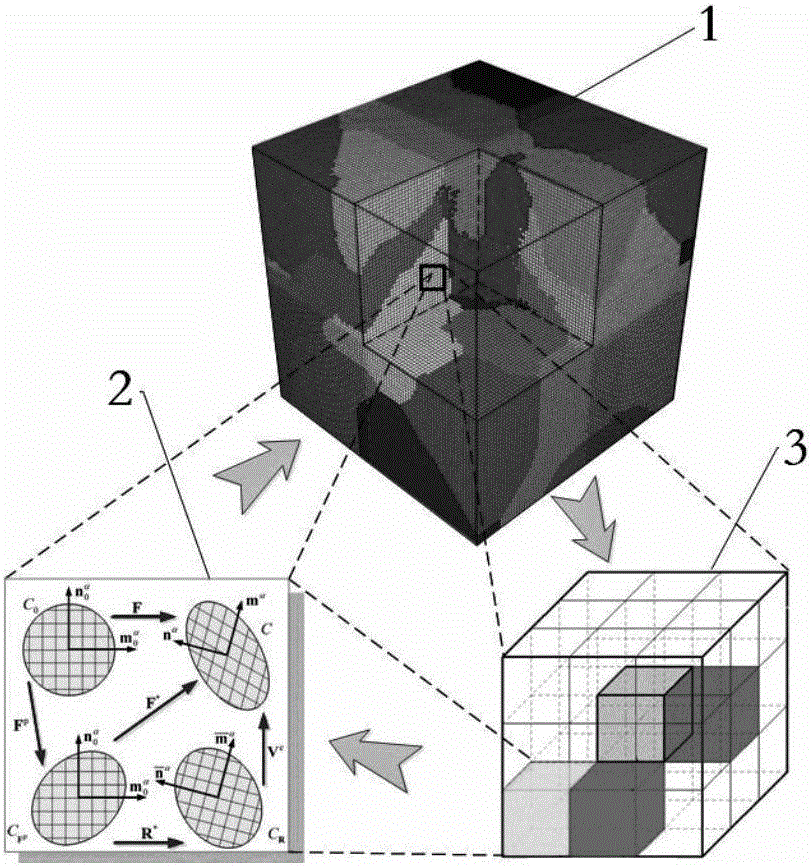

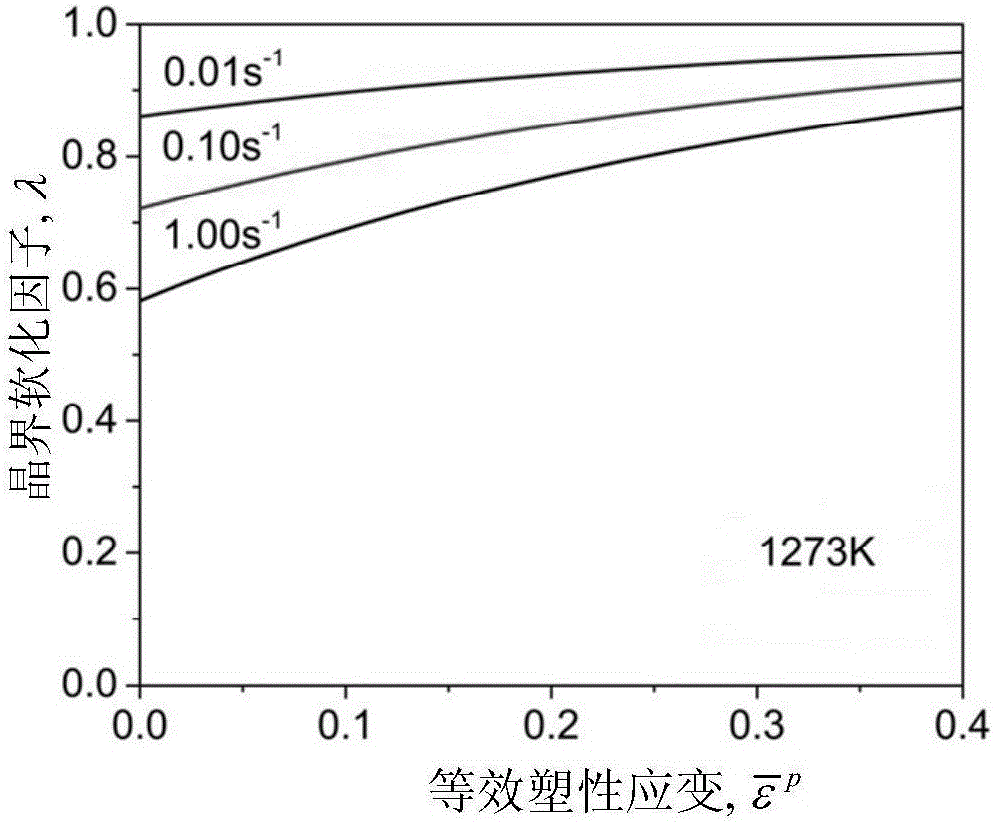

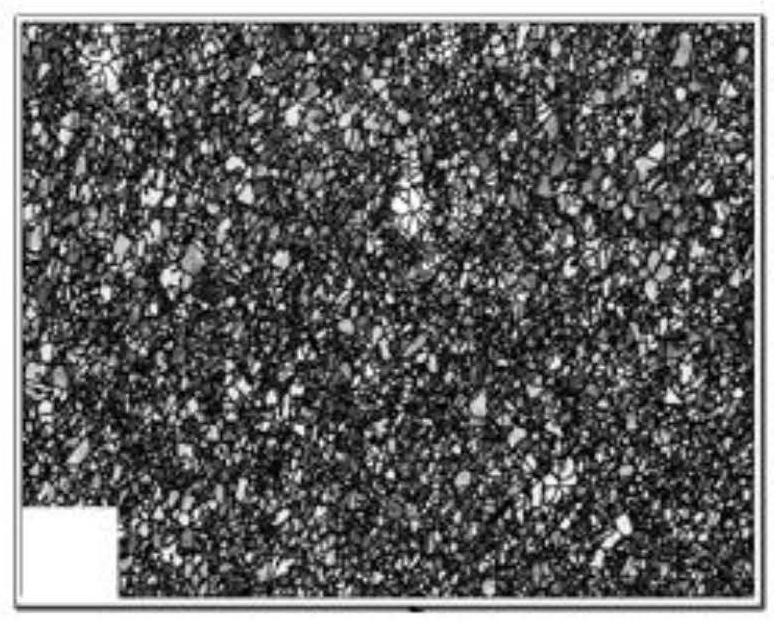

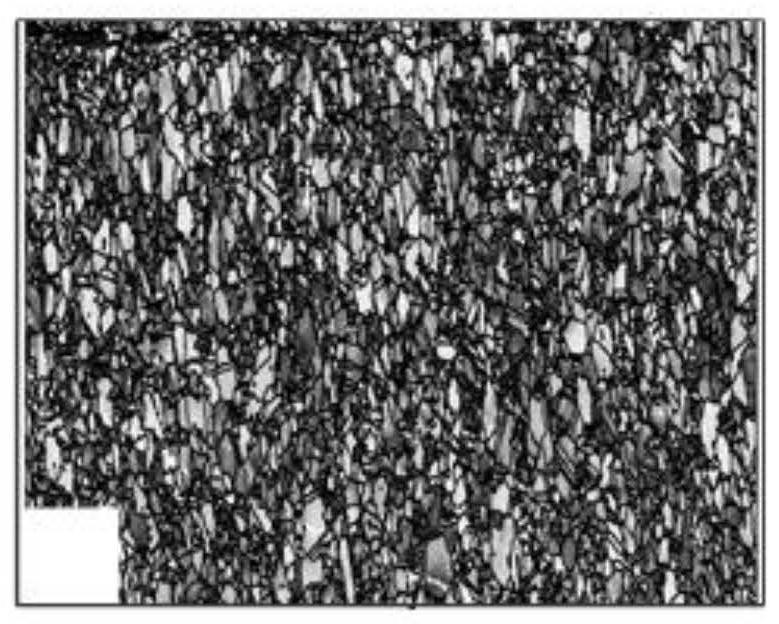

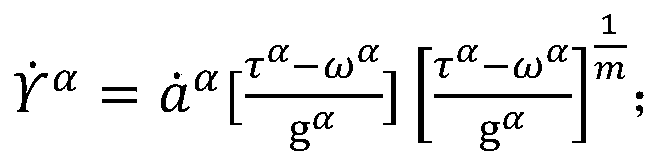

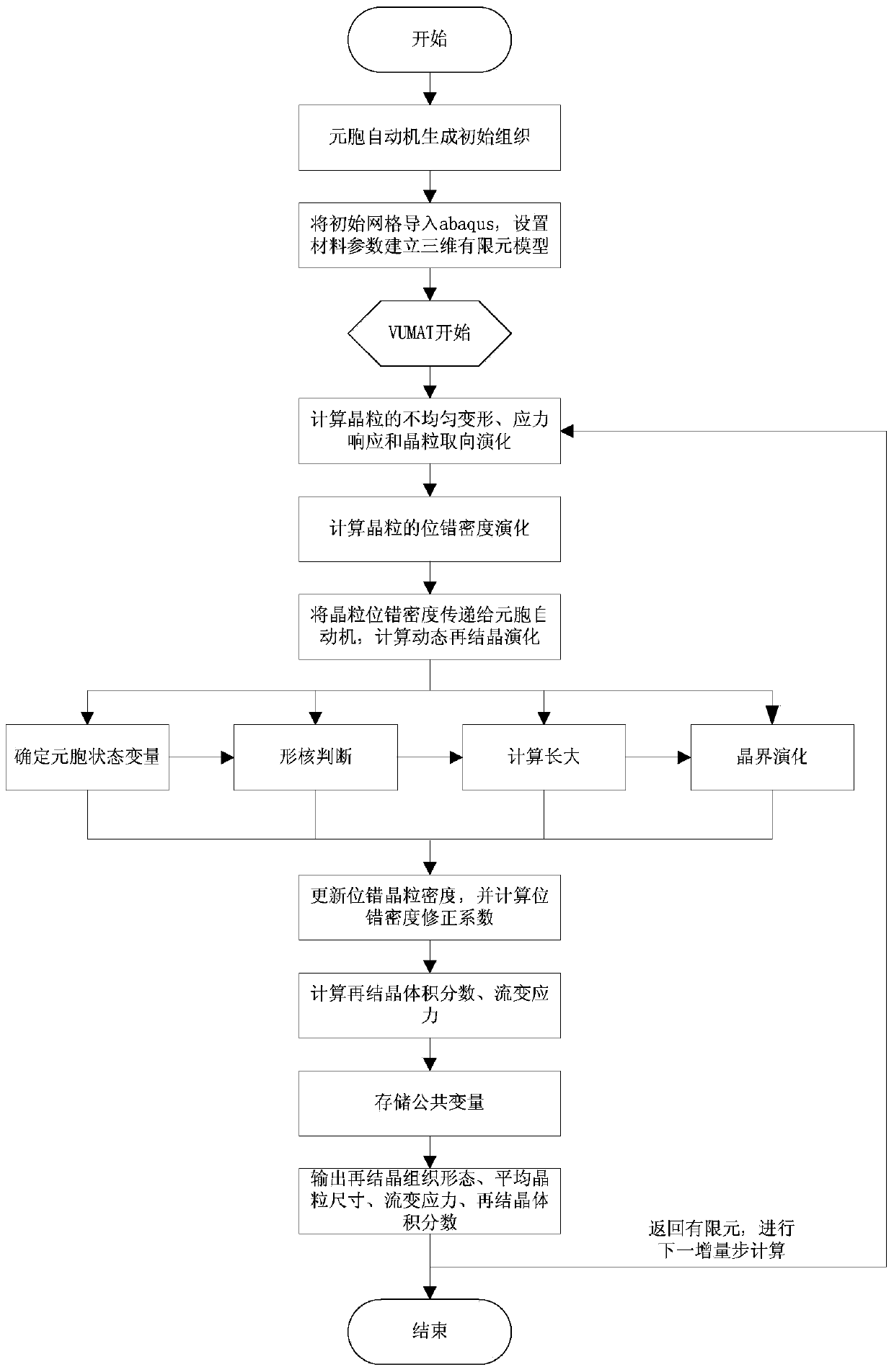

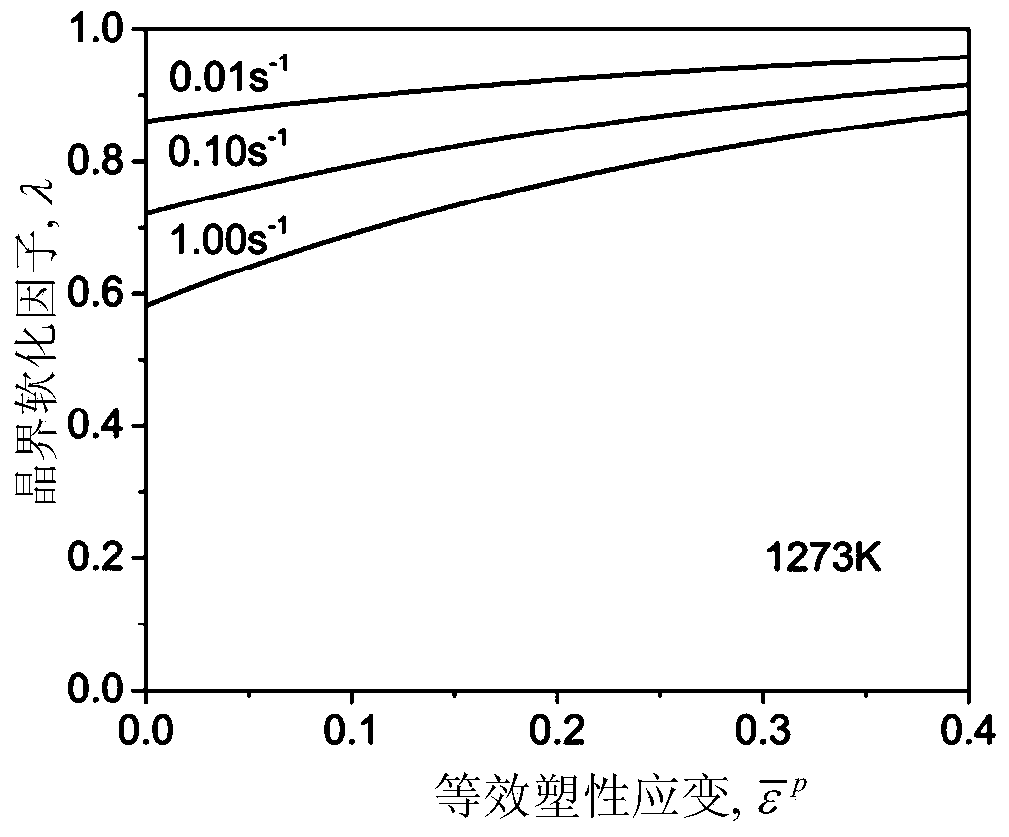

The invention provides a method for predicting coupling responses of isothermal forming and dynamic recrystallization evolution of titanium alloys. Grain stress responses, intercrystalline non-uniform deformation and non-uniform dislocation density caused by intercrystalline non-uniform deformation are obtained in an isothermal forming process of the titanium alloys and are adopted as variables and transmitted to a cellular automaton, dynamic recrystallization evolution of the grain size under the condition of non-uniform size deformation is obtained, and dynamic recrystallization nucleation and grown structure morphology as well as grain boundary evolution and updated dislocation density which are caused by the dynamic recrystallization nucleation and grown structure morphology are obtained. The obtained grain and grain boundary information including dynamic recrystallization nucleation and growth as well as the dislocation density is returned to a crystal plasticity finite element method, dislocation gliding resistance of each grain unit is updated, so that subsequent deformation of the titanium alloys is influenced, and the stress responses of the grain size are calculated according to the constitutive relation. The method realizes synchronous prediction of non-uniform deformation of the grain size in isothermal forming of the titanium alloys, dynamic recrystallization structure morphology evolution, recrystallized grain size evaluation, recrystallization kinetics, deformable bodies and grain flow stress.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Fatigue life prediction method for geometric discontinuous structure

ActiveCN110826285AIntuitiveDesign optimisation/simulationSpecial data processing applicationsElement modelCrazing

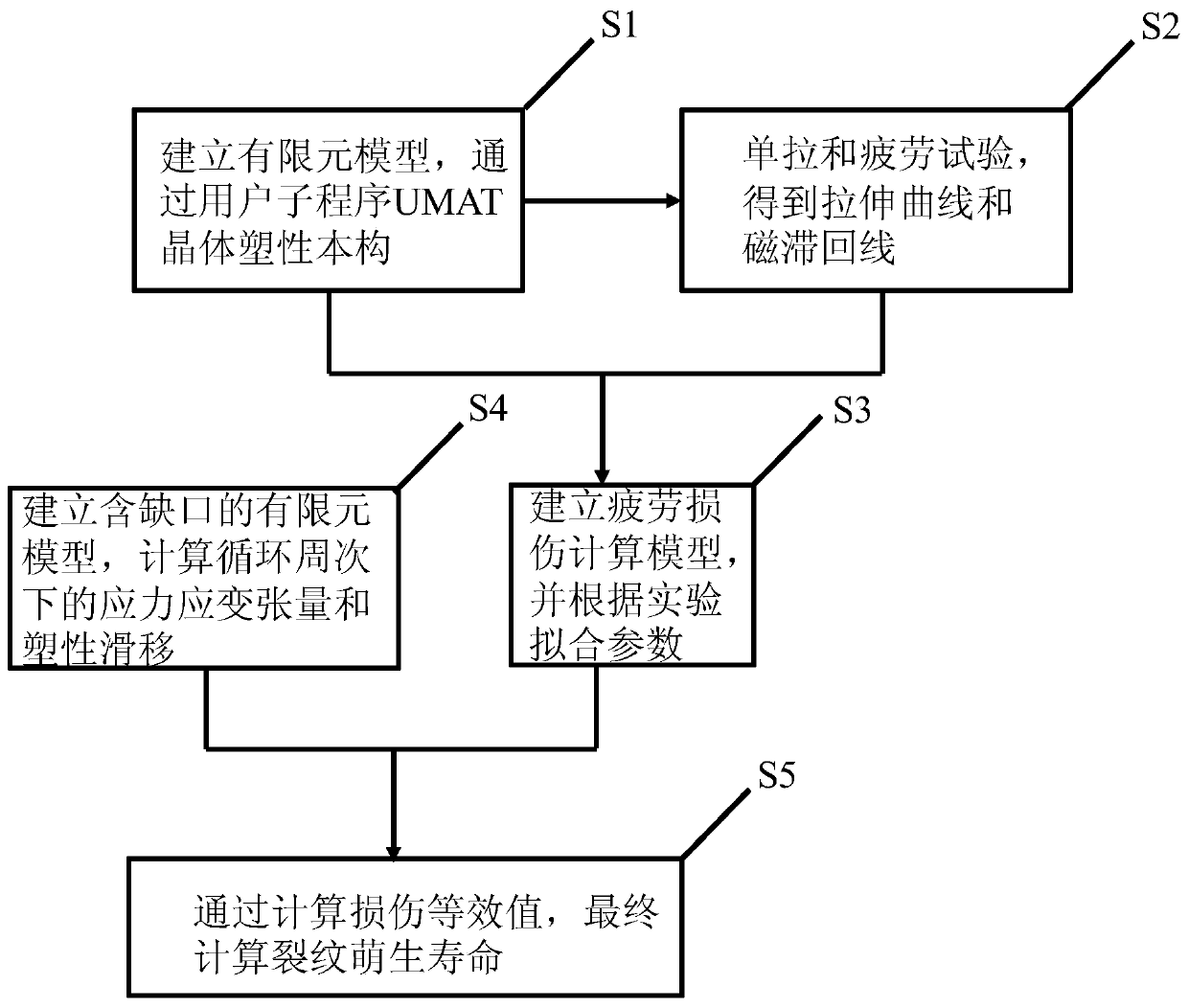

The invention provides a fatigue life prediction method for a geometric discontinuous structure. The method comprises the steps of building a geometric continuous first finite element model, defininga crystal plasticity constitutive equation, and obtaining a stress-strain relation of a material under a given cyclic load condition; carrying out a uniaxial tensile test and a uniaxial fatigue test to obtain a tensile curve and a hysteresis loop; fitting through a test parameter method to obtain a tensile curve and a hysteresis loop, and obtaining the material parameters and a fatigue plastic slip critical value required by a crystal plasticity constitutive equation; establishing a second finite element model of the geometric discontinuous structure, and obtaining a stress-strain relationshipand a single-cycle fatigue plastic slip value of each cycle; and calculating to obtain the crack initiation life of the notch sample. According to the fatigue life prediction method for the geometricdiscontinuous structure, the fatigue analysis of the geometric discontinuous structure at different temperatures can be better achieved, the crack initiation position can be accurately predicted, andthe fatigue life prediction method has the advantages of being visual, high in applicability and high in accuracy.

Owner:EAST CHINA UNIV OF SCI & TECH

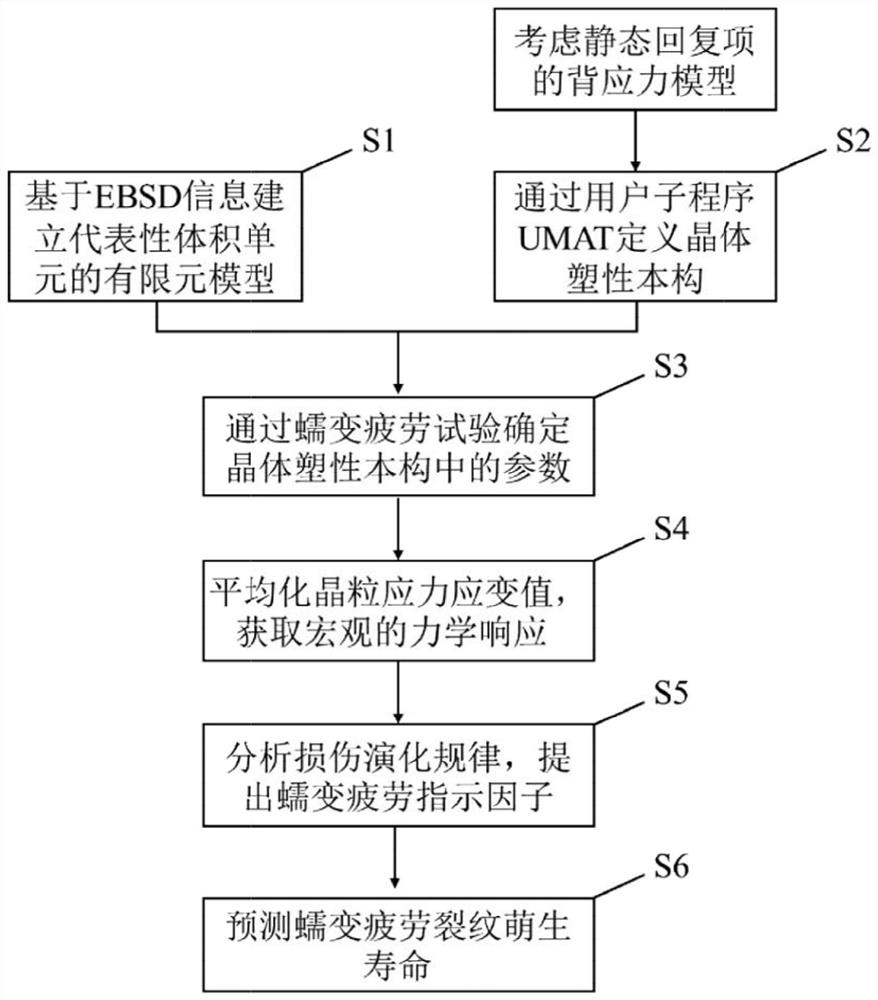

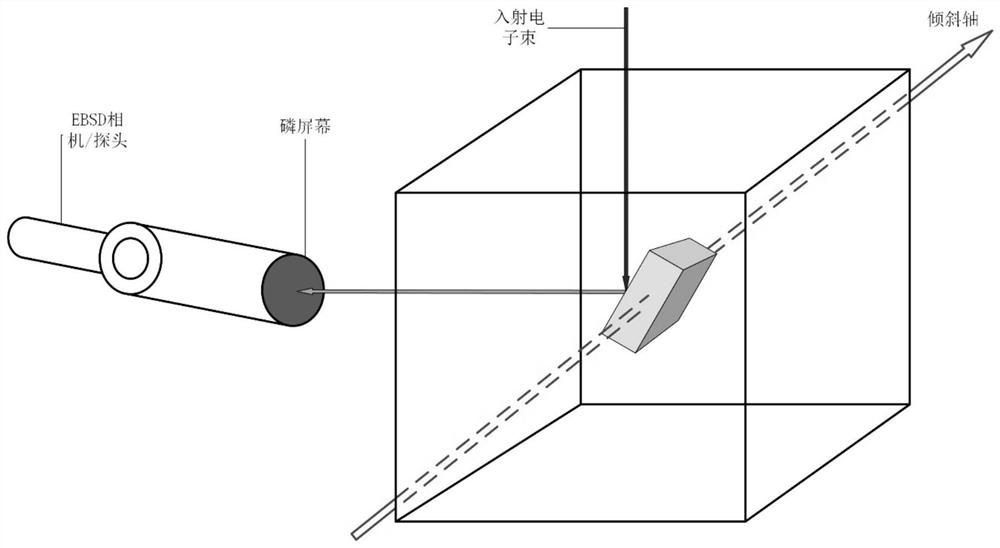

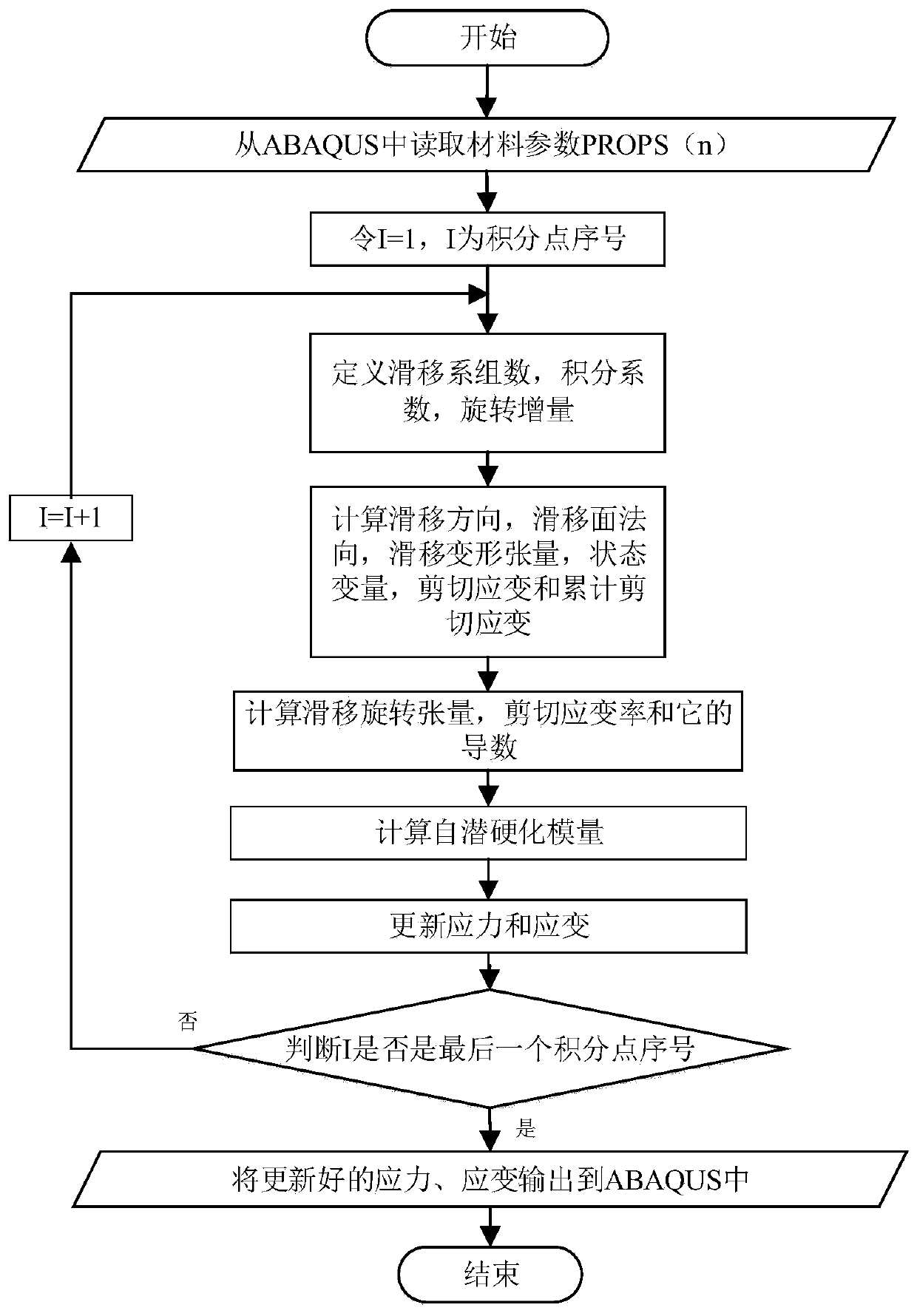

Creep fatigue life prediction method based on crystal plasticity

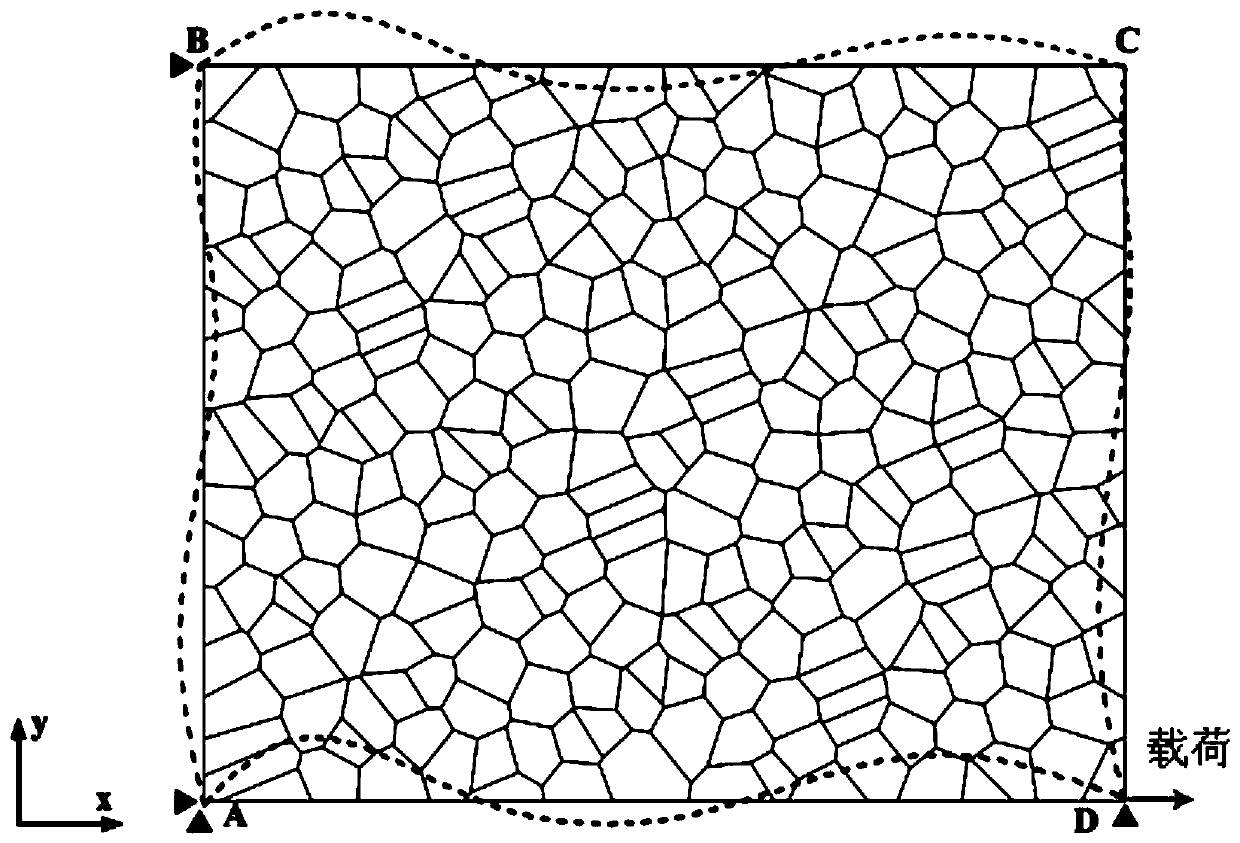

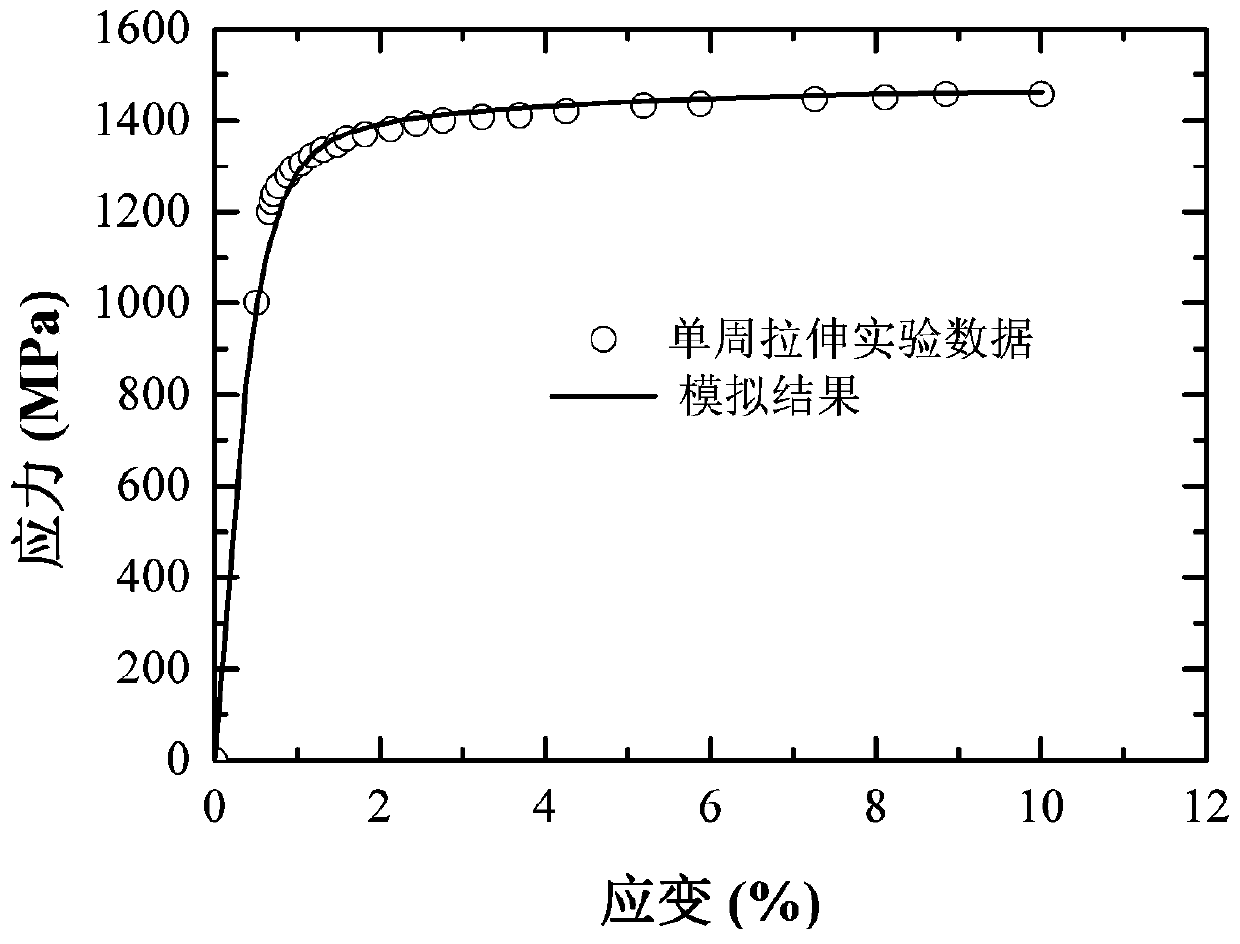

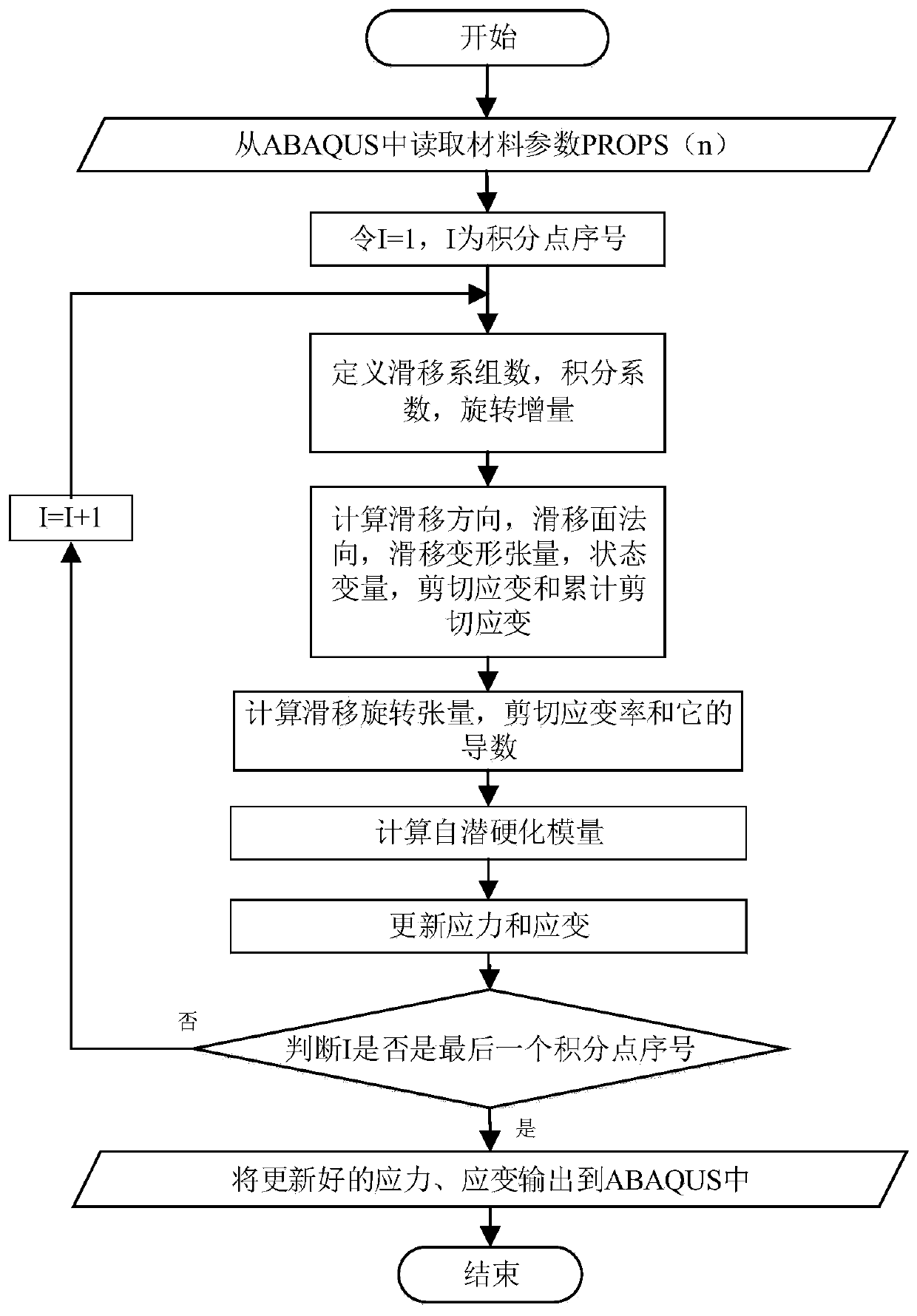

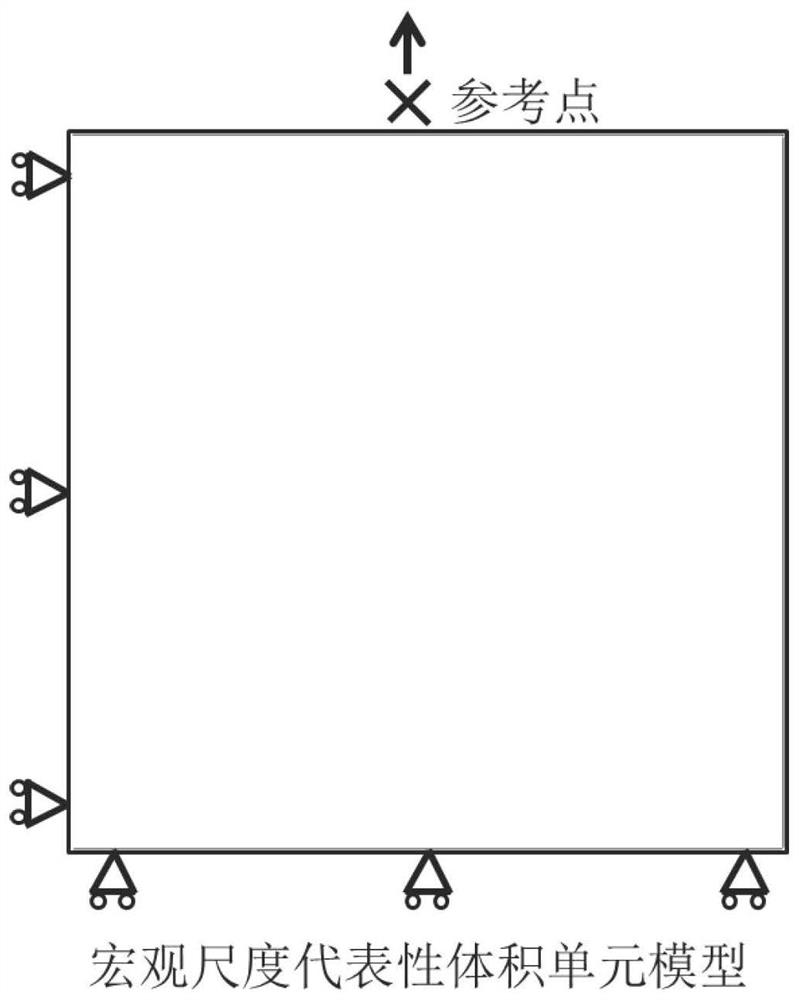

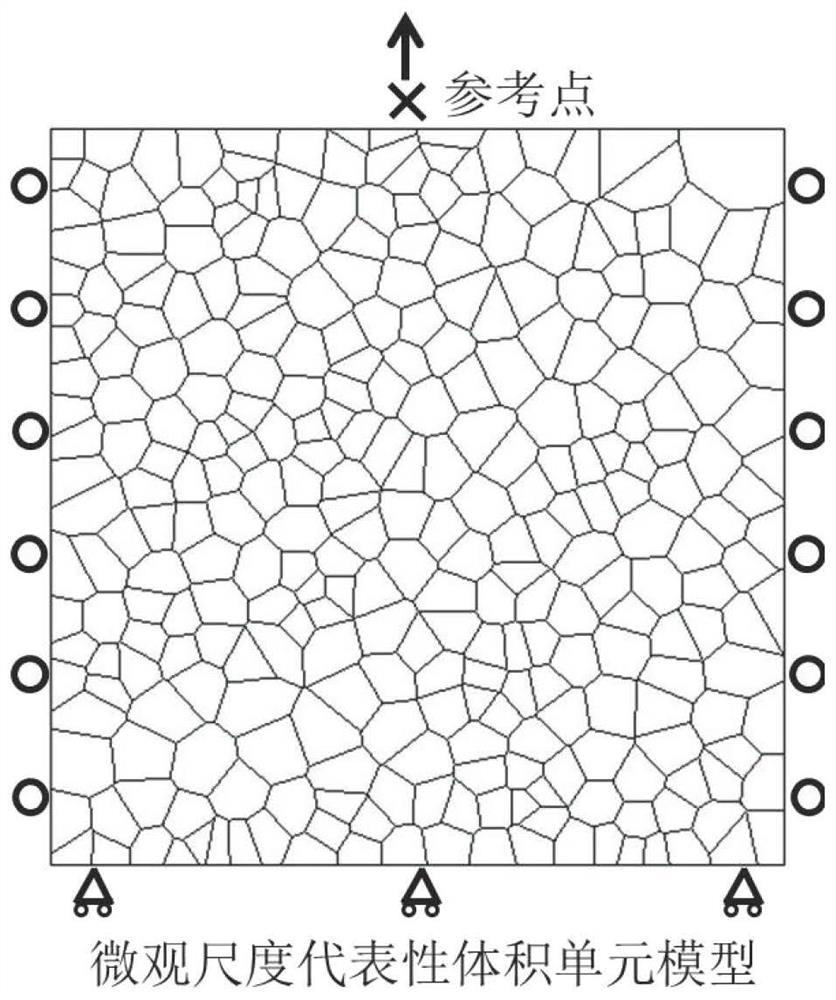

PendingCN112364535APredicted germination positionDesign optimisation/simulationConstraint-based CADCrystal plasticityCloud atlas

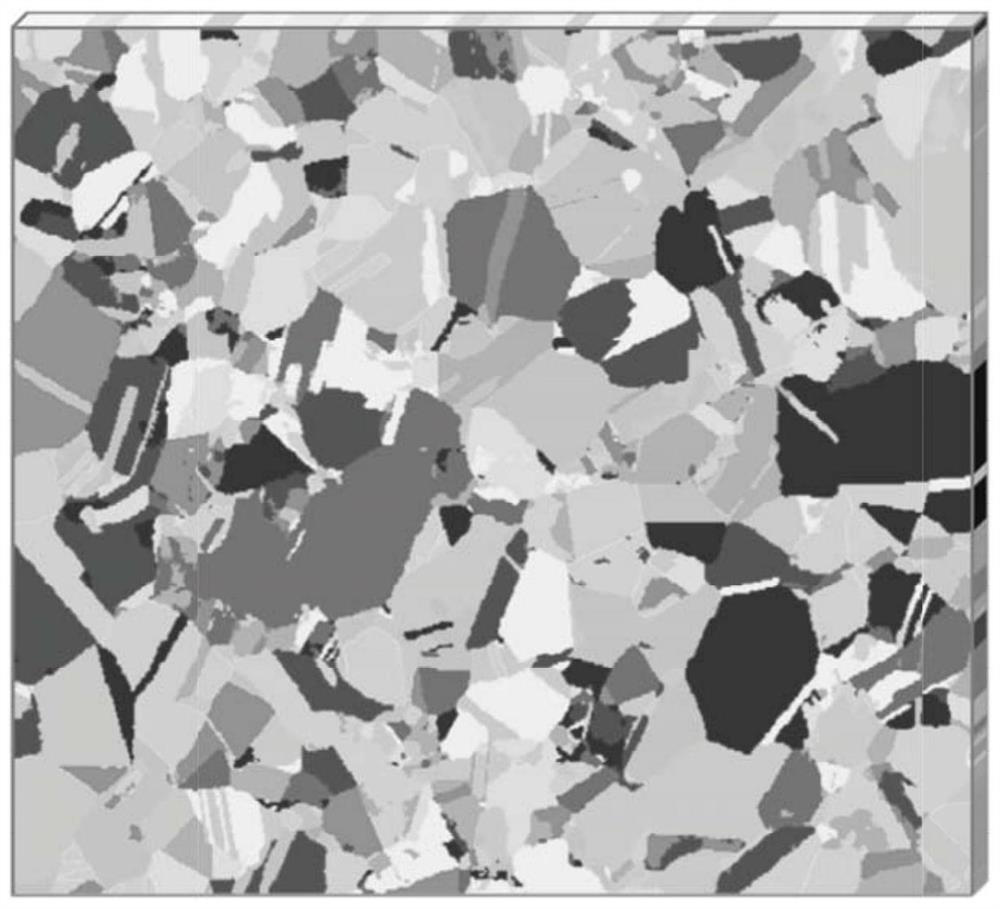

The invention provides a creep fatigue life prediction method based on a crystal plasticity theory. The method comprises the following steps: establishing a representative unit model of ABAQUS based on an electron back scattering diffraction technology; correcting the back stress model and writing the back stress model into a subprogram UMAT to obtain a creep fatigue hysteresis loop; fitting a creep fatigue hysteresis loop through a test parameter method to obtain material parameters; calculating a stress-strain value of each integral point and averaging the stress-strain values to obtain a creep fatigue hysteresis loop and a post-processing cloud atlas; extracting maximum plastic slippage and energy dissipation from the creep fatigue hysteresis loop and the post-processing cloud atlas, analyzing the change rule of the maximum plastic slippage and energy dissipation along with circulation cycles, and providing creep and fatigue indication factors; and predicting the creep fatigue crackinitiation life according to the indication factor. According to the creep fatigue life prediction method, plastic slippage and energy dissipation are used as fatigue and creep indication factors, the creep fatigue damage evolution rule can be better reflected, the crack initiation position can be accurately predicted, and the method has the advantages of being visual, high in applicability and high in accuracy.

Owner:EAST CHINA UNIV OF SCI & TECH

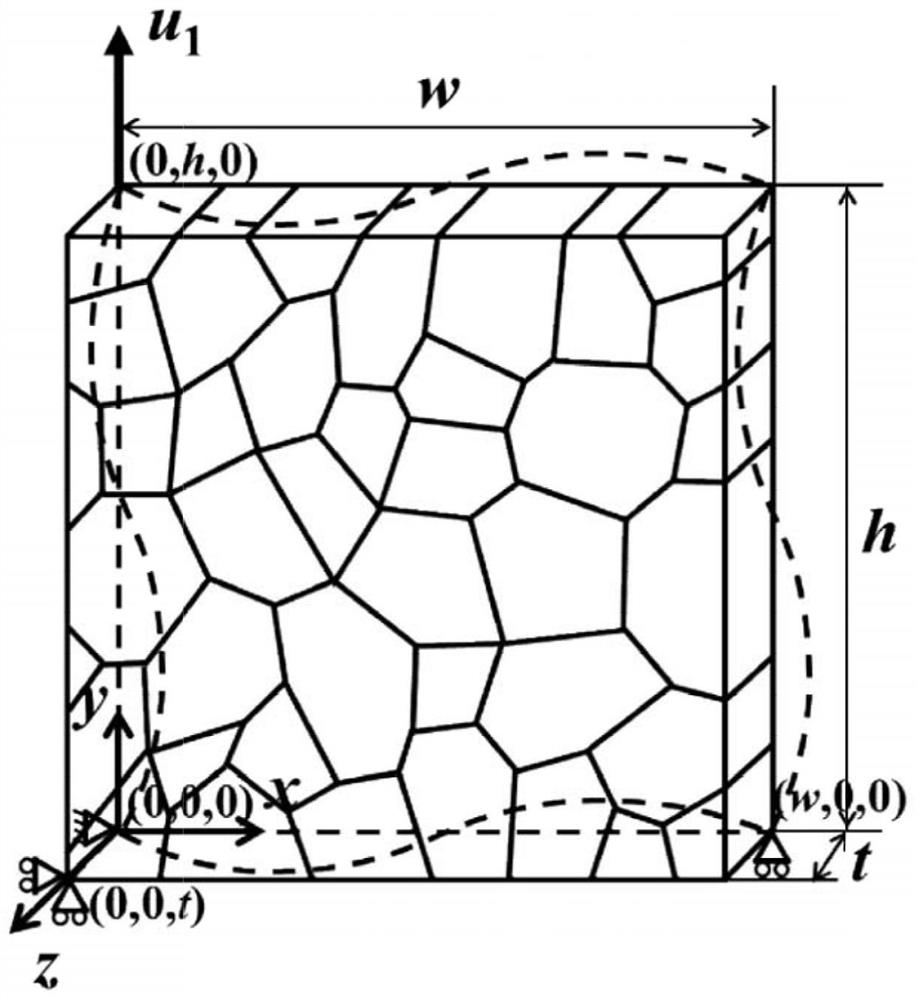

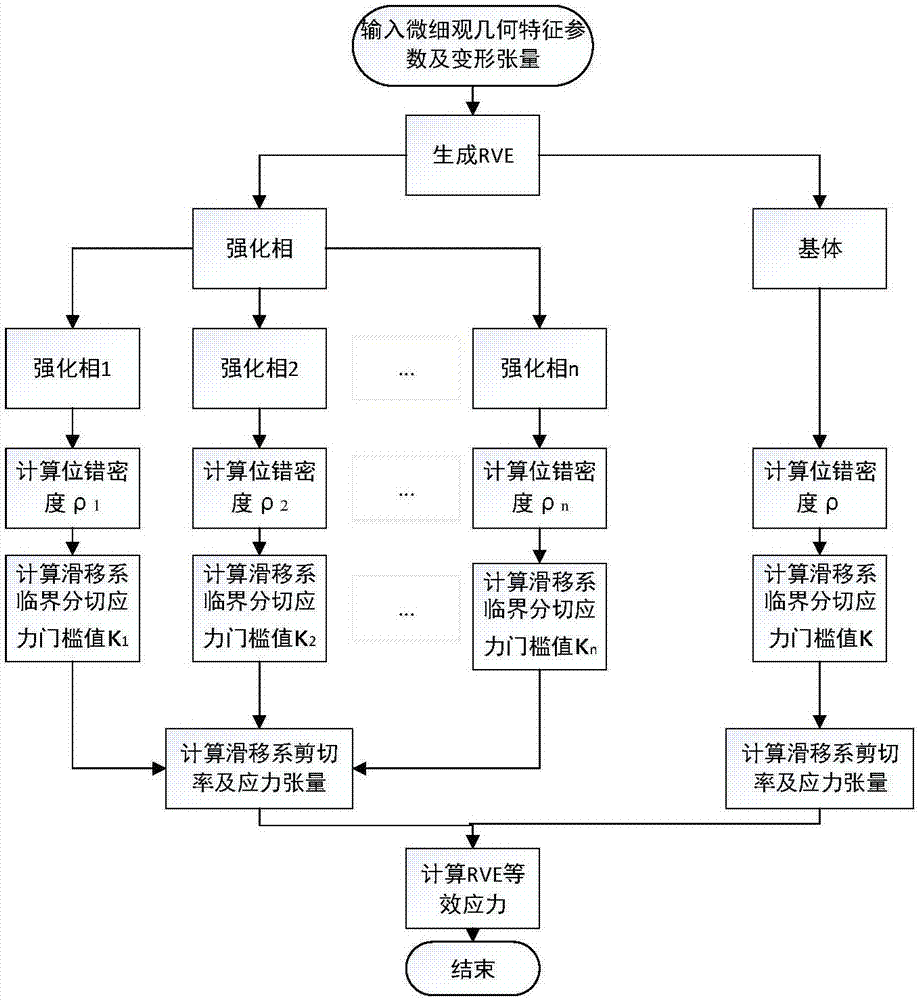

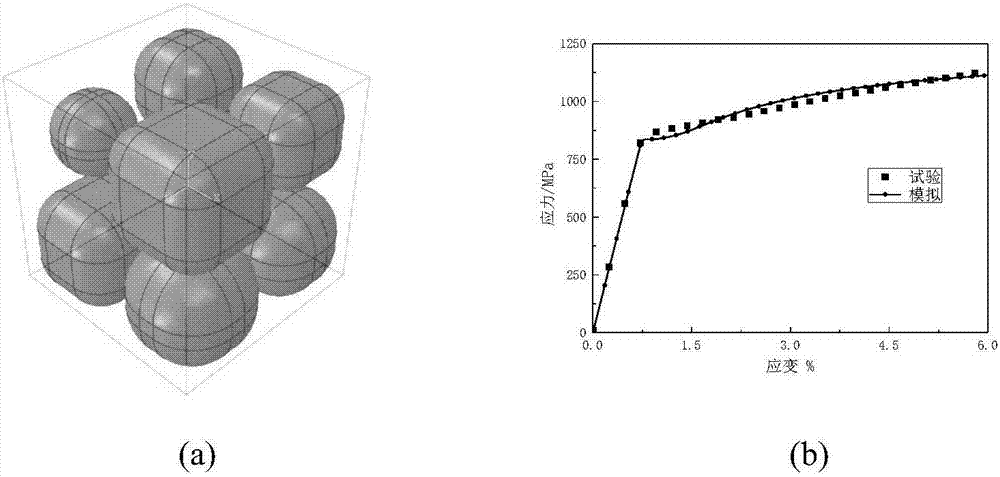

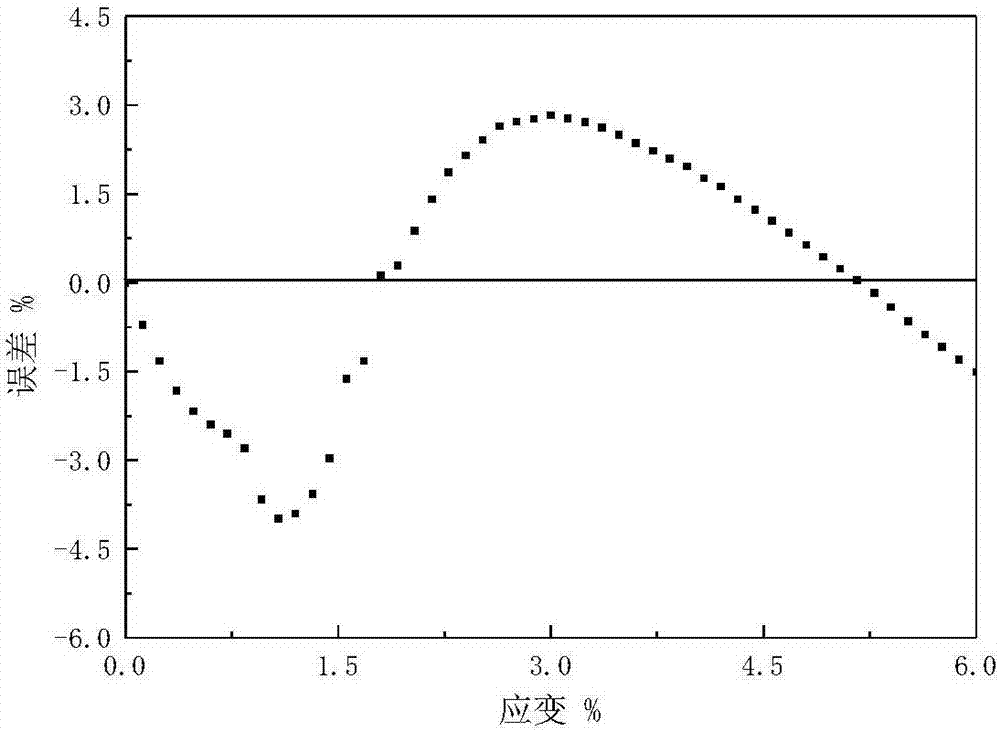

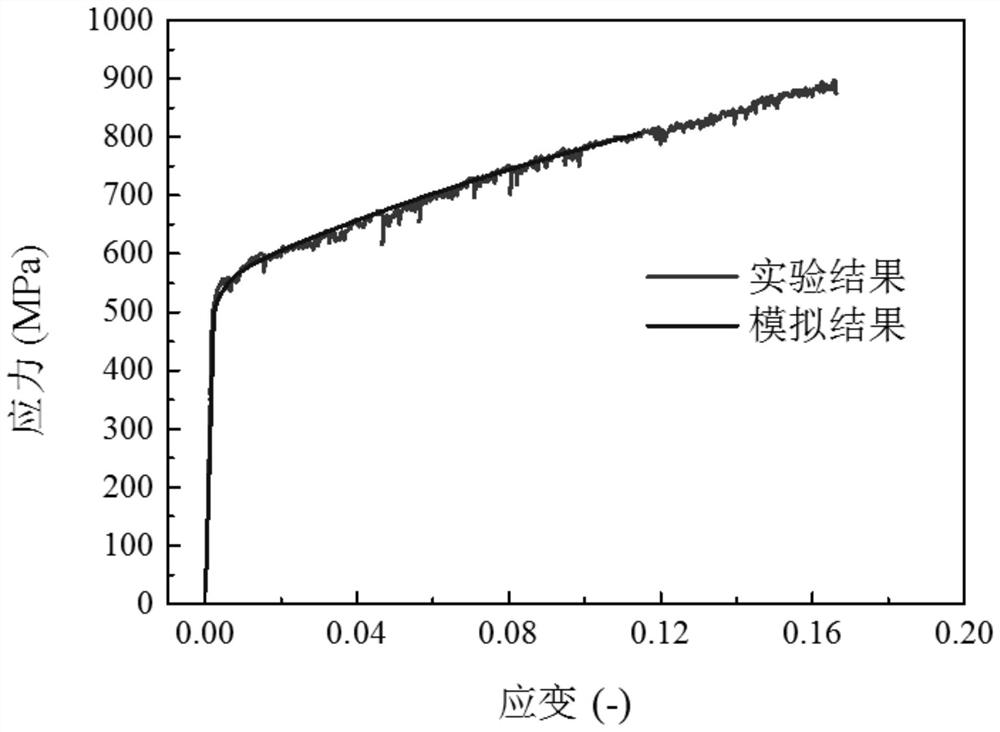

Ni3Al-based alloy constitutive model establishment method based on representative volume elements

InactiveCN106951594APredict mechanical responseIncrease the scaleConfiguration CADDesign optimisation/simulationCrystal plasticityAlloy

The invention discloses a Ni3Al-based alloy constitutive model establishment method based on representative volume elements. The method comprises the steps that (1) the representative volume elements (RVEs) used for analysis are constructed; (2) a constitutive model of a material is established based on a crystal plasticity theory, and parameters of the model are acquired through a test; (3) a constitutive model of a Ni3Al-based alloy based on the RVEs is established; and (4) the model is verified, wherein after the model is established, the tensile properties of the Ni3Al-based alloy IC10 at the temperature of 600 DEG C are subjected to simulated verification. The method has the advantages that the mechanical response of the material under a load can be predicted more effectively, and the method has a certain theoretical value and engineering significance.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

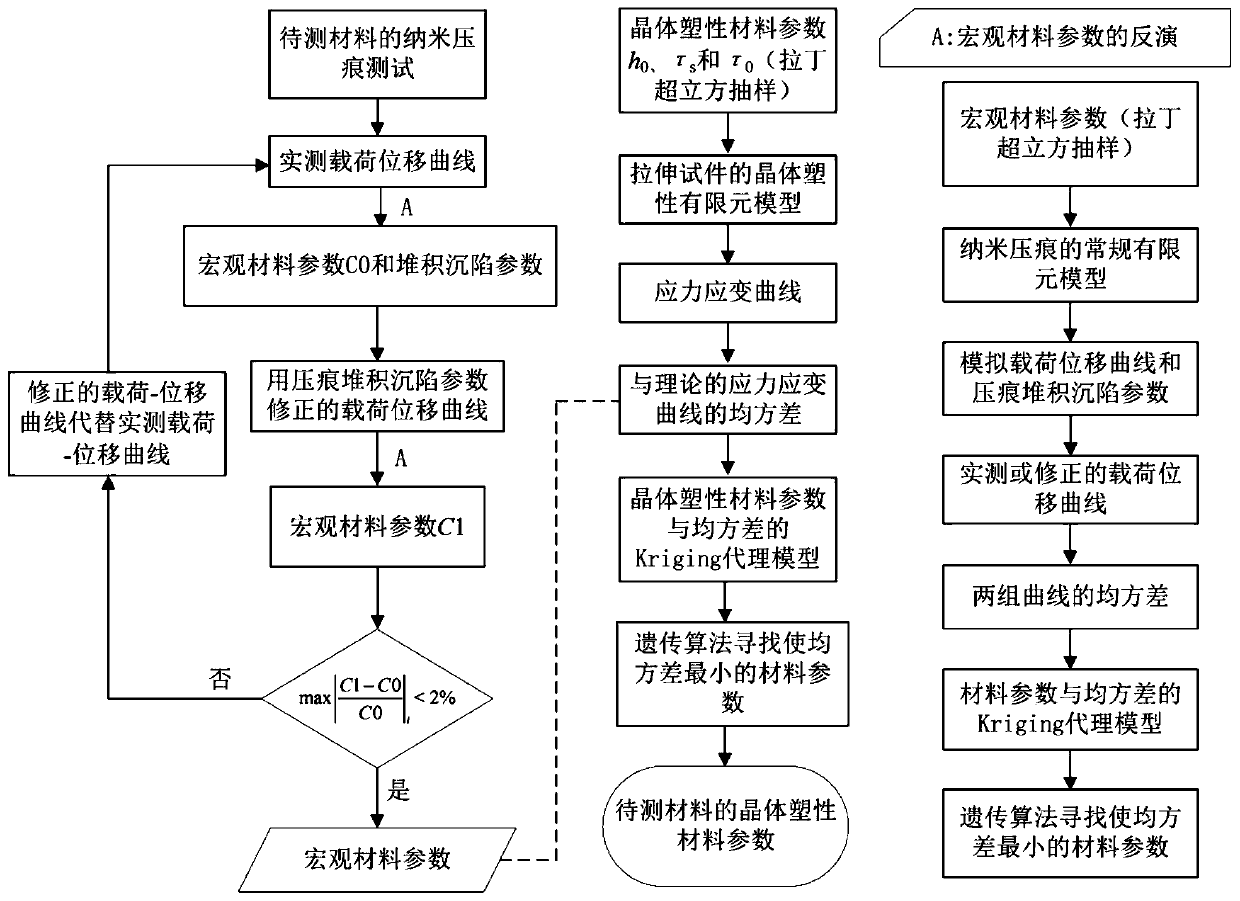

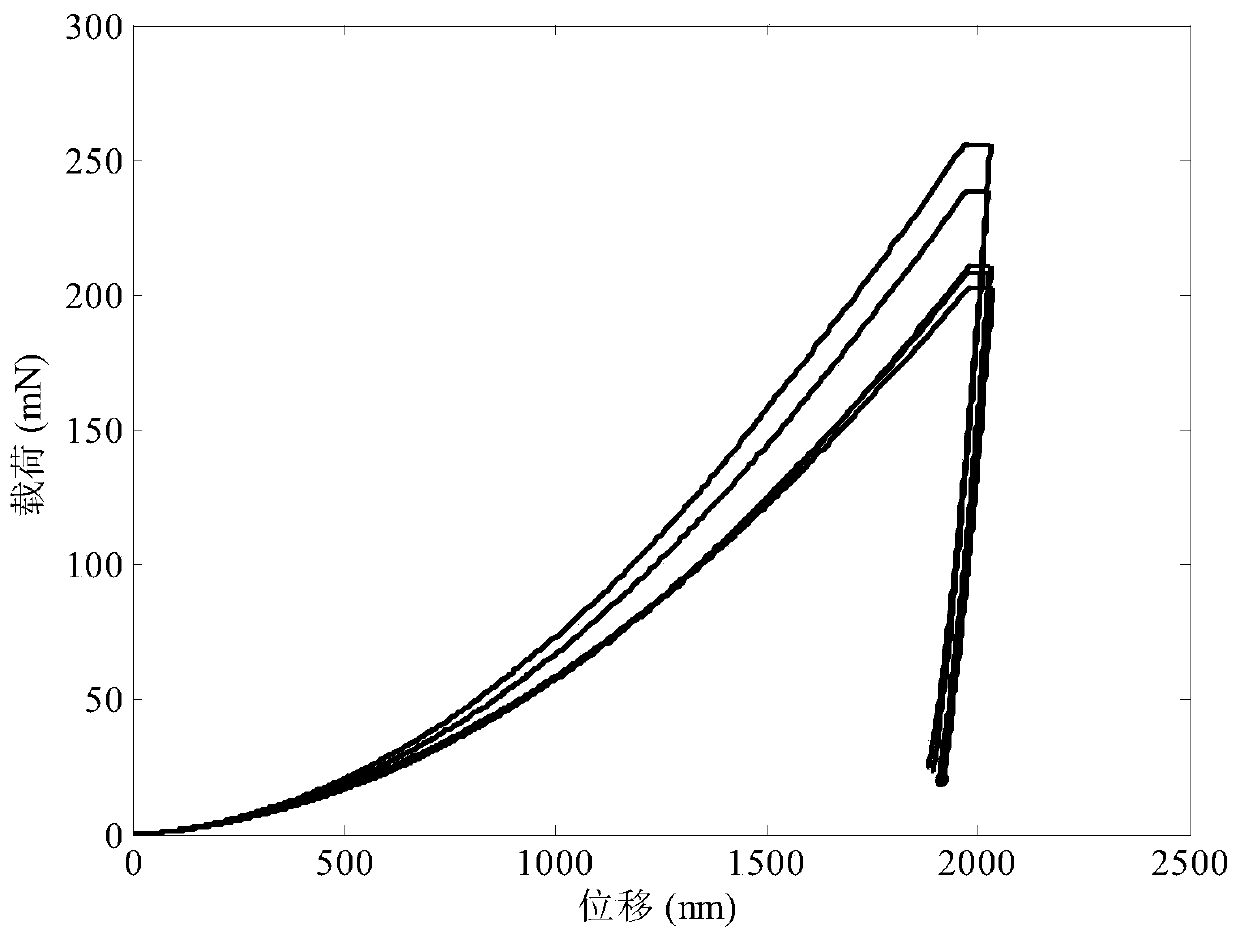

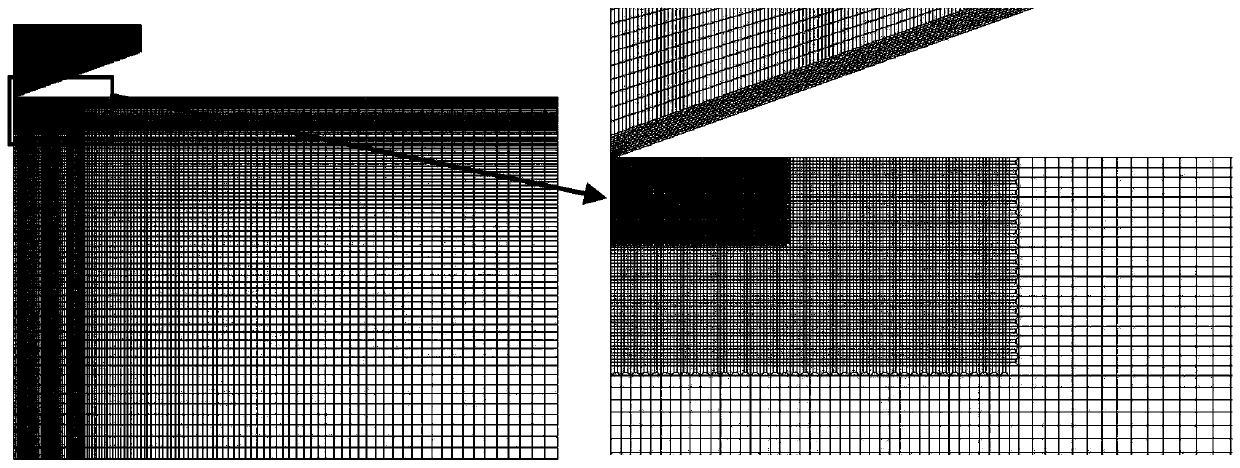

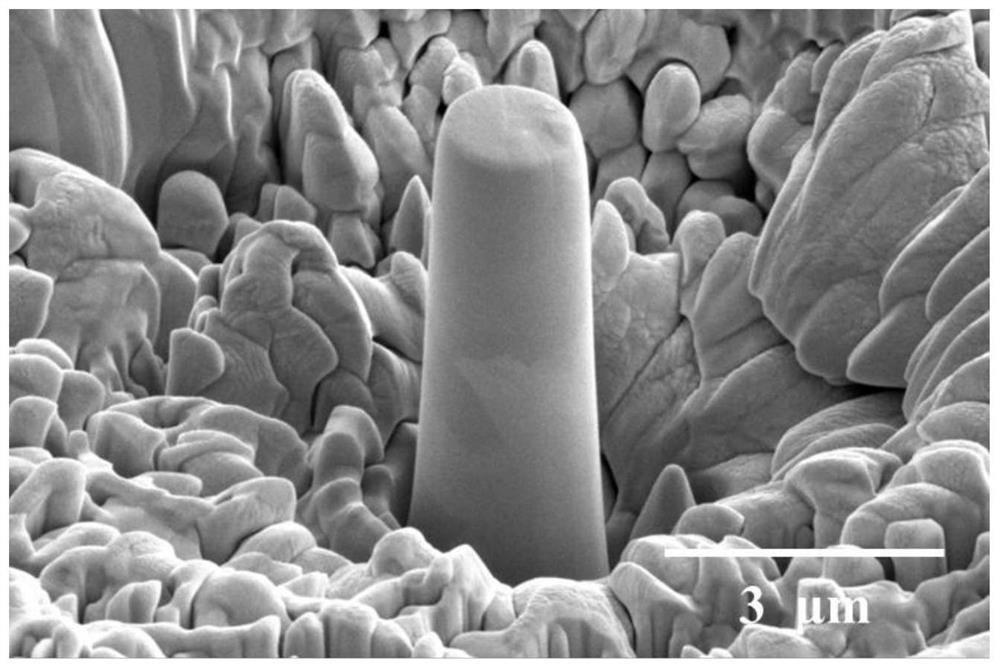

Method for realizing inversion identification of crystal plastic material parameters based on nanoindentation experiment

ActiveCN111189699AHigh precisionSmall amount of calculationPreparing sample for investigationMaterial strength using tensile/compressive forcesElement modelMacroscopic scale

The invention belongs to the technical field of characterization of mechanical properties of materials, and provides a method for realizing inversion identification of crystal plastic material parameters based on a nanoindentation experiment. The method comprises the steps that firstly, the elasticity modulus of a material is obtained through an Oliver-Parr method; secondly, a piecewise linear / power law hardening material model is utilized to establish a nanoindentation macroscopic parameter inversion model by combining MATLAB and ABAQUS, the actual nanoindentation experimental data is corrected by utilizing accumulation / subsidence parameters, and the macroscopic constitutive parameters of the indentation material are calculated by combining a Kriging agent model and a genetic algorithm; and finally, a polycrystalline finite element model of the tensile test piece based on the crystal plasticity finite element is established by combining MATLAB and ABAQUS, and the parameters of the crystal plastic material are calculated according to the constitutive parameters of the material in combination with the Kriging agent model and the genetic algorithm. Compared with the prior art, the method has the advantages that the accuracy of calculation data can be improved, the calculation amount is remarkably reduced and the calculation convergence is improved, and the method has very high practical value and reference significance in inversion identification of the crystal plastic material parameters.

Owner:DALIAN UNIV OF TECH

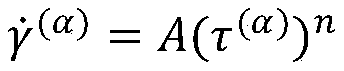

Cutting process simulation-based single-crystal copper micro-milling force forecast method

ActiveCN110597180ARealization of micro-milling force predictionAchieve forecastProgramme controlComputer controlSingle crystalProcess simulation

The invention belongs to the field of precise and efficient processing of a micro part, and particularly relates to a cutting process simulation-based single-crystal copper micro-milling force forecast method. The cutting process simulation-based single-crystal copper micro-milling force forecast method comprises the steps of initially and comprehensively considering influence of factors such as crystal deformation kinematics, a crystal plasticity constitutive relation and hardening law of rate-dependent crystal on single-crystal copper micro-milling due to the specialty of a single-crystal copper material; secondly, deducing an incremental form of a constitutive equation, writing single-crystal copper VUMAT user material sub-program by employing a Fortran language, and introducing crystalplasticity constitution into a finite element simulation; and finally, performing simulation modeling on the single-crystal copper micro-milling process by ABAQUS software to achieve single-crystal copper micro-milling force forecast. By taking finite cutting simulation as a basis, accurate forecast of a single-crystal copper micro-milling force is achieved, a technical support is provided for researching the single-crystal copper micro-milling process, the processing accuracy and efficiency of single-crystal copper micro-milling is improved, and the cutting process simulation-based single-crystal copper micro-milling force forecast method has a practical application value.

Owner:DALIAN UNIV OF TECH

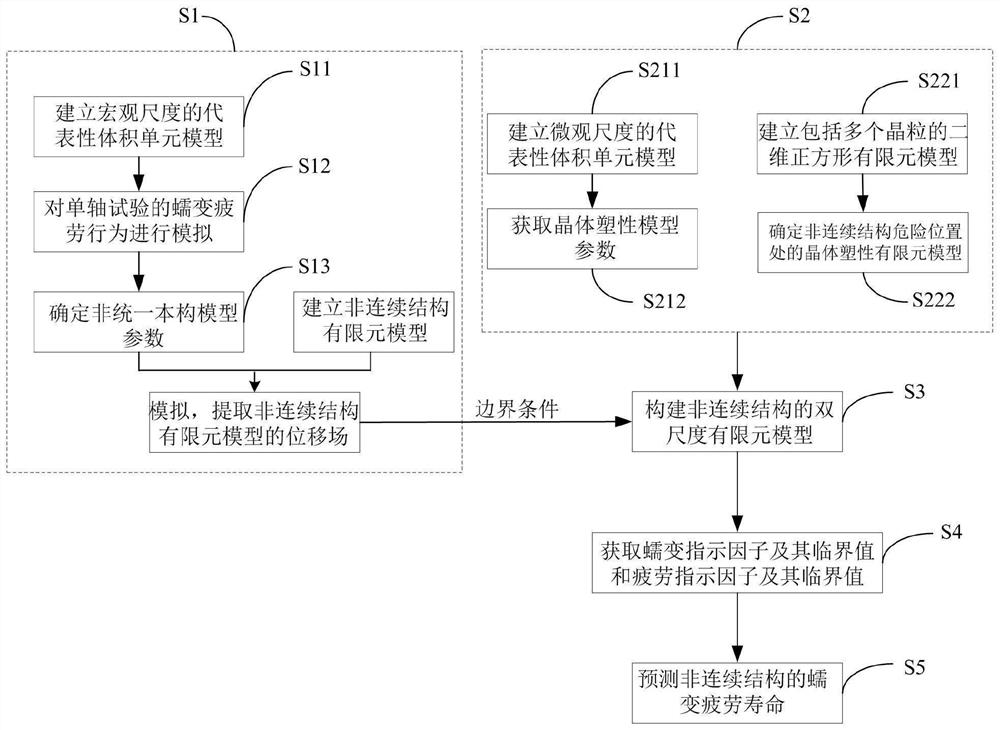

Method for predicting dual-scale creep fatigue life of discontinuous structure

PendingCN112966347AAccurate prediction of creep fatigue lifeGeometric CADDesign optimisation/simulationCrystal plasticityElement model

The invention relates to a method for predicting the dual-scale creep fatigue life of a discontinuous structure. The method comprises the following steps: extracting a displacement field of a finite element model of the discontinuous structure; obtaining crystal plasticity model parameters, and establishing a crystal plasticity finite element model at the dangerous position of the discontinuous structure; taking a displacement field of the finite element model of the discontinuous structure as a boundary condition of a crystal plasticity finite element model, and constructing a dual-scale finite element model of the discontinuous structure; acquiring a creep indication factor and a critical value thereof, and a fatigue indication factor and a critical value thereof; and predicting the creep fatigue life of the discontinuous structure. According to the method, the stress condition of the discontinuous structure on the macro scale can be reflected, the damage evolution of the discontinuous structure on the micro scale can be revealed, the dangerous position of creep fatigue crack initiation can be effectively obtained, and therefore the creep fatigue life of the discontinuous structure can be accurately predicted; and theoretical support is provided for premature failure prevention and life extension of the discontinuous structure.

Owner:EAST CHINA UNIV OF SCI & TECH

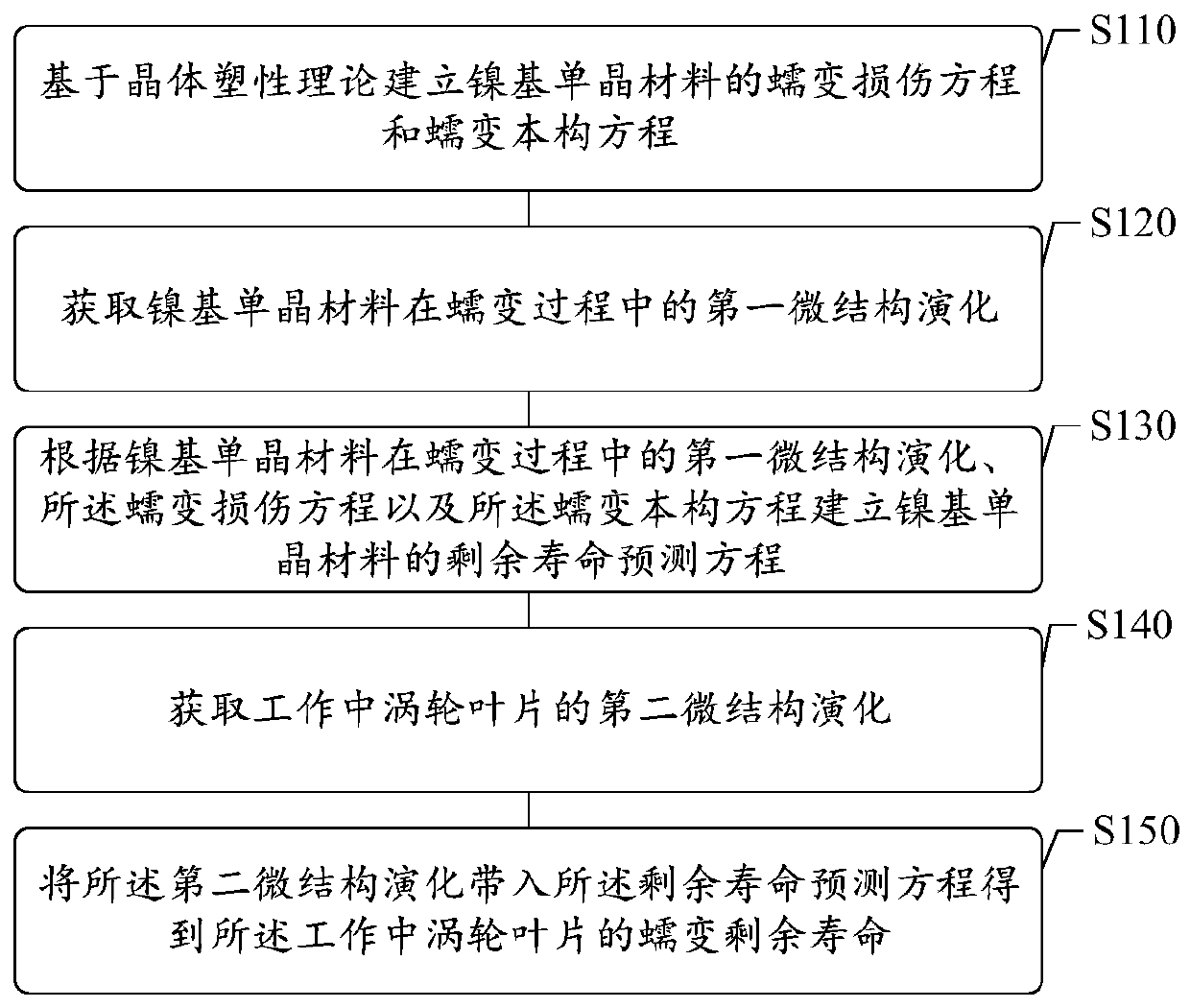

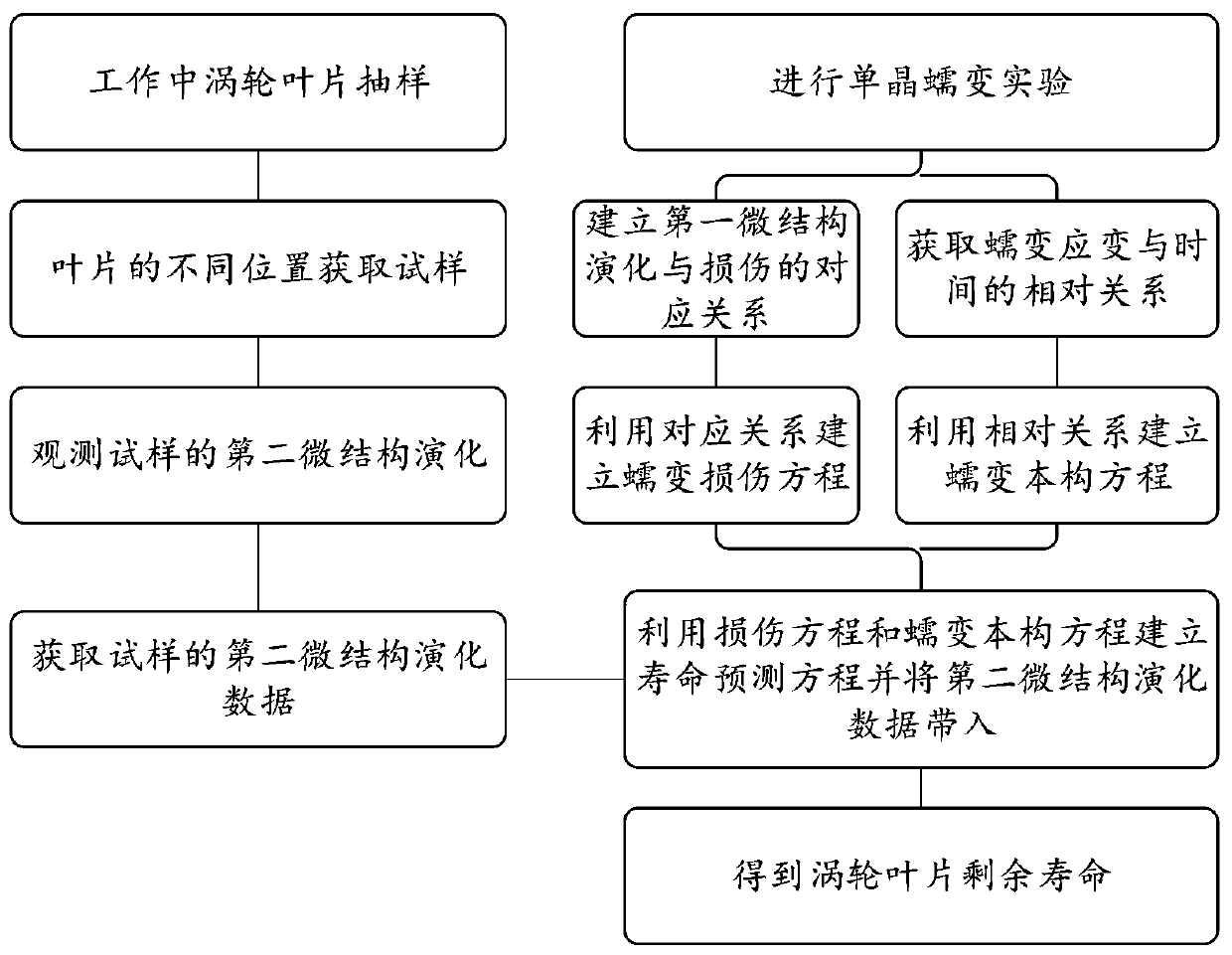

Prediction method for creep residual life of nickel-based single crystal turbine blade

ActiveCN111008495AImprove accuracyGeometric CADDesign optimisation/simulationCrystal plasticityTurbine blade

The invention relates to the technical field of reliability, and provides a prediction method for the creep residual life of a nickel-based single crystal turbine blade. The prediction method for thecreep residual life of the nickel-based single crystal turbine blade comprises the following steps: establishing a creep damage equation and a creep constitutive equation of a nickel-based single crystal material based on a crystal plasticity theory; obtaining first microstructure evolution of the nickel-based single crystal material in the creep process; establishing a residual life prediction equation of the nickel-based single crystal material according to the first microstructure evolution, the creep damage equation and the creep constitutive equation of the nickel-based single crystal material in the creep process; obtaining second microstructure evolution of the turbine blade in work; and substituting the second microstructure evolution into the residual life prediction equation to obtain the creep residual life of the turbine blade in work. The residual life of the blade can be obtained by quantitatively describing microstructure evolution of the turbine blade material in work and substituting the microstructure evolution into the creep residual life equation based on the crystal plasticity theory. Compared with the prior art, the method has better accuracy.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

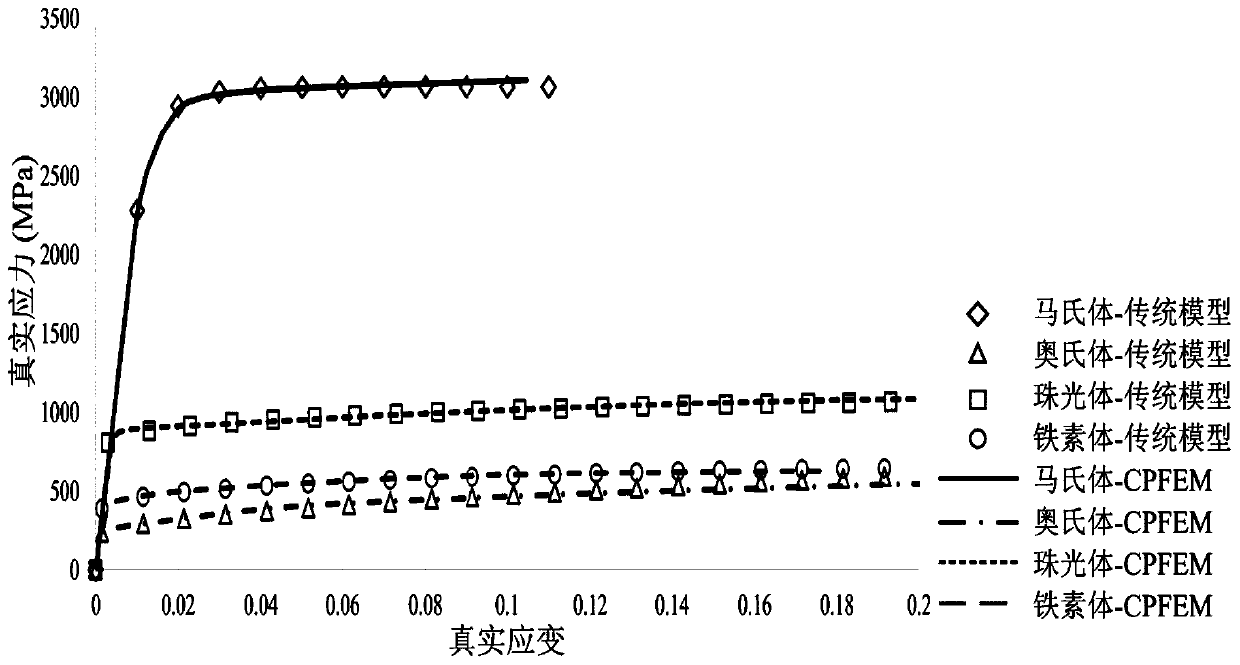

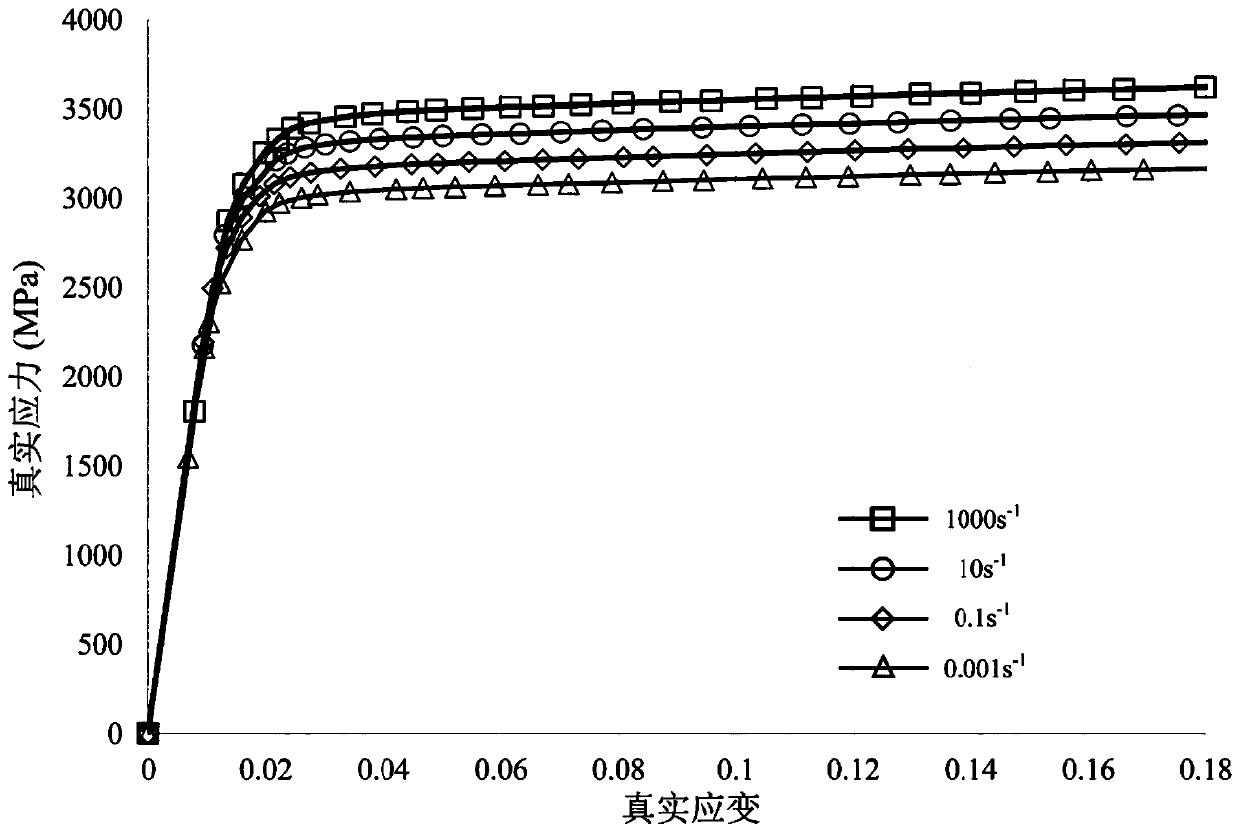

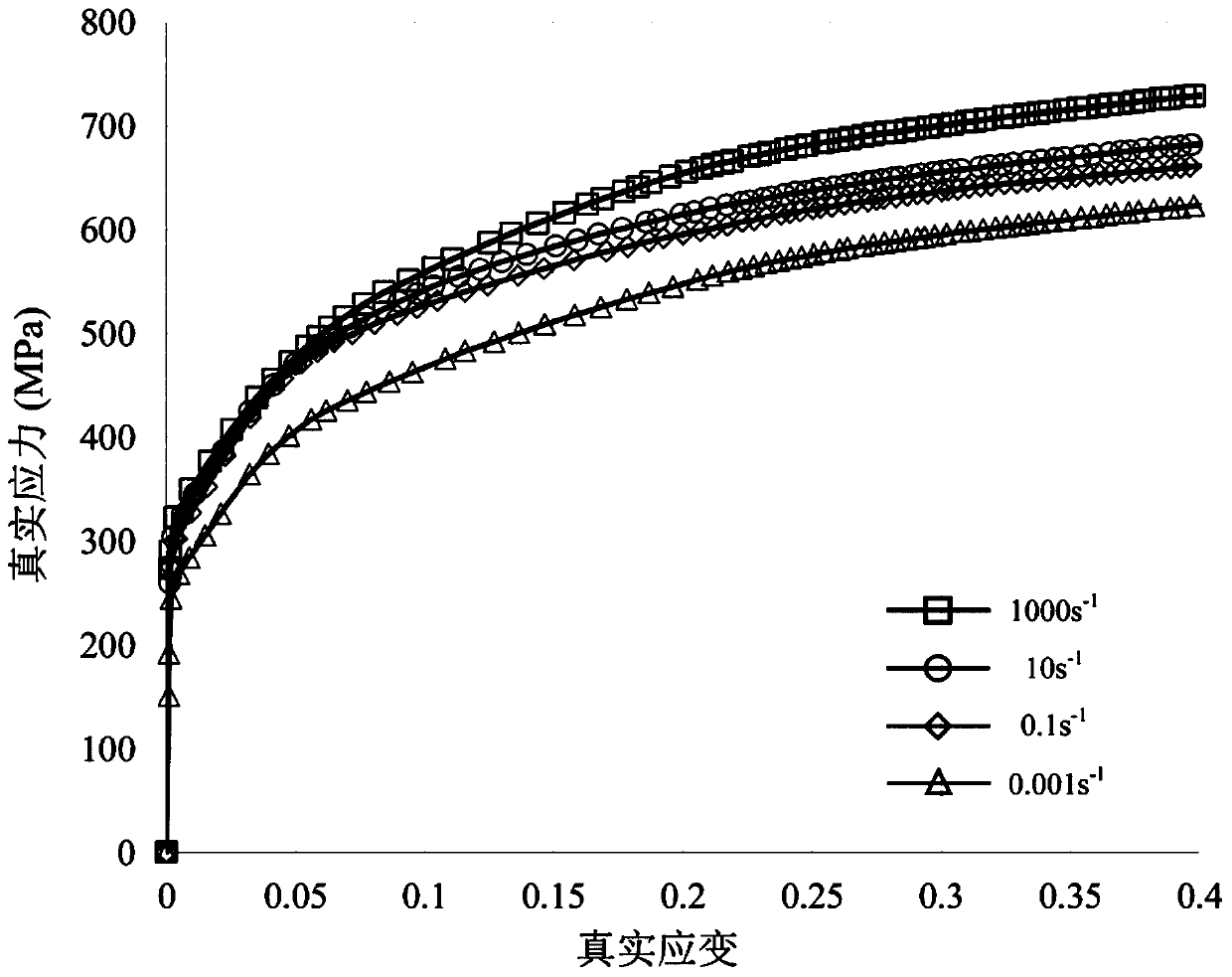

Constitutive behavior construction method for multiphase metal material for high-speed deformation process

ActiveCN111145842AEliminate cumbersomenessReduce testing costsDesign optimisation/simulationComputational materials scienceMacroscopic scaleMetallic materials

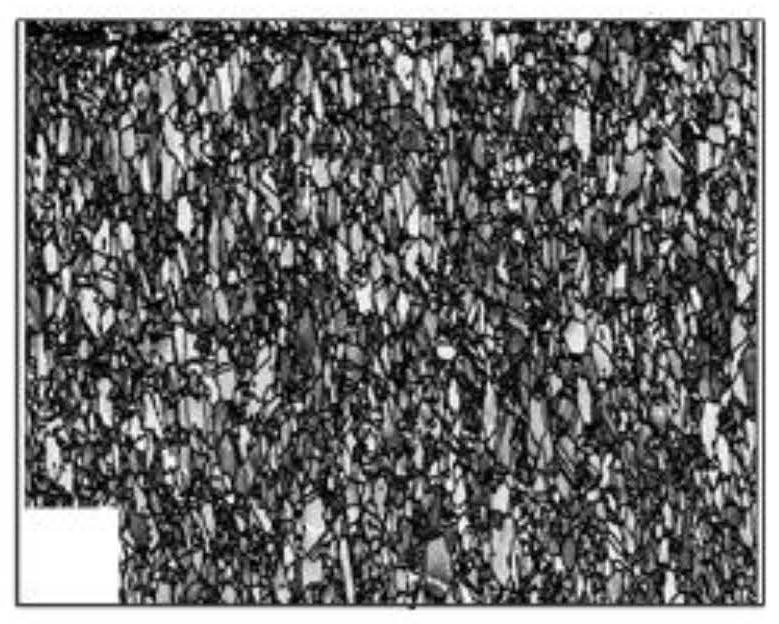

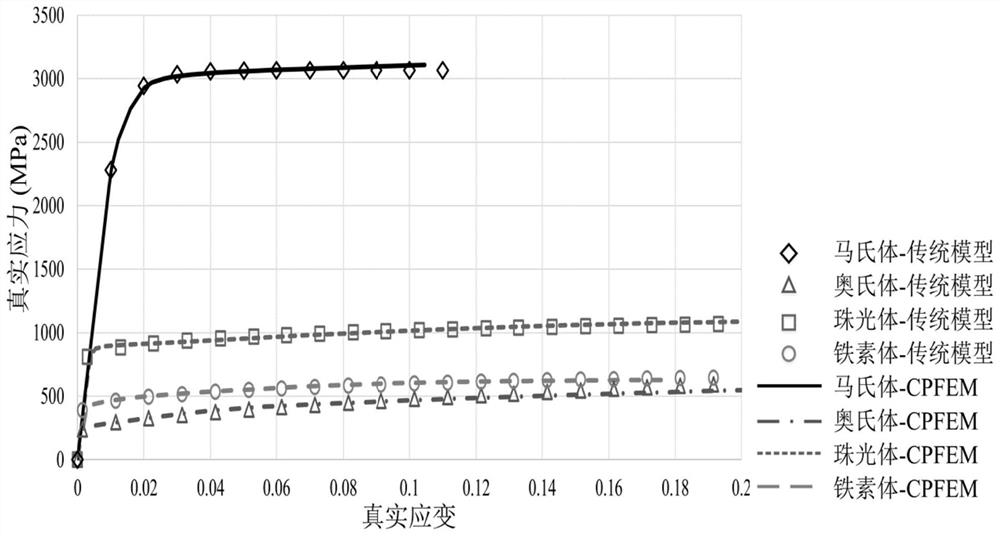

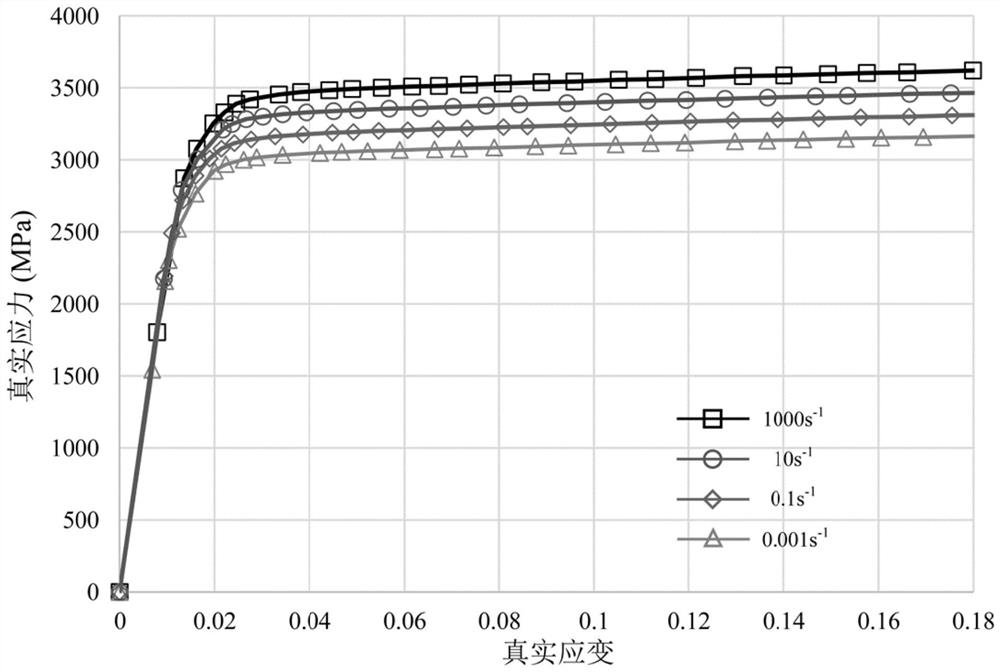

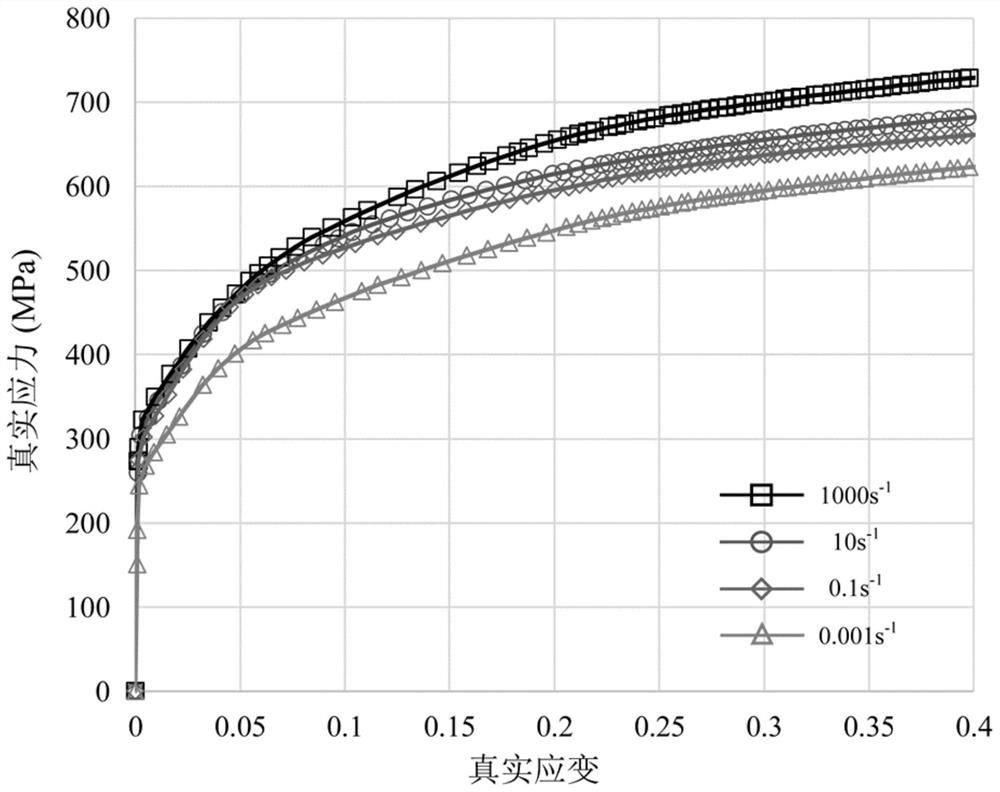

The invention discloses a rapid calculation method for constitutive behaviors of a multi-phase metal material for a high-speed deformation process. The method comprises the steps: predicting the mechanical behavior of each single pure phase in the multi-phase material through a crystal plasticity finite element method, and then predicting the macroscopic constitutive behavior shown by the materialin the multi-phase state through metallographic structure measurement and proportional mixing methods. The method can accurately and quickly predict the mechanical behavior of a single phase of the material in a high strain rate state, so that the method can be suitable for deformation processes such as high-speed machining and forging of steel, titanium alloy and other materials with complex phase components. According to the method, the problem that for the same material, after different heat treatments, the mechanical properties are significantly changed due to microstructure changes and the mechanical behaviors of the material need to be measured again is solved, so the cost can be significantly reduced in industrial production practice, the simulation and analysis efficiency can be improved, and the method has important significance for computer-aided analysis and design of the part machining deformation process.

Owner:XI AN JIAOTONG UNIV

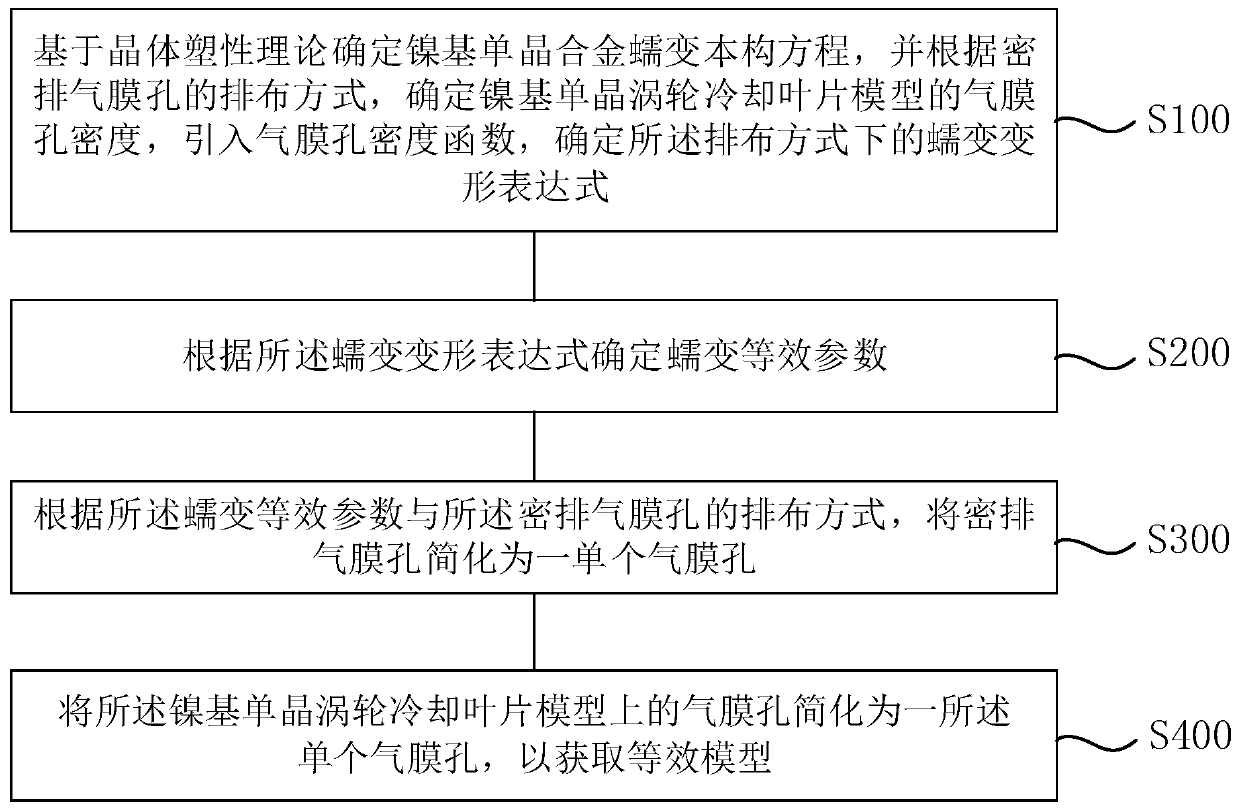

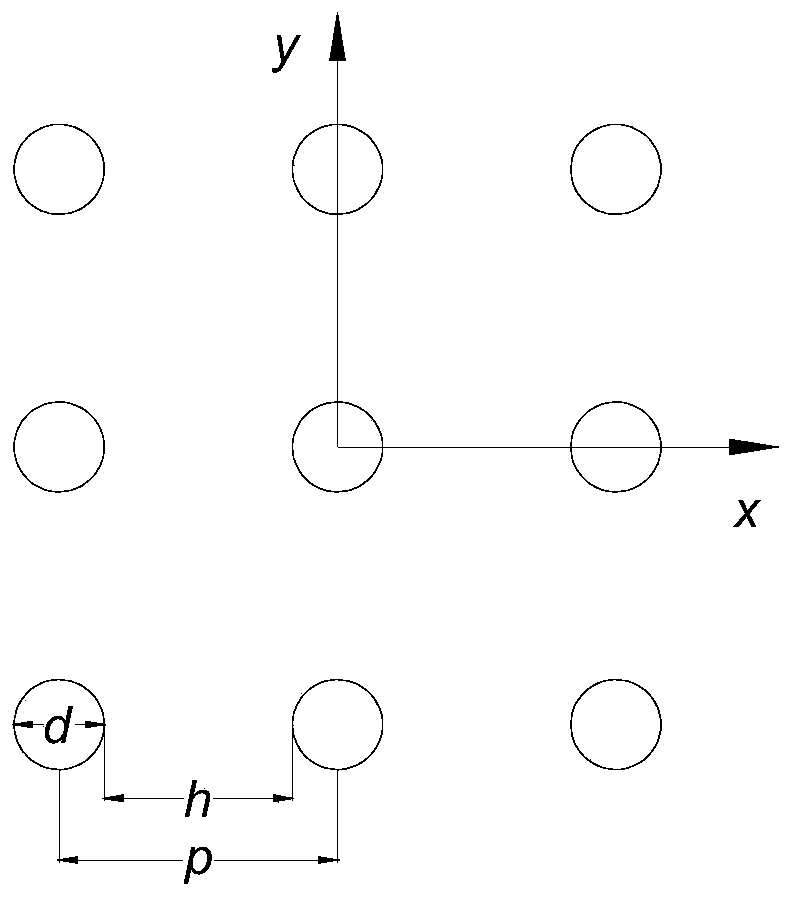

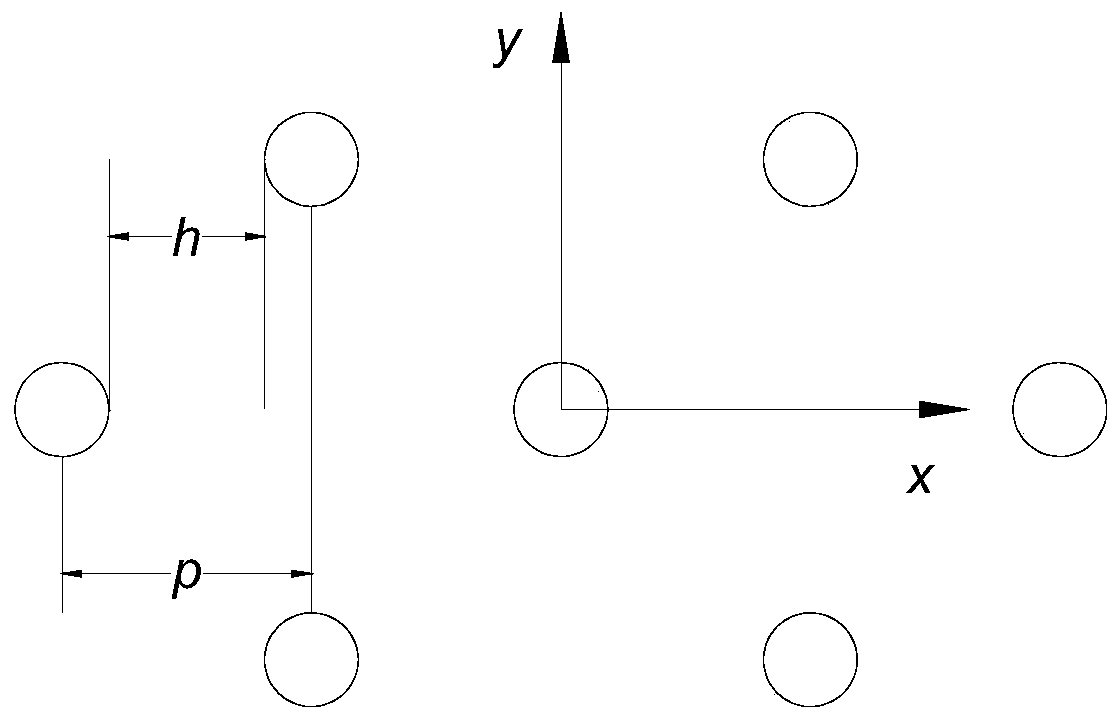

Creep equivalence and simplification method for dense exhaust film holes of nickel-based single crystal turbine cooling blade

ActiveCN110245394ASmall amount of calculationReduce intensityGeometric CADDesign optimisation/simulationCrystal plasticitySingle crystal

The invention relates to a creep equivalence and simplification method for dense exhaust film holes of a nickel-based single crystal turbine cooling blade. The method comprises the steps of determining a nickel-based single crystal alloy creep constitutive equation based on the crystal plasticity theory, determining the gas film hole density of a nickel-based single crystal turbine cooling blade model according to the arrangement mode of dense exhaust film holes, introducing a gas film hole density function, and determinig a creep deformation expression under the arrangement mode; determining the creep equivalent parameters according to the creep deformation expression; according to the creep equivalent parameters and the arrangement mode of the dense exhaust film holes, simplifying the dense exhaust film holes into a single air film hole; and simplifying the gas film hole in the nickel-based single crystal turbine cooling blade model into one single gas film hole to obtain an equivalent model. According to the creep equivalence and simplification method for the dense exhaust film holes of the nickel-based single crystal turbine cooling blade, the structural strength analysis and the service life design difficulty of the blade can be reduced.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

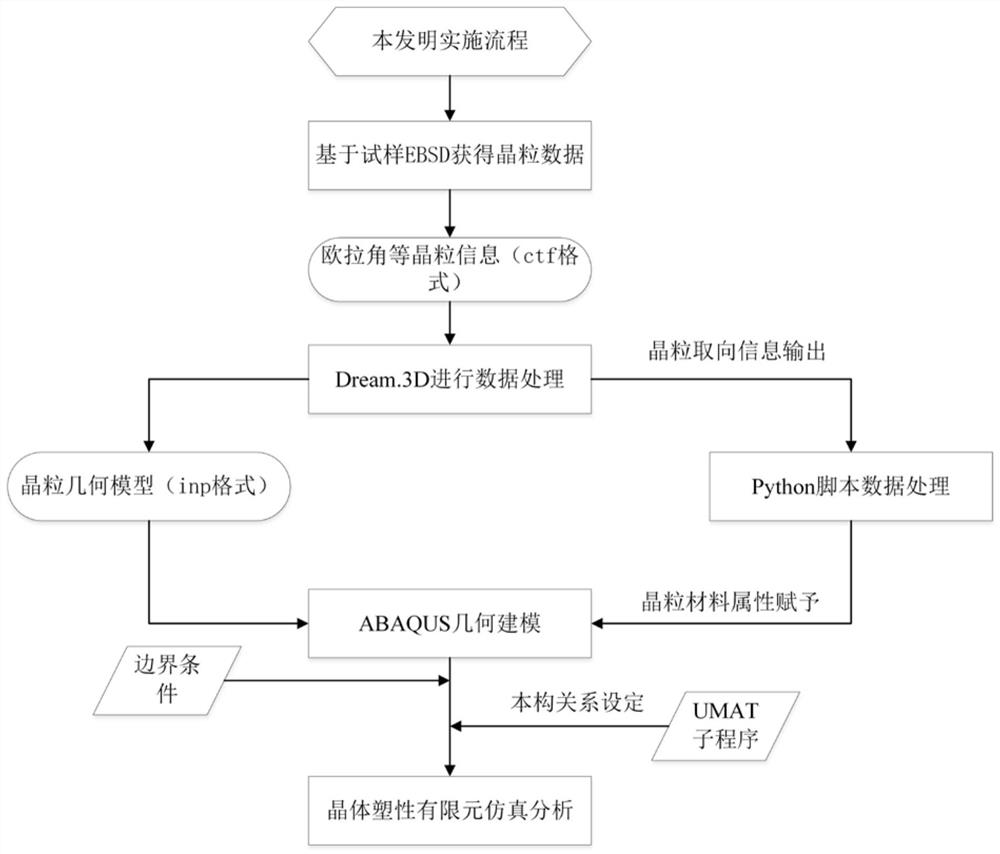

Crystal plasticity finite element modeling simulation method

PendingCN113987695AMechanical performance simulation prediction is convenientThe convenience of simulation predictionGeometric CADDesign optimisation/simulationComputational sciencePython language

The invention discloses a crystal plasticity finite element modeling simulation method. The method comprises the following steps of acquiring grain information based on EBSD analysis; importing a ctf format file generated by EBSD analysis into Drem.3D software to realize automatic reconstruction of a crystal grain structure, and outputting an input file and geometric orientation data of each crystal grain; processing the grain geometric orientation data through a Python language script to obtain average geometric orientation information of each grain; combining the grain average geometric orientation information with the input file by using a Python script to generate a complete input file with geometric model information and material attribute information; giving boundary conditions to the model in ABAQUS finite element analysis software, and setting a constitutive relation of the model by utilizing a UMAT subprogram, so that the whole crystal plasticity finite element analysis process is realized. The process of crystal plastic finite element modeling and simulation analysis is realized.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

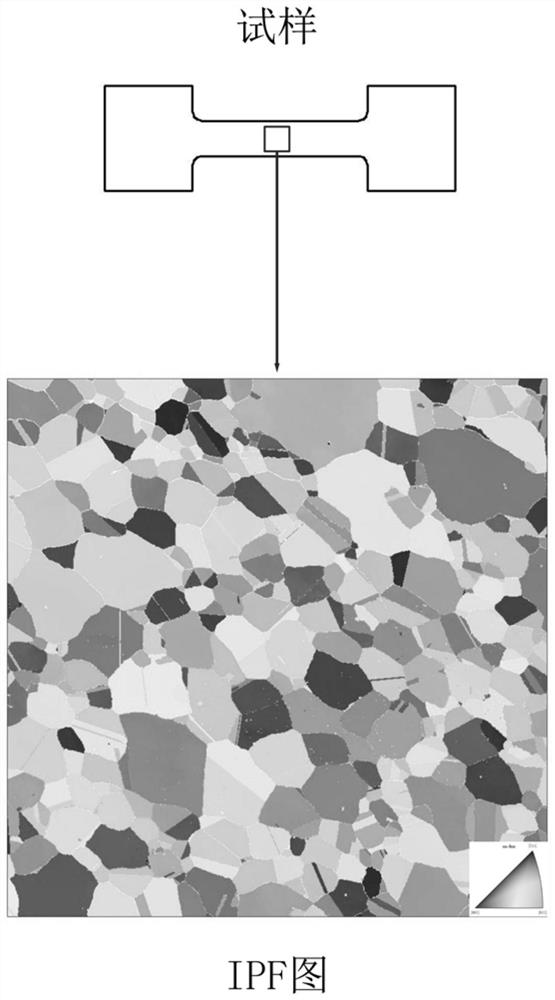

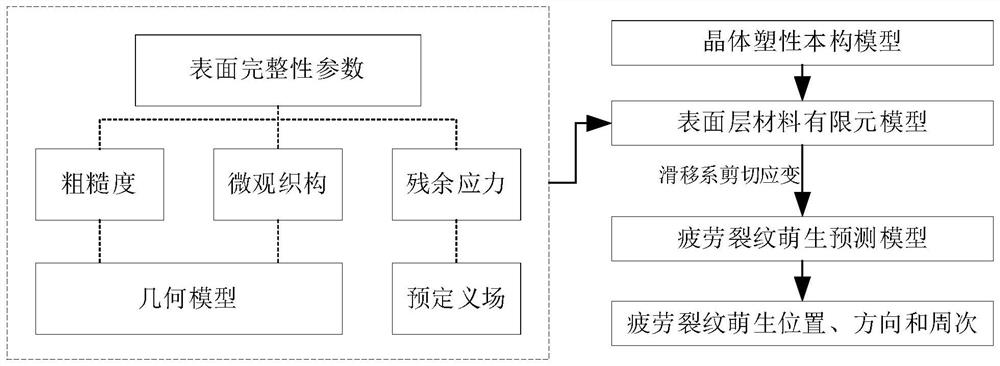

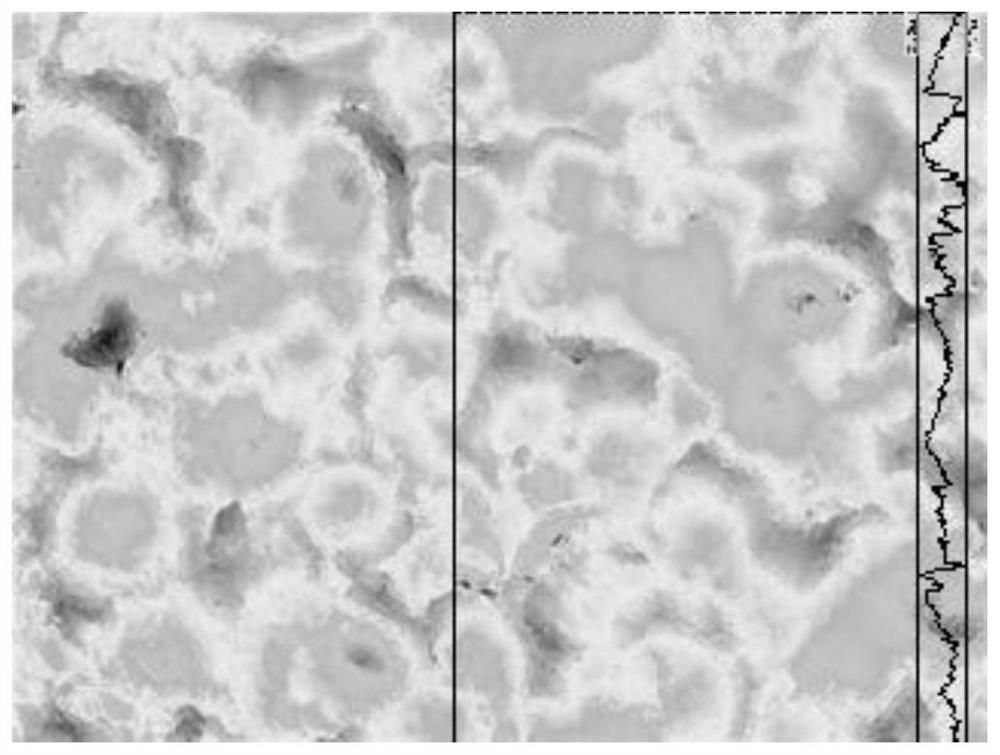

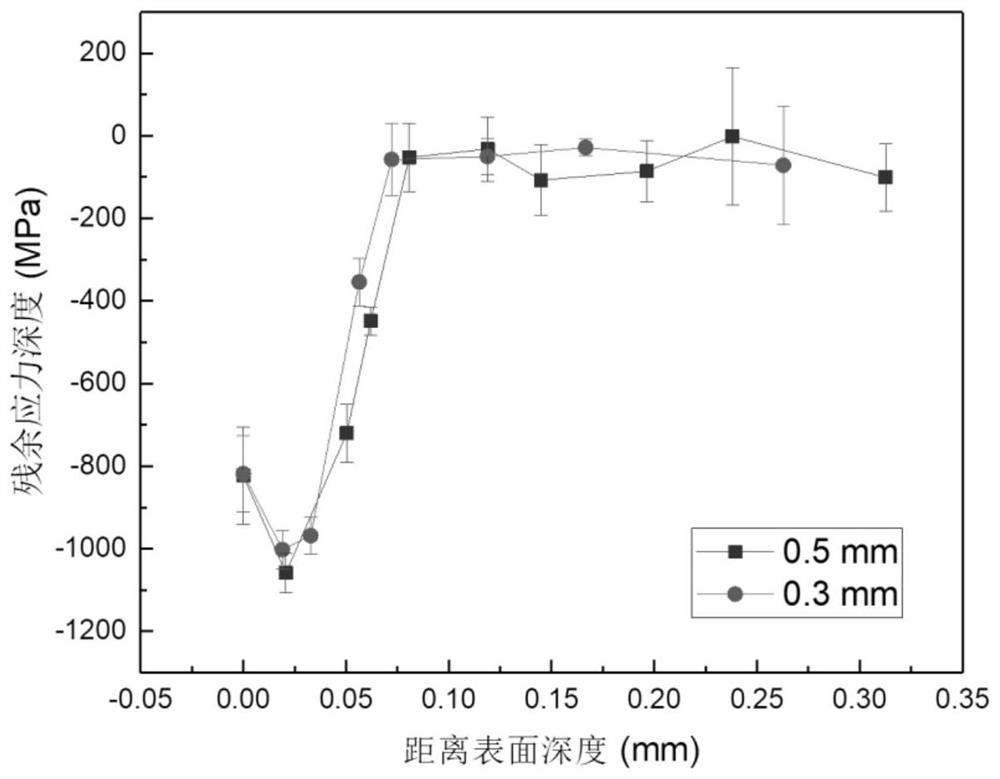

Fatigue crack initiation prediction method considering surface integrity

PendingCN114047210AForecast directionForecast WeekUsing optical meansApparatus for force/torque/work measurementCrazingMachined surface

The invention discloses a fatigue crack initiation prediction method considering surface integrity, and belongs to the field of engineering material fatigue failure. According to the method, a fatigue crack initiation micro-nano model is provided based on the crystal plasticity constitutive structure and in combination with dislocation strain energy, the fatigue crack initiation position, direction and cycle can be accurately predicted by establishing the fatigue crack initiation prediction model and in combination with crystal plasticity finite element simulation, the influence of the integrity of the machined surface, including the surface roughness, residual stress and surface layer texture, can be considered at the same time, and the method plays an important role in anti-fatigue manufacturing and failure analysis of important parts; a multilevel microstructure modeling method is adopted, martensite microstructure modeling is achieved, meanwhile, the relation between martensite block and martensite beam crystal orientation is combined, the martensite crystal orientation is accurately established, and compared with a Thiessen polygon modeling method, the method has the advantage of being high in precision, and the method plays an important role in mechanical property analysis and failure analysis of martensite materials.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

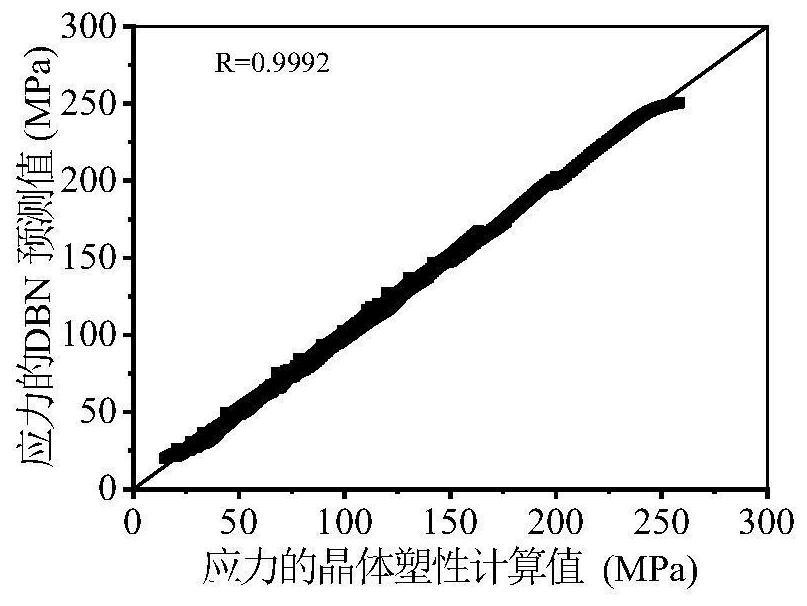

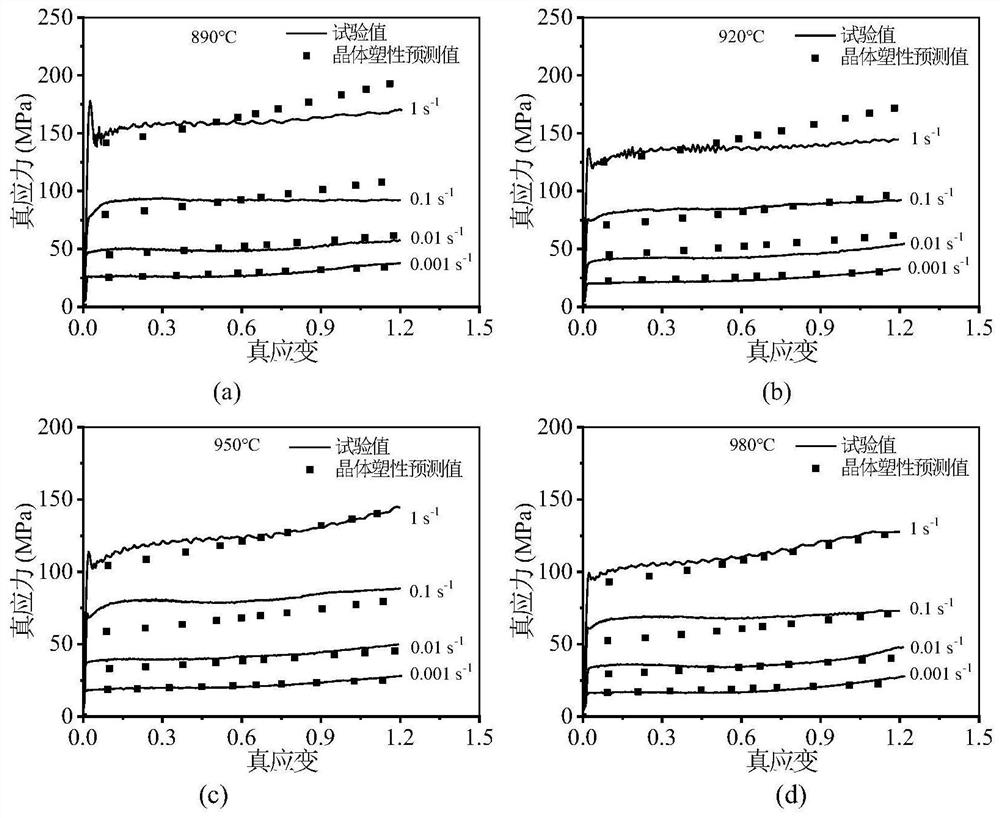

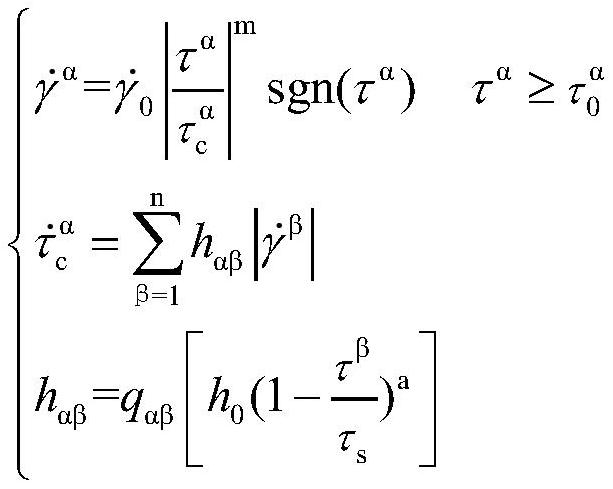

Method for determining material parameters of crystal plasticity finite element model

PendingCN112651153ADesign optimisation/simulationSpecial data processing applicationsDeep belief networkElement model

The invention discloses a method for determining material parameters of a crystal plasticity finite element model. The method comprises the following steps: (1) setting different material parameter combinations A; (2) performing crystal plasticity finite element calculation by adopting the parameter combination A to obtain true stress and true strain under different parameters; (3) establishing a deep belief neural network model by taking the parameter combination A as input and taking the true stress and true strain obtained in the step (2) as output; (4) selecting an additional material parameter combination B, calculating a crystal plasticity finite element and a deep belief neural network model to obtain true stress and true strain of different models, comparing the true stress and true strain, and verifying the accuracy of the deep belief neural network model; and (5) setting a plurality of groups of material parameter combinations C, carrying out deep belief network model calculation, comparing the calculated true stress true strain with a test value, and if the error is greater than a set value, continuing to modify the material parameter combinations C until the error is less than the set value, wherein the parameter combinations C are the material parameters of the crystal plasticity finite element model.

Owner:CENT SOUTH UNIV

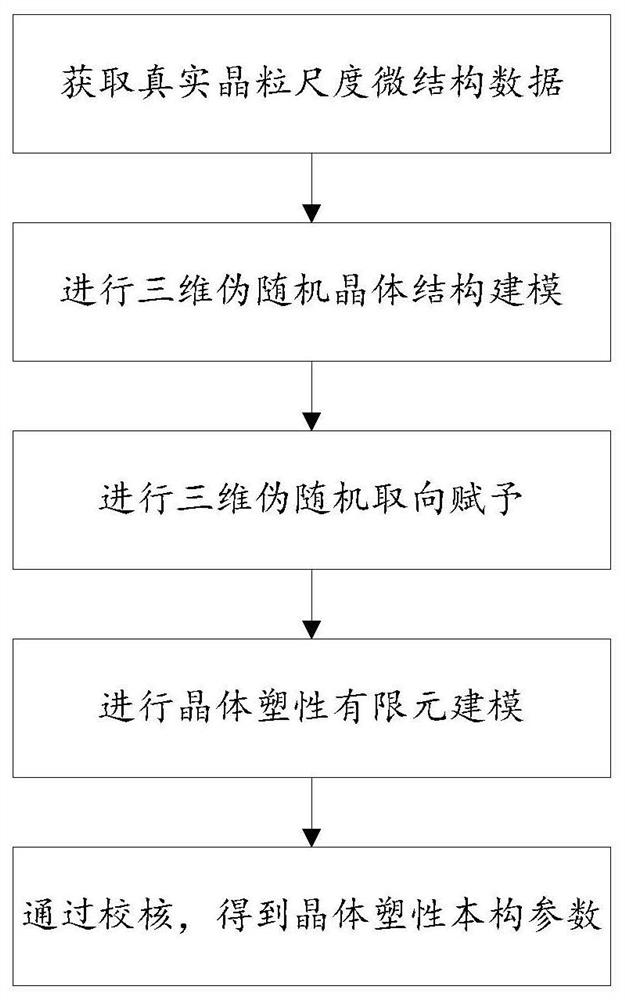

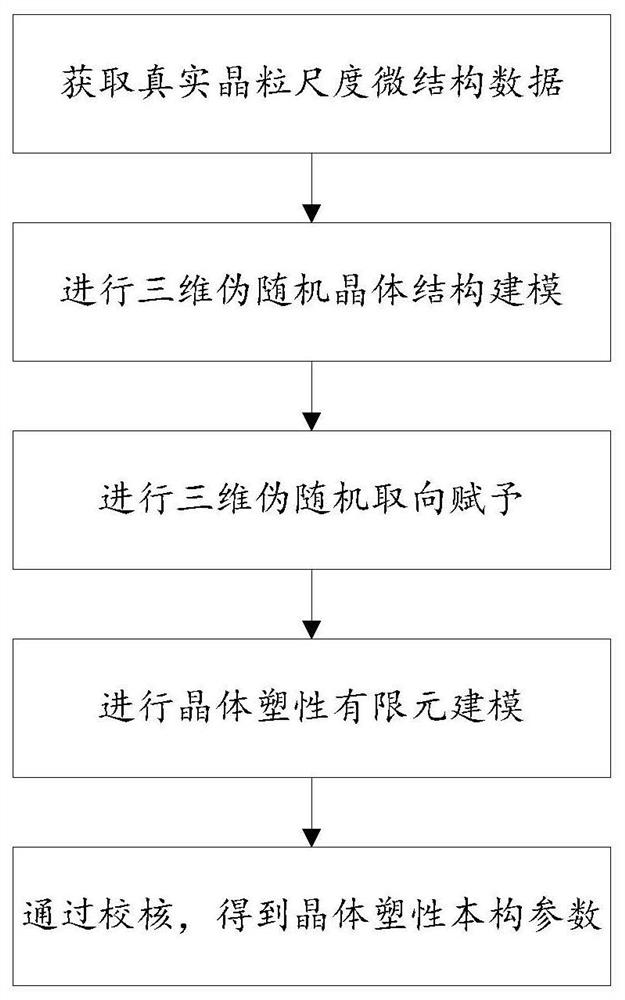

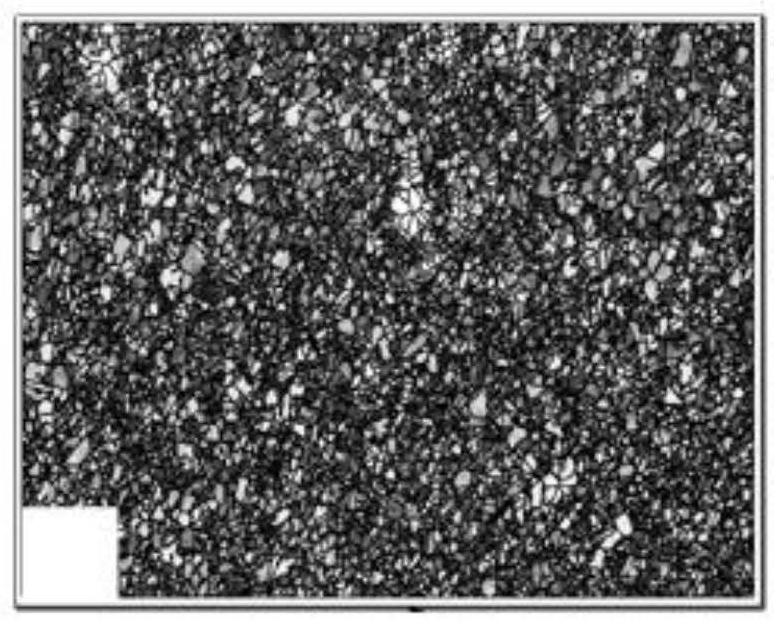

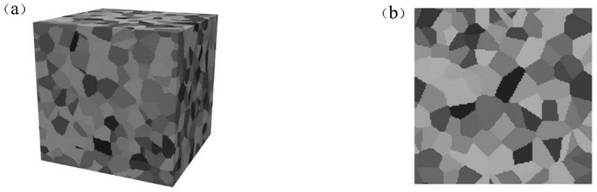

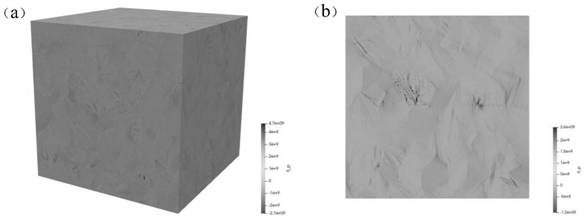

Three-dimensional crystal plasticity finite element modeling method and system for crystal material part

ActiveCN112989667AFully consider geometric elementsShorten the timeDesign optimisation/simulationSpecial data processing applicationsCrystal plasticityElement model

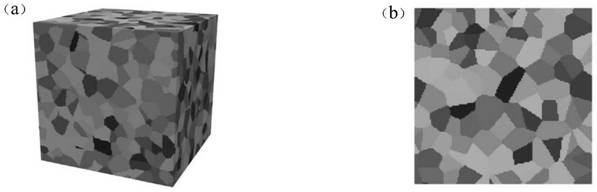

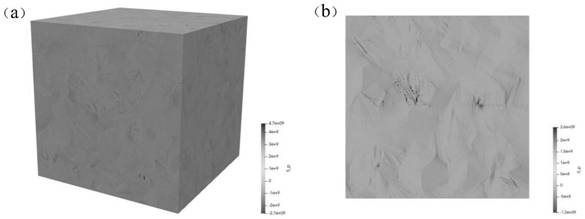

The invention discloses a three-dimensional crystal plasticity finite element modeling method and system for a crystal material part. The method comprises the steps of obtaining the data of a real crystal material part, and obtaining a distribution rule according to the obtained data, generating grain size data for the minimum directional bounding box of the crystal material part model through the obtained grain size data distribution rule, generating a grain size model of the minimum directional bounding box, removing redundancy of the grain size model to obtain a three-dimensional pseudo-random grain size microstructure of the crystal material part, iteratively giving orientation to each grain in the three-dimensional pseudo-random grain scale microstructure through the obtained grain orientation data distribution rule and the obtained crystal boundary orientation difference data distribution rule, constructing a crystal plasticity finite element model of the crystal material part through the obtained three-dimensional pseudo-random grain scale microstructure of the crystal material part and the orientation data of the grains, and realizing crystal plasticity finite element simulation. The method can be used for mechanical property simulation and service simulation.

Owner:SHANDONG UNIV

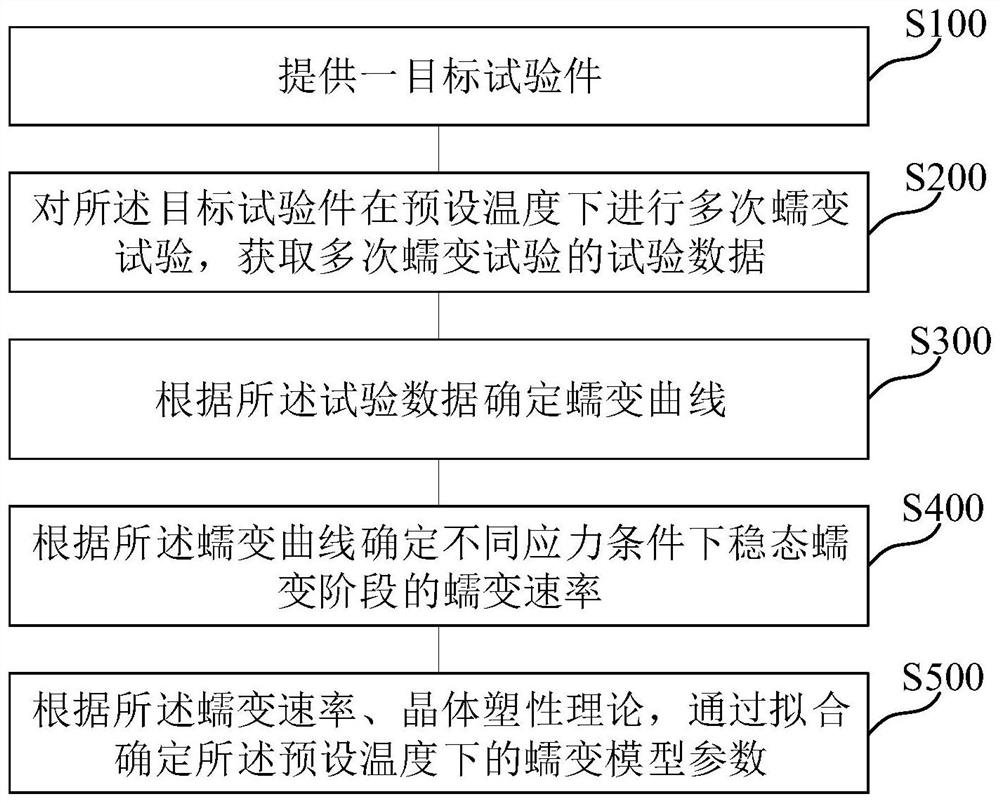

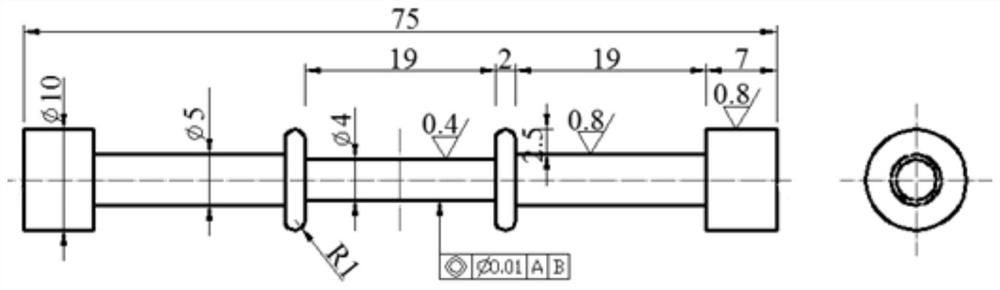

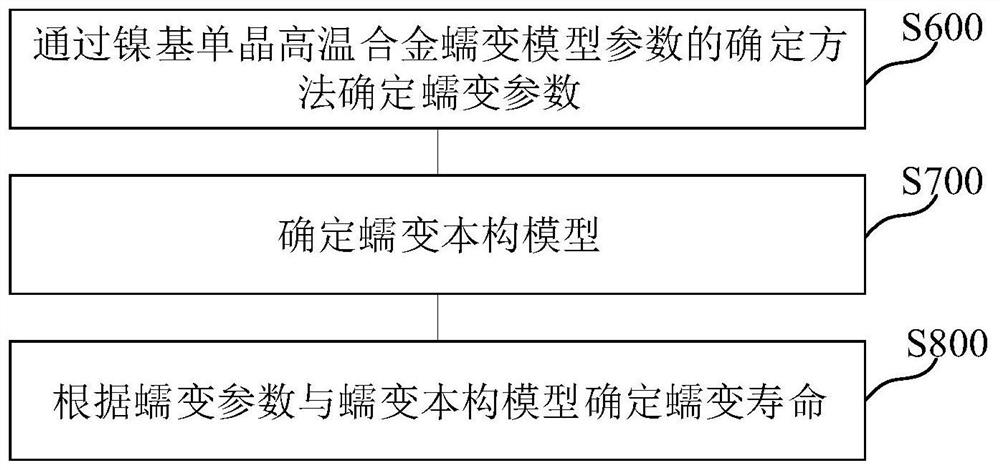

Method for determining creep model parameters and predicting creep life of nickel-based single crystal high-temperature alloy

PendingCN113125275AMaterial strength using tensile/compressive forcesCrystal plasticitySingle crystal superalloy

The embodiment of the invention provides a method for determining creep model parameters and predicting creep life of nickel-based single crystal high-temperature alloy. The method comprises the following steps: providing a target test piece; performing multiple creep tests on the target test piece at a preset temperature to obtain test data of the multiple creep tests; determining a creep curve according to the test data; determining creep rates in a steady-state creep stage under different stress conditions according to the creep curve; according to the creep rate and the crystal plasticity theory, determining creep model parameters at the preset temperature through fitting. The creep parameters obtained through the method can simulate a creep curve under any stress condition, the method can be applied to the determination of the creep parameters at any temperature, and the result is reliable.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

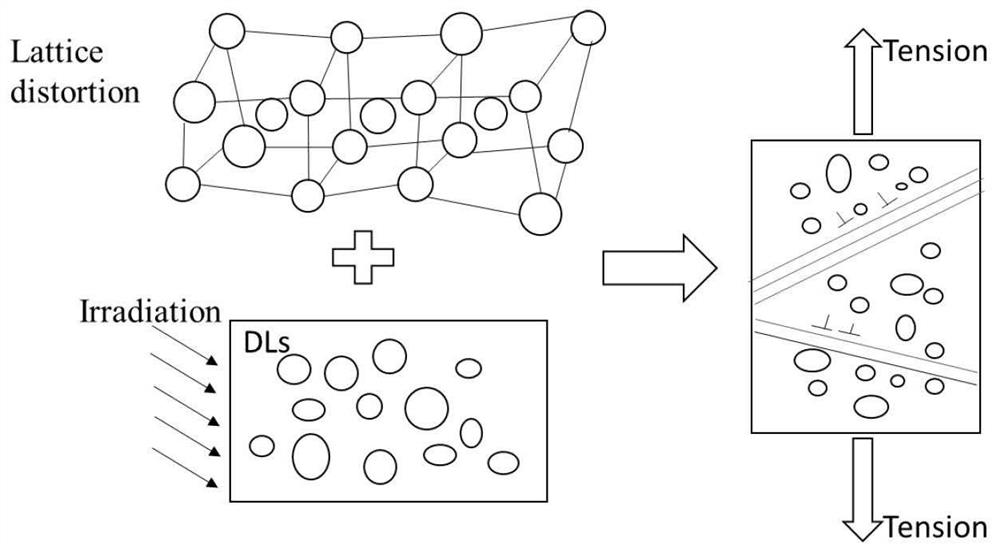

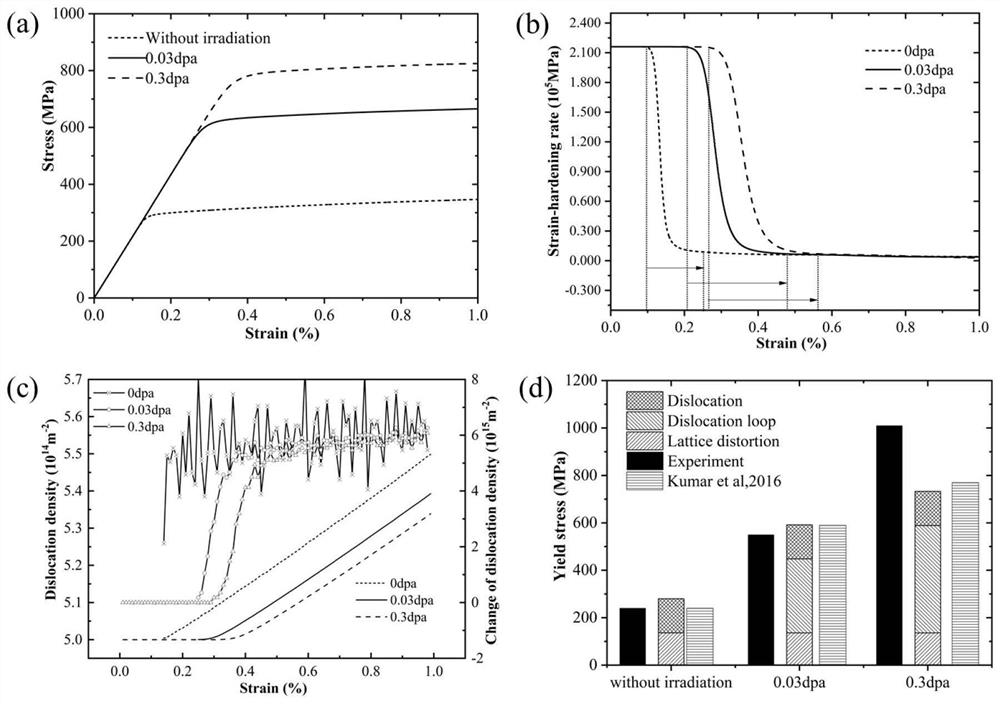

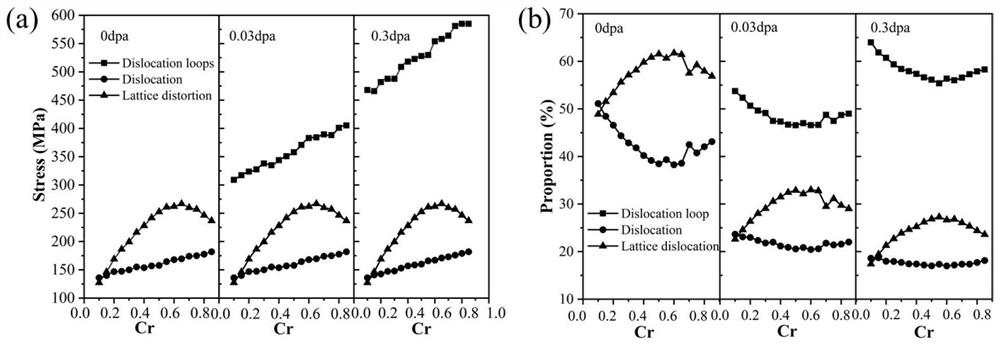

Defective structure-containing high-entropy alloy strength prediction method

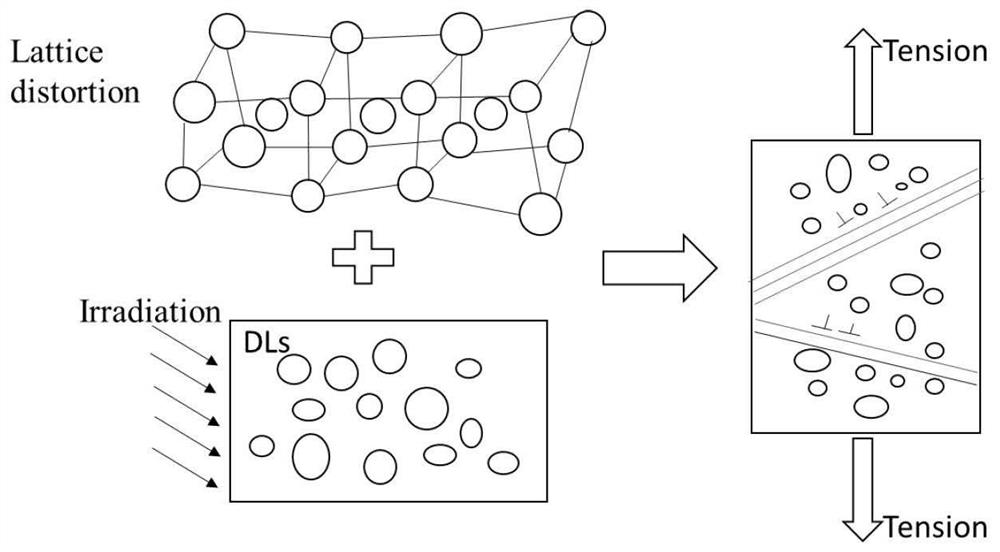

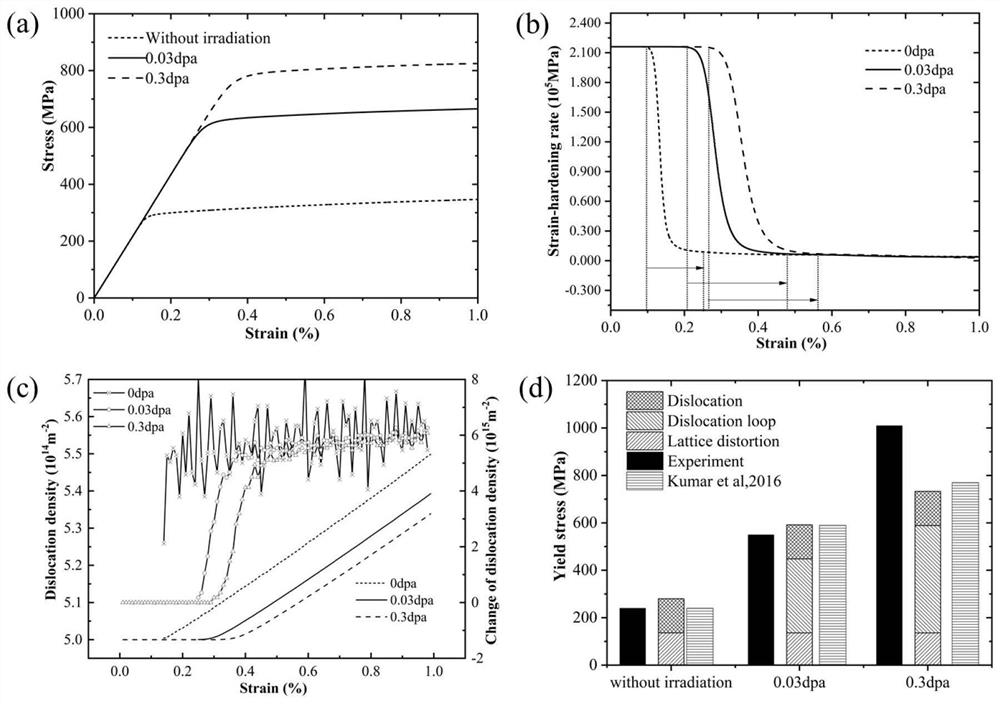

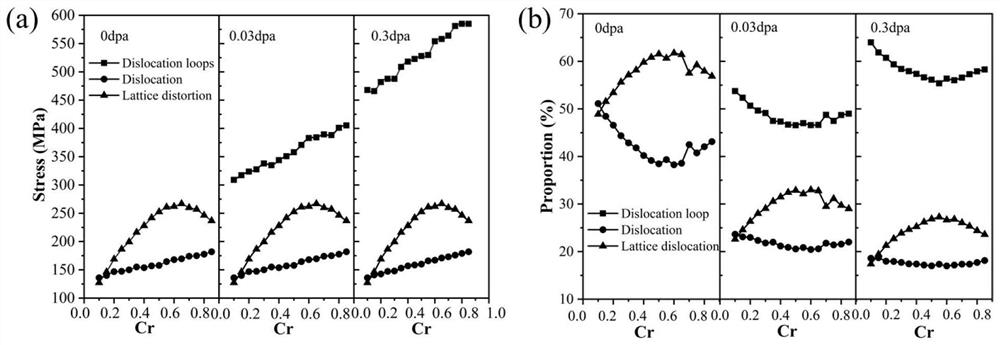

ActiveCN113094885AClear modeling processFit closelyForecastingDesign optimisation/simulationCrystal plasticityHigh entropy alloys

The invention relates to a method for predicting the strength of a high-entropy alloy with a defect structure. A dislocation theory, a crystal plasticity theory and a defect theory are effectively combined to establish a related strength theoretical model. The influence of dislocation, a dislocation ring and a serious lattice distortion effect on the performance of the high-entropy alloy is considered, and quantitative calculation of the strength of the high-entropy alloy containing the defect structure is achieved. The yield strength obtained by the prediction method provided by the invention is well matched with an experimental result. The related deformation mechanism analyzed in the method is of great significance to research and predict the influence of dislocation ring defects on the strength of the high-entropy alloy. Through the prediction method provided by the invention, the element content of the alloy is regulated and controlled, and the influence of different element contents on the yield strength is researched, so that theoretical guidance is provided for the design of the high-performance and high-entropy alloy. In the development process of the new alloy, the method effectively avoids a large number of repeated tests, shortens the research and development period of the high-performance high-entropy alloy, saves the cost, and has huge engineering value.

Owner:HUNAN UNIV

Creep fatigue residual life evaluation method based on crystal plasticity theory

PendingCN113792446AImprove applicabilityHigh precisionDesign optimisation/simulationSpecial data processing applicationsFatigue damageCrystal plasticity

The invention provides a creep fatigue residual life evaluation method based on a crystal plasticity theory. The creep fatigue residual life evaluation method comprises the following steps of: compiling a crystal plasticity constitutive equation based on dislocation density through ABAQUS finite element software; determining material parameters of the crystal plasticity constitutive equation; performing crystal plasticity finite element simulation on the representative volume unit of a to-be-tested material to obtain mechanical responses of the to-be-tested material under different creep fatigue working conditions; extracting accumulated energy dissipation of the representative volume unit of the to-be-tested material under each cycle, and determining a local energy dissipation volume ratio of the to-be-tested material and allowable creep damage and allowable fatigue damage of the to-be-tested material; and drawing a three-dimensional creep fatigue residual life evaluation diagram, and calculating the creep fatigue residual life of the to-be-tested material. According to the creep fatigue residual life evaluation method based on the crystal plasticity theory, creep fatigue residual life evaluation of the material can be better achieved. The method has the advantages of being visual, capable of achieving evaluation and high in accuracy.

Owner:EAST CHINA UNIV OF SCI & TECH

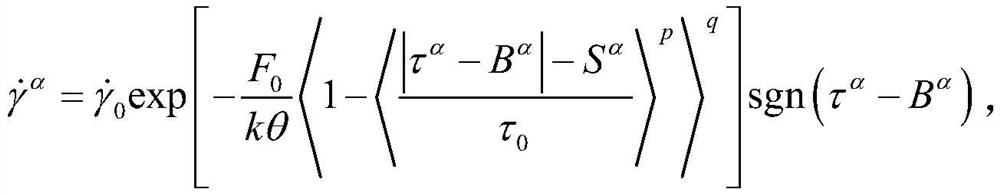

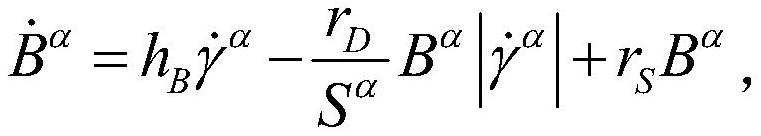

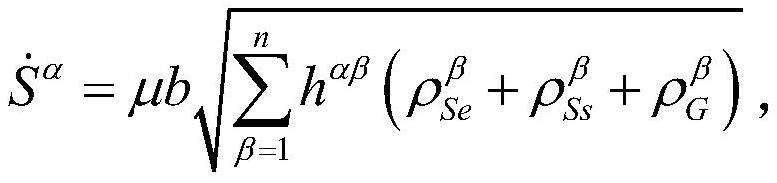

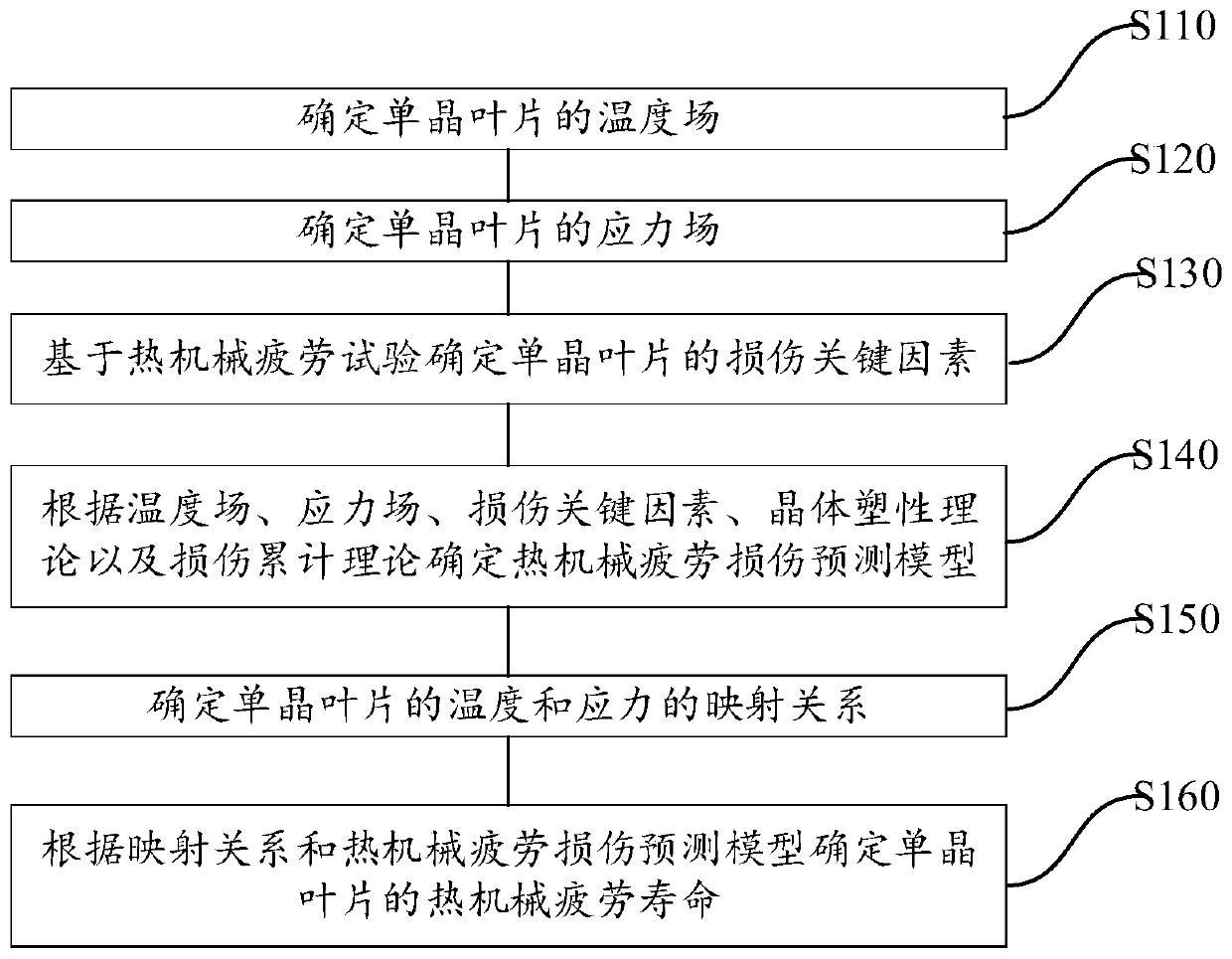

Rapid evaluation method for thermal mechanical fatigue life of engine single crystal blade

InactiveCN110096769AImprove efficiencyDesign optimisation/simulationSpecial data processing applicationsFatigue damageCrystal plasticity

The invention relates to the technical field of turbine blades, and provides a rapid evaluation method for thermal mechanical fatigue life of an engine single crystal blade. The rapid evaluation method comprises the steps of determining the temperature field of the single crystal blade; determining a stress field of the single crystal blade; determining damage key factors of the single crystal blade based on a thermal mechanical fatigue test; determining a thermal mechanical fatigue damage prediction model according to the temperature field, the stress field, the damage key factors, the crystal plasticity theory and the damage accumulation theory; determining a mapping relation between the temperature and the stress of the single crystal blade; and determining the thermal mechanical fatigue life of the single crystal blade according to the mapping relation and the thermal mechanical fatigue damage prediction model. The efficiency of life assessment can be improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Method for Predicting Coupling Response of Isothermal Forming and Dynamic Recrystallization Evolution of Titanium Alloys

ActiveCN106202675BAchieving Unified PredictionTightly deformedDesign optimisation/simulationSpecial data processing applicationsCrystallization kineticsTitanium alloy

The invention provides a method for predicting coupling responses of isothermal forming and dynamic recrystallization evolution of titanium alloys. Grain stress responses, intercrystalline non-uniform deformation and non-uniform dislocation density caused by intercrystalline non-uniform deformation are obtained in an isothermal forming process of the titanium alloys and are adopted as variables and transmitted to a cellular automaton, dynamic recrystallization evolution of the grain size under the condition of non-uniform size deformation is obtained, and dynamic recrystallization nucleation and grown structure morphology as well as grain boundary evolution and updated dislocation density which are caused by the dynamic recrystallization nucleation and grown structure morphology are obtained. The obtained grain and grain boundary information including dynamic recrystallization nucleation and growth as well as the dislocation density is returned to a crystal plasticity finite element method, dislocation gliding resistance of each grain unit is updated, so that subsequent deformation of the titanium alloys is influenced, and the stress responses of the grain size are calculated according to the constitutive relation. The method realizes synchronous prediction of non-uniform deformation of the grain size in isothermal forming of the titanium alloys, dynamic recrystallization structure morphology evolution, recrystallized grain size evaluation, recrystallization kinetics, deformable bodies and grain flow stress.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

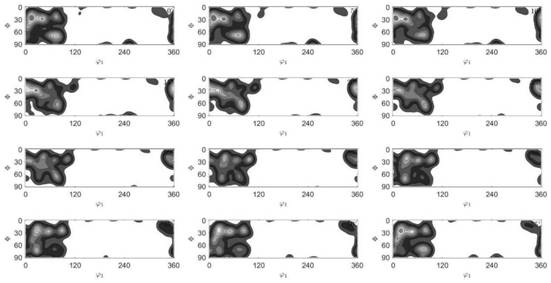

Semi-quantitative prediction and visualization method for mesoscopic stress and texture in alpha titanium deformation process

ActiveCN113358678APredict mechanical responseMaterial analysis using wave/particle radiationCrystal plasticityExperimental methods

The invention discloses a semi-quantitative prediction and visualization method for mesoscopic stress and texture in an alpha titanium deformation process, which belongs to the technical field of material plastic deformation. According to the method, the problem that mesoscopic stress is difficult to obtain by an existing simulation means or experimental method is solved, and the problems of high requirements and high cost of experimental characterization of the mesoscopic stress on equipment are avoided. According to the method, a representative volume element RVE is used as a carrier to establish a crystal plasticity model, a texture obtained through EBSD characterization or XRD measurement is imported into the representative volume element RVE, the representative volume element RVE is composed of a titanium alloy alpha phase and contains texture information of an original experimental material, slippage and twinning deformation behaviors of the alpha titanium alloy are considered in subsequent crystal plasticity simulation, mesoscopic stress and texture evolution information of the material under the action of various external loads can be obtained and visualized, and the method is of great importance to research on mesoscopic stress evolution in the alpha titanium alloy deformation process and initiation and expansion of cracks induced by mesoscopic stress.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

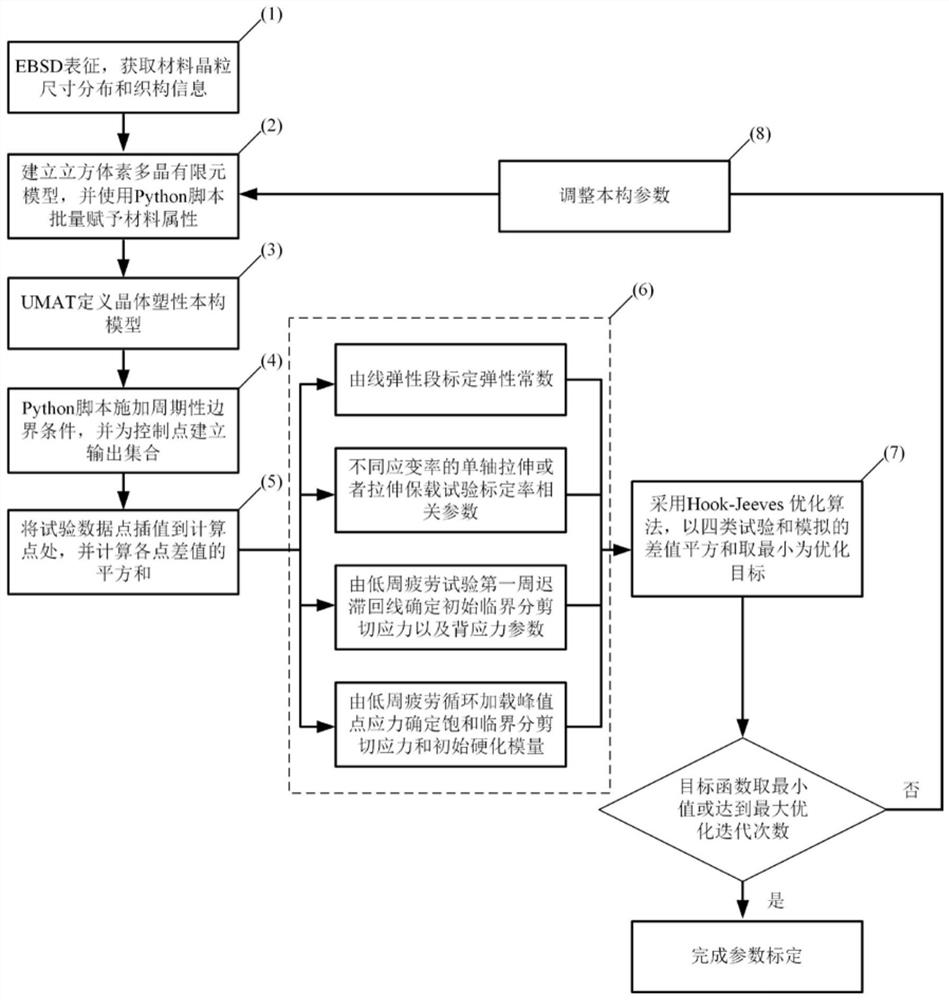

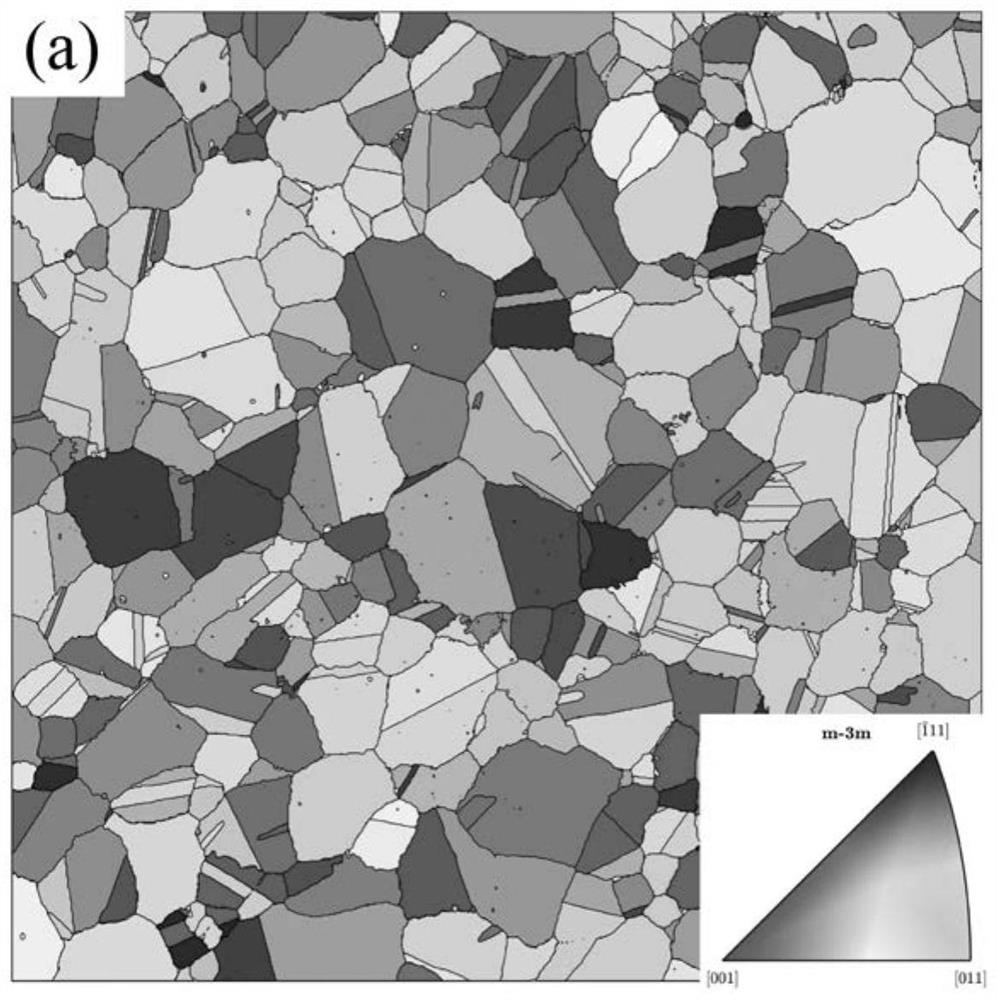

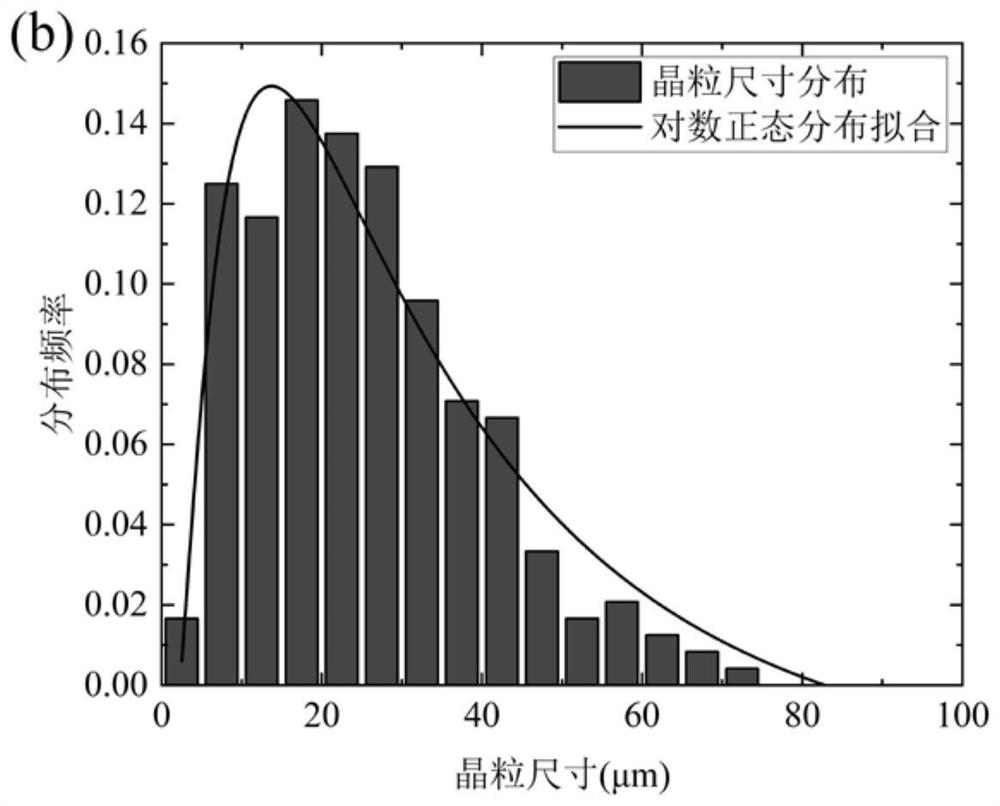

Polycrystalline crystal plasticity constitutive parameter rapid calibration method

PendingCN114496122AReduce in quantityReduce computing consumptionChemical property predictionComputational materials scienceMetallic materialsTime data

The invention discloses a rapid calibration method for plastic constitutive parameters of a polycrystalline crystal. The rapid calibration method comprises the following steps: carrying out EBSD characterization on a metal material; establishing a-cube element polycrystalline geometric model, and endowing constitutive parameters and grain orientation by means of a Python script; writing a crystal plasticity constitutive model subprogram UMAT; applying a periodic boundary condition by means of a Python script; extracting a stress-strain relationship of the polycrystalline model, and interpolating test data to calculation data points; using uniaxial tension and fatigue test stress-strain / stress-time data to calibrate constitutive parameters; taking the sum of squares of differences of test and simulation data points as an optimization target, and performing iterative optimization by adopting a Hook-Jeeves optimization algorithm; constitutive parameters are adjusted through an iterative algorithm, and material parameters are updated by means of a Python script. The method can reflect the mechanical properties of the material, remarkably reduces the finite element calculation consumption, shortens the optimization period, and improves the parameter calibration efficiency.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

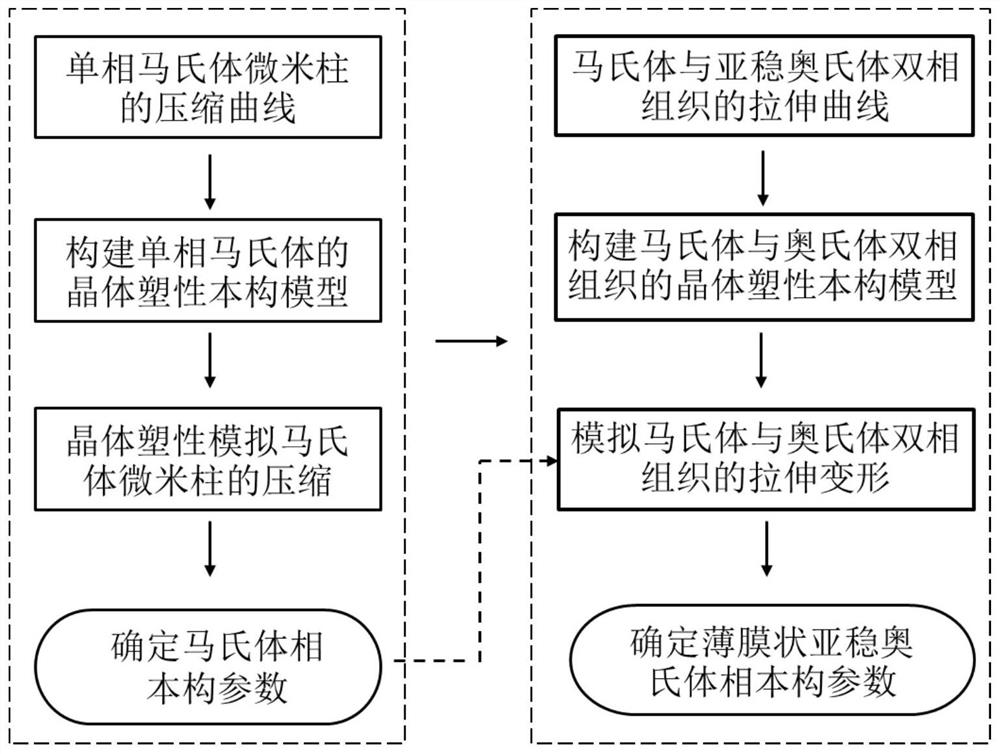

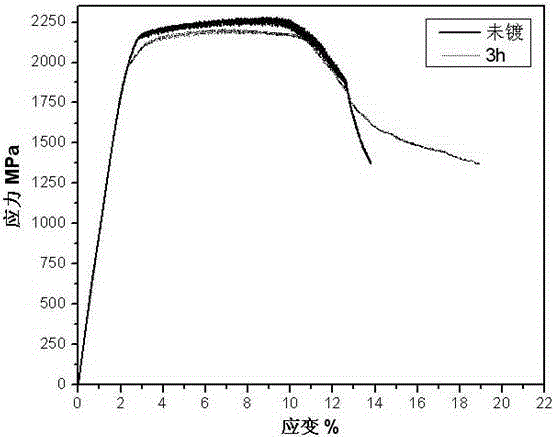

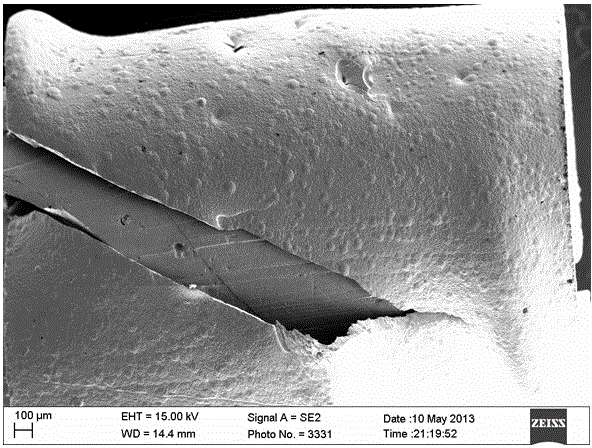

Method for determining mechanical constitutive parameters of nickel-series low-temperature steel containing film-shaped metastable austenite

ActiveCN112966342AThe method is rigorous and self-consistentSolve the challenges of measurementGeometric CADDesign optimisation/simulationCrystal plasticityMartensite

The invention provides a method for determining mechanical constitutive parameters of nickel-based low-temperature steel containing film-shaped metastable austenite, and solves the problems that the film-shaped metastable austenite and tempered martensite in the current nickel-based low-temperature steel are small in size, the volume fraction of the metastable austenite evolves continuously due to the TRIP effect, and the two-phase constitutive parameters are difficult to measure independently by using the existing method. The method comprises the following steps: firstly, processing a single-phase martensite micron column on a nickel-based low-temperature steel sample, obtaining a compression stress-strain curve of the micron column, and determining constitutive parameters of a martensite phase; then, obtaining a stress-strain curve of a martensite and metastable austenite dual-phase structure through a uniaxial tensile experiment, and meanwhile, obtaining a curve of volume fraction evolution of metastable austenite along with strain; and finally, simulating the stretching process of the martensite and metastable austenite double-phase structure by utilizing crystal plasticity, comparing the simulated and experimental stress-strain curves with the evolution curve of the volume fraction of the metastable austenite along with the strain, and determining constitutive parameters of the metastable austenite phase.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Three-dimensional crystal plastic finite element modeling method and system for crystal material parts

ActiveCN112989667BFully consider geometric elementsShorten the timeDesign optimisation/simulationSpecial data processing applicationsElement modelCrystal plasticity

The invention discloses a three-dimensional crystal plastic finite element modeling method and system for crystal material parts. The data of real crystal material parts is obtained, and the distribution law is obtained according to the obtained data; the distribution law of the obtained crystal grain size data is the minimum value of the crystal material part model. The oriented bounding box generates grain size data; generates the grain scale model of the smallest oriented bounding box; removes redundancy from the grain scale model, and obtains the three-dimensional pseudo-random grain scale microstructure of crystal material parts; through the obtained grain orientation data Distribution law and grain boundary misorientation data distribution law, iteratively assign orientation to each grain in the three-dimensional pseudo-random grain-scale microstructure; through the obtained three-dimensional pseudo-random grain-scale microstructure of crystal material parts and the grain size Orientation data, construct crystal plastic finite element model of crystal material parts; realize crystal plastic finite element simulation. The invention can be used for mechanical performance simulation and service simulation.

Owner:SHANDONG UNIV

A method for constructing the constitutive behavior of multiphase metallic materials for high-speed deformation process

ActiveCN111145842BEliminate cumbersomenessReduce testing costsDesign optimisation/simulationComputational materials scienceMacroscopic scaleMetallic materials

The invention discloses a fast calculation method for the constitutive behavior of multi-phase metal materials facing high-speed deformation process. The mechanical behavior of each single pure phase in the multi-phase material is predicted by the crystal plasticity finite element method, and then the mechanical behavior of each single pure phase in the multi-phase material is predicted by the metallographic structure measurement, The proportional mixing method predicts the macroscopic constitutive behavior exhibited by the material in the multiphase state. This method can accurately and rapidly predict the mechanical behavior of a single phase of the material under high strain rate state, so it can be applied to high-speed machining, forging and other deformation processes involving steel, titanium alloy and other materials with complex phase composition. This method avoids the need to re-measure the mechanical behavior of the material due to the significant change in the mechanical properties after different heat treatments for the same material. In practical industrial production, it can significantly reduce costs and improve simulation and analysis efficiency. Computer-aided analysis and design of part machining deformation process is of great significance.

Owner:XI AN JIAOTONG UNIV

Strength prediction method of high-entropy alloys with defect structure

ActiveCN113094885BClear modeling processFit closelyForecastingDesign optimisation/simulationCrystal plasticityHigh entropy alloys

Owner:HUNAN UNIV

A method for improving the plasticity of amorphous alloy at room temperature

Owner:TAIYUAN UNIV OF TECH

Semi-quantitative prediction and visualization of mesoscopic stress and texture during deformation of alpha titanium

ActiveCN113358678BPredict mechanical responseMaterial analysis using wave/particle radiationCrystal plasticityExperimental methods

The invention discloses a semi-quantitative prediction and visualization method of mesoscopic stress and texture in the deformation process of alpha titanium, and belongs to the technical field of material plastic deformation. The invention solves the problem that the existing simulation means or experimental method is difficult to obtain the mesoscopic stress, and avoids the high requirements and high cost of equipment for the experimental characterization of the mesoscopic stress. In this application, the representative volume element RVE is used as a carrier to establish a crystal plasticity model, and the texture obtained by EBSD characterization or XRD measurement is imported into the representative volume element RVE. The representative volume element RVE is composed of titanium alloy α phase and contains the texture information of the original experimental material. The subsequent crystal plasticity simulation takes into account the slip and twinning deformation behavior of α titanium alloy, and can obtain and visualize the mesoscopic stress and texture evolution information of the material under various external loads. The evolution of microscopic stress and the initiation and propagation of mesoscopic stress-induced cracks are crucial.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

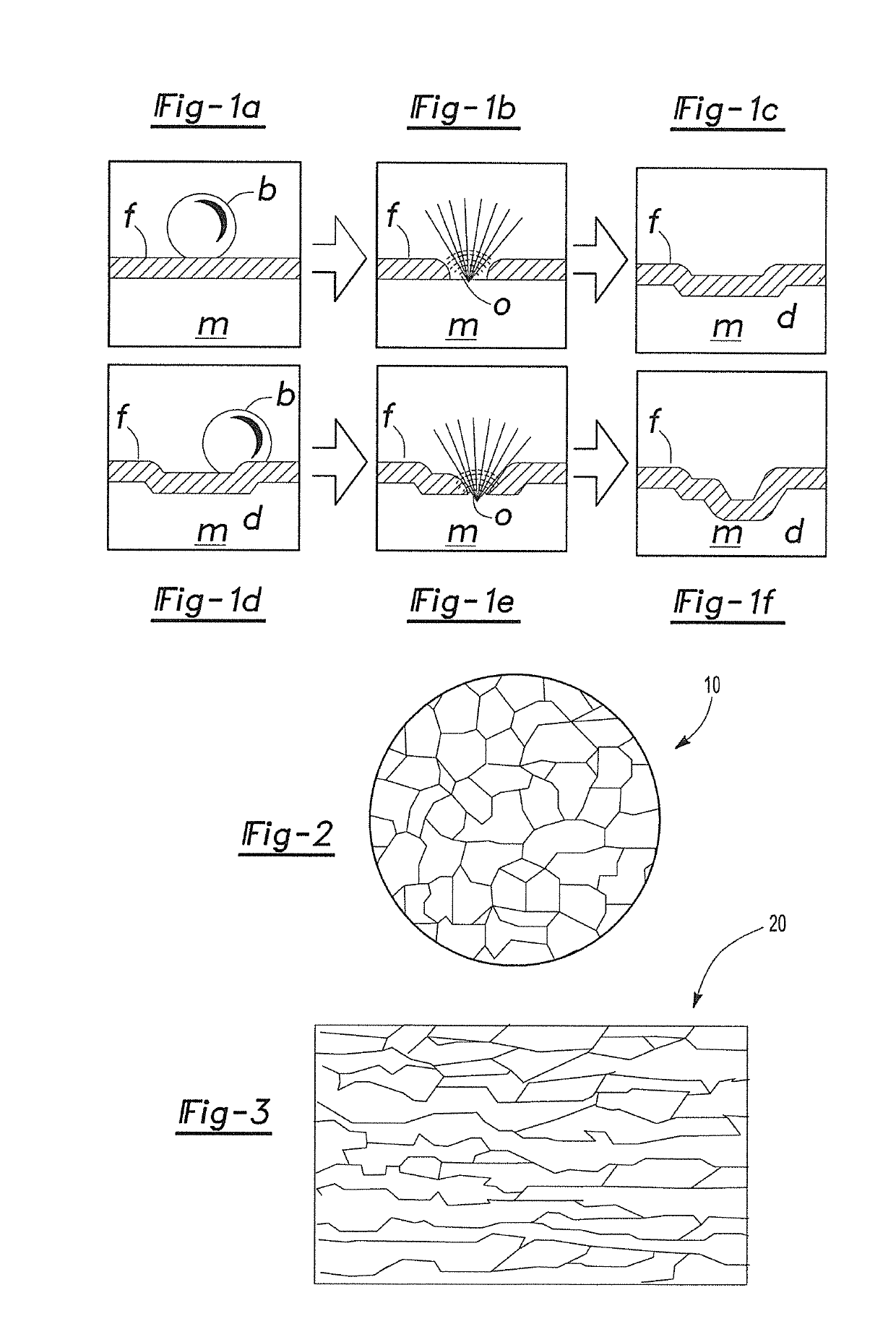

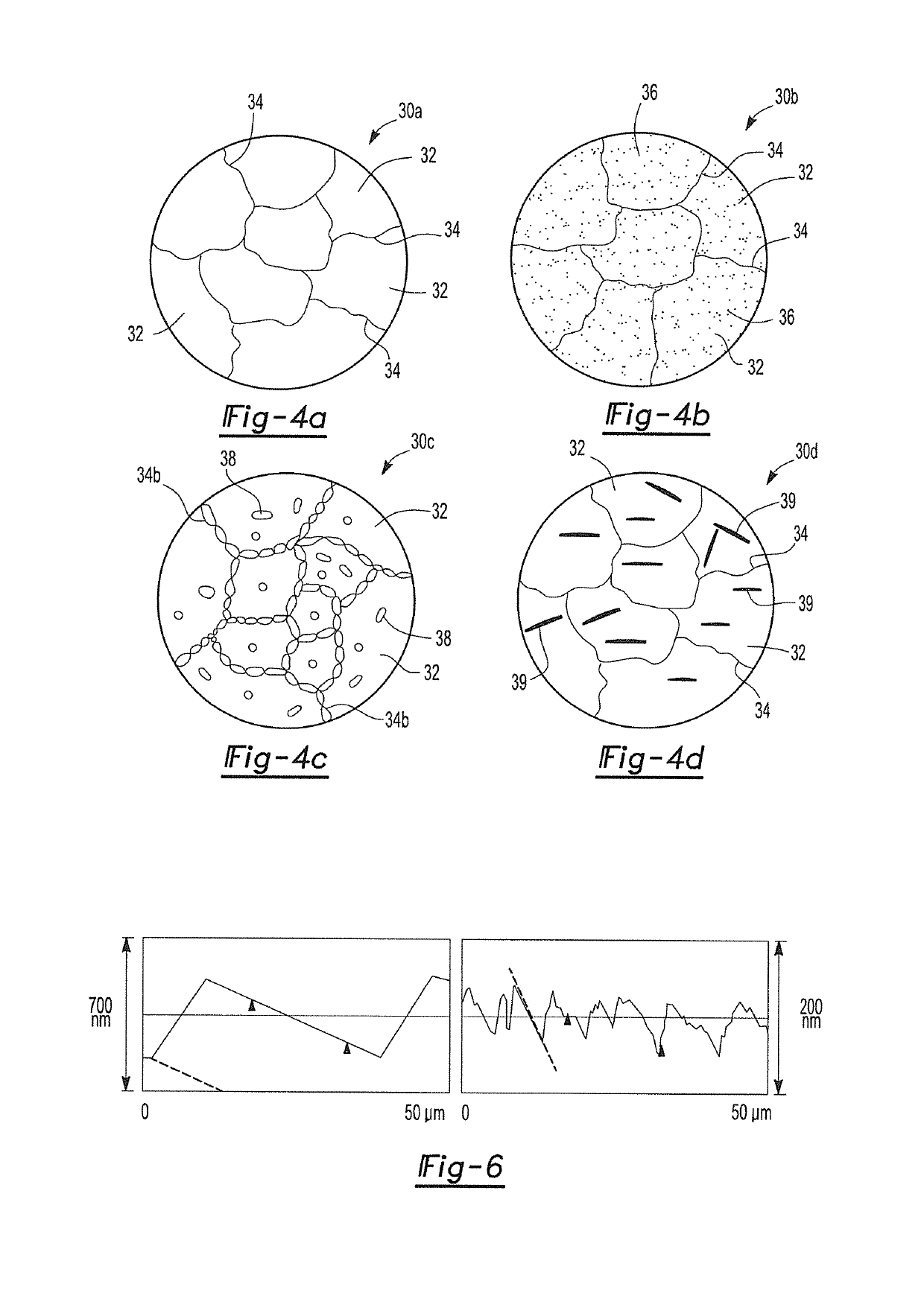

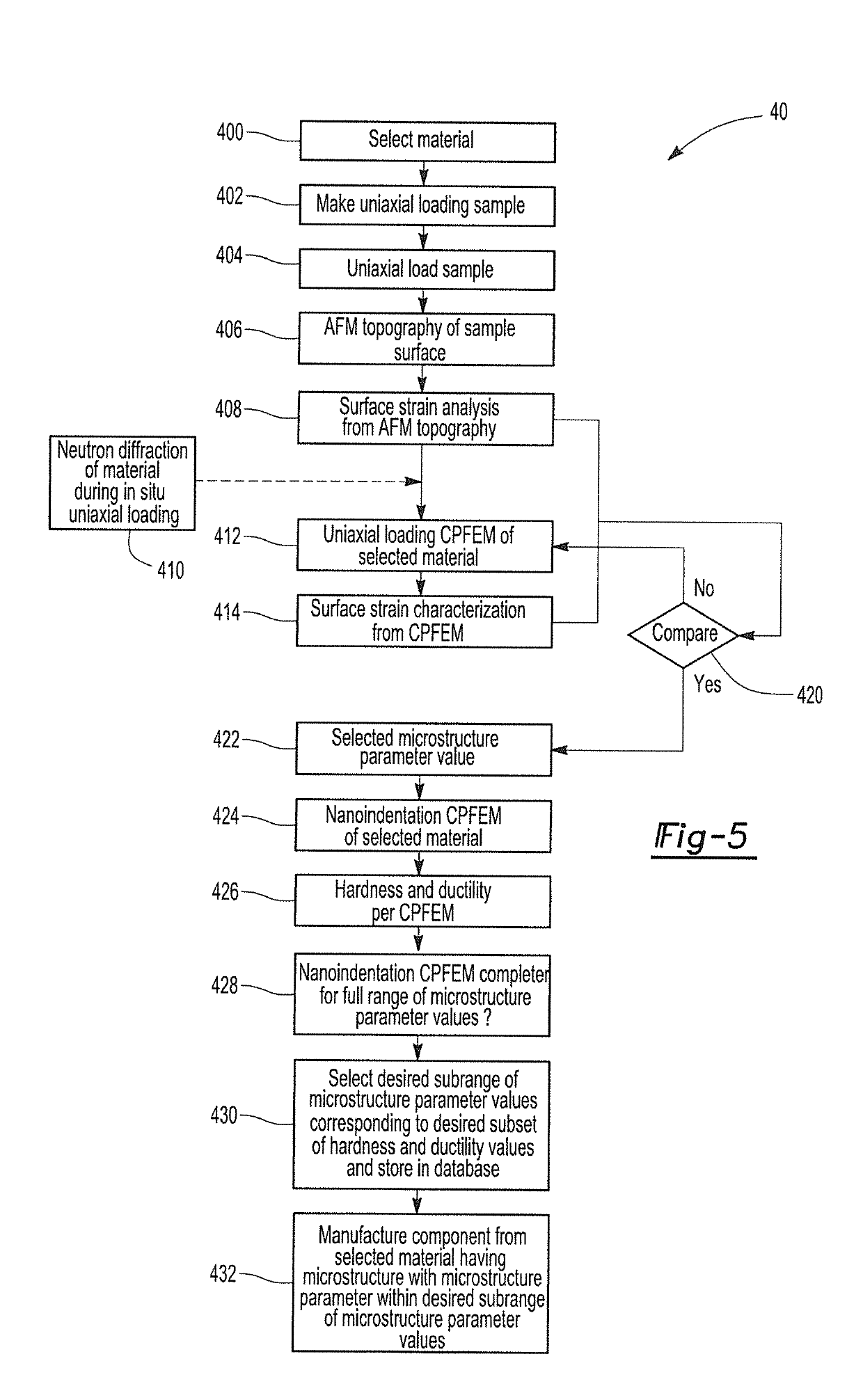

Process for design and manufacture of cavitation erosion resistant components

A process for designing and manufacturing a cavitation erosion resistant component. The process includes selecting a base material for use in a cavitation erosion susceptible environment and conducting a uniaxial loading test on a sample of the selected material. Thereafter, atomic force microscopy (AFM) topography on a surface of the tested sample is conducted and used to provide a surface strain analysis. The process also includes crystal plasticity finite element modeling (CPFEM) of uniaxial loading and CPFEM nanoindentation of the selected material over a range of values for at least one microstructure parameter. A subrange of microstructure parameter values that correlate to CPFEM nanoindentation results that provide increased CE resistance is determined. Finally, a component having an average microstructure parameter value that falls within the subrange of microstructure parameter values is manufactured.

Owner:HITACHI LTD

A Prediction Method of Single Crystal Copper Micro Milling Force Based on Cutting Process Simulation

ActiveCN110597180BRealization of micro-milling force predictionAchieve forecastProgramme controlComputer controlCrystal plasticityEngineering

The invention belongs to the field of precise and efficient processing of a micro part, and particularly relates to a cutting process simulation-based single-crystal copper micro-milling force forecast method. The cutting process simulation-based single-crystal copper micro-milling force forecast method comprises the steps of initially and comprehensively considering influence of factors such as crystal deformation kinematics, a crystal plasticity constitutive relation and hardening law of rate-dependent crystal on single-crystal copper micro-milling due to the specialty of a single-crystal copper material; secondly, deducing an incremental form of a constitutive equation, writing single-crystal copper VUMAT user material sub-program by employing a Fortran language, and introducing crystalplasticity constitution into a finite element simulation; and finally, performing simulation modeling on the single-crystal copper micro-milling process by ABAQUS software to achieve single-crystal copper micro-milling force forecast. By taking finite cutting simulation as a basis, accurate forecast of a single-crystal copper micro-milling force is achieved, a technical support is provided for researching the single-crystal copper micro-milling process, the processing accuracy and efficiency of single-crystal copper micro-milling is improved, and the cutting process simulation-based single-crystal copper micro-milling force forecast method has a practical application value.

Owner:DALIAN UNIV OF TECH

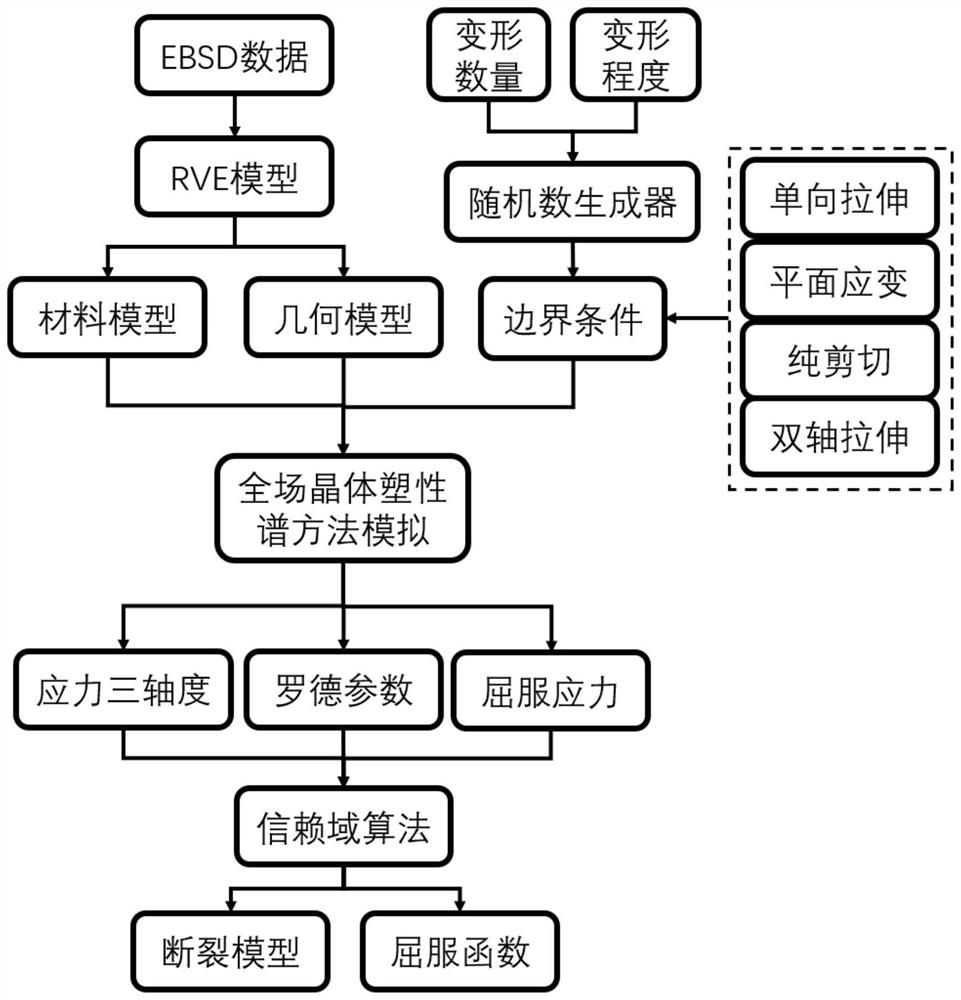

Virtual experiment method and device for anisotropic mechanical behavior of metal material

PendingCN114372403ASolve problems that are difficult to calibrate by experimental meansLow costGeometric CADDesign optimisation/simulationVoxelMetallic materials

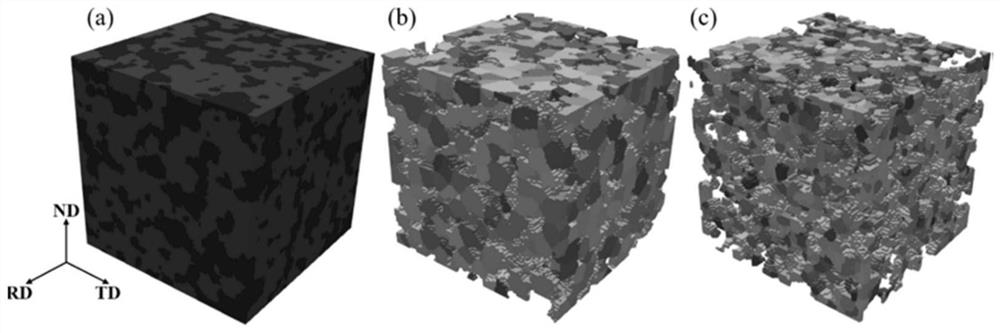

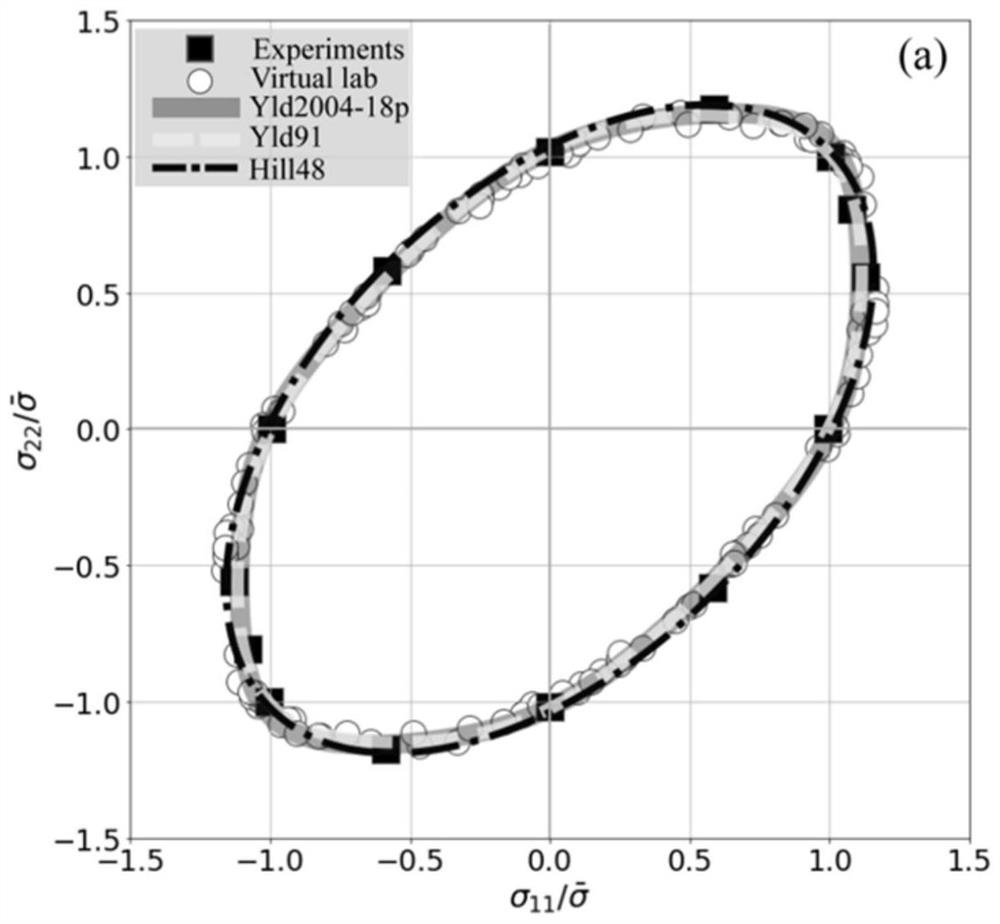

The invention relates to a virtual experiment method and device for anisotropic mechanical behaviors of a metal material. The method comprises the following steps: constructing a microstructure representative voxel model according to an electron back scattering diffraction experiment result of the metal material to be experimented; specifying a deformation number and a deformation degree, and generating any periodic boundary condition through a random number generator; performing full-field crystal plasticity simulation according to the microstructure representative voxel model and any periodic boundary condition, and extracting a yield stress point of the microstructure representative voxel model under a specified deformation degree, so as to fit yield function parameters through a trust region algorithm; and extracting the history that the stress three-axis degree and Rode parameters of the microstructure representative voxel model change along with equivalent strain under the periodic boundary condition, so as to fit fracture model parameters through a trust region algorithm. Compared with the prior art, a virtual experiment is used for replacing a traditional mechanical experiment, so that the research and development period of a metal material product is shortened, and waste of manpower, material resources and financial resources is reduced.

Owner:SHANGHAI JIAO TONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com