Three-dimensional crystal plasticity finite element modeling method and system for crystal material part

A technology of crystal material and crystal plasticity, which is applied in the field of finite element model modeling, can solve the problems of inaccurate and large differences in finite element simulation results of crystal plasticity, and achieve the effect of saving sample preparation costs and testing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] This embodiment provides a three-dimensional crystal plastic finite element modeling method for crystal material parts;

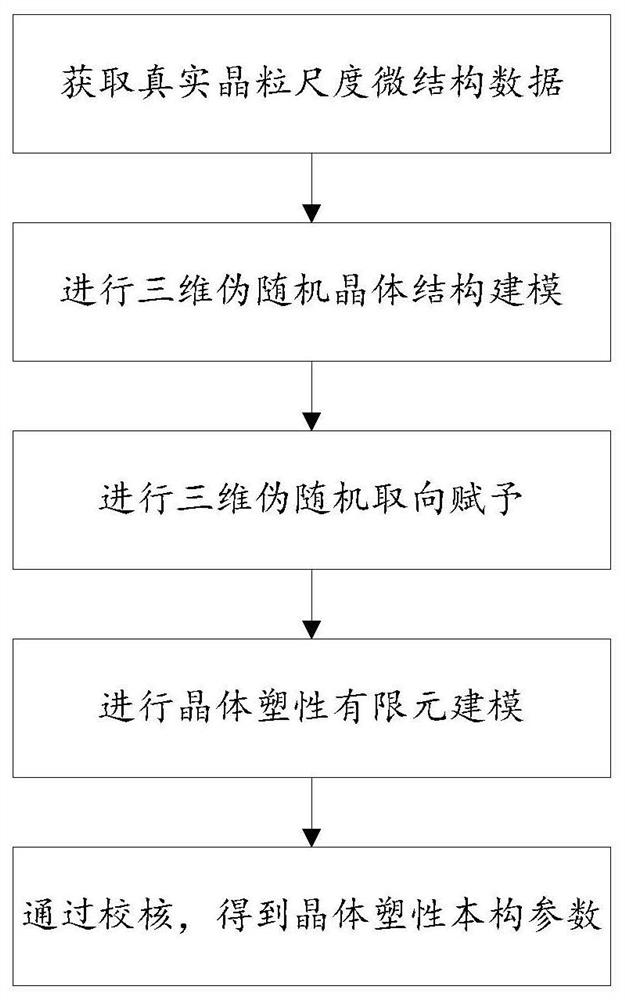

[0058] Such as figure 1 As shown, the three-dimensional crystal plastic finite element modeling method of crystal material parts includes:

[0059] S101: The obtained data includes grain size data, orientation data and grain boundary misorientation data of real crystal material parts, and distribution curves are drawn respectively according to the obtained data to obtain the distribution law of the grain size data and the distribution law of the orientation data. The distribution law and the distribution law of the misorientation data of the grain boundary;

[0060] S102: According to the acquired grain size data distribution law, iteratively generate grain size data for the minimum oriented bounding box of the crystal material part model; calculate each The seed point coordinates of the grains; based on the seed point coordinates of each grain, th...

Embodiment 2

[0186] This embodiment provides a three-dimensional crystal plastic finite element modeling system for crystal material parts;

[0187] 3D crystal plastic finite element modeling system for crystal material parts, including:

[0188]The data acquisition module is configured to: the acquired data includes grain size data, orientation data and grain boundary misorientation data of real crystal material parts, and draws distribution curves respectively according to the acquired data to obtain grain size data The distribution law of the orientation data, the distribution law of the orientation data and the distribution law of the misorientation data of the grain boundary;

[0189] The microstructure building block is configured to: iteratively generate grain size data for the minimum oriented bounding box of the crystal material part model through the acquired grain size data distribution law; Based on the grain size data, the seed point coordinates of each grain are calculated; ...

Embodiment 3

[0197] This embodiment also provides an electronic device, including: one or more processors, one or more memories, and one or more computer programs; wherein, the processor is connected to the memory, and the one or more computer programs are programmed Stored in the memory, when the electronic device is running, the processor executes one or more computer programs stored in the memory, so that the electronic device executes the method described in Embodiment 1 above.

[0198] It should be understood that in this embodiment, the processor can be a central processing unit CPU, and the processor can also be other general-purpose processors, digital signal processors DSP, application specific integrated circuits ASIC, off-the-shelf programmable gate array FPGA or other programmable logic devices , discrete gate or transistor logic devices, discrete hardware components, etc. A general-purpose processor may be a microprocessor, or the processor may be any conventional processor, o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com