Patents

Literature

243 results about "Grain orientation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The grain orientation of every piece of wood that goes into a real wooden vessel is specifically chosen for the purpose the piece will serve. Wood is stronger in its vertical grain direction than the horizontal or face grain direction, as anybody who's ever played baseball knows.

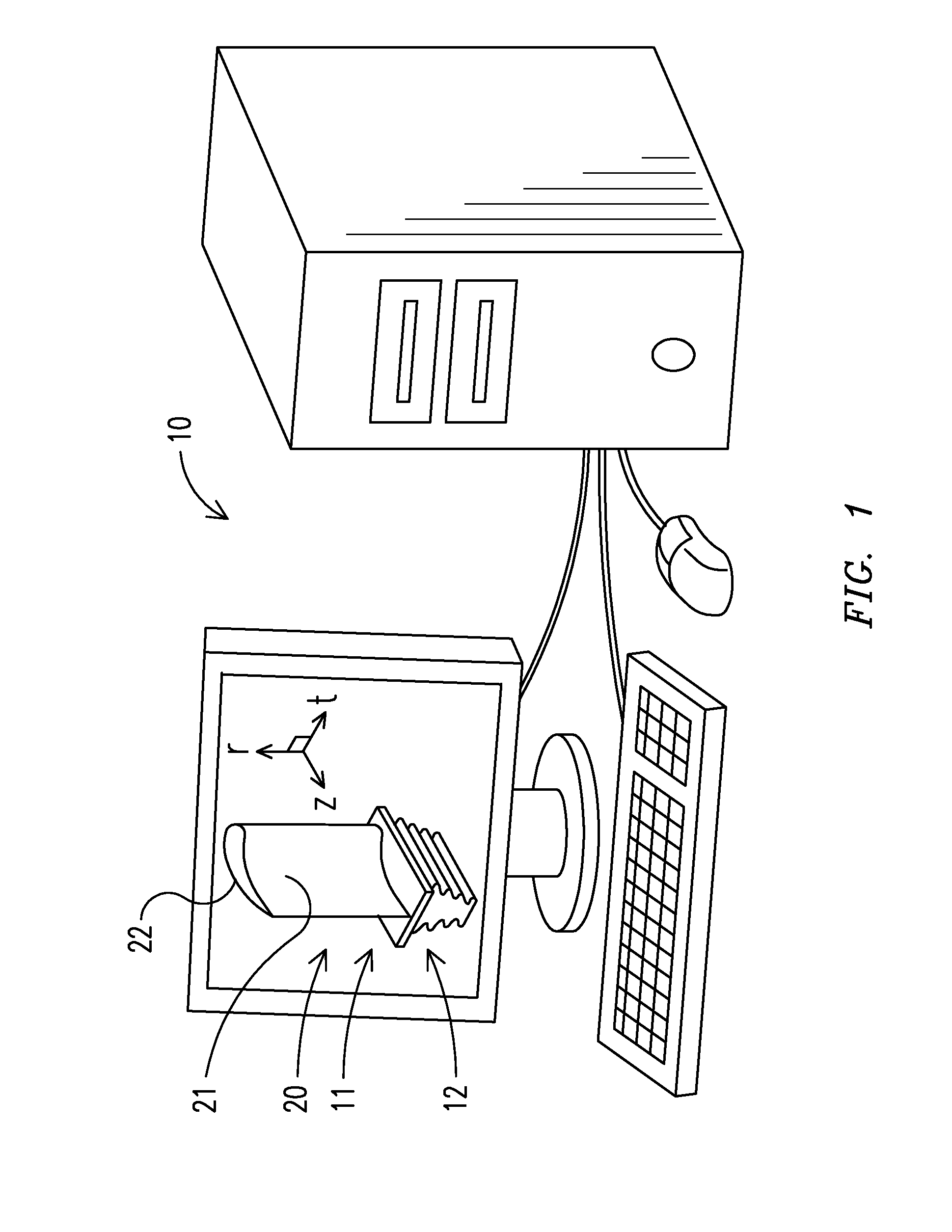

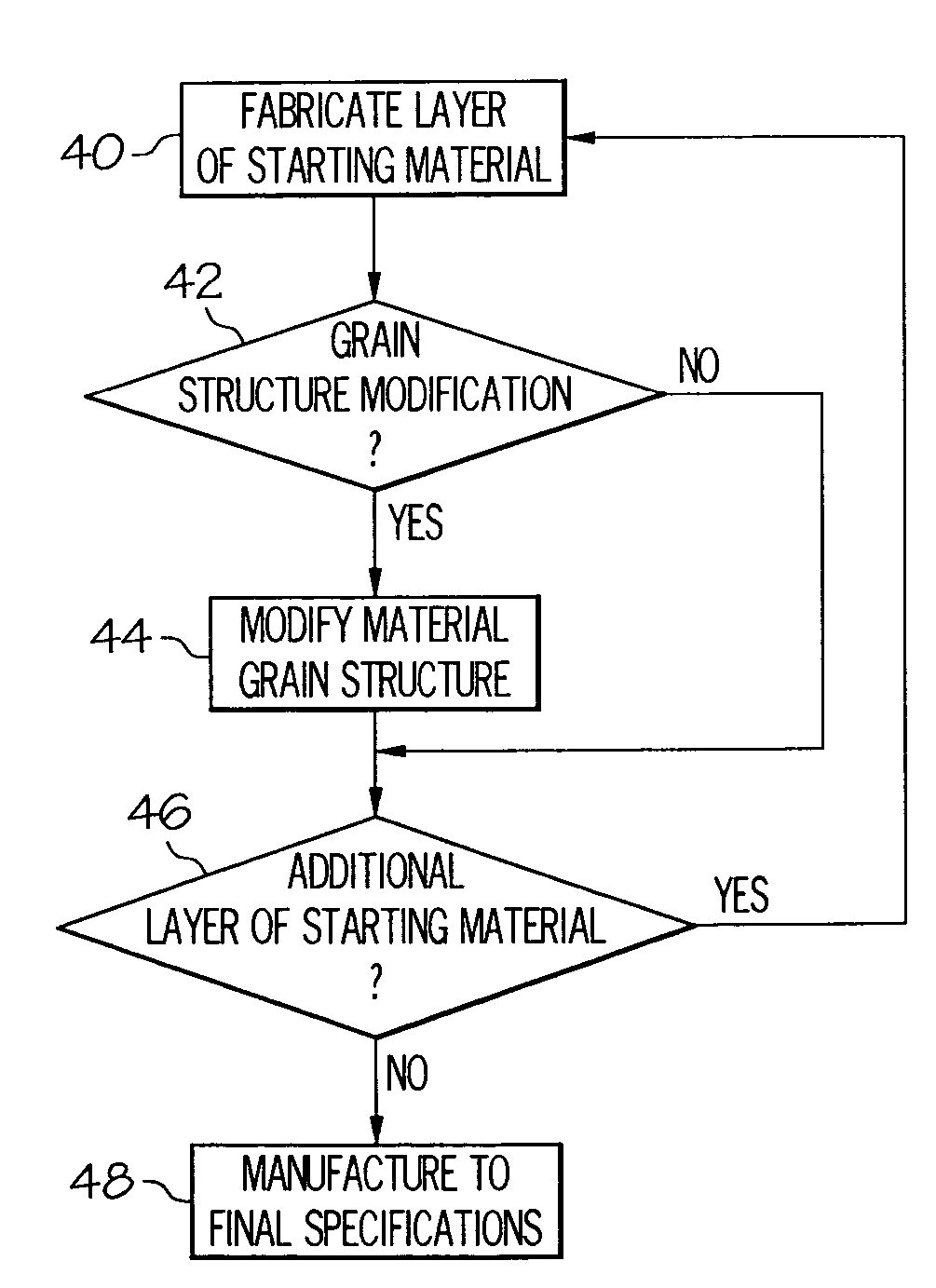

Method and apparatus for predicting the failure of a component

ActiveUS7016825B1Plug gaugesComputation using non-contact making devicesProbit modelComputer science

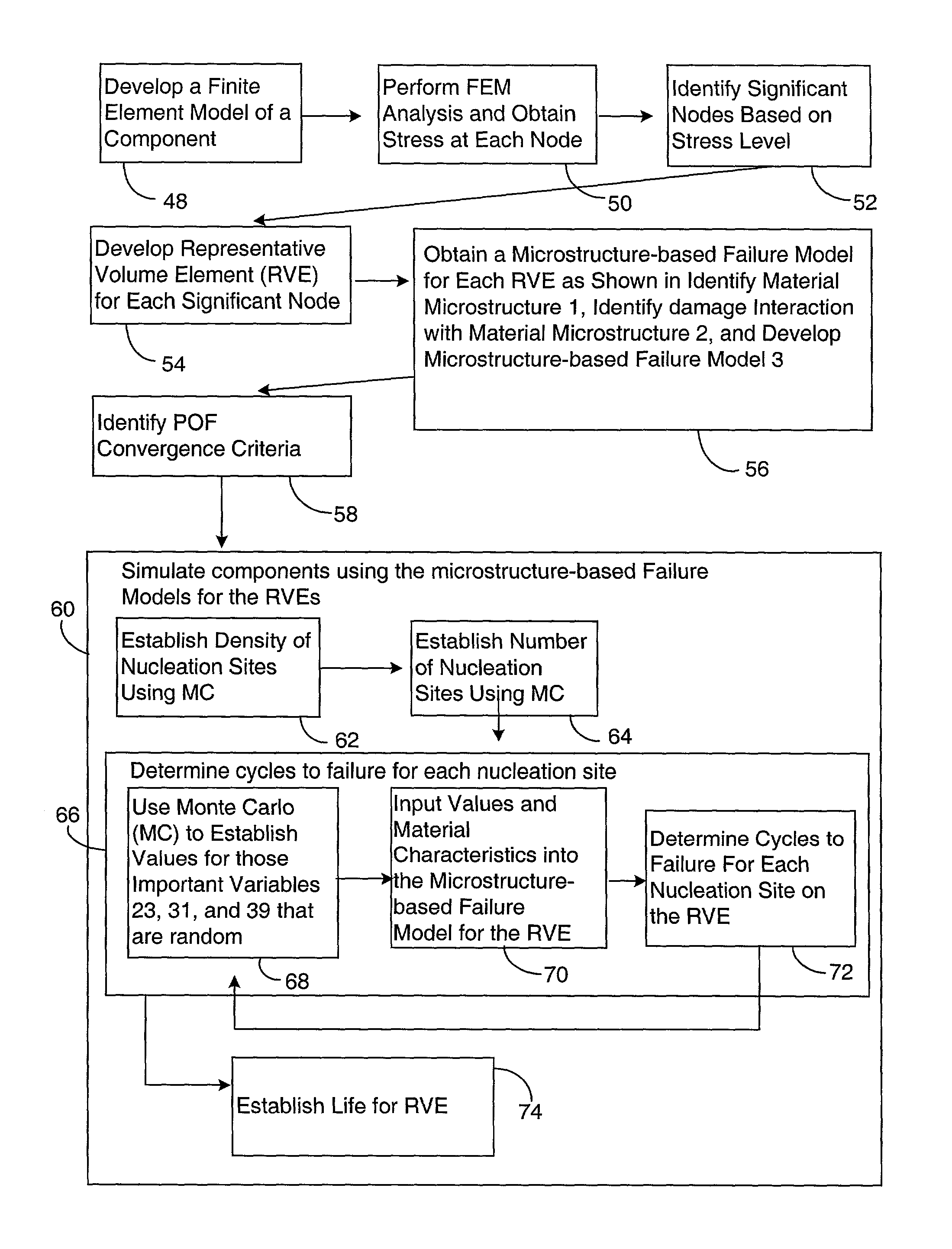

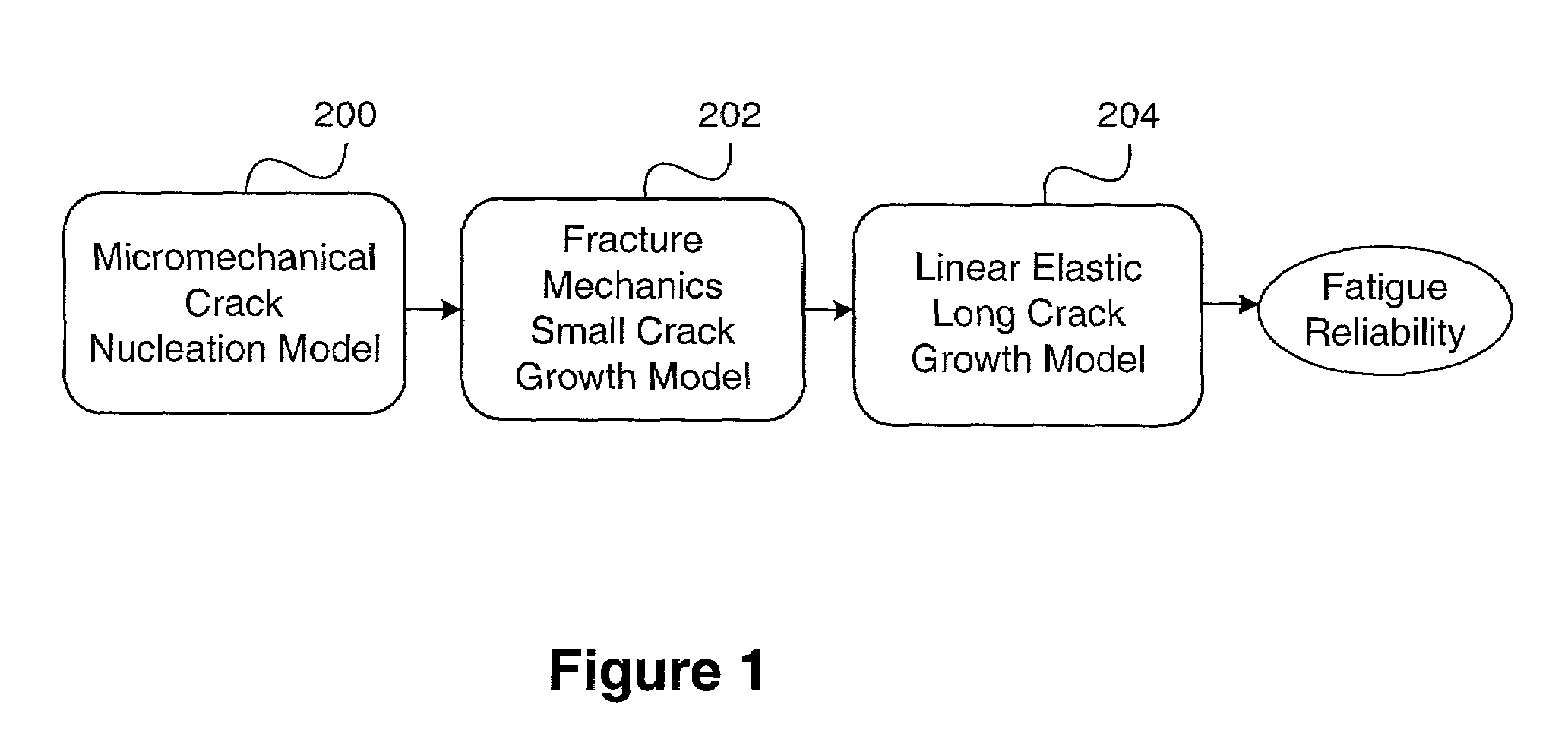

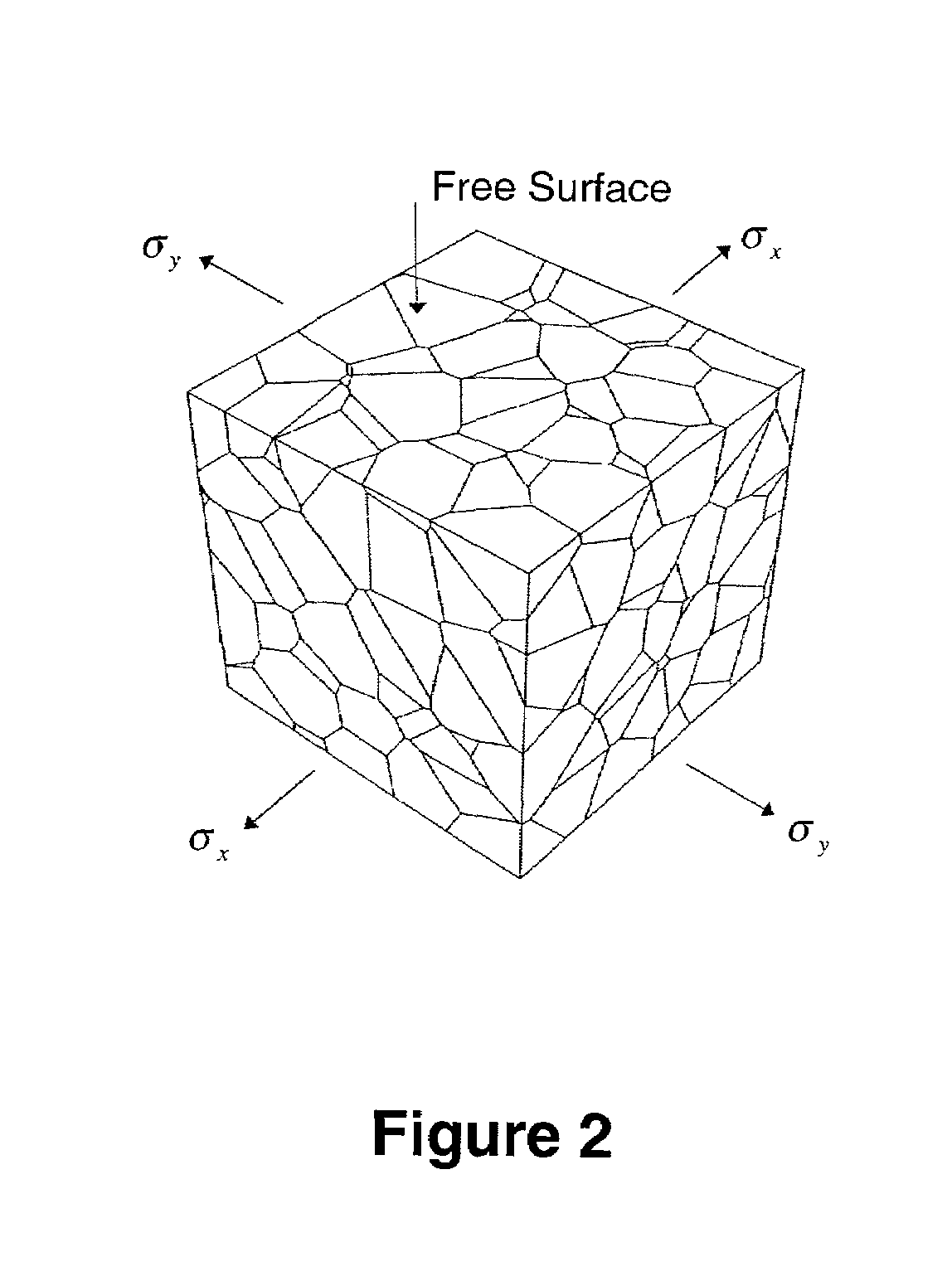

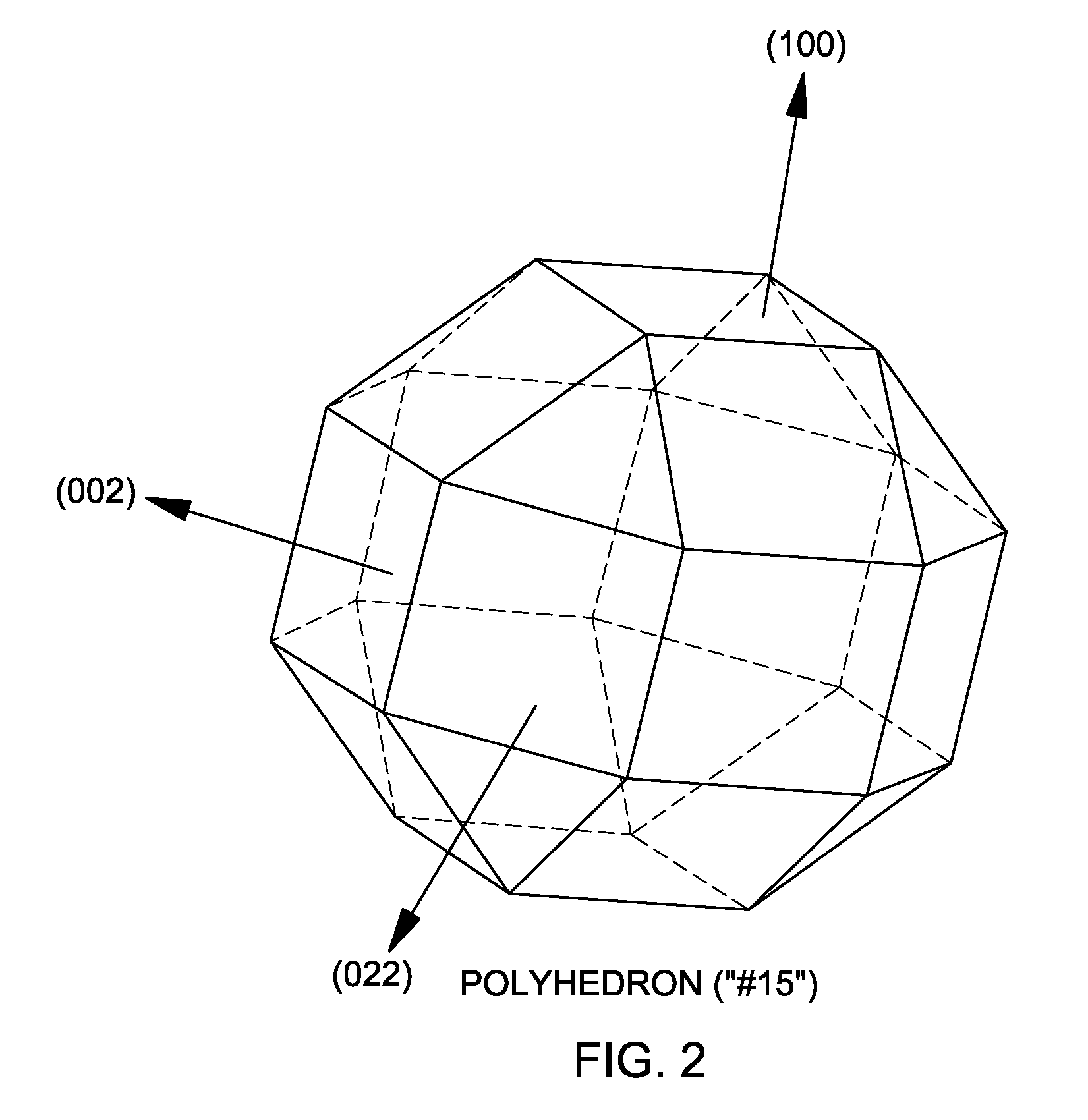

The invention provides a method and apparatus for predicting the failure of a component using a probabilistic model of a material's microstructural-based response to fatigue. The method predicts the component failure by a computer simulation of multiple incarnations of real material behavior, or virtual prototyping. The virtual prototyping simulates the effects of characteristics that include grain size, grain orientation, micro-applied stress and micro-yield strength that are difficult to simulate with real specimens. The invention provides an apparatus for predicting the response of a component to fatigue using the method.

Owner:VEXTEC CORP

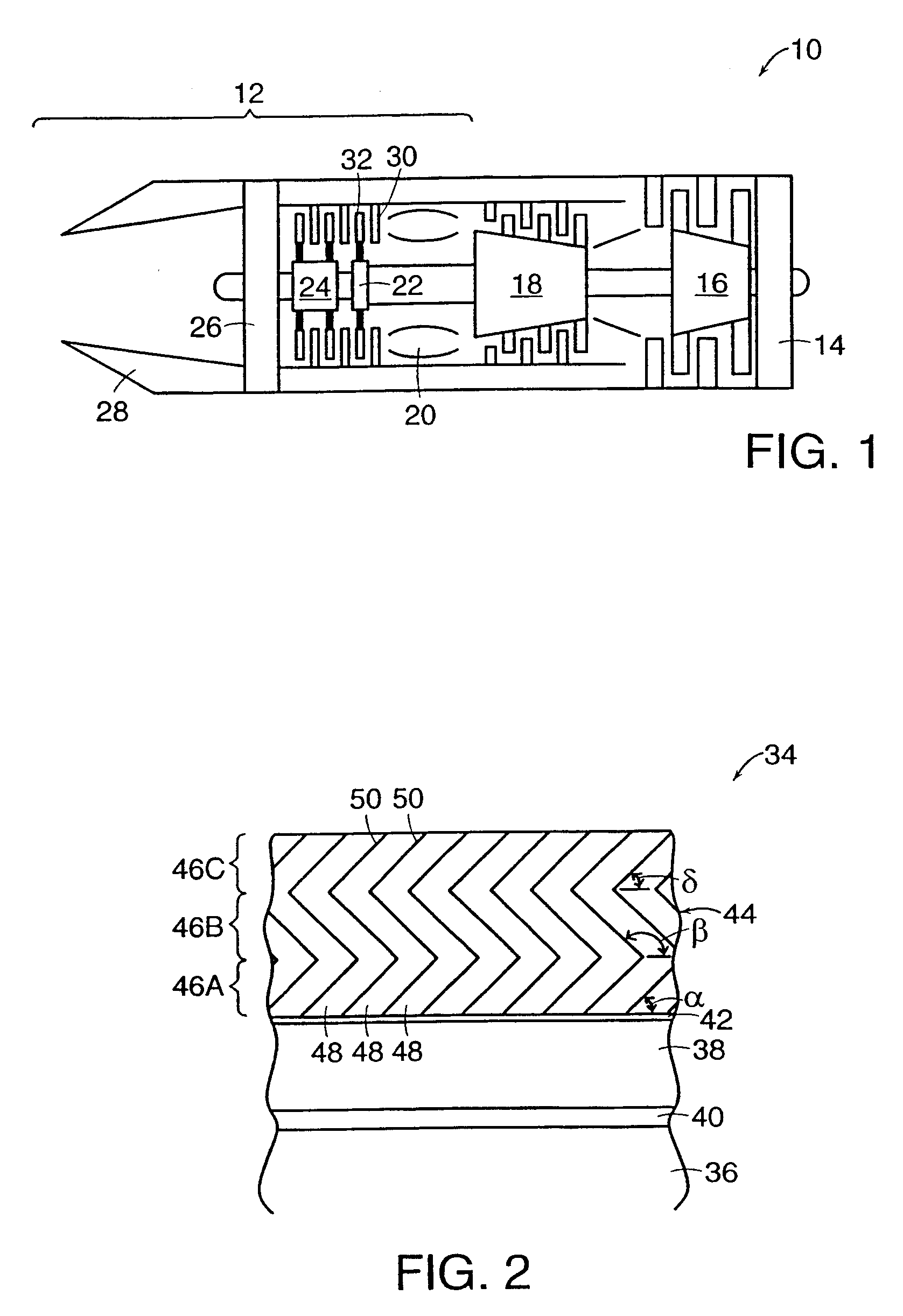

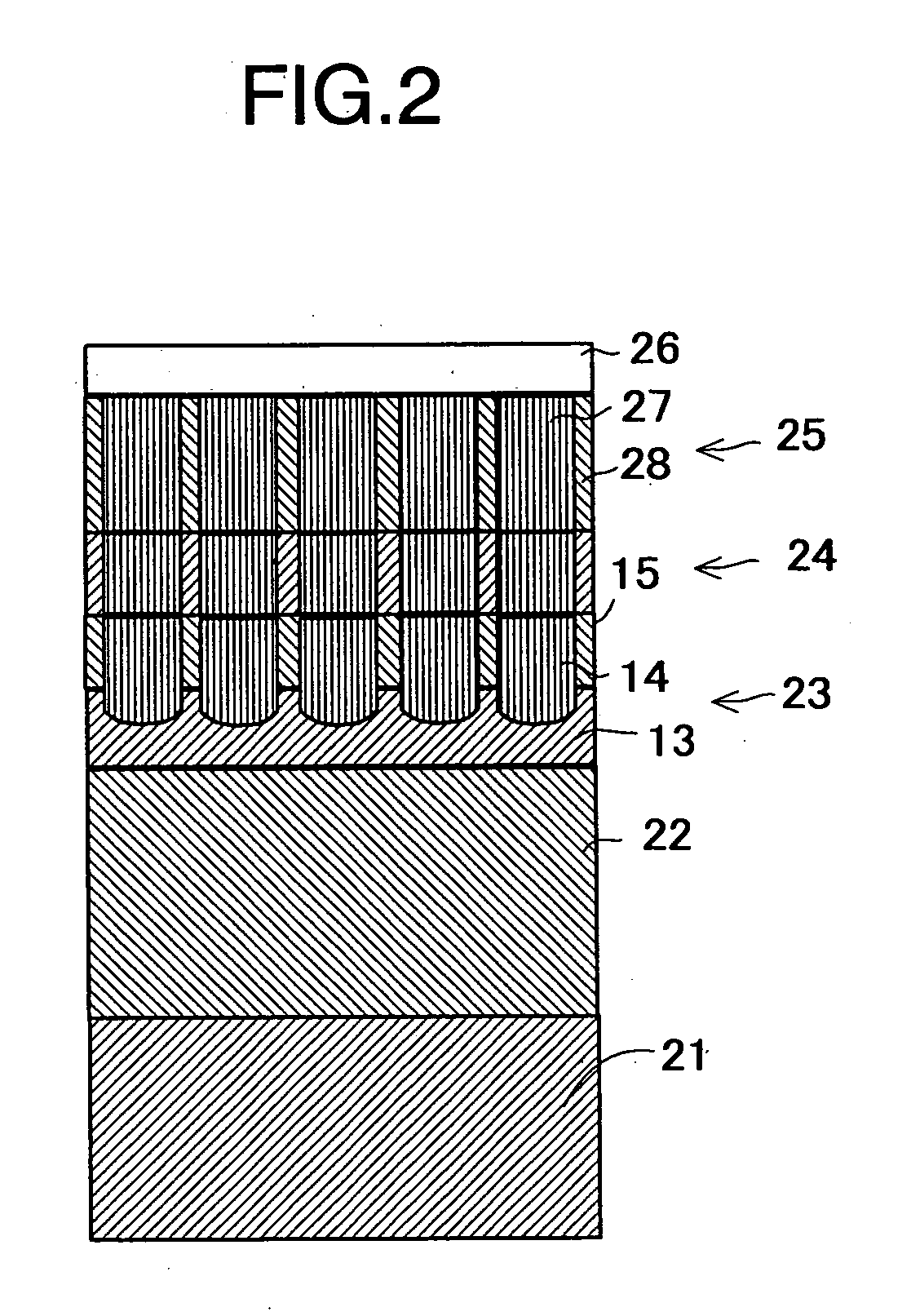

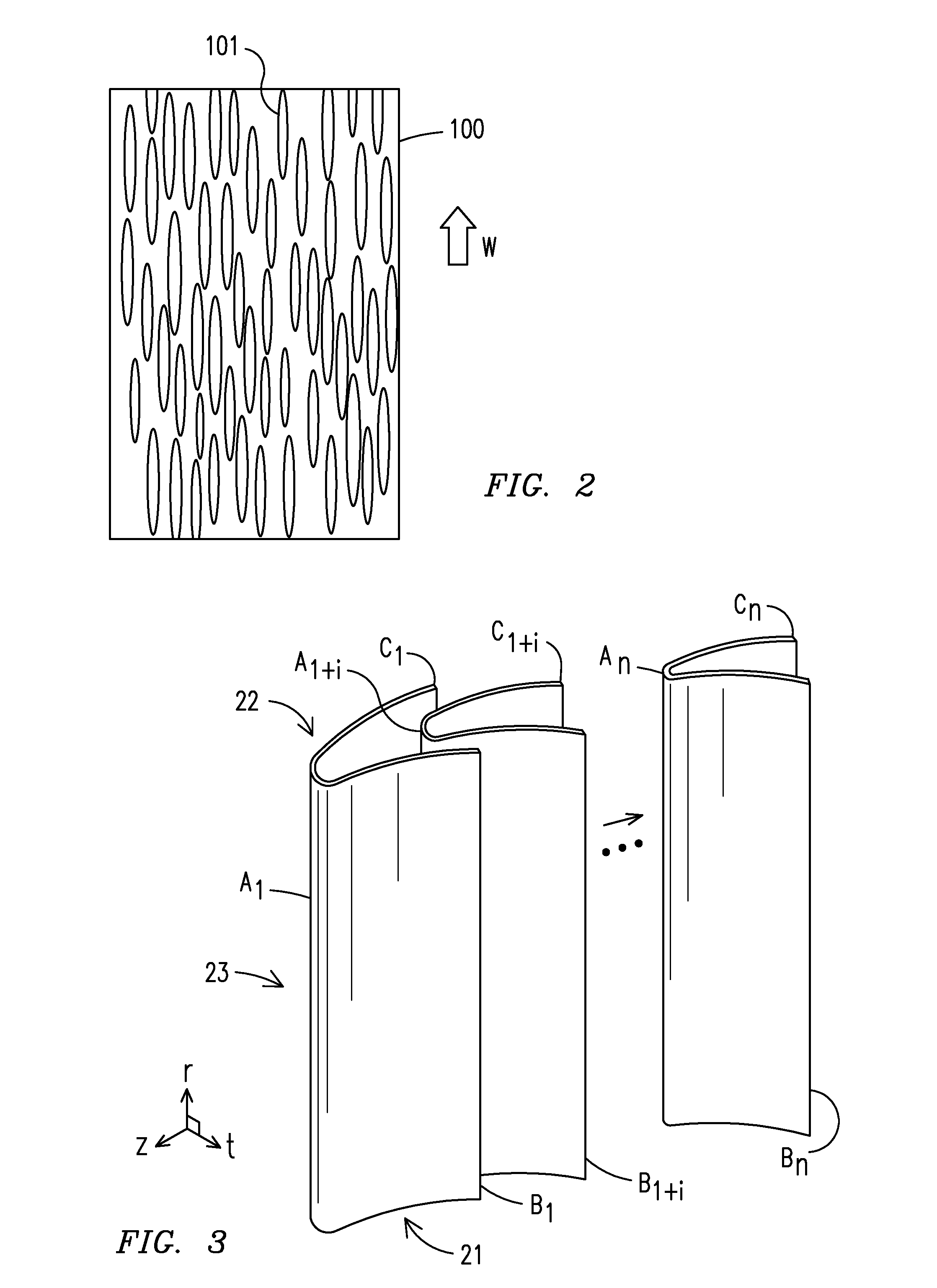

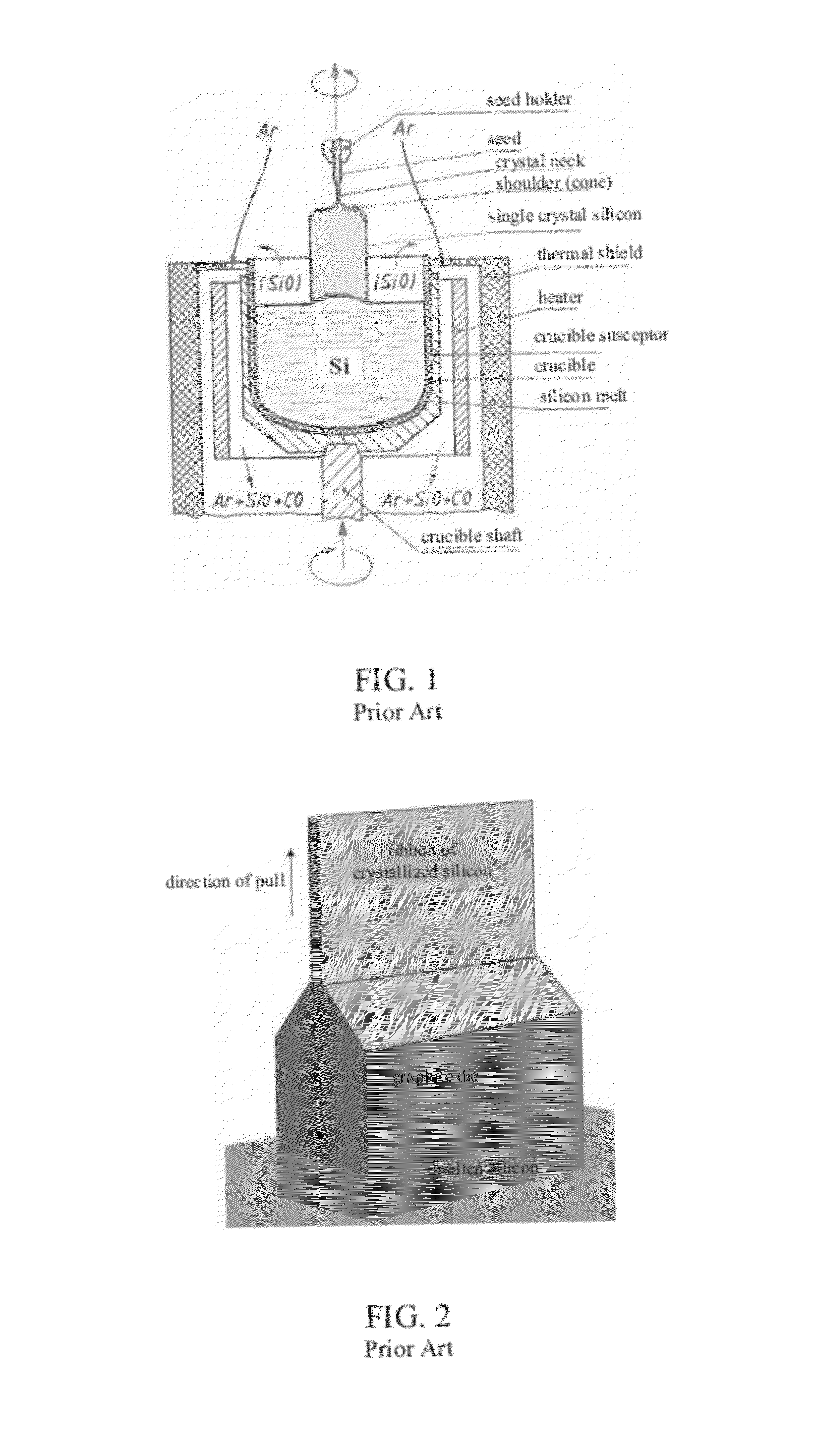

Thermal barrier coating ceramic structure

InactiveUS6455173B1PropellersSurface reaction electrolytic coatingElectron beam physical vapor depositionVapor cloud

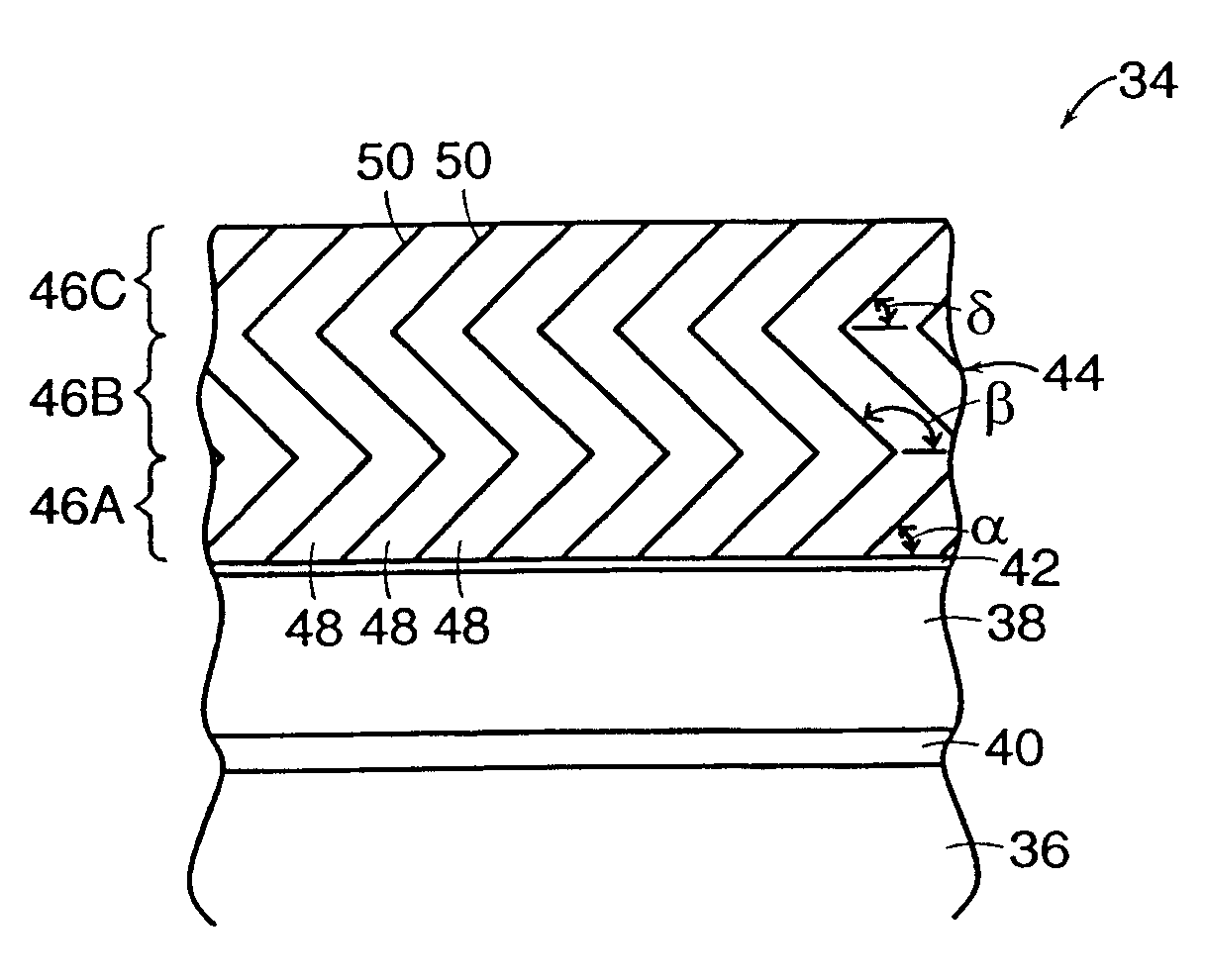

A multilayered ceramic topcoat of a thermal barrier coating system is useful for high temperature corrosive applications such as hot section components in gas turbine engines. The ceramic topcoat includes at least two layers, each having generally columnar grain microstructures with different grain orientation directions. A preferred method of producing the multilayered ceramic topcoat includes positioning a superalloy substrate at a first angled orientation relative to a ceramic vapor cloud in an electron beam physical vapor deposition apparatus for a time sufficient to grow a first ceramic layer. The substrate is then reoriented to a second, different angled orientation for a time sufficient to grow a second ceramic layer. The ceramic layers exhibit columnar microstructures having respective grain orientation directions which are related to the first and second substrate orientations. For uniformly coating a complex contoured surface such as a turbine blade airfoil, the blade can be rotated during coating deposition at each angled orientation. Alternatively, the article may be continuously reoriented according to a predetermined speed cycle to produce generally arcuate, sinusoidal, helical, or other columnar grain microstructures.

Owner:MARIJNISSEN GILLION HERMAN +4

Granular thin film, perpendicular magnetic recording medium employing granular thin film and magnetic recording apparatus

InactiveUS20050214520A1Good crystalline orientationSmall granularityNanomagnetismBase layers for recording layersLow noiseVolumetric Mass Density

A perpendicular magnetic recording medium suitable for attaining a low noise high magnetic recording density is obtained. The medium has a small average magnetic grain diameter, a small magnetic grain diameter distribution, a high perpendicular crystallographic magnetic grain orientation and a high regularity magnetic grain arrangement. The perpendicular magnetic recording medium comprises a soft magnetic layer, a granular under-layer and a perpendicular magnetic recording layer on a substrate. The granular under-layer is formed on a metal under-layer. The metal grains in the granular layer are separated by nonmagnetic inter-grain material and are partially penetrated into the metal under-layer. The perpendicular magnetic recording layer is formed on the granular layer. Then a perpendicular magnetic recording medium shows high signal to noise ratio and excellent high-density recording characteristics.

Owner:KK TOSHIBA

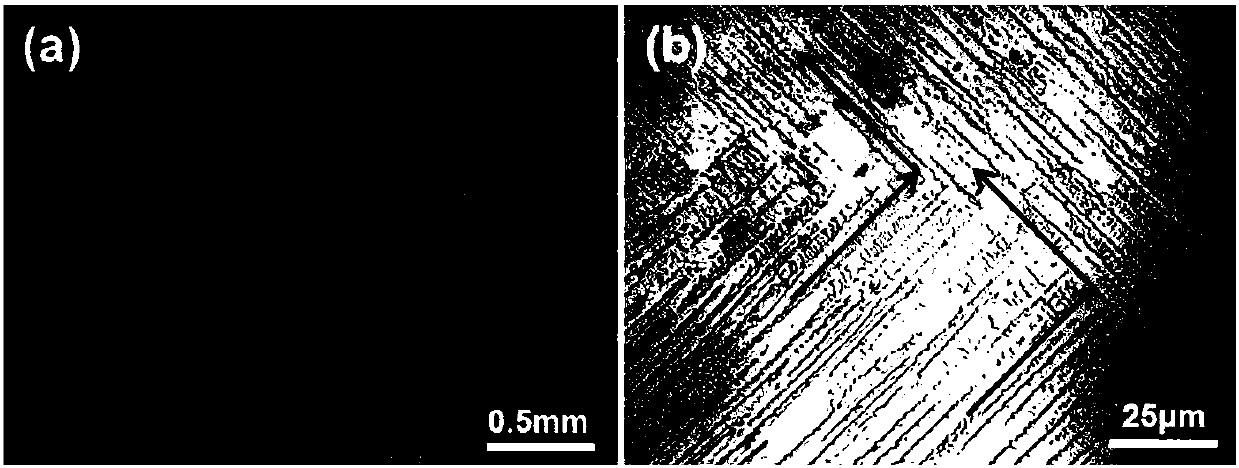

Quasi-continuous laser metal 3D printing method capable of realizing regulation of nickel base alloy crystallographic texture

ActiveCN107790717AImprove consistencyImprove microstructureAdditive manufacturing apparatusIncreasing energy efficiencyMolten bathMatch rule

The invention discloses a quasi-continuous laser metal 3D printing method capable of realizing regulation of nickel base alloy crystallographic texture. Laser output is set as a quasi-continuous lasermode, and then a laser metal 3D printing technical window is preliminarily optimized. The temperature field of a molten bath under the preliminarily optimized parameter is calculated by using a finite element heat transfer model; the temperature gradient G and the cooling rate xi of the moving boundary of the molten bath during closing of laser in a single pulse period are extracted, and the growth length L of a single pulse internal columnar dendrite is worked out according to a structure growth theoretical model; the laser parameter is optimized according to the matching rule that the ratioof the scanning speed V to pulse frequency f is 0.5-0.8L, and finally 3D printing forming is conducted according to the optimized parameter, so that a formed part with the consistent crystallographicorientation height is obtained. By regulating the heat source output mode, an effective remelting mechanism for mixed crystal or isometric crystal is introduced in the scanning direction, all columnar dendrite growth is obtained, and the consistency of grain orientation is remarkably improved.

Owner:HUNAN UNIV

Production method of oriented high-silicon-steel thin plates

The invention relates to a production method of oriented high-silicon steel thin plates, which belongs to the technical field of metal material production. The process comprises the following steps of: 1. obtaining cylindrical crystals grown in (100) directions by adopting a directional solidification method, and wherein the solidification rate is controlled between 0.6 and 15 mm / min and the temperature gradient is controlled between 60 and 400K / cm; 2. heating plate blanks at the heating temperature between 800 DEG C and 1300 DEG C, and then hot rolling the plate blanks to obtain sheet steel of 1.0-4.0mm; 3. carrying out annealing heat treatment and acid washing on the hot rolled plate blanks, and warm rolling the hot rolled plate blanks to obtain 0.4-0.8mm; and 4. carrying out heat treatment on warm rolled plates, and carrying out multiple cold rolling and secondary recrystallization annealing to obtain the oriented high-silicon steel. The production method has the advantages that the directional solidification method is utilized for controlling organization and crystal grain orientation from the material production source, a cold rolling method is used for producing alloy oriented plate materials, and the soft magnetic performance of the high-silicon steel is greatly improved. Produced cold rolled thin plates have good plate shapes.

Owner:UNIV OF SCI & TECH BEIJING

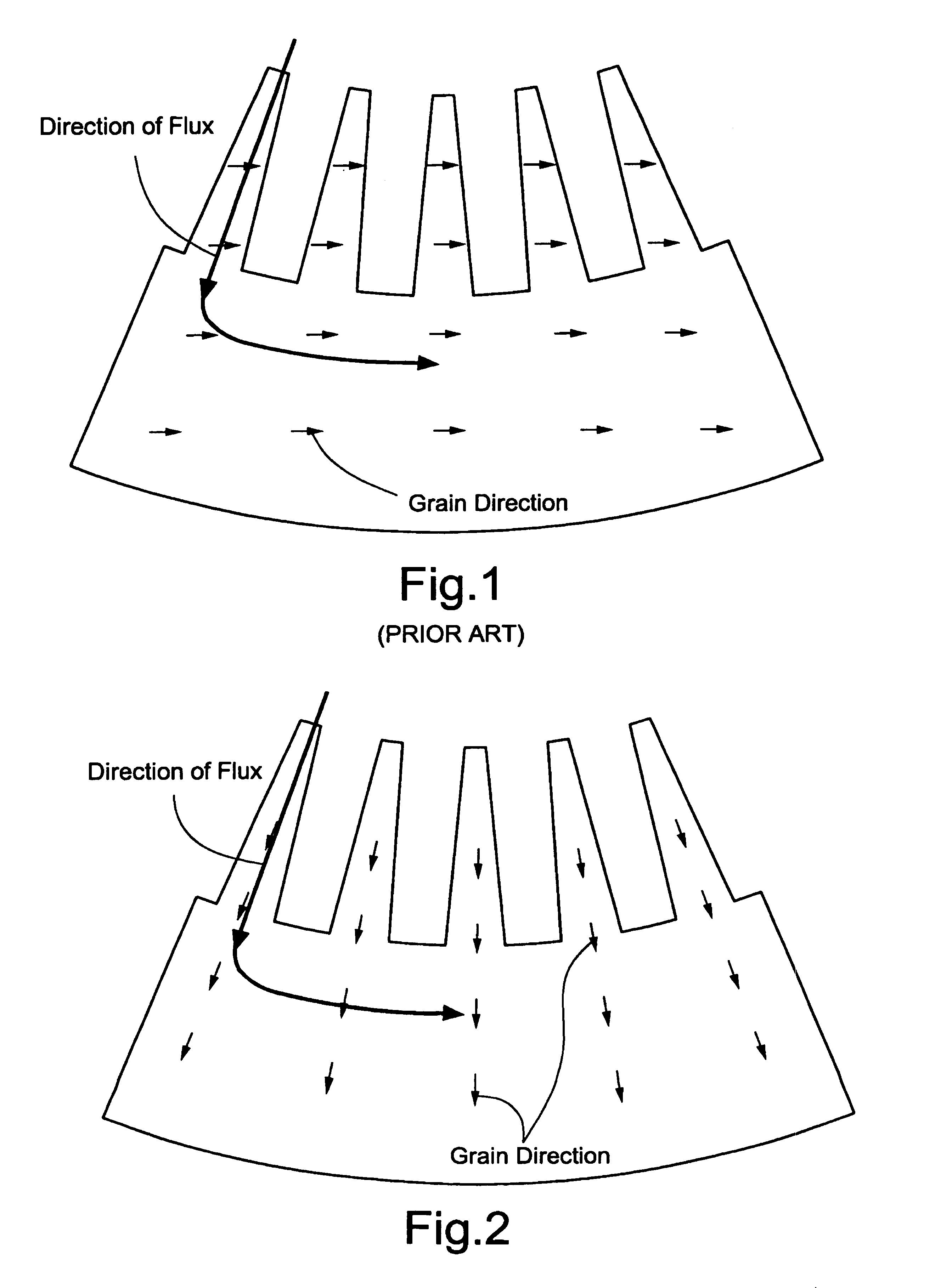

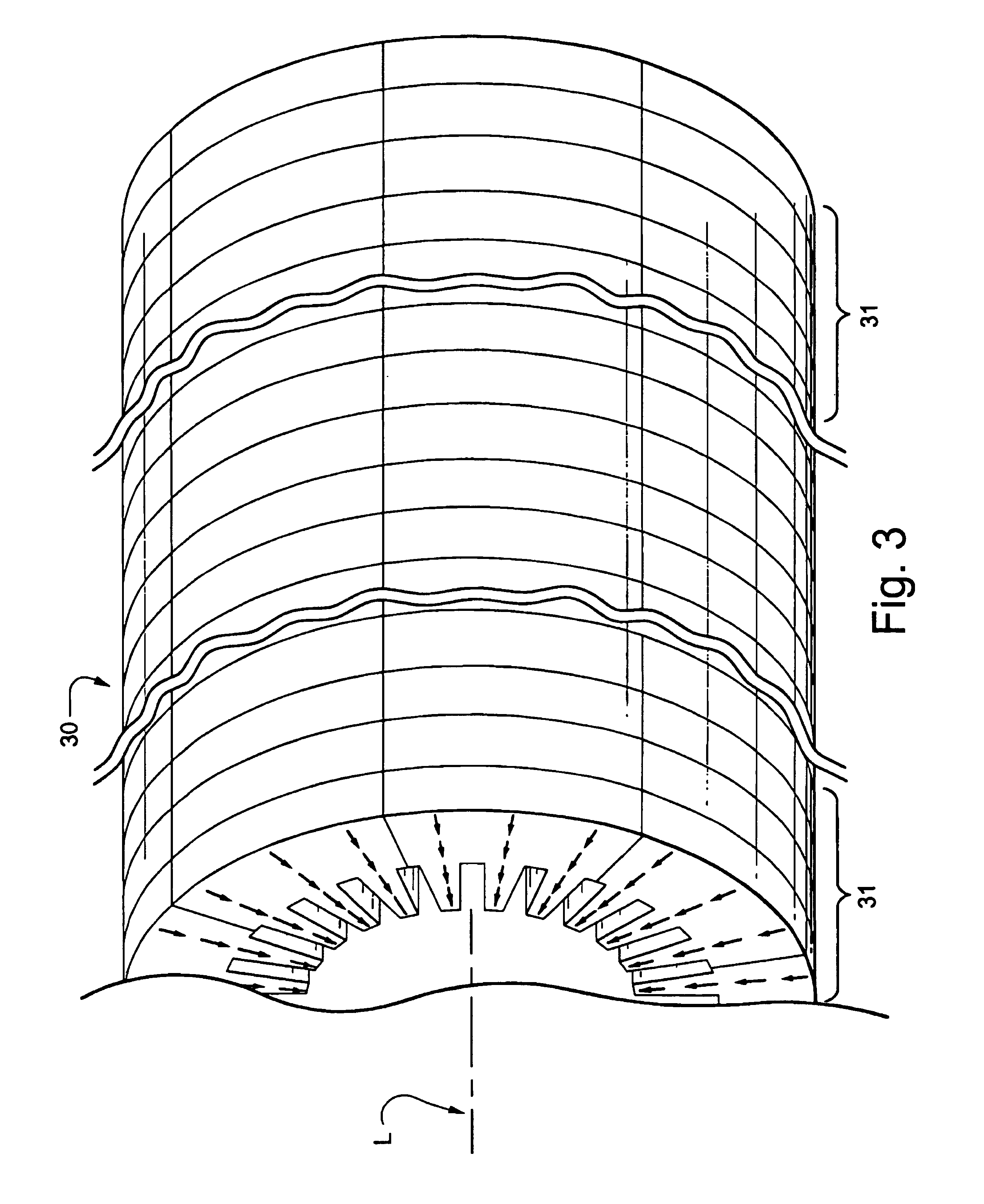

Silicon steel punching orientation modifications to lower eddy current losses at the stator core end of dynamoelectric machines

InactiveUS7057324B2High saturationLower saturation levelMagnetic circuit stationary partsMagnetic circuit characterised by magnetic materialsEddy currentMagnetic flux

The invention involves orienting the metal laminations that form a stator core end in such a way so as to reduce eddy current losses in the finger portions of the metal laminations. The metal laminations are positioned so that the grain orientation is parallel to the magnetic flux lines generated in the finger portions.

Owner:GENERAL ELECTRIC CO

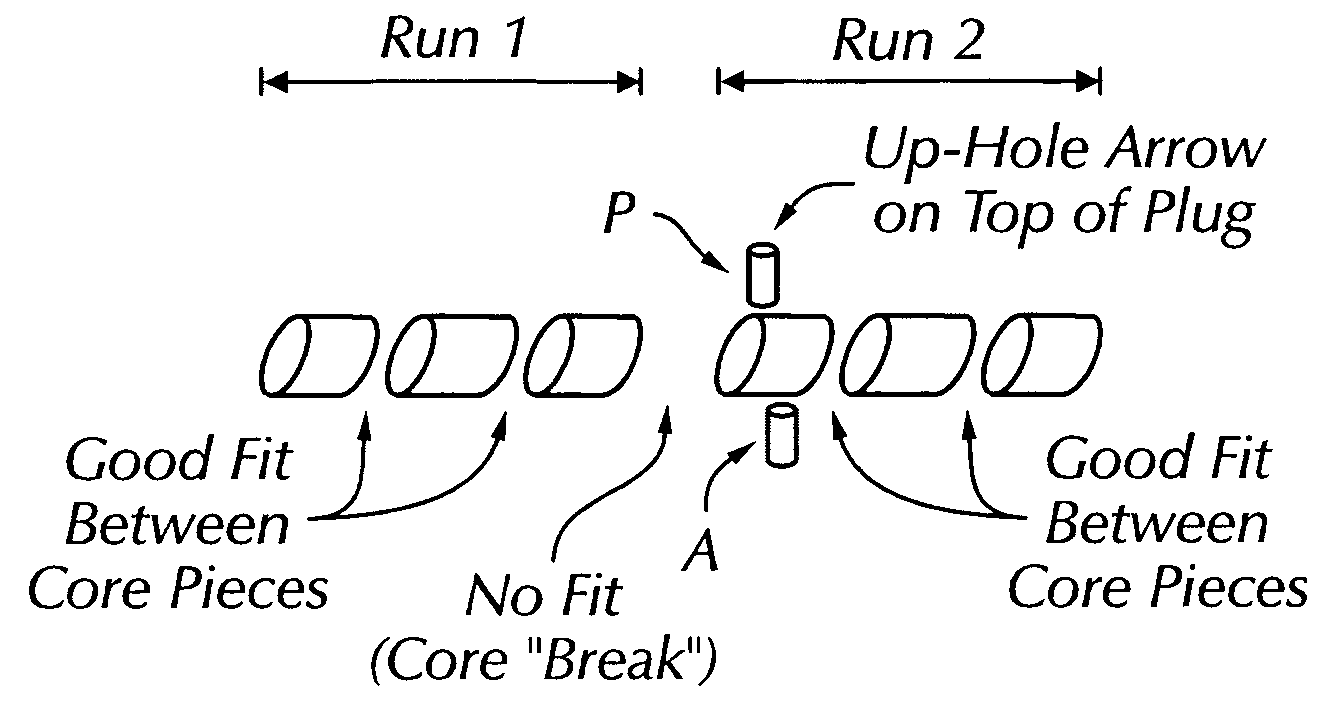

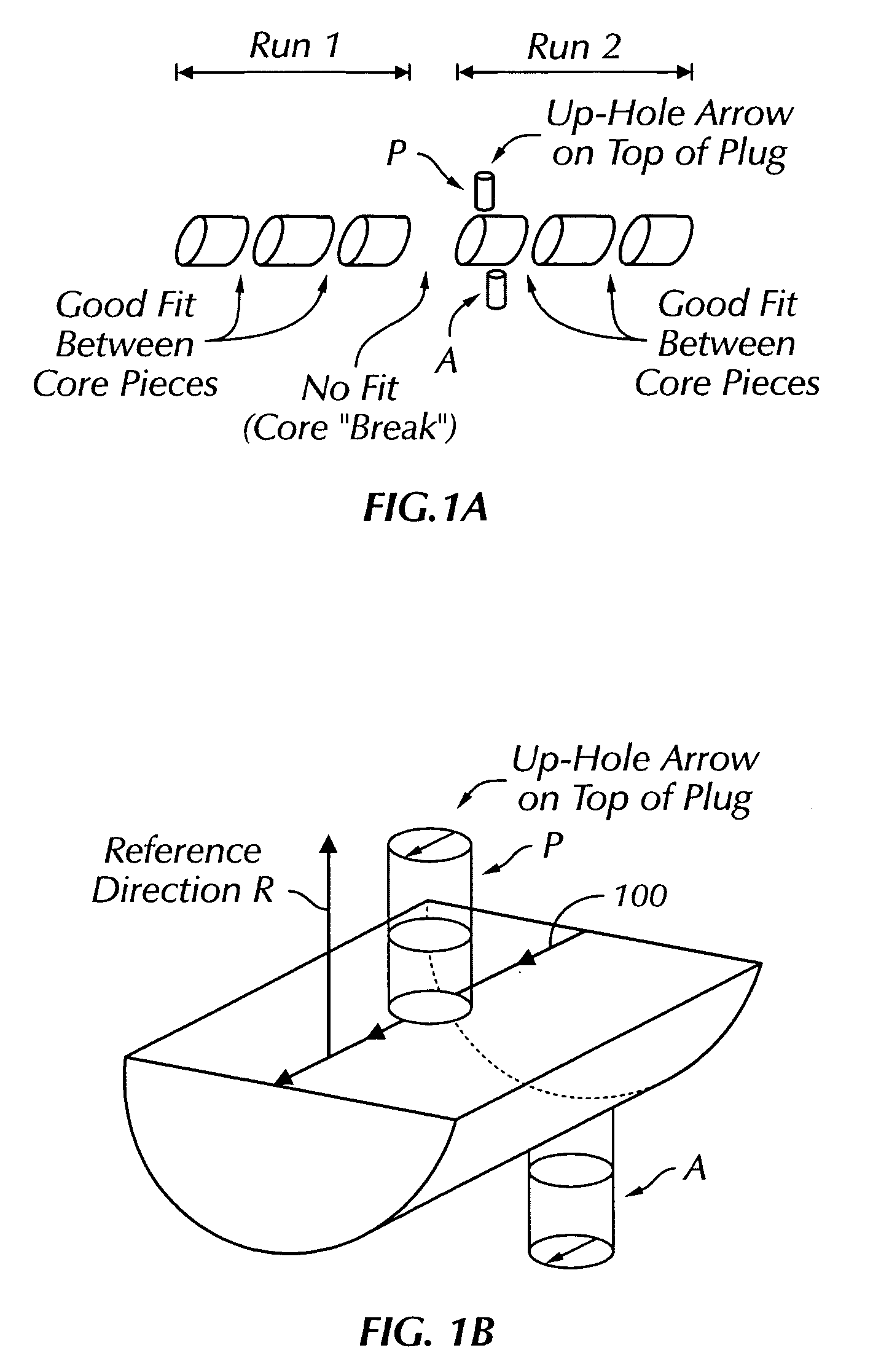

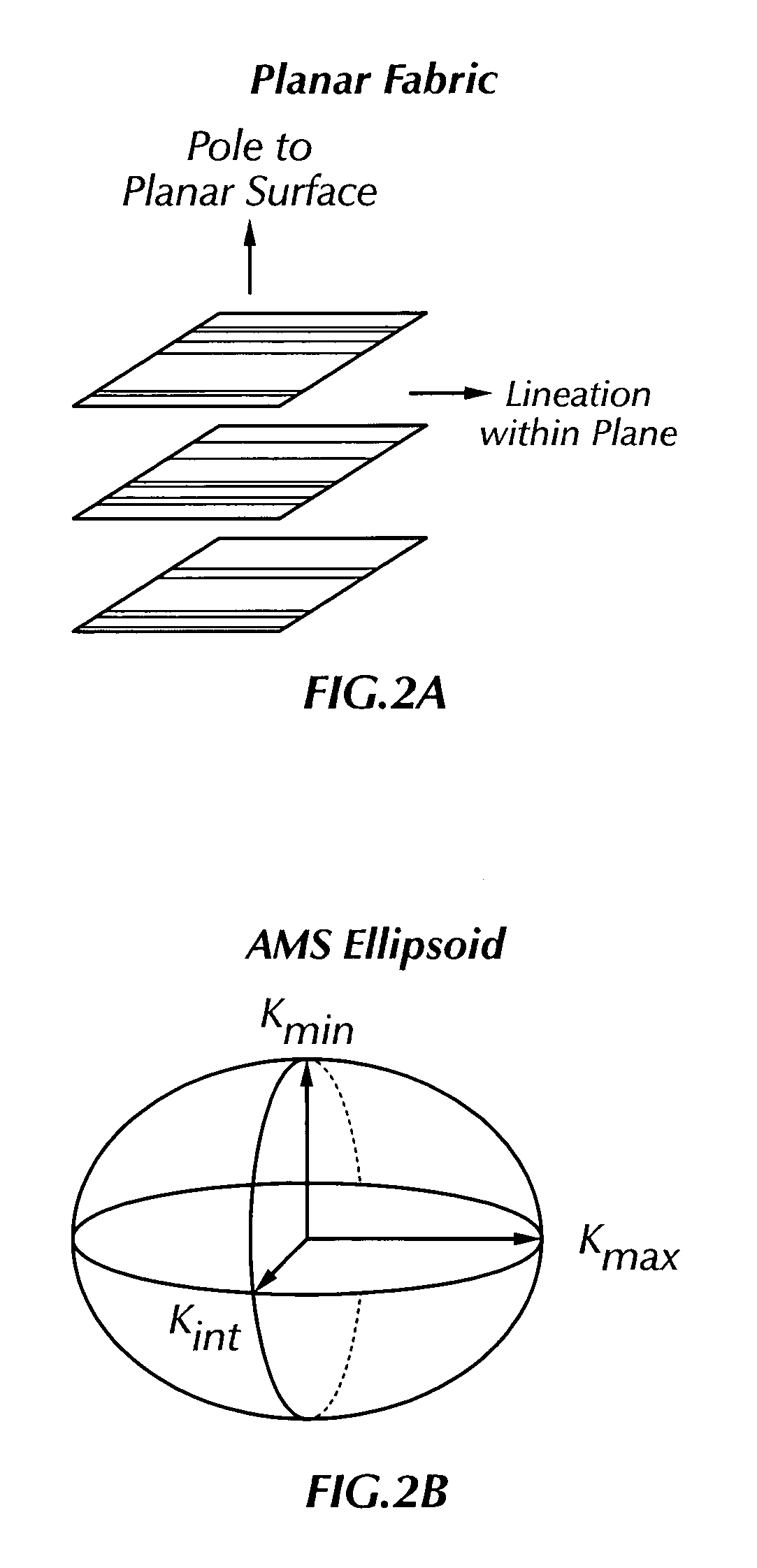

Method to characterize microfractured hydrocarbon reservoirs by artificially induced anisotropy of magnetic susceptibility

ActiveUS7126340B1Increase magnetic susceptibilityElectric/magnetic detectionAcoustic wave reradiationMagnetic susceptibilityPorosity

Subterranean hydrocarbon reservoirs are analyzed by characterizing the relative presence and character of microfractures in rock samples from the reservoirs. Core samples are saturated with a suspension of magnetite particles of known concentration. The samples are then subjected to an applied magnetic field of known strength. The anisotropy of magnetic susceptibility, or AMS, of the samples is then observed, providing a measure of grain orientation in the samples. The characteristics of the microfractures in the samples are thus available to characterize the reservoirs, and in particular the contribution of the microfractures to the porosity and permeability of formations in the reservoirs.

Owner:SAUDI ARABIAN OIL CO

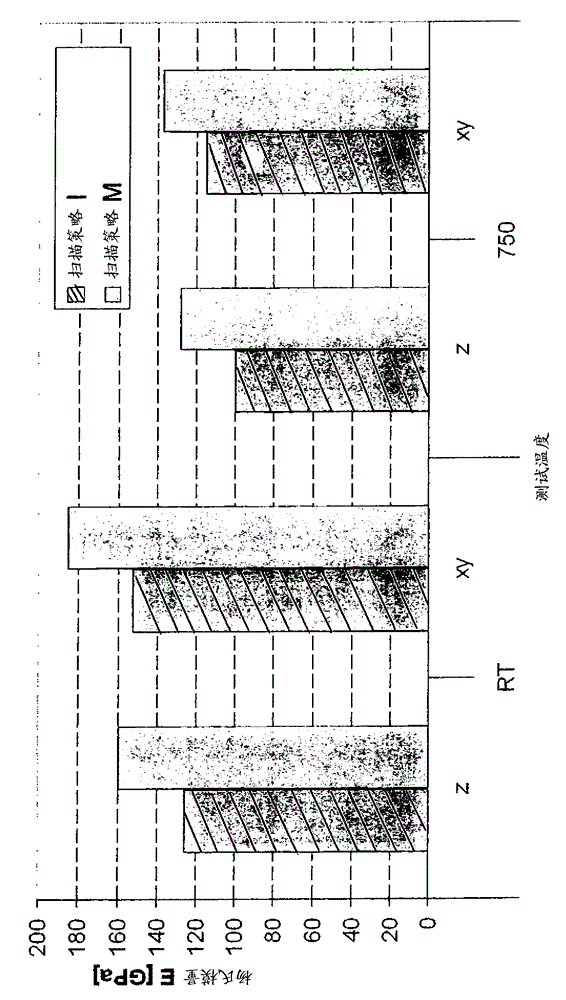

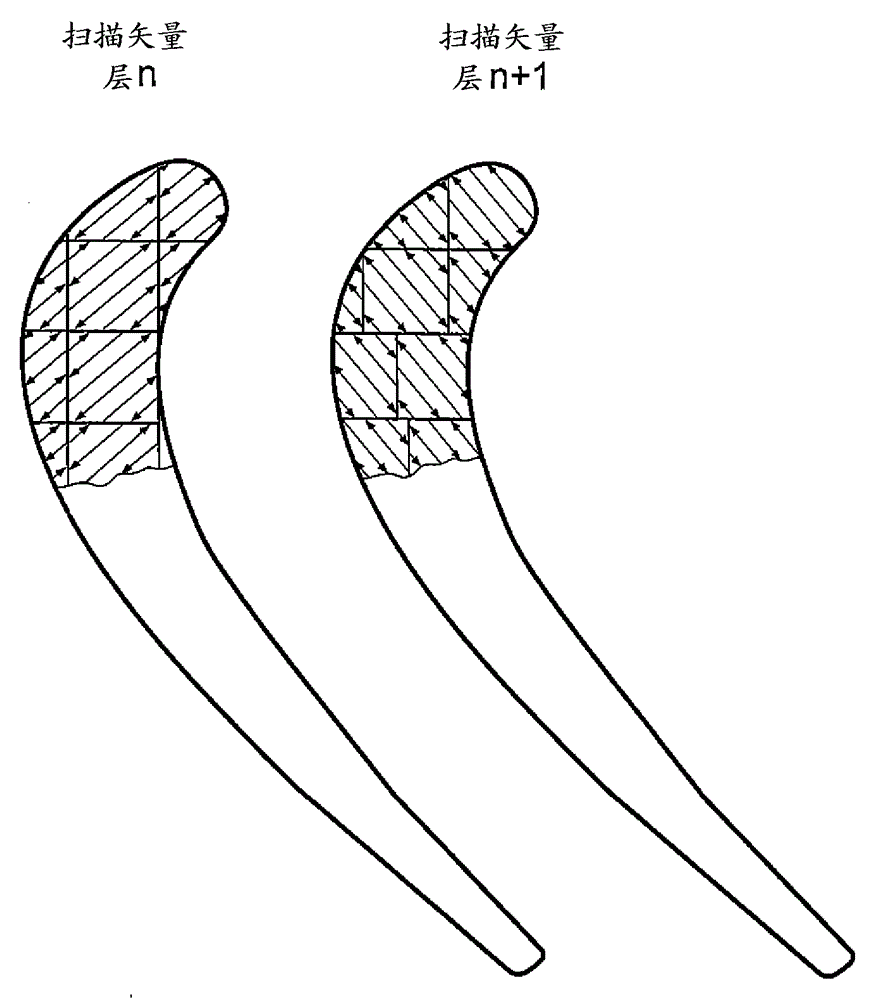

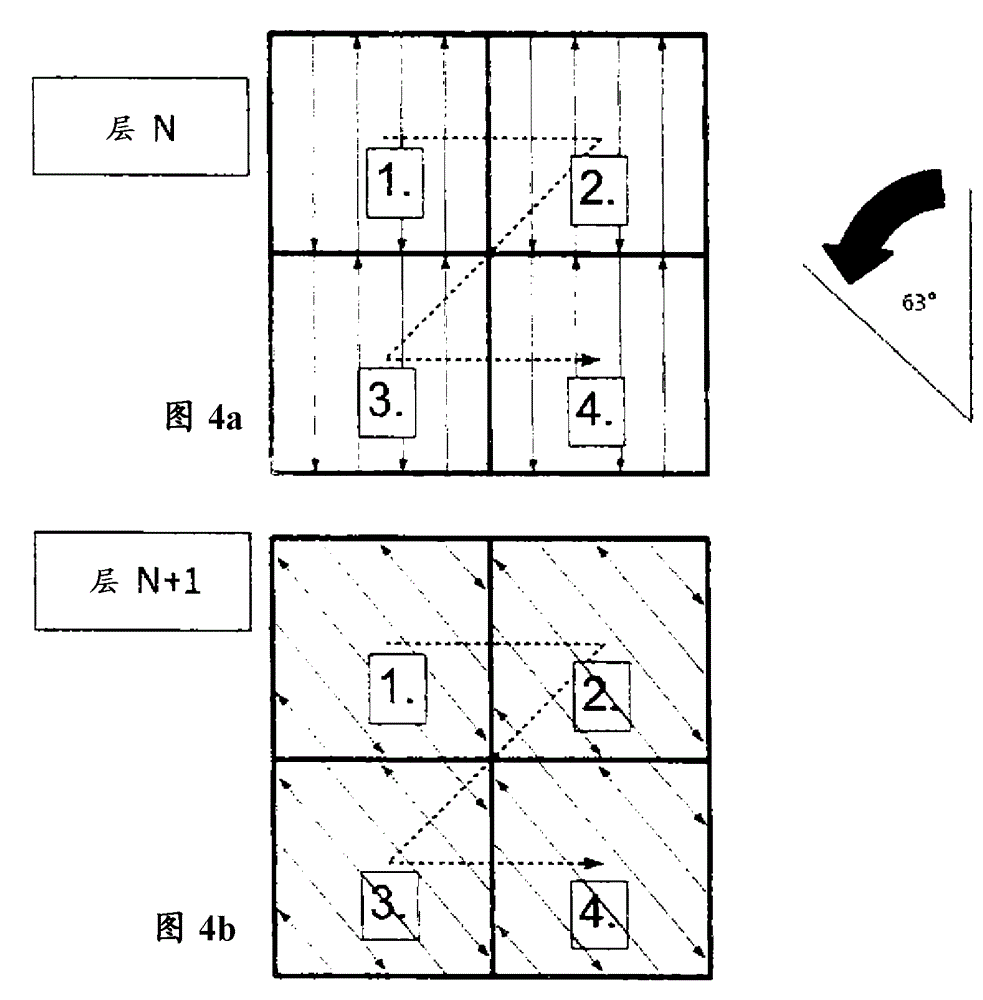

Method for manufacturing a hybrid component

The invention refers to a method for manufacturing a hybrid component (11) comprising the steps of a) manufacturing a preform (2) as a first part of the hybrid component (11), then b) successively building up on that preform (2) a second part of the component (11) from a metallic powder material (12) by means of an additive manufacturing process by scanning with an energy beam (14), thereby c) establishing a controlled grain orientation in primary and in secondary direction of at least a part of the second part of the component (11), d) wherein the controlled secondary grain orientation is realized by applying a specific scanning pattern of the energy beam (14), which is aligned to the cross section profile of said component (11) or to the local load conditions for said component (11).

Owner:ANSALDO ENERGIA IP UK LTD

Manufacturing method of ceramic mold of monocrystal turbine blade

ActiveCN103464690AImprove heat transfer performanceSolve complex and uncontrollable heat transfer problemsFoundry mouldsCeramic shaping apparatusLeading edgeTurbine blade

The invention discloses a manufacturing method of a ceramic mold of a monocrystal turbine blade. The integral ceramic mold with a special spiral crystal selector is designed and manufactured according to grain orientation requirements of the monocrystal turbine blade. When orientated solidification is used for manufacturing the monocrystal blade, the thickness of a shell at an abrupt change in a section (such as a connecting part between a blade body and a marginal plate) is increased, and the heat transfer capacity is reduced, so that crystal defects such as stray crystals are caused easily. On the premise that the casting strength requirements are met, with the adoption of topological optimization and design of a heat transfer passage, the heat transfer capacity of the mold is improved, and a temperature gradient on the leading edge of a solid-liquid interface during the orientated solidification is increased, so that the whole blade can obtain a good monocrystal organization.

Owner:XI AN JIAOTONG UNIV +1

Process for Manufacturing a Component

A method of manufacturing a component, including providing a three-dimensional computer model of the component to be produced; deconstructing the three-dimensional computer model by defining a plurality of model slices; forming a plurality of metallic foils, where each foil corresponds to a specific model slice; assembling the plurality of formed foils in a tool to form a three-dimensional component stack; and bonding the three-dimensional component stack to form the component. Characteristics of the foils may differ in various portions of the stack, such as being a different material, having a different thickness, or having a different grain orientation. The control of dimensional tolerances of internal structures, such as cooling passages, in three dimensions is devolved into two separate steps of 1) selecting a thickness of each slice / foil, and 2) controlling in two dimensions a material removal process applied to the respective foil.

Owner:MIKRO SYSYTEMS INC +1

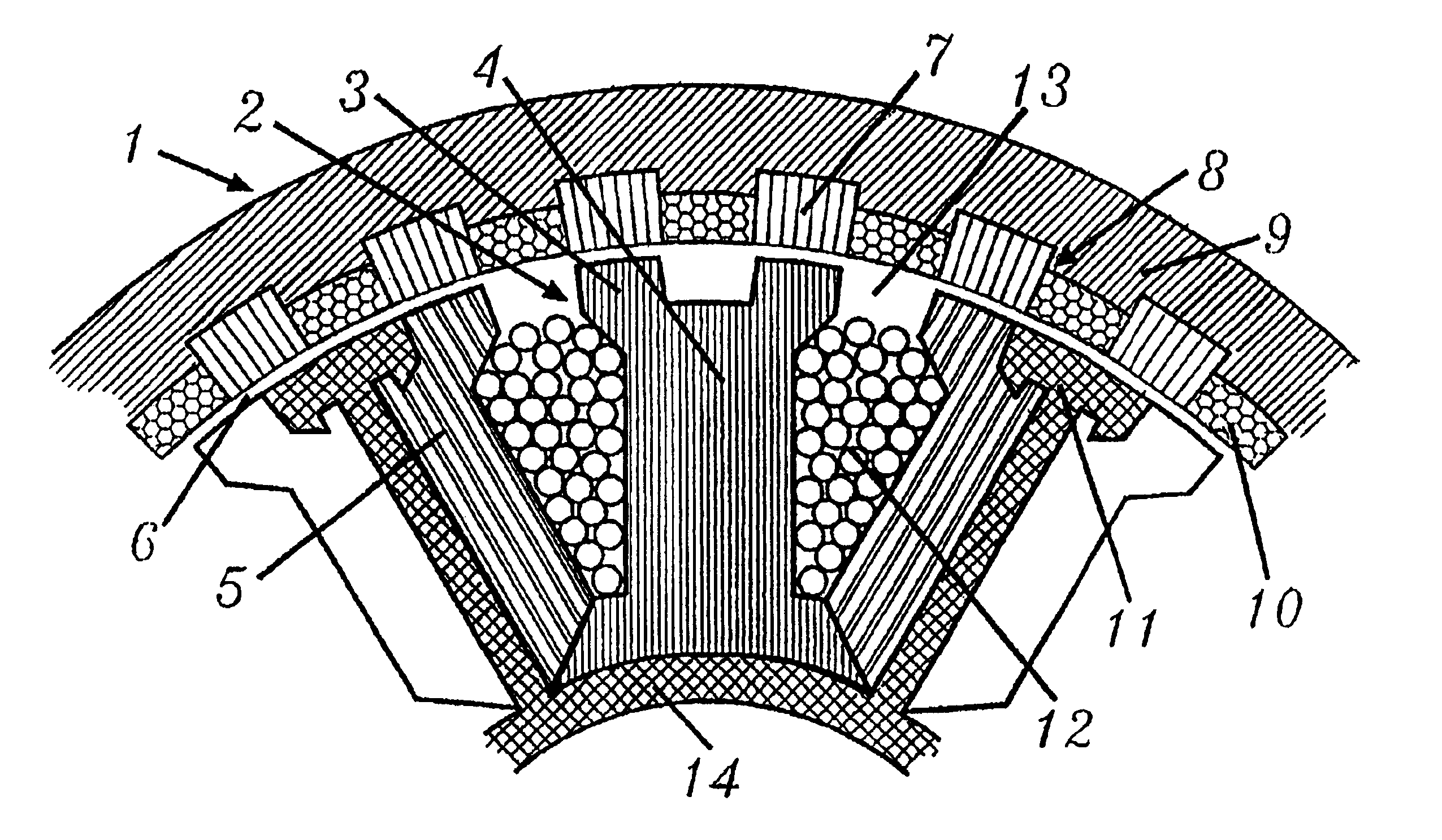

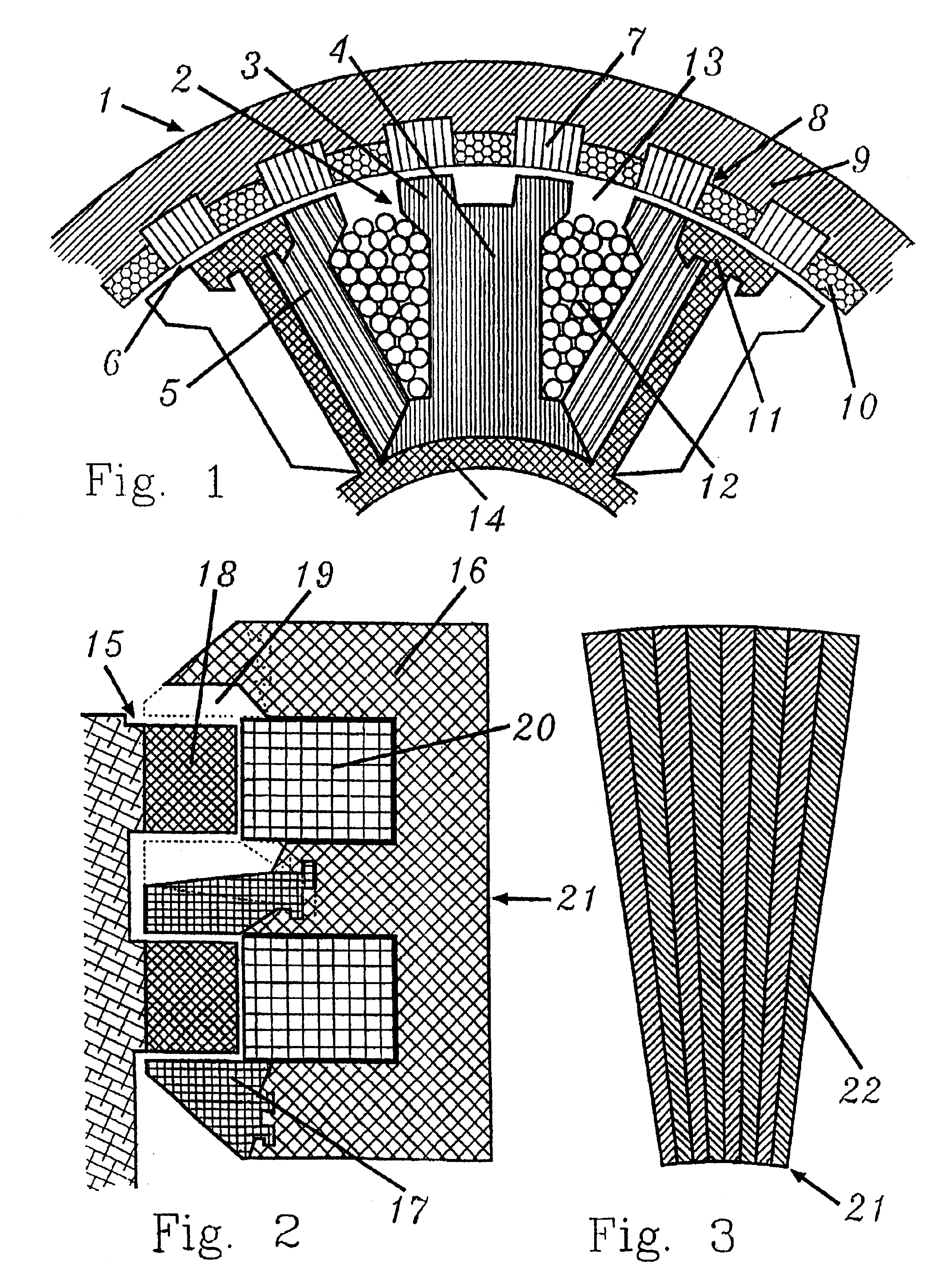

Electric machine with soft magnetic teeth

InactiveUS6960862B2Decrease of winding lossIncrease the areaSynchronous motorsMagnetic circuit stationary partsElectrical conductorDirect effects

Electric machines operating according to the reluctance principle have toothed air gap surfaces between their moving and fixed parts. The magnetizability of these teeth directly affects the performance of the machine. According to the invention, the teeth projecting into the air gap consist of a material which in relation to the remaining soft-magnetic body presents better magnetizability and / or greater magnetic saturation flux density. This material is preferably a grain-oriented electric steel sheet or a cobalt / iron alloy. Alternatively or in addition thereto, the soft-magnetic body in which the conductor coils are positioned can be made entirely of a grain-oriented material by appropriate segmentation. In this case, every other pole is non-spooled and consists of two halves separated by a non-magnetic holding element. The use of steel sheets rolled at an angle also contributes to the improved utilization of space and material in rotating machines, especially in transverse flux machines. The characteristics of the construction provided for in the invention result in the production of little cutting waste and thus raise the performance of electric machines with soft-magnetic teeth at the air gap surface and reduce losses.

Owner:HILL WOLFGANG

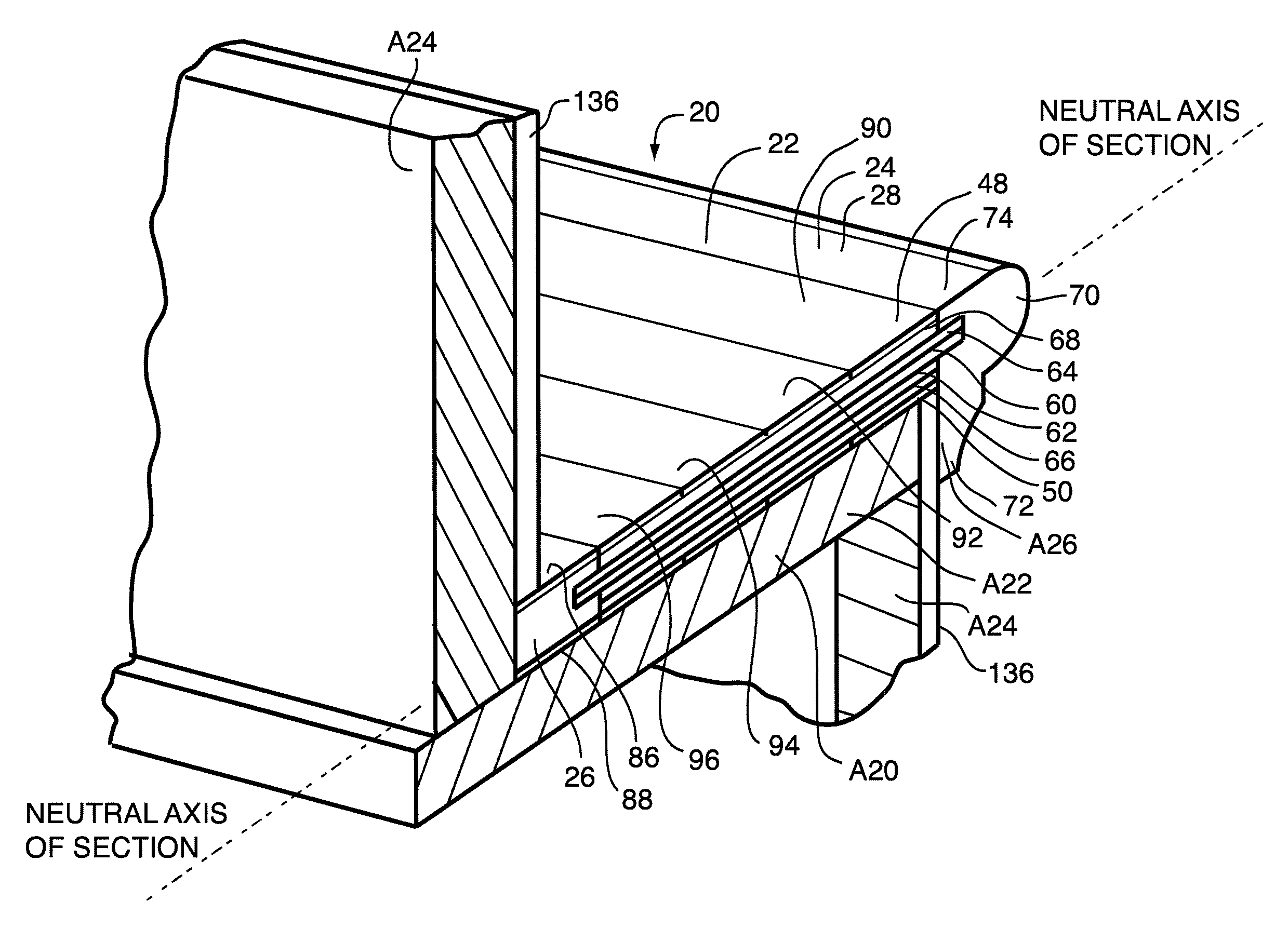

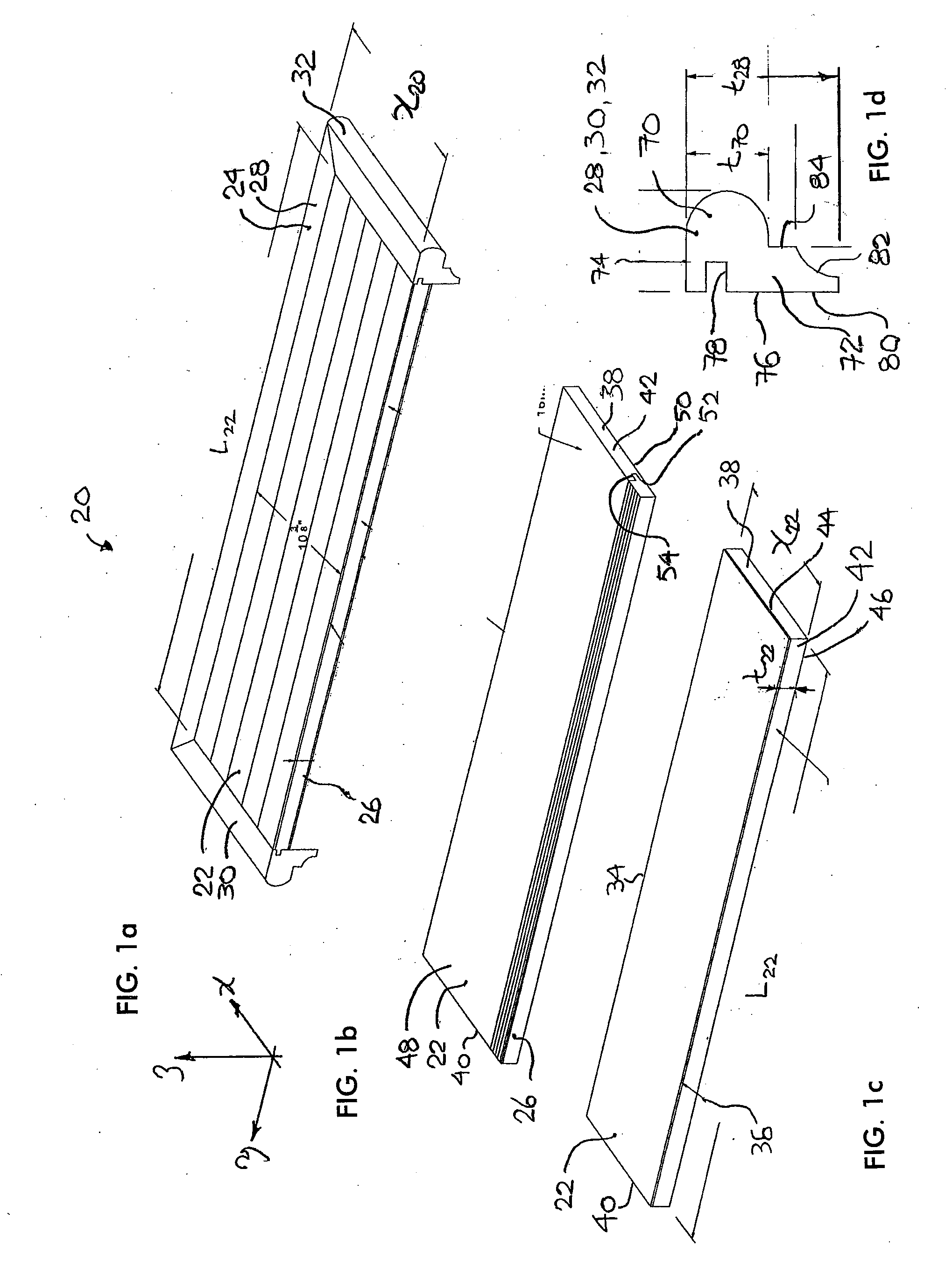

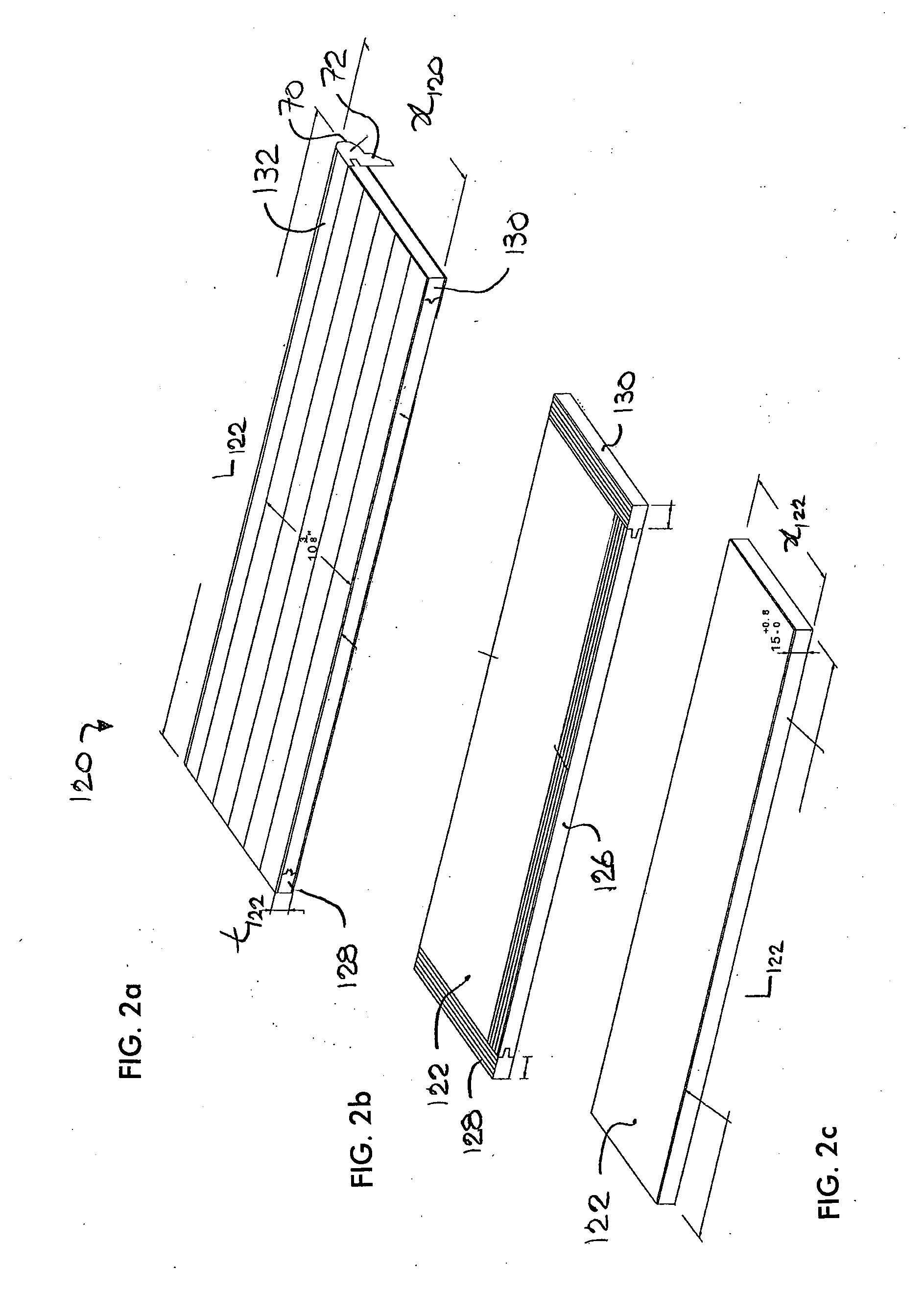

Stair tread assembly and method

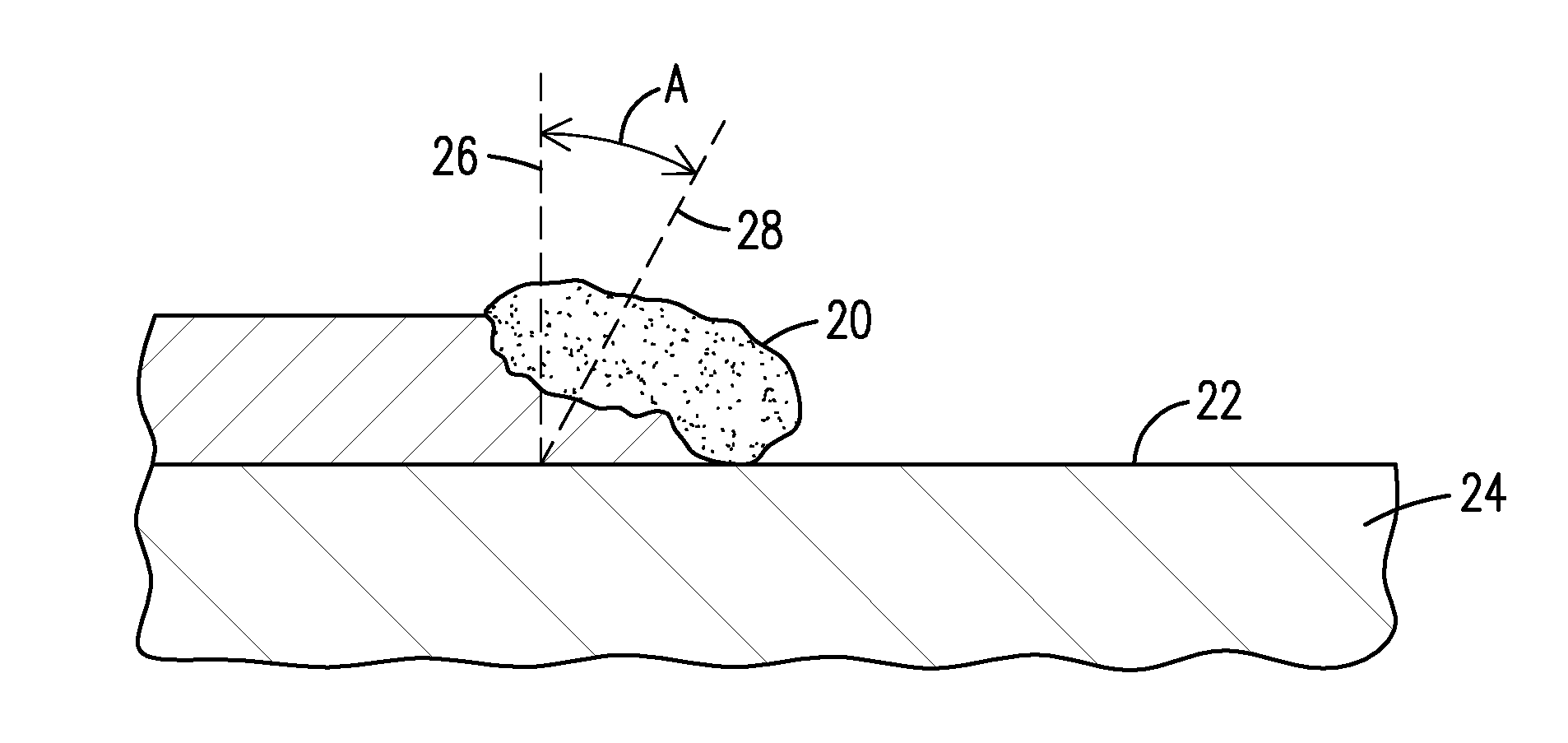

A replacement or repair stair tread assembly for covering over an existing worn stair tread includes a core that is surrounded by hardwood edge members, of which at least on edge has a bullnose. The edge members and core are mated at tongue and groove joints. The bullnose has a greater depth of section than the core. The core is a multi-ply matrix with veneer surface skins of the same grain orientation and type of wood. The multiple plies are arranged such that successive layers have cross-wise grain orientation. The plies of the core have symmetrically balanced properties relative to the neutral axis or neutral plane of the core in bending, both cross-wise and length-wise. The balanced properties may pertain to water absorption and to resistance to bending.

Owner:MOULURE ALEXANDRIA MOLDING

Cariaceous high-damping deformation magnesium alloy and its prepn process

The process relates to excellent magnesium base material, and is coriaceous high-damping deformation magnesium alloy and its preparation process. For obtaining both high damping performance and high mechanical performance, the present invention adds Cu, Si and other alloy element with small solid solubility into Mg material to reduce dislocation pinning points and to raise damping performance, while adding Zr, Mn and other crystal grain fining alloy element to raise the mechanical performance. Through conventional extrusion on ingot and intense plastic deformation, the alloy has regulated grain orientation, superfine crystal structure and raised toughness and damping performance. The present invention has wide application value.

Owner:HARBIN INST OF TECH

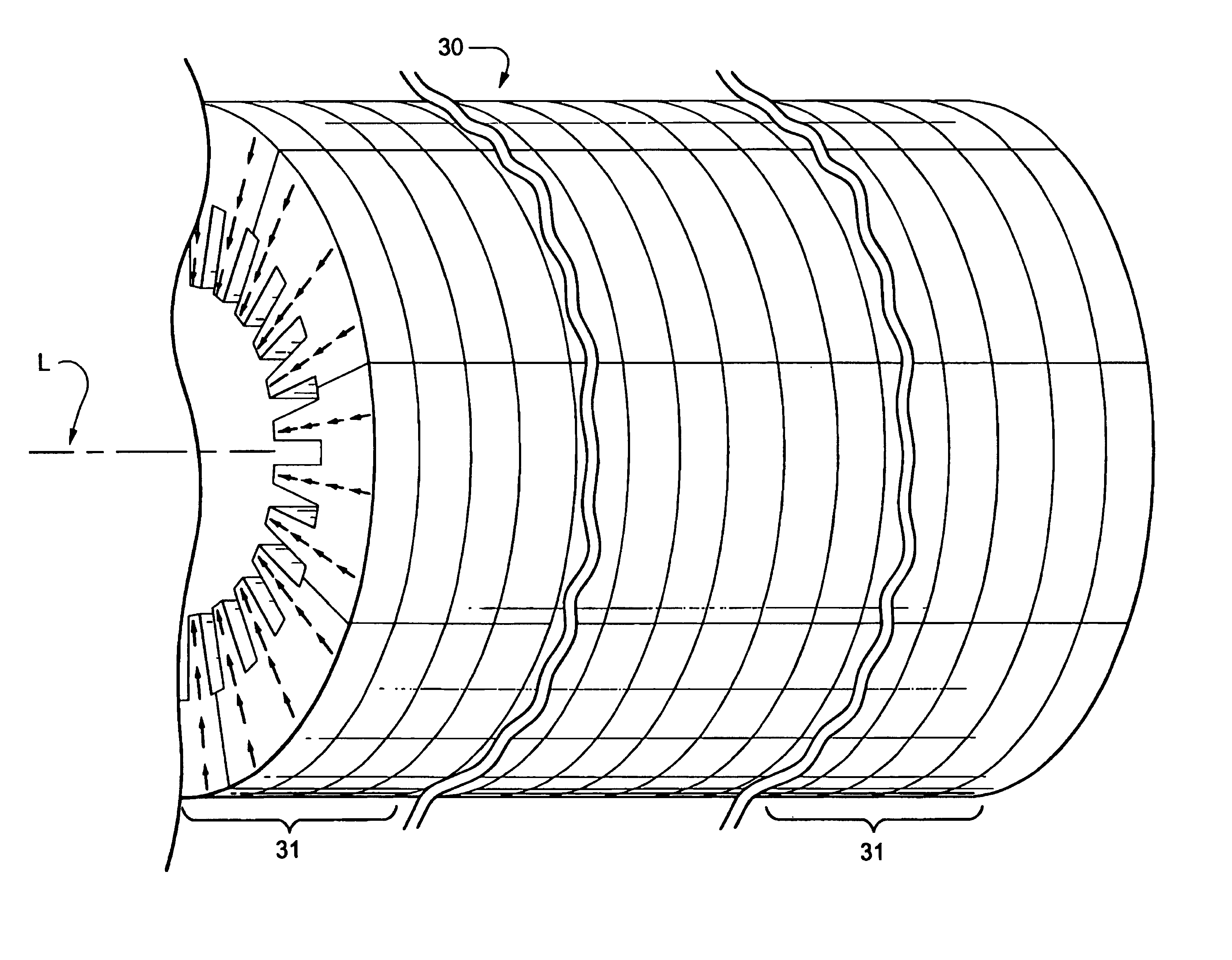

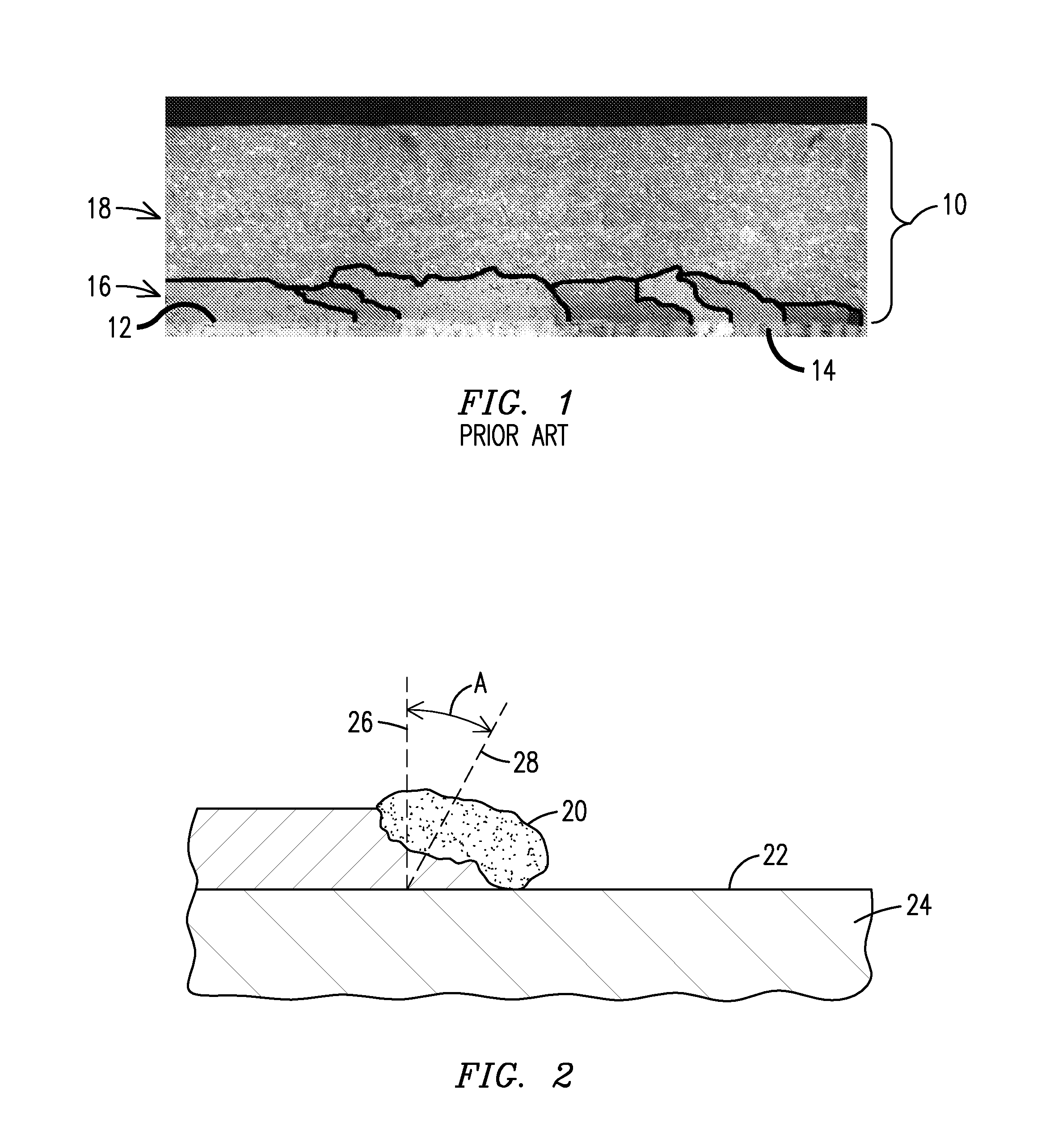

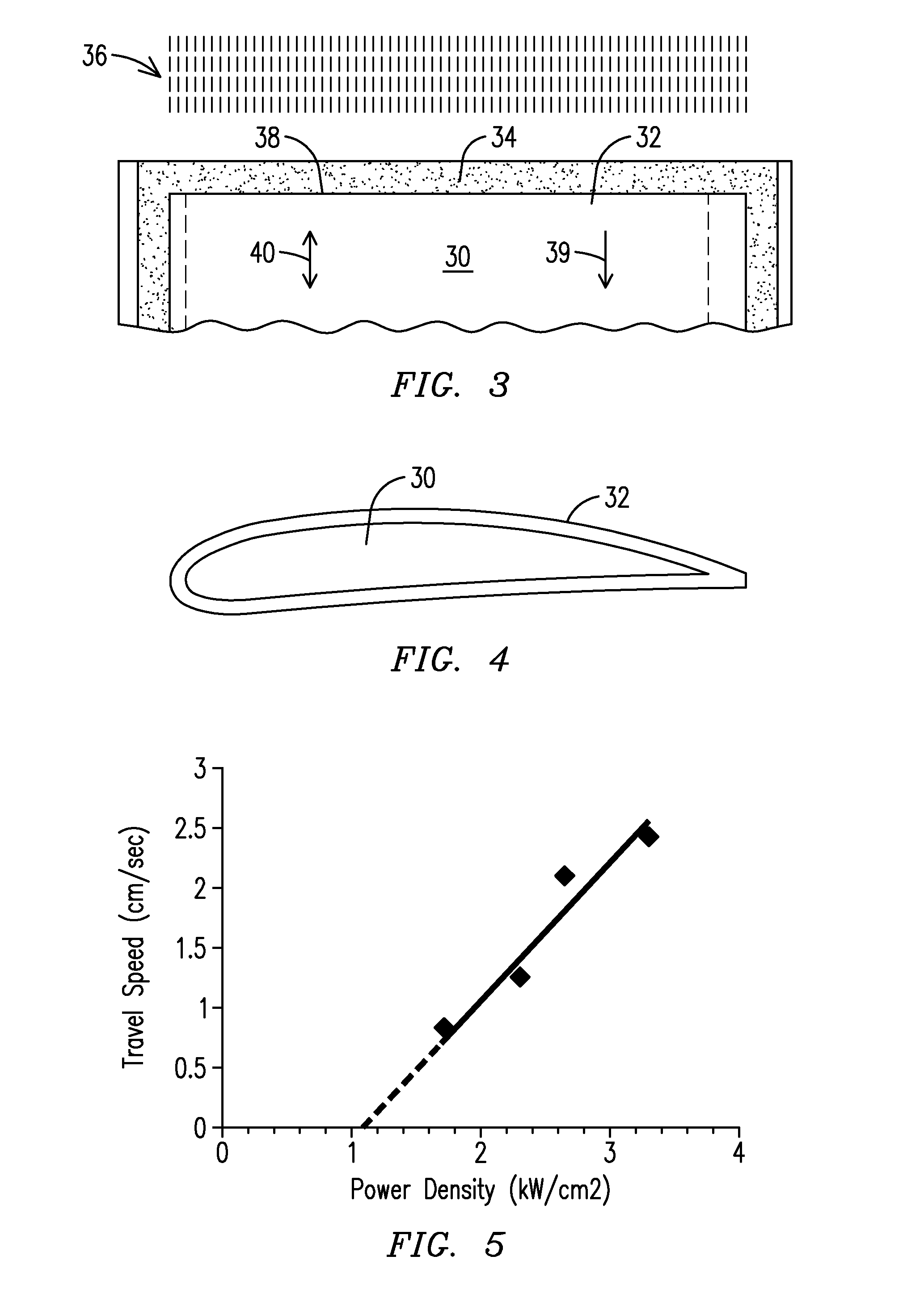

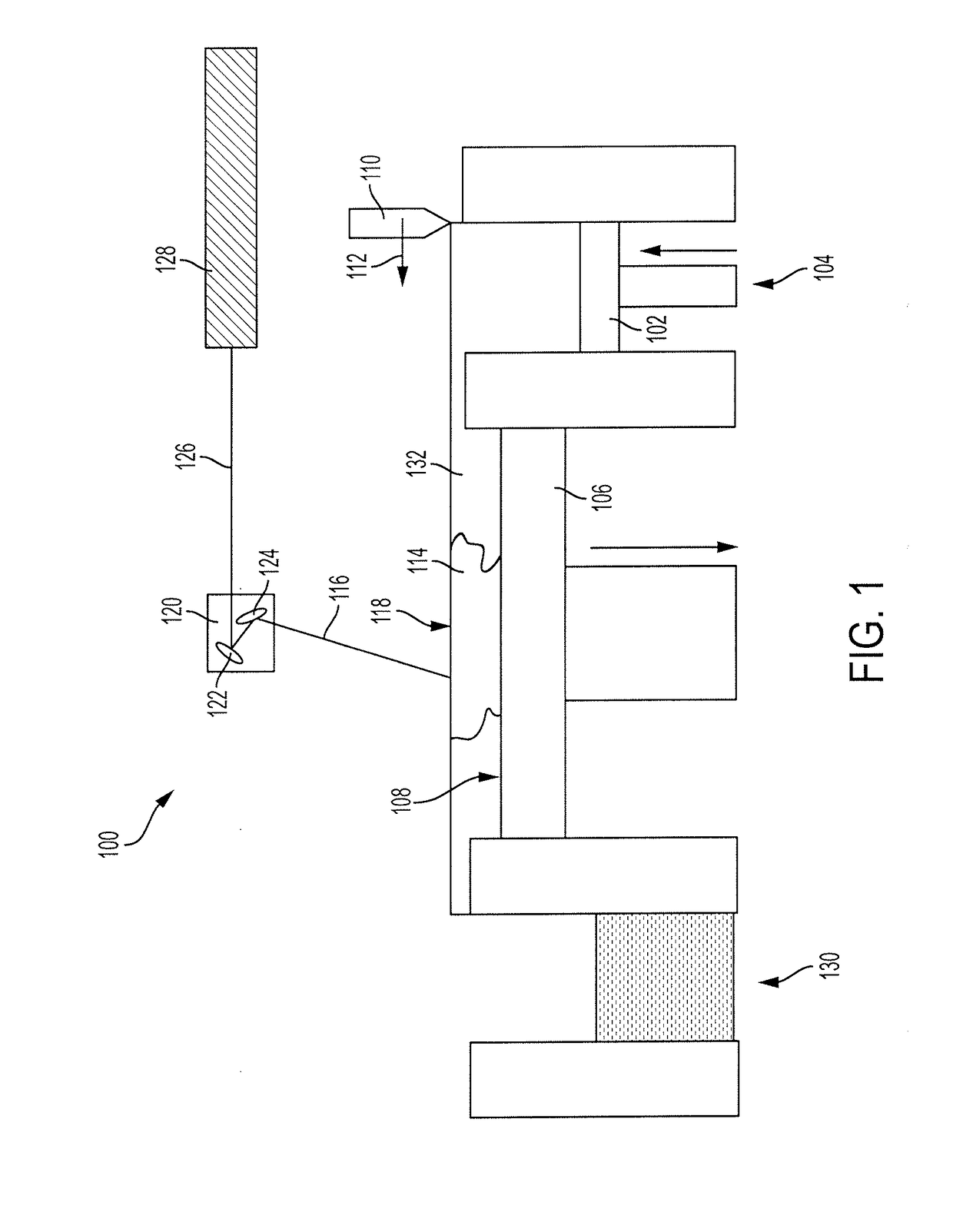

Repair of directionally solidified alloys

ActiveUS20130302533A1Inhibition of recrystallizationLess timeRadiation applicationsBlade accessoriesGratingFluidized bed

A method for epitaxial addition of repair material onto a process surface (38) of a directionally solidified component (30). The component is positioned in a fluidized bed (34) to drift particles of a repair material over the process surface as laser energy (36) is rastered across the surface to melt the particles and to fuse repair material onto the entire surface simultaneously. The component is moved downward (39) in the bed in a direction parallel to the grain orientation in the component as material is added to the surface, thereby providing continuous epitaxial addition of material to the surface without recrystallization.

Owner:SIEMENS ENERGY INC

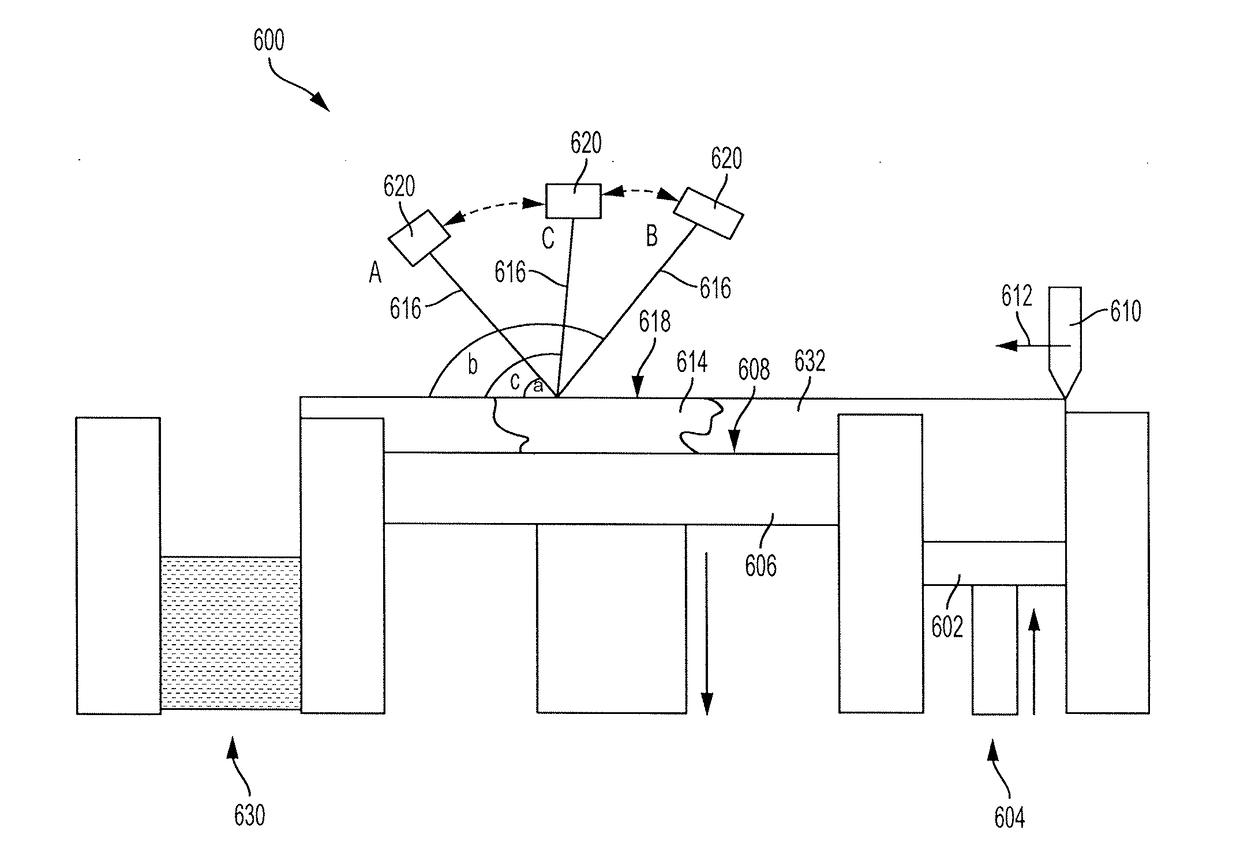

X-ray diffraction apparatus and technique for measuring grain orientation using x-ray focusing optic

InactiveUS20110038457A1Efficient excitationMaterial analysis using wave/particle radiationSoft x rayX-ray

An x-ray diffraction apparatus for measuring crystal orientation of a multiple grain sample. An x-ray excitation path is provided having a focusing optic for collecting x-rays from an x-ray source and redirecting the collected x-rays into an x-ray beam converging on a single grain of the multiple grain sample. At least one point detector and the sample are rotated relative to each other; and a grain orientation is obtained based upon diffraction patterns collected from first and second grain crystal planes within the apparatus.

Owner:X-RAY OPTICAL SYSTEM INC

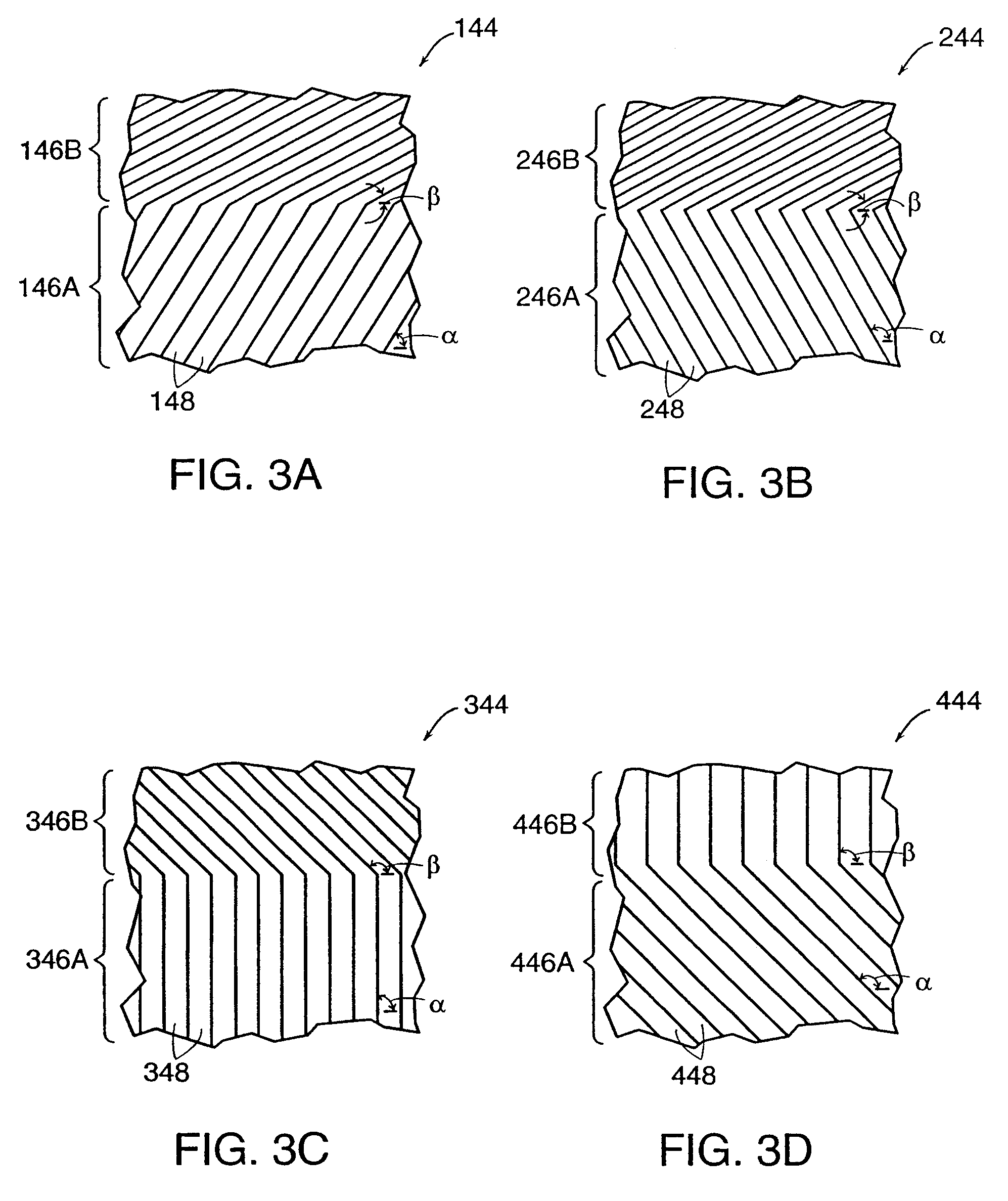

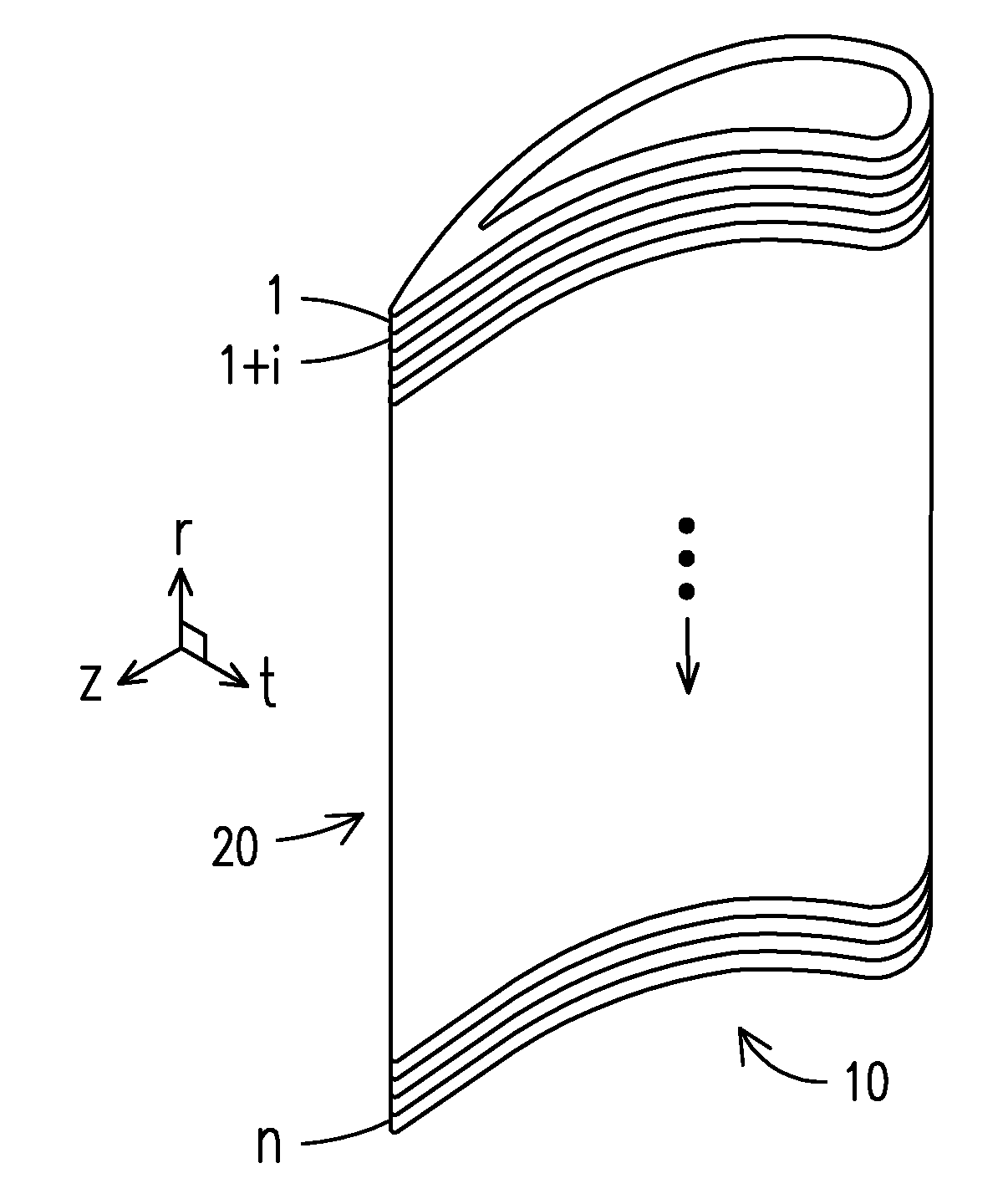

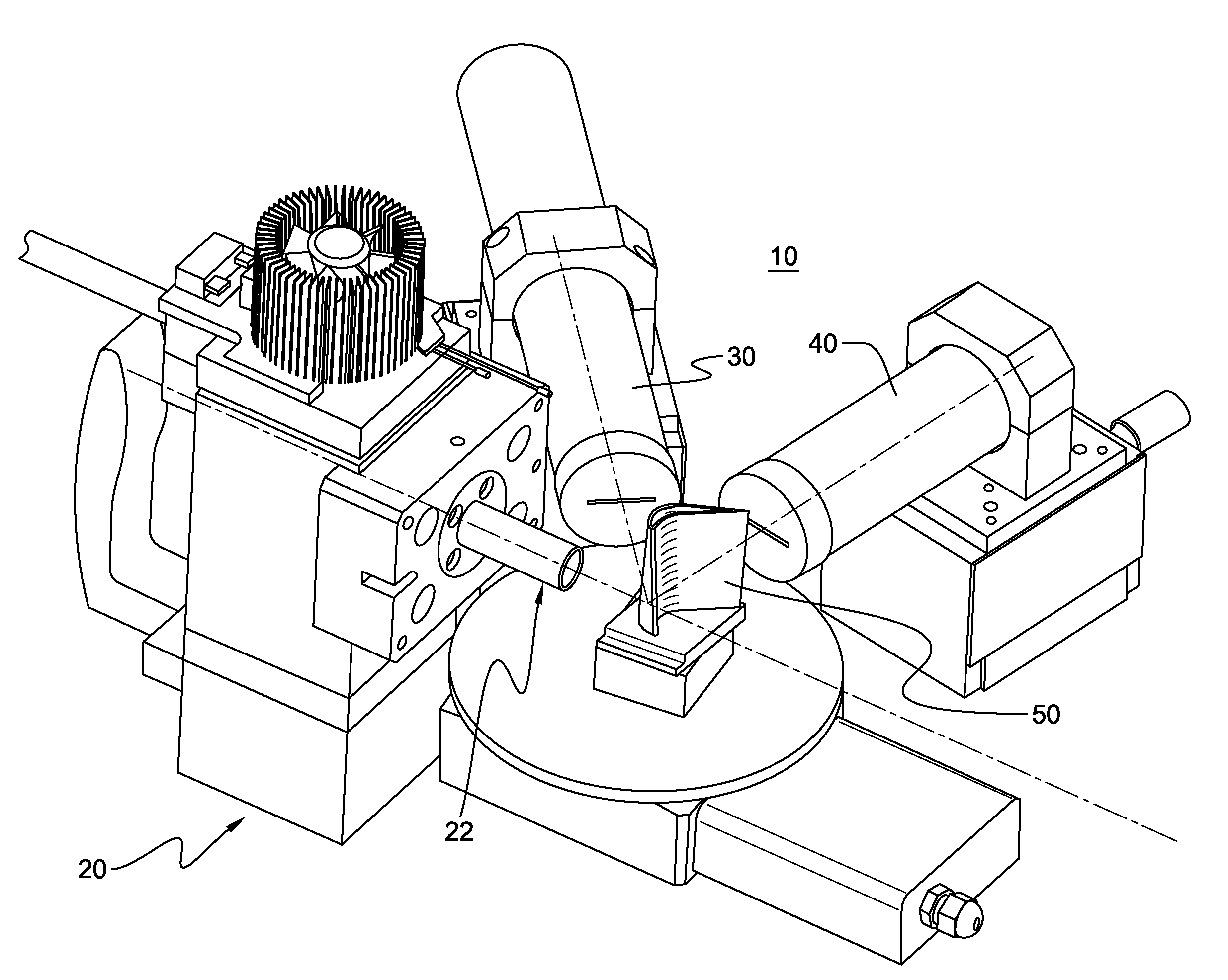

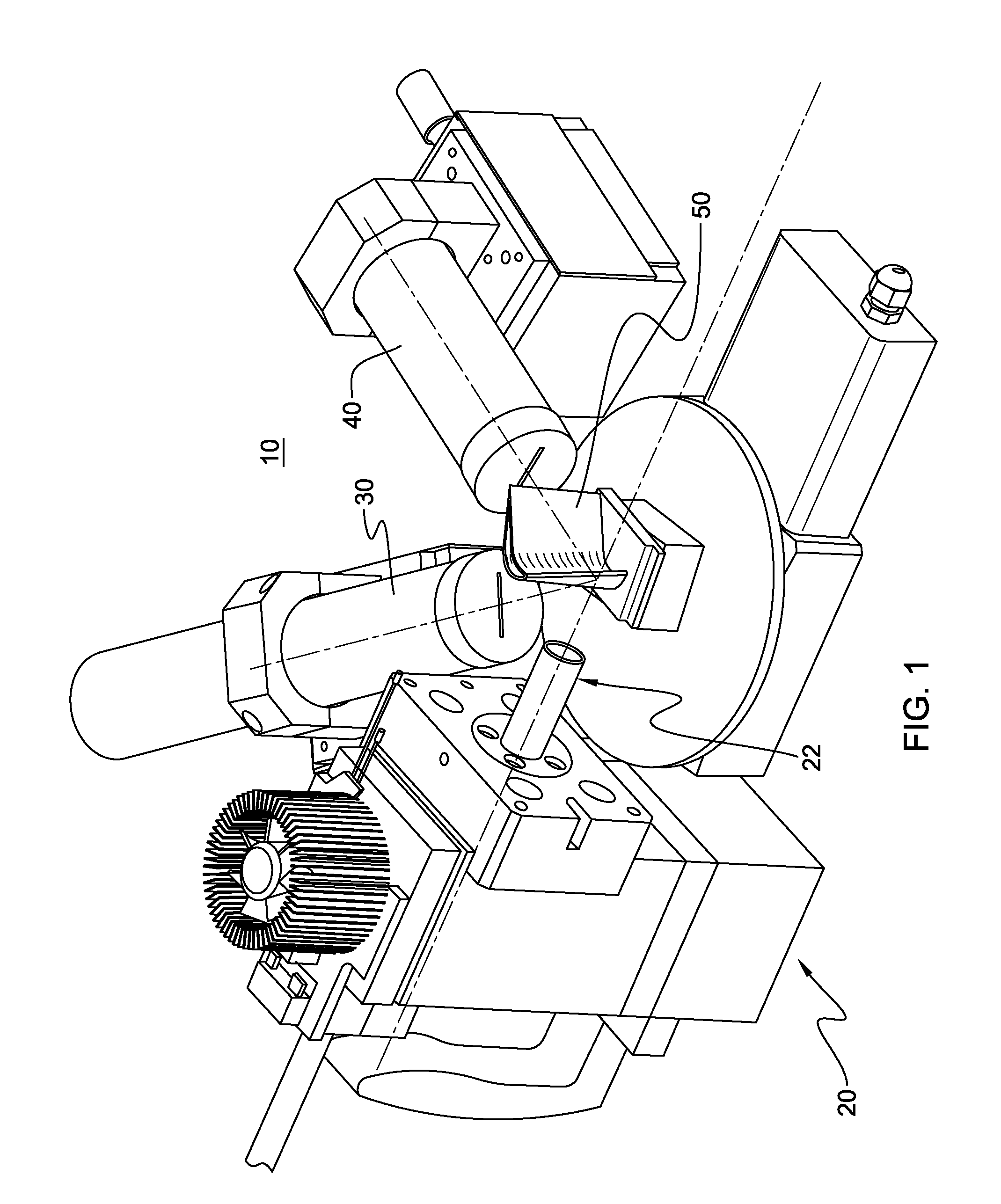

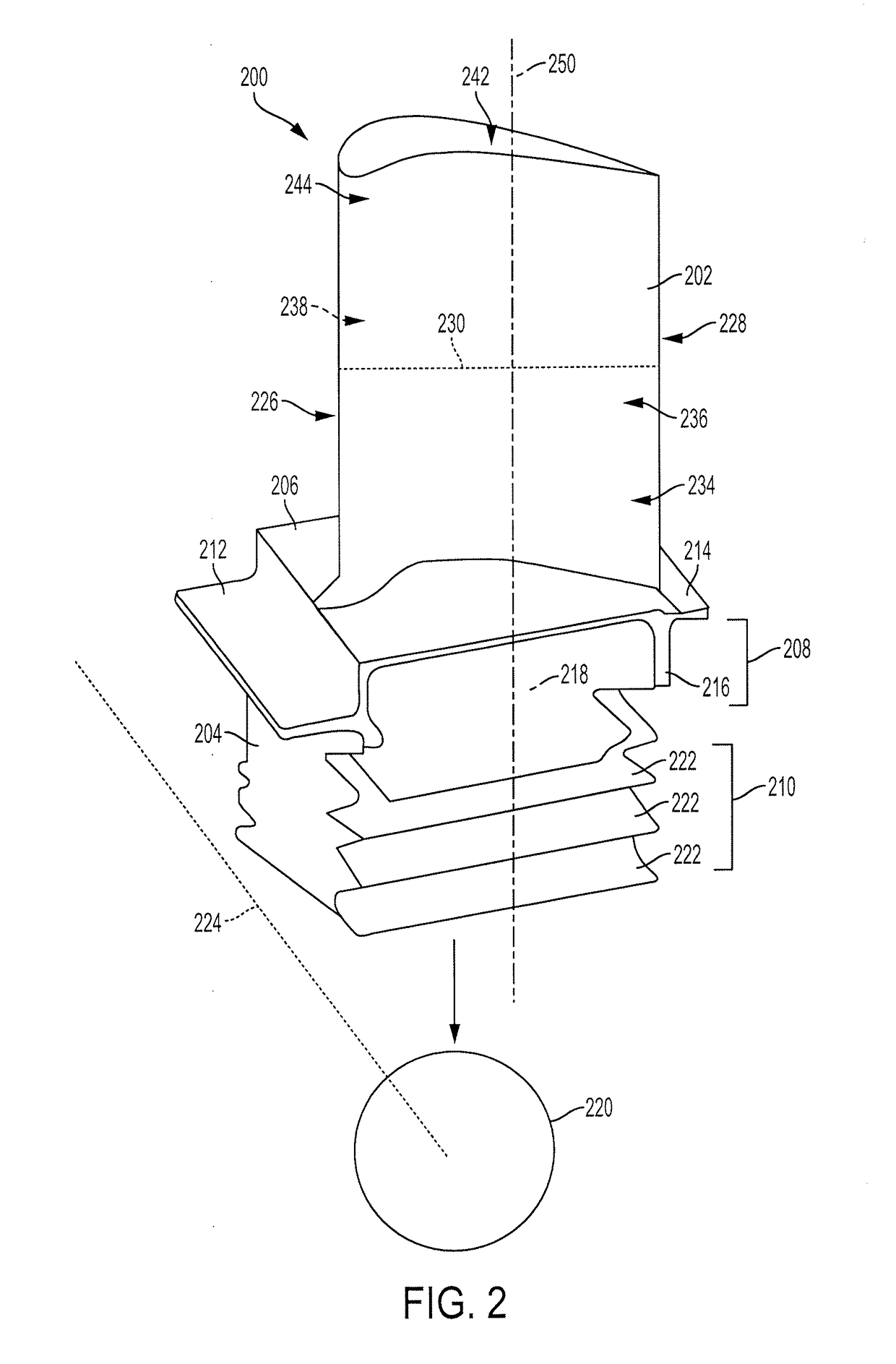

Turbine component having multiple controlled metallic grain orientations, apparatus and manufacturing method thereof

The present disclosure generally relates to turbine engine components having multiple controlled metallic grain orientations. In general, the primary grain orientation is aligned substantially perpendicular to the longitudinal axis of the turbine engine component while the secondary grain orientation is aligned substantially parallel to the longitudinal axis. Such controlled grain orientations provide the blades and vanes with increased strength to withstand the thermal-mechanical stresses of the turbine operation. The disclosure also relates to turbines having these fortified components, and methods of manufacturing the components.

Owner:GENERAL ELECTRIC CO

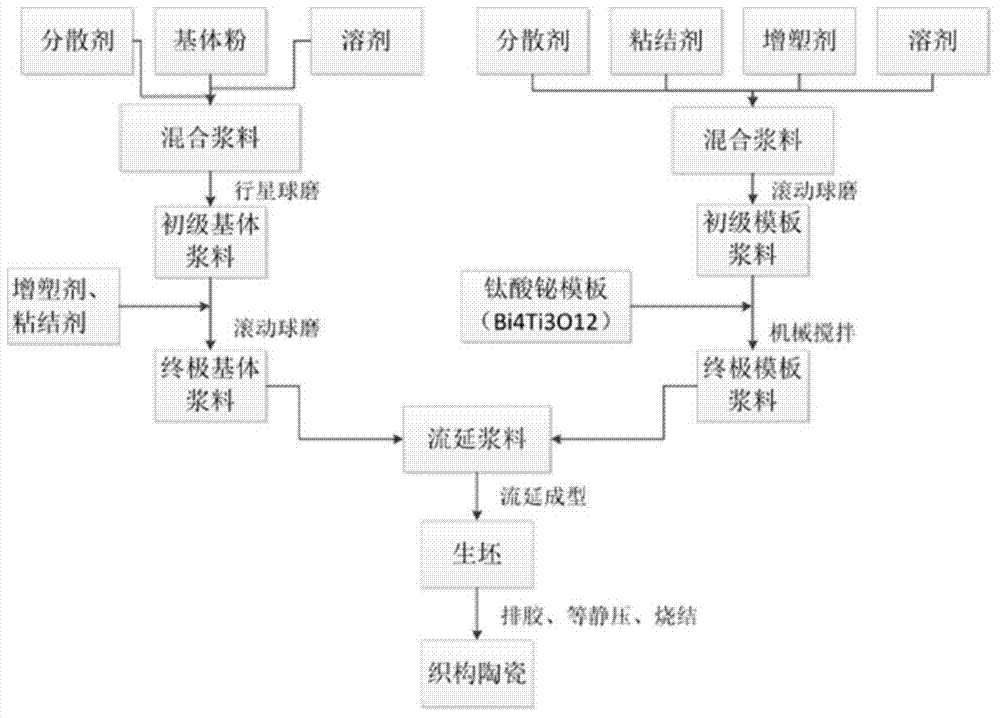

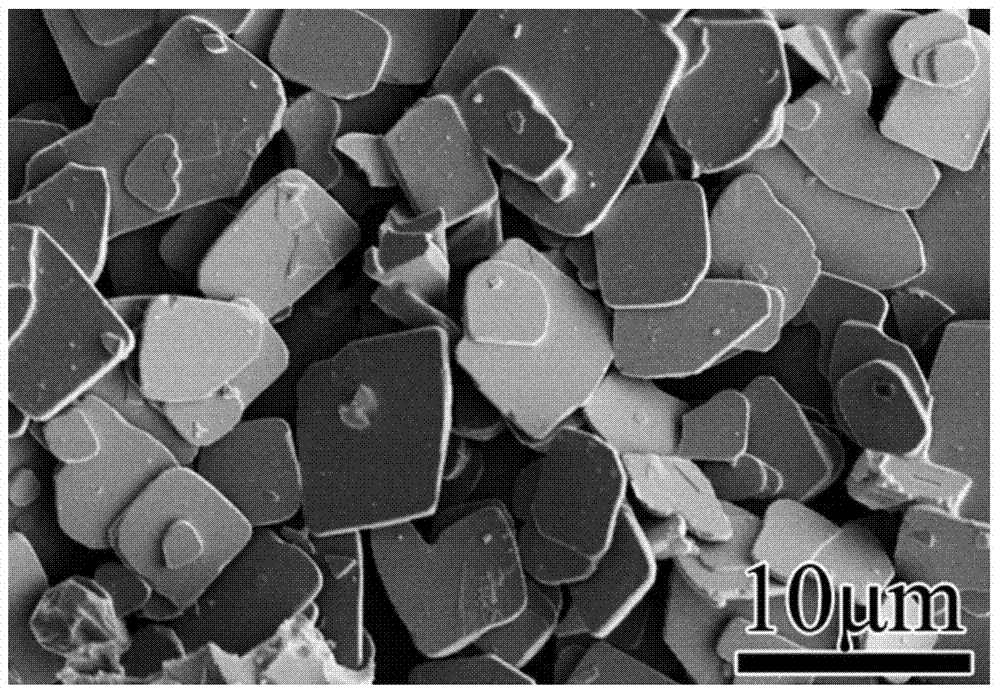

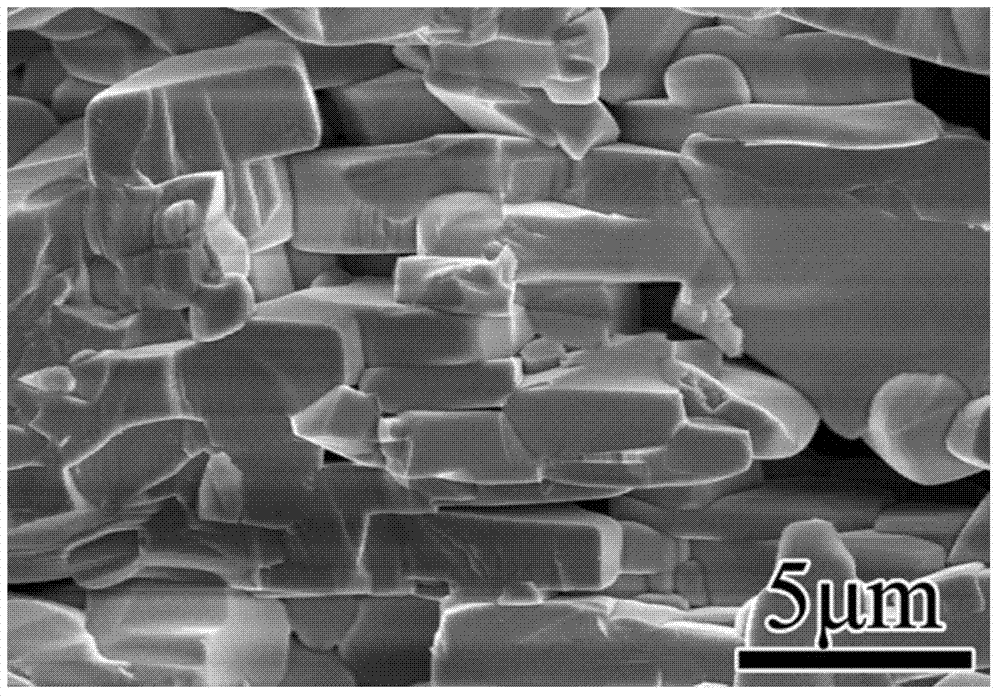

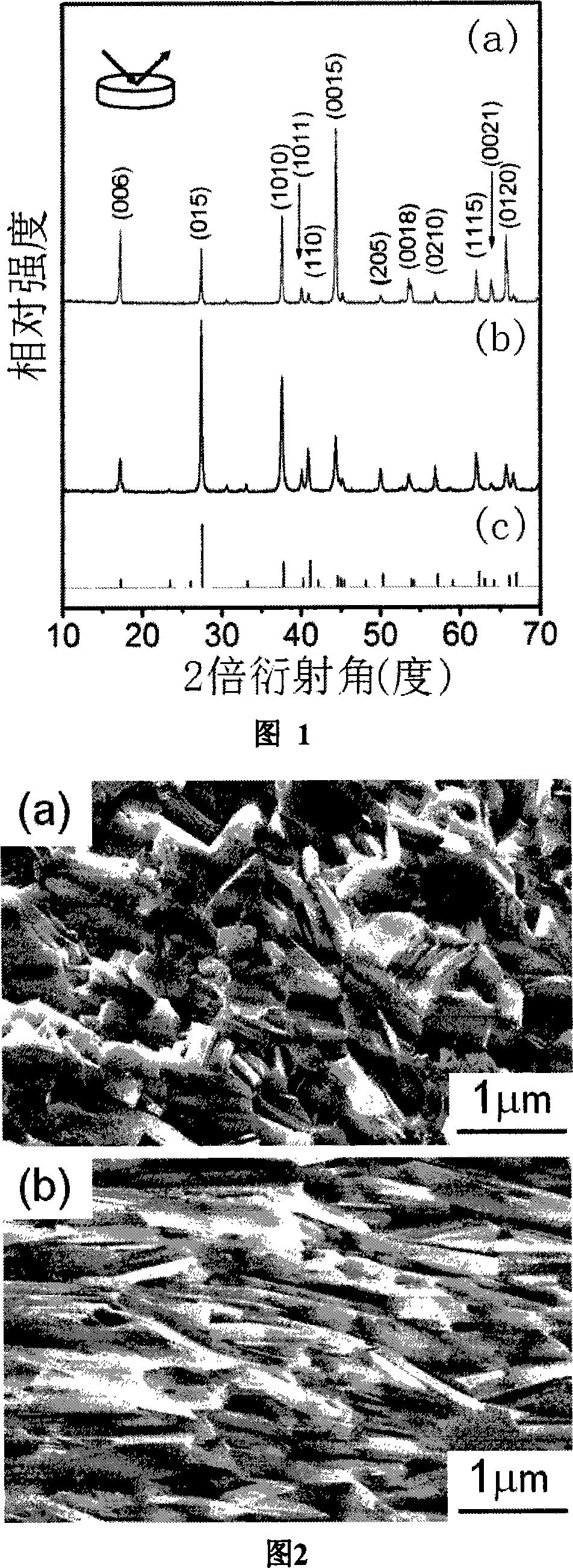

Sodium bismuth titanate-barium titanate-potassium bismuth titanate lead-free piezoelectric texture ceramic and preparation method thereof

InactiveCN103613382AExcellent piezoelectric propertiesThe original composition does not changeBarium titanatePotassium

The invention provides sodium bismuth titanate-barium titanate-potassium bismuth titanate lead-free piezoelectric texture ceramic and a preparation method thereof. The preparation method comprises the following steps: mixing a template with organic additives such as matrix powder, an organic solvent and a binder to obtain slurry by taking a Bi4Ti3O12 crystal as the template; preparing the slurry into a film sheet with thickness of 30 mu m-60 mu m through a curtain coating process; and sintering the film sheet after laminating, cutting, rubber exhausting and isostatic cool pressing to prepare a BNBK texture ceramic material with high oriented growth, wherein original components of the materials are not changed due to precise control in the process. The prepared sodium bismuth titanate-barium titanate-potassium bismuth titanate lead-free piezoelectric texture ceramic constitutes a (1-x-y)Na0.5Bi0.5TiO3-xBaTiO3-Yk0.5Bi0.5TiO3 ternary system, has good crystalline grain orientation effect, excellent performances in the lead-free piezoelectric field, a piezoelectric constant of over 210 pC / N and a Curie temperature of over 320 DEG C.

Owner:TIANJIN UNIV

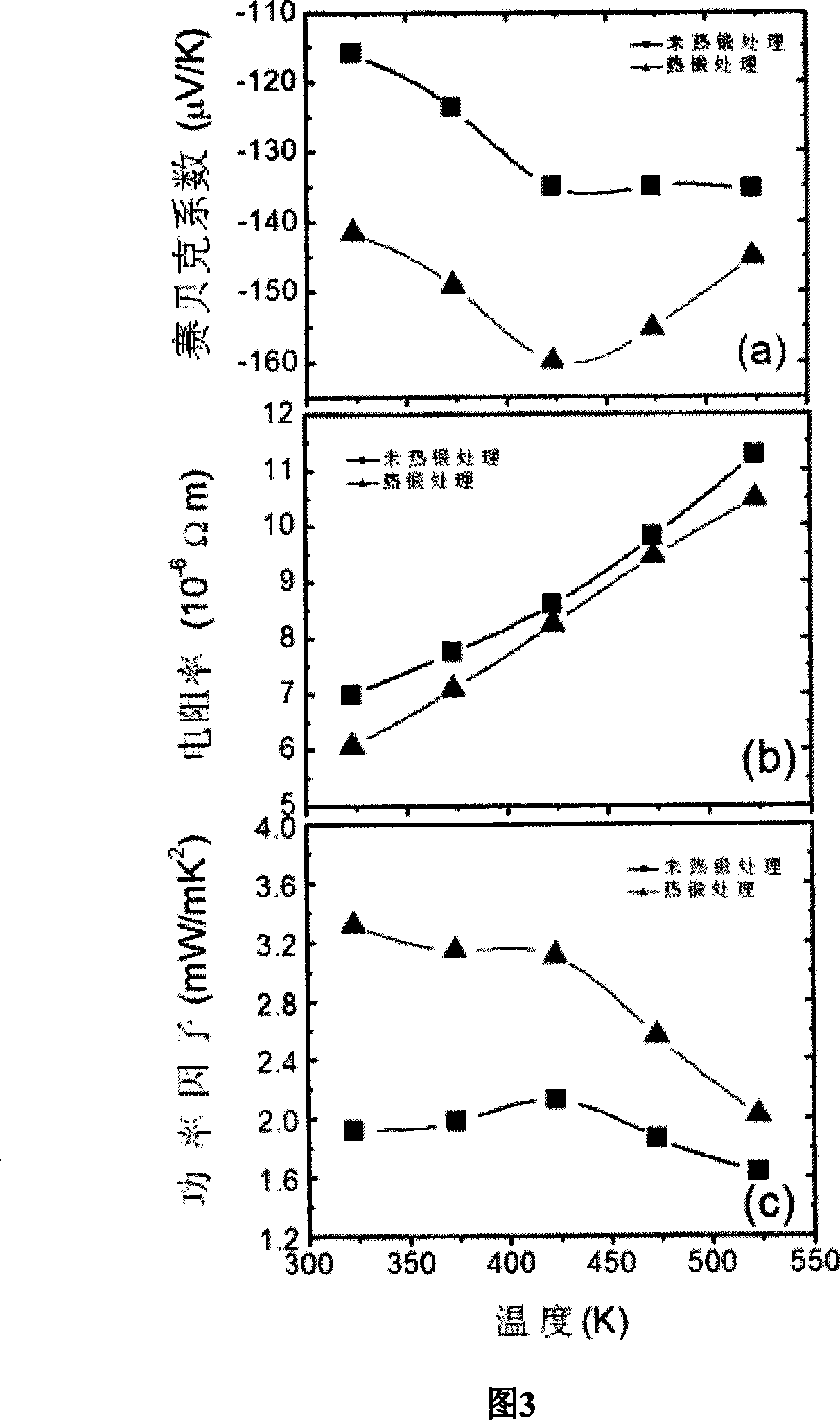

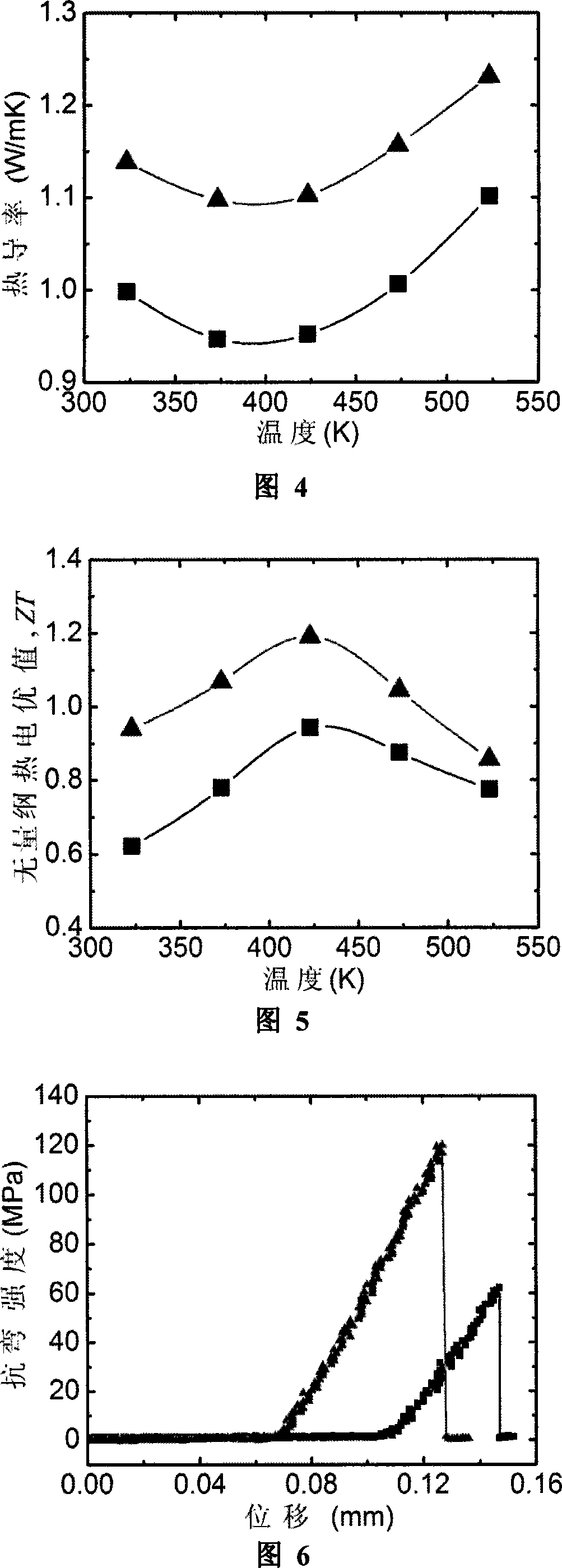

Method for preparing grain-refining preferred tropism Bi2Te3 thermoelectric materials

The invention relates to the preparing method of a fine-grained thermoelectric material with a preferred orientation of Bi2Te3 and belongs to the field of energy material technology. The method consists of two parts of synthesizing and moulding forming of compound. Weighed and proportioned, the highly-purified Bi and simple substance Te are conducted a high-powered ball milling at a certain rotating speed and under the protection of inert gases. The dry-milled compound is wet-milled and then dried to obtain a finely pulverized powder of Bi2Te3. The mass material is obtained in the process of molding through spark plasma sintering, which includes two steps, i.e. firstly, the high-dense fine-grained mass of Bi2Te3 is obtained through spark plasma sintering; secondly, a hot-forging processing is conducted to obtain a textured structure through the technique of spark plasma sintering. As the spark plasma sintering has the advantages of short duration and relatively low sintering temperature, a well-distributed fine microstructure with a preferred orientation can be obtained by controlling the sintering technique. The method improves the thermoelectrical and mechanical properties of the material by controlling the crystal grain growth and the crystal grain orientation, has the advantages of simple technique and short synthesizing and molding period.

Owner:TSINGHUA UNIV

Preparation method for high performance as cast condition neodymium iron boron magnet

ActiveCN102623166AFine grain sizeFine grainPermanent magnetsInductances/transformers/magnets manufactureMaterials preparationMagnetic energy

The invention relates to the technical field of permanent magnetic material preparation and in particular to a preparation method for a high performance as cast condition neodymium iron boron magnet. By means of the composite process combining technology of casting and large strain plastic deformation and the technology of double orientation, grain size is effectively refined, and grain boundary and grain orientation are controlled, so that the high performance neodymium iron boron magnet which is fine in grains, even in grain boundary phase distribution and complete in grain orientation is prepared, and good matching of high coercivity and high magnetic energy product is obtained.

Owner:临沂银凤新材料技术服务有限公司

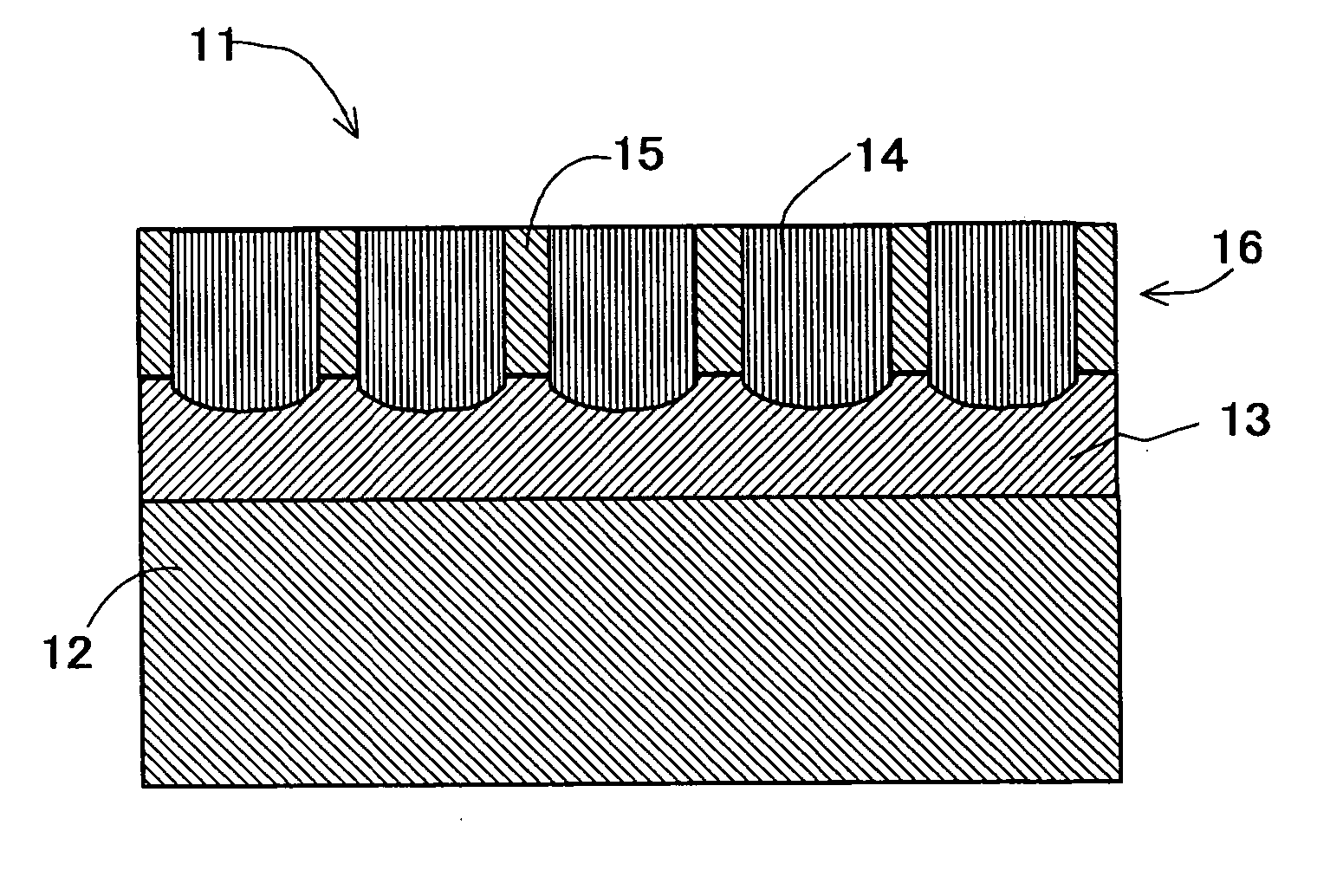

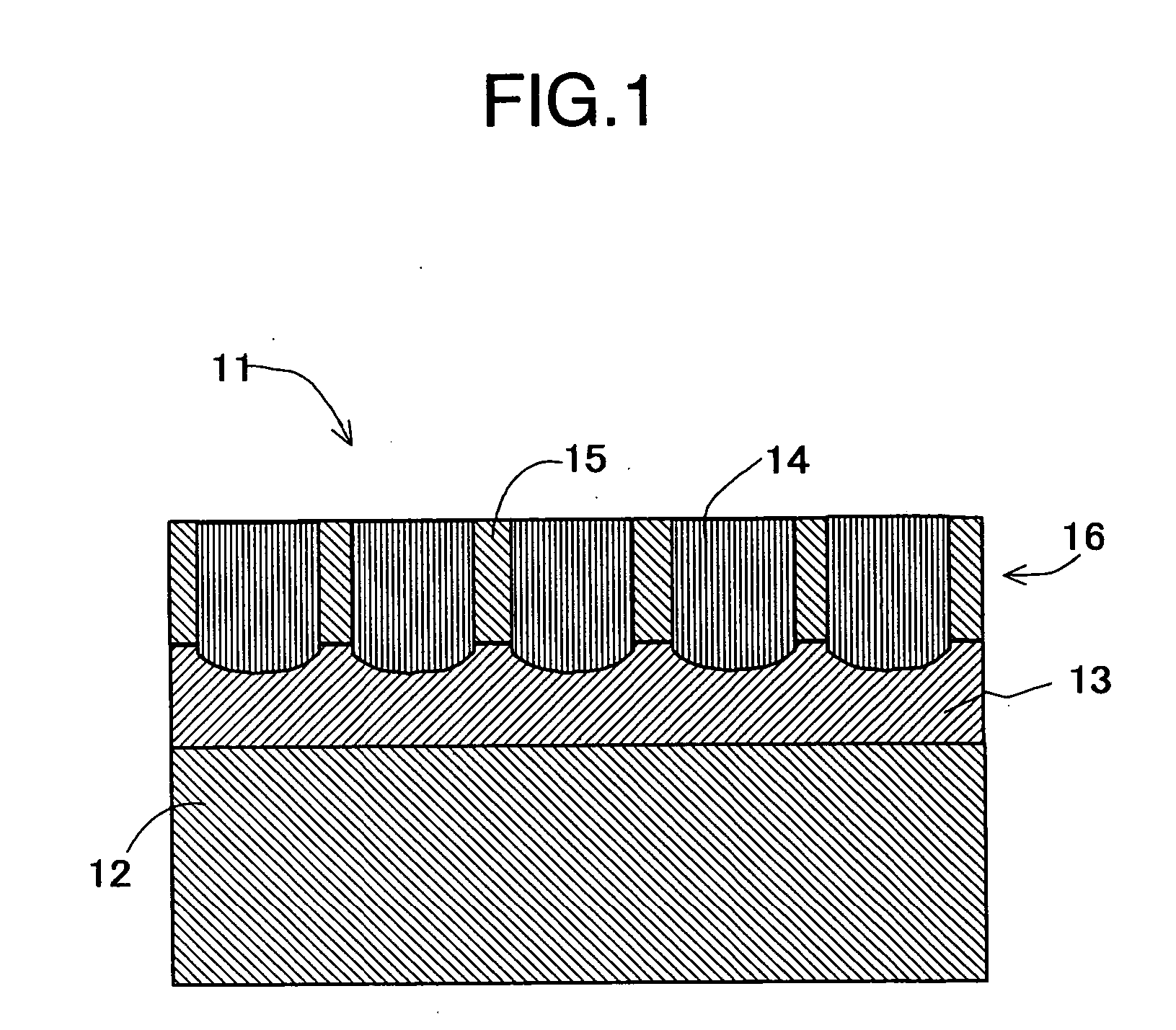

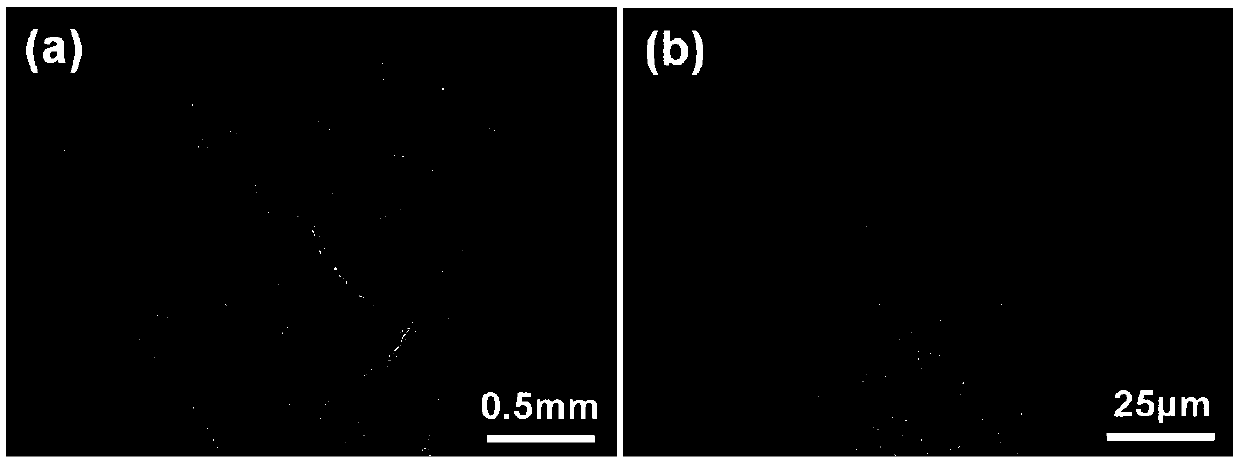

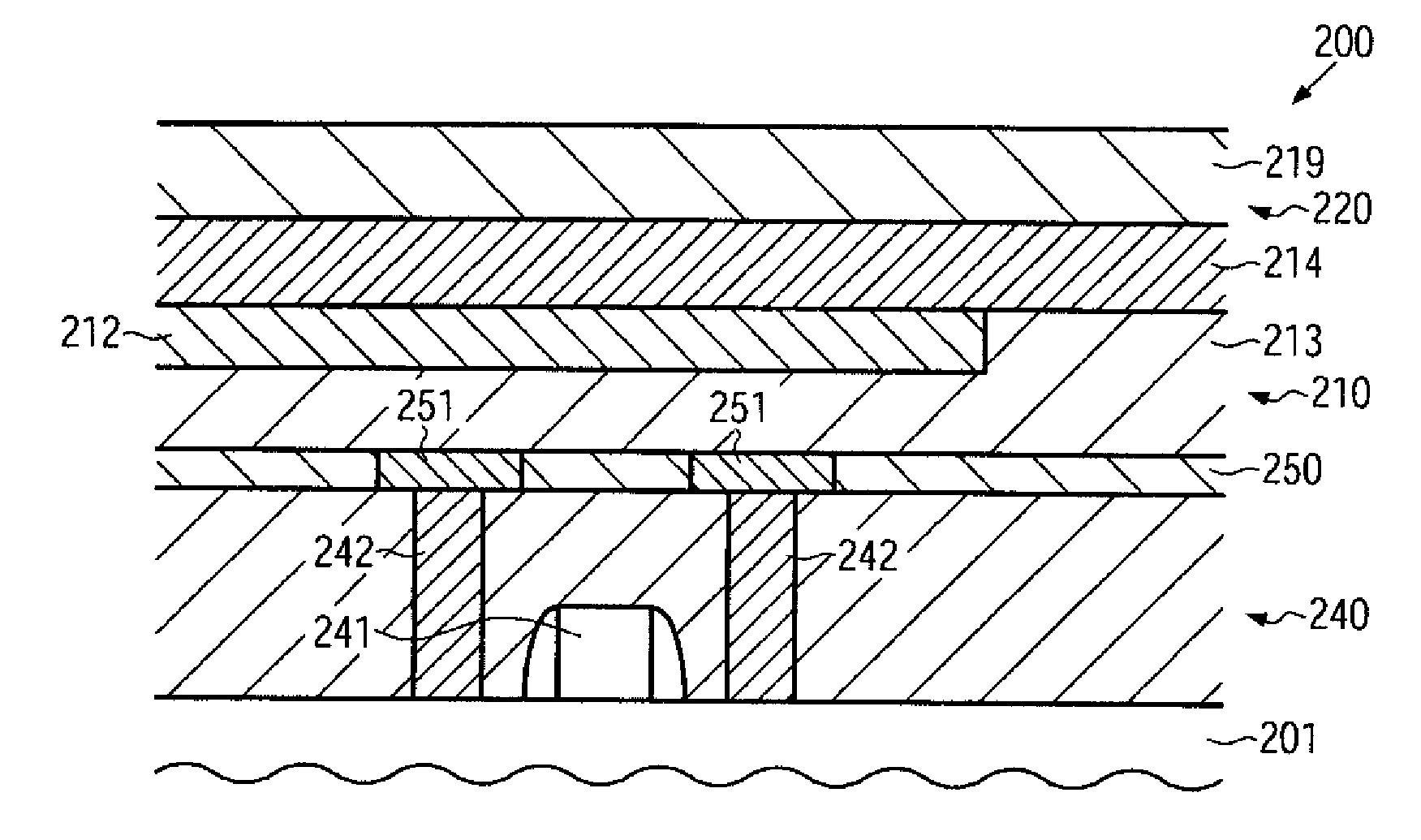

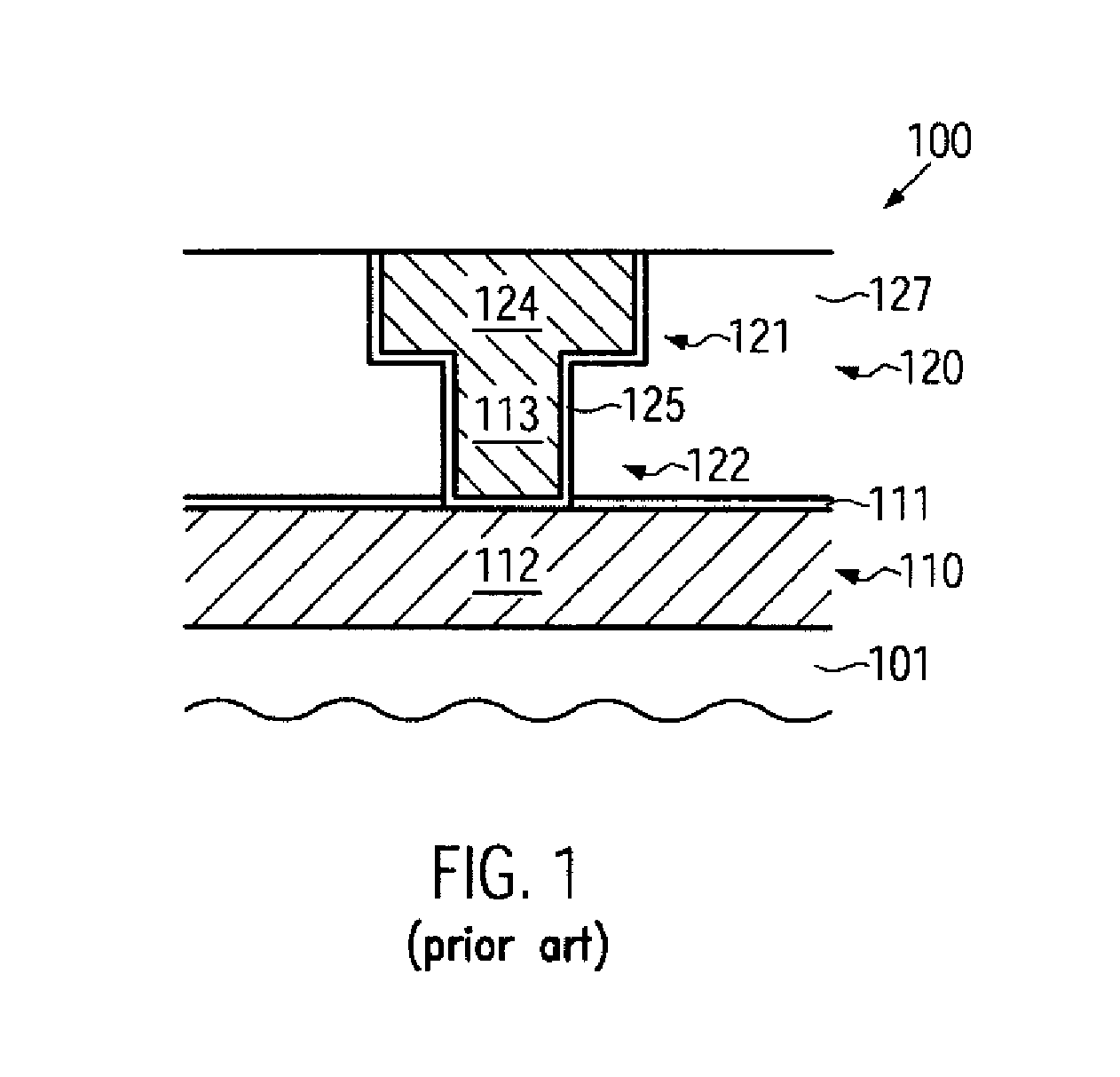

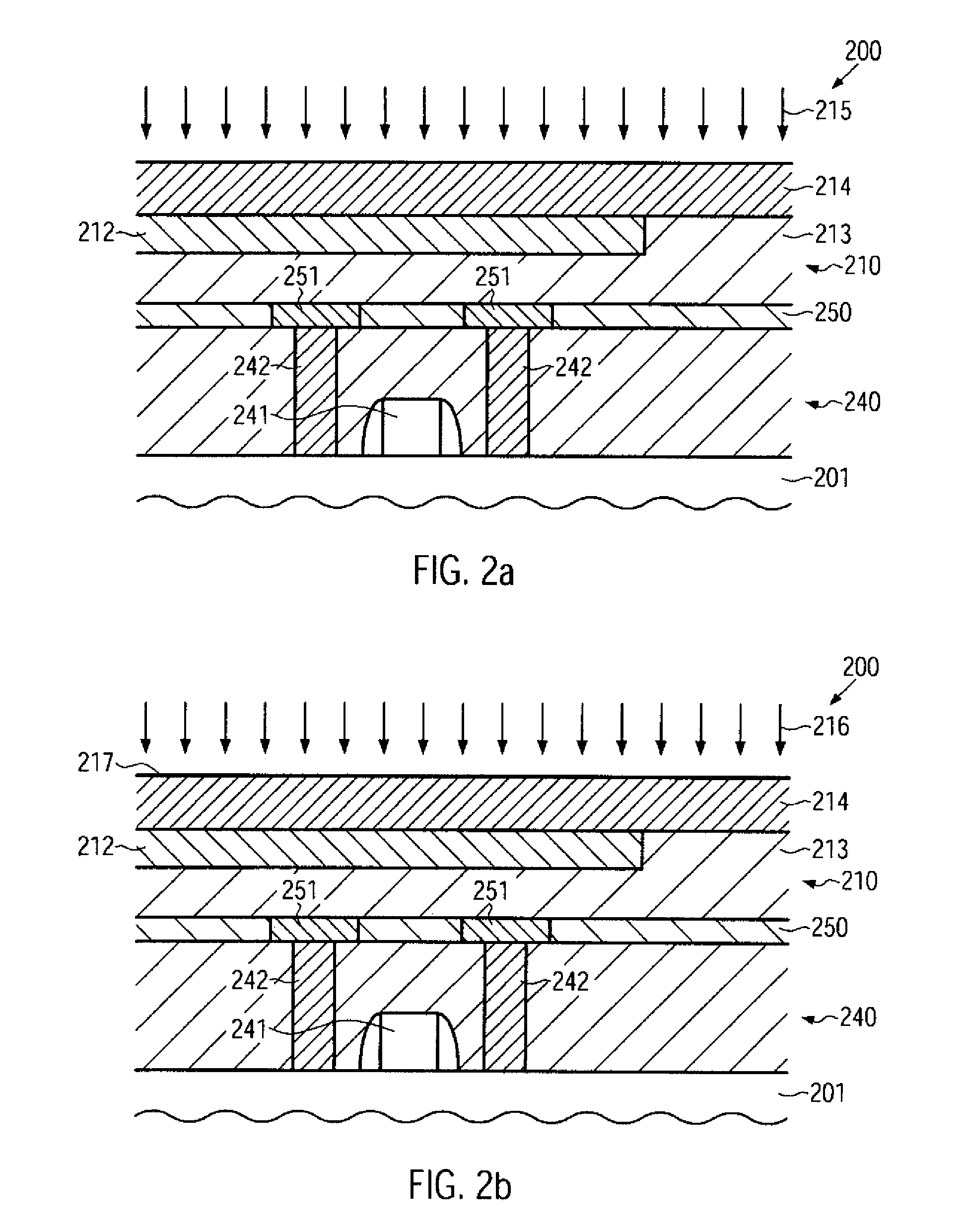

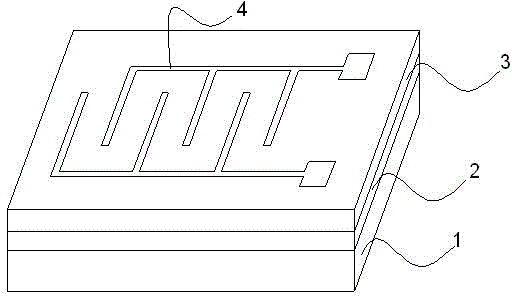

Semiconductor device having a grain orientation layer

InactiveUS20090035936A1Less random grain orientation in metal featureIncrease volumeSemiconductor/solid-state device detailsSolid-state devicesGrain structureSemiconductor

A manufacturing process of a semiconductor device includes generating a less random grain orientation distribution in metal features of a semiconductor device by employing a grain orientation layer. The less random grain orientation, e.g., a grain orientation distribution which has a higher percentage of grains that have a predetermined grain orientation, may lead to improved reliability of the metal features. The grain orientation layer may be deposited on the metal features wherein the desired grain structure of the metal features may be obtained by a subsequent annealing process, during which the metal feature is in contact with the grain orientation layer.

Owner:ALSEPHINA INNOVATIONS INC

Solid-free-form fabrication of hot gas valve discs

Owner:NORSK TITANIUM

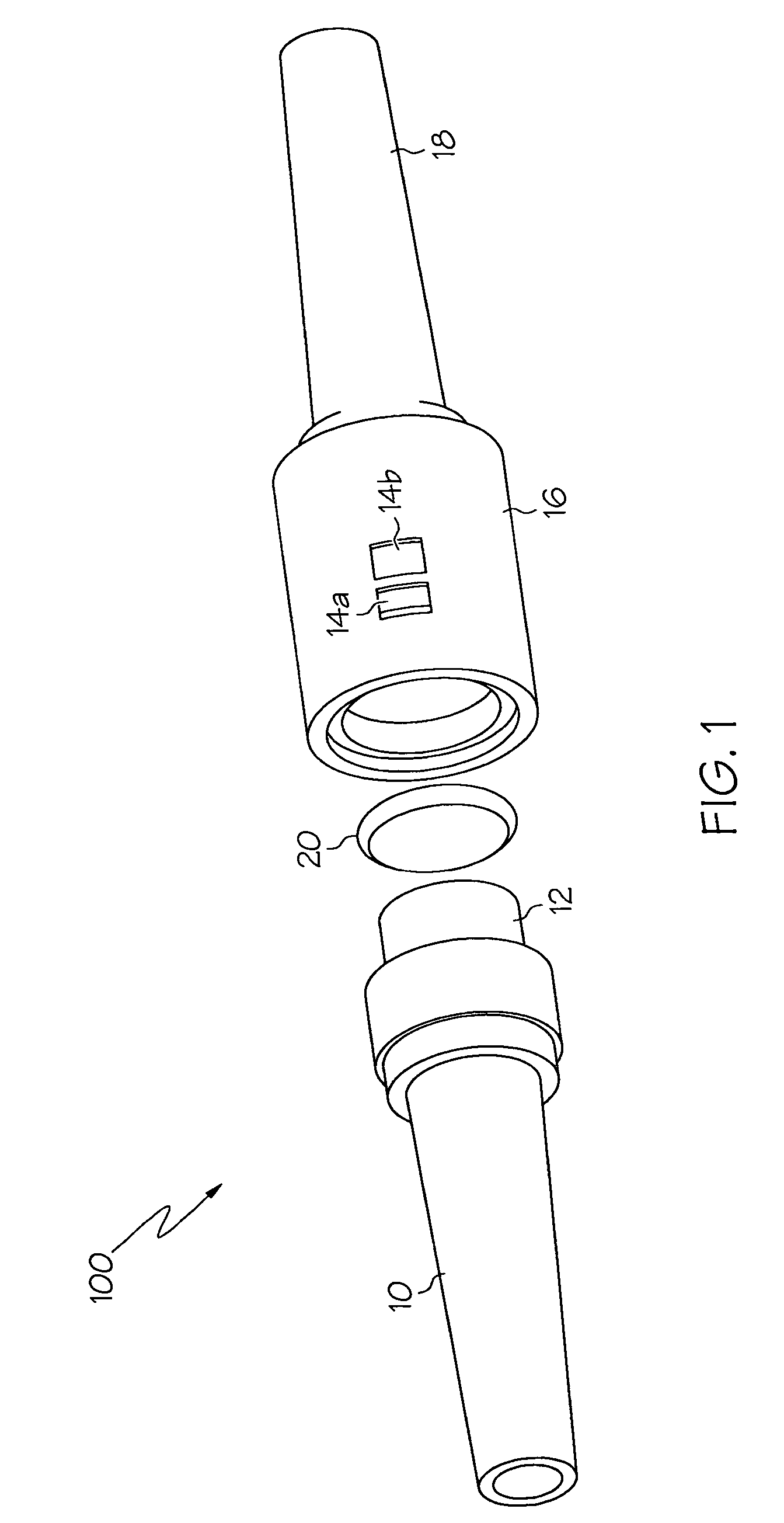

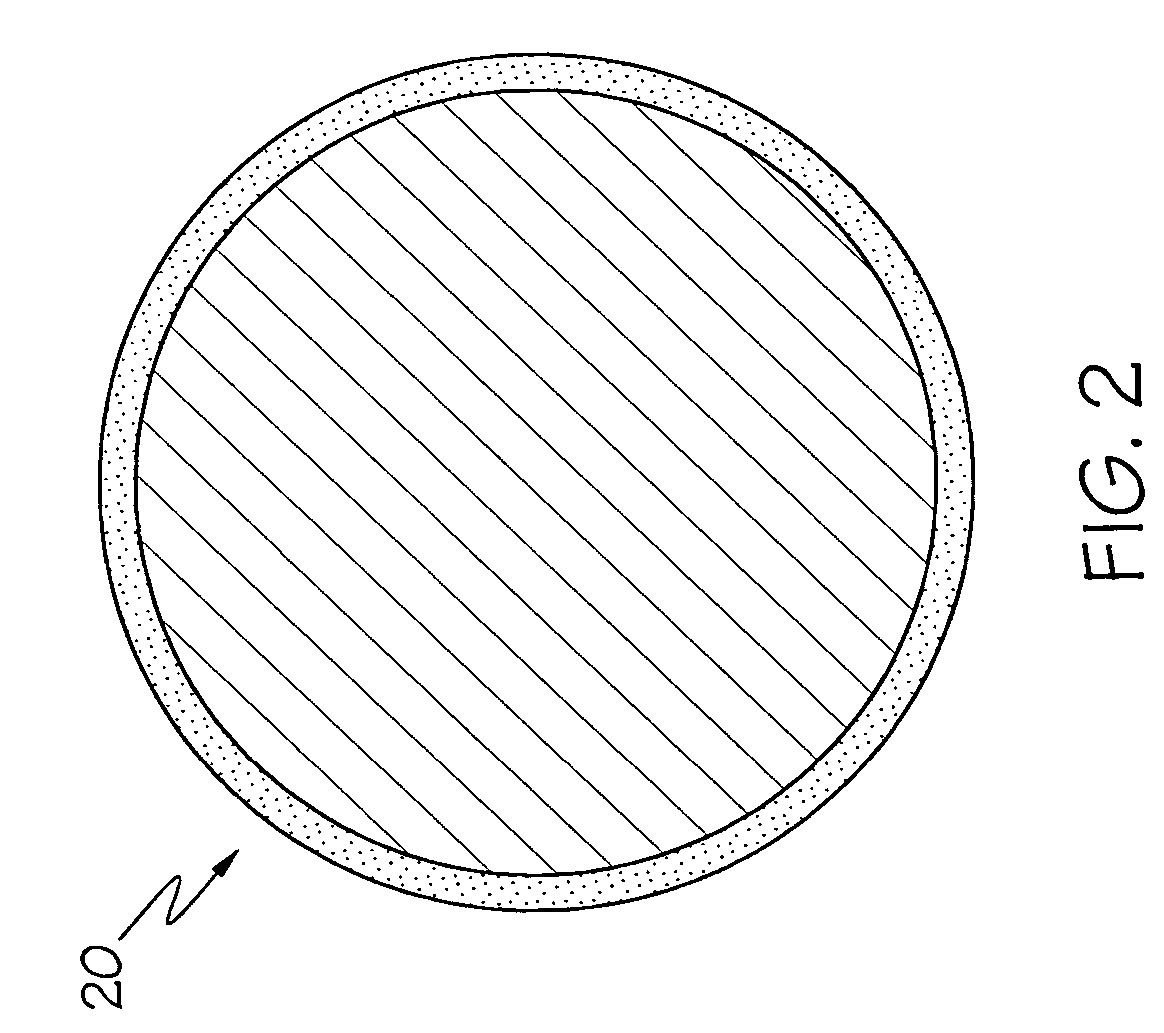

Electromagnetic acoustic transducer and methods of determining physical properties of cylindrical bodies using an electromagnetic acoustic transducer

InactiveUS6119522AElectrical transducersAnalysing solids using sonic/ultrasonic/infrasonic wavesDamping factorAcoustics

An electromagnetic acoustic transducer for inducing and sensing vibrations in a cylindrical object and methods of using an electromagnetic acoustic transducer to determine resonant frequencies and physical properties of cylindrical objects. The electromagnetic acoustic transducers produce specific modes of vibration in cylindrical objects including axial shear vibrations. The electromagnetic acoustic transducers are used to determine the temperature, dimensions, elastic constants, and damping coefficients of cylindrical objects, the magnitude of a load applied to a cylindrical object, or the texture or grain orientation of the material forming a cylindrical object.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE COMMERCE

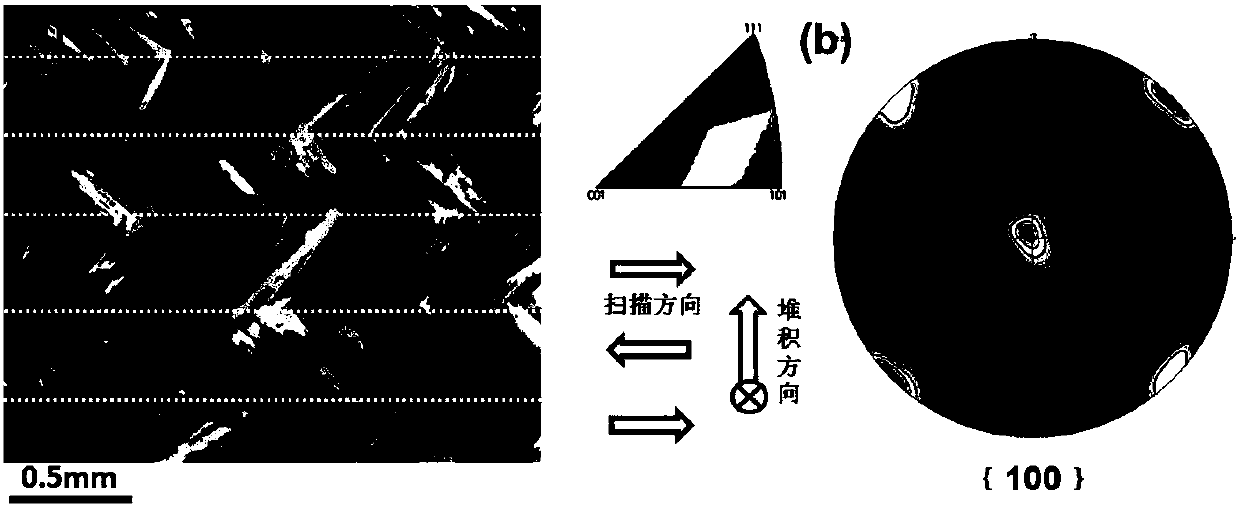

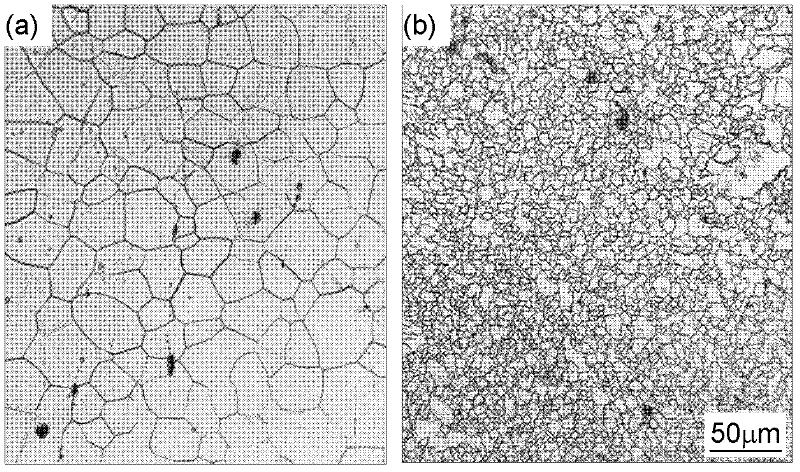

Method for establishing FDTD (Finite Difference Time Domain) ultrasonic detection simulation model of coarse crystal material based on EBSD (Electron Back-Scattered Diffraction) spectrum

ActiveCN104090033AIn-depth understanding of propagation characteristicsImprove computing efficiencyMaterial analysis using sonic/ultrasonic/infrasonic wavesSonificationCrystal orientation

The invention discloses a method for establishing an FDTD (Finite Difference Time Domain) ultrasonic detection simulation model of a coarse crystal material based on an EBSD (Electron Back-Scattered Diffraction) spectrum and belongs to the technical field of ultrasonic nondestructive detection. The method comprises the following steps: obtaining a crystal orientation spectrum of the coarse crystal material by directly using the EBSD technology, selecting a threshold value for defining crystal grains in the spectrum according to an actual crystal grain structure in a macroscopic metallograph, packing the crystal grains with color corresponding to a principal orientation, and carrying out grey processing to obtain an image consisting of square pixel points, wherein the orientations of the crystal grains are represented by eulerian angles phi1, phi and phi2 corresponding to gray values and can be used for quantitatively calculating elastic anisotropic stiffness matrixes of the crystal grains. Compared with a previous model, the model has the advantages of being capable of accurately describing the structures and the orientations of the crystal grains, realizing high operation efficiency and the like; a model basis is provided for realizing purposes of defect quantification and location and quality determination in ultrasonic detection of the coarse crystal material. The method also can be used for establishing the ultrasonic simulation models of other elastic anisotropic polycrystalline materials such as austenitic welding lines and two-phase titanium alloys; the method has bright popularization and application prospects.

Owner:DALIAN UNIV OF TECH +1

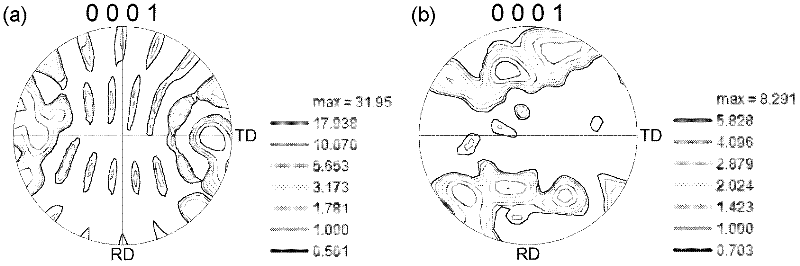

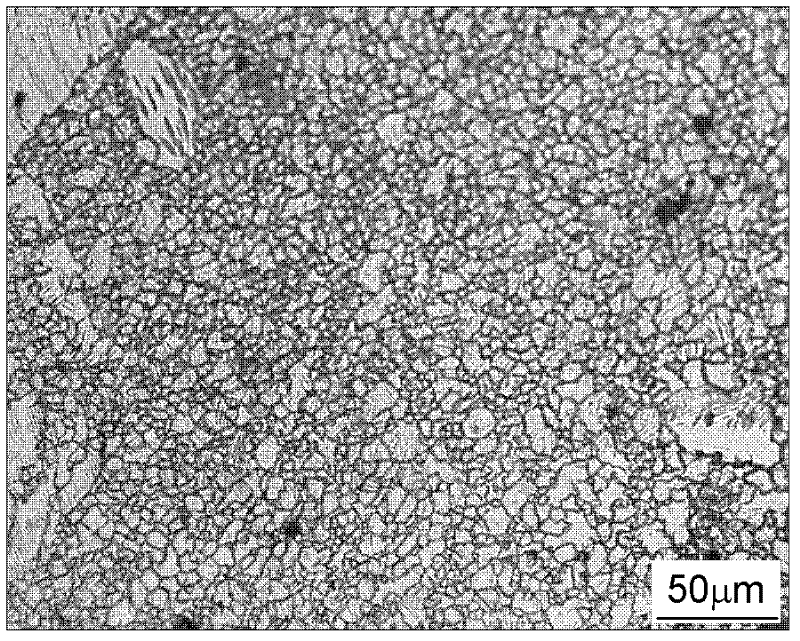

Method for weakening cardinal plane texture of magnesium alloy plate strip

InactiveCN102409273AImprove ductilityGood subsequent processing performanceCrystal twinningUltimate tensile strength

The invention relates to a method for weakening the cardinal plane texture of a magnesium alloy plate strip, which comprises the following steps of: placing the magnesium alloy plate strip between corrugated rollers, carrying out alternative rolling for many times under the temperature of 300-550 DEG C, straightening, and water quenching, or carrying out multi-channel one-way or alternative rolling for many times under the temperature of 150-300 DEG C, straightening, carrying out static recrystallization, and annealing; carrying out corrugated rolling at the temperature of over 300 DEG C, andincreasing along with the channel, wherein each flat surface which is vertical to normal direction of the plate strip is respectively applied with shearing force in different directions; inducing dynamic recrystallization, so that the orientation distribution of grains in the plate strip is randomized, and the strength of the cardinal plane texture is reduced; and carrying out corrugated rolling under the temperature of below 300 DEG C, wherein at the position in the plate strip, especially, the position where the repeated wave bending deformation is the most serious, a large amount of twin crystals are produced to enable the grain orientation to deflect, and further, the initial texture is weakened. The invention has the advantages that the process design is reasonable, the equipment is easy to manufacture, the operation process is easy to realize, the defects of the normal plastic deformation and difficulty in weakening of the texture in annealing of the magnesium alloy are overcome, and the efficiency is high. The method is suitable for the large scale of industrial production.

Owner:CENT SOUTH UNIV

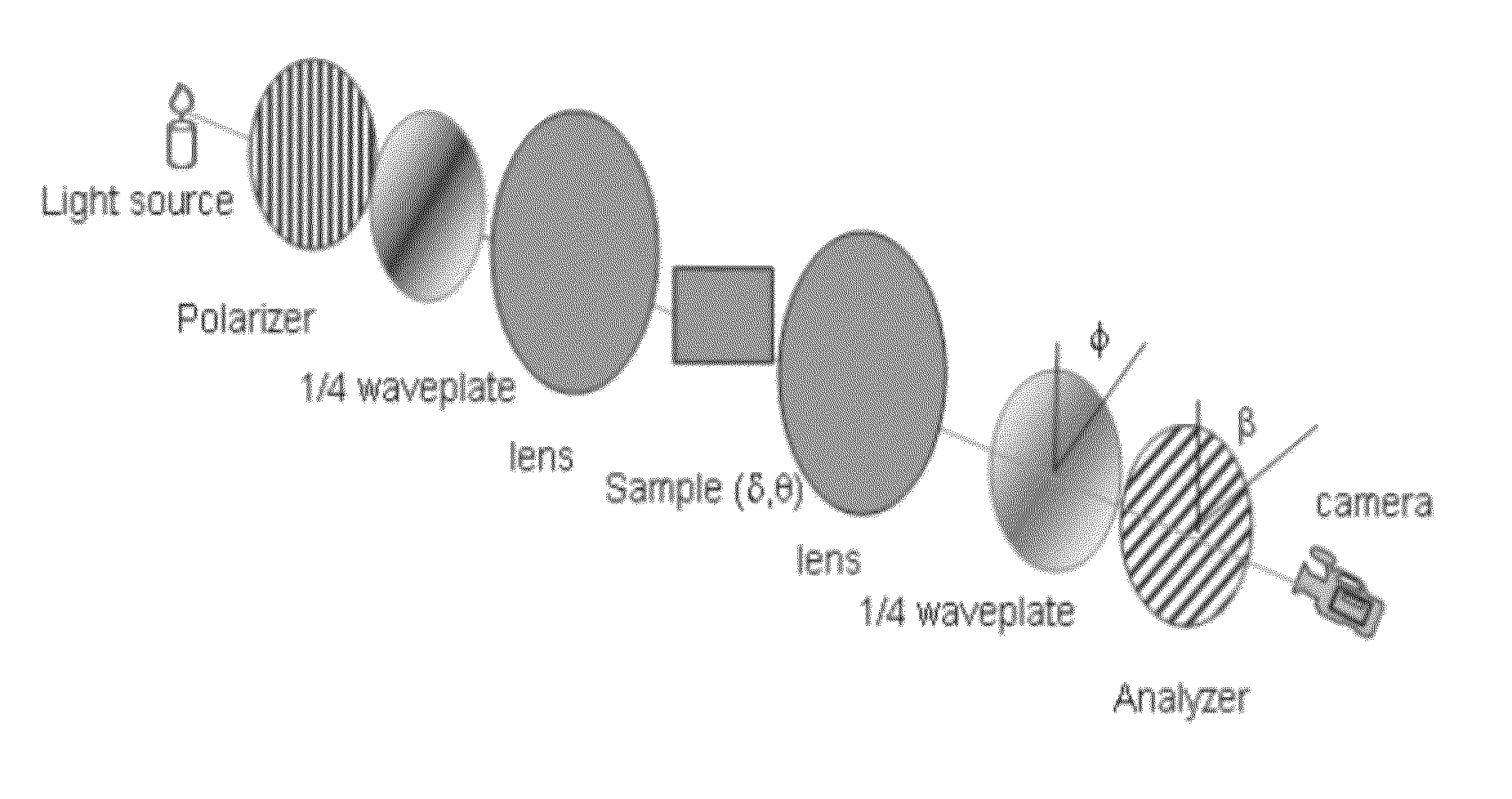

Polariscope stress measurement tool and method of use

InactiveUS8264675B1Eliminate errorsForce measurementUsing optical meansShear stressStress measurement

The present invention provides a tool for and method of using an infrared transmission technique to extract the full stress components of the in-plane residual stresses in thin, multi crystalline silicon wafers including in situ measurement of residual stress for large cast wafers. The shear difference method is used to obtain full stress components by integrating the shear stress map from the boundaries. System ambiguity at the boundaries is resolved completely by introducing a new analytical function. A new anisotropic stress optic law is provided, and stress optic coefficients are calibrated for different crystal grain orientations and stress orientations.

Owner:GEORGIA TECH RES CORP

Method for detecting orientation of large-sized crystal grains

ActiveCN102103093ARapid Batch DetectionMaterial analysis using radiation diffractionMetallic materialsPolycrystalline material

The invention discloses a method for detecting orientation of large-sized crystal grains. The method mainly comprises the following steps of: establishing and storing a database; combining the colors of the crystal grains and crystallographic data by an electron backscatter diffraction pattern (EBSP) technology; establishing the correspondence between the colors and the crystallographic data; recording corrosion conditions of different metal materials and differently-oriented crystal grains; quickly retrieving the database to search a corrosion state after a large number of samples to be detected are obtained; corroding according to the same corrosion mode; and recording the colors of the crystal grains corresponding to the orientation, which accords with the conditions, of the database under the conditions of the same light source and the same viewing angle to finally realize quick and batch orientation detection of the crystal grains. In the method, the specific color of the differently-oriented crystal grains is obtained through observation under fixed conditions by quantitatively calculating the surface energy of the crystal grain orientation and proper corrosion time, and quick and batch orientation detection of a large-sized polycrystalline material is realized corresponding to the scanning of the database so as to determine the performance of the material.

Owner:ANGANG STEEL CO LTD

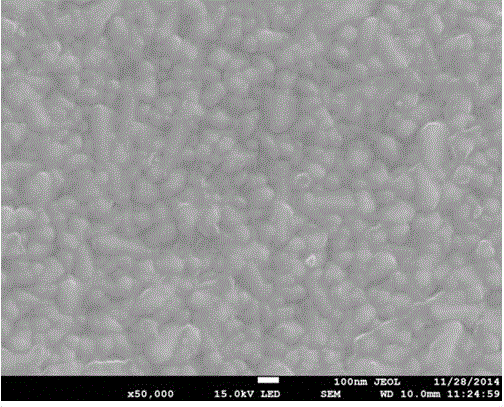

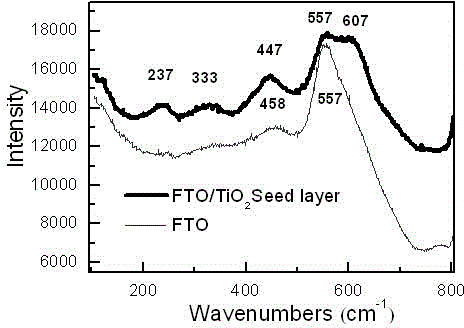

Titanium dioxide film hydrogen sensor and preparation method thereof

ActiveCN104569077AHigh detection sensitivityHigh densityMaterial resistanceVoltage sourceHydrogen sensor

The invention provides a titanium dioxide film hydrogen sensor and a preparation method thereof. The predeposited TiO2 seed crystal layer can isolate the FTO (fluorine-doped tin oxide) conducting layer and hydrothermal growth TiO2 layer, lower the drain current passing through the FTO conducting glass layer and enhance the detection sensitivity of the titanium dioxide film hydrogen sensor; the predeposited TiO2 seed crystal layer can be used as a buffer layer and seed crystal layer, provides a higher-density seed crystal layer for the next hydrothermal synthesis step of the TiO2 nano array film, and effectively increases the density of the film TiO2 nanorod array; and magnetron sputtering and hydrothermal synthesis are combined to enhance the grain orientation performance of the TiO2 nano array film, so that the finally prepared titanium dioxide film hydrogen sensor has excellent detection sensitivity and stability, and more importantly, can satisfy the requirements for hydrogen detection at 25+ / -5 DEG C, and the method does not need any additional heating system and has the advantage of lower cost than other methods. The detection limit at 25+ / -5 DEG C can reach 1 ppm, and the resistance change is up to 4% when a 1V voltage source is used as the drive.

Owner:HUBEI UNIV

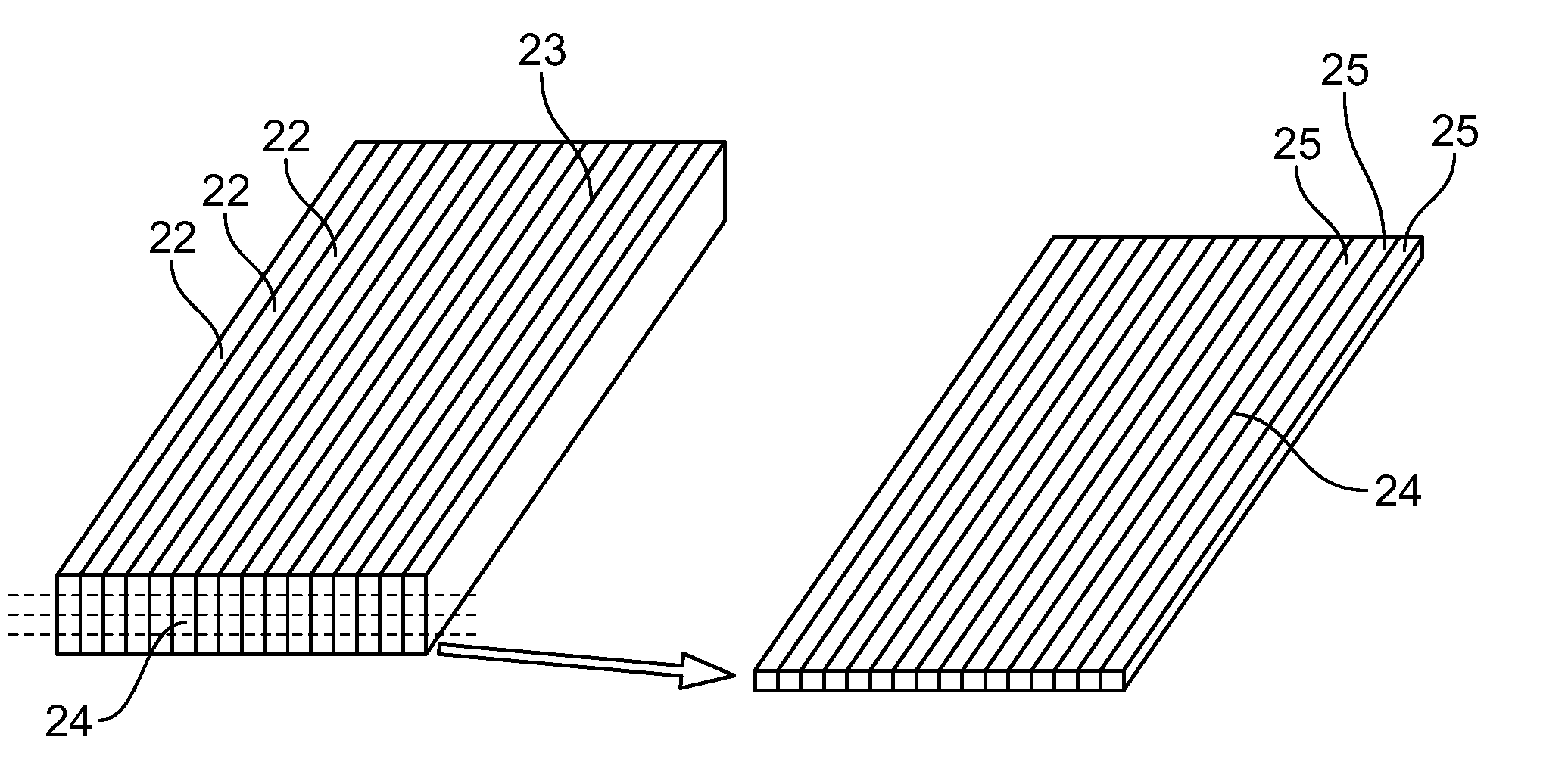

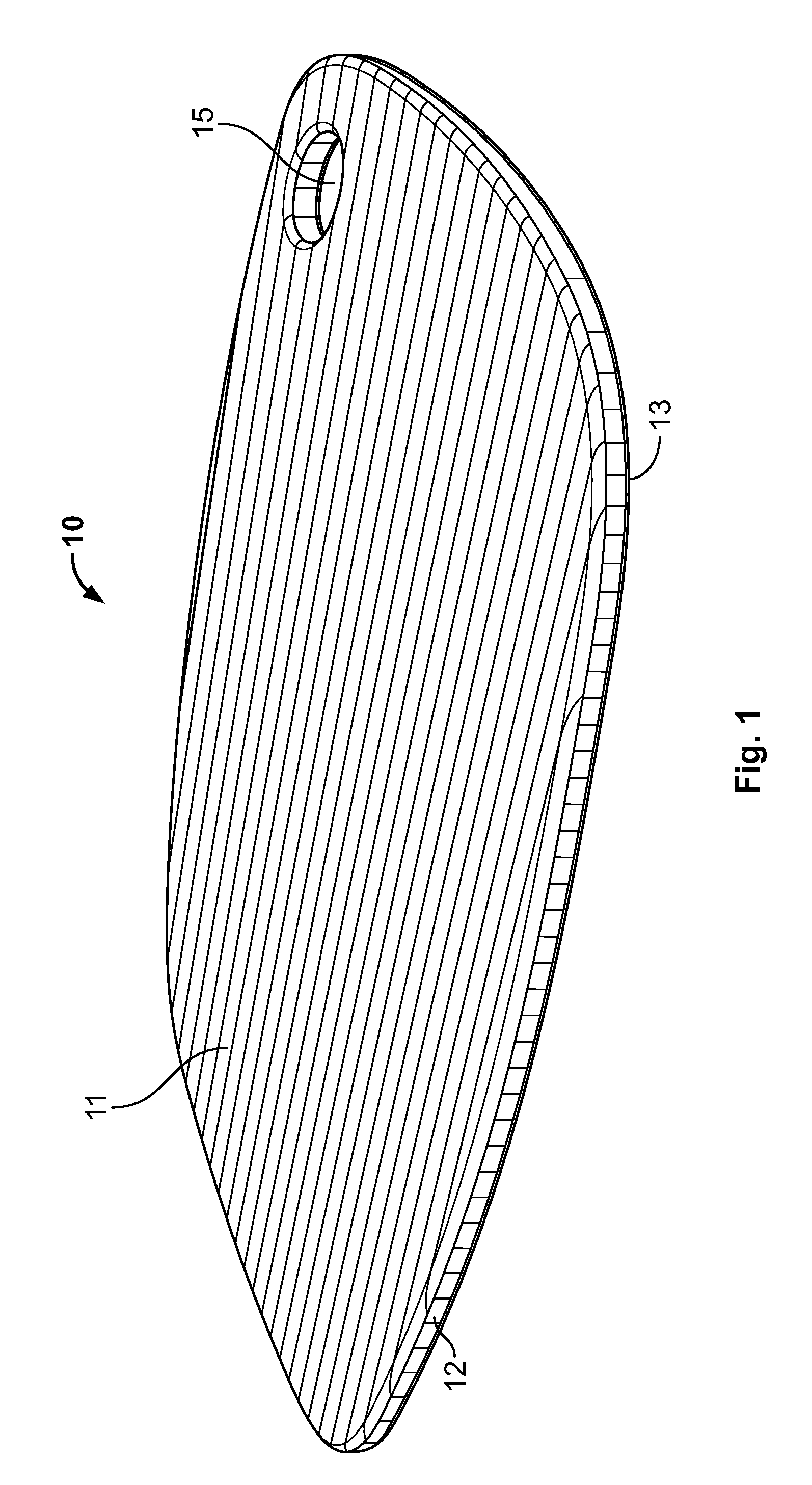

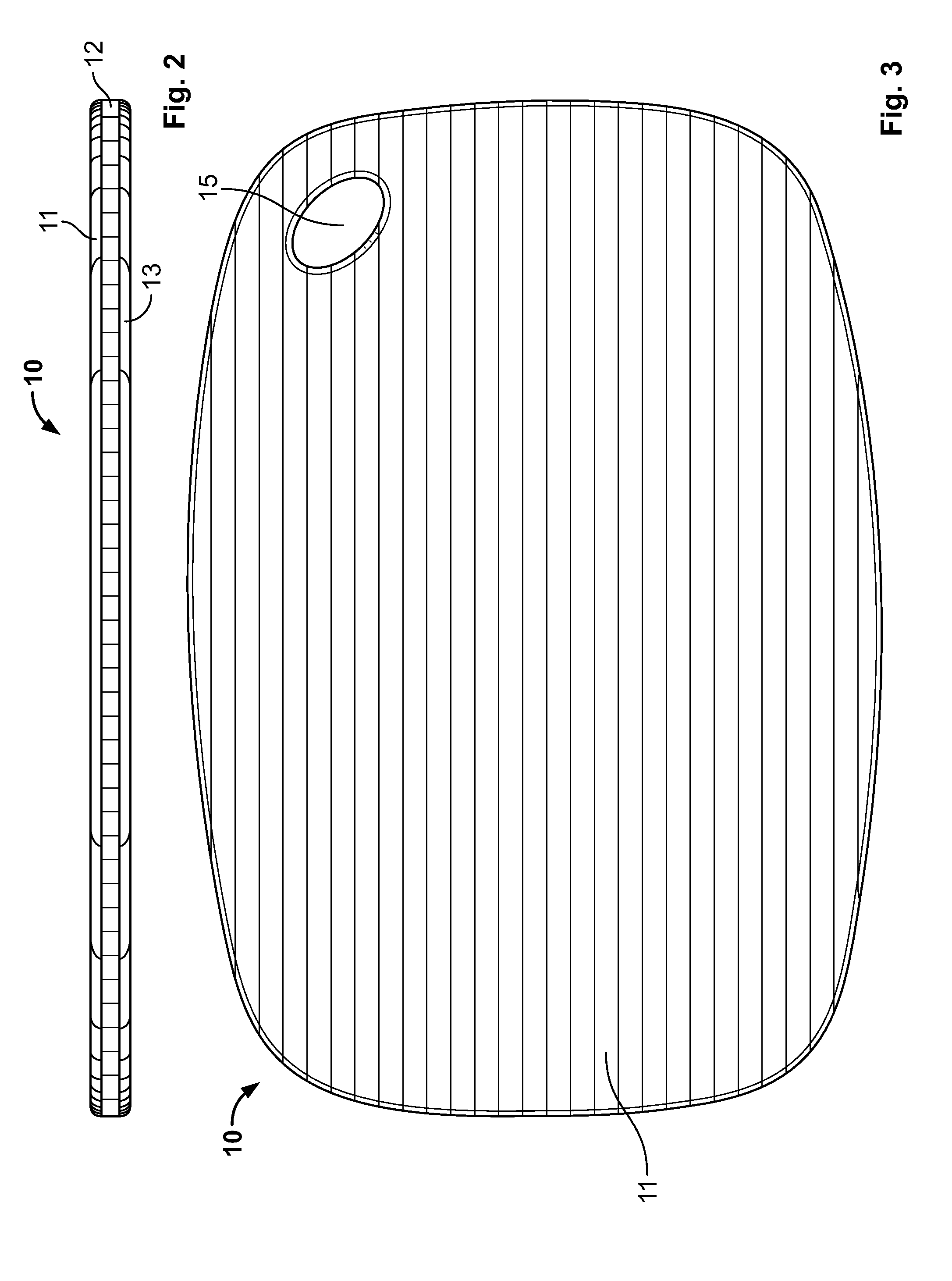

Multilayered Bamboo Article

InactiveUS20090308528A1Dishwasher safeStrong and durableLamination ancillary operationsLaminationSquare cross sectionEngineering

A multilayered bamboo article and a method for making the same is disclosed. Strips of bamboo with roughly square cross sections are secured together into layers in which the layer has parallel grain orientations. These layers are then combined together in perpendicular grain orientations to form a multilayered bamboo article. The bamboo strips and layers are secured together using a glue resistant to high temperatures when cured resulting in a strong multilayered bamboo article resistant to the effects of hot water.

Owner:SULLIVAN TOM

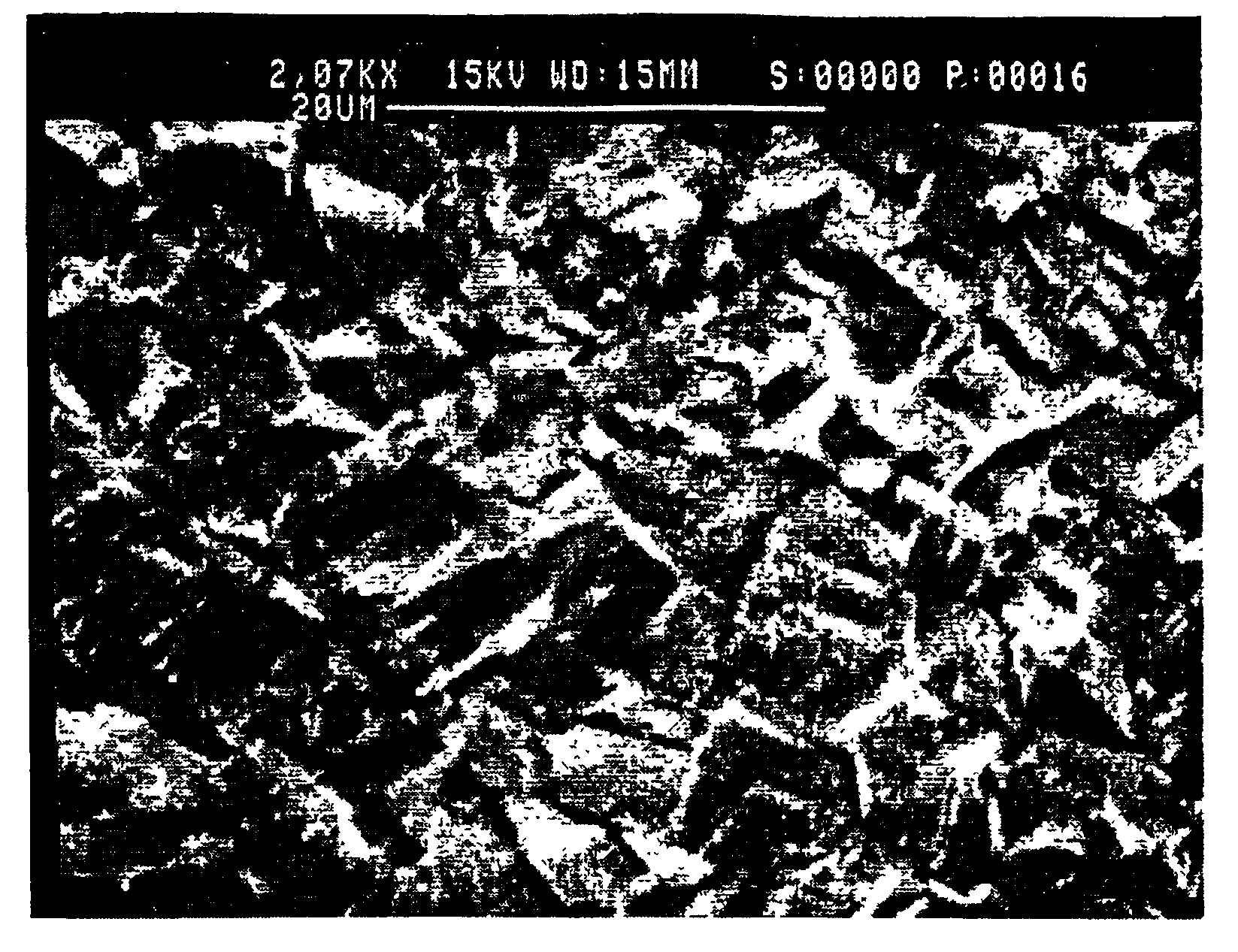

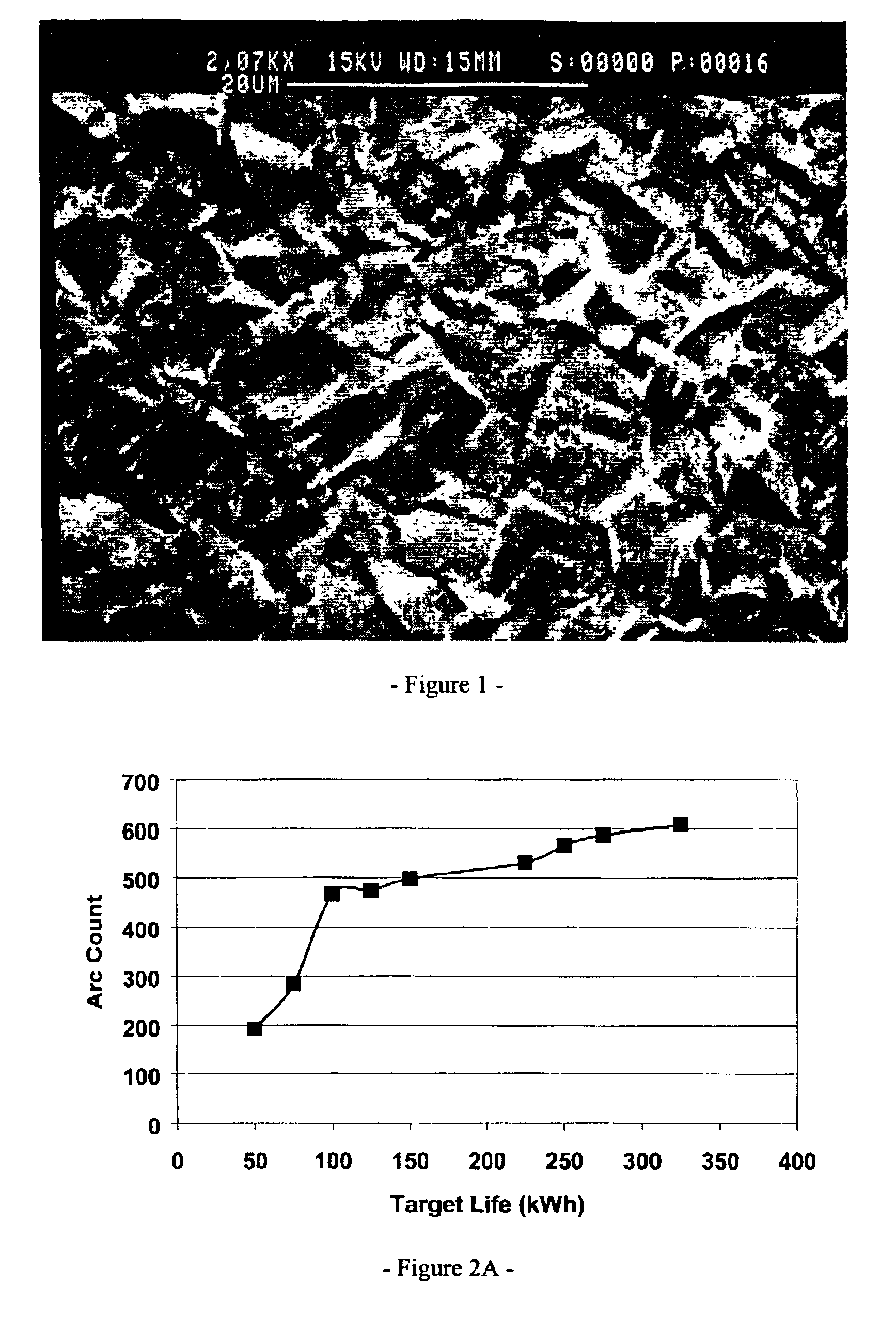

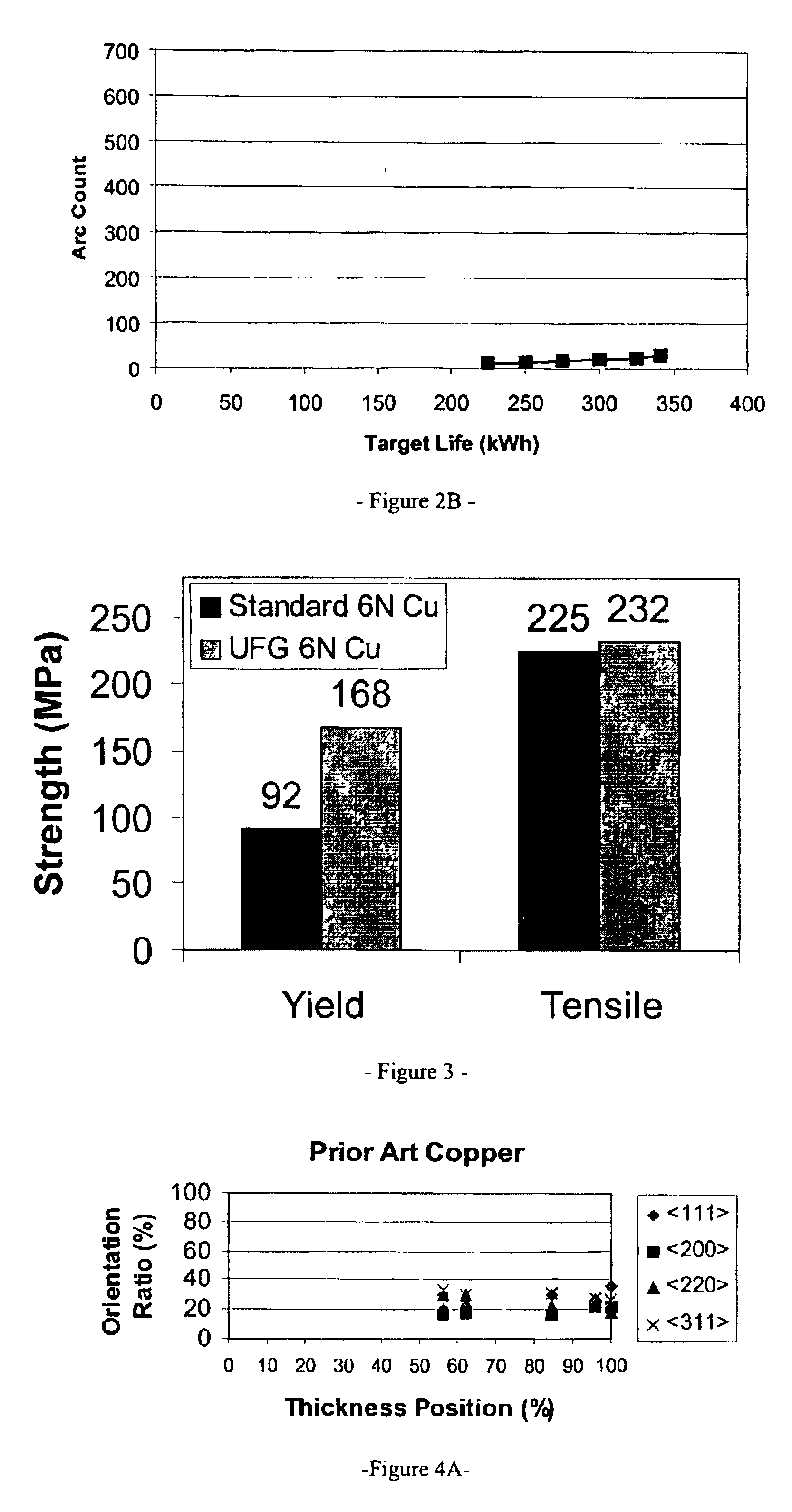

Ultrafine-grain-copper-base sputter targets

InactiveUS6896748B2Improve sputtering uniformityReducing sputter target arcingCellsVacuum evaporation coatingSputteringGrain structure

The sputter target has a composition selected from the group consisting of high-purity copper and copper-base alloys. The sputter target's grain structure is at least about 99 percent recrystallized; and the sputter target's face has a grain orientation ratio of at least about 10 percent each of (111), (200), (220) and (311). In addition, the sputter target has a grain size of less than about 10 μm for improving sputter uniformity and reducing sputter target arcing.

Owner:PRAXAIR ST TECH INC

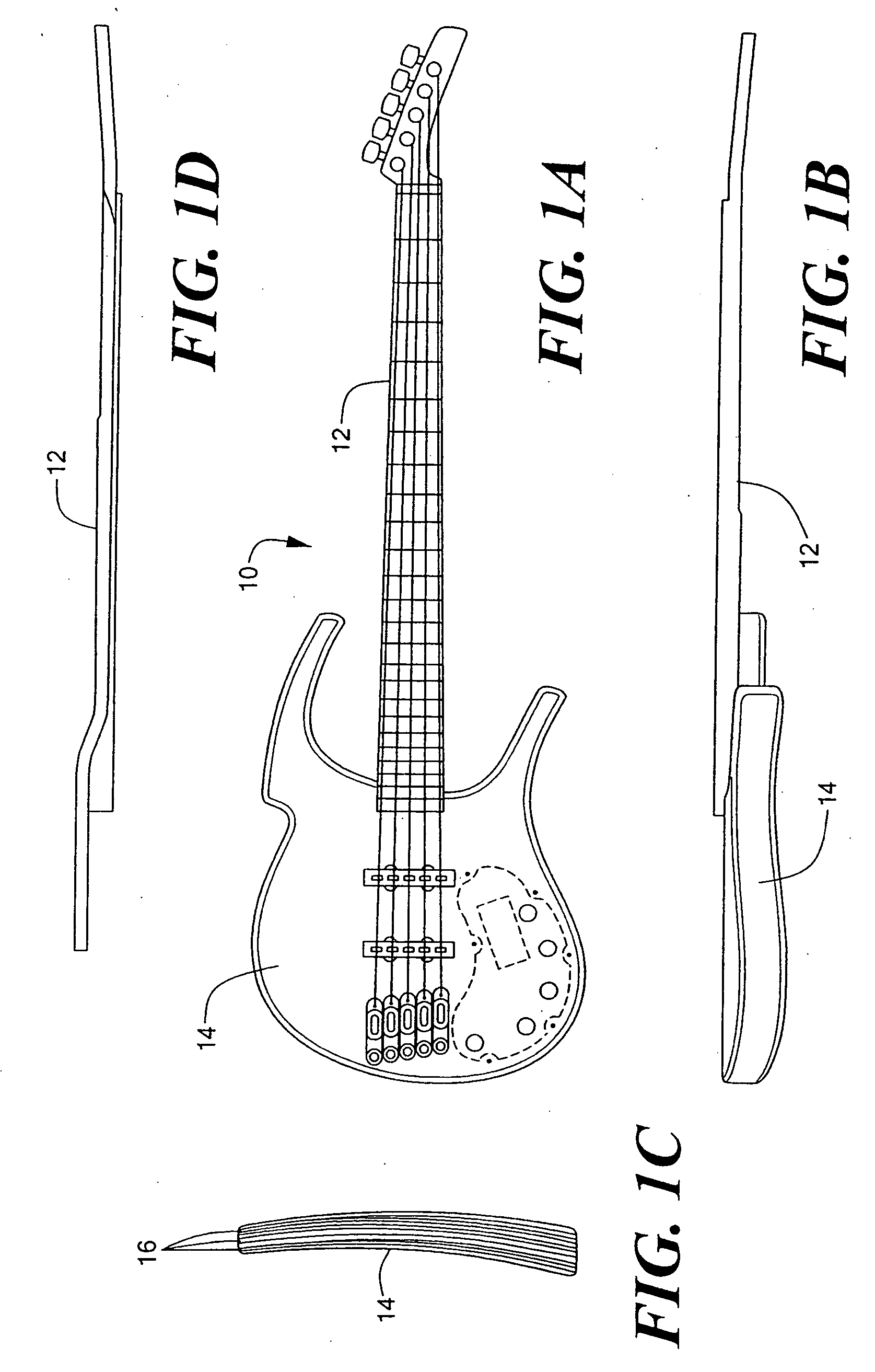

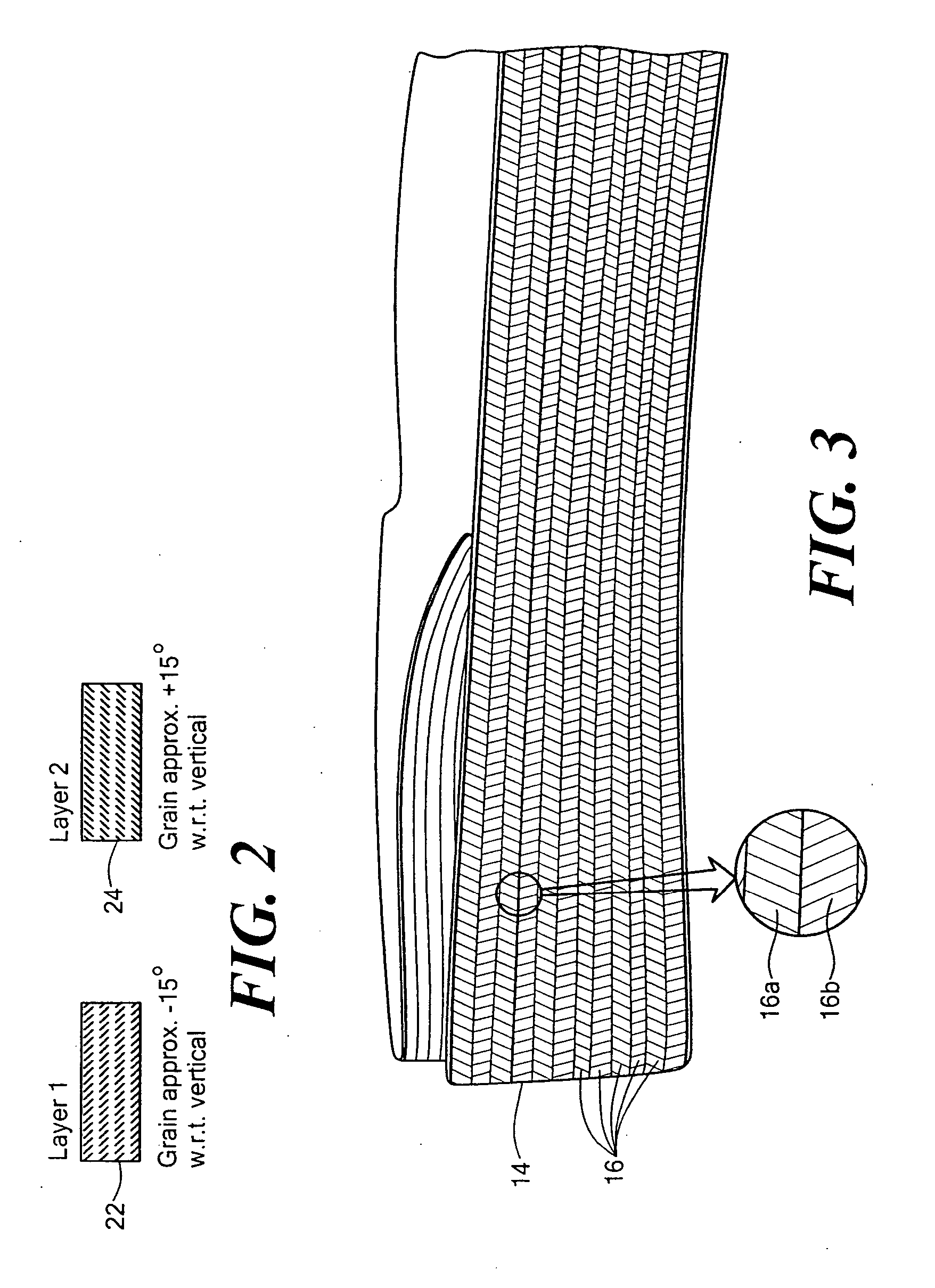

Molded laminate for musical instrument and method of manufacturing molded laminate musical instrument

InactiveUS20060272470A1High strengthGood musical soundGuitarsWood veneer joiningFiberElectric guitar

A musical instrument, such as an electric or bass guitar, is formed of a lamination of wood layers having differing grain orientations in adjacent layers, the grain orientations defining a crossing angle less than 90°. An instrument formed from such a lamination is strong and resistant to splitting and checking and produces a good musical sound. The wood layers can be molded under pressure to form curves, such as an S-curve in a neck, or deformations, such as rounded edges in a guitar body. The S-curve in the neck allows the neck to be attached to the guitar body without breaking the continuity of the wood fibers, thereby strengthening the neck. In a three-dimensional molding embodiment, a net shape or near net shape part results, which requires little or no further machining after molding.

Owner:PARKER GUITARS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com