Ni3Al-based alloy constitutive model establishment method based on representative volume elements

A constitutive model and volume element technology, applied in the field of aerospace materials, can solve the problems that are far apart, difficult to effectively describe the mechanical properties of materials, and cannot include material microscopic uncertainties, so as to achieve the effect of effective mechanical response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

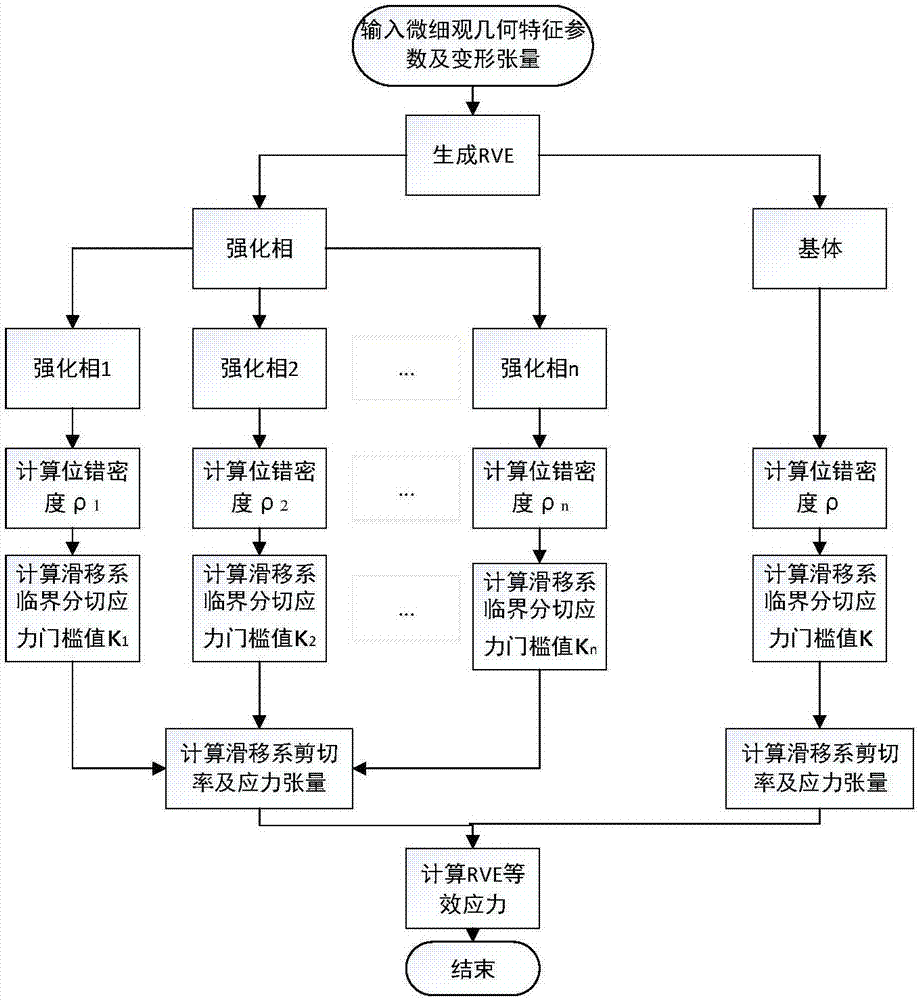

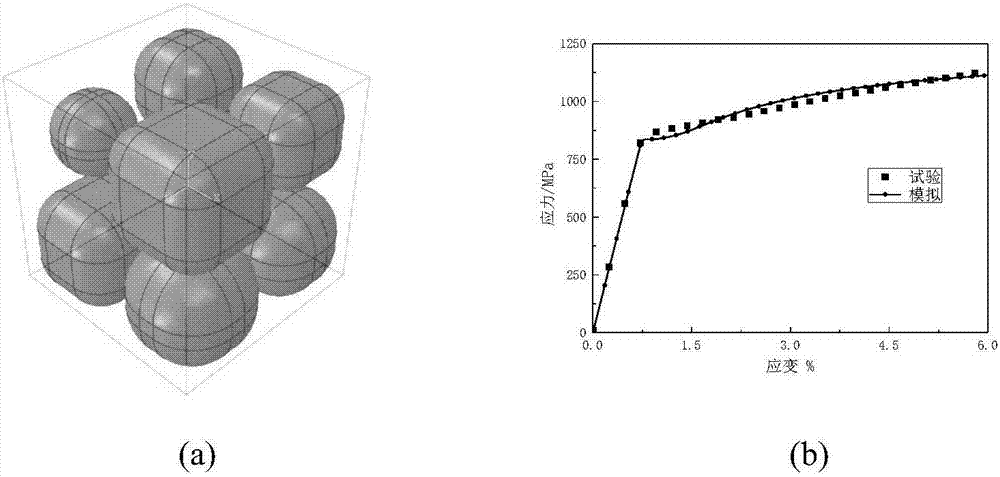

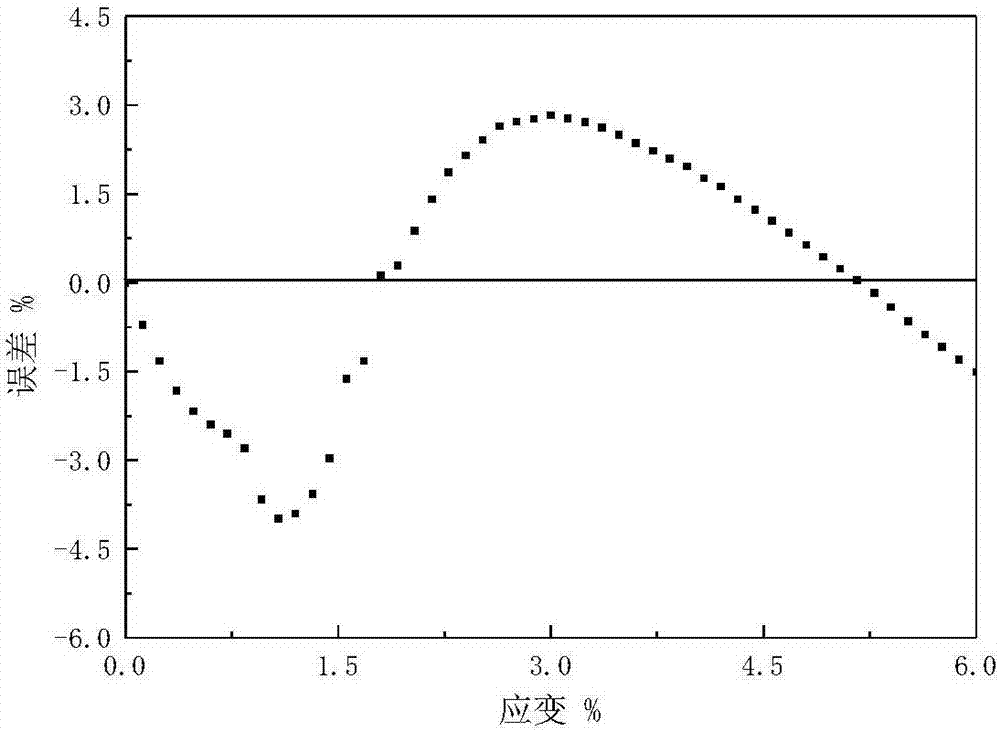

[0044] A representative volume element (RVE) based Ni 3 Al base alloy constitutive model establishment method, comprises the steps:

[0045] 1), generate the microscopic representative volume element (RVE) of the material according to the microstructure of the material through an effective method. In the RVE, both the strengthening phase and the matrix phase adopt a viscoplastic model.

[0046] 2), for Ni 3 Tensile test of Al single crystal to obtain the elastic constant C of the strengthening phase 11 、C 12 and C 44 .

[0047]3), the elastic constant C of matrix phase is obtained by nanoindentation test on pure Ni 11 、C 12 and C 44 .

[0048] 4), for Ni 3 The Al-based alloy IC10 was subjected to tensile tests under different strain loads, sliced the stretched specimens, and observed the dislocation distribution inside the material through a transmission electron microscope (TEM); and used image processing software to count the dislocations of the materials under di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com